Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

37 results about "Step-growth polymerization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

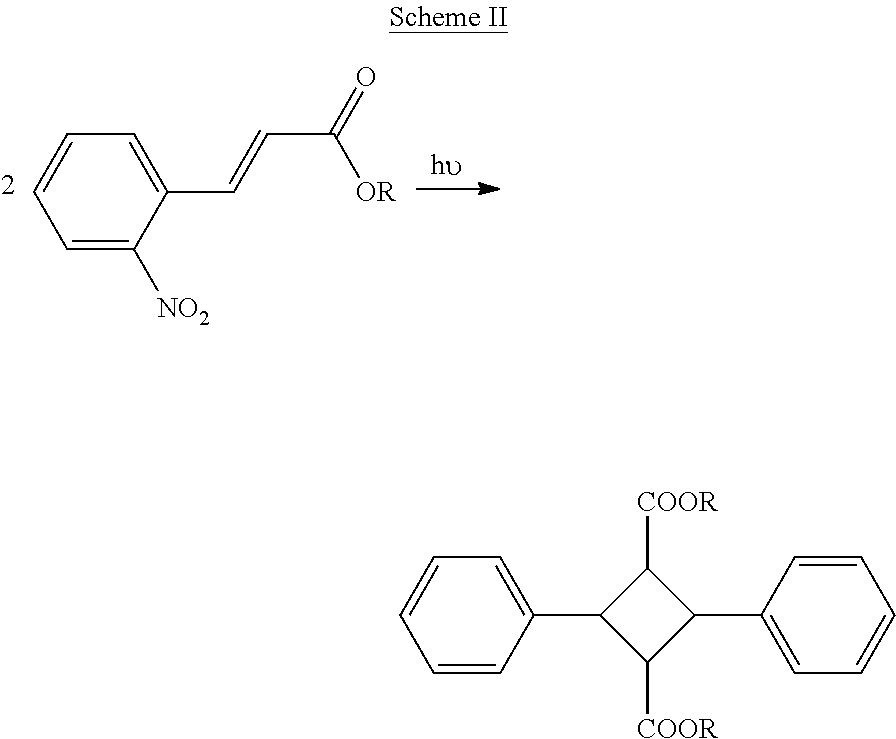

Step-growth polymerization refers to a type of polymerization mechanism in which bi-functional or multifunctional monomers react to form first dimers, then trimers, longer oligomers and eventually long chain polymers. Many naturally occurring and some synthetic polymers are produced by step-growth polymerization, e.g. polyesters, polyamides, polyurethanes, etc. Due to the nature of the polymerization mechanism, a high extent of reaction is required to achieve high molecular weight. The easiest way to visualize the mechanism of a step-growth polymerization is a group of people reaching out to hold their hands to form a human chain—each person has two hands (= reactive sites). There also is the possibility to have more than two reactive sites on a monomer: In this case branched polymers production take place.

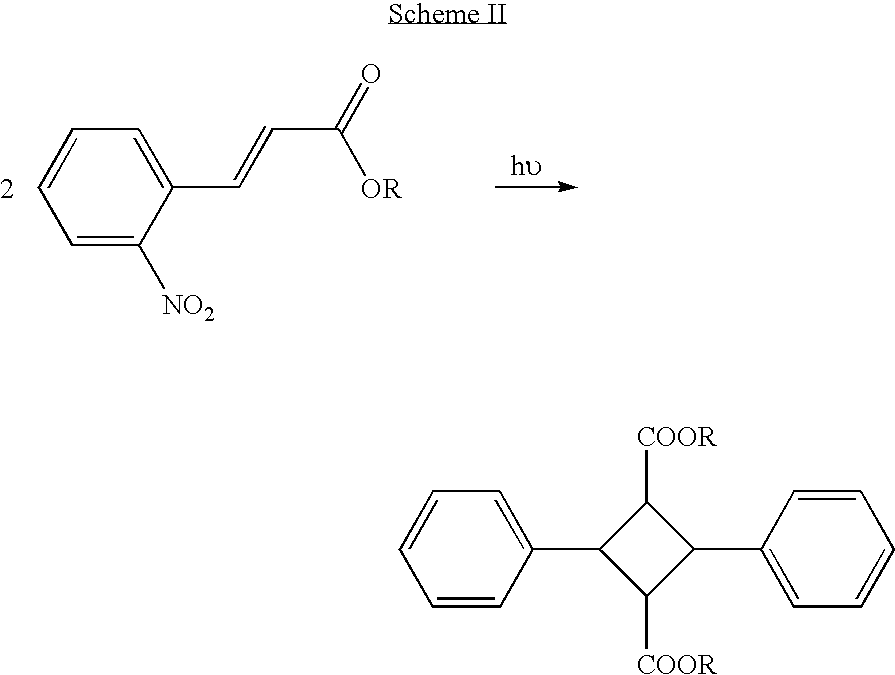

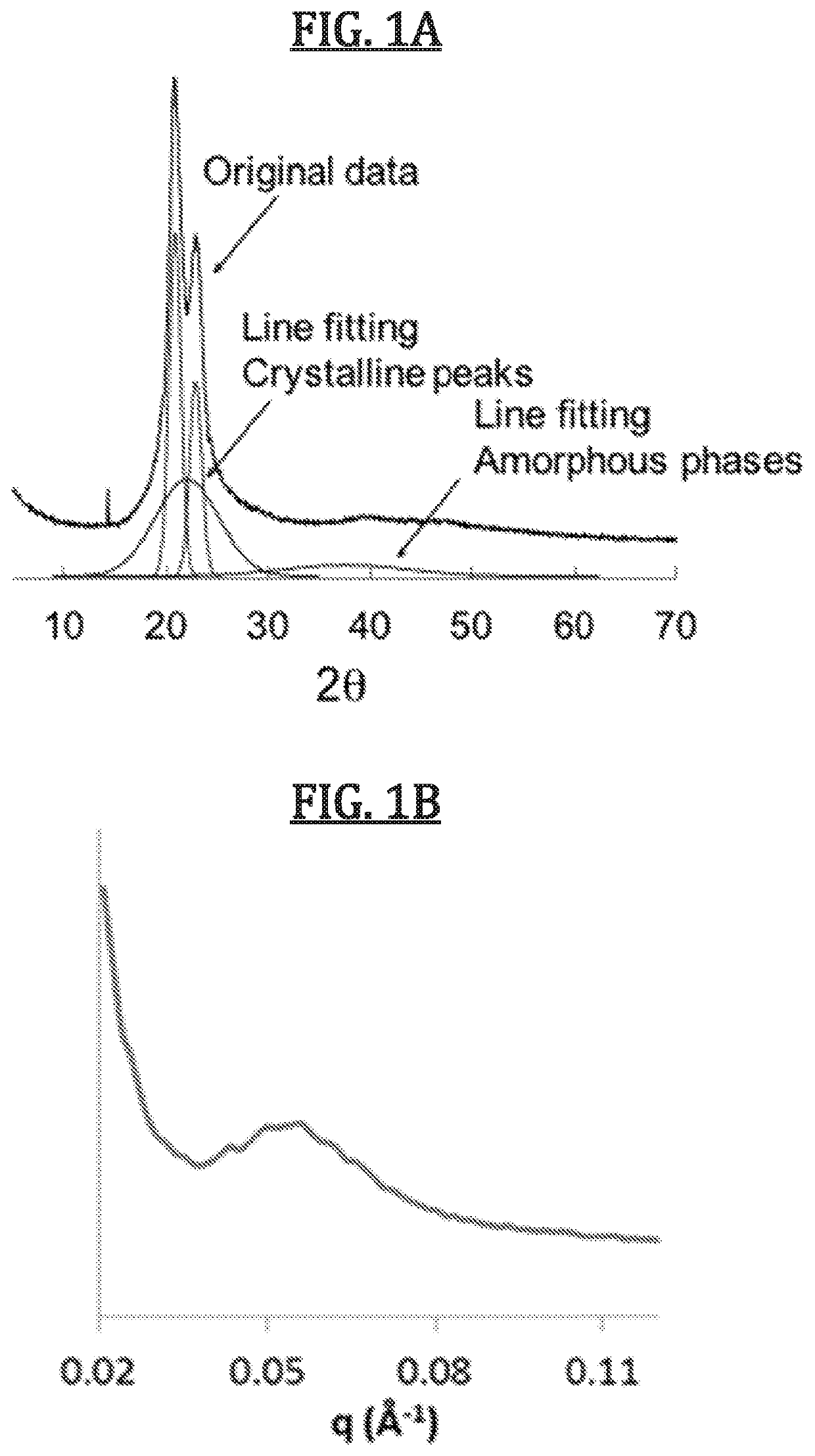

Production of ophthalmic devices based on photo-induced step growth polymerization

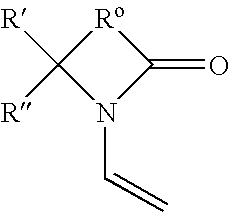

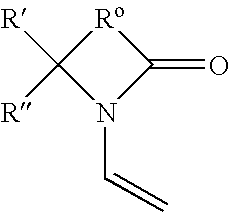

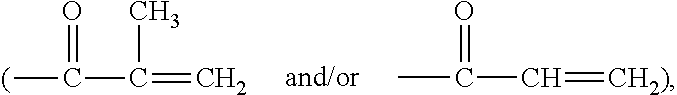

The invention provide a new lens curing method for making hydrogel contact lenses. The new lens curing method is based on actinically-induced step-growth polymerization. The invention also provides hydrogel contact lenses prepared from the method of the invention and fluid compositions for making hydrogel contact lenses based on the new lens curing method. In addition, the invention provide prepolymers capable of undergoing actinically-induced step-growth polymerization to form hydrogel contact lenses.

Owner:ALCON INC

Production of ophthalmic devices based on photo-induced step growth polymerization

The invention provide a new lens curing method for making hydrogel contact lenses. The new lens curing method is based on actinically-induced step-growth polymerization. The invention also provides hydrogel contact lenses prepared from the method of the invention and fluid compositions for making hydrogel contact lenses based on the new lens curing method. In addition, the invention provide prepolymers capable of undergoing actinically-induced step-growth polymerization to form hydrogel contact lenses.

