Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Enhance the circuitized substrate art" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method of making a circuitized substrate having at least one capacitor therein

InactiveUS20080248596A1Enhance circuitized substrate artEnhance the circuitized substrate artThin/thick film capacitorPrinted circuit aspectsCapacitanceConductive materials

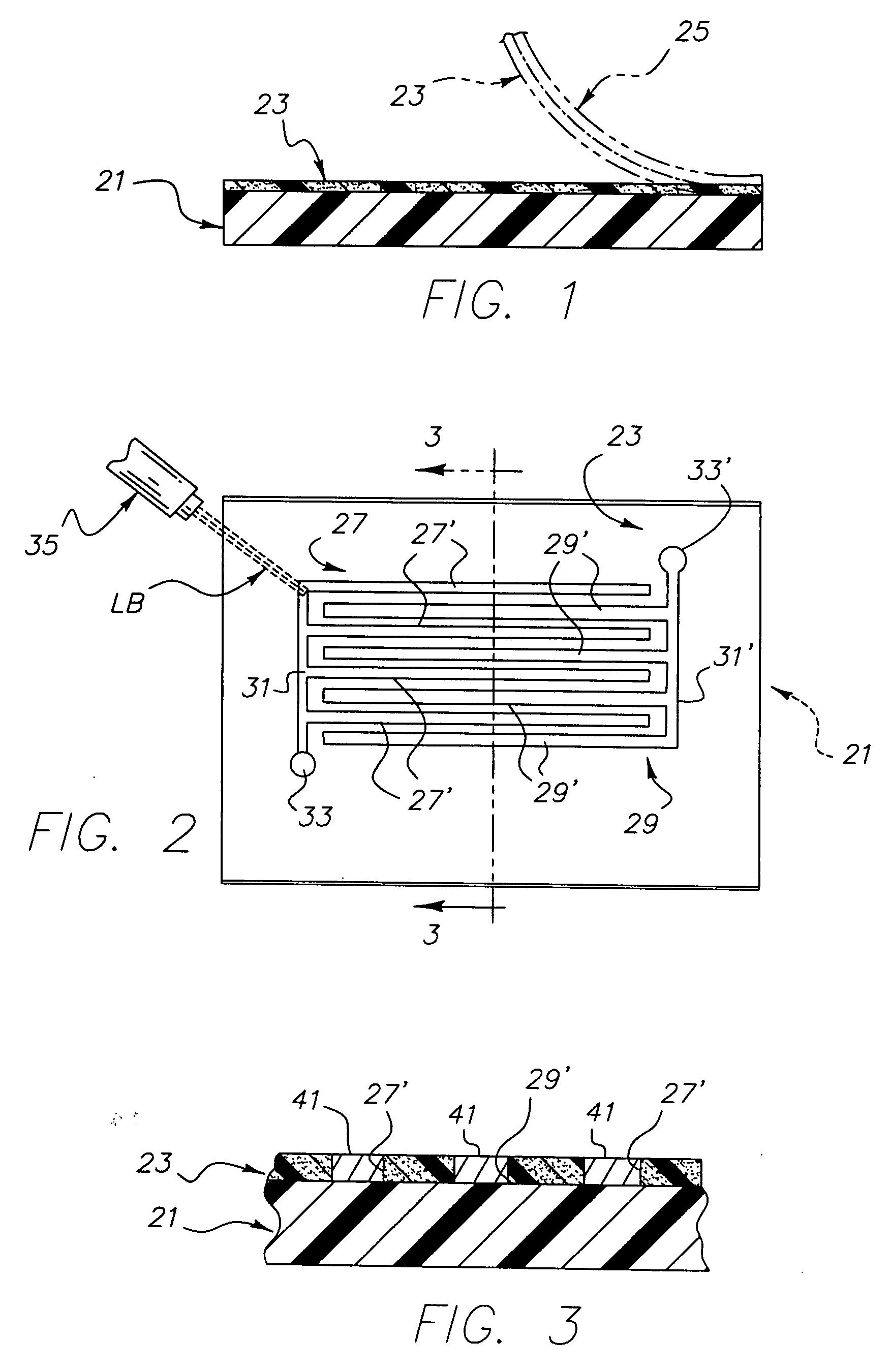

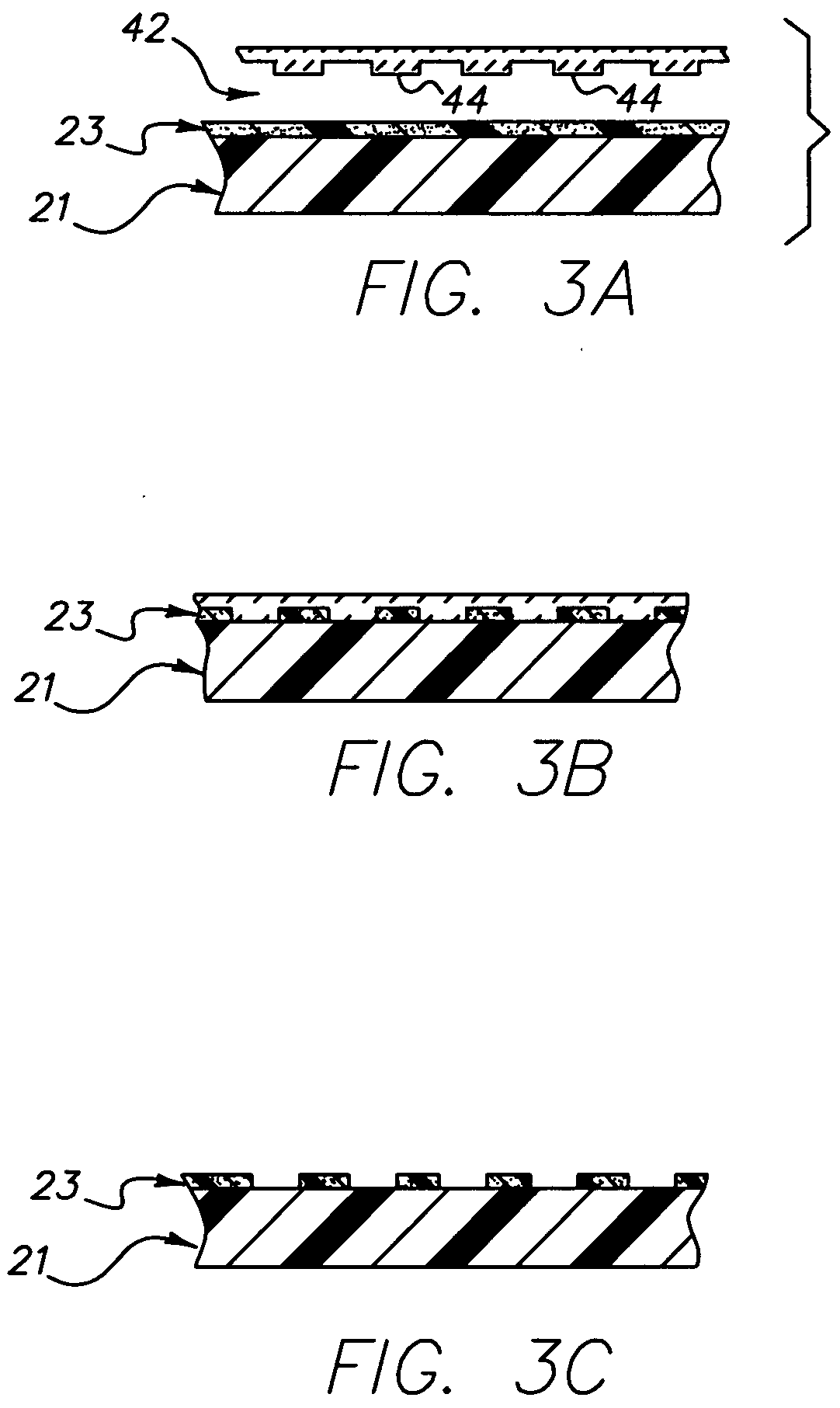

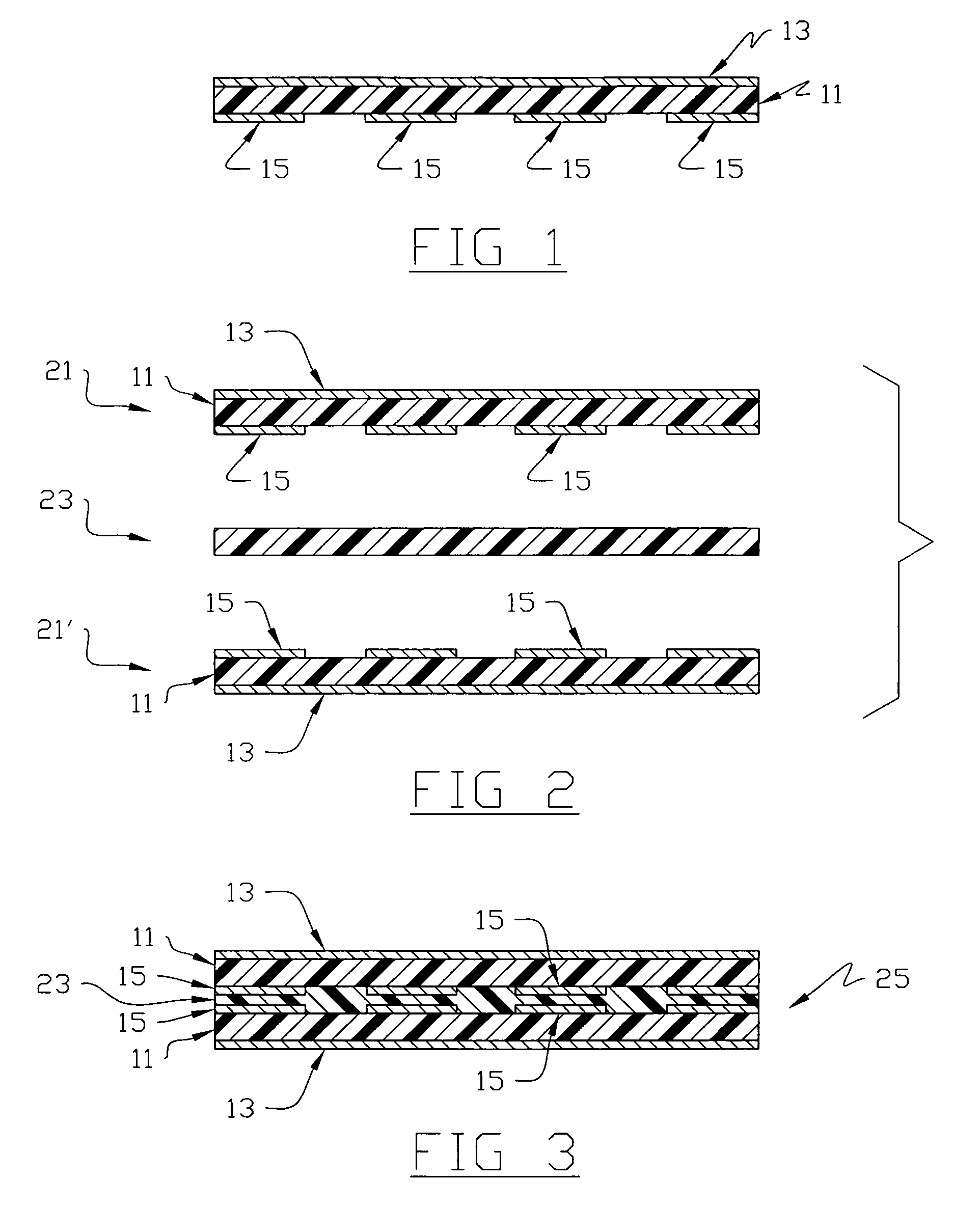

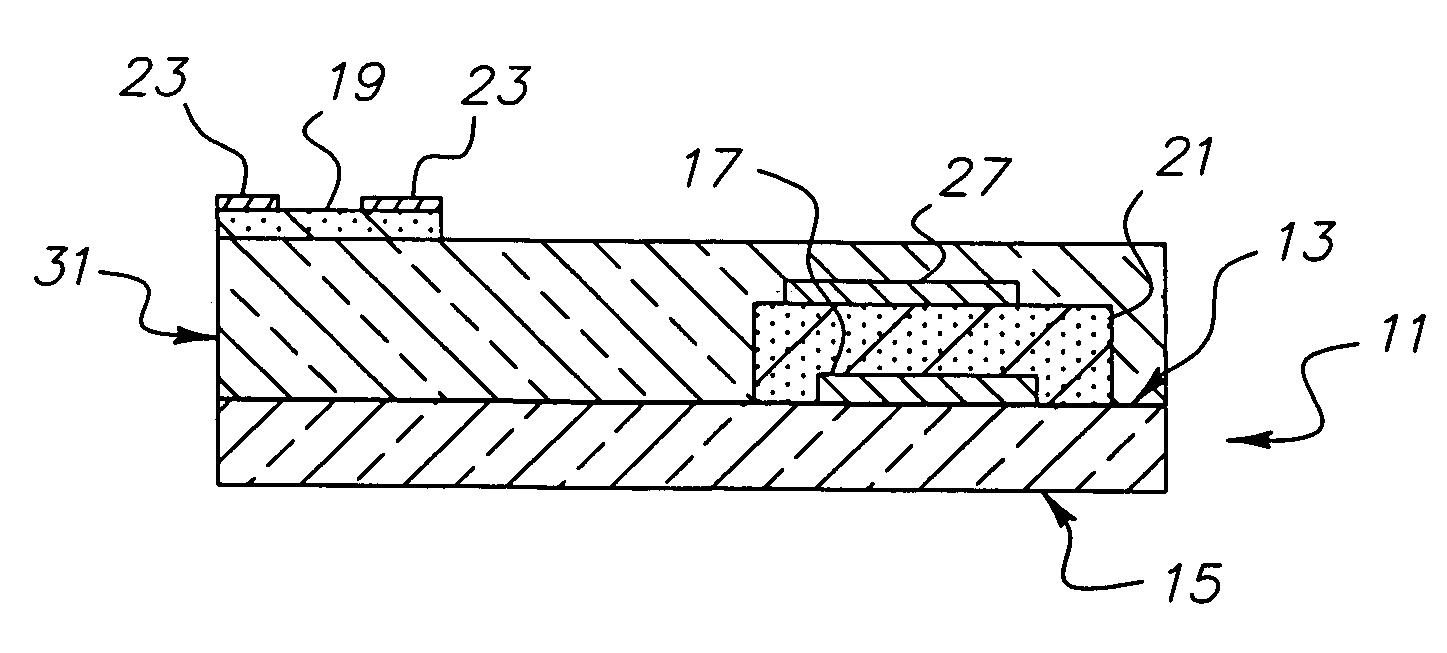

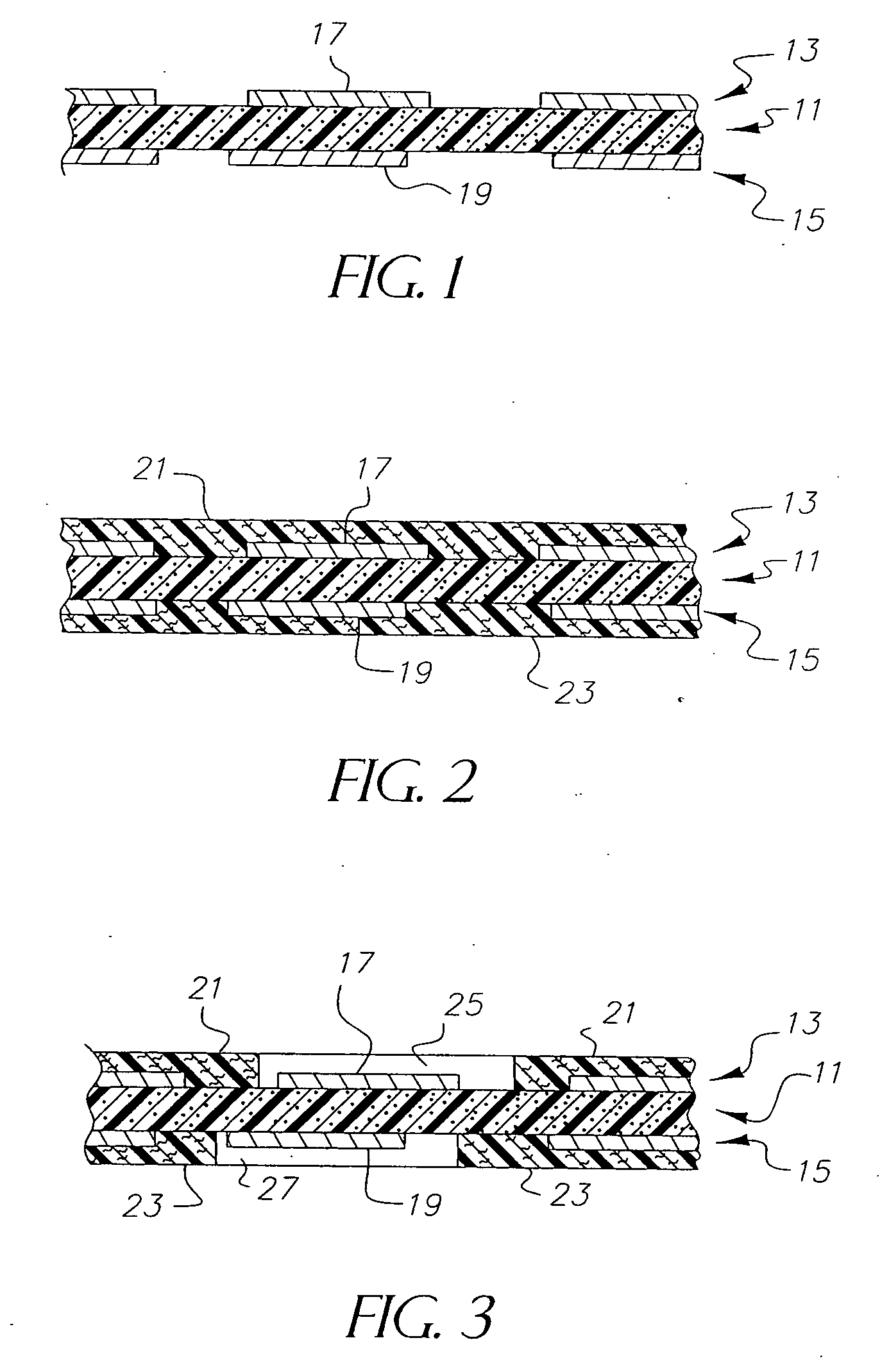

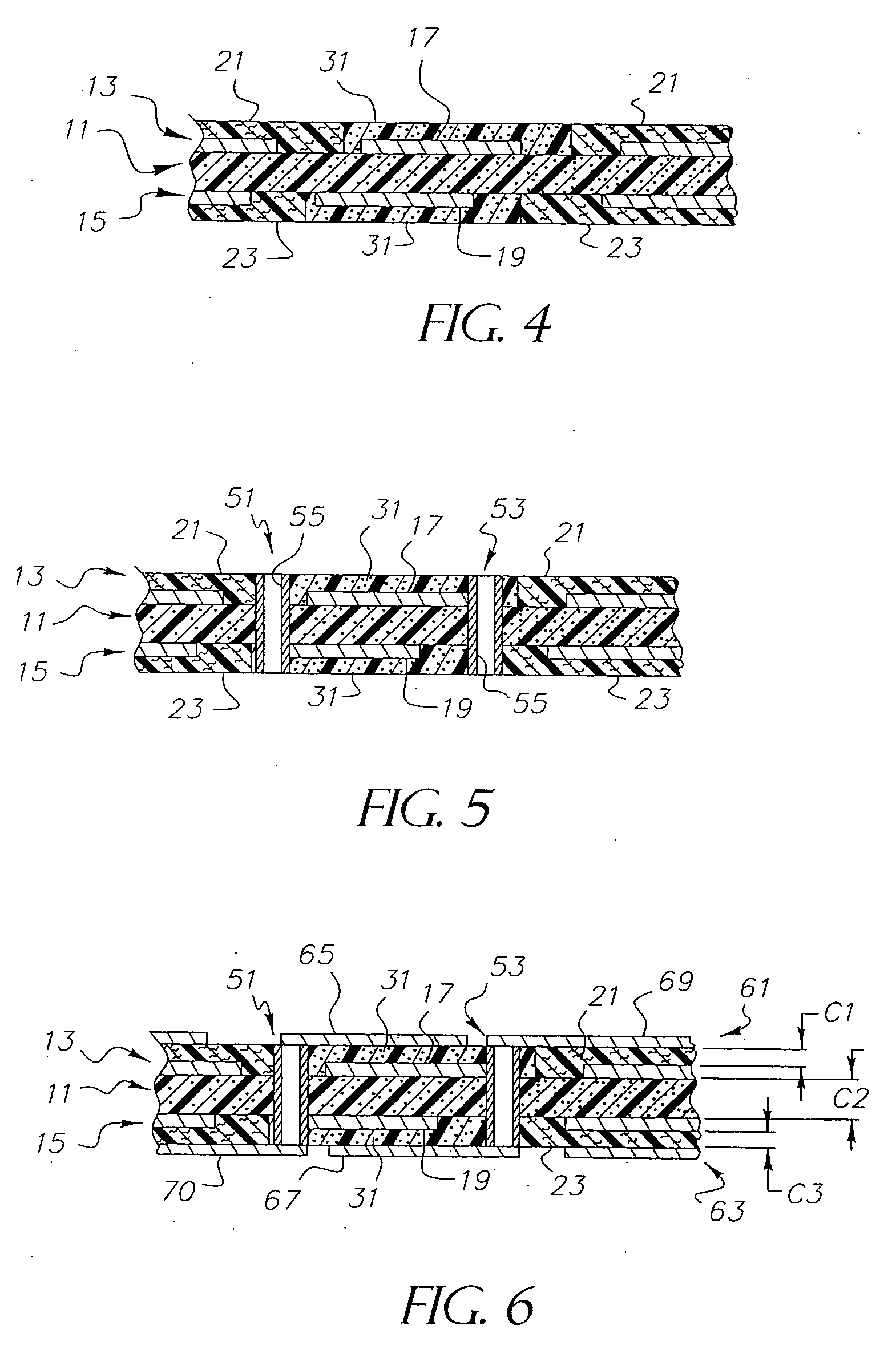

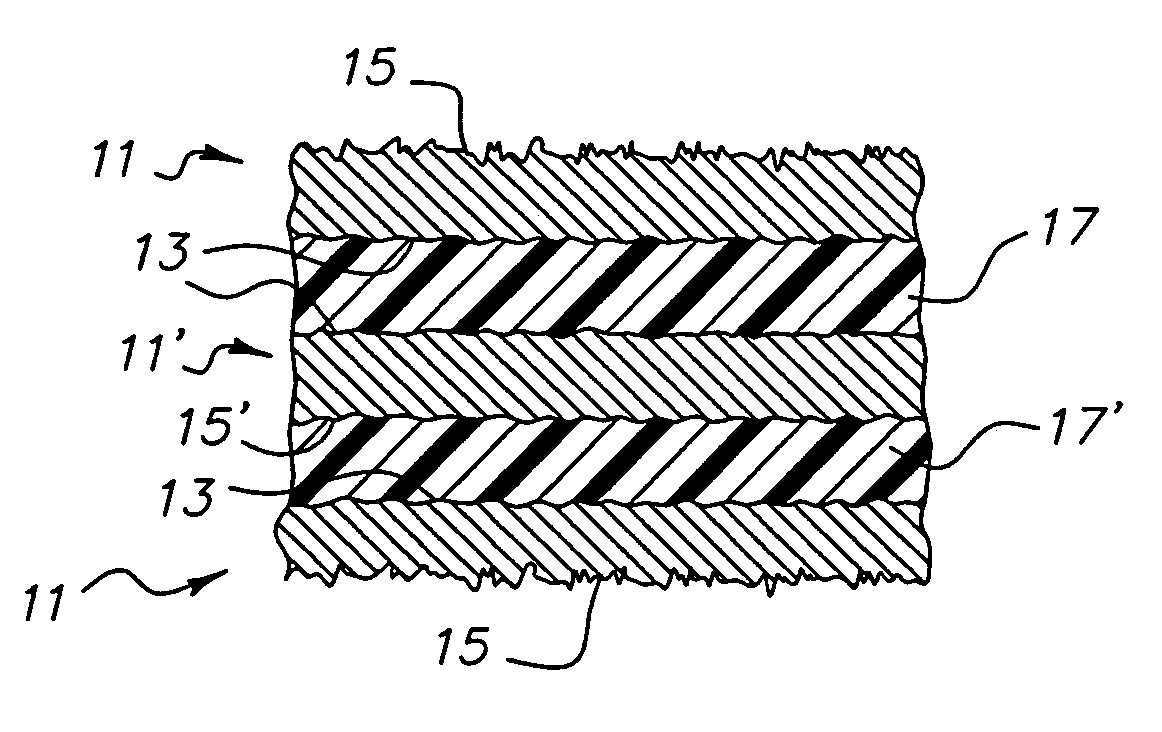

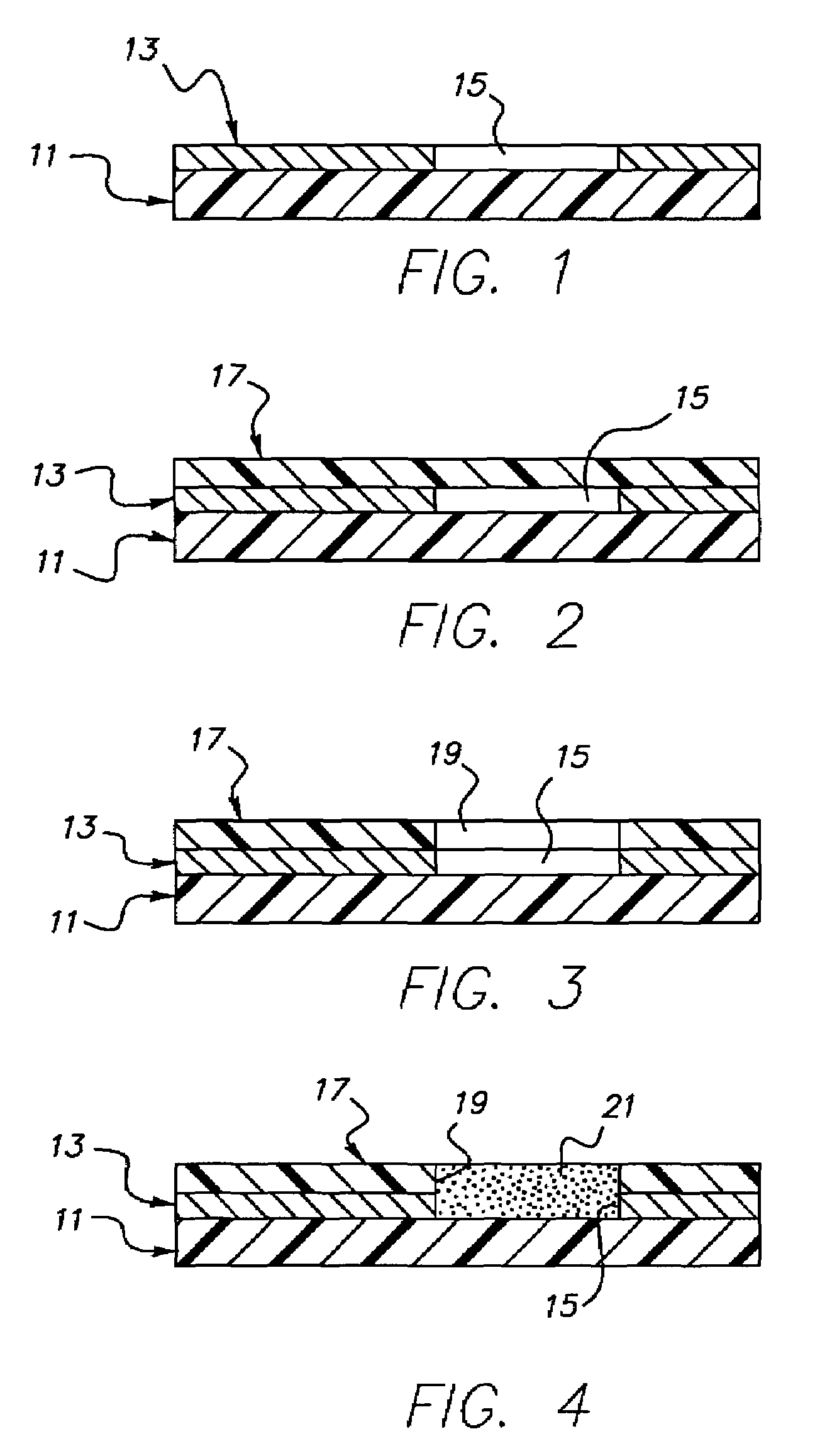

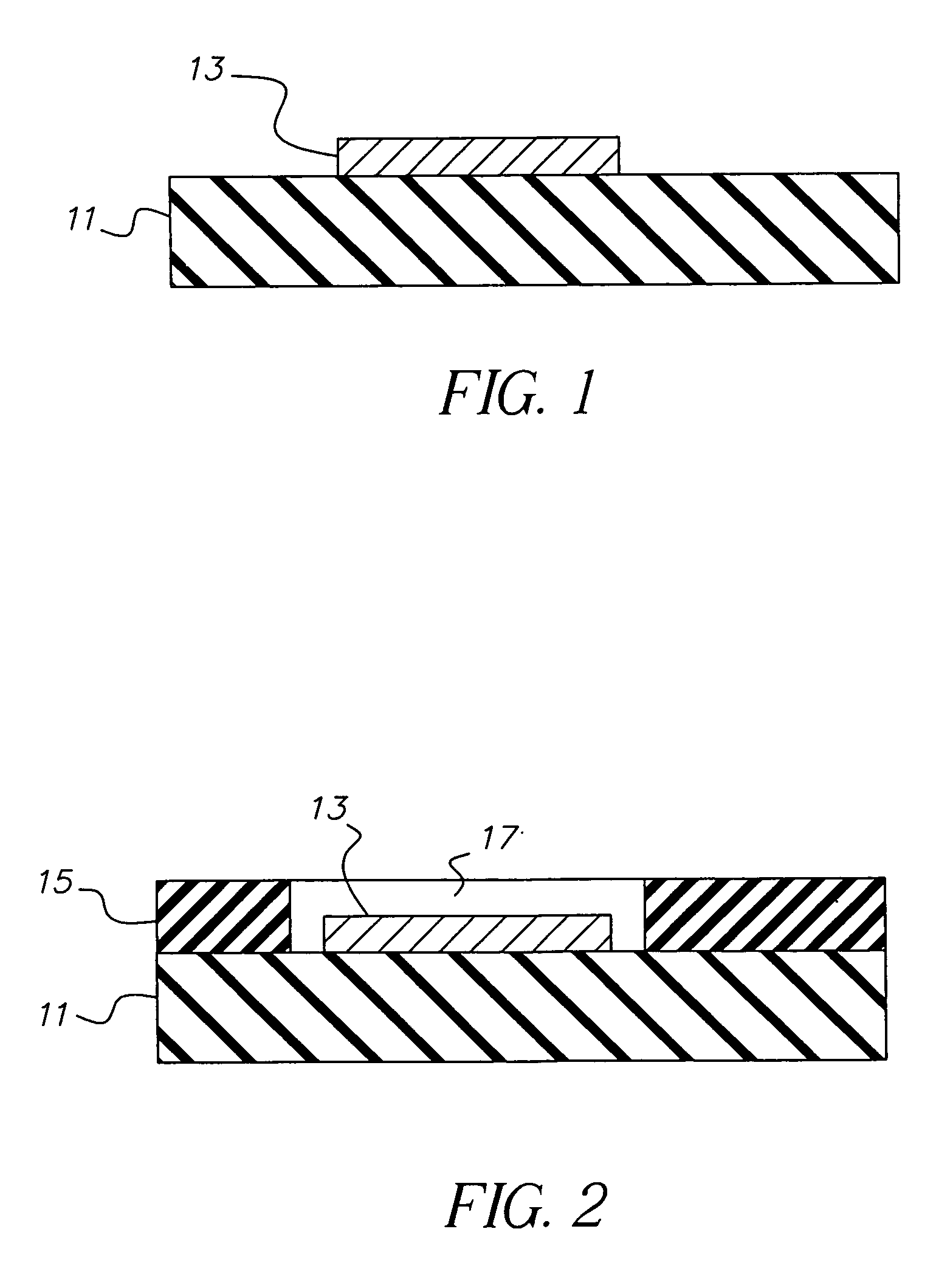

A method of making a circuitized substrate which includes at least one and possibly several capacitors as part thereof. In one embodiment, the substrate is produced by forming a layer of capacitive dielectric material on a dielectric layer and thereafter forming channels with the capacitive material, e.g., using a laser. The channels are then filled with conductive material, e.g., copper, using