Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40results about How to "Accurate welding positioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

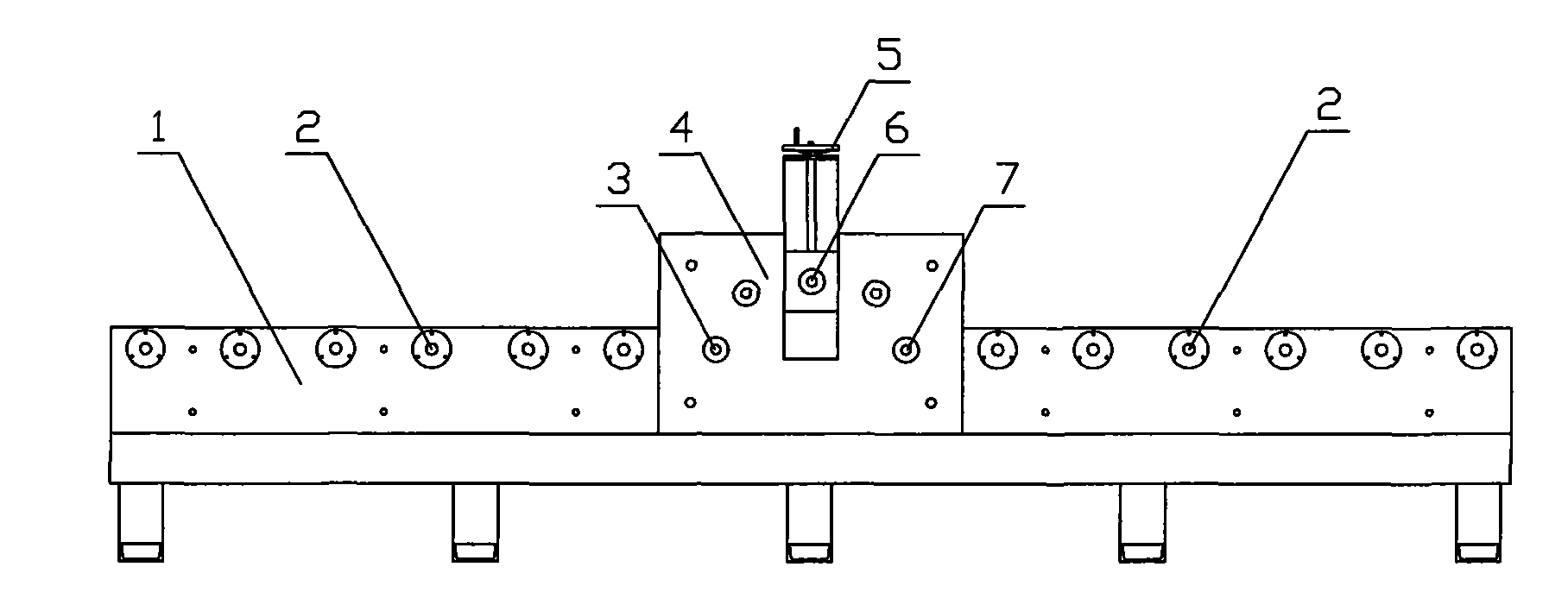

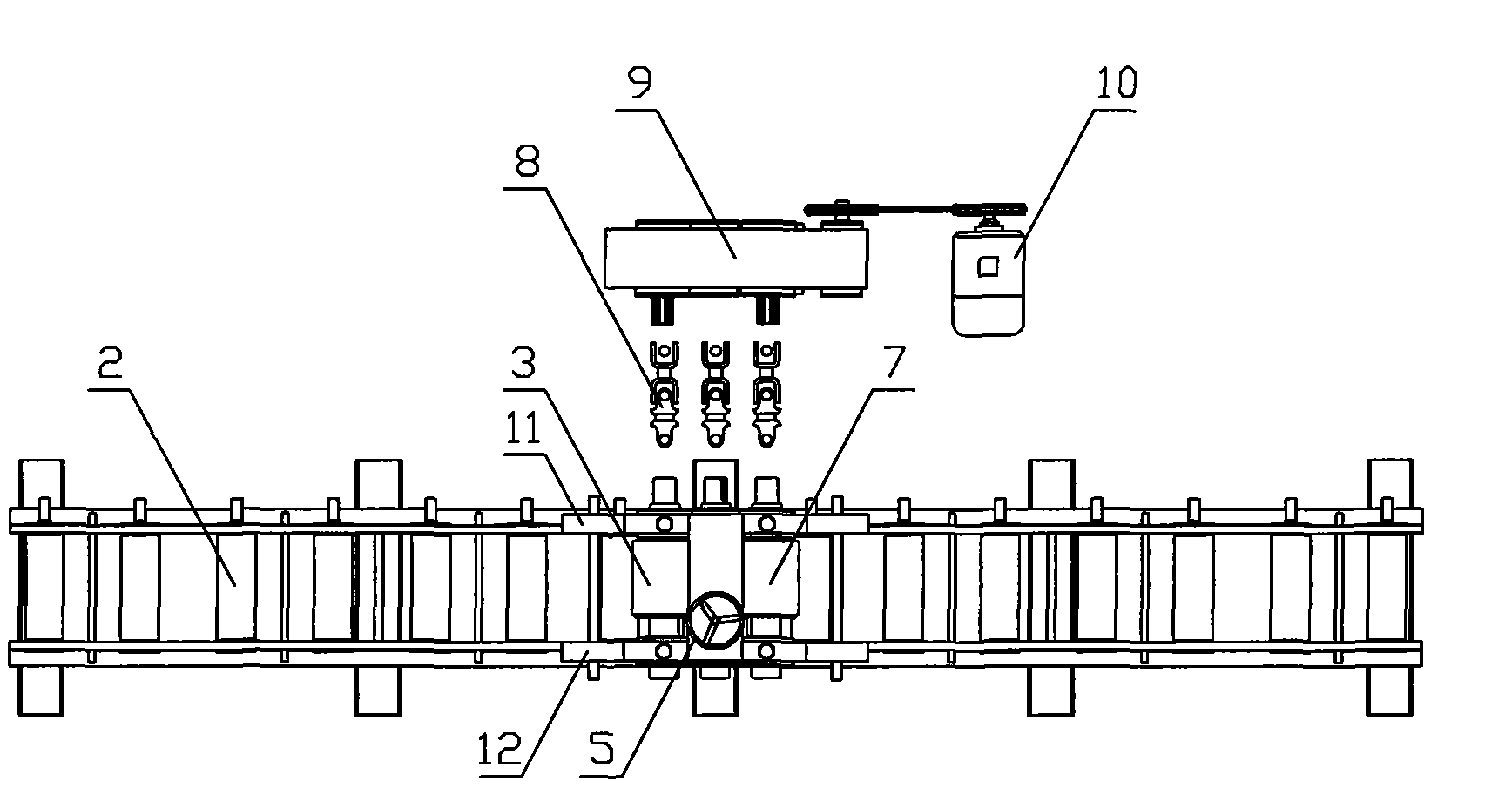

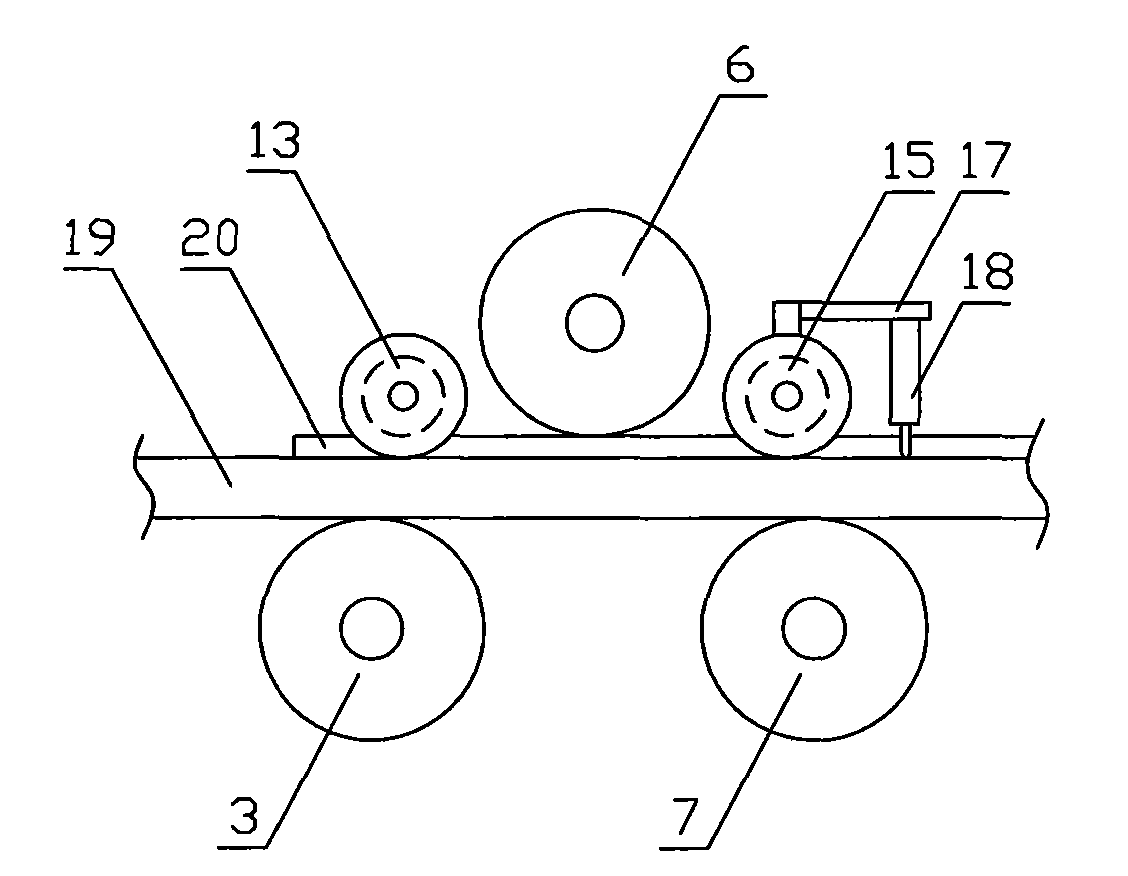

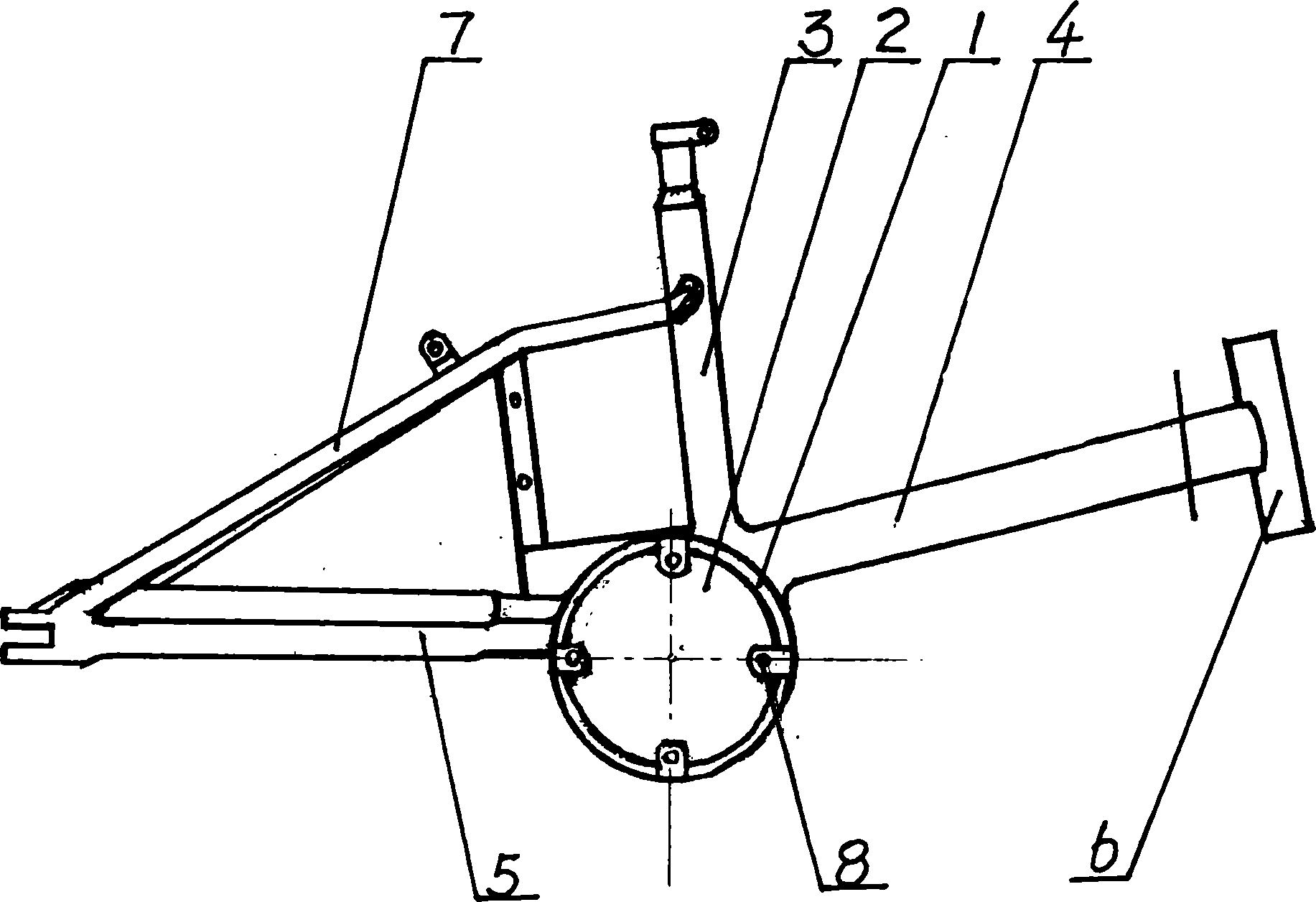

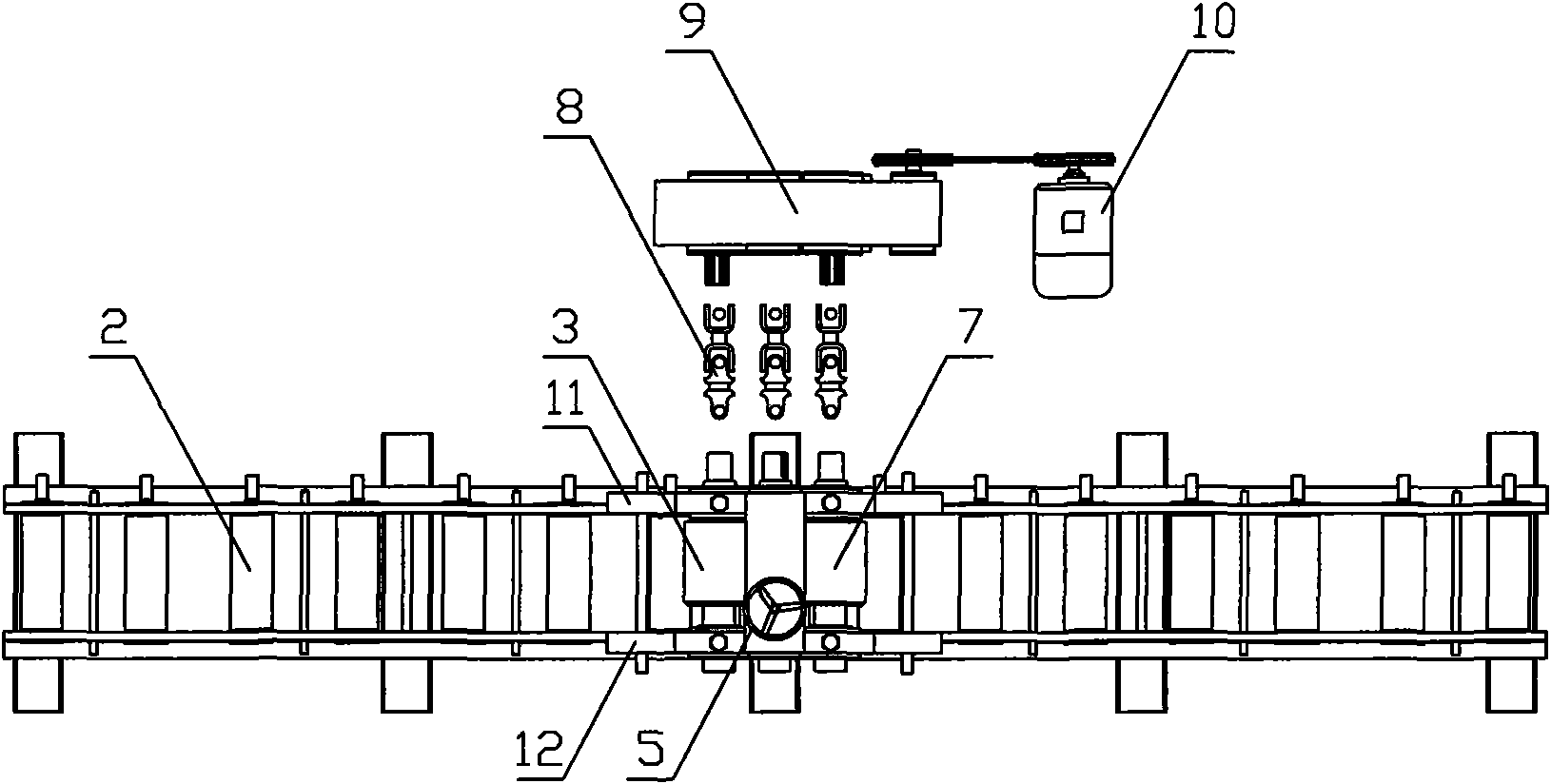

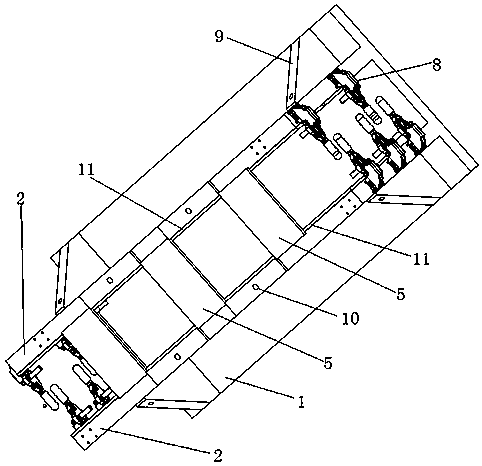

Welding device for gantry-shaped steel of forklift

InactiveCN101590578AGood technical effectReduce welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesDrive wheelUniversal joint

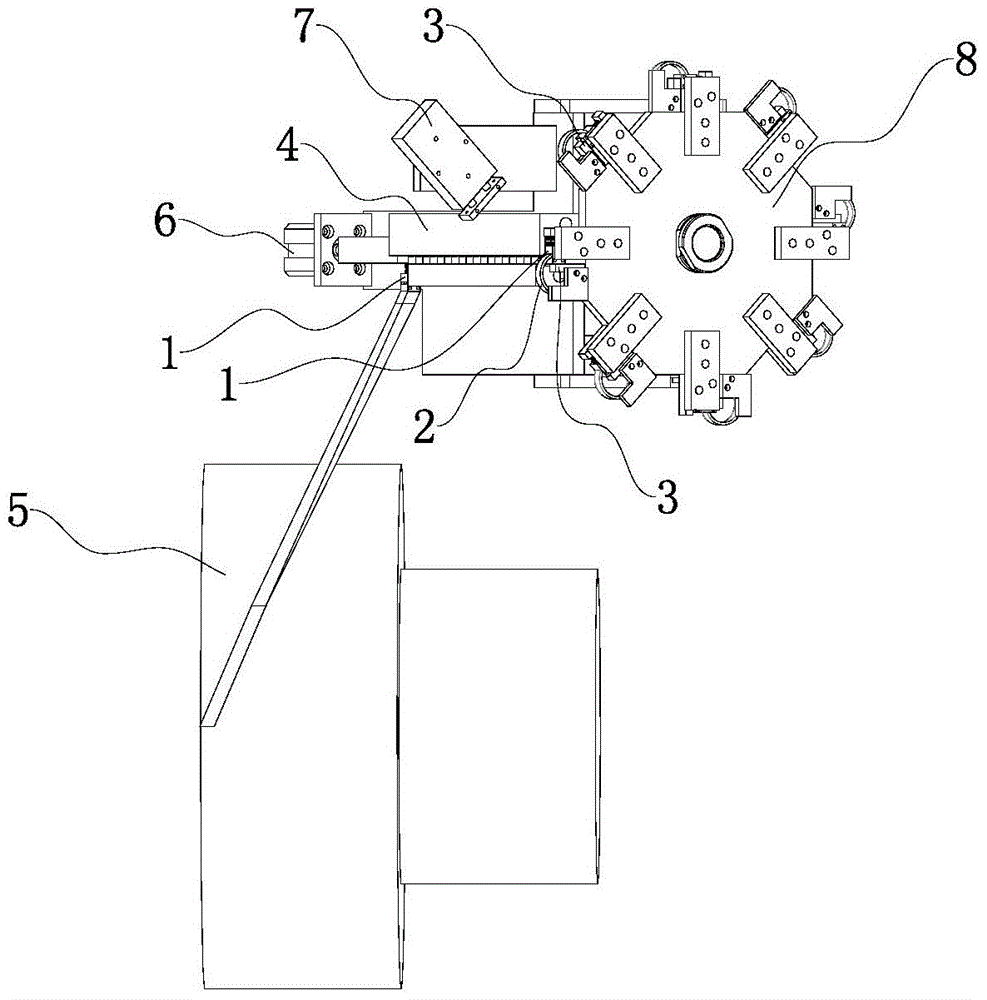

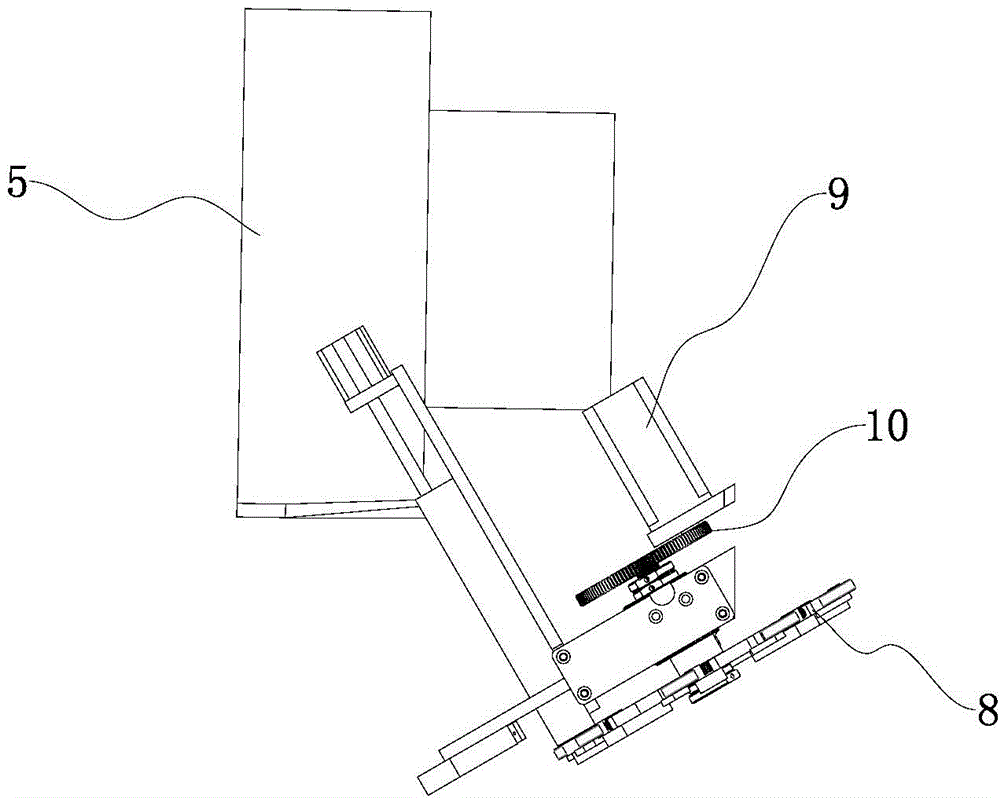

The invention relates to the field of manufacturing a forklift, and discloses a welding device for gantry-shaped steel of a forklift. The device comprises a welding platform and a welding gun arranged on the welding platform; the welding platform is arranged on a material guide platform which is provided with a plurality of guide wheels form left to right; the welding platform comprises a front support plate, a rear support plate and an upper driving wheel, a left driving wheel and a right driving wheel which are arranged between the front support plate and the rear support plate; and the upper driving wheel, the left driving wheel and the right driving wheel are connected with a gear box by an universal joint, the gear box is connected with a motor, and the left driving wheel and the right driving wheel are connected with the guide wheel. By welding both faces and positioning fillets by a fillet positioning mechanism, the device achieves the effects of accurate positioning and welding, insusceptibility to welding deformation, high welding efficiency, and cost conservation, and has wide application prospect in the field of manufacturing the forklift.

