Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

367 results about "Stock-taking" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Stock-taking or "inventory checking" or "wall-to-wall" is the physical verification of the quantities and condition of items held in an inventory or warehouse. This may be done to provide an audit of existing stock. It is also the source of stock discrepancy information.

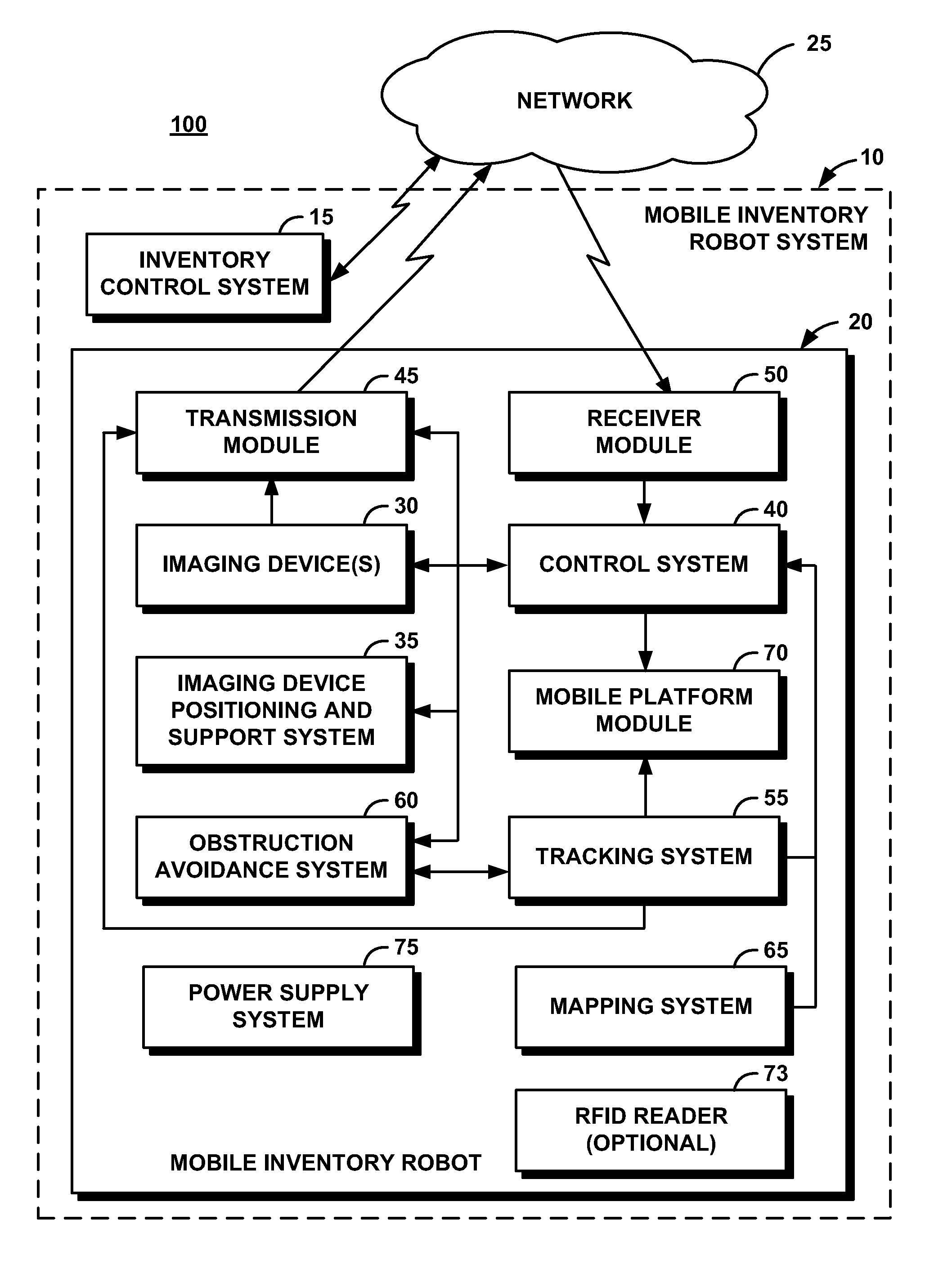

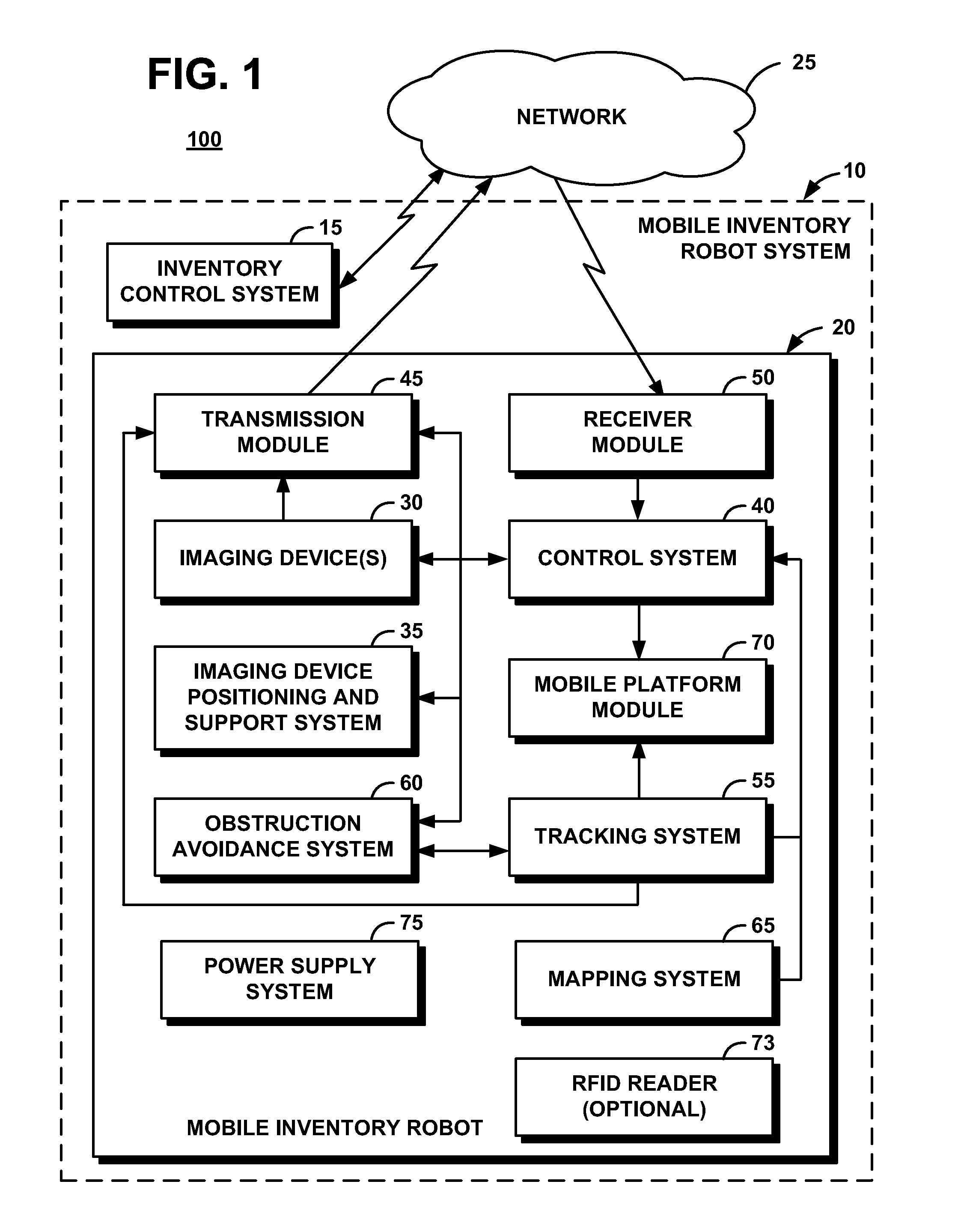

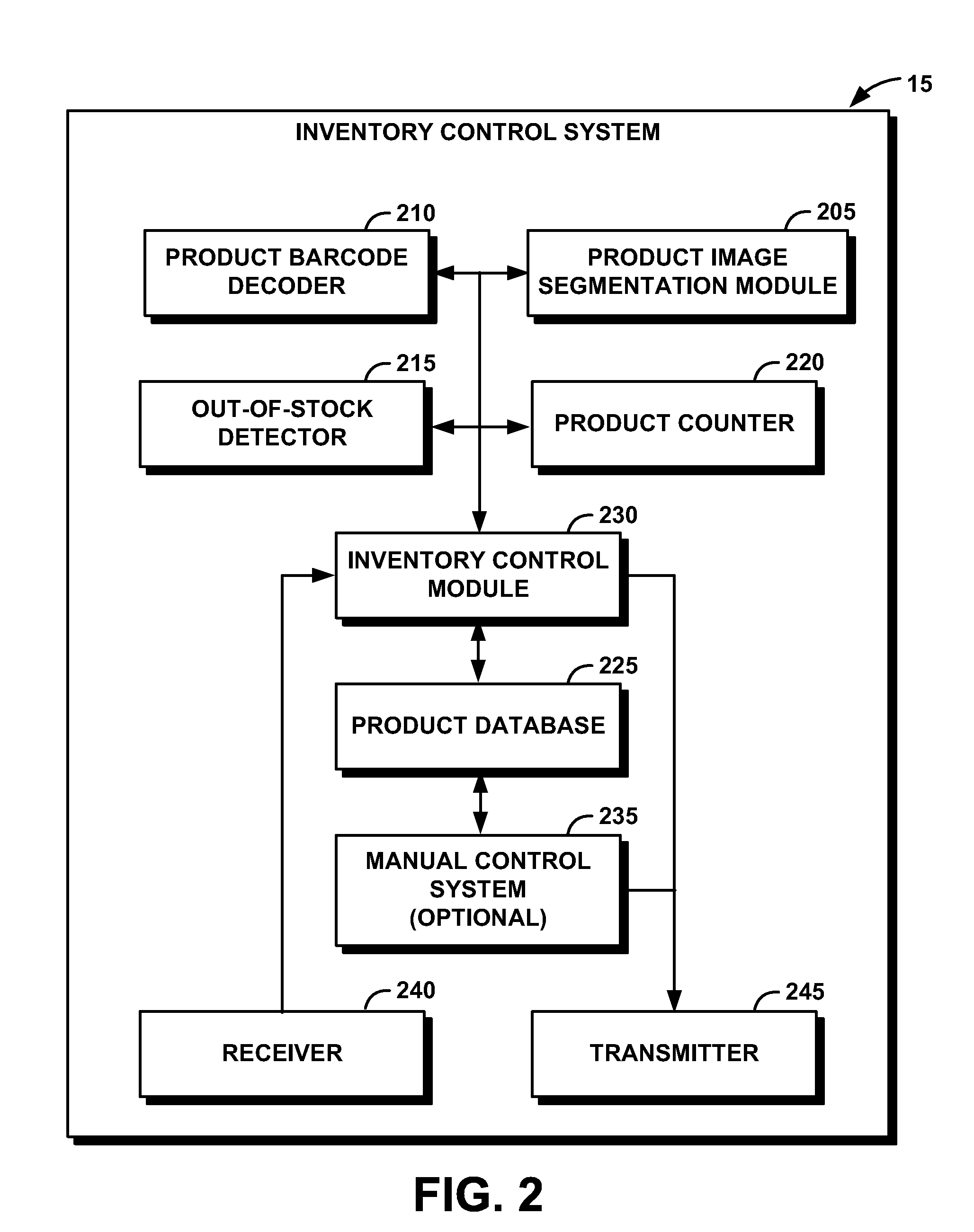

System and Method for Performing Inventory Using a Mobile Inventory Robot

InactiveUS20080077511A1Still image data retrievalVehicle position/course/altitude controlRobotic systemsBarcode

A mobile inventory robot system generates an inventory map of a store and a product database when a mobile inventory robot is manually navigated through the store to identify items on shelves, a location for each of the items on the shelves, and a barcode for each of the items. The system performs inventory of the items by navigating through the store via the inventory map, capturing a shelf image, decoding a product barcode from the captured shelf image, retrieving a product image for the decoded product barcode from the product database, segmenting the captured shelf image to detect an image of an item on the shelves, determining whether the detected image matches the retrieved image and, if not, setting an out-of-stock flag for an the item.

Owner:IBM CORP

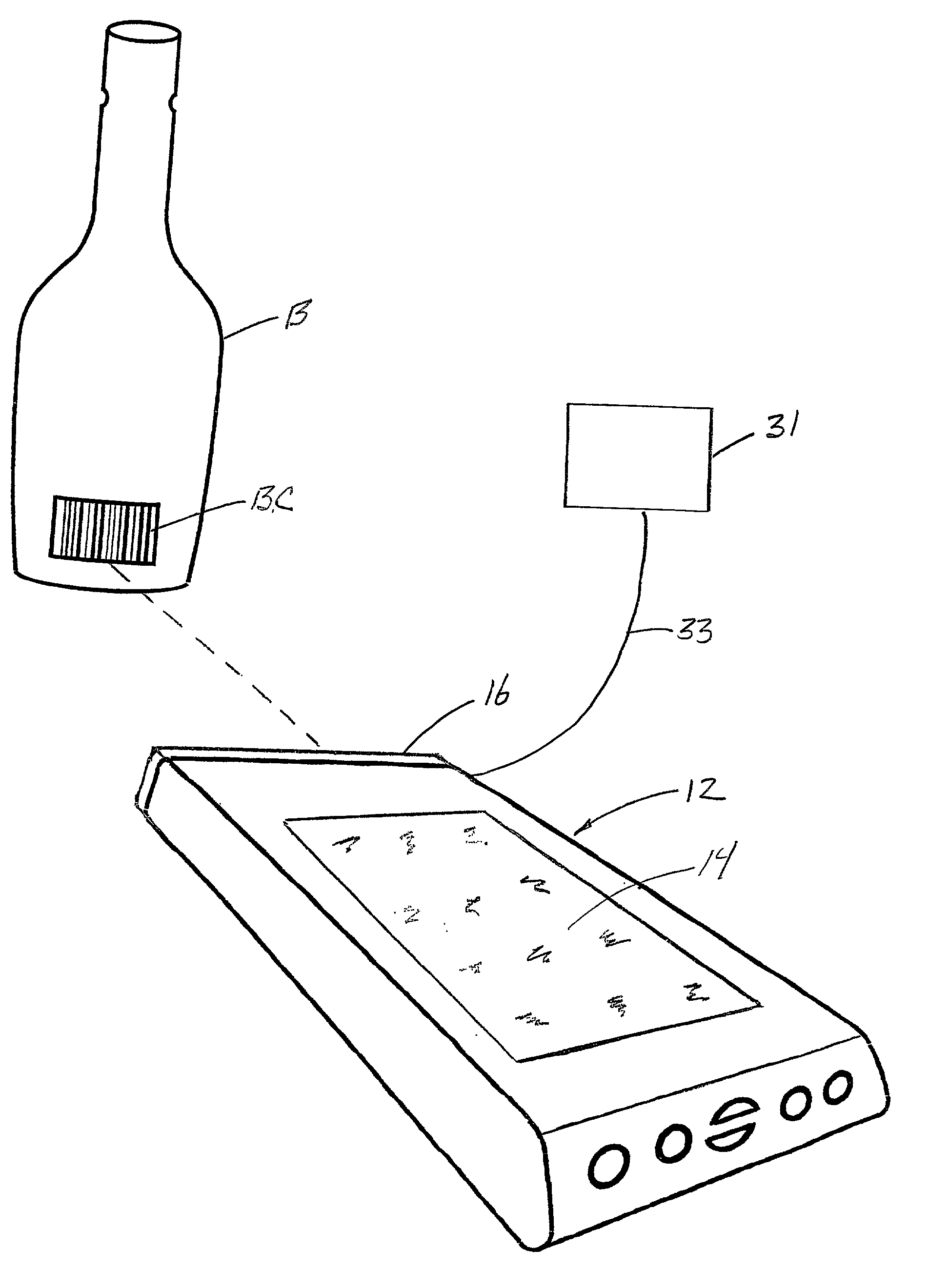

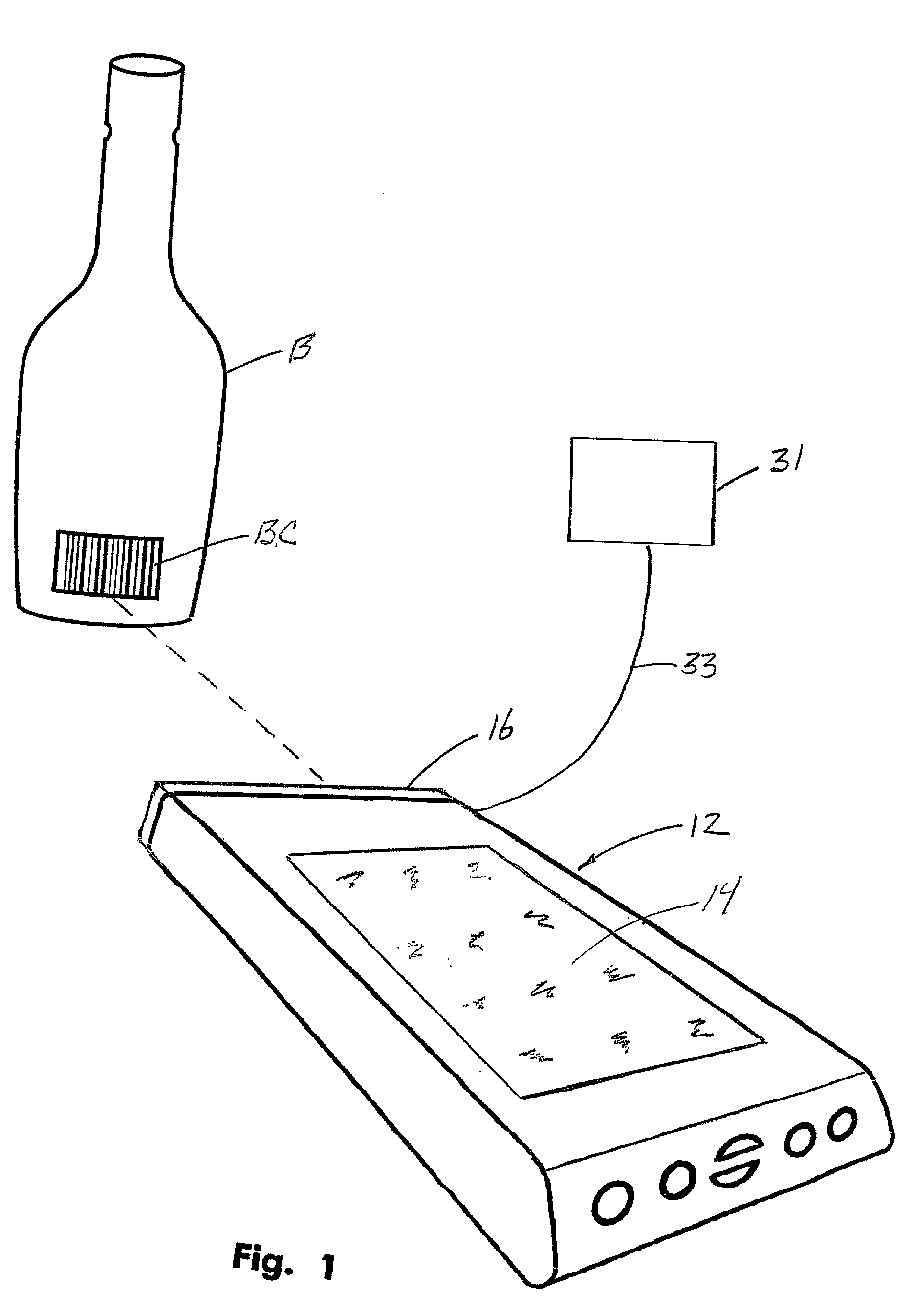

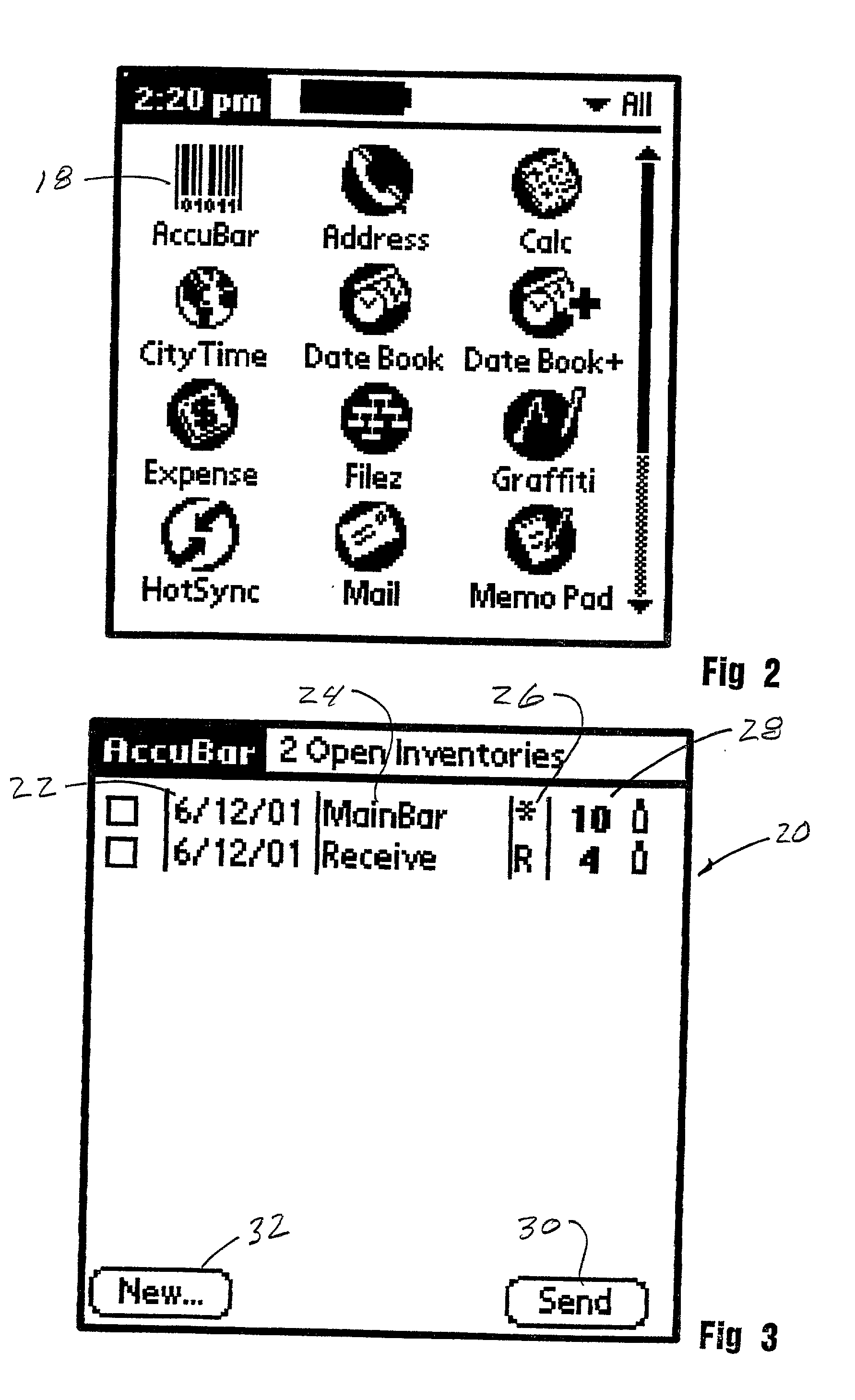

Inventory system

InactiveUS20030034392A1Accurately determinedDigital data processing detailsCo-operative working arrangementsData memoryTouchscreen

A computer-based system for taking the physical inventory of beverages dispensed in full and partially full containers so as to effectively control the theft and overpouring. The products to be inventoried, such as liquor bottles are identified by conventional barcodes that can be scanned by a scanner that is operably interconnected with a hand-held computer. The step of scanning the barcodes produces, on the touch-sensitive screen of the hand-held computer, product information concerning the product contained within the scanned bottle including a silhouette of the bottle. In accomplishing the inventory, the user indicates by touching on the silhouette of the bottle the fluid level within the bottle. This information is inputted in the computer data storage and is used to calculate the volume of beverage remaining in the bottle.

