Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

55results about "Bone-shears/bone-crushers" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

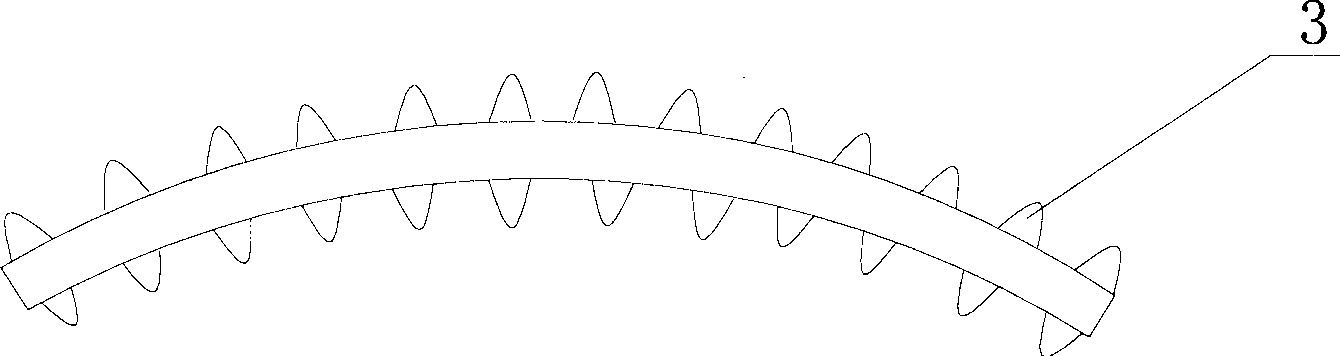

Mill, a method for producing bone transplantation material and use of a mill for such production

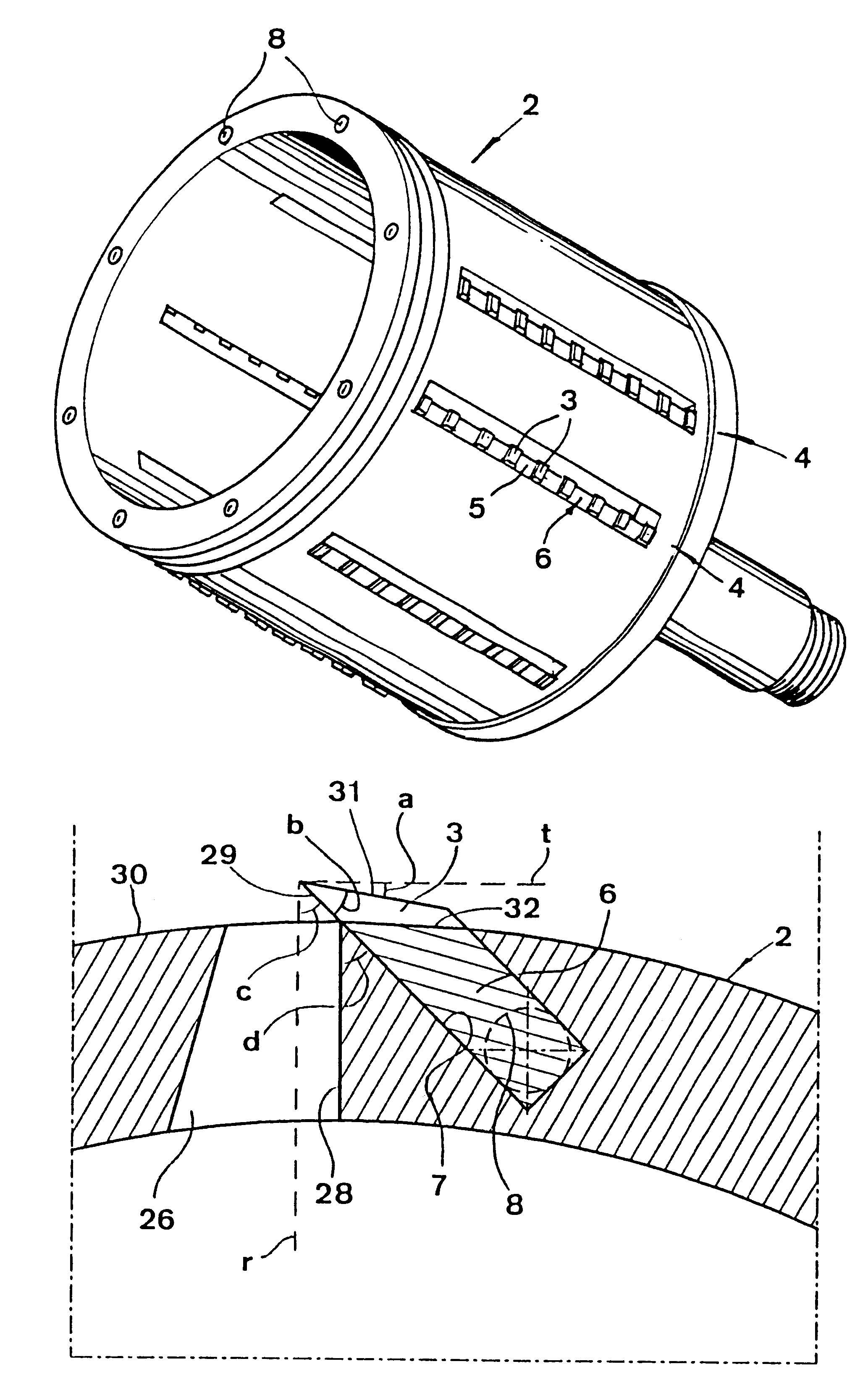

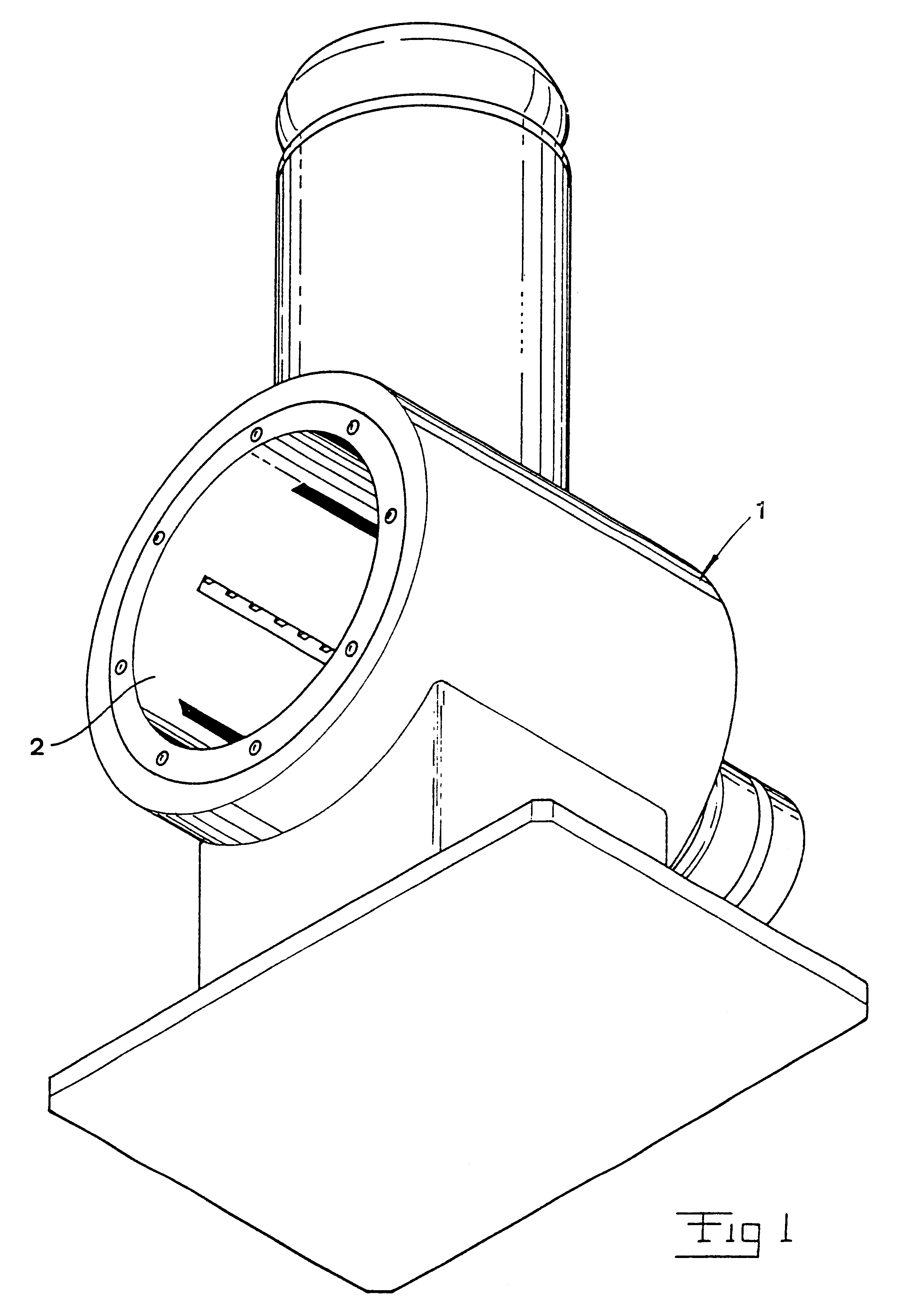

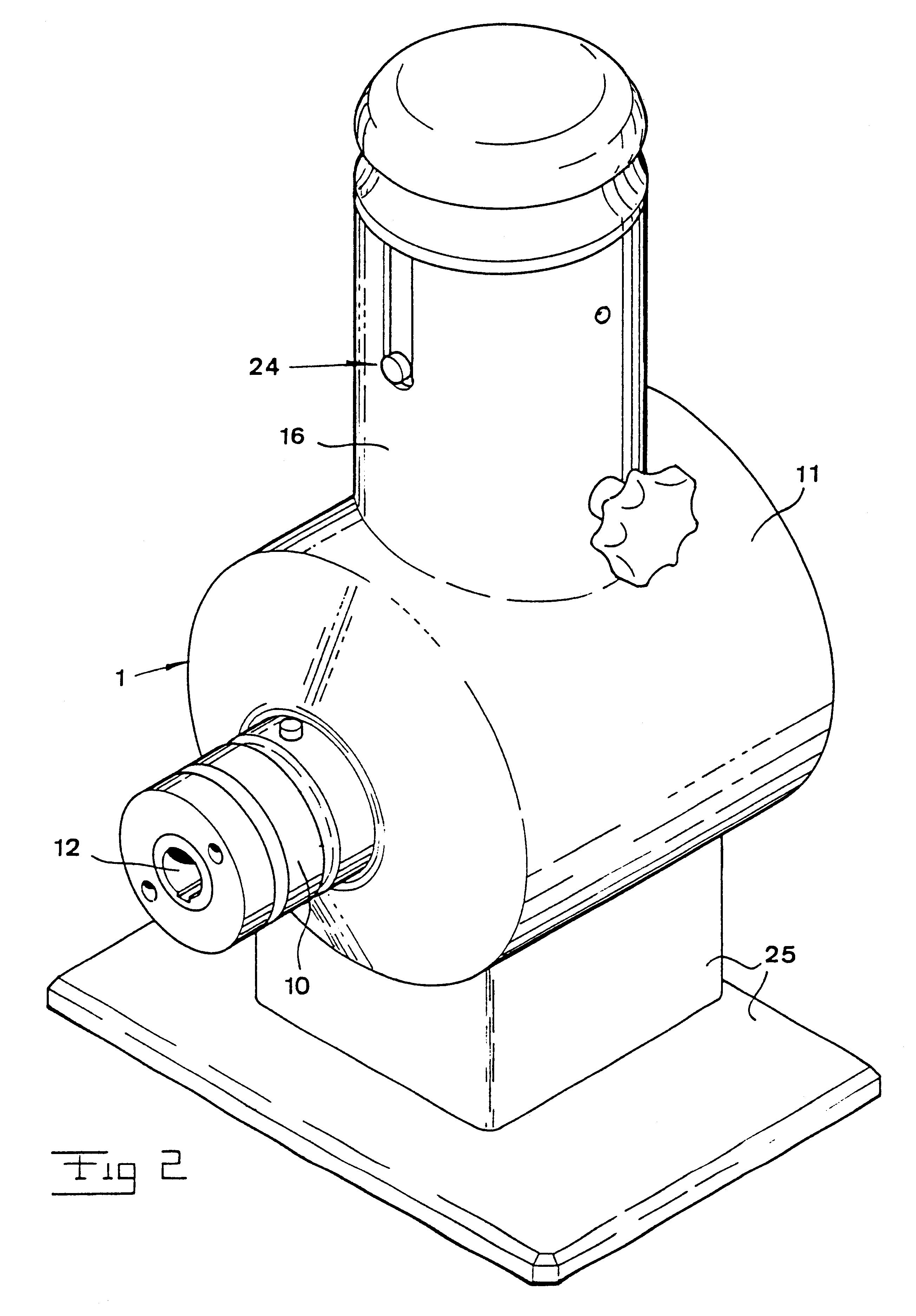

A mill comprises a casing having an opening for supply of material to be milled and a rotor rotatably supported in the casing and provided with cutting members (3) for disintegrating action on the material. The cutting members (3) are arranged in a plurality of sets (4a-d) distributed about the periphery of the rotor, and having an axial extent (arrow 33). At least two of the sets (4) have their cutting members (3) mutually displaced in axial direction.

