Filling device for vacuum system and filling method of enclosed cavity

A vacuum system and cavity technology, applied in lighting and heating equipment, indirect heat exchangers, etc., can solve problems such as difficult to control the quantity of heat pipe working medium, clean non-condensable gas, and difficult to ensure the working performance of heat pipes, etc., to achieve Convenient and quick vacuuming and filling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the objectives, technical solutions and advantages of the present invention clearer, the technical solutions in the embodiments of the present invention will be described in more detail below in conjunction with the drawings in the embodiments of the present invention. In the drawings, the same or similar reference numerals denote the same or similar elements or elements having the same or similar functions throughout. Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

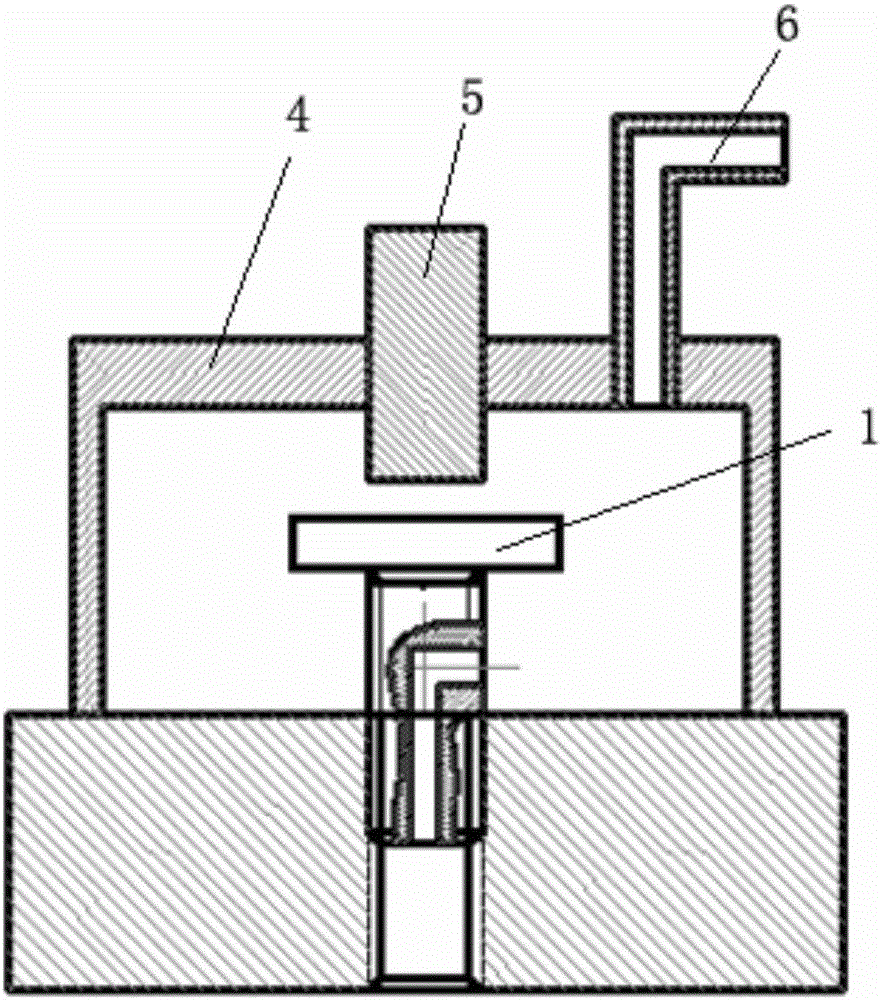

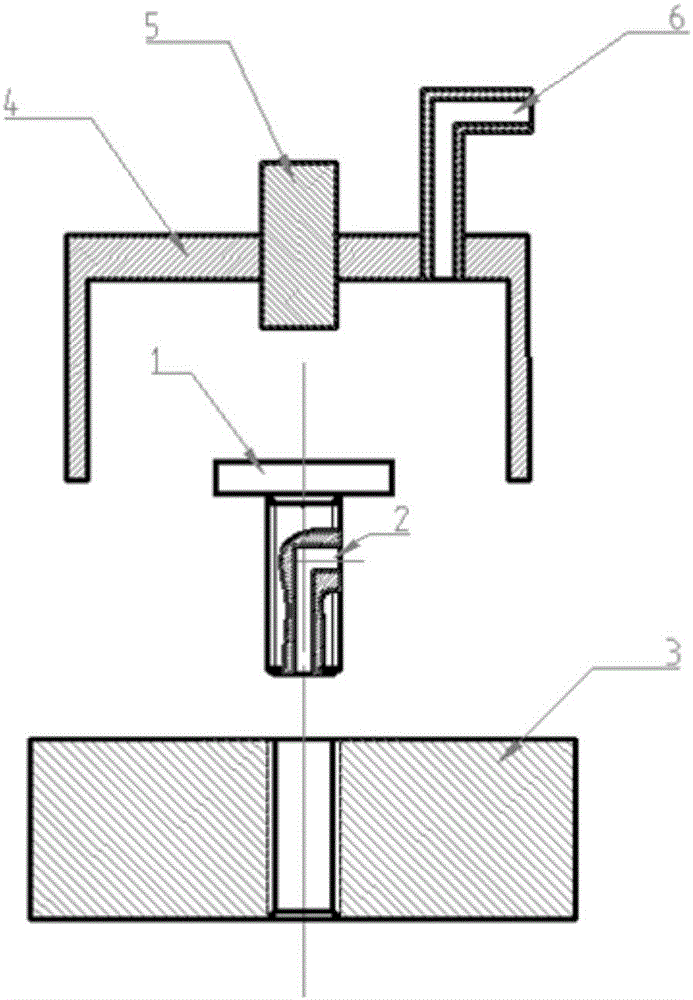

[0017] Such as figure 1 , 2 As shown, a filling device for a vacuum system, including a screw 1 with a filling channel, a cover 4 with a suction filling port 6, and a fastener for rotating the screw arranged on the cover 4 5. One end of the filling channel 2 in the screw 1 is opened on the bottom of the screw, and the other end is opened on the side of the screw. There is an internal thread matching the screw on the ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com