Owner:BIRCH STREET SYST LLC

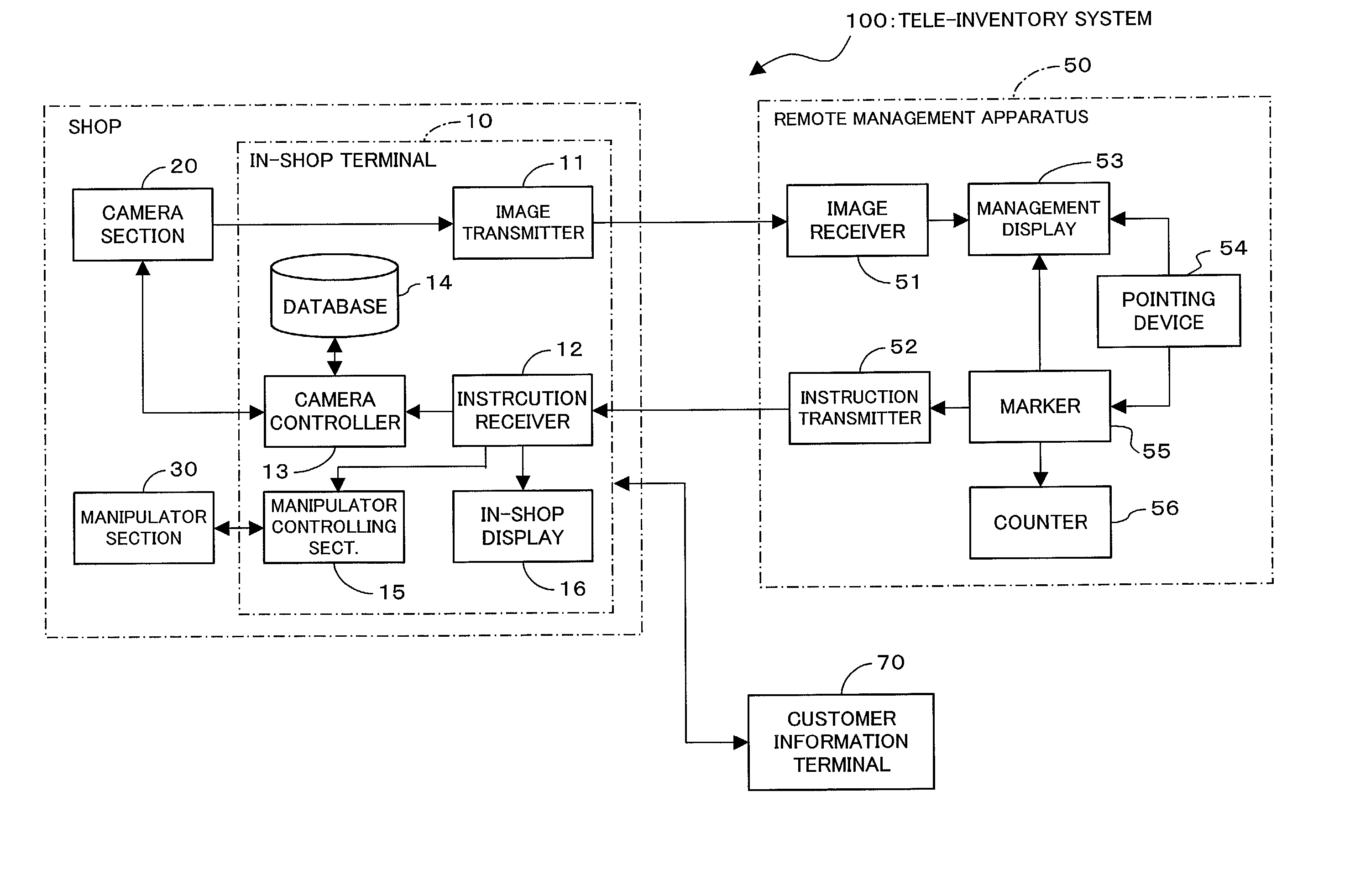

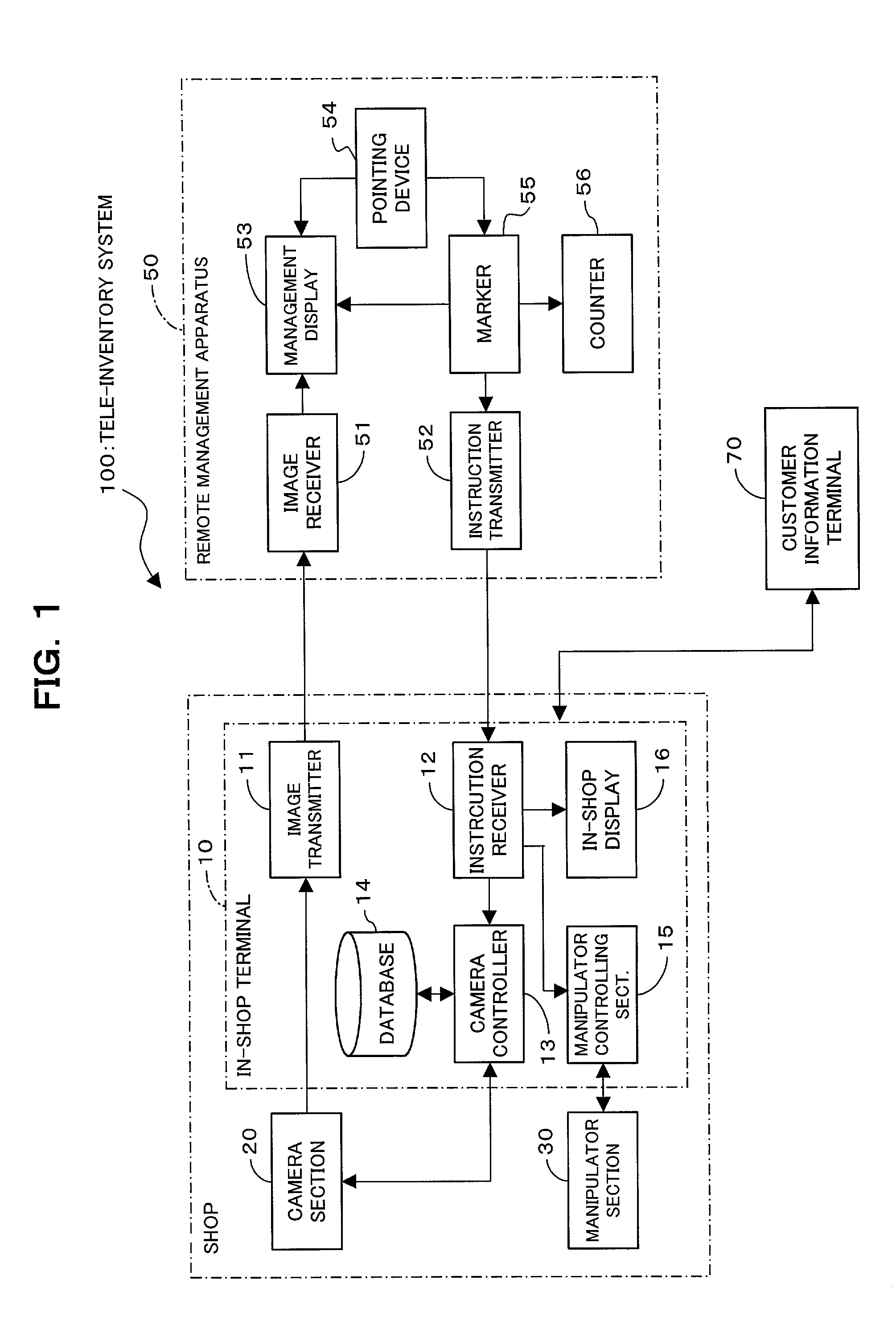

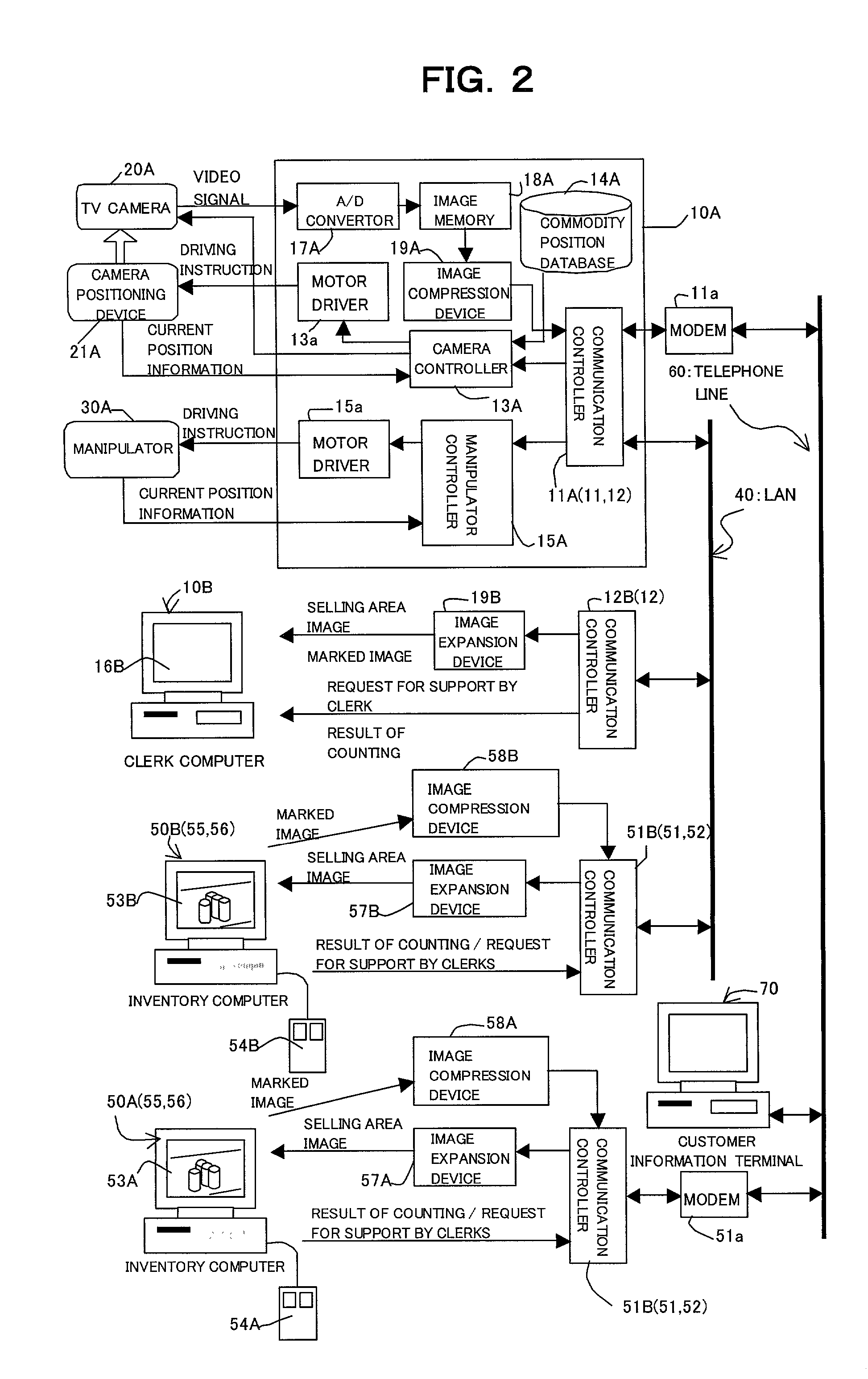

Tele-inventory system, and in-shop terminal and remote management apparatus for the system

InactiveUS20020143672A1Animal feeding devicesCharacter and pattern recognitionDisplay deviceComputer terminal

A tele-inventory system for inventorying various kinds of commodities in a shop by an operator from a remote management apparatus installed remotely from the shop, includes, at shop, a camera for taking images of object commodities to be inventoried, a image-transmitter for transmitting the taken images of the object commodities to the remote management apparatus, and, at the remote management apparatus, an image-receiver for receiving the taken images of the object commodities from the image-transmitter and display for displaying the taken images of the object commodities, whereby the operator can make an inventory of the object commodities at the remote management apparatus with consulting the taken images of the object commodities which images have been displayed on the display. With this system, it is possible to inventory commodities sold and stocked in a department store or a convenience store from a remote place.

Owner:FUJITSU LTD

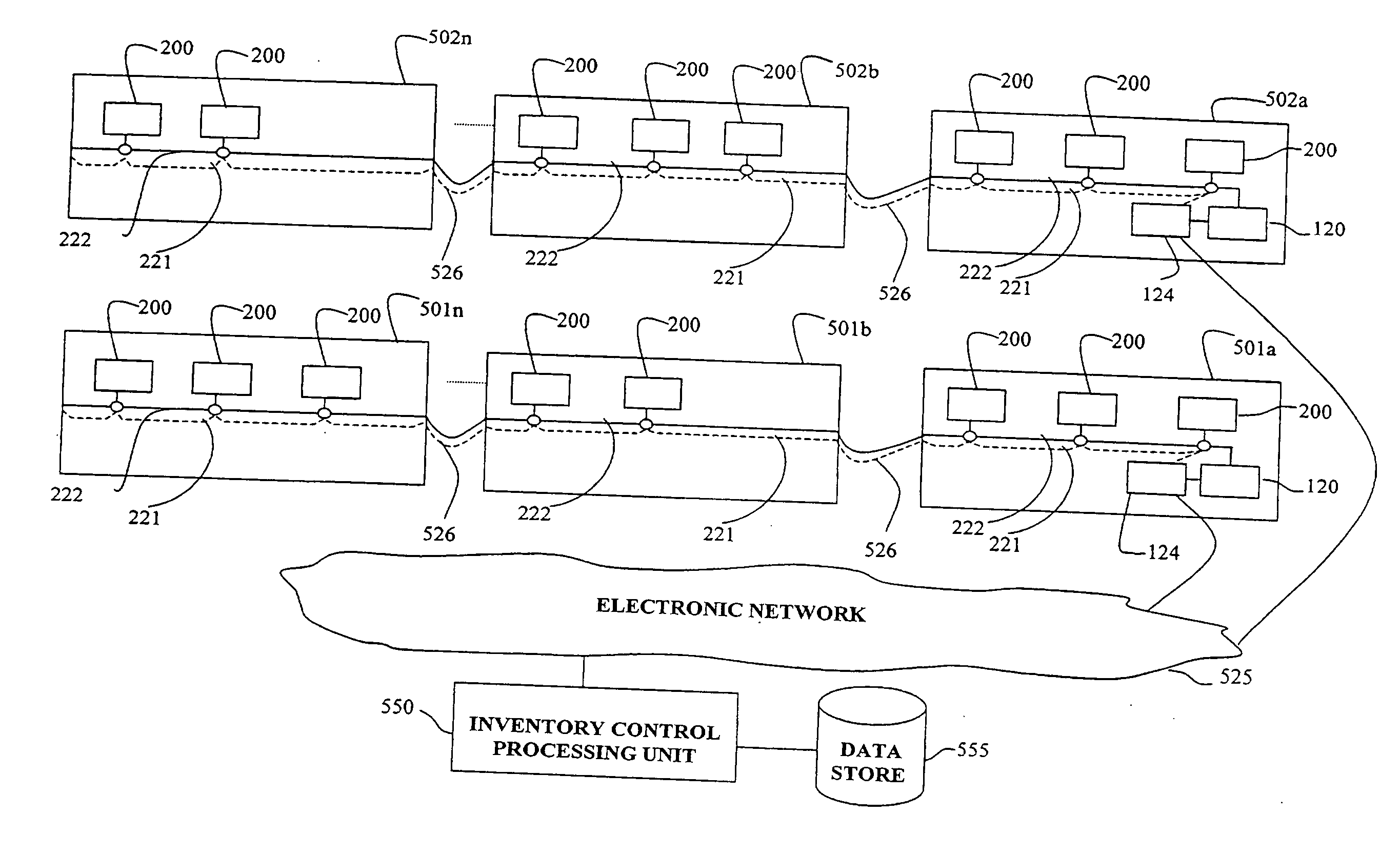

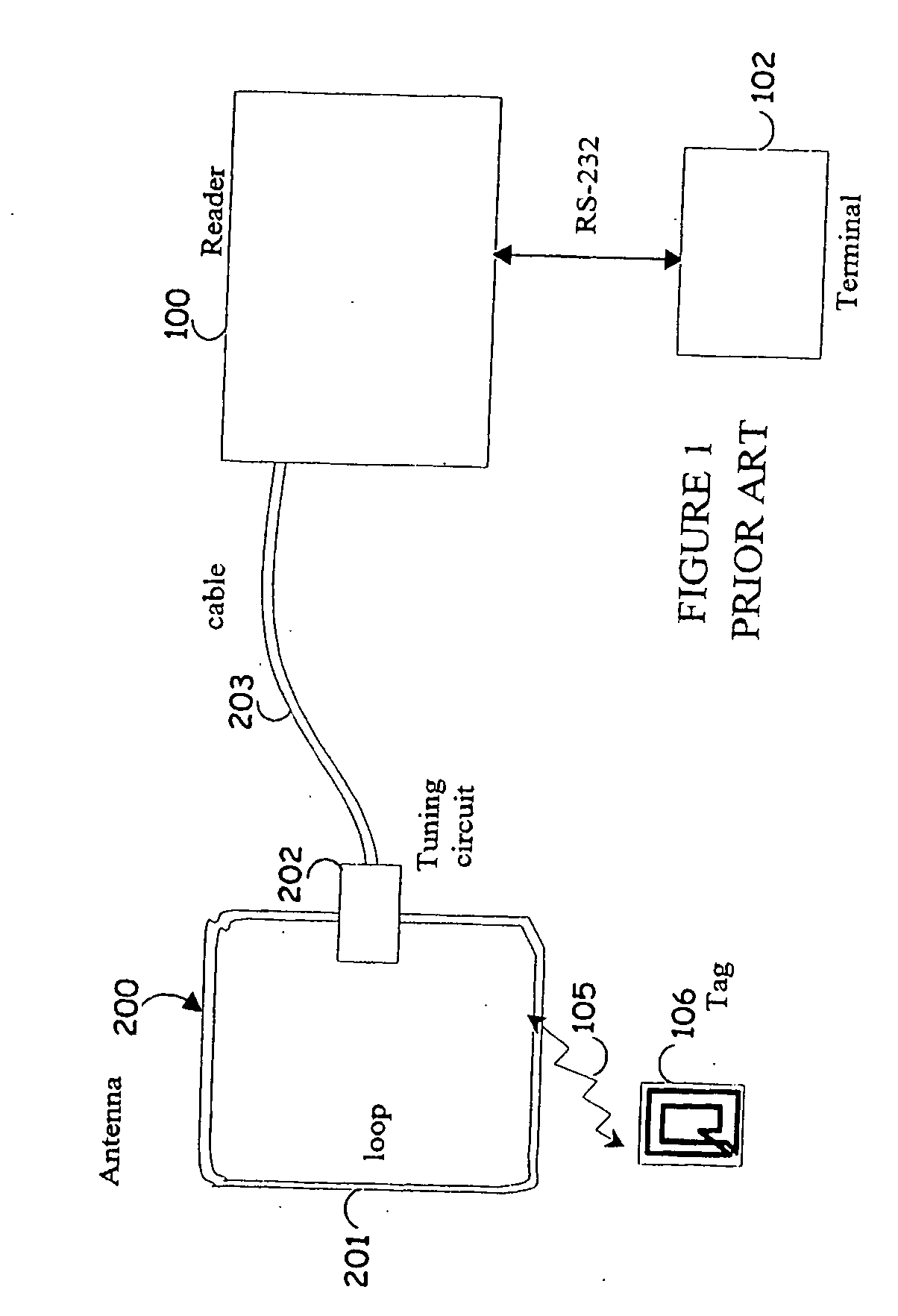

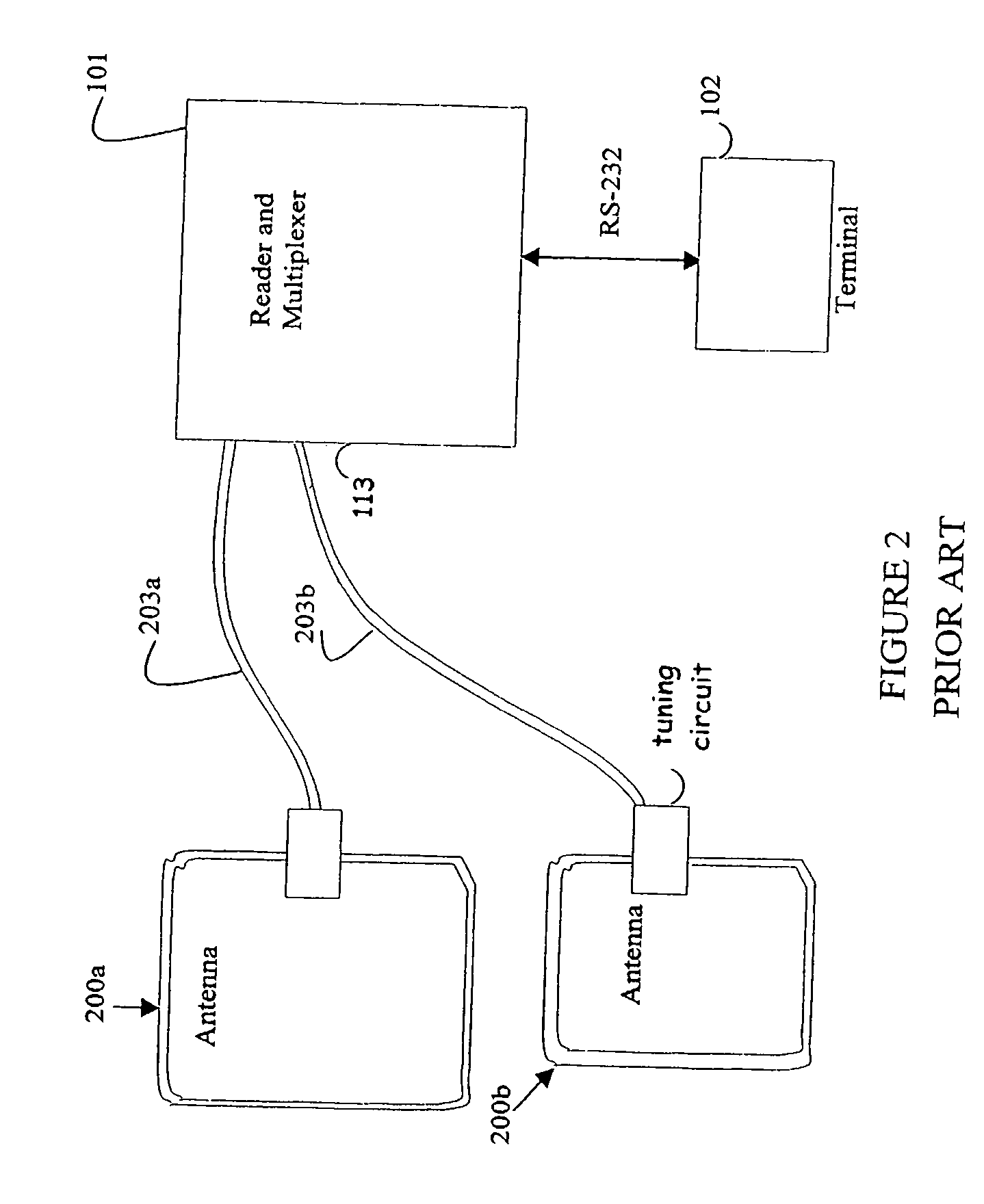

Intelligent station using multiple RF antennae and inventory control system and method incorporating same

InactiveUS20060232382A1Boost RF signal strengthAntenna supports/mountingsCash registersControl systemEngineering

An inventory control system and method that tracks inventories of items with RFID tags, includes a reader unit and an intelligent station that tracks RFID tags to determine item information of items to be inventoried. The reader unit transmits and receives RF signals. The intelligent station includes a first RF antenna connected to the reader unit by a first transmission cable through a first switch, and one or more additional RF antennae connected to the reader unit by the same first transmission cable through additional switches. An inventory control processing unit receives item information from the intelligent stations to update inventory information regarding the items to be inventoried.

Owner:SENSORMATIC ELECTRONICS CORP

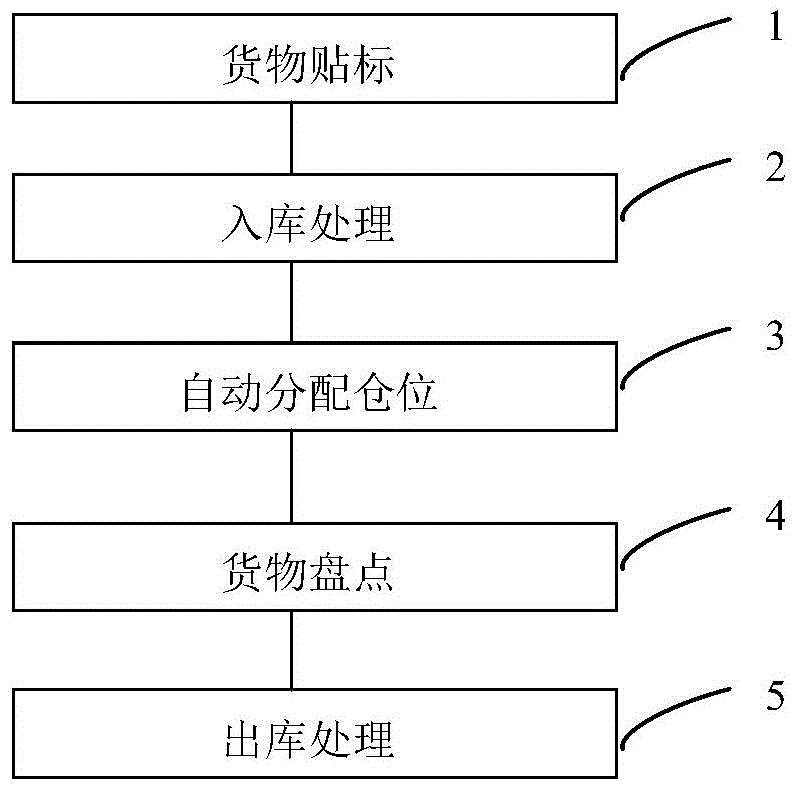

Method for intelligent storage based on internet-of things

InactiveCN105046468AImprove throughputImprove processing efficiencyCo-operative working arrangementsLogisticsInformation processingLogistics management

The invention relates to a method for intelligent storage based on the internet-of things The method includes labeling and registering goods, warehousing, automatically assigning warehouse locations, taking stock and processing ex-warehouse. RFID is used for automatically identifies goods information, which is transmitted to a background information server through a wireless network, and goods information can be inquired and maintained through the background information server to manage goods warehousing, ex-warehouse processing and stock-taking. The warehouse throughput is substantially increased, and the logistics information processing efficiency and accuracy for warehousing and ex-warehouse processing are improved.

Owner:SUZHOU HUATUO INFORMATION TECH

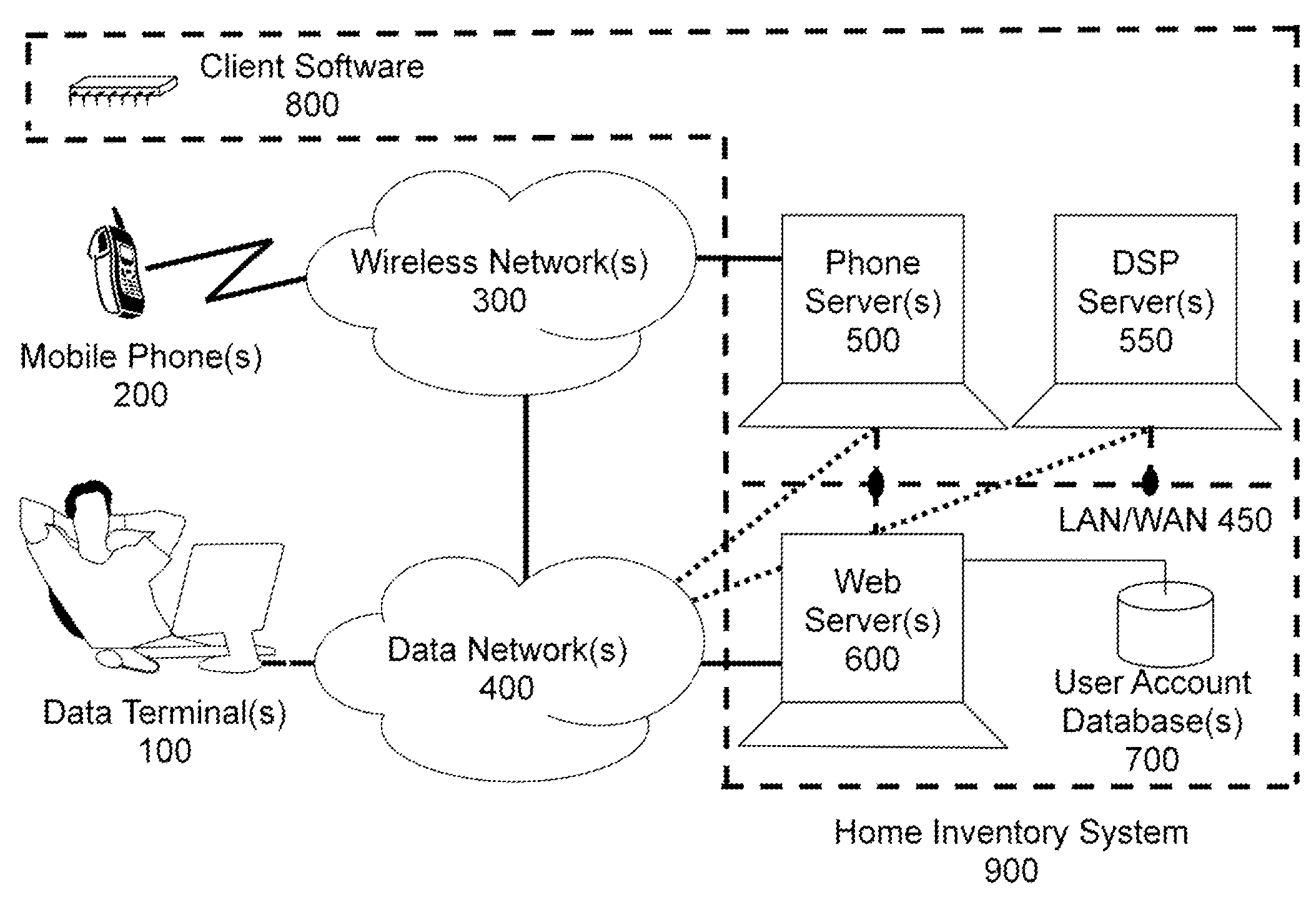

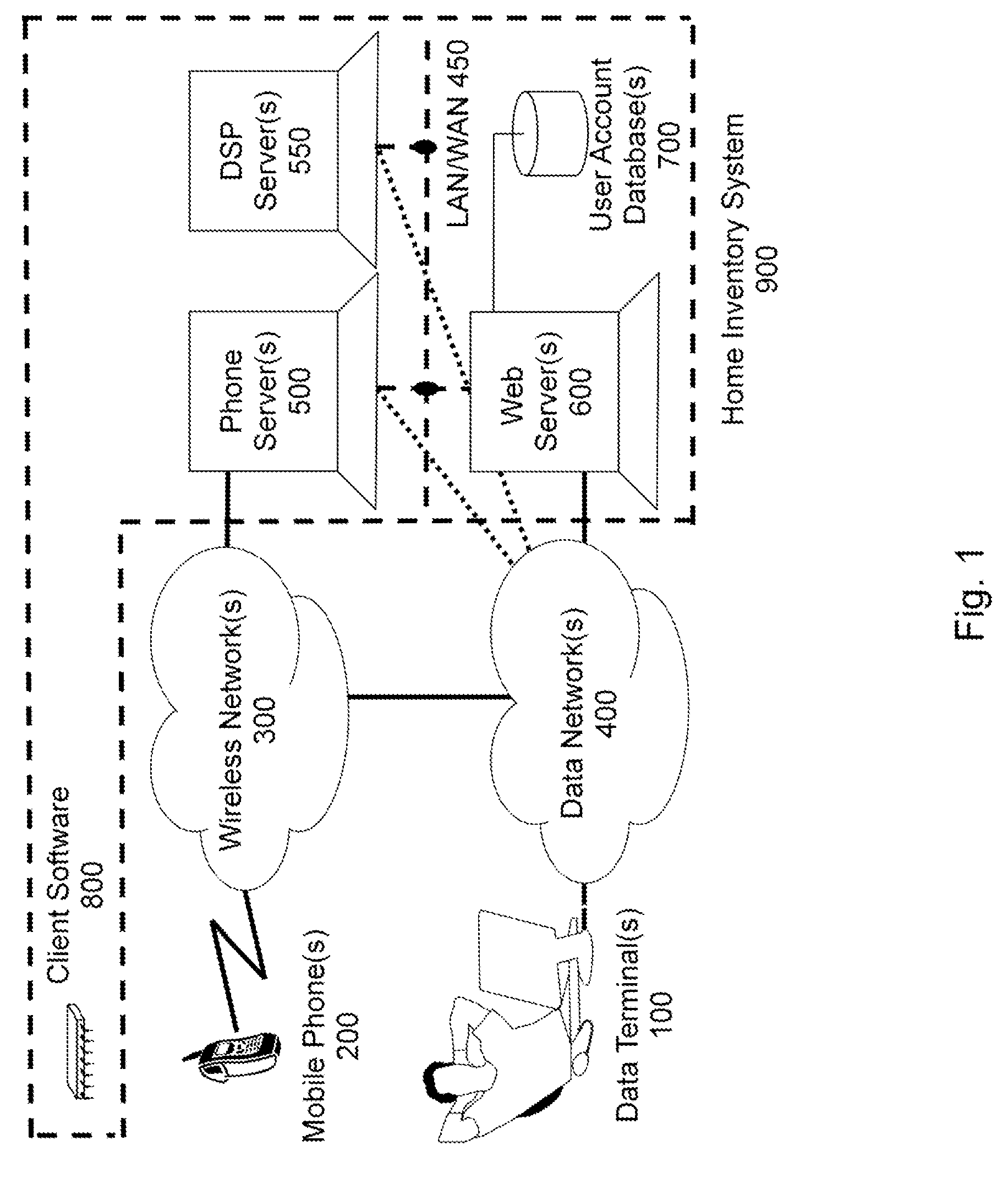

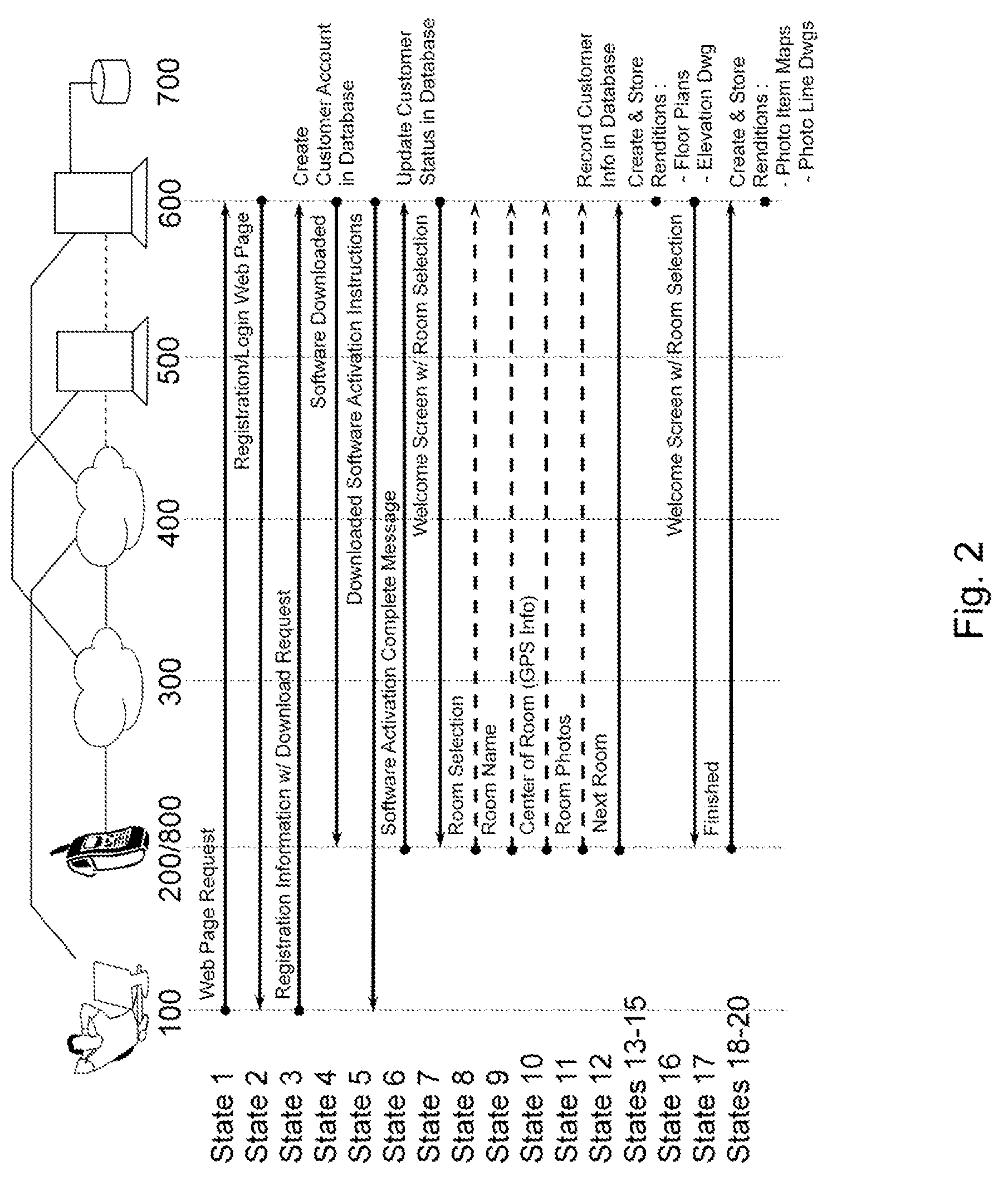

Methods and systems for inventory management

InactiveUS7899823B1Enhance identification processEasy to separateDigital data processing detailsSpecial data processing applicationsData terminalDigital imaging

