Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Down time" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

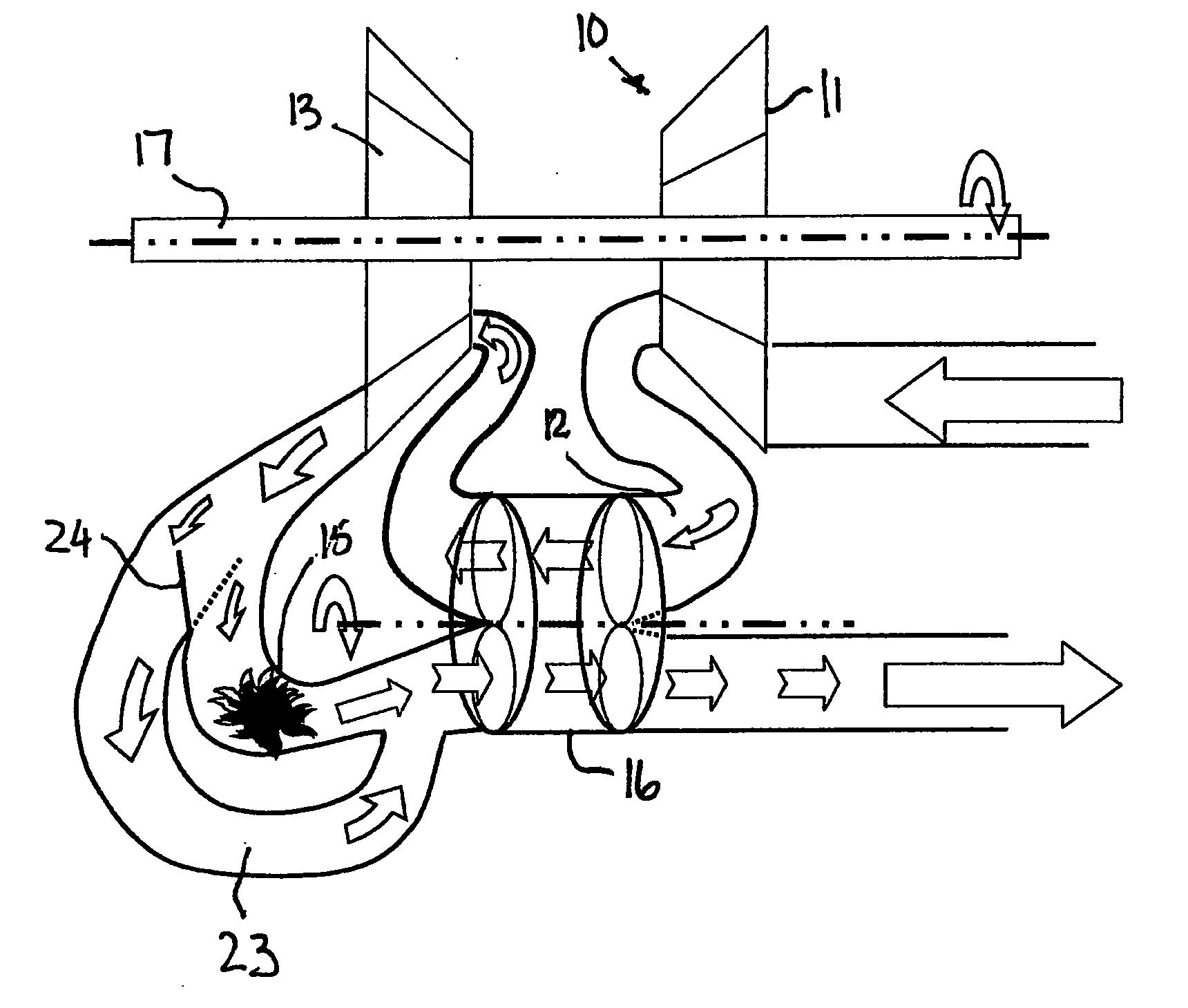

Gas turbine with external combustion, applying a rotating regenerating heat exchanger

InactiveUS20110227346A1More compactSmall sizeEngine fuctionsGas turbine plantsFlueAutomotive engineering

The invention relates to a gas turbine (10) for transforming thermal energy, for example from coal, biomass or the like, to mechanical work, comprising a compressor unit (11), a turbine unit (13, a combustion chamber (15) and a heat exchanger (14) with associated pipe system. The gas turbine (10) id configured in such way that the heat is supplied to the air flow between the compressor unit (11) and the turbine unit (13) by means of hot flue gas from the combustion chamber (15) and is brought into a compression chamber (12) arranged between the compressor unit (11) and the turbine unit (13).

Owner:ARES TURBINE

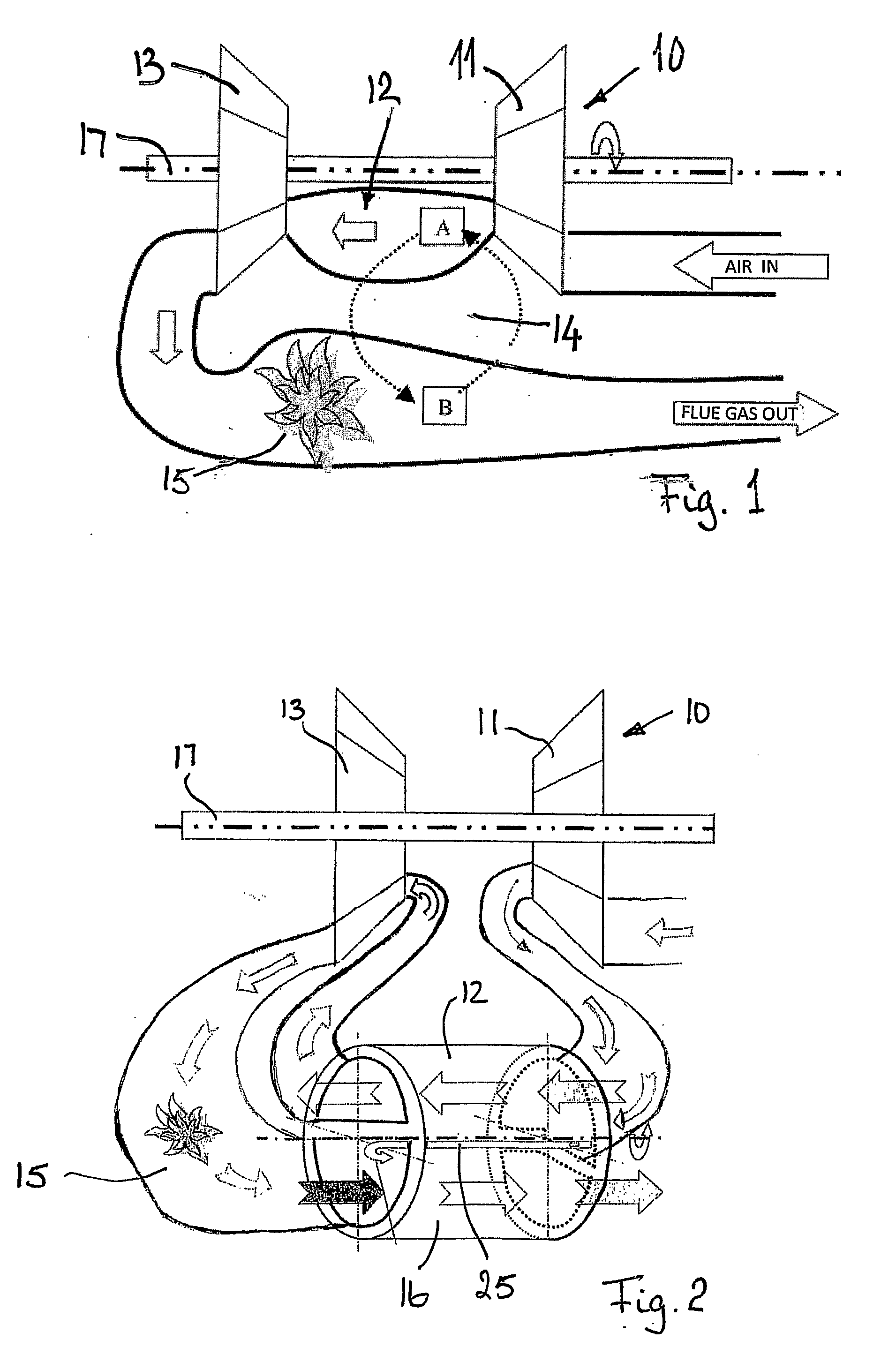

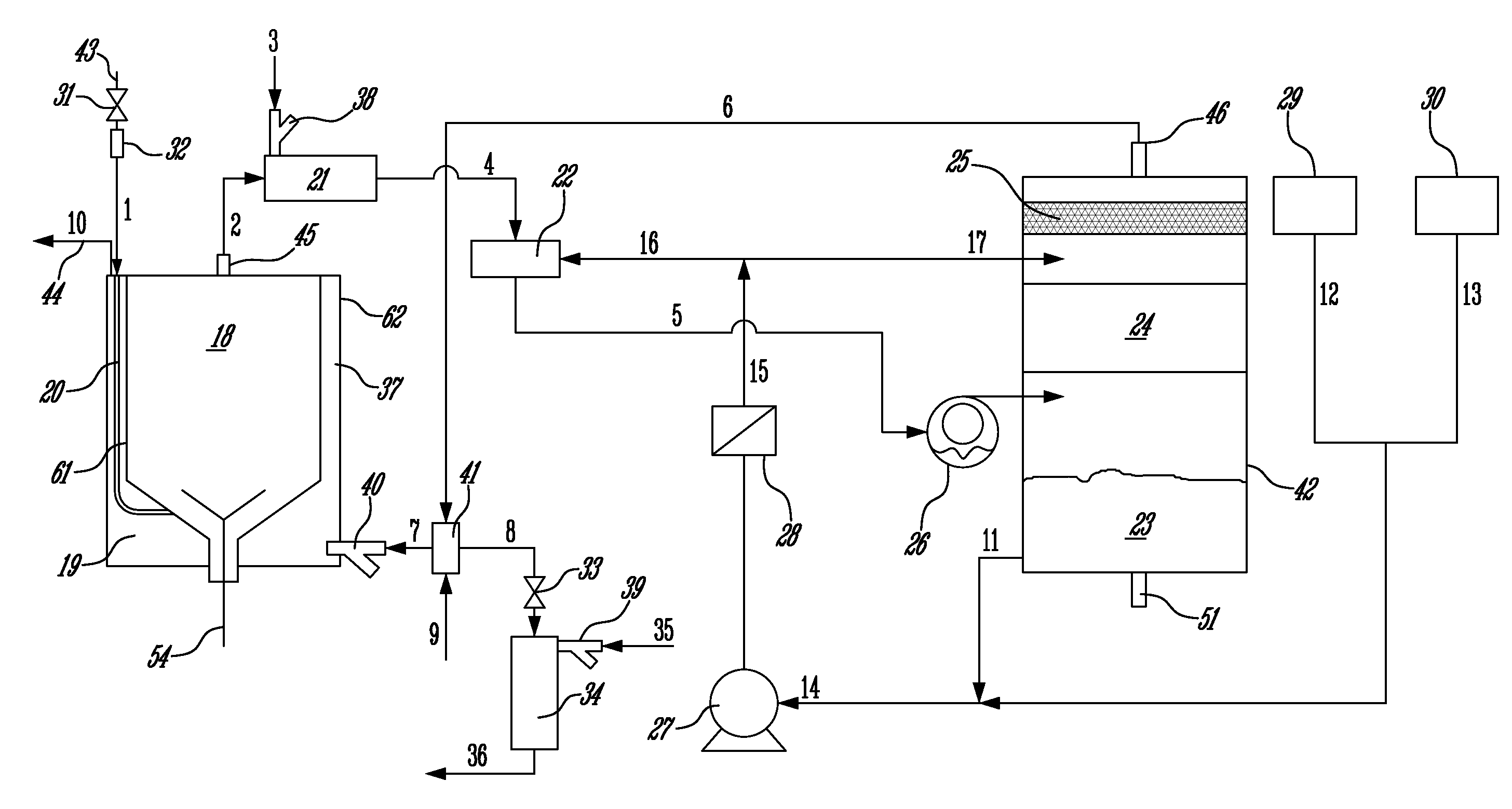

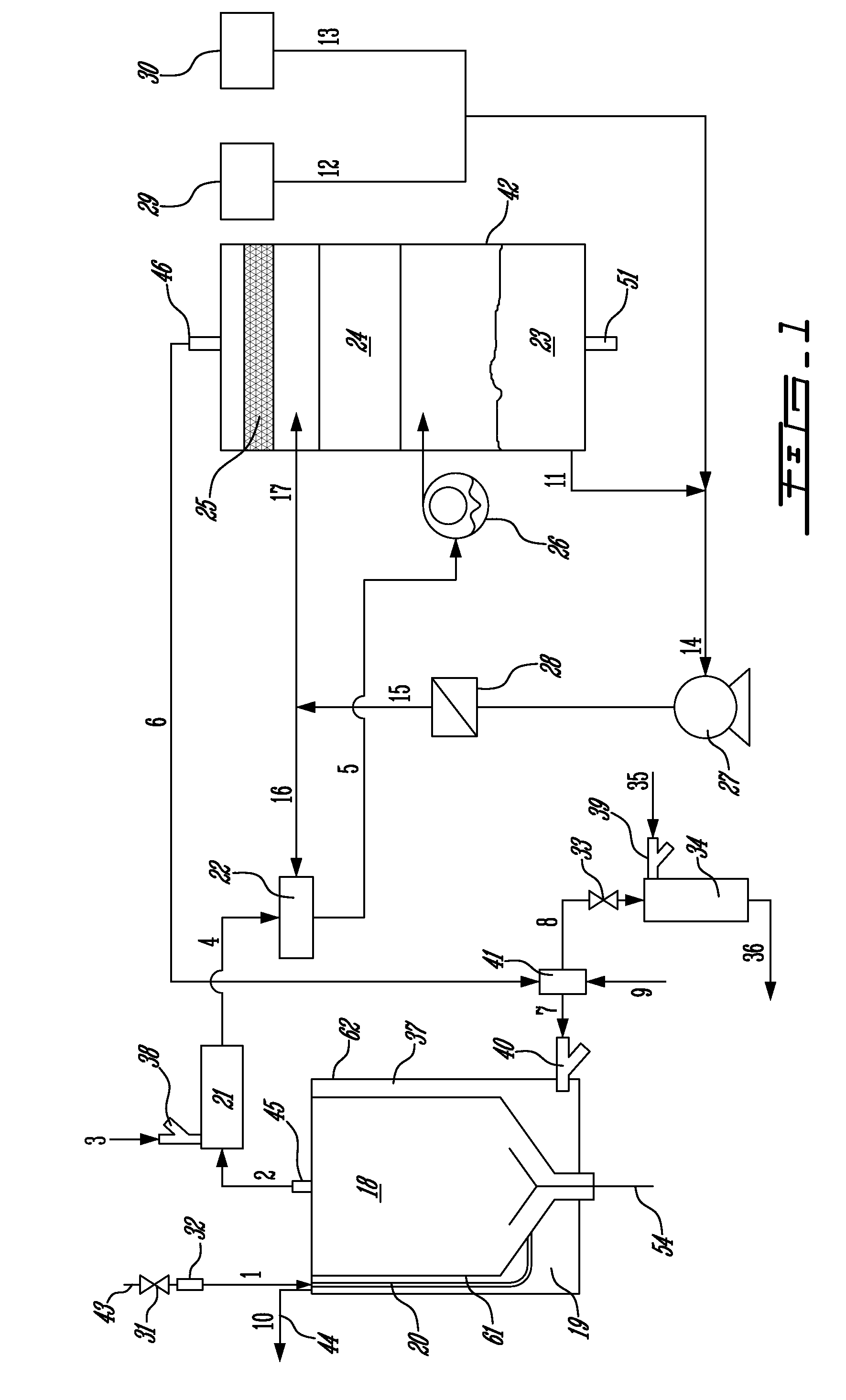

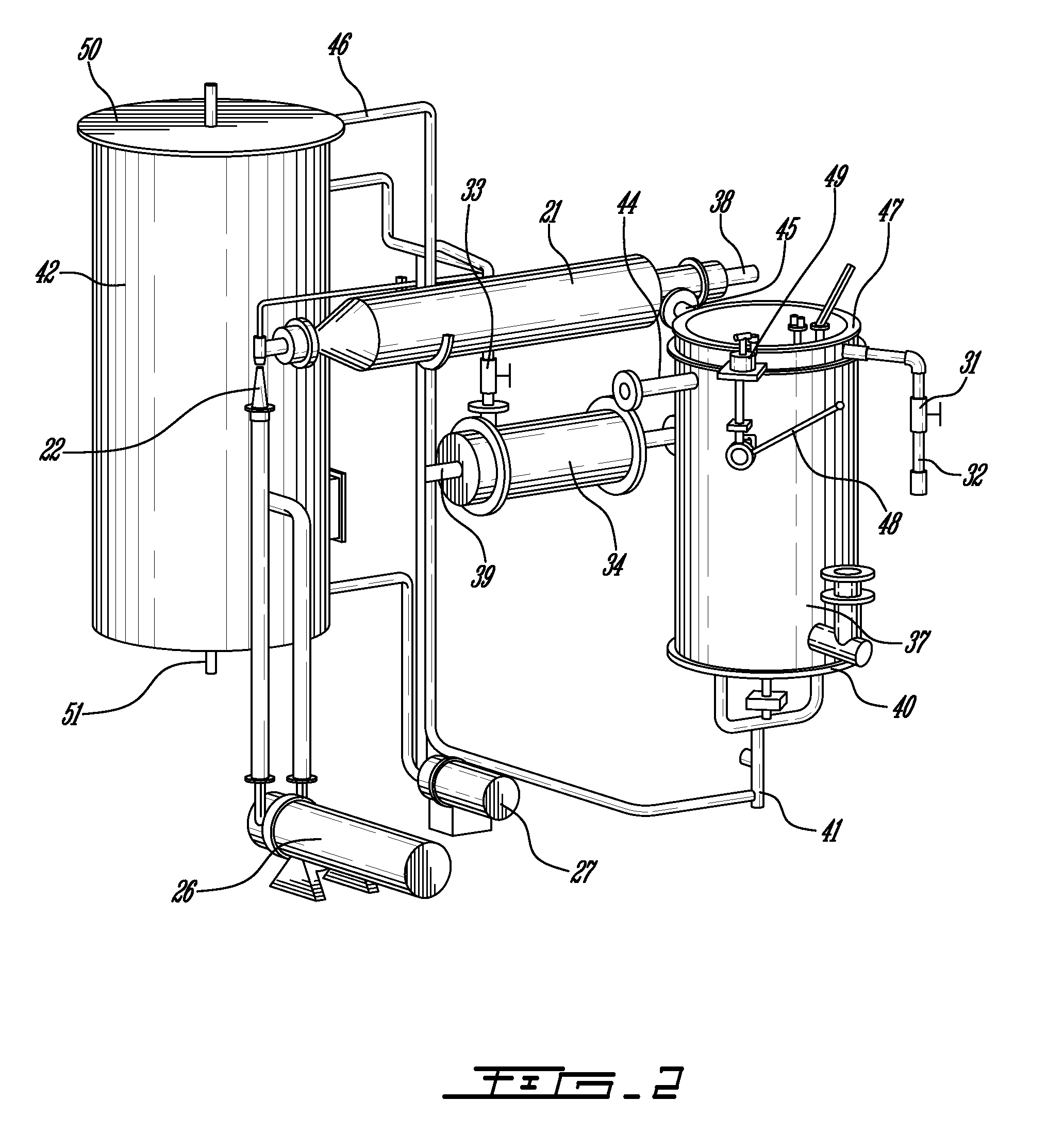

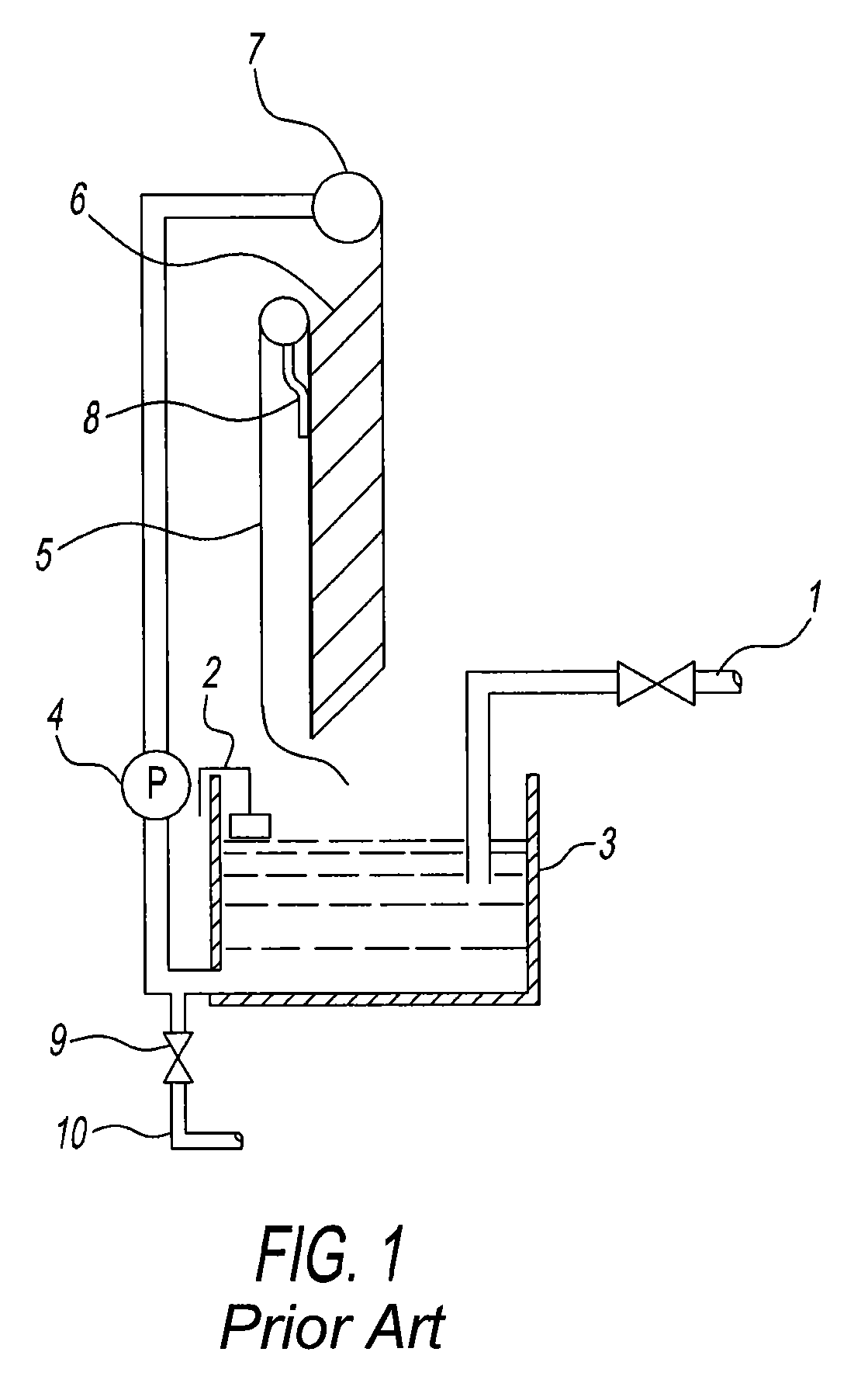

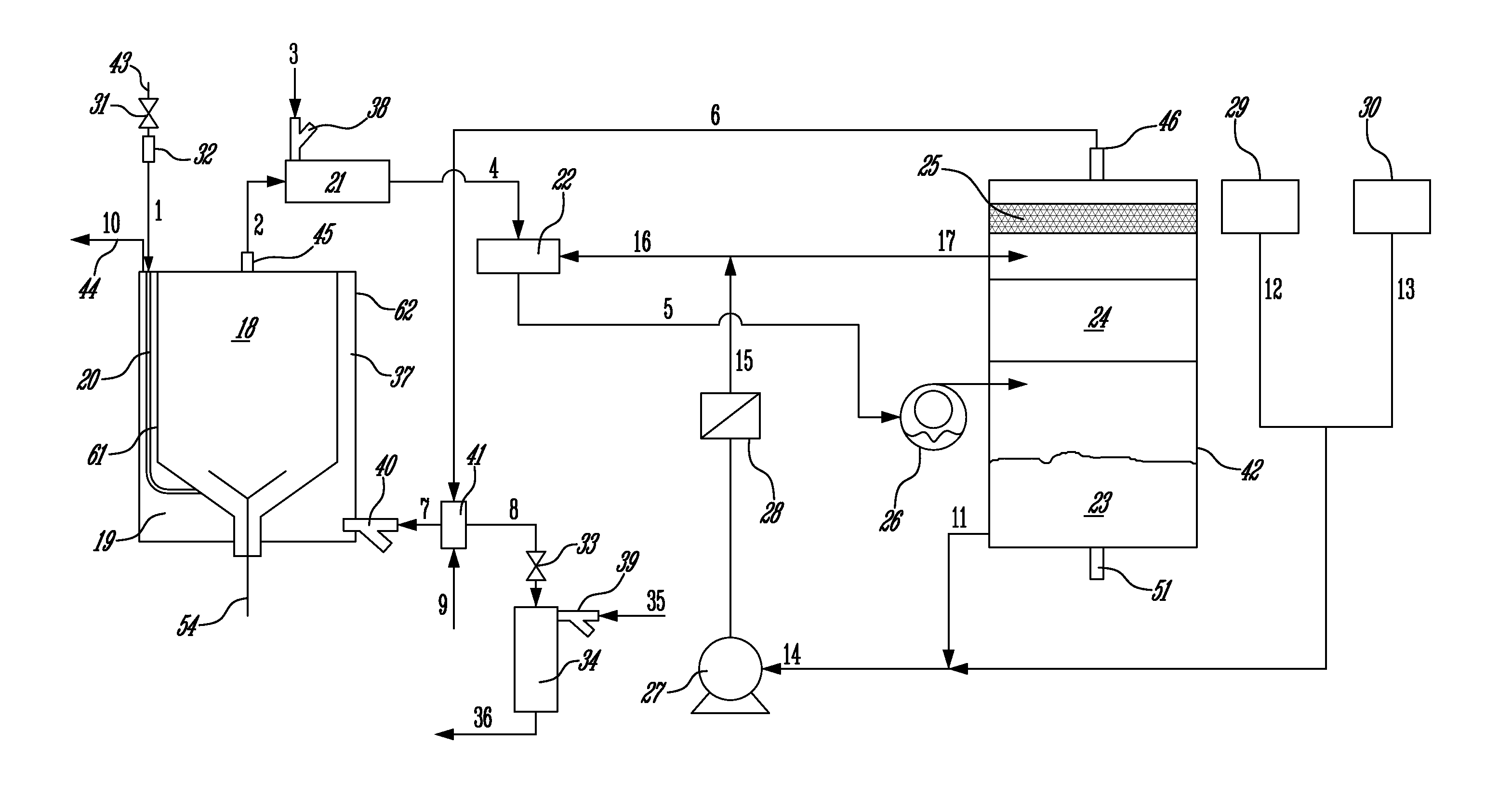

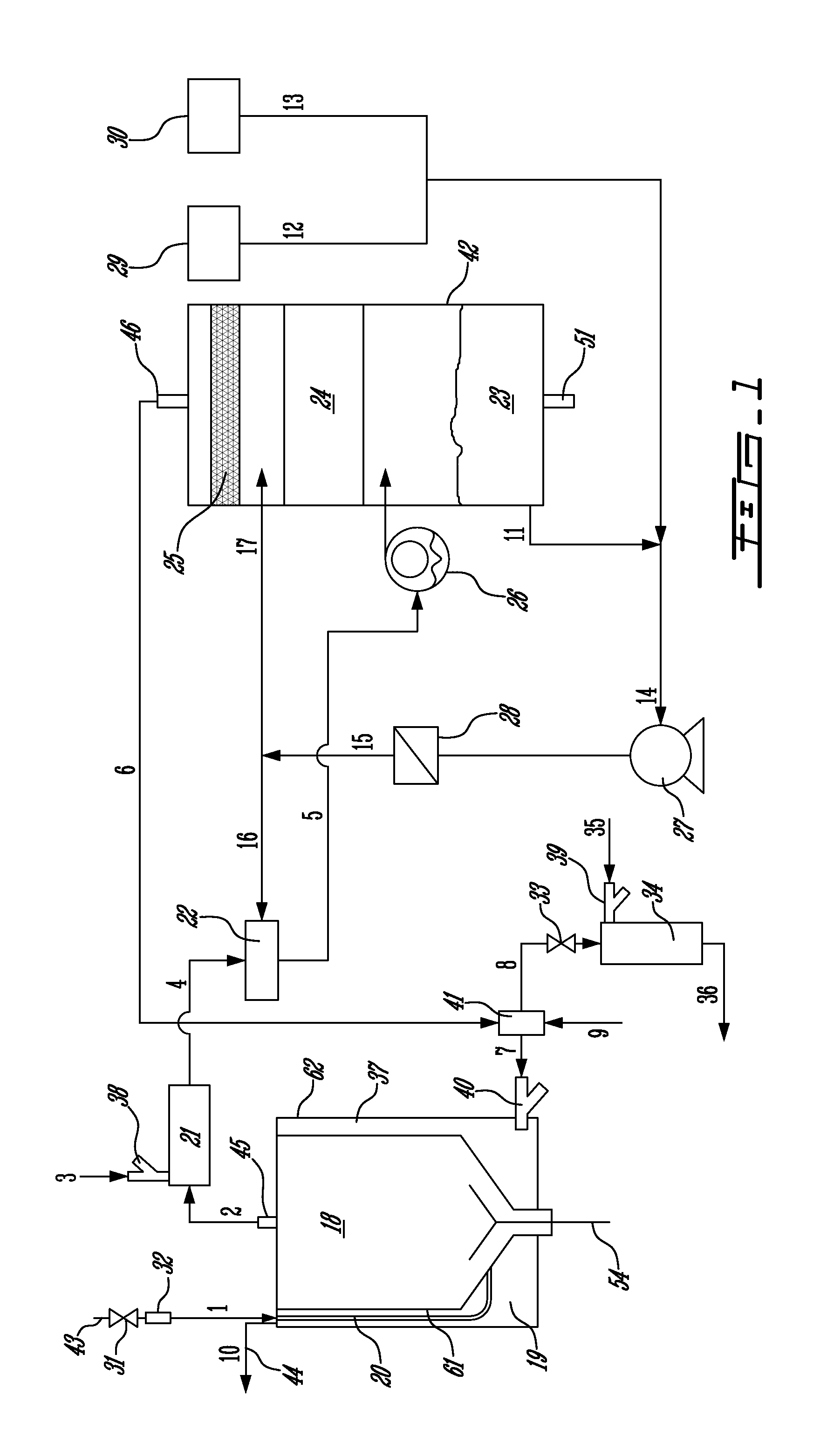

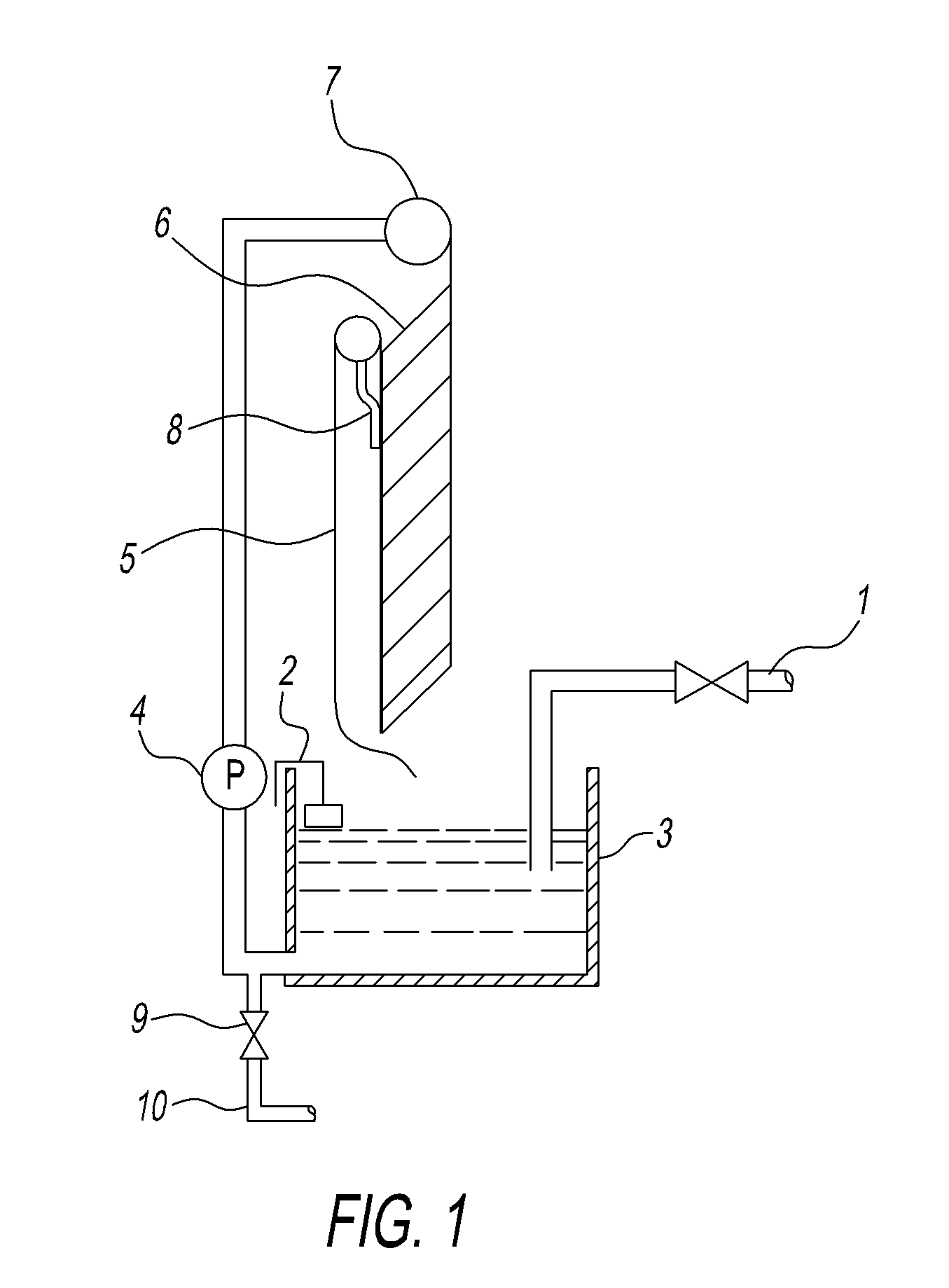

Method and apparatus for gasification of organic waste in batches

ActiveUS20100139534A1Minimum thermal inertiaCooled-down quicklySolid waste disposalEnergy inputSyngasParticulates

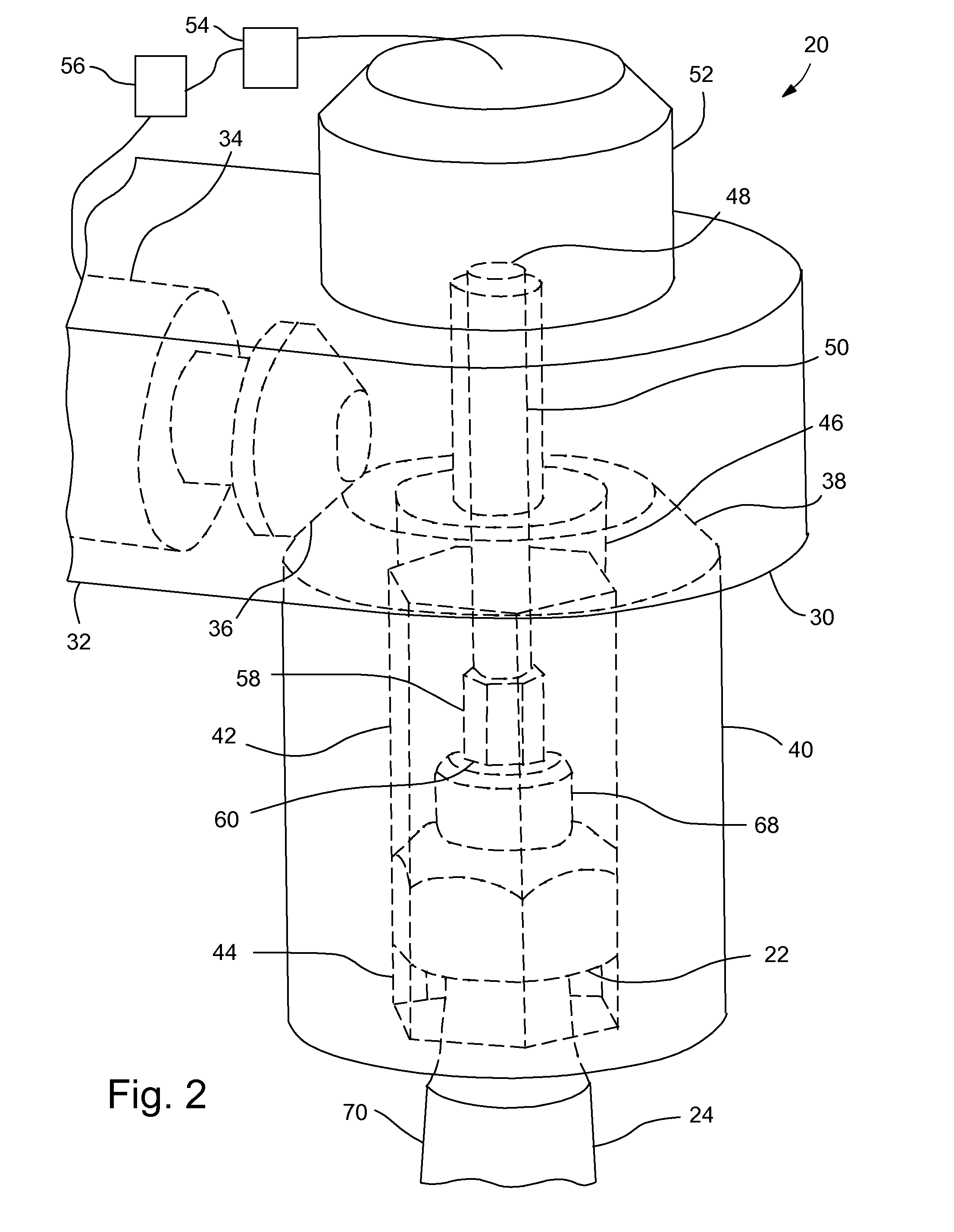

A gasification reactor for processing organic waste in batches comprises a primary gasification reactor (62) that includes a primary gasification chamber (18) and a surrounding combustion chamber (19), a secondary gasification chamber (21), a synthesis gas decontamination unit (42) and a combustible gas selector (41). The waste is loaded into the primary gasification chamber through a latched opening and heated from the combustion of a fuel in the combustion chamber (19) to convert the waste to a synthesis gas. The gasification chamber (18) has an intake (20) for introducing pre-heated process air (1) therein. The combustion chamber operates either with a conventional fuel (9) or with the produced synthesis gas (6). The secondary gasification chamber (21) thermally treats the synthesis gas (2) to eliminate tars. The decontamination unit (42) scrubs the synthesis gas of contaminants including particulates and acid gases. The clean synthesis gas (6) is directed to the combustible gas selector (41) which selectively feeds either the combustible fluid (9) or the synthesis gas (6) to the burner (40).

