Sliding-plate charging-type bone sawing machine provided with adjustable clamps

A technology of bone sawing machine and jig, which is applied in the direction of meat clamping device, deboning scissors/bone crusher, slaughtering, etc. It can solve the problems of cutting hidden dangers, time-consuming, labor-intensive, inhumane and other problems, and achieve the effect of increasing safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

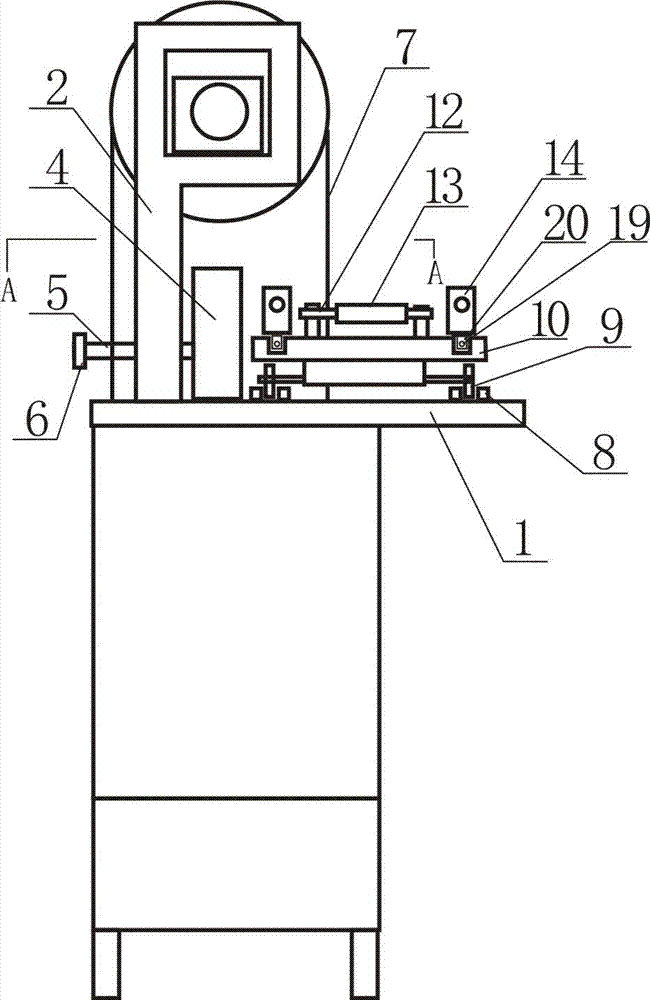

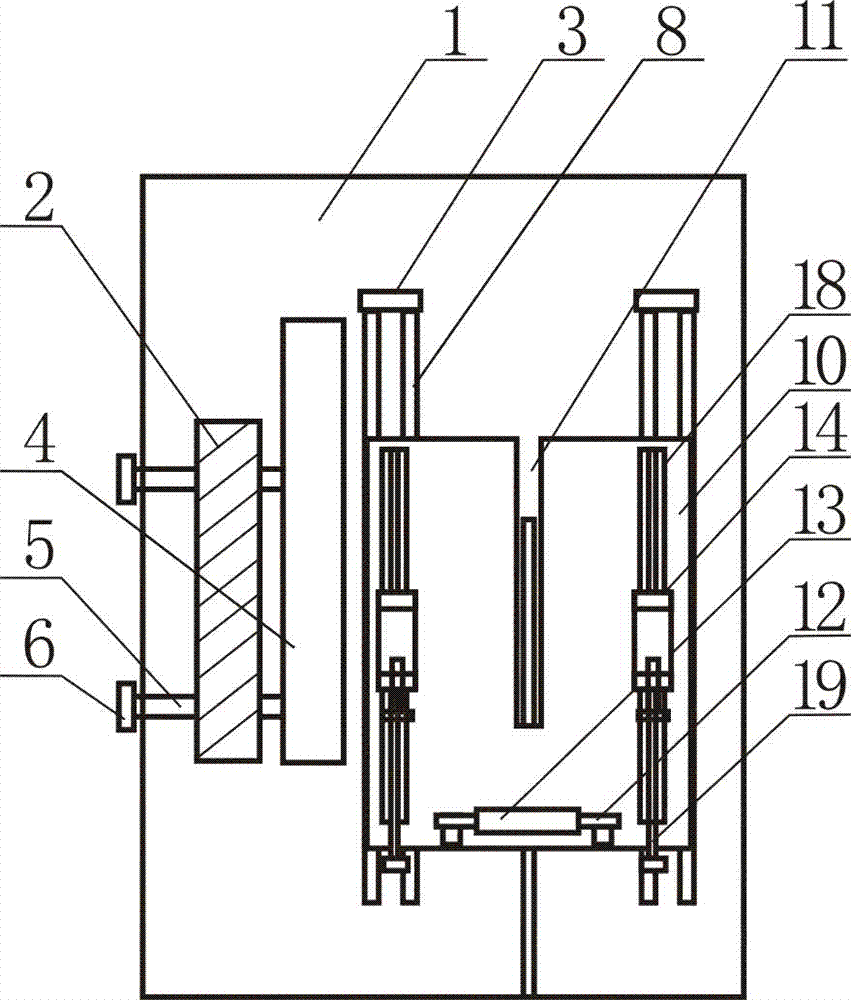

[0018] Such as figure 1 , 2 As shown, the sliding plate feeding type bone sawing machine with adjustable clamps includes a worktable 1, a frame 2 and a saw blade 7, the workbench 1 is horizontally arranged in the middle of the frame Pass through, also comprise guide rail 8 and feed slide plate 10, described guide rail 8 is arranged on the workbench 1, and described feed slide plate 10 is arranged on guide rail 8 by the pulley 9 of its bottom, and the plate of described feed slide plate 10 The surface is provided with a through groove 11 for allowing the saw blade 7 to pass through, and the through groove 11 extends from one end of the feed slide 10 to the middle part of the feed slide, and the other end of the feed slide is provided with a push-pull handle 12, so The push-pull handle 12 is a round rod-shaped structure. The surface of the push-pull handle 12 is covered with a soft rubber cover 13 .

[0019] Such as figure 2 , 3 As shown, the both sides of described feedin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com