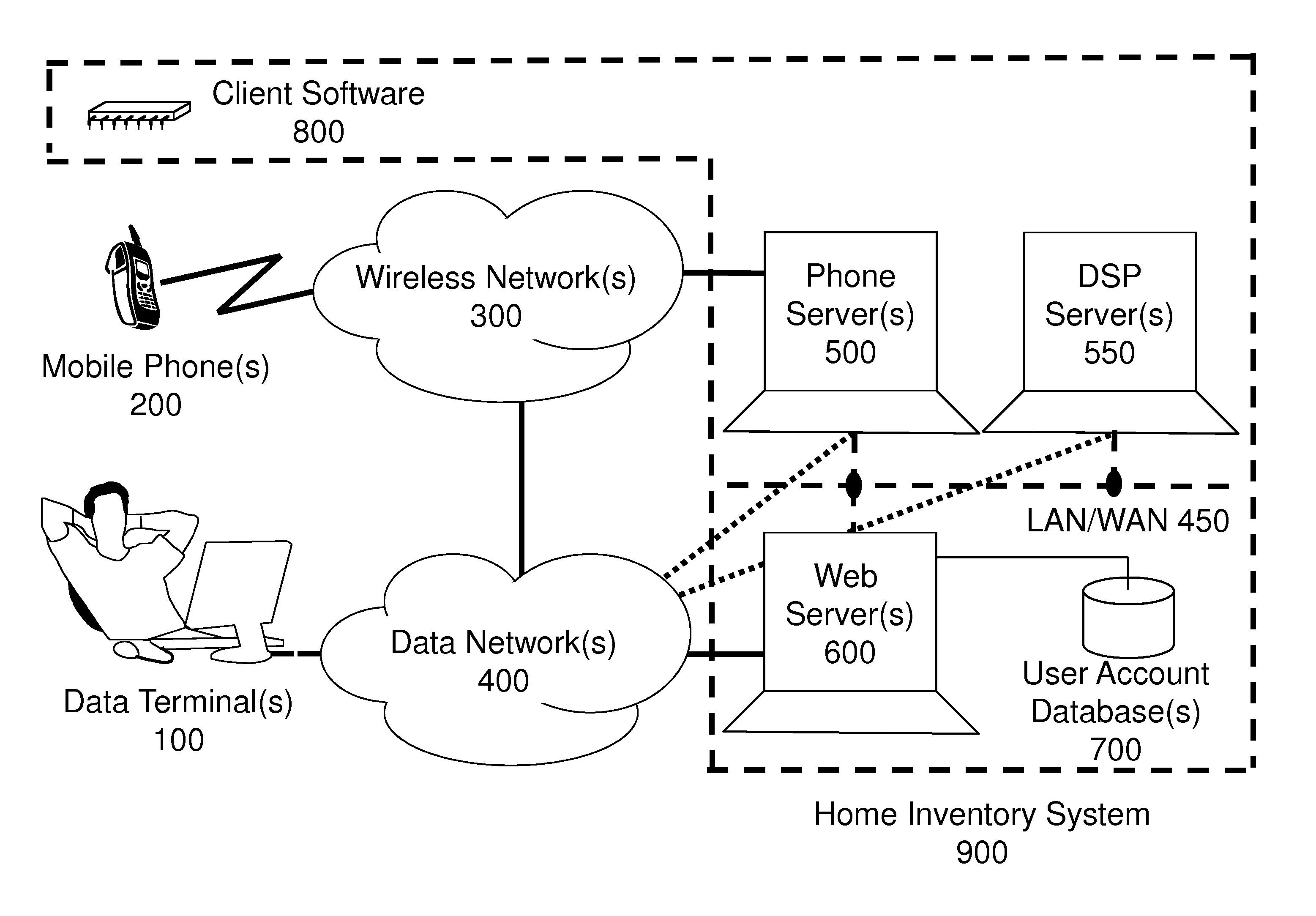

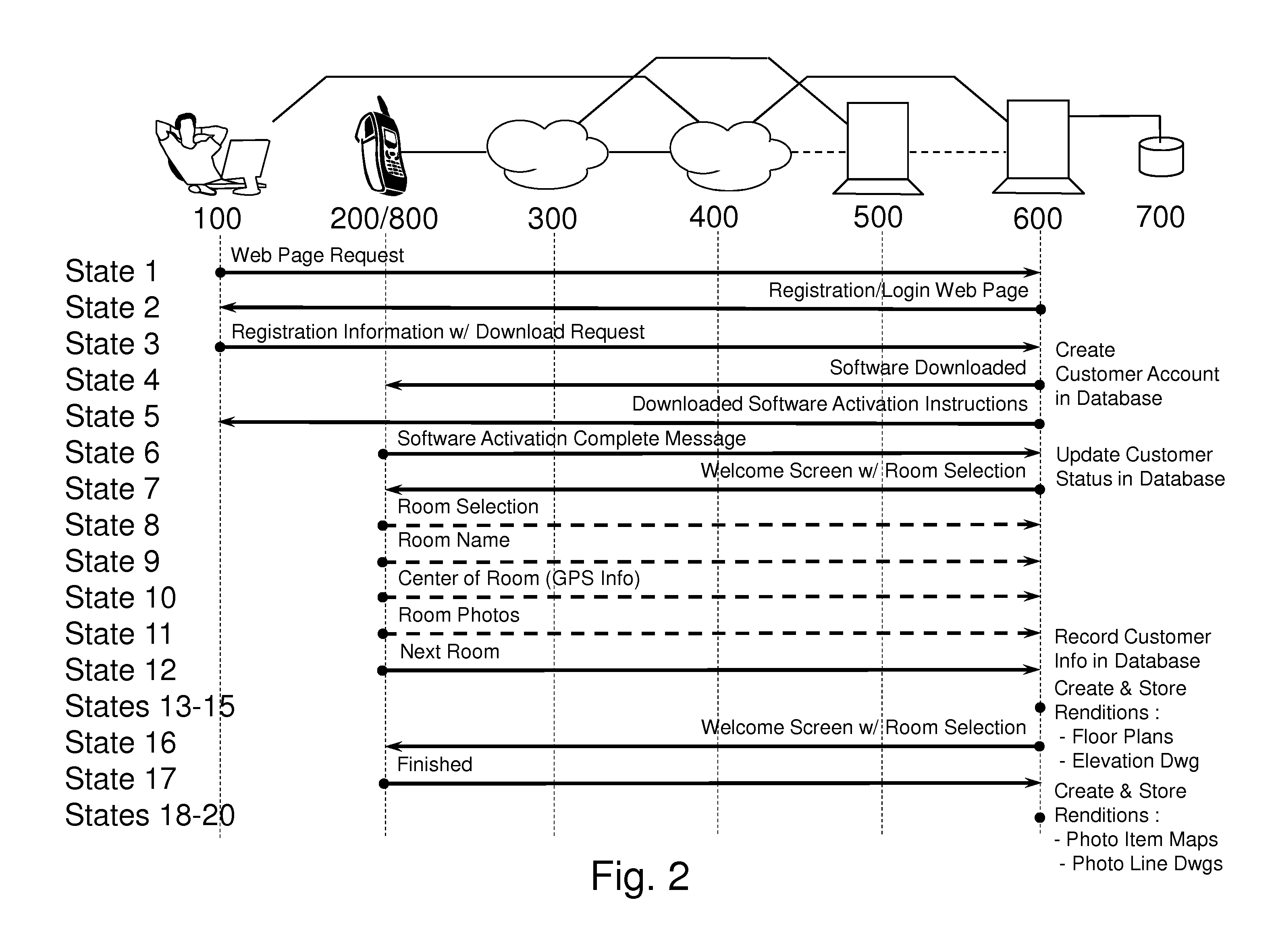

The present invention relates to inventory management solutions, and in particular, to methods and systems for inventorying items over wireless and data networks, using digital imaging, positioning, and data terminals. The user experience in performing inventory management is simplified and enhanced over existing methods.

Owner:TRANDAL DAVID S +1

Methods and systems for inventory management

InactiveUS7962485B1Simplify the data capture, organization, and secure storageLow costDigital data processing detailsSpecial data processing applicationsData terminalDigital imaging

The present invention relates to inventory management solutions, and in particular, to methods and systems for inventorying items over wireless and data networks, using digital imaging, positioning, and data terminals. The user experience in performing inventory management is simplified and enhanced over existing methods.

Owner:TRANDAL DAVID S +1

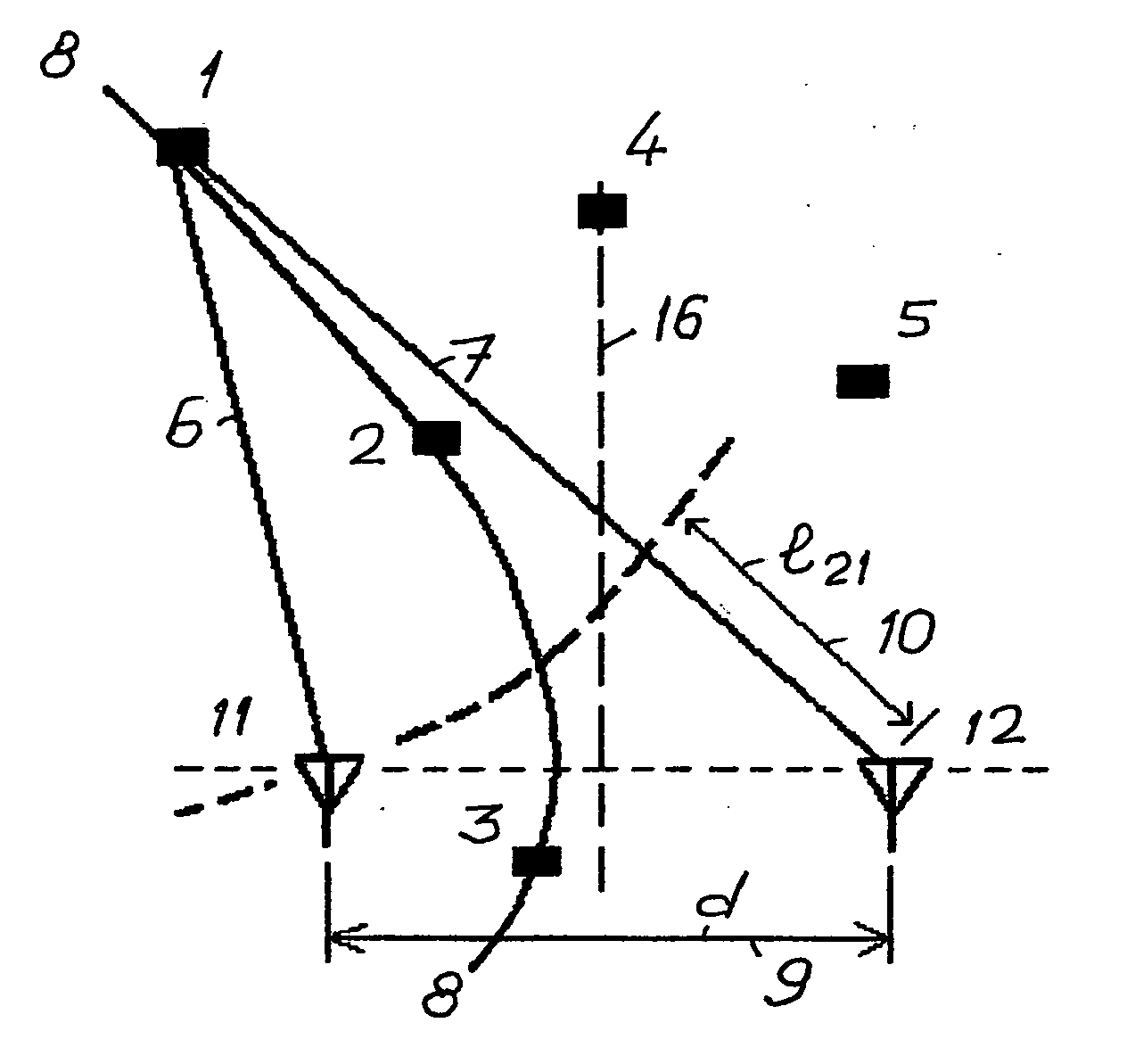

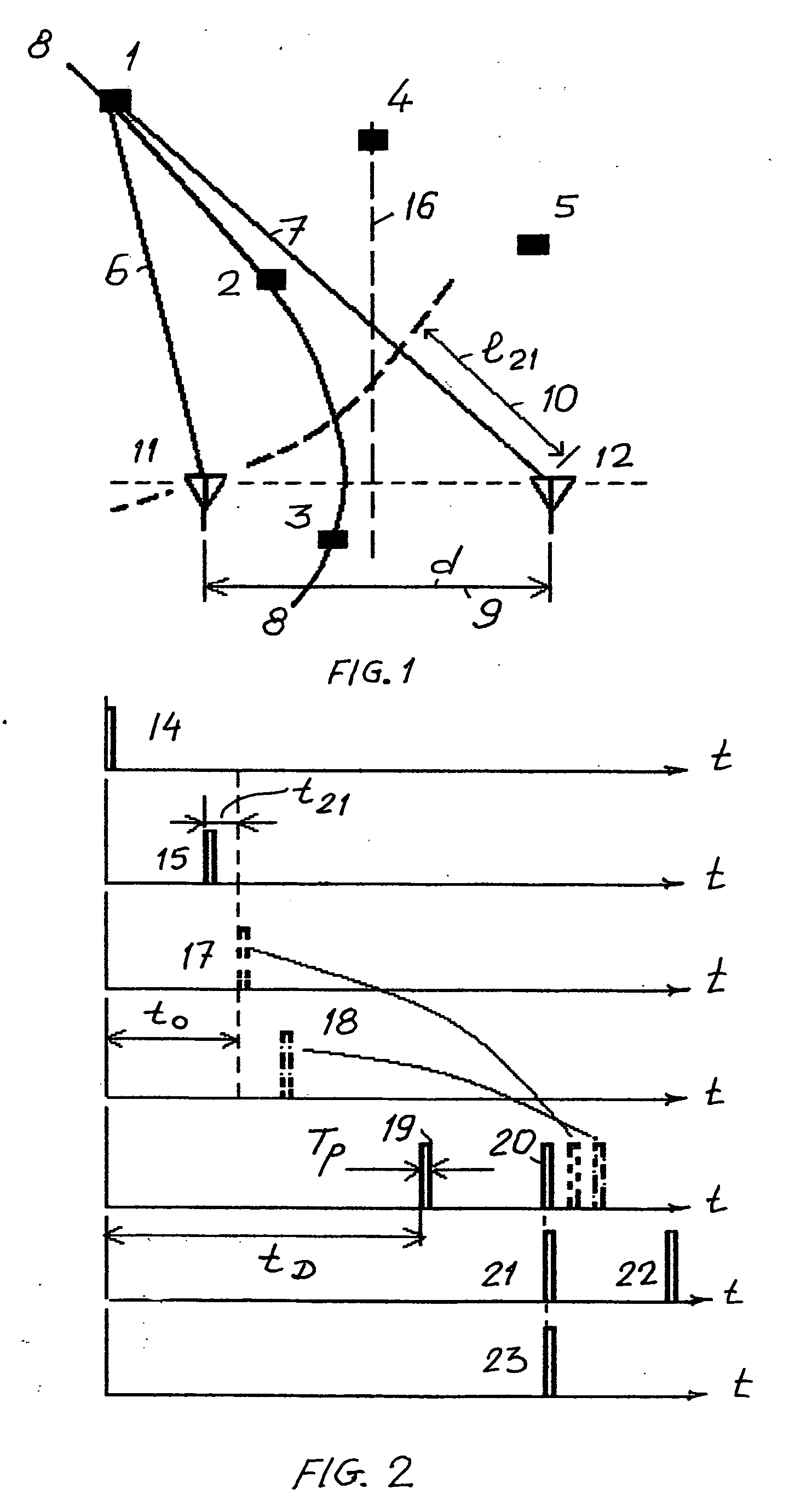

Radio frequency identification of tagged articles

InactiveUS20060192655A1Reduce search timeIncrease probabilityMemory record carrier reading problemsElectric/electromagnetic visible signallingTelecommunicationsStock-taking

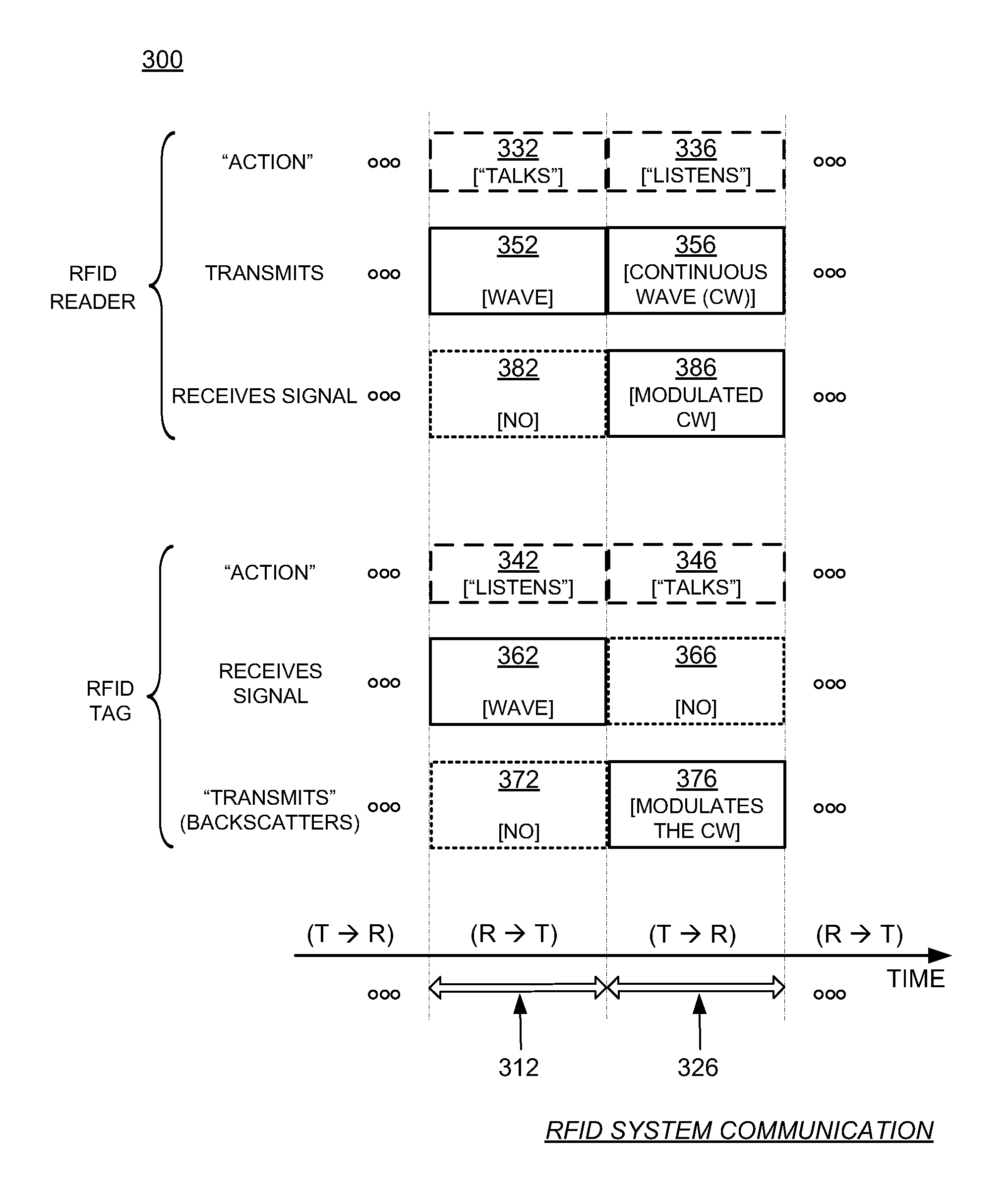

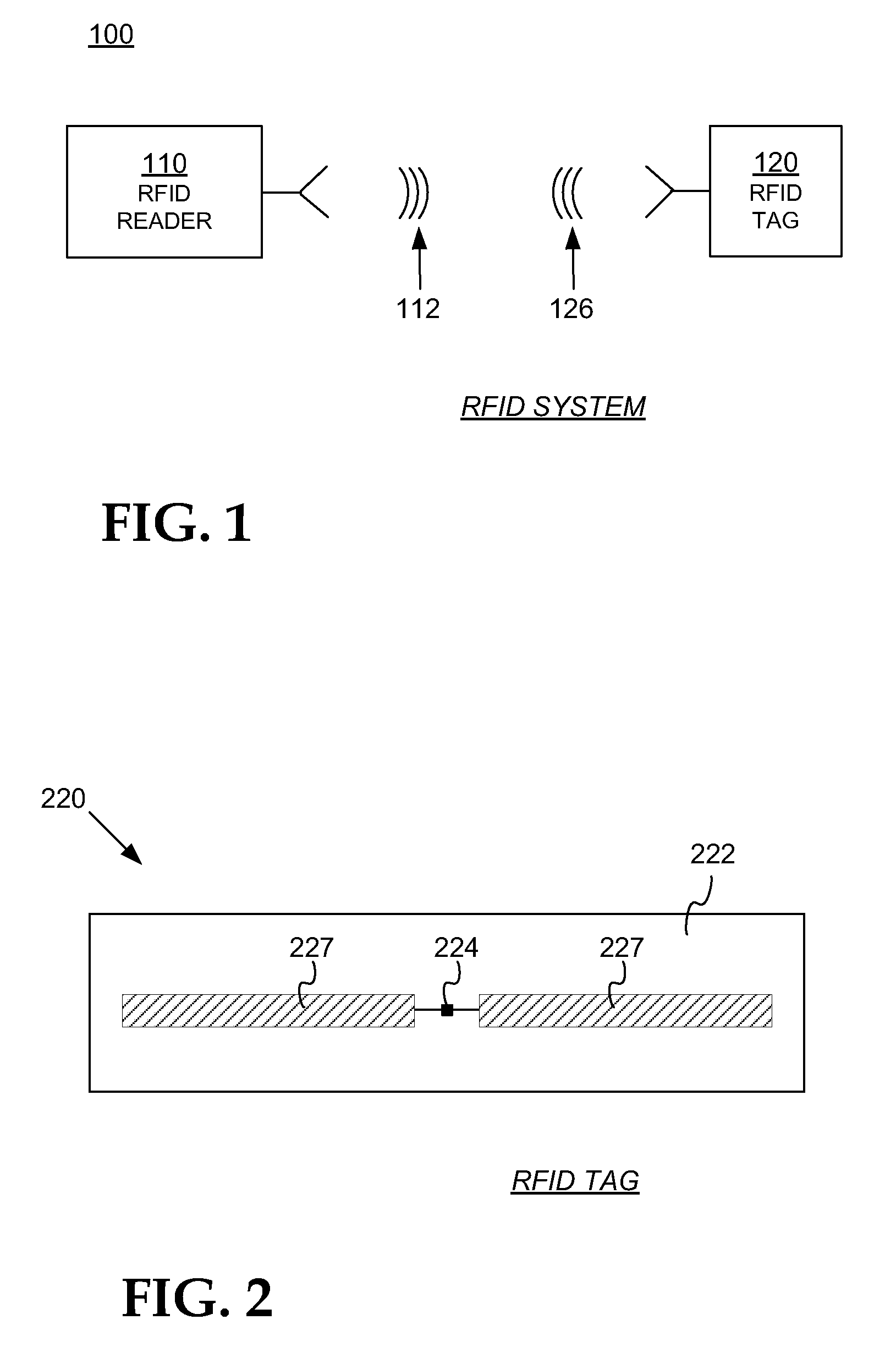

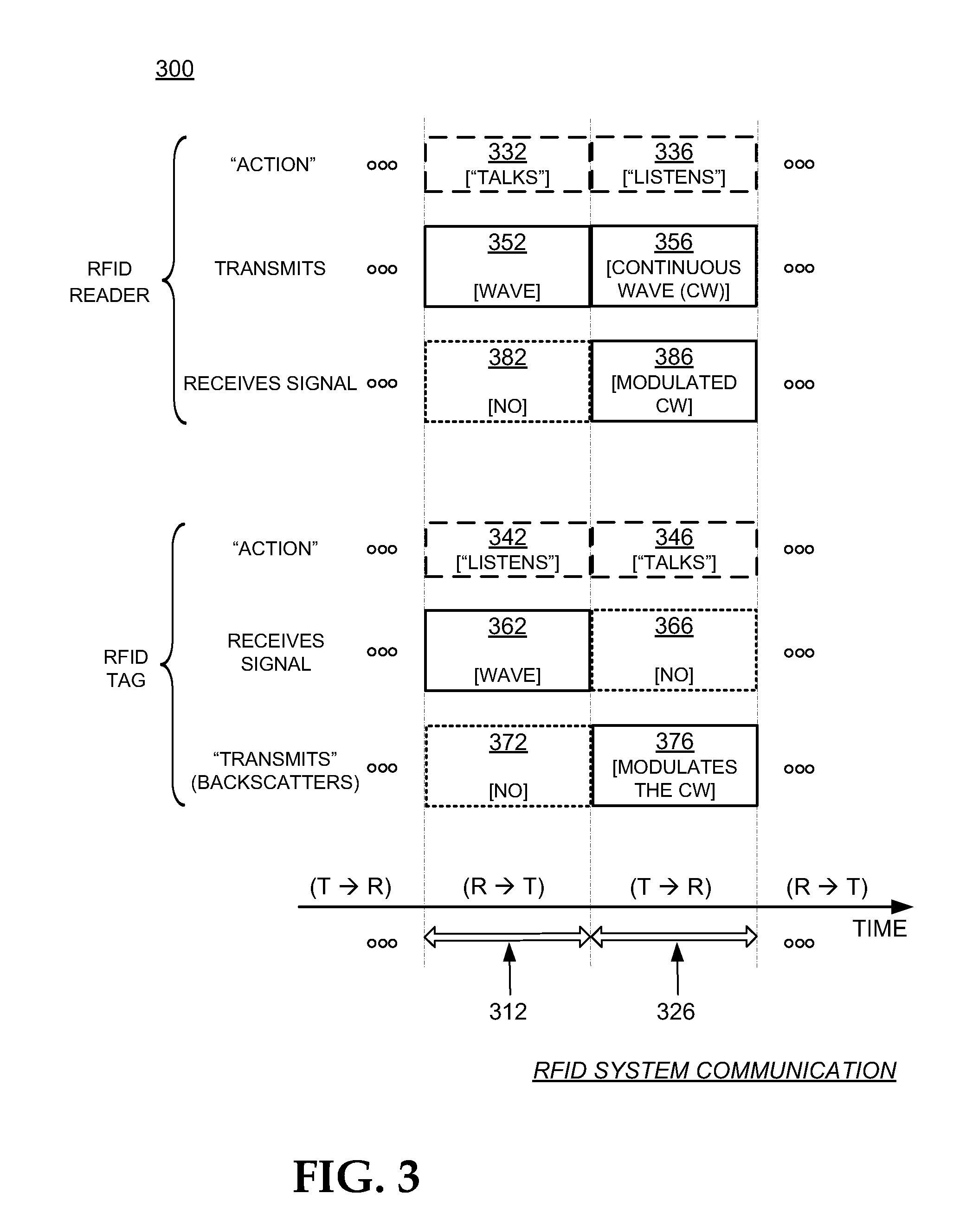

The RFID system is for automatic recognition of each one or all of a plurality of objects located within an interrogation zone. It is applicable for stock-taking or control of goods such as food. The objects provided with tags having transponders carrying RFID codes individually are sequentially scanned and activated one by one. Interrogation signals are transmitted to the tags based on the reader antennas and the configurations and locations of the tags. Signals returned from the transponders of the tags are processed for recognizing the locations of the selected tags and the electronic contents of the tags. The operation continues until the recognition and location of all tags in the entire interrogation zone have been completed.