Owner:HOVELIUS LENNART

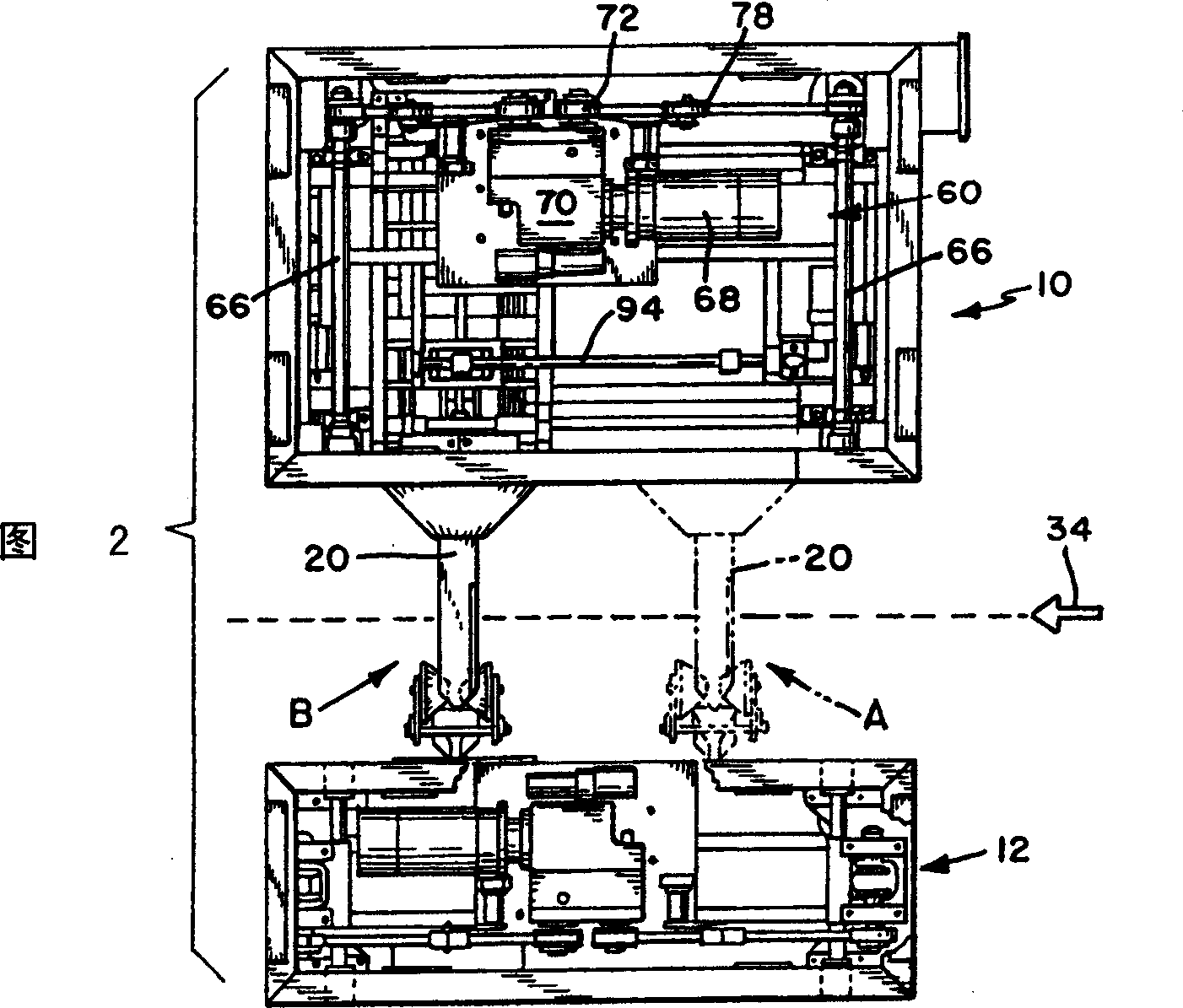

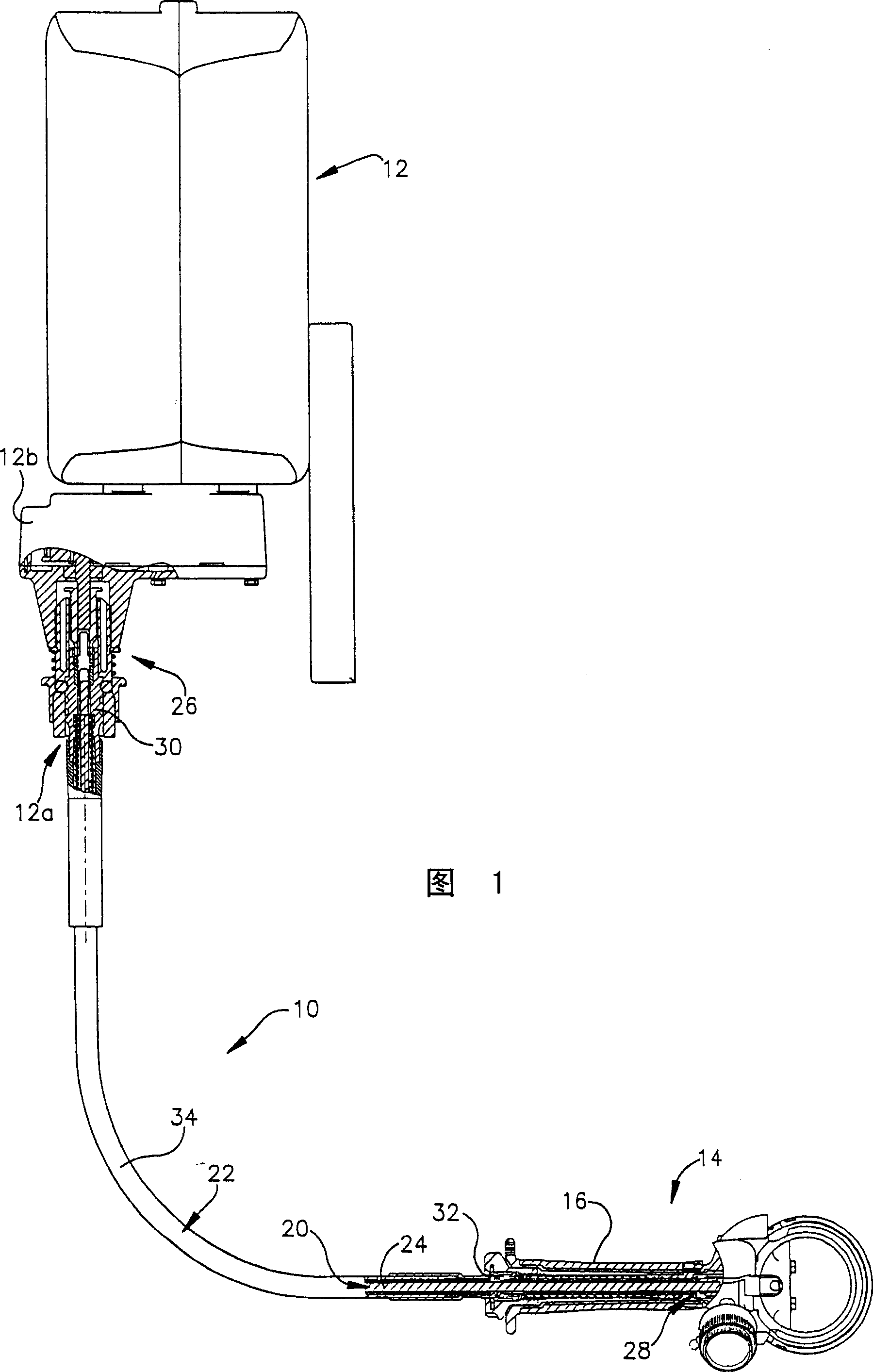

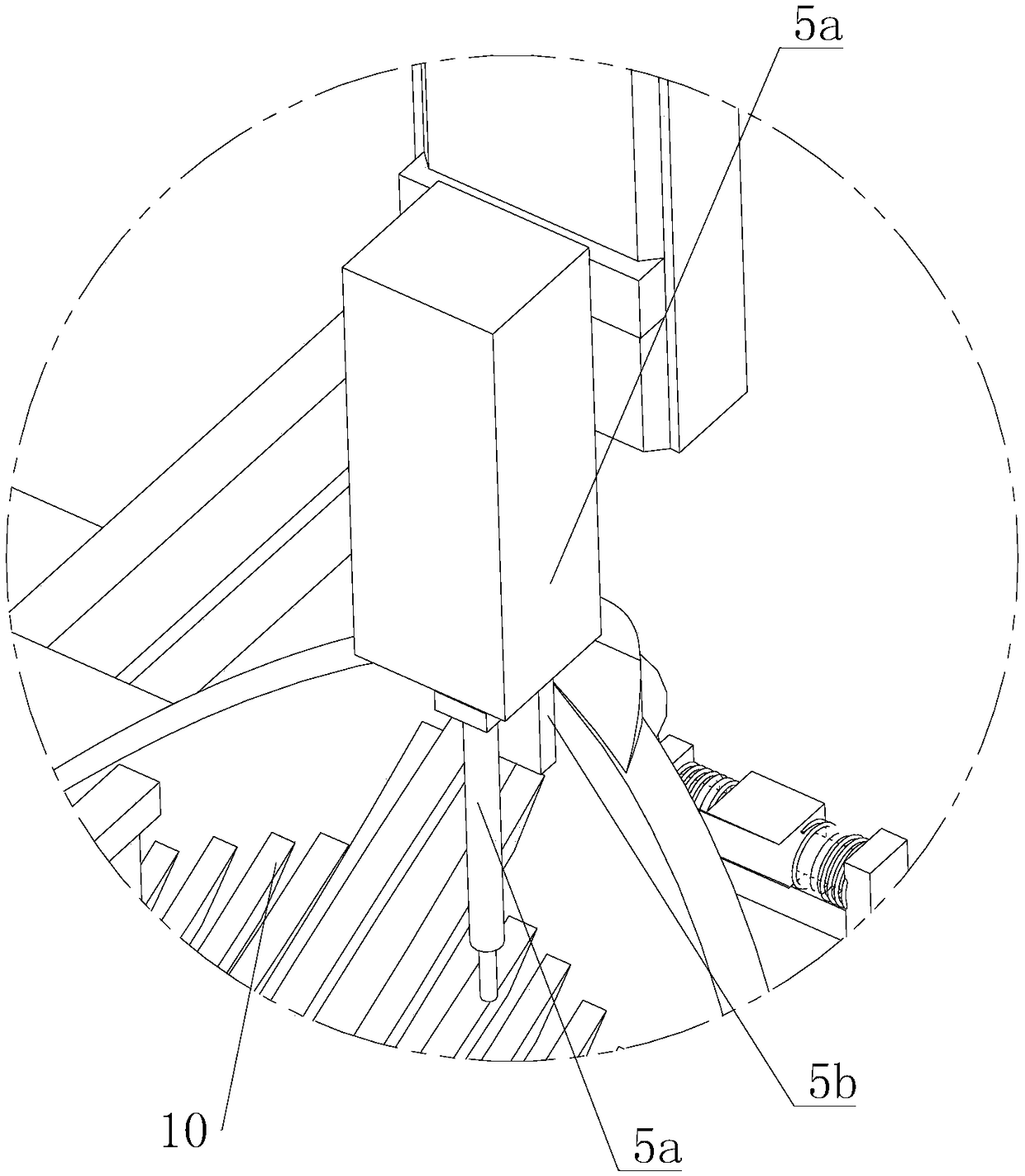

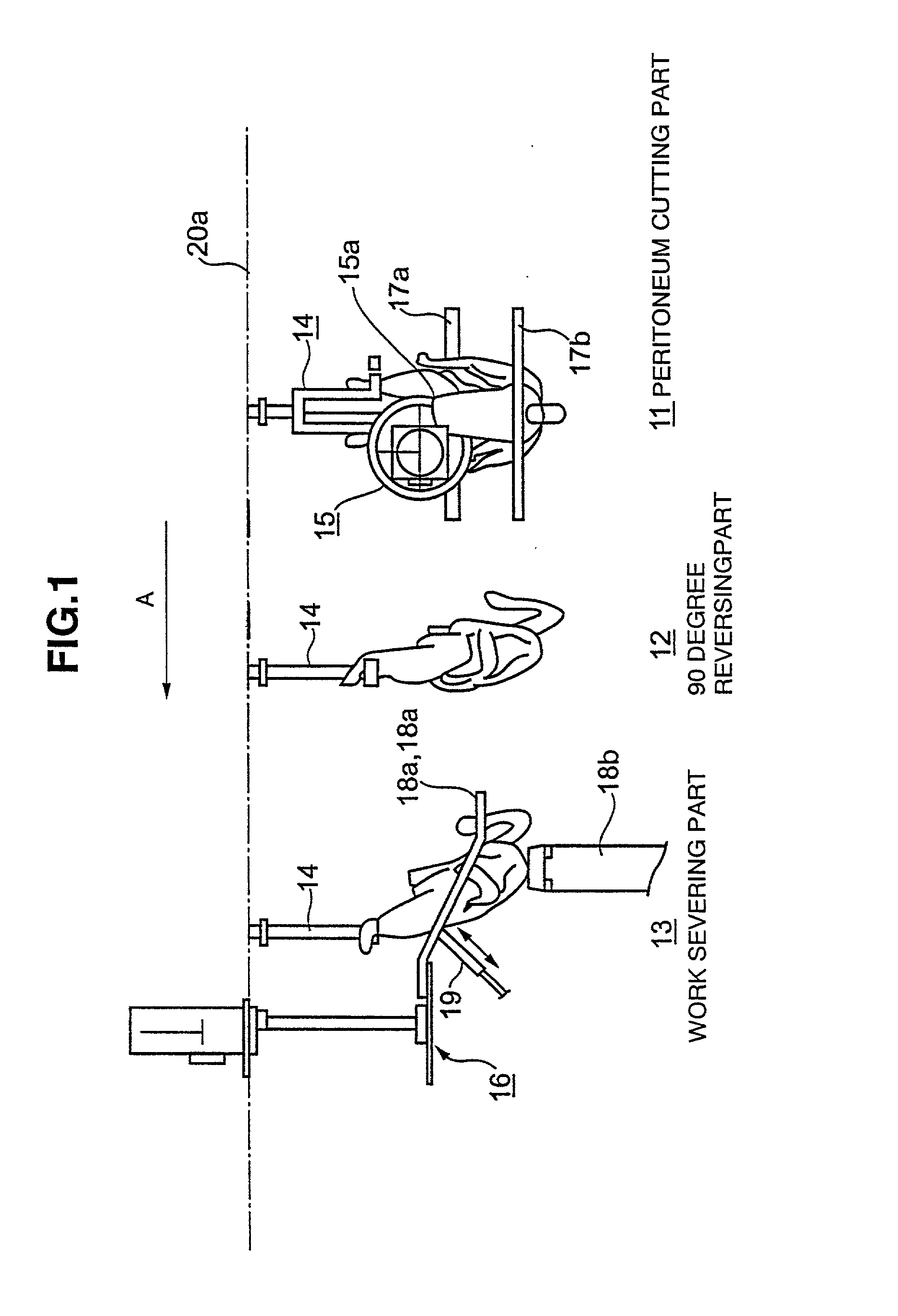

Automated saw for splitting carcasses

InactiveUS6126536AIncrease speedPrecise positioningMeat holding apparatusSplitting instrumentsMechanical engineeringEngineering

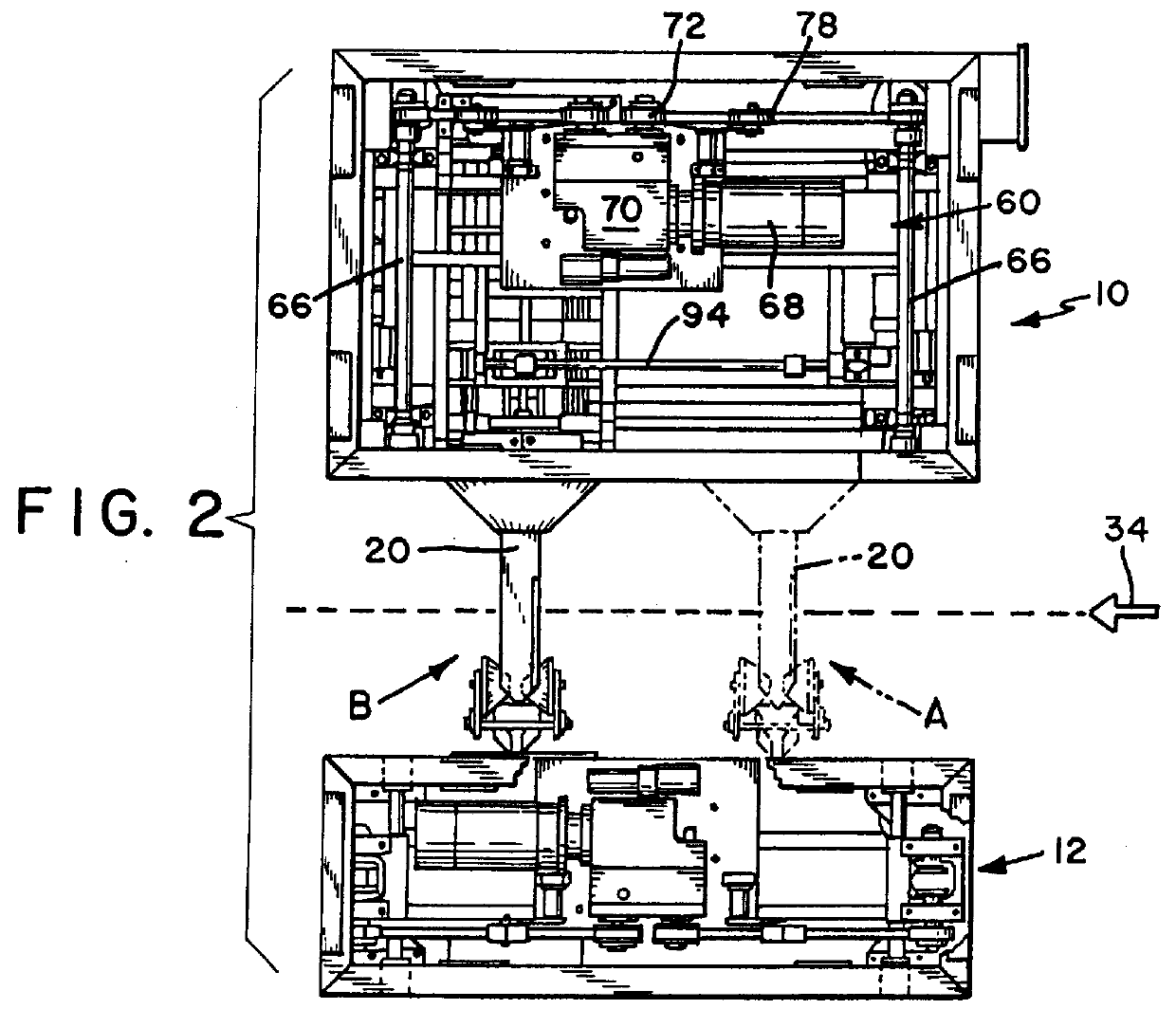

An automated saw for high speed splitting of suspended carcasses, such as hog carcasses, through the backbone as the carcasses continuously move along a carcass rail includes a splitting station and a back roller station located on opposite sides of the carcass rail. The splitting station includes a splitting saw that can be driven in three directions, including horizontally towards a carcass to begin cutting, vertically down to make the cut and horizontally parallel to the carcass rail to match the speed of the moving carcass as the cut is made. A guide roller carried by the splitting station positions the backbone in a known position relative to the saw. The back roller station includes a back roller for positioning the carcass relative to the saw as the cut is made. The back roller is also movable in three directions, including horizontally in to contact the carcass, vertically down, and horizontally parallel to the carcass rail to match the motion of the saw. The back roller and saw are structurally independent, but are accurately driven to maintain the relative position of the saw and the back roller as the cut is made.

