Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

35results about How to "Change flow area" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

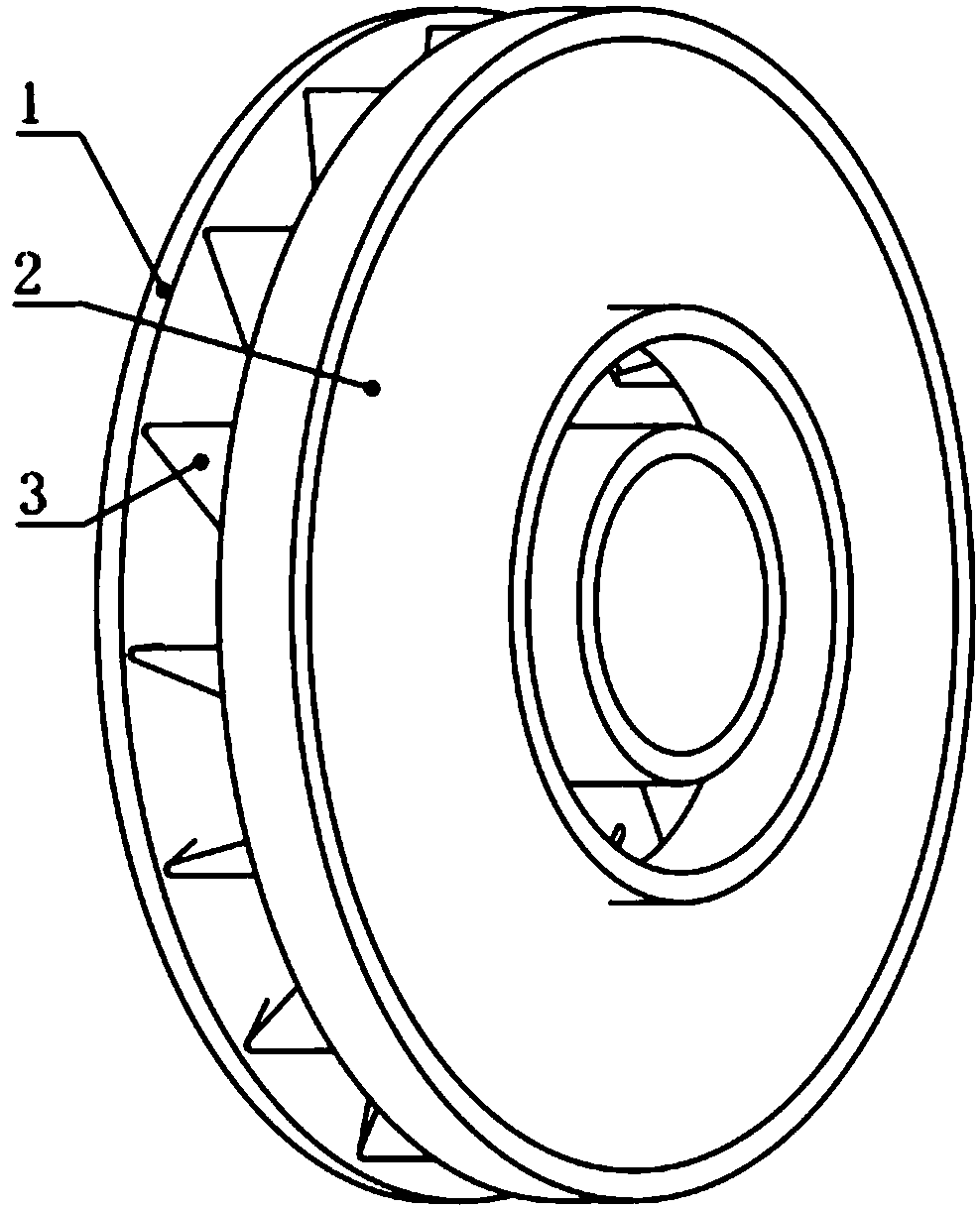

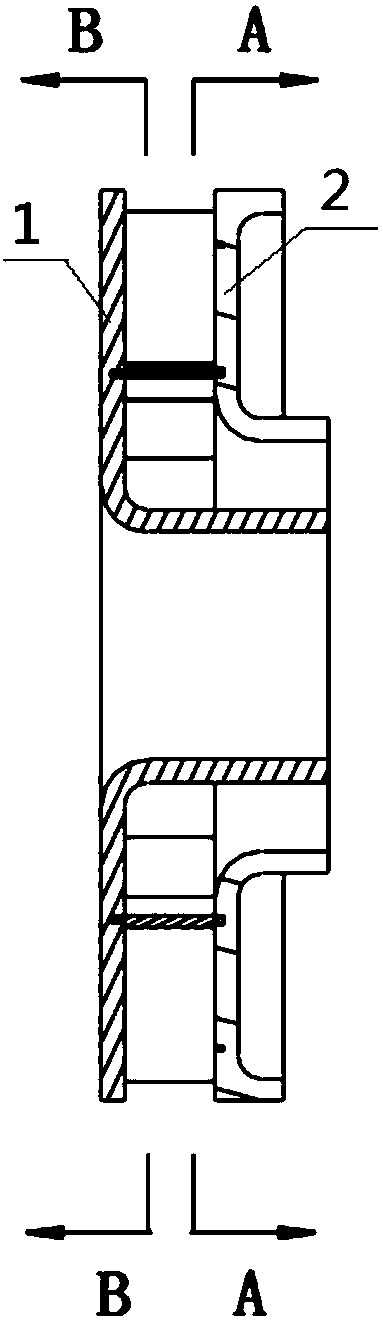

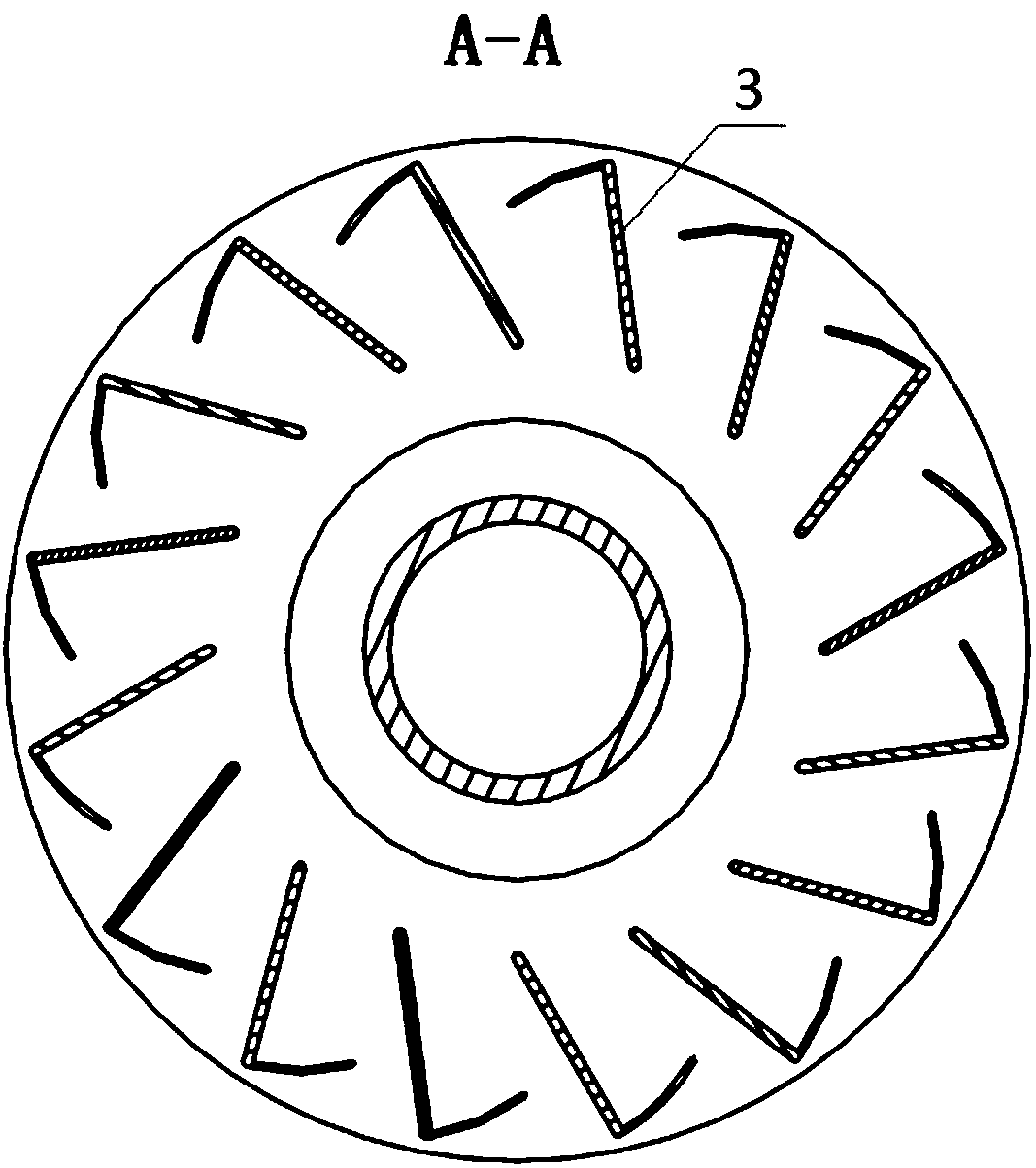

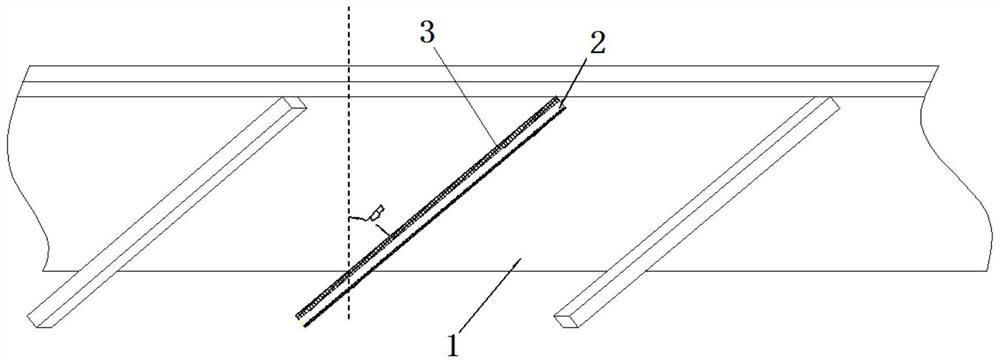

Variable flow whirlcone

ActiveCN108413442ARealize non-detachable online adjustmentIncrease profitContinuous combustion chamberEngineeringPower equipment

The invention belongs to the technical field of heat energy and power equipment and particularly relates to a variable flow whirlcone. The variable flow whirlcone comprises a rotatable inner hub, a fixed-type outer hub and rotatable blades, one sides of the rotatable blades are mounted on the fixed-type outer hub, and the other sides of the rotatable blades are mounted on the rotatable inner hub.The rotatable inner hub comprises an inner hub bottom plate and an inner hub outlet ring way, the fixed-type outer hub comprises an outer hub bottom plate and an outer hub outlet ring way, and the rotatable blades comprise rotatable blade bodies, first blade sliding shafts, first blade rotating shafts, second blade sliding shafts and second blade rotating shafts. According to the variable flow whirlcone, the blade mounting angle and the through flow area of the whirlcone can be changed, thus the flow of air entering the whirlcone and the swirling number can be changed, the defect that as for atraditional fixed-type whirlcone, the blade angle and the air flow cannot be adjusted is overcome, and non-detachable online adjustment of the whirlcone is achieved; and the time of shutting down forreplacing and test adjustment is saved, and the utilization rate of the variable flow whirlcone is increased.

Owner:中国船舶重工集团公司第七0三研究所

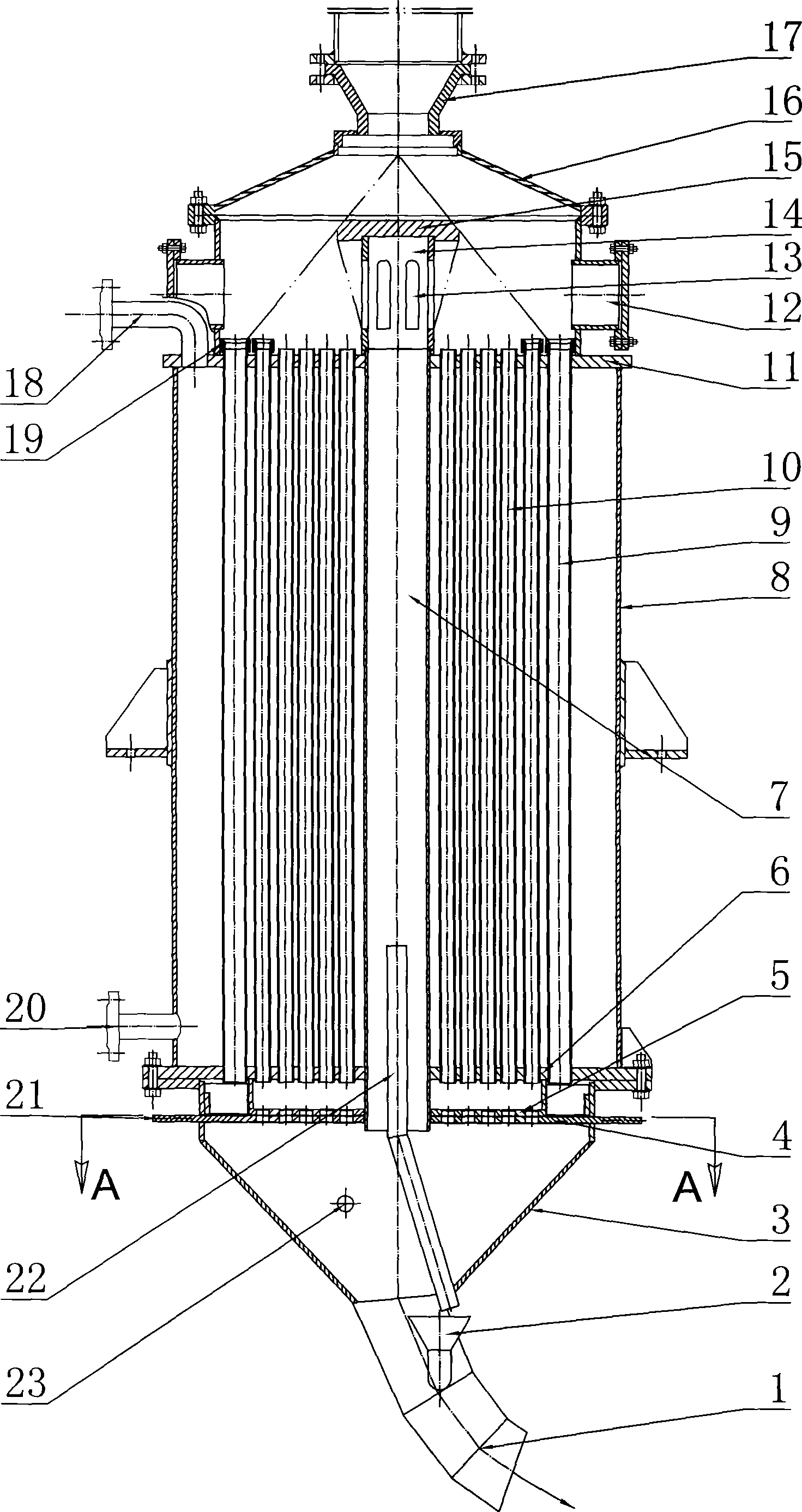

High-temperature slag economizer

InactiveCN101419031AEasy to adjust stacking heightChange dwell timeStationary tubular conduit assembliesSlagThermal water

The invention discloses a high-temperature slag economizer in the field of acid making equipment. The high-temperature slag economizer comprises a shell consisting of an upper shell, a lower shell and a heat exchange section cylinder body; the top part of the upper shell is provided with a slag inlet; the bottom of the lower shell is provided with a slag outlet; an upper tubeplate is arranged between the upper shell and the heat exchange section cylinder body; a lower tubeplate is arranged between the lower shell and the heat exchange section cylinder body; a plurality of heat exchange tubes are arranged between the upper tubeplate and the lower tubeplate; a water inlet and a water outlet are also arranged on the heat exchange section cylinder body; the centers of the upper tubeplate and the lower tubeplate are provided with central tubes; the upper end of the central tube is provided with a cylindrical central supporting seat; the side of the central supporting seat is provided with a pluralities of axial grooves; the upper end of the central supporting seat is horizontally provided with a disc-shaped feed divider; the periphery of the heat exchange tube is provided with a ring of bypassing tubes; the inside diameter of the heat exchange tube is less than that of the bypassing tube; the inside of the central tube is provided with a signal tube; and the lower part of the signal tube extends to the outside of the lower shell. The high-temperature slag economizer solves the problem that slag agglomerates and blocks the heat exchange tube, and permits the agglomerated slag to pass through the bypassing tube; and the device utilizes residual heat in the manufacturing industry of sulfuric acid to produce low-pressure steam and hot water, thereby saving fuel.