Owner:ZHEJIANG MAXIMAL FORKELEVATOR

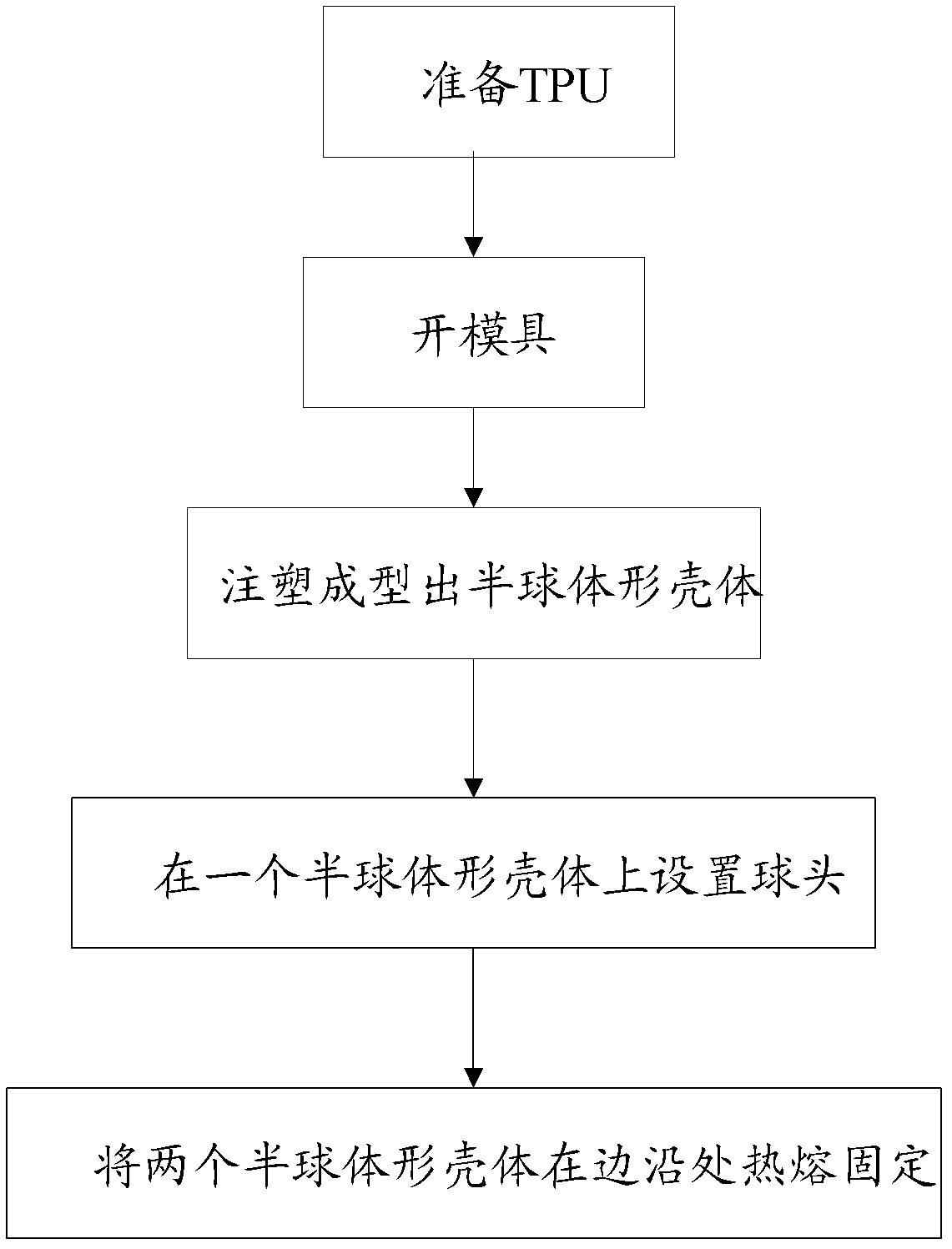

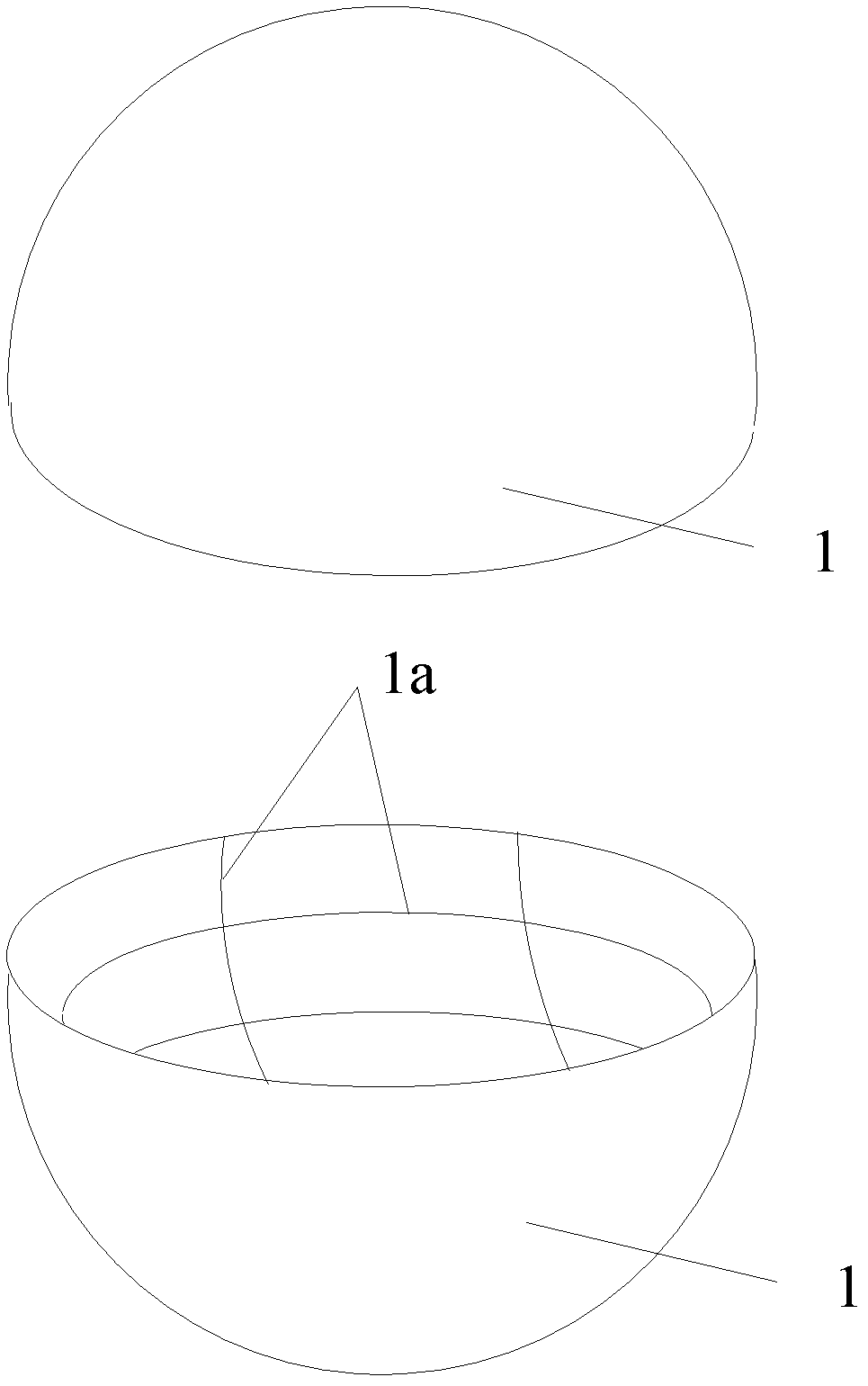

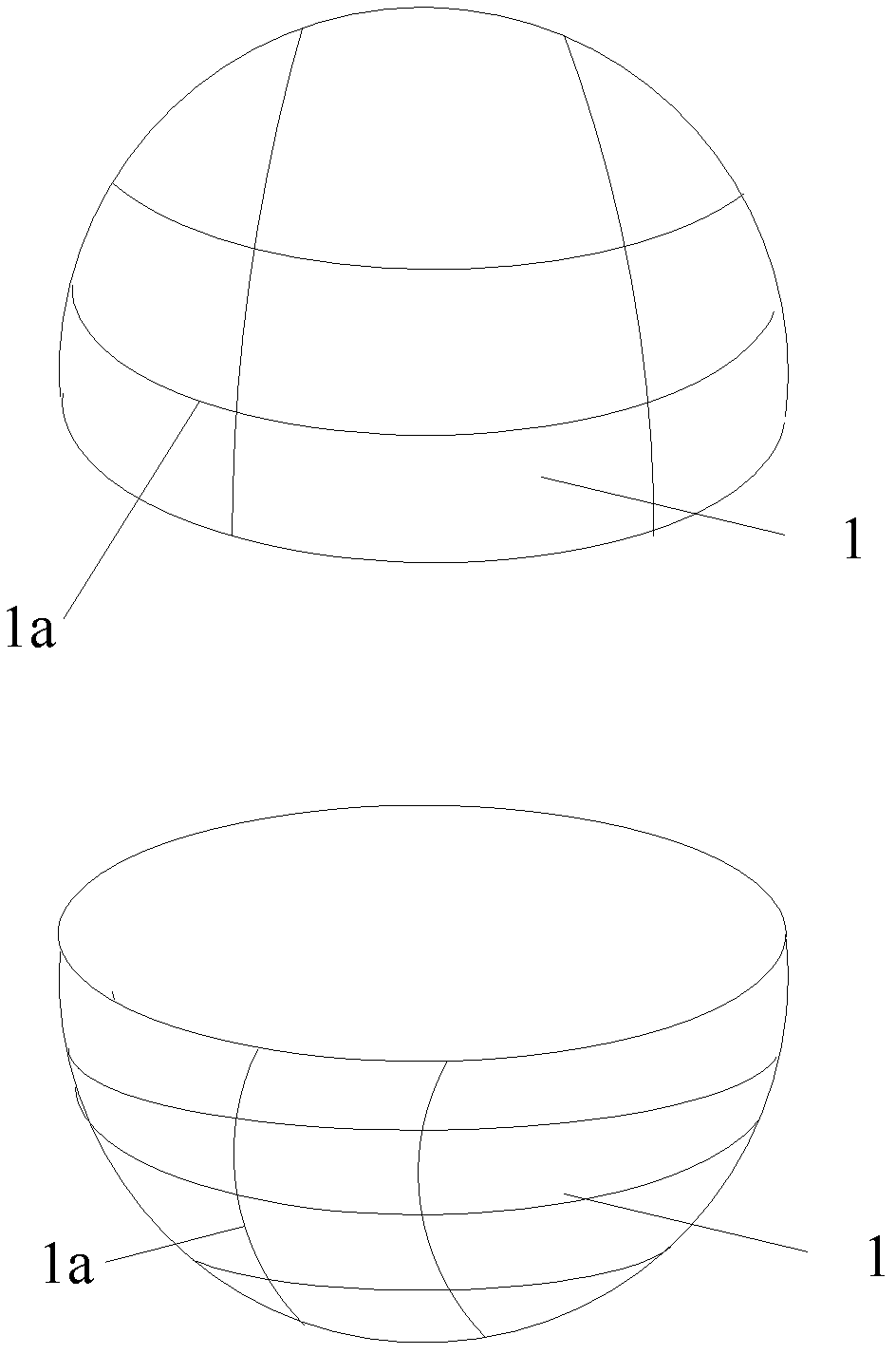

Liner of ball sports product and manufacture method thereof as well as ball sports product

InactiveCN102218835ASimple production processImprove air tightnessHollow inflatable ballsHollow articlesHot meltEngineering

The invention discloses a manufacture method for the liner of a ball sports product, which comprises the steps as follows: materials for injection moulding are prepared; corresponding dies are prepared according to the required ball sports varieties; the materials for injection moulding in step one are formed into hemispheroid shells through an injection moulding machine provided with the dies in step two; a bulb is fixed on one hemispheroid shell; and two hemispheroid shells are stuck on the edges by adopting a way of hot melting. The manufacture method for the liner of the ball sports product has the advantages of simplified manufacture procedure and high productivity effect. The invention also discloses a liner of the ball sports product and the ball sports product.

Owner:罗传兴

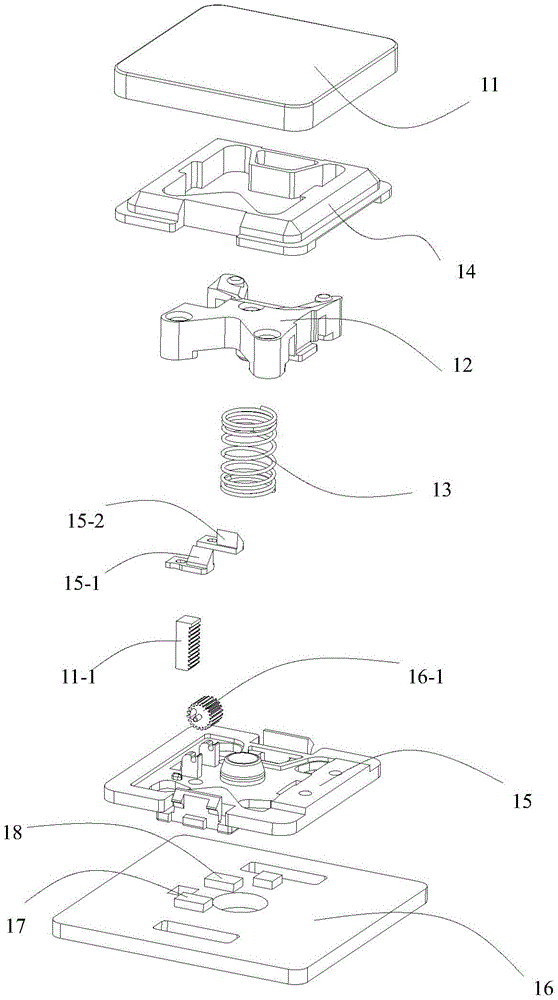

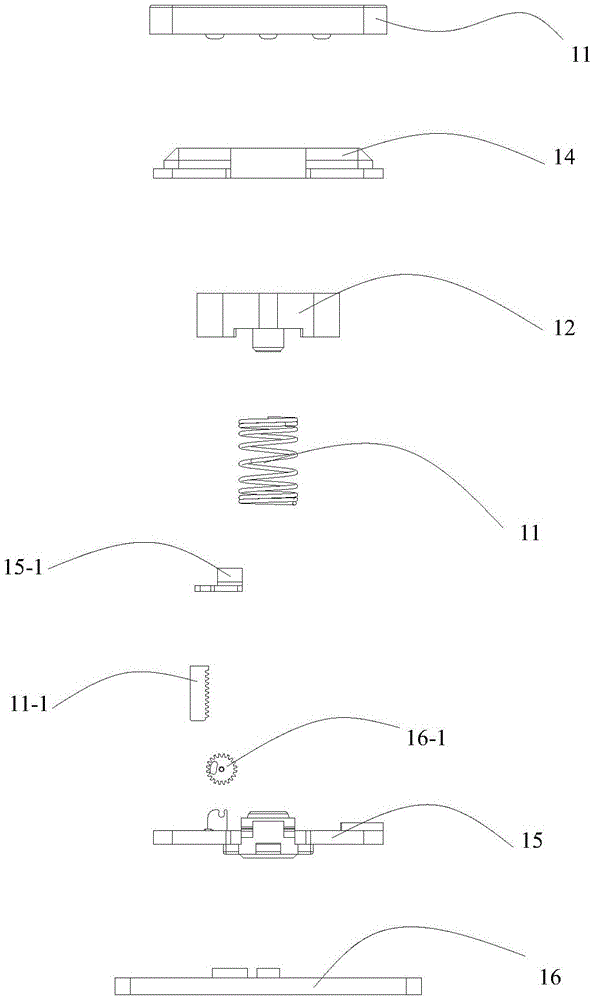

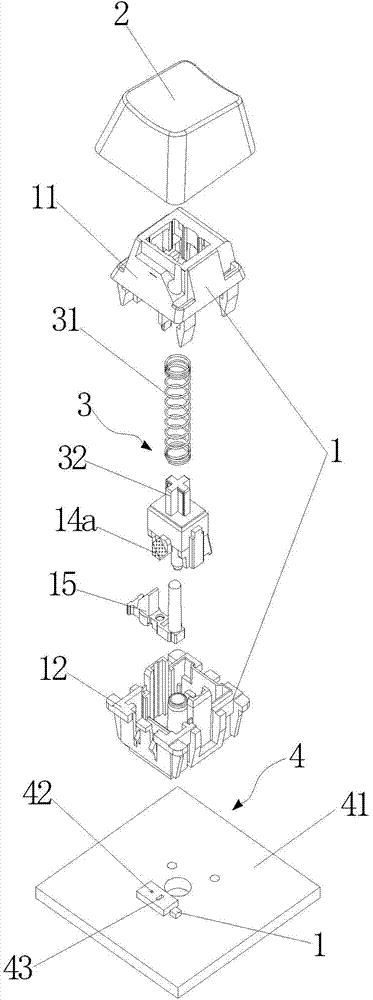

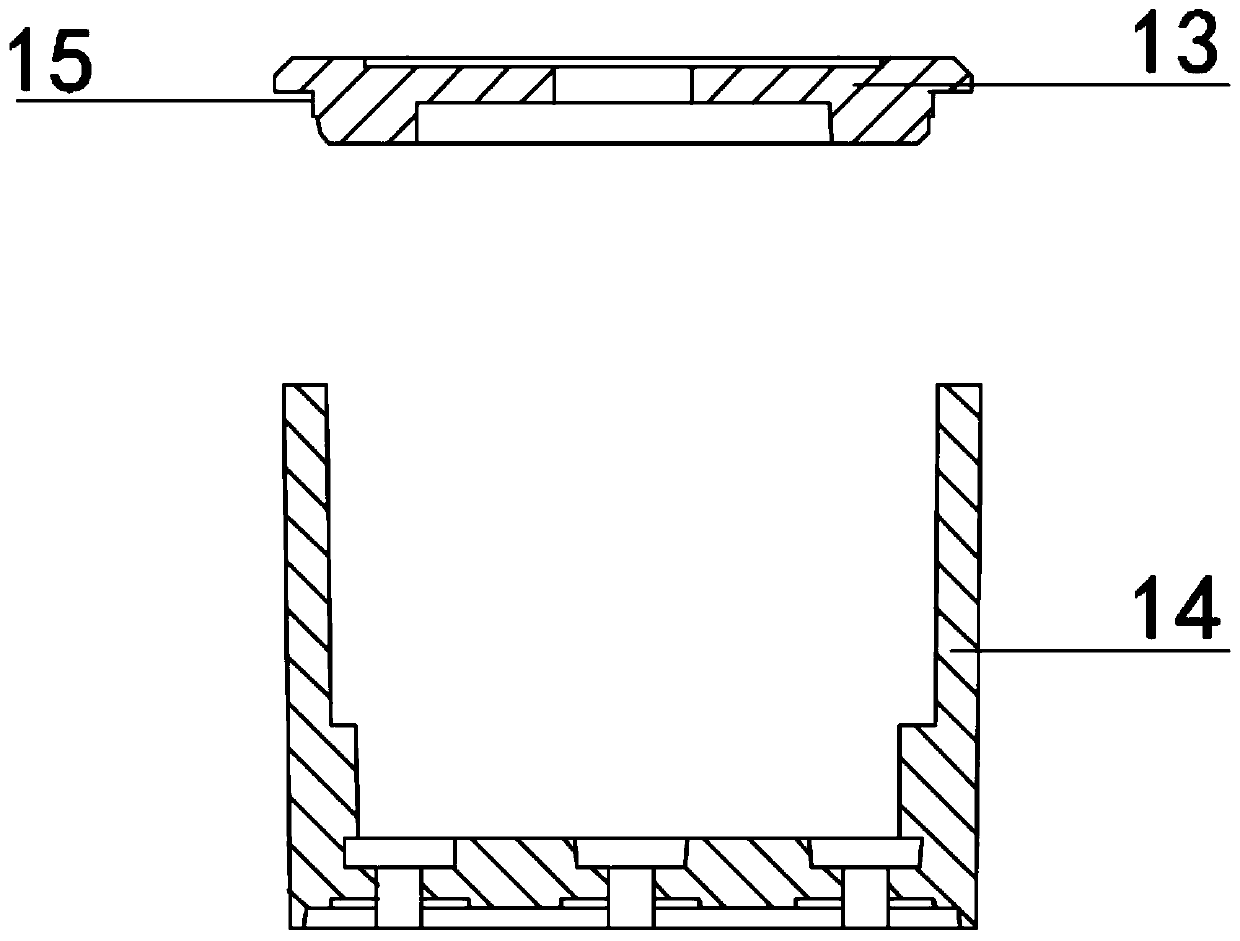

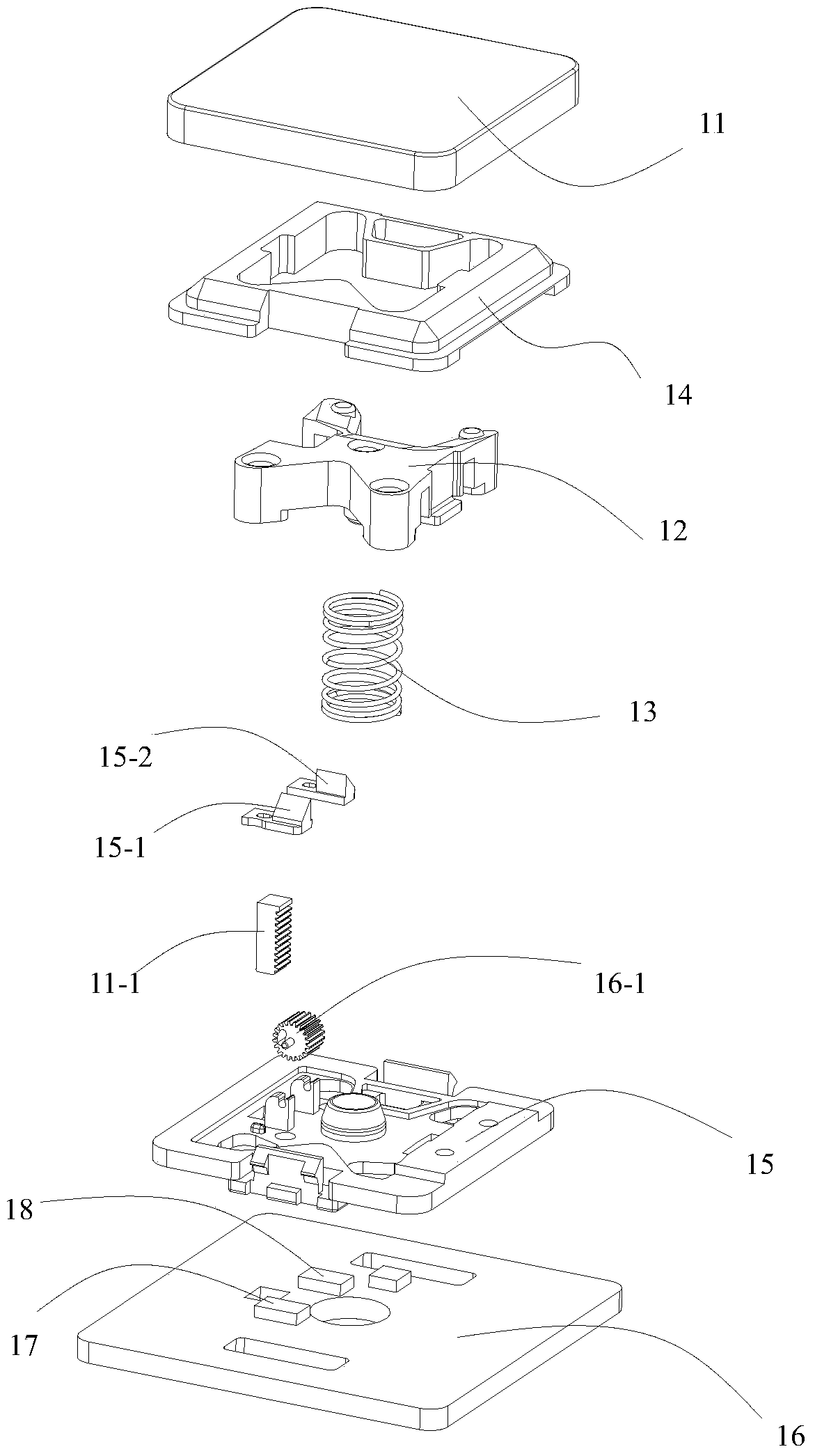

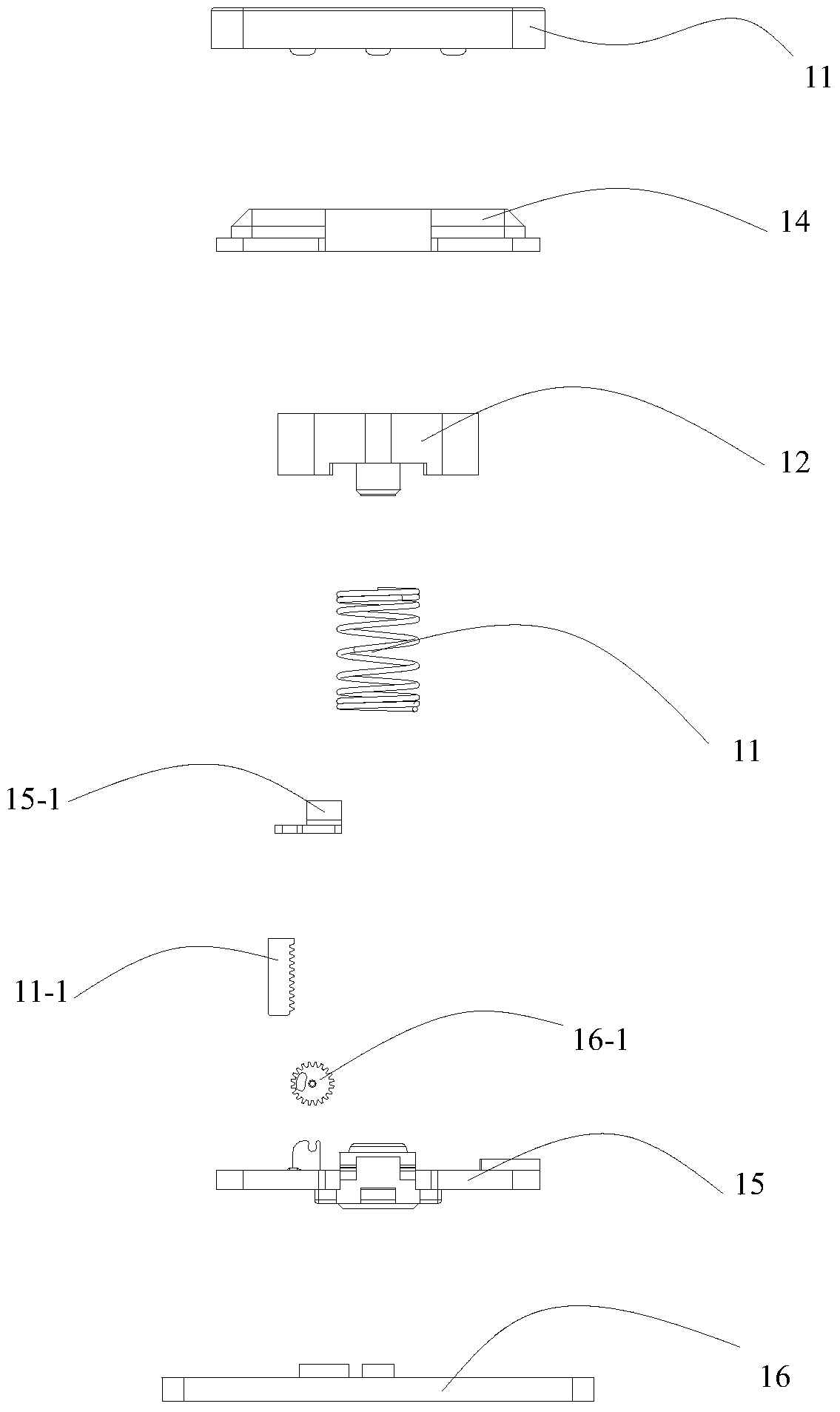

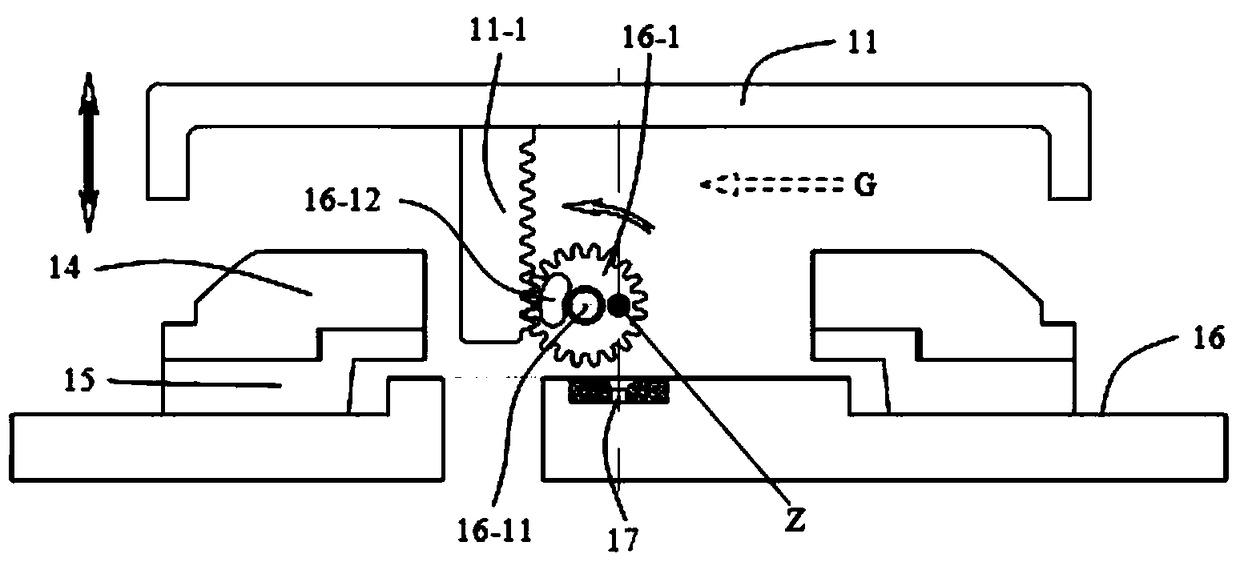

Ultrathin optical reflective input equipment switch module possessing tooth-shaped structure

ActiveCN105118714ASimple structureLow costElectric switchesEmergency protective devicesOptical reflectionEngineering

The present invention discloses an ultrathin optical reflective input equipment switch module possessing a tooth-shaped structure. The ultrathin optical reflective input equipment switch module possessing the tooth-shaped structure comprises a keycap, a key shaft, a spring, an upper fixing shell, a lower fixing shell and a PCB, and an ultrathin reflective photoelectric keyboard switch module also comprises a light emitting device and a light receiving device. A light path channel is formed between the light emitting device and the light receiving device and comprises a light path switch, and the light path switch comprises a rack located below the keycap and a gear or a cam located on the PCB. By pressing the keycap, the rack located therebelow moves up and down to drive the gear or the cam to do the radial rotary movement, thereby conducting or disconnecting the light path channel. The ultrathin optical reflective input equipment switch module possessing the tooth-shaped structure has the characteristics of being simple in structure, low in cost and low in switch module height, being convenient to assemble, etc., and the height of the ultrathin optical reflective input equipment switch module is only 1 / 3-1 / 4 of the height of a conventional mechanical shaft keyboard.

