Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

93results about How to "Delicious and unique" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Mushroom sauce soybeans

InactiveCN103445099ADelicious and uniqueThe production process is simple and environmentally friendlyFood preparationRHODIOLA ROSEA ROOTFlavor

The invention discloses mushroom sauce soybeans. The mushroom sauce soybeans consist of the following raw materials in parts by weight: 100 to 150 parts of soybeans, 10 to 20 parts of barley, 20 to 30 parts of mushrooms, 2 to 3 parts of ginseng, 1 to 2 parts of pseudo-ginseng, 1.5 to 2 parts of lucid ganoderma, 2 to 3 parts of medlar, 3 to 5 parts of astragalus membranaceus, 3 to 4 parts of acanthopanax, 1 to 2 parts of rhodiola rosea, 10 to 15 parts of millet wine, and suitable amounts of dried red pepper, aniseed, anise, soybean sauce, salt, white sugar, chicken essence, sesame oil and water. The mushroom sauce soybeans disclosed by the invention have the advantages of delicious and unique flavor, simple and environment-friendly manufacturing process and the like; meanwhile, the soybeans disclosed by the invention are additionally provided with the active ingredients of traditional Chinese medicines, such as the ginseng, the pseudo-ginseng and the lucid ganoderma, thus having a certain anti-aging effect.

Owner:DANGTU HUANGCHI VEGETABLE PRODION & MARKETING SPECIALIZED COOP

Prepared seafood and preparation method thereof

InactiveCN101965985ADelicious and uniqueFull of nutritionFood preparationCordycepsTricholoma matsutake

The invention discloses prepared seafood and a preparation method thereof. The distinctive seafood is prepared by the following steps of: cleaning seafood products such as sea cucumber, abalone, scallop, conch, sea urchin, short necked clam, shrimp, bird shellfish and the like; removing internal organs; boiling the seafood products; boiling the dry or fresh wild mushrooms such as tricholoma matsutake, cordyceps militaris, edible fungi and the like in water; fishing out the wild mushrooms; concentrating the boiling liquid and dipping the boiled seafood products in the concentrated boiling liquid under high pressure; and finally packaging the boiled seafood products which are dipped in the fresh wild mushroom flavor and the boiled wild mushrooms together. The product does not have the fishy smell of the seafood but has delicious and unique smell.

Owner:DALIAN HAIYANTANG BIOLOGY

Canned edible fungus and crocodile meat food

InactiveCN102613541AExtended shelf lifePromote circulationFood preparationBiotechnologyVegetable oil

The invention discloses a canned edible fungus and crocodile meat food, which comprises an edible fungus, vegetable oil, cordyceps militaris, crocodile meat, sugar, table salt, gourmet powder, chilli, pepper, anise, bay leaf, dried ginger, cooking wine, table vinegar and fermented soya beans. By the formula advantage, convenience is provided for a user, and the user can enjoy the edible fungus and the crocodile meat.

