150mw ultra-high pressure extraction and condensing steam turbine

A 1.150MW, ultra-high pressure technology, applied in the direction of mechanical equipment, engine components, machines/engines, etc., can solve the problems of uncontrollable steam extraction, reduced unit working efficiency, energy loss, etc., to reduce energy loss and complete machine layout Compact and energy-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

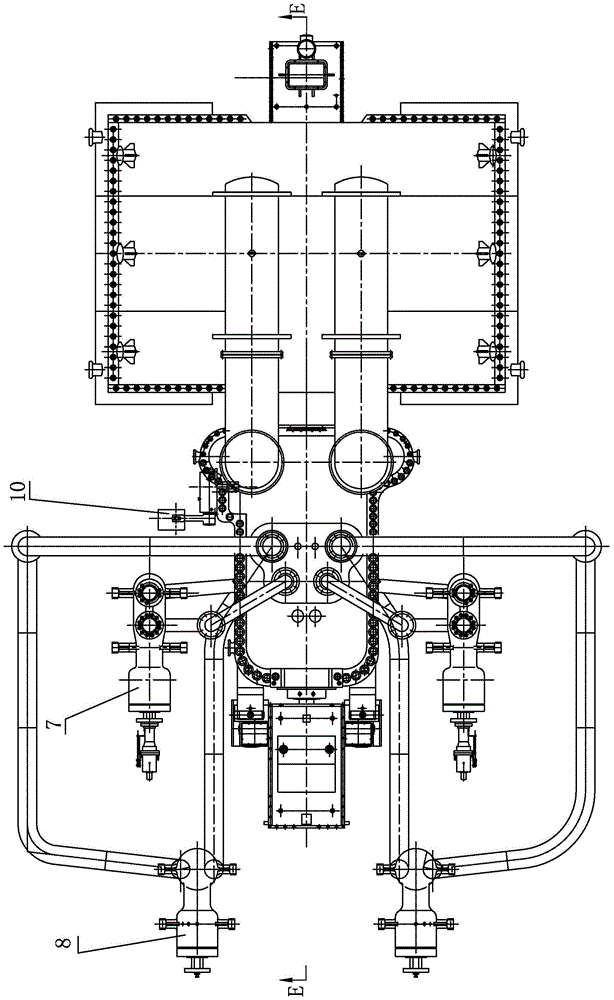

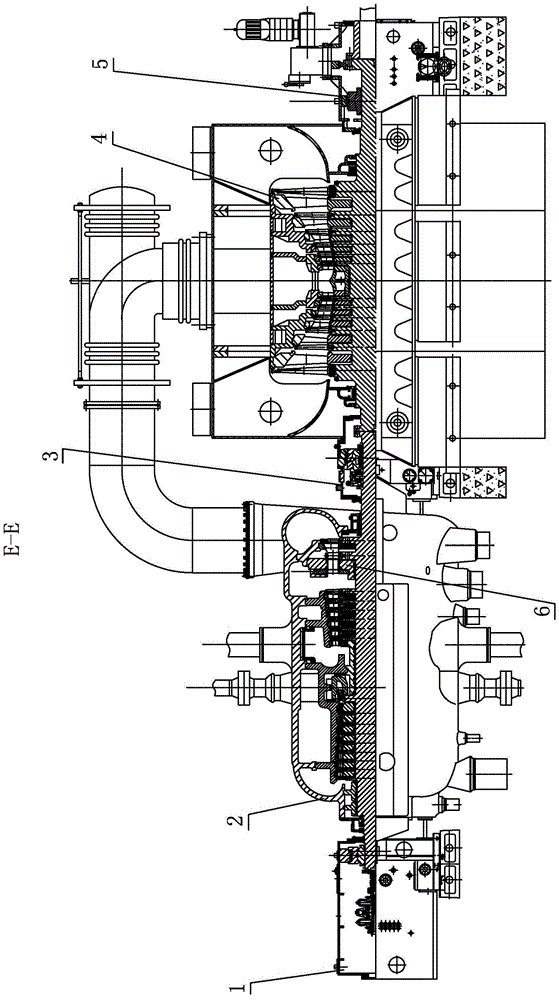

[0008] Specific implementation mode one: combine Figure 1-Figure 4 Explain that the 150MW ultra-high pressure steam extraction and condensing steam turbine in this embodiment includes a front bearing housing 1, an ultra-high pressure, medium and high pressure combined cylinder 2, a middle bearing housing 3, an ultra-high pressure and low pressure cylinder 4, a rear bearing housing 5, and a rotating partition 6. The slewing mechanism and the power mechanism 10; the ultra-high pressure, medium and high pressure combined cylinder 2 is connected between the front bearing housing 1 and the middle bearing housing 3, and the ultra-high pressure and low pressure cylinder 4 is connected between the middle bearing housing 3 and the rear bearing housing 5;