Owner:MIKOLTA OPTICAL TECH CO

Scanning galvanometer type laser welding system

InactiveCN110524109AFast spot weldingOvercoming Scan DistortionLaser beam welding apparatusOptoelectronicsLaser beams

The invention discloses a scanning galvanometer type laser welding system which comprises a laser and light path module, a power module, a galvanometer scanning module, a computer control module, a workbench and a cooling module. A laser beam is irradiated to a welded workpiece through the laser and light path module. Adjustment of a welding circuit and pulse width frequency is achieved through the power module. The galvanometer scanning module is used for enabling focused light beams to form uniform scanning patterns on a scanning plane, the computer control module is used for controlling input of all parameters, welding scanning tracks and movement of the workbench, so workpiece fixing and welding temperature control in the welding process are achieved through the workbench and the cooling module. A scanning path is reasonably selected through computer software, so that the laser beam scans and welds more welding spots within the same time, and the overall spot welding speed is increased; besides, the laser beams are reflected and focused through a light path system, scanning distortion is overcome, welding positioning is more accurate, and the welding effect is better.

Owner:DONGGUAN UNIV OF TECH +1

Electric cycle frame with motor

InactiveCN1887634AEasy to installHigh mechanical strengthMotorcyclesCycle framesVehicle frameElectric machinery

The motor frame for cycle with motor is one five-way pipe with inner diameter matching the outer diameter of the motor and has vertical frame pipe, lower frame pipe and planar fork welded onto the five-way pipe. The motor inside the five-way pipe is screw fixed and the five-way pipe may be two semi-circular cylindrical pipes or one single cylindrical pipe with connecting ears on two ends for screw fixing. The present invention has convenient motor installation, high mechanical strength, convenient welding and other advantages.

Owner:韩玉金

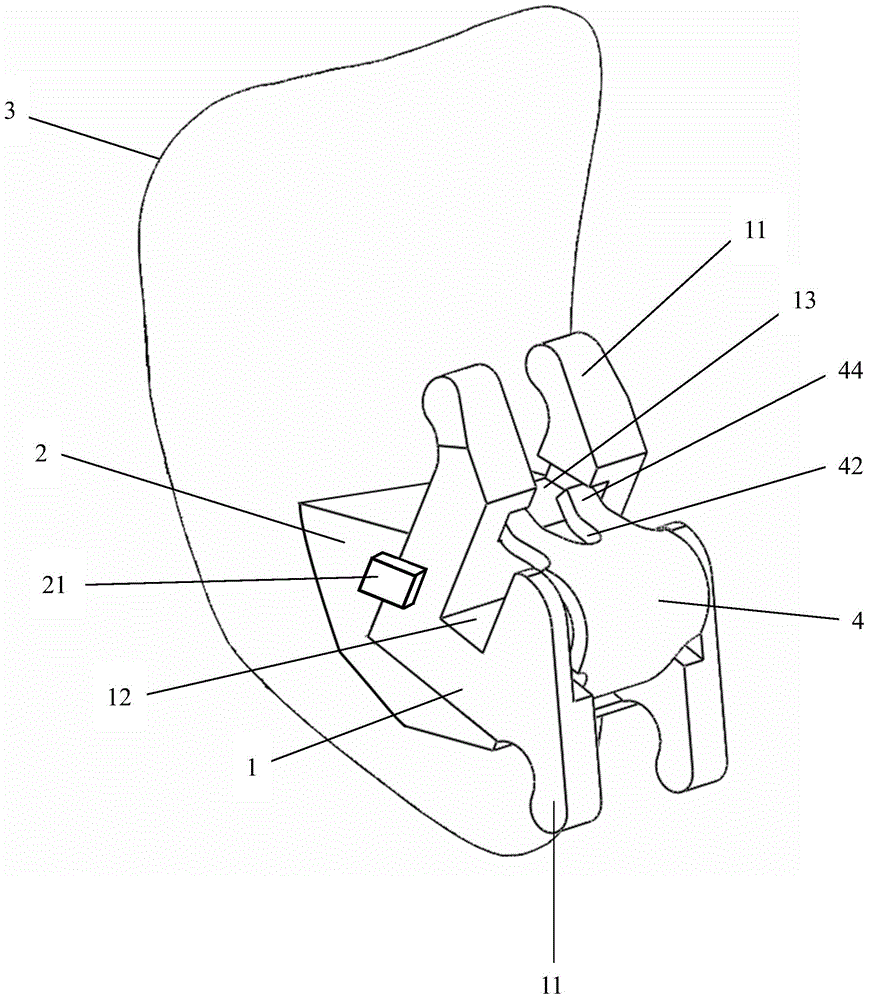

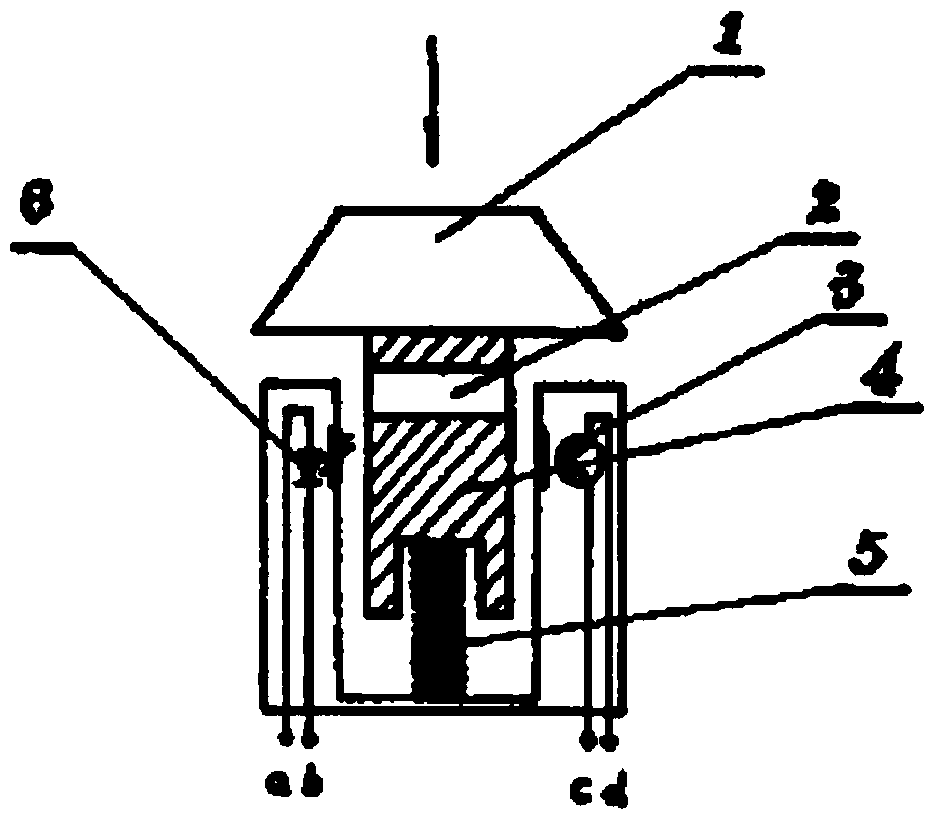

Photoelectric-integrated mechanical shaft keyboard switch module

ActiveCN105450208AReduce labor costsReduce welding costsElectronic switchingEngineeringElectrical and Electronics engineering

The invention discloses a photoelectric-integrated mechanical shaft keyboard switch module comprising a housing, a button cap installed on the upper part of the housing, and a driving device, a photoelectric switch, a moving optical assembly and a fixed optical assembly which are arranged in the housing. The moving optical assembly is installed on the driving device. The photoelectric switch comprises a PCB board, and an SMD IR tube and an SMD PT tube which are integrated on the PCB board. By pressing the button cap, the driving device is enabled to drive the moving optical assembly to move up and down, thereby controlling the relative position between the moving optical assembly and the fixed optical assembly. When light emitted by the SMD IR tube is coupled to the SMD PT tube, a light path is conducted, and the photoelectric switch is switched on; and when the light emitted by the SMD IR tube cannot be coupled to the SMD PT tube, the light path is open, and the photoelectric switch is switched off. The photoelectric-integrated mechanical shaft keyboard switch module has the advantages that the manual and welding cost is greatly lowered, the welding positioning is accurate, the production efficiency is high, and the quality stability of the product is high.

Owner:DONG GUAN LONGIDEAL IND CO LTD

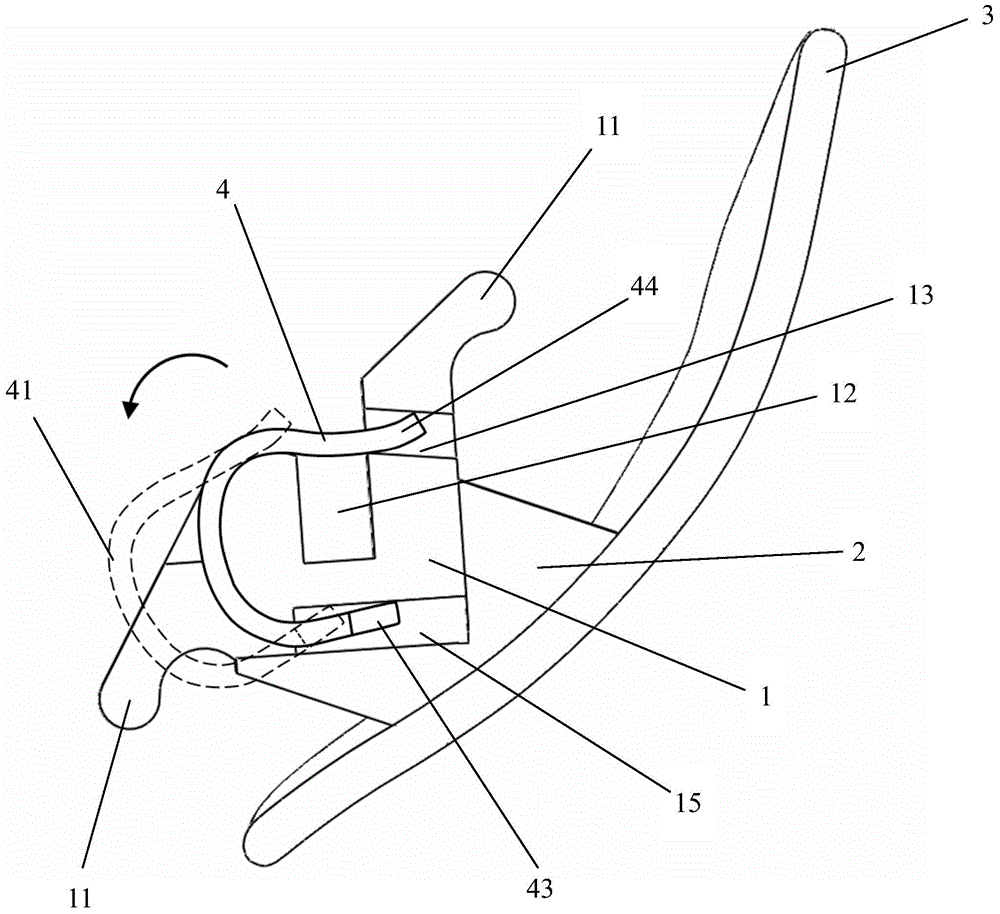

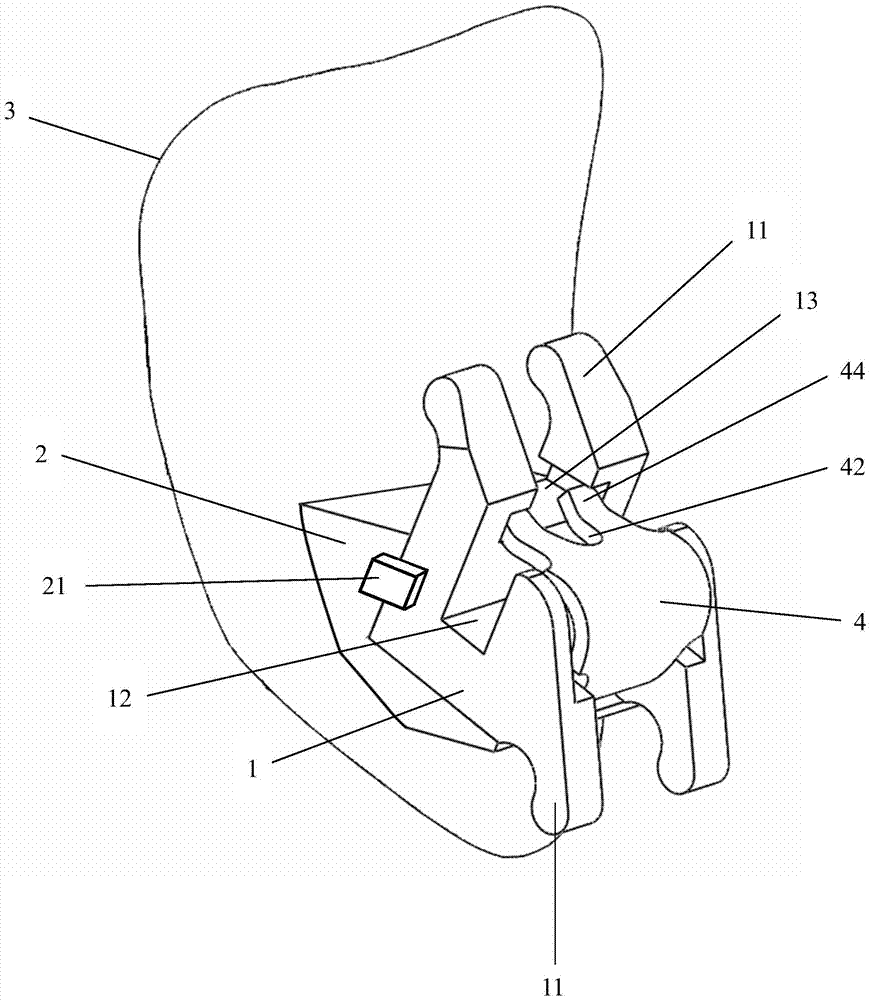

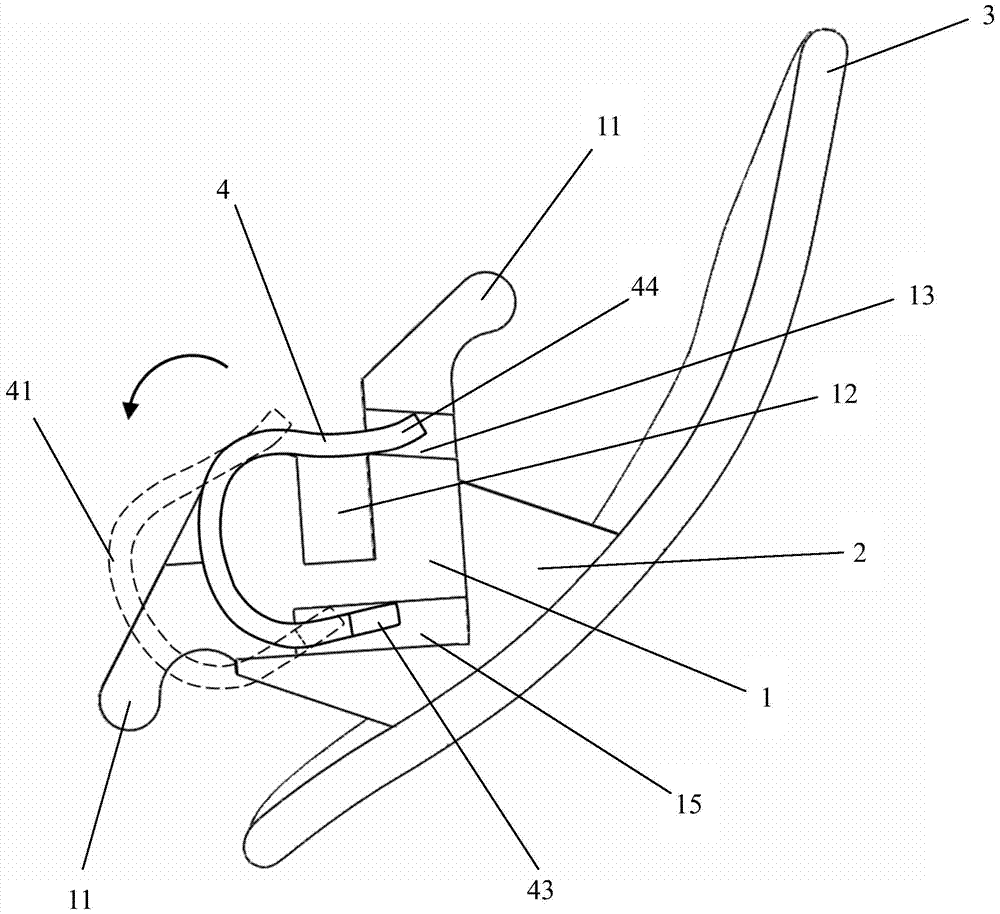

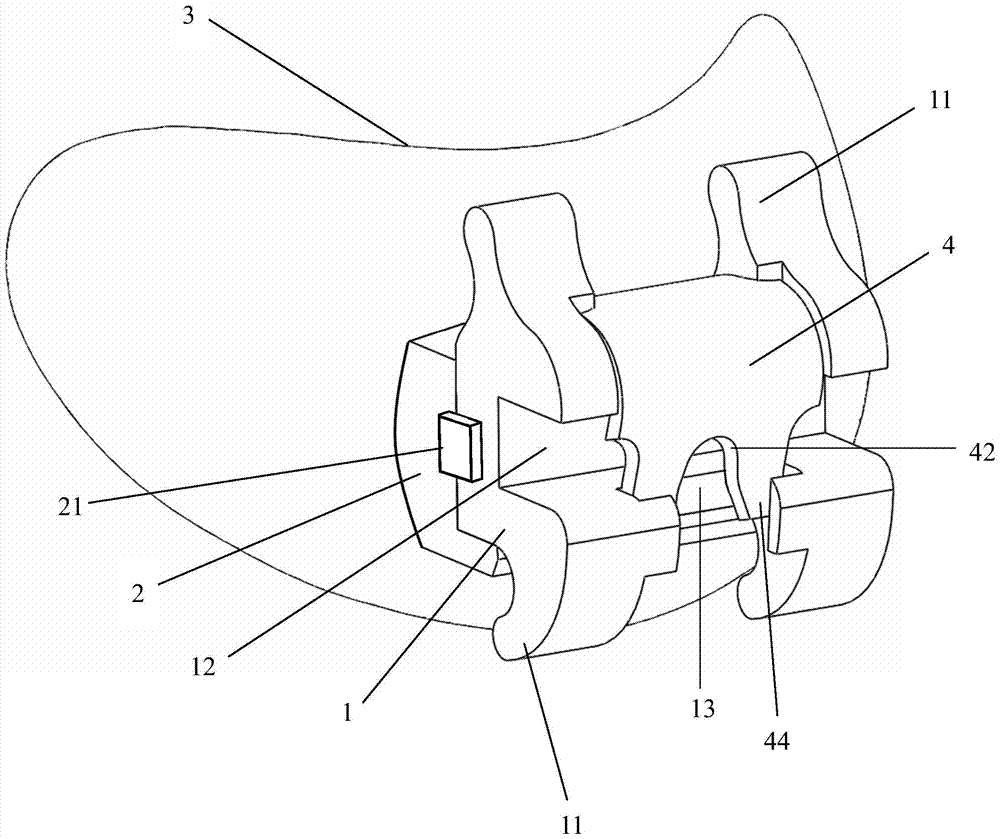

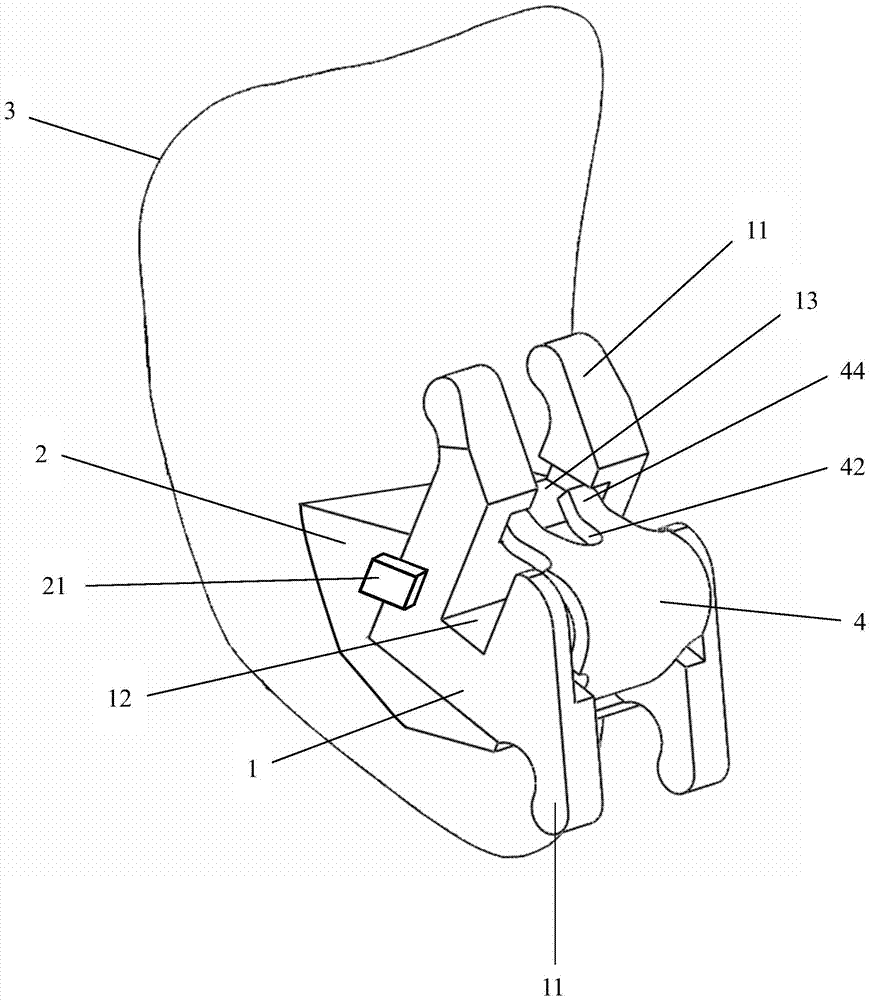

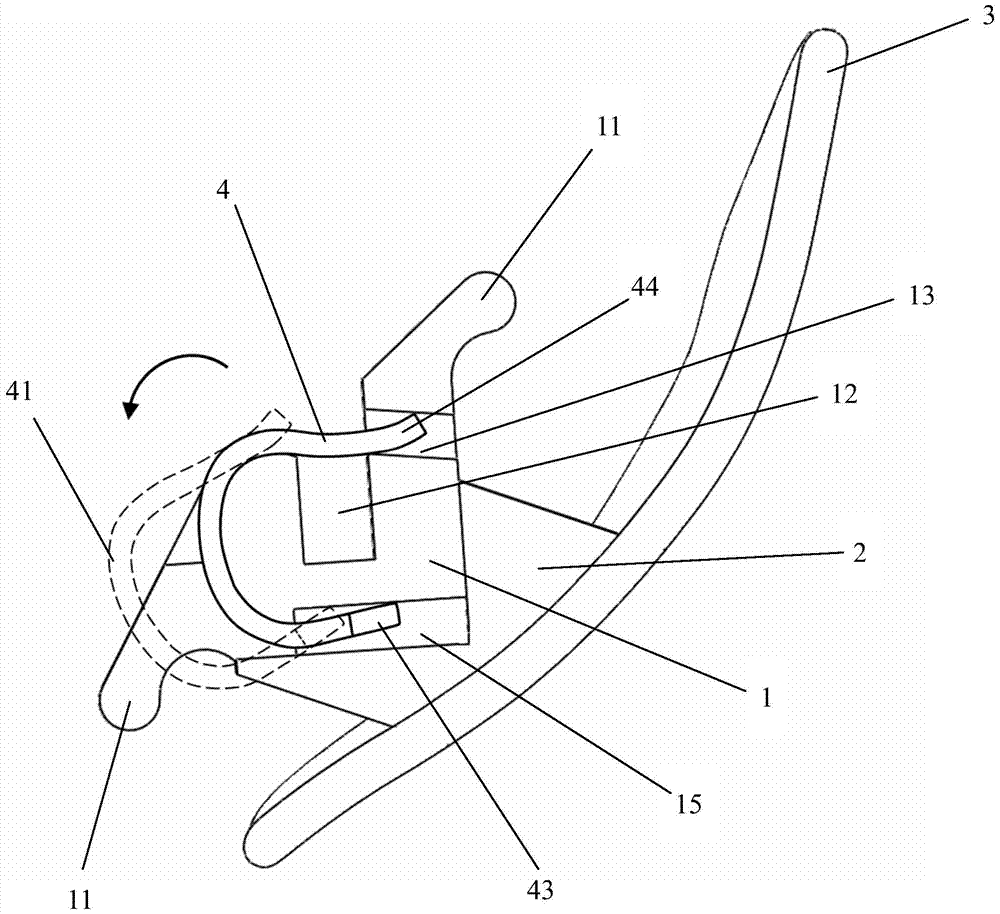

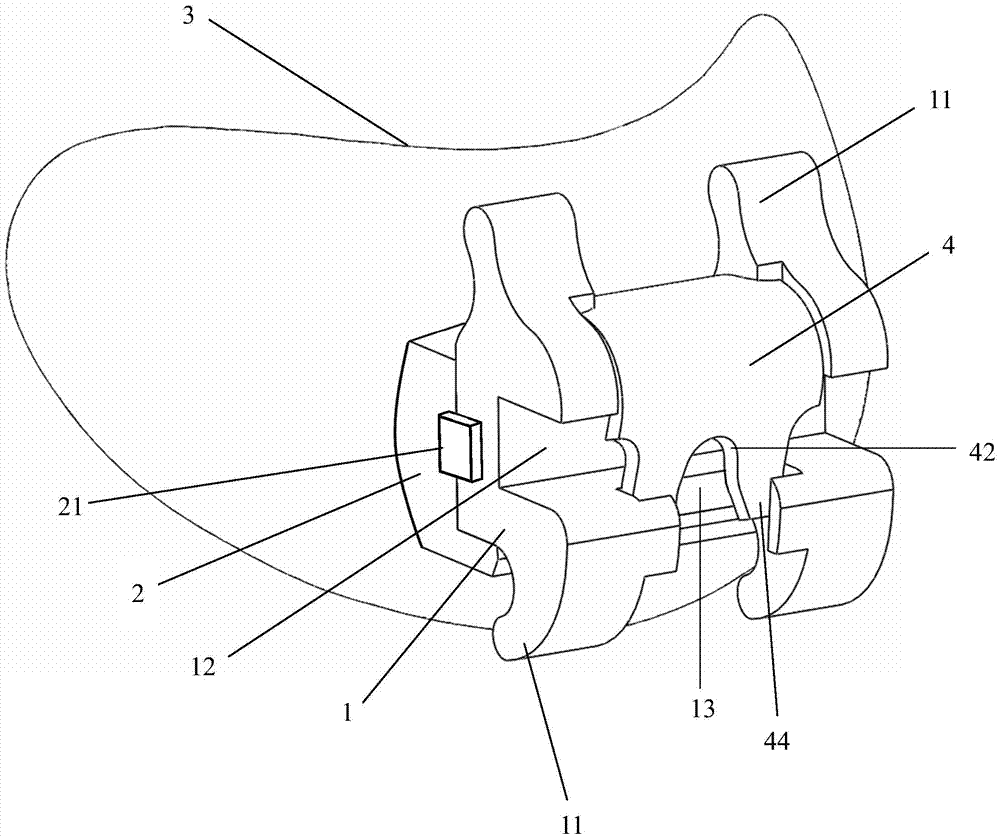

Personalized self-ligating bracket appliance with lingual straight-wire arches

The invention relates to a personalized self-ligating bracket appliance with lingual straight-wire arches. The personalized self-ligating bracket appliance comprises a plurality of self-ligating brackets formed by threading and connecting the lingual straight-wire arches, wherein lingual surface tubes are threaded and connected to the both ends of each straight-wire arch respectively; each self-ligating bracket comprises a bracket body and a bracket bottom plate which are mutually fixed through a connection body; the connection body and the bracket bottom plate are integrally moulded; the connection body and the bracket body are welded and fixed; each of the bracket body and the connection body is provided with a first contact surface and a second contact surface, and the first contact surface and the second contact surface are mutually vertical; a limit cavity cap is formed between the connection body and the bracket body; a bracket groove for each straight-wire arch to penetrate through is further formed in the middle part of the bracket body, and an anti-ligating groove is formed in one sidewall of the bracket groove; and a self-ligating elastic sheet further covers the bracket groove, one end of the self-ligating elastic sheet is limited in the limit cavity cap, and the other end of the self-ligating elastic sheet is capable of being clamped in the anti-ligating groove. The personalized self-ligating bracket appliance disclosed by the invention ensures accurate welding location between the bracket body and the bracket bottom plate, and improves the treatment effect.