Owner:彭贵书

Seasoning-contained liquid dairy product and producing method thereof

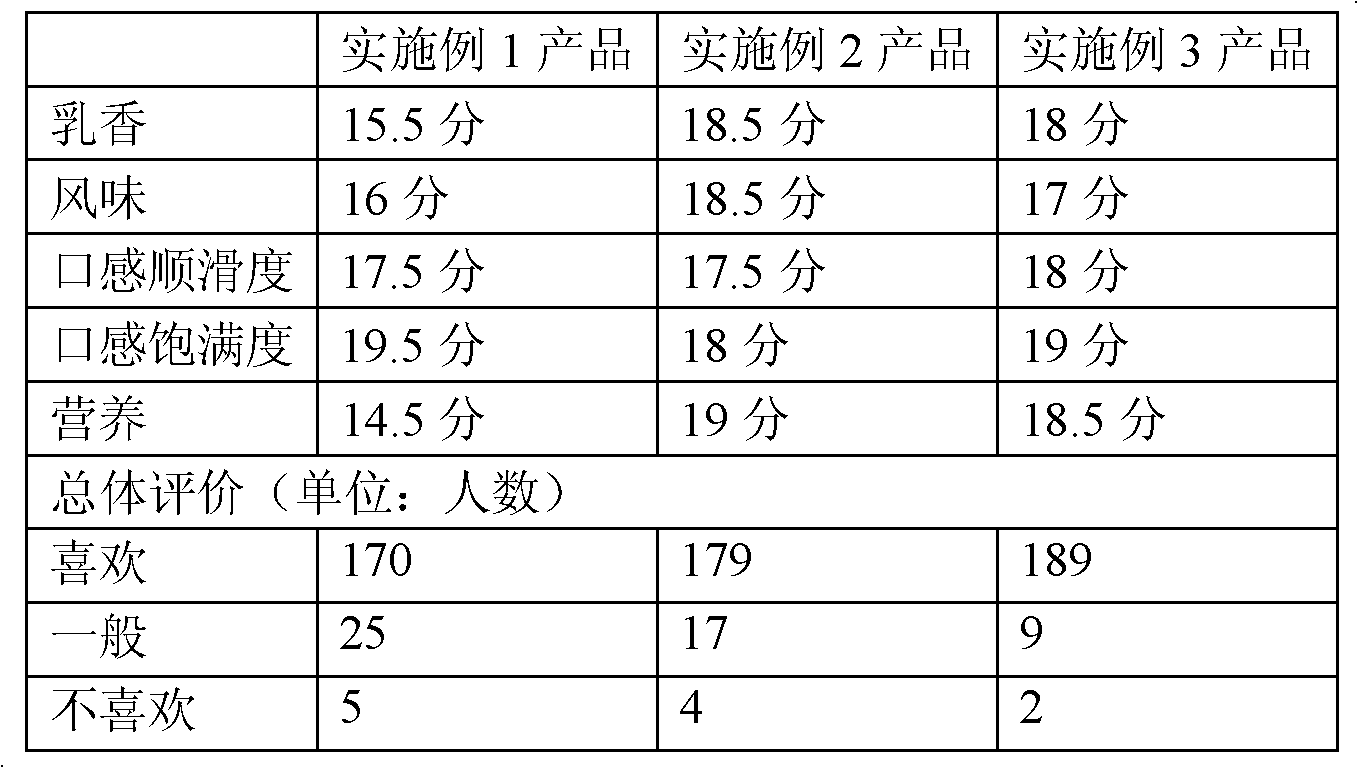

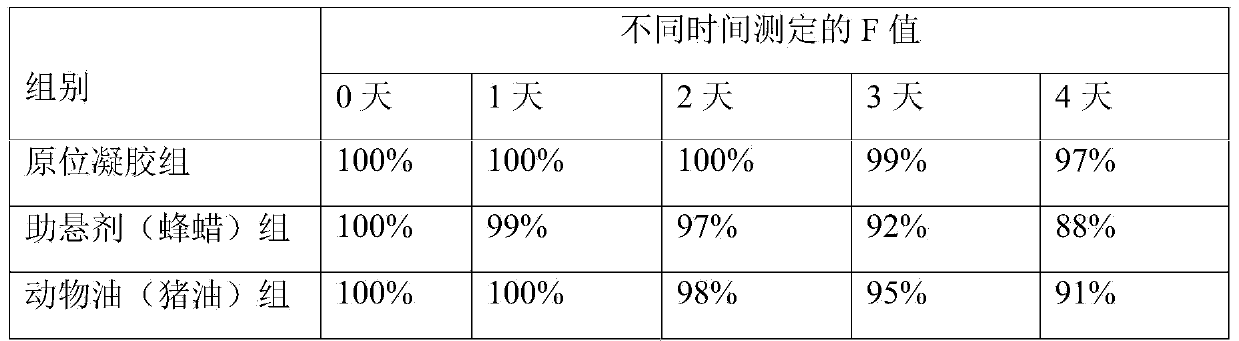

The invention provides a seasoning-contained liquid dairy product and a producing method thereof. The liquid dairy product comprises raw materials in percentage by weight as follows: 30-99.88 percent of milk, 0.05-8 percent of seasoning, 0.01-0.15 percent of humectants, 0.05-0.3 percent of edible salt, 0-2 percent of emulsifier, 0.01-1 percent of thickening agent, and 0-69.88 percent of water. In the invention, through a reasonable formula and proper technique, the seasoning is added in the liquid milk product, thereby providing the liquid milk product having unique delicious taste, and realizing the good stability and the good mouthfeeling of the product in shelf life.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Fast pickling method for parabramis pekinensis

InactiveCN102783667AReduce salt contentUnique flavorFood preparationMonosodium glutamateAdditive ingredient

The invention relates to a fast pickling method for parabramis pekinensis. According to the method, 1000g of parabramis pekinensis is matched with the following ingredients including 20 to 40g of common salt, 2 to 5g of monosodium glutamate, 2 to 5g of five-spice powder, 10 to 20g of yellow wine, 10 to 15g of pepper, 10 to 20g of ginger, 15 to 25g of edible grade sodium chloride, 2 to 8g of potassium chloride and 5 to 12g of calcium lactate, and 1000g of pork is matched with the following ingredients including 10 to 20g of common salt, 10 to 15g of sugar, 2 to 5g of monosodium glutamate, 10 to 15g of yellow wine, 5 to 10g of ginger, 5 to 10g of anise and 5 to 10g of cinnamon. The manufacture is carried out according to the following manufacture method that parabramis pekinensis is killed and cleanly washed, a centrifugal machine is adopted for eliminating water, the parabramis pekinensis belly is cut, common salt is added for pickling for 30 to 40 hours, then, salt marinade removal (partial salt is removed) is carried out, then, the parabramis pekinensis is soaked for 70 to 80 hours in marinade (the salinity is controlled to be 5 to 8 percent) boiled by the rest ingredients, then, ozone water is used for sterilization, the water is removed through the centrifugal machine, the pork is treated through a meat rolling machine, then, the ingredients are added for pickling for 12 to 15 hours, then, the pork is added into the parabramis pekinensis belly according to the quantity being 10 percent of the weight of the parabramis pekinensis, finally, a low-temperature air drying machine is used for carrying out air drying, and then, high-pressure steam sterilization vacuum package is carried out. The method has the advantages that the pickling time is short, health and sanitation are realized, the original quality of the parabramis pekinensis is maintained, in addition, the fresh flavor of pork is added, the taste is fresh and delicious, and the fragrance is intense.

Owner:ANHUI HAOZAILAI FOOD

Preparation process of fermented bean curds

InactiveCN104068130AHigh nutritional valueDelicious and uniqueCheese manufactureFood scienceSoy cheeseBiotechnology

The invention provides a preparation process of fermented bean curds and relates to the technical field of bean curd products. The preparation process is characterized by comprising the following steps: (1) selecting bean curds, airing the bean curds for one day, and then slicing the bean curds into 4-6 small bean curd blocks; (2) orderly arraying the sliced bean curds, covering the bean curds with a thin gauze, and placing the bean curds at ventilated and shady places for mildewing the bean curds; (3) mildewing at the temperature of 10-25 DEG C and with the air humidity of 30%-50% until the bean curds become dark; and (4) producing seasonings and fermenting medicinal liquor; (5) wetly immersing the seasonings in the medicinal liquor, rolling the mildewed bean curds in the seasonings for one circle, putting the mildewed bean curds into another utensil, and sealing and storing. The fermented bean curds produced by the process have a high nutritive value and a unique and delicious taste, and are relatively healthy and have a good health-care effect as containing few substances harmful to a human body.

Owner:严新喜

Frozen beverage containing glossy privet fruits and wax apples and preparation method thereof

The invention provides a frozen beverage containing glossy privet fruits and wax apples and a preparation method thereof. The frozen beverage comprises the following materials by taking the total weight of the frozen beverage as a standard: 0.5%-5% of glossy privet fruit powder and 0.5%-6% of wax apple juice. The glossy privet fruits and the wax apples are added to the frozen beverage through a reasonable formula and a proper process, therefore, the invention provides a nutritional and health care type frozen beverage and ensures that an obtained frozen beverage product has nutritional and health care effects and also has good flavor and taste.

Owner:INNER MONGOLIA YILI INDUSTRIAL GROUP CO LTD

Mushroom and beef sauce and preparation method thereof

InactiveCN104172113AAttractive aromaDeliciousFood preservationFood ingredient functionsMonosodium glutamateCollybia

The invention discloses mushroom and beef sauce and a preparation method thereof. The mushroom and beef paste is prepared by taking mushrooms such as collybia albuminosa petch, russula virescens, chanterelle, coprinus comatus, toadstool and beef as main materials, subjecting the main materials to deep processing, and mixing the obtained product with pepper, ginger, pericarpium zanthoxyli, fructus amomi, amomum tsaoko, clove seeds, star anise, monosodium glutamate, edible salt and water. The unique and novel preparation method ensures that the prepared mushroom and beef sauce has rich nutrients, attractive fragrance, delicious taste and rich mouthfeel. The grinded garlic, imperata root and the clove seeds which have antibacterial and anti-inflammation functions are added in the mushroom and beef sauce. The shelf life of food is prolonged, and the mushroom and beef sauce is suitable for industrial production.

