Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38 results about "Tooth layer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

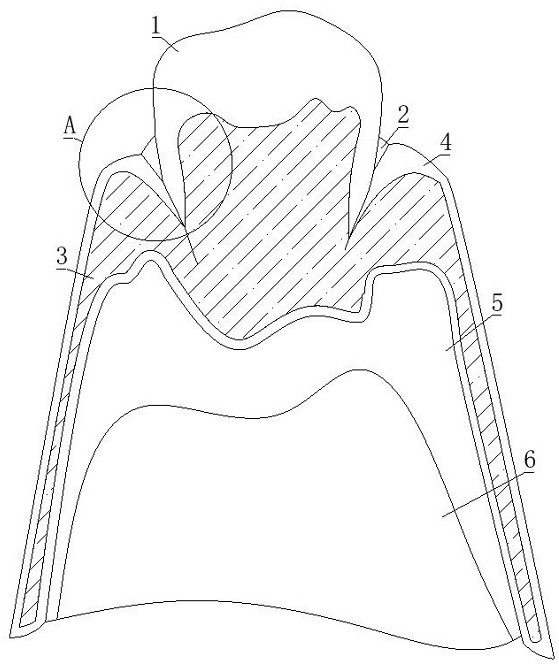

The tissue that seals the side of the tooth to prevent infection is called the gum. Teeth are fixed into jaw bones and are held in place by cement. The three main layers of a tooth are called enamel, dentine and the living layer is called the pulp.

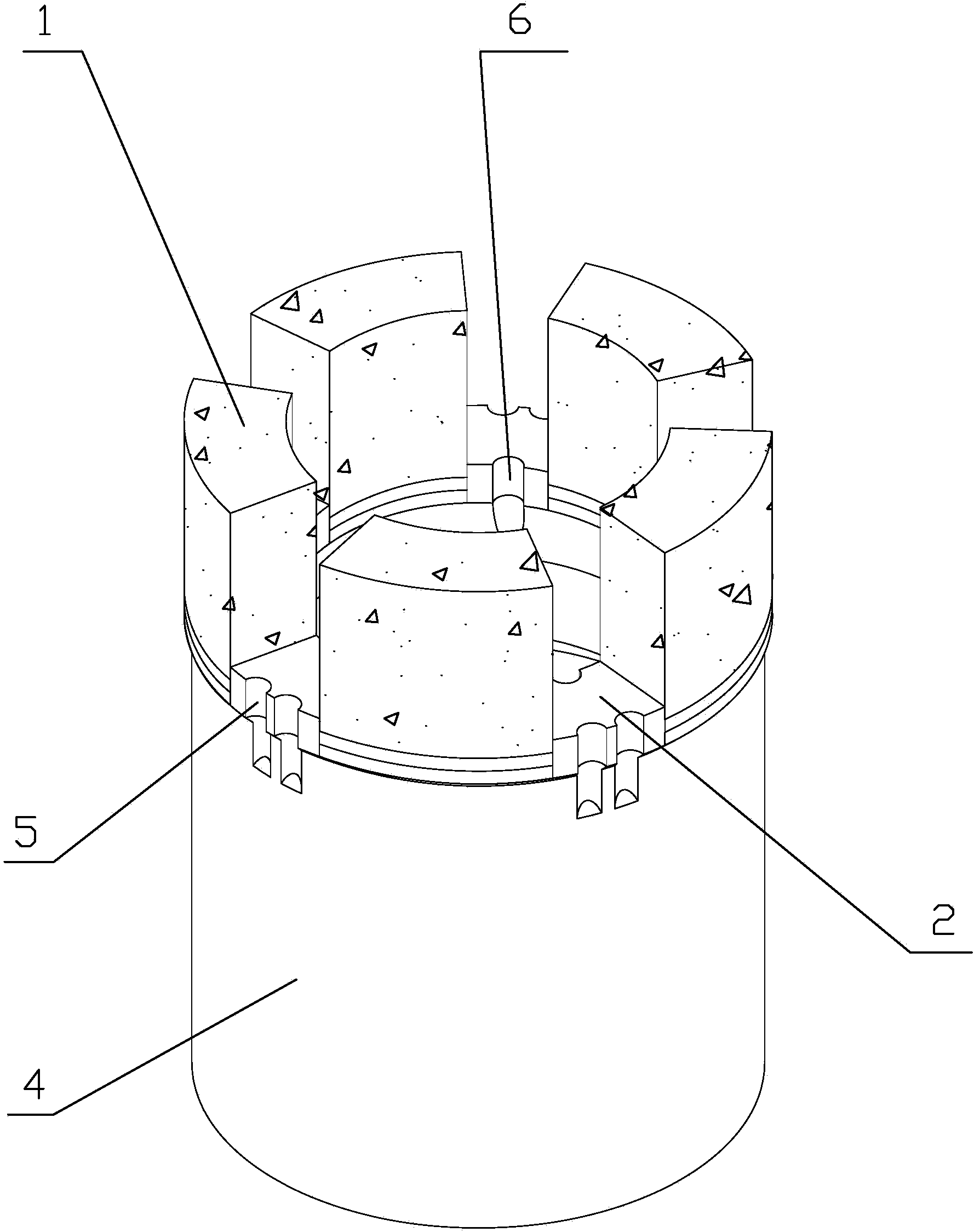

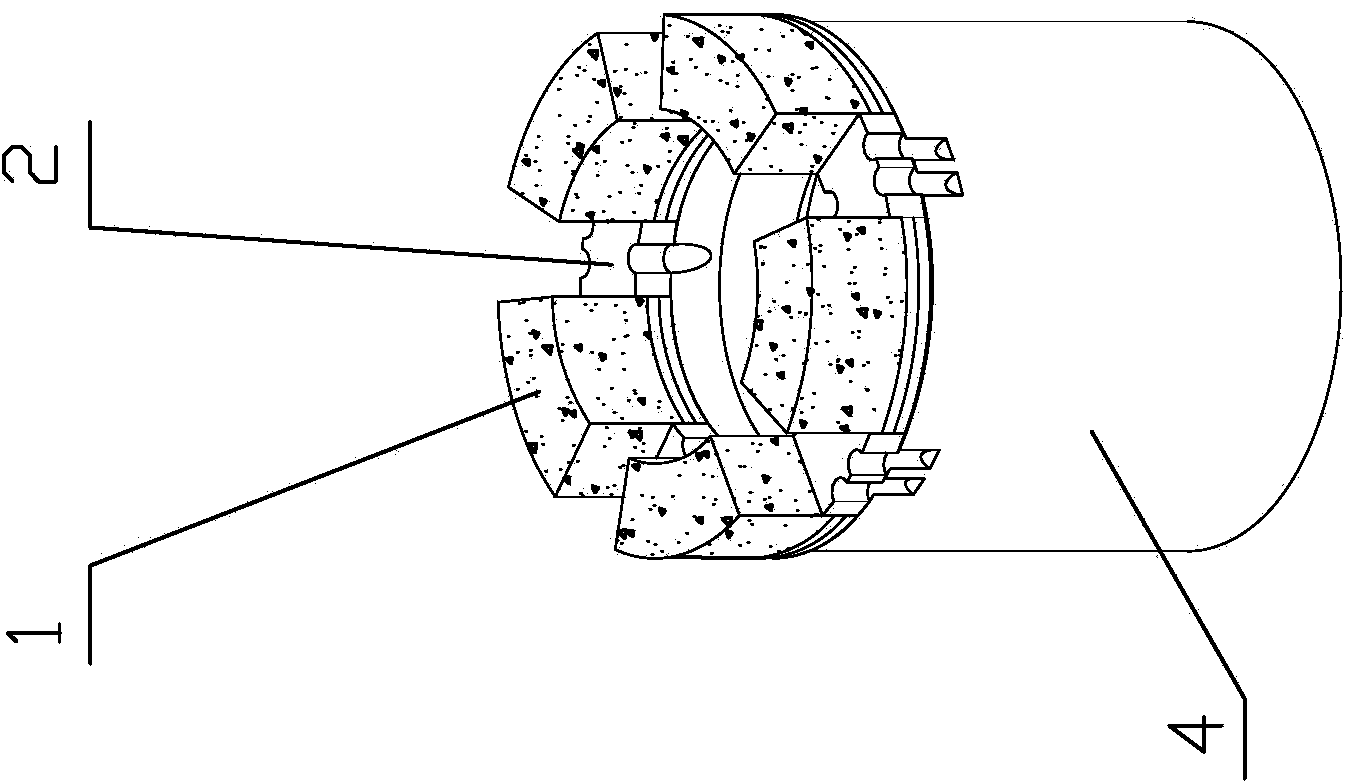

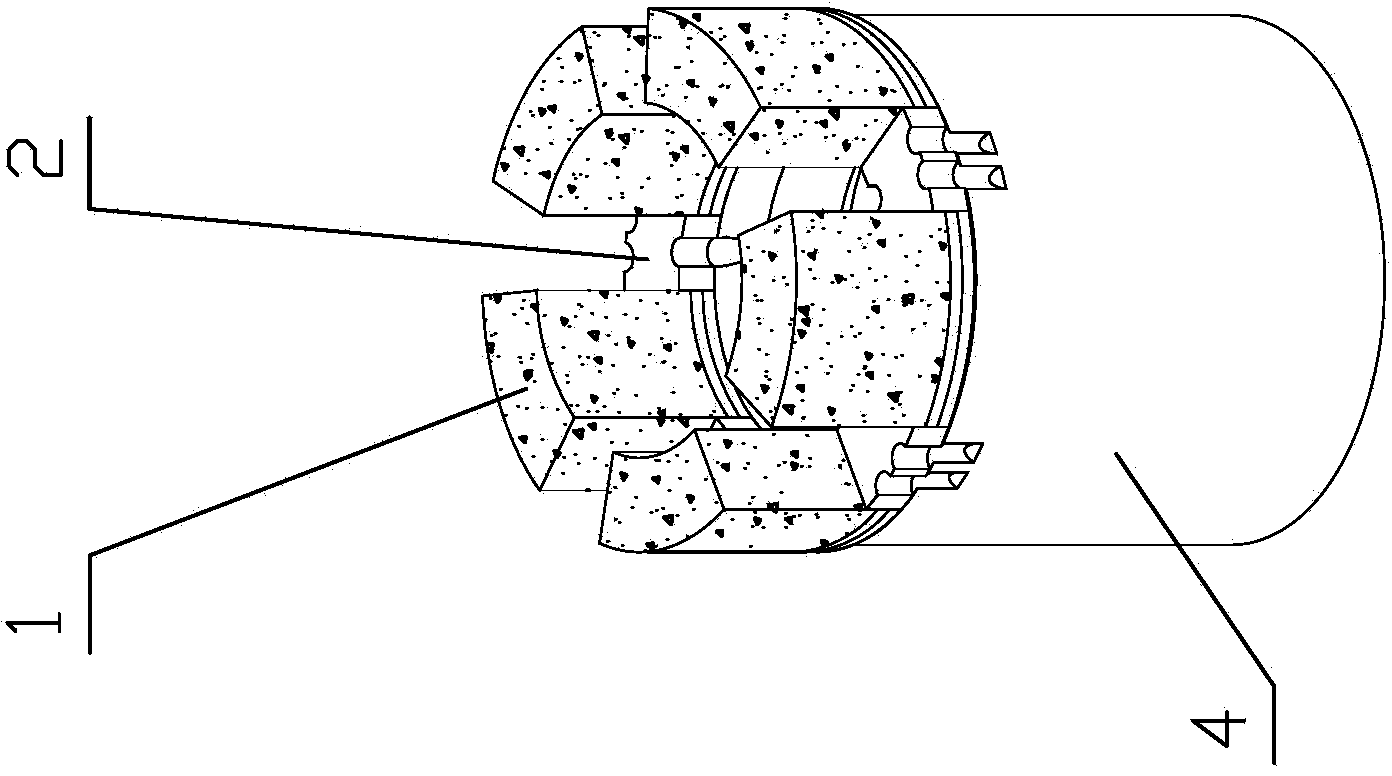

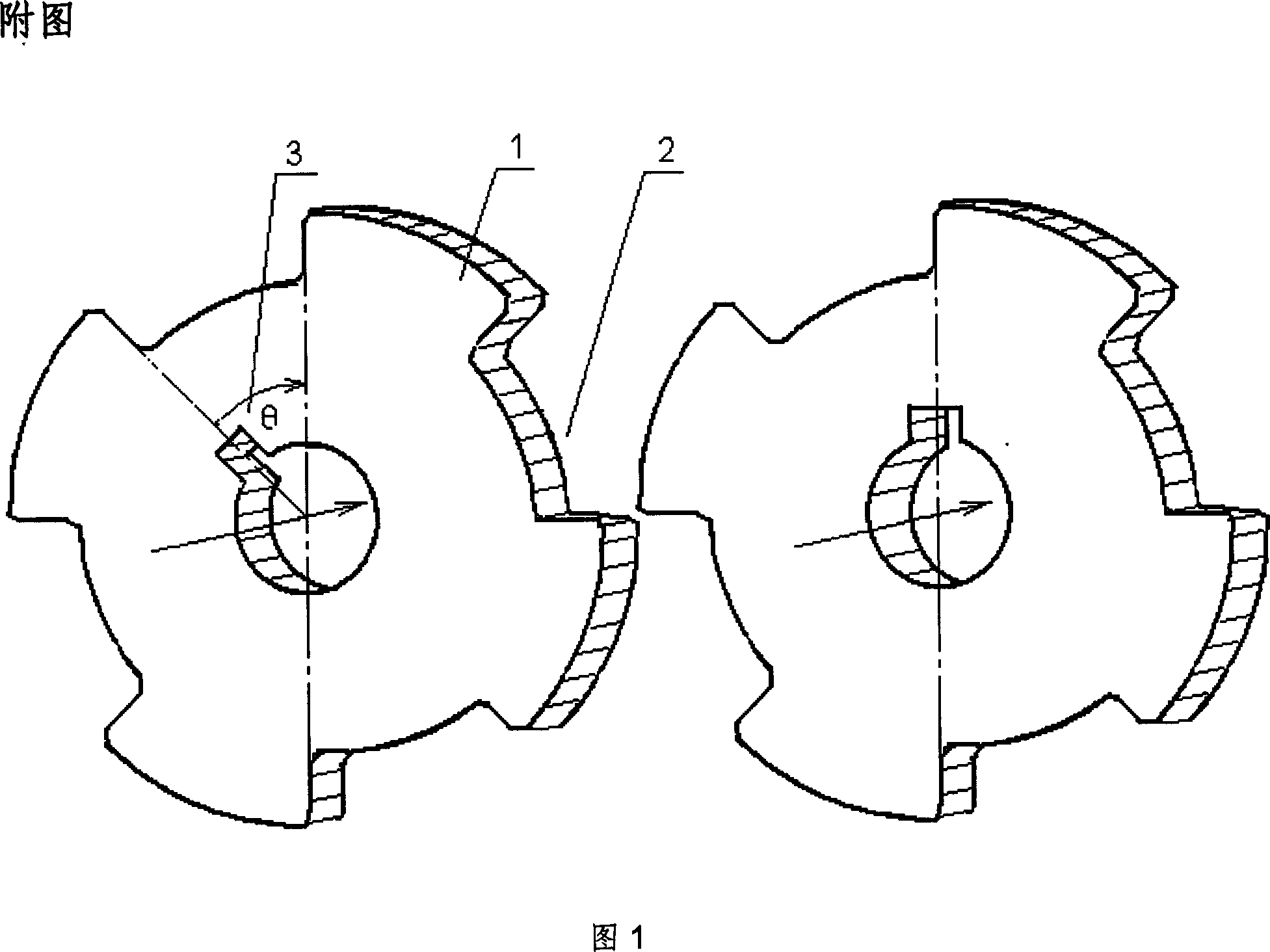

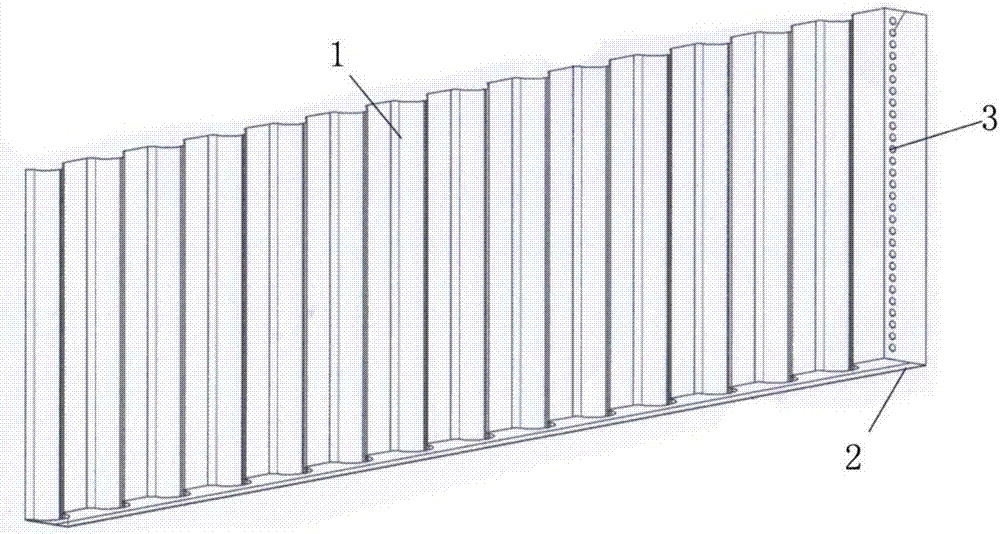

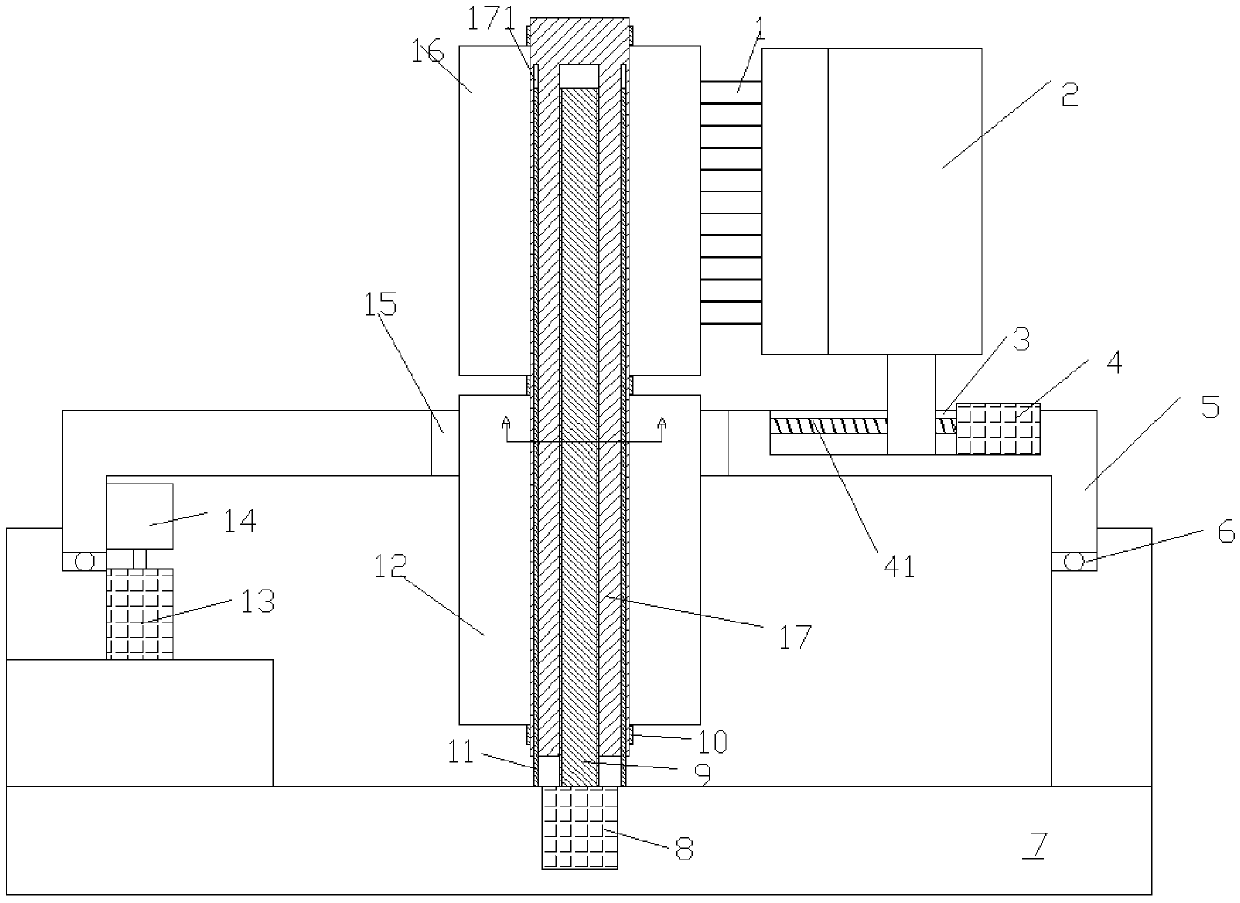

Welded high-matrix diamond core bit and manufacturing method thereof

ActiveCN103953286AIncrease heightSmall runoutDrill bitsLaser beam welding apparatusTooth layerMetal powder