Owner:杨正清

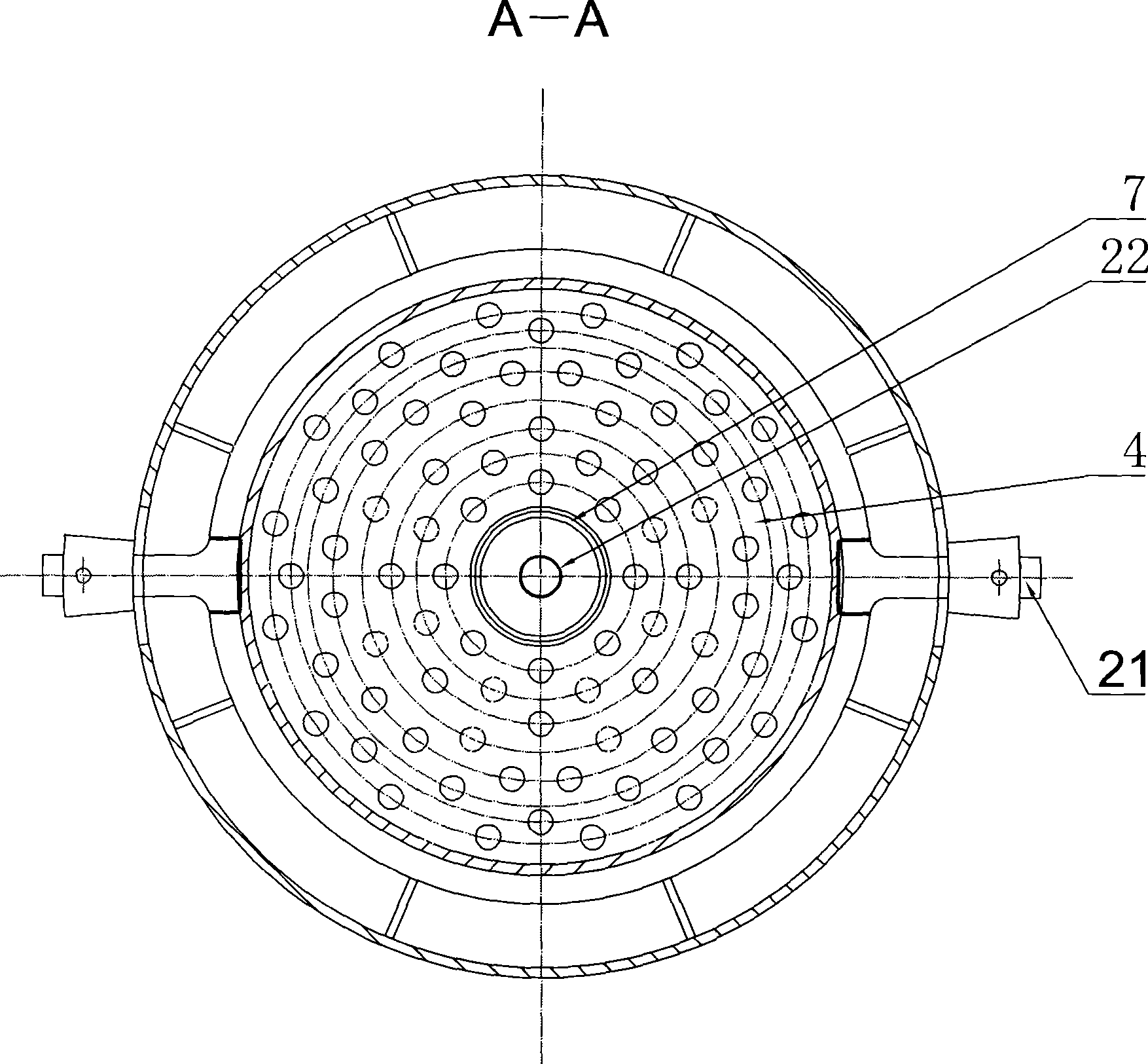

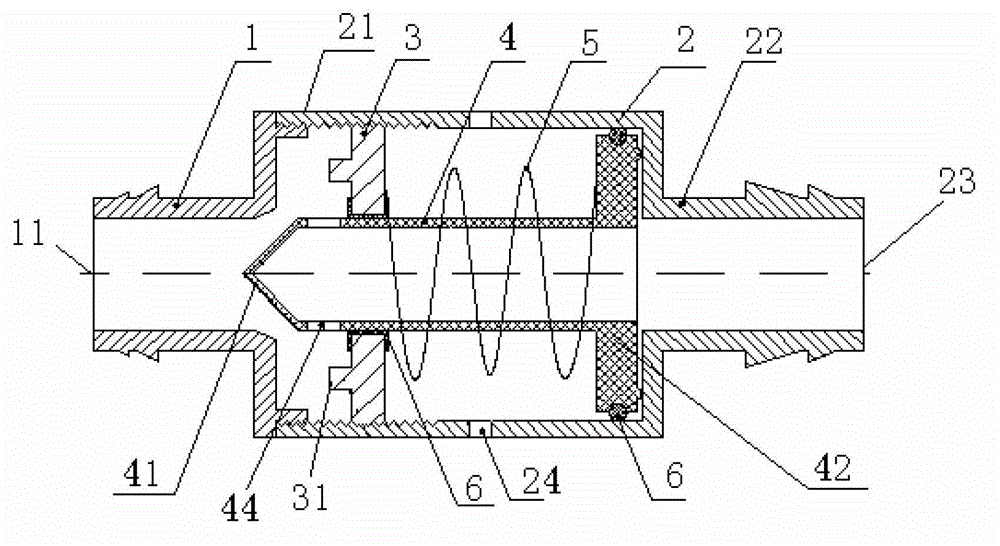

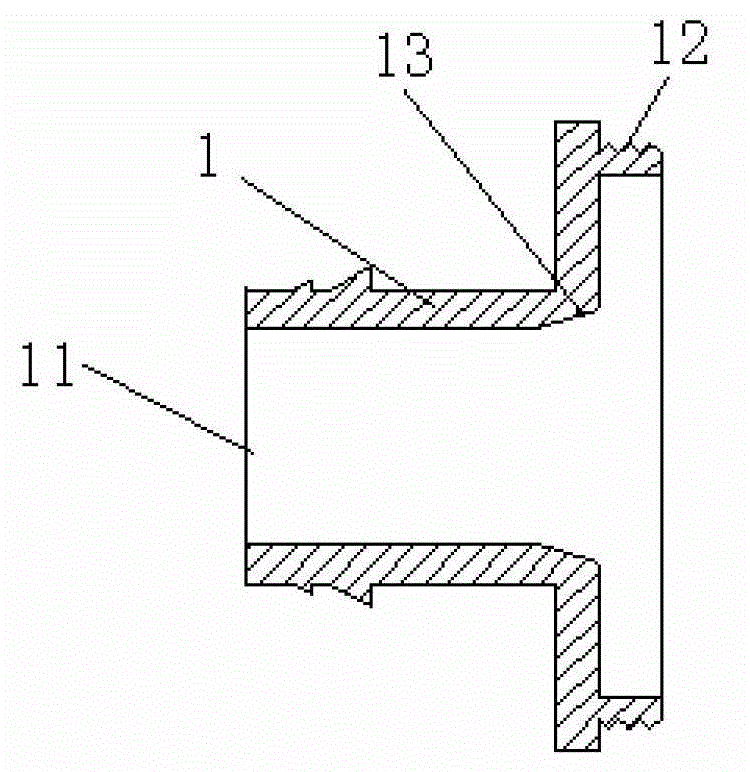

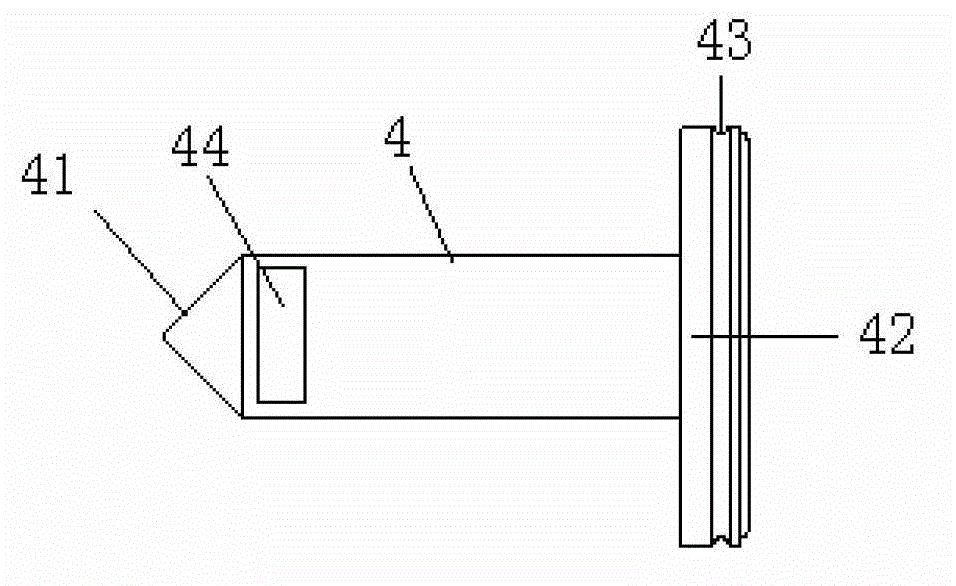

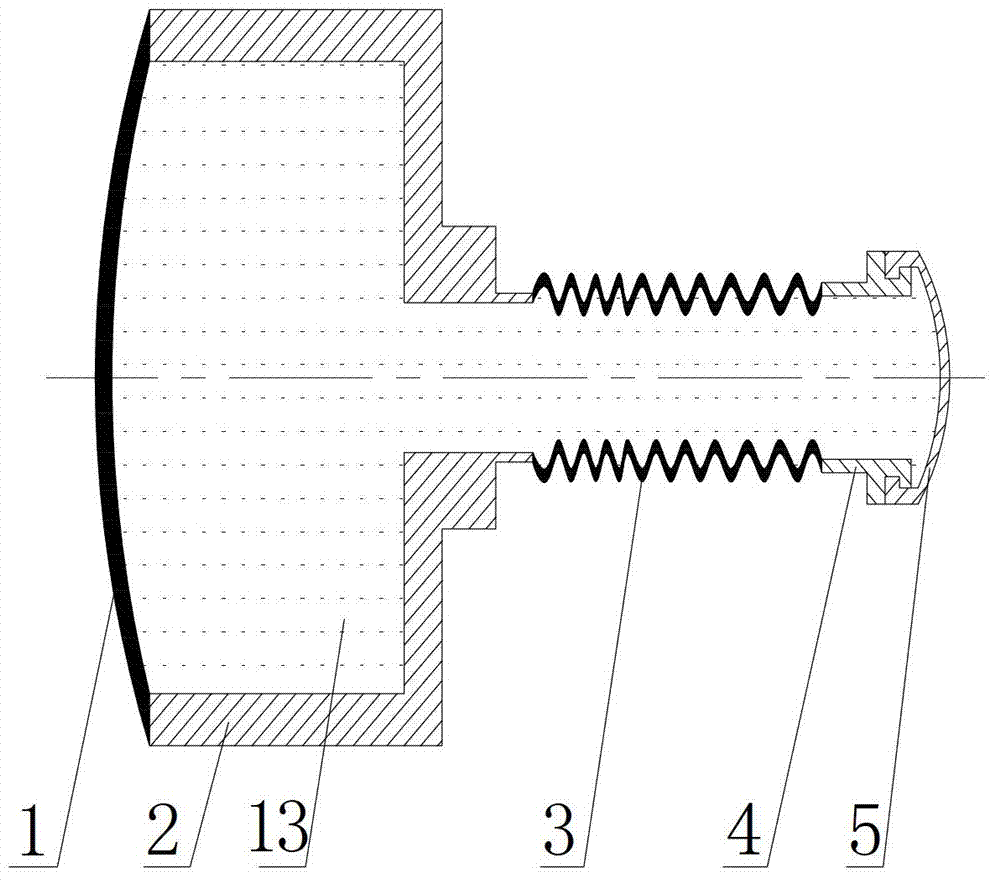

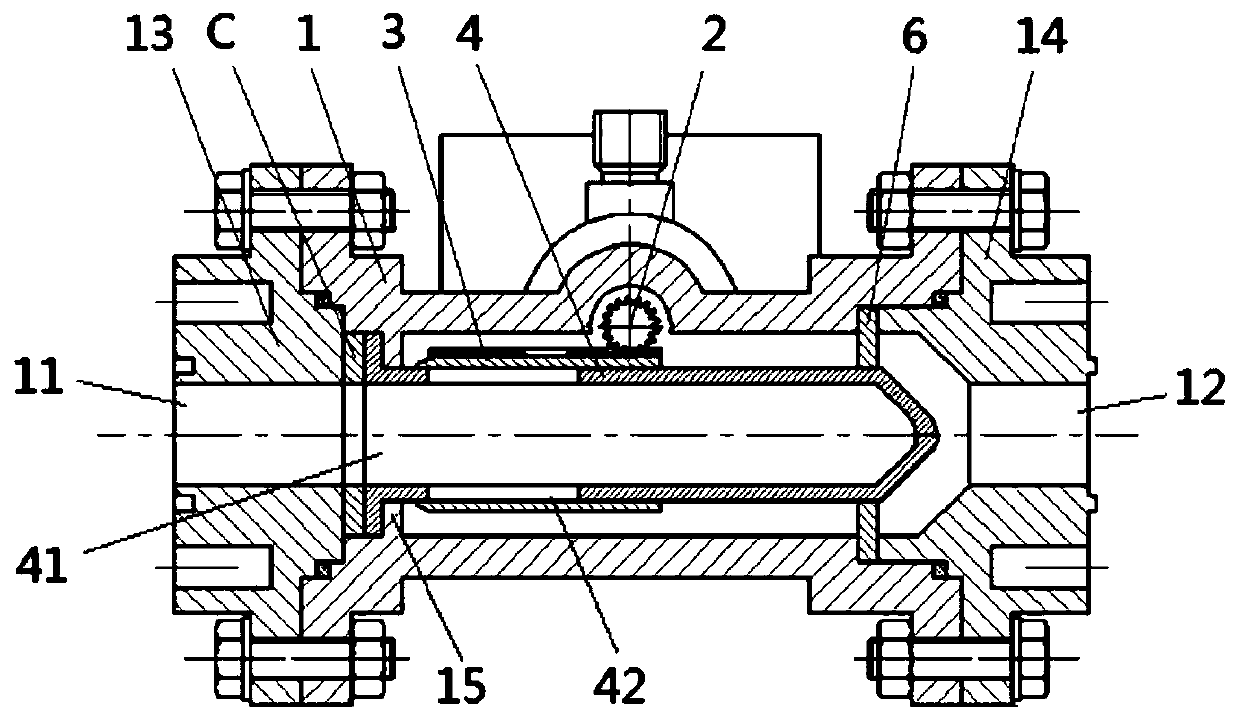

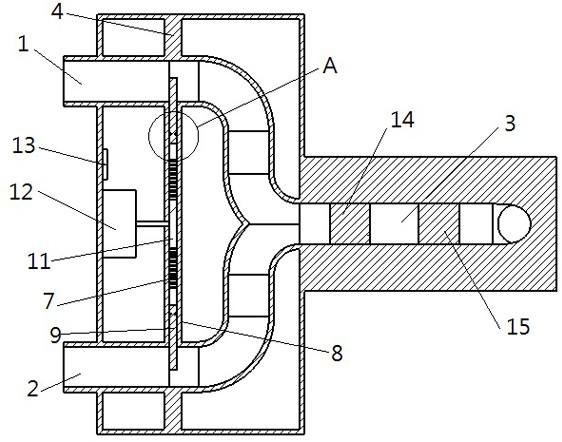

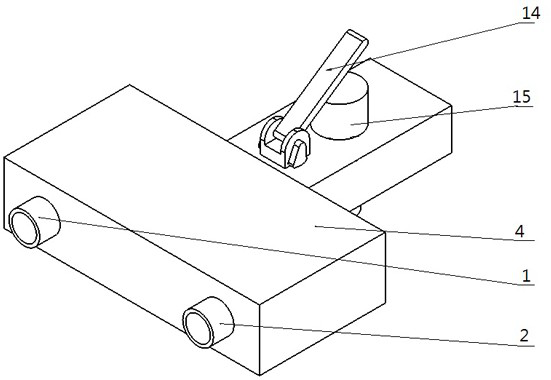

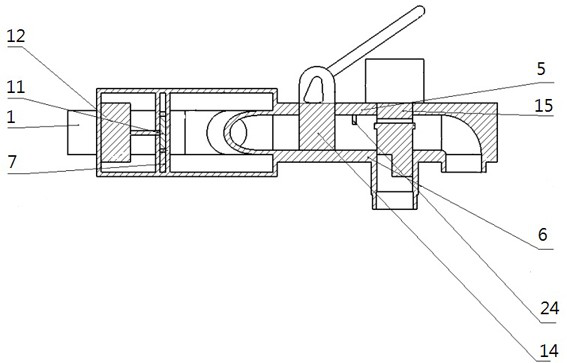

Preset pressure-adjustable capillary pressure adjuster

ActiveCN103141363AChange the preset elasticityChange flow areaWatering devicesCultivating equipmentsCapillary pressureEngineering

The invention relates to a preset pressure-adjustable capillary pressure adjuster, which is characterized by comprising an upstream shell, a downstream shell, a control body, a pressure adjusting assembly and a pressure adjusting spring, wherein one end of the upstream shell is provided with a water inlet; the pipe diameter of the other end of the upstream shell is enlarged; the downstream shell comprises a first cylinder and a second cylinder; the end part of the first cylinder is connected with the pipe diameter enlarged end of the downstream shell; circumferential threads of the control body are connected with the interior of the first cylinder; the middle part of the control body is provided with a through hole; one end of the pressure adjusting assembly is a conical closed end; the other end of the pressure adjusting assembly is an open end; the outer diameter of the open end is enlarged; the pressure adjusting assembly is provided with water inlets near the position of the conical closed end; the pressure adjusting assembly is arranged in the first cylinder; water stop assemblies are arranged between the circumferential direction of the open end of the pressure adjusting assembly and the circumferential direction of the first cylinder; the conical closed end of the pressure adjusting assembly passes through the through hole on the control body; the water inlets near the conical closed end are located in a cavity formed by the upstream shell and the control body; another water stop assemblies are arranged between the pressure adjusting assembly and the control body; and the pressure adjusting spring is sheathed with the periphery of the cylinder of the pressure adjusting assembly.

