Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

195results about "Floats removal" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

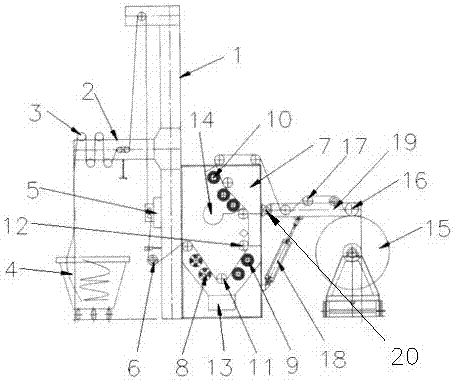

Textile cleaning device

ActiveCN104452252AGuaranteed cleanlinessKeep it clean and aesthetically pleasingMechanical cleaningPressure cleaningYarnSprayer

The invention discloses a textile cleaning device. The textile cleaning device comprises a cleaning support. A main hanging bracket is arranged above the cleaning support. An upper shaving ball blade is arranged above the main hanging bracket. A lower shaving ball blade corresponding to the upper shaving ball blade is arranged on the support. A steam sprayer connected with a steam generating device is arranged above conveying rollers through hanging rods. A first sundry groove is formed below the conveying rollers and in the support. A plurality of upper dust suction pipes are arranged on one side of the steam sprayer and the main hanging bracket. A brush is arranged above a feeding roller through the main hanging bracket, and a secondary dust suction pipeline is arranged on one side of the brush through the main hanging bracket. Yarns can be rapidly cleaned, thread residues on products with large static electricity can be rapidly removed, the cleaned products are still very straight, a multi-time thread residue and woolen yarn removing device is adopted, cleaning is complete, the quality of the products is improved, and the economic benefits are increased for enterprises.

Owner:苏州品维纺织科研有限公司

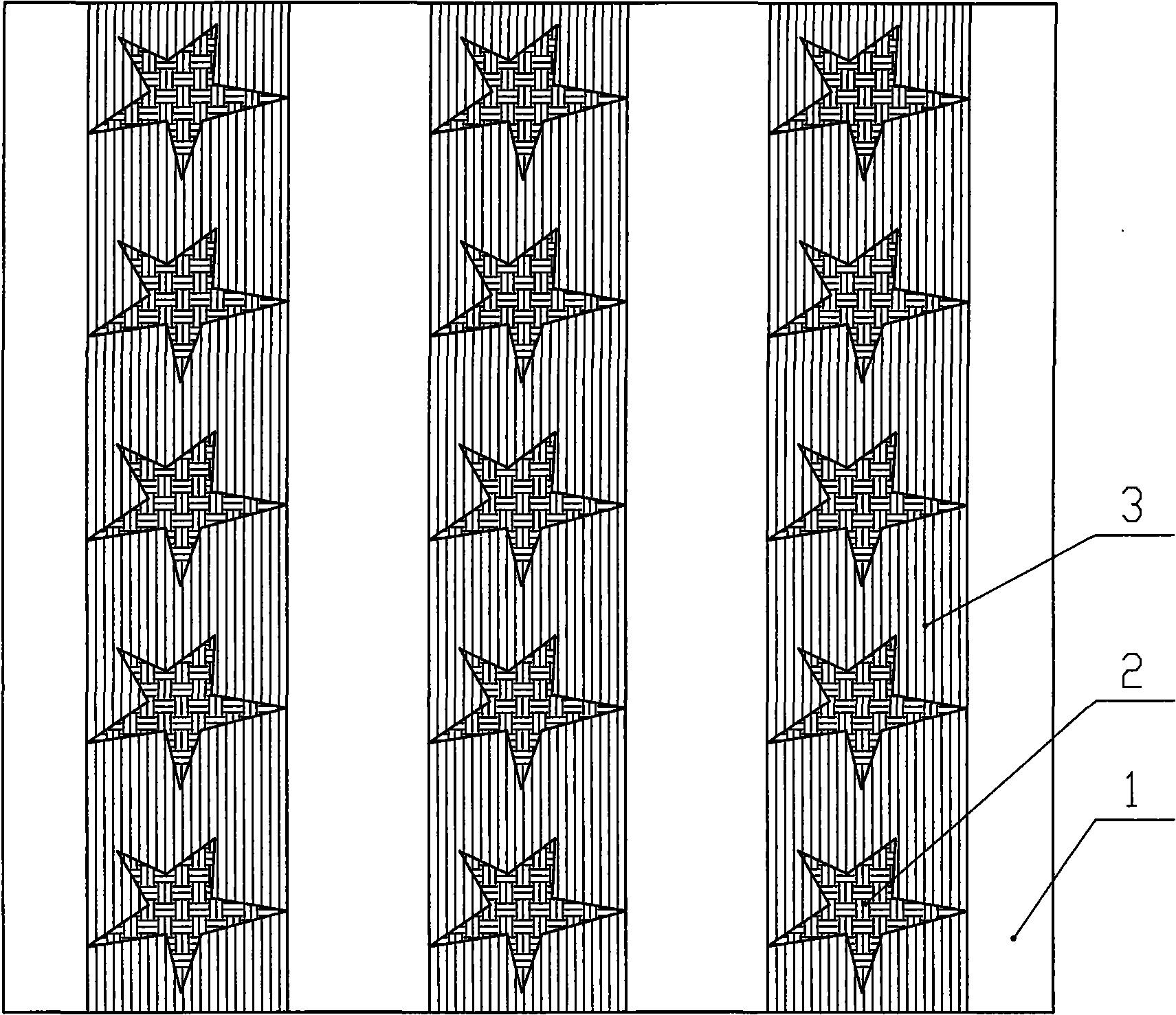

Cutting motif fabric and method of manufacture

The invention relates to a yarn-dyed fabric as well as the manufacturing method technology field thereof, in particular to a clipping and carving fabric which is applied in high-grade fashionable dresses, high-grade children dresses, high-grade bed clothes, etc., as well as the manufacturing method. The clipping and carving fabric is provided with a tabby bottom tissue and local additional tissues which are interwoven on the surface of the tabby bottom tissue. The clipping and carving fabric of the invention has the advantages of plump tissue effect like the feeling of attaching, rich meaning, perfect ornamental effect, embroidery visual effect, no bone on the fabric with patterns, soft feeling, and firm and permanent connection of the local additional tissues and the tabby bottom tissue.

Owner:倪爱东

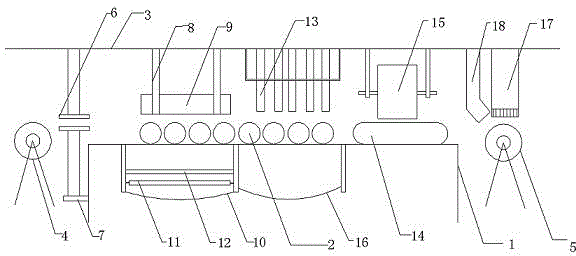

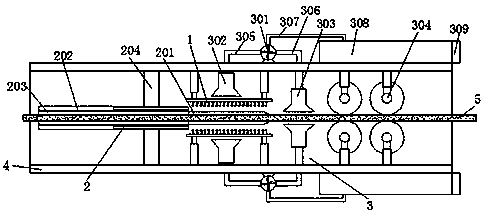

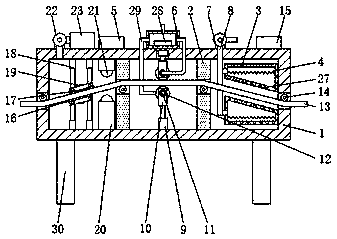

Integrated mechanical equipment for textile processing

InactiveCN107326600AGuaranteed cleanlinessShorten the timeTextile treatment containersLiquid/gas/vapor removalDanderEngineering

The invention discloses an integrated mechanical equipment for textile processing, which includes a hair removal box, a first collection cylinder is fixedly installed on the left side plate of the hair removal box, and two sets of transmission rollers are arranged inside the first collection cylinder. The first connecting cylinder is fixedly installed on the right side plate of the hair-removing box, and the cleaning box is fixedly installed on the end of the first connecting cylinder far away from the hair-removing box. The cylinder is connected and extended to the inside of the cleaning box, and the upper side and the lower side of the textile body are respectively provided with a first roller and a second roller. In the present invention, a dehairing box, a cleaning box and a drying box are arranged for use together. During processing, the textiles are passed through the dehairing box to remove dander on the surface of the textiles, and then the textiles are cleaned to keep the surface of the textiles clean. Drying textiles can save transportation time, thereby improving work efficiency and making it more convenient to use.