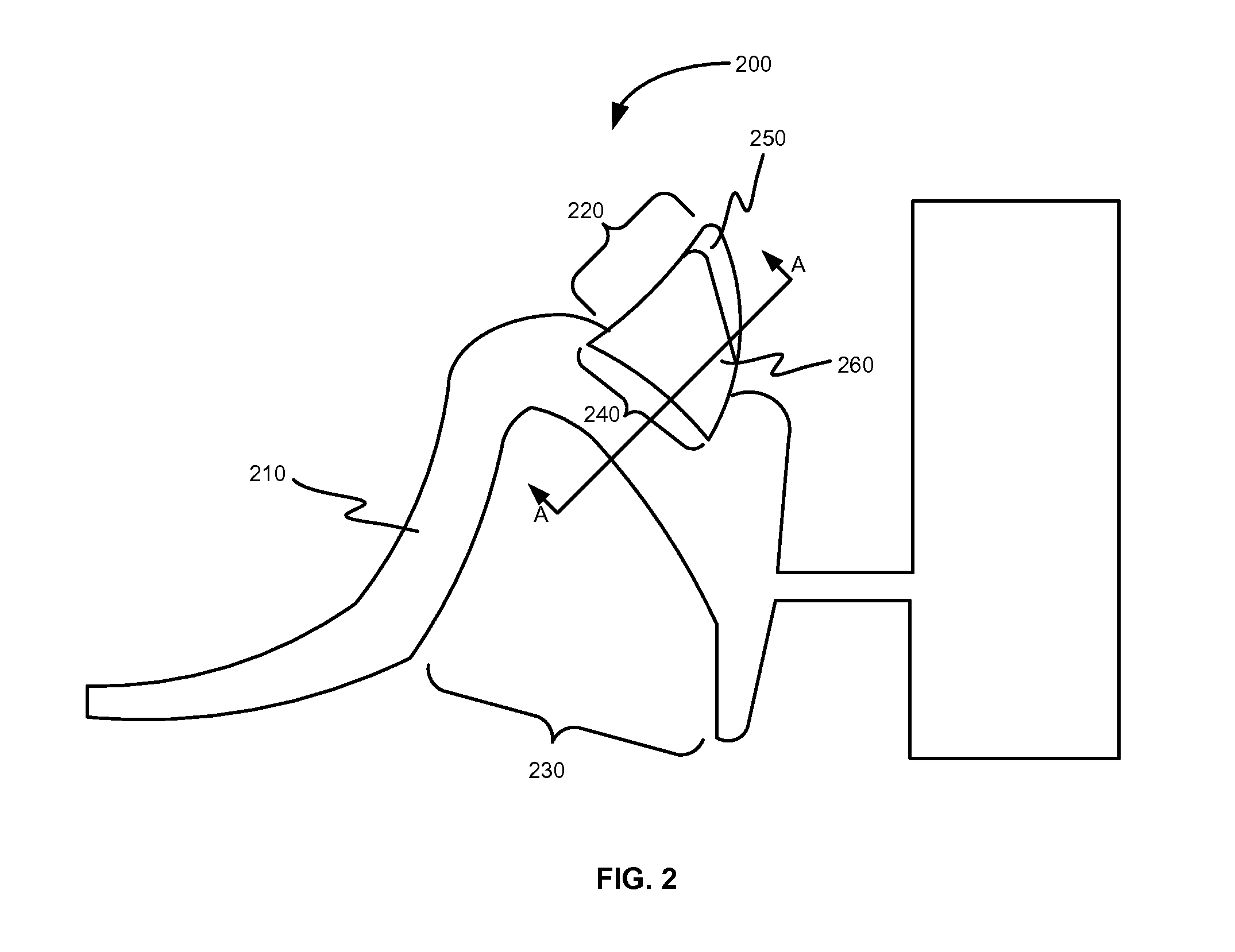

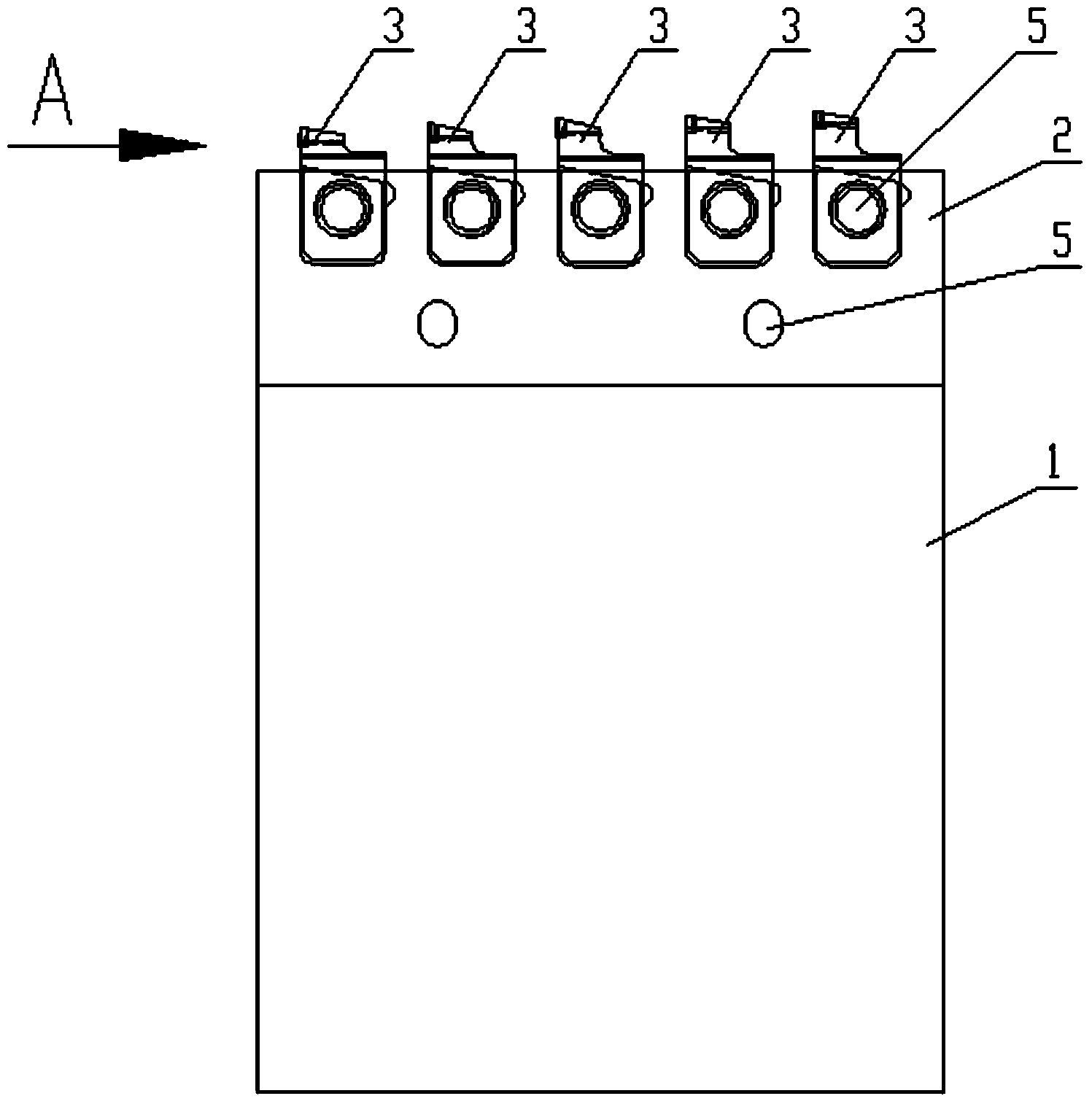

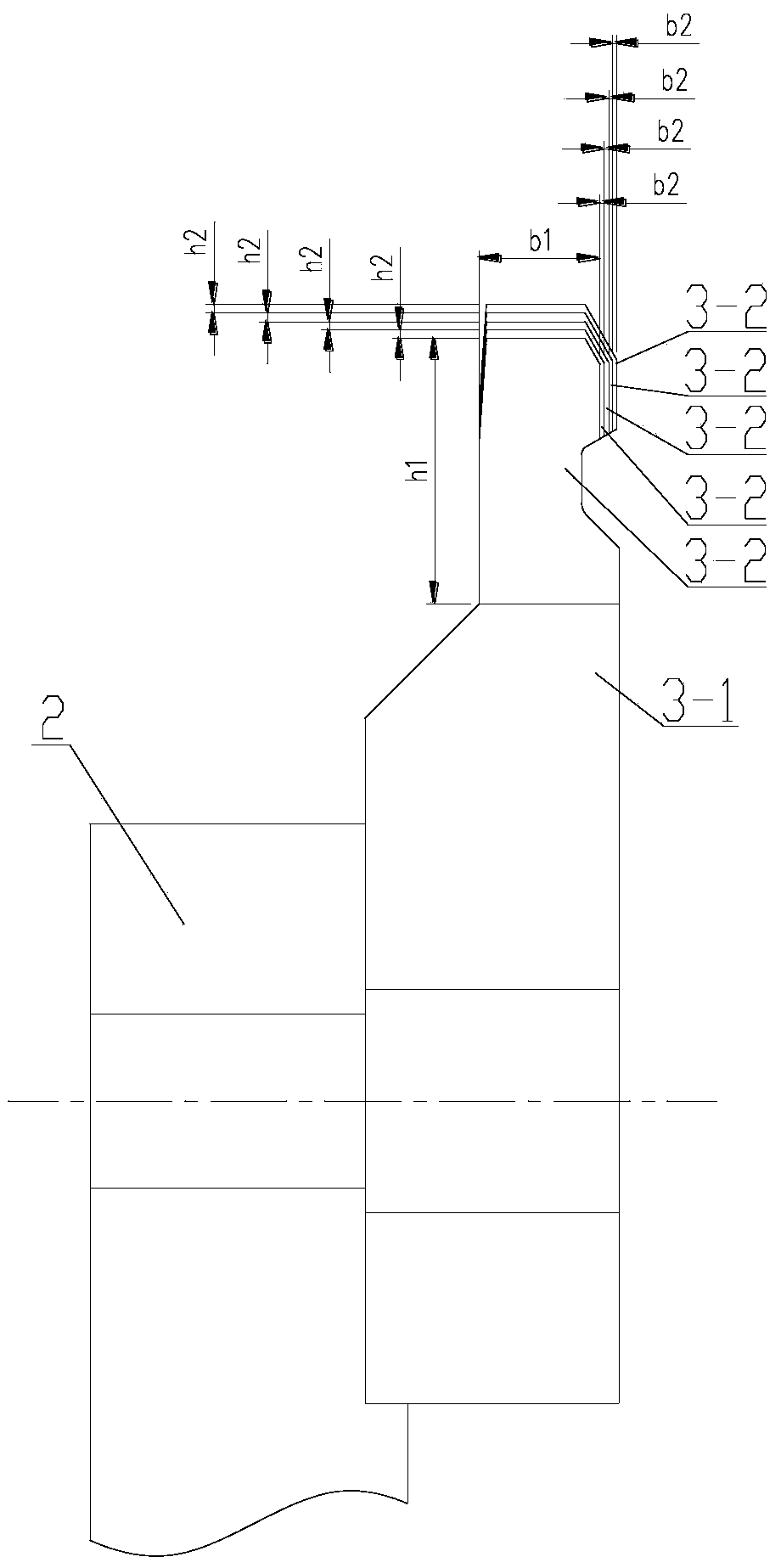

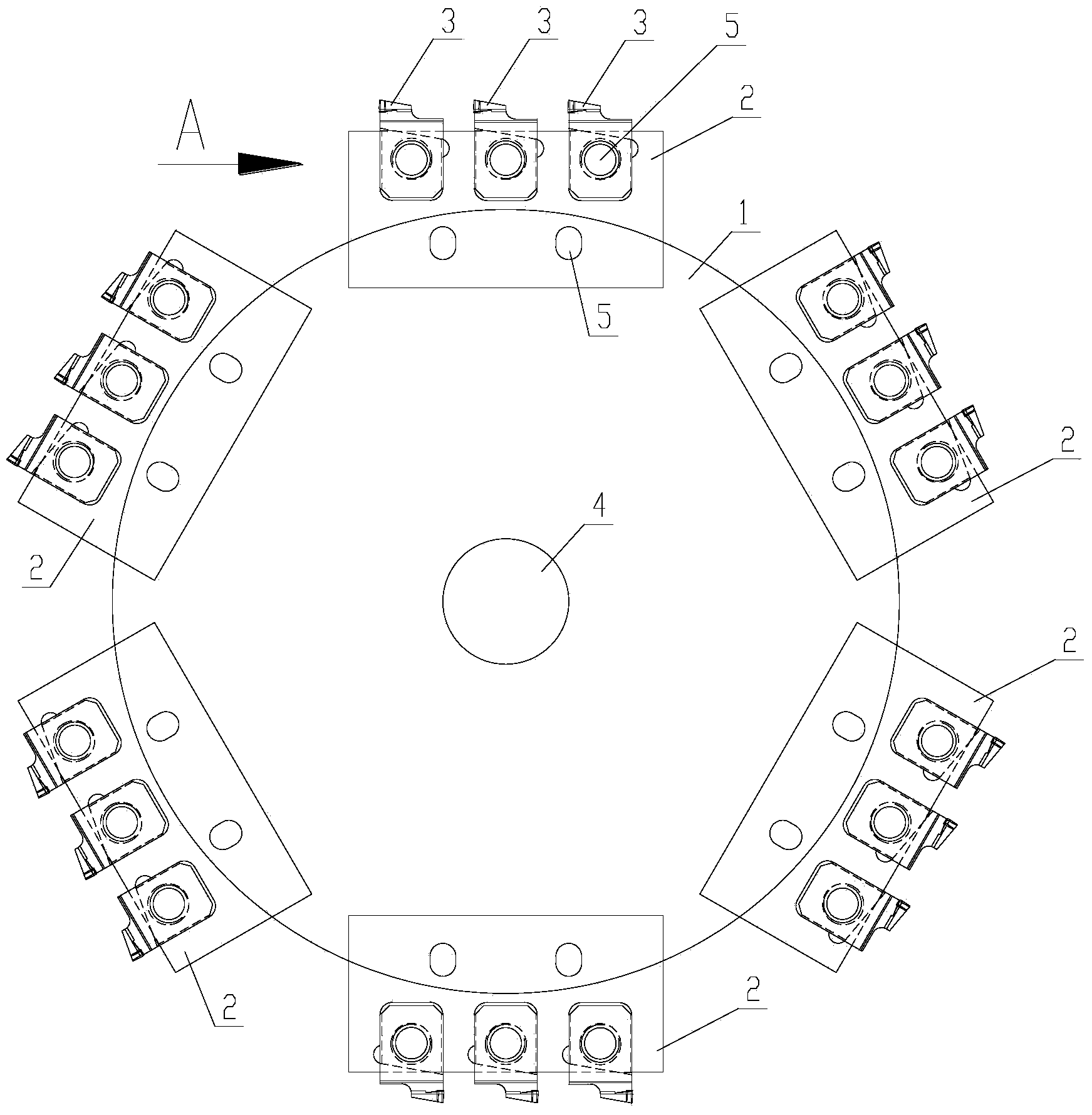

The invention discloses a welded high-matrix diamond core bit and a manufacturing method thereof. The welded high-matrix diamond core bit comprises high-matrix drill teeth, gate blocks and a steel body; the high-matrix drill teeth and the gate blocks are separately subjected to sinter molding and then are tightly connected to form a drill tooth crown; the drill tooth crown is welded on the steel body through laser; each high-matrix drill tooth comprises a working tooth layer containing rock breaking grains, a transition tooth layer not containing grains, and a welding tooth layer not containing the grains; the total height of the high-matrix drill teeth is 15 mm to 35 mm; each gate block is manufactured by sintering single powders, a variety of metal powders or alloyed powders. Since the high-matrix drill teeth are adopted for independently sintering and the self-adaptive abrasion gate blocks are designed, the sintering temperature is greatly lowered, the damage to the diamond is reduced, the height of the drill teeth is increased, the drilling efficiency and the service life of the bit are improved greatly, the bit tripping times during geological drilling is remarkably reduced, and the welded high-matrix diamond core bit is especially suitable for drilling engineering of deep wells below 1.000 meters.

Owner:桂林矿产地质研究院工程有限公司 +1

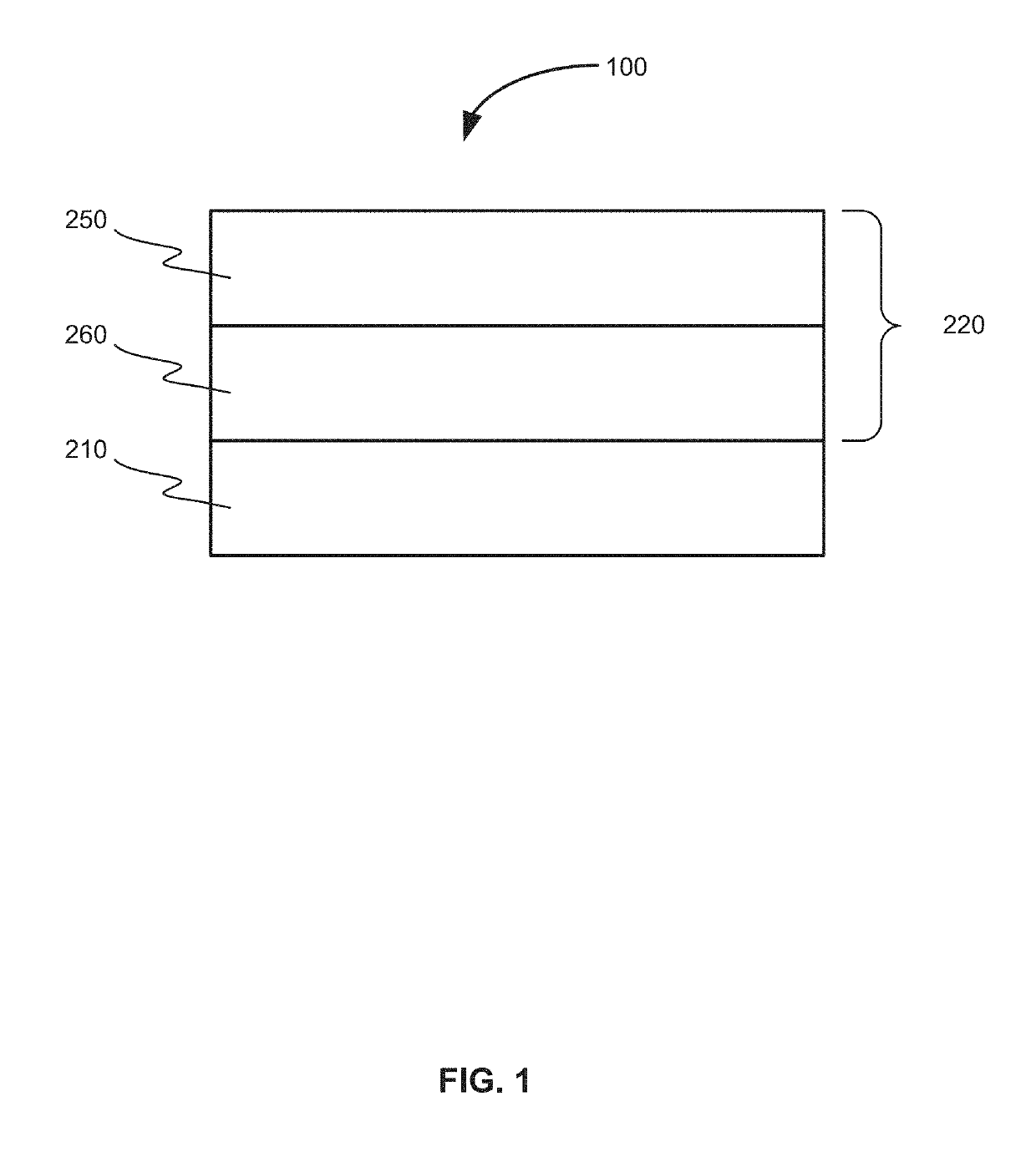

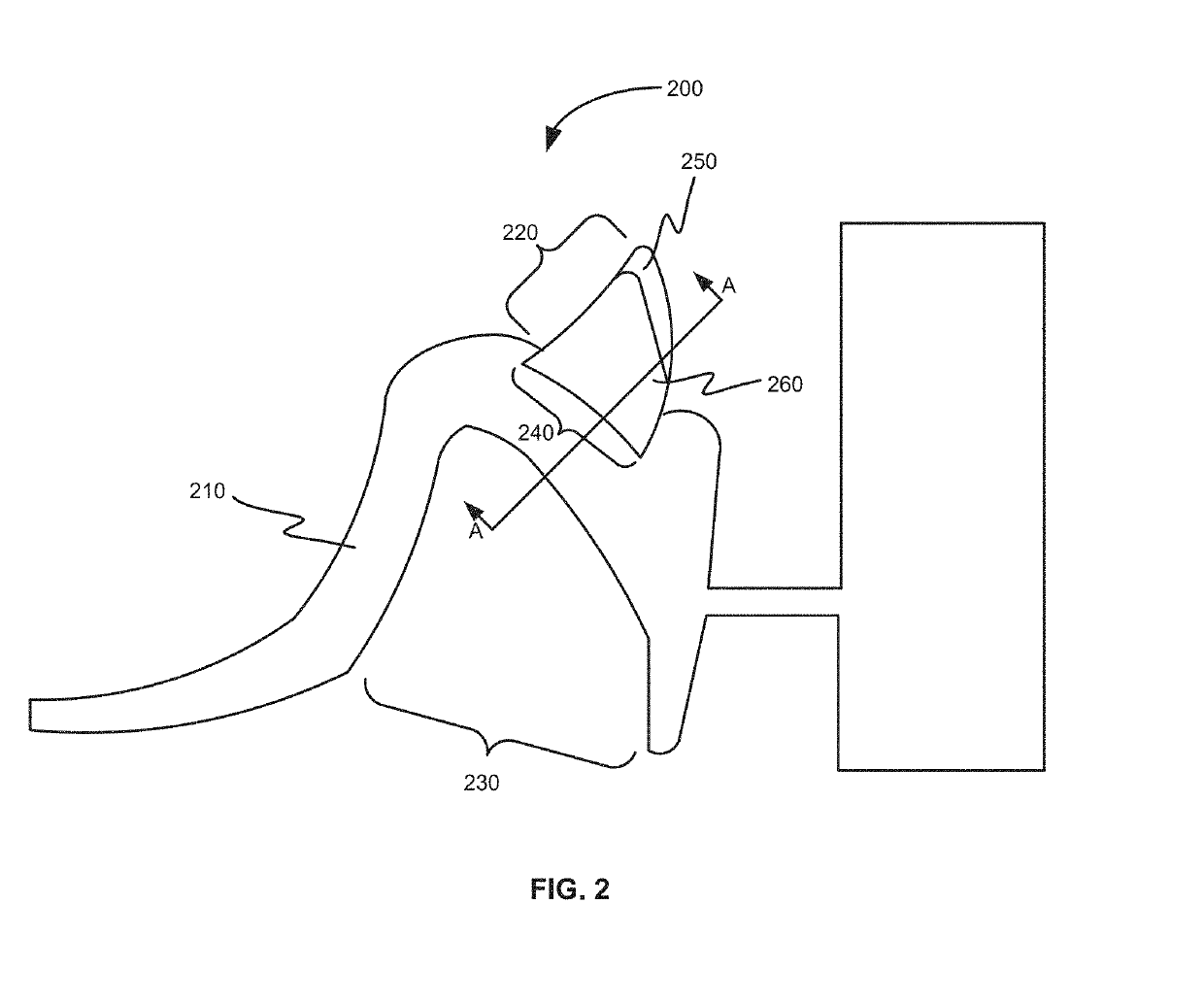

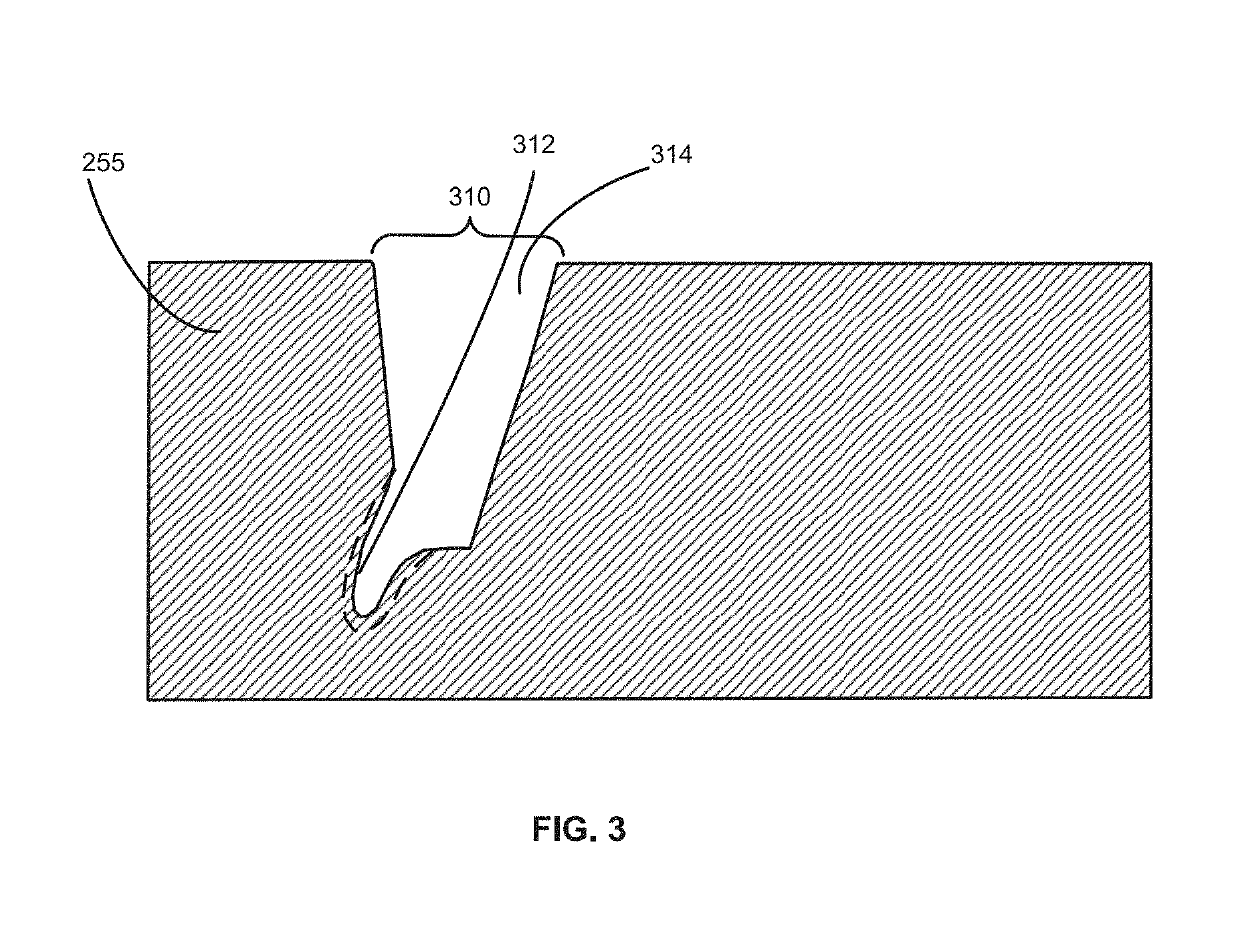

System and method for manufacturing layered dentures

A method of manufacturing a layered denture in which the enamel layer or the tooth layer is manufactured first and the denture base is manufactured last. The resulting denture may exhibit an enamel layer or a tooth layer with enhanced strength and / or resiliency. The resulting denture may have one or more of an integrated layer, balanced occlusion, and a root approximating structure.

