Scraper for processing concave profile of wood and plastic sheet materials

A plastic sheet and wood technology, applied in the field of cutting tools, can solve problems such as poor processing quality, difficult dimensional and position accuracy, and high cutting resistance of tools, so as to improve processing quality, ensure dimensional and position accuracy, and reduce cutting resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

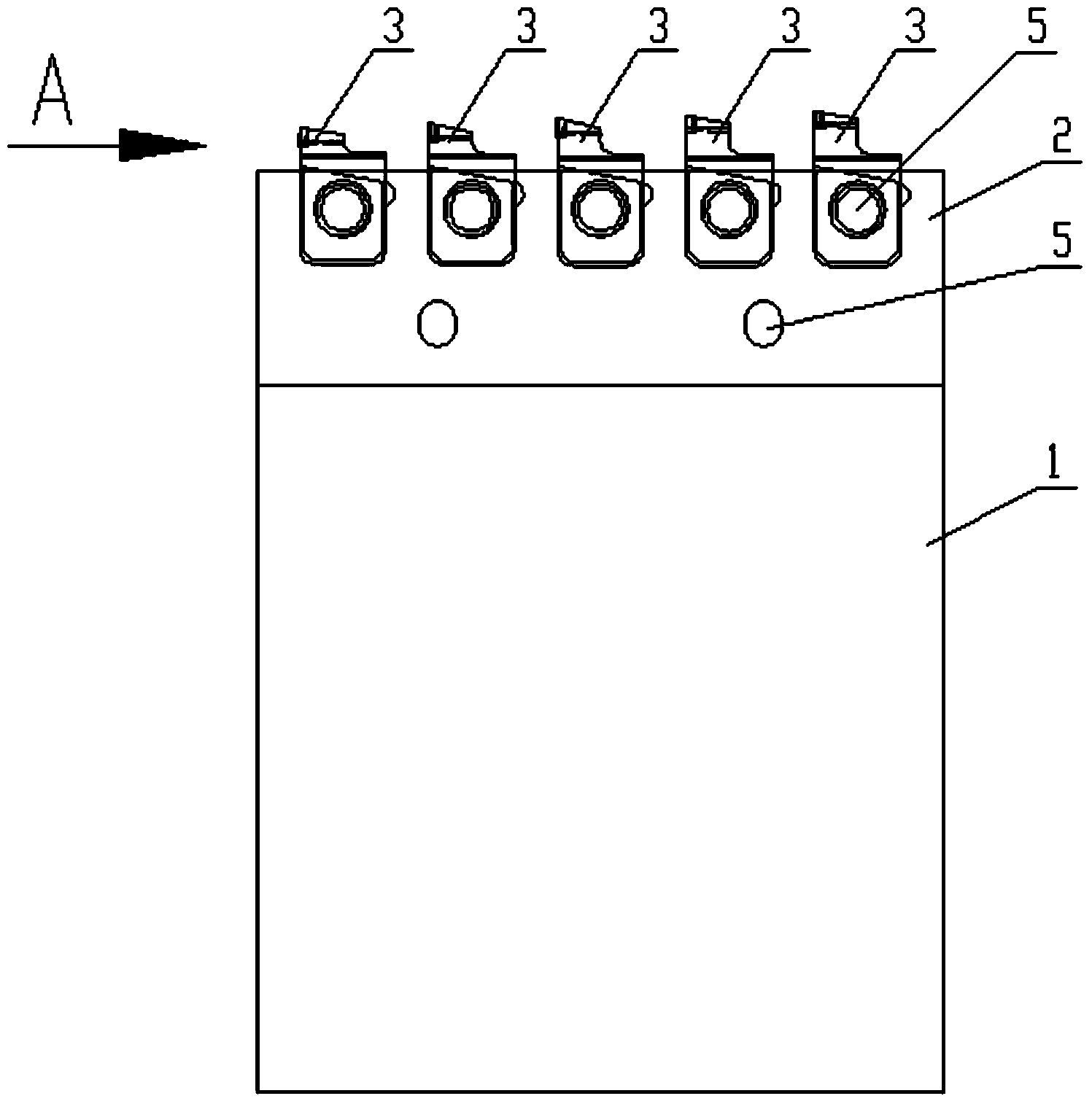

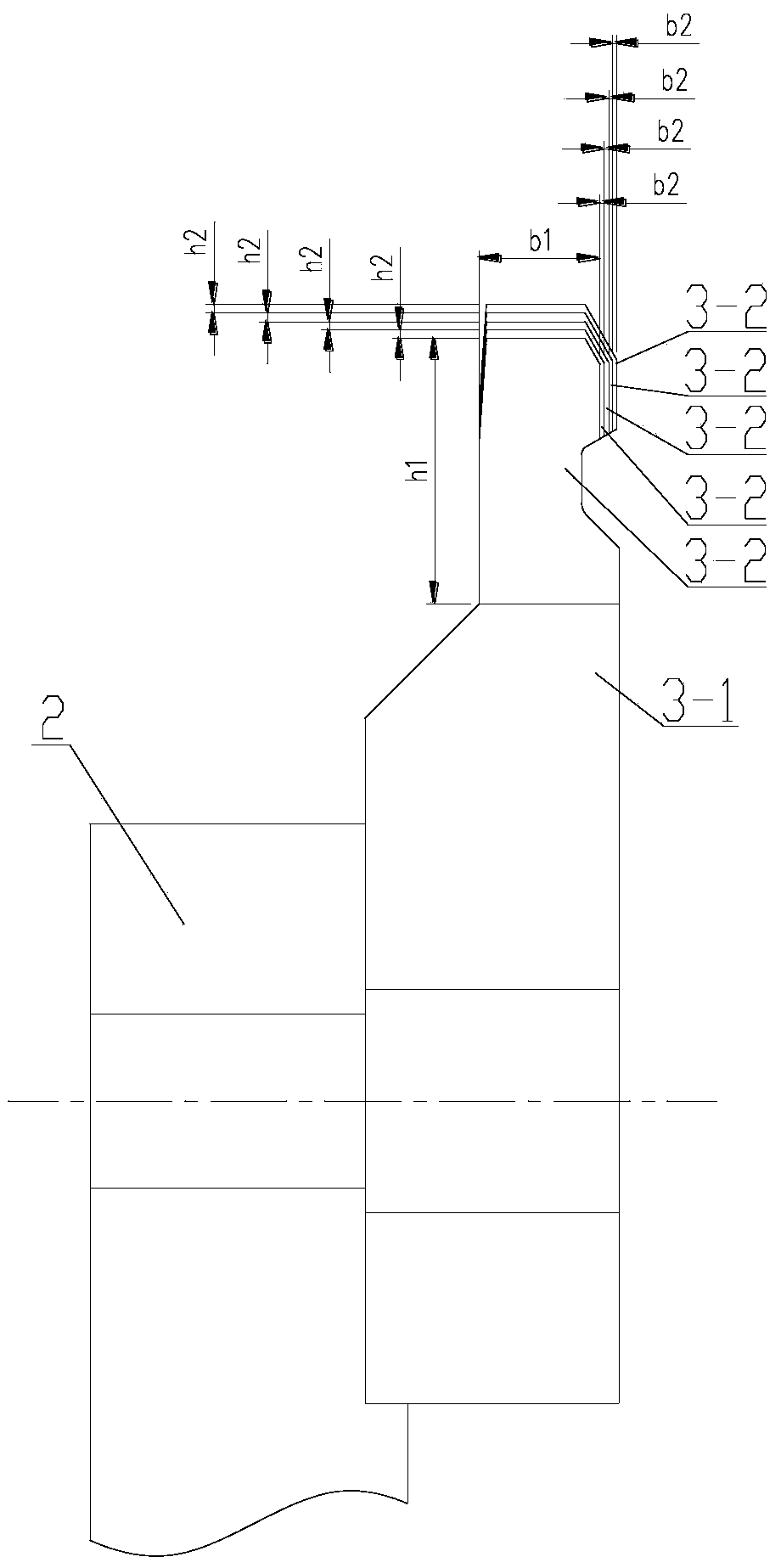

[0017] Such as figure 1 As shown, the scraper used for processing concave profiles of wood and plastic boards according to the present invention includes a cutter body 1 , a cutter tooth holder 2 and a cutter tooth 3 . The cutter tooth seat 2 and the cutter body 1 are fixed by bolts 5, the number of cutter teeth 3 is five, and the cutter teeth 3 are arranged in a straight line on the cutter tooth seat 2, and the cutter teeth 3 include the tooth body 3-1 and are welded and fixed on the The tooth head 3-2 on the tooth body 3-1 is also fixed by the bolt 5 between the tooth body 3-1 and the tooth seat 2. Such as figure 2 As shown, the height and width of the tooth head 3-2 of each knife tooth 3 increase in steps from the frontmost knife tooth 3 to the rearmost knife tooth 3 . The height dimension of the tooth head 3-2 of the first knife tooth 3 at the front is h1, the width dimension is b1, the height dimension of the tooth head 3-2 of the second knife tooth 3 in the middle is ...