Owner:梅明会

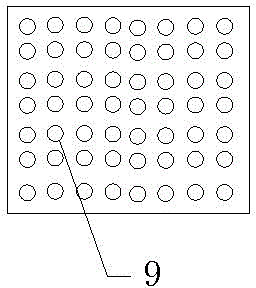

Fabric surface pilling removal equipment

InactiveCN108486815AEfficient removalRealize automatic nestingMechanical cleaningPressure cleaningEngineeringDust collector

The invention provides fabric surface pilling removal equipment which comprises a frame and two groups of pilling removal mechanisms, wherein a fabric is arranged between the two groups of pilling removal mechanisms; the two groups of pilling removal mechanisms are respectively arranged on a frame top plate and a frame bottom plate; each pilling removal mechanism comprises a pilling scraping device, a shearing device and a dust removal device; the pilling scraping device comprises a scraper and two first electric push rods; a plurality of uniformly distributed scraping hooks are arranged on the scraper; the shearing device comprises shear blades, a second electric push rod and a mounting plate; the dust removal device comprises an exhaust fan, a first dust collector, a second dust collector and a lint roller. According to the fabric surface pilling removal equipment disclosed by the invention, the two groups of upper and lower pilling removal mechanisms are used for removing pilling ontwo sides of the fabric, the pilling on two sides of the fabric can be simultaneously eliminated, the pilling removal mechanisms comprises the pilling scraping devices, the shearing devices and the dust removal devices, automatic discharging is realized, manual discharging by a user is avoided, and discharging smoothness is realized.

Owner:JIANGSU DANMAO TEXTILE

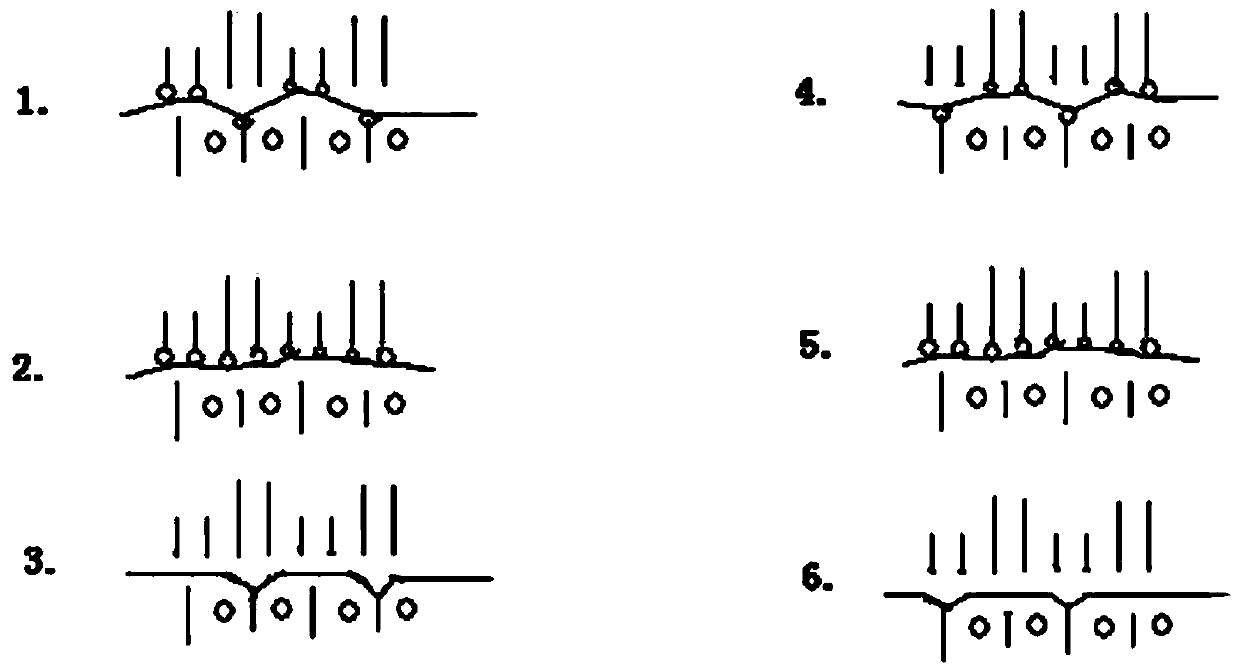

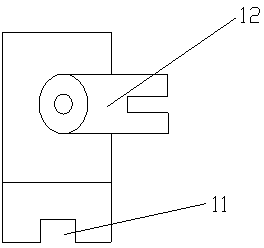

Thread-taking-up mechanism with hairbrush

InactiveCN103696199AEasy to insertThe efficiency of picking is improvedFloats removalAcute angleEngineering

The invention discloses a thread-taking-up mechanism with a hairbrush. The thread-taking-up mechanism comprises a substrate, a tool rest and a blade, wherein the tool rest is fixed on the substrate; one end of the blade is fixed at the bottom end of the tool rest; the other end of the blade is a round head; one side of the blade is forged to form a cutting edge; the substrate, the tool rest and the blade are arranged on the parallel planes; the cutting edge and the bottom end of the tool rest form an acute angle; the substrate carries out reciprocating motion along the direction of the cutting edge; the thread-taking-up mechanism also comprises a hairbrush; the hairbrush is fixed on one side of the tool rest deviating from the substrate; and the bottom end of the hairbrush is lower than the bottom end of the blade. The hairbrush synchronously swings along with the tool rest and the blade after the hairbrush is added to the thread-taking-up mechanism, so that the cloth surface in the same region is firstly brushed for 2-3 times in a reciprocating manner before the thread is picked up. The hairbrush adopts a nylon wire hairbrush with a certain hardness, and can brush a floating thread away from the cloth surface and generate a hole under the condition of not damaging the cloth surface, so that the attached floating thread is picked up and separated, and the cutting edge is easily inserted between the floating thread and the cloth surface. Thus, the pick-off efficiency is greatly improved.

Owner:SUZHOU HUALONG KNITTING TEXTILE

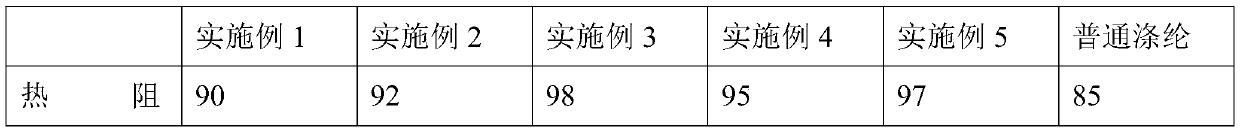

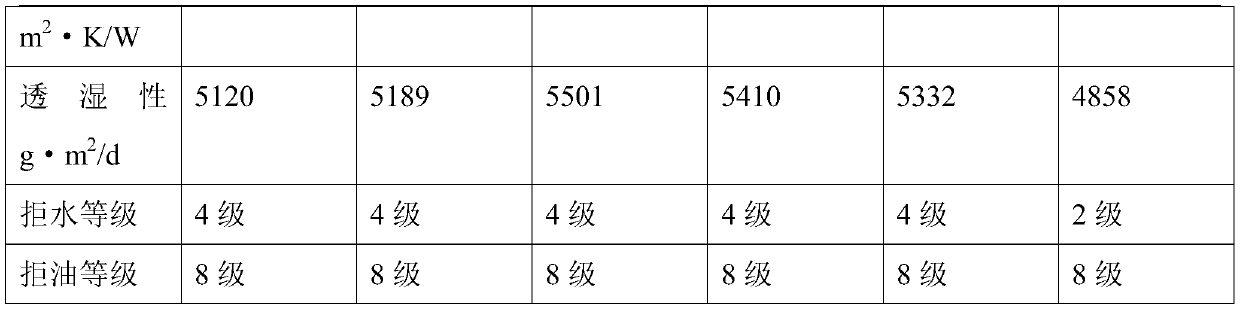

Spinning process of polyester fleece knitted fabric

The invention provides a spinning process of polyester fleece knitted fabric. The spinning process mainly uses polyester filaments and polyester staple fibers as the raw materials to prepare the weft-knitted fabric. The spinning process includes: preprocessing gray fabric; dyeing and printing; softening and pre-forming; napping; carding; shearing; turning naps into granular naps; performing kinetic energy finishing; performing finished-product forming. The polyester fleece knitted fabric spun by the spinning process is soft and fluffy in touch, breathable and warm-keeping, less prone to pilling and fading, excellent in water resistance, oil resistance and fouling resistance and durable in flame retardance and can still have excellent three proofing and flame retardance after being washed at normal temperature.