Owner:GLOBAL DENTAL SCI

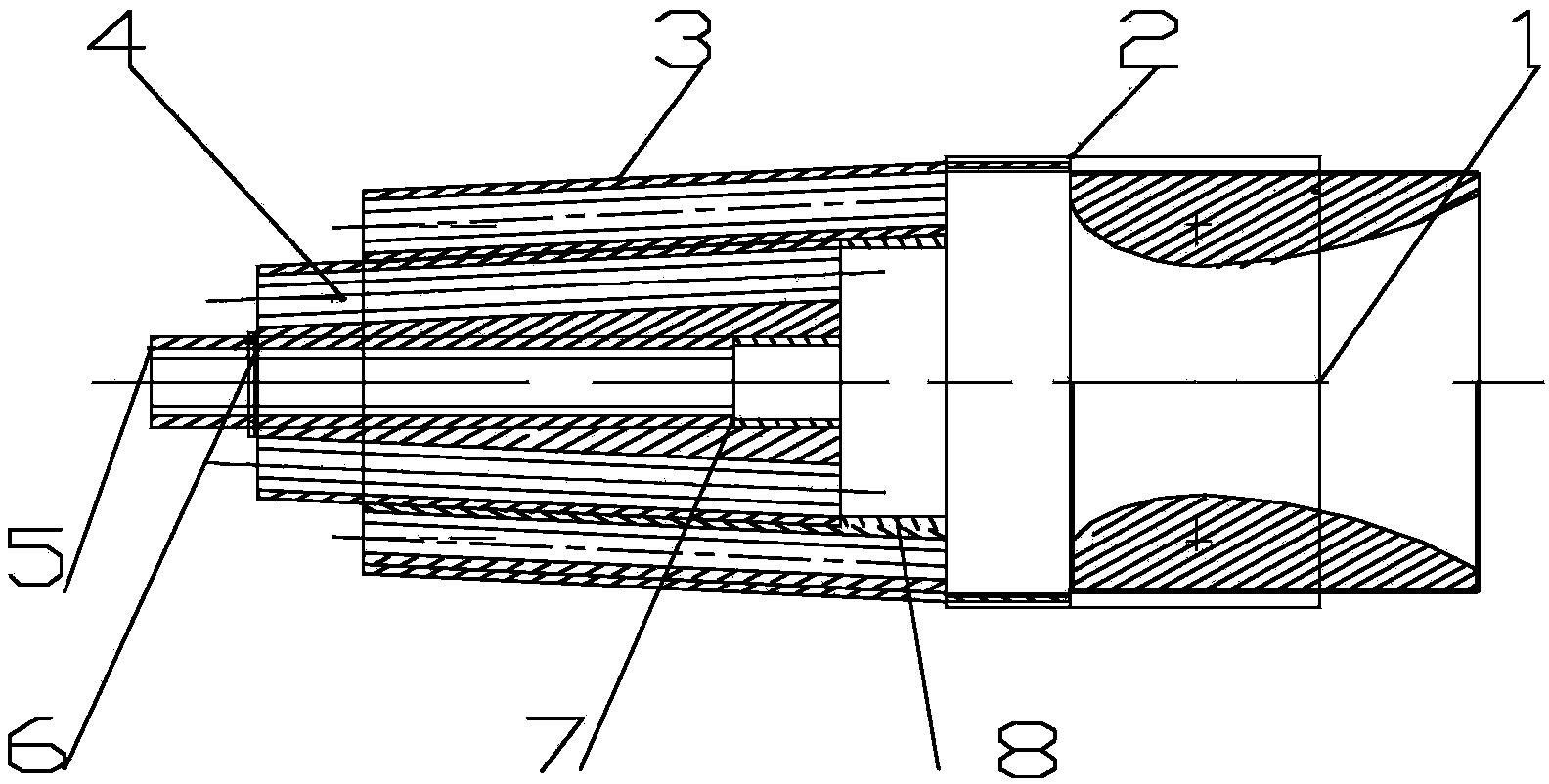

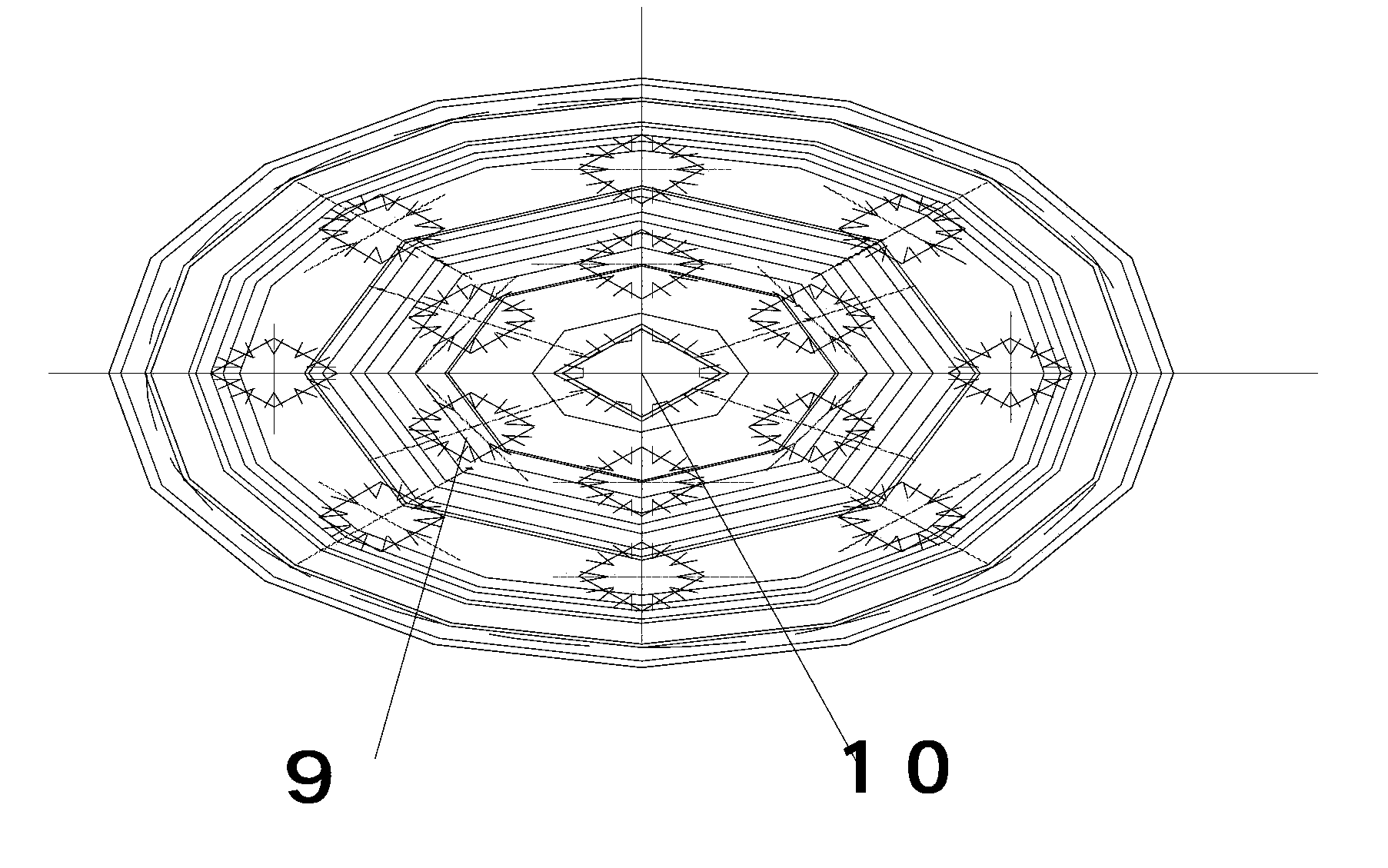

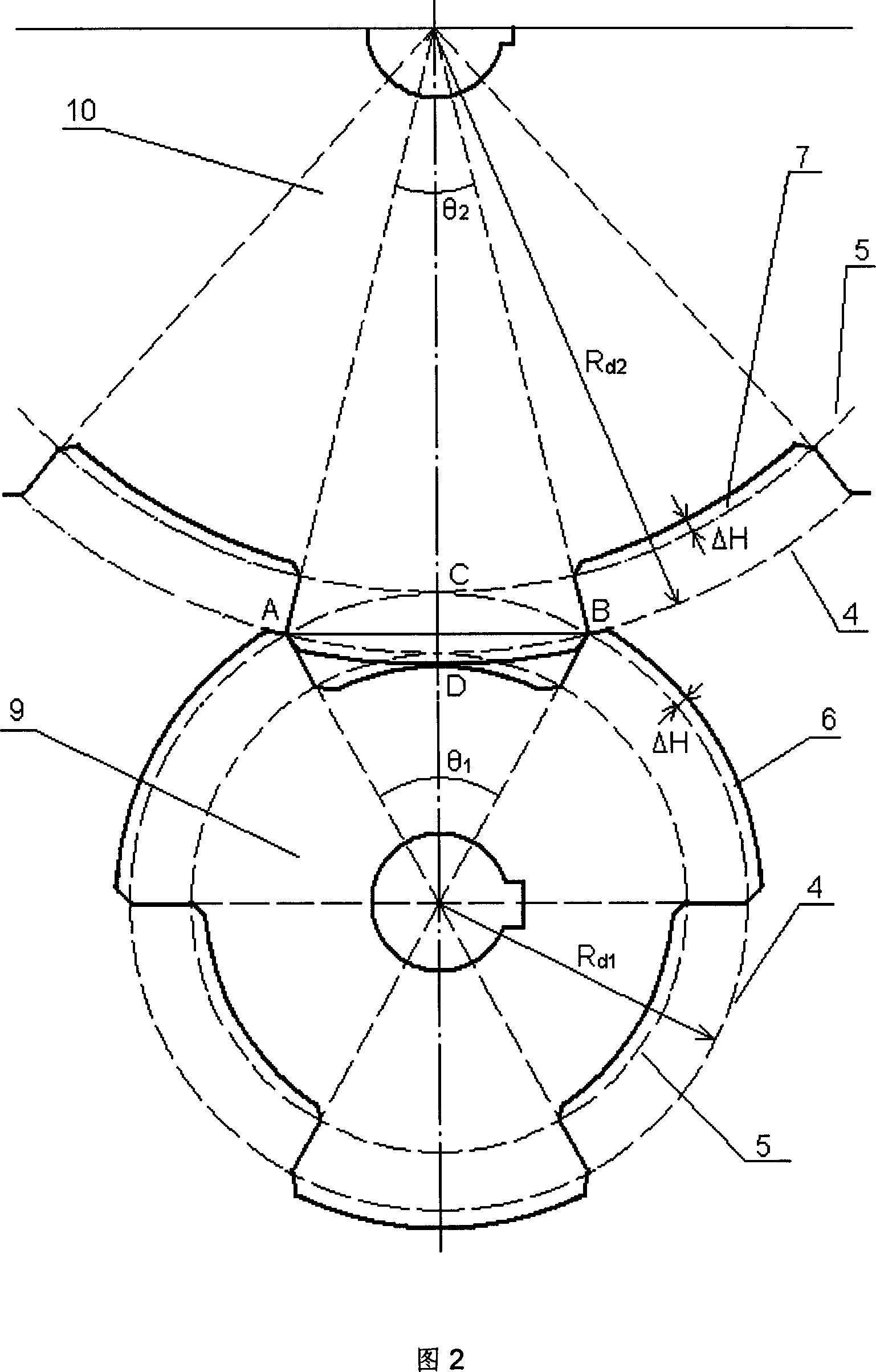

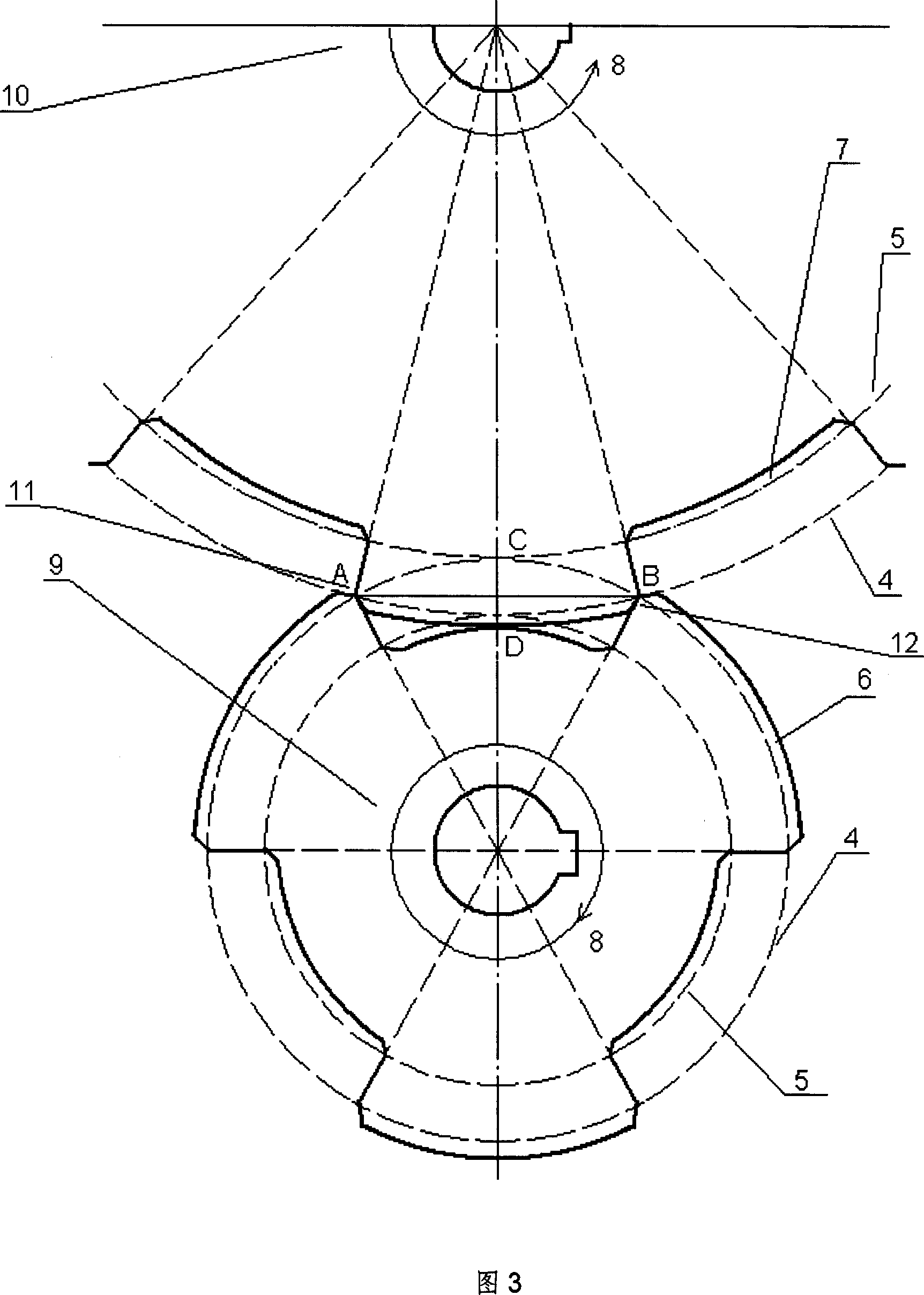

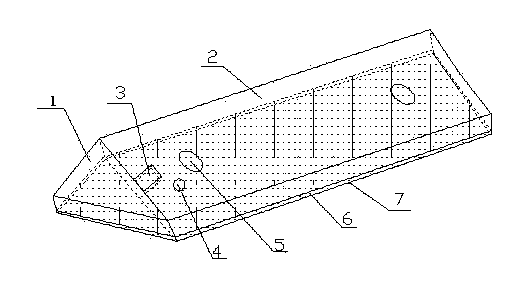

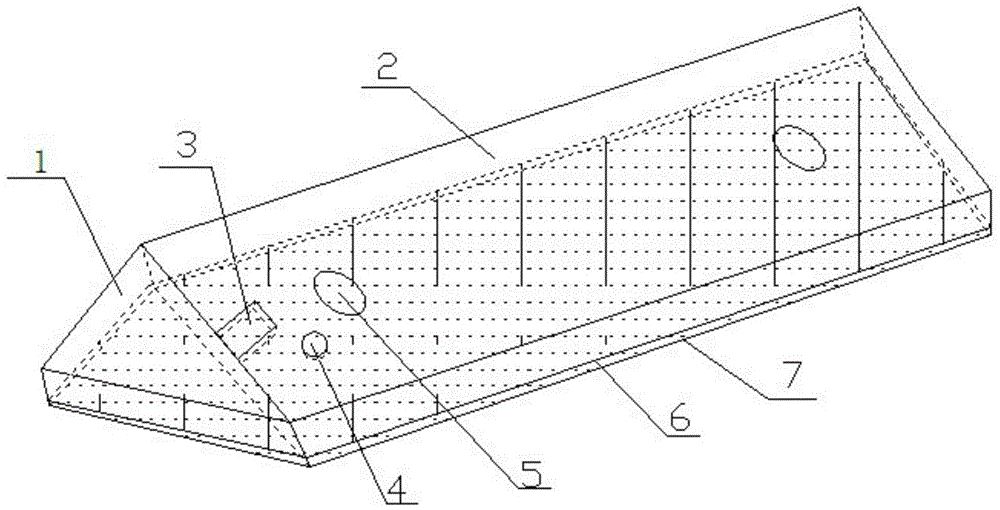

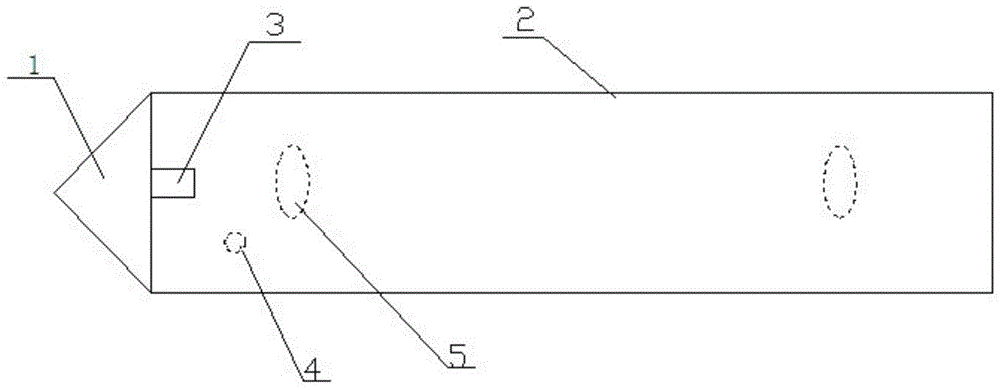

Pored inner-tooth layered nozzle with 15-degree taper angle

The invention relates to a pored inner-tooth layered nozzle with 15-degree taper angle, applicable to high-strength blowing of compressed air and fan flow, belongs to the industrial blowing nozzle, and aims to provide a nozzle, which uses high-flow low-pressure fan flow as an air source, which ensures optimal blowing range and blowing force and which is simple and reasonable in structure and light in self-weight. The nozzle comprises a main air chamber (1), a body (2), a tapered layer member I (3), a tapered layer member II (4), a tapered layer member III (5), a positioning elastic washer (6), an expansion sleeve (7), and an expansion sleeve (8); the tapered layer member I (3), the tapered layer member II (4) and the tapered layer member III (5) are provided with pore inner-tooth air outlets (9) different in quantity and size; a center outlet of the tapered layer member III (5) is a Laval structured air outlet (10). The pored inner-tooth layered nozzle with 15-degree taper angle has the advantages that compressed air and fan flow can be used as passing media; high blowing force and blowing range are provided according to the Laval principle.

Owner:NINGXIA JIAXIANG AUTOMATIC CONTROL TECH

Desensitizing dental composition

A dental composition for the treatment of dentinal hypersensitivity and in particular for the desensitization of exposed dentin, the desensitizing treatment of deep cavities, the desensitizing treatment when replacing dental layers, the stumps desensitizing treatment before placing dental prosthesis. The composition can be used as a solution or as a gel. In the first case two distinct liquid solutions for use successively on the exposed dentin are provided for. In the second case two distinct gel compounds spread successively on the exposed dentin are provided for. The first solution or the first gel compound comprises preferably three soluble potassium salts, whereas the second solution or the second gel compound comprises a calcium salt and a soluble strontium salt. In a preferred composition two solutions are provided for of which the first has solutes comprising potassium phosphate, potassium carbonate and potassium fluoride, and the second solution has solutes comprising calcium chloride and strontium chloride. For the gel composition, which may be used as toothpaste, two distinct gel compounds are provided, the first having solutes comprising potassium phosphate, potassium carbonate and potassium fluoride and the second gel compound having solutes comprising calcium chloride and strontium chloride.

Owner:G·加利和G·帕奇尼意大利医药有限公司

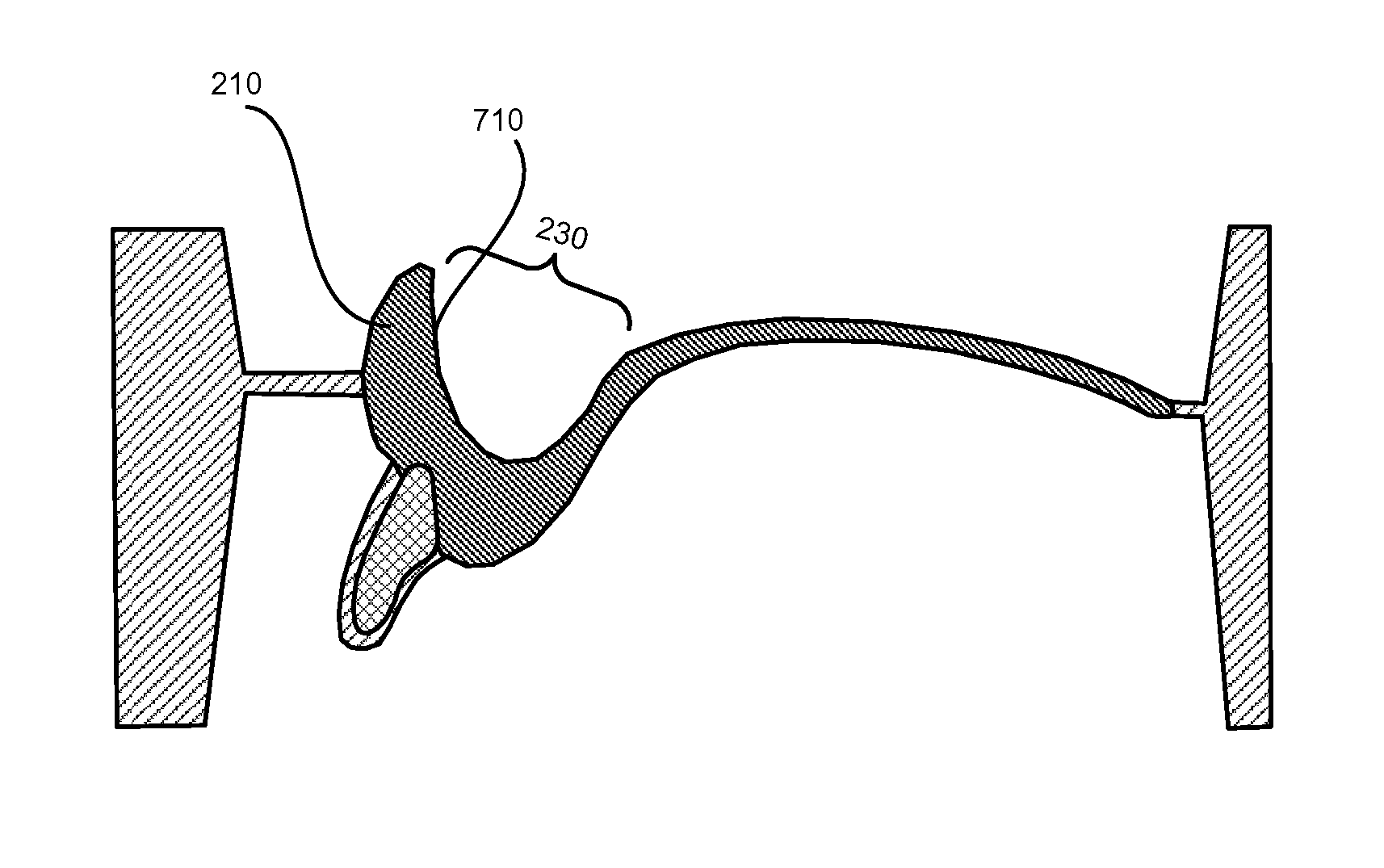

System and method for manufacturing layered dentures

ActiveUS20150342711A1Realistic appearanceDental implantsMechanical/radiation/invasive therapiesTooth layerDentures

A method of manufacturing a layered denture in which the enamel layer or the tooth layer is manufactured first and the denture base is manufactured last. The resulting denture may exhibit an enamel layer or a tooth layer with enhanced strength and / or resiliency. The resulting denture may have one or more of an integrated layer, balanced occlusion, and a root approximating structure.