Owner:ALCON INC

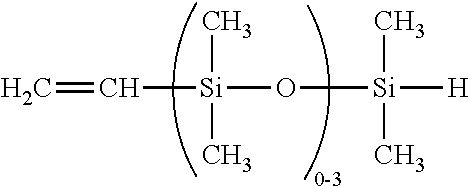

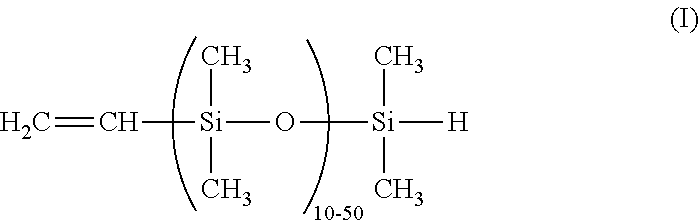

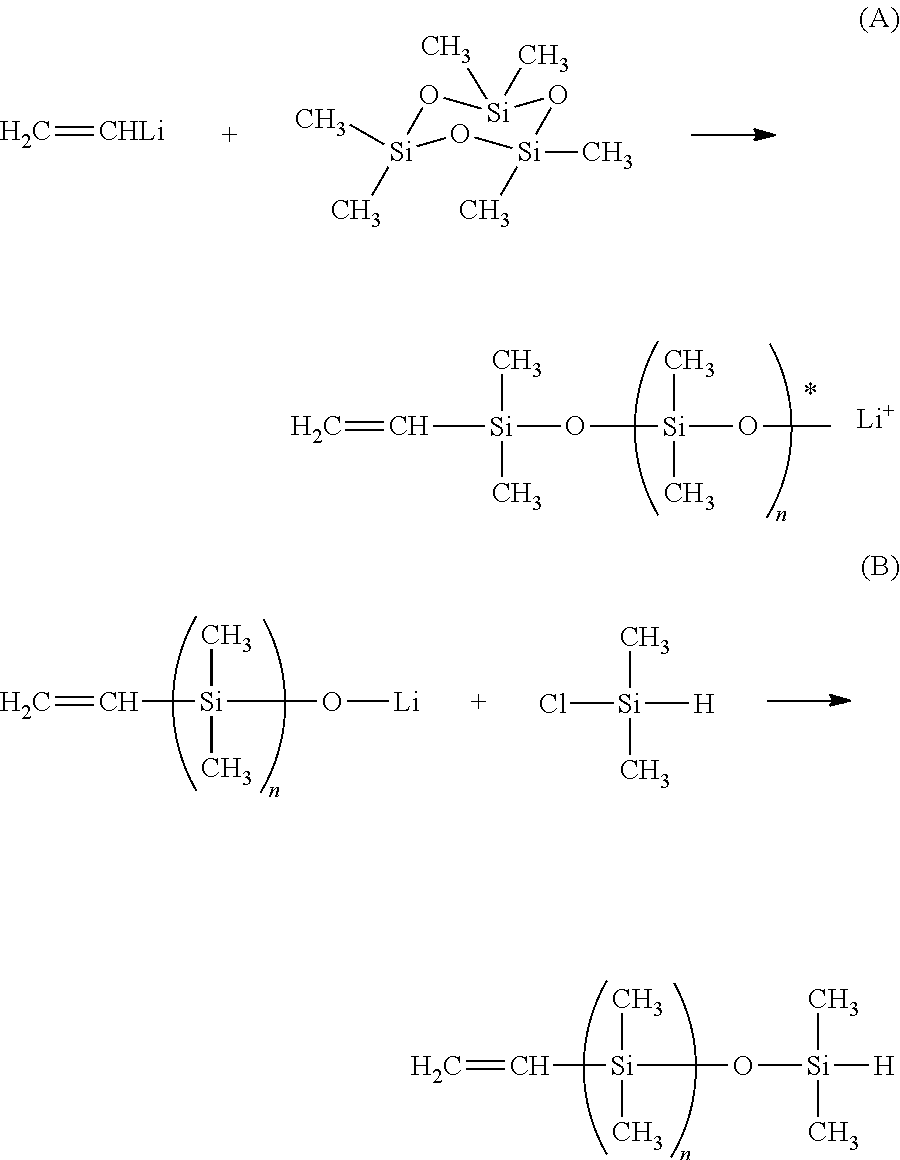

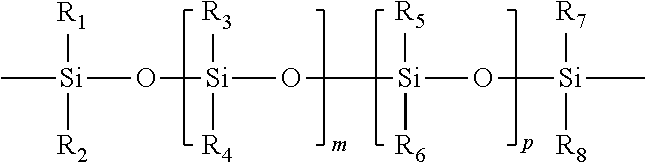

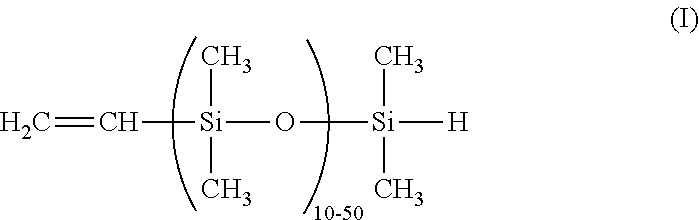

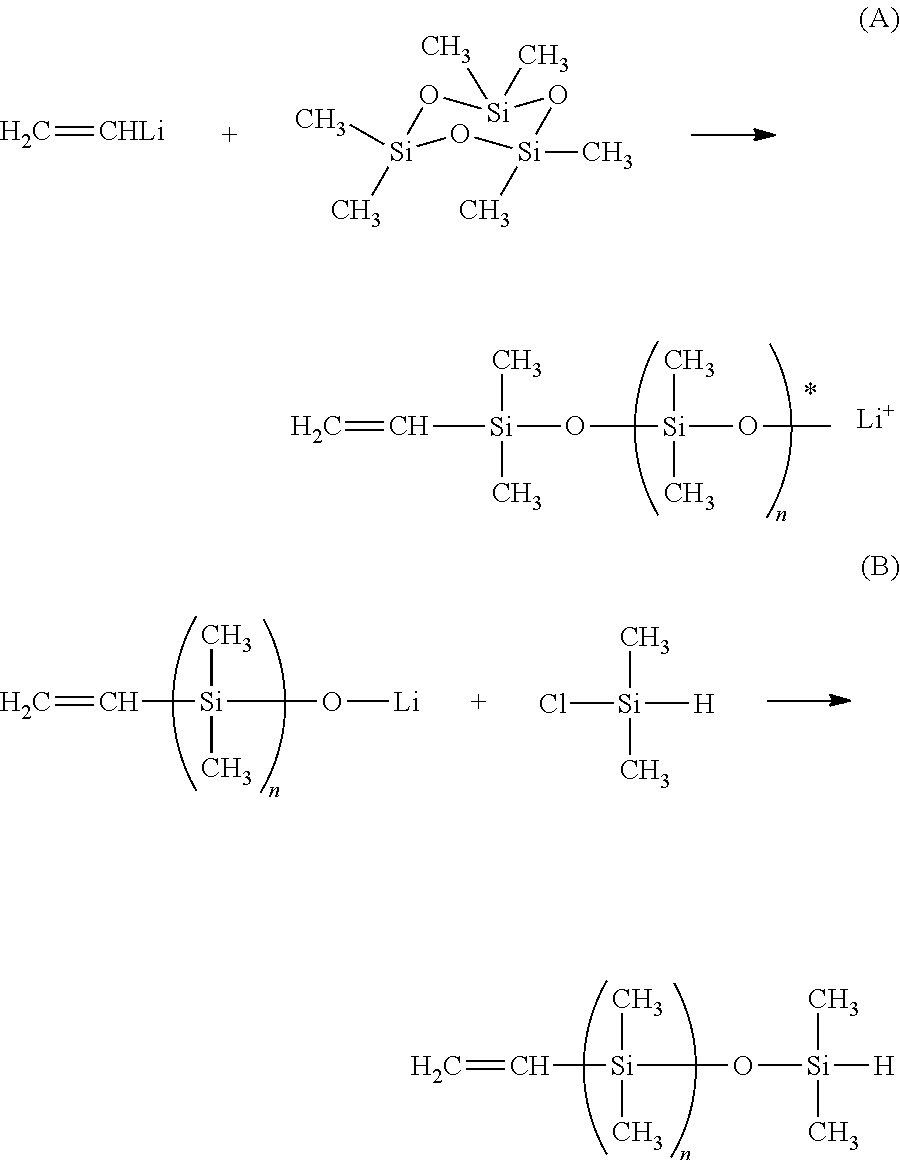

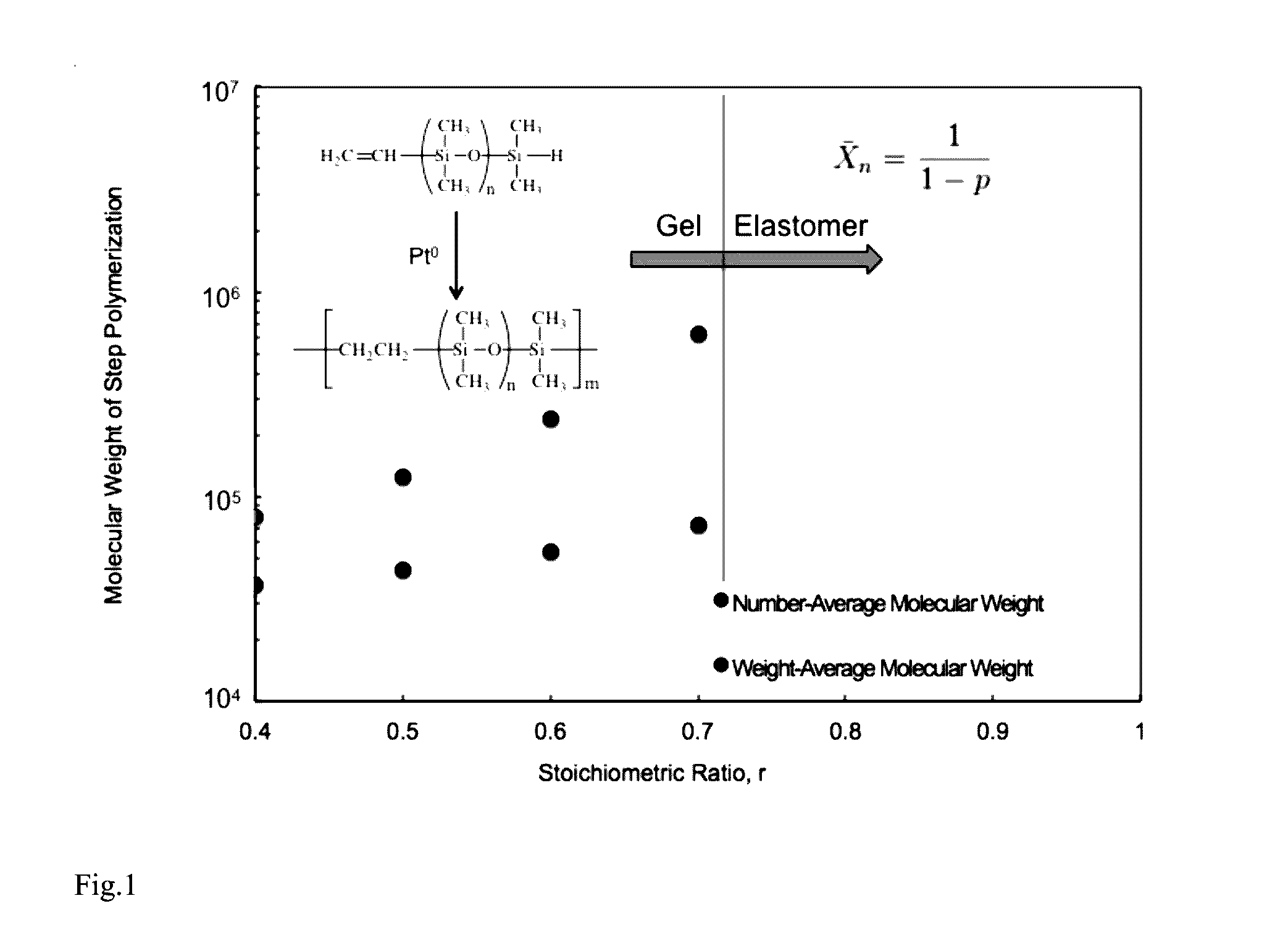

Dual functional linear siloxanes, step-growth polymers derived therefrom, and methods of preparation thereof

Linear siloxane polymers having low viscosities, precise molecular weights and two distinct polymer termini are provided. Preferred viscosities are greater than 5 cSt and less than 20,000 cSt, and the preferred functionalities at the polymer termini are one hydrogen and one vinyl group, each attached to a silicon atom. Methods for producing such siloxane polymers are also described In the presence of catalysts, such as Pt0 complexes, these siloxanes undergo step-growth polymerization to form elastomers at temperatures below 150° C.

