Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42 results about "VRML" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

VRML (Virtual Reality Modeling Language, pronounced vermal or by its initials, originally—before 1995—known as the Virtual Reality Markup Language) is a standard file format for representing 3-dimensional (3D) interactive vector graphics, designed particularly with the World Wide Web in mind. It has been superseded by X3D.

System and method for providing a functional virtual environment with real time extracted and transplanted images

InactiveUS6798407B1Digital computer detailsImage data processing detailsComputer graphics (images)VRML

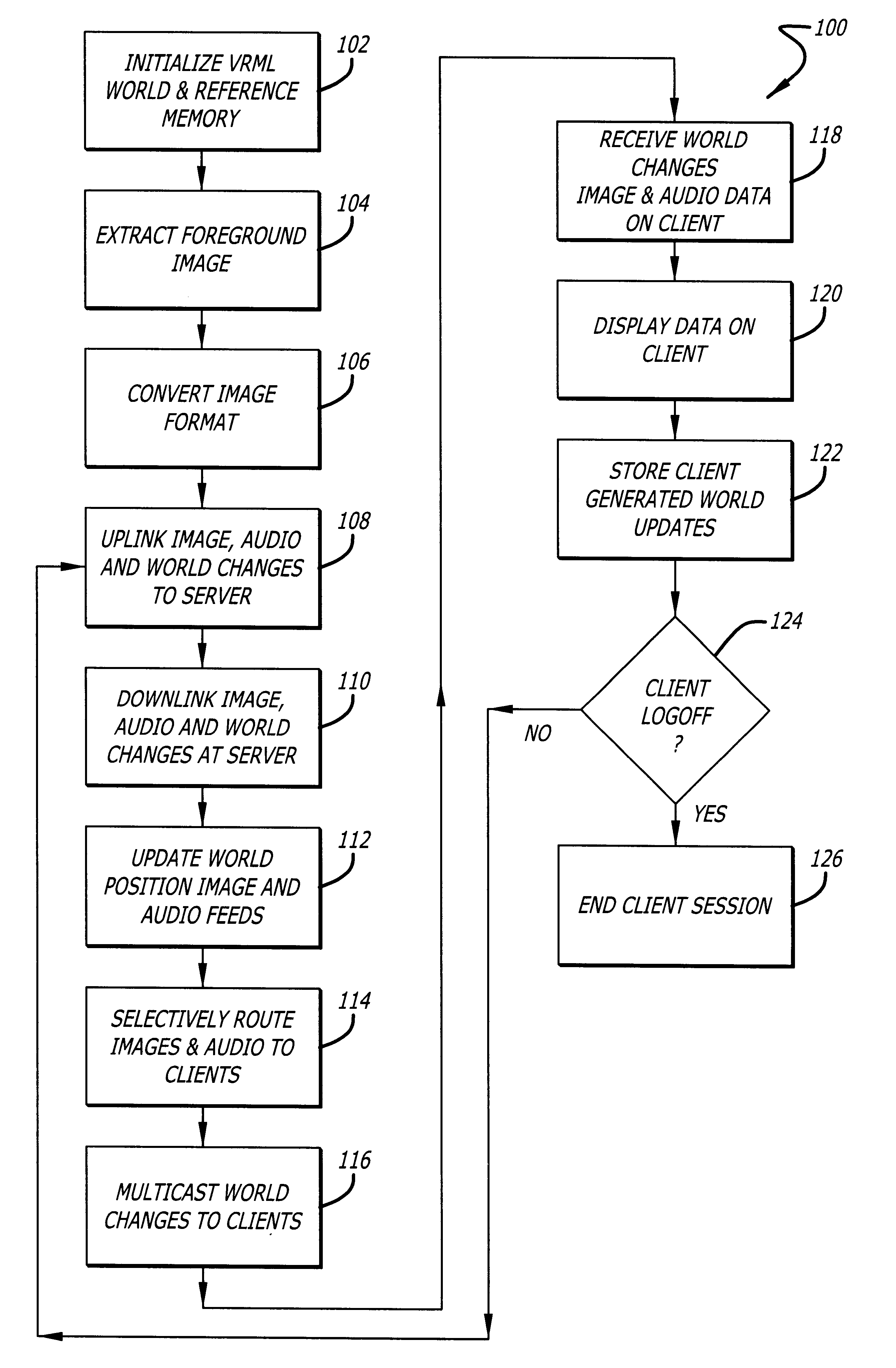

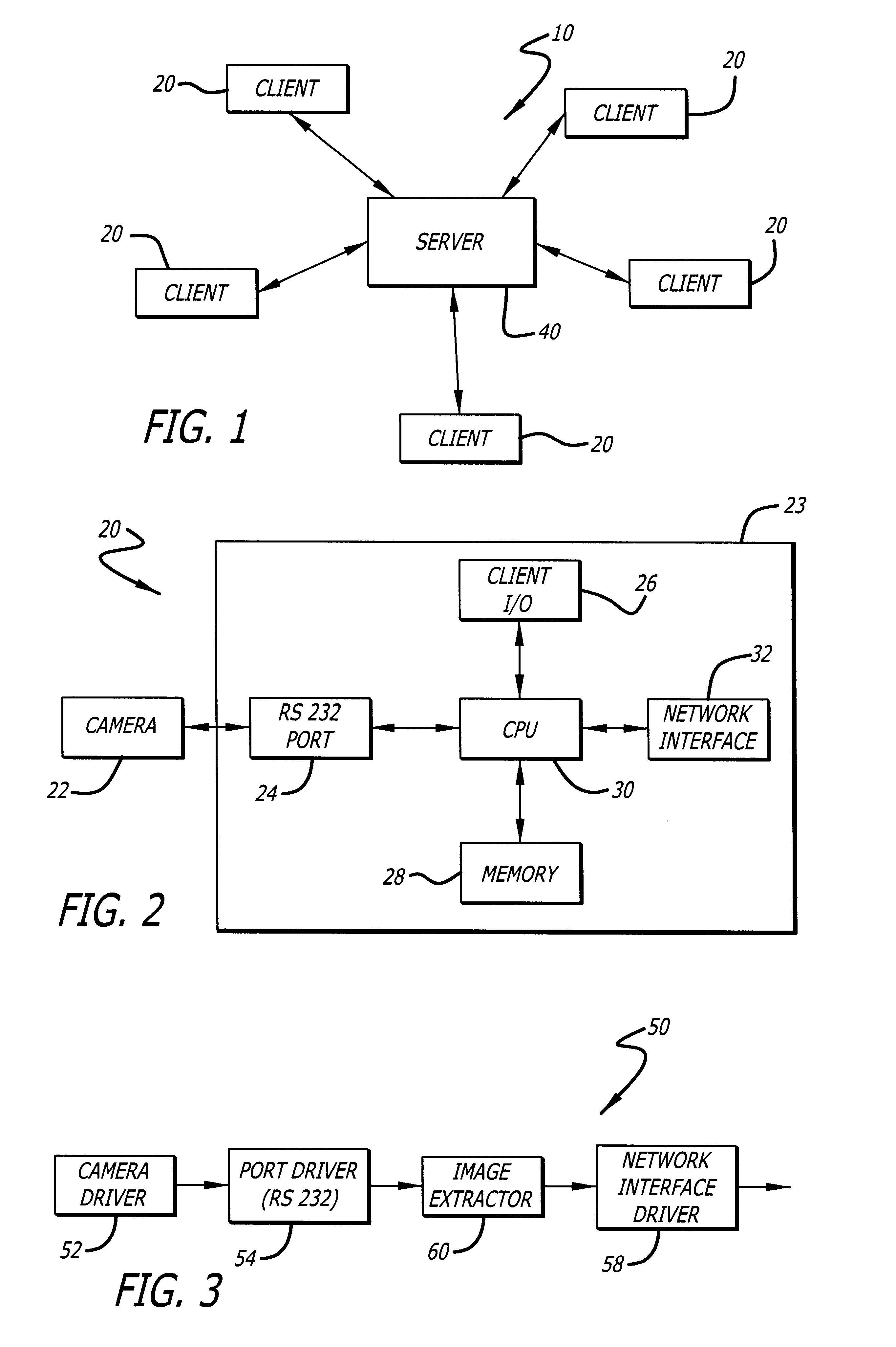

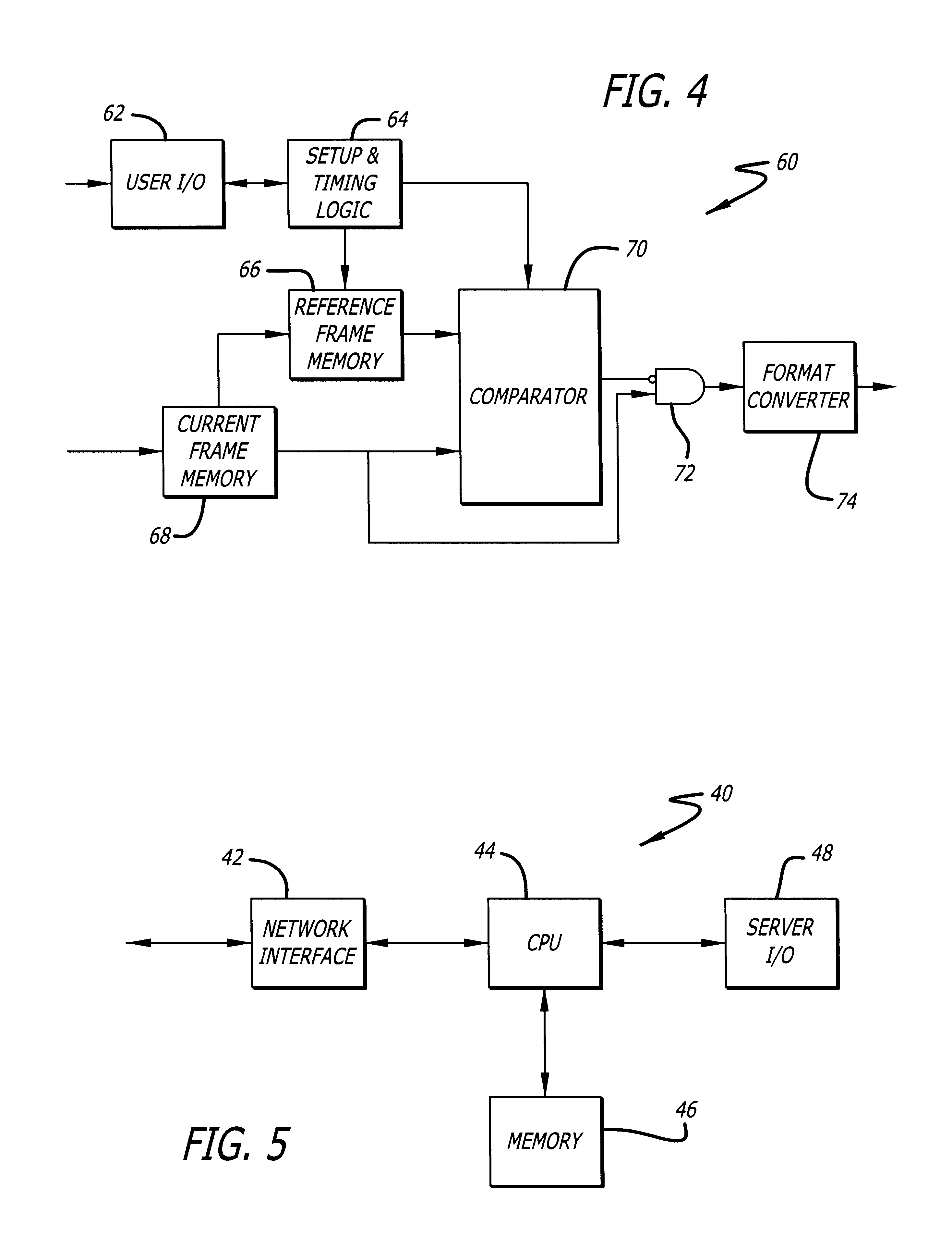

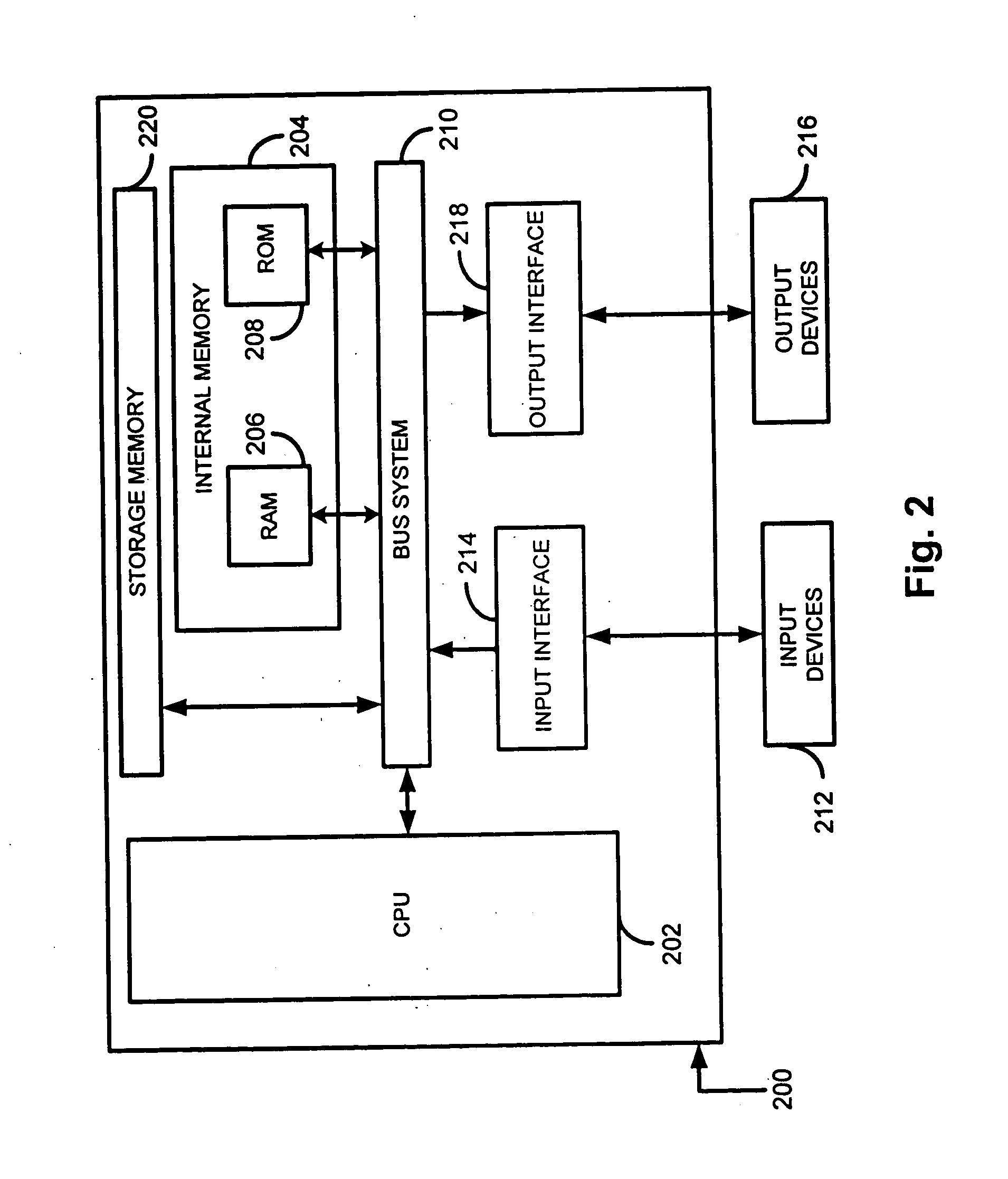

A system and method for providing a functional virtual environment with real time extracted and transplanted images. The system includes hardware and software for providing a multi-dimensional computer generated environment and for receiving a plurality of extracted video images. The system is adapted to transplant the extracted video images into the environment in a manner that preserves the virtual metaphor thereof. In the illustrative embodiment, a realistic virtual city is created in accordance with the Virtual Reality Modeling Language (VRML) protocol. The extracted images are transplanted onto an object in the environment as a texture. In the best mode, the object is invisible. The extracted video images are streamed continuously into the environment such that a live real time interaction is enabled. The environment is networked and the system is adapted to receive multiple simultaneous streams which are transplanted and exported to enable a virtual community. Within the community, users seated in their native environment, appear to walk when navigating due to the unique teaching of the present invention by which a series of stored extracted images of the user walking are transplanted into the environment and replayed for so long as the user is navigating. A separate series is displayed to each person within a predetermined range of the walker that has the walker in his field of view depending on the viewing angle of the observer. A master copy of the environment is stored on a server and downloaded to each client on the network as part of a setup process. Thereafter, local changes in the environment are uploaded to the server and subsequently downloaded to selected clients as updates. The environment will support private areas and the system is adapted to allow extracted video streams within private environments to be sent to each person in the private environment directly, bypassing the server.

