Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

139 results about "Thermal monitoring" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

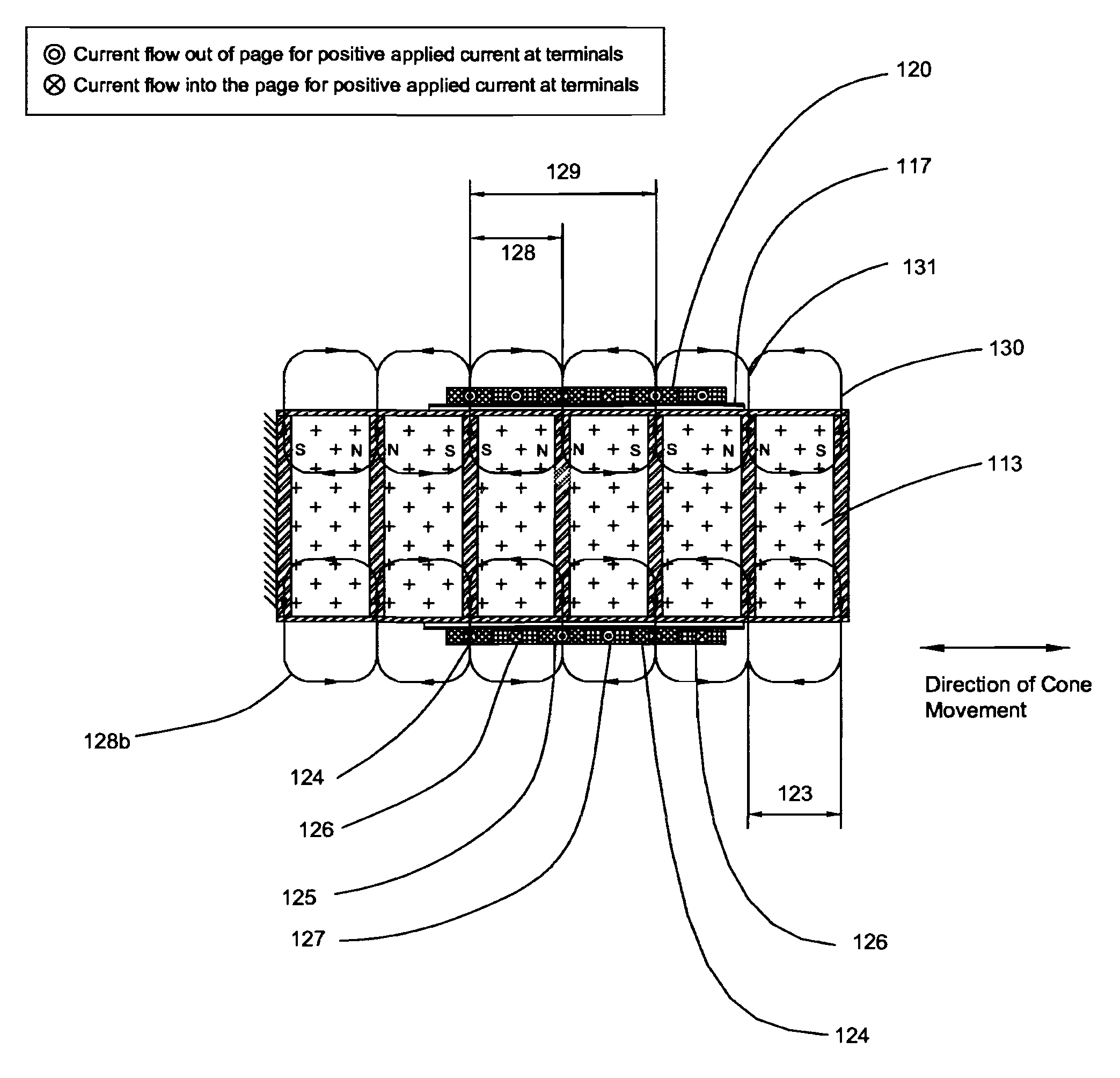

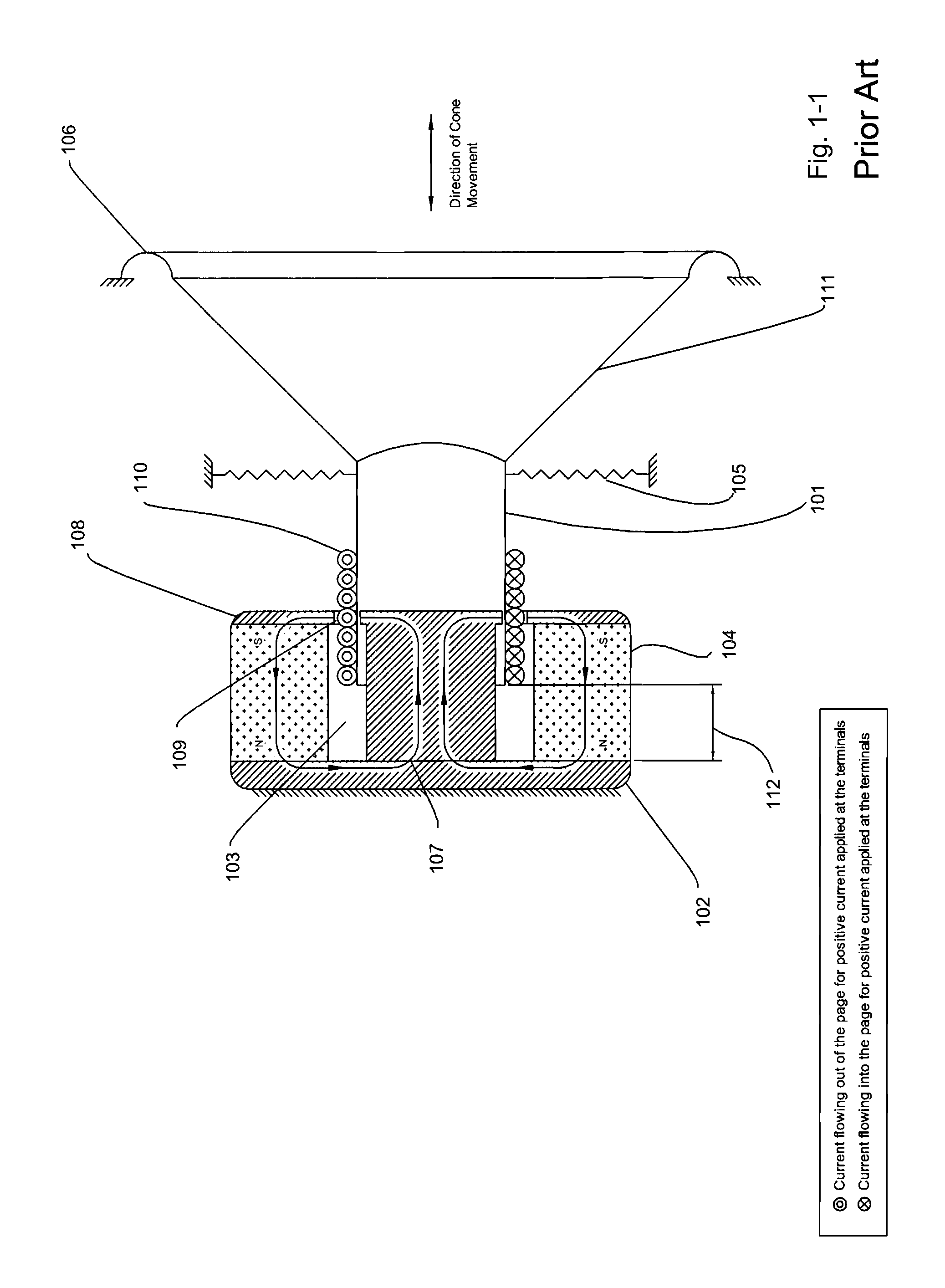

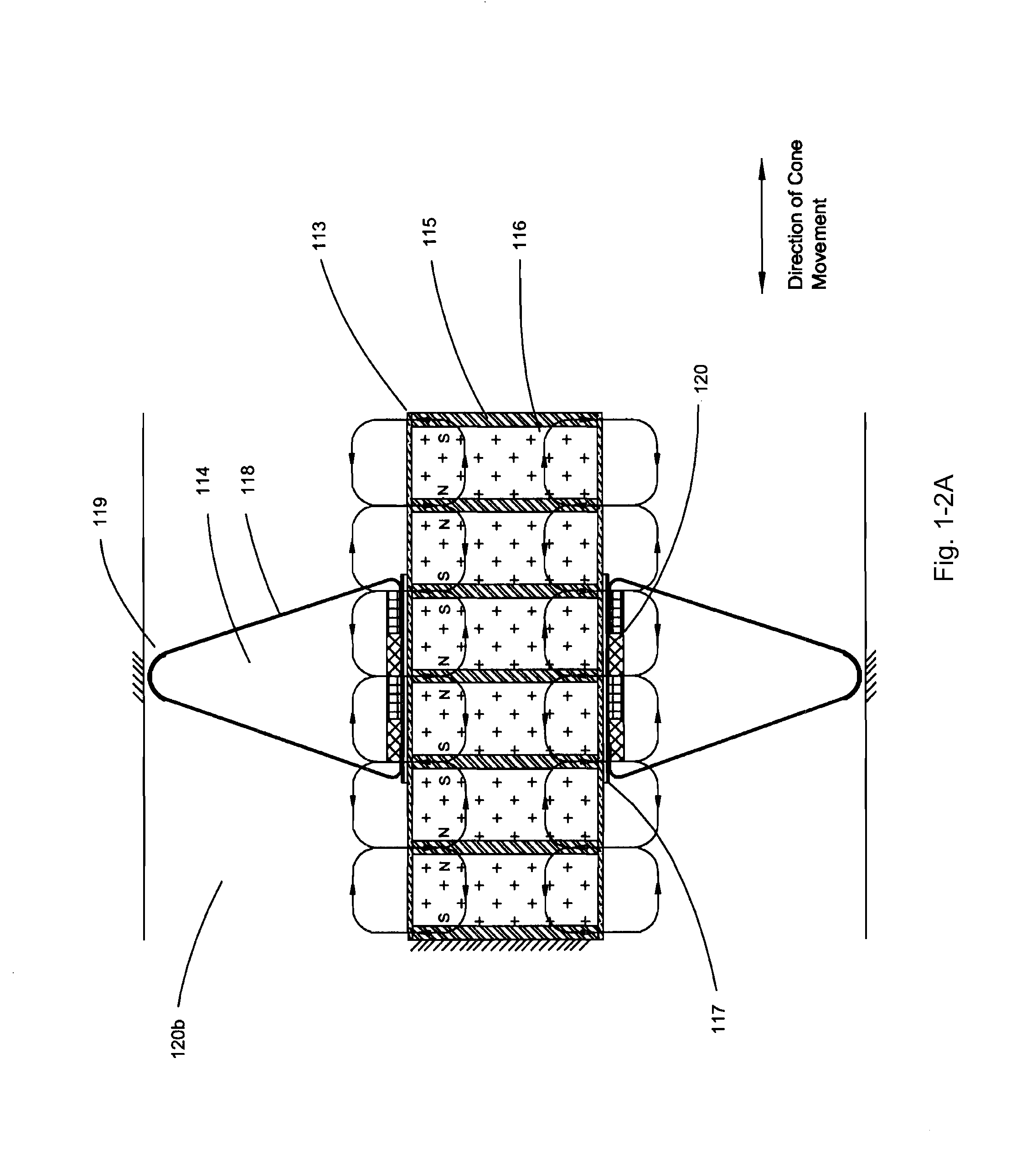

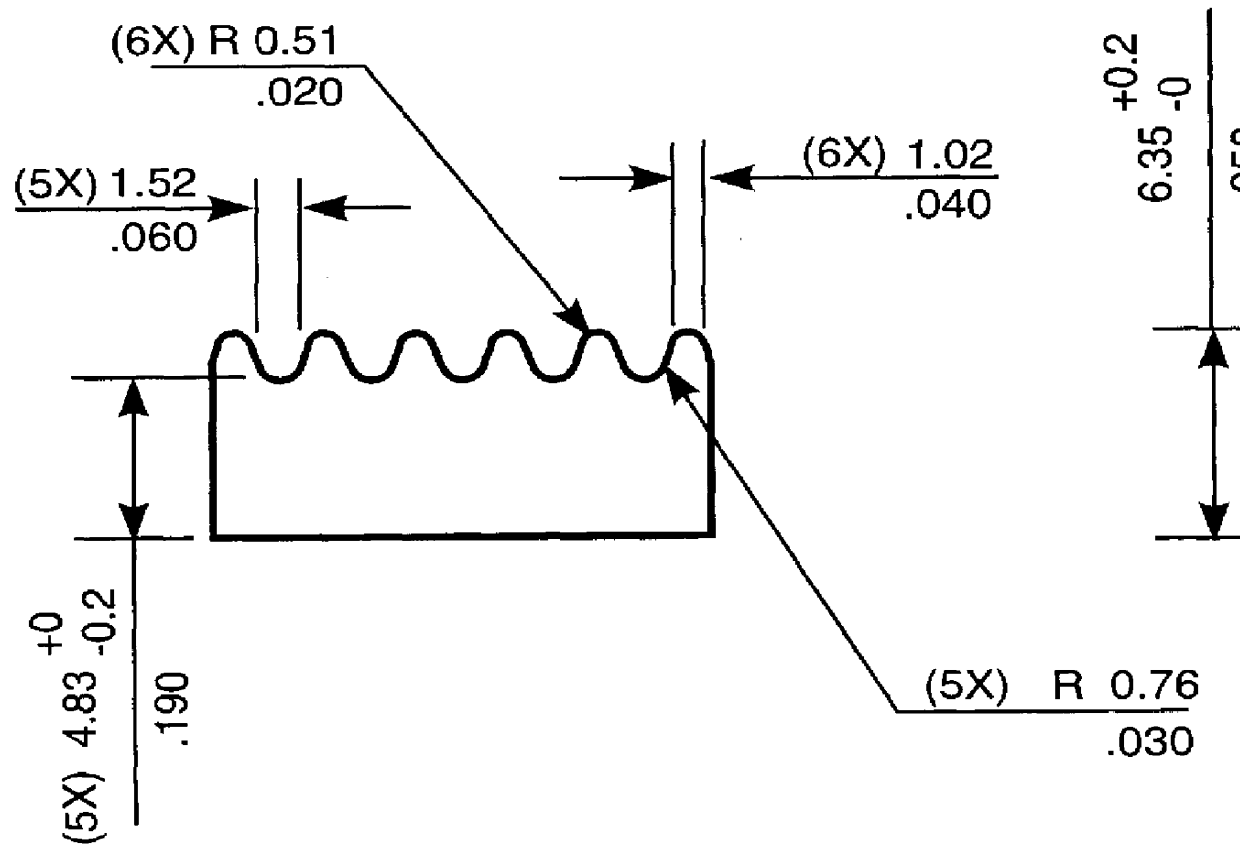

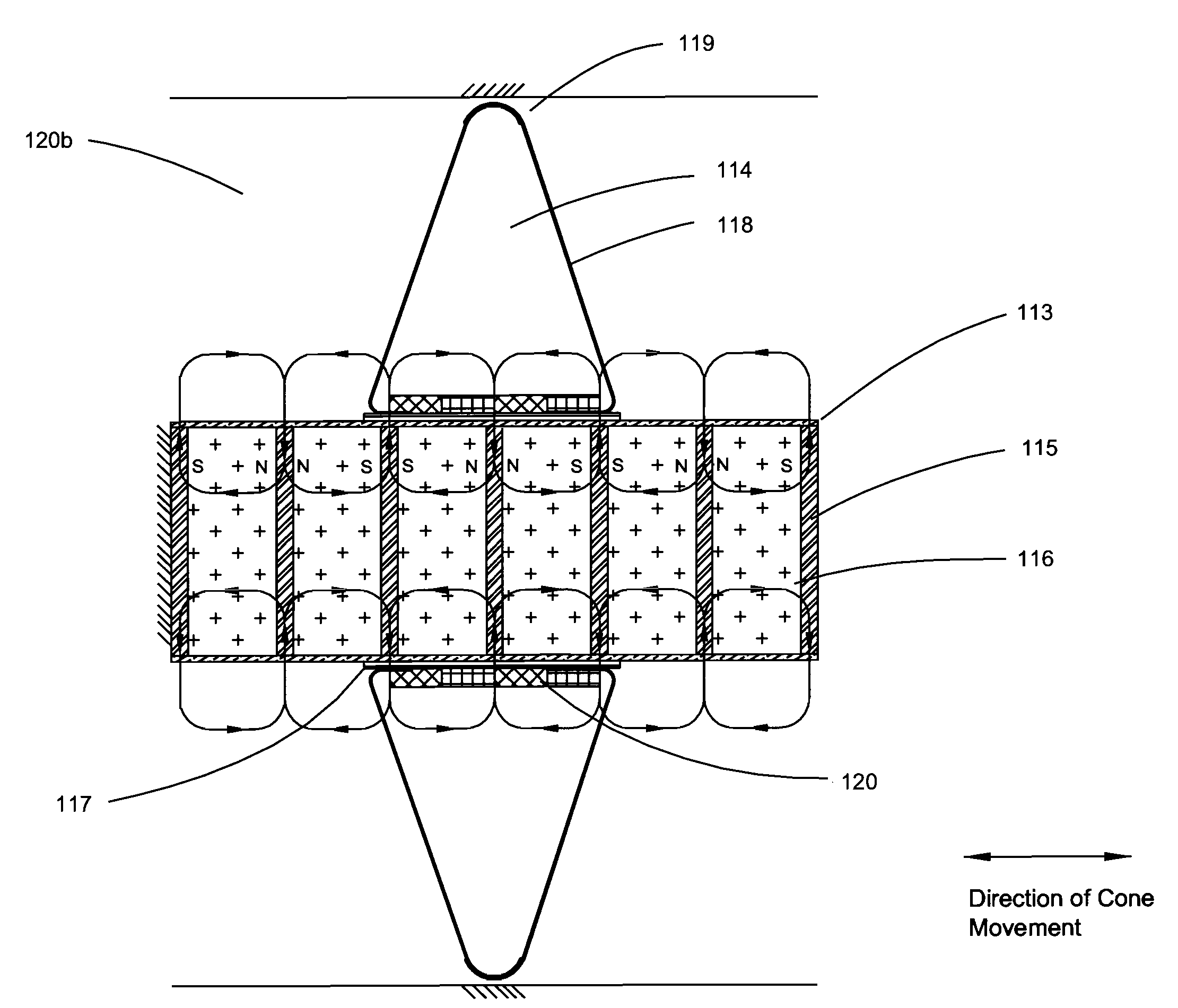

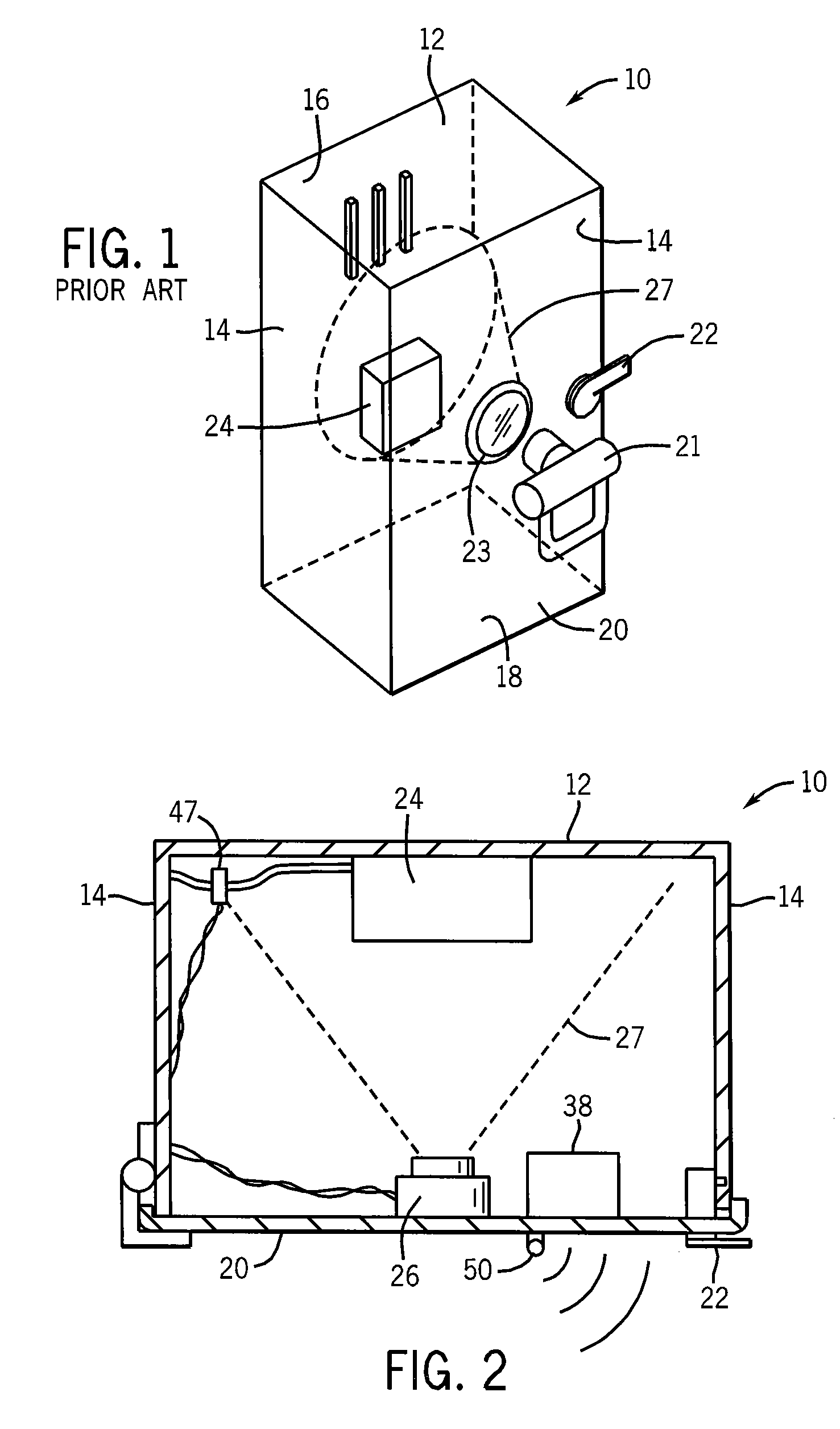

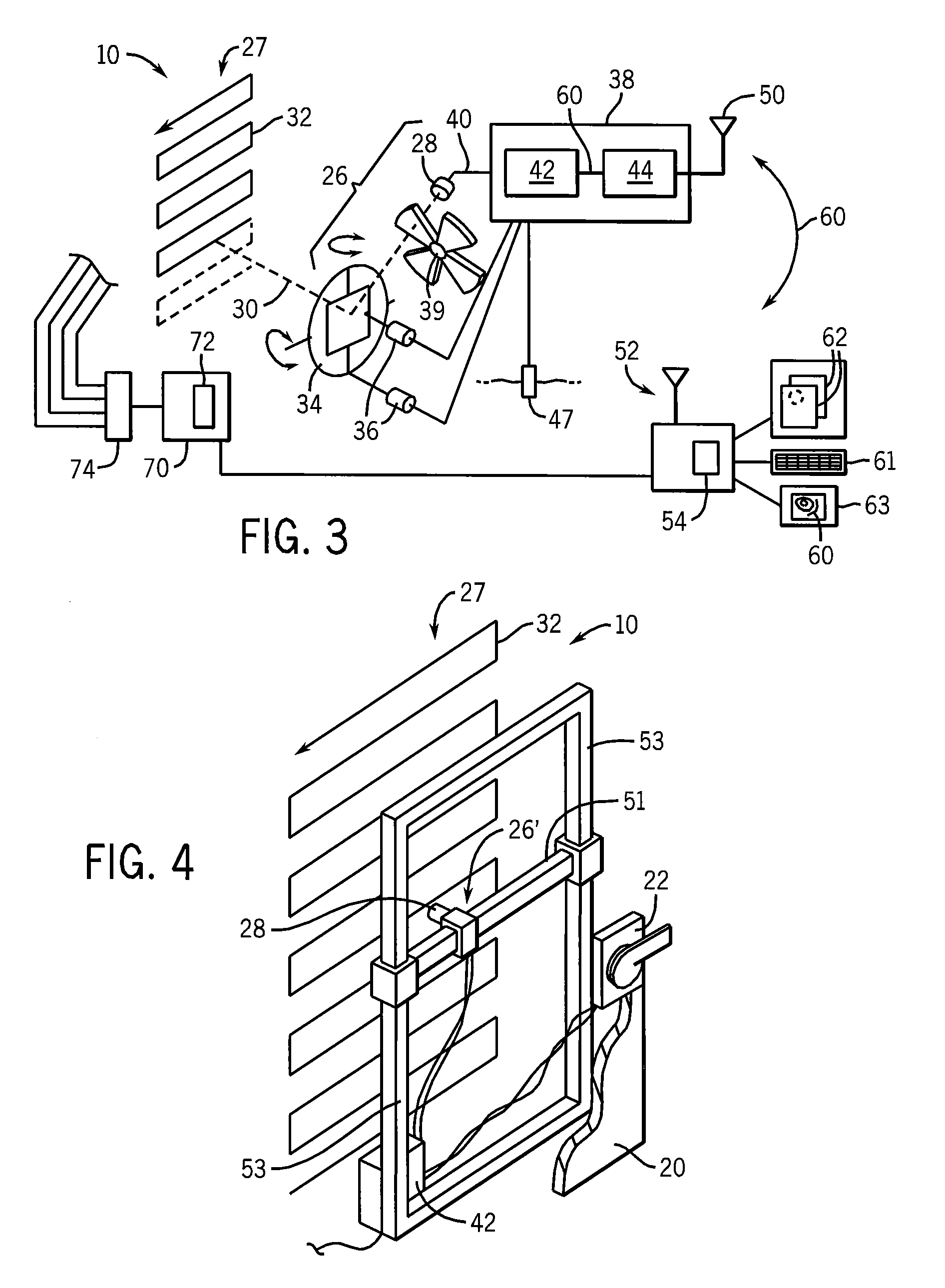

Positionally sequenced loudspeaker system

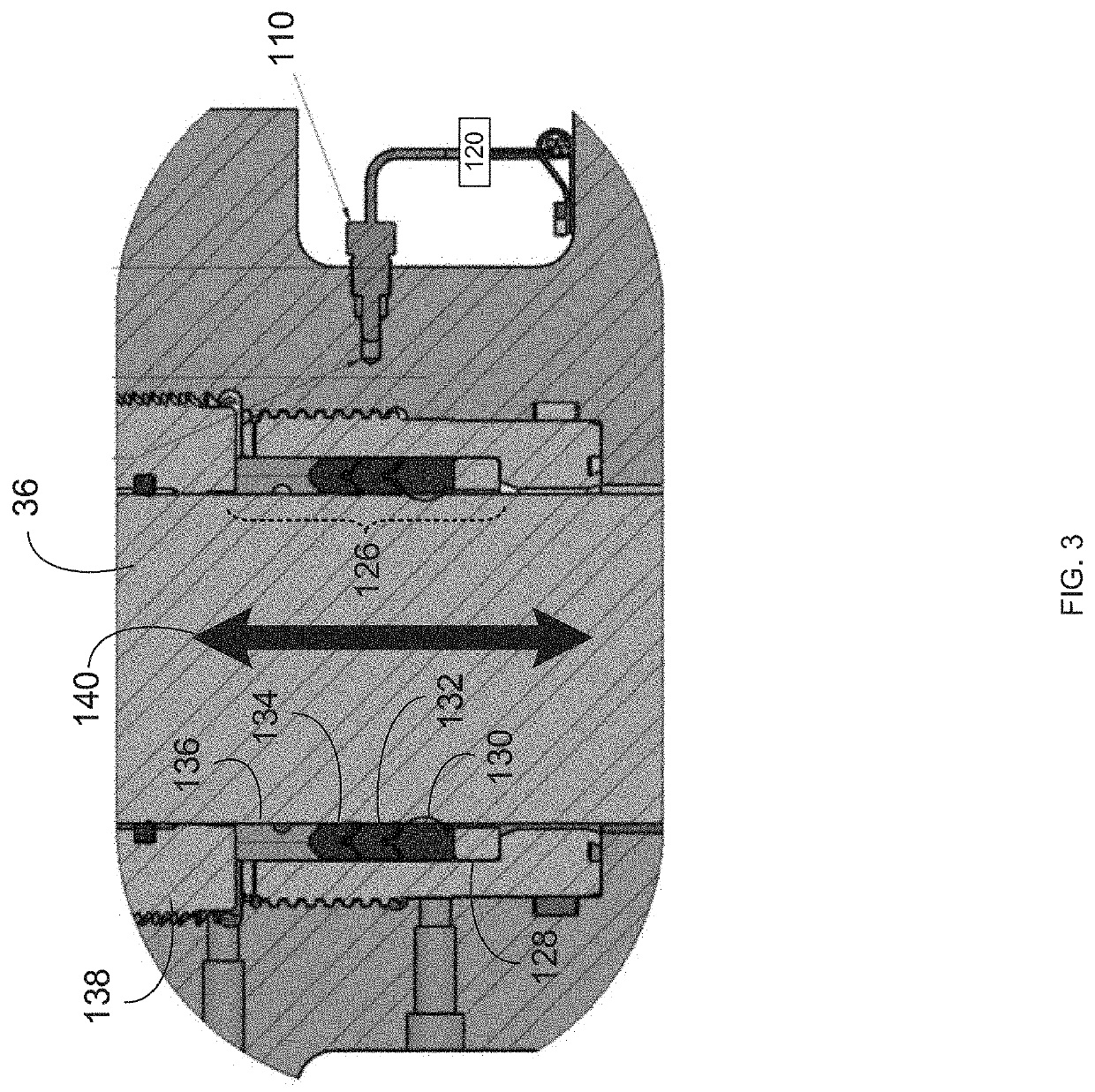

InactiveUS8284982B2Operation efficiency can be improvedHigh strengthTransducer detailsNon-planar diaphragms/conesThermal monitoringTransducer

A variety of loudspeaker arrangements may have any of multiple adjacent magnetic circuits, single magnetic circuits, an improved loudspeaker voice coil assembly, multiple voice coil windings (124-127, 315-317), and commutated current. The radial direction of flux may alternate at adjacent poles and may have a controller that commands the current through each of the windings. The position of the moving components may be measured or inferred by the controller (213). An encoding track (318a) applied to the surface of the assembly may allow the assembly to function as part of a position transducer to permit appropriate action based on position. Calculated or sensed actual position may be used to determine the relative current in each of the windings and the controller may have compensation such as a motion control algorithm, thermal monitoring, and management of the driver. The voice coil assembly (305c) may have foil conductors applied to a substrate to connect and interconnect a single or multiple voice coil windings with minimal effect on the magnetic gap (303b) width.