Owner:JARVIS PROD

Cutting device and method for bird leg and removing bone

A cutting apparatus for removing bone from the leg of fowls is composed of indexing mechanism with horse-type slotted wheel, rotary bench, feeder, spine cutter, leg meat cutter, skin removing unit, leg meat splitter, bone separating and releasing unit power system, drive system and signal executing unit. Its method is also disclosed.

Owner:郁天永

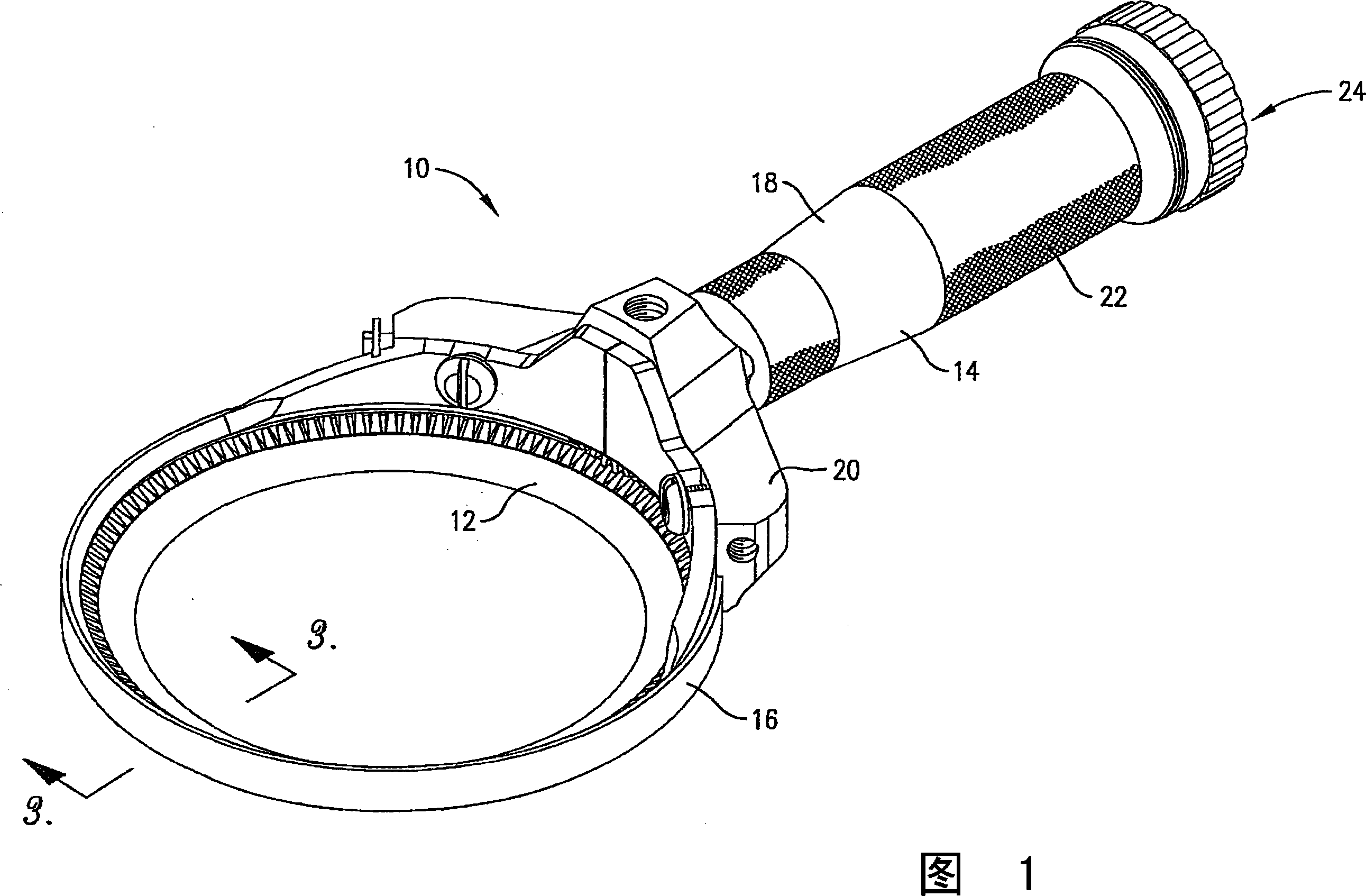

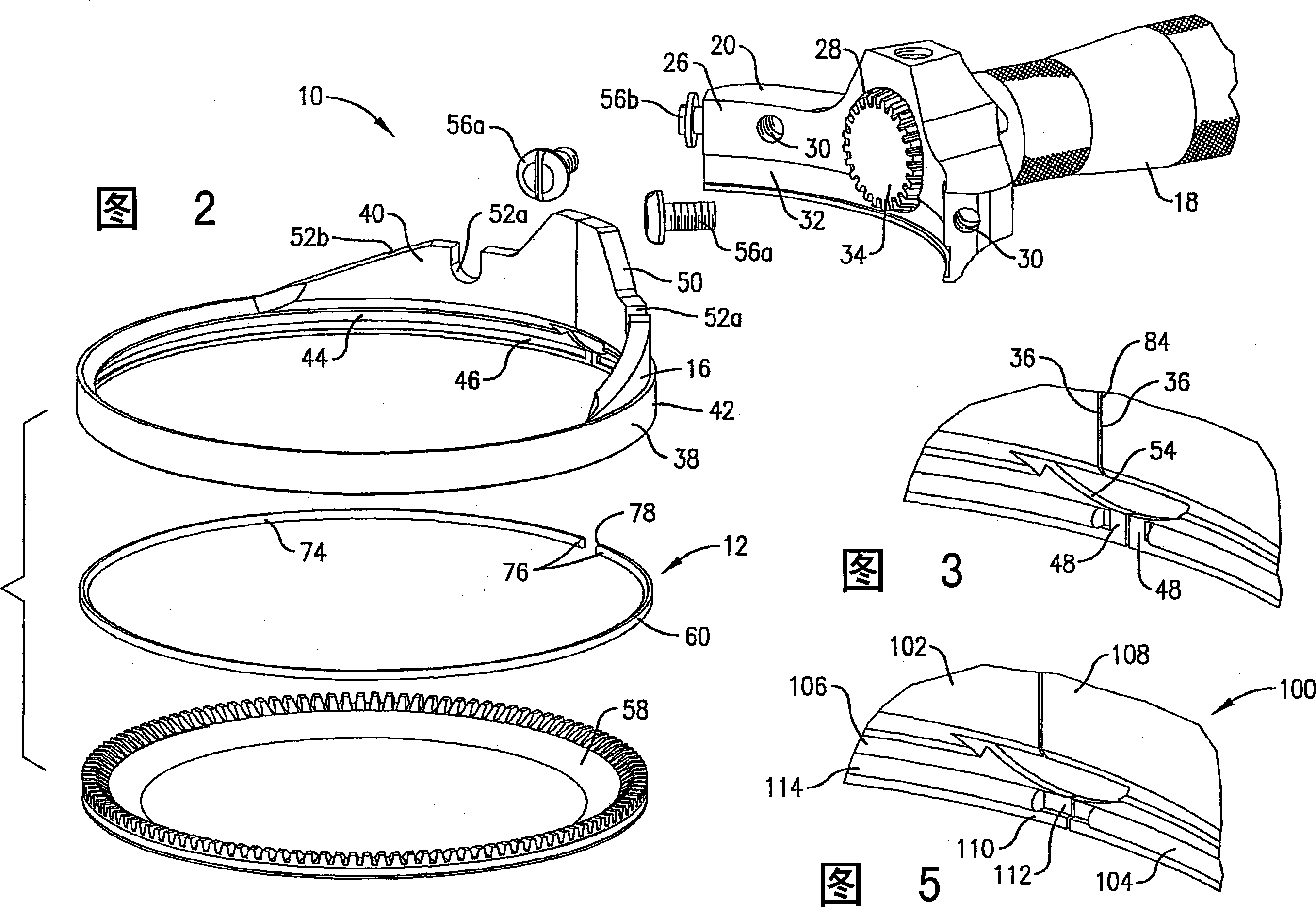

Rotary knife with blade bushing

Owner:HANTOVER

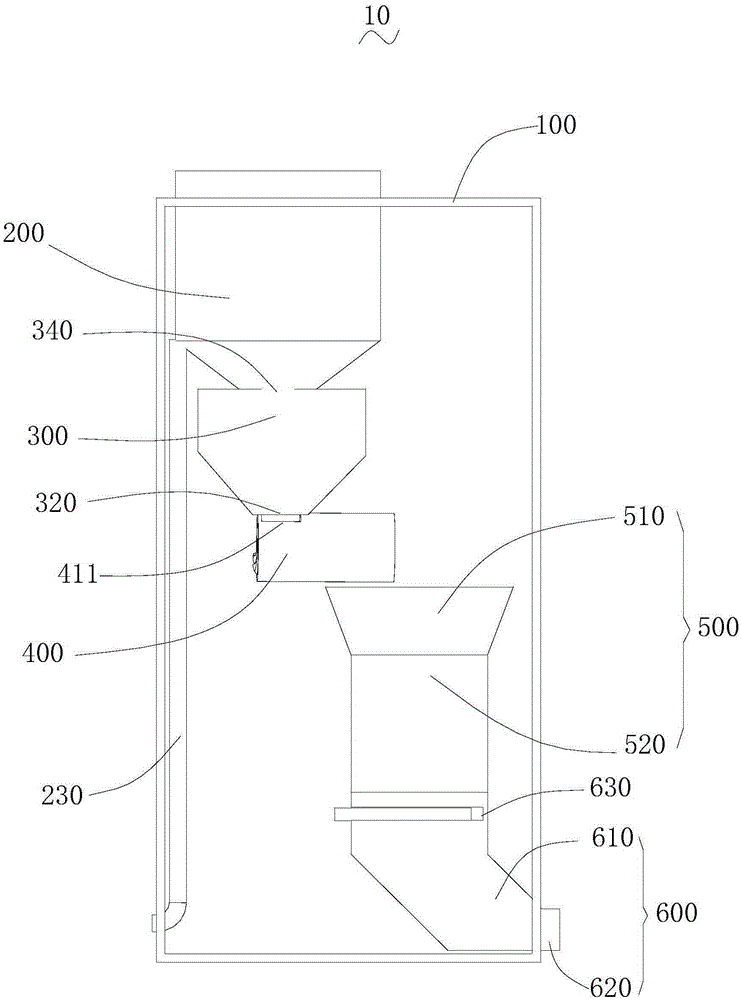

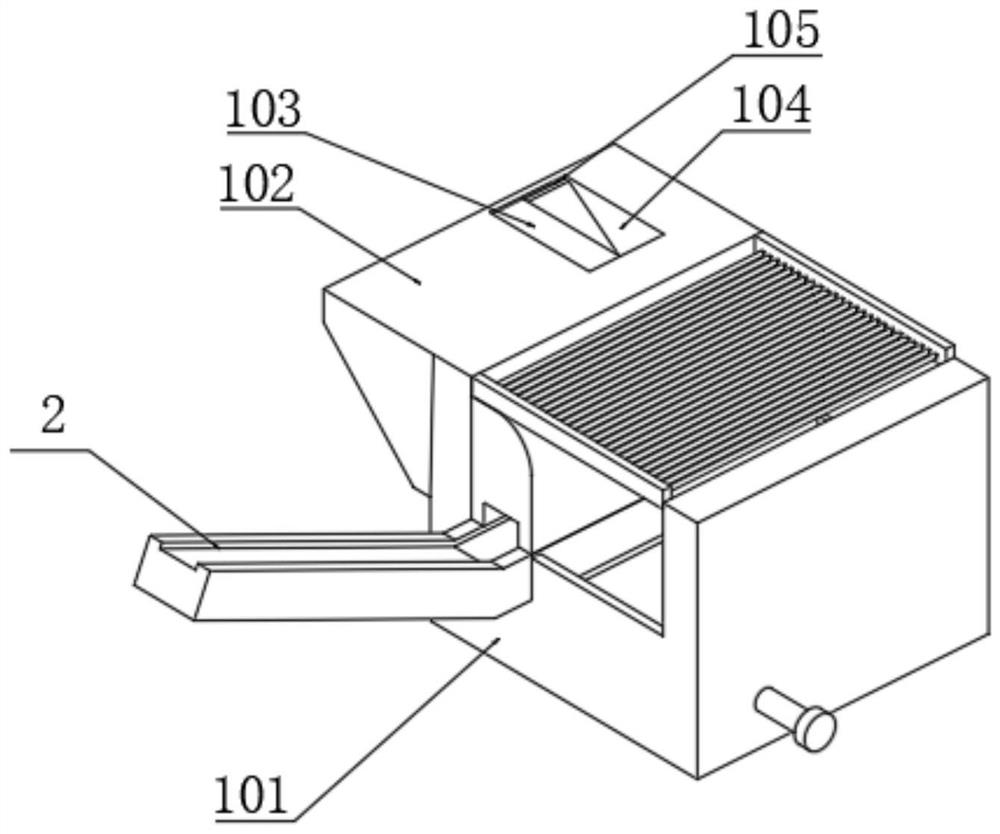

Bone crushing and screening equipment for pet dog feed production

InactiveCN112973858ARealize the rotation effectAchieve cutting effectSievingScreeningEngineeringFodder

The invention relates to crushing and screening equipment, in particular to bone crushing and screening equipment for pet dog feed production. The bone crushing and screening equipment for pet dog feed production is provided, wherein the bone crushing and screening equipment achieves automatic crushing and automatic screening and is simple in use. Th bone crushing and screening equipment for pet dog feed production comprises a supporting frame, a rotating mechanism, crushing shafts, a cutting mechanism, a discharging mechanism and a screening mechanism. The rotating mechanism is arranged on the supporting frame. The two crushing shafts are arranged on the rotating mechanism. The cutting mechanism is arranged on the rotating mechanism. The discharging mechanism is arranged on the rotating mechanism. The screening mechanism is arranged between the supporting frame and the discharging mechanism. By arranging the rotating mechanism, the rotating mechanism operates to drive the crushing shafts to operate so that bones can be crushed, and the rotating effect is achieved.