Owner:PROTERRGO

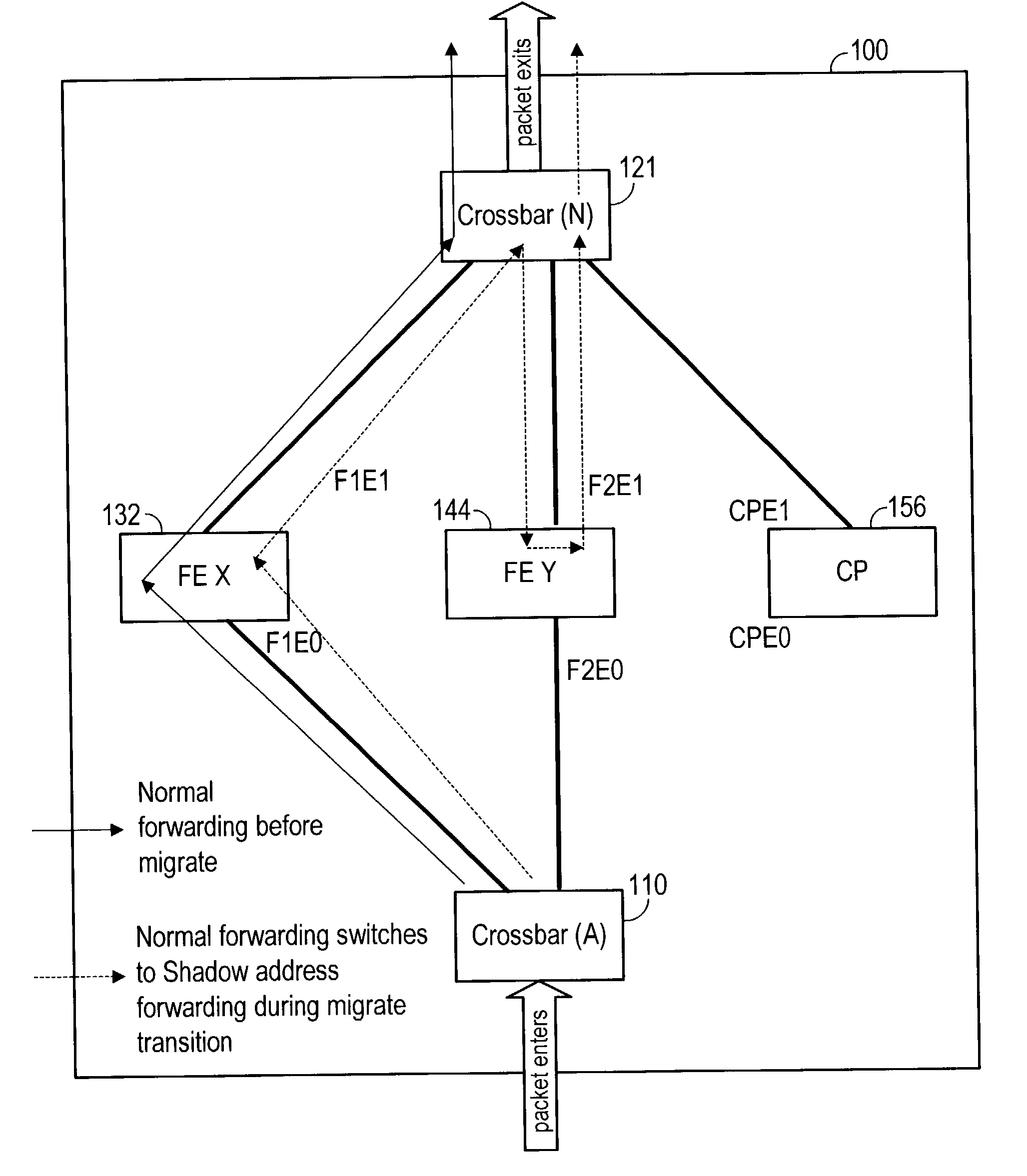

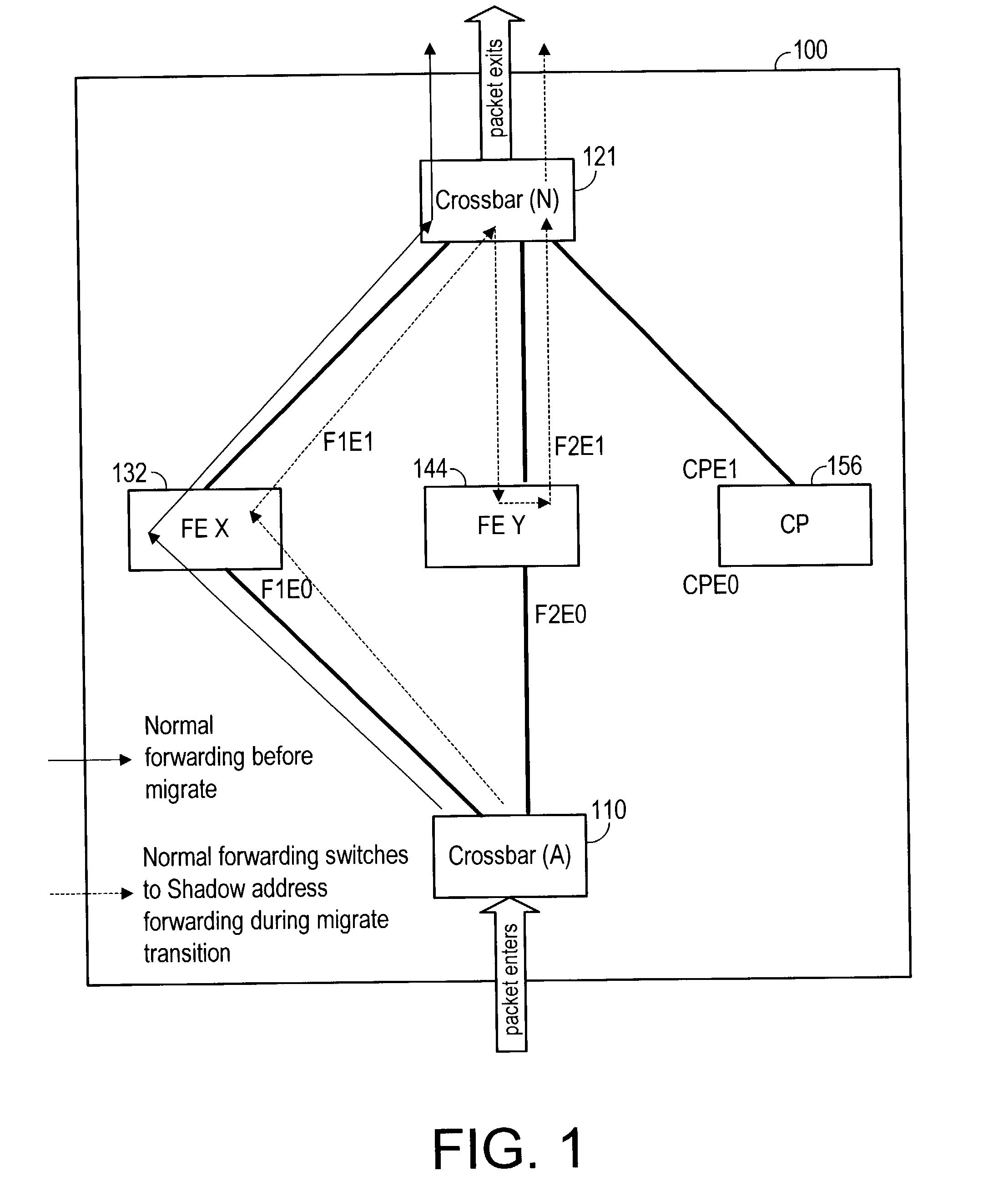

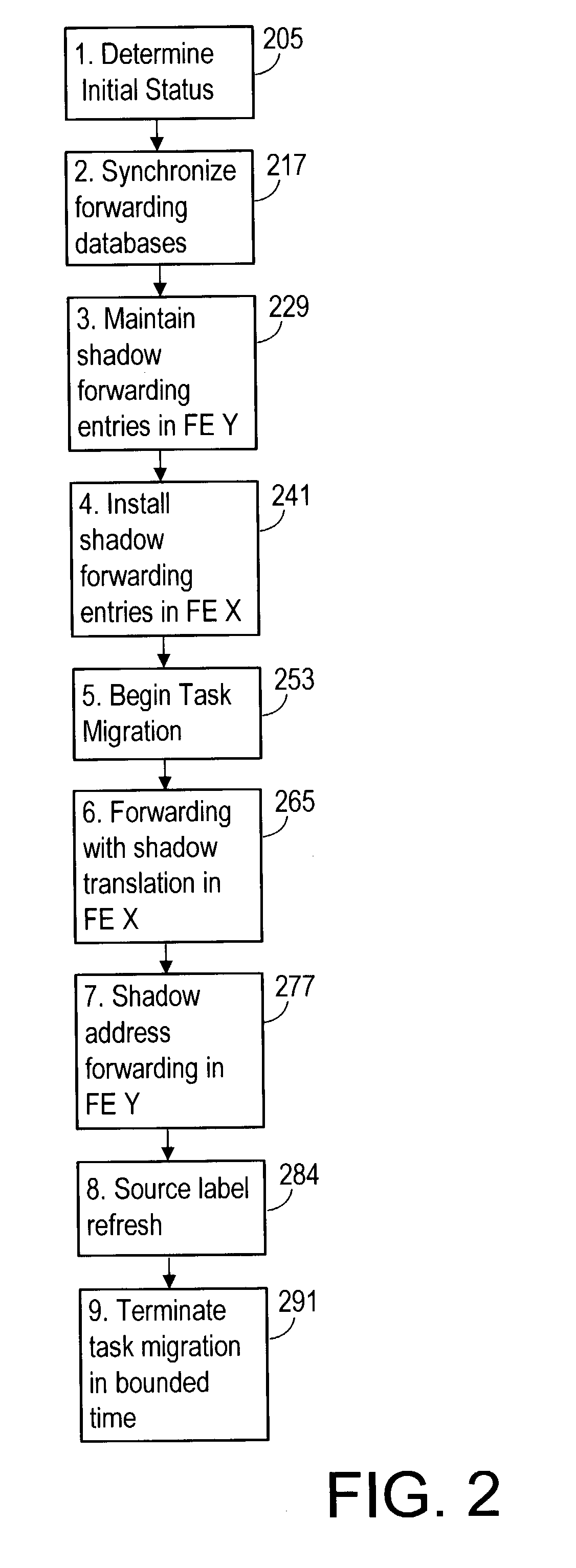

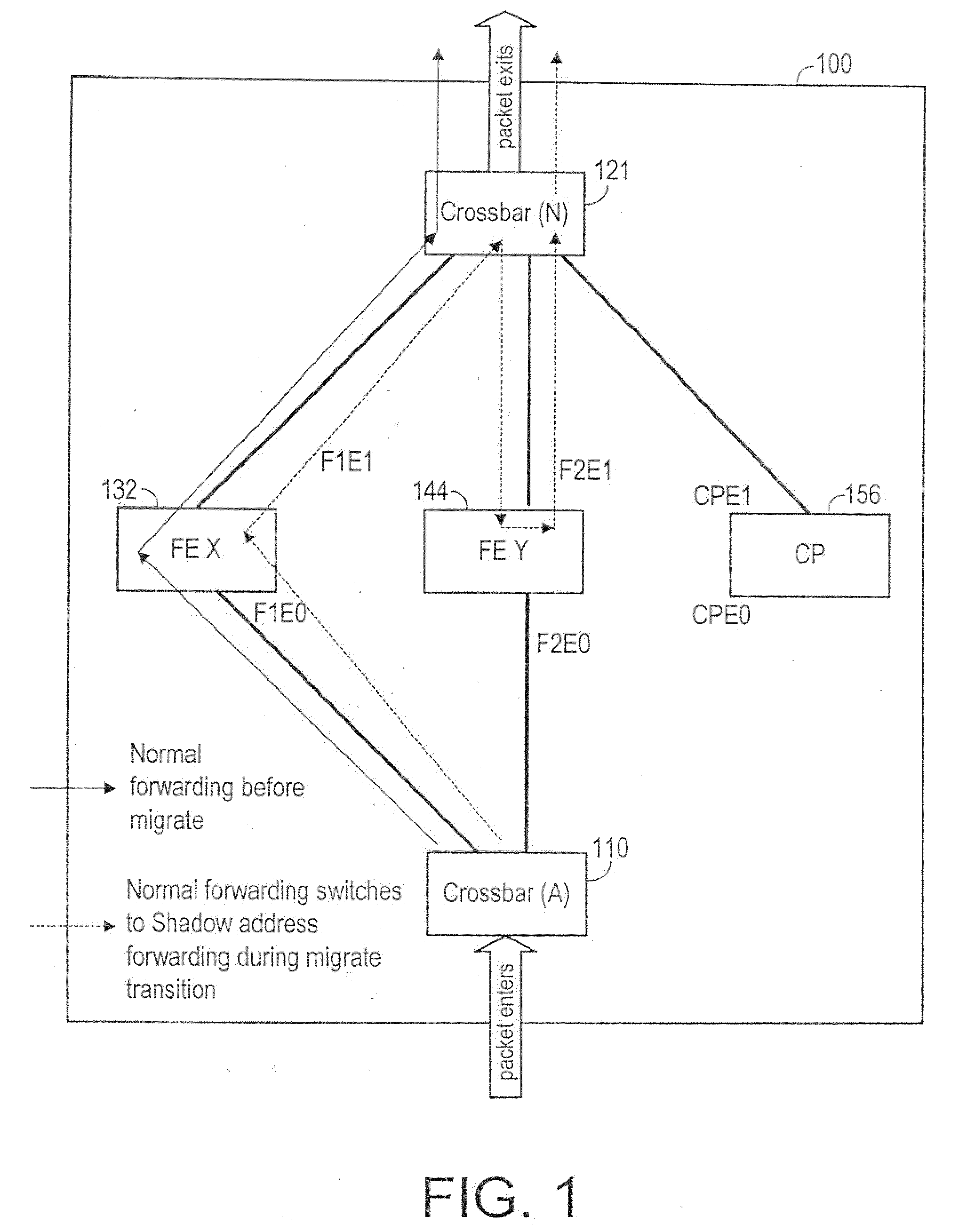

Application non disruptive task migration in a network edge switch

An apparatus and a method are described for zero packet loss task migration in an network switch in a computer network. The invention relates to active or programmable networks, i.e. networks based on packet switching algorithms and switch configurations which are subject to change. A well-defined protocol enables an intelligent switch to migrate tasks from one forwarding engine to another without any packet loss. This enables the algorithms and configurations of the switch to be updated or modified arbitrarily.

