Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Controlled downtime" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

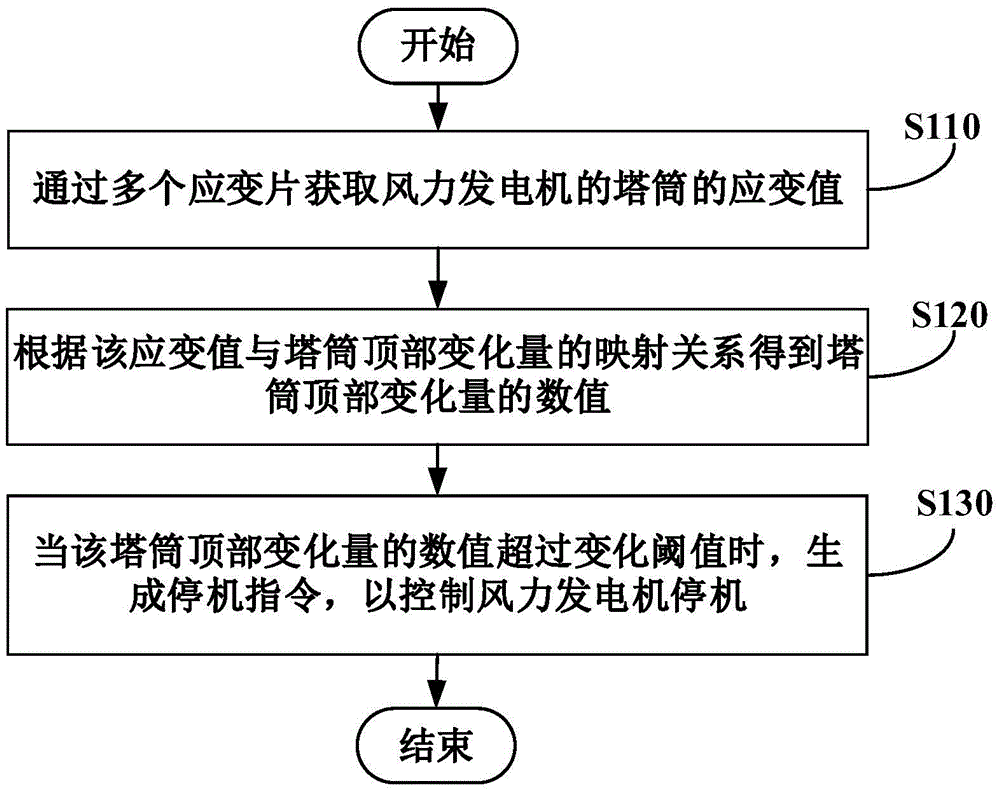

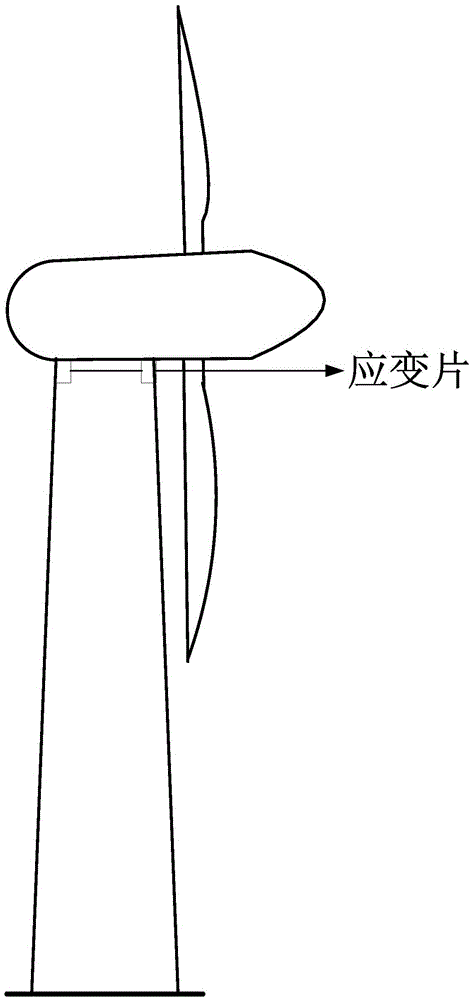

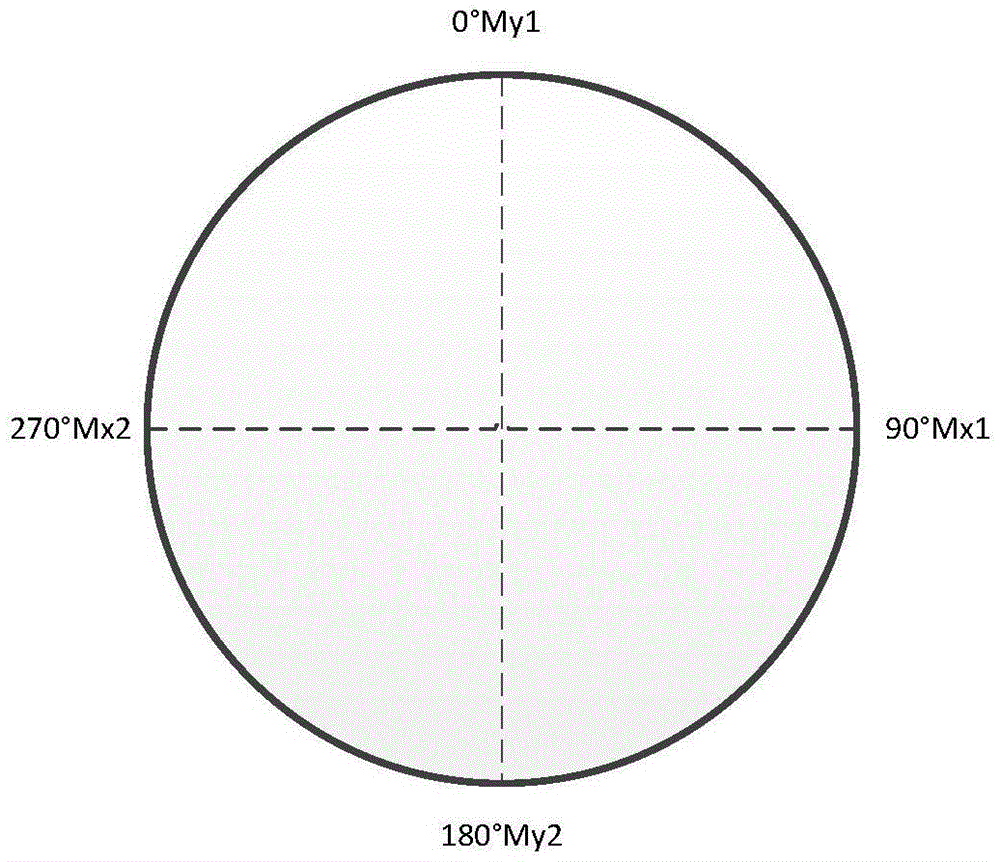

Tower state monitoring method and system for wind turbine generator

ActiveCN105604806AControlled downtimeImprove monitoring accuracyWind motor controlWind motor supports/mountsTowerTurbine

The embodiment of the invention provides a tower state monitoring method and system for a wind turbine generator. A plurality of strain discs are stuck on a flange at the top of a tower of the wind turbine generator. The method comprises the following steps: acquiring the strain value of the tower of the wind turbine generator via the strain discs; acquiring the top variation value of the tower according to a mapping relation between the strain value and the top variation value; generating a halt instruction when the top variation value exceeds a variation threshold value, so as to control the wind turbine generator to stop. According to the embodiment of the invention, the monitoring precision of the tower state of the wind turbine generator can be improved.

Owner:BEIJING GOLDWIND SCI & CREATION WINDPOWER EQUIP CO LTD

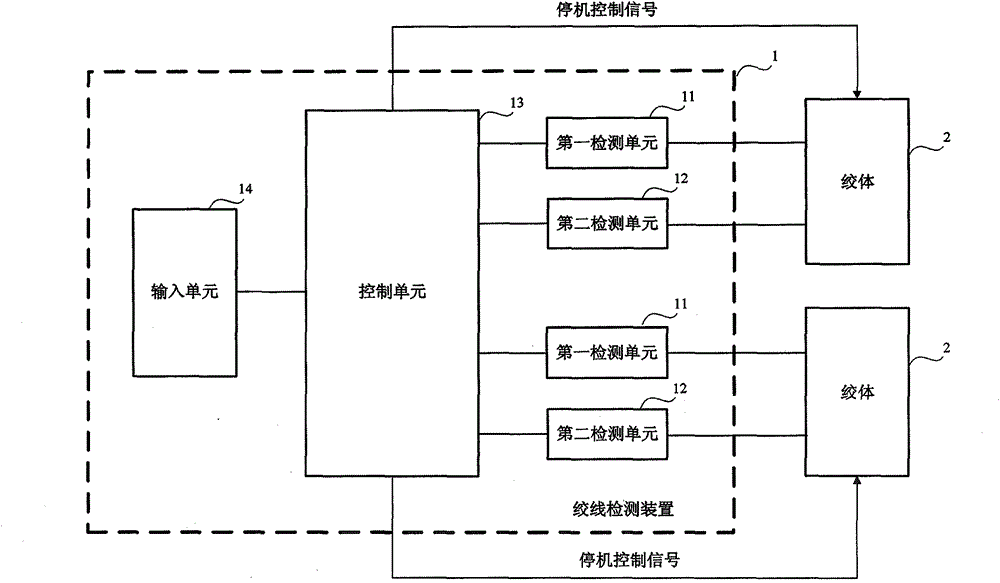

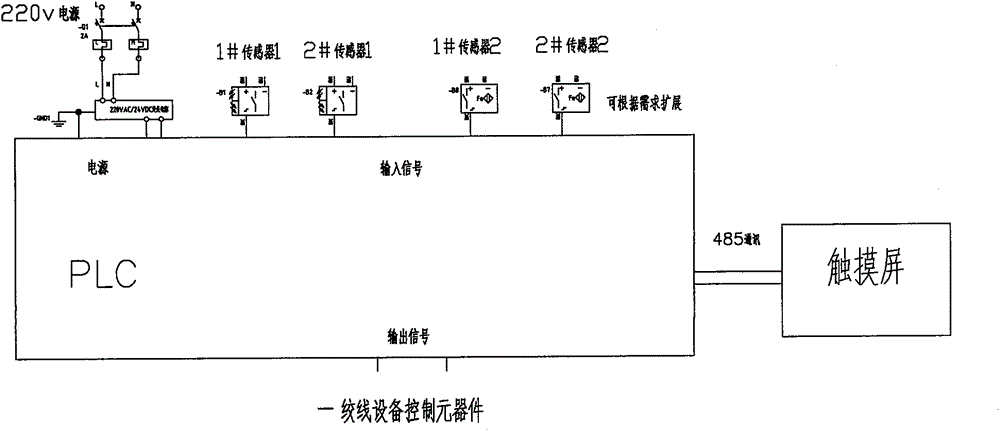

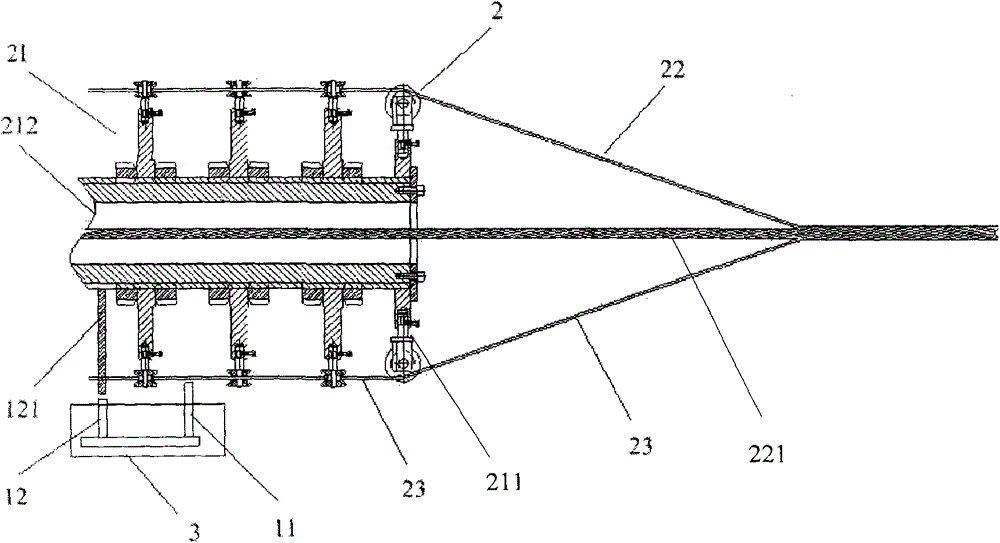

Wire stranding detection device and wire stranding equipment

InactiveCN104795183AReduce in quantityReduce the chance of failureCable/conductor manufactureMechanical pressure/force controlVIT signalsControl unit

The invention provides a wire stranding detection device and a piece of wire stranding equipment. The wire stranding detection device comprises a first detection unit, a second detection unit, and a control unit. The first detection unit and the second detection unit are arranged on a side of a single stranding body. The first detection unit is used for detecting monofilaments on the stranding body according to a detection starting control command sent by the control unit and sending a monofilament detection signal to the control unit when a monofilament is detected. The second detection unit is used for sending a detection signal indicating that the stranding body rotates a circle to the control unit each time the stranding body rotates a circle. The control unit is connected with the first detection unit and the second detection unit, and is used for sending a detection starting control command to the first detection unit, and judging whether a monofilament on the stranding body is broken or not according to the detection signal indicating that the stranding body rotates a circle, the monofilament detection signal and a preset threshold. The number of the detection units is reduced, the production cost is lowered, and the stability and reliability of detection are ensured to a certain extent.

Owner:TEBIAN ELECTRIC APP CO LTD

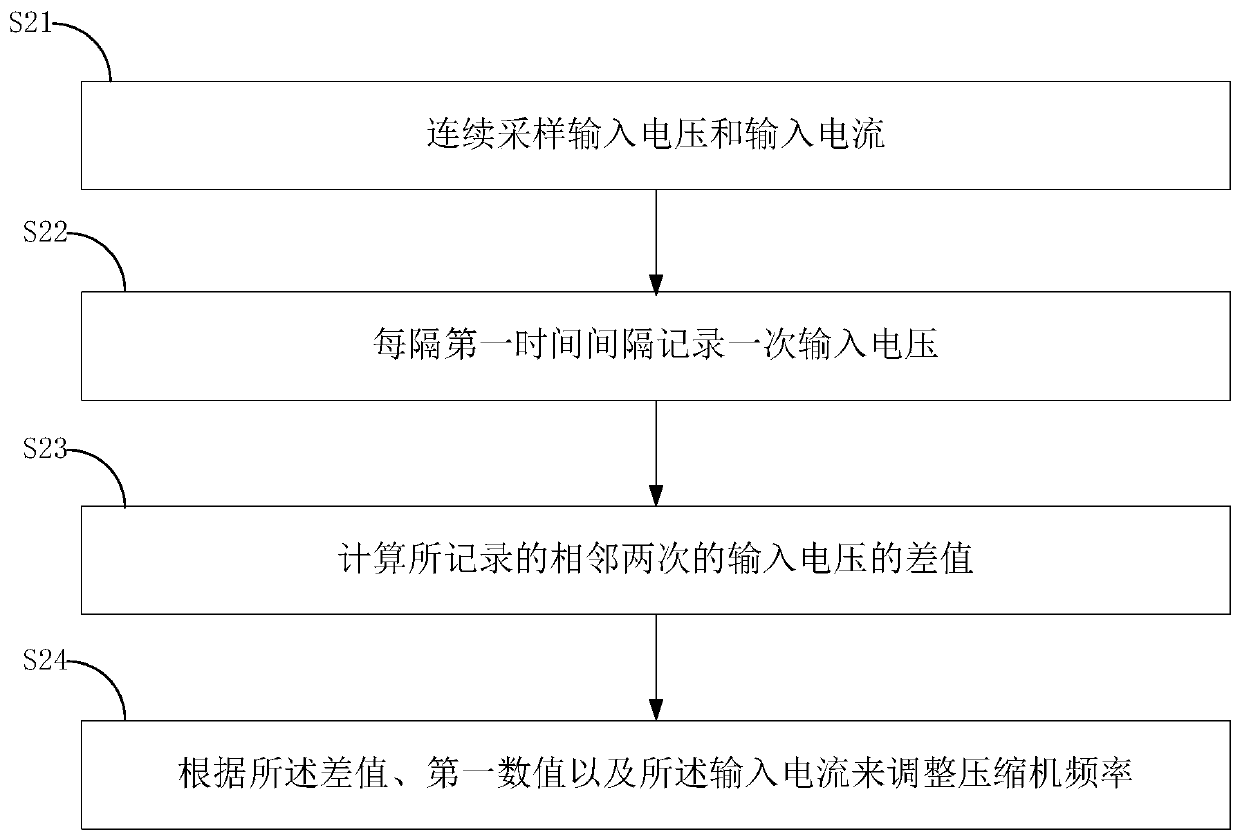

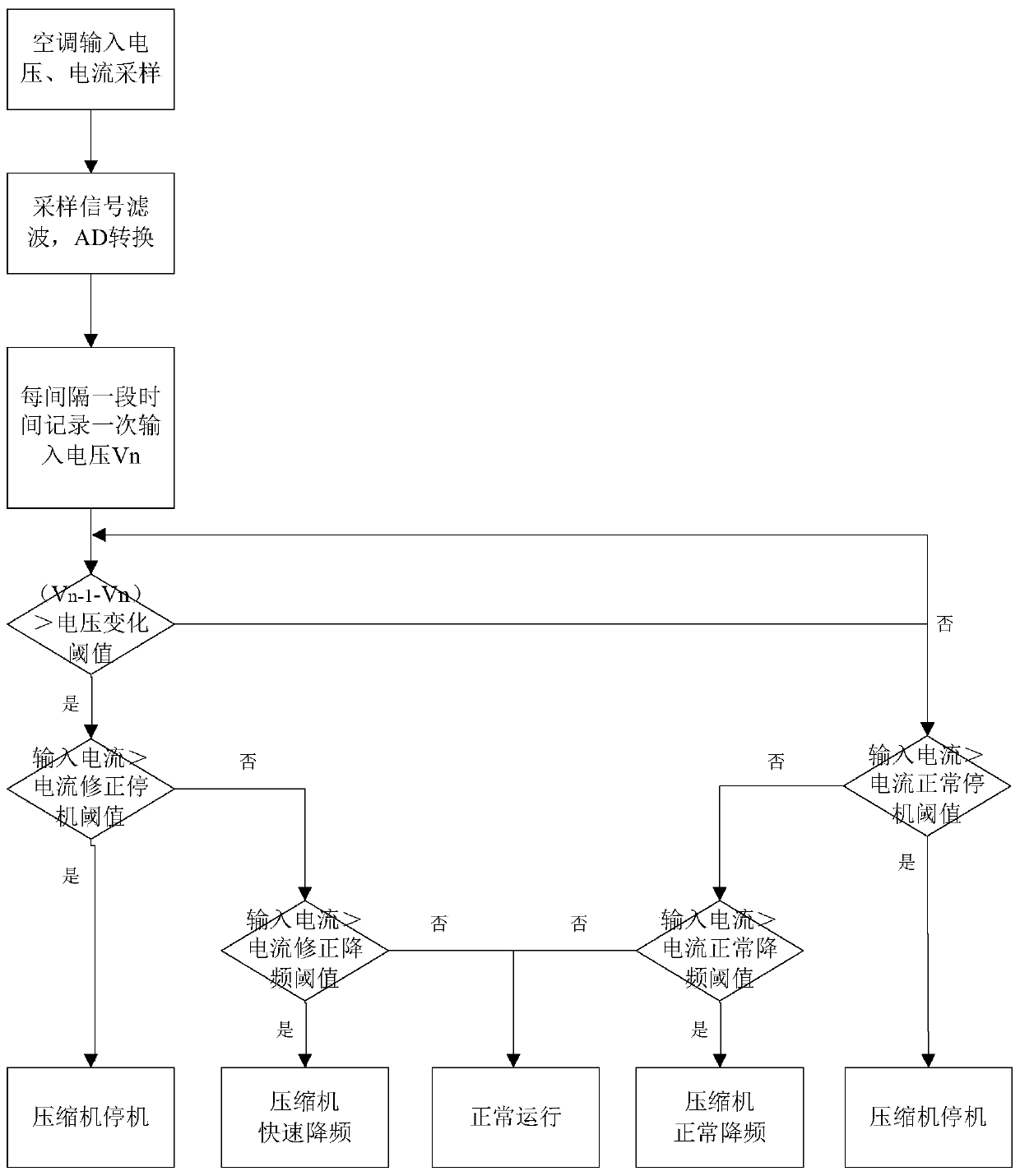

Method and device for avoiding abnormal shutdown of air conditioner caused by voltage leap and air conditioner

InactiveCN111219847AReduce abnormal downtimeImprove experienceMechanical apparatusSpace heating and ventilation safety systemsVoltage variationControl theory

The invention provides a method and device for avoiding abnormal shutdown of an air conditioner caused by voltage leap and the air conditioner, and relates to the technical field of air conditioners.The method includes the steps that input voltages and input currents are continuously sampled; the input voltages are recorded every first time interval; the difference between the recorded input voltages of every two consecutive times is calculated; and the compressor frequency is adjusted according to the difference, a voltage change threshold for comparison with the difference and the input currents. According to the method and device for avoiding the abnormal shutdown of the air conditioner caused by the voltage leap and the air conditioner, the current change is reflected through judgmentof the voltage change quantity within a certain time, different voltage change ranges correspond to different current protection values, and a compressor is controlled to reduce frequency and stop according to the voltage change so as to avoid abnormal shutdown of the compressor due to voltage fluctuations, so that the system operational stability is improved, and the user experience is improved.

