Feeding device for sheet material and image recording apparatus for recording an image thereon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

)

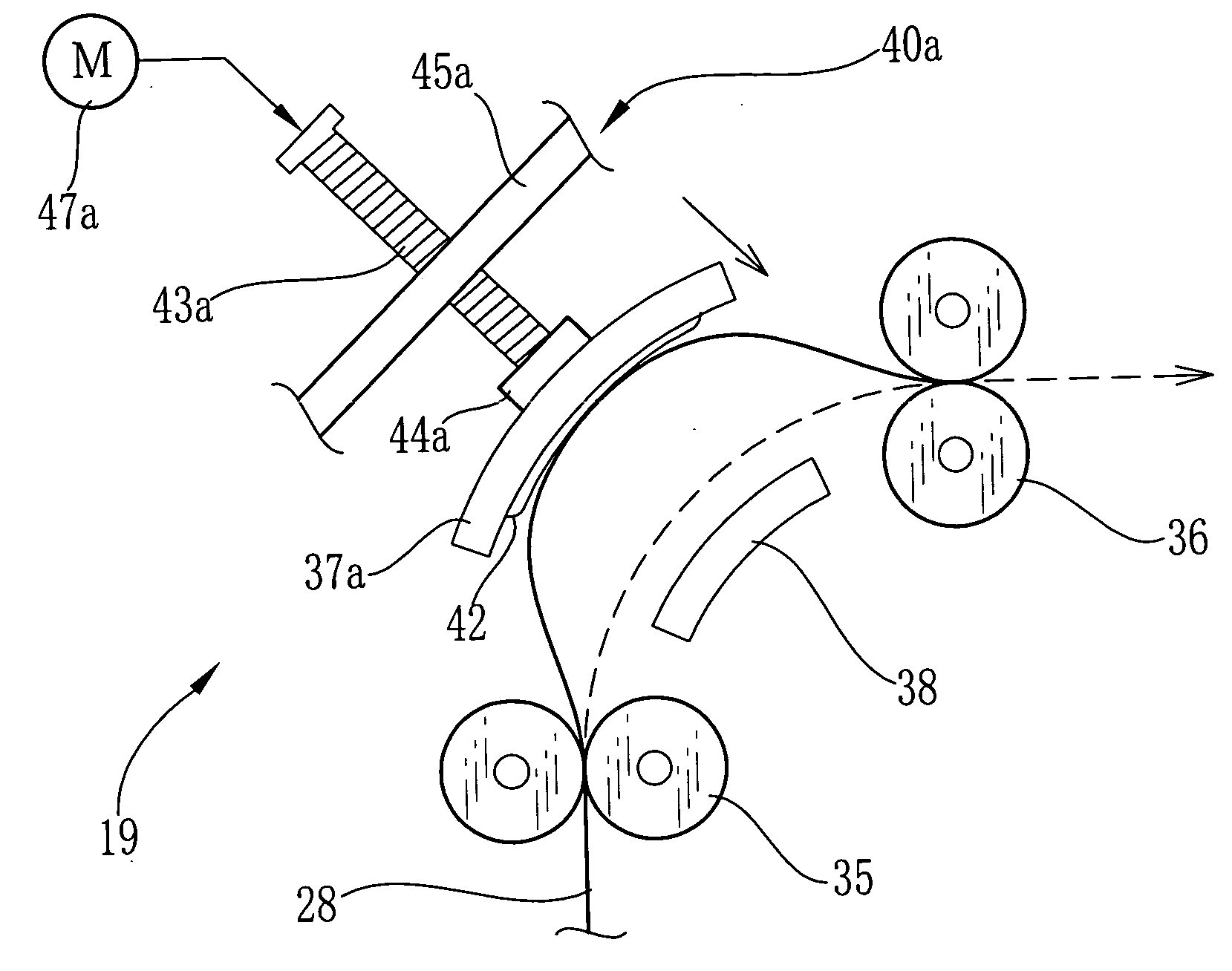

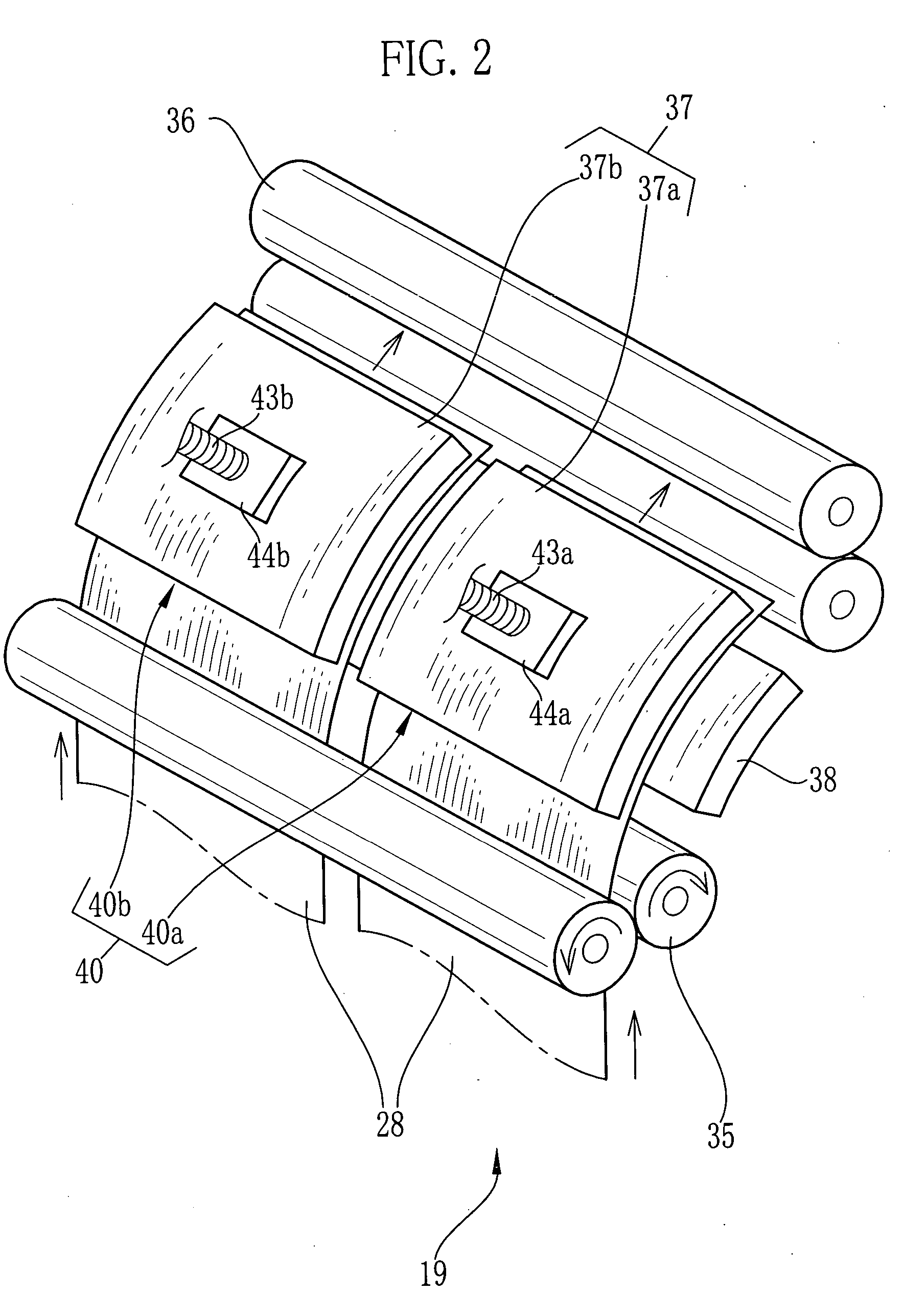

[0024]FIG. 1 is a schematic illustration showing a photographic printer 10 using a feeding device according to the present invention. The photographic printer 10 carries photosensitive materials of a cut-sheet shape in two rows. The photosensitive materials of two rows are simultaneously exposed and are outputted as photo prints. Such as shown in FIG. 1, the photographic printer 10 is constituted of magazines 12 and 13, cutters 15 and 16, a back-printing unit 18, a skew correcting unit 19, an exposing unit 21, a processing unit 22, and so forth.

[0025] The magazines 12 and 13 are disposed at predetermined positions in the photographic printer 10 to respectively contain a recording-paper roll 25 formed by winding a strip-shaped photosensitive recording paper 24 in a roll form. The photosensitive recording paper 24 is regarded as a photosensitive material. A roller pair 27 is disposed near a paper mouth of the respective magazines 12 and 13. Upon rotating the roller pair 27 by a moto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com