A Multidirectional Positioning Fixture for Turbo Pump Welding

A technology for positioning fixtures and turbo pumps, applied in welding equipment, auxiliary welding equipment, welding/cutting auxiliary equipment, etc., can solve problems affecting welding quality, etc., and achieve the effects of improving efficiency, realizing flexible adjustment, and realizing integrated clamping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

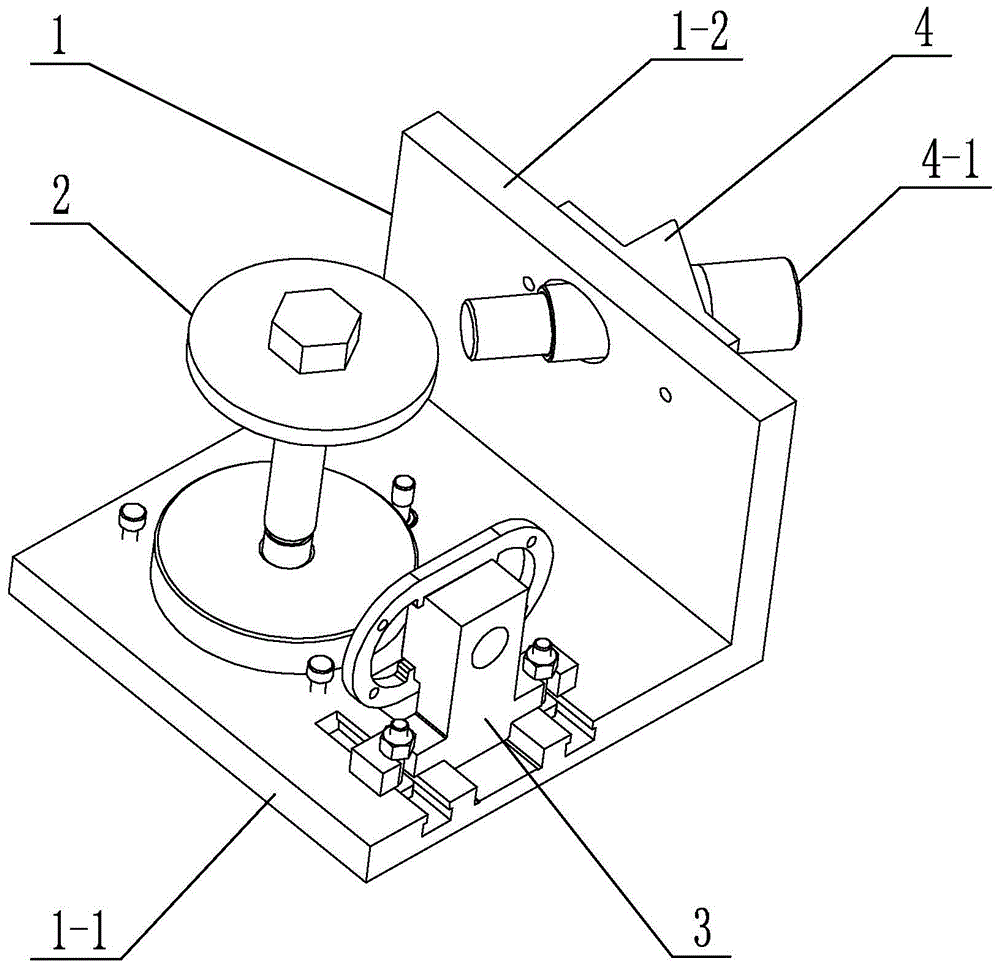

[0020] Specific implementation mode one: combine figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 Describe this embodiment. This embodiment includes an L-shaped operating panel 1, a vertical positioning assembly 2, a lateral positioning assembly 3 and a nozzle positioning assembly 4. The L-shaped operating panel 1 includes a horizontal plate 1-1 and a vertical plate 1-1. 2. The horizontal board 1-1 and the vertical board 1-2 are arranged vertically and are fixedly connected as a whole, and the vertical positioning assembly 2 and the horizontal positioning assembly 3 are both arranged on the horizontal board 1-1 and horizontally The positioning assembly 3 is located in front of the vertical positioning assembly 2, and the nozzle positioning assembly 4 is arranged on the vertical plate 1-2;