Owner:LEVIN EDUARD

RFID tag chips and tags refraining from participating in a subsequent inventorying attempt and methods

ActiveUS20080258916A1Memory record carrier reading problemsSubscribers indirect connectionComputer scienceBackscatter

Owner:IMPINJ

Methods and systems for inventory management

InactiveUS8423548B1Simplify the data capture, organization, and secure storage of a listLow costData processing applicationsDigital data processing detailsData terminalDigital imaging

The present invention relates to inventory management solutions, and in particular, to methods and systems for inventorying items and property over wireless and data networks, using digital imaging, positioning, RFID, and data terminals. The user experience in performing inventory management is simplified and enhanced over existing methods.

Owner:TRANDAL DAVID SCOTT +1

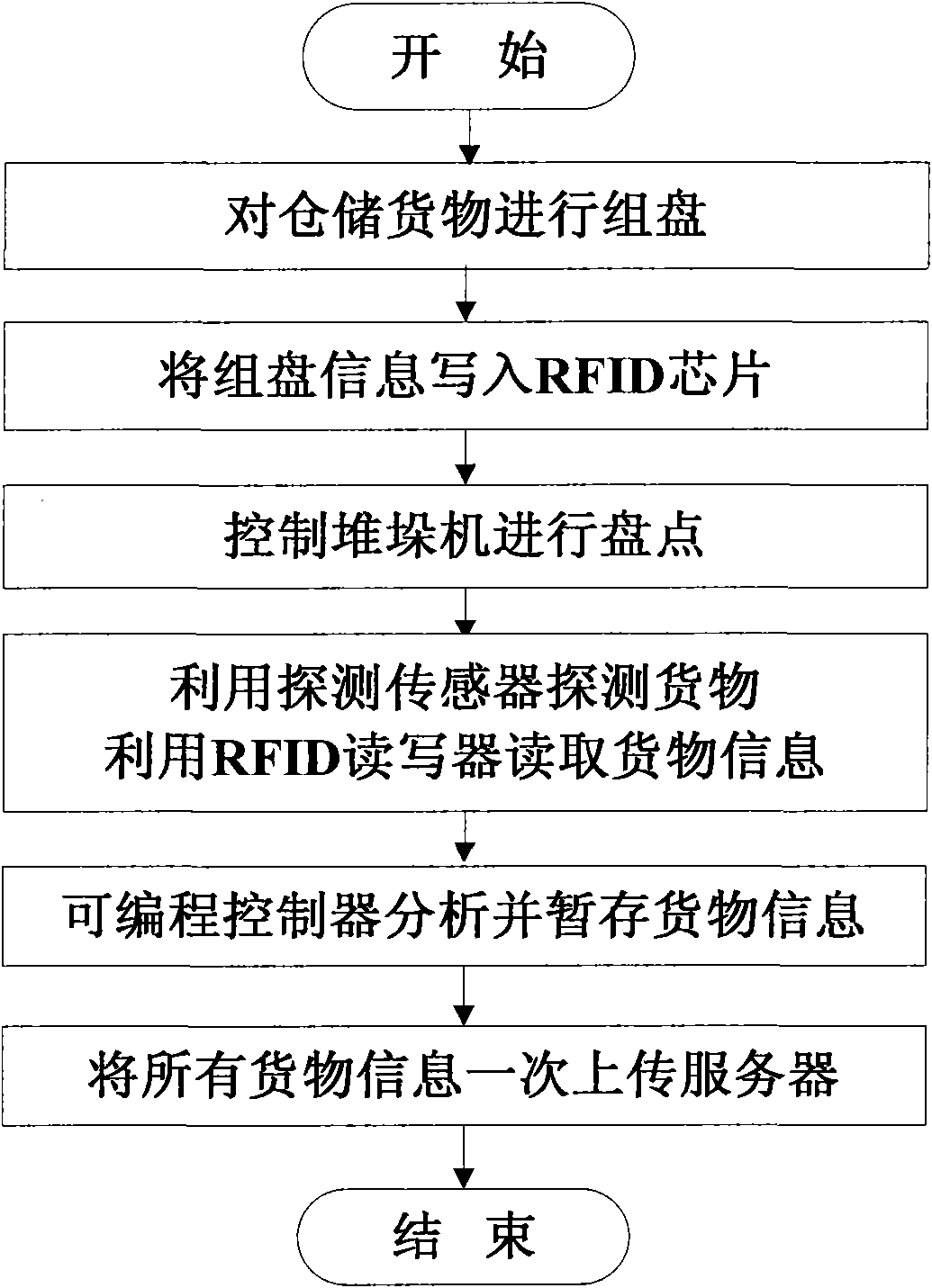

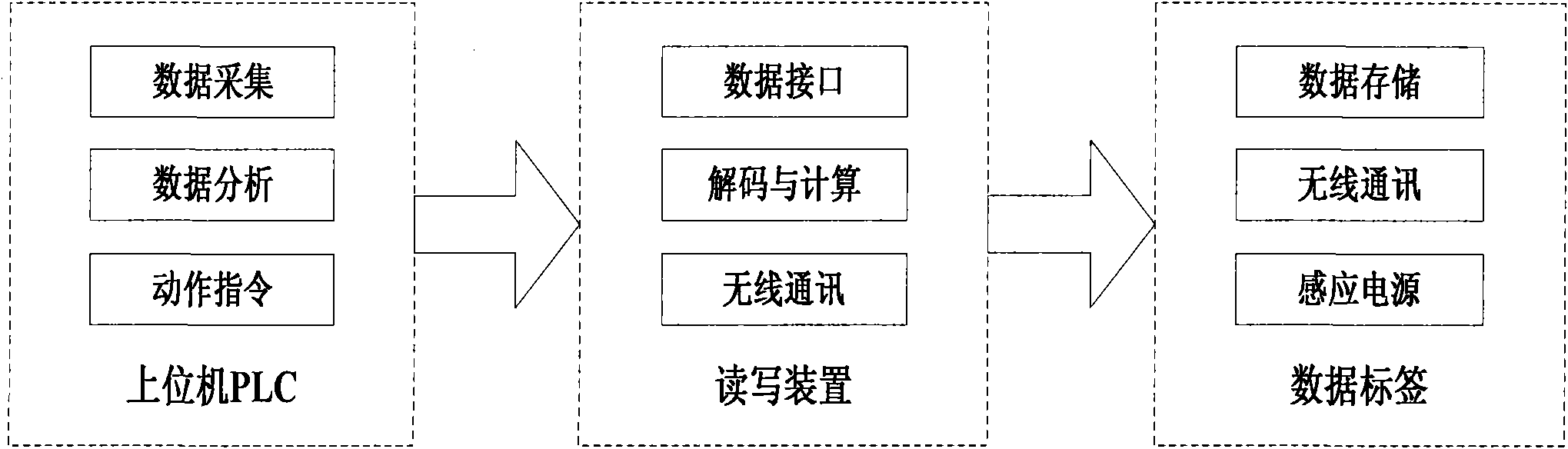

New piler cargo quick stock-taking technique based on RFID

InactiveCN101891052AFast inventory implementationImprove the problem of low inventory efficiencySensing record carriersStorage devicesData acquisitionEngineering

The invention relates to a new piler cargo quick stock-taking technique based on RFID (radio frequency identification). Quick stock-taking is carried out on the piler cargo in the automatic three-dimensional warehouse by taking RFID as the basis. The technique comprises the following steps: two sensors installed on the piler detect whether the cargo exists; two RFID reader-writers installed on the piler read the cargo information; a DP gateway is connected with the main CPU of the piler to constitute a field bus network; the serial port exchanger is connected with a supervisory control computer to complete the functions of data acquisition of the unit cargo and data rewriting and deleting of data in a chip; and the cargo information is temporarily stored and then uploaded to the main control computer at one time after all the cargo information is processed, thereby realizing quick stock-taking of the cargo.

Owner:JIANGSU LIUWEI LOGISTIC EQUIP INDAL

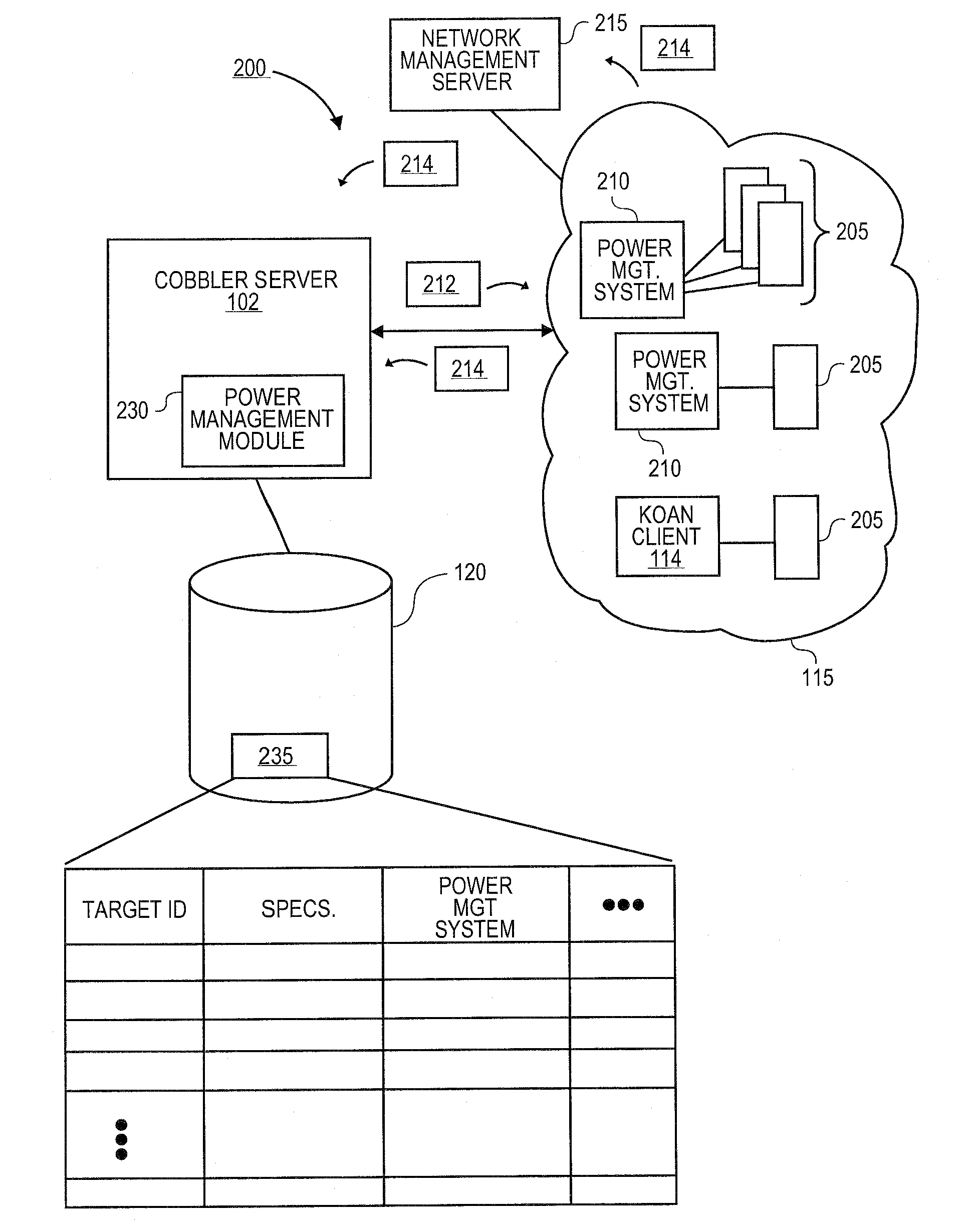

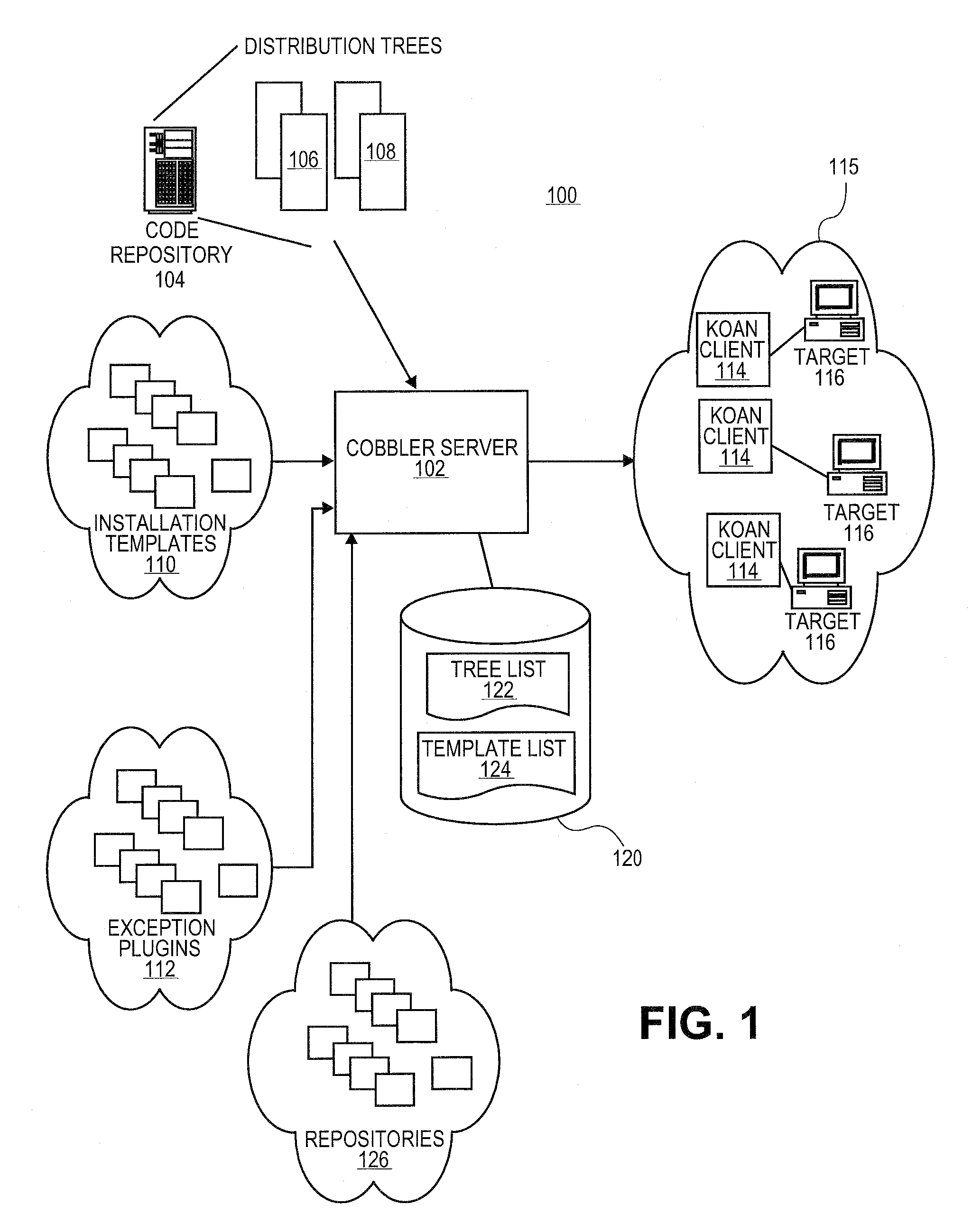

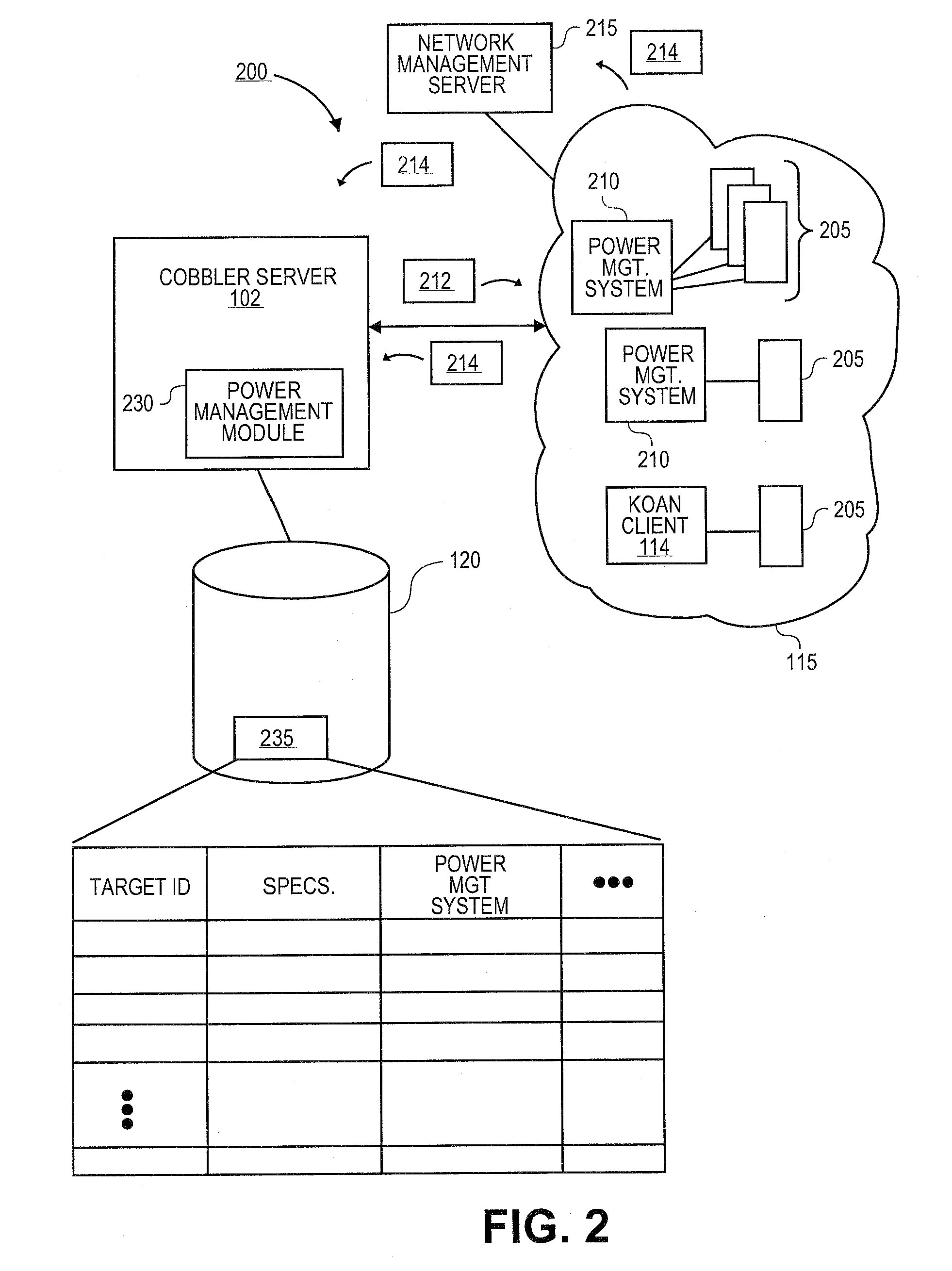

Systems and methods for inventorying un-provisioned systems in a software provisioning environment

A provisioning server can utilize an inventory tool on new target machines in order to collect specification data from the target machines, prior to provisioning software. The inventory tool can be configured to operate on the new target machines without software, such as an operating system, being installed on the new target machines. The inventory tool can be configured to communicate with the hardware of the new target machines and collect data representing the specifications of the new target machines. The inventory tool can be configured to operate and execute on any new target machine regardless of the type and configuration of the new target machine.

Owner:RED HAT

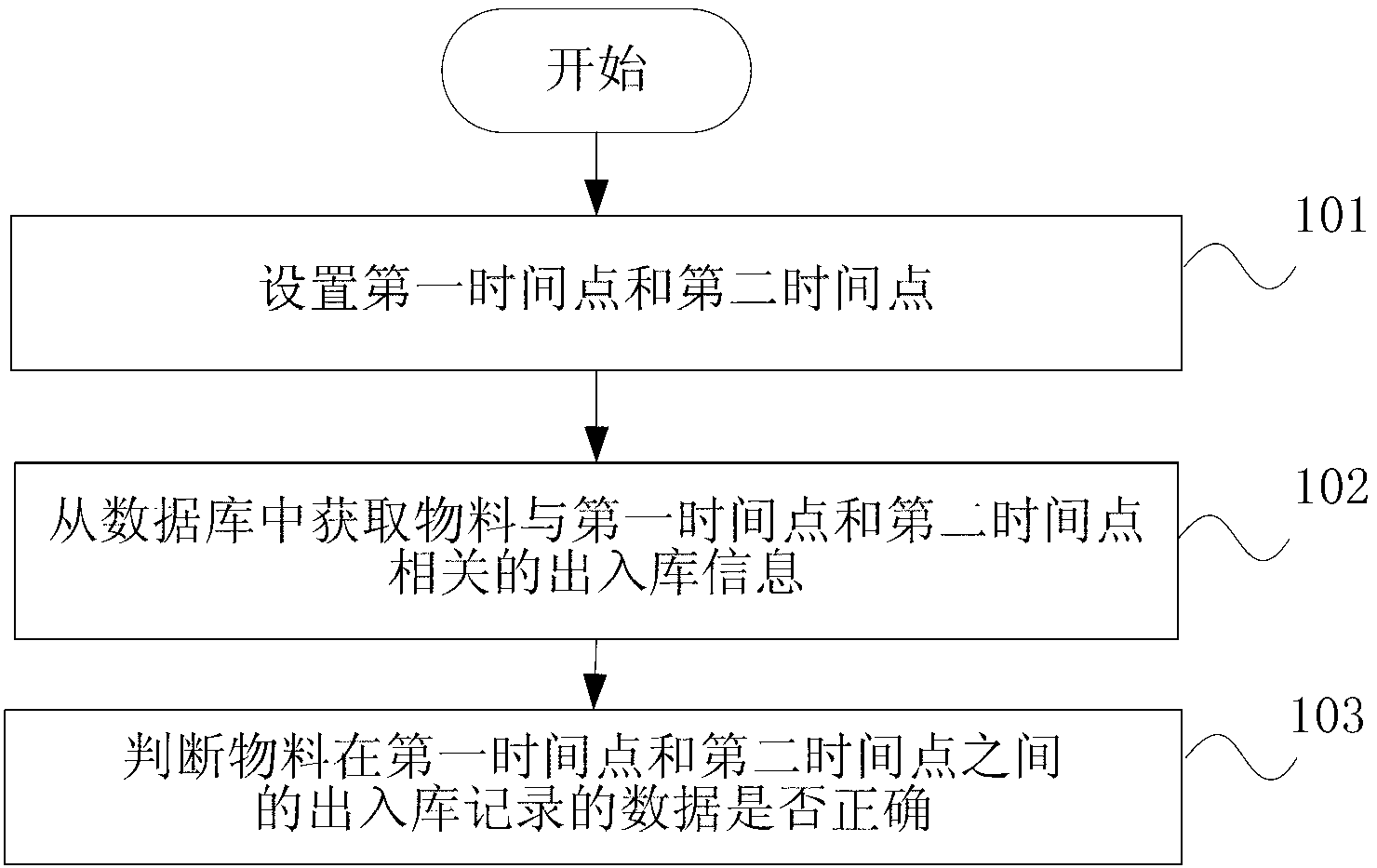

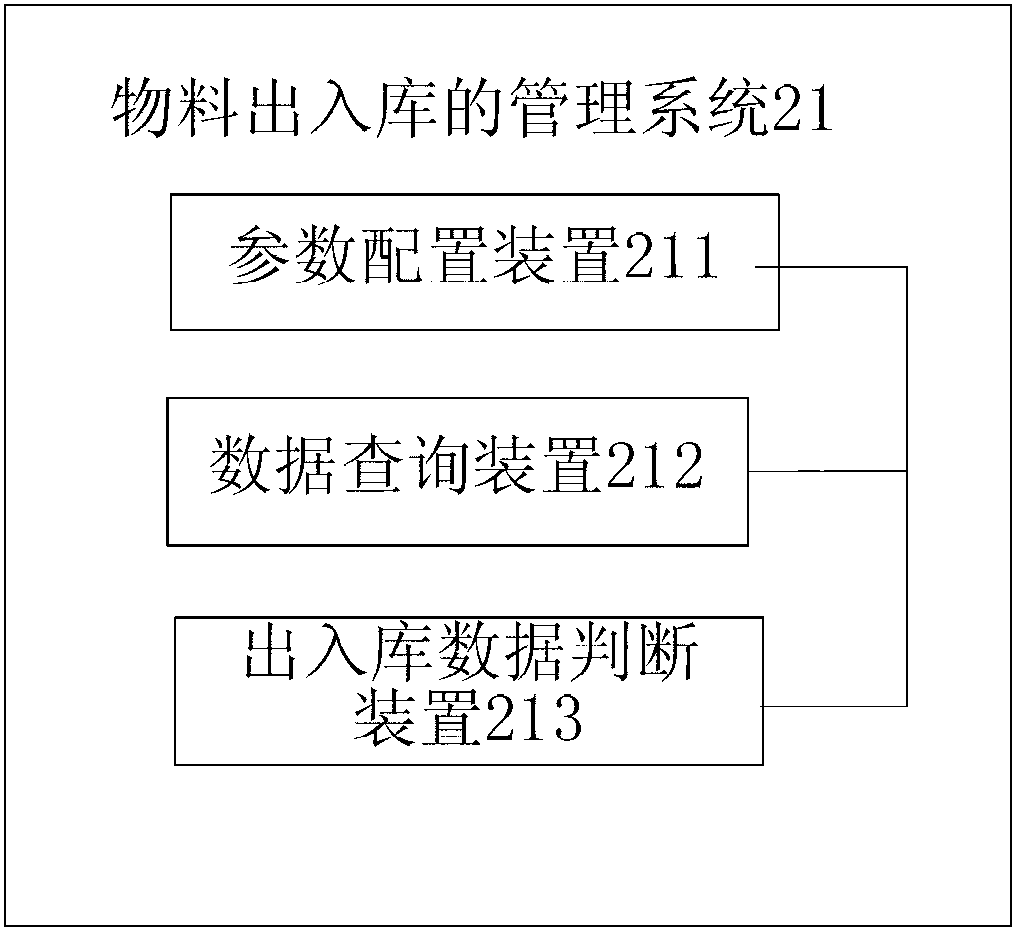

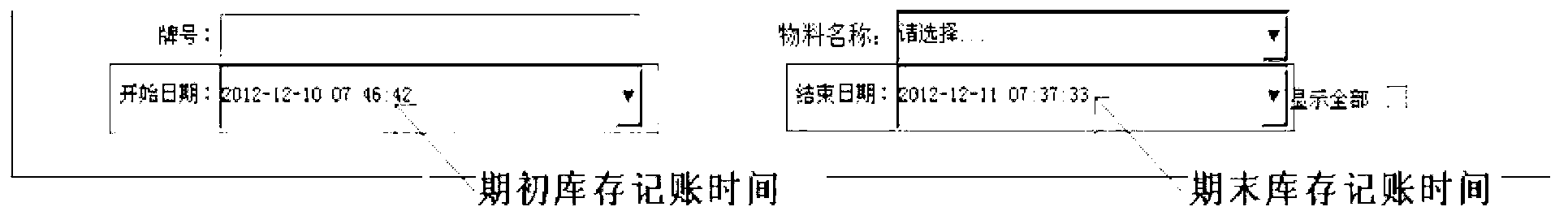

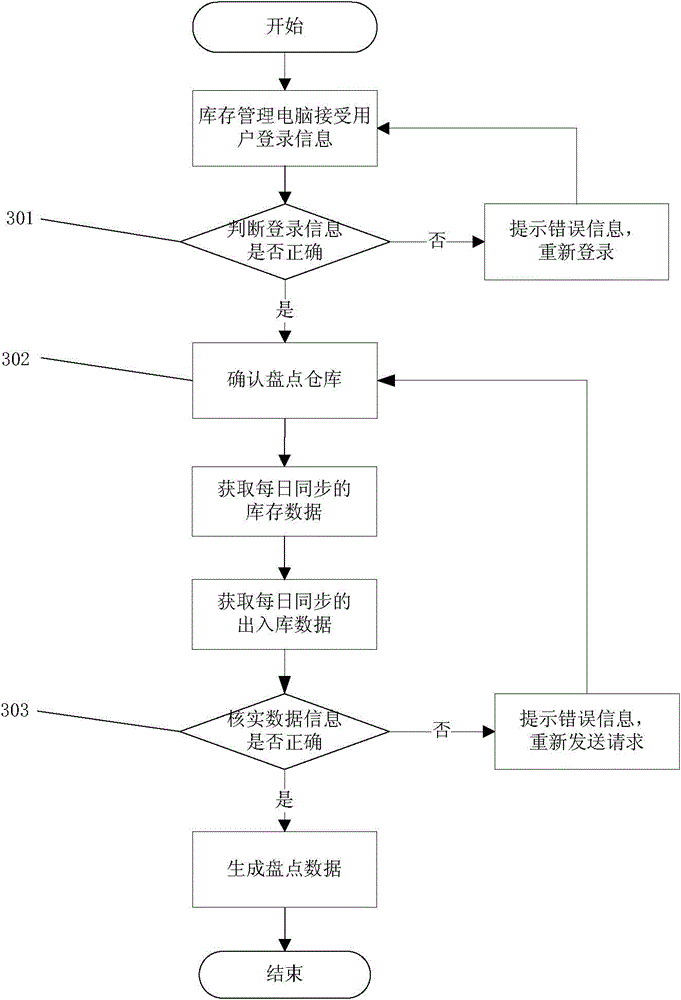

Warehouse management method and system

InactiveCN103295118APrecise positioningAvoid wide-ranging inventoryLogisticsData warehouseComputer science

The invention discloses a warehouse management method and system. The warehouse management method includes that first timing point and second timing point are set up, and data of warehouse records of materials between the first timing point and the second timing point are correct when a warehouse record difference is judged to be zero; the warehouse record difference = material warehoused in the first timing point + total number of the materials warehoused between the first timing point and the second timing point - total number of the material ex-warehoused between the first timing point and the second timing point + total number of the material warehoused from the second timing point to current timing point - total number of the material ex-warehoused from the second timing point to the current timing point - current warehouse of the materials. By the aid of the warehouse management method and system, warehouse information at any timing points can be recorded, all warehouse situations from any two optional timing points to the current timing point and the warehouse information of the two timing points can be inquired at the same time, errors leading to warehouse mistakes can be accurately allocated, so that a wide range of blind checking can be avoided, and checking efficiency can be improved.