Owner:GELEST

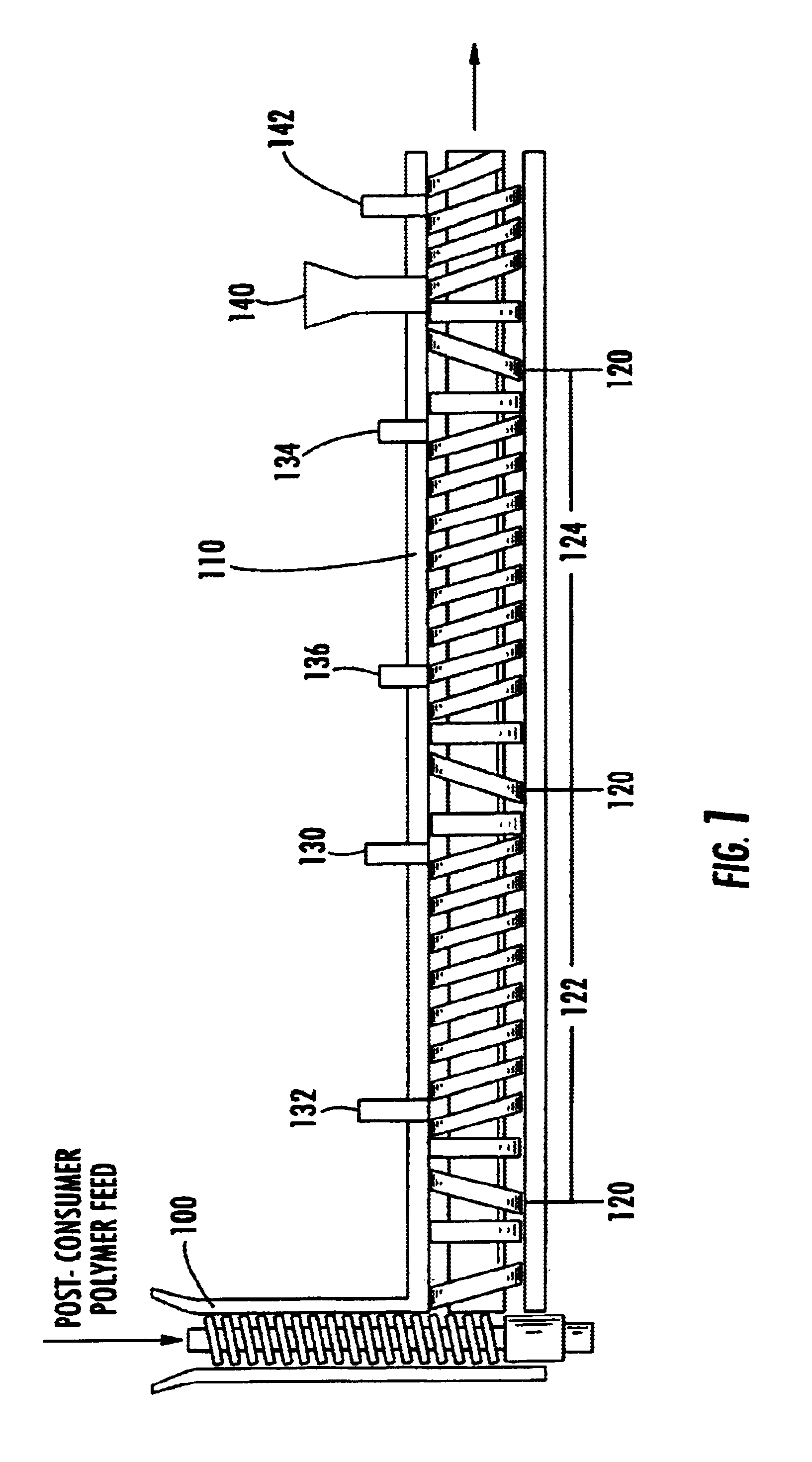

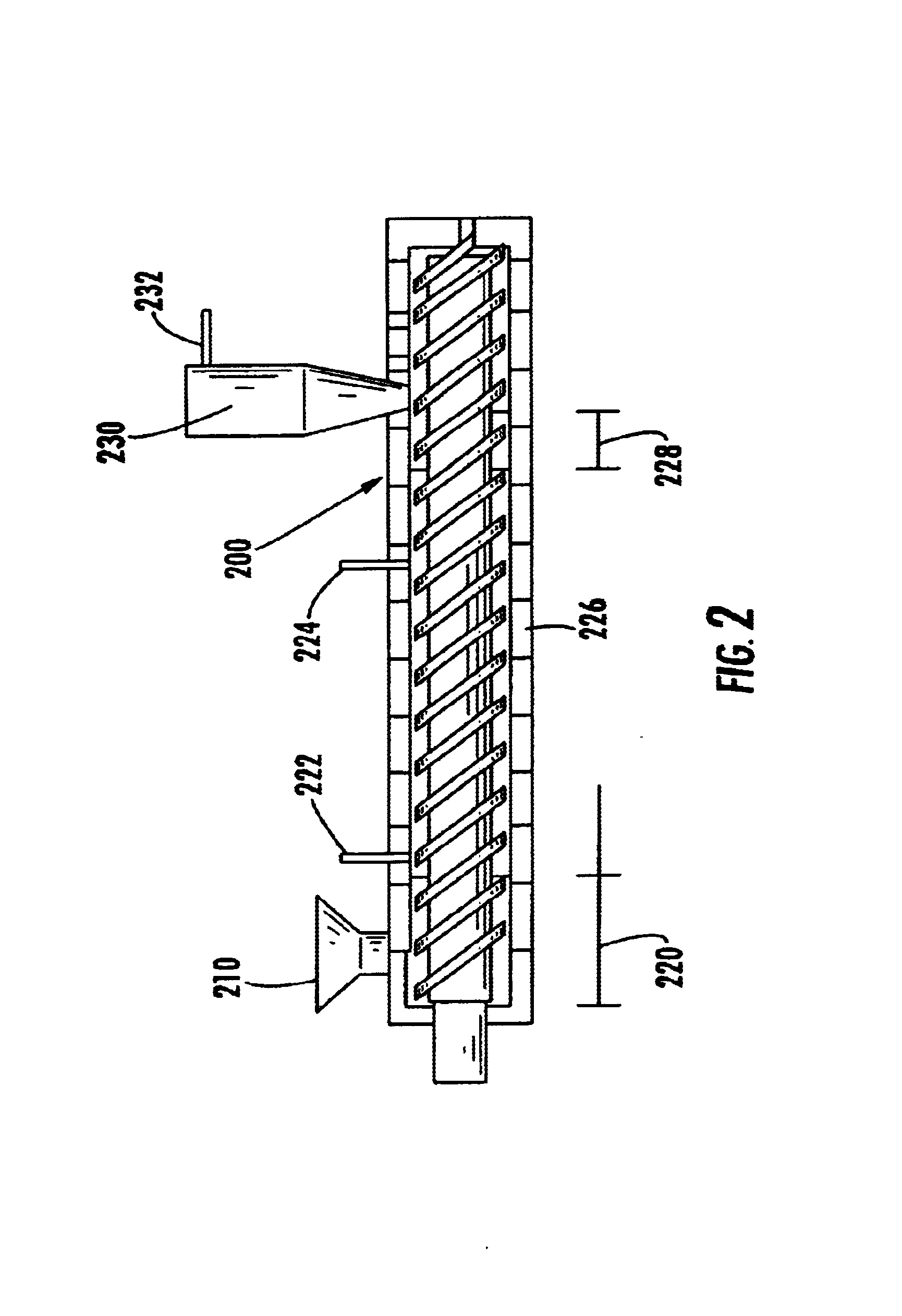

CO2-assisted deploymerization, purification and recycling of step-growth polymers

A method of depolymerizing a polymer comprises contacting a polymer with a fluid comprising carbon dioxide and at least one component, wherein the fluid plasticizes the polymer and facilitates penetration of the component into the polymer to depolymerize the polymer and form oligomeric units, monomeric units, or combinations thereof.

Owner:NORTH CAROLINA STATE UNIV

Production of ophthalmic devices based on photo-induced step growth polymerization

InactiveUS20110269869A1Low viscositySilicon organic compoundsOptical articlesFluid compositionPrepolymer

The invention provide a new lens curing method for making hydrogel contact lenses. The new lens curing method is based on actinically-induced step-growth polymerization. The invention also provides hydrogel contact lenses prepared from the method of the invention and fluid compositions for making hydrogel contact lenses based on the new lens curing method. In addition, the invention provide prepolymers capable of undergoing actinically-induced step-growth polymerization to form hydrogel contact lenses.

