Plant non-isolated state vacuumizing device and use method thereof

A vacuum device, non-isolated technology, which is applied in the field of genetic modification, can solve the problems that the operation cannot be completed in the laboratory vacuum box due to its large size, and the vacuum operation of plants cannot be realized, so as to achieve the effect of improving the efficiency of genetic modification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

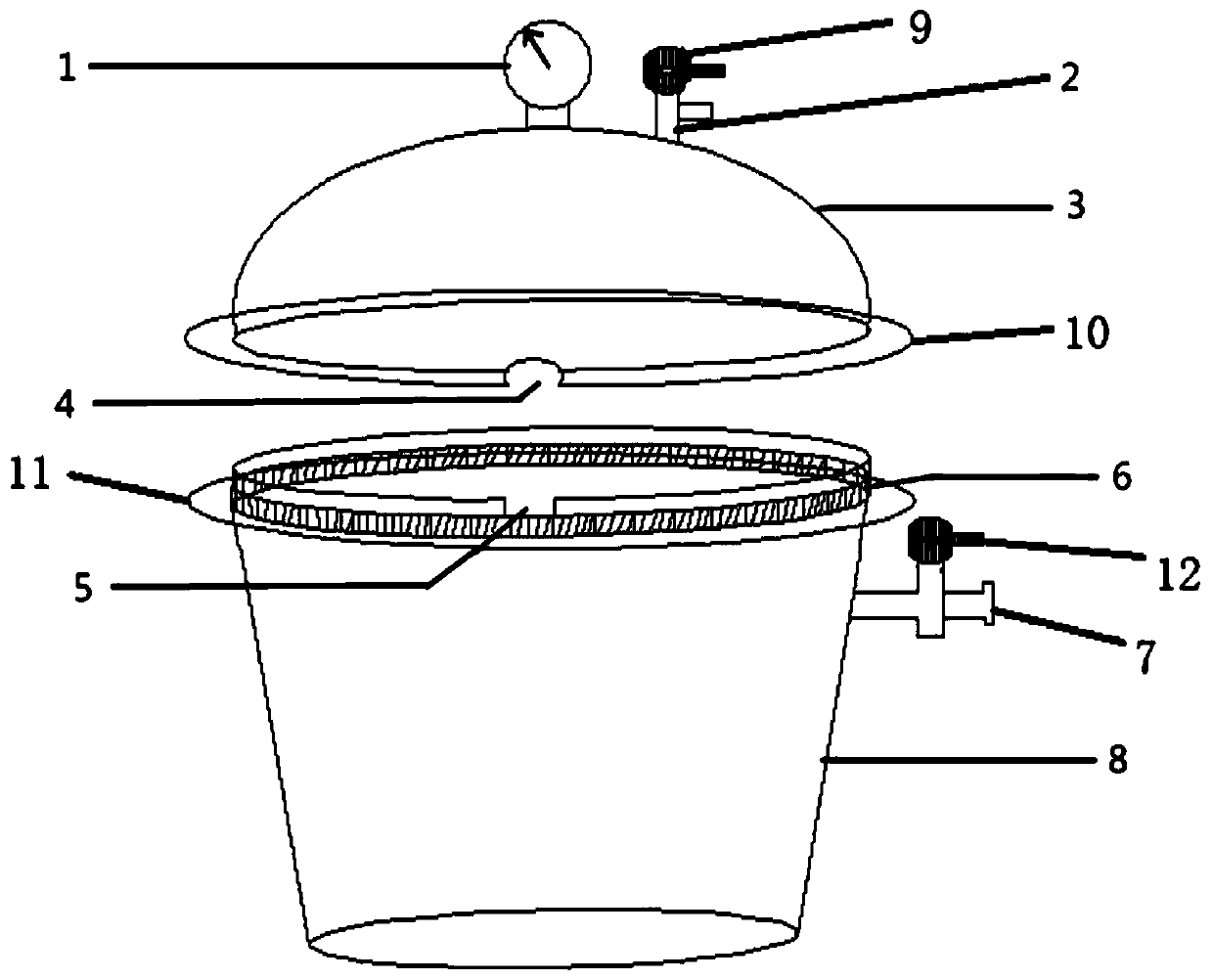

[0023] see figure 1 , a vacuum device for plants in a non-isolated state, comprising a barrel body 8, the upper end of the barrel body 8 is connected with an upper cover 3 matched with the barrel body 8 through a sealing mechanism, and an upper bayonet 4 is provided on the upper edge of the barrel body 8, and the upper end of the barrel body 8 3 The lower edge is provided with a lower bayonet 5 vertically corresponding to the upper bayonet 4 .

[0024] An air inlet pipe 7 is installed on the barrel body 8, and a valve II12 is installed on the air inlet pipe 7. The air inlet pipe 7 is used to connect with an external vacuum pump to vacuumize the inside of the device. A valve I9 is installed, and a pressure gauge 1 is installed on the top of the upper cover 3 . The provided pressure gauge 1 is used to observe the air pressure value inside the device in time to achieve a vacuum environment.

[0025] Specifically, when vacuumizing the plant in a non-isolated state, the upper...

Embodiment 2

[0032] On the basis of Embodiment 1, in addition, the upper bayonet 4 and the lower bayonet 5 are semicircular structures, and the semicircular structure makes the upper bayonet 4 and the lower bayonet 5 can be closely connected with the branches or flower stems of woody plants. Good fitting effect, can better accommodate and clamp woody plants, and is easy to operate.

[0033] Further, the sealing mechanism in this device includes an annular web I10 sleeved and fixed on the lower edge of the upper cover 3 and an annular web II11 sleeved and fixed on the upper edge of the barrel body 8 and opposite to the annular web I10. 8. The upper fitting sleeve is provided with a sealing ring 6 on the annular spoke plate II11.

[0034] When the upper cover 3 and the barrel body 8 are mated and connected, the annular web I10 and the annular web II11 are relatively close, and the sealing ring 6 located between them is pressed tightly, and the upper and lower edges of the sealing ring 6 can ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com