Oscillating sliding vane jet flow stroke-increasing hydraulic oscillator

A hydraulic oscillator and jet technology, which is used in vibration drilling, vibration generating devices, wellbore/well components, etc., can solve the problems of short service life, many rotating parts, complex structure, etc., and achieve long service life and moving parts. The effect of less and high output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

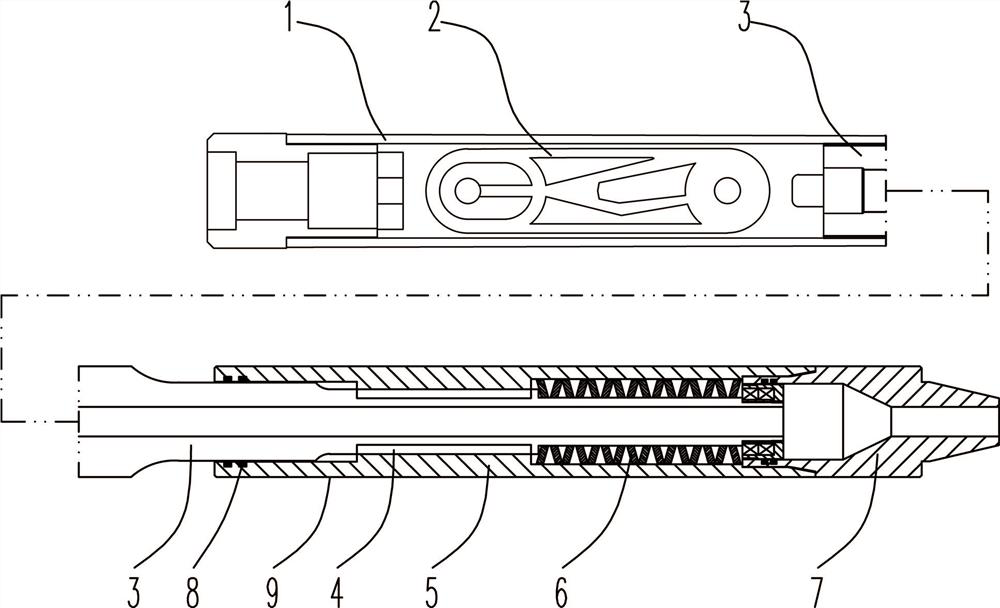

[0033] Such as Figure 1~6 Among them, an oscillating vane jet flow extended range hydraulic oscillator, the outer sleeve 1 is fixed with a vortex cavity body 2, the vortex cavity body 2 is used to generate vibration, and an inlet hole 202 is provided at one end of the vortex cavity body 2. The other end of the vortex cavity body 2 is provided with an outlet hole 203, the outlet hole 203 is located at the center of the vortex cavity 205, and a chute 21 is provided at the inlet end of the inlet hole 202 or at the inlet end of the outlet hole 203, and the sliding The block 22 is slidably installed in the chute 21. One end of the stroke of the moving slider 22 partially covers the inlet hole 202 or the outlet hole 203, and the other end of the stroke completely leaves or the outlet hole 203 to alternately limit the inlet flow. The flow cross section of the hole 202;

[0034] Leaf springs 23 are arranged on both sides of the chute 21 , and the leaf springs 23 are connected with t...

