Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

54results about "Green and white liquor treatment" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

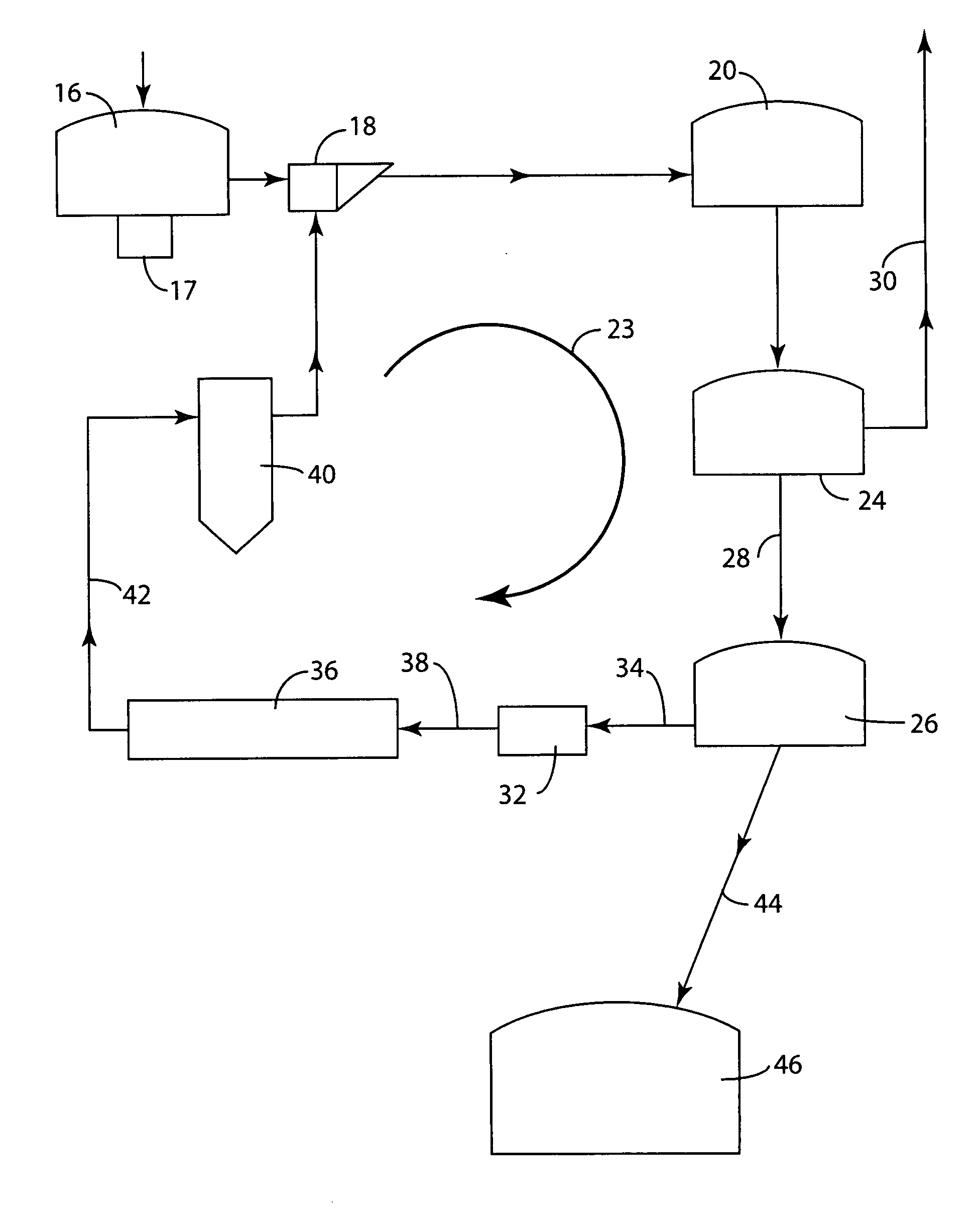

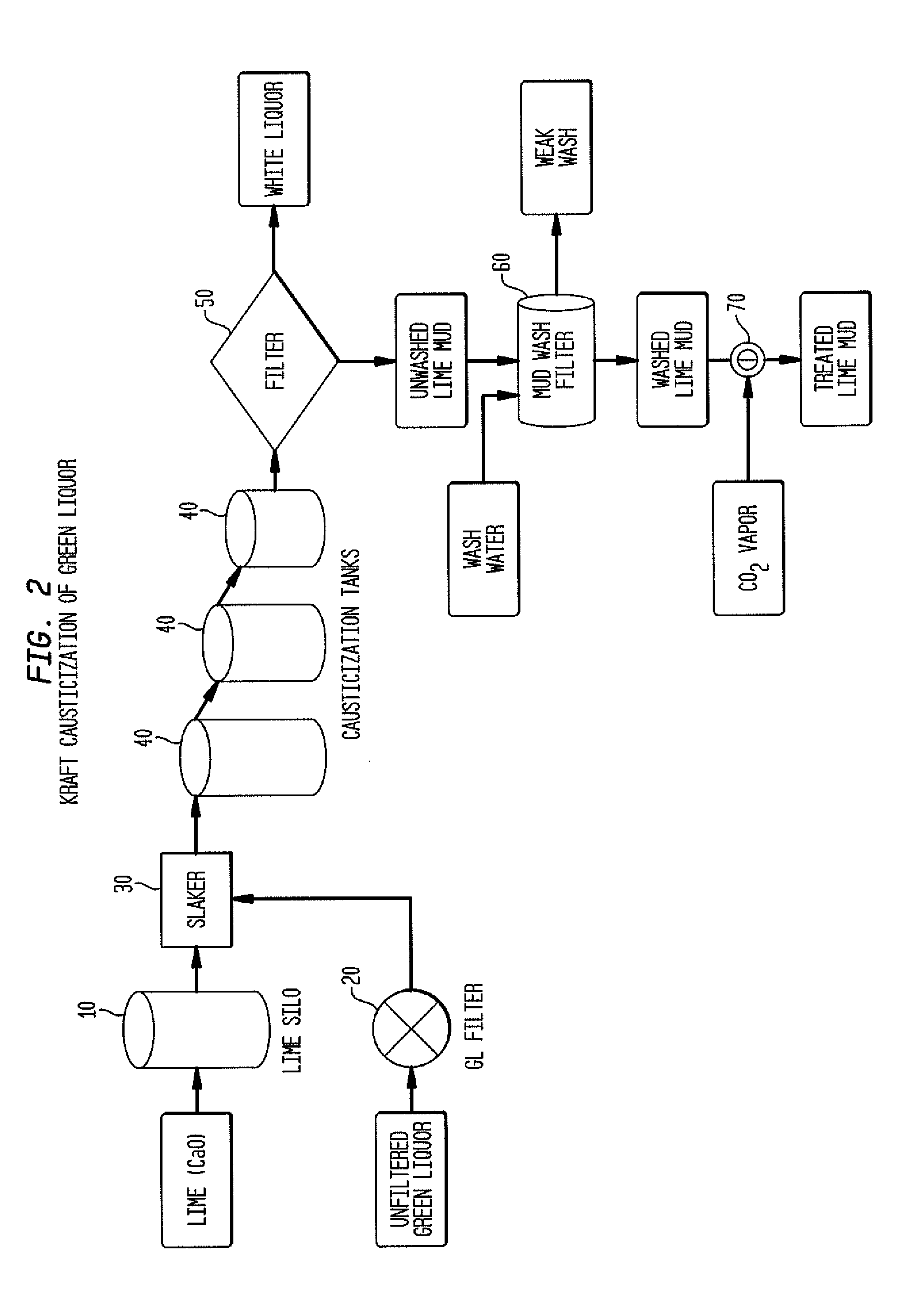

Particulate matter and methods of obtaining same from a kraft waste reclamation

InactiveUS20080219912A1Calcium/strontium/barium carbonatesGas treatmentParticulatesChemical composition

A method for obtaining particulate calcium carbonate having an average particle size less than about 12 microns is provided. The method includes the steps of (1) withdrawing from a pulp mill a mixture containing calcium carbonate; (2) treating the mixture to remove contaminants contained in the mixture to produce a treated mixture containing calcium carbonate and further having a chemical composition and / or purity which substantially inhibits the fusing together of calcium carbonate particulates; (3) recovering from the treated mixture particulate calcium carbonate having an average particle size less than about 12 microns. The calcium carbonate produced has a high surface area to volume ratio and is therefore highly reactive and suitable for numerous applications such as in the treatment of soil, filler paper production, paint production, and contaminant containment in coal stack emission assemblies.

Owner:S&S LIME

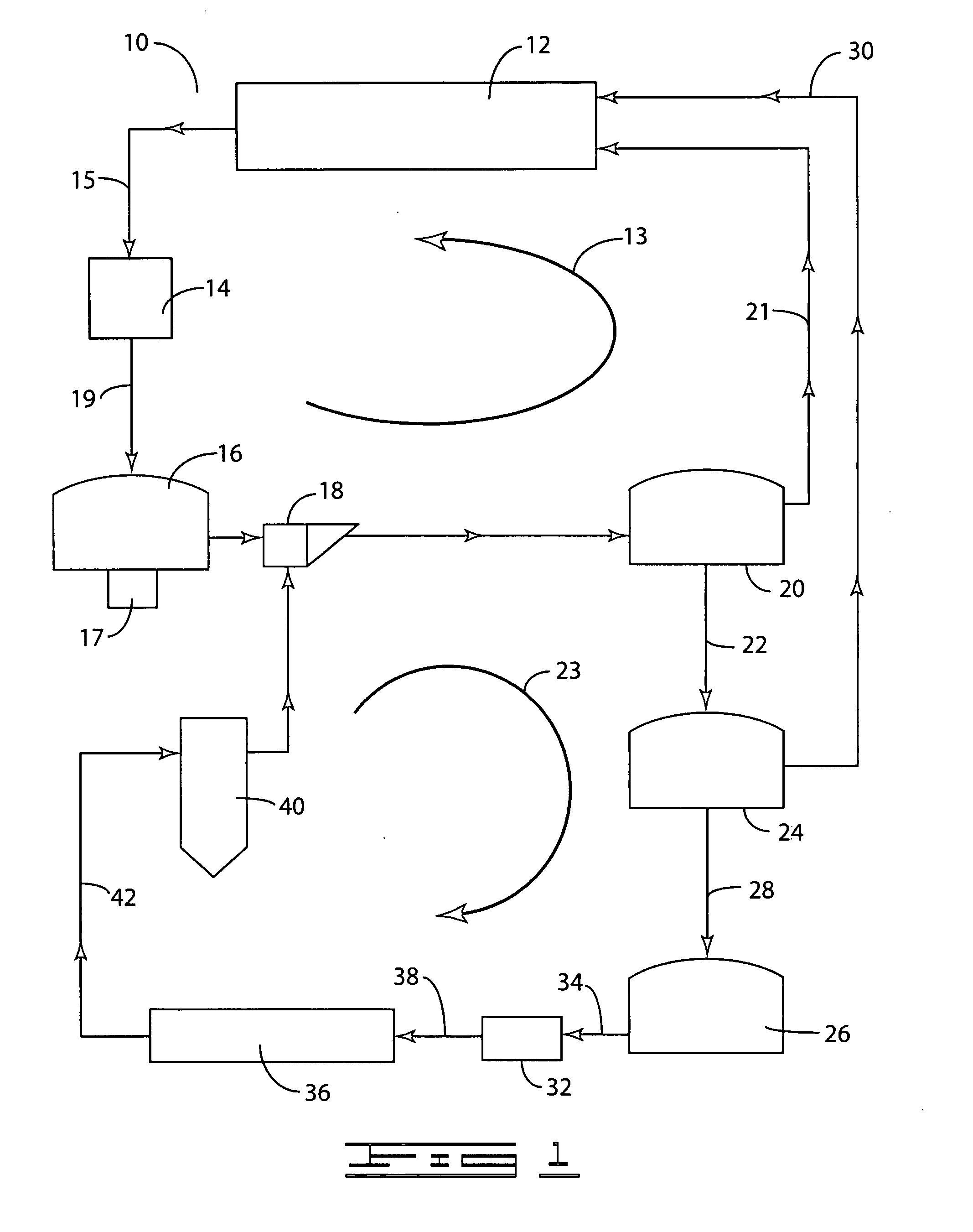

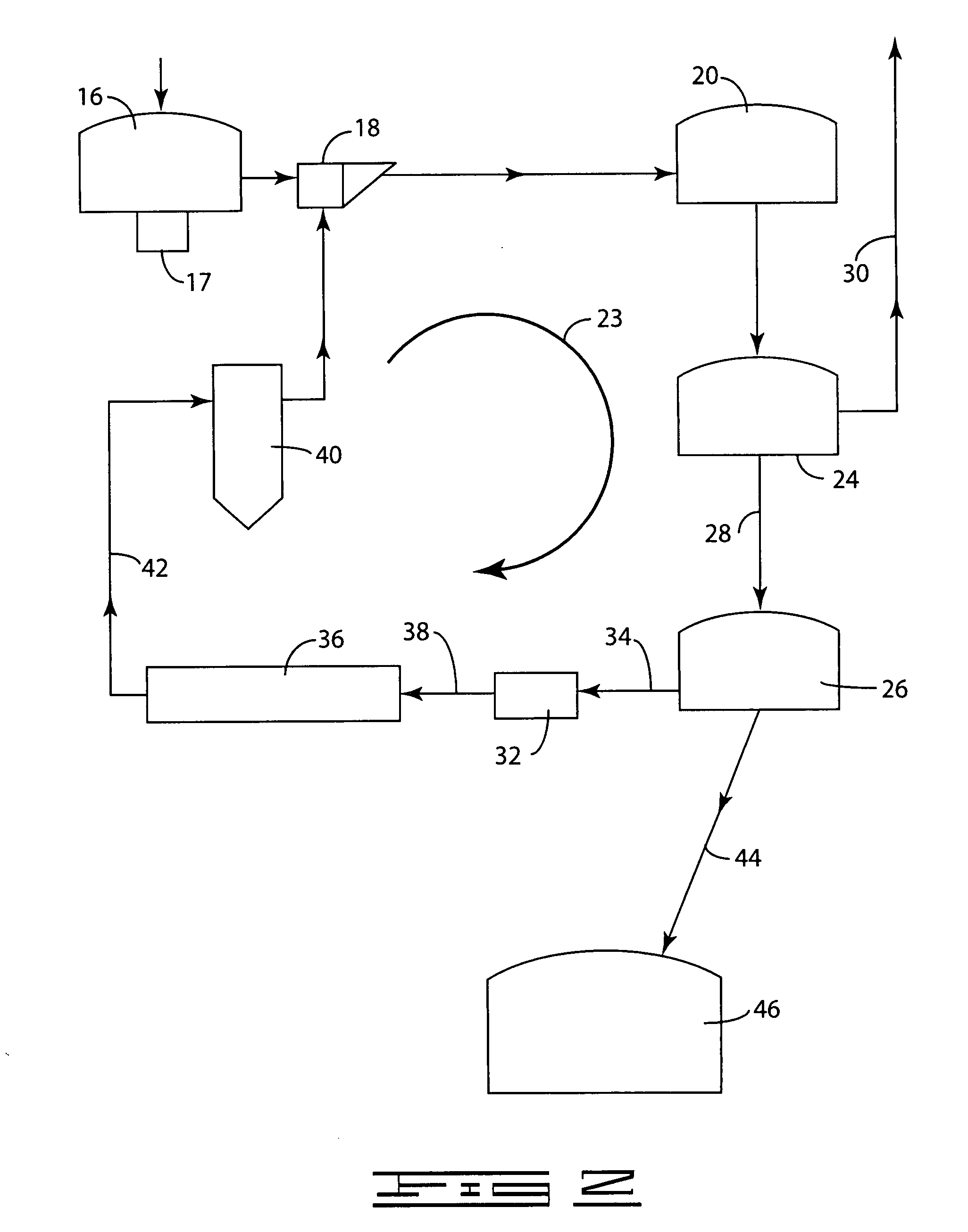

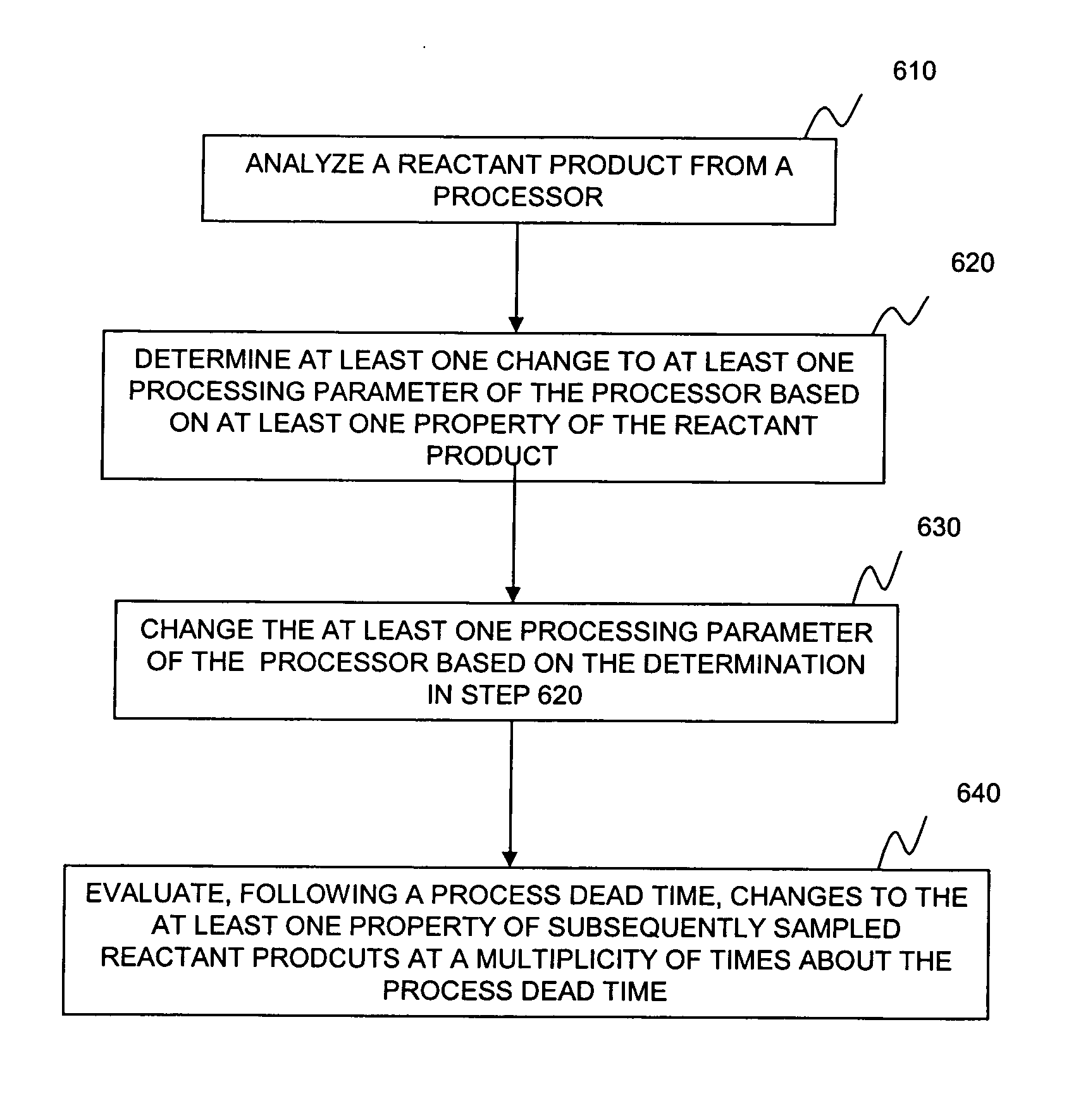

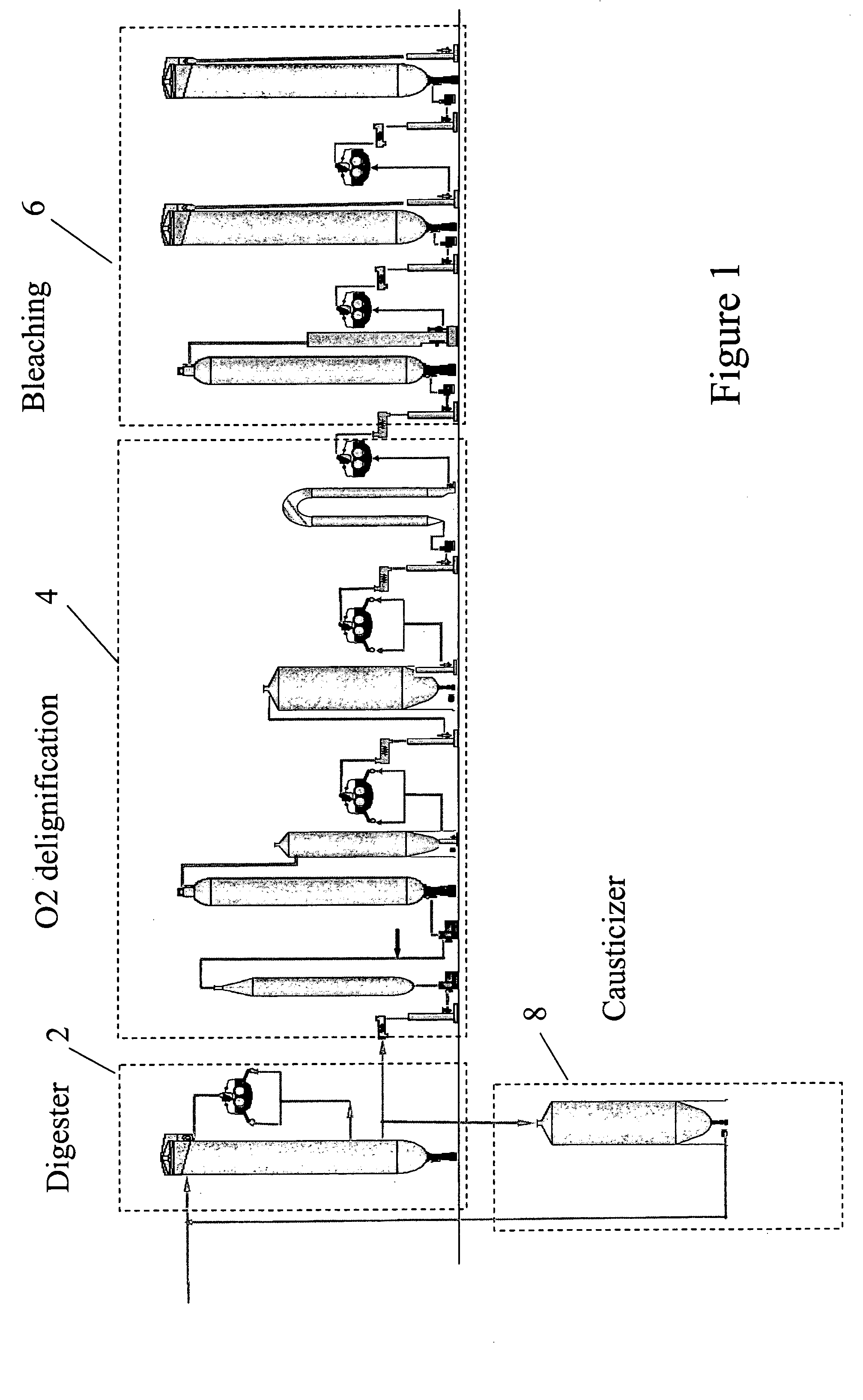

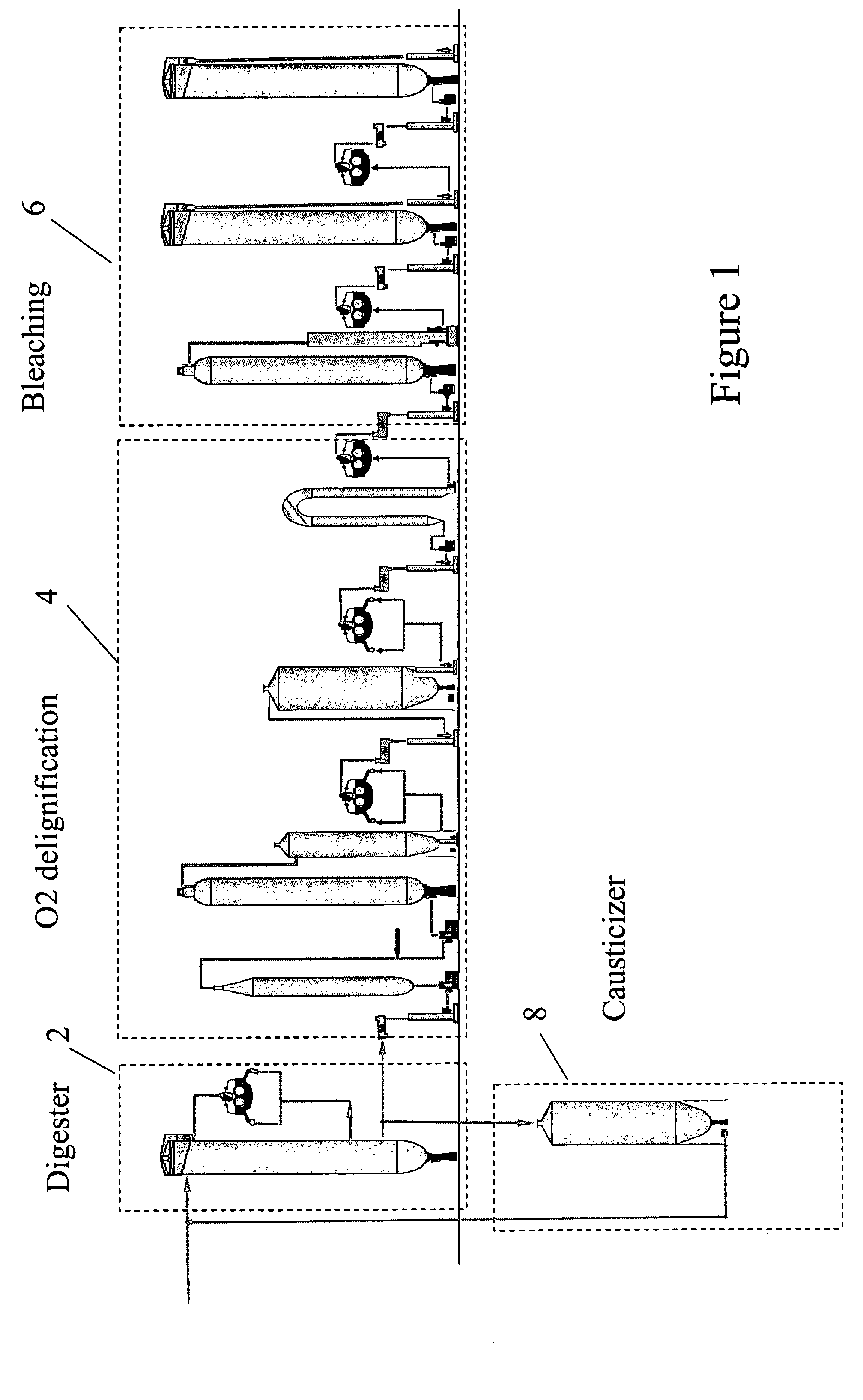

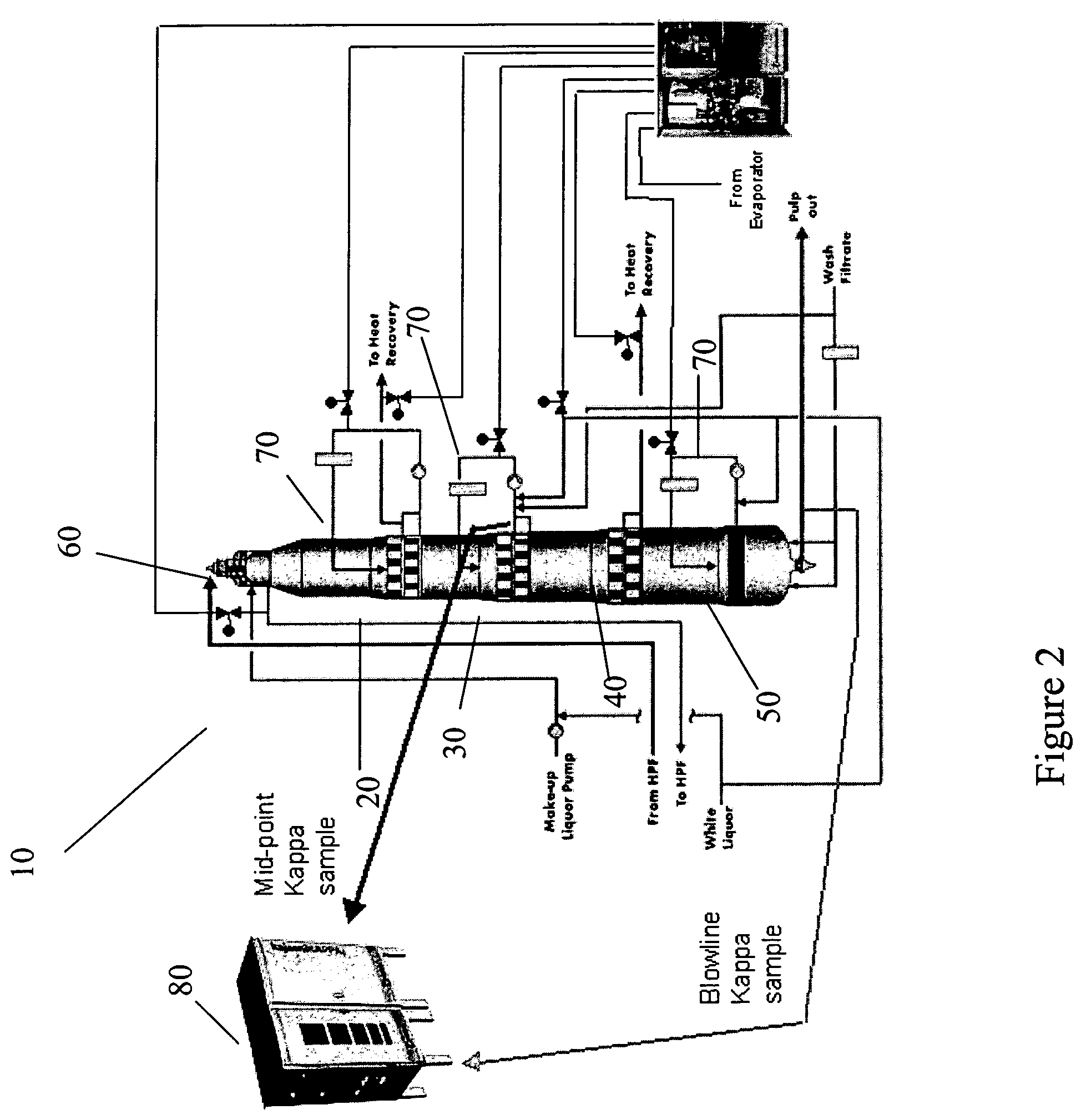

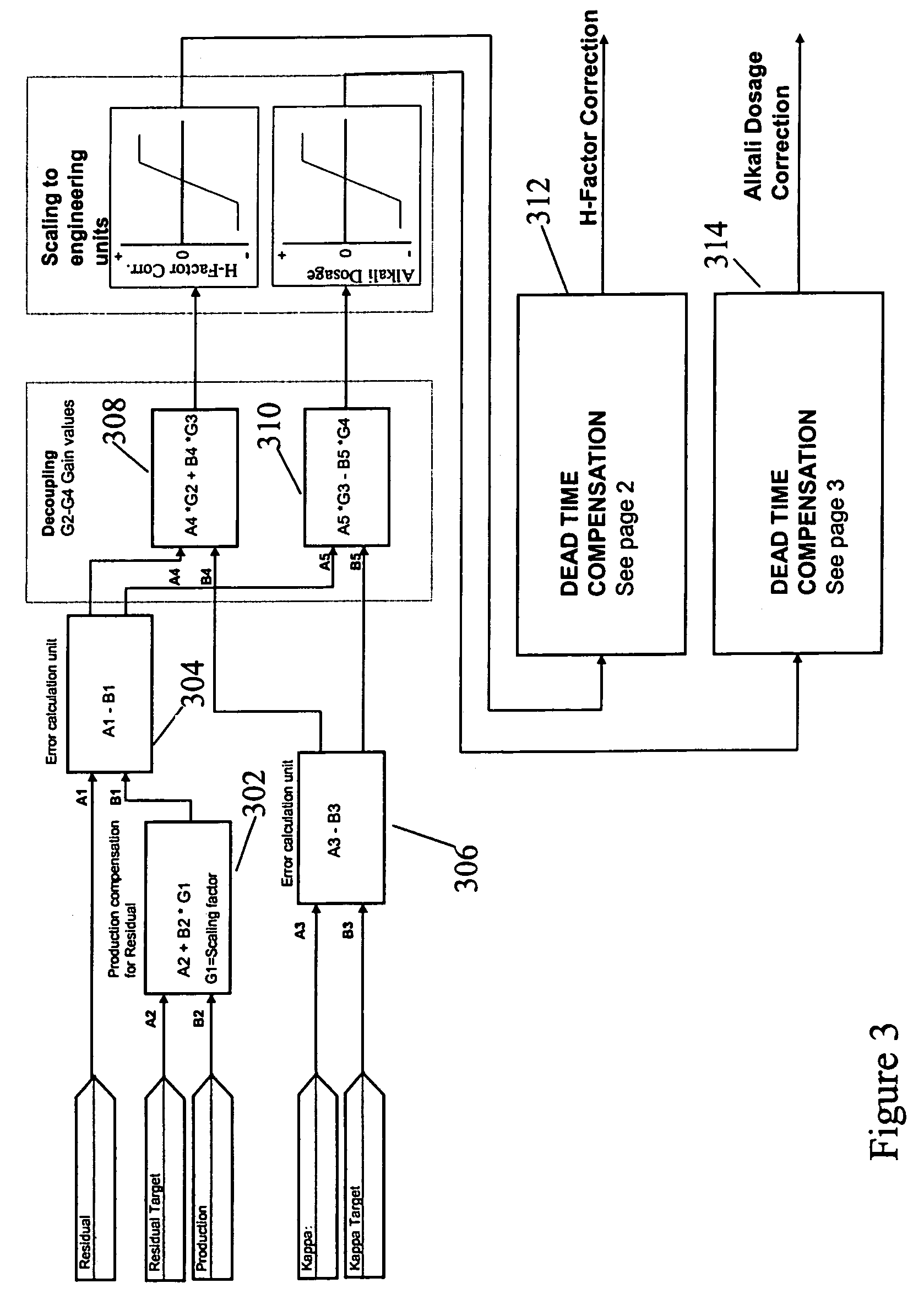

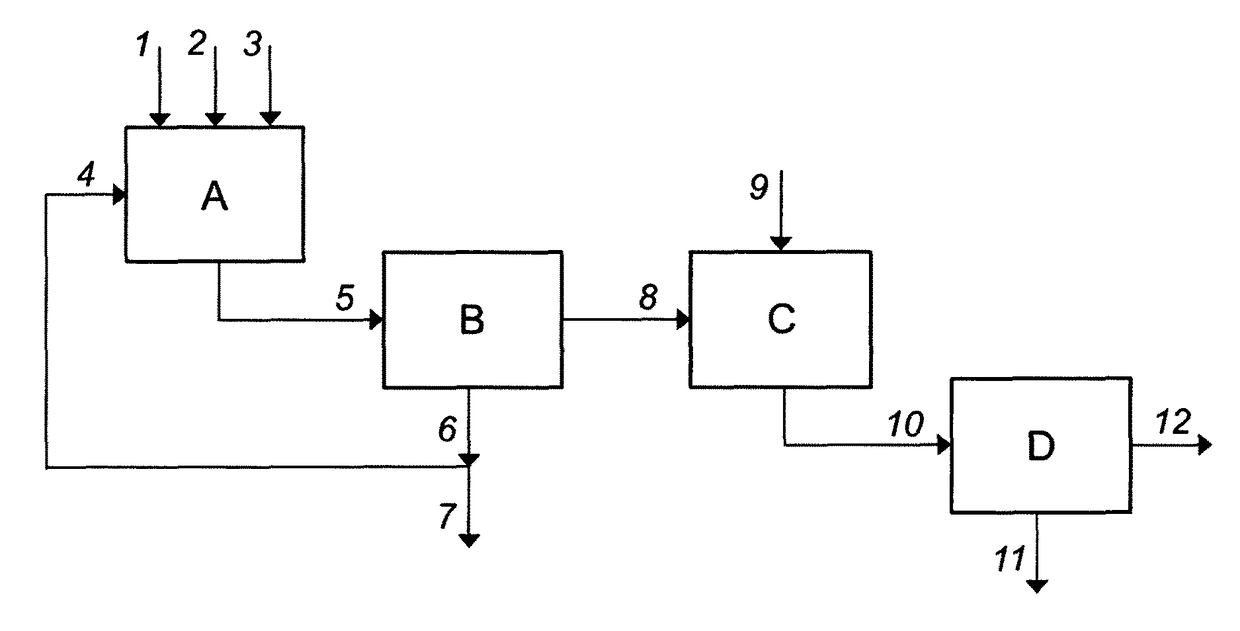

System and method for controlling a processor including a digester utilizing time-based assessments

InactiveUS20050034824A1Minimizing and avoiding instabilityReduce impactElement comparisonPaper/cardboardDead timeComputer science

A system for controlling a processor having at least one sampling port connected to a stage of the processor in order to sample a reactant product from the processor. The system includes a controller configured to control a processing parameter of the processor based on measurements of at least one property of the reactant product such that changes to the processing parameter maintain a target value for the at least one property of the reactant product. The system further includes a dead time compensator. The dead time compensator is configured, based upon a prescribed dead time related to a time before at least one effect of at least one change to the processing parameter is fully realized, to evaluate the reactant product to determine if the effect has been realized at a plurality of sequential times offset from the dead time.

