Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

91results about How to "Correct skew" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

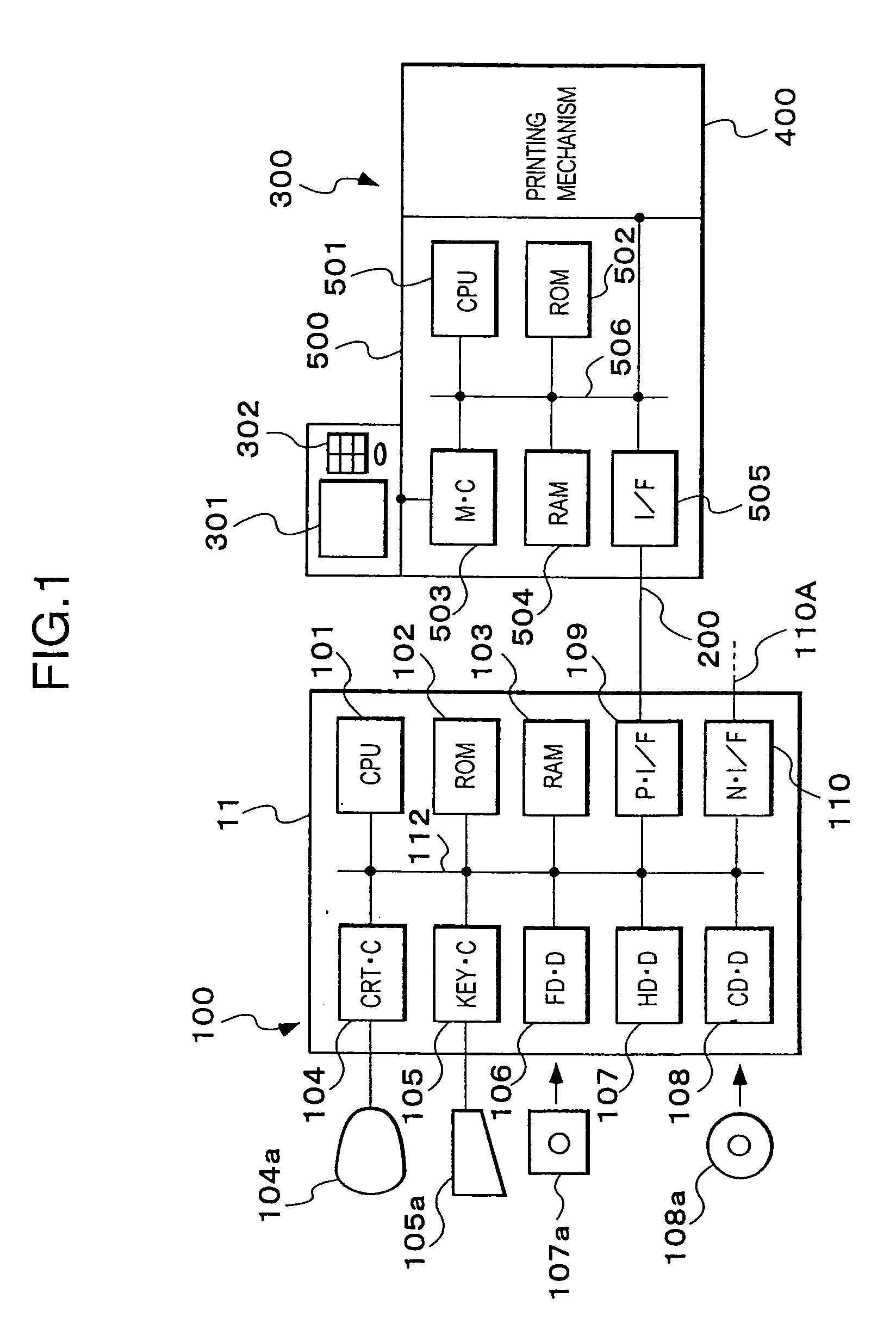

Ink jet printer, printer control unit, printer system including the same, and storage medium with the operation program of the printer control unit stored for controlling double-side printing

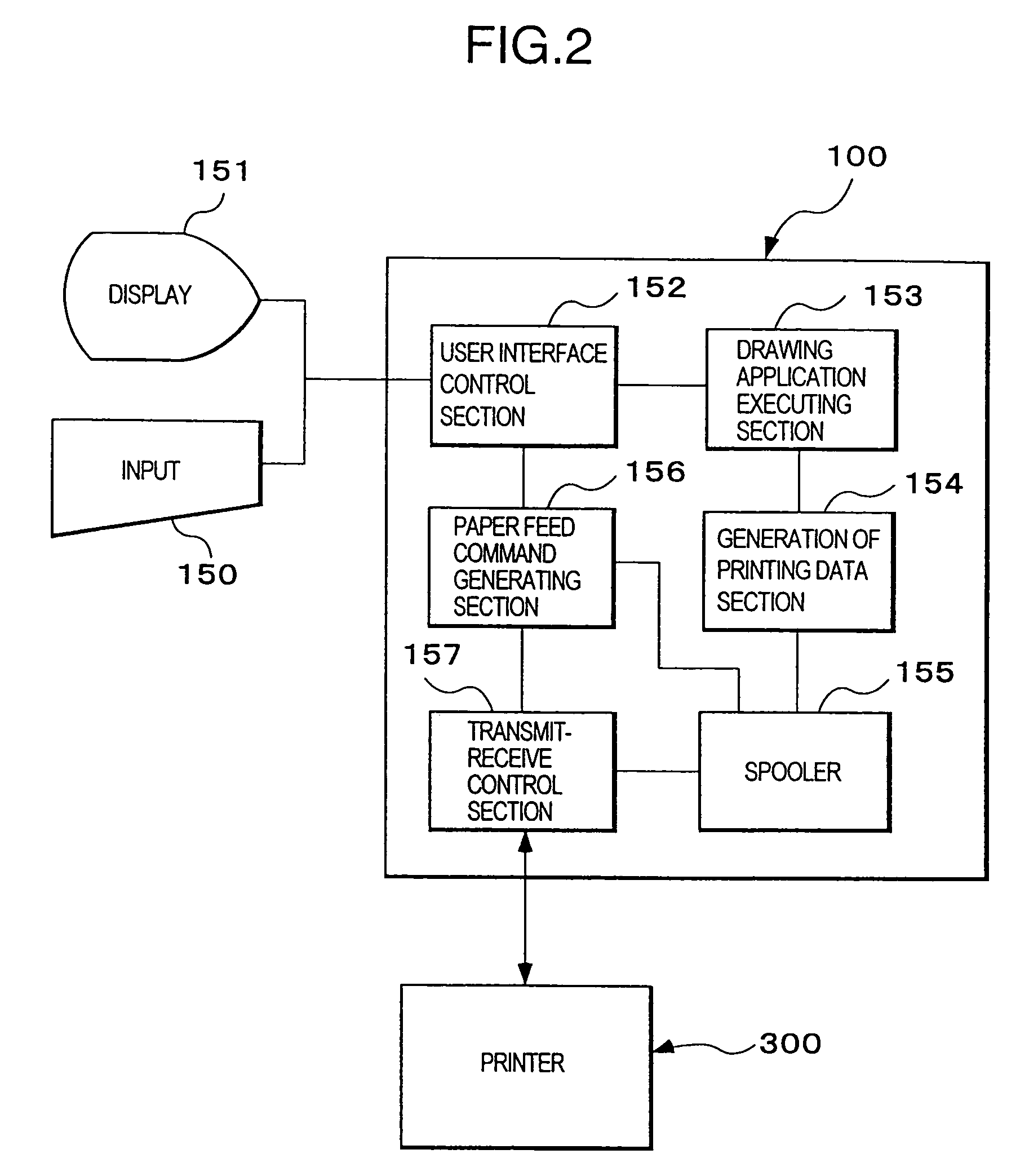

InactiveUS20050253886A1Reduce the hassle of operationQuality improvementRegistering devicesVisual representation by matrix printersComputer printingInk printer

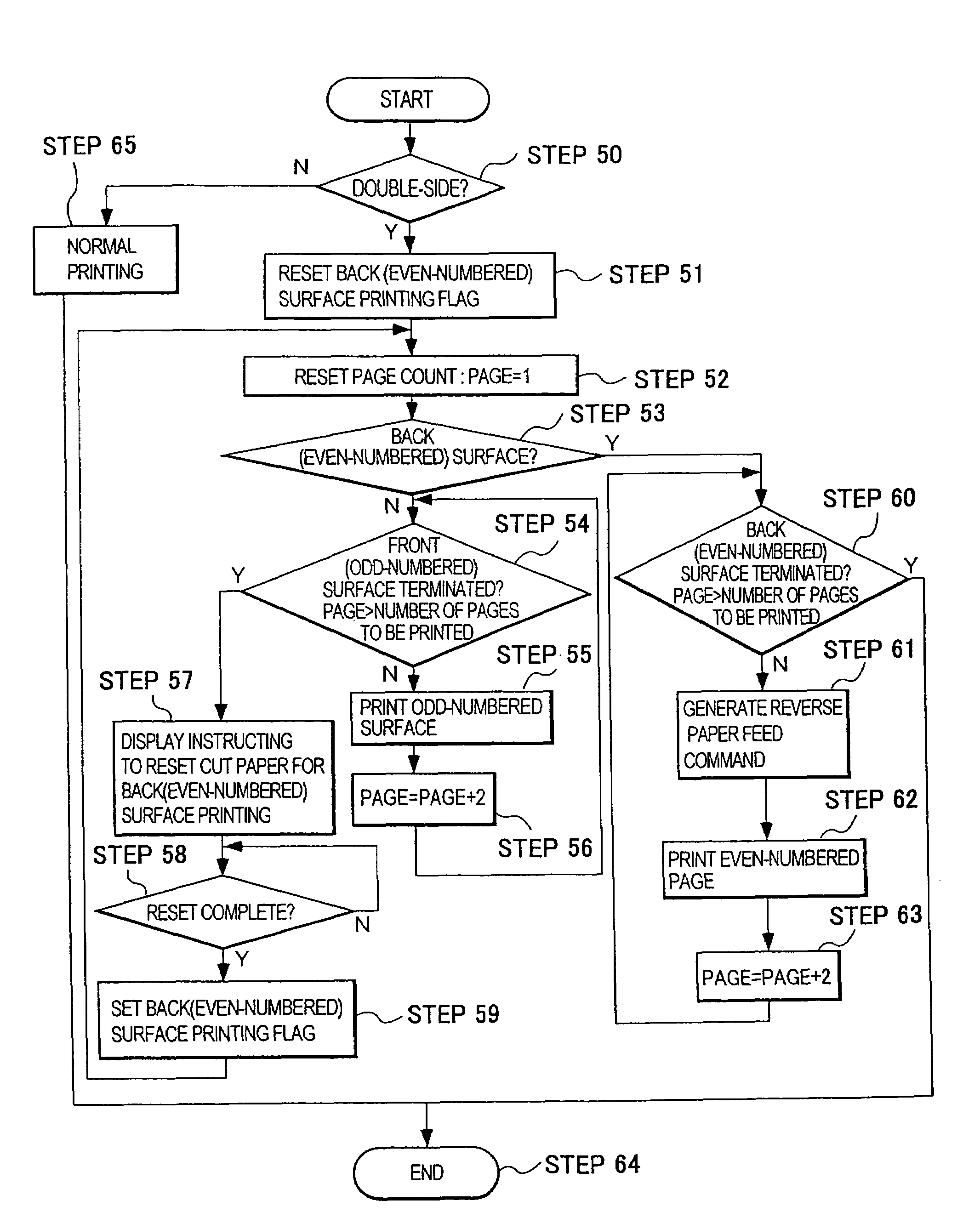

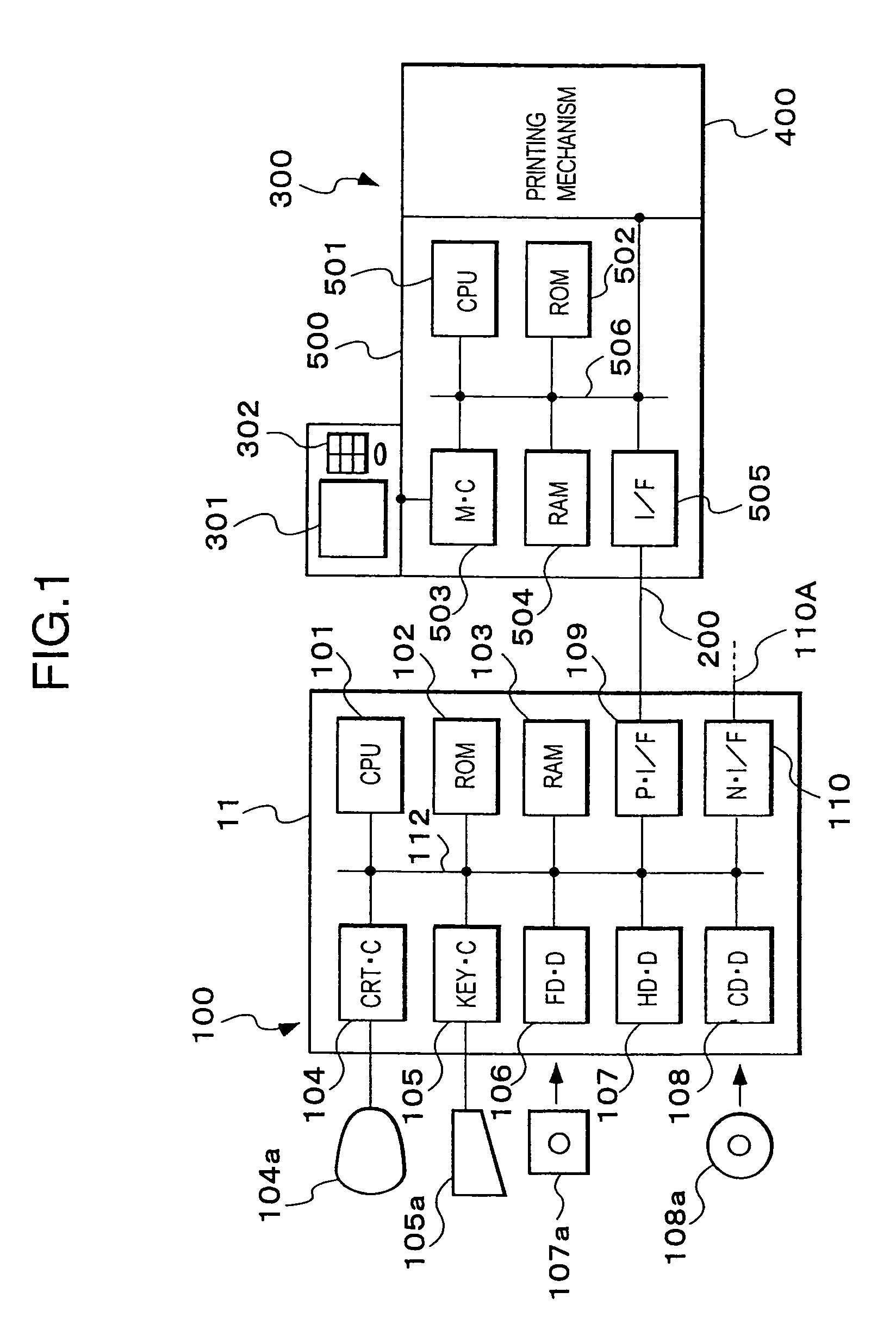

An ink jet printer with a double-side printing function enables to print page images at a proper position on both surfaces of a cut paper, is provided. When feeding the cut paper A having an image printed on the front surface, the feeding roller 407 is rotated in the direction C1 to feed the cut paper A and simultaneously the registering rollers 410a, 410b are rotated in the direction D1 to push back the cut paper. In addition, the double-side printing is easily realized in both of the cases where the ink jet printer with the double-side printing function is connected to the host, and where the ink jet printer without double-side printing function is connected to the host by having the host make an inquiry of the printer whether or not double-side printing is available (step 6). Based on the results of the inquiry, printing commands are generated and sent to the printer.