Owner:BENMAN WILLIAM J

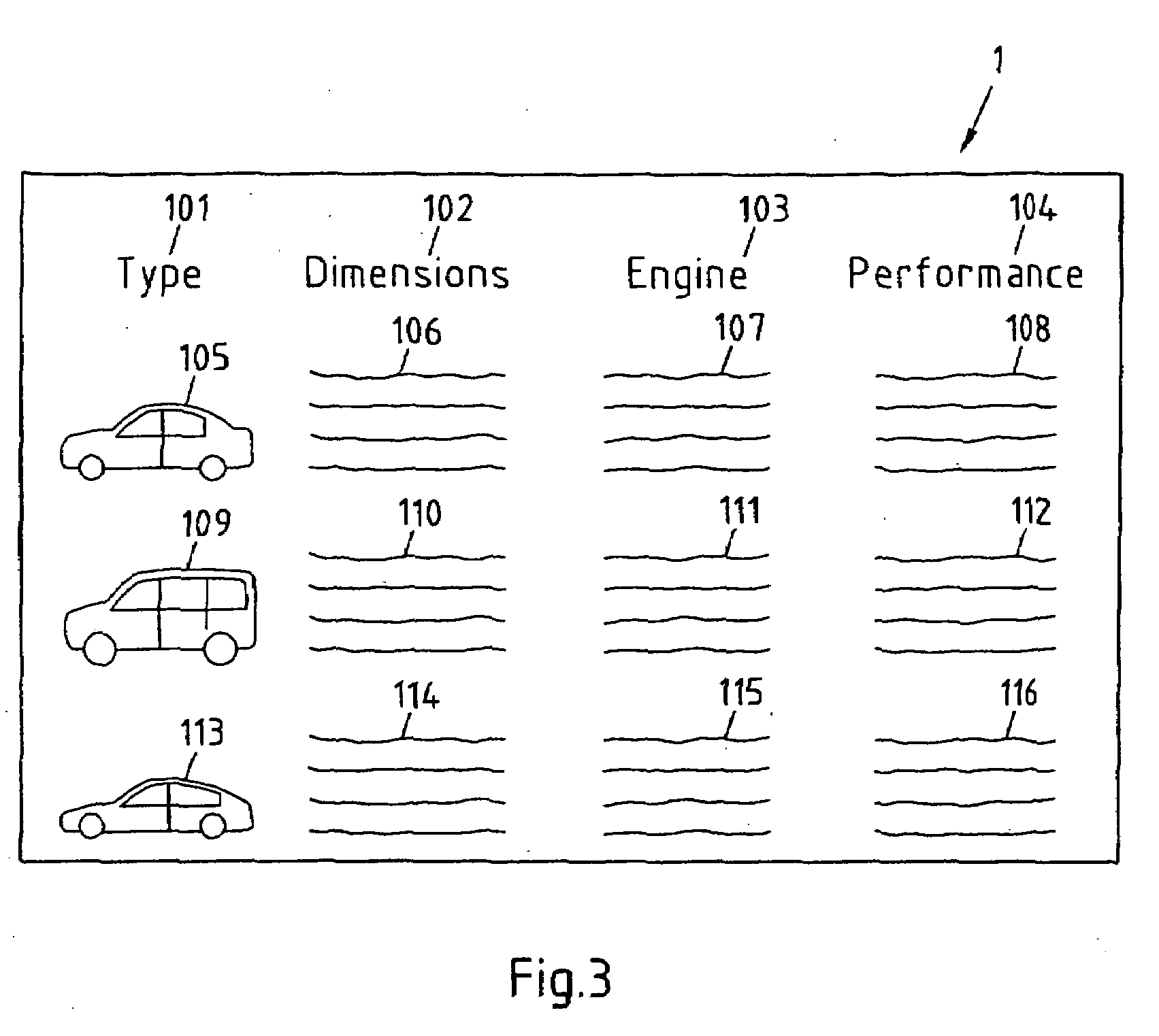

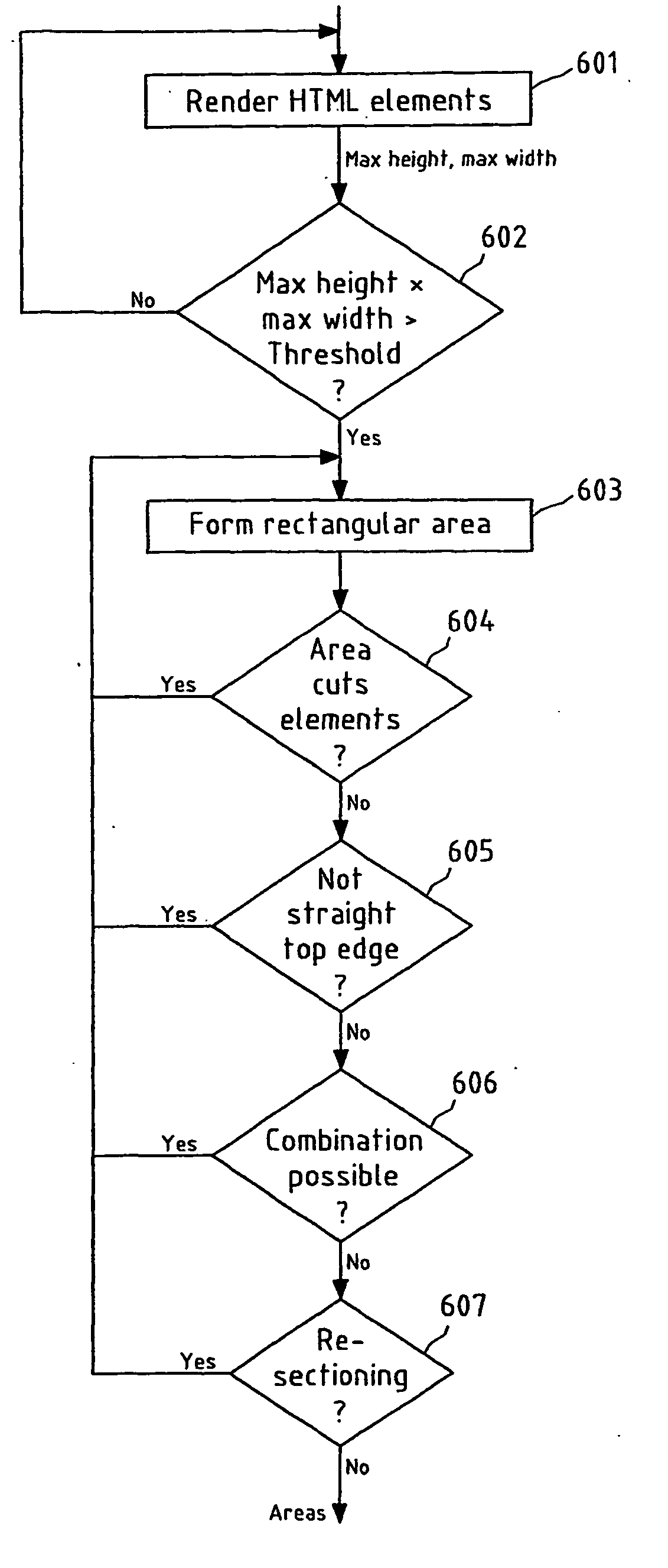

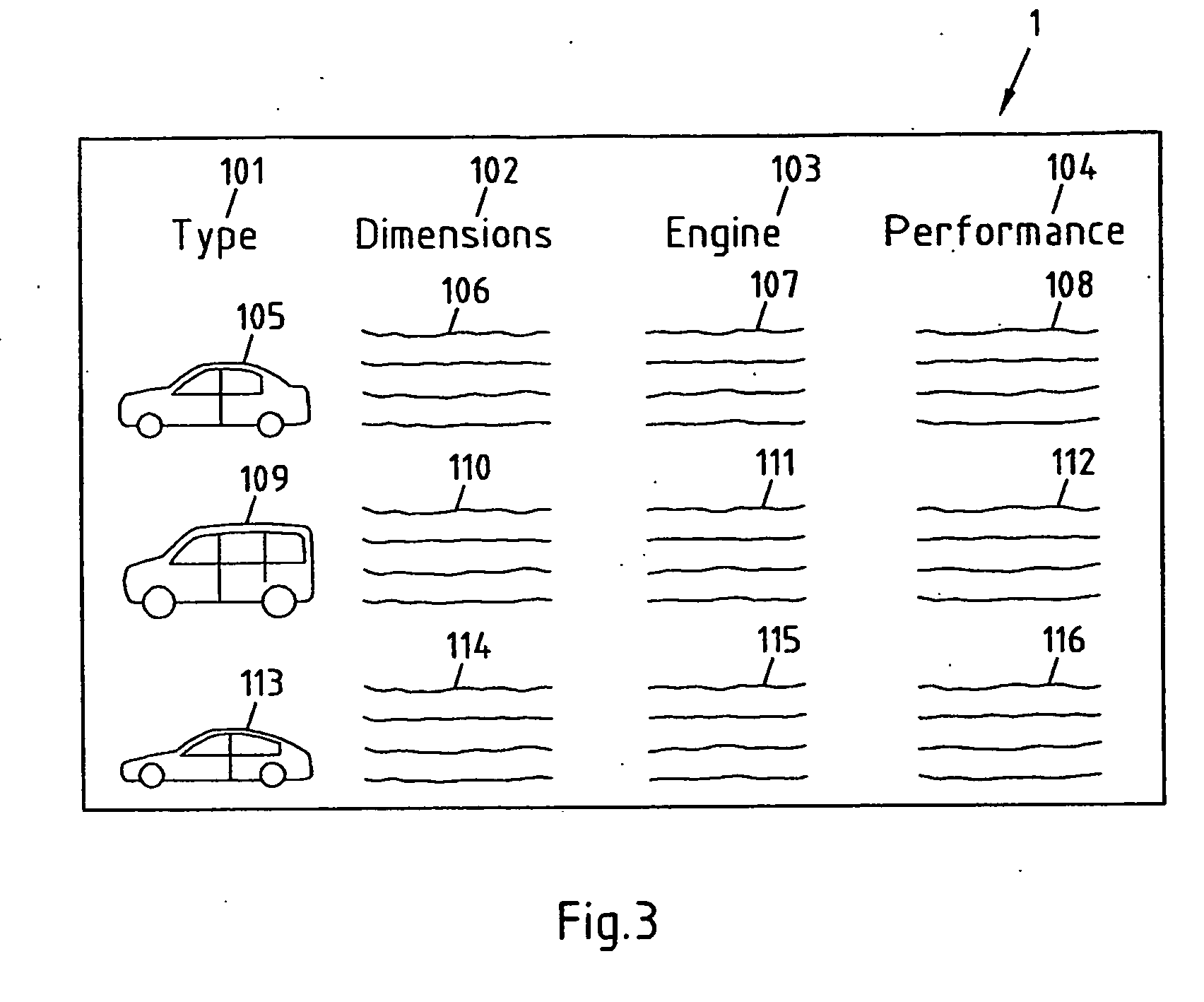

Presentation of large objects on small displays

ActiveUS20090089704A1Small sizeEasy to demonstrateDigital data information retrievalSpecial data processing applicationsDisplay deviceVRML

Owner:III HLDG 3

Method for constructing surgical virtual operation teaching and training system

InactiveCN101996507AImprove teaching qualityReduce teaching costsCosmonautic condition simulationsSimulatorsSimulationVRML

The invention provides a method for constructing a surgical virtual operation teaching and training system. The method comprises the following concrete steps: (1) acquiring various inspection data classified according to normal people and patients, intensively storing the acquired data, and constructing an integrated male virtual human model and an integrated female virtual human model; (2) carrying out geometric modeling, computational modeling and deformation computation on medical data, and carrying out modeling on bones and soft tissues by adopting a multi-outline three-dimensional reconstruction algorithm; (3) reconstructing by adopting a three-dimensional model of 3DMAX10, mapping and giving physiological characteristics to organic tissues; (4) compiling related objects and simulated scenes of a virtual operation by virtual reality modeling language (VRML); (5) carrying out preoperative preparation in the virtual operation scenes, and checking and confirming patient information; (6) carrying out complete operational details of the actual method of the virtual operation again; (7) establishing a simulated operation teaching evaluation system; and (8) carrying out comprehensive evaluation and examination on a teacher and each trainee. In the method, the simulated operation teaching system is constructed by utilizing the virtual reality technology, thereby providing a wide and transparent simulated teaching and research platform for hospitals and medical schools.

Owner:罗伟

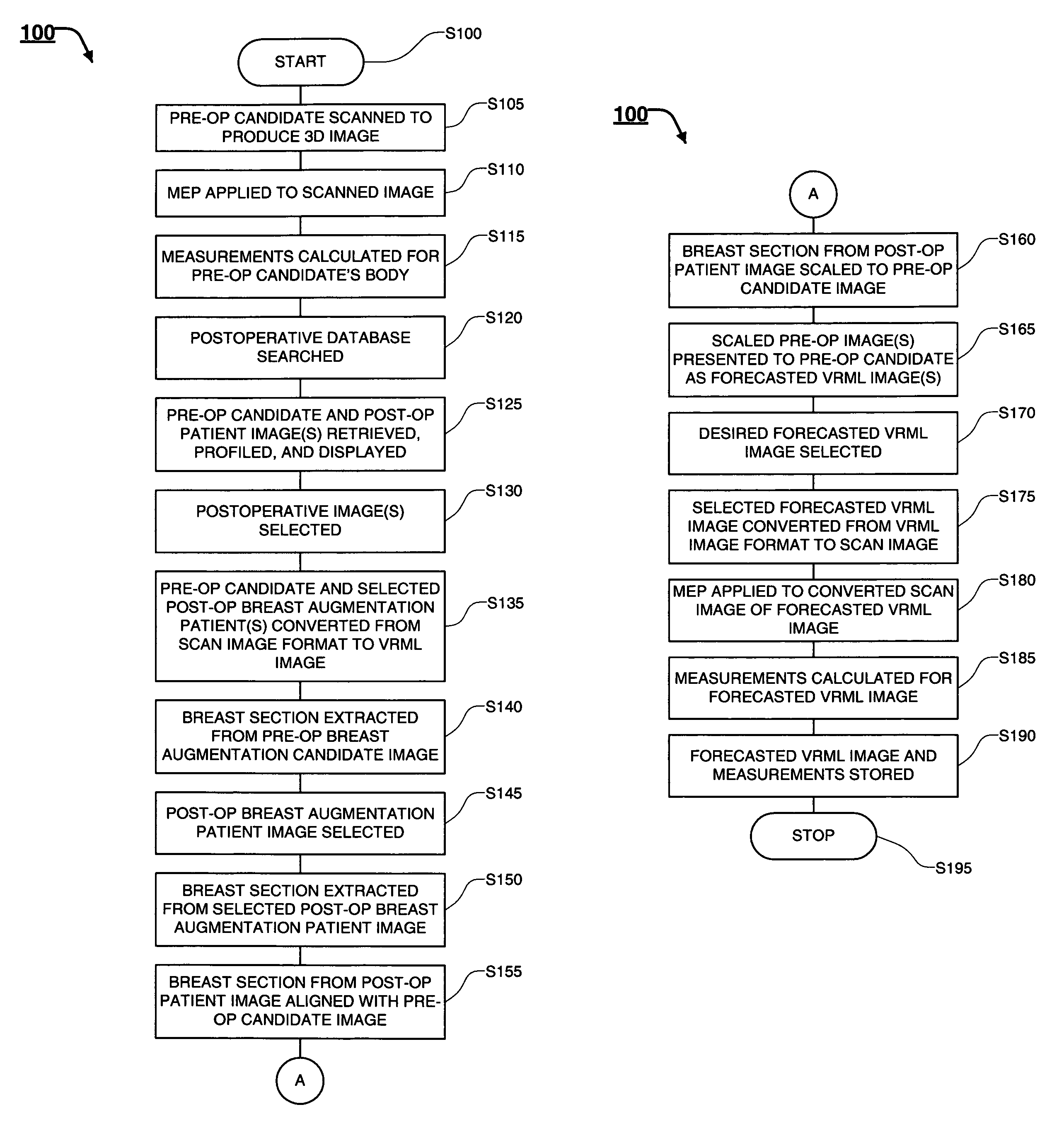

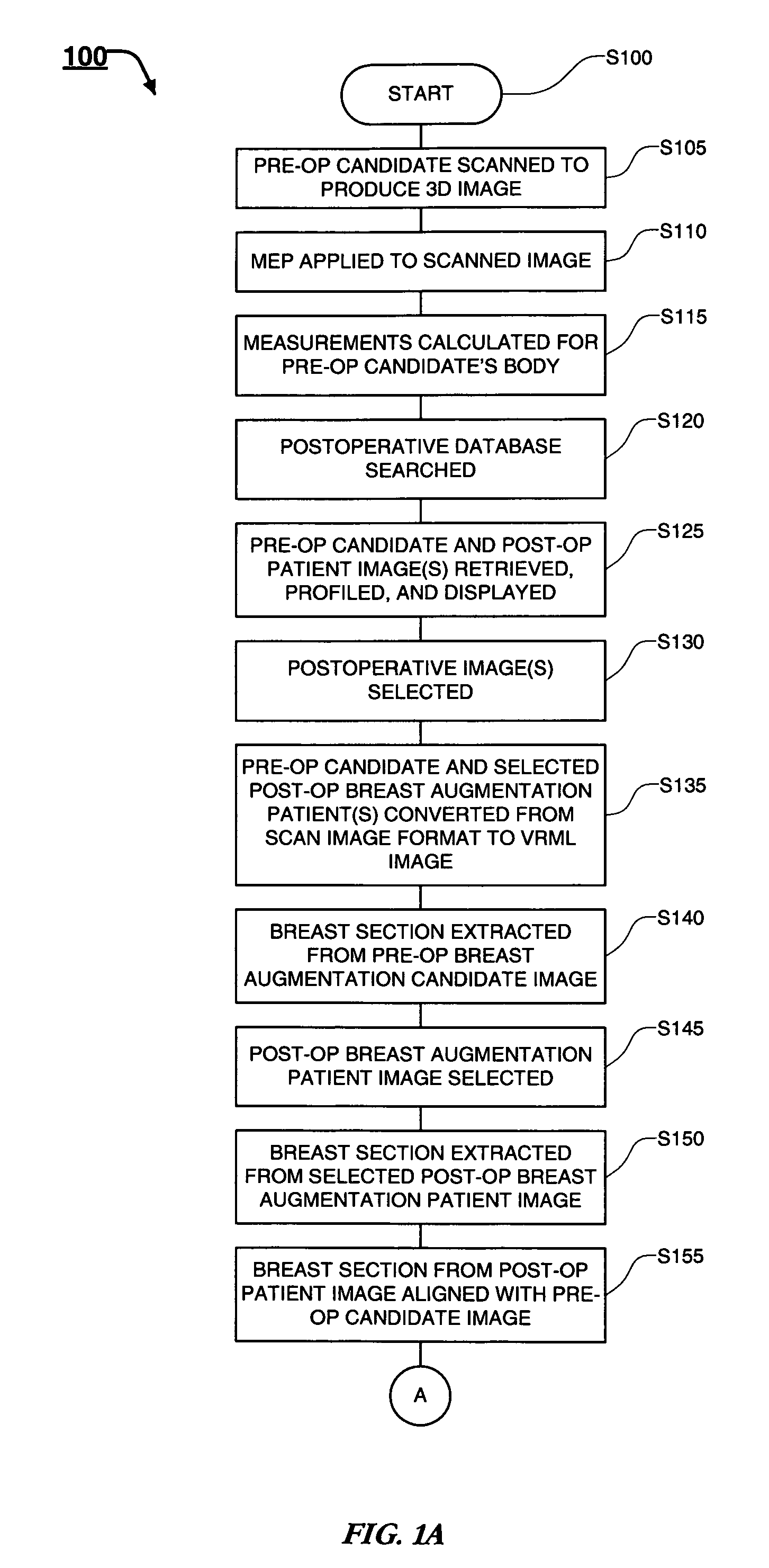

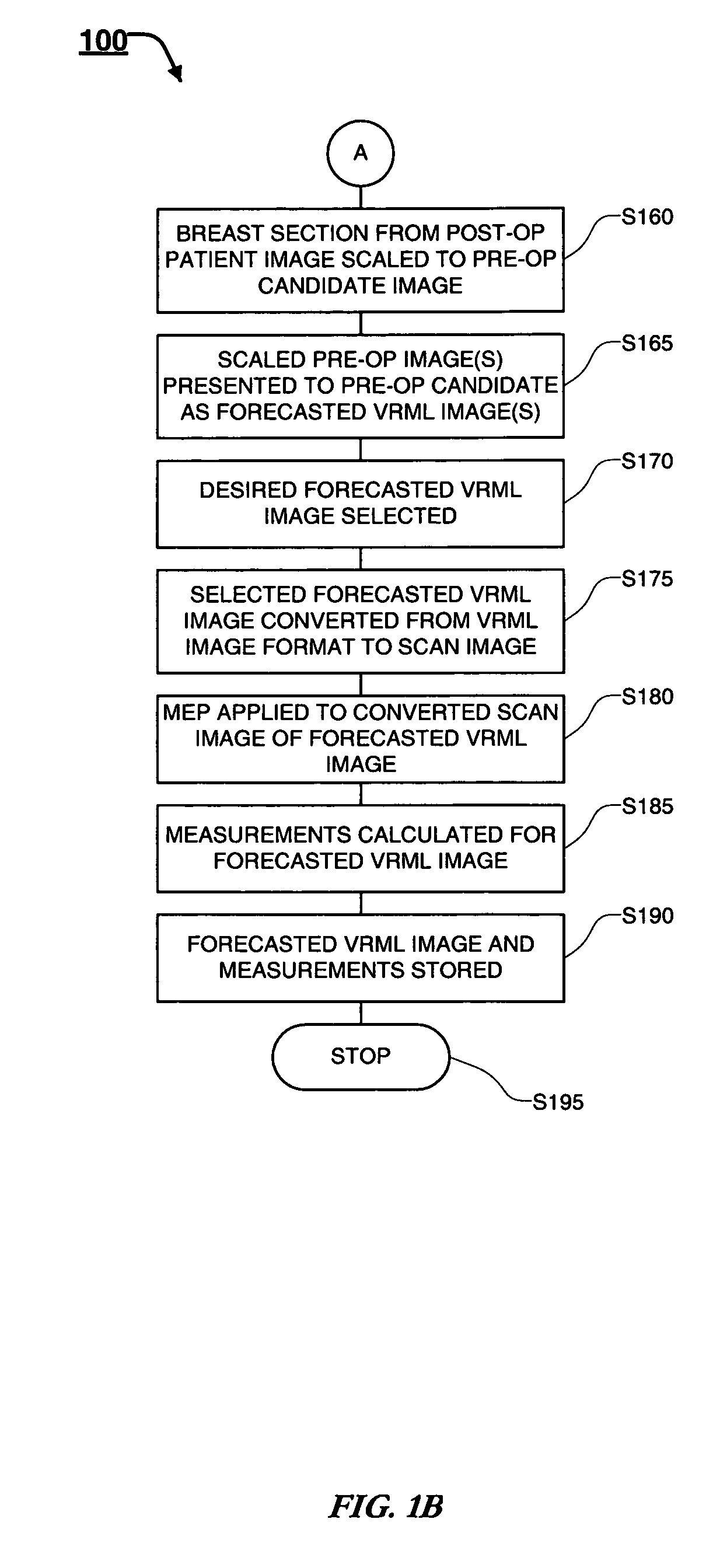

Virtual cosmetic and reconstructive surgery systems, methods, and apparatuses

ActiveUS7587075B1Accurate predictionUltrasonic/sonic/infrasonic diagnosticsMechanical/radiation/invasive therapiesBreast implantBreast augmentation

A method for producing a virtual forecasted model of a breast augmentation subject, comprising, receiving a preoperative subject's scanned image, wherein the scanned image comprises a three dimensional image, converting the scanned image from a scanned image format to a VRML image format, importing the converted VRML image into a VRML image editor, receiving, from a breast implant database, at least one modeled virtual breast implant, wherein the received virtual breast implant is selected based on a desired actual breast implant that is to be implanted in the preoperative subject, and embedding the received virtual breast implant in the preoperative subject's converted VRML image.