Owner:METABO AUTOMATION USA

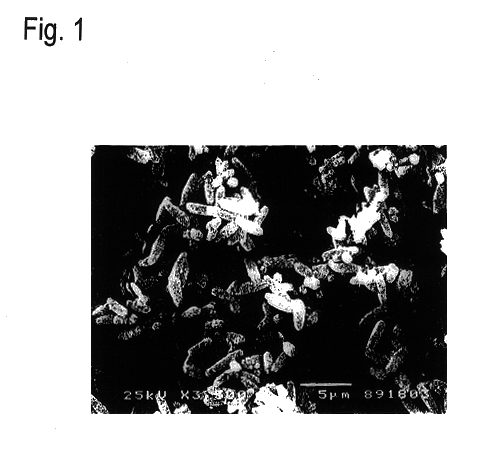

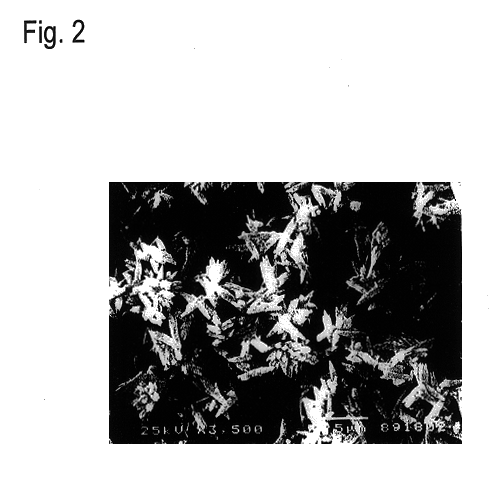

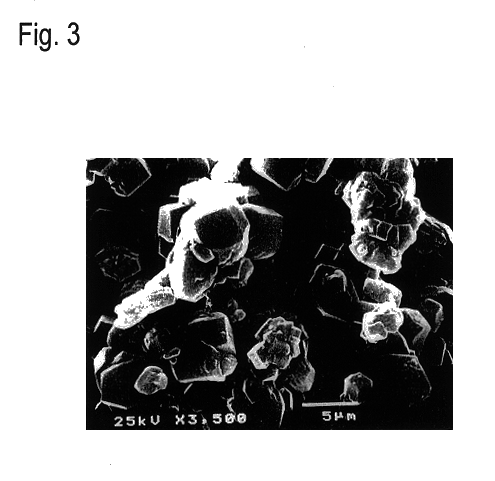

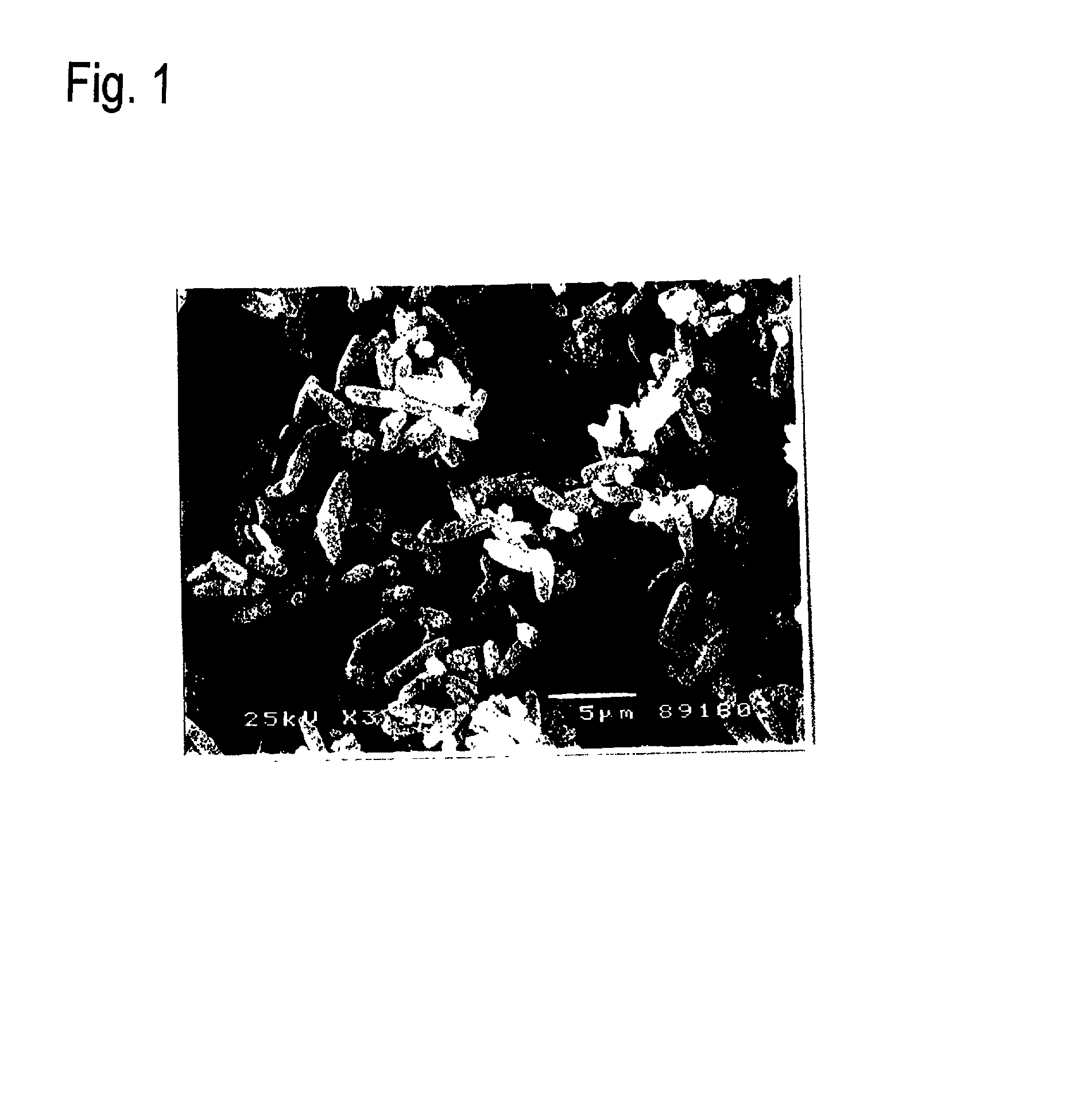

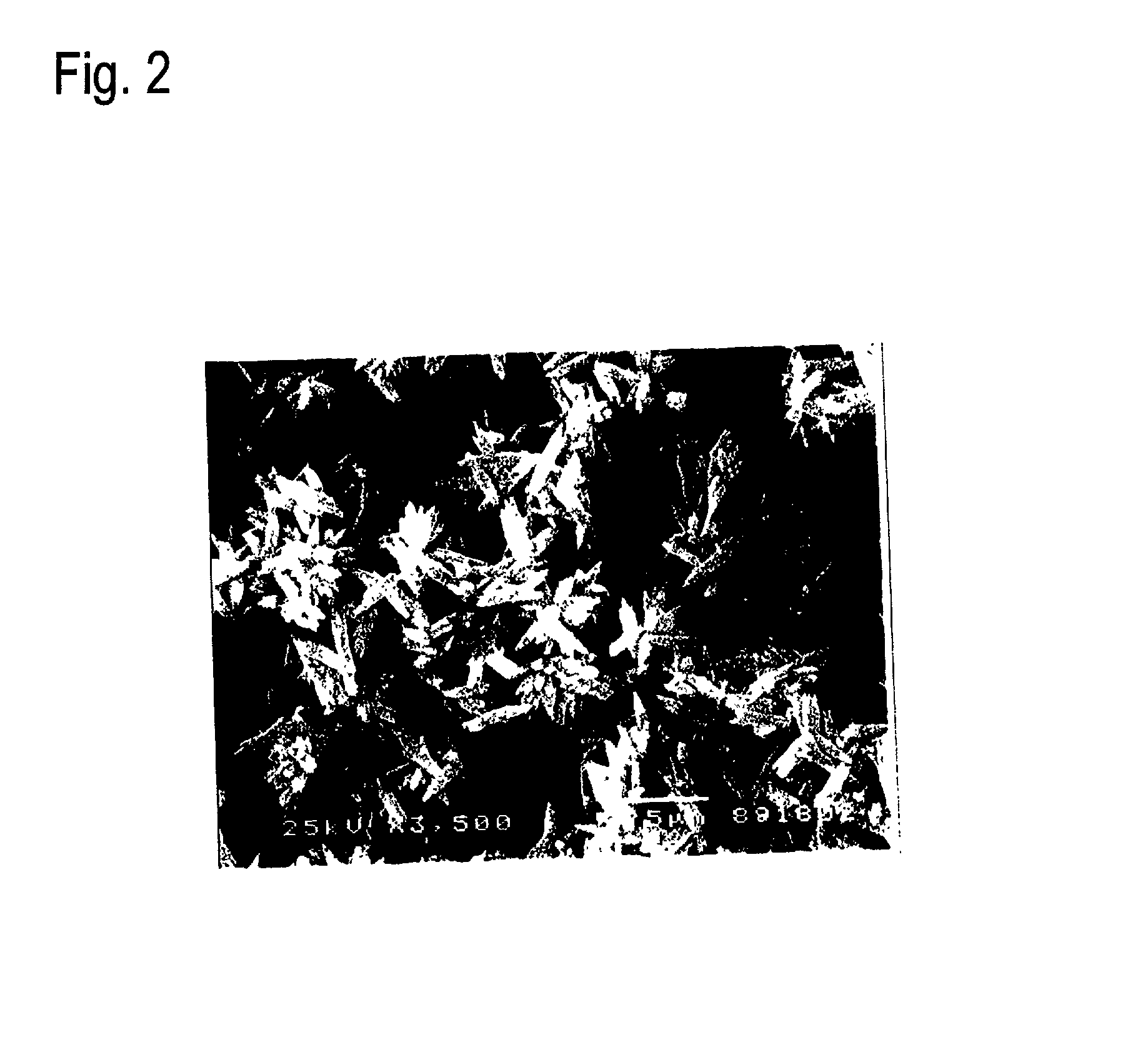

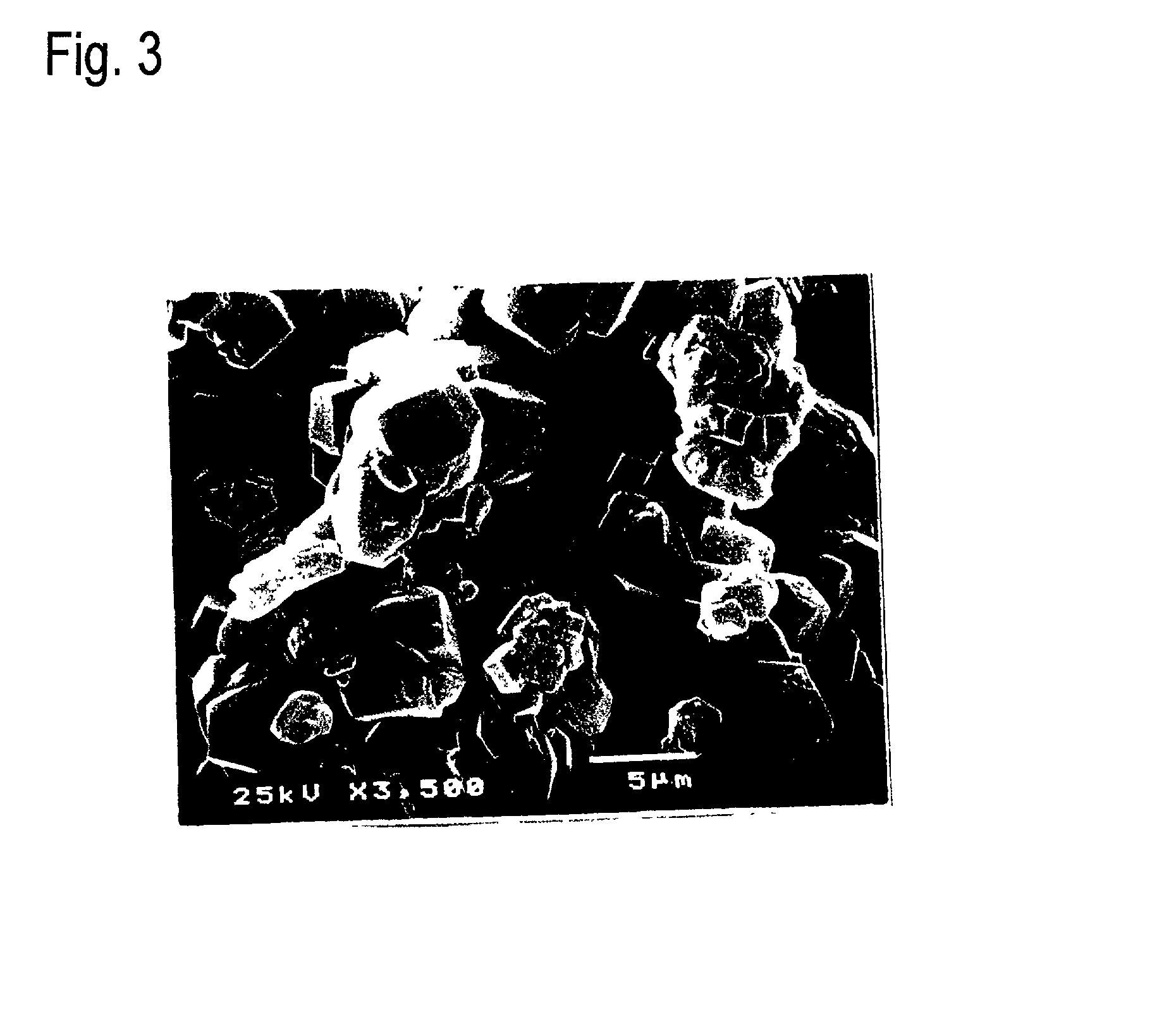

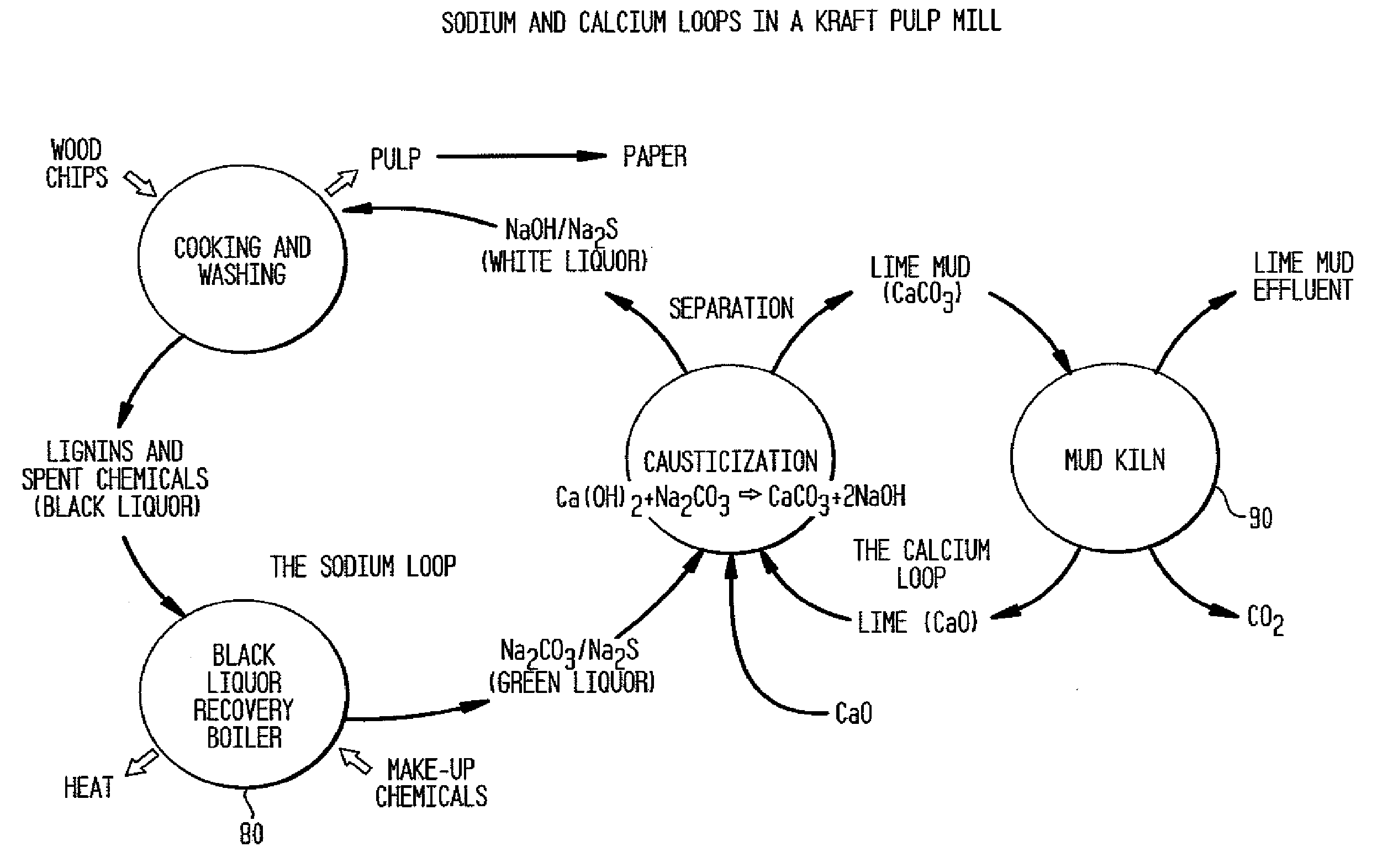

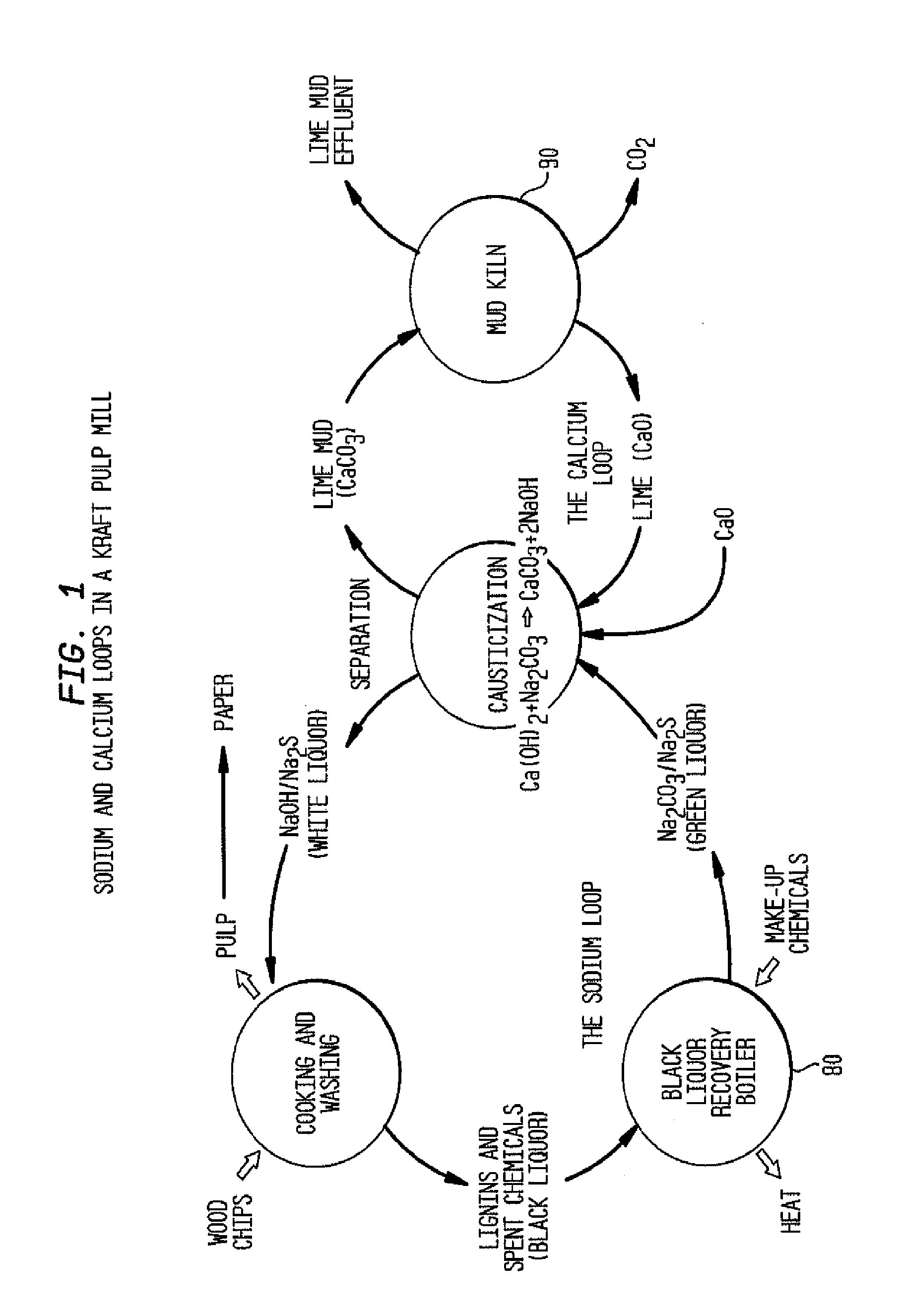

Process for preparing calcium carbonate

InactiveUS6627170B2Decreasing the amount of the filler passing through wire partsHigh aspect ratioCalcium/strontium/barium carbonatesCoatings with pigmentsWhite liquorPhysical chemistry

Inexpensive spindle- or rice-like calcium carbonate giving useful properties for brightness, opacity and wire abrasion resistance as a paper filler is provided by taking advantage of the causticization step. When a white liquor is used for slaking a quick lime, the quick lime used in the slaking reaction of a first step has a calcium carbonate content of 10% by weight or less and is slaked with the white liquor at a concentration of 20 to 60% to prepare a milk of lime. When a green liquor is used for slaking a quick lime, the quick lime used in the slaking reaction of a first step has a calcium carbonate content of 0.1 to 10% by weight and is slaked with the green liquor at a concentration of 20 to 60% to prepare a milk of lime. In a second step, causticization reaction takes place at a green liquor loading rate of 0.02 to 0.5 cc (green liquor) / min / g (quick lime) at a reaction temperature of 20 to 105° C. to afford spindle- or rice-like calcium carbonate.

Owner:NIPPON PAPER IND CO LTD

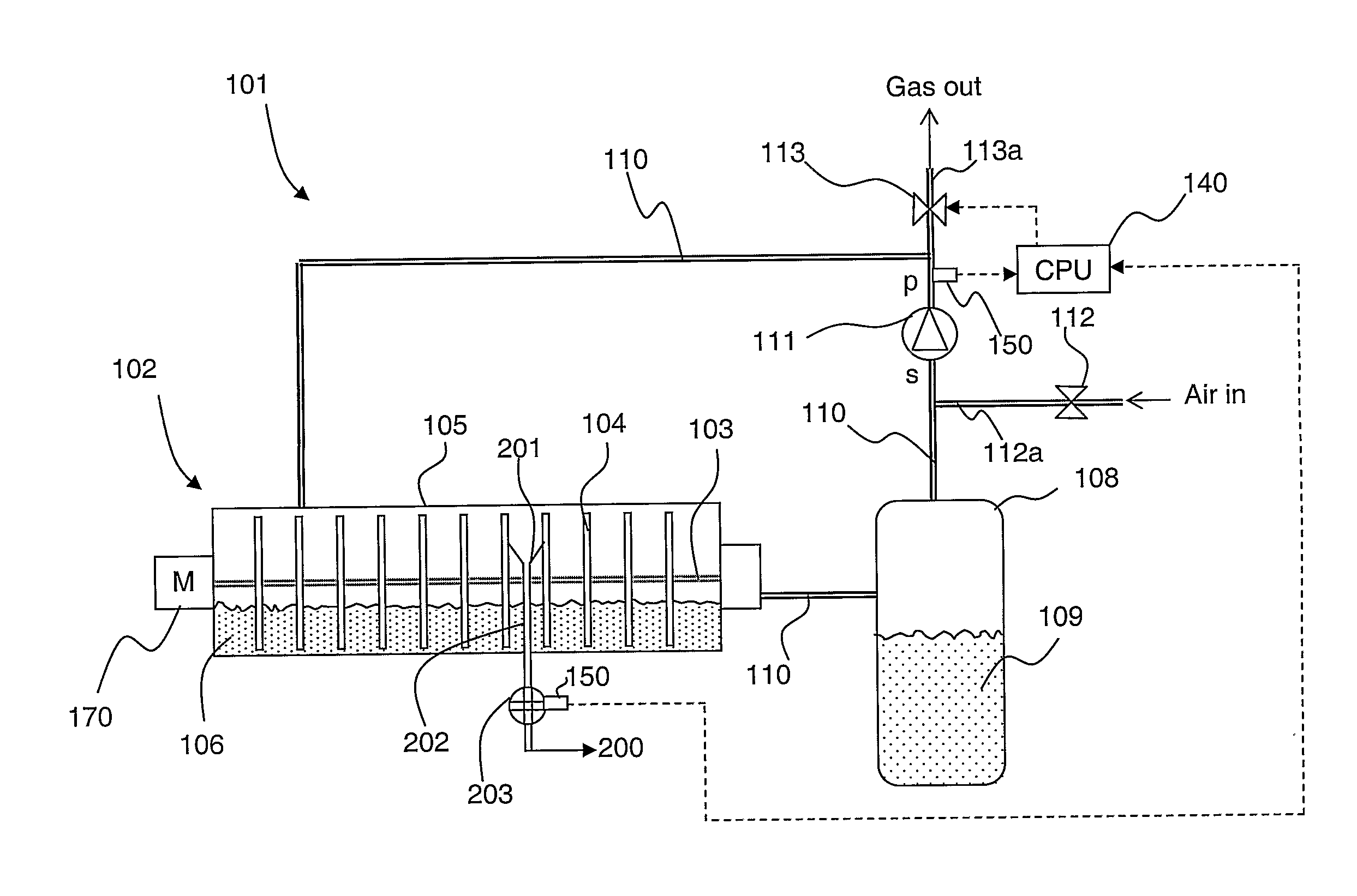

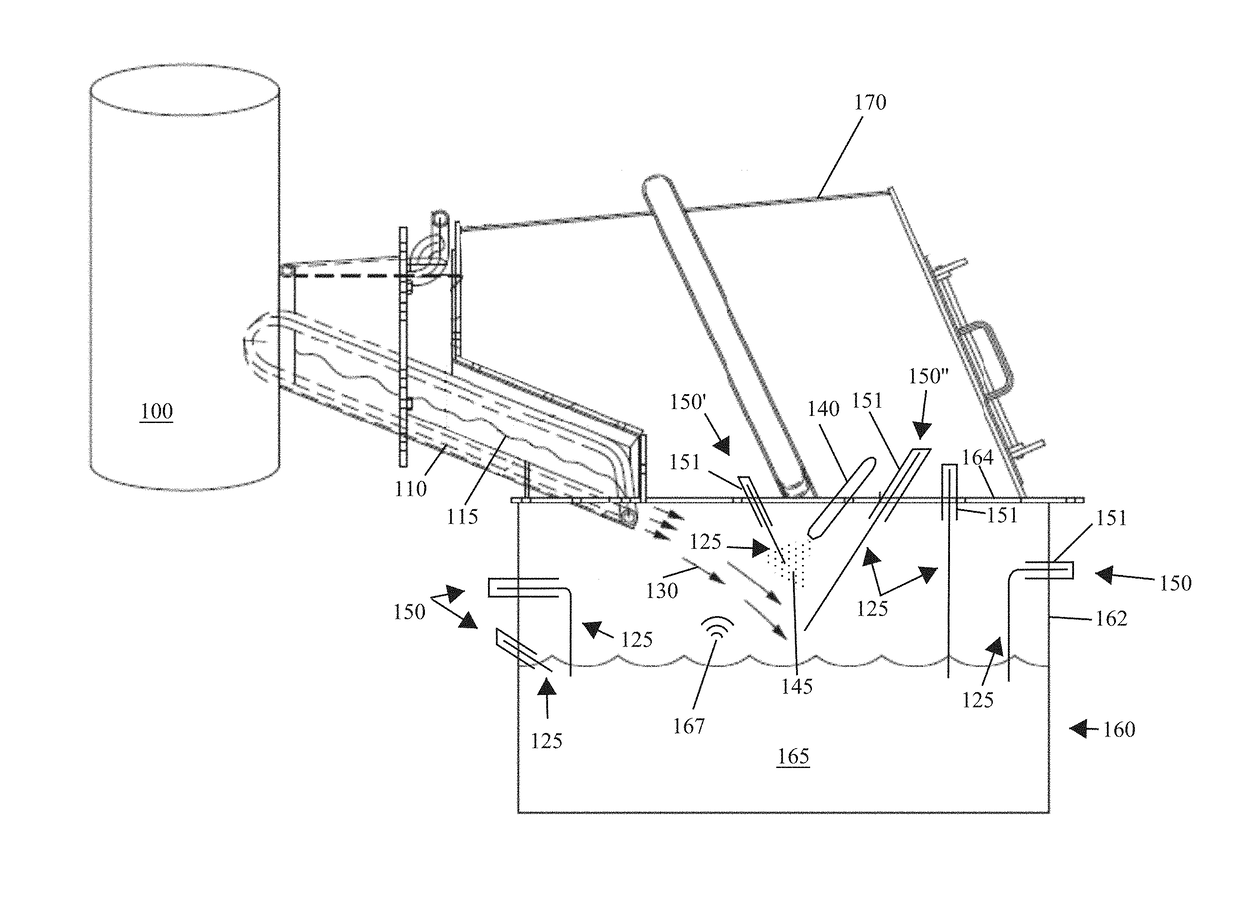

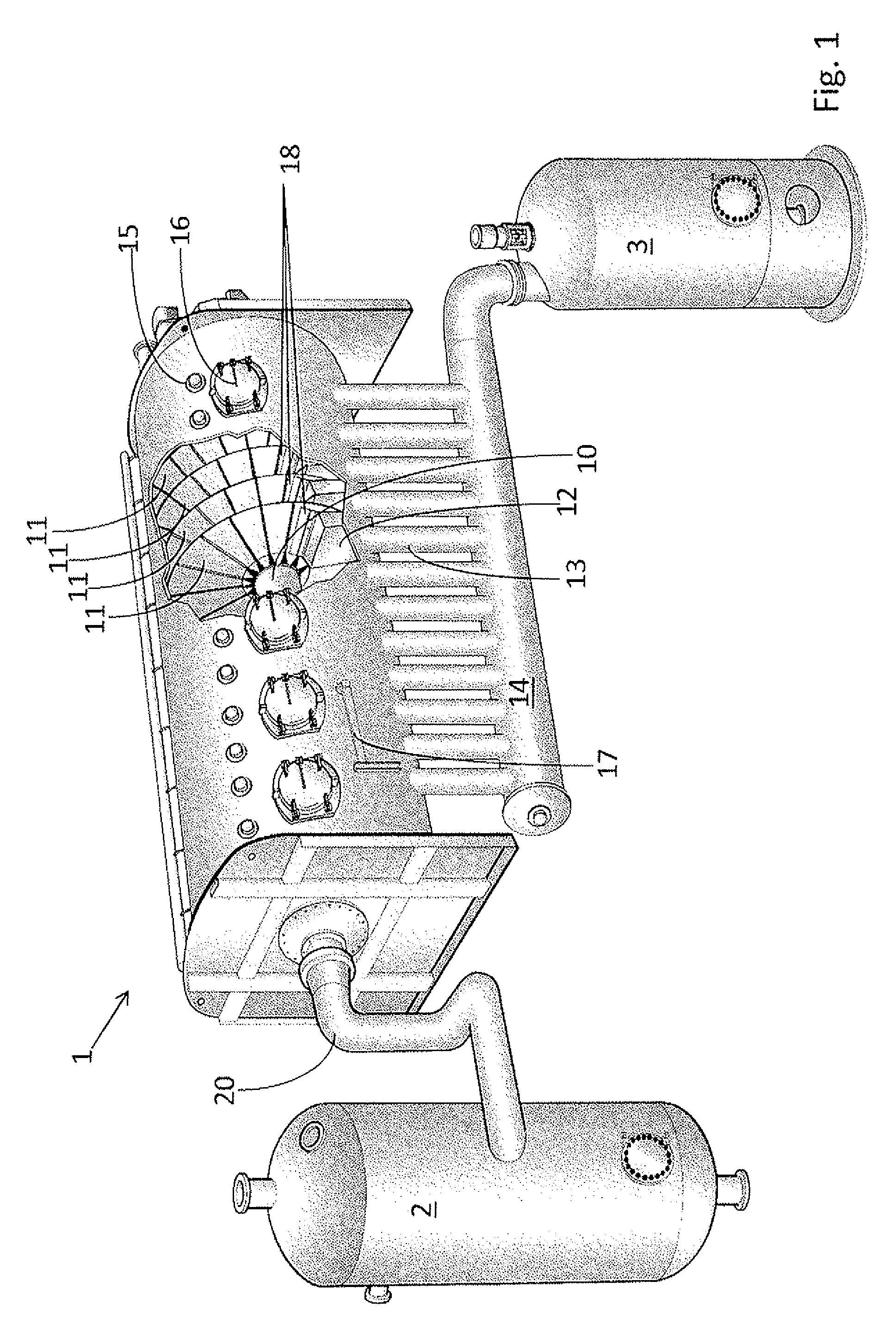

Acoustic emission system and method for predicting explosions in dissolving tank

ActiveUS20170131240A1Prevent and mitigate conditionAnalysing fluids using sonic/ultrasonic/infrasonic wavesPulp liquors combustionAcoustic emissionEngineering

The present disclosure describes a system for predicting explosions in a dissolving tank. The system includes acoustic emission sensors placed in or around the dissolving tank. By filtering the recorded frequencies to the range which is most sensitive for desired explosions “fingerprints,” it is possible to predict a smelt influx before the smelt influx occurs as well as program response actions to prevent compromising explosions.