Owner:森宝(福建)纺织科技发展有限公司

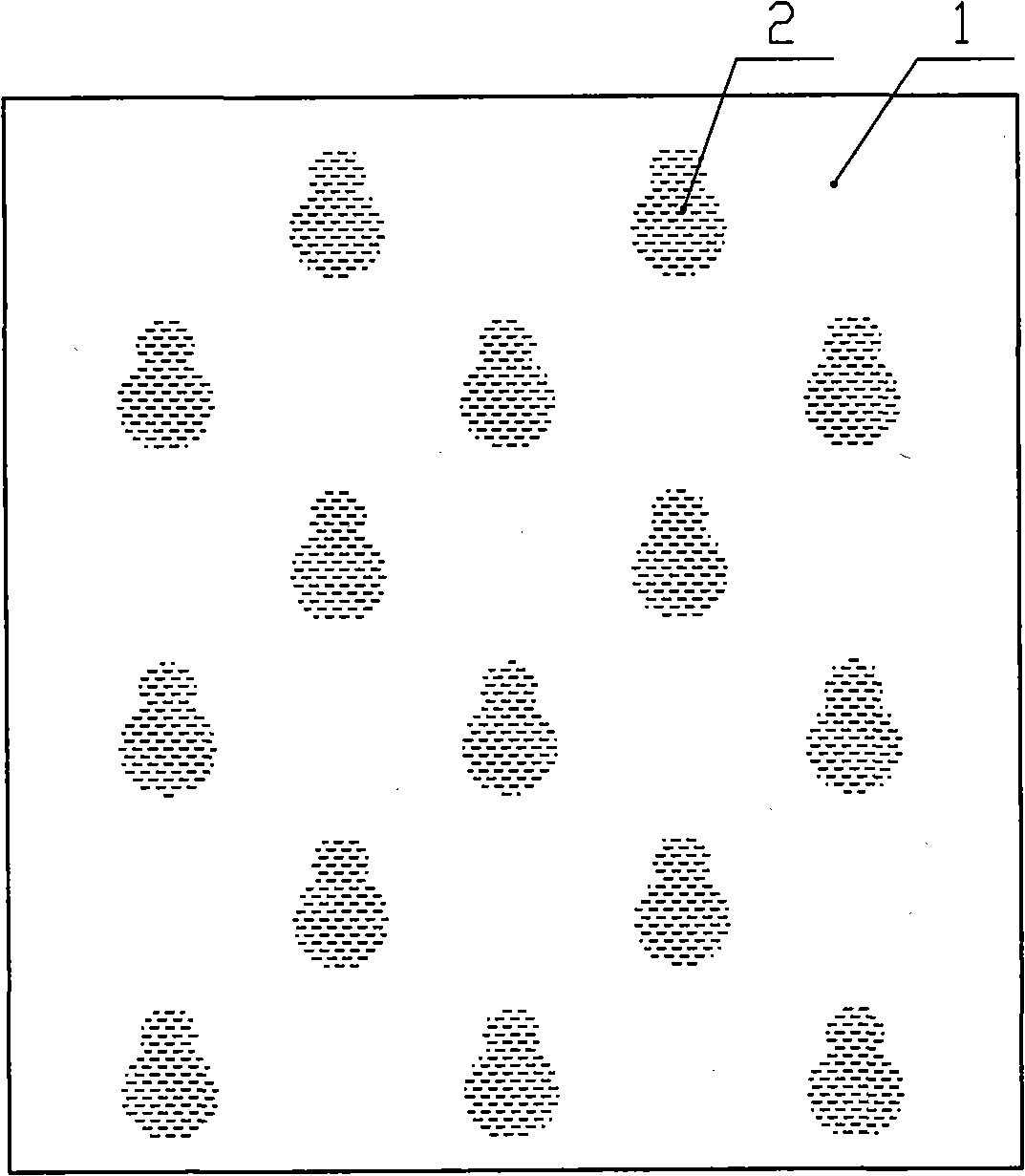

Warp-knitting dacron short pile fabric and weaving method thereof

InactiveCN107761242AShrinkage ControlNot easy to shrinkPattern makingWarp knittingFiberChemical treatment

The invention discloses a warp-knitting dacron short pile fabric and a weaving method thereof, and belongs to the technical field of warp-kitting fabric weaving. 50-75D of dacron FDY and dacron DTY composite filaments are adopted as pile yarn, 50D / 24F of polyester silk FDY or polyester silk DTY is adopted as bottom yarn, a two-comb or three-comb Tricot warp knitting machine conducts weaving to obtain gray fabric, then the procedures of pre-shaping, fuzzing process implementation, dyeing, drying, hot trimming and burnt-out are carried out, and after dehydration and drying for shaping are conducted, checking and packaging are carried out. By means of a chemical treatment method for dacron fibers, the effect of forming a three-dimensional pattern diversified in color and different in shape onthe fuzzing surface of the fabric is achieved, the gram weight of the fabric is low, and the fabric has better heat preservation performance and higher comfort degree.

Owner:JIANGSU ZHENYANG GROUP

Hair ball removing device

The invention relates to a hair ball removing device. The device comprises a housing, a motor, a blade, a blade holder, a hair ball box, a battery box and a cutter bit protecting cover, wherein the motor is arranged at the front end of the housing and is connected with the blade holder through a motor shaft; the blade is arranged on the blade holder; the cutter bit protecting cover sleeves the outer side of the cutter bit; the battery box is arranged at the rear end of the housing; the hair ball box is arranged in the middle of the housing, and an opening of the hair ball box is communicated with a cavity of the blade; an absorbing structure which is provided with a cavity is arranged in the middle of the housing and is clamped to the housing, and the cavity is communicated with the cavity of the blade; the surface of the absorbing structure is of a net-shaped structure, and an absorbing brush head is arranged at a mesh opening of the net-shaped structure. According to the scheme, the hair ball removing device has the advantages that hair balls on the clothing surface can be removed, and moreover, the original fluff on the surface can be prevented from being damaged; in addition, hair and dust in the clothing can also be quickly removed; the hair ball removing device is simple in structure and low in cost.

Owner:CHANGZHOU PEIJIE ELECTRIC FITTINGS

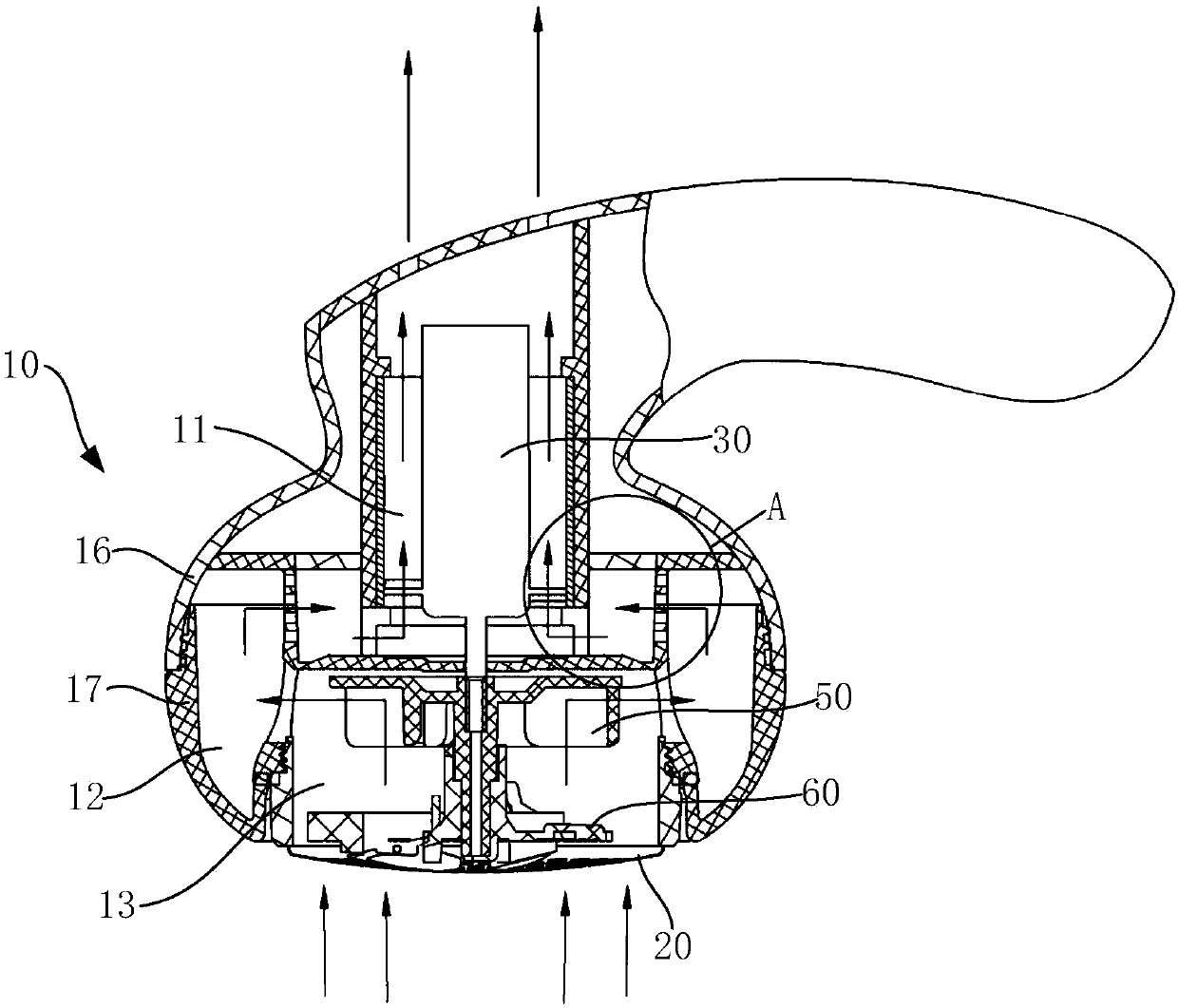

Efficient wool removing equipment for textiles

ActiveCN107974790AIncrease the speed of hair removalEasy to remove hairFloats removalBilateral symmetryStart up

The invention relates to efficient wool removing equipment and particularly relates to efficient wool removing equipment for textiles. A technical problem to be solved by the invention is to provide the efficient wool removing equipment for the textiles. The efficient wool removing equipment is high in wool removing efficiency, high in wool removing speed, and dust can be cleaned during wool removing. The efficient wool removing equipment for the textiles, provided by the invention, comprises a bottom plate and the like, wherein supporting rods which are of bilateral symmetry are arranged at the left side of the top of the bottom plate, a placement plate is arranged on the supporting rods, L-shaped plates are arranged at the right side of the top of the bottom plate, a moving mechanism isarranged at the bottom of the upper L-shaped plate, and an wool removing mechanism is arranged below the moving mechanism. According to the efficient wool removing equipment for the textiles, the effects of being high in wool removing efficiency and high in wool removing speed and cleaning the dust during wool removing are achieved; the textiles are unhaired through firstly, placing the textiles on the placement plate, then, fixing the textiles by a fixing mechanism, then, starting up the moving mechanism, moving the wool removing mechanism to a proper position, and meanwhile, a dust suction mechanism is turned on to clean out generated dust.

