Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

43results about How to "Achieve vacuum" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

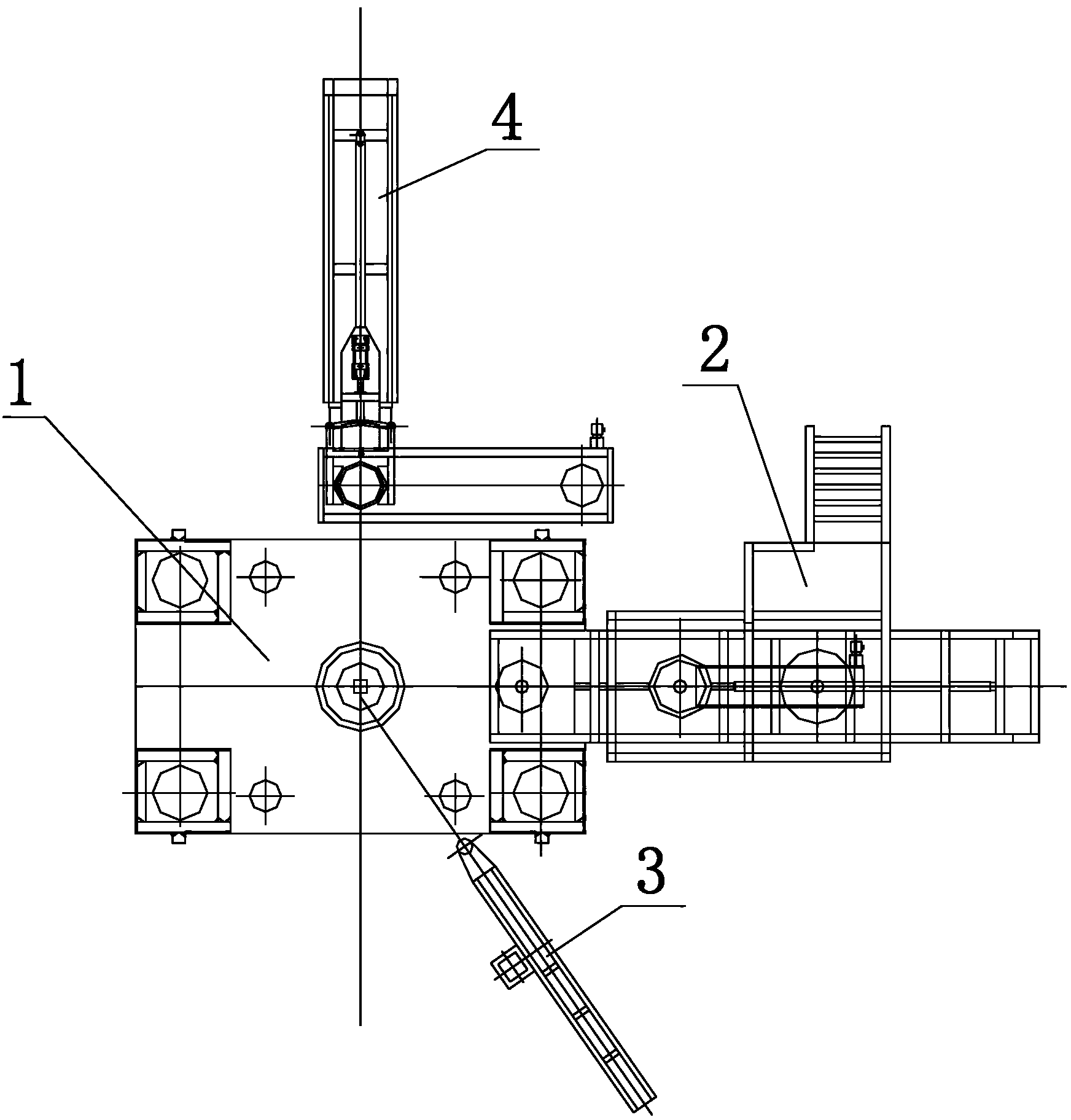

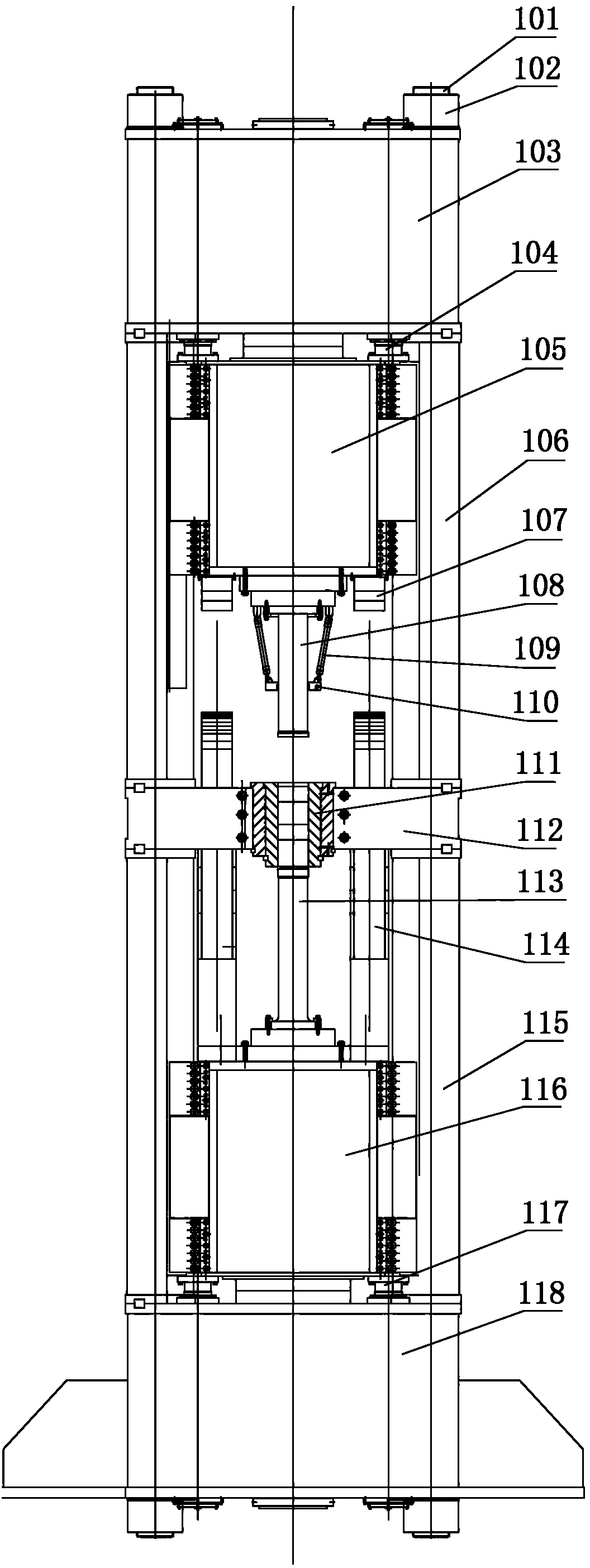

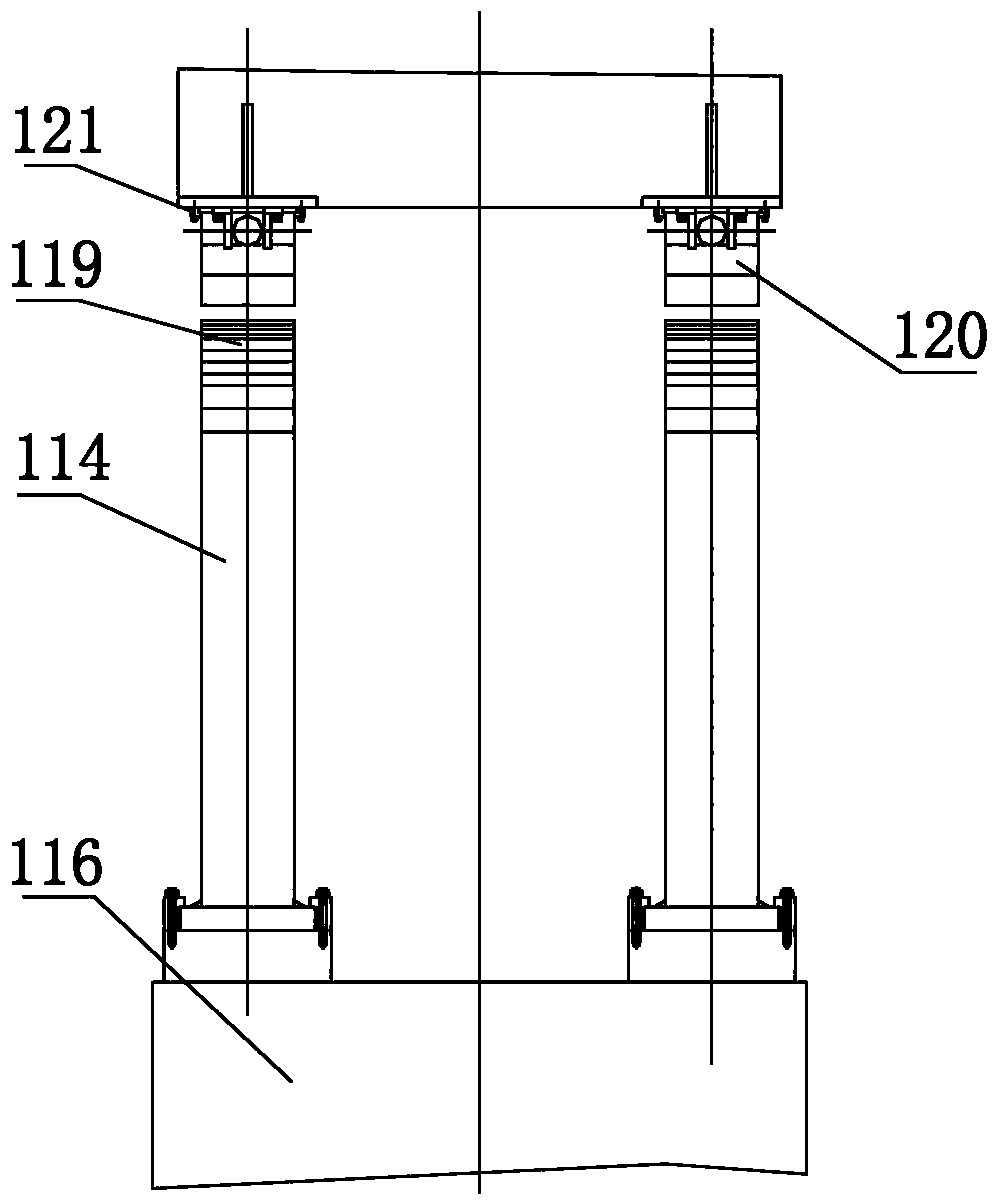

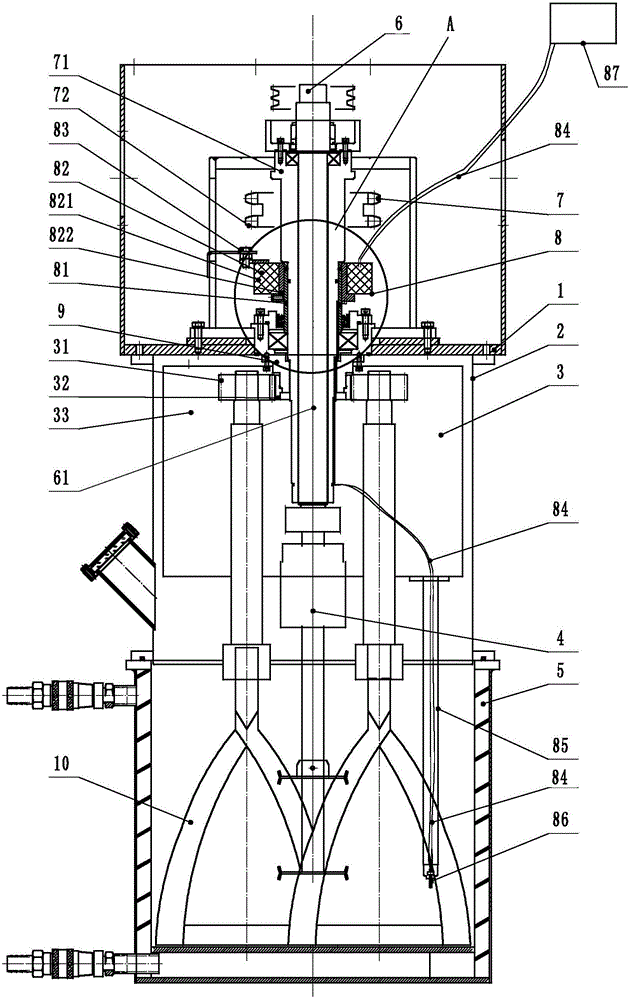

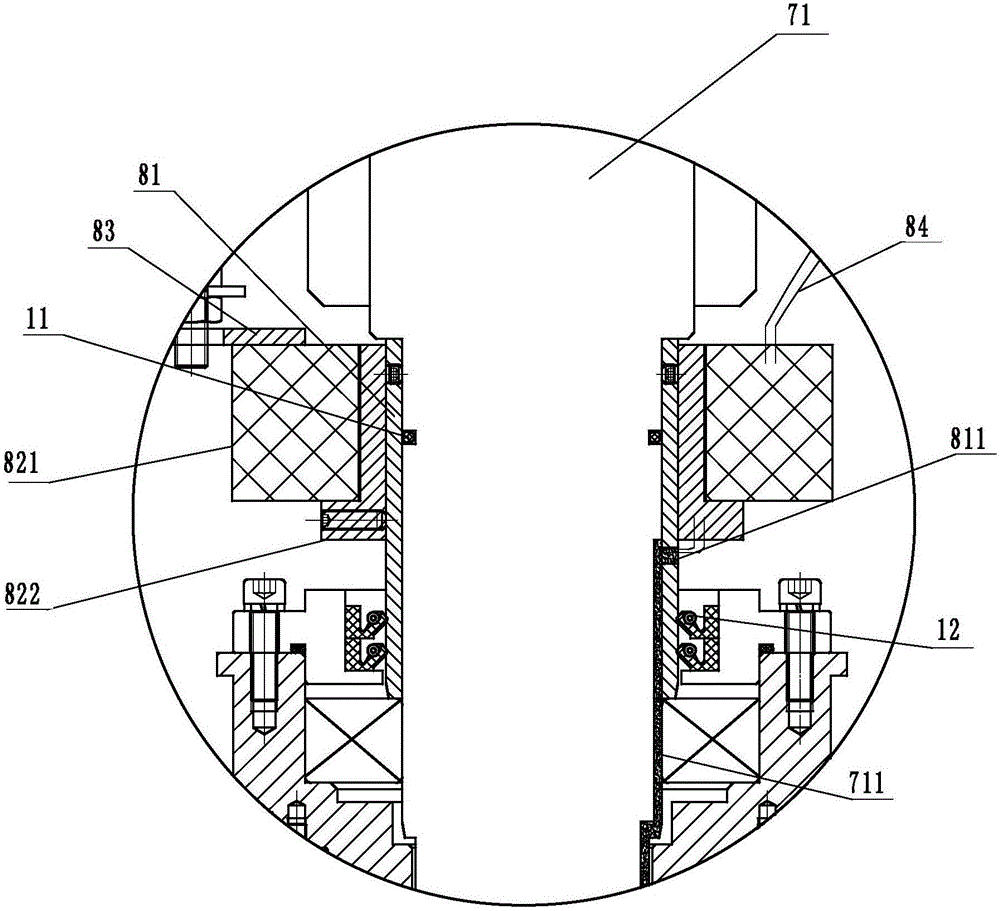

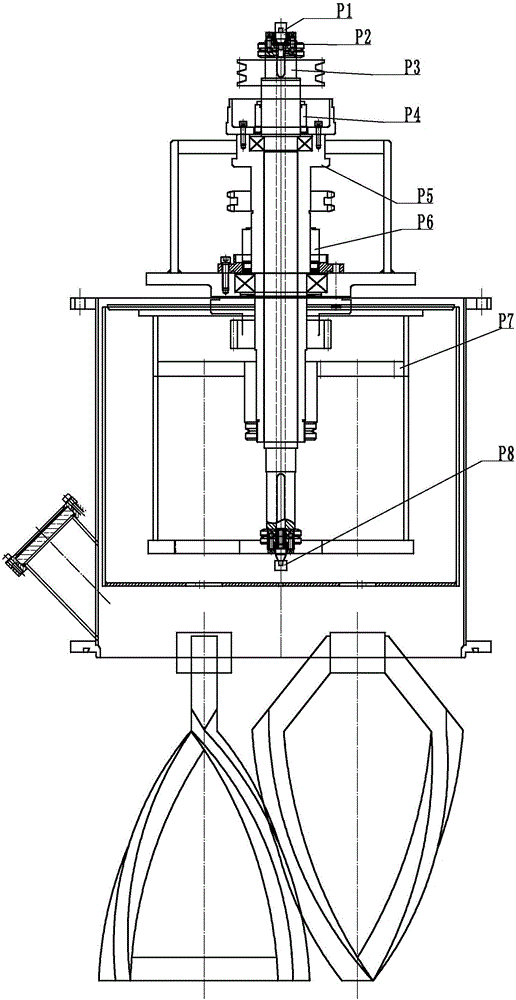

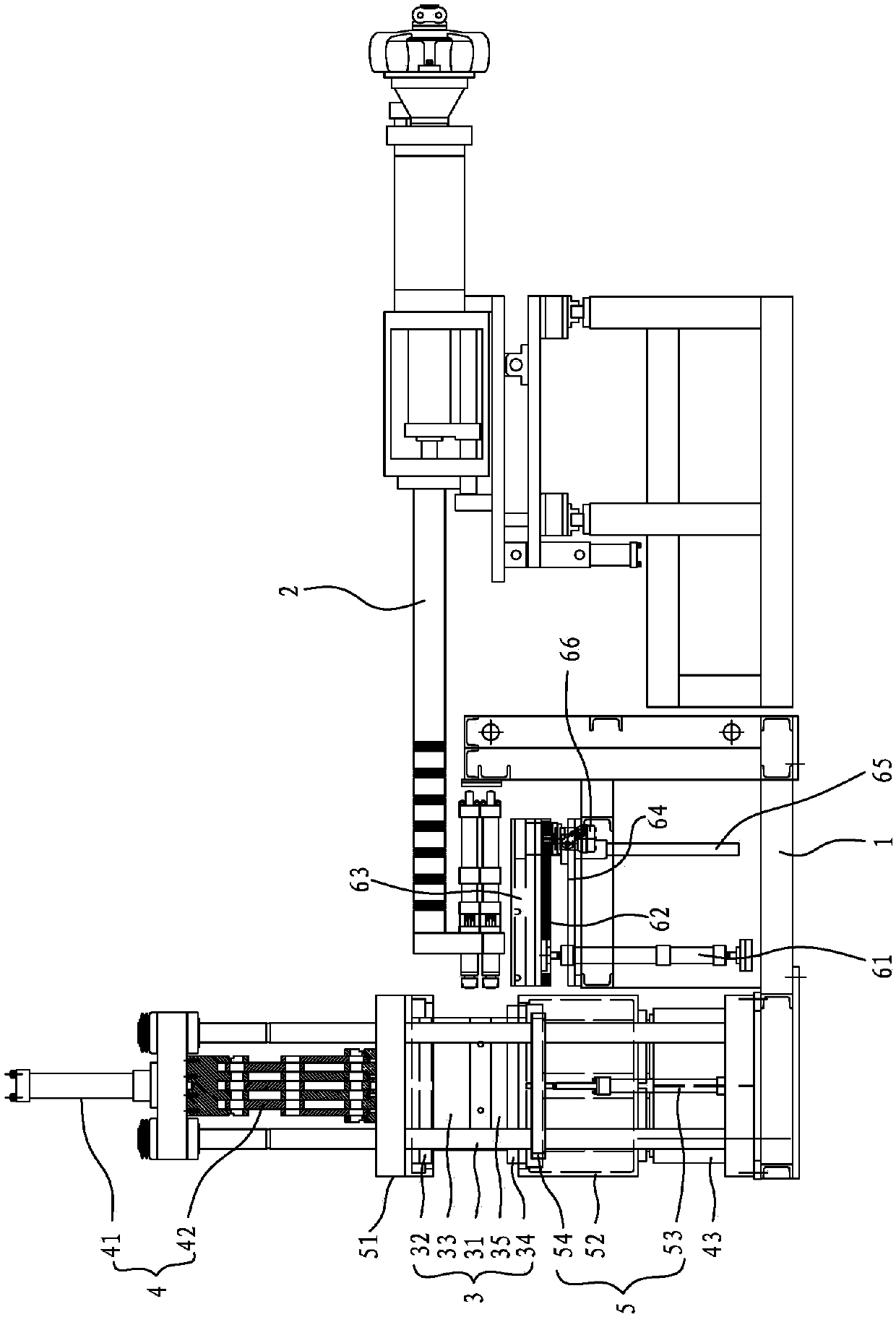

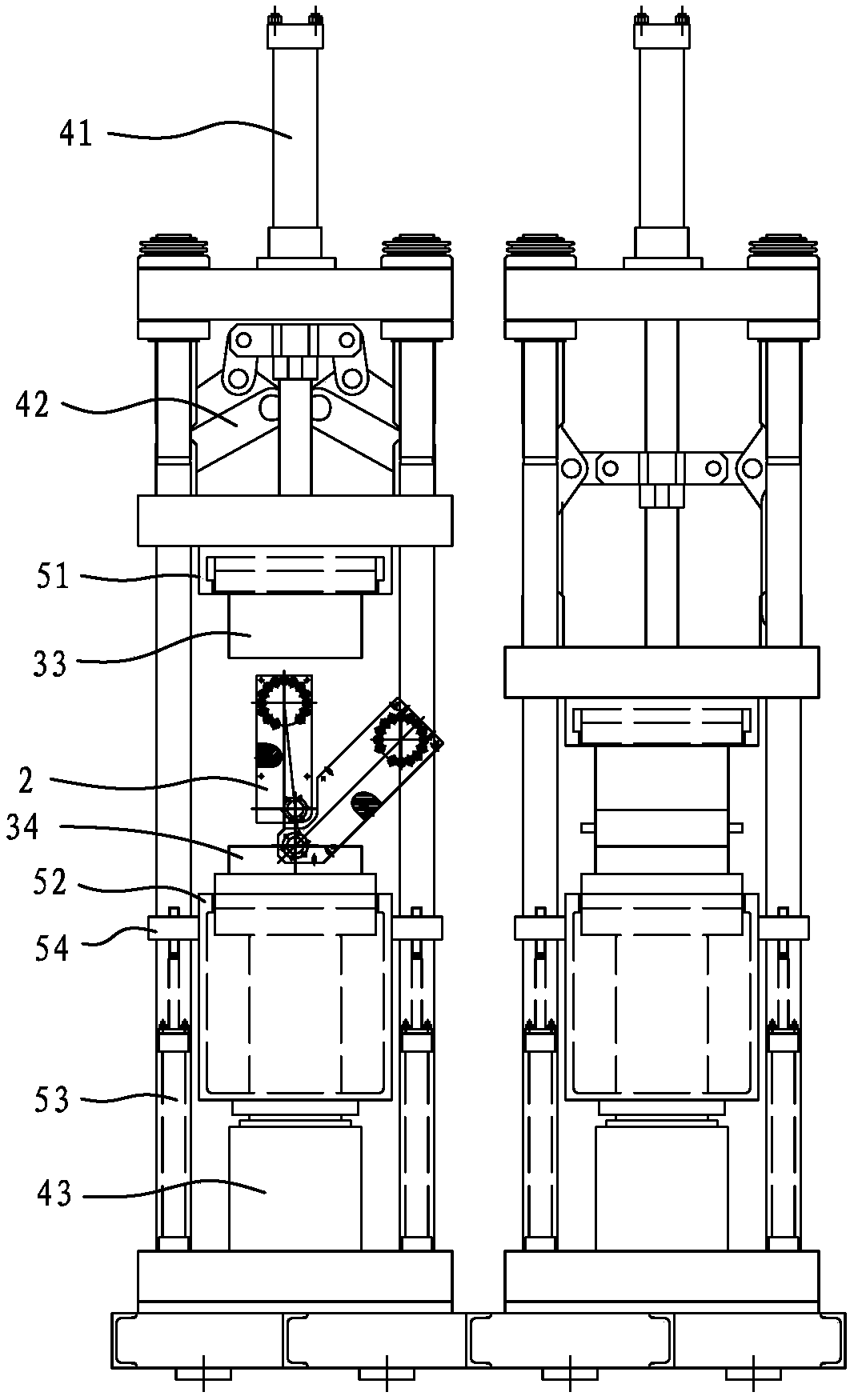

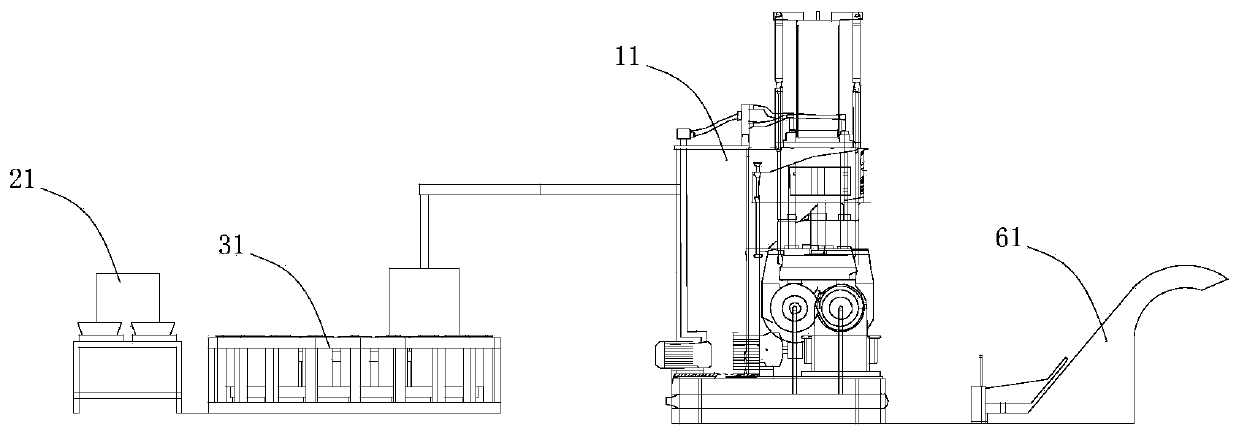

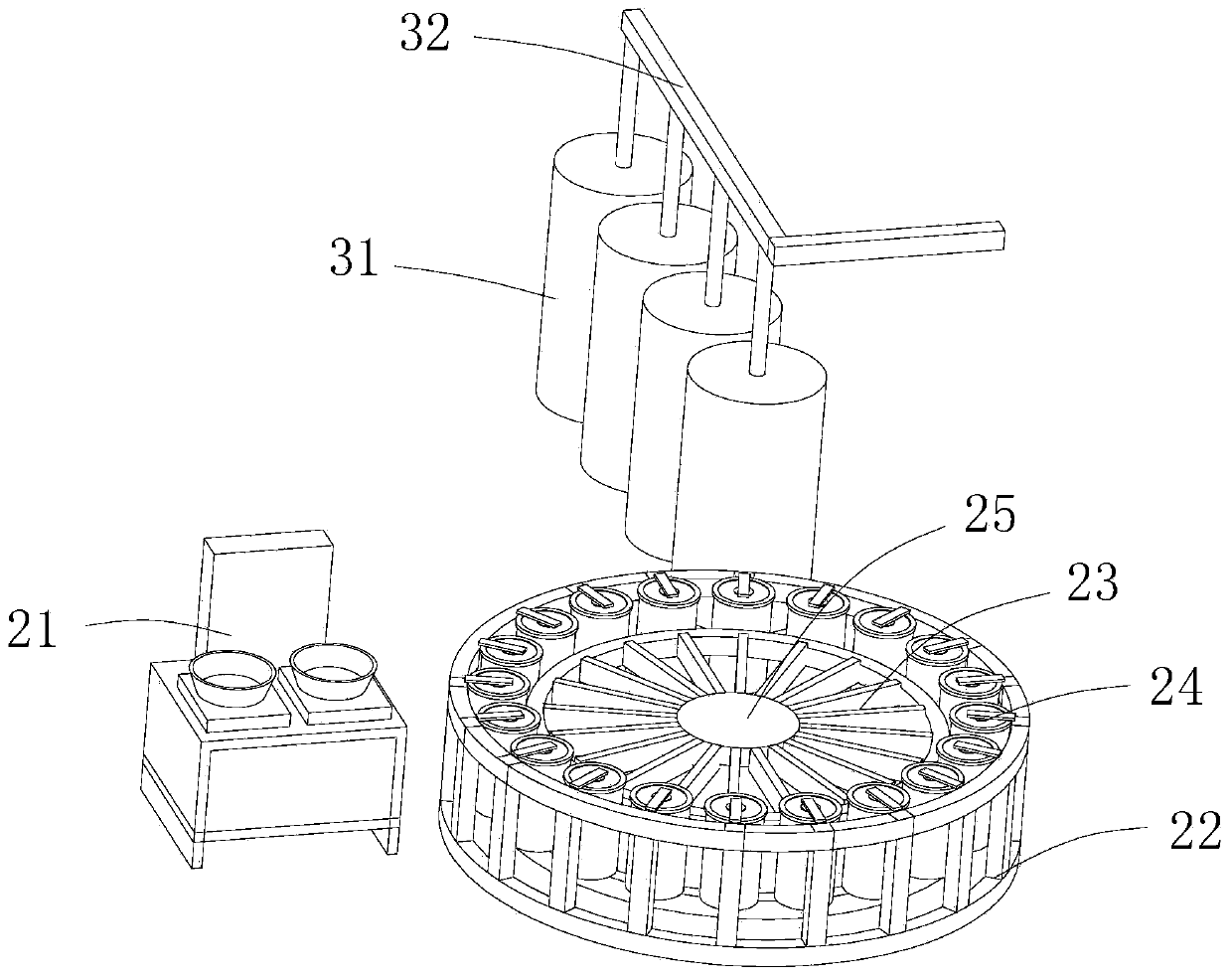

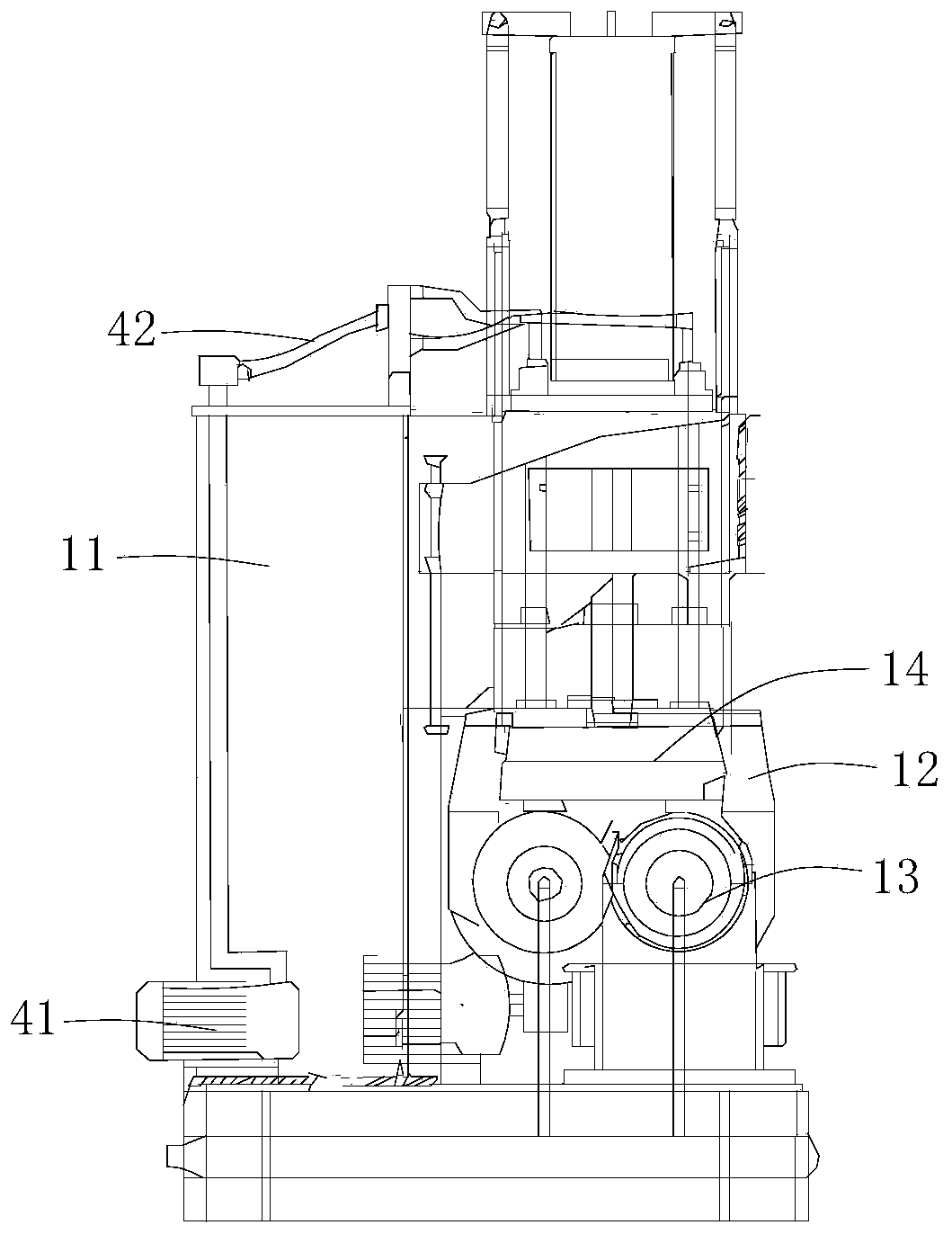

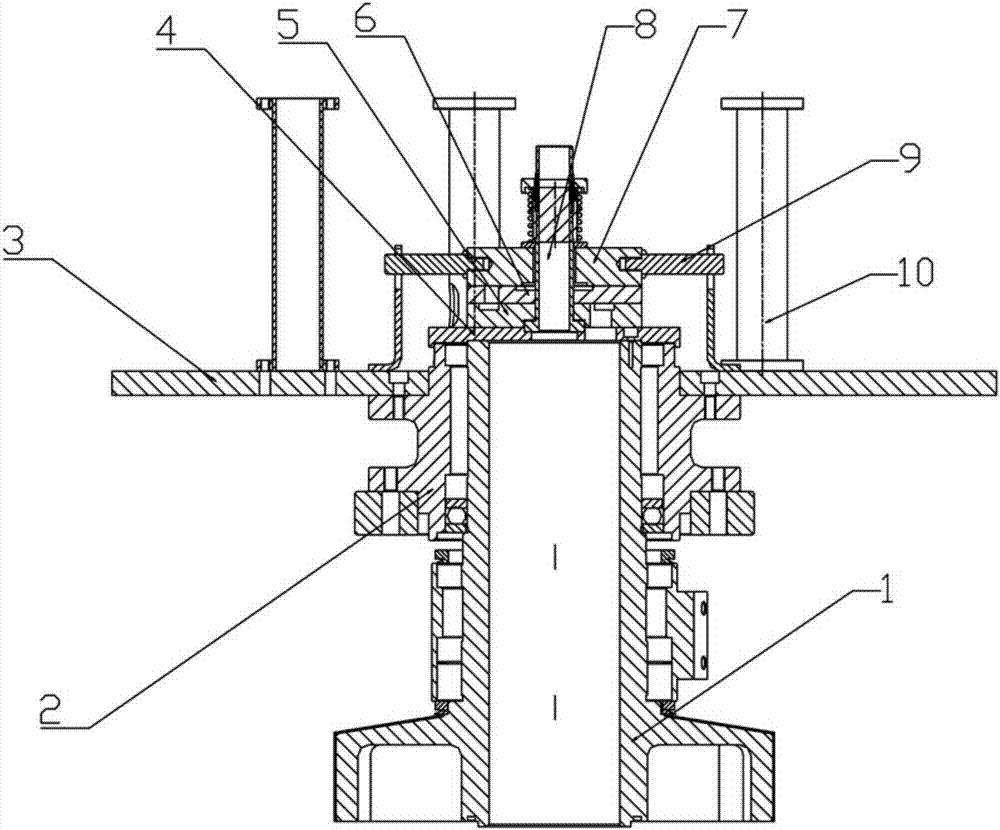

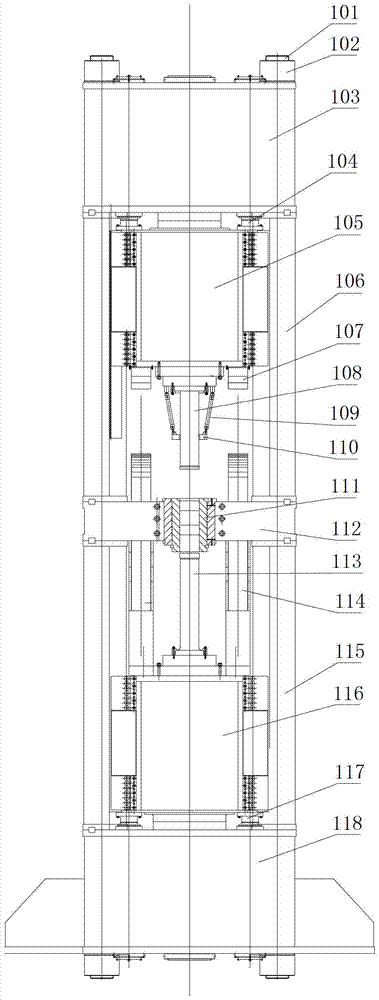

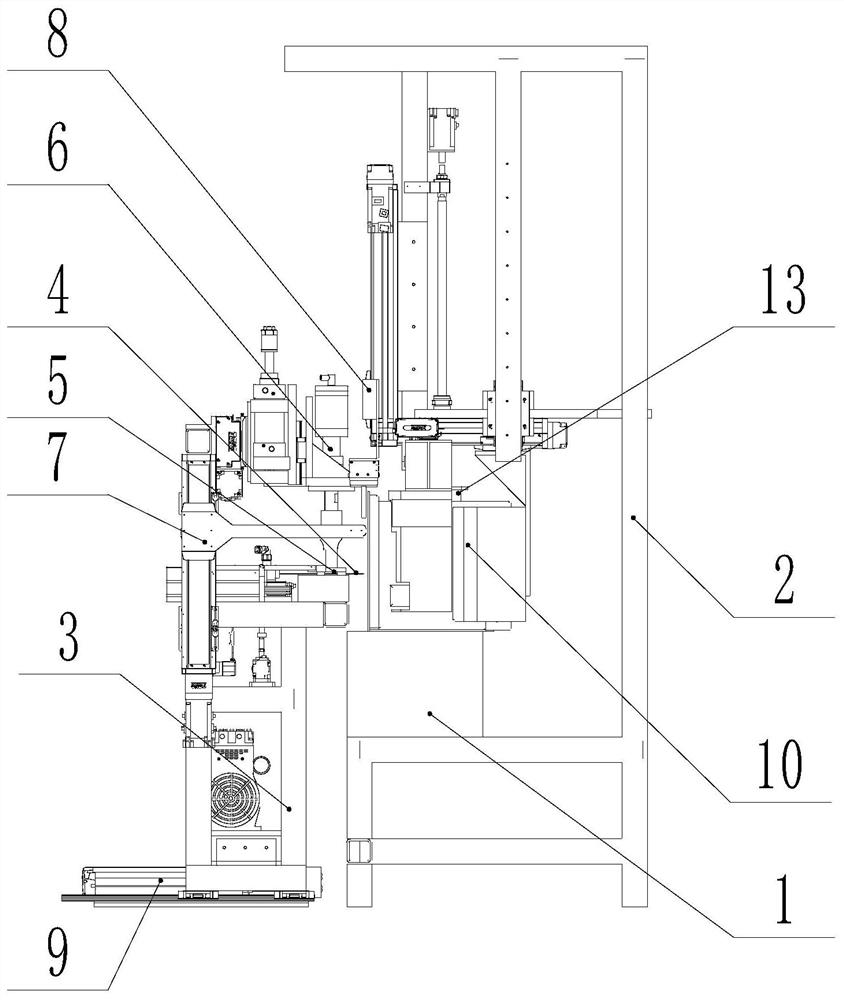

Automatic pressing production line of large explosive column

ActiveCN103265389AIncrease pressureHigh densityExplosive working-up apparatusProduction lineUltimate tensile strength