Owner:ANDRITZ INC

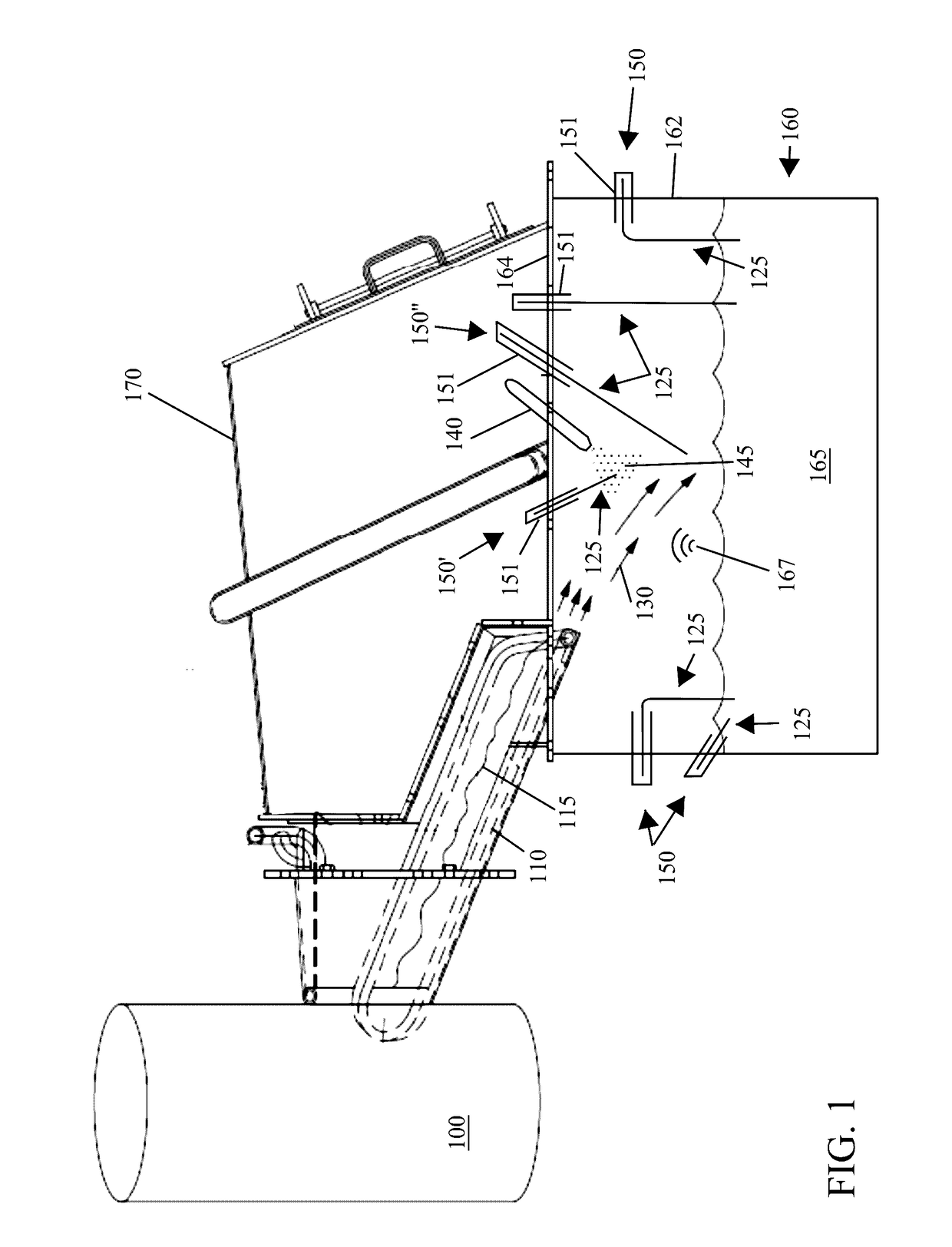

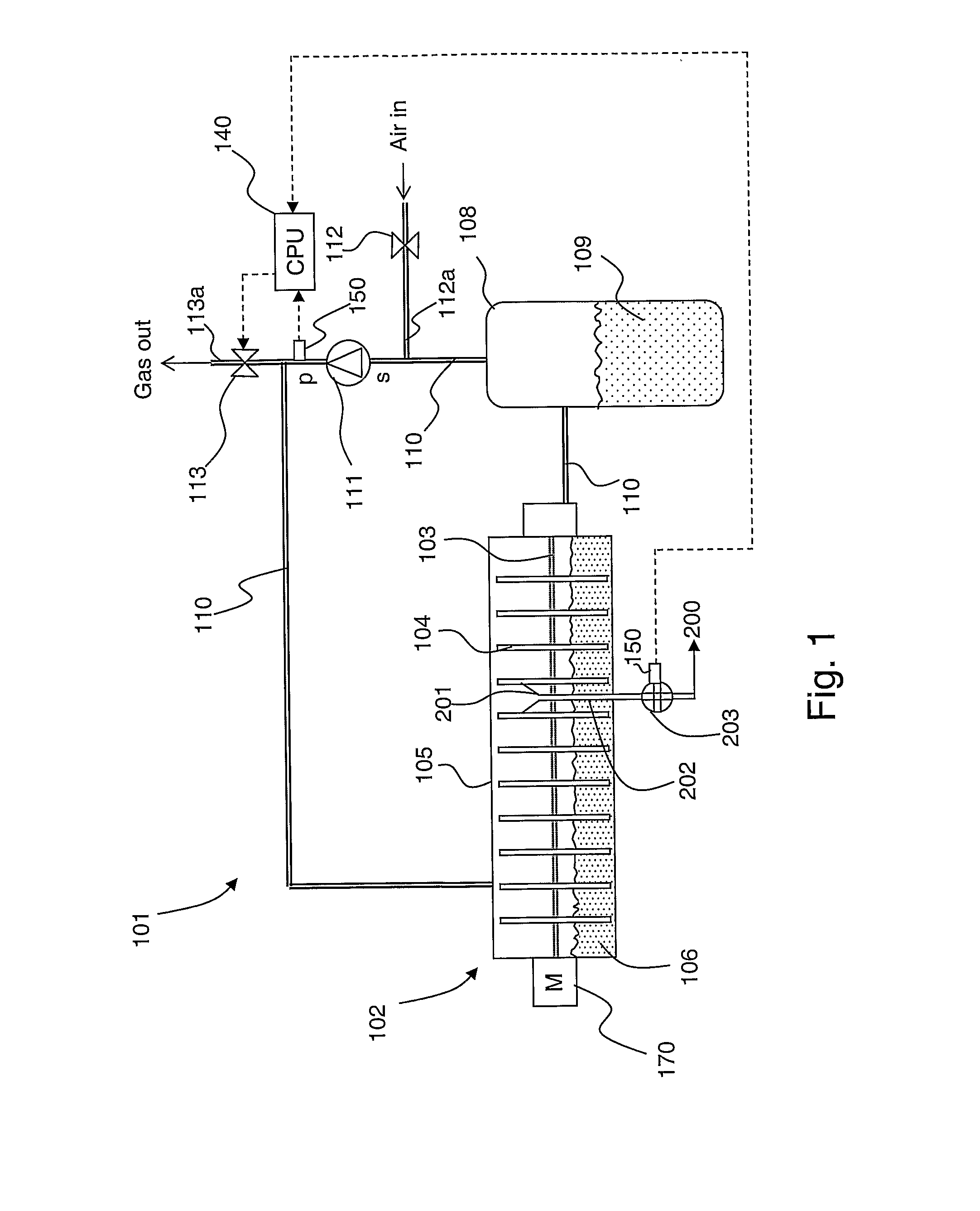

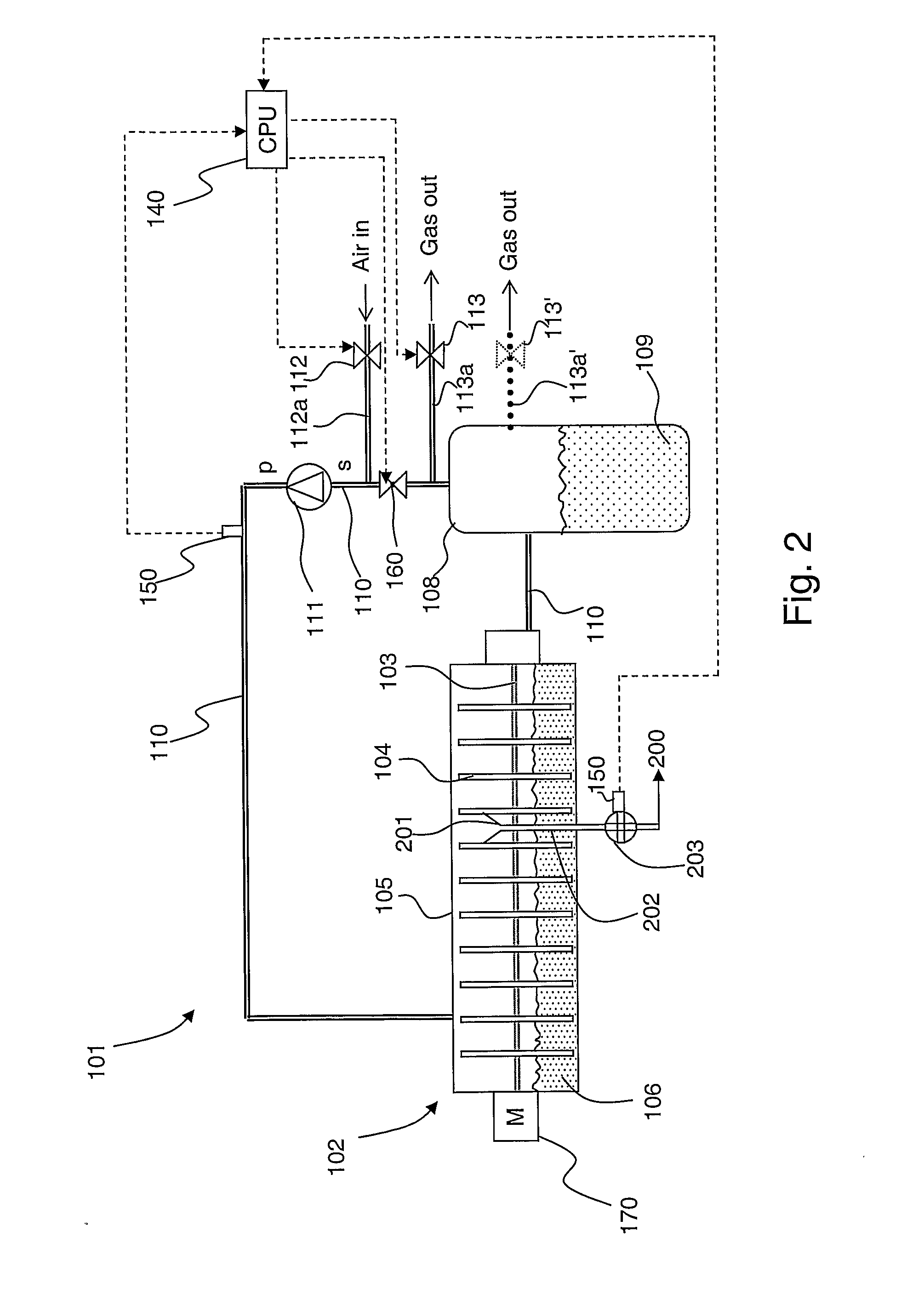

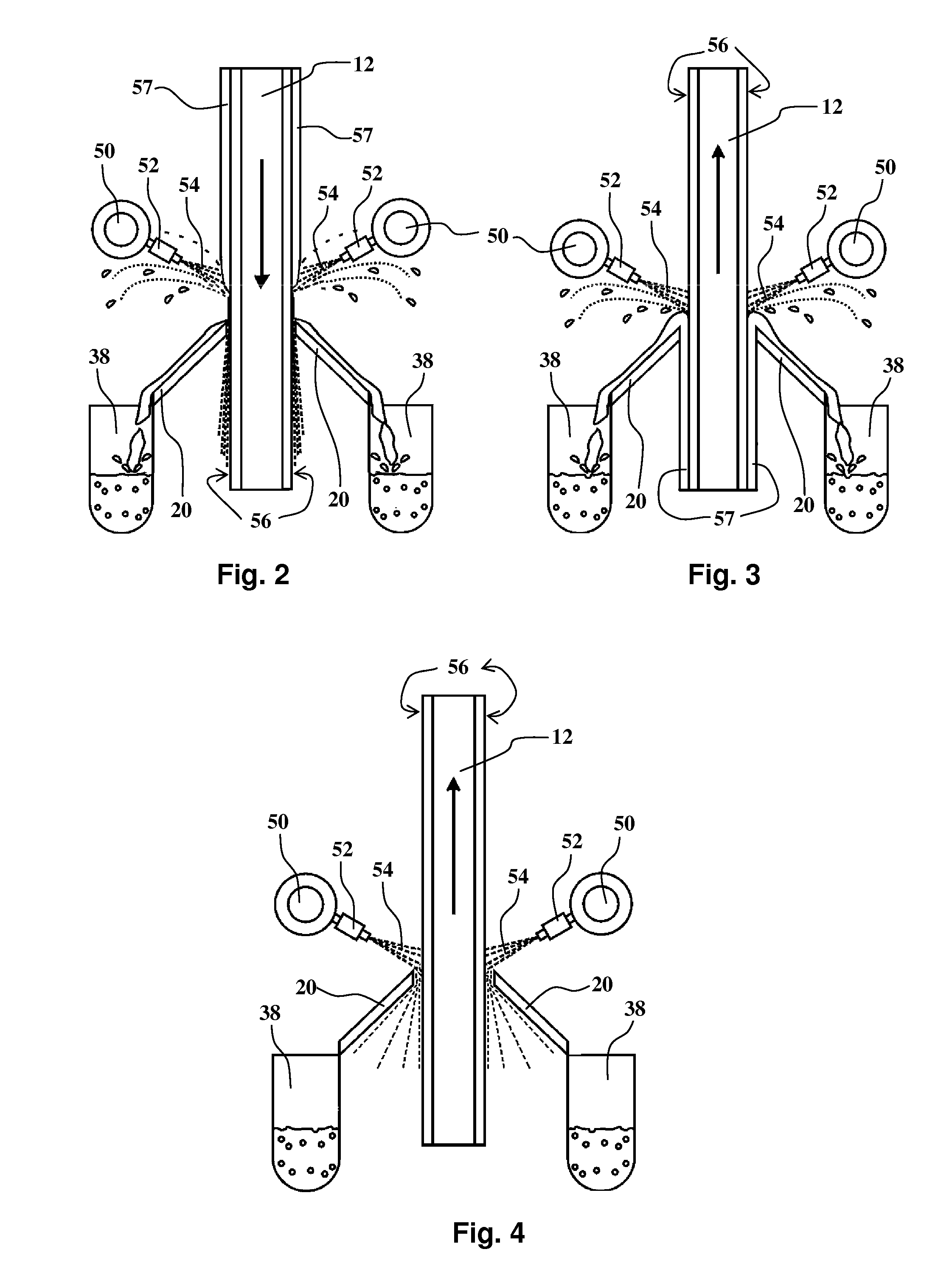

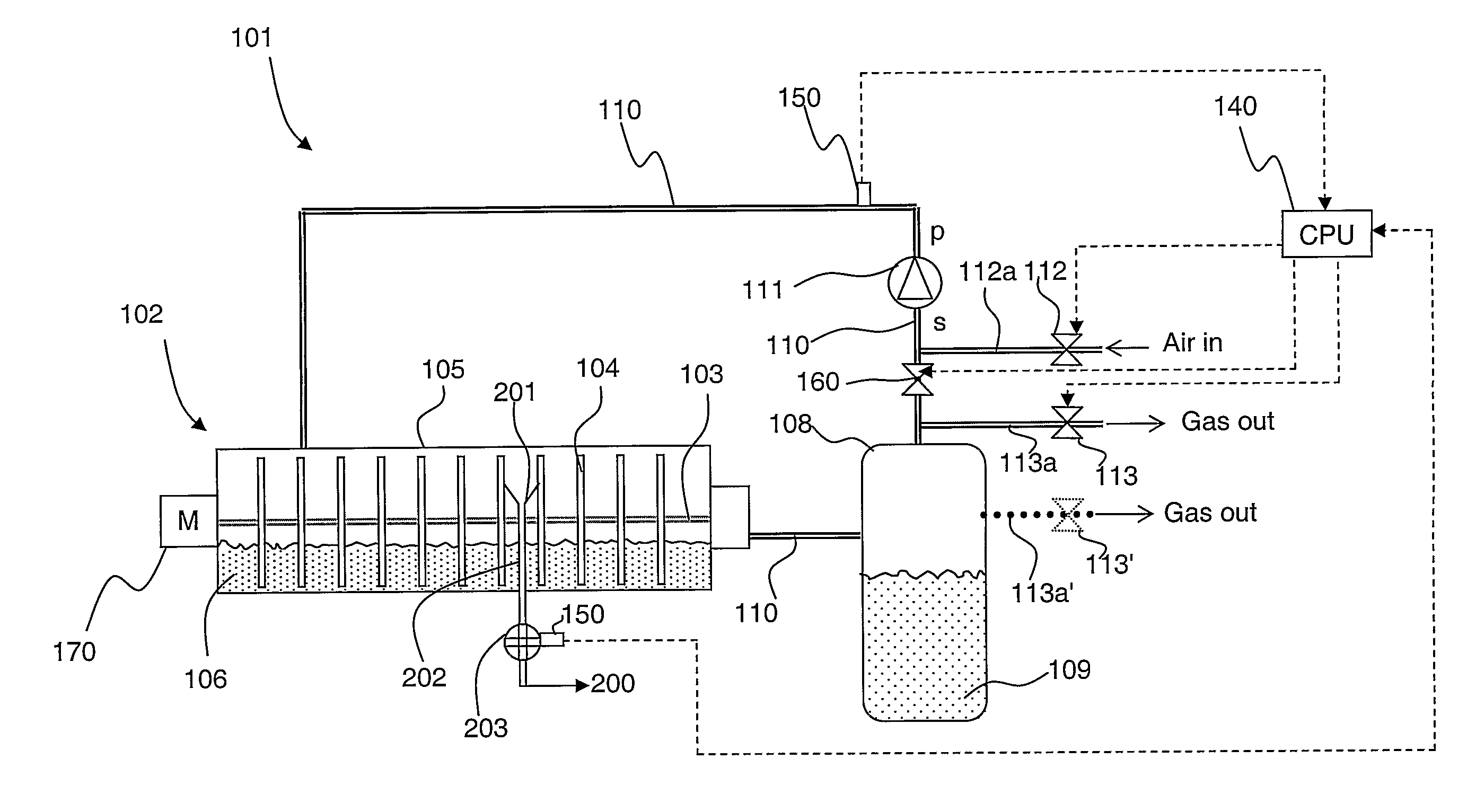

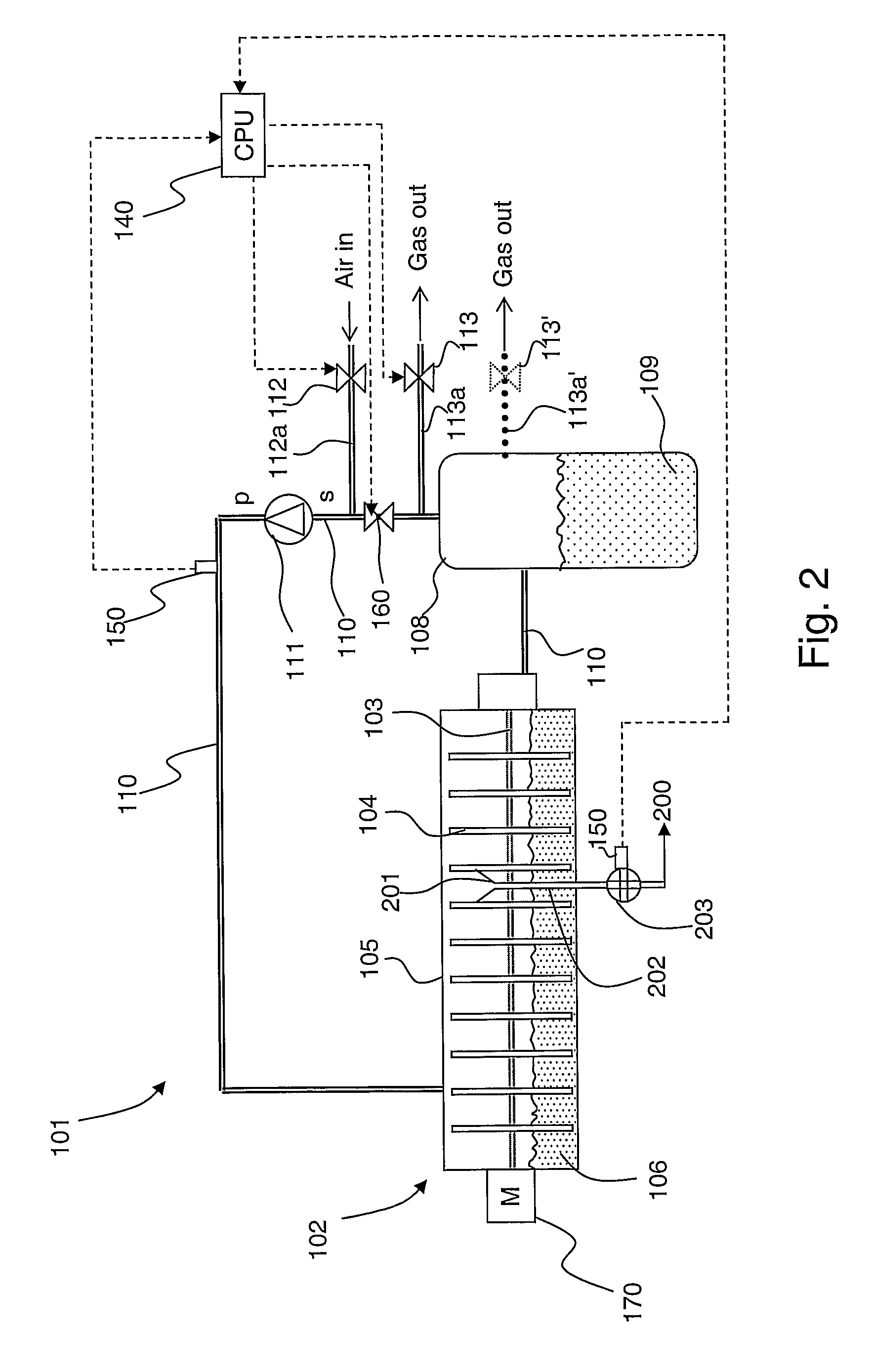

Method and Device for Washing of Lime Mud

InactiveUS20070221345A1Use minimizedPromote oxidationWater/sewage treatmentLoose filtering material filtersGas phaseFresh air

The method and an arrangement are for dewatering and washing lime slurry before the dewatered lime mud is passed to a lime mud kiln. The lime slurry is dewatered in a pressurized lime mud filter of disc or drum type. The pressurized lime mud filter is pressurized through a compressor drawing on its suction side (s) gas phase from the filtrate tank and pressurizing on the pressurized side (p) of the compressor the pressure vessel on the lime mud side of the filter. A certain pre-determined amount of gas phase in the gas circulation system is vented and an equivalent pre-determined amount of fresh air is added to the recycled gas phase with the aim of maintaining the partial pressure of oxygen gas above a certain minimum level.