Owner:GLOBAL DENTAL SCI

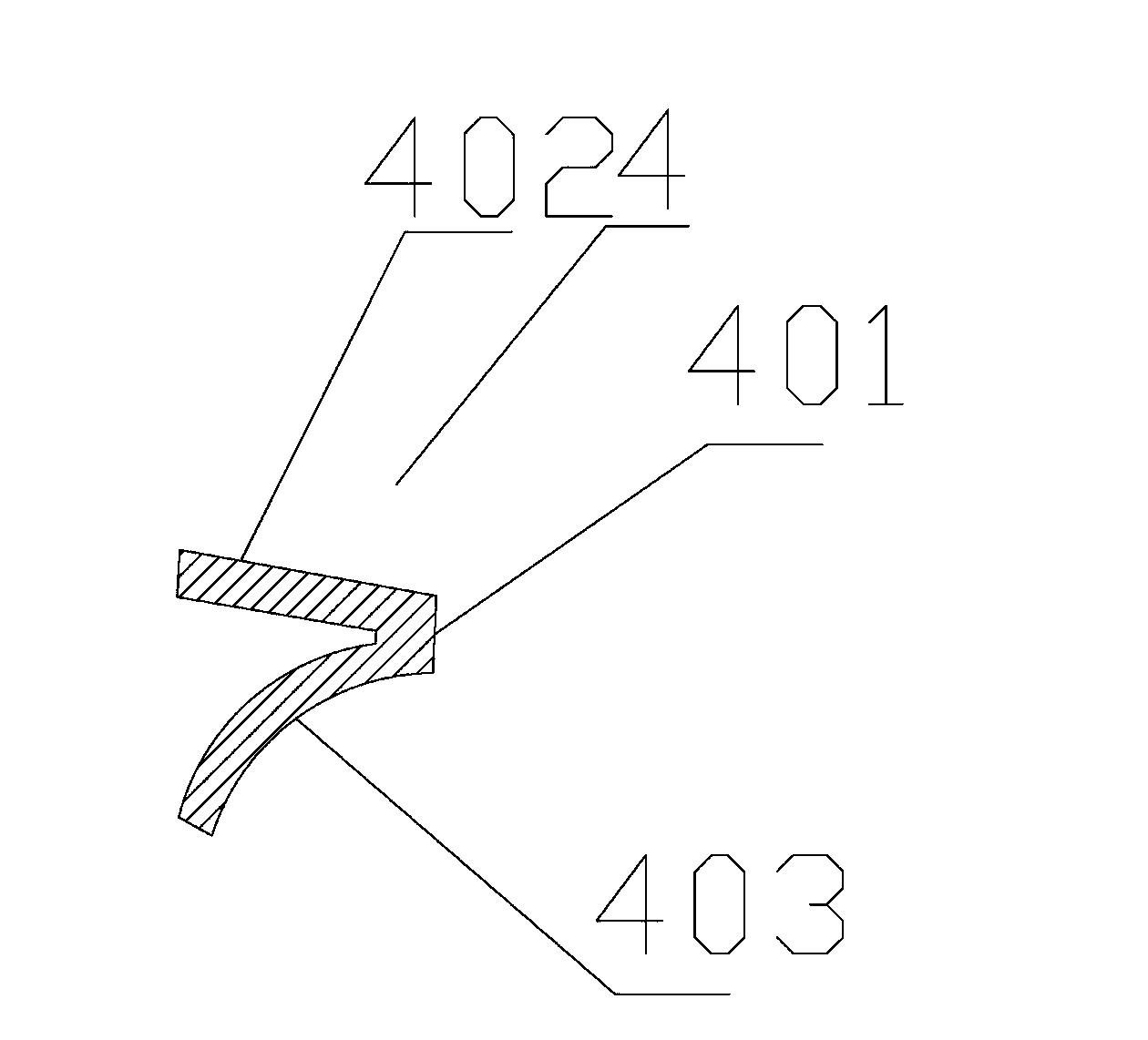

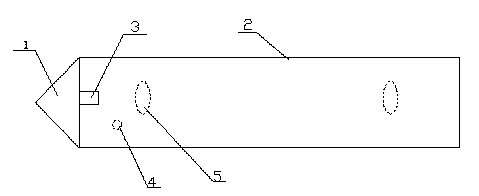

Scraper for processing concave profile of wood and plastic sheet materials

InactiveCN103624856AGuaranteed dimensional position accuracyReduce cutting resistanceWood working apparatusMetal working apparatusTooth layerPlastic film

The invention discloses a scraper for processing a concave profile of wood and plastic materials. The scraper comprises a cutter body, a blade tooth base and blade teeth, wherein the blade tooth base is detachably connected with the cutter body; the number of blade teeth is more than or equal to 2; the blade teeth are distributed on the blade tooth base in an in-line manner; the blade teeth comprise tooth bodies and tooth heads fixed on the tooth bodies; the height and width sizes of each tooth head of each blade tooth are increased from the most front blade tooth to the most rear blade tooth in an echelon manner. The scraper has the advantages that the blade tooth base and the cutter body are in detachable connection, when the blade teeth are polished, the scraper does not need to be integrally detached and replaced, and the position of the cutter body cannot be replaced, so that the accuracy of size and position of the scraper can be guaranteed; the number of blade teeth is more than or equal to 2, the blade teeth are distributed on the blade tooth base in the in-line manner, the height and width sizes of each tooth head of each blade tooth are increased from the most front blade tooth to the most rear blade tooth in an echelon manner, the cutting mode of the scraper is changed from single-tooth cutting into multi-tooth layered cutting, the scraper is subjected to small cutting resistance and is high in processing quality.

Owner:蓝帜(中国)刀具系统有限公司

System and method for manufacturing layered dentures

A method of manufacturing a layered denture in which the enamel layer or the tooth layer is manufactured first and the denture base is manufactured last. The resulting denture may exhibit an enamel layer or a tooth layer with enhanced strength and / or resiliency. The resulting denture may have one or more of an integrated layer, balanced occlusion, and a root approximating structure.

Owner:GLOBAL DENTAL SCI

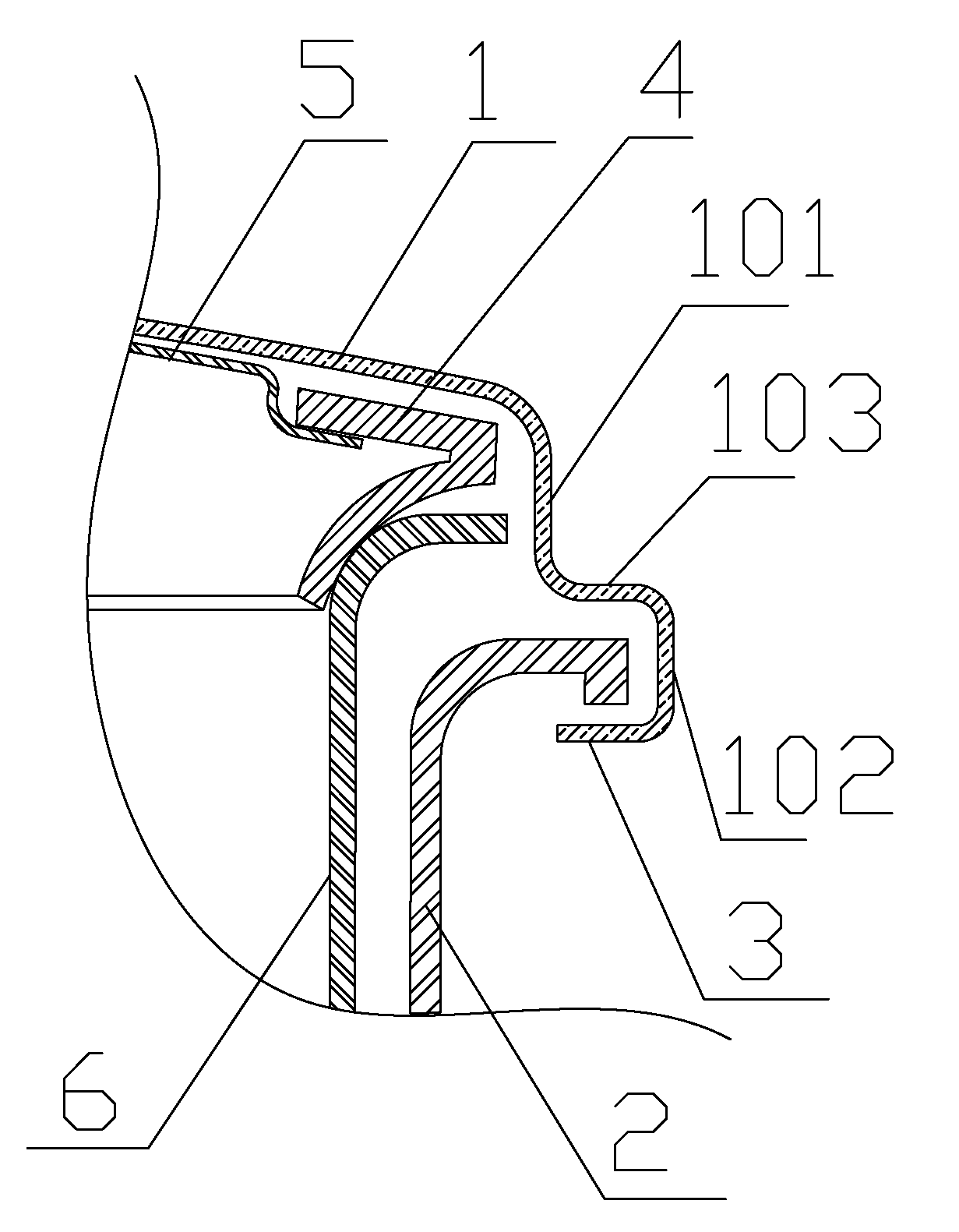

Pressure-cooker cover

InactiveCN102846189AEasy to take outEasy to take out for cleaningPressure-cookersTooth layerPressure cooking

The invention belongs to a pressure-cooker cover, and is implemented simultaneously or individually by three parts, the pressure-cooker cover, a seal ring and a support piece for fixing the seal ring, wherein the cooker cover is divided into two layers, the first layer is a cover top layer which is a circumferential wall formed by extending downward the periphery of the cover top of the cooker cover; a connecting plane is arranged at the connection between the cover top layer and a buckle teeth layer of the cooker cover; a circumferential wall formed by extending downward the periphery of the connection plane is a second buckle teeth layer; the buckle teeth layers are provided with buckle teeth for buckling the cooker body; the main body section of the seal ring is a 7-shaped ring body, one side of the ring body is designed to be a plane, and the other side is designed to be a cambered surface; the plane is adhered in the cooker cover and fixedly mounted by a plurality of T-shaped support pieces; and when the cover is closed, the cambered surface is adhered to a cooker mouth of the cooker body, which forms sealing between the cooker cover and the cooker body. The pressure-cooker cover provided by the invention has the advantages of using a small amount of material, and being firm and stable in the fixing mode, simple in structure, safe and reliable, low in manufacturing cost, low-carbon, environment-friendly and energy-saving.

Owner:朱银心

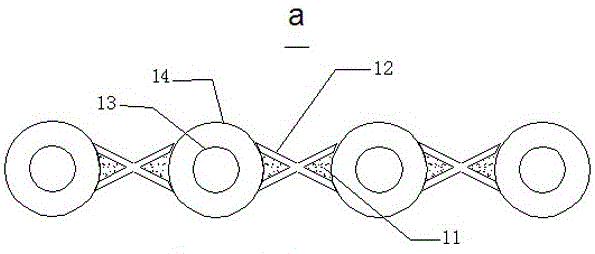

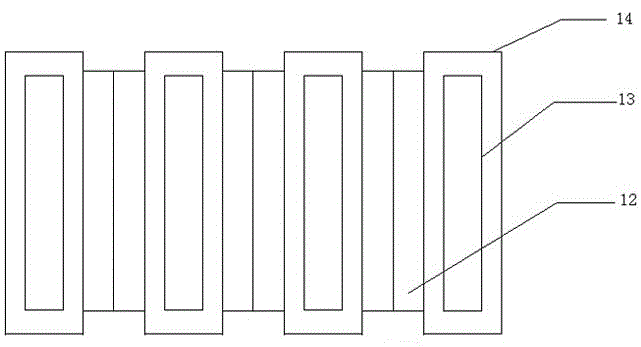

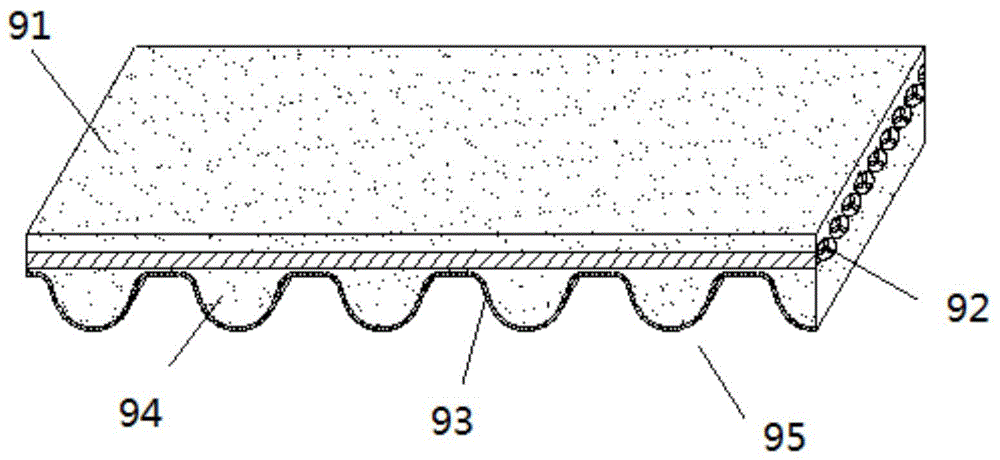

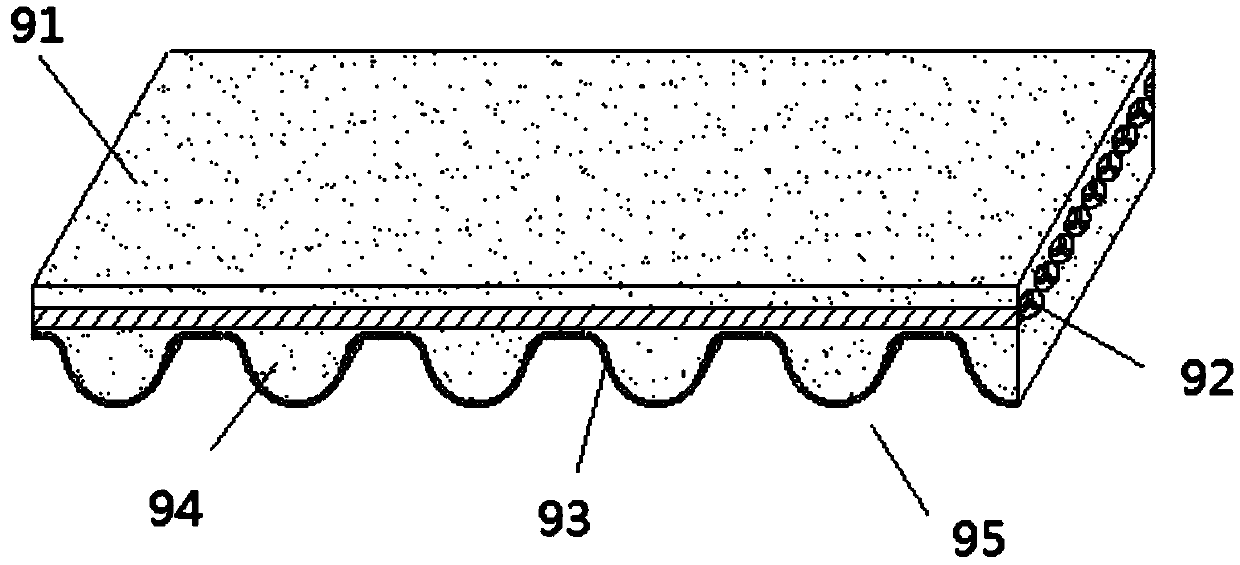

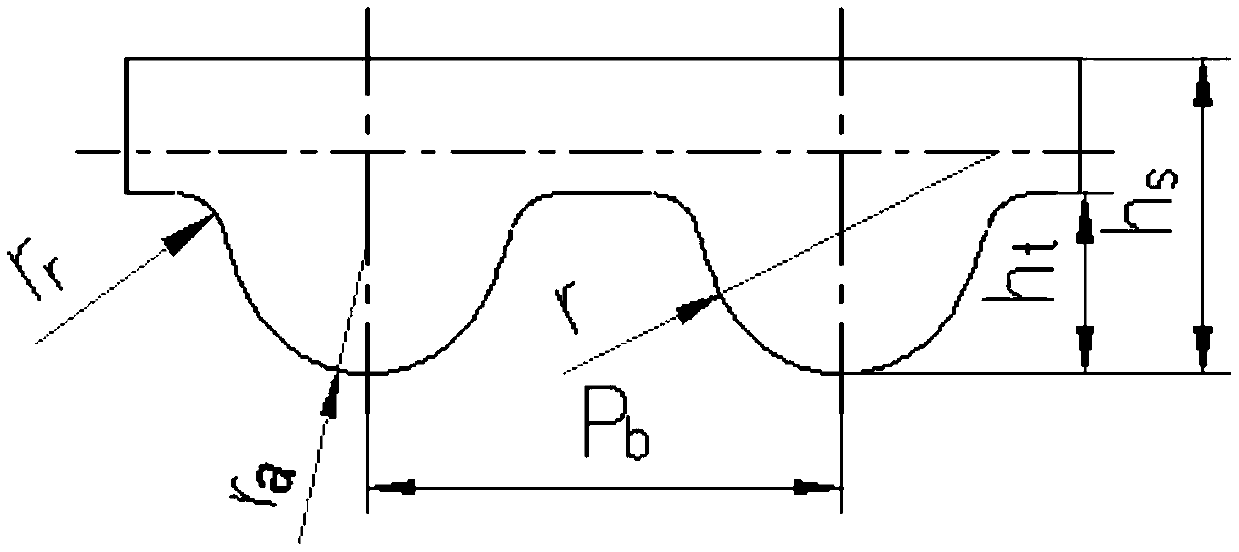

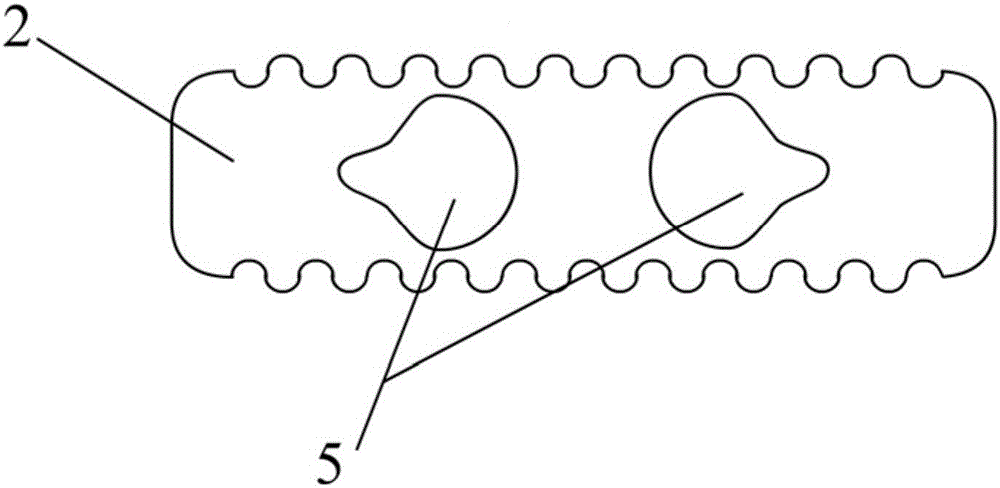

Integrated polyurethane synchronous belt and manufacturing method thereof

ActiveCN104963998AProduction and processing safetyImprove mechanical propertiesSynthetic resin layered productsLaminationTooth layerHardness

The invention discloses an integrated polyurethane synchronous belt. The integrated polyurethane synchronous belt is characterized by comprising an integrally-formed synchronous belt body composed of a hard polyurethane tooth layer and a soft polyurethane base layer, the shore hardness of hard polyurethane is 91-93 A, and the shore hardness of soft polyurethane is 55-60 A. The integrated polyurethane synchronous belt is simple in manufacturing process, safe in production and environmentally friendly.

Owner:WINSIN MATERIALS INC

Wide tooth form relay transmission gear and manufacture method therefor

InactiveCN101016945AMiniaturizationFacilitate thinningPortable liftingGearing elementsTooth layerEngineering

The invention relates to a method for producing wide-tooth gear used in power gear, which can be divided into wide tooth layer gear, wide tooth combine planet gear and wide tooth incline gear via different gear methods. The inventive tooth width is 1.2 times than present gear, while the torque of single tooth is 1.5 times of present one, with low cost and long service life, while the invention can save more than 40% material.