Owner:江西龙威宠物食品有限公司

Automated saw for splitting carcasses

An automated saw for high speed splitting of suspended carcasses, such as hog carcasses, through the backbone as the carcasses continuously move along a carcass rail includes a splitting station and a back roller station located on opposite sides of the carcass rail. The splitting station includes a splitting saw that can be driven in three directions, including horizontally towards a carcass to begin cutting, vertically down to make the cut and horizontally parallel to the carcass rail to match the speed of the moving carcass as the cut is made. A guide roller carried by the splitting station positions the backbone in a known position relative to the saw. The back roller station includes a back roller for positioning the carcass relative to the saw as the cut is made. The back roller is also movable in three directions, including horizontally in to contact the carcass, vertically down, and horizontally parallel to the carcass rail to match the motion of the saw. The back roller and saw are structurally independent, but are accurately driven to maintain the relative position of the saw and the back roller as the cut is made.

Owner:JARVIS PROD

Flexible drive shaft casing for power operated rotary knife

InactiveCN1951201AEasy to assembleReduce movementBone cleaning devicesBone-shears/bone-crushersDrive shaftCoupling

A flexible shaft drive transmission for a power driven tool. The transmission features a first end connectable to a drive motor and a second end connectable to the power driven tool. The transmission includes a flexible drive shaft assembly comprising a flexible elongated drive transmitting member, a first end of the drive transmitting member including a first coupling operatively coupled to the drive motor and a second end of the drive transmitting member including a second coupling operatively coupled to the power driven tool. The transmission further includes a tubular casing surrounding and coaxial with said drive shaft assembly and supporting said drive shaft assembly for rotation generally about a longitudinal axis of said drive shaft assembly relative to said casing. The casing includes a core comprising a spiral wound strip of material having interlocking opposing edges, a braided wire layer surrounding the core, and a polymer layer surrounding the braided wire layer.

Owner:BETTCHER INDUSTRIES

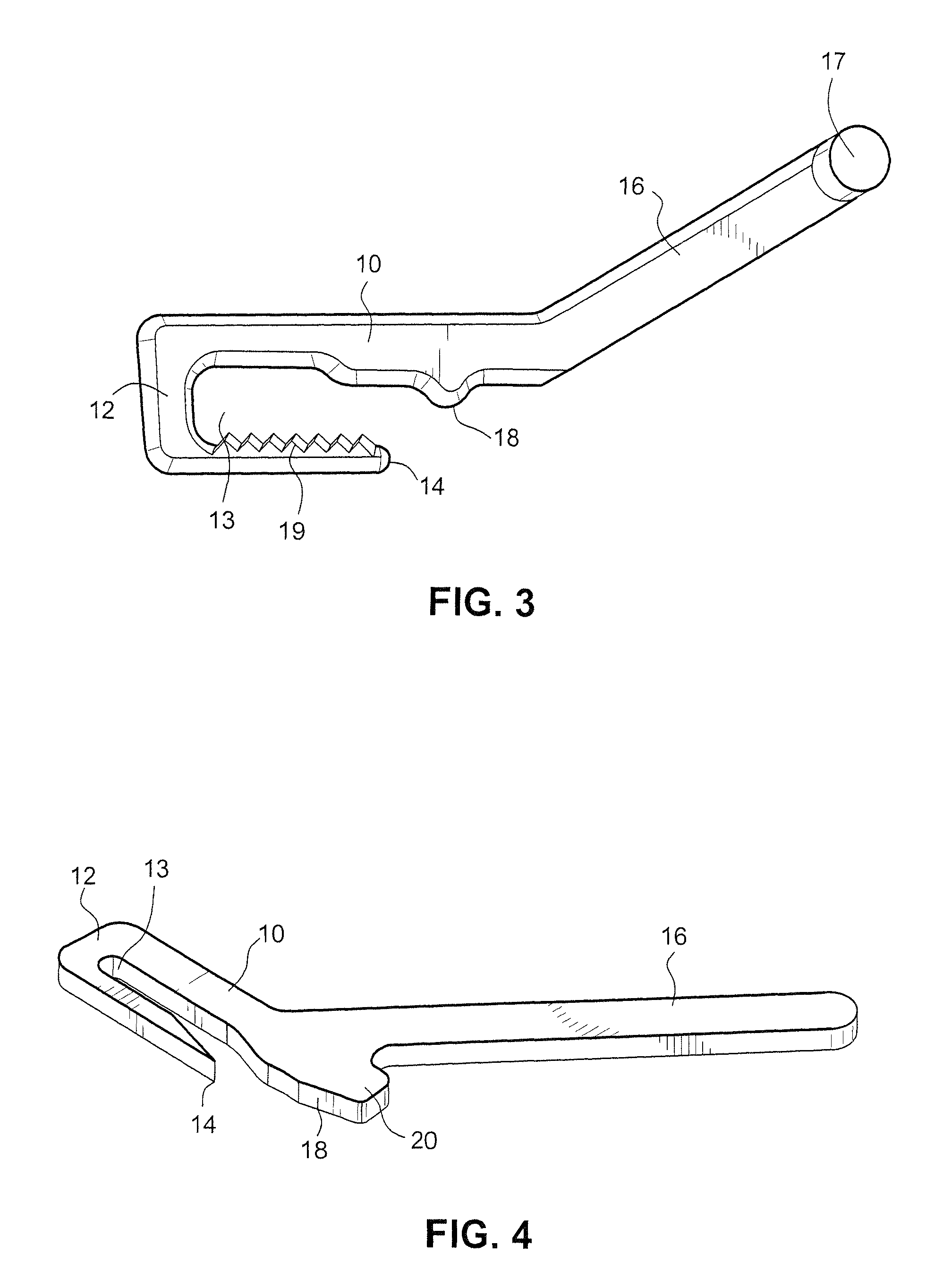

Bone splitting and breaking tool

InactiveUS8235775B1Bone-shears/bone-crushersSplitting instrumentsBiomedical engineeringMetatarsal head

A bone breaking or crushing tool for use by a hunter is designed to break the pelvic bone of a game animal. The bone breaking tool includes a U-shaped body having first and second arms joined by a front end. A handle projects at an angle from an outer side of a first arm of the U-shaped main body. A projection is formed on an inner side of the first arm of the U-shaped main body. The bone breaking tool is configured so that the first and second arms of the U-shaped main body can be slid around either side of a portion of the pelvic bone of a game animal. A hunter can then apply a force to an end of the handle to drive the projection on the inner side of the first arm into the pelvic bone to break or crush the pelvic bone.

Owner:MOY YUEY S

Bionic grinding tooth bone crushing roller

InactiveCN106720146AImprove versatilitySolve operational problemsBone-shears/bone-crushersEngineeringGRINDING TOOTH

The invention discloses a bionic grinding tooth bone crushing roller. The bionic grinding tooth bone breaking roller comprises a first crushing roller and a second crushing roller which are parallelly arranged in a machine frame in the horizontal direction, two ends of the first crushing roller and two ends of the second crushing roller are respectively and rotatably fixed to two ends of the machine frame, and the first crushing roller and the second crushing roller separately rotate clockwise and counter-clockwise under the driving of a driving mechanism; and grinding tooth blades are respectively arranged on the outer wall of the first crushing roller and the outer wall of the second crushing roller. The first crushing roller and the second crushing roller mutually rotate oppositely, and the grinding tooth blades of the first crushing roller are in meshing connection with the grinding tooth blades of the second crushing roller. According to the bionic grinding tooth bone crushing roller disclosed by the invention, grinding tooth blade groups in opposite rotation are arranged, so that the problems that through the adoption of a conventional bone crushing machine, bones are wasted and the bones slide, are solved. The bionic grinding tooth bone crushing roller disclosed by the invention is simple to operate, and low in maintenance ratio, and is suitable for grinding tooth crushing of various raw material bones.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Grinding head of conical bone cement machine

InactiveCN101530118AStable and efficient workAdjustable spacingBone-shears/bone-crushersCrusherBone cement

The invention relates to a crushing device adopting a cone crusher, in particular relates to a grinding head of a crusher with coaxial movement. The grinding head of the conical bone cement machine comprises an internal conical surface and an external conical surface; and raised blades are uniformly arranged at interval at the internal conical surface and the external conical surface. The grinding head has simple structure, convenient use, energy conservation, high crushing fineness, long service life, high production efficiency, no pollution to the bone cement product, stable quality of product and good mouth feeling when in eating.

Owner:青岛市城阳区海天水产加工厂

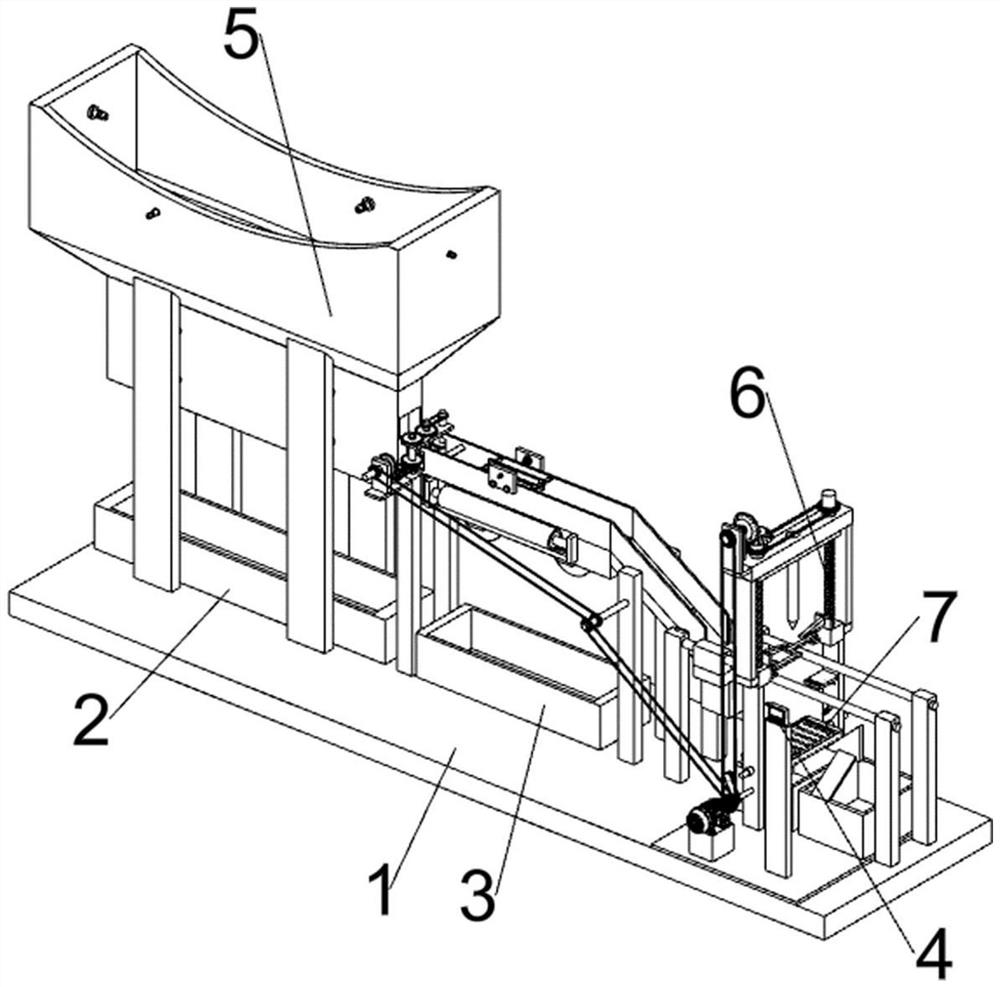

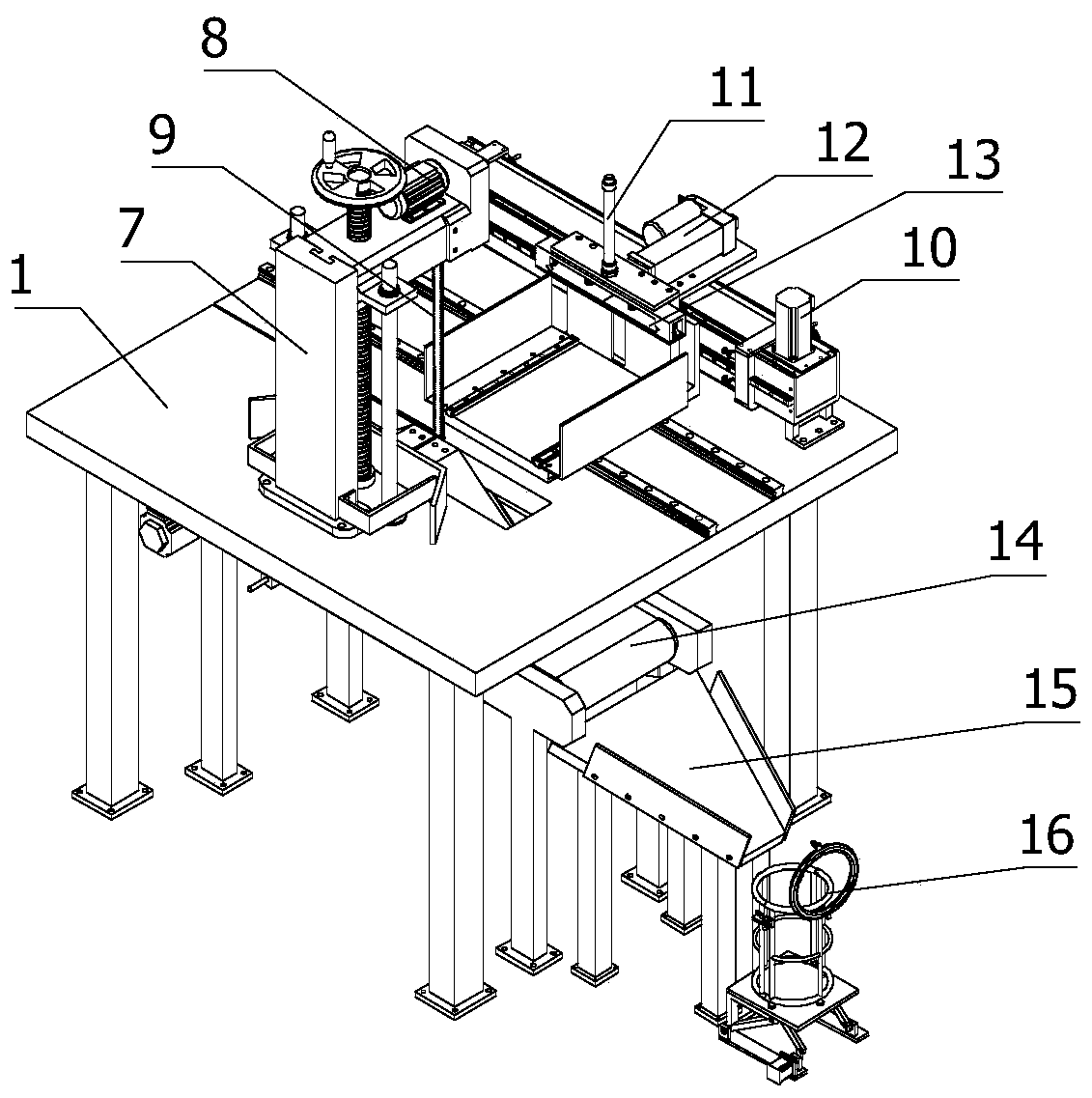

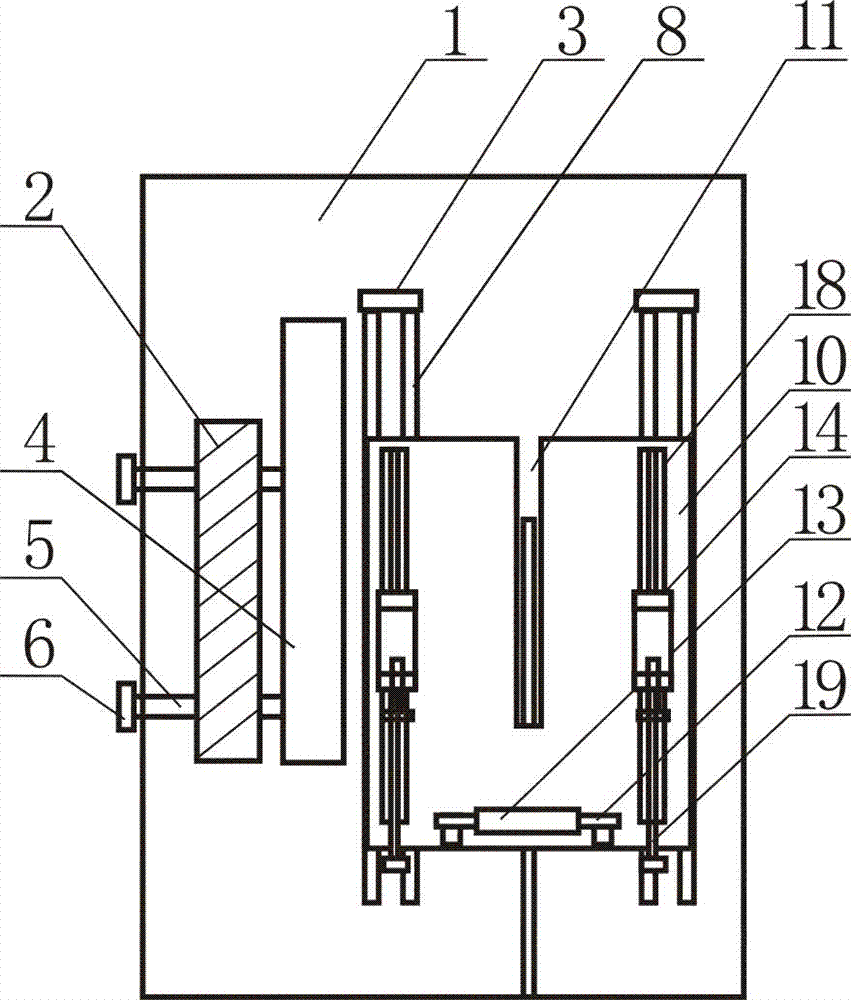

Frozen pork rib nondestructive cutting method and device

ActiveCN109042812AIncrease frictionAvoid looseBone-shears/bone-crushersEngineeringHigh pressure water