Owner:PALO ALTO NETWORKS INC

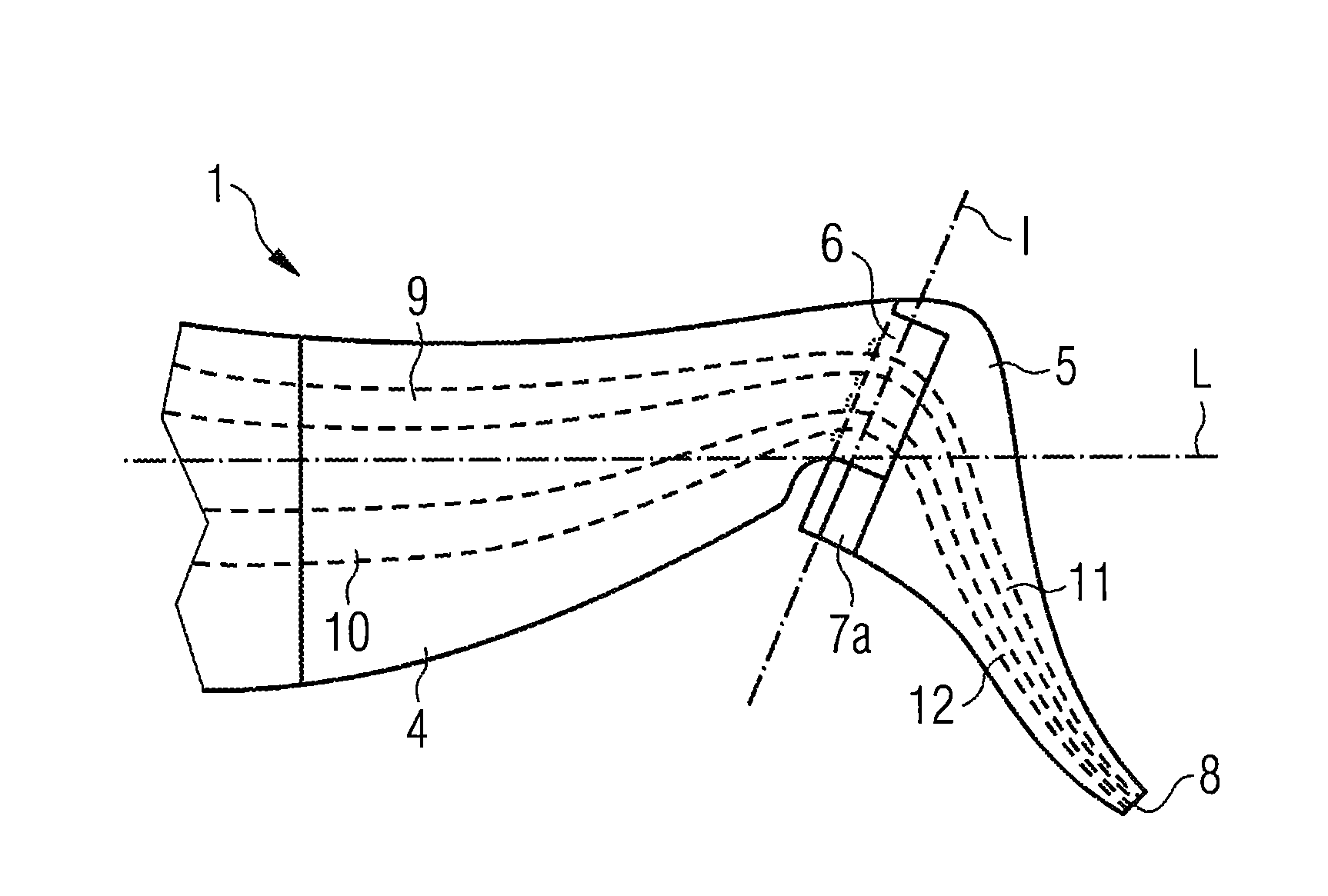

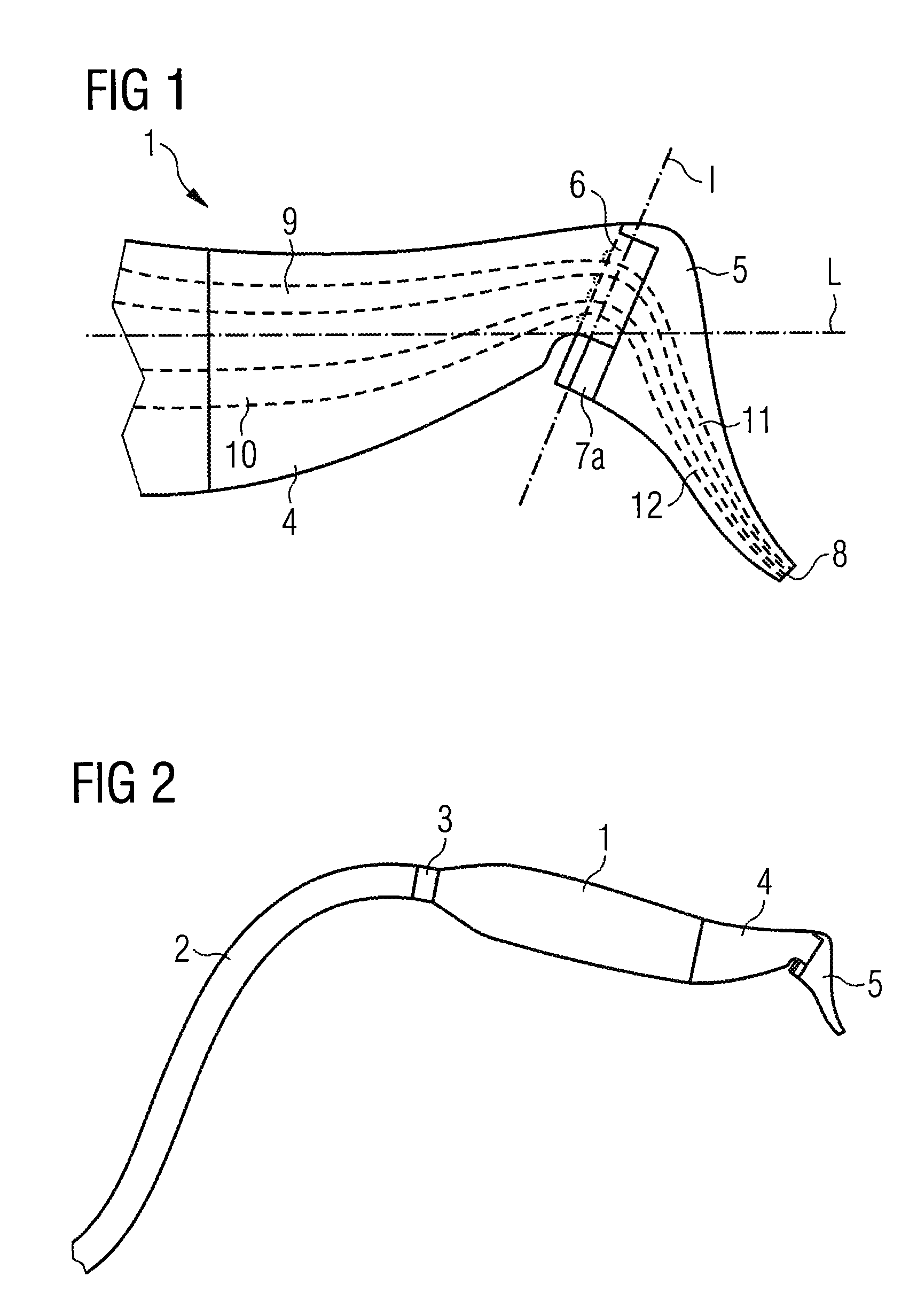

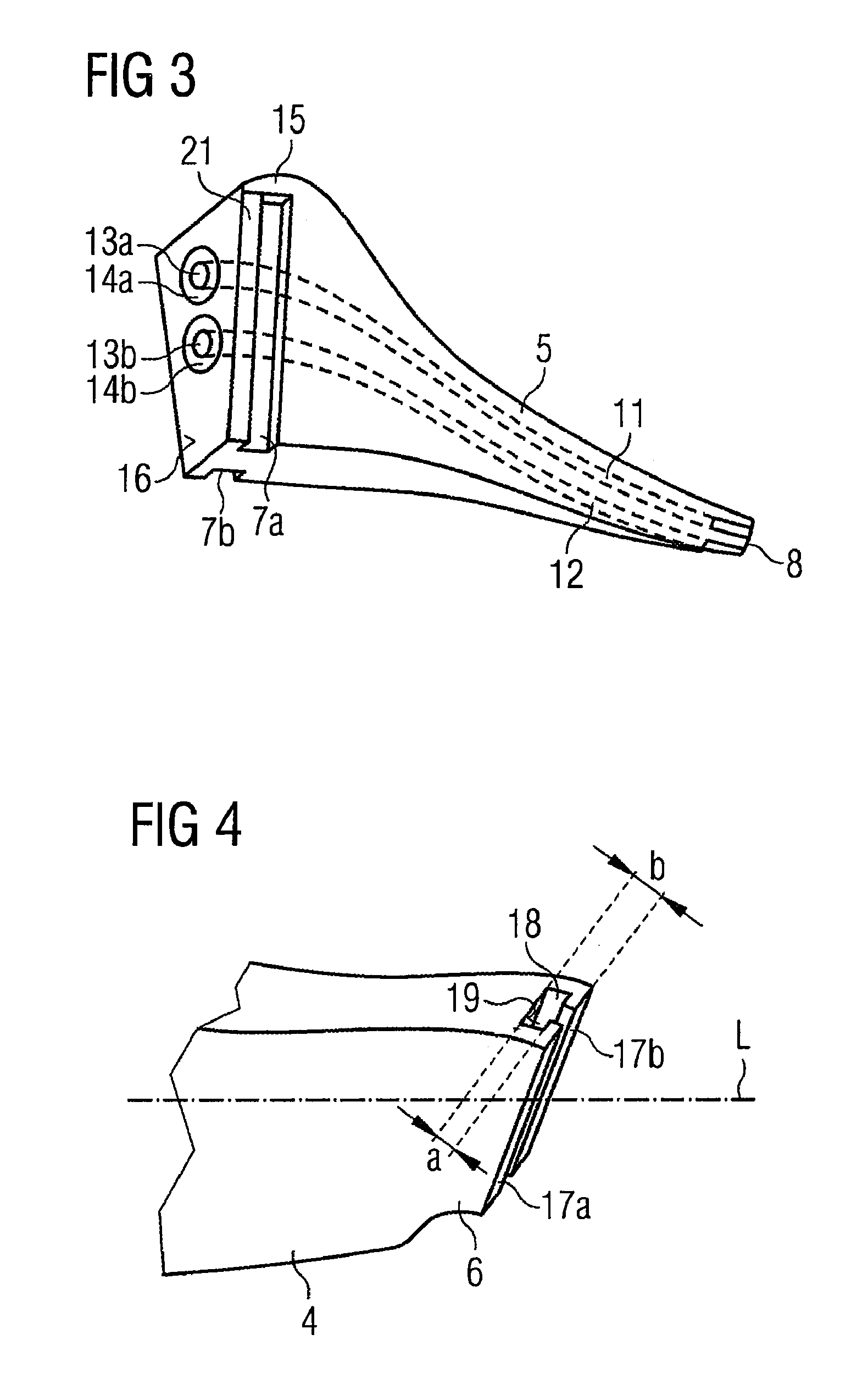

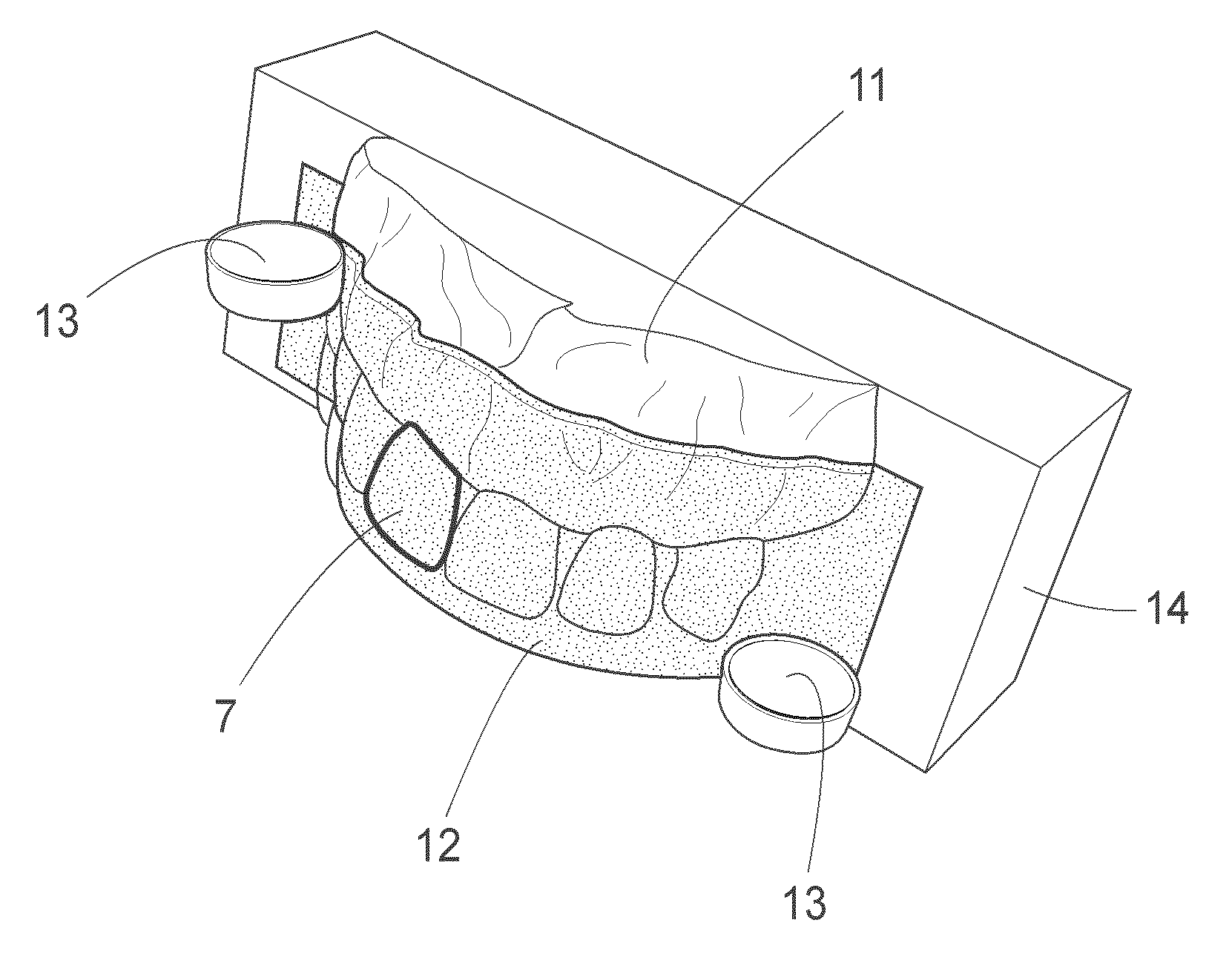

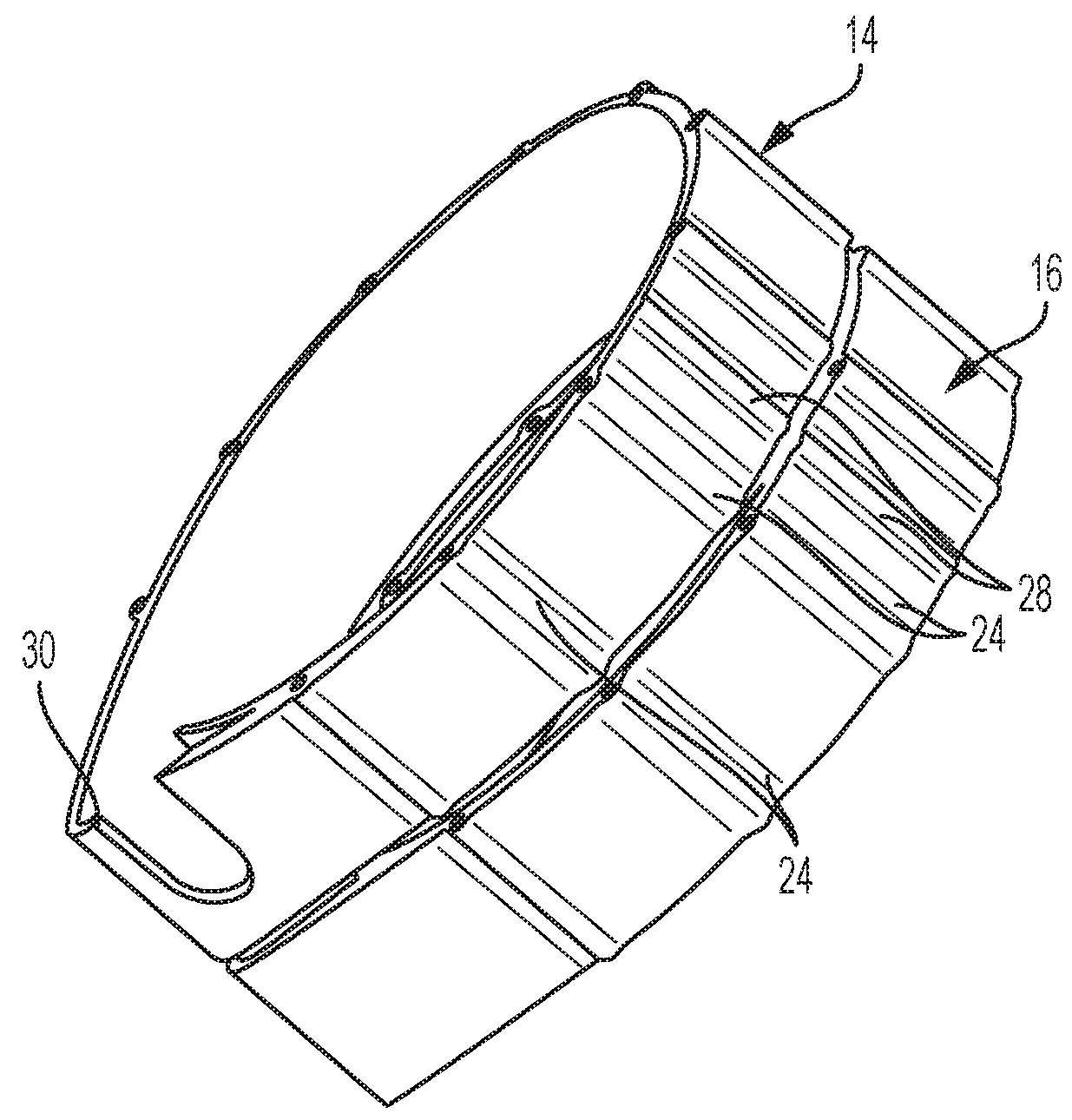

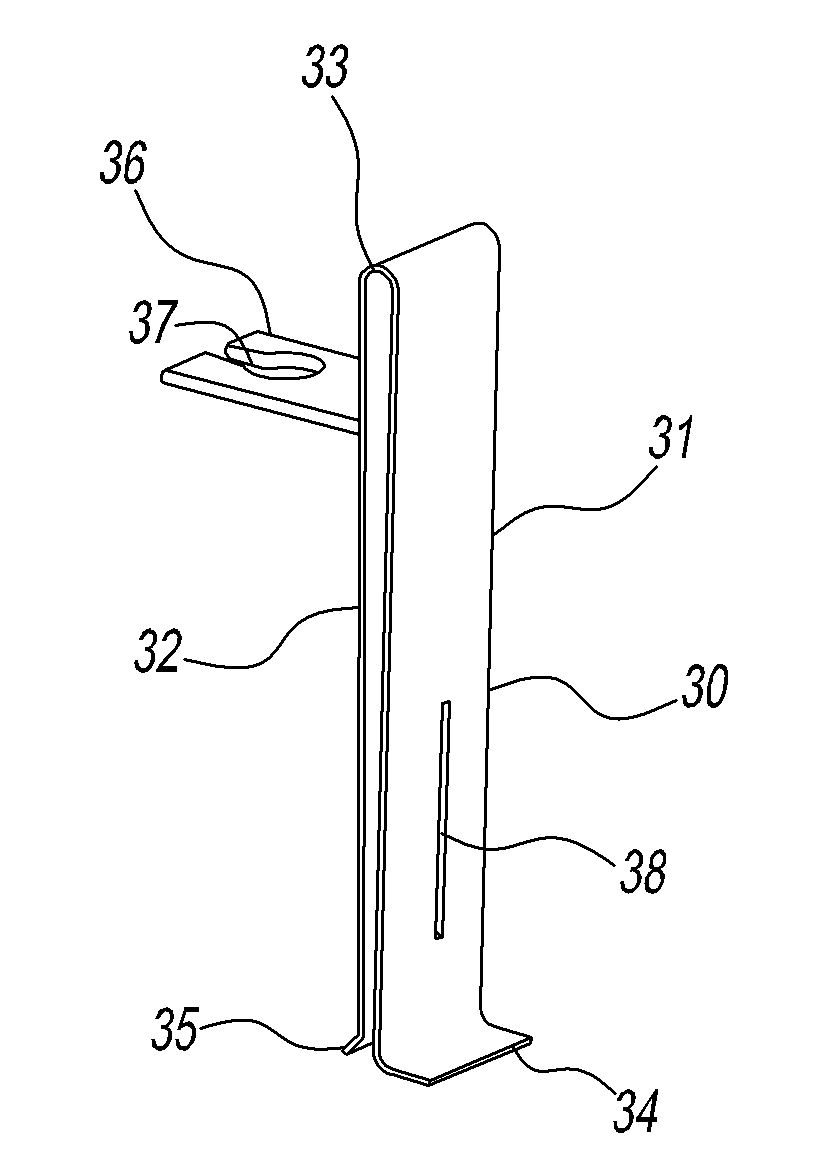

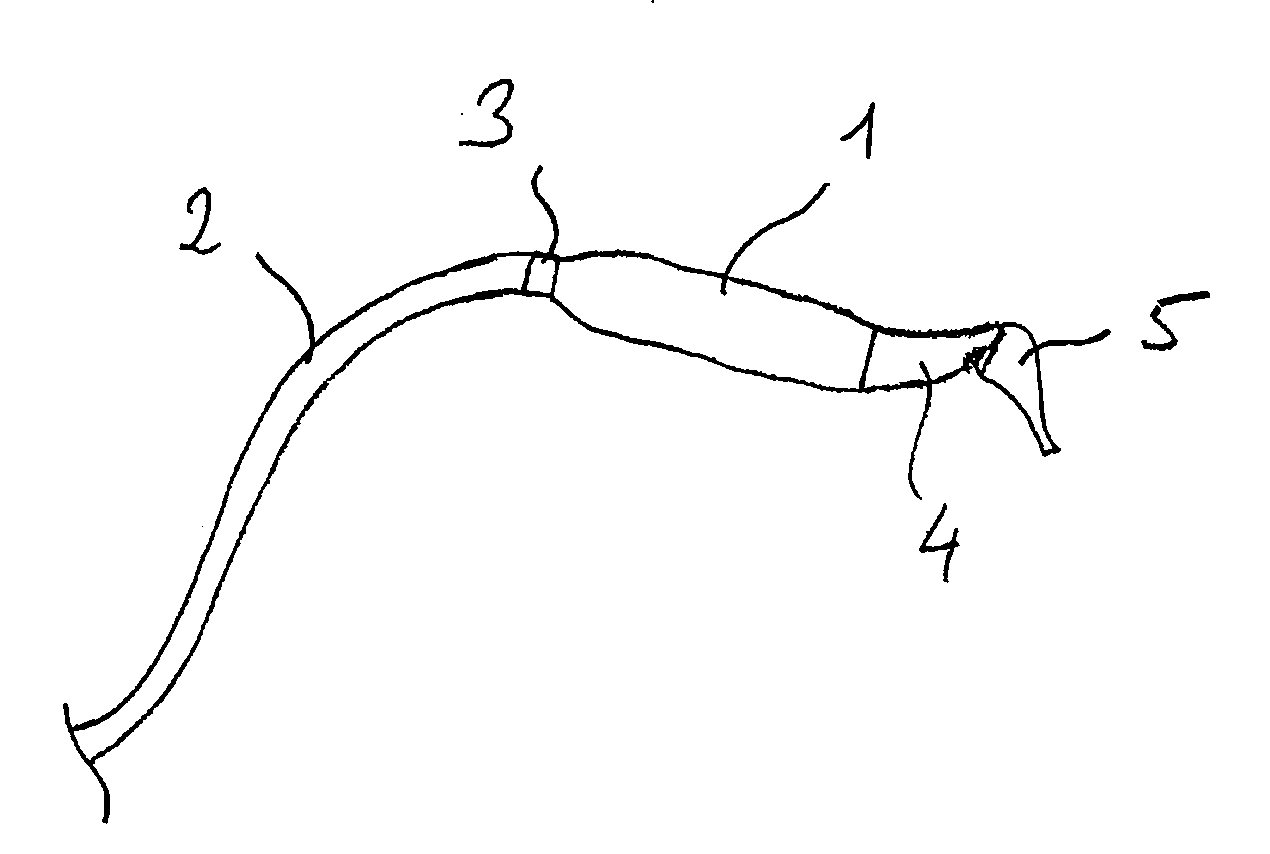

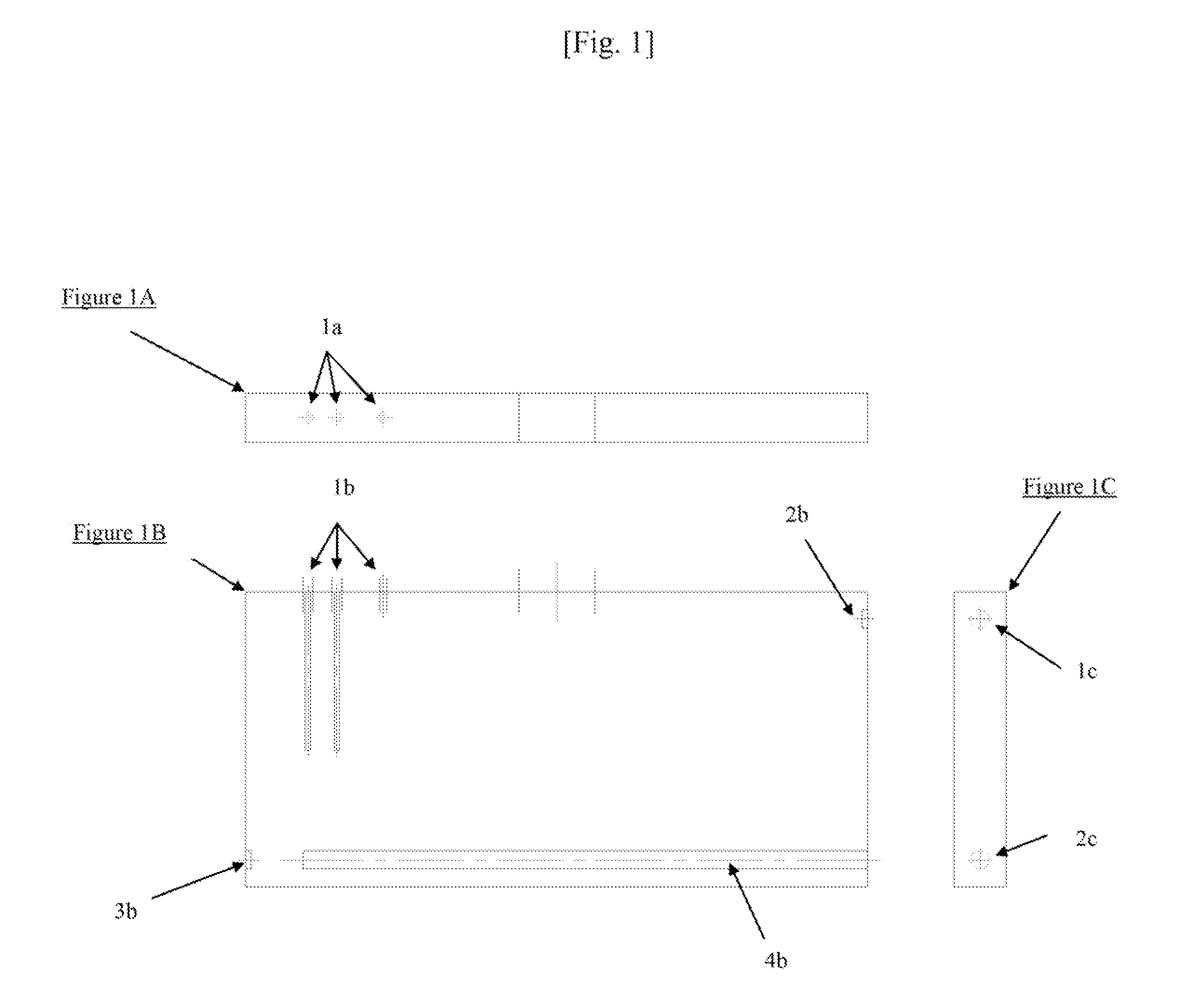

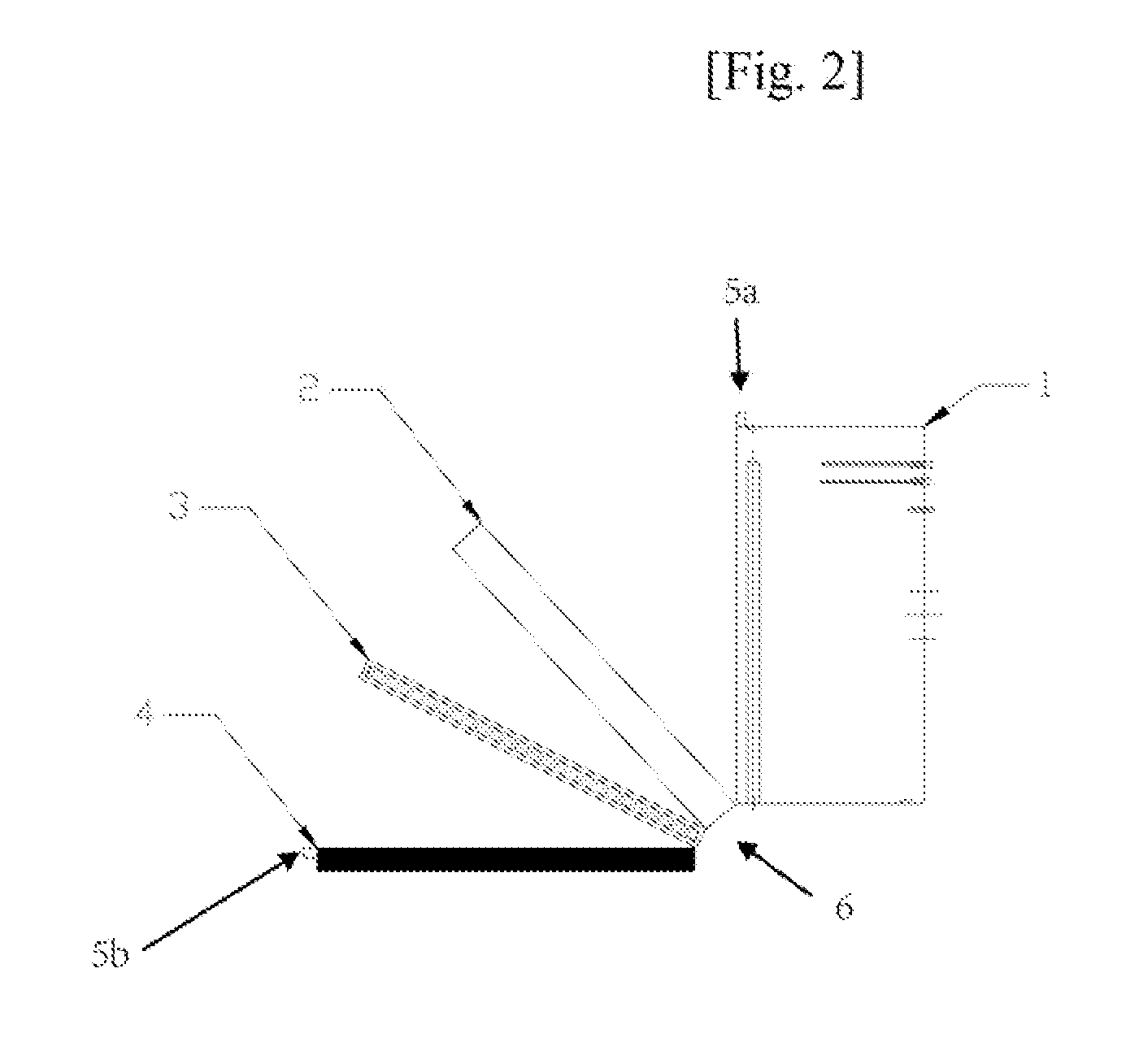

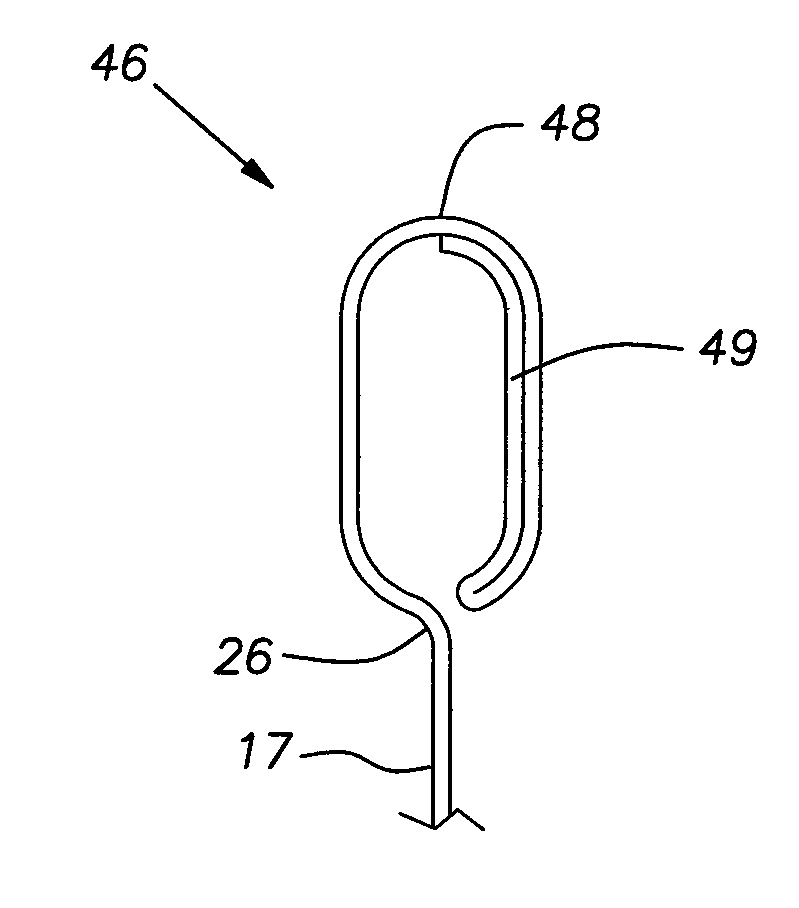

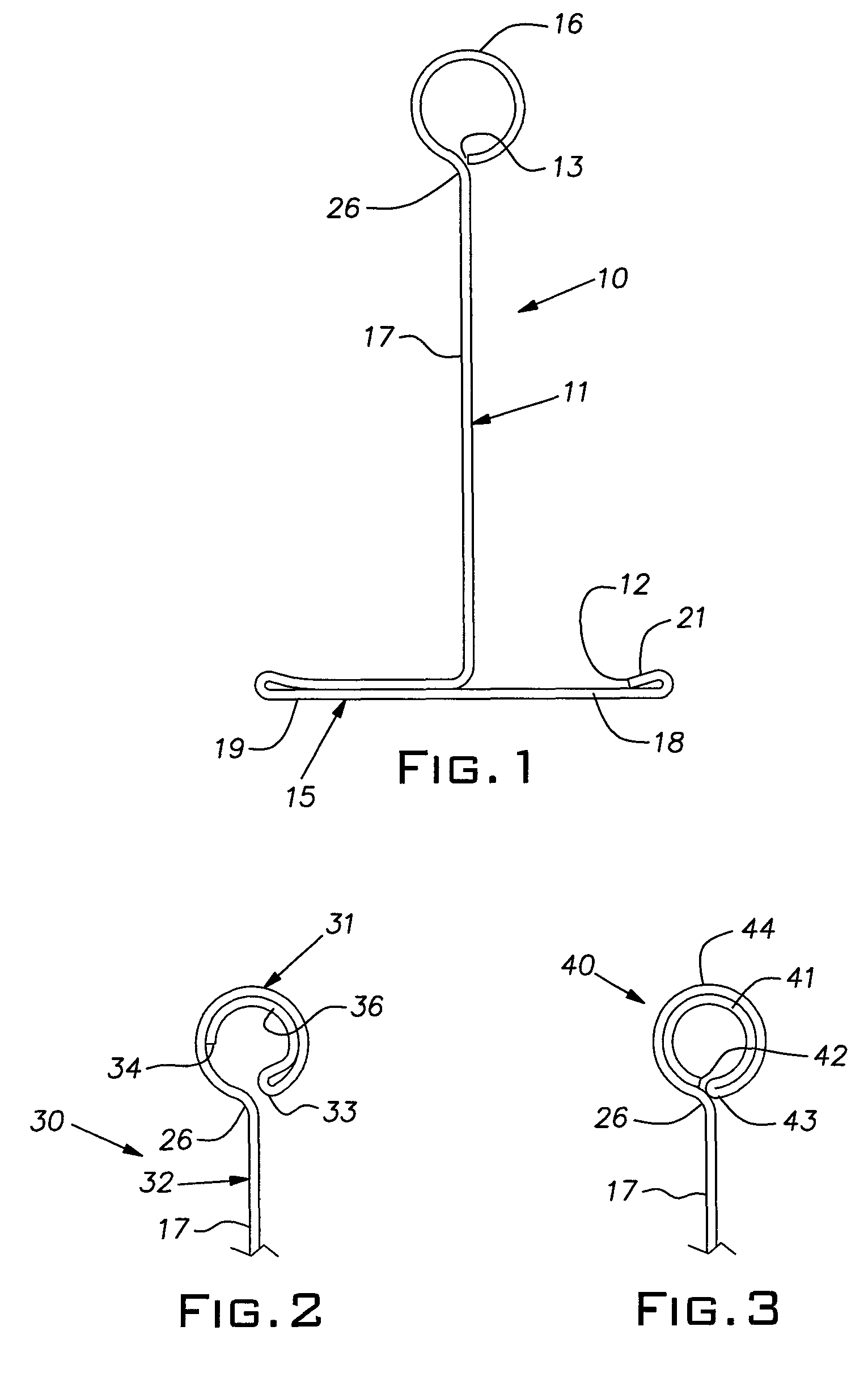

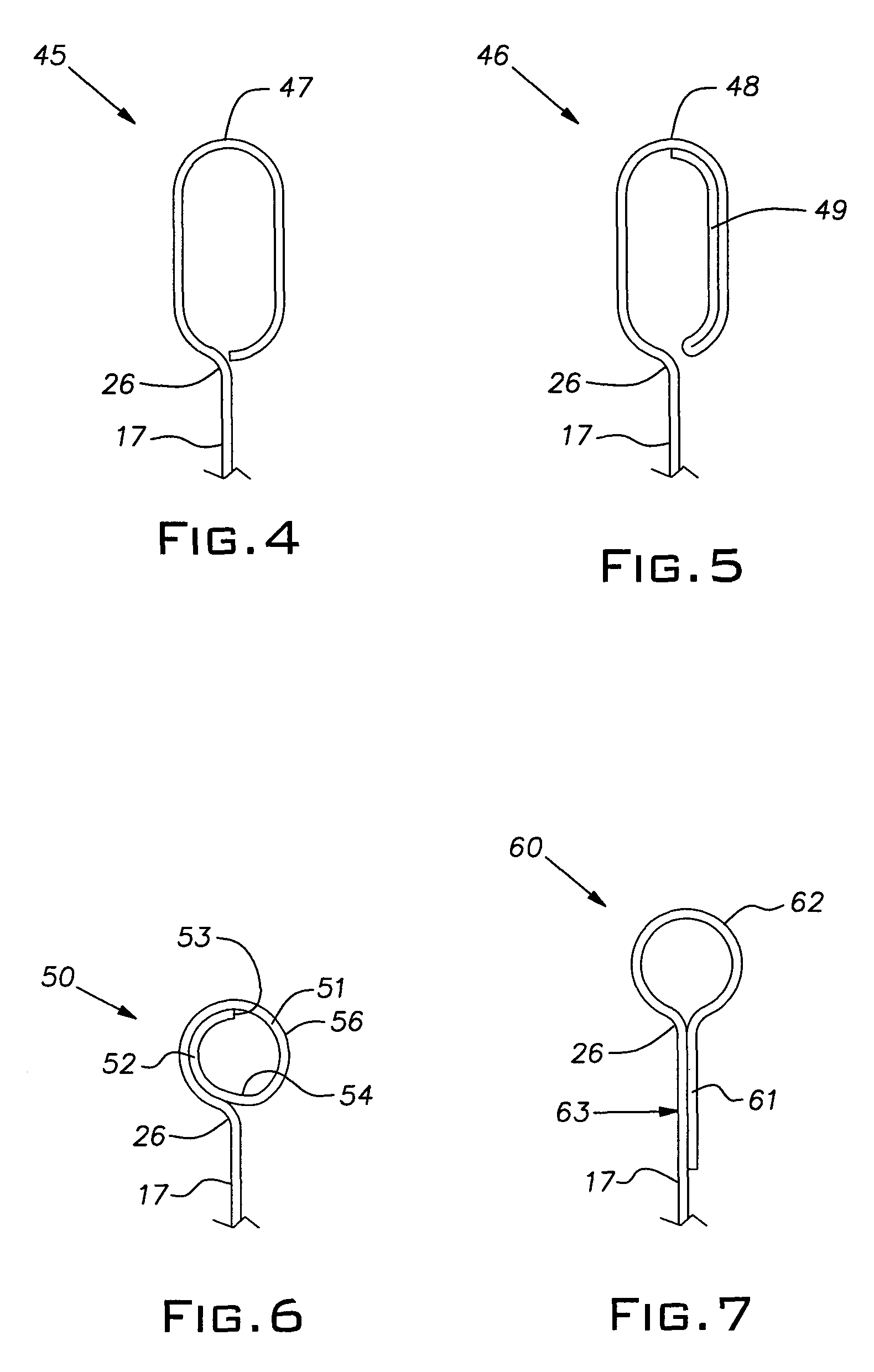

Medical handset and exchangeable nozzle for the same

ActiveUS7762812B2Down timePatients can be treated more quicklyTeeth fillingDental toolsInterference fitPowder mixture

The present invention relates to a medical handset with a nozzle having at least one nozzle line for supplying a medically active medium, such as for example an air-powder mixture and / or a fluid, in particular for the prophylactic treatment of teeth, wherein the handset has a head part with a connecting part on the head for the exchangeable connection of the handset to the nozzle, wherein at least one supply line of the handset is connected to the at least one nozzle line of the nozzle by producing a sealing-tight interference fit of a sealing face on the nozzle with a sealing face on the handle, in particular in that a tongue-and-groove connection is produced between the nozzle and the connecting part, e.g. in that a T-groove on the nozzle is inserted into a T-tongue on the handle, the axis of insertion lying roughly at right angles to the longitudinal axis of the handset.

Owner:FERTON HLDG

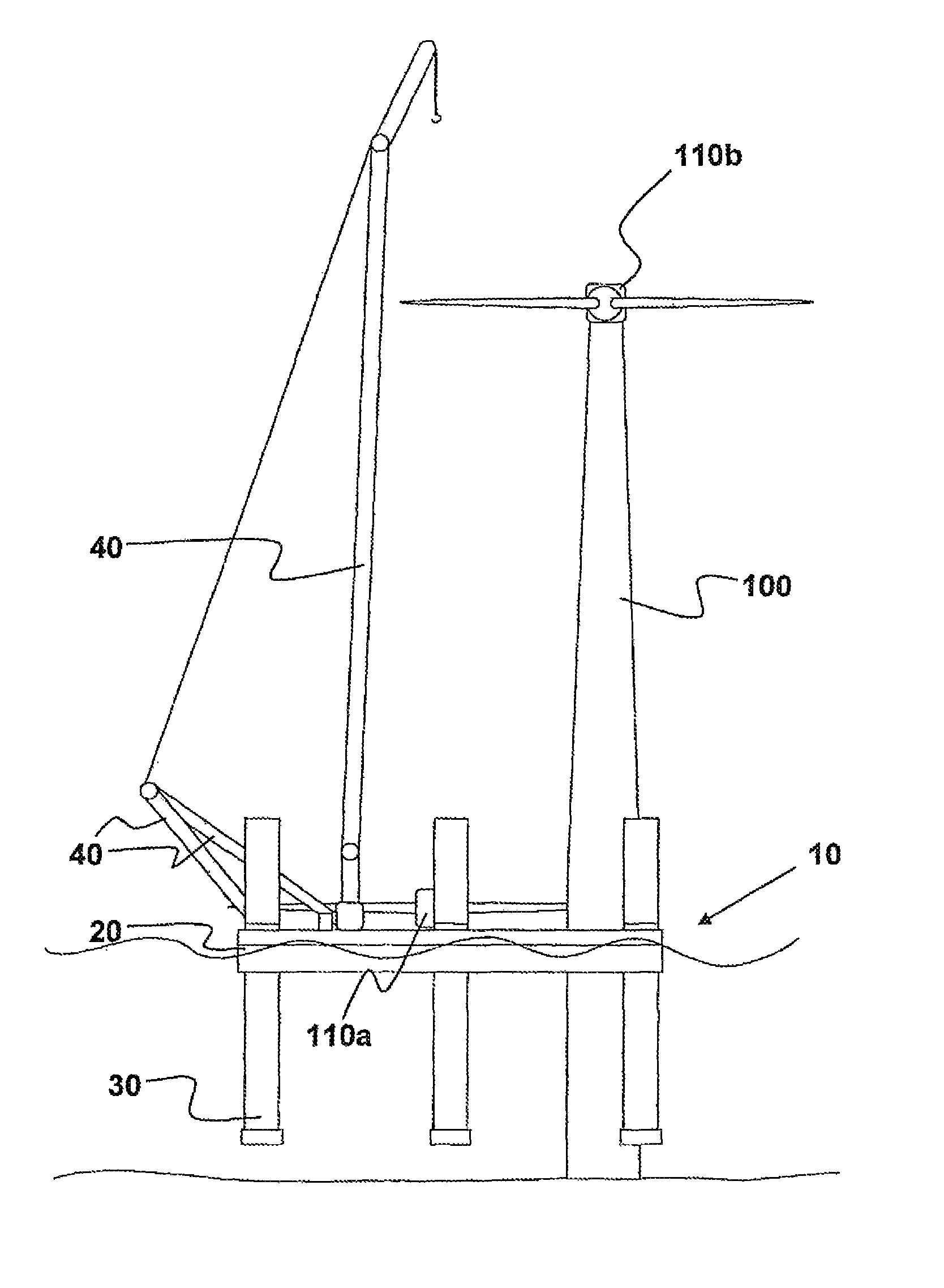

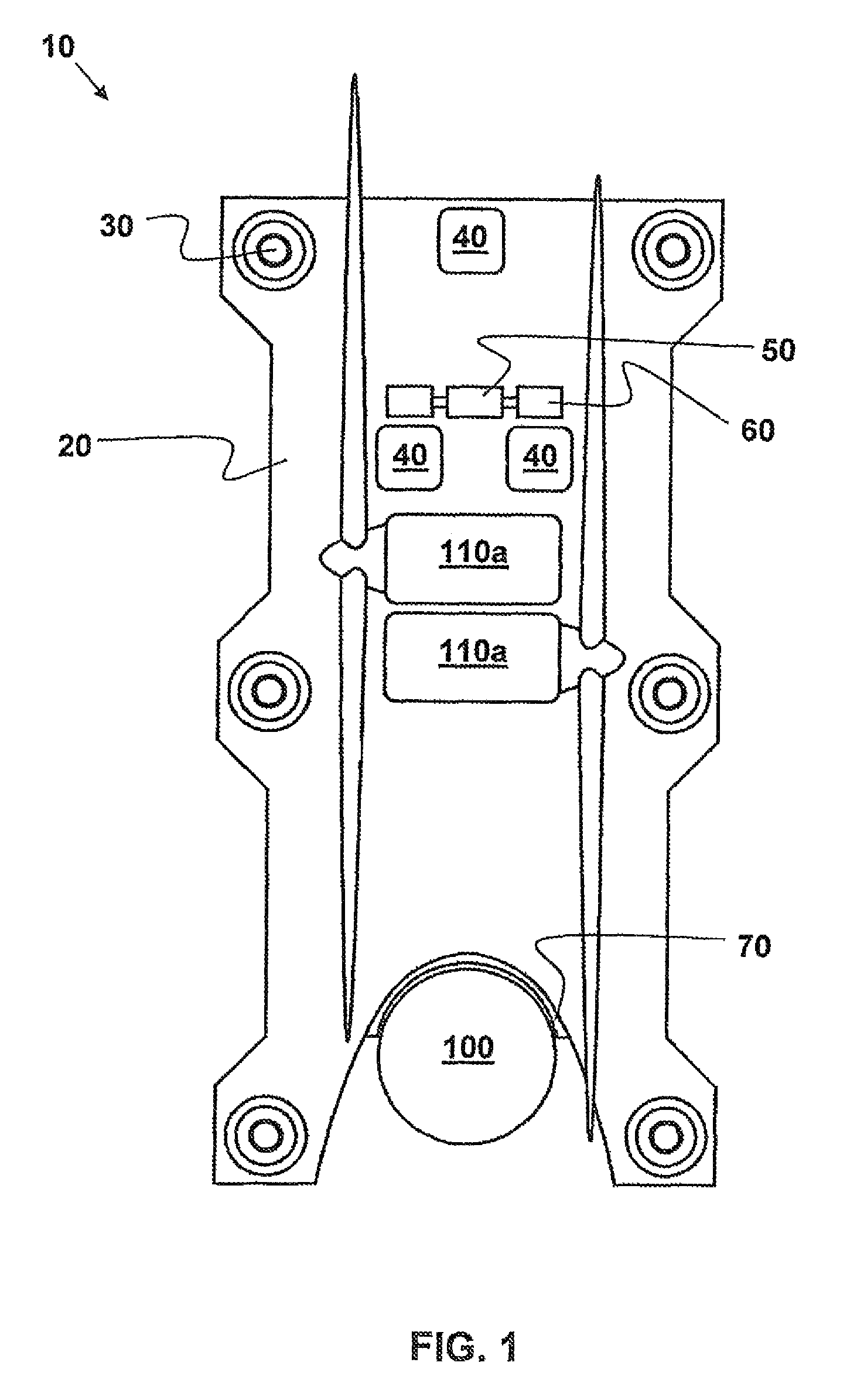

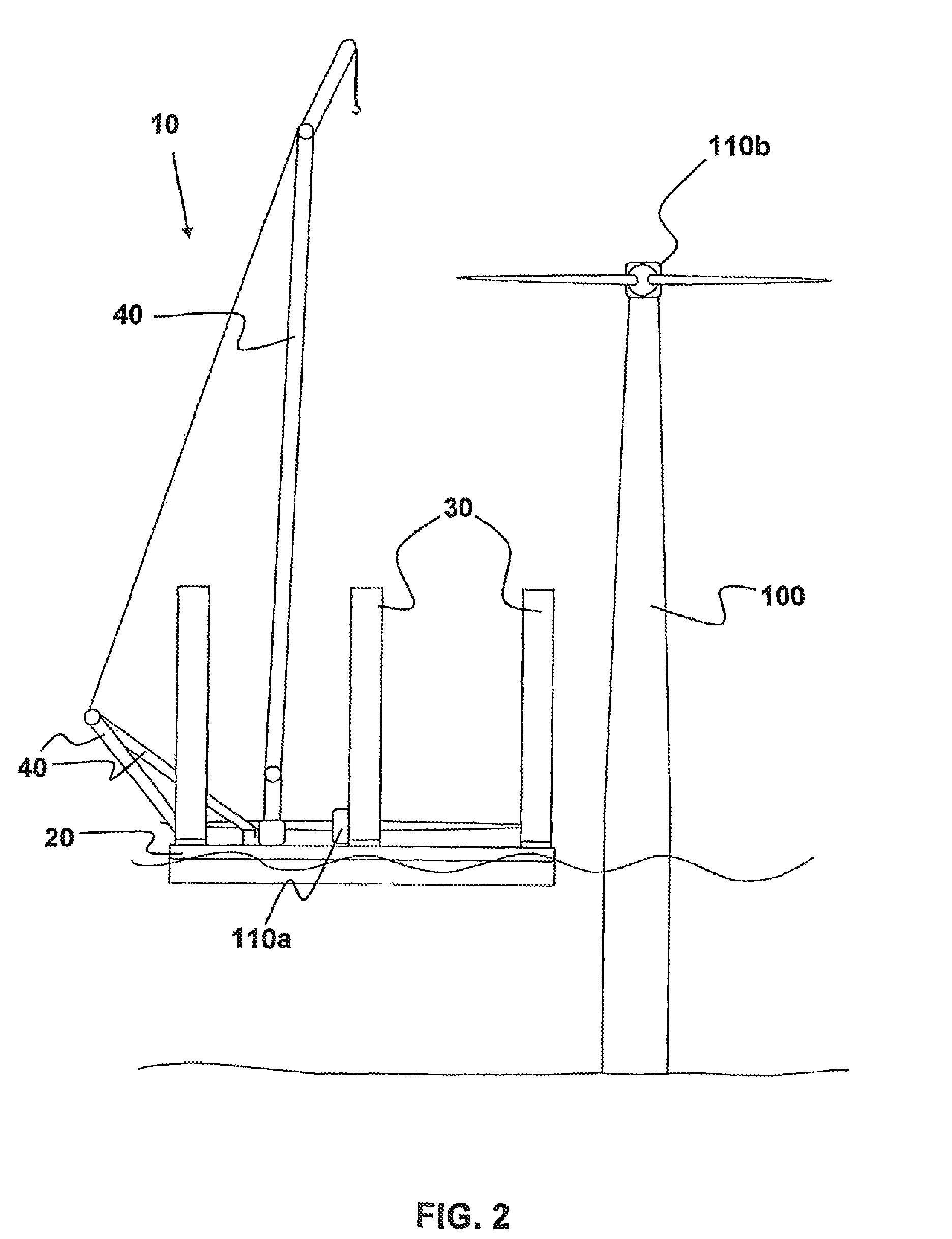

Method for transporting, erecting and replacing a nacelle including the rotor of an offshore wind turbine and watercraft for carrying out the method

InactiveUS8230802B2Quick restartProlonged down timeEngine manufactureDrilling rodsNacelleElectric generator

Method for installing (or replacing) a unit on the tower of an offshore wind turbine, which unit comprises a rotor including a hub and one or two rotor blades, and a nacelle receiving a gearbox and a generator. The method is characterized by pre-assembling the substantially functional unit ashore or on a platform, placing the functional unit on a watercraft in such a manner that the center of gravitation of the unit lies in the region of the longitudinal axis of the watercraft and the rotor blades extend in the longitudinal direction of the watercraft, transporting the functional unit to the site of the offshore wind turbine, lifting the functional unit from the watercraft using a crane aboard the watercraft, placing the functional unit on the tower of the offshore wind turbine, and fastening the functional unit on the tower of the offshore wind turbine.

Owner:AERODYN ENG GMBH

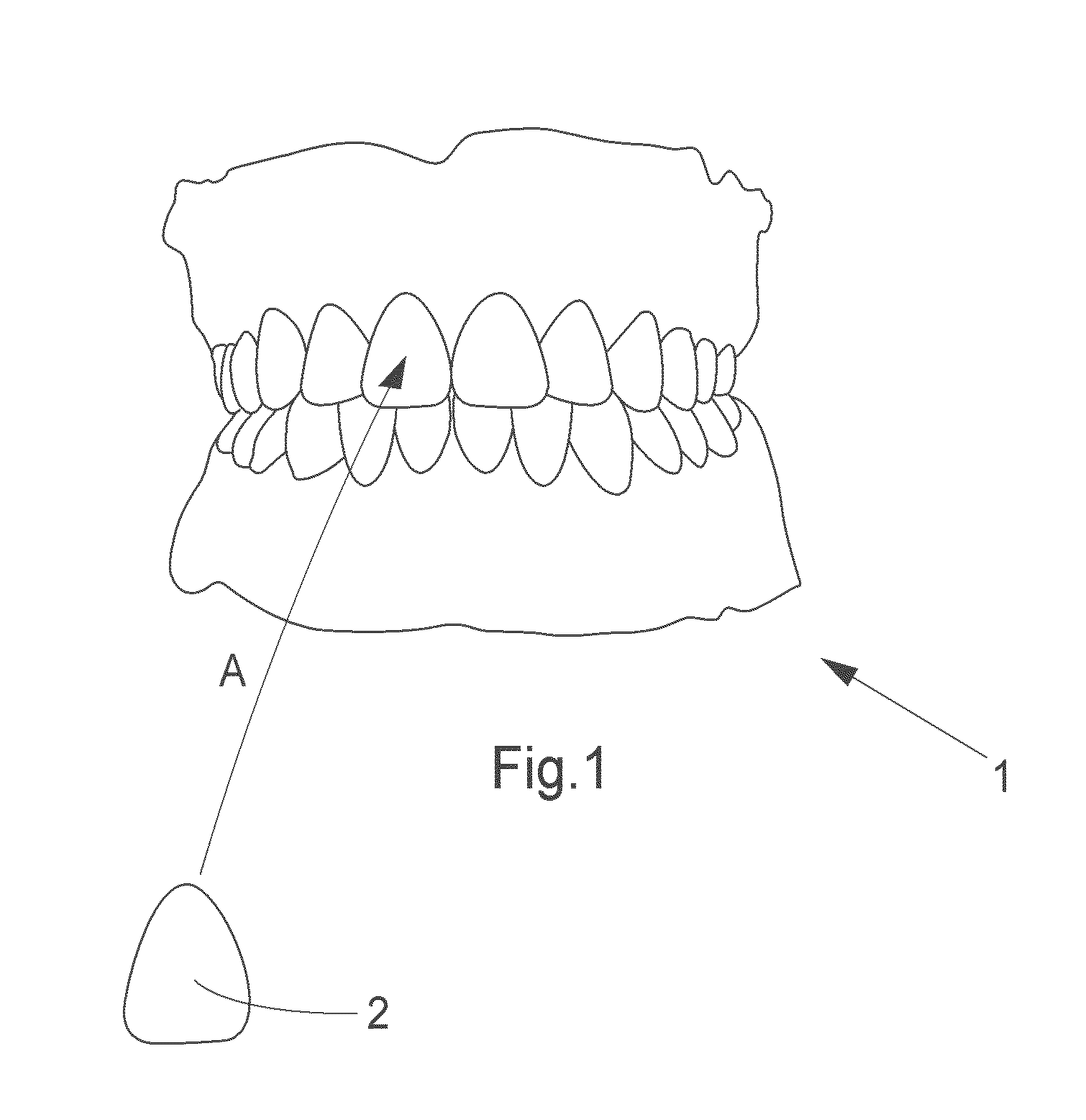

Dental product comprising at least one veneer

InactiveUS20120183921A1Improve aestheticsGood lookingFilling facetsDental toolsDental ProductTooth veneers

Certain embodiments relate to an individualized dental product ready for application. The dental product can include at least one tooth veneer which is of a ceramic material, is plate-like and has a plate thickness of at least about 0.08 mm. In some embodiments, the thickness is less than 0.2 mm, less than 0.14 mm or less than 0.1 mm. Certain embodiments also relate to a method of improving the aesthetics of a tooth. The method can include placing a dental product onto a tooth surface.

Owner:NOBEL BIOCARE SERVICES AG

Methods and apparatus for adjusting ice slab bridge thickness and initiate ice harvest following the freeze cycle

ActiveUS9625199B2Conserve waterIncrease and decrease making cycle timeLighting and heating apparatusIce productionMarine engineering

A method and apparatus for adjusting and controlling ice bridge slab thickness and / or initiation of ice harvest following a freeze cycle. This adjusting and controlling is performed through the use of adjustable float clip assemblies which set the amount of water available for ice making in a batch process. The adjustable float clip assemblies provide an ice machine user with the ability to easily adjust the ice slab bridge thickness to a single or plurality of settings, and allow for changes in ice bridge slab thickness at the site of installation.