Owner:上海雁峰纺织品有限公司

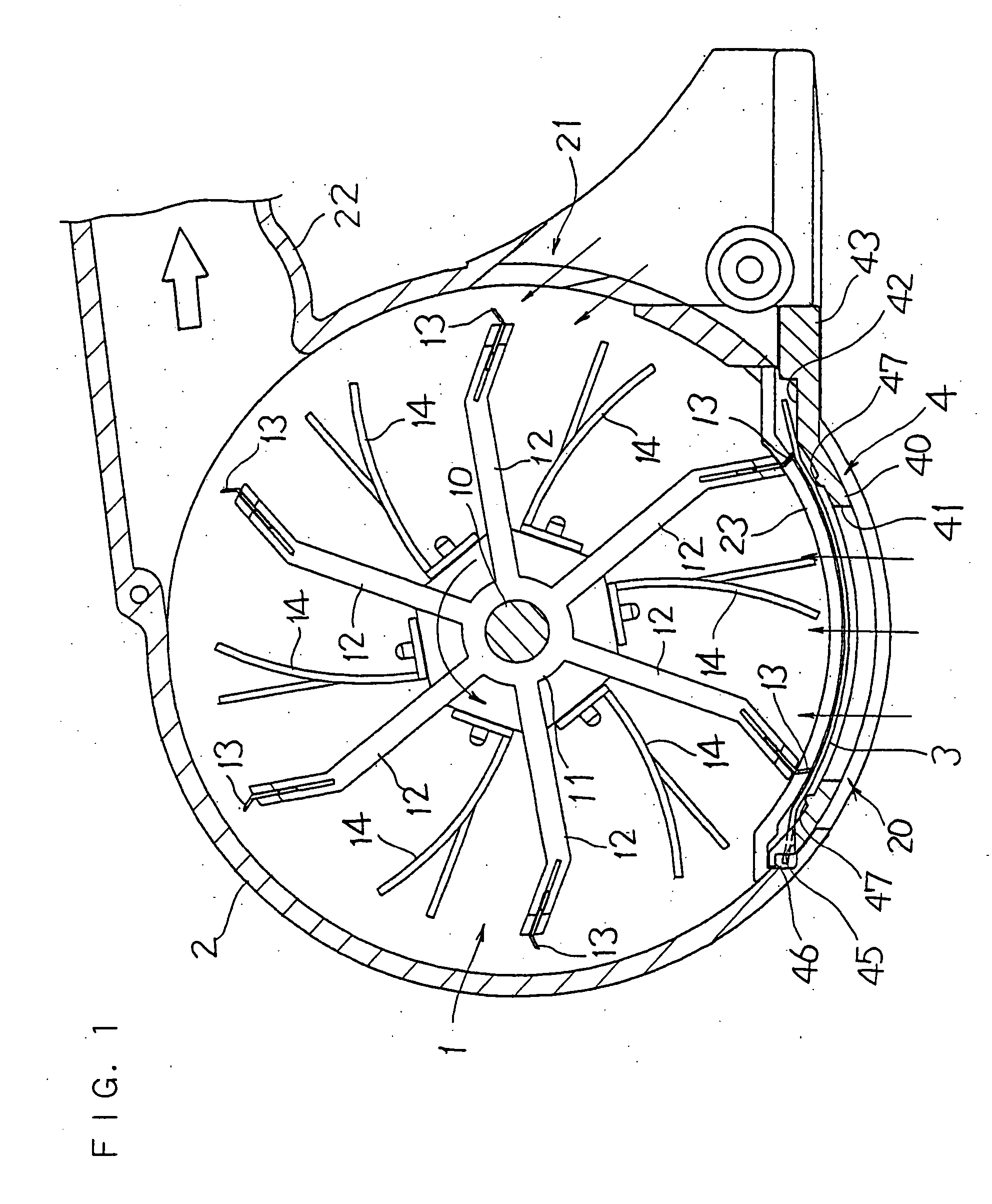

Rotary cutting apparatus

InactiveUS20060260457A1Surely and stably performReduce wind noiseFloats removalShearing machinesIn planeEngineering

In a rotary cutting apparatus, including a rotary blade having a cutting blade on the outer circumference and rotating radially in one direction; a housing for accommodating the rotary blade; and a fixed blade in the form of a plate attached to the housing along the outer circumference of the rotary blade, for cutting objects protruding from the blade holes of the fixed blade into the housing by the function of the cutting blade of the rotary blade that comes into slide-contact with the inner surface of the fixed blade, the fixed blade is supported at only one end by hooking one edge of the fixed blade on an upstream side in a rotation direction of the rotary blade onto a hook protrusion, and attached so that it is freely displaceable in an in-plane direction and a direction crossing the plane.