The invention relates to the field of preparation of frozen pork ribs, in particular to a frozen pork rib nondestructive cutting method and device. The frozen pork rib nondestructive cutting device comprises a worktable, a left side positioning apparatus, a right side positioning apparatus, a separation apparatus, a cross driving mechanism and a high-pressure water cutter, wherein the cross driving mechanism is arranged above the worktable, the high-pressure water cutter is connected to the output end of the cross driving mechanism, the top of the worktable is provided with a feeding assembly,the top of the feeding assembly is provided with a separation guide member, the left side positioning apparatus and the right side positioning apparatus are symmetrically installed on the top of theseparation guide member, the separation apparatus is arranged on the same end of the left side and right side positioning apparatuses, the side of the right side positioning apparatus is provided witha strutting apparatus, a foot stepping feeding apparatus is arranged below the worktable, and the foot stepping feeding apparatus is connected with the left side positioning apparatus in a transmission manner. By adopting the high-pressure water cutter, the influence of a vibrating force for pork ribs can be prevented, and the cutting stability and the completeness of the pork ribs after being cut can be further improved.

Owner:FUJIAN YAMING FOOD

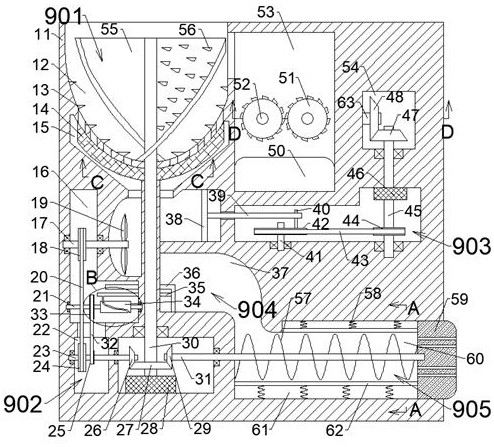

Pork processing byproduct treatment device

InactiveCN111990442AEfficient separation treatmentSievingBone cleaning devicesBiotechnologyPork meat

The invention relates to the field of pork, in particular to a pork processing byproduct treatment device. The technical aim of the invention is to provide the pork processing byproduct treatment device. According to the technical scheme, the pork processing byproduct treatment device comprises an operation control screen, a sorting mechanism, a bone marrow extraction mechanism, a screening mechanism and the like, wherein the upper part of a working main bottom plate is sequentially connected with a first collecting basket and a second collecting basket; and the operation control screen is arranged above the working main bottom plate. The device achieves the effects that byproducts after pork processing in a pork processing plant are efficiently separated and treated, internal bones are separated, and residual minced meat on the surfaces of the bones is scraped and separated in an automatic conveying process; and the bones are automatically and vertically fixed through automatic operation, bone marrow parts in the bones are extracted and separated, and meanwhile, during bone marrow extraction, broken bones mixed in the bone marrow are separated to obtain available bone marrow.

Owner:湘潭百嘉香食品贸易有限公司

Bone crusher

The invention relates to a bone crusher. The bone crusher comprises a roasting mechanism, a crushing mechanism, a grinding mechanism, and a discharging mechanism; a roasting chamber is arranged in the roasting mechanism, and the roasting chamber is provided with a roasting inlet and a roasting outlet; the crushing mechanism comprises an outer cylinder and an inner roller; the outer cylinder and the inner roller are arranged to be coaxial, the inner roller is arranged in the outer cylinder, the inner roller and the outer cylinder rotate in opposite directions, the outer surface of the inner roller is provided with a first crushing tooth, the inner surface of the outer cylinder is provided with a second crushing tooth, a crushing channel is formed between the inner roller and the outer cylinder, and one end of the crushing channel is communicated with the roasting outlet; the grinding mechanism is connected with the other end of the crushing channel far away from the roasting outlet; the discharging mechanism is arranged on the bottom of the grinding mechanism, the discharging mechanism comprises a discharging channel, and one end of the discharging channel is connected with the grinding mechanism; the inner diameter of the outer cylinder reduces from the end close to the roasting outlet to the other end gradually. The bone crusher is used for crushing and grinding animal bone, and smashing bone into powder, so that nutrients in bone can be absorbed by plant easily, and offensive odor caused by decaying of bone in long time storing is avoided.

Owner:绍兴熔岩机械有限公司

Pig fan rib cutting equipment

ActiveCN111543465AConsistent widthReduce security risksMeat holding apparatusMeat packaging/handling/transportingStructural engineeringMechanical engineering

The invention relates to the field of food processing, in particular to pig fan rib cutting equipment. The pig fan rib cutting equipment comprises a working platform, a cutting assembly, a clamping and pushing assembly and a collecting assembly. A discharging through groove is formed in the working platform in a penetrating mode. Two groups of inclined discharging plates are symmetrically arrangedon the discharging through groove. The cutting assembly comprises a lifting tensioning mechanism, a cutting driving mechanism and a double-sided saw blade. The clamping and pushing assembly comprisesa horizontal displacement mechanism, a clamping mechanism and a cutting and pushing mechanism. The clamping mechanism comprises a clamping plate capable of clamping a bone. The collecting mechanism comprises a conveying belt, a triangular discharging frame and a packing machine. According to the pig fan rib cutting equipment disclosed by the invention, the widths of cut and formed pig fan ribs can be consistent, potential safety hazards are reduced, the pig fan ribs can be subjected to double-face cutting in the back-and-forth movement process of the output end of the horizontal displacementmechanism through the double-face saw blade, the cut pig fan ribs are collected and packaged through the collecting assembly, the labor intensity of workers is further reduced, and the working efficiency is improved.

Owner:福建易太食品发展有限公司

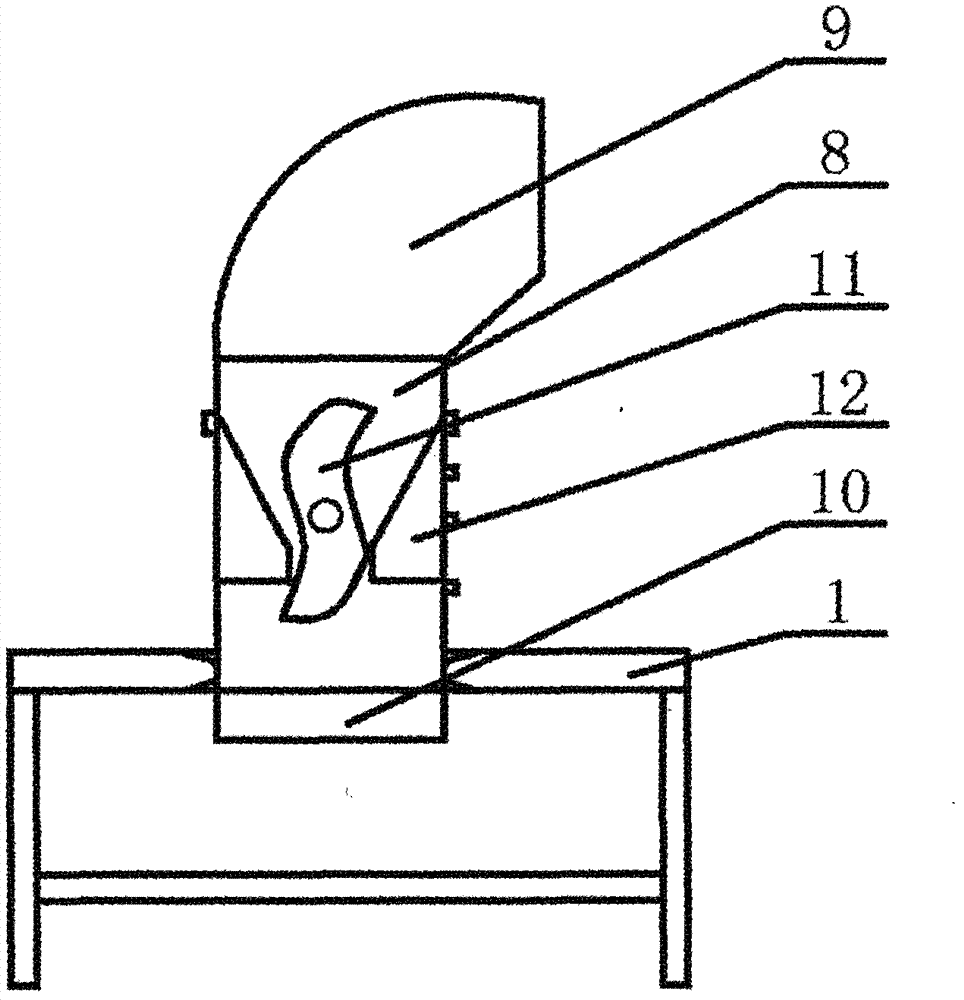

Shank cutting device for live pigs

The invention discloses a shank cutting device for live pigs. The shank cutting device comprises an oil damper, a fixing frame, a cutting disk, a connecting shaft, a power device, a fixed cross beam, pulley supports, pulleys and a holding device, wherein the holding device comprises a holding box, cutting holes, support frames, and a holding opening; the oil damper is fixedly connected to the lower end of the upper part of the fixing frame; the cutting disk is arranged at the lower end of the oil damper; the power device is movably connected with the fixing frame through the connecting shaft; the fixed cross beam is arranged at the lower part of the power device; the holding box is arranged at the upper part of the holding device; the cutting holes are formed in the upper surface of the holding box; the holding opening is formed in the front side of the holding box; the upper end of the support frame is connected to the upper surface of the holding box; the lower end of the support frame is fixedly connected to the upper part of the fixed cross beam; the pulleys are fixedly connected to the lower end of the fixing frame through the pulley supports. The shank cutting device for live pigs is simple in structure, convenient to use and high in cutting efficiency.

Owner:CHONGQING MINGGAO FOOD CO LTD

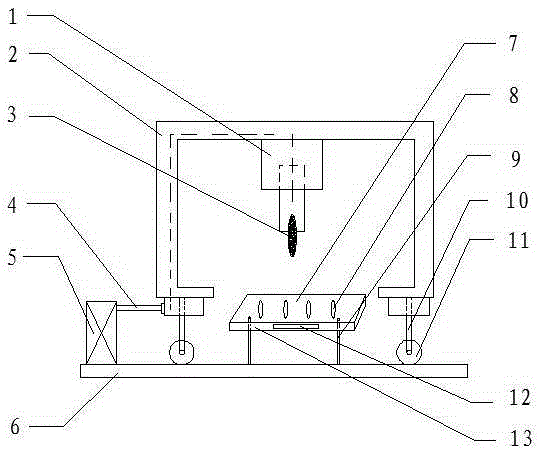

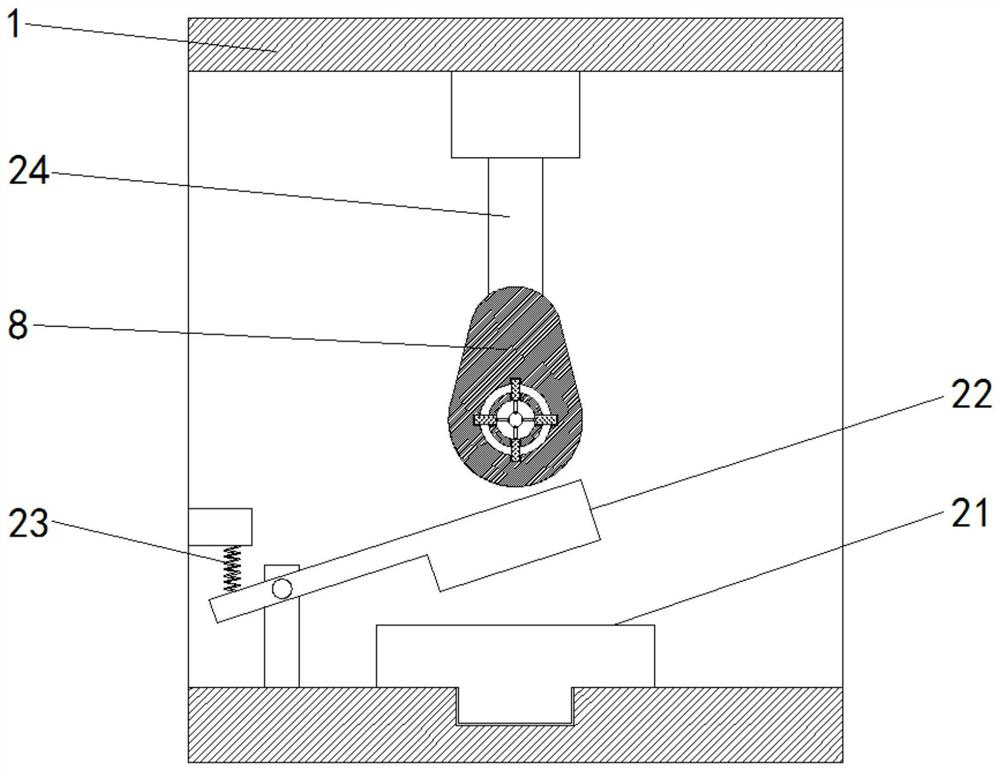

Bone-meat separation fine minced meat processing device

InactiveCN112056364AAvoid cloggingRealize the effect of automatic dredgingBone-shears/bone-crushersMeat shaping/cuttingLean meatMechanical engineering

The invention discloses a bone-meat separation fine minced meat processing device. The bone-meat separation fine minced meat processing device comprises a box body, and a transmission cavity is formedin the box body; lean meat on ribs is separated from the ribs through spurs on a spiral plate according to theoretical knowledge of centrifugal force, and the separated lean meat is subjected to primary extrusion to realize first-step fragmentation; by means of an arc-shaped scraping fan at the lower end of an ellipsoidal plate, lean meat on the ellipsoidal plate is scraped off to prevent blockage, meanwhile, the lean meat is guided to smoothly fall down from a middle leaking groove, and the effect of pushing the lean meat to the upper face of a fan knife is achieved through a gear connectingrod structure; and springs are additionally arranged on the periphery of a barrel at the lower end, so that the refined lean meat is prevented from blocking a meat outlet hole, and the automatic dredging effect is achieved.