Owner:NOVAPTUS SYST

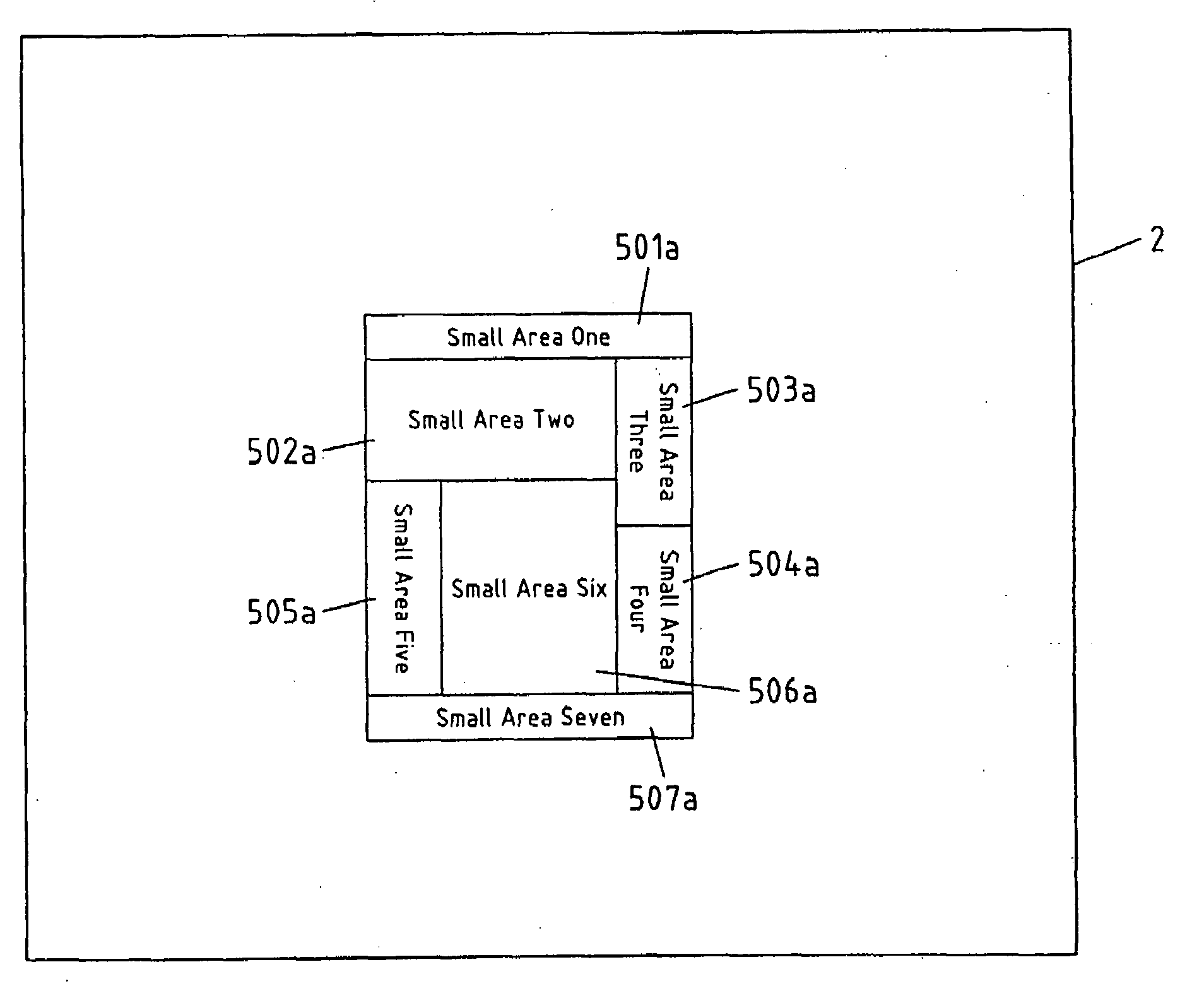

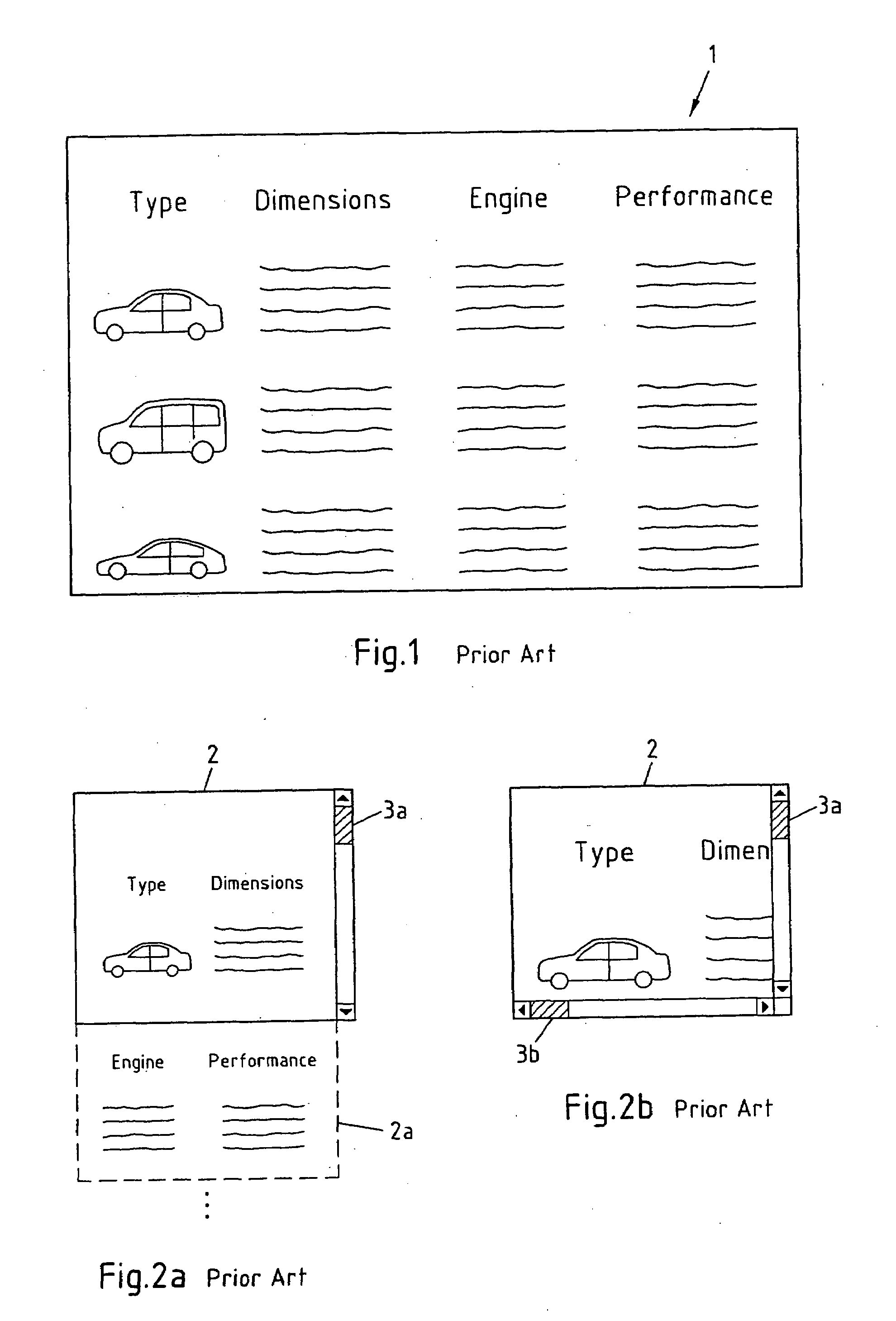

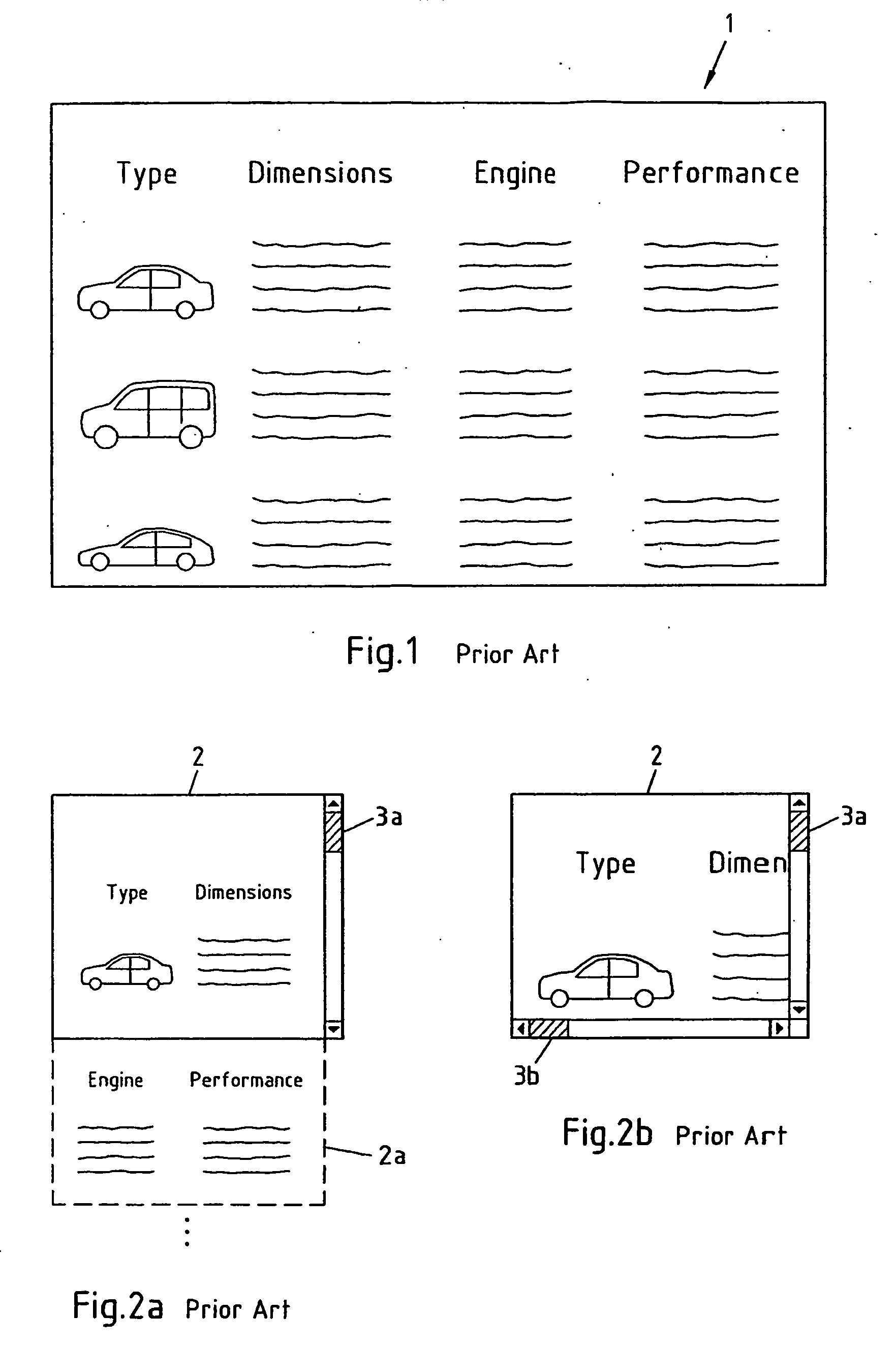

Presentation of large objects on small displays

InactiveUS20070124669A1Small sizeEasy to demonstrateDigital data information retrievalSpecial data processing applicationsDisplay deviceVRML

A method for presenting at least a part of an object is shown, comprising at least partially dividing at least one object into a plurality of sub-objects, presenting the plurality of sub-objects in a first representation, making at least one sub-object of the plurality of sub-objects an active sub-object, and in response to a user operation on the at least one active sub-object, presenting at least one of the at least one active sub-objects in a second representation. The at least one object may be a 2D object, e.g. a Hypertext Markup Language HTML page or a page of a text document, or a 3D object, e.g. a Virtual Reality Markup Language VRML object, and said display may be integrated in a portable electronic device. The invention further relates to a device, a system, a computer program and a computer program product.

Owner:NOKIA CORP

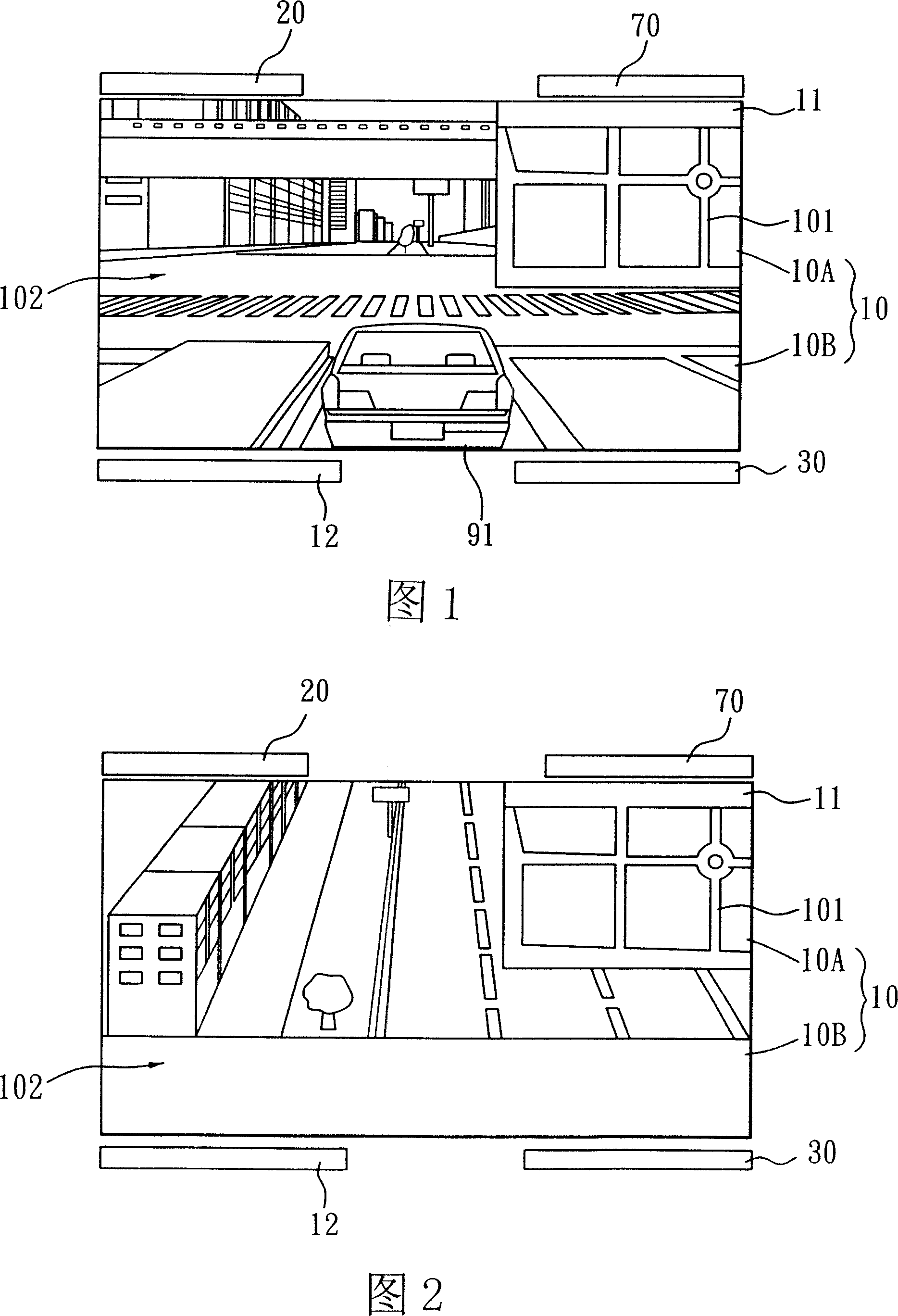

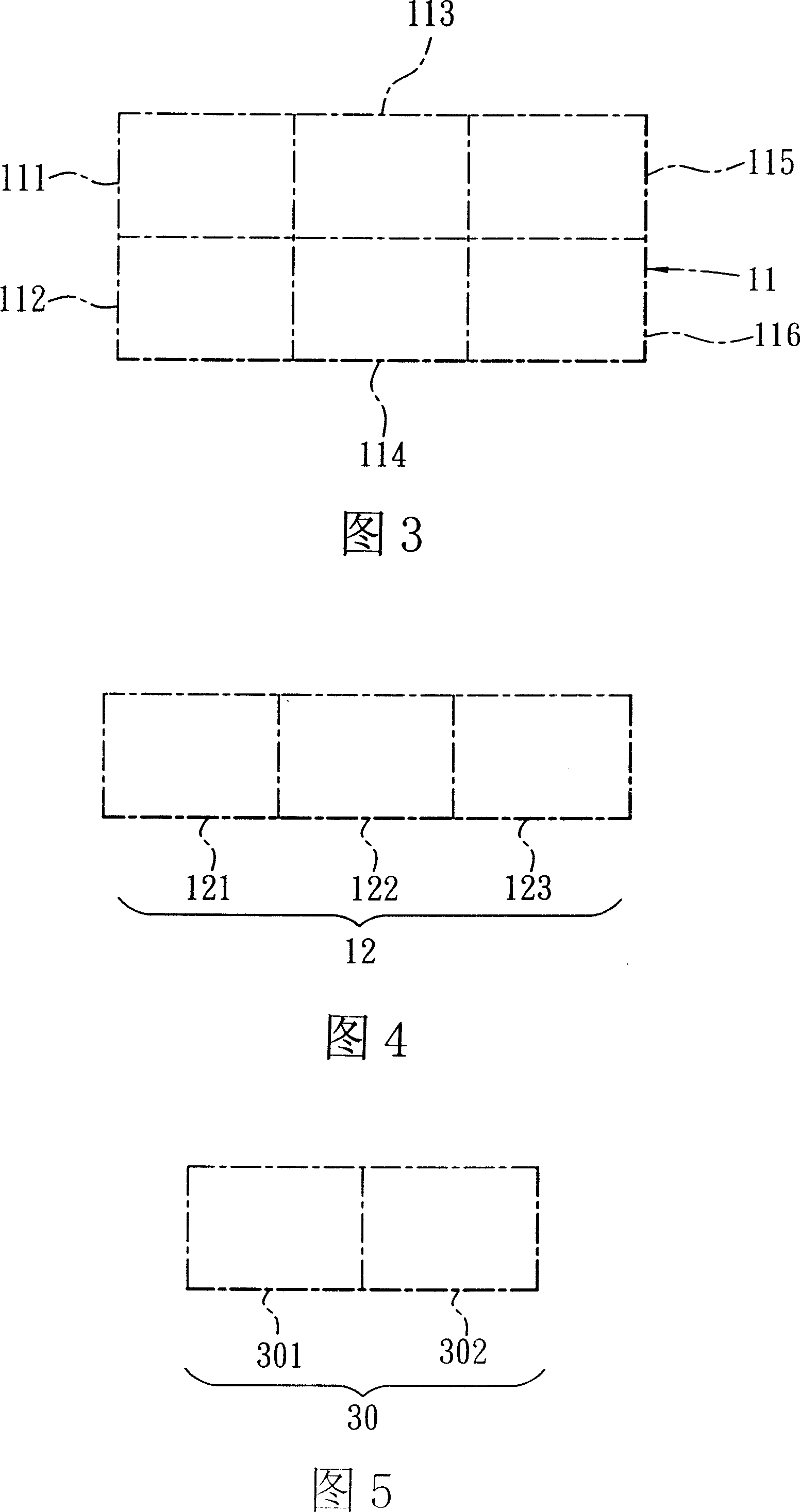

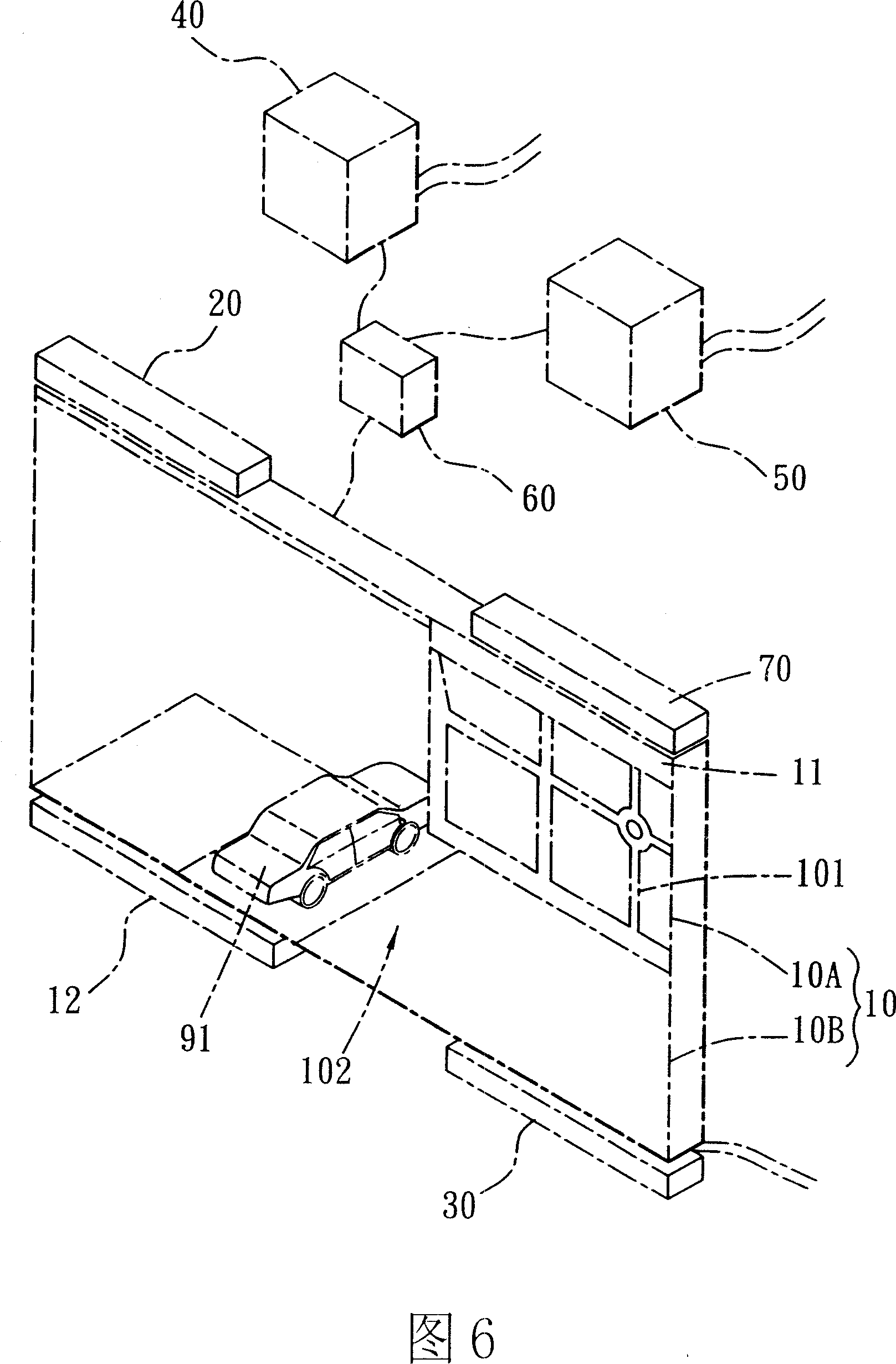

Simulated three-D real environment guidance system

InactiveCN101101217AInstruments for road network navigationNavigational calculation instrumentsThree dimensional simulationVehicle dynamics

The invention relates to a three-dimensional simulation of reality navigation system, including a show part that at least has: a first window, with a first control division, controls the first window to show the vertical overlooking the two-dimensional image of the location of an object; a second window, with a second control division, controls the second window to display a virtual reality modeling language (VRML) format 3-D images, the 3-D image is used to display and record the dynamic information of the subject; the two-dimensional, three-dimensional images with each other constitute a navigation system. The invention has the son mother switch window, switches / at the same time displays the two-dimensional images and three-dimensional images, and to the point of overlooking the images showed more changes, but also indicates the car with his vehicle dynamics.

Owner:FENG CHIA UNIVERSITY

Virtual cosmetic and reconstructive systems, methods, and apparatuses

InactiveUS7424139B1Accurate predictionUltrasonic/sonic/infrasonic diagnosticsMedical simulationComputer graphics (images)VRML

The virtual surgery systems, methods, and apparatuses that provide for the prediction, evaluation, and validation of various cosmetic and reconstructive surgical procedures. The virtual surgery systems, methods, and apparatuses utilize a scanner, measurement software, queries to a postoperative patient scan catalog, conversion of a preoperative image to a Virtual Reality Modeling Language (VRML) image, grafting and scaling of chosen postoperative surgery candidates, conversion from the converted VRML image to a scanner readable format, and measuring the forecasted VRML image.