Owner:梁爱华

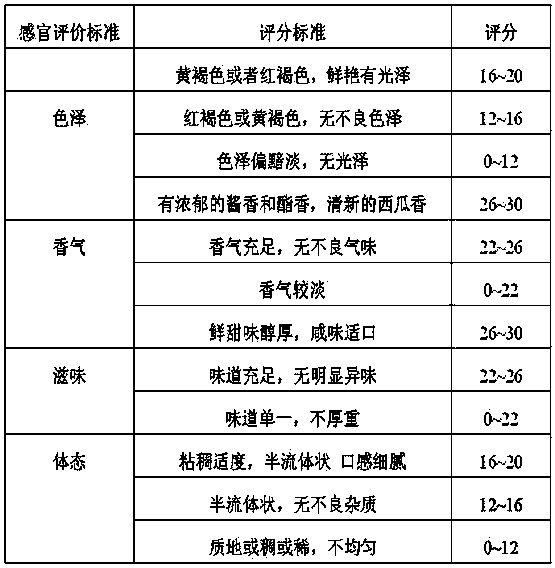

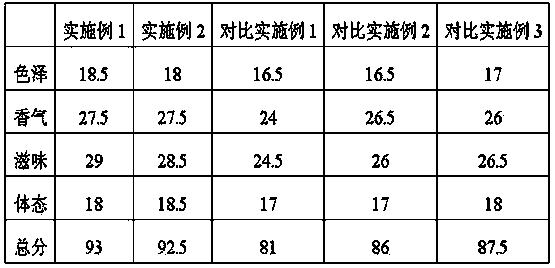

Mushroom and watermelon sauce and preparation method thereof

InactiveCN104207104ANutritional balanceThe color is brownish yellow with lusterFood preparationBiotechnologyNutrition

Owner:INST OF AGRO FOOD SCI & TECH SHANDONG ACAD OF AGRI SCI

Production method of fermented soybeans in water

InactiveCN106174042AAvoid contamination rateShort preparation timeFood ingredient as taste affecting agentNatural extract food ingredientsSoybean productBlood lipids

The invention relates to technical field of fermented food, in particular to a production method of fermented soybeans in water. The method comprises following steps sequentially: soybean selection, washing and soaking, cooking, primary fermentation, secondary mixing and fermentation, mixing, filling, boxing and tertiary fermentation. Fermented soybean products produced with the method have balanced nutrition, the stable quality, the delicious and unique taste and the health-care effects of enhancing immunity, reducing blood sugar, blood lipid and cholesterol, clearing heat and removing toxins, the production time is short with the method, the products can be directly sent for sale after secondary fermentation, and microbial contamination is effectively avoided.

Owner:GUIZHOU XIANGXIAMEI FOOD CO LTD

Method for breeding flying chickens with nourishing function

ActiveCN103975897AHas a nourishing functionDelicious and uniqueFood processingAnimal feeding stuffZoologyNutrient

Owner:衡山县开云镇跃进养殖专业合作社

Medicinal composition with liver protecting function and preparation method of medicinal composition

ActiveCN103735675AImprove protectionImprove liver functionDigestive systemPlant ingredientsLiver functionPuerarin

The invention relates to a medicinal composition with a liver protecting function and a preparation method of the medicinal composition, and belongs to the field of traditional Chinese medicine. The medicinal composition is prepared from the following raw medicines by weight: 28 to 38 parts of sea buckthorn, 32 to 52 parts of puerarin, 22 to 32 parts of gardenia and 19 to 25 parts of nutmeg, and an optimum dosage form of the medicinal composition is a soft capsule. Dialectical theories are adopted and scientific compatibility and formula of the medicines are utilized to prepare the medicinal composition according to theories of the traditional Chinese medicine and physiological characteristics of the liver, and functional pharmacological experiments prove that a health-care product provided by the invention has good functions of protecting the liver, promoting the liver cell to be repaired, and improving the liver function and regeneration, and the medicine is safe and reliable.

Owner:JILIN UNIV

Production process of milk soy

InactiveCN1398547ADelicious and uniqueHigh nutritional valueMilk preparationFood preparationNutritive valuesFlavor

The production process of milk soy includes the technological steps of extracting casein as protein material from fresh animal colostrums, protein hydrolysis to prepare yeast, fermentation, brewing, filtering, disinfection, cooling, classifying and packing. The said milk soy has amino acids and peptides produced by the casein, special flavor, rich P and Ca, rich nutritious components and no chemical additive and is safe and good for health.

Owner:许多海 +2

Processing method for smoked butterfish products

InactiveCN104824718ALong storage timeGreat tasteFood thermal treatmentMeat/fish preservation using chemicalsGift givingRaw material

The invention discloses a processing method for smoked butterfish products. The processing method has the advantages that existing conventional icy fresh butterfishes or fresh butterfishes are processed into the smoked butterfish products which have long shelf time and beneficial to export after raw material treatment, pickling, frying, soaking, smoking, packaging and the like; fishy smell is well eliminated during pickling and frying, smell, nutrition and health care of the smoked butterfish products are improved greatly through pickling and smoking, and the obtained smoked butterfish products are rich in nutrition and taste unique and delicious; any preservative chemical additives are not added, and accordingly, the products are green and healthy, are good choices for gift giving and family feasts and are beneficial to popularization.

Owner:广西金海环岛渔业有限公司

Lactation period milk goat feed and use method thereof

InactiveCN106343179AAdd flavorPrevent common diseasesFood processingAnimal feeding stuffDiseaseDrug additive

The invention discloses a lactation period milk goat feed and a use method thereof. The feed is mainly prepared by mixing and crushing silo corn, corn flour, salt, calcium hydrophosphate, rice bran, peanut meal, sodium humate and Chinese herbal medicines in parts by weight at two stages, feed formulas at different stages are different, and the feed are used at different stages. The lactation period milk goat feed has complete nutrients and also comprises multiple Chinese herbal medicines capable of preventing diseases, promoting healthcare and lactation and improving the flavor of goat milk, the multiple Chinese herbal medicines are compatibly used, supplement each other and have a synergistic effect, the commonly seen diseases of a goat are prevented, the lactation of the milk goat is promoted, the lactation yield is increased, the culture benefit is increased, the materials of the feed are mainly natural materials, no medicated additive is added, no drug residue is left in a goat milk product, a goat milk food is safe and healthy and has a unique delicious flavor, in addition, the preparation method of the feed is simple, the cost is low, and the lactation period milk goat feed is an ideal feed for the milk goat.