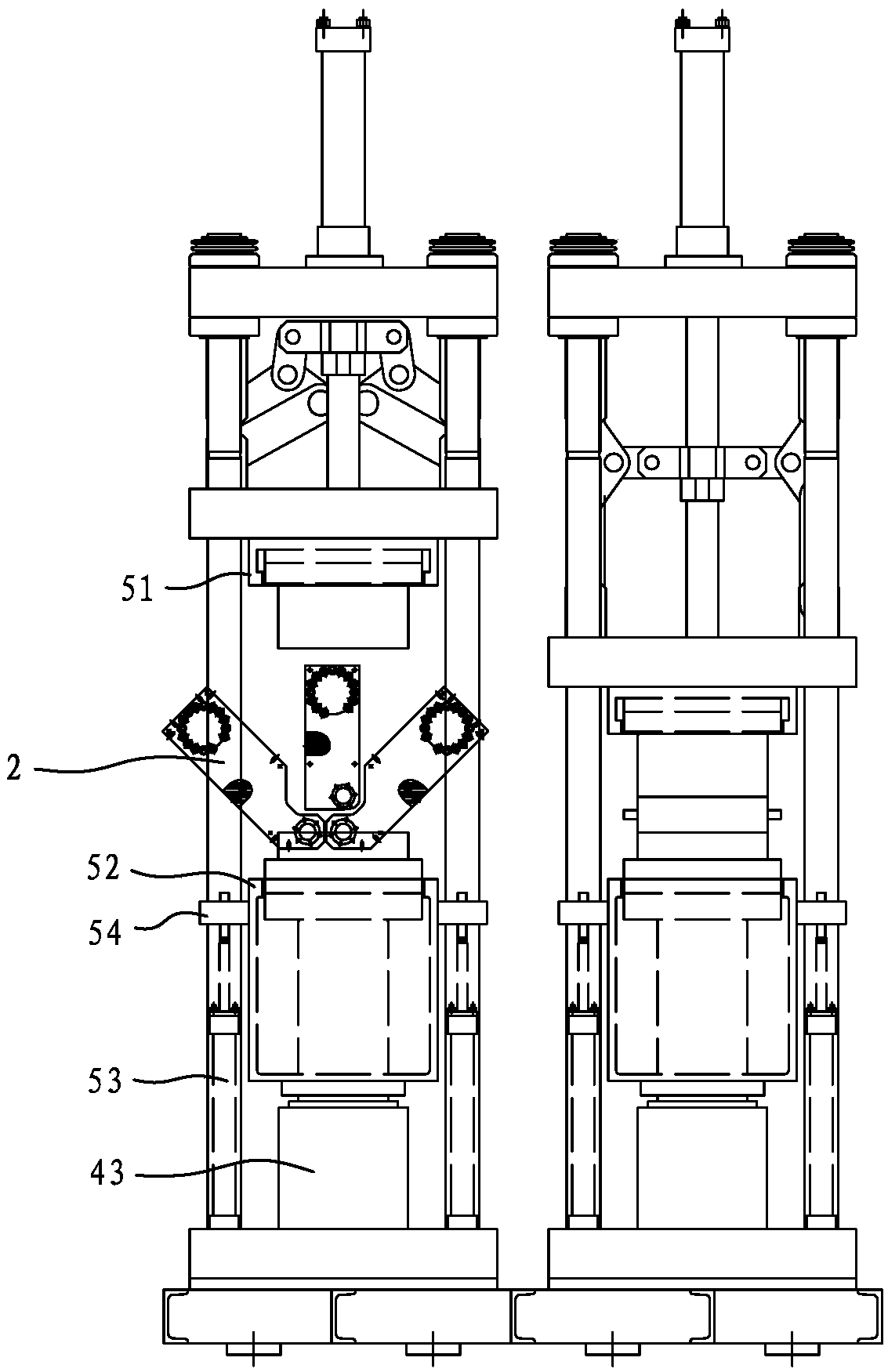

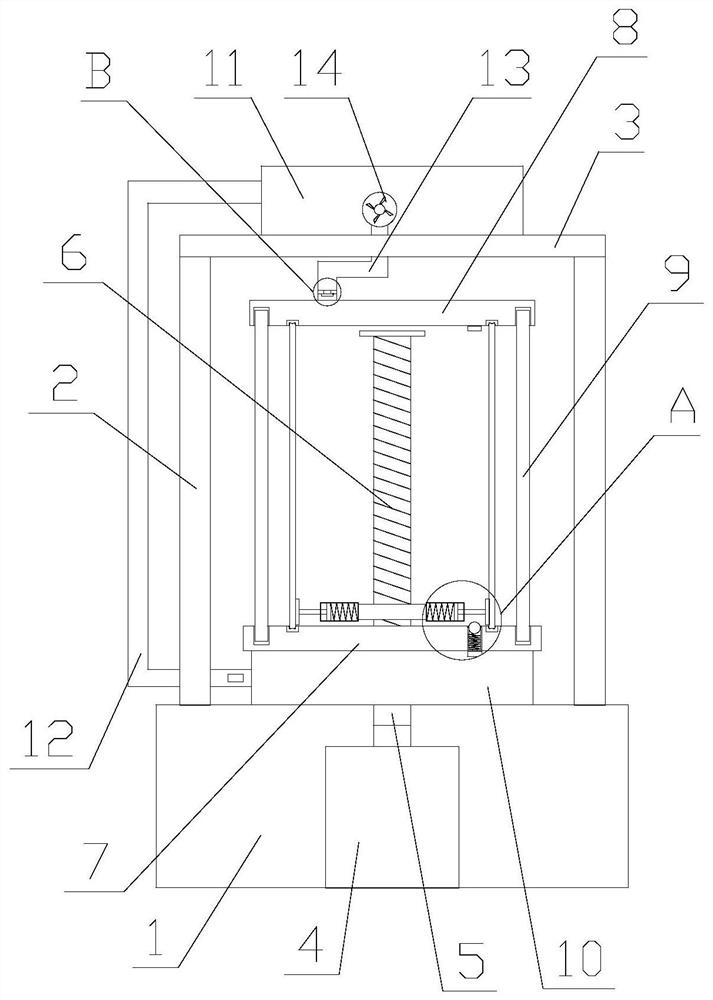

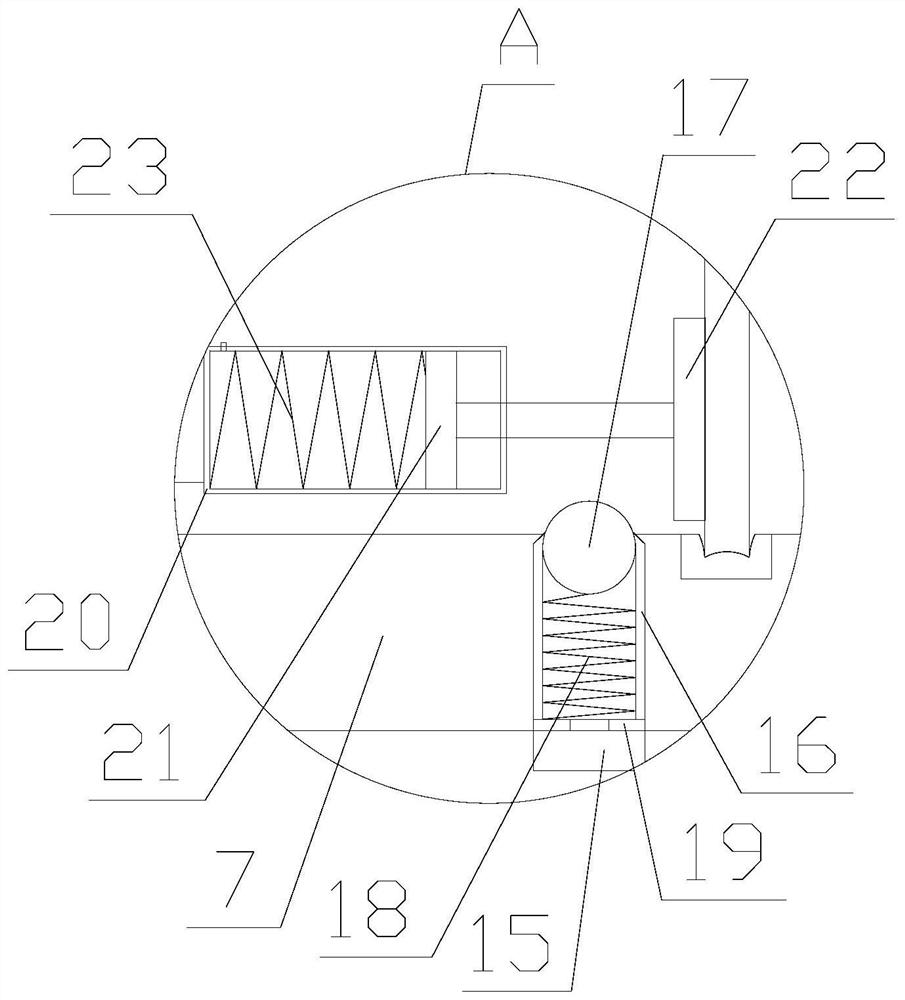

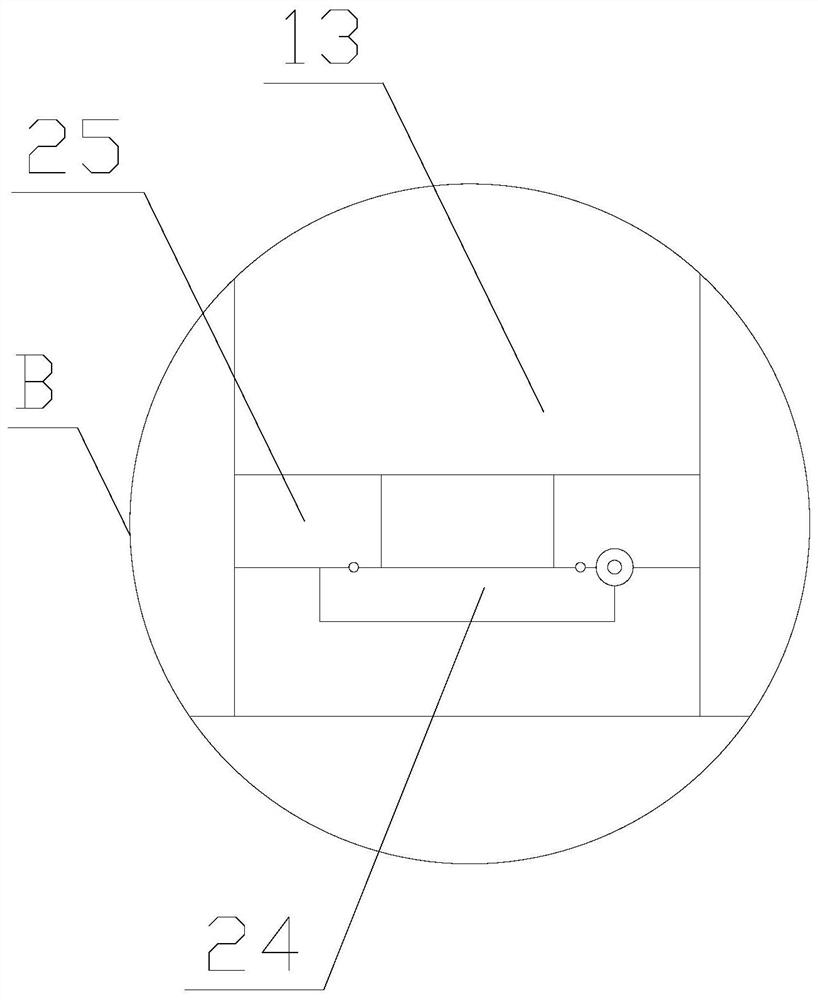

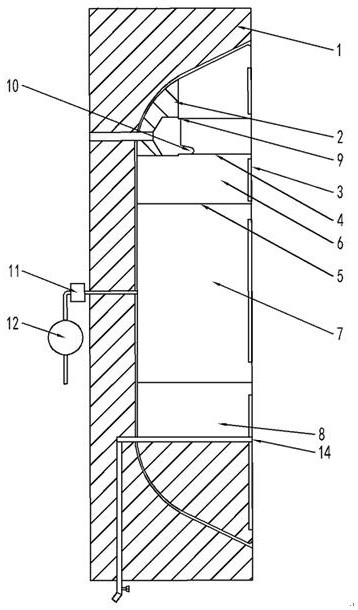

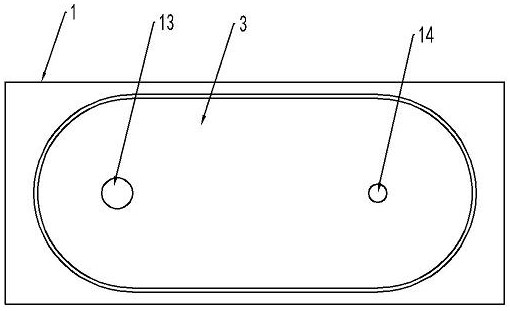

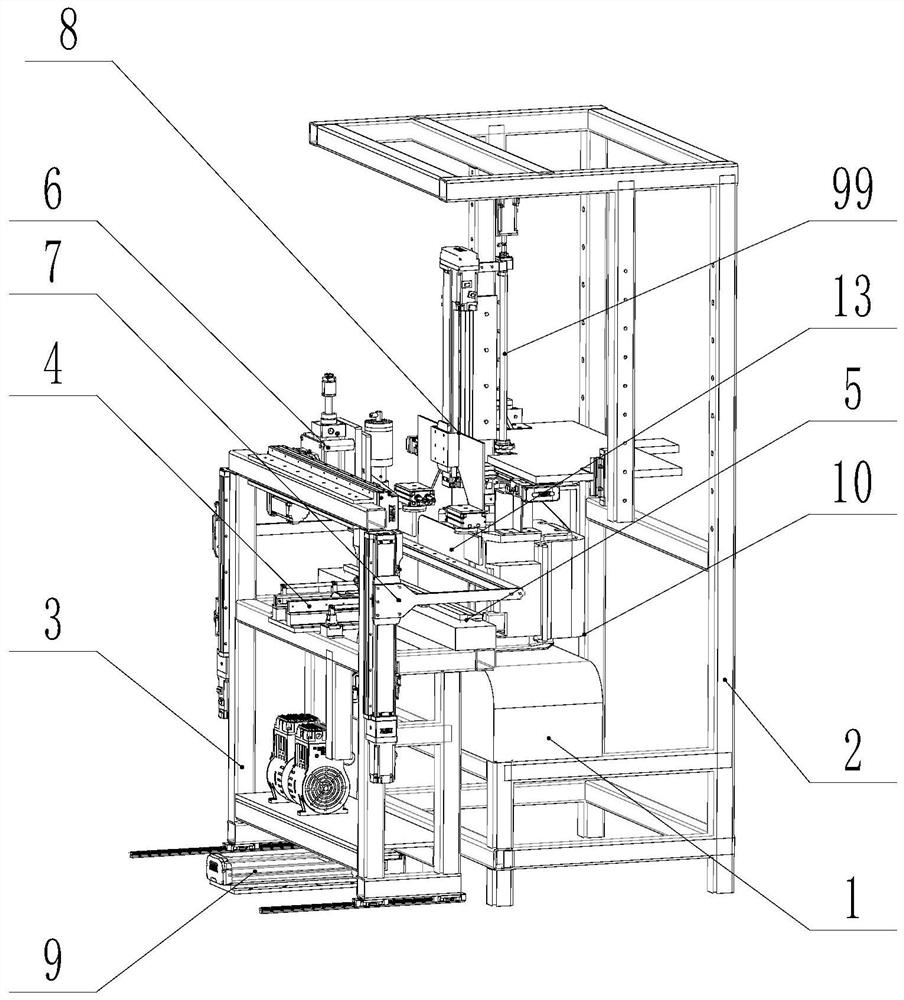

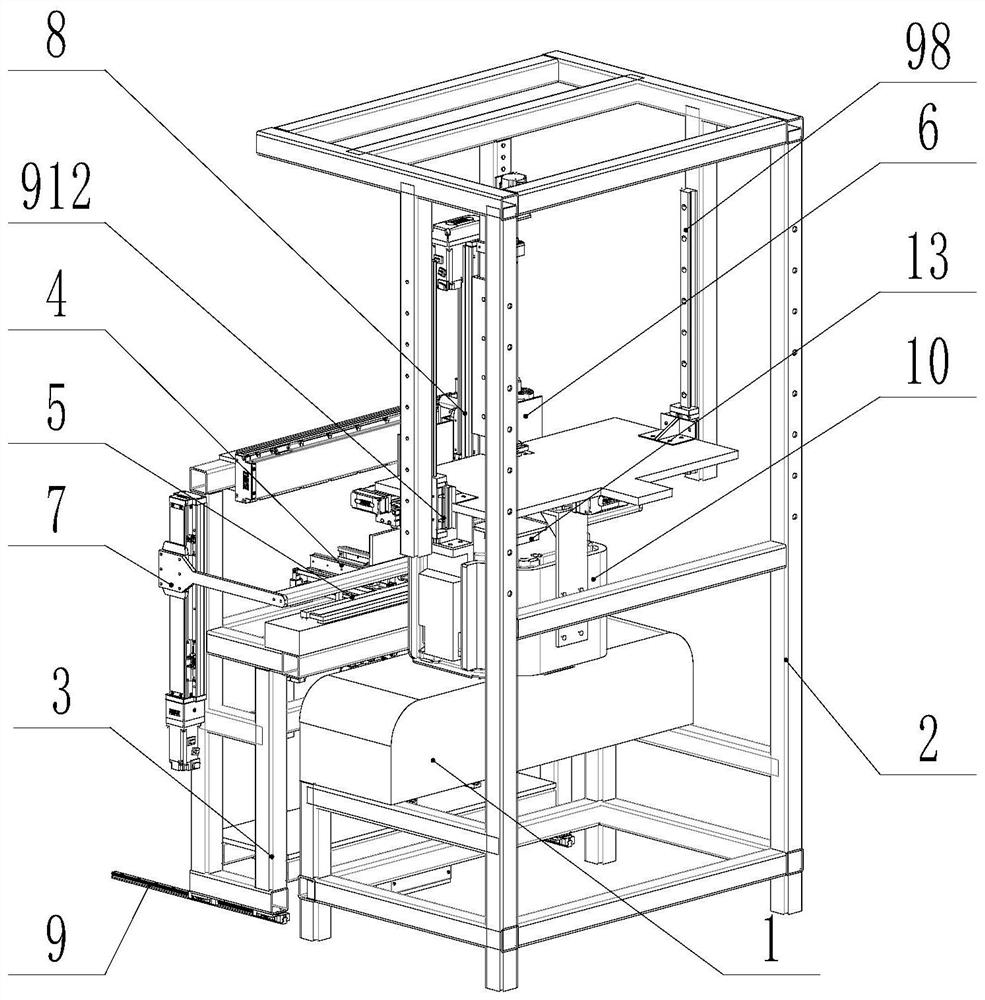

The invention relates to an automatic pressing production line of a large explosive column. The automatic pressing production line comprises a hydraulic press, which is composed of an upper beam, an upper return cylinder, an upper slide block with a cylinder, an upper punch, a middle girder with a die sleeve, and a lower beam. The automatic pressing production line is characterized by also comprising an automatic weighing and feeding device, a powder smoothing device and an automatic discharge device, which are arranged at the periphery of the hydraulic press; a lower return cylinder is arranged at the upper part of the lower beam; the lower return cylinder is connected with a lower slide block with a cylinder; a lower punch is arranged on the lower slide block with the cylinder; an automatic evacuating device is arranged at the lower part of the upper slide block with the cylinder; and mechanical limiting devices are arranged on the upper slide block with the cylinder and the lower slide block with the cylinder. The automatic pressing production line has the advantages that full-automatic operation of feeding, smoothing, two-way control and discharge of the explosive column can be achieved through the production line; the labor intensity of operating personnel can be greatly reduced; the production efficiency of a large-tonnage hydraulic press is improved; potential safety hazards are avoided; air bubbles of the explosive column in the pressing process can be reduced; the compact evenness and the accuracy of the explosive column are improved; and the product quality is also ensured.

Owner:TIANJIN TIANDUAN PRESS CO LTD

Method for measuring first coulombic efficiency of lithium batteries and material system preference method

InactiveCN101662040AAchieve vacuumAvoid enteringFinal product manufactureSecondary cellsPre-chargeEngineering

The invention discloses a method for measuring the first coulombic efficiency of lithium batteries and a material system preference method. The preference method comprises the following steps: a) preparing a plurality of lithium batteries of different material systems, and connecting the batteries after liquid injection and ageing to a coulombic metering device; b) vacuumizing the interiors of thebatteries by using a vacuumizing device; c) charging the batteries, recording charging coulombic values, then discharging the batteries, and recording discharging coulombic values; d) calculating thefirst coulombic efficiency of each lithium battery according to the recorded coulombic values; and e) comparing the first coulombic efficiency of each battery, and preferably selecting a material system of an lithium ion battery. The method vacuumizes the interiors of the batteries to eliminate bubbles generated in the pre-charging process when the batteries are charged and discharged for the first time so that the measured first coulombic efficiency is not affected by pre-charging gas production to better reflect the electrochemical properties of a battery system, and the preference of the battery material system is achieved.

Owner:SHENZHEN BAK BATTERY CO LTD

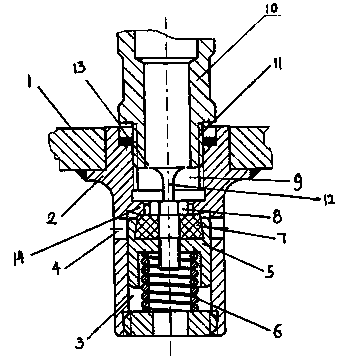

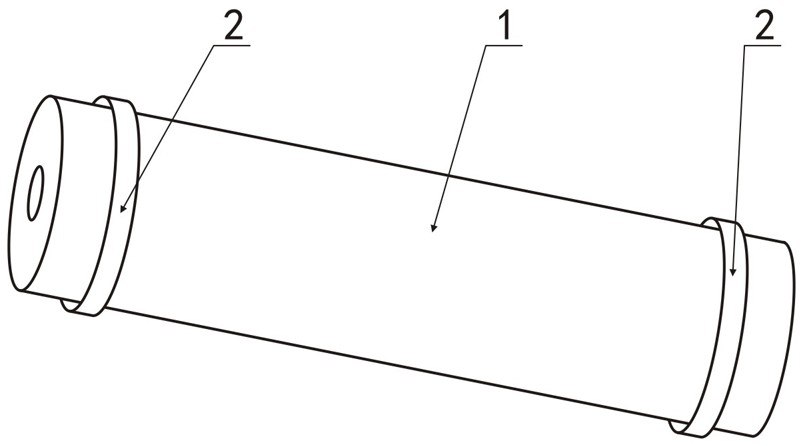

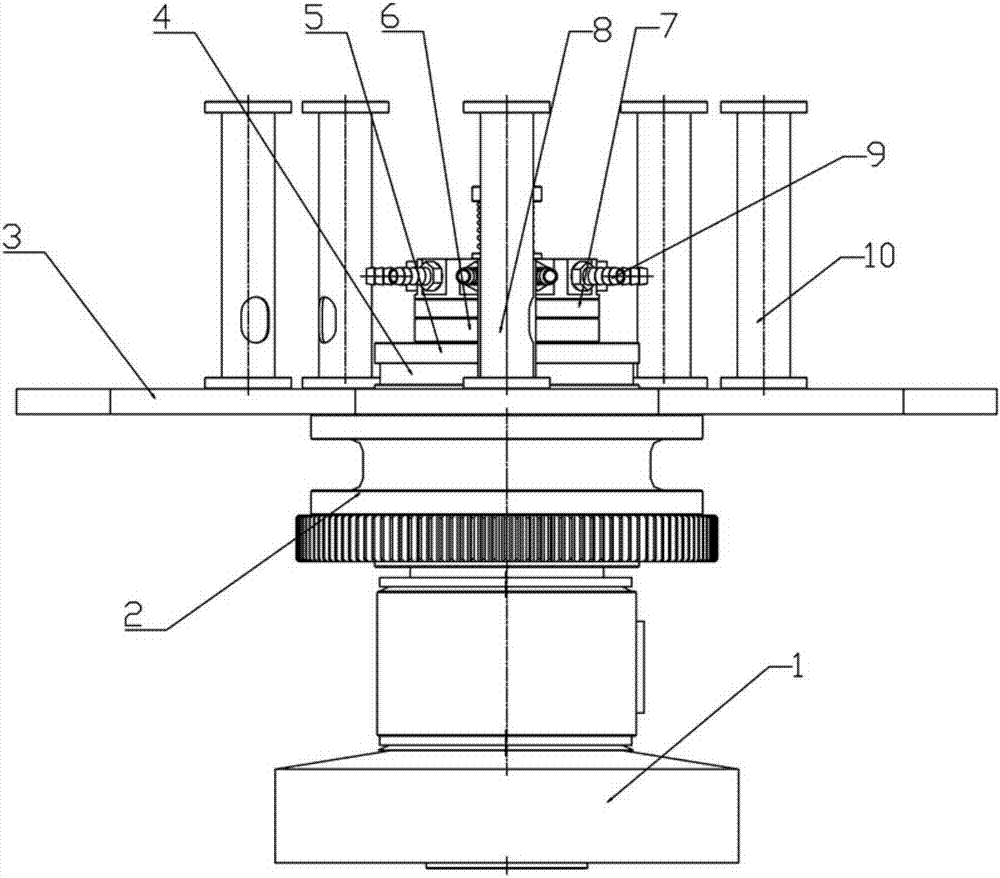

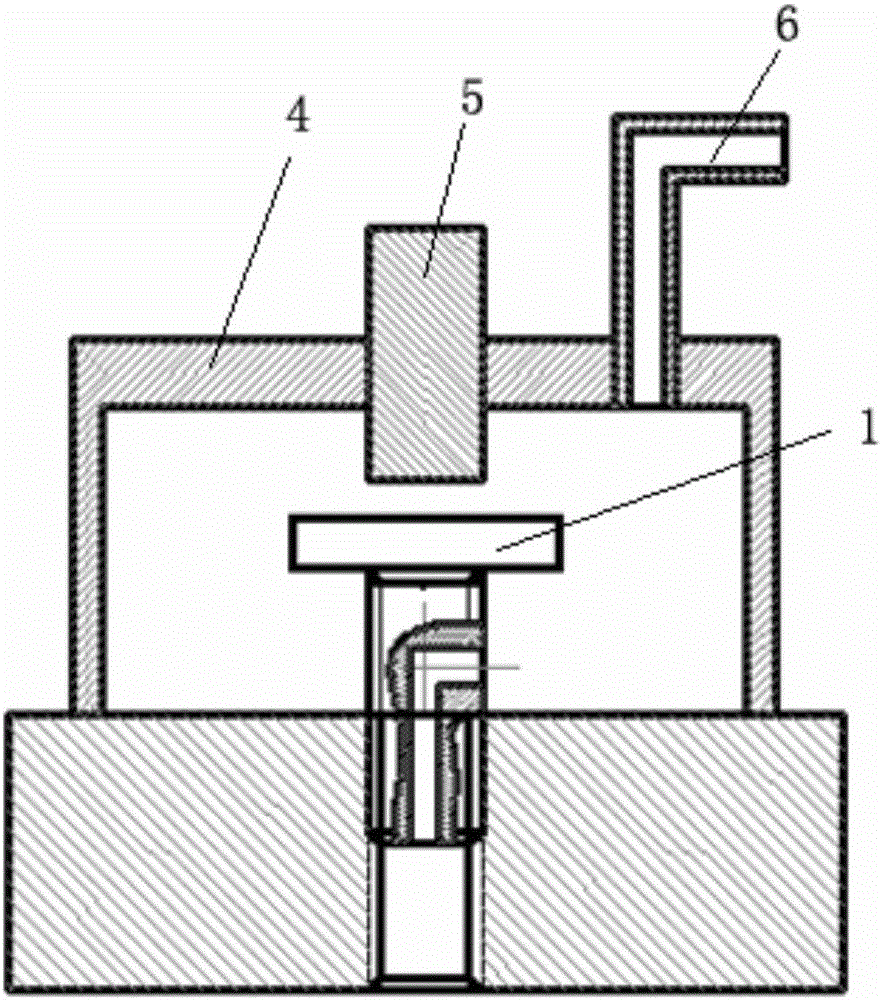

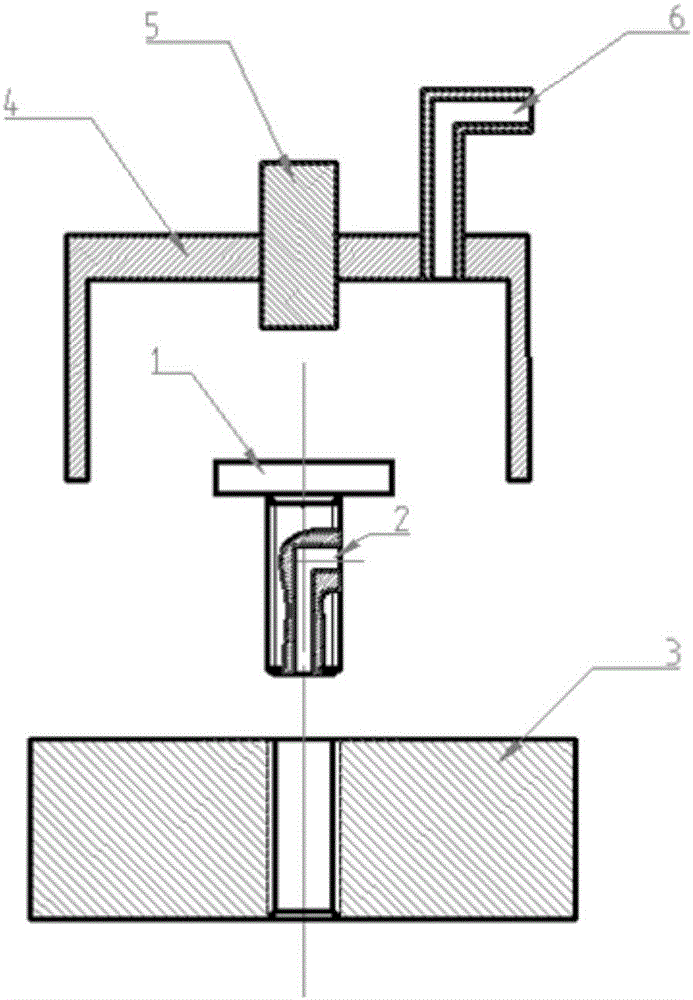

Vacuuming and nitrogen inflating device for sealed packaging box

ActiveCN104369896AAchieve vacuumRealize functionPackaging by pressurising/gasifyingNitrogenEngineering

The invention discloses a vacuuming and nitrogen inflating device for a sealed packaging box. The vacuuming and nitrogen inflating device solves the problems that an existing vacuuming and nitrogen inflating device for a sealed packaging box is complex in structure and complicated in operation process. The vacuuming and nitrogen inflating device comprises a vacuuming valve body (2) which is fixedly arranged on a packaging box body (1); a lower valve body cavity (3) and an upper valve body cavity (9) are communicated and formed in the vacuuming valve body (2); a ventilation hole (4) communicated with the interior of the sealed packaging box is formed in the wall of the lower valve body cavity (3); a plunger piston (5) is arranged in the lower valve body cavity (3); a compressed spring (6) is arranged between the bottom end face of the plunger piston (5) and the bottom surface of the lower valve body cavity (3); a sealing pad (7) is connected to the top end face of the plunger piston (5) by a sealing pad pressing-connecting bolt (8) in a pressed mode; external threads at one end of a vacuuming tube (10) and internal threads (11) arranged at the port of the top of the upper valve body cavity (9) are connected together. The vacuuming and nitrogen inflating device has the advantages of being simple in structure and convenient to operate.