Owner:METABO PAPER SWEDEN

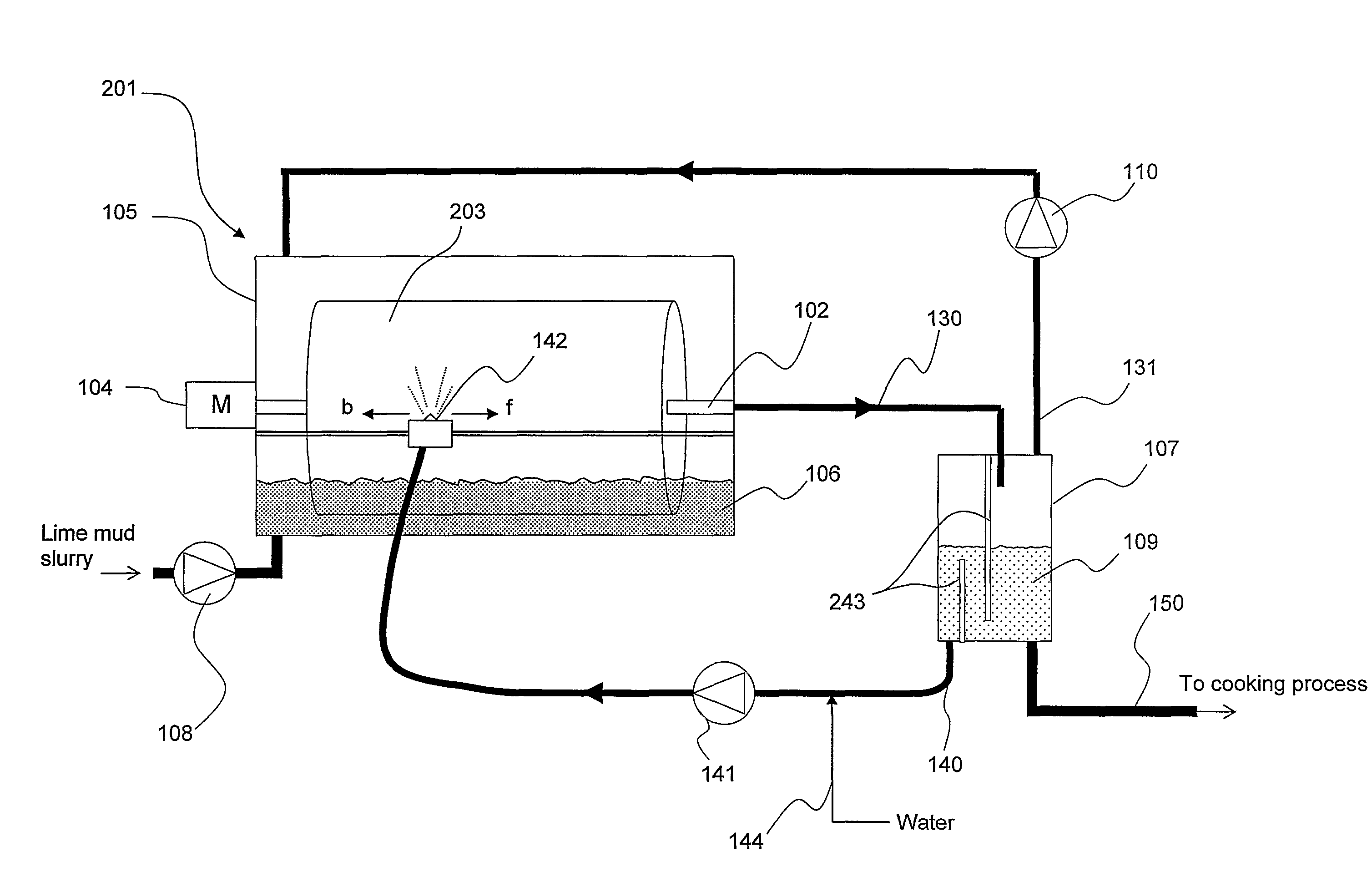

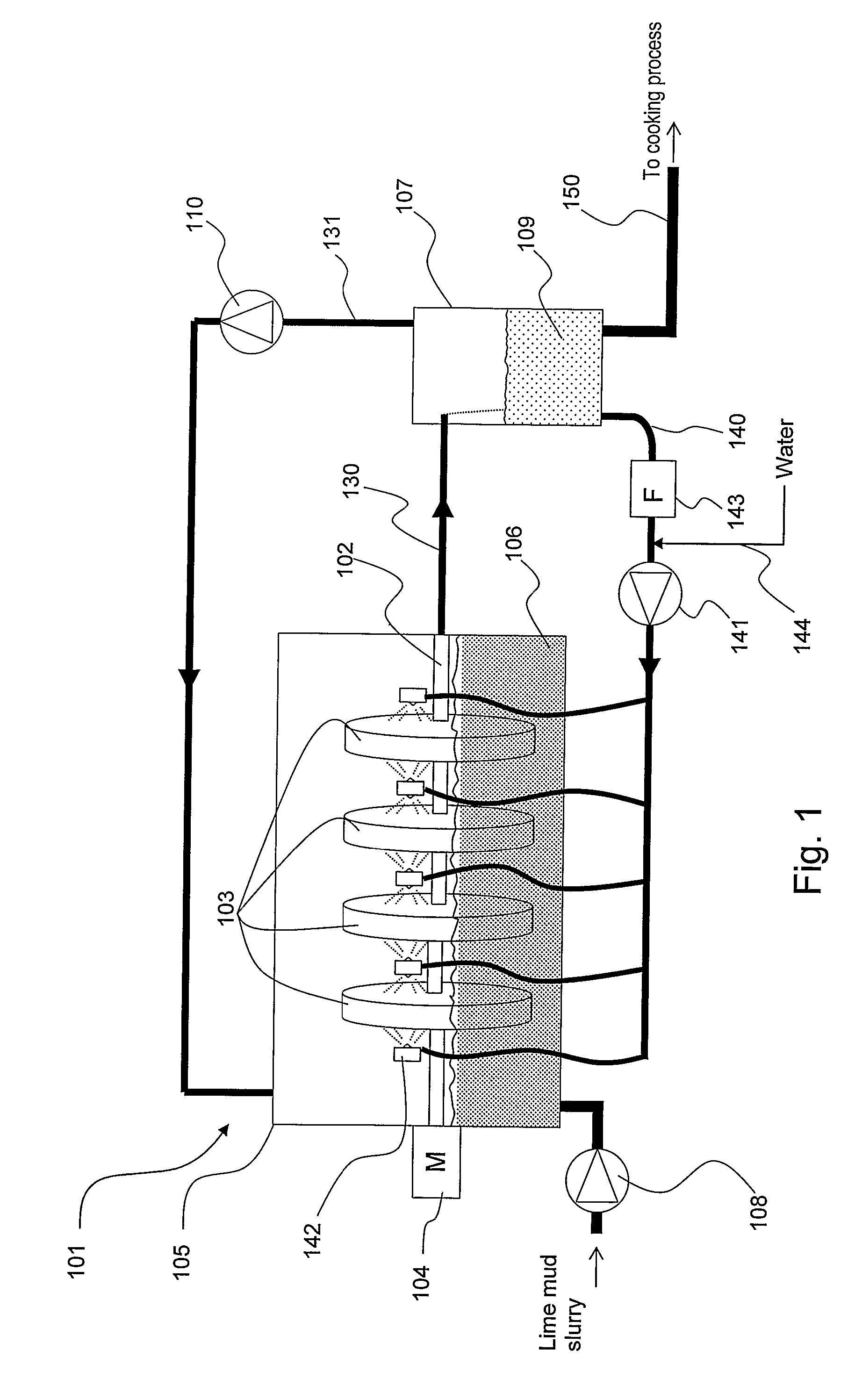

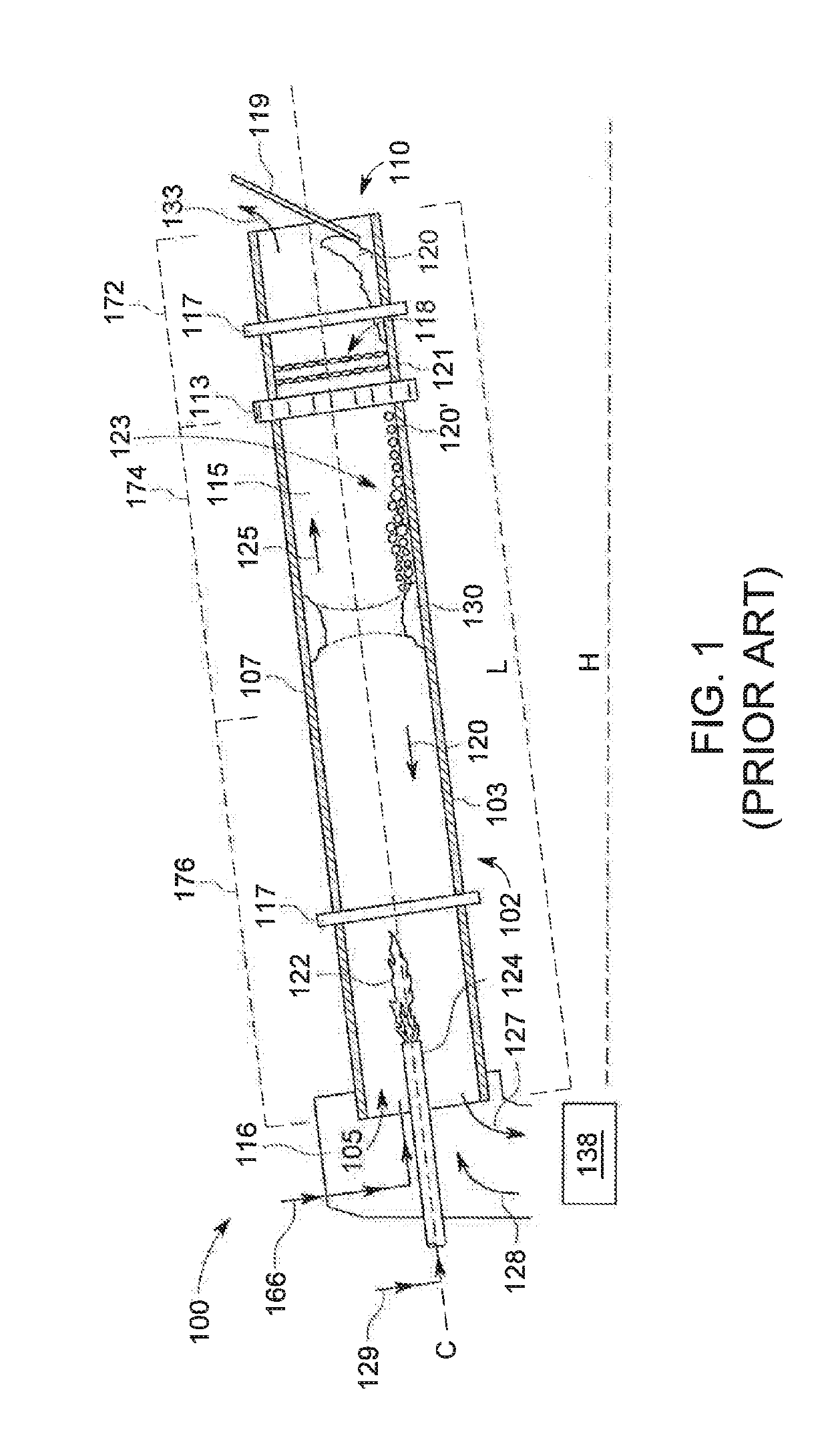

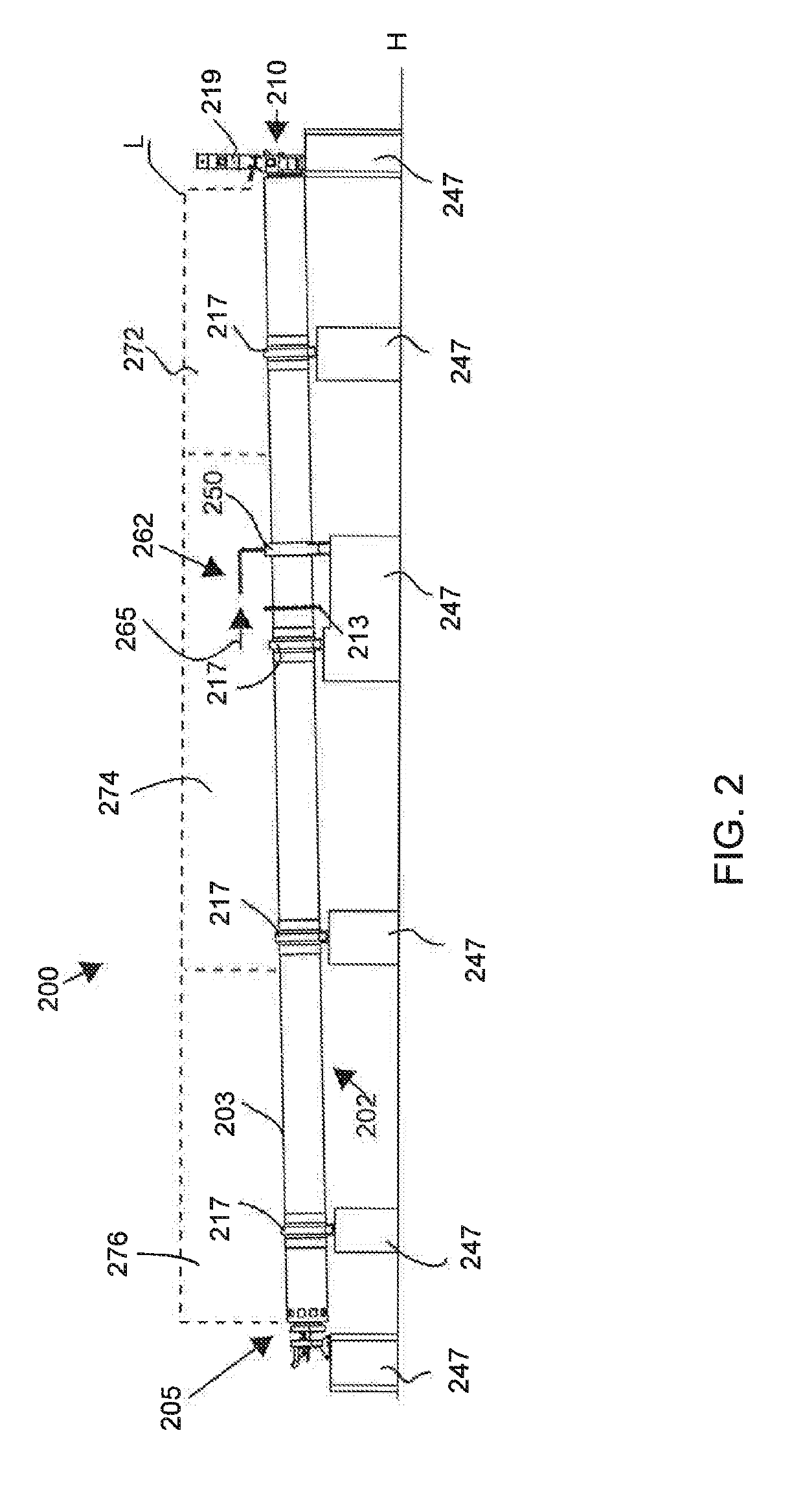

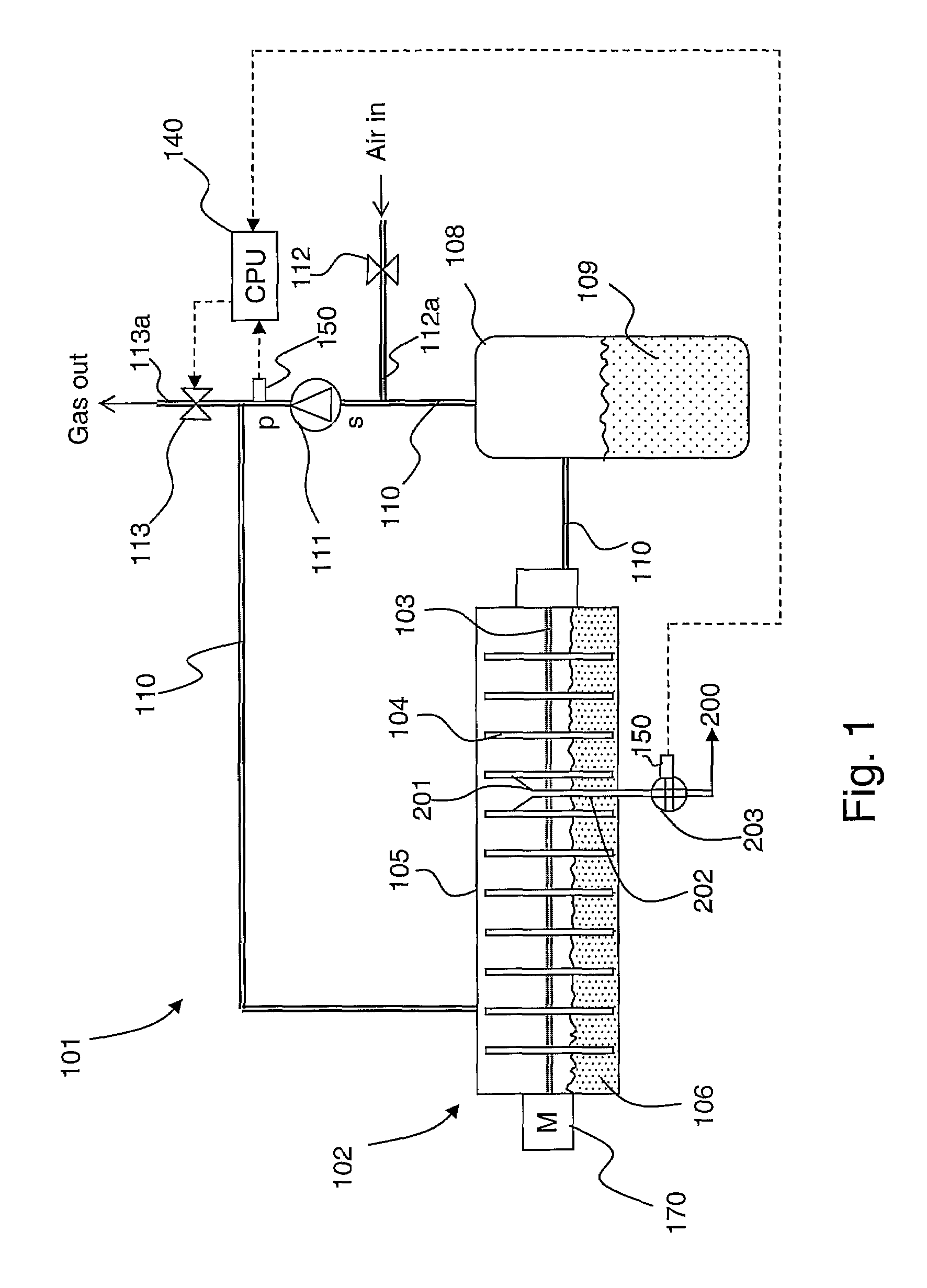

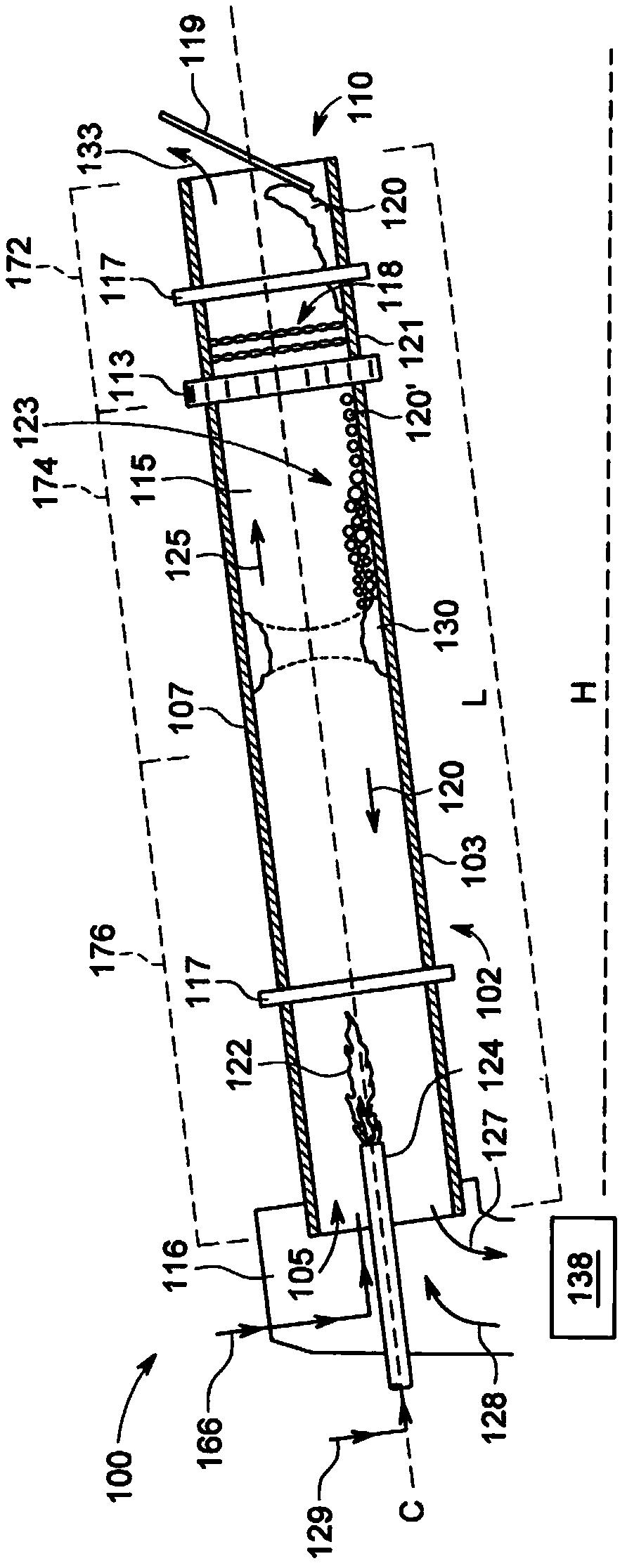

Method and device for cleaning of filter

The method and arrangement is for cleaning at least one of filter sheets and filter cakes in a pressurized white liquor filter with spray nozzles and driving fluid. The white liquor filter is used in a causticizing process in which green liquor is causticized before the white liquor filter by the addition of lime and in which it forms during the process a lime mud slurry. The white liquor filter 101 is used to separate white liquor from the lime mud. The driving fluid for the spray nozzle is constituted principally by the filtrate that is obtained from the filter.

Owner:METABO PAPER SWEDEN

Process for preparing calcium carbonate

InactiveUS20030059362A1Excellent abrasion resistanceLess sharp edgeCalcium/strontium/barium carbonatesCoatings with pigmentsWhite liquorReaction temperature

Inexpensive spindle- or rice-like calcium carbonate giving useful properties for brightness, opacity and wire abrasion resistance as a paper filler is provided by taking advantage of the causticization step. When a white liquor is used for slaking a quick lime, the quick lime used in the slaking reaction of a first step has a calcium carbonate content of 10% by weight or less and is slaked with the white liquor at a concentration of 20 to 60% to prepare a milk of lime. When a green liquor is used for slaking a quick lime, the quick lime used in the slaking reaction of a first step has a calcium carbonate content of 0.1 to 10% by weight and is slaked with the green liquor at a concentration of 20 to 60% to prepare a milk of lime. In a second step, causticization reaction takes place at a green liquor loading rate of 0.02 to 0.5 cc (green liquor) / min / g (quick lime) at a reaction temperature of 20 to 105° C. to afford spindle- or rice-like calcium carbonate.

Owner:NIPPON PAPER IND CO LTD

Acoustic emission system and method for predicting explosions in dissolving tank

ActiveUS10012616B2Prevent and mitigate conditionAnalysing fluids using sonic/ultrasonic/infrasonic wavesPulp liquors combustionAcoustic emissionEngineering

The present disclosure describes a system for predicting explosions in a dissolving tank. The system includes acoustic emission sensors placed in or around the dissolving tank. By filtering the recorded frequencies to the range which is most sensitive for desired explosions “fingerprints,” it is possible to predict a smelt influx before the smelt influx occurs as well as program response actions to prevent compromising explosions.

Owner:ANDRITZ INC

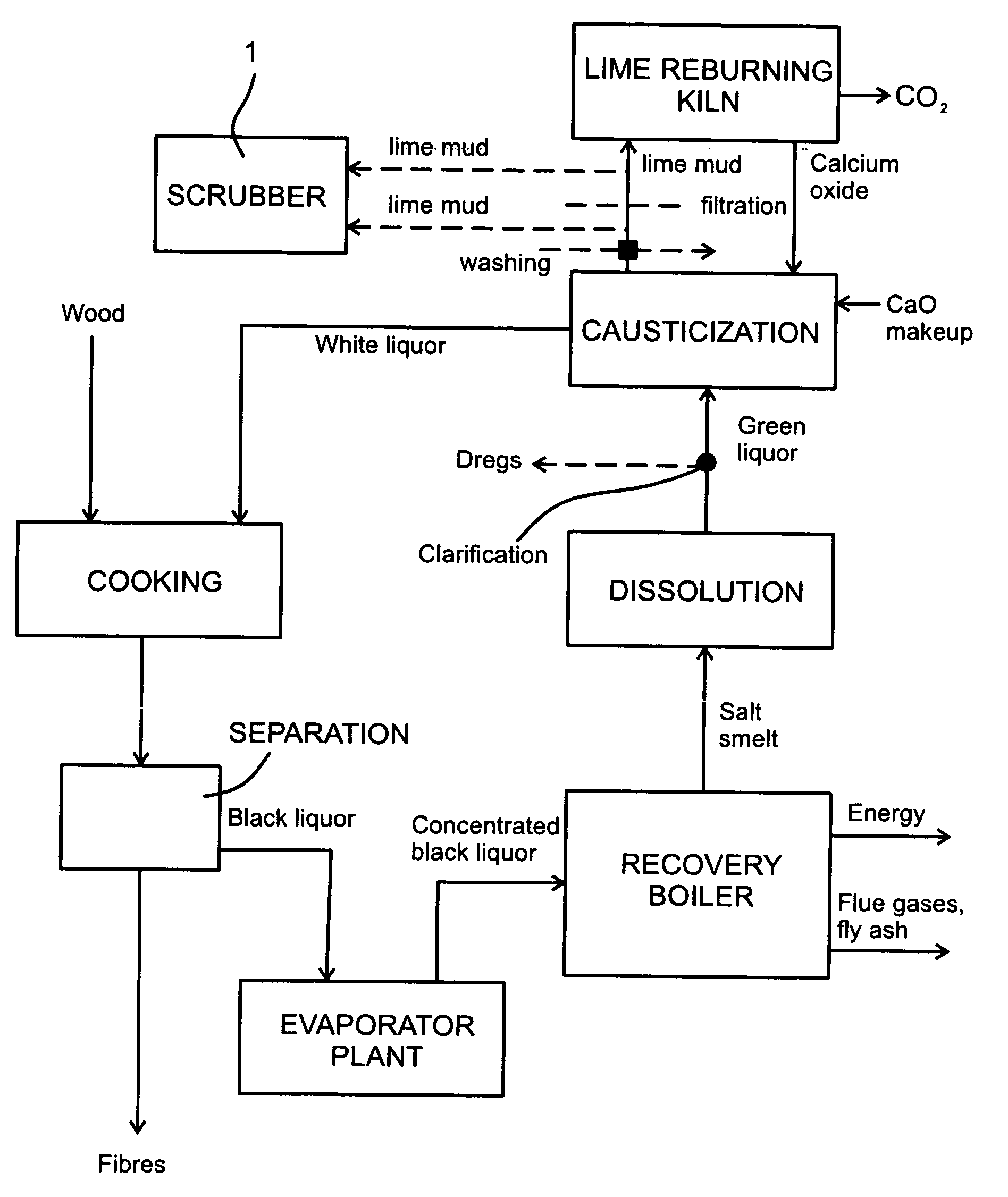

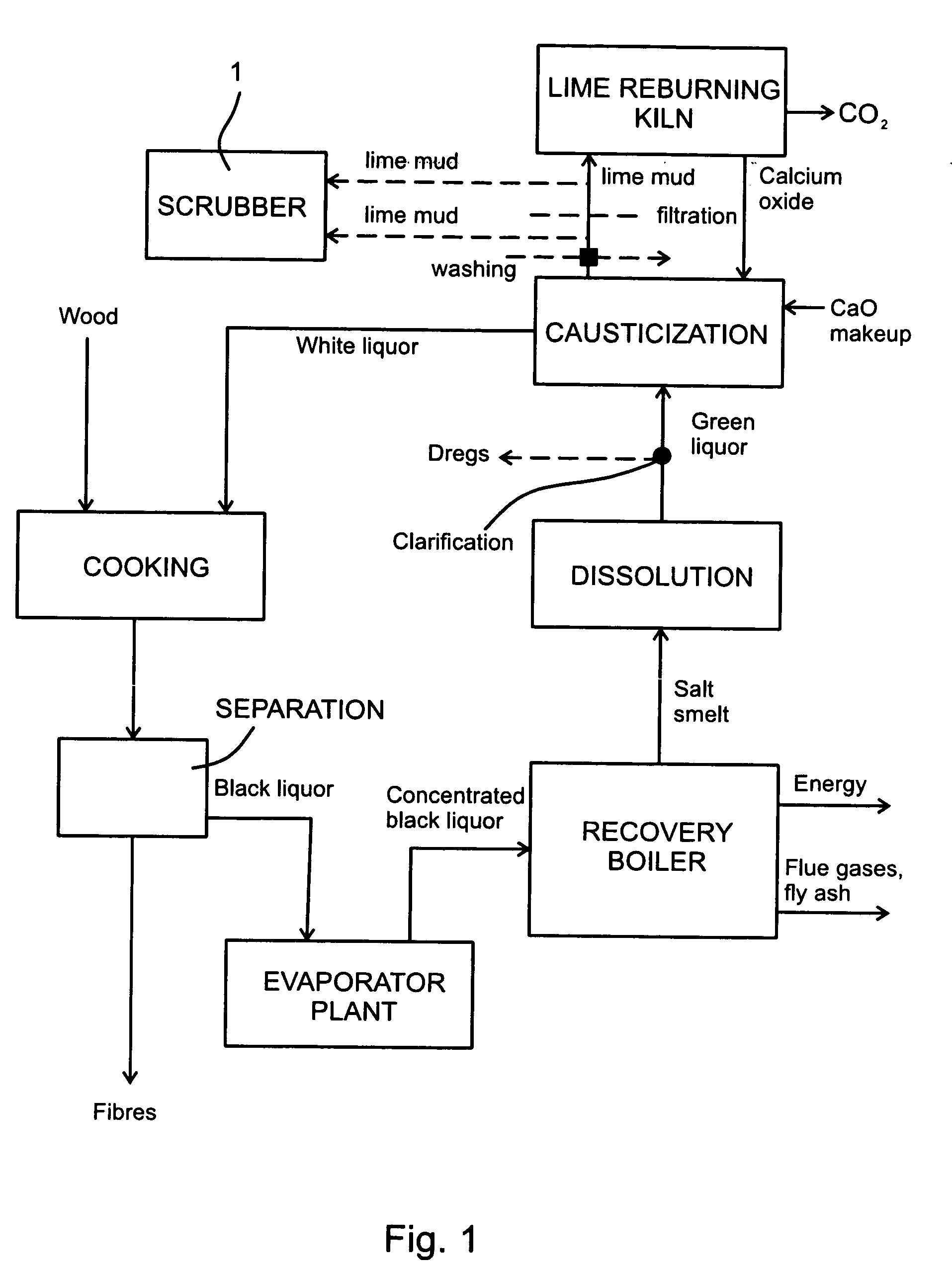

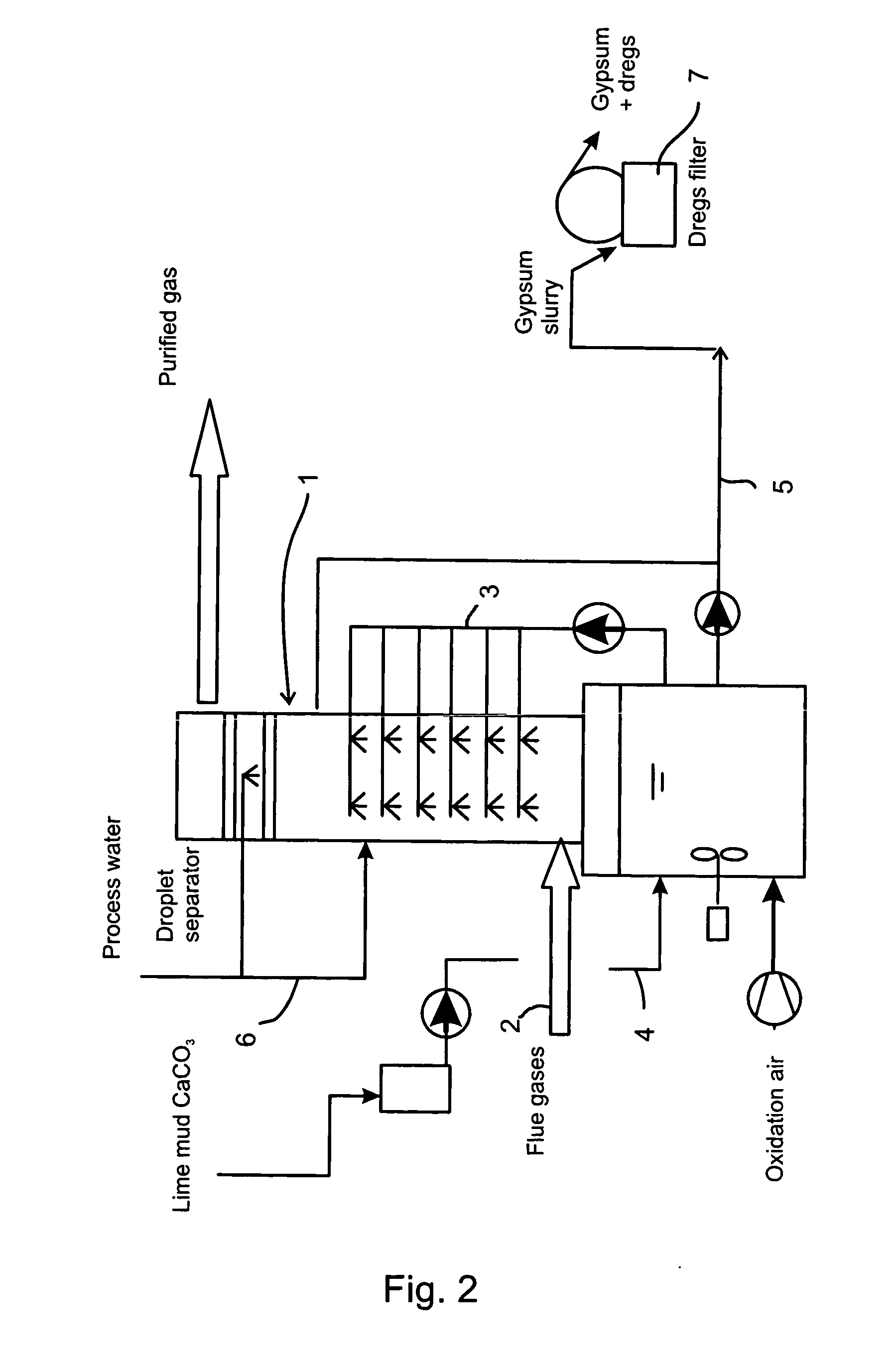

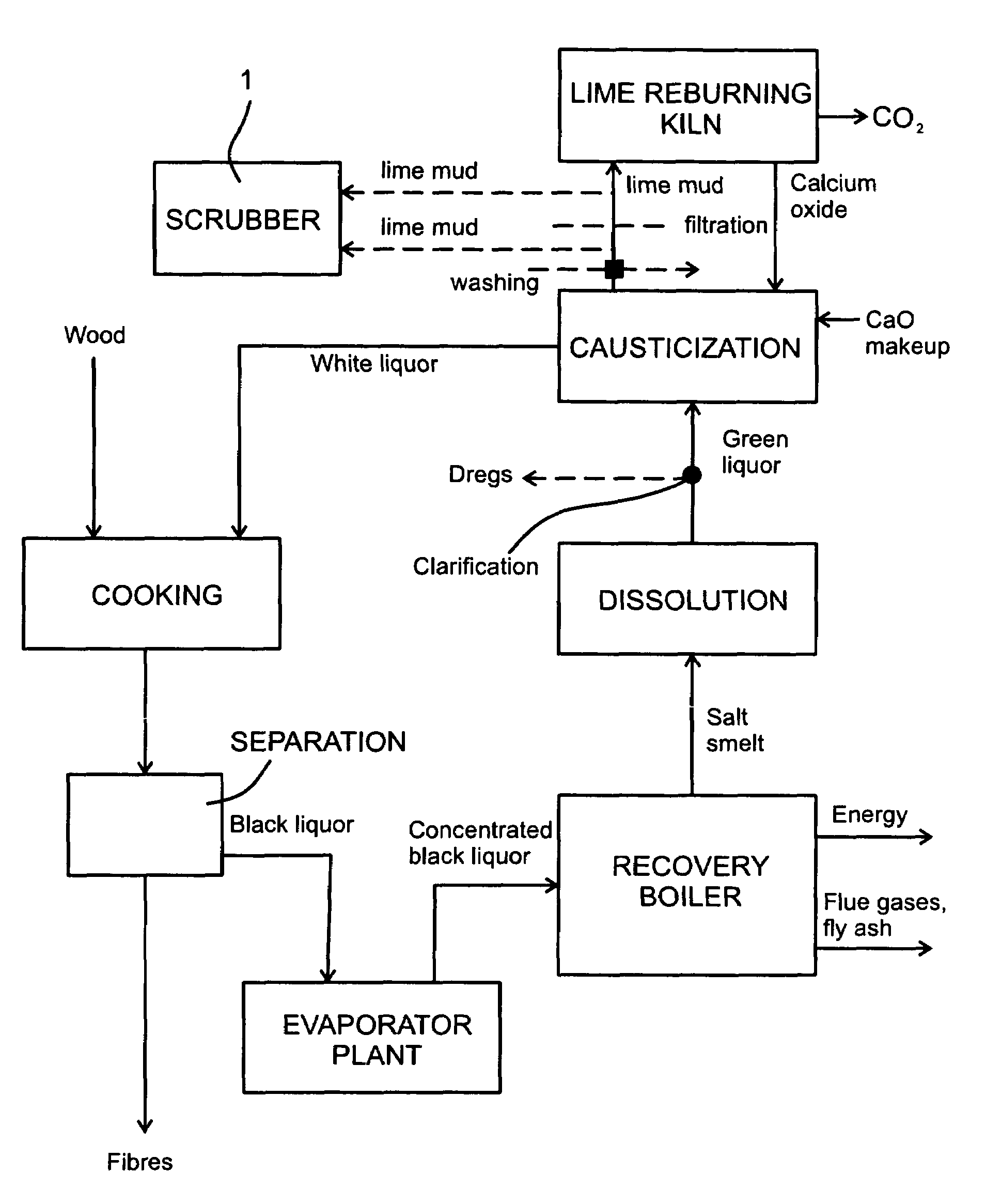

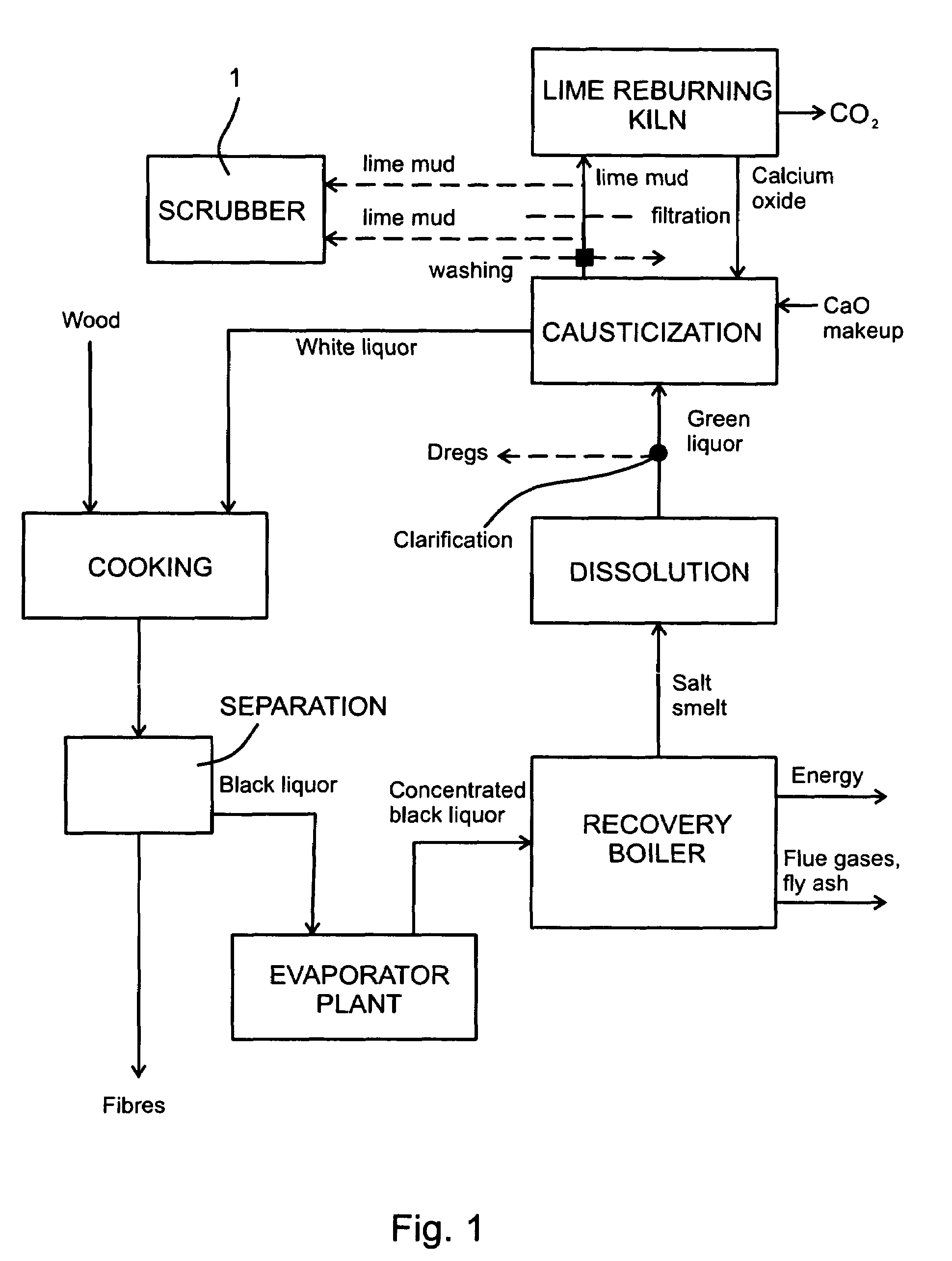

Method for processing flue gases

ActiveUS20070092422A1Low investment costReduce caustic makeupDispersed particle separationAlkali metal sulfides/polysulfidesFlue gasSulfate

In a method for processing flue gases, flue gases from an incineration plant for non-condensable gases of a kraft pulp mill are scrubbed by means of a calcium compound. The calcium compound is lime mud taken from the chemical recirculation of the kraft pulp mill after causticization and before a lime reburning kiln, and it is used in the scrubbing of gas as a substance reacting with sulphur dioxide.

Owner:METSO POWER OY

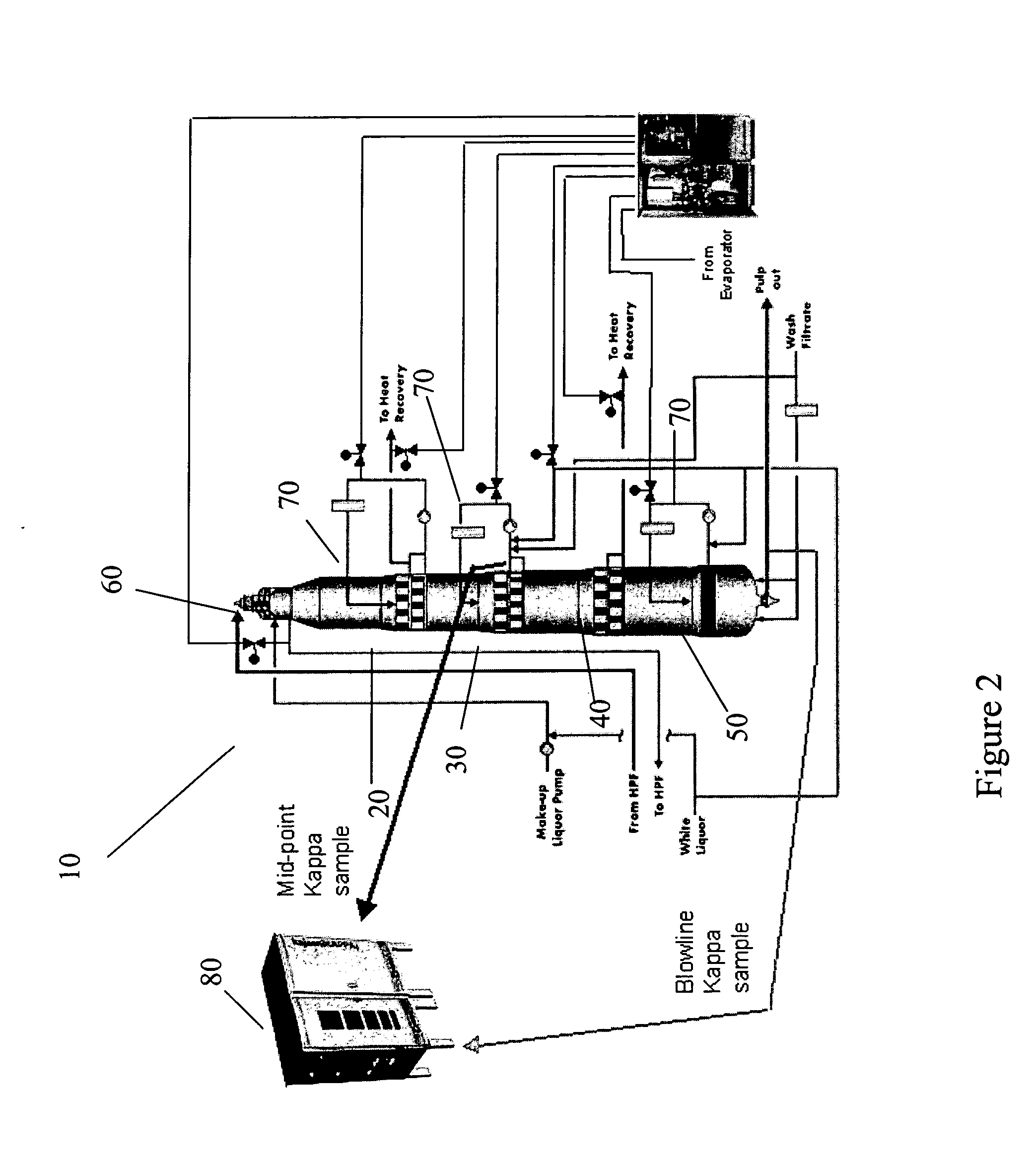

System and method for controlling a processor including a digester utilizing time-based assessments

InactiveUS7204914B2Minimizing and avoiding instabilityReduce impactWithdrawing sample devicesDigestersDead timeComputer science

A system for controlling a processor having at least one sampling port connected to a stage of the processor in order to sample a reactant product from the processor. The system includes a controller configured to control a processing parameter of the processor based on measurements of at least one property of the reactant product such that changes to the processing parameter maintain a target value for the at least one property of the reactant product. The system further includes a dead time compensator. The dead time compensator is configured, based upon a prescribed dead time related to a time before at least one effect of at least one change to the processing parameter is fully realized, to evaluate the reactant product to determine if the effect has been realized at a plurality of sequential times offset from the dead time.

