Two-direction meat-bone crushing output mechanism

An output mechanism, two-way technology, used in deboning shears/bone crushers, meat processing, meat processing equipment, etc., can solve the problem of continuous and stable output of materials, low rebound force and crushing force at the crossing, and the life of the flying knife. Reduce and other problems to achieve the effect of improving service life, promoting multiple extrusion and crushing, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

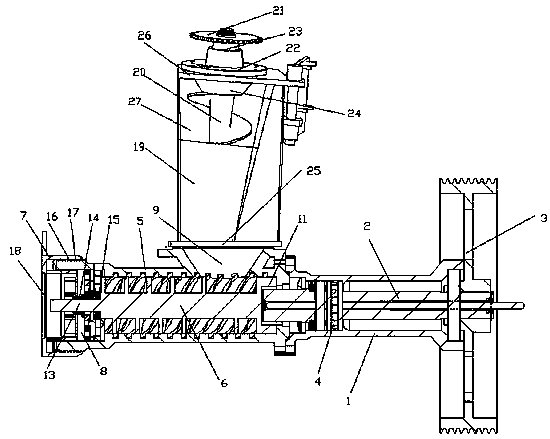

[0020] Such as Figure 1~3 As shown, a bidirectional meat and bone crushing output mechanism disclosed by the present invention is installed on a meat and bone crusher, and its structure includes a driving part, a crushing and conveying part and a conical screw conveying part.

[0021] Specifically, the drive part includes a synchronous shaft housing 1, a synchronous shaft 2, and a synchronous pulley 3, wherein the synchronous shaft 2 is installed in the synchronous shaft housing 1 through a bearing 4, and the front end of the synchronous shaft 2 is a regular polygonal structure (regular hexagonal , square, regular triangle, etc.), and the rear end is equipped with a synchronous pulley 3, the synchronous pulley is connected to the motor through a belt, and the motor drives the synchronous pulley to rotate, so that the synchronous shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com