Owner:SHANXI JIANGHUAI HEAVY IND

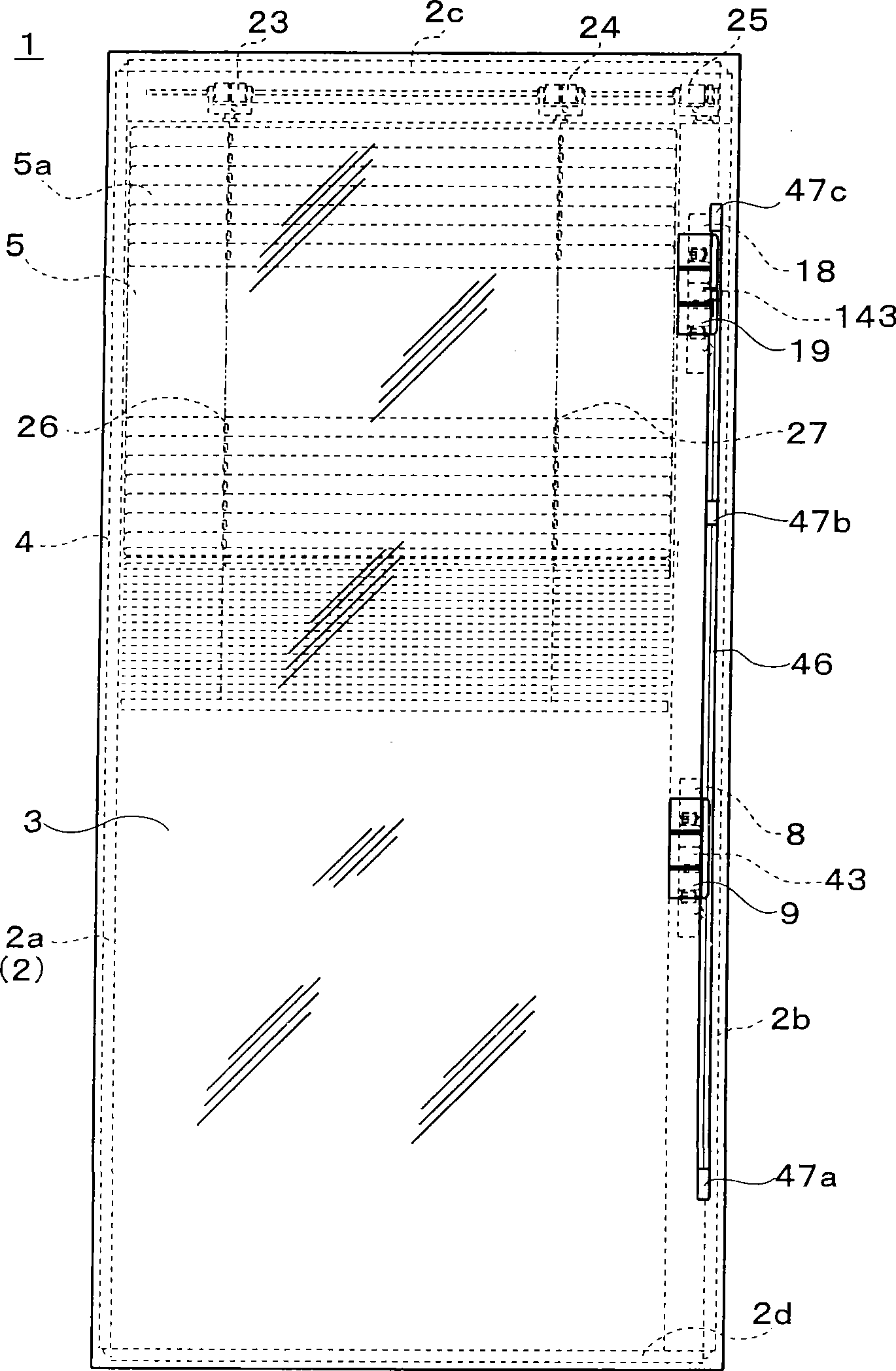

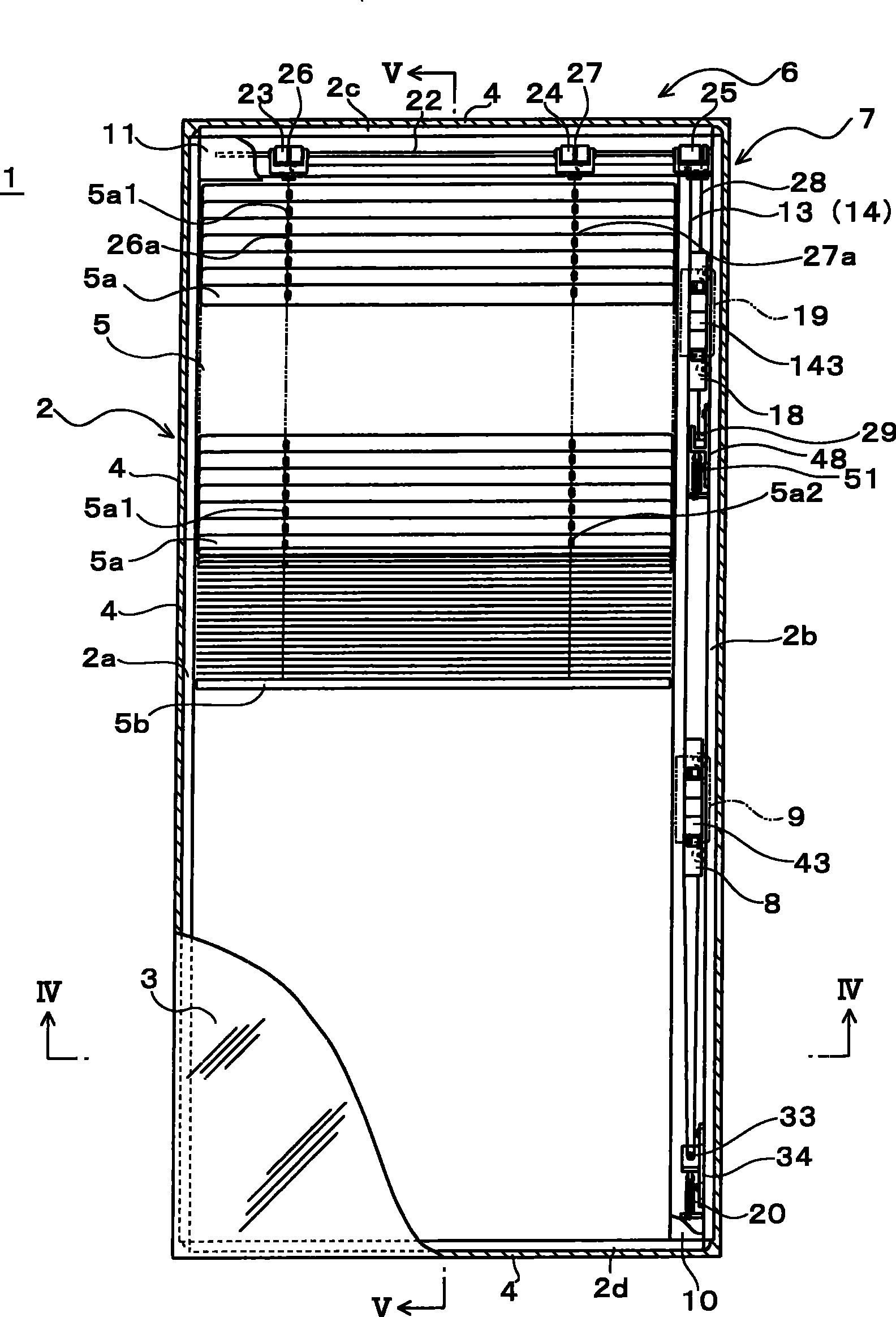

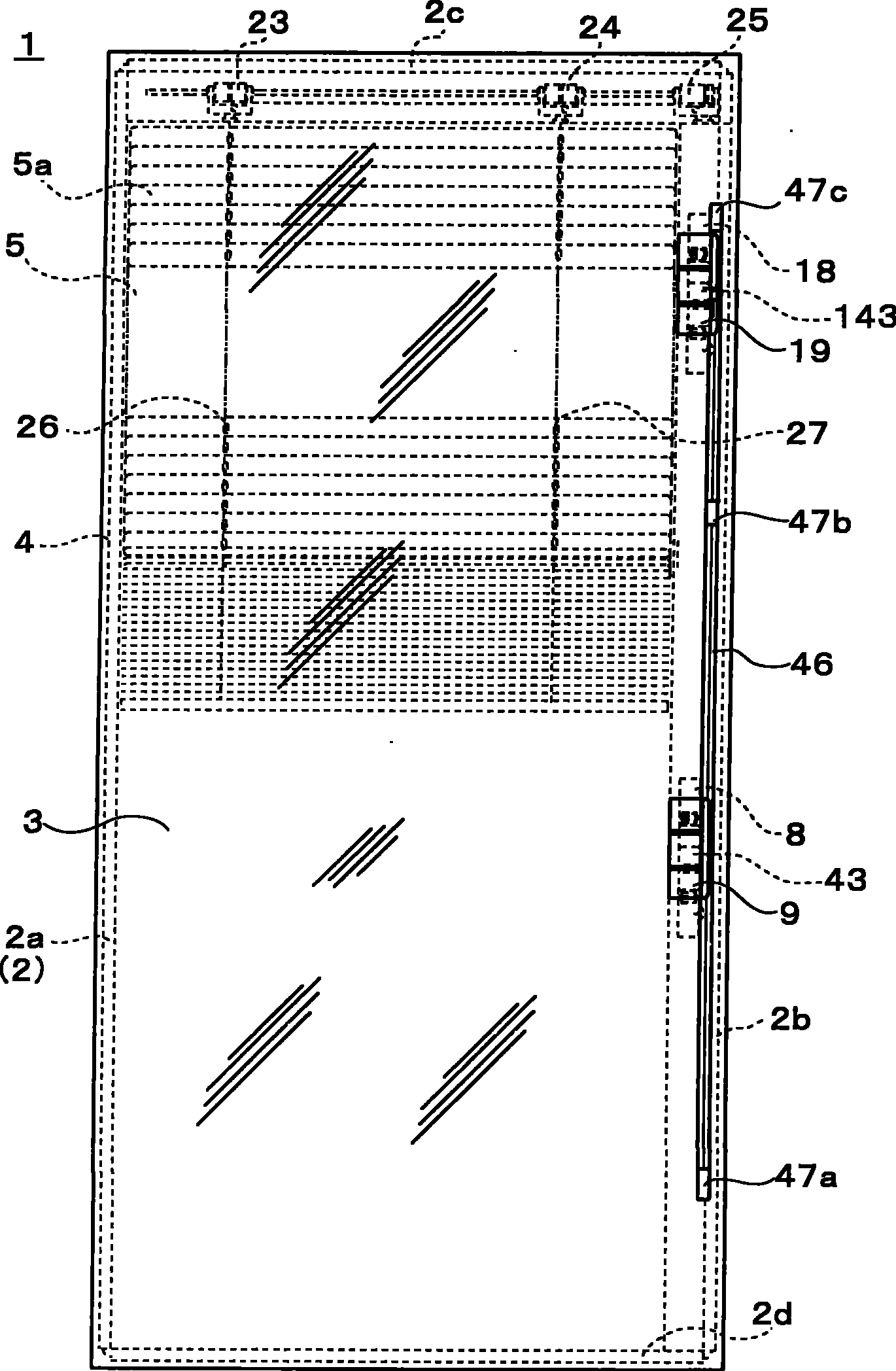

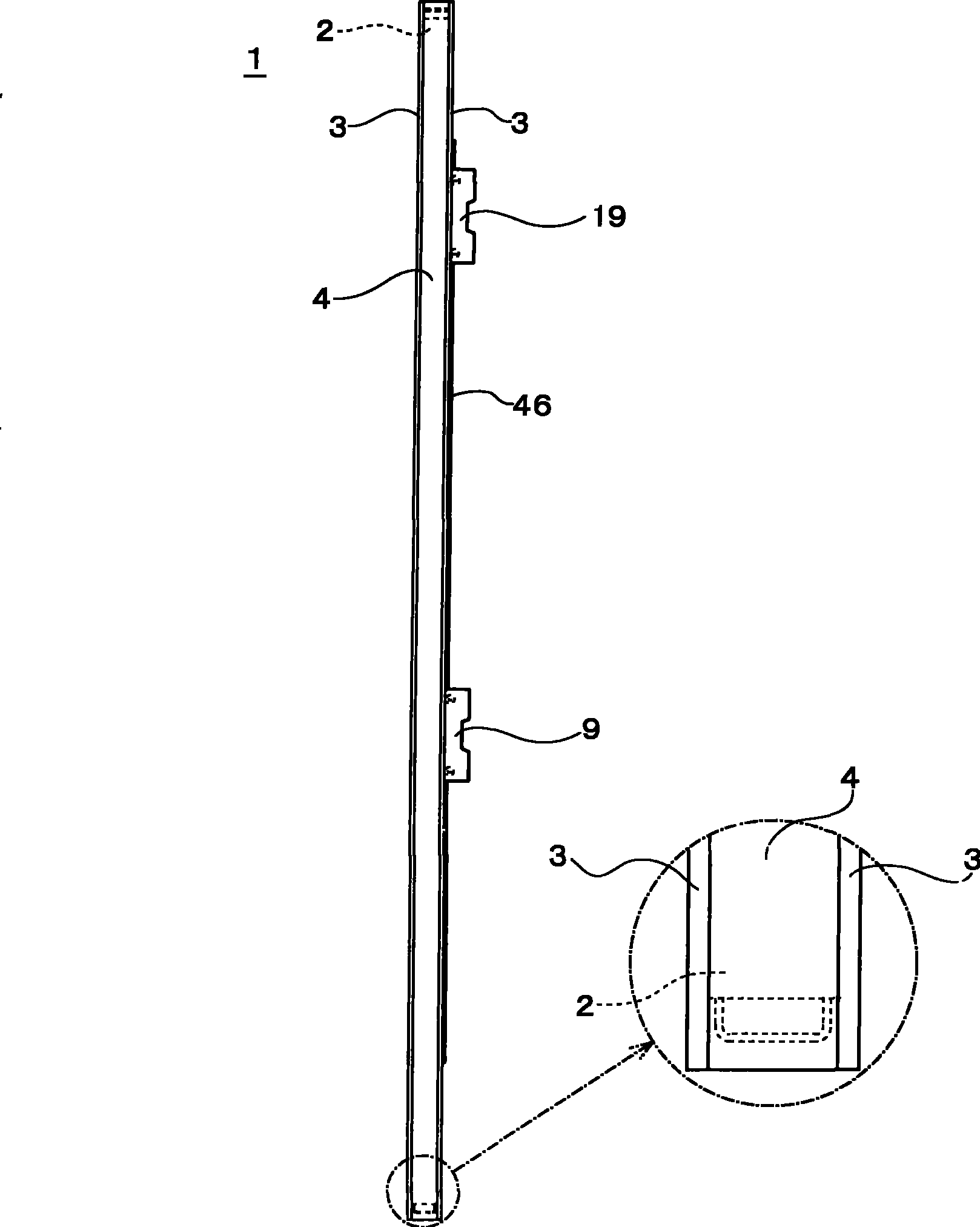

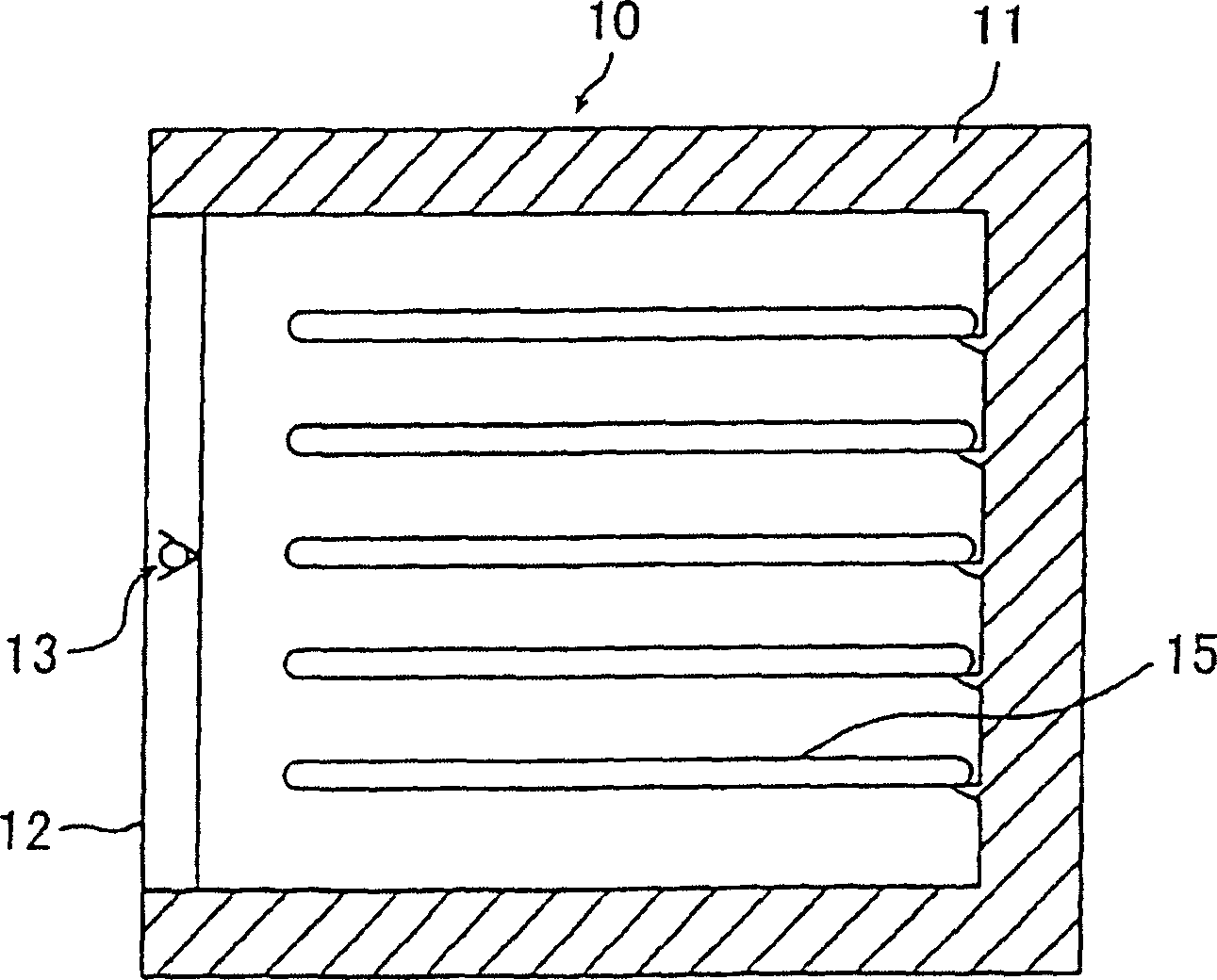

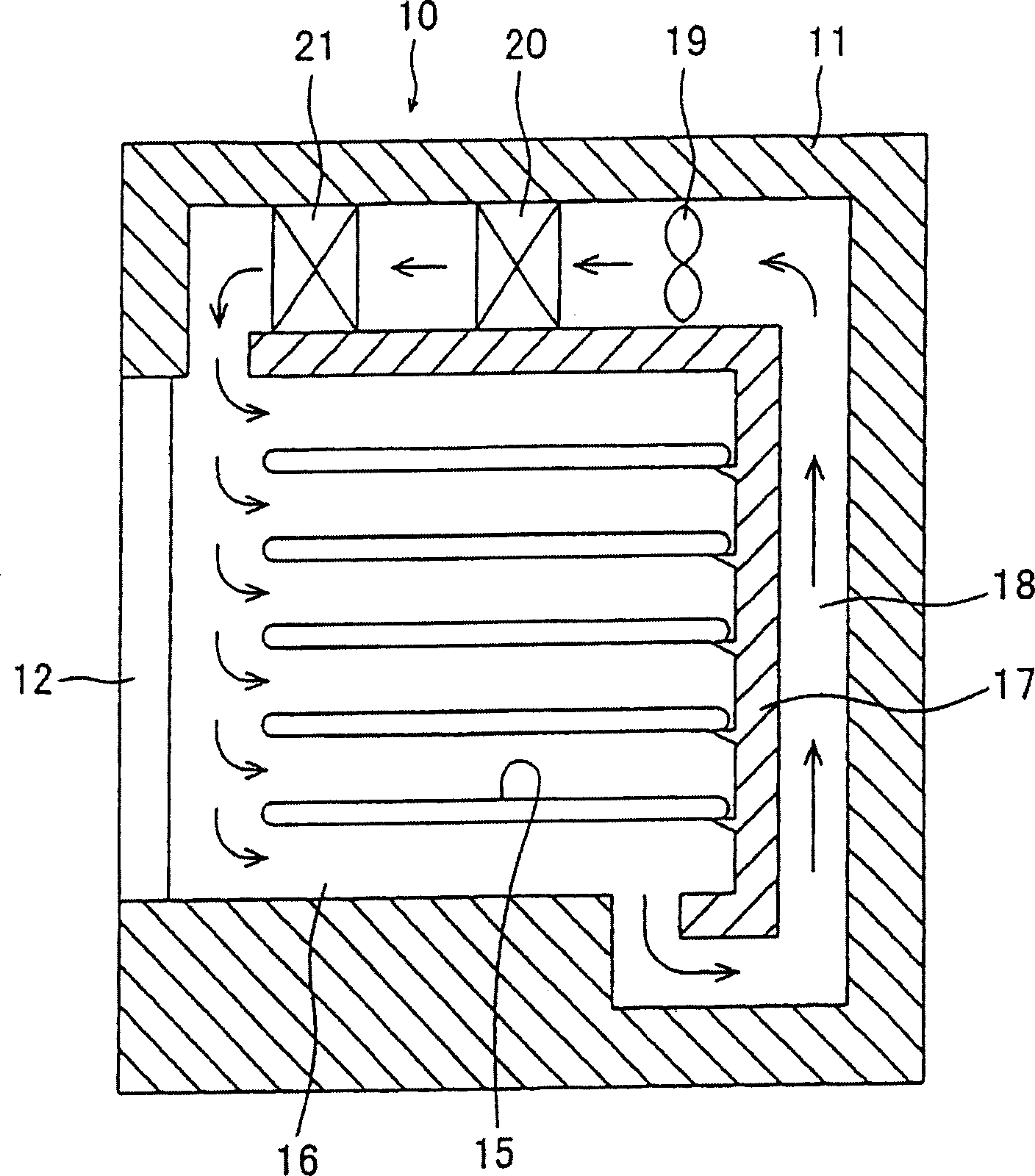

Shutter

The invention relates to a window shutter. The window shutter main body is disposed in a supporting frame which is clamped by a front glass plate and a back glass plate; a lifting stopper and a lifting operator for are disposed on the front glass plate for operating lifting mechanism, an angle regulating stopper and an angle regulating operator are also disposed on the front glass plate for operating angle regulating mechanism; in which, a magnet is disposed on the lifting stopper which moves up and down in the supporting frame, another magnet is disposed on the lifting operator which moves up and down on the front surface of the glass plate, while the two magnets make the lifting stopper and the lifting operator to attract each other. The lifting mechanism comprises a first lifting string and a second lifting string for lifting the leaves, while the angle regulating mechanism comprises a first regulating string and a second regulating string for regulating the angle of the leaves; the angle regulating stopper and the angle regulating operator control the first and second angle regulating string by the up-and-down operation.

Owner:高野隆一

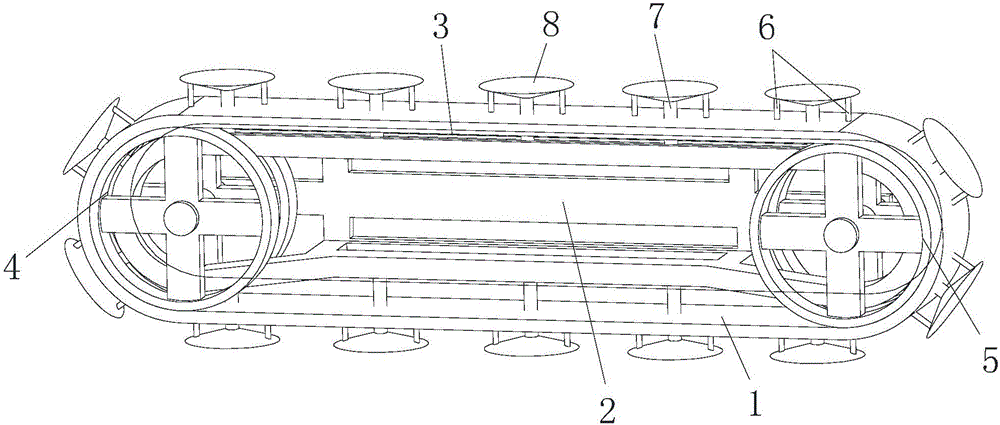

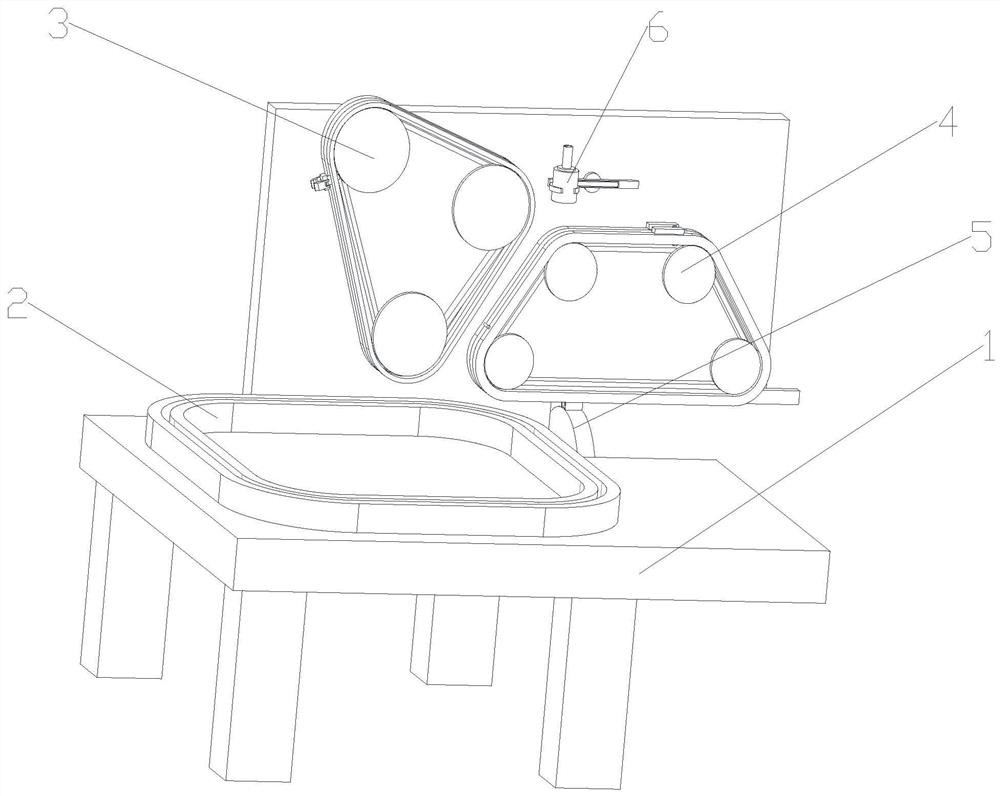

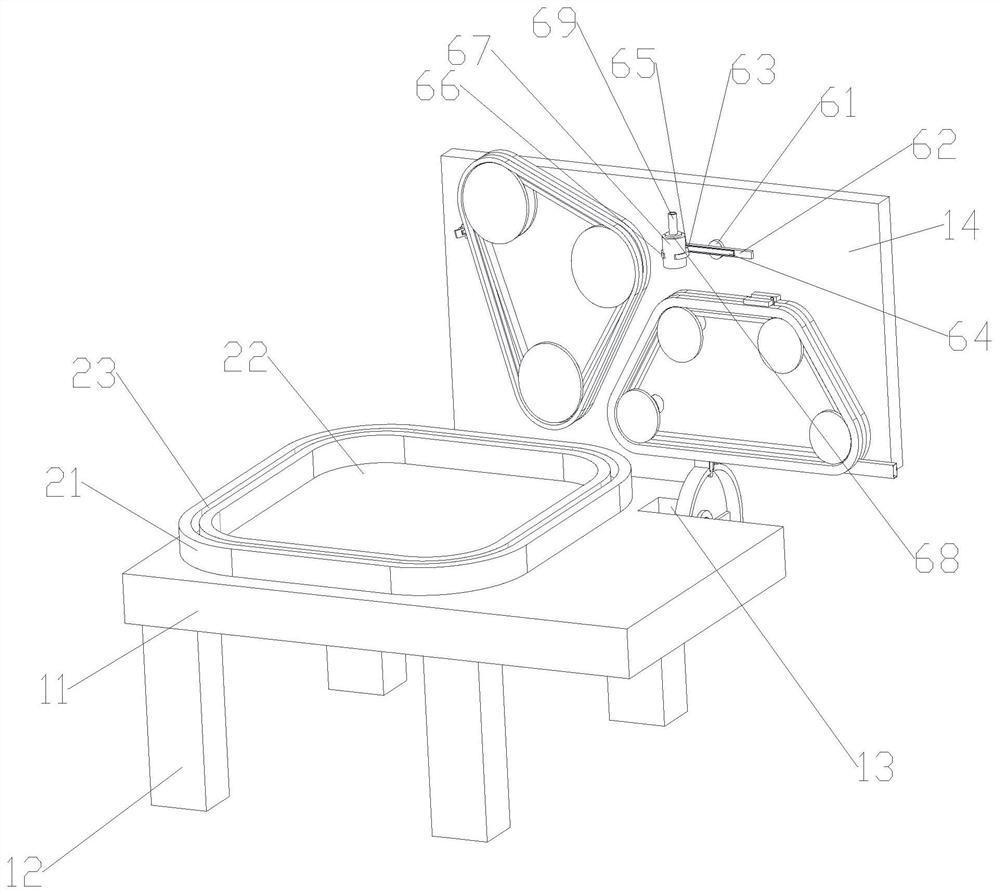

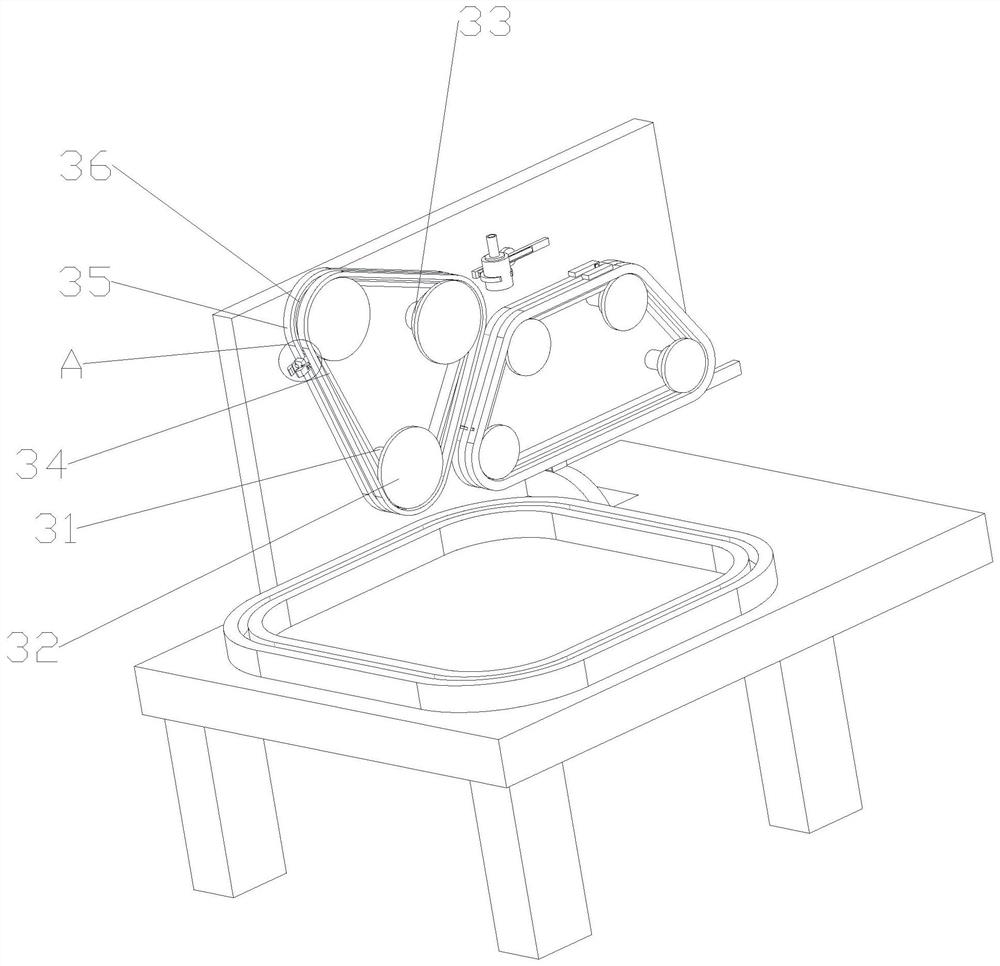

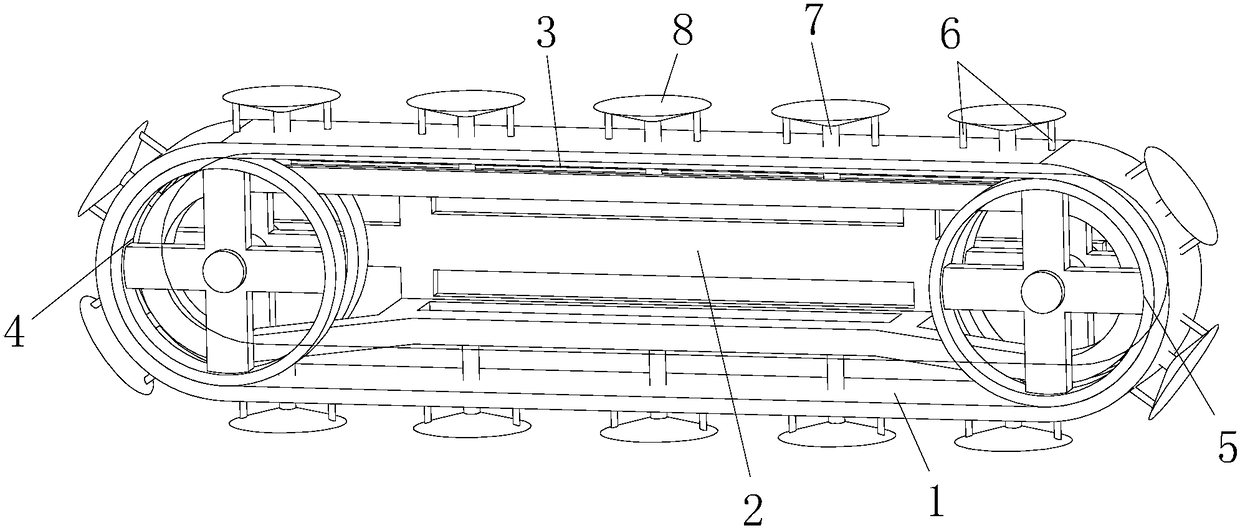

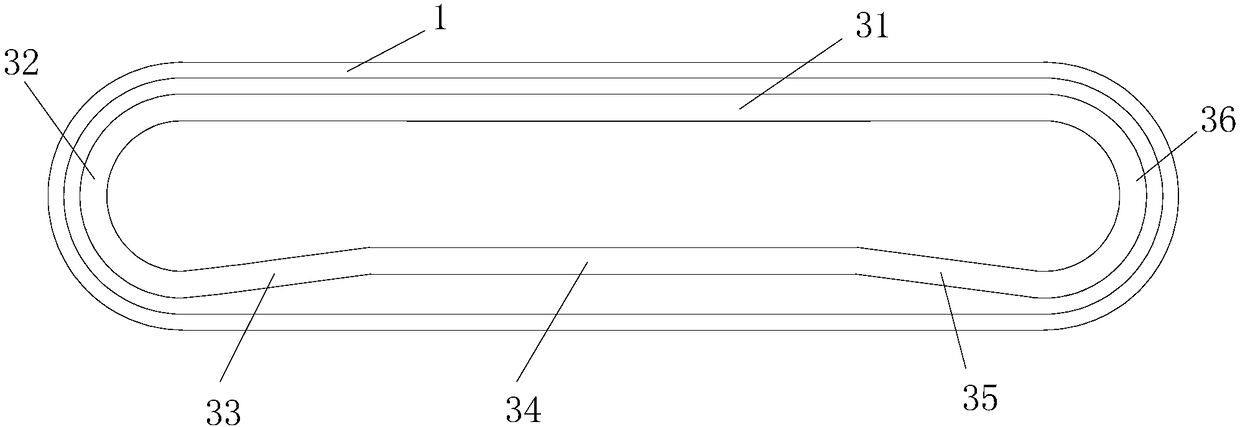

Sucker crawler-driven bionic device used for climbing and clinging to smooth surfaces

The invention discloses a sucker crawler-driven bionic device used for climbing and clinging to smooth surfaces. The device comprises a rack. A driving wheel and a tension wheel are further arranged on the rack. An annular crawler is mounted on an outer circle of the driving wheel and an outer circle of the tension wheel. A plurality of vacuum suckers are distributed on the circumferential circle of the annular crawler at equal intervals. The sides, connected with the annular crawler, of the vacuum suckers are provided with main handles. One ends of the main handles are connected with the vacuum suckers, and the other ends of the main handles are provided with main handle tensile force applying mechanisms. The problems such as complex mechanisms, difficult unsealing after vacuumization of suckers, low speed and noncontinuity in the crawling process of multi-sucker wall climbing robots are solved, and the device can climb the smooth surfaces at any angle.