Owner:厦门儒也斯水晶有限公司

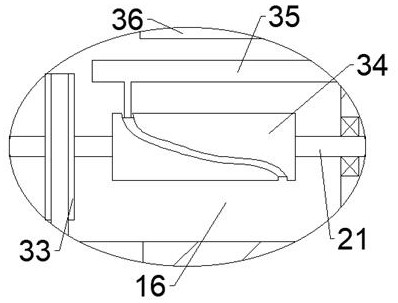

Method of separating meat of a poultry with bones and apparatus for use in such method

Owner:MAYEKAWA MFG CO LTD

Waste collecting device for meat cutting processing

InactiveCN113695354AReduce speedPrevent spoilageSievingBlood collection/stirring apparatusAgricultural scienceWaste collection

The invention relates to the technical field of meat waste collection, in particular to a waste collecting device for meat cutting processing. The device comprises a feeding assembly. The feeding assembly comprises a feeding cabinet, the feeding assembly is fixedly connected with a conveyor, the side, far away from the feeding assembly, of the conveyor is fixedly connected with a crushing assembly, and the output end of the crushing assembly is fixedly connected with a screening assembly. According to the waste collecting device, cut bones can be fed through the feeding assembly, and then the cut bones are conveyed through the conveyor; and a first rotating rod can be driven to rotate through a second motor, bone materials from a feeding box are crushed, the crushed bone materials are conveyed into a screening groove to be screened, small-particle broken residues can fall on a storage plate on the lower side to be collected, large-particle broken residues are conveyed in a vibrating mode, the air drying operation is accelerated through fans to prevent the bone materials against deterioration, the bone materials are bagged and collected through the output end, and the bone materials are used as feed and other things to be subjected to secondary utilization.

Owner:重庆德佳肉类科技发展有限公司

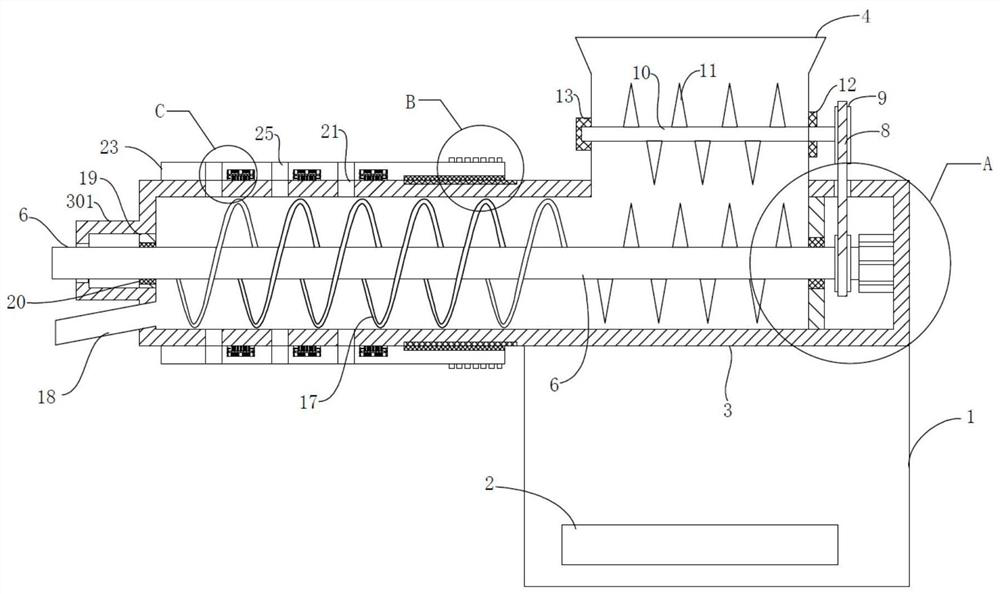

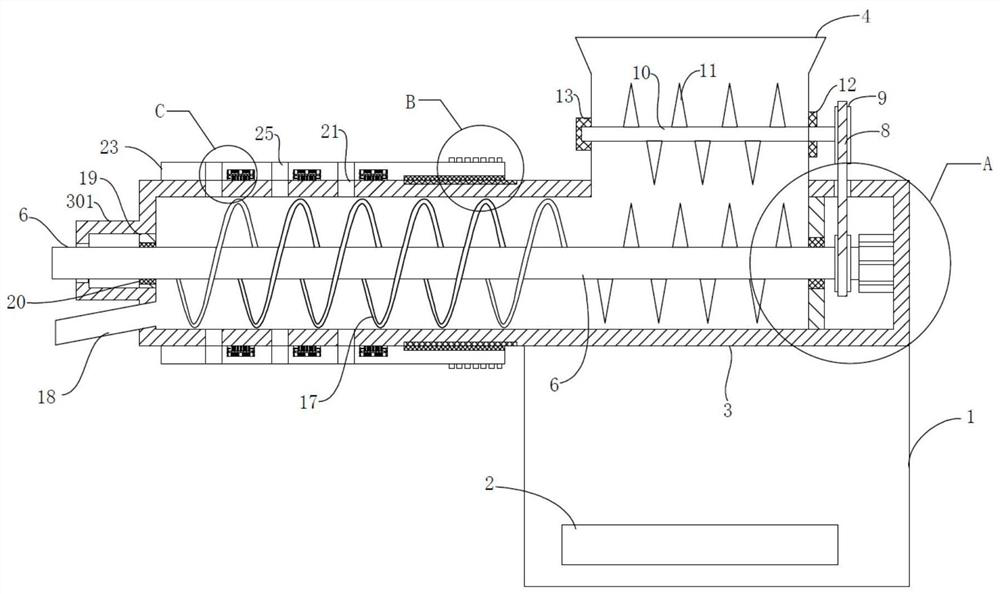

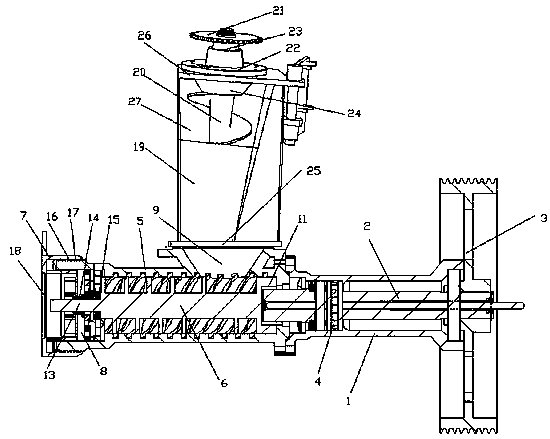

Bone crushing machine

InactiveCN105285049AExtended service lifeControl Size UniformityBone-shears/bone-crushersDrive shaftElectric machinery

The present invention provides a bone crushing machine which is durable and has a good bone crushing effect. The bone crushing machine includes a body rack, a working chamber arranged in the body rack, a material inlet arranged at one end of the working chamber and a material outlet arranged at the other end of the working chamber. An electric motor and a screw blade set driven by a transmission shaft are arranged within the working chamber, a filtering net is arranged at the material outlet, and the density of the screw blade set is gradually increased from the material inlet to the material outlet. The provided bone crushing machine can control the size uniformity of bone particles and ensure bone crushing effect by arranging the filtering net in the material outlet and controlling the sizes of via holes of the filtering net. The density of the screw blade set is gradually increased from the material inlet to the material outlet, which can enable the bones to be cut and crushed gradually within the working chamber and improve the bone crushing effects, and at the same time slow the impacts on the transmission shaft and extend the use life of the bone crushing machine.

Owner:李培生

Continuous shank bone marrow taking production process

ActiveCN110124846ANo meltingNon stickyBone-shears/bone-crushersWet separationCrusherBiomedical engineering

The invention relates to a continuous shank bone marrow taking production process. Bone marrow powder is a common health food, in a plurality of brands, the Jinnuo three marrow powder is uniquely identified in the industry by using a special bone marrow and bone marrow extraction technology, at present, bovine bone marrow acquisition basically depends on manual work, the efficiency is low, the labor is large, and the increasing yield cannot be met. The continuous shank bone marrow taking production process mainly comprises the following steps of quick freezing, crushing, vibration separating and buoyancy separating, mainly equipment used by the process involves a belt type instant freezer, a hammer crusher, a rolling machine and the like, the equipment can easily connect into an automaticproduction line, large-scale production can be realized, the bone marrow extraction rate is increased, and meanwhile, small-particle bone substance required by production of bone meal can be obtainedwhile the bone marrow is obtained.

Owner:JIANGSU NUOPULE BIOTECH CO LTD

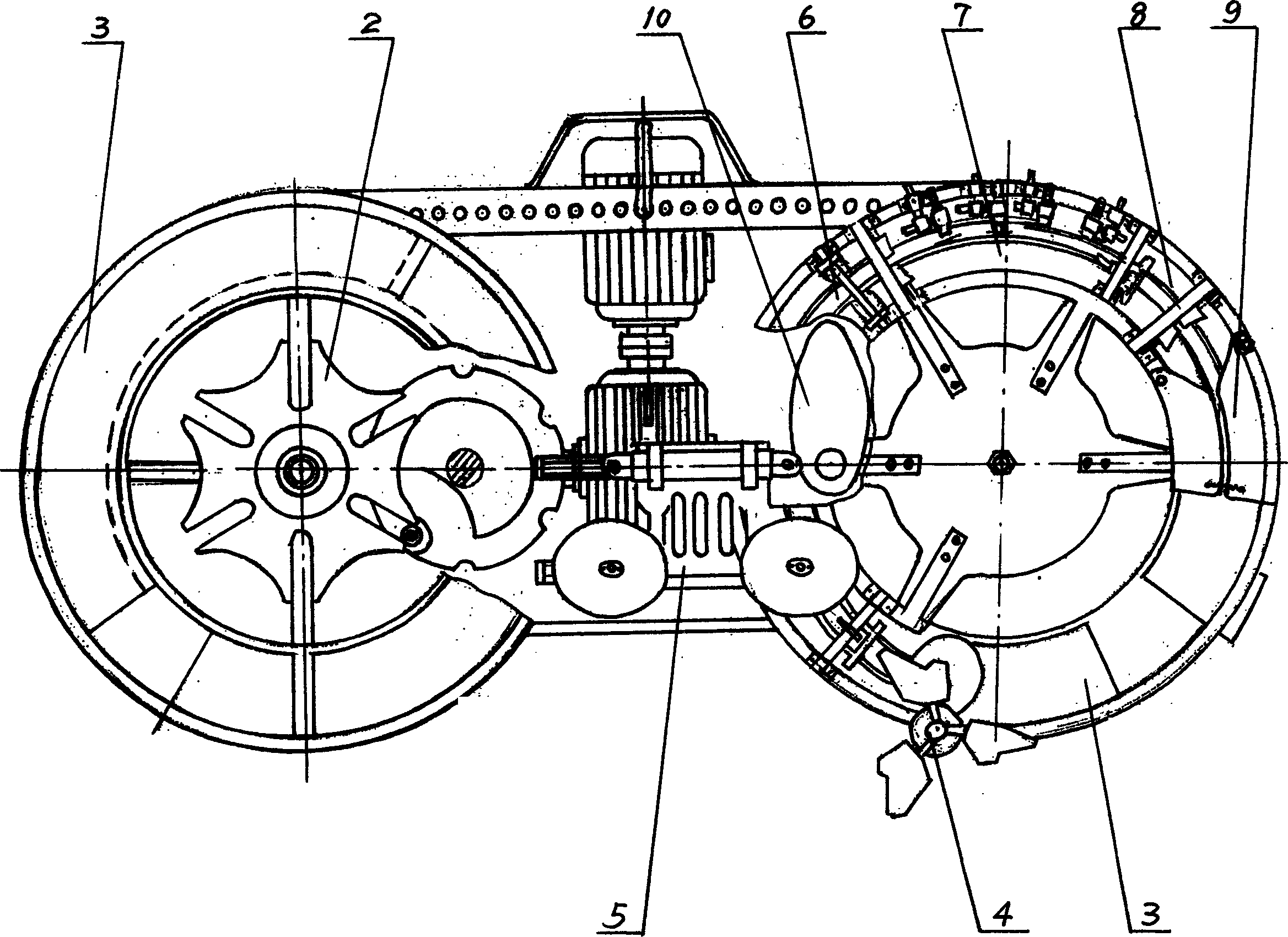

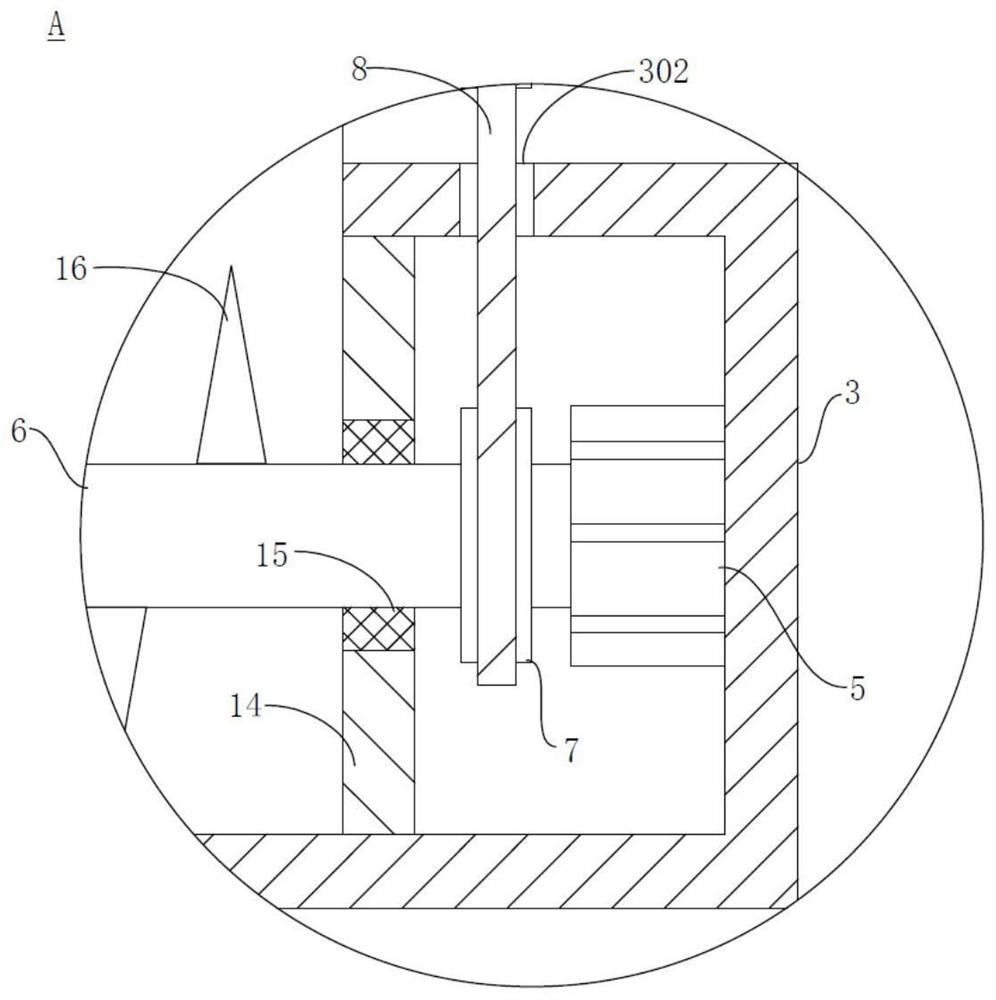

Skeleton breaking machine

InactiveCN103583662AConvenient fixed cutUniform sizeBone-shears/bone-crushersEngineeringRight trapezoid

The invention provides a skeleton breaking machine, comprising a rack, a motor, a belt and the like. The skeleton breaking machine is characterized in that two sets of fixed cutters are arranged in a machine shell and are fixed on two opposite sidewalls of the machine shell respectively. The fixed cutters are alternatively arranged with moving cutters which are spirally arranged on a main shaft. The moving cutters are in an axis symmetric structure. A feeding angle alpha is 10-45 degrees, and the fixed cutters are in a right trapezoid structure. A feeding angle beta is 20-70 degrees, and both the moving cutters and the fixed cutters have a certain feeding angle so as to facilitate fixed cutting of various livestock skeletons. The moving cutters and the fixed cutters have appropriate thickness and gaps, and cut materials are uniform in size, and have no fine particles, and solid and liquid in a subsequent stewing process are guaranteed to be separated easily. Each moving cutter is engaged with the fixed cutters in sequence, so that cutting efficiency and cutting continuity are guaranteed, the defects of large cutting power consumption and large vibration and shock are prevented; and working efficiency is improved while energy consumption is reduced.