selected deposition techniques, e.g., sputtering, electro-less plating and electroplating. A second dielectric layer is then formed atop the capacitor and a capacitor “core” results. This “core” may then be combined with other dielectric and conductive layers to form a larger, multilayered PCB or chip carrier. In an alternative approach, the capacitive dielectric material may be photo-imageable, with the channels being formed using conventional exposure and development processing known in the art. In still another embodiment, at least two spaced-apart conductors may be formed within a metal layer deposited on a dielectric layer, these conductors defining a channel there-between. The capacitive dielectric material may then be deposited (e.g., using lamination) within the channels.

Owner:ENDICOTT INTERCONNECT TECH

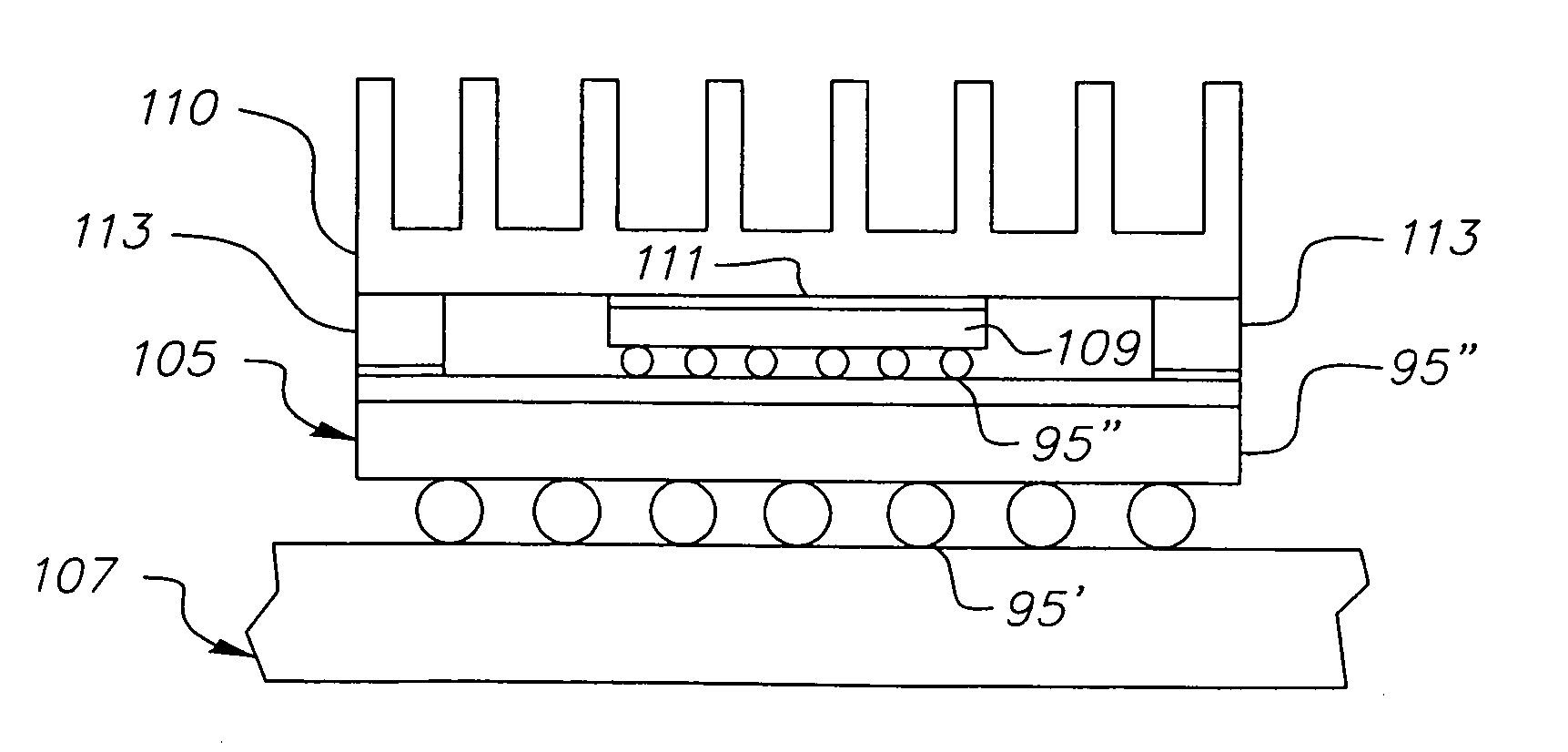

High speed circuitized substrate with reduced thru-hole stub, method for fabrication and information handling system utilizing same

InactiveUS6995322B2Enhance the circuitized substrate artIncrease speedCurrent interference reductionSemiconductor/solid-state device detailsSignal routingResonance

