Gas turbine with external combustion, applying a rotating regenerating heat exchanger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

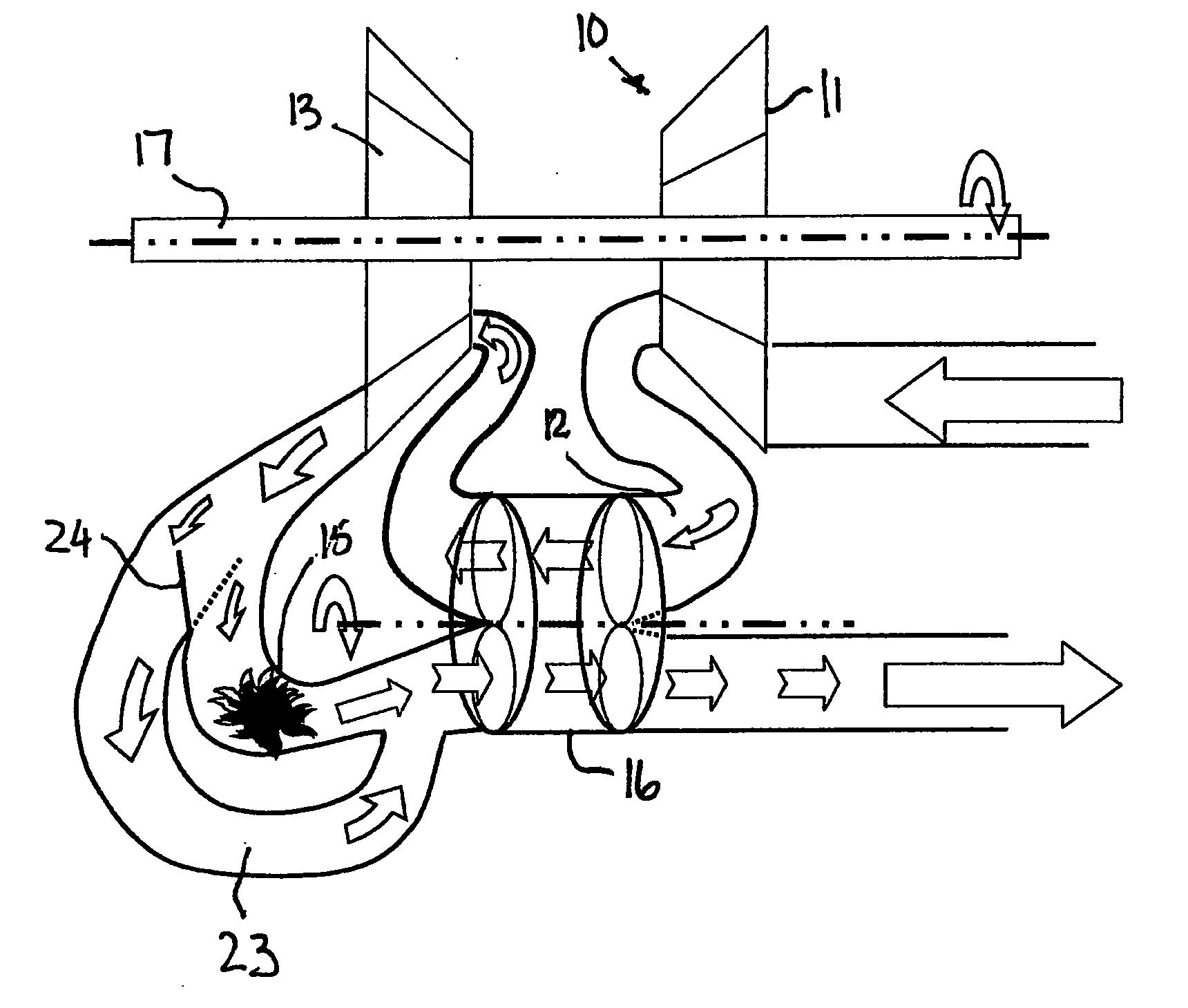

[0042]FIG. 1 shows schematically and very simplified a sketch of the principle applied according to the present invention. A gas turbine 10 comprises a compressor unit 11 employed for compressing air from a pressure p1 of 1 bar to a pressure p2 of 2 bar, while the temperature as a consequence of the compression is increased from T1=20° C. to a temperature of T2=200° C. Across the compressor unit the air velocity is increased from v1=1 m3 / sec to a velocity of v2=0.86 m3 / sec. In the compression chamber 12 between the compressor unit 11 and the turbine unit 13 of the turbine 10, the compressed gas is heated further by means of a regenerative heat exchanger 14 to a temperature of T2=800° C. while the pressure is maintained at a pressure of p3=2 bar. The velocity of the air is due to the heating increased to v3=1.83 m3 / sec. Then, the compressed and heated gas is directed to the turbine unit 13 where the air is expanded to a pressure of p4=1 bar and where the temperature is reduced to T4=...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com