Owner:METABO AUTOMATION USA

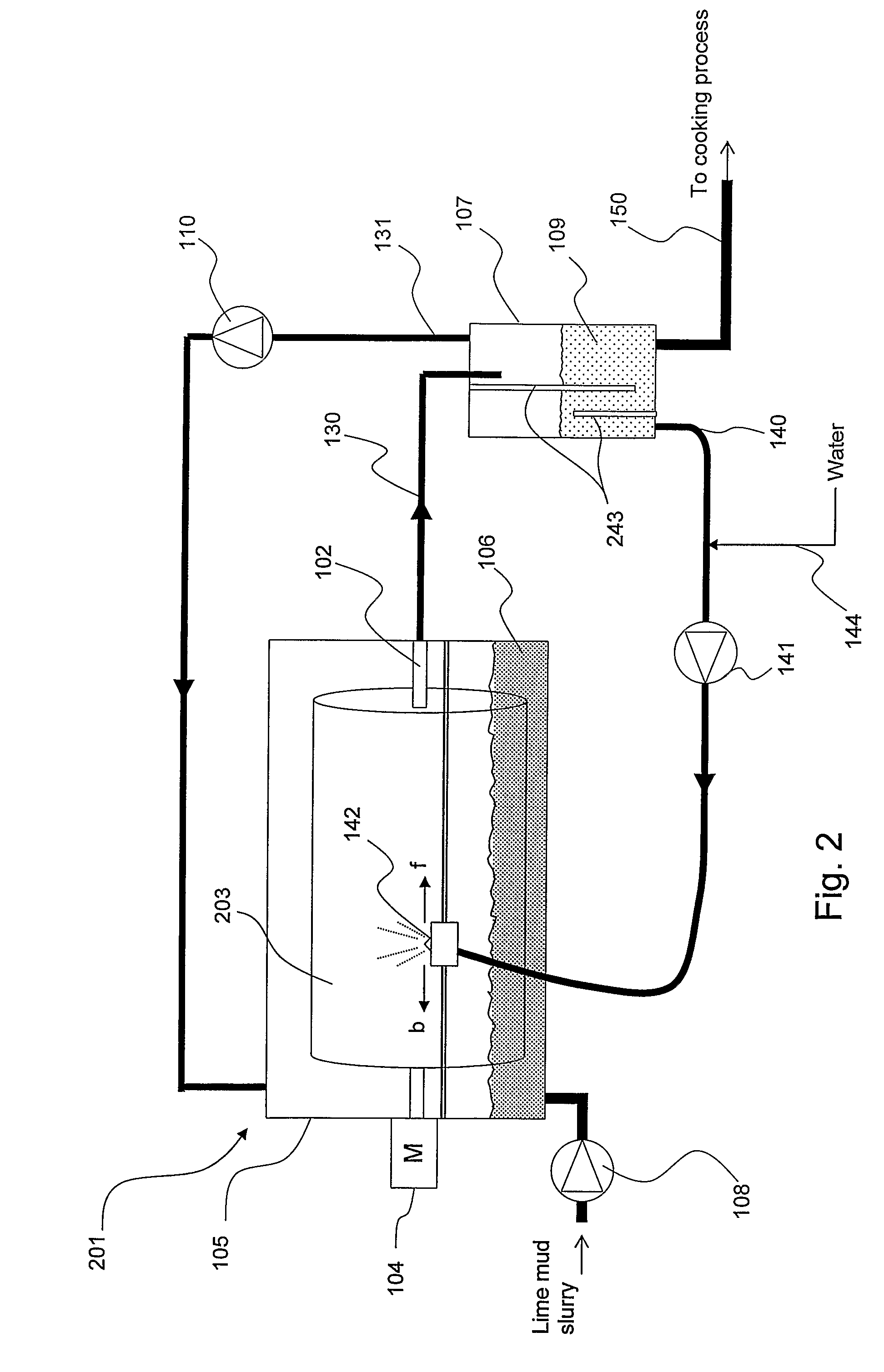

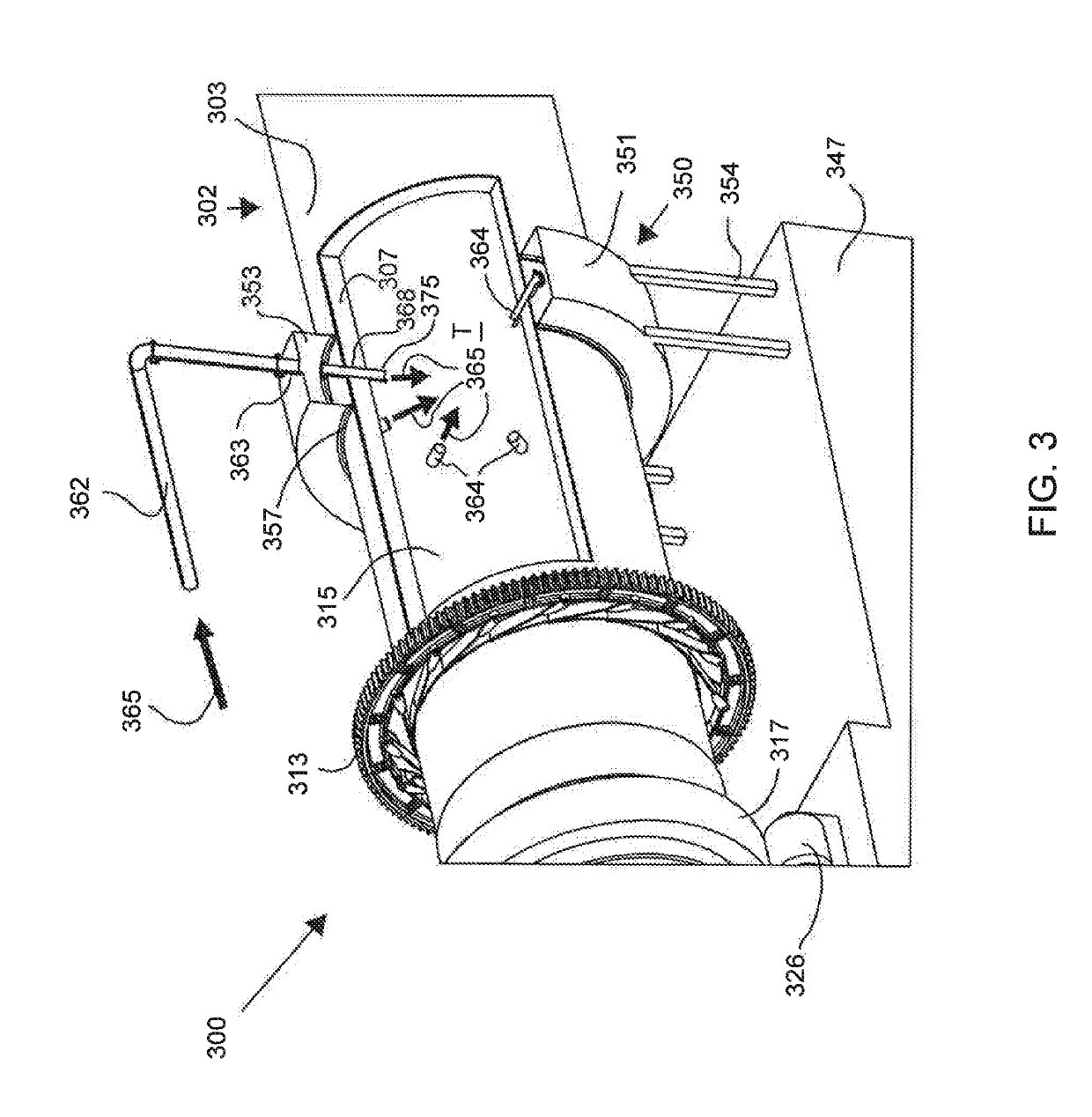

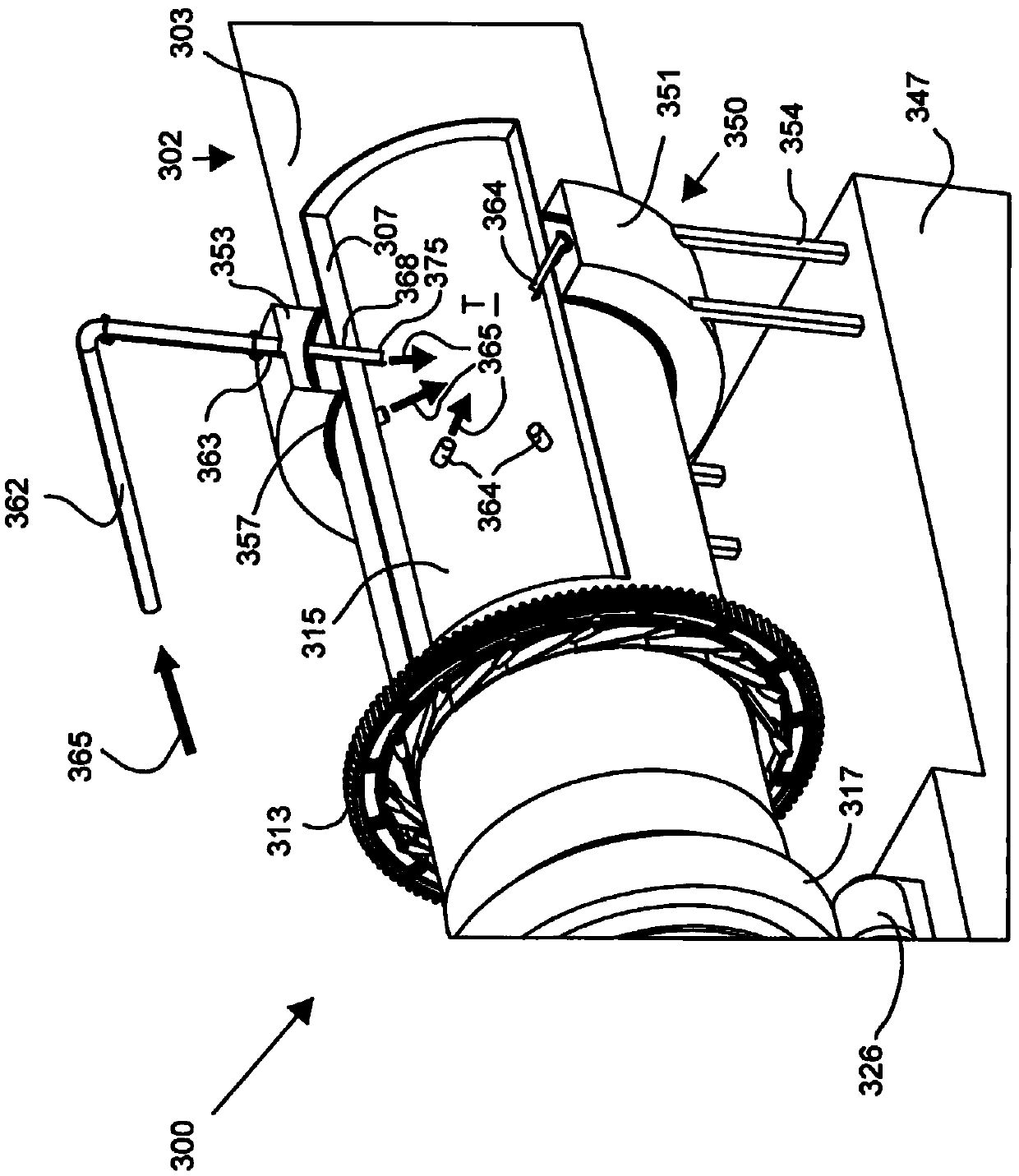

Process and system for reducing ringing in lime kilns

ActiveUS20190093950A1Mitigate nitrous oxide ( “ NOx ” ) emissionReduce thermal NO<sub>x </sub>Rotary drum furnacesGreen and white liquor treatmentCombustorLime kiln

This application discloses exemplary processes and systems for reducing mineral ring accumulation in calcination kiln. The processes and systems comprise inserting non-condensable gases (“NCGs”) in a preheating zone of a calcination kiln, upstream of the burner end. The pre -heating zone may be characterized by temperatures ranging from 1,300° F. to 1,750° F. The system may desirably comprise a plenum for inserting the NCGs into the rotating calcination kiln at the pre-heating zone.

Owner:ANDRITZ INC

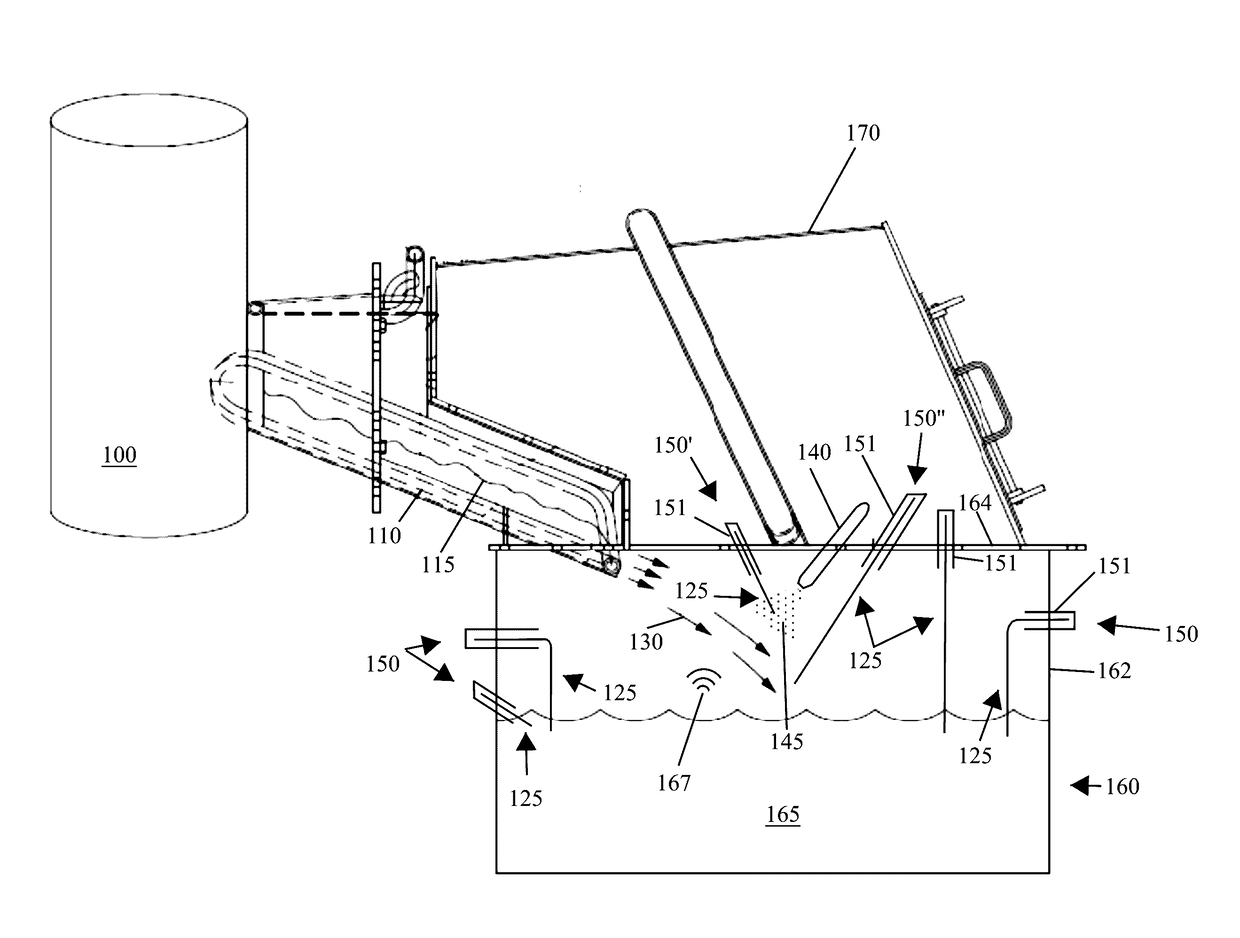

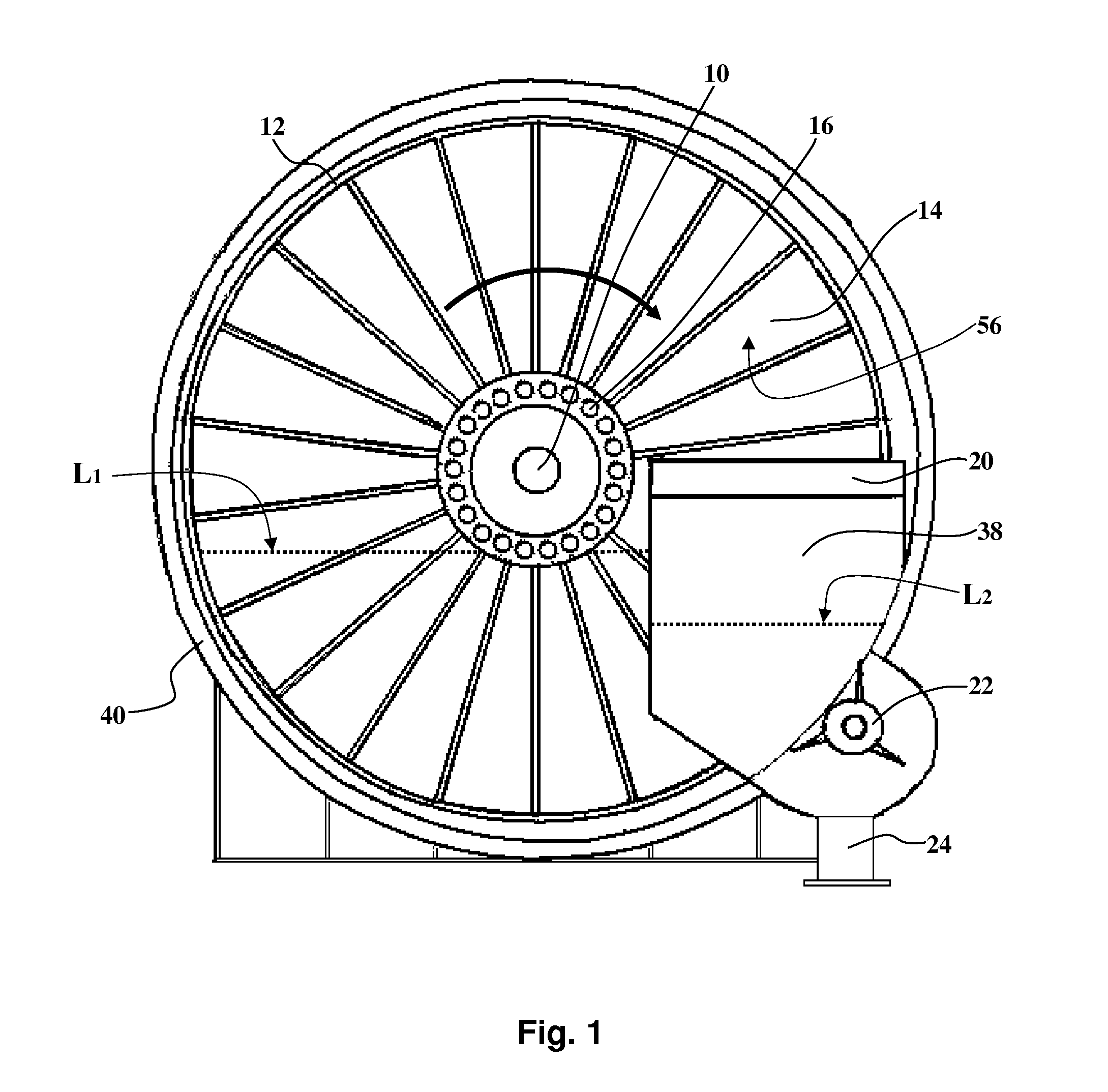

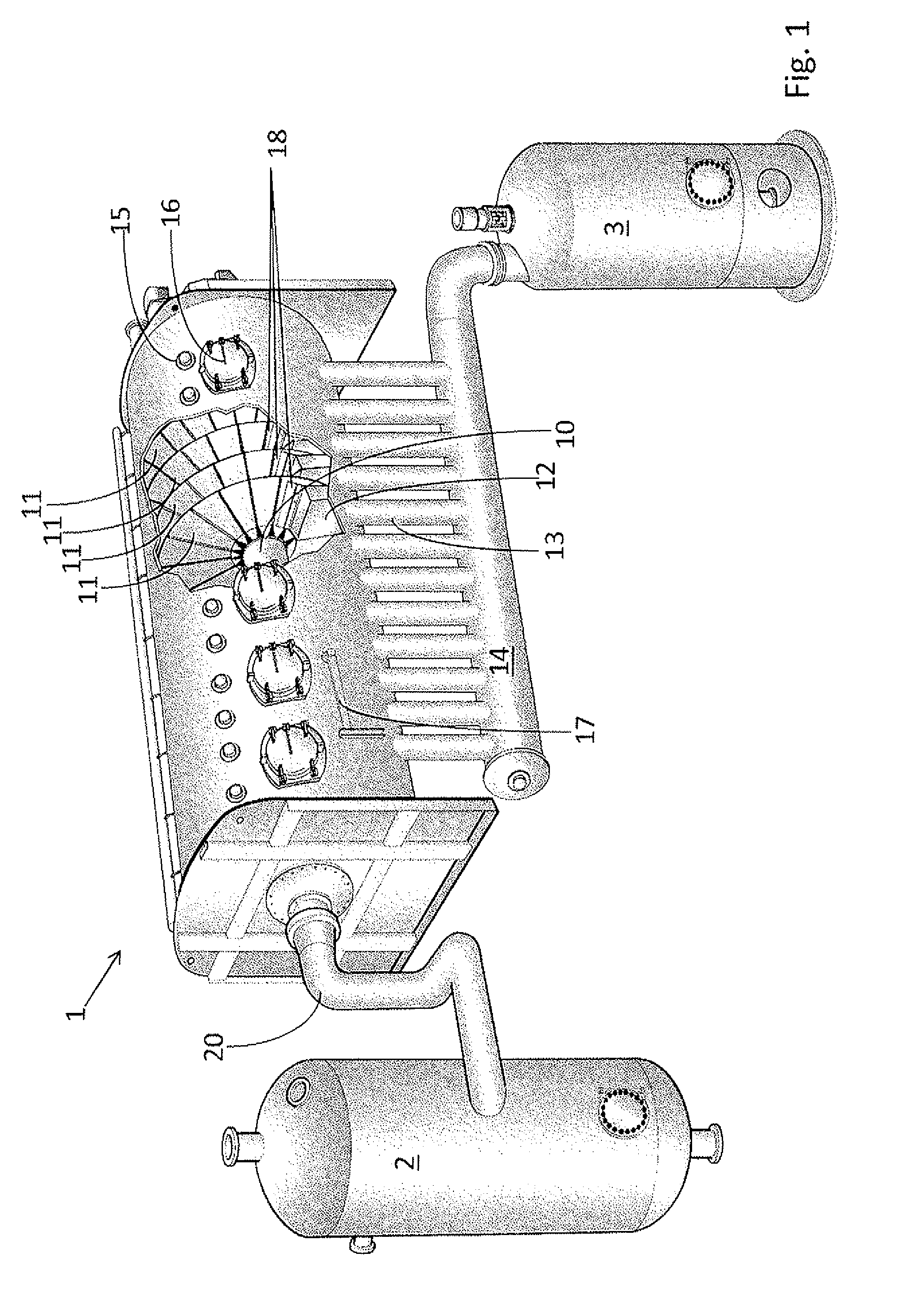

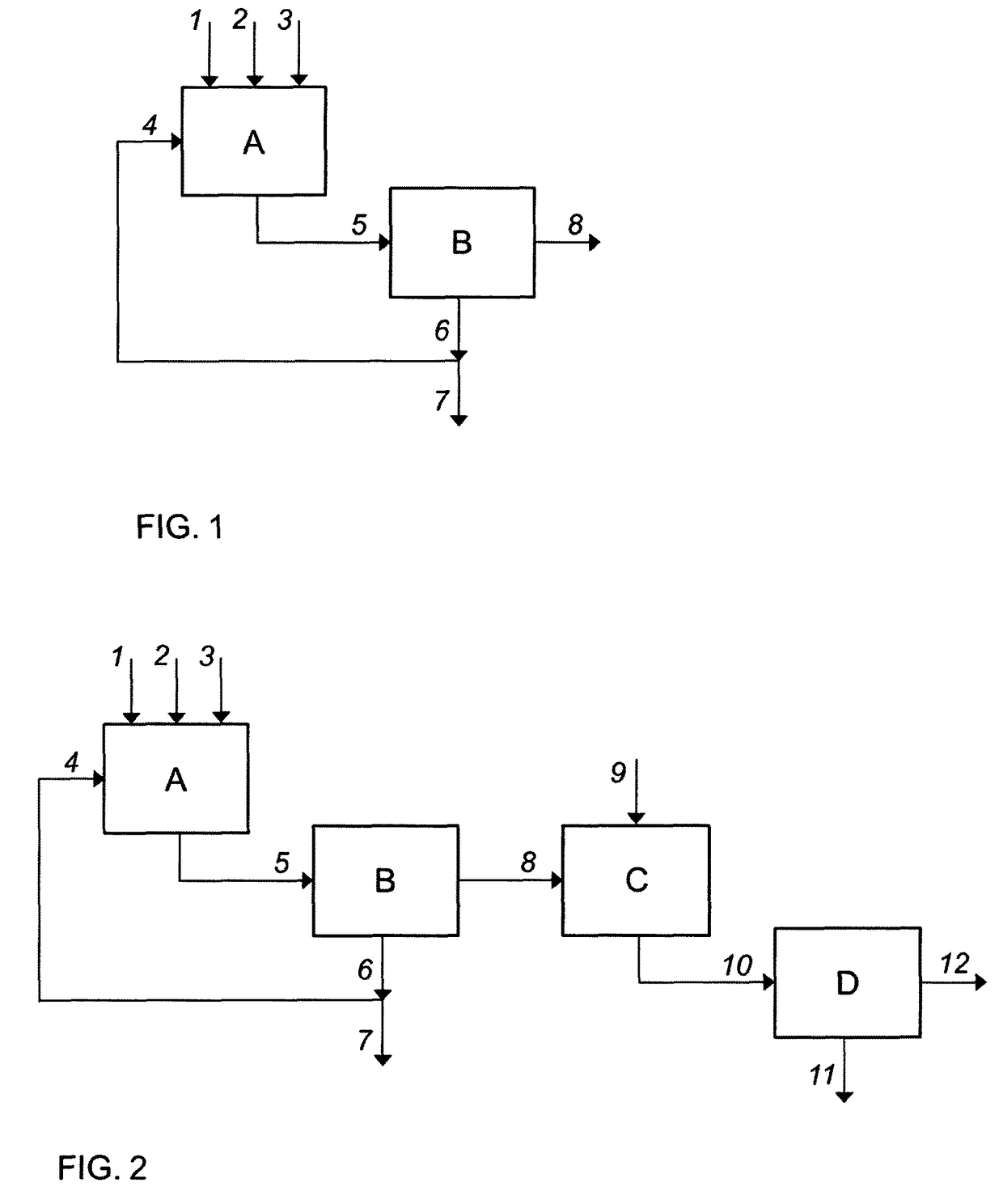

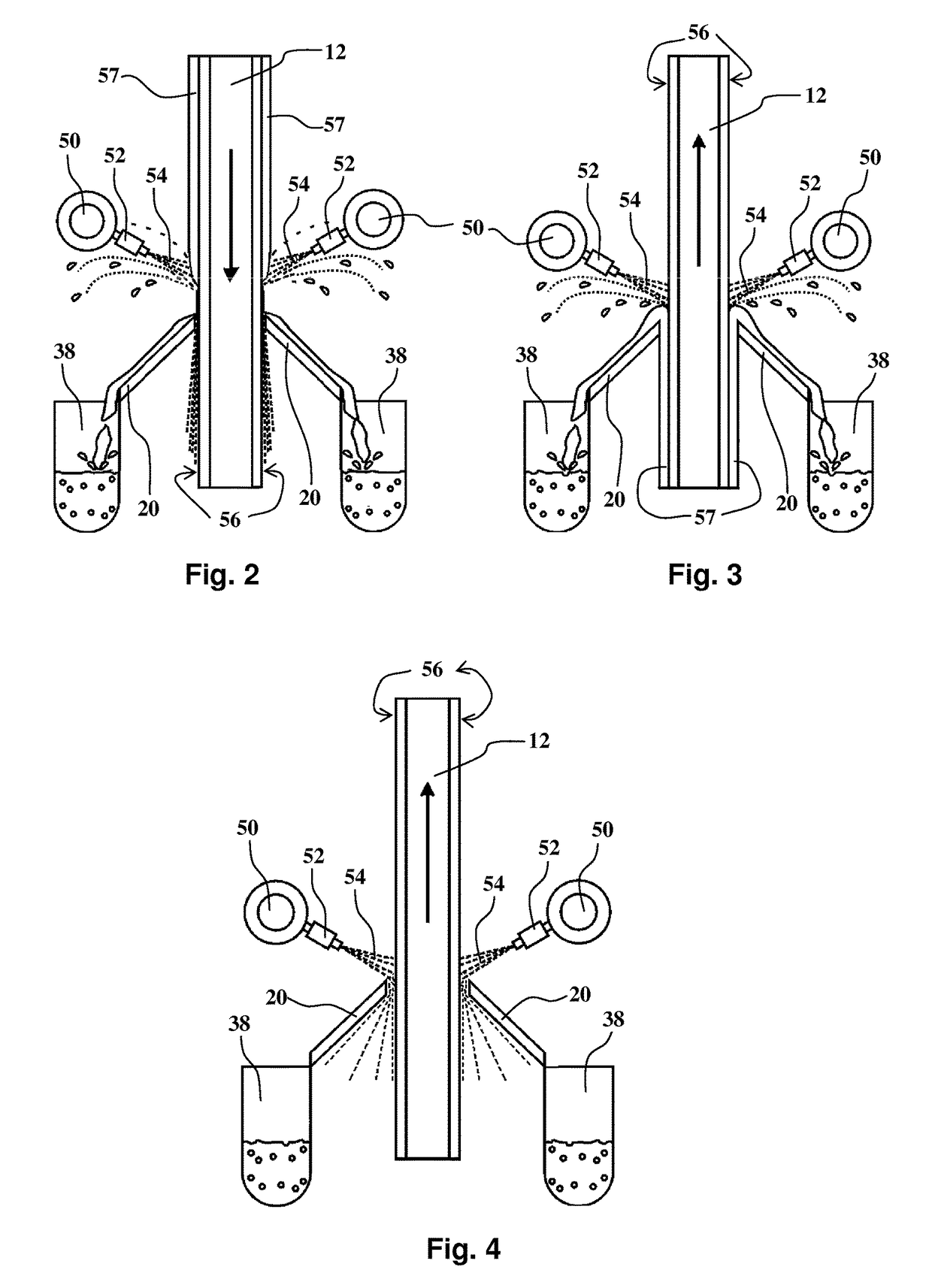

Method for removing the precoat layer of a rotary filter

ActiveUS20150290566A1Easy to cleanEffective penetrationWater/sewage treatmentLoose filtering material filtersSludgeSlurry

A method associated for treating a precoat on a rotating filtering surface of lime sludge filter including: accumulating a precoat of lime sludge on the filtering surface by rotating the filtering surface in a first direction through a lime sludge slurry; after accumulating the precoat, rotating the filtering surface in an opposite direction to the first direction; while rotating the filtering surface in the opposite direction, spraying a liquid onto the precoat on the filtering surface wherein the spraying is applied to the precoat above a scraper adjacent the filtering surface and the spraying removes at least a portion of the precoat from the filtering surface, and flowing the removed precoat over the scraper and into a basin.

Owner:ANDRIZ OY

Method and device for washing of lime mud

InactiveUS7686964B2Promote oxidationWater/sewage treatmentLoose filtering material filtersGas phaseFresh air

The method and an arrangement are for dewatering and washing lime slurry before the dewatered lime mud is passed to a lime mud kiln. The lime slurry is dewatered in a pressurized lime mud filter of disc or drum type. The pressurized lime mud filter is pressurized through a compressor drawing on its suction side (s) gas phase from the filtrate tank and pressurizing on the pressurized side (p) of the compressor the pressure vessel on the lime mud side of the filter. A certain pre-determined amount of gas phase in the gas circulation system is vented and an equivalent pre-determined amount of fresh air is added to the recycled gas phase with the aim of maintaining the partial pressure of oxygen gas above a certain minimum level.

Owner:METABO PAPER SWEDEN

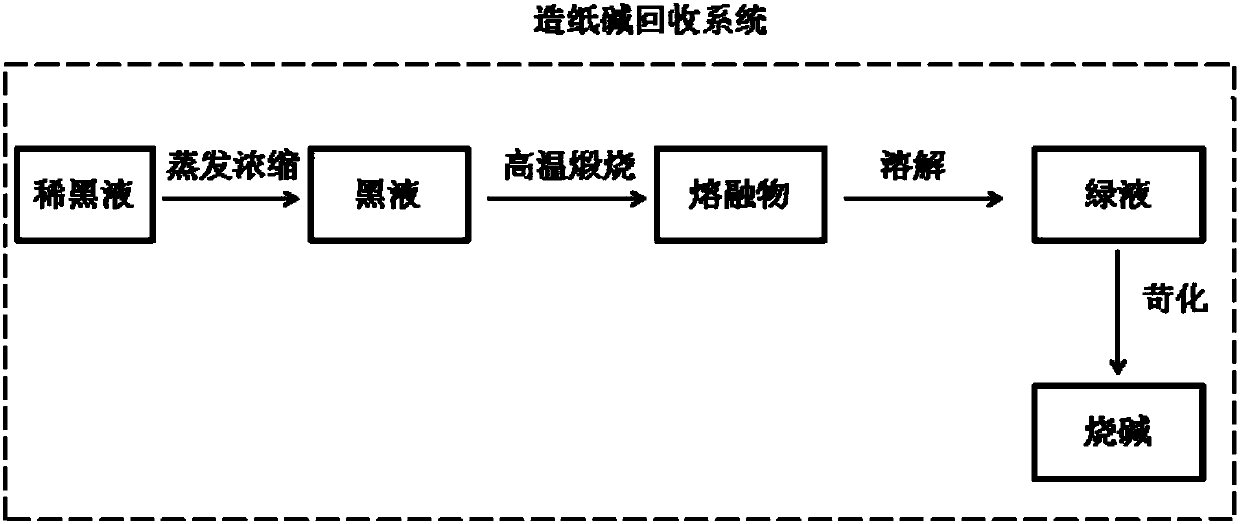

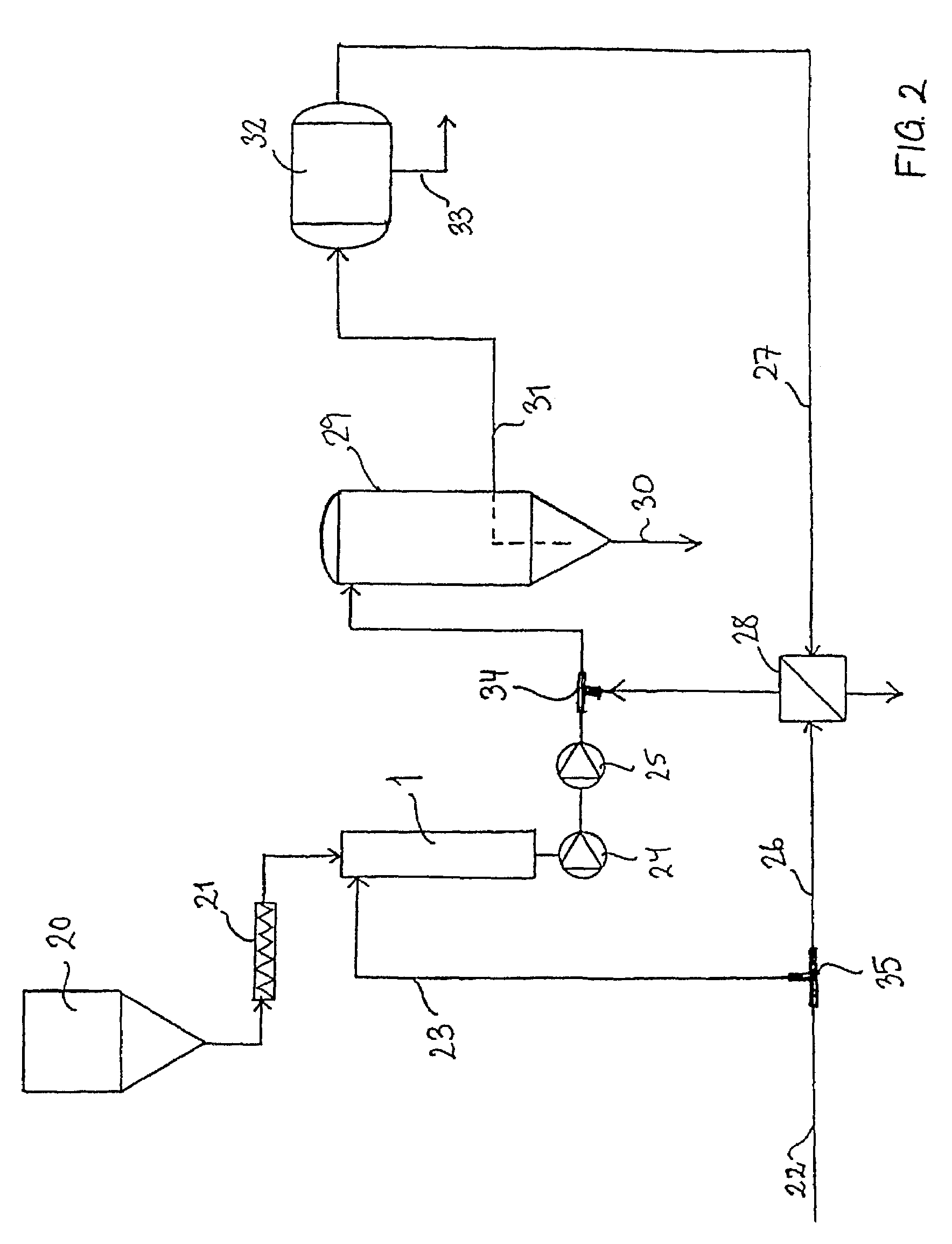

Optimizing process for alkali recovery of papermaking waste liquid

The invention discloses an optimizing process for alkali recovery of papermaking waste liquid, the optimizing process comprises black liquor extraction, evaporation concentration, high-temperature calcining and causticization, the black liquor extraction section is used for extracting dilute black liquor from pulping cooked liquor, the evaporation concentration section is used for heating the black liquor of the black liquor extraction section by virtue of steam from the high-temperature calcining section; the high-temperature calcining working section is used for first concentrating the blackliquor with the concentration of 50% obtained by the evaporation concentration section further to the concentration of 65%, the obtained black liquor is sent to an alkali furnace for high-temperaturecalcining, a melt is formed by the calcined black liquor, and the melt is dissolved into water obtain green liquor; and the causticization section is used for reacting the green liquor with limestoneto obtain a sodium hydroxide solution. According to the optimizing process, the process is simple and feasible, the recycling efficiency of the black liquor is high, and the quality is guaranteed.