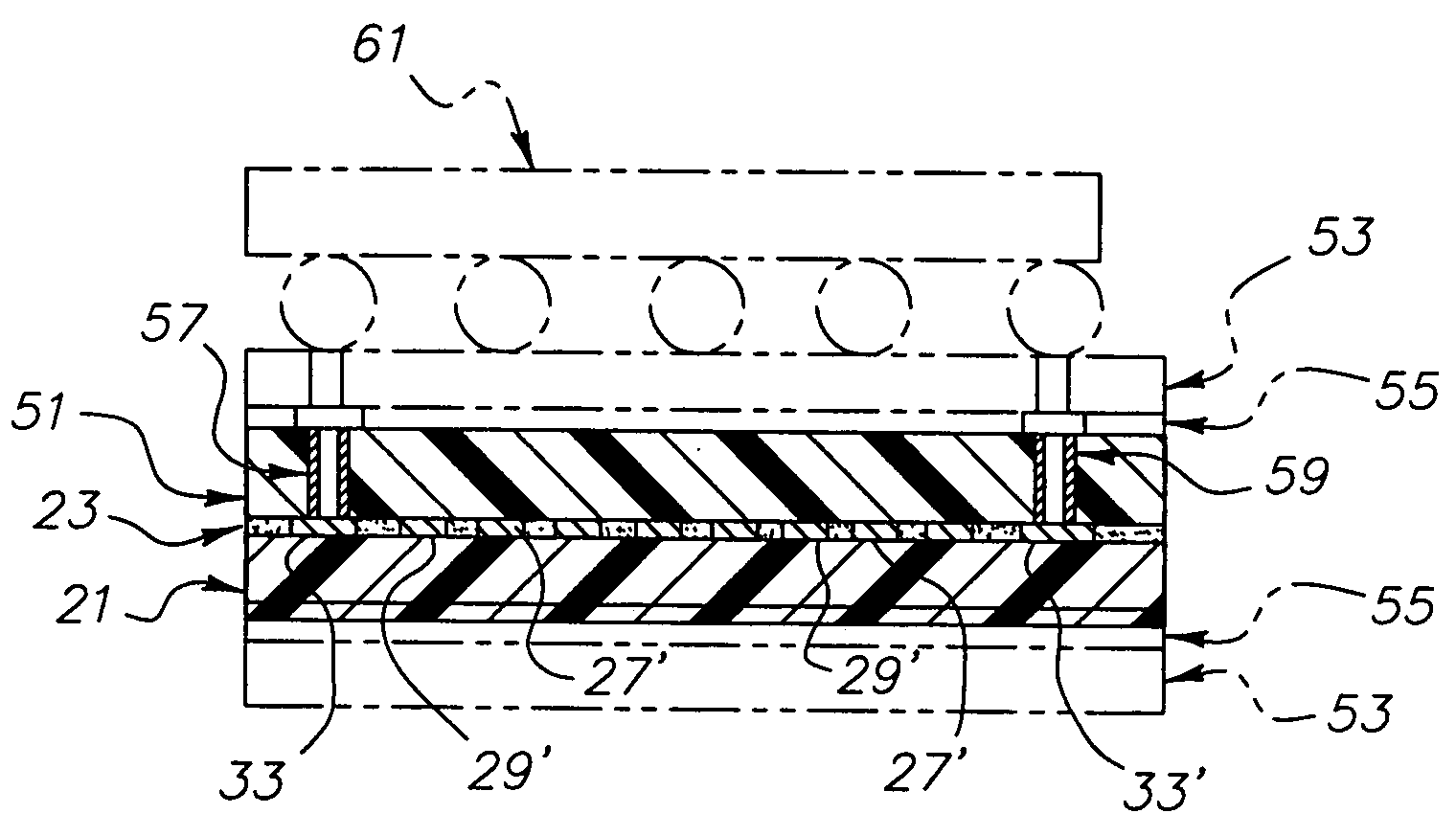

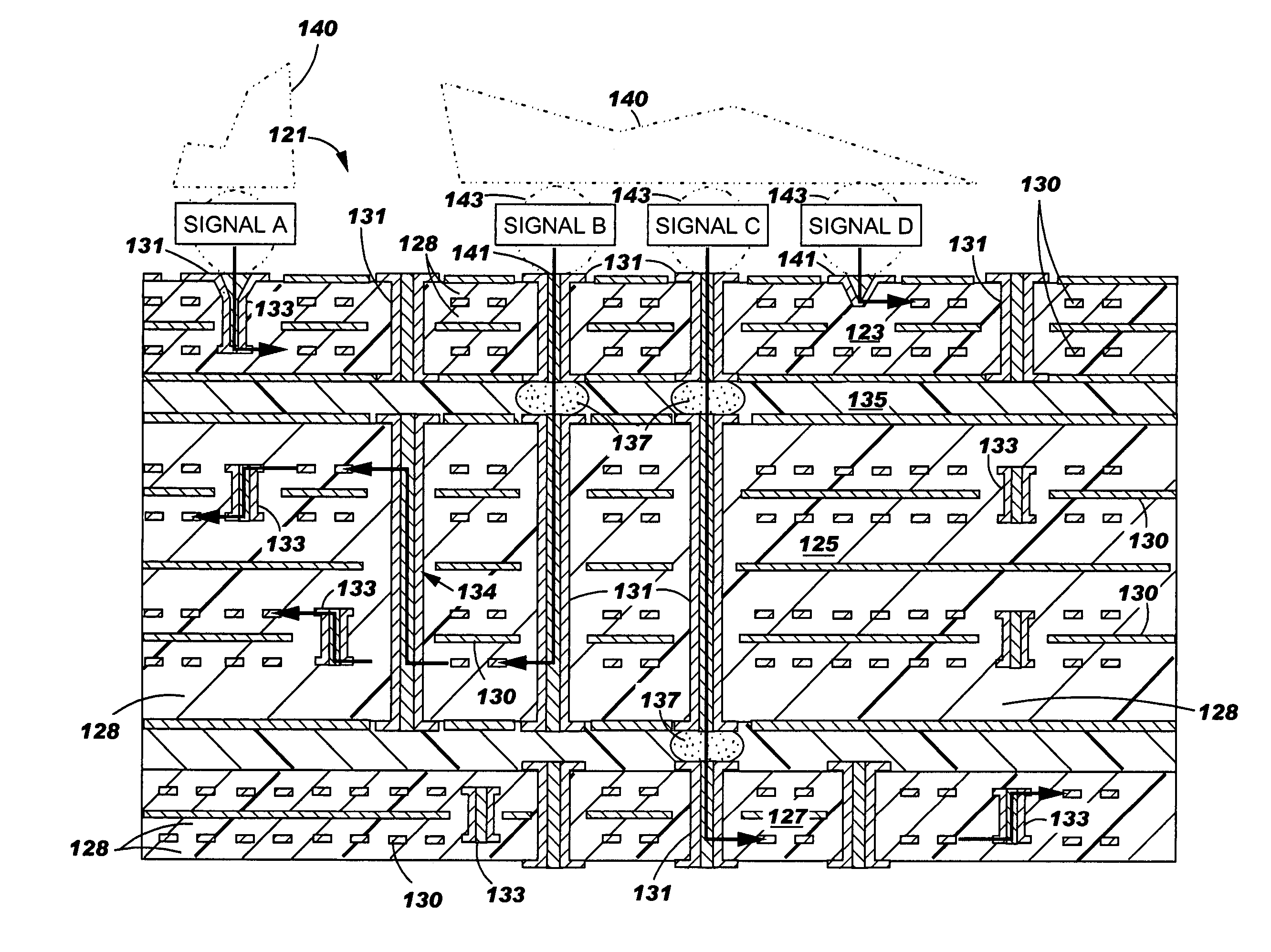

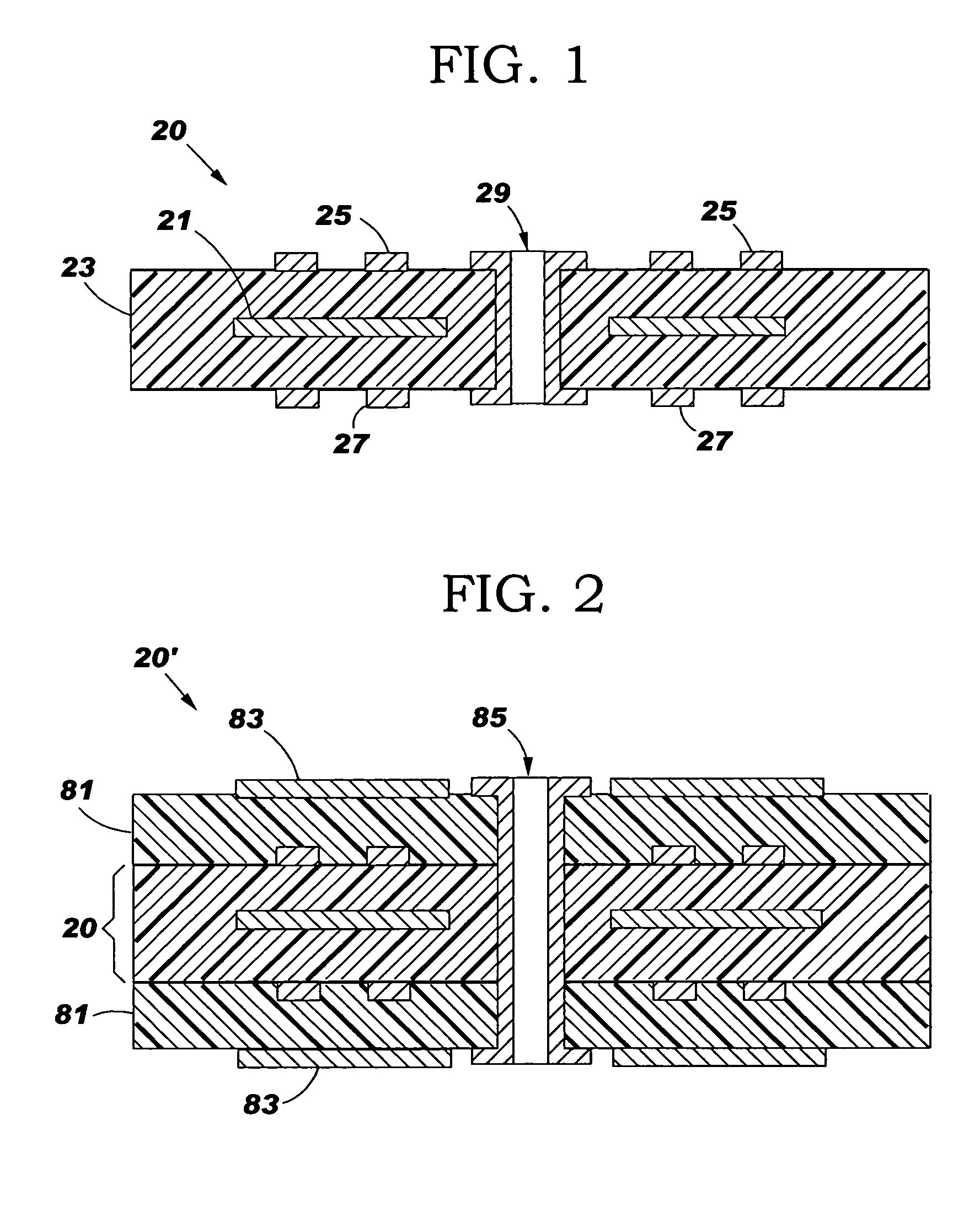

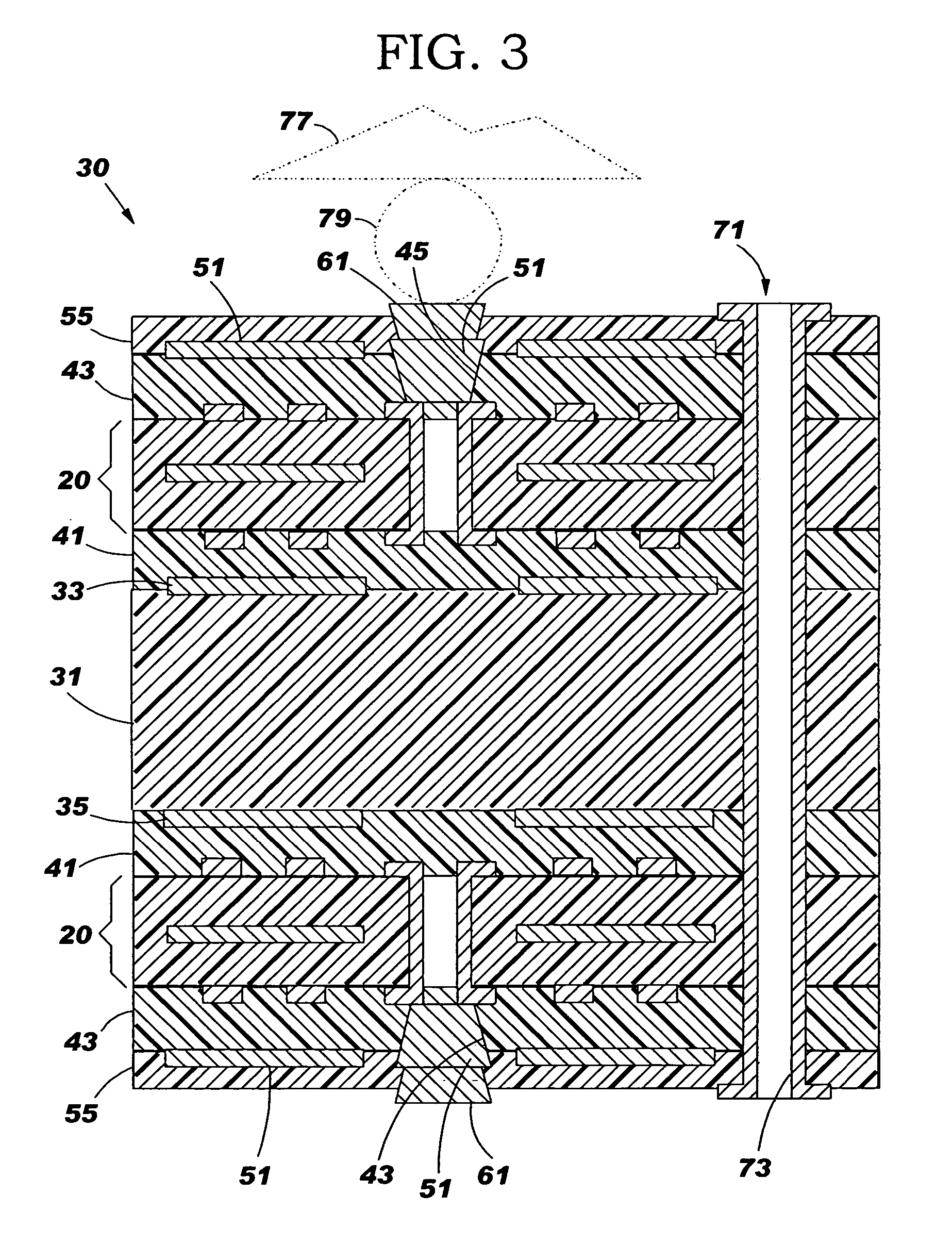

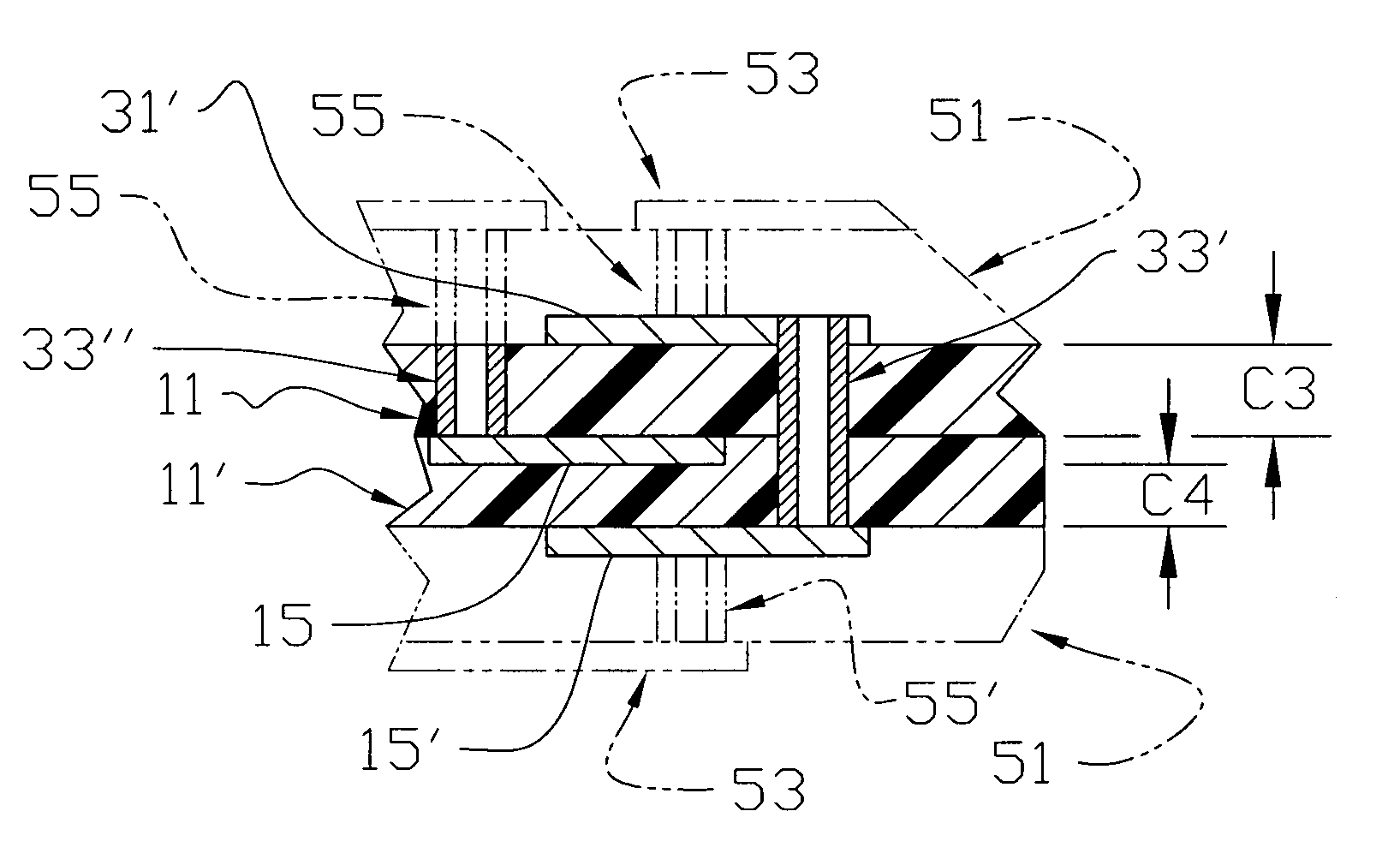

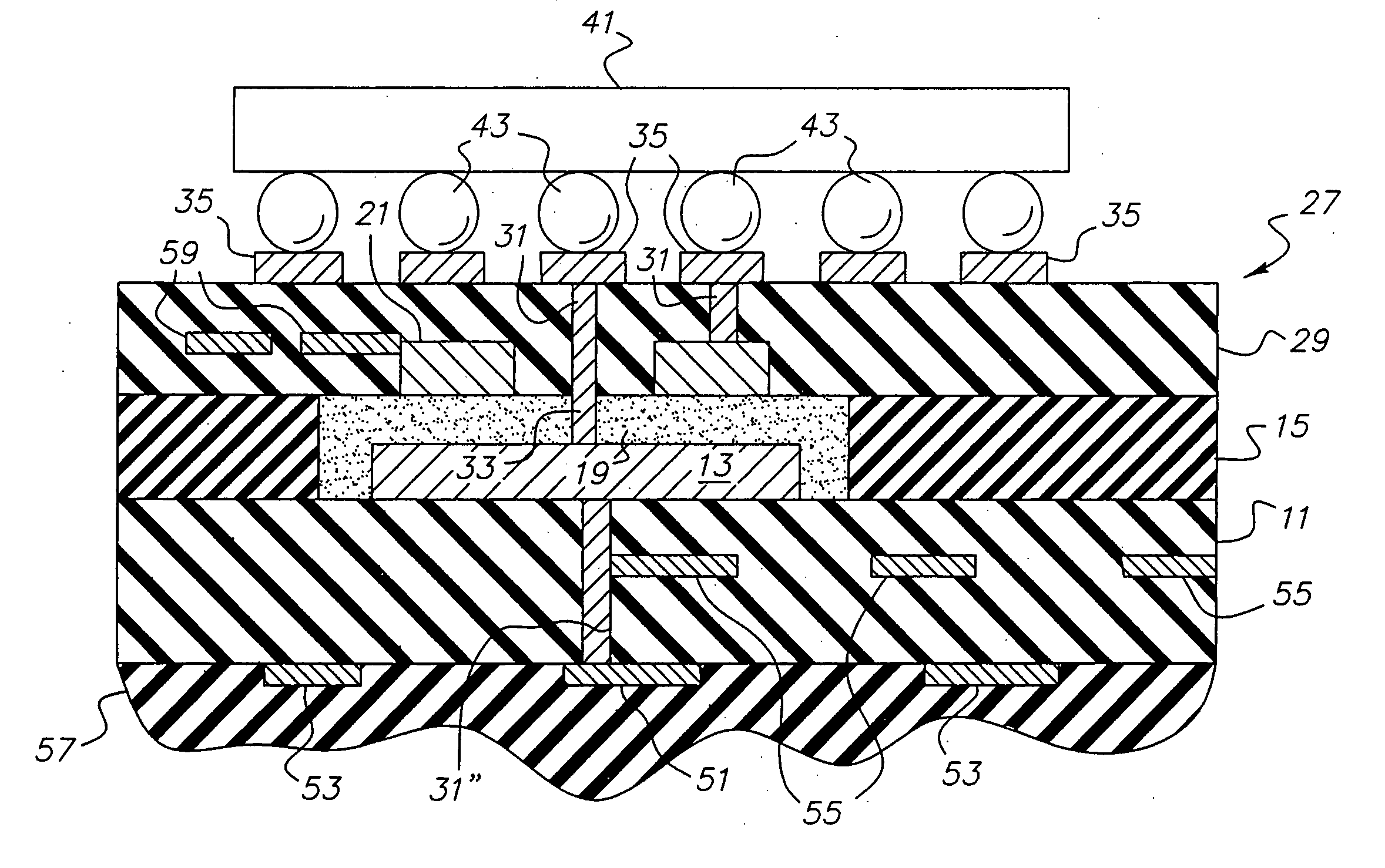

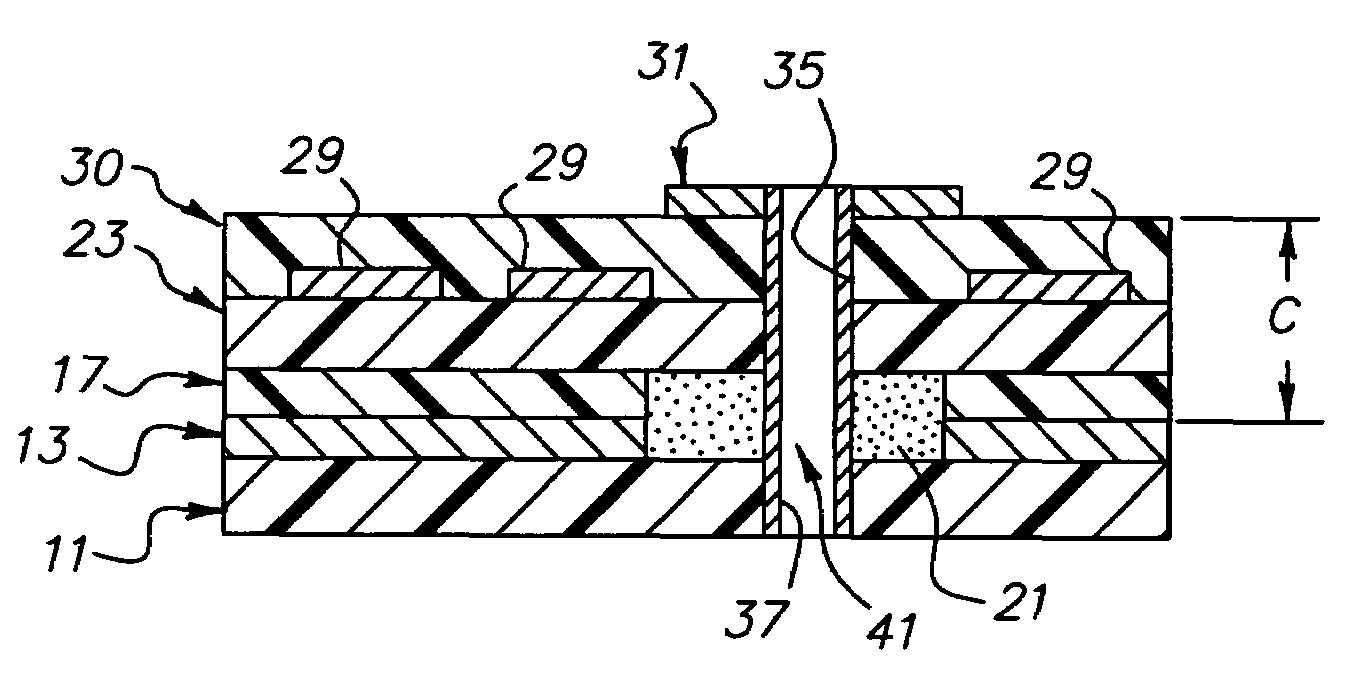

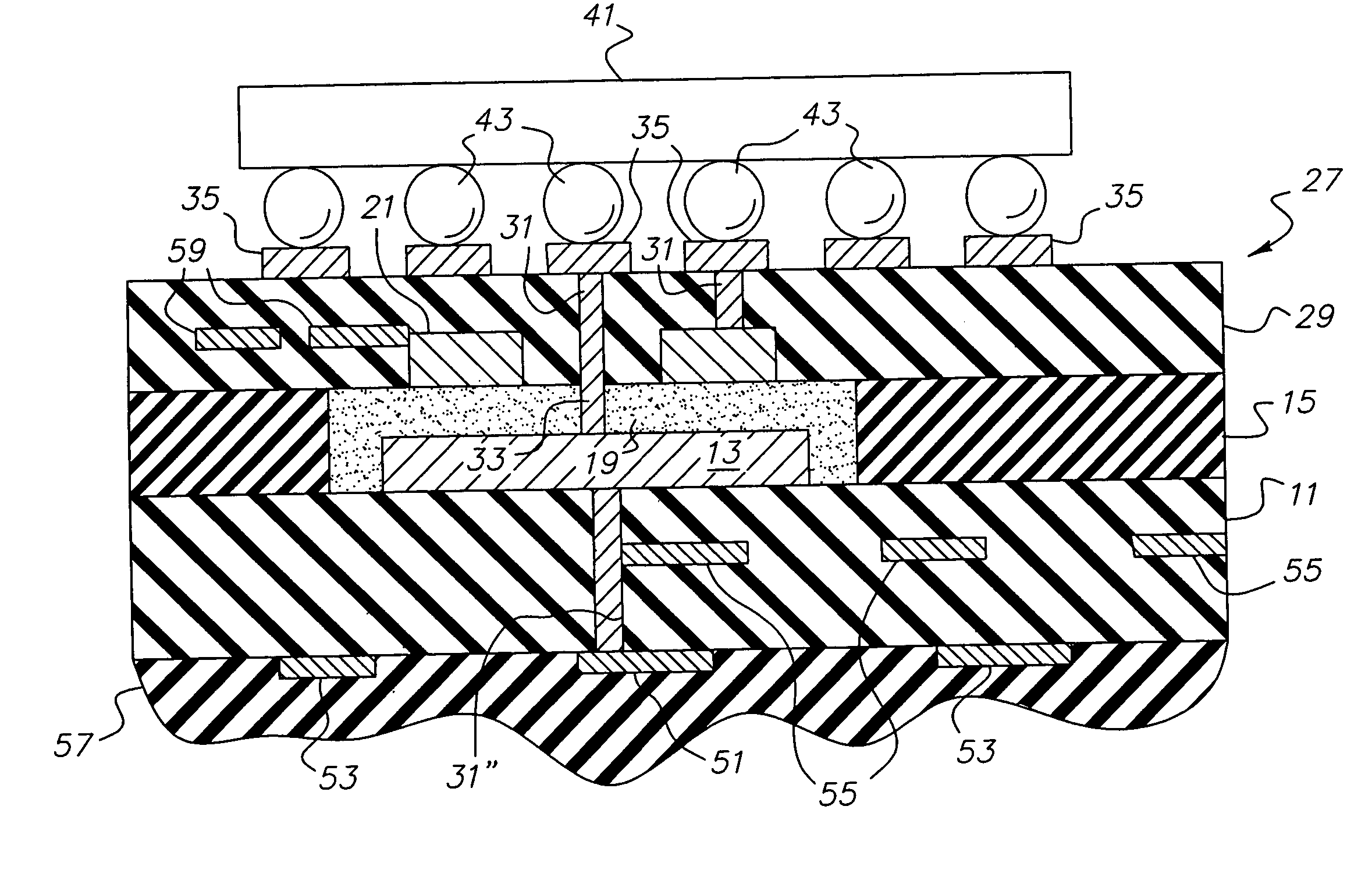

A circuitized substrate including a plurality of conductive and dielectric layers and also a plurality of conductive thru-holes therein for passing high speed signals, e.g., from one component to another mounted on the substrate. The substrate utilizes a signal routing pattern which uses the maximum length of each of the thru-holes wherever possible to thereby substantially eliminate signal loss (noise) due to thru-hole “stub” resonance. A multilayered circuitized substrate assembly using more than one circuitized substrate, an electrical assembly using a circuitized substrate and one or more electrical components, a method of making the circuitized substrate and an information handling system incorporating one or more circuitized substrate assemblies and attached components are also provided.