Owner:SHANDONG UNIV OF SCI & TECH

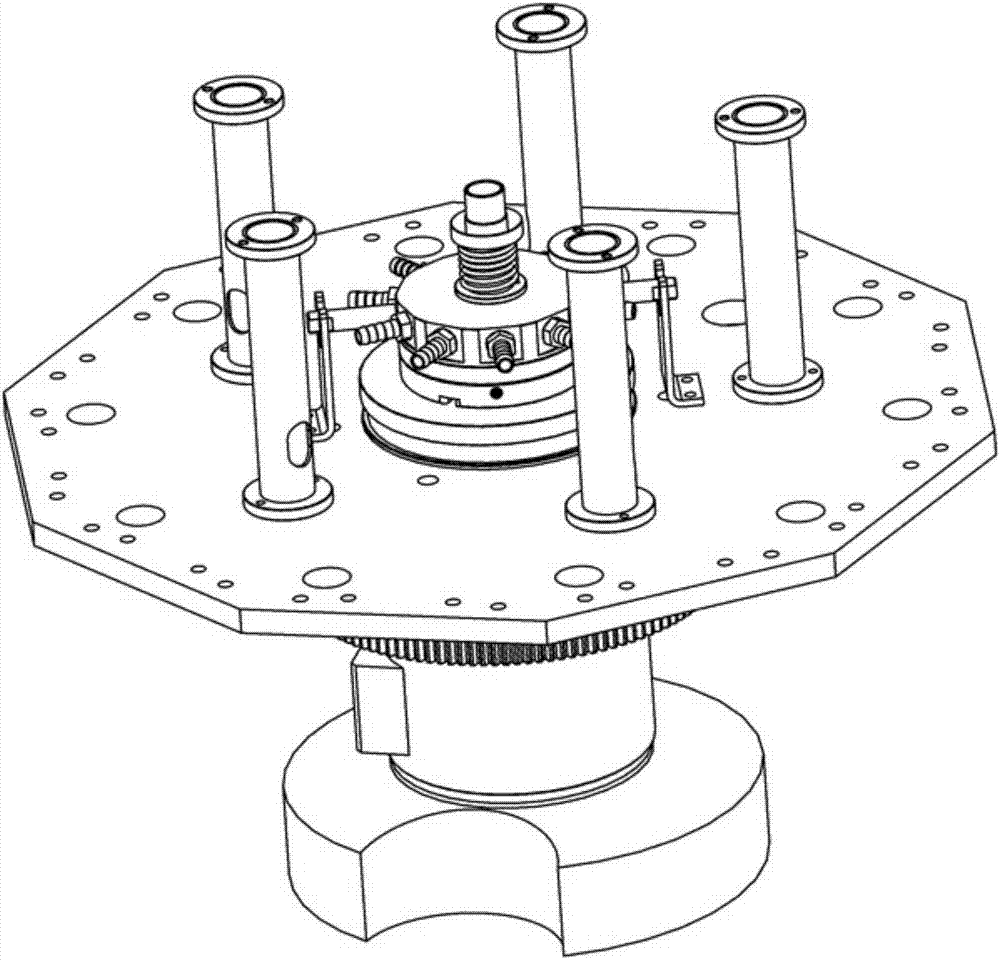

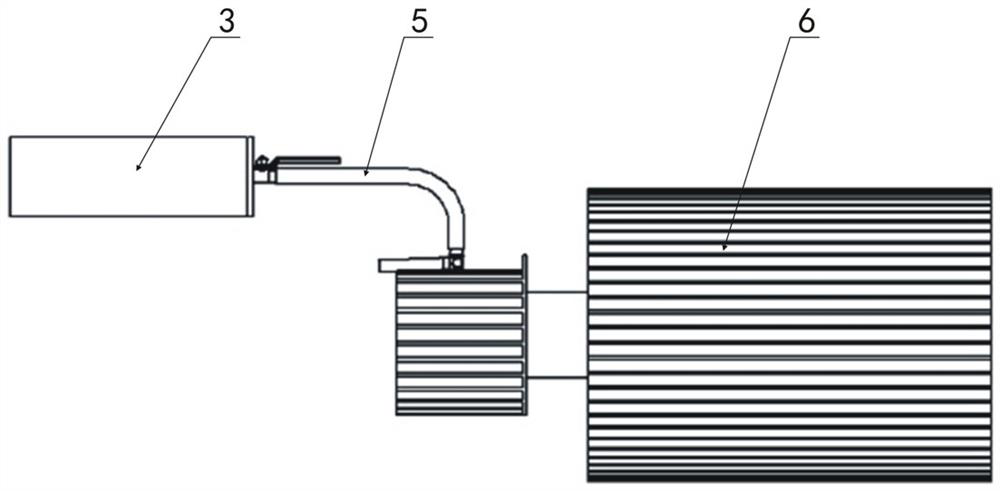

Planetary vacuum stirrer dynamic temperature measuring device

ActiveCN106693794AGuaranteed StrengthLow costRotary stirring mixersTransportation and packagingLow speedFixed frame

The invention relates to a planetary vacuum stirrer dynamic temperature measuring device comprising a cross beam, an upper barrel, a planetary part, a stirring barrel, a high-speed transmission part, a low-speed transmission part and a dynamic temperature measuring part; the dynamic temperature measuring part comprises a hollow sleeve, a through-hole type conductive slip ring, a slip ring fixing frame, a temperature measuring wire, a temperature measuring rod, a temperature measuring probe and a temperature information receiving / displaying device; the through-hole type conductive slip ring is composed of a slip ring stator and a slip ring rotor; the hollow sleeve is fixed on a hollow low-speed shaft; the slip ring rotor is fixed on the hollow sleeve, and the slip ring stator is arranged on the cross beam through the sliding ring fixing frame; the temperature information receiving / displaying device is connected with the slip ring stator by the temperature measuring wire; the temperature measuring rod is fixed on a planetary box, and the temperature measuring probe is arranged at the lower part of the temperature measuring rod. The dynamic temperature measuring device can more accurately detect a real-time temperature of a material, is suitable for a vacuumizing state, also has the advantages of simpler structure, long service life of the conductive slip ring and good equipment stability, and can simply realize vacuum retaining of equipment.

Owner:LIUZHOU HUT CHEM MACHINERY

Production device and process for bubble-free shoe materials

The invention discloses a production device and process for bubble-free shoe materials. The production device for the bubble-free shoe materials comprises a rack, a material injection mechanism, a forming mold, a mold opening and drawing mechanism and a vacuumizing mechanism. The vacuumizing mechanism is provided with an upper vacuum cover, a lower vacuum cover, an ascending oil cylinder and a vacuum generator. By means of the arranged independent vacuumizing mechanism, during processing of semi-finished shoe materials through an upper mold body and a lower mold body while a color division plate is drawn out, the upper mold body, the lower mold body and the semi-finished shoe materials on the upper mold body and the lower mold body are totally put in an inner cavity formed by the upper vacuum cover and the lower vacuum cover and are then totally vacuumized, all bubbles concealed in the semi-finished shoe materials are eliminated, then pressurizing is performed through a pressurizing cylinder, heating is performed through an upper heating plate and a lower heating plate, and then the finished shoe materials are formed. By means of the production device and process for the bubble-free shoe materials, the high-quality bubble-free shoe materials can be formed, and the market competitiveness of the production device is greatly improved.

Owner:福建钜闽机械有限公司

Shutter

The invention relates to a window shutter. The window shutter main body is disposed in a supporting frame which is clamped by a front glass plate and a back glass plate; a lifting stopper and a lifting operator for are disposed on the front glass plate for operating lifting mechanism, an angle regulating stopper and an angle regulating operator are also disposed on the front glass plate for operating angle regulating mechanism; in which, a magnet is disposed on the lifting stopper which moves up and down in the supporting frame, another magnet is disposed on the lifting operator which moves up and down on the front surface of the glass plate, while the two magnets make the lifting stopper and the lifting operator to attract each other. The lifting mechanism comprises a first lifting string and a second lifting string for lifting the leaves, while the angle regulating mechanism comprises a first regulating string and a second regulating string for regulating the angle of the leaves; the angle regulating stopper and the angle regulating operator control the first and second angle regulating string by the up-and-down operation.

Owner:高野隆一

Polishing device for alloy pipeline

InactiveCN111941168AImprove sanding effectIntelligent grindingRevolution surface grinding machinesGrinding drivesElectric machineryPolishing

The invention relates to a polishing device for an alloy pipeline. The polishing device comprises a base, a fixing rod, a cross rod, a driving mechanism, a polishing mechanism, a fixing mechanism anda cleaning mechanism, the driving mechanism comprises a motor, a driving shaft, a walking ring and a first lead screw, and the fixing mechanism comprises a first fixing plate, a second fixing plate and a second lead screw; and the cleaning mechanism comprises a first water tank, a second water tank, a connecting pipe, a water inlet pipe, a water pump and a water outlet pipe. According to the polishing device for the alloy pipeline, polishing of the inner wall of the alloy pipeline is achieved through the polishing mechanism, and uniform polishing of the inner wall of the alloy pipeline is achieved through a polishing block in a rotating manner, so that the polishing effect is improved, and a polished product is more attractive; the alloy pipeline is fixed through the fixing mechanism, so that the inner wall of the alloy pipeline is vacuumized; and polished dust is cleaned through the cleaning mechanism, so that the situation that air pollution and harm to an operator are caused due todust suppression is prevented, and intelligent polishing of the alloy pipeline is achieved.

Owner:南京宜泽新材料科技有限公司

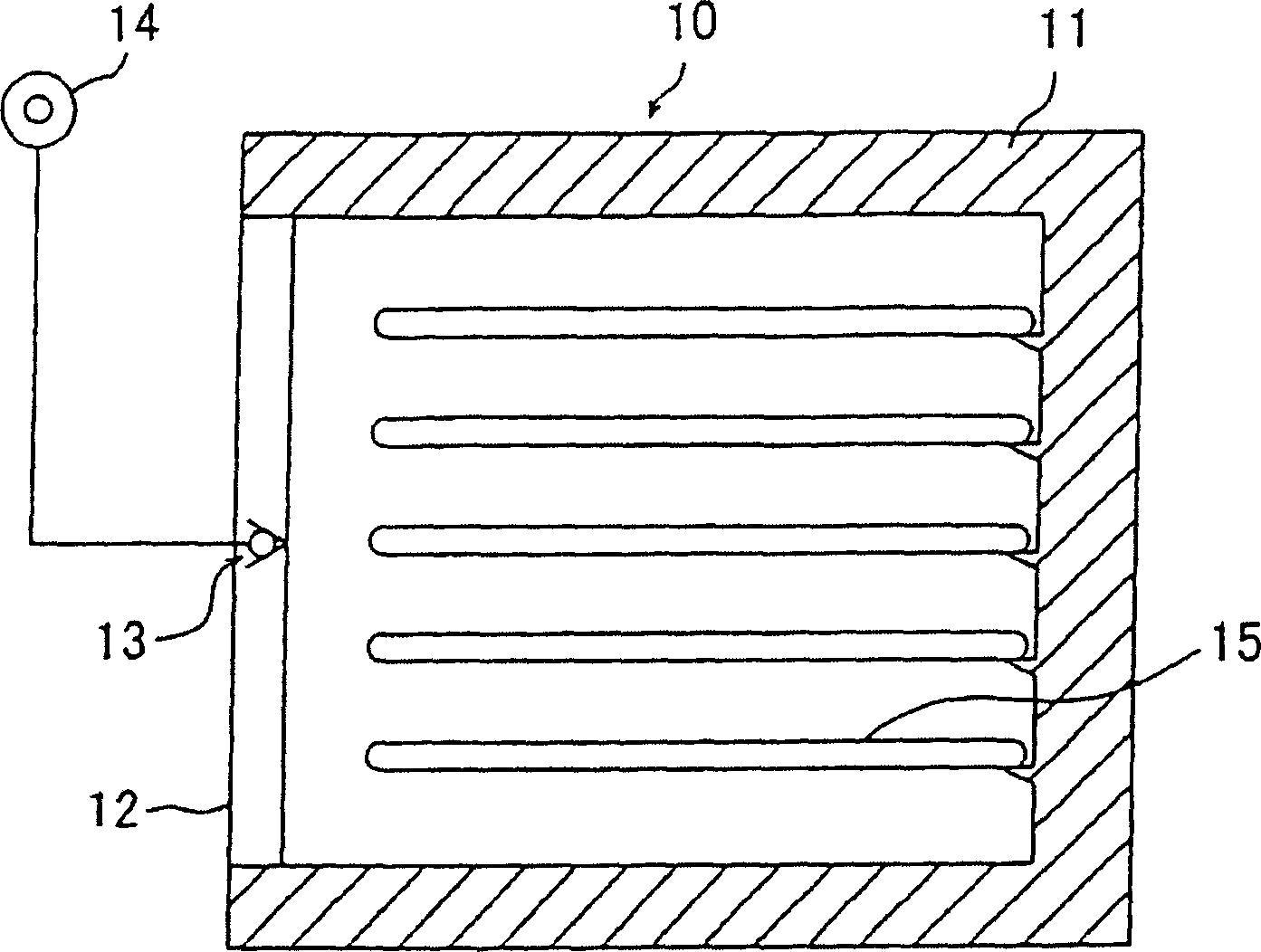

Dehydration drying method and apparatus, and substrate processing apparatus

InactiveCN1639849ADoes not affect processing timeAvoid deformationDrying solid materials without heatSemiconductor/solid-state device manufacturingDehydrationChemistry

The dehydration drying method dehydrates and dries the substrate. The substrate (15) is dehydrated and dried without rotation while the substrate (15) is housed in a carrier (10) for carrying the substrate (15) between devices for performing some processing.

Owner:EBARA CORP

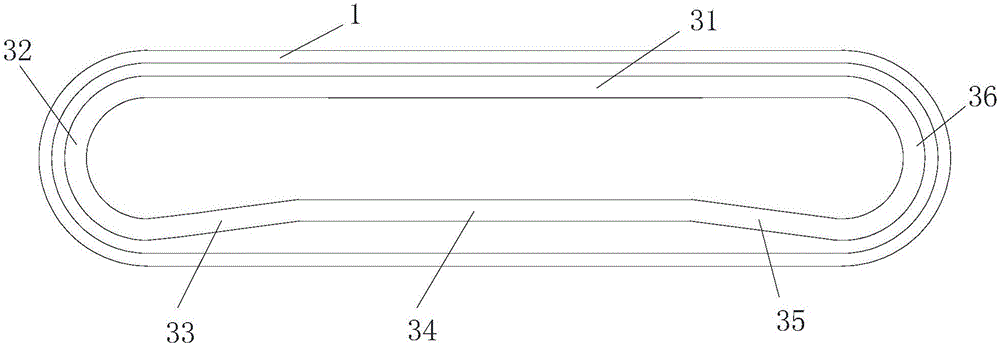

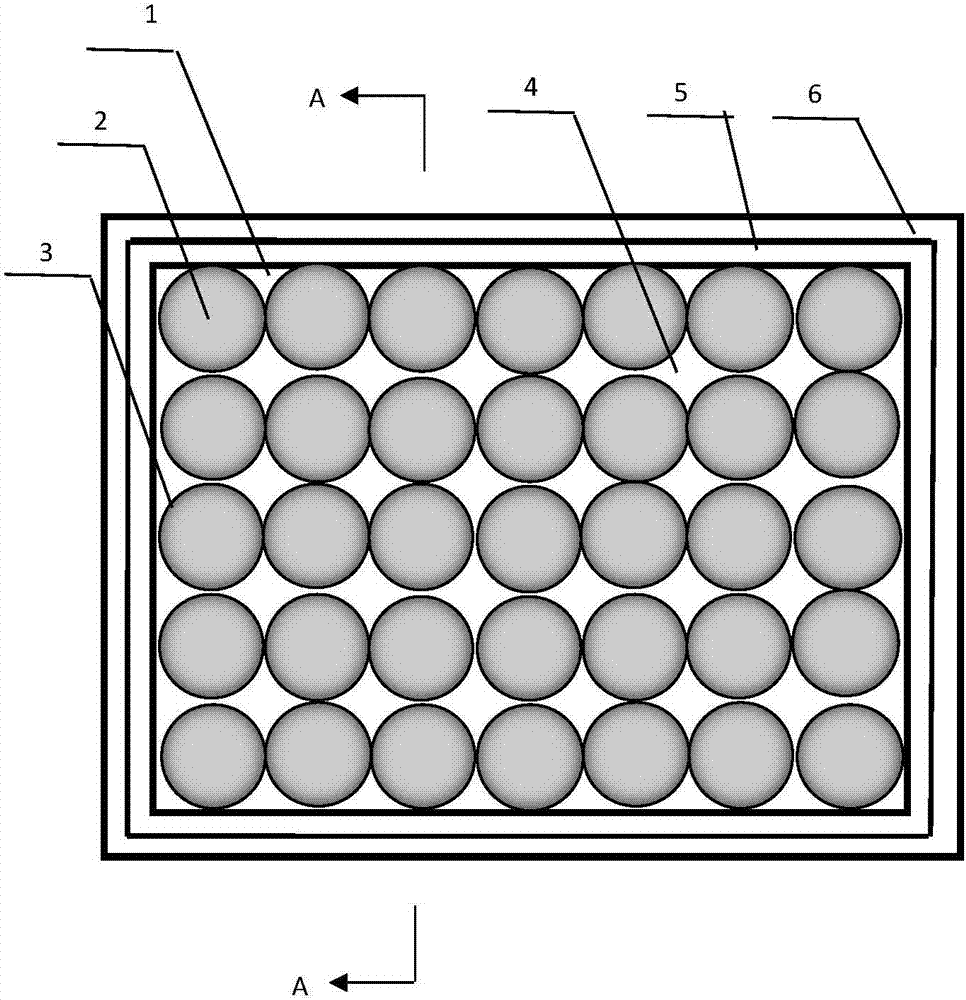

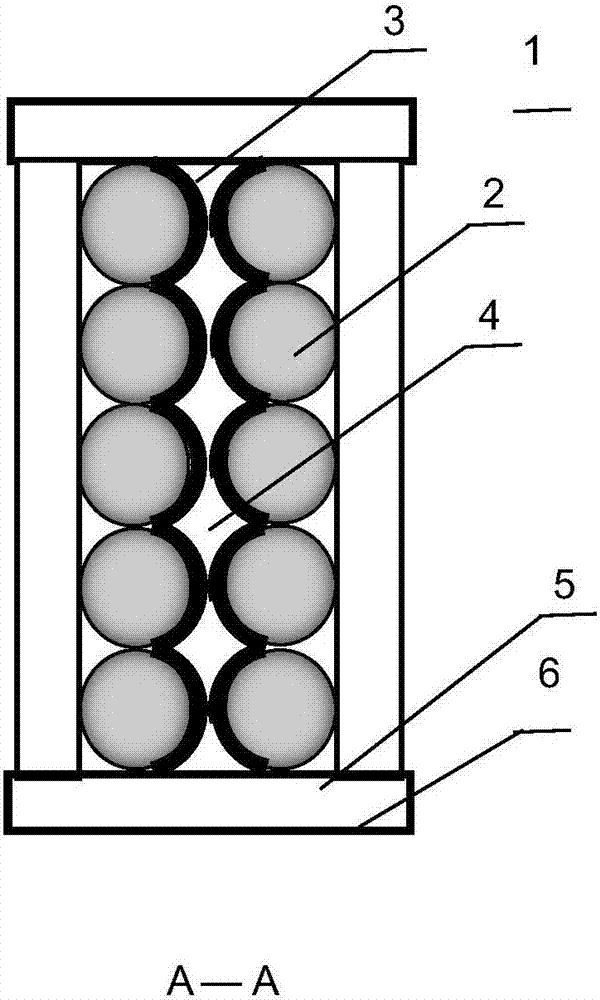

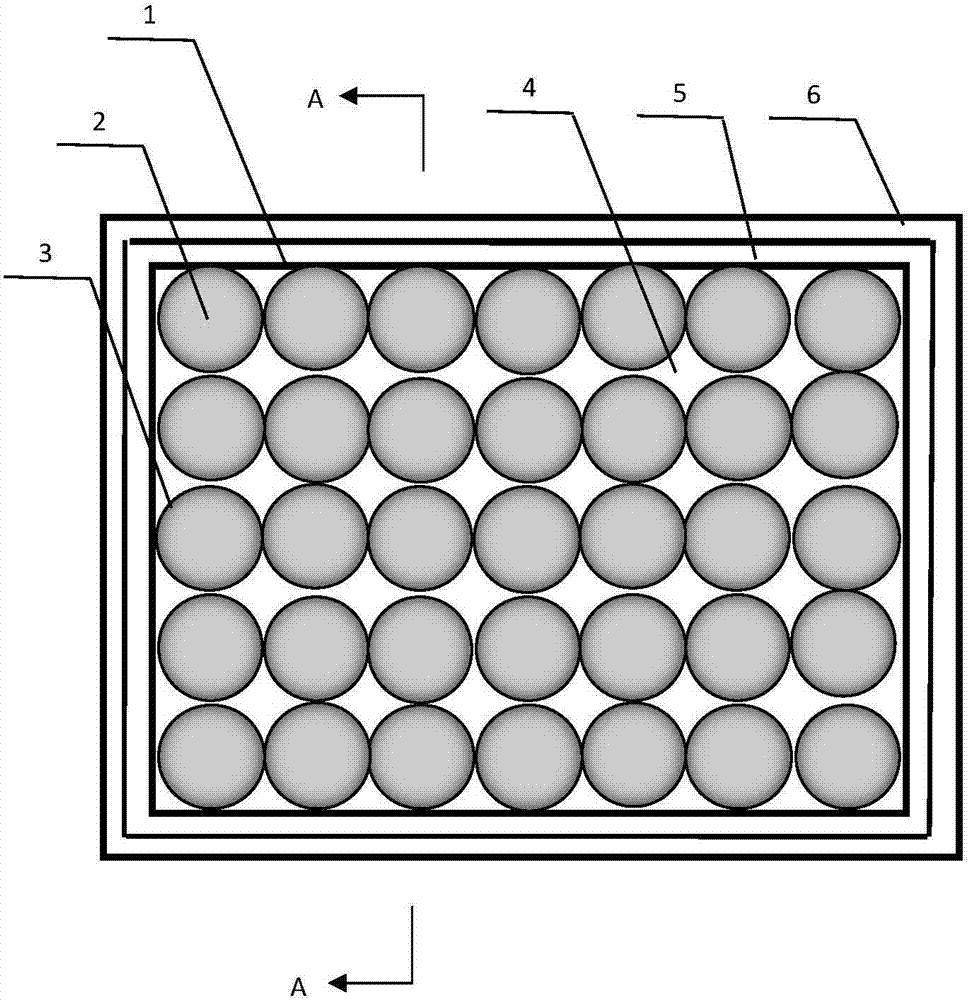

Orderly and densely arranged microcavity structure membrane vacuum glass

InactiveCN106863922AAchieve vacuumTo achieve sound insulationGlass/slag layered productsMetal layered productsBrickMetal framework

The invention belongs to the field of special glassmaterial processing and production, and relates to an orderly and densely arranged microcavity structure membrane vacuum glass, which comprises a microcavity glass plate. One layer or two layers of densely arranged microspheres are arranged in the glass plate; a layer of thin film is arranged on the surface of each microsphere; a microcavity exists between every two adjacent microspheres densely arranged in each layer or between two layers. According to the novel orderly vacuum optical microcavity glass provided by the invention, sunshine in a visible region spectral region is allowed to penetrate through, lighting power is saved, a spherical shell thin film can obstruct infrared radiation, and a vacuum microcavity has effects of insulating cold, heat and sound; the glass can split beams in multiple colors selectively, so that the light reflection can be reduced; the glass has the advantages of fog resistance and frosting resistance; the glass has a curtain function, is unviewable from outdoor to indoor, and is visible from indoor to outdoor; the glass comprises the main materials: glass and a metal frame, and is applicable to a large standard modularized building material brick in the future, and convenient to build and install the whole wall body.

Owner:JILIN UNIV

Sealing method and sealing device for packaging bag

PendingCN114802889AAchieve vacuumPackaging under vacuum/special atmospherePumping vacuumMechanical engineering

The invention discloses a sealing method and device for a packaging bag, and the method comprises the steps: a material is loaded into a to-be-sealed packaging bag, the material falls into a containing part at the lower part of the to-be-sealed packaging bag, and the upper part of the to-be-sealed packaging bag is a vacant part; the bag receiving seat supports the bottom of a to-be-sealed package, and a bag opening of the to-be-sealed package bag is placed between a first vacuum cavity of the first vacuum block and a first vacuum cavity of the second vacuum block in the horizontal direction; the first vacuum block and the second vacuum block are closed to form a vacuum chamber, and the first vacuum block and the second vacuum block clamp the vacant part, so that a bag opening to be sealed and packaged is placed in a third vacuum cavity of the vacuum chamber; and the vacuum chamber is vacuumized. A first vacuum block, a second vacuum block, a bag receiving seat and a controller are arranged, and the first vacuum block and the second vacuum block are driven to be closed to form a vacuum chamber; the bag receiving base is driven to move so that the bag opening of the packaging bag to be sealed can be located between the first vacuum block and the second vacuum block, and therefore vacuumizing of the packaging bag to be sealed is achieved.

Owner:石国成 +2

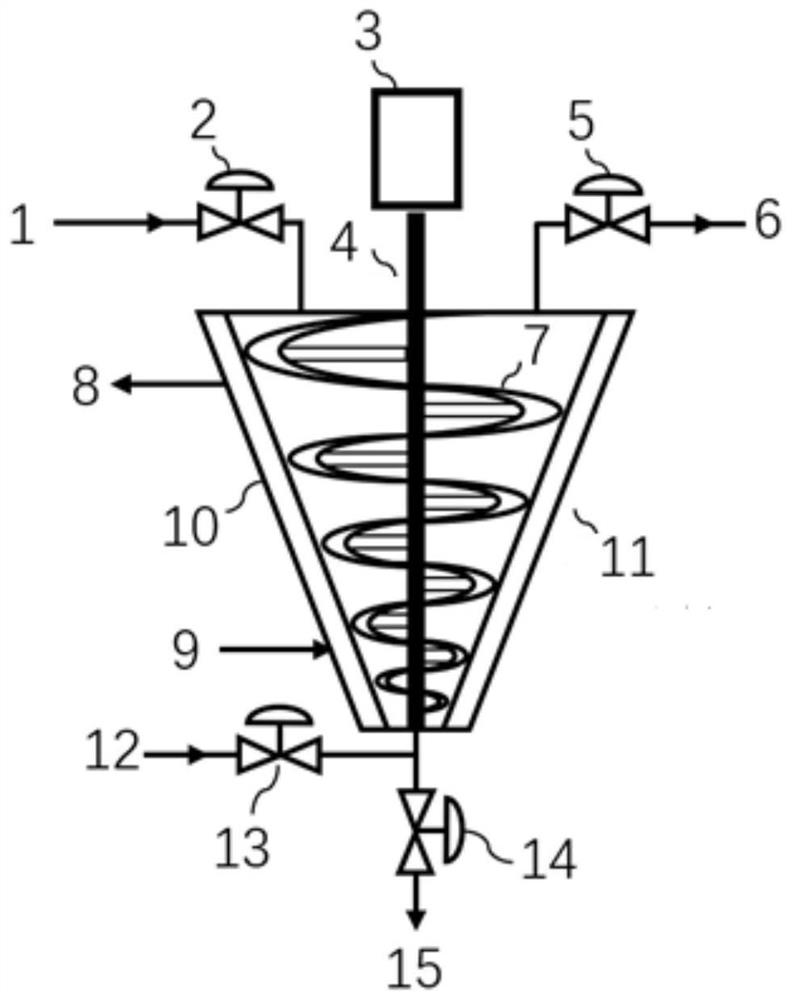

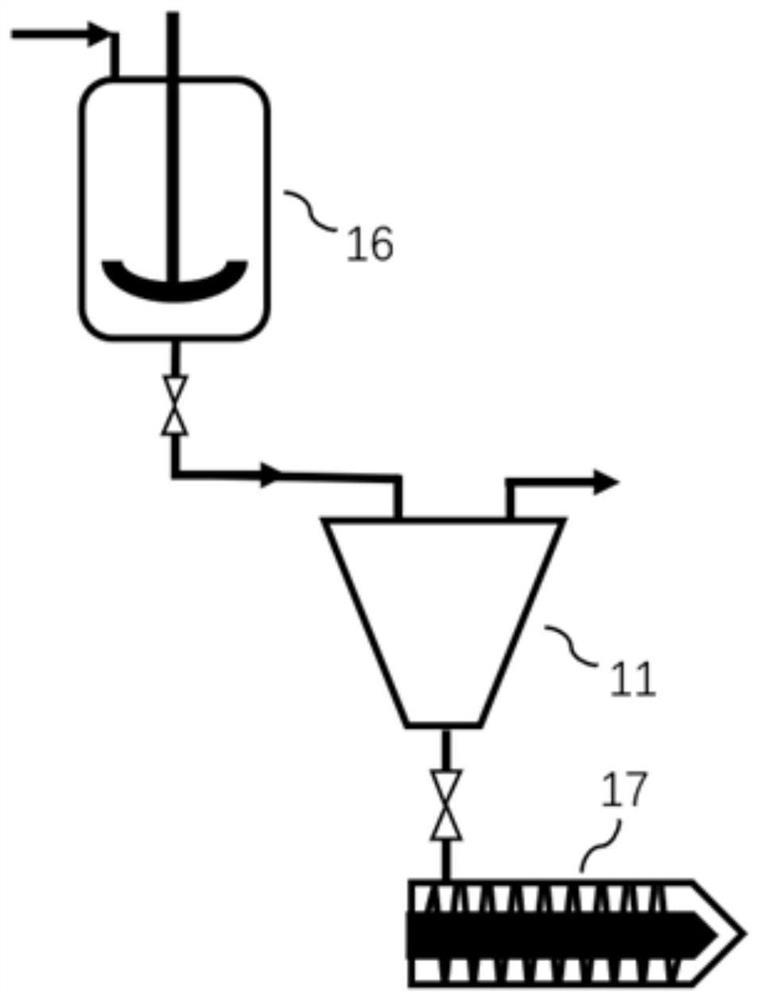

Preparation method and preparation device of semi-aromatic polyamide

ActiveCN112480396ASimple processReduce the number of devicesChemical/physical/physico-chemical stationary reactorsFeed devicesPolymer sciencePtru catalyst

The invention relates to the technical field of semi-aromatic polyamide, in particular to a preparation method and a preparation device of semi-aromatic polyamide. The preparation method of the semi-aromatic polyamide comprises the following steps: under the action of a catalyst, salifying a diacid monomer and one or more of a diamine monomer, lactam and omega-amino acid in a water phase to obtaina salt solution; conveying the salt solution into a polymerization kettle through a pipeline to carry out polymerization reaction; after the polymerization reaction is finished, subjecting the polymerization kettle to pressure relief and cooling, and then crushing prepolymer solids through stirring in the kettle; and drying the crushed prepolymer solid in the polymerization kettle, and carrying out solid-phase polymerization to obtain the semi-aromatic polyamide. The preparation method is short in technological process and high in synthesis efficiency, and the prepared semi-aromatic polyamideis low in terminal amino group and terminal carboxyl group content and high in intrinsic viscosity. According to the preparation device, the number of equipment in the production process is reduced,and the investment cost and the operation cost of the equipment are remarkably reduced.