Owner:INT CENT FOR BAMBOO & RATTAN

Lime causticization product brightness improvement via pre-slaking

ActiveUS20130129601A1Promote recoveryQuantity minimizationCalcium/strontium/barium carbonatesPigmenting treatmentParticulatesWater use

A method for obtaining particulate calcium carbonate exhibiting improved brightness and color and having uniformity of size such that when the particles are formed in the causticization process in a kraft pulp mill, the time required to separate the particles from liquors in which they are suspended is minimized and the amount of liquor recovered is maximized, with minimal dilution by water used for washing. The method includes the steps of a) slaking calcium oxide in water or an alkaline liquor containing as dissolved species predominantly sodium hydroxide; b) mixing the slaked lime with green liquor from a kraft pulping process to complete a causticization reaction that produces white liquor and lime mud; c) separating the lime mud from the white liquor; and d) milling a portion of the lime mud for use as a white mineral pigment in applications where such pigments are typically used.

Owner:SPECIALITY MINERALS (MICHIGAN) INC

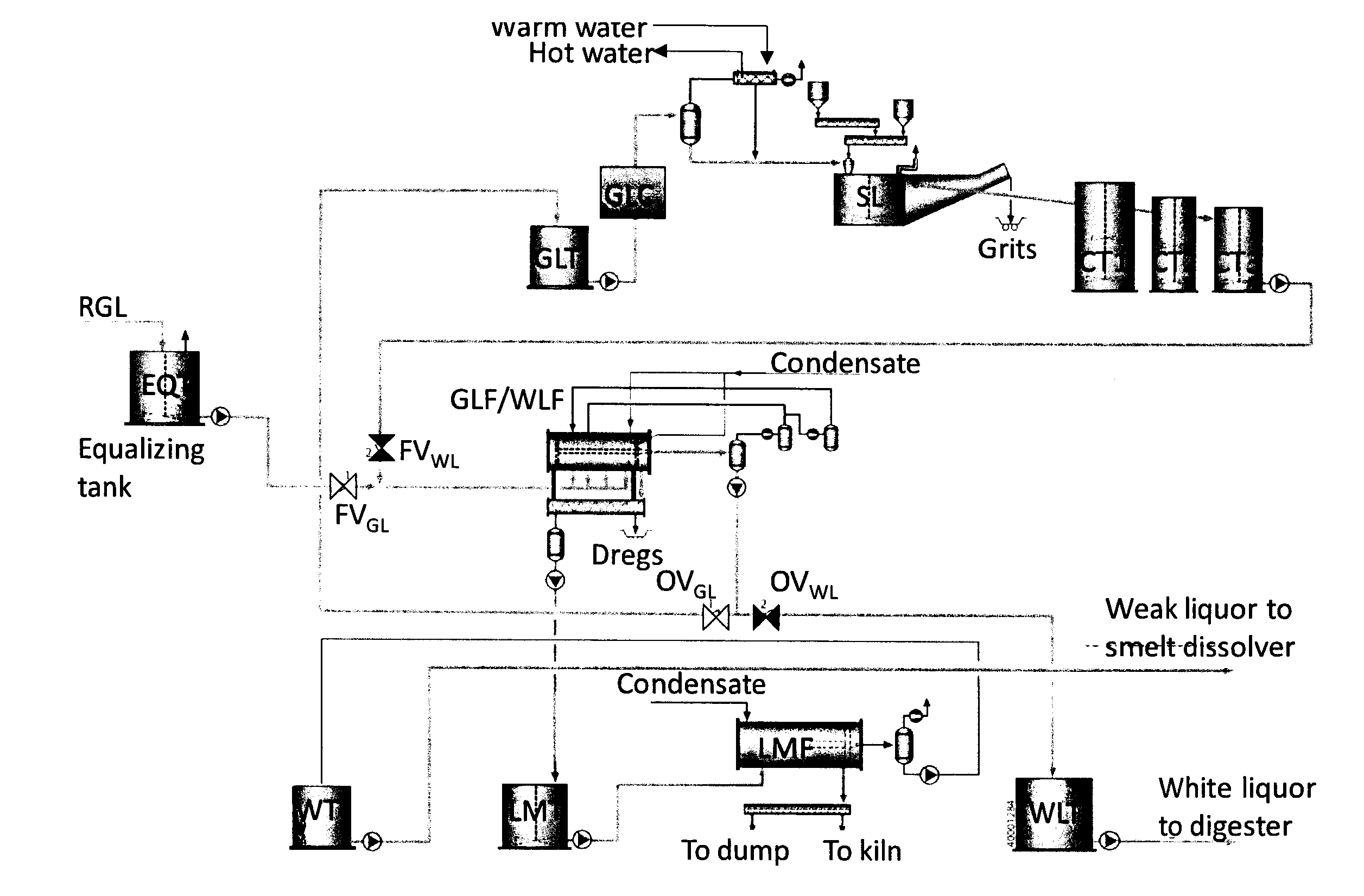

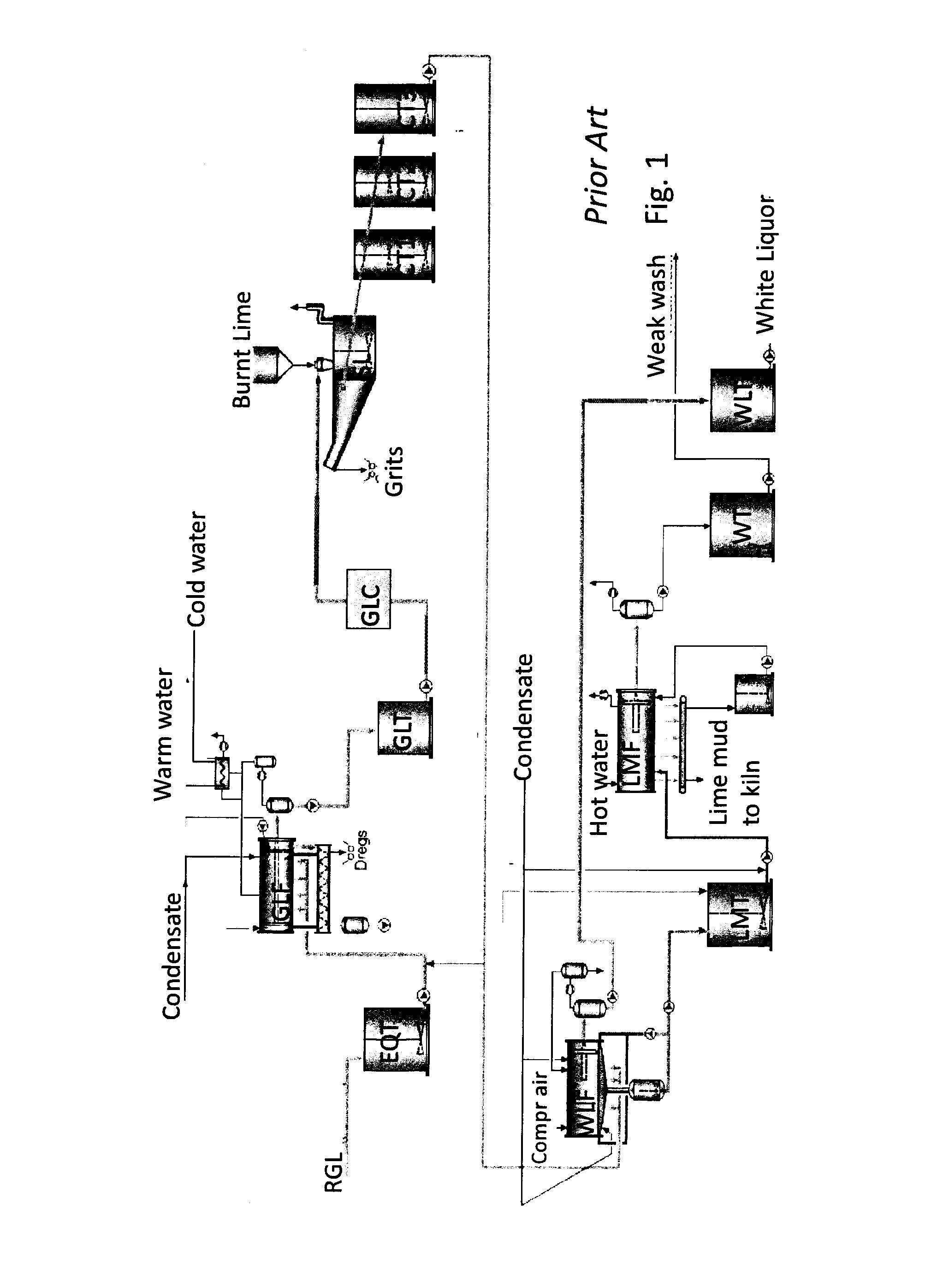

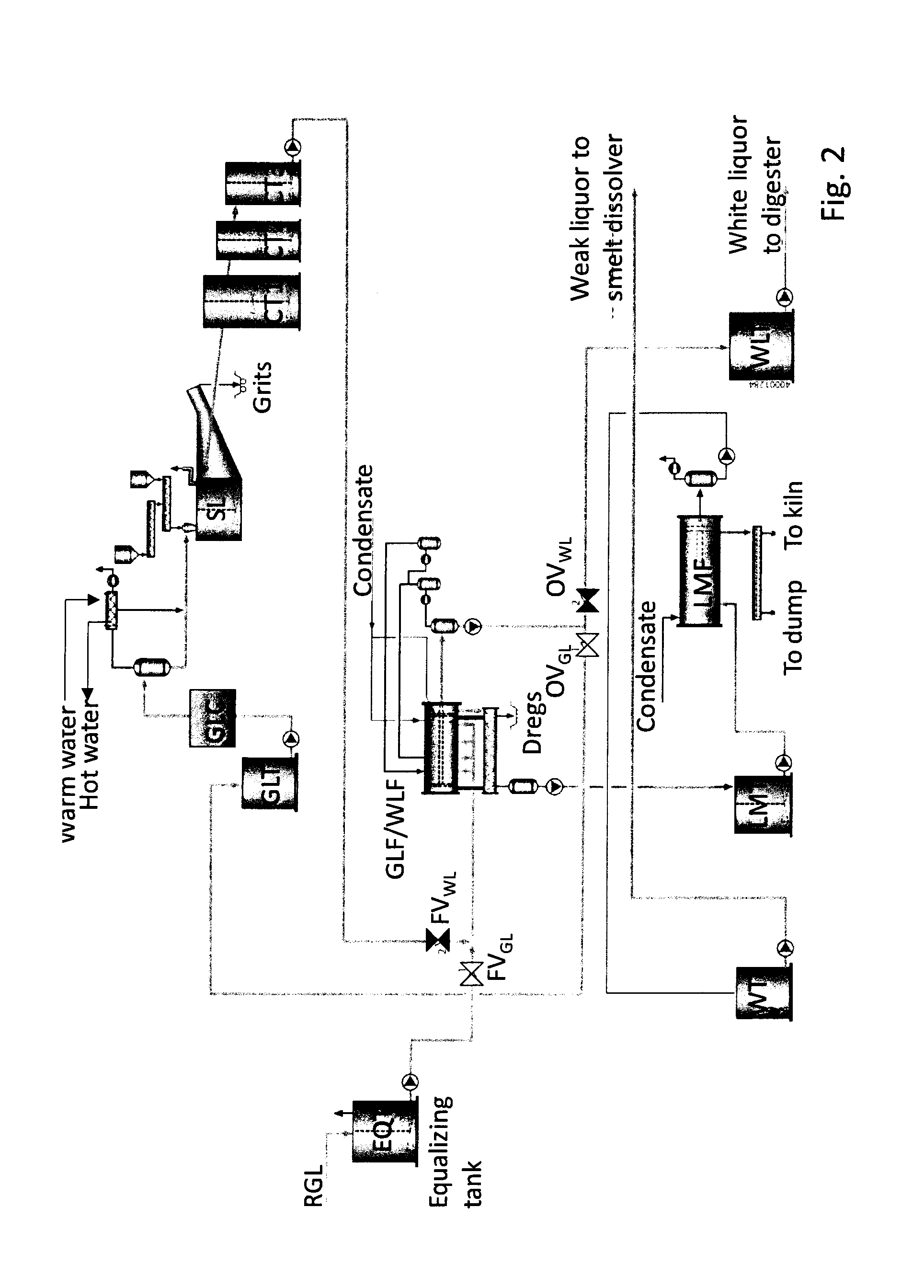

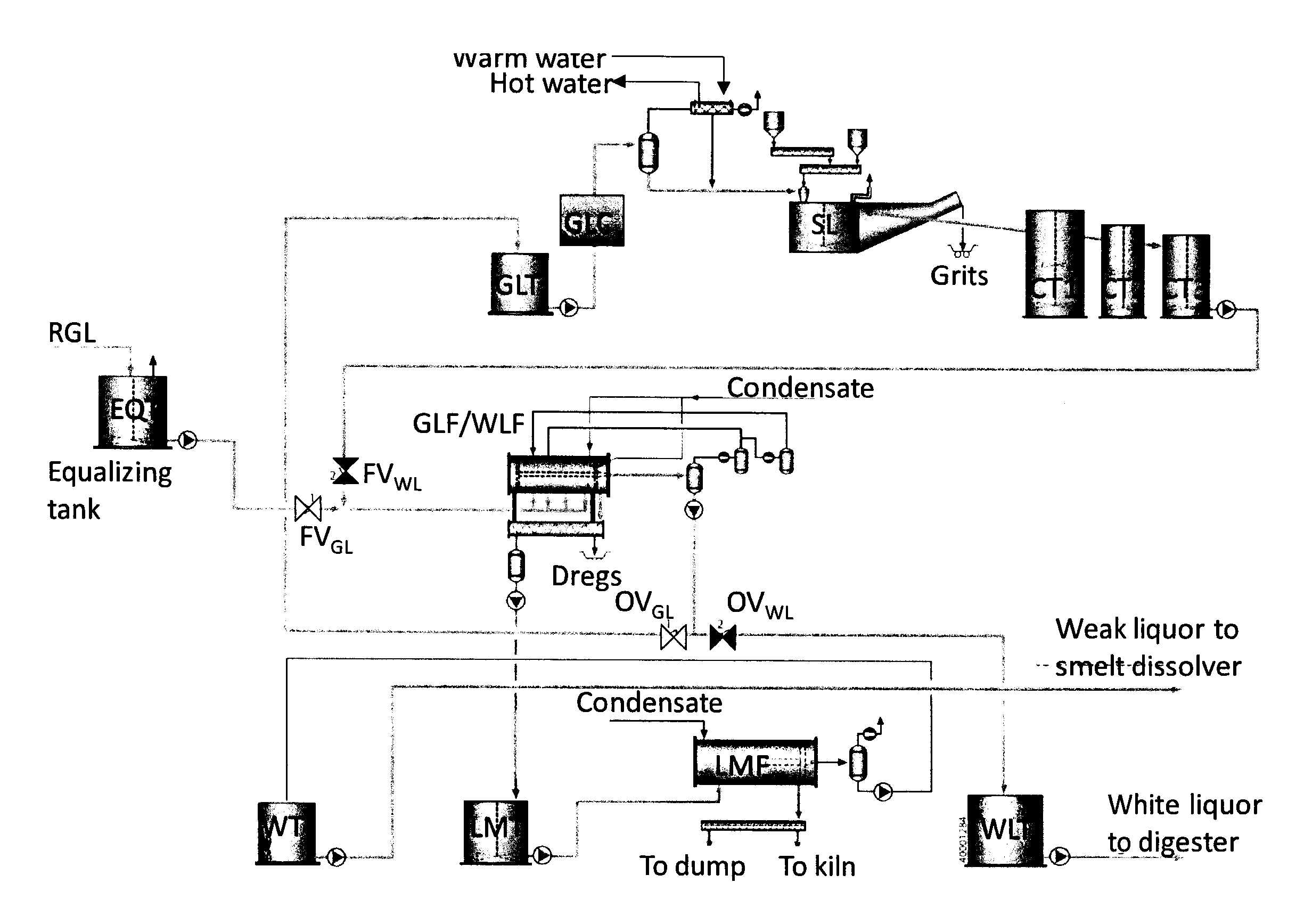

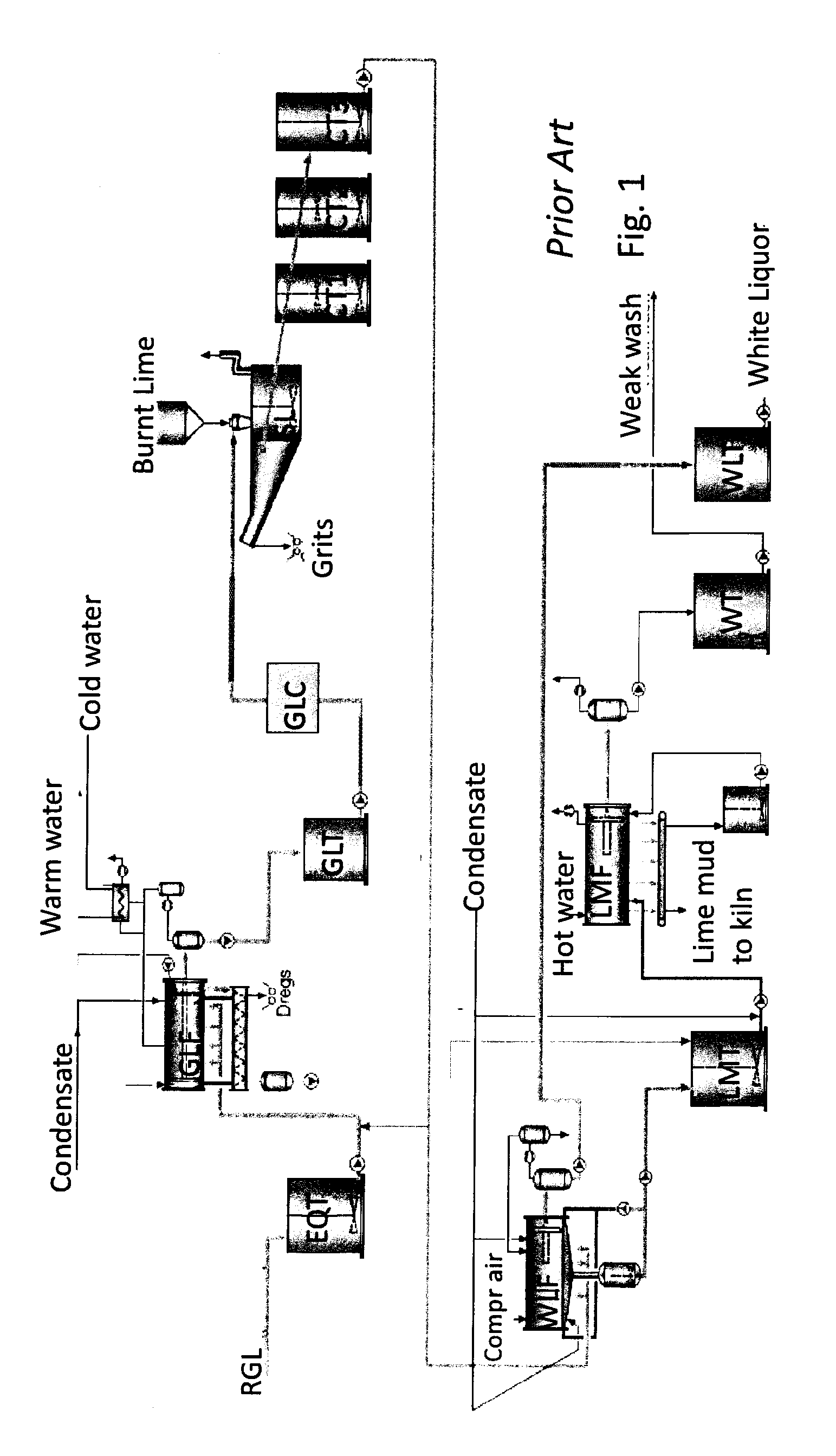

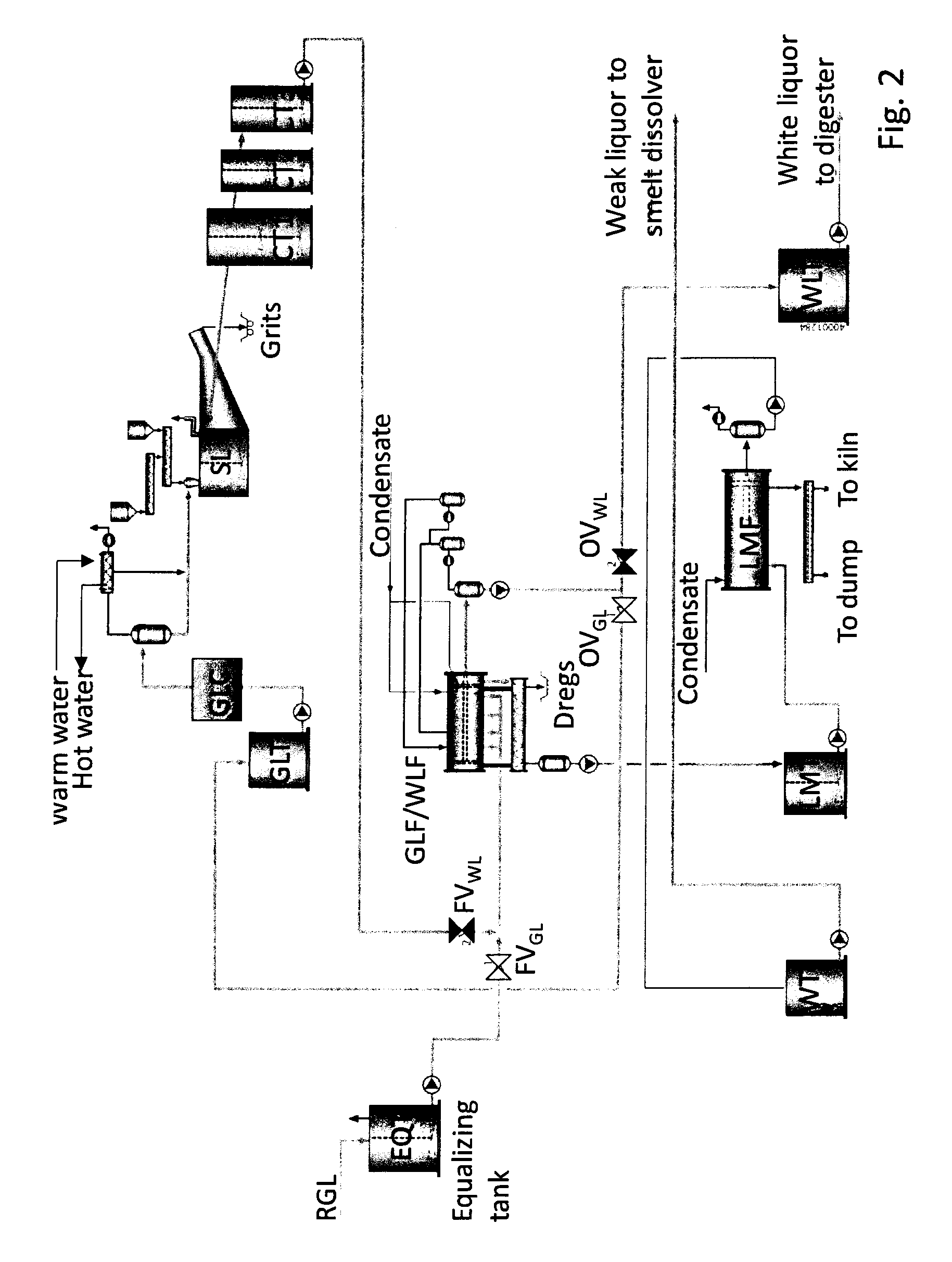

Method for the causticizing process for producing white liquor

ActiveUS20140374039A1Efficient processReduce contentPulp liquors combustionPulp by-products recoveryWhite liquorKraft process

The method is for preparation of white liquor in a chemical recovery process of the kraft process. The green liquor separation process and the white liquor separation process are taking place in the same common filter apparatus with no dedicated green liquor separation apparatus or any dedicated white liquor separation apparatus. The white liquor separation process and the green liquor separation process are conducted in sequence in the same filter apparatus. The white liquor separation process has a part of the cycle time in the range 20-50% of the total cycle time in the same filter apparatus.

Owner:VALMET AB

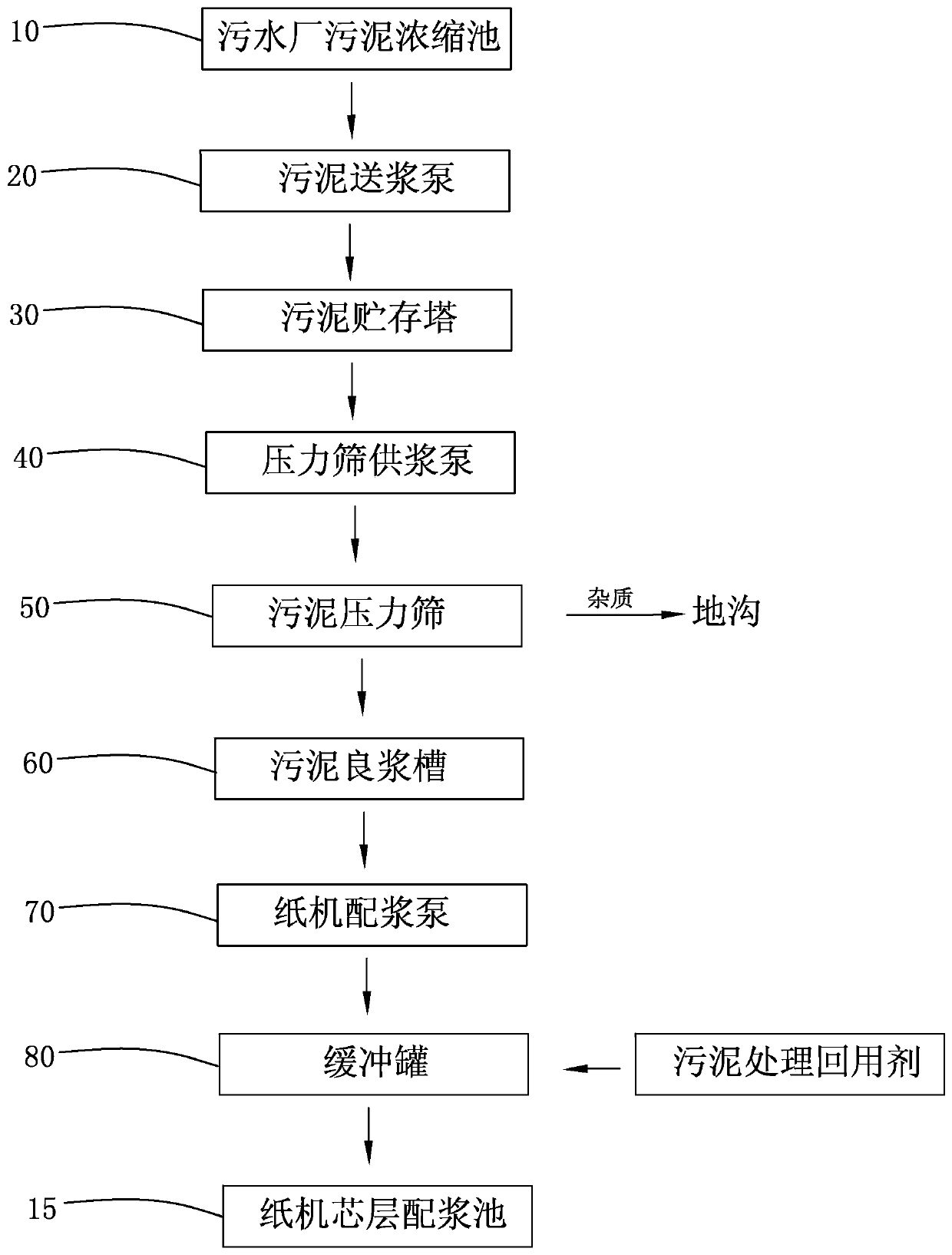

Production method for recycling fiber through cleaning light dreg of OCC pulping line

ActiveCN106192520AEfficient use ofReduce consumptionGreen and white liquor treatmentPulp gases treatmentFiberFreeze-drying

The invention relates to a production method for recycling fiber through cleaning light dreg of an OCC pulping line. The production method comprises the following steps: broken material collection: collecting the light dreg discharged from a cylinder screen on a breaking section on the OCC pulping line; light dreg cleaning: enabling pulp-water mixture to flow in a light dreg cleaning tank, and carrying out spraying cleaning on the light dreg by virtue of multiple spraying water pipes; dreg water separation: enabling white water floating at the upper part to flow into a concentrated white water collecting pool through difference of elevation, and intermittently discharging relatively heavy dreg water at the lower part of the cleaning tank to a discharging tank through a pneumatic switch valve; recycling and freeze-drying: introducing white water to a light dreg cleaning line for circular use, quickly freezing recycled pulp into recycled pulp blocks, and carrying out vacuum drying on the recycled pulp blocks, so as to obtain freeze-dried recycled fibers. Compared with the prior art, the production method has the advantages that paper pulp in the light dreg is recycled, so that the raw material consumption is reduced, and the production cost is lowered; the waste material is recycled, so that the current environmental requirements are met; and by utilizing a freeze-drying manner, the preserving property is good, the finished product is light and is convenient to transport.

Owner:LIANSHENG PAPER IND LONGHAI

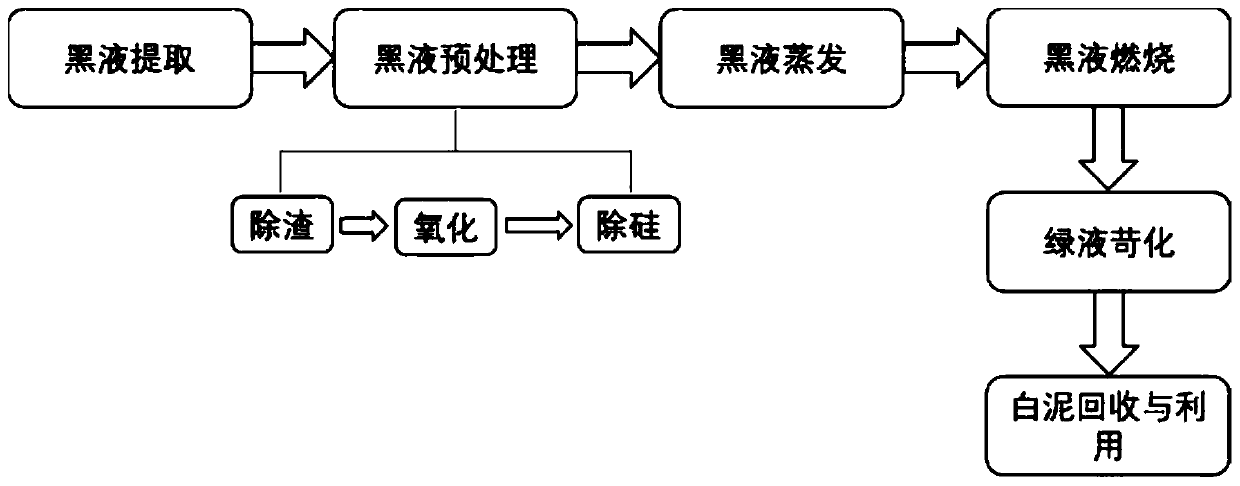

Method for comprehensively recycling pulping waste liquid

InactiveCN111287011AEliminate pollutionLow efficiencyPulp liquors combustionGreen and white liquor treatmentBlack liquorWhite liquor

The invention discloses a method for comprehensively recycling pulping waste liquid, which comprises the following steps: extracting dilute black liquid from pulping cooking liquid, pretreating the dilute black liquid, and finally evaporating and concentrating the pretreated dilute black liquid by using a mixed-flow indirect evaporation method; then performing combustion with a jet furnace so thathigh-temperature flue gas generated after organic matters in the black liquid are combusted rises in the furnace, and inorganic matters are molten, flow into a dissolving tank from a chute below thecombustion furnace and dissolved in dilute white liquid or water to form green liquid, with the green liquid comprising Na2CO3 and Na2S; carrying out a causticization reaction on the green liquid formed by inorganic melt dissolved in dilute white liquid or water; and finally, recycling a product generated by the causticization reaction of the green liquid. According to the method, the problems ofserious pulping and papermaking wastewater pollution and high treatment difficulty in the prior art are solved.

Owner:SHAANXI UNIV OF SCI & TECH

Method for the causticizing process for producing white liquor

ActiveUS9187863B2Reduce contentImprove drynessPulp by-products recoveryPulping with inorganic basesWhite liquorKraft process

Owner:VALMET AB

Method for processing flue gases

ActiveUS7591988B2Low costLow investment costDispersed particle separationAlkali metal sulfides/polysulfidesFlue gasKraft paper

In a method for processing flue gases, flue gases from an incineration plant for non-condensable gases of a kraft pulp mill are scrubbed by means of a calcium compound. The calcium compound is lime mud taken from the chemical recirculation of the kraft pulp mill after causticization and before a lime reburning kiln, and it is used in the scrubbing of gas as a substance reacting with sulphur dioxide.