Owner:SEIKO EPSON CORP

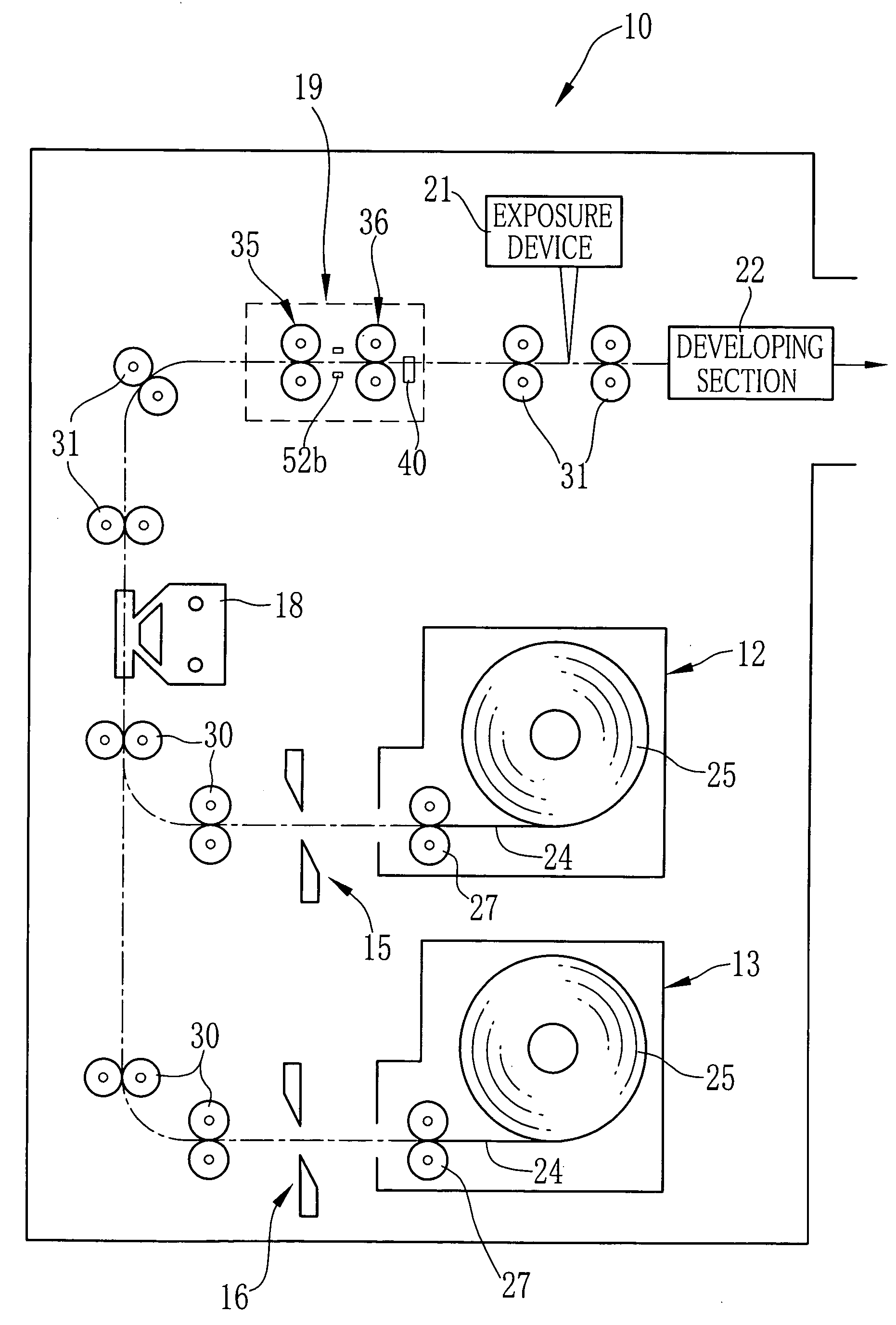

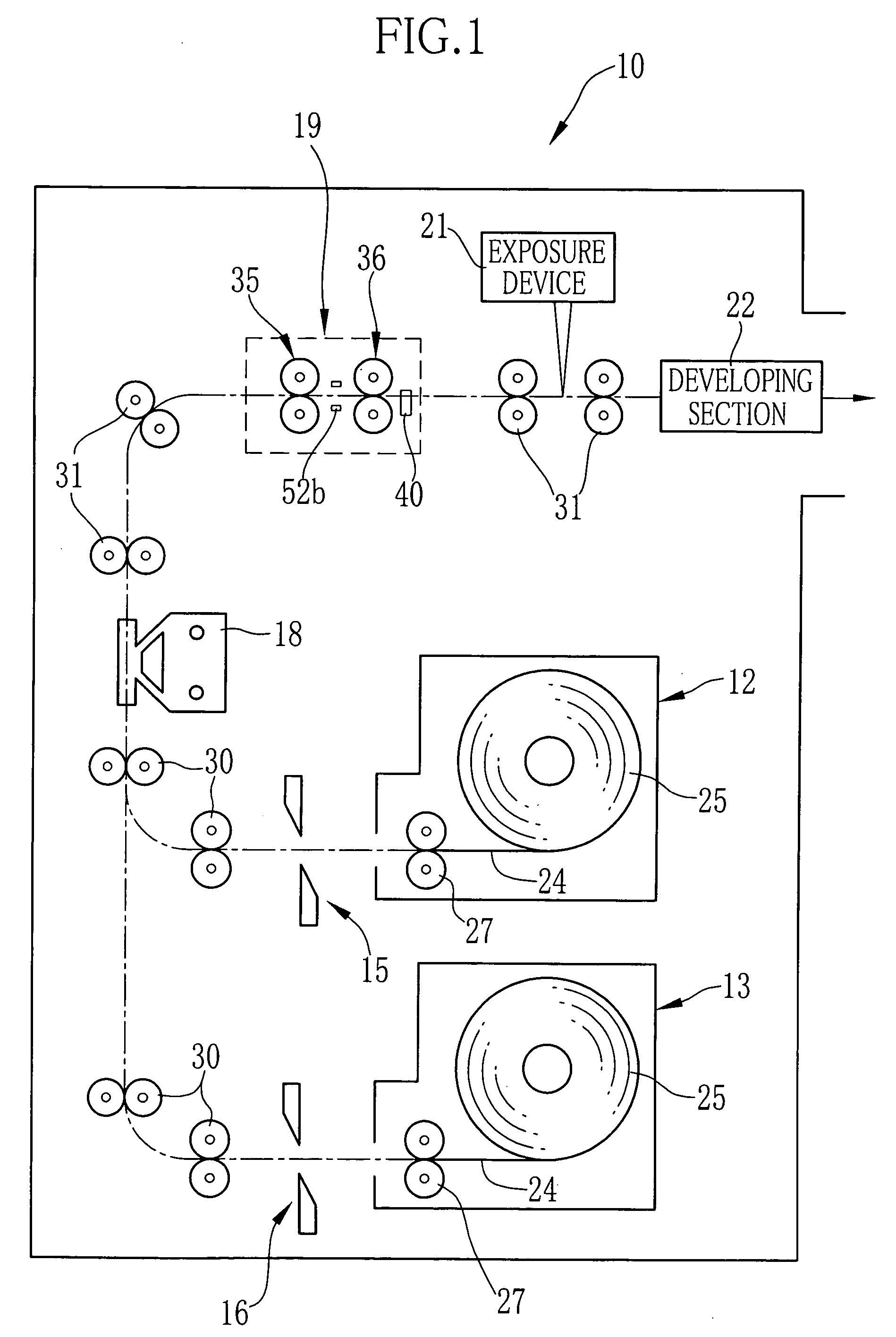

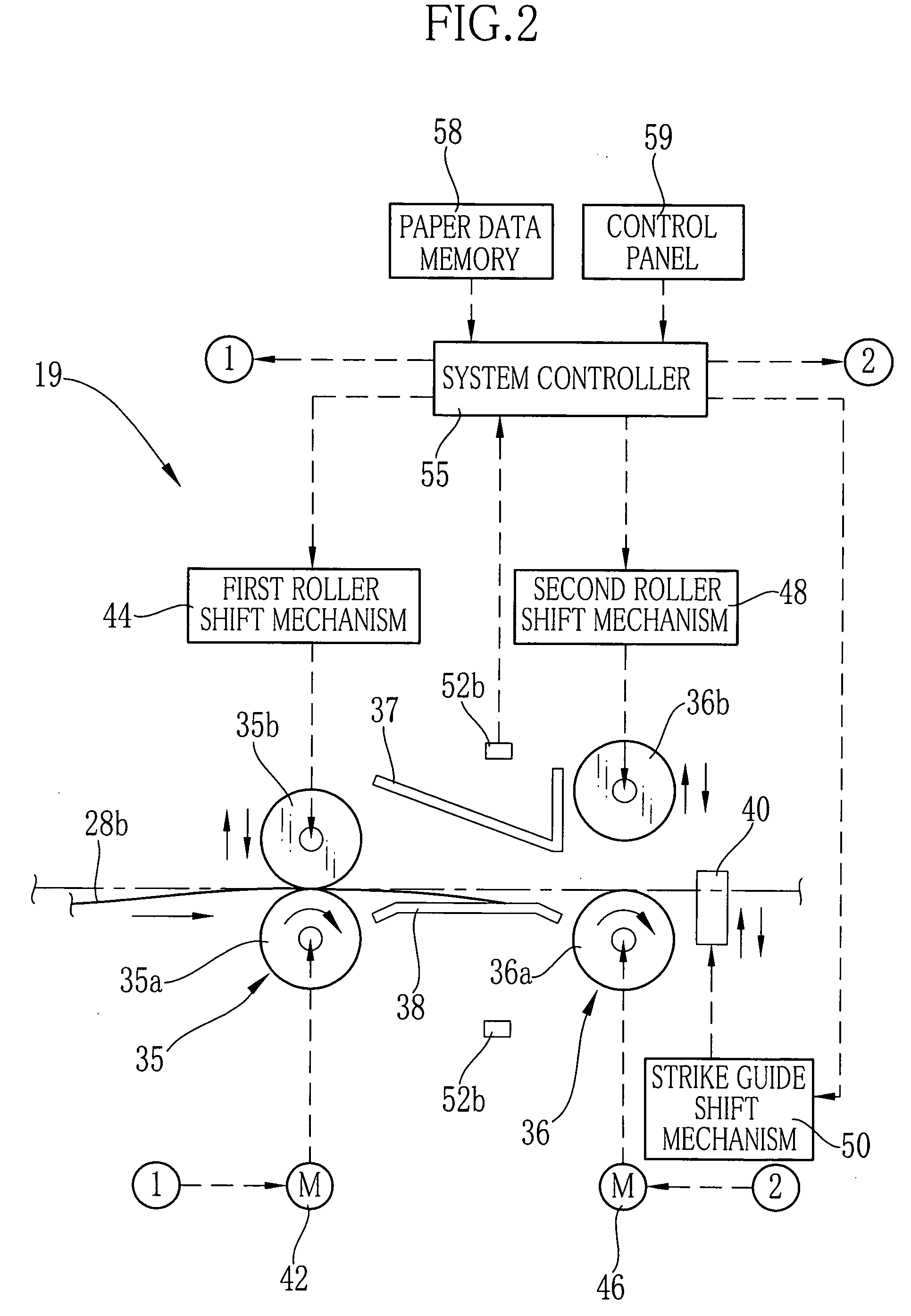

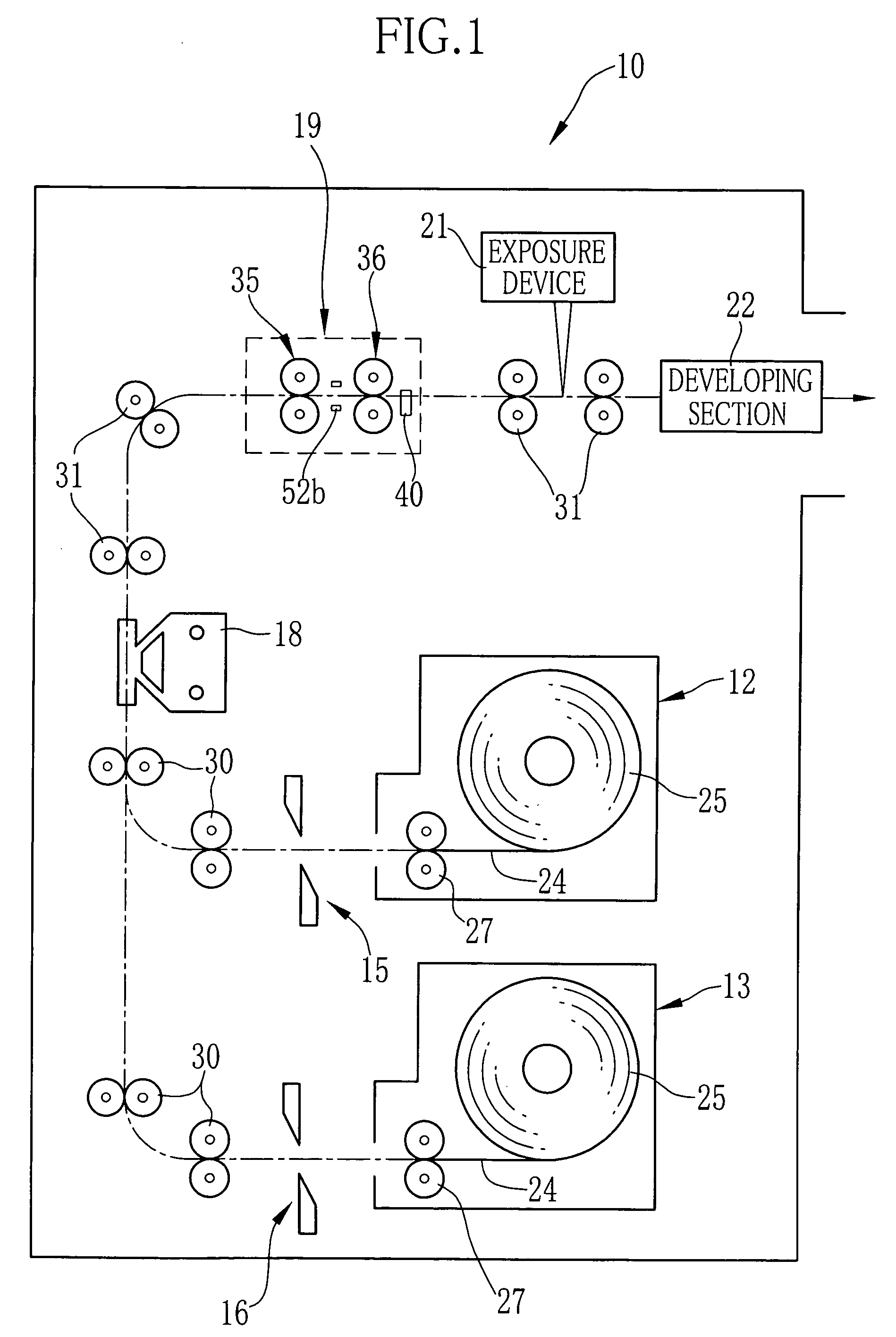

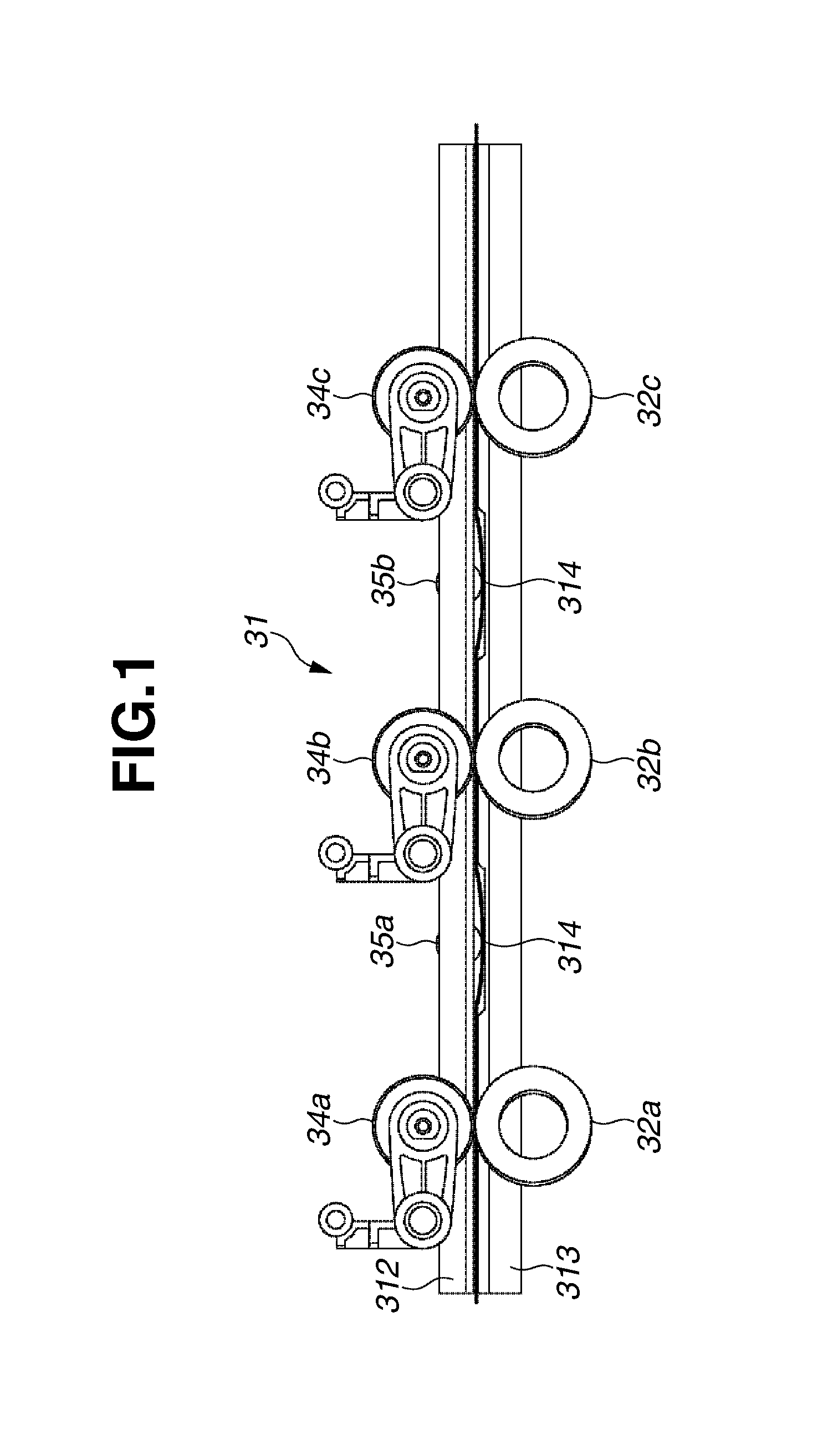

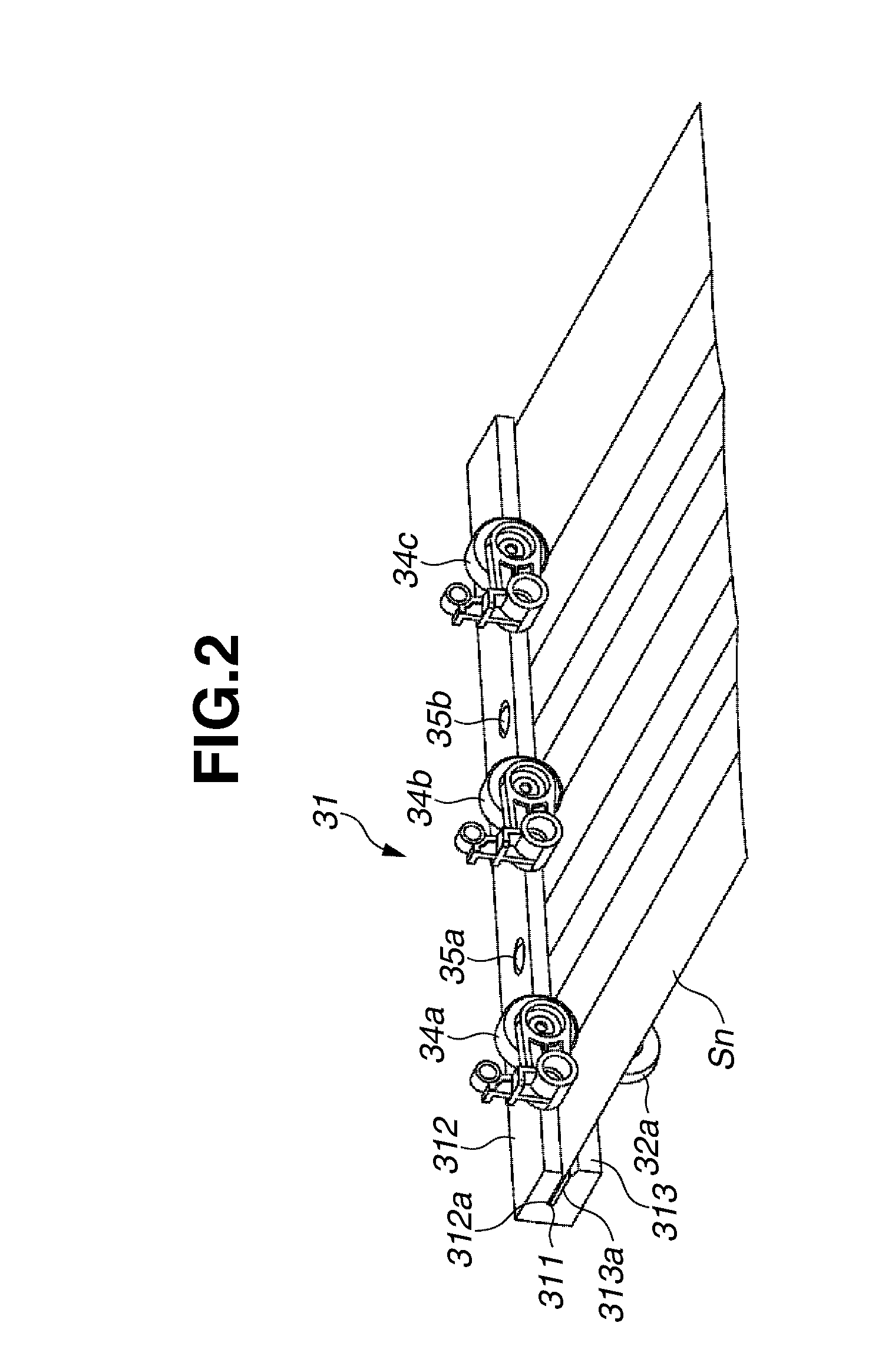

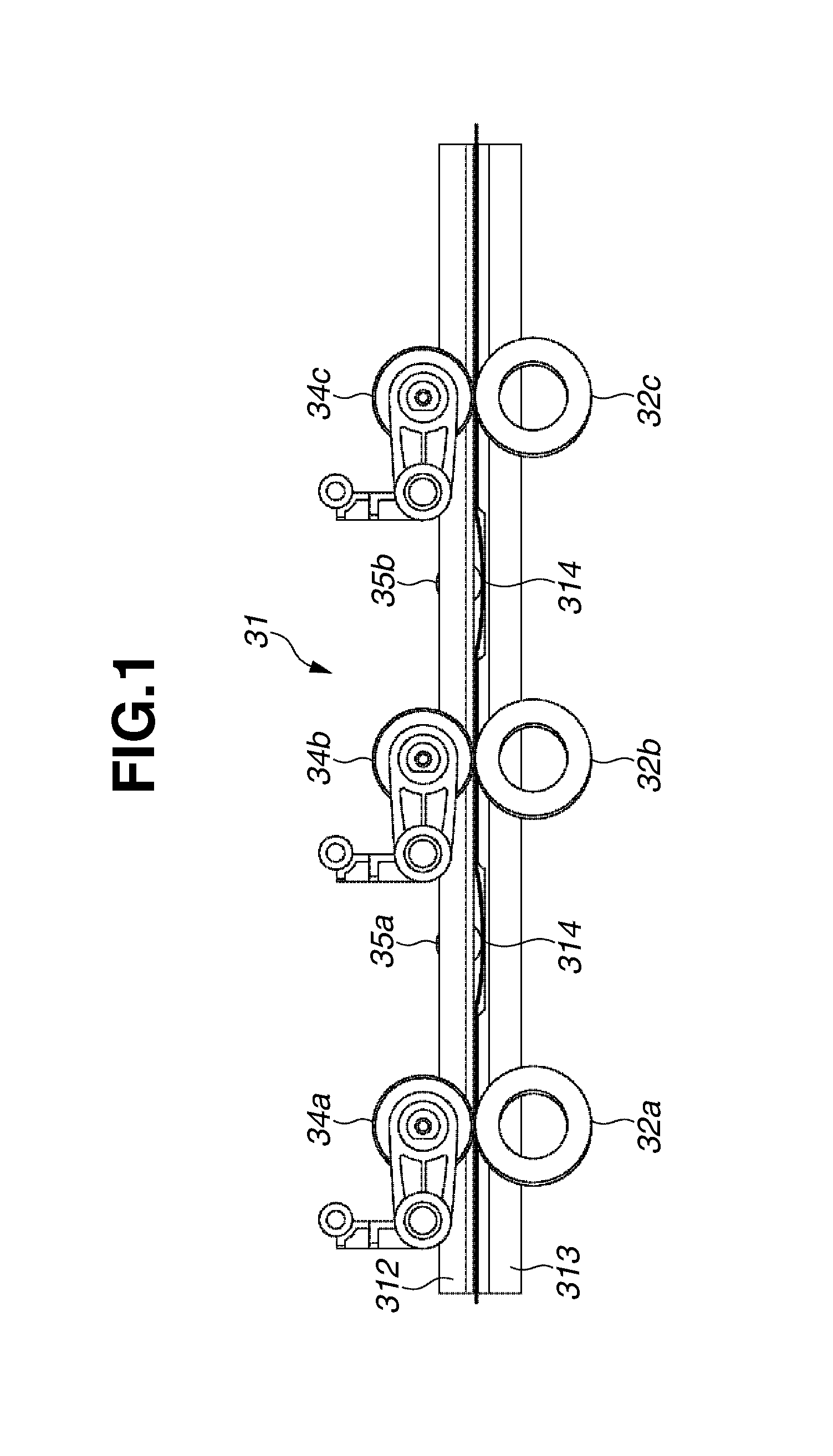

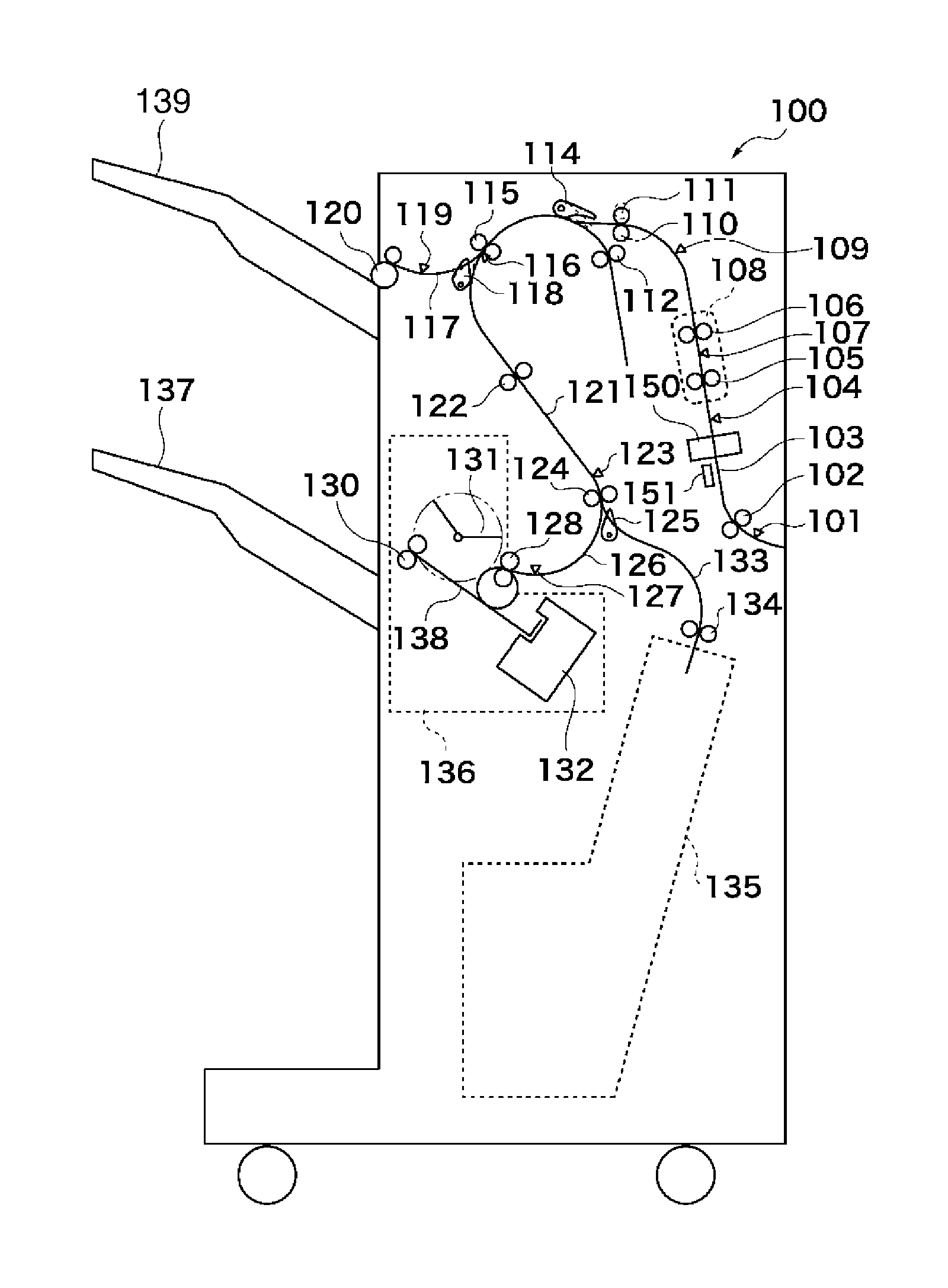

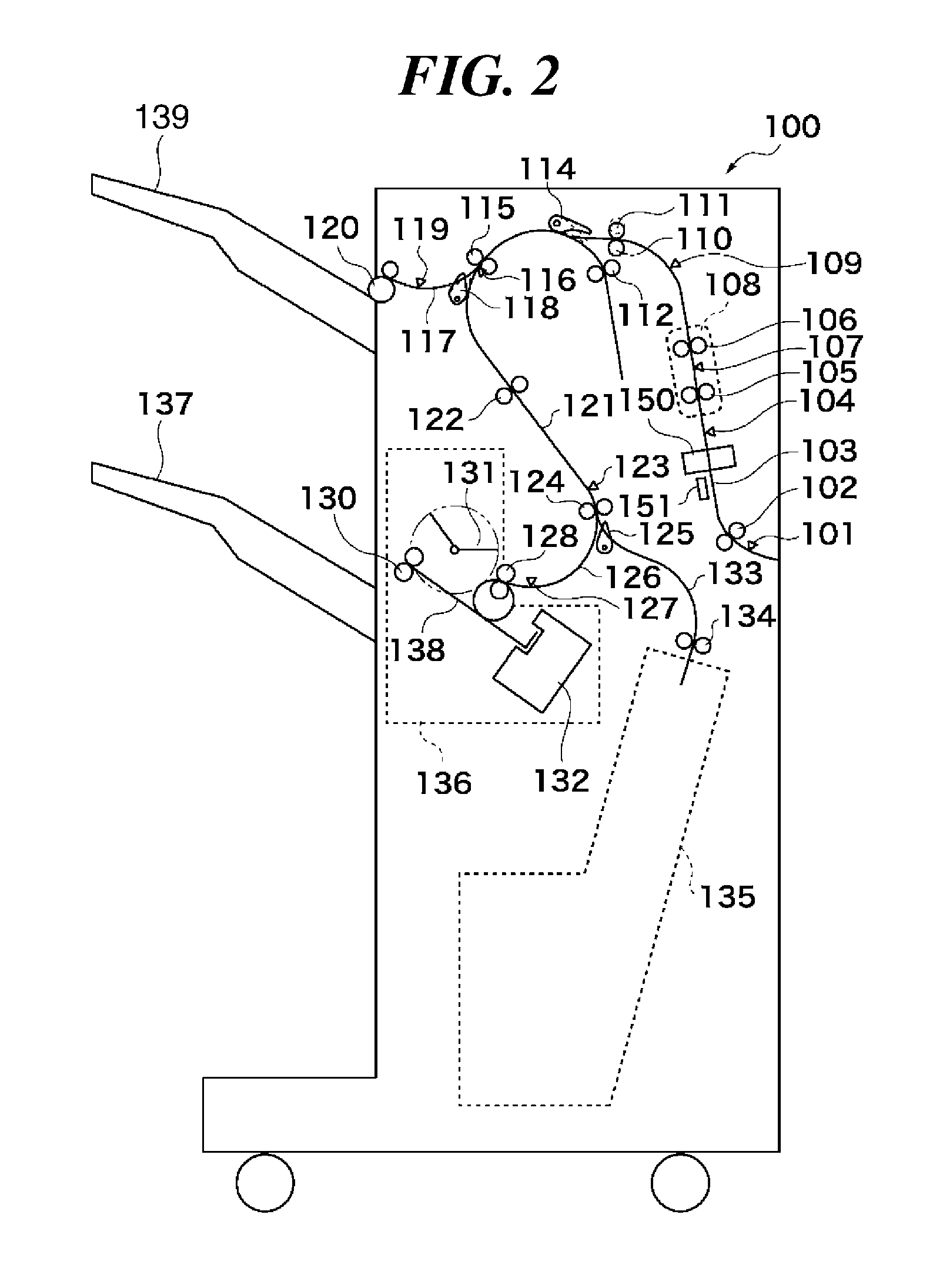

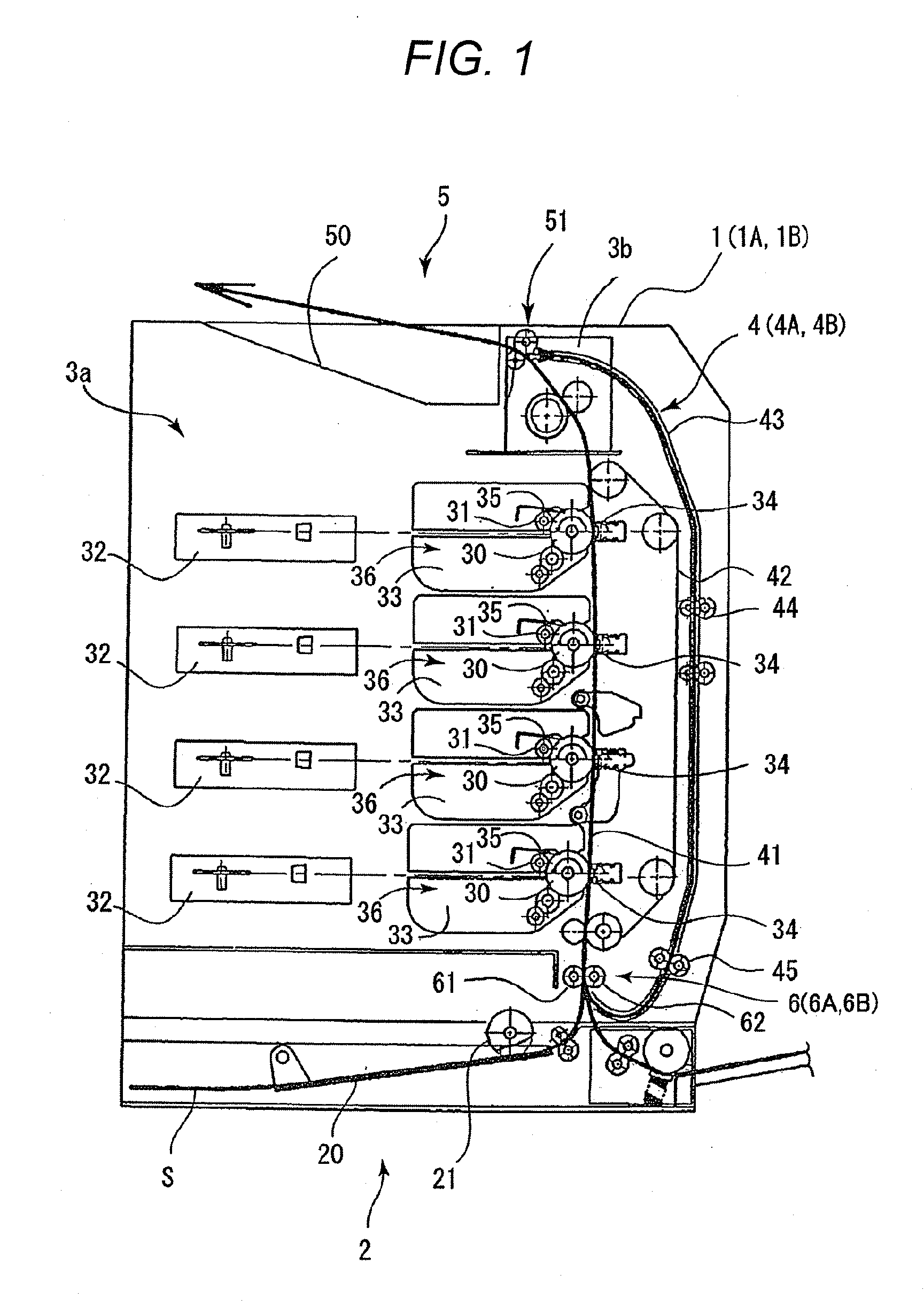

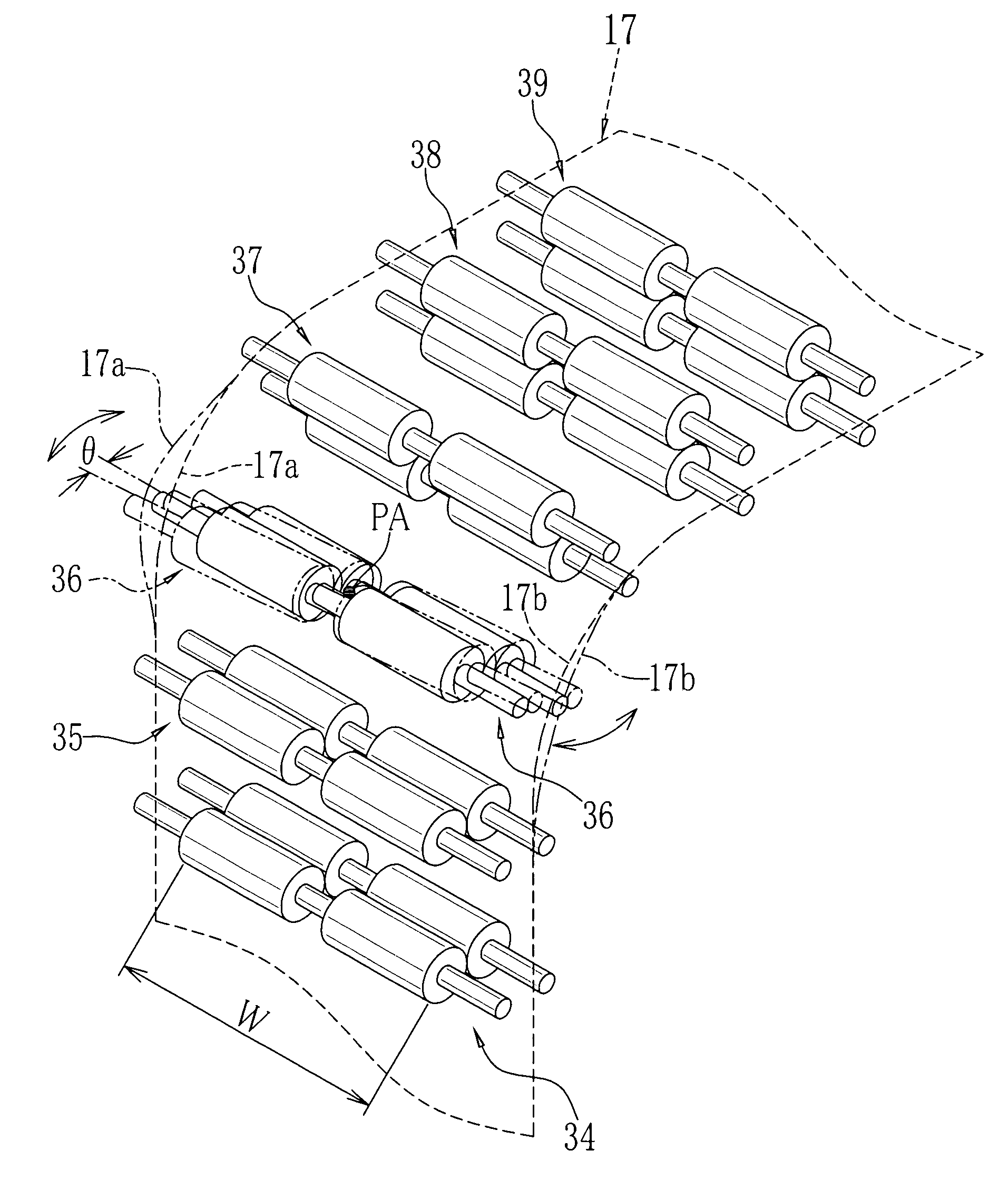

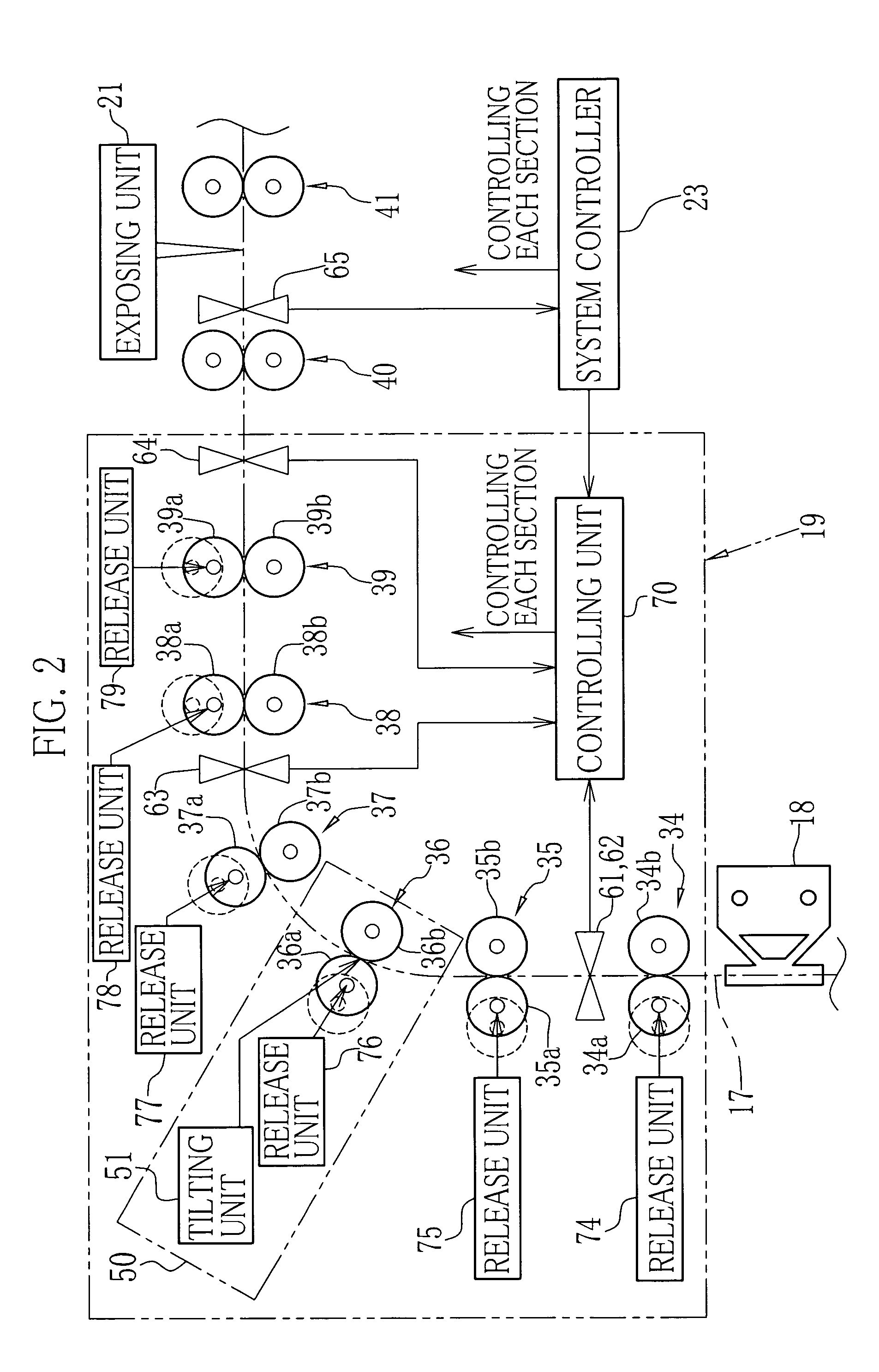

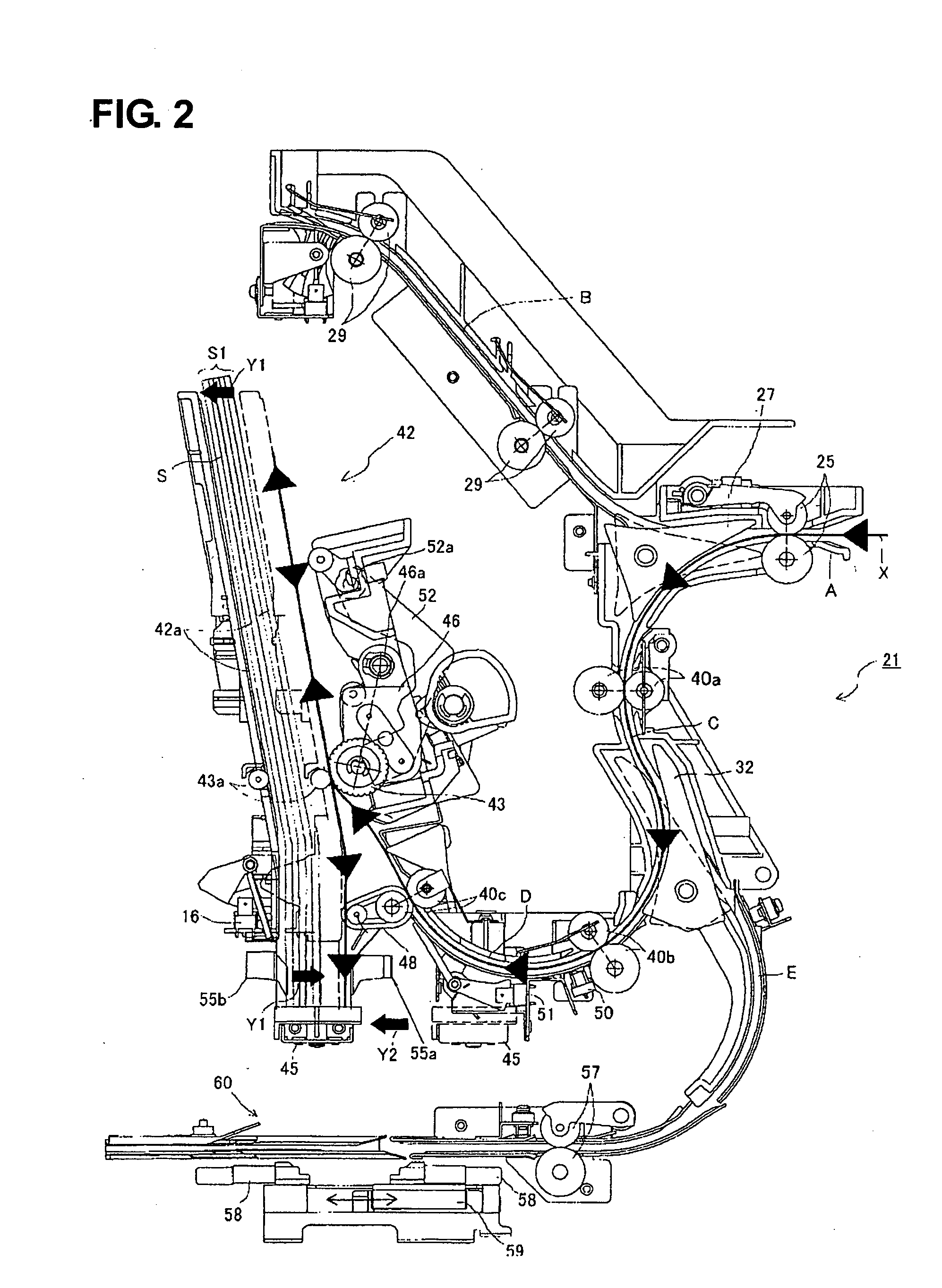

Conveyer and image recording apparatus

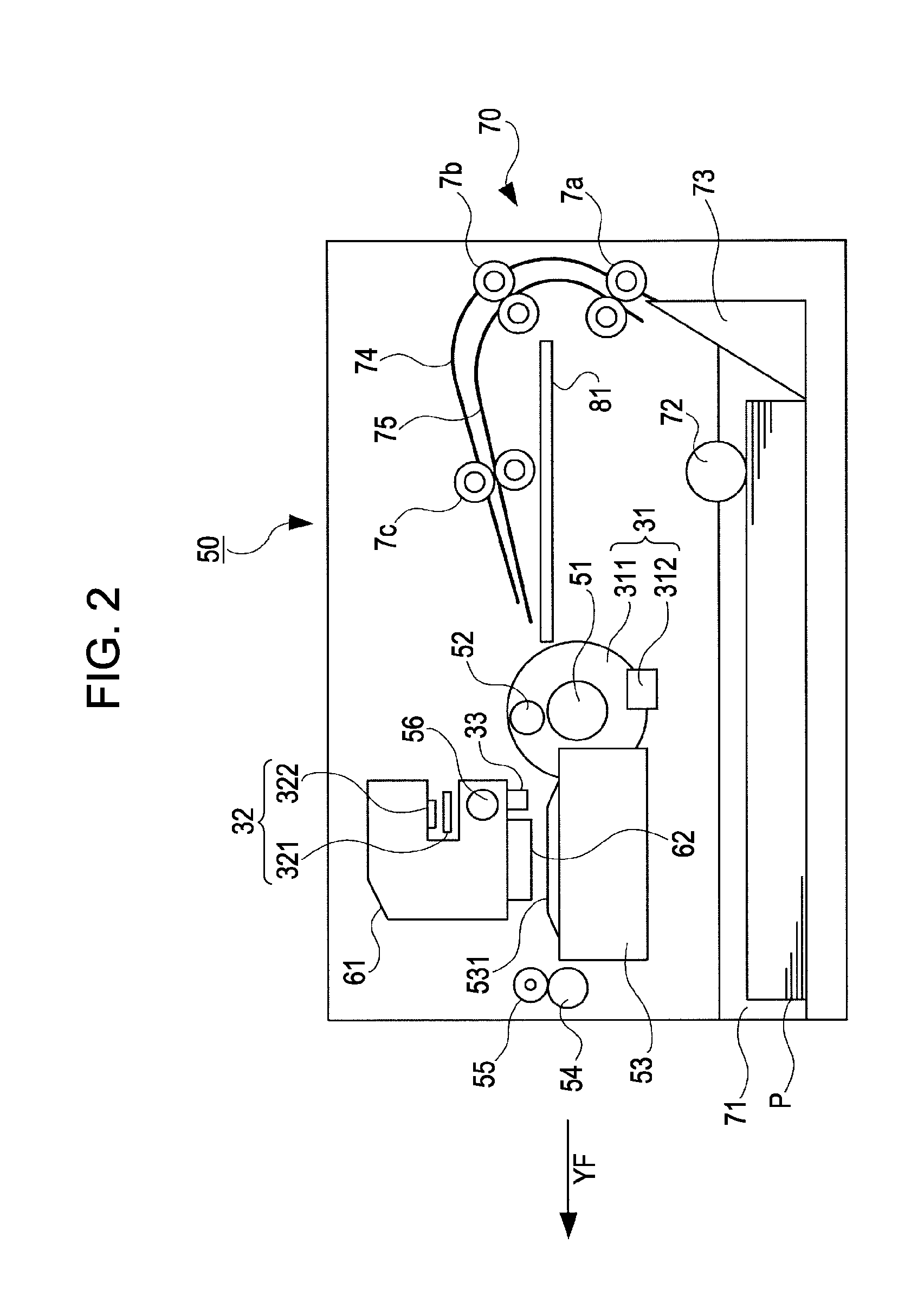

InactiveUS20050206072A1Short timeCorrect skewRegistering devicesFunction indicatorsLeading edgeTransmission belt

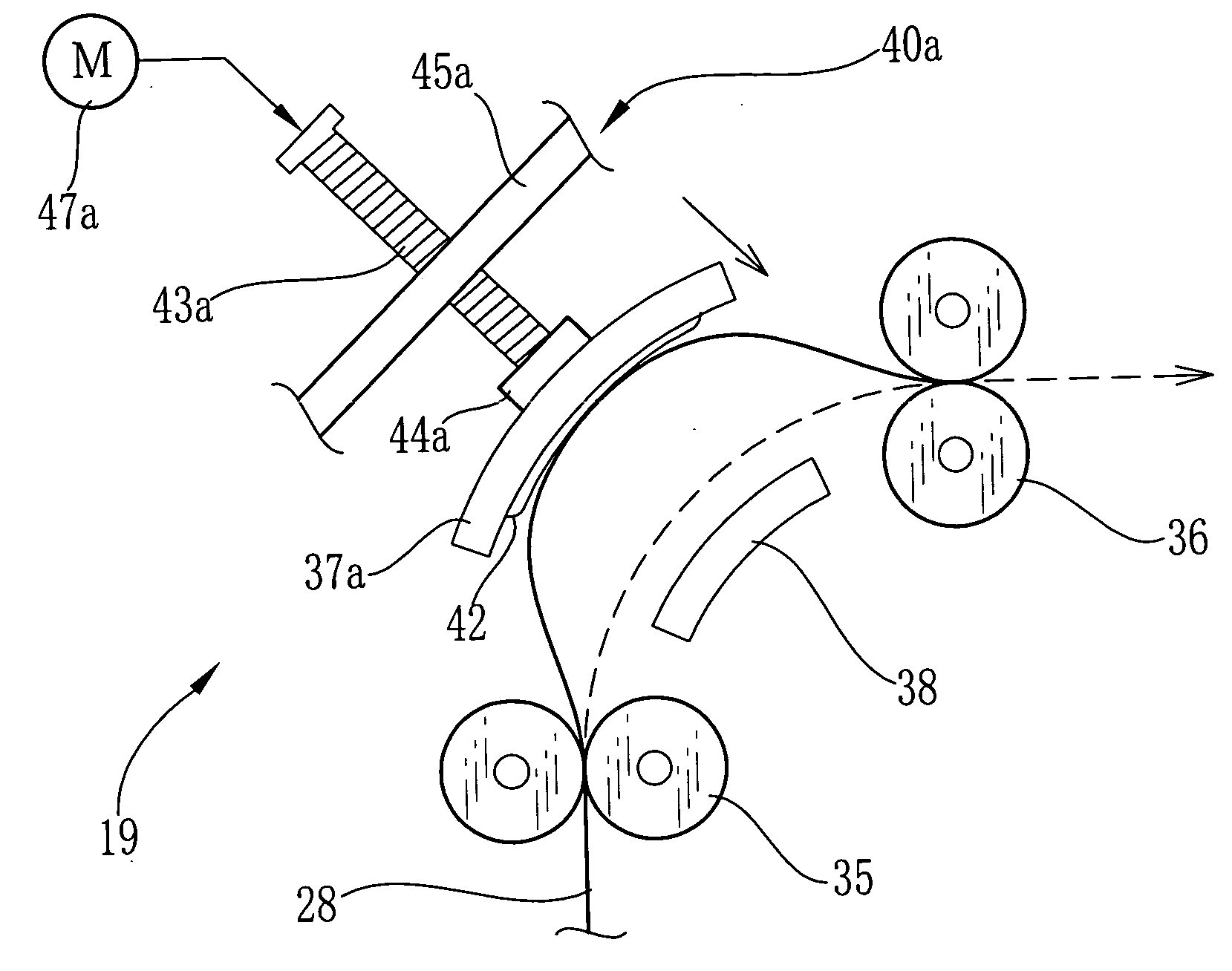

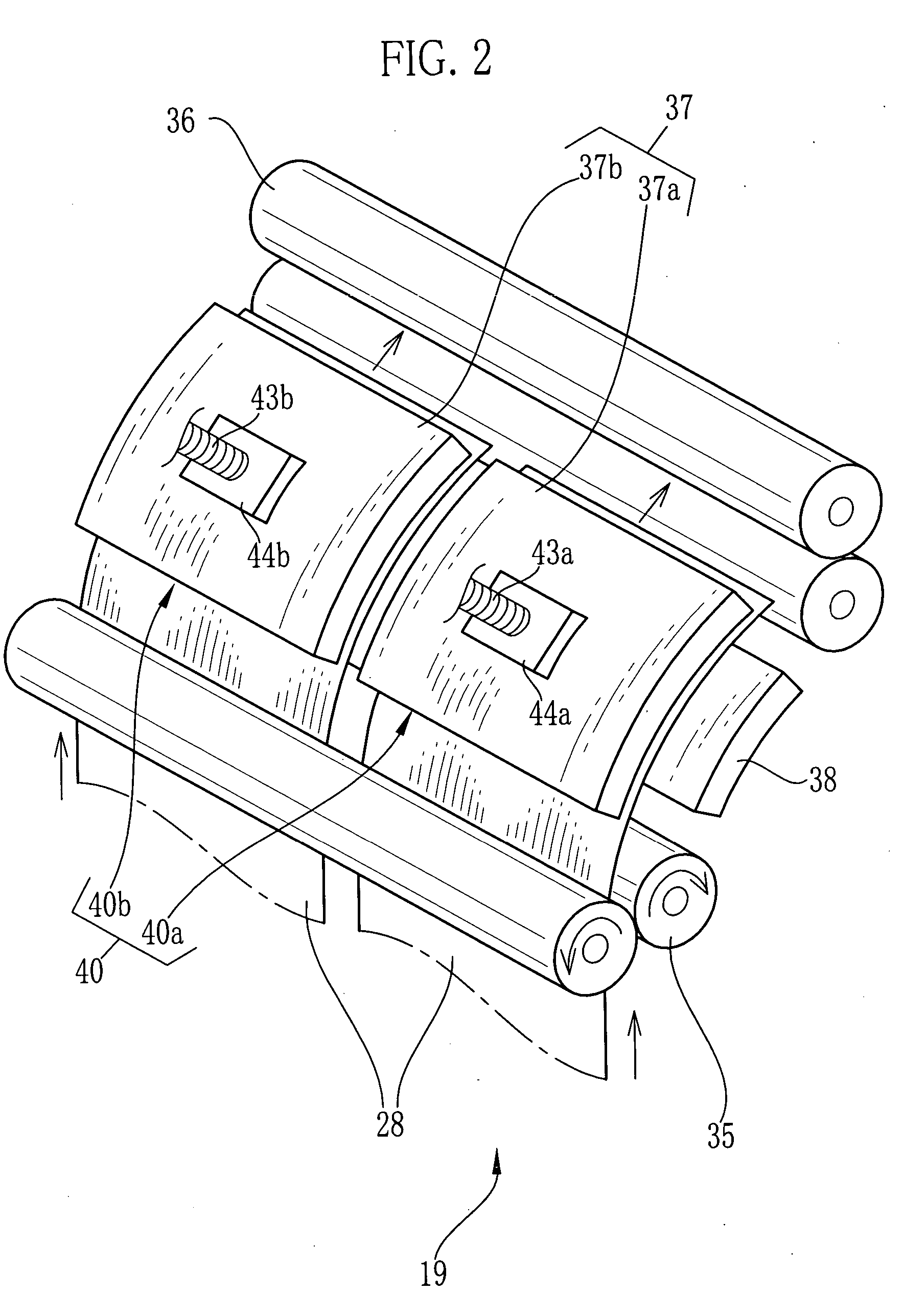

On a paper path in a photo printer, a skew corrector is provided to correct skew of recording sheets simultaneously in two lines. The skew corrector consists of a first conveyer roller pair, a second conveyer roller pair and a strike guide. The recording sheets are conveyed by the first conveyer roller pair after their leading edges strike on the strike guide, to bend the recording sheets flexibly between the first conveyer roller pair and the strike guide, thereby to correct skew of each recording sheet. A necessary transport amount for correcting the skew of the recording sheet is calculated on each line based on detection signals from photo sensors, which are disposed between the first and second conveyer roller pairs, and a width of the recording sheet. The recording sheets of the respective lines are conveyed by the largest necessary transport amount among the calculated ones.

Owner:FUJIFILM HLDG CORP +1

Conveyer and image recording apparatus