Owner:上海精功齿科技术有限公司

Automatic electric resistance welding equipment for hoop spring hook

InactiveCN1799750AImprove working conditionsEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesElectrical resistance and conductanceCompression device

The invention relates to a basket spring hook automatic electric welding device which comprises a feeding device, an electric welding machine, a basket exchange rotation compression device fixed on the support and formed by a rotation lifting device, an air-powered compression device, a servo-rotation device and an air-powered supporting device, and a control board. The basket is arrange don the dual-position clamping-material station of said rotation lifting device; the spring hook via vibration automation discharging and high-pressure air nozzle is blown to the air-powered clamp and absorbed by another air-powered clamp to be transferred to the basket welding position; two electrodes of said electric resistance welding machine will clamp two work-pieces to weld a spring hook via electric loop, then said two electrodes are reset; and the servo-rotation device can rotate the basket for 30 degrees to repeat aforementioned steps until welding 12 spring hooks on the basket. The inventive device has the advantages of lower technique demand; continuous operation; improved efficiency; quick operation of air-powder clamp; accurate welding positioning; improved product quality; and smooth welded appearance.

Owner:孙光斌

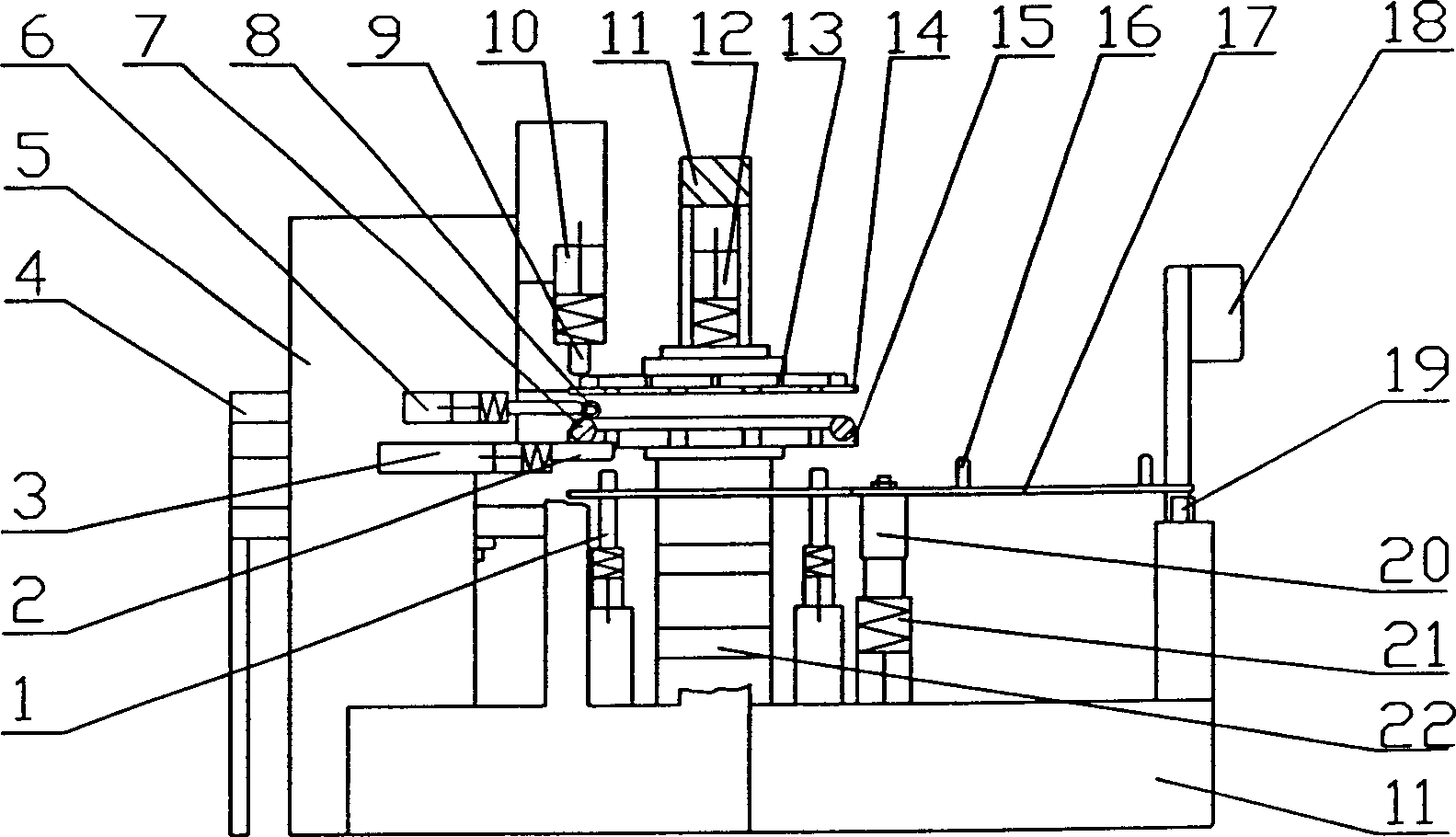

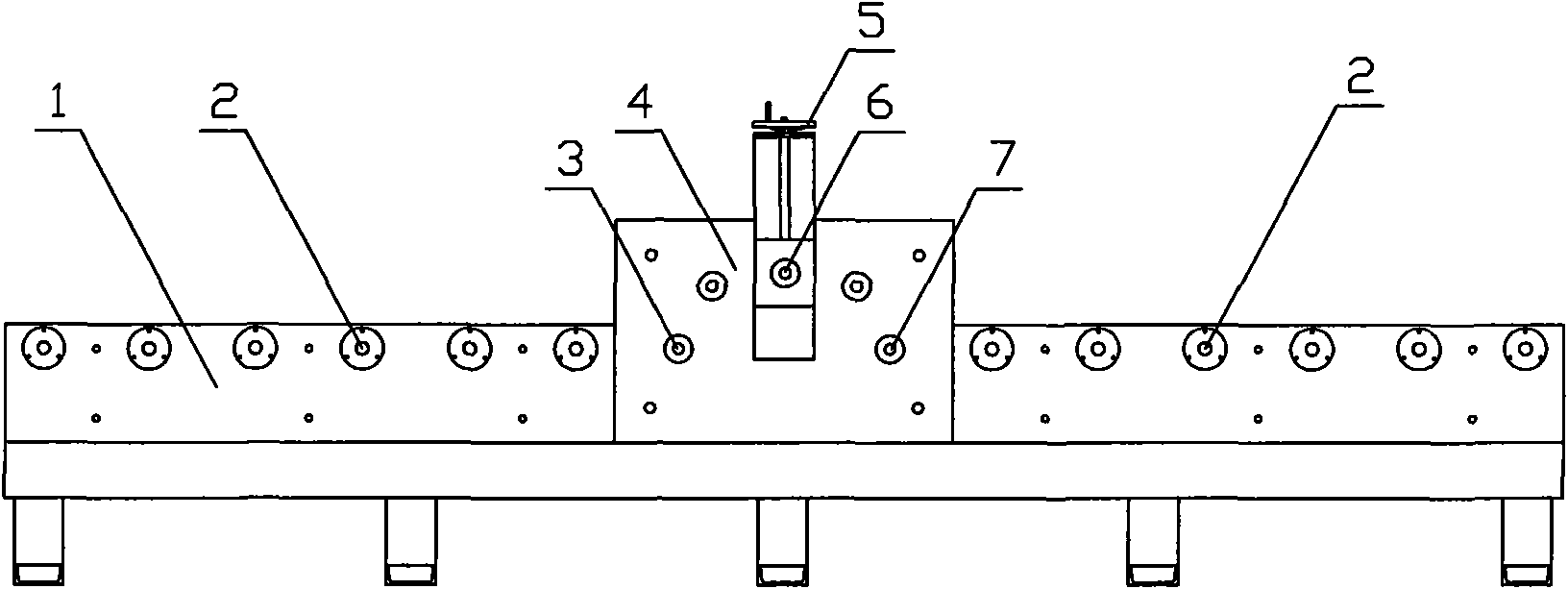

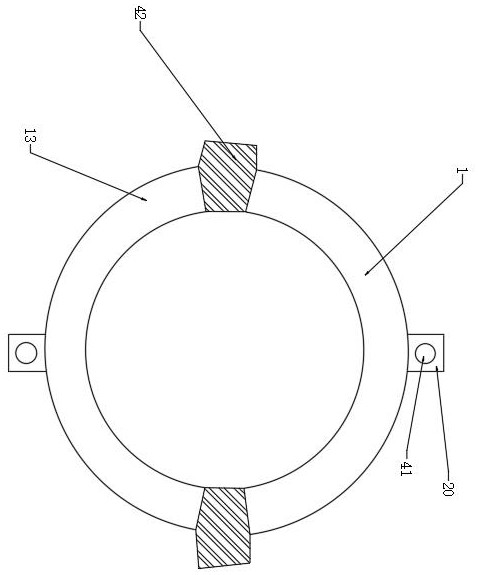

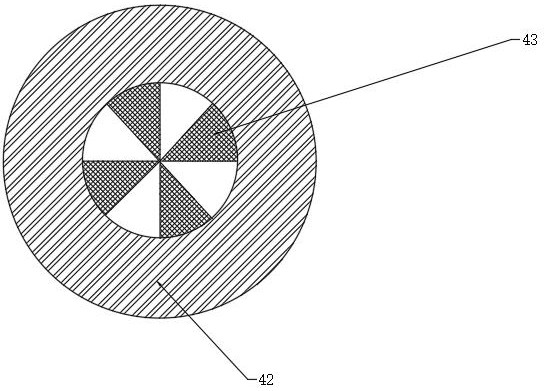

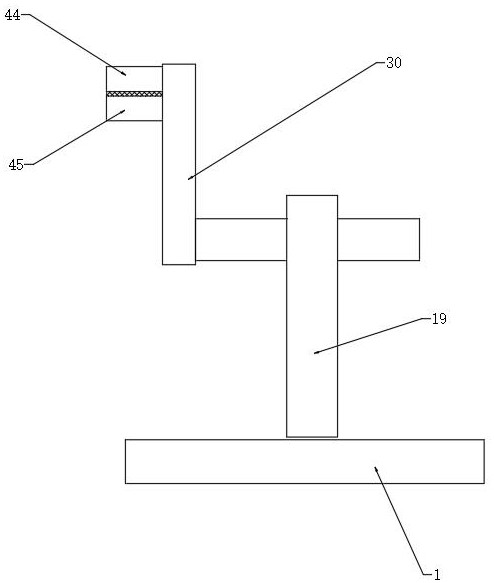

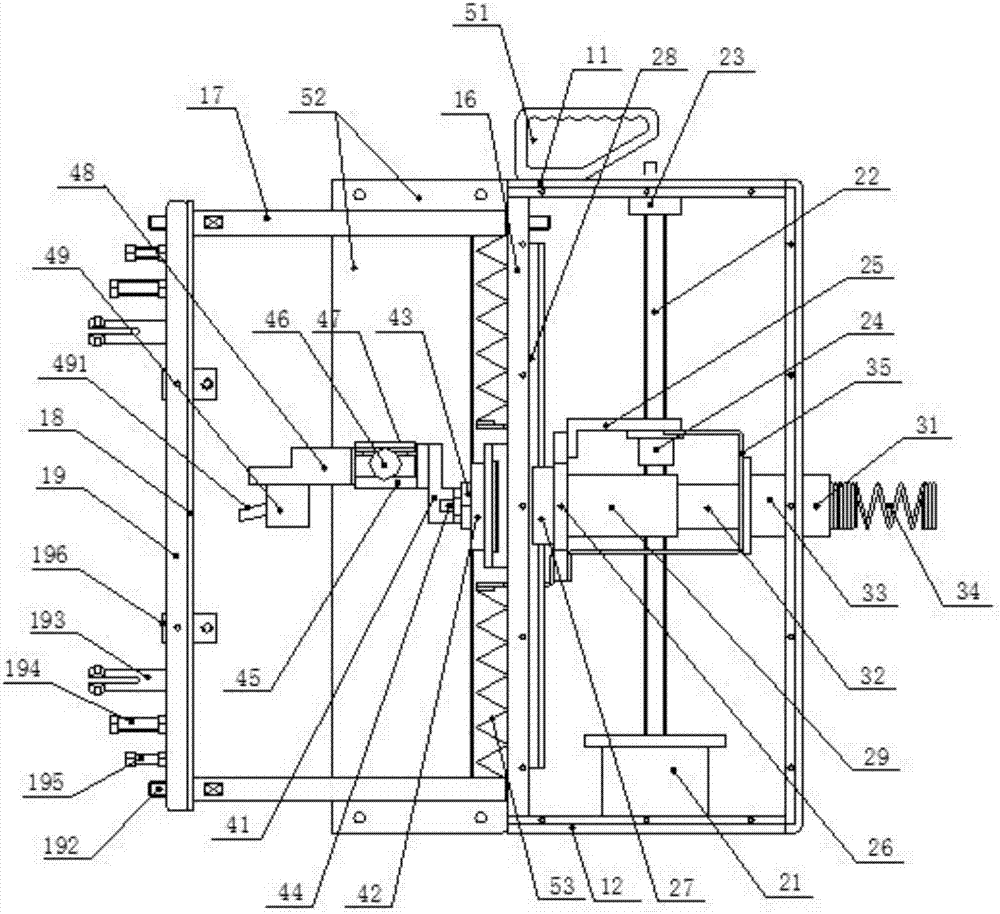

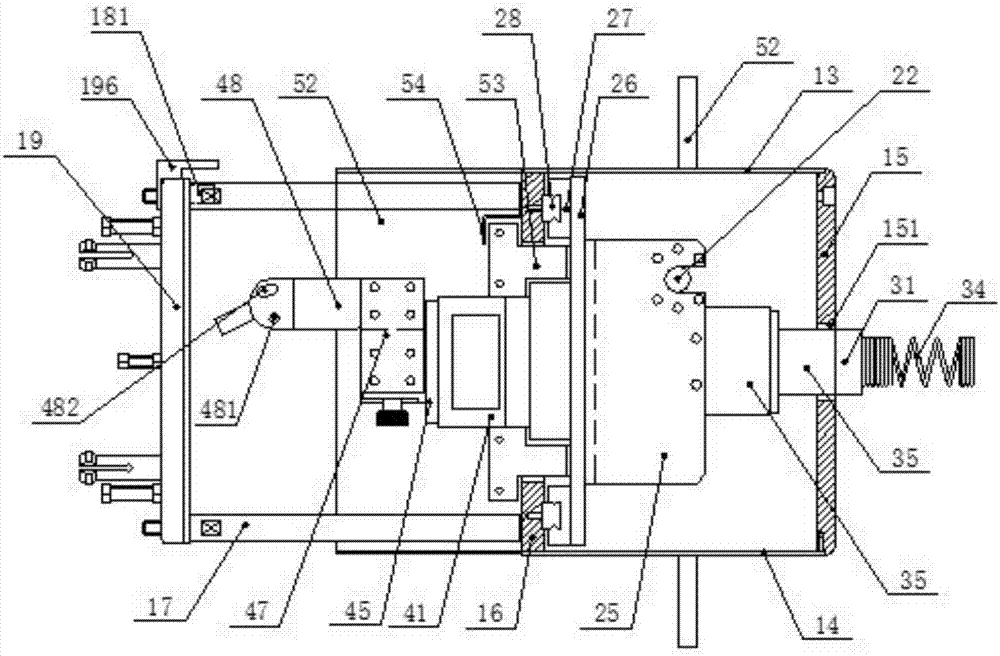

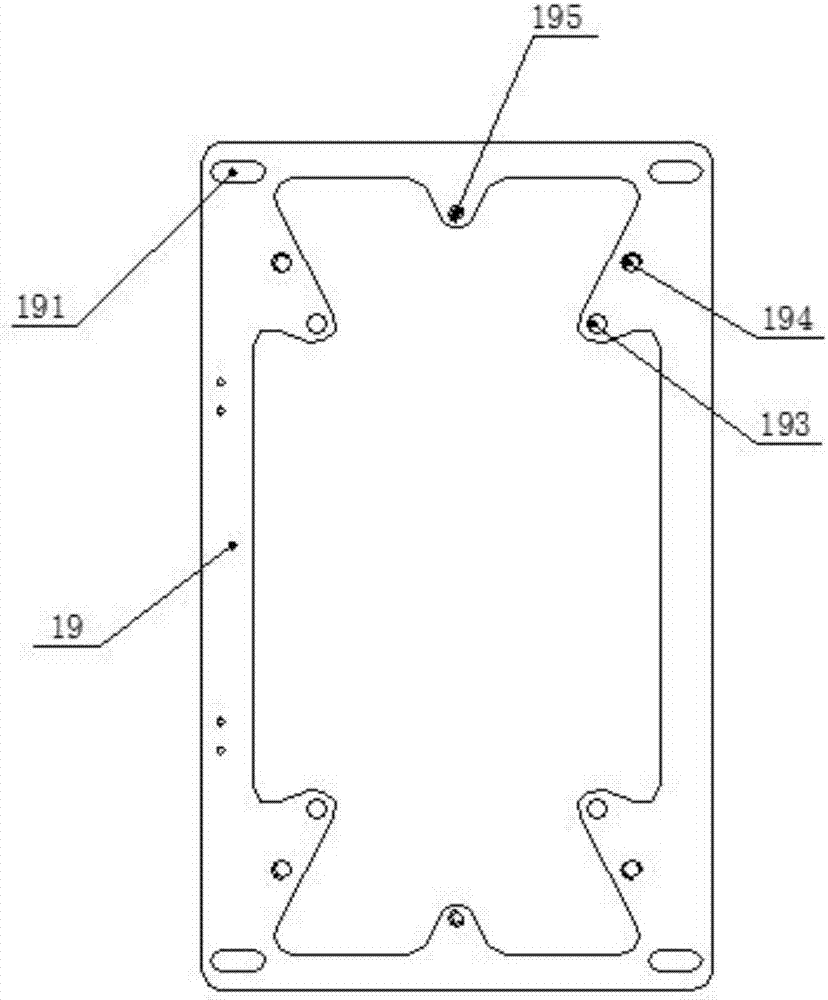

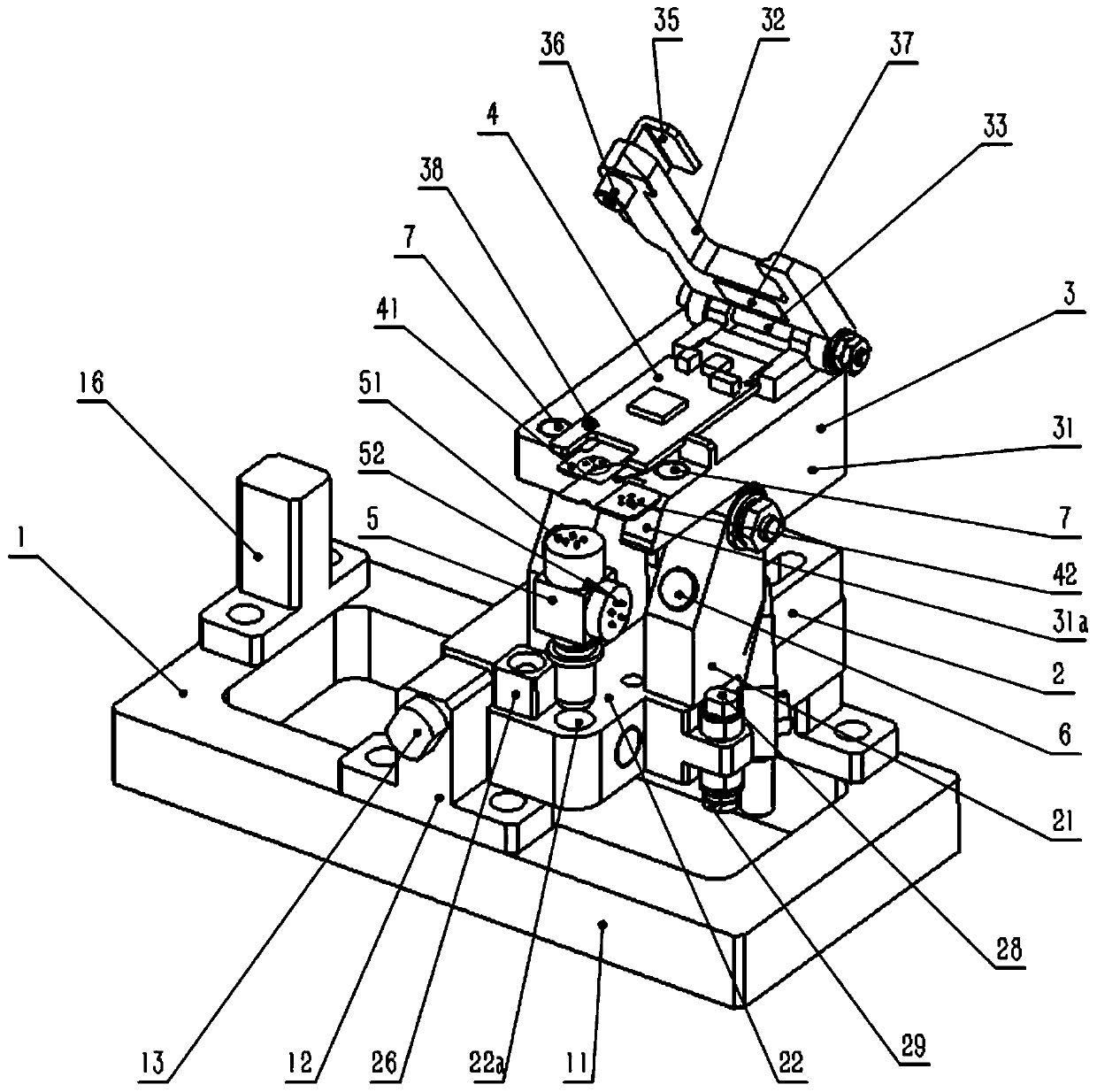

Fuel tank end cover welding machine

InactiveCN104325227AGood welding process controlAccurate welding positioningWelding/cutting auxillary devicesAuxillary welding devicesFuel tankMachine tool

The invention discloses a fuel tank end cover welding machine, and relates to the technical field of mechanical manufacturing. The fuel tank end cover welding machine comprises a base, a left rack and a right rack; the left rack and the right rack are arranged on the base; a clamping device for clamping a workpiece to be welded is arranged between the left rack and the right rack; one end of the clamping device is connected with a machine tool main shaft which is arranged on the left rack and driven by a main shaft stepping motor, and the other end of the clamping device is connected with a clamping shaft arranged on the right rack; welding guns and driving devices for driving the welding guns to move are arranged at the positions, above the clamping device, of the left rack and the right rack. The welding machine can solve the problems that a fuel tank end cover is large in welding investment, maintenance and production cost is high, and interchangeability and welding quality of equipment are poor.