Owner:PENTAIR FLOW SERVICES

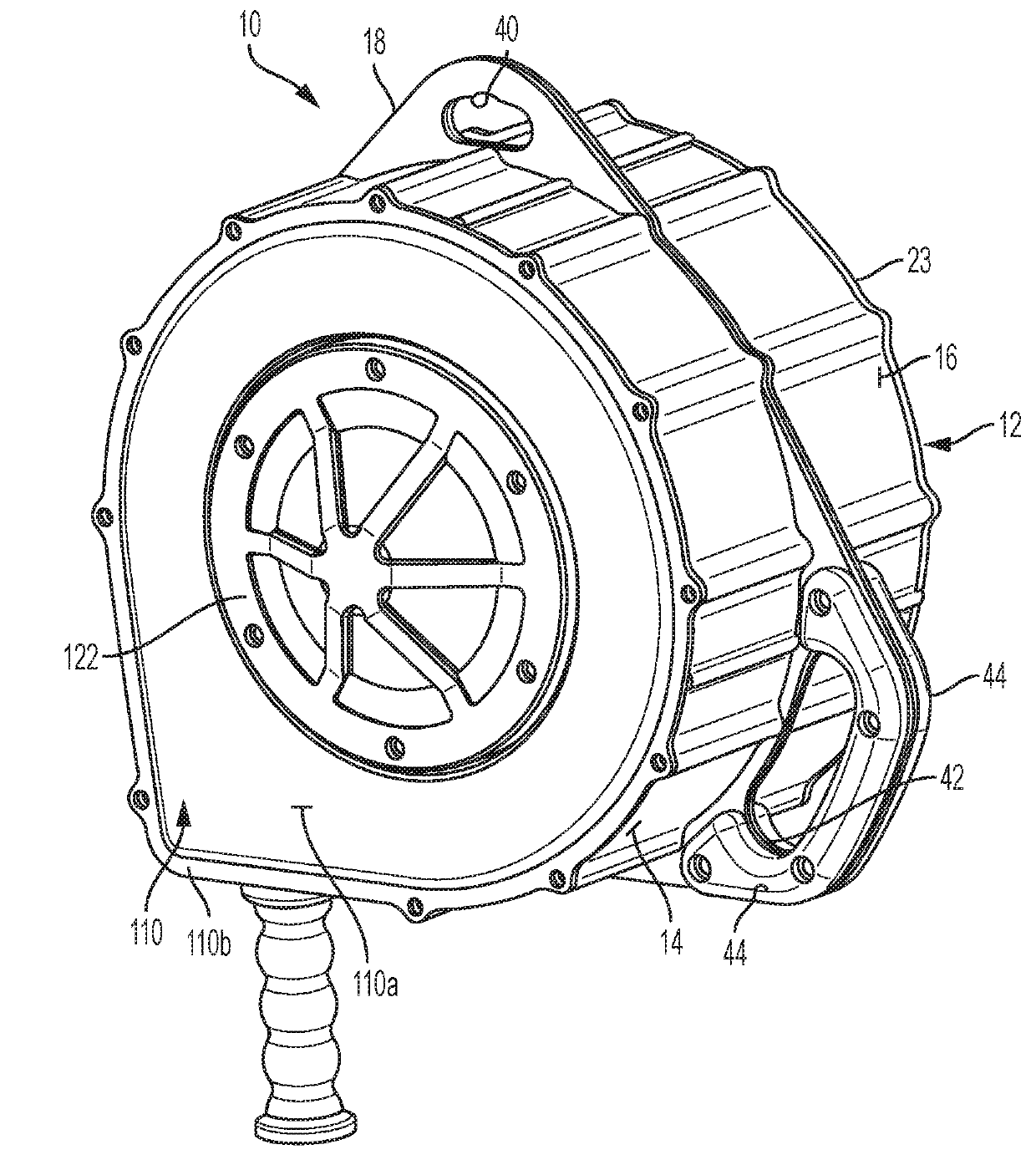

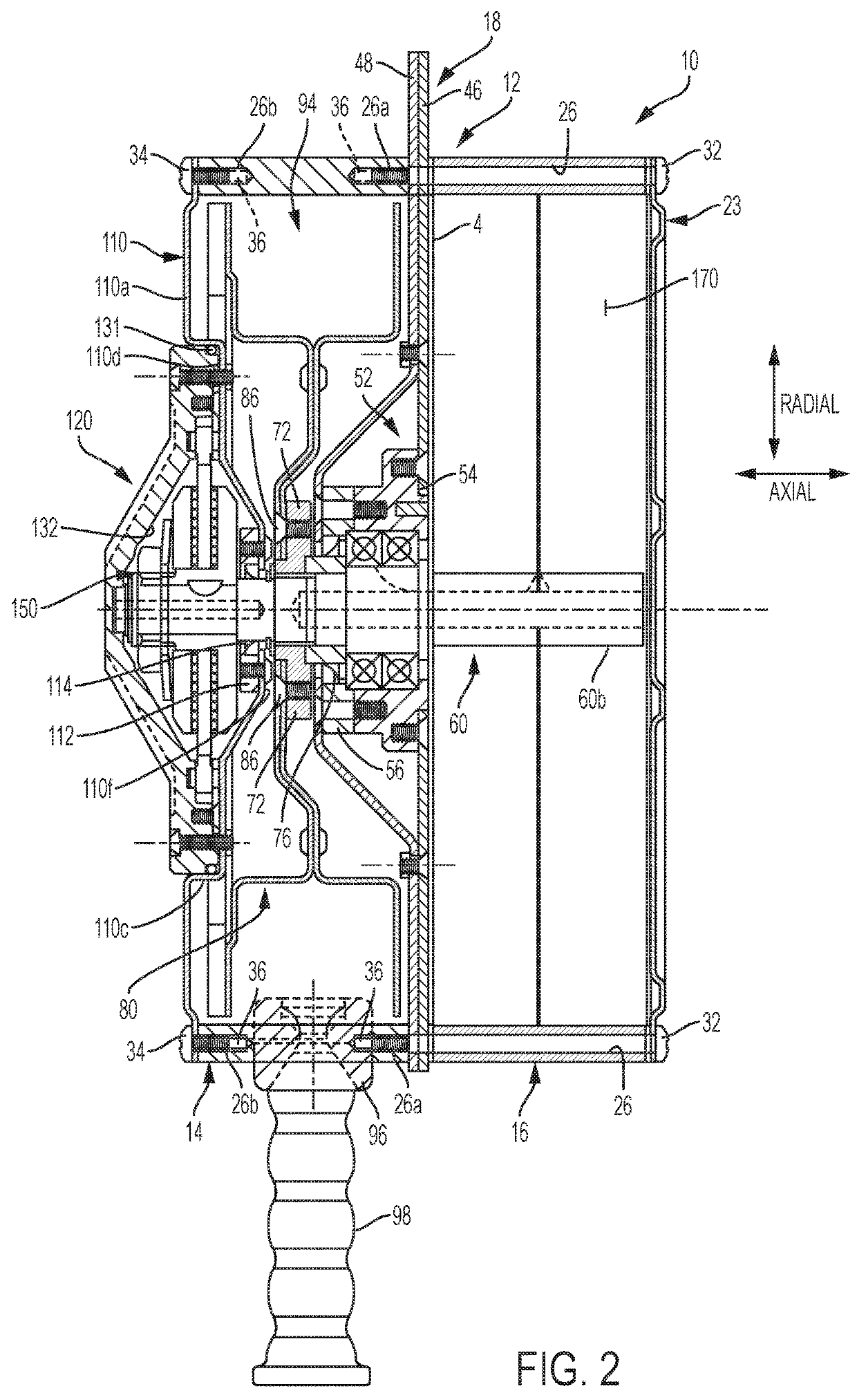

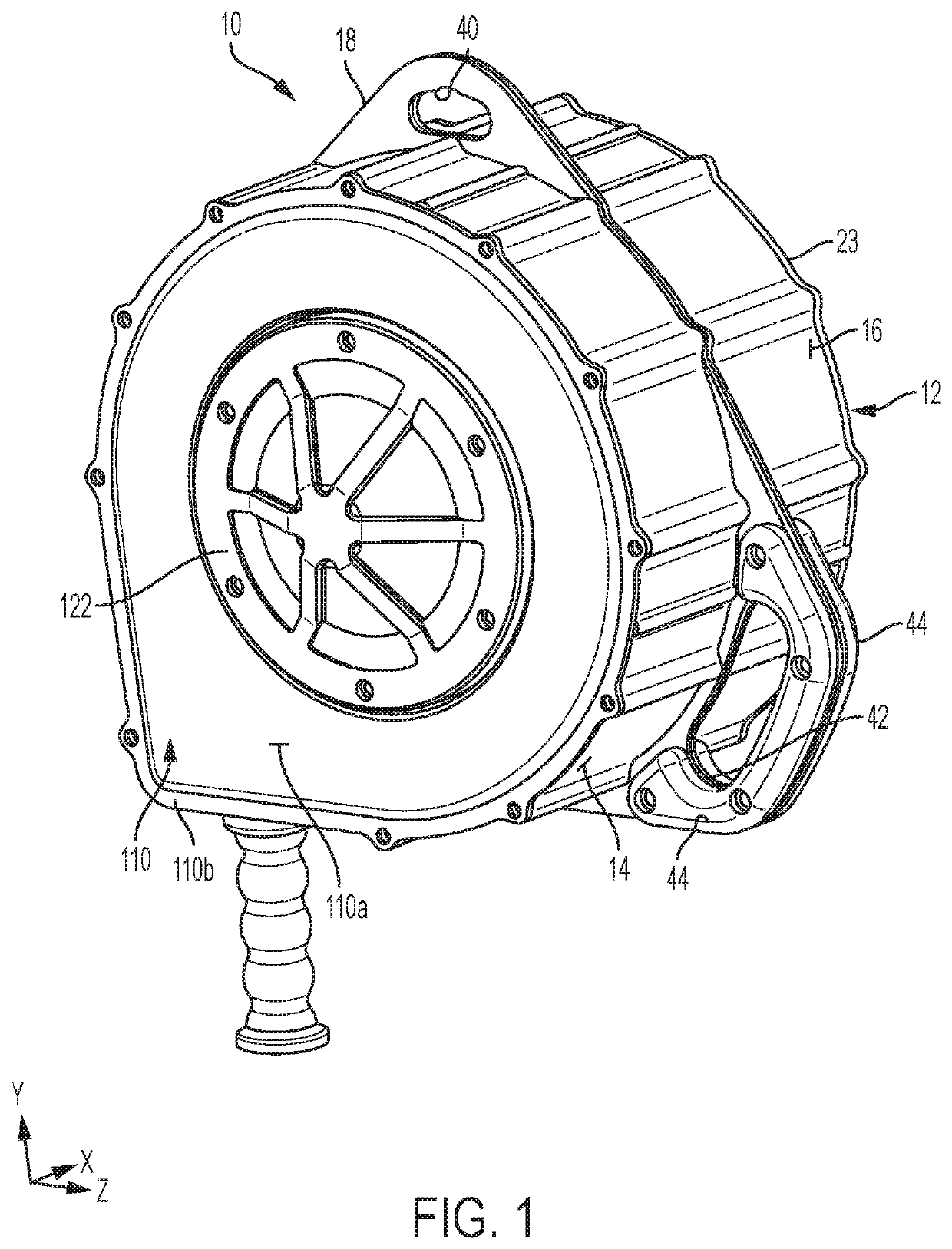

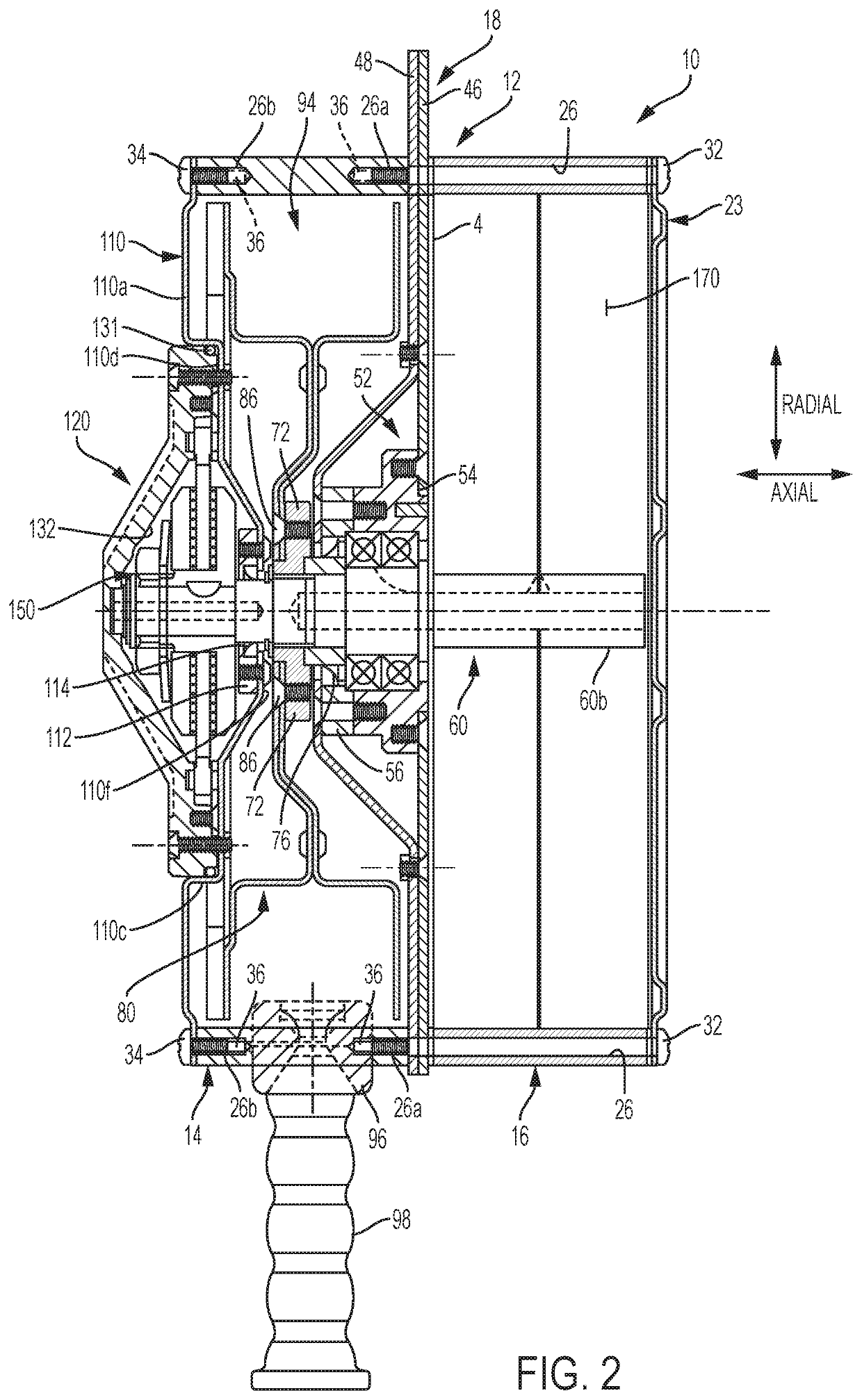

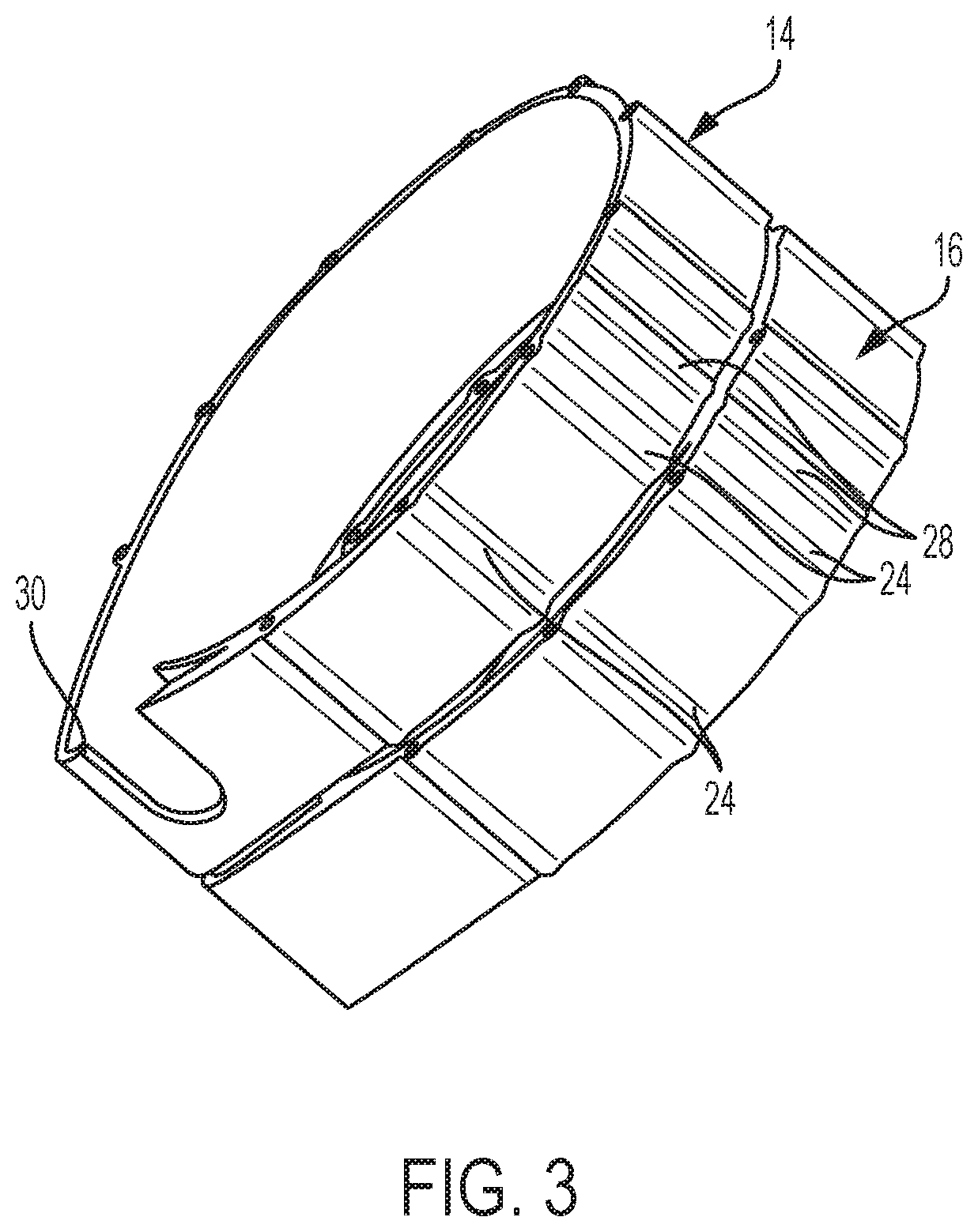

Sealed retractable fall arrest block

ActiveUS20180161608A1Extrusion process is simpleEasy to replaceSafety beltsBuilding material handlingEngineeringClutch

A retractable fall arrest block comprising a spring side housing member and a drum side housing member. A center support wall, defining a bearing housing, is secured between the housing members. A bearing assembly is mounted in the bearing housing to support a spindle. A spring side housing member is mounted to a spring side of the center support wall and a spring side cover is mounted to the spring side housing member opposite the center support wall to define a spring housing. A drum side housing member is mounted to a drum side of the center support wall, and a drum side cover is mounted to the drum side housing member to define a drum housing. The spindle extends into both housings. A spring is mounted in the spring housing. A drum is positionally fixed to the spindle in the drum housing. A clutch assembly is mounted to the spindle to stop the drum from unwinding.

Owner:RELIANCE INDUSTRIES LIMITED

Method and apparatus for gasification of organic waste in batches

ActiveUS9139785B2Minimum thermal inertiaCooled-down quicklySolid waste disposalEnergy inputParticulatesCombustor

A gasification reactor for processing organic waste in batches comprises a primary gasification reactor (62) that includes a primary gasification chamber (18) and a surrounding combustion chamber (19), a secondary gasification chamber (21), a synthesis gas decontamination unit (42) and a combustible gas selector (41). The waste is loaded into the primary gasification chamber through a latched opening and heated from the combustion of a fuel in the combustion chamber (19) to convert the waste to a synthesis gas. The gasification chamber (18) has an intake (20) for introducing pre-heated process air (1) therein. The combustion chamber operates either with a conventional fuel (9) or with the produced synthesis gas (6). The secondary gasification chamber (21) thermally treats the synthesis gas (2) to eliminate tars. The decontamination unit (42) scrubs the synthesis gas of contaminants including particulates and acid gases. The clean synthesis gas (6) is directed to the combustible gas selector (41) which selectively feeds either the combustible fluid (9) or the synthesis gas (6) to the burner (40).

Owner:PROTERRGO

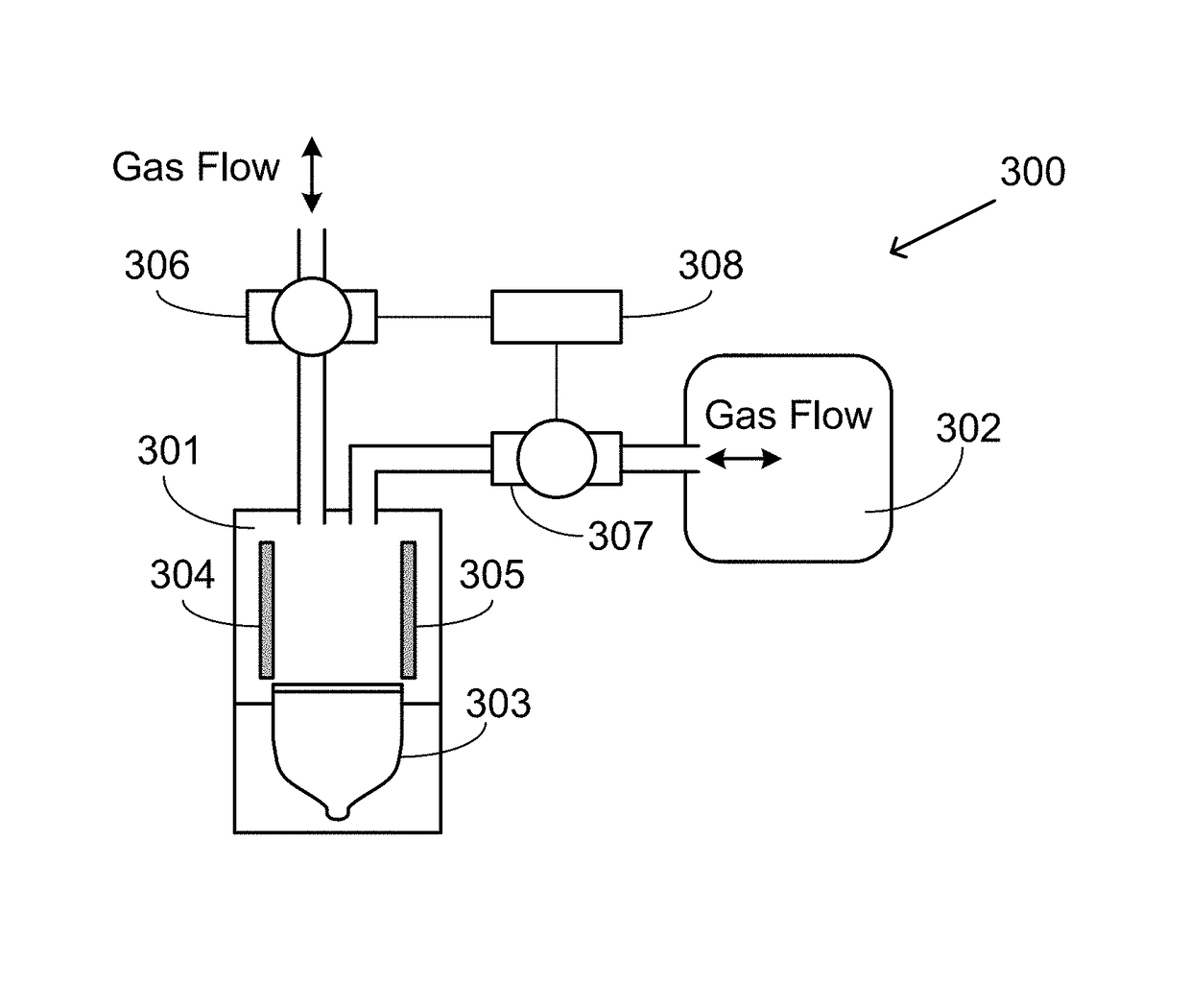

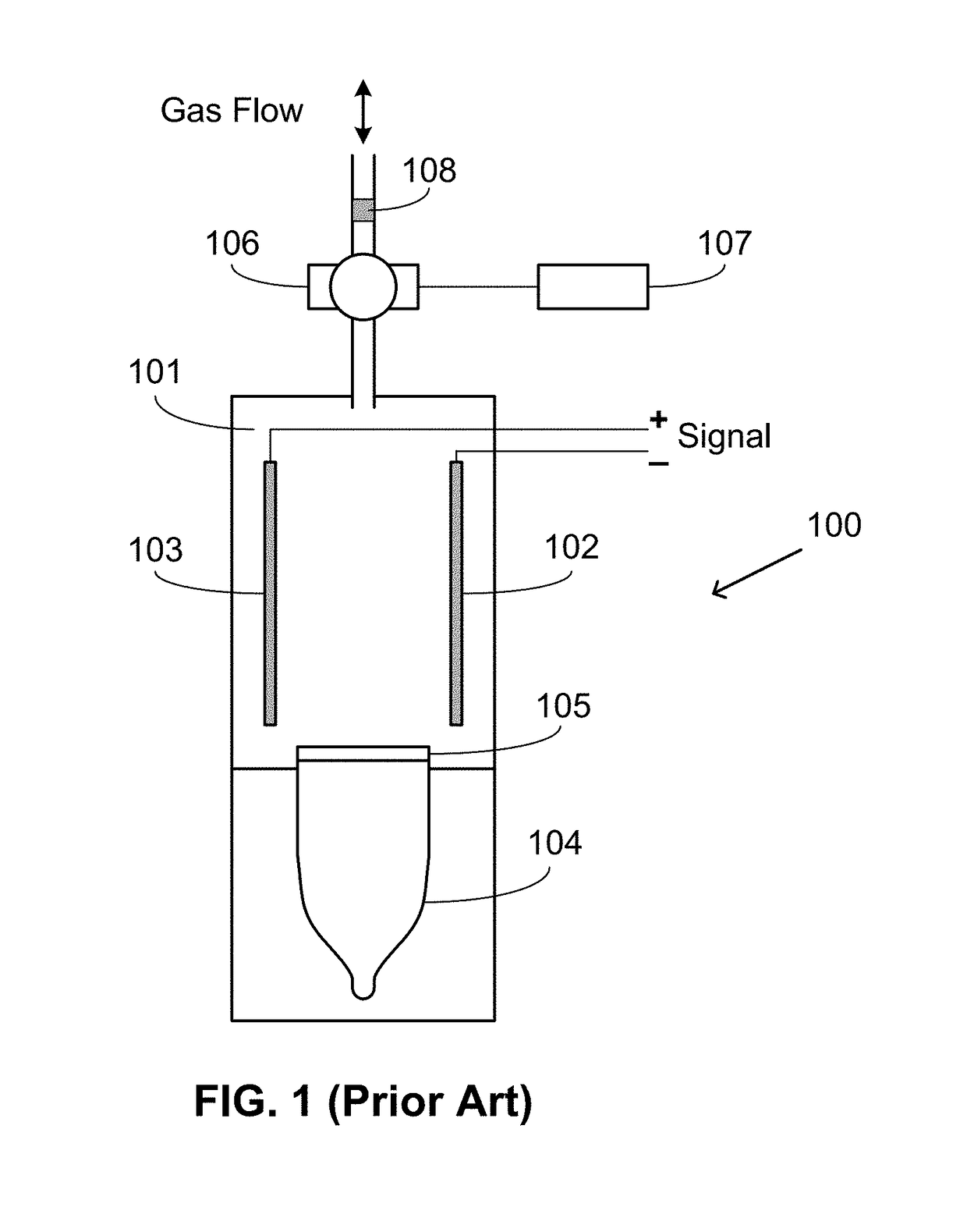

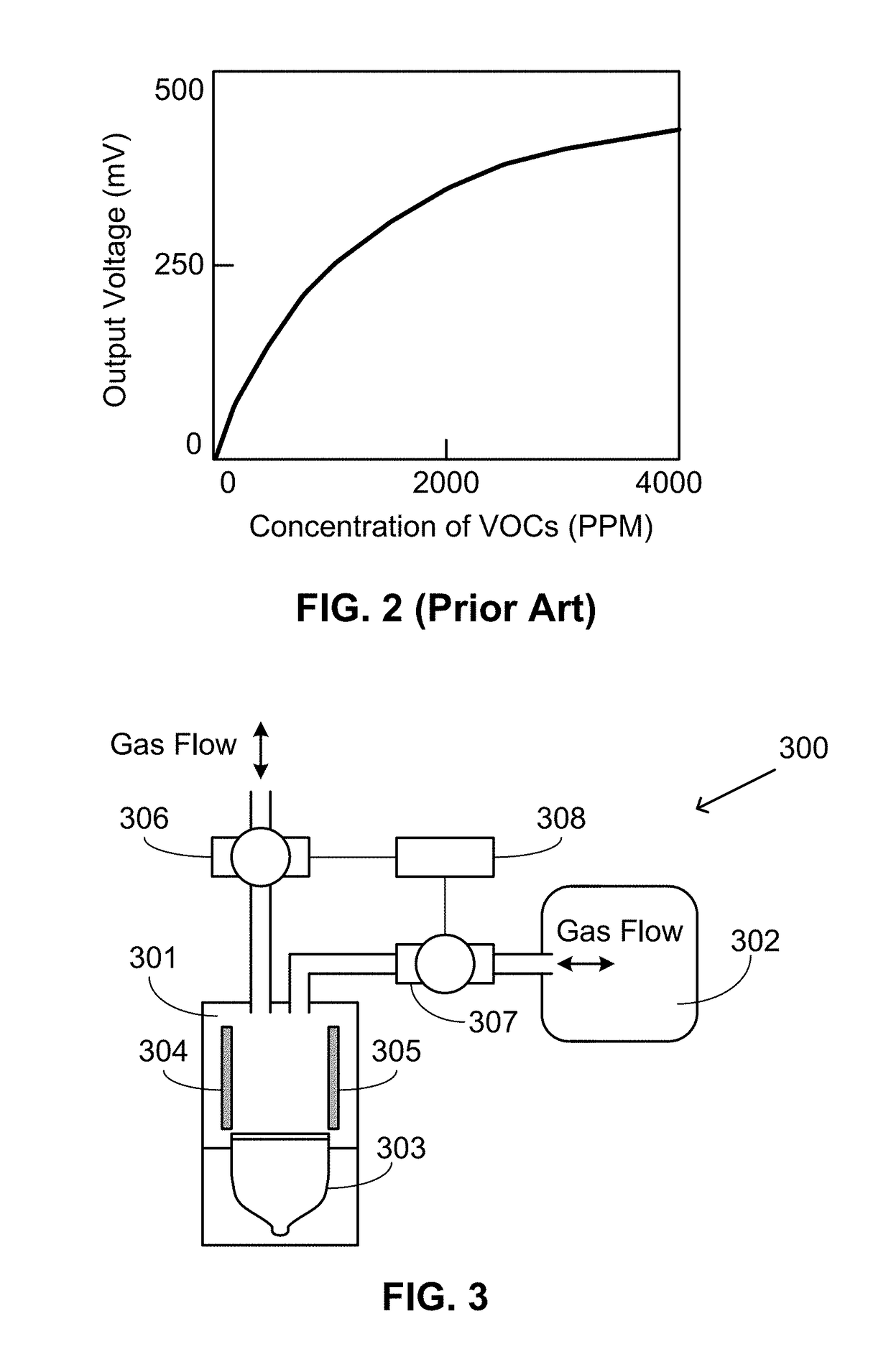

Photo ionization detector with self-calibration

ActiveUS10101298B1Cost downDown timeMaterial analysis by electric/magnetic meansGas analyser calibrationCalibration gasHelium ionization detector

The present invention discloses a photoionization detector (PID) system that can perform calibrations automatically. The PID system comprises a measurement gas chamber and one or more calibration gas chambers. The one or more calibration gas chambers each hold a type of calibration gas. In one embodiment, a volatile organic compounds (VOCs) measurement and a calibration measurement are conducted in the same gas chamber. In another embodiment, VOCs and calibration measurements are conducted in different gas chambers either simultaneously or at different times.

Owner:JIAXING BROADSENS TECH LTD

Methods and apparatus for adjusting ice slab bridge thickness and initiate ice harvest following the freeze cycle

ActiveUS20140013781A1Conserve waterIncrease and decrease making cycle timeLighting and heating apparatusIce productionMarine engineering

A method and apparatus for adjusting and controlling ice bridge slab thickness and / or initiation of ice harvest following a freeze cycle. This adjusting and controlling is performed through the use of adjustable float clip assemblies which set the amount of water available for ice making in a batch process. The adjustable float clip assemblies provide an ice machine user with the ability to easily adjust the ice slab bridge thickness to a single or plurality of settings, and allow for changes in ice bridge slab thickness at the site of installation.