Owner:CHINA AGRI UNIV

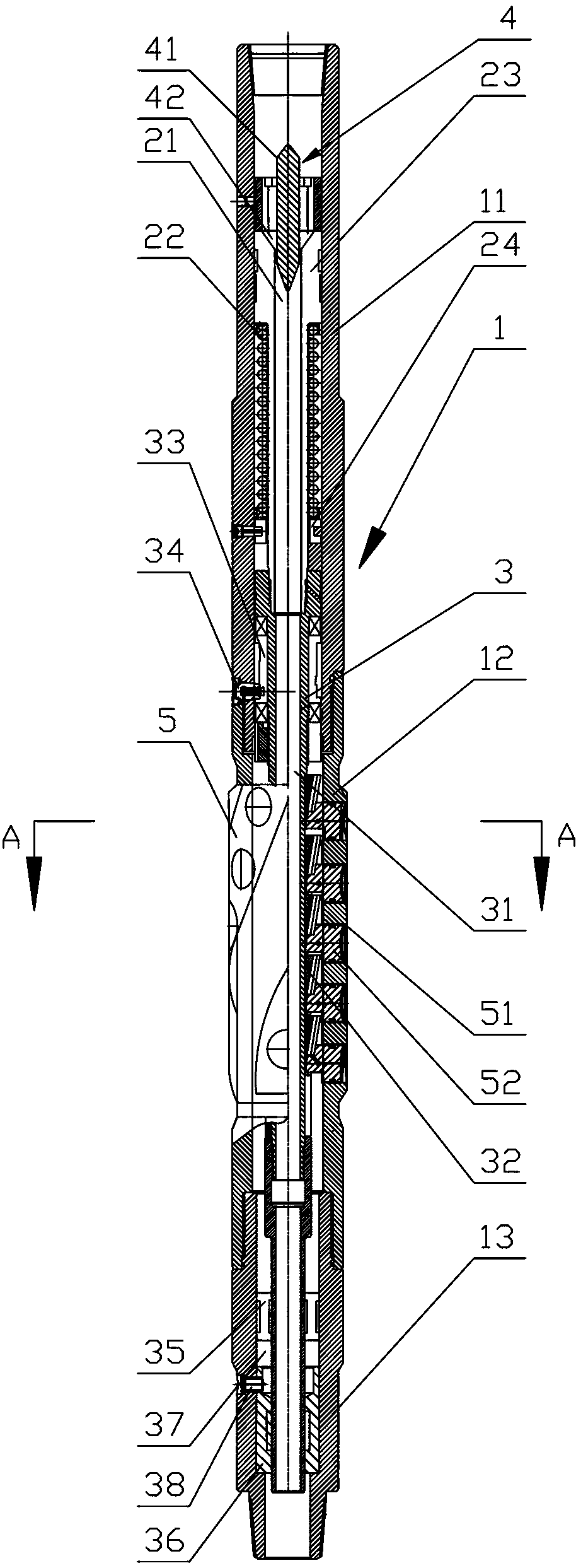

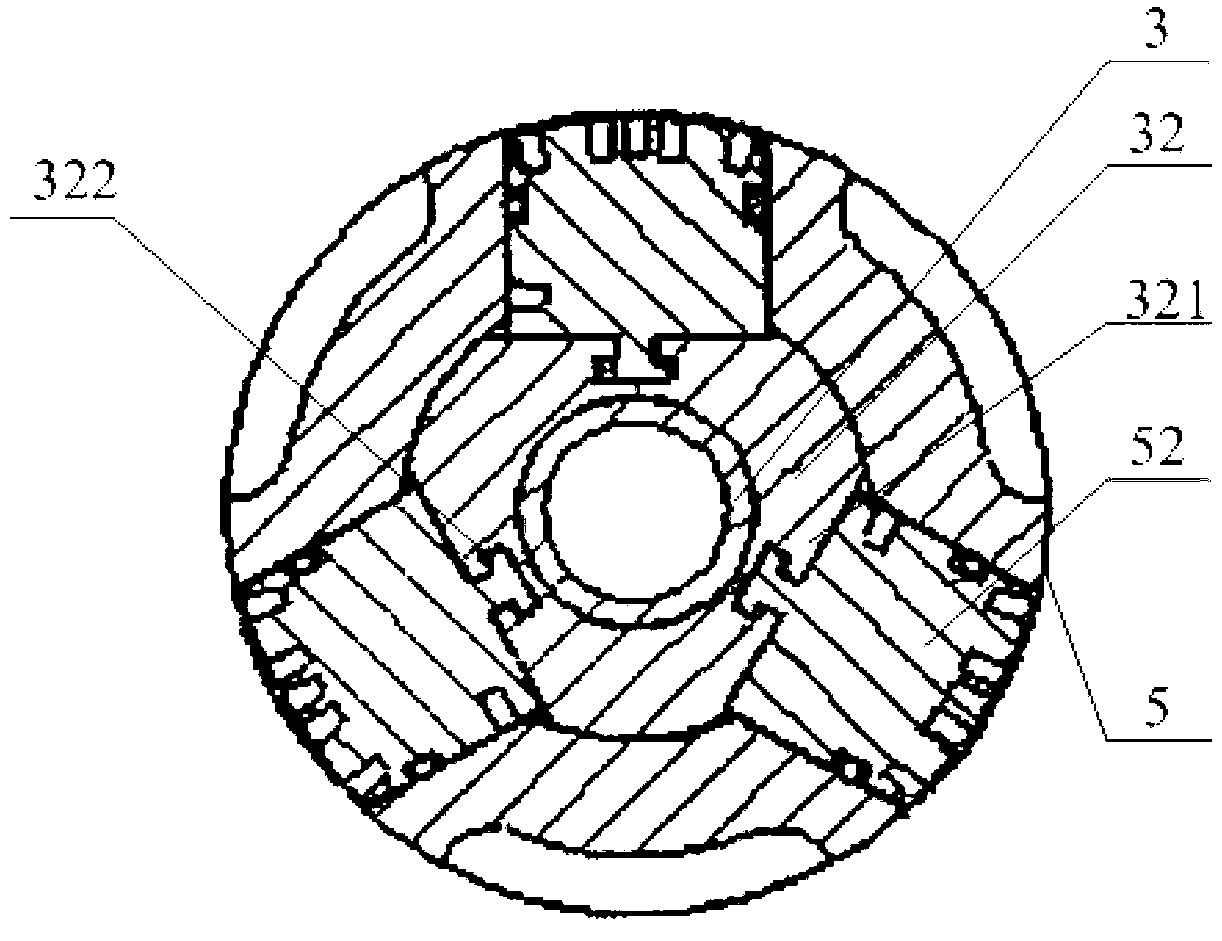

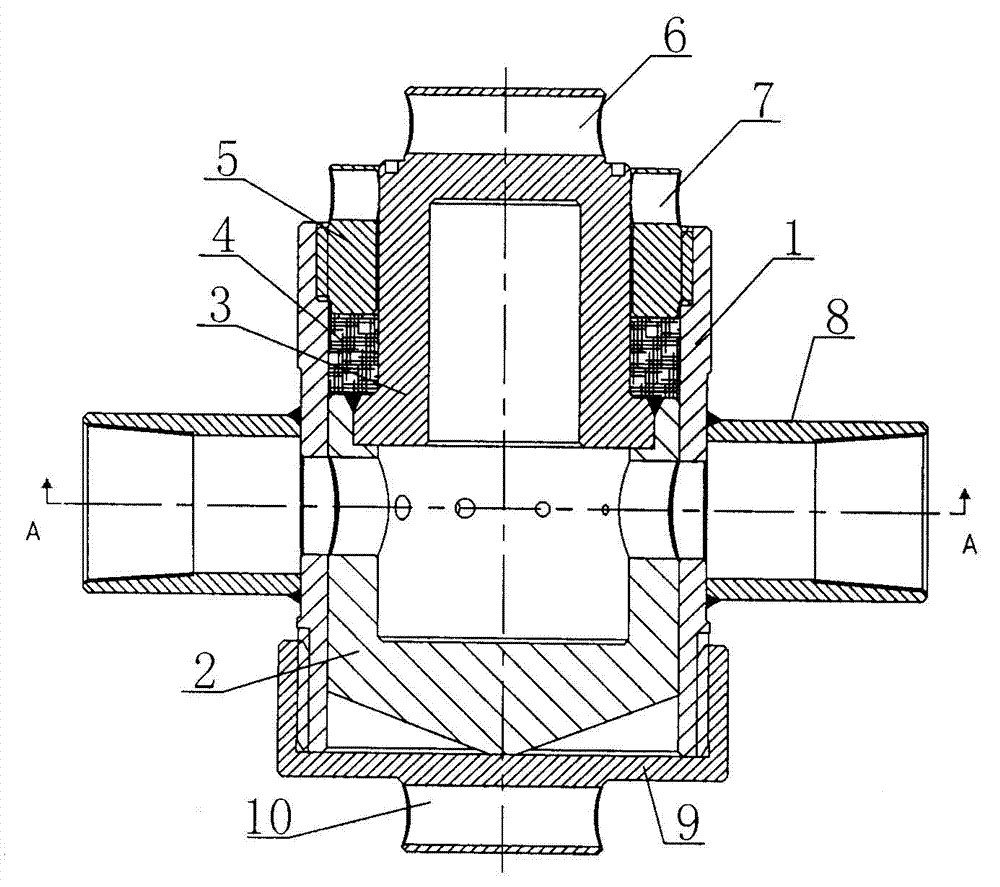

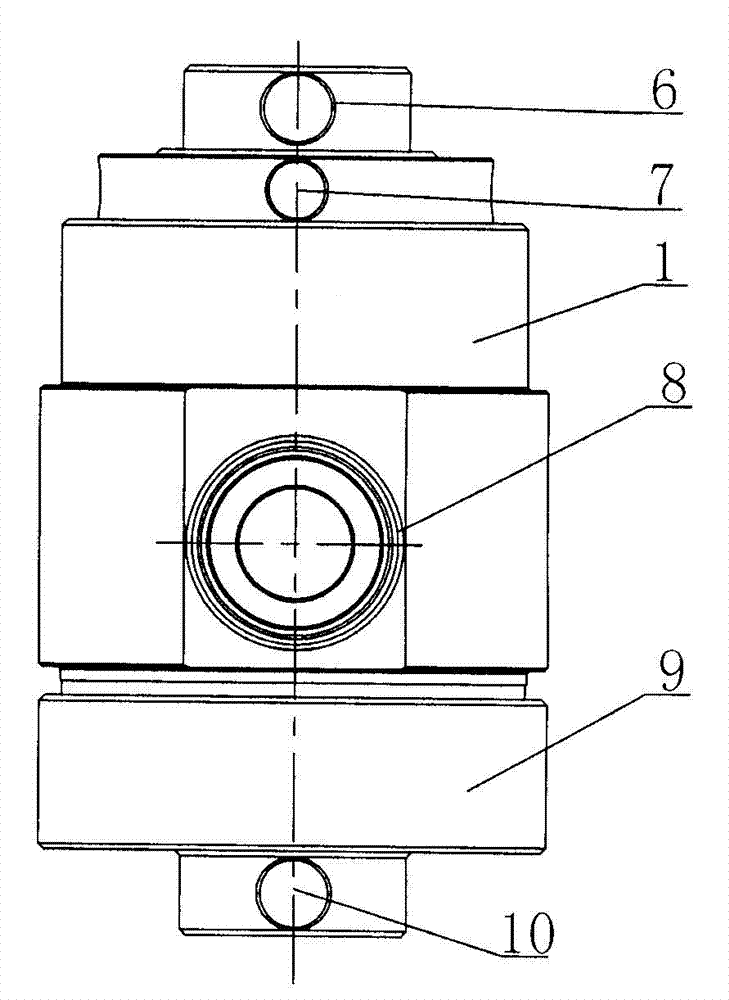

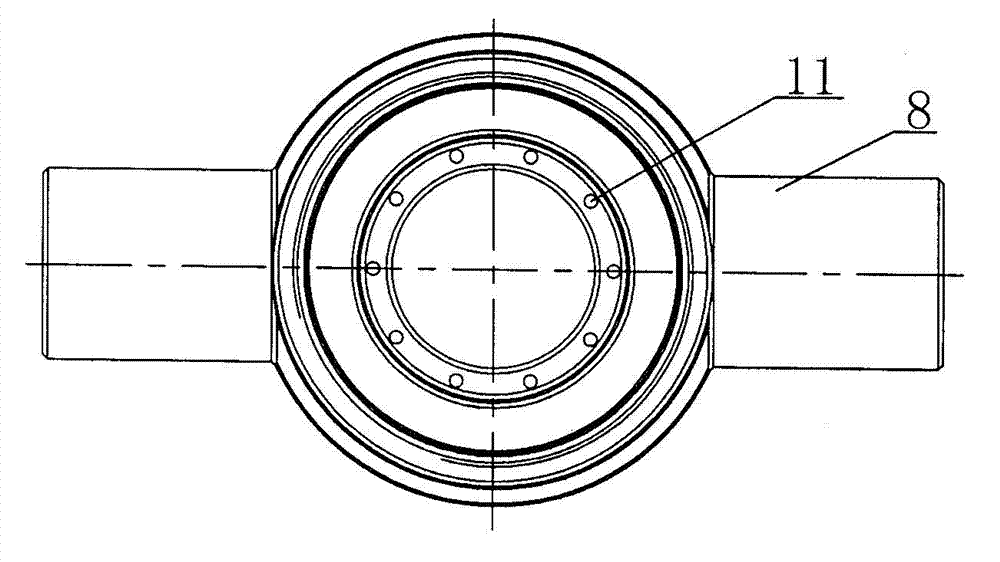

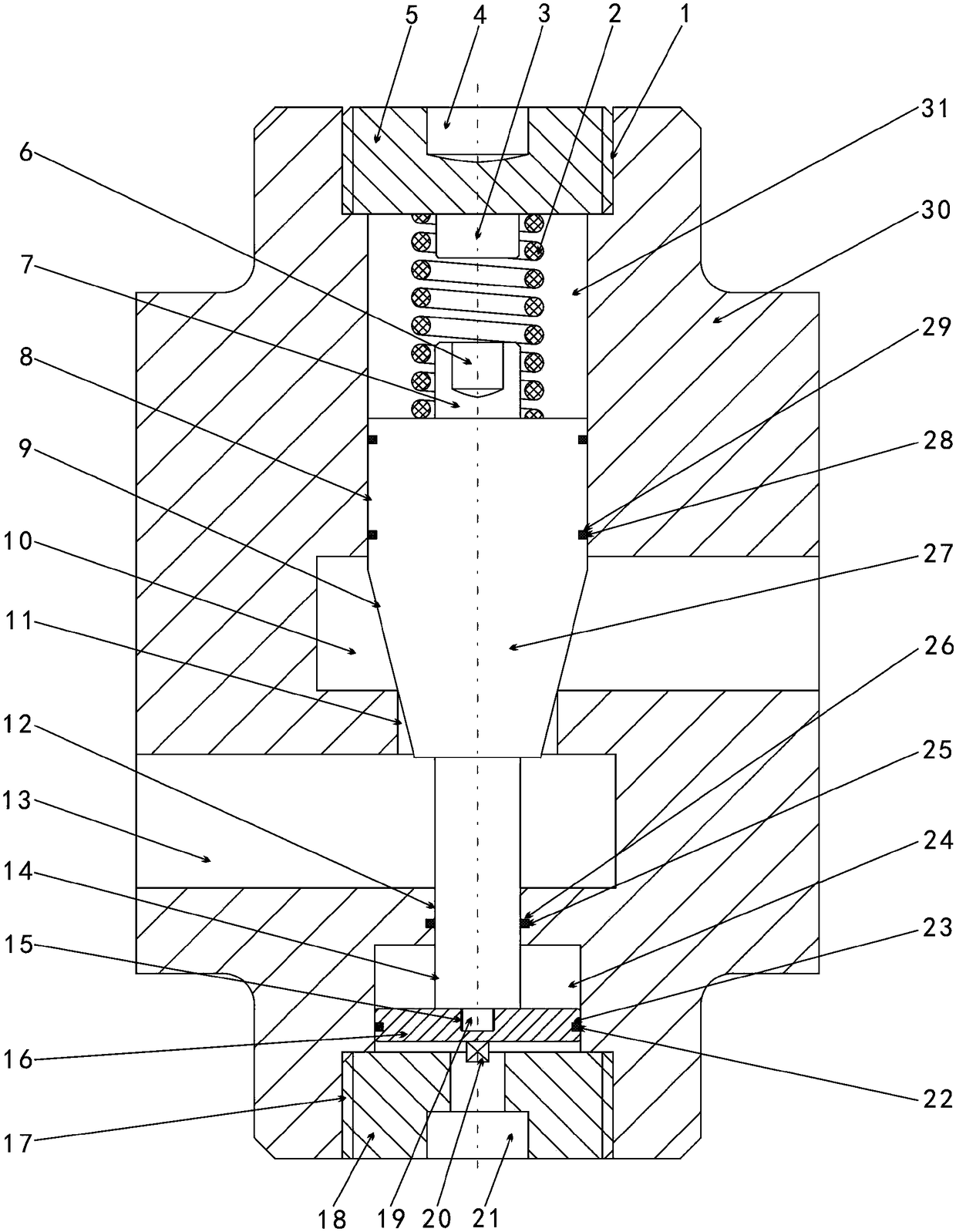

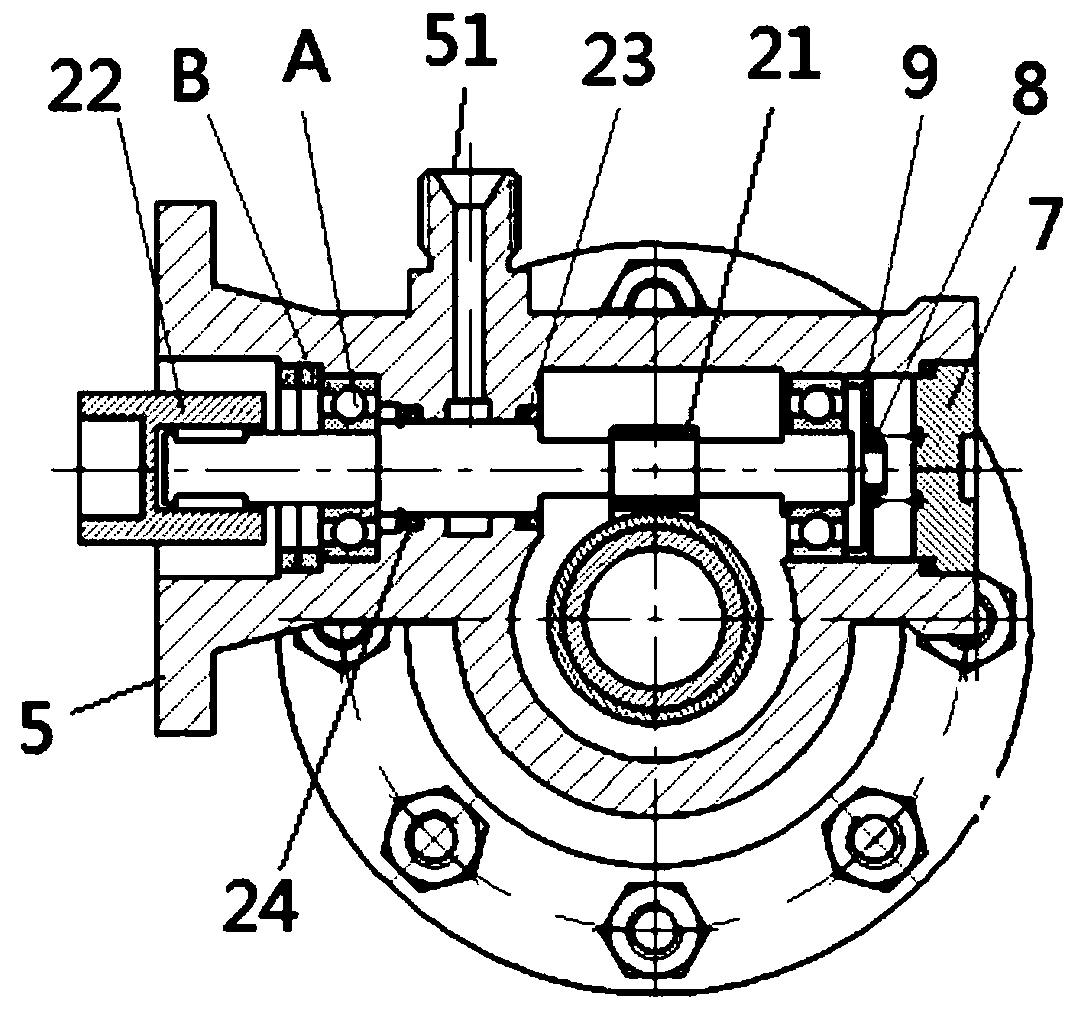

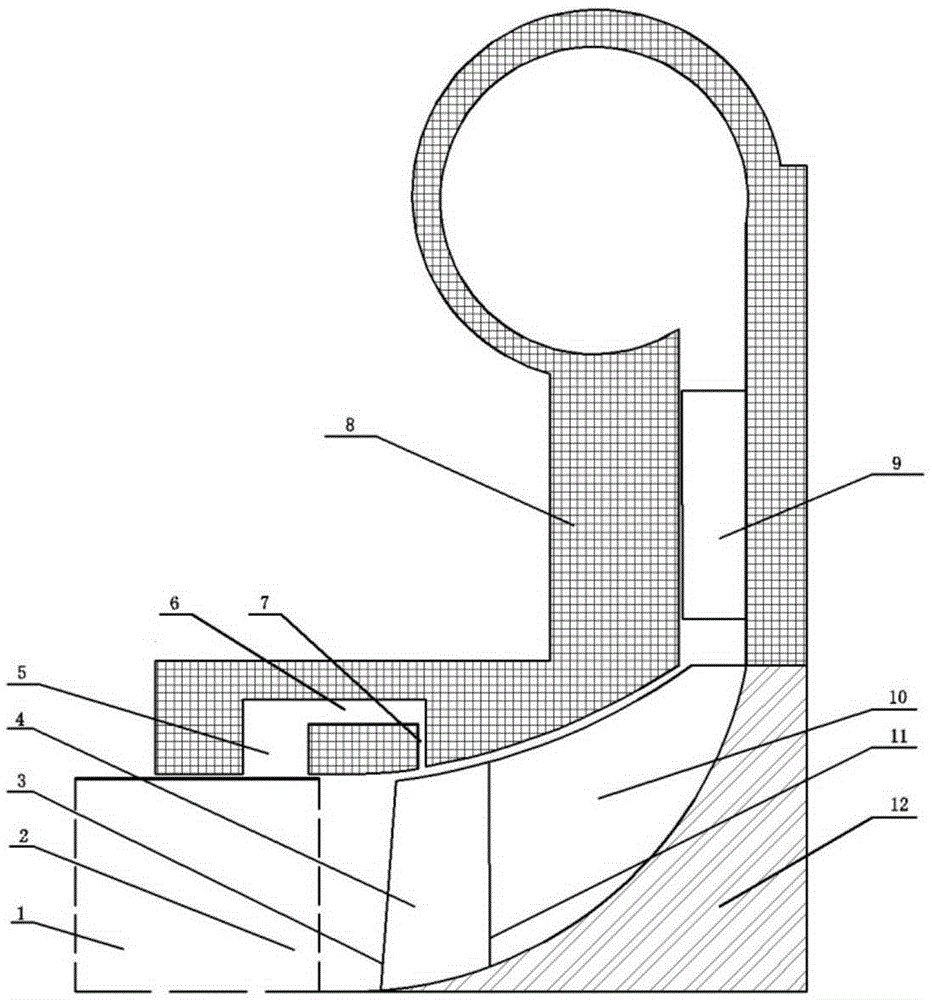

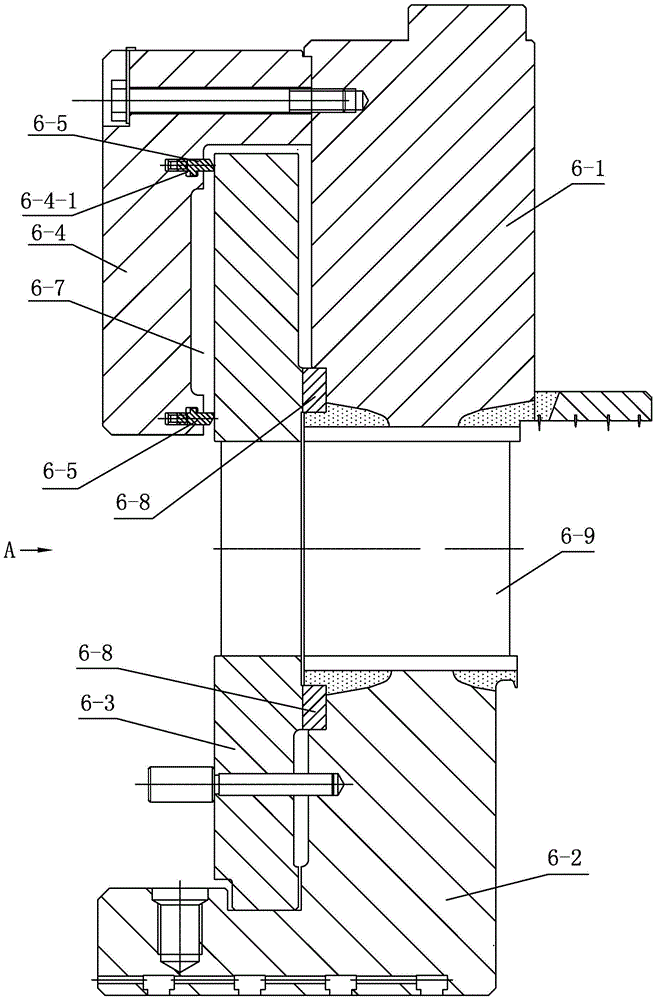

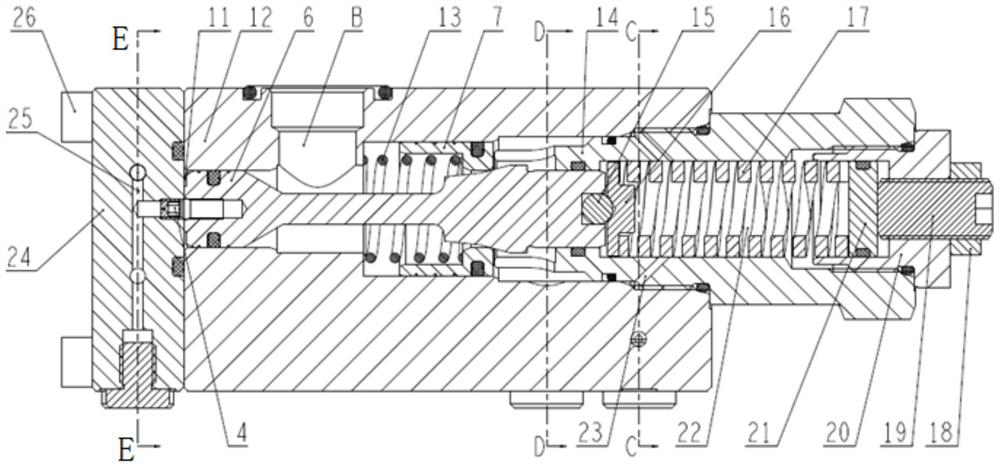

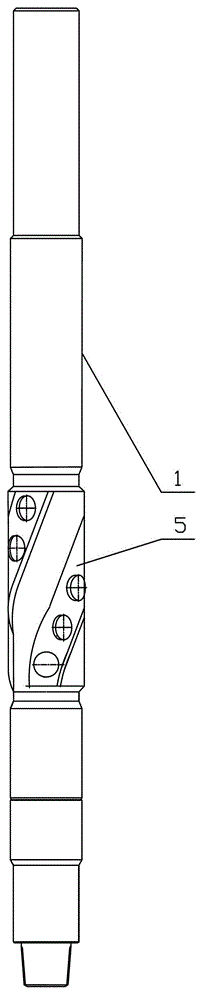

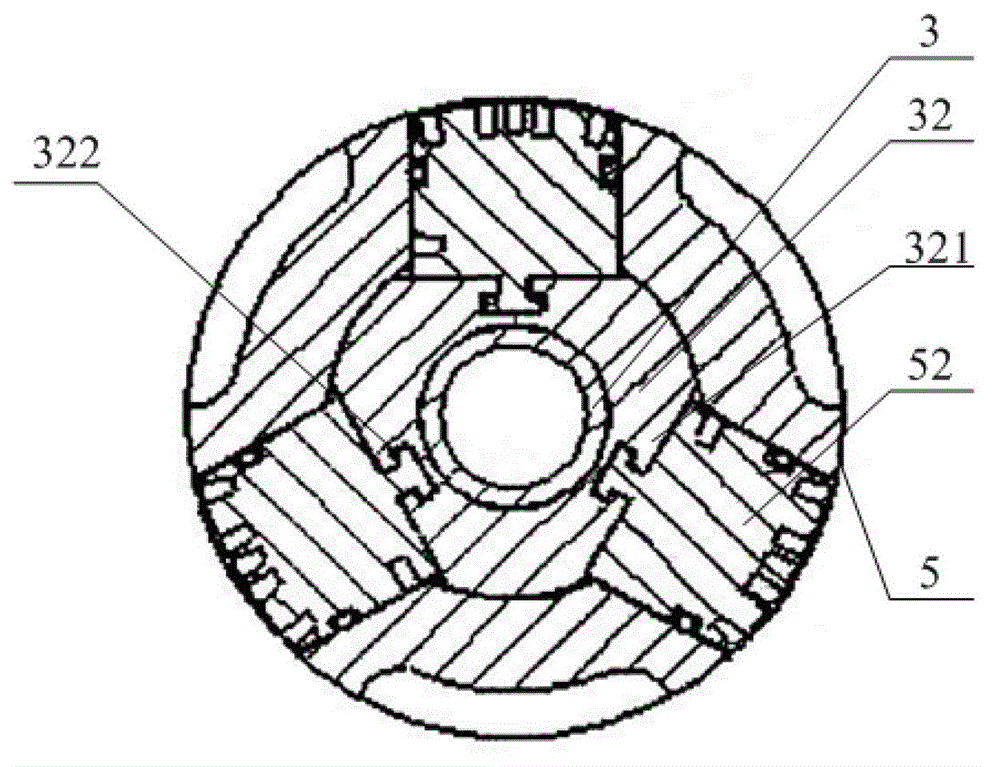

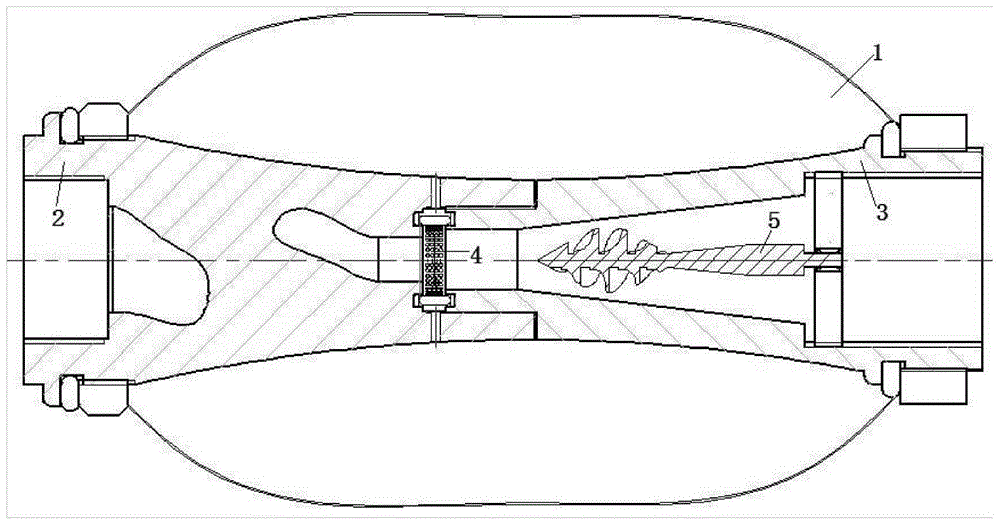

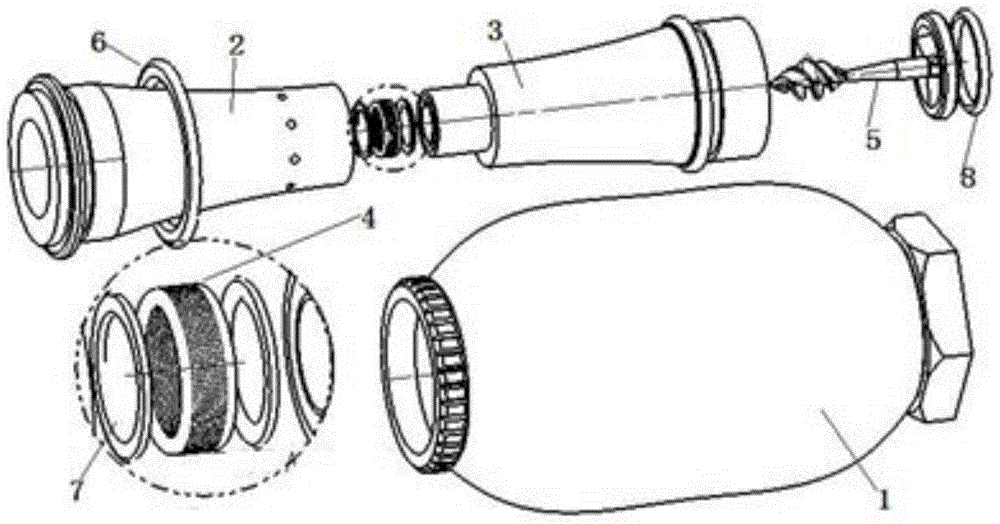

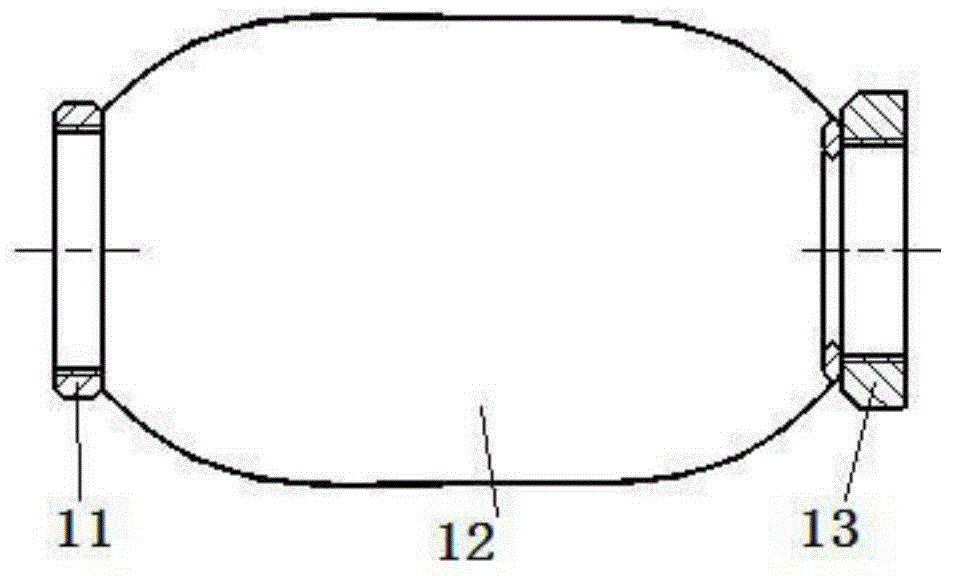

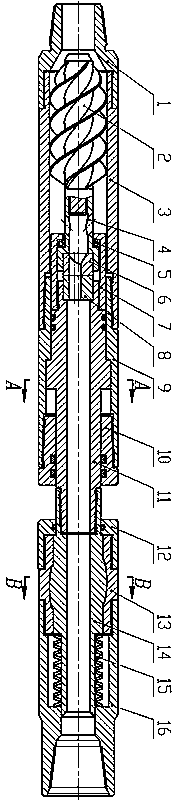

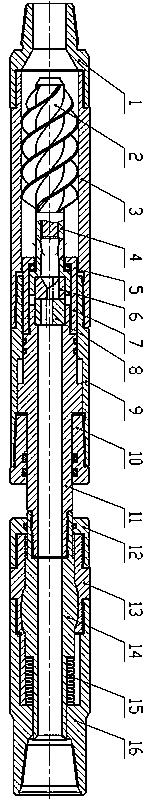

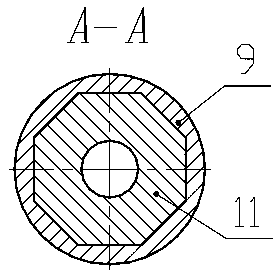

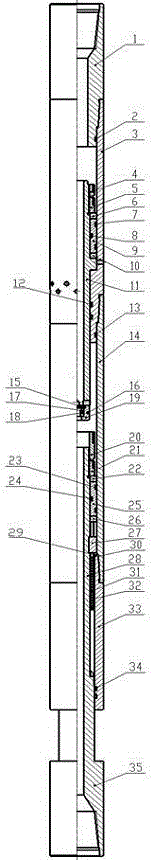

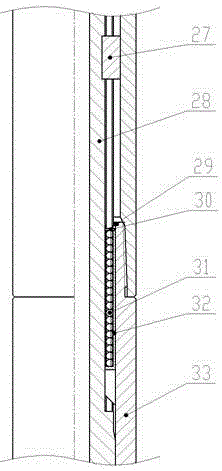

Variable-diameter stabilizer and variable-diameter stabilizer system

ActiveCN103015892AGuarantee safe and reliableChange flow areaDirectional drillingEngineeringHigh pressure