Owner:NOVAPTUS SYST

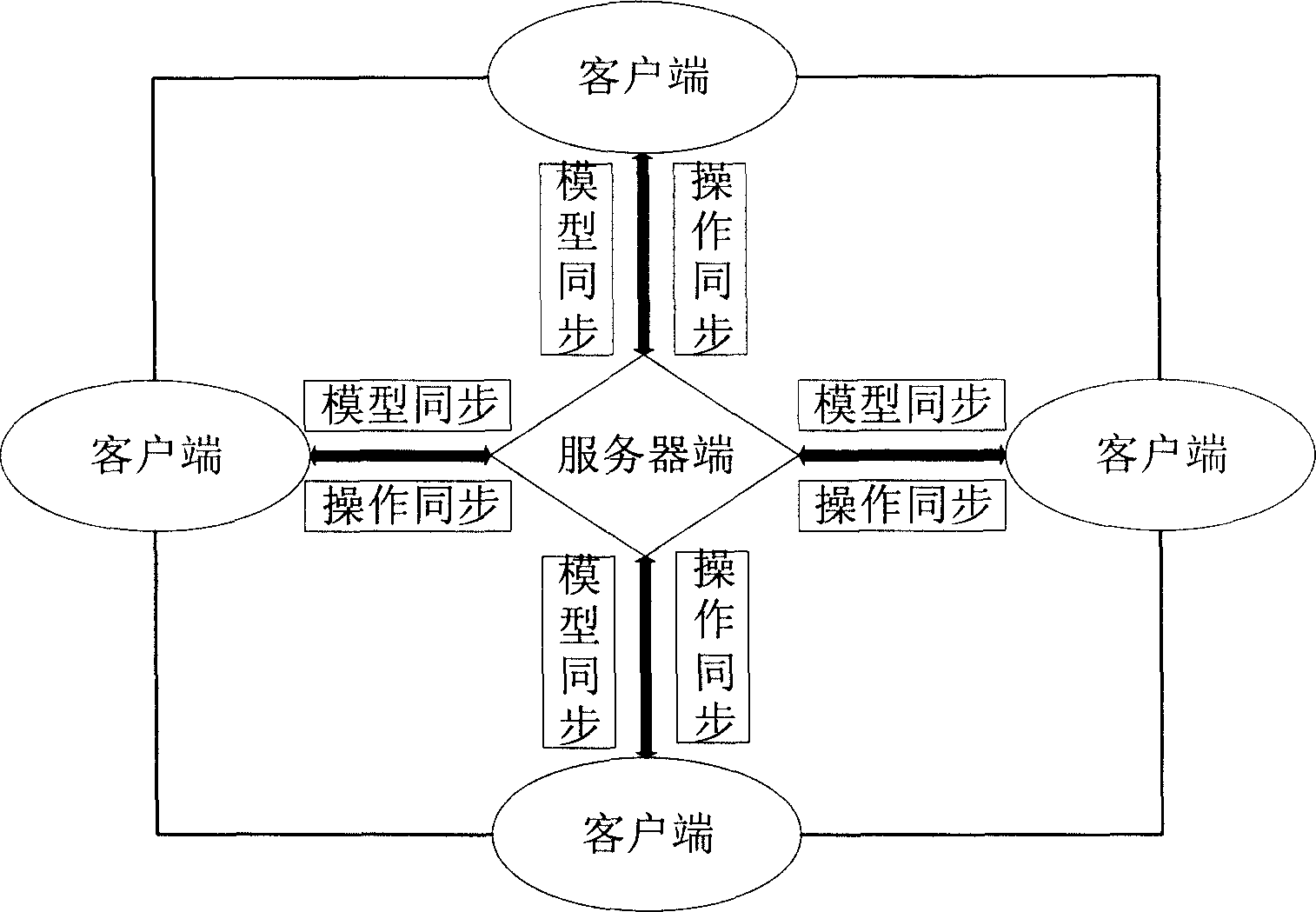

Method for model postil and operation transmission in universal type synergic communion system

InactiveCN1731733AImprove real-time communication efficiencyReduce misunderstandingSpecial service provision for substationSpecial data processing applicationsStream socketVRML

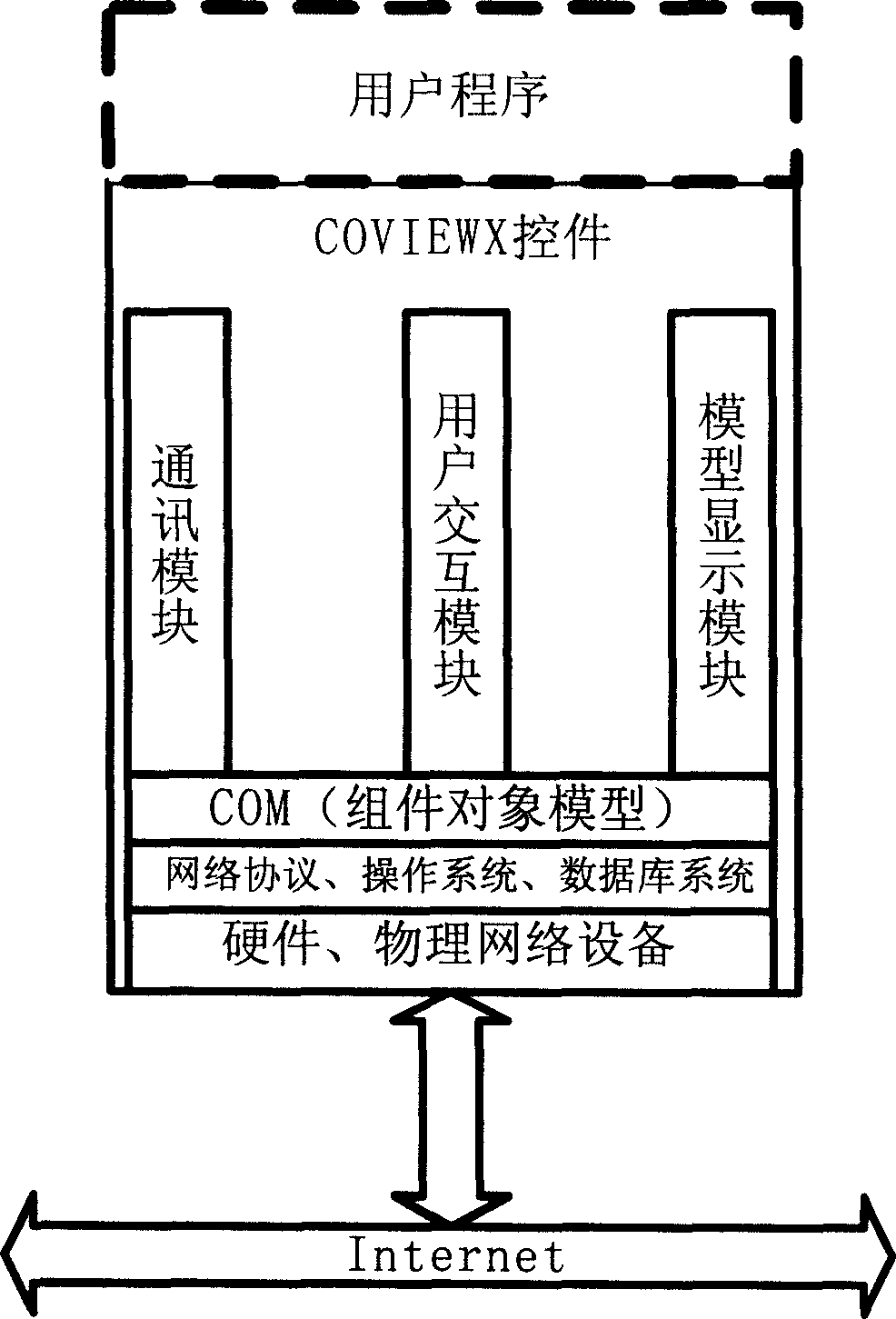

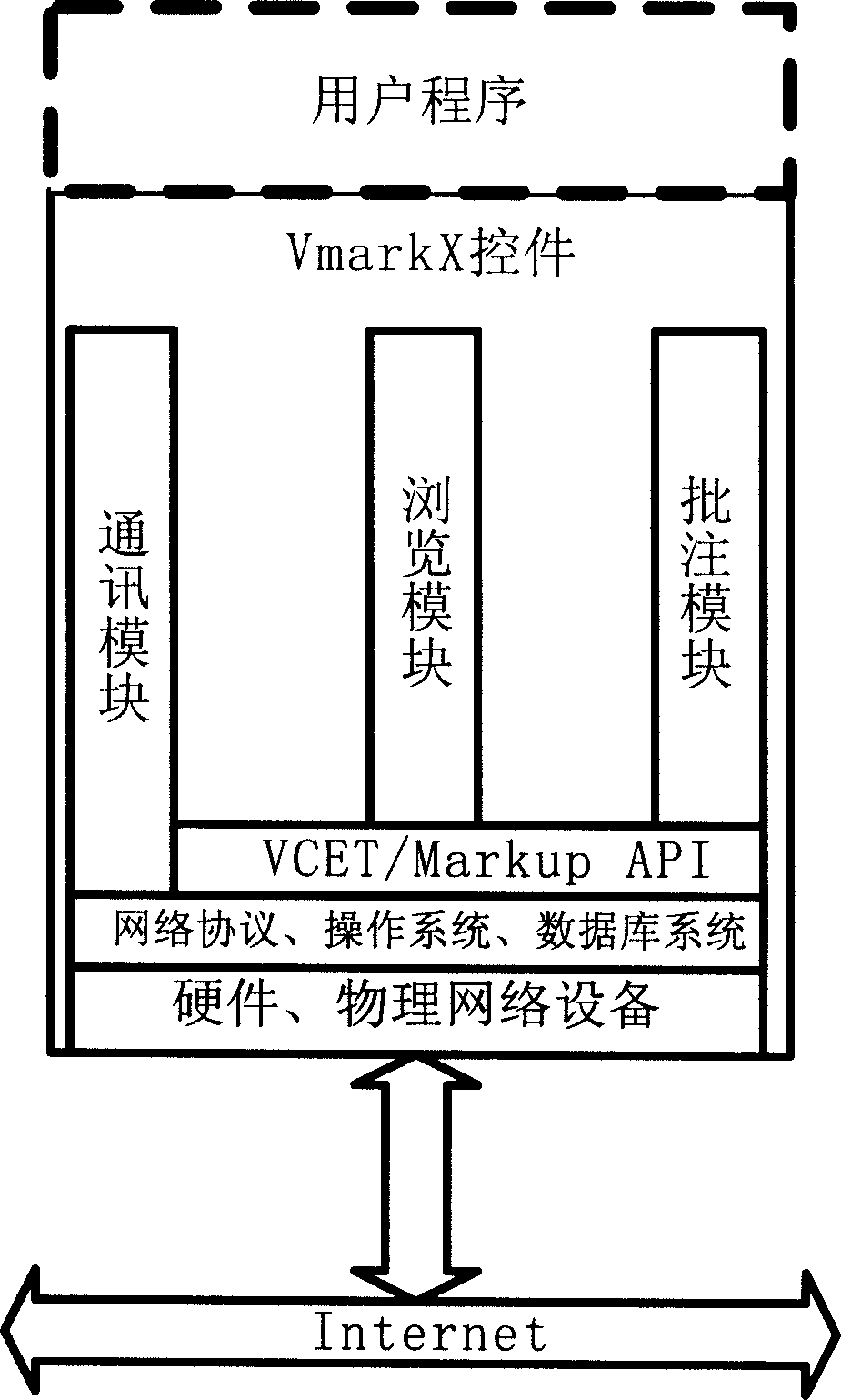

Disclosed is an invention, which cooperates with CAD for production design. It is characterized in that: employing the separate transmission mechanism of model synchronization and operation synchronization between client and server to realize real time synergetic design; also employing stream sockets for information exchange. For three-dimensional model, server terminal and each client terminals are provided with: model display module based on VRML files, customer interchange and communication modules; for two-dimensional model, the server terminal and client terminals are provided with communication module, remark module based on VECT library and communication module. The invention has the advantage of improving the real time communication efficiency between designers, of shorting production-developing cycle.

Owner:TSINGHUA UNIV

Apparatus and method for displaying subsurface anomalies and surface features

ActiveUS20050090988A1High resistivityIncreased resistivityElectric/magnetic detection for well-loggingSeismic signal processingAbove groundVRML

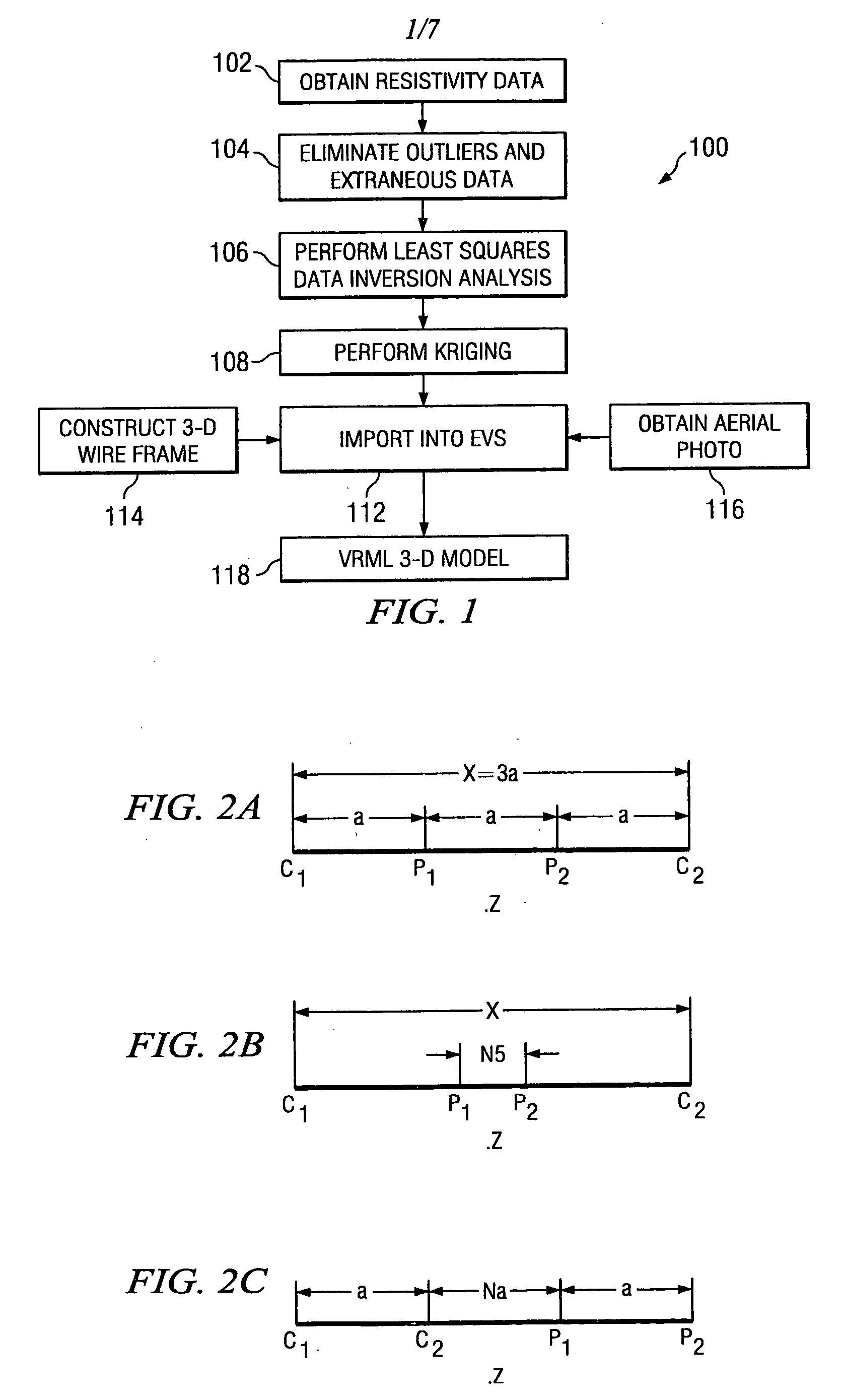

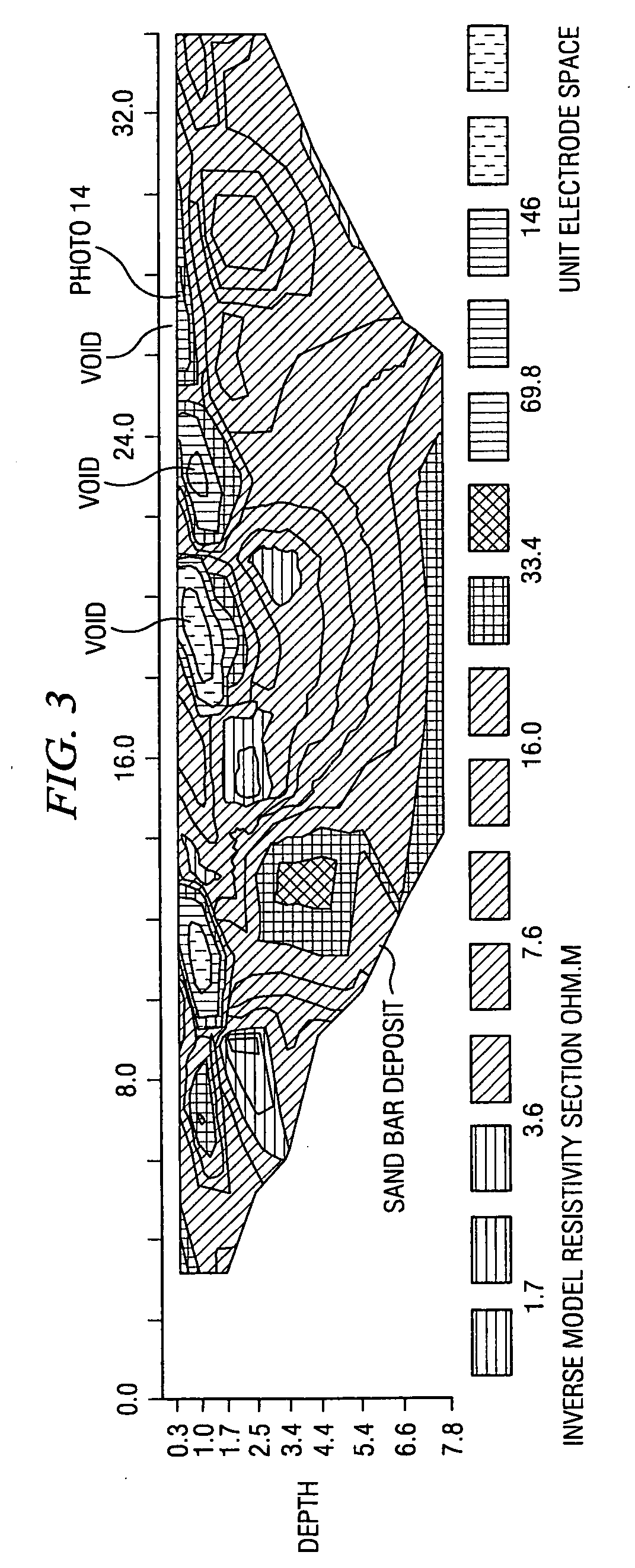

The present invention provides a method of combining various types of data and software in order to arrive at a composite graphical representation of a construction site, including surface and subsurface features. A 2-D or 3-D graph of subsurface contoured surfaces is created. A 3-D wire-frame model of surface and subsurface features is created. Aerial photographs of the site can be incorporated and the aerial photographs contoured surfaces and wire-frame model are to produce a complete Visual Reduction Modeling Language (VRML) model of both surface and subsurface features. The VRML model allows the user to identify and visualize a relationship between sub-surface features and above ground features.

Owner:BRYANT CONSULTANTS

Hotel reservation system based on 3D panorama APP

InactiveCN105930912AFacilitate communication and consultationEnhanced interactionReservationsHTML5VRML

The invention provides a hotel reservation system based on a 3D panorama APP. The system comprises a query module, a user module and a 3D panorama module. Through module connection and information exchange, the user can comprehensively and visually understand the product information of a merchant, has an immersive experience, and can reserve goods in real time. The merchant can well, comprehensively and quickly display products. The product promotion cycle is shortened. The promotional cost is reduced. The 3D panorama system is a great user experience platform for the user, and is a great promotional trading platform for the merchant. According to the hotel reservation system provided by the invention, compared with traditional VRML and FLASH technical frameworks, the used HTML5 technical framework enables the hotel reservation system to exceed platform limits and has greatly improved universality; and the problems of different standards, plug-in dependence, being closed, poor integration and the like of other technical frameworks are solved.