Owner:蒋成英

Process for processing curried onion clyster dumplings

ActiveCN101849643ADelicious and uniqueSuitable for various tastesFood preparationMonosodium glutamateFood flavor

The invention relates to a technology for processing curried onion clyster dumplings. The process is characterized by taking onion and curry powder as base materials, taking skin aspic as a soup substrate, taking streaky pork, seaweed, soybean salad oil and the like as auxiliary materials, adding condiments such as soy sauce, ginger, salt, monosodium glutamate, soft sugar and the like, and mixing the materials to prepare a stuffing. The dumplings are prepared by the following steps of: material pretreatment, dumpling wrapper preparation, stuffing preparation, dumpling making, frozen packaging and the like. The dumpling has the advantages of unique flavor, proper amount of soup, and fresh and concentrated taste.

Owner:TAIXIANG GRP TECH DEV

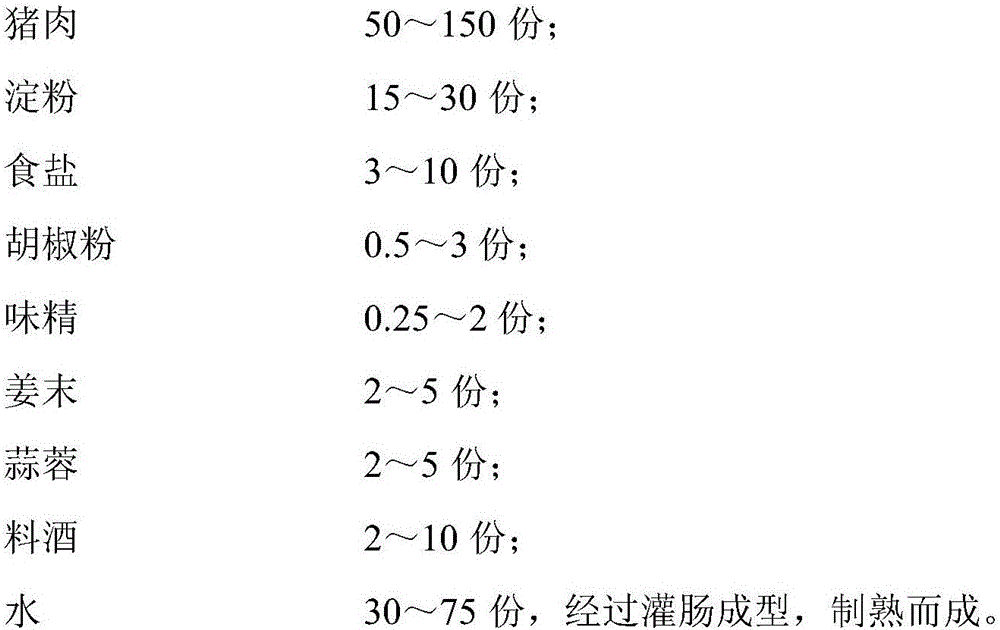

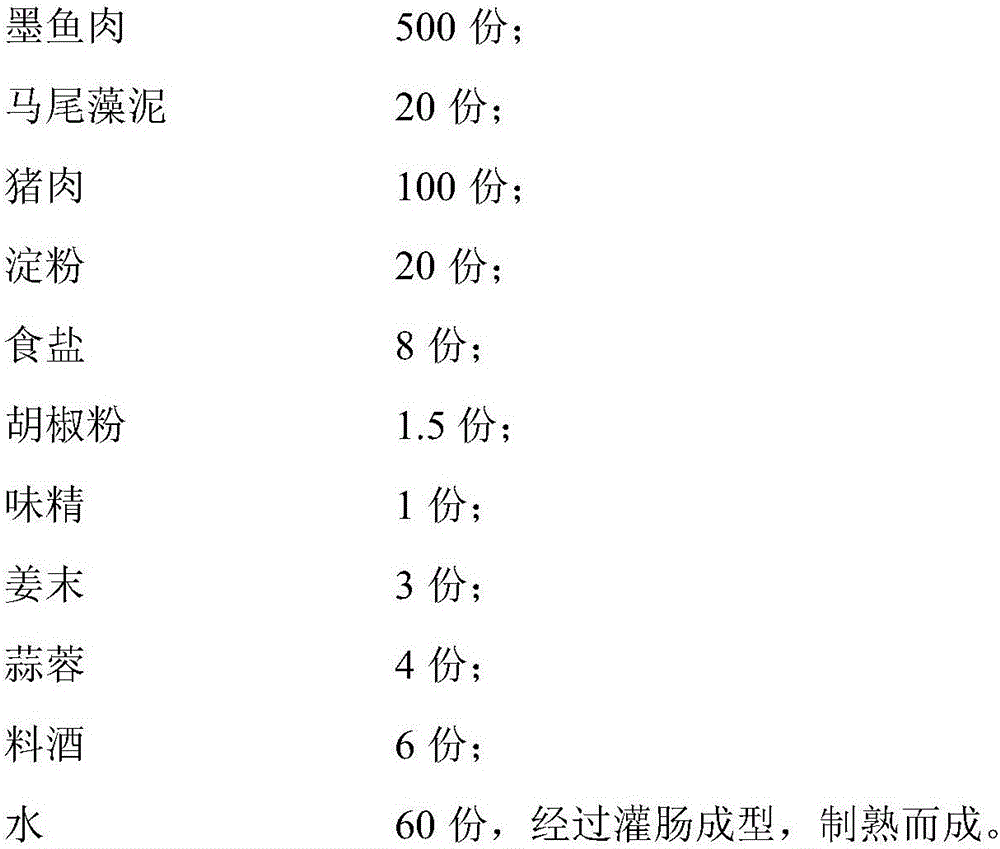

Gulfweed-cuttlefish sausages and making method thereof

The invention relates to the technical field of producing and processing of foods, and discloses gulfweed-cuttlefish sausages and a making method thereof. The gulfweed-cuttlefish sausages provided by the invention are based on a healthy diet idea and a thought of collocation of meat and vegetables, cuttlefish is used as a main raw material, gulfweed and pork are used as auxiliary materials, and salt, pepper powder, gourmet powder, white granulated sugar and the like are used as seasonings, so that the healthy and nutritive gulfweed-cuttlefish sausages are made, a food additive is not used completely, and the gulfweed-cuttlefish sausages are rich in nutrition, safe and reliable; marine raw materials which are low in price, rich in nutrition, delicious in taste and easy to obtain are used, the gulfweed-cuttlefish sausages are processed through a simple stable technology, and the original flavor and the original nutrition of product raw materials are reserved to the maximum extent, so that the obtained gulfweed-cuttlefish sausages are complete in color, aroma and taste, free from powder and residues when being chewed, and rich in certain elasticity, and besides, have the delicate fragrance of the gulfweed and the delicate freshness of the cuttlefish. The gulfweed-cuttlefish sausages provided by the invention are simple in preparation technology, delicious and unique, and a good-quality food which is rich in nutrition and high in cost performance ratio is provided for vast masses.