Owner:LIUZHOU DONGHAI AUTO PARTS

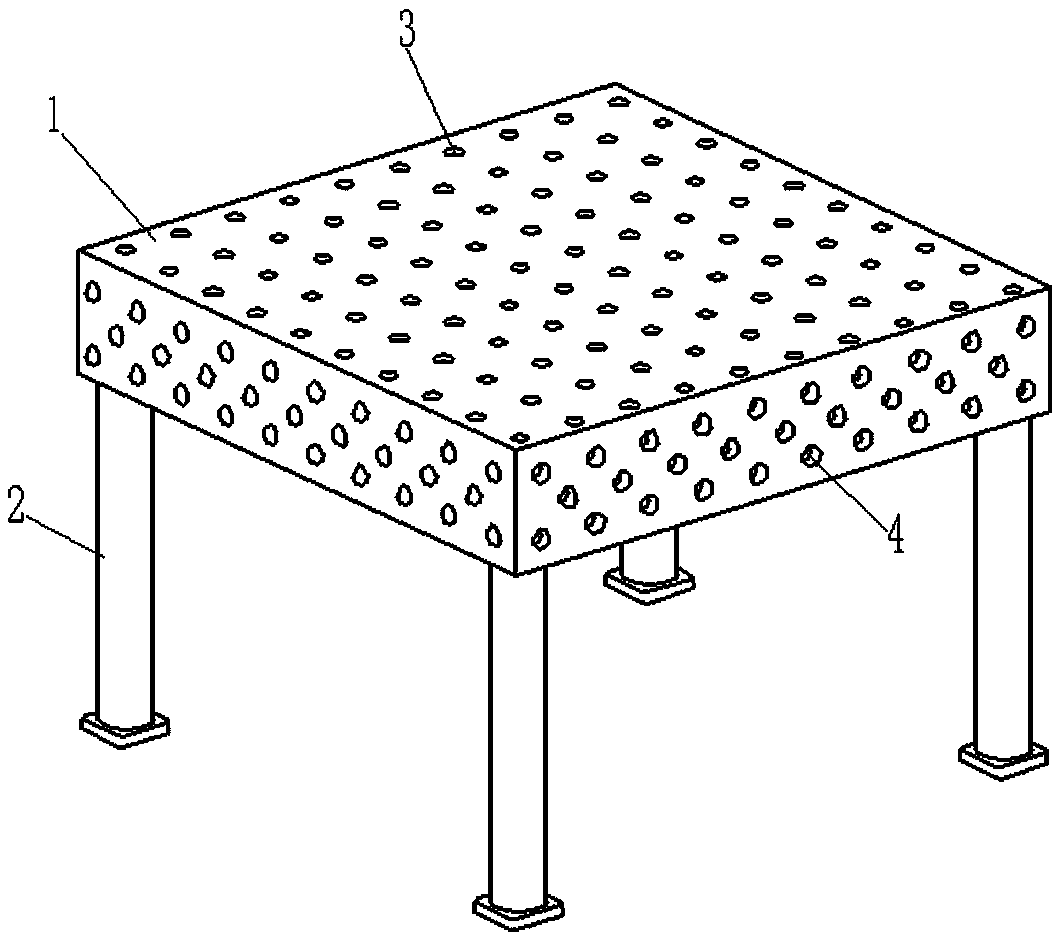

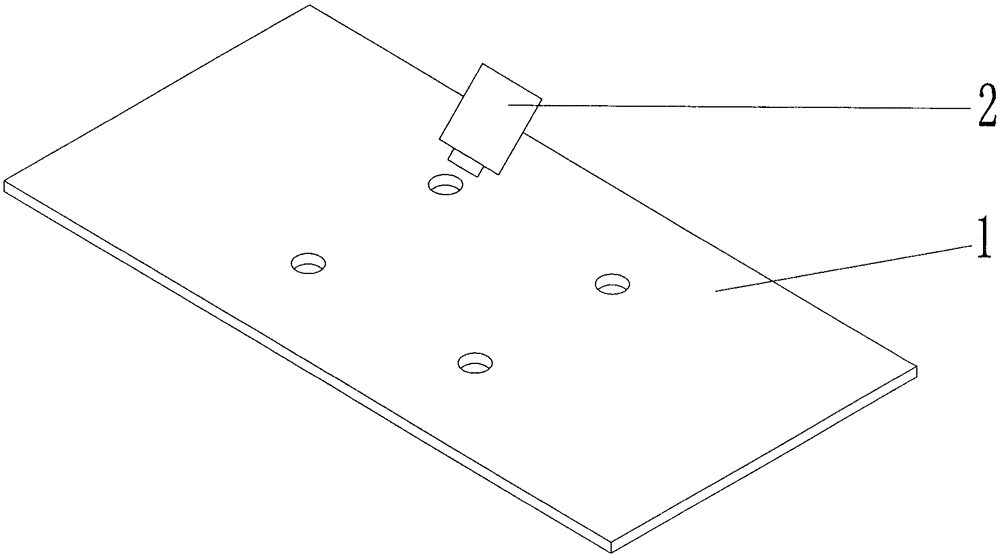

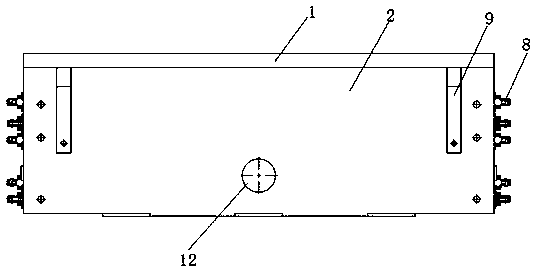

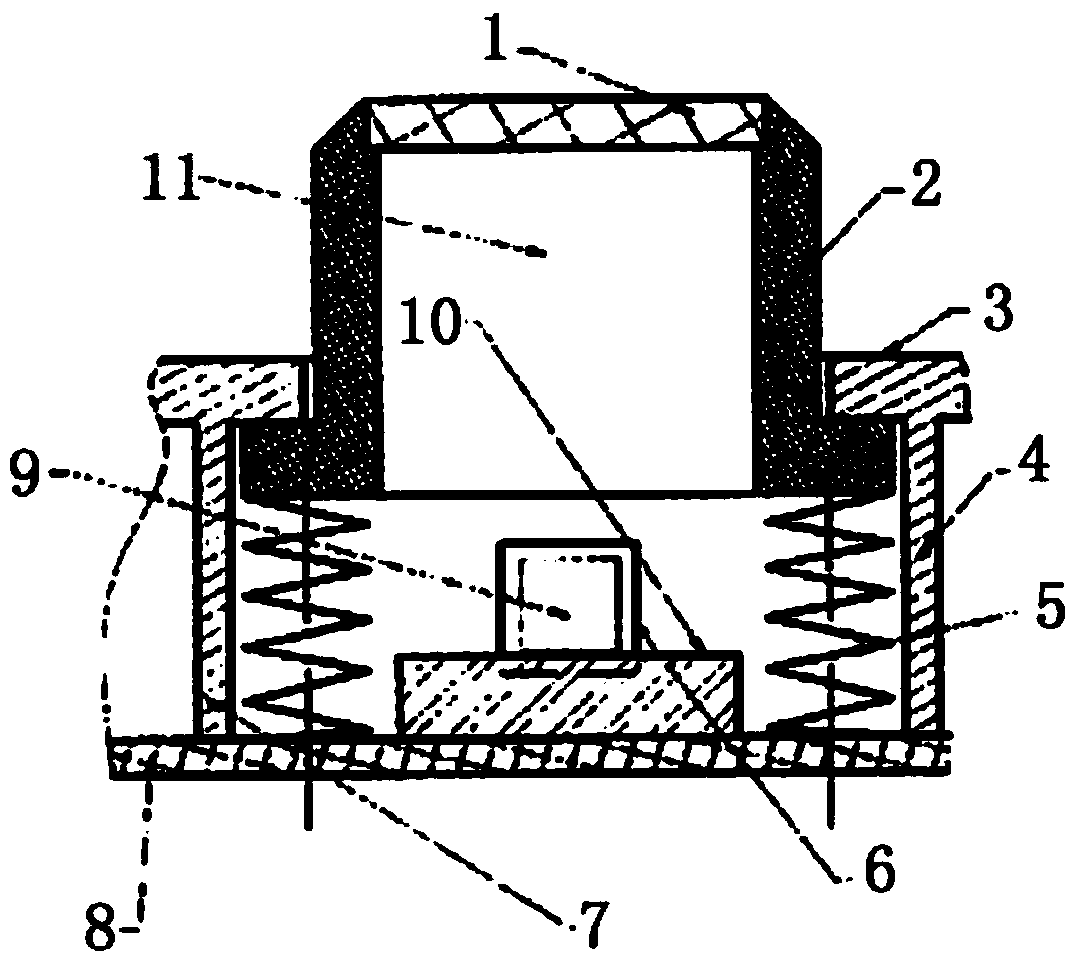

Convenient-to-position welding platform

InactiveCN107931935APrecise positioningAvoid installationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMagnet

The invention provides a convenient-to-position welding platform. The convenient-to-position welding platform comprises a flat plate 1 and supporting legs 2 connected with the flat plate1. The convenient-to-position welding platform is characterized in that the convenient-to-position welding platform further comprises magnets 3; the flat plate 1 is in a cuboid shape; grooves 4 are formed in the upper surface and the side surface of the flat plate 1; the magnets 3 are embedded into the grooves 4; and the grooves 4 are distributed in a matrix mode. The convenient-to-position welding platform hasthe beneficial effects that the welding platform can easily position a workpiece without any clamp, and is quite concise in structure; and meanwhile welding position is more accurate, and the weldingquality is guaranteed.

Owner:NANTONG HAOTAI WELDING MATERIAL CO LTD

Automatic welding machine of pressure gage connector

InactiveCN104128688AIncrease productivityAccurate welding positioningWelding/cutting auxillary devicesAuxillary welding devicesEngineeringCopper

The invention discloses an automatic welding machine of a pressure gage connector. The automatic welding machine comprises a welding die used for clamping a copper connector and a spring tube. The output end of a feeding guide rail is opposite to the welding die, the input end of the feeding guide rail is connected with a vibrating plate, a heating tube and an air cylinder for feeding the copper connector into the welding die are arranged on the feeding guide rail, and the air cylinder is connected with a cooling mechanism. According to the automatic welding machine of the pressure gage connector, the vibrating plate is used for selecting the copper connector, manual operation is replaced, production efficiency is greatly improved, the selected copper connector is fed in the feeding guide rail through the vibrating plate, the feeding guide rail adopts the heating tube for heating, the copper connector in the feeding guide rail is made to reach welding temperature, the copper connector is fed in the welding die by the air cylinder to be welded, the copper connector does not need to be heated through manual operation, welding locating is more accurate, the stability of product quality is guaranteed, automatic machining is achieved in the whole process, energy consumption is lowered, and environmental protection is facilitated.

Owner:开平市京华仪表配件有限公司

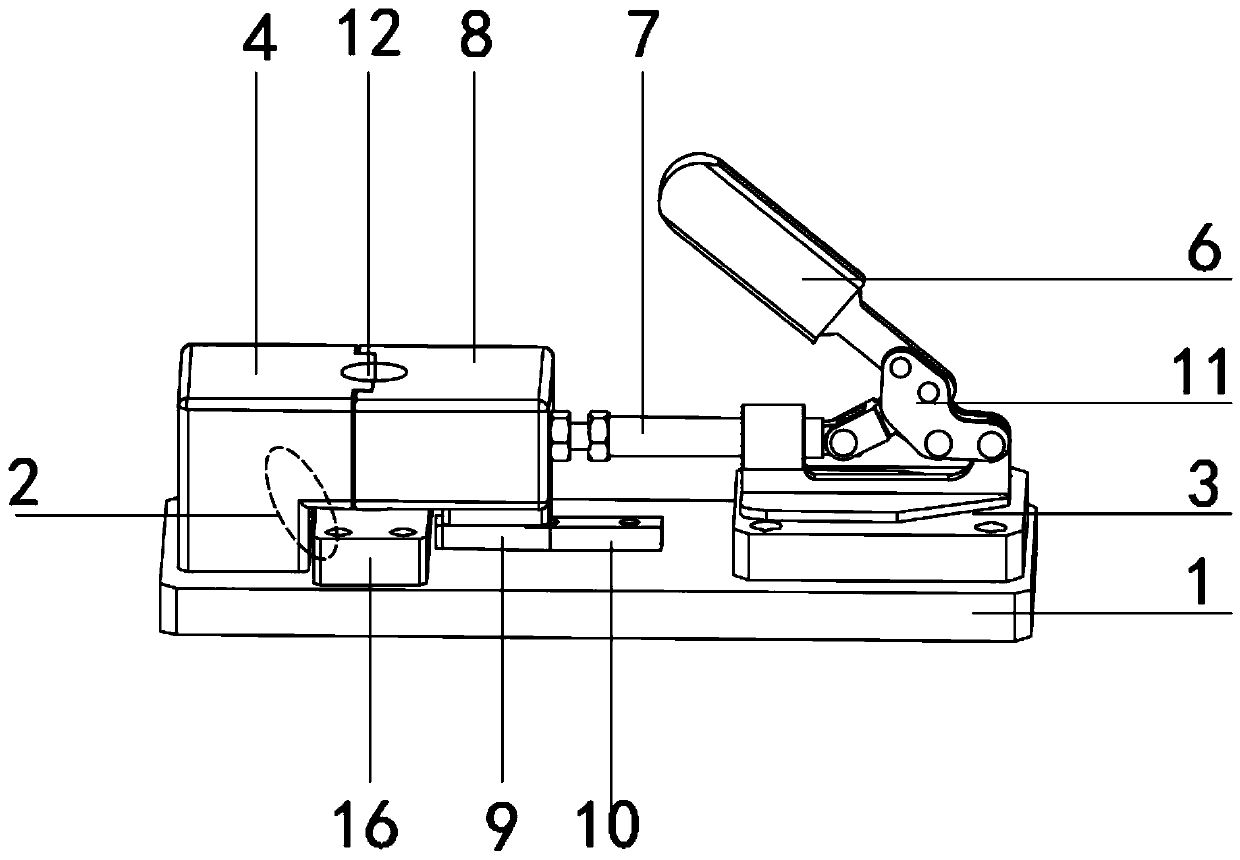

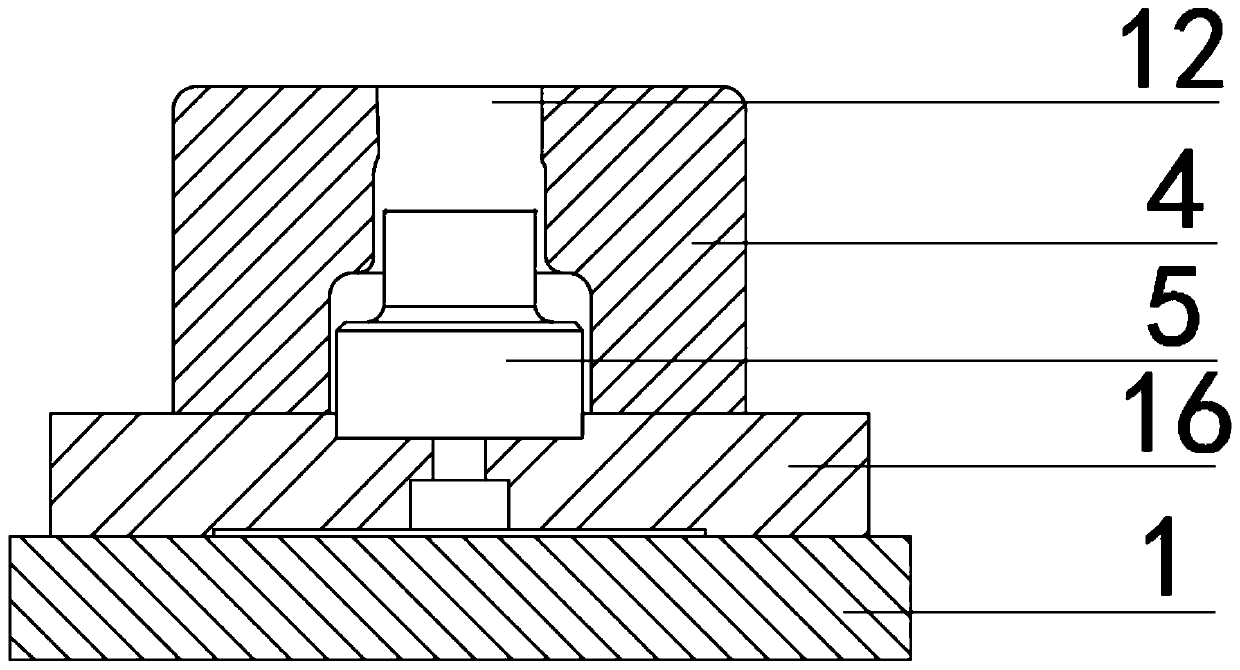

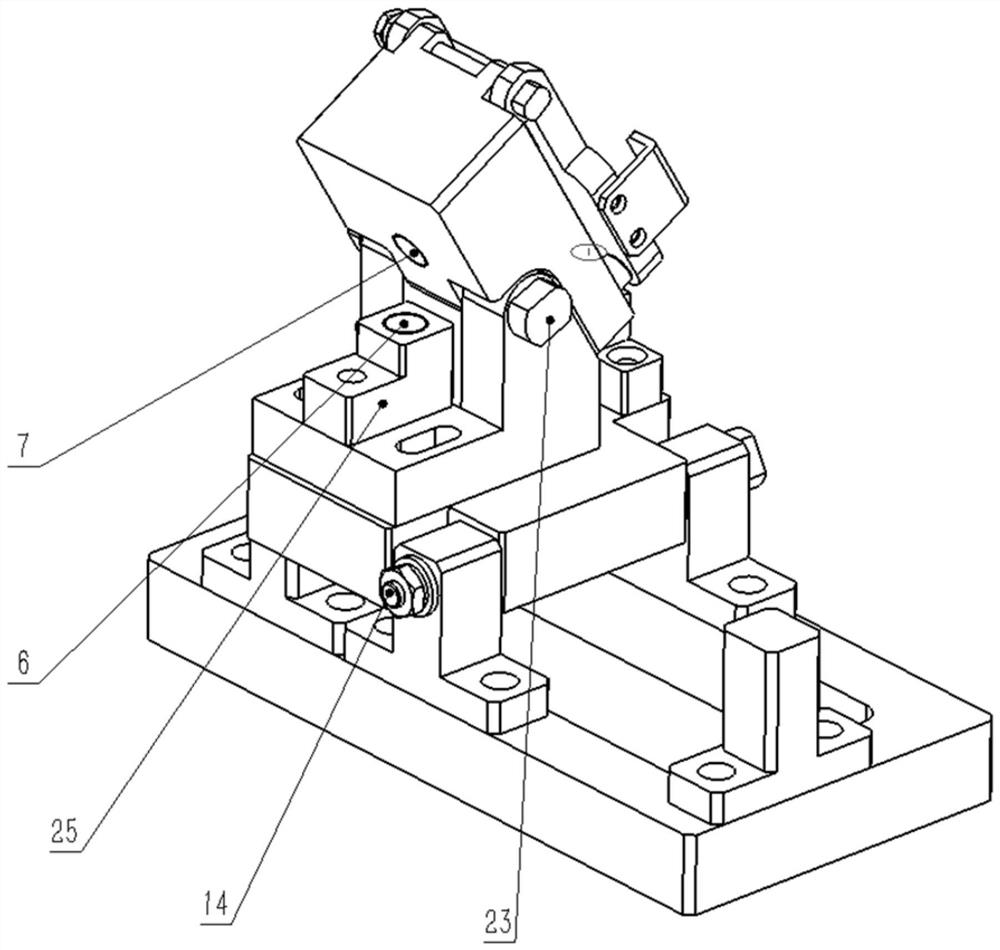

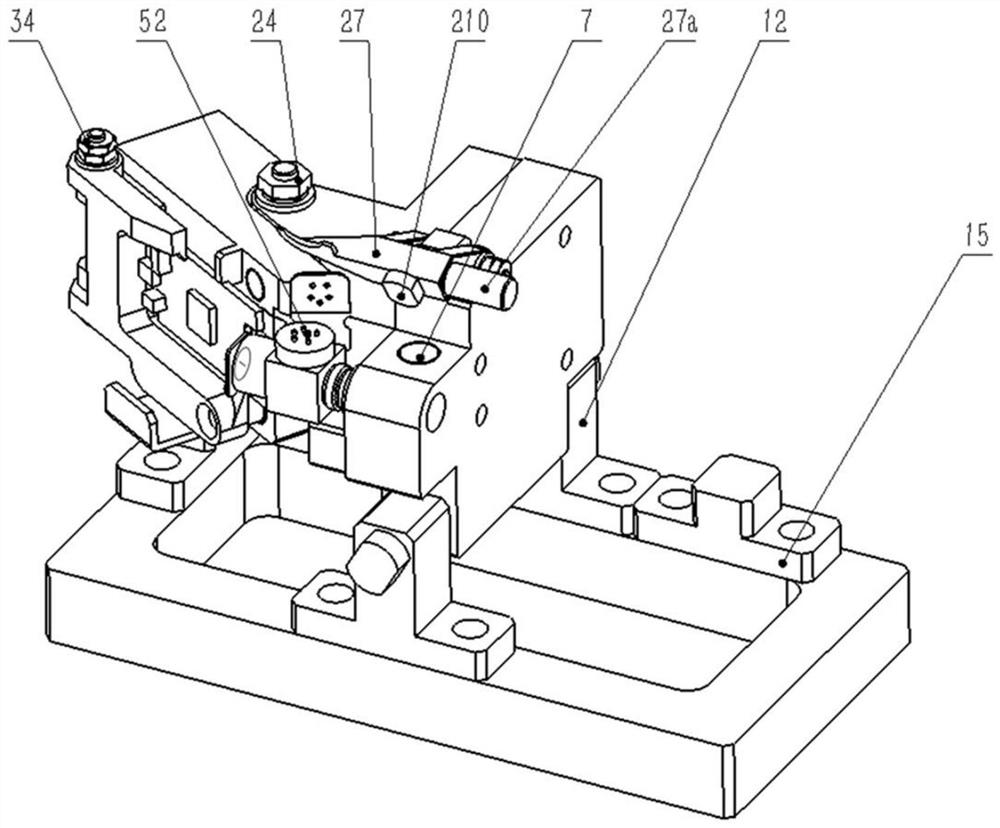

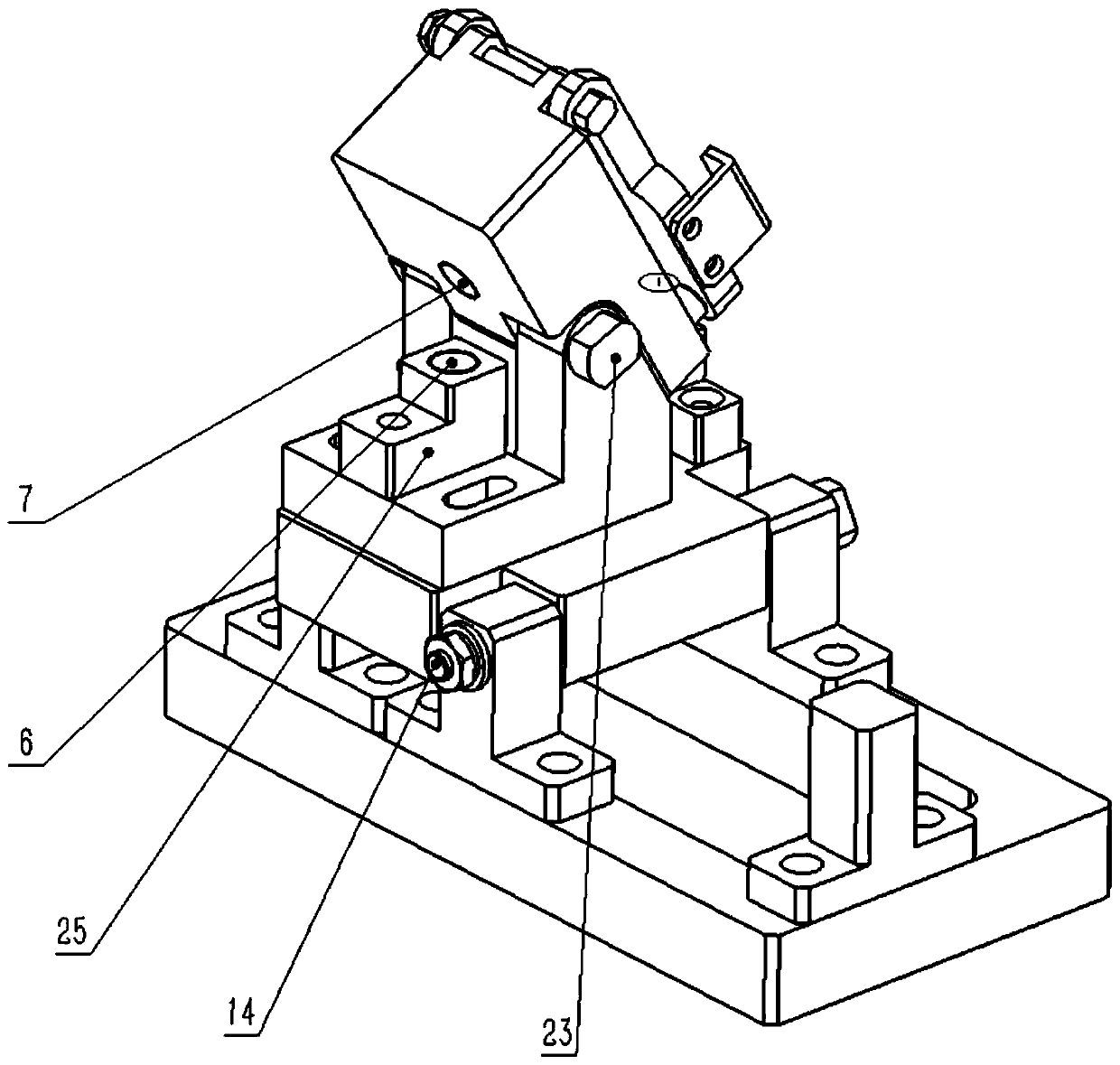

Electrochemical gas sensor ultrasonic welding tool and method

InactiveCN111230384ASimple structureEasy to operateWelding/cutting auxillary devicesAuxillary welding devicesElectrochemical gas sensorUltrasonic welding

The invention provides an electrochemical gas sensor ultrasonic welding tool. The electrochemical gas sensor ultrasonic welding tool comprises a base plate. A containing mechanism for containing an electrochemical gas sensor lower shell is arranged at one end of the length direction of the base plate, and a pressing mechanism cooperating with the containing mechanism to press the electrochemical gas sensor lower shell on the containing mechanism is arranged at the end, away from the containing mechanism, of the base plate. The tool is simple in structure and convenient to operate, the weldingquality and the consistency can be improved, and the situation of pseudo soldering or material overflowing is avoided. The invention further provides an electrochemical gas sensor ultrasonic welding method.