Owner:NINGBO AUX ELECTRIC +1

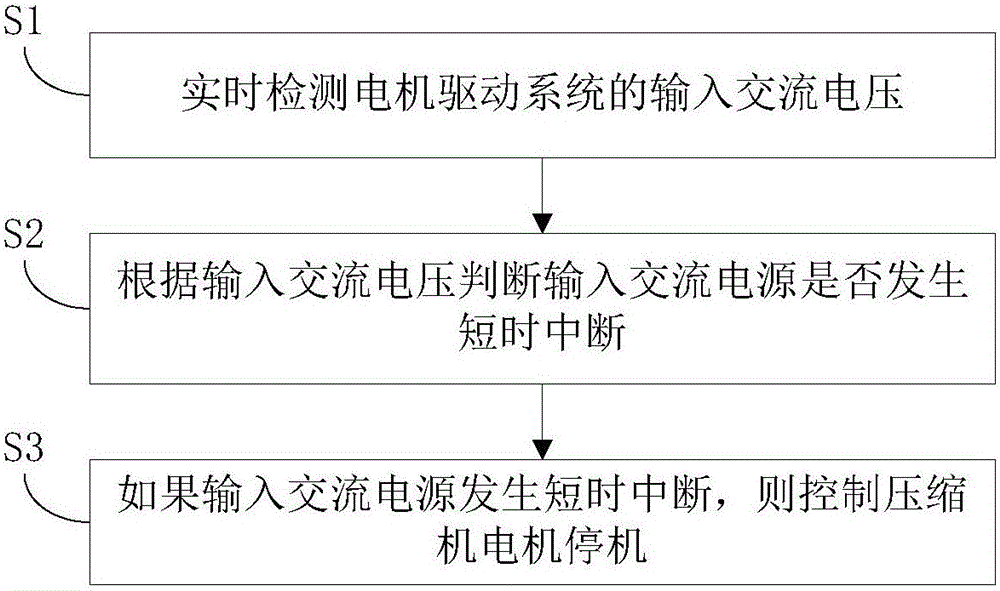

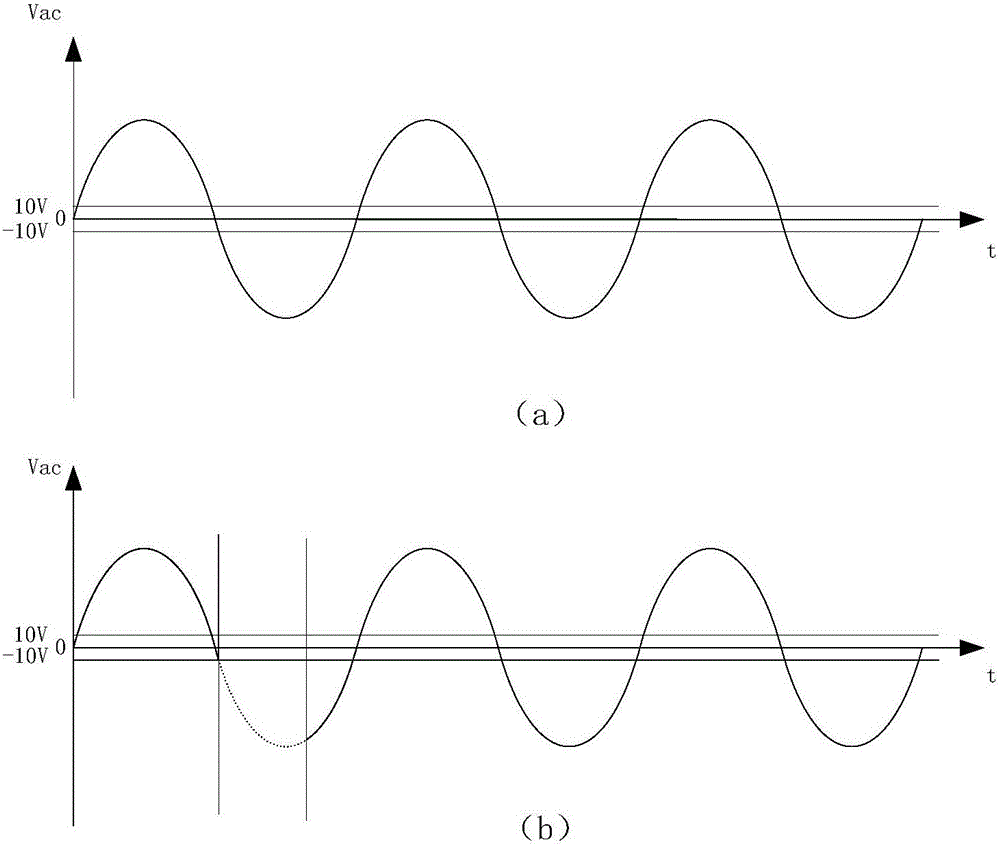

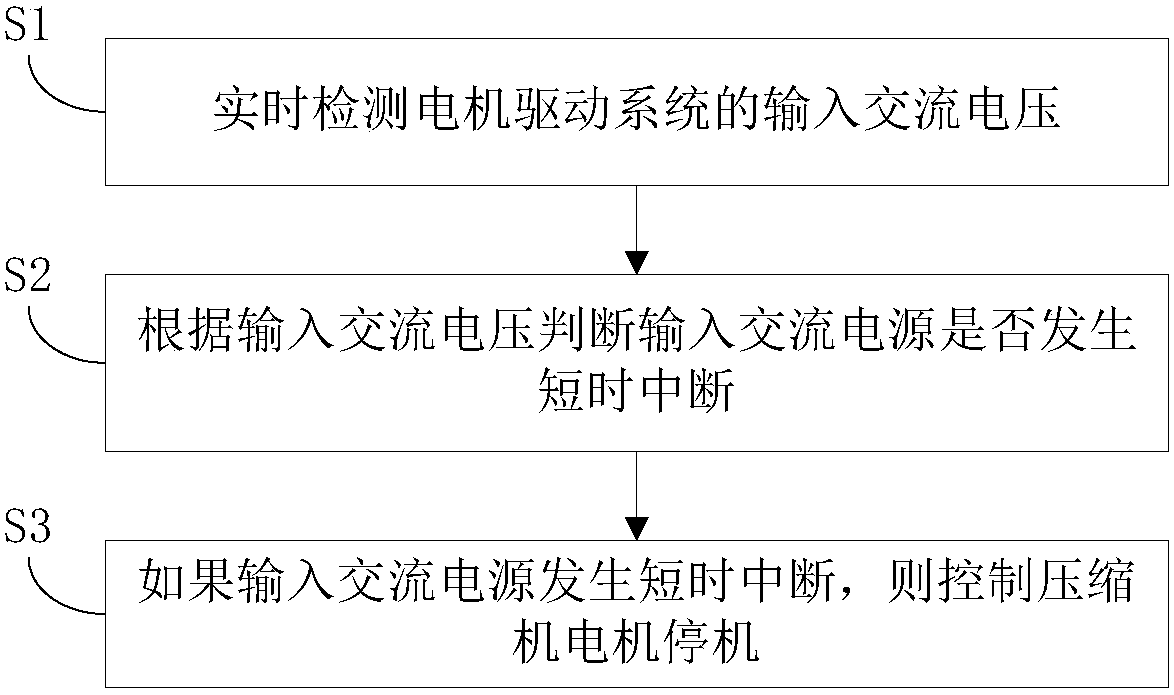

Electrolytic capacitor-free motor driving system and control method and device thereof

ActiveCN106208869AAvoid damageGuaranteed uptimeElectronic commutation motor controlAC motor controlCapacitanceElectric machine

The invention discloses an electrolytic capacitor-free motor driving system and a control method and device thereof. The method comprises the following steps of detecting an input AC voltage of the motor driving system in real time; judging whether an input AC power supply is disconnected for a short time or not according to the input AC voltage; and controlling a compressor motor to stop if the input AC power supply is disconnected for a short time. By the method, the compressor motor can be timely controlled to stop when the input AC power supply is disconnected for a short time, so that the compressor motor is effectively prevented from being out-of-control or the motor driving system is effectively prevented from being damaged, and the stable and reliable running of the compressor motor and the motor driving system is ensured.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

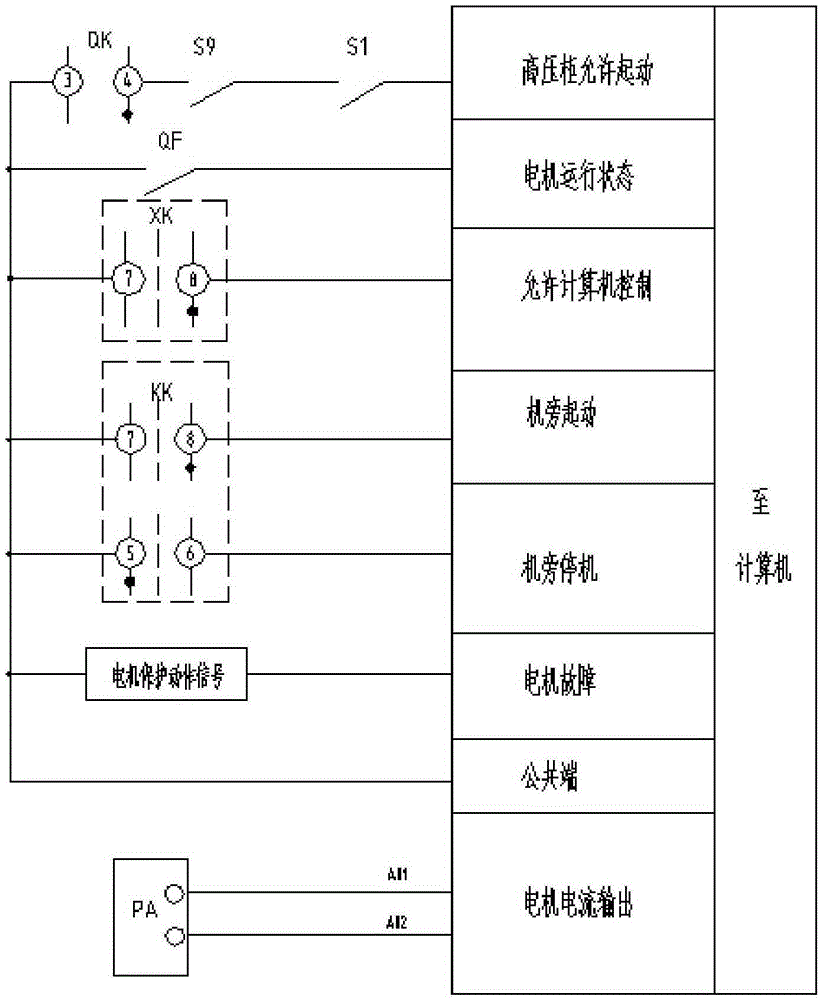

On-off control circuit for 10kV motor

ActiveCN105334761APerfect start preparationIncrease operational pertinenceProgramme control in sequence/logic controllersMicrocomputerAutomatic control

The invention discloses an on-off control circuit for a 10kV motor, and belongs to the field of high-voltage motor control. The on-off control circuit comprises automatic air switches ZK, a microcomputer integrated protection device 1n, breakers QF, a control switch KK, a selection switch XK, intermediate relays ZJT and ZJH, indicator lamps, a selector switch QK and emergency stop buttons JA. The positive end of one automatic air switch ZK is connected with the terminal X1 of the microcomputer integrated protection device 1n, and the terminal X6 of the microcomputer integrated protection device 1n is connected with the negative end of the corresponding automatic air switch ZK to form a power source loop of the microcomputer integrated protection device 1n; the negative end of one automatic air switch ZK is connected with one end of the switching-on allowing signal lamp beside the motor, the other end of the automatic air switch ZK is connected with one end of a normally closed auxiliary contact of the corresponding breaker QF, and the other end of the normally closed auxiliary contact of the corresponding breaker QF is connected with a control contact of the selection switch XK to form a loop allowing the corresponding indication lamp to be turned on. Manual control and automatic control can be switched through the on-off control circuit.

Owner:ANHUI MASTEEL ENG & TECH GRP

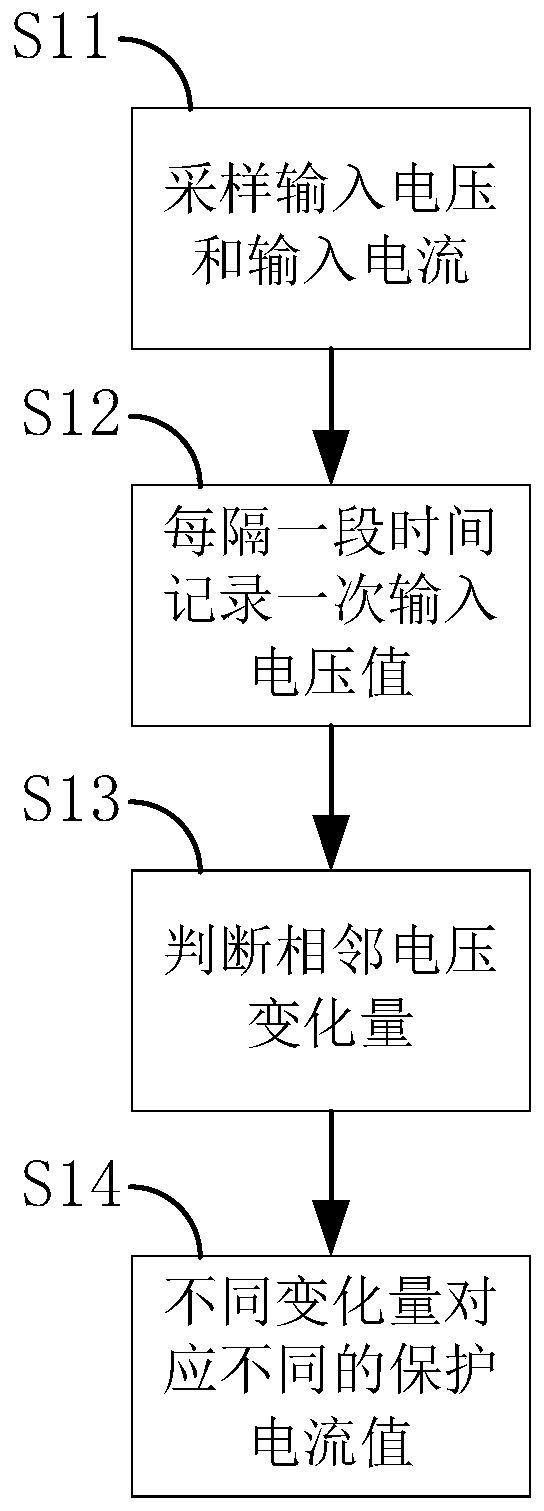

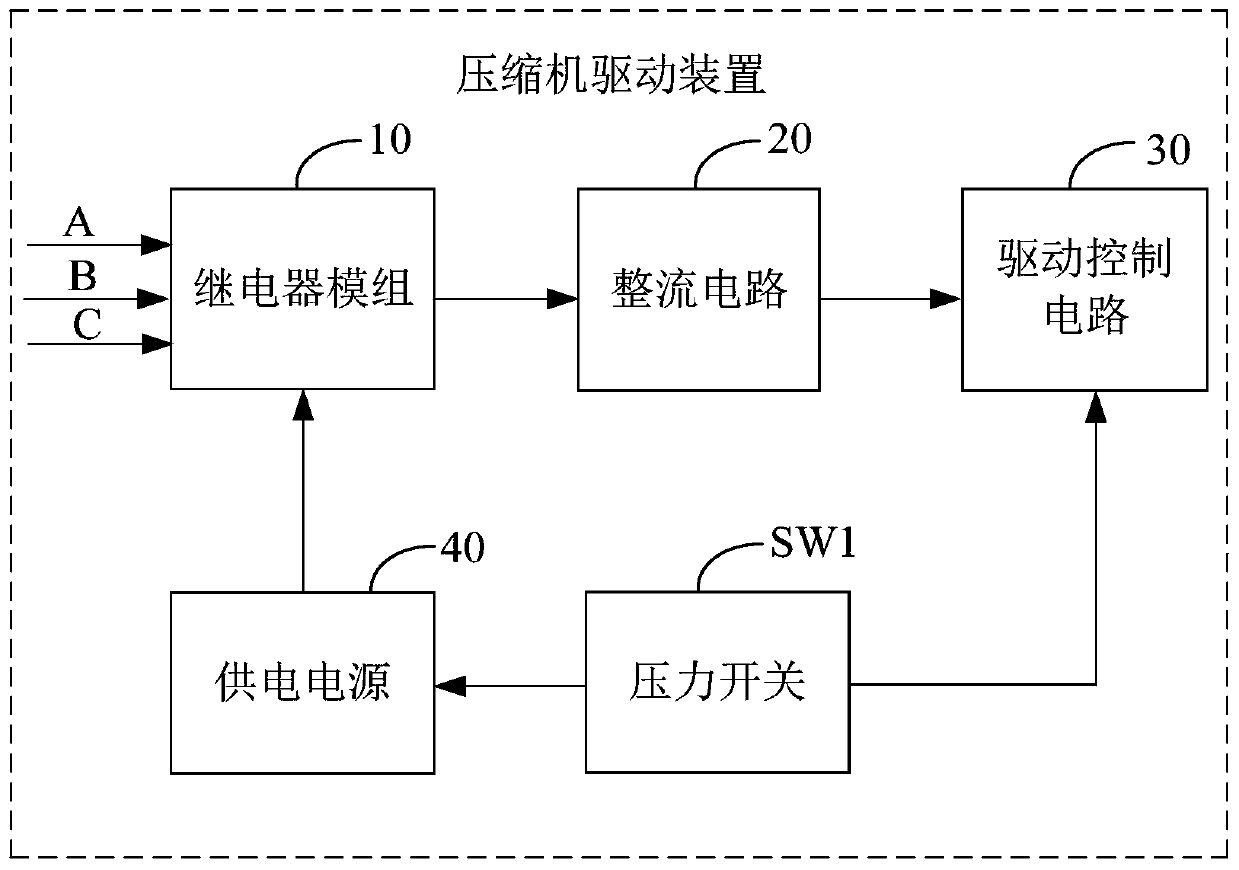

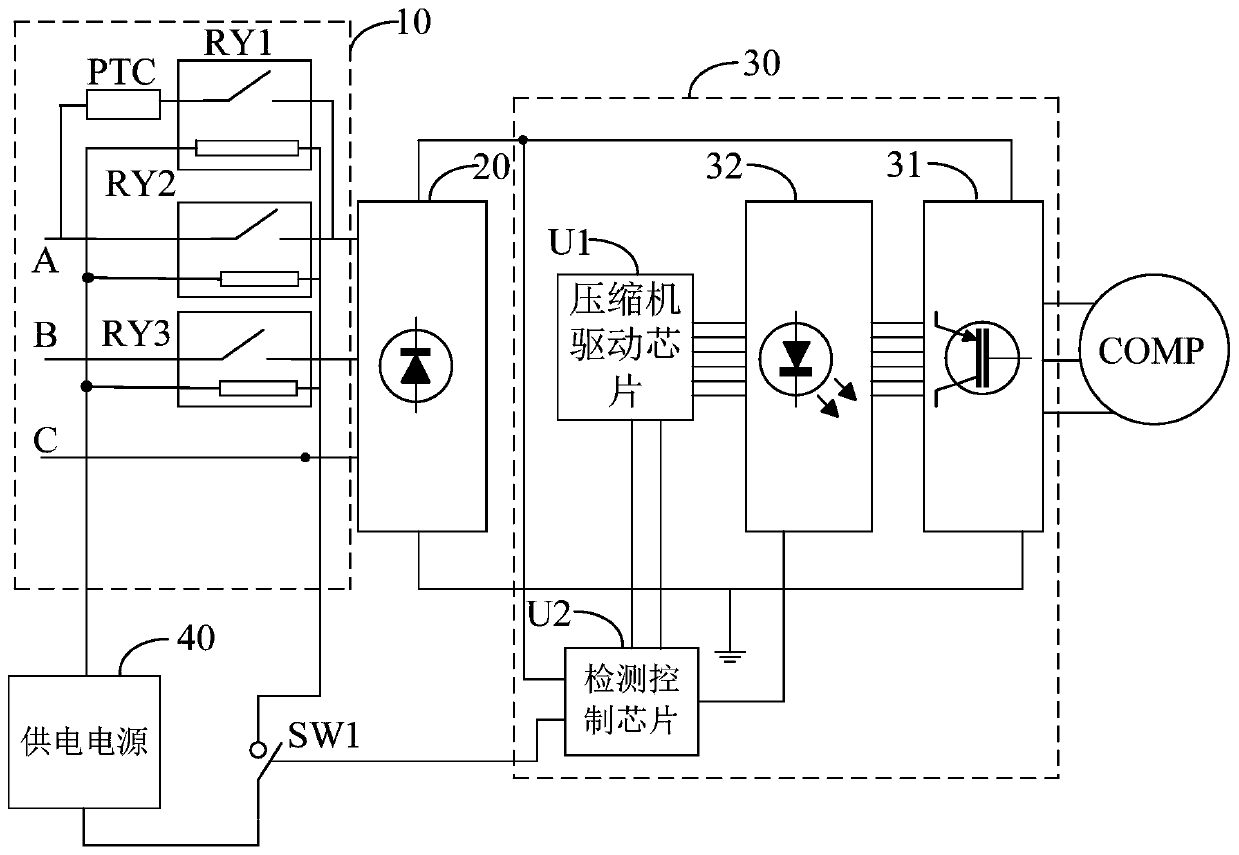

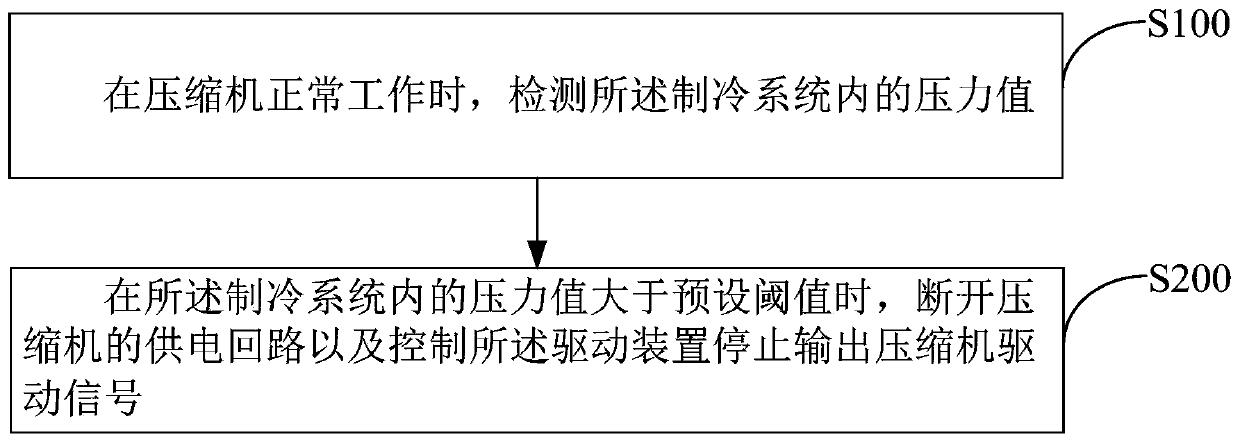

Compressor driving device, compressor pressure protection method and air conditioner

InactiveCN110594953AControlled downtimeGuaranteed uptimeMechanical apparatusAC motor controlStopped workPower conditioner

The invention discloses a compressor driving device, a compressor pressure protection method and an air conditioner. The compressor driving device is used for driving a compressor of a refrigerating system and comprises a three-phase alternating current power supply input end, a relay module, a rectifying circuit and a driving control circuit which are sequentially connected, wherein the rectifying circuit is used for converting accessed alternating current into direct current and outputting the direct current to a direct current bus; the driving control circuit is used for converting the direct current output by the direct current bus into compressor drive electric energy to drive the compressor to work; a pressure switch is connected in series with power supply circuit of the relay module; the pressure switch is used for detecting pressure value in the refrigerating system, and when the detected pressure value is larger than preset pressure threshold value, the power supply circuit of the relay module is disconnected; and the driving control circuit is also used for detecting the switching state of the pressure switch and controlling the compressor to stop working when the pressure switch is switched off. With the compressor driving device, safe and reliable operation of the compressor is realized.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD +1