Owner:LINGNAN NORMAL UNIV

Method for processing instant dried fresh water fish slices

The invention discloses a method for processing instant dried fresh water fish slices, which comprises the following steps of: a, adding salt to cut fish slices, and uniformly agitating for pickling; b, washing the fish slices processed in the step a clean and draining water; c, adding a fishy smell removing solution to the fish slices processed in the step b, uniformly agitating and pickling; d, baking the fish slices processed in the step c with constant hot air into dried fish slices; e, adding flavouring seasonings to the dried fish slices processed in the step d according to different taste requirements; f, vacuum packaging the dried fish slices processed in the step e with stretch films; and g, sterilizing the dried fish slices processed in the step f at a high temperature and under a high pressure. The dried fresh water fish slices processed by using the method do not need to be processed any longer and can be instantly eaten. When chewed, the dried fresh water fish slices aredelicious, and maintain the nutrient components of the fresh water fish.

Owner:HUNAN PROVINCE JINWANJIA FOOD

Beefsteak, soy sauce chafing dish soup

InactiveCN101147605ARich in proteinRich in mineralsFood preparationBiotechnologyMonosodium glutamate

The present invention discloses a beef steak spiced chafingdish soup. Its raw material composition includes (by wt%) 53% of fresh beef steak, 36% of water, 5% of salted and fermented soya paste containing 16 flavouring materials, 2% of sauce, 0.5% of ginger, 0.5% of garlic, 1% of chillic powder, 1% of white sugar and monosodium glutamate; in which the salted and fermented soya paste containing 16 flavouring materials is characterized by that in 40kg of salted and fermented soya paste 50g of cassia bark powder, 10g of kaempferia root powder, 60g of Chinese prickly ash powder, 80g of star aniseed powder, 5g of tsaoko fruit powder, 10g of nutmeg powder and others are added. The invented chafingdish soup contains r4ich protein, mineral and amino acids, its nutrients are rich and taste is unique and palatable.