Owner:南京艾伊科技有限公司

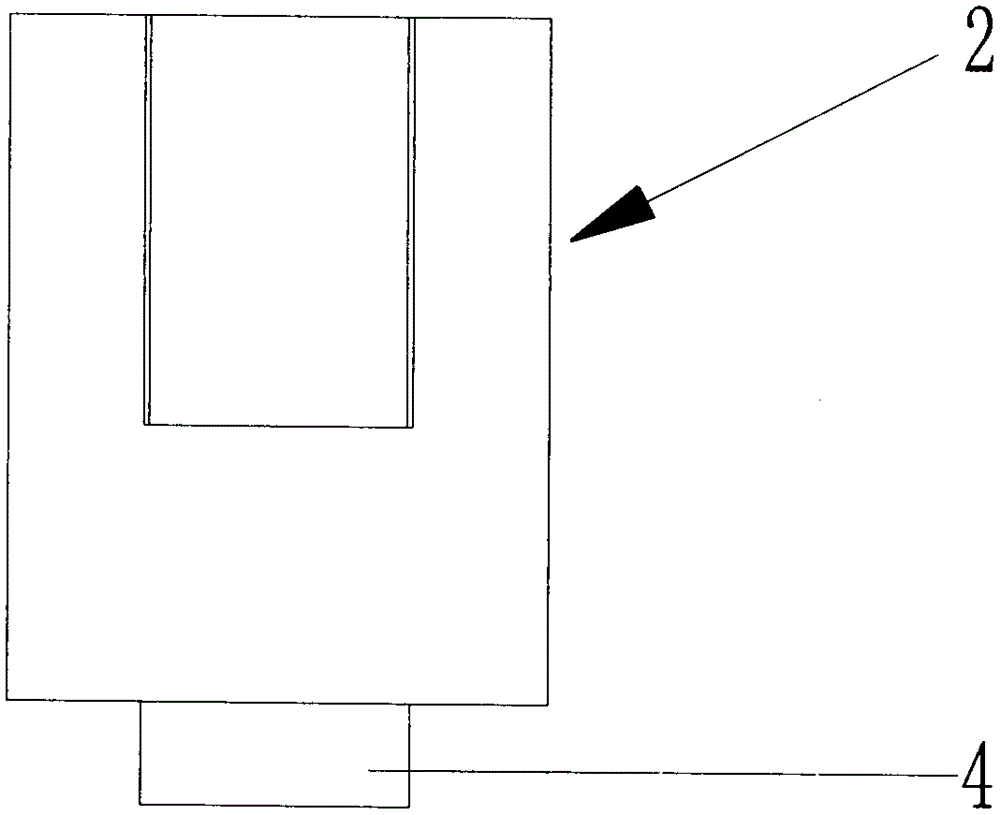

Double-screw bolt assisting mounting device

InactiveCN105397378ASimple structurePracticalWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding

The invention discloses a double-screw bolt assisting mounting device. The double-screw bolt assisting mounting device comprises a mounting plate and double-screw bolts, wherein a plurality of positioning holes are formed in the mounting plate; positioning columns are arranged at the lower ends of the double-screw bolts; the diameters of the positioning columns are matched with those of the location holes. The double-screw bolt assisting mounting device disclosed by the invention has the advantages that the structure is simple, the practicality is high, no additional requirements for a tank body structure are made, the welding positioning is accurate, the welding can be performed from the back, no welding spots are formed in the front surface of the mounting plate, and the double-screw bolt assisting mounting device is beautiful. In addition, manual measurement for positioning is not needed, so that the mounting time is greatly shortened and the working efficiency is improved.

Owner:镇江船舶电器有限责任公司

A flexible printed circuit board welding tool and welding method

ActiveCN111515601BPrecise positioningStable positionWelding/cutting auxillary devicesAuxillary welding devicesPrinted circuit boardWelding process

The invention relates to the field of communication technology, and discloses a flexible printed circuit board welding tool and a welding method, wherein the tool includes a support seat, a rotating shaft seat and a positioning seat, the rotating shaft seat is installed on the supporting seat, and the top of the rotating shaft seat is rotatably connected to the positioning seat. The supporting seat is provided with a positioning hole on the first side of the rotating shaft seat. The positioning hole is used to install the optical device. The top surface of the positioning seat is used to fix and assemble the PCB board connected with the first flexible board. The first welding position on the top surface of the optical device is welded, the top of the first side of the rotating shaft seat is set as a first slope, and a matching detachable connection structure is provided between the first slope and the bottom surface of the positioning seat. The flexible printed circuit board welding tool and welding method provided by the present invention can quickly locate the relative position of the first flexible board and the optical device, the welding positioning is accurate, the reliability is high, the stability and accuracy of the welding process are improved, and the soft The board and optical components are accurately soldered.

Owner:WUHAN RAYCUS FIBER LASER TECHNOLOGY CO LTD

A manufacturing method of a personalized lingual straight wire arch self-locking bracket appliance

The invention relates to a manufacturing method of a personalized lingual straight wire arch self-locking bracket appliance. The manufacturing method comprises the following steps: 1) Obtaining a digital dentition model; 2) The bracket body of the tooth position according to the tooth position and the connecting body are placed in the middle of the lingual side of the corresponding teeth along the track and plane of the straight wire arch, and the last molar at both ends of the straight wire arch is placed on the lingual tube body; 3) Casting a metal bracket base-connection body, metal bracket body and lingual tube; 4) Weld and assemble the bracket body, bracket base-connector, and self-locking shrapnel through the fixture; 5) Make a personalized bracket positioner; 6) According to The lingual straight wire arch pattern selected during tooth alignment by computer is used to prepare the straight wire arch and assemble it with the bracket positioner. The manufacturing method of the present invention adopts computer technology, rapid prototyping technology and precision casting technology, and has the advantages of simple and convenient operation method, high production efficiency, accurate positioning of the manufactured appliance, short chairside operation time, and better therapeutic effect.

Owner:上海精功齿科技术有限公司

Welding device for gantry-shaped steel of forklift

InactiveCN101590578BReduce welding efficiencyImprove welding efficiencyWelding/cutting auxillary devicesAuxillary welding devicesDrive wheelUniversal joint

The invention relates to the field of manufacturing a forklift, and discloses a welding device for gantry-shaped steel of a forklift. The device comprises a welding platform and a welding gun arranged on the welding platform; the welding platform is arranged on a material guide platform which is provided with a plurality of guide wheels form left to right; the welding platform comprises a front support plate, a rear support plate and an upper driving wheel, a left driving wheel and a right driving wheel which are arranged between the front support plate and the rear support plate; and the upper driving wheel, the left driving wheel and the right driving wheel are connected with a gear box by an universal joint, the gear box is connected with a motor, and the left driving wheel and the right driving wheel are connected with the guide wheel. By welding both faces and positioning fillets by a fillet positioning mechanism, the device achieves the effects of accurate positioning and welding, insusceptibility to welding deformation, high welding efficiency, and cost conservation, and has wide application prospect in the field of manufacturing the forklift.

Owner:ZHEJIANG MAXIMAL FORKELEVATOR

A starter coil bridge line welding positioning tool

ActiveCN113770635BNo pollutionAct as frictionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

Owner:常州市武进亚太机电配件有限公司

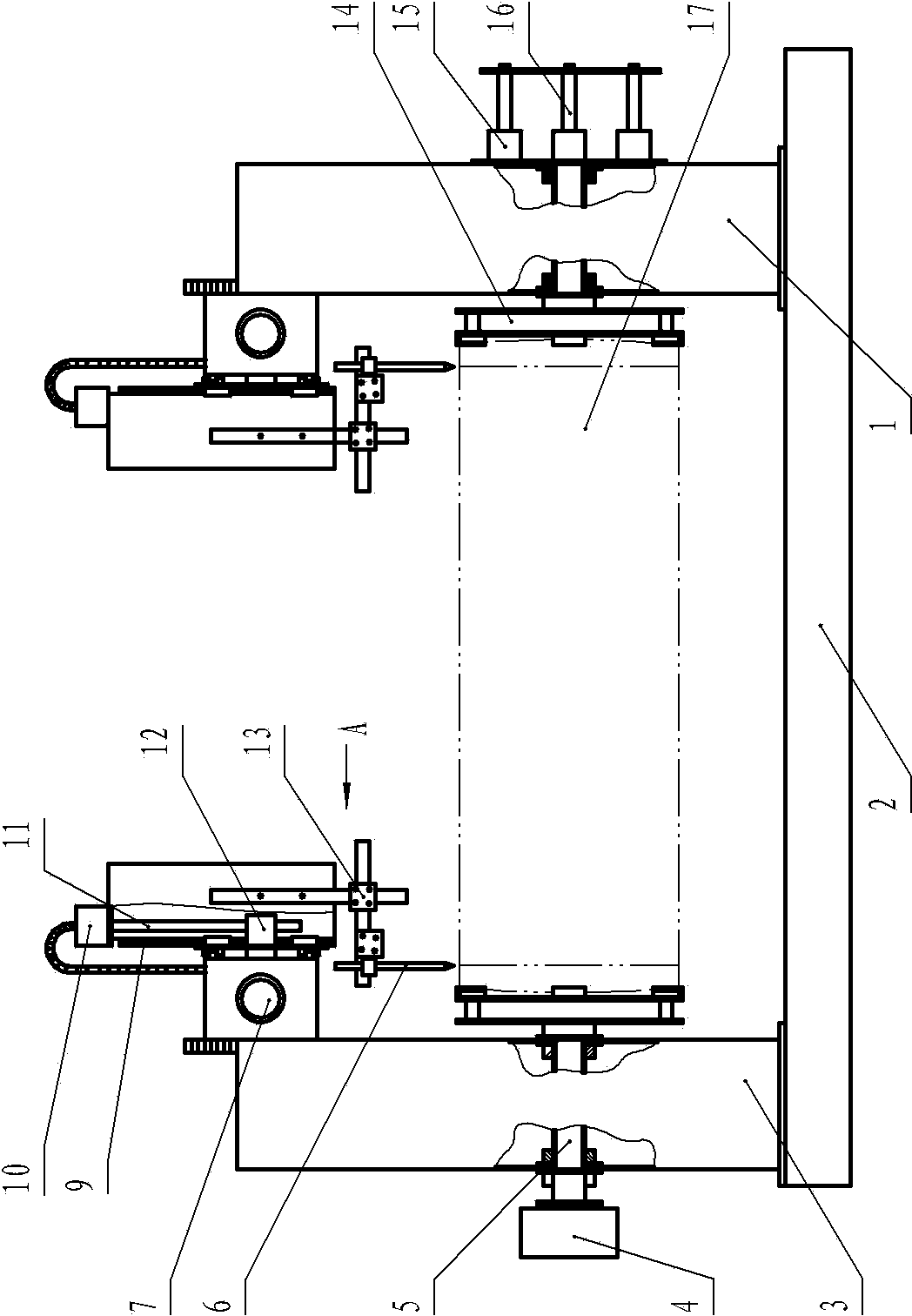

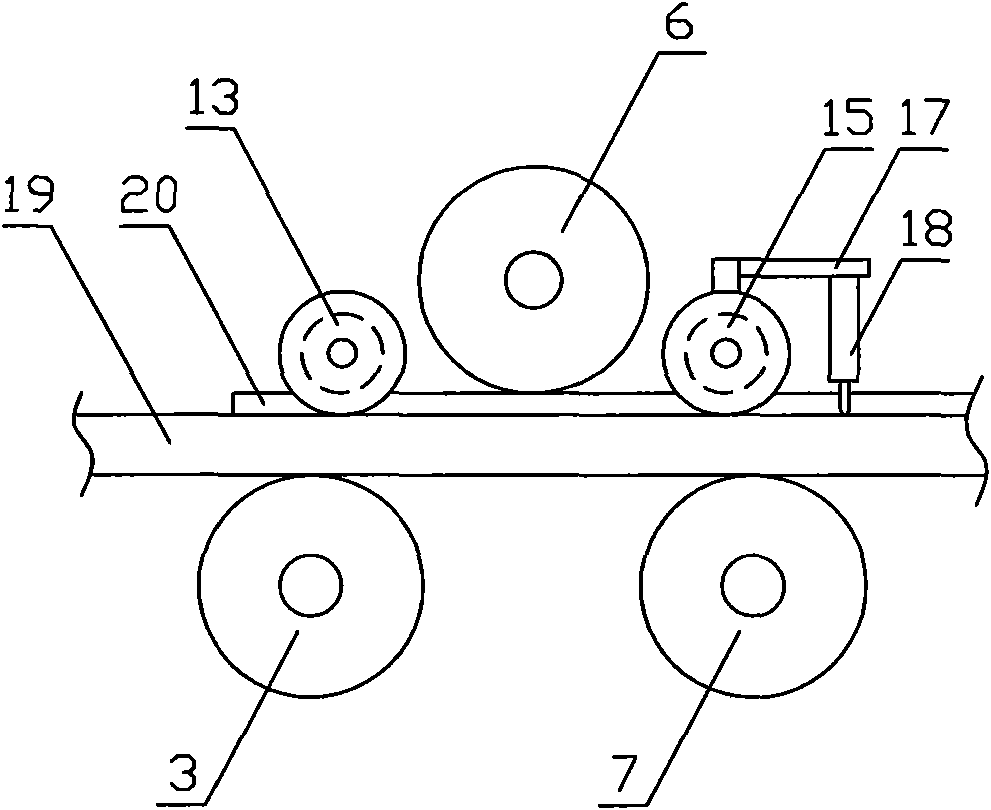

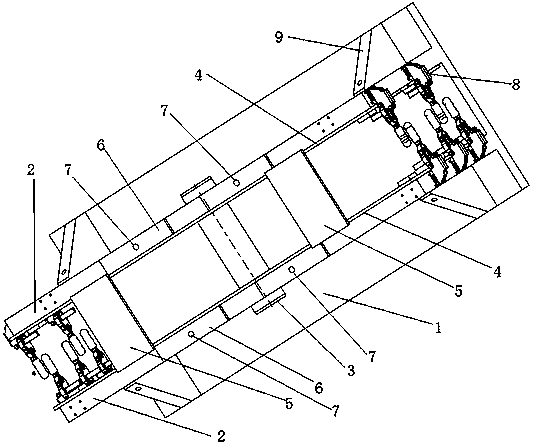

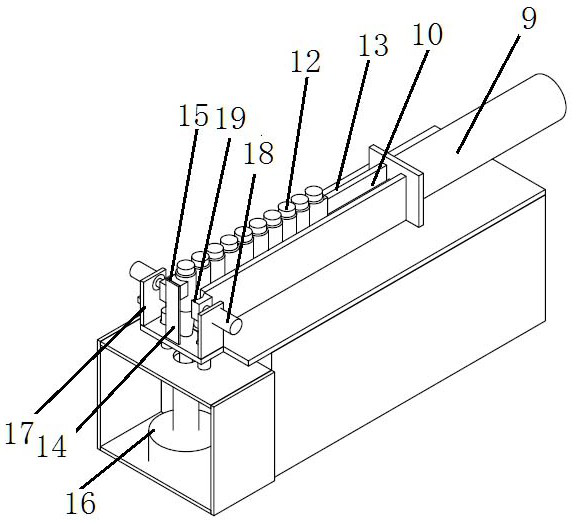

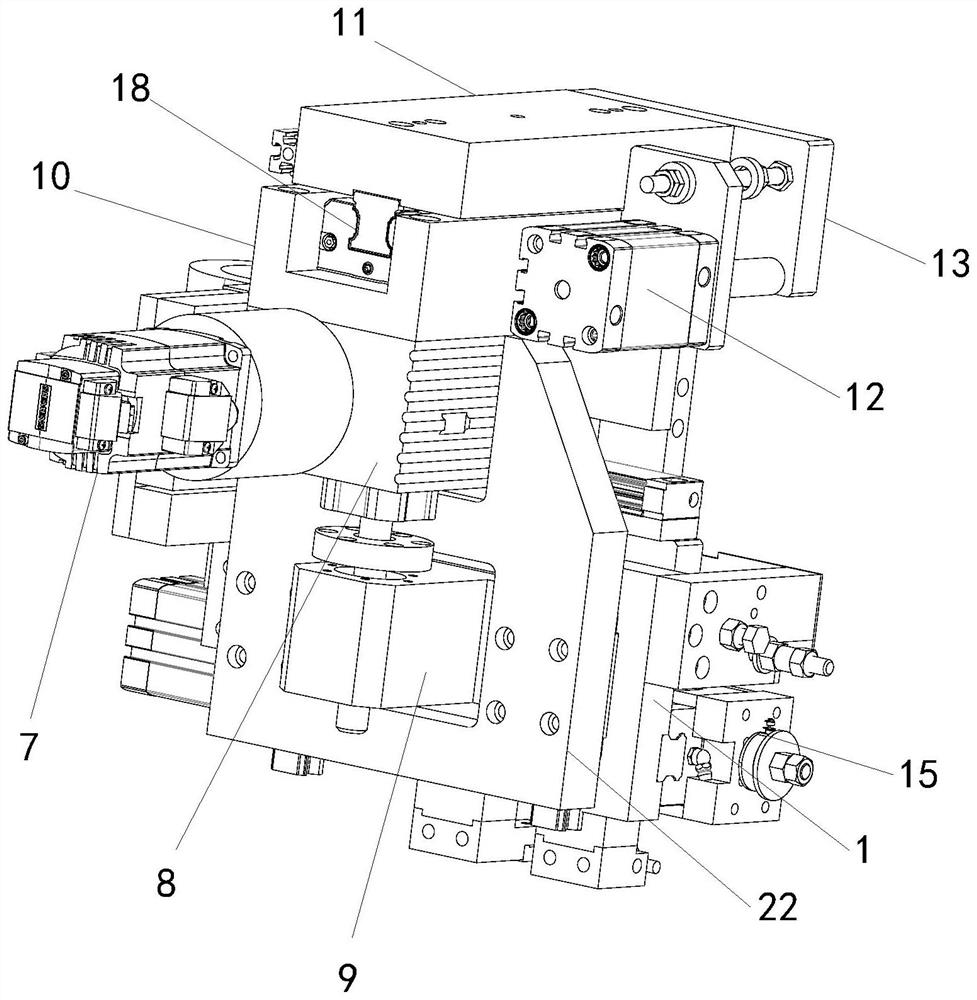

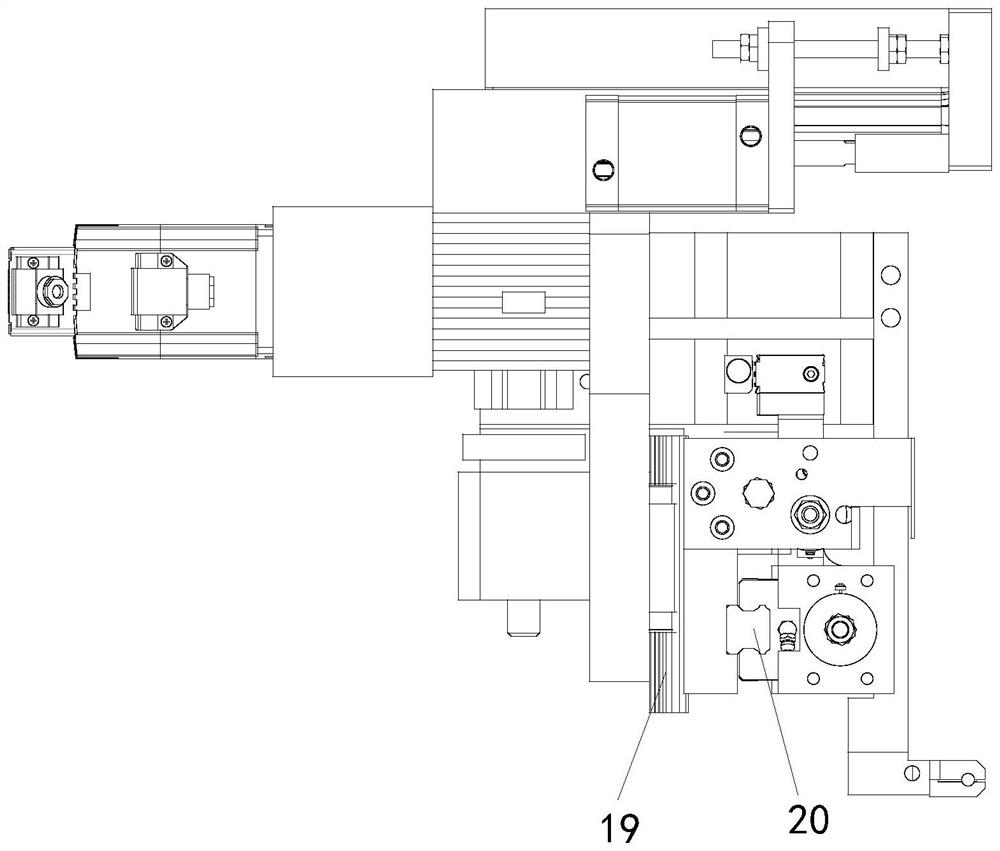

Automatic welding machine for single row tube and tubular plate of an air condenser

ActiveCN107414256AReduce welding errorsAccurate welding positioningElectrode holder supportersWelding accessoriesWeld seamEngineering

The invention discloses an automatic welding machine for a single row tube and a tubular plate of an air condenser. The automatic welding machine comprises a welding gun mechanism and further comprises a support mechanism, a positioning mechanism, a movement adjusting mechanism and a guide wire sleeve mechanism. The positioning mechanism is adopted to precisely position the automatic welding machine and the tubular plate; two motors are adopted to control up-down motion and movement in a curve of the welding gun mechanism; the welding positioning is precise and the welding error of the single row tube and the tubular plate of the air condenser is small; and the movement adjusting mechanism is adopted to enable the welding gun mechanism to automatically move along the outline of a single row tube hole and to finish welding of the single row tube and the single row tube hole. The automatic welding machine improves the welding efficiency, avoids the welding error caused by an artificial factor, is uniform in weld seam, contains fewer air bubbles and impurities, improves the welding quality and prolongs the service life of the air condenser.

Owner:刘双杰

A personalized lingual straight wire arch self-locking bracket appliance

The invention relates to a personalized self-ligating bracket appliance with lingual straight-wire arches. The personalized self-ligating bracket appliance comprises a plurality of self-ligating brackets formed by threading and connecting the lingual straight-wire arches, wherein lingual surface tubes are threaded and connected to the both ends of each straight-wire arch respectively; each self-ligating bracket comprises a bracket body and a bracket bottom plate which are mutually fixed through a connection body; the connection body and the bracket bottom plate are integrally moulded; the connection body and the bracket body are welded and fixed; each of the bracket body and the connection body is provided with a first contact surface and a second contact surface, and the first contact surface and the second contact surface are mutually vertical; a limit cavity cap is formed between the connection body and the bracket body; a bracket groove for each straight-wire arch to penetrate through is further formed in the middle part of the bracket body, and an anti-ligating groove is formed in one sidewall of the bracket groove; and a self-ligating elastic sheet further covers the bracket groove, one end of the self-ligating elastic sheet is limited in the limit cavity cap, and the other end of the self-ligating elastic sheet is capable of being clamped in the anti-ligating groove. The personalized self-ligating bracket appliance disclosed by the invention ensures accurate welding location between the bracket body and the bracket bottom plate, and improves the treatment effect.

Owner:上海精功齿科技术有限公司

Welding tool and welding method for flexible printing circuit board

ActiveCN111515601APrecise positioningStable positionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringWelding process

The invention relates to the technical field of communication and discloses a welding tool and a welding method for a flexible printing circuit board. The tool comprises a supporting seat, a rotatingshaft seat and a positioning seat. The rotating shaft seat is mounted on the supporting seat, the top of the rotating shaft seat is rotatably connected to the positioning seat, a positioning hole is formed in the first side of the rotating shaft seat on the supporting seat and is used for mounting an optical device, the top surface of the positioning seat is used for fixedly assembling a PCB connected to a first soft plate, the first soft plate is used for welding a first welding position located on the top surface of the optical device, the top of a side surface of a first side of the rotating shaft seat is a first bevel, and a matched detachable connecting structure is arranged between the first bevel and a bottom surface of the positioning seat. The welding tool and the welding method for the flexible printing circuit board provided by the invention can position relative positions of the first soft plate and the optical device quickly, are accurate to weld and position and high in reliability, and improve the stability an d accuracy of a welding process, so that the soft plate and the optical device are welded accurately.

Owner:WUHAN RAYCUS FIBER LASER TECHNOLOGY CO LTD

Welding fixture sharing upper counterweight frame and lower counterweight frame

PendingCN111375959AAccurate welding positioningNo usage errorsWelding/cutting auxillary devicesAuxillary welding devicesStructural engineeringWelding

The invention discloses a welding fixture sharing an upper counterweight frame and a lower counterweight frame. The welding fixture is formed by connecting a base plate and two vertical plates which are perpendicular to the base plate; the lengths of the base plate and the vertical plates are consistent with the length of the upper counterweight frame or the lower counterweight frame; the heightsof the vertical plates are greater than the width of a panel of the lower counterweight frame, and is less than the width of a panel of the upper counterweight frame; through circular holes corresponding to the position of a circular hole of the upper counterweight frame are formed in the vertical plates; a pin rod is matched with the circular holes in diameter; when the lower counterweight frameis fixed, the panel of the lower counterweight frame is aligned with the outer sides of the vertical plates; a plurality of connecting strips are pressed against the panel of the lower counterweight frame and the side plates of the vertical plates; when the upper counterweight frame is fixed, the panel of the upper counterweight frame is aligned with the inner sides of the vertical plates; the outer side of the panel of the upper counterweight frame exceeds the vertical plates; the pin rod penetrates through the circular holes and is locked; and extending base plates are mounted on the side surfaces of the vertical plates. By using the welding fixture, welding and positioning can be performed accurately; measurement and alignment are not required to be performed; and in addition, the uppercounterweight frame and the lower counterweight frame can be shared, so that the reliability is improved.