Owner:ALCON INC

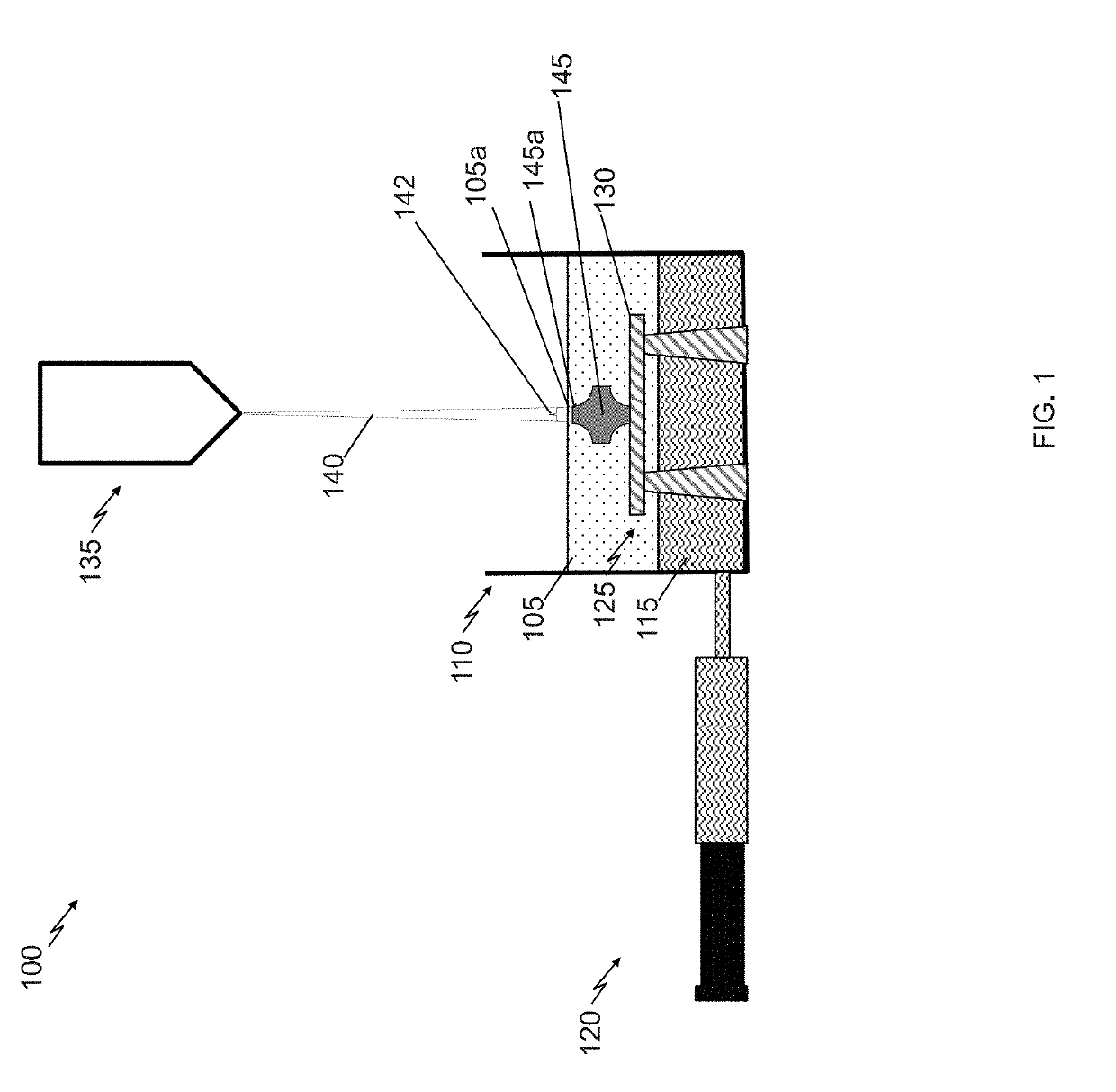

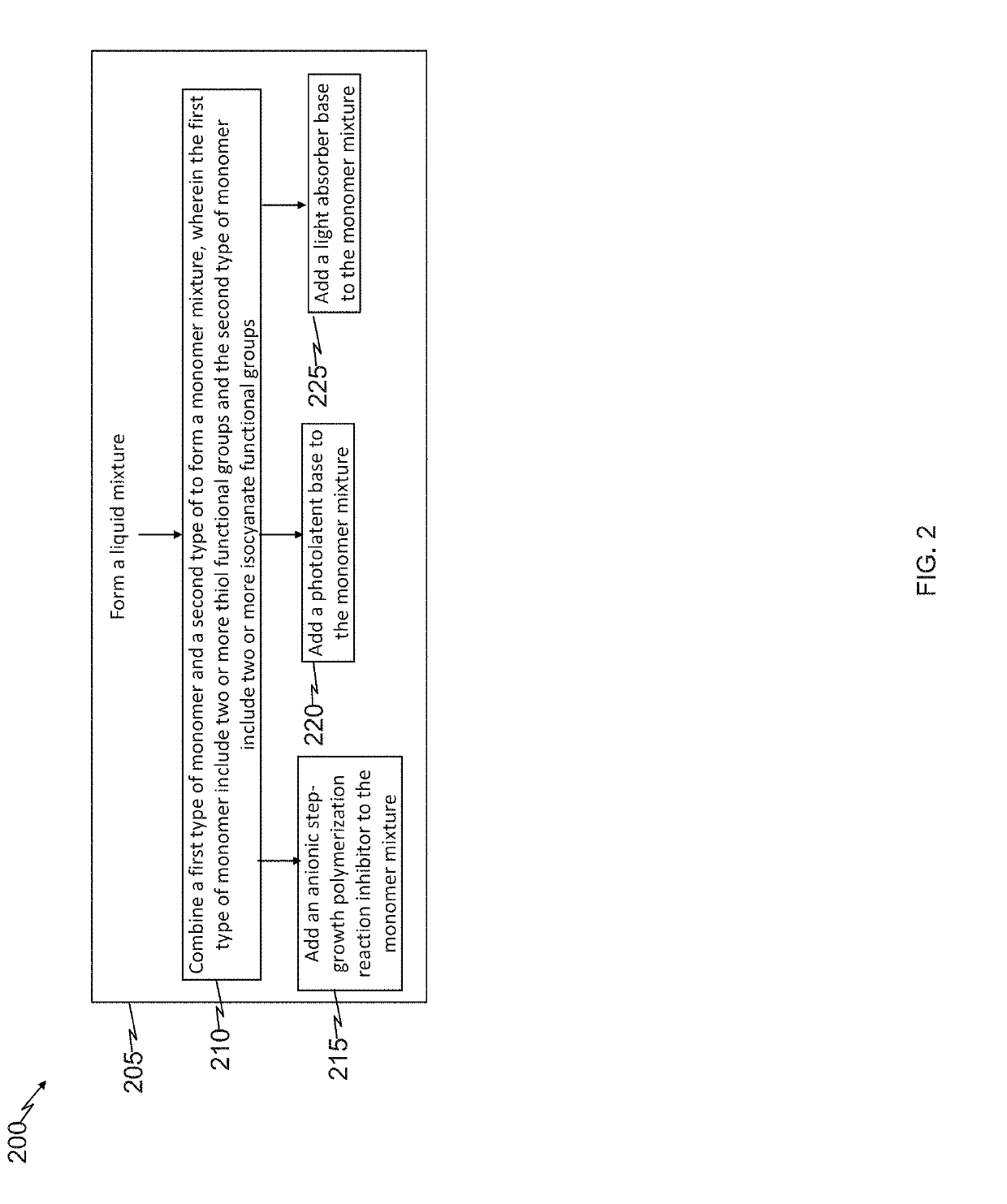

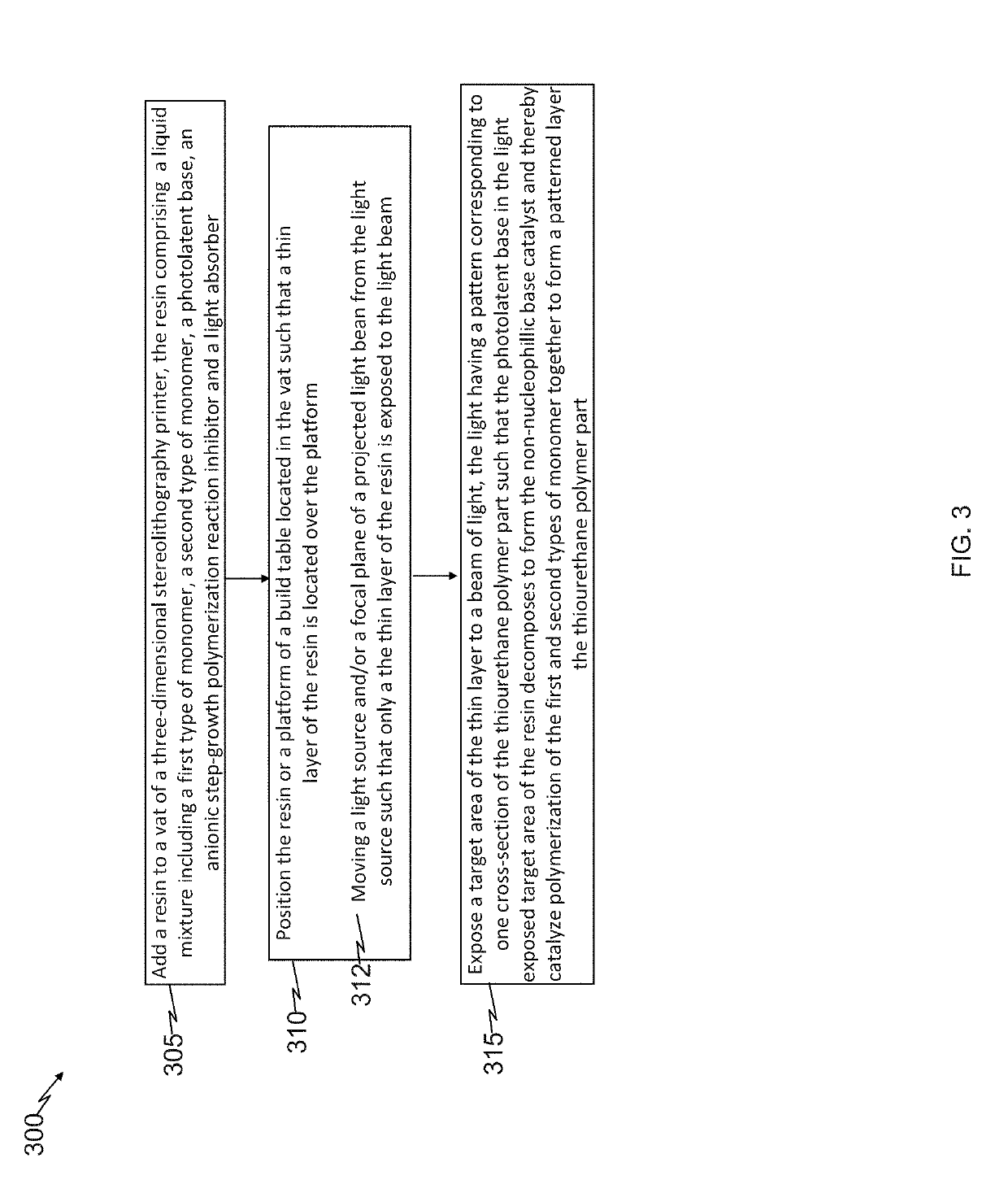

Vat resin with additives for thiourethane polymer stereolithography printing

ActiveUS20190127596A1Fast curingReduce curing stressAdditive manufacturing apparatusInksLength waveAbsorbance

A vat resin for three-dimensional stereolithography printing of a thiourethane polymer part comprising a liquid mixture including a first type of monomer, a second type of monomer, a photolatent base decomposable upon exposure to a light to form a non-nucleophillic base catalyst having a pKa greater than 7, an anionic step-growth polymerization reaction inhibitor having an acidic group configured to form an acid-base pair with the non-nucleophillic base and a light absorber having an absorbance in the liquid mixture that is greater than an absorbance of the photolatent base at a wavelength of the light used for the exposure. Methods of preparing the vat resin and three-dimensional stereolithography printing a thiourethane polymer part using the vat resin are also disclosed.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST +1

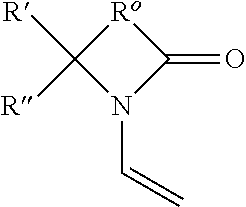

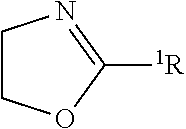

Actinically-crosslinkable amphiphilic prepolymers

The invention provide a class of actinically-crosslinkable amphiphilic prepolymers which comprise at least one polysiloxane segment, at least one polyoxazoline segment, and two terminal ene groups. The present invention is also related to a medical device comprising a silicone hydrogel material obtained from step-growth polymerization of a polymerizable material comprising a prepolymer of the invention and to a method for producing contact lenses from a prepolymer of the invention.