The invention provides a variable-diameter stabilizer. The variable-diameter stabilizer comprises a housing, an upper mandrel and a lower mandrel, wherein an upper high-pressure mud cavity is formed in the upper mandrel in the direction of the axial line of a housing, a lower high-pressure mud cavity is formed in the lower mandrel in the direction of the axial line of the housing, the variable-diameter stabilizer further comprises a mud pressure changing device, the mud pressure changing device comprises a mushroom head assembly and a center hole, the center hole is formed in the upper end of the upper mandrel, the diameter of the upper end of the center hole is larger than that of the lower end, and the center hole is communicated with the upper high-pressure mud cavity; the mushroom head assembly is arranged above the center hole and fixed on the inner wall of the housing; and when the variable-diameter stabilizer is positioned in a working state, the area of passage of mud at the mushroom head assembly and the center hole is maximum, the pressure born by the variable-diameter stabilizer in the working state can be effectively reduced, and the variable-diameter stabilizer is safe and reliable. The invention further provides a variable-diameter stabilizer system, which can effectively reduce the pressure born by the variable-diameter stabilizer in the working state, and the variable-diameter stabilizer is safe and reliable.

Owner:四川伟创石油装备制造有限公司 +1

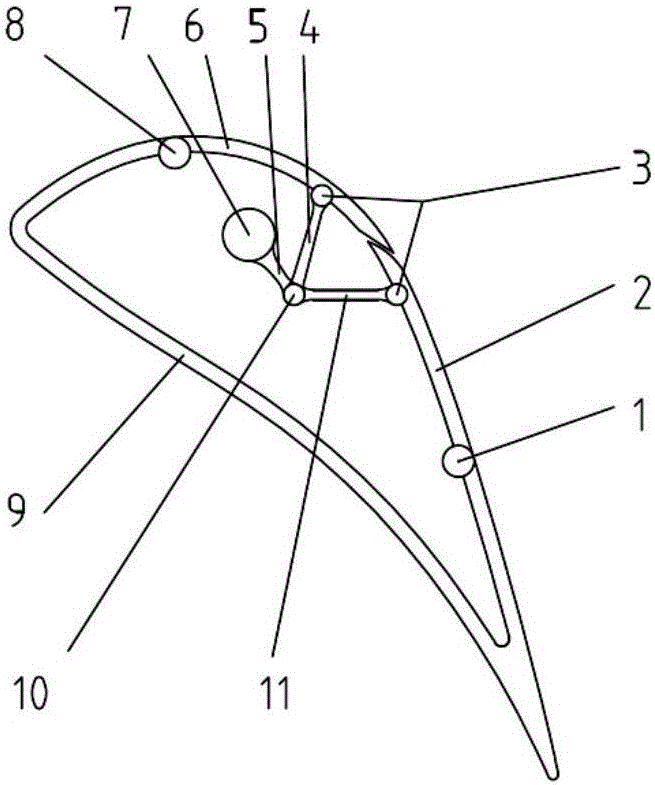

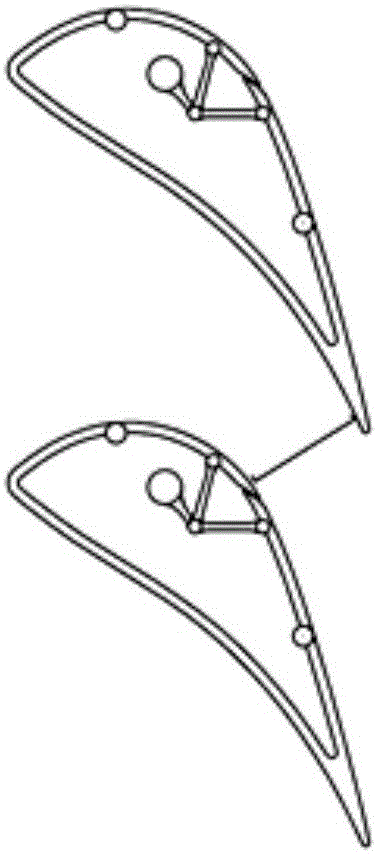

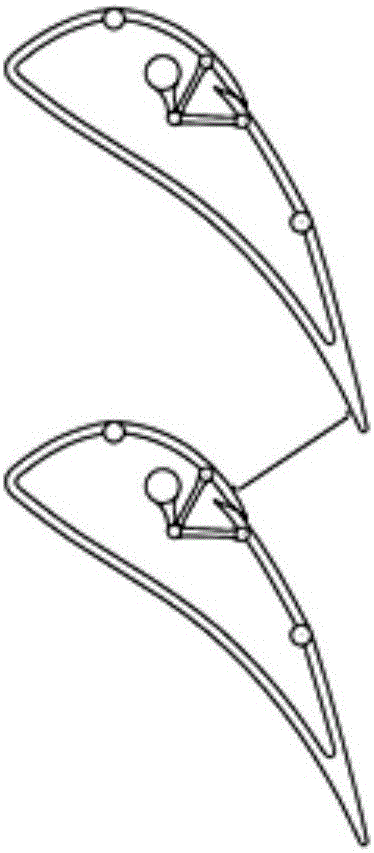

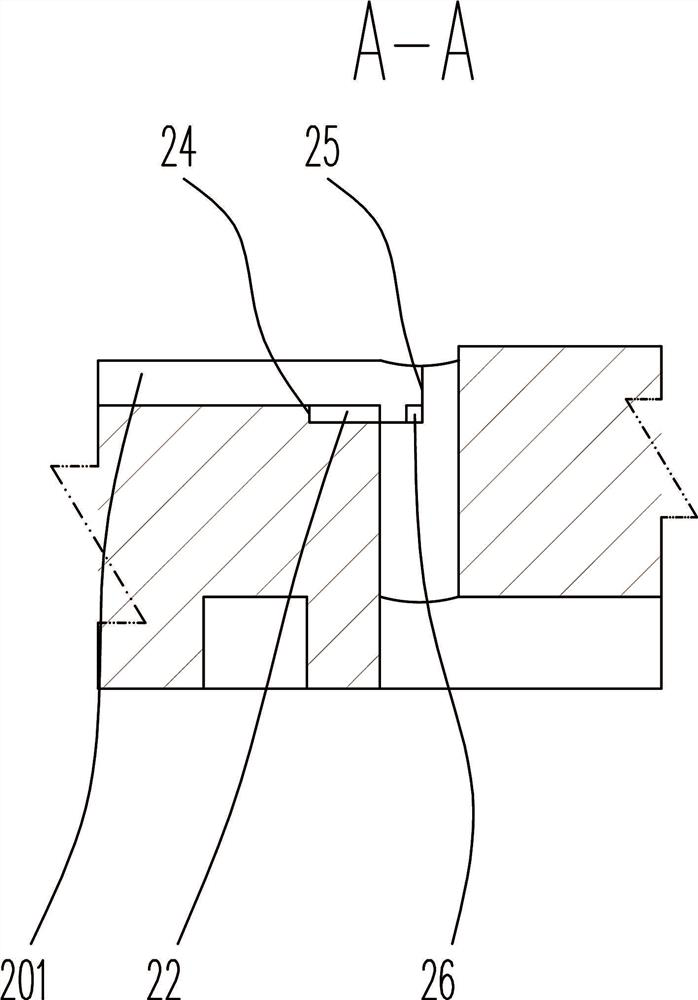

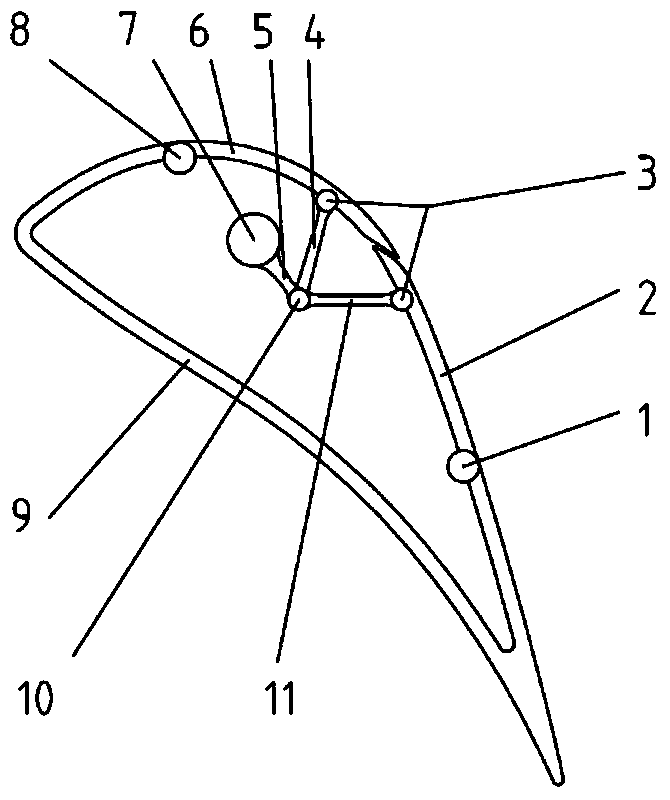

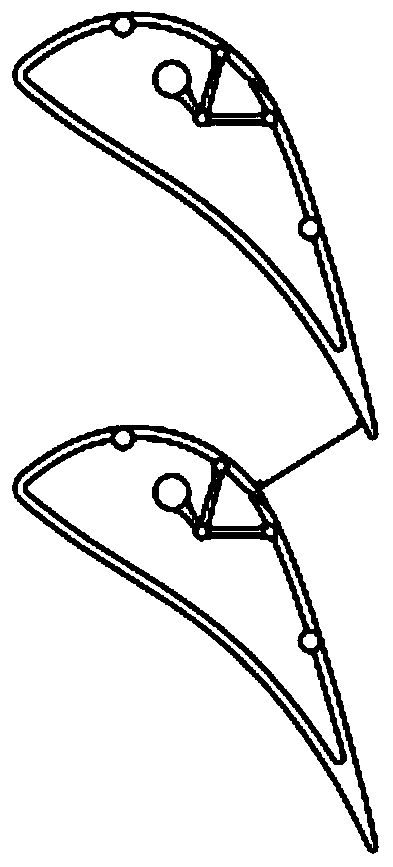

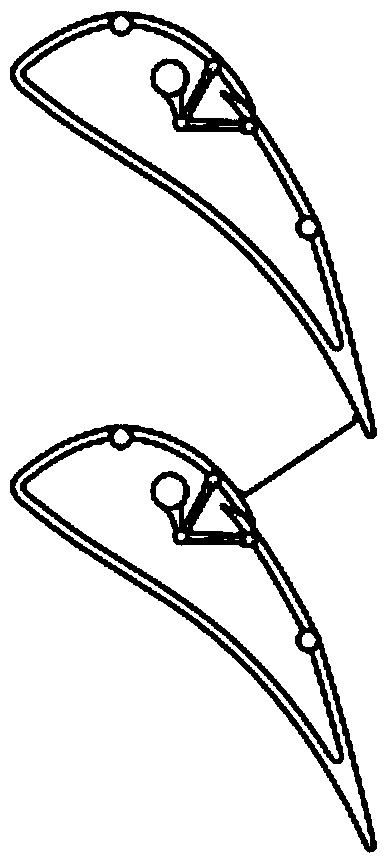

Turbine guide vane, turbine and aircraft engine

The invention relates to a turbine guide vane, a turbine and an aircraft engine. The turbine guide vane comprises a movable part and a fixed part (9), the fixed part (9) is fixed relative to a turbine case, the movable part is connected with the fixed part (9) and located on one side of the suction surface of the turbine guide vane, and the movable part can move relative to the fixed part (9) so as to change the flow area between every two adjacent turbine guide vanes. Compared with the manner that the front edge or the tail edge of the turbine guide vane is arranged to be of a rotatable structural form in the prior art, the turbine guide vane has the advantages that the movable part is arranged on one side of the suction surface of the turbine guide vane, cooling of the interior of the turbine guide vane is not influenced, the whole vane, from the front edge to the tail edge, of the turbine guide vane can be cooled by taking corresponding cooling measures, and the condition that the life is shortened due to the fact that some portions of the turbine guide vane are impacted by high-temperature fuel gas is prevented.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

Current limiting device with hole diameter adjustable

InactiveCN103114829AExtend self-spray cyclePrecise managementFluid removalCurrent limitingDifferential pressure

The invention discloses a current limiting device with a hole diameter adjustable. Two symmetric through holes are formed in a cylinder wall of a mandrel seat. The portions, with the two through holes, of the cylinder wall are respectively and fixedly connected with an outer connecting tube with inner threads. A cylinder opening at one end of the mandrel seat is provided with a sealing cover through threads. A mandrel in a stepped shape and capable of rotating is composed of the mandrel and a hole shrinkage connecting shaft. The mandrel with a cylindrical sealing cavity is matched with an inner hole of the mandrel seat in a movable mode. Through holes arranged symmetrically and with hole diameters enlarged gradually are formed in the mandrel along the radial direction. The two symmetric through holes in the mandrel with the largest diameters and the two symmetric through holes in the mandrel seat are the same in the hole diameter and are matched in a mode of coaxial line. A cylinder opening of the other end of the mandrel seat is provided with a gland nut through threads. An inner hole of the gland nut is movably matched with the connecting shaft. The connecting shaft between a mandrel bumper and the gland nut is provided with a sealing piece. According to the current limiting device with the hole diameter adjustable, under the condition that shutdown operation is not needed, the hole diameter of an oil nozzle can be adjusted conveniently to adjust flow and oil extraction differential pressure can be adjusted and controlled according to variation of oil temperature so that blowing period of an oil well can be prolonged, operation is simple and time and labor are saved.

