Stator rib for motors

A stator rib and stator technology is applied in the manufacture of motor generators, electrical components, electromechanical devices, etc., and can solve the problems of difficult processing and reduced efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

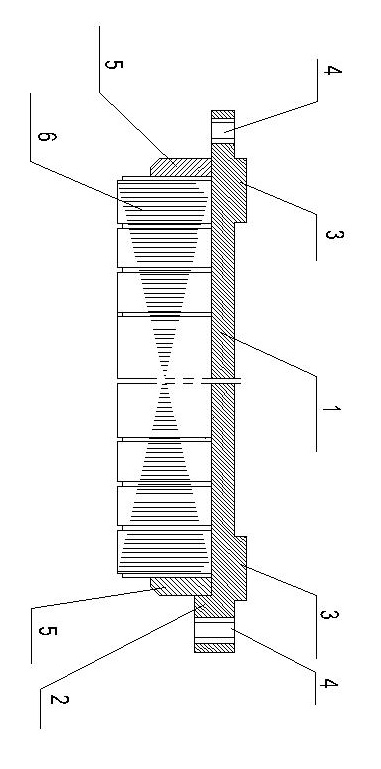

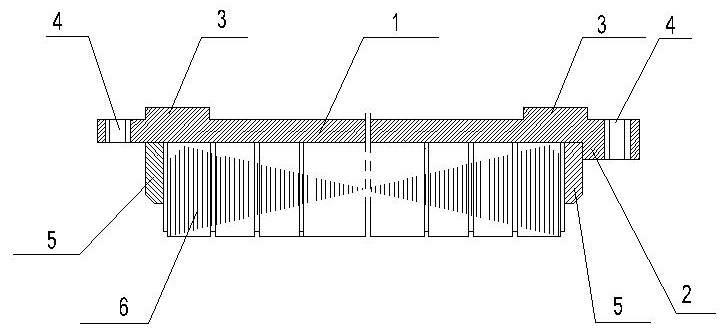

[0010] As shown in the attached picture, after 7 stacks of stator punching sheets are integrated into the motor stator, the stator ribs are evenly welded on the surface of the outer circle of the motor stator. Generally, 6 or 8 stator ribs are welded on the outer circle of the stator. Together with a sectional view of the stator.

[0011] As shown in the accompanying drawings, the stator bar includes a square bar steel 1, a stator ring holder 2 is processed on the back of one end of the square bar steel, and two ring rib plate clamps 3 are processed on the front of the square bar steel. Both ends of the bar steel are processed with threaded holes 4 for installing the motor windshield.

[0012] When processing the stator ribs, the length of the bar steel 1 is determined according to the specifications of the motor stator, and the distance between the ri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com