Owner:LONGYAN CIGARETTE FACTORY

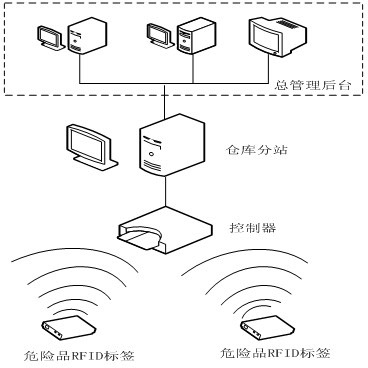

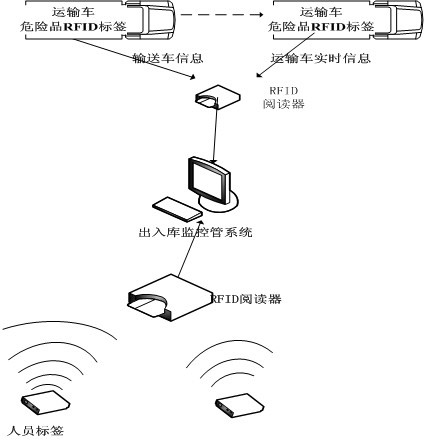

Dangerous goods monitoring method based on radio frequency identification

InactiveCN102663572ARealize dynamic trackingImprove work efficiencyCo-operative working arrangementsLogisticsData acquisitionEngineering

The invention is a dangerous goods monitoring method based on radio frequency identification, and the method specifically comprises: unified coding of electronic product; monitoring of the dangerous goods storage; monitoring of warehousing and stock removal; monitoring of dangerous goods transportation; environmental pollution accident danger source cross-regional monitoring and decision analysis: the method mainly solves 1, problem of large consumption of manpower and material resources; 2, problem of inaccuracy of statistics and of too complicated operation; 3, problem of incapability of realizing overall process real-time monitoring from dangerous goods production to storage, transportation, and destruction; 4, problem of being unable to adopt emergency measure and carry out first aid treatment after accident; [and] 5, problem of health and unguaranteed safety of the working personnel for regular safety inspection of the dangerous goods. The object of the method is to carry out automatic data acquisition of the work links like dangerous goods receiving inspection, warehousing, moving and shifting, inventory, and the like, to guarantee the speed and accuracy of data input in each link of the dangerous goods management, to ensure the enterprise to grasp timely and accurately the real data of the storage.

Owner:YANGZHOU UNIV

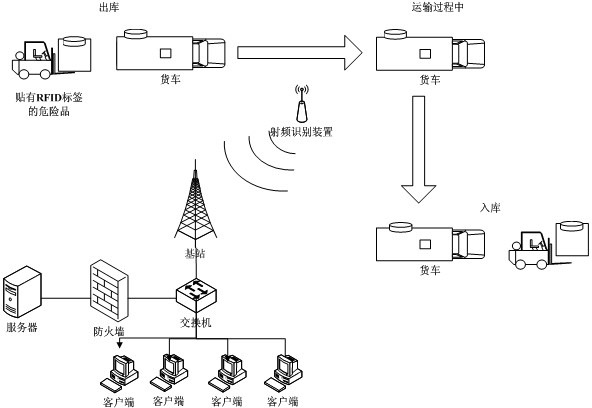

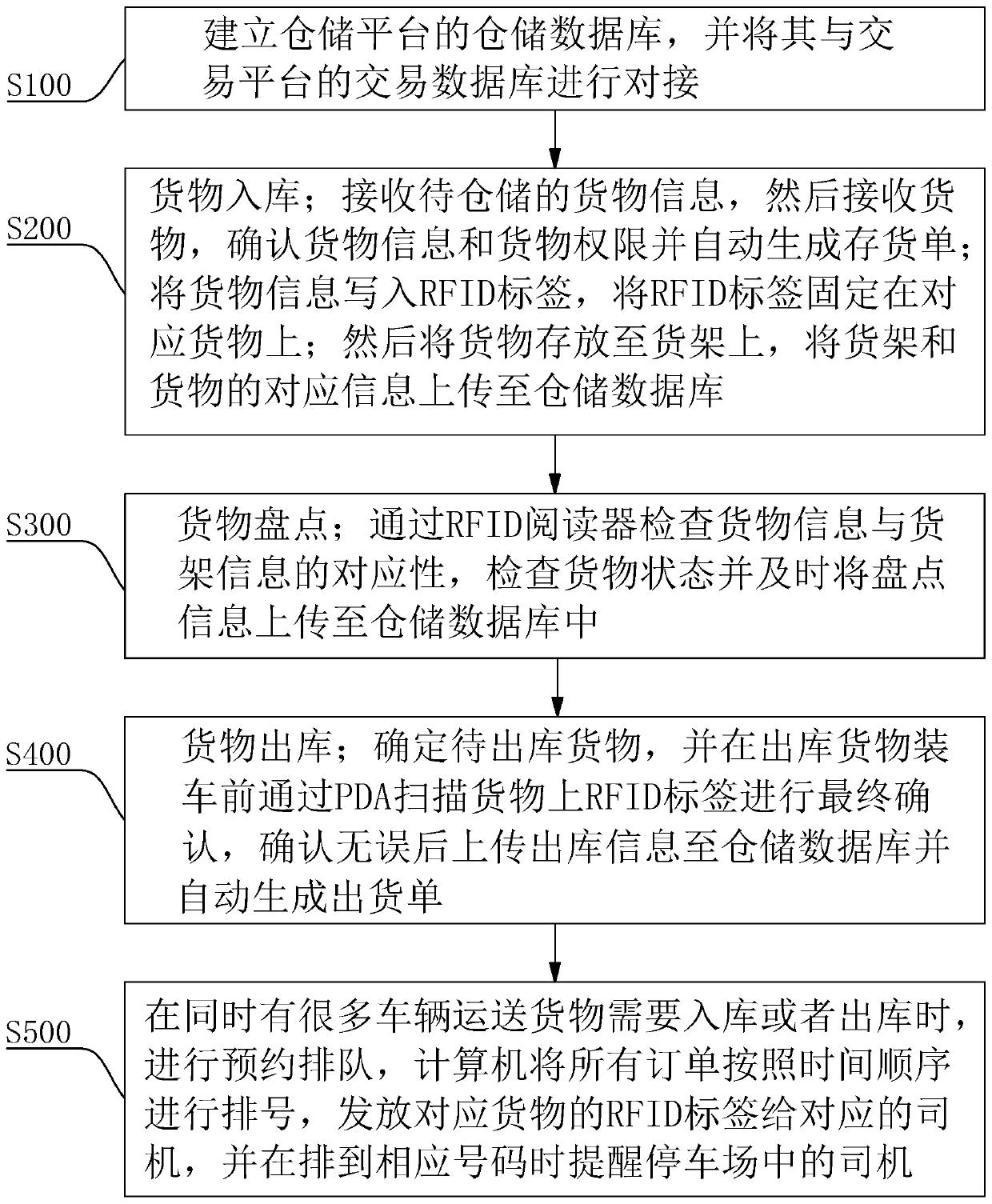

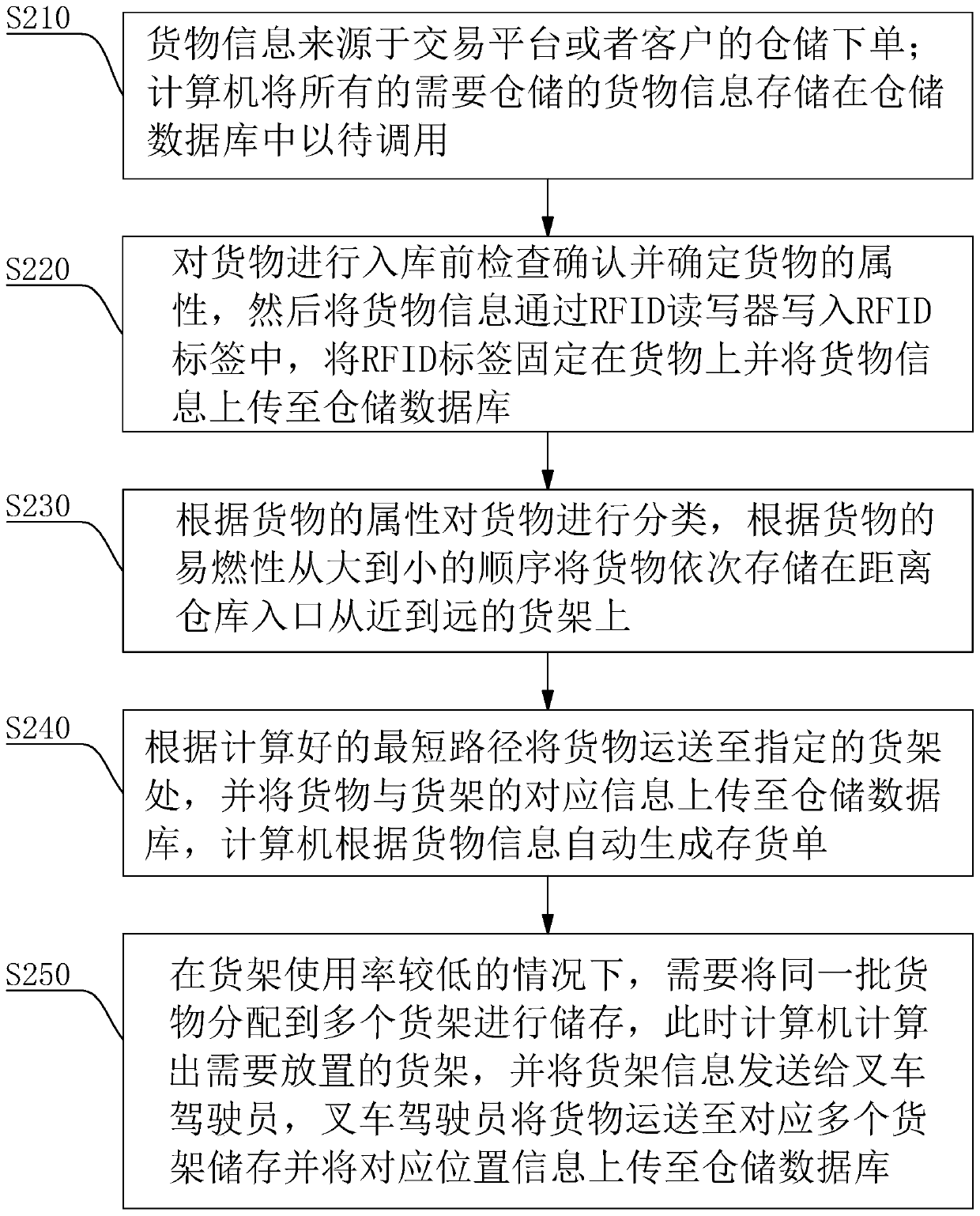

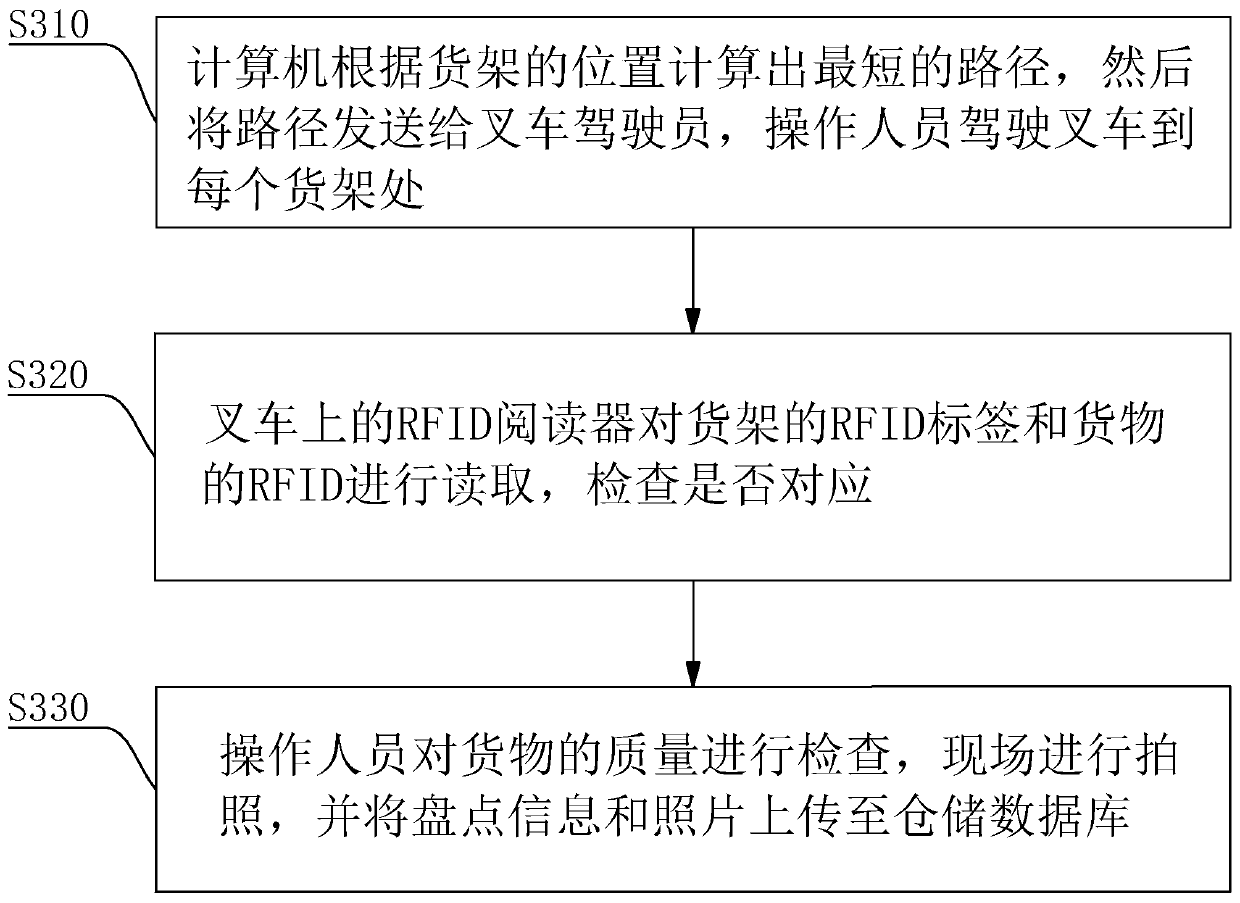

Management method of intelligent warehousing platform based on RFID

PendingCN111091322AFlexible and efficient managementReduce participationCo-operative working arrangementsLogisticsTransaction dataFinancial transaction

The invention discloses a management method of an intelligent warehousing platform based on RFID and relates to the technical field of warehouse management, and aims to solve the technical problems that existing warehouse management needs participation of a large number of operators and is low in efficiency, and the technical scheme is characterized by comprising the steps of S100, establishing awarehouse database of a warehouse platform, and integrating the warehouse database with a transaction database through a computer; S200, warehousing goods; receiving goods information and goods, and writing the goods information into the RFID tags and fixed to the corresponding goods; storing the goods on a goods shelf, and uploading corresponding information of the goods shelf and the goods; S300, checking the goods; checking the correspondence between the goods information and the shelf information through the RFID reader, checking the goods state and uploading inventory information; S400, delivering and determining the goods out of the warehouse scanning the RFID tags before truck loading for final confirmation, uploading and delivering warehouse information after confirmation, and automatically generating a shipment list. The effect of greatly improving the management efficiency of the warehouse management system is achieved.

Owner:南通中实纺织交易市场有限公司

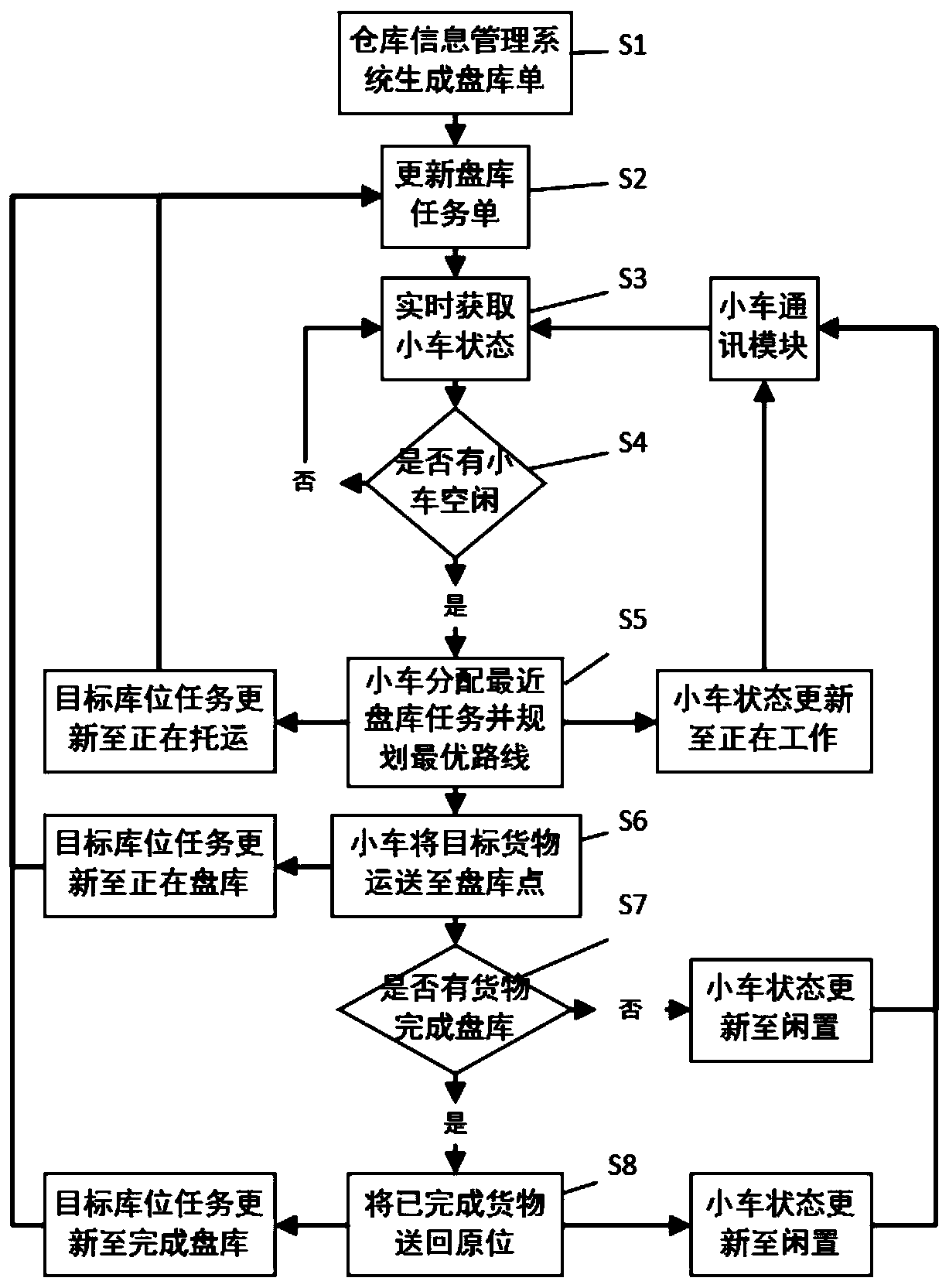

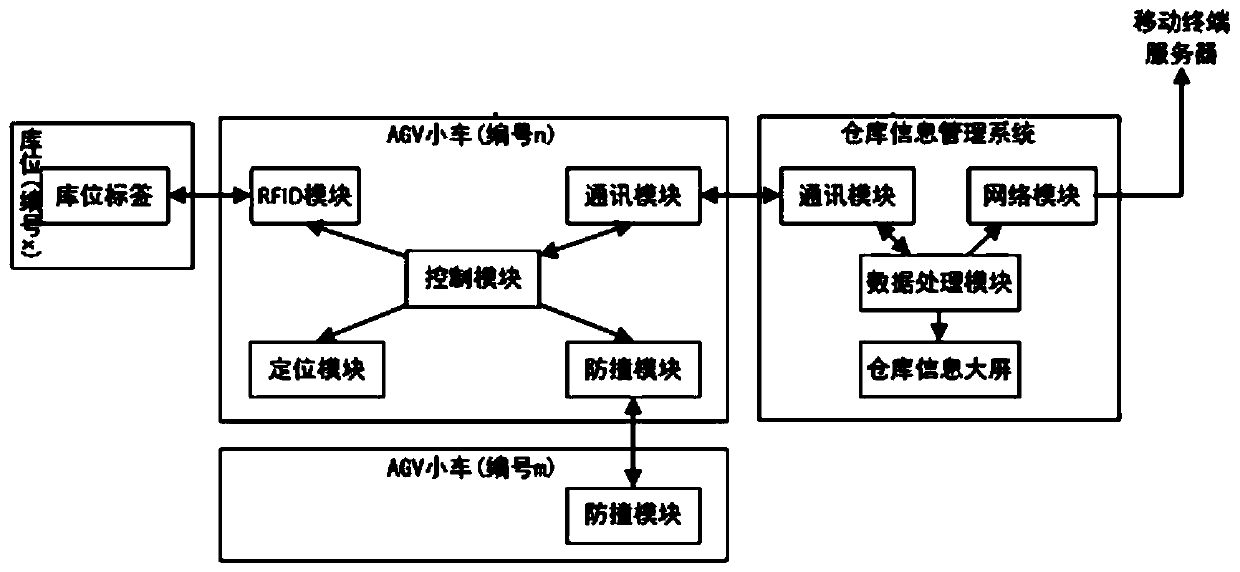

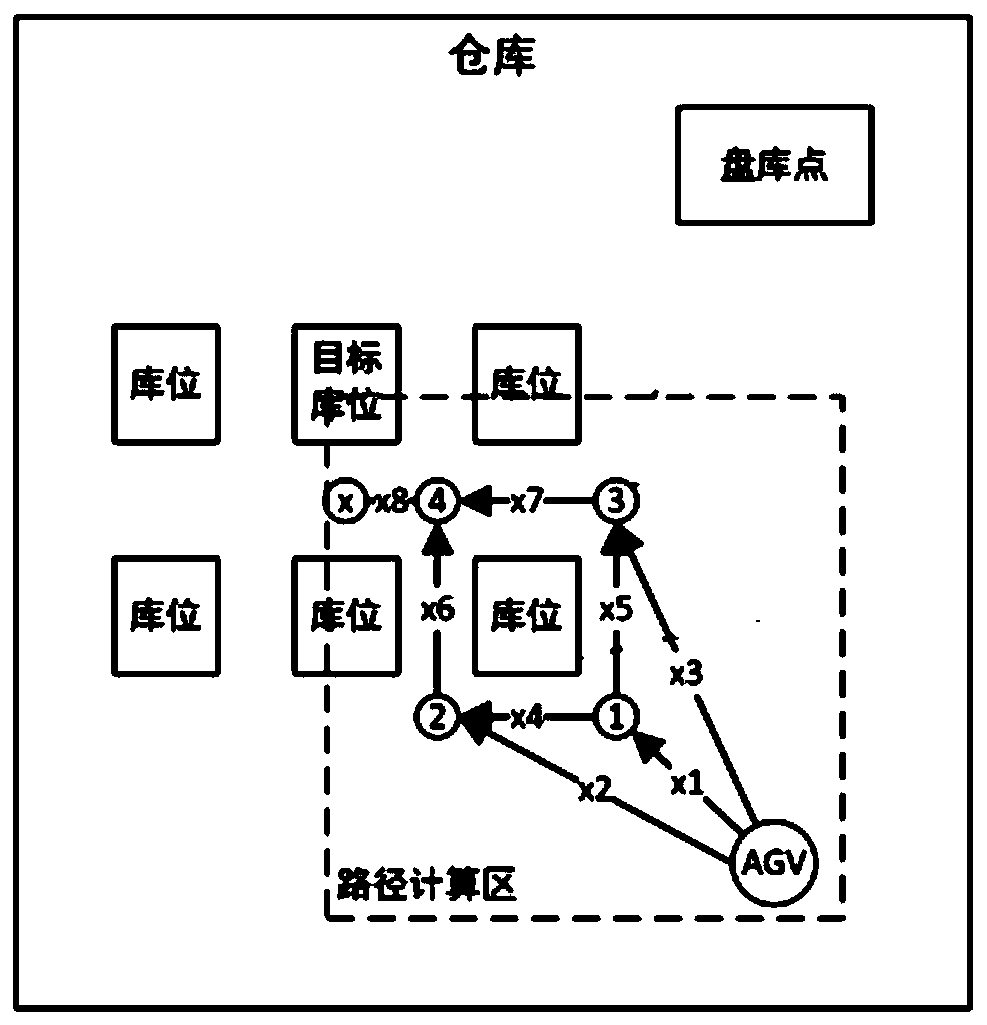

RFID warehouse logistics inventory making method and system based on AGV

PendingCN111144825AImprove versatilityImprove stabilityCo-operative working arrangementsLogisticsLogistics managementStock-taking

The invention discloses an RFID warehouse logistics inventory making method and system based on AGVs. The method comprises the following steps that (1) a warehouse information management system generates an inventory making task list and allocates the inventory making task list to idle AGVs; (2) the idle AGVs recognize target storage location labels through an RFID module to reach the target storage location, and sends the goods of the target storage location to an inventory position according to a planned optimal driving route; and (3) if the inventory of the goods is completed, the AGVs reaching the inventory position sends the inventory completed goods back to an original warehouse position, and if the inventory of the goods is not completed, the method continues to return to the step (1) until the inventory task list is completely completed. The problems that a traditional method is low in efficiency and high in labor cost are solved.