Owner:KARAMAY SHENGLI PLATEAU MACHINERY CO LTD

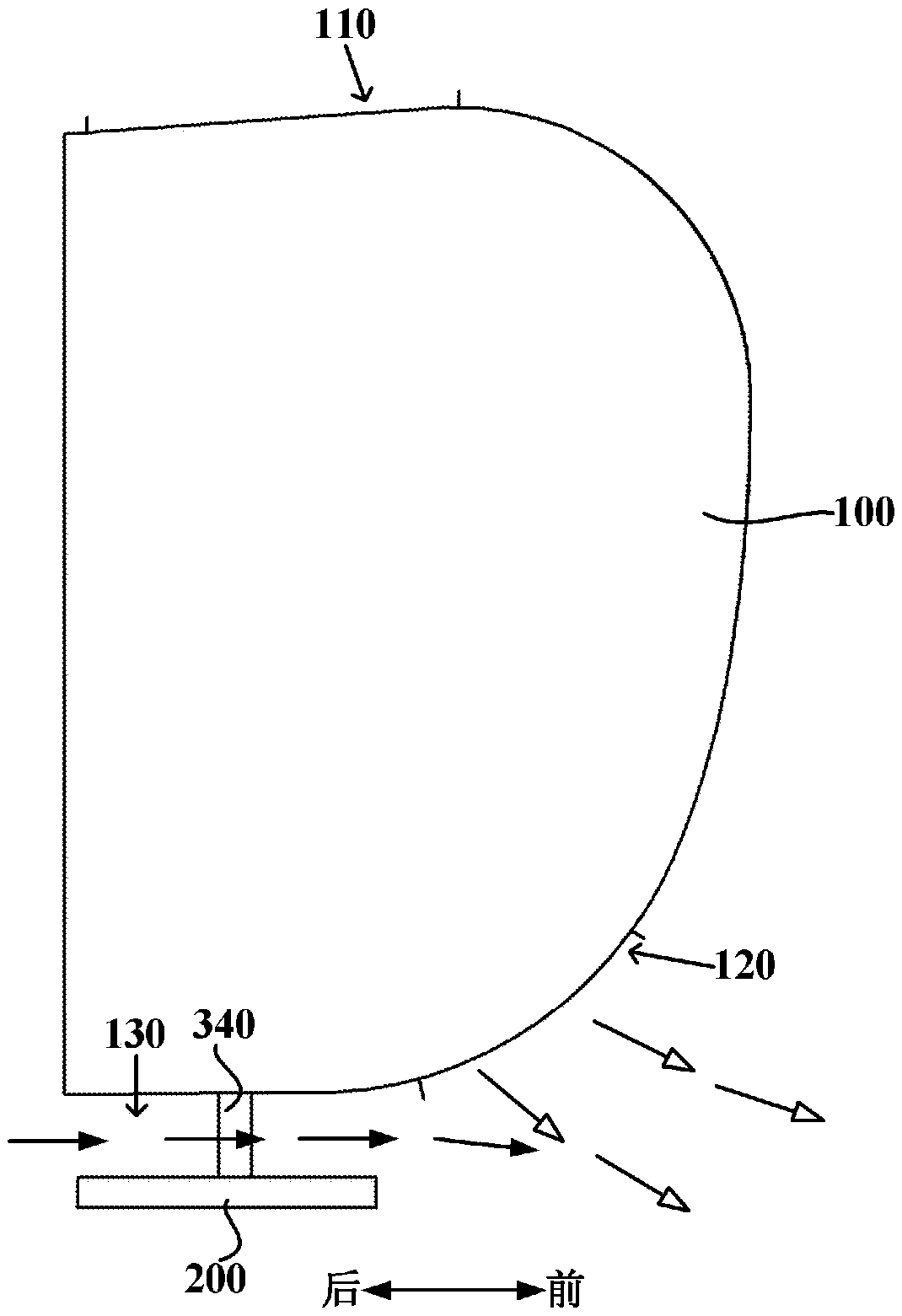

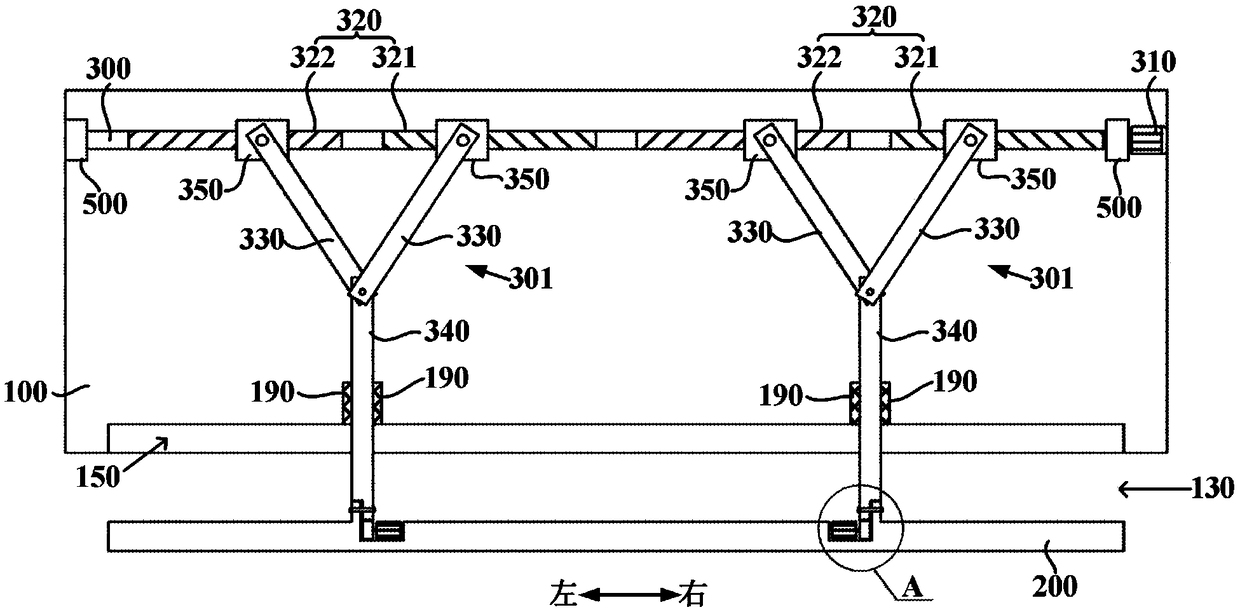

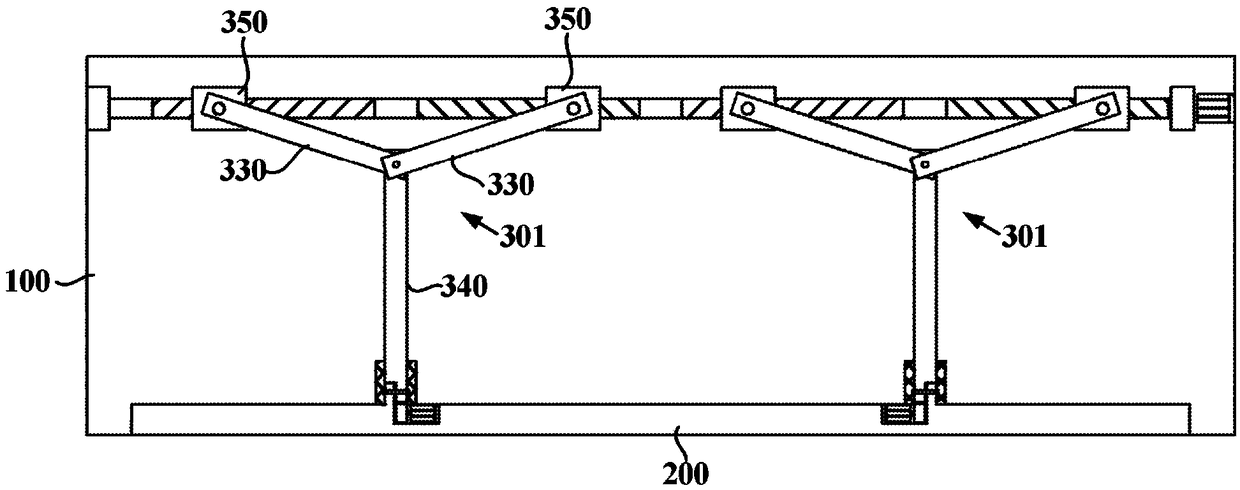

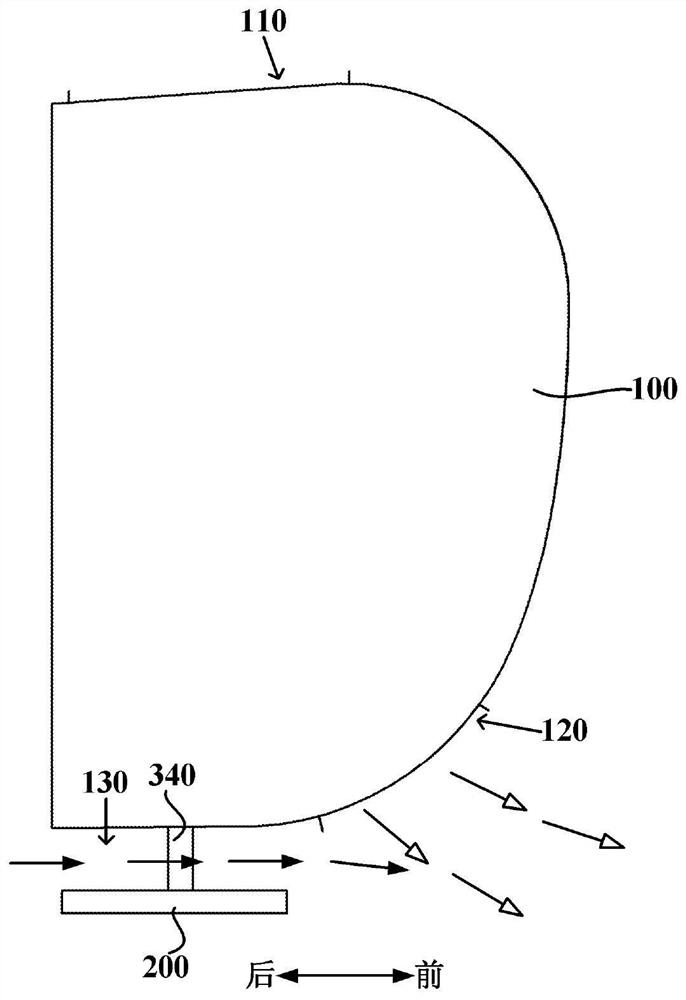

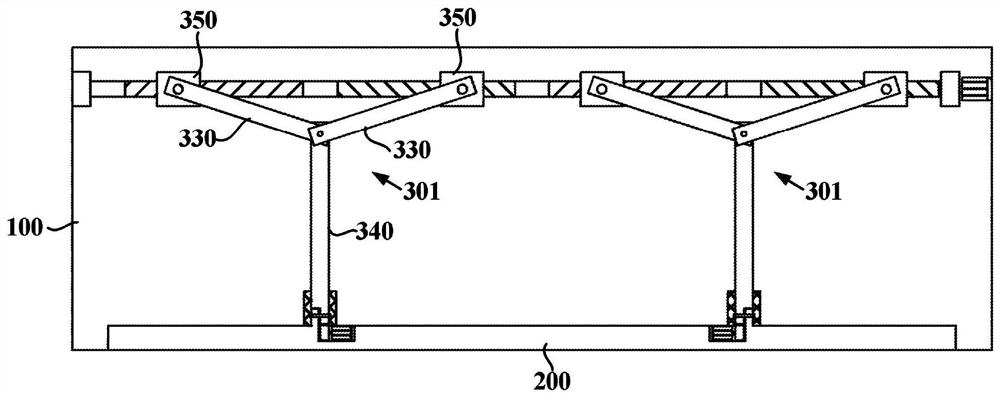

Indoor unit of wall-mounted air conditioner

The invention provides an indoor unit of a wall-mounted air conditioner. The indoor unit comprises a shell, wherein an air outlet is formed in the bottom of the front side of the shell; a drainage plate is arranged below the shell, and a mixed air channel is formed between the drainage plate and the bottom face of the shell, and indoor air flows to the air outlet through the mixed air channel andis mixed with outlet air from the air outlet; a lead screw is parallel to the length direction of the shell, is rotatably installed on the shell and is provided with at least one threaded section group, and each threaded section group comprises a left-handed threaded section and a right-handed threaded section; a first motor is used for driving the lead screw to rotate; at least one bracket assembly comprises two ball sliding blocks which are installed on the left-handed threaded section and the right-handed threaded section correspondingly; the upper ends of two upper rods are hinged to the two ball sliding blocks correspondingly; and the upper end of a lower rod is hinged to the lower ends of the two upper rods, the lower end of the lower rod is connected to the drainage plate, and whenthe lead screw rotates in a positive direction or in a reverse direction, the upper ends of the two upper rods are driven to move transversely in a backward direction or in an opposite direction by the two ball sliding blocks, so that the lower rod is driven to move transversely up and down by the two upper rods, the drainage plate is driven to move transversely up and down, and the overflowing area of the mixed air channel is changed.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

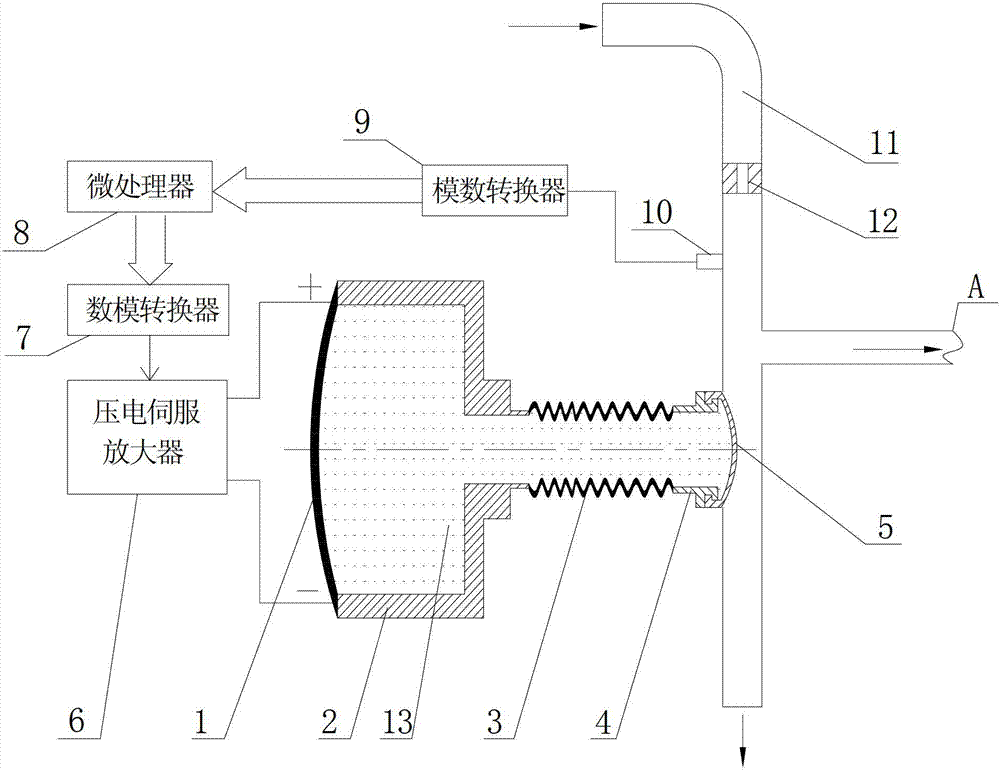

Bellows-type piezoelectrically-hydraulically-actuated microfluidic servo valve and actuating device thereof

InactiveCN102818069AIncrease elasticityAchieve flow controlOperating means/releasing devices for valvesElectricityMicrofluidics

The invention relates to a bellows-type piezoelectrically-hydraulically-actuated microfluidic servo valve and an actuating device thereof and belongs to the technical field of microfluidic control. The problems of poor sealing reliability and instability in amplification factors of hydraulic amplification by means of matching piezoelectric actuating with a hydraulic amplifier in existing microfluidics are solved. A first accommodating cavity retainer of the servo valve is in the shape of a drum, a through hole is arranged at the center bottom of the drum, a piezoelectric diaphragm covers and is fixed on the first accommodating cavity retainer, an outlet side of the first accommodating cavity retainer and an inlet side of a second accommodating cavity retainer are communicated in a sealing manner through a bellows, and an elastic diaphragm covers and is fixed on an outlet side of the second accommodating cavity retainer. The actuating device comprises a piezoelectric servo amplifier, a digital-to-analog converter, a microprocessor, an analog-to-digital converter and a pressure sensor. The bellows-type piezoelectrically-hydraulically-actuated microfluidic servo valve and the actuating device thereof are applicable to a piezoelectrically-hydraulically-actuated microfluidic system.

Owner:HARBIN INST OF TECH

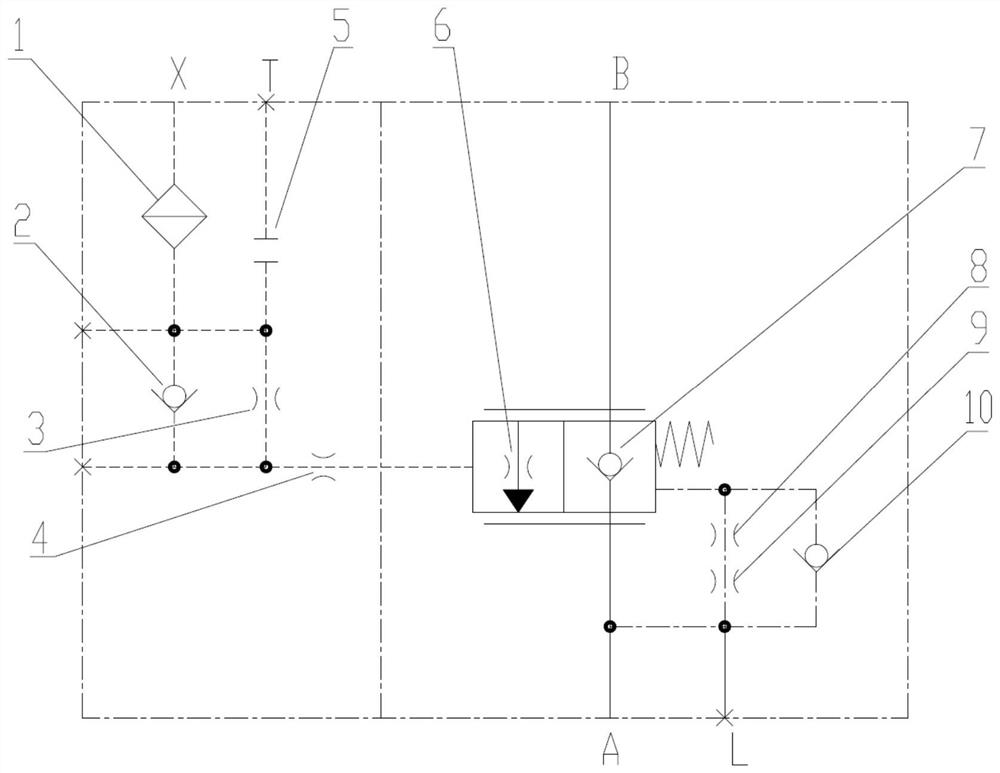

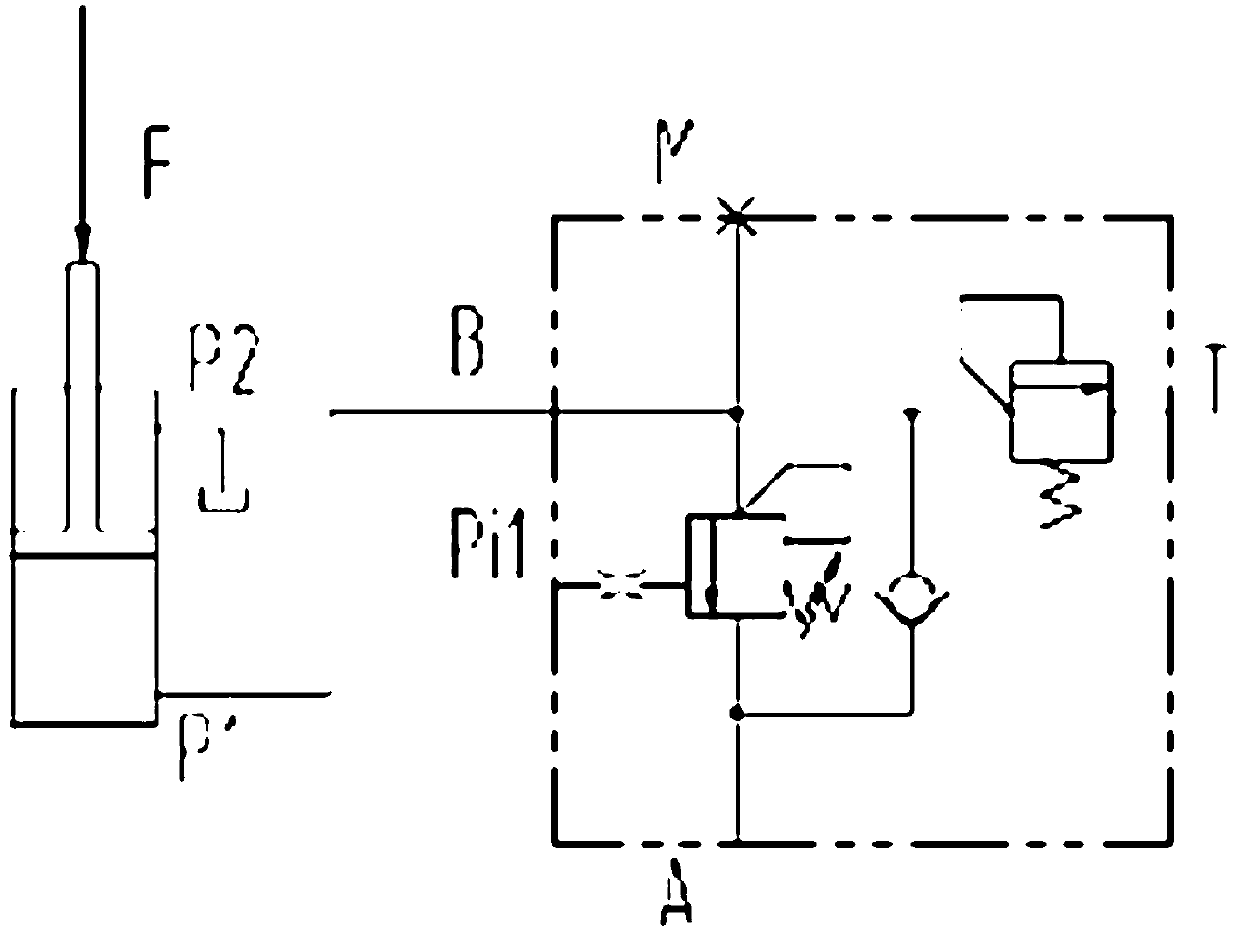

Gas-liquid two-fluid through-flow coupling adjusting device

ActiveCN108506543AChange flow areaTo achieve coupling regulationEqualizing valvesSafety valvesAtmospheric pressureAir cavity

The invention discloses a gas-liquid two-fluid through-flow coupling adjusting device. The adjusting device comprises a valve body, an adjusting cap, a spring, a valve core, an air cavity cover and anair pressure plate, wherein an upper inner screw through hole which is in threaded connection with the adjusting cap is formed in the upper surface of the valve body, a lower inner screw through holewhich is in threaded connection with the air cavity cover is formed in the lower surface of the valve body, and an air inlet hole is formed in the middle of the air cavity cover; the valve body is internally provided with a liquid inlet cavity, a liquid outlet cavity, an upper through hole, a circular control hole, an air pressure adjusting cavity and a lower through hole; the valve core comprises an upper cylindrical section, a conical section and a lower cylindrical section, and the conical section is narrowed from top to bottom; and the upper end and the lower end of the spring abut against the upper surface of the adjusting cap and the upper surface of the upper cylindrical section respectively, the lower end surface of the lower cylindrical section is vertically connected with the upper surface of the air pressure plate, and the outer cylindrical surface of the air pressure plate is attached to the inner cylindrical surface of the air pressure adjusting cavity. The adjusting device is applied to a low-pressure low-flow system and has the advantages of being low in device cost, small in required installation space, timely in response and capable of making sure the continuous and stable gas-liquid flux flow matching effect.