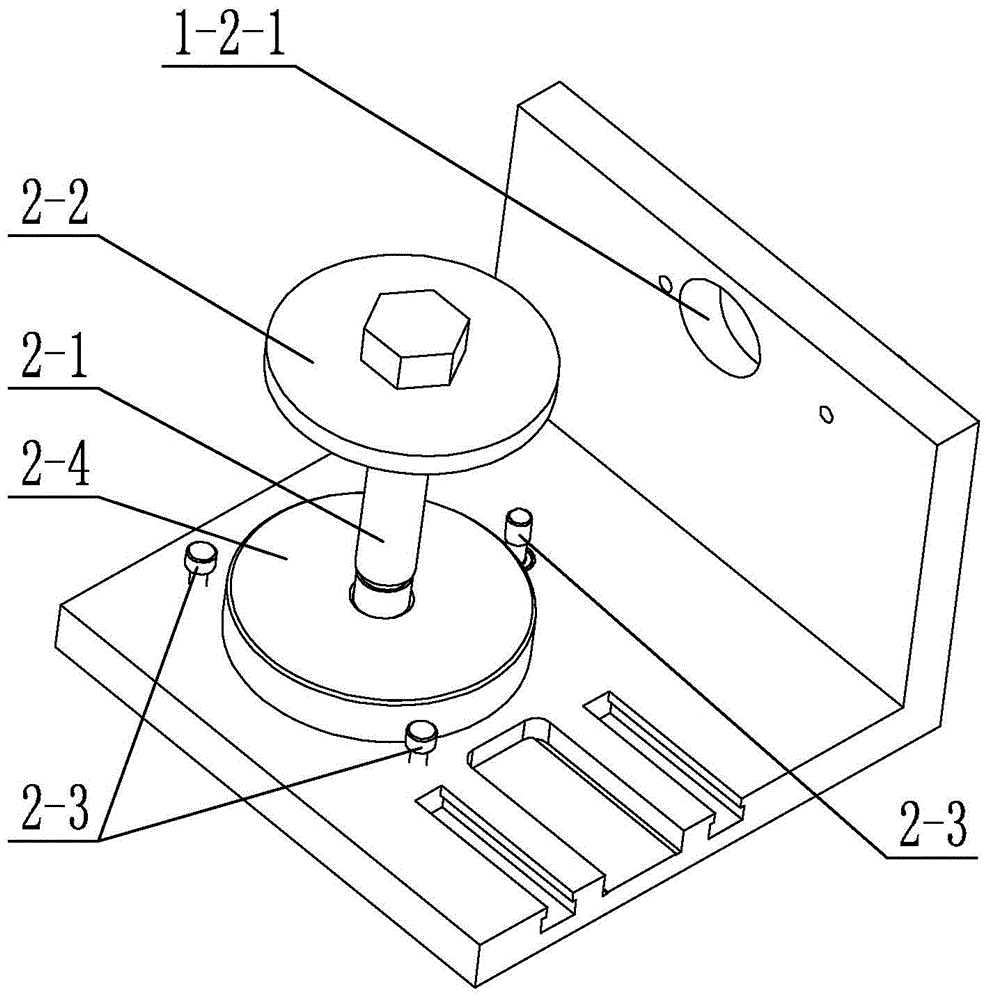

[0021] The vertical positioning assembly 2 includes a mandrel 2-1, a pressing block 2-2, a base 2-4 and at least two first fixing bolts 2-3, and the base 2-4 is fi...