Owner:INDUCTION SPEAKER TECH

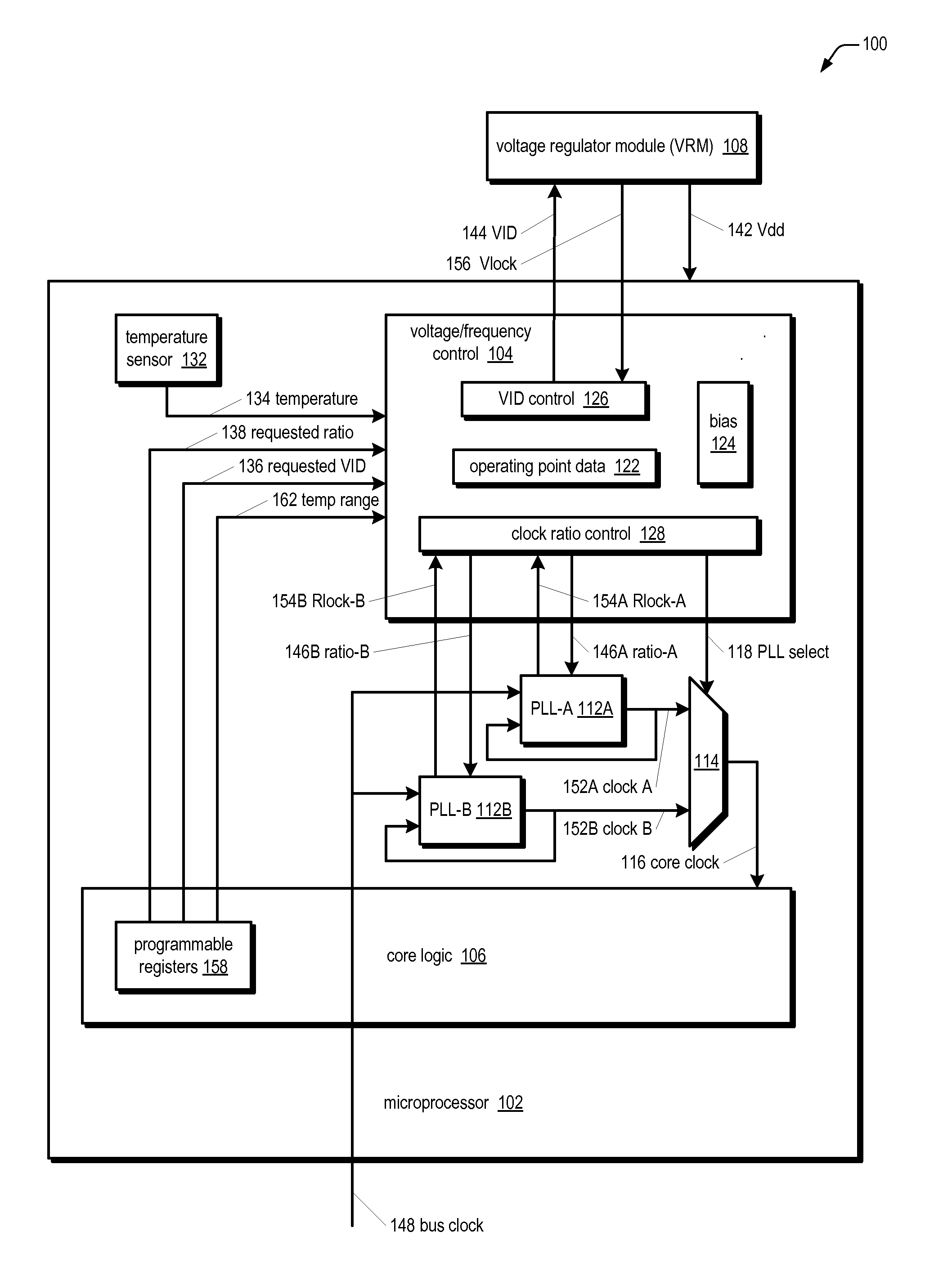

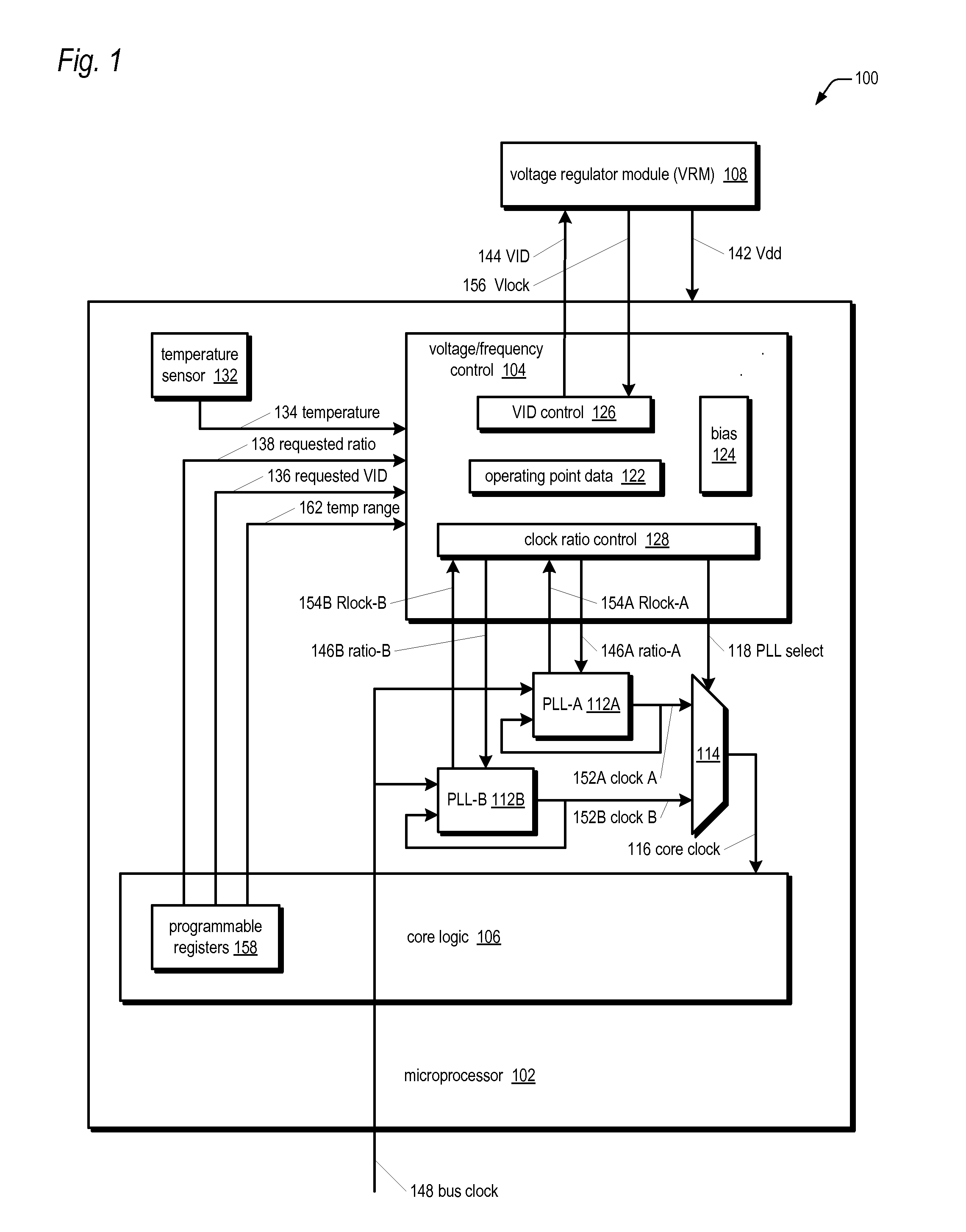

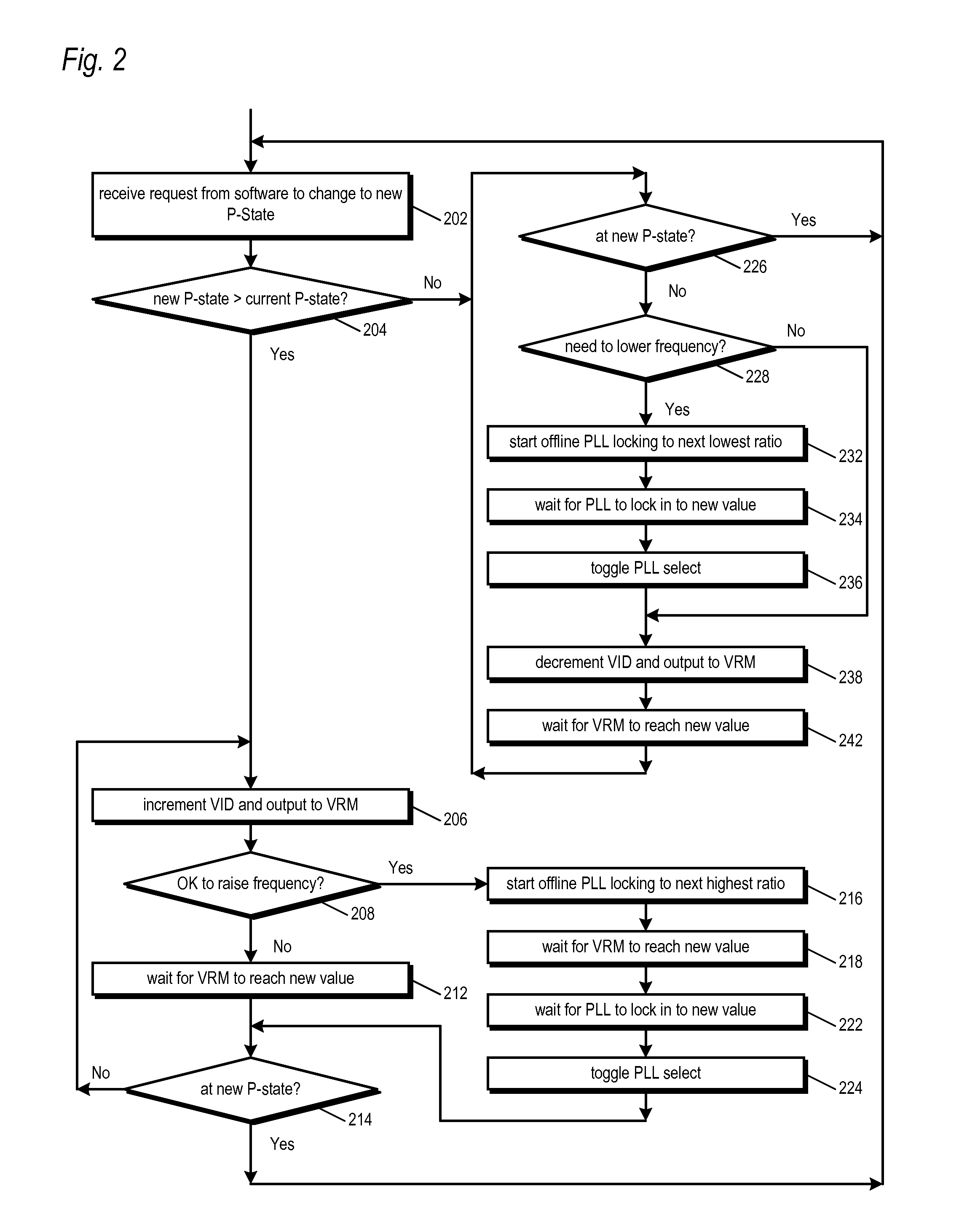

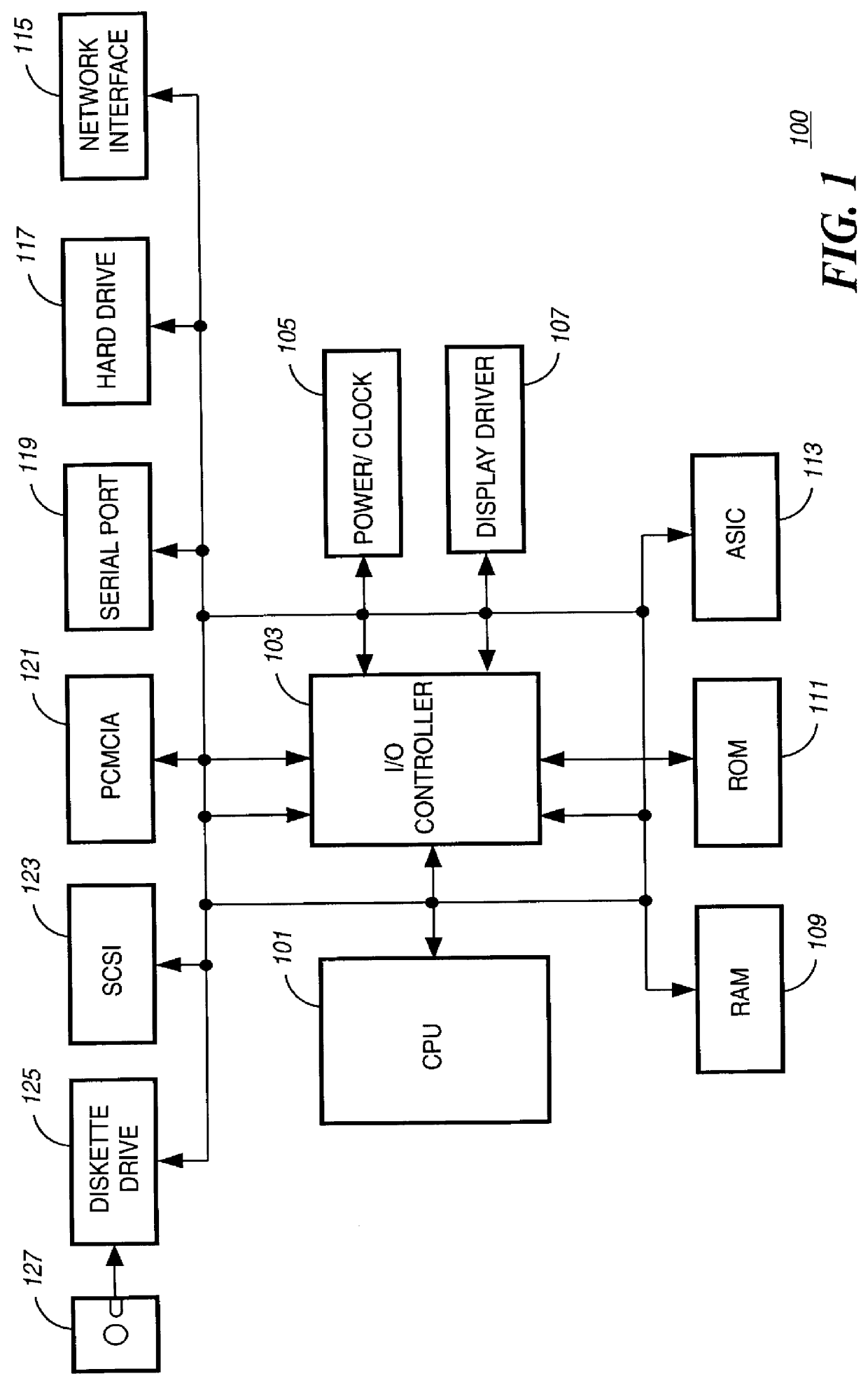

Microprocessor with improved thermal monitoring and protection mechanism

ActiveUS20080036613A1Improve performanceEnergy efficient ICTVolume/mass flow measurementThermal monitoringOperating point

A microprocessor including a temperature sensor that monitors a temperature of core logic of the microprocessor during operation thereof, and operating point information from which may be determined N operating points at which the microprocessor core may reliably operate at a first temperature. Each of the N operating points has a different combination of operating frequency and voltage. The N operating points comprise a highest operating point, a lowest operating point, and a plurality of operating points intermediate the highest and lowest operating points. The microprocessor also includes a control circuit that transitions operation of the core logic among the N operating points to attempt to keep the operating temperature of the core logic provided by the temperature sensor within a temperature range whose upper bound is the first temperature.

Owner:VIA TECH INC

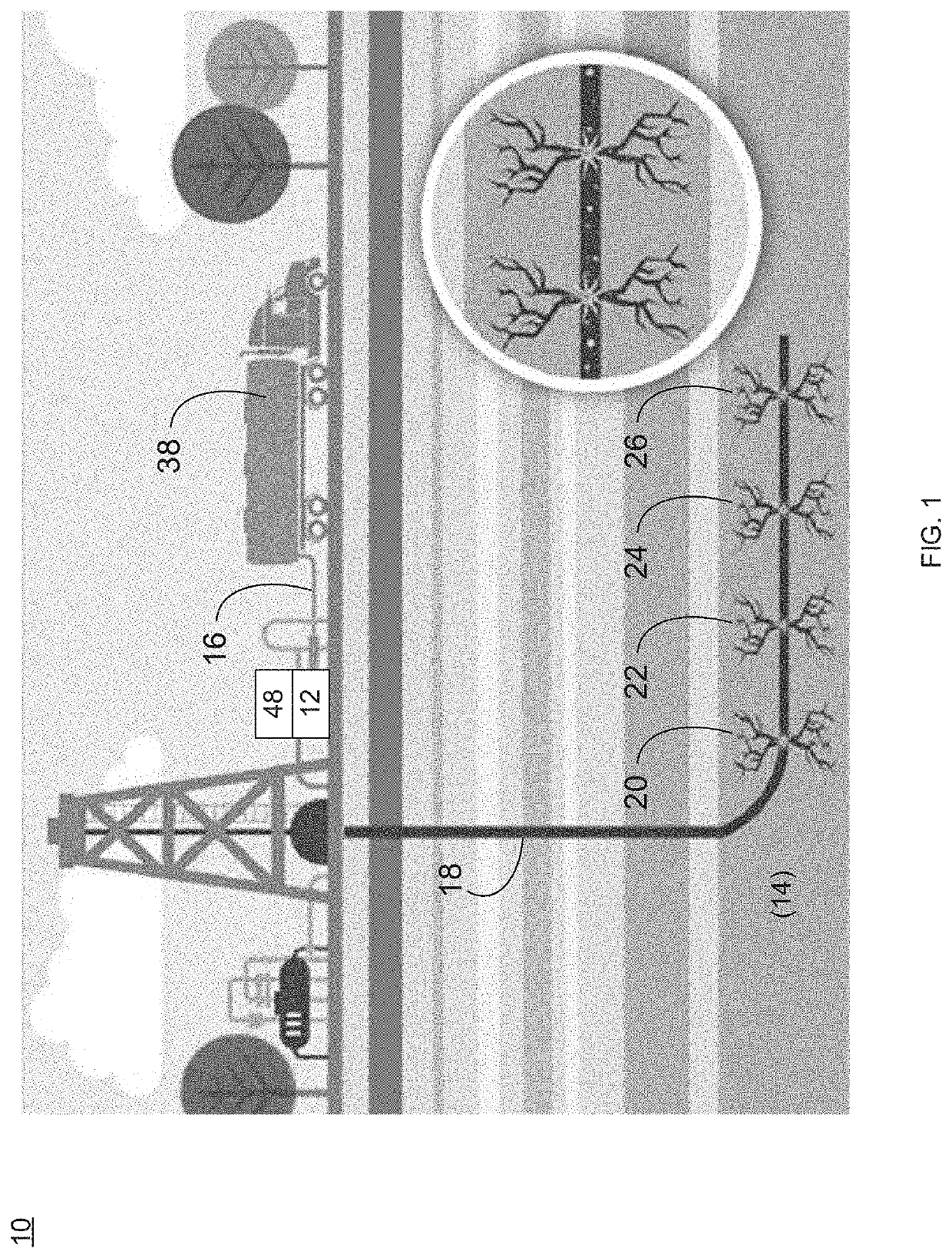

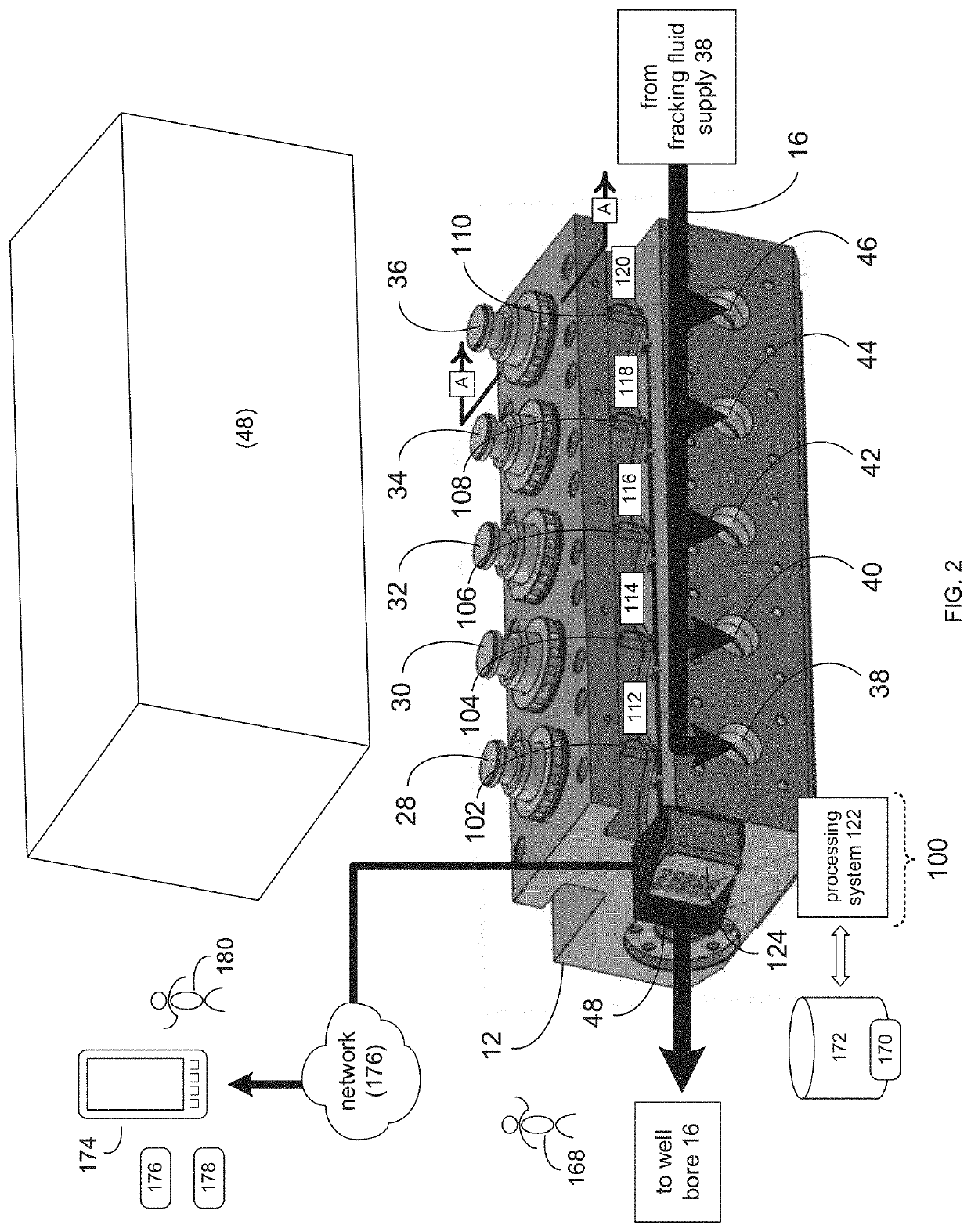

Thermal Monitoring System and Method

InactiveUS20210306720A1Thermometer detailsThermometers using electric/magnetic elementsThermal monitoringProcess engineering

A thermal monitoring system includes: one or more thermal sensors configured to monitor the temperature of one or more portions of a fracking pump and generate one or more thermal indication signals; a processing system configured to receive the one or more thermal indication signals and associate the one or more thermal indication signals with one or more operating temperatures of the one or more portions of the fracking pump; and an indication system configured to provide a thermal condition indicator based, at least in part, upon the one or more operating temperatures of the one or more portions of the fracking pump.

Owner:SALT & LIGHT ENERGY EQUIP LLC

Data center thermal monitoring

ActiveUS20100085196A1Easy assessment processReduce downtimeDigital data processing detailsCompression machines with non-reversible cycleThermal monitoringData center

Owner:GOOGLE LLC

Thermal monitoring system for semiconductor devices

A method for monitoring the operating temperature of a semiconductor device. The method comprising the steps of: placing a thermal coupling material between the bottom of the semiconductor device and the top of a printed circuit board for inserting the device thereinto; inserting a sensor so to be at least partially covered by the thermal coupling material; and measuring the temperature from the sensor within a predetermined time interval. In accordance with another aspect of the invention, an apparatus is described to carry out the above process.

Owner:IBM CORP

Zoned thermal monitoring

An integrated circuit includes a first temperature sensing device providing an indication of a sensed temperature, a correlation oscillator circuit positioned adjacent to the first temperature sensing device, a plurality of other oscillator circuits, and storage locations storing calibration factors associated with at least the first temperature sensing device and the plurality of other oscillator circuits. A temperature calculation circuit determines temperatures of various locations in the integrated circuit. Each of the temperatures is determined according to an oscillation frequency of a respective one of the other oscillators, the oscillation frequency of the correlation ring oscillator, the temperature of the first temperature sensing device, and one or more stored calibration factors.

Owner:ADVANCED MICRO DEVICES INC

Positionally Sequenced Loudspeaker System

InactiveUS20090028371A1High strengthEasy to operateNon-planar diaphragms/conesTransducer casings/cabinets/supportsThermal monitoringElectrical conductor

A variety of loudspeaker arrangements may have any of multiple adjacent magnetic circuits, single magnetic circuits, an improved loudspeaker voice coil assembly, multiple voice coil windings (124-127, 315-317), and commutated current. The radial direction of flux may alternate at adjacent poles and may have a controller that commands the current through each of the windings. The position of the moving components may be measured or inferred by the controller (213). An encoding track (318a) applied to the surface of the assembly may allow the assembly to function as part of a position transducer to permit appropriate action based on position. Calculated or sensed actual position may be used to determine the relative current in each of the windings and the controller may have compensation such as a motion control algorithm, thermal monitoring, and management of the driver. The voice coil assembly (305c) may have foil conductors applied to a substrate to connect and interconnect a single or multiple voice coil windings with minimal effect on the magnetic gap (303b) width.

