Grinding head of conical bone cement machine

A technology of bone slime machine and grinding head, which is applied in the direction of boning scissors/bone crusher, etc., which can solve the problems of easy wear, high cost, and large size of the grinding head, and achieve control of crushing fineness and good cutting and grinding effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

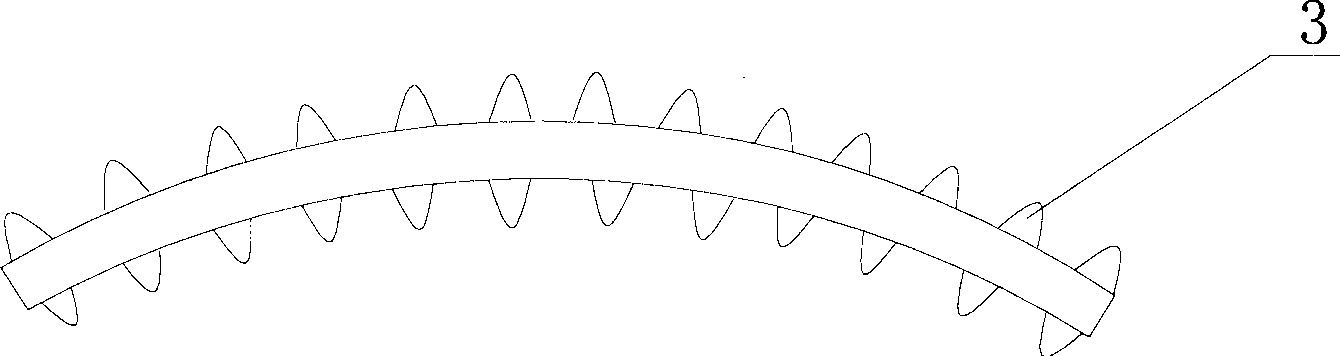

[0018] The grinding head can be used in combination with the inner grinding head 1 and the outer grinding head 2. The inner grinding head 1 is a dynamic grinding head, which is driven by the transmission shaft and can move axially; the outer grinding head 2 is fixed on the bone clay machine. Grinding, the outer grinding head 2 is set on the inner grinding head 1, and the two have a certain distance. Each grinding head includes an inner cone surface and an outer cone surface respectively. The two conical surfaces of the inner grinding head 1 and the outer grinding head 2 are respectively provided with raised blades 3, the raised blades 3 protrude 1 mm from the surface of the cone, and the raised blades 3 are linear.

[0019] The center of the grinding head is provided with a hollowed-out circular feeding port 5, and the position close to the feeding port 5 on the inner cone surface and the outer tapered surface is respectively provided with an arc-shaped feeding groove 4 along ...

Embodiment 2

[0021] The grinding head can be used in combination with the inner grinding head 1 and the outer grinding head 2. The inner grinding head 1 is a dynamic grinding head, which is driven by the transmission shaft and can move axially; the outer grinding head 2 is fixed on the bone clay machine. grind. The dynamic grinding and the fixed grinding respectively include an inner cone surface and an outer cone surface. The two cone surfaces of the inner grinding head 1 and the outer grinding head 2 are respectively provided with a raised blade 3, and the raised blade 3 protrudes 1.5mm from the surface of the cone. The raised blade 3 is arc-shaped.

[0022] The center of the grinding head is provided with a hollowed-out circular feeding port 5, and the position close to the feeding port 5 on the inner cone surface and the outer tapered surface is respectively provided with an arc-shaped feeding groove 4 along the radial direction, and the feeding groove 4 The opening is towards the fee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com