Owner:SHANDONG GUANGYIN NEW MATERIALS

Full-automatic vacuum packaging unit for chicken feet

ActiveCN113928633AReduce the proportionAvoid artificial pollutionPackaging by pressurising/gasifyingMaterial transferEngineering

The invention discloses a full-automatic vacuum packaging unit for chicken feet, and relates to the field of food production. The full-automatic vacuum packaging unit comprises a supporting mechanism. A rotary material transferring mechanism is arranged at the top end of the supporting mechanism, a clamping and material conveying mechanism is connected to the top of the rear end of the supporting mechanism, and the clamping and material conveying mechanism is arranged at the front end of the top of the supporting mechanism. A material filling mechanism is arranged on the right side of the clamping and material conveying mechanism, and the rear end of the material filling mechanism is connected to the front end of the top of the supporting mechanism in a chain mode. A slitting mechanism is arranged at the bottom end of the material filling mechanism, a material filling and packaging mechanism is arranged at the top end of the material filling mechanism, and the material filling and packaging mechanism is arranged at the front end of the top of the supporting mechanism. The supporting mechanism comprises a supporting table. The bottom end of the supporting table is fixedly connected with a plurality of supporting bases, and the rear end of the supporting table is fixedly connected with a slitting connecting bracket in a chain mode. Meanwhile, when the full-automatic vacuum packaging unit is used, the rotary material transferring mechanism is arranged and cooperates with the clamping and material conveying mechanism in the feeding process, and therefore the pollution caused by manual errors to the filled chicken feet in the material conveying process is avoided.

Owner:安徽小胡鸭食品有限责任公司

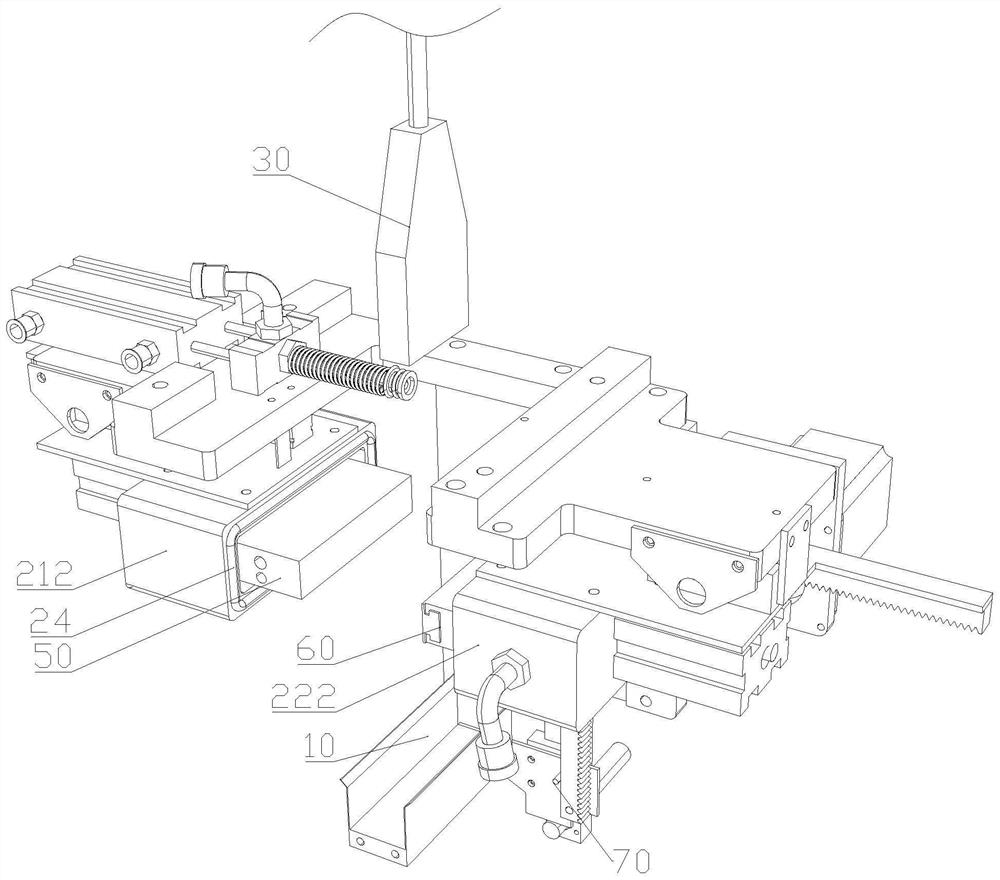

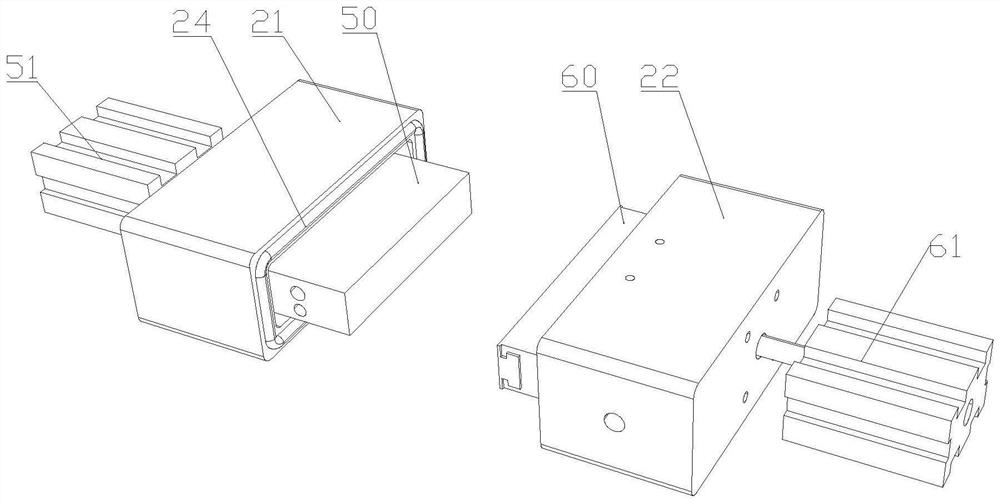

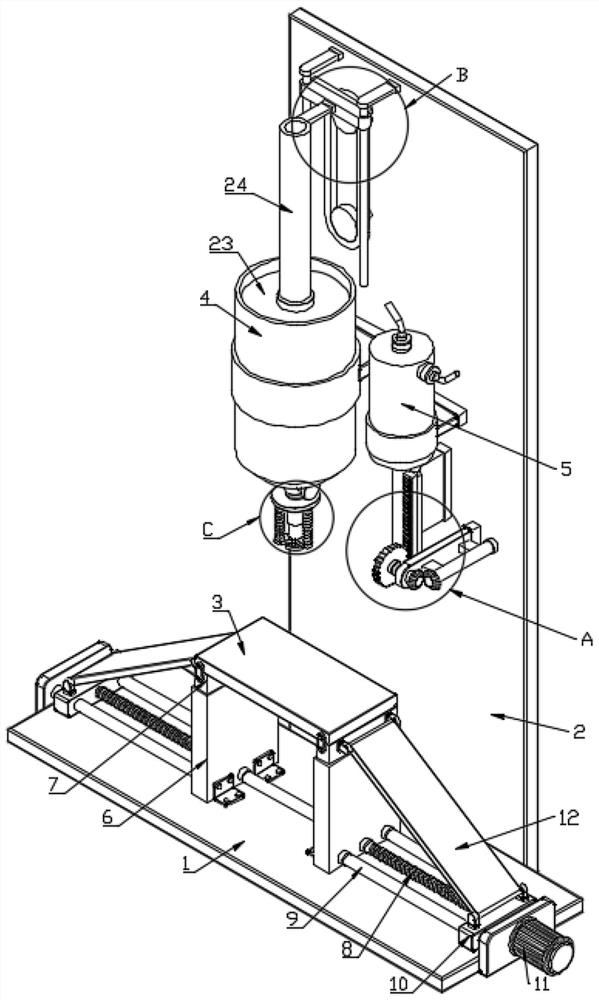

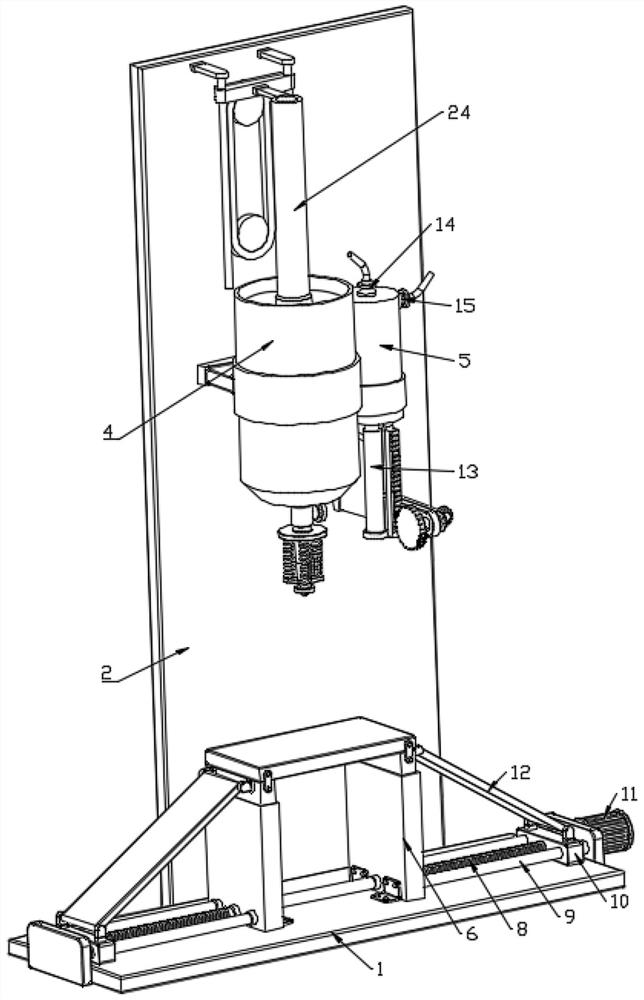

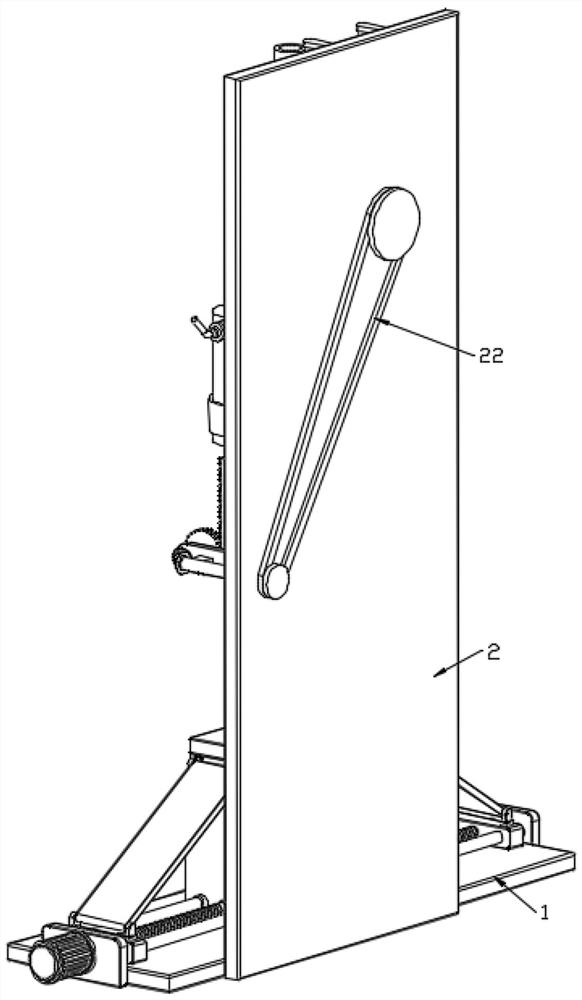

Battery pack vacuum liquid injection device and method

ActiveCN114497922AIncrease vacuumImprove infusion absorbencyFinal product manufactureCell component detailsPumping vacuumBattery cell

The invention relates to a battery pack vacuum liquid injection device and method.The battery pack vacuum liquid injection device comprises a base, a vertical plate and a transverse plate, the vertical plate is fixedly installed on the side portion of the base and is perpendicular to the base, the transverse plate is movably arranged on the base through a thread lifting mechanism and is parallel to the base, and the transverse plate is used for containing a battery; a liquid supply cylinder and an air suction cylinder are fixedly installed on the side, facing the transverse plate, of the vertical plate, the liquid supply cylinder is used for containing electrolyte, an exhaust mechanism is installed on the liquid supply cylinder, and when liquid injection is conducted on the battery, a bottom outlet of the liquid supply cylinder is connected with the battery through an elastic sealing mechanism; an air pumping mechanism for vacuumizing the battery is mounted on the air pumping cylinder, and the air pumping mechanism is connected with the air exhausting mechanism through a one-way transmission mechanism, so that finally, the synchronism of vacuumizing and liquid injection is realized, only the battery is vacuumized, and the process efficiency, the battery vacuum degree, the liquid injection absorptivity, the product consistency and the quality are improved.

Owner:SHENZHEN BROTHERS AUTOMATION TECH CO LTD

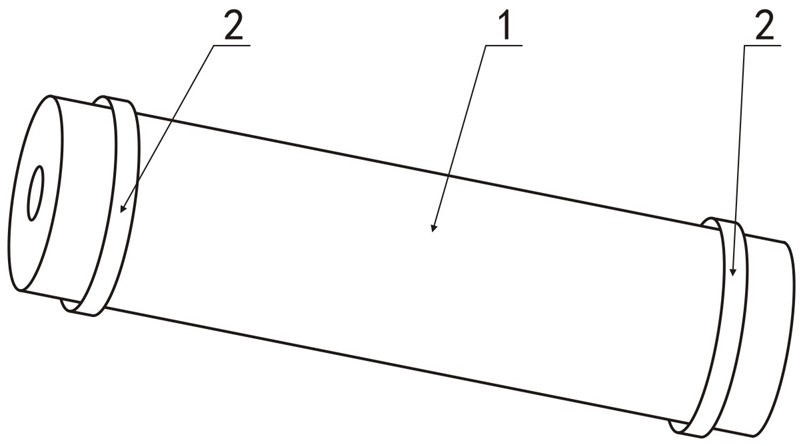

Vacuum heat treatment method for thin-film capacitor core

ActiveCN113643898AImprove local heating uniformityIncrease the air gapThin/thick film capacitorStacked capacitorsRubber ringThin membrane

The invention discloses a vacuum heat treatment method for a thin-film capacitor core. The method comprises the following steps: sleeving the positions, close to two ends, of the thin-film capacitor core, with insulating high-temperature-resistant rubber rings; arranging the thin-film capacitor core in a core tank body and sealing the thin-film capacitor core through a tank cover; vacuumizing the core tank body by adopting a vacuum pump; placing the core tank body in a drying oven, wherein air is contained in the drying oven; setting a heating program of the drying oven, then starting the drying oven, and performing heat treatment according to a preset temperature; after the procedure of heat treatment via the drying oven is completed, taking out the thin-film capacitor core, and removing the rubber rings so as to complete vacuum heat treatment of the thin-film capacitor core. According to the invention, the local heating uniformity of each part of the thin-film capacitor core is obviously improved, the shrinkage of the capacitor is consistent, the air gap and internal stress of the capacitor are improved, the voltage resistance and charge-discharge capacity of the capacitor are obviously improved, the service life of the capacitor is prolonged, and the vacuum pump for vacuumizing is small in power and low in noise, and is beneficial to energy conservation and noise reduction.