Owner:METSO POWER OY

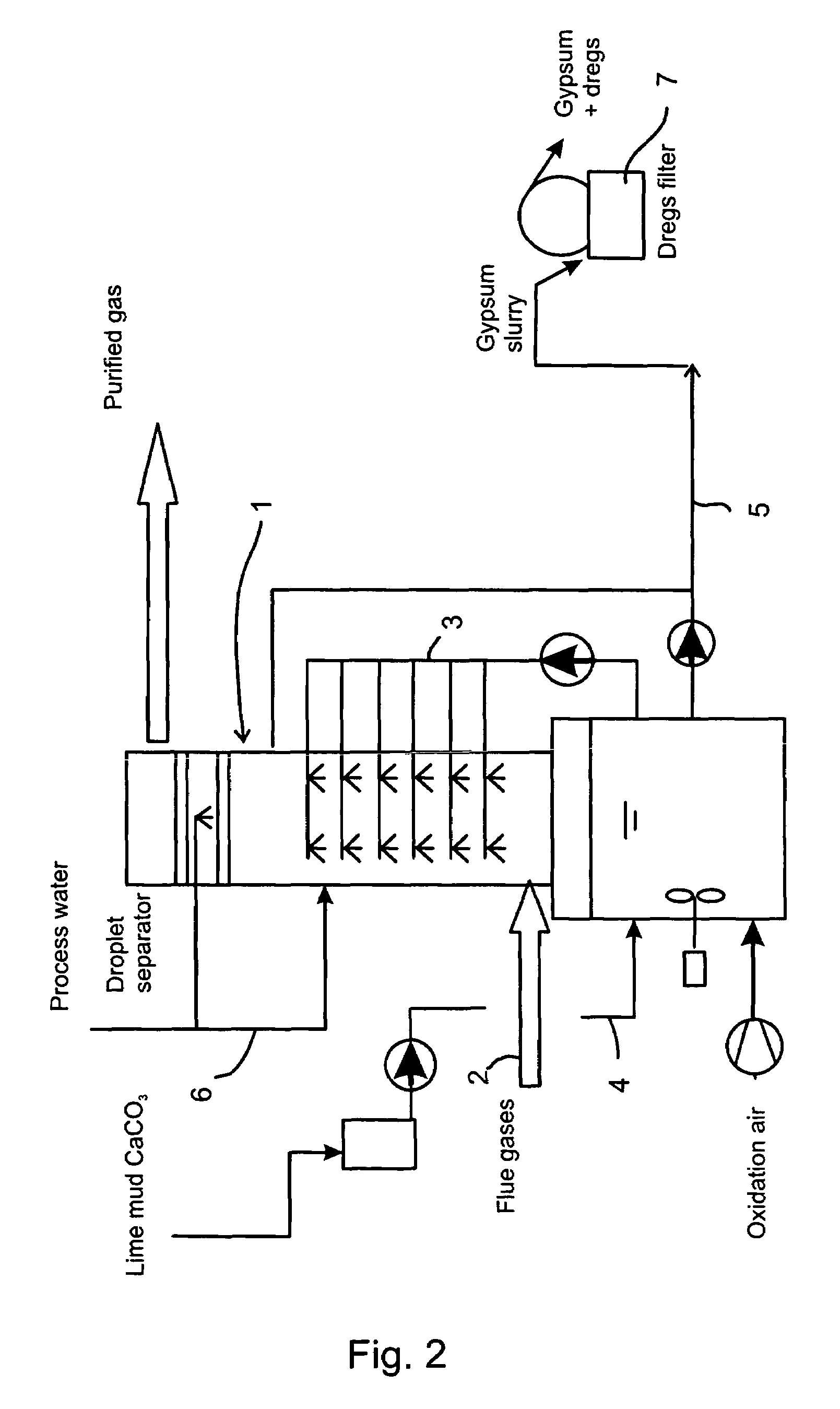

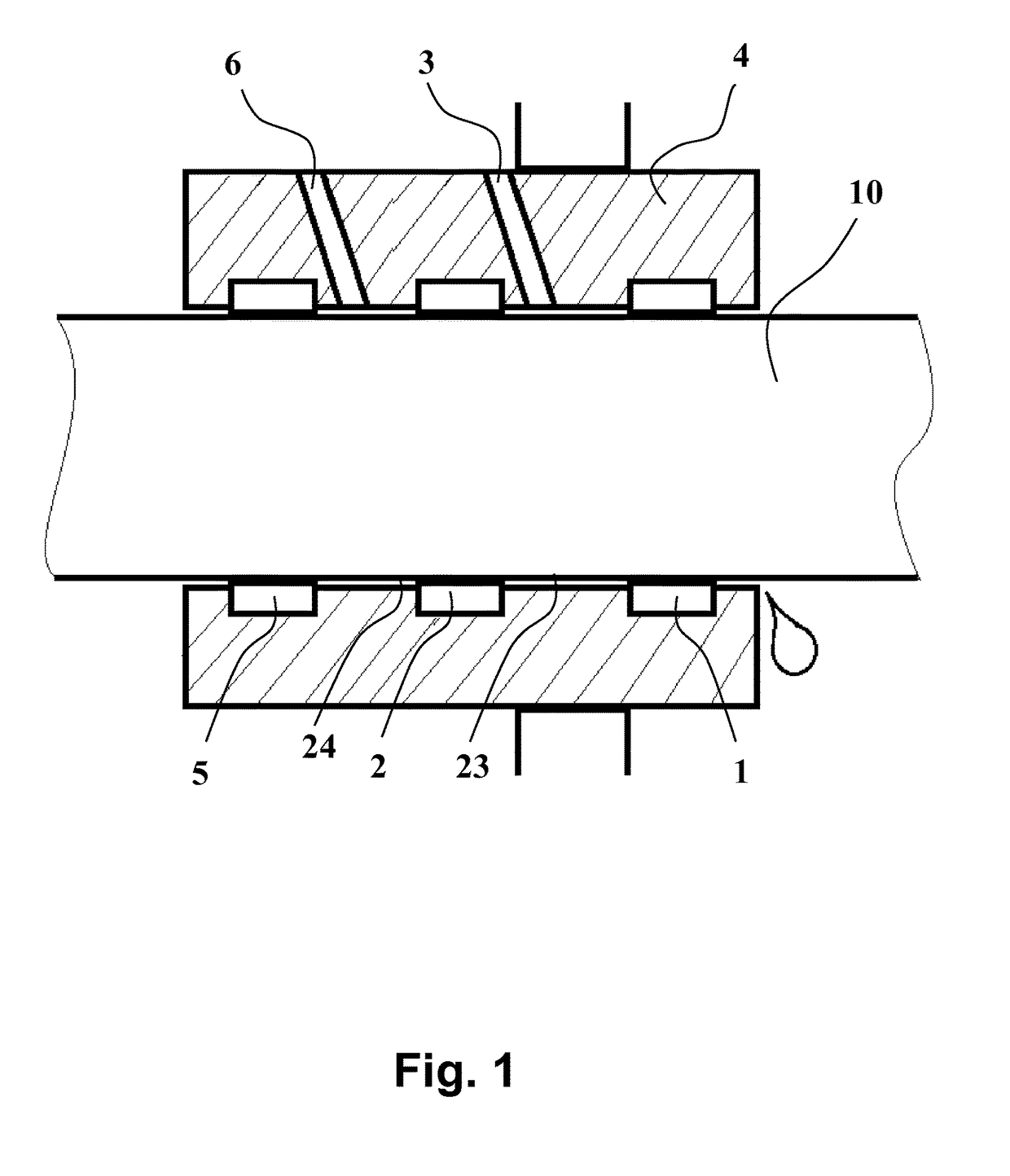

A method of feeding a sealing medium into a liquor filter and a liquor filter

InactiveUS20170183818A1Inhibit wearSlow leakEngine sealsWashing/displacing pulp-treating liquorsPulp and paper industryChemical pulp

A method and a liquor filter, in which liquor filter sealing medium is fed via a sealing medium channel (3) into an innermost sealing zone formed by an innermost sealing member (1), an outer seal (2) and the space between them at a causticizing plant of a chemical pulp mill. The sealing medium used is an alkaline sealing liquid and / or gas, which does not substantially dilute the liquor being filtered. Advantageously the sealing medium is filtrate from the liquor filter and / or gas taken from the interior of the liquor filter.

Owner:ANDRIZ OY

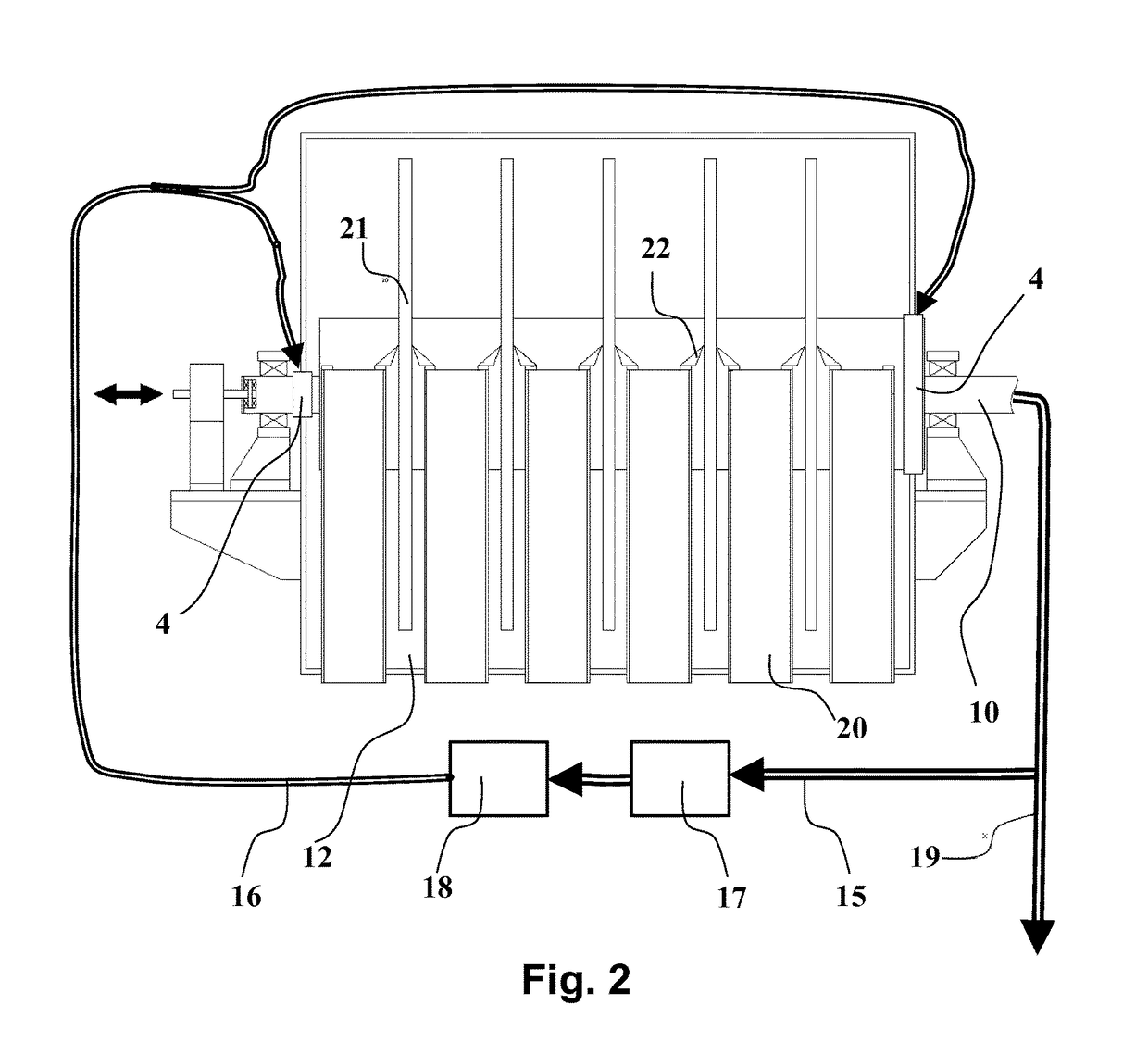

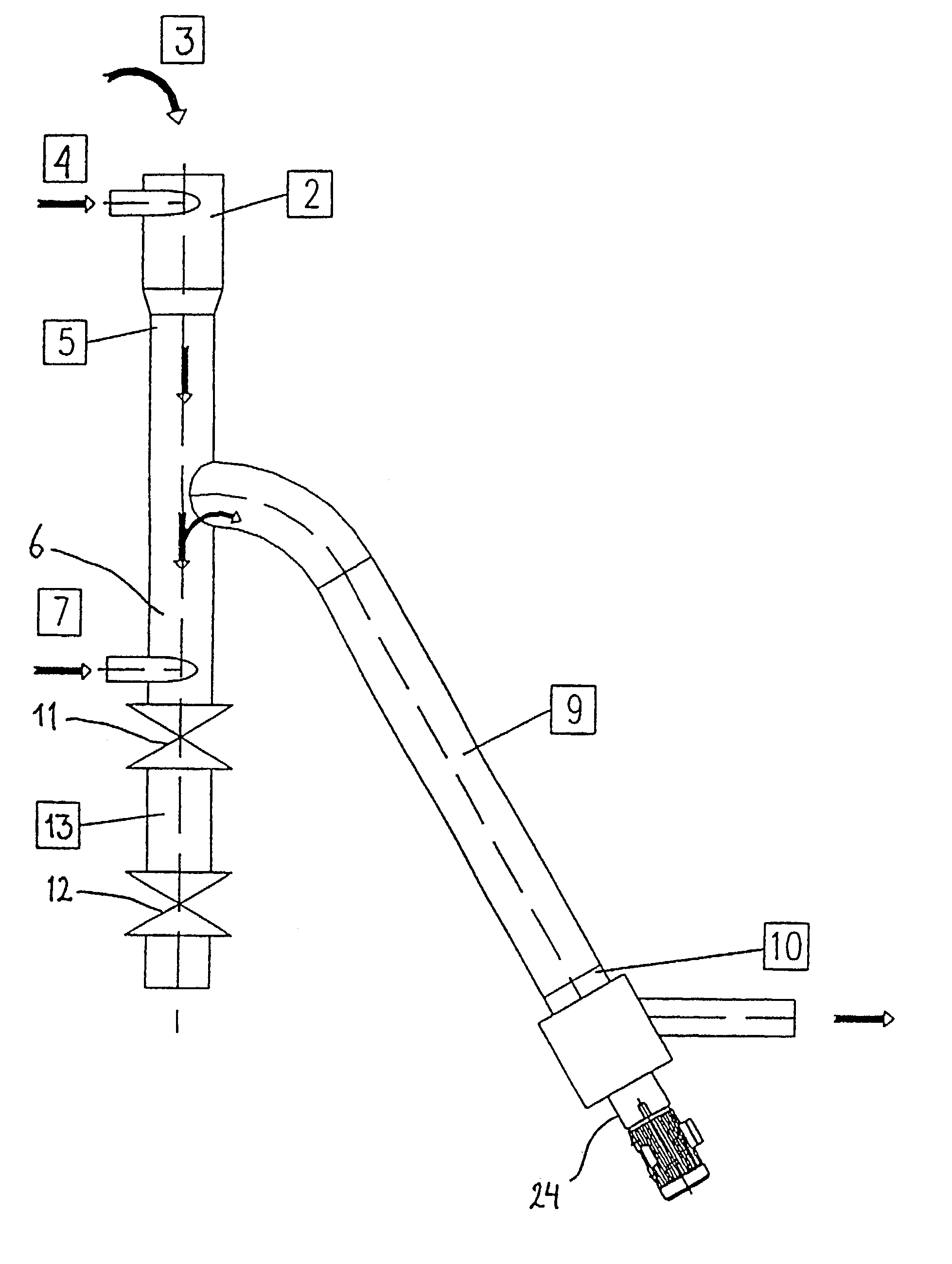

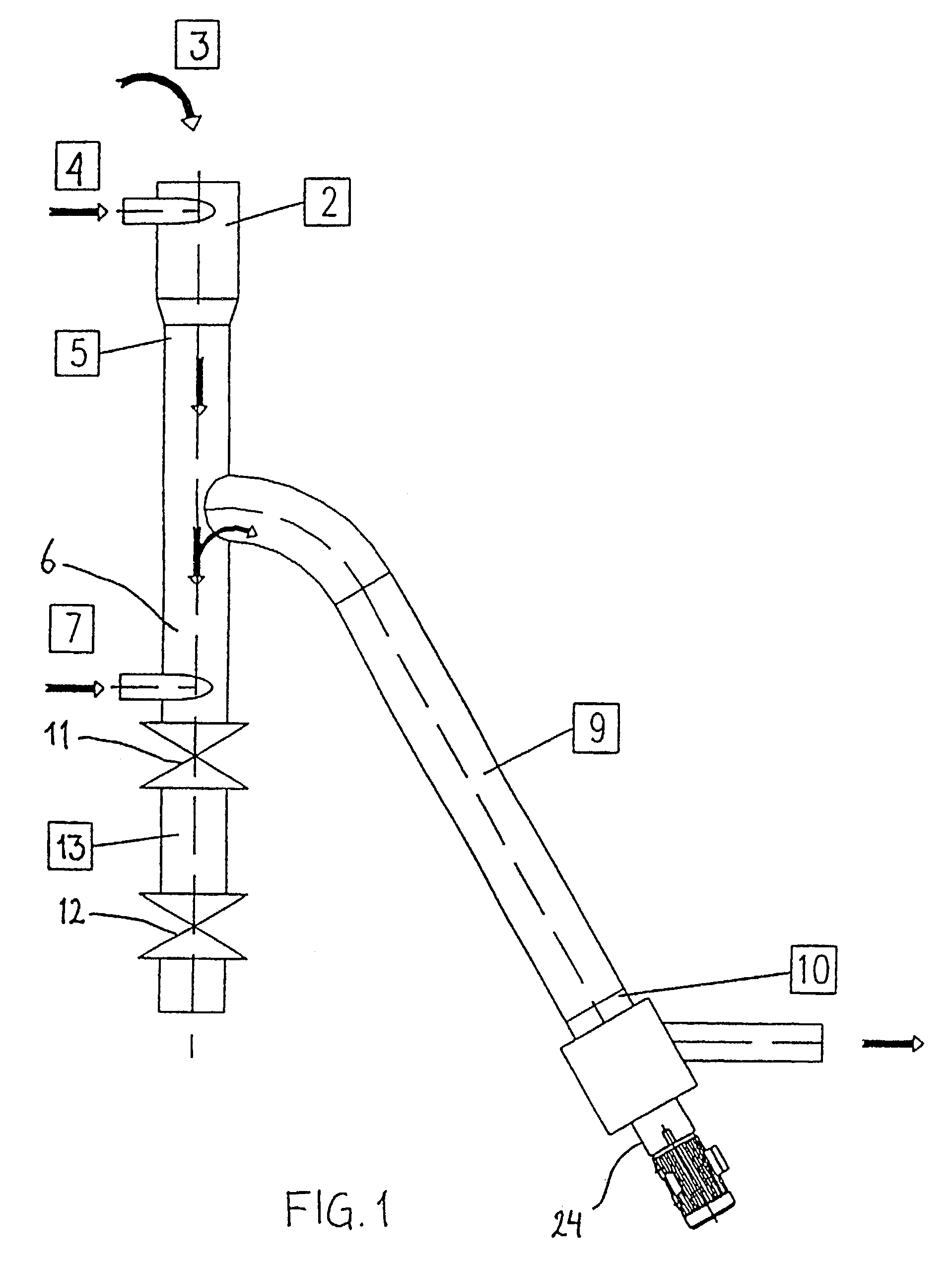

Feeding device and process and feeding system which utilize the feeding device

InactiveUS7179437B2Avoid boilingImprove reaction speedCalcium/strontium/barium carbonatesPulp liquors combustionProcess engineeringSlurry

Feeding device for feeding burned lime to a reaction vessel for causticizing a soda liquor to caustic soda. The feeding device, in its upper part, comprises an inlet for a slurry of the burned lime and the soda liquor for formation of said slurry inside said feeding device. The system further comprises a tall and slender feed vessel having a lower part having an outlet defined therein for the slurry. The outlet, via a pump, is operatively connected to the reaction vessel. The process and the feeding system utilize the feeding device, in which process the slurry is created of the burned lime and a first part of the soda liquor, a second part being preheated before addition to the slurry, whereafter slaking and causticizing reactions are completed under elevated temperature and pressure.

Owner:METABO PAPER SWEDEN

Wheat straw pulp black liquor alkali recovery method

InactiveCN105586800AReduce dye loadReduce high-load pollutionPulp liquors combustionGreen and white liquor treatmentRecovery methodWhite liquor

The invention discloses a wheat straw pulp black liquor alkali recovery method. The method includes the following steps that firstly, black liquor is evaporated and concentrated, and the concentration of the concentrated black liquor is 40-44% after evaporation; secondly, the concentrated black liquor obtained after evaporation is further evaporated and concentrated through tertiary air by means of a disk evaporator and then enters an alkali furnace to be pyrolysed and combusted, and finally green liquor is prepared in a dissolving tank; thirdly, the green liquor is processed in a causticizing department, the green liquor obtained in the second step and an excessive amount of ash are placed in a causticizing devuce, causticizing temperature is higher than 95 DEG C, and white liquor is obtained after filtration. According to the method, the technological process is simple, investment is small, and lignin is recycled while organic matter dyeing loads are reduced, wherein the concentration of the green liquor is 110-120 g / L, the amount of the excessive amount of ash is 3-5%, the causticizing degree is larger than 85%, the amount of white mud residual alkali is smaller than 2%, the dryness degree of white mud is larger than 50%, and the concentration of the white liquor is larger than 80g / L.

Owner:常州市精尔锐工具制造有限公司

Process And System For Reducing Ringing In Lime Kilns

ActiveCN109553310APrecise temperature regulationEmission reductionRotary drum furnacesGreen and white liquor treatmentThermodynamicsCombustor

This application discloses exemplary processes and systems for reducing mineral ring accumulation in calcination kiln. The processes and systems comprise inserting non-condensable gases (NCGs) in a preheating zone of a calcination kiln, upstream of the burner end. The pre heating zone may be characterized by temperatures ranging from 1,300 DEG F to 1,7500 DEG F. The system may desirably comprise aplenum for inserting the NCGs into the rotating calcination kiln at the pre-heating zone.