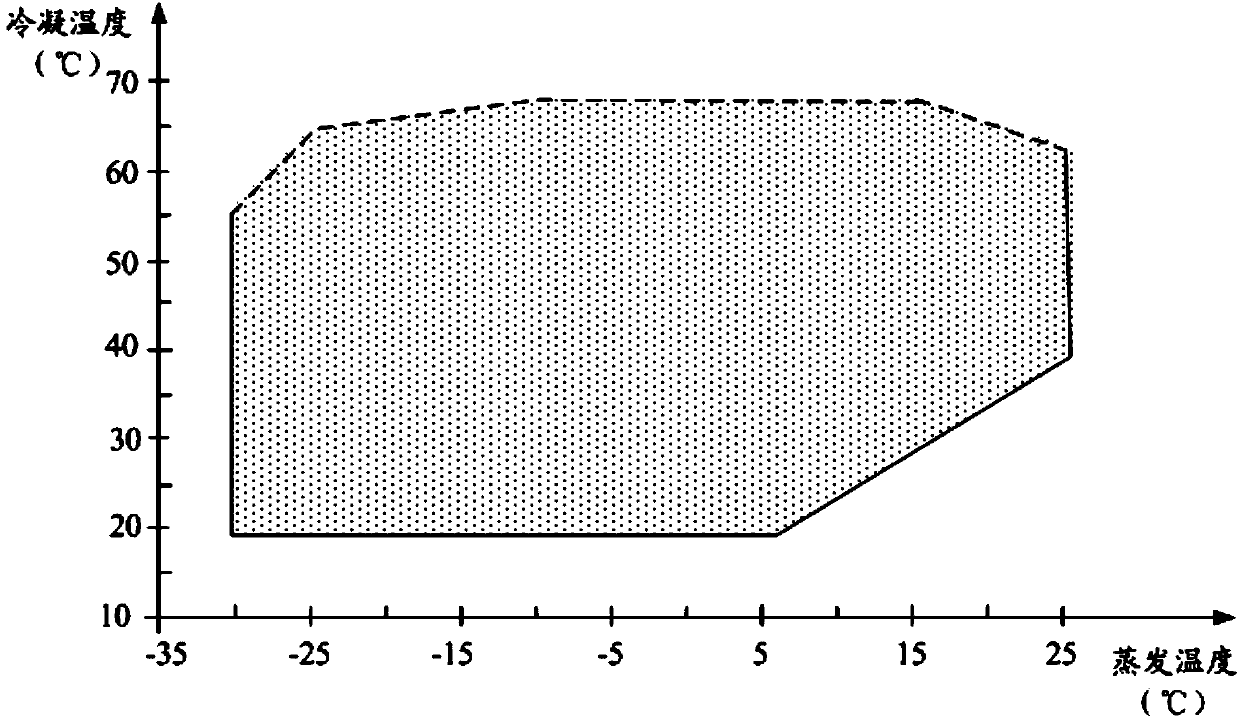

Control method and device and air conditioner

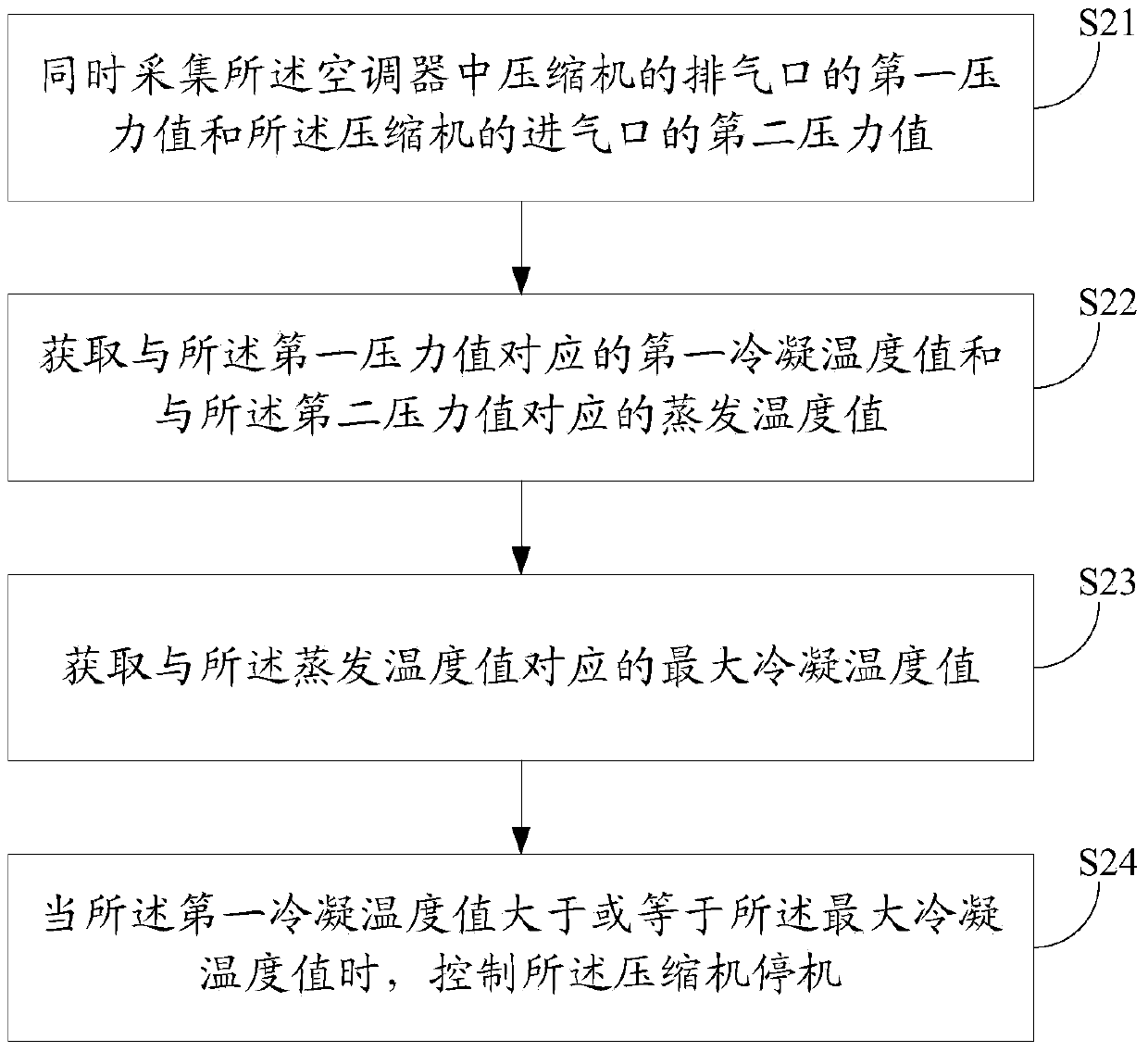

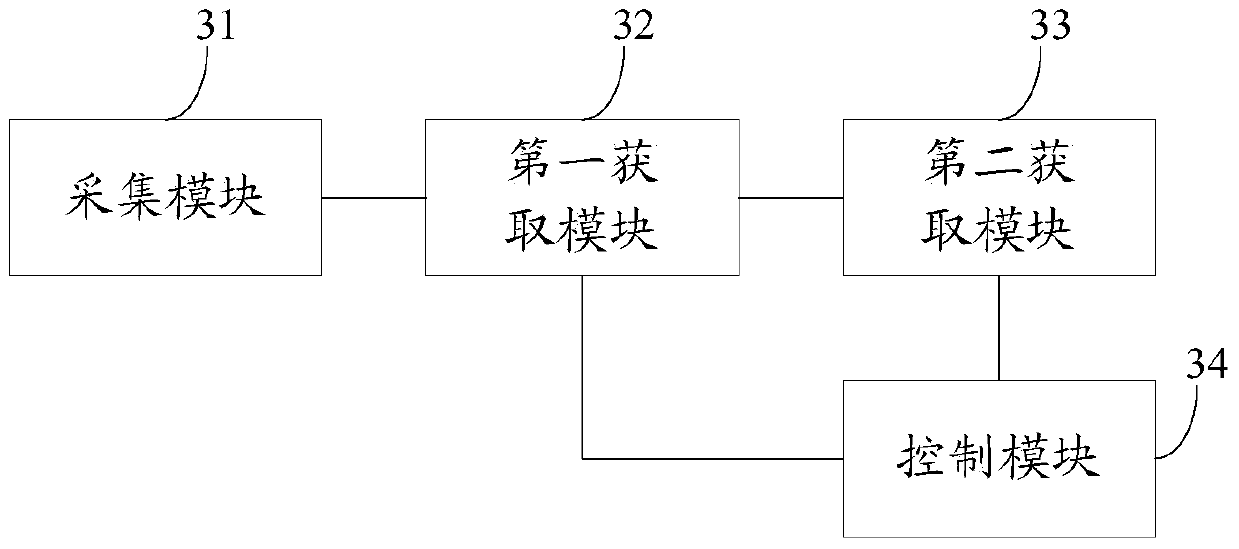

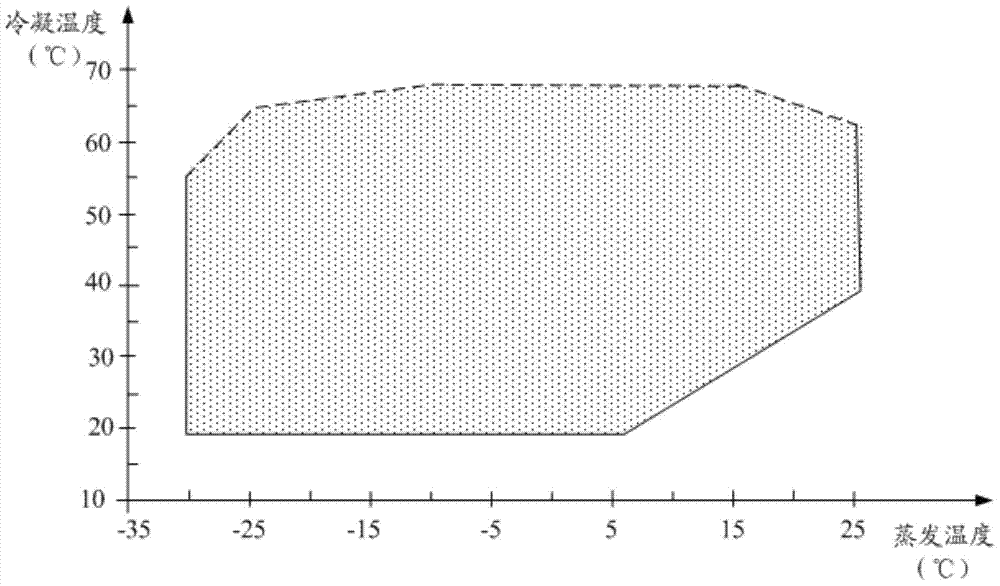

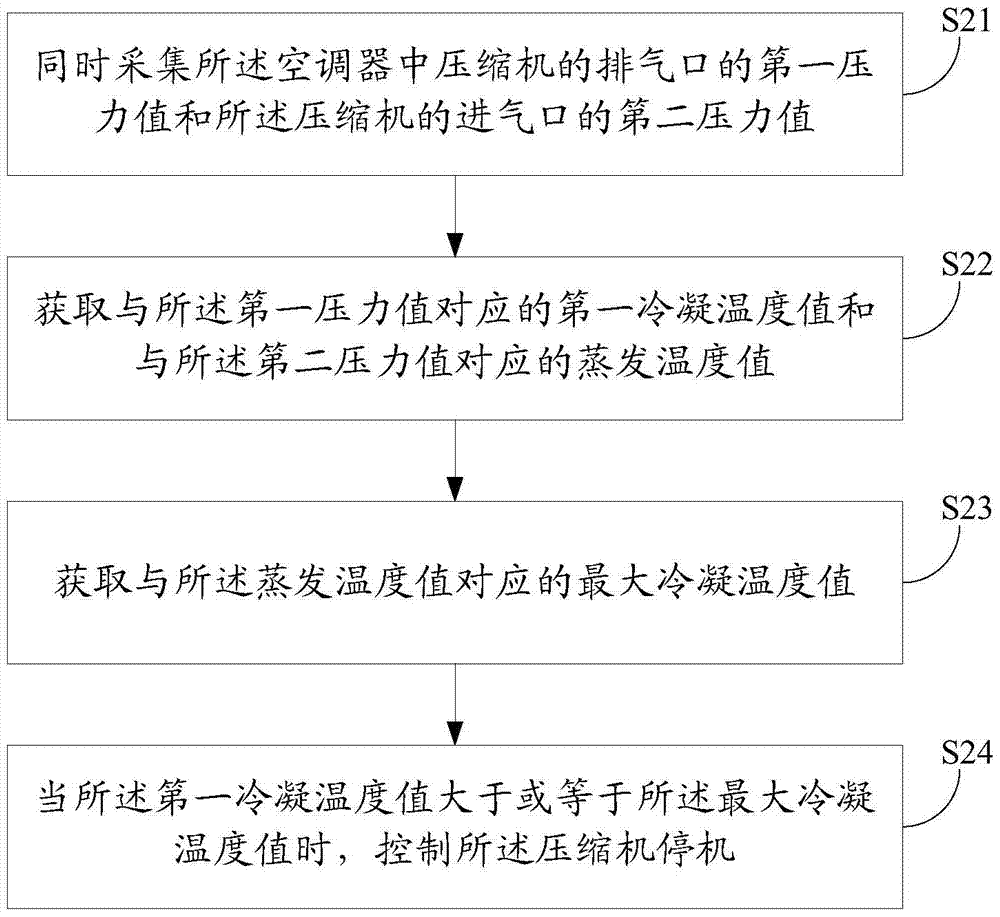

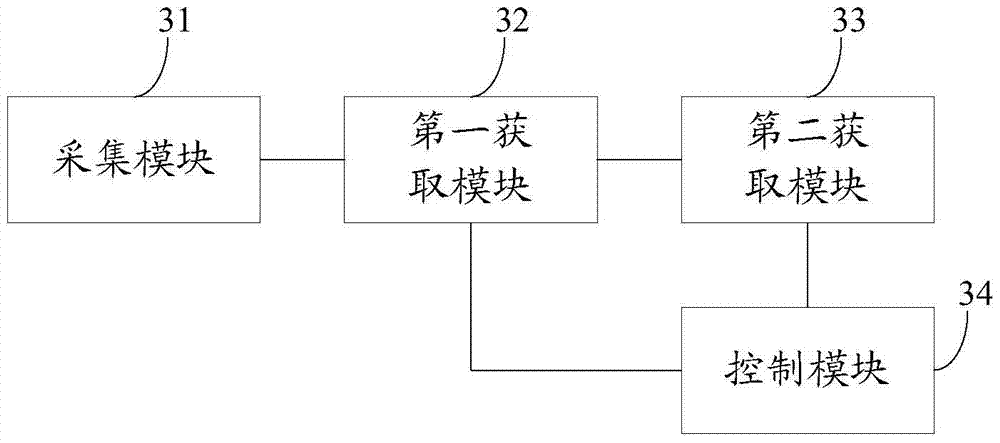

ActiveCN104048388AControlled downtimeImprove reliabilitySpace heating and ventilation safety systemsLighting and heating apparatusBoundary valuesCondensation temperature

The embodiment of the invention discloses a control method and device and an air conditioner. A first pressure value of an exhaust opening of a compressor and a second pressure value of an air inlet are detected at the same time, the first pressure value is converted into a corresponding first condensation temperature value, namely, actual condensation temperature, the second pressure value is converted into a corresponding evaporation temperature value, and the maximum condensation temperature value corresponding the evaporation temperature value is obtained. When the first condensation temperature value is larger than or equal to the maximum condensation temperature value, actual pressure of the exhaust opening of the compressor exceeds a high pressure boundary value within the rated pressure range, the compressor is immediately controlled to be shut down, shutdown protection is immediately carried out on the compressor once the actual pressure of the exhaust opening exceeds the high pressure boundary value within the rated pressure range, and reliability for carrying out shutdown protection on the compressor is improved.

Owner:GREE ELECTRIC APPLIANCES INC

Detection and calibration control method of travel distance and location of running mechanism

PendingCN109883445AControlled downtimeHigh precisionUsing electrical meansElectrical controlEngineering

The invention discloses a detection and calibration control method of travel distance and a location of a running mechanism, and belongs to the technical field of the electrical control. The method comprises the following steps: a, determining a positioning region of a running mechanism displacement encoder; b, determining a static magnetic grid positioning point and a static magnetic grid calibration point; c, demarcating a zero point location of the running mechanism corresponding to the displacement encoder, thereby obtaining a relation formula of a running mechanism location and a displacement encoder code value signal; performing primary calibration on the location of the displacement encoder detection when the static magnetic grid sensor passes through magnetic steel at a lower sidethereof; performing secondary calibration on the location of the displacement encoder detection when the static magnetic grid sensor passes through the next magnetic steel, thereby accomplishing the detection and calibration control of the travel distance and location of the running mechanism. The real-time dynamic calibration and precise control are performed on the running mechanism by adoptingthe double data of the displacement encoder combined with the static magnetic grid sensor, the detection precision and reliability are obviously improved, and the control method has the features of being convenient for operation and good in adaptability.

Owner:SINOHYDRO JIAJIANG HYDRAULIC MACHINERY +1

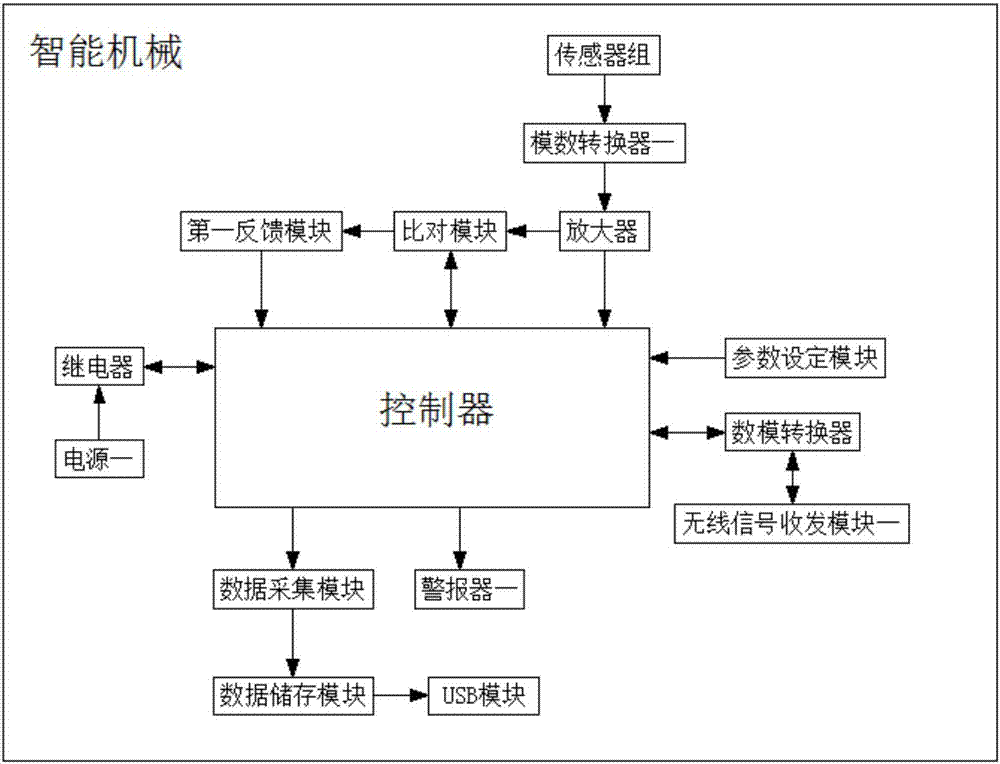

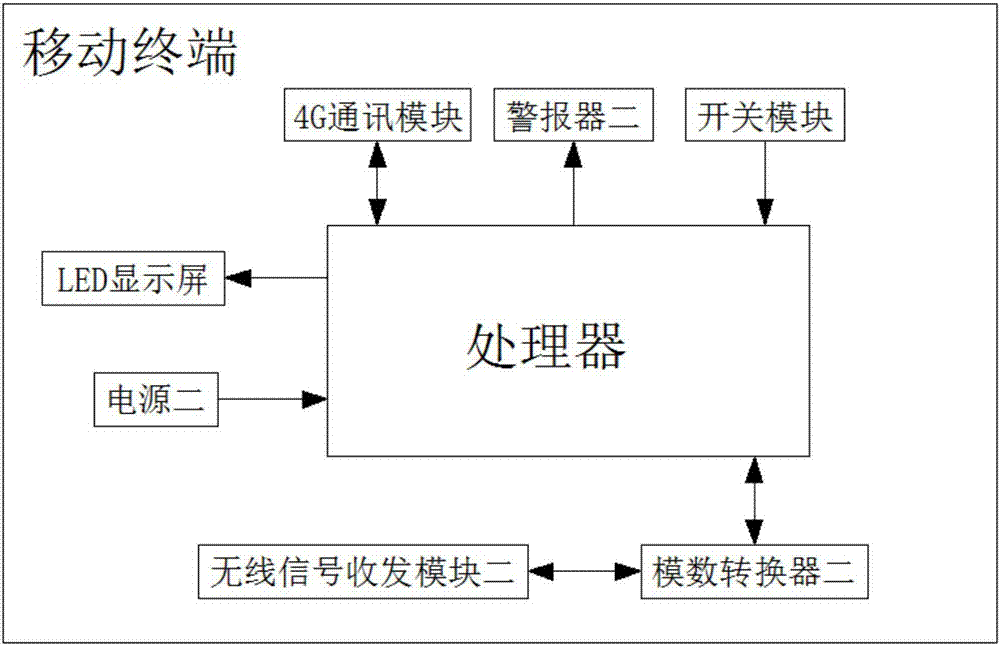

Excavator control system with automatic early warning function

InactiveCN106906867AWith automatic warning functionReal time monitoringSoil-shifting machines/dredgersStopped workElectricity

The invention discloses an excavator control system with an automatic early warning function. The excavator control system comprises intelligent mechanical equipment and a mobile terminal which are in both-way electric connection with each other, wherein the intelligent mechanical equipment comprises a controller; the input end of the controller is electrically connected with the output ends of a first feedback module, an amplifier and a parameter setting module; and the output end of the controller is electrically connected with the input end of a data acquisition module. The excavator control system has the advantages that through the connection between a wireless signal receiving-transmitting module I and a wireless signal receiving-transmitting module II, information detected by a sensor group can be transferred to the mobile terminal; an alarm is given by an alarming device II; a relay can be controlled by operating personnel through a switch module, and then an excavator is powered off and stops working; and the maintenance can be carried out timely. Therefore, the excavator control system can assist the operating personnel in quickly knowing the fault condition of the unmanned excavator, thereby avoiding the occurrence of a greater loss.