Owner:PENTAIR FLOW SERVICES

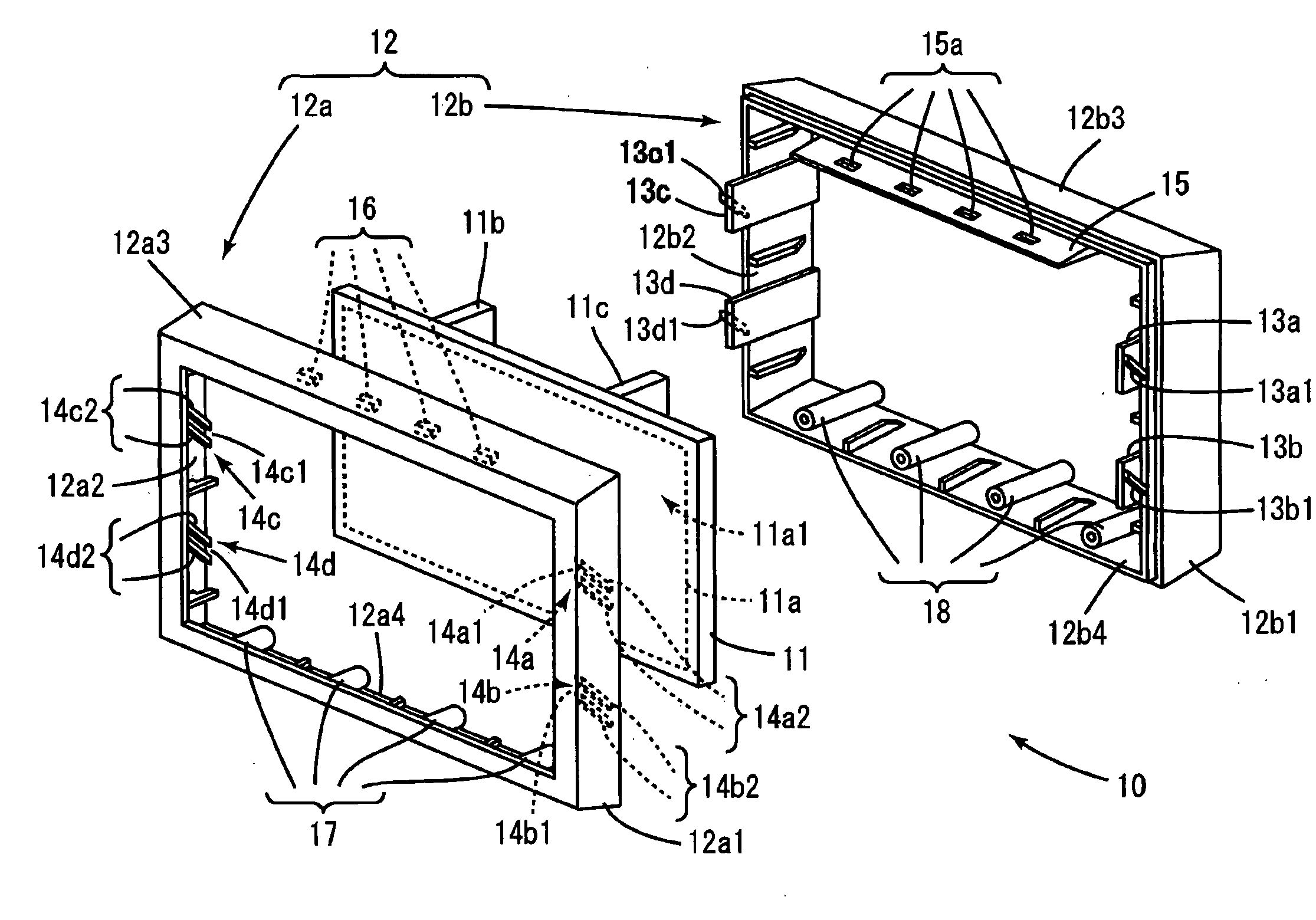

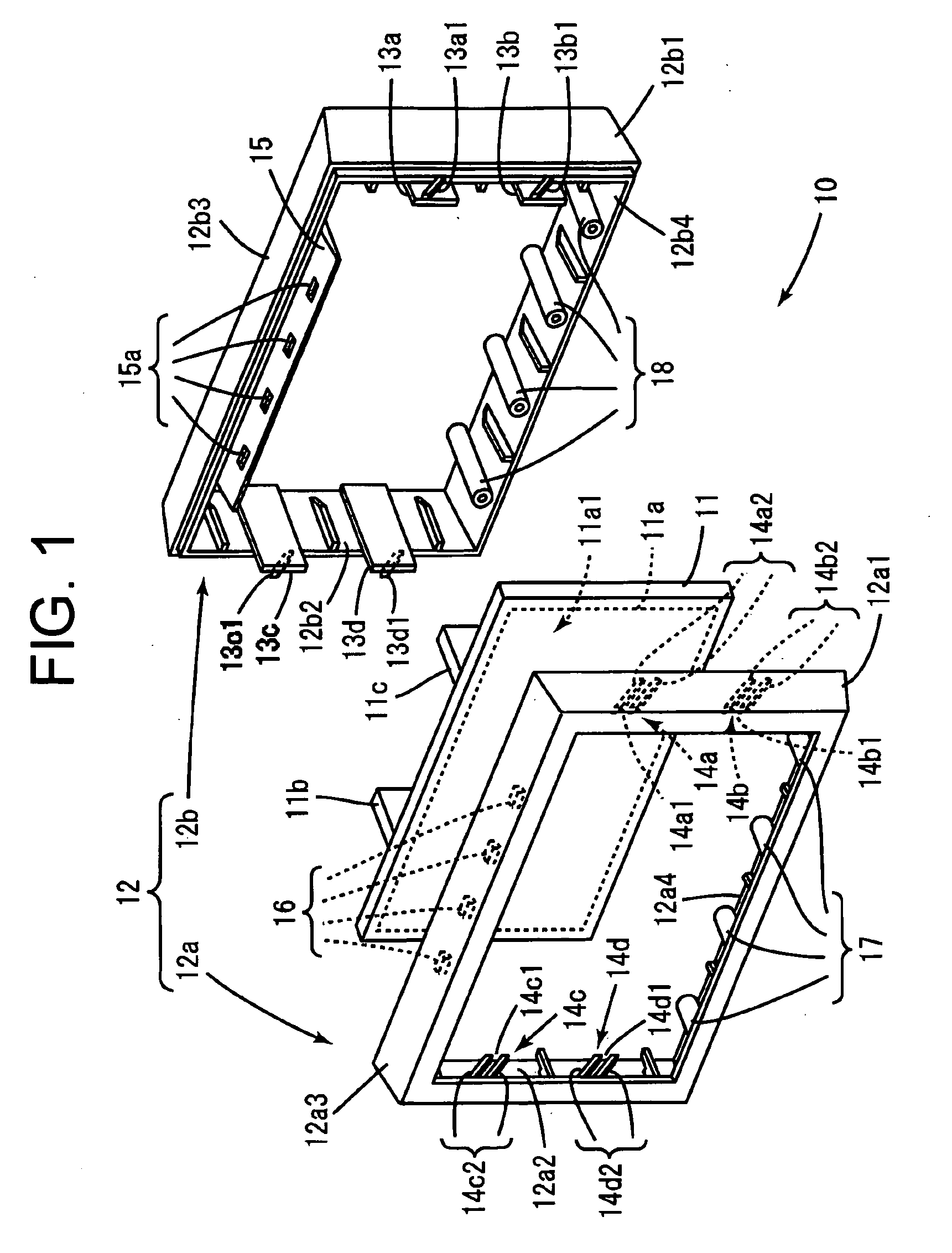

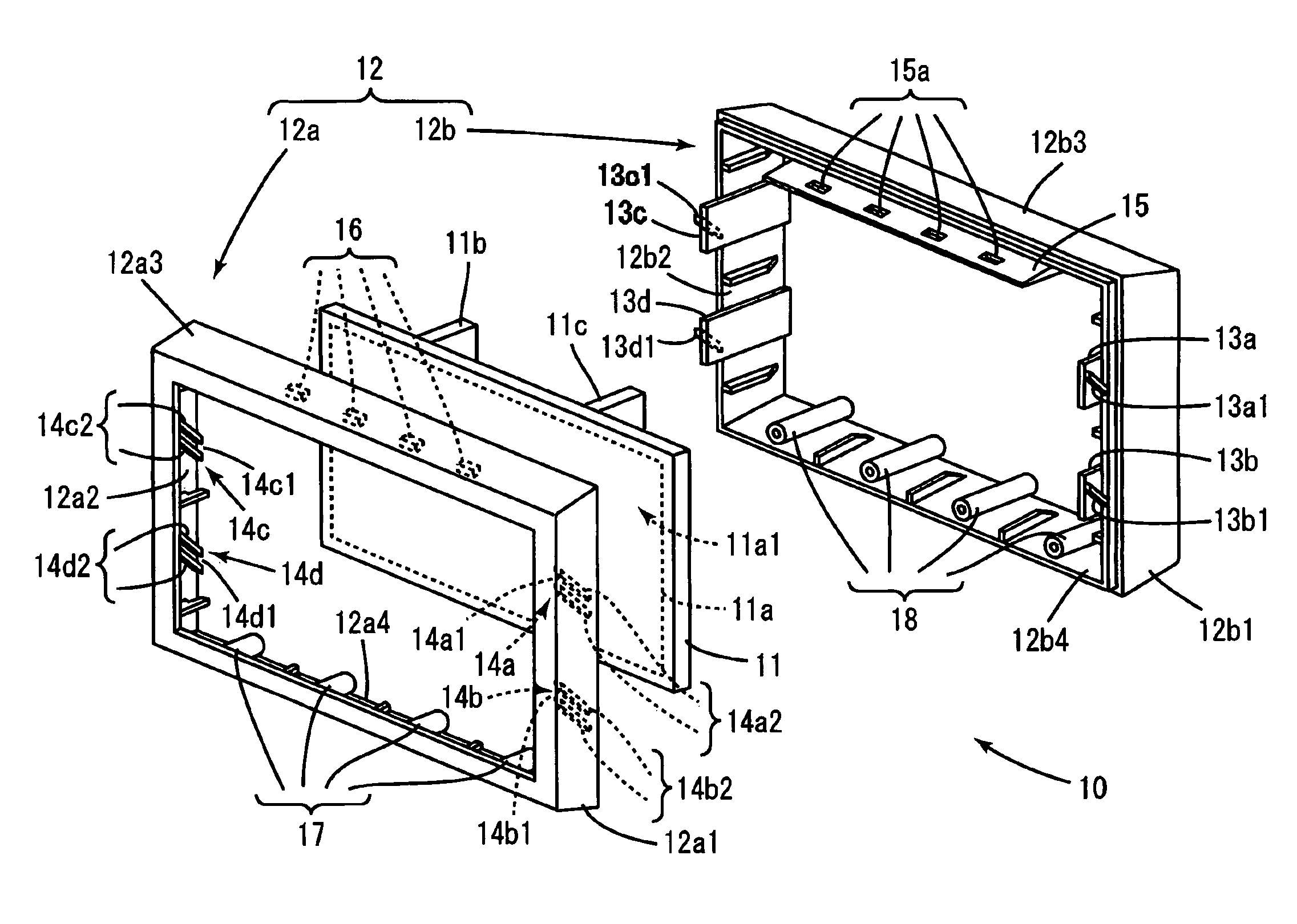

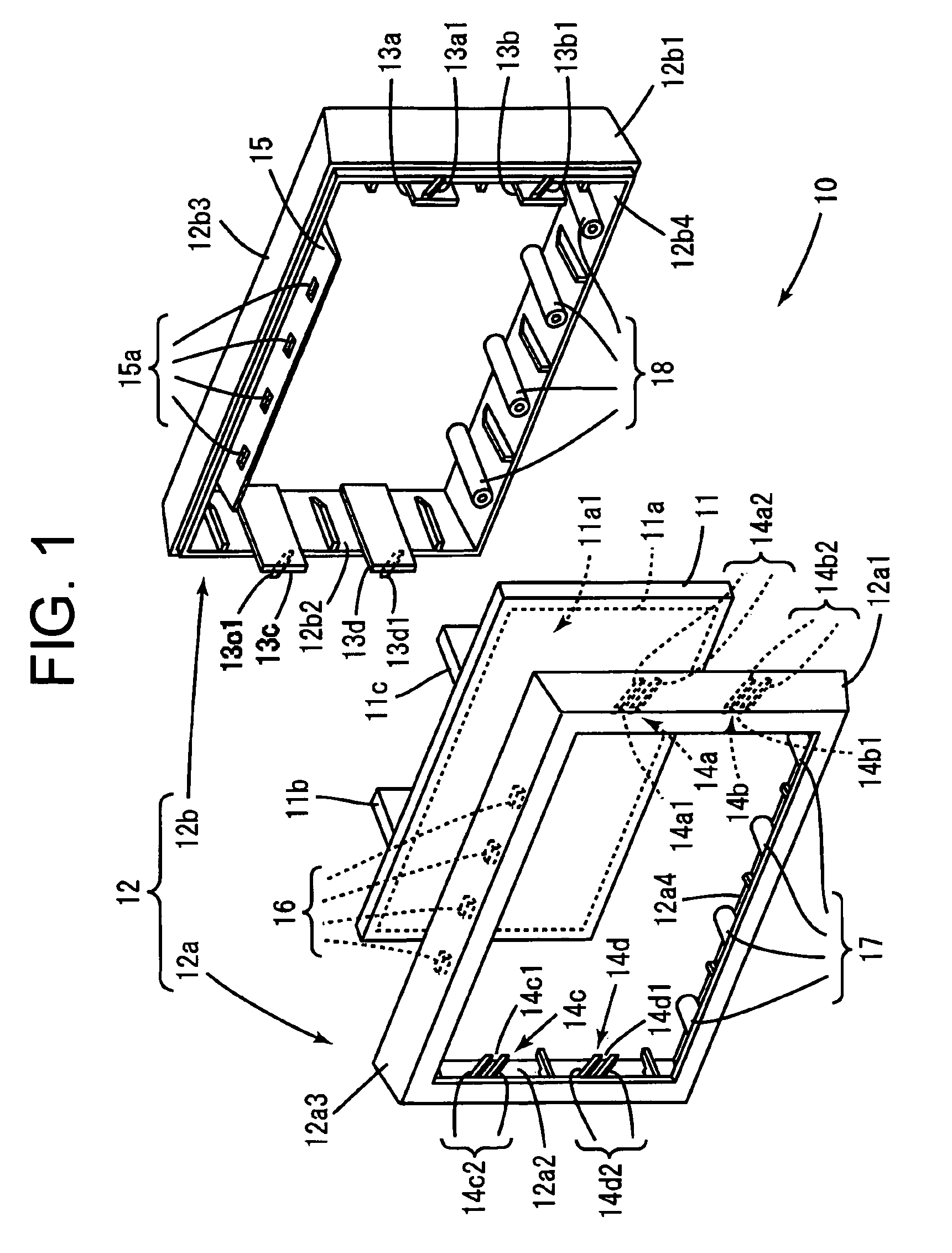

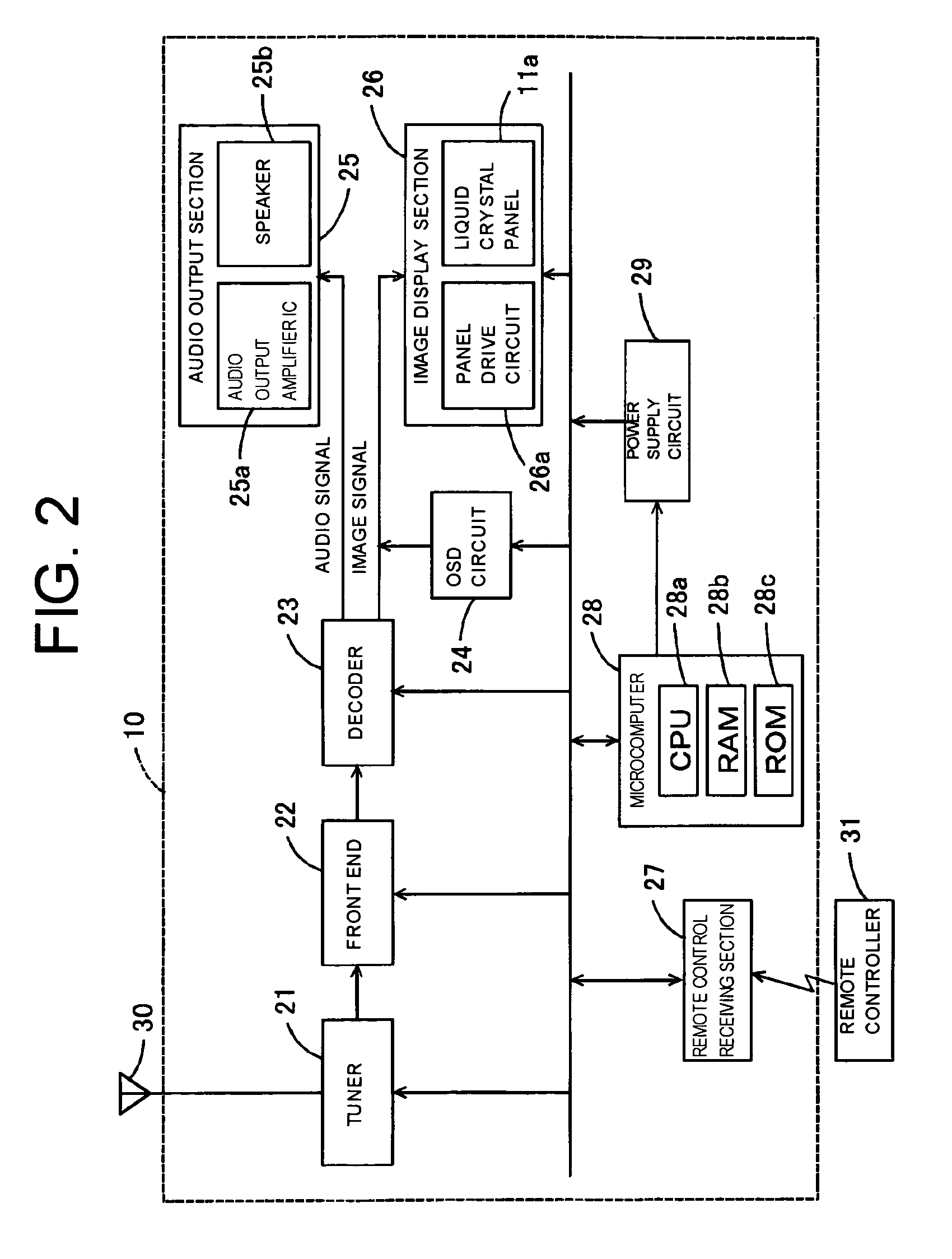

Assembling structure for plat-panel display unit, and flat-panel television

InactiveUS20080238269A1Down numberDown timeTelevision system detailsDigital data processing detailsDisplay deviceEngineering

Owner:FUNAI ELECTRIC CO LTD

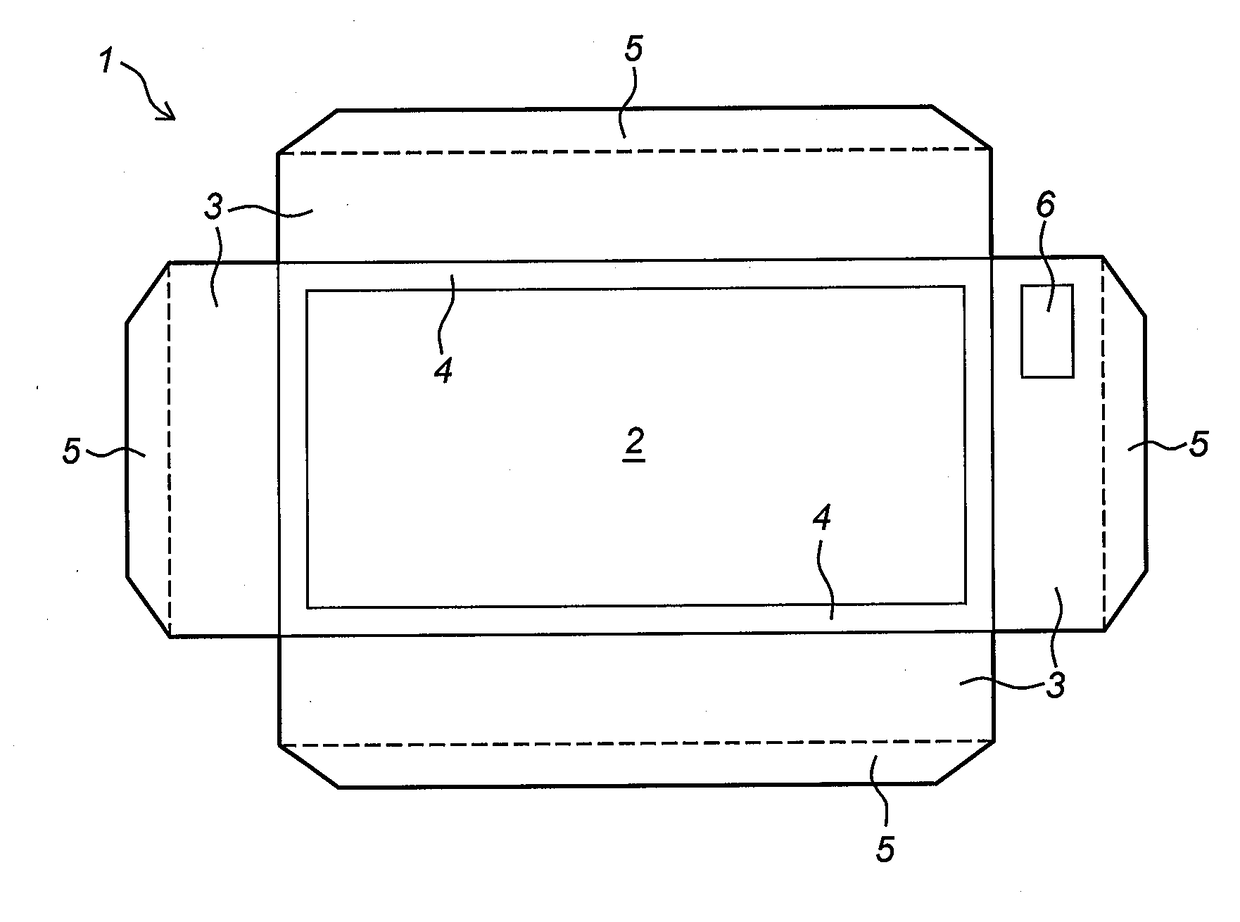

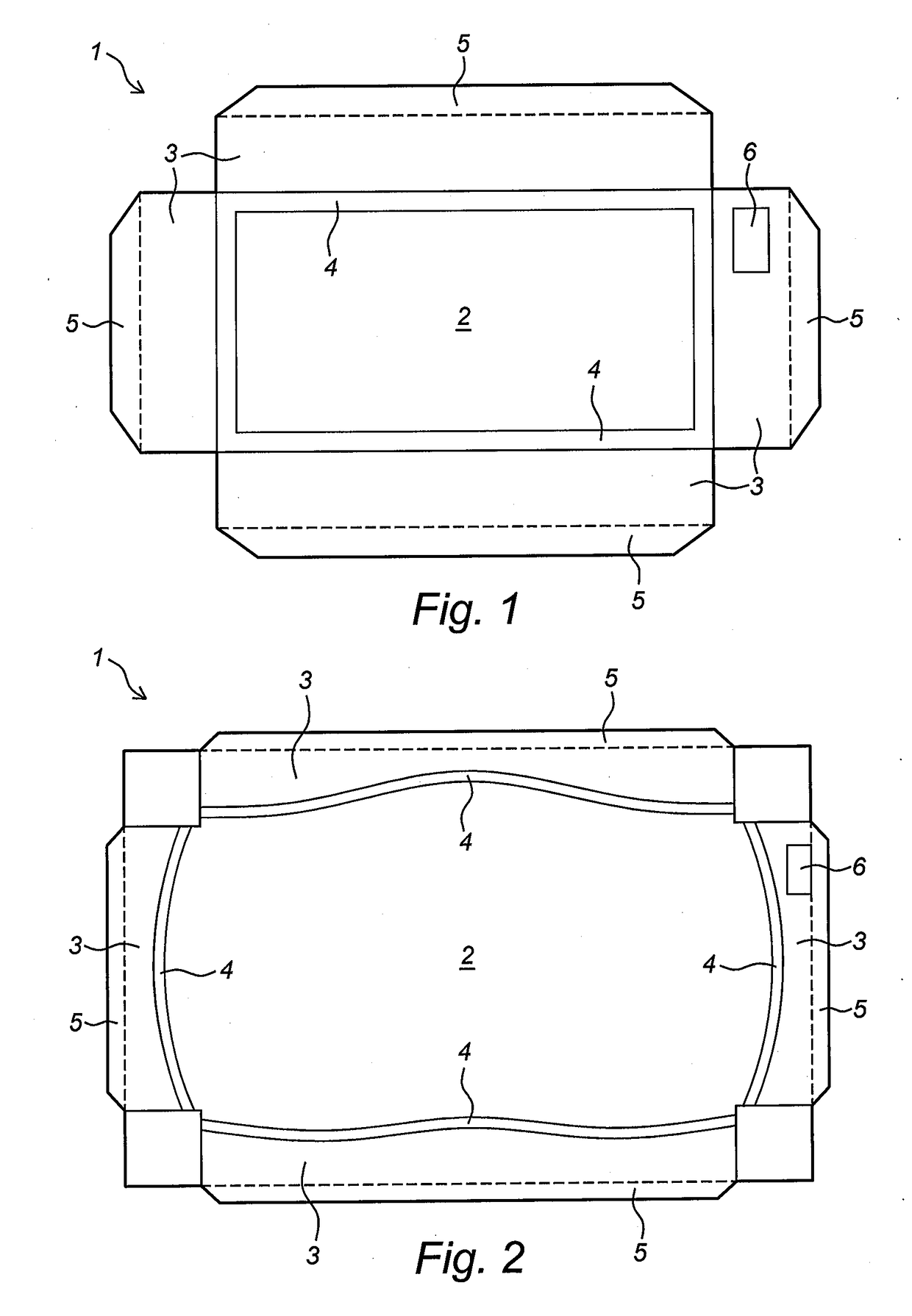

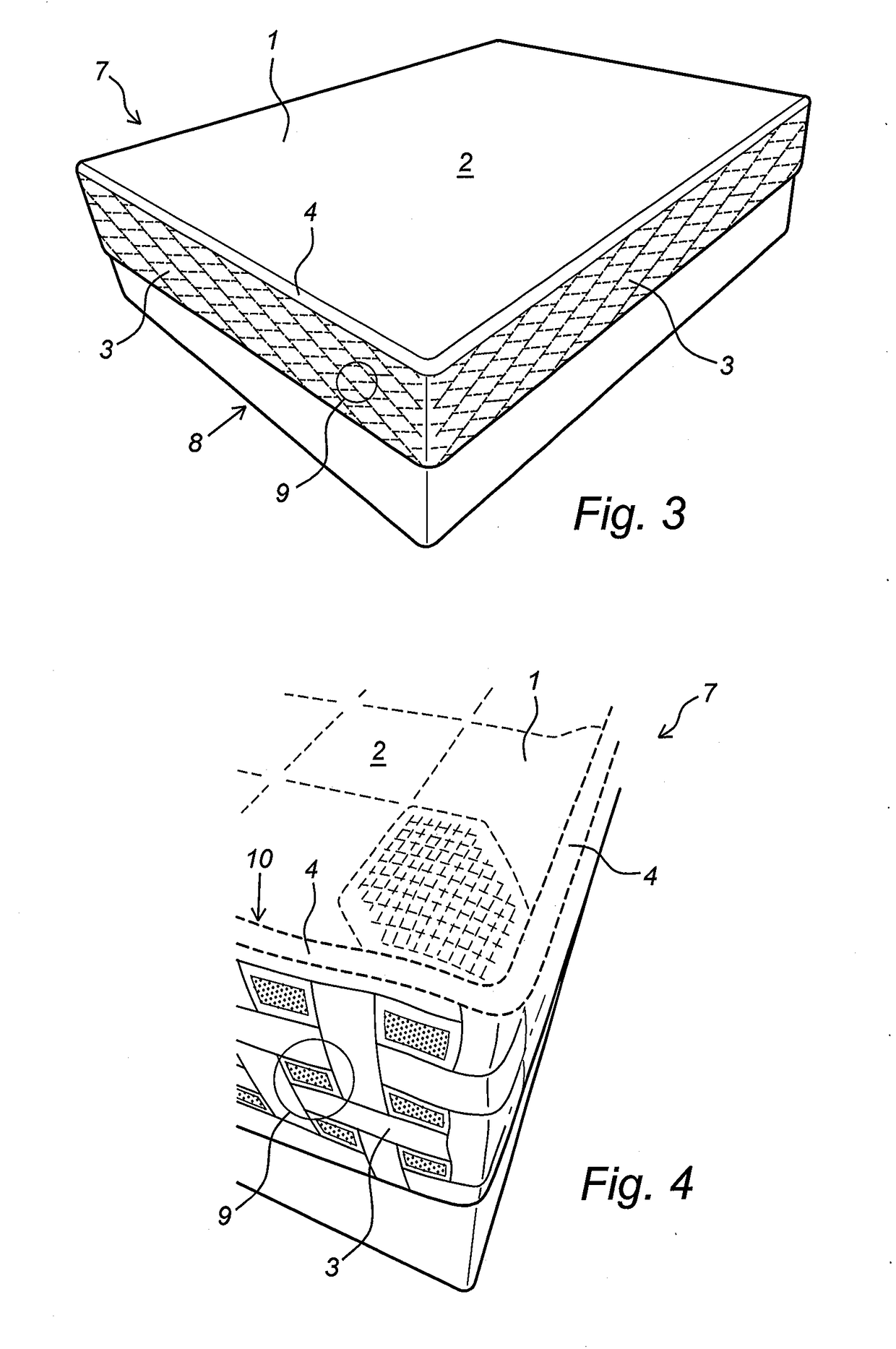

Knitted Mattress Cover, Mattress and Method for Manufacturing a Knitted Mattress Cover

InactiveUS20170347814A1Reduce labor costsEliminate needBlanketBed linenMechanical engineeringEngineering

Owner:INNOTEX BEHEER

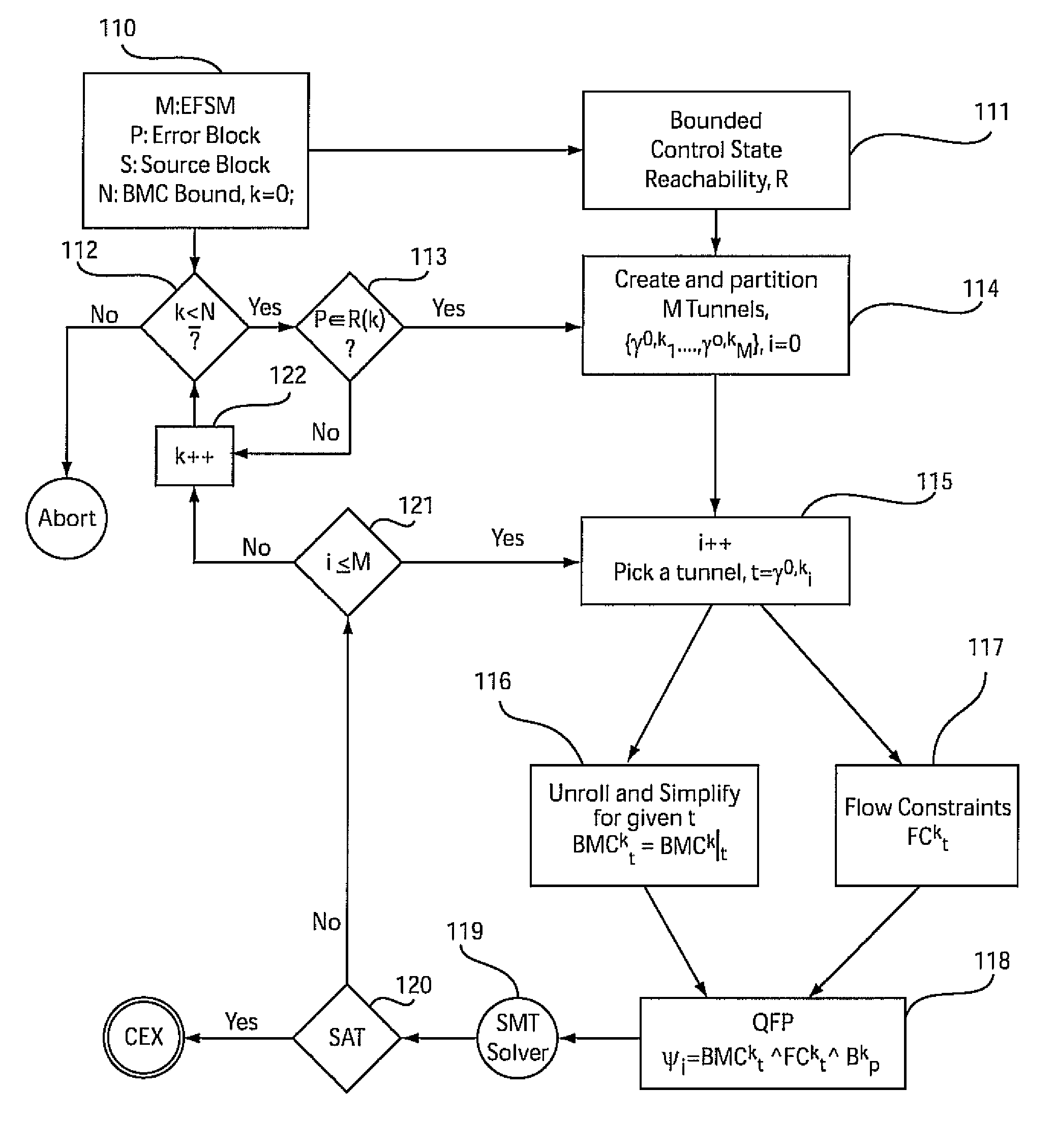

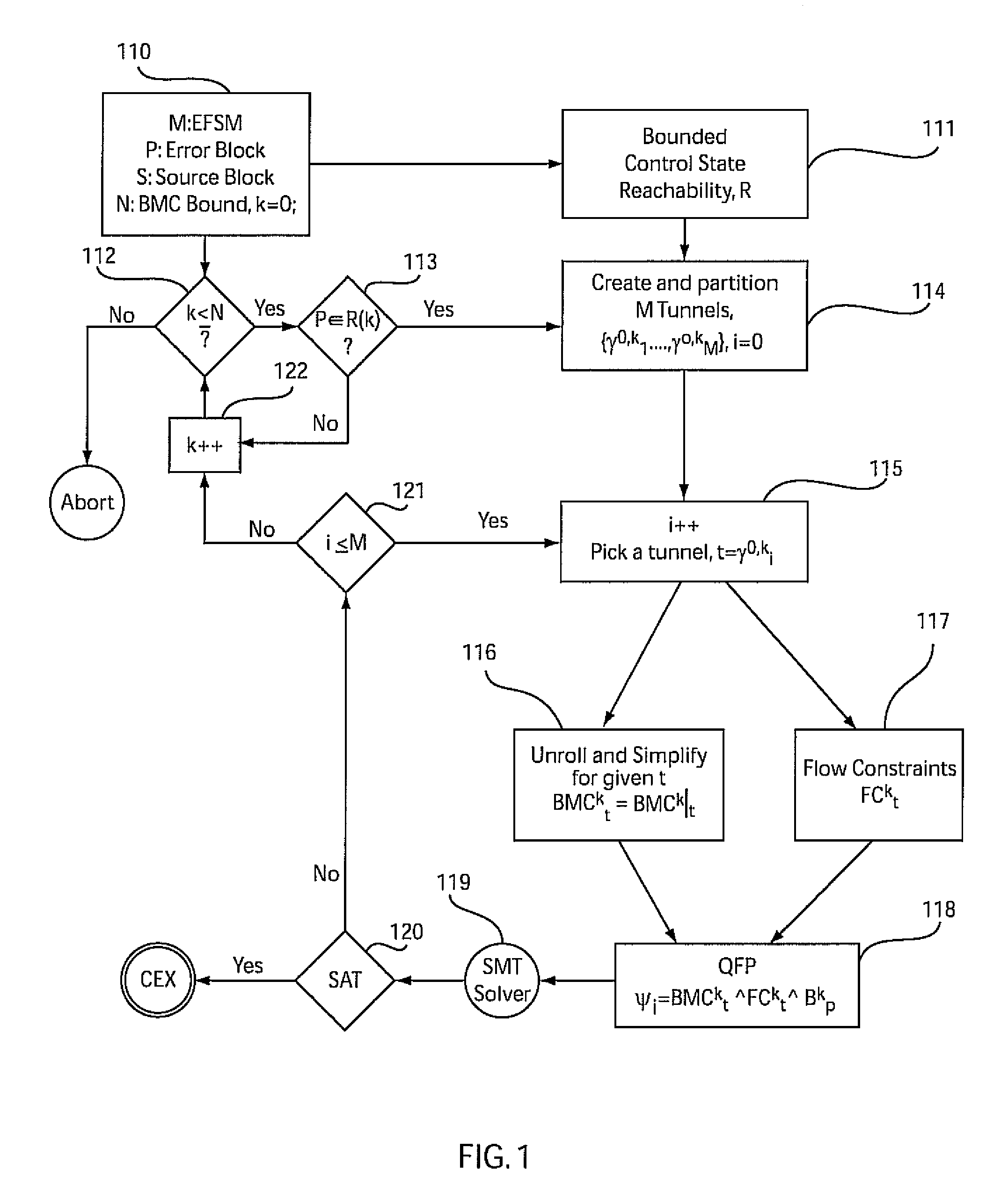

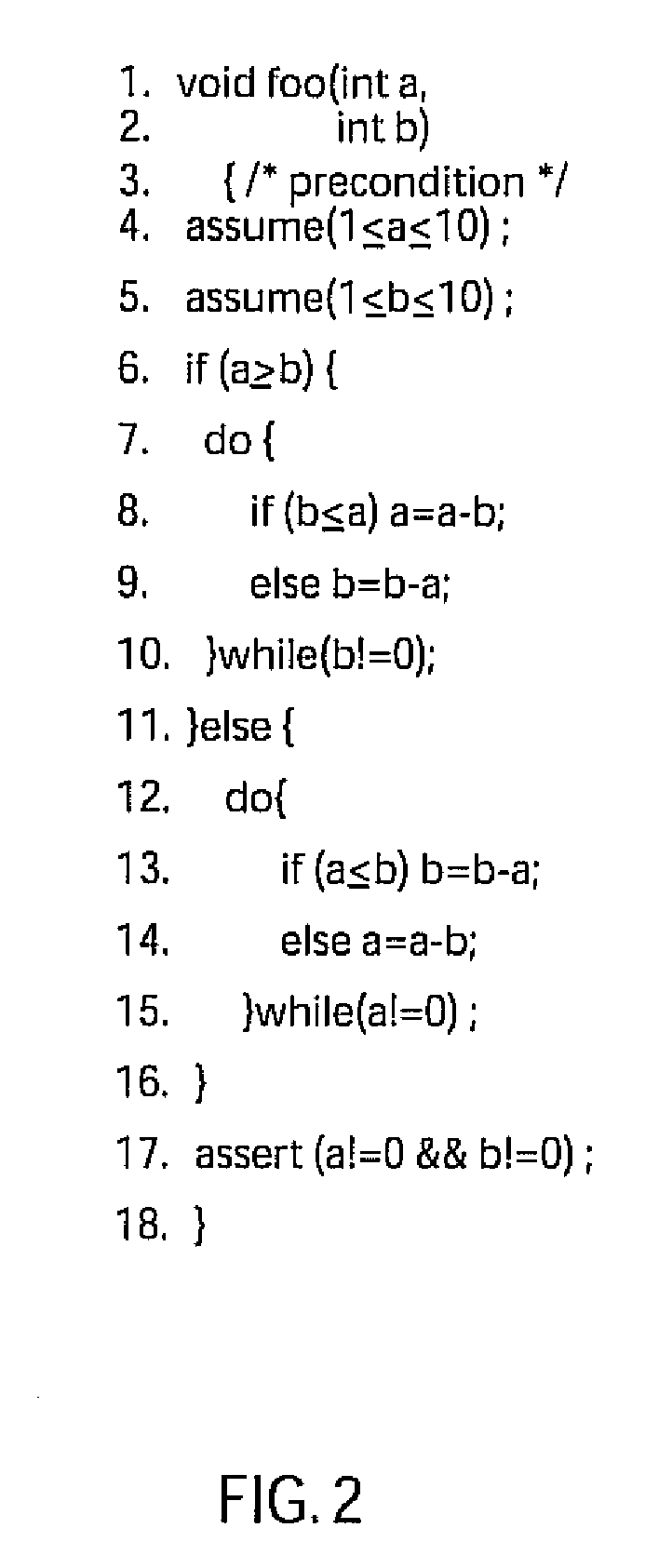

Parallelizing bounded model checking using tunnels over a distributed framework

InactiveUS20100011057A1Down timeReduce communication overheadAnalogue computers for electric apparatusMultiple digital computer combinationsMain processing unitComputer program

A system and method for bounded model checking of computer programs includes decomposing a program having at least one reachable property node for bounded model checking (BMC) into sub-problems by employing a tunneling and slicing-based (TSR) BMC reduction method. The sub-problems of the TSR method are partitioned in a distributed environment, where the distributed environment includes at least one master processing unit and at least one client unit. The sub-problems are solved by each client independently of other clients to reduce communication overhead and provide scalability.