Owner:NKG

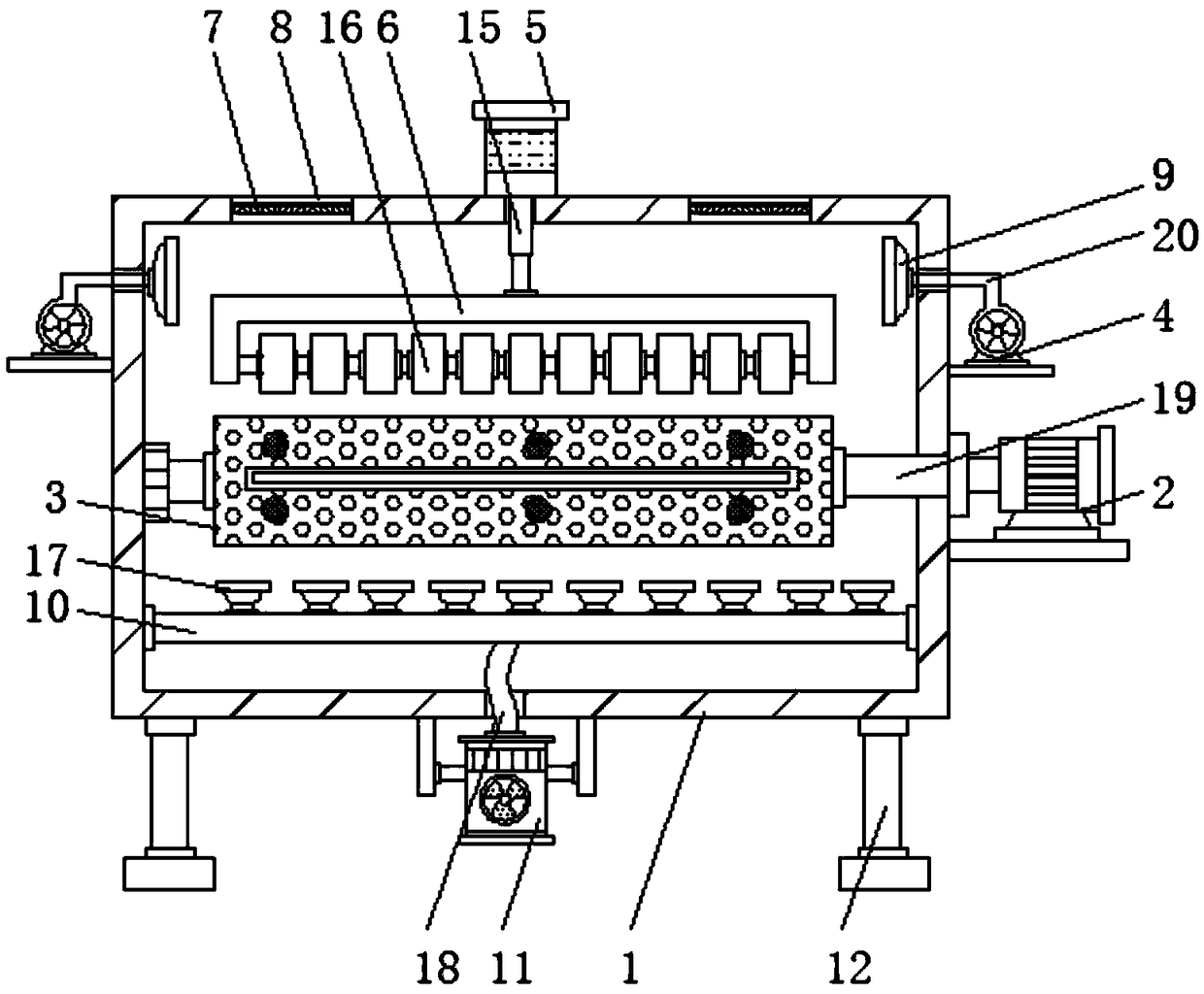

Efficient drying device for flocked cloth

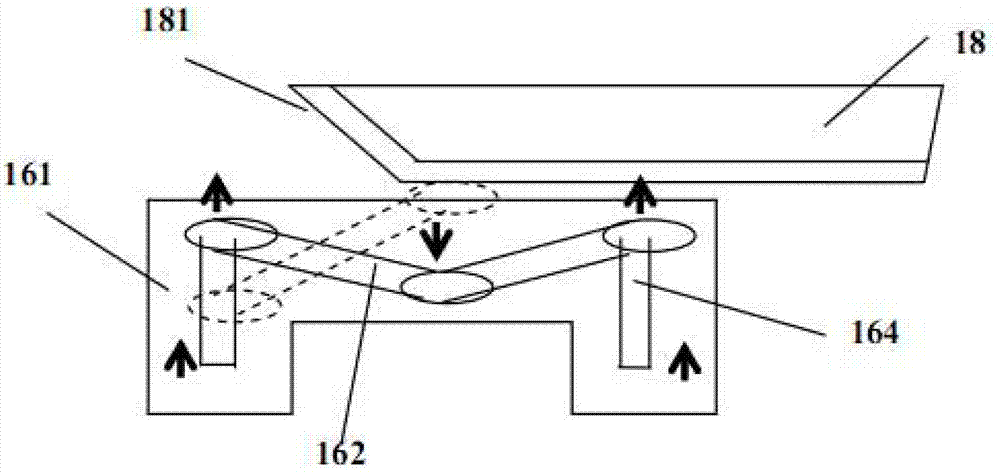

PendingCN108759406AEvenly heatedImprove drying efficiencyDrying gas arrangementsFloats removalBristleEngineering

The invention discloses an efficient drying device for flocked cloth. The efficient drying device for the flocked cloth comprises a drying box and a cloth hanging barrel, wherein the cloth hanging barrel is arranged in the drying box; a rotary motor is installed on the sidewall of the drying box; an output shaft of the rotary motor is rotationally connected with the cloth hanging barrel through arotary shaft; a hot-air spray pipe is arranged below the cloth hanging barrel; hot-air nozzles distributed at an equal interval are formed in the hot-air spray pipe; a cleaning frame is arranged abovethe cloth hanging barrel; brush wheels distributed at an equal interval are rotationally arranged at the inner side of the cleaning frame; and uniformly-distributed bristles are formed at the outer side of each brush wheel. According to the efficient drying device for the flocked cloth, through the continuous rotation of the cloth hanging barrel and under the hot-air injection of the hot-air nozzles, the flocked cloth on the cloth hanging barrel is much uniformly heated, so that the drying efficiency for the flocked cloth is greatly increased, and the drying effect for the flocked cloth is greatly improved; and moreover, the brush wheels arranged at the inner side of the cleaning frame are capable of effectively eliminating flock and dust left on the flocked cloth, and the dried flocked cloth is cleaner.

Owner:浙江唐艺织物整理有限公司

Processing equipment for ensuring surface cleanness of textile fabric

InactiveCN107338611AImprove processing qualityGuarantee processing qualityTextile treatment containersFloats removalAgricultural engineeringCatheter

The invention discloses processing equipment for ensuring surface cleanness of a textile fabric. The processing equipment comprises a fixed seat, wherein a first cloth guiding roller is connected between two first bearings; a second cloth guiding roller is connected between two second bearings; a third cloth guiding roller is connected between two third bearings; a supporting rod is connected to the bottom of each third bearing; an ejection rod is connected to the bottom of a supporting seat; a turn plate is lapped to the left side of the top of a rotating rod; a water pipe is connected to the bottom of each water collecting hood; an electric heating tube is clamped between every two arc-shaped grooves; a blower is connected to the left side of a guide pipe; a suction ventilator is connected to one end, away from a suction hood, of the guide pipe; a cleaning pipe is connected to the bottom of the guide pipe; a filter screen is connected to an inner cavity of the guide pipe. The processing equipment disclosed by the invention has the advantage of improving the processing quality of the textile fabric; the problems that the operation of improving the processing quality of the fabric is complex, more flows are required, and the processing quality of the cloth is difficult to guarantee are solved.

Owner:秦泽坤

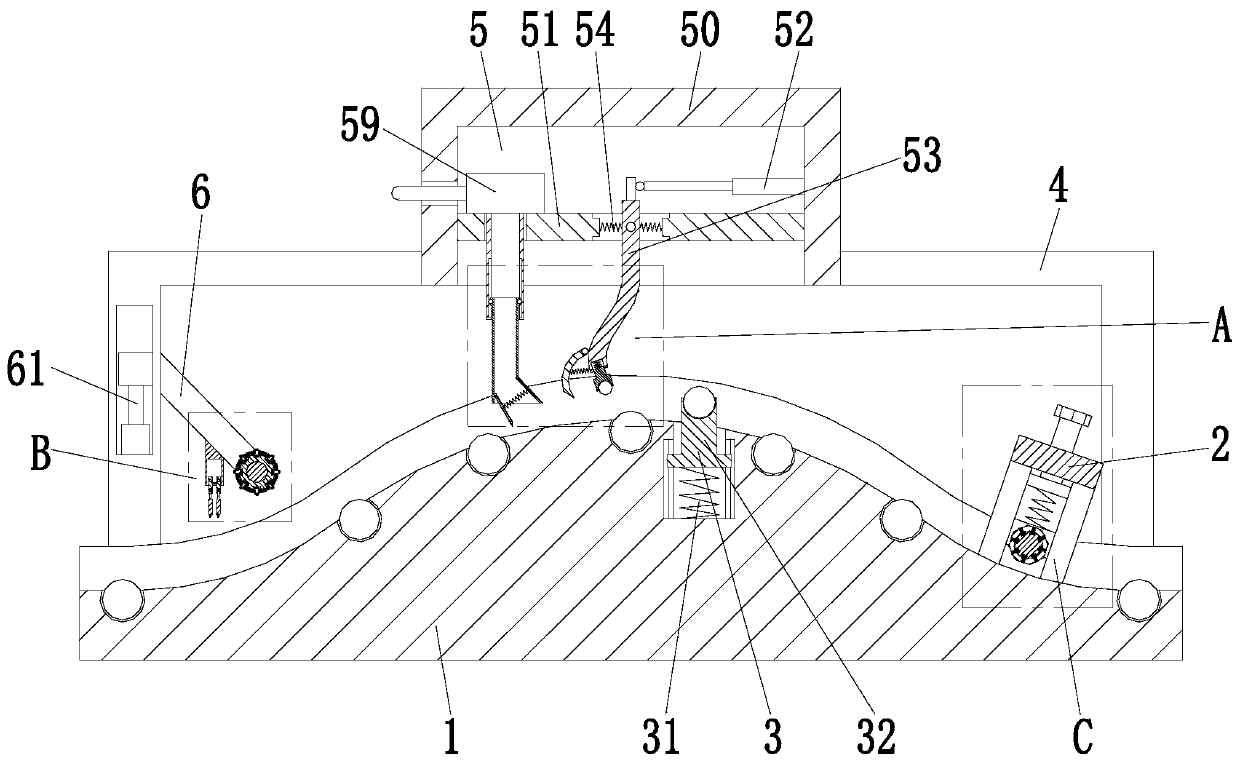

A textile yarn ball removing device

The invention relates to the technical field of textiles and particularly relates to a textile yarn ball removing device. The device includes a conveyer belt, a yarn ball removing mechanism, a yarn ball collecting gear and a telescopic pipe. The yarn ball removing mechanism is connected to the yarn ball collecting gear through the telescopic pipe, and is a circular truncated cone cavity. A first-stage screen plate and a second-stage screen plate are disposed inside the yarn ball removing mechanism. The cavity wall between the first-stage screen plate and the second-stage screen plate is connected to bent pipes. The first-stage screen plate is provided with motors downward. The second-stage screen plate is provided with cutting heads downward. The motors are connected to the cutting heads through connecting shafts. The telescopic pipe is also provided with a flattening structure. The textile yarn ball removing device is provided, a textile is put on a conveying pathway, and yarn ball removing cutters are started to remove yarn balls in a pilling zone through cutting. The working surface is large, and yarn ball removing effects are good. The device can be popularized and applied to production lines to achieve large-scale yarn ball removing.