Embodiment 2

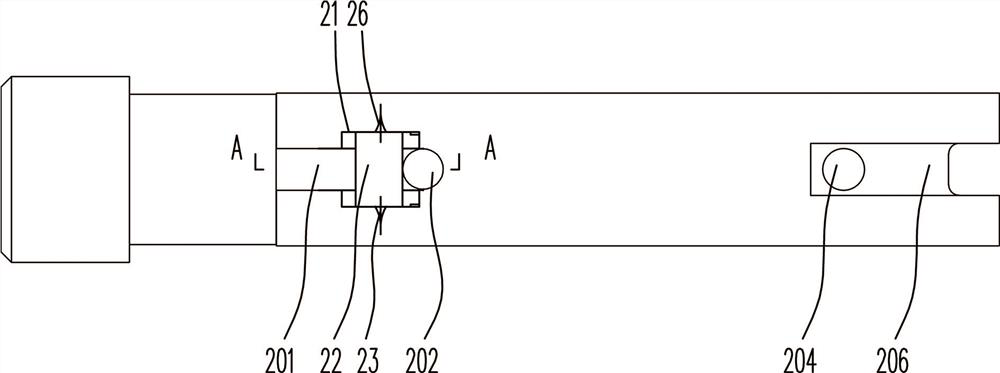

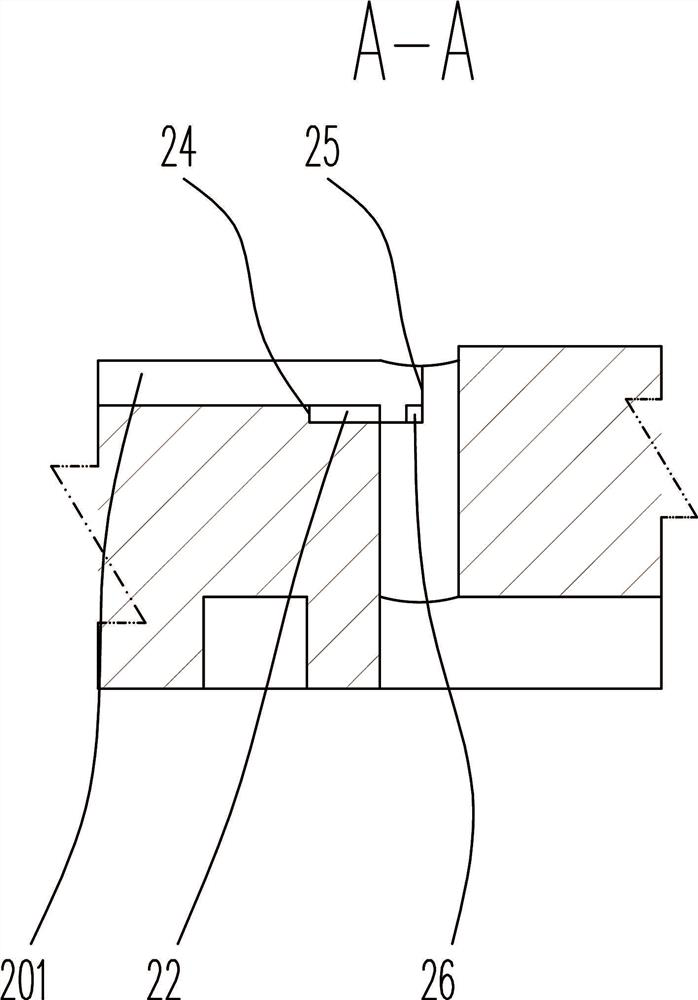

[0037] On the basis of Example 1, the preferred scheme is as Figure 2~3 In the vortex cavity, both sides of the back side of the vortex body 2 are provided with an inlet channel 201, the inlet channel 201 communicates with the inlet hole 202, and the chute 21 is arranged at the position where the inlet channel 201 and the inlet hole 202 are connected, and the chute 21 The bottom surface of the movable slider 22 is lower than the bottom surface of the inlet channel 201, and the top surface of the movable slider 22 is flush with the bottom surface of the inlet channel 201. With this structure, the disturbance to the pressure medium is reduced.

[0038] The preferred solution is as figure 2 Among them, the chute 21 widens to both sides, and the width of the chute 21 and the movable slider 22 is greater than the width of the inlet channel 201;

[0039] The two end surfaces of the chute 21 form a first collision surface 24 and a second collision surface 25 for colliding with th...

Embodiment 3

[0041] On the basis of Examples 1 and 2, different from Example 2, the preferred scheme is as Figure 4~6Among them, the chute 21 is lower than the bottom surface of the vortex cavity 205 , and the upper surface of the movable slider 22 is flush with the bottom surface of the volute cavity 205 . With this structure, the movable slider 22 is arranged at the position of the volute cavity 205, which is convenient for arrangement and processing. The upper surface of the movable slider 22 is flush with the bottom surface of the scroll chamber 205 . Disturbances of the pressure medium, in particular vortex-forming pressure medium, are then reduced.

[0042] The preferred solution is as Figure 4~6 Among them, the width of the chute 21 is greater than the diameter of the outlet hole 203, the step between the chute 21 and the outlet hole 203 constitutes the second impact surface 25, and the step at the end of the chute 21 away from the outlet hole 203 constitutes the first impact su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com