Owner:NEC CORP

Assembling structure for flat-panel display unit, and flat-panel television

InactiveUS8169553B2Down numberDown timeTelevision system detailsDigital data processing detailsDisplay deviceEngineering

Owner:FUNAI ELECTRIC CO LTD

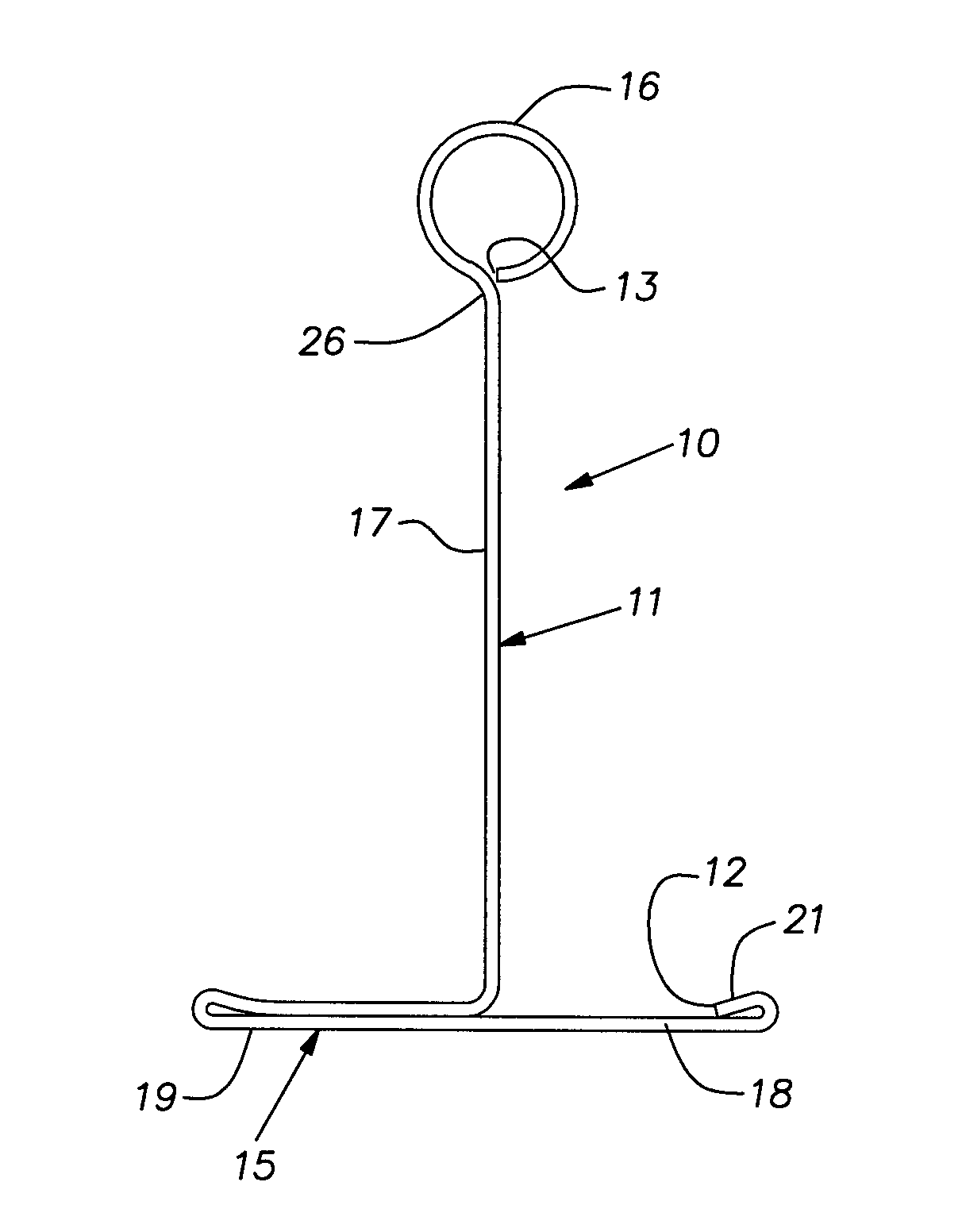

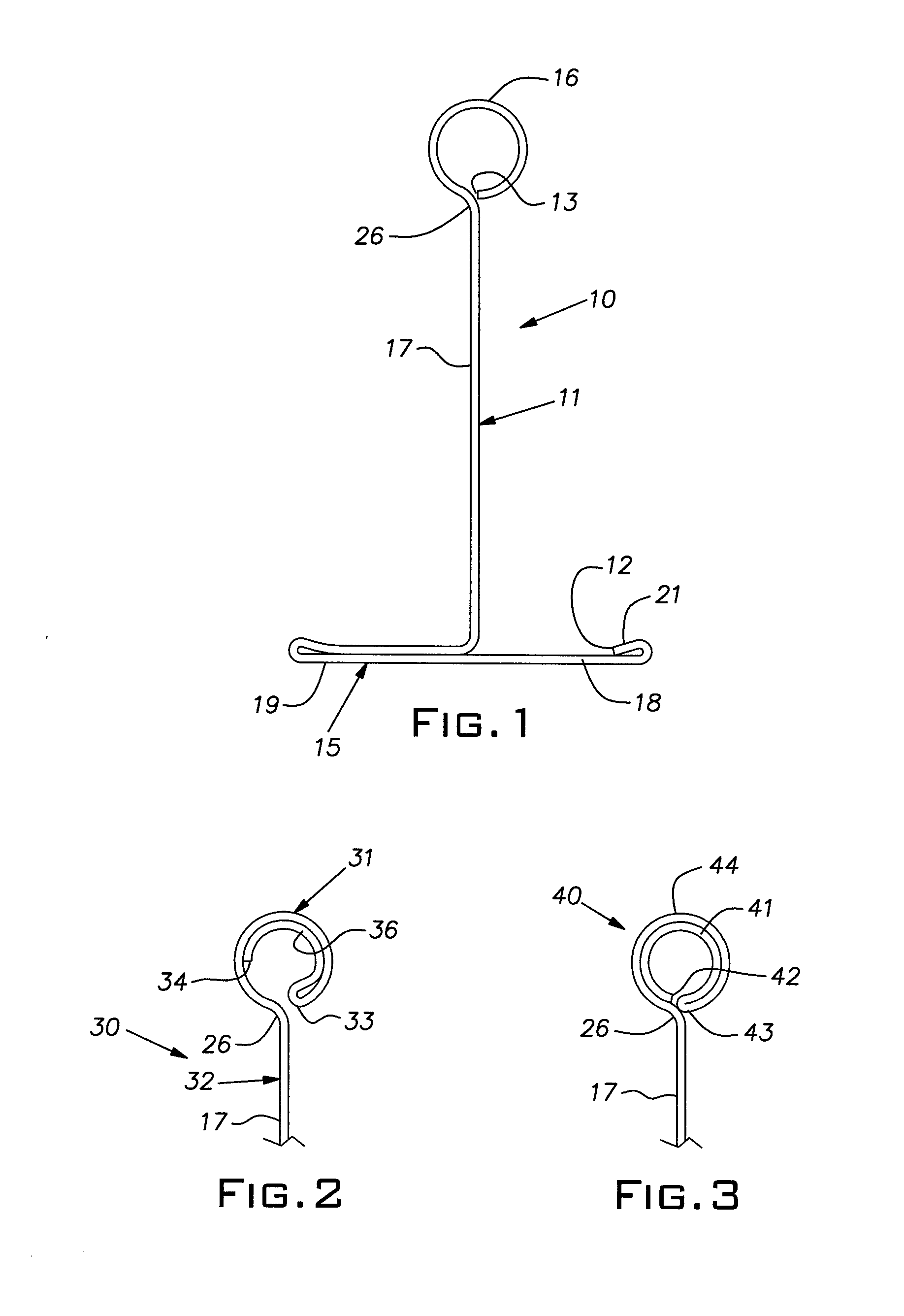

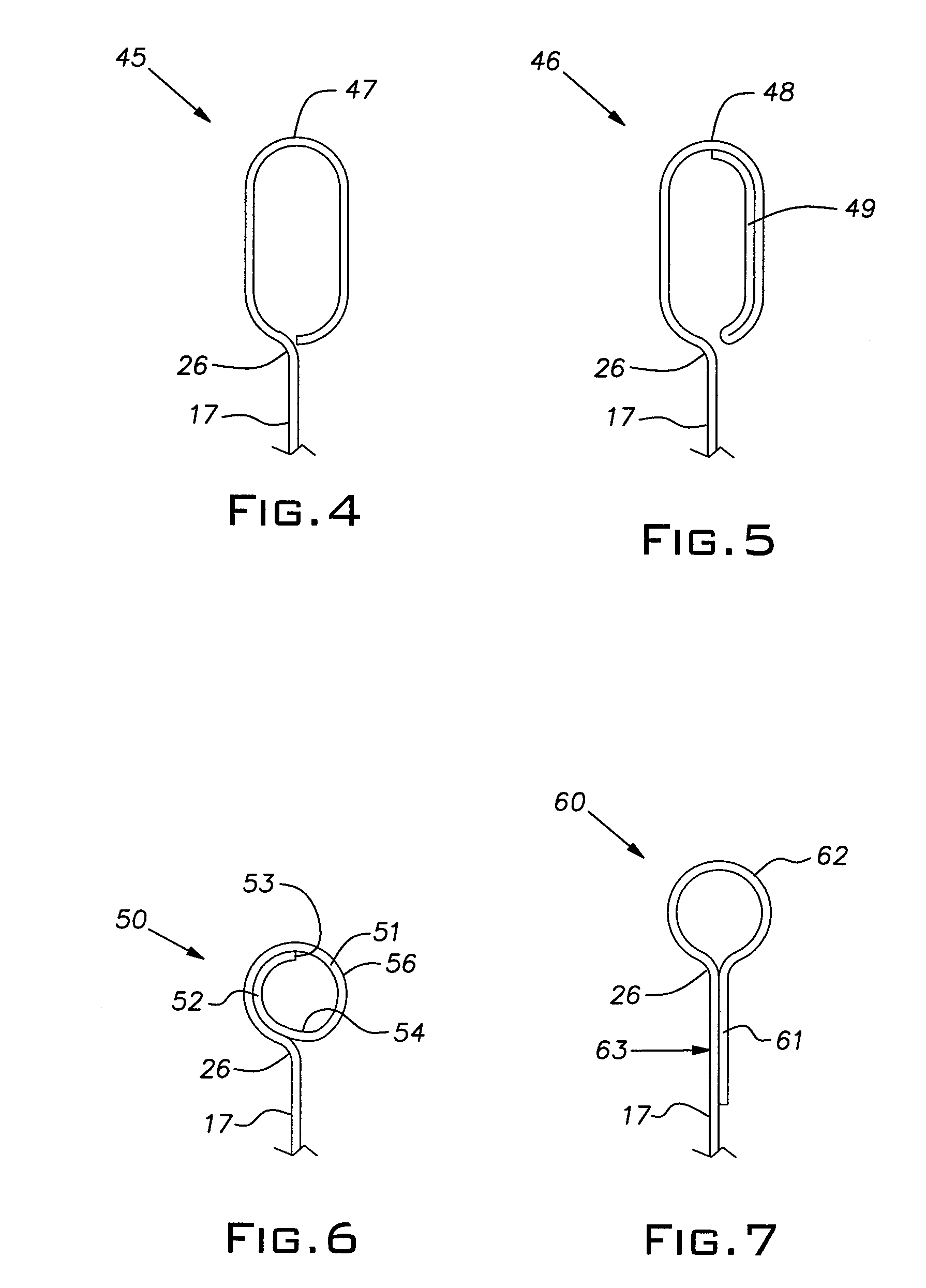

Single web grid with reinforced bulb

InactiveUS20080289280A1High strengthIncrease beam intensityCeilingsWallsEngineeringMechanical engineering

Manufacture of roll formed one piece sheet metal grid tees that affords different load ratings with the same gauge and quality of sheet stock and the same overall cross-section dimensions by varying the width of the strip used to make the tees and disposing material added for increased load rating at the area of the hollow reinforcing bulb of the tees.

Owner:USG INTERIORS INC

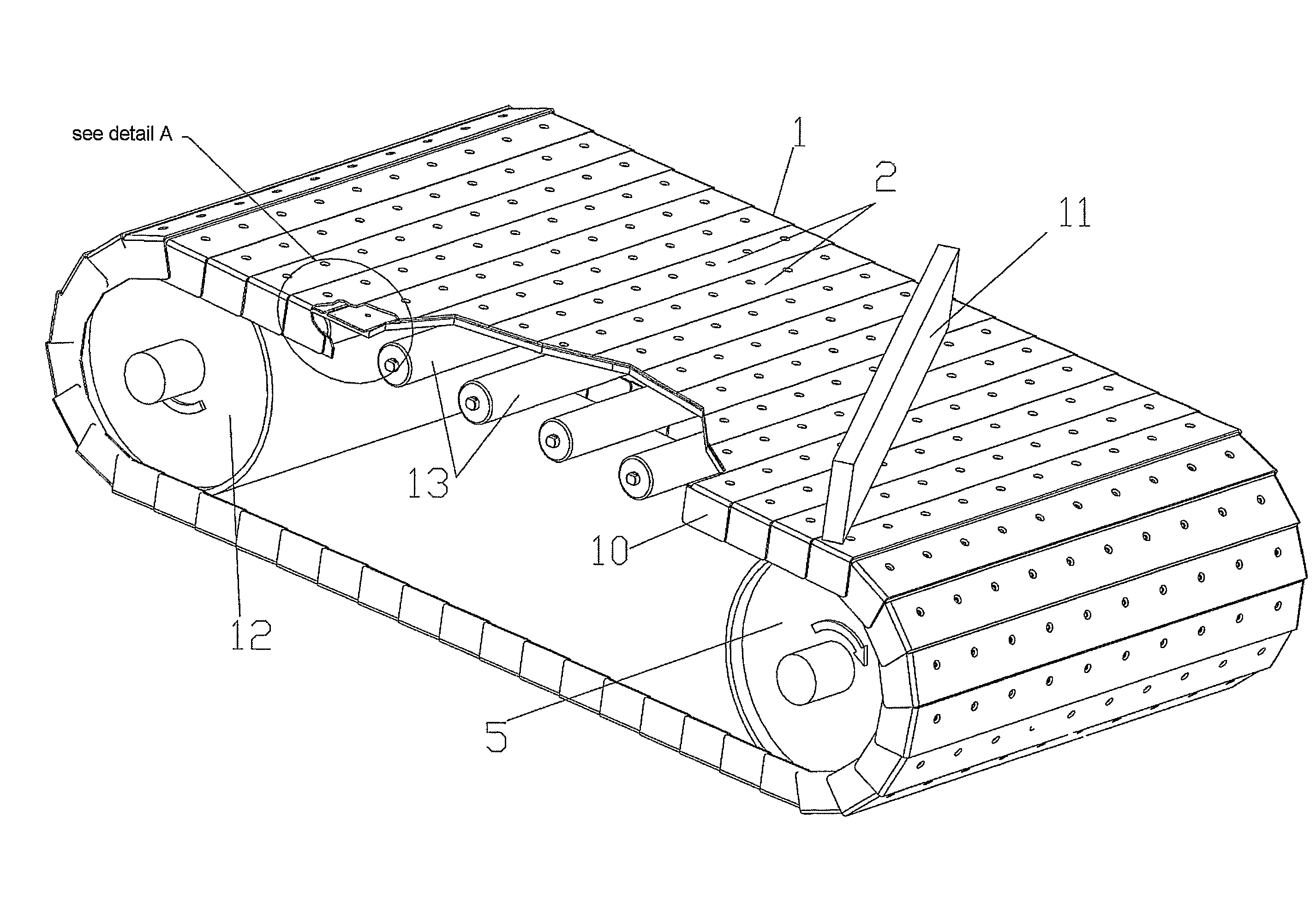

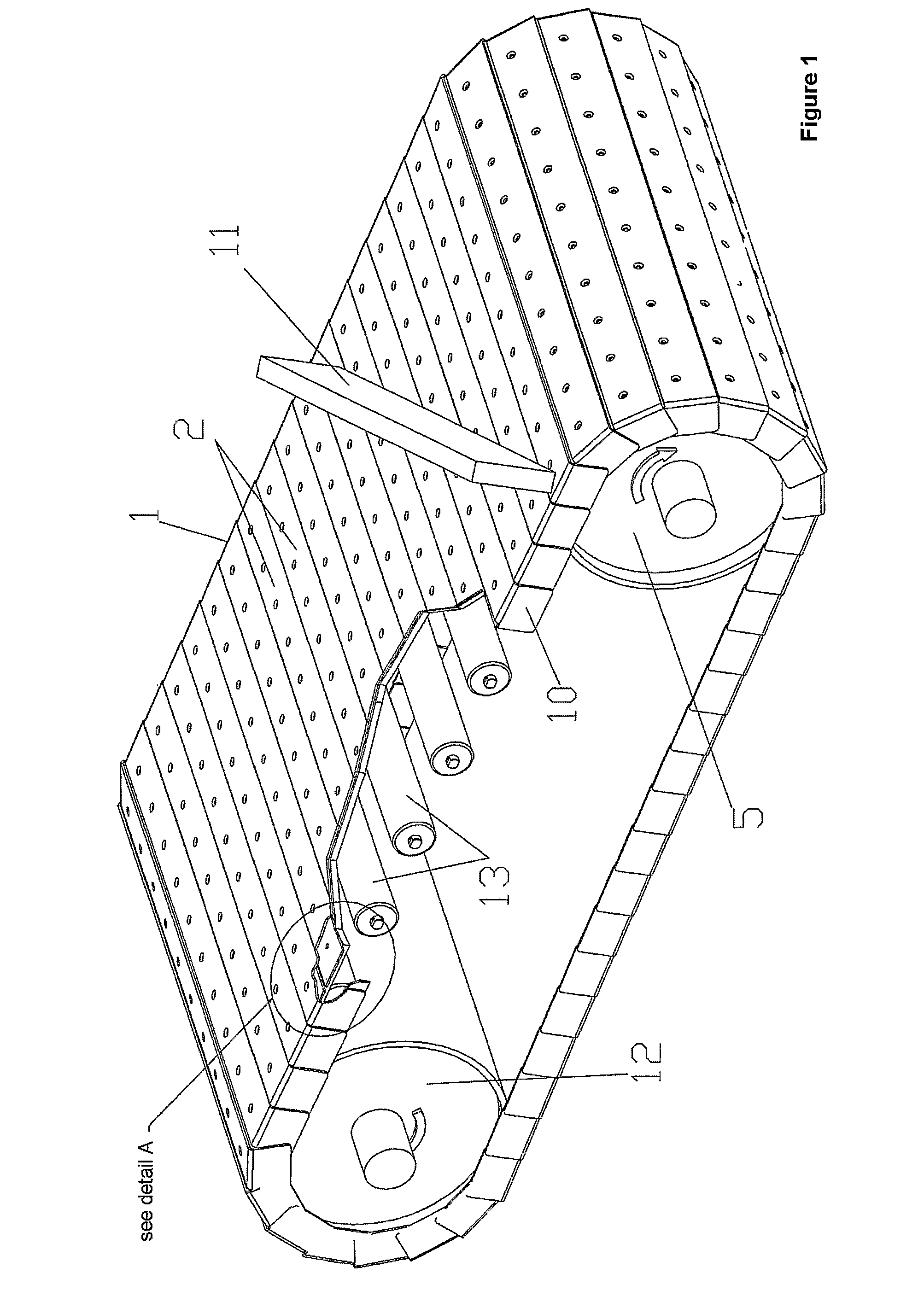

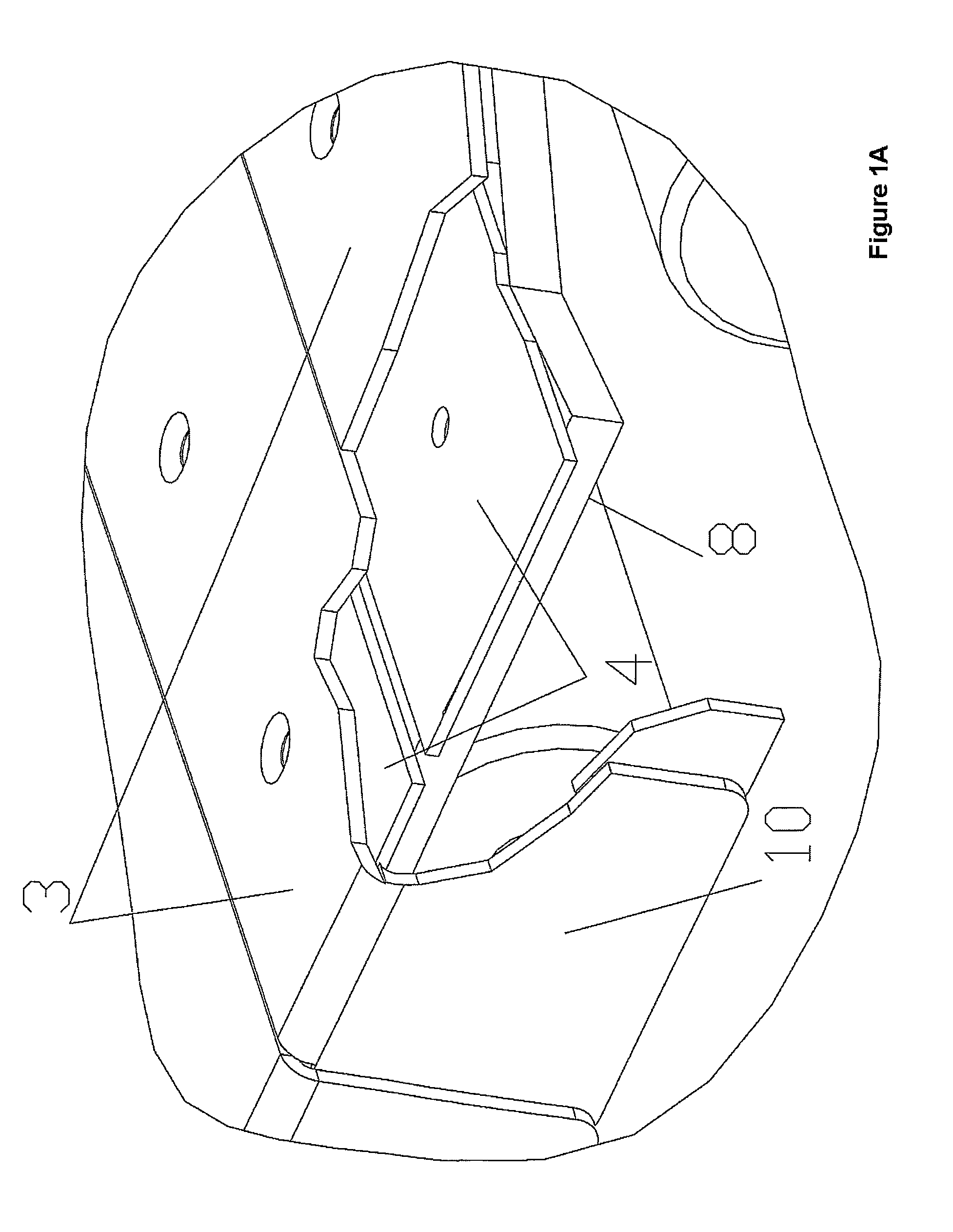

Conveyor belt with overlapping planar surface plates

A conveyor belt (1) includes a metallic net belt (8) functionally driven by at least a traction drum (5), tensioned by at least a return drum (12) and supported by a plurality of independent transversal rollers (13). Belt (1) supports individually a plurality of plates (2) partially overlapping one another, so as to form a flat continuous transport surface as a mobile reliable plane that is resistant to extreme mechanical stress. Each of said plates (2) is suitably shaped so that an upper portion of one plate overlaps a lower portion of the following plate.

Owner:MAGALDI POWER SPA

Medical handset and exchangeable nozzle for the same

ActiveUS20080145814A1Disinfection is accelerated and eliminatedDown timeTeeth fillingDental toolsInterference fitPowder mixture

The present invention relates to a medical handset with a nozzle having at least one nozzle line for supplying a medically active medium, such as for example an air-powder mixture and / or a fluid, in particular for the prophylactic treatment of teeth, wherein the handset has a head part with a connecting part on the head for the exchangeable connection of the handset to the nozzle, wherein at least one supply line of the handset is connected to the at least one nozzle line of the nozzle by producing a sealing-tight interference fit of a sealing face on the nozzle with a sealing face on the handle, in particular in that a tongue-and-groove connection is produced between the nozzle and the connecting part, e.g. in that a T-groove on the nozzle is inserted into a T-tongue on the handle, the axis of insertion lying roughly at right angles to the longitudinal axis of the handset.

Owner:FERTON HLDG

Sealed retractable fall arrest block

ActiveUS10744354B2Extrusion process is simpleEasy accessSafety beltsArchitectural engineeringStructural engineering

A retractable fall arrest block comprising a spring side housing member and a drum side housing member. A center support wall, defining a bearing housing, is secured between the housing members. A bearing assembly is mounted in the bearing housing to support a spindle. A spring side housing member is mounted to a spring side of the center support wall and a spring side cover is mounted to the spring side housing member opposite the center support wall to define a spring housing. A drum side housing member is mounted to a drum side of the center support wall, and a drum side cover is mounted to the drum side housing member to define a drum housing. The spindle extends into both housings. A spring is mounted in the spring housing. A drum is positionally fixed to the spindle in the drum housing. A clutch assembly is mounted to the spindle to stop the drum from unwinding.

Owner:RELIANCE INDUSTRIES LIMITED

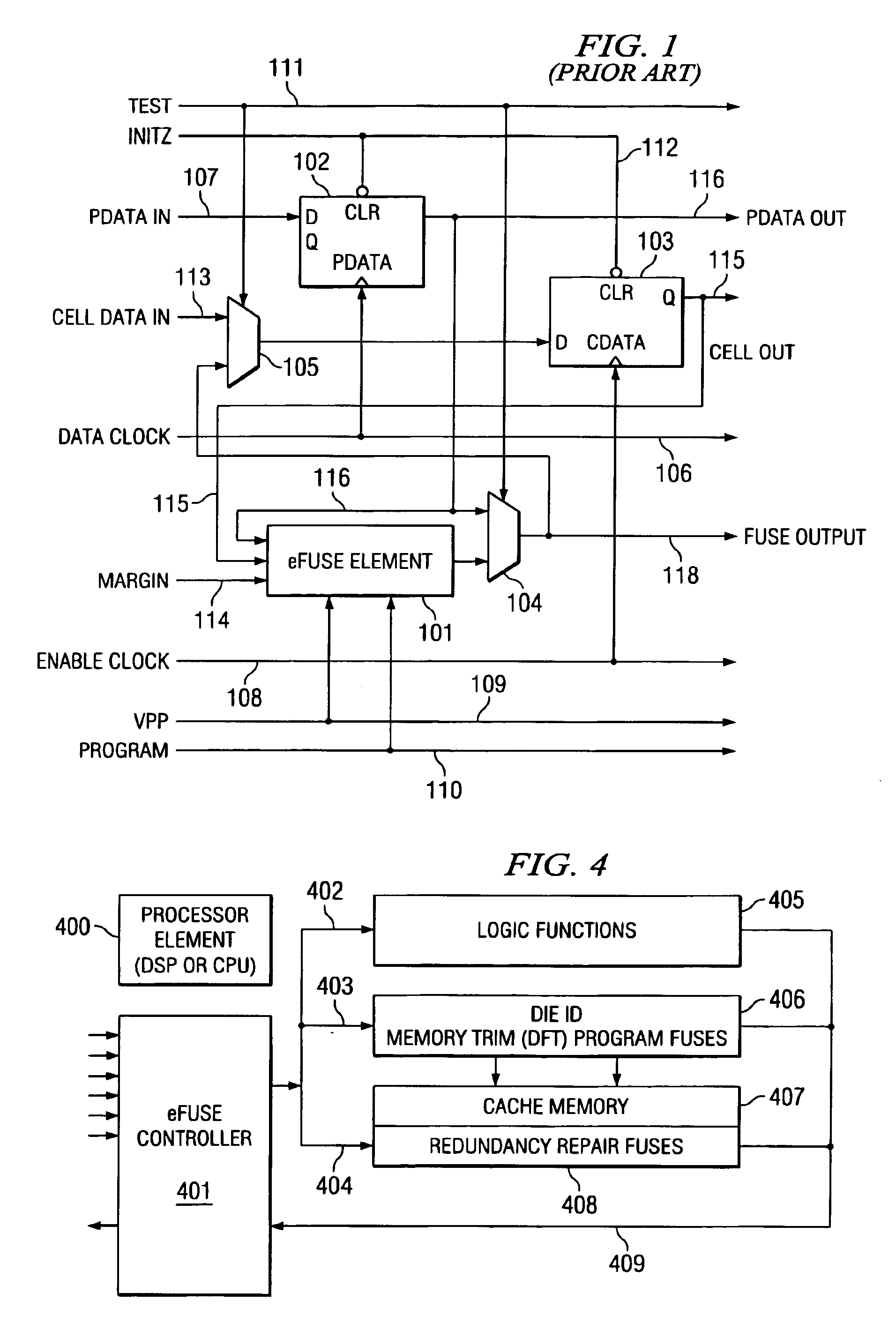

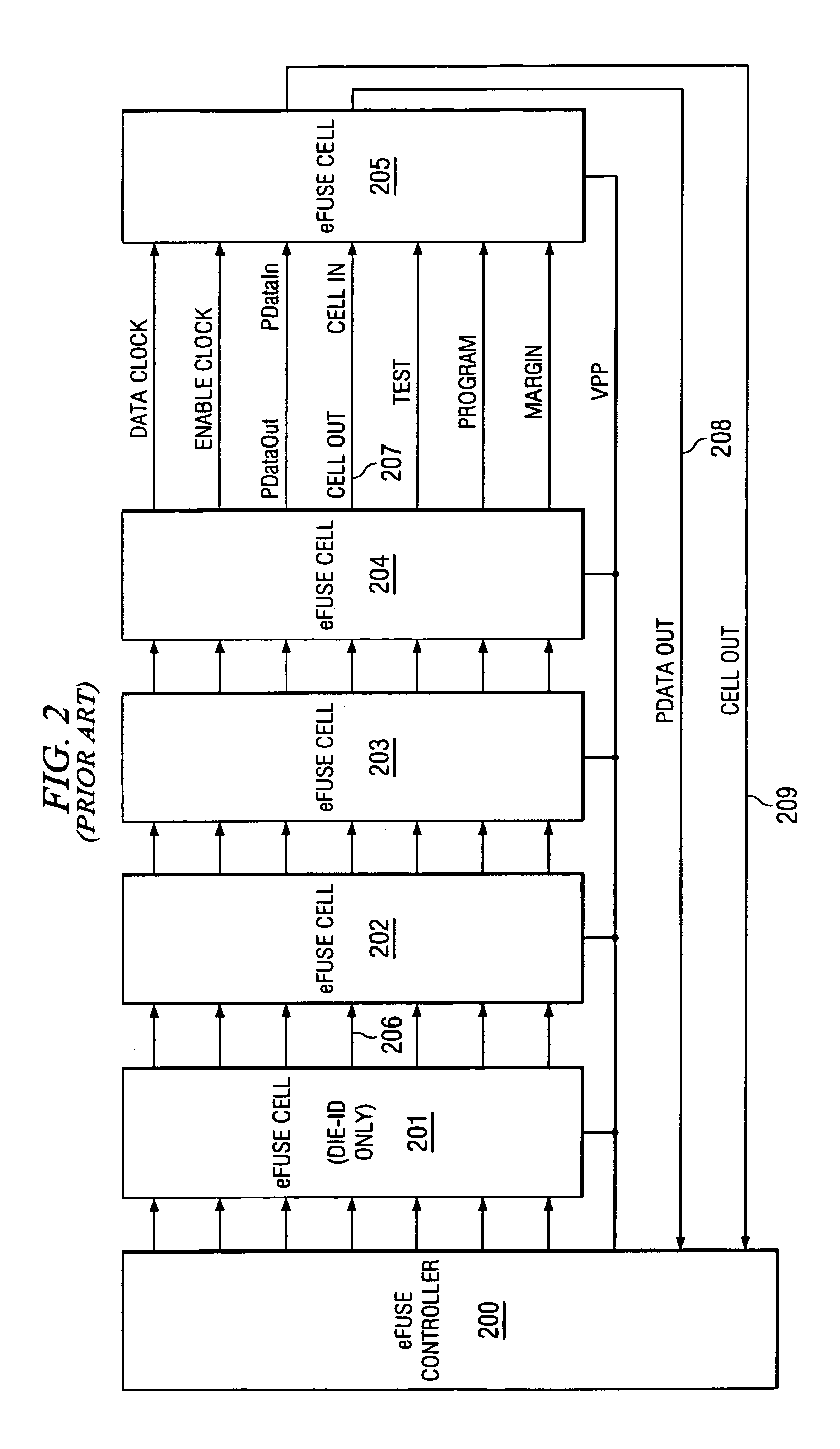

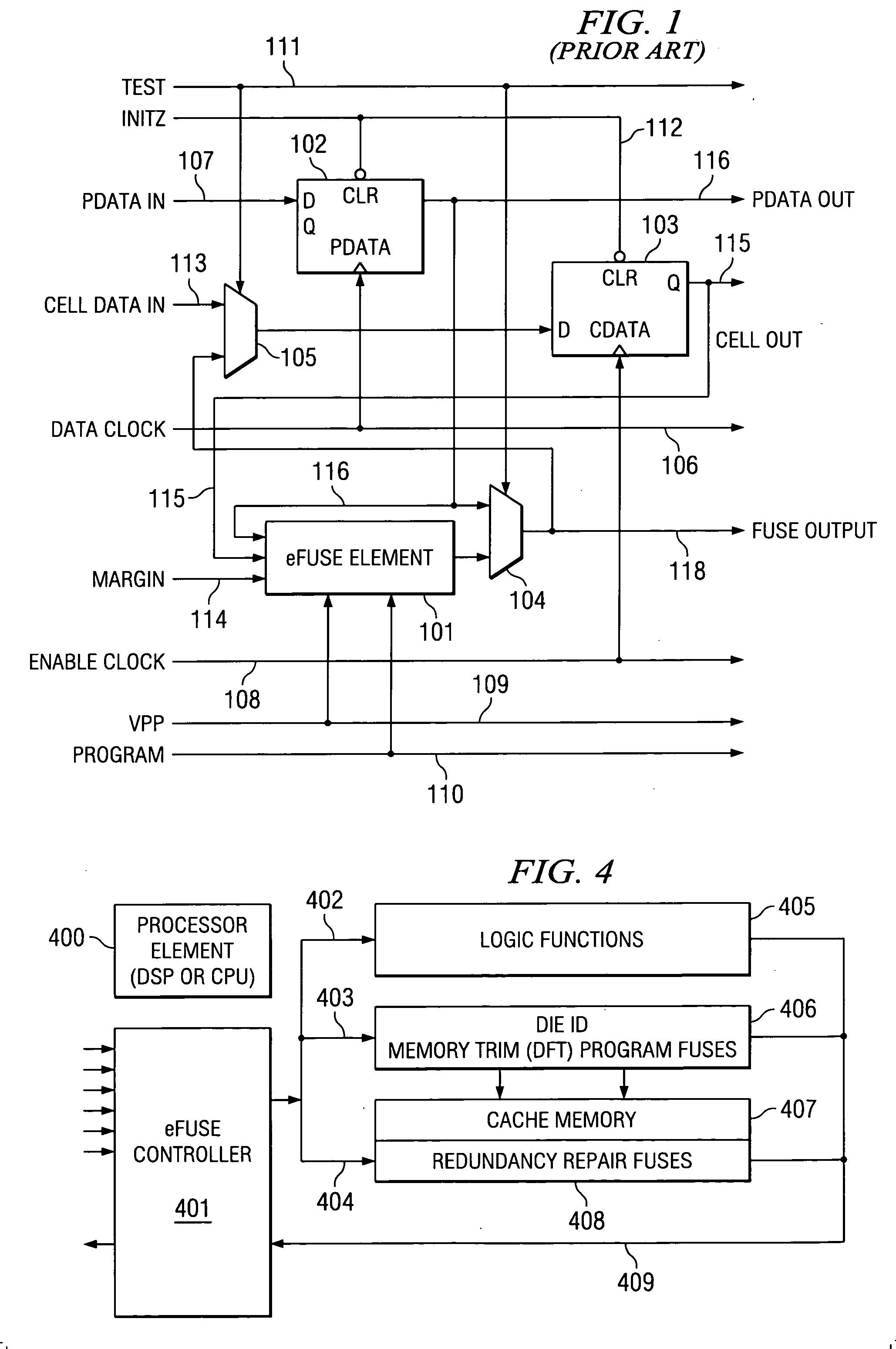

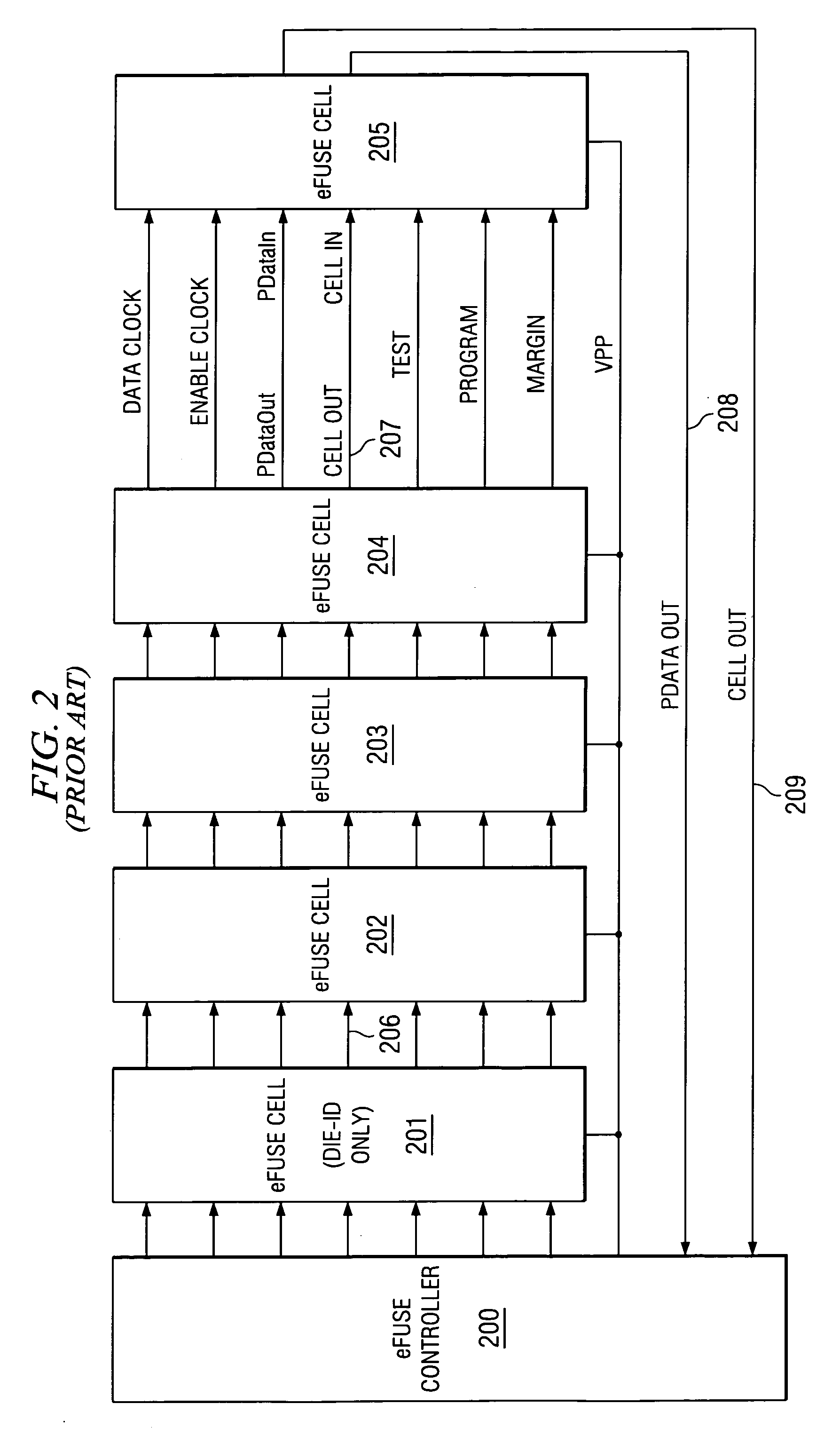

Electrical fuse control of memory slowdown

InactiveUS6928011B2Efficient non-volatile methodMaterial-handling overhead is minimalDigital storageElectricityMemory interface

Electrical fuses (eFuses) are applied to the task of memory performance adjustment to improve upon earlier fuse techniques by not requiring an additional processing step and expensive equipment. Standard electrical fuse (eFuse) hardware chains provide a soft test feature wherein the effect of memory slow-down can be tested prior to actually programming the fuses. Electrical fuses thus provide a very efficient non-volatile method to match the logic-memory interface through memory trimming, drastically cutting costs and cycle times involved.