Owner:YICHUAN TECH CHENGDU CO LTD

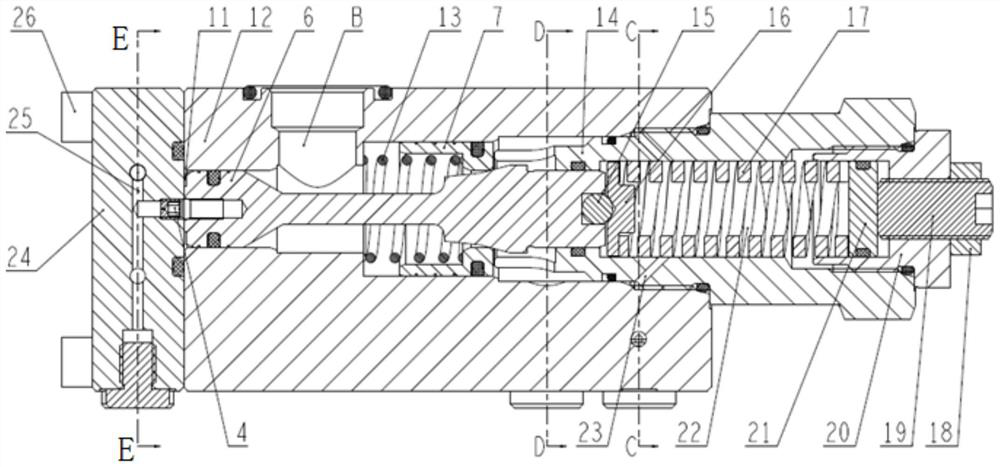

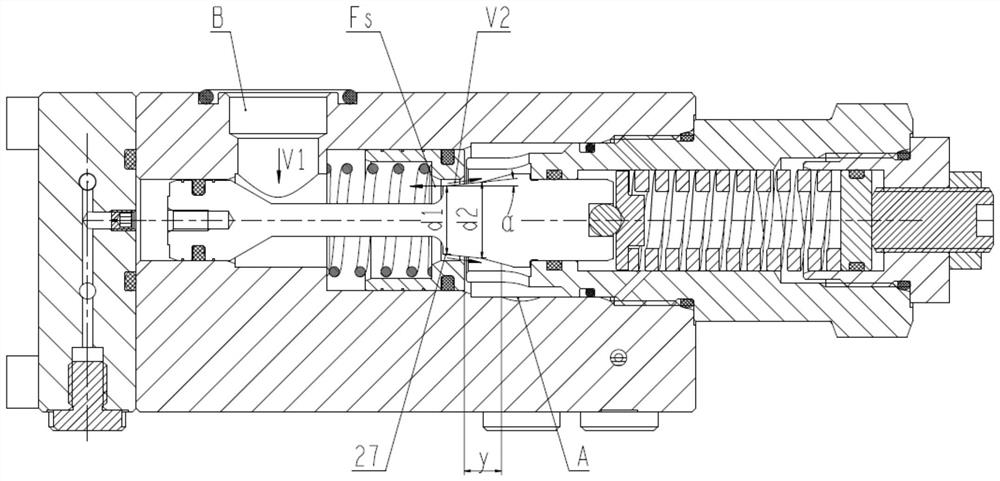

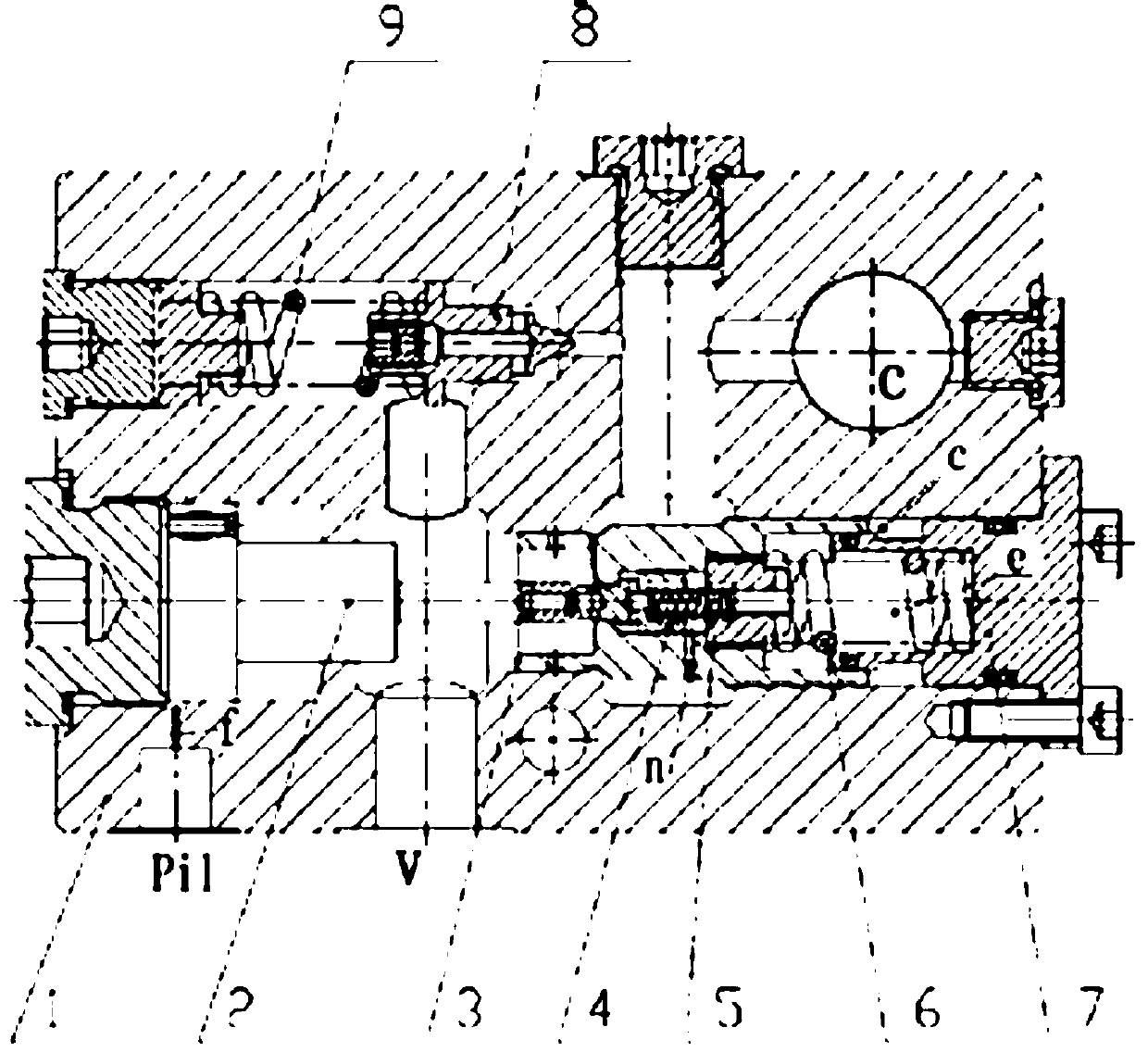

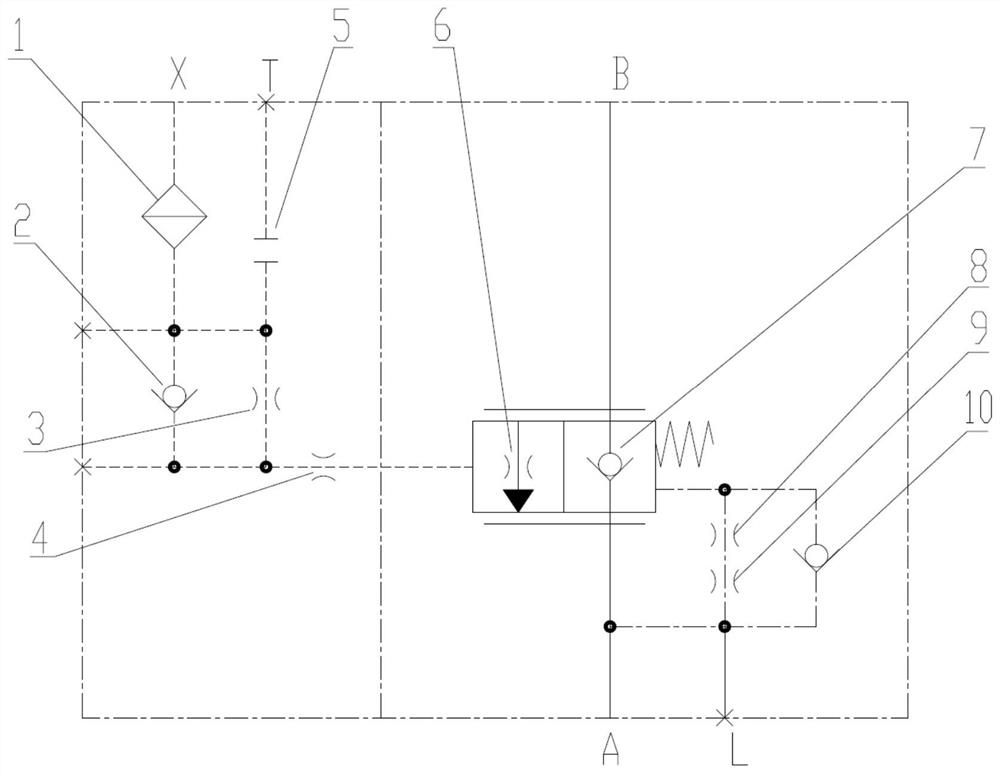

Hydrodynamic compensation balance valve

The invention discloses a hydrodynamic compensation balance valve. A pilot control end cover assembly comprises a control end cover valve body, and a pilot oil channel is arranged on the control end cover valve body; a valve element assembly comprises a throttling valve element, a main spring and an adjusting valve seat; a one-way valve seat assembly comprises a one-way valve and a one-way valve spring; a balance valve body assembly comprises a balance valve body and a valve seat; the throttling valve element is provided with a throttling opening with the angle of alpha; the right end inner wall conical surface of the one-way valve is mutually matched with a throttling opening conical surface of the throttling valve element to form opening and closing sealing; and the one-way valve moves to the left when the amplitude of variation rises, the one-way valve function of the balance valve to an oil opening B from an oil opening A is realized, the throttling valve element is started to theright under the action of pilot control pressure when the amplitude of variation declines, the balance valve function from the oil opening B to the oil opening A is realized, with the increasing of loading pressure, the opening size of the throttling opening of the throttling valve element is controlled by hydrodynamics generated by an annular overcurrent channel with the angle of the throttling valve element of alpha, and load-flow compensation is realized.

Owner:JIANGSU ADVANCED CONSTR MASCH INNOVATION CENT LTD +1

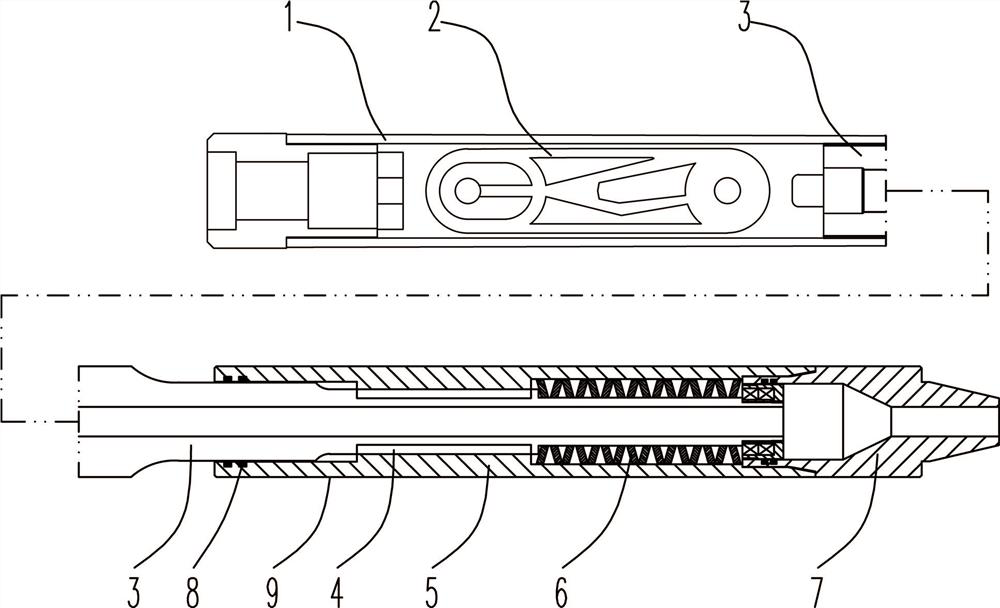

Step-less adjustment valve and liquid rocket

PendingCN109780247AChange flow areaRealize regulationOperating means/releasing devices for valvesSlide valveReciprocating motionEngineering

The invention provides a step-less adjustment valve and a liquid rocket. The step-less adjustment valve comprises a main shell, a liquid inlet and a liquid outlet formed in the main shell and furthercomprises a valve cup arranged in the main shell, a shift structure, and a driving device, wherein the valve cup is provided with a cup opening communicated with the liquid inlet and a flowing throughopening molded in the cup wall, and the flowing through hole communicates with the liquid outlet; the shift structure is movably arranged on the outer surface of the cup wall of the valve cup; and the driving device is connected with the shift structure and drives the shift structure to reciprocate in a linear mode on the valve cup so as to change the flowing through area of the flowing through hole.

Owner:BEIJING XINGJI RONGYAO SPACE TECH CO LTD

New load-sensitive balance valve

A novel load sensitive balance valve is composed of a valve body, a control piston, a main balance spool and a pilot spool spring. The new balance valve is mainly composed of a one-way function component, an overflow function component, and a throttling spool component that plays the main role of flow control; When it is blocked, the high pressure in the load chamber acts on the right side of the main balance spool to greatly reduce the action area, forming a feedback signal; the force of the load acting on the balance spool will change with the change of the load, thereby changing the balance The flow area of the valve maintains the flow stability and ensures the smooth movement of the boom; according to the oil flow direction, when the balance valve is in front of the hydraulic cylinder, the oil enters from the oil inlet and flows out through the one-way valve flow channel in the valve body. The pressure loss is small.

Owner:宋珊珊

Intelligent shower equipment

PendingCN114439078AChange flow areaChange water flowDomestic plumbingTemperature controlElectric control

According to the intelligent shower equipment provided by the invention, the water temperature can be controlled without manually adjusting the faucet, and the operation is convenient. The temperature control mechanism comprises a cold water pipeline, a hot water pipeline and a water outlet pipeline, and is characterized in that the cold water pipeline and the hot water pipeline are arranged in a shell of the temperature control mechanism, a rack is arranged in a sliding rail attached to the rack in the shell in a sliding mode, and rack check blocks are arranged at the two ends of the rack; the rack check blocks are slidably inserted into the hot water pipeline and the cold water pipeline respectively, a gear meshed with the rack is arranged above the rack, the gear is in transmission connection with a servo motor, the servo motor is arranged on the inner wall of the shell, a single-chip microcomputer is arranged on the inner wall, and the single-chip microcomputer has a memory selection function. A front temperature sensor I and a front temperature sensor II are arranged in the cold water pipeline and the hot water pipeline, a rear temperature sensor is arranged in the water outlet pipeline, and the temperature sensors are in electric control connection with the servo motor and the single-chip microcomputer.

Owner:WUXI PROFESSIONAL COLLEGE OF SCI & TECH

Lower oscillation sliding vane jet flow stroke-increasing hydraulic oscillator

ActiveCN112112568AFew moving partsExtended service lifeVibration devicesVibration drillingEngineeringReciprocating motion

The invention provides a lower oscillation sliding vane jet flow stroke-increasing hydraulic oscillator. A vortex cavity is fixedly arranged in an outer sleeve and used for generating vibration; a flow inlet hole is formed in one end of the vortex cavity, and a flow outlet hole is formed in the other end of the vortex cavity and located in the circle center position of the vortex cavity; a slidinggroove is formed in one side of the flow outlet hole and internally provided with a movable sliding block sliding in the axial direction; and one end of the stroke of the movable sliding block partially covers the flow outlet hole, and the other end of the stroke of the movable sliding block completely leaves the flow outlet hole so as to alternately limit the through-flow section of the flow outlet hole. By the adoption of the scheme that the movable sliding block is arranged in the vortex cavity, the movable sliding block is driven by vibration of the vortex cavity to reciprocate, and therefore the through-flow area of a flow inlet channel is changed, the vibration amplitude of the vortex cavity is increased, the vibration frequency is reduced, and then the vibration form meeting the underground construction requirement is obtained, namely the proper amplitude and vibration frequency are obtained. According to the structure of the lower oscillation sliding vane jet flow stroke-increasing hydraulic oscillator, the number of movable components is small, the service life is long, the pressure loss of a drive component is extremely low, and the output efficiency is high.

Owner:SINOPEC OILFIELD EQUIP CORP +1

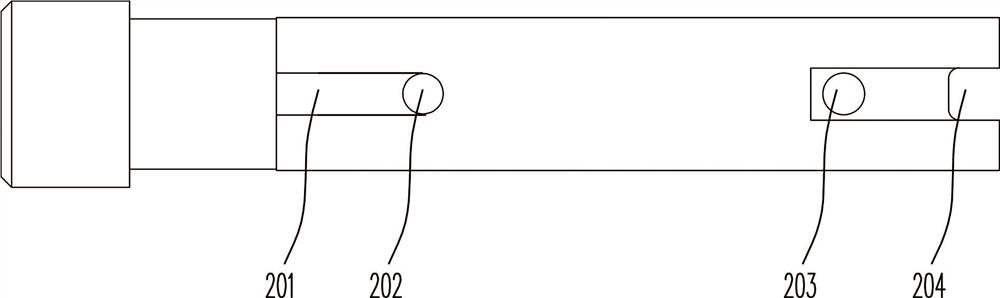

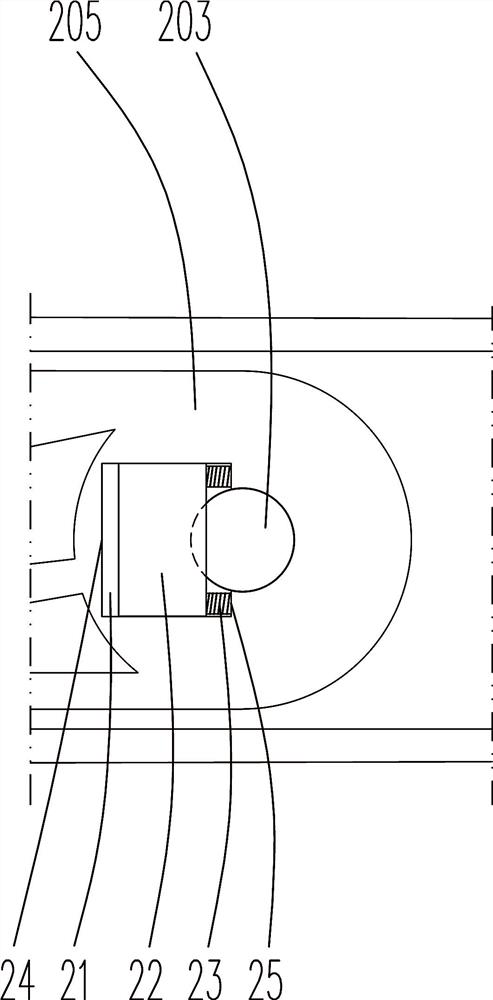

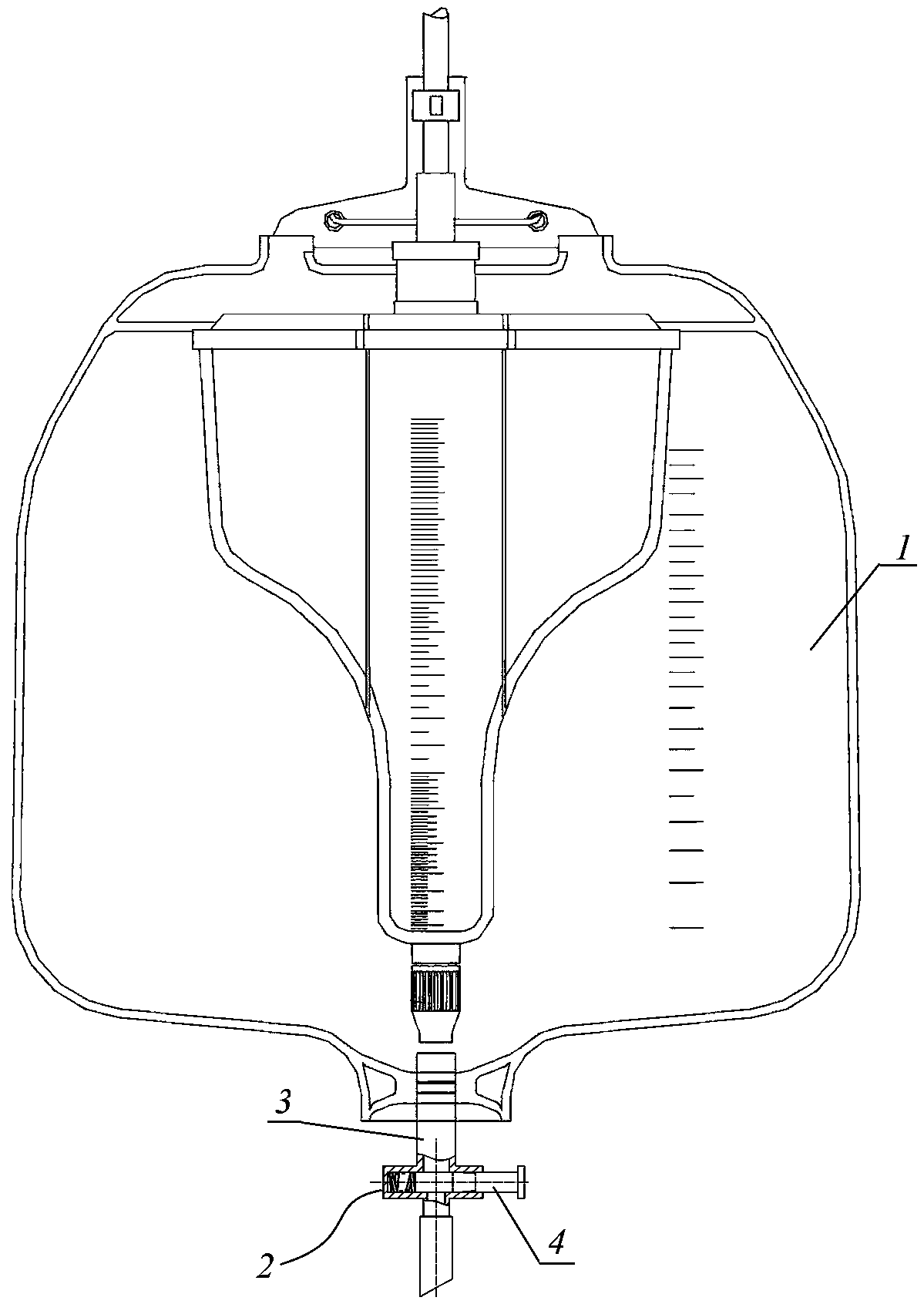

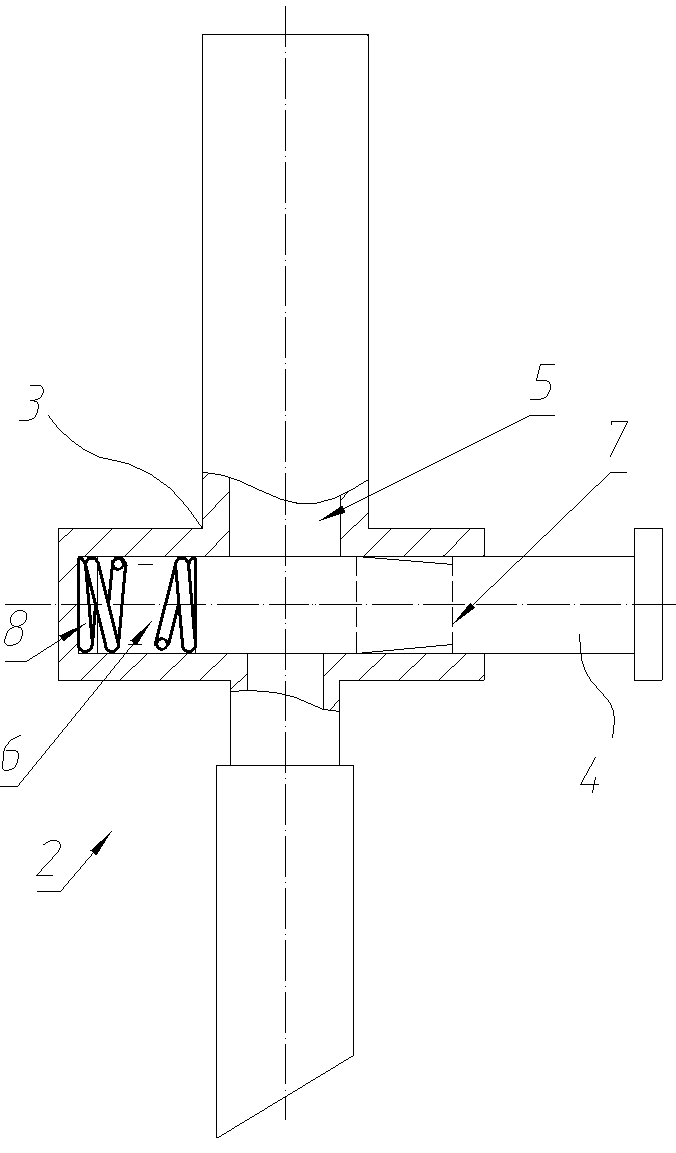

Drain switch and urine collection bag using drain switch

InactiveCN109010950APrevent splashChange flow areaIntravenous devicesSuction drainage systemsEngineeringCoil spring

The invention relates to a drain switch and a urine collection bag using the drain switch. The drain switch comprises a valve body and a valve core. The valve body comprises a vertical passage for discharging liquid and a transverse passage communicating with and intersecting with the vertical passage. The valve core is a piston guided to be inserted in the transverse passage. The piston is provided with a liquid flow passage for forming a valve port. The flow area of the liquid flow passage is changed from small to large in an opening movement direction of the piston to make the liquid flow amount change from small to large when the piston is opened. A coil spring is disposed between the inner end surface of the piston and the corresponding end of the transverse passage. The coil spring is used for applying an acting force to the piston to move the piston toward a closed position. With the above technical scheme, the change of the flow area when the piston is opened can be realized bychanging the flow area of the liquid flow passage, thereby realizing the change of the liquid flow amount from small to large, and compared with the prior art, the drain switch is capable of better control of liquid flow rate in the early stage when the piston is opened and avoiding splashing of liquid.

Owner:河南省人口和计划生育科学技术研究院

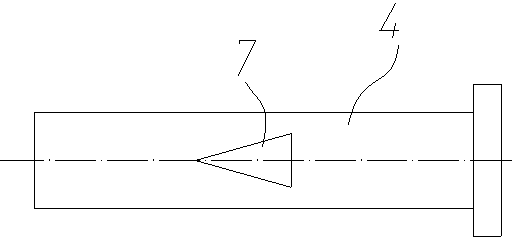

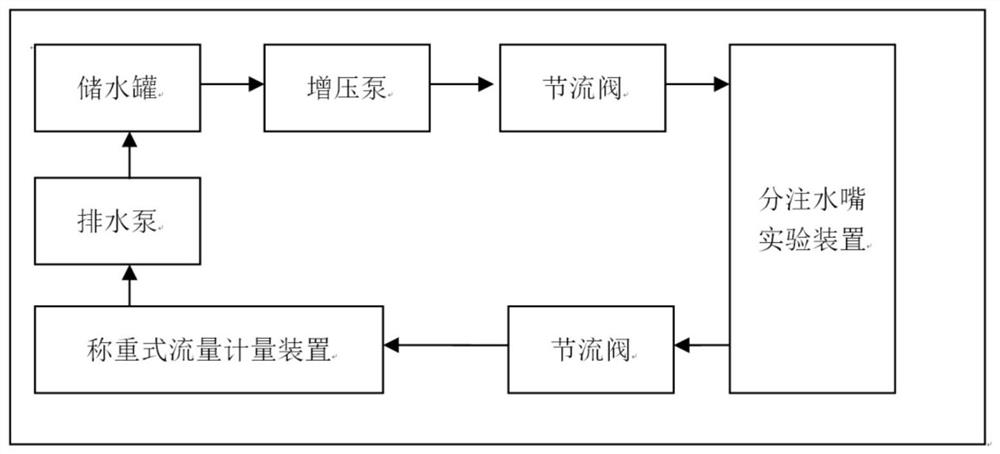

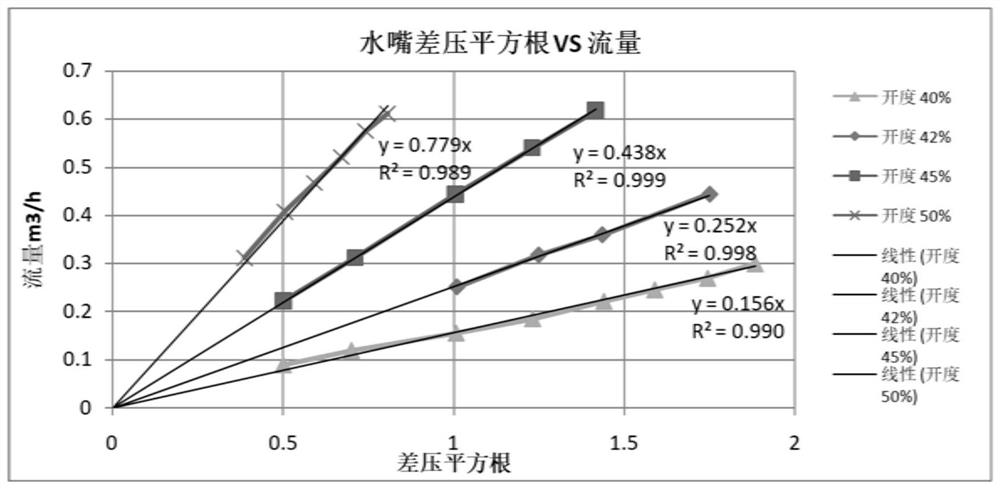

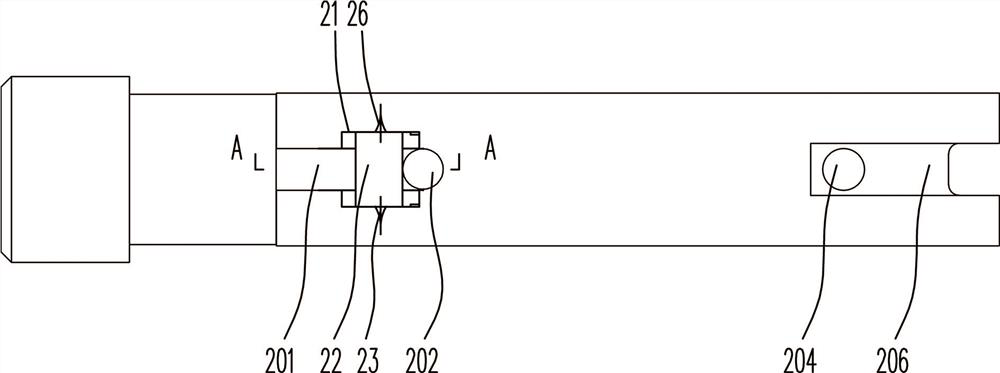

Method for realizing intelligent separate injection by utilizing opening degree of water nozzle in separated layer water injection

The invention provides a method for realizing intelligent separate injection by utilizing the opening degree of a water nozzle in separate layer water injection. The method for realizing intelligent separate injection by utilizing the opening degree of the water nozzle in the separate layer water injection comprises the following steps of: obtaining a linear relationship between the opening degreeof the water nozzle and a flow coefficient through an experiment, and controlling the water injection quantity of each layer section by utilizing the overflowing capacity of different water nozzles and the generated pressure loss to achieve the purpose of separated layer quantitative water distribution. The size of a water distribution nozzle is obtained through a nozzle loss curve method; groundequipment sends information through pressure waves to set the opening degree of a water nozzle of an intelligent water distributor, so that the overflowing area of the water nozzle is changed, and the expected injection allocation amount is achieved. According to the method for realizing intelligent separate injection by utilizing the opening degree of the water nozzle in the separate layer waterinjection, the problem that the size of the water nozzle needs to be changed through labor in a traditional method is solved, the intelligent water distributor only needs to simply send an instruction, and the operation amount of water well injection allocation is greatly reduced. The intelligent water distributor has great significance in improving the economical efficiency and the flexibility of separate injection.

