Automatic electric resistance welding equipment for hoop spring hook

A spring hook, resistance welding technology, applied in resistance welding equipment, welding equipment, welding equipment and other directions, can solve the problems of complex spring hook shape, long welding time for a single piece, difficult quality control, etc., to improve working conditions and welding time. Long, smooth appearance weld

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

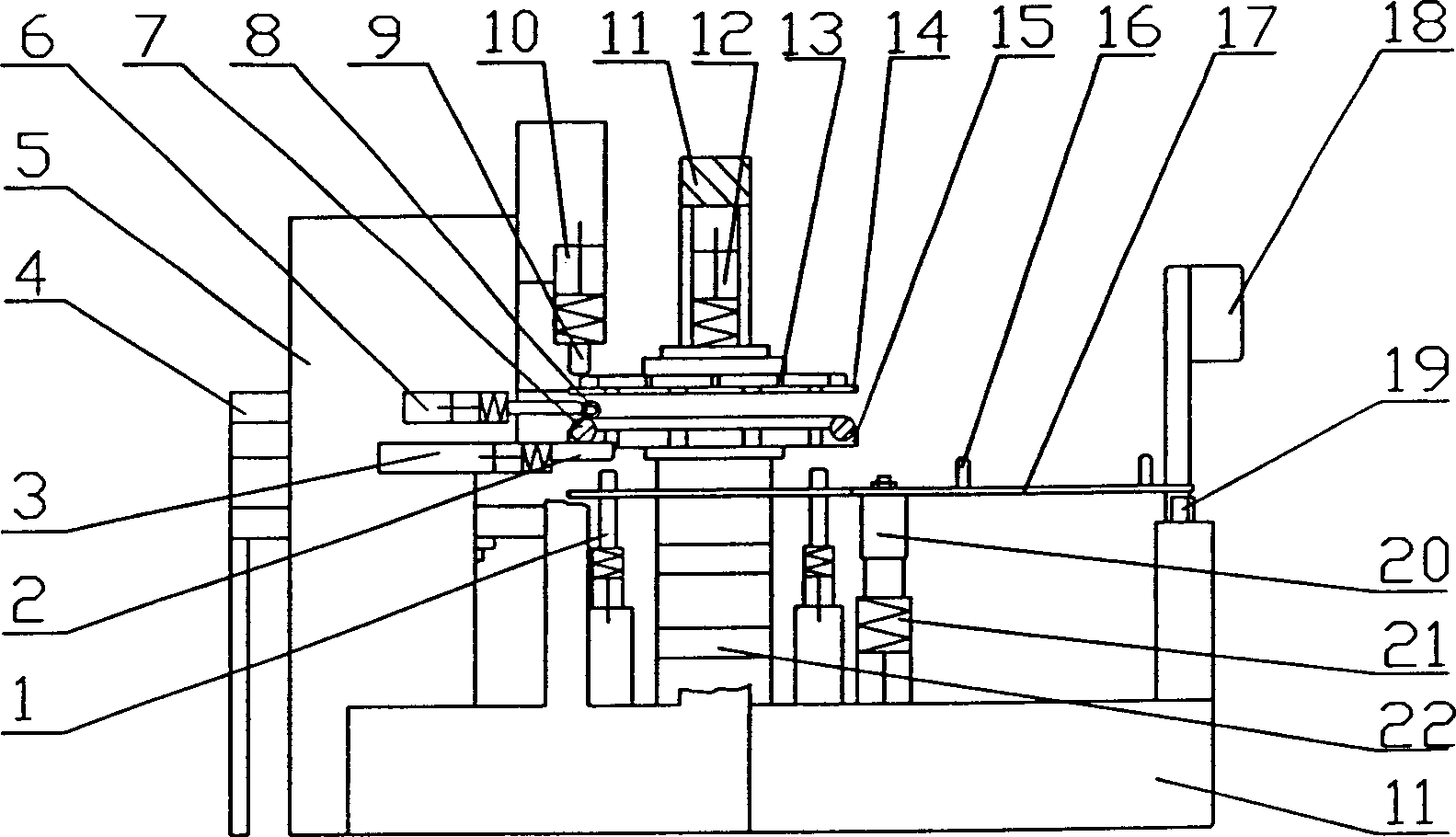

[0014] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0015] The automatic resistance welding equipment of the basket spring hook is composed of a feeding mechanism, a resistance welding machine 5, a basket replacement and rotation pressing mechanism and a console 18 fixed on the bracket 11.

[0016] Feeding mechanism: a vibrating motor 25 is installed at the center of the bottom of the discharge tray 4. There is a groove-shaped outlet matching the shape of the spring hook 8 around the discharge tray 4, and a high-pressure gas nozzle 24 is arranged at the outlet, and the gas The station continuously supplies high-pressure gas to the spray head 24 through the pipeline.

[0017] Resistance welding machine 5: the positive electrode 9 and the negative electrode 2 are installed on the cylinder rods of the two cylinders 10 and 3 respectively. The top of the negative pole cylinder seat on the machine is also fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com