Owner:NANCHANG UNIV

Web 3D image display system

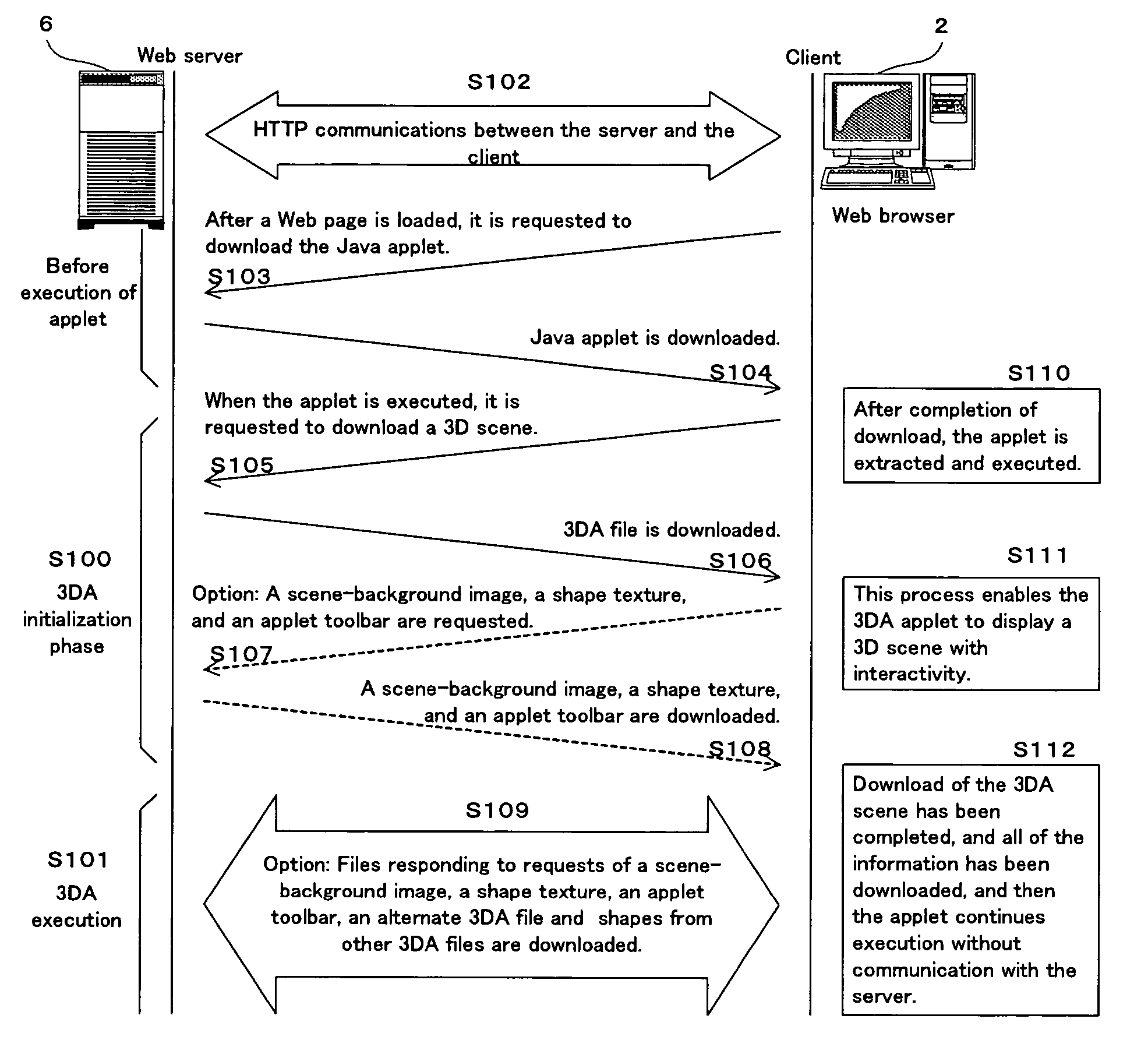

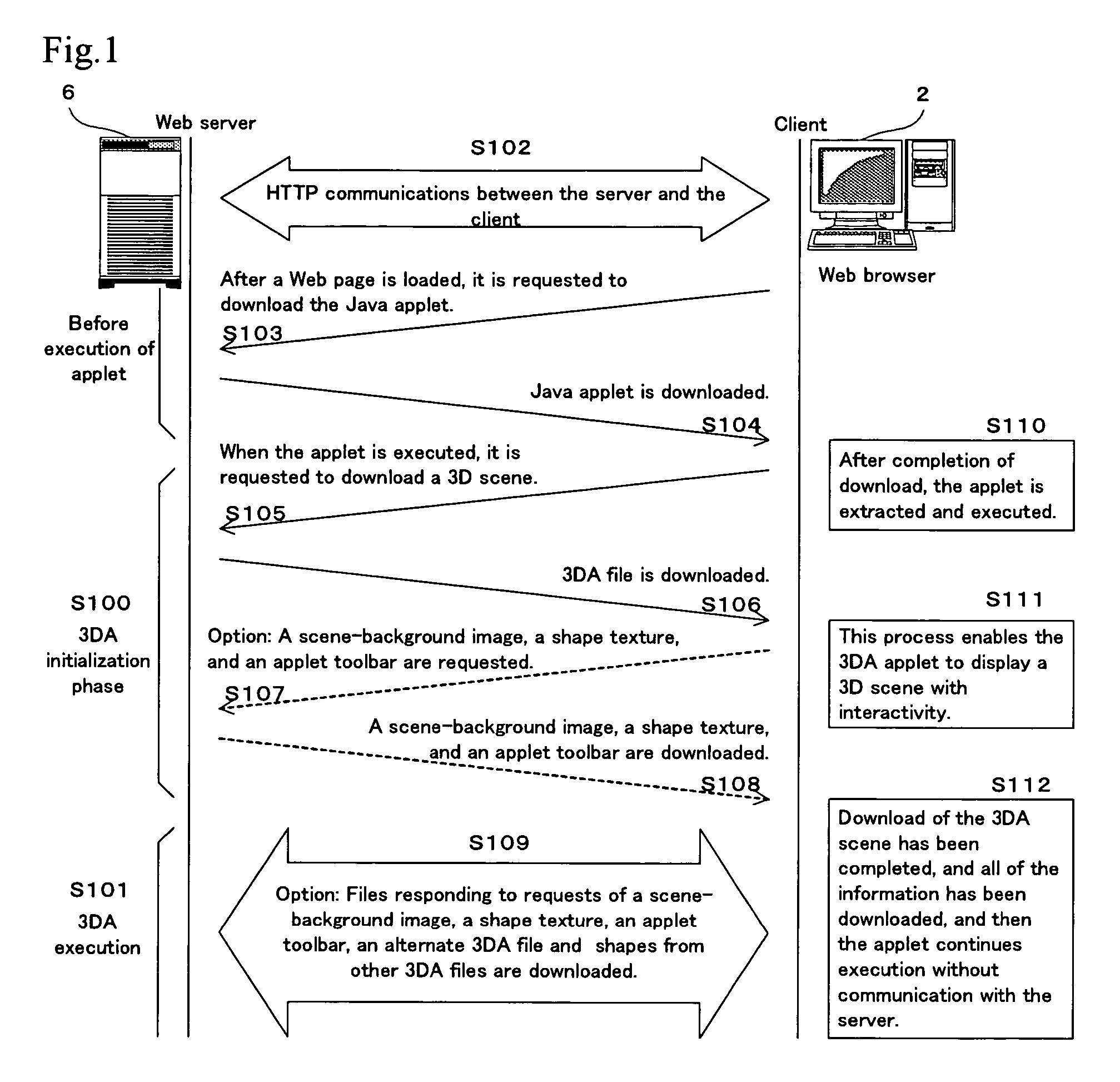

A Web-based 3D-image display system that downloads 3D-image files from a Web server and smoothly displays 3D -images on a Web browser. The Web-based 3D-image display system is provided with a Web server storing compressed 3D files that have been edited and created based on 3D-scene information extracted from a VRML file or the like, and a 3DA applet for displaying 3D scenes; and a Web browser for displaying the 3D scene. The Web browser requests and downloads the 3D applet from the Web server and requests and downloads the compressed 3D file from the Web server by executing the 3D applet. After downloading and receiving all information, the Web browser continuously displays an interactive 3D -scene by executing, independently of the Web server, real-time 3D-rendering and 3D-motion algorithms using the 3D applet.

Owner:KAGA ELECTRONICS CO LTD

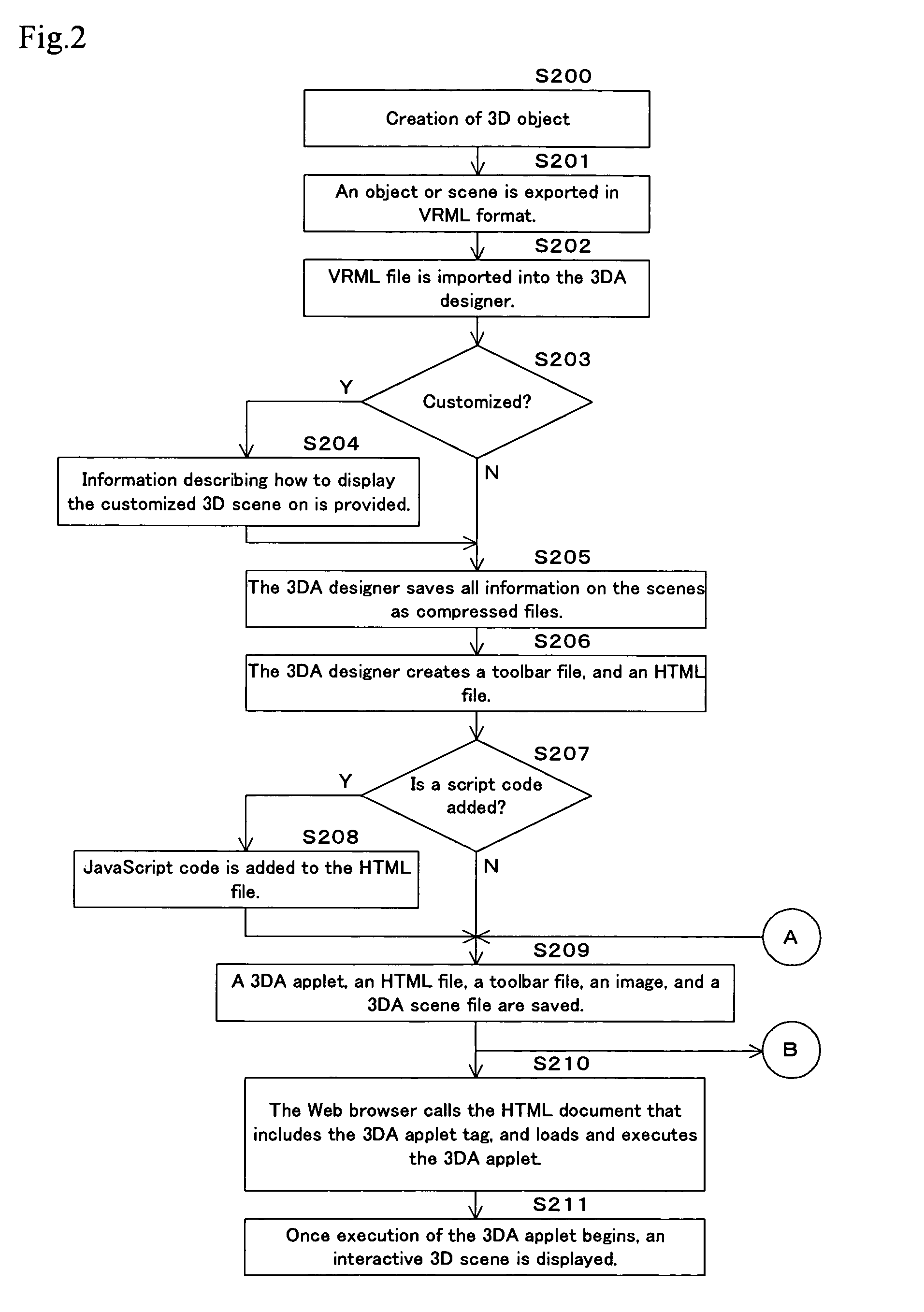

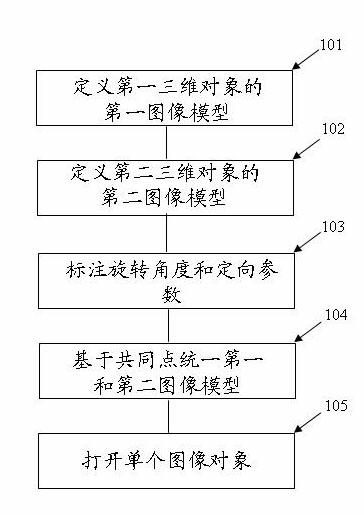

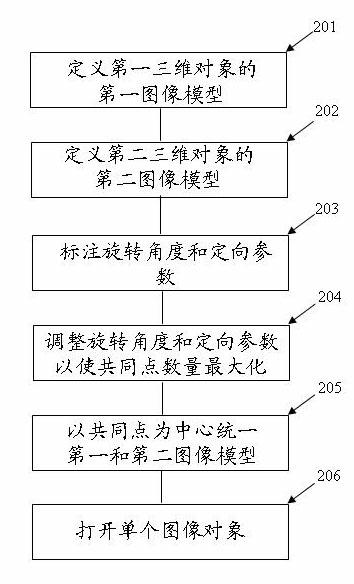

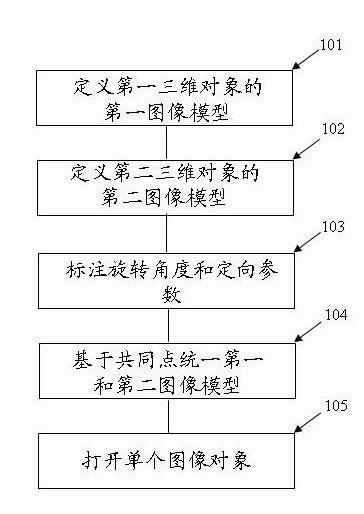

Manual assembly method of virtual three-dimensional model based on VRML-JAVA

The invention relates to a manual assembling method of a virtual three-dimensional model based on VRML-JAVA, comprising the following steps: (1) establishing a part 3D model and a rendering model thereof; (2) defining a VRML assembling model; (3) determining an assembling group, parts contained in the assembling group, and the number of the parts; (4) determining a part assembling sequence; (5) selecting the parts with a correct assembling sequence; (6) dynamically transferring part nodes; (7) determining a manual movement interference range of the parts; (8) manually moving the parts along a three-dimensional direction in a VRML scene; (9) monitoring the current position state of the parts; (10) determining if assembling positions of the parts are correct; and (11) completing all part assembly. The invention can overcome the dependence on object sample pieces and effectively enhance the assembly design benefit of the parts, has functions of assembling the parts with off-site cooperated with manual operation, detecting collision interference, prompting correct assembly information and enhancing the appearance reality sense of the parts and can randomly manually move the parts to assemble or disassemble by observing from any position along a triaxial direction.

Owner:SHENZHEN UNIV

Method for three-dimensional inventory link

InactiveUS20070198695A1Digital computer detailsElectric digital data processingNetwork operations centerVRML

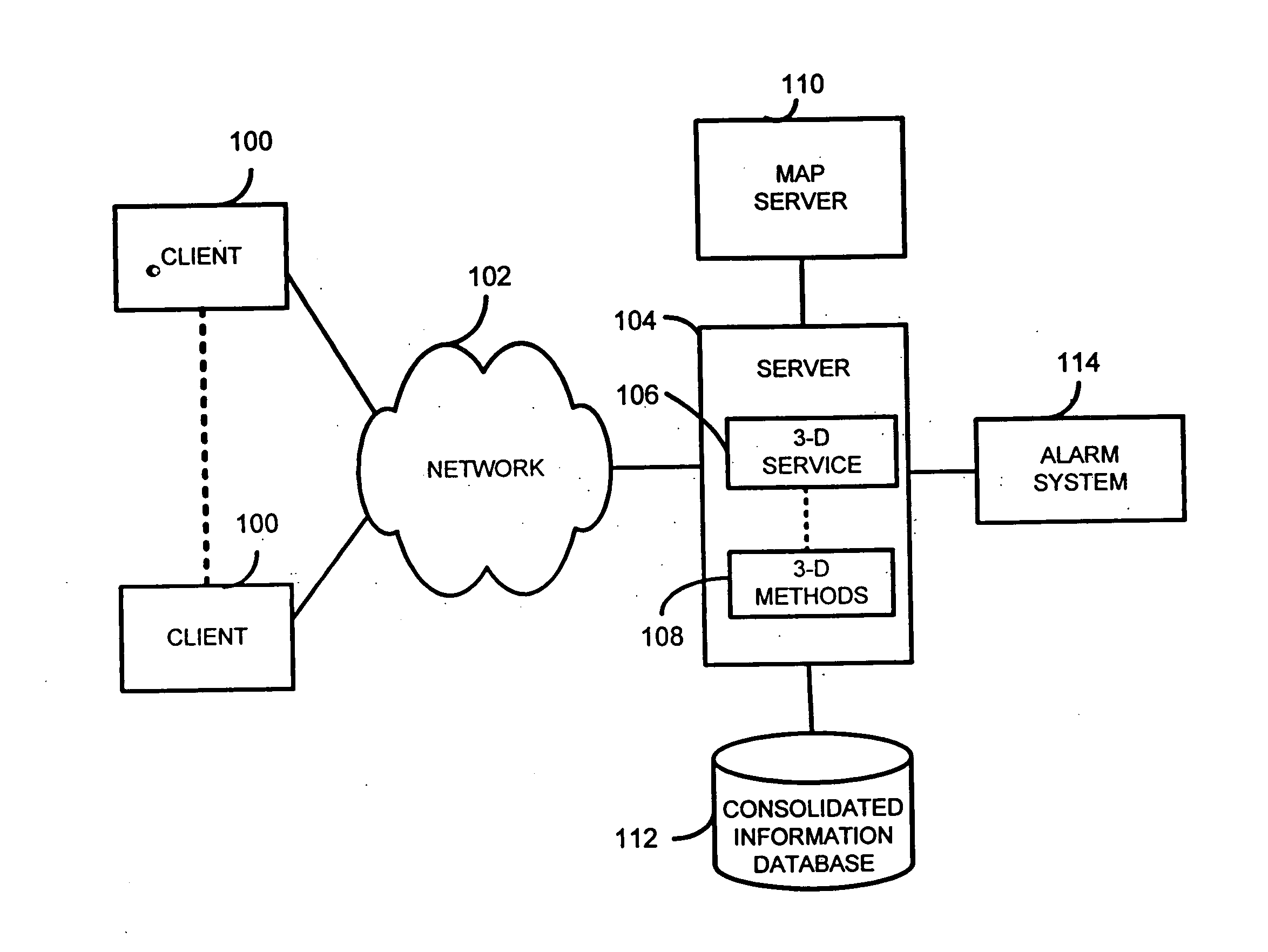

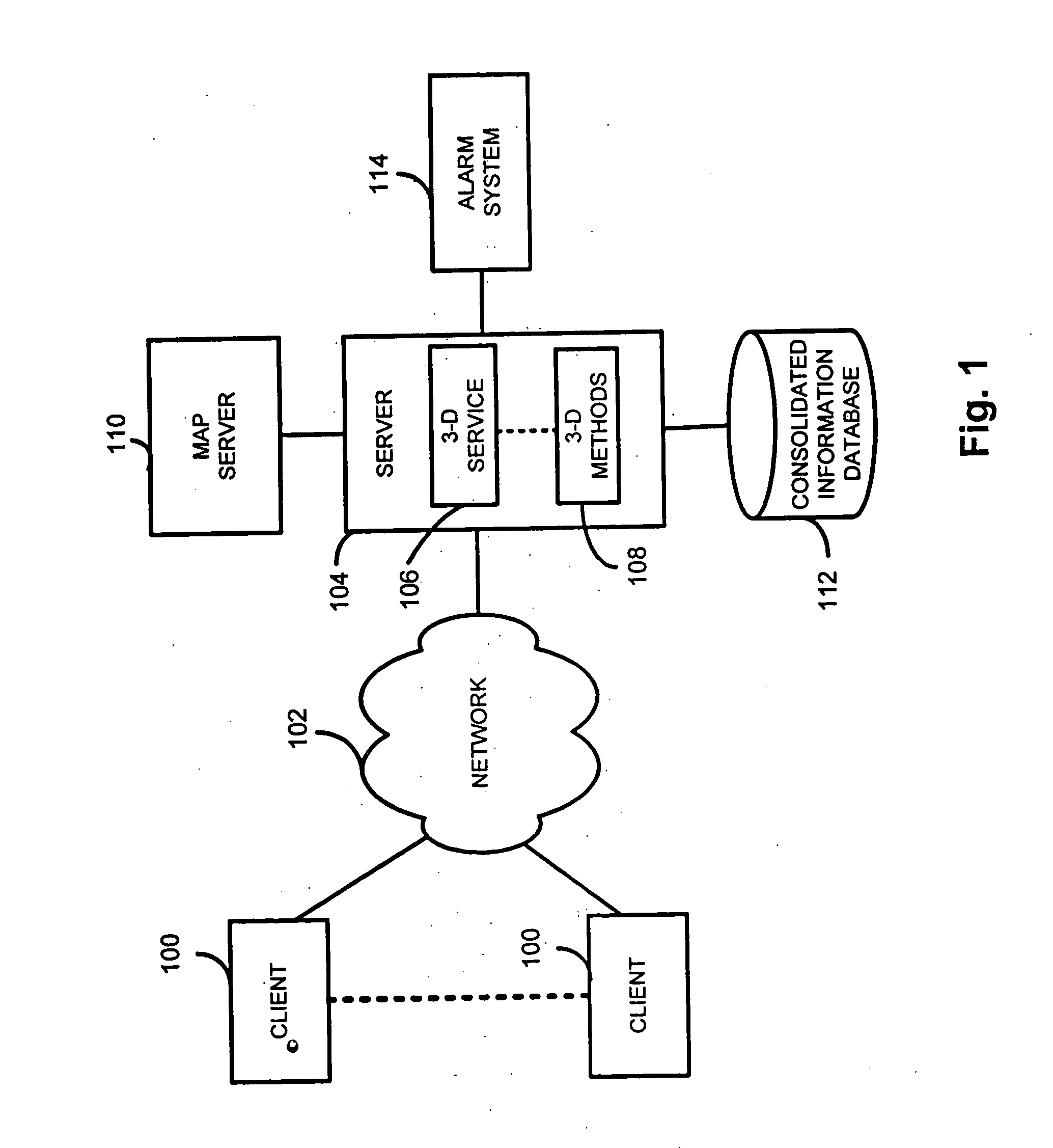

In accordance with the teachings of the present invention, a method is presented for providing an end user with a virtual reality experience. A server generates three-dimensional information. The three-dimensional information is generated using real-time alarm information representing an alarm, VRML schema information and meta-data. A client receives the three dimensional information. A three-dimensional image of a network operations center including a device responsible for the alarm is presented in a GUI. Operating the GUI allows the end user to experience moving through the operations center to the location of the device responsible for the alarm.