Owner:吉林省高丽王朝食品有限责任公司

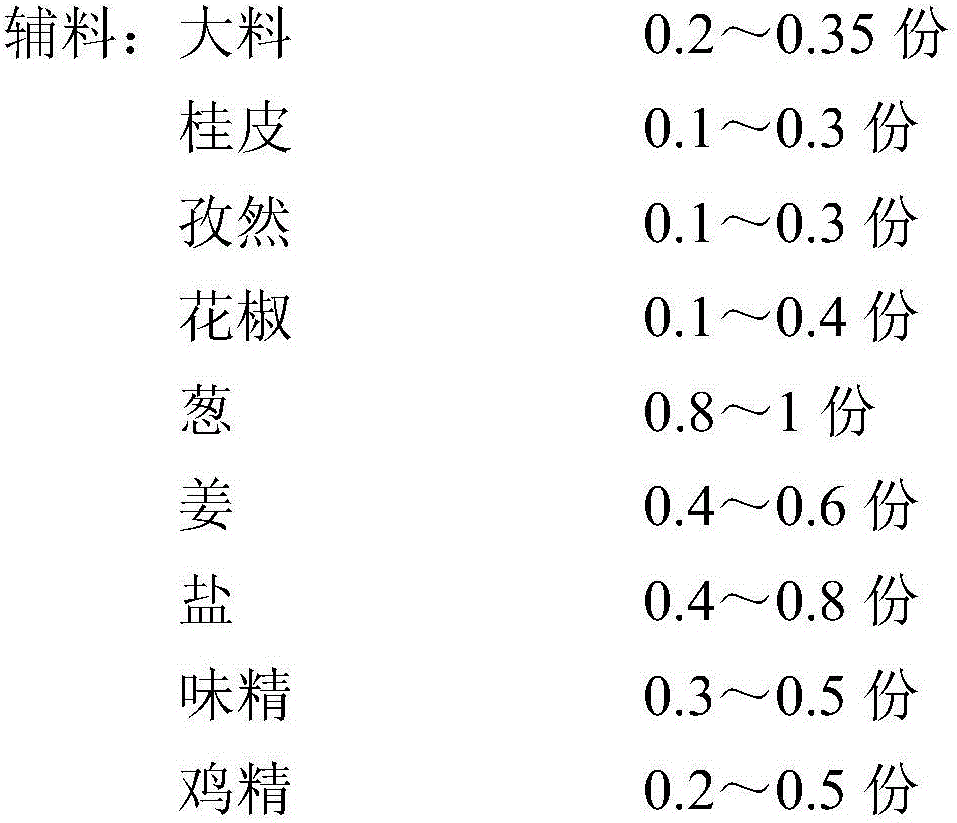

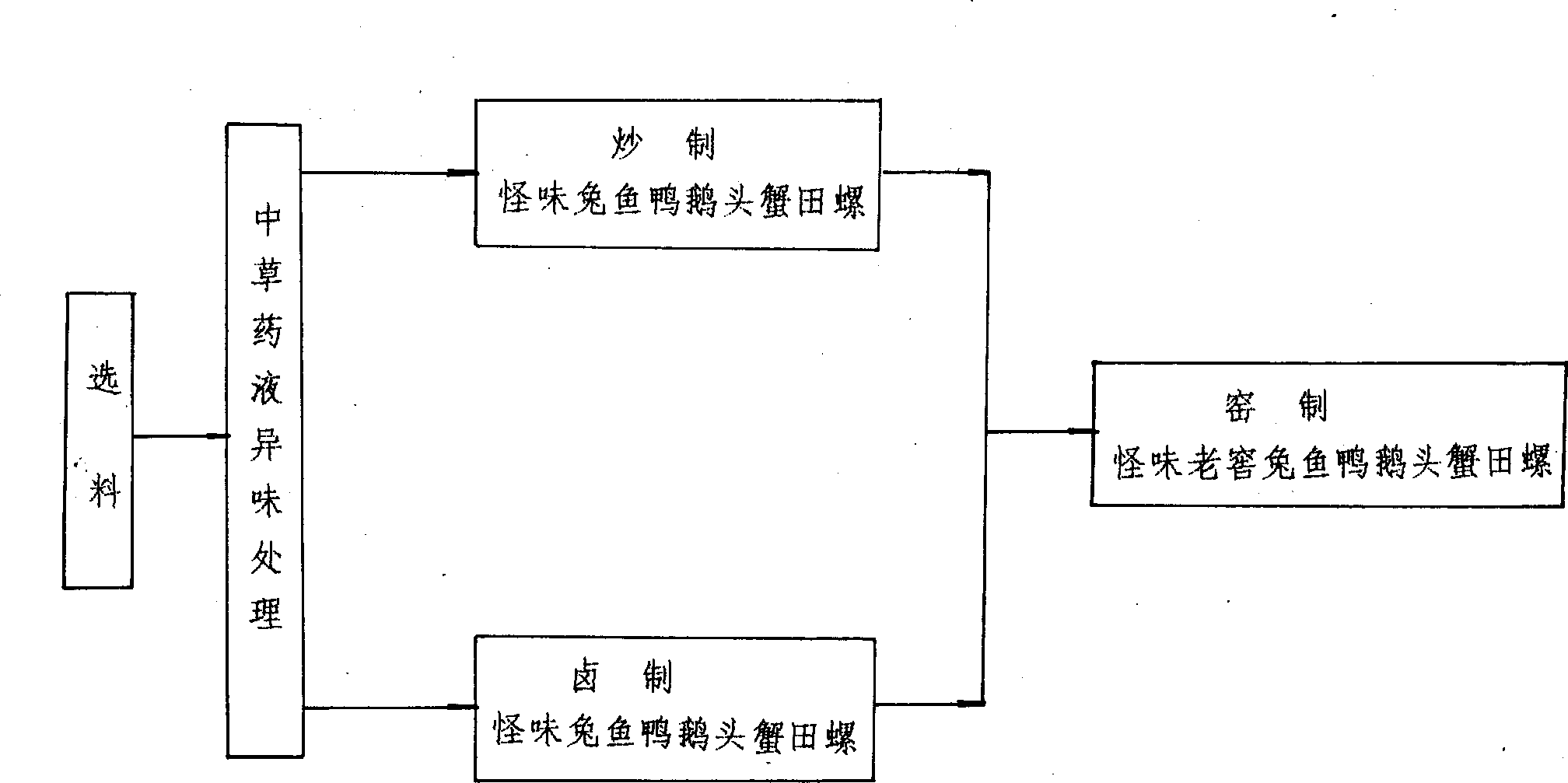

Making method of snail-flavored chilli paste and snail-flavored chilli paste

InactiveCN106262725ASimple preparation processDelicious and uniqueFood scienceIllicium verumAmomum tsao-ko

The invention discloses a making method of snail-flavored chilli paste. The method comprises the following steps that the snail-flavored chilli paste is prepared from, by weight, 400-600 parts of edible oil, 7-8 parts of ligusticum chuanxiong, 7-8 parts of amomum tsao-ko, 1.5-2.5 parts of clove, 2.5-3.5 parts of anise, 7-8 parts of cinnamon, 5.5-6.5 parts of fructus amomi, 4.5-5.5 parts of myrcia, 250-300 parts of minced ginger, 250-300 parts of minced garlic, 50-100 parts of thick broad-bean sauce, 50-100 parts of a western chilli paste, 10-30 parts of snail meat, 50-100 parts of chilli raw materials, 5-15 parts of pepper, 5-10 parts of chicken powder, 3-5 parts of aginomoto, 5-10 parts of sugar and 50-100 parts of sesame oil; then, classified addition is performed and stir-frying is performed to obtain the snail-flavored chilli paste. The making method of the chilli paste is simple in making technology and short in making period, does not comprise fermentation and other steps, and is suitable for homemade eating and also suitable for large-scale mass production.

Owner:梁相斌

Preserved fried and cooked diced mutton product and production method thereof

The invention discloses a preserved fried and cooked diced mutton product and belongs to the field of foods, in particular to meat products. The diced fried and cooked mutton product is prepared from mutton serving as a main raw material and is prepared by the following steps of: dicing the mutton, namely dicing the mutton into diced meat; steaming the mutton, namely boiling the mutton into boiling seasoning liquid for at least 2 seconds, putting the mutton into a steamer and steaming the mutton for 8 to 25 minutes in the boiling seasoning liquid; frying and mixing, namely throwing the steamed diced mutton into edible oil at the temperature of between 120 and 140 DEG C, adding preservation extract which is 3 to 10 weight percent of the mutton, frying and packaging. The fried and cooked diced mutton is prepared by an innovative method, and the product serves as a seasoning of various cooked wheaten foods or dishes and has delicious and unique taste. The product is convenient to use andprocess.

Owner:ANHUI PROVINCE GUZHEN COUNTY ZHENGHUA SHEEP IND

Diced mutton product and production method thereof

The invention discloses a diced mutton product and a production method thereof, belongs to the field of foods, in particular to meat products. The diced mutton product takes mutton as a main raw material and is prepared by the following steps: dicing the mutton, namely dicing the mutton into diced meat; steaming the mutton, namely putting the mutton into boiling seasoning liquid for over at least2 seconds, putting the mutton into a steamer and steaming the mutton for 8 to 25 minutes in the boiling seasoning liquid; frying and mixing, namely throwing the steamed diced mutton into edible oil at the temperature of between 120 and 140 DEG C, frying and packaging. The diced mutton prepared by an innovative method can be used as seasoning for various cooked wheaten foods or dishes and has delicious and unique taste. The diced mutton product is convenient to use and process.

Owner:朱计平

Method for producing meat-sandwiched dried bream

The invention discloses a method for producing meat-sandwiched dried bream, in particular a method for pickling dried bream with folk flavors, and belongs to a method for producing fish food. The method comprises the following steps of: slaughtering fresh bream, removing haslet, pickling, discharging brine for the first time, soaking in the brine, discharging the brine for the second time, filling meat in the bream, airing at low temperature and packaging. The bream produced by the method is unique in flavor, good in mouthfeel, long in quality guarantee period, low in cost, and convenient to eat; and the process for producing the bream is simple.

