Automatic bone chopping device for food processing

A food processing and driving shaft technology, applied in the direction of deboning shears/bone crushers, etc., can solve the problems of low work efficiency and consumption of artificial physical strength, and achieve the effects of high bone cutting efficiency, convenient use and stable operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

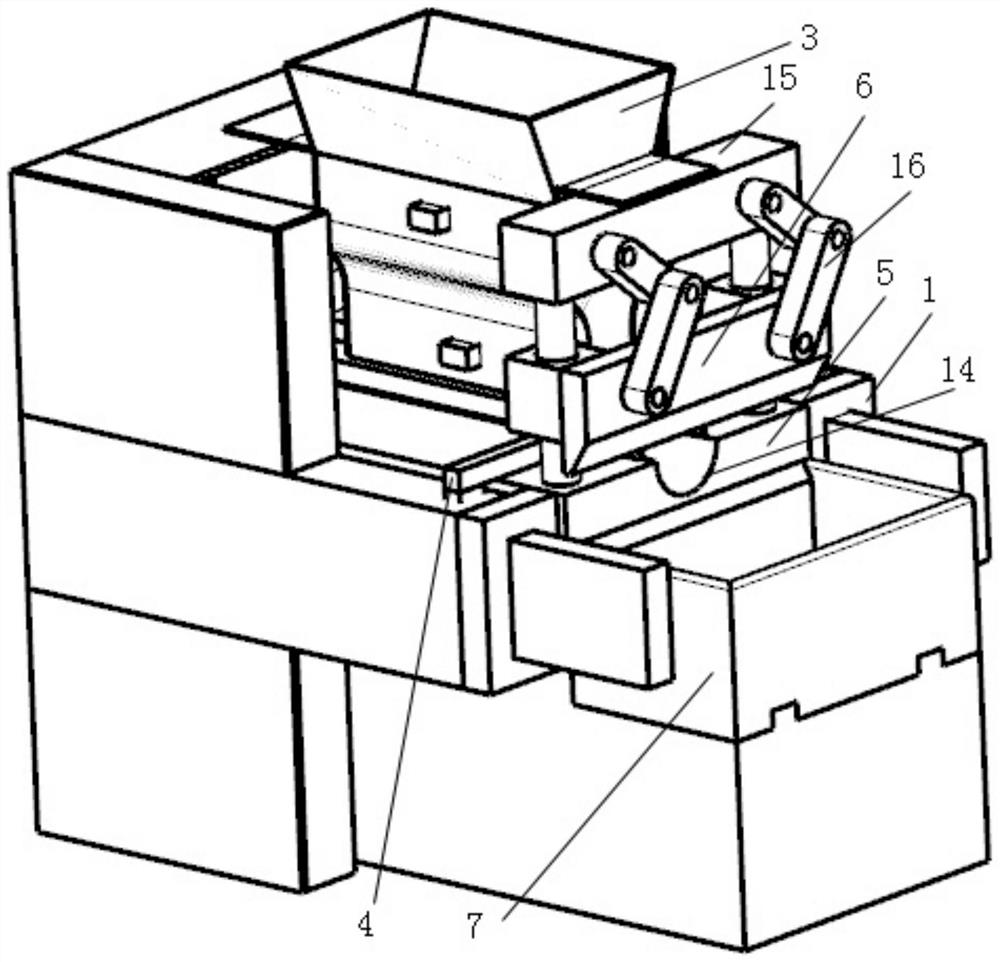

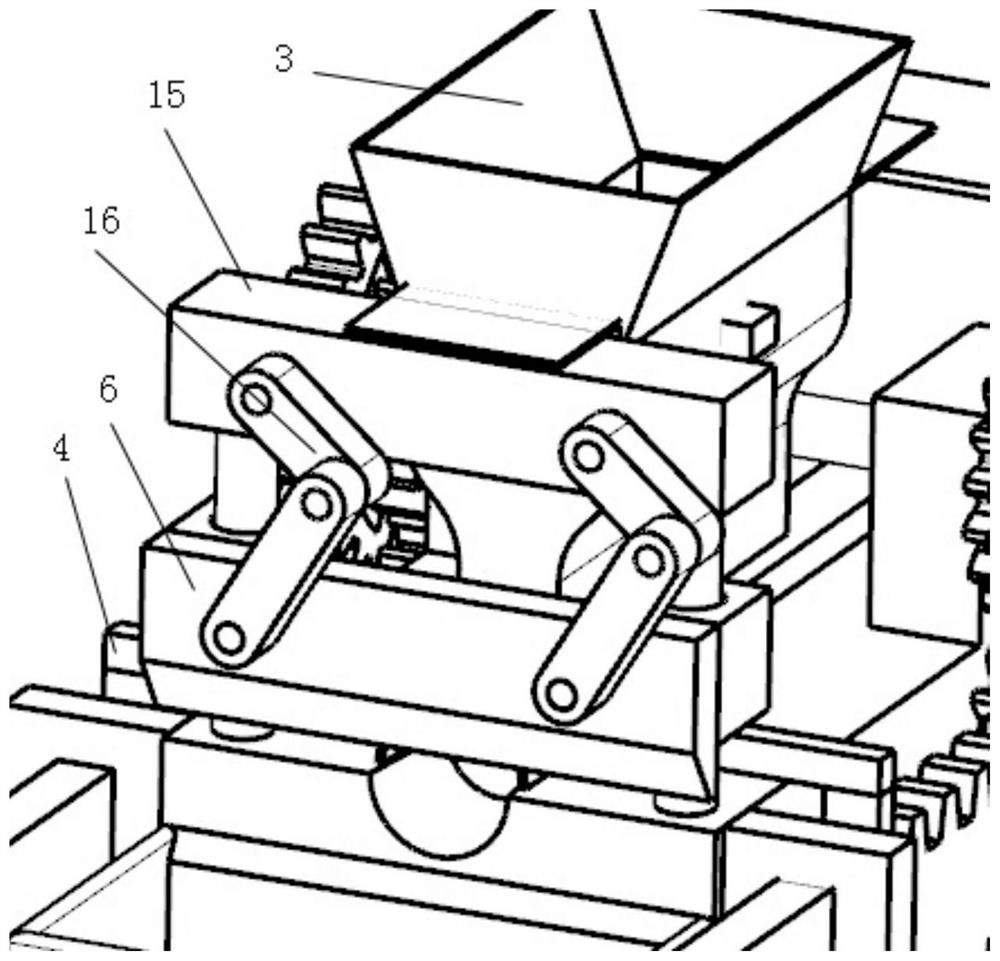

[0020] A kind of automatic bone chopping device for food processing of the present invention, as Figure 1-2 As shown, it includes a frame 1, and the frame 1 is provided with a rotating shaft group that is driven by gear meshing. The rotating shaft group is connected to a motor, and the rotating shaft group is provided with an incomplete gear group. The rack 2 on 1, the rack 2 can do reciprocating linear motion, the rack 2 is fixedly connected with the pushing plate 4, the lower hopper 3 is arranged on the frame 1, and the bottom of the outlet of the lower hopper 3 is fixed in the frame 1 The cutting board 5, the outlet of the lower hopper 3 is a strip outlet, the cutting board 5 is provided with a strip groove 14 corresponding to the outlet of the lower hopper 3, slide rails are arranged on both sides of the strip groove 14 of the cutting bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com