Owner:ALCON INC

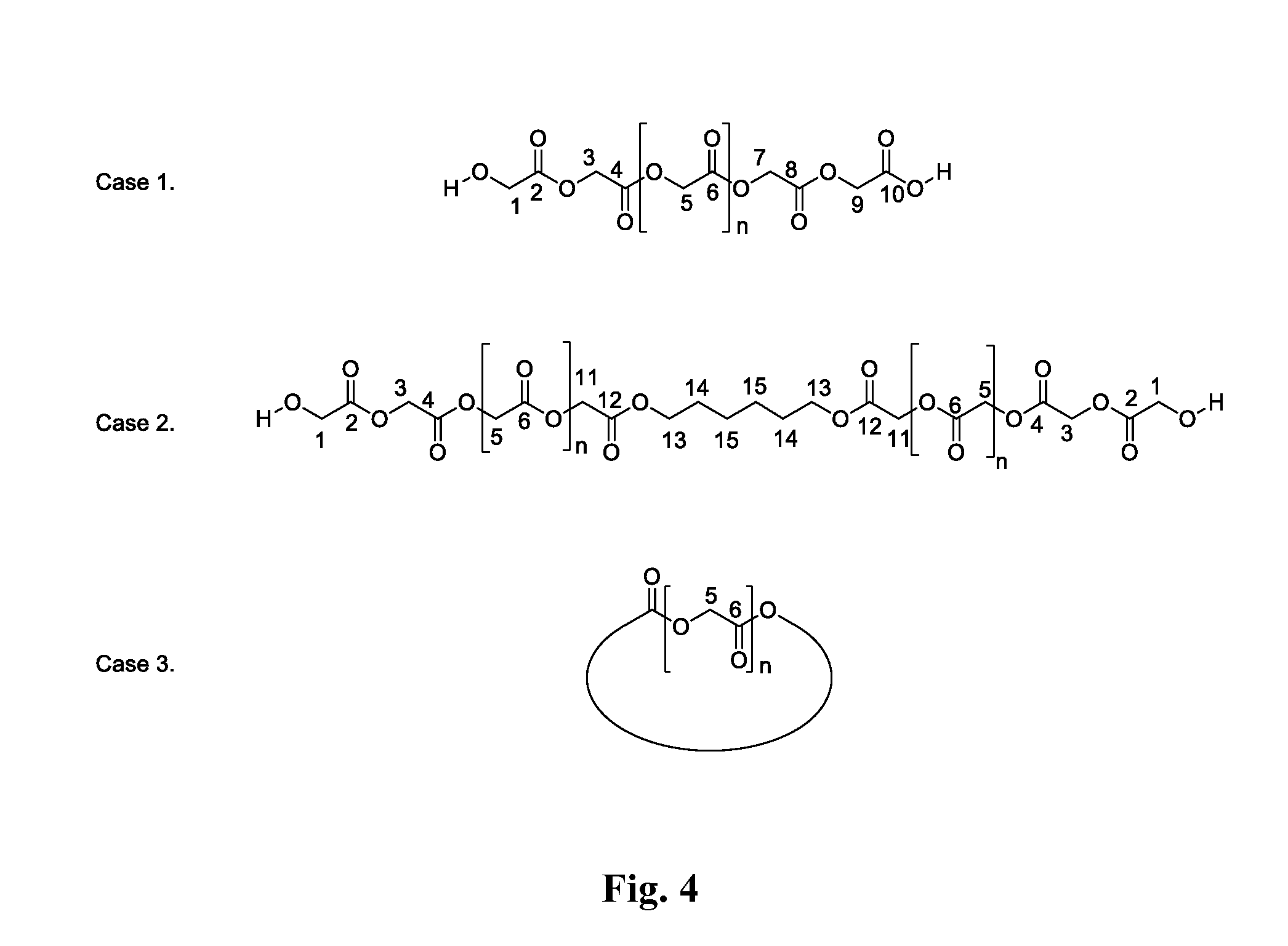

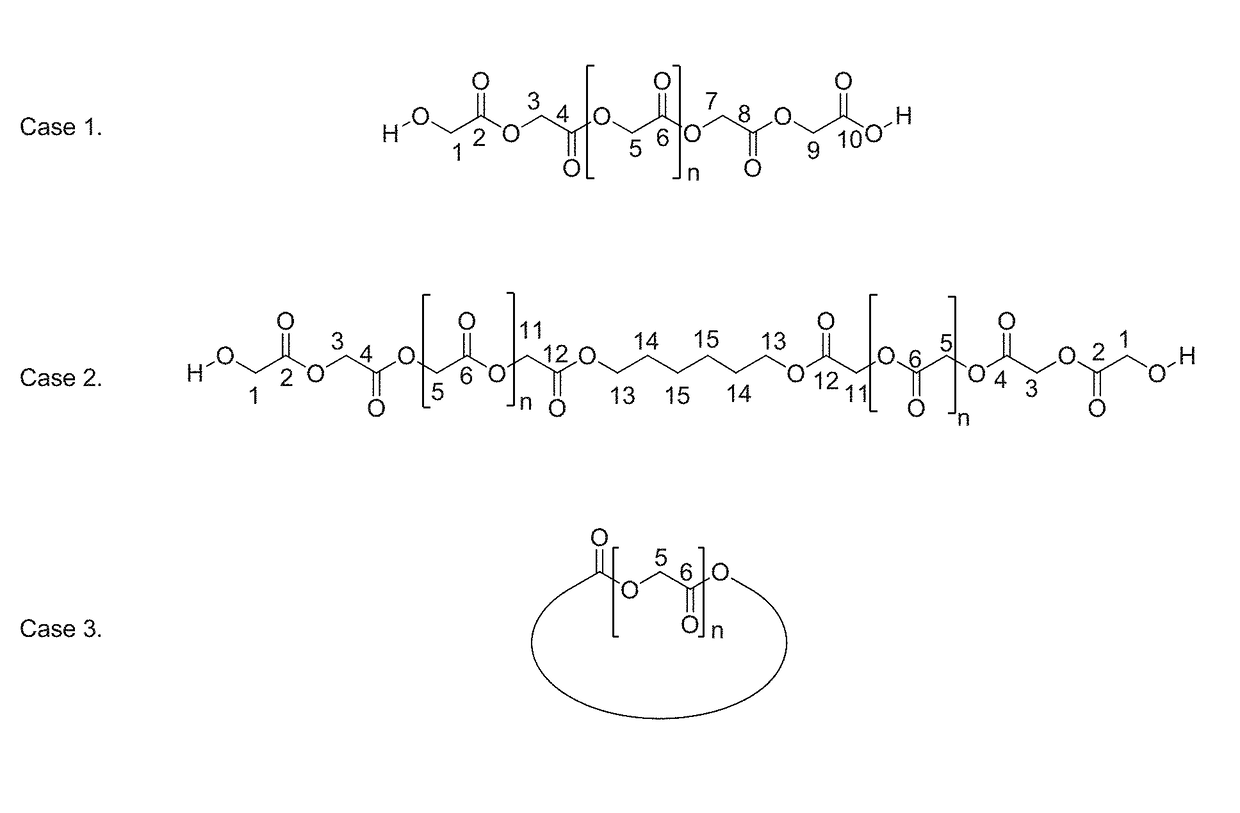

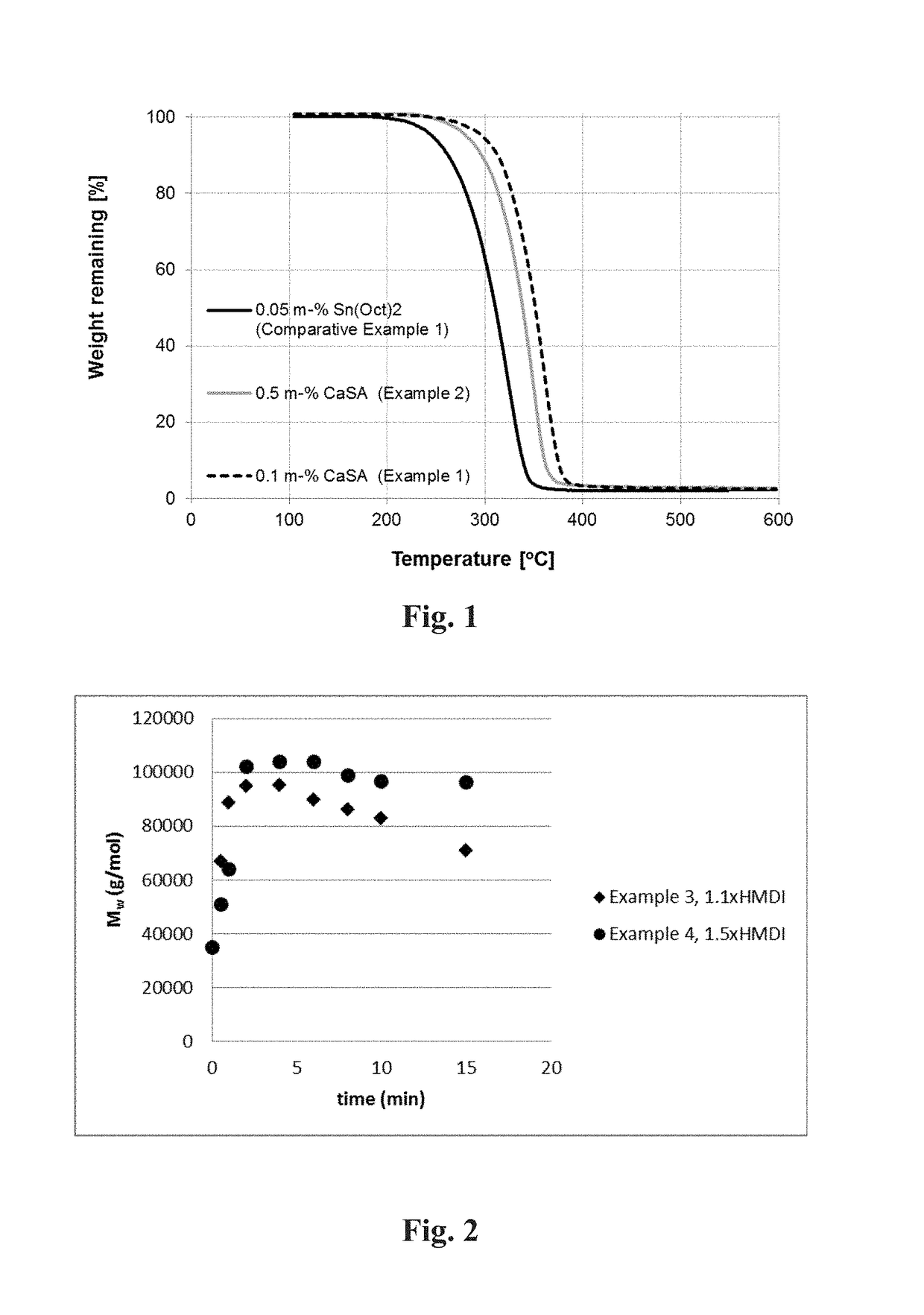

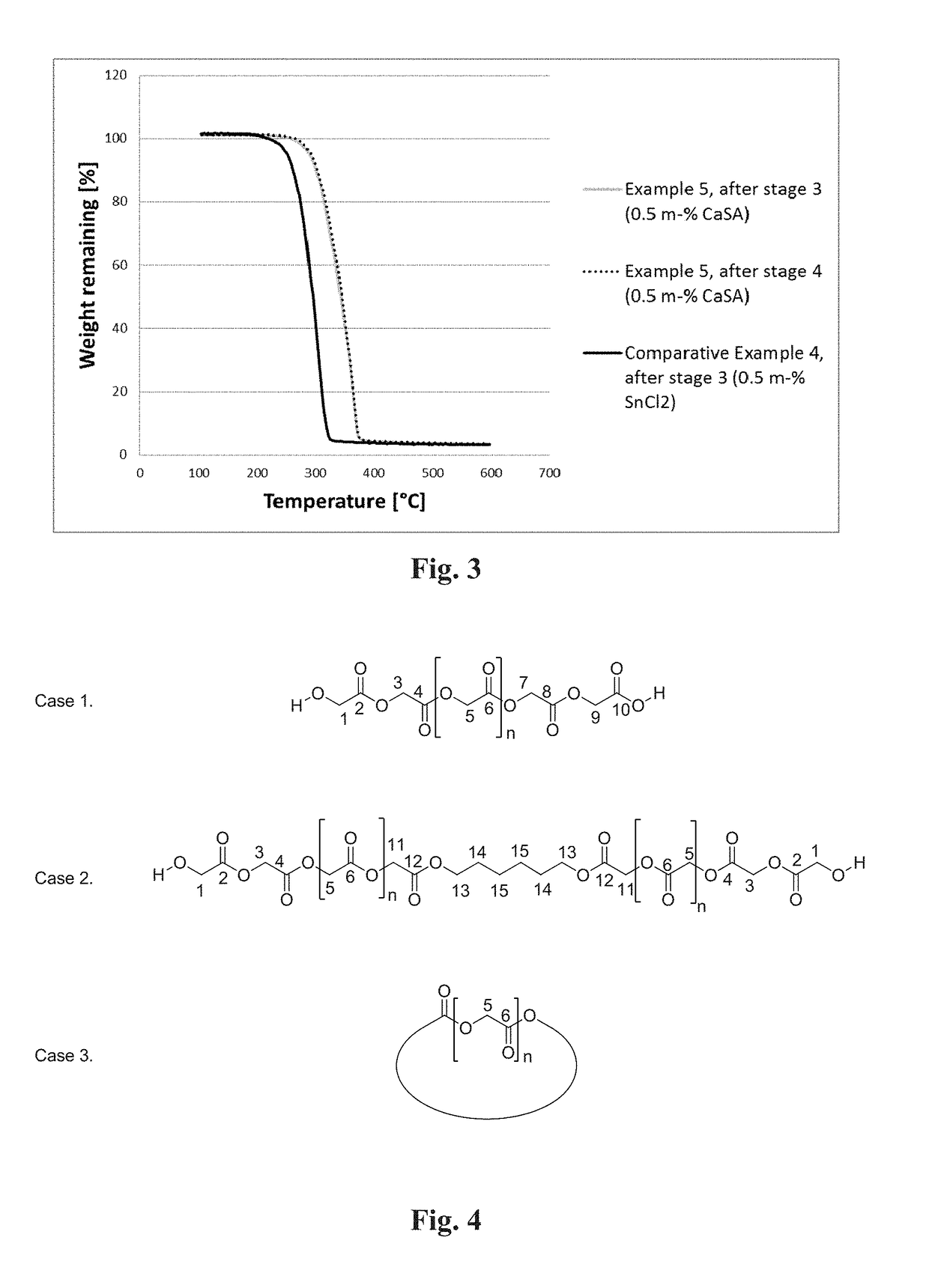

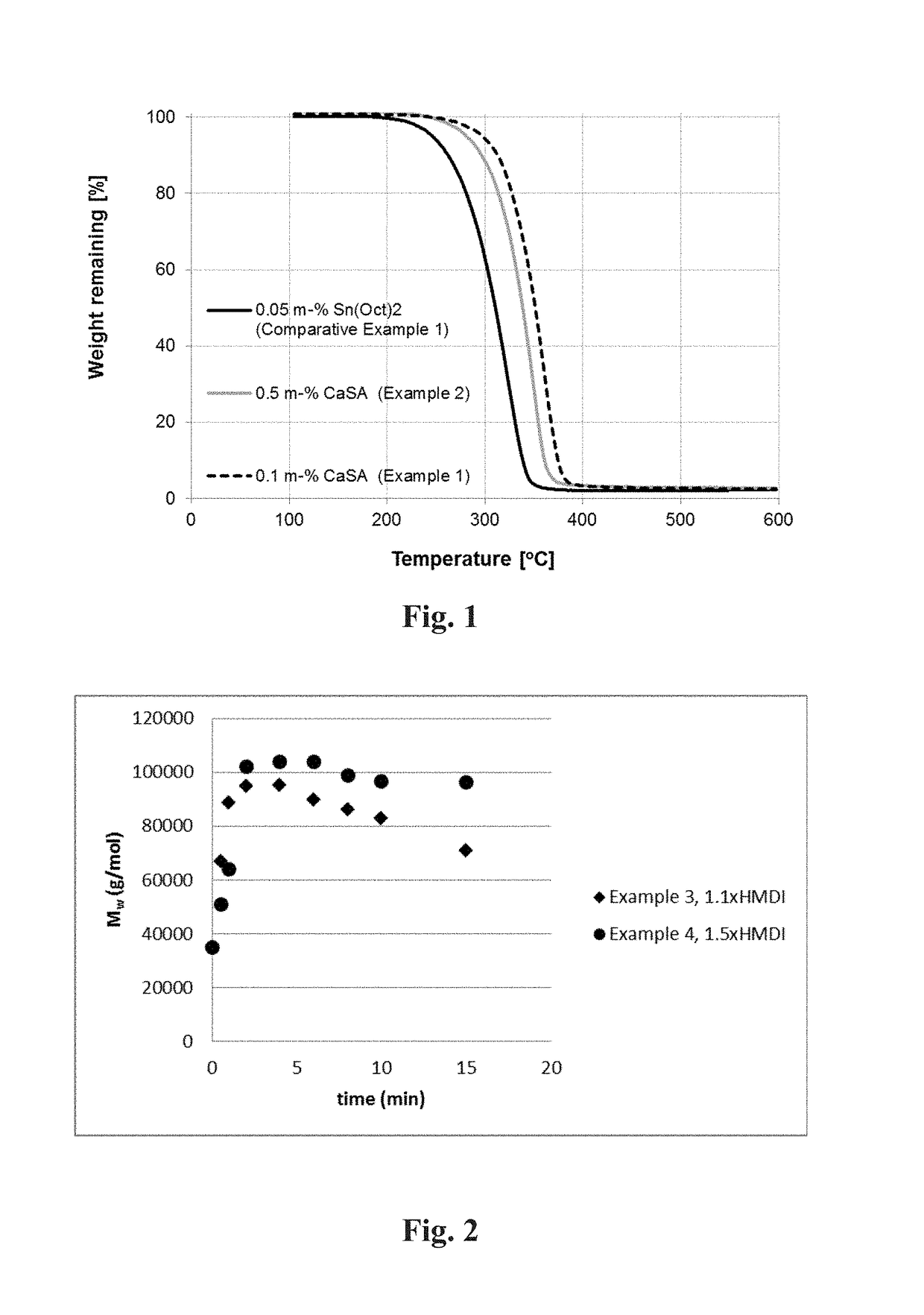