Owner:SHENZHEN SOURCE TECH CO LTD

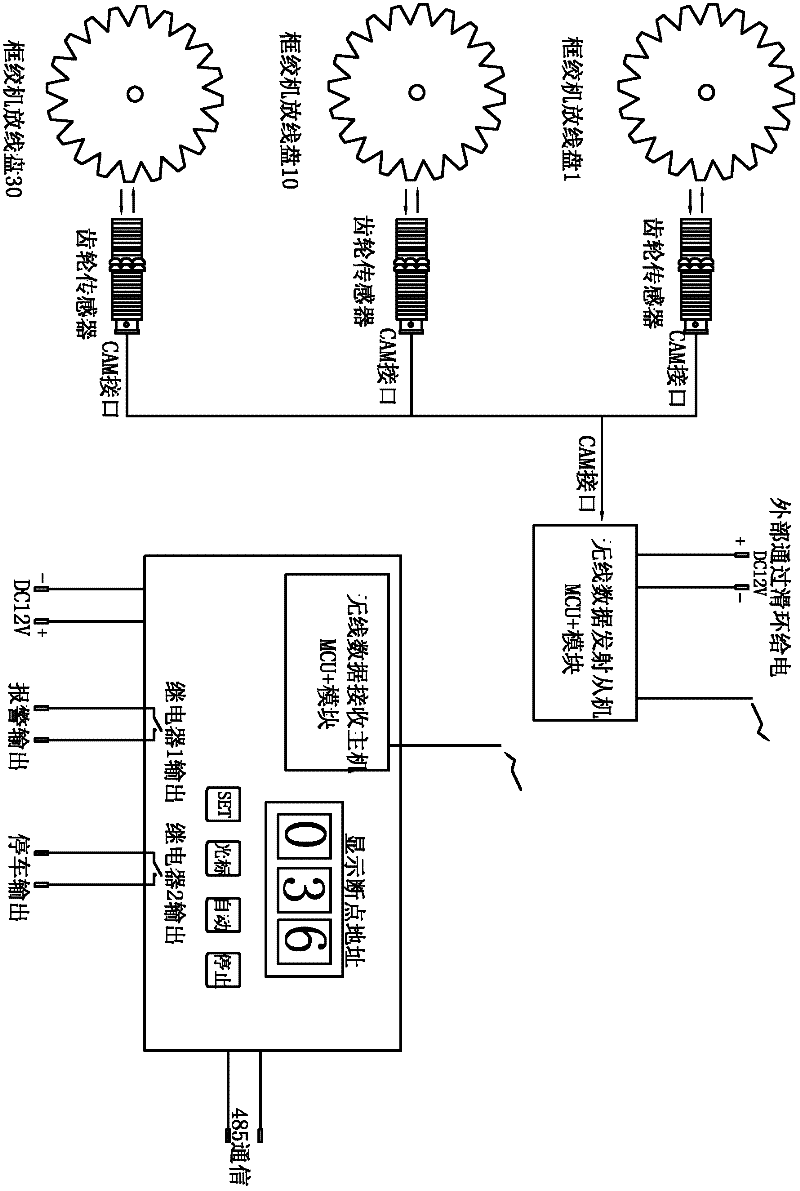

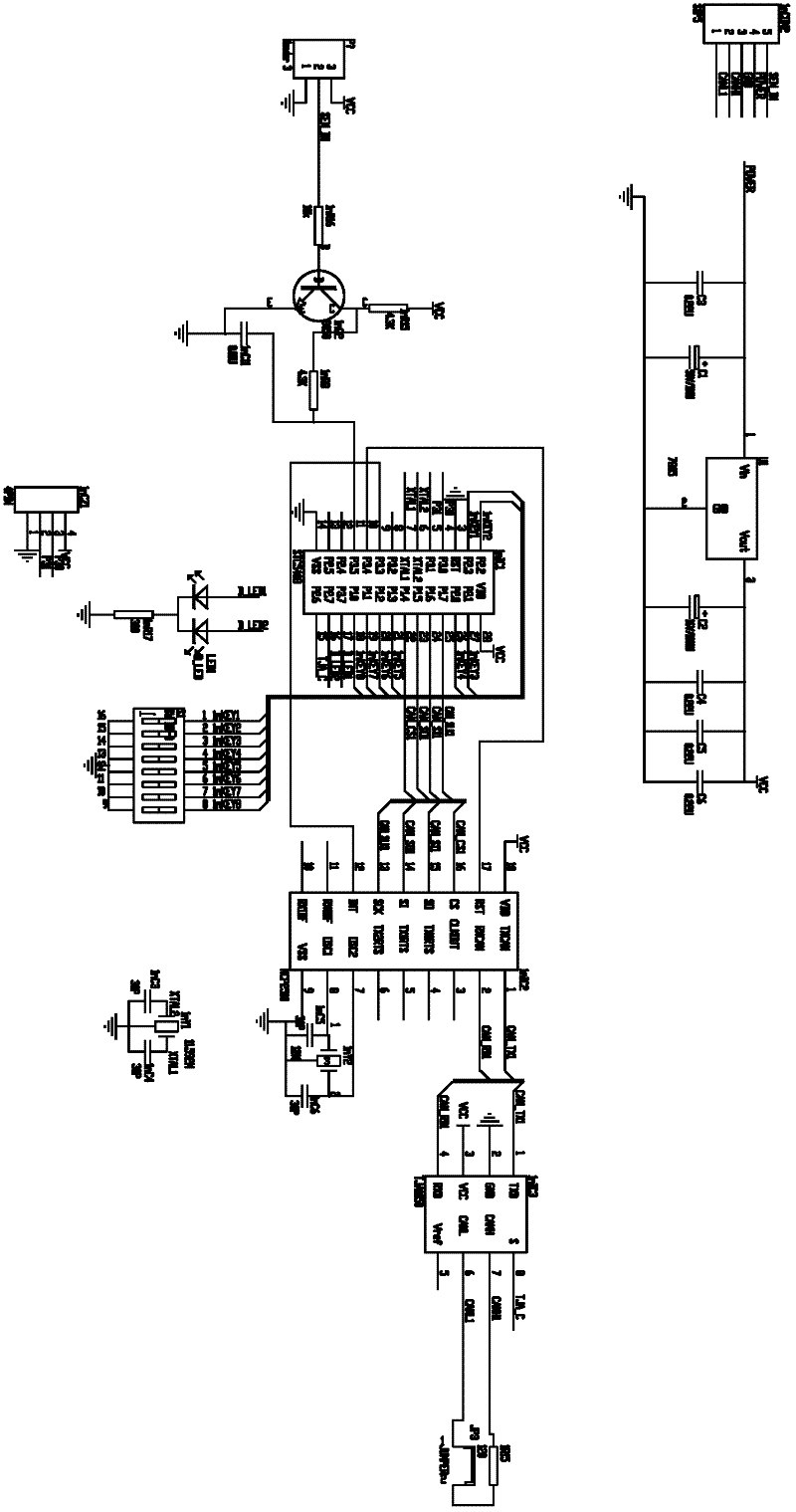

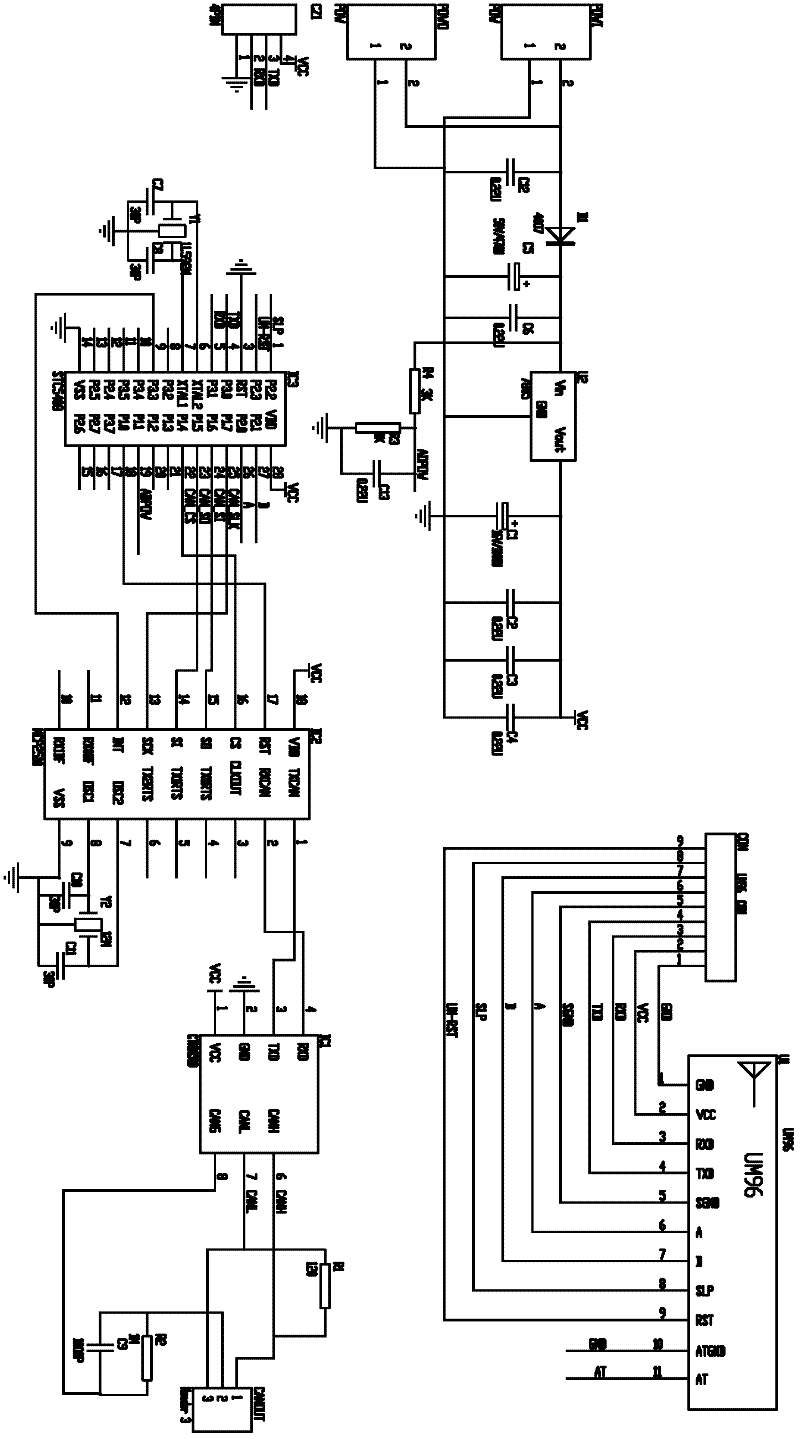

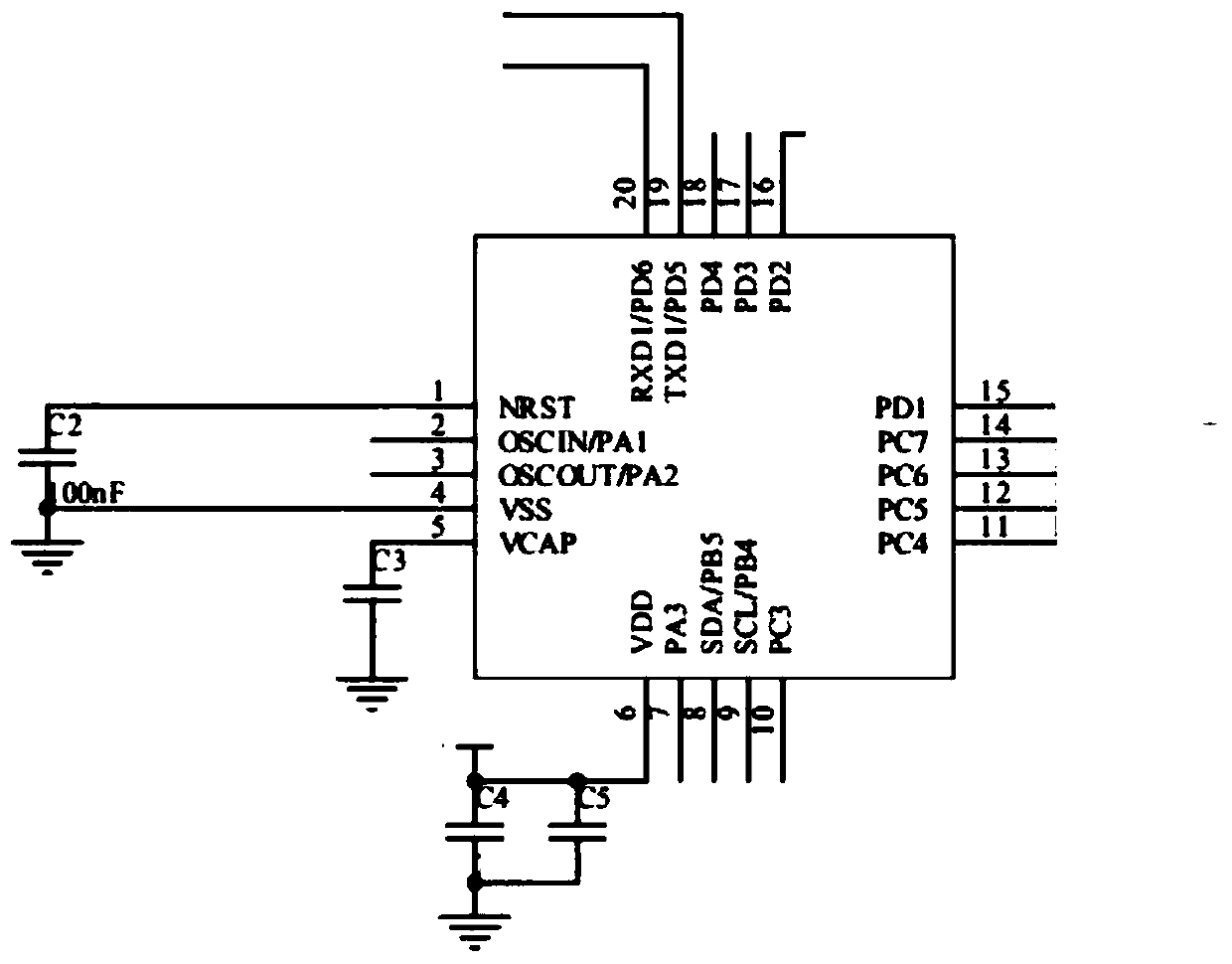

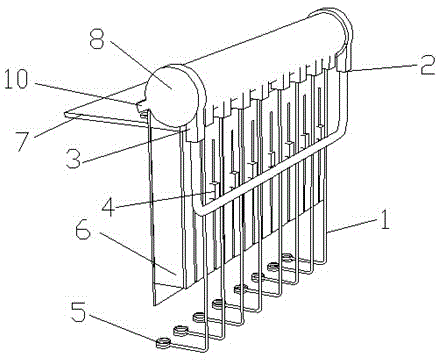

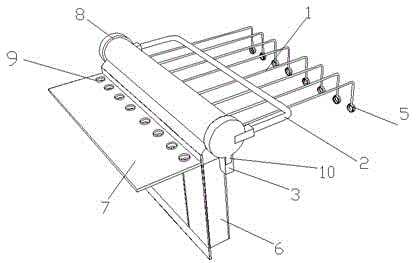

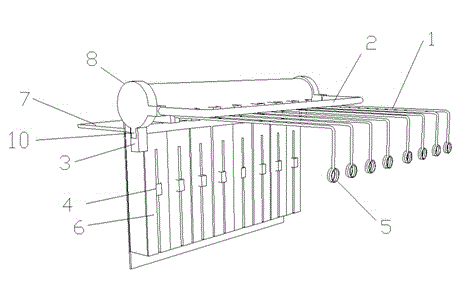

Intelligent frame-type strander break line stop apparatus

InactiveCN102231307AImprove anti-jamming performanceReduce the amount of wiringCable/conductor manufactureCamEngineering

The invention discloses an intelligent frame-type strander break line stop apparatus. The apparatus comprises: a plurality of sensors, MCUs, a wireless sub-transmitter, a wireless receiving host. Quantities of the sensors are corresponding to the quantities of payoff reels of the frame-type strander. The sensors are used for detecting whether each payoff reel rotates or not and outputting pulse signals according to rotation states of each payoff reel. The quantities of the MCUs are corresponding to the quantities of the sensors. MCUs are used for postponing outputting the output pulse signals of the sensors. The wireless sub-transmitter comprises a wireless transmitting module, wherein signal output terminals of the MCUs are connected with the wireless transmitting module through a CAM bus. The wireless receiving host comprises a wireless receiving module. And the wireless receiving host is used to receive wireless sub-transmitter signals and output alarm and stop control signals. By using the invention, intelligent monitoring of working states of the frame-type strander can be achieved, and instant alarm and stop can be performed.

Owner:温州市洞头友邦电子电器厂

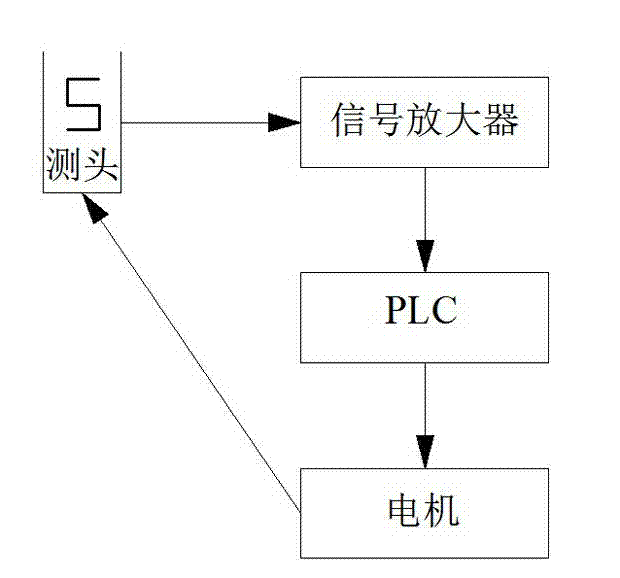

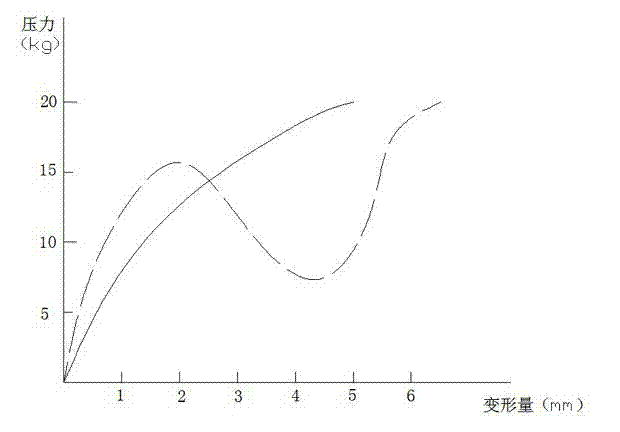

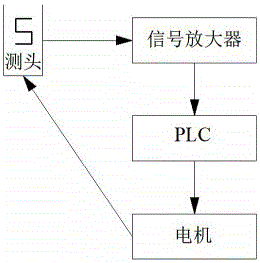

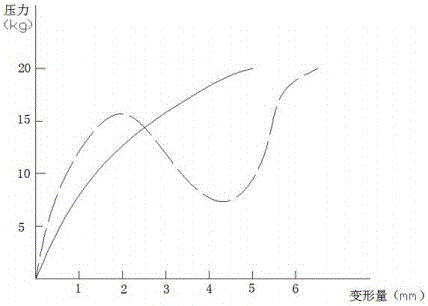

Pressure tester with intelligent sensing function

InactiveCN102768125AControlled downtimeRecord pressureStructural/machines measurementAudio power amplifierProgrammable logic controller

The invention discloses a pressure tester with an intelligent sensing function. The pressure tester comprises a motor, a tester main body and a testing platform, and is characterized by further comprising a measuring head, an enlarger and a PLC (programmable logic controller), wherein the measuring head is controlled by the motor, is used for applying pressure, is connected with the tester main body and is positioned above the testing platform, a force sensor is arranged in the measuring head, acquires force signals in real time and transmits the signals to the enlarger connected with the force sensor, the enlarger feeds back the signals to the PLC, and the PLC is connected with the motor and controls the motor to run or stop according to the fed-back signals. The pressure tester has the advantages that damage moment of a screen can be reliably judged, and the pressure tester can be reliably controlled to stop; pressure on the screen is recorded when the screen is damaged, and pressure resisting times of the screen under certain pressure can be recorded.