InactiveUS7467793B2Short timeCorrect skewRegistering devicesFunction indicatorsLeading edgeImage recording

On a paper path in a photo printer, a skew corrector is provided to correct skew of recording sheets simultaneously in two lines. The skew corrector consists of a first conveyer roller pair, a second conveyer roller pair and a strike guide. The recording sheets are conveyed by the first conveyer roller pair after their leading edges strike on the strike guide, to bend the recording sheets flexibly between the first conveyer roller pair and the strike guide, thereby to correct skew of each recording sheet. A necessary transport amount for correcting the skew of the recording sheet is calculated on each line based on detection signals from photo sensors, which are disposed between the first and second conveyer roller pairs, and a width of the recording sheet. The recording sheets of the respective lines are conveyed by the largest necessary transport amount among the calculated ones.

Owner:FUJIFILM HLDG CORP +1

Atomic force microscopy scanning and image processing

InactiveUS20070251306A1Correct skewCorrective tiltNanotechnologyScanning probe techniquesAtomic force microscopyTopographic profile

A topographic profile of a structure is generated using atomic force microscopy. The structure is scanned such that an area of interest of the structure is scanned at a higher resolution than portions of the structure outside of the area of interest. An profile of the structure is then generated based on the scan. To correct skew and tilt of the profile, a first feature of the profile is aligned with a first axis of a coordinate system. The profile is then manipulated to align a second feature of the profile with a second axis of the coordinate system.