Owner:XUANCHENG VALIN PRECISION TECH

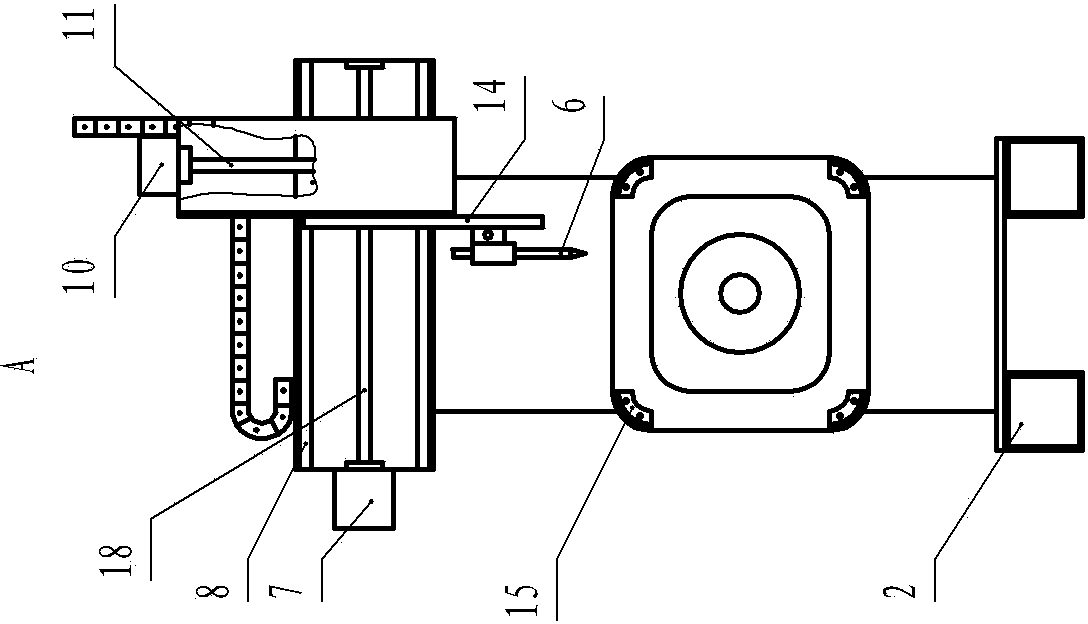

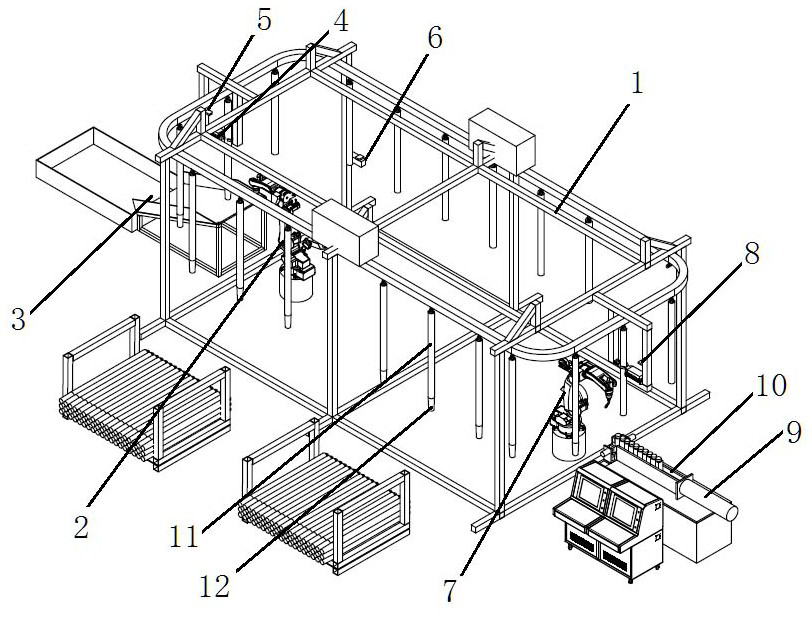

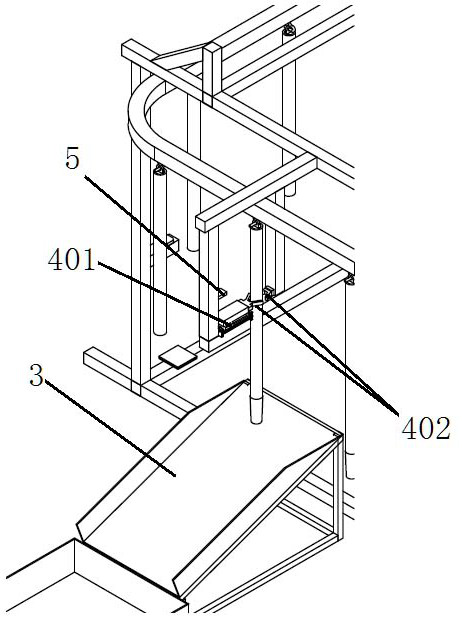

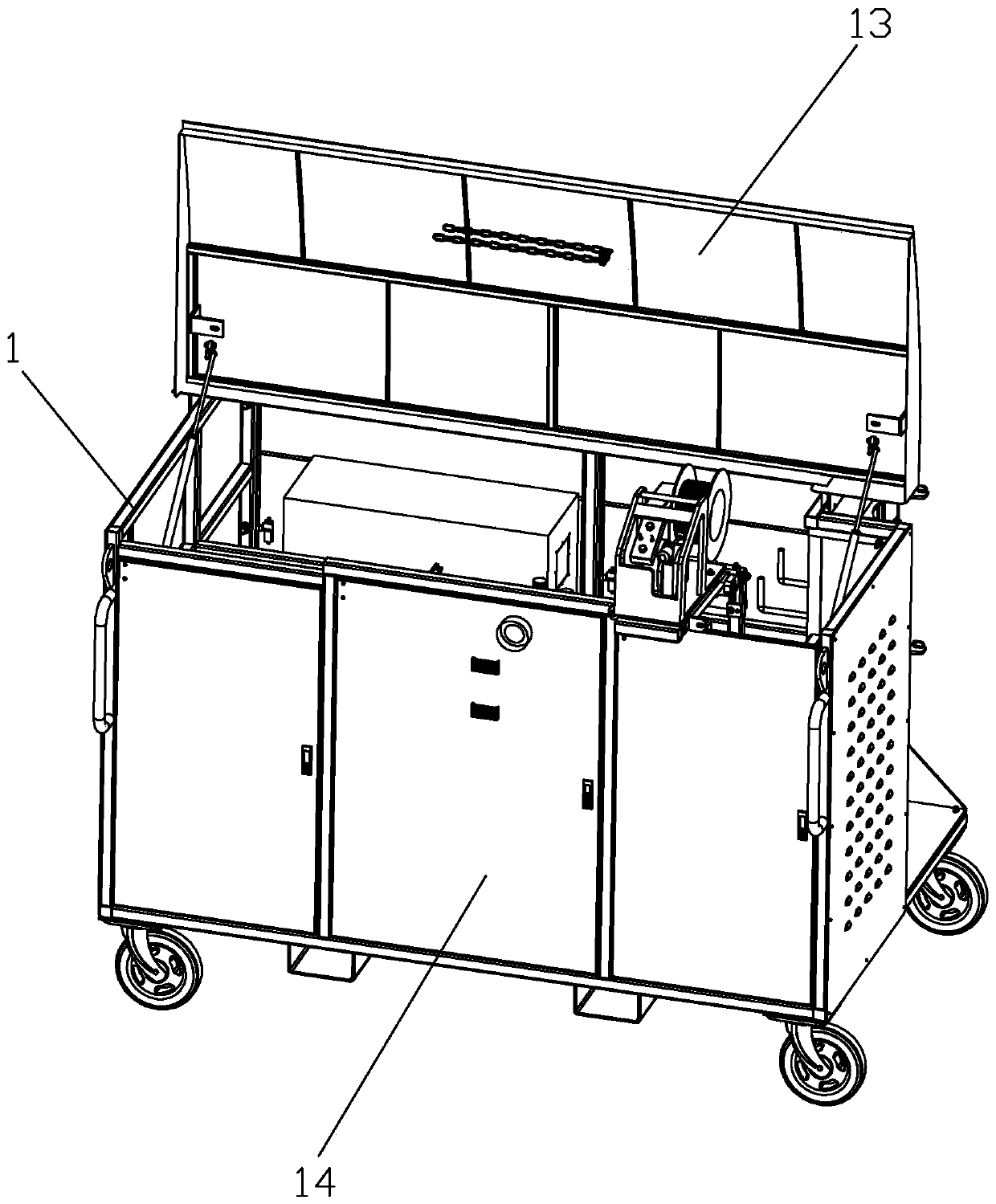

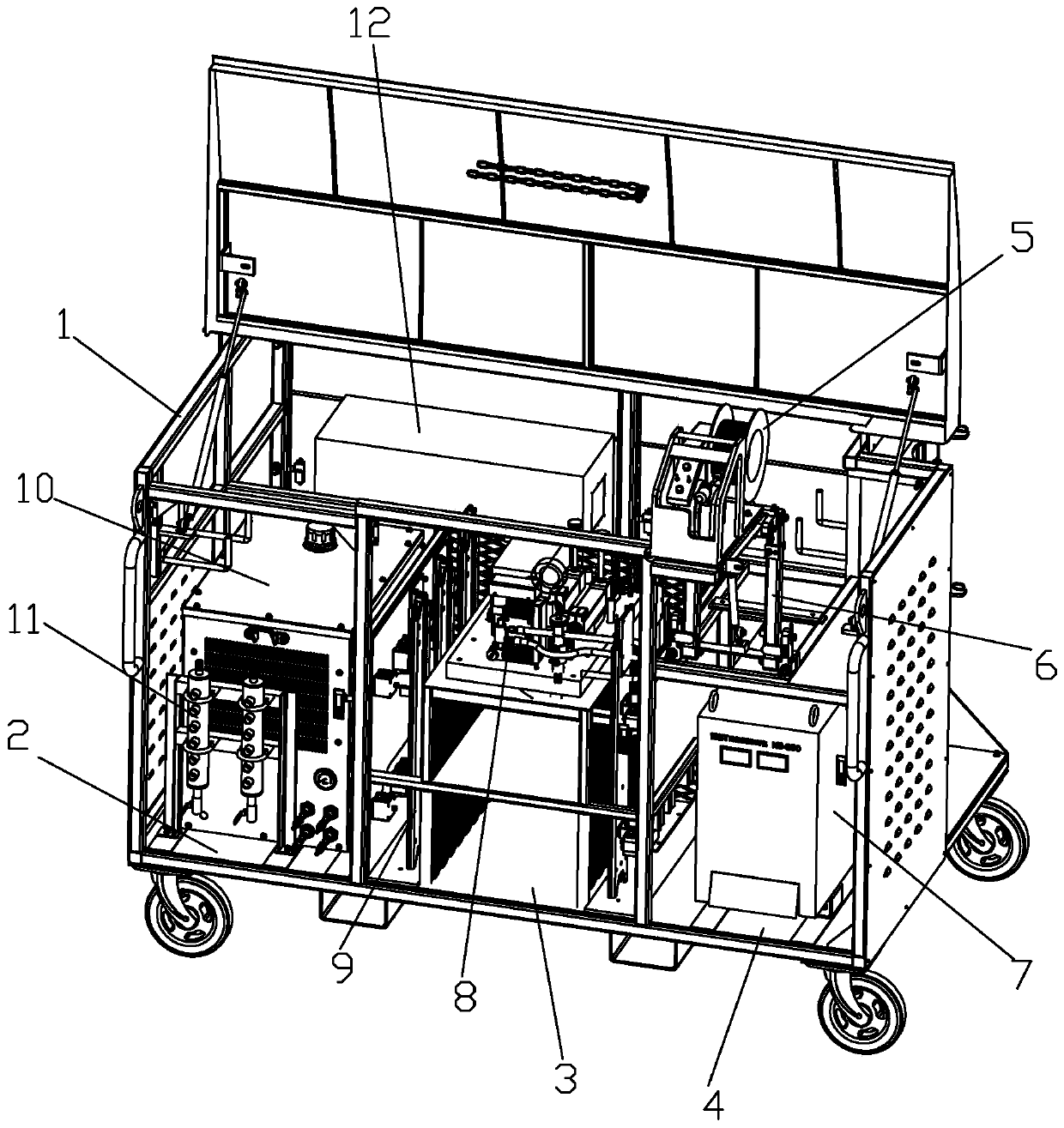

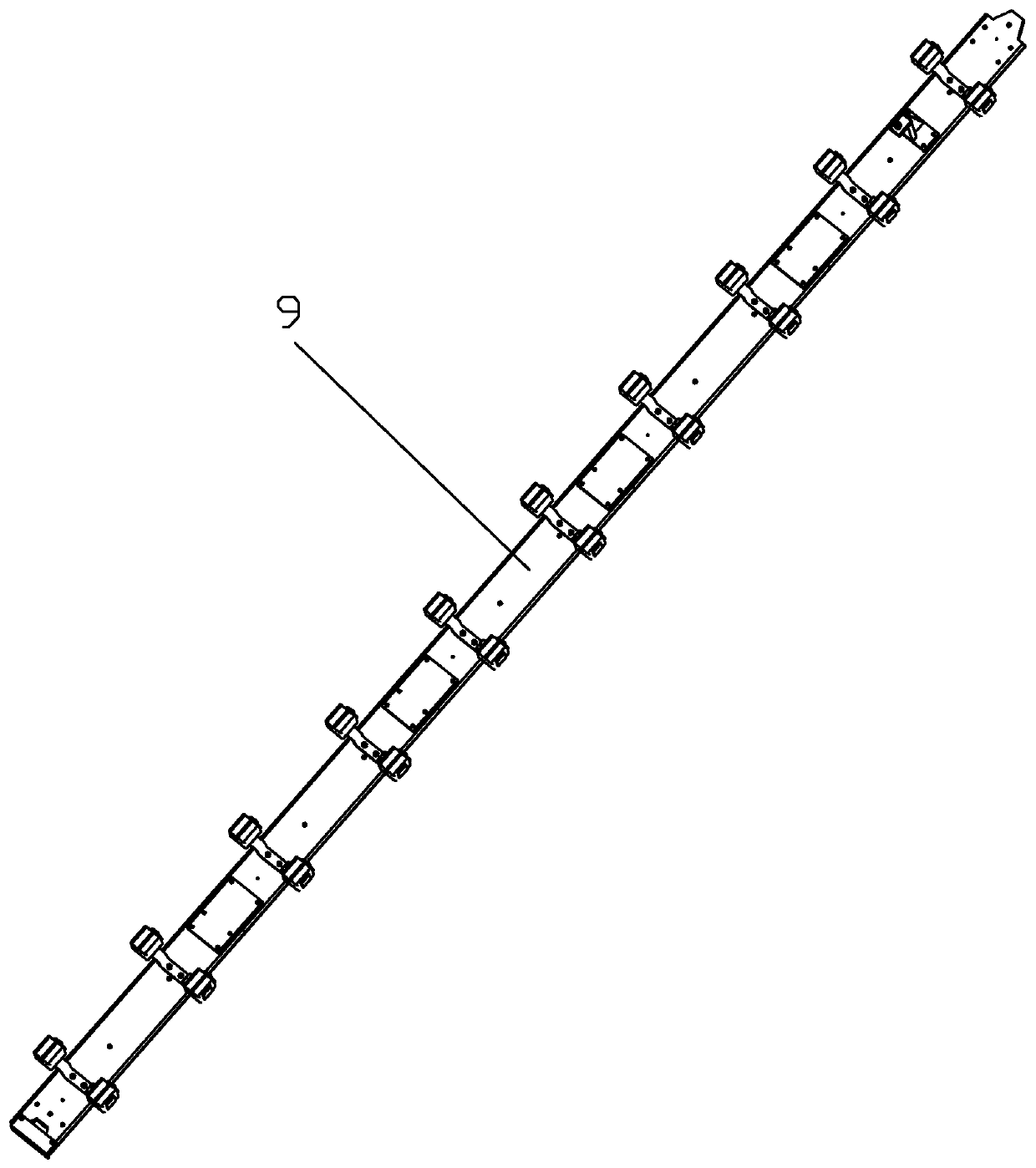

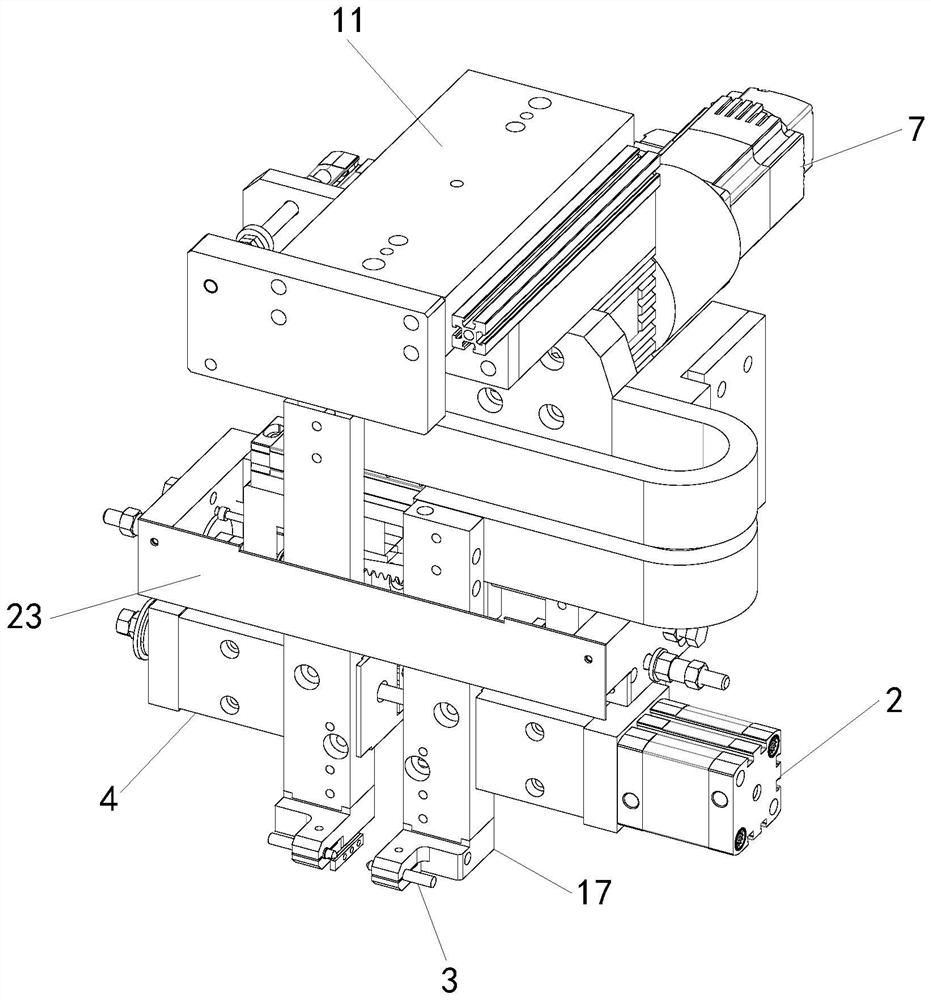

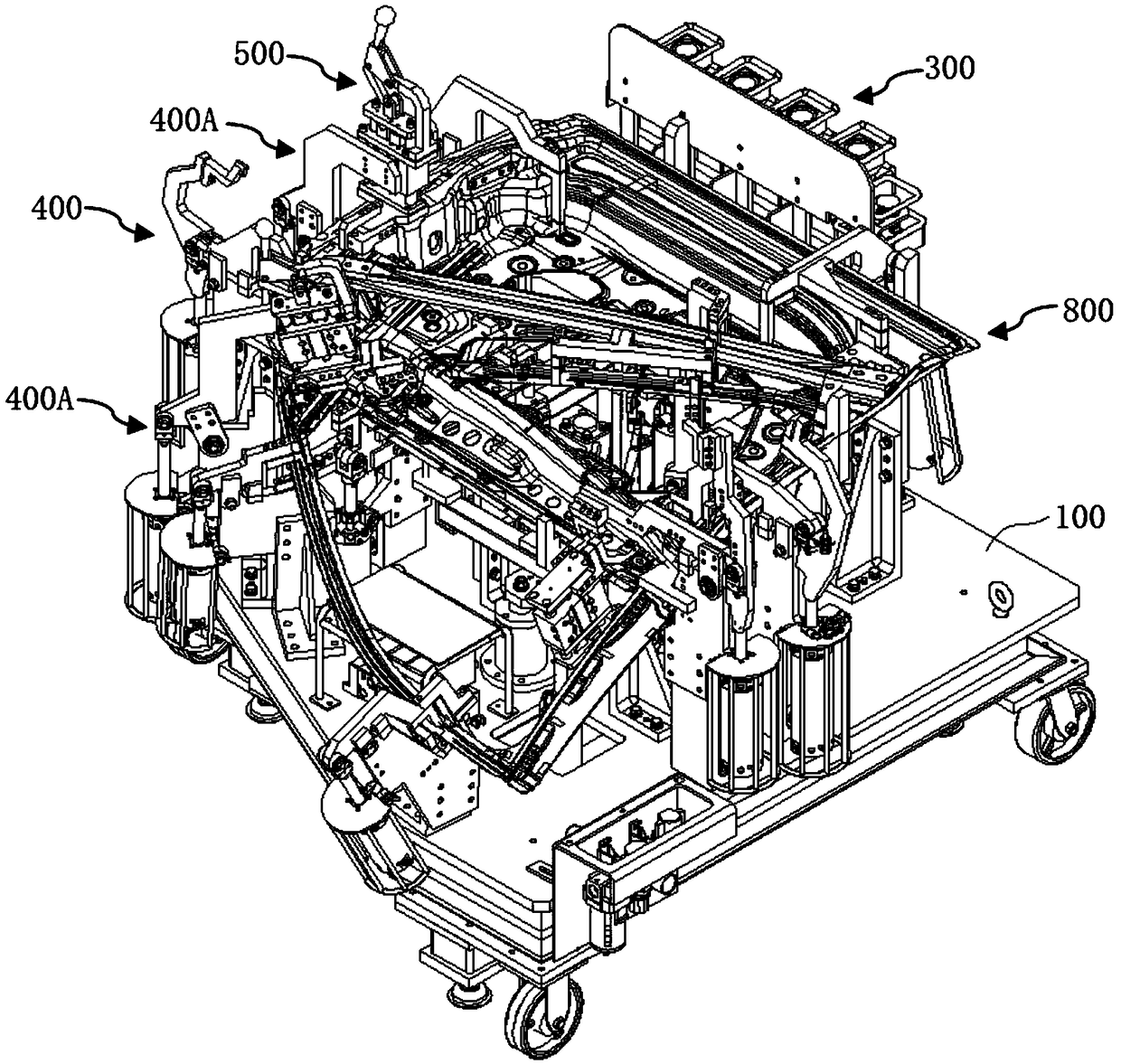

Automatic cutting and welding system for repairing hammerhead of crust breaker

PendingCN114012223AAccurate welding positioningNeutral goodWelding/cutting auxillary devicesAuxillary welding devicesPhysicsEngineering

An automatic cutting and welding system for repairing a hammerhead of a crust breaker comprises a suspension type annular conveyor, the annular conveyor is connected to a control system, a plurality of hooks are arranged on a conveying chain on the annular conveyor at intervals and move along with the conveying chain, a feeding and discharging work station, a cutting work station and a welding work station are arranged in the periphery of the annular conveyor, a cutting robot is installed on the cutting work station, and a hammer rod clamping mechanism, a hammer head clamping and feeding mechanism, a second material detection sensor and a welding robot are installed on the welding work station. The system can be used for electrolytic aluminum enterprises, and can effectively reduce the cost and improve the efficiency.

Owner:HENAN POLYTECHNIC UNIV

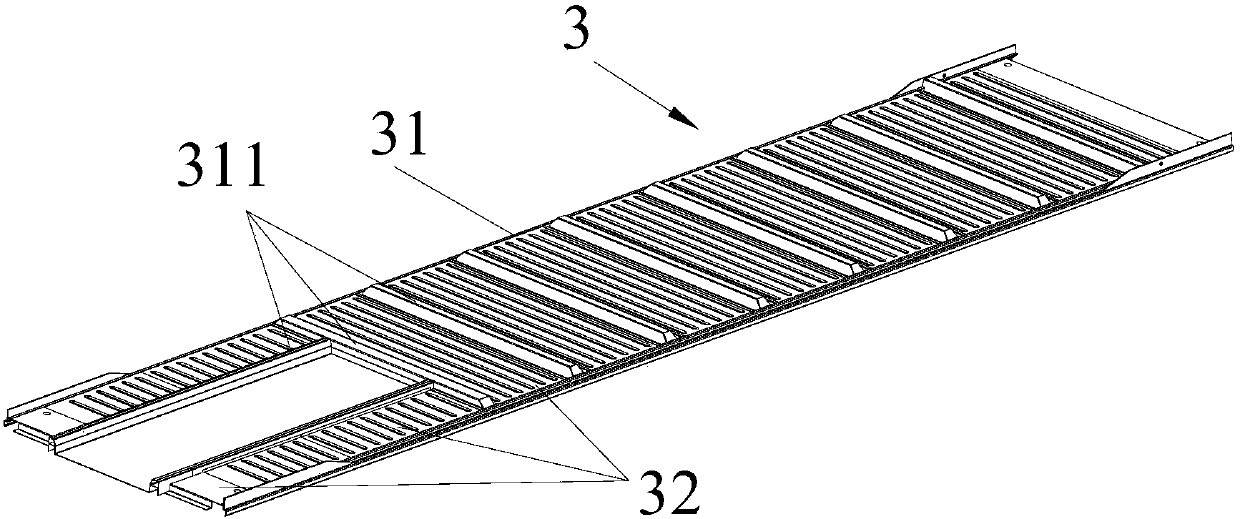

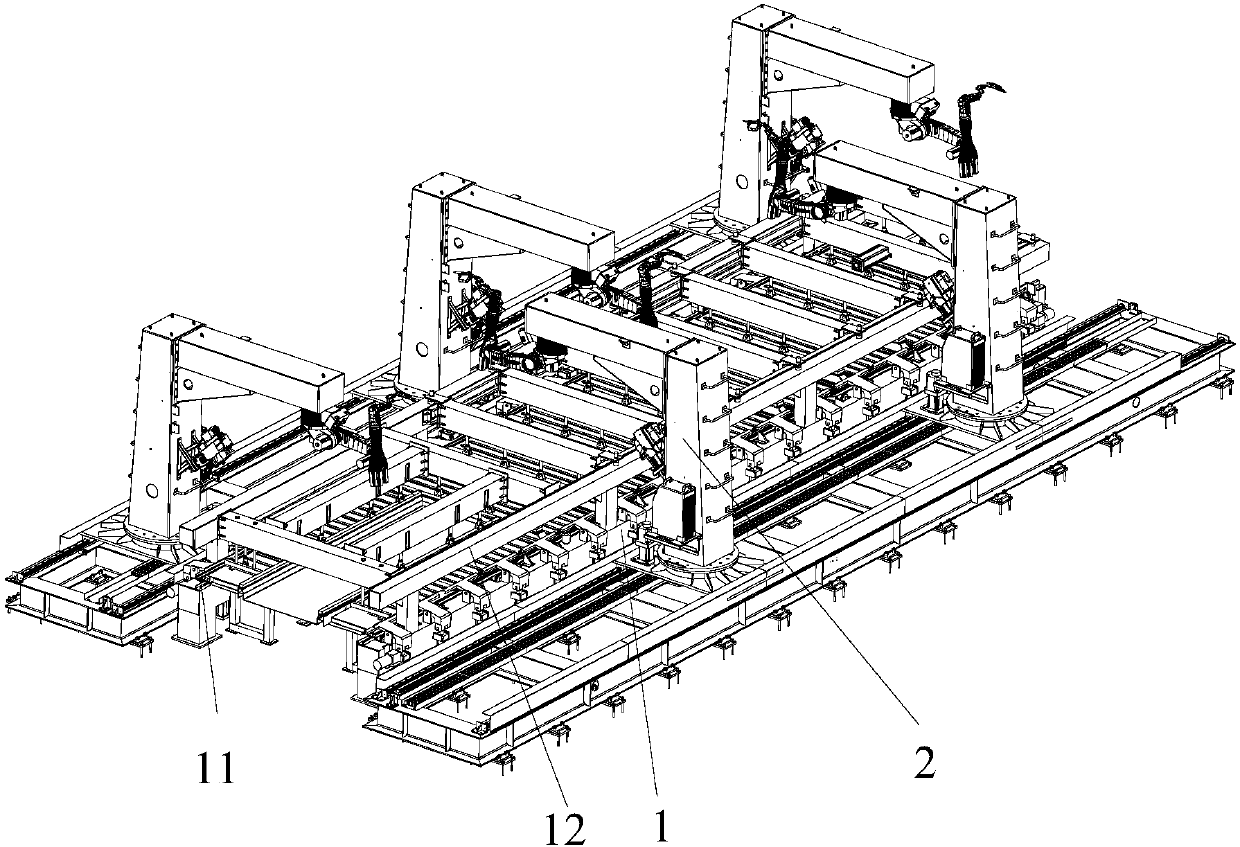

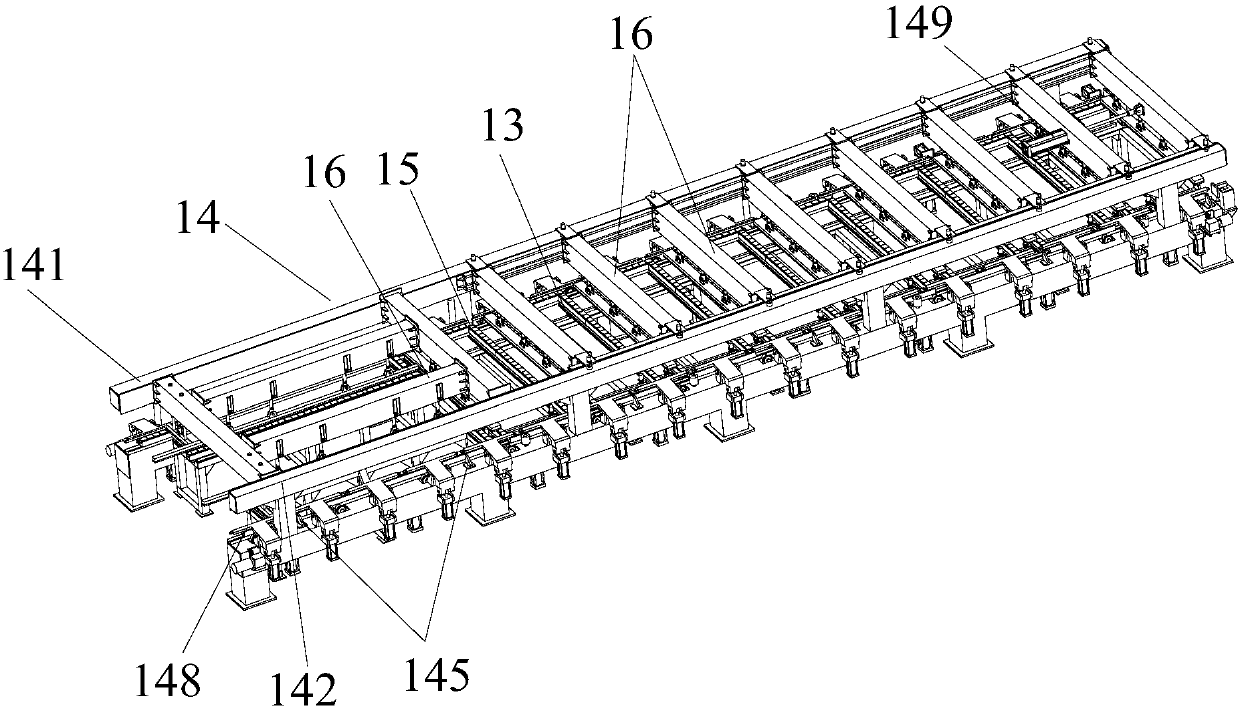

Workpiece thin plate welding processing system and processing method

ActiveCN106112339BRealize automatic transportationAccurate welding positioningWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMachining system

Owner:CHANGSHA CTR ROBOTICS

A longitudinal seam welding device and welding method for the inner wall of a storage tank

ActiveCN107755856BSimple structureReasonable designElectrode supporting devicesDomestic vesselsControl systemWelding power supply

The invention discloses a longitudinal seam welding device for the inner wall of a storage tank and relates to the field of equipment manufacturing. The longitudinal seam welding device comprises a movable welding trolley. The movable welding trolley is provided with a cooling platform, a welding platform and a wire feeding platform which are sequentially arranged in the horizontal direction. Thewire feeding platform is divided into an upper-layer platform body and a lower-layer platform body. A wire feeder and a wire feeding overturning mechanism are arranged on the upper-layer platform body. A welding power source is arranged on the lower-layer platform body. A detachable vertical position welding trolley and a welding trolley guide rail are arranged on the welding platform. A cooling water tank and a cooling water circulation system are arranged on the cooling platform. A digital control and electrical apparatus control system is arranged on one side of the cooling platform. A gascylinder frame assembly is arranged on one side of the wire feeding platform. All the components are electrically connected with the digital control and electrical apparatus control system. By the adoption of the device, the automatic welding solution of vertical seams under the pure inverted mounting construction process of a vertical cylinder body and the inner side of the vertical cylinder bodyis provided, the comprehensive automatic operation is achieved, and the production efficiency is improved greatly.