Owner:KUSN MINGJIU ELECTROMECHANICAL

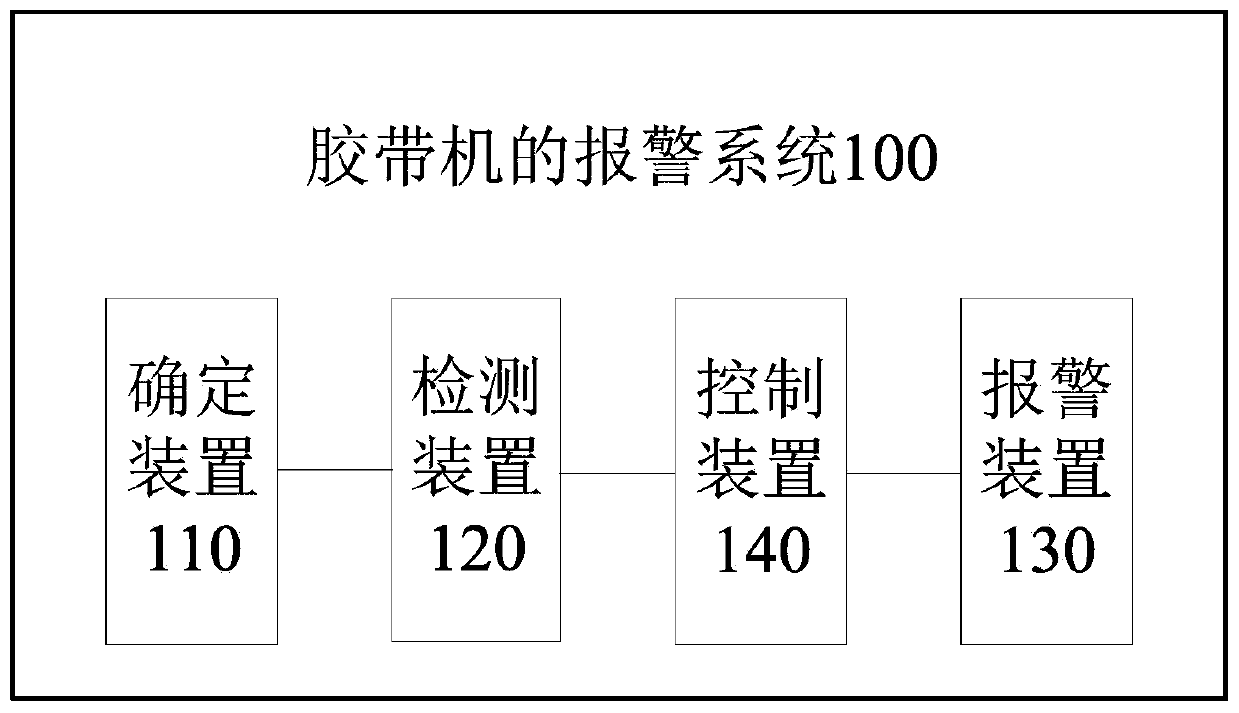

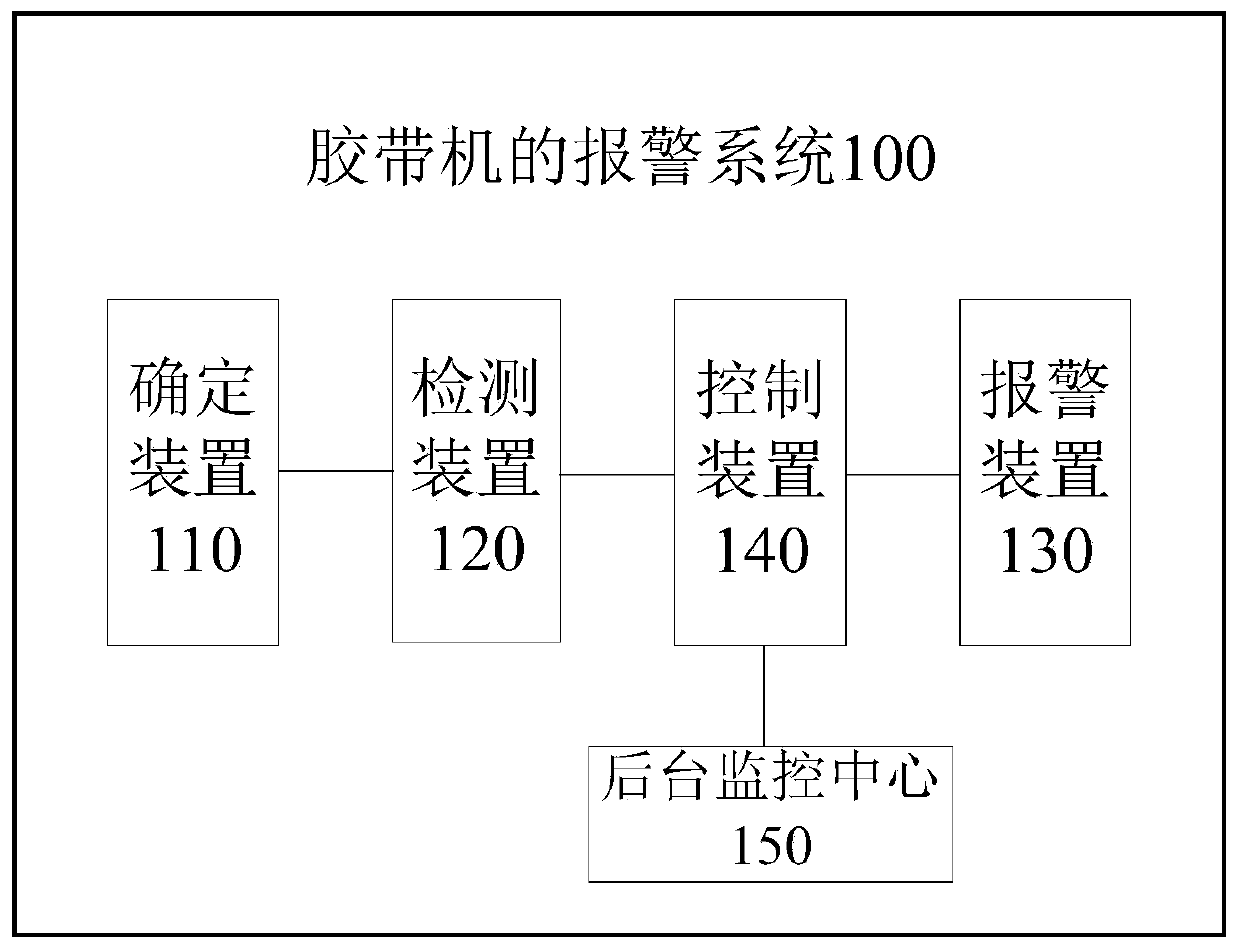

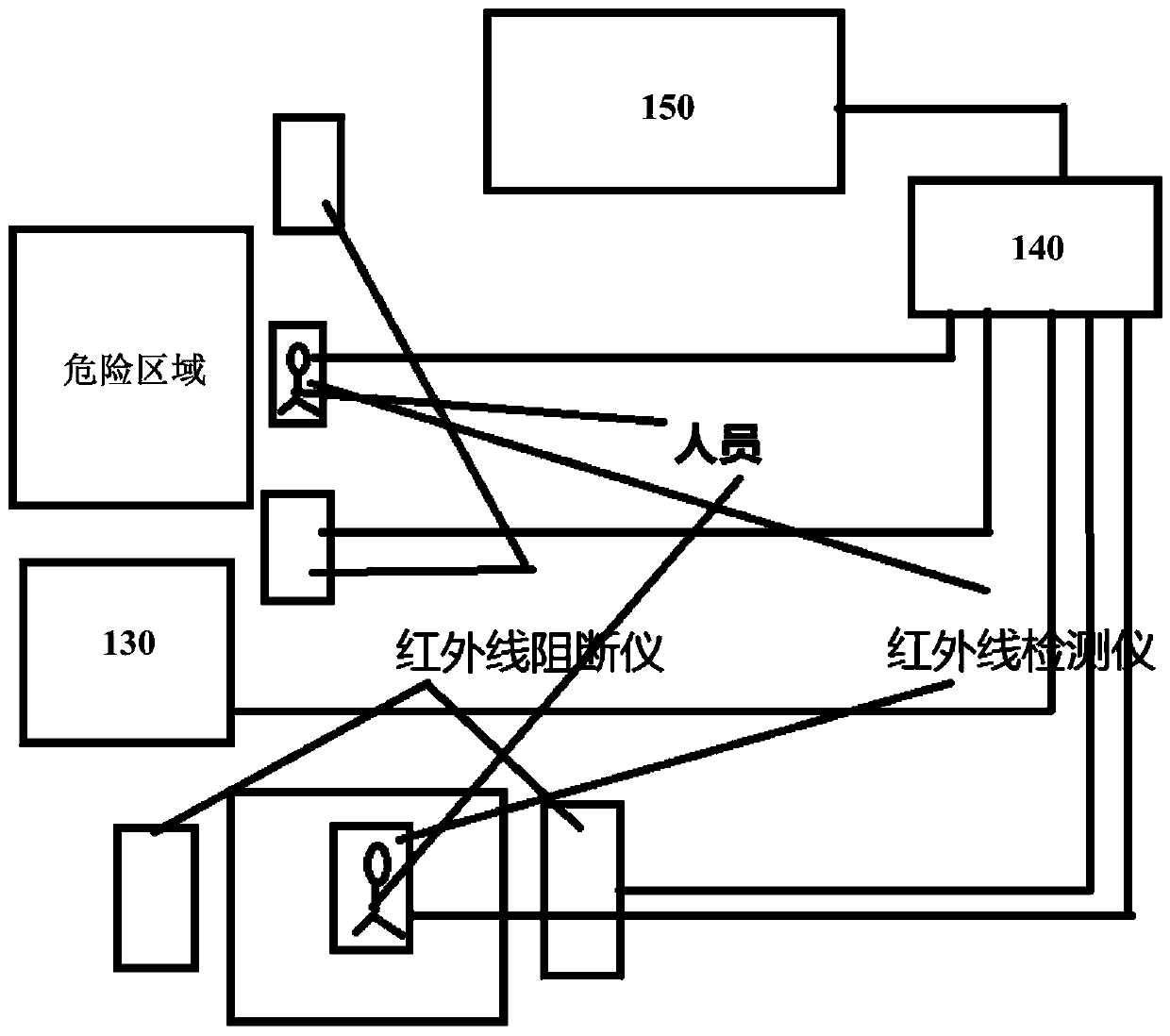

Alarm system and method of sealing-tape machine

PendingCN111422586AImprove securityImprove production safetyConveyorsControl devices for conveyorsAlarm messageAlarm device

The invention provides an alarm system and method for a sealing-tape machine. The system comprises a determining device which determines a first dangerous region and a second dangerous region, the second dangerous region is contained in the first dangerous region, and the sealing-tape machine is located in the second dangerous region; the detection device is used for detecting the first dangerousarea and the second dangerous area so as to judge whether a person exists in the first dangerous area and the second dangerous area or not; the alarm device is arranged in the first dangerous area andgives an alarm when being started; and the control device is respectively connected with the detection device and the alarm device, controls the alarm device to be started when the detection device detects that a person is in the first dangerous area, and sends alarm information to the background monitoring center when the detection device detects that a person is in the second dangerous area. Danger grading can be performed on the area where the adhesive tape machine is located, grading alarm is performed according to the danger grading, the alarm reliability is improved, alarm prompting canbe performed in time when personnel enter the dangerous area, and the personnel safety is improved.

Owner:HUOLINHE OPENCUT COAL IND CORP LTD OF INNER MOGOLIA +1

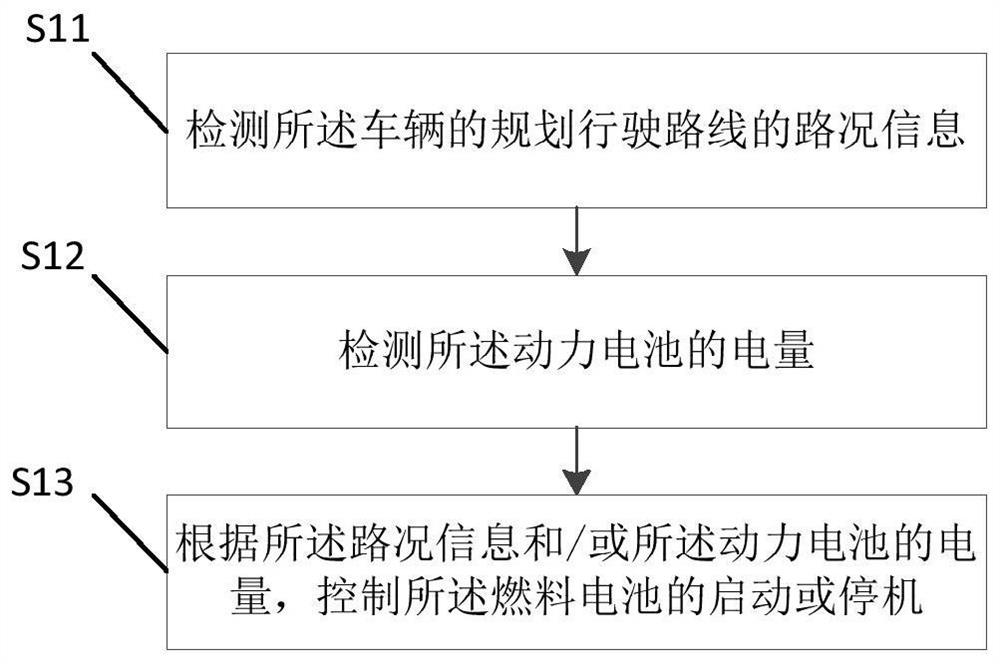

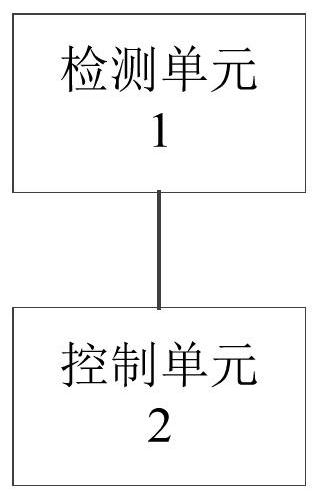

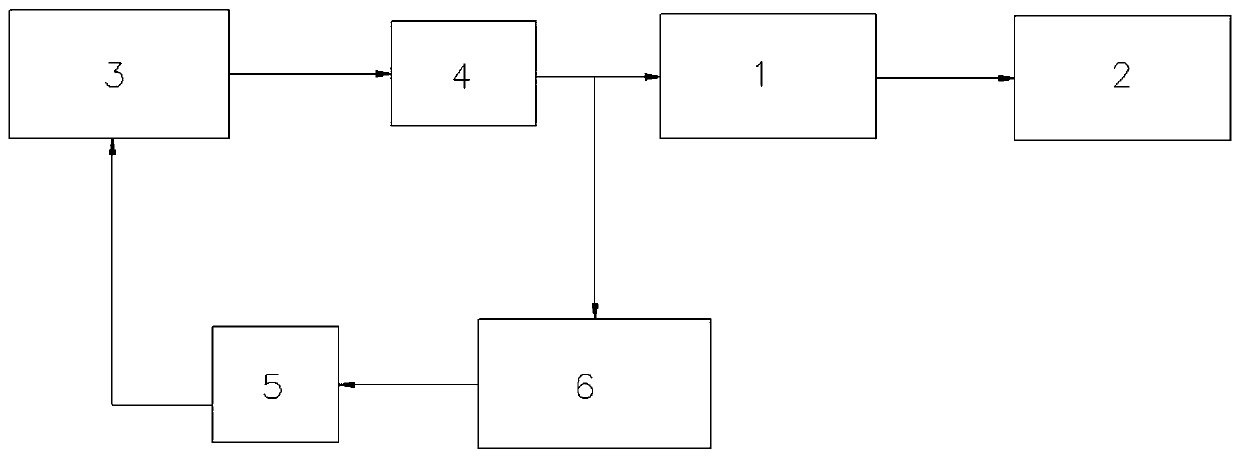

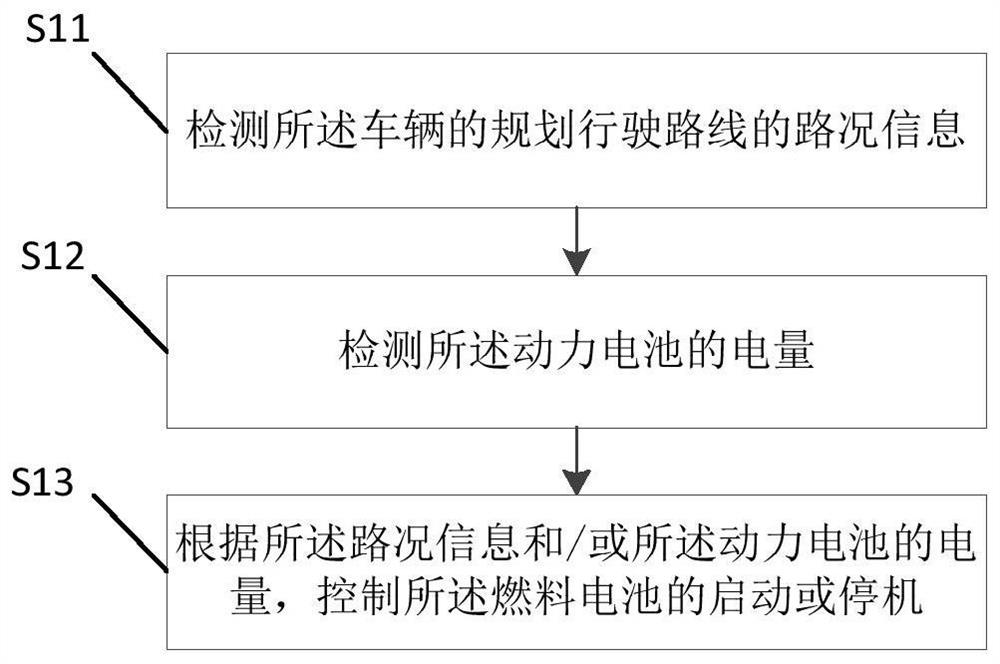

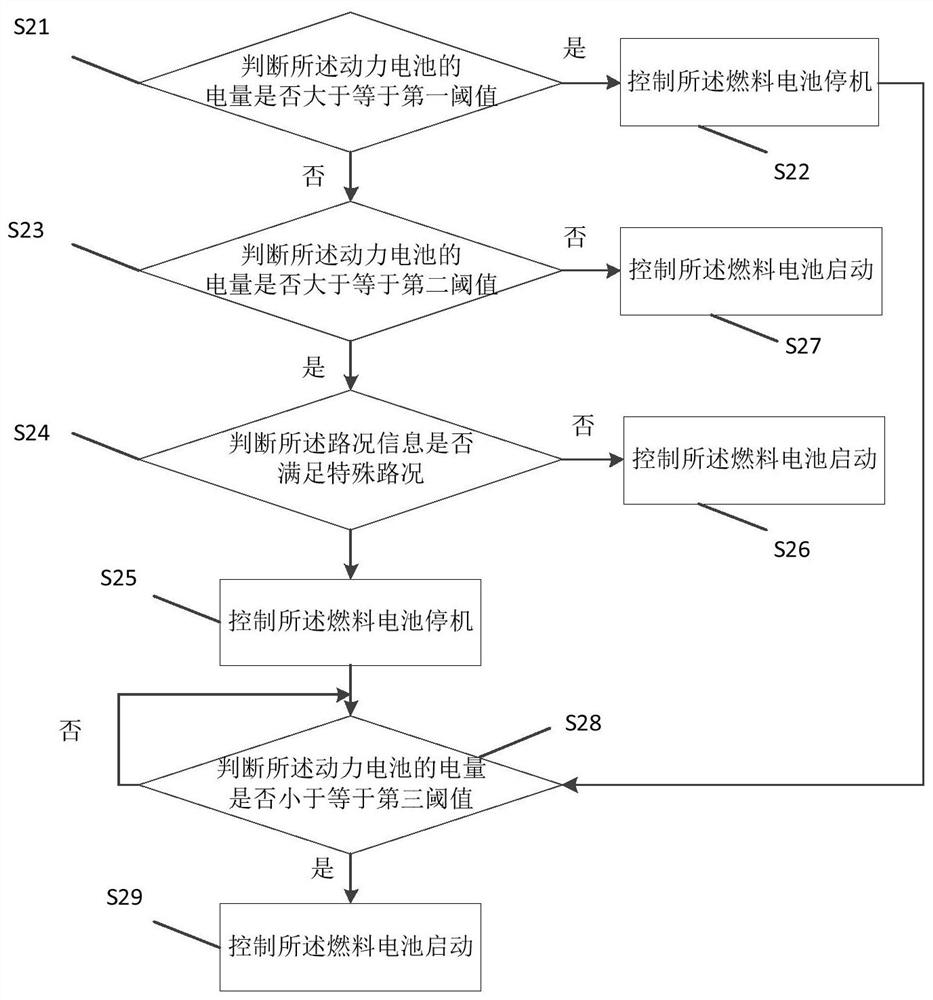

Method and device for controlling fuel cell of vehicle

ActiveCN112810502AReduce the number of starts and stopsExtended service lifeNavigation instrumentsVehicular energy storagePower batteryFuel cells

The invention relates to the technical field of vehicle control, and provides a method and device for controlling the fuel cell of a vehicle. The vehicle comprises a fuel cell and a power cell. The method comprises the following steps: detecting road condition information of a planned driving route of the vehicle; detecting the electric quantity of the power cell; and controlling the fuel cell to start or stop according to the road condition information and / or the electric quantity of the power cell. The electric energy of the power cell can be saved, and the service life of the fuel cell is prolonged.

Owner:GREAT WALL MOTOR CO LTD

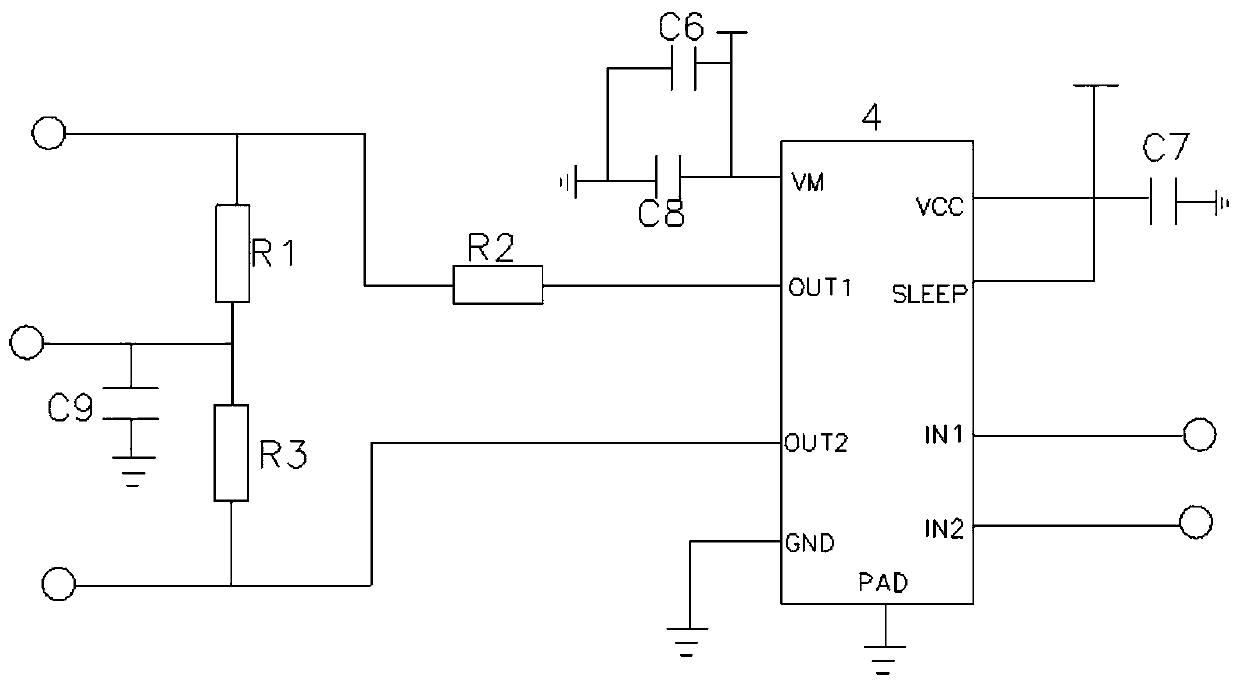

Direct current brush motor stalling detection device and method

InactiveCN109709484AControlled downtimeControl brakeDynamo-electric machine testingElectrical resistance and conductanceMotor drive

The invention discloses a direct current brush motor stalling detection device and method. The device includes a direct current motor, a moving part and a detection module; the detection module includes a control chip, a motor driving chip, an ADC conversion module and a resistance network; the control chip is connected to the direct current motor through the motor driving chip; the direct currentmotor is connected to the moving part; the control chip is connected to the resistance network through the ADC conversion module; and the motor driving chip is connected to the resistance network. The device and method are simple in structural principle; fast detection can be performed when the stalling of the motor occurs; and the motor can be controlled to stop or brake, so that the motor can be prevented from continuously stalling to generate faults such as structural stuck and damages.