Owner:TTM TECH NORTH AMERICA LLC +1

Capacitor material with metal component for use in circuitized substrates, circuitized substrate utilizing same, method of making said circuitized substrate, and information handling system utilizing said circuitized substrate

ActiveUS7025607B1Enhance circuitized substrate artEnhance the circuitized substrate artPrinted circuit aspectsSolid-state devicesNanometreInformation handling system

A material for use as part of an internal capacitor within a circuitized substrate includes a polymer resin and a quantity of nano-powders including a mixture of at least one metal component and at least one ferroelectric ceramic component, the ferroelectric ceramic component nano-particles having a particle size substantially in the range of between about 0.01 microns and about 0.9 microns and a surface within the range of from about 2.0 to about 20 square meters per gram. A circuitized substrate adapted for using such a material and capacitor therein and a method of making such a substrate are also provided. An electrical assembly (substrate and at least one electrical component) and an information handling system (e.g., personal computer) are also provided.

Owner:TTM TECH NORTH AMERICA LLC +1

Capacitor material for use in circuitized substrates, circuitized substrate utilizing same, method of making said circuitized substrate, and information handling system utilizing said circuitized substrate

InactiveUS20060151863A1Enhance circuitized substrate artEnhance the circuitized substrate artSemiconductor/solid-state device detailsPrinted circuit aspectsNanometreInformation handling system

A material for use as part of an internal capacitor within a circuitized substrate includes a polymer (e.g., a cycloaliphatic epoxy or phenoxy based) resin and a quantity of nano-powders of ferroelectric ceramic material (e.g., barium titanate) having a particle size substantially in the range of from about 0.01 microns to about 0.90 microns and a surface area for selected ones of said particles within the range of from about 2.0 to about 20 square meters per gram. A circuitized substrate adapted for using such a material and capacitor therein and a method of making such a substrate are also provided. An electrical assembly (substrate and at least one electrical component) and an information handling system (e.g., personal computer) are also provided.

Owner:TTM TECH NORTH AMERICA LLC

High speed circuitized substrate with reduced thru-hole stub, method for fabrication and information handling system utilizing same

InactiveUS20050039950A1Eliminate signal lossEnhance the circuitized substrate artCurrent interference reductionSemiconductor/solid-state device detailsEngineeringInformation handling system

A circuitized substrate including a plurality of conductive and dielectric layers and also a plurality of conductive thru-holes therein for passing high speed signals, e.g., from one component to another mounted on the substrate. The substrate utilizes a signal routing pattern which uses the maximum length of each of the thru-holes wherever possible to thereby substantially eliminate signal loss (noise) due to thru-hole “stub” resonance. A multilayered circuitized substrate assembly using more than one circuitized substrate, an electrical assembly using a circuitized substrate and one or more electrical components, a method of making the circuitized substrate and an information handling system incorporating one or more circuitized substrate assemblies and attached components are also provided.

Owner:TTM TECH NORTH AMERICA LLC +1

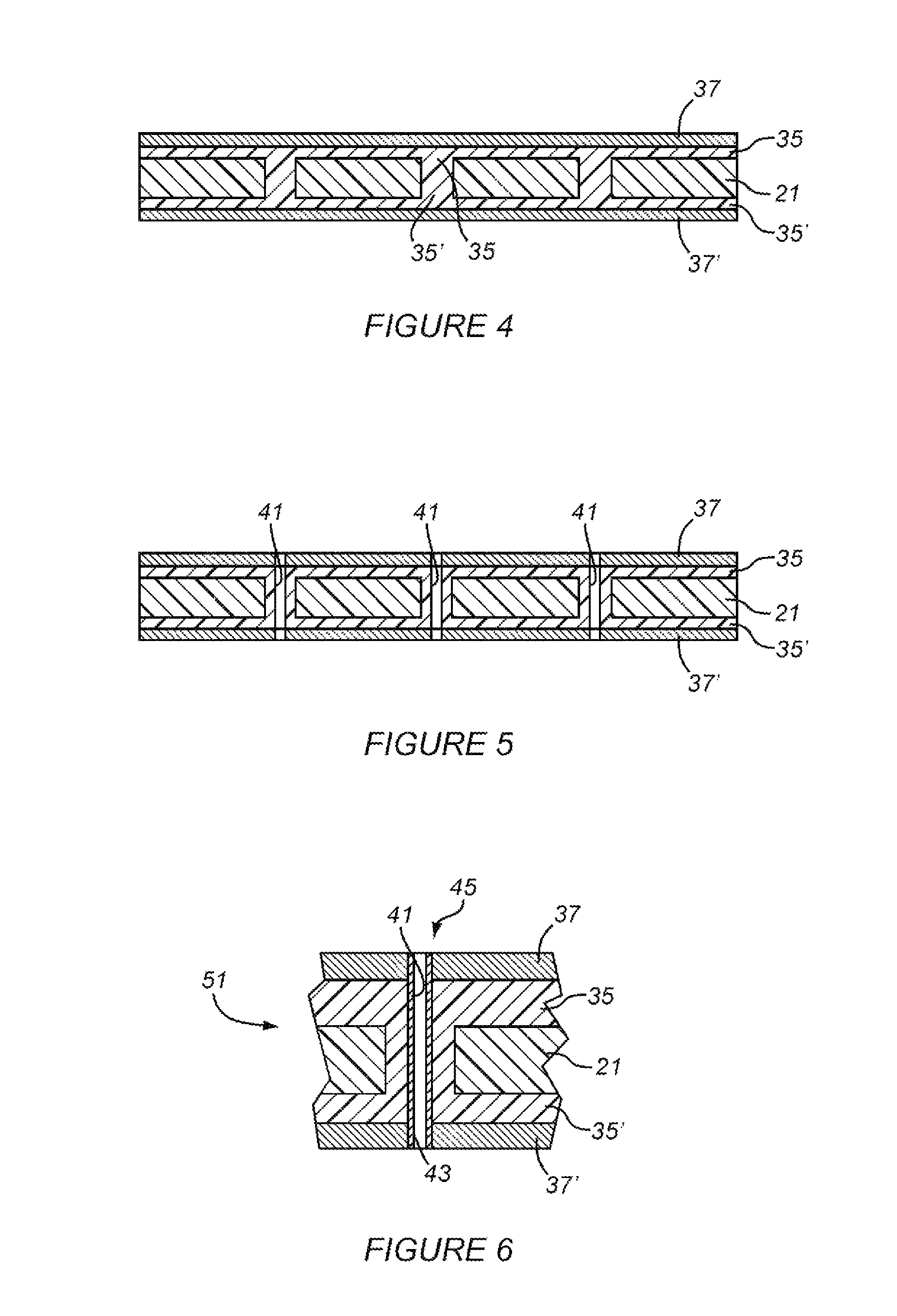

Method of making an internal capacitive substrate for use in a circuitized substrate and method of making said circuitized substrate

InactiveUS20060154434A1Enhance circuitized substrate artEnhance the circuitized substrate artPrinted circuit aspectsSemiconductor/solid-state device manufacturingDielectricCapacitance

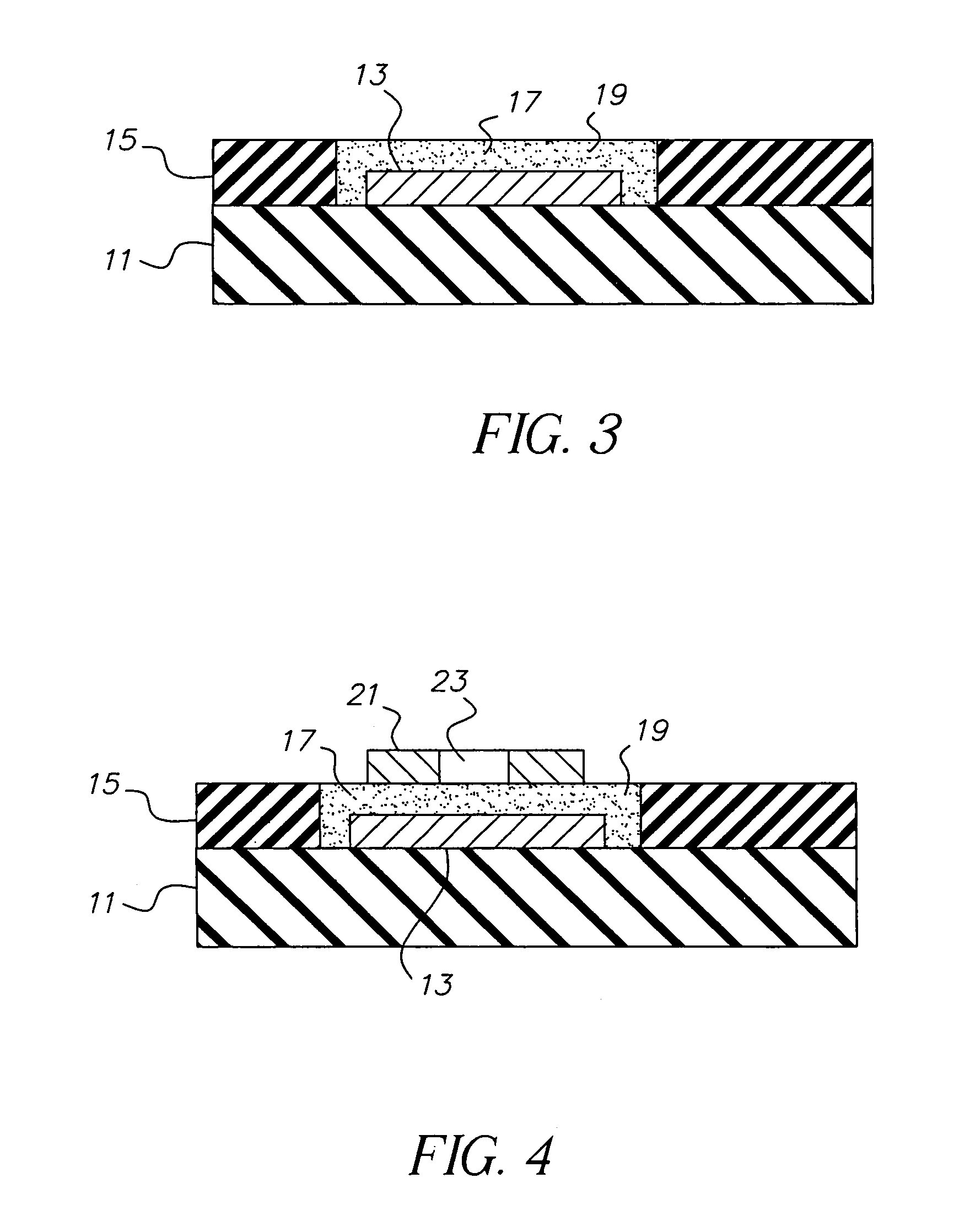

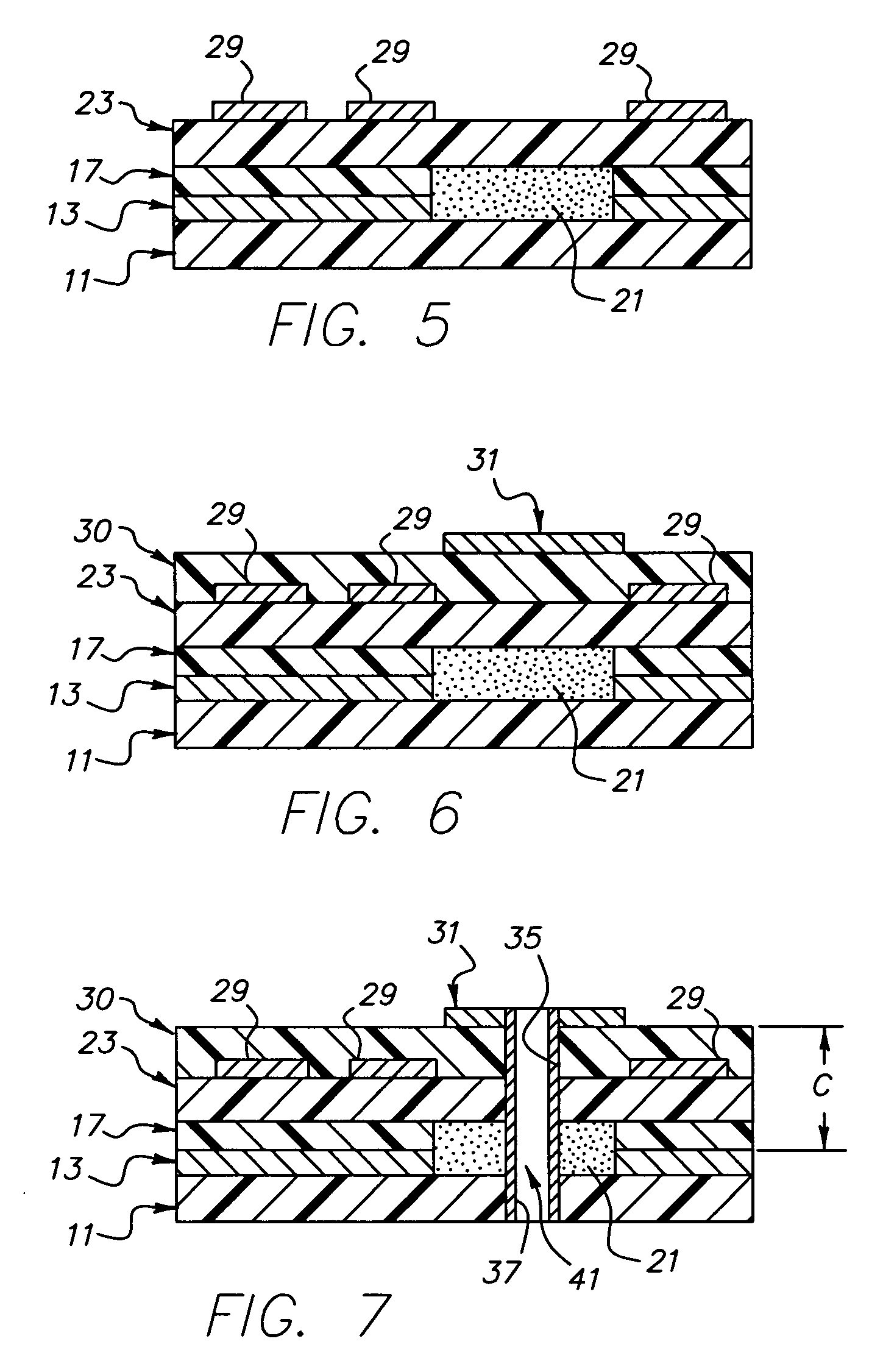

A method of forming a capacitive substrate in which first and second conductors are formed opposite a dielectric, with one of these electrically coupled to a thru-hole connection. Each functions as an electrode for the resulting capacitor. The substrate is then adapted for being incorporated within a larger structure to form a circuitized substrate such as a printed circuit board or a chip carrier. Additional capacitors are also possible.

Owner:TTM TECH NORTH AMERICA LLC

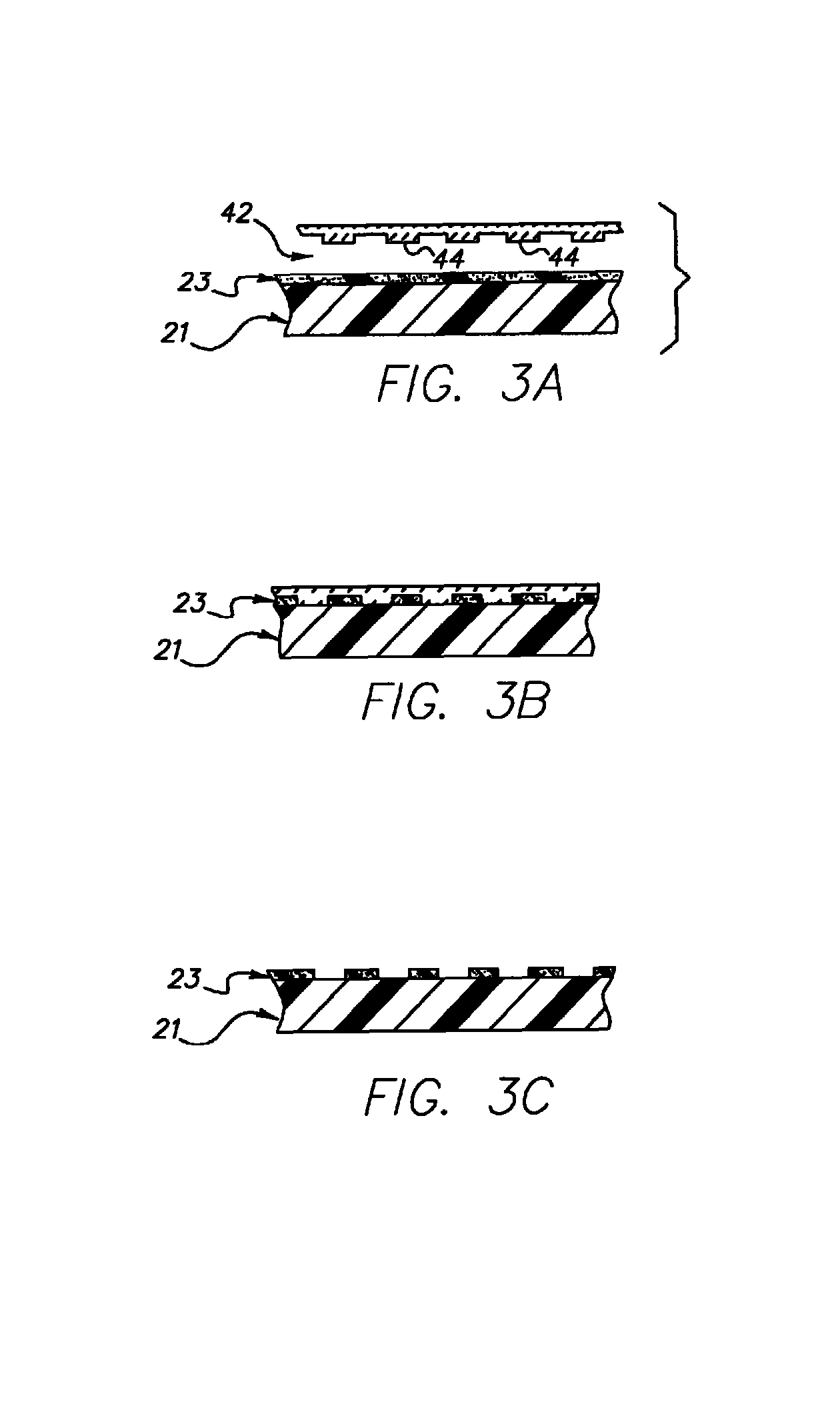

Method of making a capacitive substrate for use as part of a larger circuitized substrate, method of making said circuitized substrate and method of making an information handling system including said circuitized substrate

InactiveUS20070010065A1Enhance the circuitized substrate artLow costPrinted circuit aspectsSemiconductor/solid-state device manufacturingCapacitanceElectrical conductor