Owner:南京奥特自动化有限公司

Synchronous pressure welding device

InactiveCN114833435ARealize spot weldingAchieving horizontal give wayResistance electrode holdersNuclear energy generationGear wheelControl engineering

The invention provides a synchronous pressure welding device, and relates to the technical field of welding equipment. Comprising a horizontal moving mechanism, a vertical moving mechanism and a welding mechanism, the welding mechanism is connected with the vertical moving mechanism through a first sliding rail, and the vertical moving mechanism is connected with the horizontal moving mechanism through a second sliding rail; the welding mechanism comprises a fixing base, a pressurizing air cylinder, a synchronous gear assembly and two electrodes, the two electrodes are oppositely arranged on two mounting frames, the two mounting frames are connected with two movable sliding blocks correspondingly, the inner side walls of the two movable sliding blocks are connected with the side wall of the fixing base through third sliding rails, and the pressurizing air cylinder is connected with one movable sliding block; the synchromesh gear assembly comprises a synchromesh gear, an upper rack and a lower rack, wherein the upper rack and the lower rack are meshed with the synchromesh gear. The two racks are connected with the two movable sliding blocks through connecting pieces correspondingly. The welding device is balanced in welding pressure, capable of adapting to welding positions of strip springs of different batches, capable of horizontally moving, high in horizontal receding matching degree and accurate in welding positioning.

Owner:成都纽安能杰自动化科技有限公司

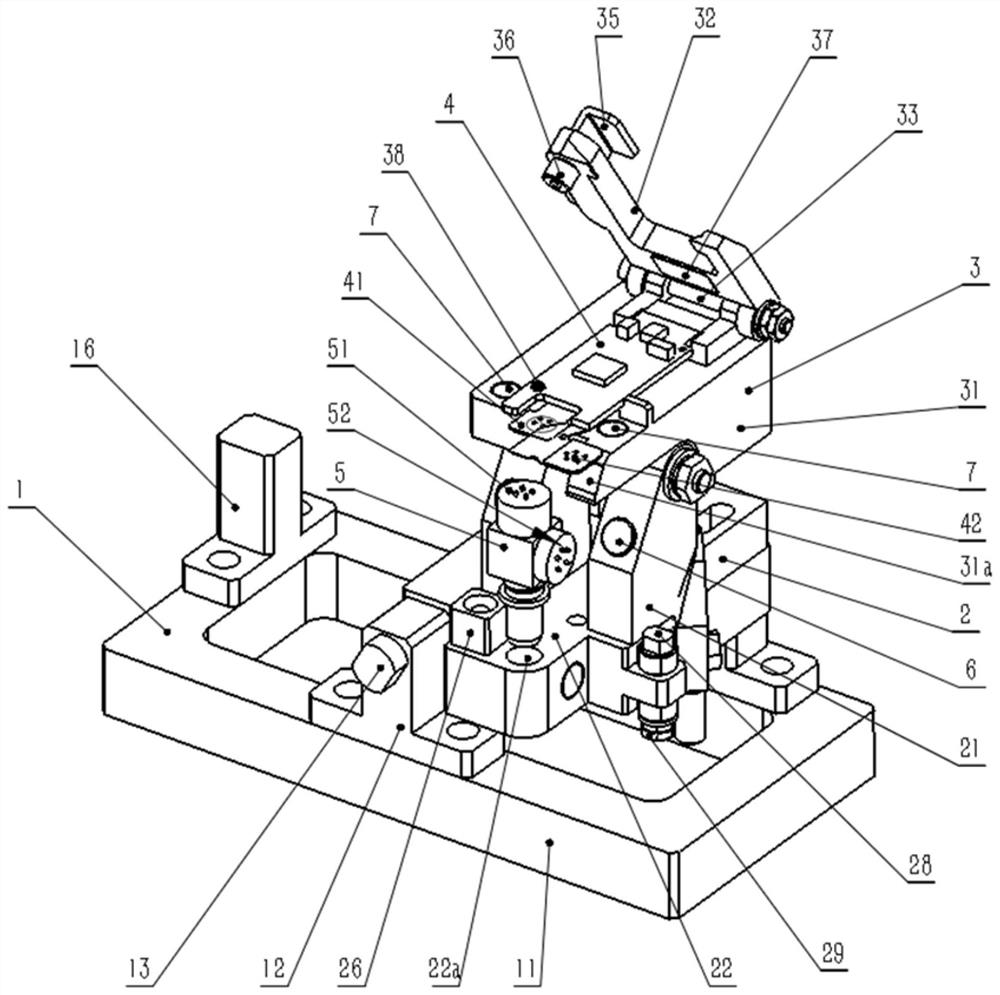

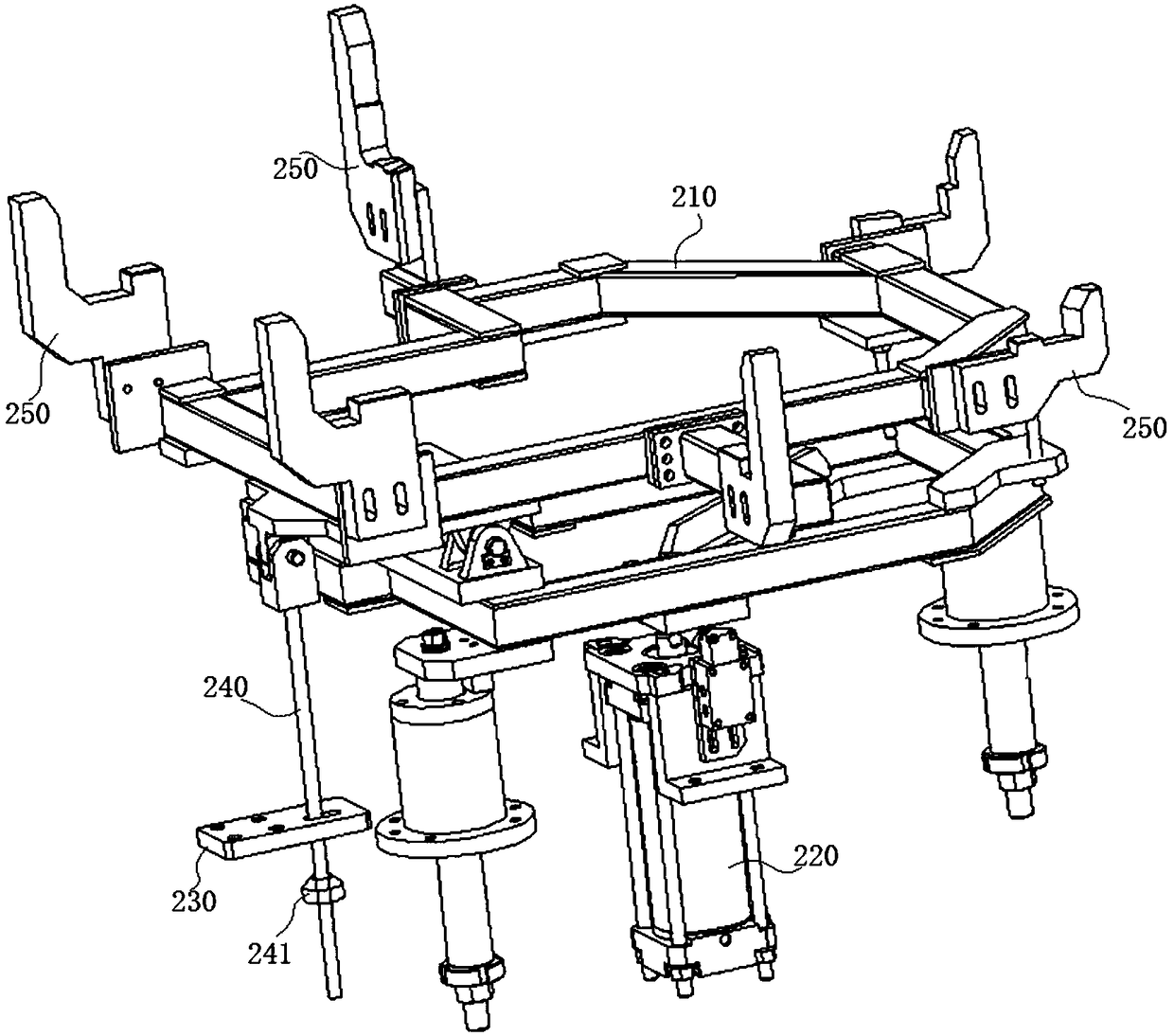

Welding positioning device for automobile sheet metal parts

ActiveCN108788596APrecision weldingAccurate welding positioningWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMetal

The invention discloses a welding positioning device for automobile sheet metal parts and belongs to the field of automobile welding. The welding positioning device for automobile sheet metal parts comprises a substrate. A placing platform for supporting a workpiece is arranged on the substrate, a plurality of upper edge claw units for locking the edge of the workpiece and upper hole claw units for locking hole positions in the workpiece are arranged around the placing platform, and upper hole positioning units are arranged at the upper ends of the upper hole claw units. The welding positioning device for automobile sheet metal parts disclosed by the invention overcomes the defect that the automobile welding positioning precision is not high in the prior art. The invention provides the welding positioning device for automobile sheet metal parts. The welding positioning device for automobile sheet metal parts can position and clamp the sheet metal parts precisely, so that the welding quality is guaranteed.

Owner:芜湖安韬谱智能装备股份有限公司

An ultra-thin optical reflective input device switch module with tooth structure

ActiveCN105118714BSimple structureLow costElectric switchesEmergency protective devicesEngineeringCam

The present invention discloses an ultrathin optical reflective input equipment switch module possessing a tooth-shaped structure. The ultrathin optical reflective input equipment switch module possessing the tooth-shaped structure comprises a keycap, a key shaft, a spring, an upper fixing shell, a lower fixing shell and a PCB, and an ultrathin reflective photoelectric keyboard switch module also comprises a light emitting device and a light receiving device. A light path channel is formed between the light emitting device and the light receiving device and comprises a light path switch, and the light path switch comprises a rack located below the keycap and a gear or a cam located on the PCB. By pressing the keycap, the rack located therebelow moves up and down to drive the gear or the cam to do the radial rotary movement, thereby conducting or disconnecting the light path channel. The ultrathin optical reflective input equipment switch module possessing the tooth-shaped structure has the characteristics of being simple in structure, low in cost and low in switch module height, being convenient to assemble, etc., and the height of the ultrathin optical reflective input equipment switch module is only 1 / 3-1 / 4 of the height of a conventional mechanical shaft keyboard.

Owner:MIKOLTA OPTICAL TECH CO

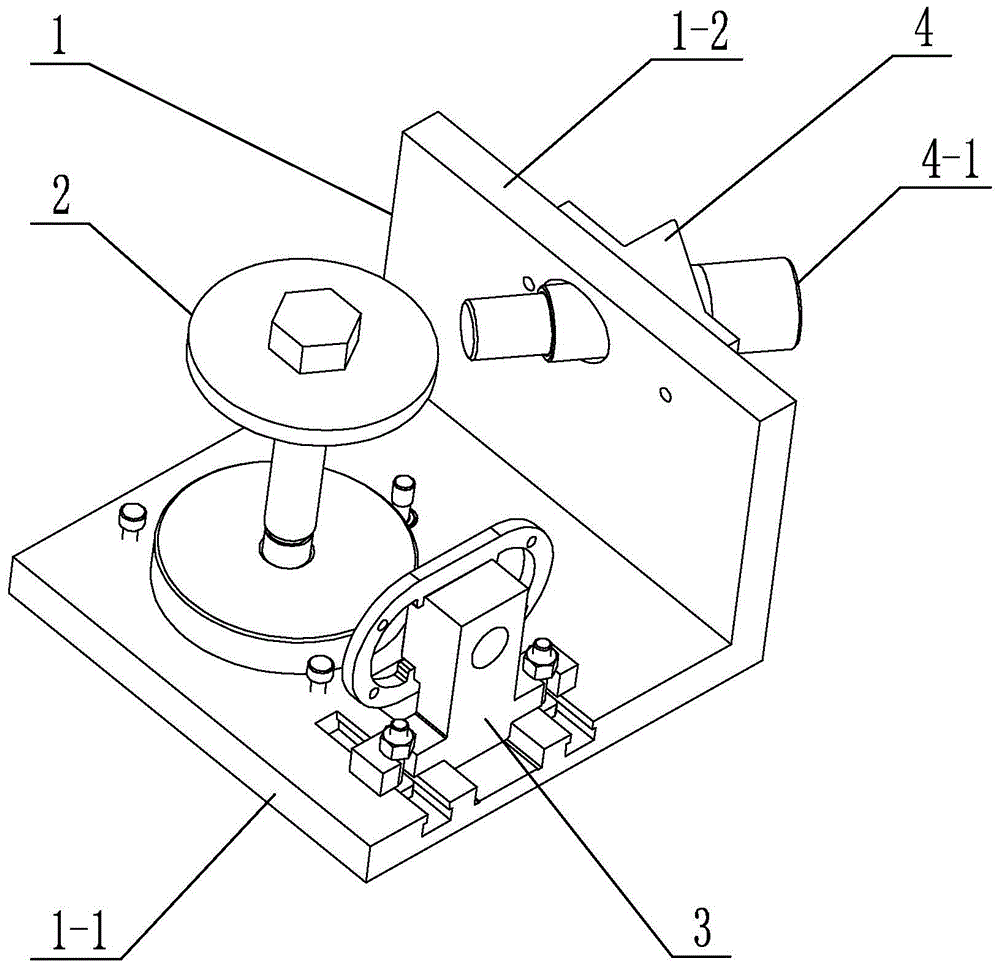

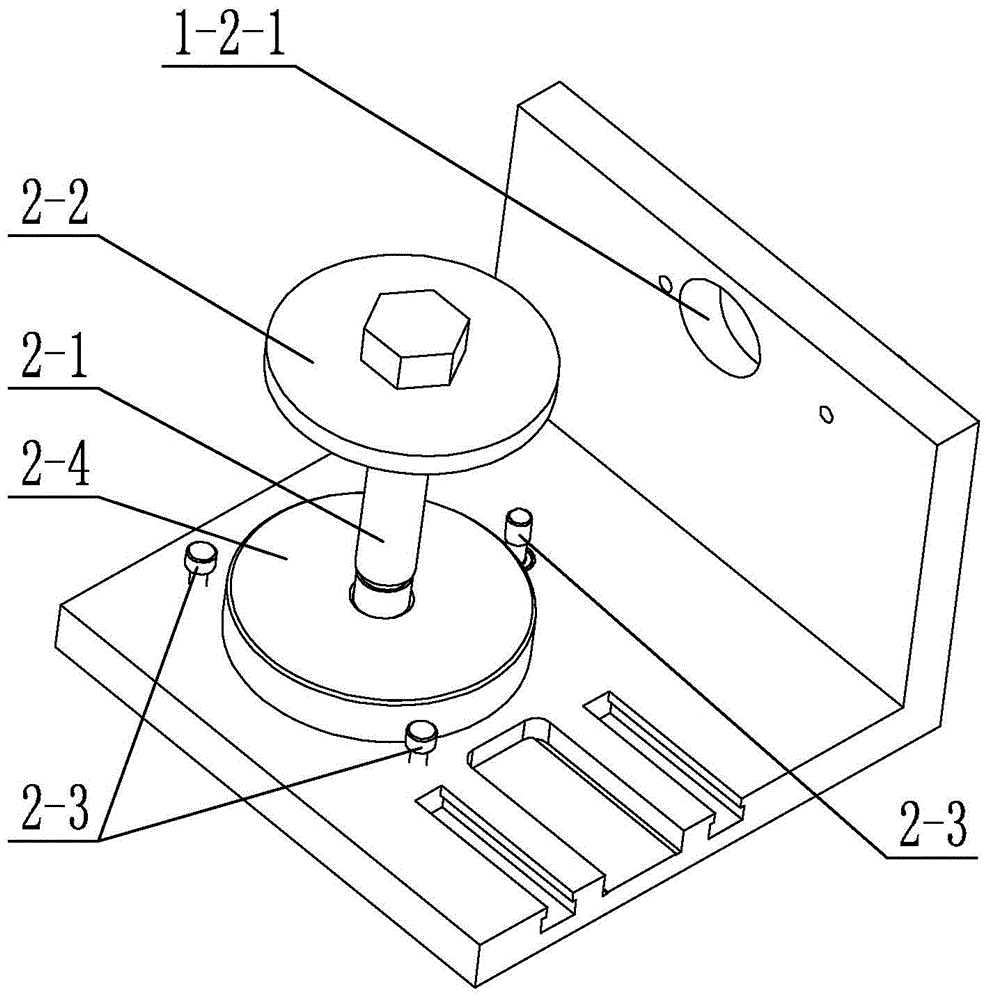

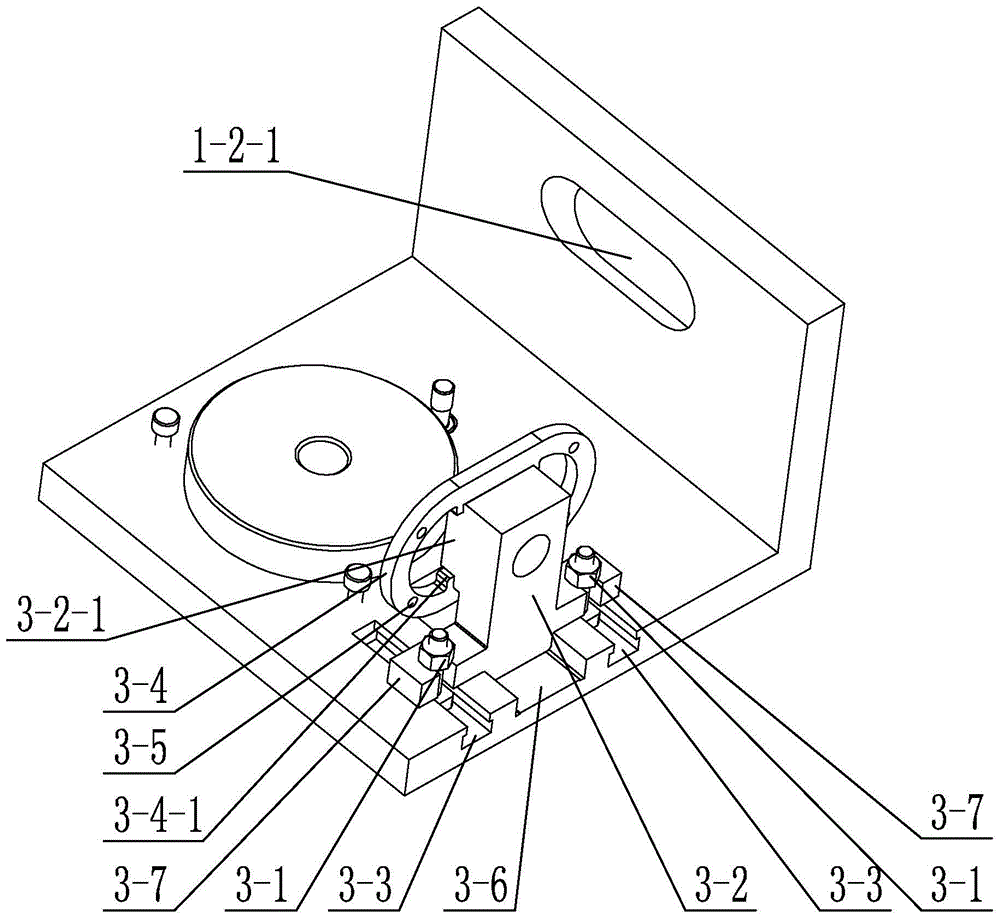

A Multidirectional Positioning Fixture for Turbo Pump Welding

InactiveCN105234619BFit tightlyAccurate welding positioningWelding/cutting auxillary devicesAuxillary welding devicesSpray nozzleEngineering

The invention relates to a multidirectional positioning clamp and discloses a multidirectional positioning clamp for welding of a turbopump. The problem that gaps between all parts of a body part of an existing turbopump structure exist in the welding process to seriously affect the welding quality is solved. The multidirectional positioning clamp for welding of the turbopump comprises an L-shaped operation board, a vertical positioning assembly, a transverse positioning assembly and a nozzle positioning assembly, wherein the L-shaped operation board comprises a horizontal board and a vertical board which are perpendicularly arranged and are fixedly connected into a whole; the vertical positioning assembly and the transverse positioning assembly are arranged on the horizontal board; the transverse positioning assembly is located in front of the vertical positioning assembly; the nozzle positioning assembly is arranged on the vertical board; a mandrel is sleeved with a pump shell, a diversion outer shell and a pump base of the turbopump in sequence from top to bottom; a compression pressure block is tightly attached to the pump shell of the turbopump; a compression pressure sheet is fixedly connected to the end face, close to the mandrel, of a transverse positioning block and tightly attached to an air inlet flange of the turbopump. The multidirectional positioning clamp for welding of the turbopump is used for the welding process of the turbopump.

Owner:HARBIN INST OF TECH

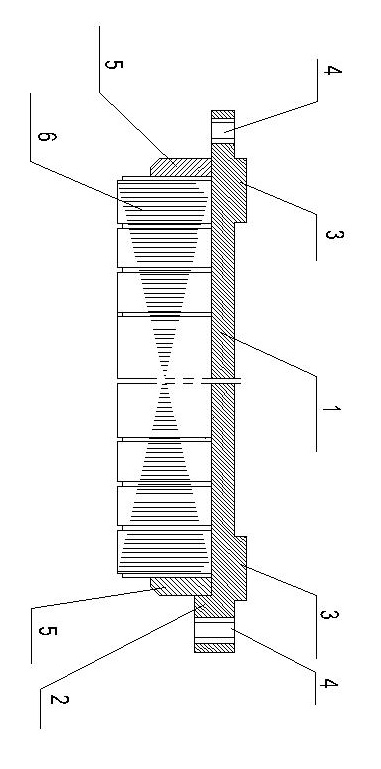

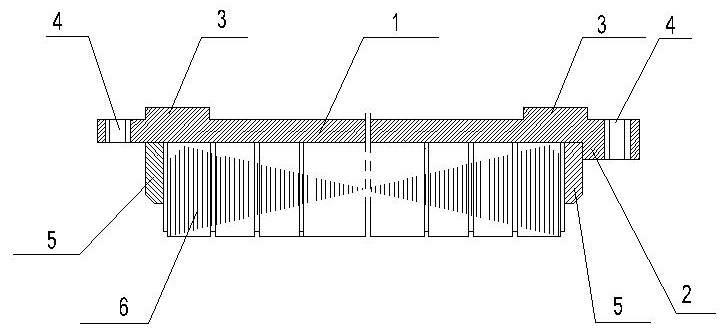

Stator rib for motors

InactiveCN102355095AAccurate welding positioningPrecise positioningManufacturing dynamo-electric machinesEngineeringSteel bar

The invention belongs to the technical field of motor processing production. For solving the technical problems of processing difficulty and efficiency reduction caused by taking steel bars as stator ribs currently, the invention adopts a technical scheme as follows: a stator rib for motors comprises a quadrate steel bar; and the stator rib for motors is characterized in that a stator pressing-ring clamped platform is processed on the back of one end of the quadrate steel bar, two looped rib plate clamped platforms are processed on the front face of the quadrate steel bar, and screwed holes for installing a motor wind deflector are processed at the two ends of the quadrate steel bar. When the stator rib is welded to a stator core, the positioning is accurate, the subsequent processing is simple, and the efficiency is high; and when the stator core and a motor base are assembled, the positioning is easy, and a position relation between the stator core and the motor base can be guaranteed.

Owner:SHANDONG HUALI ELECTRIC MOTOR GRP

A photoelectric integrated mechanical axis keyboard switch module

The invention discloses a photoelectric-integrated mechanical shaft keyboard switch module comprising a housing, a button cap installed on the upper part of the housing, and a driving device, a photoelectric switch, a moving optical assembly and a fixed optical assembly which are arranged in the housing. The moving optical assembly is installed on the driving device. The photoelectric switch comprises a PCB board, and an SMD IR tube and an SMD PT tube which are integrated on the PCB board. By pressing the button cap, the driving device is enabled to drive the moving optical assembly to move up and down, thereby controlling the relative position between the moving optical assembly and the fixed optical assembly. When light emitted by the SMD IR tube is coupled to the SMD PT tube, a light path is conducted, and the photoelectric switch is switched on; and when the light emitted by the SMD IR tube cannot be coupled to the SMD PT tube, the light path is open, and the photoelectric switch is switched off. The photoelectric-integrated mechanical shaft keyboard switch module has the advantages that the manual and welding cost is greatly lowered, the welding positioning is accurate, the production efficiency is high, and the quality stability of the product is high.

Owner:DONG GUAN LONGIDEAL IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com