Owner:INDUCTION SPEAKER TECH

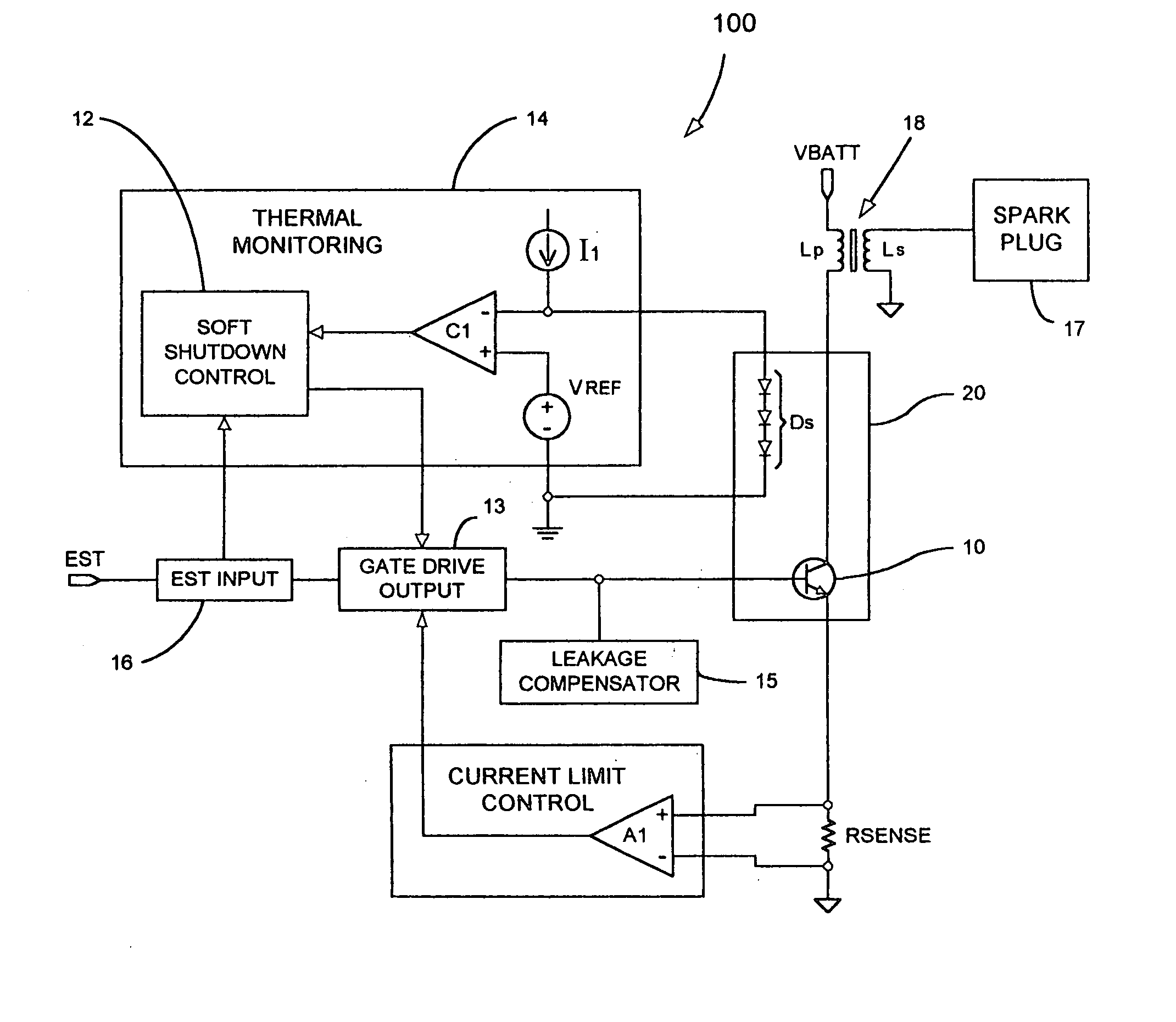

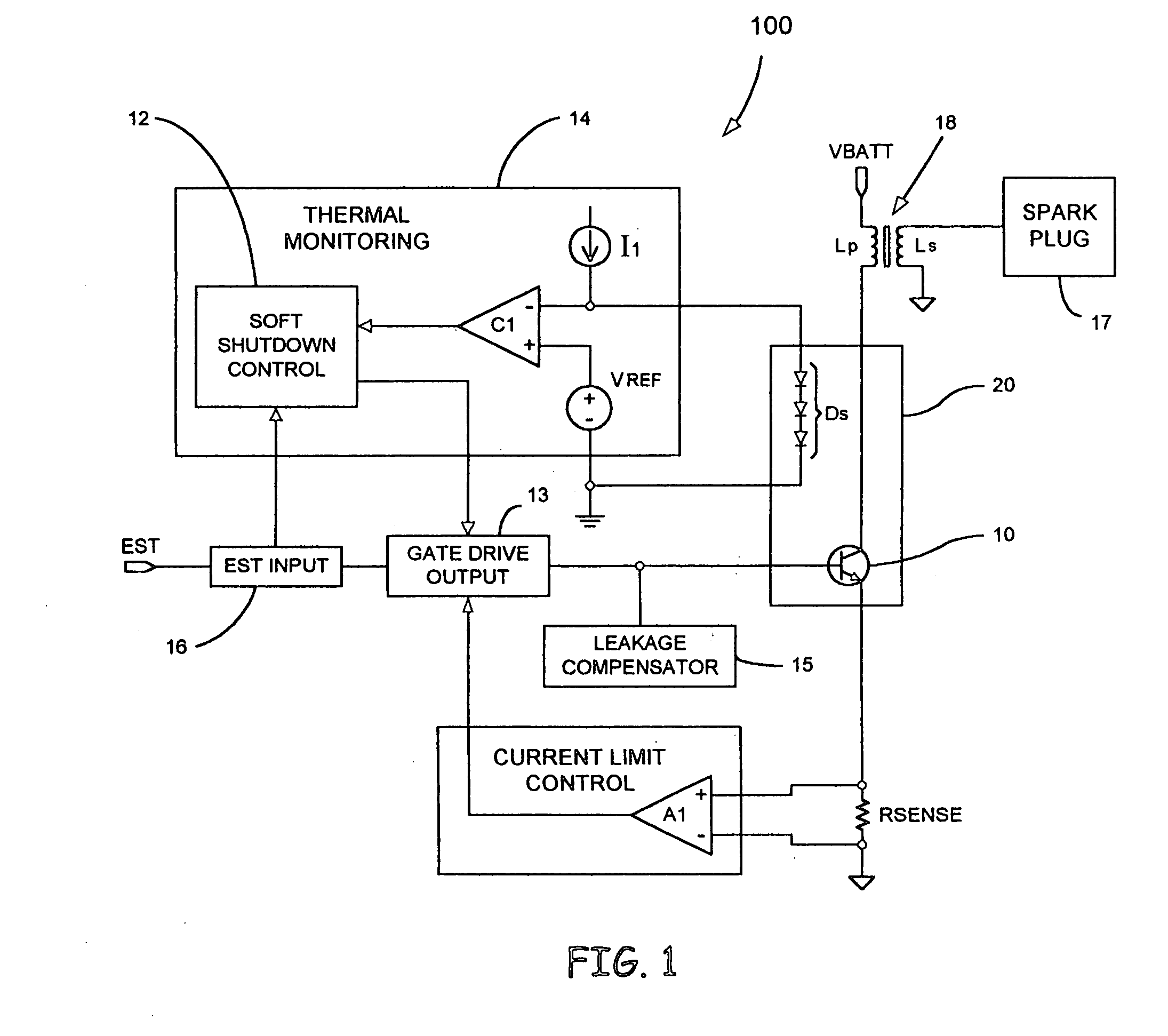

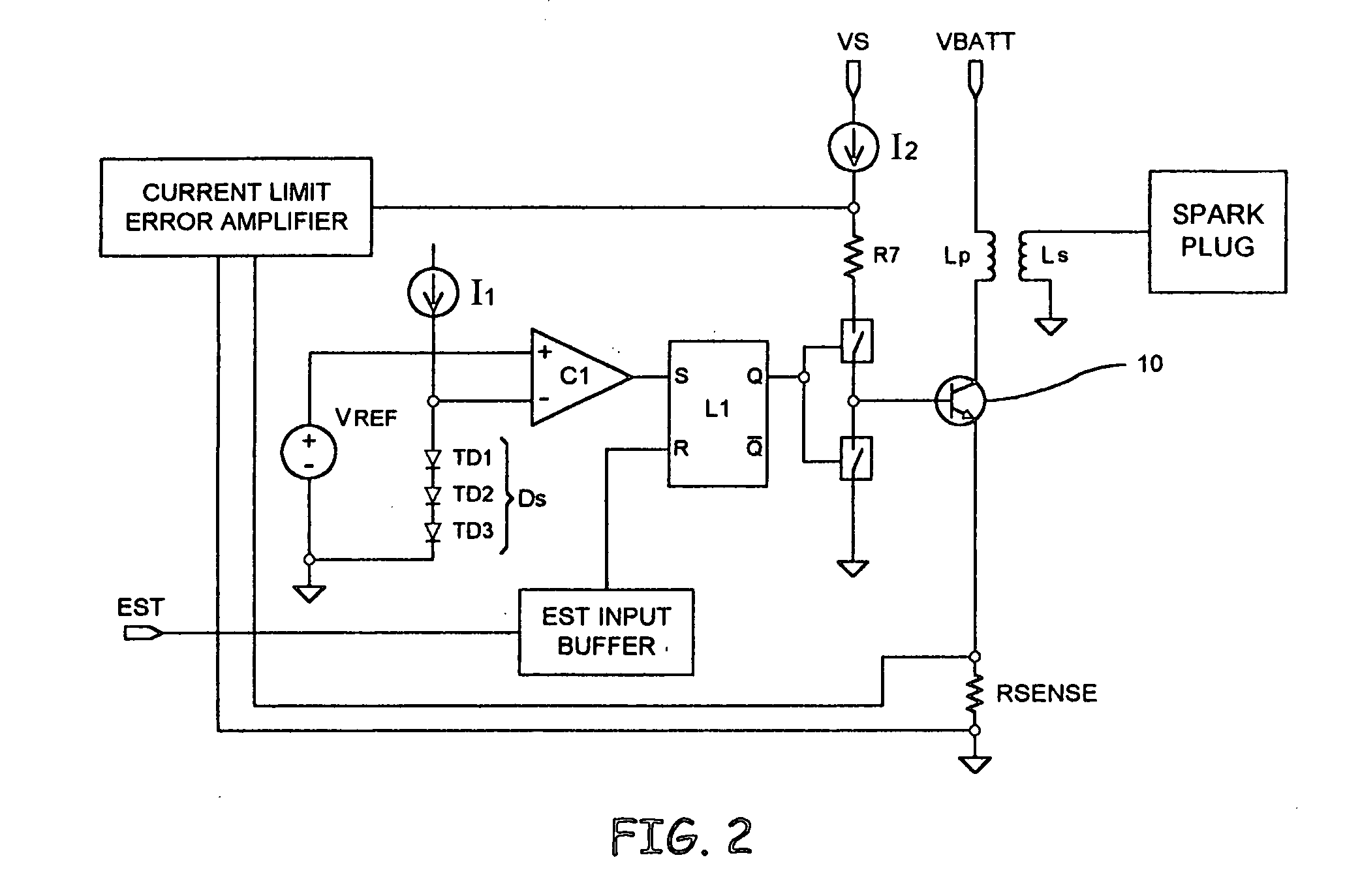

Automotive ignition system with sparkless thermal overload protection

ActiveUS20050178372A1Electrical controlThermometers using electric/magnetic elementsThermal monitoringDriving current

An interface for providing thermal overload protection includes a switching device, a temperature indicating device, a drive circuit and a thermal monitoring circuit. The thermal monitoring circuit is coupled across the temperature indicating device and provides a shutdown signal to the drive circuit when the temperature of the switching device is above a predetermined temperature level as indicated by a temperature signal provided by the temperature indicating device. The drive circuit responds to the shutdown signal by removing current sources and current sinks from a control terminal of the switching device at which point leakage currents cause the switching device to reduce a drive current to an inductive load.

Owner:DELPHI TECH IP LTD

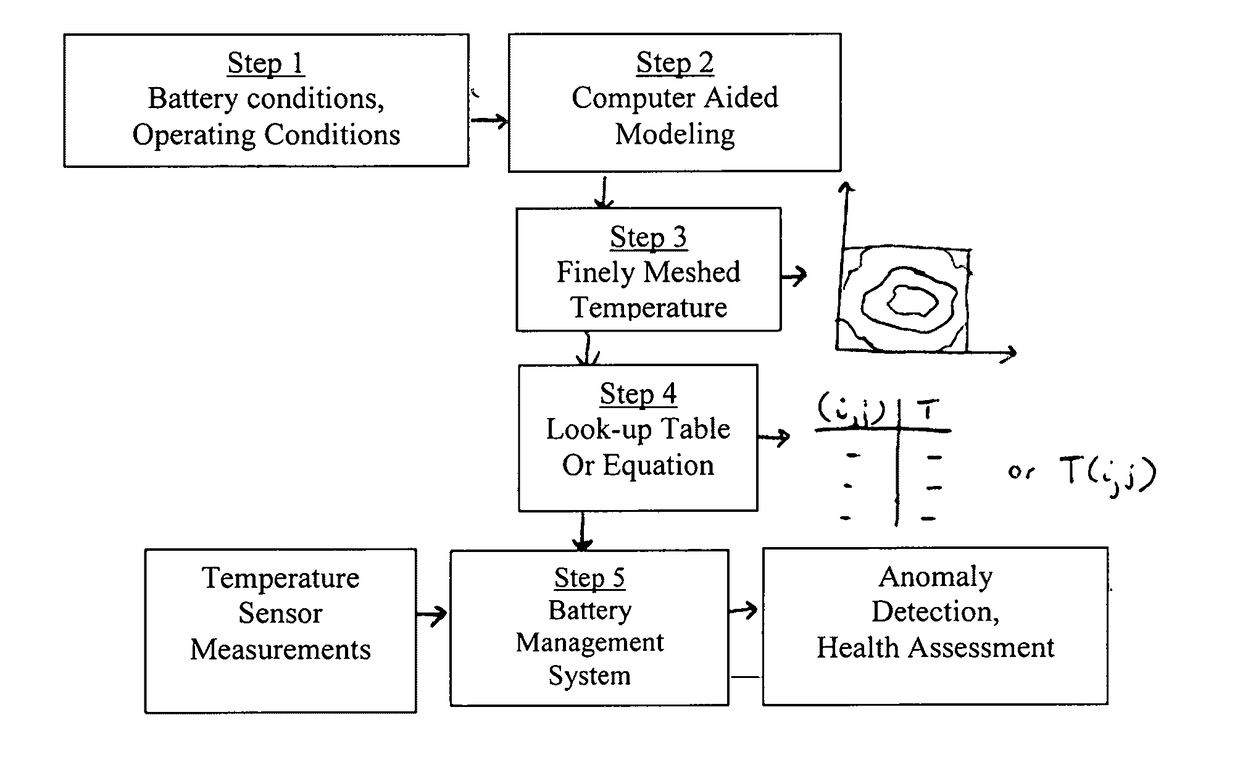

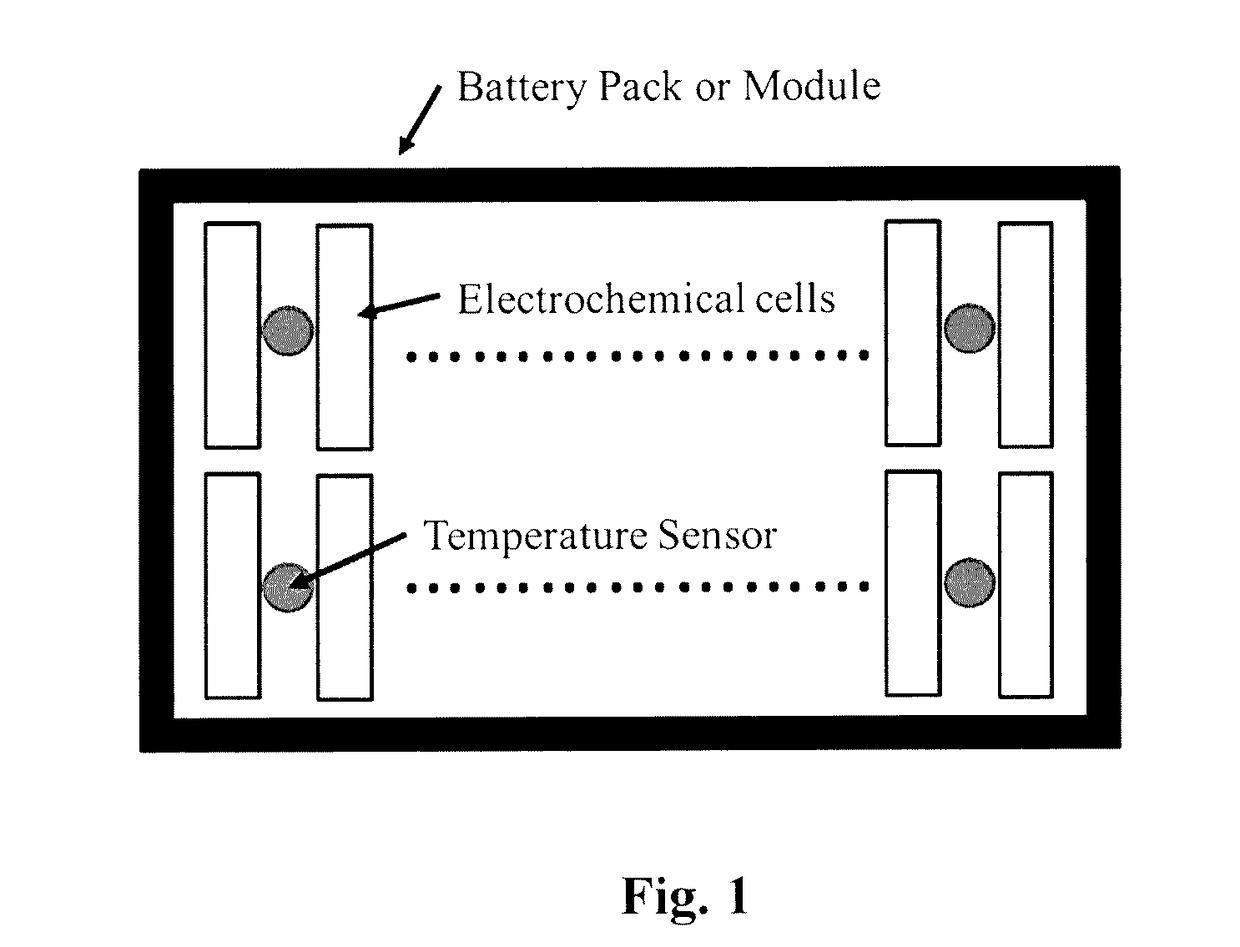

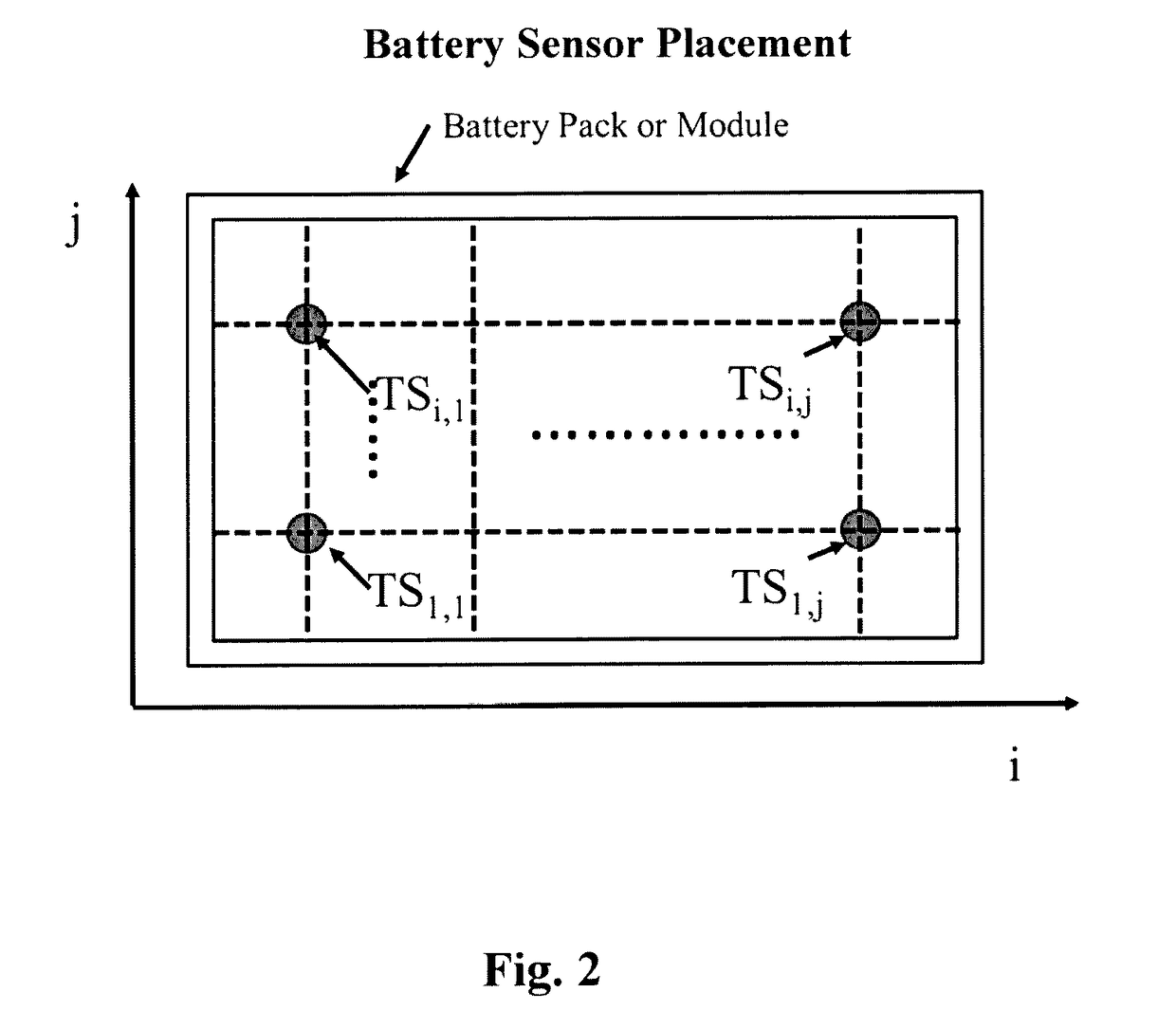

Thermal Monitoring of Battery Packs

InactiveUS20170117725A1Thermometer detailsThermometers using value differencesThermal monitoringComputer-aided

A computer-aided health monitoring method is described for thermal monitoring of a battery pack that consists of using modeling to determine temperature distributions representative of safe battery operating conditions and a technique is described for comparing sensor measurements to a look-up table of the pre-modeled temperature profiles under various operating conditions. In one embodiment a simplified model of temperature distribution is described.

Owner:OXFORDIAN

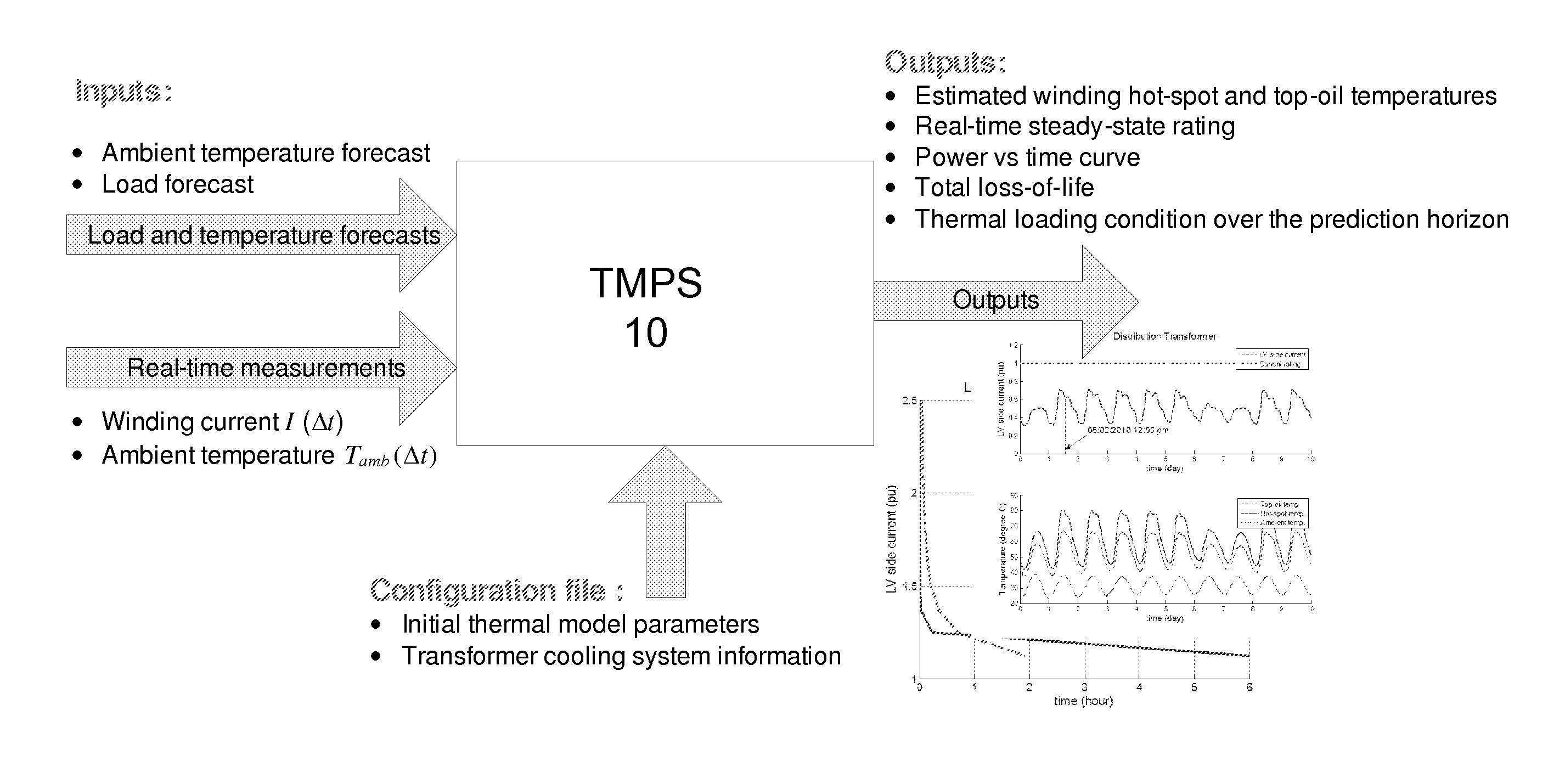

Oil-immersed transformer thermal monitoring and prediction system

InactiveUS20160252401A1Thermometer detailsThermometers using electric/magnetic elementsThermal monitoringTransformer

A real time thermal monitoring and prediction system (TMPS) is provided for use in monitoring and operating a transformer. The TMPS may be used to estimate a maximum loading level for the transformer over a future time period using a dynamic thermal model for the transformer and ambient temperature forecasts. The transformer may be loaded to its maximum loading level during power congestion or a service restoration process.