Owner:XIAN HUIJING INTELLIGENT TECH

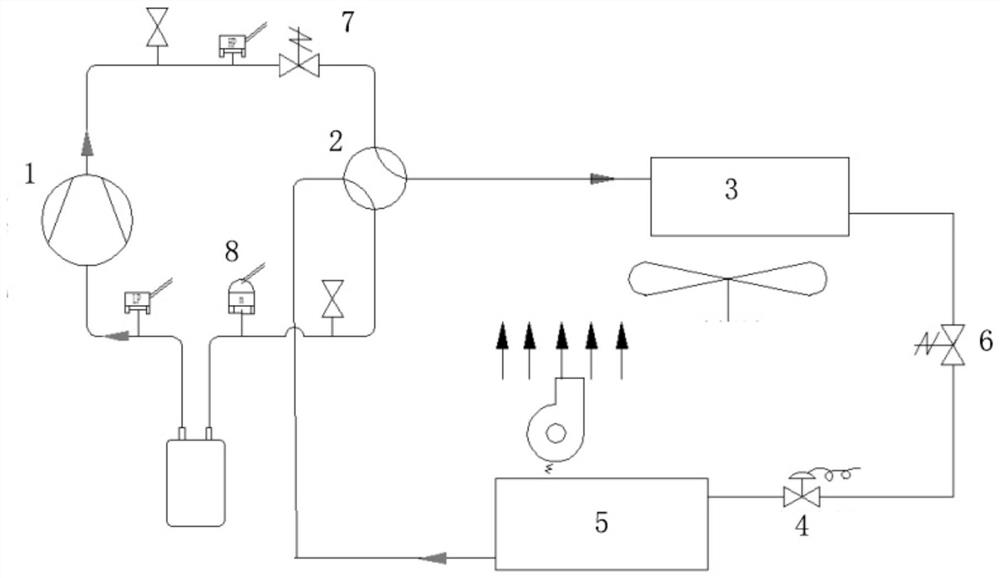

New energy bus heat pump air conditioning unit and control method thereof

PendingCN113525015AAvoid submersionImprove electrical insulation resistanceAir-treating devicesVehicle heating/cooling devicesFour-way valveNew energy

The invention relates to a new energy bus heat pump air conditioning unit and a control method thereof. The new energy bus heat pump air conditioning unit comprises a compressor, a four-way valve, a condenser, a throttling device and an evaporator, a blocking device used for blocking a refrigerant from flowing back into the compressor from the four-way valve is arranged between the compressor and the condenser, an electromagnetic valve is arranged between the condenser and the throttling device, the electromagnetic valve is connected with a controller circuit; and the controller is used for firstly closing the electromagnetic valve and then controlling the compressor to stop. By controlling the electromagnetic valve and delaying shutdown of the compressor, the process of evacuating the liquid refrigerant in the compressor after the air conditioner is shut down is achieved, most of the refrigerant is isolated in a pipeline between the blocking device and the electromagnetic valve and in the condenser, and therefore it is guaranteed that the interior of the compressor is basically gaseous refrigerant; and a binding post in the compressor is prevented from being submerged by the liquid refrigerant, so that the electrical insulation resistance of the air conditioning unit in a shutdown state is improved.

Owner:青岛朗进新能源设备有限公司

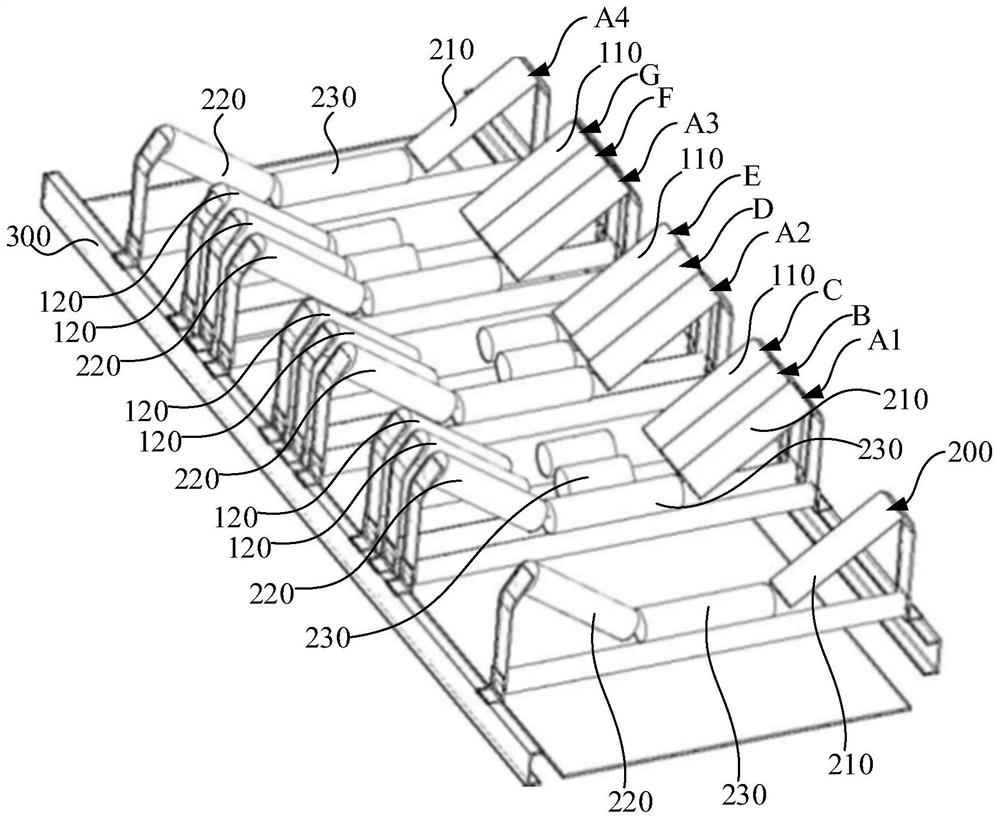

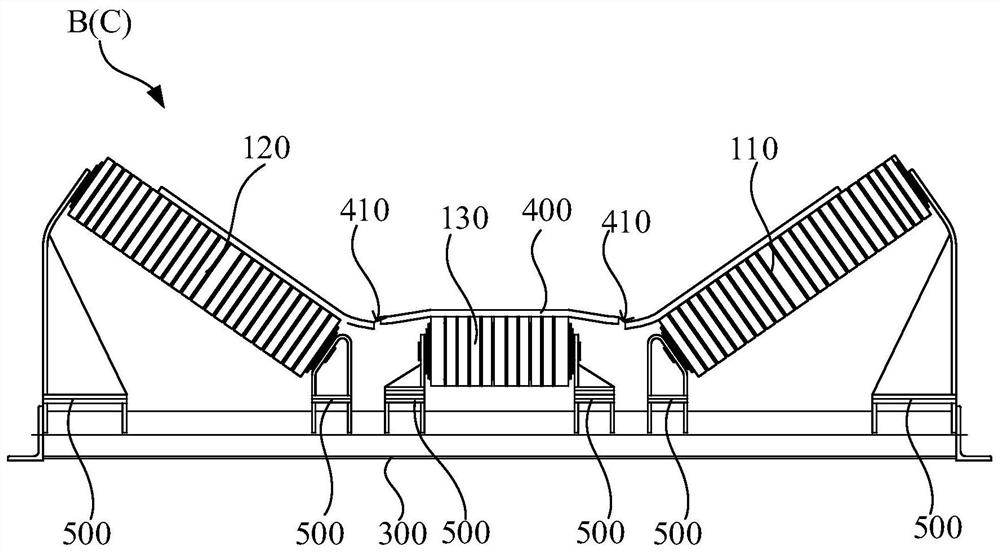

Belt tear opening shaping structure and belt conveyor

Owner:SHENHUA TIANJIN COAL TERMINAL

Vehicle fuel cell control method and device

ActiveCN112810502BReduce the number of starts and stopsExtended service lifeFuel cell controlNavigation instrumentsPower batteryFuel cells

The invention relates to the technical field of vehicle control, and provides a method and device for controlling a fuel cell of a vehicle. The vehicle includes a fuel cell and a power battery, and the method includes: detecting road condition information of a planned driving route of the vehicle; detecting the electric quantity of the power battery; and controlling according to the road condition information and / or the electric quantity of the power battery Startup or shutdown of the fuel cell. The invention can save the electric energy of the power battery and prolong the service life of the fuel battery.

Owner:GREAT WALL MOTOR CO LTD

Engine-driven generator and control method and system thereof

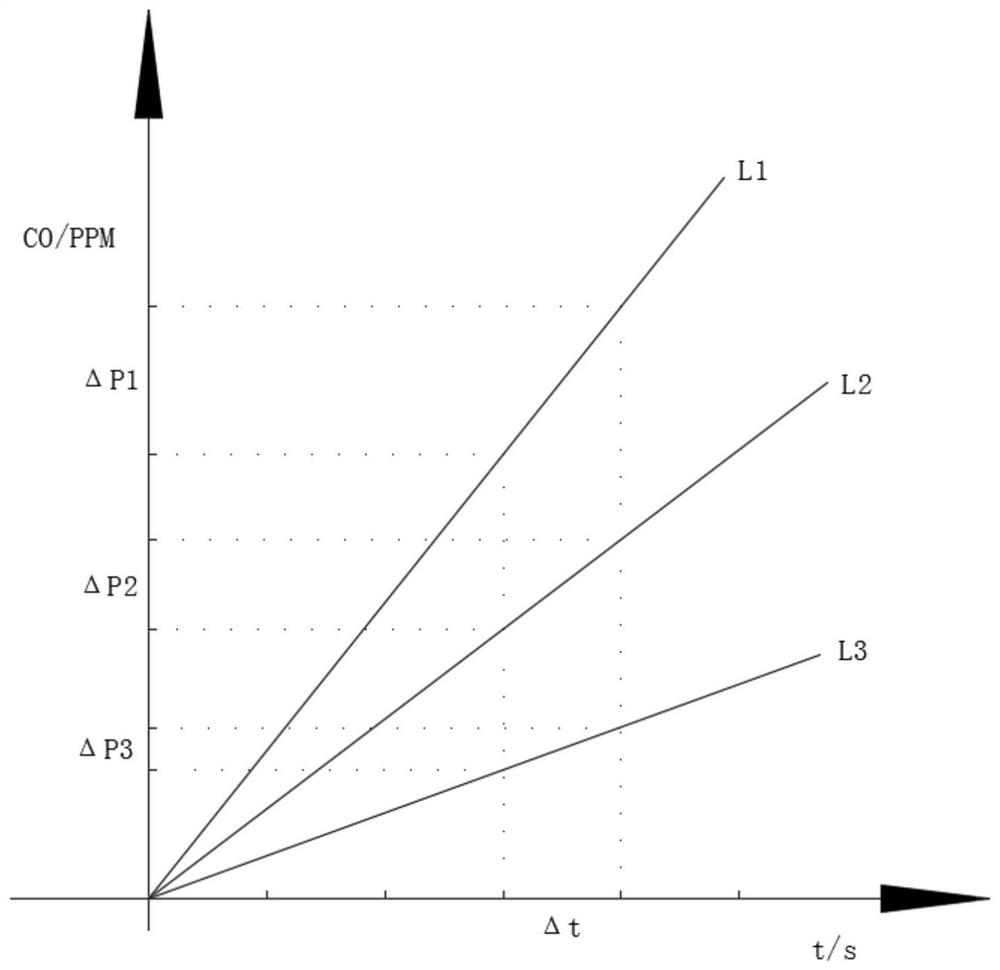

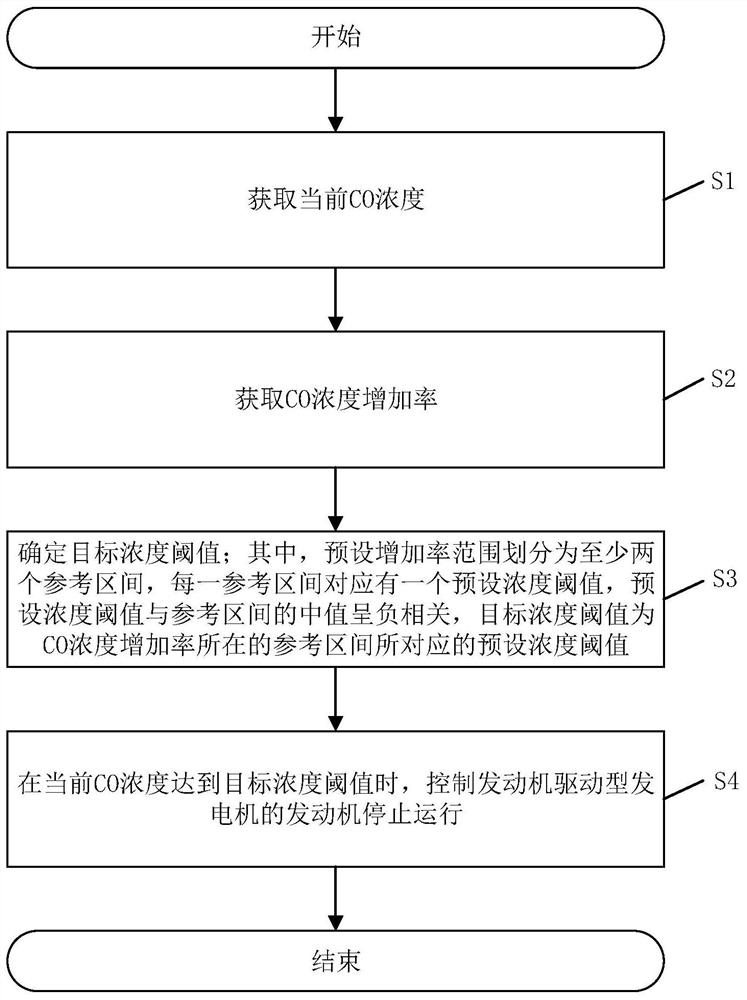

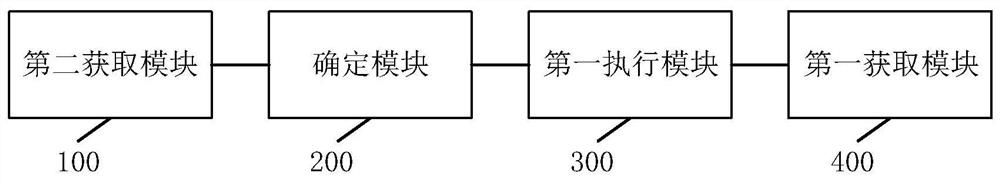

ActiveCN113374587AControlled downtimeShutdown delayInternal combustion piston enginesEngine controllersElectric generatorEngineering

The invention discloses an engine-driven generator and a control method and system thereof. The control method comprises the following steps that the current CO concentration is obtained, the CO concentration increasing rate is obtained, a target concentration threshold value is determined, and an engine of the engine-driven generator is controlled to stop running when the current CO concentration reaches the target concentration threshold value; wherein the preset increase rate range is divided into at least two reference intervals, each reference interval corresponds to a preset concentration threshold value, the preset concentration threshold value is in negative correlation with a median value of the reference intervals, and the target concentration threshold value is the preset concentration threshold value corresponding to the reference interval where the CO concentration increasing rate is located. According to the control method, the appropriate target concentration threshold value can be determined according to the CO concentration increasing rate, so that the engine is controlled to stop in advance or in a delayed manner, the purpose of preventing the CO concentration from exceeding the standard is achieved, and the safety of a user is improved.

Owner:LONCIN MOTOR +2

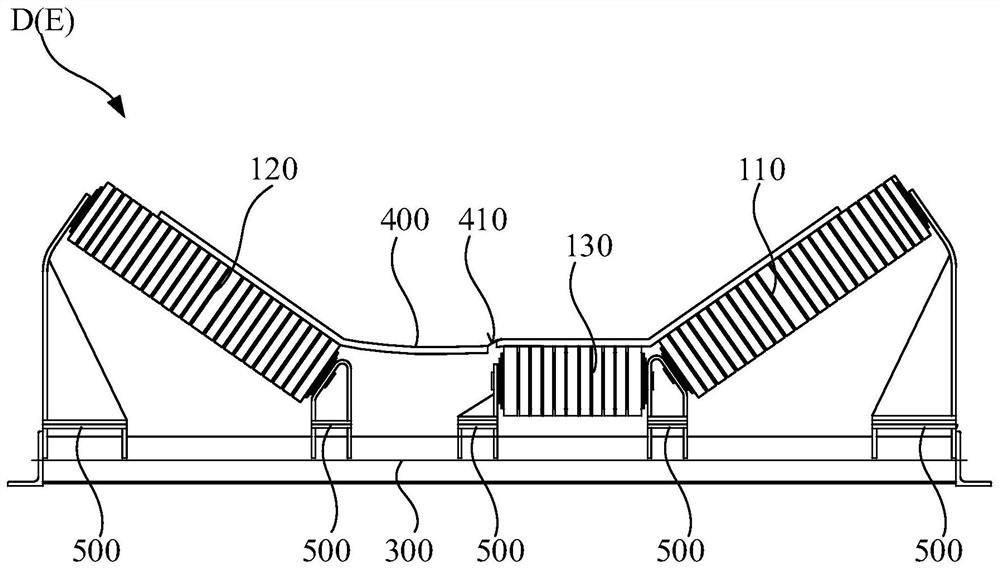

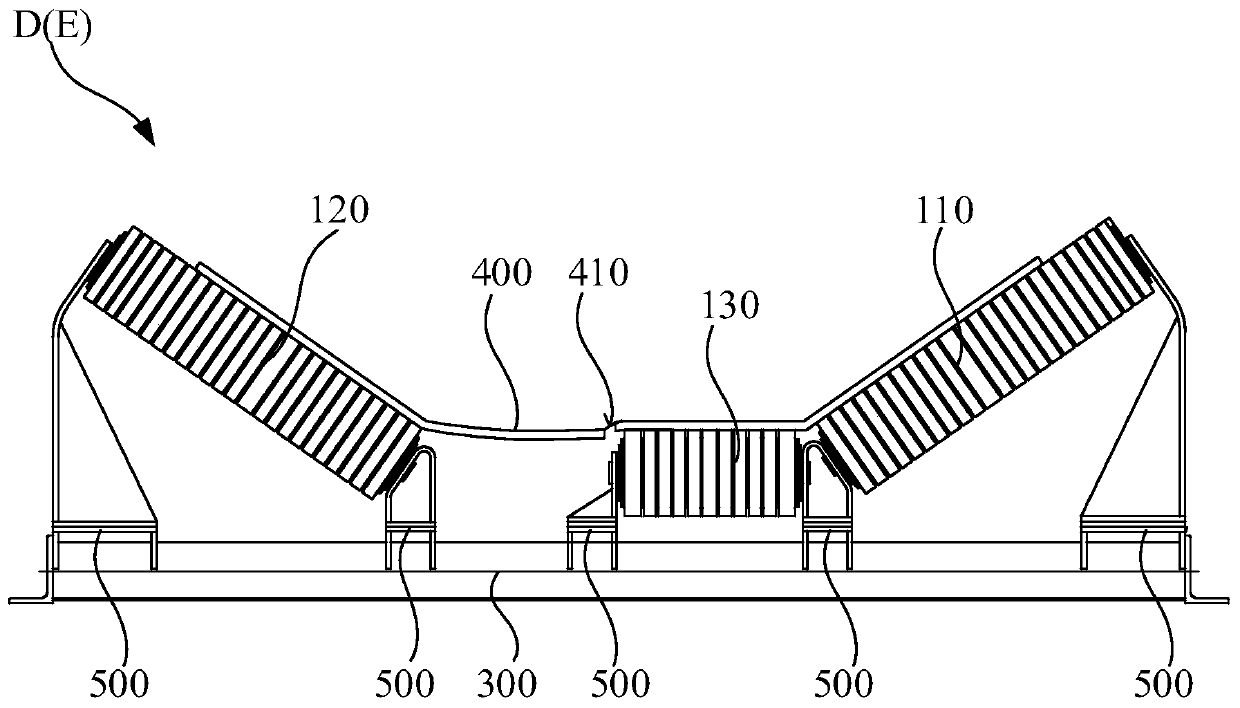

Belt tearing opening shaping structure and belt conveyor

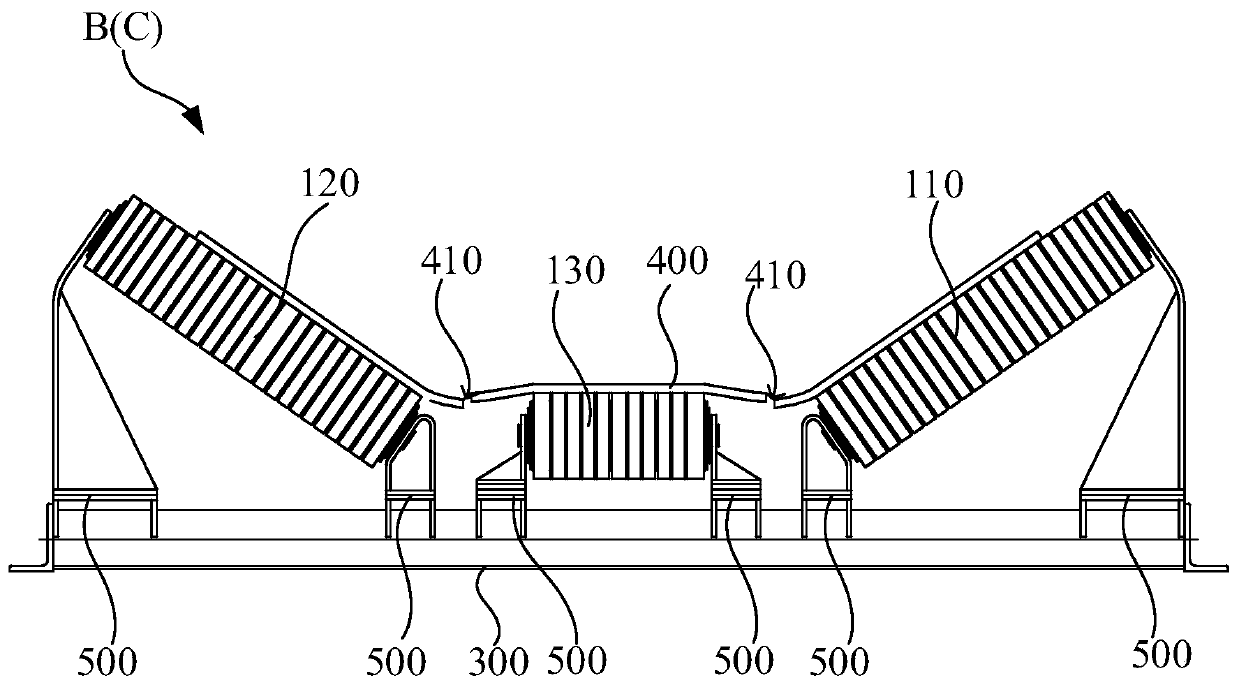

The invention relates to a belt tearing opening shaping structure and a belt conveyor. The belt tearing opening shaping structure comprises a shaping carrier roller set, a groove type carrier roller set and a carrier roller frame. The shaping carrier roller set comprises a middle shaping carrier roller, a first side shaping carrier roller and a second side shaping carrier roller, and the first side shaping carrier roller and the second side shaping carrier roller are arranged at the two ends of the middle shaping carrier roller. The first side shaping carrier roller and the second side shapingcarrier roller are obliquely arranged and are inclined towards the middle shaping carrier roller. The middle shaping carrier roller and the first side shaping carrier roller are arranged at an interval, or the middle shaping carrier roller and the second side shaping carrier roller are arranged at an interval. The shaping carrier roller set is arranged in parallel to the groove type carrier roller set in the length direction, and the groove type carrier roller set comprises a middle carrier roller. The groove type carrier roller set and the shaping carrier roller set are both arranged on thecarrier roller frame, and the distance between the middle shaping carrier roller and the bottom of the carrier roller frame is larger than the distance between the middle carrier roller and the bottomof the carrier roller frame. According to the mechanism, it is guaranteed that a tearing opening is detected by a tearing detecting device, a worker can repair the belt conveyor in time, and economiclosses are reduced.