Owner:SEAGATE TECH LLC

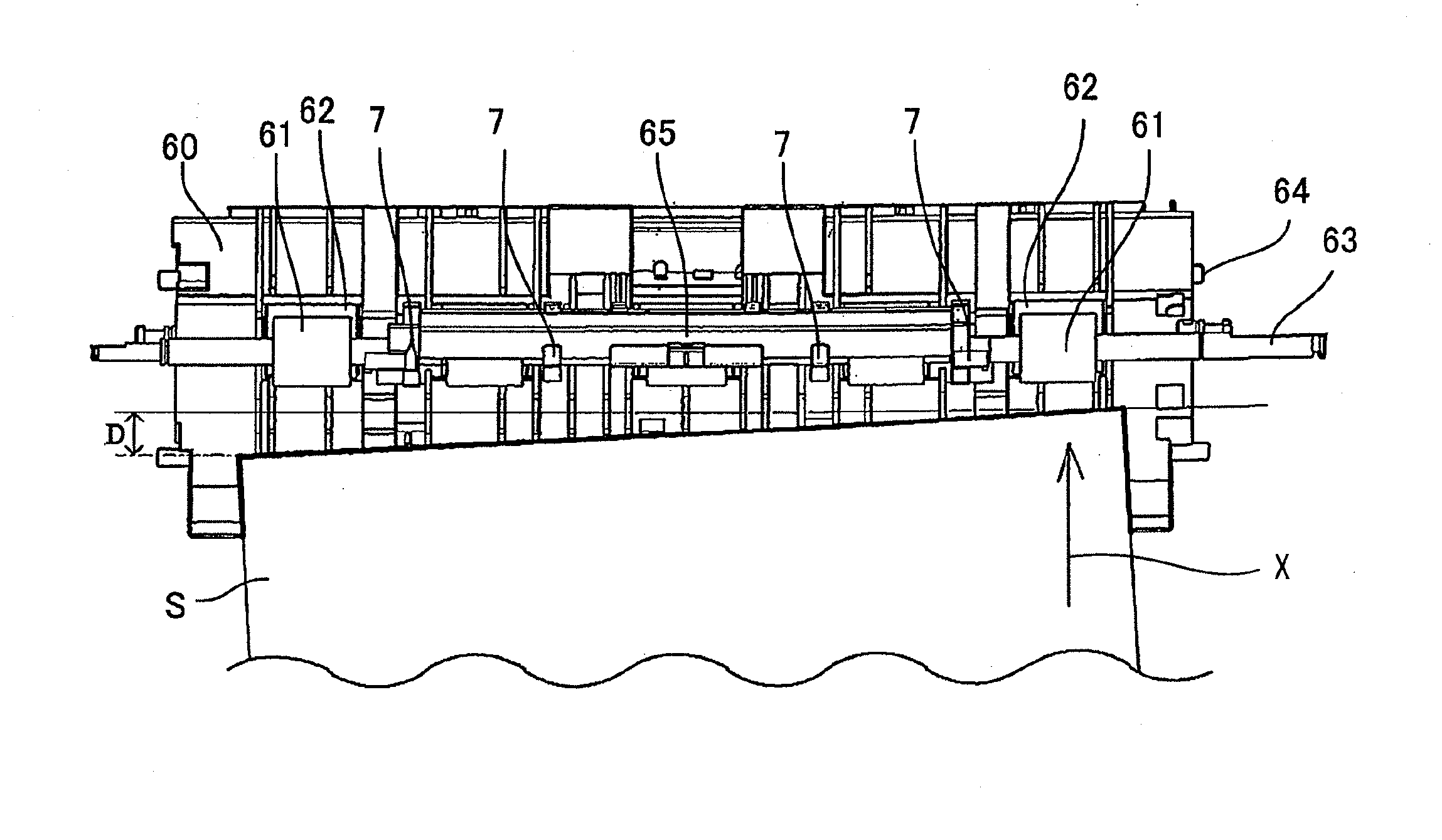

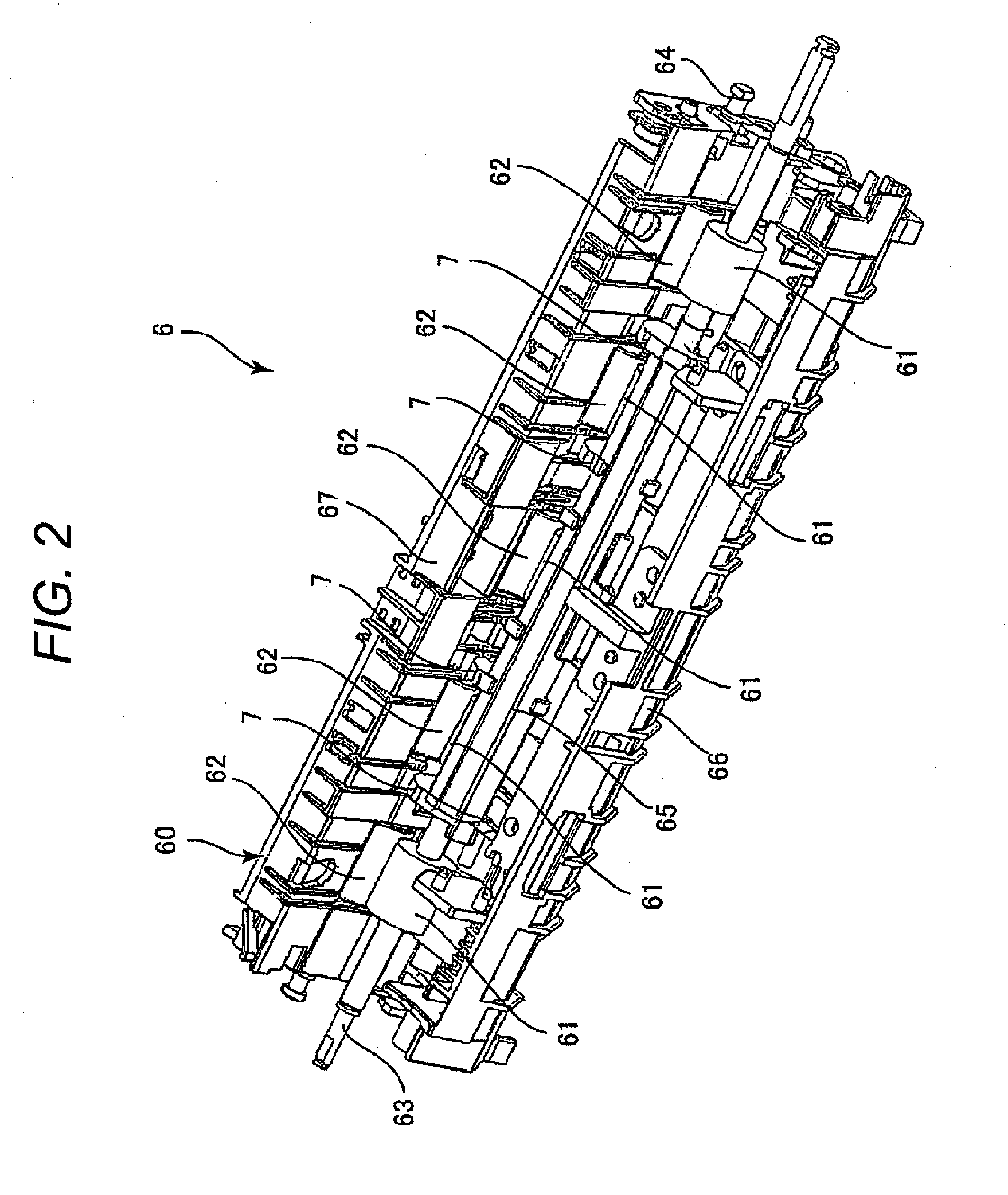

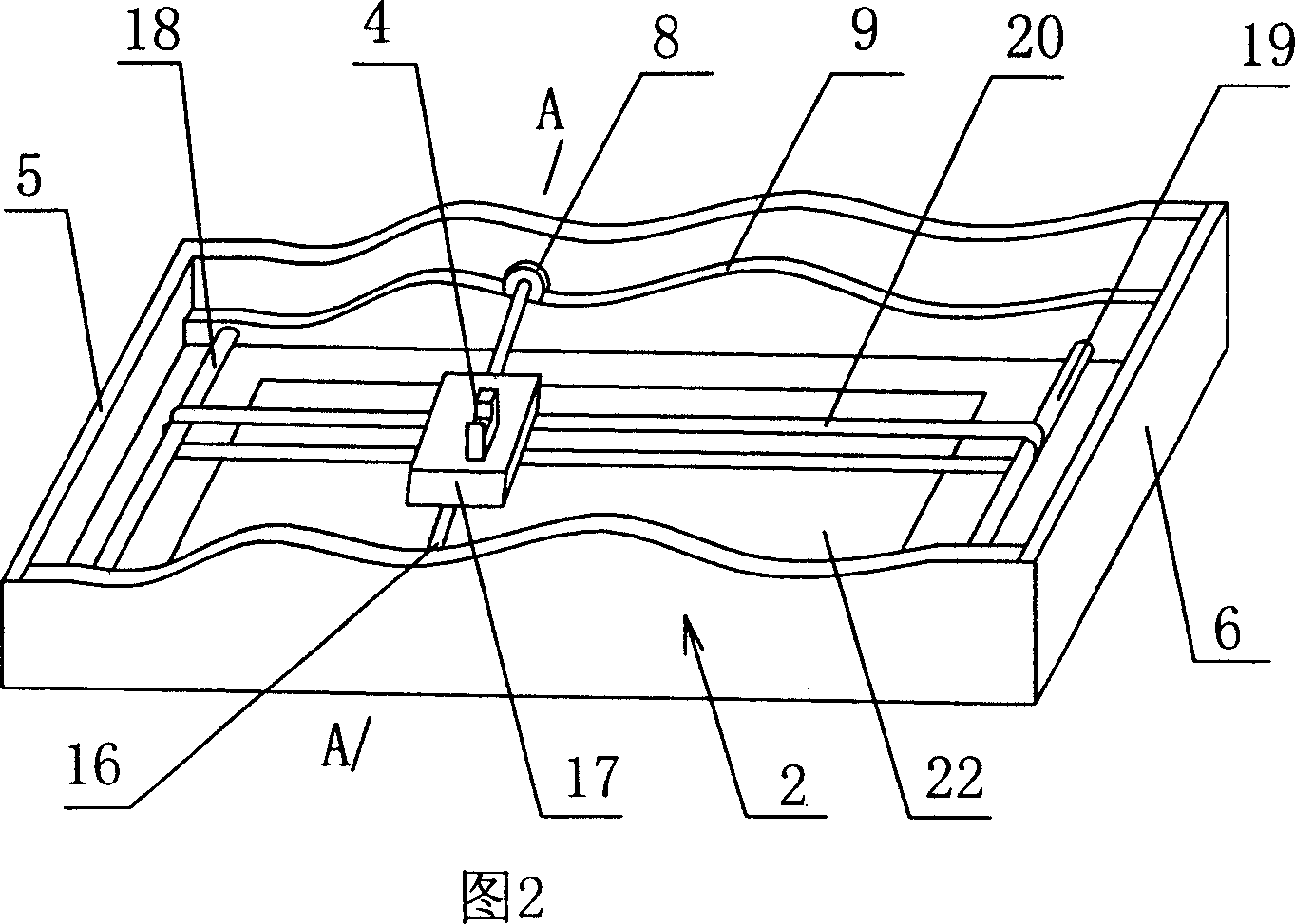

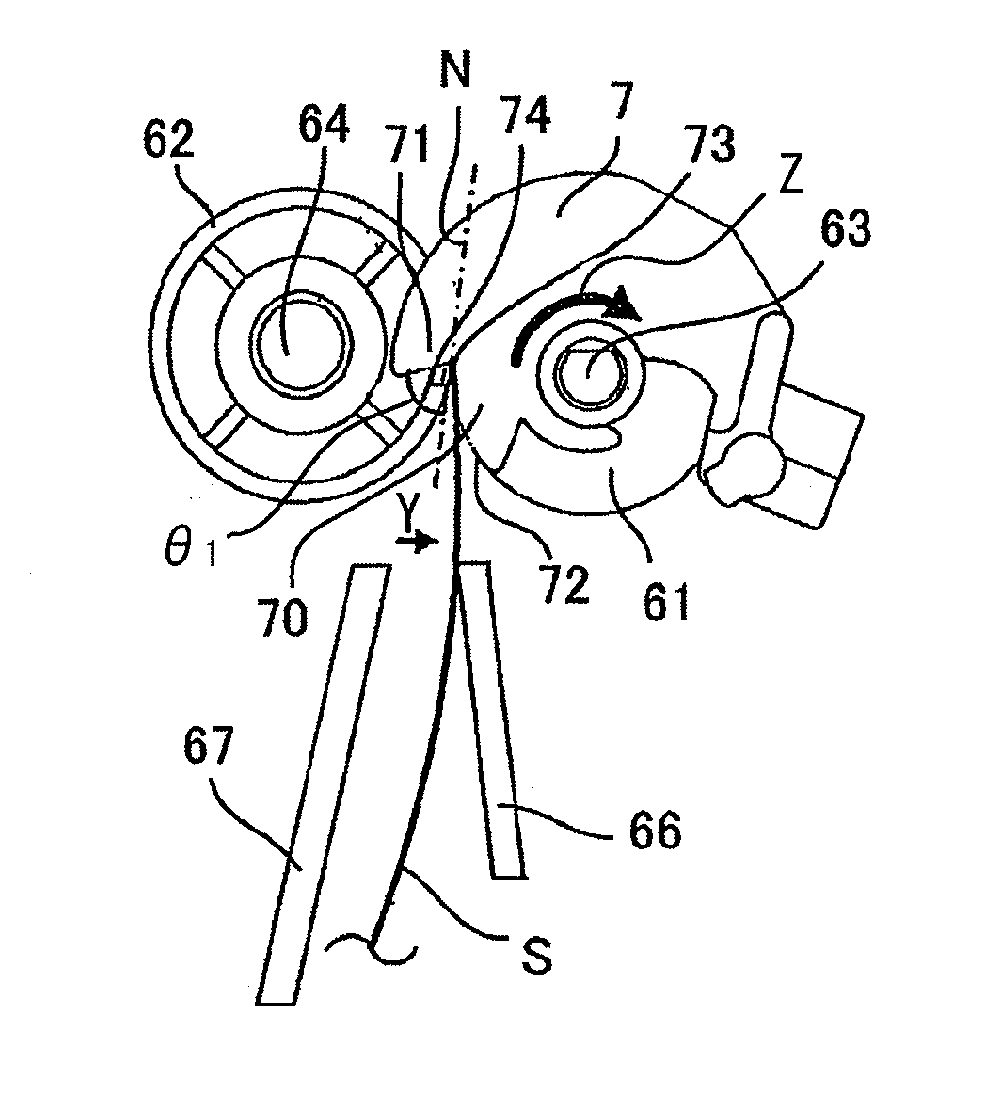

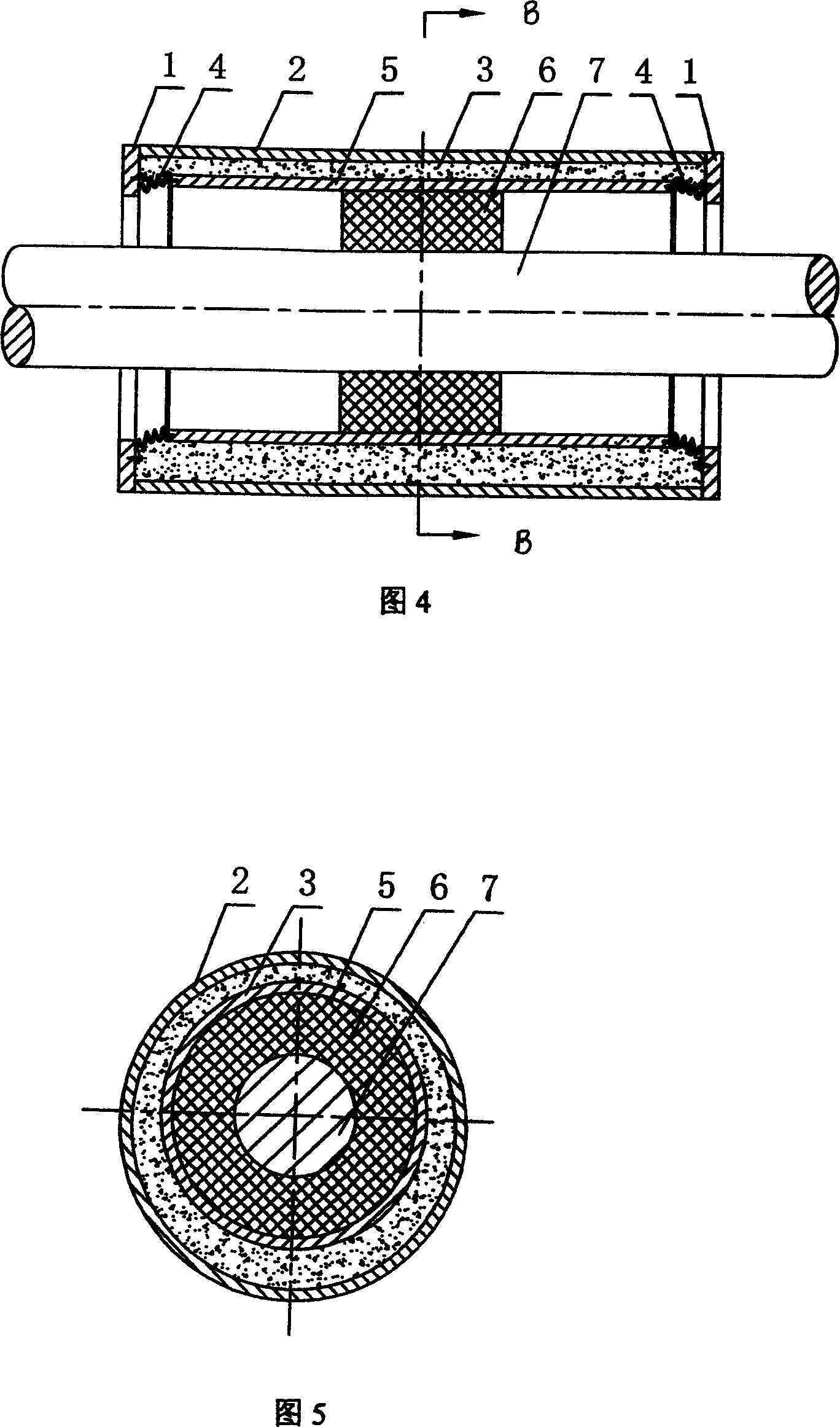

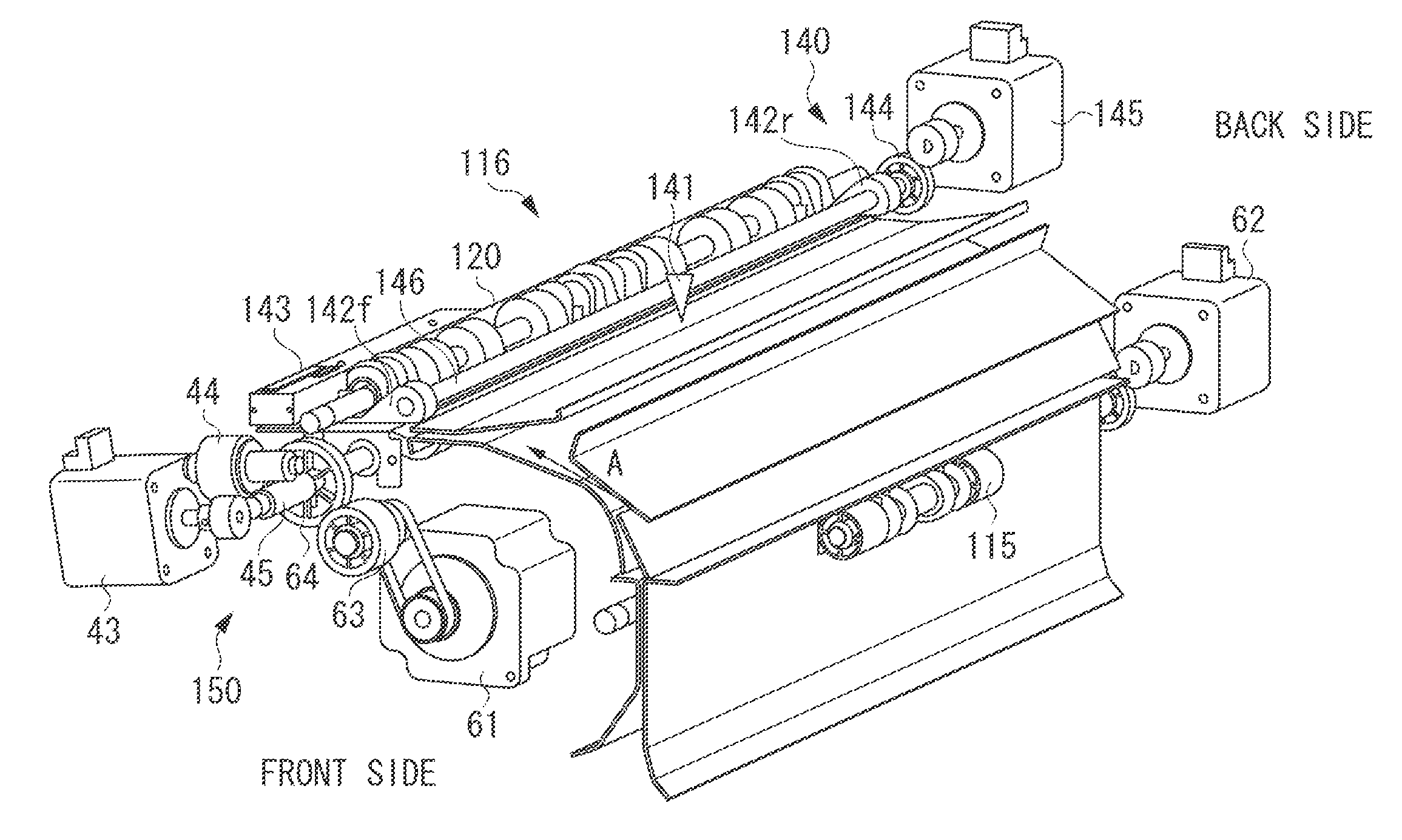

Feeding device for sheet material and image recording apparatus for recording an image thereon

InactiveUS20050156373A1Quickly and accurately skewEasy to processRegistering devicesArticle feedersComputer printingImage recording

A photographic printer carries paper sheets in two rows. A skew correcting unit is disposed at a passage of the paper sheets. The skew correcting unit comprises a pre-resist roller pair, a resist roller pair, carrying guides, and pressing mechanisms for moving the carrying guides in an approaching direction to the paper sheet and in a separating direction there from. When correcting the skew of the paper sheet, the pressing mechanism is actuated to move the carrying guide toward a deflection portion of the deflected paper sheet. In virtue of this, an anterior end of the paper sheet is pressed against the resist roller pair. Even if the paper sheet has stiffness, the skew thereof is quickly and accurately corrected.

Owner:FUJIFILM CORP +1

Ink jet printer, printer control unit, printer system including the same, and storage medium with the operation program of the printer control unit stored for controlling double-side printing

InactiveUS7576875B2Reduce the hassle of operationQuality improvementDigitally marking record carriersRegistering devicesEngineeringControl unit

An ink jet printer with a double-side printing function enables to print page images at a proper position on both surfaces of a cut paper, is provided. When feeding the cut paper A having an image printed on the front surface, the feeding roller 407 is rotated in the direction C1 to feed the cut paper A and simultaneously the registering rollers 410a, 410b are rotated in the direction D1 to push back the cut paper. In addition, the double-side printing is easily realized in both of the cases where the ink jet printer with the double-side printing function is connected to the host, and where the ink jet printer without double-side printing function is connected to the host by having the host make an inquiry of the printer whether or not double-side printing is available (step 6). Based on the results of the inquiry, printing commands are generated and sent to the printer.