Owner:南京南大数字科技有限责任公司

Centrifugal Compressor Case Bleed Air Recirculation Structure with Variable Geometry

InactiveCN104019058BChange flow areaOptimize all working conditionsPump componentsPump controlAxial compressorBleed air

The invention aims at providing a gas-entraining recycling structure for a cartridge receiver of a centrifugal-type gas compressor with a variable geometric dimension. The gas-entraining recycling structure comprises a volute shell and a gas compressor impeller which is arranged in the volute shell, wherein a primary blade and a splitter blade are respectively arranged on the gas compressor impeller along the circumferential direction of the gas compressor impeller; a ring-shaped gas control slot is arranged in the volute shell; a reflux ring is fixed in the gas control slot; the reflux ring respectively forms a reflux slot, a gas absorbing slot and a reflux channel with inner walls of volute shell in left-side, right-side and outer-side directions of the gas control slot; the reflux slot, the reflux channel and the gas-absorbing slot are communicated in sequence; the gas absorbing slot is arranged between the front edge of the primary blade and the front edge of the splitter blade; a gas compressor gas inlet path is formed between the front edge of the primary blade and the end part of the volute shell; a slide sleeve capable of moving along the gas compressor gas inlet path is arranged in the gas compressor gas inlet path. The gas-entraining recycling structure disclosed by the invention can improve the reflux amount of the gas-entraining recycling structure to achieve the purpose of optimizing all working conditions of the gas compressor.

Owner:HARBIN ENG UNIV

Oscillating sliding vane jet flow stroke-increasing hydraulic oscillator

ActiveCN112112569AIncrease vibration amplitudeReduce vibration frequencyVibration devicesVibration drillingVibration amplitudeReciprocating motion

The invention provides an oscillating sliding vane jet flow stroke-increasing hydraulic oscillator. A vortex cavity is fixedly arranged in an outer sleeve and used for generating vibration; a flow inlet hole is formed in one end of the vortex cavity, and a flow outlet hole is formed in the other end of the vortex cavity and located in the circle center of the vortex cavity; a sliding groove is formed in the inlet end of the flow inlet hole or the inlet end of the flow outlet hole; a movable sliding block is installed in the sliding groove in a sliding manner; one end of the stroke of the movable sliding block partially covers the flow inlet hole or the flow outlet hole, and the other end of the stroke of the movable sliding block completely leaves the flow inlet hole or the flow outlet hole so as to alternately limit the through-flow section of the flow inlet hole; and leaf springs are arranged on the two sides of the sliding groove and connected with the movable sliding block. By theadoption of the scheme that the movable sliding block is arranged in a flow inlet channel or the vortex cavity, the movable sliding block reciprocates through vibration of the vortex cavity, and therefore the through-flow area of the flow inlet channel or a flow outlet channel is changed, the vibration amplitude of the vortex cavity is increased, the vibration frequency is reduced, and then the vibration form meeting the underground construction requirement is obtained, namely the proper amplitude and vibration frequency are obtained.

Owner:SINOPEC OILFIELD EQUIP CORP +1

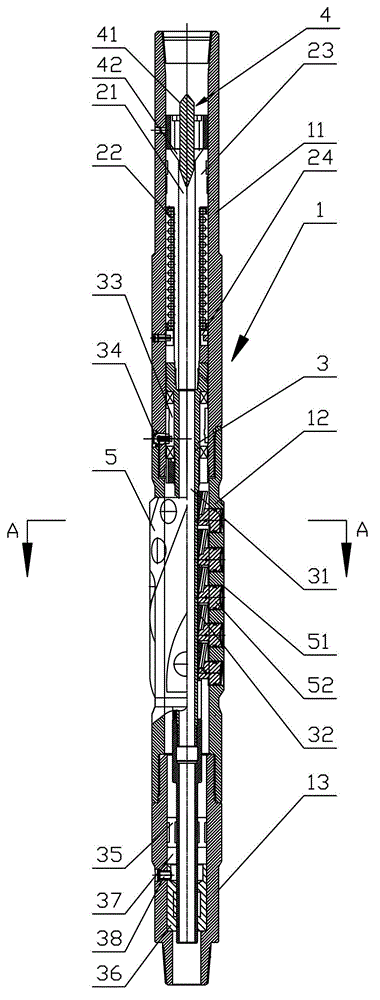

Sand control screen pipe flow control system, method and device and petroleum downhole drilling and production tool

ActiveCN111894532AGood elasticity and plasticityChange flow areaInsulationFluid removalControl systemPetroleum oil

The invention belongs to the technical field of petroleum and natural gas exploitation, and discloses a sand control screen pipe flow control system, method and device and a petroleum downhole drilling and production tool. Fluid enters a fixed-precision sand blocking layer through a rectangular through hole in a protection module, first-stage sand control treatment is conducted, and the fluid enters an overflowing area control module and then enters a pipeline through a screen; and when the flow of a screen pipe needs to be adjusted, a heating cavity supplies heat through power supply of a power transmission cable, memory metal is heated, a sliding block is stretched and moved through the two-way memory effect of the memory metal, the position of the sliding block in an overflowing area control structure is changed, the overflowing area of the fluid is changed, and screen pipe flow control is achieved. According to the sand control screen pipe flow control system, method and device andthe petroleum downhole drilling and production tool, the flow of the fluid flowing through the screen pipe is adjusted in real time in the petroleum field production process; the method for controlling the oil well yield at the position of the sand control screen pipe is provided through the characteristics of the memory metal; and the flow of the fluid of the sand control screen pipe is adjustedin real time in the petroleum field production process. Compared with a sand control screen pipe in the prior art, the flow of the sand control screen pipe is controlled.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

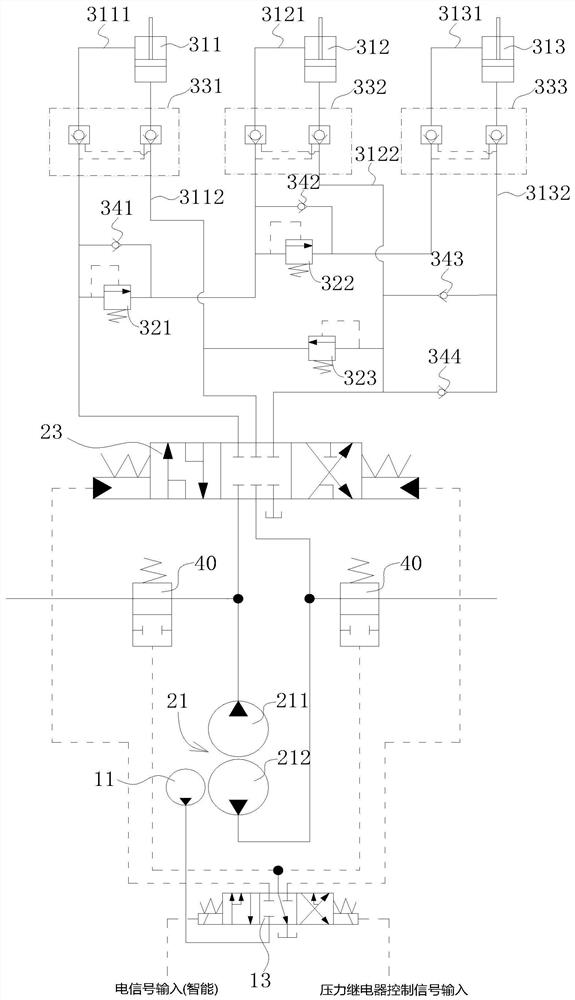

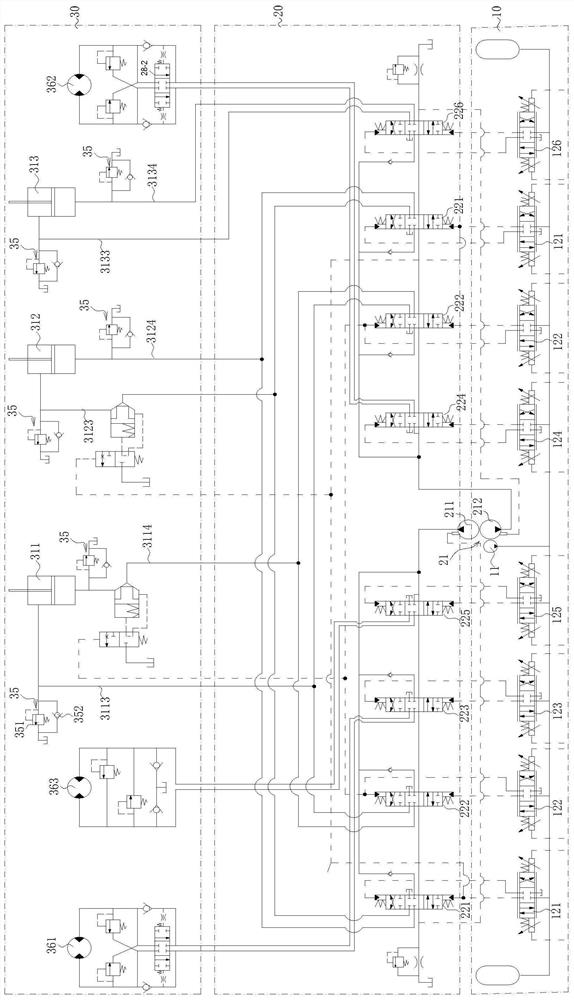

A Double Working Mode Excavator Hydraulic System

ActiveCN110905033BAvoid confusionRealize comprehensive utilizationSoil-shifting machines/dredgersProcess engineeringControl valves

Owner:HEFEI UNIV OF TECH

HP type coal mill

ActiveCN113908930AImprove performanceExtend your lifeGrain treatmentsVertical cylinderIndustrial engineering

The invention provides an HP type coal mill. The HP type coal mill comprises a static ring, a nozzle ring mounting cavity, a rotary nozzle ring and a first protection plate, wherein the static ring comprises an upper annular expanding cylinder, a vertical cylinder and a lower annular expanding cylinder, and the vertical cylinder is connected with the upper annular expanding cylinder and the lower annular expanding cylinder; the coal mill is provided with the cylindrical nozzle ring mounting cavity, and the axis of the nozzle ring mounting cavity is vertical; the rotary nozzle ring is arranged in the nozzle ring mounting cavity, the rotary nozzle ring can rotate along the axis of the rotary nozzle ring, and a plurality of blades are uniformly distributed on the peripheral surface of the rotary nozzle ring in the circumferential direction; and the first protection plate is an expanding annular plate, the first protection plate is attached to the inner wall face of the upper annular expanding cylinder and fixedly connected with the upper annular expanding cylinder, and the first protection plate protects the upper annular expanding cylinder. According to the coal mill, the discharge amount of pebble coal is reduced, the performance of the coal mill is improved, meanwhile, the abrasion of the annular expanding cylinder and the abrasion of a shell are obviously reduced, the overhaul period is prolonged, and the maintenance cost is reduced.

Owner:浙江浙能乐清发电有限责任公司 +1

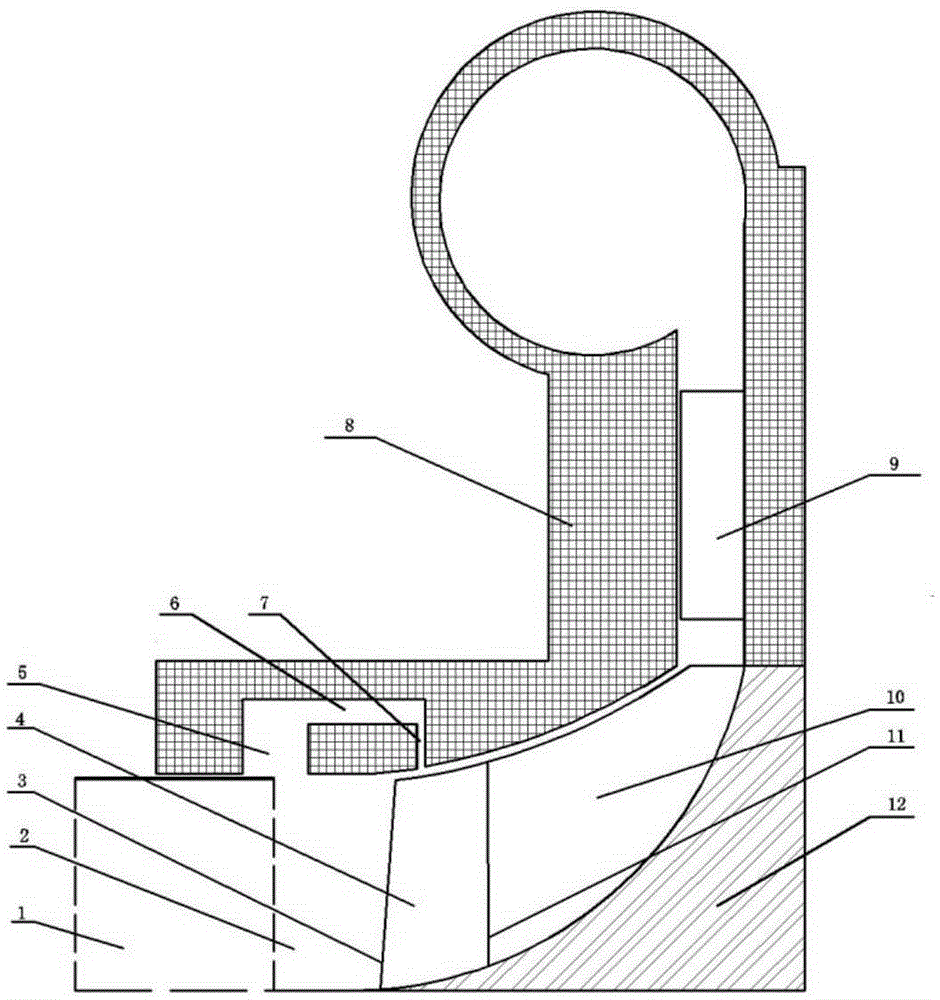

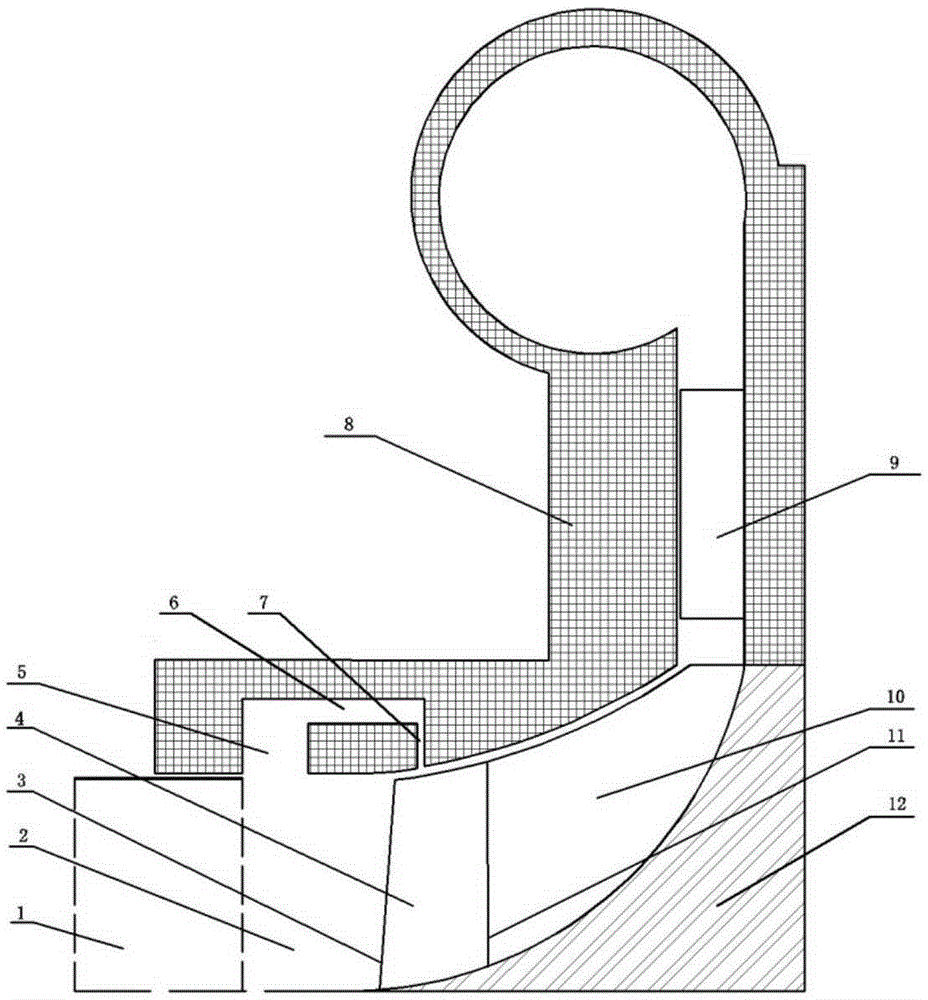

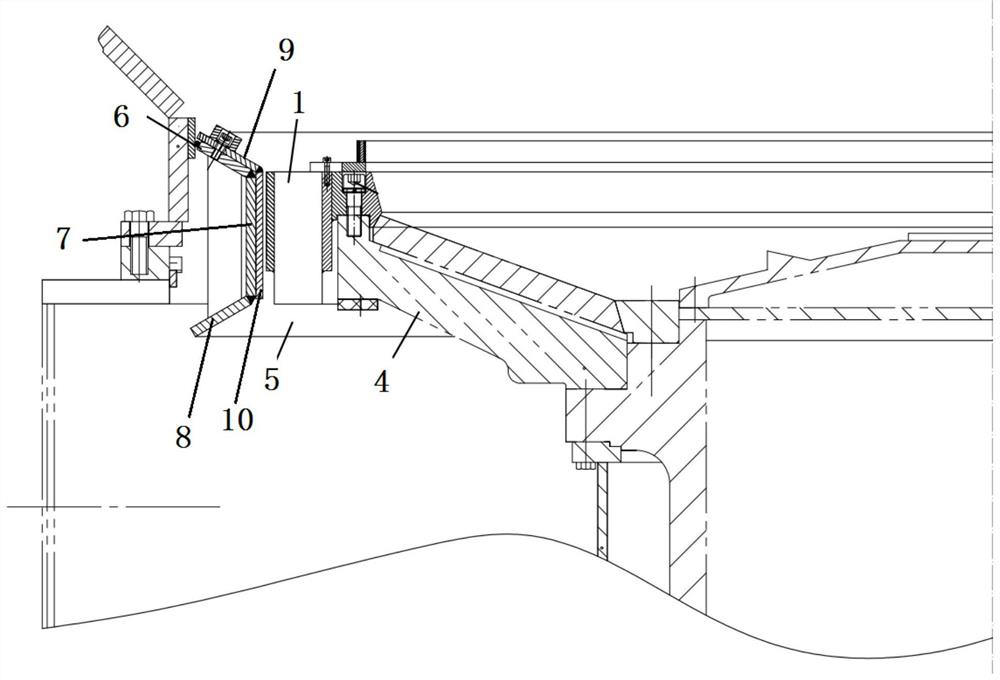

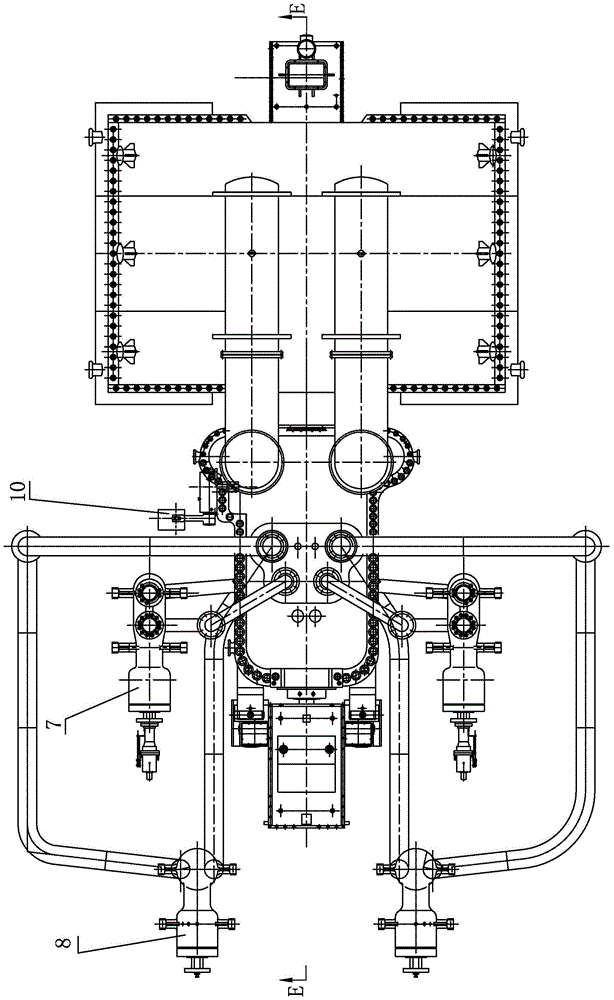

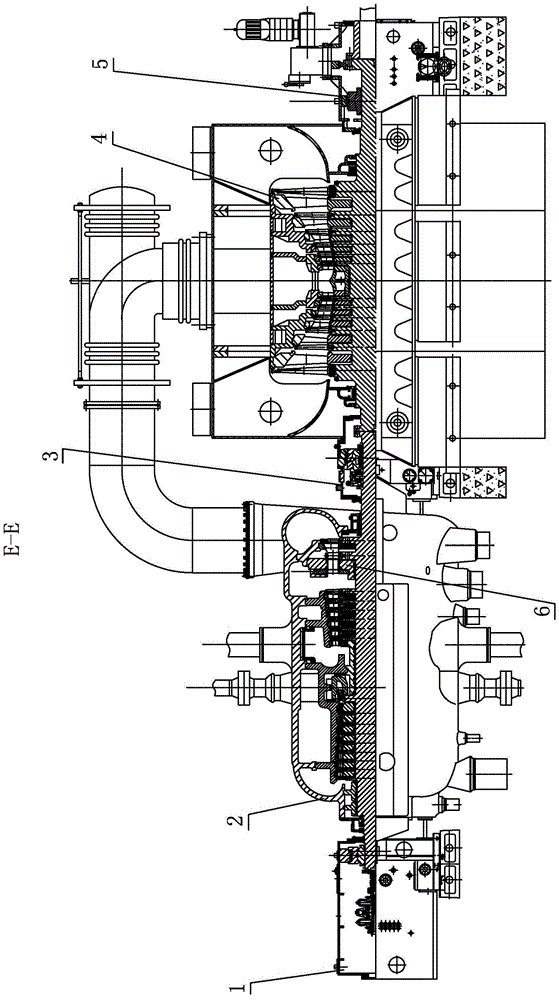

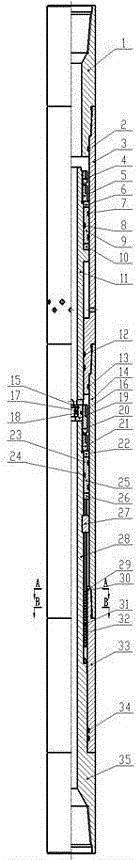

150mw ultra-high pressure extraction and condensing steam turbine

ActiveCN105201566BImprove work efficiencySimple structureMachines/enginesEngine componentsCogenerationEngineering