Owner:TEXAS INSTR INC

Application for non disruptive task migration in a network edge switch

An apparatus and a method are described for zero packet loss task migration in an network switch in a computer network. The invention relates to active or programmable networks, i.e. networks based on packet switching algorithms and switch configurations which are subject to change. A well-defined protocol enables an intelligent switch to migrate tasks from one forwarding engine to another without any packet loss. This enables the algorithms and configurations of the switch to be updated or modified arbitrarily.

Owner:PALO ALTO NETWORKS INC

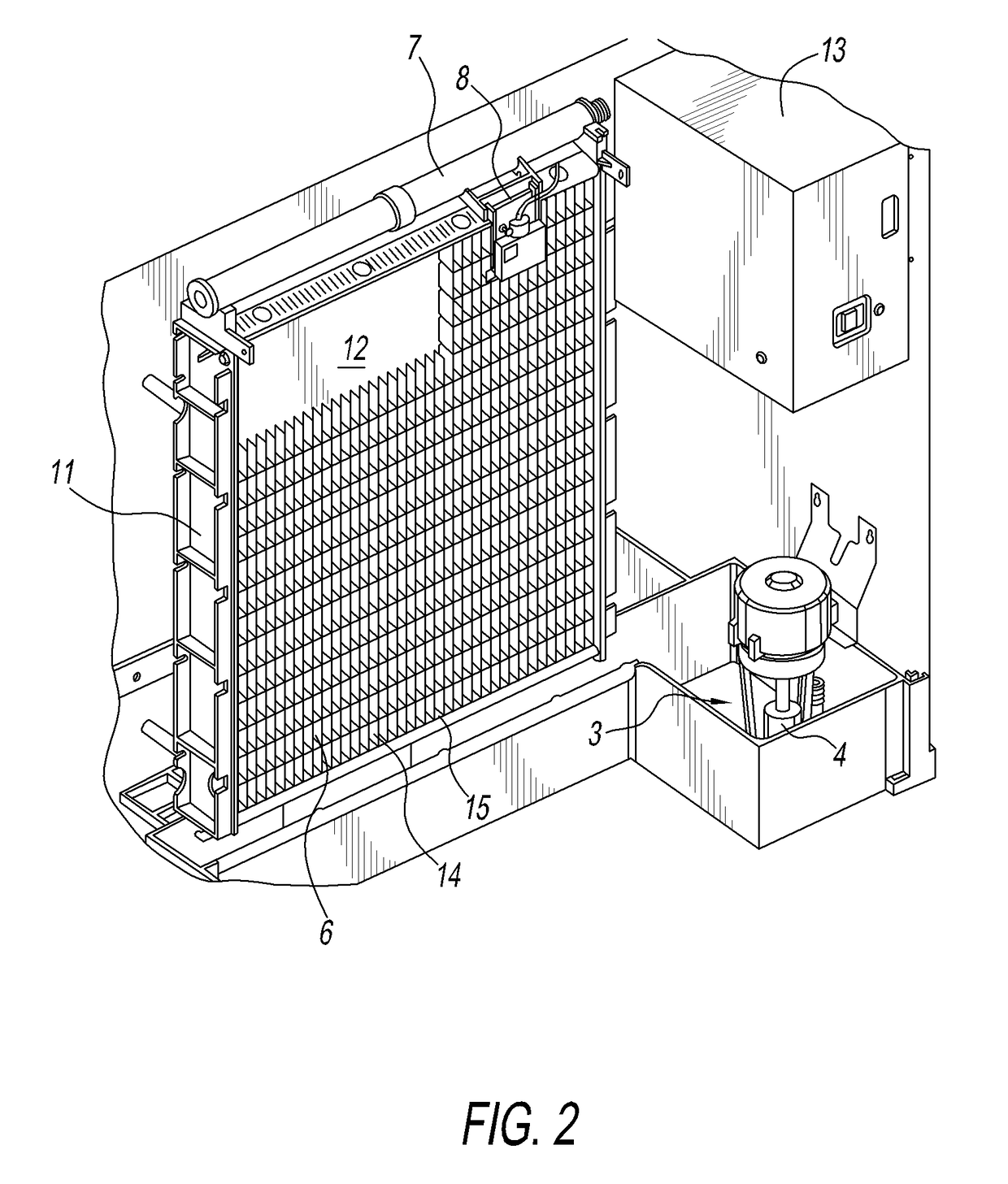

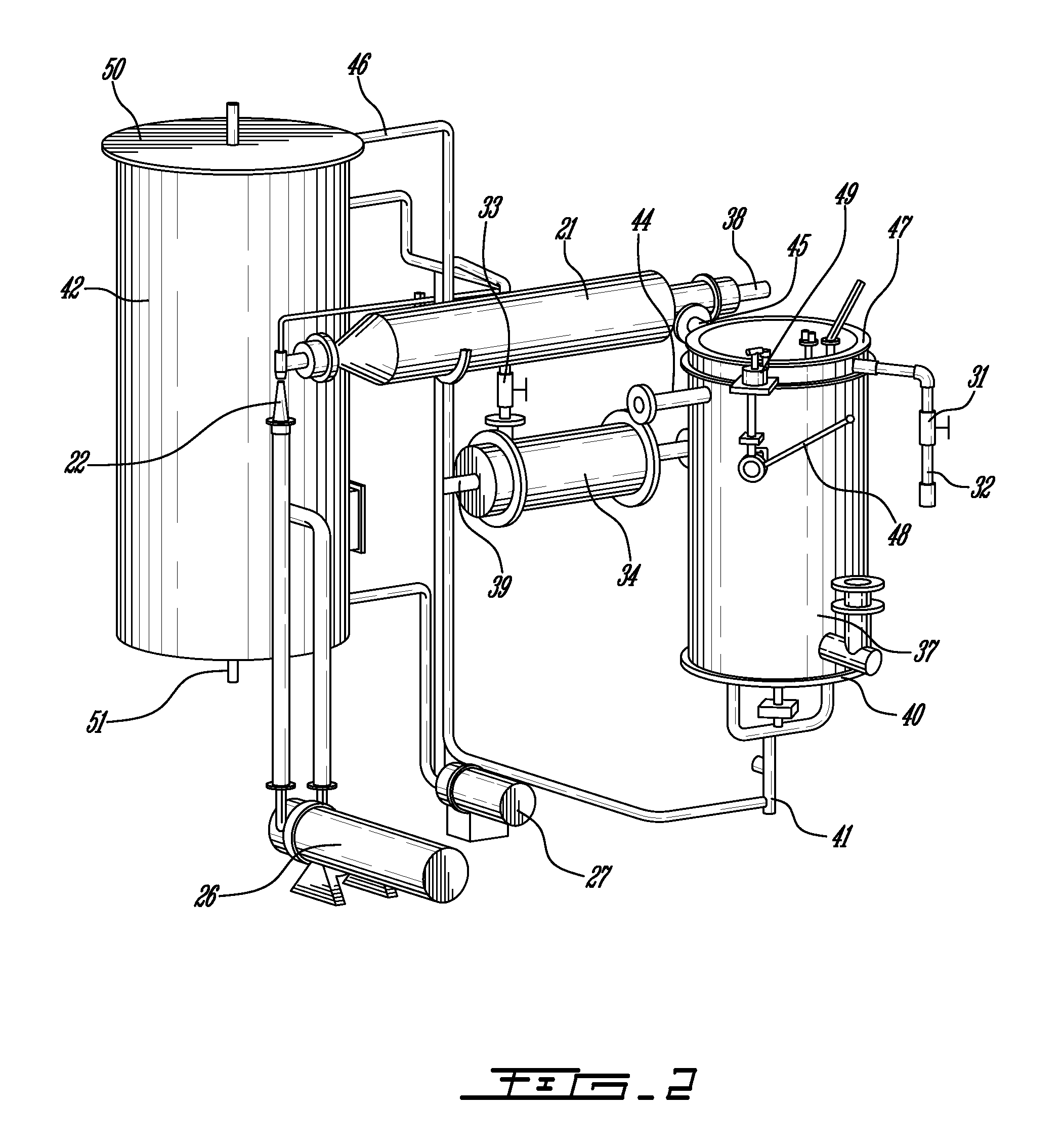

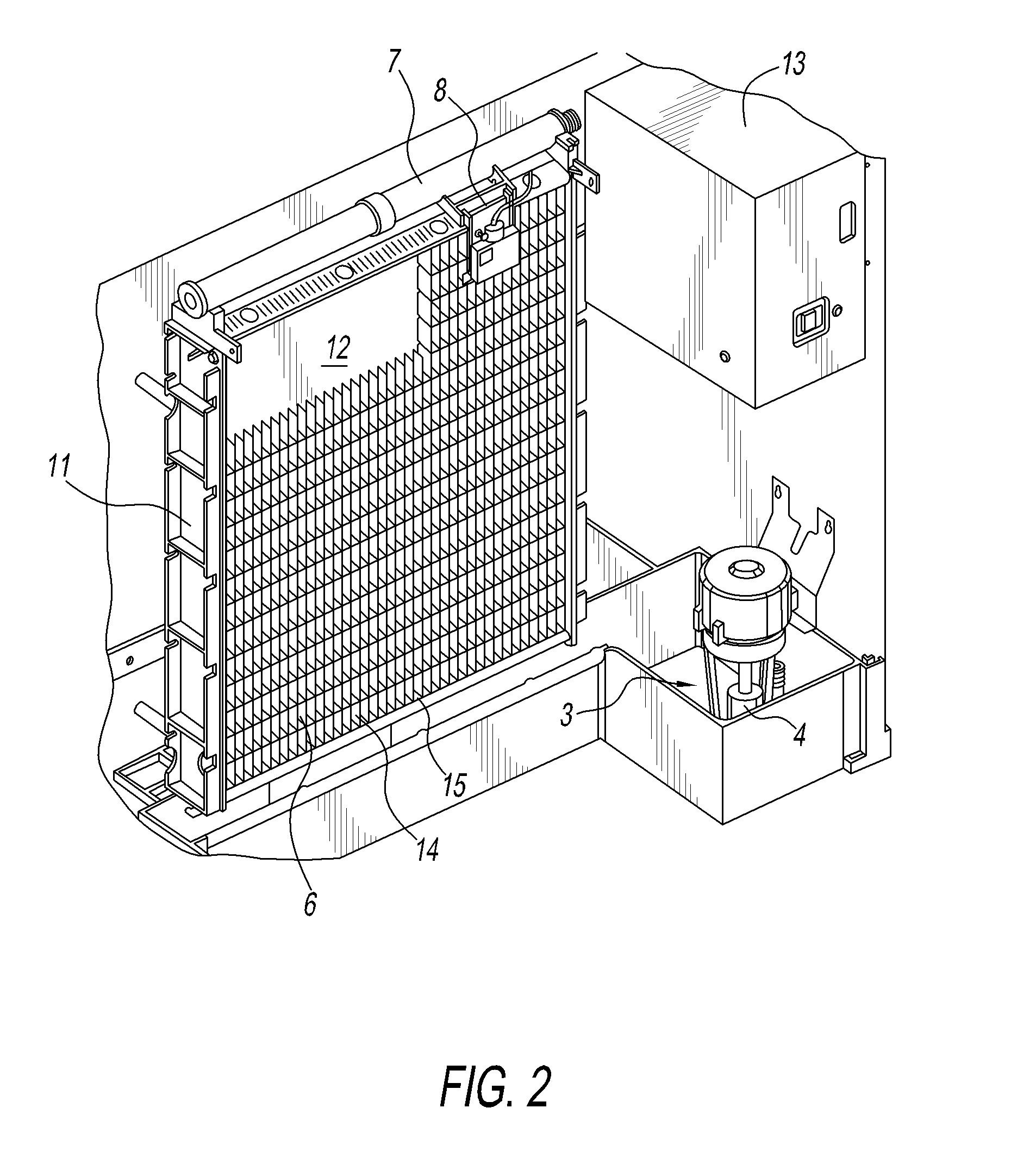

Photo-bioreactor with Particle Separation and Water Recovery System

InactiveUS20110053257A1Low costEasy maintenanceBioreactor/fermenter combinationsBiological substance pretreatmentsWater useSystems design

The Photo-bioreactor with Particle Concentration and Water Recovery System is a bioreactor system designed to propagate algae under fully closed, controlled conditions. The system is highly efficient and has a reduced turnaround time compared to similar photo-bioreactors. The system has an integrated, gravity-flow biomass harvest and water recovery system that allows the operator to simultaneously harvest the cell concentrate and recycle the water used in the growth media. The bioreactor's scale can range from a single bench-top unit to multiple, large-scale commercial units in a manifold type array, and can utilize sunlight or artificial light.

Owner:RAGSDALE IAN LANE +1

Two roll sugarcane crushing mill

Owner:NIKAM BHAUSAHEB BAPURAO

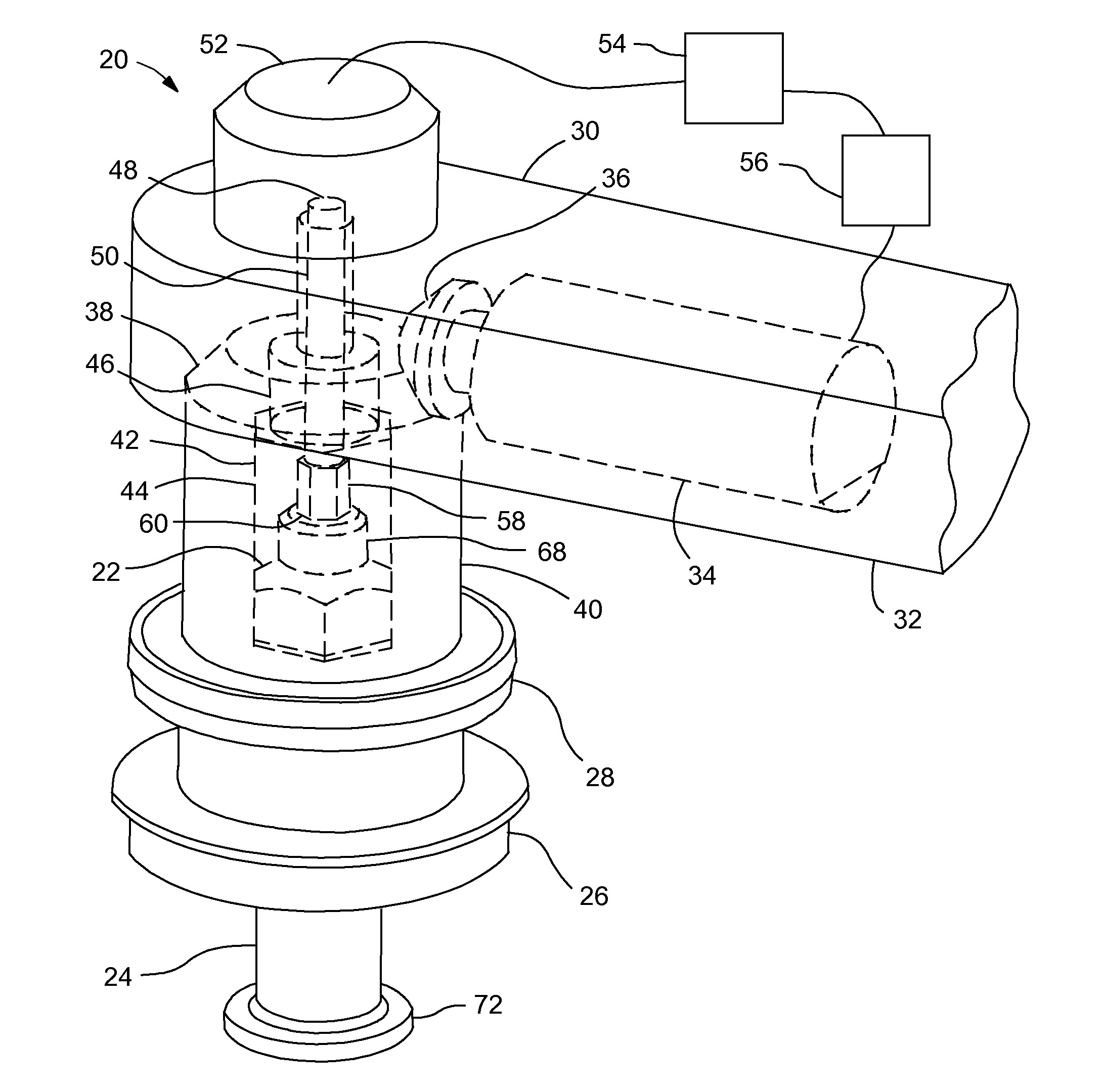

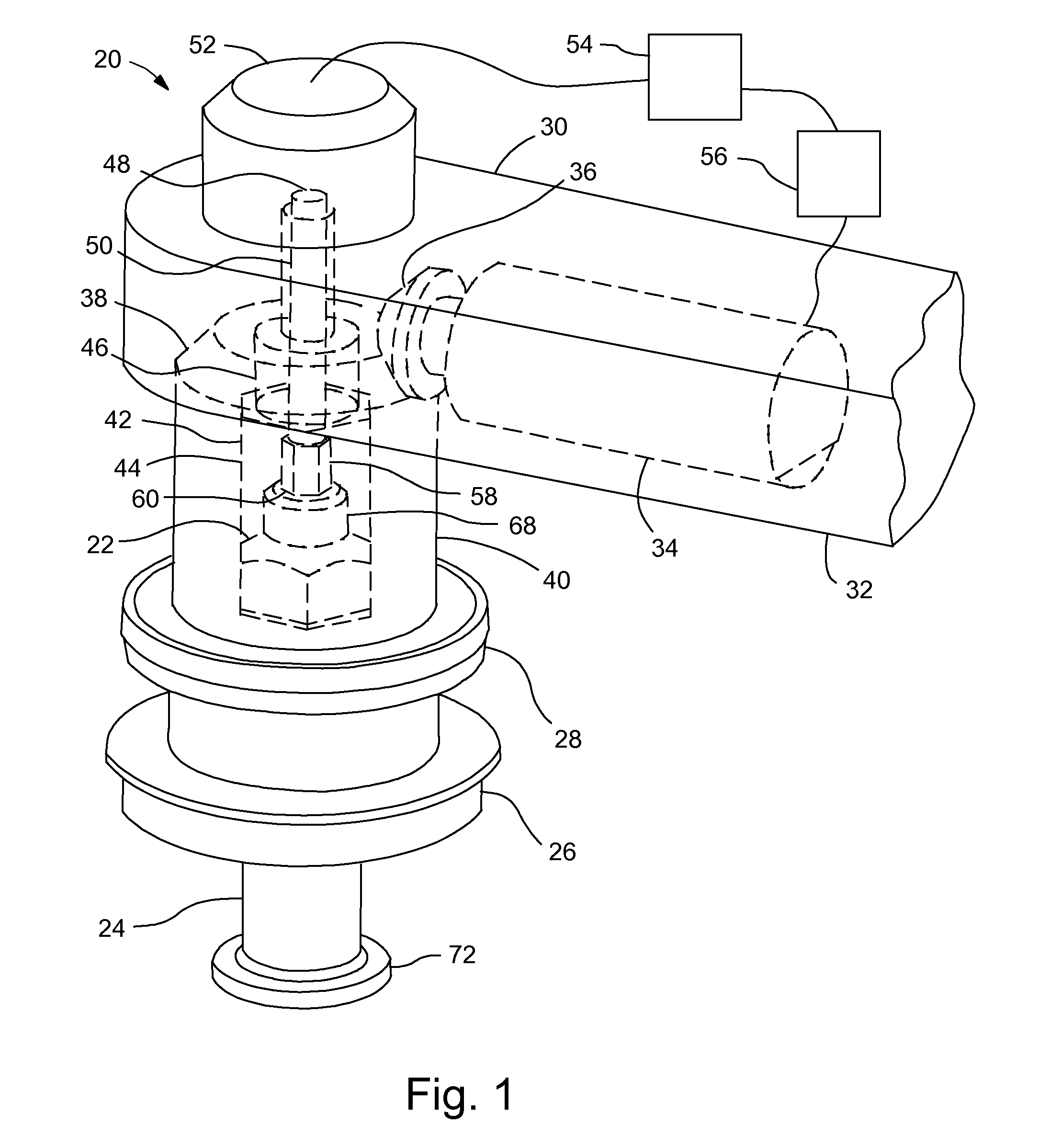

Hold and drive tool with disengagement capability

A hold and drive tool and method of operation for fastening parts together with a stud and nut. The tool may comprise a tool body including a drive member therein, with the drive member rotationally driven by a power source; a nut drive member engaging the drive member and including a nut engaging portion received on the nut and rotating the nut relative to the stud; a hold member including a hold shaft connected to a hold bit, with the hold bit located in the nut drive member and received on a hold feature on the stud to prevent the stud from rotating relative to the hold member; and a clutch secured to the tool body and the hold shaft, with the clutch selectively allowing for and preventing rotation of the hold shaft relative to the tool body.

Owner:GM GLOBAL TECH OPERATIONS LLC

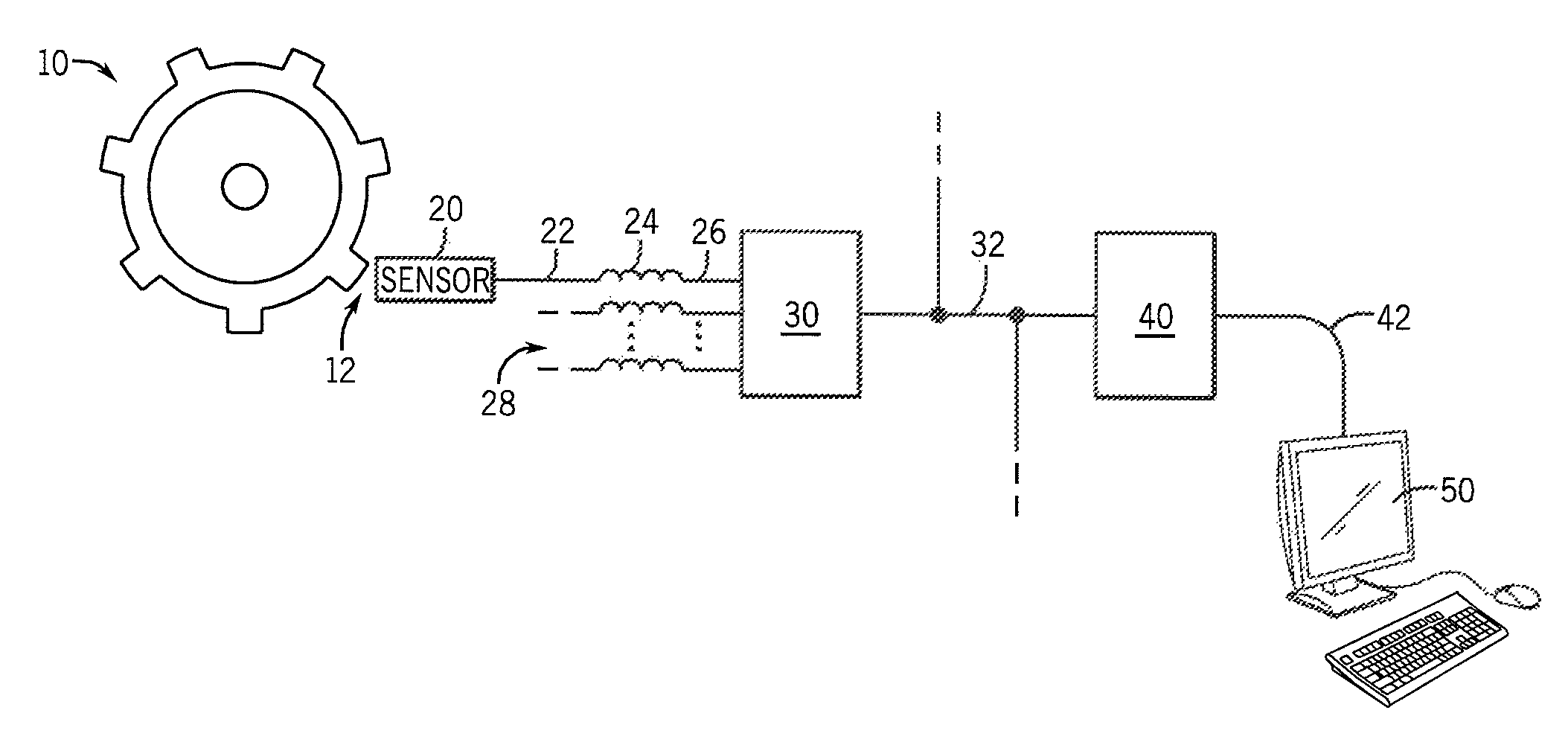

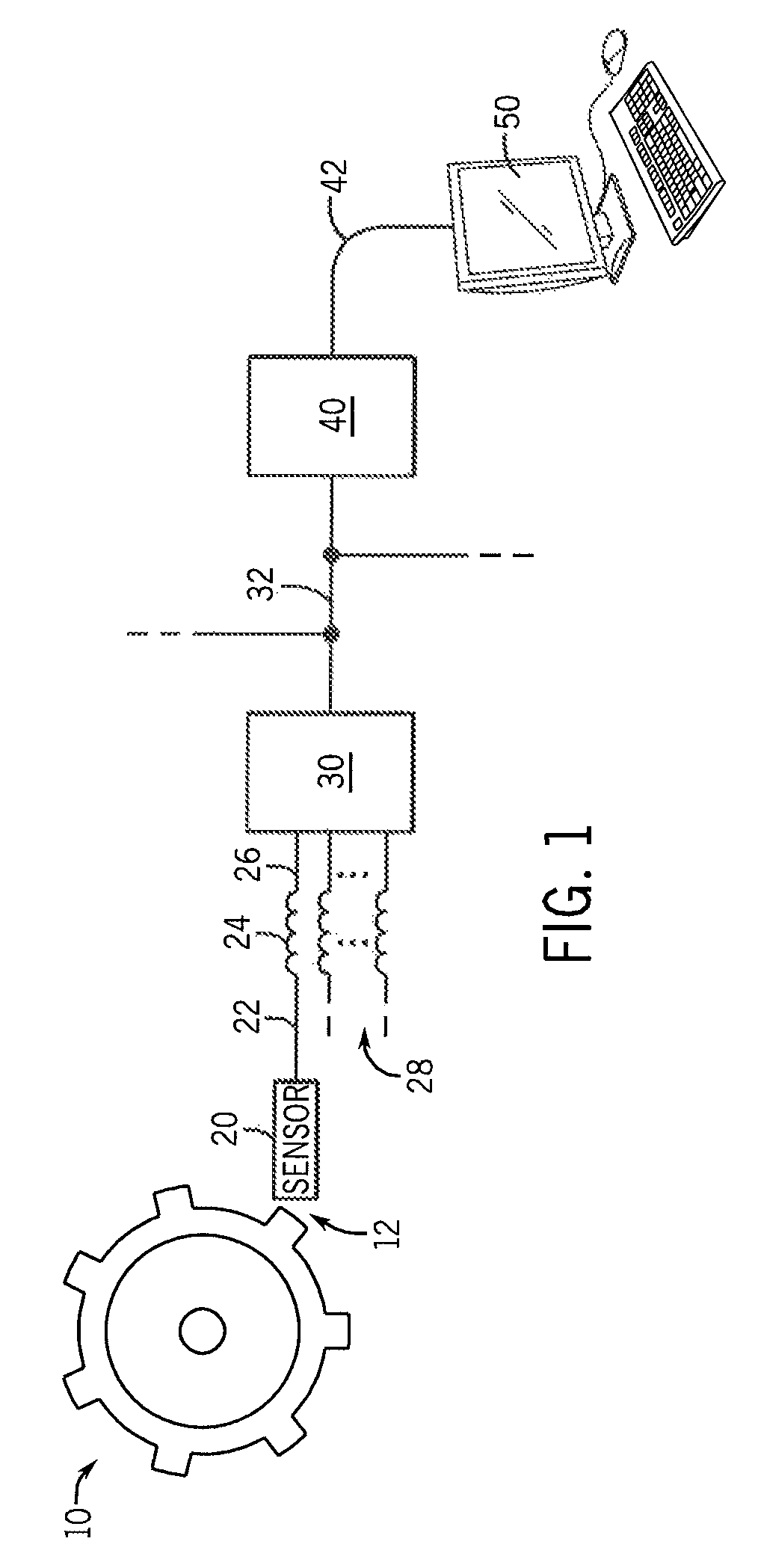

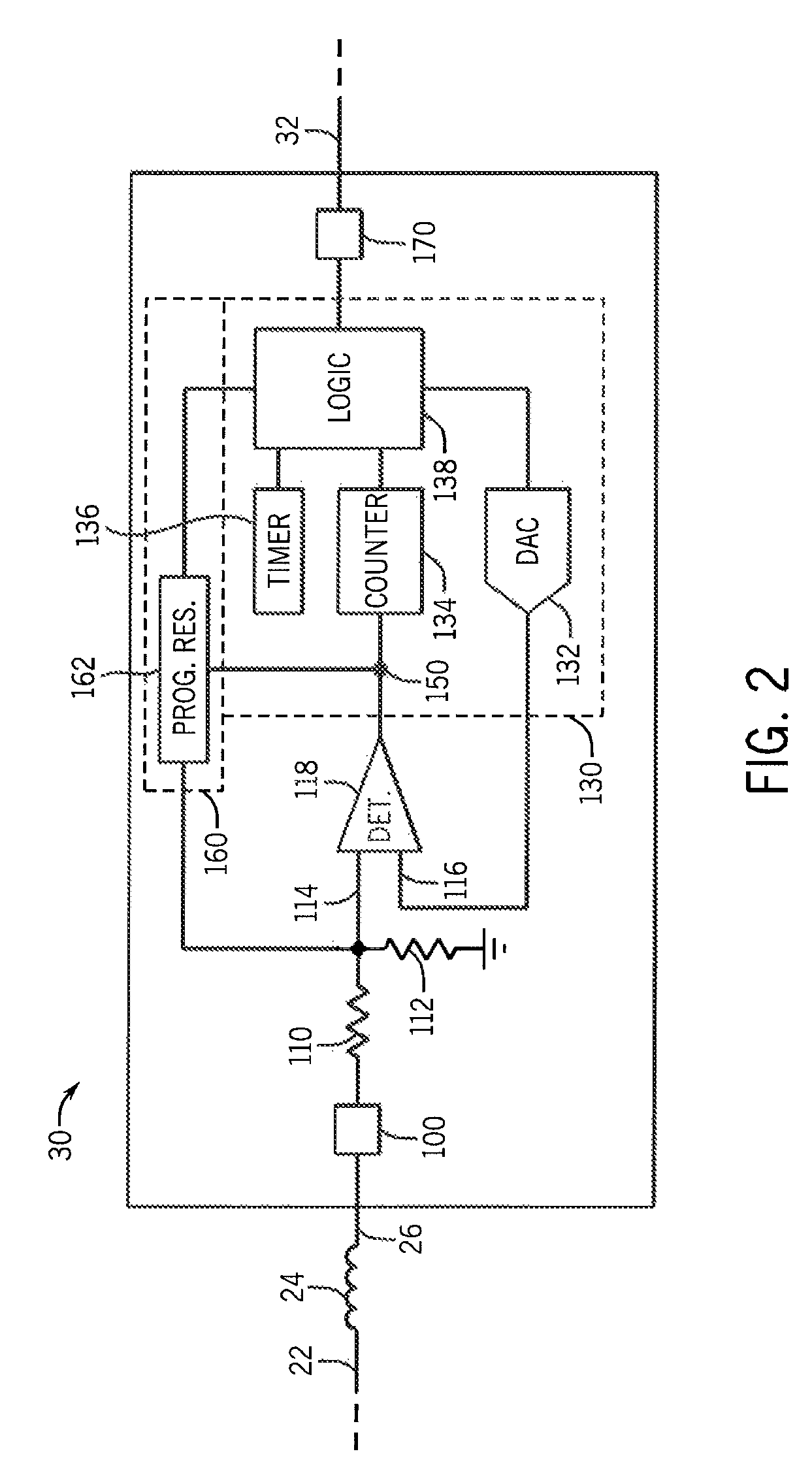

Adaptive threshold voltage for frequency input modules

ActiveUS8981756B2Improve balanceAccurate settingSpectral/fourier analysisResistance/reactance/impedenceHysteresisElectricity

Systems and methods for an industrial I / O controller circuit for frequency input modules that measure the frequency of an electrical input signal using adaptive threshold voltage and / or adaptive hysteresis feedback are shown and described. The systems and methods provide advantages in that the I / O controller circuit can better distinguish between actual input pulses from the electrical input signal, as opposed to unwanted Electromagnetic Interference (EMI) induced input pulses. This maximizes the amount of EMI rejection, independent of the frequency of the moving machine, and results in less time to commission and adjust a sensor, fewer false frequency measurements and less system down time.

Owner:ROCKWELL AUTOMATION TECH

Electrical fuse control of memory slowdown

InactiveUS20050213411A1Efficient non-volatile methodMaterial-handling overhead is minimalRead-only memoriesElectricityMemory interface

Owner:TEXAS INSTR INC

Single web grid with reinforced bulb

Manufacture of roll formed one piece sheet metal grid tees that affords different load ratings with the same gauge and quality of sheet stock and the same overall cross-section dimensions by varying the width of the strip used to make the tees and disposing material added for increased load rating at the area of the hollow reinforcing bulb of the tees.