Owner:SHENHUA TIANJIN COAL TERMINAL

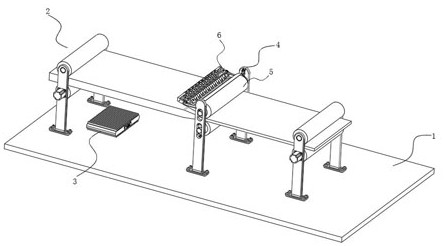

A press roller machine for home textile fabric production

ActiveCN113403793BControlled downtimeCannot be effectively clearedMechanical cleaningPressure cleaningForeign matterIndustrial engineering

Owner:南通祥元纺织有限公司

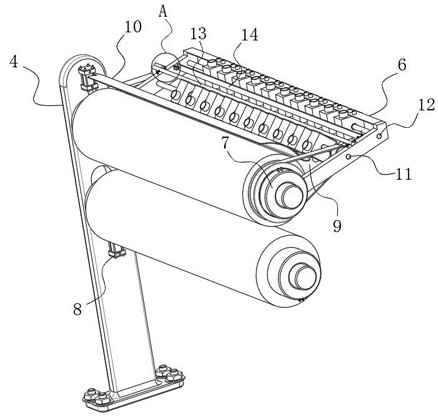

Pressure tester capable of intelligently sensing

InactiveCN107436265AControlled downtimeRecord pressureMaterial strength using repeated/pulsating forcesAudio power amplifierTester device

The invention discloses an intelligent sensing pressure tester, which includes a motor, a main body of the tester, and a test platform, and is characterized in that it also includes: a measuring head for applying pressure controlled by the motor, an amplifier and a PLC, the measuring head and the The main body of the tester is connected and located above the test platform. There is a force sensor inside the above-mentioned measuring head. The above-mentioned force sensor collects the force signal in real time and transmits the signal to the amplifier connected to it. The above-mentioned amplifier feeds back the signal to the PLC. The above-mentioned PLC is connected to the motor and Control the motor to run or stop according to the feedback signal. The benefits are: 1. It can reliably judge when the screen is damaged and control the shutdown of the pressure tester; 2. Record the pressure when the screen is damaged, and at the same time record the withstand voltage times of the screen under a certain pressure.

Owner:HUANGSHI XIANDA ELECTRIC CO LTD

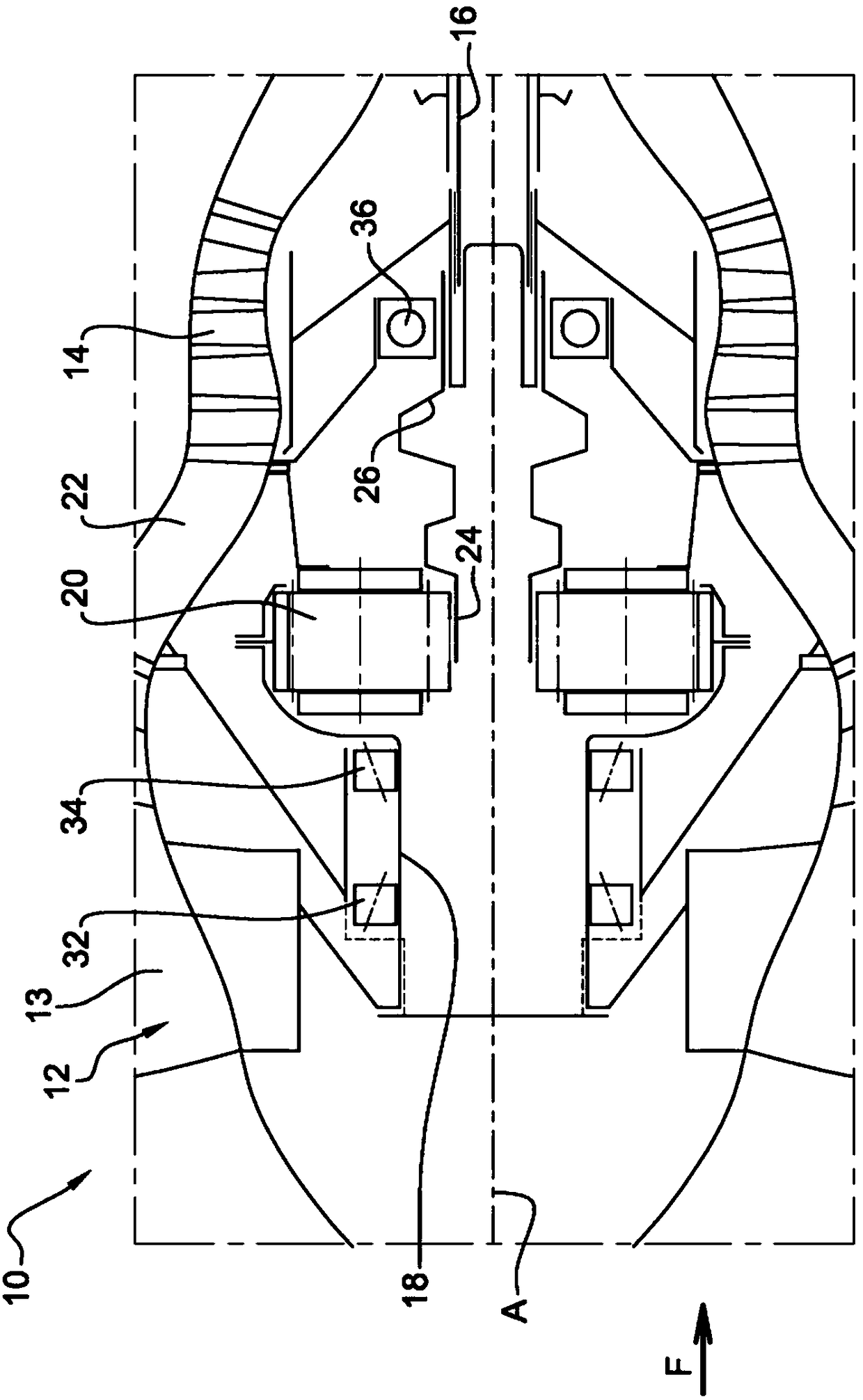

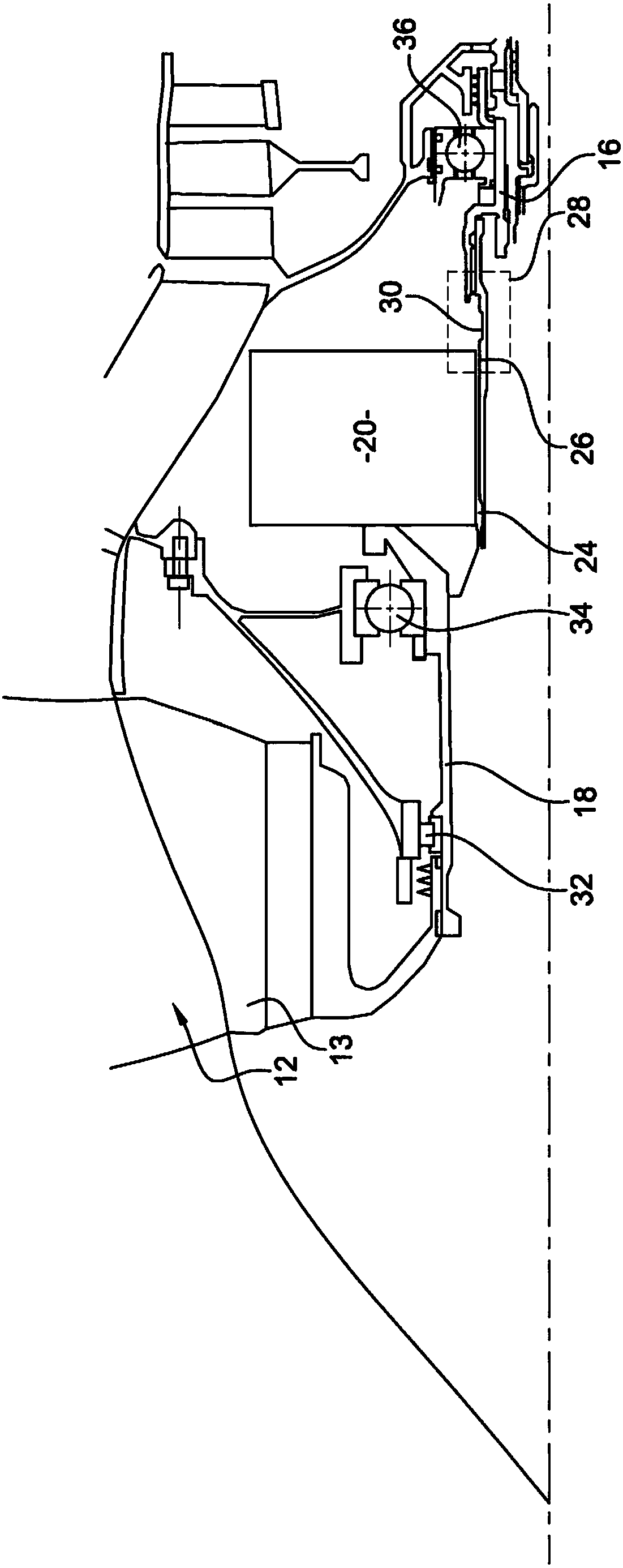

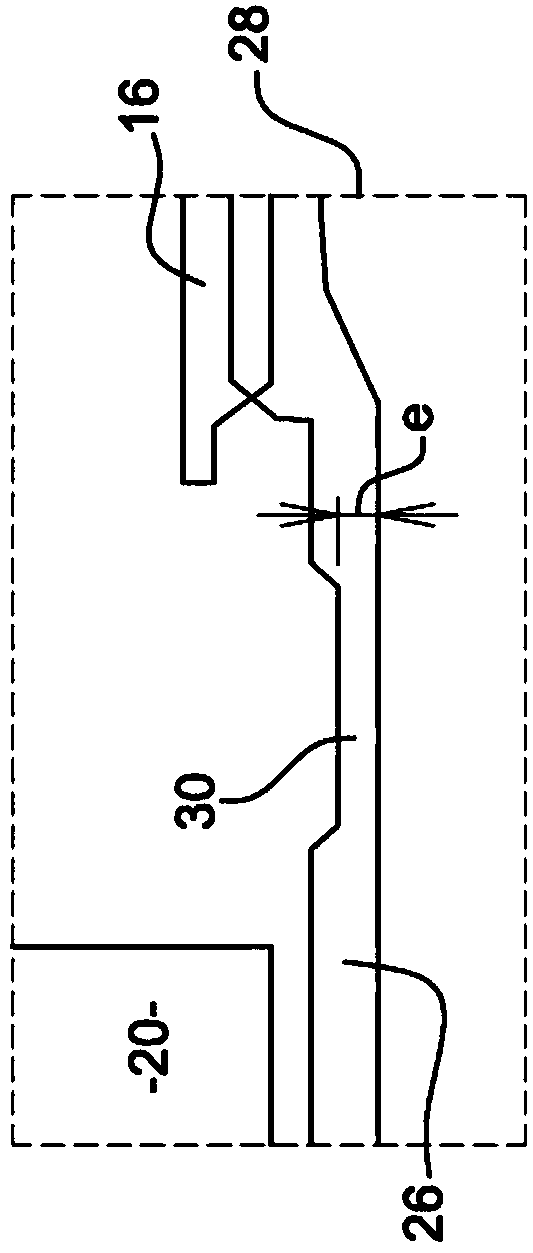

Turbomachines including means for decoupling fans

The invention relates to a turbomachine comprising a fan shaft (12) driven by a turboshaft (16) via a device (20) for reducing the rotational speed, characterized in that the turbomachine comprises a Decoupling means (28) between the device (20) and the turbine shaft (16) capable of decelerating in response to exceeding a determined resistive torque applied to the turbine shaft (16) by the deceleration device (20) The device (20) and the turbine shaft (16) are decoupled.

Owner:SAFRAN AIRCRAFT ENGINES SAS

Control method, device and air conditioner

ActiveCN104048388BControlled downtimeImprove reliabilitySpace heating and ventilation safety systemsLighting and heating apparatusBoundary valuesCondensation temperature

The embodiment of the present invention discloses a control method, device and air conditioner, simultaneously detecting the first pressure value of the exhaust port of the compressor and the second pressure value of the air inlet port, and converting the first pressure value into the corresponding first condensation The temperature value, that is, the actual condensation temperature, converts the second pressure value into the corresponding evaporation temperature value, and obtains the maximum condensation temperature value corresponding to the evaporation temperature value, when the first condensation temperature value is greater than or equal to the maximum condensation temperature value , indicating that the actual pressure of the discharge port of the compressor exceeds the high-pressure boundary value of the rated pressure range, and the compressor is immediately controlled to stop, so that once the actual discharge port pressure exceeds the high-pressure boundary value of the rated pressure range, the compressor is immediately activated. Shutdown protection improves the reliability of compressor shutdown protection.

Owner:GREE ELECTRIC APPLIANCES INC

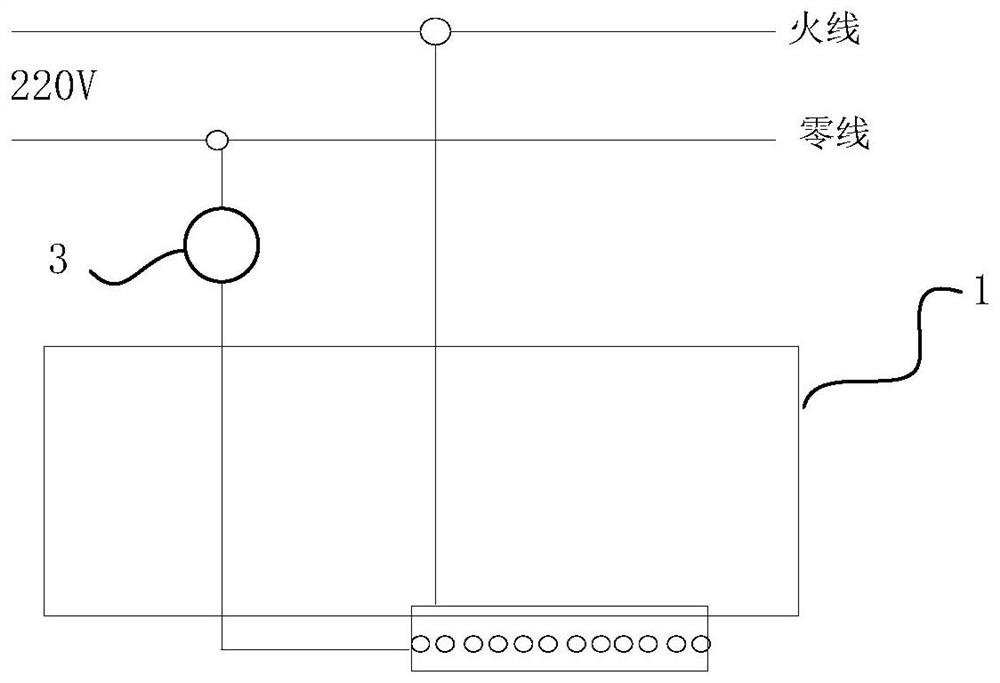

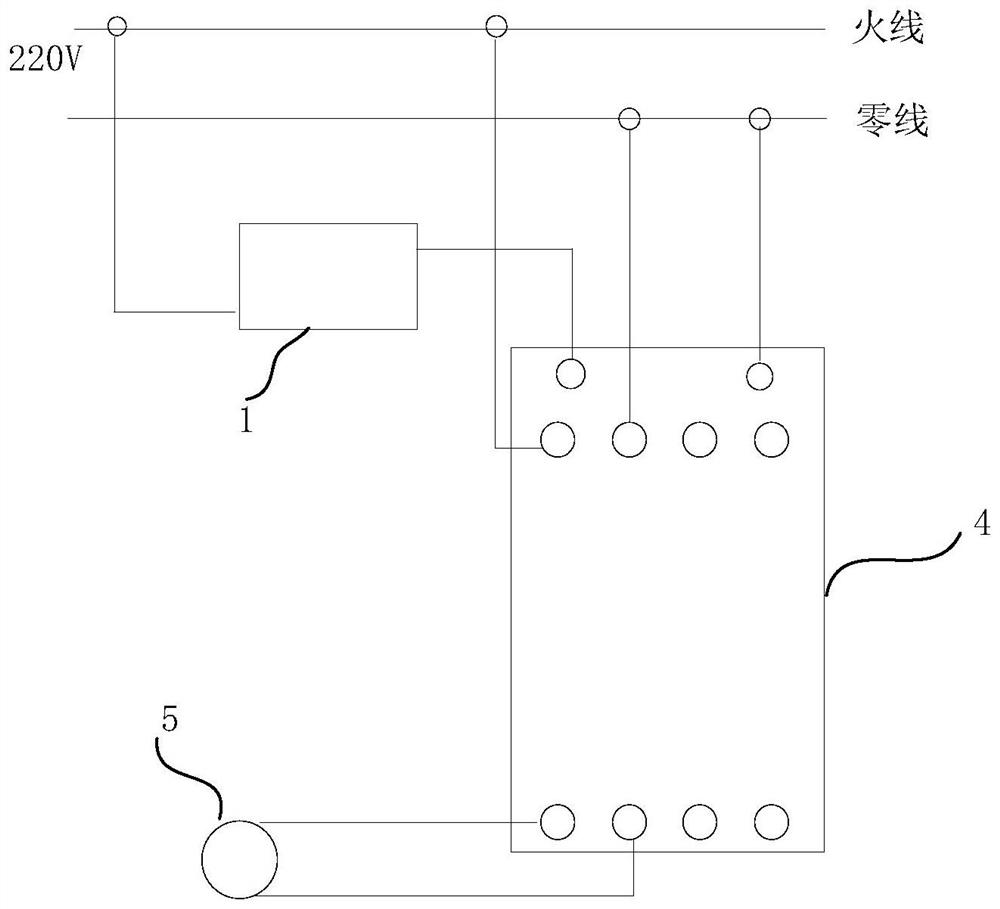

Remote control device and raised dust spraying system

PendingCN114019887AControlled downtimeAvoid wastingProgramme controlComputer controlWireless controlRemote control

The invention discloses a remote control device, which is characterized in that the remote control device comprises a wireless control device, the wireless control device is in wireless communication connection with a mobile phone device, the wireless control device comprises a switch contact, and the switch contact of the wireless control device and a load device are connected in series in a power supply circuit. According to the invention, if an operator forgets to turn off a switch or it is inconvenient for the operator to enter a construction site in severe weather, the operator can remotely turn off the load device through the mobile phone device, so that waste of hydroelectric energy can be avoided, and manpower can be liberated to a great extent. The invention further discloses a raised dust spraying system.

Owner:THE FOURTH OF CHINA EIGHTH ENG BUREAU

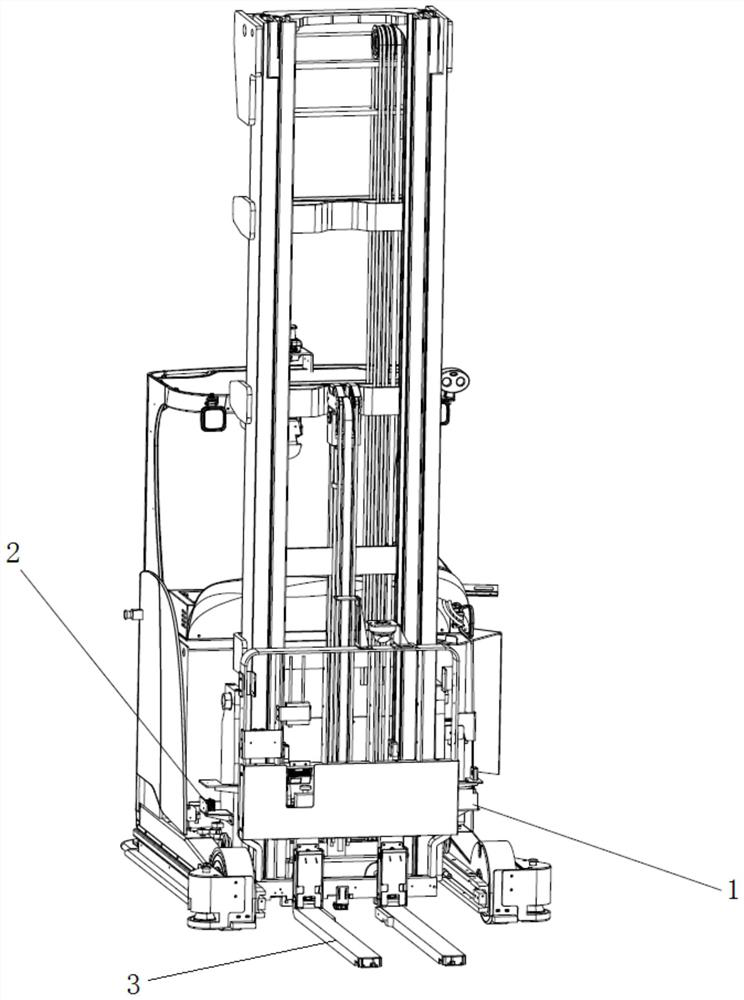

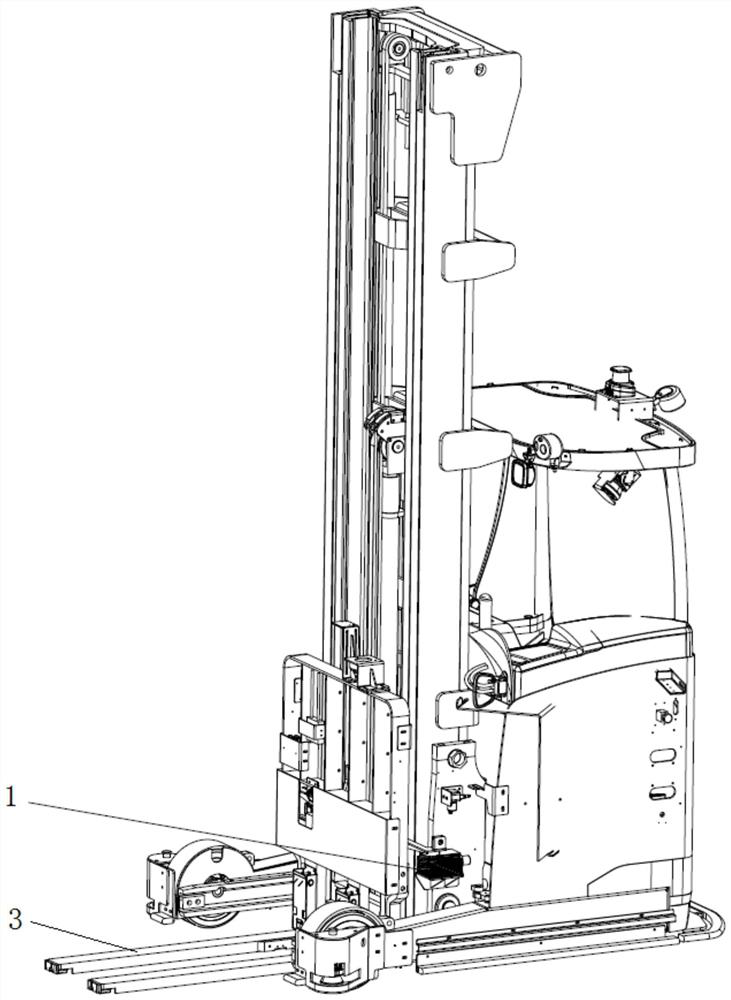

Forklift and forklift protection system thereof

ActiveCN111960332AControlled downtimeImprove securitySafety devices for lifting equipmentsInformation controlControl engineering

The invention discloses a forklift and a forklift protection system thereof. The forklift protection system comprises a fork, a first sensor, a second sensor and a controller, wherein the first sensorand the second sensor are electrically connected with the controller; the first sensor is connected with the fork and is used for detecting the lifting height of the fork and sending first height information to the controller; the second sensor is used for detecting the lifting height of the fork and sending second height information to the controller; and the controller is used for generating afault instruction when a lifting height difference corresponding to the first height information and the second height information exceeds a preset value so as to control the forklift to stop. According to the technical scheme, the problem of feedback errors caused by damage of a digging rope encoder when a fork AGV fork is lifted is solved, and the safety of the forklift is improved.