The invention relates to a turbine, in particular to a 150MW ultrahigh pressure steam extraction and condensing type turbine, and aims to solve the problems that steam is extracted from a steam extraction pipeline connection pipe of a 150MW turbine unit and the extraction flow of steam cannot be controlled so that energy loss is caused, and the turbine unit efficiency is reduced. The turbine comprises a front bearing box, an ultrahigh pressure and high-intermediate pressure combined cylinder, a middle bearing box, an ultrahigh pressure and low pressure cylinder, a rear bearing box, a rotary baffle, a rotary mechanism and a power mechanism; the ultrahigh pressure and high-intermediate pressure combined cylinder is connected between the front bearing box and the middle bearing box, and the ultrahigh pressure and low pressure cylinder is connected between the middle bearing box and the rear bearing box; the rotary baffle is mounted in the ultrahigh pressure and high-intermediate pressure combined cylinder and comprises a plate body outer ring, a plate body inner ring, a rotary ring, a cover ring, an elastic sealing ring, a connection convex handle and a stationary blade; the rotary ring is arranged between the cover ring and the plate body outer ring, and the cover ring is connected with the plate body outer ring. The 150MW ultrahigh pressure steam extraction and condensing type turbine is used for heating power generation of combined heat and power generation.

Owner:HARBIN TURBINE +1

A hydraulic power compensation balance valve

The invention discloses a hydraulic power compensation balance valve. The pilot control end cover assembly includes a control end cover valve body, and a pilot oil channel is arranged on the control end cover valve body; the valve core assembly includes a throttle valve core, a main spring, a regulating valve Seat; one-way valve seat assembly includes one-way valve and one-way valve spring; balance valve body assembly includes balance valve body and valve seat; throttle valve core is provided with a throttle port with an angle of α; the inner wall of the right end of the one-way valve The conical surface and the conical surface of the throttle port of the throttle spool cooperate with each other to form an openable seal; the one-way valve moves to the left during the luffing operation to realize the function of the one-way valve from the oil port A to the oil port B of the balance valve. During the luffing operation, the throttle spool opens to the right under the action of the pilot control pressure to realize the balance valve function from oil port B to oil port A, and as the load pressure increases, the angle through the throttle spool is α The hydraulic force generated during the annular flow channel controls the size of the throttle opening of the throttle spool to achieve load-flow compensation.

Owner:JIANGSU ADVANCED CONSTR MASCH INNOVATION CENT LTD +1

Variable diameter stabilizer and its system

ActiveCN103015892BGuarantee safe and reliableChange flow areaDirectional drillingEngineeringHigh pressure

The invention provides a variable-diameter stabilizer. The variable-diameter stabilizer comprises a housing, an upper mandrel and a lower mandrel, wherein an upper high-pressure mud cavity is formed in the upper mandrel in the direction of the axial line of a housing, a lower high-pressure mud cavity is formed in the lower mandrel in the direction of the axial line of the housing, the variable-diameter stabilizer further comprises a mud pressure changing device, the mud pressure changing device comprises a mushroom head assembly and a center hole, the center hole is formed in the upper end of the upper mandrel, the diameter of the upper end of the center hole is larger than that of the lower end, and the center hole is communicated with the upper high-pressure mud cavity; the mushroom head assembly is arranged above the center hole and fixed on the inner wall of the housing; and when the variable-diameter stabilizer is positioned in a working state, the area of passage of mud at the mushroom head assembly and the center hole is maximum, the pressure born by the variable-diameter stabilizer in the working state can be effectively reduced, and the variable-diameter stabilizer is safe and reliable. The invention further provides a variable-diameter stabilizer system, which can effectively reduce the pressure born by the variable-diameter stabilizer in the working state, and the variable-diameter stabilizer is safe and reliable.

Owner:四川伟创石油装备制造有限公司 +1

A movable drug mixer

InactiveCN104756970BAvoid contactReduce spreadFlow mixersInsect catchers and killersPesticide pollutionEngineering

The invention discloses a moveable chemical mixer. The chemical mixer comprises a drug bag, a shrinkage section, an expansion section, a leaking screen and a spiral organ; the spiral shrinkage section is in threaded connection with the expansion section, and the leaking screen is adaptively connected with the shrinkage section and the expansion section; the spiral organ is arranged in the expansion section and in threaded connection with the expansion section; both ends of the drug bag are in threaded connection with the shrinkage section and the expansion section. By adopting the chemical mixer, pesticide is integrated to the mixer, so that the online mixing is realized, the mechanical structure is simplified, flowing path of the pesticide is greatly reduced, pesticide pollution to agricultural implements are reduced, and environment is protected; besides, the mixing efficiency of the chemical mixer is improved.

Owner:NANJING FORESTRY UNIV

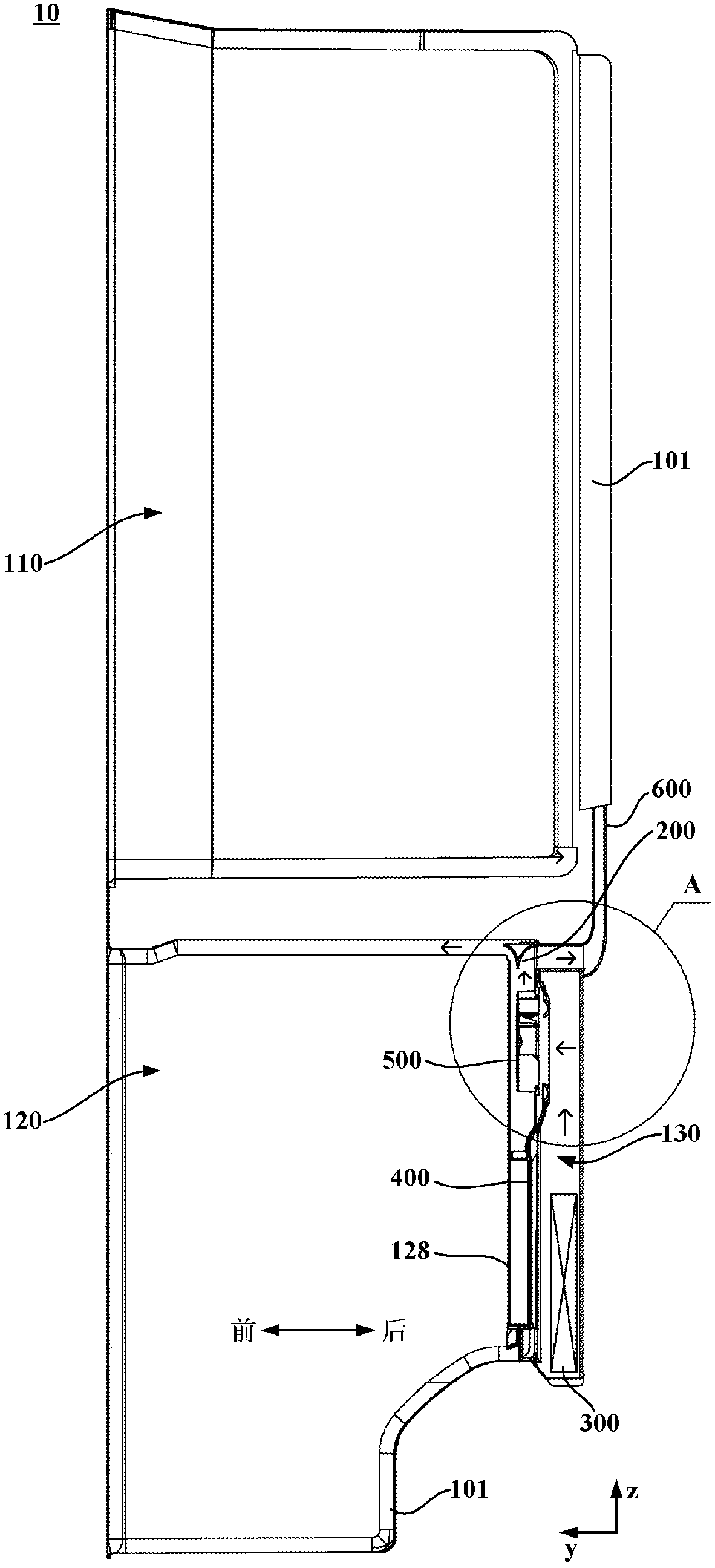

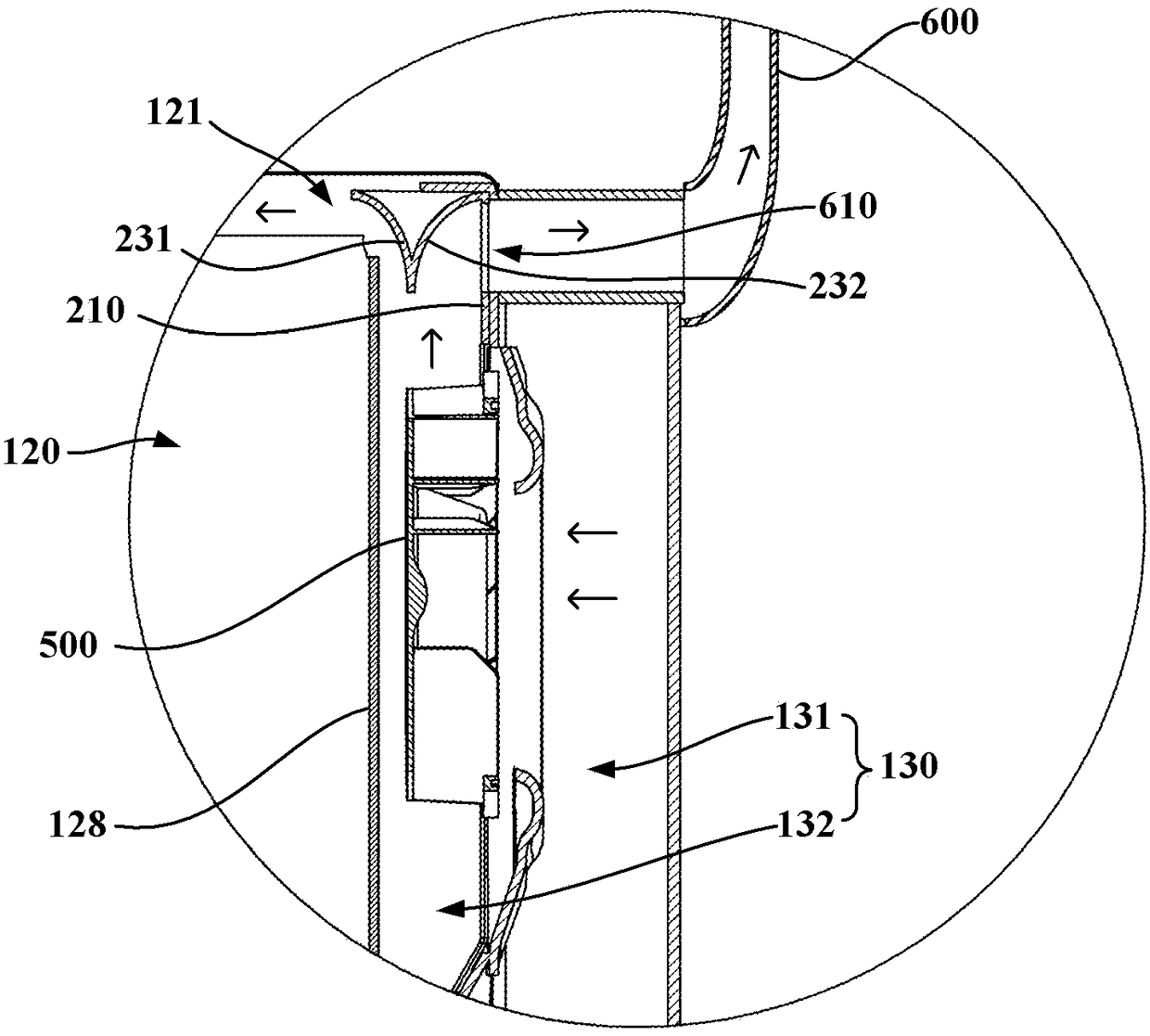

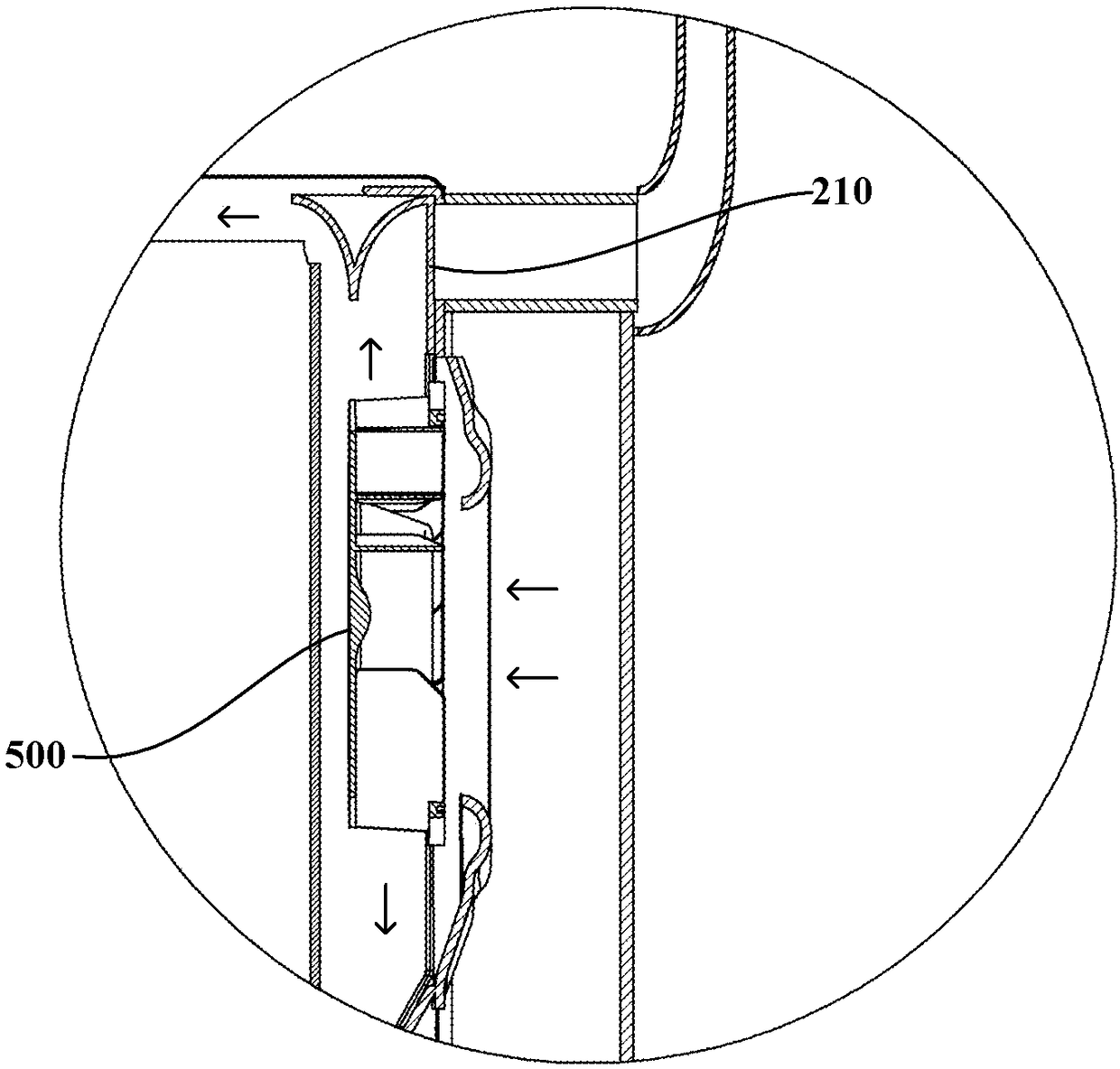

refrigerator

ActiveCN106123443BAdjust cooling capacityEasy to adjust cooling capacityLighting and heating apparatusDomestic refrigeratorsCold airAir volume

The invention provides a refrigerator. The refrigerator comprises a freezing chamber, a refrigerating chamber, a cooling chamber and an air quantity adjusting part. The cooling chamber is provided with an evaporator, is located behind the freezing chamber, and is provided with a freezing air inlet leading to the freezing chamber and a refrigerating air inlet leading to the refrigerating chamber. The refrigerating air inlet is located right behind the freezing air inlet. The air quantity adjusting part is movably arranged between the freezing air inlet and the refrigerating air inlet and is configured to be controlled to move in the transverse direction of the refrigerator so as to open or close the refrigerating air inlet; and after the refrigerating air inlet is opened, the air quantity adjusting part can be controlled to move front and back to be close to or far away from the freezing air inlet so as to adjust the open area of the freezing air inlet. An air supplying structure of the refrigerator is simple, the effective volume of the refrigerating chamber is not occupied by the air supplying structure excessively, and when the refrigerating chamber stops refrigerating, no cold air is accumulated in a refrigerating air channel.

Owner:HAIER SMART HOME CO LTD

An anti-stick-slip torsional impact drilling tool

InactiveCN106050177BChange flow areaIncrease drilling speedVibration devicesInterference fitDrive shaft

The invention relates to a stick slip prevention torsion impact drilling tool which is used for improving the penetration rate and well quality in the field of drilling engineering. By the adoption of the stick slip prevention torsion impact drilling tool, the problem that a drilling tool and a well body are severely damaged by the stick slip phenomenon in the drilling process. According to the technical scheme, the lower end of an output shaft is connected with a screw thread of a drill bit; the upper end of an outer shell is connected with a screw thread at the lower end of an upper connector; the lower end of the outer shell is connected with a screw thread at the upper end of a transmission shell; the outer circle of a movable valve ring is in interference fit with a stepped hole in the lower portion of an inner cavity of a movable valve seat; the outer circle of a static valve is in interference fit with a stepped hole in the upper portion of an inner cavity of a transmission shaft; the lower end of a spiral rotor is connected with a screw thread at the upper end of the movable valve seat; the transmission shaft is arranged in an inner cavity of the transmission shell; the external octagon shape in the middle of the transmission shaft is in clearance fit with the internal octagon shape in the middle of the inner cavity of the transmission shell; the lower end of a spiral shell is connected with a screw thread at the upper end of the output shaft; and the upper end of a spiral shaft is connected with a screw thread at the lower end of the transmission shaft, and a spline of the spiral shaft is in clearance fit with a spline of the spiral shell. The stick slip prevention torsion impact drilling tool generates high-frequency micro-amplitude circumferential reciprocating swing, the stick slip phenomenon can be prevented, and the penetration rate is increased.

Owner:SOUTHWEST PETROLEUM UNIV

Wall-mounted air conditioner indoor unit

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD +1

Turbine vanes, turbines and aero engines

The invention relates to a turbine guide vane, a turbine and an aircraft engine. The turbine guide vane comprises a movable part and a fixed part (9), the fixed part (9) is fixed relative to a turbine case, the movable part is connected with the fixed part (9) and located on one side of the suction surface of the turbine guide vane, and the movable part can move relative to the fixed part (9) so as to change the flow area between every two adjacent turbine guide vanes. Compared with the manner that the front edge or the tail edge of the turbine guide vane is arranged to be of a rotatable structural form in the prior art, the turbine guide vane has the advantages that the movable part is arranged on one side of the suction surface of the turbine guide vane, cooling of the interior of the turbine guide vane is not influenced, the whole vane, from the front edge to the tail edge, of the turbine guide vane can be cooled by taking corresponding cooling measures, and the condition that the life is shortened due to the fact that some portions of the turbine guide vane are impacted by high-temperature fuel gas is prevented.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

A low-friction variable-diameter hydraulic thruster

ActiveCN104295231BSolve the problem of difficult pressurizationPressurized and stableDrilling rodsBorehole drivesPiston ringEngineering

The invention relates to a low-friction-drag variable-diameter hydraulic thruster used for petroleum and natural gas drilling. According to the technical scheme, an upper connector is connected with an auxiliary cylinder through threads, the auxiliary cylinder is connected with a main cylinder through threads, the main cylinder is connected with a spline cylinder through threads, a piston is arranged in the auxiliary cylinder, a second piston cushion cover, a first piston ring and a first piston cushion cover are sequentially arranged on the piston, a first press cap and a first anti-loose cap are both connected with the piston through threads, a mandrel is arranged in the main cylinder and the spline cylinder, a semi-ring is arranged in the middle of the mandrel, a fourth piston cushion cover, a second piston ring and a third piston cushion cover are sequentially arranged on the head of the mandrel, a second pressing cap and a second anti-loose cap are connected with the mandrel through threads, a nozzle base is located between the piston and the mandrel, a nozzle is arranged in the nozzle base, four steel ball bases are evenly distributed between the mandrel and the spline cylinder, and steel balls are arranged in the steel ball bases. According to low-friction-drag variable-diameter hydraulic thruster, drilling pressure which is high enough, stable and uniform can be obtained by a drill bit in the true sense, the bridge over phenomenon can be prevented, and the low-friction-drag variable-diameter hydraulic thruster is used for drilling.

Owner:SOUTHWEST PETROLEUM UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com