Owner:CHINA TOBACCO ZHEJIANG IND

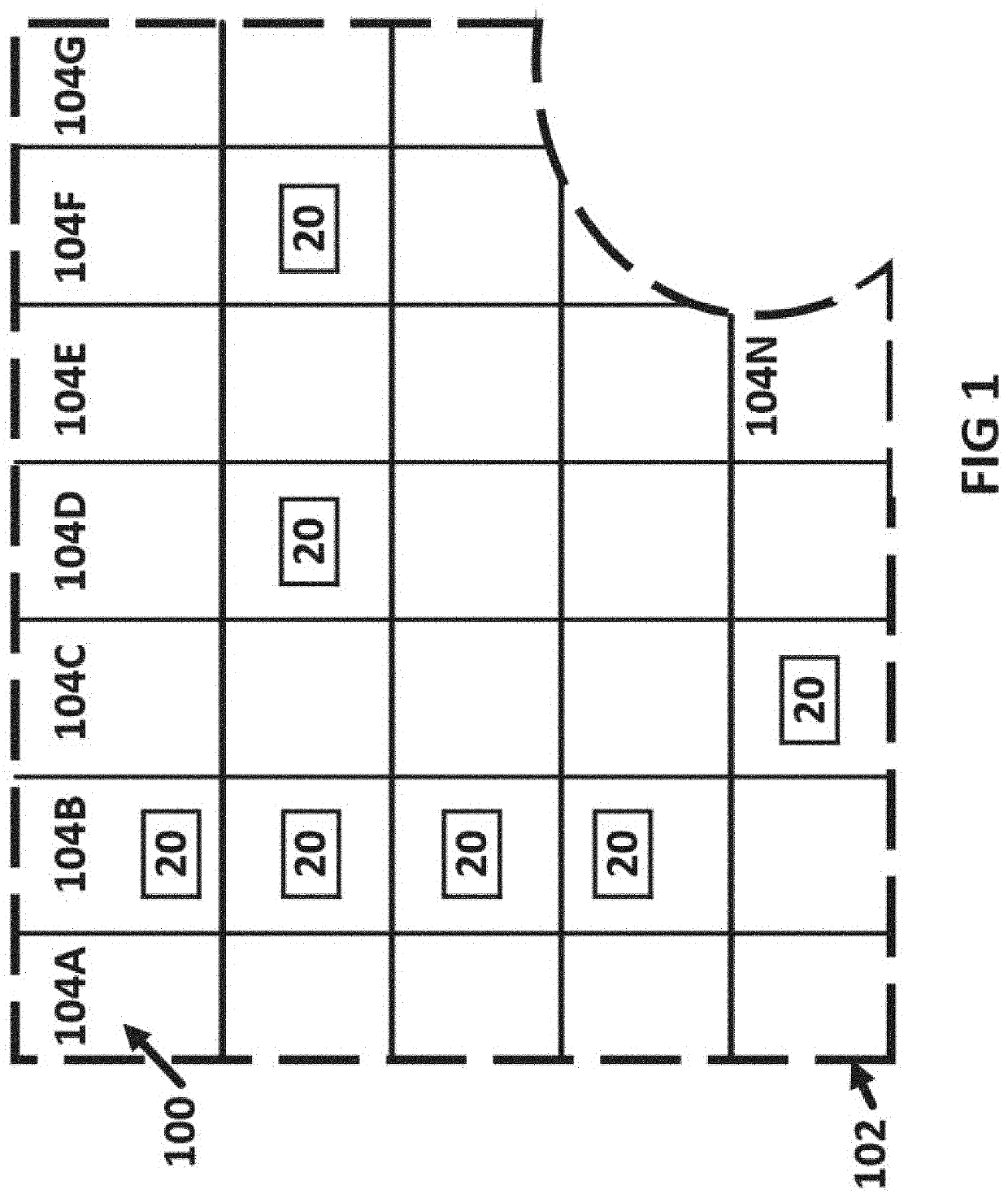

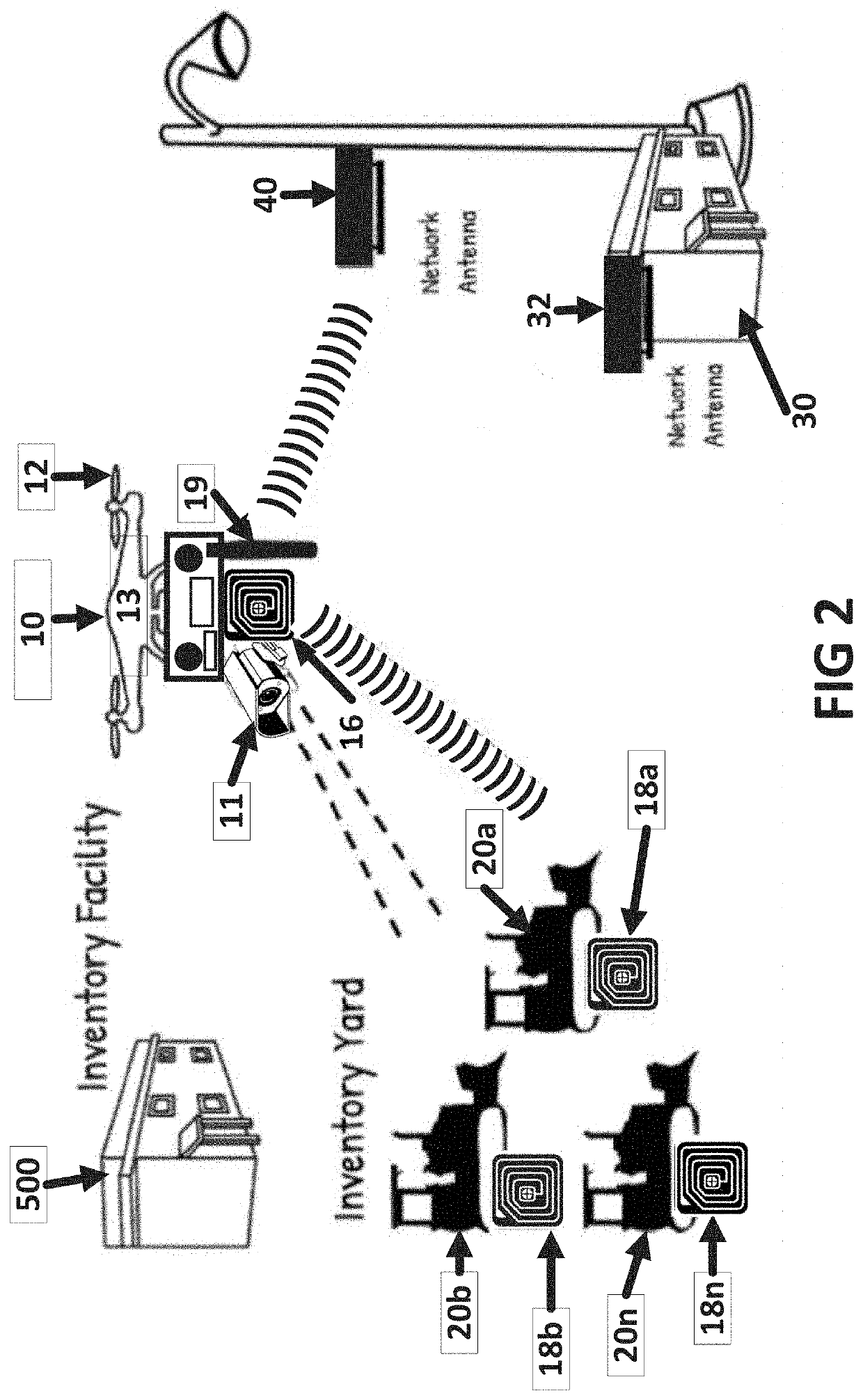

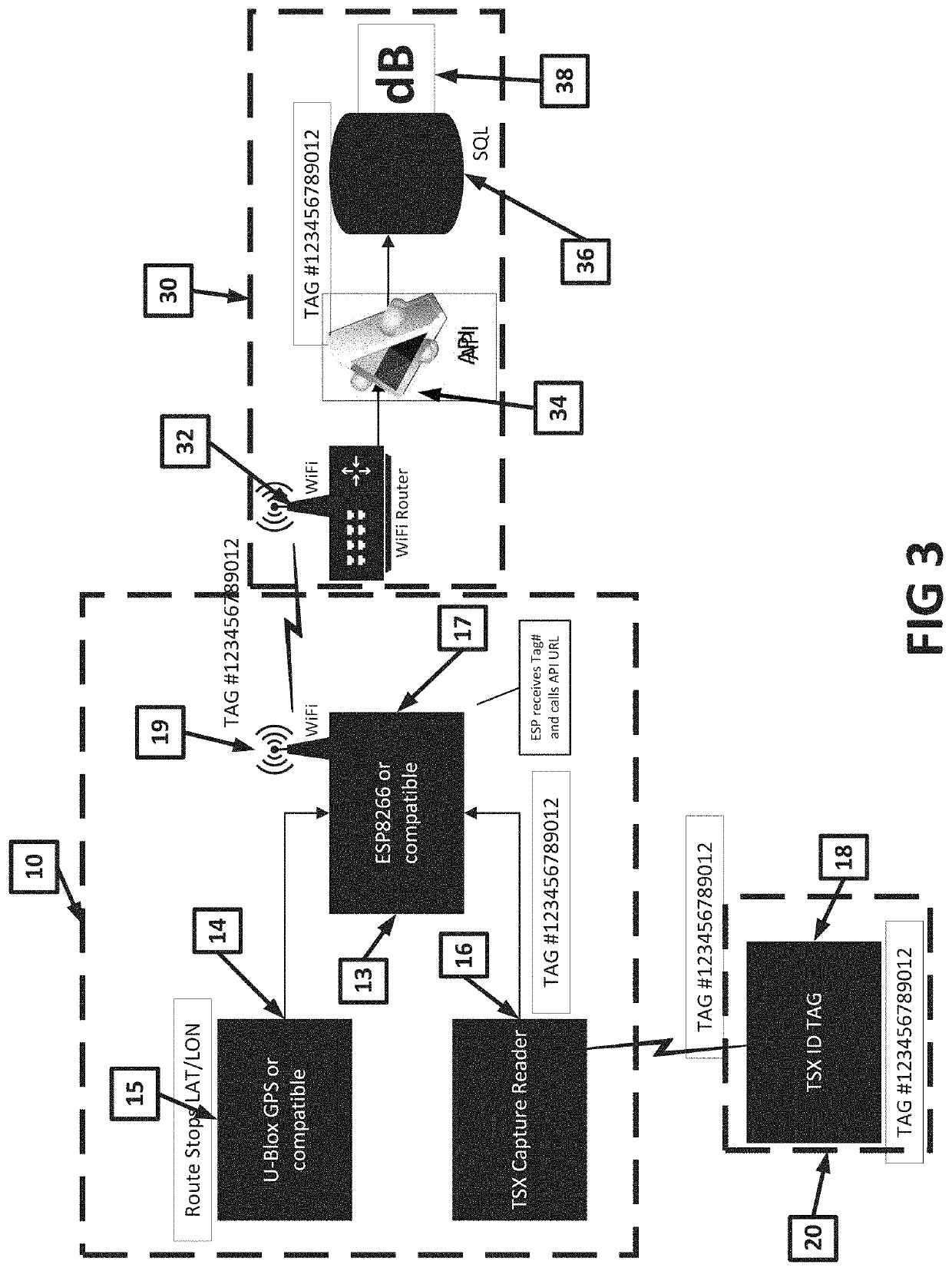

System and method for taking asset inventory across a wide area

A system for taking inventory over a wide area includes a database. The database stores a geofenced area divided into two or more waypoints and a route defined as path within the geofenced area across at least two waypoints. At least one mobile asset is disposed at a position in a yard corresponding to the at least one waypoint. The mobile asset has a readable tag having information about the asset thereon. An aerial vehicle having a tag reader flies along the route within the geofenced area for communicating with each tag along a route, reading the information and storing the information read from each tag.

Owner:WIRELESS DATA SYST INC

Radiofrequency identification and barcode combined inventory management method

The invention discloses a radiofrequency identification and barcode combined inventory management method. The radiofrequency identification and barcode combined inventory management method includes section bar identification management, section bar warehouse-in management, section bar inventory verification and section bar warehouse-out operation, in other words, radiofrequency identification cards are adhered on the front and back surfaces of storage locations, and owing to characteristics of capability of being repeatedly read and written and remote non-contact scanning of the radiofrequency identification cards, radiofrequency identification tags of the storage locations are automatically scanned while material barcodes are scanned, so that material information stored in the radiofrequency identification cards is consistent to scanned barcode information, relevant material information of the storage locations is transmitted to a manufacturing execution system, and the purpose that information in the manufacturing execution system is consistent to the information of the radiofrequency identification cards of the storage locations in a field is achieved. The radiofrequency identification and barcode combined inventory management method has the advantage that characteristics of radiofrequency identification and characteristics of the barcodes are effectively utilized and are combined with one another, so that material objects and the system can be conveniently and quickly synchronized.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

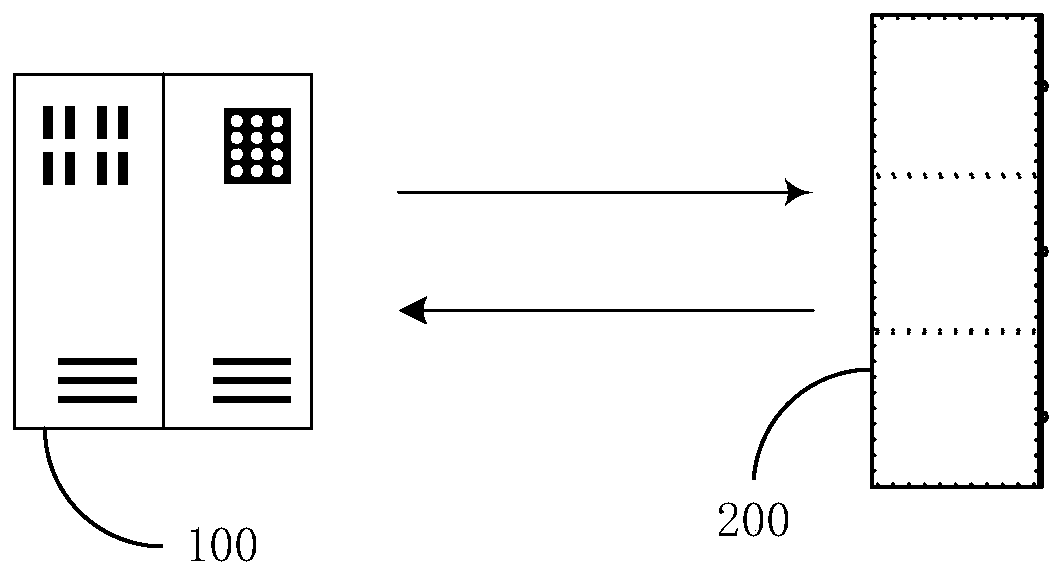

Stock Information processing method of nonferrous metal delivery database on the basis of bar code technology and stock Information processing system of nonferrous metal delivery database on the basis of bar code technology

InactiveCN105447661AThe process is simple and convenientFast processLogisticsInformation processingNonferrous metal

The present invention relates to a stock Information processing method of a nonferrous metal delivery database on the basis of the bar code technology and a stock Information processing system of a nonferrous metal delivery database on the basis of the bar code technology. The stock Information processing method comprises a commodity put-in-storage information processing submethod, a commodity put-out-storage sub-information processing method and a commodity stock-taking information processing submethod. The stock Information processing system comprises a stock management computer, a scanning hand-held set and a remote management server. The scanning hand-held set includes a data processor, a bar-code scanner, a keyboard, a display screen and a thermal printer; the stock management computer is connected with the data processor and the remote management server; the data processor is connected with the bar-code scanner, the keyboard, the display screen and the thermal printer. Compared with the prior art, the stock Information processing method of a nonferrous metal delivery database on the basis of the bar code technology and the stock Information processing system of a nonferrous metal delivery database on the basis of the bar code technology are able to improve the production efficiency, reduce the labor cost, decrease the operation error ratio, and the like.

Owner:上海汉笙信息科技有限公司

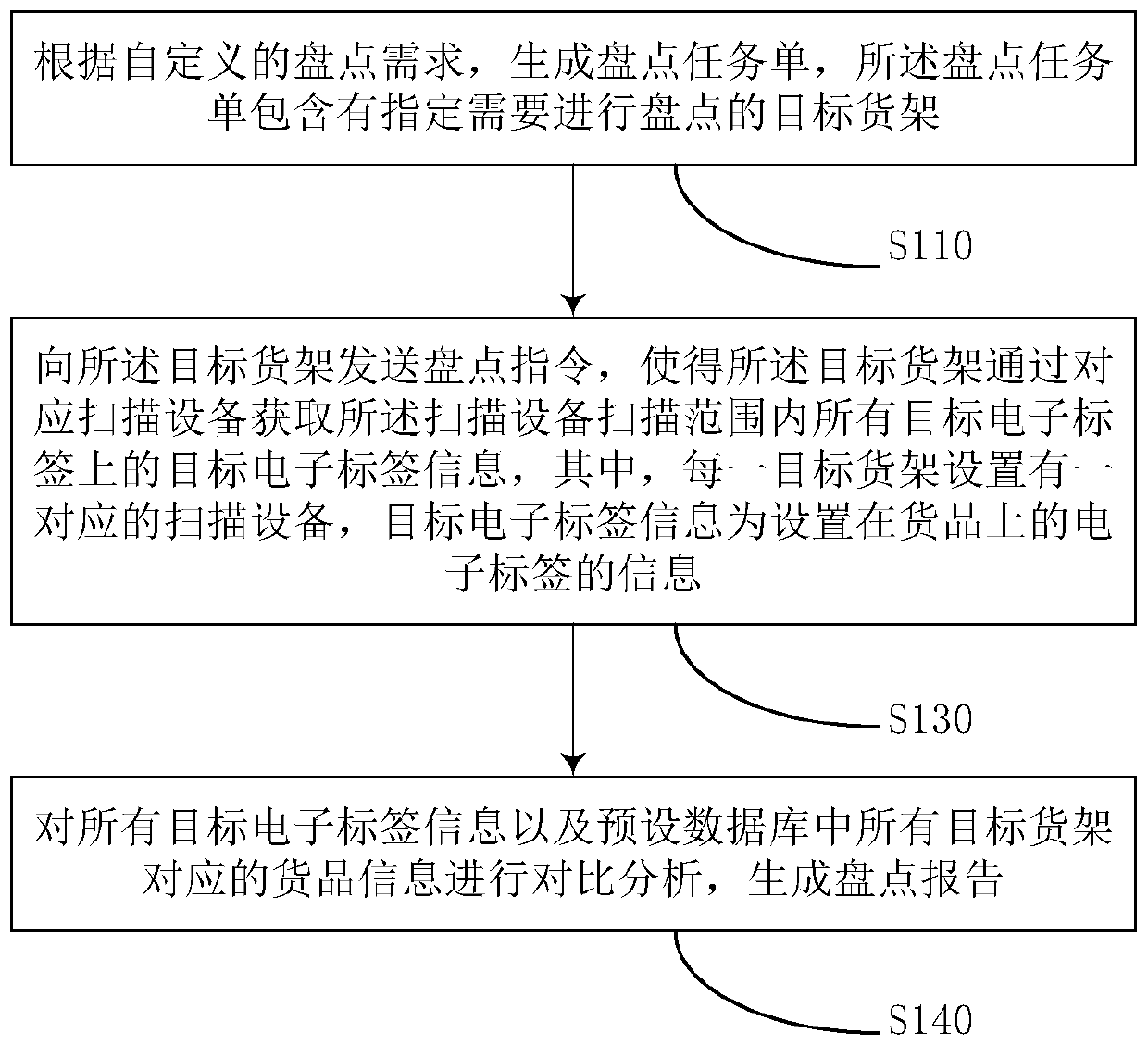

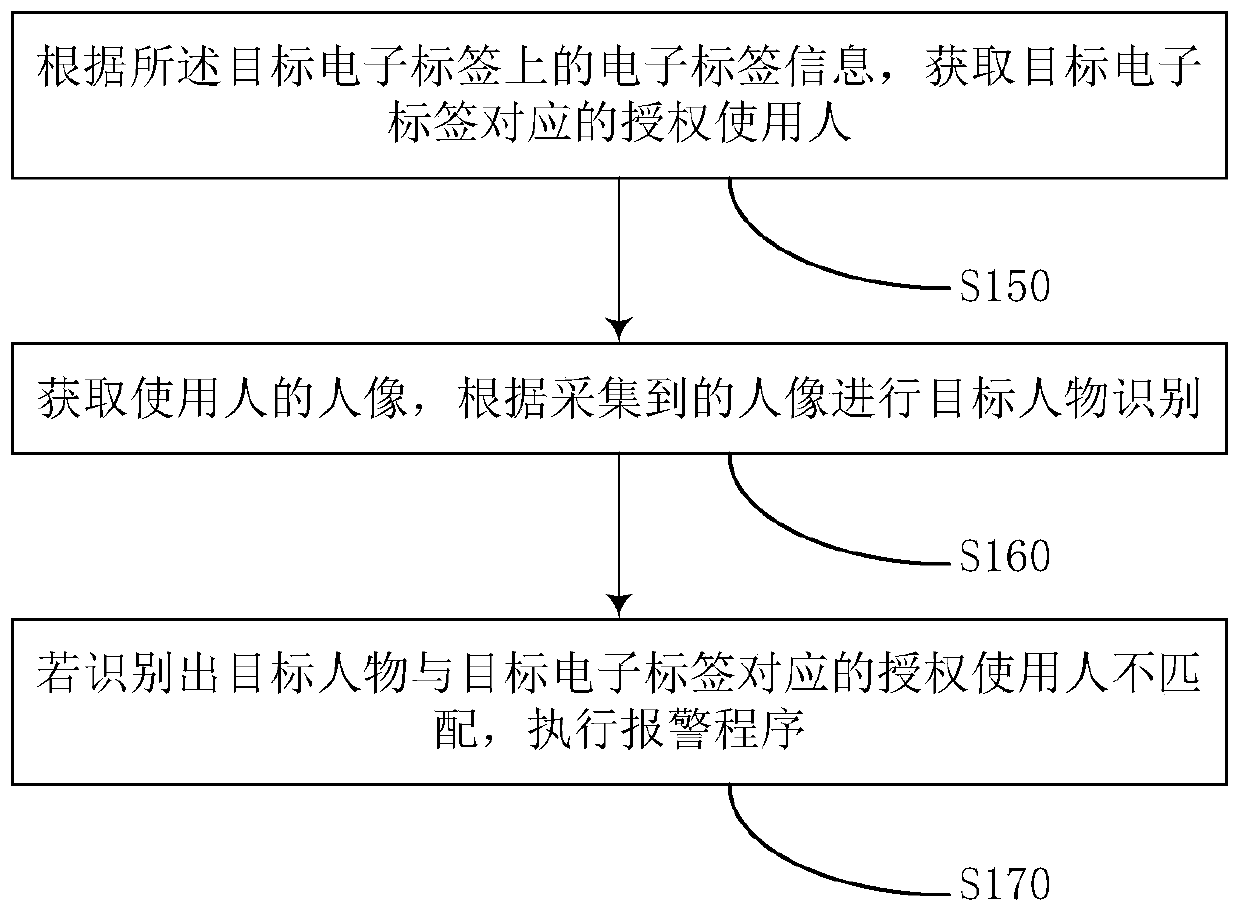

Shelf inventory method based on radio frequency identification and related device

ActiveCN110677174AInventory realizationImprove completenessEncryption apparatus with shift registers/memoriesParticular environment based servicesElectronic taggingRadio frequency

The invention discloses a shelf inventory method and device based on radio frequency identification, computer equipment and a storage medium, and belongs to the technical field of wireless radio frequency identification, and the method comprises the steps: generating an inventory task list according to a self-defined inventory demand, wherein the inventory task list comprises a target goods shelfwhich is specified to be subjected to inventory; sending an inventory instruction to the target shelf, so that the target shelf acquires target electronic tag information on all target electronic tagsin a scanning range of scanning equipment through the scanning equipment; and performing comparative analysis on all the target electronic tag information and the goods information corresponding to all the target shelves in the preset database to generate an inventory report. In this way, complex manual operation is reduced, and the intelligent degree and the inventory efficiency of warehouse shelf inventory are improved.

Owner:PING AN TECH (SHENZHEN) CO LTD

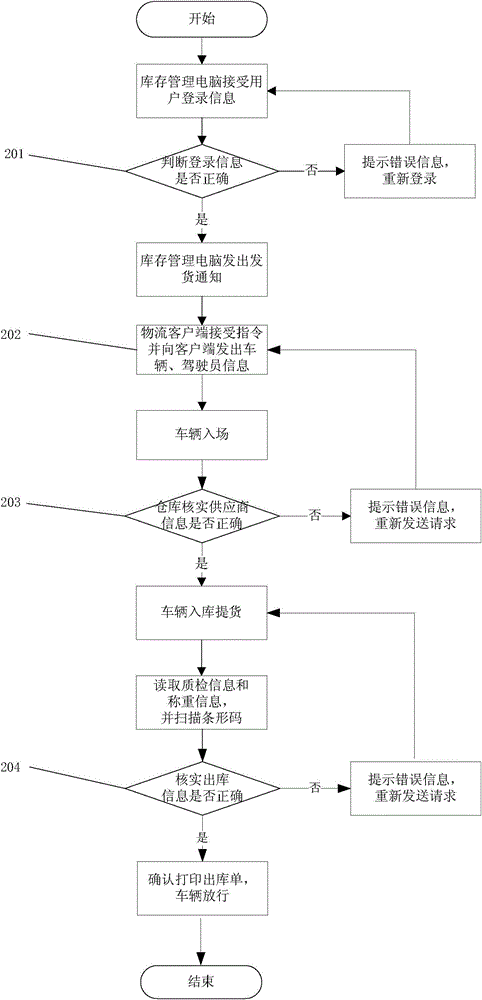

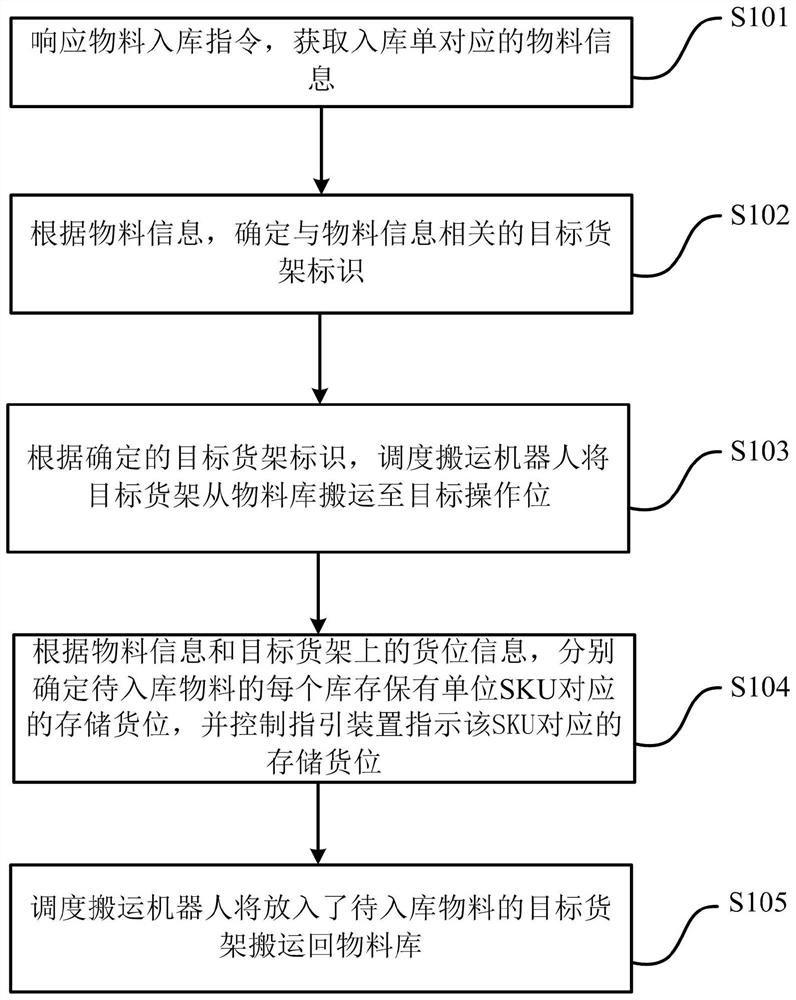

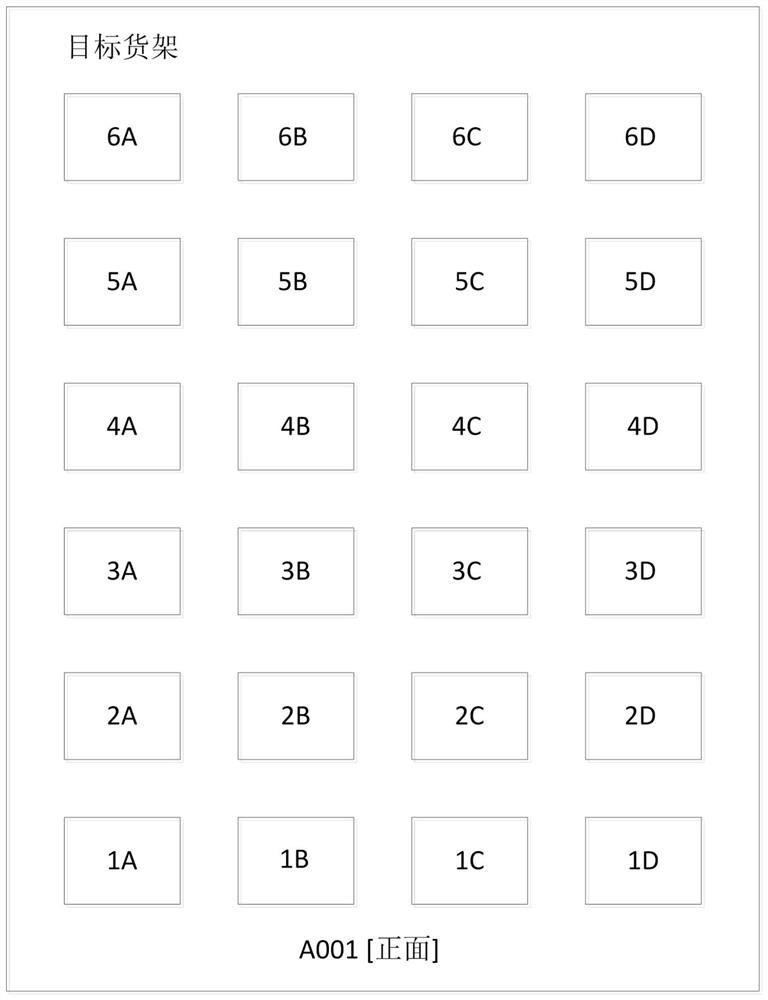

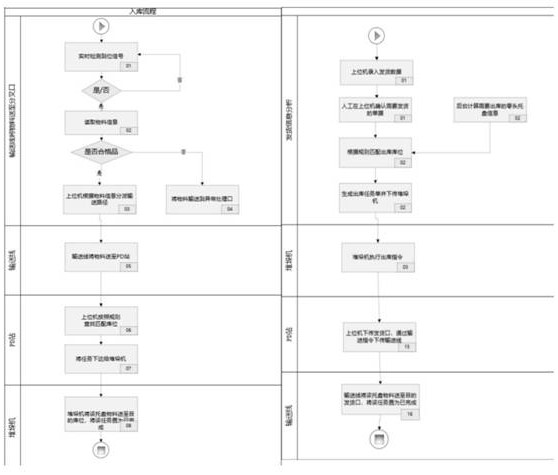

Methods for controlling warehousing, delivery and inventory of materials and material management system

ActiveCN112678407AReduce work intensityShorten delivery timeStorage devicesStock keeping unitMaterials management

The invention provides methods for controlling warehousing, delivery and inventory of materials and a material management system. The method for controlling warehousing of materials comprises the following steps: acquiring material information corresponding to a warehousing list in response to a material warehousing instruction; determining a target shelf identifier related to the material information according to the material information; scheduling a carrying robot to carry a target shelf from a material warehouse to a target operation position according to the determined target shelf identifier; determining a storage goods allocation corresponding to each stock keeping unit (SKU) of to-be-warehoused materials respectively according to the material information and goods allocation information on a target shelf, and controlling a guiding device to indicate the goods allocation corresponding to the SKU; and scheduling the carrying robot to carry the target shelf where the to-be-warehoused materials are placed back to the material warehouse. According to the embodiment of the invention, the carrying robot is scheduled to carry the shelves to the target operation position, and a worker only needs to warehouse, deliver and check the materials at the target operation position according to an operation instruction of a laser guiding device and the corresponding display of display equipment, so that the working efficiency is improved.