Owner:ANHUI HAOZAILAI FOOD

Hot fragrant mushroom pork sauce and preparation method thereof

InactiveCN104855937ADelicious and uniqueThe production process is simple and environmentally friendlyFood preparationBiotechnologyPork meat

The invention belongs to the field of food, and particularly relates to a hot fragrant mushroom pork sauce and a preparation method thereof. The hot fragrant mushroom pork sauce comprises the following raw materials in parts by weight: 10-20 parts of a rapeseed oil, 2-4 parts of a sesame oil, 30-50 parts of chili sauce, 10-20 parts of pork, 5-10 parts of dry fragrant mushrooms, 2-4 parts of seed powder of Chinese prickly ash, 2-4 parts of ginger powder, 2-4 parts of fennel powder, 2-4 parts of chili powder, 1-2 parts of ginseng, 1-2 parts of pseudo-ginseng, 1-2 parts of fleeceflower roots, 1-2 parts of Chinese wolfberry, 1-2 parts of astragalus membranaceus and 2-4 parts of white sugar. The hot fragrant mushroom pork sauce disclosed by the invention is delicious and unique in taste and simple and environment-friendly in preparation technology, and besides, effective components of traditional Chinese medicine such as the ginseng, the pseudo-ginseng, the fleeceflower roots, the Chinese wolfberry and the astragalus membranaceus are added, so that the hot fragrant mushroom pork sauce has a certain effect of ageing resistance.

Owner:TONGCHENG JIAMING AGRI DEV

Beef jerky with exploded serosity and making method of beef jerky

The invention relates to beef jerky with exploded serosity and a making method of the beef jerky. The beef jerky is prepared from the following components of beef, cheese, butter, coconuts fruits, coconut milk, eggs, red wine, salt and peppers in a certain proportion, and is prepared through the following steps of pickling, baking, making serosity, stuffing the serosity, re-baking, packaging and the like. The making method of the made beef jerky disclosed by the invention is unique. The making method comprises the following steps of firstly pickling the beef, prebaking the pickled beef at low temperature, stuffing the serosity made from the cheese, the butter, the coconut fruits and the coconut milk into holes in the beef, and re-baking the beef. Because of the baking of the beef twice and the explosion of the serosity in the holes in the beef, unique mouth feel is formed, and the made beef jerky is fresh, fragrant, sweet and delicious.

Owner:ANHUI XIANGZEYUAN FOOD

Beef noodle thin soup and preparation technology thereof

InactiveCN106360557ADelicious and uniqueImprove immunityFood ingredient functionsBiotechnologyCodonopsis

The invention belongs to the technical field of foods, and particularly relates to beef noodle thin soup and a preparation technology thereof. The beef noodle thin soup comprises main materials and auxiliary materials, and traditional Chinese medicines are also added. A specific preparation method of the beef noodle thin soup comprises the following steps of placing thoroughly-cleaned ox bones, thoroughly-cleaned beef, thoroughly-cleaned scallions and thoroughly-cleaned ginger in a pot together, putting water, and performing stewing for 20-30 hours so as to prepare thin soup; and adding the auxiliary materials namely star anise, Chinese cinnamon, cumin seeds, Chinese prickly ash, scallions, ginger, salt, gourmet powder, chicken essence, curry powder, and a spicy sauce to the made thin soup, and performing boiling over. The traditional Chinese medicines can also be added to the thin soup, namely radix codonopsis, raw radix astragali, bighead atractylodes rhizomes and glossy ganoderma are thoroughly cleaned, then dicing is performed, and the diced radix codonopsis, the diced raw radix astragali, the diced bighead atractylodes rhizomes and the diced glossy ganoderma are put into a gauze bag; and at the same time, the gauze bag is put in the thin soup for boiling over, so that the beef noodle thin soup is prepared.

Owner:王君

Spicy beef jerky and preparation method thereof

InactiveCN107183545ADelicious and uniqueTaste and flavor are mellow and deliciousFood ingredient as taste affecting agentLipidic food ingredientsFlavorChemistry

The invention provides a spicy beef jerky and a preparation method thereof. The beef jerky is prepared through 1kg of fresh beef, 100-200g of vegetable oil, 50-90g of chilli, 40-80g of cedrela sinensis, 2-10g of mentha haplocalyx, 1-3g of star aniseed powder, 2-10g of green prickleyash, 5-15g of garlic, 1-6g of cinnamon, 1-6g of lemon juice, 3-8g of edible salt, and 400-800ml of water. According the spicy beef jerky, cedrela sinensis and mentha haplocalyx are ingeniously mixed to prepare the beef jerky, and the prepared beef jerky is delicious and unique in taste; chilli, star aniseed powder, green prickleyash, garlic, cinnamon and lemon juice are added to enable mellow and tasty flavor and mouthfeel of the beef jerky; the beef jerky is proper in spice and is welcomed by customers; the spicy beef jerky is a novel flavored jerky product having the advantages of being green, complete in nutrition, leisure and convenient; in addition, the preparation process is simple; the process parameters are easily controlled; the production cost is low; and the preparation method is very suitable for the beef deep processing and mass production.