Owner:ABB INC

In-cabinet thermal monitoring method and system

ActiveUS20100044567A1Avoid disadvantagesTelevision system detailsSubstation/switching arrangement detailsThermal monitoringSwitchgear

Owner:ROCKWELL AUTOMATION TECH

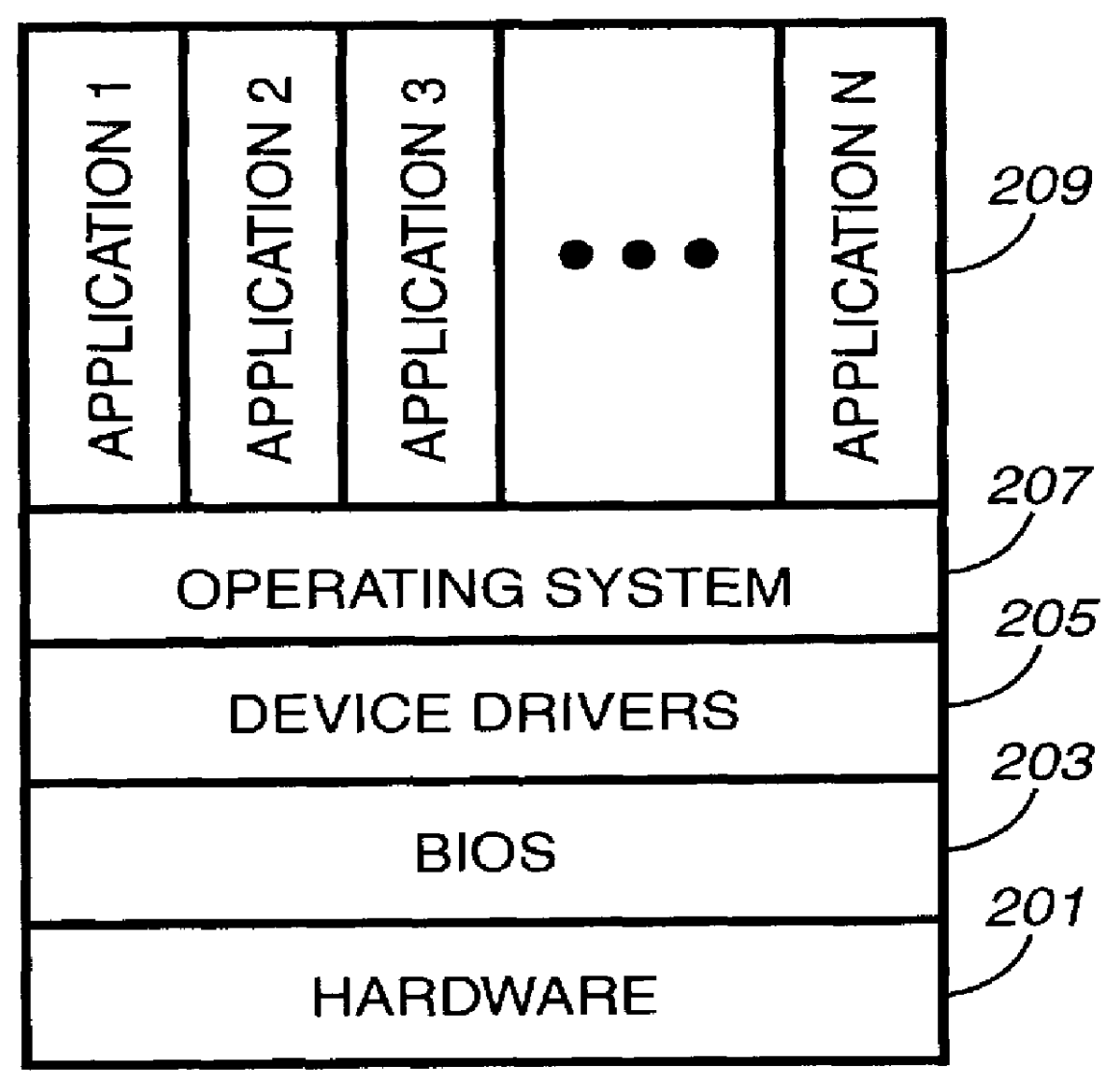

Thermal monitoring and response apparatus and method for computer unit

ActiveUS20060262474A1Reliable operation of systemReduce maintenance costsThermometer detailsDigital data processing detailsThermal monitoringBackplane

Thermal conditions within a computer unit are monitored. A system-level temperature sensor responds to intake cooling air. A subsystem-level temperature sensor responds to the temperature of a subsystem-level component, preferably a motherboard or a backplane. When the temperature sensed by of the system-level temperature sensor falls outside of a critical limit, it is determined whether the temperature sensed by the subsystem-level temperature sensor generally correlates with the temperature sensed by the system-level temperature sensor. If there is no correlation, the operation of the computer unit is continued.

Owner:NETWORK APPLIANCE INC

Zoned thermal monitoring

An integrated circuit includes a first temperature sensing device providing an indication of a sensed temperature, a correlation oscillator circuit positioned adjacent to the first temperature sensing device, a plurality of other oscillator circuits, and storage locations storing calibration factors associated with at least the first temperature sensing device and the plurality of other oscillator circuits. A temperature calculation circuit determines temperatures of various locations in the integrated circuit. Each of the temperatures is determined according to an oscillation frequency of a respective one of the other oscillators, the oscillation frequency of the correlation ring oscillator, the temperature of the first temperature sensing device, and one or more stored calibration factors.

Owner:ADVANCED MICRO DEVICES INC

Thermal monitoring and response apparatus and method for computer unit

ActiveUS7370242B2Guaranteed uptimeUptime is increasedThermometer detailsError detection/correctionThermal monitoringCritical limit

Owner:NETWORK APPLIANCE INC

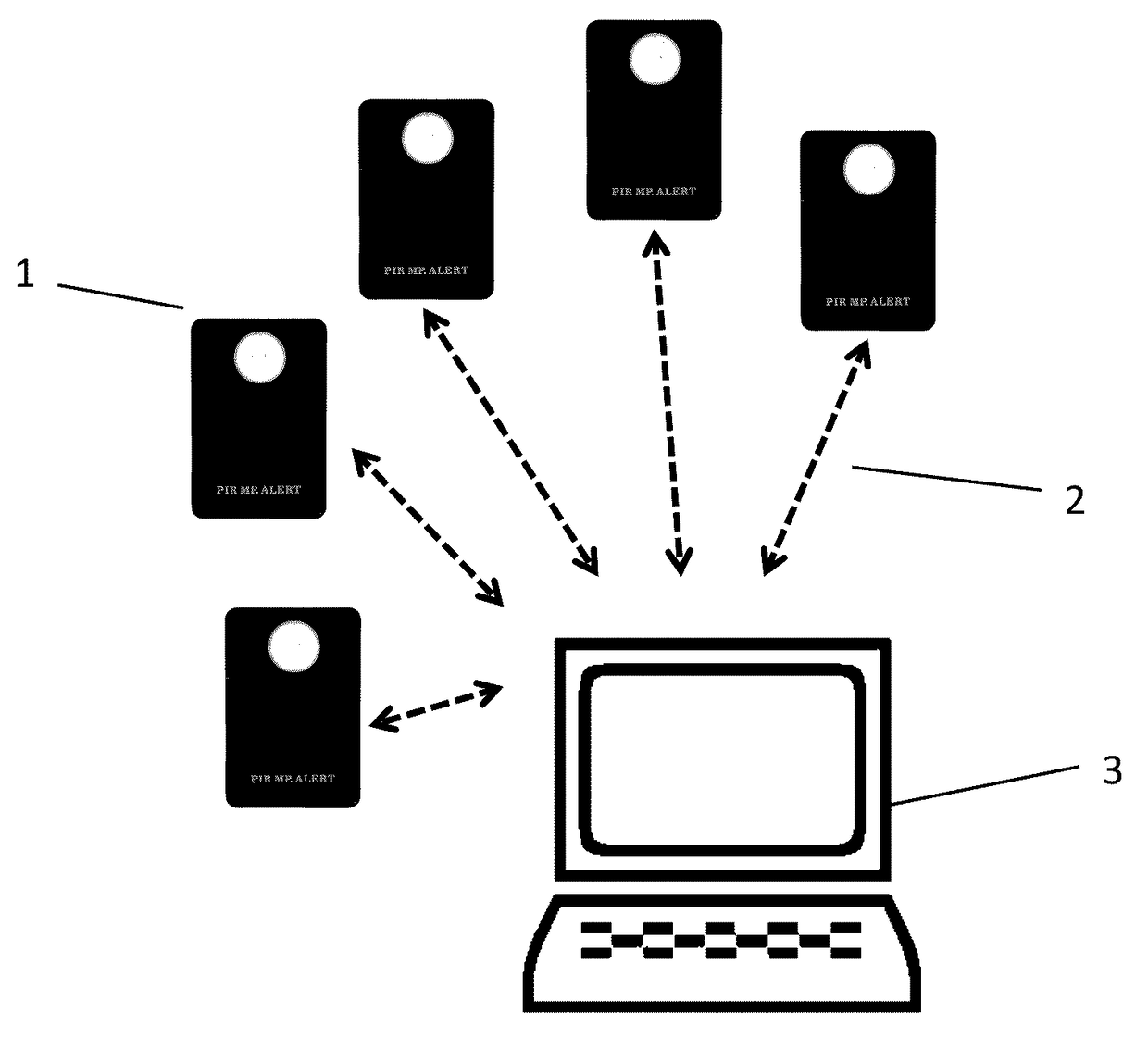

System and method for territory thermal monitoring

InactiveCN1639751ALimited timeLimit qualitySolar heating energyPhotometryThermal monitoringExtinction

System for the thermal monitoring of a territory, comprising a plurality of local devices installed on the territory to be monitored and having means for acquiring environmental data able to detect the presence of a significant thermal variation in the surrounding area, a central control station, comprising means for storing logistical-technical data and data about the available rescue means relating to the territory to be monitored, means for transmitting / receiving data between the central control station and the local devices, and means for the integrated processing of the environmental data acquired by the local devices and of the data stored in the central control station, able to provide at their output a model of evolution of the event and a plan of intervention for the extinction thereof.

Owner:GS GESTIONE SISTEMI

Processor Temperature Measurement Through Median Sampling

ActiveUS20080125915A1Accurate temperature readingAccurate fan controlSampled-variable control systemsTemperature control using digital meansTemperature controlThermal monitoring

Temperature readings obtained within a computer system from the location of monitored circuit elements may be oversampled at least three times, and a median average of the three parameter readings rather than the arithmetic mean may be used for controlling a device, e.g. a fan, configured to regulate the environmental parameter, e.g. temperature, a the location of the monitored circuit elements. For example, when a CPU temperature reading is requested by the system comprising the CPU, a thermal monitoring system may acquire at least three consecutive temperature readings of the CPU, discard the highest temperature reading and the lowest temperature reading, and return the median reading to be used in controlling a fan configured to regulate temperature at the location of the CPU, resulting in more accurate temperature readings and more accurate fan control. In various implementations, more than three readings may be considered at a time, and running averages based on median values may be computed in a variety of ways to obtain a temperature control value to control the fan.

Owner:MICROCHIP TECH INC

Thermally activated electrical interrupt switch

InactiveUS20090302990A1Ensure integrity of operationElectrothermal relaysHeating/cooling contact switchesThermal monitoringElectricity

A thermally activated electrical interrupt device incorporates a thermally activated portion engaging with an electrical interrupt portion. The thermally activated material expands when heated, causing an interrupt control rod to open an electrical contact. When the interrupt device is placed into an interrupt state, a reset mechanism maintains the interrupt control rod in the interrupt state until specifically reset. An actuating shaft is in operational communication with at least one electrical contact. The actuating shaft is maintained in a thermal monitoring position until an interrupt control rod is moved via a thermally expanding material and engages with the actuating shaft, releasing it from the thermal monitoring position. The actuating shaft is projected via a biasing member to cause a change in state of the electrical contact. The actuating shaft remains in the interrupt state until the user resets the switch.