Owner:AMERICAN TELEPHONE & TELEGRAPH CO

Virtual simulation hospital nursing teaching and training system and construction method thereof

InactiveCN107067862ABroad simulation teachingBroad research platformCosmonautic condition simulationsSimulatorsInteraction layerGraphics

The invention discloses a virtual simulation hospital nursing teaching and training system, and a method of constructing the virtual simulation hospital nursing teaching and training system by using a computer multimedia technology and a 3D graphics algorithm of VRT and a virtual reality technology of WEB VRML. The virtual simulation hospital nursing teaching and training system comprises a hospital admission nursing module, a hospitalization nursing module, a patient treatment module, and a hospital discharge nursing module. Each module is composed of an interaction layer, a function layer, a driver layer, an integration layer, and a resource layer. The virtual simulation hospital nursing teaching and training system is constructed using the current advanced virtual reality technology, and thus, a wider and convenient simulation teaching and research platform is provided for all levels of hospitals and medical colleges and universities. The virtual simulation hospital nursing teaching and training system is mainly used for teaching and training students in medical colleges and universities and newly-employed medical staff in hospitals in order to reduce teaching cost, reduce medical risk, save training resources and improve the quality of teaching and training.

Owner:张小来

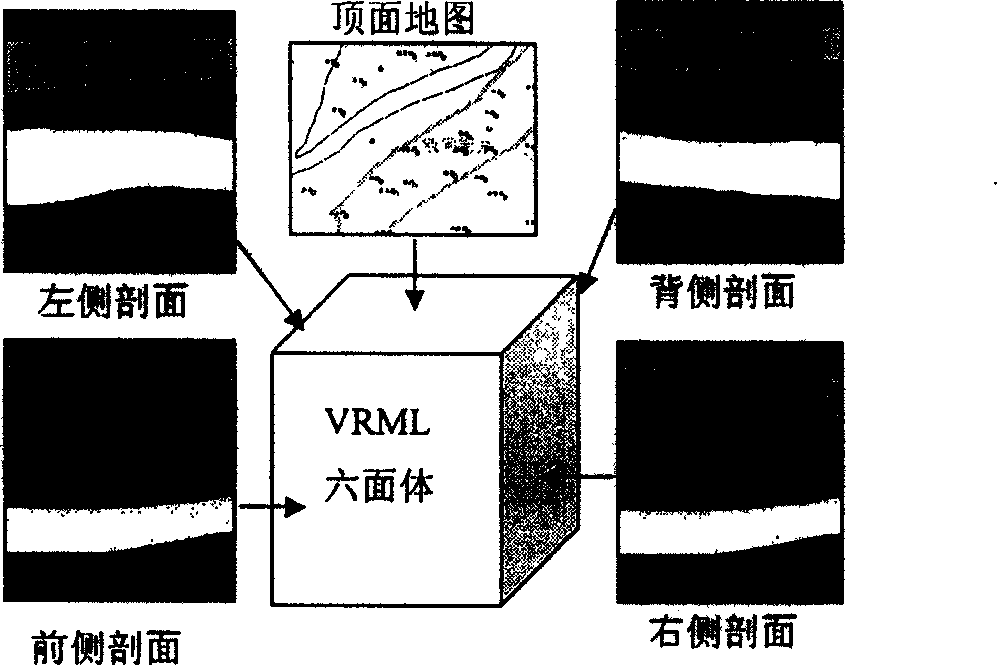

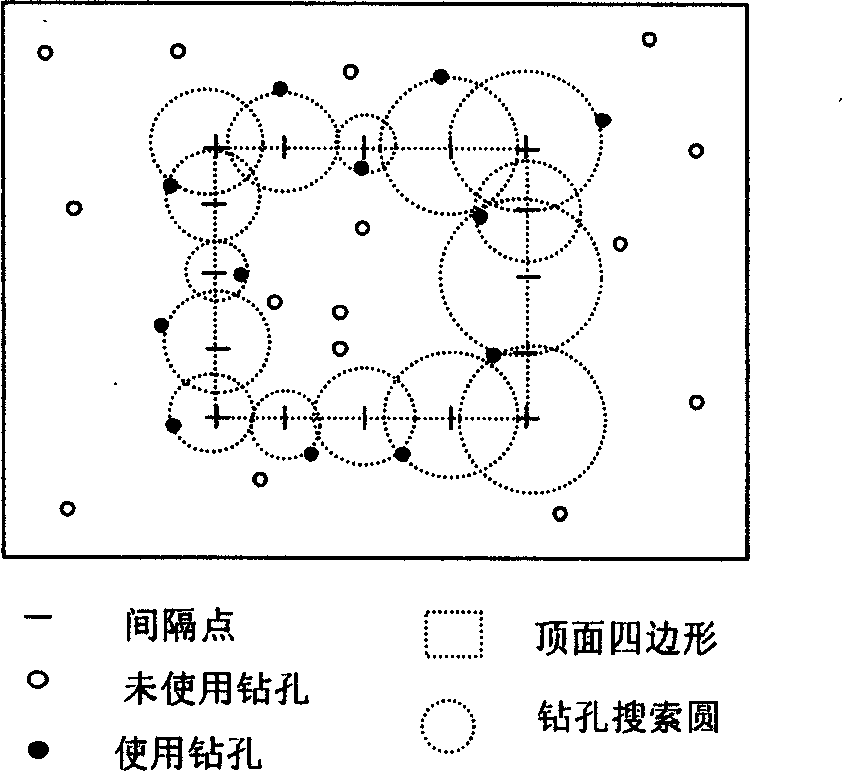

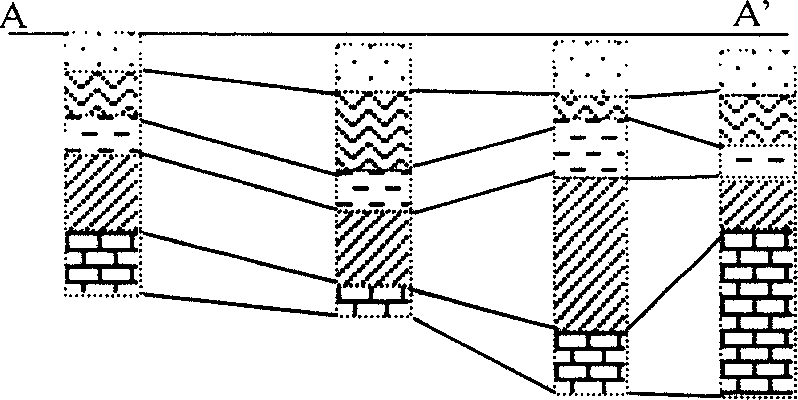

Real-time three-dimensional geology modeling method based on GIS and virtual reality

InactiveCN1595455ANo additional processing costsReduce manual intervention3D modellingLithologyGraphics

The invention relates to a real time three-dimensional geology modeling method based on the GIS technique and the virtual realization technique. It pastes the picture on the surface of the hexahedron through the VRML. The pictures of the four sides are used to represent the lithologic character variation with the depth, and to construct the main body of the model. The top picture uses the two-dimensional map of the hexahedron located area, which comes from the two-dimensional GIS electric map. The graph processing of the bottom of the hexahedron is omitted. It is a new geology modeling method implemented with the VRML as the modeling instrument under the GIS conditions. The method uses the drilling data effectively without the complicated data processing.

Owner:NANJING UNIV

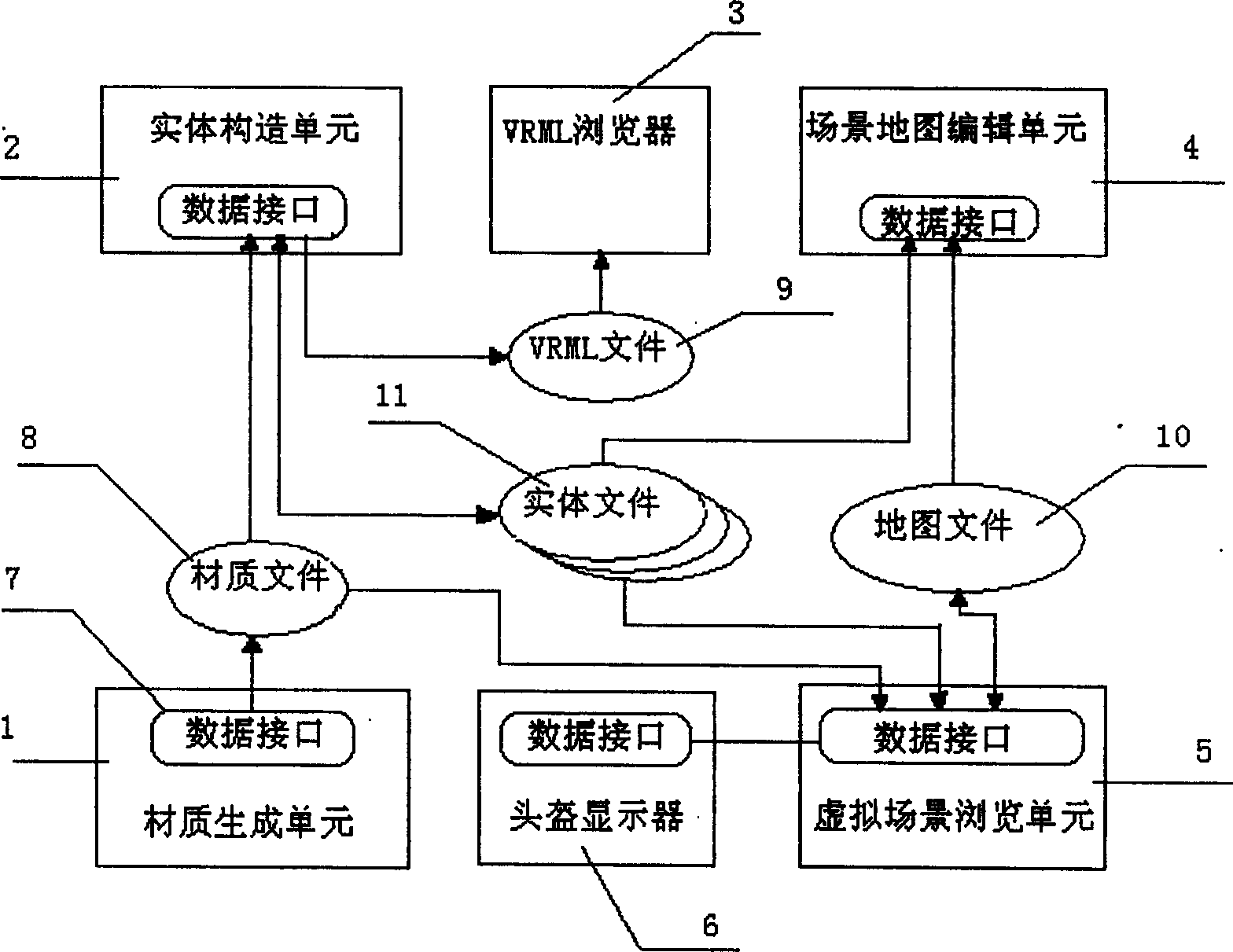

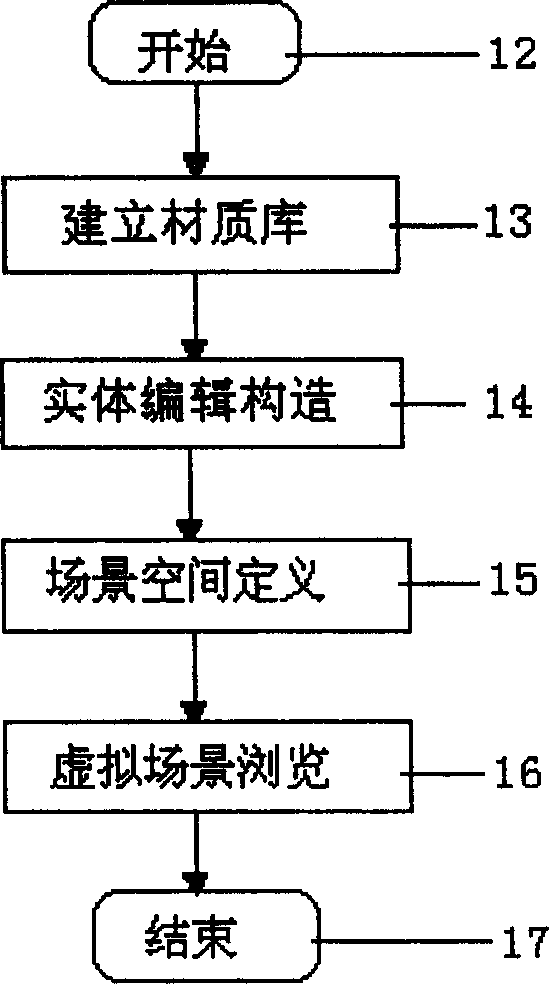

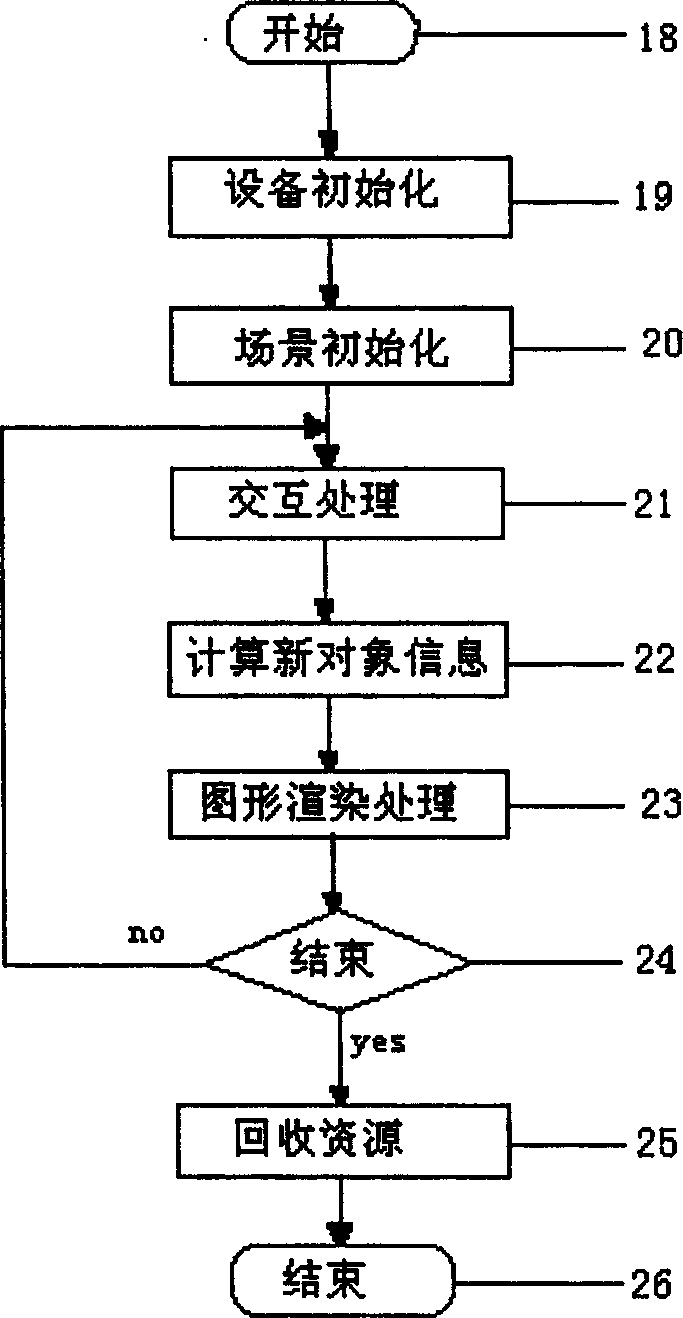

Virtual fractal spectacle three dimensional roaming system

The invention relates to a 3D roaming system of virtual fractional scenes, including a material quality generating unit, an entity constructing unit, a VRML browser, a scene map editing unit and a virtual scene browsing unit, and its working flows: starting; initializing device; initializing scene; interactive processing: receiving the information including forward, backward, look-up, look-down, turning left and turning right, and making corresponding transformation on a 3D model and the observed state; calculating object information; pattern romancing processing; ending and otherwise returning to interactive processing recovering resources. It has the advantages of simple structure, low cost, convenient operation, fast generating of scene environment, etc, and perfects the virtual-reality entity base, applied to the requirements of virtual battlefield training and virtual driving training.

Owner:沈阳工业学院

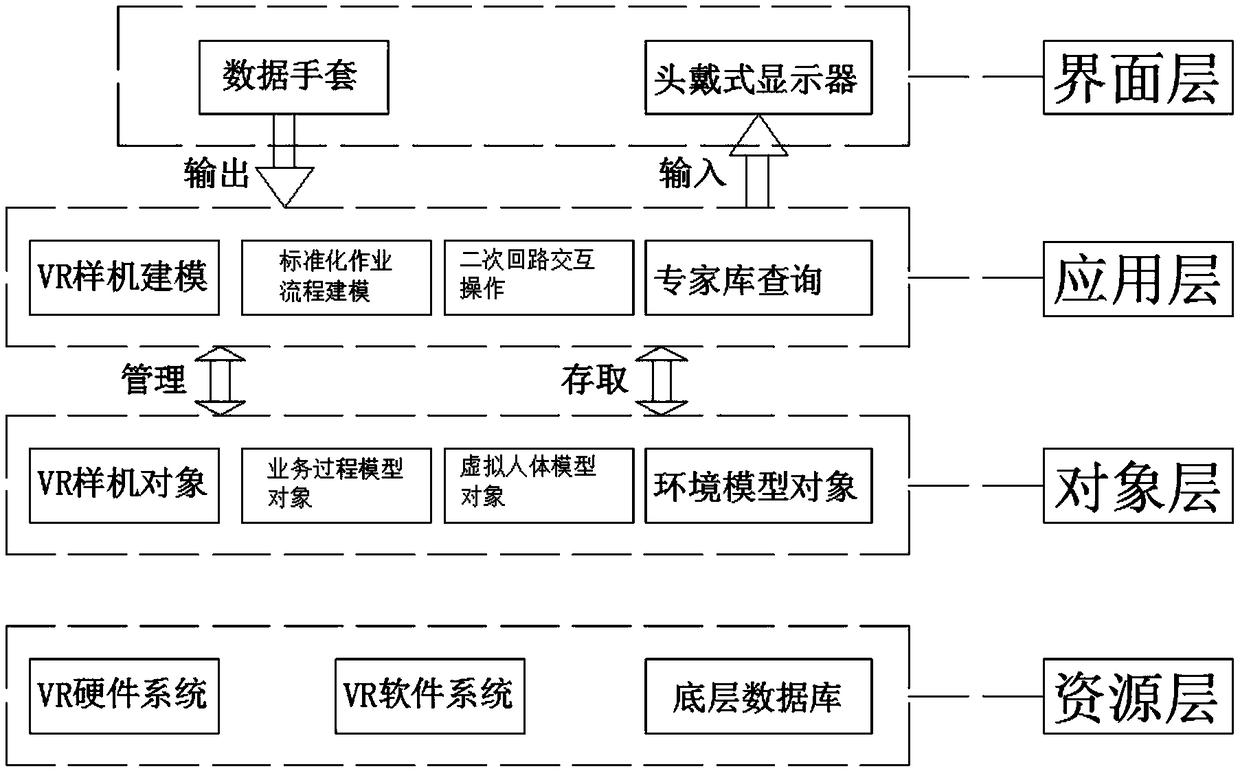

Relay protection simulation training platform construction method based on VR technology

InactiveCN108711327AHigh riskImprove securityCosmonautic condition simulationsSimulatorsInteraction controlTransformer

The invention relates to a relay protection simulation training platform construction method based on the VR technology. A simulation training platform comprises a host, an interaction device and an experience device. The interaction device and the experience device are connected with the host and arranged on the body of an operator. The construction method comprises steps of using the VRML technology to carry out modeling and forming a model database, wherein the model database is stored in the host. In the model database, through the VRML technology, according to the physical structure of atransformer substation and actual work of a maintenance worker, a virtual transformer substation electrical device model is obtained through carrying out of geometrical modeling, physical modeling andbehavior modeling. Through the Java and / or JavaScript language, scripts are compiled so that function extension is performed on the VRML. Through the Java, communication and interaction control between the operator, the experience device and the interaction device and the transformer substation simulation training system are achieved. An expert database is stored in the host. A typical defect analysis library and a typical operation simulation library for secondary maintenance of the transformer substation are provided.

Owner:STATE GRID BAODING ELECTRIC POWER SUPPLY CO +2

Dummy body form application method

The invention discloses an application method of virtual mannequin. The virtual mannequin consists of at least 100 sections and 40-70 data points which represent all the sections respectively. The file format of the mannequin is physical data defined by CAD software and file of VRML format. The application method comprises that: the native places and birthplaces of father and mother of the applied object and the birthplace of the applied object are confirmed; and the district bodily form of the applied virtual mannequin is confirmed; the age period of the applied object is confirmed; comparing with the physical data of mannequin defined by CAD software and file of VRML format, the data of the bodily form of the applied object is input, and the applied virtual mannequin is confirmed again. Therefore, research precision can be improved greatly in a short time, and according to different districts and age periods, bases are provided for suitability of clothes production, making of specification standard of clothes, research and analysis of clothes function and accurate data measurement of human body.