Owner:SEIKO EPSON CORP

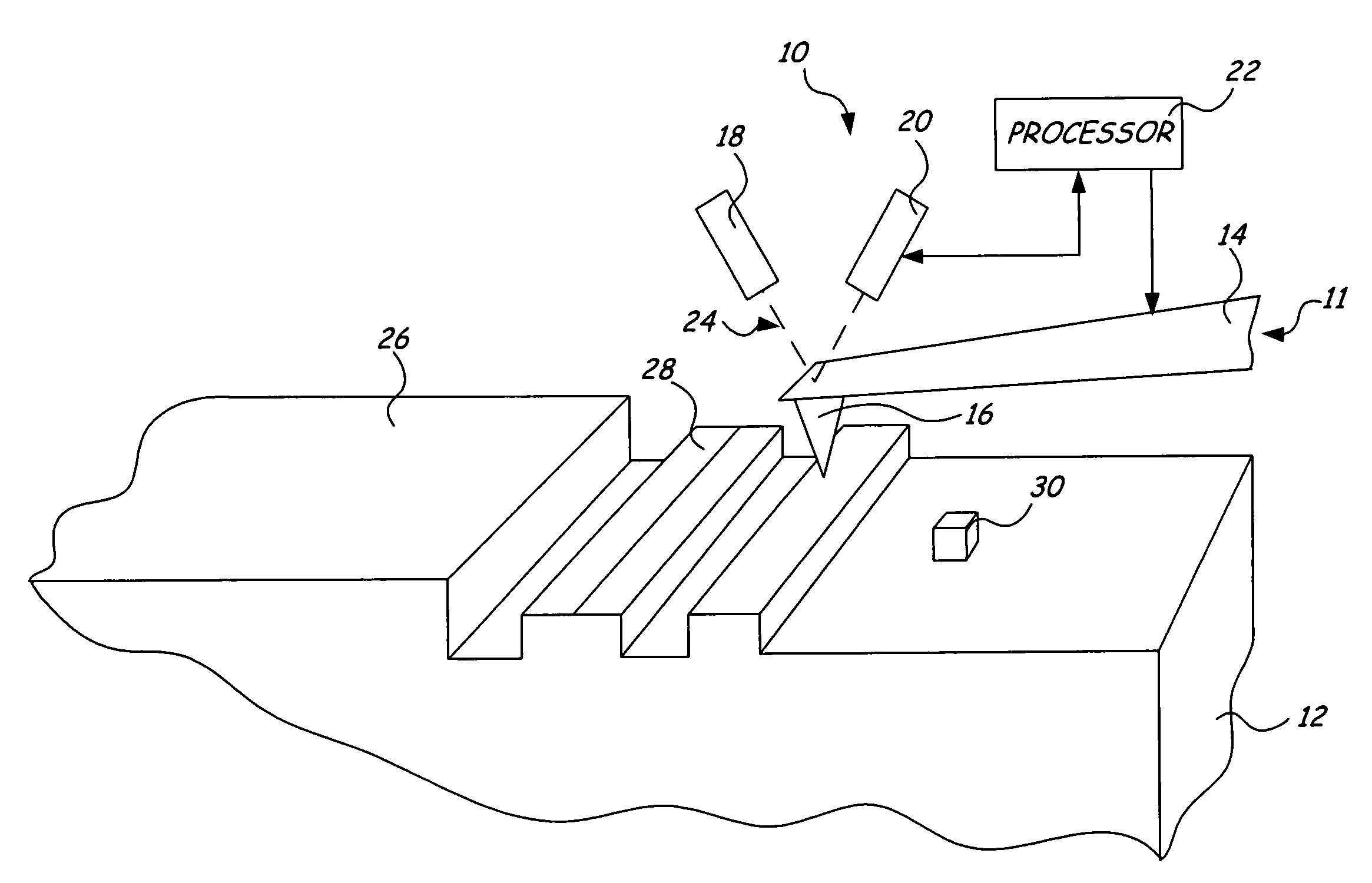

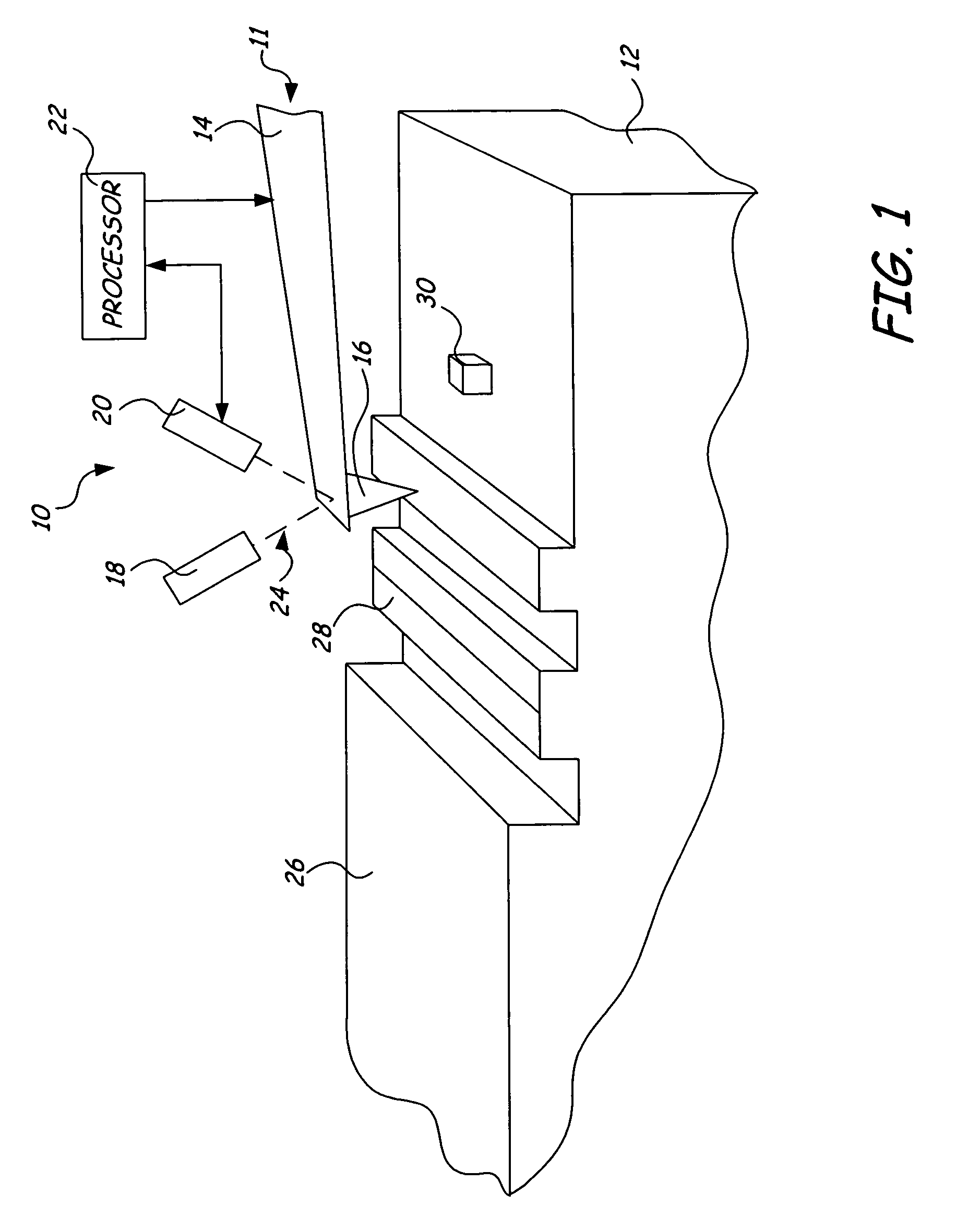

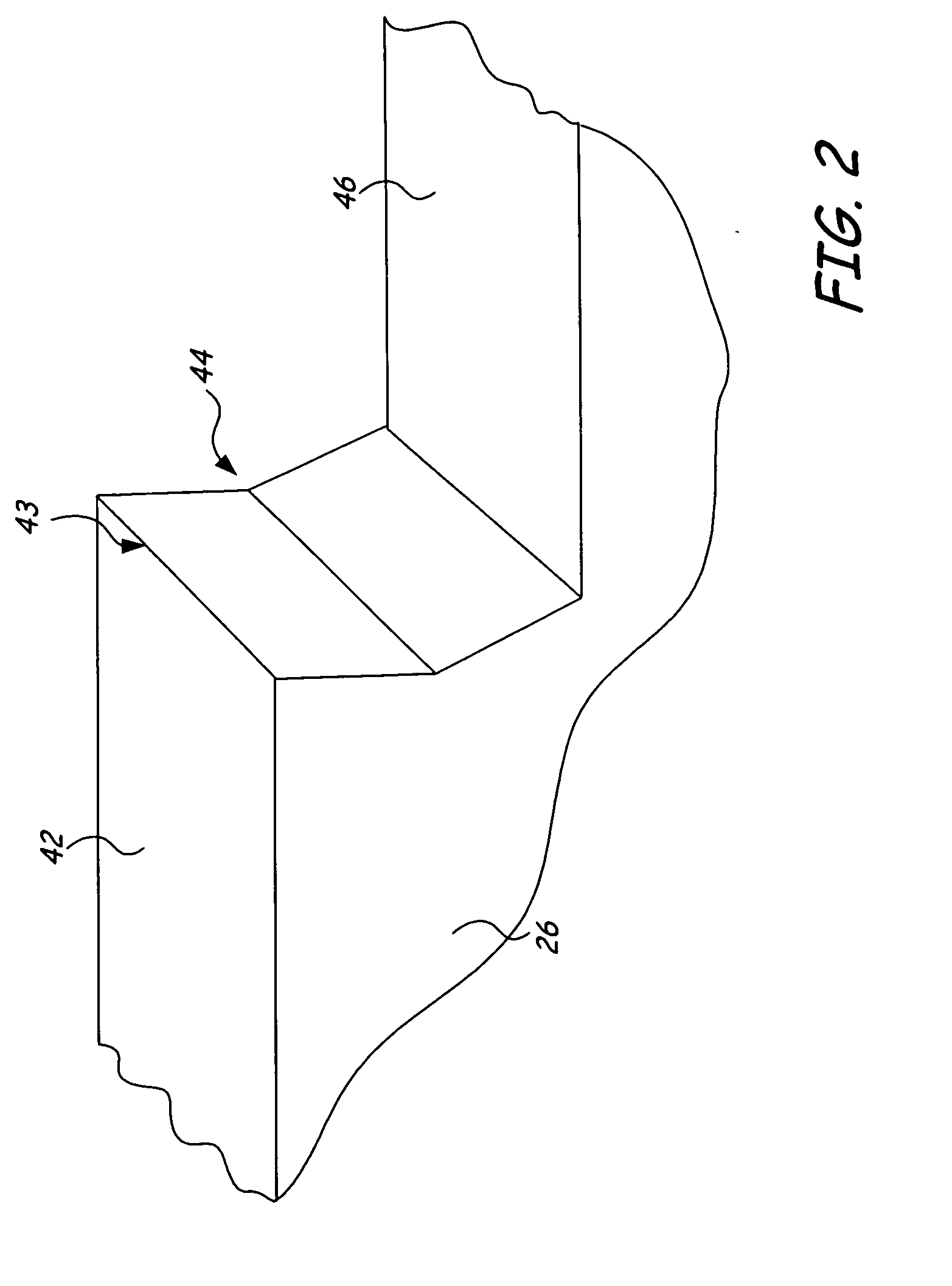

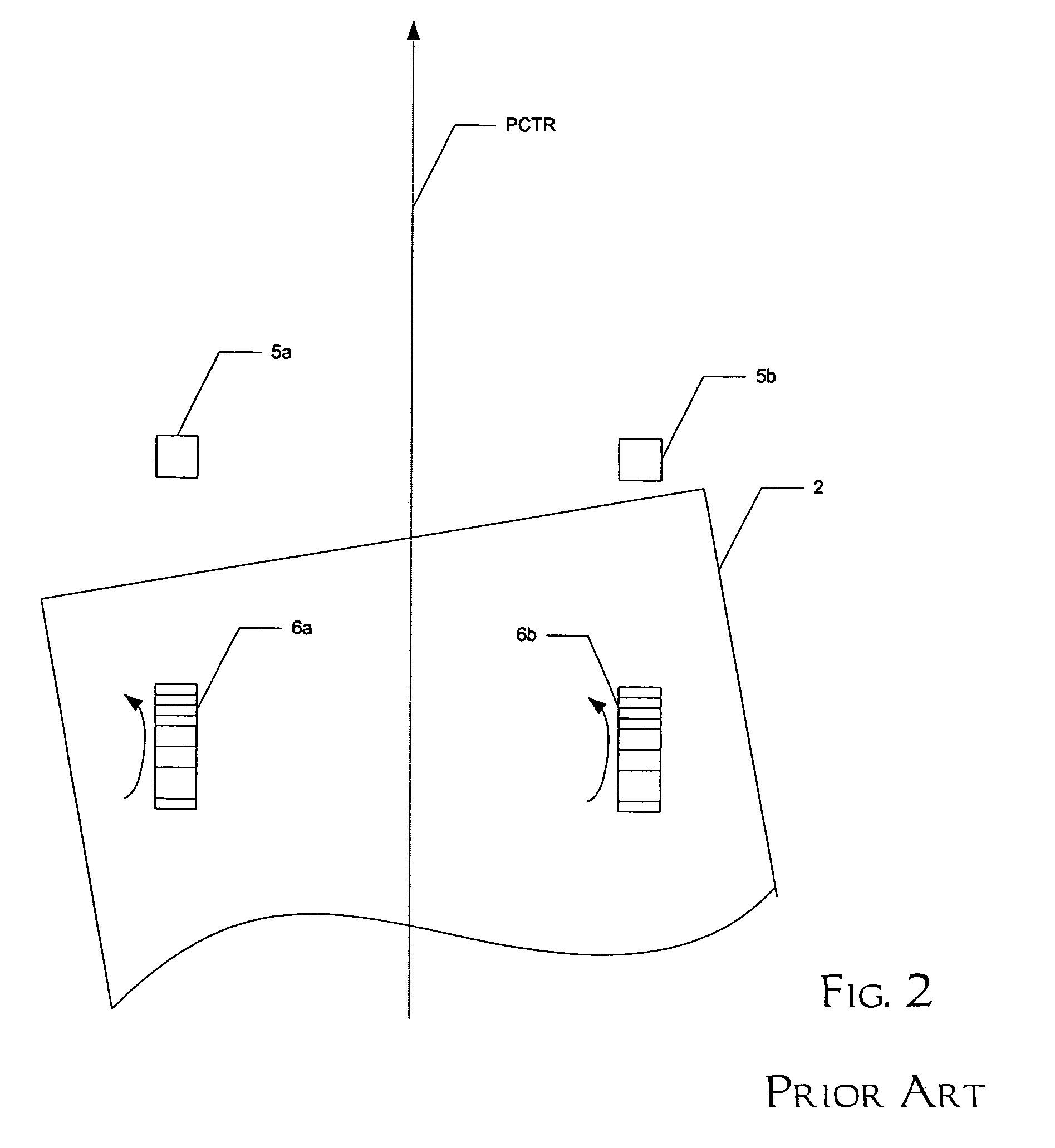

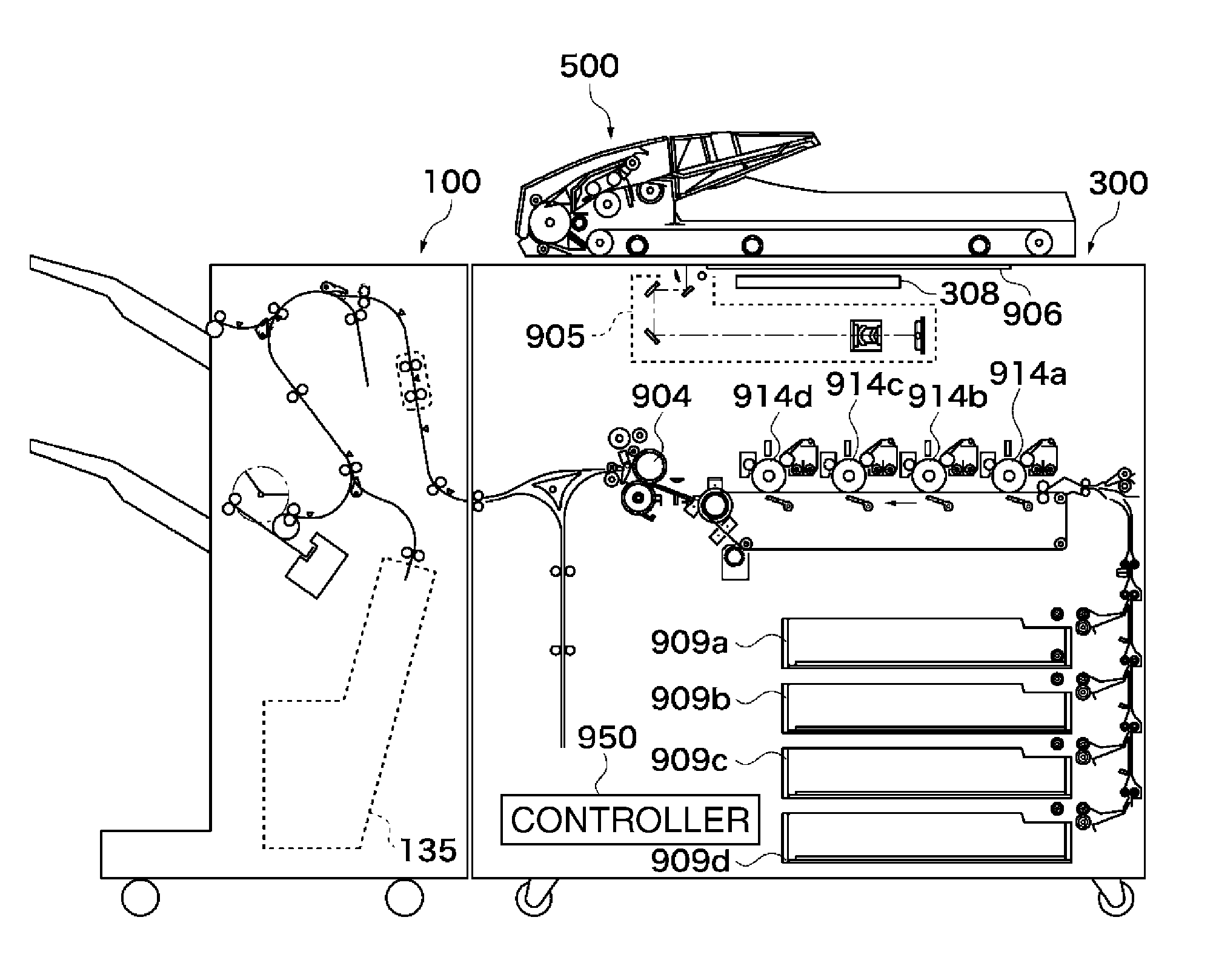

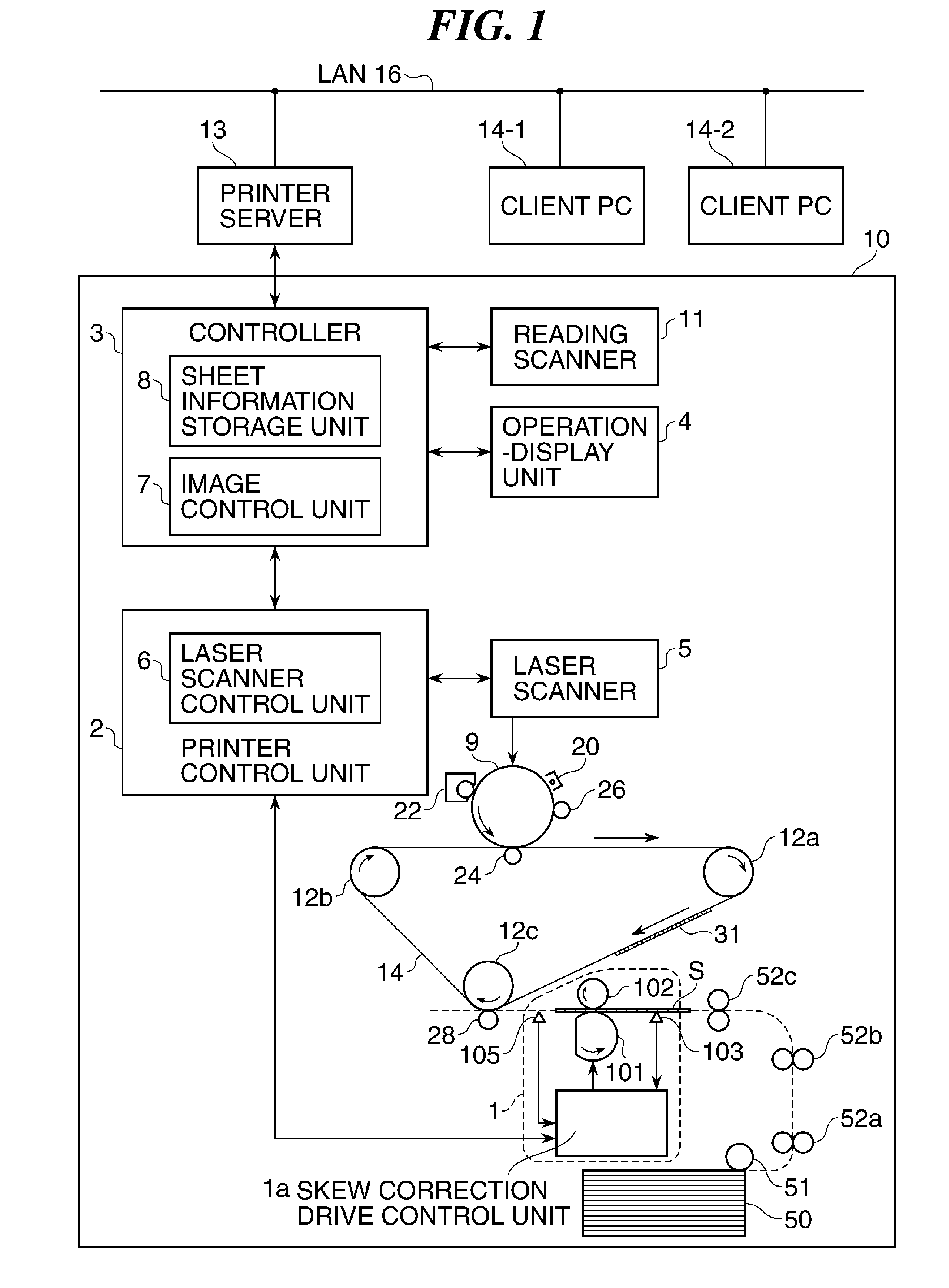

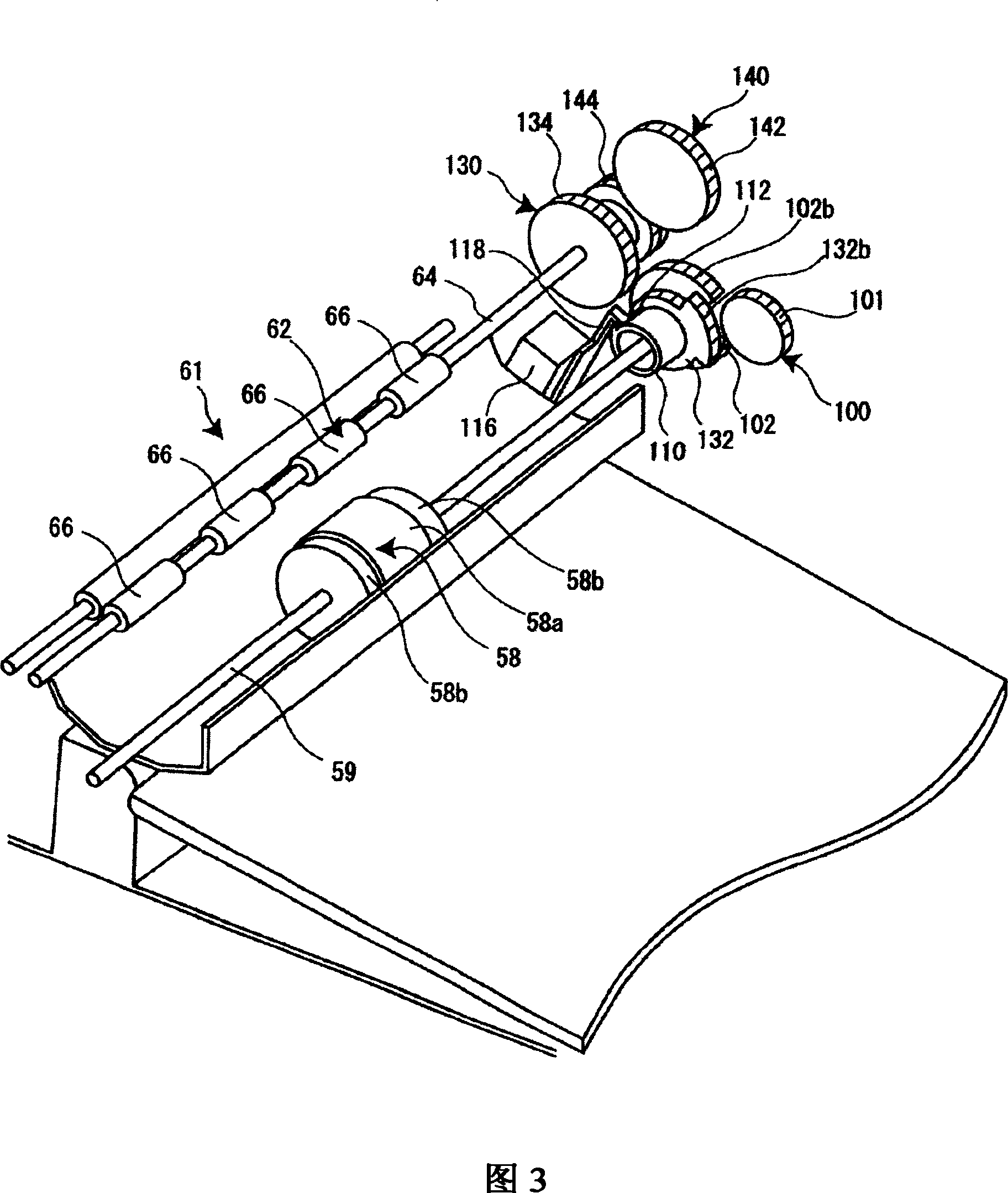

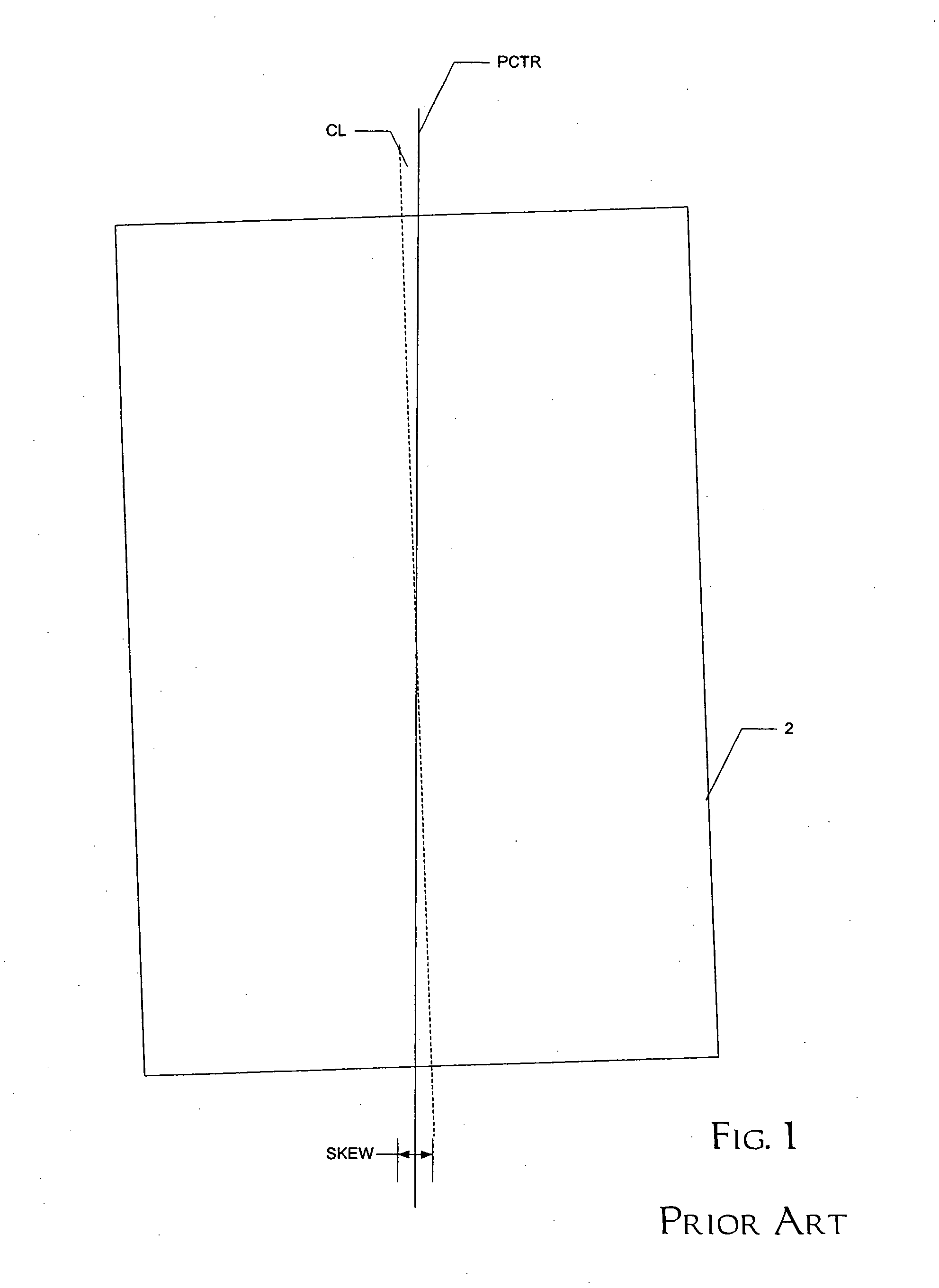

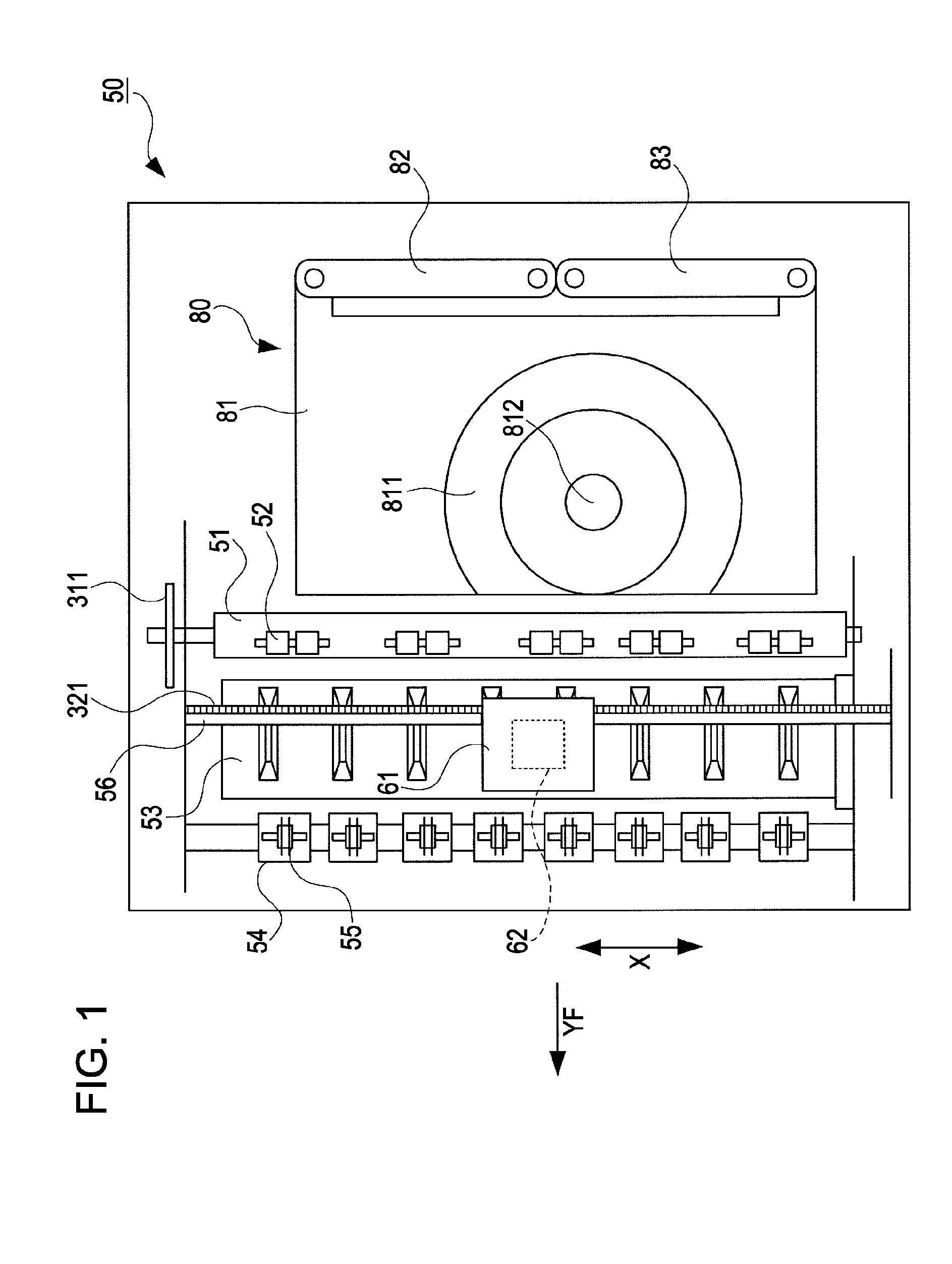

Adjustment of skew registration of media to a developed image in a printing machine

ActiveUS7088948B2Adjustable positionCorrect skewElectrographic process apparatusArticle feedersControl signalWorkstation

A printing machine (10) including a registration station (45) for applying a skew adjustment received from a human operator is disclosed. The registration station (45) includes independently controllable motors (52a, 52b) that drive corresponding urging rollers (56a, 56b) as controlled by control circuitry (24), for example in response to the position of a media sheet as sensed by sensors (58a, 58b; 60a, 60b) at the registration station (45). The machine operator can enter a skew adjustment value at a user interface (25a), or at a networked computer workstation with which the printing machine (10) communicates via a network interface (25b). The control circuitry (24) calculates differential control signals for controlling the motors (52a, 52b) to effect the skew correction. The differential control signals may be differential timing delays, such as prior to deactivation of the motors (52a, 52b), or may be a differential velocity signal for driving the motors (52a, 52b).

Owner:COMML COPY INNOVATIONS INC

Sheet conveyance apparatus and image forming apparatus including the same

InactiveUS20090160125A1Prevent bucklingPreventing a sheet from bucklingRegistering devicesElectrographic process apparatusReference surfaceSheet material

A sheet conveyance apparatus includes a reference surface extending along a sheet conveyance direction and configured to regulate the position of a side edge of a sheet to be conveyed, a skew conveyance mechanism configured to convey the sheet obliquely so that the side edge of the sheet collides against the reference surface, and a sheet deforming unit configured to deform the side edge of the sheet when the sheet is conveyed toward the reference surface by the skew conveyance mechanism.