Owner:USG INTERIORS INC

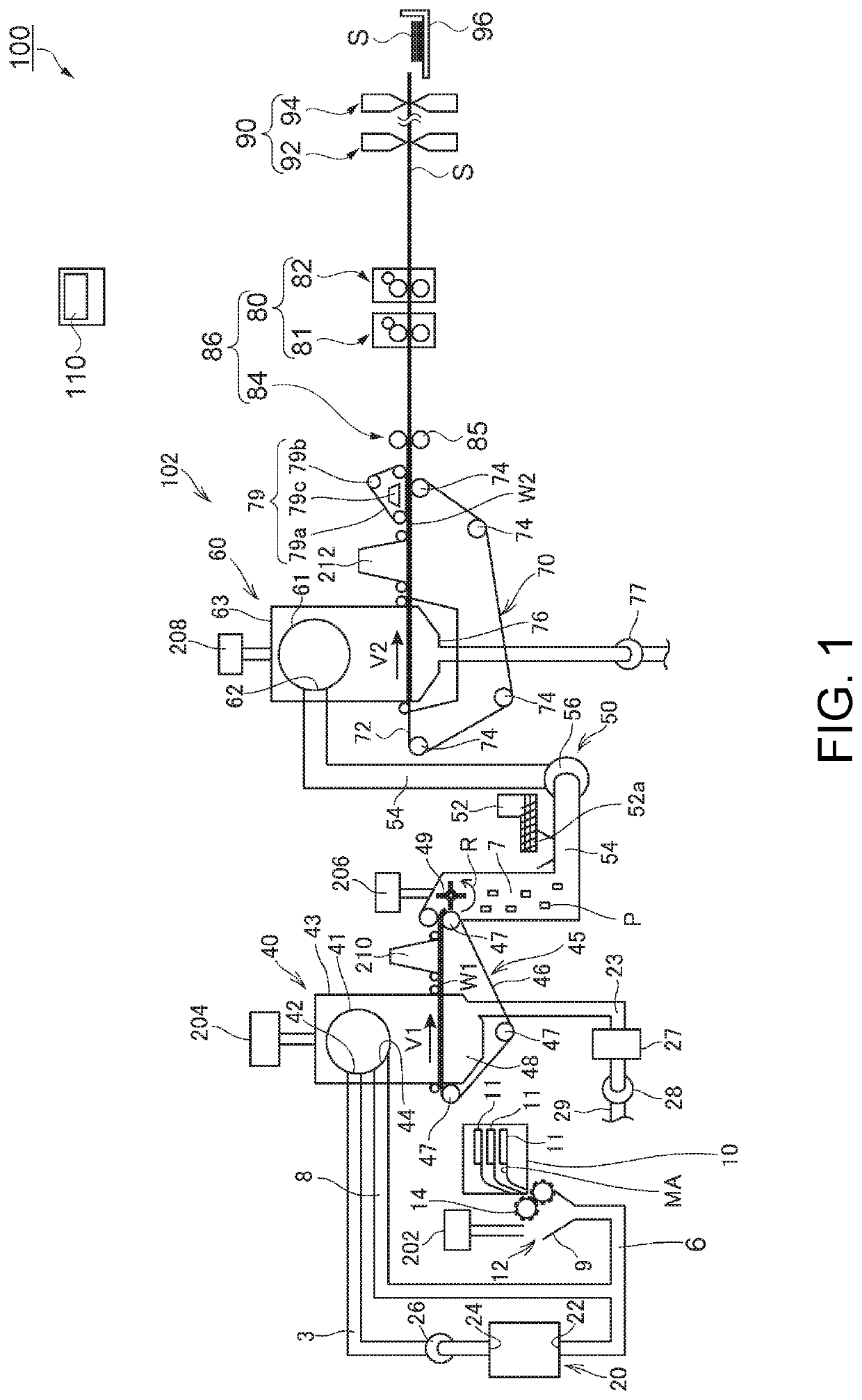

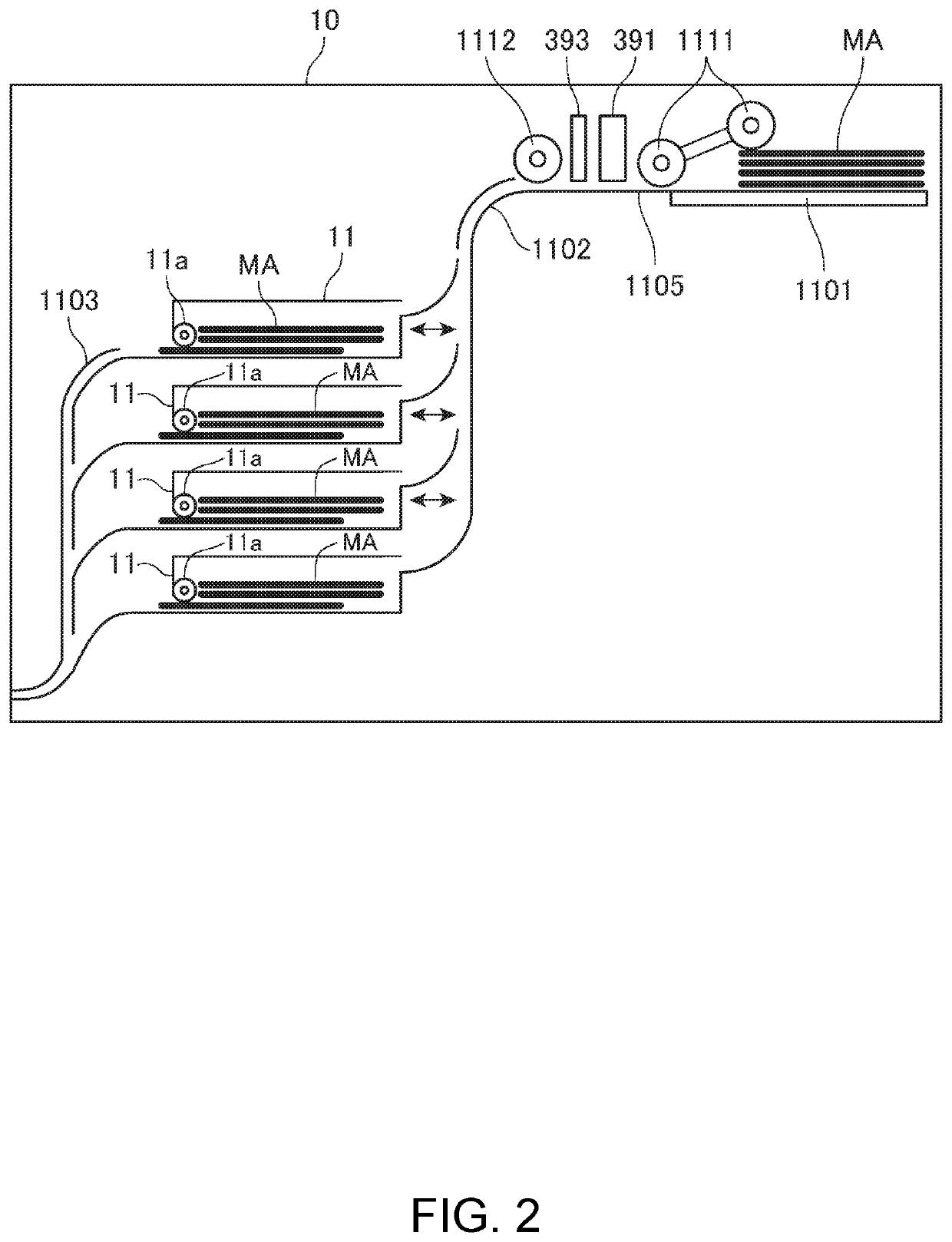

Sheet manufacturing apparatus, sheet manufacturing system, control method of a sheet manufacturing apparatus, and sheet manufacturing method

ActiveUS11008707B2Quickly restoring to working conditionQuality andDryer sectionWood working apparatusFiberManufactured apparatus

Provided is technology improving the efficiency (productivity) of a sheet manufacturing apparatus. A sheet manufacturing apparatus 100 manufactures sheets S by heating with heaters 81 and 82 a mixture (second web W2) of resin and fiber produced by defibrating feedstock MA. The heaters 81 and 82 each have a first roller 171, a second roller 172 that holds the second web W2 with the first roller 171, and a moving mechanism 190. The moving mechanism 190 can switch the first roller 171 and second roller 172 to a position holding the second web W2, and a first roller 171 and second roller 172 are separated and do not hold the second web W2. The heaters 81 and 82 are configured as units that can removably installed to the sheet manufacturing apparatus 100.

Owner:SEIKO EPSON CORP

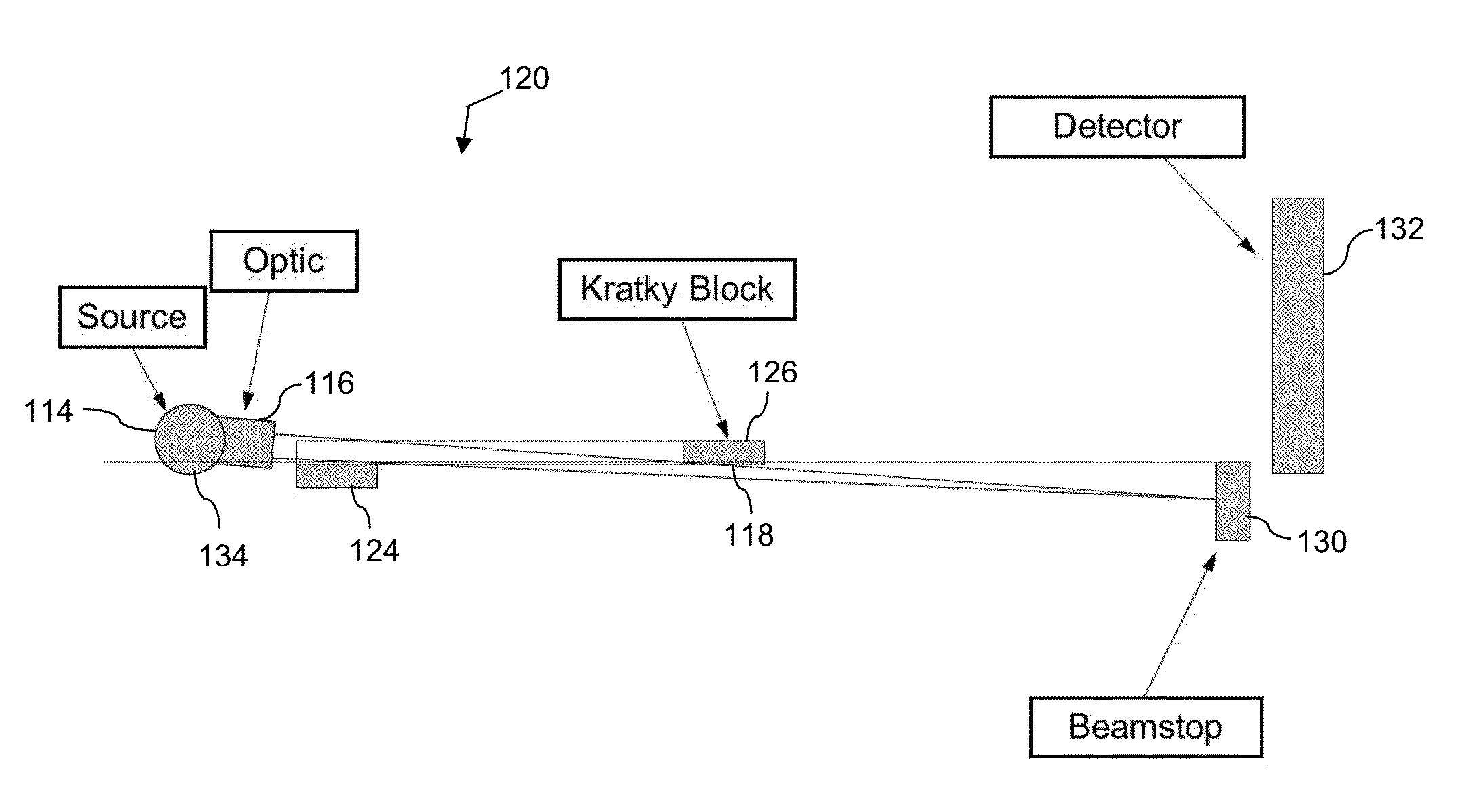

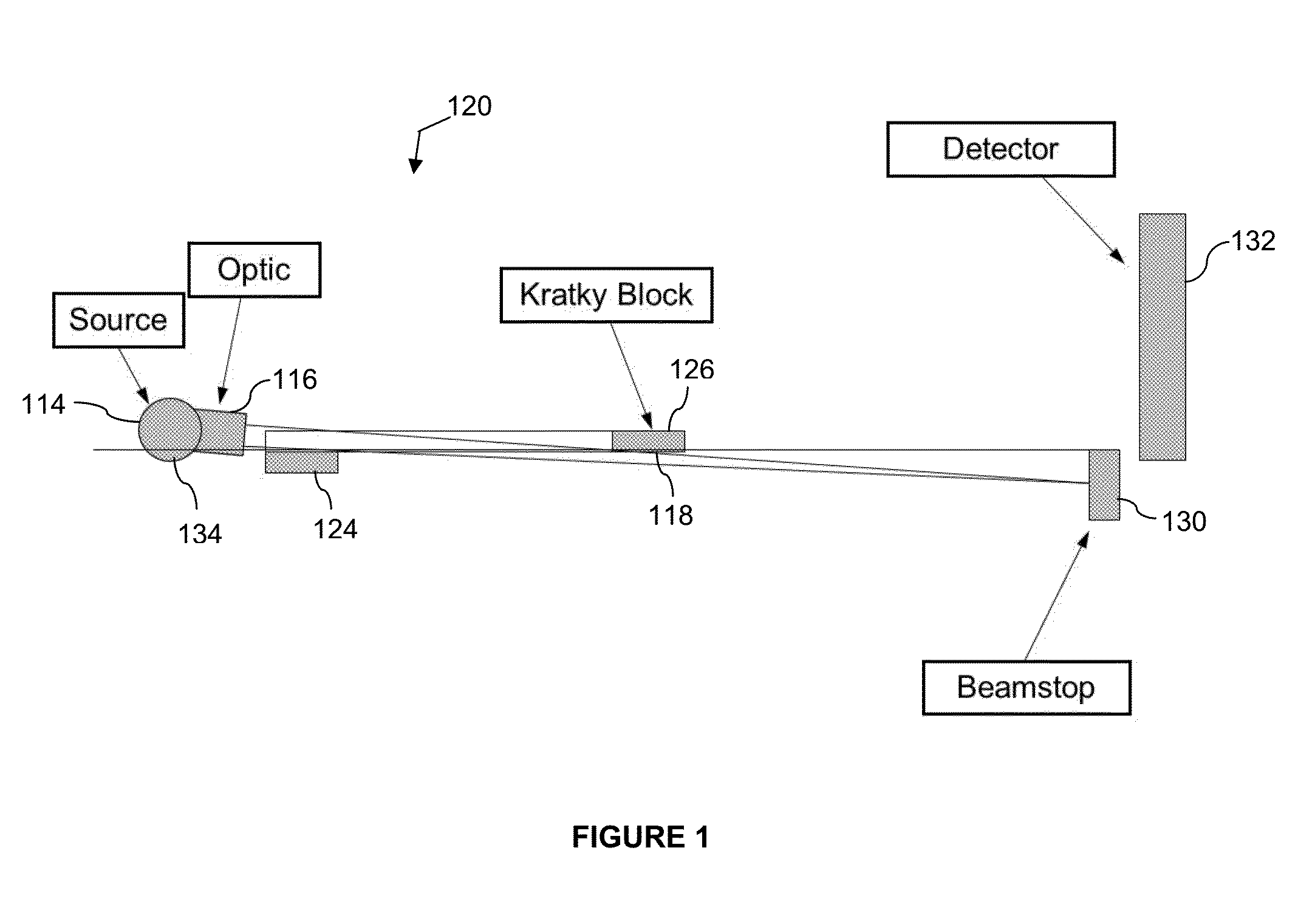

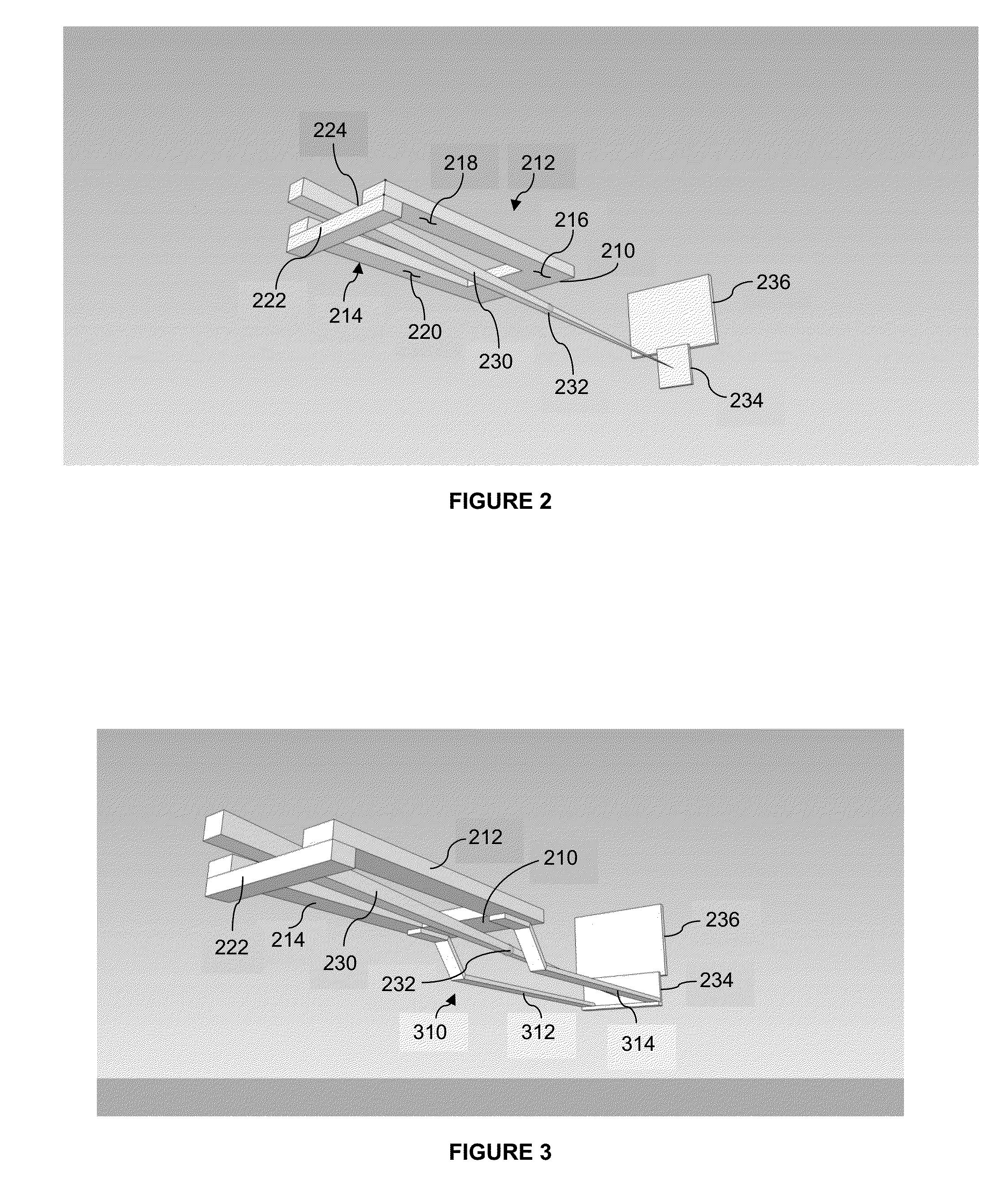

High performance kratky assembly

ActiveUS20150241366A1Improve performanceEliminate the stress related stability problemMaterial analysis using wave/particle radiationHandling using diaphragms/collimetersLight beamX-ray

An assembly for Kratky collimator is provided. The assembly may be used for a small angle x-ray camera or system requiring such filtering. The assembly may include a first block with a first working surface and a second block with a second working surface. The first and second blocks may be aligned with the first working surface pointing an opposite direction of the second working surface and the first working surface being aligned in a common plane with the second working surface. In some implementations, the first block may comprise a crystal material. In some implementations, an extension may of the first block may be configured position a beamstop.

Owner:RIGAKU INNOVATIVE TECH

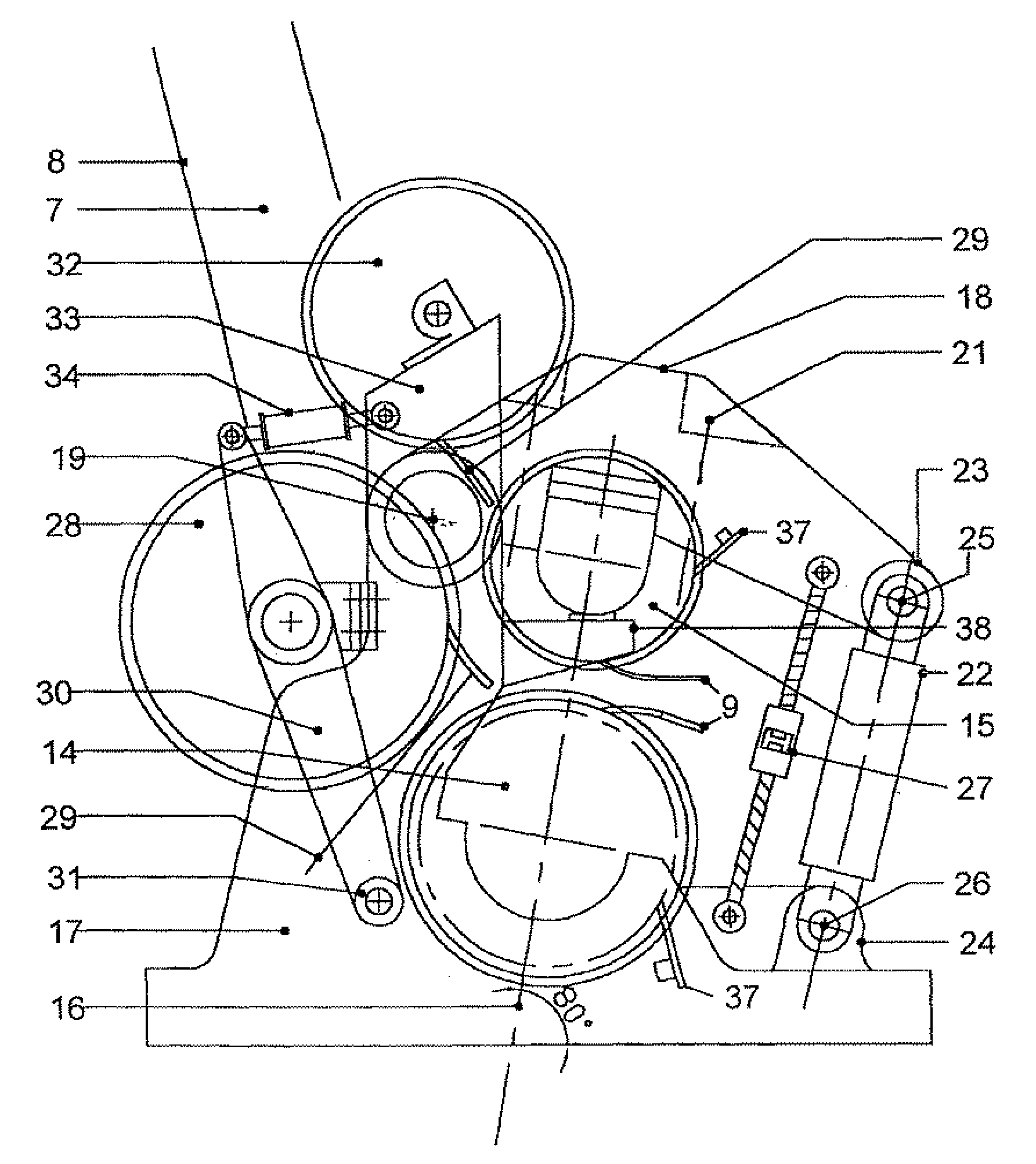

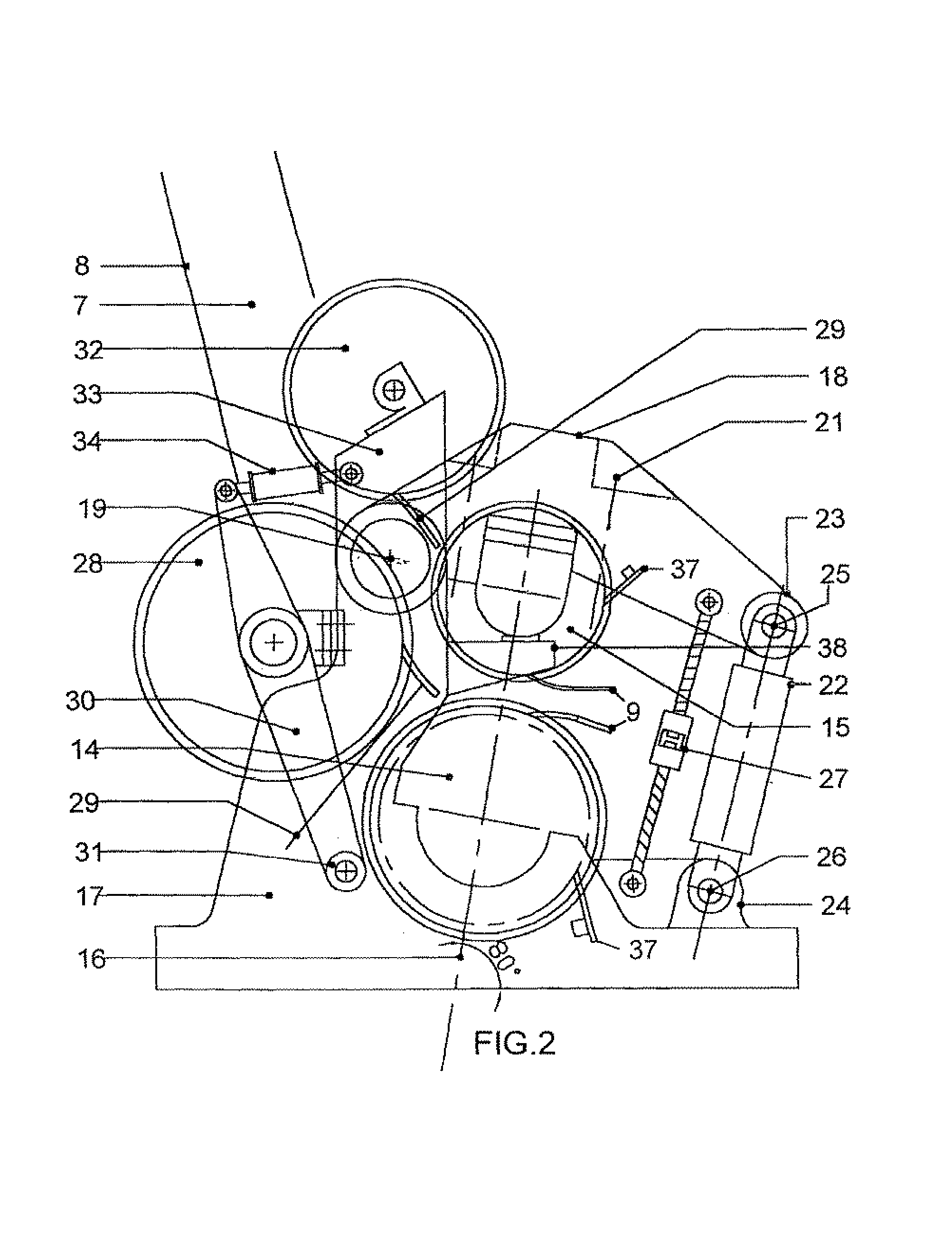

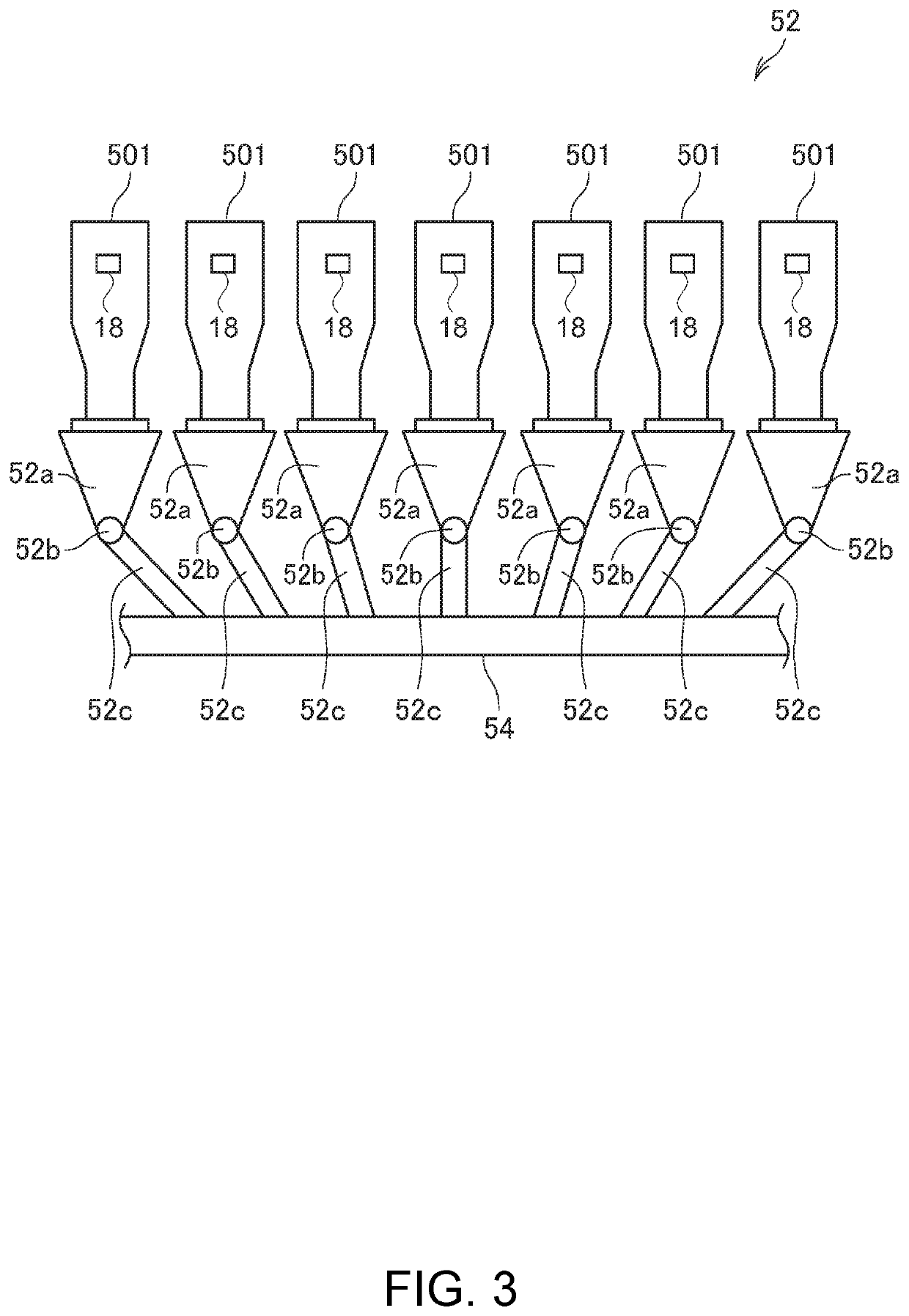

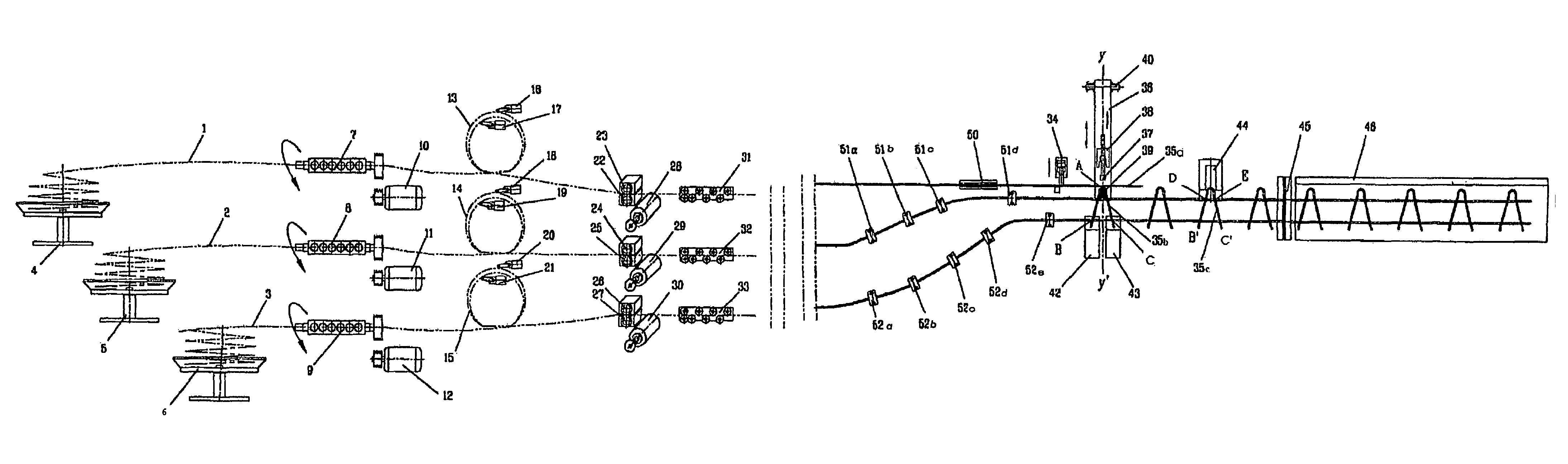

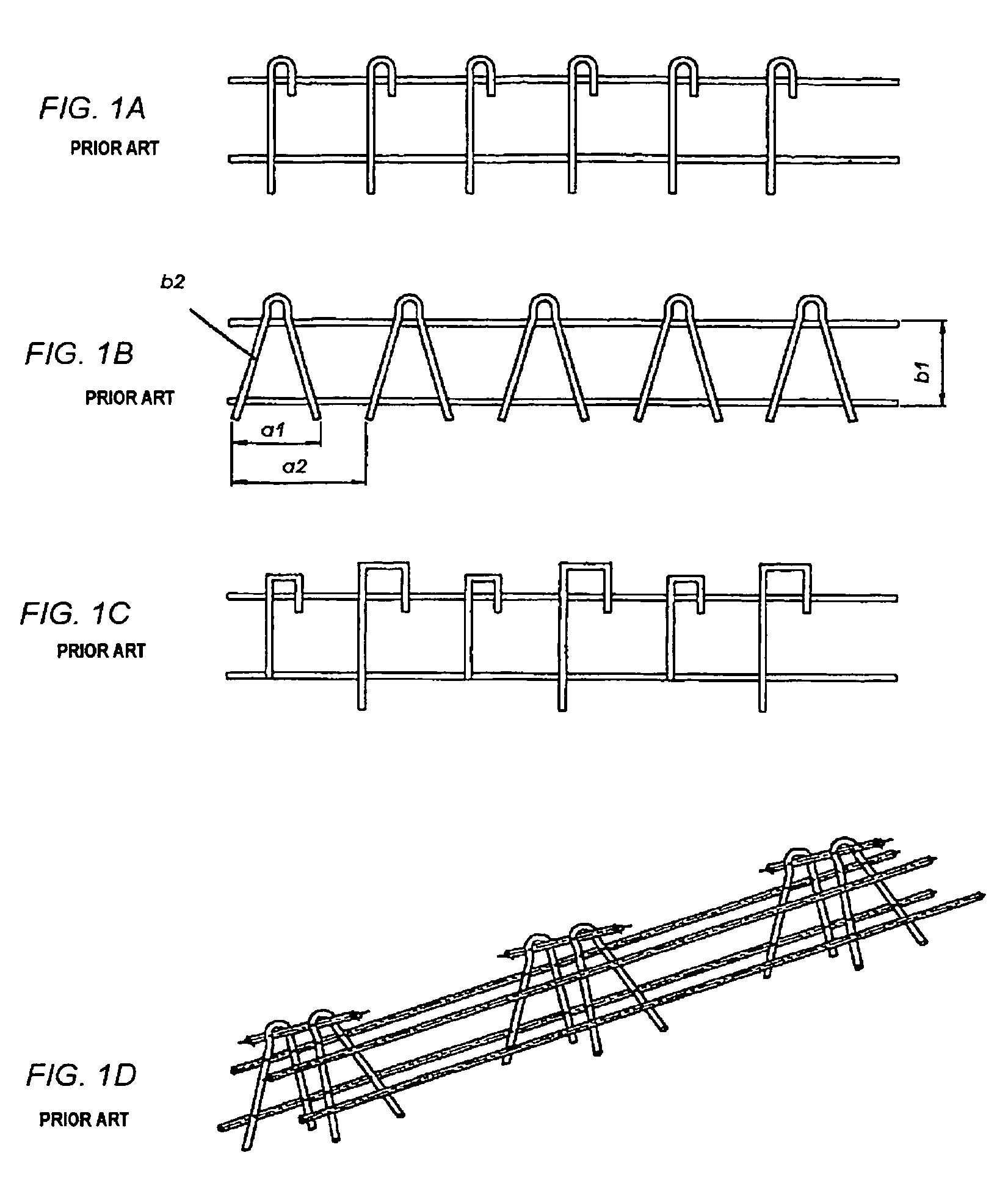

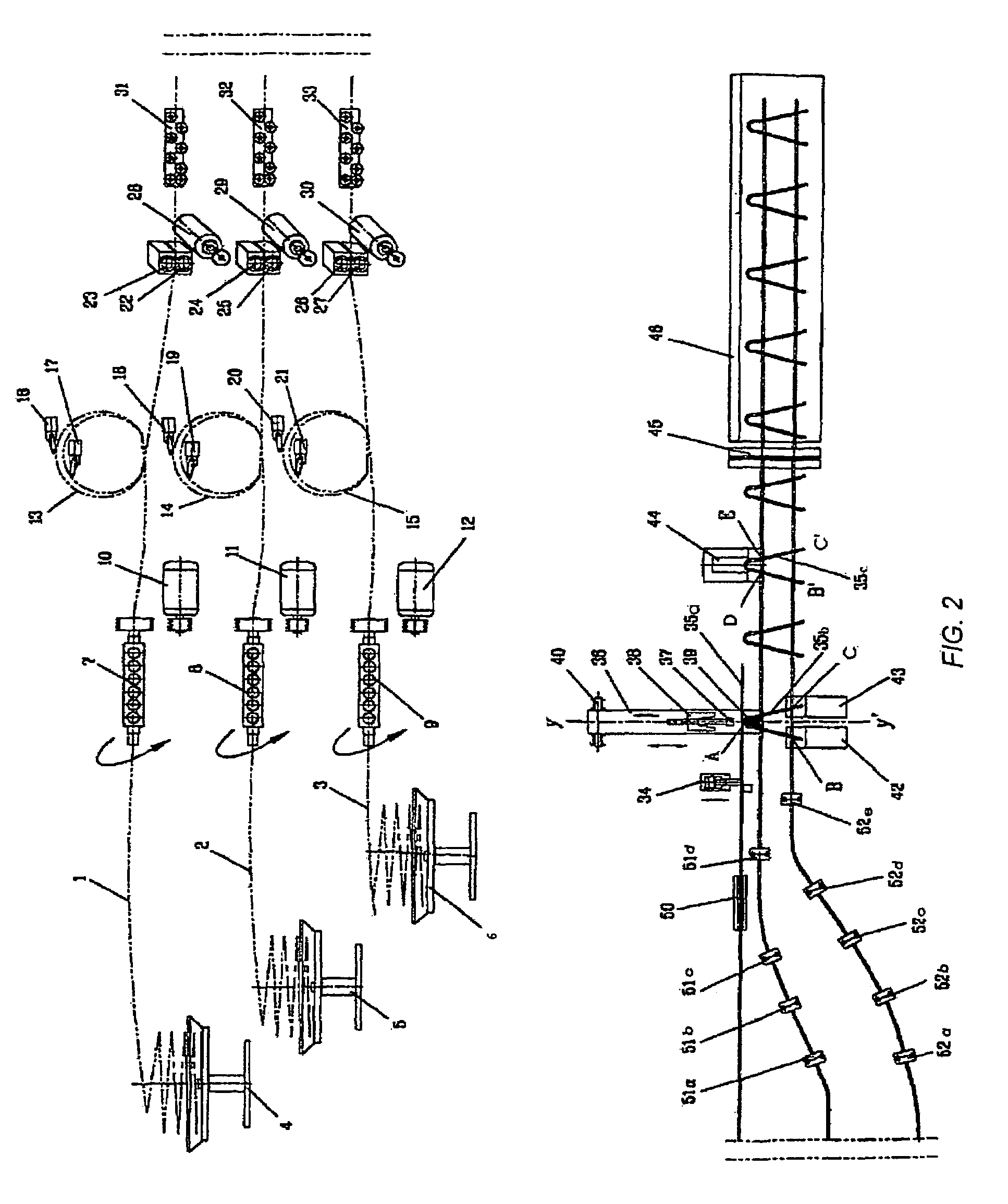

Method and machine for the production of reinforcement and dowel side frames for concrete reinforcement from wire or rod or other material of prismatic cross section

ActiveUS7607210B2Simple and fast productionQuality improvementMetal rolling stand detailsWire networkWire rodEngineering

According to the method, the transversal wire or rebar to be formed (1) and the longitudinal wires or rebars or other material of prismatic cross section (2), (3) are fed to the main forming and welding machine subsystem, in a stepwise manner, at the appropriate distance each time, through a driving mechanism (22-30). At this location, the transversal wire (1) is cut and then formed upon the action of a press (36). Welding of the formed transversal frame with one of the two longitudinal wires is performed while the formed transversal wire is still restrained by the action of the press (38) at the formation location. Welding with the second longitudinal wire is performed at the next production step, simultaneously with the welding of the next transversal frame with the first longitudinal wire, at the formation location. After the welding action, the transversal frame is released by the press and the forming tools (37-39), and the next production step is initiated. The product is made in a continuous shape and is cut at the proper lengths, by a cutter (45).

Owner:ANAGNOSTOPOULOS ANTONIOS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com