Owner:THERMAL INTERRUPT DEVICES

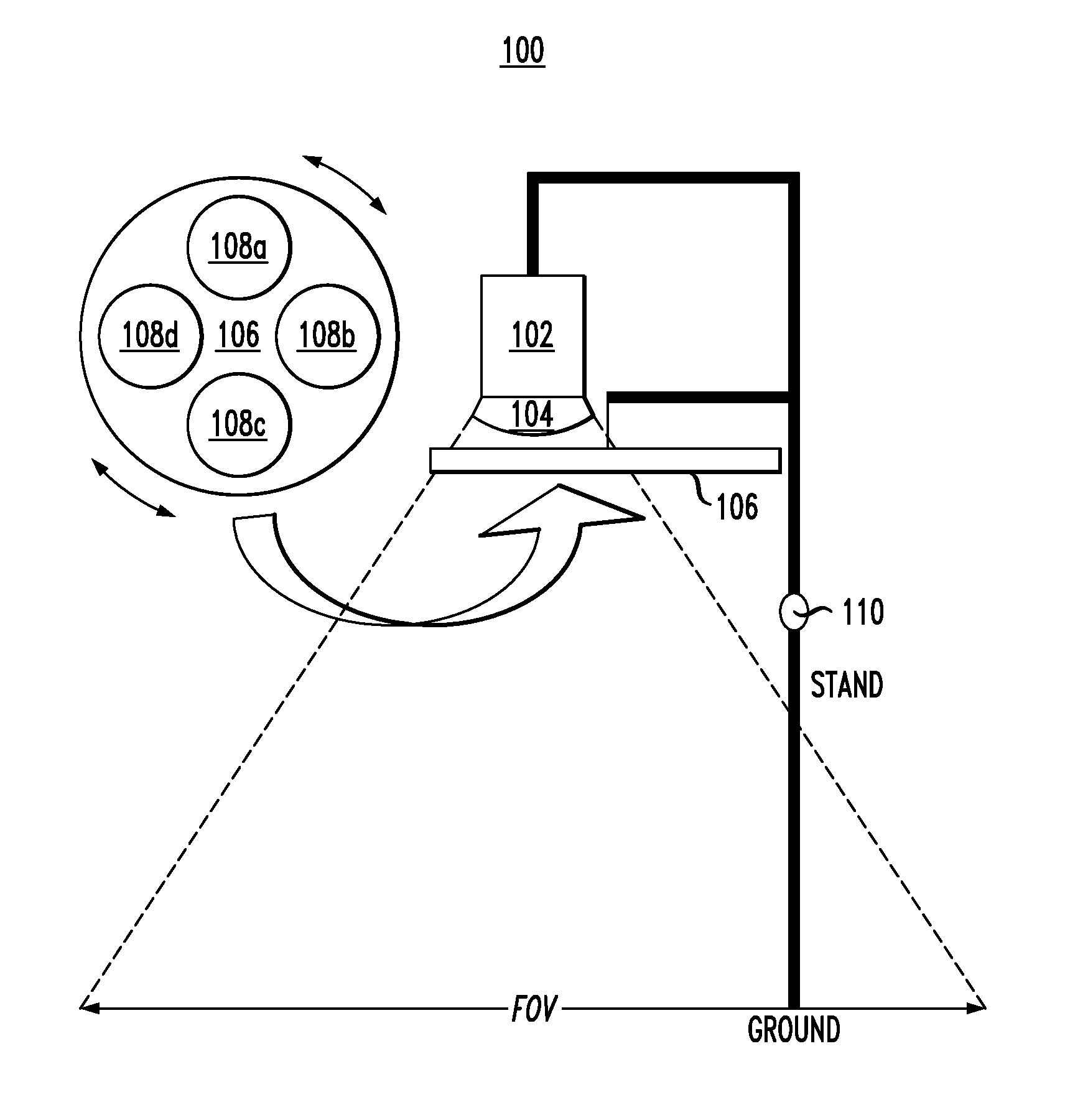

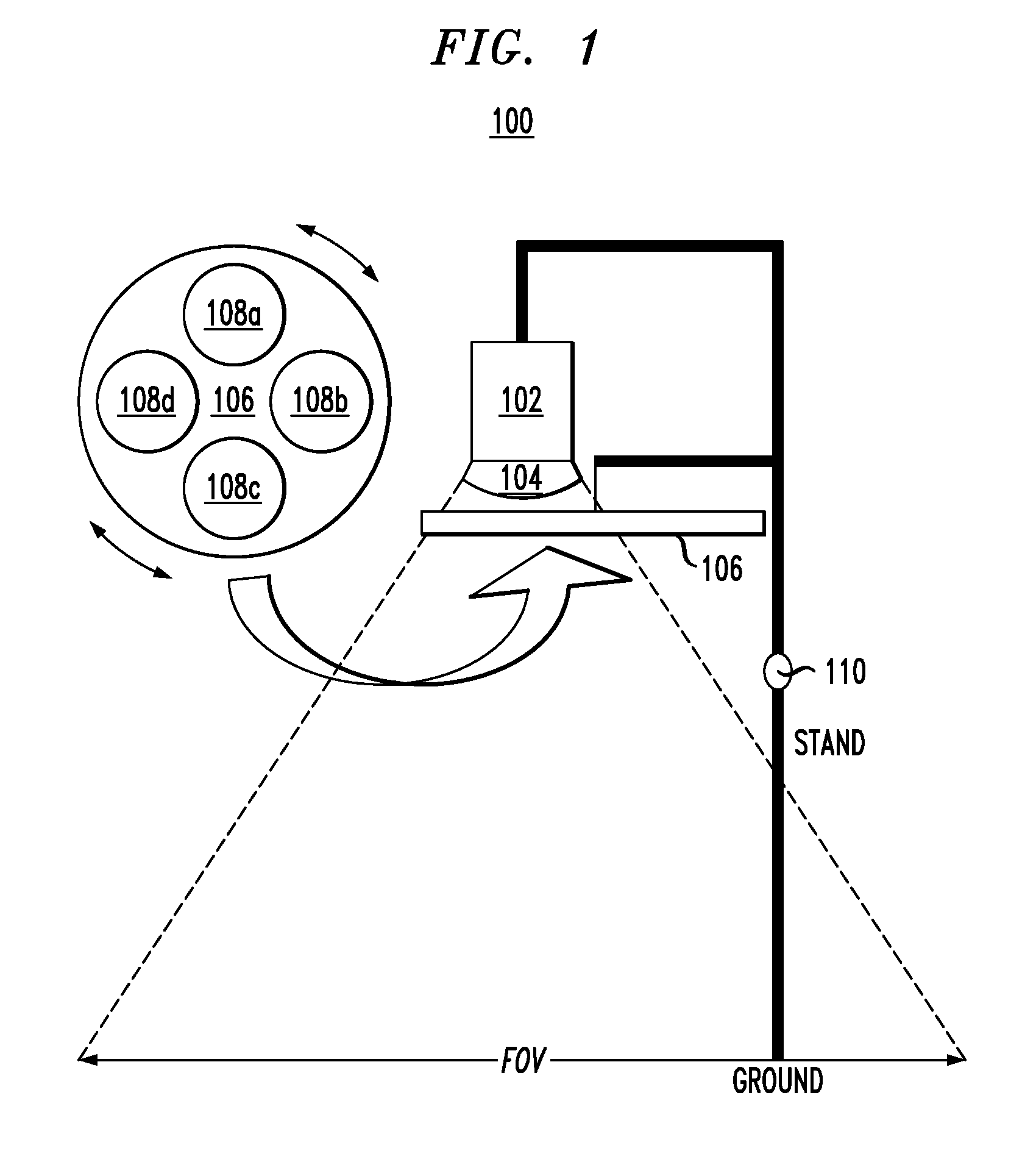

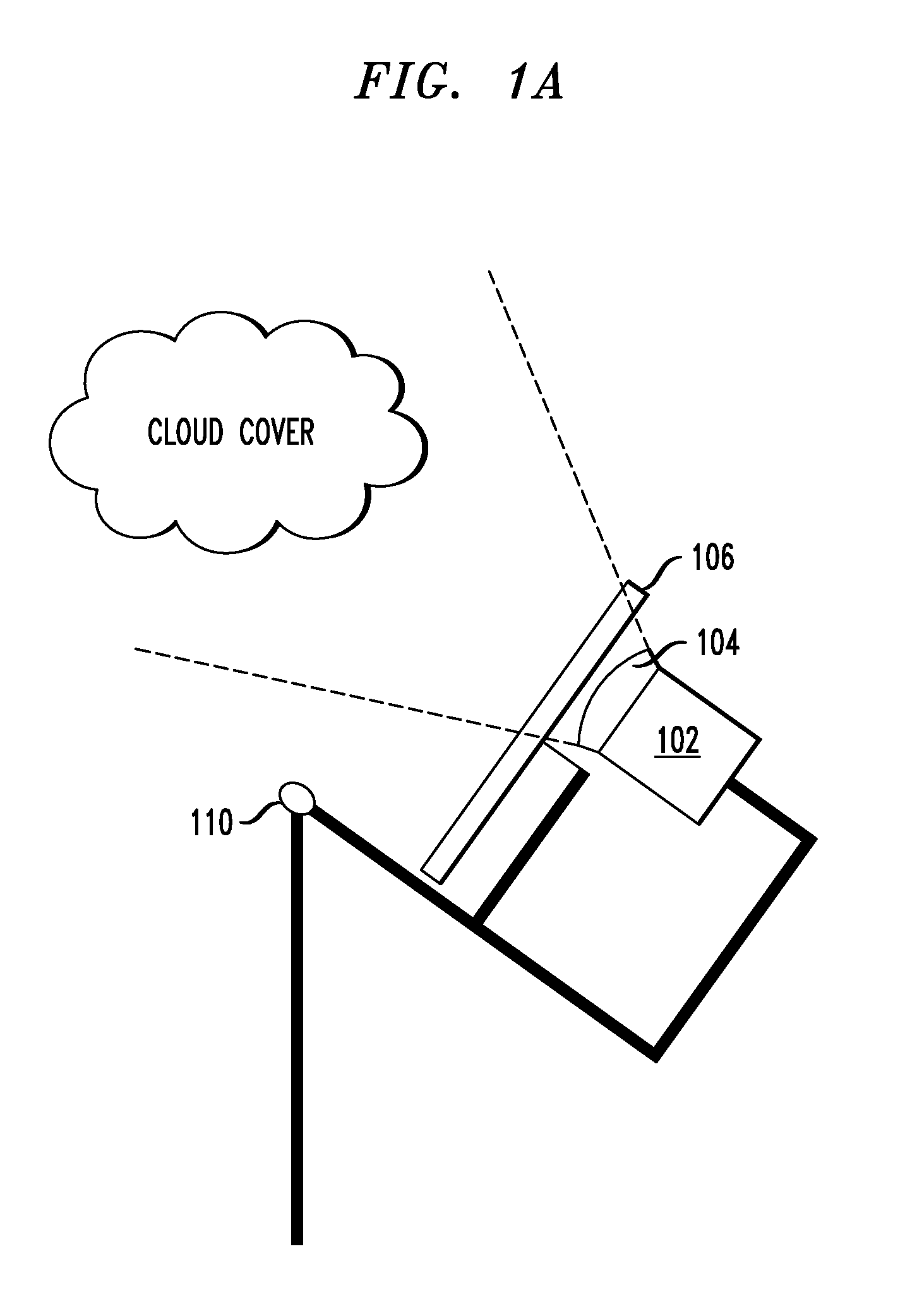

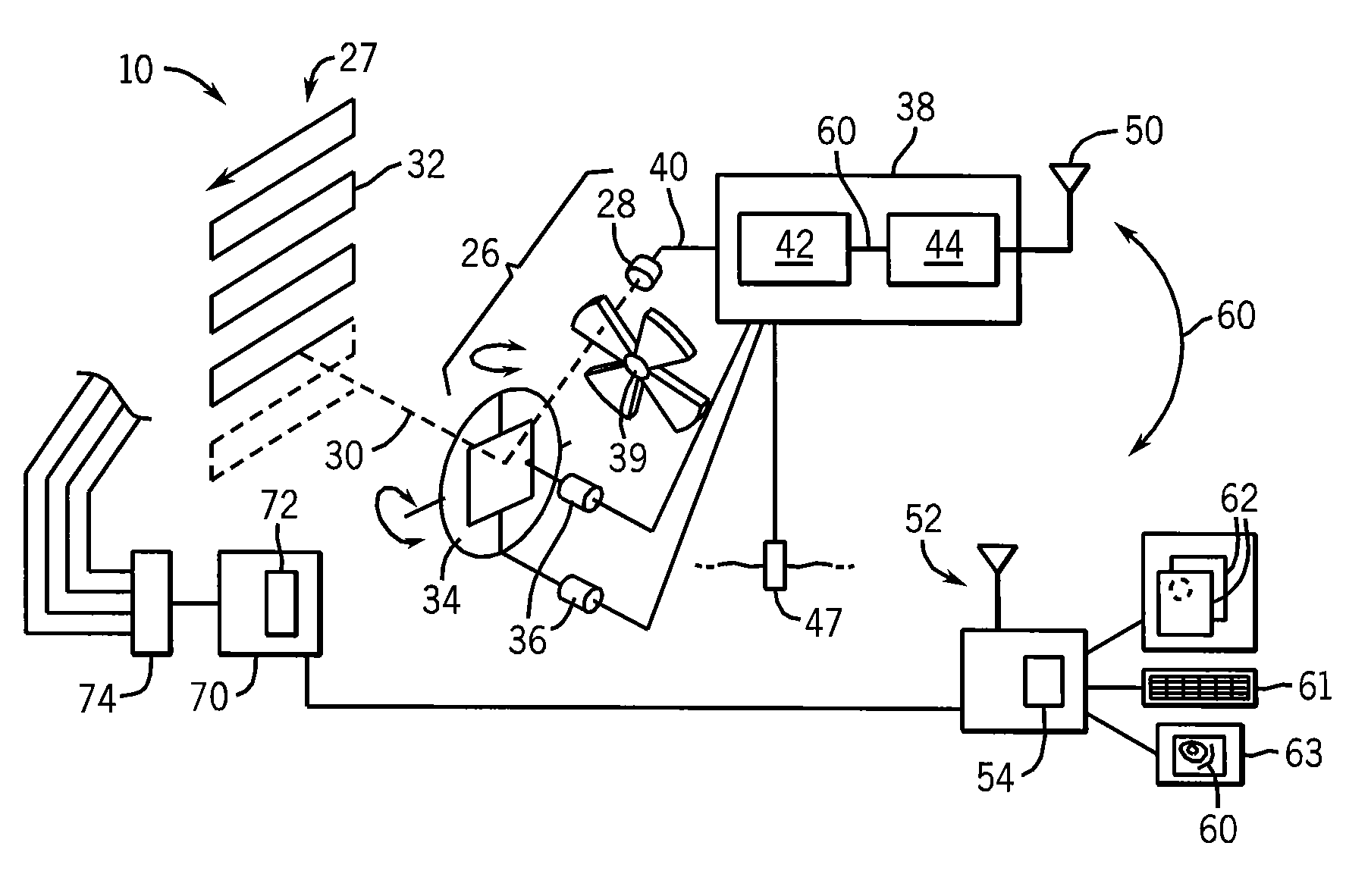

Large-Area Monitoring Using Infrared Imaging System

InactiveUS20150161779A1Improve time resolutionImage enhancementSolar heating energyThermal monitoringFisheye lens

An imaging system and use thereof for large-area monitoring with very high temporal resolution are provided. In one aspect, an imaging system includes a camera equipped with curved optics having a field of view of from about 0.01 miles to about 1.5 miles; and interchangeable light filters positioned in front of the camera configured to change one or more of an intensity and an amplitude of light captured by the imaging system. The curved optics may include a hemispherical mirror configured to reflect an image of objects in front of the mirror, and the camera may be positioned facing a reflective surface of the hemispherical mirror so as to capture the image reflected in the hemispherical mirror. Alternatively, the curved optics may include a fisheye lens mounted to the camera. An imaging network of the present imaging systems and a method for use thereof for thermal monitoring are also provided.

Owner:IBM CORP

Infrared Thermal Monitoring System for Industrial Application

ActiveUS20190310137A1Improve detection accuracyLow costTelevision system detailsSwitchgear arrangementsThermal monitoringEvent triggered

A thermal monitoring system includes thermal monitoring devices that generate sensor data including thermal images depicting monitored elements (e.g. of an electrical switchgear system). The sensor data for all monitoring devices installed at a local deployment is collected by a gateway device, and relevant data from multiple local deployments is further aggregated by a cloud management system for further analysis. New event triggering rules determining how the thermal monitoring devices filter or record the sensor data are generated based on the aggregated data during a continuous learning process. The system detects patterns in the sensor data for the monitoring devices and / or local deployments as a whole and tracks deviations from these patterns, improving the accuracy of the event detection over time.

Owner:ADVANCETREX SENSOR TECH CORP

Device for thermal monitoring of the terminals of an electrical connection device

InactiveUS20140168845A1Coupling device detailsThermally actuated switchesThermal monitoringElectricity

The subject matter of the invention is a device for thermal monitoring of a connection device, said connection device comprising at least two terminals to be monitored, including at least one active terminal, the device comprising at least one electrically conductive fault-initiating element electrically connected to a protective conductor, and electrically insulating detection means for detecting abnormal heating, in thermal contact with each terminal to be monitored, the detection means preventing each fault-initiating element from coming into electrical contact with an active terminal so long as these detection means are not subject to a threshold temperature, and the detection means releasing the fault-initiating element when they are subject to a temperature higher than or equal to the threshold temperature in such a way that this fault-initiating element comes into electrical contact with an active terminal, the thermal monitoring device being characterized in that each fault-initiating element comprises a fixed part and a part that can be moved between a “no fault” position, in which it is held at a distance from an active terminal by the detection means, and a “fault” position in which it is released by the detection means and comes into electrical contact with an active terminal.

Owner:CHARLES

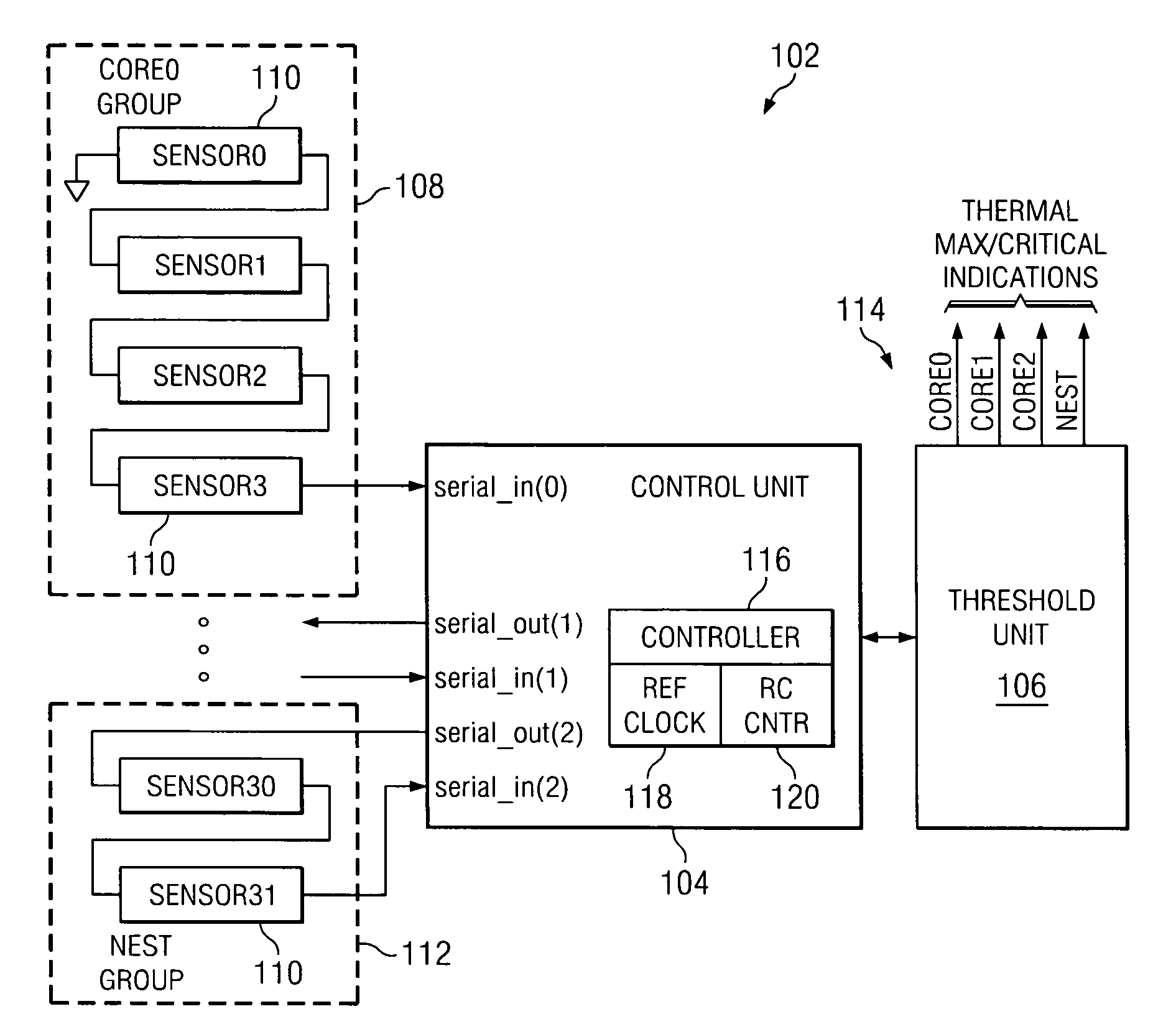

System and method for thermal monitoring of IC using sampling periods of invariant duration

InactiveUS7197419B2Thermometer detailsDigital data processing detailsThermal monitoringMonitoring temperature

A system and method are provided for monitoring temperature within a specified integrated circuit. Usefully, the system comprises at least one oscillator device proximate to the integrated circuit for generating signal pulses at a frequency that varies as a function of the temperature adjacent to the oscillator device. The system further comprises a control unit for establishing sample acquisition periods of invariant time duration based on an time invariant reference clock. A sampling component is coupled to count the number of pulses generated by the oscillator device during each of a succession of the time invariant sample acquisition periods, and a threshold component responsive to the respective count values for the succession of sample acquisition periods provides notice when at least some of the count values have a value associated with a prespecified excessive temperature level.

Owner:INT BUSINESS MASCH CORP

Automotive ignition system with sparkless thermal overload protection

ActiveUS6955164B2Electrical controlThermometers using electric/magnetic elementsDriving currentThermal monitoring

An interface for providing thermal overload protection includes a switching device, a temperature indicating device, a drive circuit and a thermal monitoring circuit. The thermal monitoring circuit is coupled across the temperature indicating device and provides a shutdown signal to the drive circuit when the temperature of the switching device is above a predetermined temperature level as indicated by a temperature signal provided by the temperature indicating device. The drive circuit responds to the shutdown signal by removing current sources and current sinks from a control terminal of the switching device at which point leakage currents cause the switching device to reduce a drive current to an inductive load.

Owner:DELPHI TECH IP LTD

Apparatus, system, and method for determining a time-temperature history of an aftertreatment device

ActiveUS20090019833A1Thermometer detailsTemperature measurement in motorsThermal monitoringThermal contact

An apparatus, system, and method are disclosed for determining a time-temperature history of an aftertreatment device. The apparatus includes an aftertreatment device comprising a substrate, and at least one thermal monitoring member (TMM) in thermal contact with the substrate. The TMMs may comprise a material that exhibits an electrical resistivity change at temperature over time. The apparatus may include a controller configured to measure the electrical resistivity of at least a portion of the TMMs, and to determine a thermal history based on the electrical resistivity measures.

Owner:CUMMINS FILTRATION IP INC

On-line thermal monitoring system of heat transfer symmetry of crystallizer copper pipe and method thereof

InactiveCN101879583ACalculate Heat FluxSimple structural designMaterial heat developmentThermal monitoringProcess optimization

The invention belongs to the technical field of steelmaking continuous casting, and relates to an on-line thermal monitoring system of heat transfer symmetry of a crystallizer copper pipe on a continuous casting machine. The system comprises the crystallizer copper pipe which can monitor the heat transfer symmetry, a temperature data collection and storage module and an industrial control computer. The on-line thermal monitoring system is characterized in that a plurality of temperature measuring elements are embedded at the back of the copper pipe, and the temperature measuring elements are distributed in a 'cross' shape and in a symmetrical form based on the central section of the copper pipe. The invention comprehensively utilizes on-site actual measuring data and a computer numerical simulation technology, researches the heat transfer symmetry of a crystallizer by monitoring the surface temperature of the copper pipe, determines longitudinal distribution of heat flow of the crystallizer according to the transient heat flow calculated by the temperature of the copper pipe, calculates the temperature field of a continuous casting billet and the shell thickness of a solidification billet through a heat transfer mathematical model, and finally compares the situation of symmetrical surfaces. The invention can provide a basis for structural design of the crystallizer copper pipe and production process optimization of the crystallizer so as to promote the continuous casting billet to uniformly grow in the crystallizer.