Owner:曹瑞涛 +1

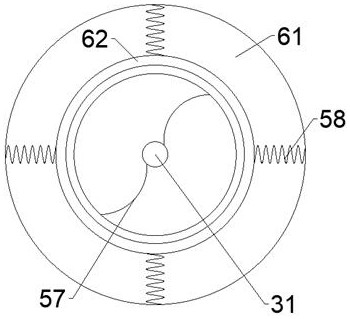

Separators for flesh and bone separation

ActiveCN111642547BAvoid wastingImprove separation rateBone-shears/bone-crushersRotational axisDrive shaft

The invention discloses a separator for bone and meat separation, which comprises a base box, a separation cylinder is fixedly arranged above the base box, and a transmission shaft extends into a feeding trough on which a plurality of first separating cylinders are fixedly arranged. Knives; a section of the rotating shaft close to the feed tank is fixedly provided with a plurality of second separating knives, and other sections of the rotating shaft are fixedly provided with screw auger blades; the separating cylinder is provided with a plurality of inner leakage holes, A plurality of leak holes and grooves are opened on the outer drum, guide rails are arranged in the grooves, slide plates are movable between the guide rails, and the slide plates are connected with the bottom wall of the groove. There is a spring, and a brush is fixedly arranged on the side of the slide plate away from the spring. The invention provides a separator for bone and meat separation, which can regulate and limit the size of the separated meat particles, and can also clean the internal leakage hole after use, clean and odorless, simple in operation, and simple in structure. Well worth promoting.

Owner:BENGBU COLLEGE

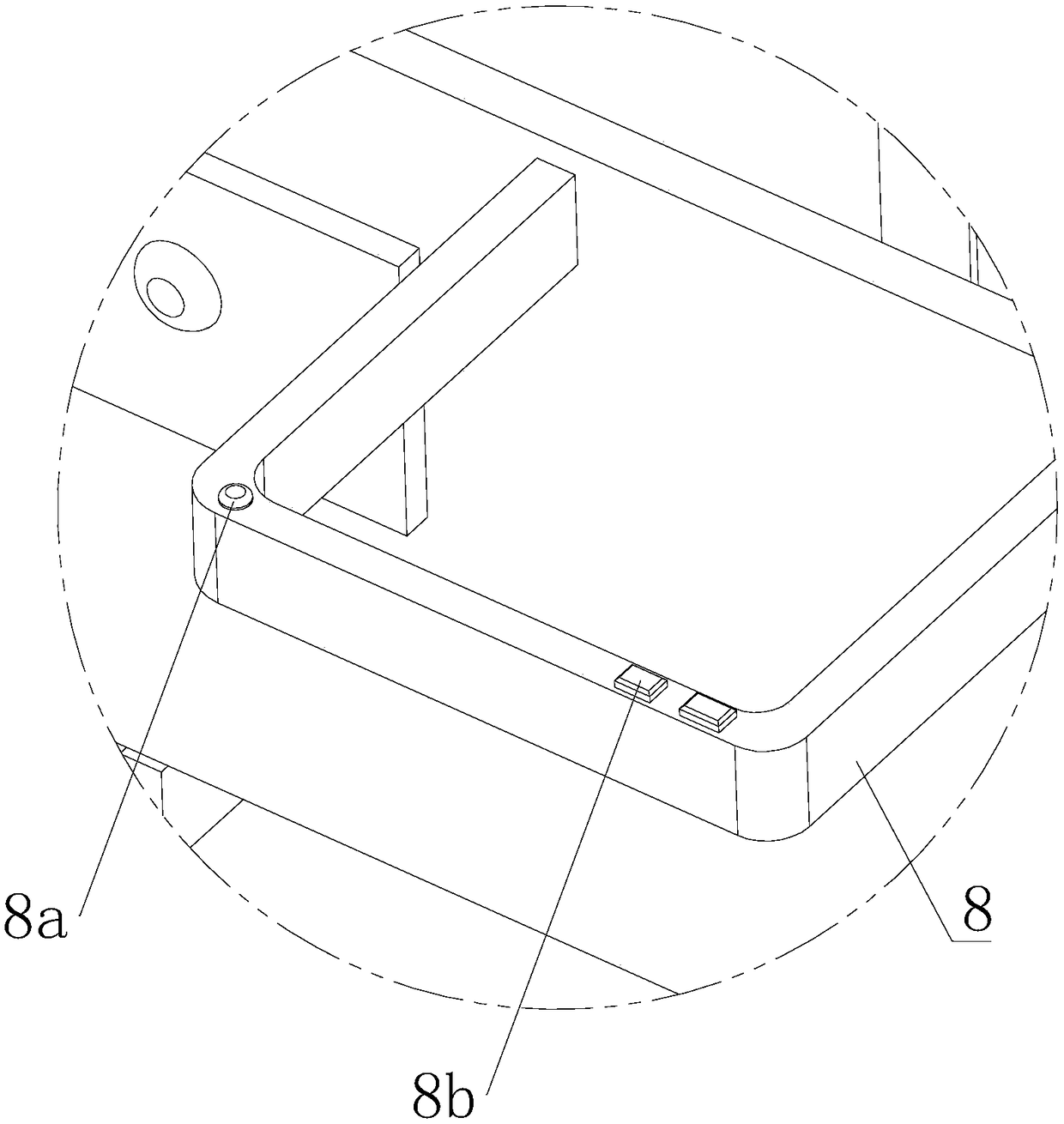

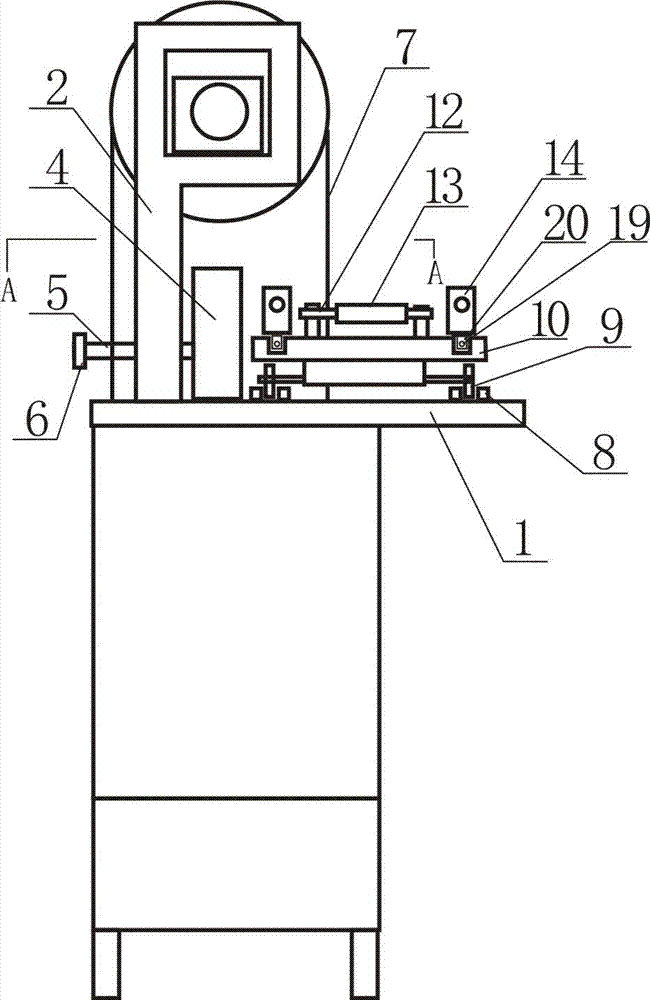

Sliding-plate charging-type bone sawing machine provided with adjustable clamps

InactiveCN104757088AReduce laborSimple and fast operationMeat holding apparatusBone-shears/bone-crushersPush pullEngineering

The invention discloses a sliding-plate charging-type bone sawing machine provided with adjustable clamps. The sliding-plate charging-type bone sawing machine comprises a workbench, a machine rack, a saw blade, a guide rail, and a charging sliding plate; the guide rail is arranged on the workbench; the charging sliding plate is arranged on the guide rail via pulleys arranged on the bottom of the charging sliding plate; the plate surface of the charging sliding plate is provided with a through groove, and the through groove is penetrated by the saw blade; the two sides of the charging sliding plate is provided with sliding grooves; adjustment screws are arranged in the sliding grooves; the parts of the adjustment screws in the sliding grooves are provided with sliding blocks; and each sliding block is provided with a bone material clamp which is capable of realizing horizontal rotating relative to the sliding blocks via hinge joint. The sliding-plate charging-type bone sawing machine is provided with the sliding plate and a push pull knob, so that labor of operators is reduced greatly, and operation is extremely simple; operators are kept far away from the saw blade, so that the sliding-plate charging-type bone sawing machine is safer and more reliable; the sliding-plate charging-type bone sawing machine is provided with the bone material clamps, so that cutting safety is improved; the bone material clamps are arranged on the sliding blocks, and are capable of realizing horizontal rotating relative to the sliding blocks, so that relative position of the bone material clamps arranged on the two sides of the sliding-plate charging-type bone sawing machine can be adjusted, and bone materials with different shape can be clamped.

Owner:广东宏益鳄鱼产业有限公司

Smart home meat chopping equipment suitable for pure meat and meat with bones

The invention relates to the technical field of smart home, and discloses smart home meat chopping equipment suitable for pure meat and meat with bones. The smart home meat chopping equipment comprises a rack, a supporting rod is inserted into the top of the rack, an ejector rod is slidably connected into the supporting rod, a buffer spring sleeves the outer side of the ejector rod, a sliding rodis slidably connected to the inner bottom of the rack, the bottom of the sliding rod is fixedly connected with a supporting spring, and the left side of the sliding rod is movably connected with a pawl. According to the smart home meat chopping equipment suitable for pure meat and meat with bones, a driving shaft rotates to drive a worm gear to rotate, the worm gear drives a worm to rotate, the worm drives a ratchet wheel to rotate, the ratchet wheel drives a swing rod to swing, the swing rod drives a bottom plate to move, meanwhile, the driving shaft rotates to drive a clamping block to rotate, and the clamping block drives a cam to rotate, the cam drives a chopping knife to swing, and through cooperative use of the chopping knife and a tension spring, the effects of automatic meat chopping and high meat chopping quality are achieved.

Owner:陶秋桐

Separator for bone-meat separation

ActiveCN111642547AAvoid wastingImprove separation rateBone-shears/bone-crushersEngineeringMechanical engineering

The invention discloses a separator for bone-meat separation. The separator comprises a base box, wherein a separation cylinder is fixedly disposed above the base box, a transmission shaft extends into a feeding groove, and multiple first separation cutters are fixedly disposed on the transmission shaft; multiple second separation cutters are fixedly disposed at a section, close to the feeding groove, of a rotation shaft, and spiral auger blades are fixedly disposed on other sections of the rotation shaft; and multiple inner leak holes are formed in the separation cylinder, multiple outer leakholes and grooves are formed in an outer rotation cylinder, a guide rail is disposed in each groove, slide plates are movably disposed between the guide rails, a spring is connected and disposed between each slide plate and the bottom of each groove, and a brush is fixed on the side, remote from the spring, of each slide plate. The invention provides the separator for bone-meat separation, wherein particle sizes of separated meat can be adjusted and limited, the inner leak holes can be cleaned easily and effectively after use, operations are clean without odor, operations are simple, the structure is concise, and the separator is highly worthy for promotion.