Owner:HENGYUANXIANG GRP

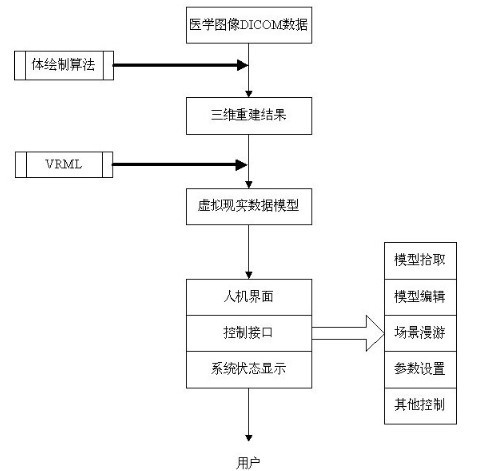

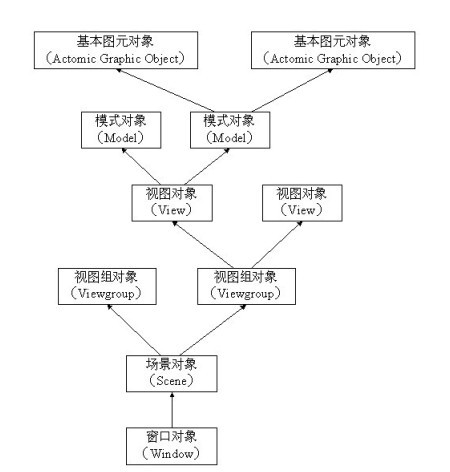

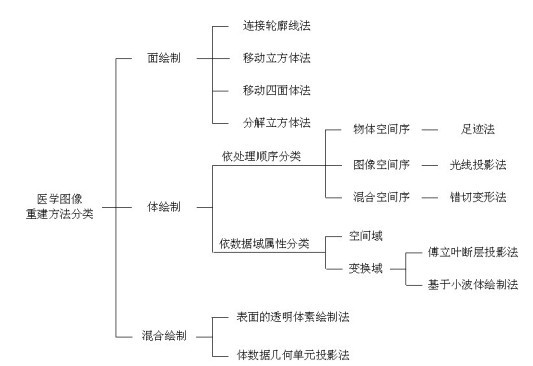

IDL based method for three-dimensionally visualizing medical images

The invention relates to an IDL based method for three-dimensionally visualizing medical images. The method comprises the following steps of: converting DICOM data into three-dimensional visualized medical images through volume rendering algorithm, converting the medical images into a virtual reality data model through VRML interactive description, and controlling the displayed graphics state through a human-computer interface on a GUI (Graphical User Interface) and a control interface so as to form visualized virtual images, wherein the volume rendering algorithm comprises the following steps of: defining an object in an object graphics system; calling the object through an object-creating OBJ_NEW function; respectively calling a pattern object, a viewing object, viewing group objects and a scene object by utilizing ADD calling format; drawing the scene object in a window object by utilizing a window object DRAW method; and completely deleting the objects by utilizing the OBJ_DESTROY function after display is accomplished. The method has the advantages of meeting the basic requirements of visualization of the medical images, and being capable of carrying out corresponding operations, such as volume rendering, slicing, and the like.

Owner:NANTONG UNIVERSITY

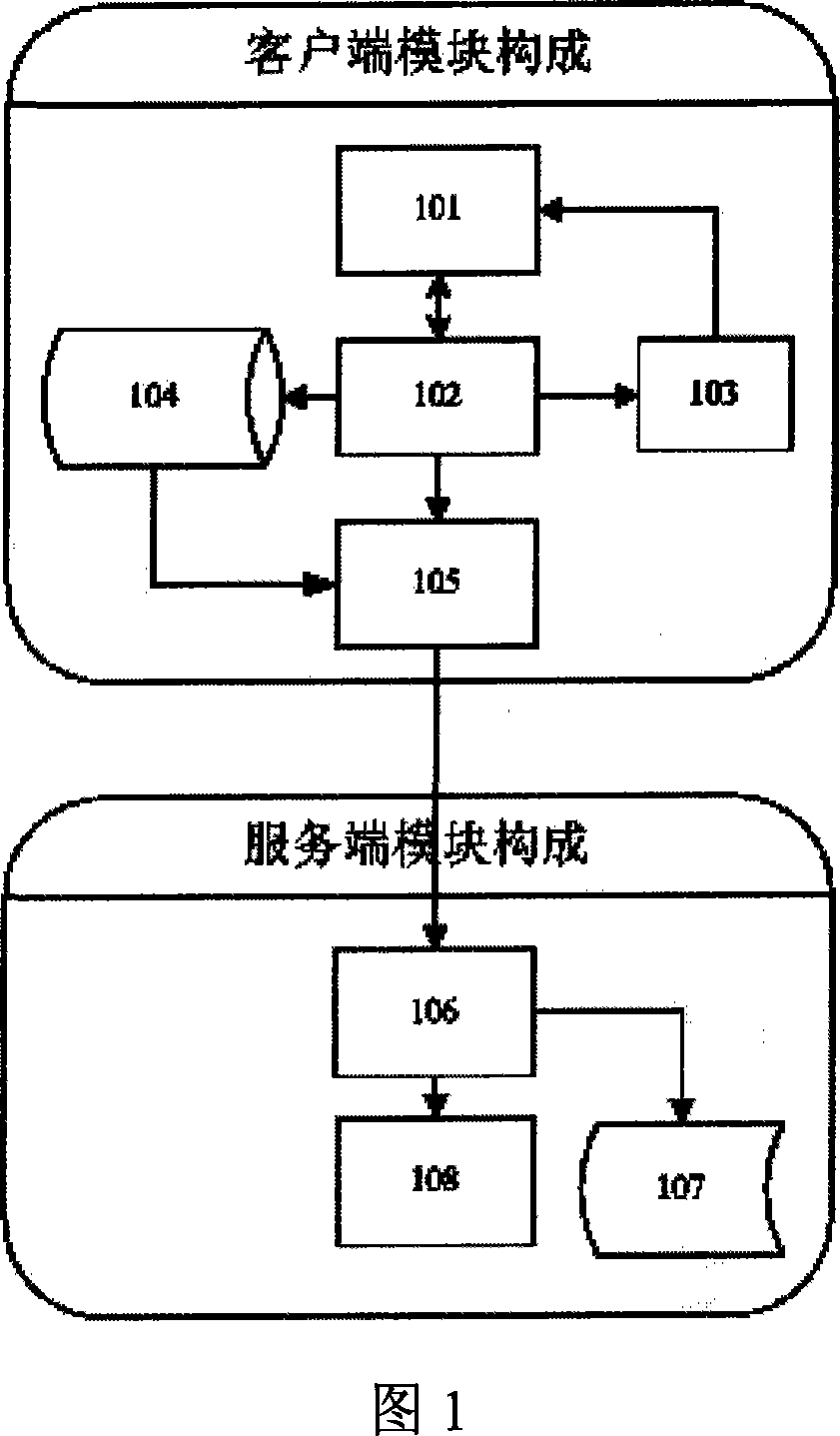

Interactive physics experiment teaching device based on WEB and its control method

InactiveCN101221697AImprove teaching effectRealize 3D physics experimentsTransmissionElectrical appliancesVRMLData memory

The invention relates to a teaching aid for physical experiment teaching, in particular to a WEB-based interactive physical experiment teaching device and a control method thereof. The device consists of a client end module subsystem and a server end subsystem, wherein the client end module subsystem consists of a three-dimensional instrument display module, an interactive operation data processing module, a client end effect processing module, a local temporary operation data memory, and an interactive operation result data transmission module; and the server end subsystem consists of a service data processing module, a server end data memory module and a numerically controllable physical experiment instrument. During control, a VRML client end sends a request for virtual three-dimensional data to the server, the server returns the data after verification, and the VRML processing program at the client end displays the results at a client end interface and judges whether the client end finishes the operation. The method solves the defect that CAI experiment teaching lacks simulated interaction, thereby realizing interactive three-dimensional physical experiment and simulation, and improving teaching effects.

Owner:FUJIAN NORMAL UNIV

Human body skeleton modeling method

The invention discloses a human body skeleton modeling method, and relates to the technical field of human body skeleton modeling. The modeling method comprises the steps that sensors are installed on the human body joints and connected with a detecting host; action catching is carried out through the sensor arrays installed on the joints, fitting is carried out on data points in a video to form a spline; the edge contour curve is processed through a smooth and optimization algorithm of the spline; the limbs are abstracted into simple rigid geometric solids according to the layer structure of the joint connecting bodies of the human body, and a sample of a human body skeleton model is established through a VRML; skeleton models of the limbs can be obtained by changing the sample model. The human body skeleton features are analyzed and recognized through the action recognizing technology based on the video, operation is easy, the quick and accurate modeling purpose can be achieved, and online analyzing is achieved.

Owner:HEFEI VRVIEW INFORMATION TECH

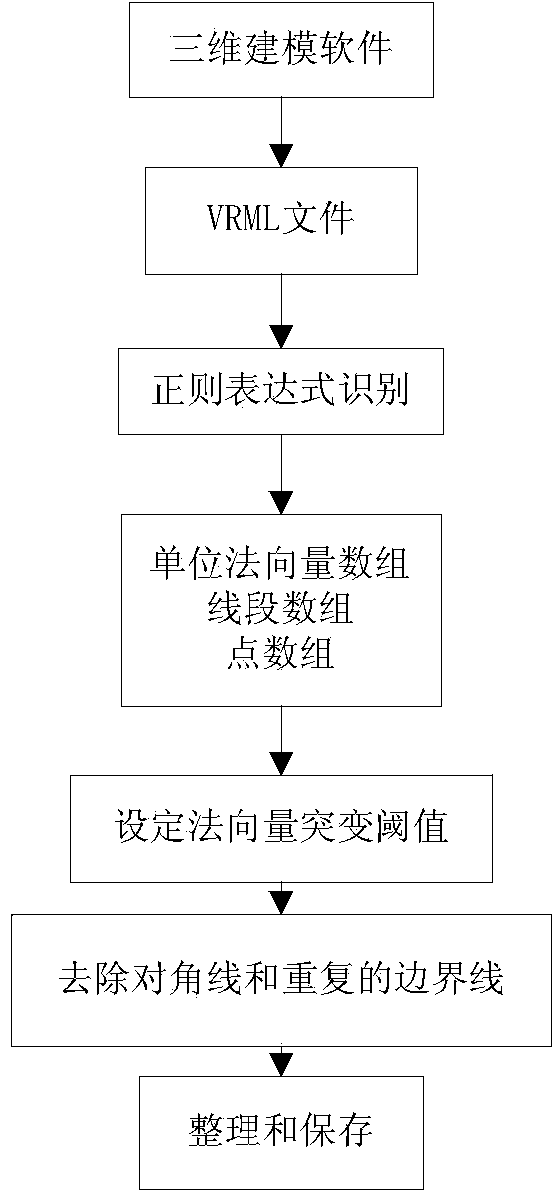

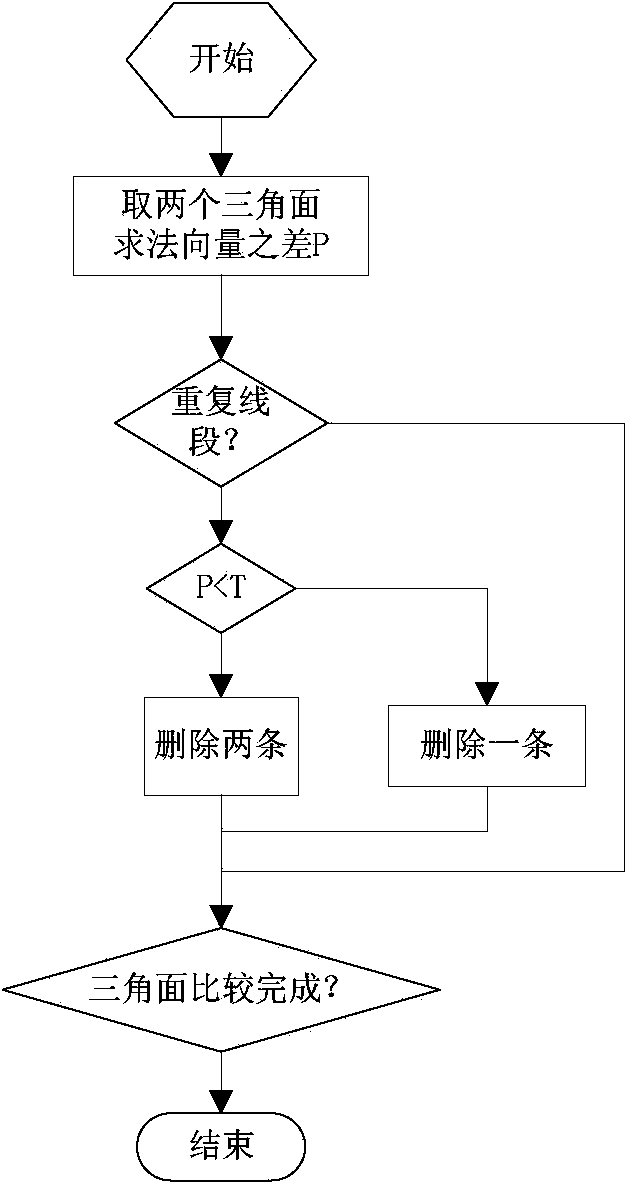

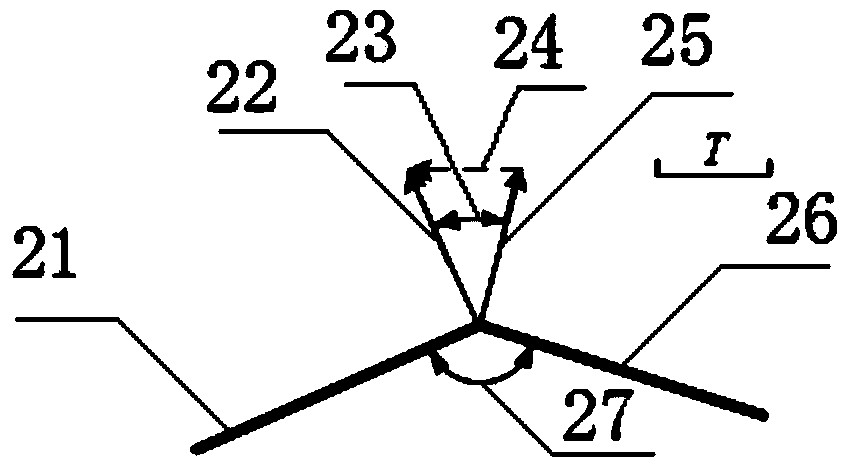

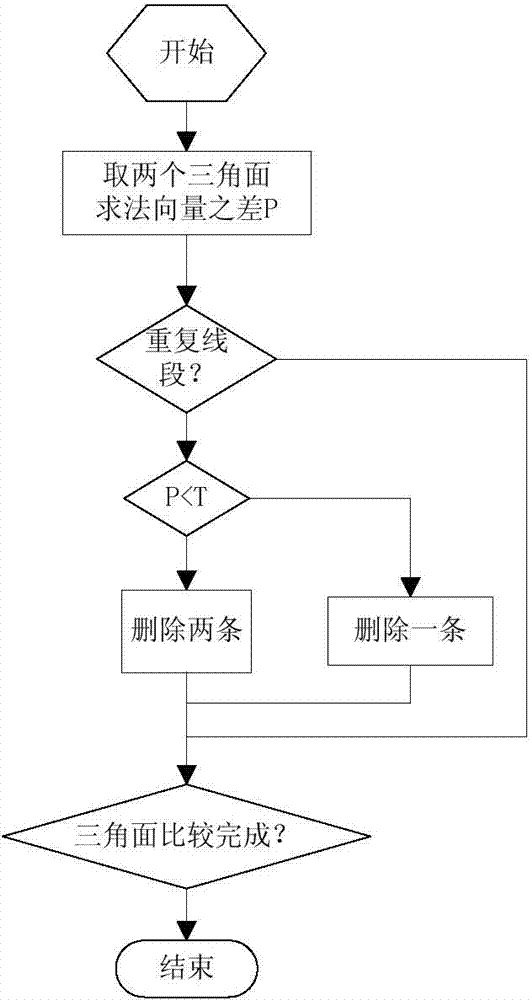

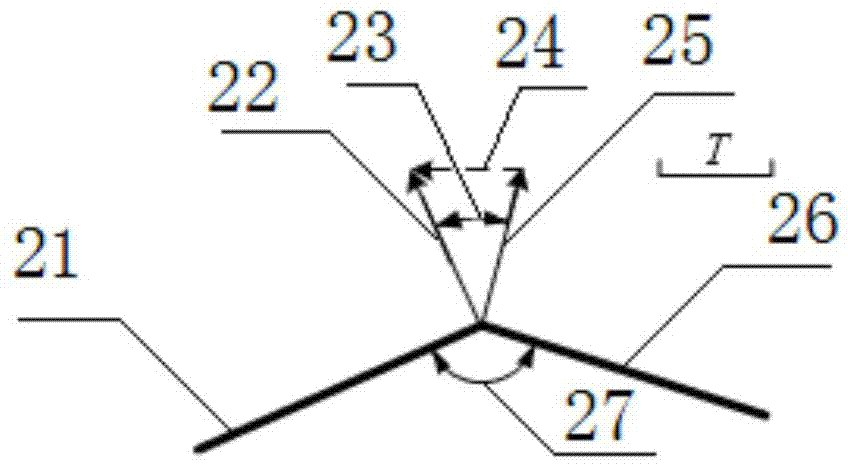

Three-dimensional model boundary line extraction method based on VRML technique

ActiveCN103631993AAccurately getReduce data volumeSpecial data processing applicationsArray data structureDiagonal

The invention provides a three-dimensional model boundary line extraction method based on a VRML technique. The boundary line extraction method includes the following steps of (1) reading a VRML file, recognizing text data through a regular expression and then storing the data in an array in a certain form, (2) setting a normal vector mutation threshold value T which is called a threshold value T for short by a user, wherein the value depends on the largest curvature value on a three-dimensional model, and the larger the curvature value is, the larger the threshold value is, (3) subtracting normal vectors in a unit normal vector array two by two to obtain a vector module, comparing the vector module with the threshold value T, and deleting diagonal lines and repeated boundary lines according to a comparison result, (4) arranging a remaining line segment to obtain a boundary line array, writing the boundary line array and a coordinate array into a data form document, and storing the data form document in a disk of a computer. The method is wide in application range and can be used for processing any three-dimensional model with complicated appearance.

Owner:JIANGSU XINDA COMM TECH

Method for defining MPEG 4 animation parameters for an animation definition interface

InactiveUS6970172B2Easy and inexpensive implementationInexpensive and easily followed methodImage codingAnimationAnimationProcess adaptation

A process is defined for the rapid definition of new animation parameters for proprietary renderers. The process accommodates the peculiarities of proprietary models. In a first step, a proprietary model is animated in a standard modeler and the animated models are saved as VRML files. A converter is used to extract the meaning of a newly defined animation parameter by comparing two or more of the VRML files. Thus, the output of this process is the model and a table describing the new animation parameter. This information is read by the renderer and used whenever the animation parameter is required. The process can easily be used to generate new shapes from the original model.