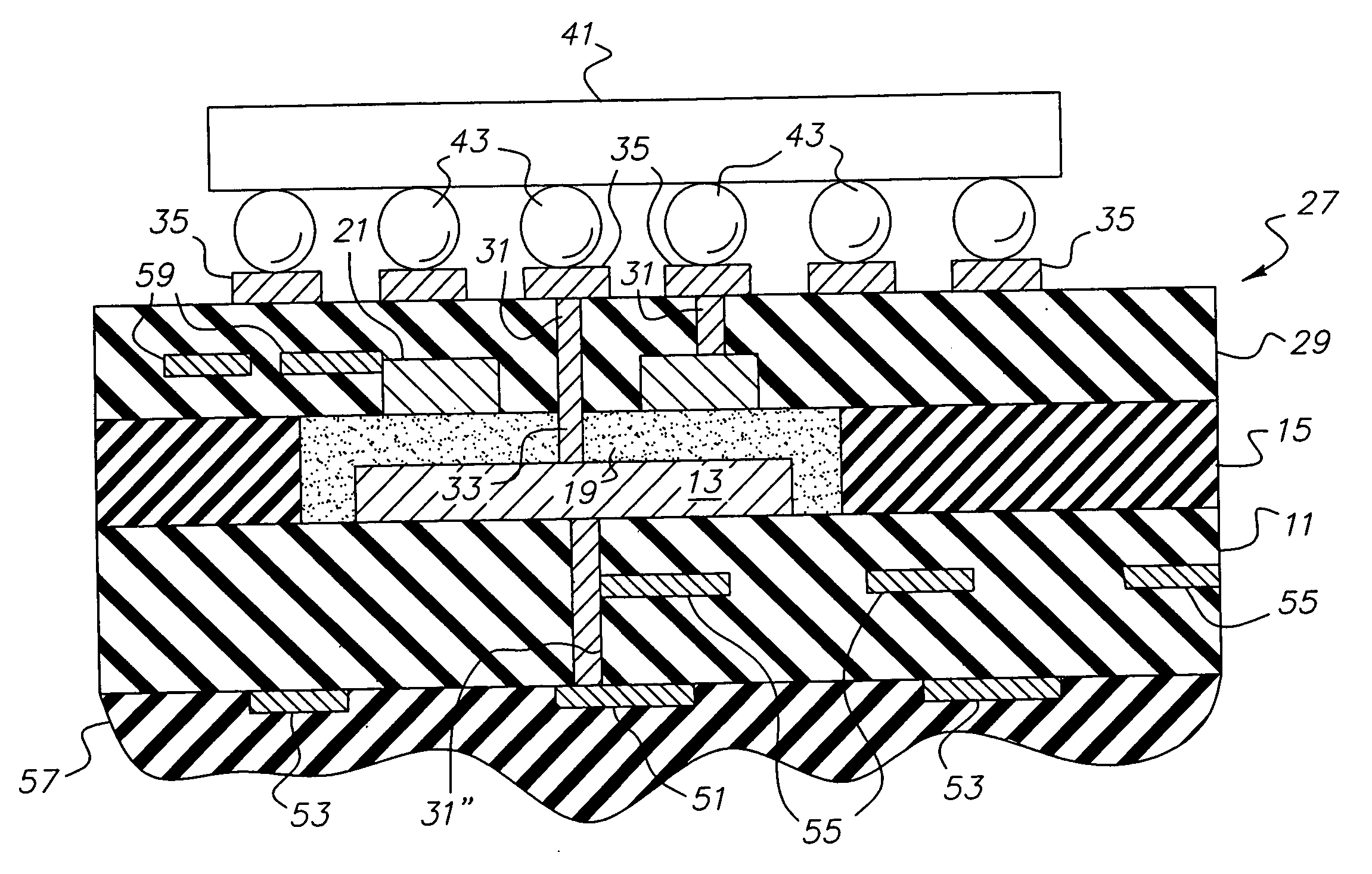

A method of forming a capacitive substrate in which at least one capacitive dielectric layer of material is screen or ink jet printed onto a conductor and the substrate is thereafter processed further, including the addition of thru-holes to couple selected elements within the substrate to form at least two capacitors as internal elements of the substrate. The capacitive substrate may be incorporated within a larger circuitized substrate, e.g., to form an electrical assembly. A method of making an information handling system including such substrates is also provided.

Owner:TTM TECH NORTH AMERICA LLC

Circuitized substrate with internal resistor, method of making said circuitized substrate, and electrical assembly utilizing said circuitized substrate

InactiveUS20080087459A1Reduce capacitanceImprove the immunityPrinted resistor incorporationConductive pattern formationNanometreCapacitance

A circuitized substrate which utilizes at least one internal (embedded) resistor as part thereof, the resistor comprised of a material including resin and a quantity of powders of nano-particle and / or micro-particle sizes. The resistor serves to decrease the capacitance in the formed circuit while only slightly increasing the high frequency resistance, thereby improving circuit performance through the substantial elimination of some discontinuities known to exist in structures like these. An electrical assembly (substrate and at least one electrical component) is also provided.

Owner:TTM TECH NORTH AMERICA LLC +1

Capacitive substrate and method of making same

InactiveUS20070275525A1Enhance circuitized substrate artEnhance the circuitized substrate artSemiconductor/solid-state device detailsSolid-state devicesDielectricCapacitance

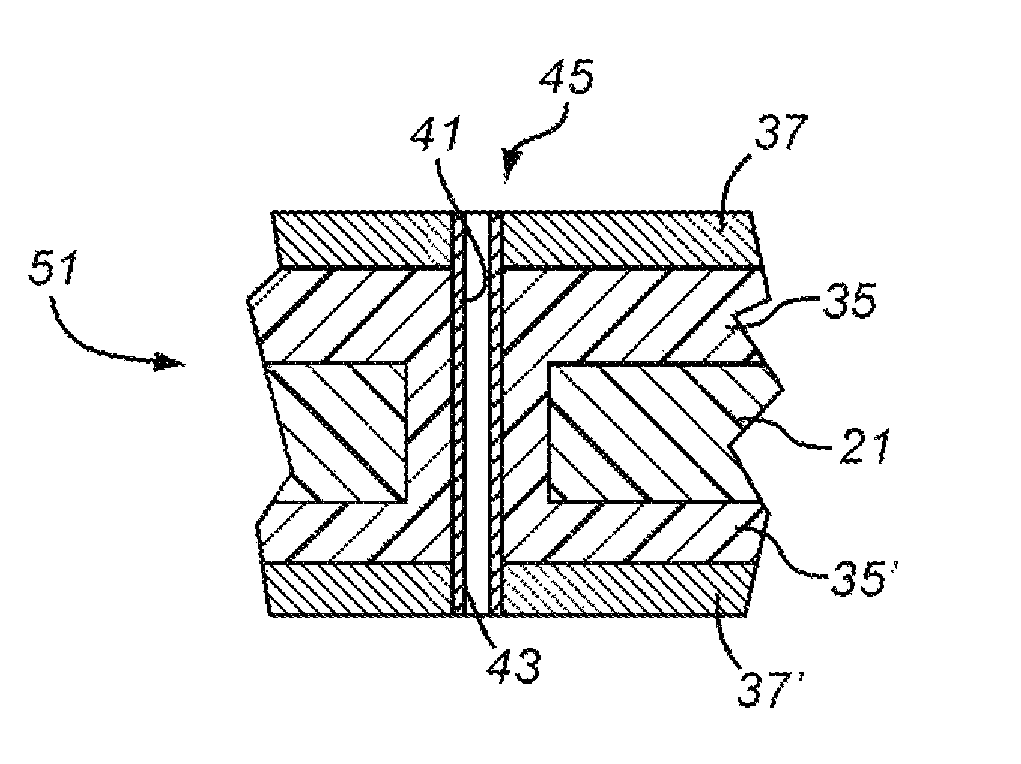

A capacitive substrate and method of making same in which first and second glass layers are used. A first conductor is formed on a first of the glass layers and a capacitive dielectric material is positioned over the conductor. The second conductor is then positioned on the capacitive dielectric and the second glass layer positioned over the second conductor. Conductive thru-holes are formed to couple to the first and second conductors, respectively, such that the conductors and capacitive dielectric material form a capacitor when the capacitive substrate is in operation.

Owner:TTM TECH NORTH AMERICA LLC

Method of making a capacitive substrate using photoimageable dielectric for use as part of a larger circuitized substrate, method of making said circuitized substrate and method of making an information handling system including said circuitized substrate

InactiveUS20070010064A1Enhance artEnhance the circuitized substrate artPrinted circuit aspectsSemiconductor/solid-state device manufacturingCapacitanceEngineering

A method of forming a capacitive substrate in which at least one capacitive dielectric layer of material is screen or ink jet printed onto a conductor and the substrate is thereafter processed further, including the addition of thru-holes to couple selected elements within the substrate to form at least two capacitors as internal elements of the substrate. Photoimageable material is used to facilitate positioning of the capacitive dielectric being printed. The capacitive substrate may be incorporated within a larger circuitized substrate, e.g., to form an electrical assembly. A method of making an information handling system including such substrates is also provided.

Owner:I3 ELECTRONICS

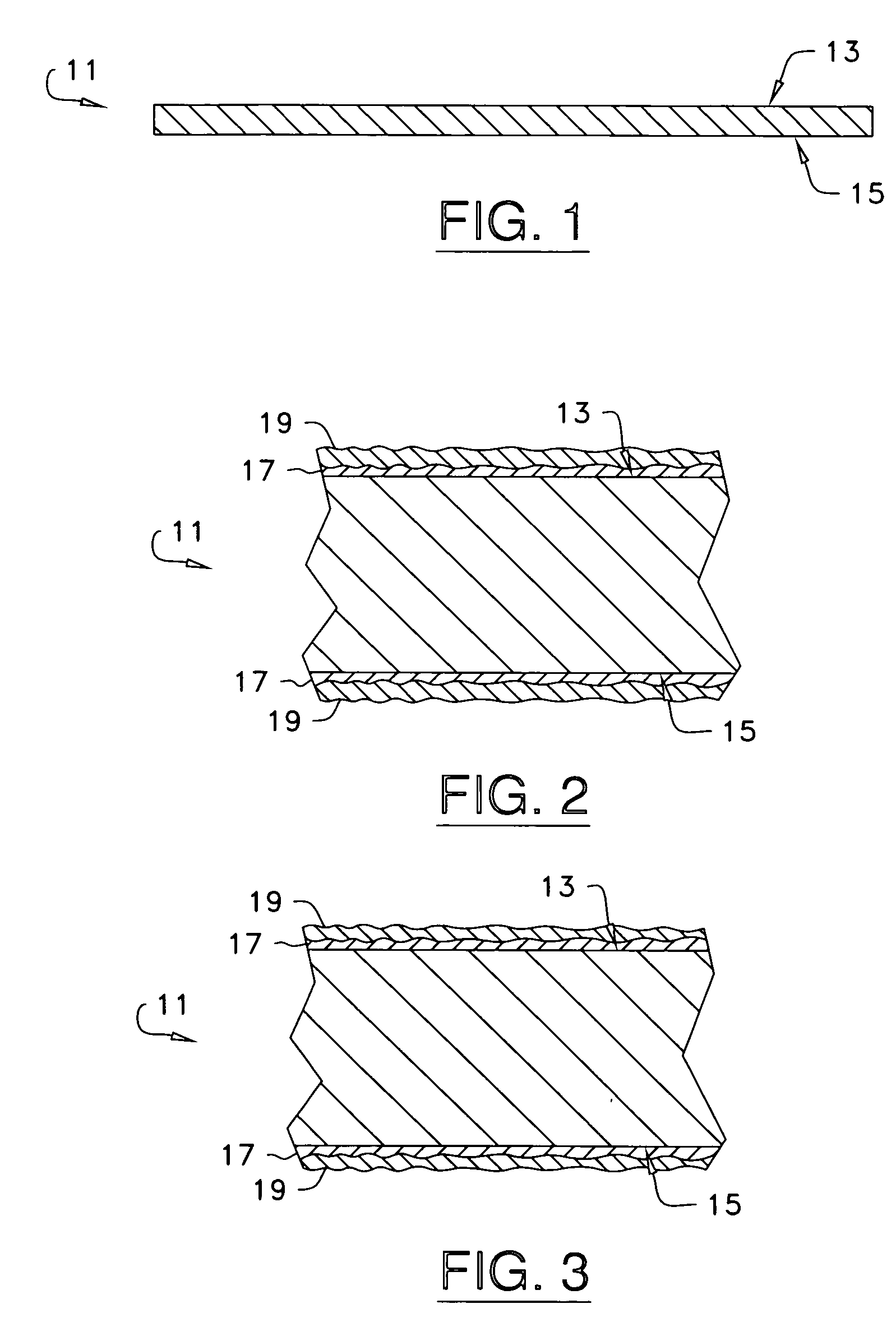

Circuitized substrates utilizing three smooth-sided conductive layers as part thereof, method of making same, and electrical assemblies and information handling systems utilizing same

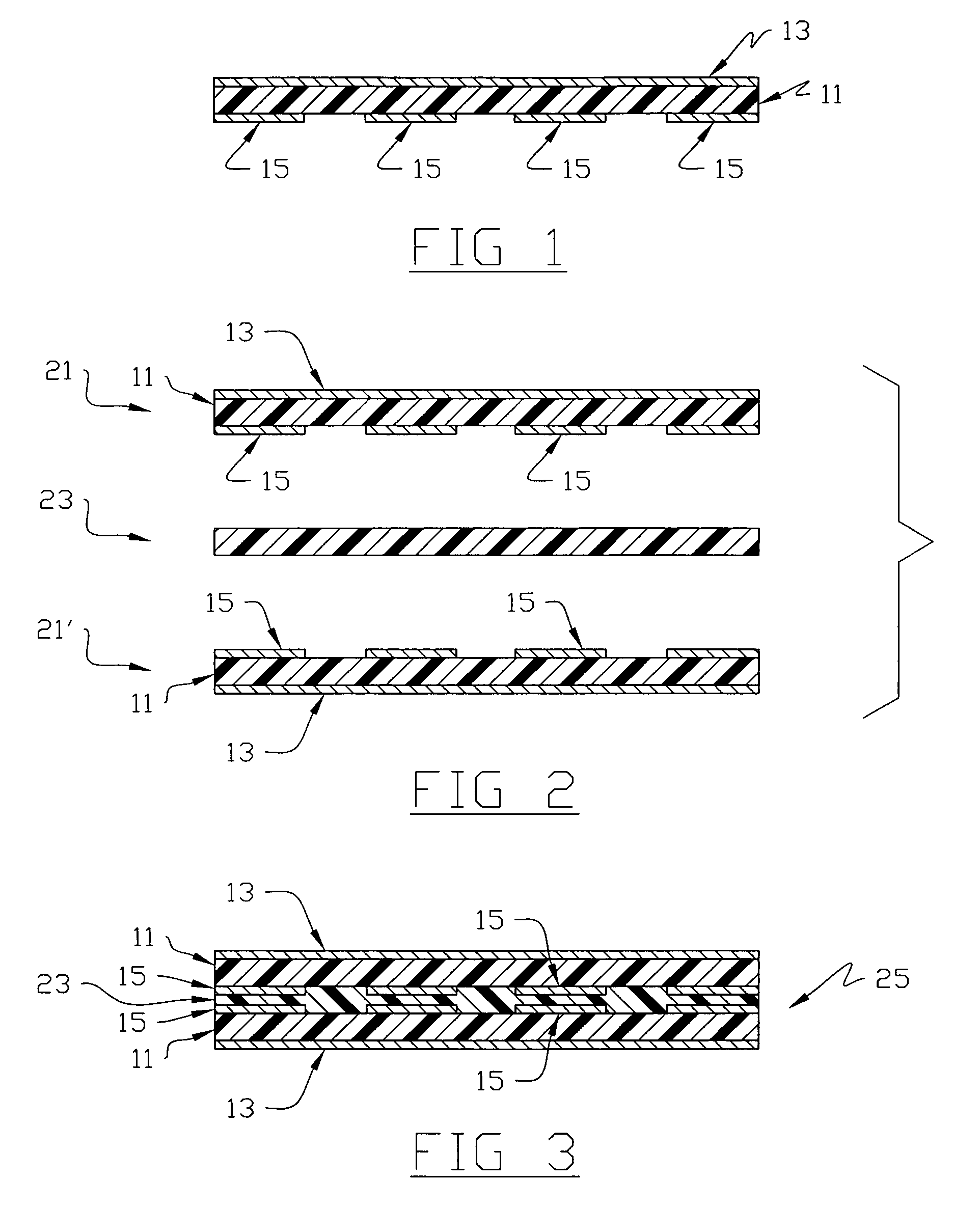

InactiveUS6964884B1Enhance the circuitized substrate artLow costInsulating substrate metal adhesion improvementPrinted circuit aspectsChemical treatmentOrganic layer

A circuitized substrate in which three conductive layers (e.g., electroplated copper foil) are bonded (e.g., laminated) to two dielectric layers. Each of the foil surfaces which physically bond to a respective dielectric layer are smooth (e.g., preferably by chemical processing) and may include a thin, organic layer thereon. One of the conductive layers may function as a ground or voltage (power) plane while the other two may function as signal planes with a plurality of individual signal lines as part thereof. An electrical assembly and an information handling system utilizing such a circuitized substrate are also provided, as is a method of making the substrate.

Owner:I3 ELECTRONICS +1

Circuitized substrate utilizing three smooth-sided conductive layers as part thereof and electrical assemblies and information handling systems utilizing same

InactiveUS20060180343A1Enhance the circuitized substrate artLow costInsulating substrate metal adhesion improvementSemiconductor/solid-state device detailsChemical treatmentInformation processing

A circuitized substrate in which three conductive layers (e.g., electroplated copper foil) are bonded (e.g., laminated) to two dielectric layers. Each of the foil surfaces which physically bond to a respective dielectric layer are smooth (e.g., preferably by chemical processing) and may include a thin, organic layer thereon. One of the conductive layers may function as a ground or voltage (power) plane while the other two may function as signal planes with a plurality of individual signal lines as part thereof. An electrical assembly and an information handling system utilizing such a circuitized substrate are also provided, as is a method of making the substrate.

Owner:I3 ELECTRONICS

Apparatus and method for making circuitized substrates in a continuous manner

InactiveUS7293355B2Enhance the circuitized substrate artPrinted circuit assemblingPrinted circuit aspectsElectrical conductorEngineering

Owner:I3 ELECTRONICS

Method of making an internal capacitive substrate for use in a circuitized substrate and method of making said circuitized substrate

InactiveUS7384856B2Enhance the circuitized substrate artLow costPrinted circuit aspectsSemiconductor/solid-state device manufacturingCapacitanceDielectric

Owner:TTM TECH NORTH AMERICA LLC

Method of making a capacitive substrate using photoimageable dielectric for use as part of a larger circuitized substrate, method of making said circuitized substrate and method of making an information handling system including said circuitized substrate

InactiveUS7429510B2Enhance the circuitized substrate artLow costPrinted circuit aspectsSemiconductor/solid-state device manufacturingCapacitanceElectrical conductor

A method of forming a capacitive substrate in which at least one capacitive dielectric layer of material is screen or ink jet printed onto a conductor and the substrate is thereafter processed further, including the addition of thru-holes to couple selected elements within the substrate to form at least two capacitors as internal elements of the substrate. Photoimageable material is used to facilitate positioning of the capacitive dielectric being printed. The capacitive substrate may be incorporated within a larger circuitized substrate, e.g., to form an electrical assembly. A method of making an information handling system including such substrates is also provided.

Owner:I3 ELECTRONICS

Capacitor material with metal component for use in circuitized substrates, circuitized substrate utilizing same, method of making said circuitized substrate, and information handling system utilizing said circuitized substrate

InactiveUS20060154501A1Enhance the circuitized substrate artLow costPrinted circuit aspectsSolid-state devicesInformation processingPolymer resin

A material for use as part of an internal capacitor within a circuitized substrate includes a polymer resin and a quantity of nano-powders including a mixture of at least one metal component and at least one ferroelectric ceramic component, the ferroelectric ceramic component nano-particles having a particle size substantially in the range of between about 0.01 microns and about 0.9 microns and a surface within the range of from about 2.0 to about 20 square meters per gram. A circuitized substrate adapted for using such a material and capacitor therein and a method of making such a substrate are also provided. An electrical, assembly (substrate and at least one electrical component) and an information handling system (e.g., personal computer) are also provided.