Owner:NANNING UNIV

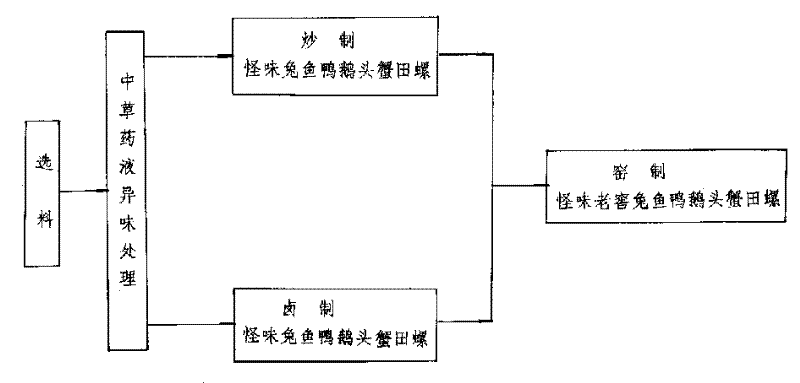

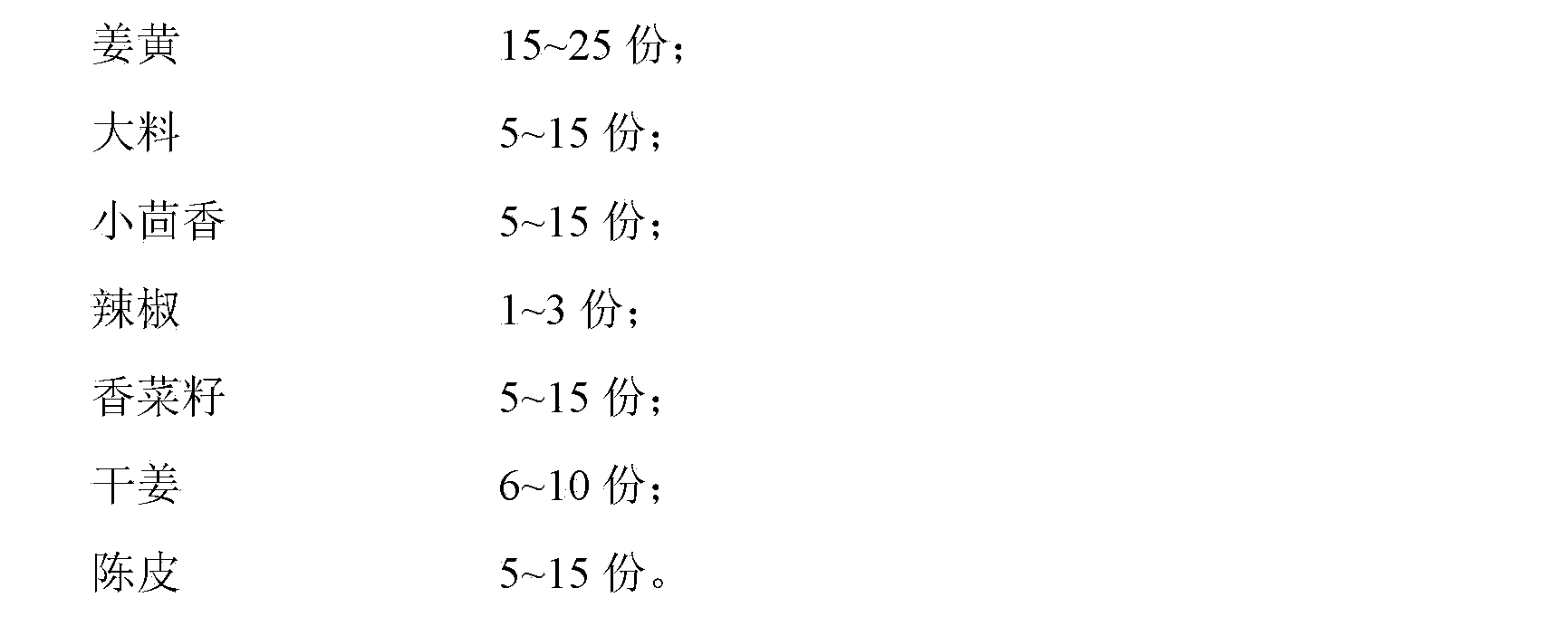

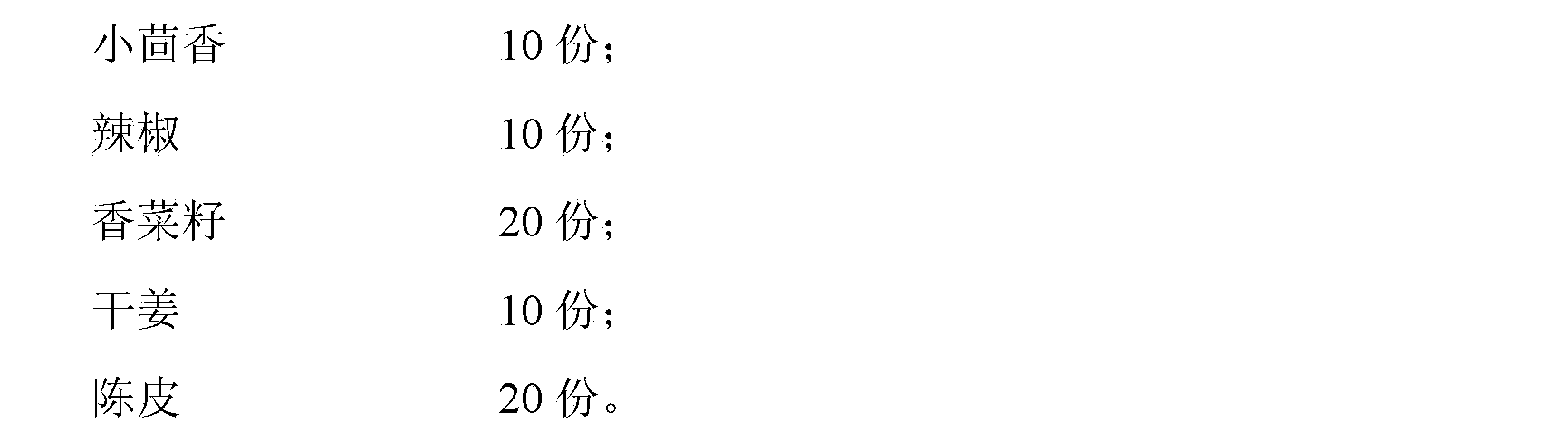

Curry powder

InactiveCN103876090ADelicious and uniquePure Natural Nutritional IngredientsFood shapingFood preparationAdditive ingredientUmami

The invention relates to a curry powder. The curry powder is composed of the following components in parts by weight: 15 to 25 parts of turmeric, 5 to 15 parts of aniseed, 5 to 15 parts of fennel, 1 to 3 parts of pepper, 5 to 15 parts of caraway seed, 6 to 10 parts of dry ginger, and 5 to 15 parts of dried orange peel. The curry powder has a unique flavor, is composed of pure natural nutrients, and has the advantages of palatable taste, rich fragrance, and rich nutrients. Moreover, the raw materials of the curry powder are all normal materials in the markets, thus the cost is low, and the curry powder has a vast market prospect.

Owner:TIANJIN LANSHI SEASONING

Steamed stuffed bun stuffing composite condiment

InactiveCN103876095ADelicious and uniquePure Natural Nutritional IngredientsFood preparationMonosodium glutamateFlavor

The invention relates to a steamed stuffed bun stuffing composite condiment. The condiment comprises compositions in parts by weight: 15-25 parts of edible salt, 5-15 parts of monosodium glutamate, 5-15 parts of starch, 1-3 parts of black pepper, 5-15 parts of Illicium verum, 6-10 parts of foeniculum vulgare, 5-15 parts of onion powder, 2-6 parts of garlic powder, 2-6 parts of ginger powder, 6-10 parts of cinnamomum tamala, 2-6 parts of alpinia officinarum Hance., 1-2 parts of clove, 3-7 parts of dried orange peel, 0.5-1.5 parts of tsaoko fruit, 0.1-0.3 part of angelica dahurica, 0.5-1.5 parts of rhizoma kaempferiae, 0.5-1.5 parts of pepper, 0.5-1.5 parts of cuminum cyminum, 0.5-1.5 parts of laurel leaf and 0.1-0.5 part of silicon dioxide. The steamed stuffed bun stuffing composite condiment has unique taste and also has pure natural nutrition compositions, and is palatable in saltiness degree, protruding in delicate flavor, nose-greeting in fragrance, abundant in nutrition and delicious in taste. Also, the employed food materials are common materials in the market, and therefore the composite condiment is low in cost and has wide market prospect.

Owner:TIANJIN LANSHI SEASONING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com