Owner:HANGCHA GRP +1

A novel flat knitting machine intelligent color selecting device

The invention provides a novel flat knitting machine intelligent color selecting device which can make a flat knitting machine stop to prevent inferior-quality products on the condition of yarn breakage. The novel flat knitting machine intelligent color selecting device mainly comprises connecting rods, a switch rod, a sensor, gear buttons, yarn outlet fasteners, a gear device, a fixing plate, a rotary switch, yarn inlet holes and a dimmer. Through technical improvement, the rotary switch is additionally provided with the sensor; in case of yarn breakage, the phenomenon that it is impossible to stop a flat knitting machine because of insulation is avoided. Through the installation and use of the product, the novel flat knitting machine intelligent color selecting device is stable in performance and low in error rate.

Owner:绍兴市柯桥区柯桥中学

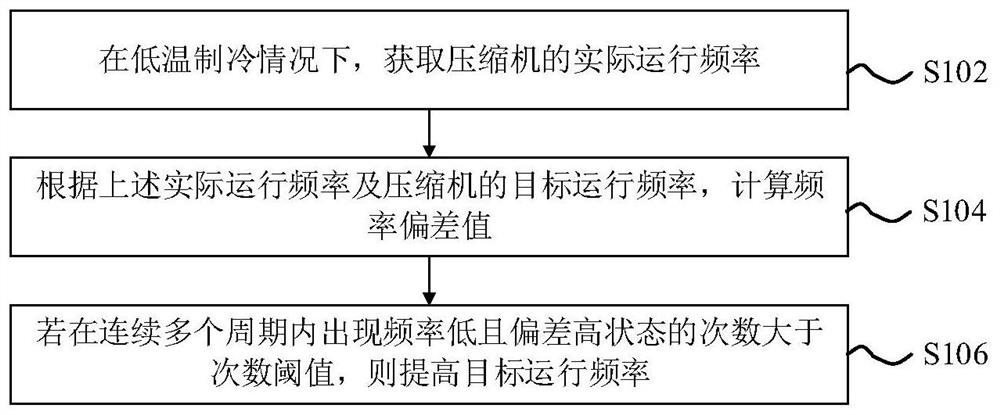

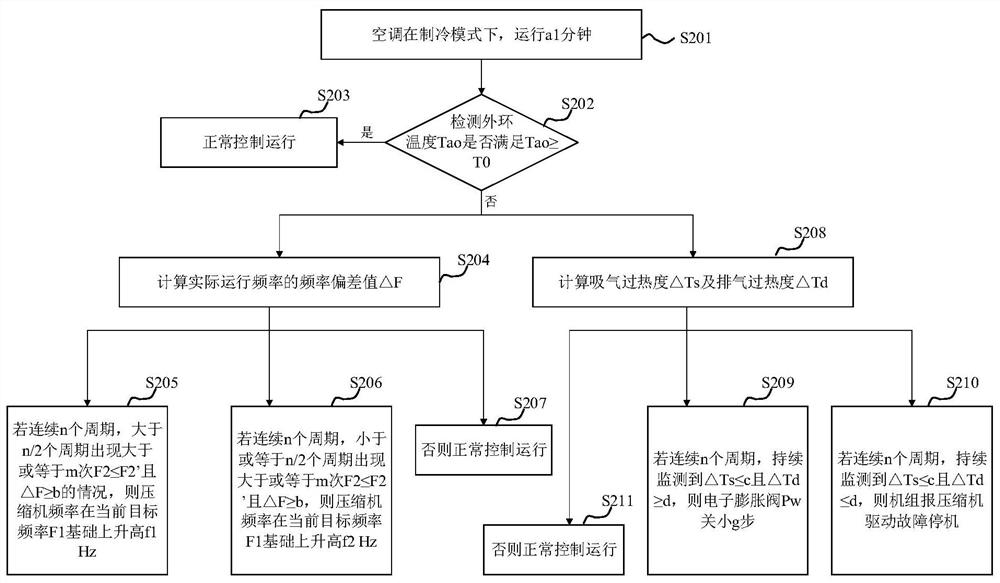

Control method and device for low-temperature refrigeration of air conditioner and air conditioner

ActiveCN113465113BImprove running stabilityAvoid unconnected downtime protectionMechanical apparatusSpace heating and ventilation safety systemsFrequency meterRefrigeration

The invention provides a method and device for controlling low-temperature refrigeration of an air conditioner, and an air conditioner. The method includes: obtaining the actual operating frequency of a compressor in the case of low-temperature refrigeration; and calculating the frequency according to the actual operating frequency and the target operating frequency of the compressor. Deviation value; if the number of low-frequency and high-deviation states in multiple consecutive cycles is greater than the number threshold, then increase the target operating frequency. The present invention can determine whether to increase the target operating frequency according to the actual operating frequency and the size of the frequency deviation value in a certain period. By increasing the target operating frequency, the operating stability of the air conditioner during cooling operation in transitional seasons can be increased, and compressors and compressors can be avoided. The drive is not connected to shutdown protection.

Owner:NINGBO AUX ELECTRIC +1

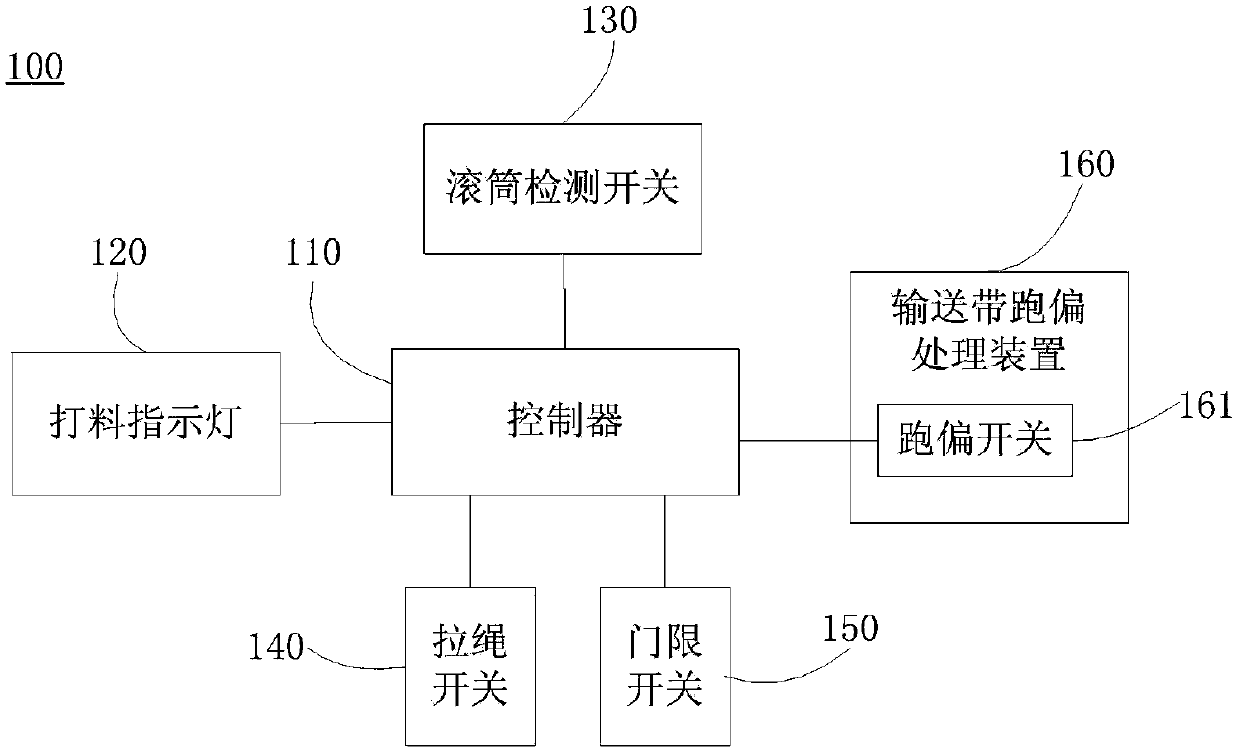

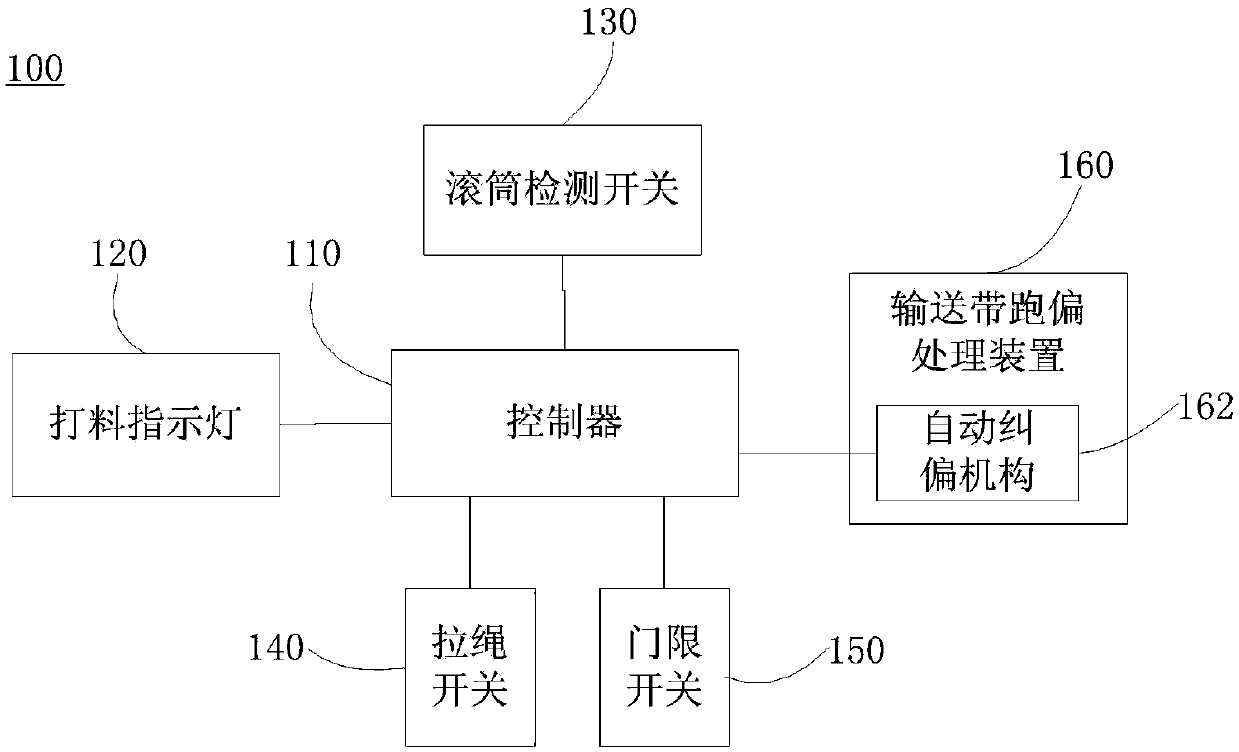

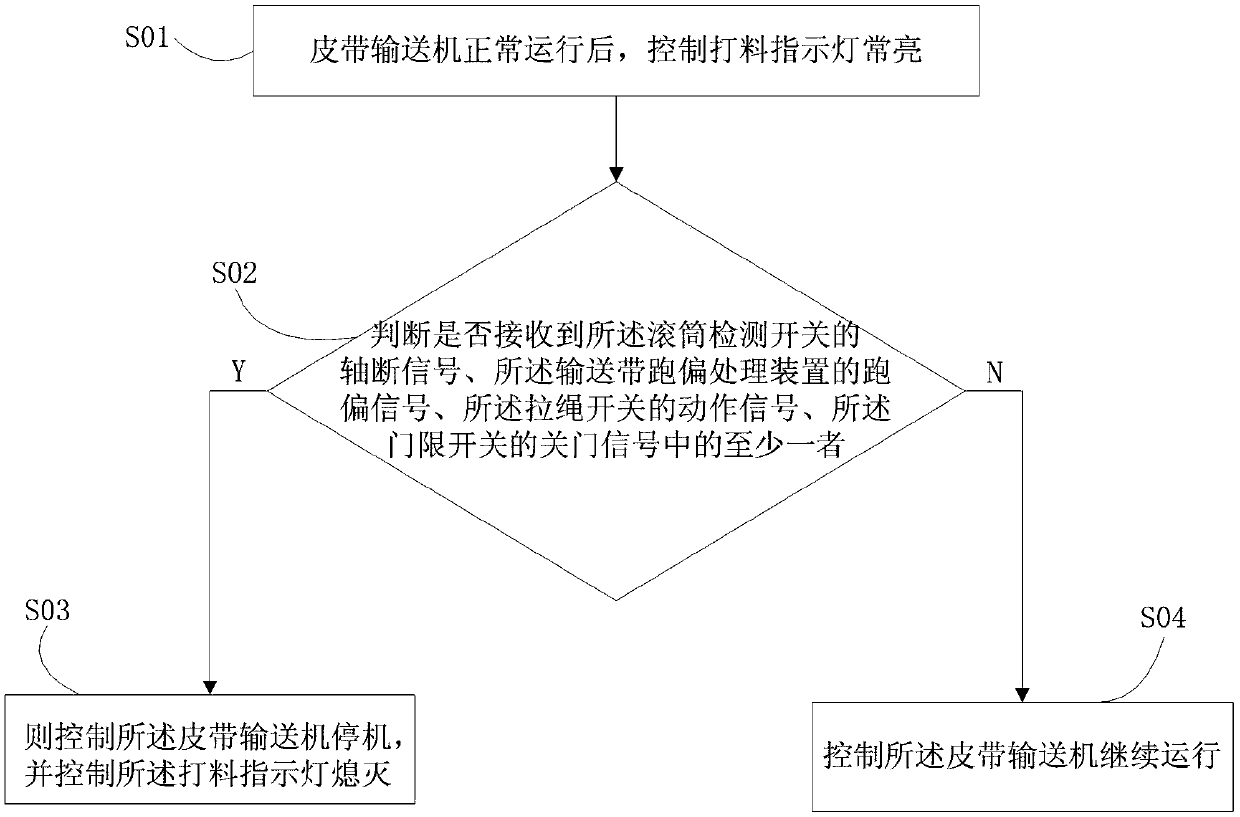

Aluminum oxide belt conveying system and method

InactiveCN109533869ASatisfy the large supplyFulfil requirementsConveyorsControl devices for conveyorsEngineeringDelivery system

The invention discloses an aluminum oxide belt conveying system. The aluminum oxide belt conveying system comprises a controller, a belt conveyor, a material beating indication lamp, a roller detection switch, a conveying belt off-tracking treatment device, a pull rope switch and a door limiter switch, wherein the belt conveyor, the material beating indication lamp, the roller detection switch, the conveying belt off-tracking treatment device, the pull rope switch and the door limiter switch are connected with the controller. The material beating indication lamp is mounted on an aluminum oxidewarehouse material beating platform. The roller detection switch is arranged on a roller bearing seat and matched with the outer diameter of a roller. The conveying belt off-tracking treatment deviceand the pull rope switch are arranged in the conveying direction of the belt conveyor. The door limiter switch is arranged at an inlet of a maintenance platform of the belt conveyor. When the belt conveyor operates normally, if the controller receives one or more of a shaft rupture signal of the roller detection switch, an off-tracking signal of the conveying belt off-tracking treatment device, an actuating signal of the pull rope switch and a door closing signal of the door limiter switch, the belt conveyor is controlled to stop and the material beating indication lamp is controlled to be off, so that the site emergency stop occurring when an accident is caused is achieved; and the aluminum oxide belt conveying system is high in automation degree and safety. The invention further discloses an aluminum oxide belt conveying method.

Owner:YUNNAN YONGXIN ALUMINUM

Electrolytic capacitor motor drive system and its control method and device

ActiveCN106208869BControlled downtimeAvoid getting out of controlElectronic commutation motor controlAC motor controlCapacitanceMotor drive

The invention discloses an electrolytic capacitor-free motor driving system and a control method and device thereof. The method comprises the following steps of detecting an input AC voltage of the motor driving system in real time; judging whether an input AC power supply is disconnected for a short time or not according to the input AC voltage; and controlling a compressor motor to stop if the input AC power supply is disconnected for a short time. By the method, the compressor motor can be timely controlled to stop when the input AC power supply is disconnected for a short time, so that the compressor motor is effectively prevented from being out-of-control or the motor driving system is effectively prevented from being damaged, and the stable and reliable running of the compressor motor and the motor driving system is ensured.

Owner:GD MIDEA AIR-CONDITIONING EQUIP CO LTD +1

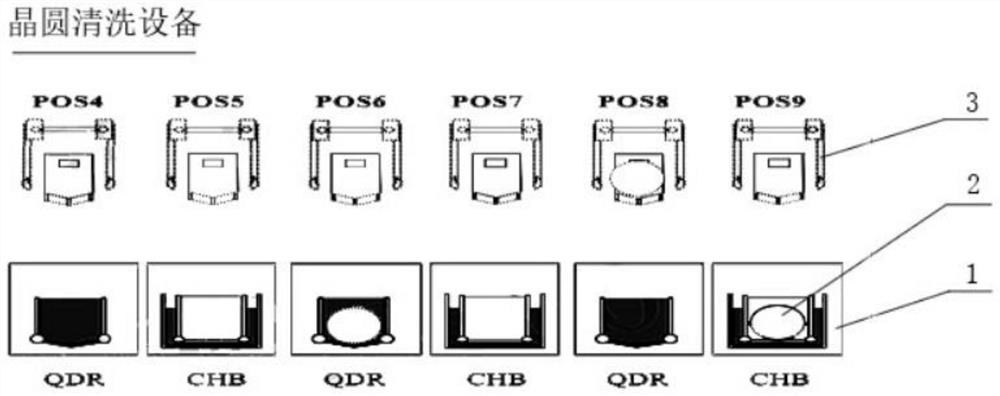

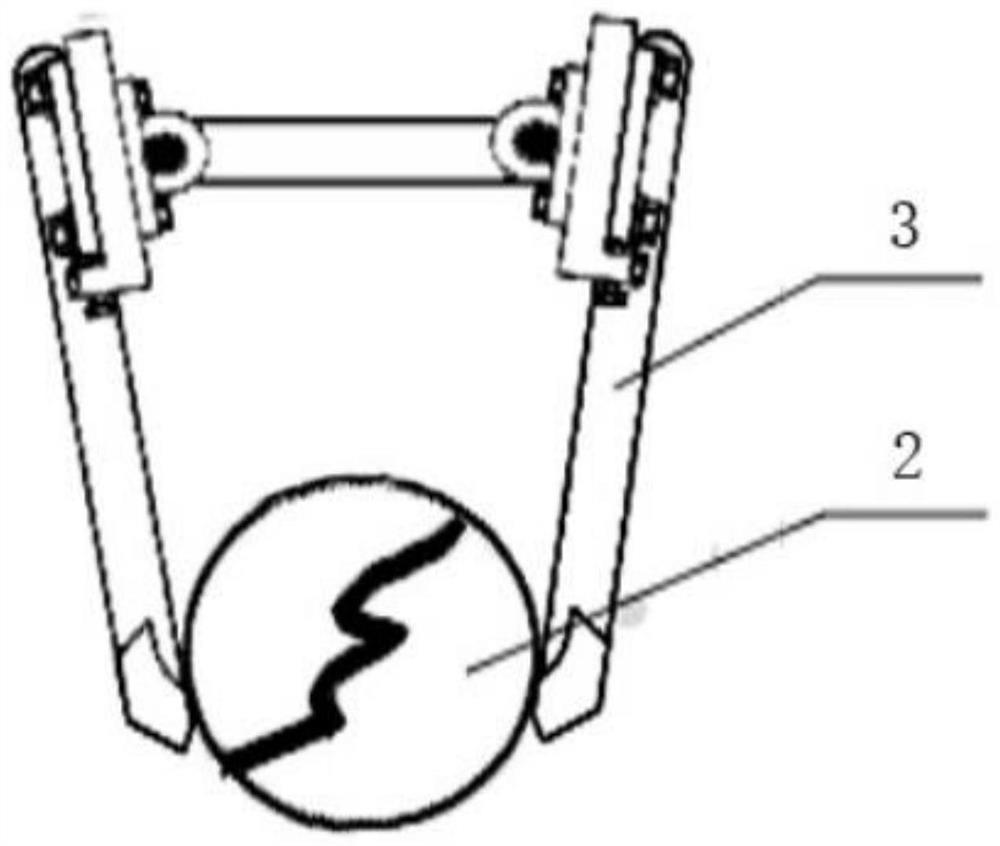

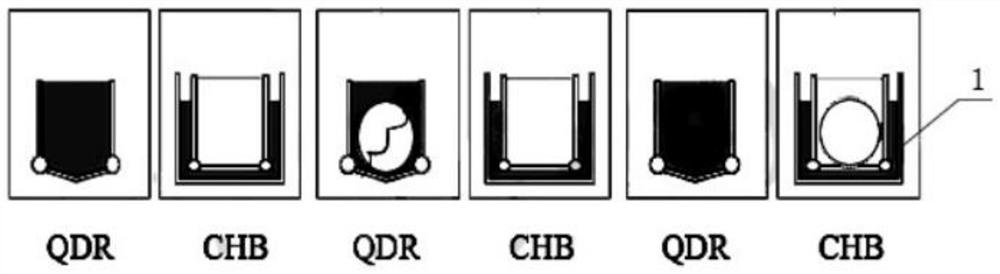

Semiconductor wafer detection device and method and wafer cleaning system

PendingCN114256080ASolve pollutionControlled downtimeSemiconductor/solid-state device testing/measurementSemiconductor/solid-state device manufacturingWaferProcess engineering

The invention discloses a semiconductor wafer detection device and method and a wafer cleaning system, relates to the technical field of semiconductor equipment, and aims to solve the problems of wafer pollution and equipment shutdown caused by the fact that wafer damage is not detected in time in the wafer cleaning process. The semiconductor wafer detection device comprises an automatic clamping mechanism; the image sensor is arranged on the automatic clamping mechanism, and the controller communicates with the image sensor. The semiconductor wafer detection method comprises the following steps: receiving a wafer image transmitted by the image sensor, and controlling the wafer cleaning equipment to stop under the condition of determining that the wafer is damaged according to the wafer image and a wafer initial image. The semiconductor wafer detection device provided by the invention is used for detecting the wafer damage state in a semiconductor cleaning process and preventing the influence of wafer damage on productivity.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com