Owner:BEIJING JISHUITAN HOSPITAL

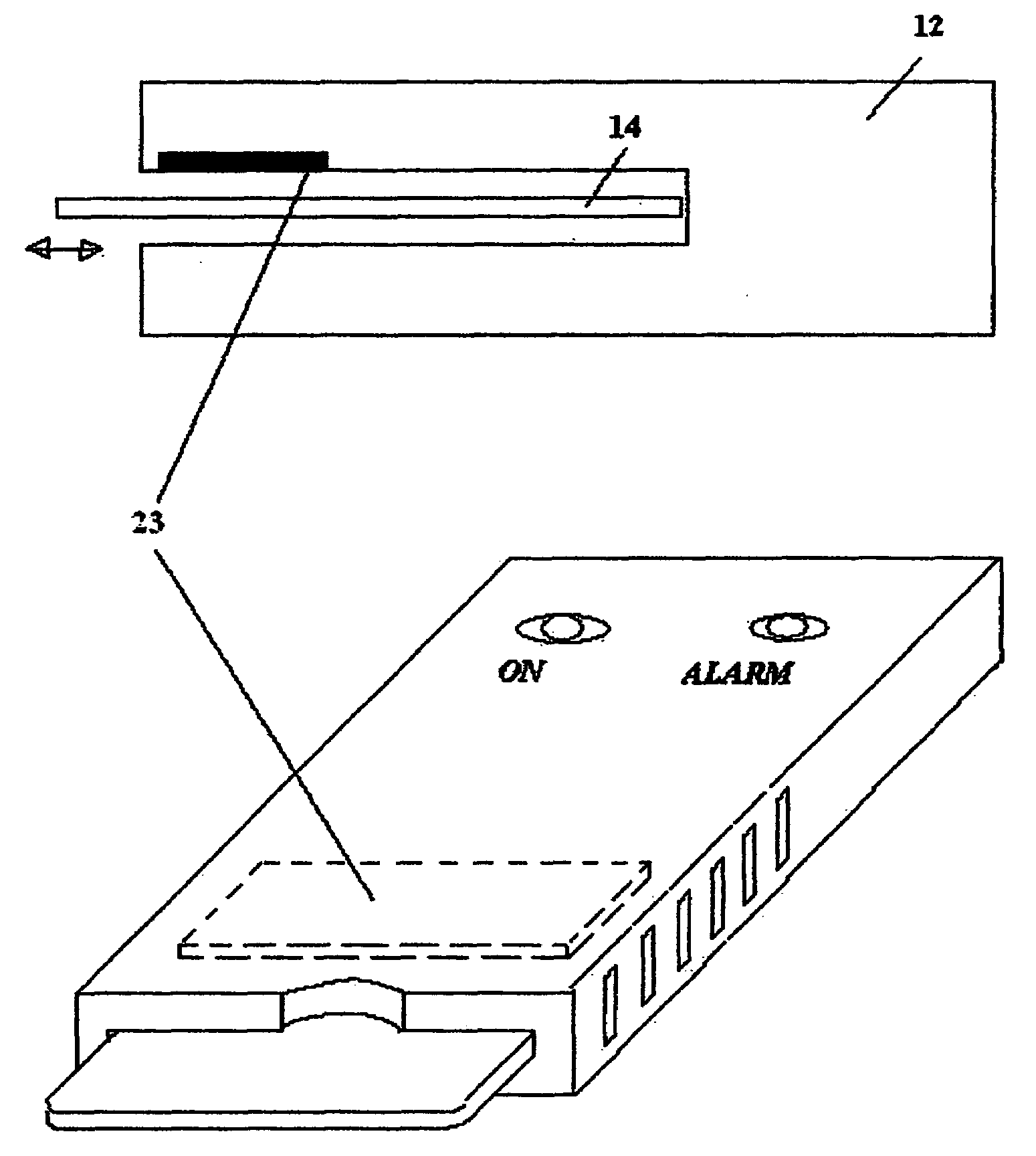

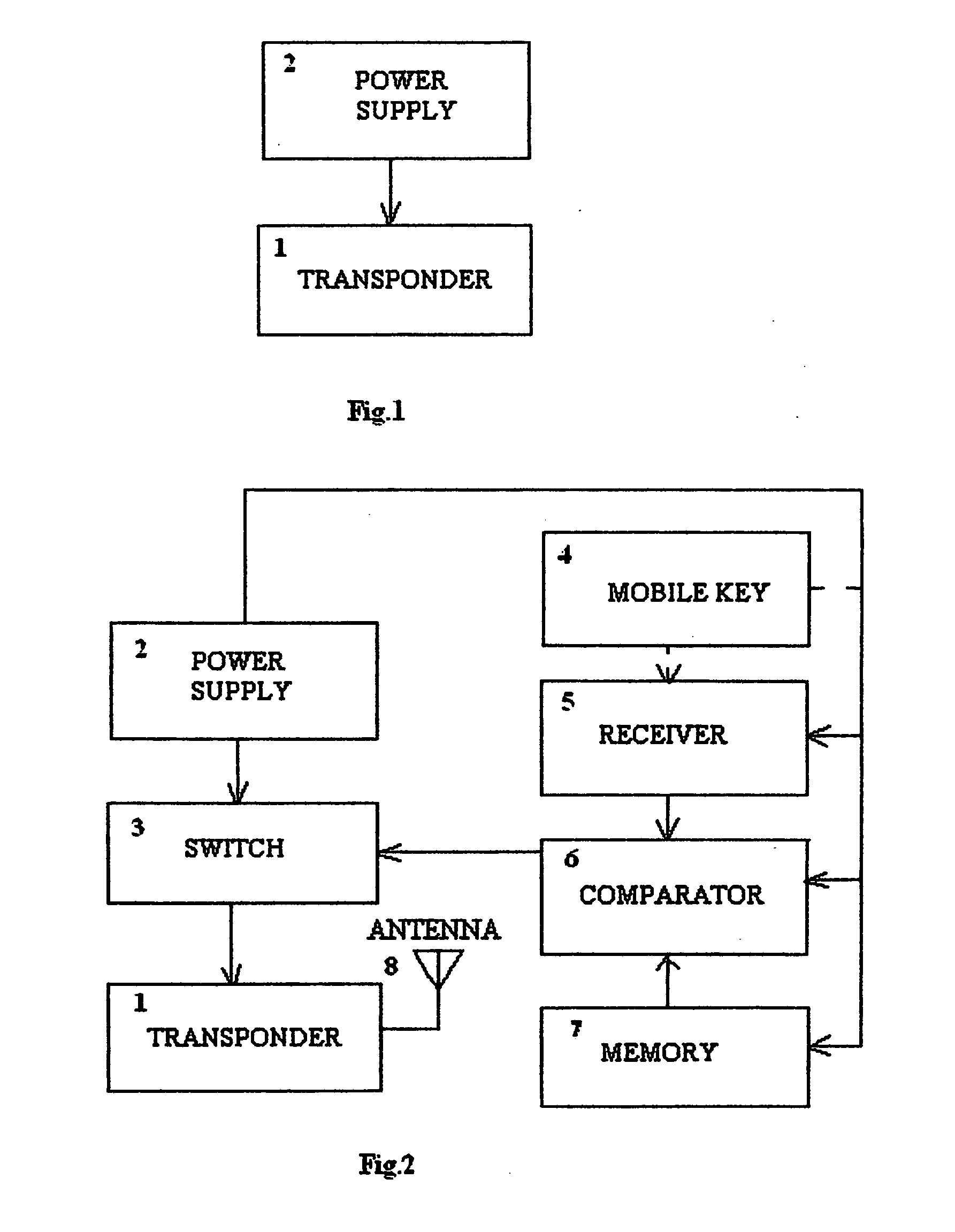

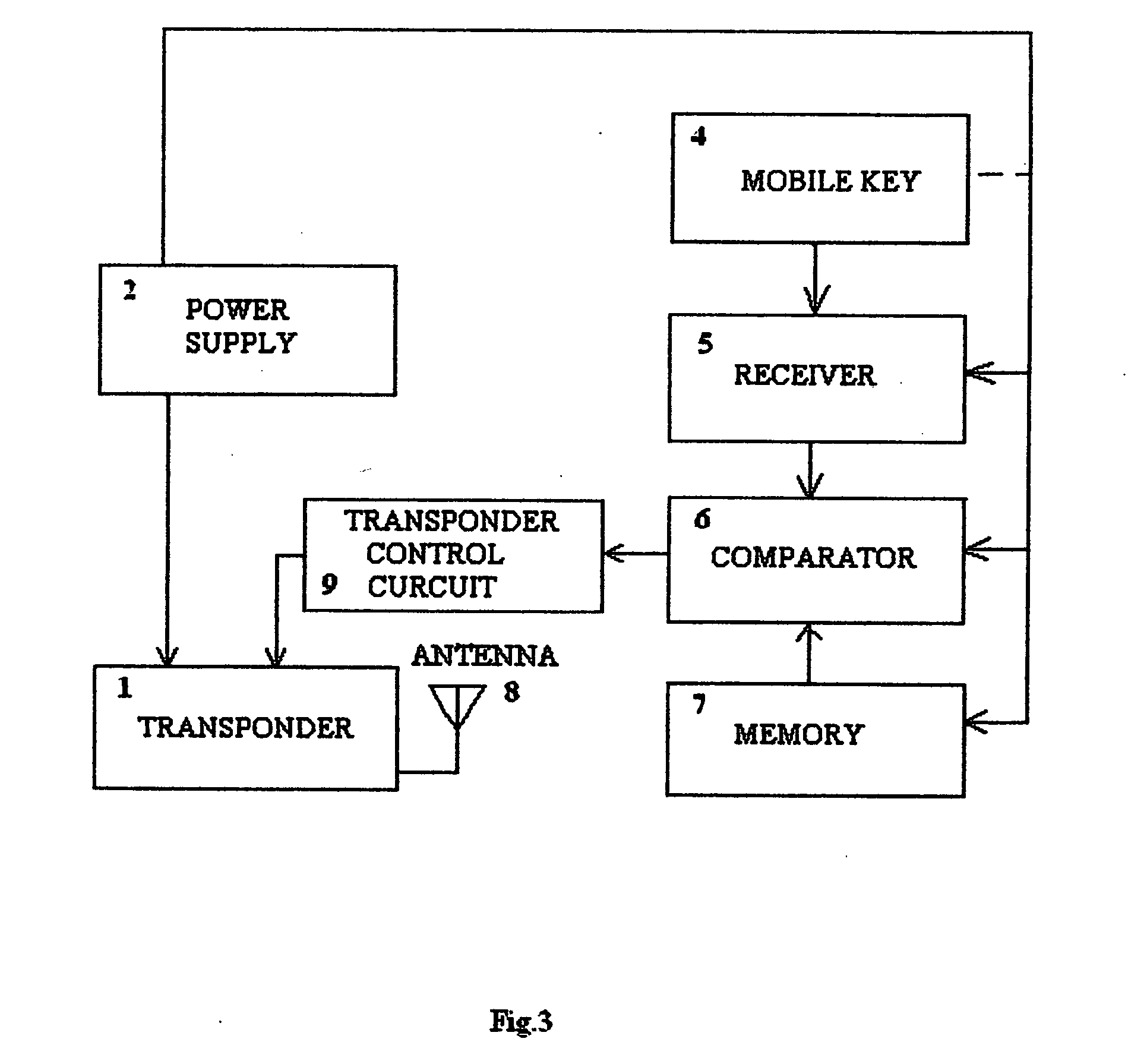

RFID tag with security features

InactiveUS20080204237A1Reduce search timeComplicated processAnti-theft devicesBurglar alarm by hand-portable articles removalComputer hardwareStock-taking

The apparatus is applicable for stock-taking or for controlling items such as vehicles located in a garage. The device is provided with tags having transponders carrying RFID codes individually which may be activated by secure key, in the form of a card, to recognize an authorized access to the items. Auxiliary RFID transponders may be activated by a primary RFID transponder through induced voltage. A receiver upon receiving a signal of electronic code from the secure key will compare it with legitimate electronic codes in the transponder memory. If the code coincides with a legitimate electronic code, a transponder recognition device creates a signal to operate the primary transponder to transmit an information signal carrying the RFID codes.

Owner:LEVIN EDUARD

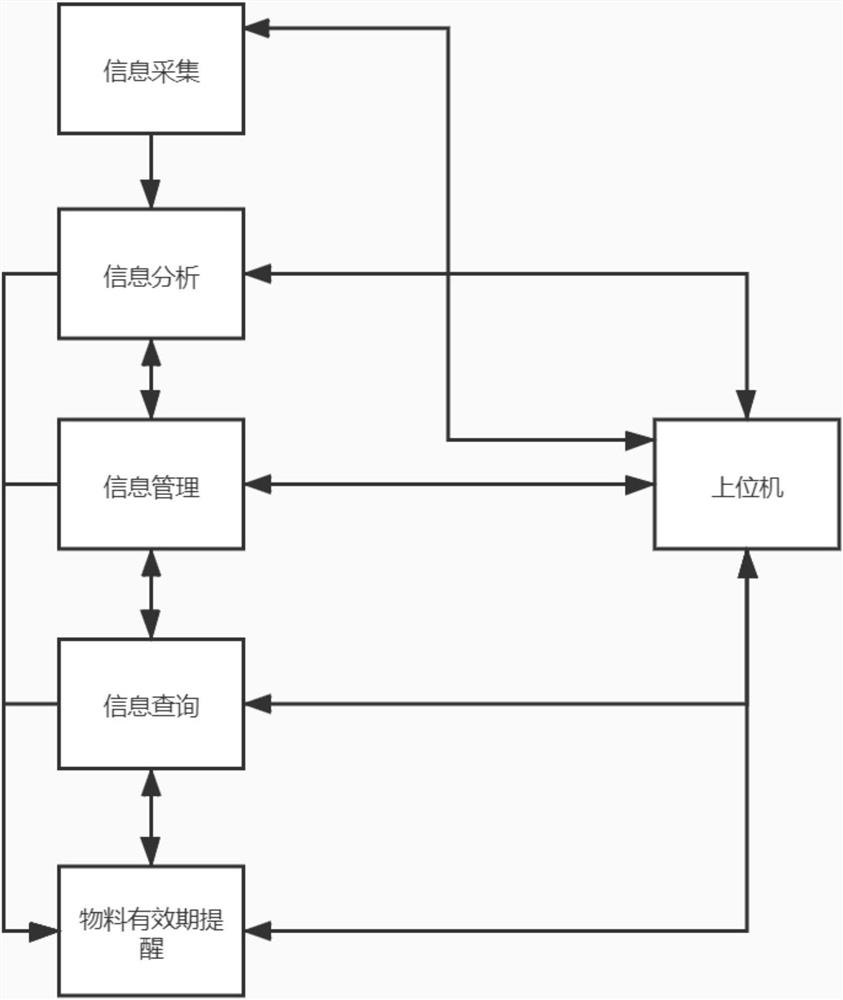

Material warehouse-in and warehouse-out device and system thereof

InactiveCN112249574ASolve the labor-intensiveReduce backlogStorage devicesSoftware systemControl system

The invention discloses a material warehouse-in and warehouse-out device which comprises a conveying line, a transfer device and a roadway stacking machine, the conveying line, the transfer device andthe stacking machine are all connected with an upper computer through a PLC and a network server, and a WMS-based material warehouse-in and warehouse-out system and a WCS control system are arrangedin the upper computer. The material warehouse-in and warehouse-out device and the material warehouse-in and warehouse-out system therein are used for carrying out material warehouse-in, inventory andwarehouse-out work, all products and equipment are connected with product storage labels in series through a software system, the whole warehouse-in and warehouse-out process is digitized and displayed through the software system, the warehouse-in and warehouse-out conditions of materials or cargos in a storage workshop are reflected in detail, the materials or the cargos are sequentially discharged according to the length of storage time, the problem of material or cargo overstock caused by long-term storage is reduced, the materials are evenly distributed at different warehouse positions ina warehouse through storage scheduling of inventory commodities, and multiple warehouse positions can work at the same time during warehouse-out working. The production efficiency is improved, and product tracing is facilitated.

Owner:青岛星华智能装备有限公司

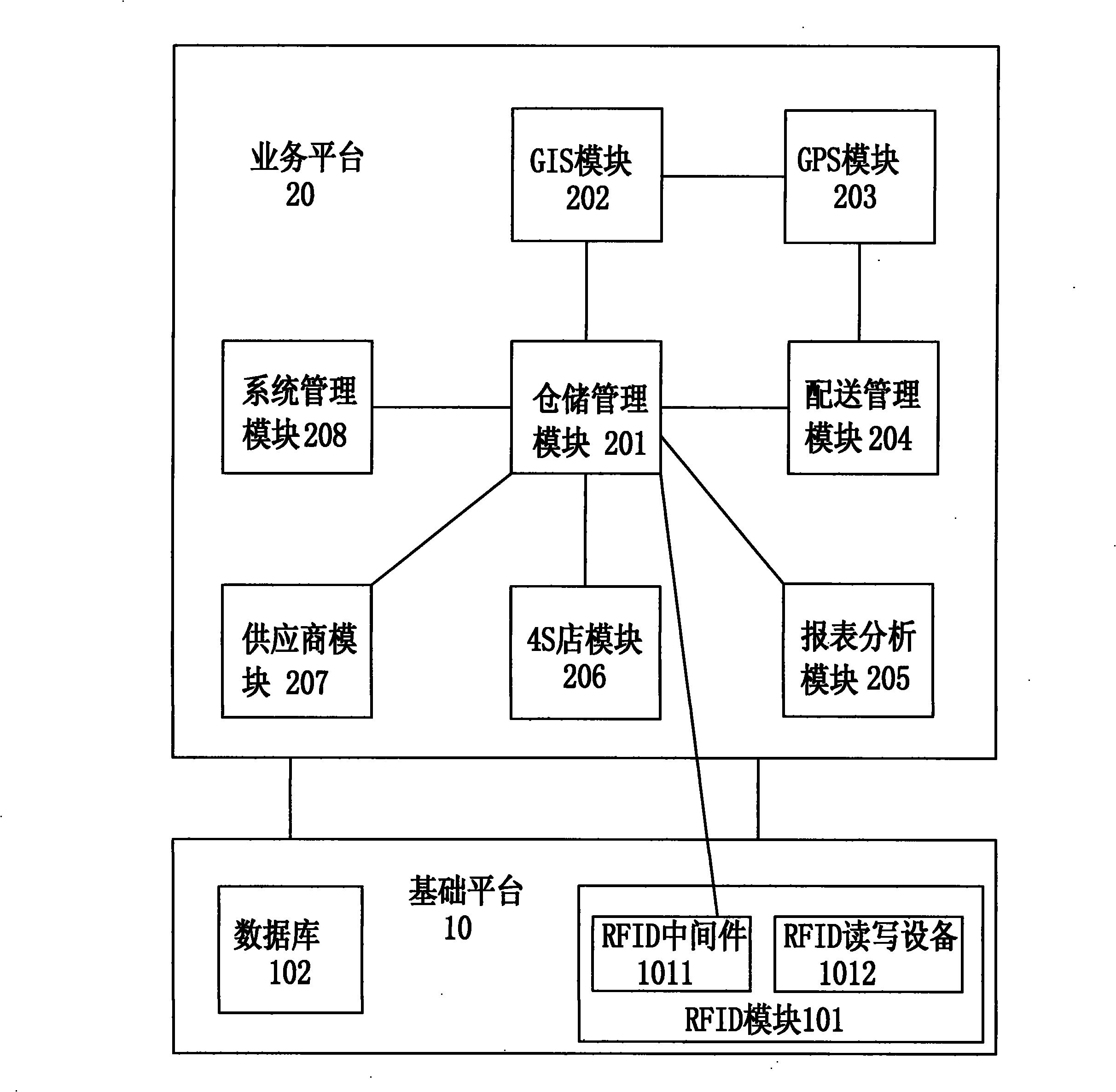

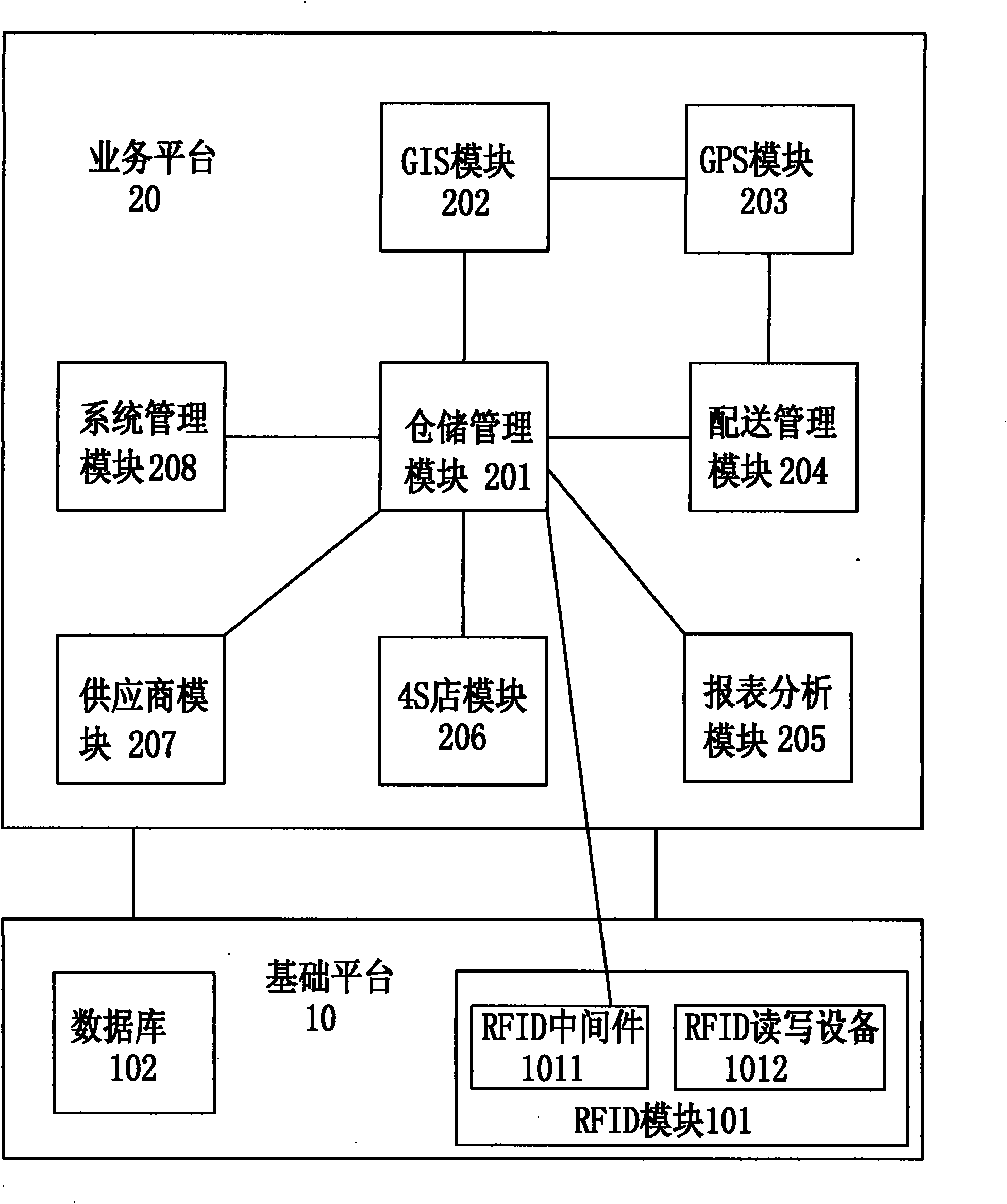

Radio frequency warehousing comprehensive management information system

InactiveCN102184462AQuality improvementAugmentation happens exactlyData processing applicationsCo-operative working arrangementsGlobal information systemSystems management

The invention discloses a radio frequency warehousing comprehensive management information system, which comprises a base platform and a service platform, wherein the service platform comprises a warehousing management module, a GIS (Global Information System) module, a GPS (Global Positioning System) module, a distribution management module, a statement analysis module, a 4S (Sale, Spare part, Service and Survey) shop module, a supplier module and a system management module; the base platform comprises an RFID (Radio Frequency Identification) module and a database; the RFID module comprises RFID middleware and RFID reading and writing equipment; the warehousing management module is connected with the RFID middleware, the GIS module, the GPS module, the distribution management module, the statement analysis module, the 4S shop module, the supplier module and the system management module respectively; the GPS module is also connected with the GIS module and the distribution management module respectively; and the supplier module is also connected with the system management module. The system has high inspection efficiency; and quality of stock taking operation can be improved and cargoes can be tracked.

Owner:FENGSHEN LOGISTICS CO LTD

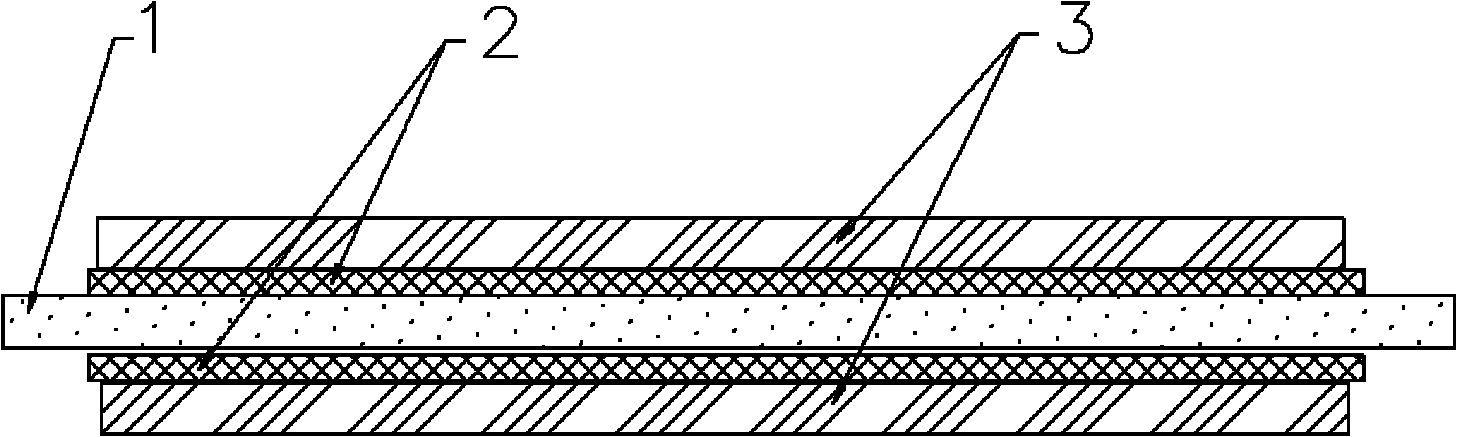

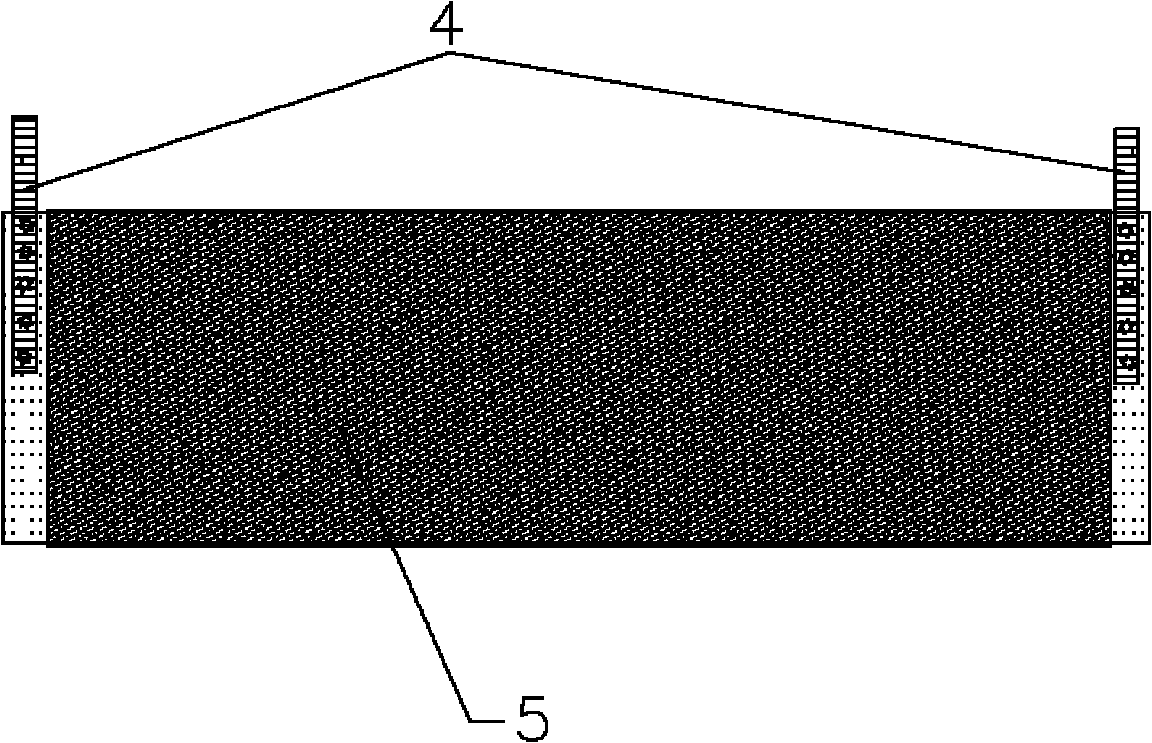

Coating process for cathode material lithium iron phosphate and lithium ion battery thereof

InactiveCN101934269ASolve the phenomenon of material dropImprove qualityLiquid surface applicatorsElectrode manufacturing processesHigh rateSodium-ion battery

The invention discloses a coating process for a cathode material lithium iron phosphate and a lithium ion battery thereof. The coating process comprises the following steps of: coating a layer of mixed stock taking LixNiyCozMnpMqO2 as an active substance on a current collector aluminum foil, and oven-drying the mixed stock; and on such a basis, coating a layer of mixed stock taking the lithium iron phosphate material as the active substance, and oven-drying the mixed stock. The coating process for the lithium iron phosphate material can be applied to the production of cylindrical aluminum-shelled lithium ion batteries suitable for high-rate discharge, and has the advantages of solving the problem of material fall caused by poor bonding between the lithium iron phosphate material and the current collector aluminum foil and producing the high-quality rate-type lithium ion batteries, along with simplicity and reliability.

