Pressure tester with intelligent sensing function

A technology of intelligent perception and tester, which is applied to the testing of machines/structural components, instruments, measuring devices, etc., which can solve problems such as futility and inability to perceive whether the screen has been damaged

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following describes the present invention in detail with reference to the drawings and specific embodiments.

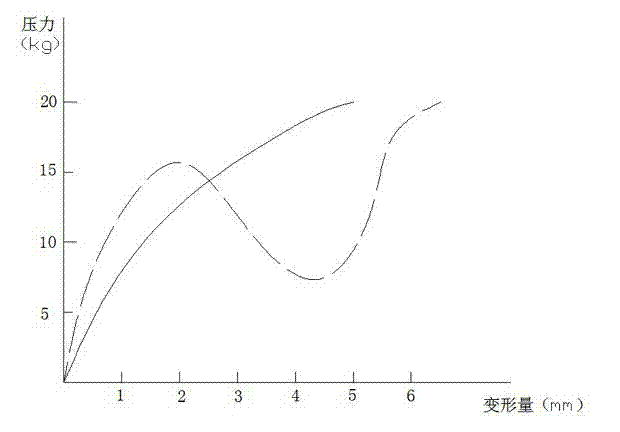

[0014] The intelligent sensing pressure tester of the present invention has the same basic structure as the existing pressure tester: including the motor, the main body of the tester, and the test platform. The most important difference is that it has the intelligent sensing function and can sense the pressure test process. Whether the screen has been damaged, stop the destructive test in time, and record the pressure when the screen is damaged and the number of pressure resistance under a certain pressure.

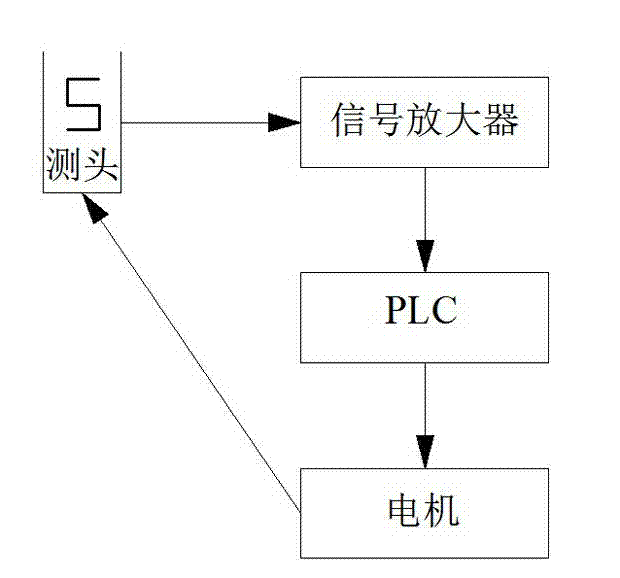

[0015] See figure 1 , The pressure tester of the present invention also includes: a probe for applying pressure controlled by a motor, an amplifier and a PLC (programmable logic controller). Among them, the probe is connected to the main body of the tester and is located above the test platform. There is a force sensor inside the probe. The force sensor col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com