Owner:安徽职业技术学院

Clothing clamping automatic proceeding brushing machine

InactiveCN104173017AEasy to moveMechanical cleaningPressure cleaningEngineeringMechanical engineering

The invention discloses a clothing clamping automatic proceeding brushing machine which comprises a brushing machine body, a brush board, clothing moving clamps and a brush roller, wherein the brush board is fixedly mounted at the upper end of the brushing machine body; the brush roller is arranged in the center of the brush board; a brush head is mounted on the brush roller; a movable clamp horizontal guide rail and a movable clamp vertical guide rail are arranged on the brush board on the two sides of the brush roller; the movable clamp horizontal guide rail and the movable clamp vertical guide rail are arranged in a mutually perpendicular manner; a movable clamp placing groove is formed in the intersection of the movable clamp horizontal guide rail and the movable clamp vertical guide rail; the clothing moving clamps are correspondingly placed in the movable clamp placing groove; the four clothing moving clamps are connected through fixed connecting rods; roller clamping grooves are formed in the bottoms of the clothing moving clamps; transmission rollers are arranged in the movable clamp horizontal guide rail and the movable clamp vertical guide rail; the clothing moving clamps are connected with the transmission rollers through the roller clamping grooves; clothing clamps are mounted at the upper ends of the clothing moving clamps. Through the adoption of the approach, the full-automatic and all-directional clothing brushing treatment can be realized, as the clothing is clamped by the clothing moving clamps and moves conveniently on the special rails, the automatic and all-directional brushing is realized conveniently.

Owner:WUXI CAIYUN MACHINERY & EQUIP

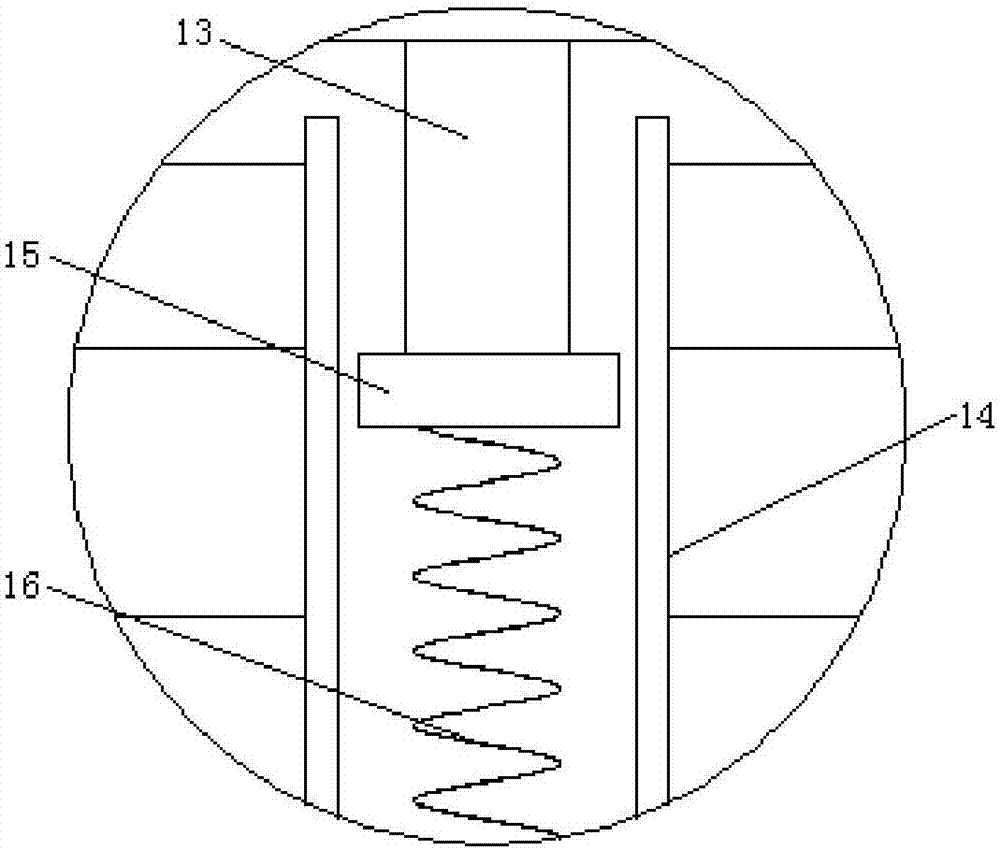

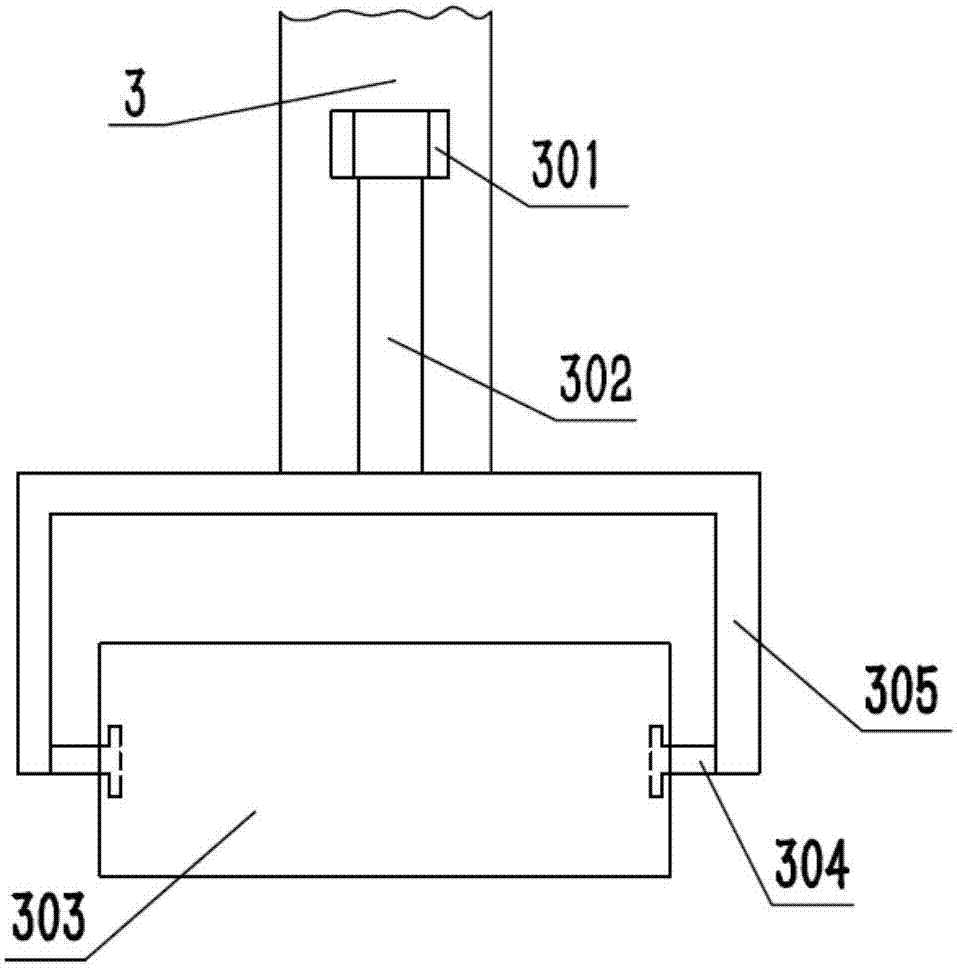

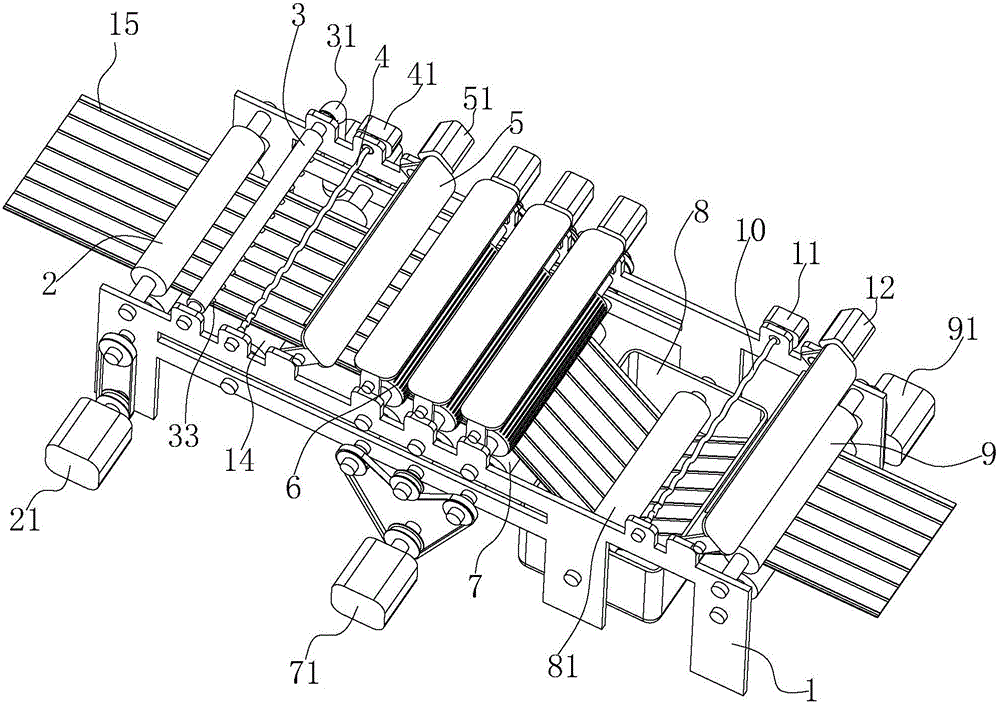

Fluff treatment device for lint manufacturing

ActiveCN106930032AReasonable structureEasy loading and unloadingFloats removalFinal product manufactureEngineeringStructural engineering

The invention discloses a fluff treatment device for lint manufacturing. The device comprises a hair brush mounting rack and a hair brush, wherein one side of the hair brush is provided with a hair brush part; the hair brush mounting rack is provided with two parallel lug plates; strip-shaped mounting holes are symmetrically formed on the two lug plates; an opening is formed on the side part of one end of each strip-shaped mounting hole so as to form an opened strip-shaped mounting hole; a mounting component is fixed on one side, back to a hair brushing part, of the hair brush; two lug shafts are symmetrically arranged on the mounting component and are respectively arranged in the two strip-shaped mounting holes; a spring is arranged between the hair brush mounting rack and the mounting component; the lug shafts are driven and restricted by the resilience provided by the spring in the strip-shaped mounting holes; and spring resilience is overcome by external force to ensure that the lug shafts move toward the openings along the strip-shaped mounting holes, and are separated from the hair brush mounting rack by the openings. The fluff treatment device for lint manufacturing is mounted on lint cutting equipment, the structure of the device is reasonable, the hair brush arranged on the device can be conveniently mounted, dismounted or replaced, and the fluff adhered to fabrics is separated from the fabrics in time; and therefore, the device has good practicability.