Owner:AMERICAN TELEPHONE & TELEGRAPH CO

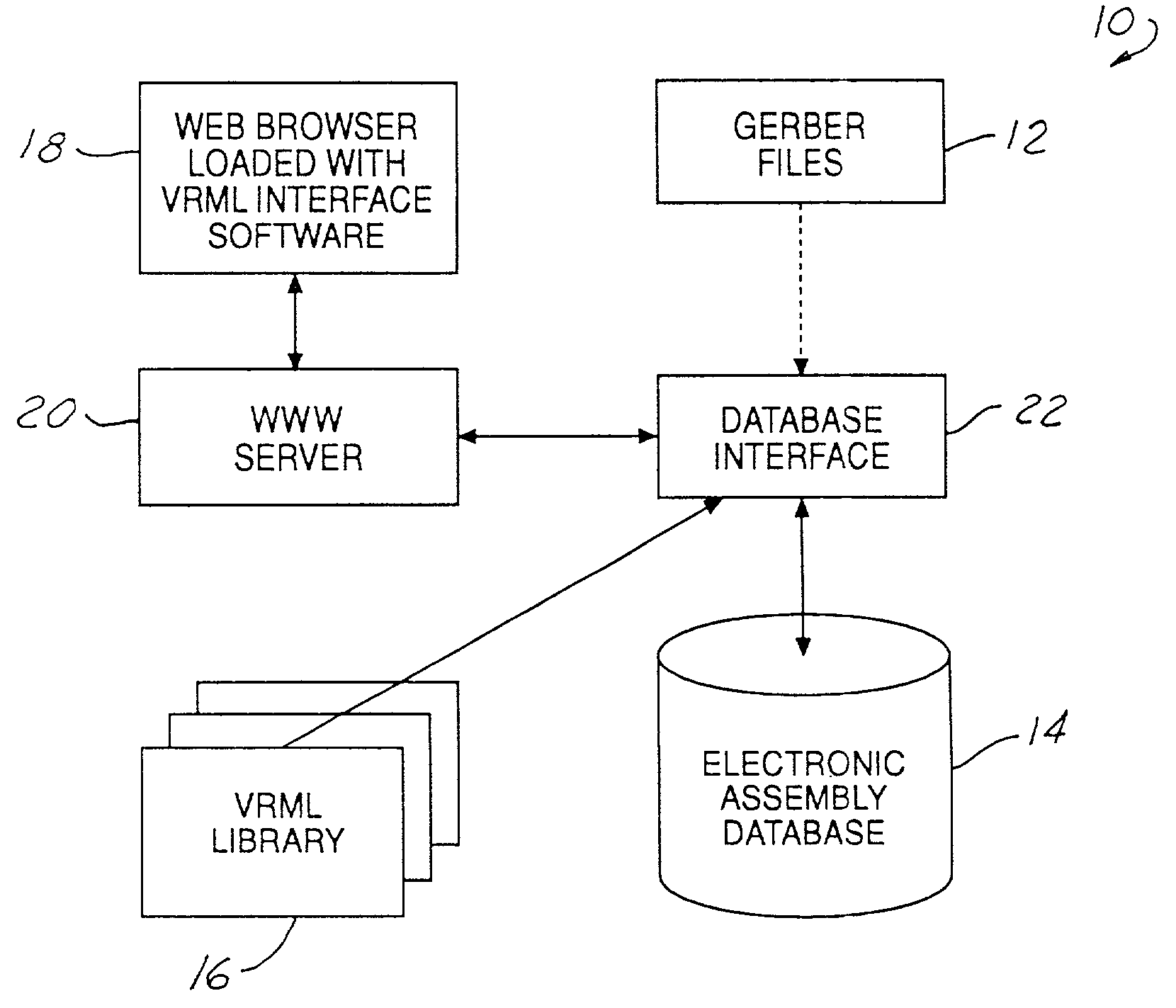

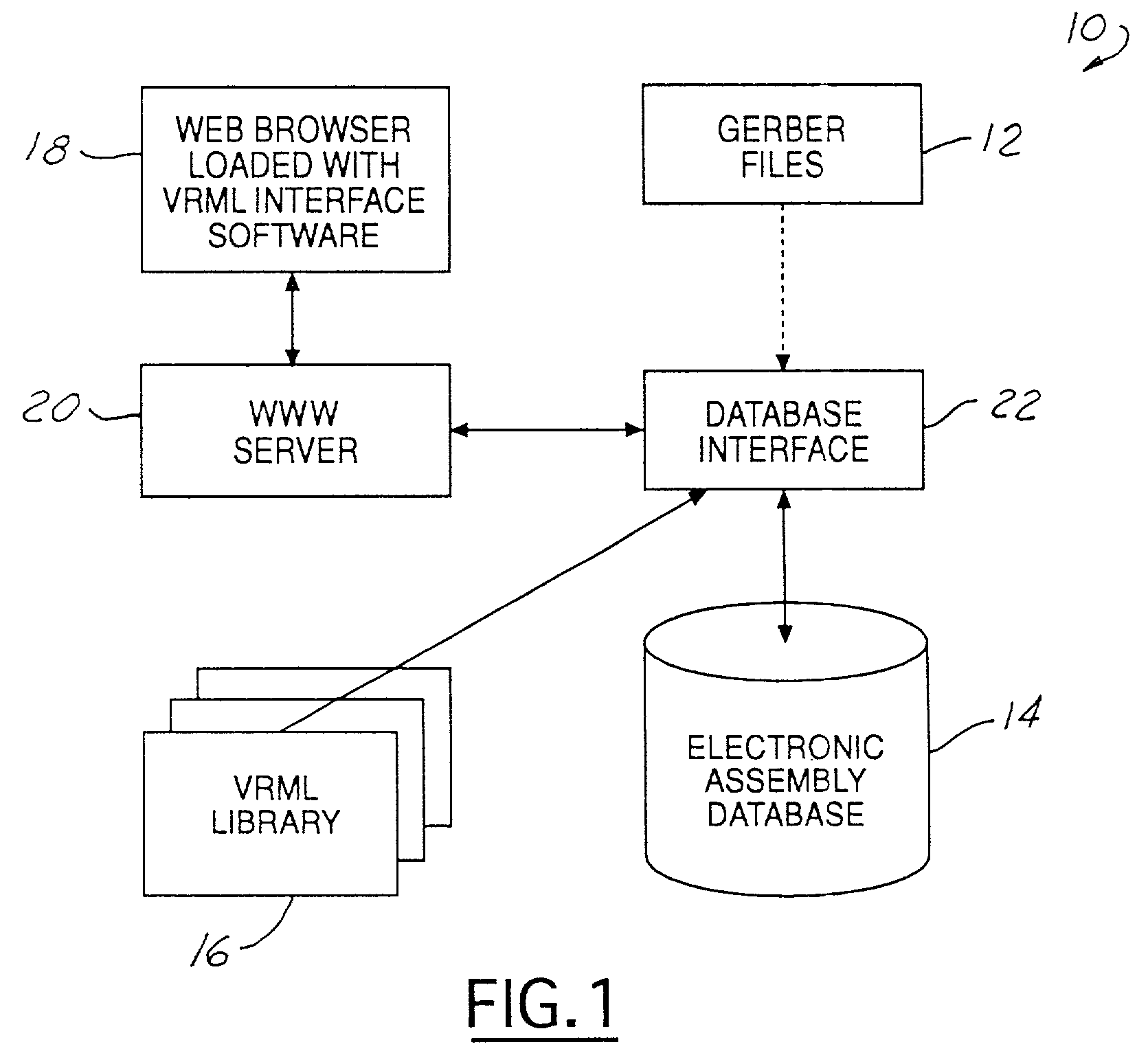

VRML interface software for image and data compilation

InactiveUS7146579B2Low costEasy to manufactureComputer aided designSoftware simulation/interpretation/emulationDatabase interfaceDynamic compilation

A method to compile images and data created on different software platforms into a platform-independent image begins when a PCB assembler utilizes a VRML interface to make a request to show an image of a PCB or any part of a PCB. The request is sent to a WWW server, which in turn, contacts a database interface, such as CGI. The requested image data is stored on at least one external database and is likely comprised of many individual elements created on many different software platforms, such as Gerber or CAD. The database interface retrieves the requested image data from the external databases and funnels it to the PCB assembler via the WWW server. Finally, the VRML interface software compiles all of the multi-platform data and generates a new, software- and processor-independent image.

Owner:VISTEON GLOBAL TECH INC

Method for constructing surgical virtual operation teaching and training system

InactiveCN101996507BImprove teaching qualityReduce teaching costsCosmonautic condition simulationsSimulatorsSimulationVRML

The invention provides a method for constructing a surgical virtual operation teaching and training system. The method comprises the following concrete steps: (1) acquiring various inspection data classified according to normal people and patients, intensively storing the acquired data, and constructing an integrated male virtual human model and an integrated female virtual human model; (2) carrying out geometric modeling, computational modeling and deformation computation on medical data, and carrying out modeling on bones and soft tissues by adopting a multi-outline three-dimensional reconstruction algorithm; (3) reconstructing by adopting a three-dimensional model of 3DMAX10, mapping and giving physiological characteristics to organic tissues; (4) compiling related objects and simulated scenes of a virtual operation by virtual reality modeling language (VRML); (5) carrying out preoperative preparation in the virtual operation scenes, and checking and confirming patient information;(6) carrying out complete operational details of the actual method of the virtual operation again; (7) establishing a simulated operation teaching evaluation system; and (8) carrying out comprehensive evaluation and examination on a teacher and each trainee. In the method, the simulated operation teaching system is constructed by utilizing the virtual reality technology, thereby providing a wide and transparent simulated teaching and research platform for hospitals and medical schools.

Owner:罗伟

Virtual reality construction method based on VRML

InactiveCN102568029AQuick buildThe actual display image is compact3D-image rendering3D modellingComputer graphics (images)ModelSim

The invention provides a modeling method of a three-dimensional object. The method comprises the following steps that: a basic object type is used to construct a three-dimensional object, which includes at least one object assembly; mapping is carried out on the object; and a light system parameter is arranged to realize a virtual reality effect. According to the modeling method of a three-dimensional object, a lifelike virtual reality scene can be realized rapidly and effectively.

Owner:SANDA UNIVERSITY

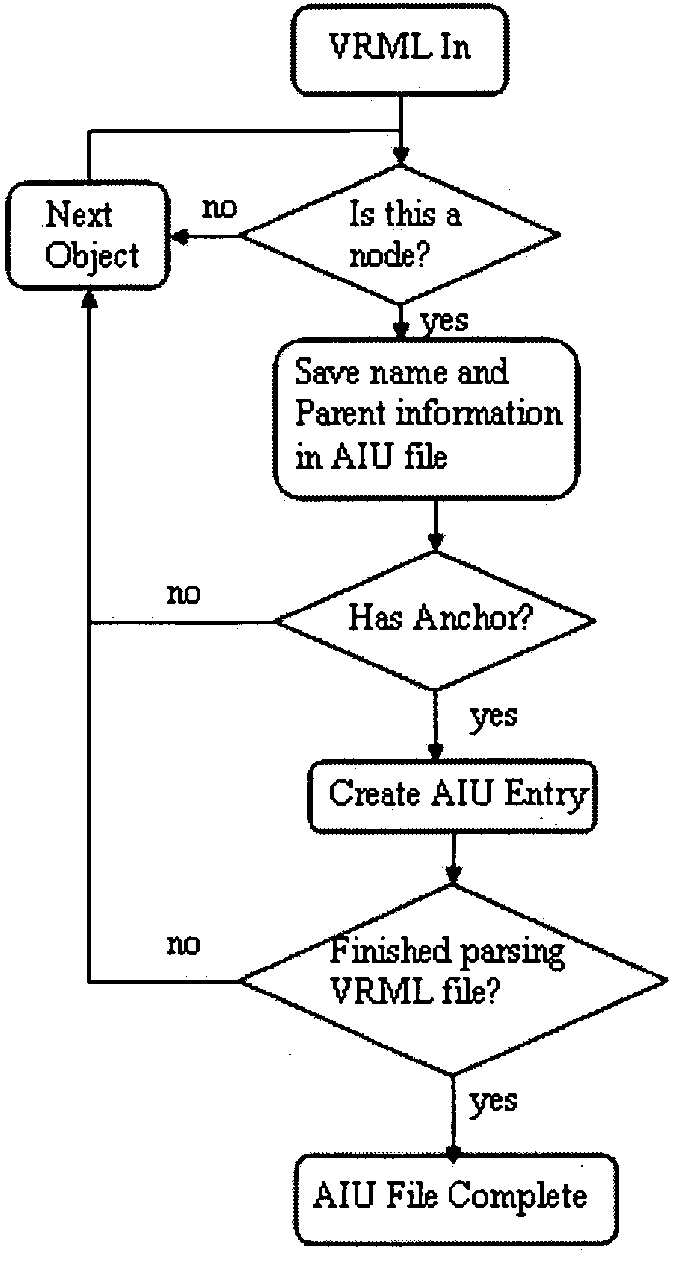

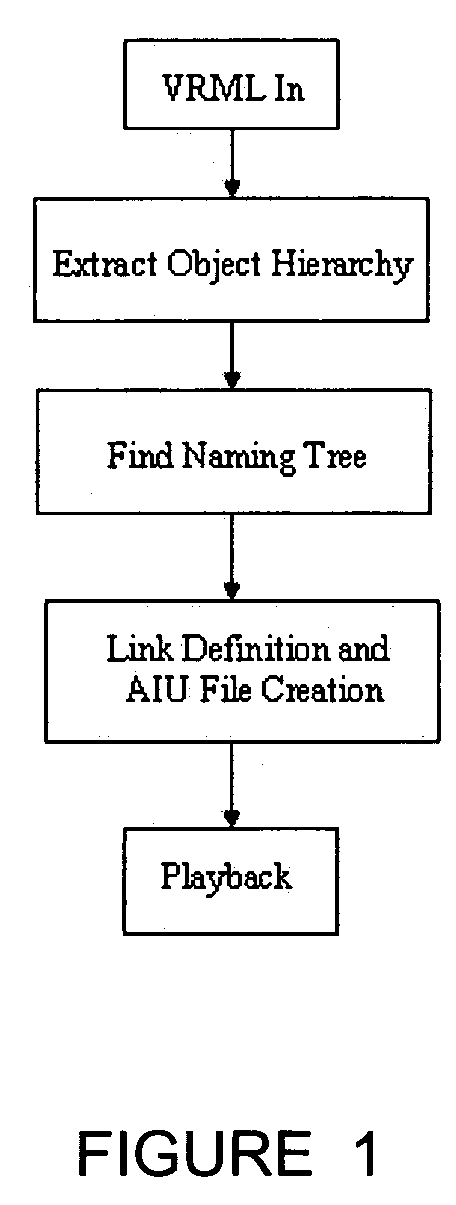

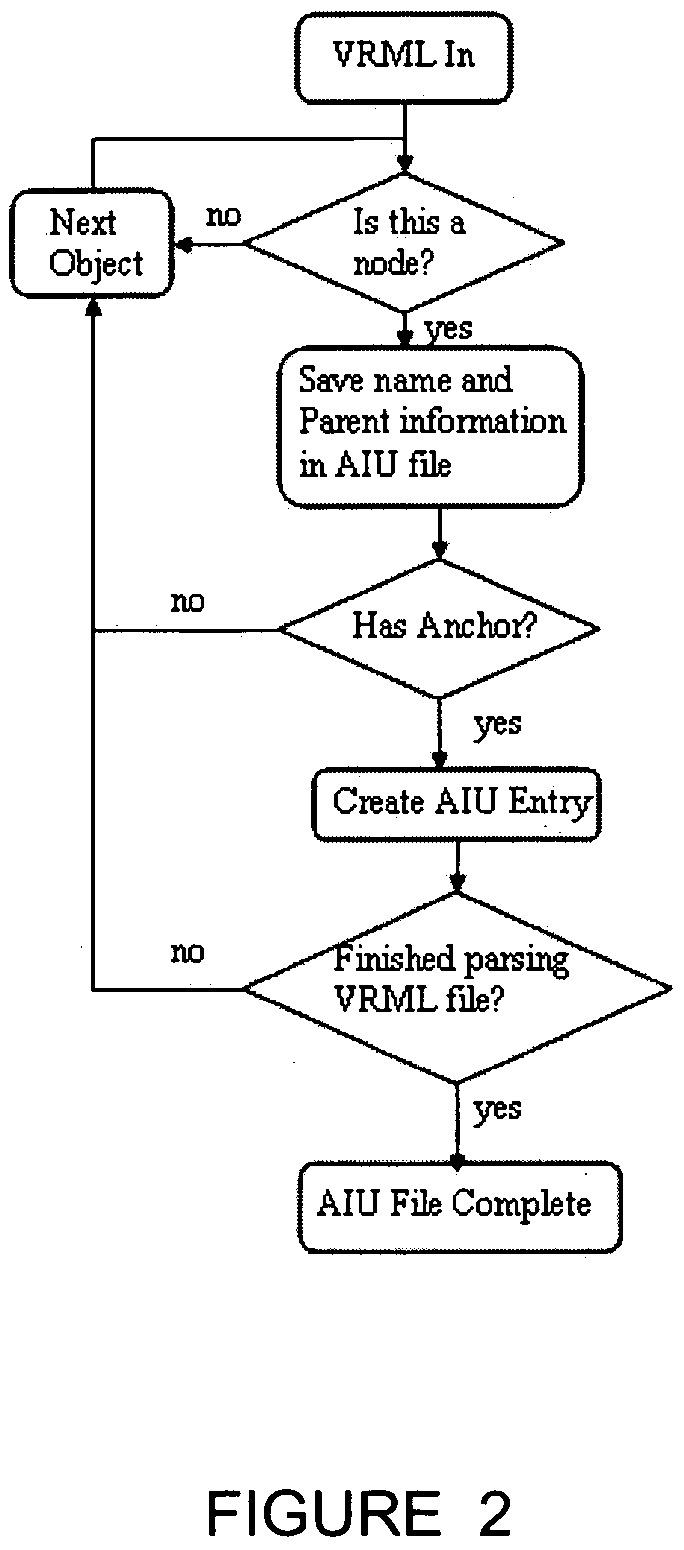

Method and apparatus for automated authoring and hyperlinking of VRML documents

InactiveUS20050151744A1Without any changeImprove abilitiesDigital data information retrievalDigital computer detailsHyperlinkVRML

A method for automated authoring and hyperlinking of VRML (Virtual Reality Modeling Language) documents comprises inputting of a VRML file structured in Standard Generalized Markup Language (SGML); extracting a hierarchy of Anchorable Information Units (AIU's) from the VRML file; associating respective anchor nodes with each of the AIU'S to be hyperlinked; entering the respective anchor nodes into an AIU file utilizing VRML AIU specification language; and associating the AIU file with the VRML file.

Owner:SIEMENS CORP RES INC

Human skeleton modeling method

The invention relates to a human skeleton modeling method and relates to the technical field of human skeleton modeling. The modeling method comprises steps as follows: sensors are mounted at all joints of a human body and connected with a detection host; motion capture is performed by the sensor array mounted at all the joints and data points in a video are fitted to form a spline; an edge contour curve is processed with fairing and optimization algorithms of the spline; according to a joint connector hierarchical structure of the human body, all limbs are abstracted into simple rigid geometric entities and a sample of human skeleton models is constructed with the VRML (virtual reality modeling language); the skeleton models of all the limbs can be obtained through transformation on the basis of the sample model. Analysis recognition is performed on human skeleton characteristics with a video-based motion recognition technology, the operation is simple, rapid and accurate modeling can be realized, and online analysis is realized.

Owner:ANHUI RUIHONG MDT INFOTECH

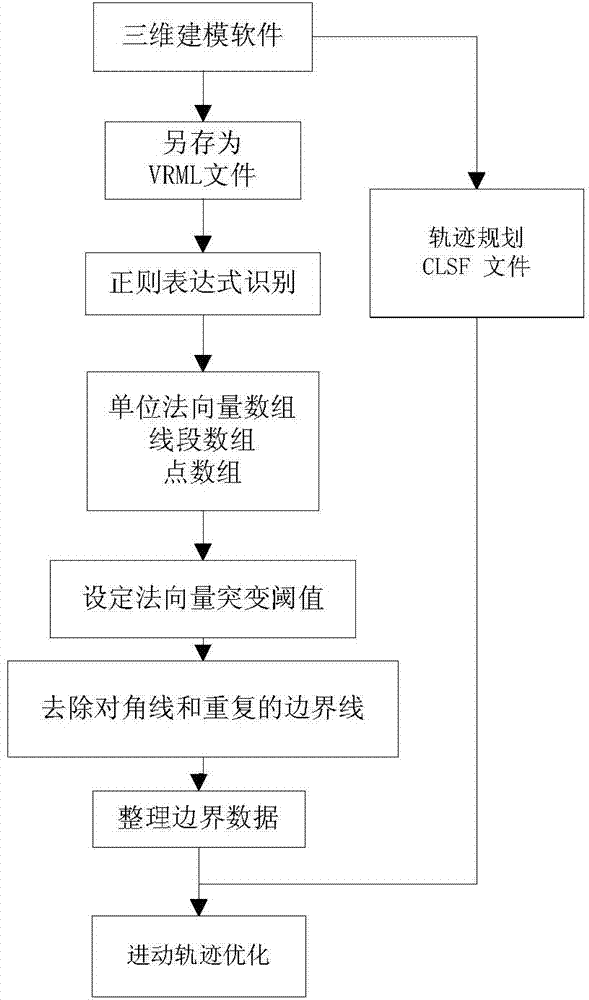

Trajectory optimization method for procession of mould pneumatic grinding wheel based on three-dimensional boundary extraction

ActiveCN103761353AAccurately getReduce data volumeSpecial data processing applicationsSi modelEngineering

The invention discloses a trajectory optimization method for the procession of a mould pneumatic grinding wheel based on a three-dimensional boundary extraction. The trajectory optimization method comprises the following steps: (1) modeling, and storing a CLSF (Cutter Location Source File) file of a trajectory planning and a VRML (Virtual Reality Markup Language) file of a model; (2) reading the VRML file, adopting a regular expression to identify text data, and then storing the data into an array; (3) setting 'normal vector mutation threshold value' by a user, wherein the value is obtained according to a maximum curvature on 3D model (three-dimensional model), the curvature is larger, the threshold value is larger; (4) taking vector modules after normal vectors in a unit normal vector group are conducted for the pairwise difference, comparing the vector module with a threshold and deleting diagonal lines and repeated boundary lines according to the comparison results; (5) setting the rest of line segments to obtain a boundary line array; and (6) calculating the distance between the center of a contact surface of any processing point and every boundary on a trajectory plan, and carrying out posture optimization on relative positions of the boundary lines and the processing points. According to the method, the problem of boundary in a pneumatic grinding wheel procession process path can be considered, and the effect is significant.

Owner:郎溪品旭科技发展有限公司

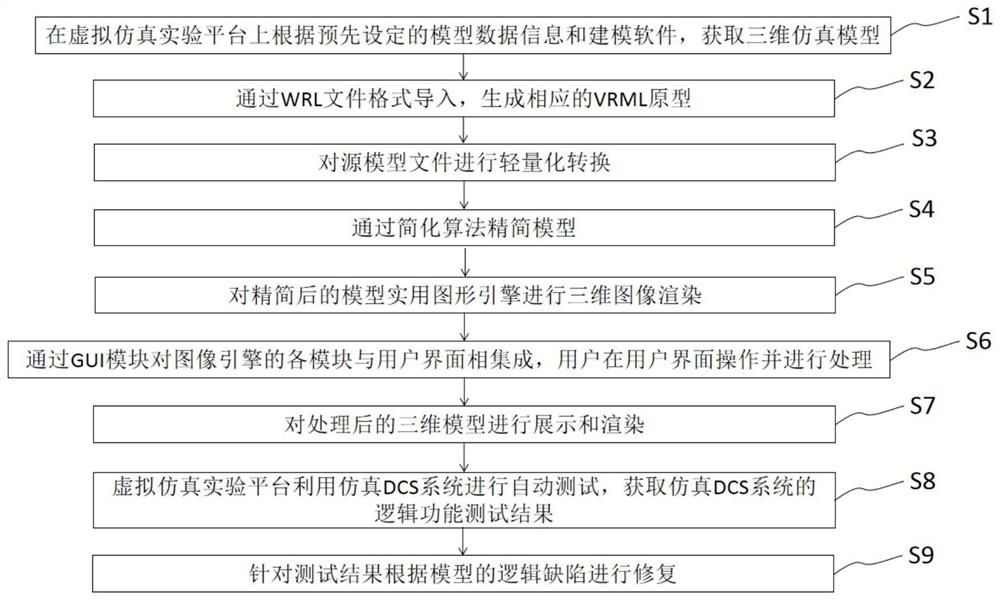

Efficient virtual simulation experiment platform testing method based on cloud rendering

PendingCN112001018AImprove experienceImprove interactivityGeometric CADSoftware testing/debugging3d imageData information

The invention discloses an efficient virtual simulation experiment platform testing method based on cloud rendering. The method comprises the following steps: acquiring a three-dimensional simulationmodel on a virtual simulation experiment platform according to preset model data information and modeling software; generating a corresponding VRML prototype through WRL file format import; carrying out lightweight conversion on the source model file; simplifying the model through a simplified algorithm; performing three-dimensional image rendering on the simplified model by using a graphic engine; integrating each module of the image engine with a user interface through a GUI module, and operating and processing on the user interface by a user; displaying and rendering the processed three-dimensional model; enabling the virtual simulation experiment platform to carry out automatic testing by using a simulation DCS system to obtain a logic function test result of the simulation DCS system;and repairing the test result according to the logic defect of the model. The testing method has high interactivity and rich user experience, and meanwhile, the intelligence of the simulation systemis improved.

Owner:成都威爱新经济技术研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com