Owner:黄振强

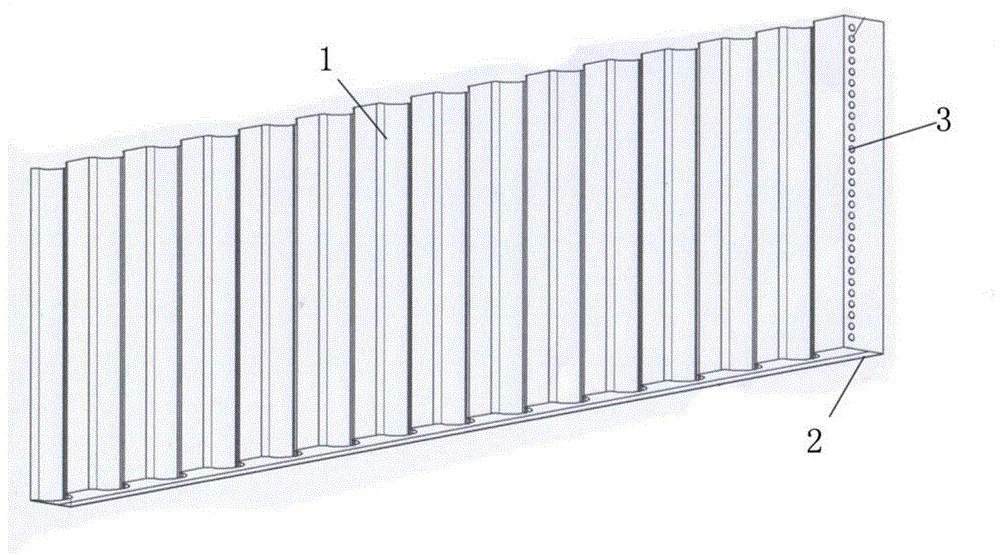

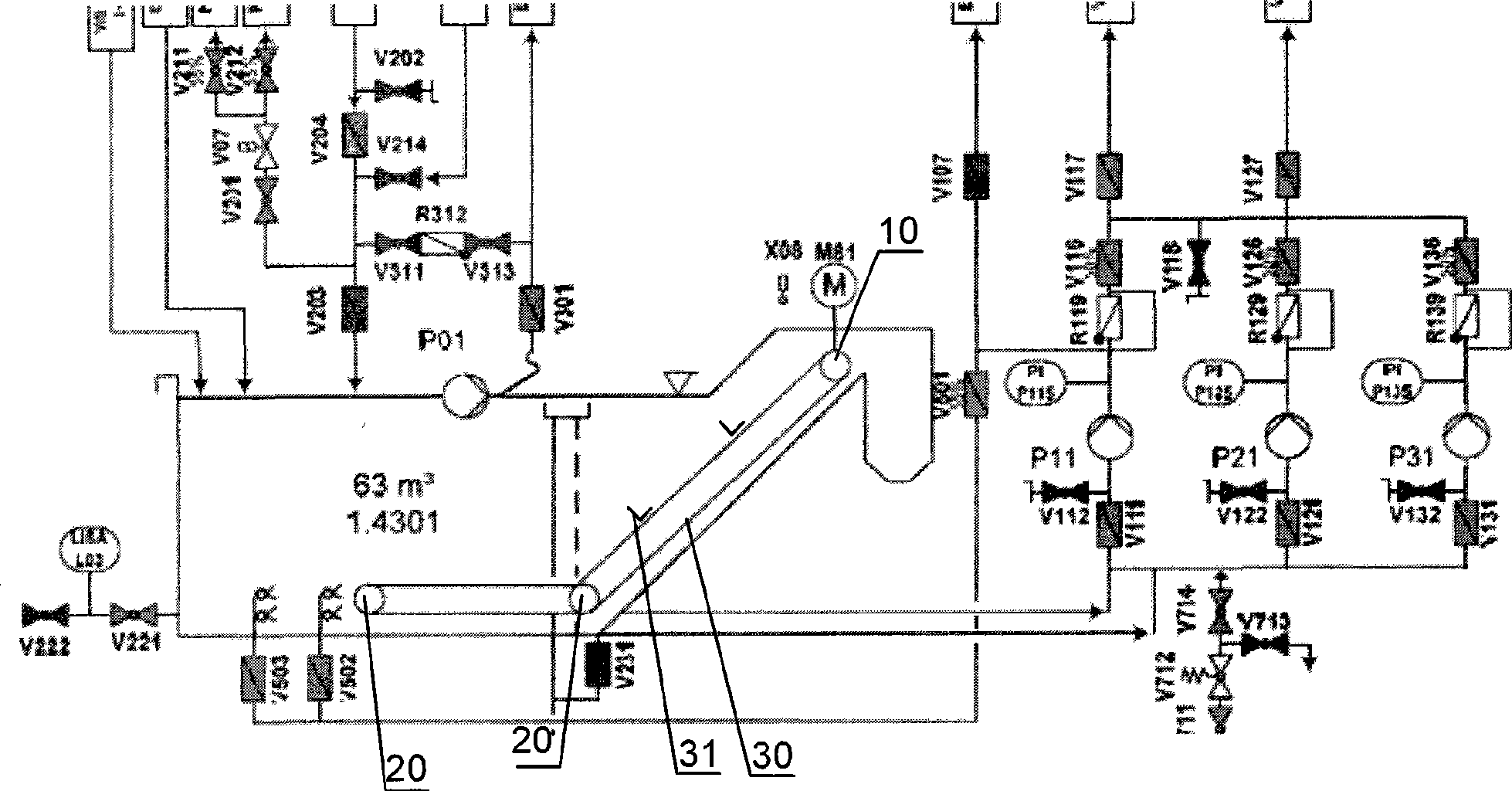

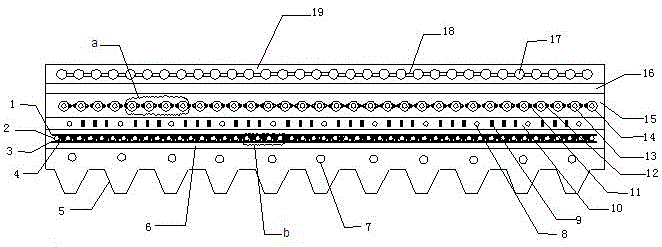

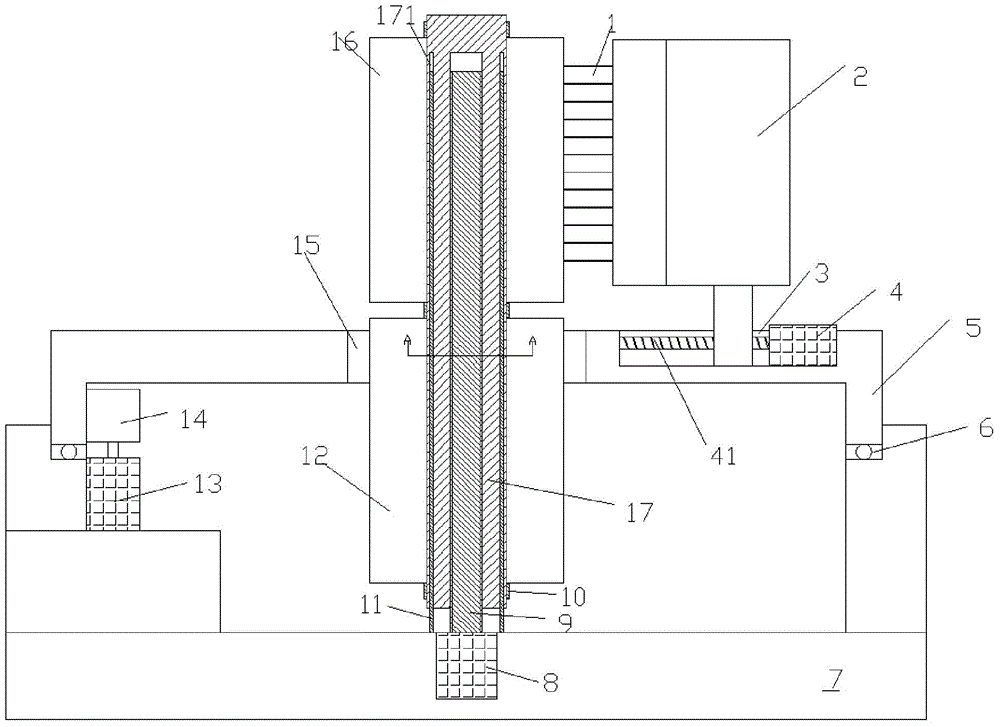

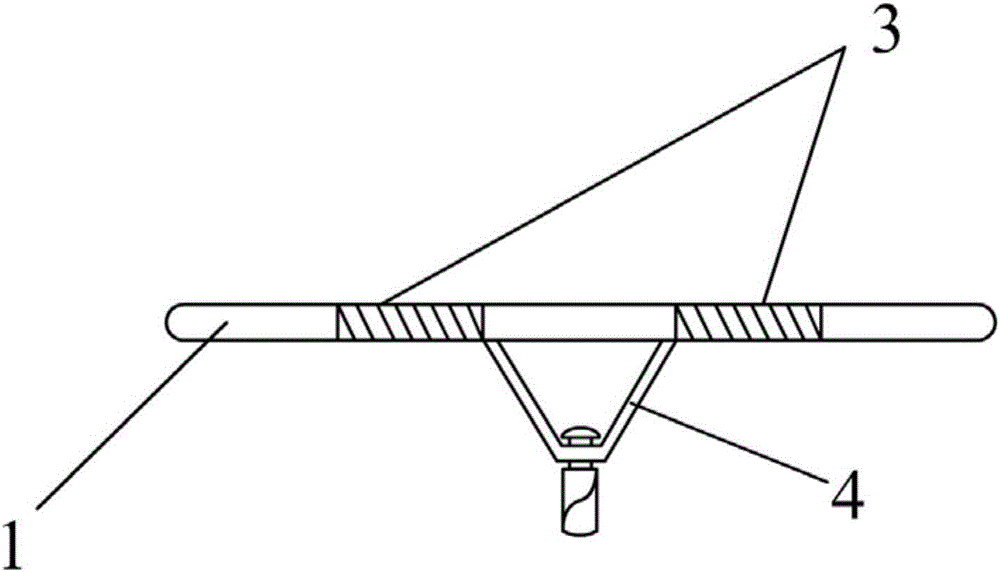

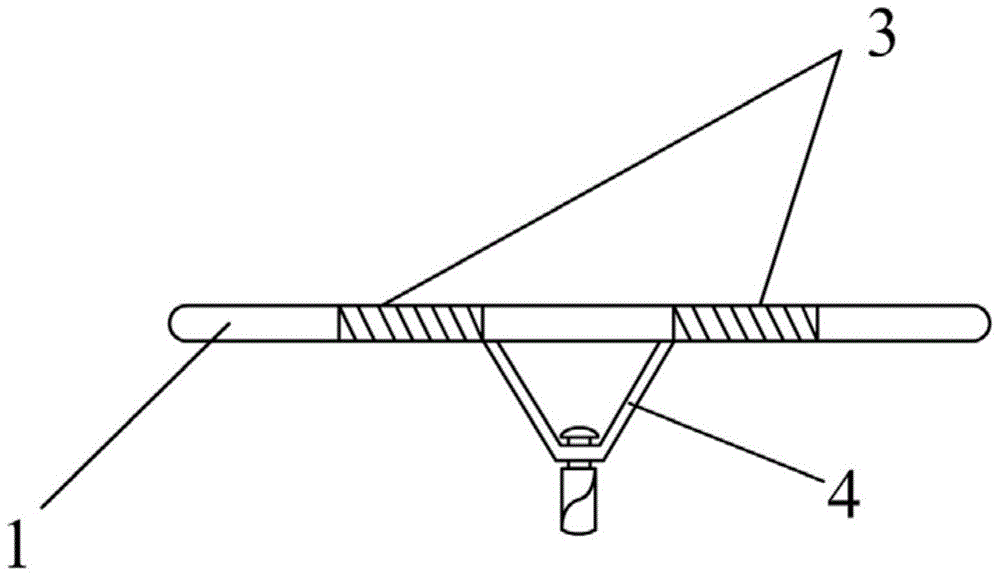

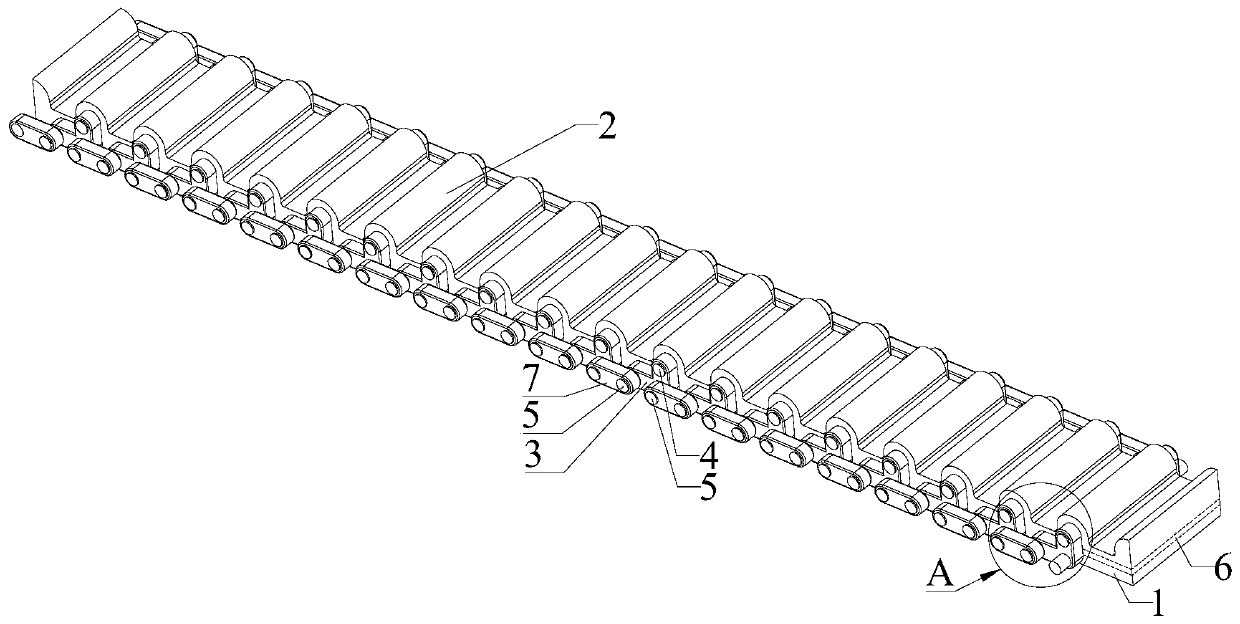

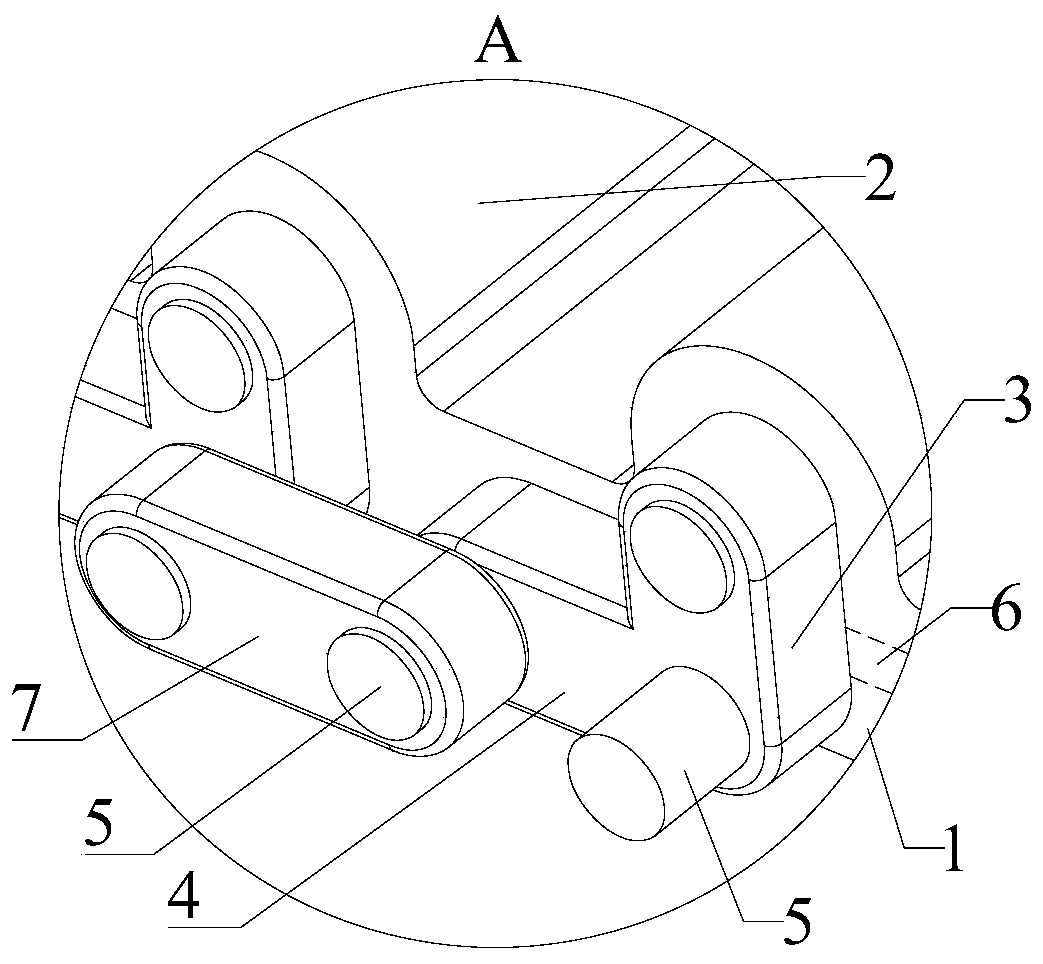

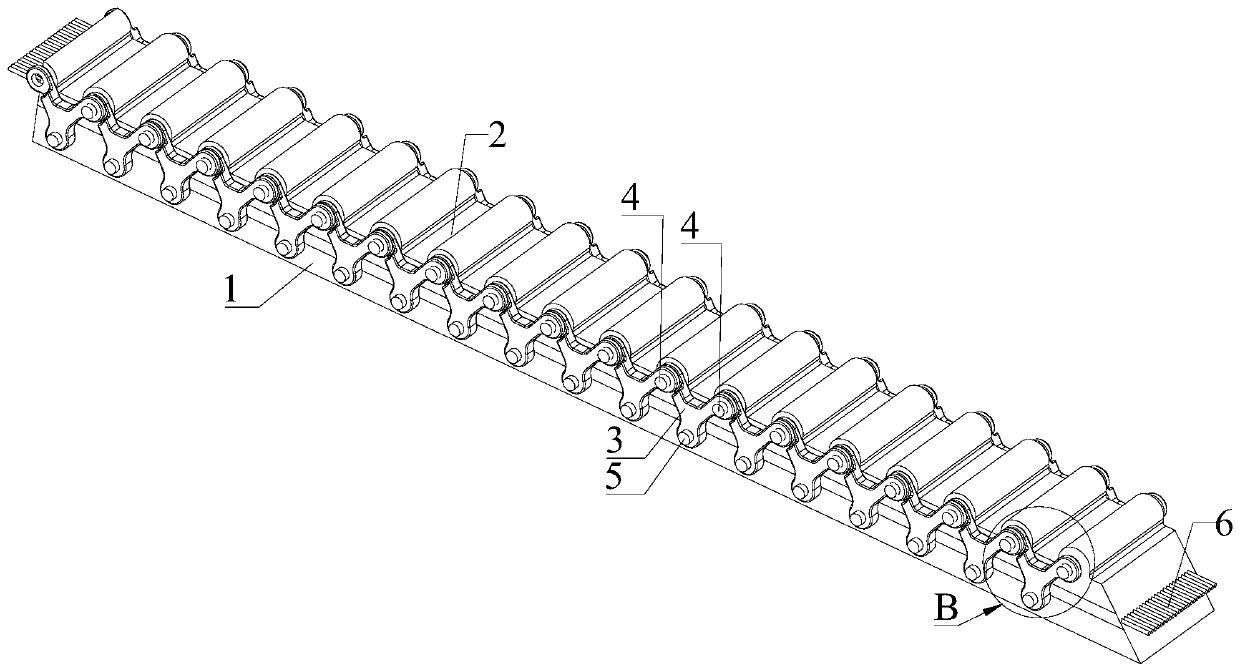

Guide mechanism for scum scraping chain

ActiveCN101444774APlay a guiding roleInhibit sheddingLiquid surface applicatorsCoatingsTooth layerDrive wheel

The invention relates to a guide mechanism for a scum scraping chain for an automobile painting waste paint treatment system. The guide mechanism comprises a driving wheel and a driven wheel which are respectively and transversely arranged at the top part and the bottom part of a groove, two parallel scum scraping chains respectively bypass the driving wheel and the driven wheel, scraping plates are transversely arranged on the two scum scraping chains, and a guide rail for the scum scraping chains to pass through is arranged on a scum scraping chain positioned at the front end of the driving wheel. Since the guide rail is arranged on the scum scraping chain, the guide rail plays the role of guidance to the scum scraping chains, meanwhile, the scraping plate finishes the task of scum scraping before the scum scraping chains pass through the guide rail, when the scum scraping chains enter in the guide rail, the scum attached to the scum scraping chains is peeled off by the guide rail, so that the scum scraping chains are matched with the gear of the driving wheel in a basic clean state, therefore, the phenomenon that the scum is attached to the wheel teeth layer by layer is avoided, and the scum scraping chains can be effectively prevented form falling off.

Owner:CHERY AUTOMOBILE CO LTD

Diesel vehicle engine synchronous belt

A diesel vehicle engine synchronous belt comprises an endless belt. The endless belt comprises second asbestos cloth, first aramid fiber cords, first asbestos cloth, second adhesive glue, a tooth layer, a fourth adhesive layer, first heat emission holes, second heat emission holes, polyester staple fibers, a third adhesive layer, first adhesive glue, reinforcing ribs, steel cords, asbestos cloth covers, a second adhesive layer, an imitation lining leather elastic layer, second aramid fiber cords, third aramid fiber cords and a first adhesive layer; the second aramid fiber cords are embedded in the first adhesive layer in the width direction of the synchronous belt, the third aramid fiber cords are connected between two adjacent second aramid fiber cords, the imitation lining leather elastic layer is under the first adhesive layer, and the second adhesive layer is arranged under the imitation lining leather elastic layer. The diesel vehicle engine synchronous belt has the advantage that the steel cords and the aramid fiber cords serve as a reinforced skeleton simultaneously.

Owner:DAISHAN HEINER RUBBER BELT

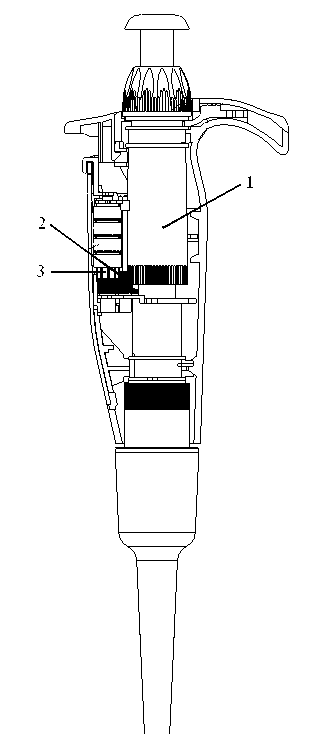

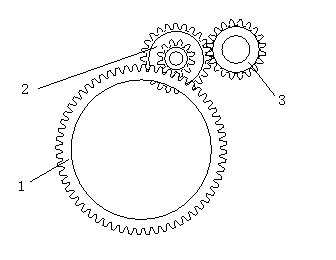

Dosage adjustment device of pipettor

InactiveCN102974416ARelieve fatigueThe adjustment process is smooth and smoothBurettes/pipettesPunchingDosage adjustment

The invention discloses a dosage adjustment device of a pipettor. The dosage adjustment device of the pipettor comprises a round tube part provided with a tooth punching end, double-layer gears and a digit wheel, wherein the tooth punching end of the round tube part is meshed with a small tooth layer of the double-layer gears, a big tooth layer of the double-layer gears is meshed with the digit wheel, the inside of the round tube part drives a sliding rod to slide, and anti-skid threads are arranged at the other end, opposite to the tooth punching part, of the outside of the round tube part and are used for rotation of the outside to adjust a dosage. Because a plurality of compact gears are meshed, on the premise that accurate dosage adjustment is ensured, strength for rotating adjustment is greatly reduced. Great strength is not needed, the dosage can be adjusted easily and accurately, the whole adjustment process is smooth in motion, and the dosage adjustment device of the pipettor is suitable for routine work carried out every day.

Owner:TOPSCIEN INSTR NINGBO

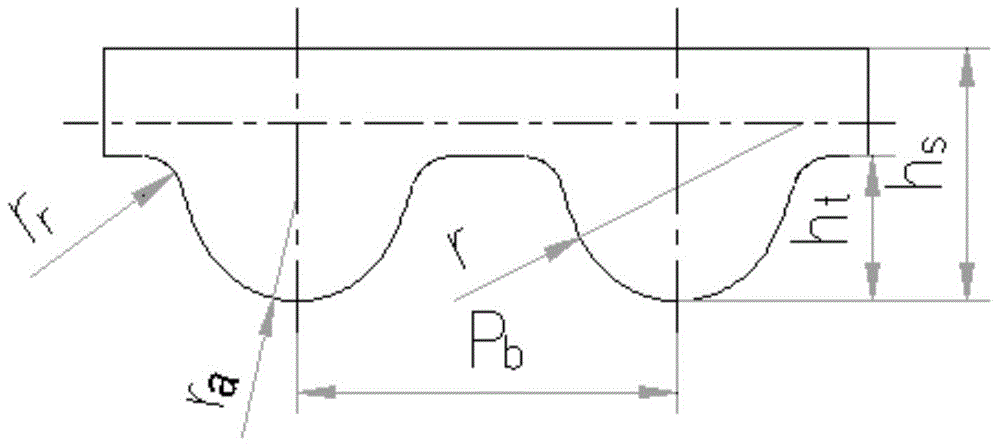

Open timing belt and preparation method

ActiveCN104482111AImprove working environmentImprove production environmentDriving beltsBeltsGlass fiberTooth layer

The invention discloses an open timing belt and a preparation method thereof. A linear belt body of a transmission flat belt is composed of a chloroprene rubber outer layer, a glass fiber layer, a chloroprene rubber belt tooth layer and elastic nylon cloth which coats the belt tooth layer, wherein teeth on the chloroprene rubber belt tooth layer are circular arc-shaped teeth.