Owner:CANON KK

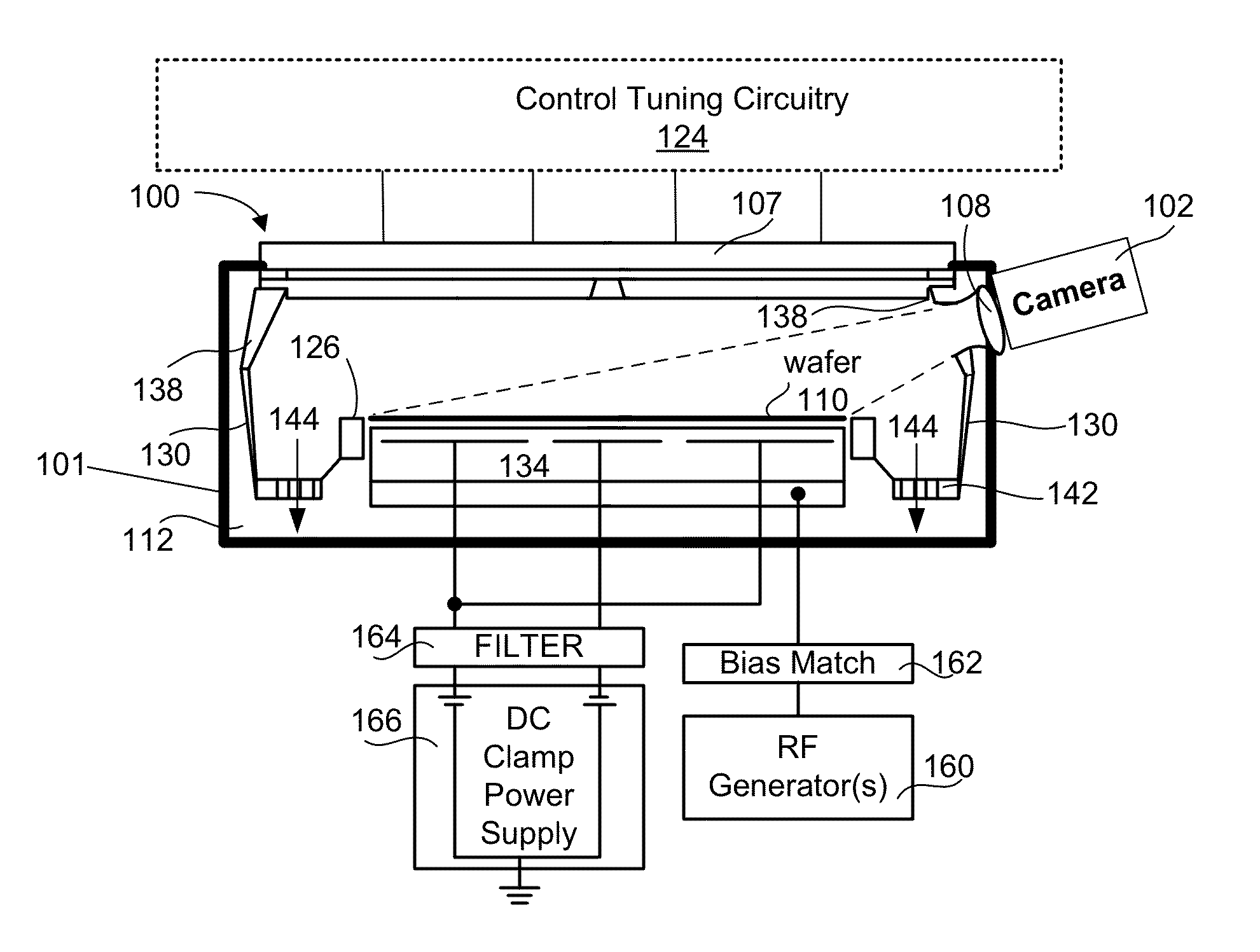

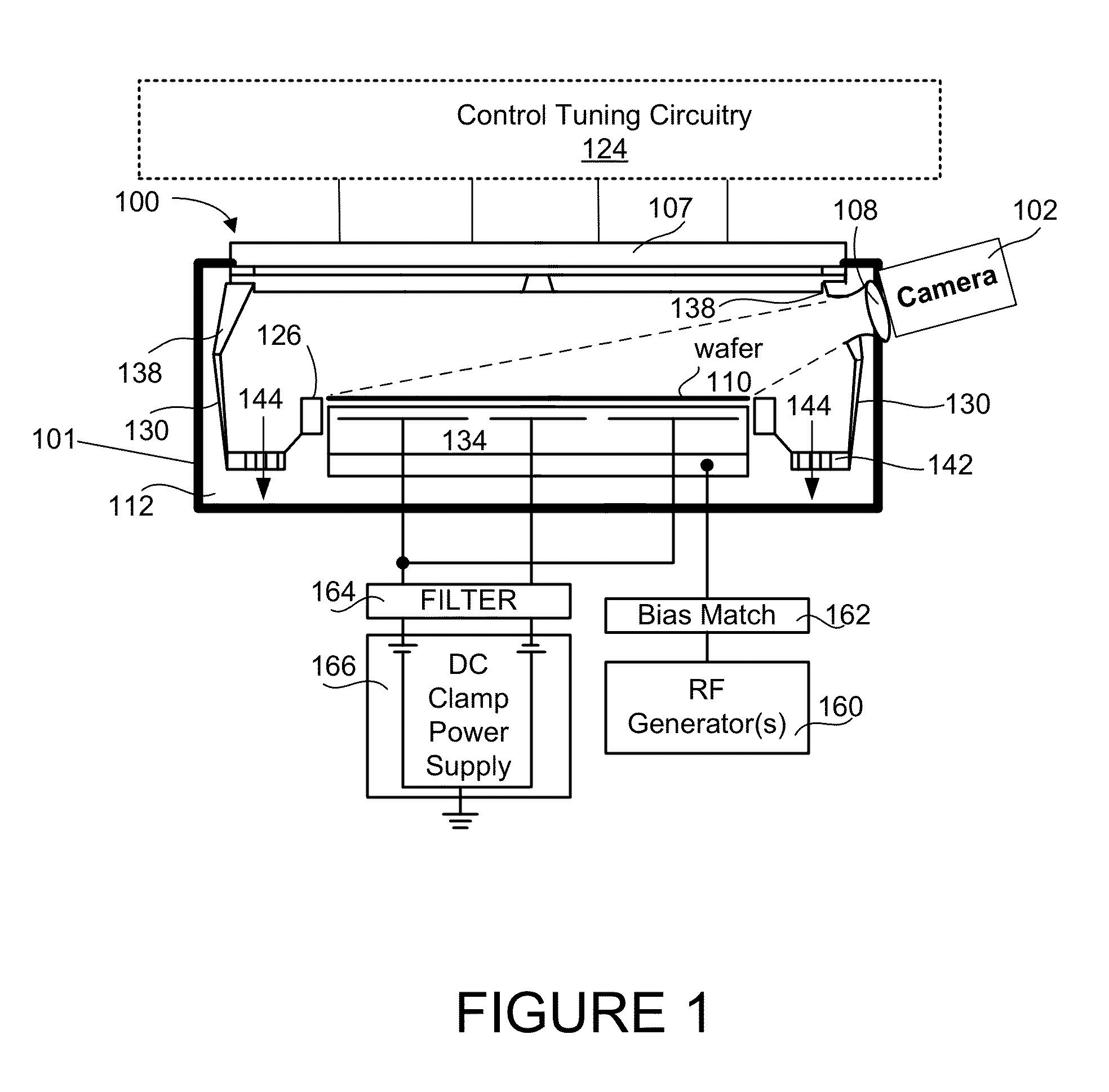

Systems and methods for detecting endpoint for through-silicon via reveal applications

ActiveUS20150311129A1Accurate detectionExact matchSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingReference patternsSemiconductor

Systems and methods for processing a semiconductor wafer includes a plasma processing chamber. The plasma processing chamber includes an exterior, an interior region with a wafer receiving mechanism and a viewport disposed on a sidewall of the plasma processing chamber providing visual access from the exterior to the wafer received on the wafer receiving mechanism. A camera is mounted to the viewport of the plasma processing chamber on the exterior and coupled to an image processor. The image processor includes pattern recognition logic to match images of emerging pattern captured and transmitted by the camera, to a reference pattern and to generate signal defining an endpoint when a match is detected. A system process controller coupled to the image processor and the plasma processing chamber receives the signal from the image processor and adjusts controls of one or more resources to stop the etching operation.

Owner:LAM RES CORP

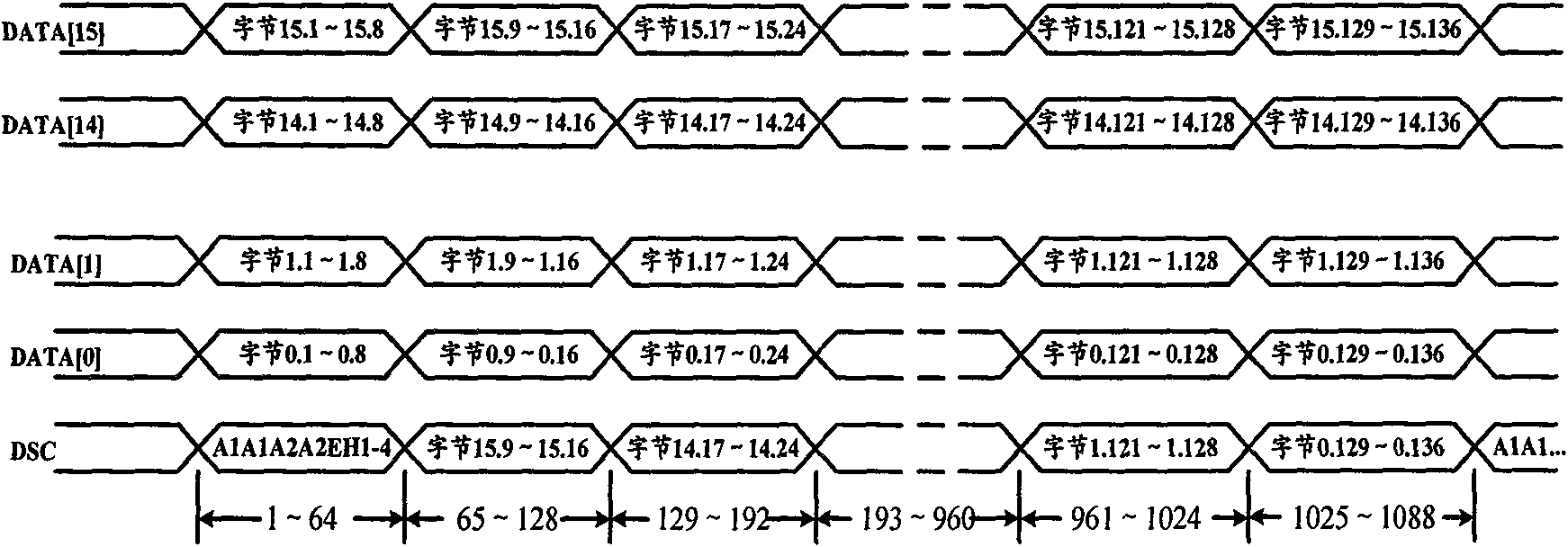

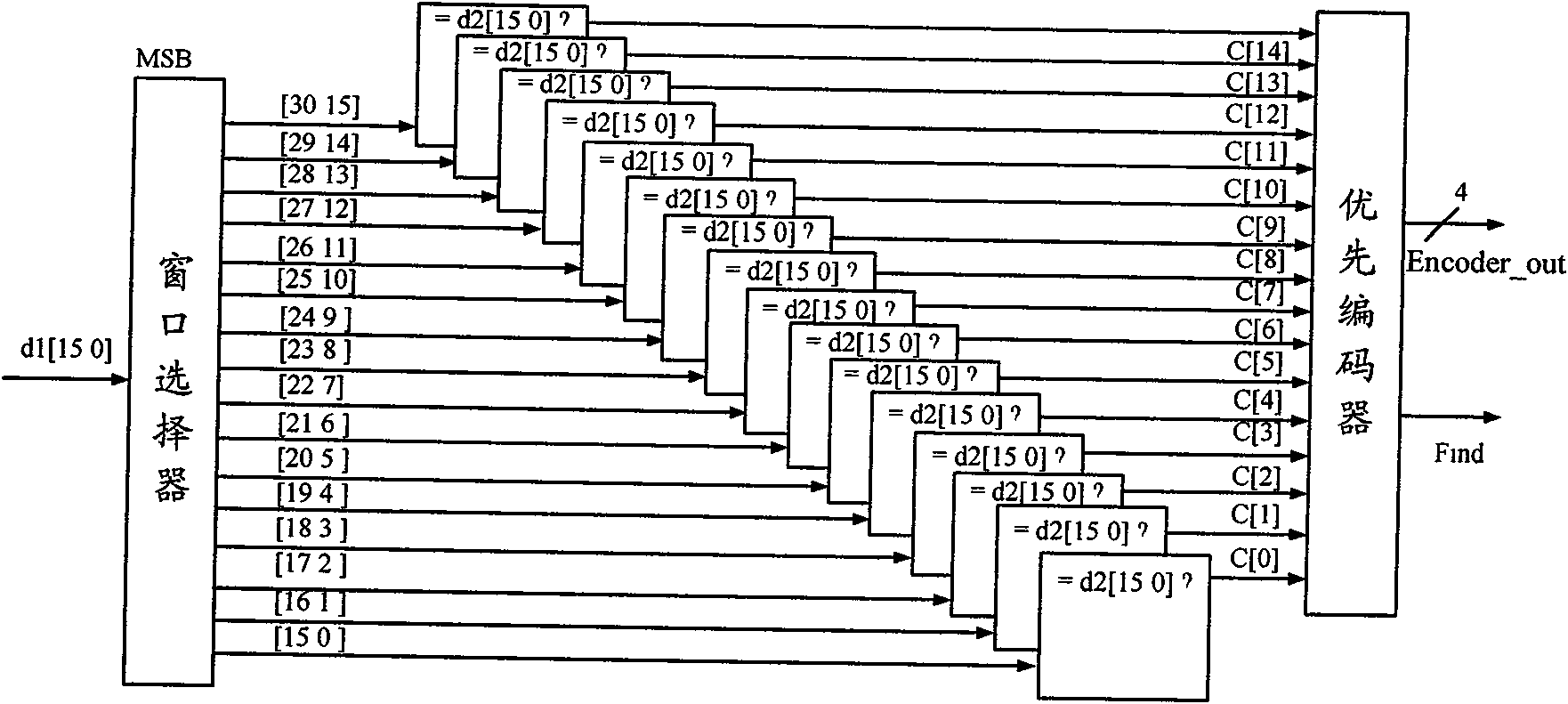

Deskew device and method applied to high-speed parallel optical interconnection system

InactiveCN101552766AIncrease the maximum operating frequencyReduced fan-outTransmissionLogic circuit coupling/interface arrangementsHome positionSlide window

The invention relates to a deskew device and method applied to a high-speed parallel optical interconnection system, which can be applied to a 40 Gbps very short distance optical transmission system. The frame alignment circuit of a deskew channel adopts a window comparator and a priority encoder, and determines the frame original position according to the search of frame delimiters, so as to realize the frame alignment. The data of each data channel is compared with the copy information of each data channel borne in the deskew channel after frame alignment so as to obtain the skewing amount of each data channel, and each data channel is aligned with the deskew channel, thereby achieving the alignment of 16 data channels. The fan-out of the circuit can be effectively reduced, the operating speed can be improved, and the device resource can be saved; moreover, a sliding window generator designed based on a shift register is matched with the window comparator to work, thereby being capable of adjusting the skewing amount among channels in wider range and improving the design flexibility and practicability.

Owner:SOUTHEAST UNIV

Sheet conveyance apparatus having skew conveyance mechanism with sheet deforming unit and image forming apparatus including the same

InactiveUS7900914B2Preventing a sheet from bucklingCorrect skewRegistering devicesElectrographic process apparatusMechanical engineeringReference surface

A sheet conveyance apparatus includes a reference surface extending along a sheet conveyance direction and configured to regulate the position of a side edge of a sheet to be conveyed, a skew conveyance mechanism configured to convey the sheet obliquely so that the side edge of the sheet collides against the reference surface, and a sheet deforming unit configured to deform the side edge of the sheet when the sheet is conveyed toward the reference surface by the skew conveyance mechanism.

Owner:CANON KK

Sheet processing apparatus, method of controlling the same, and image forming apparatus

ActiveUS20100072693A1Increase in sizeCorrect skewRegistering devicesElectrographic process apparatusPunchingAbutment

A sheet processing apparatus which is cable of moving a sheet without applying extra load to the movement of the sheet in the case of laterally moving the sheet for sorting after completion of punching of holes in the sheet. A sheet is conveyed toward an abutment member. The sheet comes into abutment with the abutment member, whereby skew of the sheet is corrected. A punching unit punches holes in the sheet in abutment with the abutment member. A shift unit shifts the punched sheet that has been punched by the puncher in a direction intersecting with a conveying direction of the conveying unit. A controller causes the shift unit to start shifting the sheet in response to separate between the punched sheet and the abutment member.

Owner:CANON KK

Sheet conveying apparatus and image forming apparatus

ActiveUS20120080838A1InhibitionCorrect skewRegistering devicesArticle feedersSheet materialRadius part

A sheet conveying apparatus including: a conveying roller pair conveying a sheet by a nip portion; a shutter portion which is rotatably supported on a rotary shaft of the first conveying roller; a same radius portion, provided in the shutter portion, which is formed to have substantially the same radius as a radius of the first conveying roller; an abutment portion, provided in the shutter portion, and against which the leading edge of the sheet is abutted; and a boundary portion, provided in a boundary of the abutment portion and the same radius portion, which guides the leading edge of the sheet to the nip portion when the shutter portion is rotated by abutting the leading edge of the sheet against the boundary portion.

Owner:CANON KK

Sheet conveyance device, image reading apparatus and image forming apparatus using sheet conveyance device

InactiveUS20120262765A1Correct skewEasy to set upRegistering devicesFunction indicatorsEngineeringTime difference

A sheet conveyance device that is capable of correcting skew of a sheet like an index sheet without complicating a use setting and without increasing a cost significantly. A plurality of conveyance units are arranged in a direction intersecting a sheet conveyance direction to convey a sheet. At least three detection sensors are arranged in a direction intersecting the conveyance direction at an upstream side from the conveyance units to detect the sheet. A skew amount computation unit measures a time difference between detection timings of a front end of the sheet by two of the at least three detection sensors except the detection sensor that detects first, and computes a front-end skew amount according to the time difference. A speed change unit makes the conveyance speeds of the conveyance units be different according to the front-end skew amount so as to correct the skew of the sheet.

Owner:CANON KK

Sheet processing apparatus, method of controlling the same, and image forming apparatus

ActiveUS7954811B2Correct skewIncrease in sizeRegistering devicesElectrographic process apparatusPunchingImage formation

A sheet processing apparatus which is cable of moving a sheet without applying extra load to the movement of the sheet in the case of laterally moving the sheet for sorting after completion of punching of holes in the sheet. A sheet is conveyed toward an abutment member. The sheet comes into abutment with the abutment member, whereby skew of the sheet is corrected. A punching unit punches holes in the sheet in abutment with the abutment member. A shift unit shifts the punched sheet that has been punched by the puncher in a direction intersecting with a conveying direction of the conveying unit. A controller causes the shift unit to start shifting the sheet in response to separate between the punched sheet and the abutment member.

Owner:CANON KK

Equipment for rectifying whole backbone

InactiveCN101049272ARestoration of biomechanical phenomenaGap narrowing improvementMedical scienceEngineeringElectrical and Electronics engineering

Owner:章瑛

Sheet conveying apparatus and image forming apparatus

ActiveUS8807559B2Suppressing the occurrence of local deformation of the sheetCorrect skewRegistering devicesArticle feedersLeading edgeEngineering

A sheet conveying apparatus including: a conveying roller pair conveying a sheet by a nip portion; a shutter portion which is rotatably supported on a rotary shaft of the first conveying roller; a same radius portion, provided in the shutter portion, which is formed to have substantially the same radius as a radius of the first conveying roller; an abutment portion, provided in the shutter portion, and against which the leading edge of the sheet is abutted; and a boundary portion, provided in a boundary of the abutment portion and the same radius portion, which guides the leading edge of the sheet to the nip portion when the shutter portion is rotated by abutting the leading edge of the sheet against the boundary portion.

Owner:CANON KK

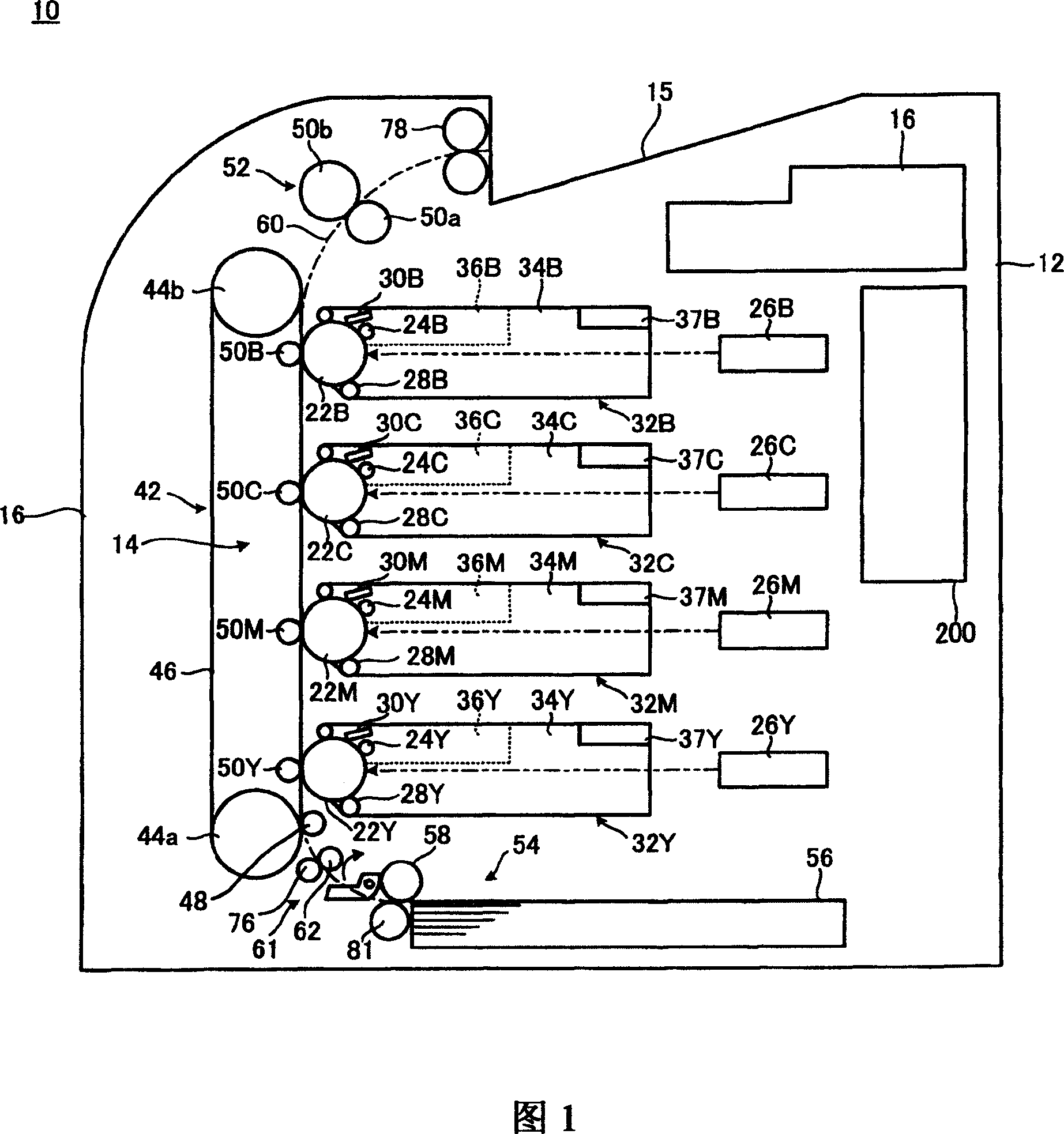

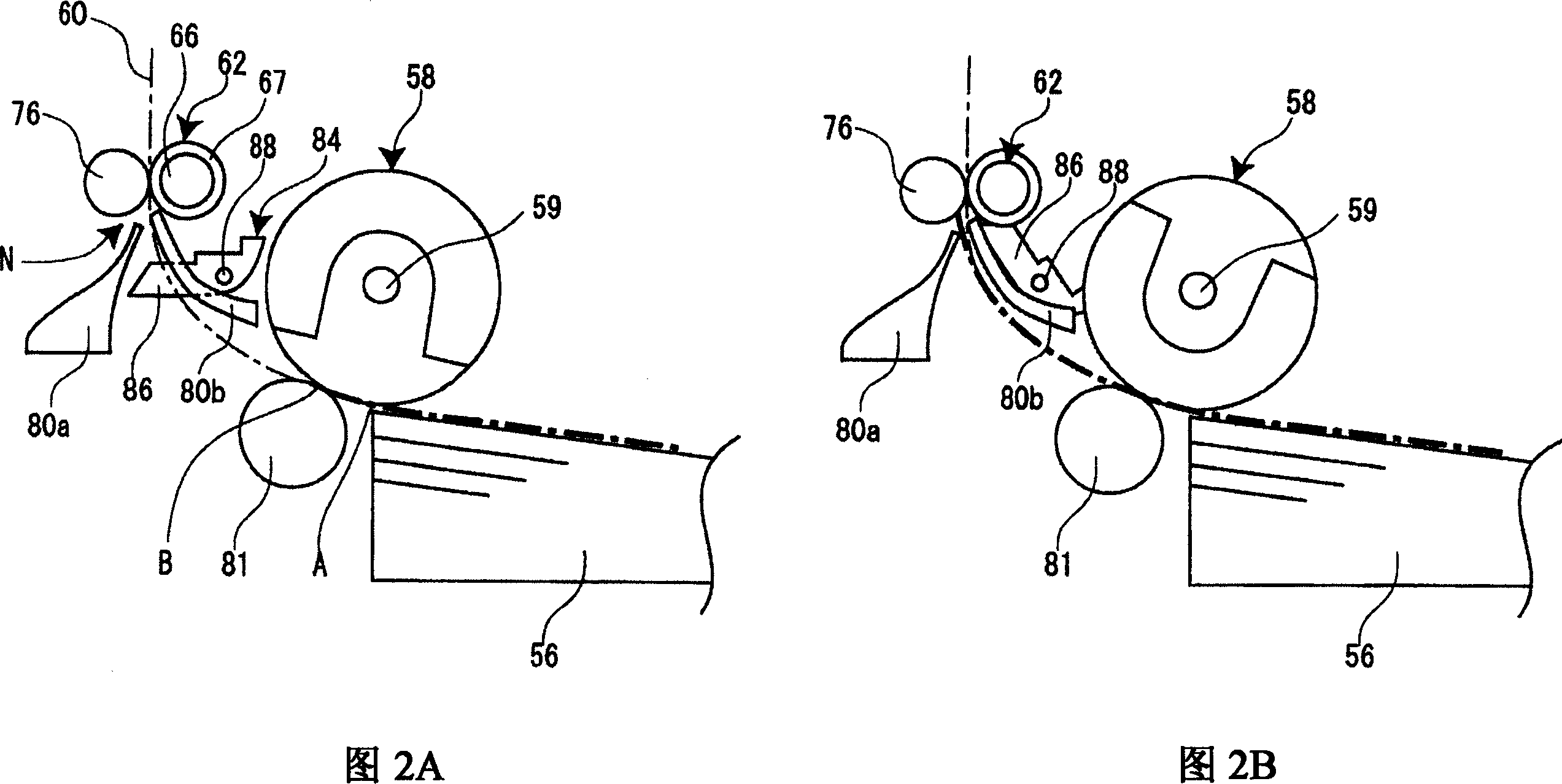

Image forming apparatus and conveyance device

InactiveCN1987671AImprove skewEffective correctionElectrographic process apparatusLeading edgeImage formation

Owner:FUJIFILM BUSINESS INNOVATION CORP

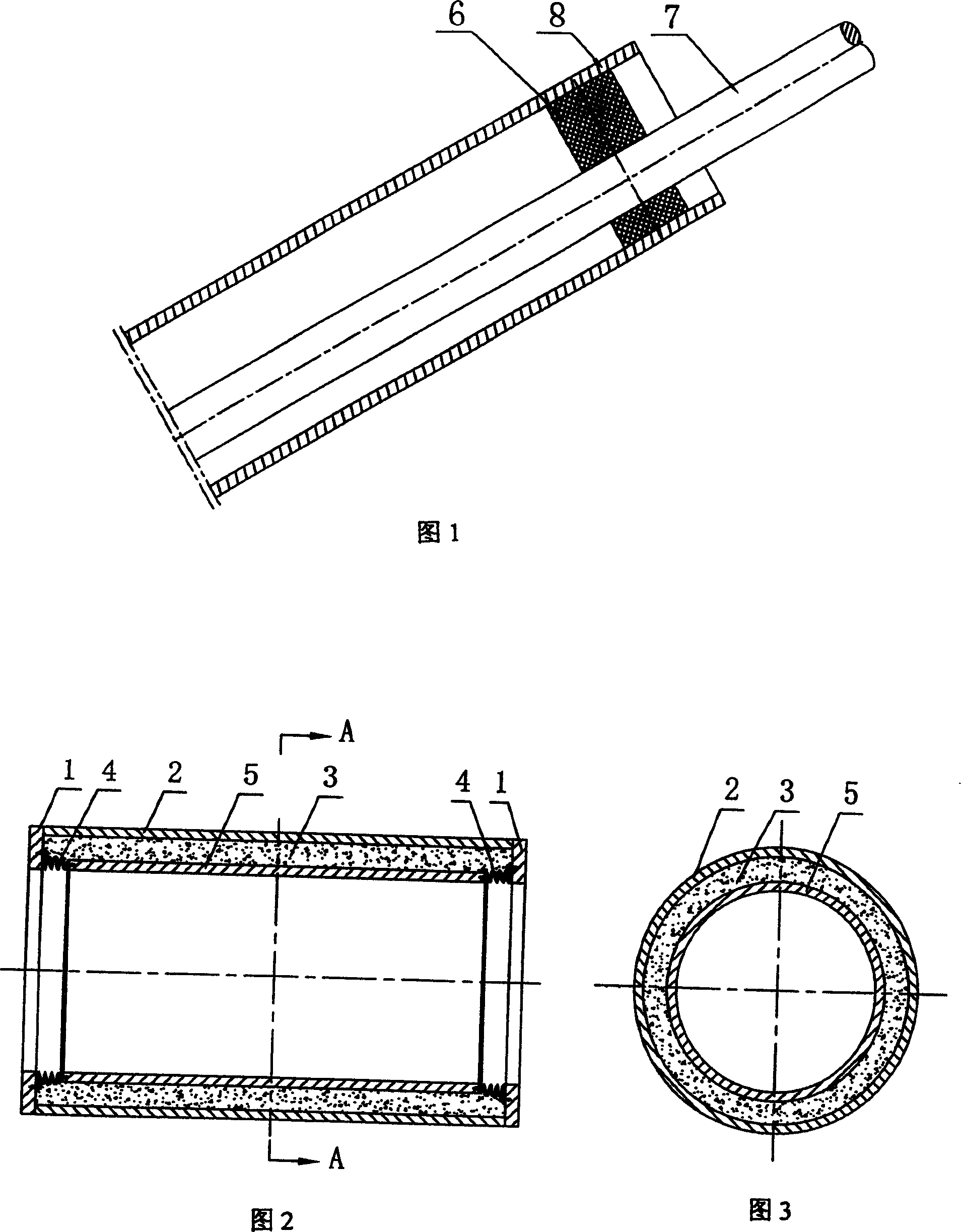

Skew-inhaul-cable deviation-rectifying device

InactiveCN1936188AAdjust axis deviationCorrect skewCable-stayed bridgeBridge structural detailsEngineeringSteel tube

The invention relates to a canting-pull dragline error correcting device that includes external steel pipe, inner steel pipe, end seal board, sealing component, and filling material. The external steel pipe is outside the inner steel pipe, two ends of external steel pipe extending out of inner steel pipe a certain distance. The end seal board has two components, as well as the sealing component. The end seal board seals inner and external steel pipe with sealing component to form sealing cavity, the filling material is filled in it. The filling material could flow between the external steel pipe and the inner steel pipe. Adjusting the location of inner steel pipe, the axis of canting-pull dragline could be superposition with that of pre-buried pipe. It could be widely used in canting-pull bridge structure and arch bridge structure.