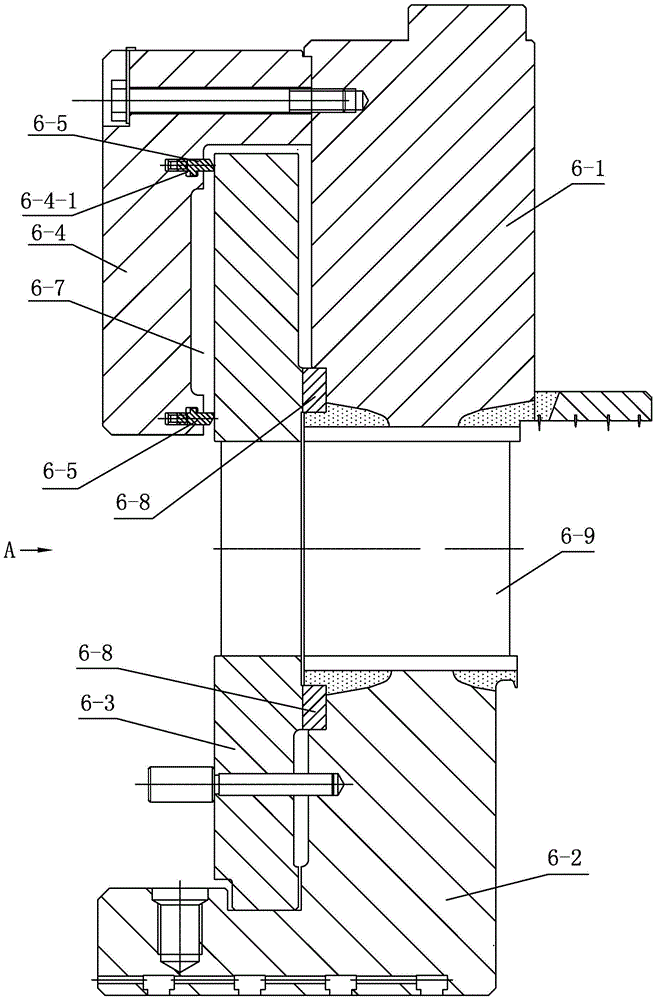

[0009] A rotating partition 6 is installed in the ultra-high pressure, medium and high pressure joint cylinder 2, and the rotating partition 6 includes the outer ring 6-1 of the board, the inner ring 6-2 of the board, the rotating ri...

specific Embodiment approach 2

[0012] Specific implementation mode two: combination Figure 4 Explain that the rotary mechanism of this embodiment includes a lever 9-2, a connecting rod 9-3 and a swing rod 9-4; the power mechanism 10 is an oil motor, and the oil motor is installed on the outer surface of the casing of the ultra-high pressure, medium and high pressure cylinder 2, The piston rod of the oil motor is rotationally connected to one end of the lever 9-2, the other end of the lever 9-2 is connected to one end of the connecting rod 9-3, and the other end of the lever 9-2 is rotationally and sealed installed in the ultra-high pressure, medium and high pressure joint cylinder 2 On the shell, the connecting rod 9-3 and the swing rod 9-4 are arranged in the ultra-high pressure, high and medium pressure joint cylinder 2, the other end of the connecting rod 9-3 is connected with the swing rod 9-4, and the swing rod 9-4 is connected with the connecting convex Shank 6-6 connection. In this way, there is a ...

specific Embodiment approach 3

[0013] Specific implementation mode three: combination image 3 Note that the outer ring 6-1 of the plate in this embodiment is an outer ring of a chromium-molybdenum alloy steel plate, and the inner ring 6-2 of the plate is an inner ring of a chromium-molybdenum steel plate. In this way, the chrome-molybdenum alloy steel is used, and the temperature resistance can reach 500°C, so it can operate safely at 400°C for a long time. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com