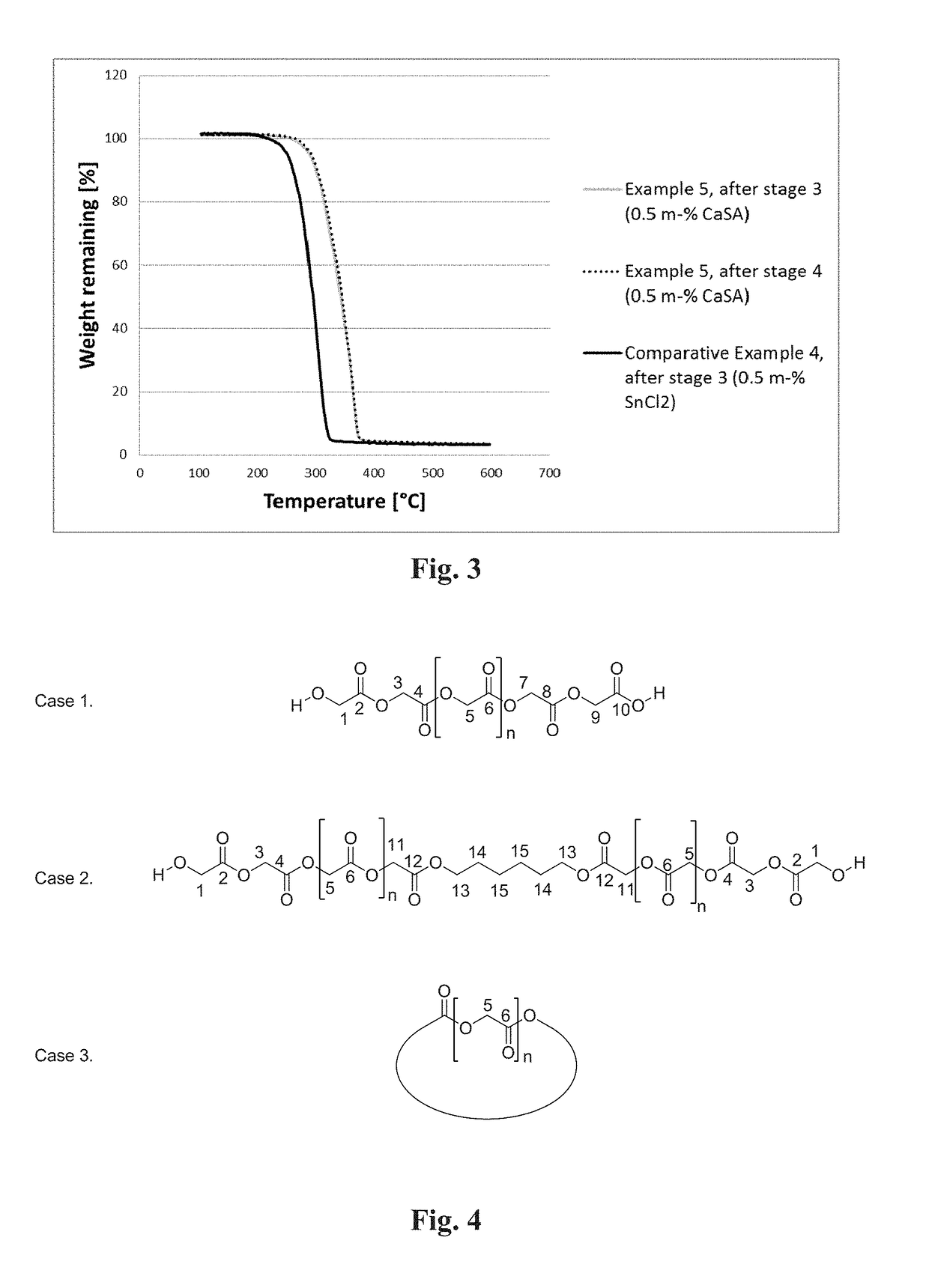

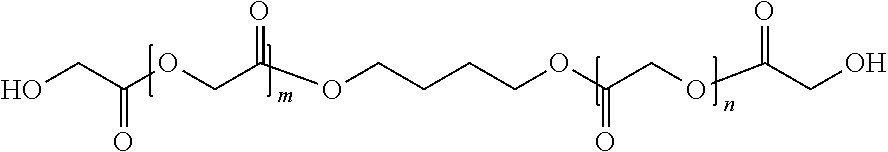

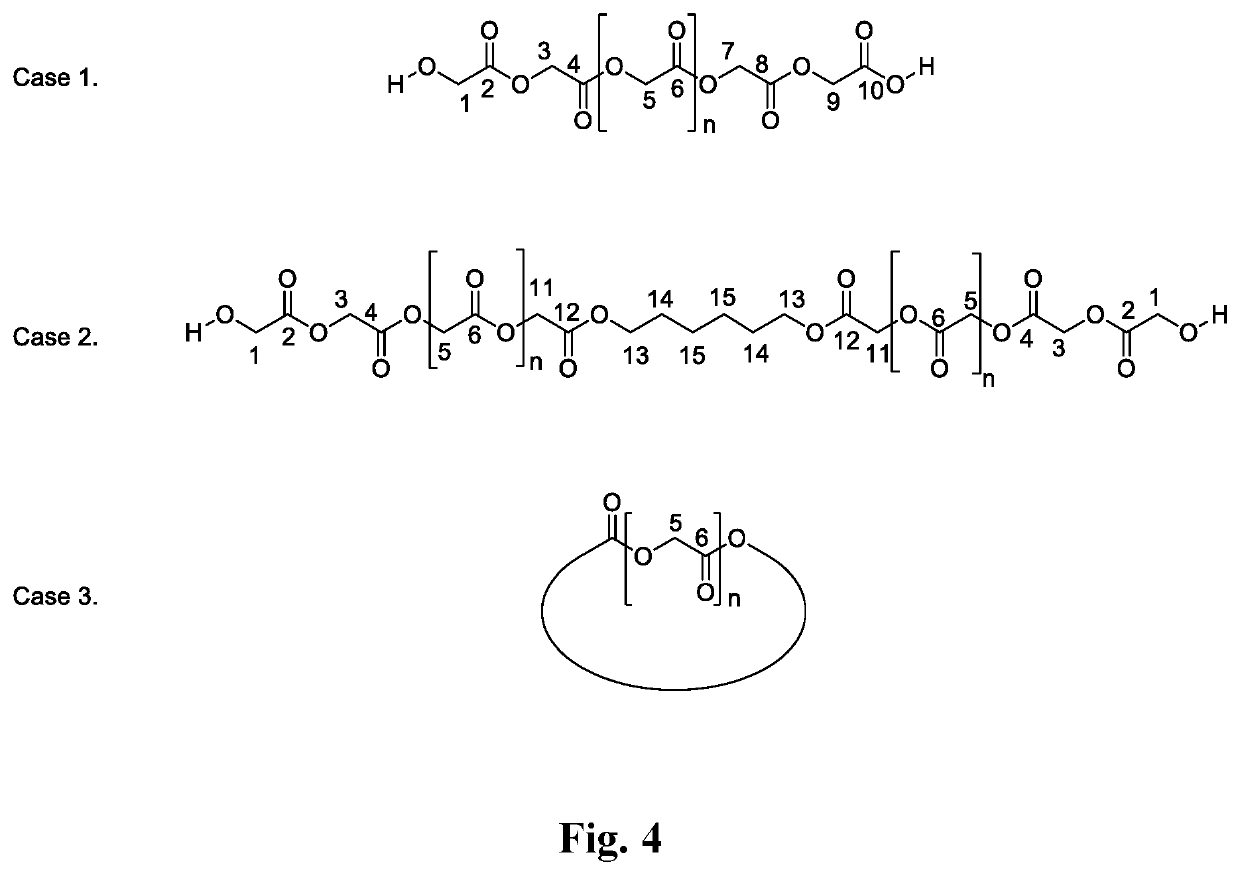

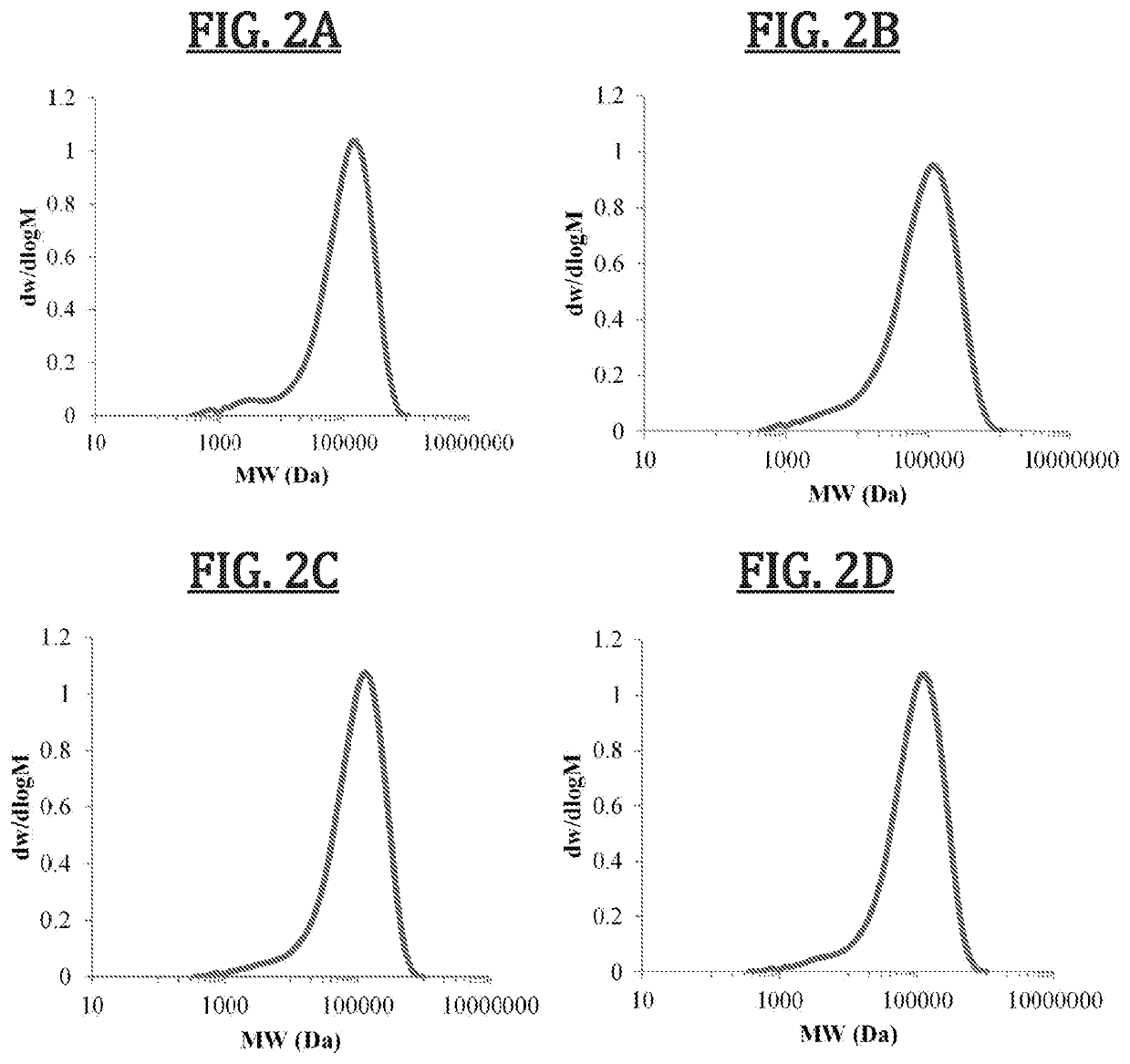

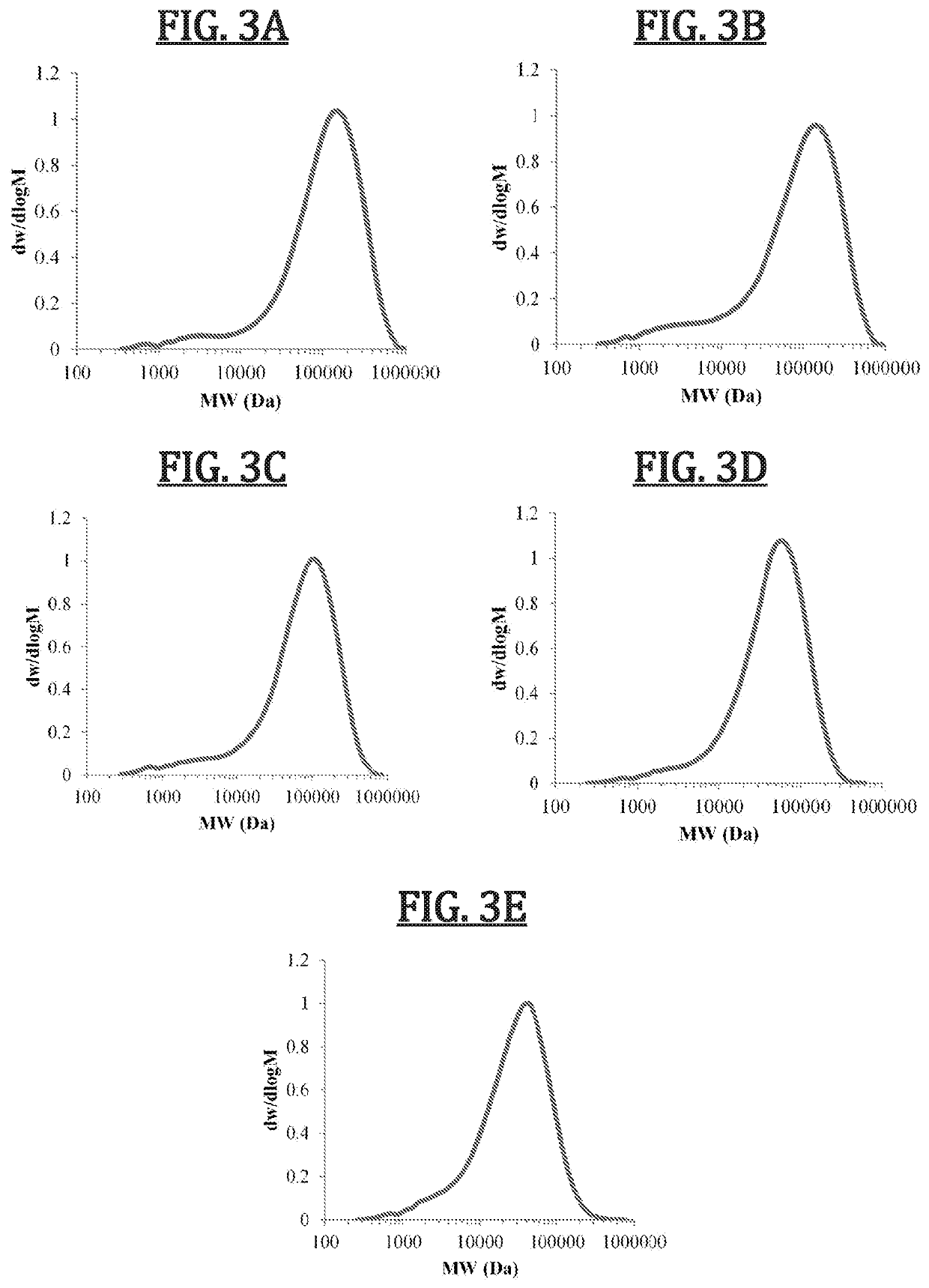