Owner:CHENGDU HONGMING ELECTRONICS CO LTD

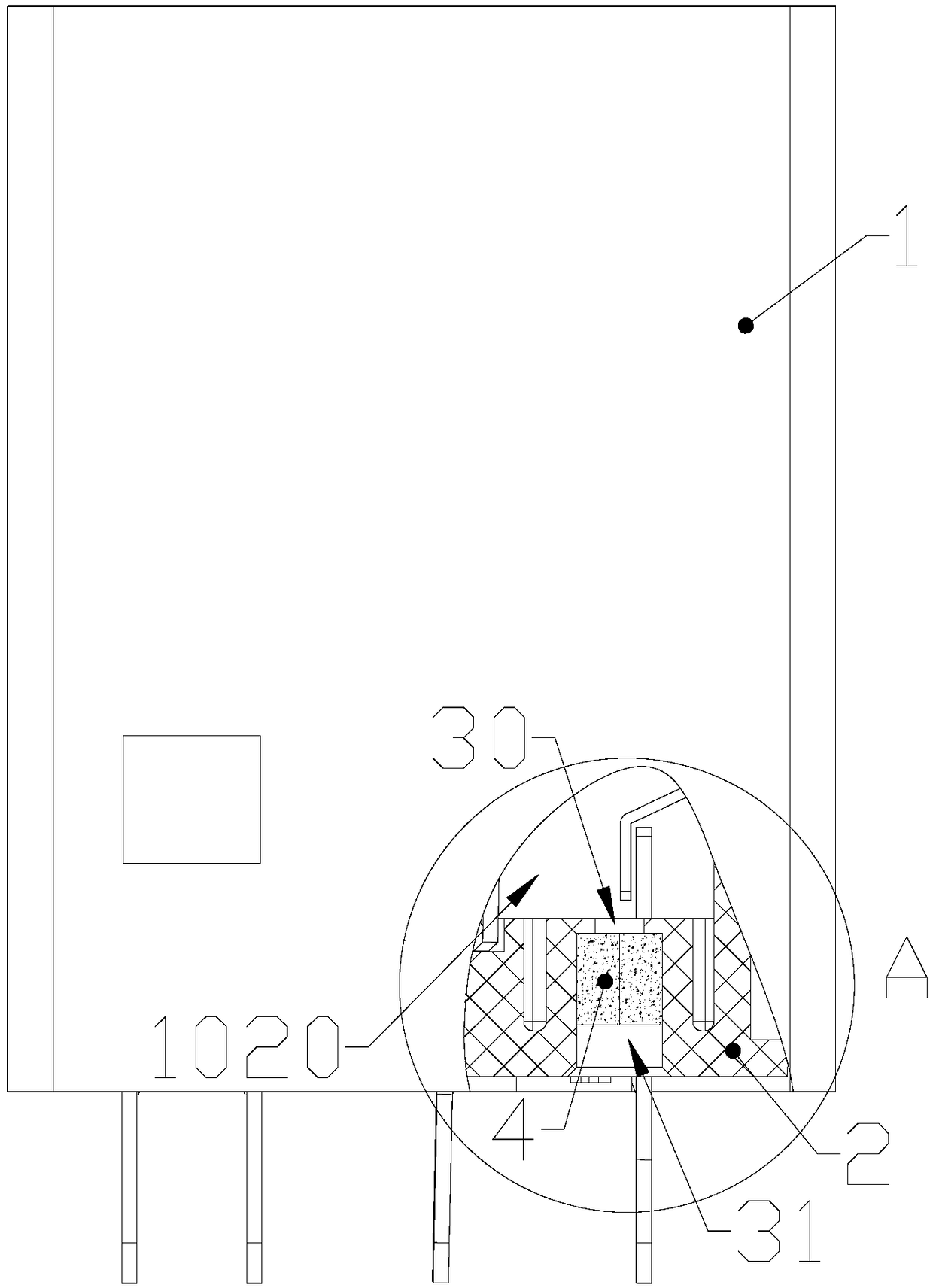

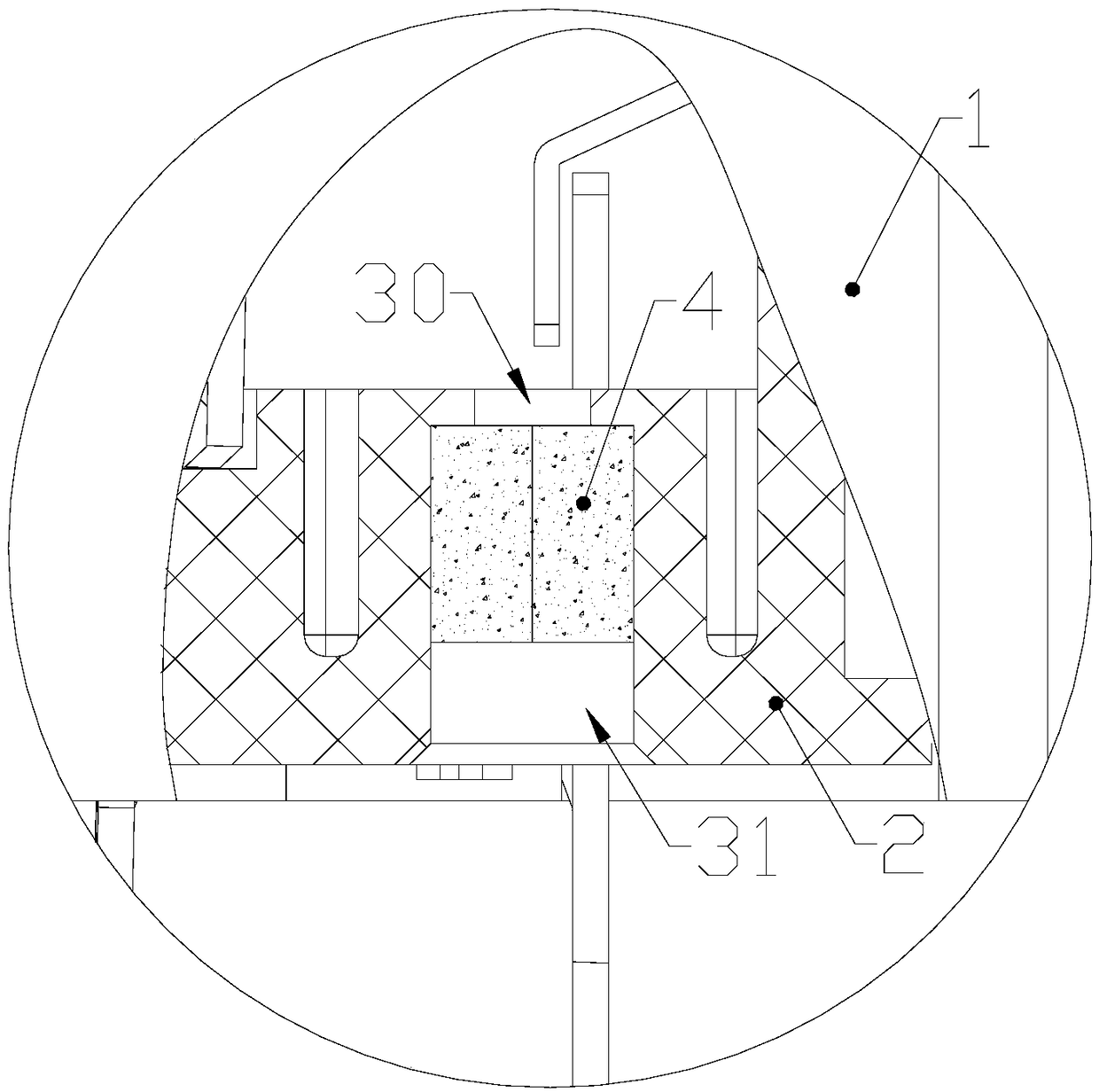

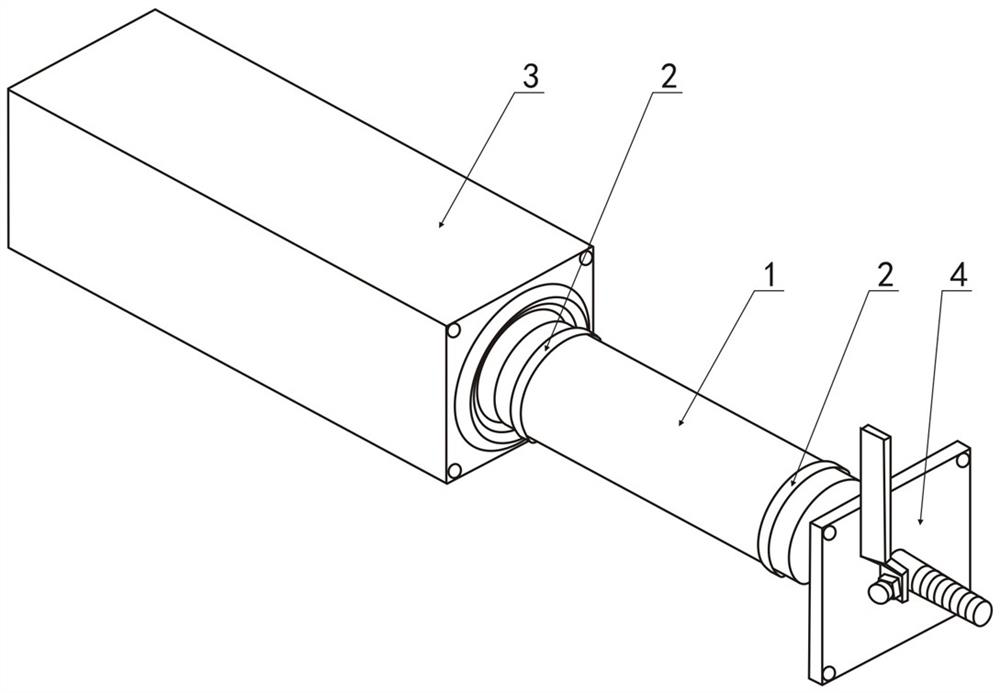

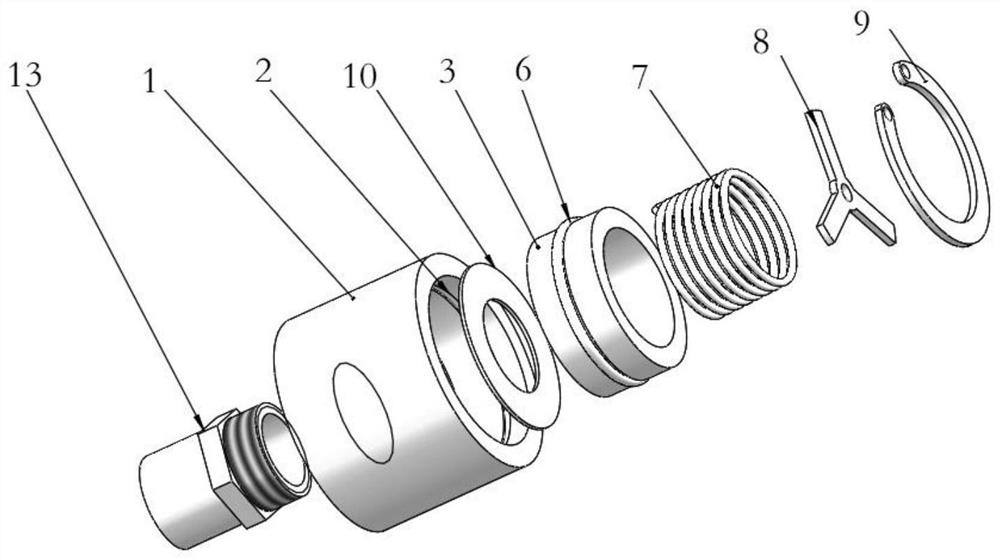

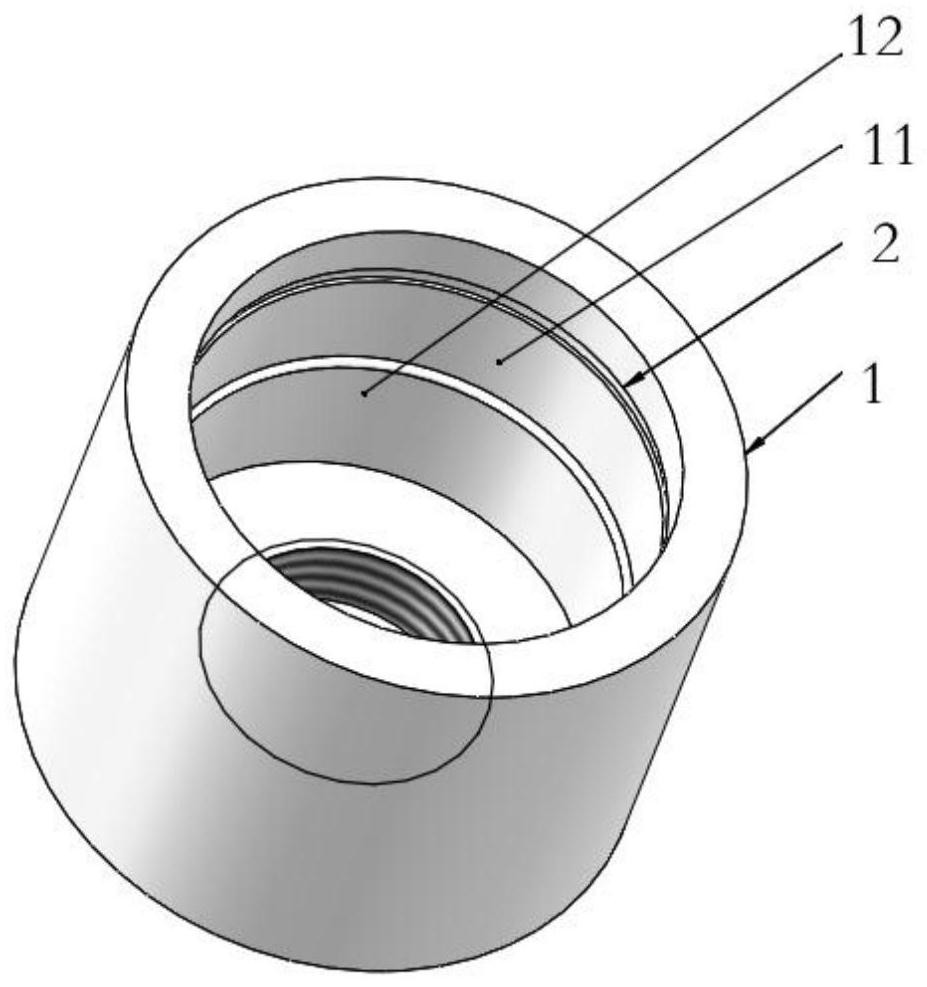

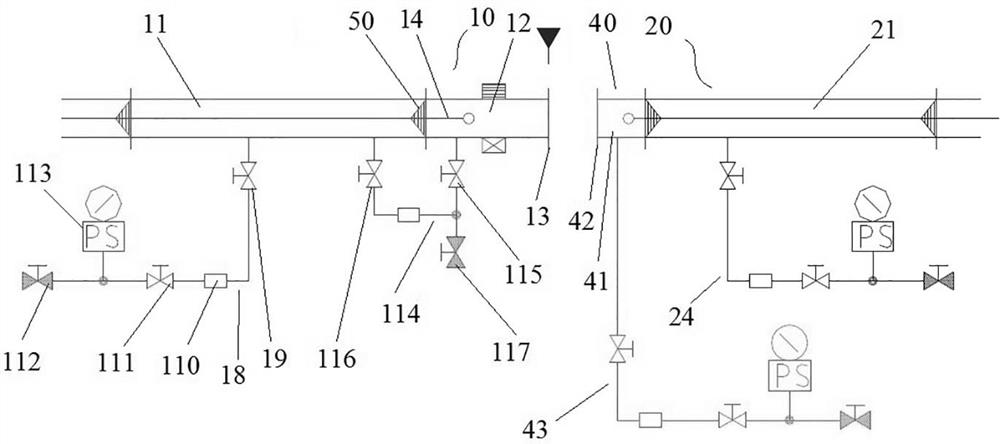

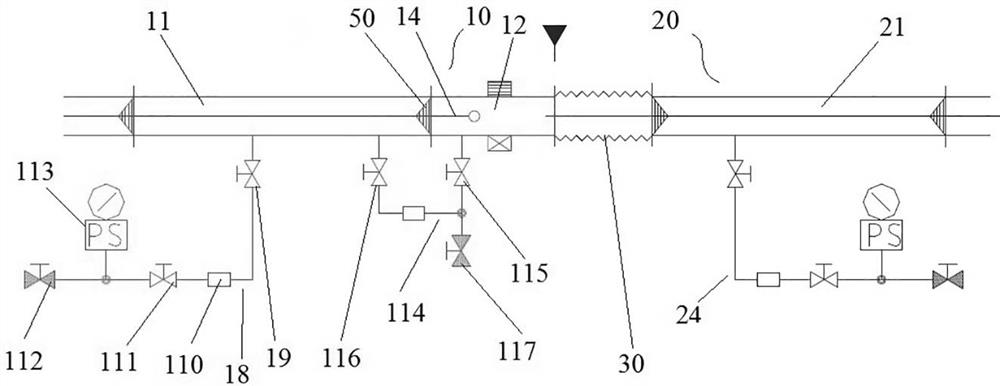

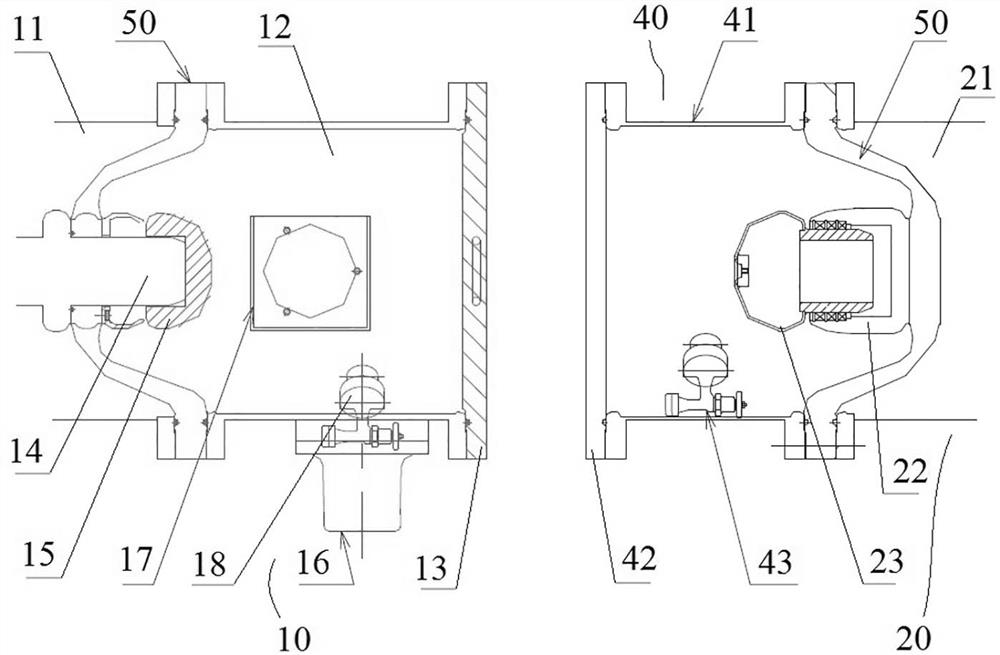

Relay, relay vacuumizing and air inflation system and relay vacuumizing and air inflation method

PendingCN108899249ADoes not affect contact resistanceSimple structureElectromagnetic relay detailsInterference fitLow voltage

The invention relates to the field of a low-voltage electric appliance, in particular to a relay. The relay comprises a cover case and a base connected with the cover case, wherein the cover case andthe base are matched to form a sealed installing space; an air inflation opening is formed in the base; an elastic sealing body in interference fit with the air inflation opening is arranged in the air inflation opening; the outer side of the elastic sealing body is tightly attached to the inner side of the air inflation opening; an air pin penetrates through the middle part of the elastic sealingbody, so that the vacuumizing or the air inflation is performed in the installation space. The elastic sealing body of the relay forms a first seal of the air inflation opening; the vacuumizing operation, the air inflation operation and the sealing operation continuity of the relay are favorably improved; the operation efficiency is improved; further, the air tightness of the vacuumizing and airinflation operation of the relay is ensured. The invention also provides a relay vacuumizing and air inflation system, which has the advantages that the operation is simple and convenient; the work efficiency is high; the air tightness of the product is high. The invention also provides a relay vacuumizing and air inflation method, which has the advantages that the operation is simple; the feasibility is high; the method is applicable to automatic production; the air tightness of the product is good; the qualified rate is high.

Owner:ZHEJIANG CHINT ELECTRIC CO LTD

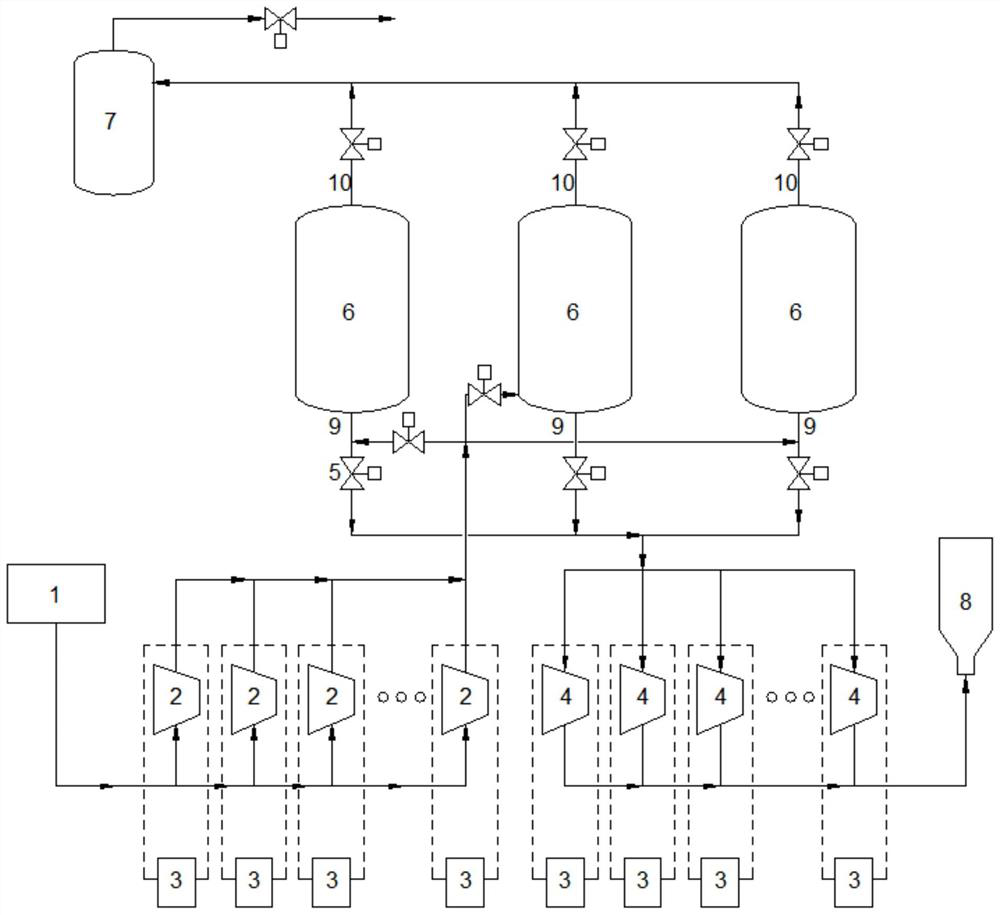

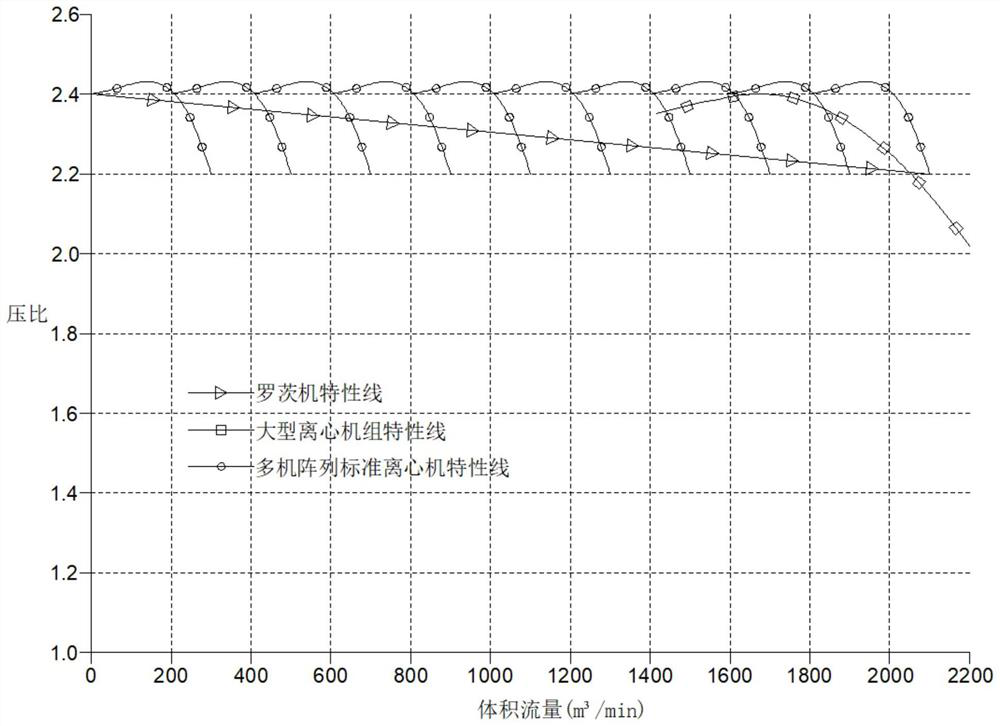

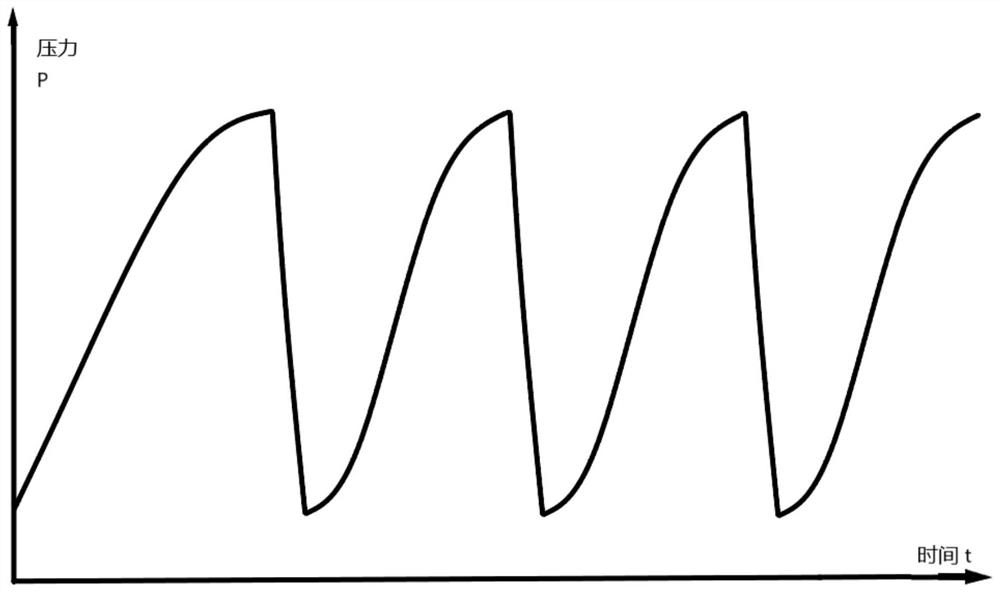

VPSA gas separation system and control method thereof

PendingCN114225633AReduce the number of inputsExpand the range of adjustable working conditionsDispersed particle separationFrequency changerConverters

The invention provides a VPSA gas separation system which comprises a plurality of turbines arranged in parallel and a gas separation assembly, the turbines are used for conveying air to the gas separation assembly or vacuumizing the gas separation assembly, each turbine is connected with a driving motor and a frequency converter, and all the frequency converters are in communication connection with a control device. The control device is used for controlling output of the frequency converter. The problems that in the prior art, a customized large centrifugal unit is high in manufacturing cost, high in efficiency, small in working interval and small in adjustable working condition range are solved, and the effects that the working condition adjusting range of the centrifugal unit is expanded, and the production cost and the maintenance cost of the centrifugal unit are reduced are achieved.