Owner:BENGBU COLLEGE

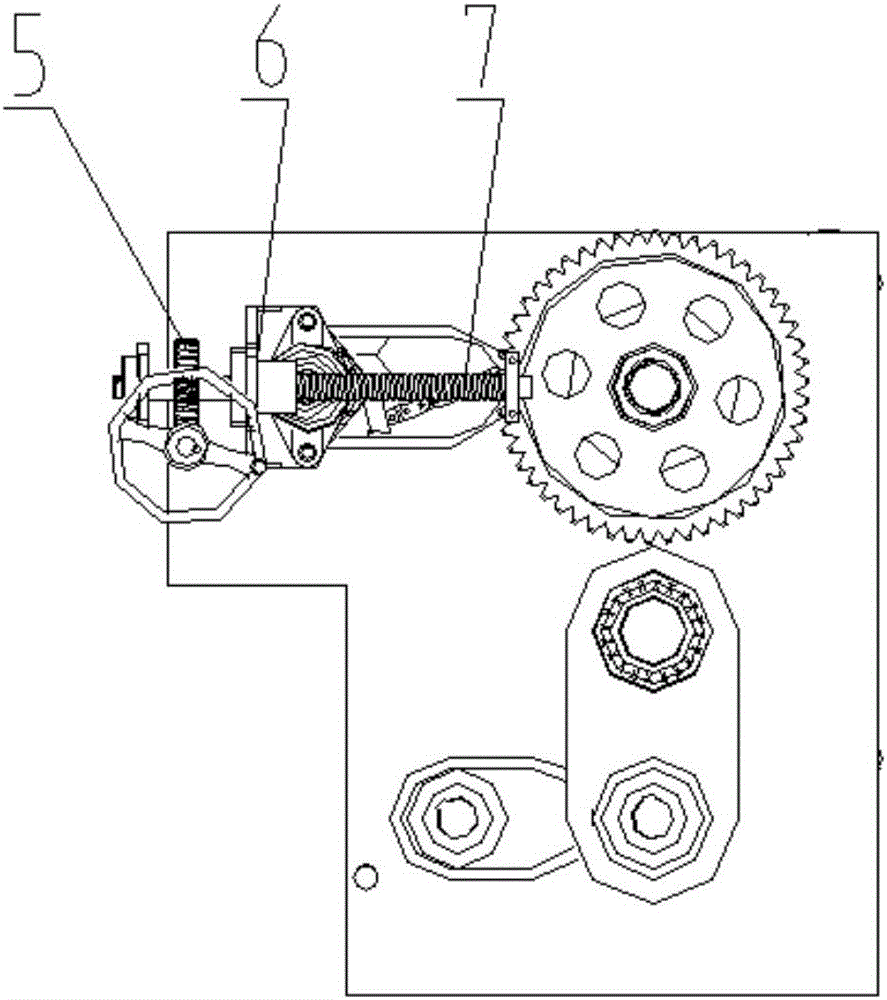

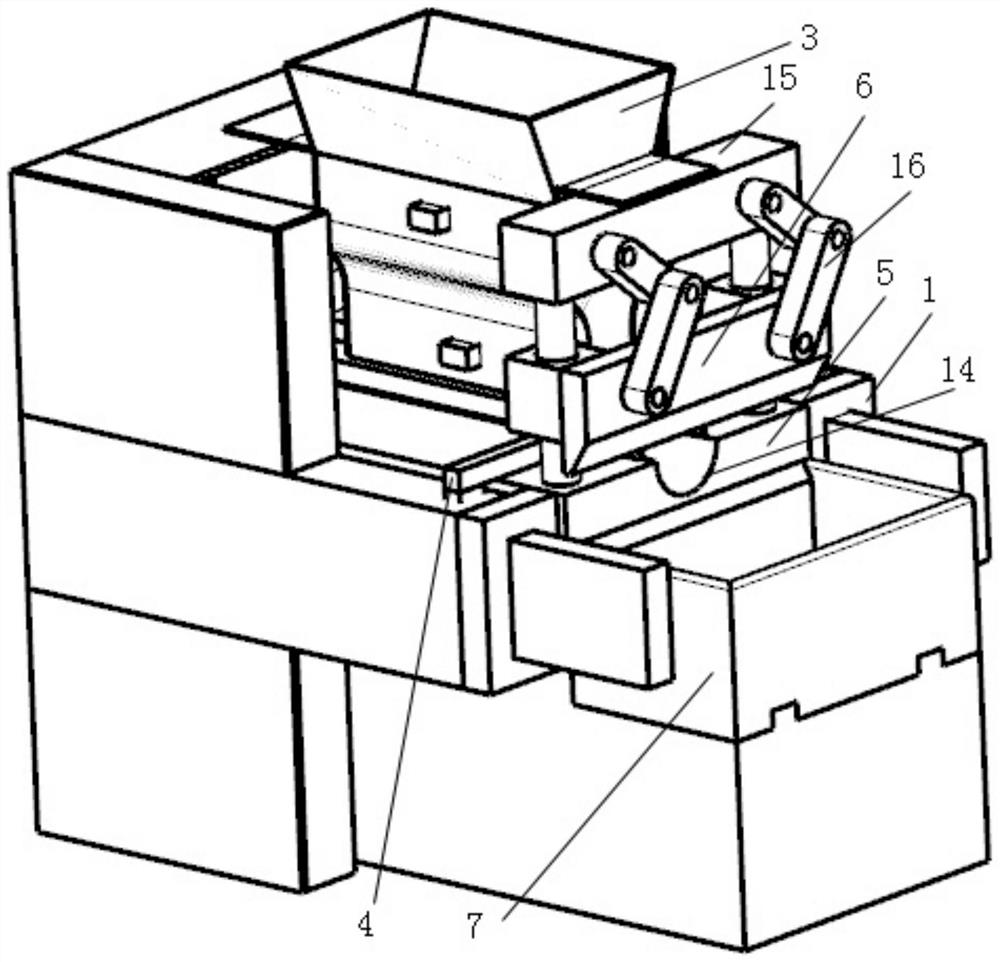

Automatic bone chopping device for food processing

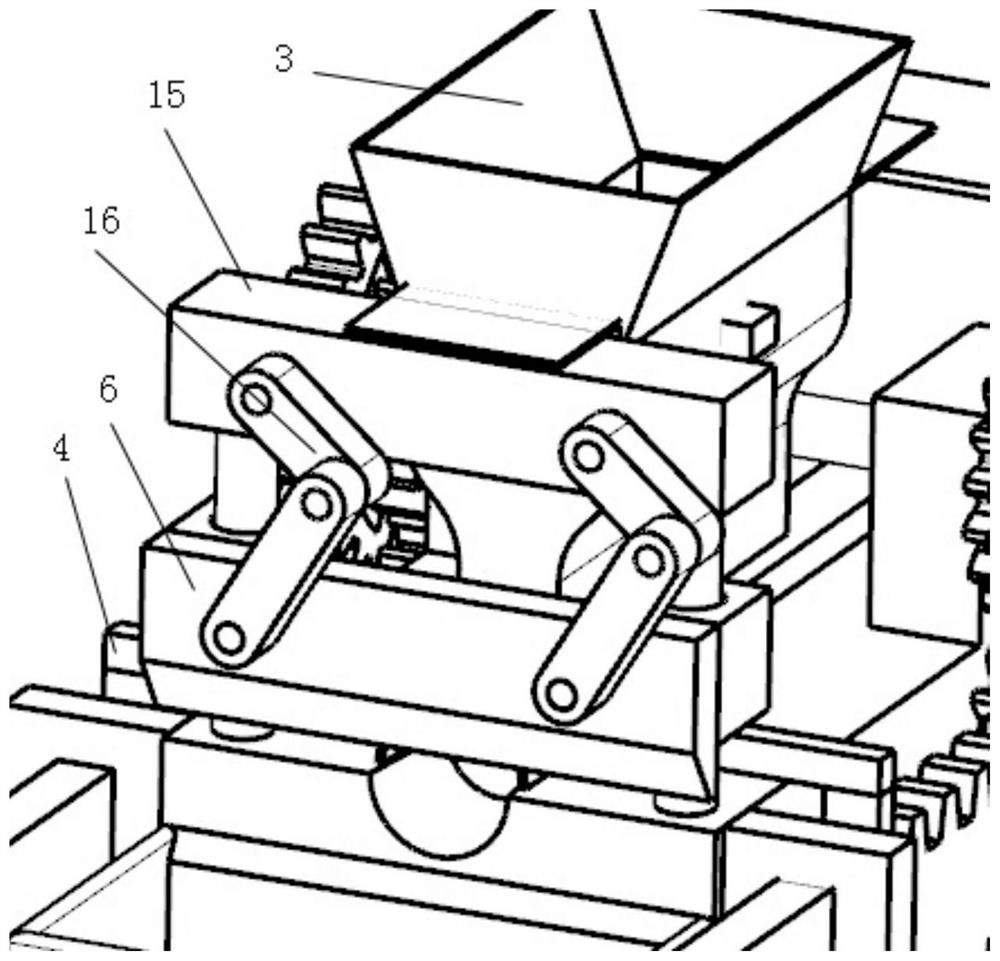

PendingCN112042719ASimple structureEasy to useBone-shears/bone-crushersGear wheelAgricultural engineering

The invention discloses an automatic bone chopping device for food processing. The automatic bone chopping device for food processing comprises a machine frame and a rotating shaft set; the rotating shaft set is arranged on the machine frame and driven by gear engagement; the rotating shaft set comprises a driving shaft, a transmission shaft and a driven shaft; the driving shaft is connected witha motor; the rotating shaft set is provided with an incomplete gear set; the incomplete gear set is engaged with a rack arranged on the machine frame; the rack is fixedly connected with a pushing plate; a discharging hopper is arranged on the machine frame; an outlet of the discharging hopper is a strip-shaped outlet; a cutting board fixed in the machine frame is arranged below the outlet of the discharging hopper; a strip-shaped groove corresponding to the outlet of the discharging hopper is formed in the cutting board; the pushing plate is located on the cutting board; a fodder chopper mechanism is further arranged above the cutting board; the fodder chopper mechanism comprises a fodder chopper; the fodder chopper is located on the end side of the discharging end of the cutting board; and a material collecting box fixed to the machine frame is arranged below the fodder chopper. According to the automatic bone chopping device for food processing in the invention, after bone materialsare put in, discharging, pushing, bone chopping and collecting can be carried out sequentially; therefore, the bone chopping efficiency is high; manpower is greatly saved; and the device is stable torun, and safe and reliable to chop bone.

Owner:SHAANXI UNIV OF SCI & TECH

Two-direction meat-bone crushing output mechanism

The present invention discloses a two-direction meat-bone crushing output mechanism. The two-direction meat-bone crushing output mechanism adopts two conveying mechanisms for two times of extrusion processing of meat and bones, in which the diameter of a conical screw conveying part is becoming smaller and smaller, thereby producing extruding and gripping effect on the meat and bones to realize the pre-cutting of the meat and bones; while a screw shaft with two kinds of screw pitches is used in a crushing conveying part, making materials get gradually increased non-uniform push force in the process of forward movement; at the same time, extrusion force on the materials is strengthened with the cooperation of reverse threaded grooves on the inner wall of a charging barrel, making the materials be initially extruded and crushed before entering cutter blades, which not only improves the crushing effect, but also reduces the damage to the cutter blades and prolongs the service life of thecutter blades.

Owner:锦岸机械科技江苏有限公司

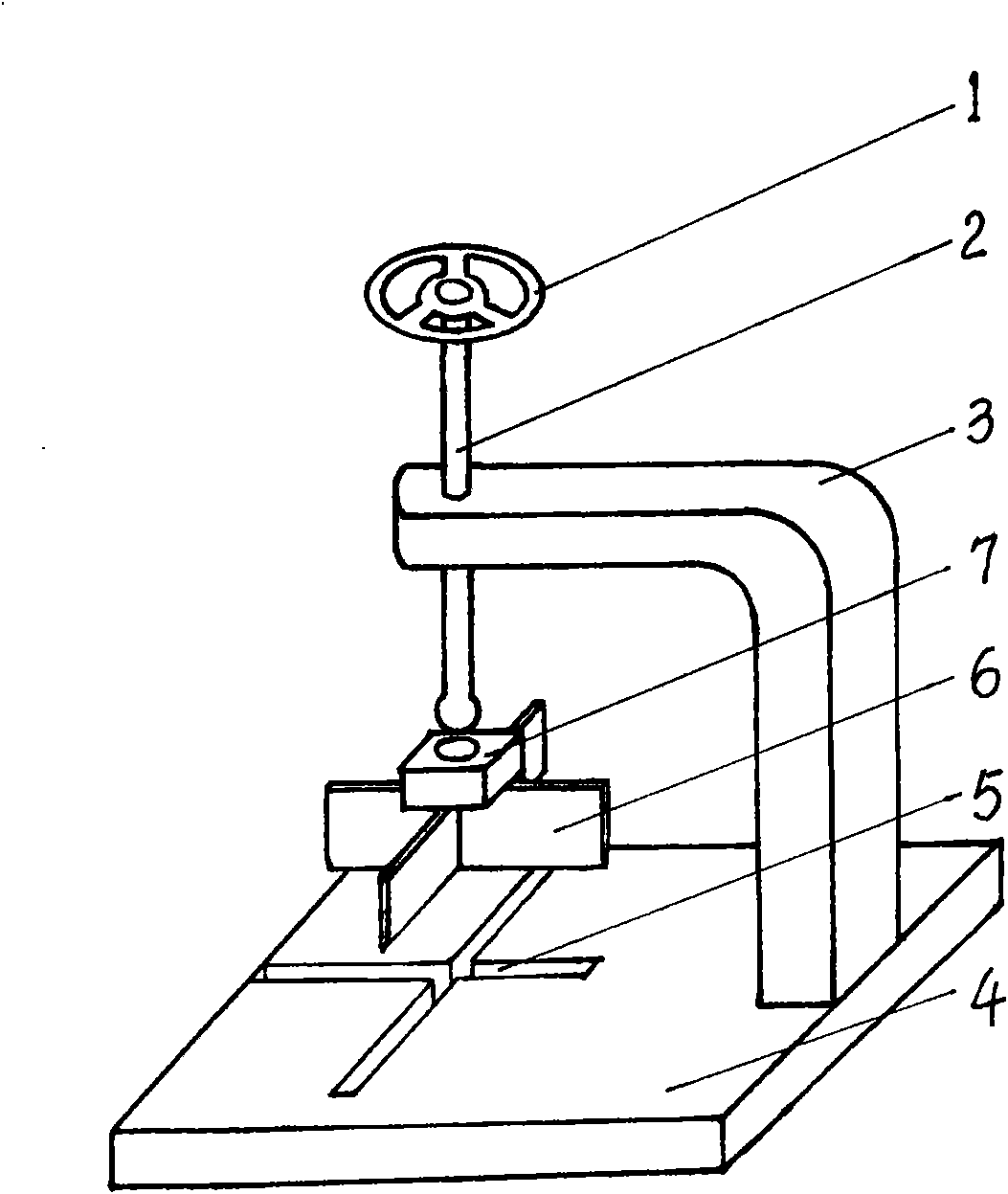

Bone breaking cross cutter for kitchen

InactiveCN102599224ANot easy to collapseThorough processingBone-shears/bone-crushersEngineeringHead shape

The invention discloses a bone breaking cross cutter for a kitchen, which belongs to a tool class for the kitchen, and can help people break and crush bones of edible animals safely and quietly in the kitchen, and comprises a base, a bracket, a hand wheel, a lead screw and a cross cutter, wherein the base is in a flat shape, one side of the base is vertically connected upwards to the bracket with two bracket arms being approximately in a right-angle shape, the upper end of the bracket is arranged right above the base surface, a downward screw hole is processed on the end of the bracket, the lead screw with the hand wheel is screwed into the screw hole, the lower end of the lead screw is processed into a ball head shape, two rectangular iron sheets are processed into a whole in a cross shape, the lower edges of the two rectangular iron sheets are respectively processed into an edge shape so as to form the cross cutter, an intersected point of the cross cutter is fixedly connected with a ball bowl with the inside being processed into a ball-shaped cavity so as to accommodate the ball head on the lower end of the lead screw, and the cross cutter is movably connected with the ball head through the ball bowl.

Owner:陈烁

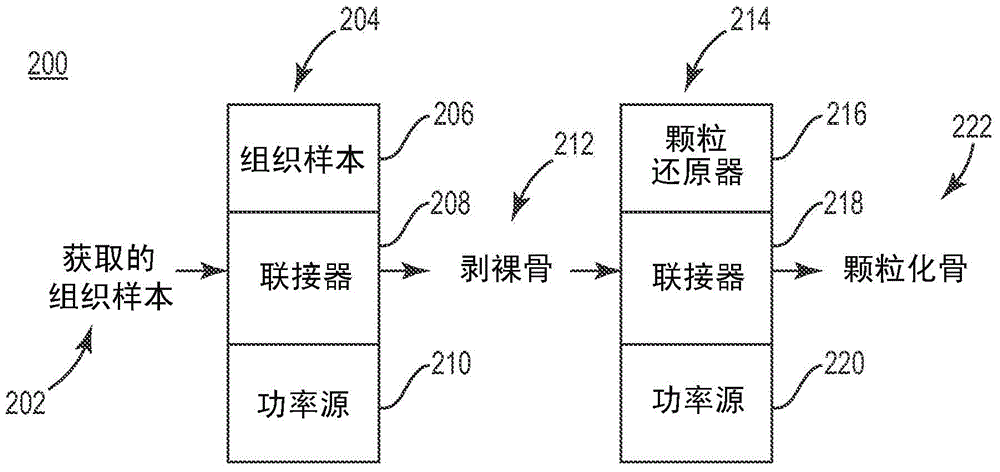

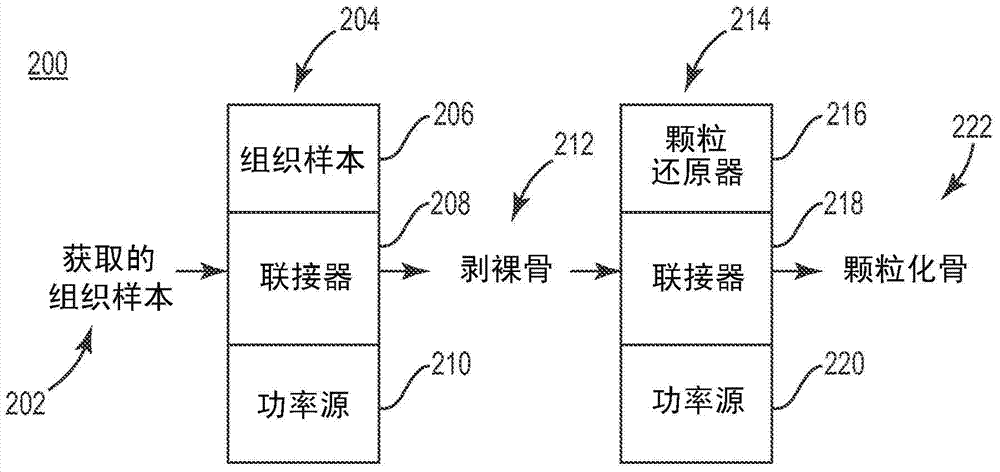

Bone processing systems and methods

Owner:MEDTRONIC INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com