A longitudinal seam welding device and welding method for the inner wall of a storage tank

A technology for longitudinal seam welding and storage tanks, which is applied to welding equipment, welding accessories, electrode support devices, etc., can solve the problems of low work efficiency and inability to automate operations, and achieve convenient operation, reduced labor intensity, and accurate welding positioning Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

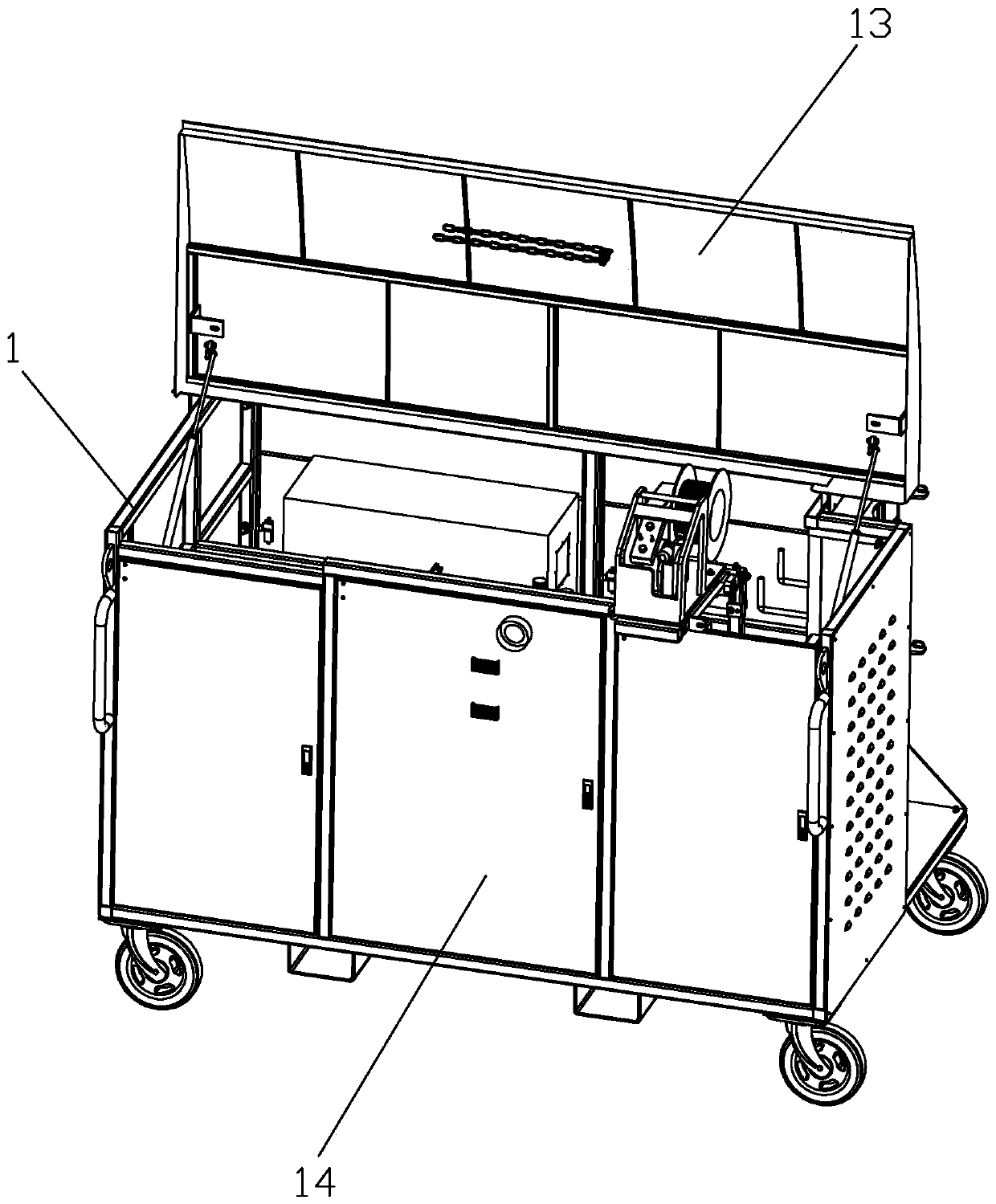

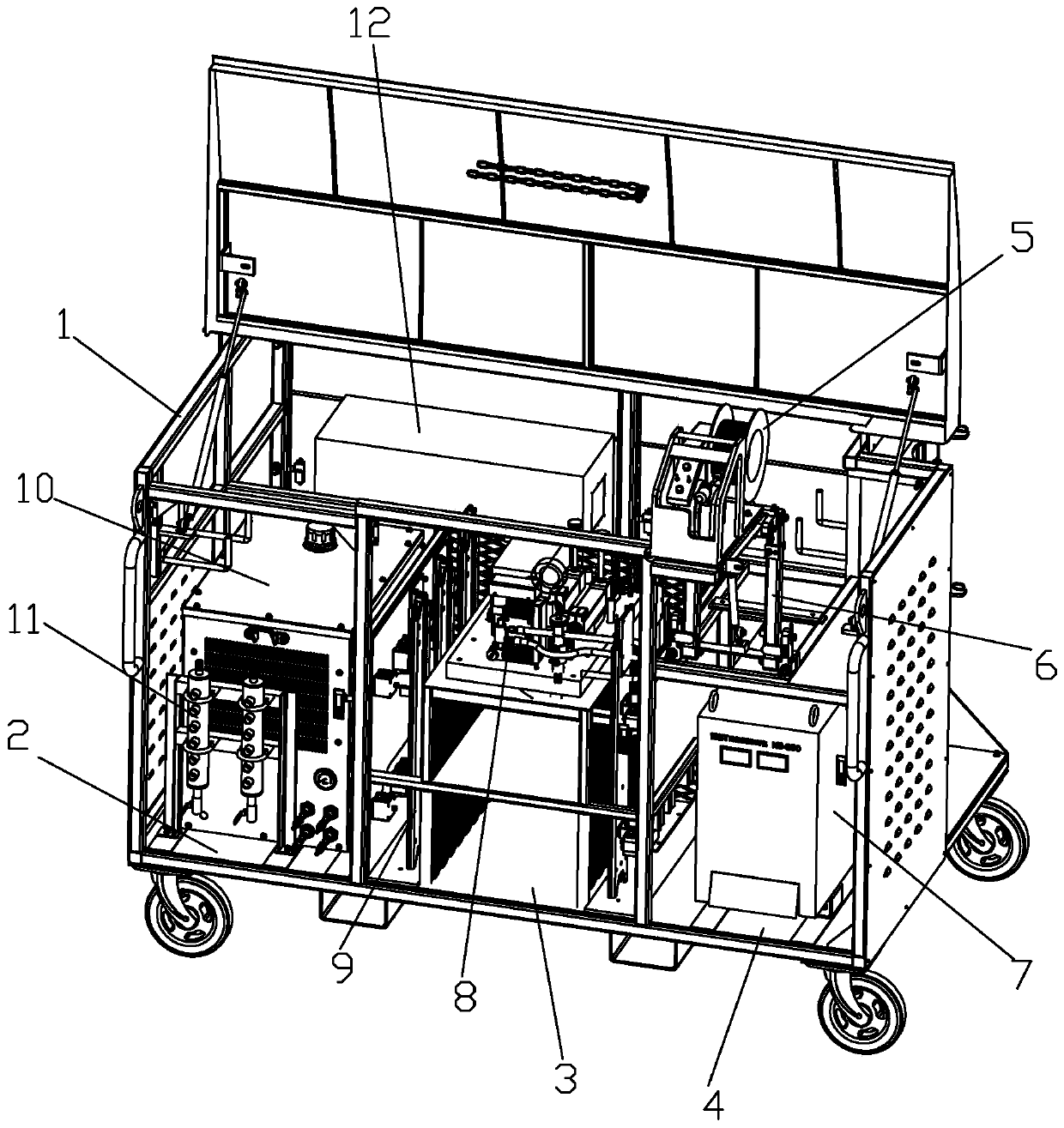

[0028] A storage tank inner wall longitudinal seam welding device provided in this embodiment has a structure such as Figure 1-5 shown.

[0029] The device includes a movable welding trolley 1, and the movable welding trolley 1 has an installation platform, and the installation platform includes a cooling platform 2, a welding platform 3 and a wire feeding platform 4 arranged in sequence along the horizontal direction. The top of the movable welding trolley 1 is provided with a hinged openable and closable flip shield 13 , and its sides are respectively provided with openable and closable safety doors 14 corresponding to the cooling platform 2 , welding platform 3 and wire feeding platform 4 .

[0030] The wire feeding platform 4 is divided into an upper platform and a lower platform. The upper platform is provided with a welding wire feeder 5 and a wire feeding turning mechanism 6 , and the lower platform is provided with a welding power source 7 . The wire feeding turning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com