Owner:UNIV OF SCI & TECH BEIJING

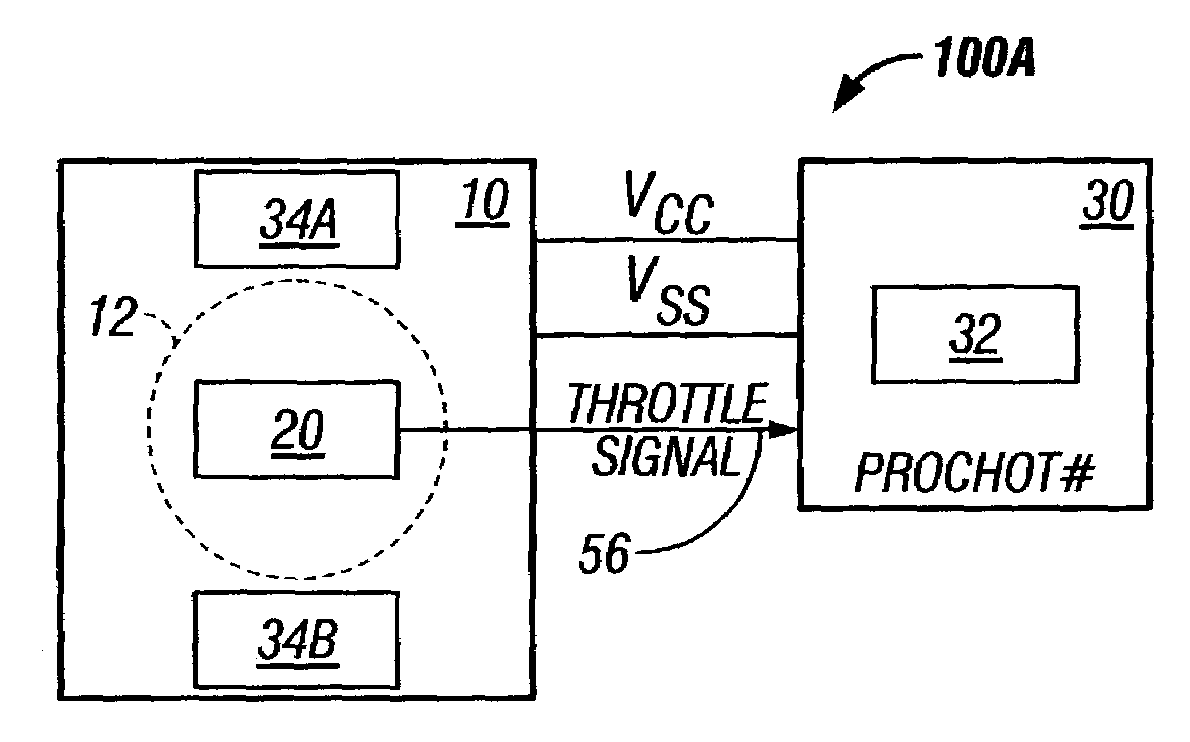

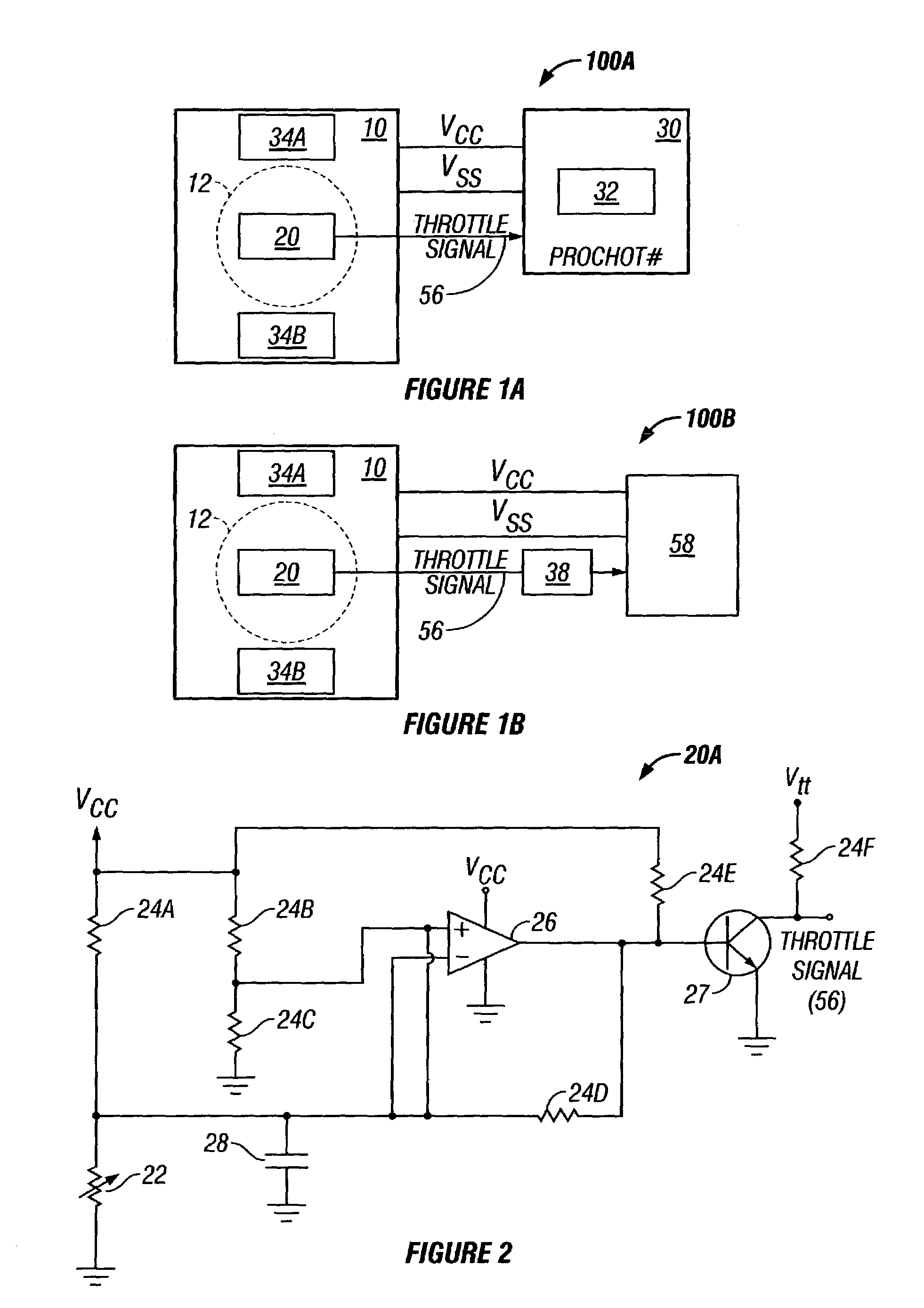

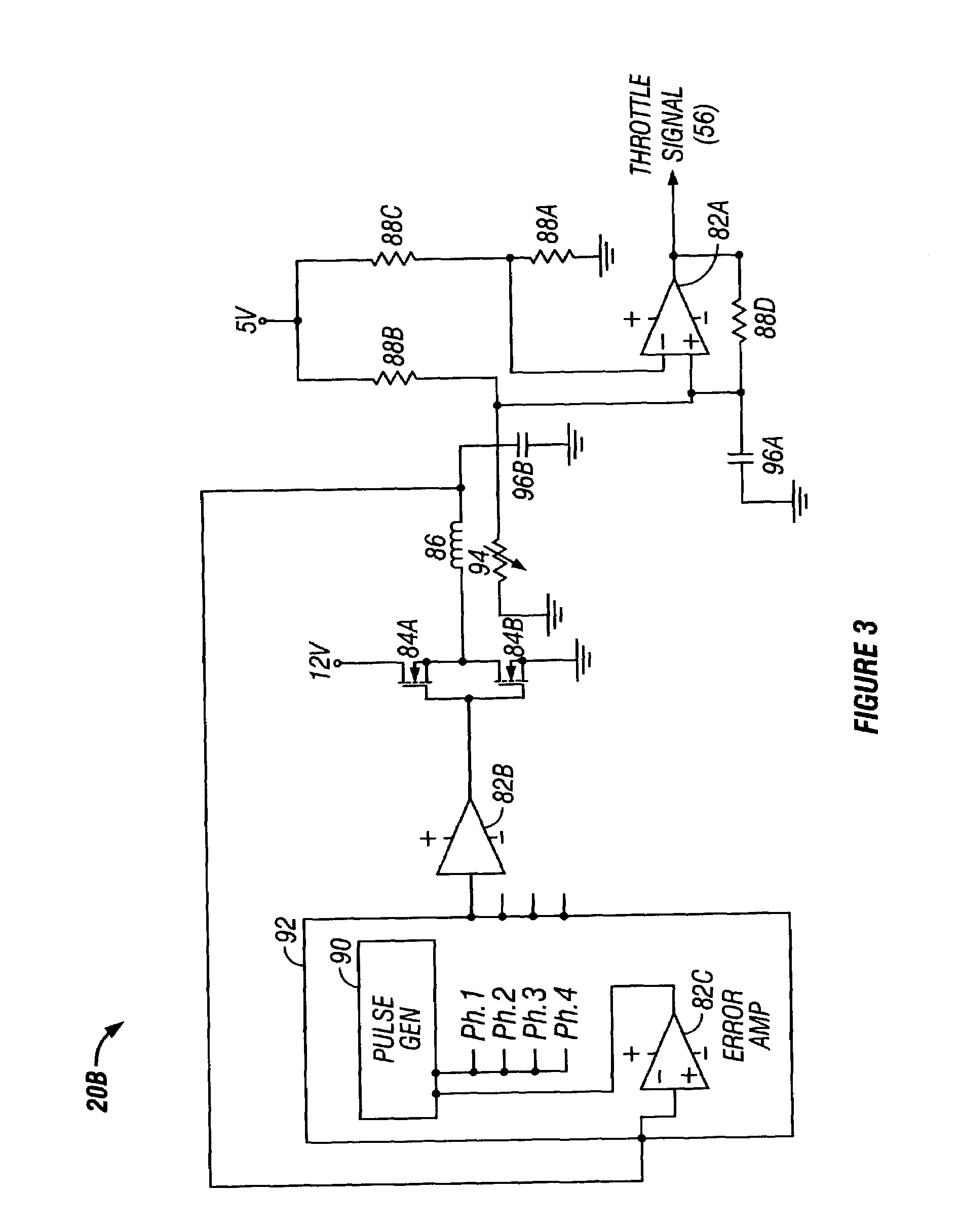

Control of voltage regulator thermal condition

A system and method for automatically adjusting microprocessor activity following thermal stress of a voltage regulator is disclosed. A thermal monitoring circuit determines whether the voltage regulator has exceeded a predetermined temperature. The thermal monitoring circuit may employ a temperature-sensing component such as a thermistor to determine the temperature or may derive the temperature indirectly, based on the average input (or output) current. When the over-temperature condition occurs, a signal activates the PROCHOT#, or similar, pin on a microprocessor, throttling the microprocessor clock. Where the microprocessor includes no internal power-reducing feature, the signal throttles an external clock coupled to the microprocessor. In either case, execution of the microprocessor is slowed down. At all times, the voltage regulator maintains the ability to supply continuous current to the microprocessor.

Owner:TAHOE RES LTD

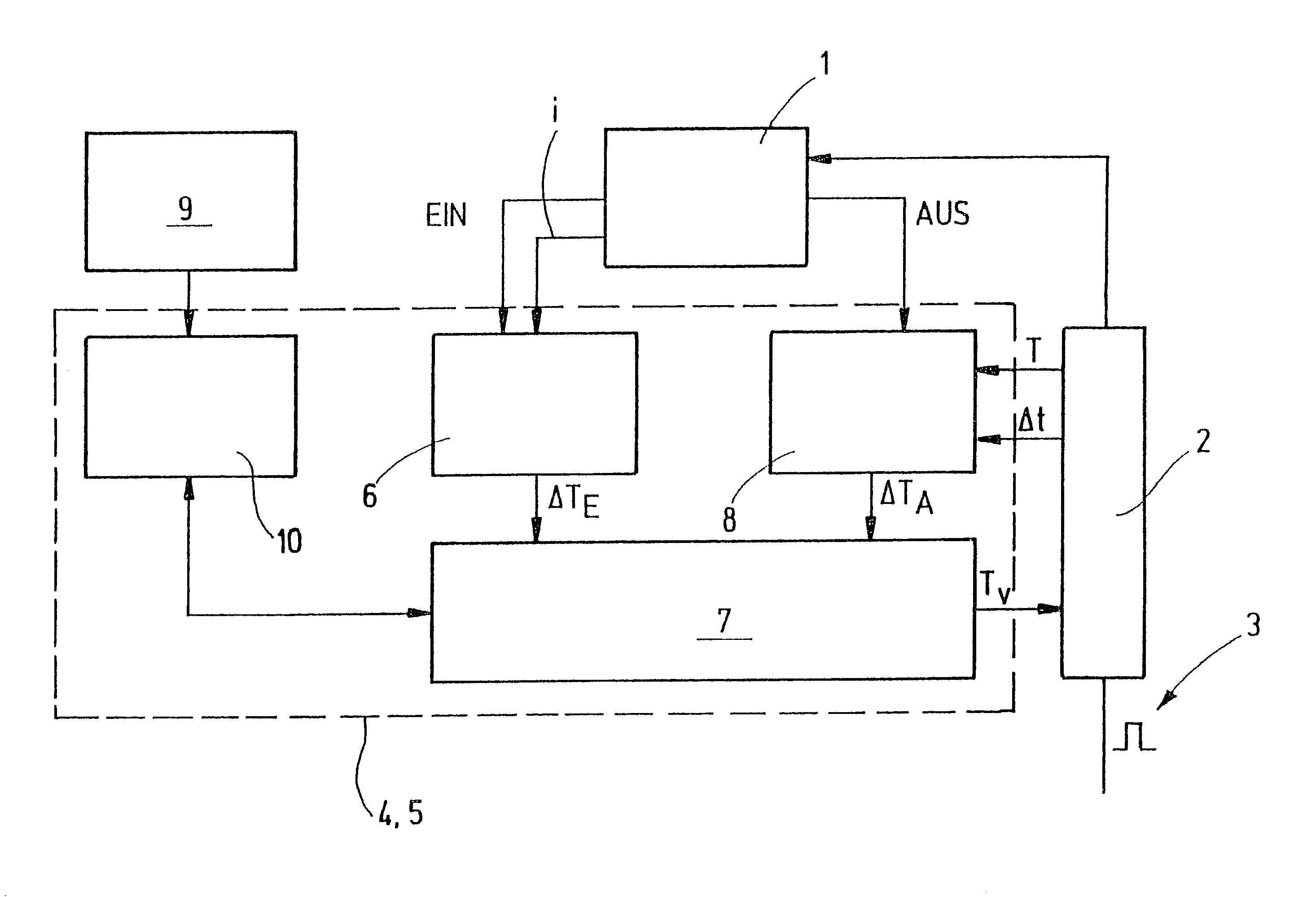

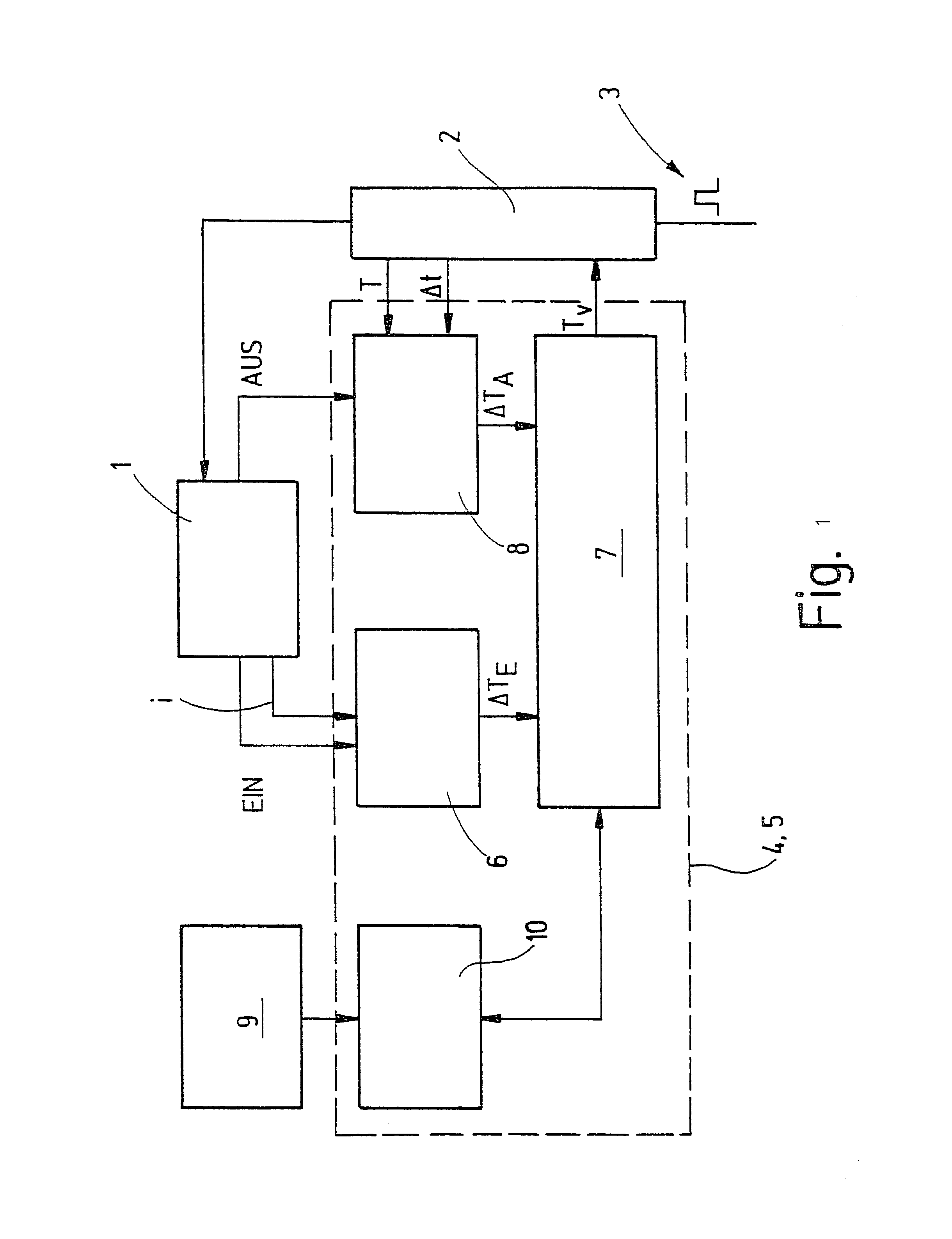

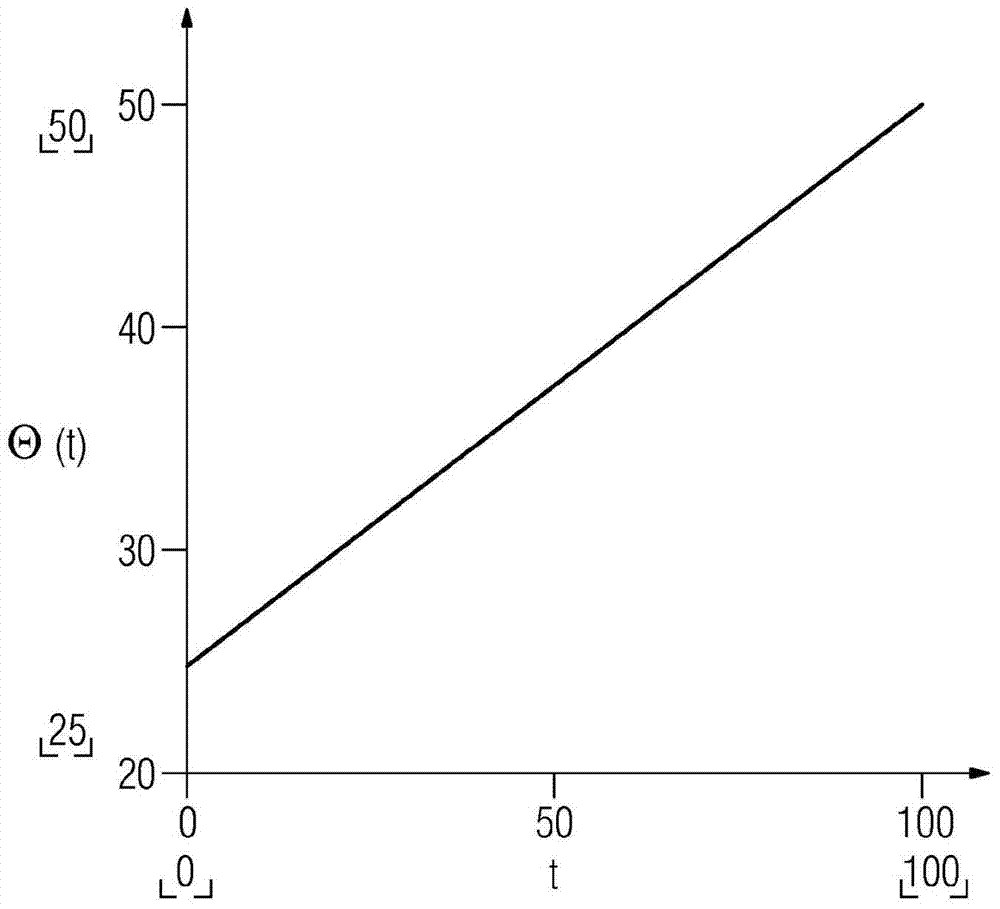

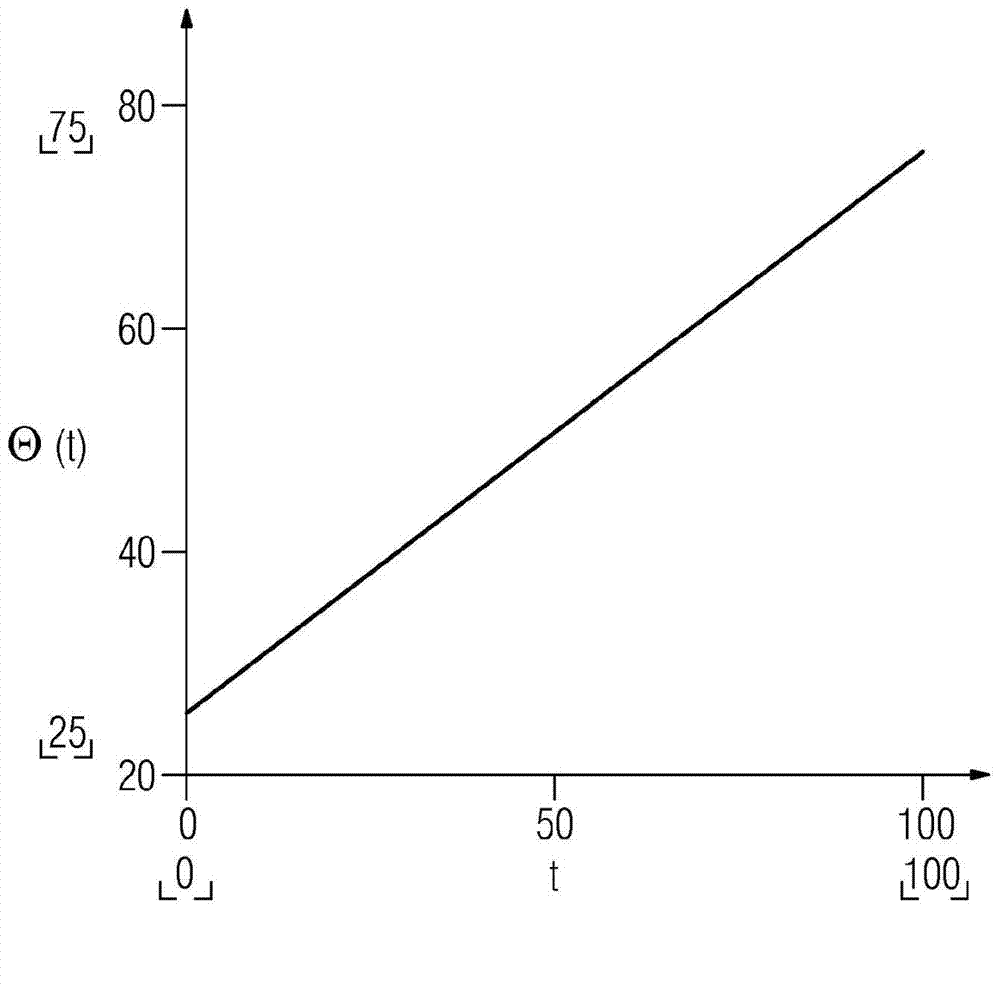

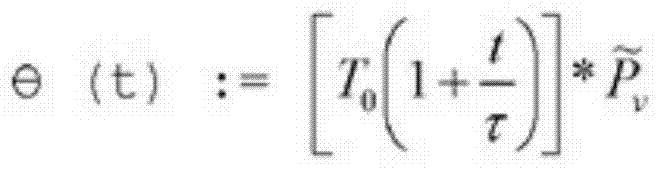

Electric starter device for an internal combustion engine

The invention relates to an electric starter for an internal combustion engine, having a thermal monitoring protector (4) for turning the starter (1) off when its limit operating temperature is reached. The starter is characterized by a device (5) for ascertaining a virtual operating temperature (TV); the device (5) ascertains the virtual operating temperature (TV) as a function of at least one operating parameter that affects the operating temperature of the starter (1).

Owner:ROBERT BOSCH GMBH

Thermal monitoring of a converter

ActiveCN103718406ATesting electric installations on transportEmergency protective arrangements responsive to undesired changesThermal monitoringEngineering

The thermal monitoring of a converter for an electric motor of a vehicle should be improved. Therefore, the invention relates to a method in which the temperature of the converter is measured. In addition, the output power of the converter is determined. The temperature of the converter is estimated by means of a thermal model of the converter having the output power as an input variable. The estimated temperature is compared with the measured temperature, and a corresponding monitoring signal is provided. Thus, a deviation of the measured temperature for the calculated temperature and thus a corresponding error in the cooling system can be detected even in the partial-load range.