Embodiment 2

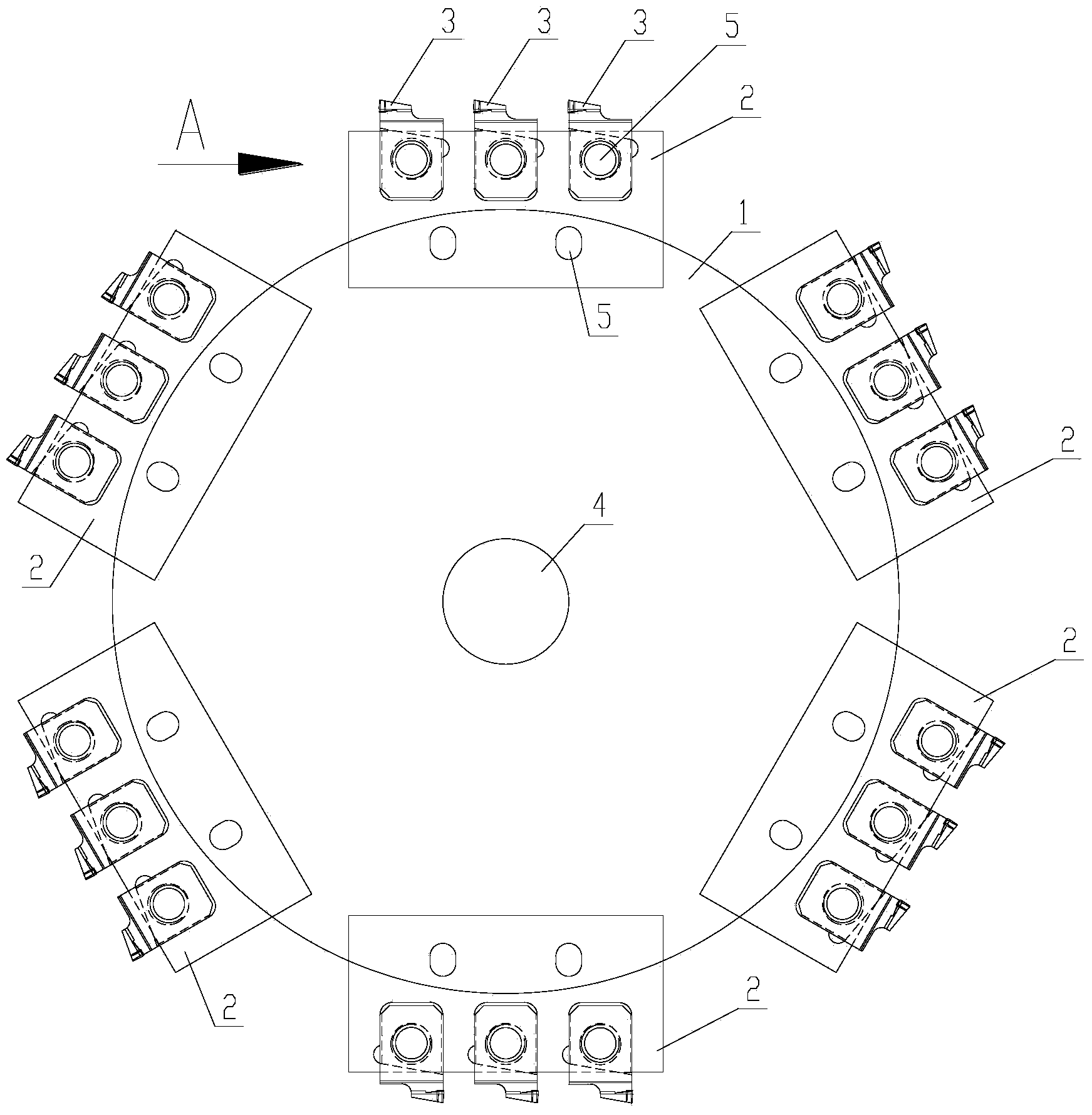

[0020] Such as image 3 As shown, the cutter body 1 is in the shape of a disc, and the center of the cutter body 1 is provided with a central axis hole 4, and there are 6 tooth holders 2 evenly distributed on the outer peripheral edge of the cutter body 1, and the cutter holder 2 and the cutter body 1 are connected by bolts. 5 is fixed, and three cutter teeth 3 are arranged in a straight line on each cutter tooth seat 2. The cutter teeth 3 include a tooth body 3-1 and a tooth head 3-2 welded and fixed on the tooth body 3-1. Also be fixed by bolt 5 between body 3-1 and cutter tooth seat 2. Such as Figure 4 As shown, the height and width of the tooth head 3-2 of each knife tooth 3 increase in steps from the frontmost knife tooth 3 to the rearmost knife tooth 3 . The height dimension of the tooth head 3-2 of the first knife tooth 3 at the front is h1, the width dimension is b1, the height dimension of the tooth head 3-2 of the second knife tooth 3 in the middle is h1+h2, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com