Frozen pork rib nondestructive cutting method and device

A technology of cutting equipment and cutting methods, applied in the direction of boning shears/bone crushers, etc., can solve the problems of rib fragmentation, waste, shaking, etc., and achieve the effect of increasing friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] Below in conjunction with accompanying drawing and embodiment of description, specific embodiment of the present invention is described in further detail:

[0051] refer to Figure 1 to Figure 12 Shown a kind of frozen pork ribs without damage cutting method, comprises the following steps:

[0052] Step 1. Cut the whole piece of frozen pork ribs into 10 parts. The specific steps for cutting the whole piece of frozen pork ribs into 10 parts are as follows:

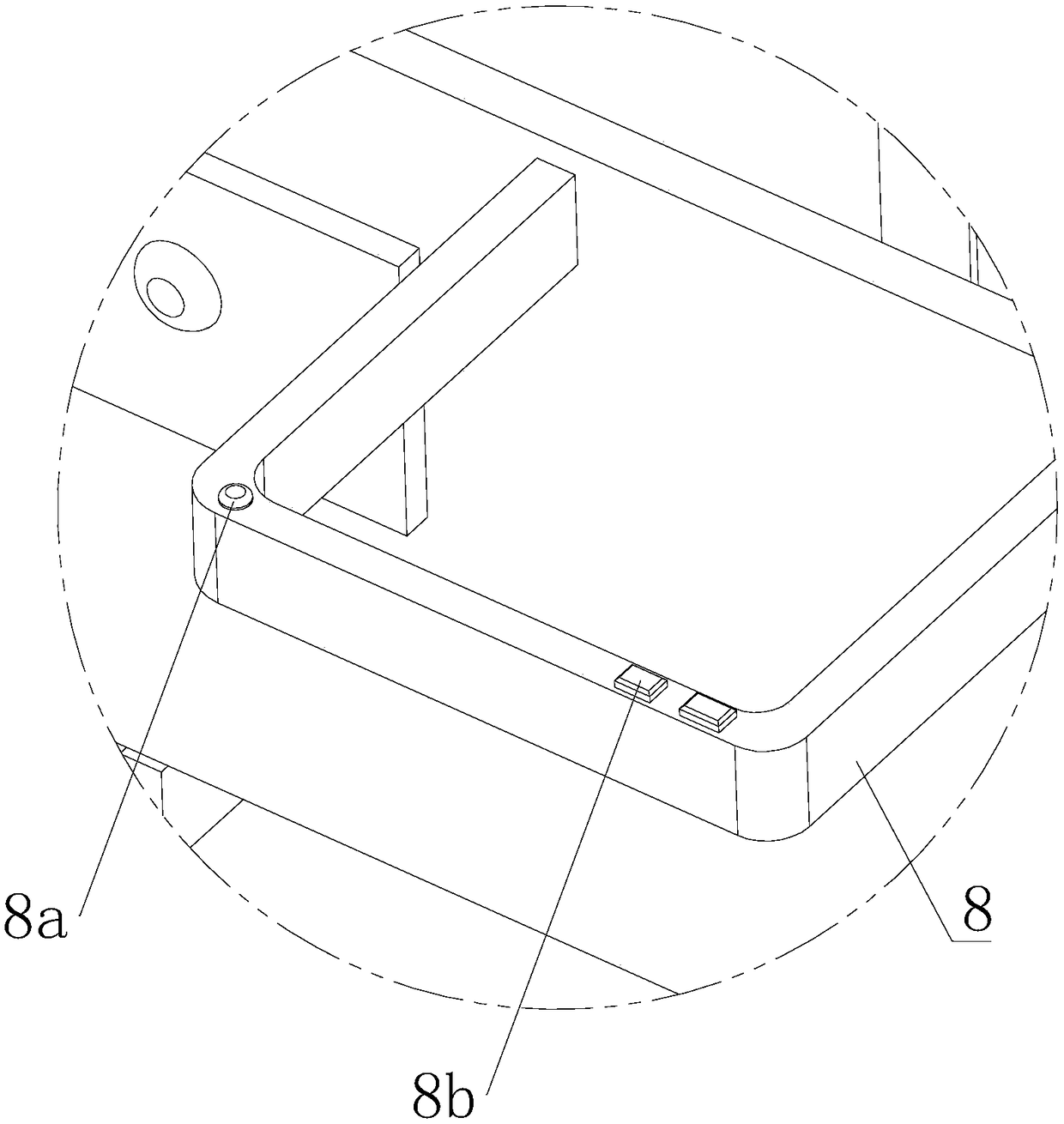

[0053] (1), the whole piece of frozen ribs 10 after thawing is put into a specific positioning device for positioning; the positioning device is composed of a left positioning device 2 and a right positioning device 3;