Glycolic acid polymers and method of producing the same

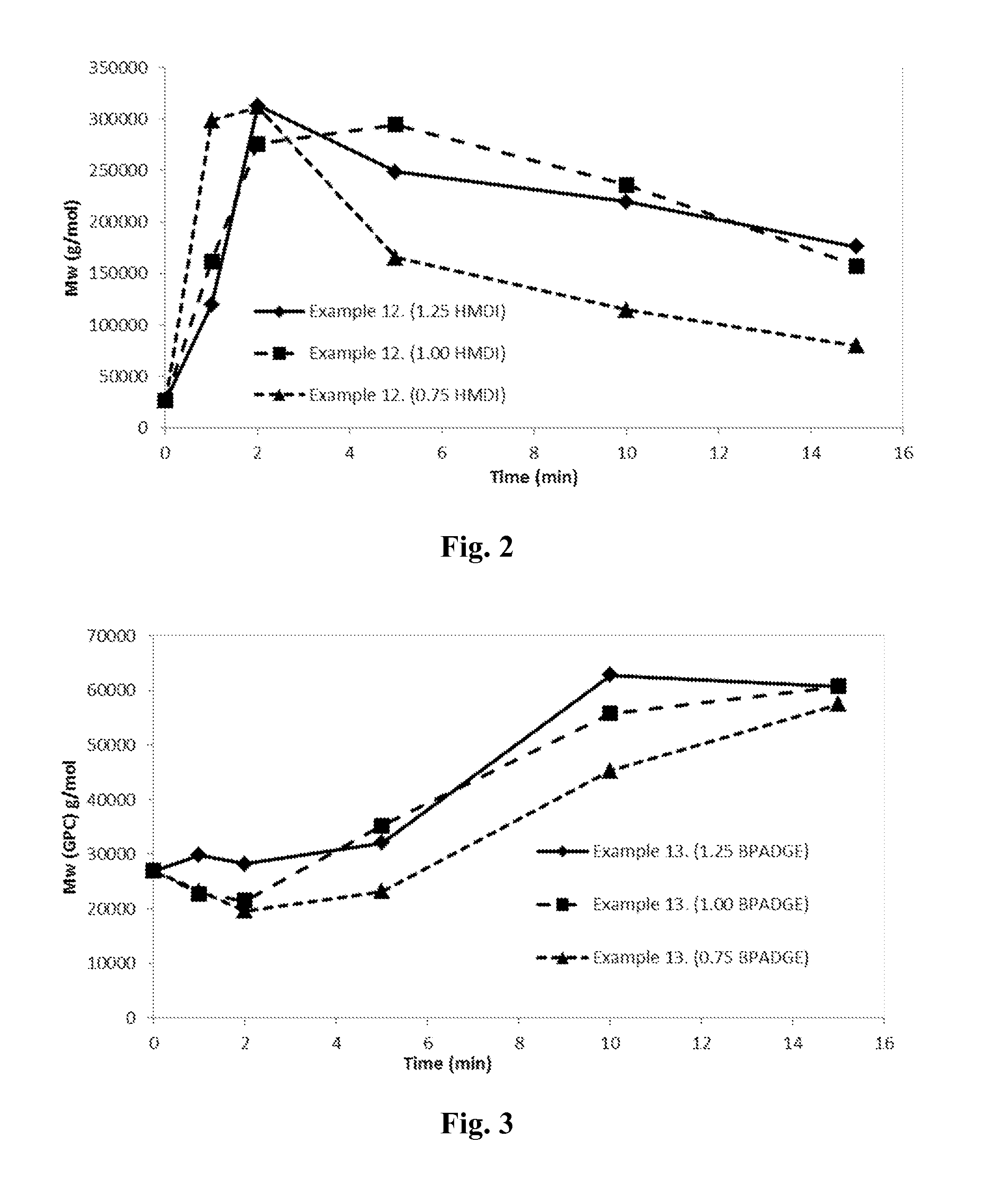

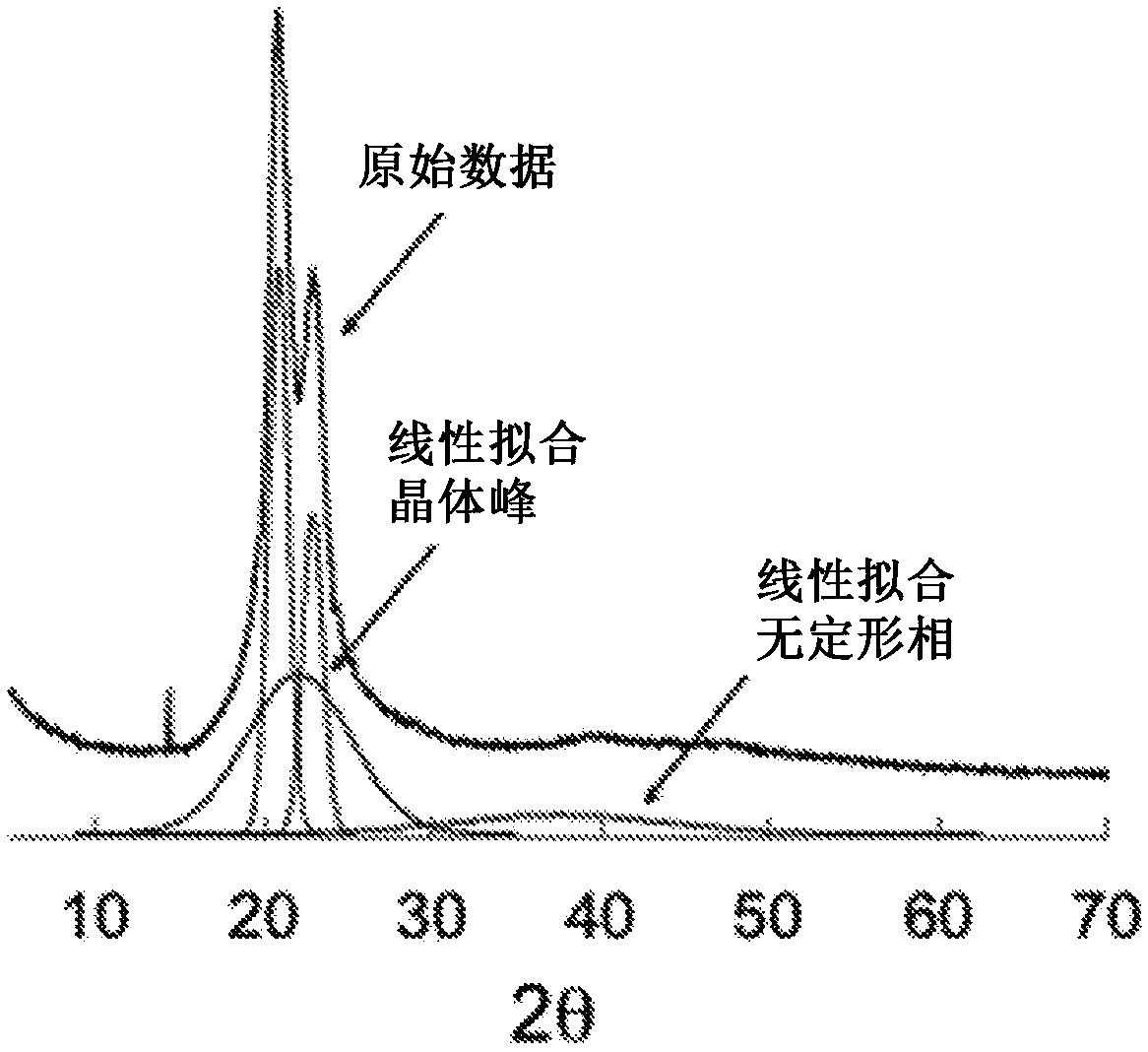

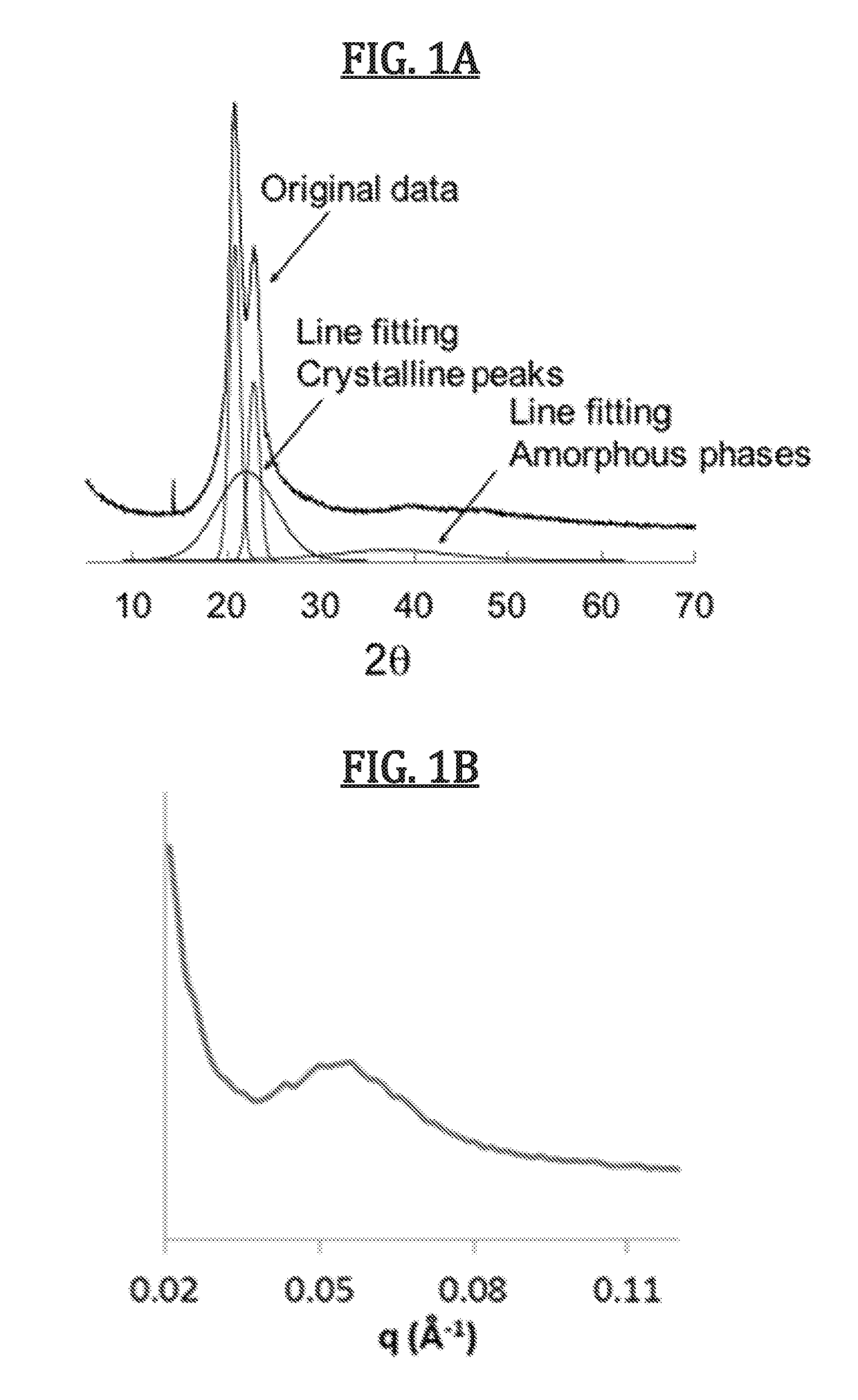

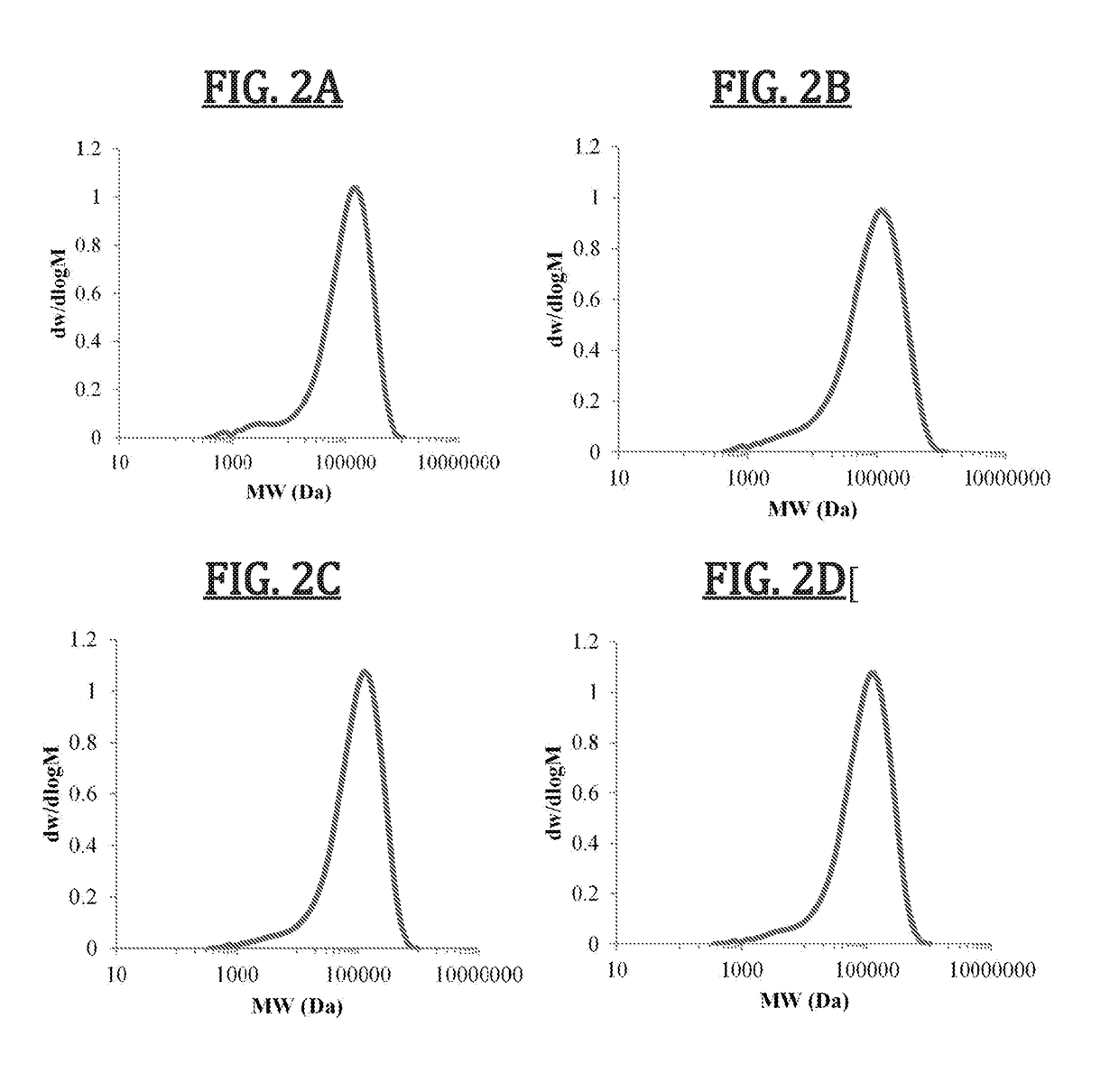