Owner:I3 ELECTRONICS

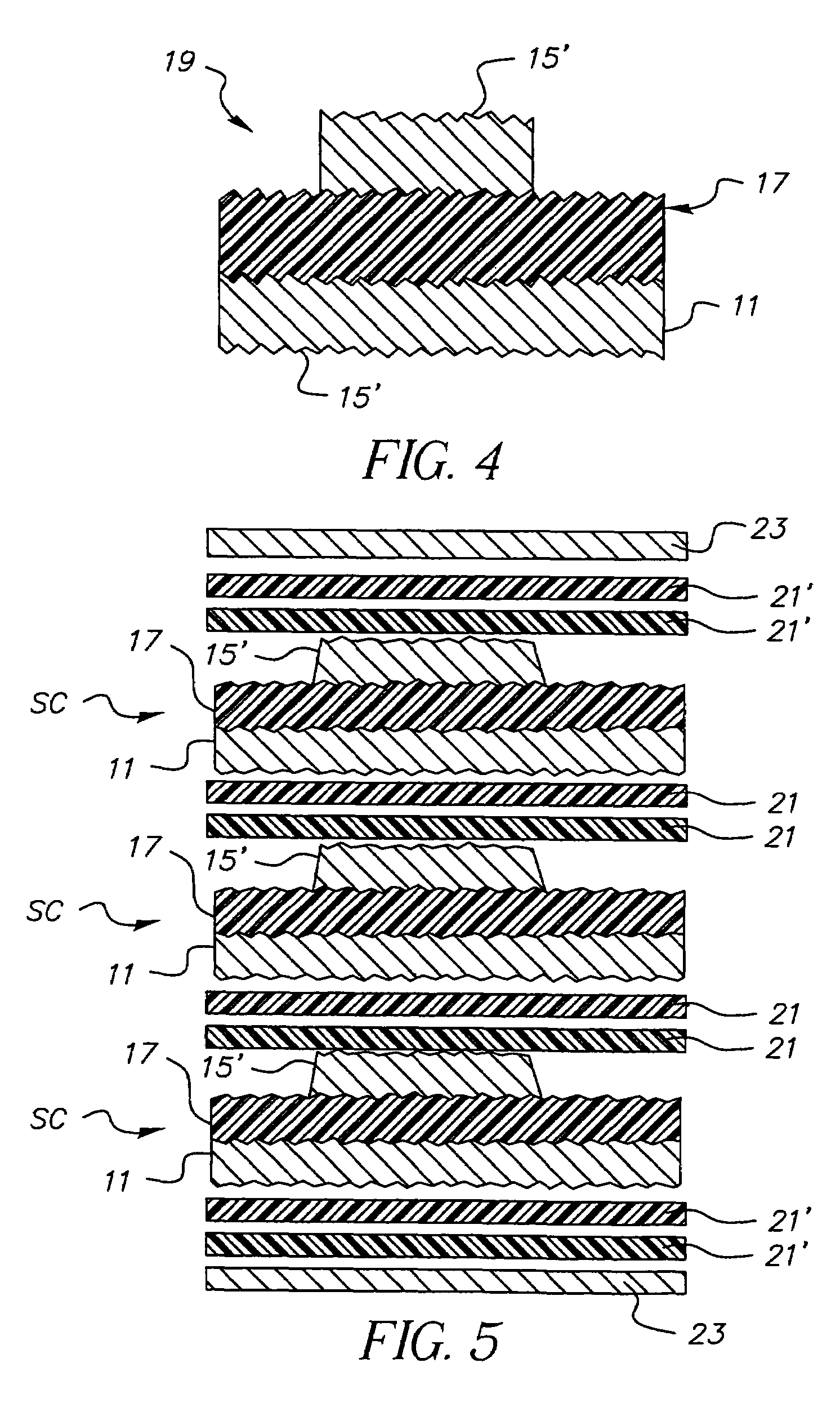

Power core for use in circuitized substrate and method of making same

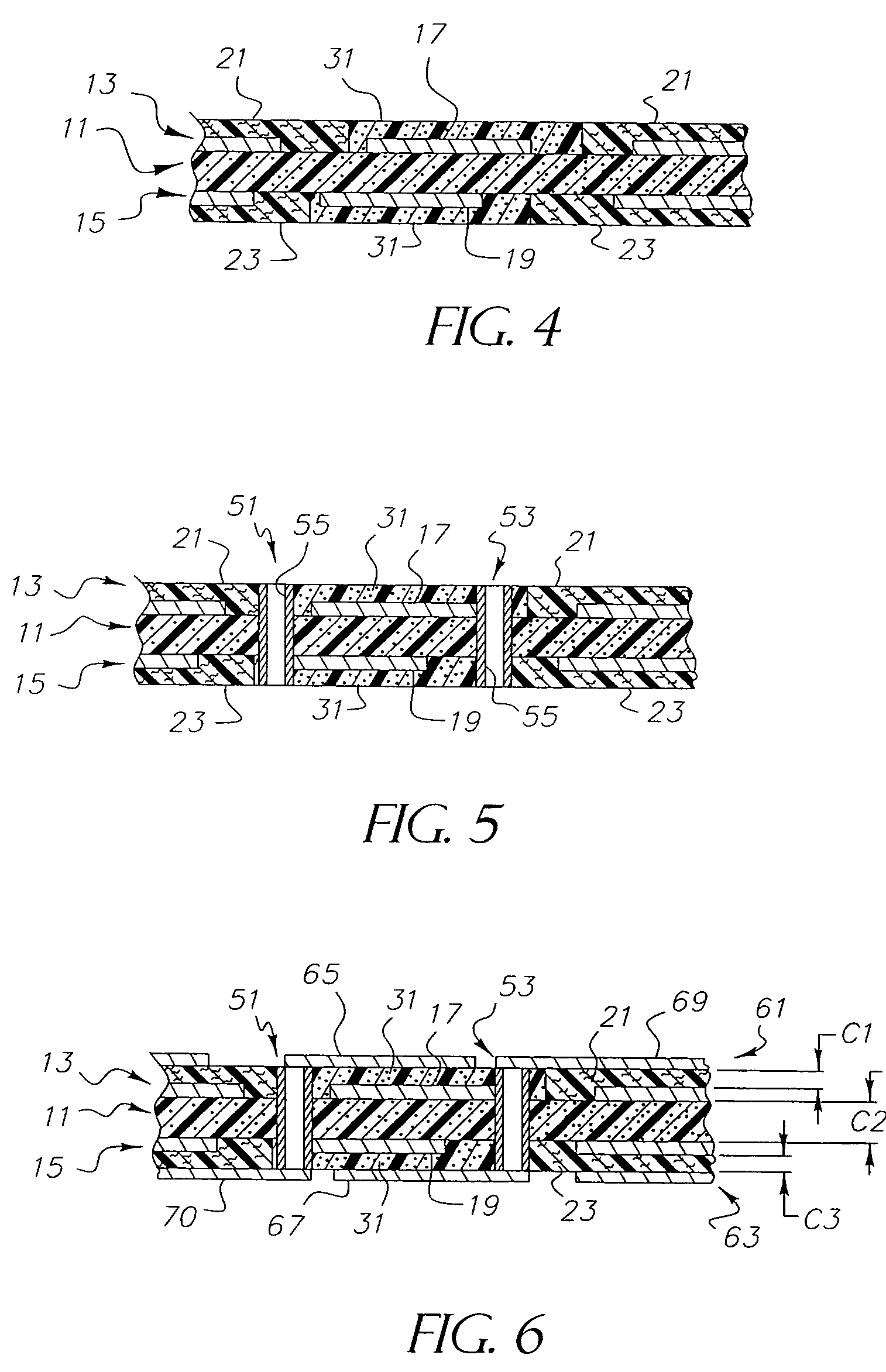

ActiveUS20110284273A1Enhance the circuitized substrate artLow costLine/current collector detailsPrinted circuit aspectsGlass fiberEngineering

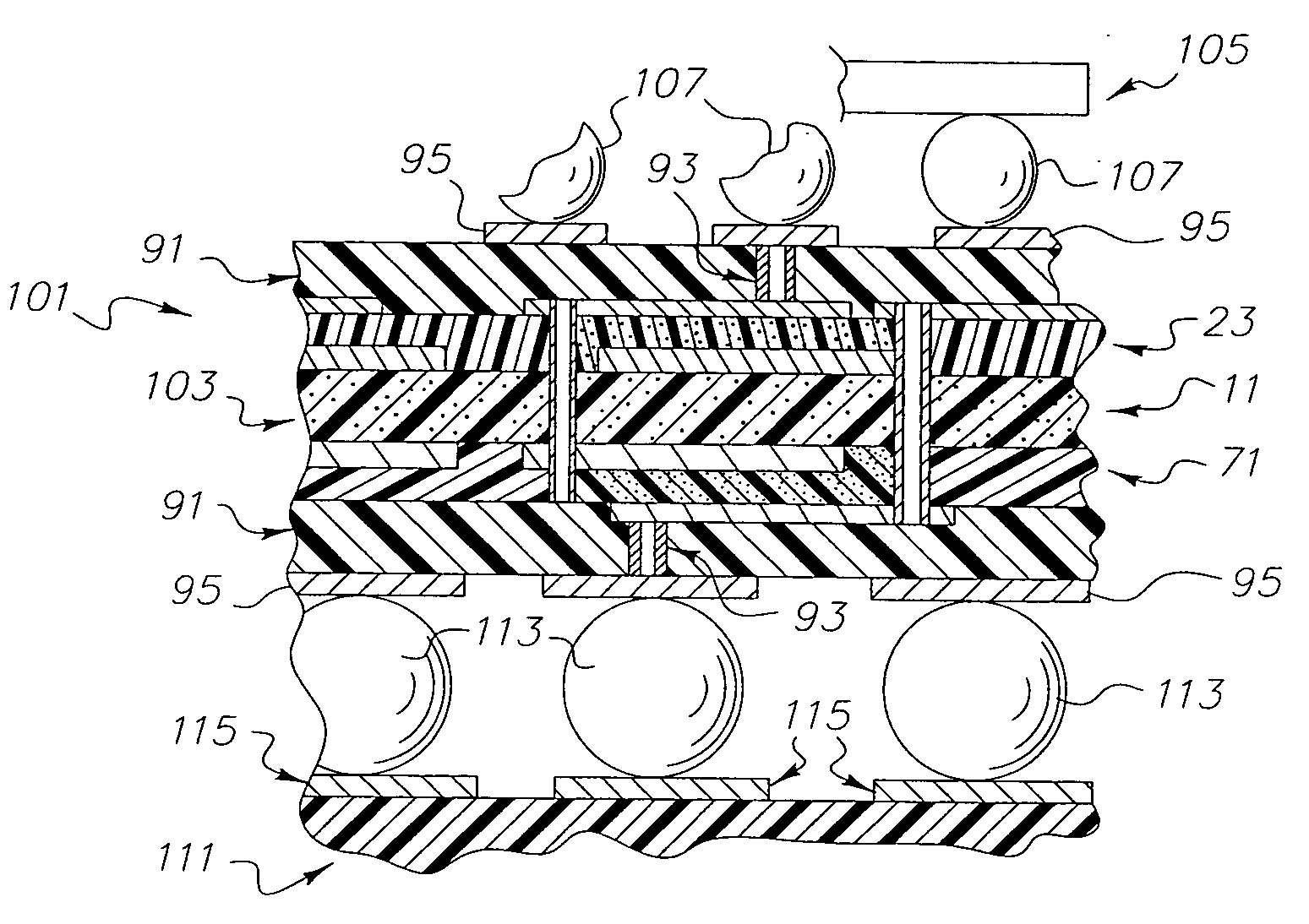

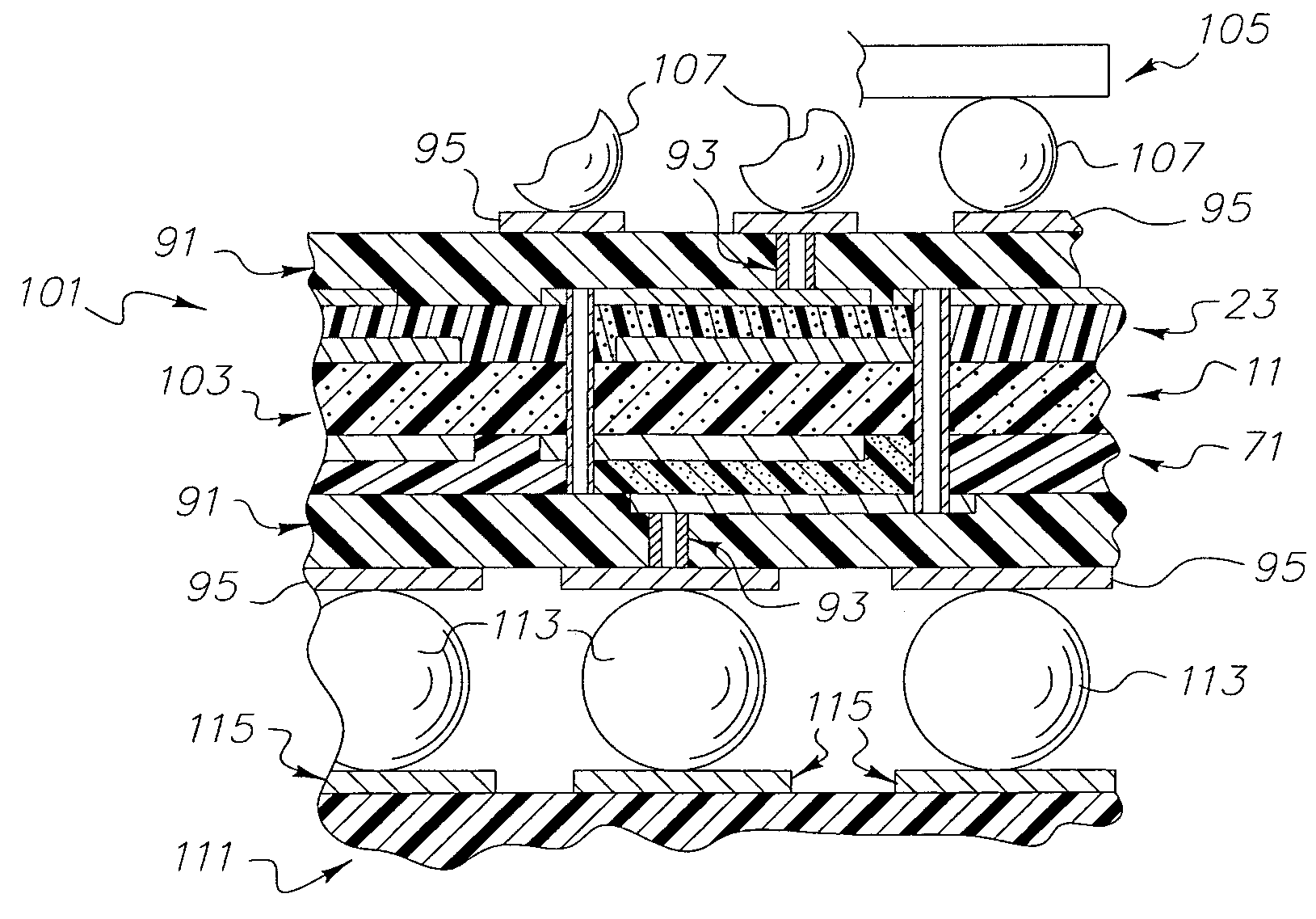

A power core adapted for use as part of a circuitized substrate, e.g., a PCB or LCC. The core includes a first layer of low expansion dielectric and two added layers of a different low expansion dielectric bonded thereto, with two conductive layers positioned on the two added low expansion dielectric layers. At least one of the conductive layers serves as a power plane for the power core, which in turn is usable within a circuitized substrate, also provided. Methods of making the power core and circuitized substrate are also provided. The use of different low expansion dielectric materials for the power core enables the use of support enhancing fiberglass in one layer while such use is precluded in the other two dielectric layers, thus preventing CAF shorting problems in highly precisely defined thru holes formed within the power core.

Owner:TTM TECH NORTH AMERICA LLC

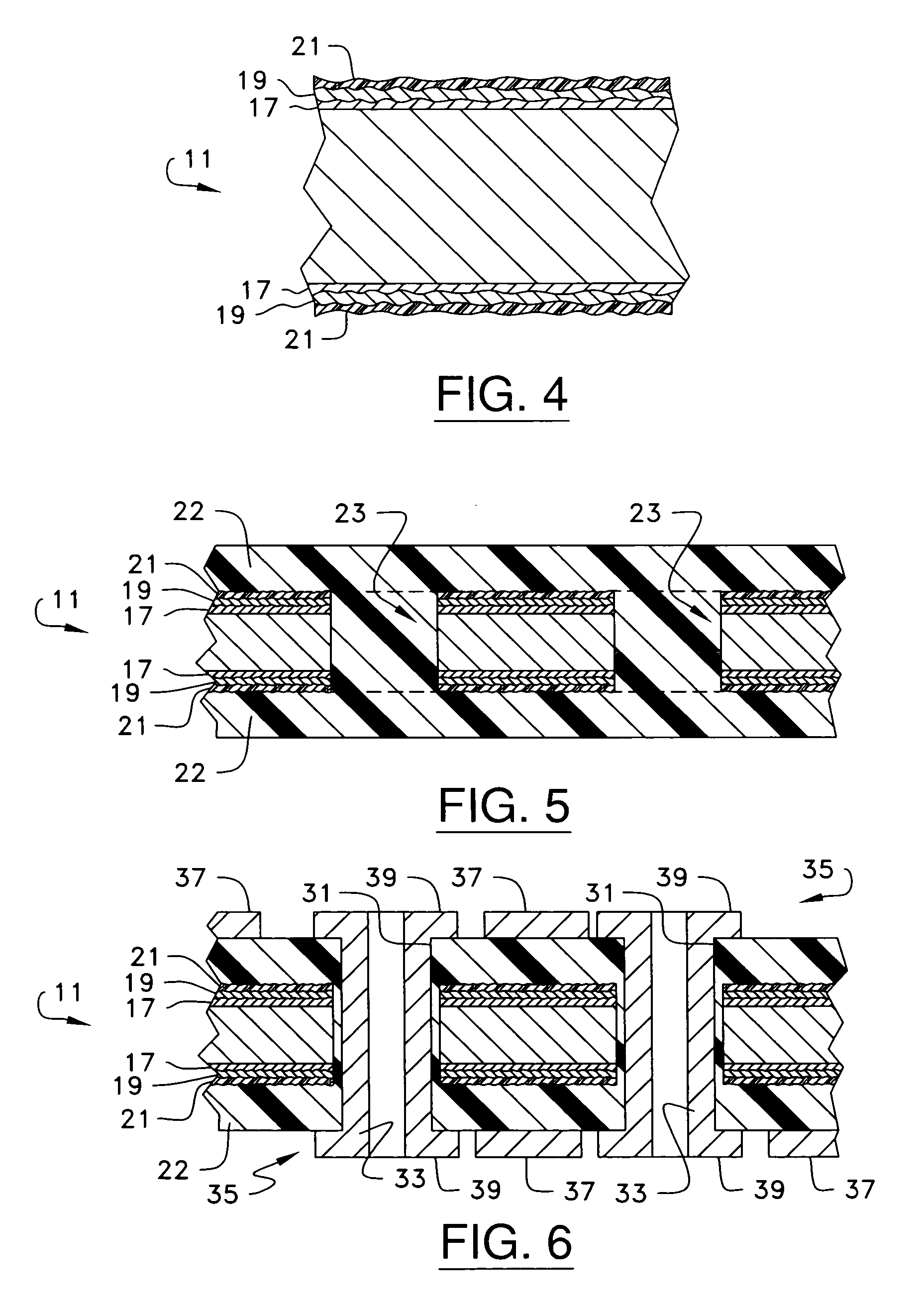

Apparatus and method for making circuitized substrates having photo-imageable dielectric layers in a continuous manner

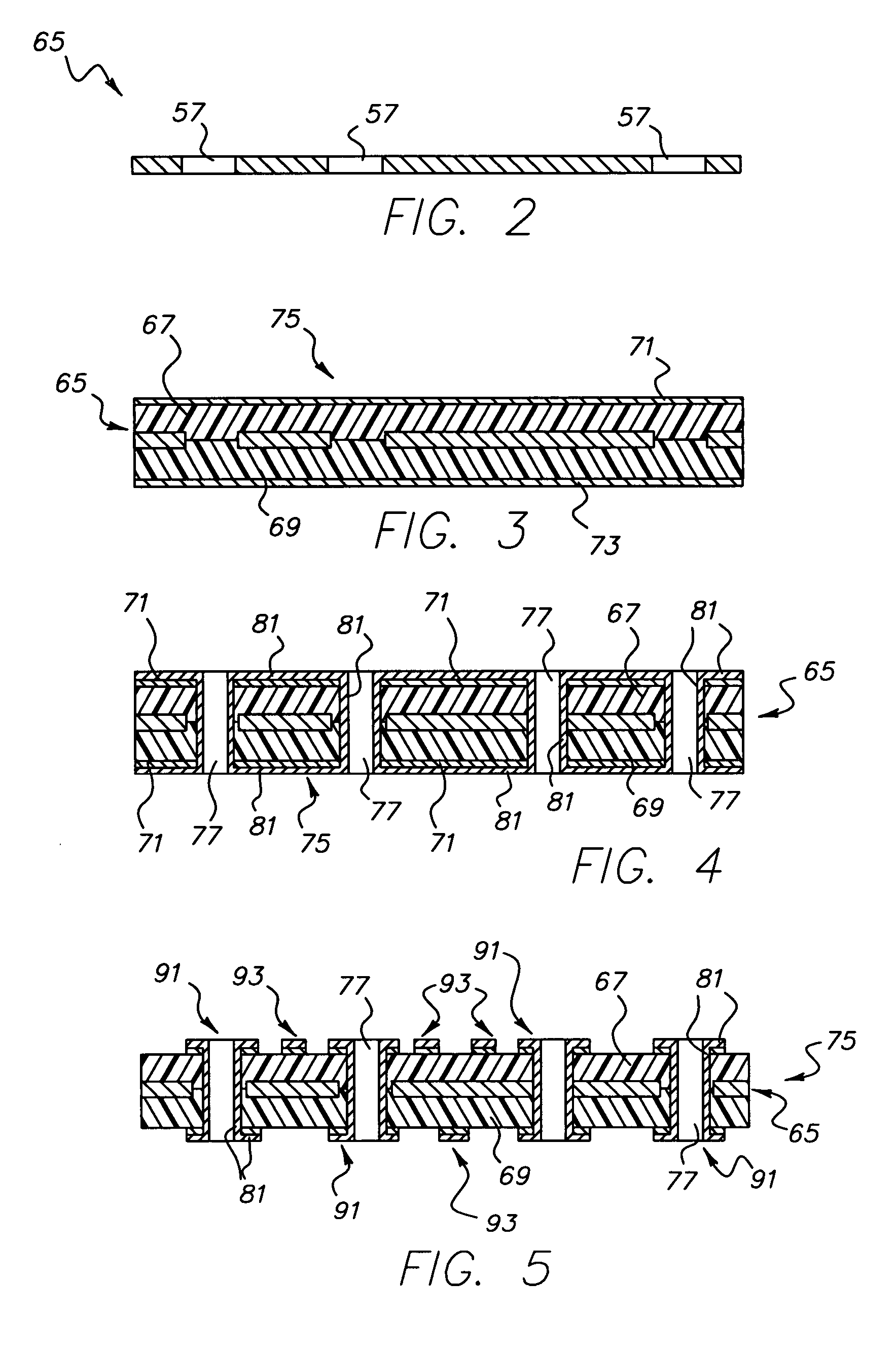

InactiveUS20060240364A1Enhance circuitized substrate artEnhance the circuitized substrate artPrinted circuit aspectsSemiconductor/solid-state device manufacturingPrinted circuit boardEngineering