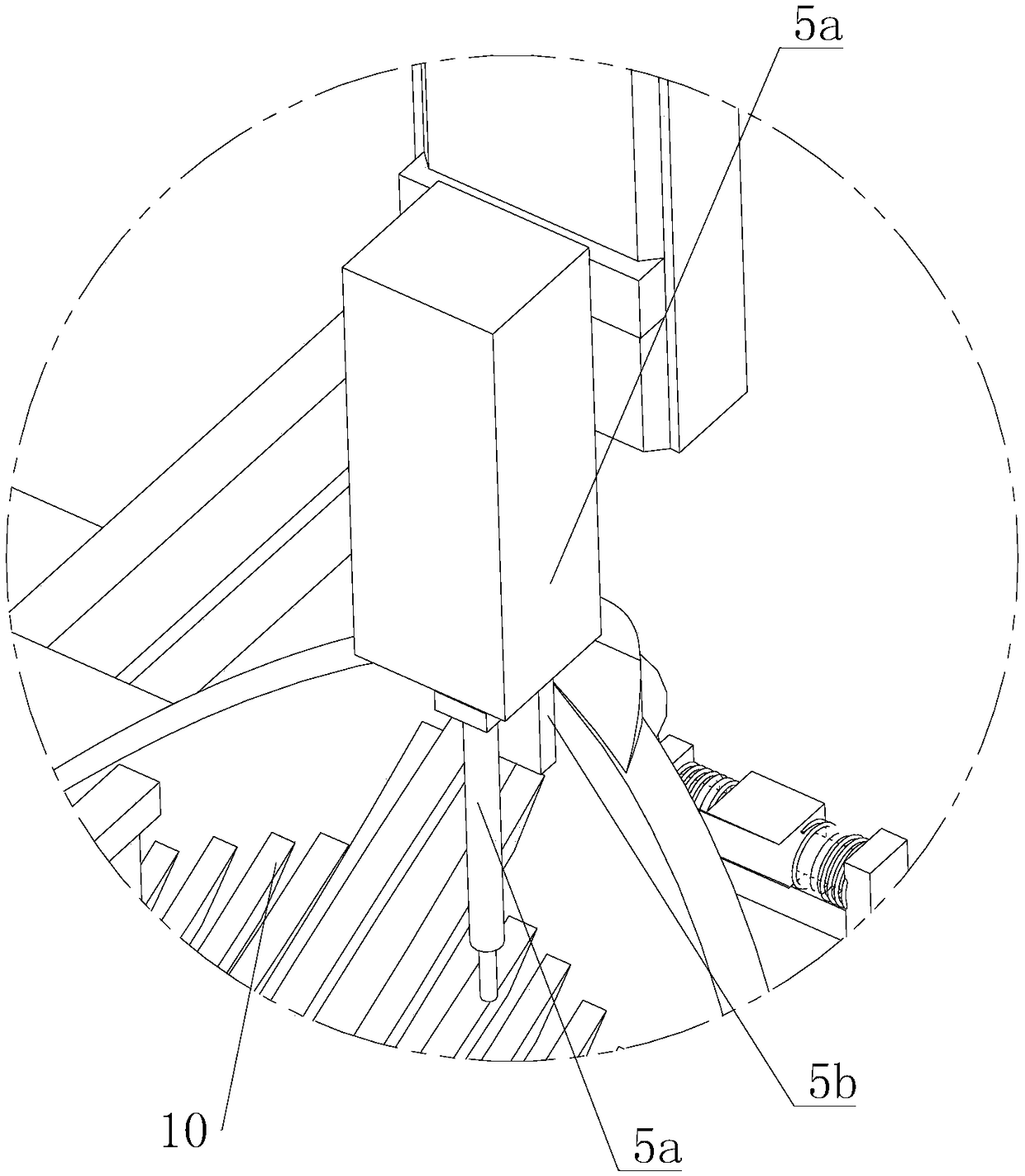

[0054] (2), the cross-shaped driving mechanism 5 drives the high-pressure water knife 5a to descend and approach the spine area of the frozen spare ribs 10, the cross-shaped driving mechanism 5 drives the high-pressure water knife 5a to do horizontal movement, and uses the spine as a cutting line ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com