Owner:NINGBO GUL TZ RUBBER BELT

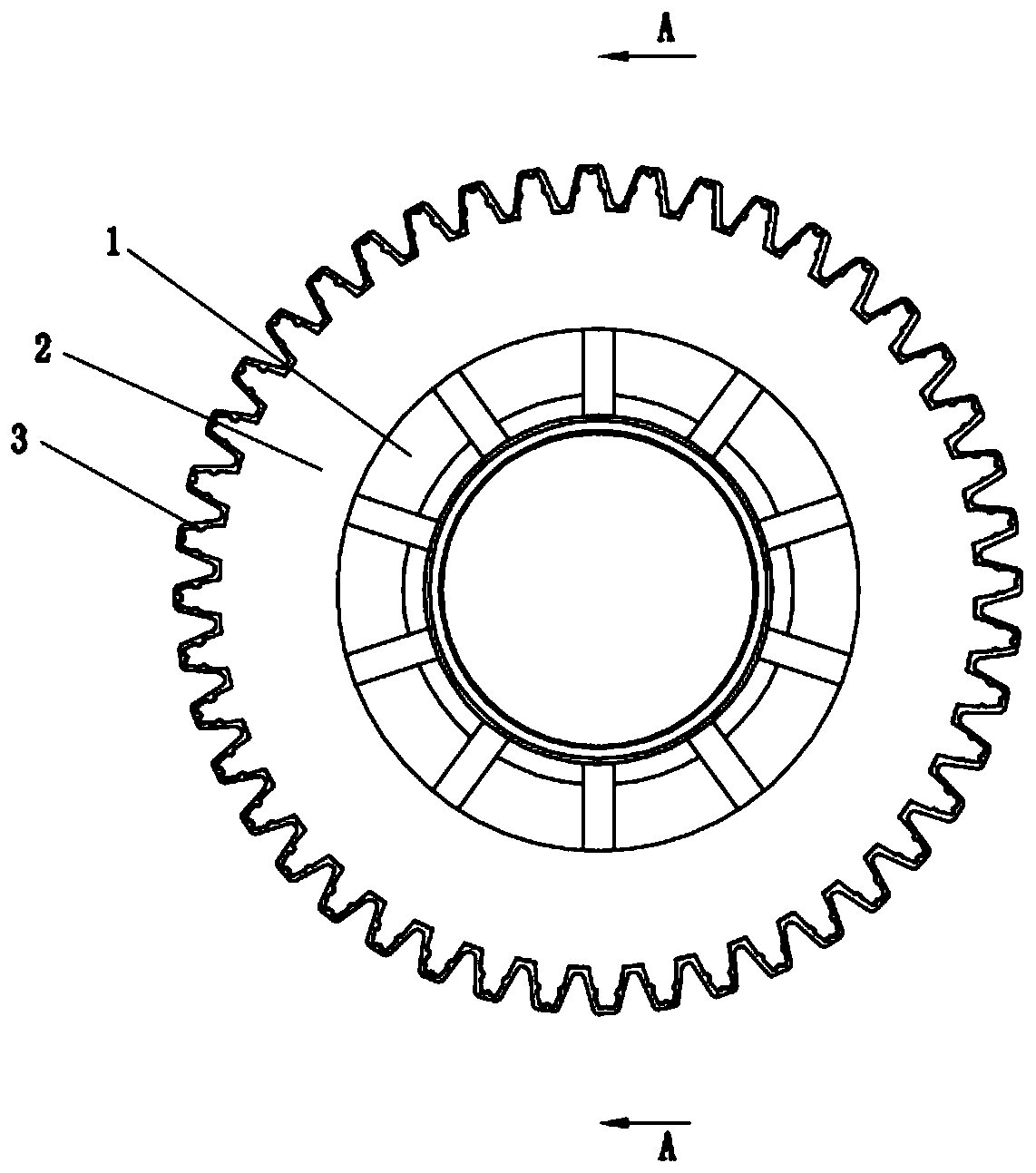

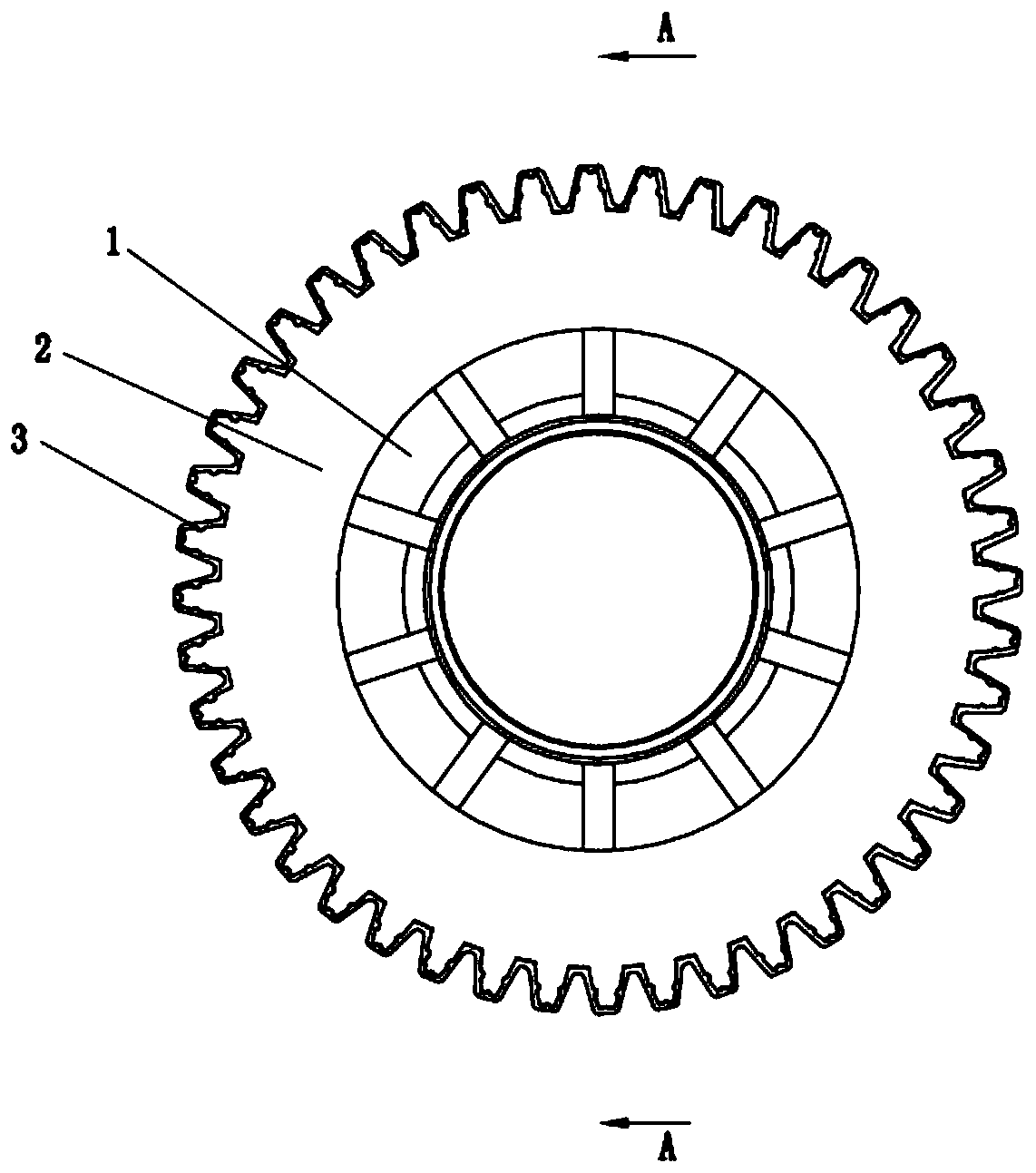

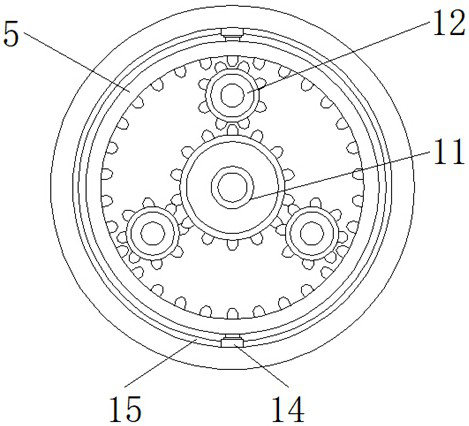

Multi-layer metal/resin gear, as well as manufacturing process and application thereof

PendingCN110030364AFit closelyGuaranteed coaxialPortable liftingGearing elementsLow noiseTooth layer

The invention discloses a multi-layer metal / resin gear which comprises a metal core part with a wheel axle part and a hub part, and a resin gear ring part surrounding the periphery of the hub part. The multi-layer metal / resin gear is characterized in that the wheel axle part and the hub part of the metal core part are integrally molded through a forging or casting manner; the resin gear ring partcomprises a support ring with bulging teeth and an outer tooth layer; the support ring is molded on the periphery of the metal core part through a first resin; and the outer tooth layer is formed by asecond resin so as to be coated on the periphery of the support ring. According to a manufacturing process provided by the invention, the processing efficiency is improved, and the manufacturing costis greatly reduced. The multi-layer metal / resin gear provided by the invention has the advantages of good transmission fit relation, high strength, high precision, high output torque, operation stability, low noise and the like.

Owner:浙江美亚特精密机械有限公司

Integrated polyurethane synchronous belt and preparation method thereof

ActiveCN104963998BProduction and processing safetyImprove mechanical propertiesSynthetic resin layered productsLaminationTooth layerHardness

The invention discloses an integrated polyurethane synchronous belt. The integrated polyurethane synchronous belt is characterized by comprising an integrally-formed synchronous belt body composed of a hard polyurethane tooth layer and a soft polyurethane base layer, the shore hardness of hard polyurethane is 91-93 A, and the shore hardness of soft polyurethane is 55-60 A. The integrated polyurethane synchronous belt is simple in manufacturing process, safe in production and environmentally friendly.

Owner:WINSIN MATERIALS INC

Firm and intelligent lathe tool

InactiveCN104209544AEasy to fixPlay a shock absorbing effectWorkpiecesTurning toolsTooth layerCompression device

The invention discloses a firm and intelligent lathe tool, and relates to the field of industrial machines. The firm and intelligent lathe tool comprises a tool bit and a tool bar. The tool bit is connected with the tool bar, a high temperature warning lamp is arranged on the surface of the connecting position of the tool bit and the tool bar, and a battery is arranged inside the tool bar. A plurality of grooves are formed in the upper surface of the tool bar, a shock absorption layer is arranged on the lower surface of the tool bar, and a dense tool tooth layer is arranged on the lower surface of the shock absorption layer. When the temperature of the tool bit exceeds a material bearing temperature, the high temperature warning lamp can light up, the tip end of a blade compression device is inserted into one groove, the lathe tool can be fixed more firmly, the damping effect can be achieved in the operating process of the lathe tool through the shock absorption layer, the compression strength of a tool rest and the lathe tool can be increased through the dense tool tooth layer, when cutting resistance is large, the lathe tool cannot loose, so that cutting precision is improved, and working efficiency is improved.

Owner:郑翔

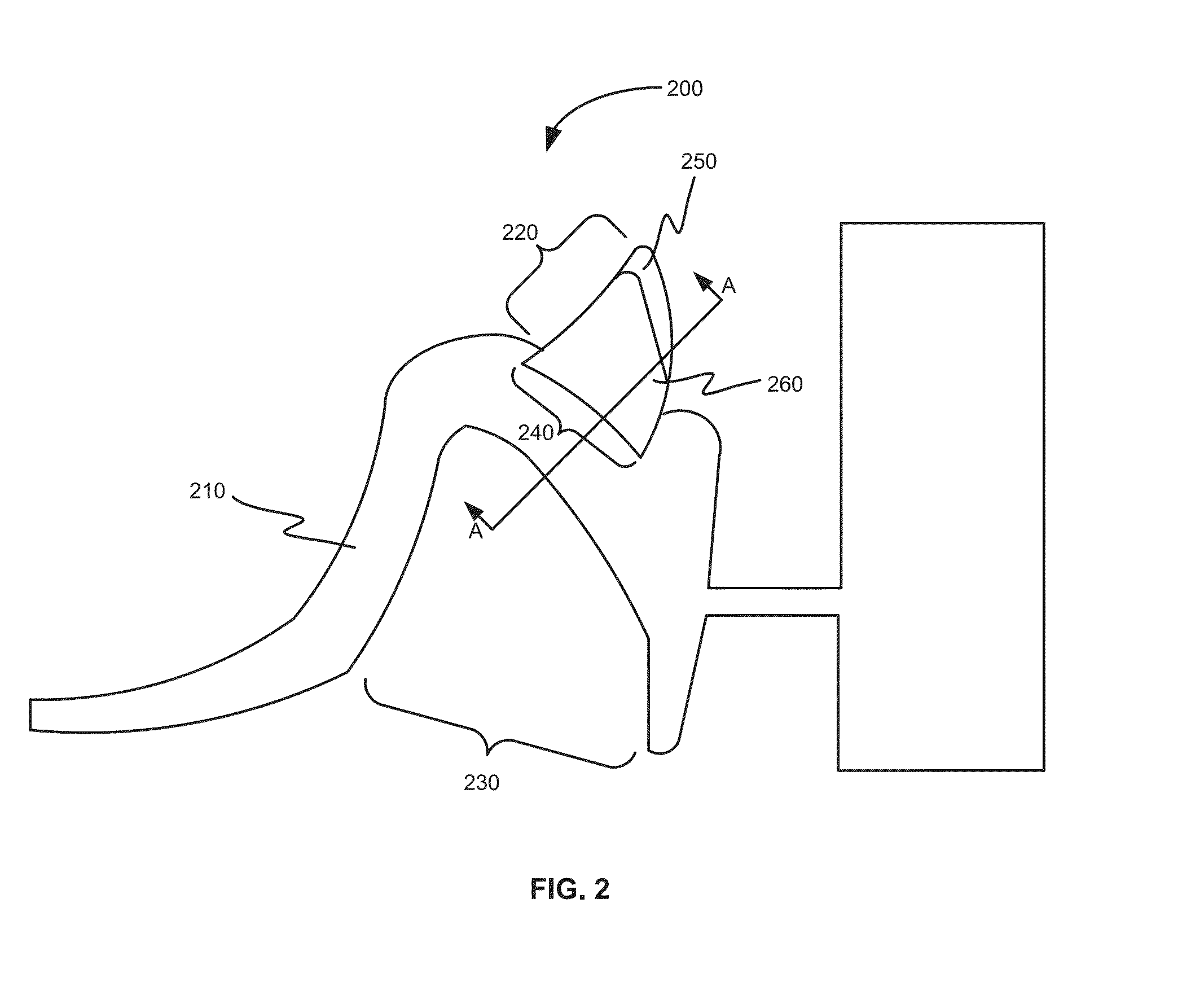

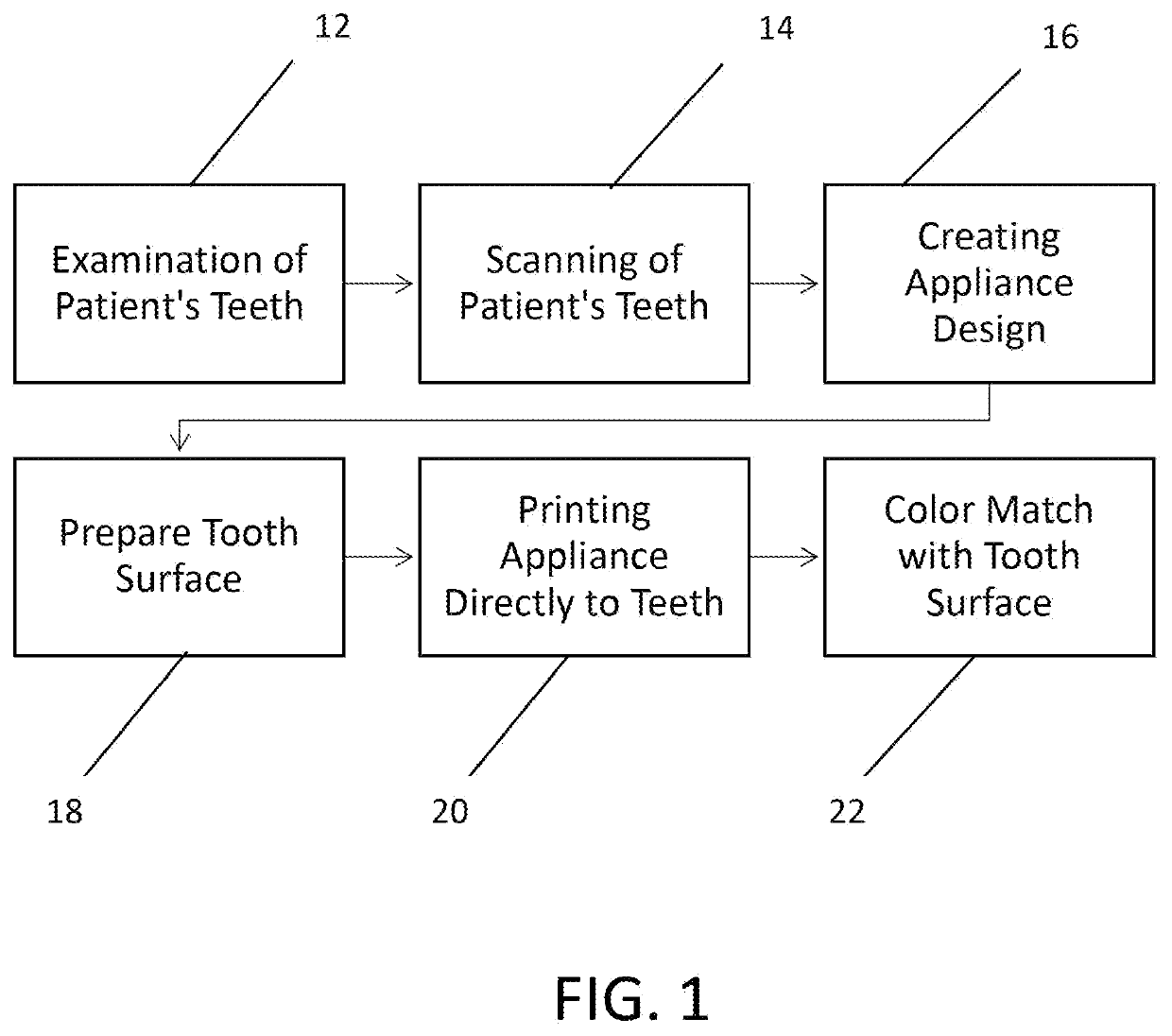

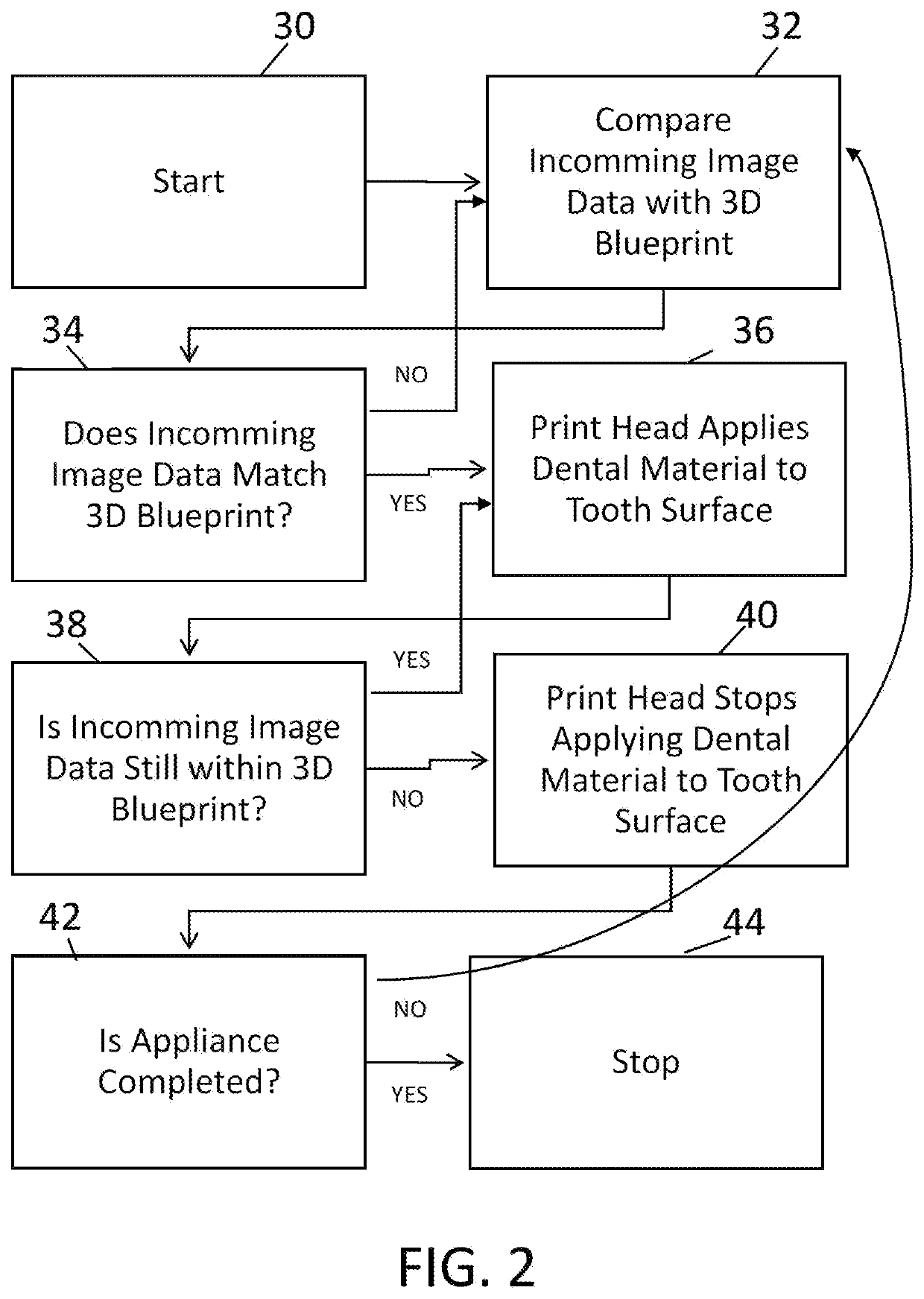

Methods for Direct Printing of Orthodontic and Dental Appliances onto the Teeth of a Patient

PendingUS20220125553A1Accurate identificationImpression capsMechanical/radiation/invasive therapiesAnatomical structuresDental instruments

A method for directly printing orthodontic and dental appliances on the teeth of a patient. The tooth is scanned with a scanner which is communicated with a computer controller configured to recognize the anatomy of the tooth. The surface of a tooth of the patient is then prepared in order to receive the type of appliance designated for the patient. Using image data from the print head, the computer controller prepares a three-dimensional blueprint or design of an appropriate orthodontic or dental appliance. The computer controller controls the type and amount of material that is distributed through the print head only when the print head passes over the recognized anatomy so as to directly print the corresponding appliance onto the tooth layer by layer as the print head makes successive passes over the surface of the tooth.

Owner:LEMCHEN MARC

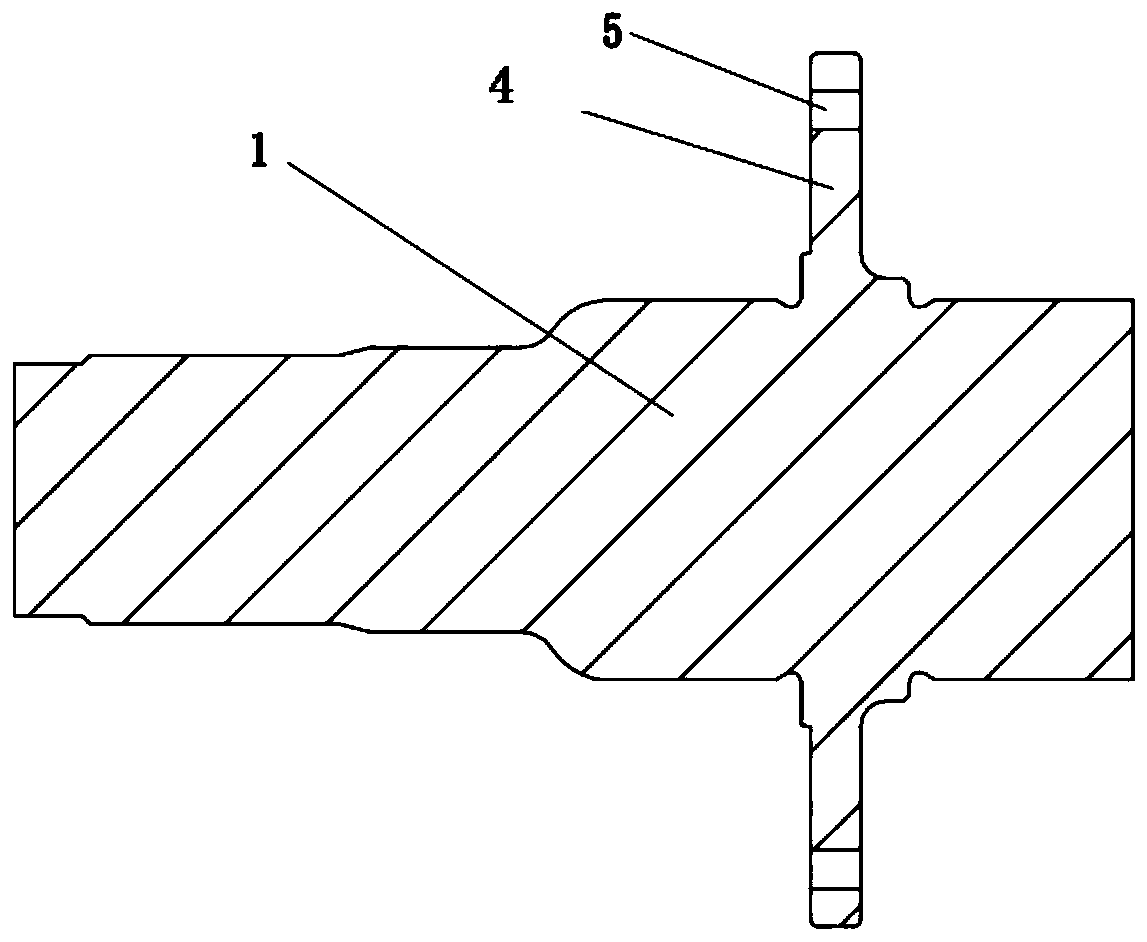

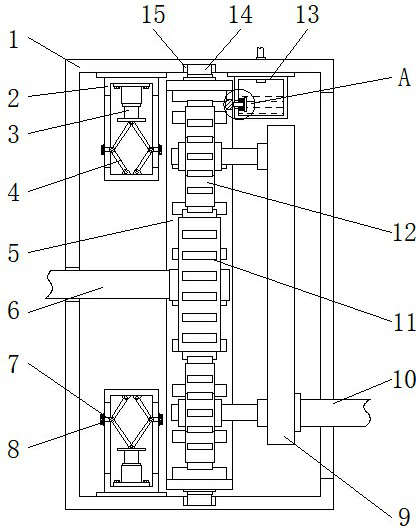

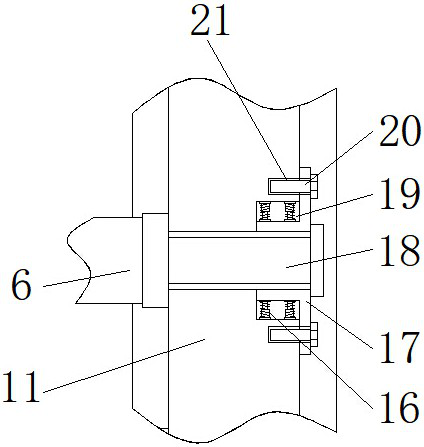

Splice type variable tooth thickness planetary transmission speed change device

InactiveCN111895043AReasonable structureIncrease the lengthGear lubrication/coolingToothed gearingsTooth layerEngineering

The invention discloses a splice type variable tooth thickness planetary transmission speed change device. The splice type variable tooth thickness planetary transmission speed change device comprisesa box body, pneumatic stretching and contracting rods and L-shaped plates, wherein the top end and the bottom end of one side of the inner portion of the box body are both fixedly connected with installation boxes, and the bottom ends of the inner portions of the installation boxes are both fixedly connected with the pneumatic stretching and contracting rods, one sides of connection blocks are all provided with braking pieces in a welded manner, the middle position of the inner portion of the box body is rotatably connected with a tooth layer, and the middle position of one side of the innerportion of the box body is fixedly connected with a first driving shaft. According to the splice type variable tooth thickness planetary transmission speed change device, by means of the installationsof a sun wheel and an installation shaft, fastening bolts are made to break away from the inner portions of internal threads by rotating the fastening bolts, then the L-shaped plates are moved out offixed grooves, the sun wheel is made to break away from the outer side of the installation shaft, replacement of the sun wheel is realized, appearance of the situation of excessive wear of the sun wheel is avoided, and the convenience of the splice type variable tooth thickness planetary transmission speed change device in use is increased.