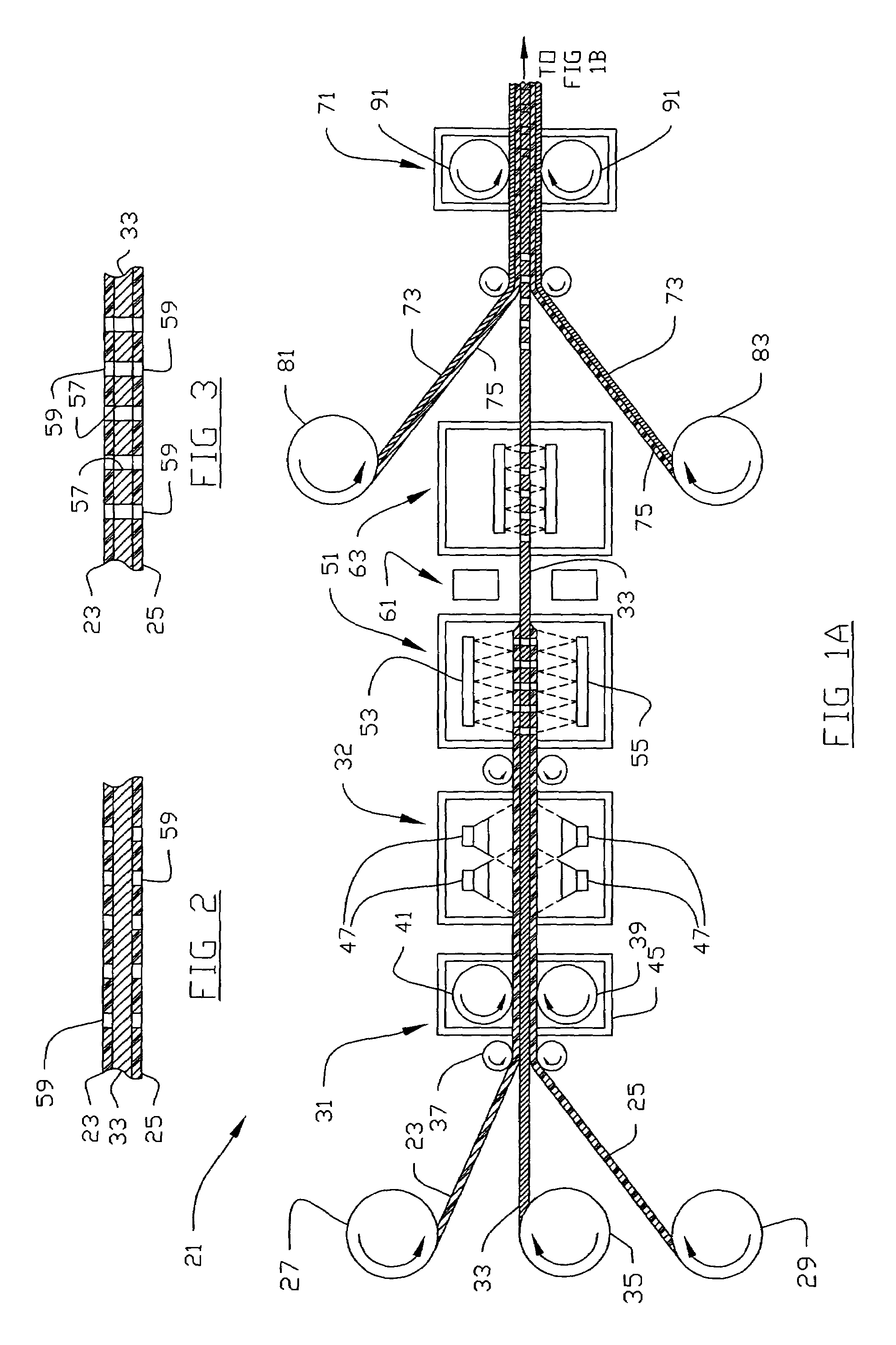

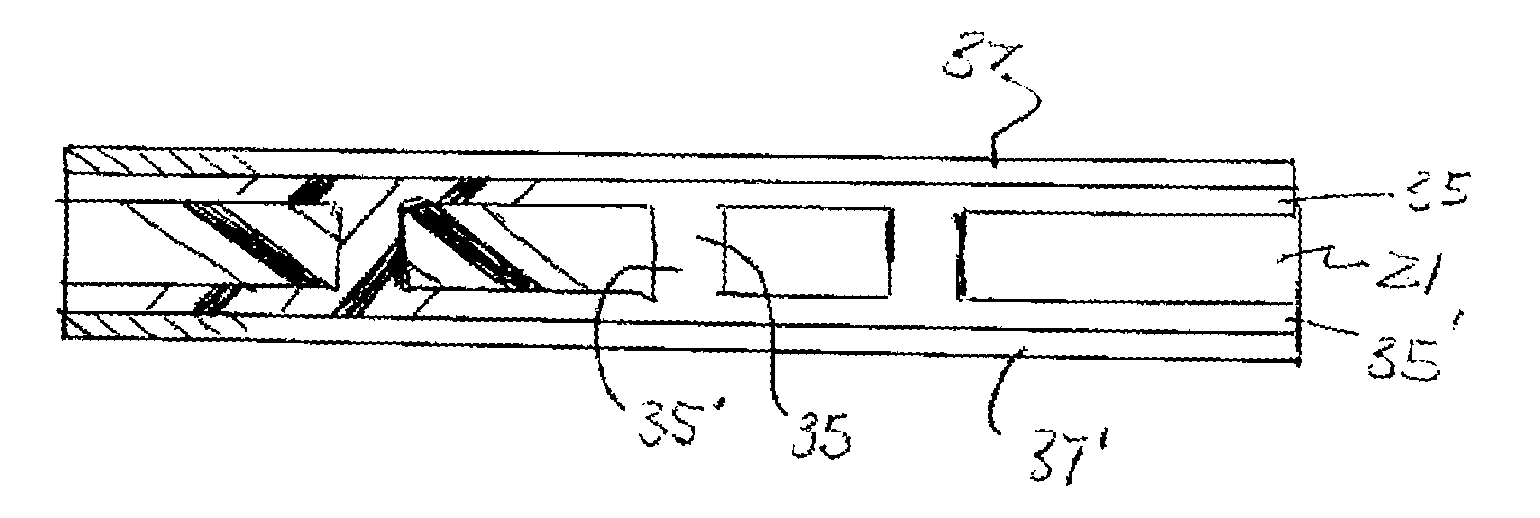

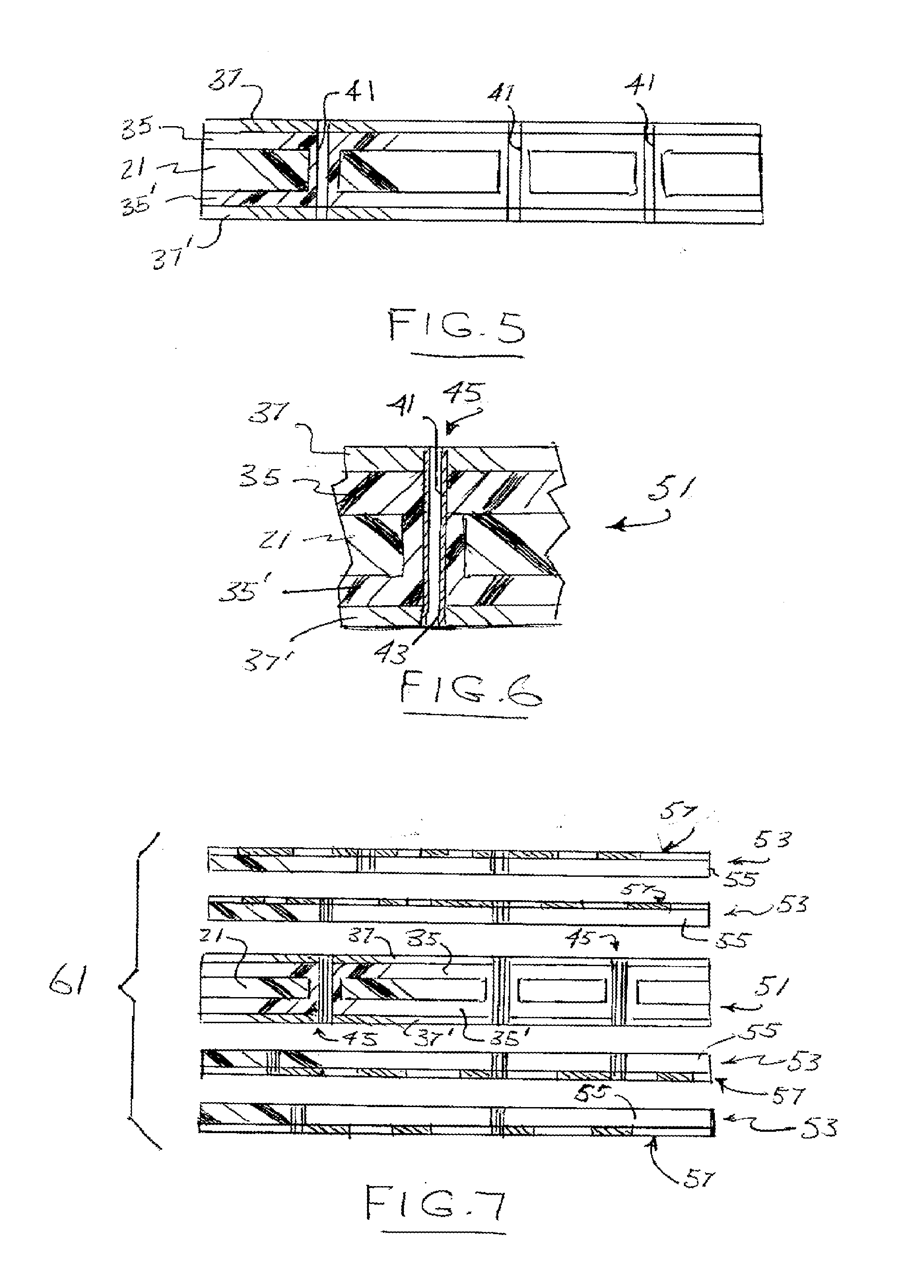

Apparatus and method for making circuitized substrates using a continuous roll format in which a layer of conductor is fed into the apparatus, layers of photo-imageable dielectric are applied to opposite sides of the conductor layer, thru-holes are formed through the composite, and then metal layers are added over the dielectric and then patterns (e.g., circuit) are formed therein. Several operations are performed in addition to these to form the final end product, a circuitized substrate (e.g., printed circuit board), all while the conductor layer of the product is retained in a solid format, up to the final separation from the continuous layer.