Owner:浙江斯泰堡纺织有限公司

Drying and fold removal integrated machine for spinning

InactiveCN109594275AImprove drying efficiencyEasy to useMechanical cleaningPressure cleaningProcess engineering

The invention discloses a drying and fold removal integrated machine for spinning. The drying and fold removal integrated machine for spinning comprises a machine body, wherein partition boards are fixedly connected with two sides in the machine body; fixed blocks are fixedly connected with the top and the bottom of the right side of an inner cavity of the machine body; air outlet holes are formedin the surfaces of the fixed blocks; heating wires are fixedly connected into the fixed blocks; a storage battery, a heating box, a fan and a control panel are fixedly connected with the top of the machine body from left to right in sequence. By cooperative use of the storage battery, the heating box, the fan, the control panel, an air outlet pipe, the heating wires, a heater, steam outlet pipes,first electric telescopic rods, a bracket, a steam press wheel and steam outlet holes, the drying and fold removal integrated machine for spinning is convenient to use, has high drying efficiency, and can remove folds on the surface of the fabric during fabric processing, folds cannot appear on the surface of the fabric, following processing of the fabric cannot be affected, demands of people canbe met, and the machine is convenient to use.

Owner:管洪化

Waste silk clearing device for textile fabric processing

InactiveCN107354658AGuarantee product qualityAvoid removalHeating/cooling textile fabricsFloats removalPulp and paper industryPiston

The invention discloses a waste silk cleaning device for textile cloth processing, which includes a cleaning box, a first transmission roller connected between two first bearings, and a second transmission roller connected between two second bearings. The bottom of the piston plate is connected with a support spring, the middle part of the bottom of the movable rod is connected with a transmission rod, and the lower side of the transmission rod is inserted with a rotating rod, and the right side of the rotating rod is connected with a turntable. The end of the tube far away from the cleaning box is connected to the suction fan, and the middle part of the top of the cleaning box is provided with a port, the inside of the port is provided with a conduit, the bottom of the conduit is connected to a dust cover, and the left side of the adjustment plate A rack is connected, and the left side of the rack meshes with the transmission gear. The invention has the advantage of reducing the long time spent on removing waste silk from the textile cloth, and solves the problems that the waste silk removal on the textile cloth takes a long time and the poor removal effect of the waste silk will reduce the production quality of the textile cloth.

Owner:姚飞

Fuzz removing machine

The invention provides a fuzz removing machine, relates to the technical field of household cleaning devices, and aims to solve the technical problem that an existing fuzz removing machine cannot clean flocks or dust. The fuzz removing machine comprises a shell, a cutter net, a motor, a turbine, a chip-removing wheel and a blade wheel, wherein an opening is formed in the shell, and the cutter netcovers the opening; the shell is provided with a first chamber and a second chamber, and is enclosed with the cutter net to form a third chamber; the shell is provided with a first communicating holeand a second communicating hole; the motor is arranged in the first chamber, the rotating shaft of the motor extends into the third chamber; the turbine is arranged on the motor and is positioned in the first chamber; and the chip removing wheel and the blade are positioned in the third chamber, and are connected with the rotating shaft of the motor. The fuzz removing machine is provided with theturbine generating relatively large suction, which can be used for sucking flocks and dust on clothes into the second chamber, and clothes polluted by dispersing flocks and dust when the fuzz removingmachine is used for removing fuzz can be prevented.

Owner:SHANGHAI FLYCO ELECTRICAL APPLIANCE

Surface wrinkle removal finishing method for rolled gray cloth

InactiveCN107237079AReduce generationImprove finishing effectMechanical cleaningPressure cleaningWrinkle skinEngineering

The invention discloses a surface wrinkle removal finishing method for rolled gray cloth. A feeding device is used for conveying the rolled gray cloth out, a wrinkle removal roll is used for removing wrinkles on the surface of the rolled gray cloth, and a detection device is used for detecting a deckle edge position on the edge of the deckle edge of wrinkle-removed gray cloth and is specifically used for detecting the edge position and the width of the deckle edge; deckle edges on the edge of the gray cloth are trimmed by virtue of a trimming device according to a detection signal, and the trimmed gray cloth is rolled up by virtue of a rolling device. According to the surface wrinkle removal finishing method for the rolled gray cloth utilizing the optimal design, the surface of the gray cloth is subjected to wrinkle removal by virtue of the wrinkle removal roll, the edge position is changed after wrinkle removal, and then the deckle edges are trimmed according to the detected edge position, so that the finishing effect is greatly improved, and the waste is effectively reduced.

Owner:ANHUI LIANGLIANG TEXTILE CO LTD

Shell fabric drying room with fuzz removal function

InactiveCN104153142AAvoid damageDrain in timeLiquid/gas/vapor removalFloats removalDrive shaftEngineering

The invention discloses a shell fabric drying room with a fuzz removal function. The shell fabric drying room comprises a conveying belt, a drying oven, a plurality of fuzz suction channels and fuzz removal rotary plates, wherein the conveying belt is arranged at the bottom of the drying oven, transmission shafts are arranged at the two ends of the conveying belt, a plurality of heating rollers are arranged in the conveying belt, and the fuzz suction channels are formed in the drying oven. Rotary motors are arranged in the fuzz suction channels, rotary rods are connected onto the rotary motors, the fuzz removal rotary plates are arranged at the tail ends of the rotary rods and connected with the rotary rods through lifting cylinders, a plurality of blades are arranged on the fuzz removal rotary plates, the fuzz suction channels are communicated through a first pipeline, and a first exhaust fan is arranged at the tail end of the first pipeline. Shell fabrics can be dried by the heating rollers in the conveying belt, and fuzz removal is performed on the shell fabrics through the fuzz removal rotary plates in the drying oven.

Owner:YANCHENG INST OF TECH

Lint removing device for textiles

InactiveCN110804825AEasy to replaceEasy to installMechanical cleaningPressure cleaningAir blowerMechanical engineering

The invention relates to the technical field of textile processing and discloses a lint removing device for textiles, which comprises a cleaning box; a movable door is arranged on the front surface ofthe cleaning box, an air blower is fixedly mounted at the top of the cleaning box, and an exhaust pipe is fixedly connected to the bottom of the left side of the air blower. According to the lint removing device for the textile, part of the lint on the surface of a textile product is sucked into a storage box through the air blower, the exhaust pipe and a blowing pipe; the textile product is introduced between a plurality of sticky rollers through positioning rollers, and the lint on the surface of the textile product is removed through the sticky rollers at the time; the textile product is guided out through a discharge port; after a period of time, the movable door is opened, and a U-shaped limiting plate is pulled out and inserted into a limiting groove, so that a connecting plate is fixed through the U-shaped limiting plate, a rectangular insert and a rectangular receiving groove; the float removing device is more stable to mount, the structure is simplified, the lint removing effect is better, and the sticky rollers are convenient to replace.

