Automatic welding machine of pressure gage connector

An automatic welding machine and pressure gauge technology, applied in welding equipment, welding equipment, auxiliary welding equipment, etc., can solve the problems of inaccurate welding positioning of joints, low production efficiency, unstable quality, etc., to achieve stable product quality and improve production. Efficiency, the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

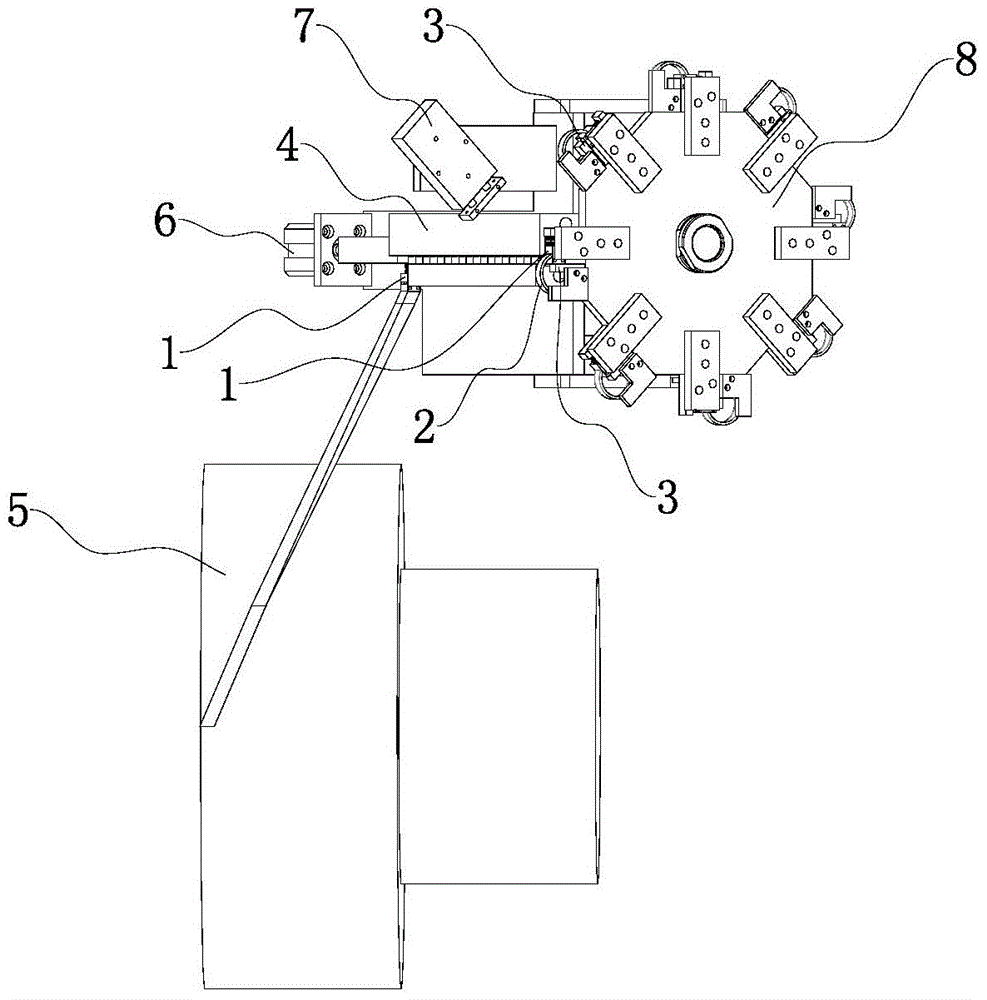

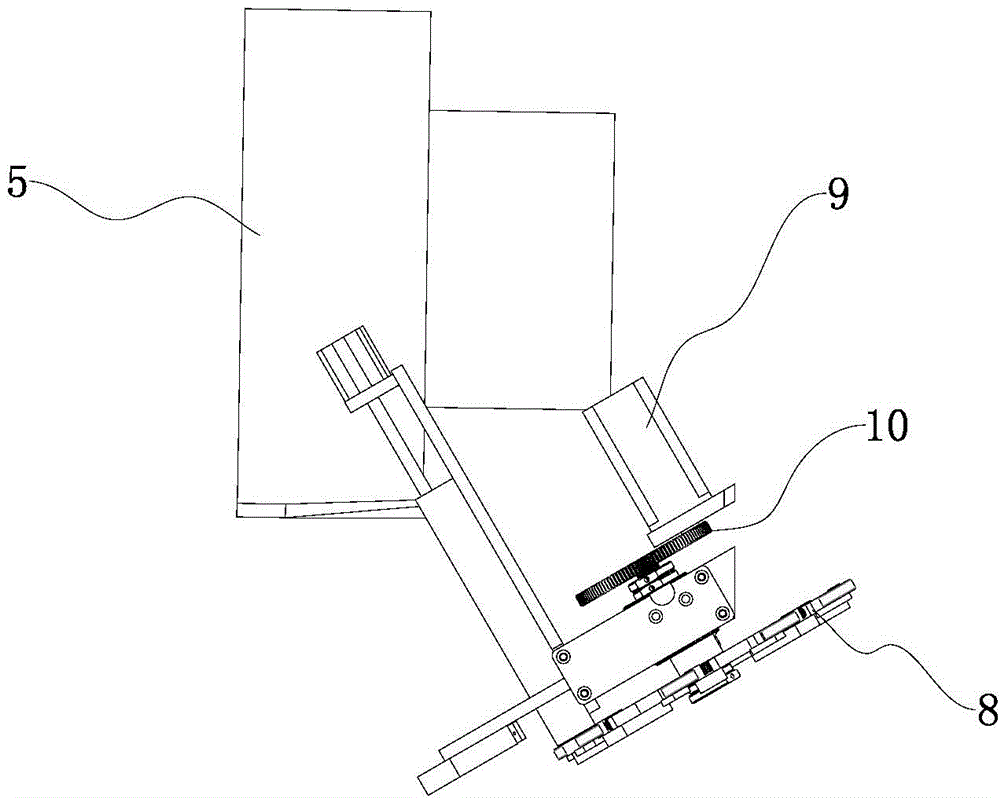

[0010] Reference figure 1 with figure 2 , The automatic welding machine for pressure gauge joints of the present invention includes a welding mold 3 for clamping the copper joint 1 and the spring tube 2, the output end of a feeding rail 4 is opposite to the welding mold 3, and the input of the feeding rail 4 The end is connected with a vibration plate 5, the feeding guide 4 is provided with a heating tube and a cylinder 6 for sending the copper joint into the welding mold, and a cooling mechanism 7 is connected to the cylinder 6. This kind of pressure gauge joint automatic welding machine uses a vibrating plate to select copper joints, which replaces manual operation and greatly improves production efficiency. The vibrating plate sends the sorted copper joints into the feeding rail guide, and the feeding rail guide is heated by the heating tube To make the internal copper joints reach the welding temperature, the cylinder 6 sends the copper joints into the welding mold 3 for w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com