Owner:I3 ELECTRONICS

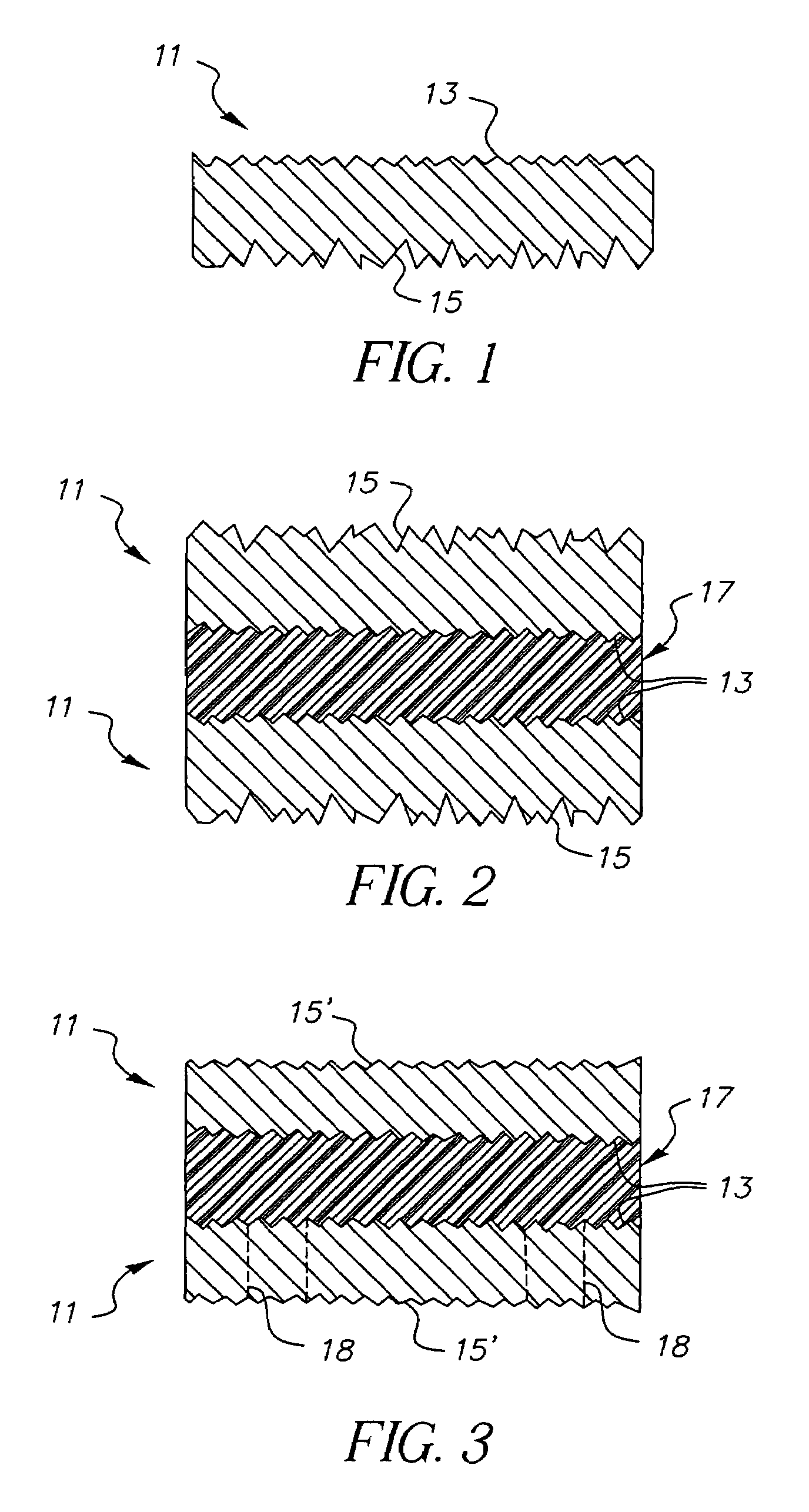

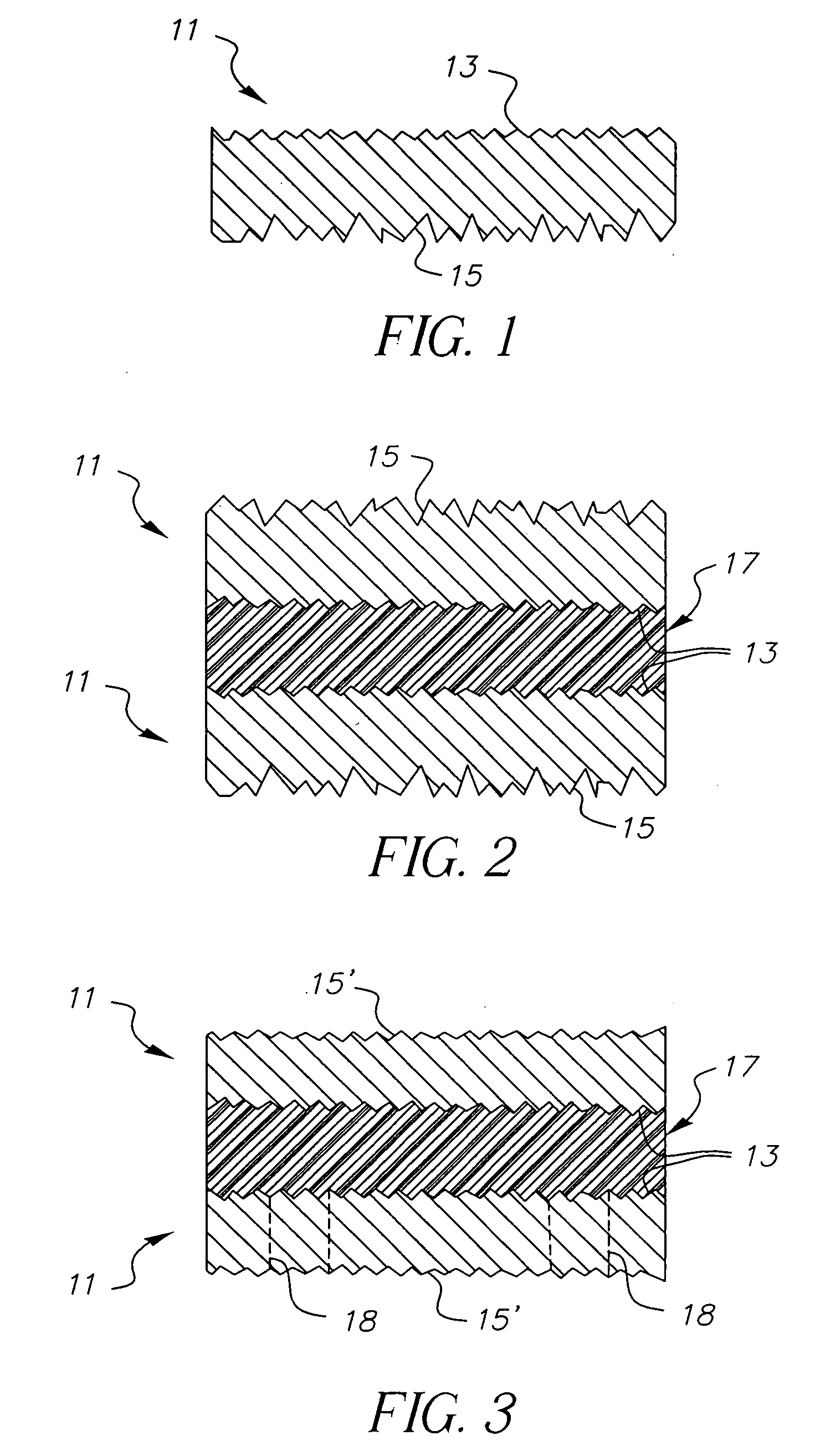

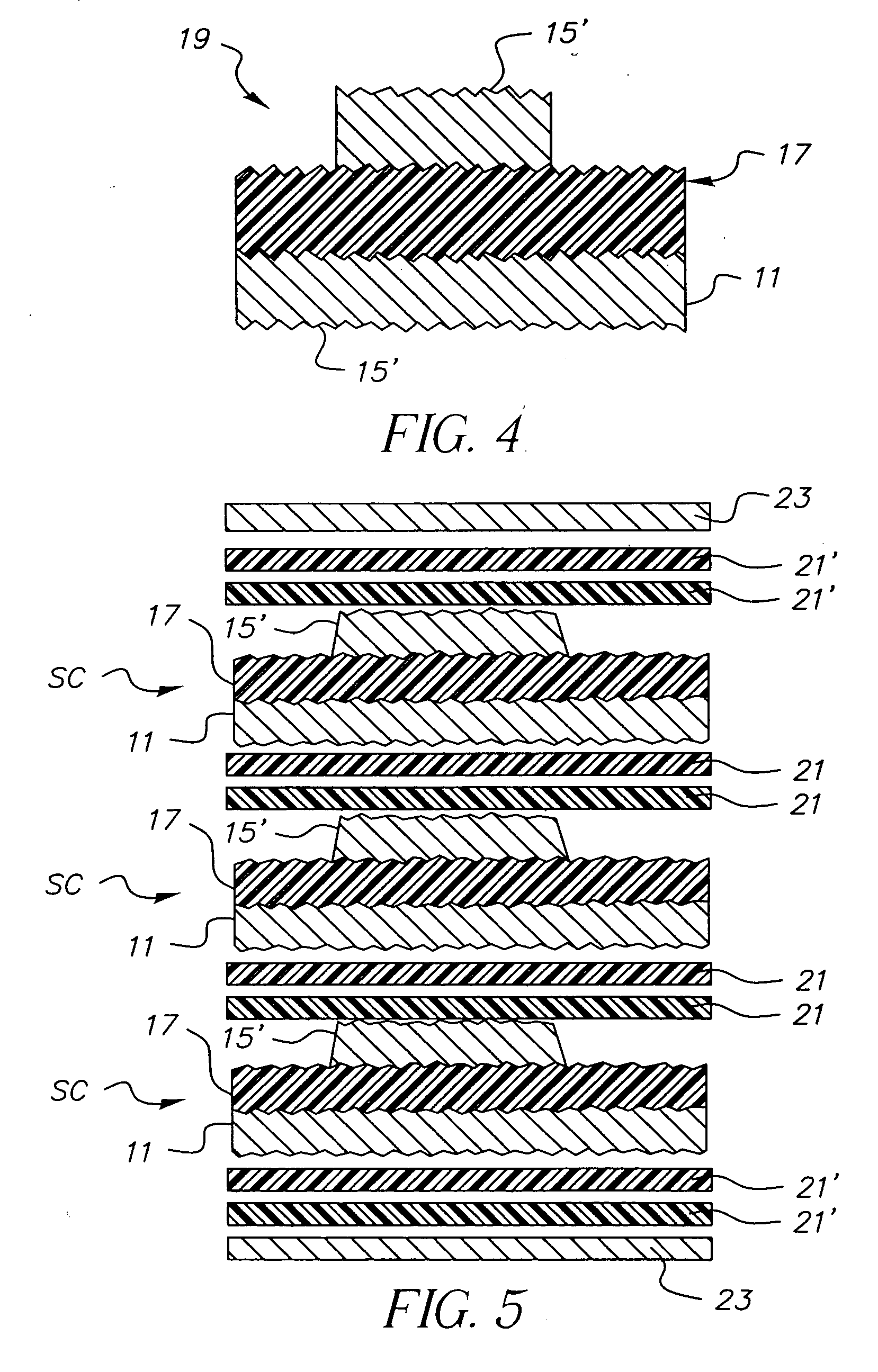

Method for making a multilayered circuitized substrate

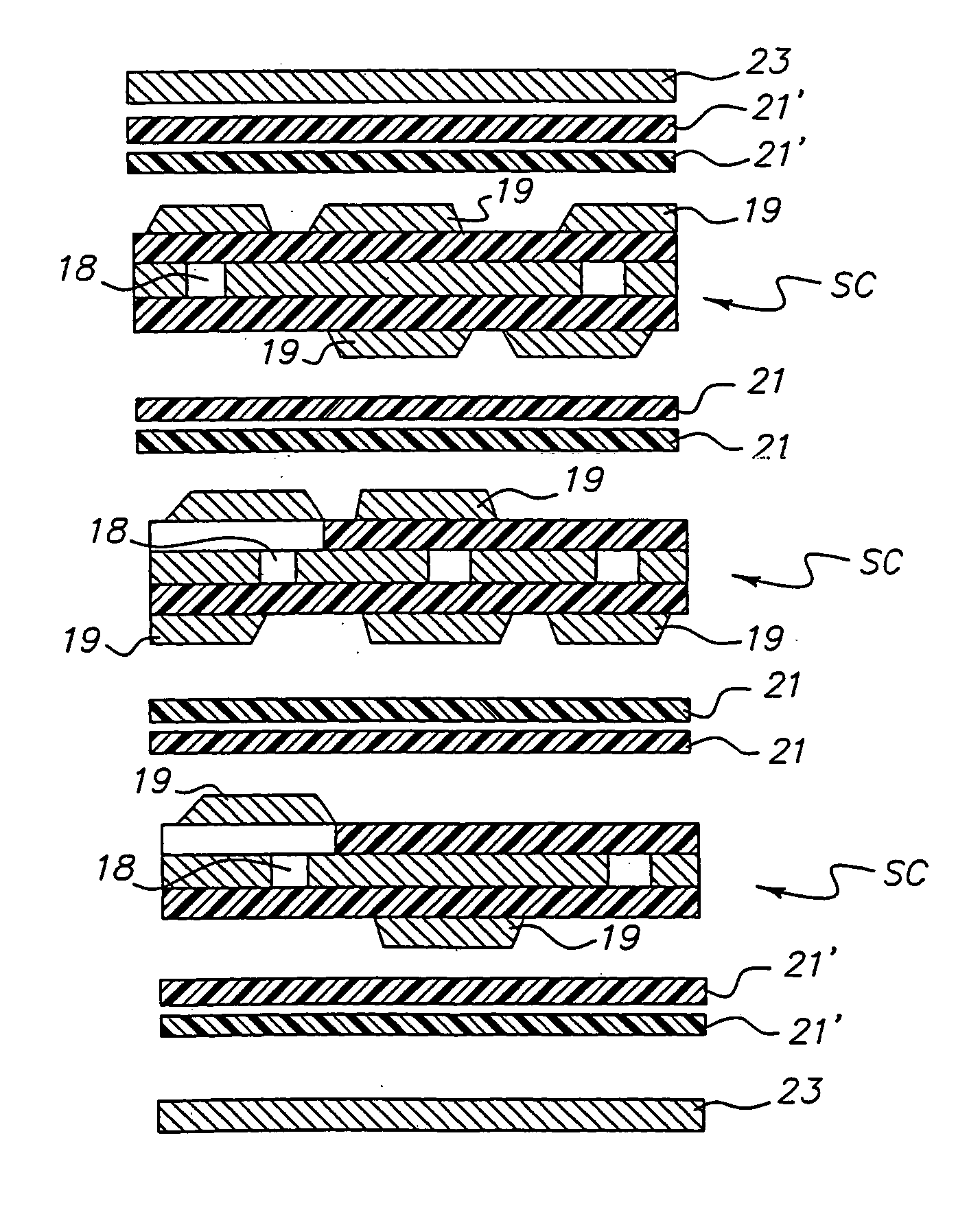

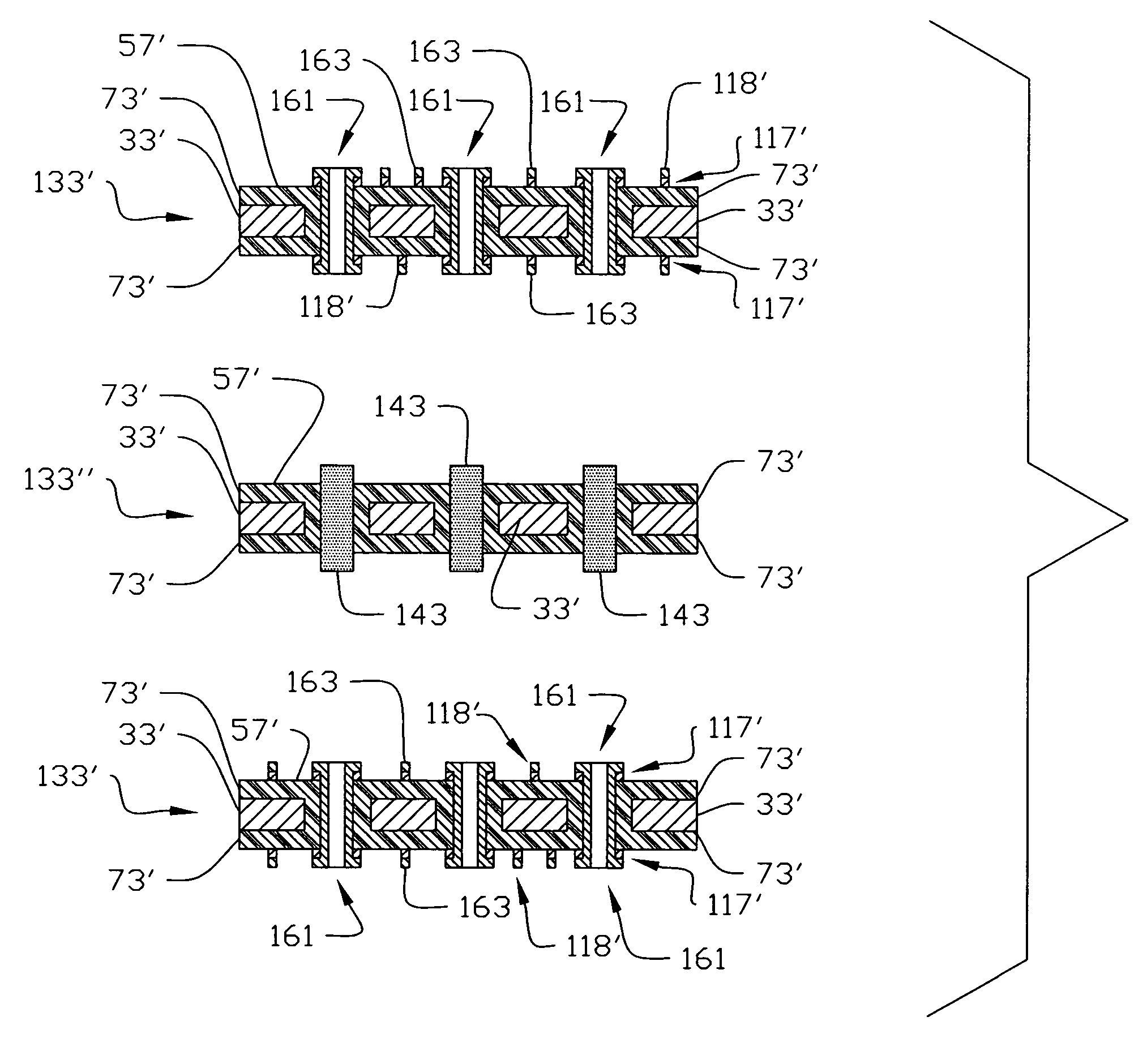

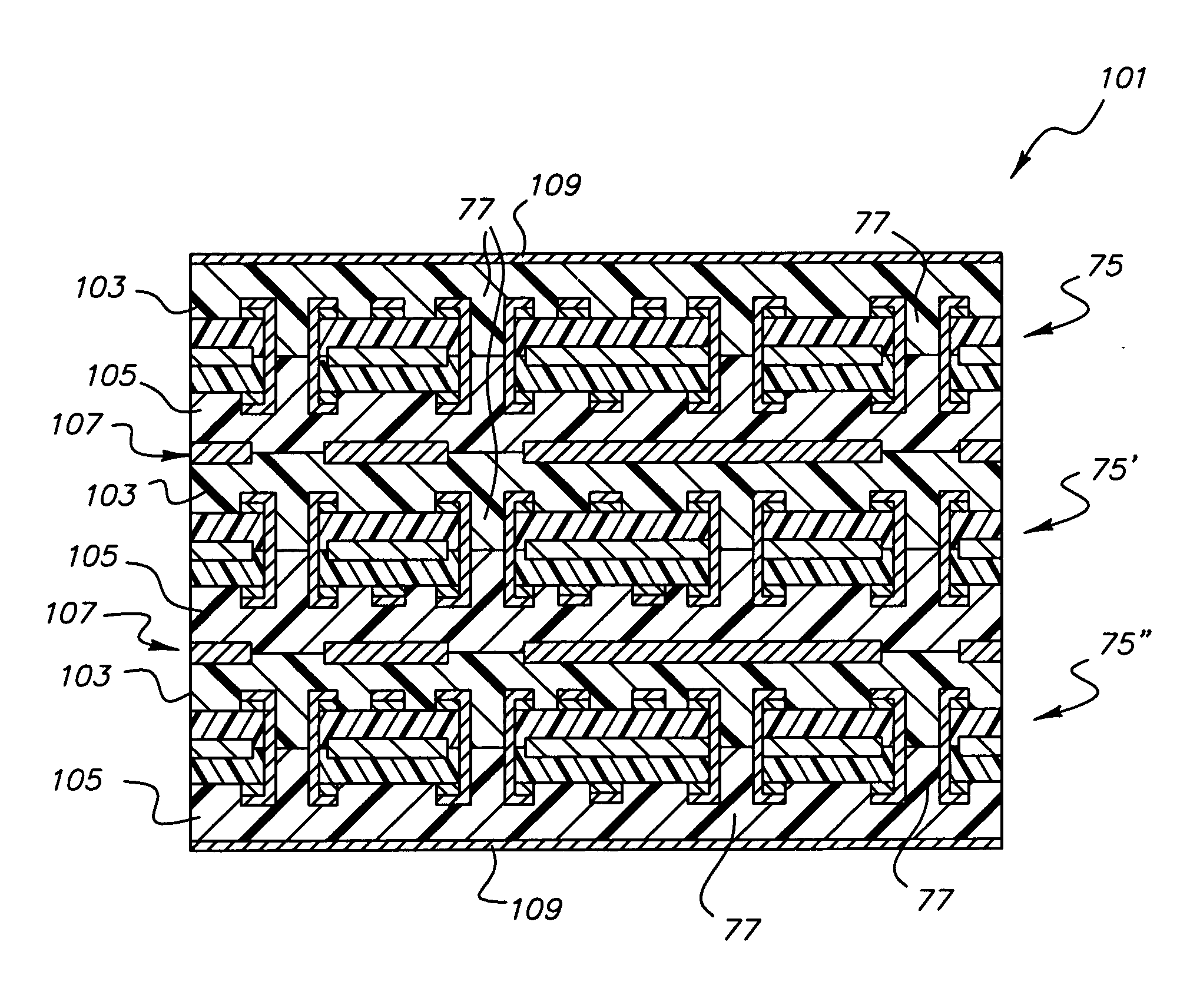

InactiveUS20070199195A1Enhance circuitized substrate artEnhance the circuitized substrate artPrinted circuit assemblingPrinted circuit aspectsDielectricFiber

A method of making a multilayered circuitized substrate in which a continuous process is used to form electrically conductive layers which each will form part of a sub-composite. The sub-composites are then aligned such that openings within the conductive layers are also aligned, the sub-composites are then bonded together, and a plurality of holes are then laser drilled through the entire thickness of the bonded structure. The dielectric layers used in the sub-composites do not include continuous or semi-continuous fibers therein, thus expediting hole formation there-through,

Owner:I3 ELECTRONICS

Circuitized substrate with internal resistor, method of making said circuitized substrate, and electrical assembly utilizing said circuitized substrate

InactiveUS7687724B2Enhance the circuitized substrate artLow costPrinted resistor incorporationElectrical connection printed elementsCapacitanceNanoparticle

A circuitized substrate which utilizes at least one internal (embedded) resistor as part thereof, the resistor comprised of a material including resin and a quantity of powders of nano-particle and / or micro-particle sizes. The resistor serves to decrease the capacitance in the formed circuit while only slightly increasing the high frequency resistance, thereby improving circuit performance through the substantial elimination of some discontinuities known to exist in structures like these. An electrical assembly (substrate and at least one electrical component) is also provided.

Owner:TTM TECH NORTH AMERICA LLC +1

Capacitor material for use in circuitized substrates, circuitized substrate utilizing same, method of making said circuitized substrate, and information handling system utilizing said circuitized substrate

InactiveUS7541265B2Enhance the circuitized substrate artLow costSemiconductor/solid-state device detailsPrinted circuit aspectsBarium titanatePersonal computer

A material for use as part of an internal capacitor within a circuitized substrate includes a polymer (e.g., a cycloaliphatic epoxy or phenoxy based) resin and a quantity of nano-powders of ferroelectric ceramic material (e.g., barium titanate) having a particle size substantially in the range of from about 0.01 microns to about 0.90 microns and a surface area for selected ones of said particles within the range of from about 2.0 to about 20 square meters per gram. A circuitized substrate adapted for using such a material and capacitor therein and a method of making such a substrate are also provided. An electrical assembly (substrate and at least one electrical component) and an information handling system (e.g., personal computer) are also provided.

Owner:TTM TECH NORTH AMERICA LLC

Apparatus and method for making circuitized substrates in a continuous manner

InactiveUS20060240641A1Enhance circuitized substrate artEnhance the circuitized substrate artPrinted circuit assemblingPrinted circuit aspectsEngineeringElectrical conductor

Apparatus and method for making circuitized substrates using a continuous roll format in which layers of conductor and dielectric are fed into the apparatus, bonded, and passed on to other nearby work stations in which various processes such as hole formation, circuitization and, finally, segmentation occur. The resulting substrates can then be individually bonded to other, like substrates to form a larger multi-layered substrate with a plurality of conductive thru-holes, conductive and dielectric layers as part thereof.

Owner:I3 ELECTRONICS

Capacitive substrate and method of making same

InactiveUS20090206051A1Enhance the circuitized substrate artLow costElectric discharge heatingElectrolytic capacitorsDielectricCapacitance

A capacitive substrate and method of making same in which first and second glass layers are used. A first conductor is formed on a first of the glass layers and a capacitive dielectric material is positioned over the conductor. The second conductor is then positioned on the capacitive dielectric and the second glass layer positioned over the second conductor. Conductive thru-holes are formed to couple to the first and second conductors, respectively, such that the conductors and capacitive dielectric material form a capacitor when the capacitive substrate is in operation.

Owner:TTM TECH NORTH AMERICA LLC

Method of making a capacitive substrate for use as part of a larger circuitized substrate, method of making said circuitized substrate and method of making an information handling system including said circuitized substrate

InactiveUS7449381B2Enhance the circuitized substrate artLow costPrinted circuit aspectsSemiconductor/solid-state device manufacturingCapacitanceElectrical conductor

A method of forming a capacitive substrate in which at least one capacitive dielectric layer of material is screen or ink jet printed onto a conductor and the substrate is thereafter processed further, including the addition of thru-holes to couple selected elements within the substrate to form at least two capacitors as internal elements of the substrate. The capacitive substrate may be incorporated within a larger circuitized substrate, e.g., to form an electrical assembly. A method of making an information handling system including such substrates is also provided.

Owner:TTM TECH NORTH AMERICA LLC

Power core for use in circuitized substrate and method of making same

ActiveUS8198551B2Enhance the circuitized substrate artLow costLine/current collector detailsPrinted circuit aspectsGlass fiberEngineering

A power core adapted for use as part of a circuitized substrate, e.g., a PCB or LCC. The core includes a first layer of low expansion dielectric and two added layers of a different low expansion dielectric bonded thereto, with two conductive layers positioned on the two added low expansion dielectric layers. At least one of the conductive layers serves as a power plane for the power core, which in turn is usable within a circuitized substrate, also provided. Methods of making the power core and circuitized substrate are also provided. The use of different low expansion dielectric materials for the power core enables the use of support enhancing fiberglass in one layer while such use is precluded in the other two dielectric layers, thus preventing CAF shorting problems in highly precisely defined thru holes formed within the power core.

Owner:TTM TECH NORTH AMERICA LLC

Substrate having internal capacitor and method of making same

InactiveUS8607445B1Enhance the circuitized substrate artLow costPrinted circuit assemblingThin/thick film capacitorCapacitanceConductive materials

A method of making a circuitized substrate which includes at least one and possibly several capacitors as part thereof. In one embodiment, the substrate is produced by forming a layer of capacitive dielectric material on a dielectric layer and thereafter forming channels with the capacitive material, e.g., using a laser. The channels are then filled with conductive material, e.g., copper, using selected deposition techniques, e.g., sputtering, electro-less plating and electroplating. A second dielectric layer is then formed atop the capacitor and a capacitor “core” results. This “core” may then be combined with other dielectric and conductive layers to form a larger, multilayered PCB or chip carrier. In an alternative approach, the capacitive dielectric material may be photo-imageable, with the channels being formed using conventional exposure and development processing known in the art.

Owner:TTM TECH NORTH AMERICA LLC

Method of treating conductive layer for use in a circuitized substrate and method of making said substrate having said conductive layer as part thereof

ActiveUS20060121738A1Enhance the circuitized substrate artLow costPrinted circuit aspectsSemiconductor/solid-state device manufacturingSemiconductor chipDielectric layer

A method of treating a conductive layer to assure enhanced adhesion of the layer to selected dielectric layers used to form a circuitized substrate. The conductive layer includes at least one surface with the appropriate roughness to enable such adhesion and also good signal passage if the layer is used as a signal layer. The method is extendible to the formation of such substrates, including to the formation of multilayered substrates having many conductive and dielectric layers. Such substrates may include one or more electrical components (e.g., semiconductor chips) mounted thereon and may also be mounted themselves onto other substrates.

Owner:TTM TECH NORTH AMERICA LLC

Method for making a multilayered circuitized substrate

InactiveUS7627947B2Enhance the circuitized substrate artPrinted circuit assemblingPrinted circuit aspectsDielectricFiber

A method of making a multilayered circuitized substrate in which a continuous process is used to form electrically conductive layers which each will form part of a sub-composite. The sub-composites are then aligned such that openings within the conductive layers are also aligned, the sub-composites are then bonded together, and a plurality of holes are then laser drilled through the entire thickness of the bonded structure. The dielectric layers used in the sub-composites do not include continuous or semi-continuous fibers therein, thus expediting hole formation there-through.

Owner:I3 ELECTRONICS

Method of making circuitized substrates utilizing smooth-sided conductive layers as part thereof

InactiveUS7383629B2Enhance the circuitized substrate artLow costDecorative surface effectsSolid-state devicesChemical treatmentOrganic layer

A circuitized substrate in which two conductive layers (e.g., electroplated copper foil) are bonded (e.g., laminated) to an interim dielectric layer. Each of the two foil surfaces which physically bond to the dielectric are smooth (e.g., preferably by chemical processing) and include a thin, organic layer thereon, while the outer surfaces of both foils are also smooth (e.g., preferably also using a chemical processing step). One of these resulting conductive layers may function as a ground or voltage plane while the other may function as a signal plane with a plurality of individual signal lines as part thereof. An electrical assembly and an information handling system utilizing such a circuitized substrate are also provided, as is a method of making the substrate.

Owner:WACHOVIA CAPITAL FINANCE NEW ENGLAND AS AGENT +1

Circuitized substrates utilizing smooth-sided conductive layers as part thereof

InactiveUS20080259581A1Enhance the circuitized substrate artLow costPrinted electric component incorporationPrinted circuit aspectsChemical treatmentOrganic layer

A circuitized substrate in which two conductive layers (e.g., electroplated copper foil) are bonded (e.g., laminated) to an interim dielectric layer. Each of the two foil surfaces which physically bond to the dielectric are smooth (e.g., preferably by chemical processing) and include a thin, organic layer thereon, while the outer surfaces of both foils are also smooth (e.g., preferably also using a chemical processing step). One of these resulting conductive layers may function as a ground or voltage plane while the other may function as a signal plane with a plurality of individual signal lines as part thereof. An electrical assembly and an information handling system utilizing such a circuitized substrate are also provided.

Owner:I3 ELECTRONICS

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com