Owner:哈尔滨首捷智能科技有限公司

A kind of opening synchronous belt and preparation method thereof

ActiveCN104482111BImprove working environmentImprove production environmentDriving beltsBeltsGlass fiberTooth layer

Owner:NINGBO GUL TZ RUBBER BELT

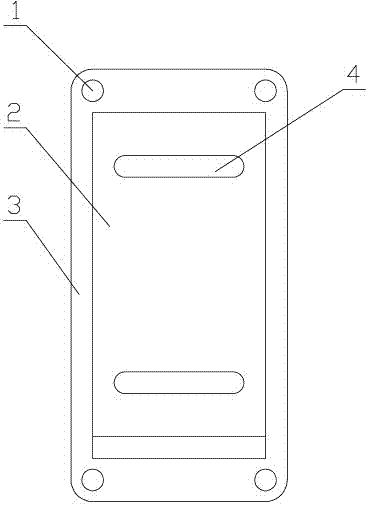

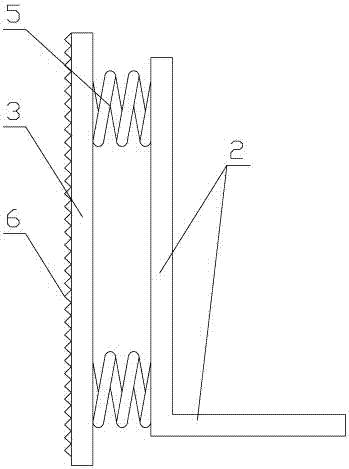

Novel circuit breaker mounting rack

InactiveCN107978494ANovel structural designEasy to useProtective switch detailsTooth layerEngineering

The invention relates to a novel circuit breaker mounting rack which comprises a rectangular mounting plate, wherein bolt mounting holes are formed in four corners of the rectangular mounting plate; anon-slip fastening tooth layer is arranged on the back of the rectangular mounting plate; the front side of the rectangular mounting plate is connected with a mounting bracket plate of which the section is L-shaped by virtue of a plurality of springs; and a plurality of kidney-shaped round mounting holes are formed in the mounting bracket plate. The novel circuit breaker mounting rack disclosed by the invention is simple and novel in structural design and obvious in using effect, and has an excellent actual application and popularization value.

Owner:HUBEI ENG INST

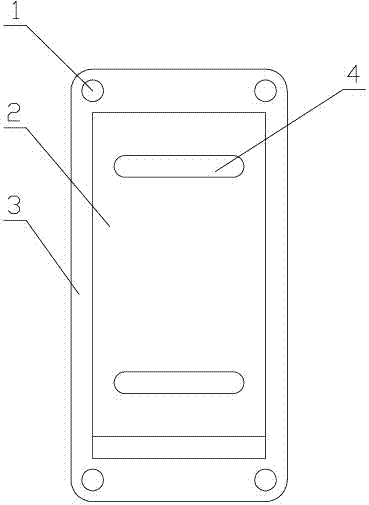

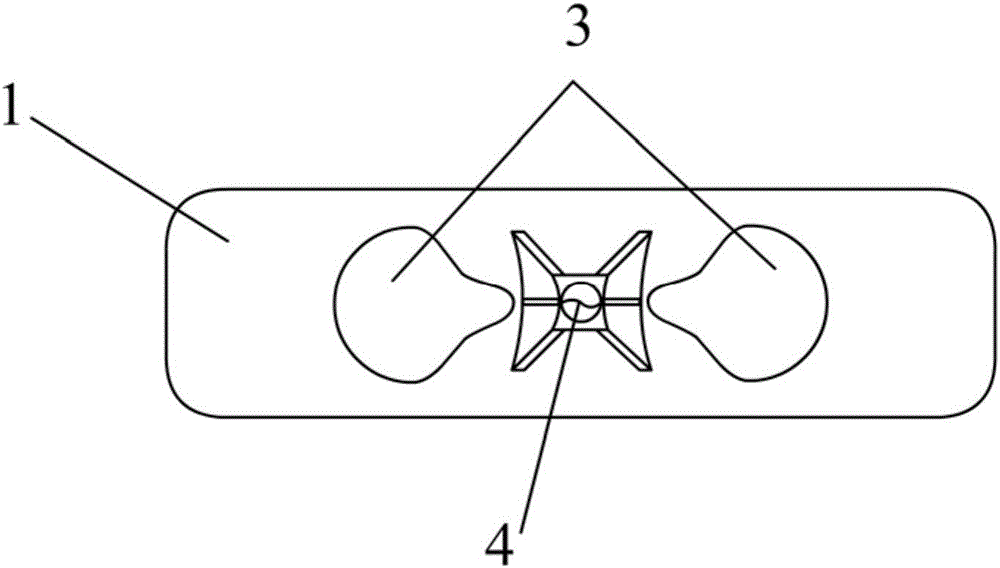

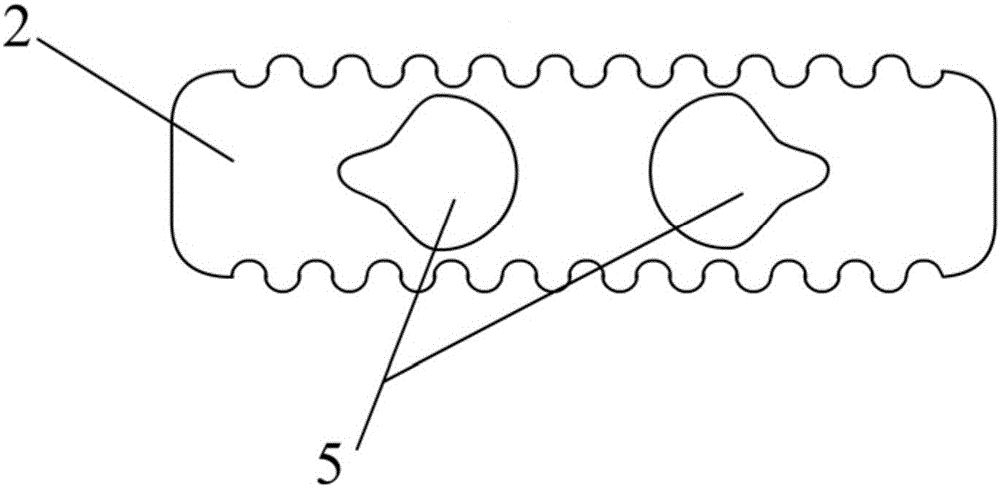

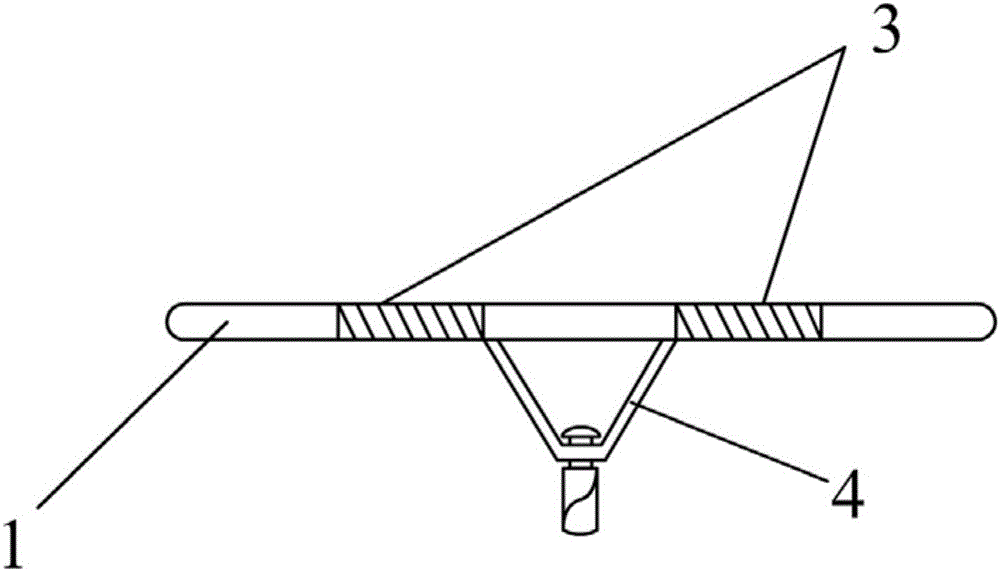

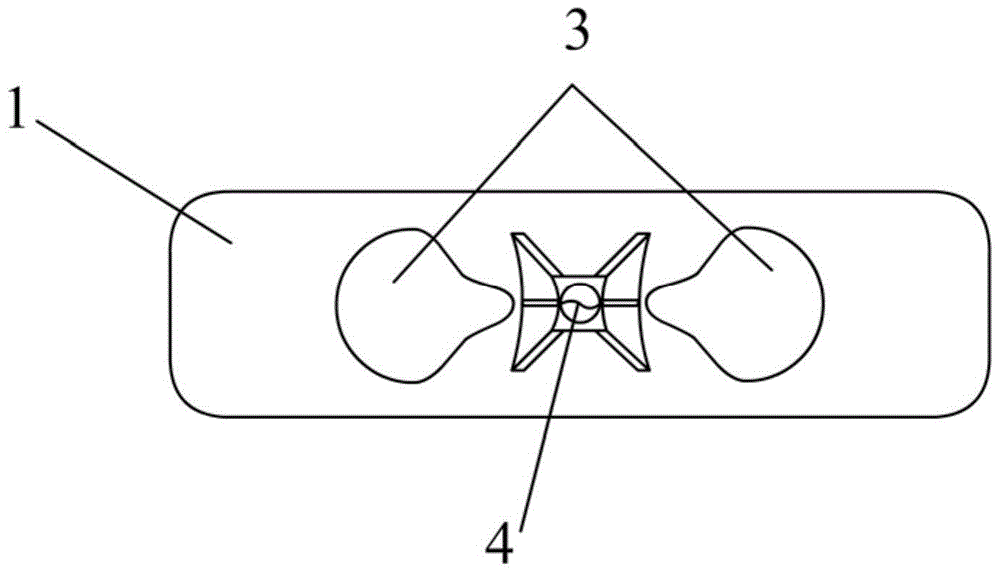

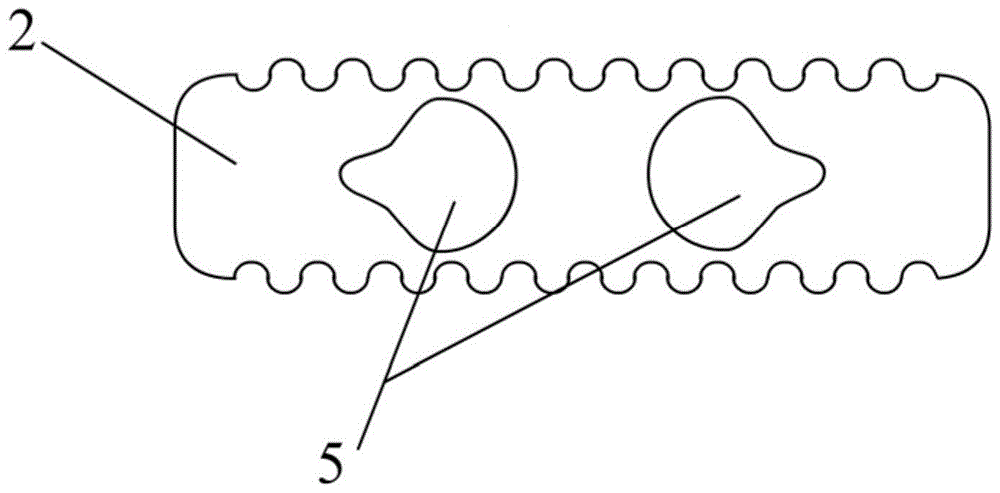

Embroidery thread branching device

The invention relates to an embroidery thread branching device, including a branching plate, a fixing plate, a normal phase opening, a branching cone, and a reverse phase opening; the branching cone includes a branching table, a concave groove, a rotating head; the fixing plate includes a hook tooth layer, and a middle layer; the middle place of the long edge bisector of the branching plate is provided with a branching cone, the left and right sides of the branching plate are provided with two normal phase openings; the two sides of long edge bisector of the fixing plate are provided with two reverse phase openings; the top end of the branching table is provided with a rotating head, the left and right sides of the branching table are provided with two pieces of concave grooves; the upper and lower surfaces of the fixing board are the hook tooth layer, the middle of two layers of hook tooth layers is a middle layer.

Owner:ZHEJIANG HETAIXING CHEM FIBER CO LTD

Guide mechanism for scum scraping chain

ActiveCN101444774BPlay a guiding roleInhibit sheddingLiquid surface applicatorsCoatingsTooth layerEngineering

The invention relates to a guide mechanism for a scum scraping chain for an automobile painting waste paint treatment system. The guide mechanism comprises a driving wheel and a driven wheel which are respectively and transversely arranged at the top part and the bottom part of a groove, two parallel scum scraping chains respectively bypass the driving wheel and the driven wheel, scraping plates are transversely arranged on the two scum scraping chains, and a guide rail for the scum scraping chains to pass through is arranged on a scum scraping chain positioned at the front end of the drivingwheel. Since the guide rail is arranged on the scum scraping chain, the guide rail plays the role of guidance to the scum scraping chains, meanwhile, the scraping plate finishes the task of scum scraping before the scum scraping chains pass through the guide rail, when the scum scraping chains enter in the guide rail, the scum attached to the scum scraping chains is peeled off by the guide rail, so that the scum scraping chains are matched with the gear of the driving wheel in a basic clean state, therefore, the phenomenon that the scum is attached to the wheel teeth layer by layer is avoided, and the scum scraping chains can be effectively prevented form falling off.

Owner:CHERY AUTOMOBILE CO LTD

Branching device for multi-folded yarn

The invention relates to a branching device for a multi-folded yarn. The branching device comprises a branching plate, a fixed plate, positive phase holes, a branching cone and negative phase holes, wherein the branching cone comprises a branching table, grooves and a rotary head; the fixed plate comprises hook tooth layers and a middle layer; the branching cone is arranged at the middle position of a long-side bisector of the branching plate; two positive phase holes are formed in the left side and the right side of the branching cone; two negative phase holes are formed in two sides of the long-side bisector of the fixed plate; a rotary head is arranged at the top end of the branching table; two grooves are formed in the left side and the right side of the branching table; and the hook tooth layers are arranged on the upper surface and the lower surface of the fixed plate; and the middle layer is arranged between the two hook tooth layers.

Owner:福建源嘉轻纺有限公司

A line splitting tool that is easy to operate by one person

The invention relates to a branching tool capable of facilitating single-person operation. The branching tool comprises a branching plate, a fixed plate, positive phase holes, a branching cone and negative phase holes, wherein the branching cone comprises a branching table, grooves and a rotary head; the fixed plate comprises hook tooth layers and a middle layer; the branching cone is arranged at the middle position of a long-side bisector of the branching plate; two positive phase holes are formed in the left side and the right side of the branching cone; two negative phase holes are formed in two sides of the long-side bisector of the fixed plate; a rotary head is arranged at the top end of the branching table; two grooves are formed in the left side and the right side of the branching table; and the hook tooth layers are arranged on the upper surface and the lower surface of the fixed plate; and the middle layer is arranged between the two hook tooth layers.

Owner:QINGDAO QIANFENG CAPART INTL CORP +1

Enhanced synchronous belt

The invention discloses an enhanced synchronous belt which comprises a belt body layer, wherein a tooth layer is arranged on the inner side of the belt body layer. The enhanced synchronous belt further comprises an enhancing unit which comprises a first connecting part, a first shaft arranged in the tooth layer and a second shaft arranged on the belt body layer. The first shaft and the second shaft are connected to the first connecting part, separately. In the enhanced synchronous belt, the enhancing unit can fix the tooth layer to the belt body tightly to enhance the strength of the belt bodyof the synchronous belt and the shearing strength of the tooth layer, so that the service life of the synchronous belt is prolonged effectively and the labor cost and the material cost caused by replacing the synchronous belt frequently are lowered.