Owner:FAERSHENG ZHUDIAN NEW MATERIAL

Sheet carrying device with tilted skew correction and force releasing carriers

ActiveUS7540496B2Correct skewReduce the amount requiredRegistering devicesFunction indicatorsEngineeringControl unit

Owner:FUJIFILM CORP

Sheet conveyance apparatus and image forming apparatus

ActiveUS20130285316A1Improve correction performanceIncrease productivityRegistering devicesFunction indicatorsSeparated stateControl unit

A sheet conveyance apparatus includes a conveyance roller pair, a conveyance roller driving unit, a registration roller pair, a registration driving unit, a separation and press-contact unit configured to set the registration roller pair to a separated state and to a press-contact state, and a control unit. After a sheet has stopped at a stop position immediately before the registration roller pair, the registration roller pair having been set to the separated state is set to the press-contact state. The registration roller pair is rotated backward during formation of a loop in the sheet.

Owner:CANON KK

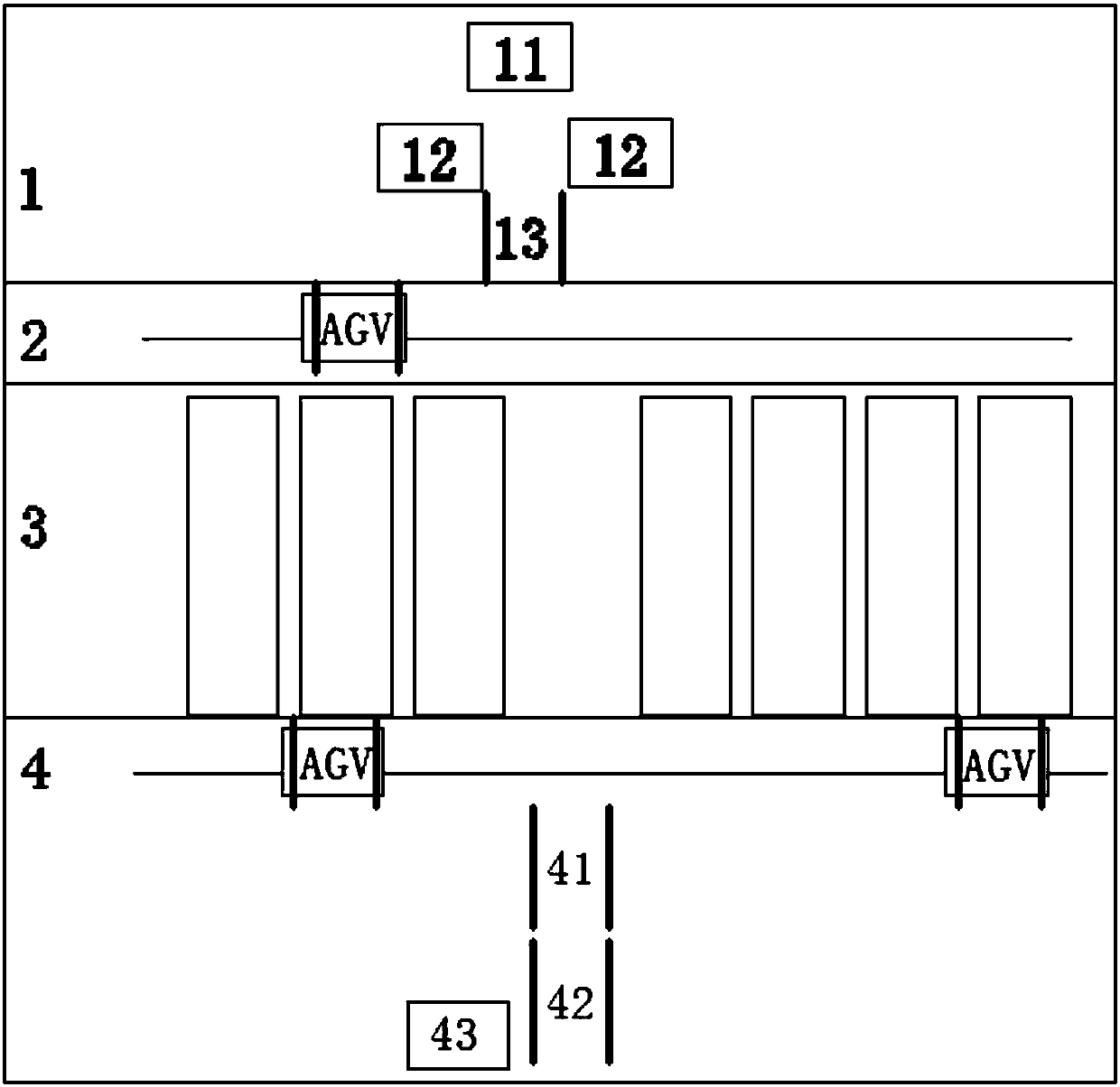

Vehicle bumper repairing, maintaining, carrying and storing system

ActiveCN107685792AIncrease the switching frequencyReduce labor intensityVehiclesProduction lineControl system

The invention discloses a vehicle bumper repairing, maintaining, carrying and storing system which is characterized by comprising a repairing and maintaining region, a conveying region, a storage location region, a guiding and fetching region and a control system. An inlet side of the repairing and maintaining region is connected with an injection molding machine at a previous station, and an outlet side of the repairing and maintaining region is connected with an inlet side of the conveying region; an inlet side of the storage location region is connected with an outlet side of the conveyingregion, and an outlet side of the storage location region is connected with an inlet side of the guiding and fetching region; an outlet side of the guiding and fetching region is connected with an inlet side of a coating production line at a next station. Each of the conveying region and the guiding and fetching region comprises at least one lift type AGV (automatic guide vehicle). The storage location region comprises a plurality of storage locations, and the storage locations are parallelly arrayed. The vehicle bumper repairing, maintaining, carrying and storing system has the advantages that flexible manufacturing production takt and requirements can be met by the multiple lift type AGV and the storage locations, the bumper type switching frequencies can be increased, labor environmentscan be improved, the labor intensity of workers can be relieved, the error rates of the workers can be lowered, labor loss in carrying procedures can be prevented, and bumpers can be efficiently intelligently managed.

Owner:HEBEI UNIV OF TECH

Recording paper conveying device, document feeding device and image forming apparatus including these devices

ActiveUS20130099441A1Preventing unnecessary deflectionReduce spacingRegistering devicesFunction indicatorsLeading edgeEngineering

A recording paper conveying device includes a registration roller pair and a conveyor roller pair adjacent to the registration roller pair. By rotating the conveyor roller pair, a sheet of recording paper is fed until leading edge of the sheet abuts the registration roller pair in stationary state so that the sheet is deflected by a prescribed amount. Then, conveyor roller pair is rotated at the constant velocity, and while the sheet is kept deflected, rotation of the registration roller pair is started, to start feeding of the sheet by the registration roller pair. While the registration roller pair is kept rotating, rotation of the conveyor roller pair is suspended, and then, the conveyor roller pair is returned to the state of rotation before suspension. Thus, unnecessary deflection of the sheet just in front of the registration roller pair can be prevented.

Owner:SHARP KK

Adjustment of skew registration of media to a developed image in a printing machine

ActiveUS20050019076A1Adjustable positionCorrect skewElectrographic process apparatusArticle feedersControl signalWorkstation

A printing machine (10) including a registration station (45) for applying a skew adjustment received from a human operator is disclosed. The registration station (45) includes independently controllable motors (52a, 52b) that drive corresponding urging rollers (56a, 56b) as controlled by control circuitry (24), for example in response to the position of a media sheet as sensed by sensors (58a, 58b; 60a, 60b) at the registration station (45). The machine operator can enter a skew adjustment value at a user interface (25a), or at a networked computer workstation with which the printing machine (10) communicates via a network interface (25b). The control circuitry (24) calculates differential control signals for controlling the motors (52a, 52b) to effect the skew correction. The differential control signals may be differential timing delays, such as prior to deactivation of the motors (52a, 52b), or may be a differential velocity signal for driving the motors (52a, 52b).

Owner:COMML COPY INNOVATIONS INC

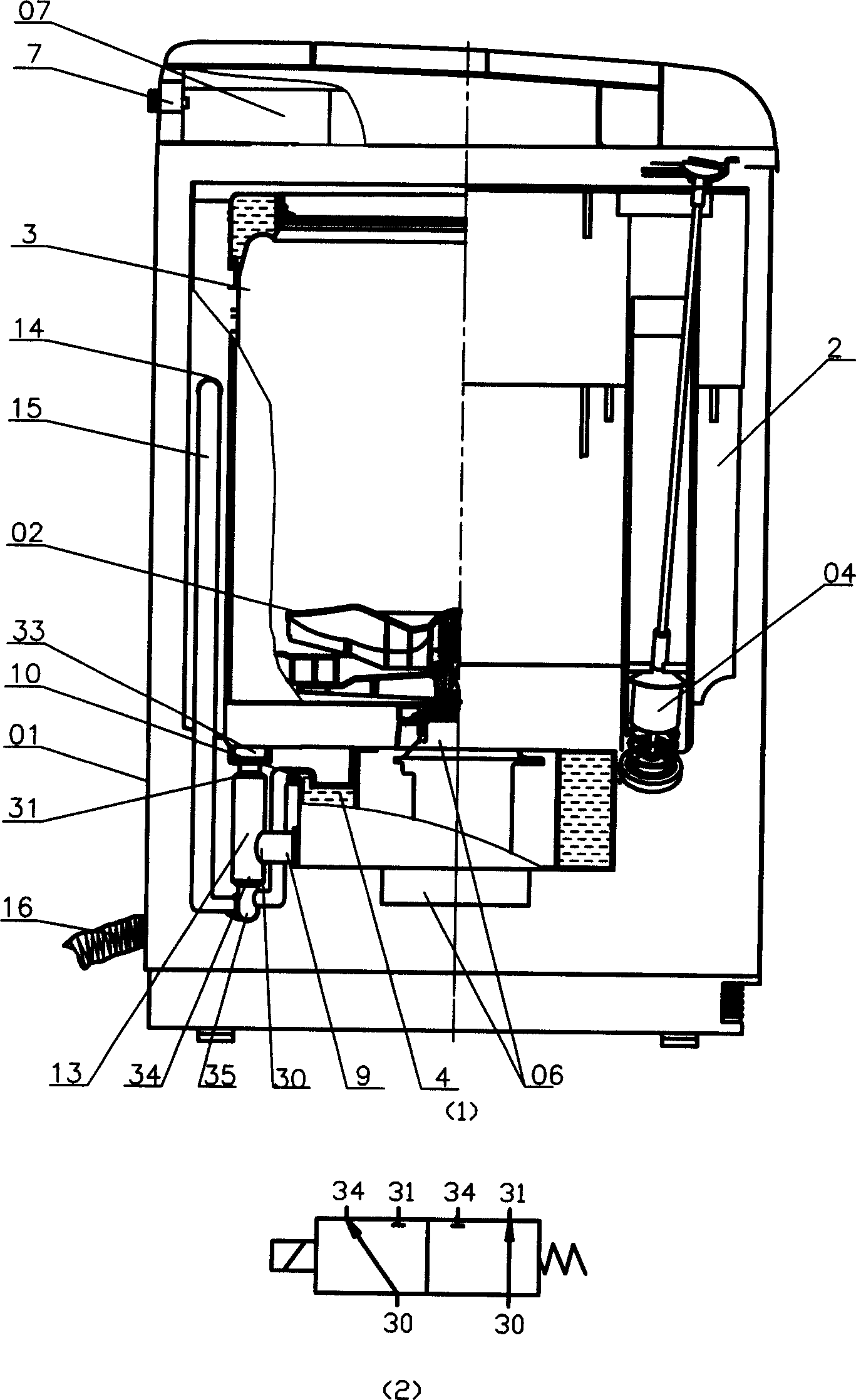

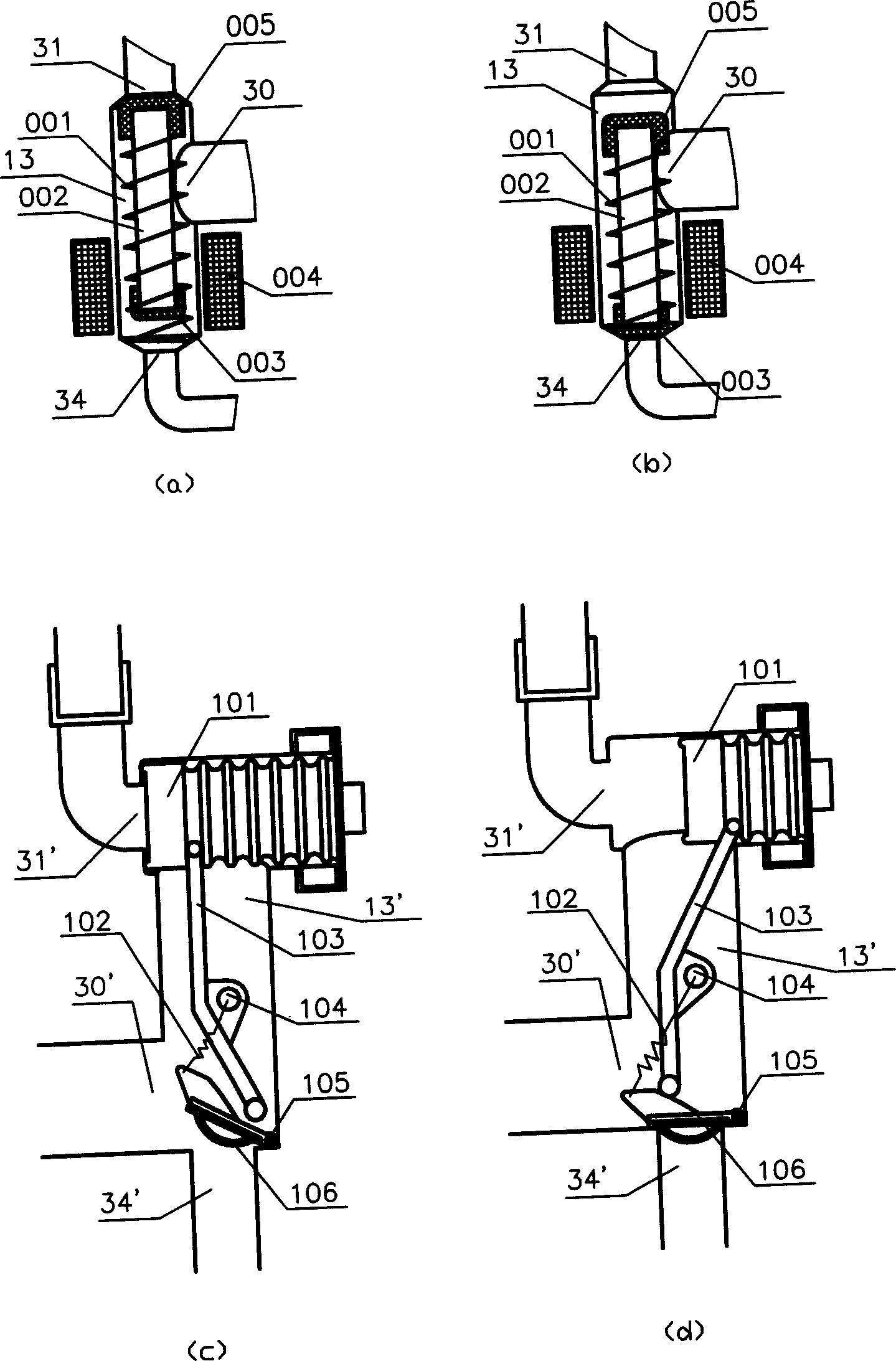

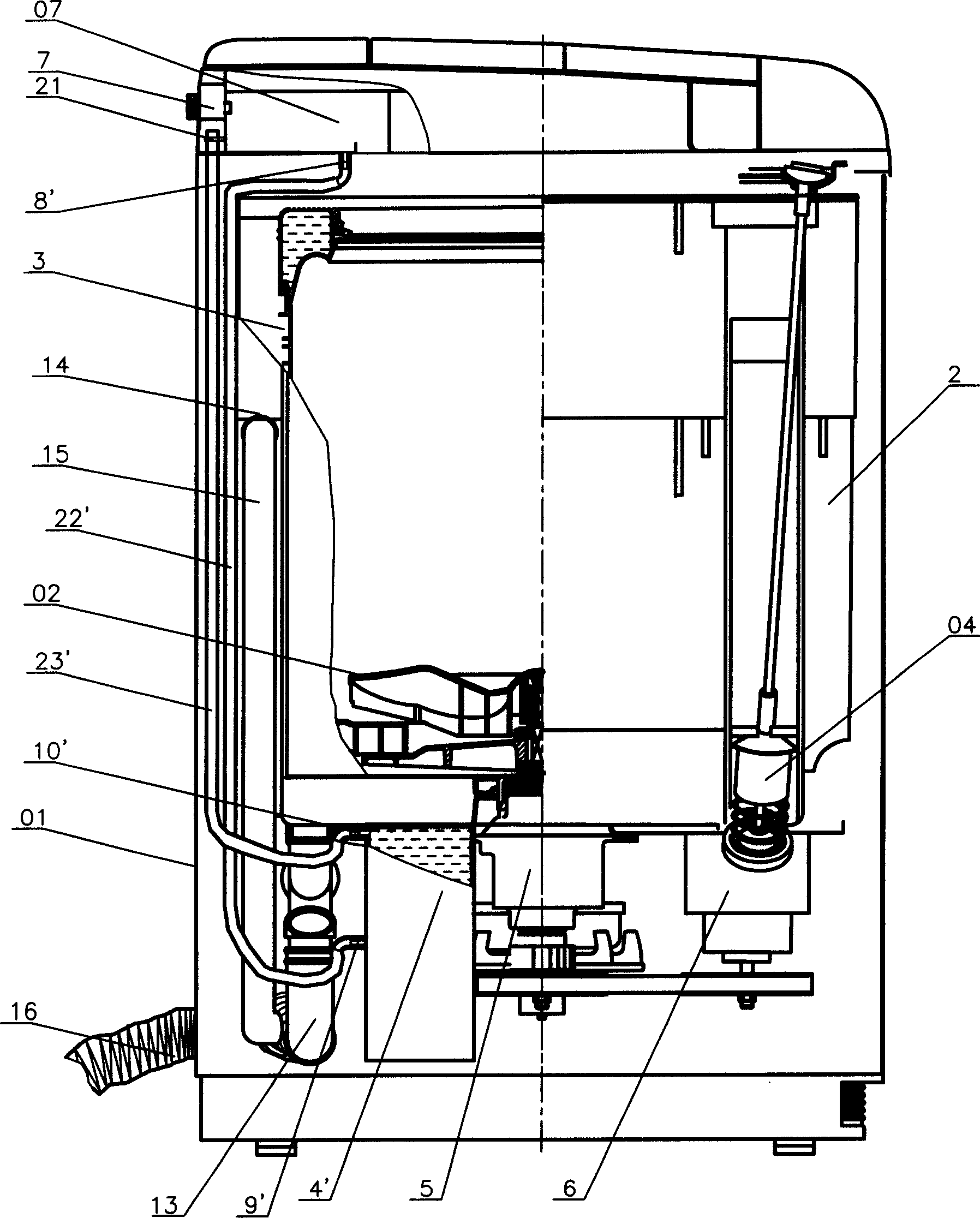

Impeller or agitator type full-automatic washing machine

ActiveCN1635210AReduce shipping weightQuality assuranceOther washing machinesWashing machine with receptaclesImpellerElectric motor

The invention relates to a wave wheel type or stirring type full-automatic washing machine. The system suspended in the outer casing comprises: a water bucket, a dewatering bucket arranged in the water bucket, and a driving mechanism arranged on the bottom of the water bucket for transmitting the rotary of the bucket; wherein, The system comprises a chamber with an and inlet for filling liquid. The chamber can be designed to a mode of automatic filling water as the machine starting. The chamber is used for filling cheap liquid to an enough mass after the machine is transported to the mounting position, reducing the weight of the machine during transport, correcting the water bucket deflection, and reducing vibration noise and cost.

Owner:JINLING ELECTRICAL CO LTD

Printing apparatus and control method of the same

InactiveUS20100033529A1Improve accuracyReduced wear and tear on partsTypewritersOther printing apparatusMechanical engineeringEngineering