Owner:江门市新会区德盈化工有限公司

Tail processing device for garment manufacturing and processing method thereof

The invention discloses a tail processing device for garment manufacturing and a processing method thereof. The tail processing device comprises a rail and a rail power device, a thread end sucking machine, piecework sensors, a hanger and a control device, wherein the hanger is fixed on the rail; the thread head sucking machine is arranged below the rail; the piecework sensors are fixed at the periphery of the rail; the rail power device, the thread head sucking machine and the piecework sensors are all connected with the control device; and the rail power device drives the rail to rotate, and synchronously drives the hanger thereon to pass through the thread end sucking machine and the piecework sensors. According to the tail processing device for garment manufacturing and the processing method thereof, the thread end sucking machine and the piecework sensors are arranged at the periphery of the rail, so that garment is hung on the rail and circularly rotates along with the rail; when the garment passes through the thread end sucking machine, thread ends on the garment are sucked by the thread end sucking machine, and the piecework is performed by the piecework sensors, thereby achieving the automation of tail processing during garment manufacturing.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Waste silk cleaning device for textile fabric processing

ActiveCN110835820AConvenient drying workImprove convenienceMechanical cleaningPressure cleaningElectric machineryProcess engineering

The invention discloses a waste silk cleaning device for textile fabric processing, and relates to the field of waste silk cleaning of textile fabrics. The waste silk cleaning device for textile fabric processing comprises a bottom plate, wherein a first side machine frame, a second side machine frame, a fixing plate, a dust collector and a collecting box are fixedly mounted on the top outer surface of the bottom plate; a second sliding groove is formed in the bottom plate; a second sliding block is mounted inside the second sliding groove in a sliding manner; an auxiliary seat is fixedly mounted at the top of the second sliding block; an auxiliary plate is fixedly mounted on the top outer surface of the auxiliary seat; a supporting plate is fixedly mounted on the top outer surface of theauxiliary plate; a motor is fixedly mounted on the outer surface of the bottom of the supporting plate; a screw rod and a fixed-mounted limiting rod are fixedly mounted on the top outer surface of thesupporting plate in a rotary manner respectively; and an output shaft of the motor penetrates through the supporting plate and is fixedly connected with the screw rod. The device replaces the traditional manual method for cleaning waste silk of textile fabrics, improves the working efficiency of workers and reduces the working intensity.

Owner:安徽省拥家户外用品科技有限公司

Lint remover for textile fabric

InactiveCN107829252AMeet the Ironing TreatmentAchieve ironingFloats removalHand ironDrive motorTextile

The invention discloses a lint remover for textile fabric. The lint remover comprises a base, a box and a handle, wherein a water storage bin and a drive bin are uniformly arranged in the box througha partition board, a drive motor is mounted in the drive bin through bolts, an output end of the drive motor extends into a cutting bin formed in the base, a cutter head is detachably arranged at theoutput end of the drive motor, a cover plate is detachably mounted at the bottom of the cutting bin, lint holes are uniformly formed in the cover plate, a steam bin surrounds the inside of the base on the outer side of the cutting bin, an ironing board is arranged at the top of the steam bin, steam holes are uniformly formed in the ironing board, a steam pipe is arranged at the base top on one side of the box, one end of the steam pipe is connected fixedly with the steam bin, the other end of the steam pipe extends to the inner top end of the water storage bin, and the handle is fixedly connected with one side of the box. The lint remover can iron the fabric while effectively shearing lint on the fabric surface and has good practicability.

Owner:丽水遂智科技咨询有限公司

Cutting device for knitted fabric

InactiveCN107604628APromote combustionRealize levelingSevering textilesFloats removalEngineeringScrew thread

The invention discloses a cutting device for knitted fabric. The device comprises a machine base comprising a locating mechanism, a fixed plate, a lifting mechanism and an aerator; the locating mechanism comprises a cylinder and a threaded hole, an air opening and a heating groove are formed in the cylinder, a hollow sphere is arranged in the heating groove, and multiple heat dissipation holes areformed in the hollow sphere; a threaded rod is in threaded connection with the threaded hole, multiple support plates are arranged on the threaded rod in the circumferential direction, and each support plate is provided with an arc plate; multiple through holes are formed in the fixed plate; each through hole is provided with a press spring connected to a first tapered wedge; the first tapered wedge is provided with an auxiliary rod rotatably connected to a circular shaft; the circular shaft is connected to a circular blade in a sleeved mode; a limiting groove is formed in the circular shaft;the lifting mechanism comprises an air cylinder and a mobile plate provided with multiple second tapered wedges; the aerator is connected to the air opening. The cutting device for the knitted fabricmainly solves the problems that an existing knitted fabric thread residue removing mode is large in manual labor intensity and low in removing efficiency.

Owner:宁波源生针织有限公司

Cloth surface brushing machine

PendingCN107338610AQuick bristle cleaningReduce workloadMechanical cleaningPressure cleaningEngineeringPulley

The invention discloses a cloth surface brushing machine. The machine comprises a frame, a cloth spreading wheel fixing rack is fixedly arranged at one side of the frame, a cleaning assembly is fixed at the other side of the frame, the cloth spreading wheel fixing rack is provided with a plurality of cloth spreading wheels in a staggered manner, a cloth-to-be-processed storage box is arranged below the cloth spreading wheels, a correcting instrument is fixedly arranged below the cloth spreading wheel fixing rack, a tensioning pulley is arranged at the lower end of the correcting instrument, the cleaning assembly comprises a plurality of cleaning rollers, brushing rollers, adjusting wheels and delivery wheels, and a rolling mechanism is arranged at one side of the cleaning assembly. The machine has the advantages of simple structure principle, high automation degree, realization of rapid brushing cleaning of a cloth surface through adopting two groups of brushing rollers, high working efficiency, and reduction of the workload of workers.

Owner:南通奇呈印染机械有限公司

Fabric cleaning device

ActiveCN108166189AAchieve cleaningAvoid deformationLiquid/gas/vapor removalFloats removalDrive shaftEngineering

The invention belongs to the technical field of washing and cleaning devices for fabrics, and specially discloses a fabric cleaning device. The fabric cleaning device includes a rack, and a conveyingbelt arranged on the rack; a horizontal cleaning roller is arranged above the conveying belt, and the cleaning roller is a hollow roller; the cleaning roller is fixedly connected to a drive shaft along a central axis; the drive shaft passes through the cleaning roller; one end of the drive shaft is fixedly connected to a motor; the motor is fixed on the rack; and a cleaning portion, a cutting portion for cutting hair bulbs on the surface of the knitted fabric, a hair bulb collection portion, and a supporting portion are arranged on the cleaning roller. The invention can solve the problem thathigh-speed rotation will result in deformation of the knitted fabric and the hair bulbs on the surface of the knitted fabric are difficult to remove while the knitted fabric is cleaned by using the prior art.

Owner:NINGBO HIGH TECH ZONE SHENGWENTU TEXTILE CO LTD

Carding machine for surface treatment of cloth

InactiveCN111172693AGuaranteed tensionMake sure to combMechanical cleaningPressure cleaningCardingMechanical engineering

The invention provides a carding machine for surface treatment of cloth. The carding machine comprises a base, a limiting unit, an auxiliary unit, a fixing frame, an execution unit and a carding unit.The carding machine for surface treatment of the cloth is capable of solving the problems that may frequently exist in the carding process: a, the efficiency is low in the process of manually cardingthe fluff surface of the cloth by using rakes, and the rakes are easy to scratch the surface of the cloth and damage the surface of the cloth; and b, in the process of carding the surface of cloth, the surface tension of the cloth is insufficient, such that the cloth is wrinkled in the process of carding the surface of the cloth, the carding of the cloth is influenced, and fluff balls on the surface of the cloth are difficult to clean completely; and the carding quality of the cloth is reduced.

Owner:盛萍萍

Dehairing machine for textile

InactiveCN108396499ASimple structureEasy to operateFloats removalAgricultural engineeringDrive motor

The invention discloses a dehairing machine for textile. The dehairing machine comprises a base, wherein two supporting columns are arranged at the upper end of the base respectively; conveying rollers are connected with the top ends of the two supporting columns; a box body is arranged on the two supporting columns; the box body is provided with a fabric inlet and a fabric outlet; a fabric is arranged on the two conveying rollers; the fabric sequentially penetrates through the fabric inlet and the fabric outlet; two dehairing mechanisms are arranged at one side, close to the fabric inlet, inthe box body; each dehairing mechanism comprises a driving motor, a retractable rod, a net pressing plate and a dehairing brush; the output end of each driving motor is connected with the corresponding retractable rod and a roller is connected with the end part of each retractable rod; the surface of each roller is fixedly connected with the corresponding dehairing brush; two ends of each roller are connected with a connecting rod and the end part of each connecting rod is connected with the corresponding horizontally-arranged net pressing plate; a collection box is arranged at one side of each driving motor and each collection box is connected with a conveying pipeline; a hair suction device is connected with the bottom part of each conveying pipeline and a hair suction opening is formedone side, close to the corresponding roller, of each hair suction device. The dehairing machine for the textile has the advantages of simple structure, convenience for operation, high dehairing efficiency and manpower saving.

Owner:响水县玉帛纺织有限公司

Napping machine for producing flax yarn

InactiveCN105926233ASmooth sandingImprove washing effectHeating/cooling textile fabricsFloats removalYarnPulp and paper industry

The invention discloses a napping machine for producing flax yarns. According to the napping machine, a blowing device is mounted above a napping device, so that napping operation can be thoroughly completed at one time, meanwhile the cut villi can be blown off, and then the quality of a napped product can be ensured. According to the napping machine, the blowing device is mounted above the napping device, villi can be relatively easily napped on the surfaces of the flax yarns due to the wind blown by the blowing device, the cut villi on the napped flax yarns can be blown off by the wind of the blowing device, then no cut villi can be hidden in the flax yarns, a relatively good later washing effect can be achieved, and drying operation can be implemented after simple washing. As a heating device is added behind a humidifying device, another blowing device is also mounted to blow the heating device, the surfaces of the flax yarns can be rapidly heated by the heating device, and then later flax yarn napping operation can be implemented successfully.

Owner:芜湖金凯亚麻科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com