Owner:VALEO EAUTOMOTIVE GERMANY GMBH

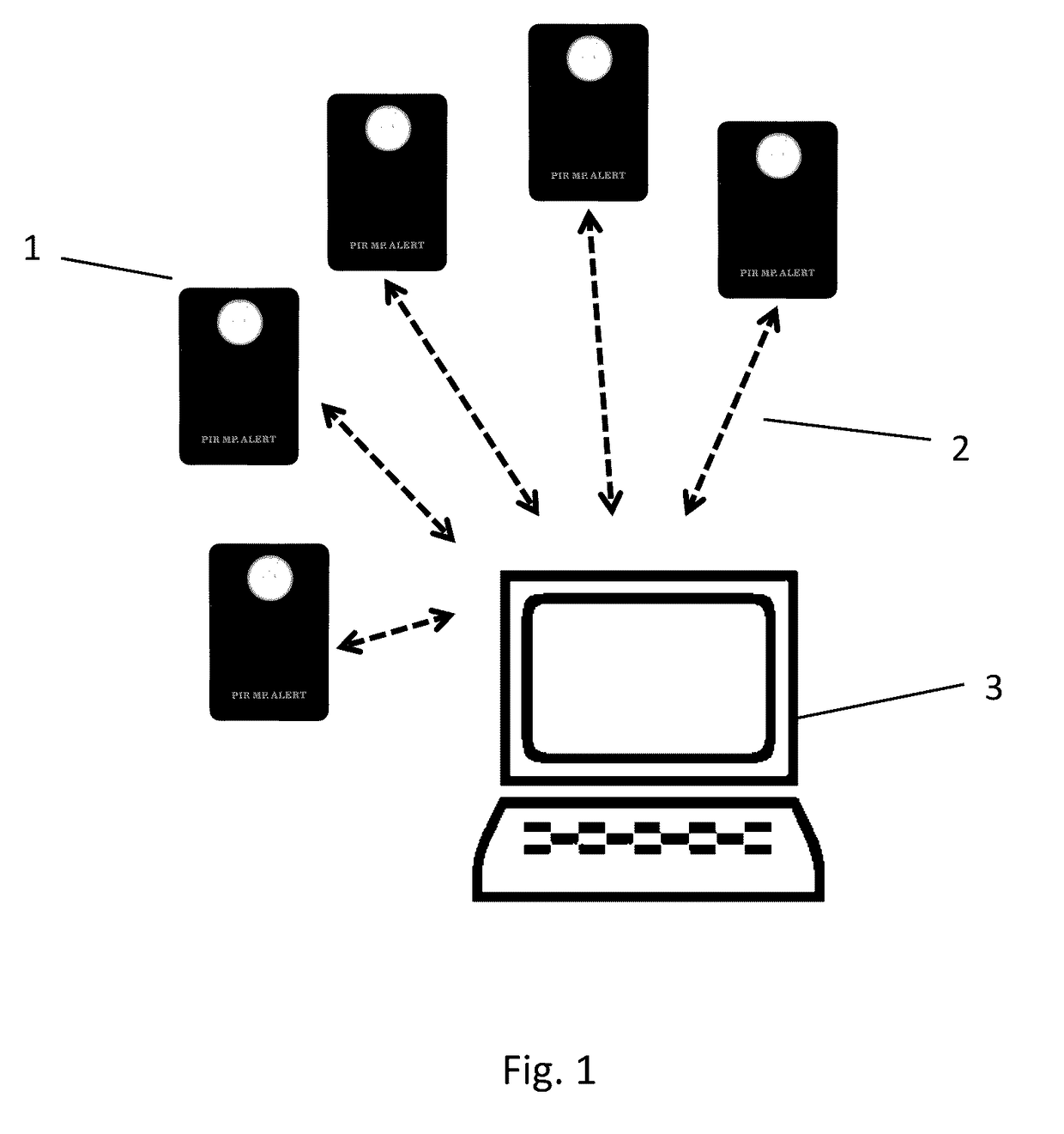

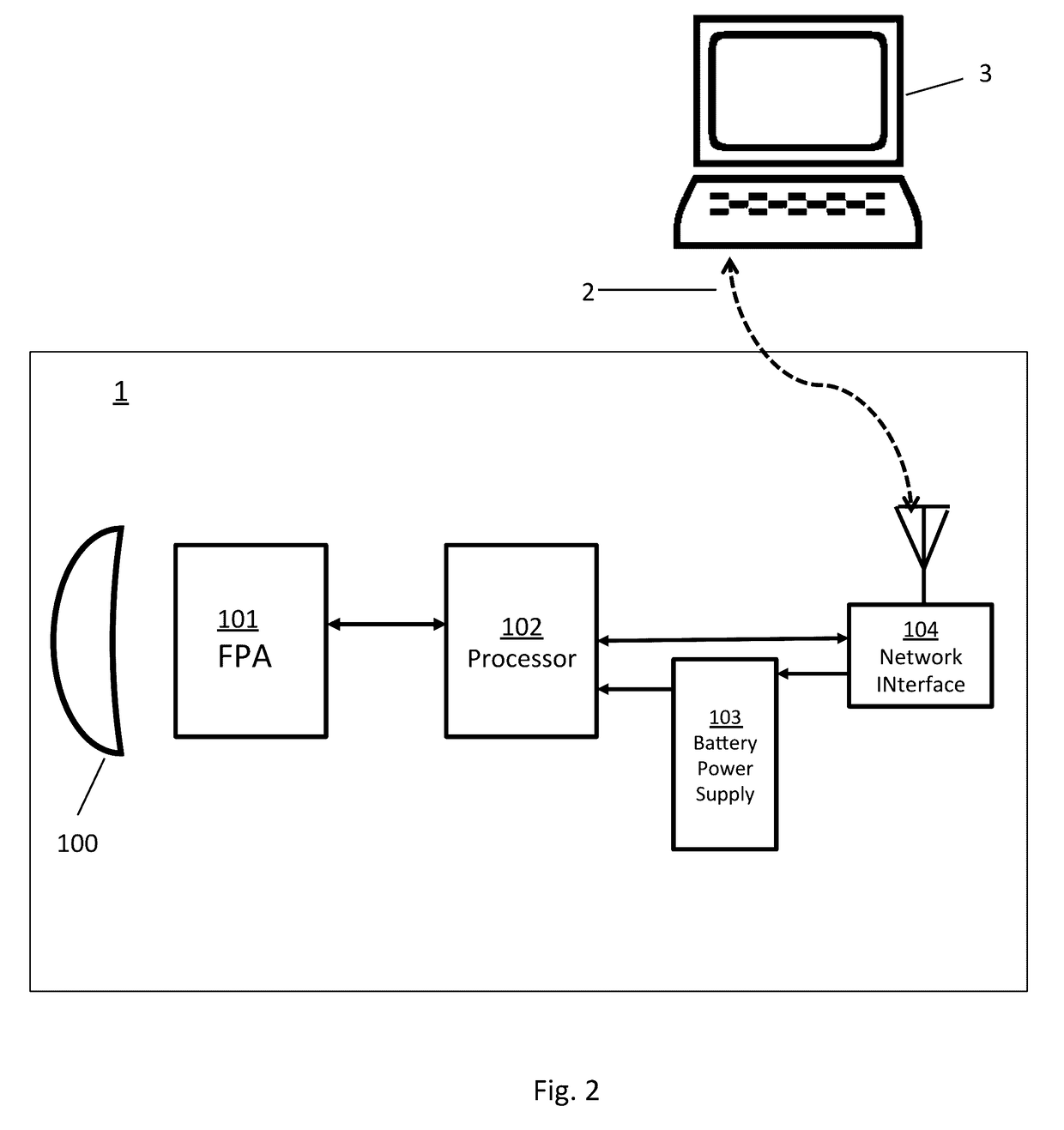

Thermal imaging based monitoring system

InactiveUS20170150069A1Television system detailsCharacter and pattern recognitionThermal monitoringPower mode

Systems and methods for thermal monitoring of a Field of View (FOV), including at least one thermal imaging module. The thermal imaging module includes an Infrared Focal Plane Array (IR FPA) and optics for producing a thermal image of a scene including a portion of the FOV, at least one processor, a battery based power supply controlled by the processor, and a network interface to the processor. Also included is an application executing on the processor, configured to put the module into a low power mode, wherein only minimal timing and network interface functions are operable, for at least one of predetermined intervals or in response to a network wake-up command, power up module and acquire thermal image data of the scene, segment the image of the scene into two or more regions, perform thermographic analysis to determine the temperature of each region, return to low power mode and repeat, and at least one system controller in communication with the modules over the network.

Owner:SEEK THERMAL

In-cabinet thermal monitoring method and system

InactiveUS7989769B2Avoid disadvantagesExtremely cost-effectiveTelevision system detailsSwitchgear arrangementsThermal monitoringEngineering

Thermographic imaging equipment is incorporated directly into cabinets housing electrical switchgear to provide for dedicated, nearly continuous monitoring of the contained equipment. A mechanical scanning technique may allow low-cost sensors to provide essentially continuous thermographic monitoring. Dedicated thermal imaging equipment allows automatic analysis through predefined temperature threshold maps.

Owner:ROCKWELL AUTOMATION TECH

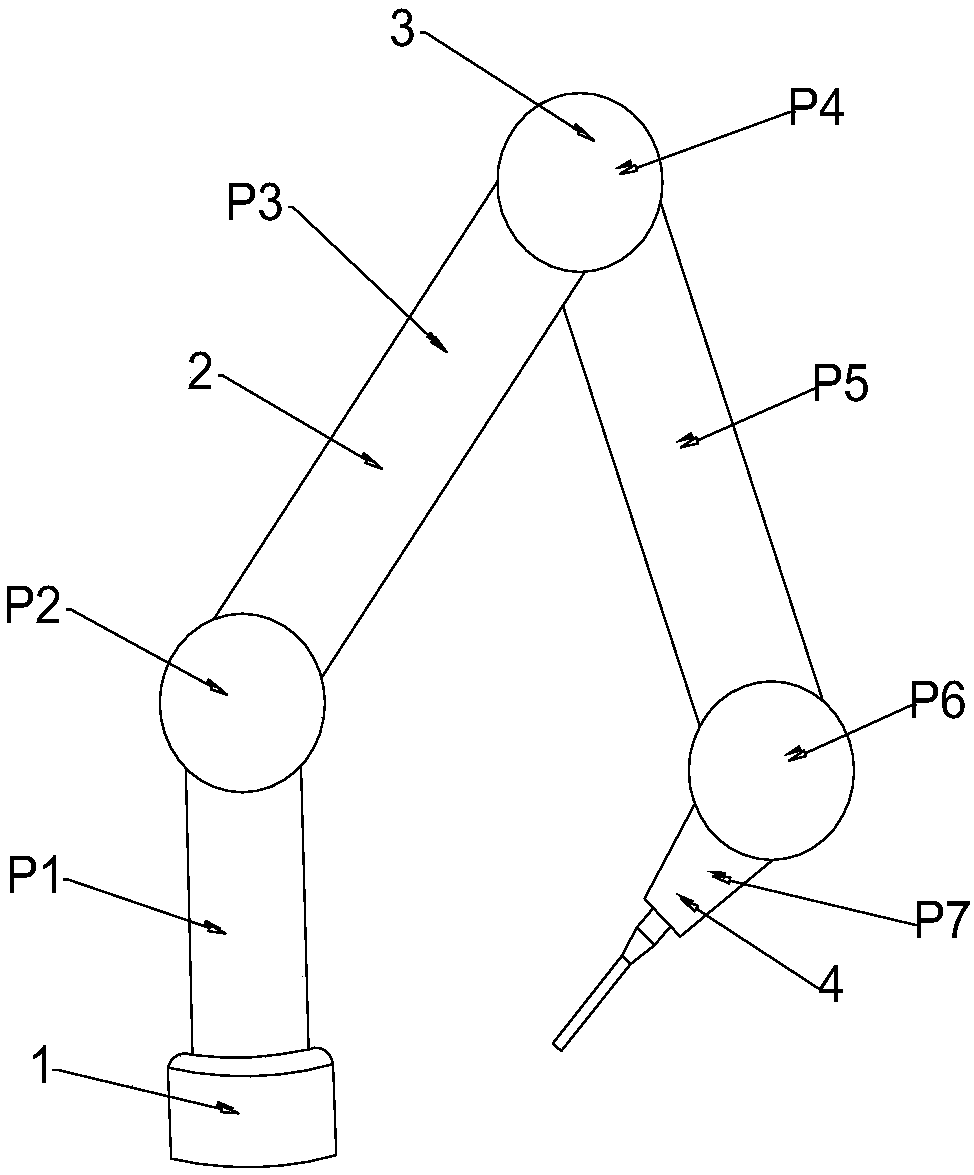

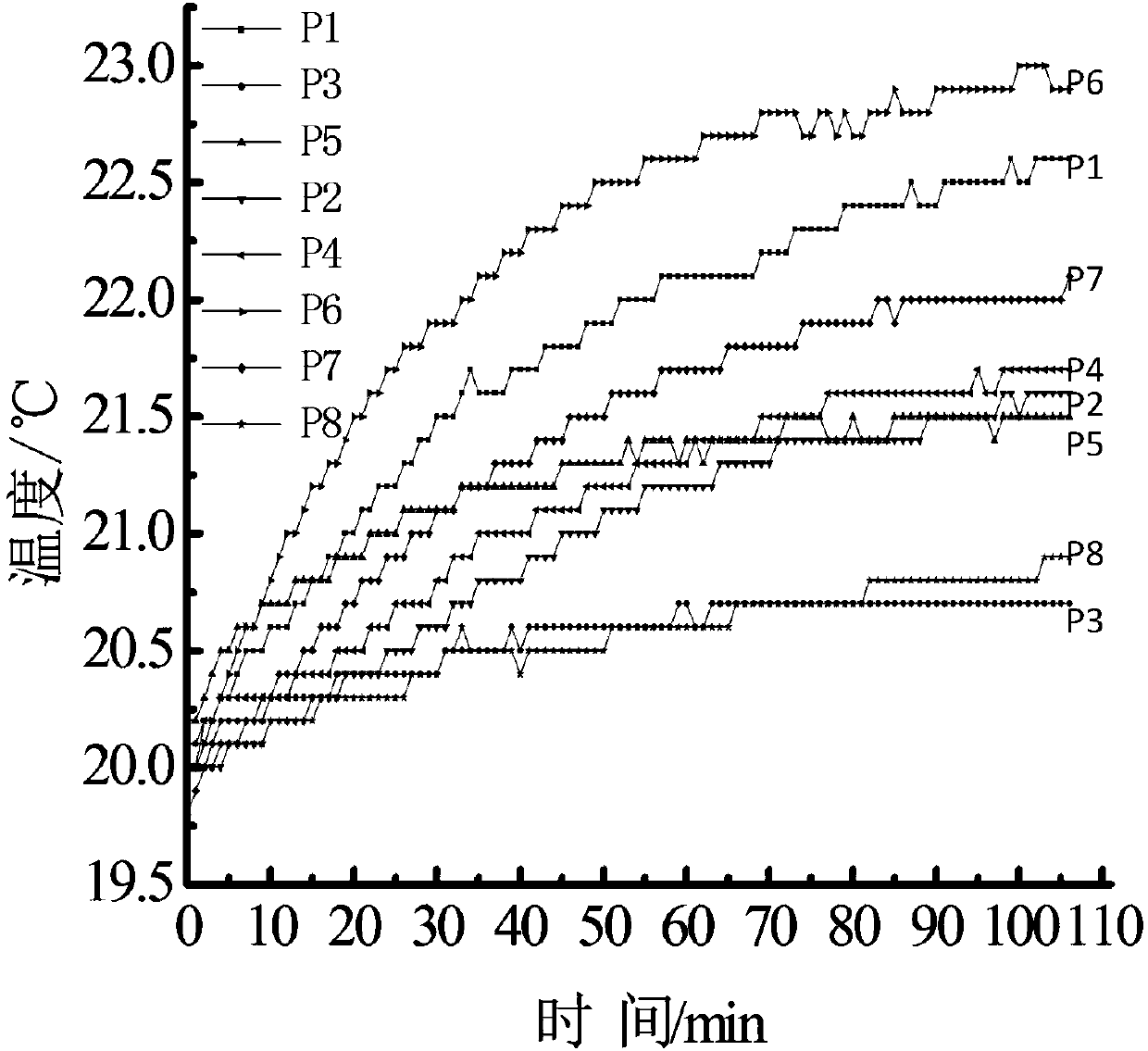

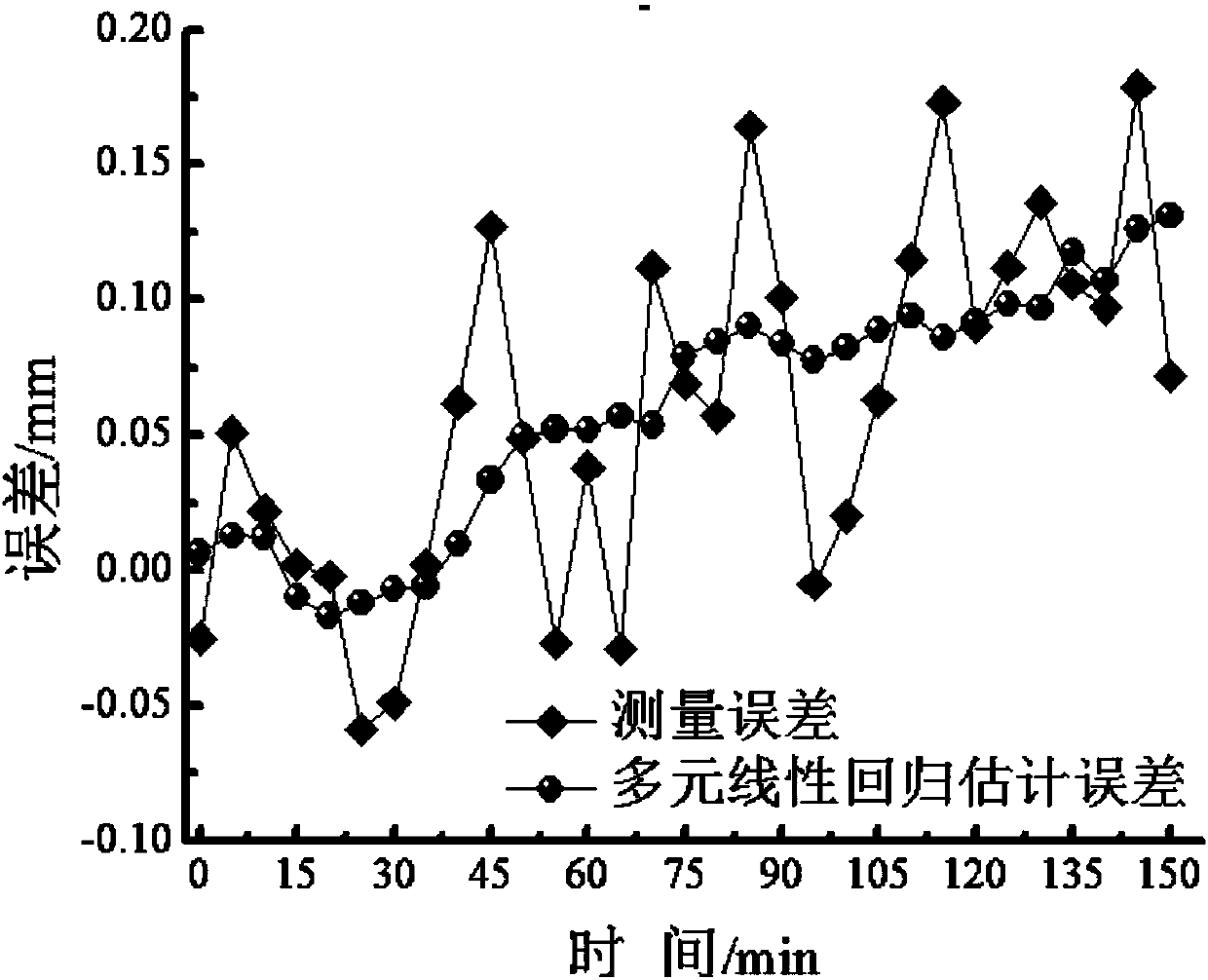

Thermal deformation recognition and correction method for coordinate measurement machine of articulated arm type

InactiveCN107607070AHigh measurement accuracyRealization of thermal deformation error compensationMeasurement devicesThermal monitoringObservational error

The invention discloses a thermal deformation recognition and correction method for a coordinate measurement machine of an articulated arm type, and the method comprises the steps: setting thermal monitoring points on a substrate of an articulated arm, a measurement arm, a joint and a measurement head, and recording to the temperature rise-time changing curve of each monitoring point; operating the coordinate measurement machine to measure a standard gauge block, wherein each thermal monitoring point is equivalent to a temperature rise value of lab temperature; measuring errors, and building an experiment error compensation model of the temperature rise values of seven thermal monitoring points of the articulated arm and a thermal deformation error value according to an MLR (Multiple Linear Regression) algorithm; determining a to-be-determined parameter through the least square method, and carrying out the compensation for a measurement result of the coordinate measurement machine of the articulated arm type. The method can obtain the mapping relation of a length measurement error of the coordinate measurement machine of the articulated arm type with the temperature rise changes between the corresponding temperature monitoring points. A machine body thermal deformation error compensation model based on the MLF (Multiple Linear Fitting) is constructed based on the mapping relation, thereby achieving the compensation for the thermal deformation error, and improving the measurement error of the articulated arm.

Owner:CHINA JILIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com