Owner:SEIKO EPSON CORP

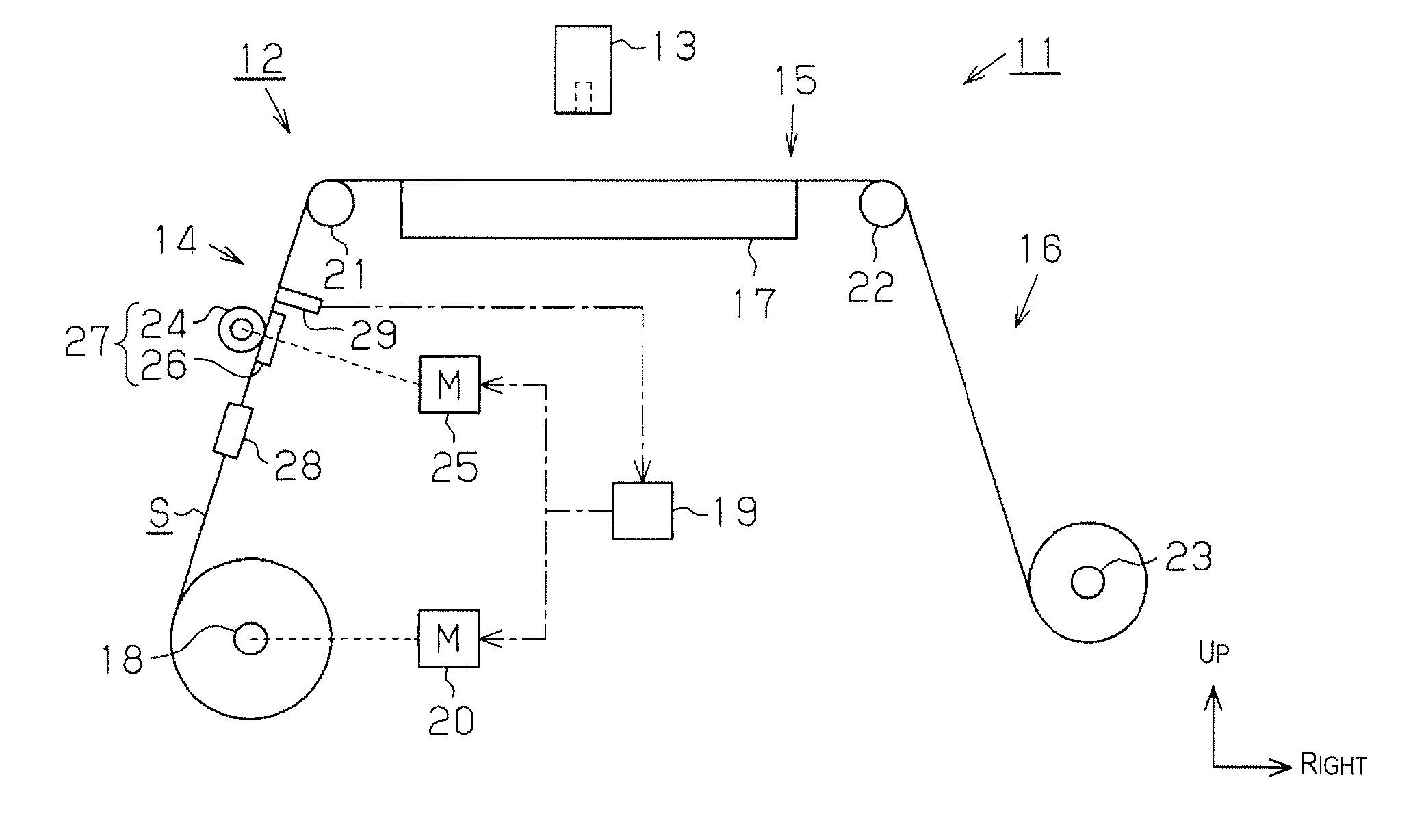

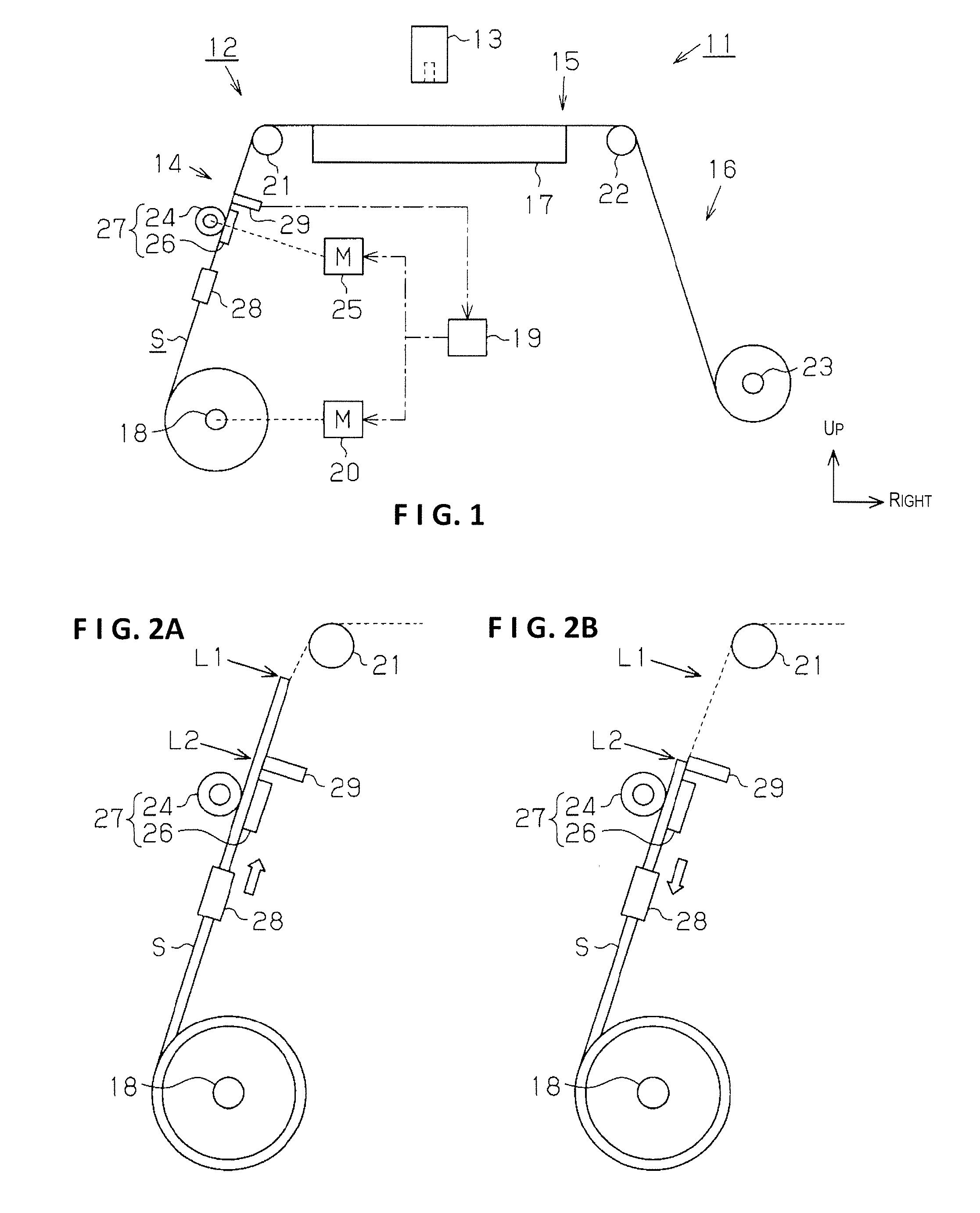

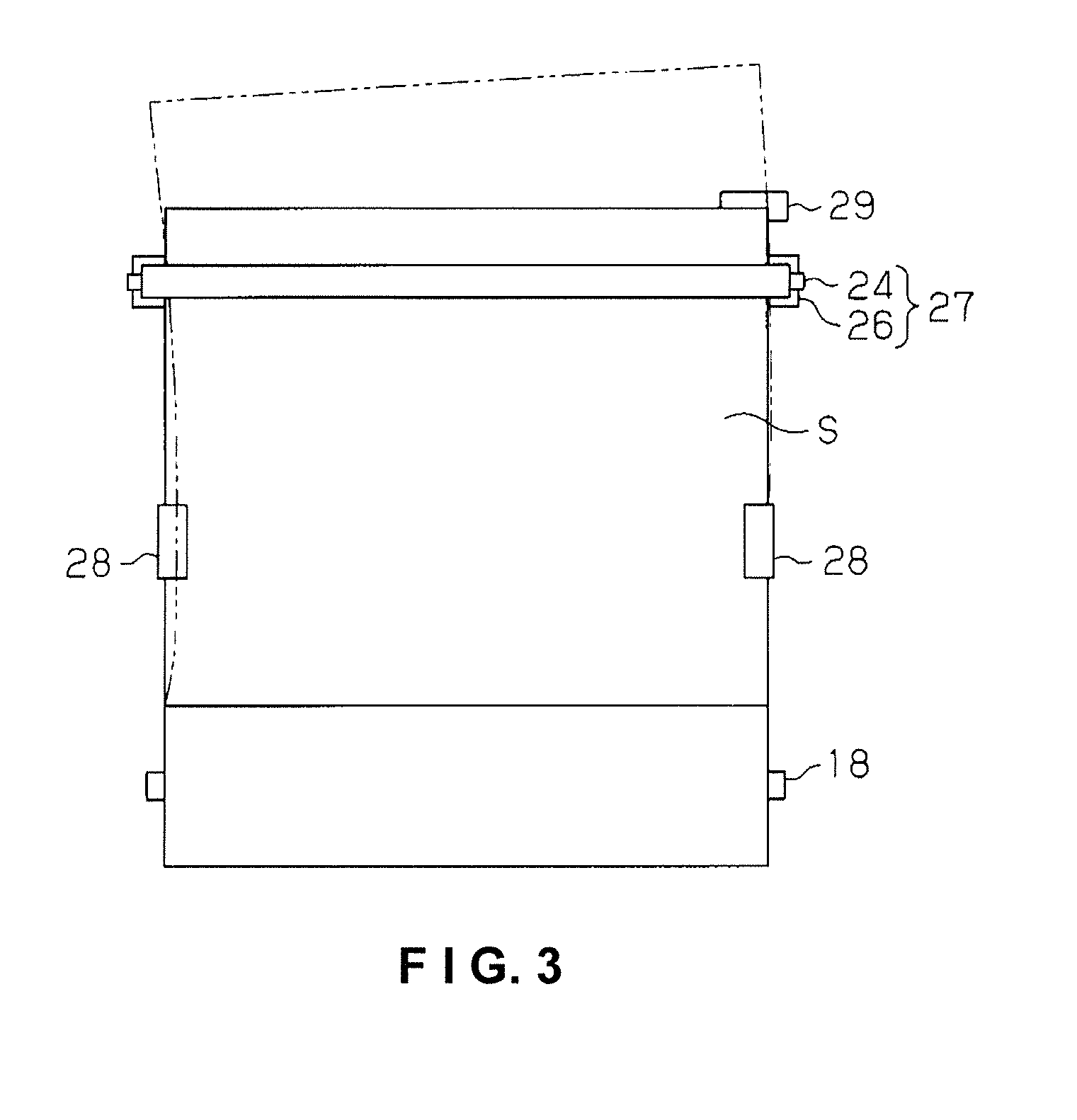

Conveying apparatus, recording apparatus, and conveying method

ActiveUS20110205278A1Skewing of the recording medium can be correctedCorrect skewFilament handlingFunction indicatorsMechanical engineeringRecording media

A conveying apparatus includes a holding part that holds a recording medium in the form of a roll and rotates, a clamping unit that clamps the recording medium downstream from the holding part along a conveying route, a regulating member that regulates a position of a side end of the recording medium in a width direction intersecting the conveying direction between the holding part and the clamping unit in the conveying route, a drive unit that rotatably drives the holding part in a forward direction to unwind the recording medium and a reverse direction to rewind the recording medium, and a controller that controls a drive state of the drive unit. The controller controls the drive unit so that, after the holding part is driven forward, the holding part is driven in reverse.

Owner:SEIKO EPSON CORP

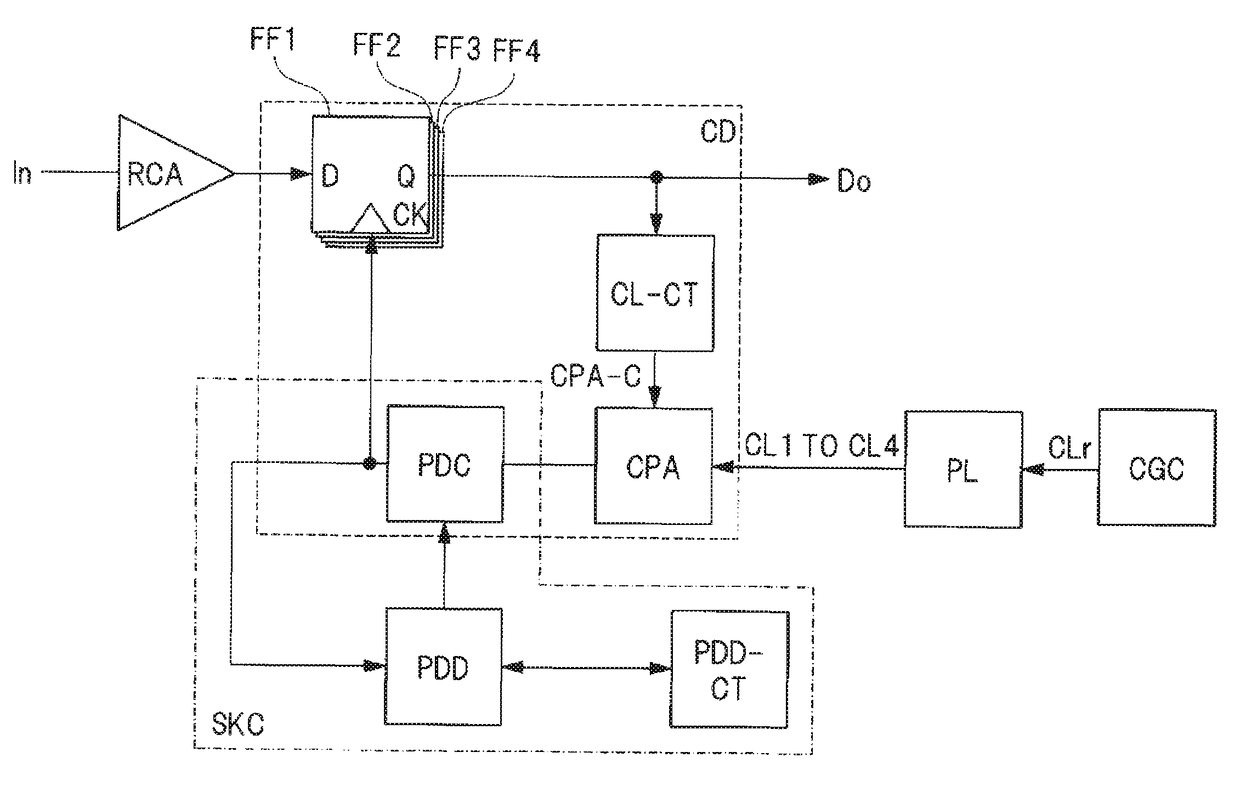

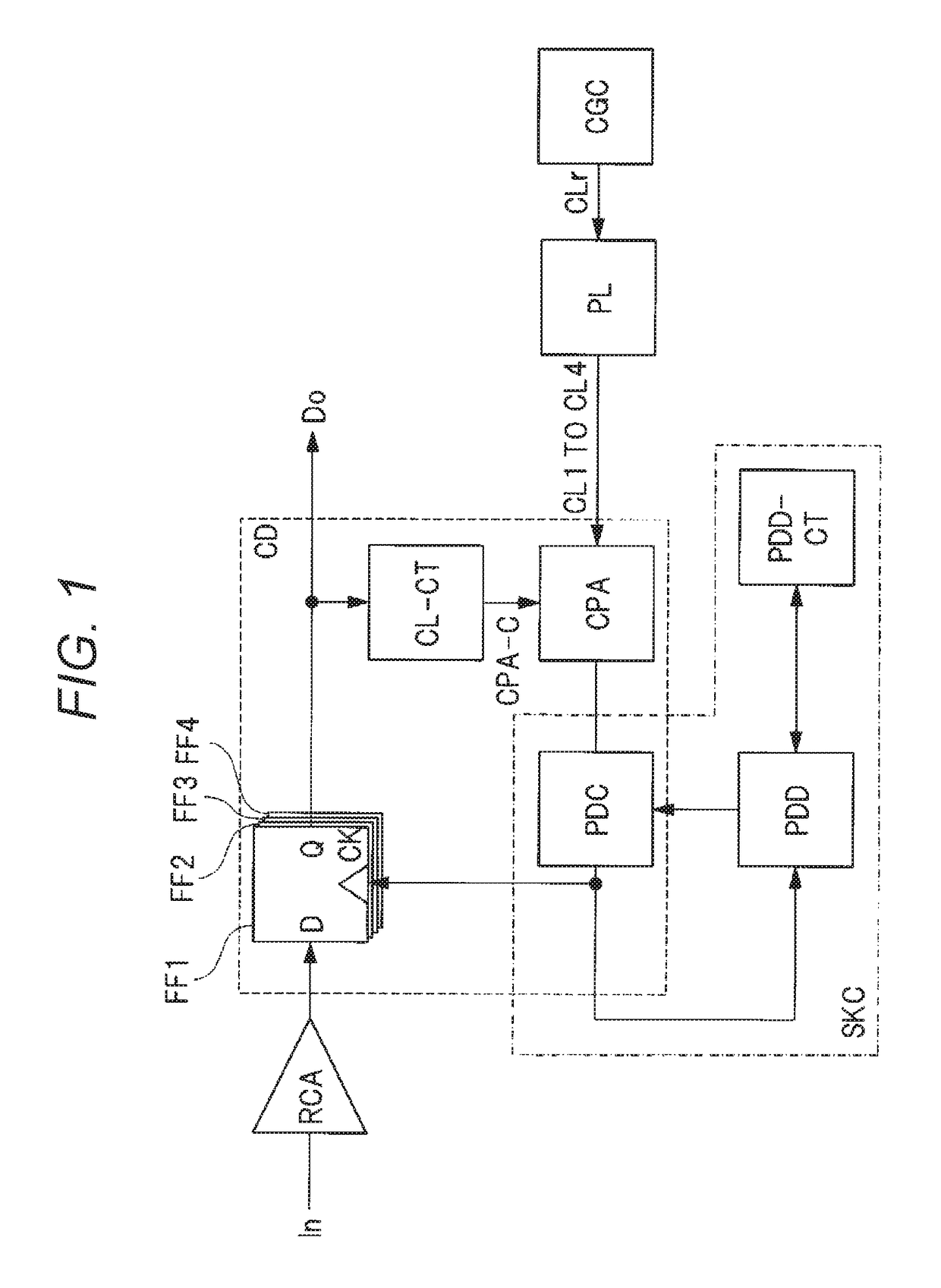

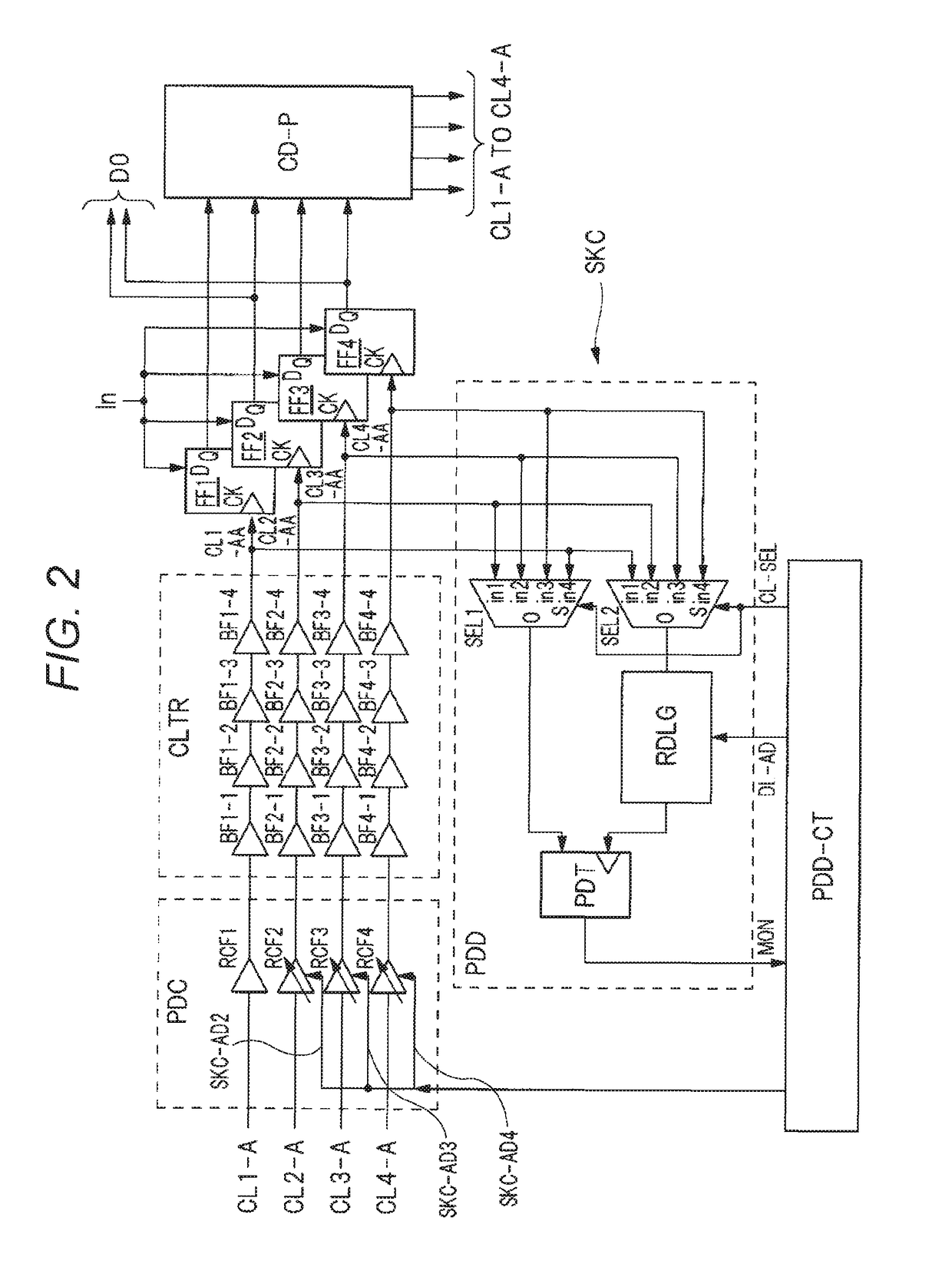

Skew adjustment circuit, semiconductor device, and skew calibration method

InactiveUS9722590B1Shorten the overall cycleErroneous operationChannel dividing arrangementsPulse automatic controlEngineeringClock phase

A skew adjustment circuit includes: flip flop circuits for taking in an input signal in response to first clock signals; a clock phase adjustment circuit for adjusting phases of second clock signals, based on the second clock signals generated based on a reference clock signal and an output signal from the flip flop circuits; a phase interval detection circuit for detecting a phase interval between the first clock signals, based on a reference value; and a phase interval adjustment circuit for performing adjustment such that phase intervals become equal to each other between the second clock signals adjusted by the clock phase adjustment circuit, based on a skew adjustment signal from the phase interval detection circuit. The reference value is obtained by calibration, and the second clock signals adjusted by the phase interval adjustment circuit are provided as the first clock signals to the flip flop circuits.

Owner:HITACHI LTD

Adhesive dispensing apparatus and image forming apparatus

ActiveUS20070023148A1Increasing size of apparatusIncreasing size of costMechanical working/deformationLamination ancillary operationsLeading edgeAdhesive

An adhesive dispensing apparatus for dispensing an adhesive on a sheet bundle includes a support device for supporting the sheet bundle, a dispensing device disposed adjacent to the support device for dispensing the adhesive on an edge of the sheet bundle supported by the support device, and a transport device disposed adjacent to the support device for transporting the sheet bundle from the edge, to which the adhesive is applied, as a leading edge in a transport direction. A refilling device is provided for refilling the adhesive to the dispensing device, and a moving device moves the dispensing device between a dispending position where the adhesive is dispensed to the edge of the sheet bundle and a refilling position where the adhesive is supplied to the dispensing device from the refilling device.

Owner:NISCA KK

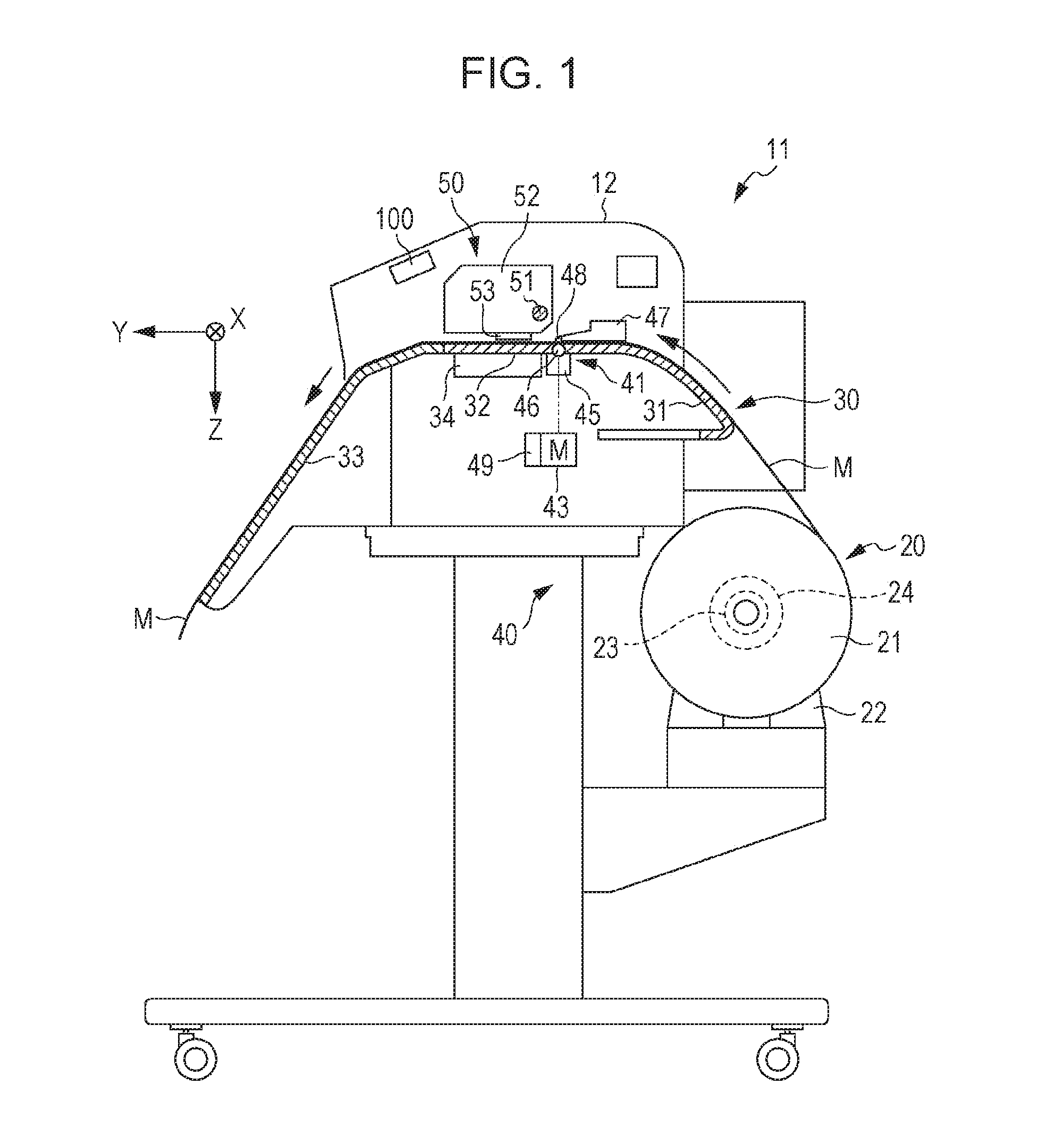

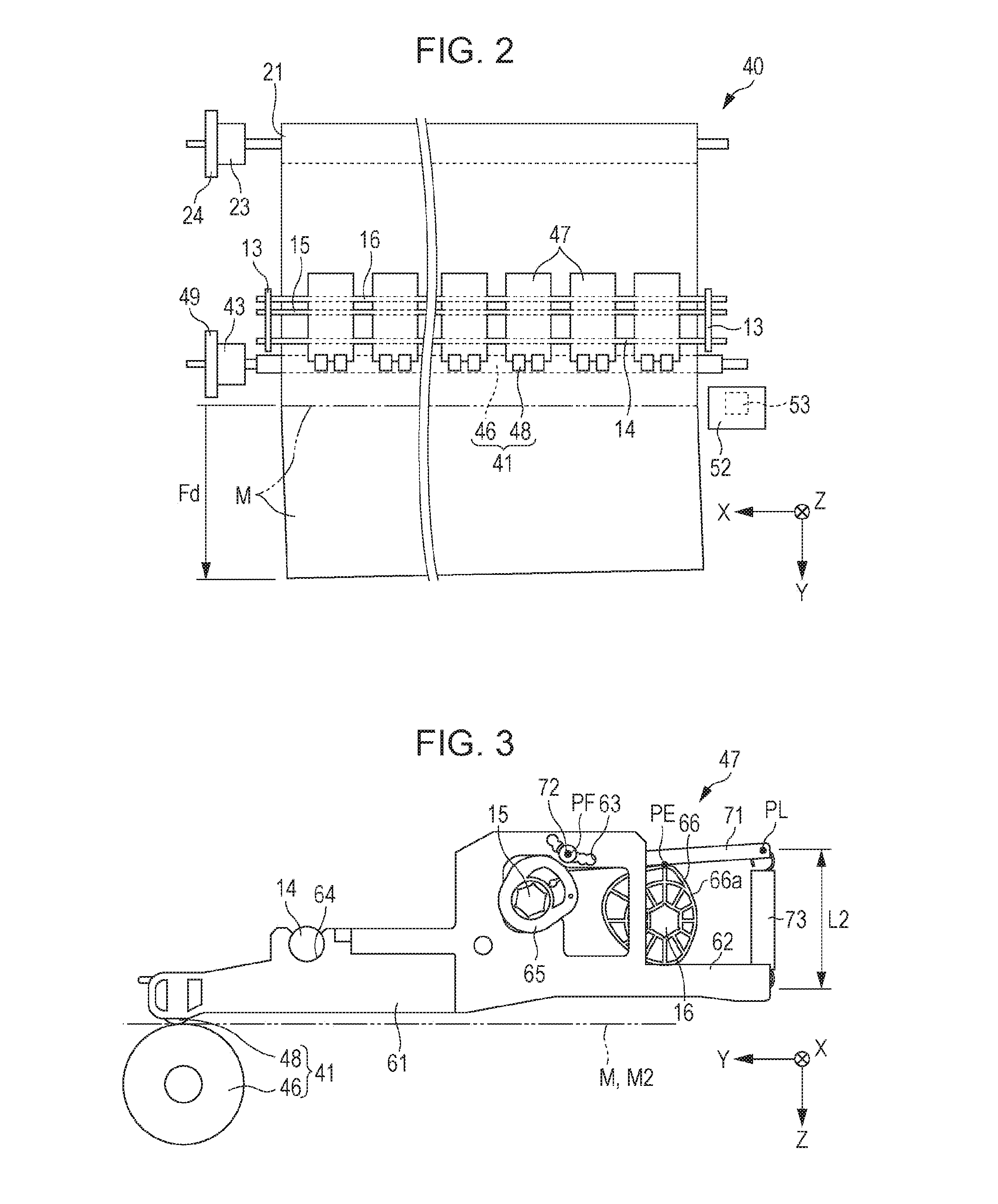

Transport Apparatus and Printer Apparatus

ActiveUS20160272452A1Skew of the medium can be correctedCorrect skewOther printing apparatusWebs handlingEngineeringMechanical engineering

Owner:SEIKO EPSON CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com