Owner:ANDRITZ AG

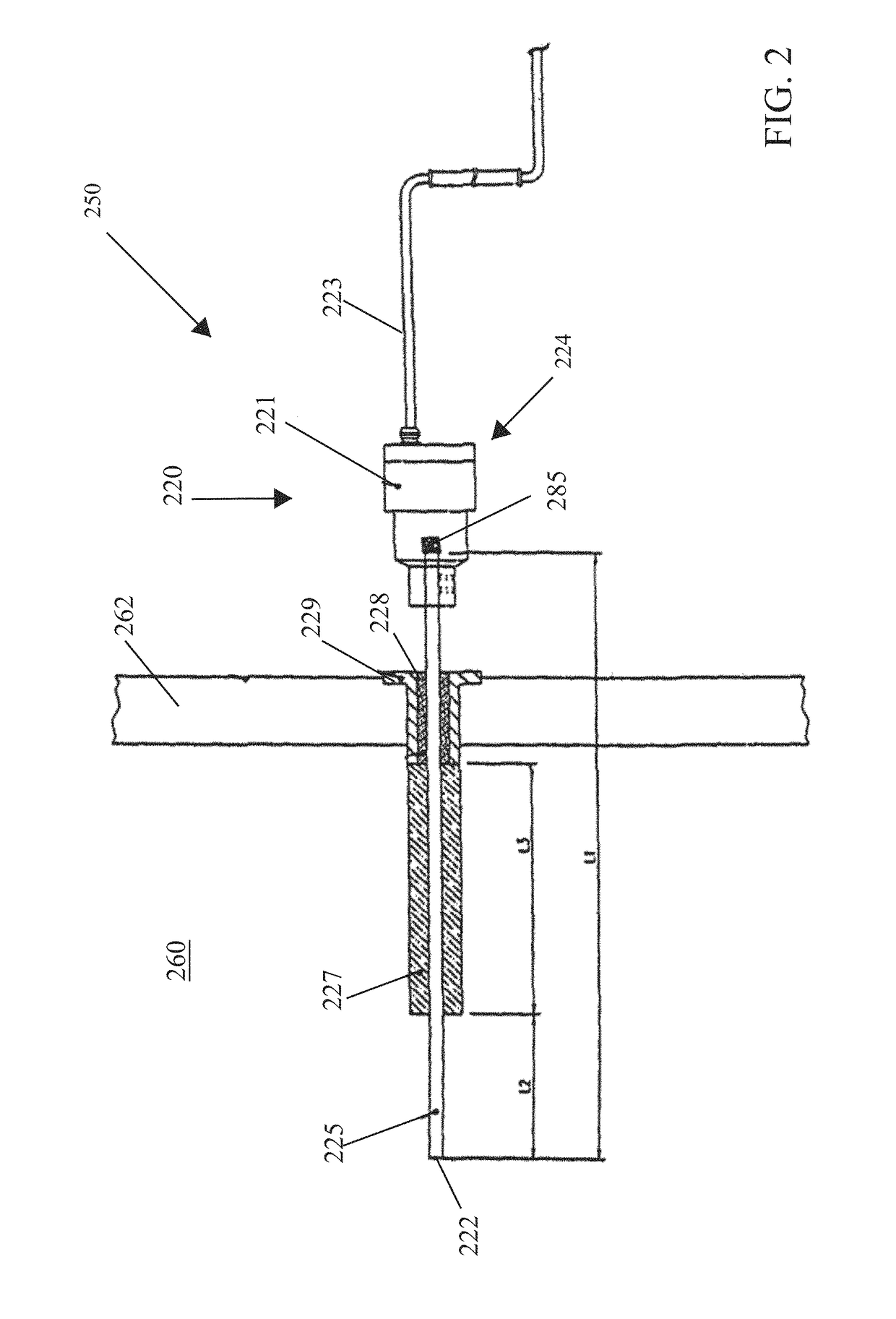

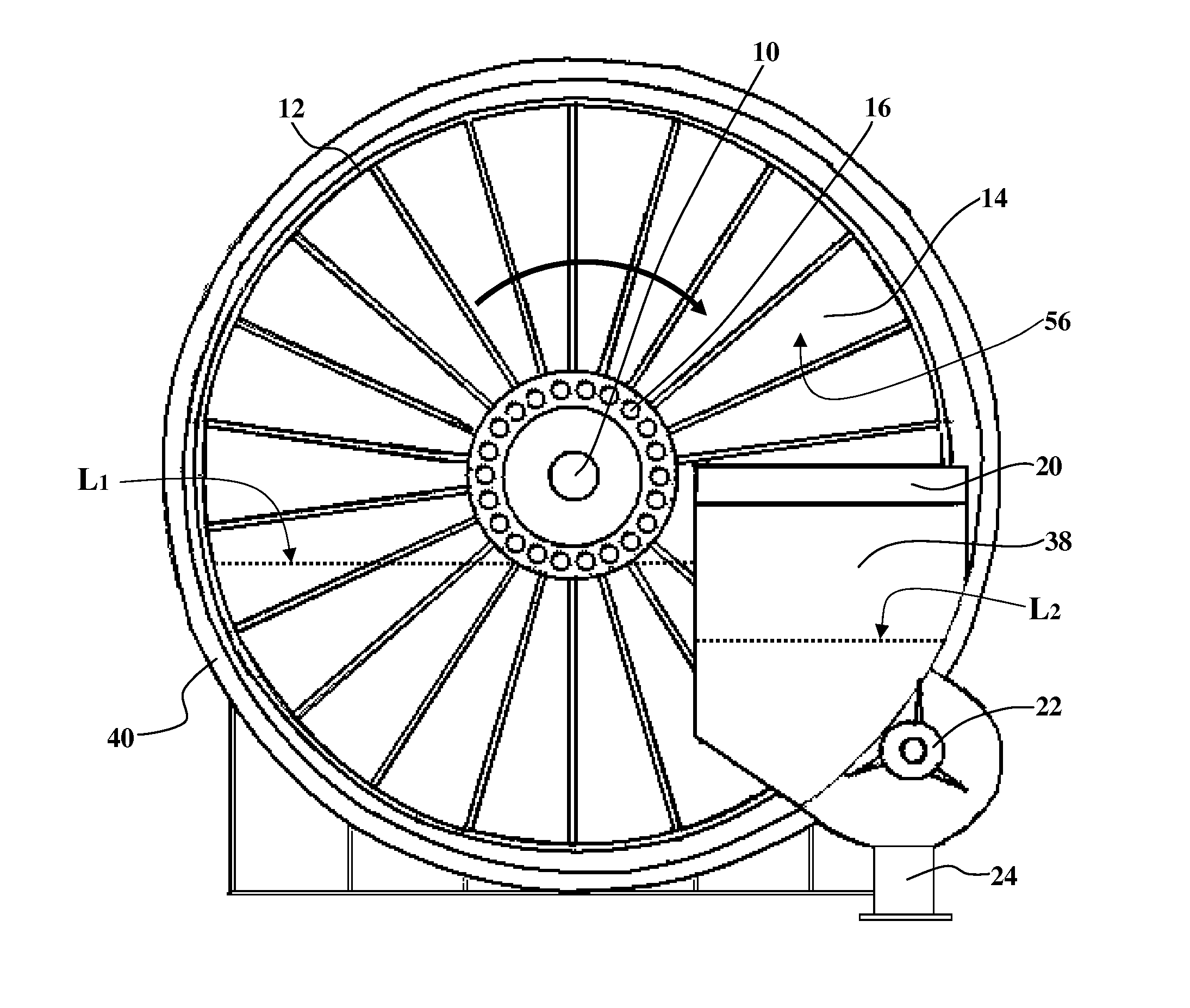

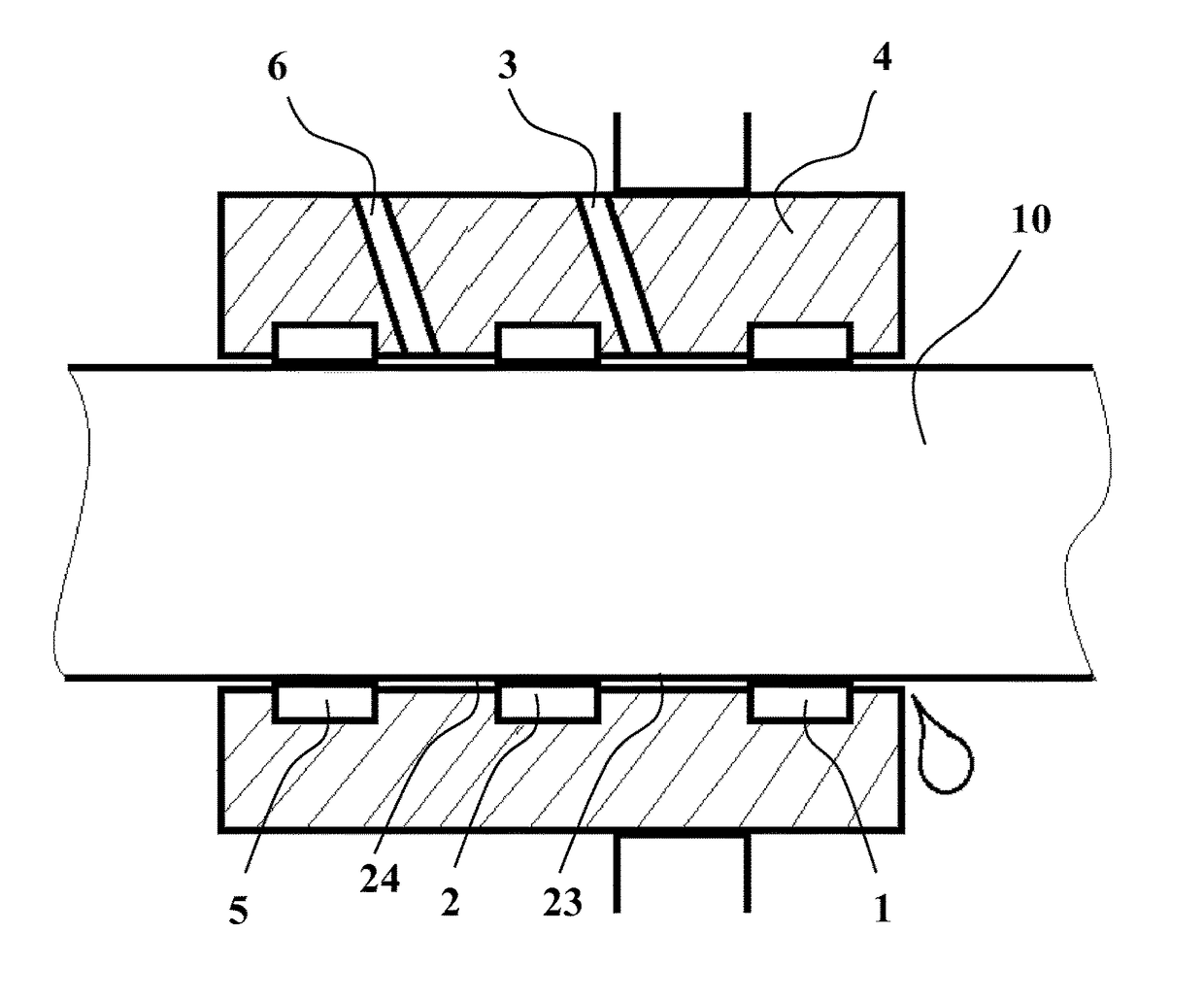

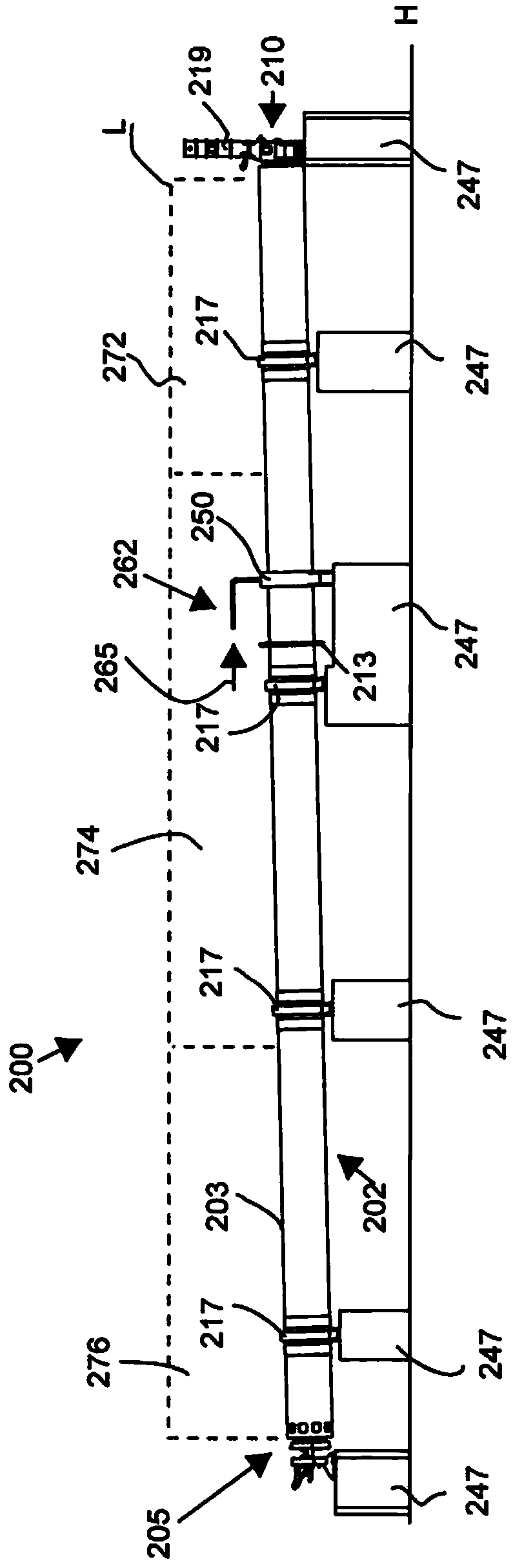

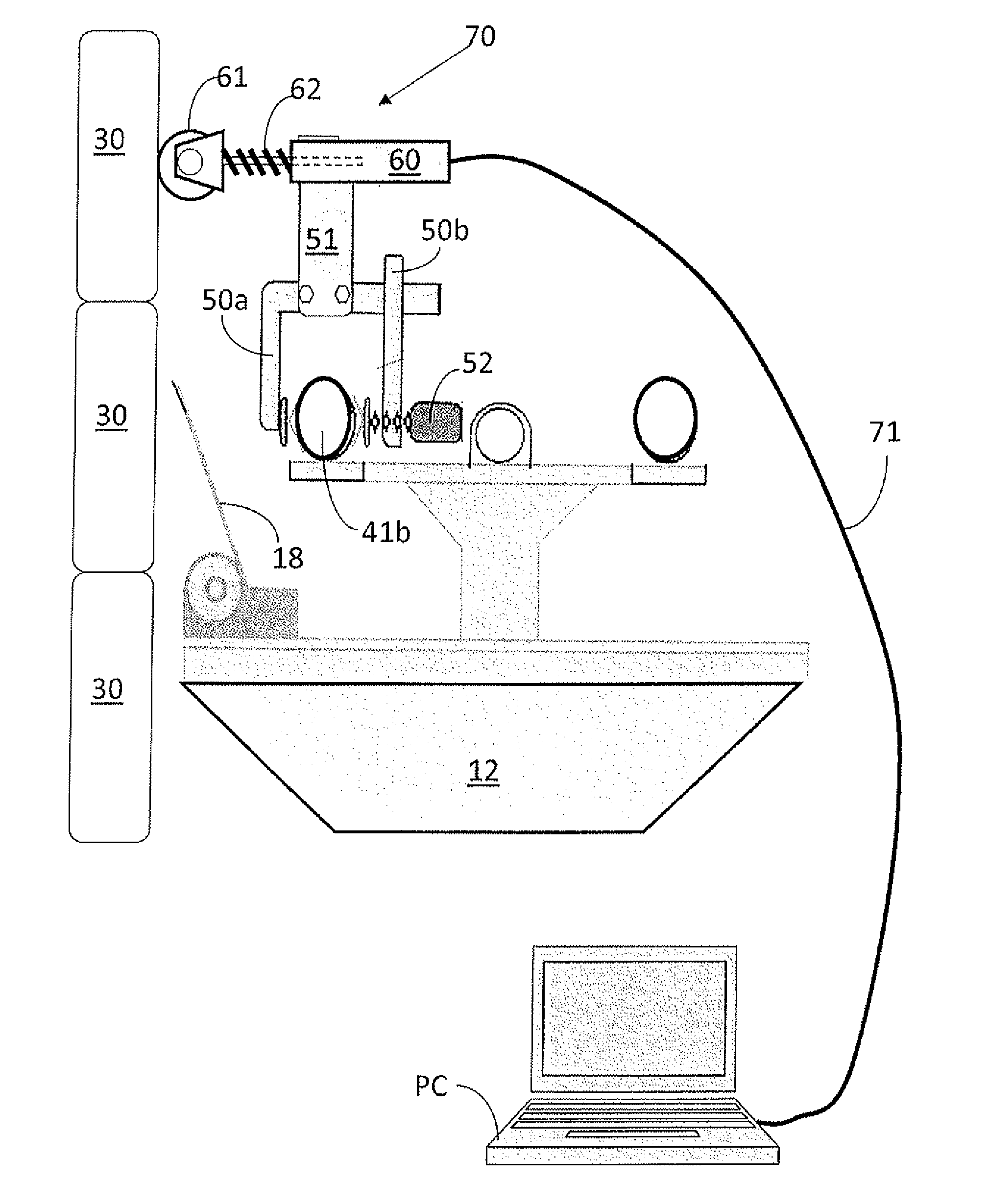

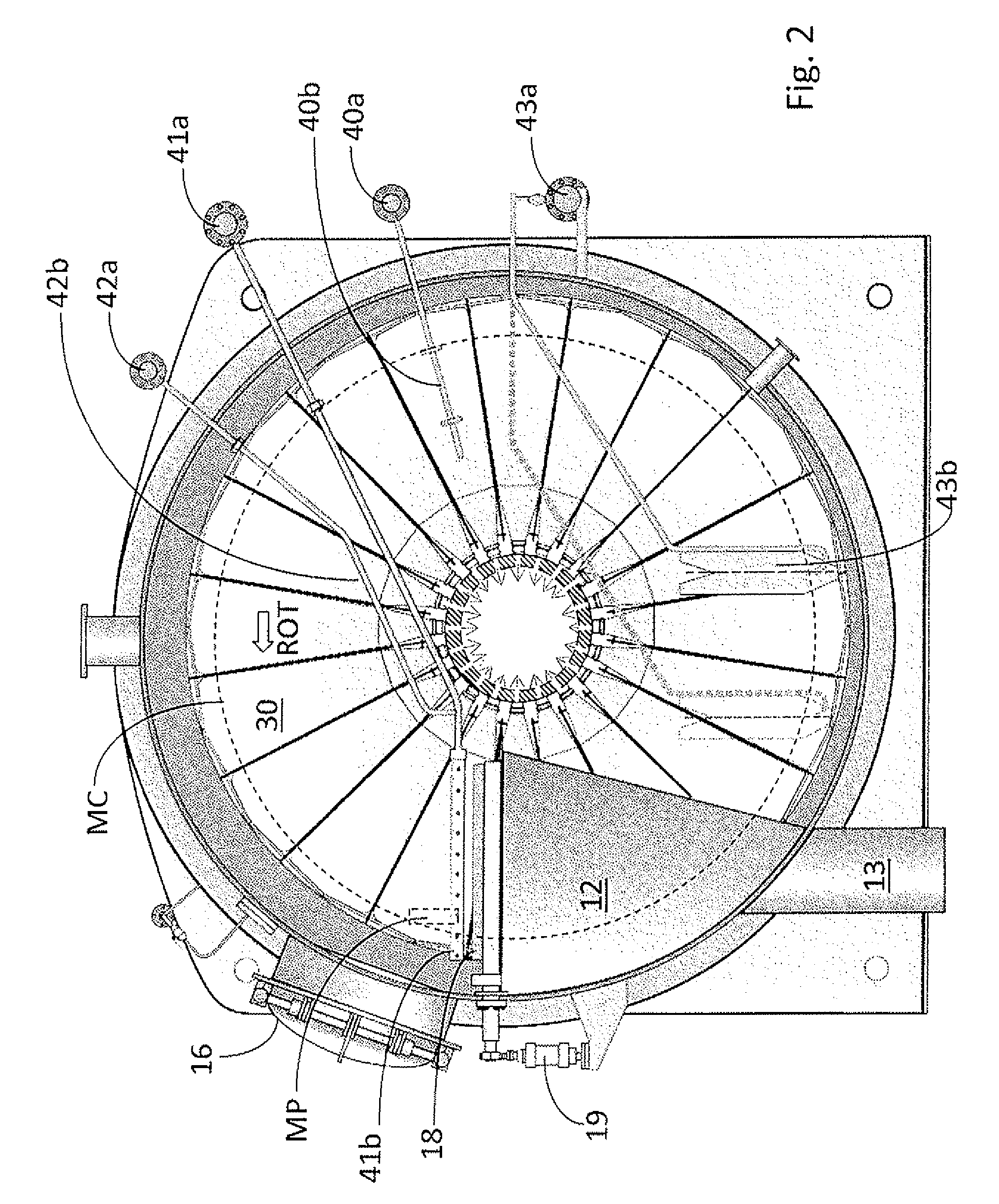

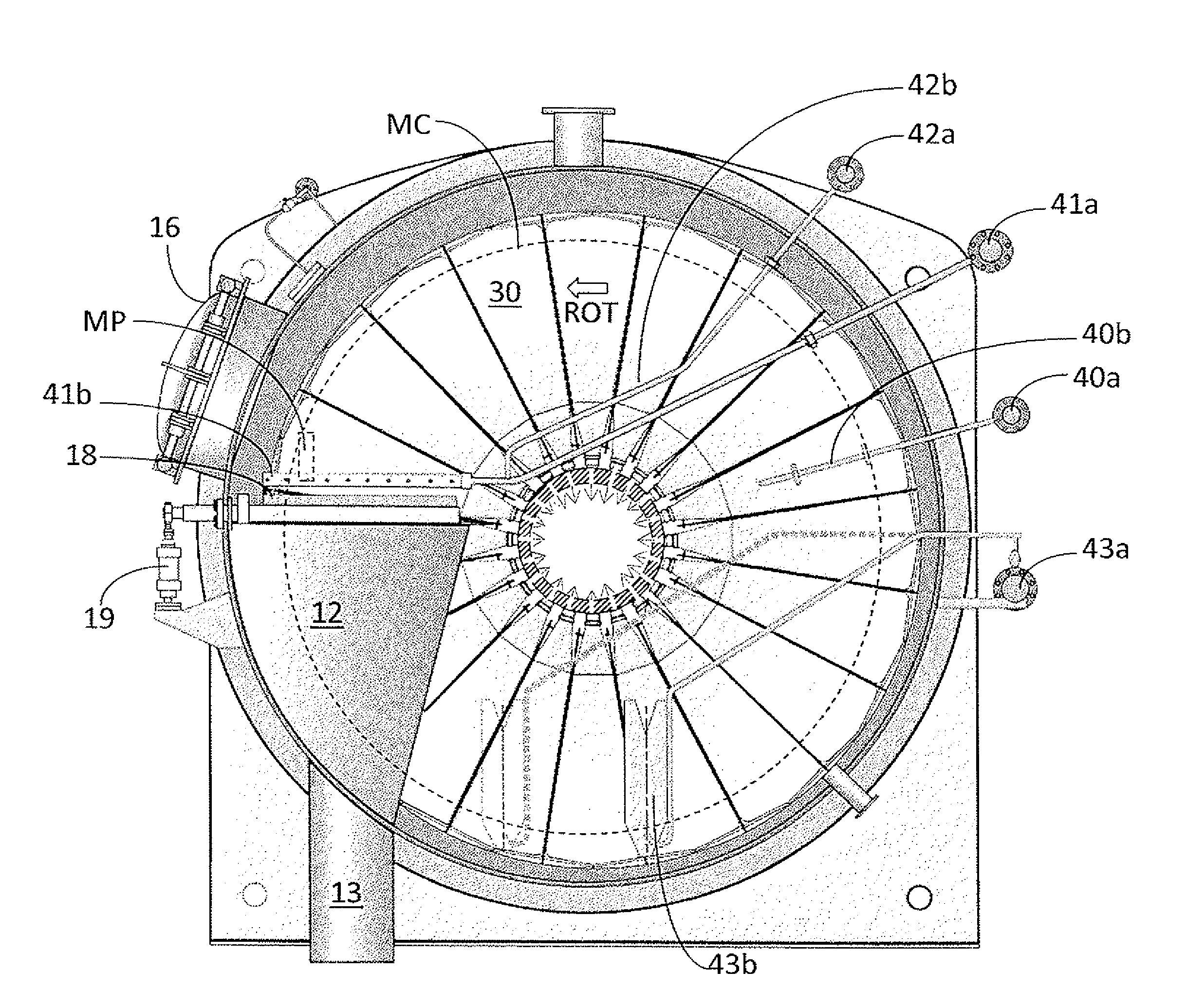

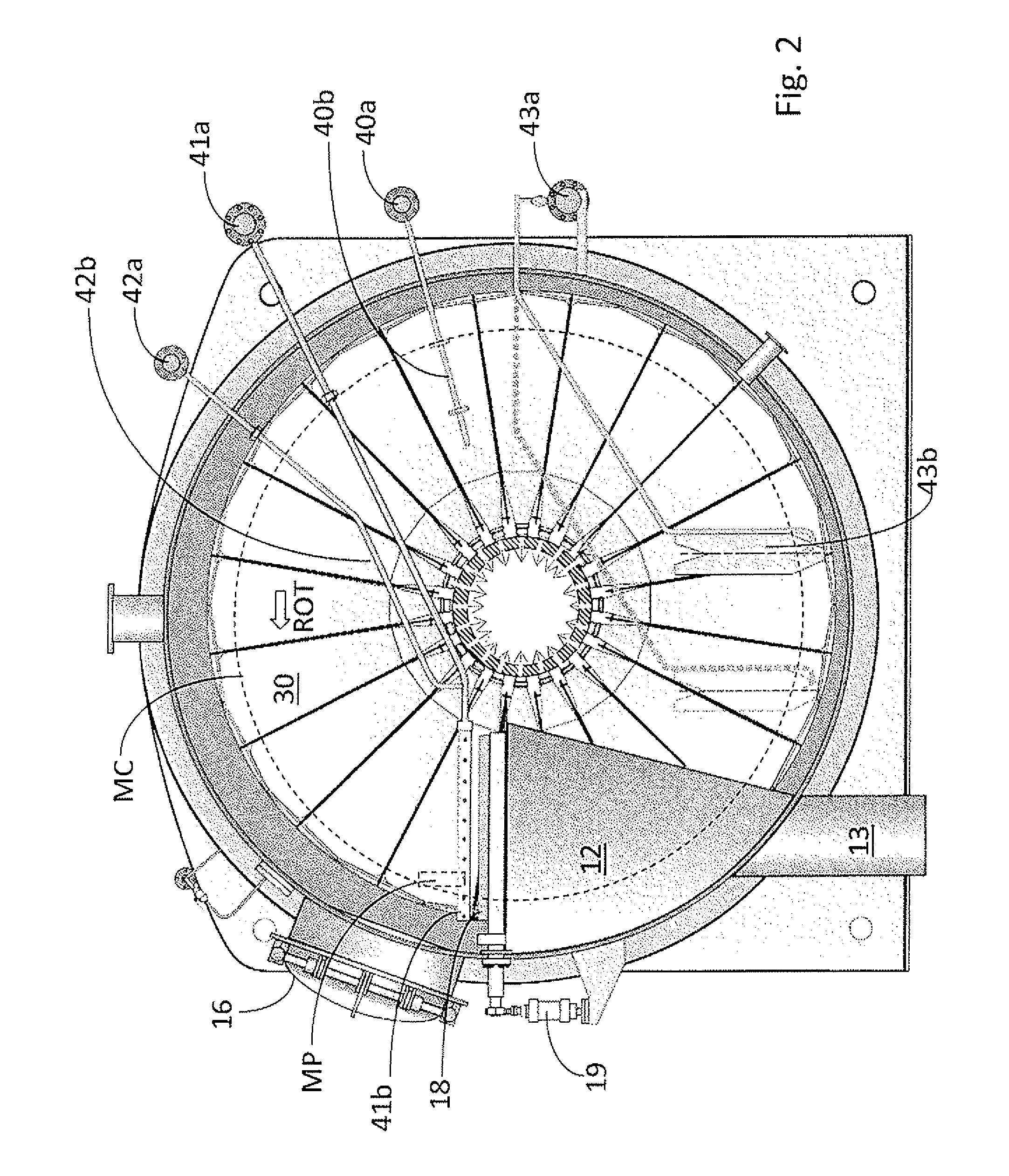

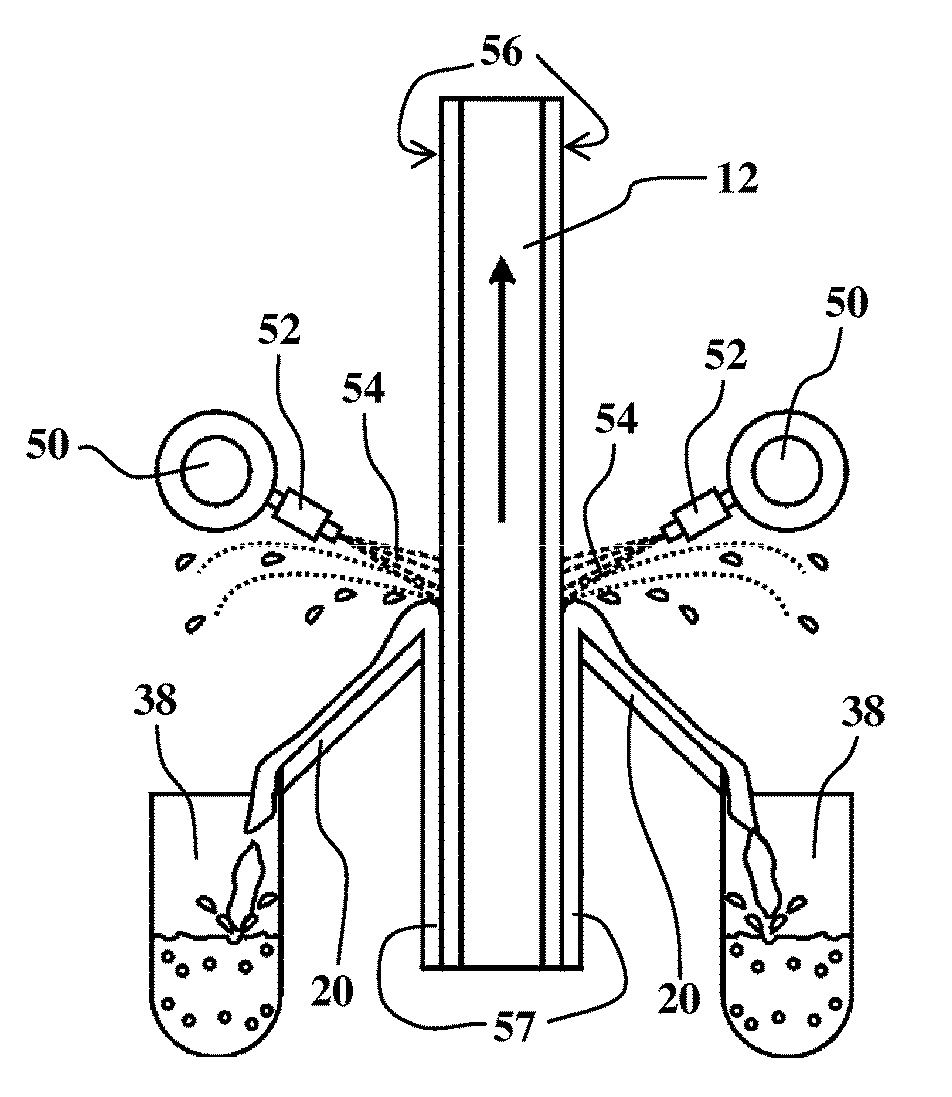

Method and equipment for measuring the filter sectors in disc filters

ActiveUS9364779B2Washing/displacing pulp-treating liquorsFeeler-pin gaugesEngineeringData transmission

The method and equipment relates to the measurement of deflections of filter sectors in a disc filter. The filter discs in the disc filter are constituted by a number of filter sectors, and the distance between a position fixed relative to the filter, most commonly the scraper itself, and the filter surface is conventionally measured by manual measurement methods. The equipment is instead used that has a measuring head with a quick-release coupling for its mounting fixed in the filter, and a position sensor in the measuring head that measures the distance between the measurement arrangement and the surface of the filter disc in order to form momentary measurement results. The momentary measurement results are transferred by a data transfer link from the measurement arrangement to a data collection unit PC that has a memory.

Owner:VALMET AB

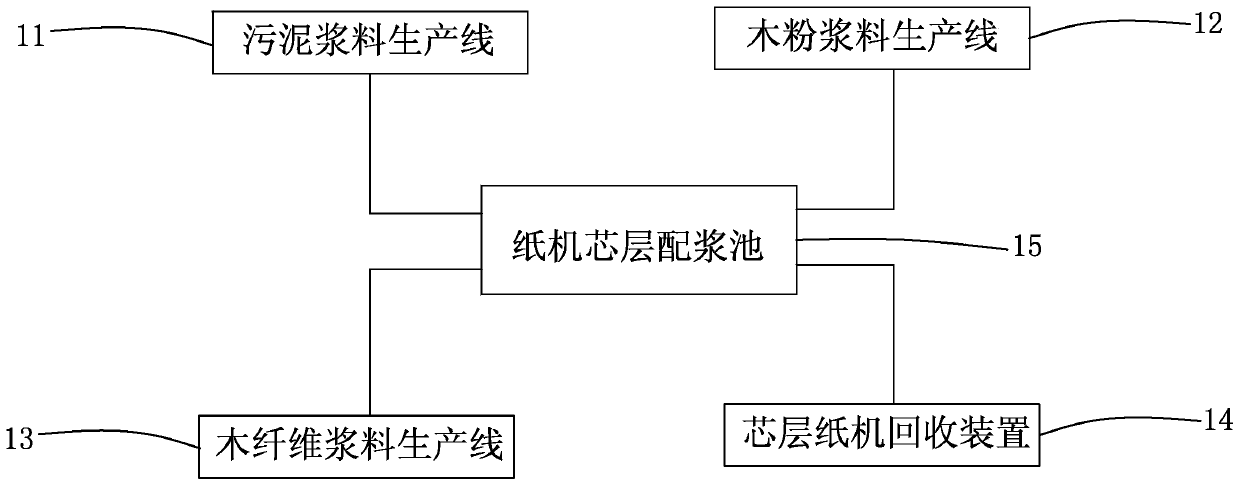

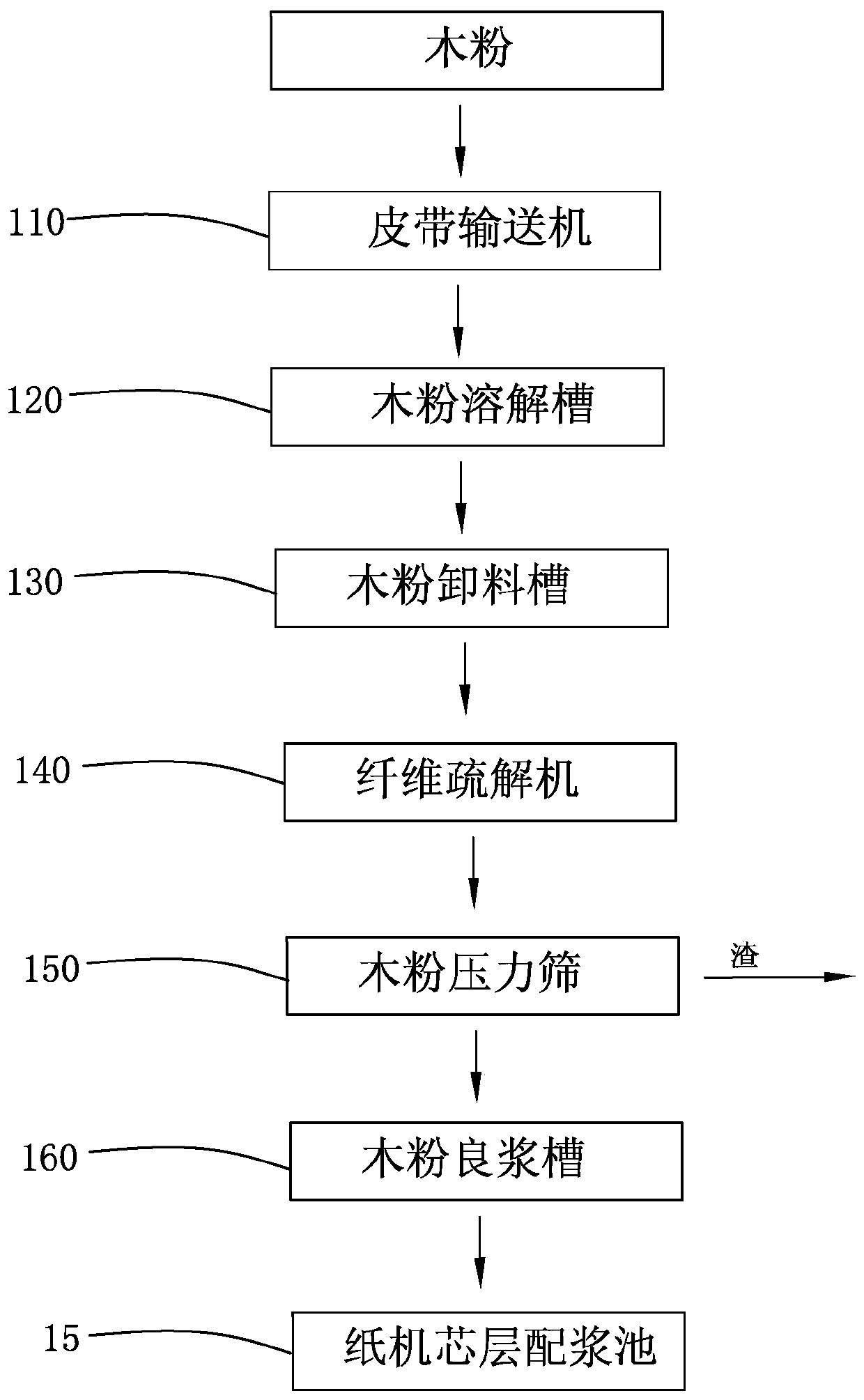

Process for preparing slurry of novel core layer of coated duplex board with grey back

PendingCN110219200AImprove quality performanceReduce manufacturing costWaste product additionPaper recyclingFiberProduction line

A process for preparing slurry of a novel core layer of a coated duplex board with a grey back is disclosed. Raw materials for the core layer are produced by setting a sludge slurry production line, awood powder slurry production line, a wood fiber slurry production line and a core layer waste paper recovery device. Sludge accepts, wood powder accepts, wood fiber accepts, and core layer waste paper slurry are fully mixed according to a ratio of 5-7%:10-15%:10-15%:63-75% in a core layer slurry preparing pool of a paper machine to prepare the core layer, thus improving quality performance of the coated duplex board with a grey back and reducing the production cost of a paper mill.

Owner:DONGGUAN JIANHUI PAPER CO LTD

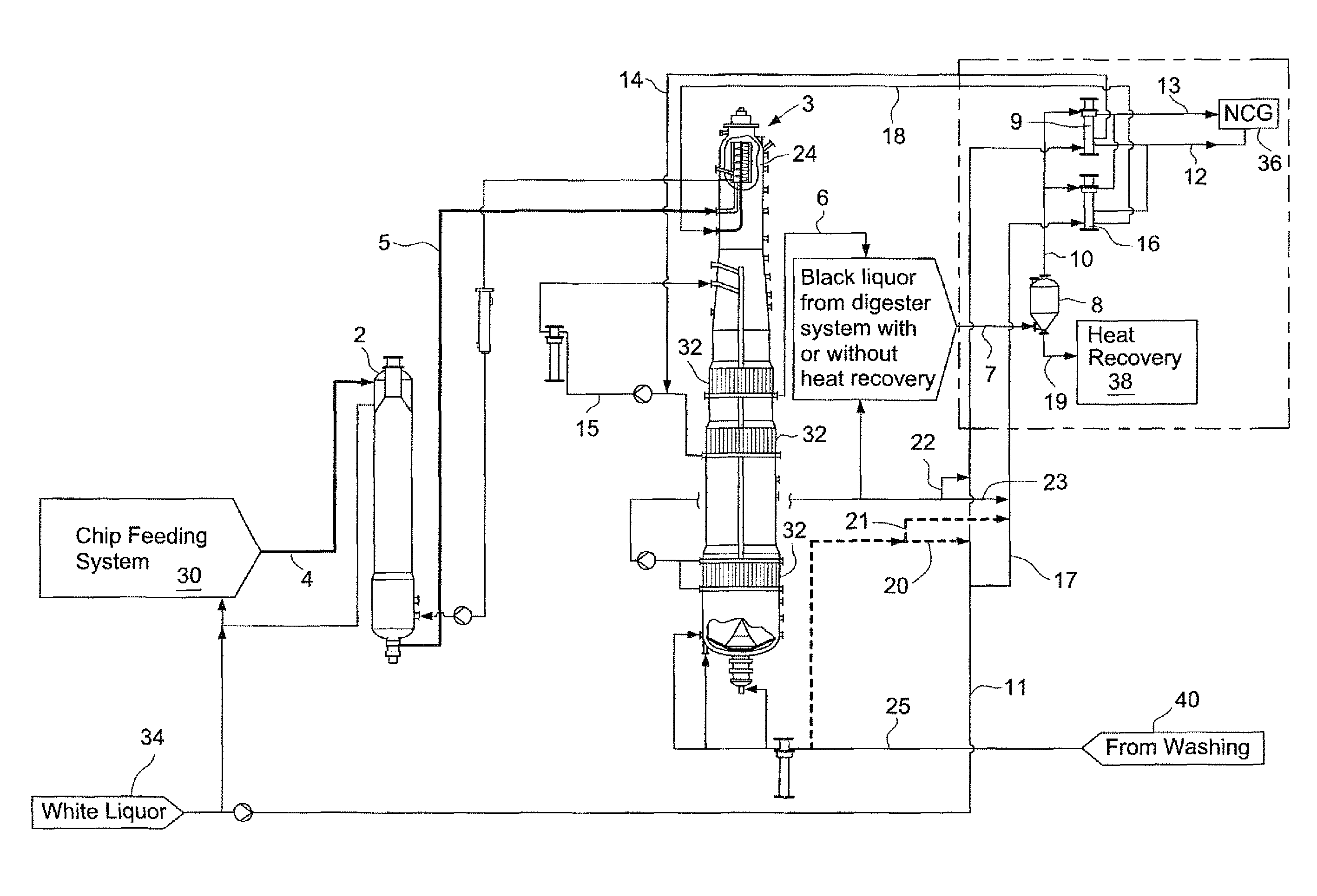

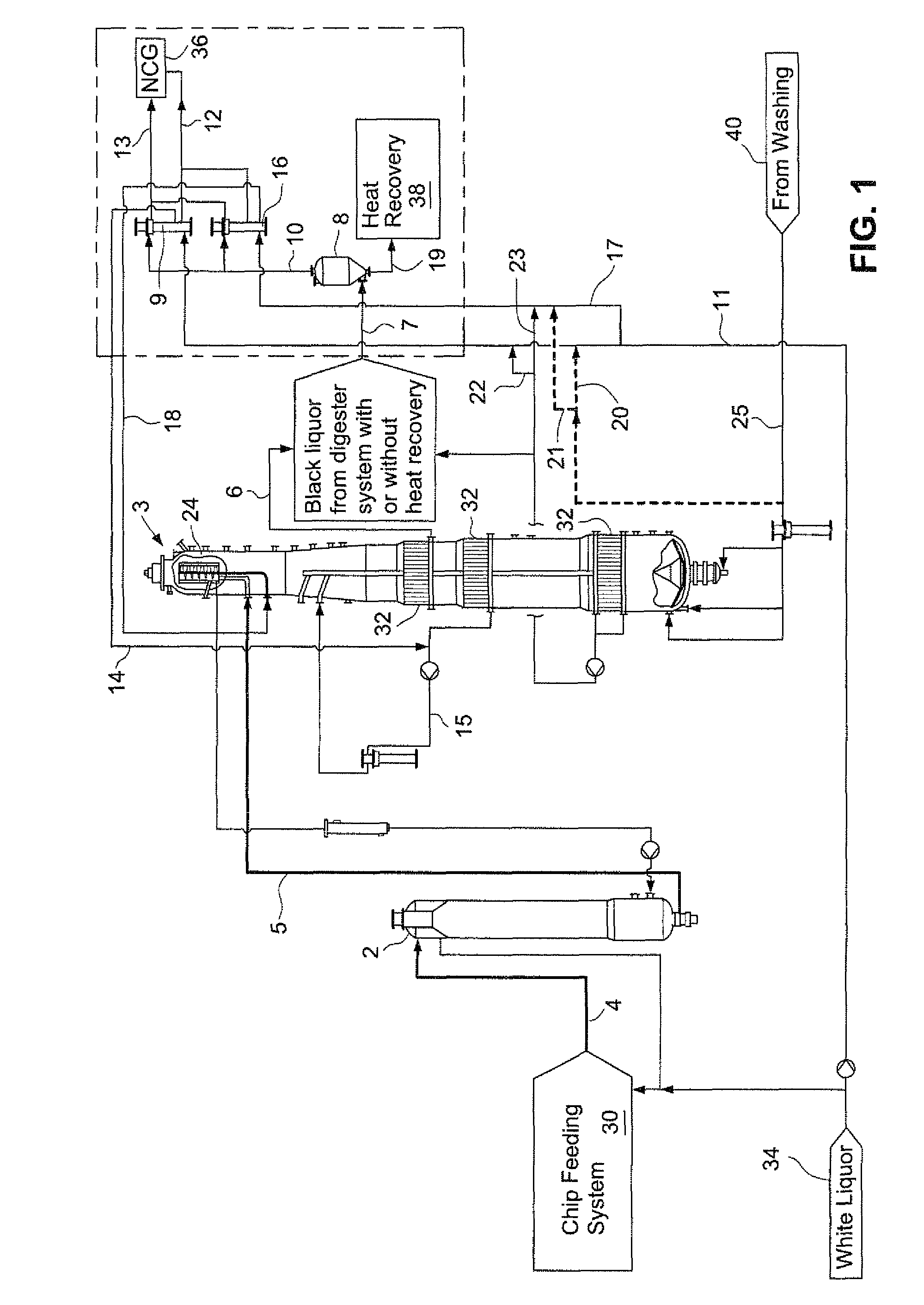

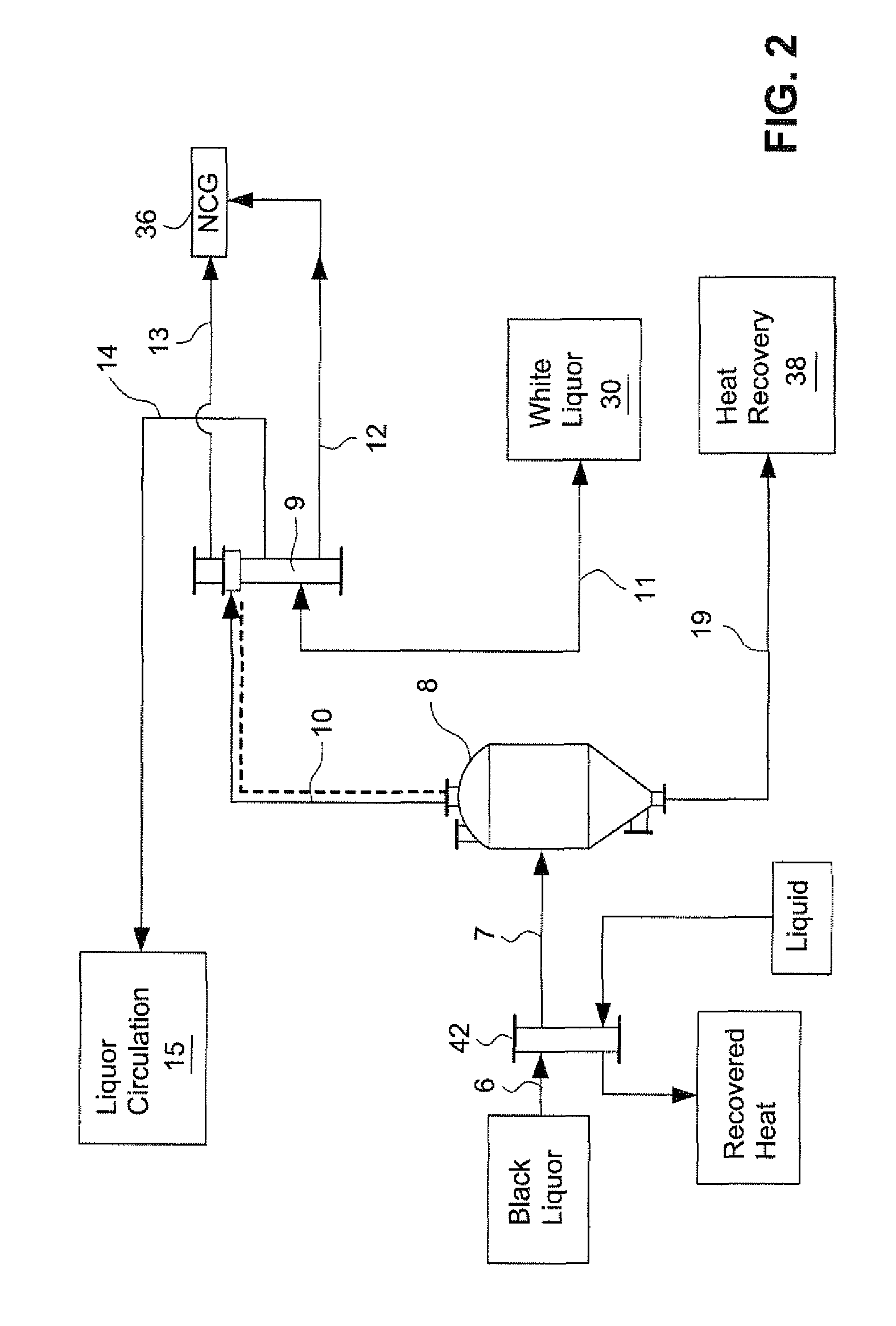

Heat recovery from spent cooking liquor in a digester plant of a chemical pulp mill

InactiveUS8808498B2Maintain good propertiesImprove energy economyDigestersGreen and white liquor treatmentBlack liquorWhite liquor

A method for heating white liquor or a mixture of white liquor and another liquid for use in a digester system of a chemical pulp mill, the method including the steps of: producing black liquor in the digester system; extracting black liquor from the digester system, flashing the extracted black liquor and thereby generating flashed black liquor and flash vapor; directing the flash vapor through a heat exchanger to heat a white liquor flowing through the heat exchanger; the flashed black liquor flows to at least one of a heat recovery or evaporation stage, and the heated white liquor flows to the digester system.

Owner:ANDRITZ INC

Method and equipment for measuring the filter sectors in disc filters

ActiveUS20150128434A1Minimize durationAngles/taper measurementsWashing/displacing pulp-treating liquorsEngineeringData transmission

The method and equipment relates to the measurement of deflections of filter sectors in a disc filter. The filter discs in the disc filter are constituted by a number of filter sectors, and the distance between a position fixed relative to the filter, most commonly the scraper itself, and the filter surface is conventionally measured by manual measurement methods. The equipment is instead used that has a measuring head with a quick-release coupling for its mounting fixed in the filter, and a position sensor in the measuring head that measures the distance between the measurement arrangement and the surface of the filter disc in order to form momentary measurement results. The momentary measurement results are transferred by a data transfer link from the measurement arrangement to a data collection unit PC that has a memory.

Owner:VALMET AB

Method for leaching recovery-boiler ash

ActiveUS9719209B2Reduce addEfficient pricePulp liquors combustionPulp by-products recoveryChemical recoverySolid fraction

A method to be used in conjunction with a single-stage or multi-stage process for leaching ash originating from the recovery boiler of a pulp mill, particularly when the ash contains a significant amount of carbonate, wherein calcium compounds, such as calcium oxide (CaO) or calcium hydroxide (Ca(OH)2), are employed as additives in one or more leaching stages, a liquid fraction formed in the leaching process is utilized outside the main chemical recovery cycle, such as a substitute for purchased sodium hydroxide in the bleaching line of the pulp mill, and a solids fraction may be mixed with a black-liquor stream of the mill or subjected to further processing to separate calcium compounds for recycle.

Owner:ANDRIZ OY

Method for removing the precoat layer of a rotary filter

ActiveUS9636611B2Easy to cleanEffective penetrationGreen and white liquor treatmentRegeneration of alkali lyeSludgeSlurry

A method associated for treating a precoat on a rotating filtering surface of lime sludge filter including: accumulating a precoat of lime sludge on the filtering surface by rotating the filtering surface in a first direction through a lime sludge slurry; after accumulating the precoat, rotating the filtering surface in an opposite direction to the first direction; while rotating the filtering surface in the opposite direction, spraying a liquid onto the precoat on the filtering surface wherein the spraying is applied to the precoat above a scraper adjacent the filtering surface and the spraying removes at least a portion of the precoat from the filtering surface, and flowing the removed precoat over the scraper and into a basin.

Owner:ANDRIZ OY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com