Owner:NINGBO VEKEN BATTERY

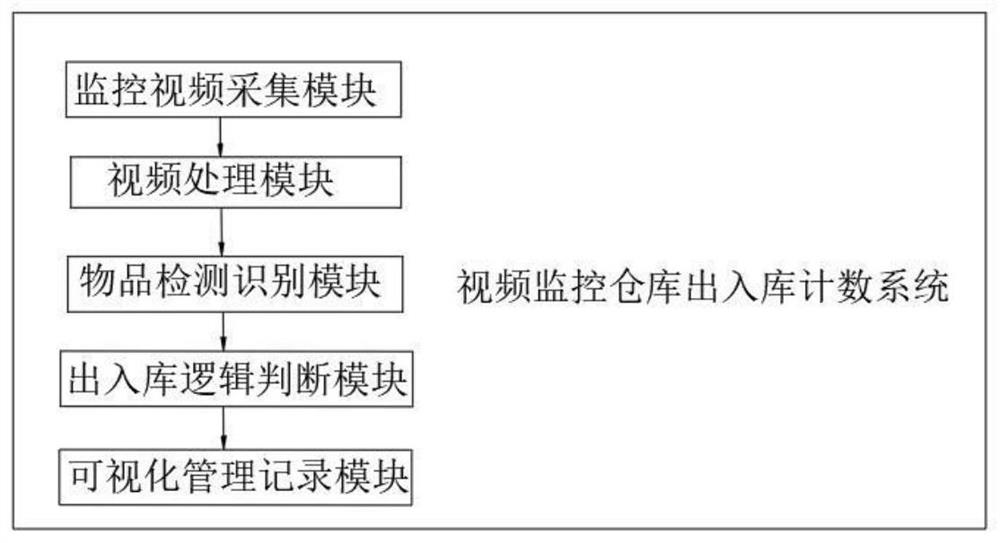

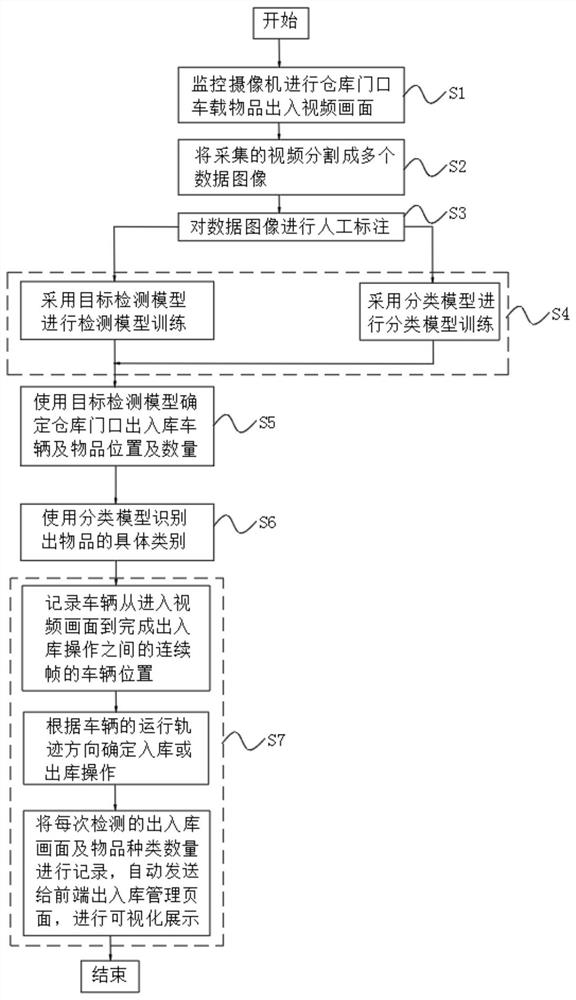

Video monitoring warehouse in-out warehouse counting system and method based on deep learning

PendingCN112001228AImprove efficiencyGuaranteed real-timeCharacter and pattern recognitionLogisticsVideo monitoringIn vehicle

The invention discloses a video monitoring warehouse in-out warehouse counting system and method based on deep learning, and relates to the technical field of deep learning. The system comprises a monitoring video acquisition module, a video processing module, an article detection and identification module, a warehouse-in and warehouse-out logic judgment module and a visual management recording module. The method comprises the following steps: S1, acquiring a monitoring video; S2, segmenting the acquired video; S3, performing manual marking; S4, respectively carrying out detection model training and classification model training; S5, the positions and the number of the vehicle-mounted articles are determined; S6, accurately identifying the article; and S7, identifying, recording and displaying the vehicle information. According to the invention, warehouse-in and warehouse-out conveying images can be recorded in real time, traceless searching in the subsequent storage inventory processis avoided, the whole process does not depend on participation of people, the types and the number of warehouse-in and warehouse-out articles are recorded in real time by accurately detecting and identifying the articles in the video images, and high efficiency, real-time performance, accuracy and intelligence of warehouse warehouse-in and warehouse-out article supervision are ensured.

Owner:上海品览数据科技有限公司

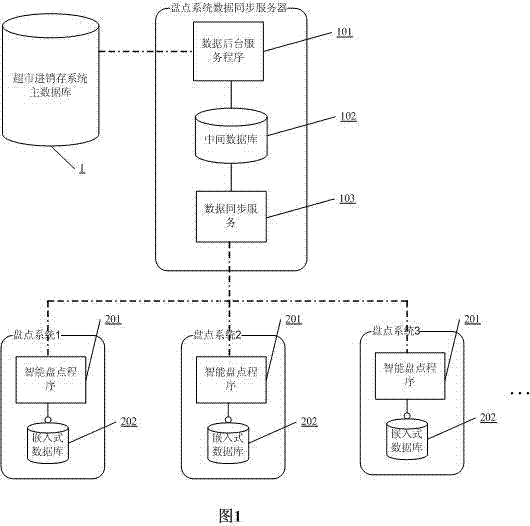

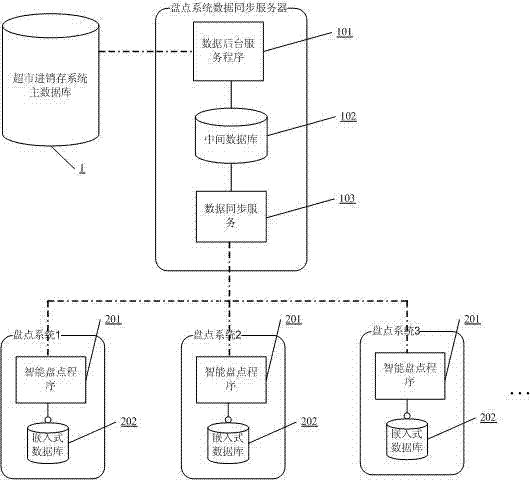

Wireless inventory verification system based on database synchronization

InactiveCN102393935ARealize data transmissionPlay a foolproof roleLogisticsData synchronizationVerification system

A wireless inventory verification system based on database synchronization relates to a wireless inventory verification device. The wireless inventory verification system comprises a main database of a supermarket inventory management system, a data synchronism server of an inventory system, and inventory systems. The supermarket inventory management system is connected with the data synchronism server of the inventory system, and the data synchronism server of the inventory system is connected with a plurality of inventory systems. The supermarket inventory verification is easily achieved without network, and the inventory data is easily uploaded under the unobstructed wireless network to replace the conventional paper and pen copying and manual entering, thereby the efficiency is increased greatly and the inventory accuracy is improved.

Owner:CHANGSHA WIN EXPERT NETWORK TECH

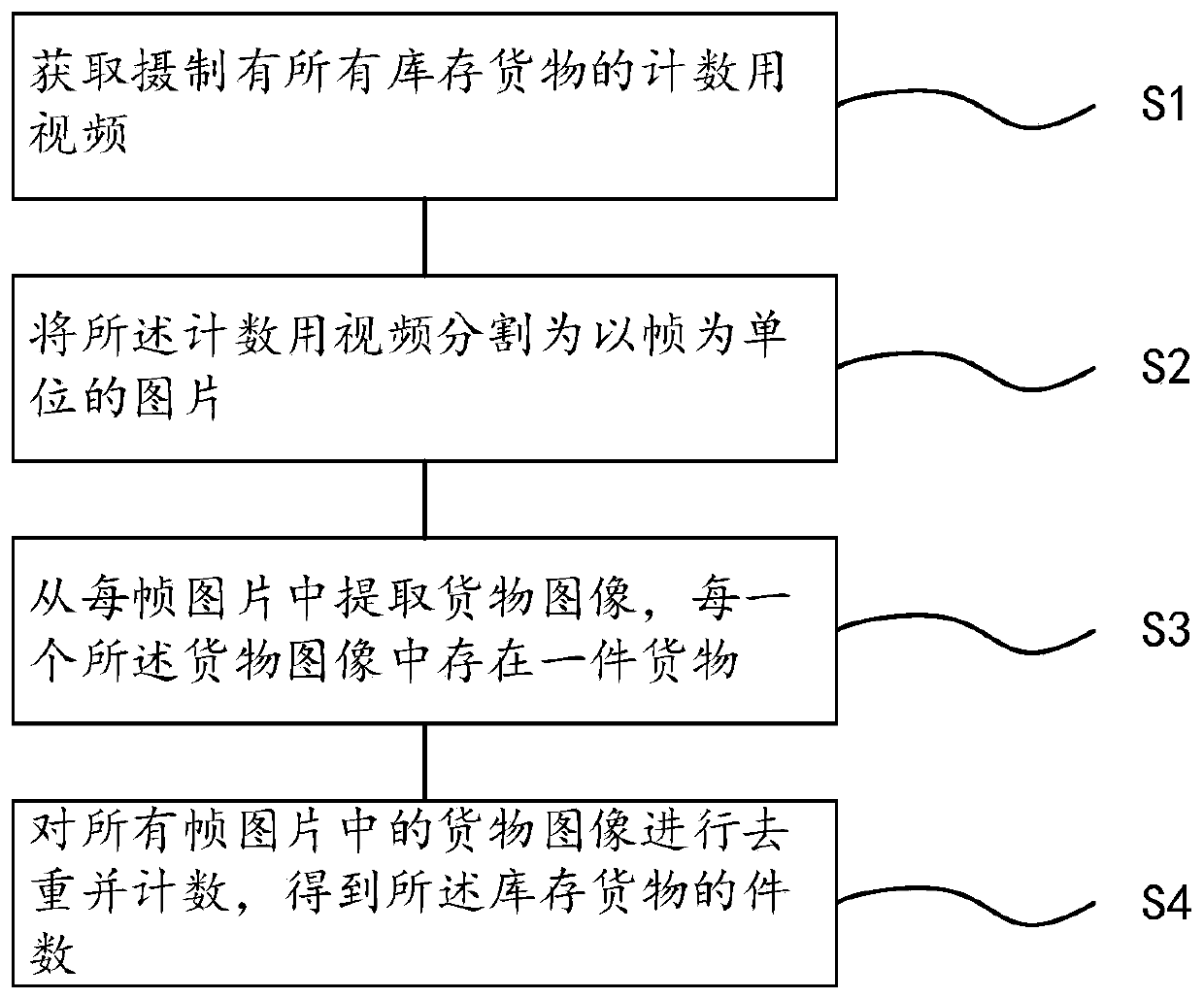

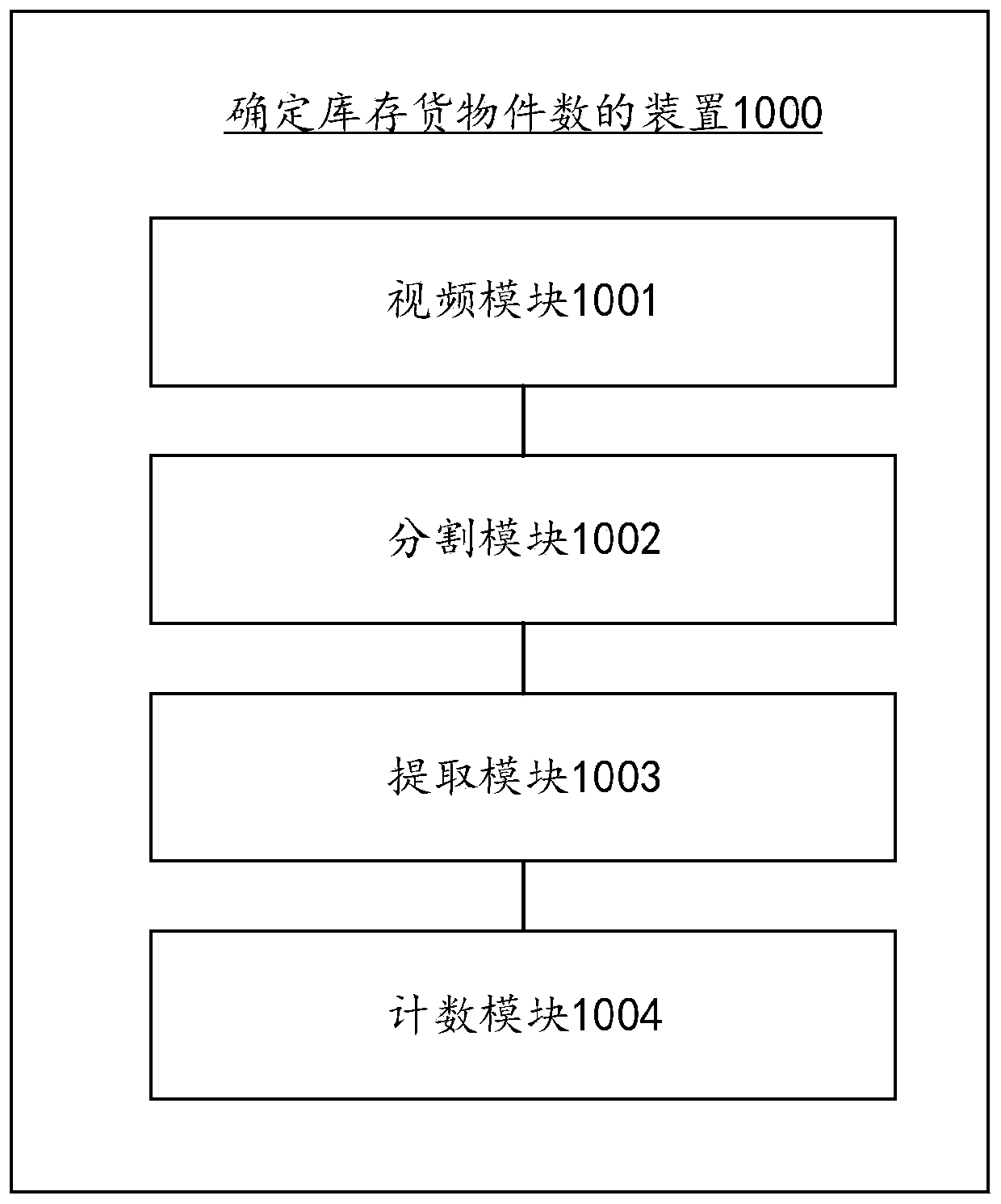

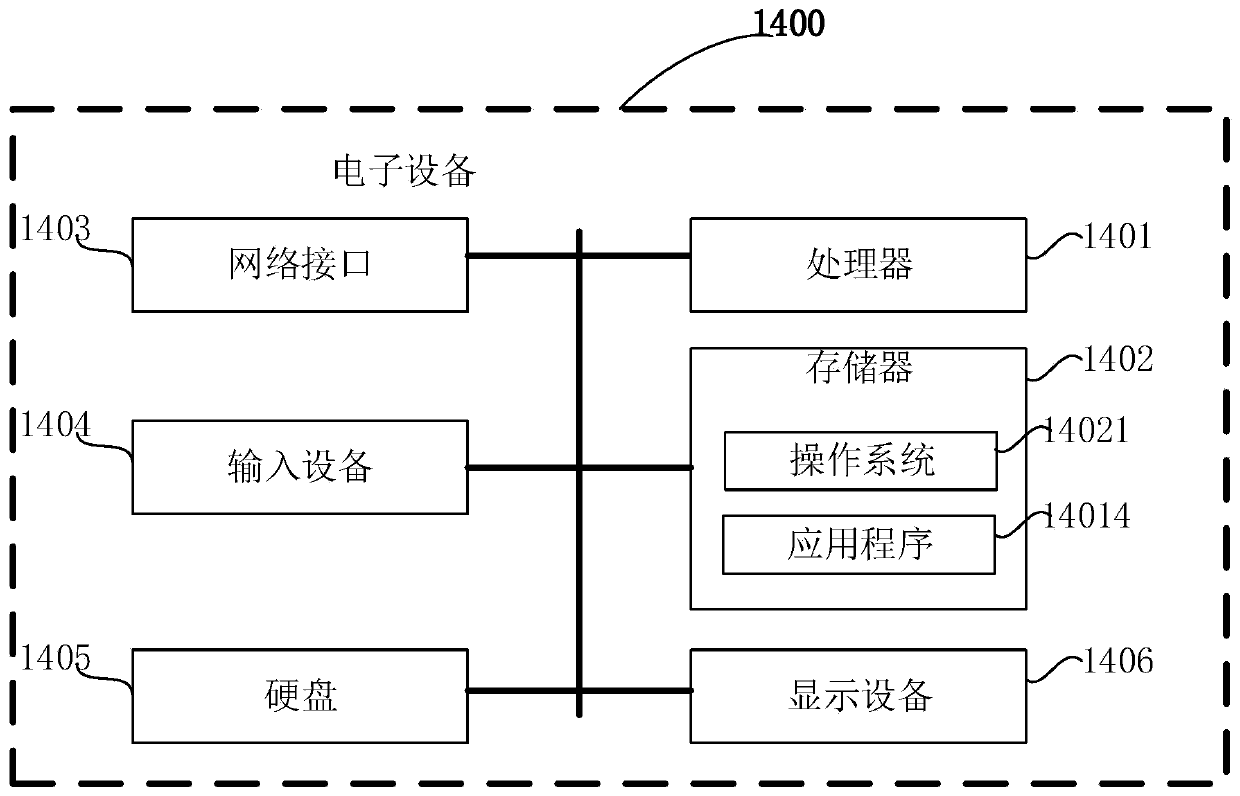

Method for determining number of inventory goods, warehouse inventory method, device and appartus

InactiveCN110929626AProcessing speedLow costCharacter and pattern recognitionLogisticsCounting NumberStock-taking

The invention provides a method for determining the number of inventory goods, a warehouse inventory method, device and apparatus, and the method for determining the number of inventory goods comprises the steps: obtaining a counting video of all inventory goods; dividing the video for counting into pictures in units of frames; extracting a inventory image from each frame of picture, wherein one cargo exists in each inventory image; and carrying out duplicate removal and counting on the cargo images in all the frame pictures to obtain the number of the inventory cargoes. Video counting is performed on the inventory cargoes, the processing speed is high, the cost is low, and the warehouse inventory efficiency can be improved.

Owner:上海欧冶物流股份有限公司

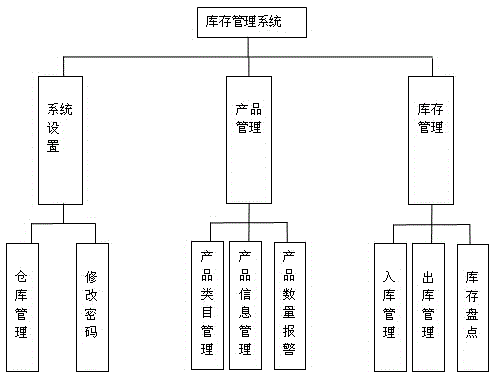

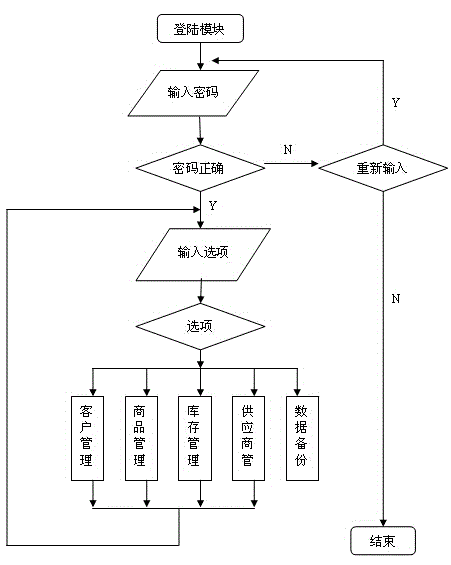

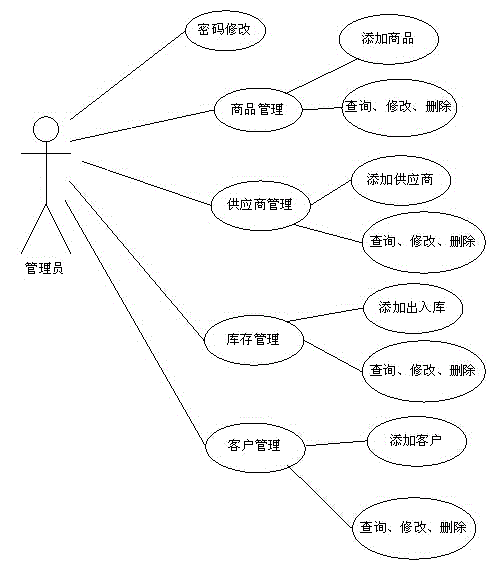

Commodity inventory management information system

InactiveCN104318414AImprove resource utilizationImprove accuracyLogisticsSpecial data processing applicationsInformation processingData stream

The invention discloses a commodity inventory management information system, and relates to the computer management system. The commodity inventory management information system uses a Browser / Server structure as an overall structure of the commodity inventory management information system, and is provided with a system setup unit, a product management unit and an inventory management unit, wherein the system setup unit comprises a store management module and a password change module, the product management unit comprises a product category management module, a product information management module and a product quantity alarm module, the inventory management module comprises a warehousing management module, a warehouse exit management module and an inventory verification module, and data flows, data elements, data storage, data processing and external items of all the above modules are described through a data dictionary, corresponding database lists are built, and the database lists are connected with a database through a JDBC (java database connectivity) technology of the Java language. The commodity inventory management information system can avoid commodity business management randomness, improves accuracy and speed of commodity information processing, and accurately and timely grasps internal market information and other external information of a company so as to improve decision ability of company leaders.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

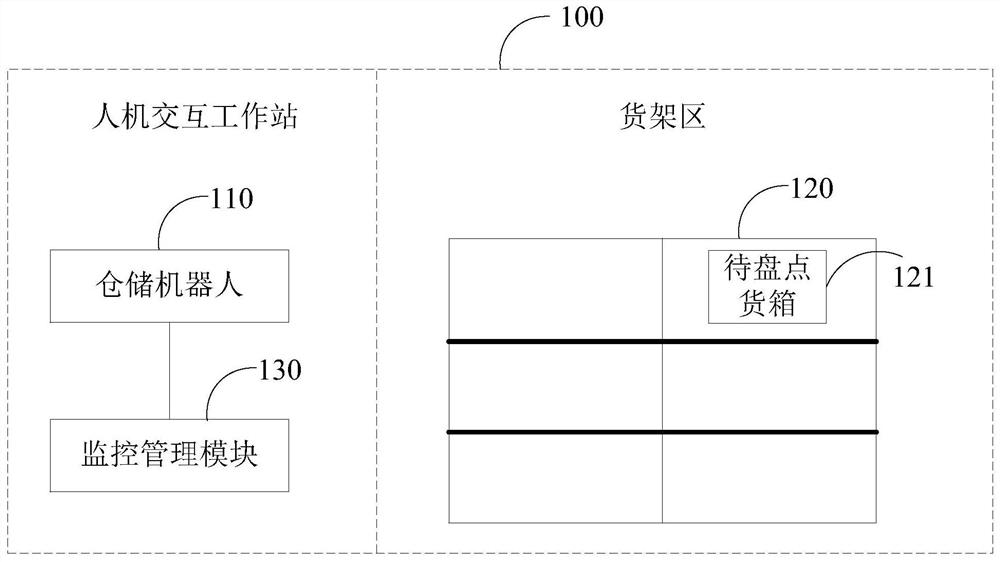

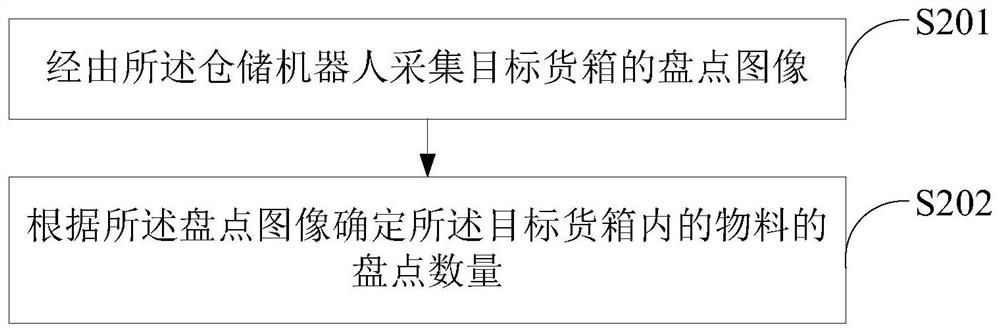

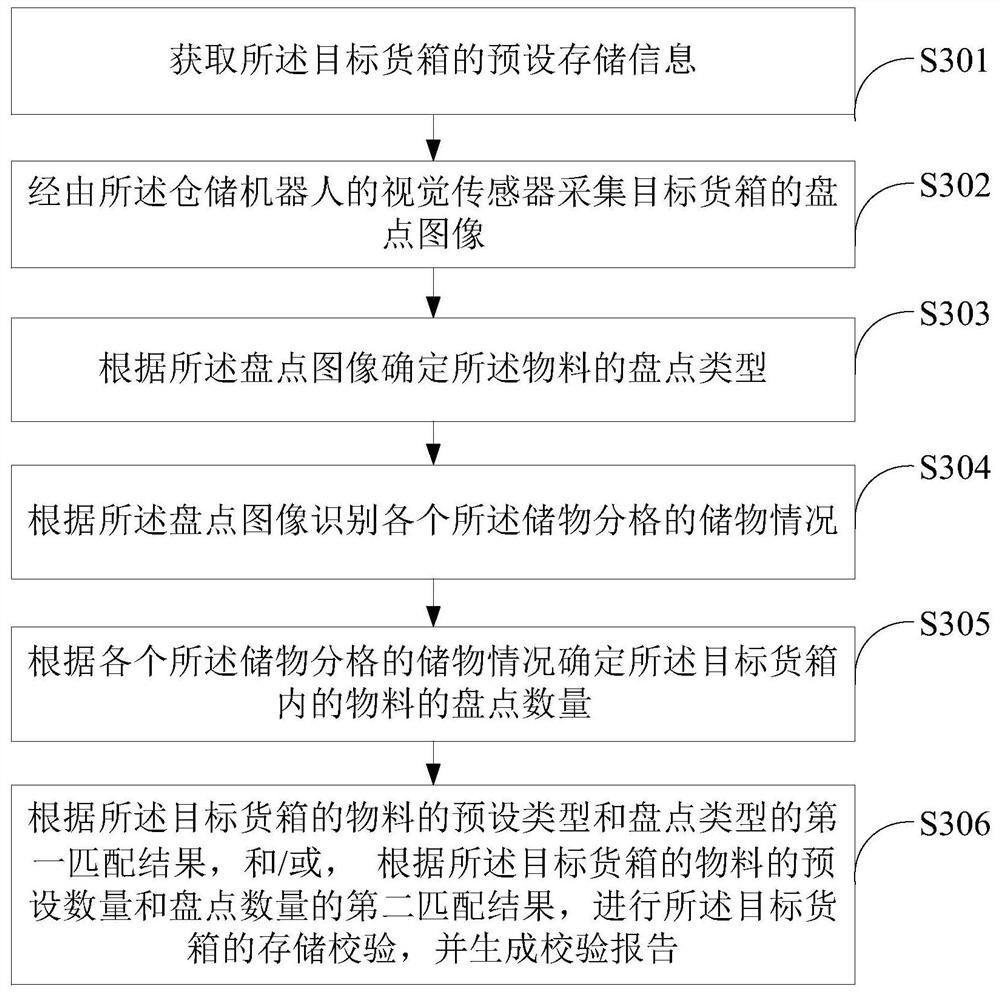

Material inventory method and device, warehousing robot and warehousing system

PendingCN111767972ARealize automatic inventoryImprove inventory efficiencyImage enhancementImage analysisEngineeringProcess engineering

The embodiment of the invention provides a material inventory method and device, a warehousing robot and a warehousing system. The material inventory method is applied to the warehousing robot, and the method comprises the following steps of collecting an inventory image of a target container through the warehousing robot, and determining the inventory quantity of the materials in the target container according to the inventory image. The embodiment of the invention discloses a technical scheme. The inventory image of the target container is collected through the warehousing robot, the quantity of the materials of the target container is determined through image recognition of the inventory image, in-situ and automatic inventory of the materials is achieved, cross-region movement of the container does not need to be conducted, the material inventory efficiency is greatly improved, and the inventory cost is reduced.

Owner:HAI ROBOTICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com