Owner:CHONGQING CHONGNENG POWER MASCH CO LTD

An environmentally friendly mixing equipment for wear-resistant high-performance rubber materials for vehicles

The invention discloses an environment-friendly mixing equipment for wear-resistant high-performance rubber materials for vehicles, comprising a banburying device, comprising a body, an banburying chamber arranged on the body, two banburying rollers arranged on the banburying chamber, An opening in the upper part of the mixing chamber, a pressing piece that can move up and down to close the opening, and a vacuuming part used for vacuuming the mixing chamber; the pressing piece is provided with a feed hole, an oil inlet hole and a vacuum pump Air port; conveying device, located on the side of the internal mixing device, used to transport the semi-finished products processed in the internal mixing chamber to the open-mixing equipment; A feeding part in the mixing chamber, the feeding part is connected with the feeding hole. The invention sets up material storage, saves the time of stopping and waiting for ingredients, and has high work efficiency; and the air in the mixing chamber can be completely exhausted by means of vacuuming, so as to ensure that the raw materials will not be oxidized during the refining process. and affect the final product performance.

Owner:日照市昊德尔橡塑制品有限公司

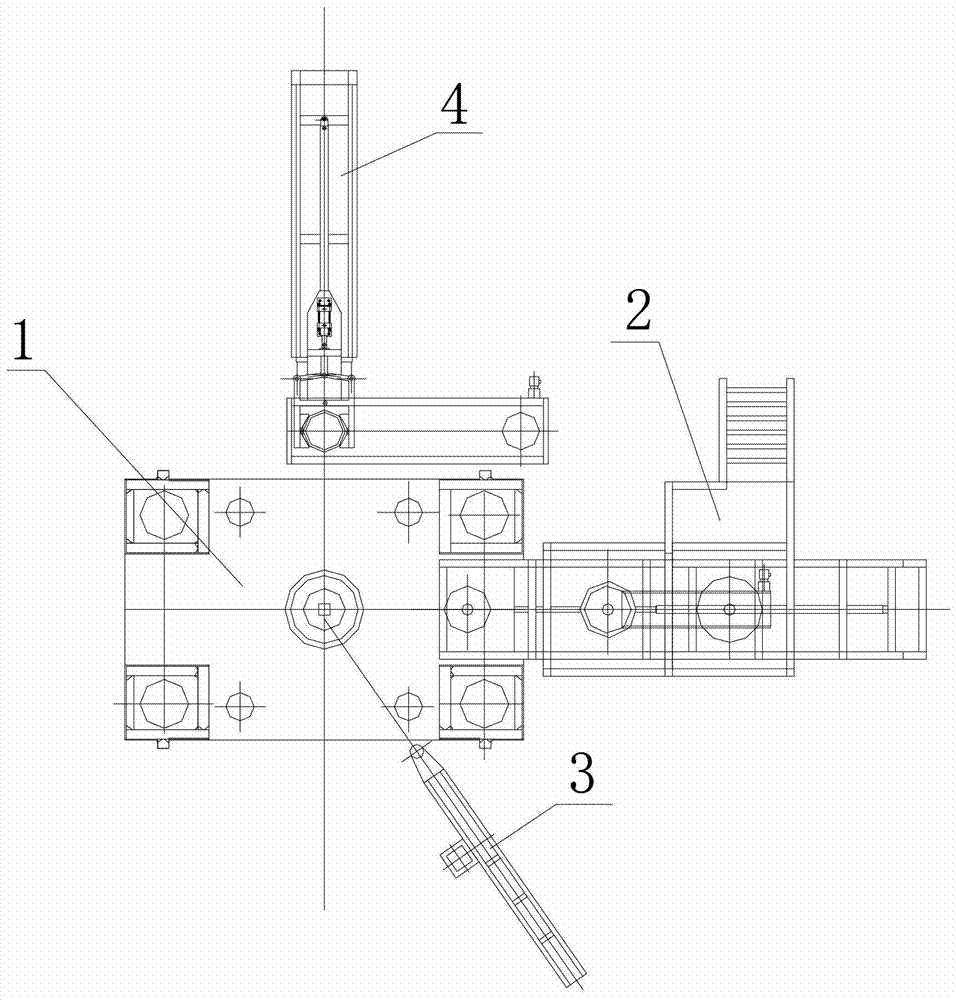

Food packing machine vacuum chamber mounting assembly

PendingCN107097992AAchieve vacuumSimple trachea arrangementPackaging by pressurising/gasifyingFood packagingEngineering

The invention discloses a food packing machine vacuum chamber mounting assembly. The food packing machine vacuum chamber mounting assembly is provided with a vertical column, a shaft sleeve, a cavity mounting plate, an air dividing base, a middle shaft and a connecting bracket. The shaft sleeve is rotatably mounted on the vertical column in a sleeving mode; the cavity mounting plate is fixed at the upper end of the shaft sleeve; the air dividing base is fixedly mounted at the upper end of the vertical column; the middle shaft is mounted on the air dividing base; an air dividing bottom disc, an air dividing middle disc and an air dividing upper disc are sequentially laminated on the air dividing base and are rotatably mounted on the middle shaft in a sleeving mode; air channels are formed in the air dividing bottom disc, the air dividing middle disc and the air dividing upper disc and communicate with the air dividing bottom disc, the air dividing middle disc and the air dividing upper disc; a vacuum pipe connector is arranged on the air dividing upper disc and communicates with the air channel in the air dividing upper disc; and the connecting bracket is connected with the cavity mounting plate and the air dividing upper disc. In the process of station rotation, air pipes are not wound in the vacuum pumping process.

Owner:芜湖裕东自动化科技有限公司

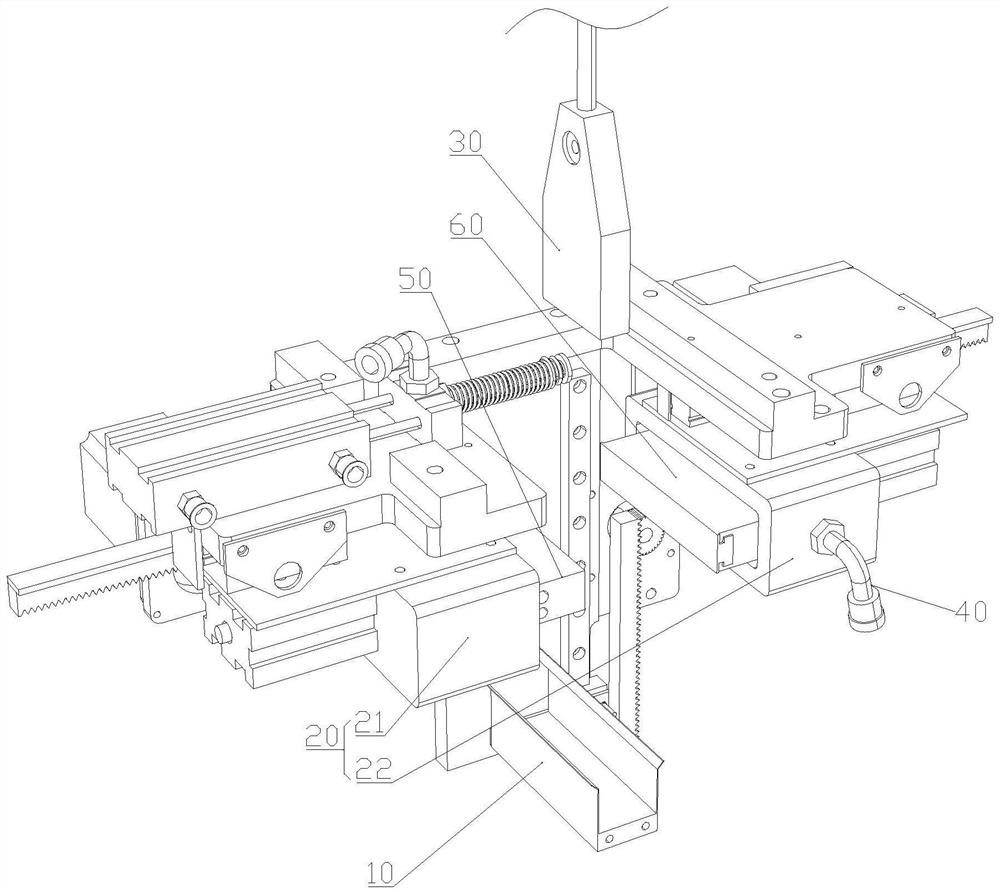

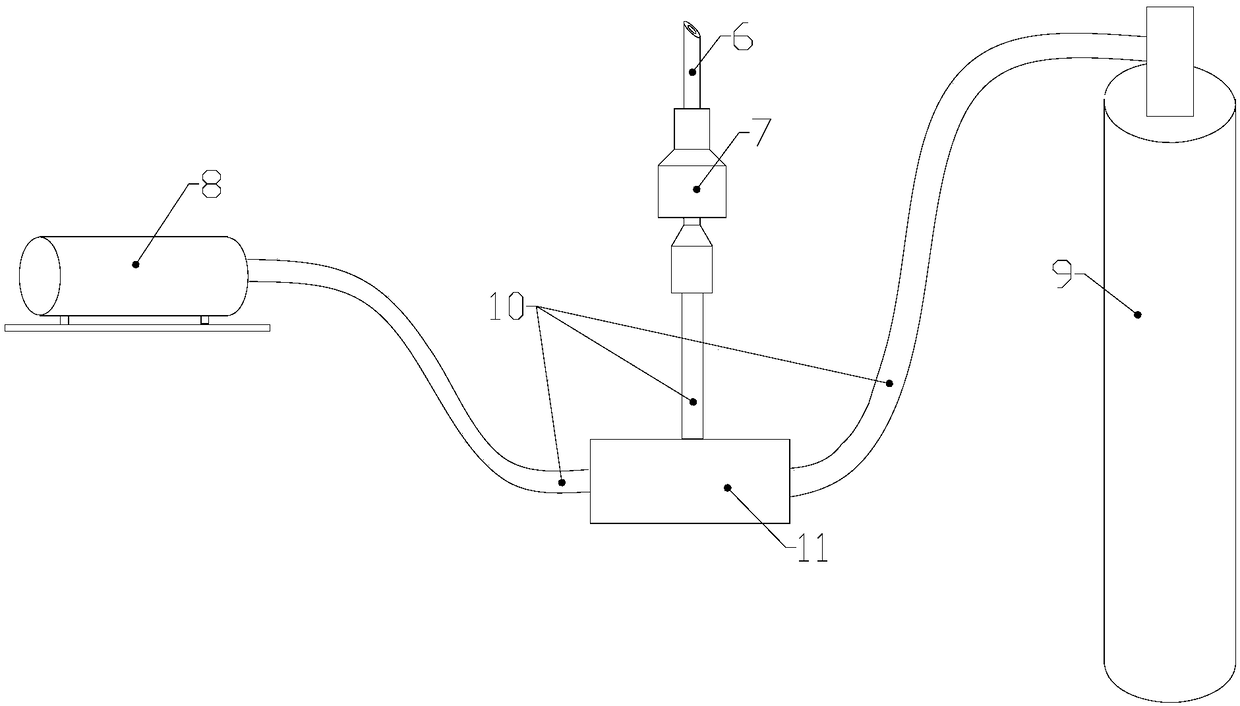

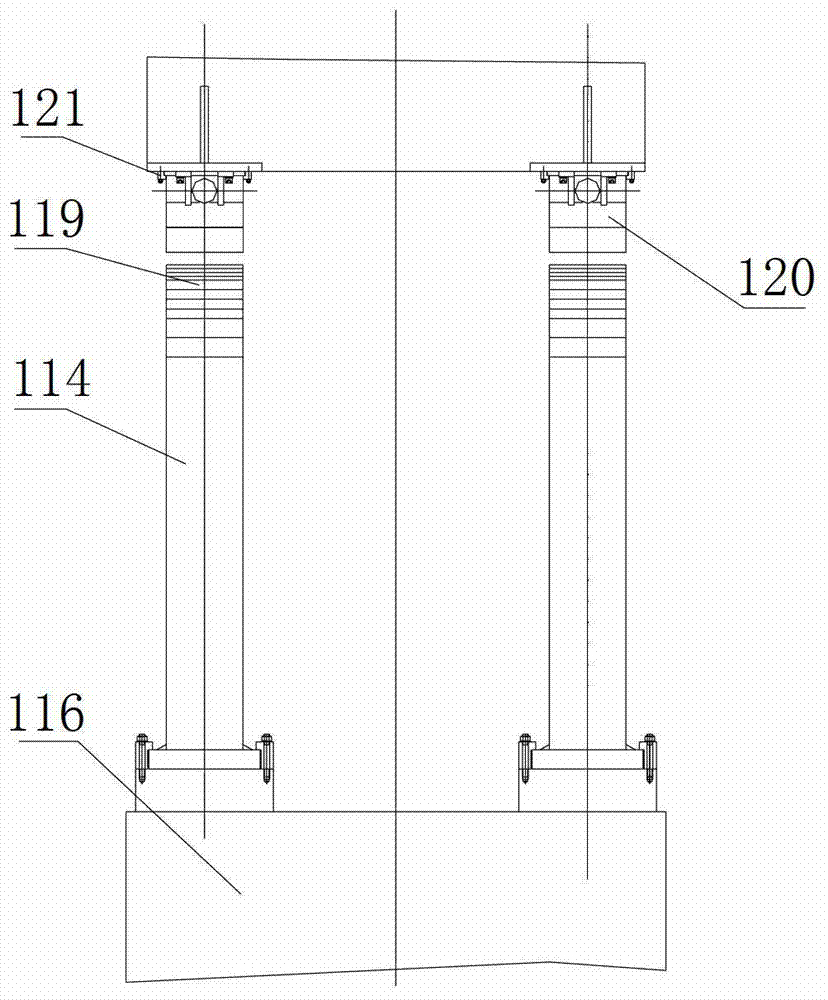

Automatic pressing production line for large explosive grains

ActiveCN103265389BIncrease pressureHigh densityExplosive working-up apparatusProduction lineEngineering