specific Embodiment approach 2

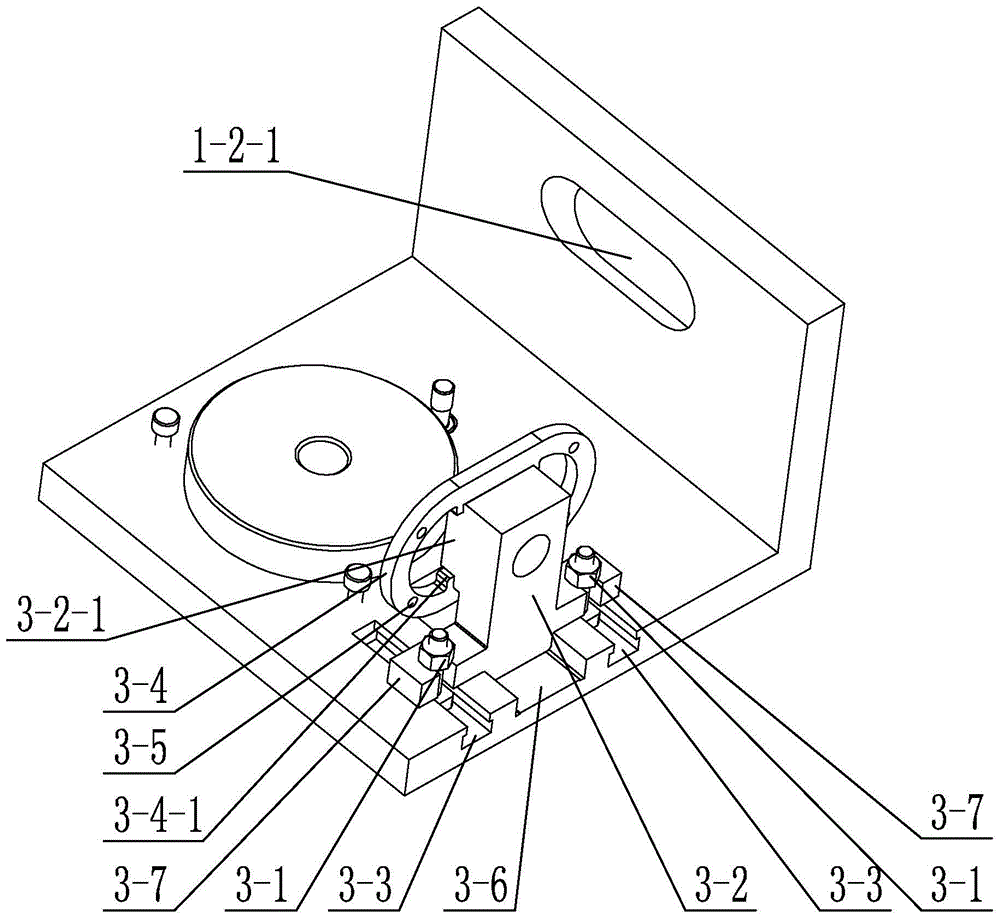

[0025] Specific implementation mode two: combination figure 1 , image 3 , Figure 4 and Figure 6 To illustrate this embodiment, the lateral positioning assembly 3 in this embodiment also includes two positioning bolts 3-1, two sub-sliding rails 3-3 and two pulling ears 3-7, and the horizontal plate 1-1 is Two sub-sliding rails 3-3 are provided, and the two sub-sliding rails 3-3 are respectively located on both sides of the main sliding rail 3-6, and each sub-sliding rail 3-3 is parallel to the main sliding rail 3-6. A positioning bolt 3-1 is arranged in the strip slide rail 3-3, and a pulling ear 3-7 is fixedly connected to both sides of the horizontal positioning block 3-2, and the pulling ear 3-7 is connected with the positioning bolt 3-1. One-to-one correspondence is provided, and each pull ear 3-7 slides and fits with the sub-slide rail 3-3 where the positioning bolt 3-1 is located through its corresponding positioning bolt 3-1.

[0026] In this embodiment, the setti...

specific Embodiment approach 3

[0027] Specific implementation mode three: combination figure 1 , Figure 4 and Figure 6 This embodiment is described. In this embodiment, both the pressing block 2-2 and the base 2-4 are disc-shaped and arranged coaxially. In this embodiment, the disc-shaped pressing block 2-2 corresponds to the shape of the pump casing 5-1, and such setting is more conducive to its close contact with the pump casing 5-1. The disc-shaped base 2-4 corresponds to the shape of the pump base 5-3, and such setting is more conducive to its close contact with the pump base 5-3. Other unmentioned structures and connections are the same as those in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com