Owner:邝立辉

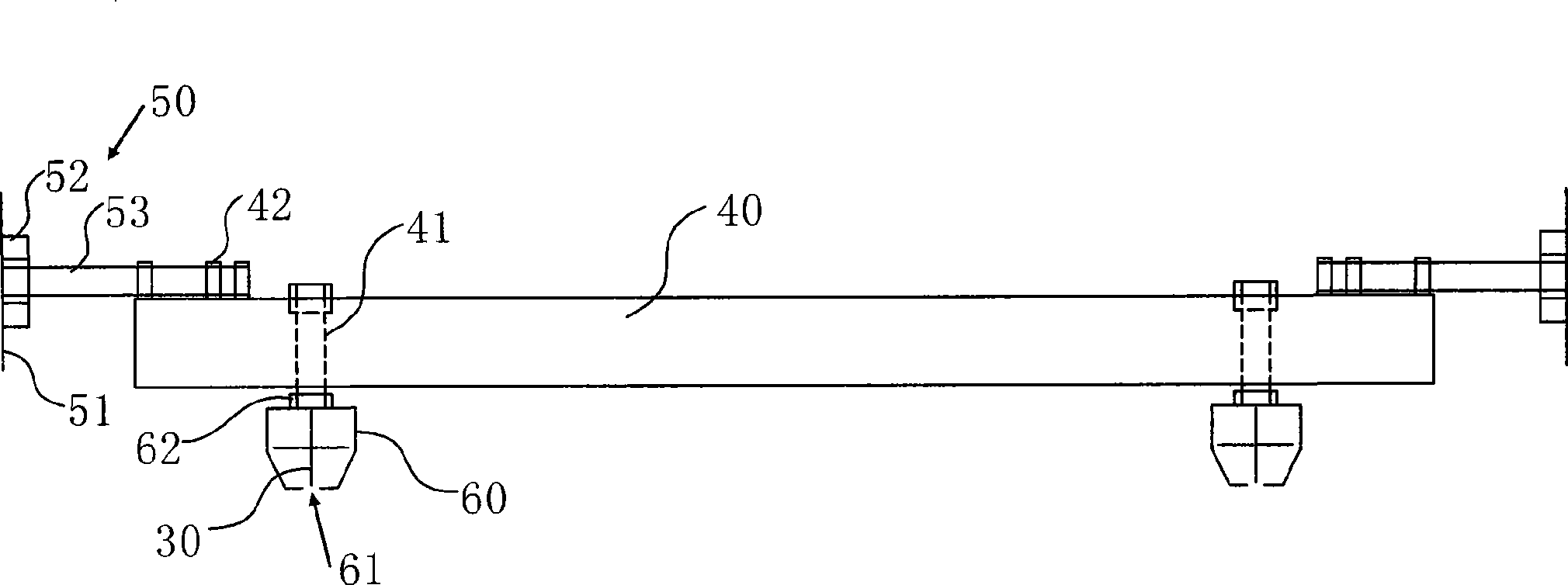

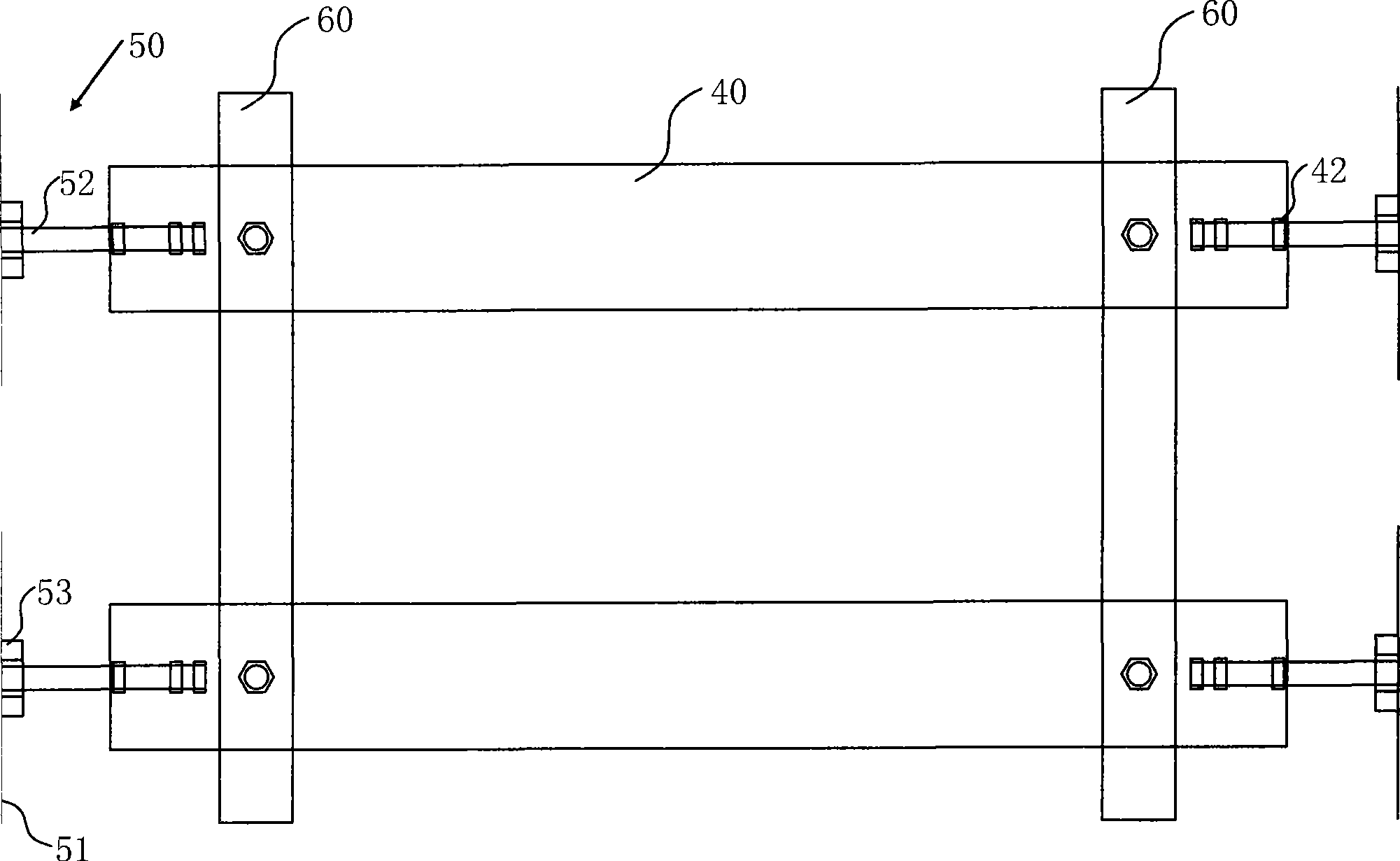

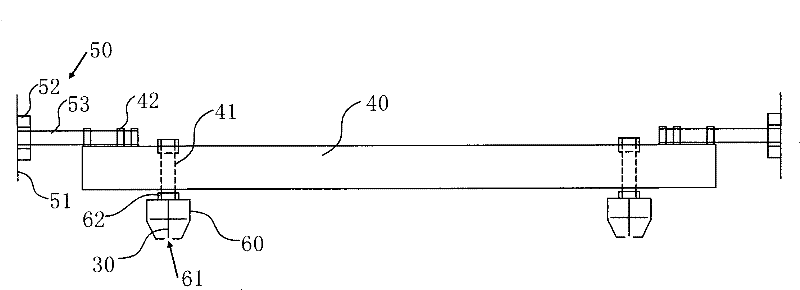

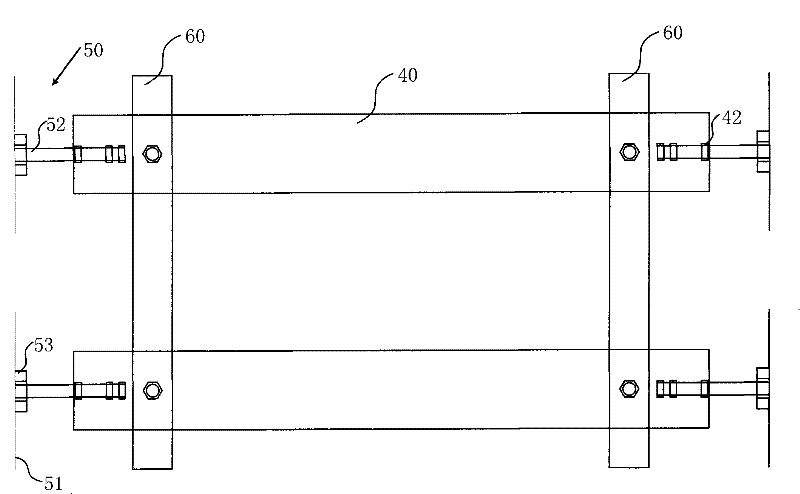

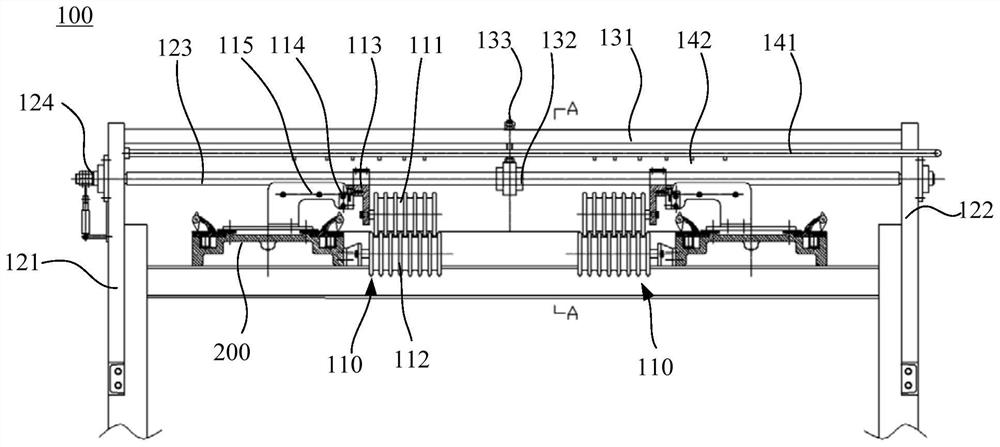

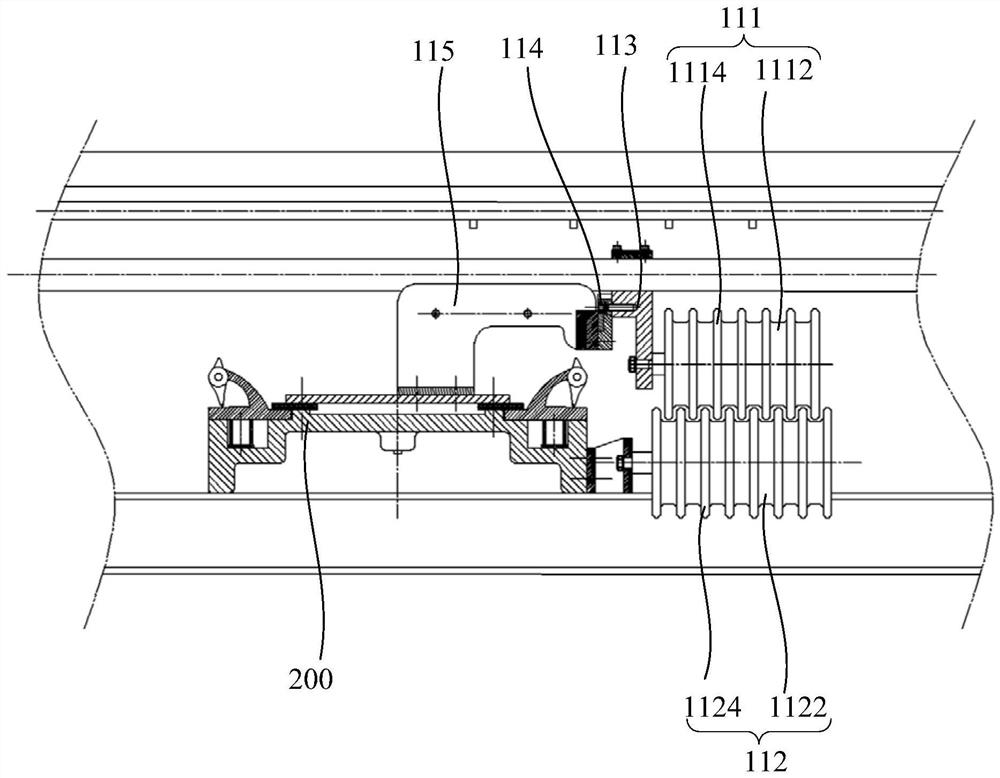

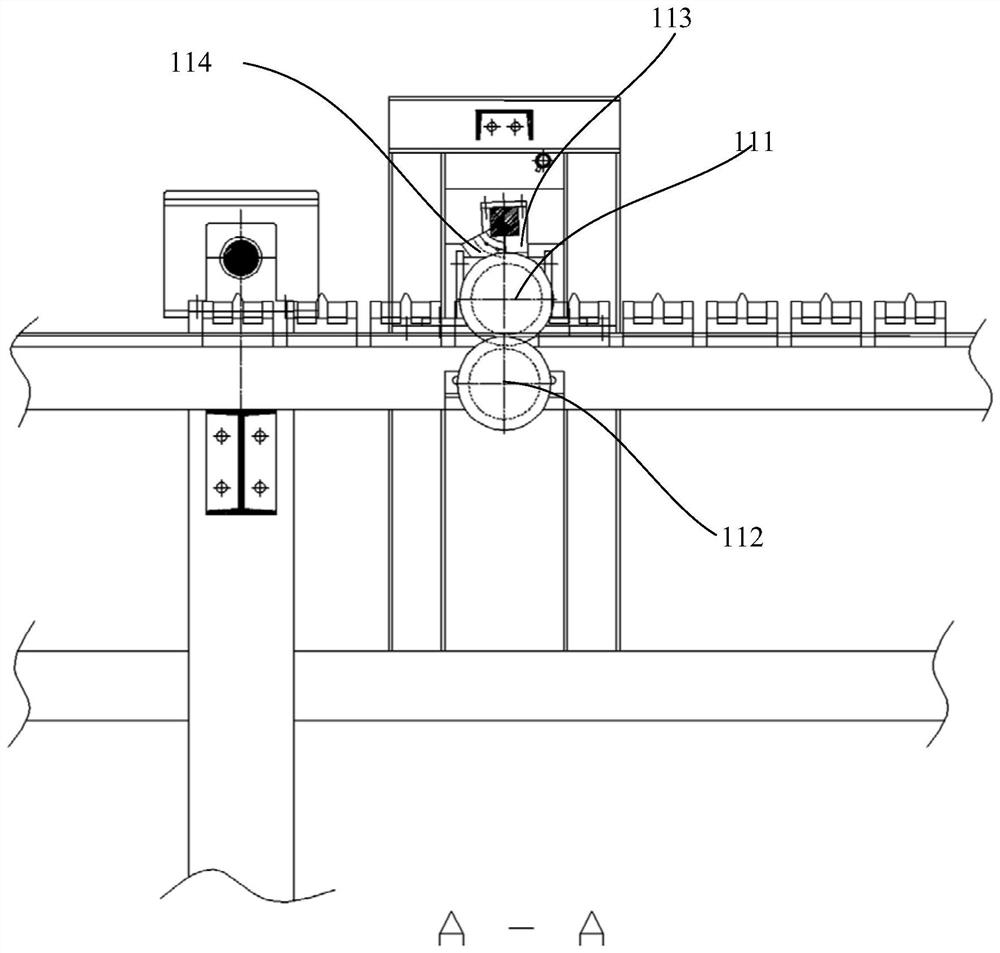

Stentering auxiliary device and mercerizing machine

PendingCN114411369AReduce or eliminate color varianceReduce tensionMercerising of indefinite length fabricsStretchingTooth layerStructural engineering

The invention relates to a tentering auxiliary device and a mercerizing machine. The tentering auxiliary device comprises at least one pair of tentering assemblies which are respectively arranged on cloth clip chain rails on two sides of the mercerizing machine so as to respectively pull two opposite sides of a fabric. The tentering assembly comprises a first tentering roller, a second tentering roller and a mounting base. The first stentering roller and the second stentering roller are provided with annular tooth layers, the first stentering roller is movably connected with the mounting base, the second stentering roller is used for being connected to a clip chain track and is arranged opposite to the first stentering roller, and the first stentering roller can be close to the second stentering roller, so that the annular tooth layers of the first stentering roller are embedded to be used for clamping the side part of the fabric in a matched manner. The side part of the fabric is pressed between the two teeth, so that the tensile force of the areas on the two sides of the fabric can be increased, the warp density of the areas on the two sides of the fabric is close to or consistent with that of the middle part of the fabric, and the color difference in the fabric edge caused by different amounts of alkali liquor in the middle and the two sides of the fabric is reduced or eliminated.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD

Intelligent firm lathe tool

InactiveCN104785805AEasy to fixPlay a shock absorbing effectWorkpiecesTurning toolsTooth layerIndustrial machine

The invention discloses an intelligent firm lathe tool, and relates to the field of industrial machines. The intelligent firm lathe tool comprises a tool bit and a tool bar. The tool bit is connected with the tool bar. A high temperature alarm lamp is arranged on the surface of the position where the tool bit is connected with the tool bar. A battery is arranged inside the tool bar. A plurality of grooves are formed in the upper surface of the tool bar. A shock absorption layer is arranged on the lower surface of the tool bar. A fine tool tooth layer is arranged on the lower surface of the shock absorption layer. When the temperature of the tool bit is higher than the material bearing temperature, the high temperature alarm lamp will be turned on, the tip of a blade compressing device is inserted into the grooves, and the lathe tool is fixed more firmly; the lathe tool has the shock absorption effect during working due to the shock absorption layer, and the compressing intensity of a tool rest and the lathe tool is increased due to the fine tool tooth layer; when bearing the large cutting resistance, the lathe tool will not loosen, so that the cutting precision is improved, and the working efficiency is improved.

Owner:中山市鸿程科研技术服务有限公司

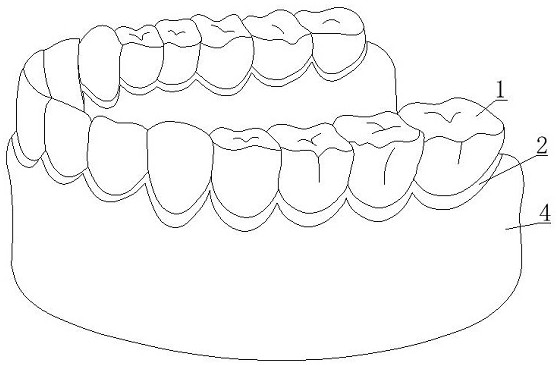

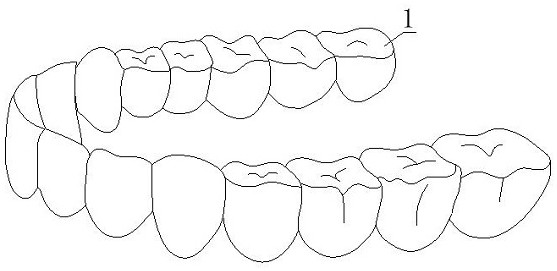

A spliced metal denture and manufacturing method thereof

ActiveCN111449780BIncreased load-bearing capacityNot easy to looseAdditive manufacturing apparatusFoundry mouldsSoft layerTooth layer

The invention discloses a spliced metal denture and a manufacturing method thereof, belonging to the technical field of metal dentures, comprising tooth enamel surface layer, hard layer, wrapped soft layer and tooth edge, the middle part of the hard layer protrudes upwards , forming a raised block, the upper surface of the raised block is provided with a layer of tooth enamel surface layer, the lower end of the wrapped soft layer is close to the gums, and the wrapped soft layer is consistent with the upper surface of the gums, the raised The connection between the block and the side forms an oblique downward tooth groove, the upper end of the wrapped soft layer is located in the tooth groove on both sides of the hard layer, and the inner surface of the wrapped soft layer is in contact with the hard layer. Layers are connected to each other. Metal alloy is used as the framework of the denture, and the load-bearing performance of the denture is significantly improved; the wrapped soft layer is closely connected with the inner wall of the oral cavity, the denture is not easy to loose, and the local performance of the denture is optimized.

Owner:AI JIA DENTAL LAB

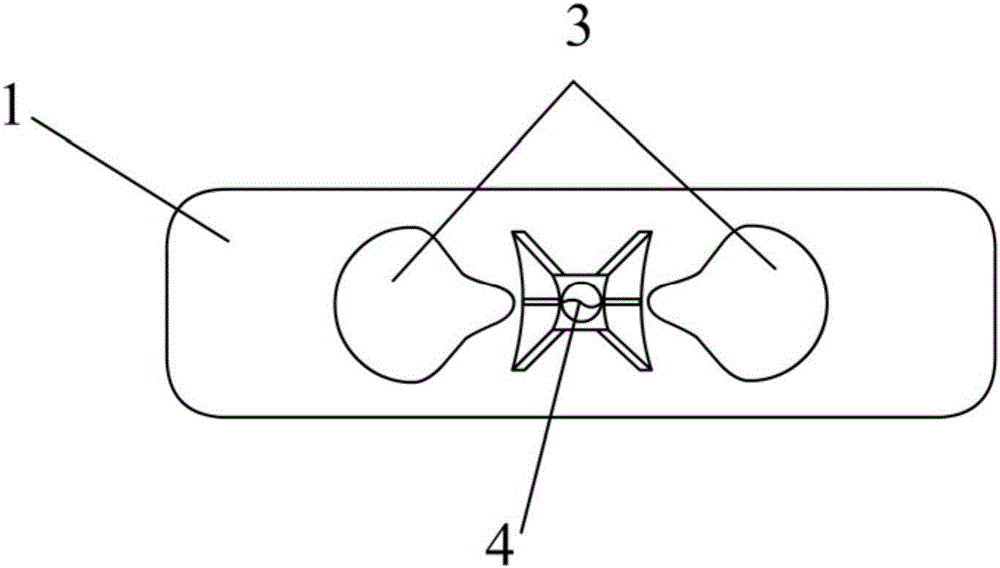

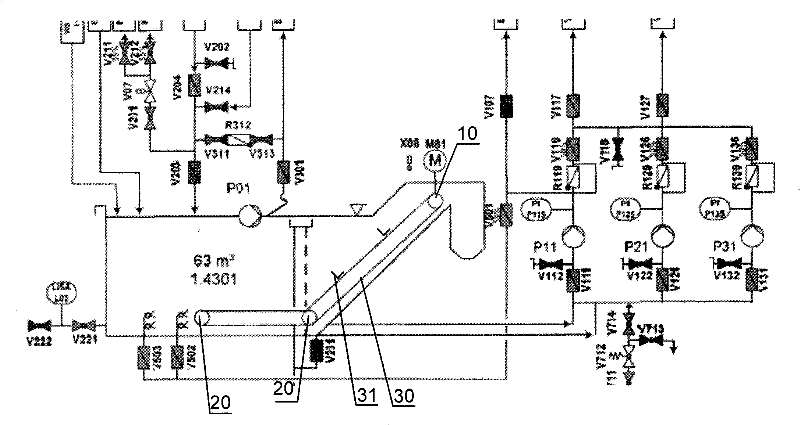

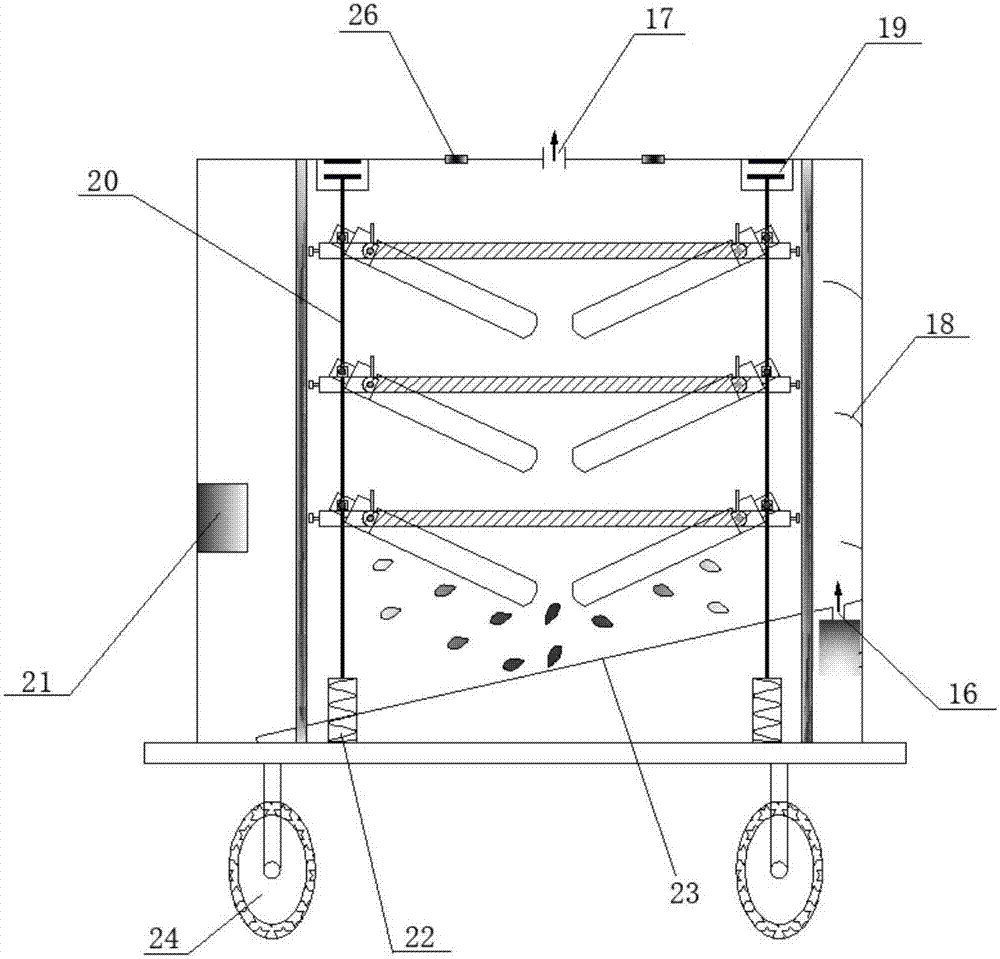

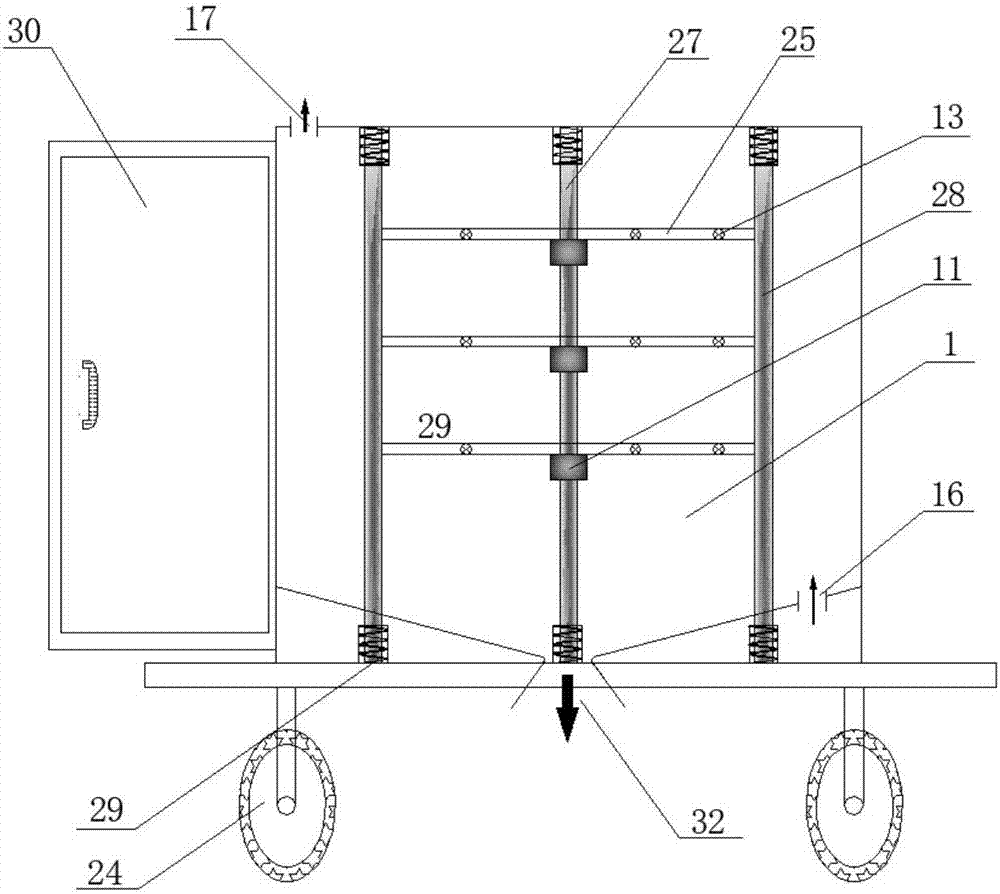

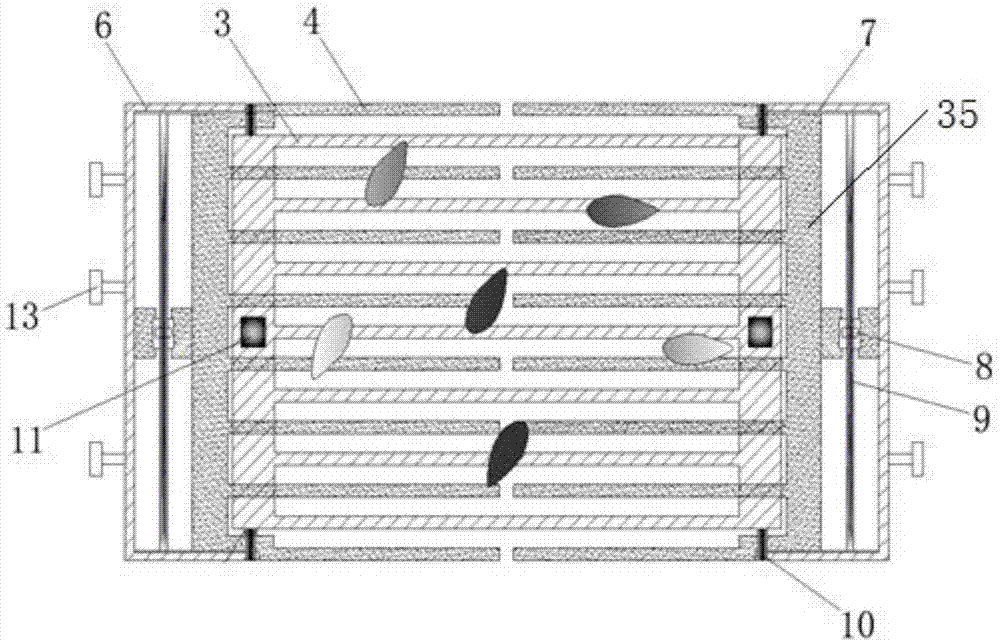

Chinese wolfberry vibration dewatering device and method

ActiveCN107455776AReduce incorporationShorten the drying cycleFood processingFruits/vegetable preservation by dehydrationTooth layerLycium barbarum fruit

The invention discloses a Chinese wolfberry vibration dewatering device and method. The Chinese wolfberry vibration dewatering device comprises a comb tooth layer, a dehydrating cabinet main body, a plurality of cylinders, and a plurality of guide rails, wherein the dehydrating cabinet main body is a closed space surrounded by a bottom plate, side plates and a cover plate; the cylinders are symmetrically arranged on the inner side perpendicular to the left end and the right end of the bottom plate, of the dehydrating cabinet main body; planes formed by the cylinders at two ends are respectively parallel to the inner side wall of the dehydrating cabinet main body; the guide rails are respectively and vertically fixed to each cylinder, and all the cylinders at each end are fixed to the guide rails; the number of the guide rails at one end is the same as that of the guide rails at the other end, and the height of the guide rails at one end is the same as that of the guide rails at the other end; and the comb tooth layer is arranged between the guide rails at the two ends. According to the Chinese wolfberry vibration dewatering device disclosed by the invention, the comb tooth layer, the cylinders and a vibrating motor are arranged, so that in a conventional drying process, the doping of impurities is reduced, and the phenomenon of uneven air-drying and the influence of weather are avoided; and half comb teeth and fixed comb teeth in the comb tooth layer cooperate, so that the multilayer repeated vibrating and air-drying treatment of Chinese wolfberries is realized, and the drying cycle of the Chinese wolfberries can be greatly shortened.

Owner:CHANGAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com