The invention relates to an automatic pressing production line for large-scale explosive powder columns, which includes a hydraulic press consisting of an upper beam, an upper return cylinder, an upper cylinder slider, an upper punch, a middle beam equipped with a die sleeve, and a lower beam. The characteristics are: It includes an automatic weighing and feeding device, a powder smoothing device and an automatic discharging device arranged on the side of the hydraulic press. The upper part of the lower beam is equipped with a lower return cylinder, which is connected with the slider of the lower belt cylinder, and the lower belt cylinder slides The block is equipped with a lower punch, an automatic vacuum device is provided at the lower part of the upper cylinder slider, and a mechanical limit device is provided on the upper cylinder slider and the lower cylinder slider. The advantages are: this production line can realize the fully automatic operation of explosive column feeding, smoothing, two-way pressing and discharging, which can not only greatly reduce the labor intensity of operators, improve the production efficiency of large-tonnage hydraulic presses, avoid potential safety hazards, and It can reduce the air bubbles in the powder column during the pressing process, improve the mass density uniformity and precision of the powder column, and ensure the product quality.

Owner:TIANJIN TIANDUAN PRESS CO LTD

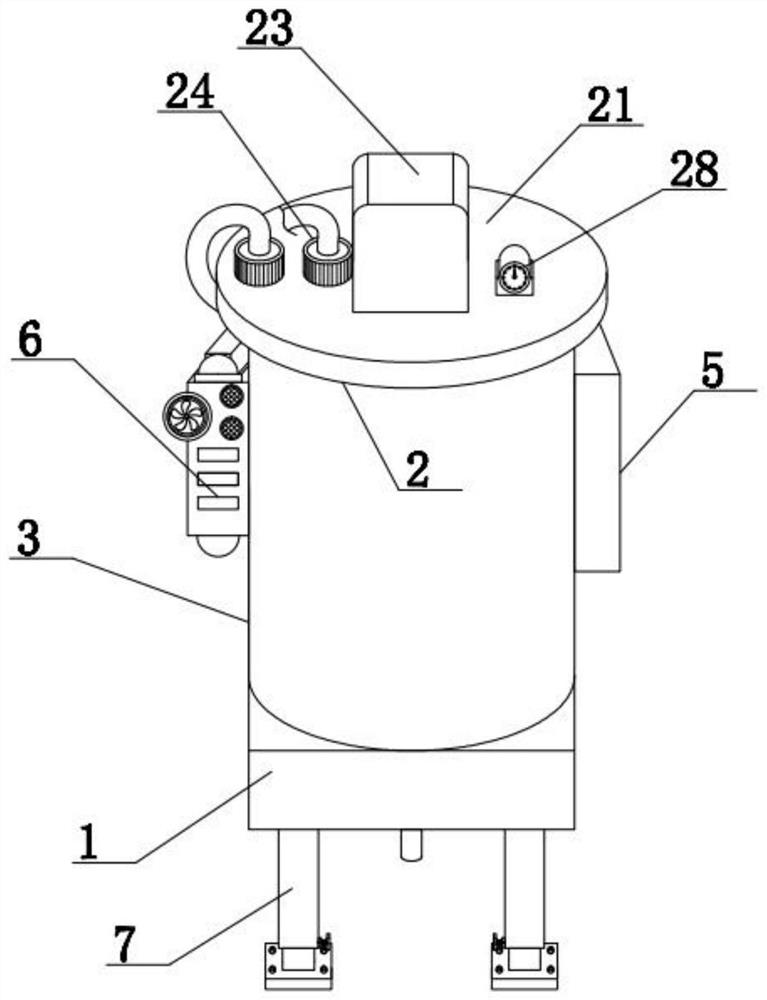

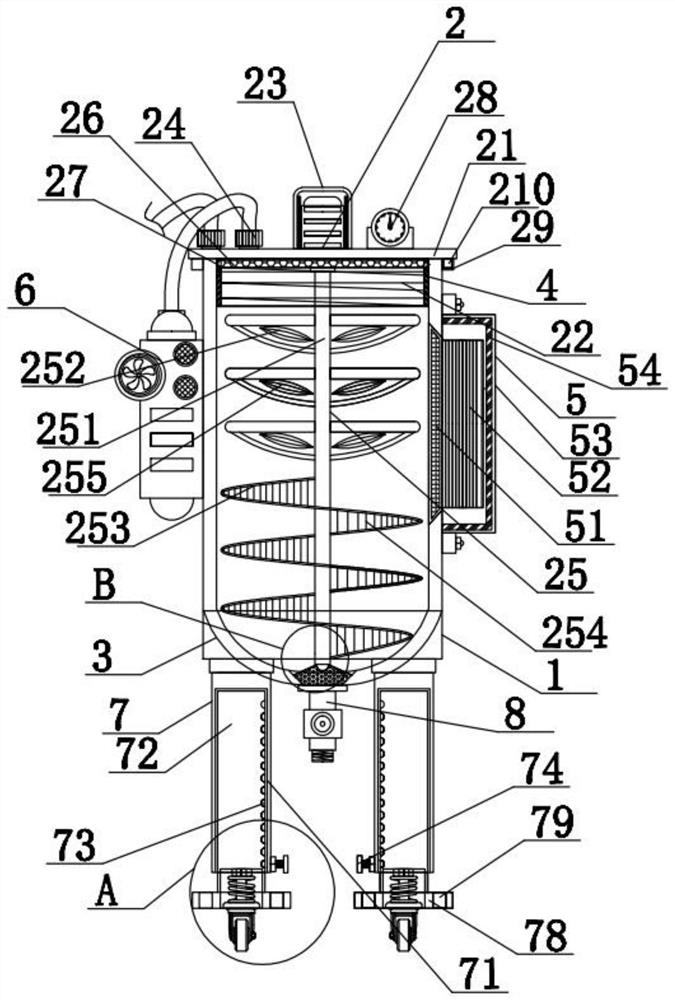

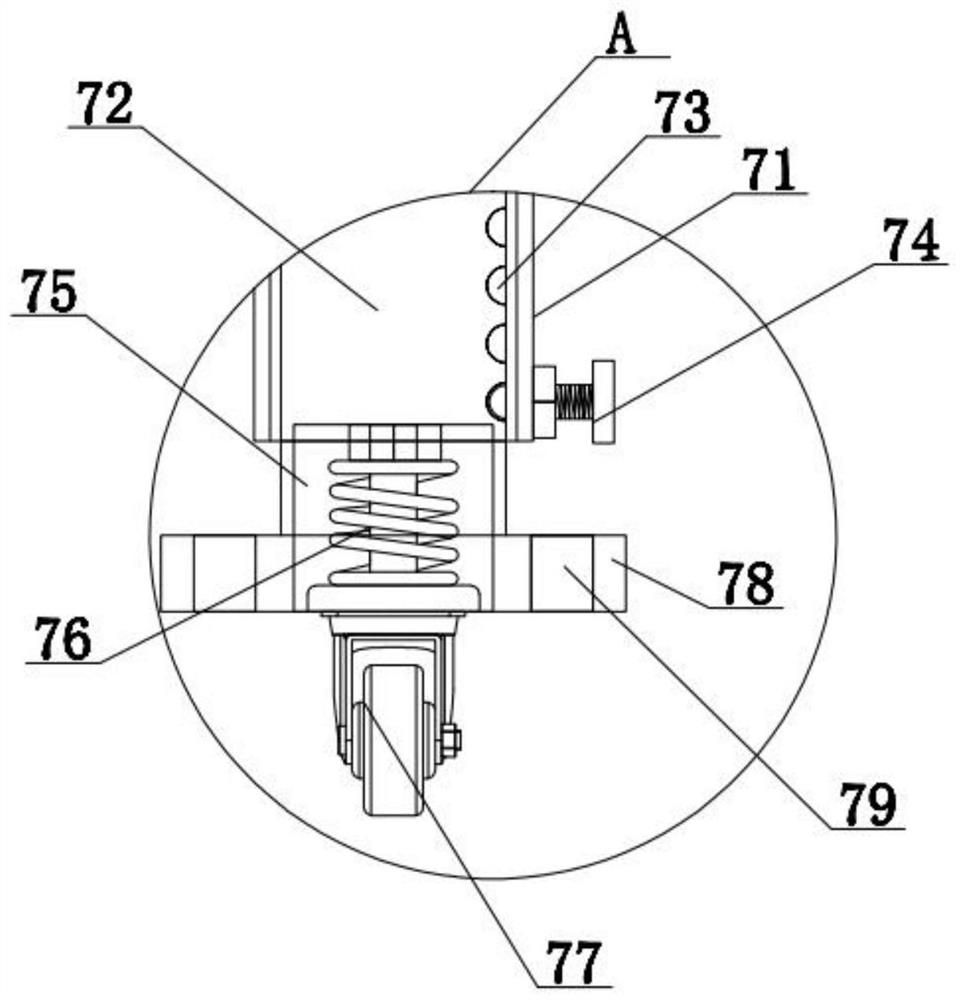

PUR hot melt adhesive multifunctional reaction kettle with double-mixing stirring function and stirring method

PendingCN114192072AAchieve vacuumRealize up and down rollTransportation and packagingRotary stirring mixersPhysicsPropeller

The invention discloses a PUR hot melt adhesive multifunctional reaction kettle with a double-mixing stirring function, the PUR hot melt adhesive multifunctional reaction kettle comprises a base, the top of the base is fixedly provided with a reaction kettle body, the inner side of the upper end of the reaction kettle is provided with an internal thread, and the top of the reaction kettle body is in threaded connection with a stirring mechanism through the internal thread. By adopting the structure, the driving motor is arranged to drive the stirring frame to rotate, so that the rotating shaft drives the propeller and the stirring paddle to rotate, a material is driven to roll through the propeller, and meanwhile, the stirring paddle is arranged to further stir and mix the rolled material, so that the mixing reaction efficiency of the device is effectively improved; when the reaction kettle is used, gas in the reaction kettle can be pumped through the vacuum pump, so that the vacuum of the reaction kettle is realized, and nitrogen and other gases required by reaction can be introduced through the other access port, so that the reaction kettle has the function of avoiding bottom crystallization and precipitation, and is wide in application range and worthy of popularization and application.

Owner:常州威斯敦粘合材料有限责任公司

Multifunctional bed for defecation and bathing

PendingCN112089344AAchieve vacuumRealize the function of direct exclusionBathsDouchesEngineeringPhysical therapy

The invention discloses a multifunctional bed for defecation and bathing. The multifunctional bed comprises a bathtub body, wherein an arm-chair similar to a riding arm-chair is arranged on the bathtub body, and the arm-chair is convenient for the aged to bath; and a supporting device for supporting a human body to lie flat is arranged in the arm-chair and driven by a driving device, and a closestool convenient for the human body to squat is arranged in a groove. An air bag is arranged for inflation, so that the groove in the bathtub body is filled, and the bathtub body can support the human body to lie flat. Through a pull belt on the surface of the air bag and at the bottom of the bathtub body, the flatness of the upper end face of the air bag is controlled. Through the driving device, inflation, deflation and vacuumizing of the air bag are achieved. Through the closestool and a cylinder arranged on the air bag, the defecation function is achieved. Through an electric heating wire, the heating function of a surface layer of the bed body is achieved. A bathing water heater and the closestool are assembled, and through a drainage port, a shower hose and a rubber plug, the functionof draining water after bathing is achieved.

Owner:魏红喜

Shaping device for bagged FOSB packaging bags

InactiveCN112429305ACompact structureFit closelyPackaging by pressurising/gasifyingWrapper twisting/gatheringPumping vacuumEngineering

The invention discloses a shaping device for bagged FOSB packaging bags. The shaping device comprises a shaping machine frame, a sealing machine frame, a FOSB conveying belt, a vacuumizing device, anopening clamping device, an ultrasonic sealing device, a FOSB front-end upturning device, a FOSB front-end shaping device, a sealing station horizontal driving device and a FOSB back side surface shaping device. The FOSB conveying belt, the FOSB front-end shaping device and the FOSB back side face shaping device are installed on the shaping machine frame, the sealing station horizontal driving device is arranged on the ground on one side of the shaping machine frame, the sealing machine frame is fixed to the movable end of the sealing station horizontal driving device, and the FOSB front-end upturning device, the vacuumizing device, the opening clamping device and the ultrasonic sealing device are all fixed to the sealing machine frame. According to the shaping device for the bagged FOSB packaging bags, the bagged FOSB packaging bags can be vacuumized and automatically shaped, the shaping efficiency is improved, the whole process is fully automatically carried out, and the labor cost is reduced.

Owner:无锡迪渊特科技有限公司

A kind of film capacitor core vacuum heat treatment method

ActiveCN113643898BImprove local heating uniformityIncrease the air gapThin/thick film capacitorStacked capacitorsRubber ringEngineering

The invention discloses a vacuum heat treatment method for a film capacitor core, which comprises the following steps: coating the film capacitor core with insulating high-temperature-resistant rubber rings near the two ends; placing the film capacitor core in a core tank and passing through the tank The lid is sealed; the core tank is evacuated by a vacuum pump; the core tank is placed in an oven with air in it; the temperature rise program of the oven is set, and then the oven is started to perform heat treatment according to the preset temperature; after the oven heat treatment program is completed , Take out the film capacitor core, remove the rubber ring, and complete the vacuum heat treatment of the film capacitor core. The present invention significantly improves the local heating uniformity of each part of the core of the film capacitor, and the shrinkage of the capacitor is consistent, the air gap and internal stress of the capacitor are improved, the voltage resistance and charge and discharge capacity of the capacitor are significantly improved, and the service life of the capacitor is improved. The vacuum pump used for vacuuming has low power and low noise, which is beneficial to energy saving and noise reduction.

Owner:CHENGDU HONGMING ELECTRONICS CO LTD

Battery explosion venting structure

PendingCN113629347AImprove sealingAchieve vacuumSecondary cellsCell component detailsEngineeringMechanical engineering

A disclosed battery explosion venting structure comprises a cylindrical shell, a movable explosion venting body arranged in the shell, and an elastic piece arranged in the shell and used for controlling the position of the movable explosion venting body, wherein the elastic piece is arranged in an inner cavity of the movable explosion venting body. During liquid injection, a liquid injection connector is in threaded connection with the shell, the movable explosion venting body is extruded to move from the sealing section to the liquid injection section, due to the fact that the outer diameter of the sealing ring is smaller than the inner diameter of the liquid injection section, liquid injection / vacuumizing can be conducted, after liquid injection is completed, the movable explosion venting body is pushed to the sealing section through the elastic piece to be sealed, the functions of vacuumizing, liquid injection and explosion venting are achieved, the structure is simple, sealing of a battery is facilitated, and repeated use can be realized.

Owner:SHAANXI OLYMPUS POWER ENERGY CO LTD

A sucker track-driven bionic device for climbing on smooth surfaces

The invention discloses a suction cup crawler drive bionic device for climbing on a smooth surface, which comprises a frame, a drive wheel and a tensioner wheel are arranged on the frame, and an annular track is installed on the outer ring of the drive wheel and the tensioner wheel. A plurality of vacuum suction cups are distributed at equal intervals on the periphery of the annular crawler. A main handle is provided on the side where each vacuum suction cup is connected to the annular crawler. One end of the main handle is connected to the vacuum suction cup, and the other end is provided with a main handle tension applying mechanism. The invention solves the problems of complex mechanism, difficulty in unsealing after vacuum of the suction cups, low speed, discontinuity and the like during the crawling process of the wall-climbing robot with multiple suction cups, and can climb on a smooth plane with any angle.

Owner:SHANDONG UNIV OF SCI & TECH

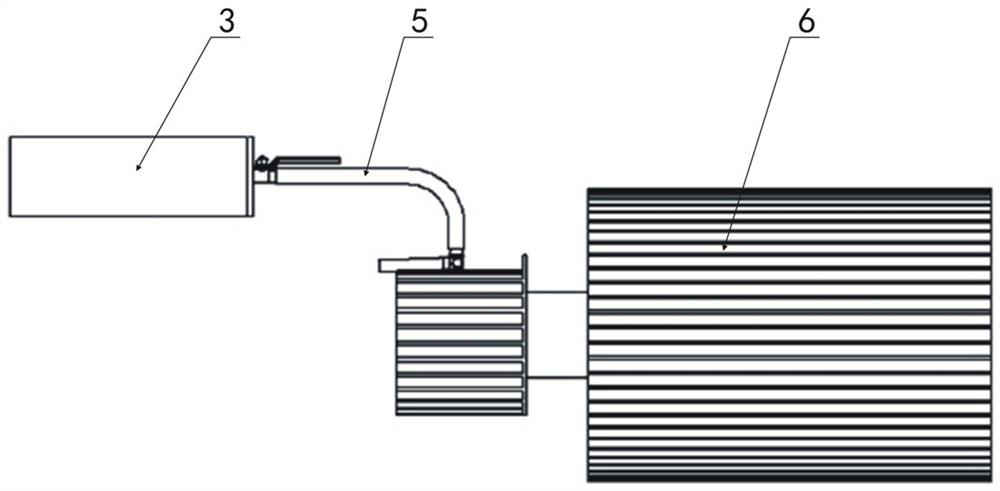

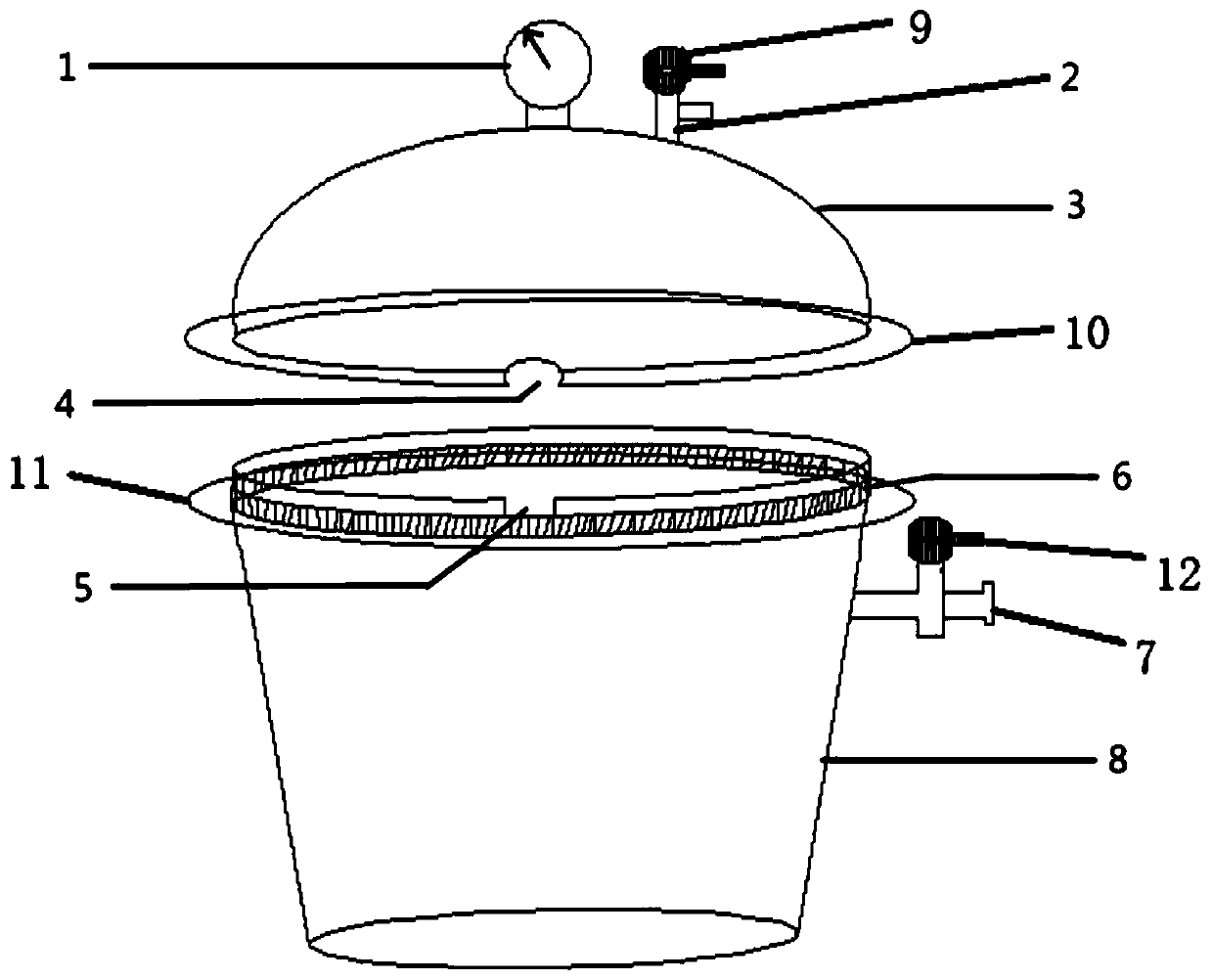

Plant non-isolated state vacuumizing device and use method thereof

InactiveCN110594126AImprove transgenic efficiencyAchieve vacuumPositive displacement pump componentsPumpsTransgenic technologyEngineering

The invention discloses a plant non-isolated state vacuumizing device, and relates to the technical field of transgenosis. The plant non-isolated state vacuumizing device comprises a barrel body, wherein the upper end of the barrel body is connected with an upper cover through a sealing mechanism, the upper cover is matched with the barrel body, the upper edge of the barrel body is provided with an upper bayonet, and the lower edge of the upper cover is provided with a lower bayonet vertically corresponding to the upper bayonet. A use method of the plant non-isolated state vacuumizing device comprises the steps of 1, placing a tissue to be genetically modified of a non-isolated plant in the barrel body; and 2, covering the upper cover to form a closed space with the barrel body, wherein the upper bayonet and the lower bayonet are used for allowing the tissue to be genetically modified to pass through. According to the plant non-isolated state vacuumizing device, the defect that vacuumizing can not be carried out caused by wood plant agrobacterium infection is overcome, branches or flower stalks of the wood plant are placed into an open vacuum container, gaps between the upper bayonet and the lower bayonet and the plant are sealed by using semi-flowable flexible glue, vacuumizing is carried out by a vacuum pump, vacuumizing of the plant tissue in a non-isolated state is realized, and agrobacterium-mediated transgenic efficiency can be remarkably improved.

Owner:SHANGHAI ACAD OF AGRI SCI

Filling device for vacuum system and filling method of enclosed cavity

A filling device for a vacuum system and a filling method for a closed cavity, including a screw with a filling channel, a cover with a suction filling port, and a fastening screw for rotating the screw provided on the cover One end opening of the filling channel in the screw is set on the bottom of the screw, the other end opening is set on the side of the screw, and a cavity with an internal thread matching the screw is provided on the cavity that needs to be vacuumed. The screw is sealed and installed on the interface, and the cover is sealed and installed on the outside of the interface, so that a sealed space is formed in the cover, and the fastener on the cover is tightly connected with the cover and the fastener can The cover body rotates while moving up and down, the fasteners correspond to the positions of the screws, and the screws are screwed out or screwed into the interface through the fasteners. The invention is a filling device for a vacuum system with simple structure and convenient operation, simple processing and operation, and effectively solves the problems of filling and sealing.

Owner:湖南中科泰通热能科技发展有限公司

Butt joint method of newly-built GIS bus and existing GIS bus and GIS bus system

PendingCN114447871APrevent leakageReduce the number of connectionsLine/current collector detailsSwitchgear arrangementsOperating systemBus

The invention relates to a butt joint method of a newly-built GIS bus and an existing GIS bus and a GIS bus system. The GIS bus system comprises an existing GIS bus, a newly-built GIS bus and a detachable bus; the existing GIS bus reserved joint cylinder is used for being connected to a reserved bus and is provided with a butt joint end which is in butt joint with a detachable bus and is communicated with the detachable bus. The reserved cover plate is used for blocking the butt joint end of the reserved joint cylinder, so that the reserved joint cylinder forms an independent closed air chamber; the reserved joint is arranged on the insulator at the butt joint of the reserved bus and the reserved joint cylinder, is positioned in the reserved joint cylinder and is used for connecting a corresponding central conductor; and an inflating and deflating device is arranged on the reserved joint cylinder. The reserved joint cylinder can be directly connected to the butt joint end of the reserved bus of the GIS when the existing GIS is constructed, and when the GIS is expanded, the cylinder cover plate on the reserved joint cylinder is directly disassembled, so that the butt joint end of the reserved joint cylinder can be in butt joint with the detachable bus, the expansion of the GIS is realized, and the butt joint operation efficiency can be improved.

Owner:HENAN PINGZHI HIGH VOLTAGE SWITCHGEAR +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com