InactiveUS20160060387A1High molecular weightEfficient use ofPolyurea/polyurethane coatingsMonocomponent polyesters artificial filamentPolyesterPolymer science

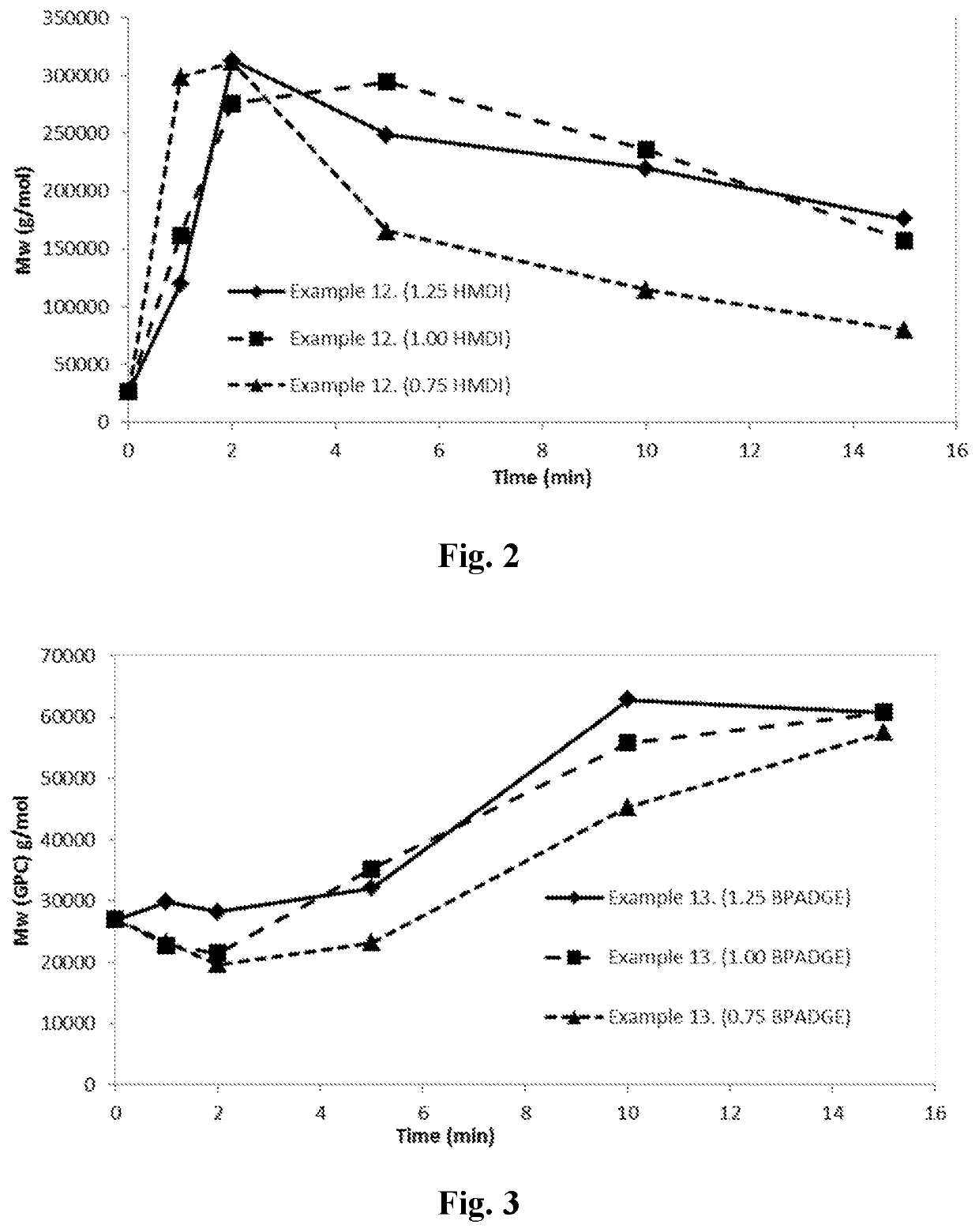

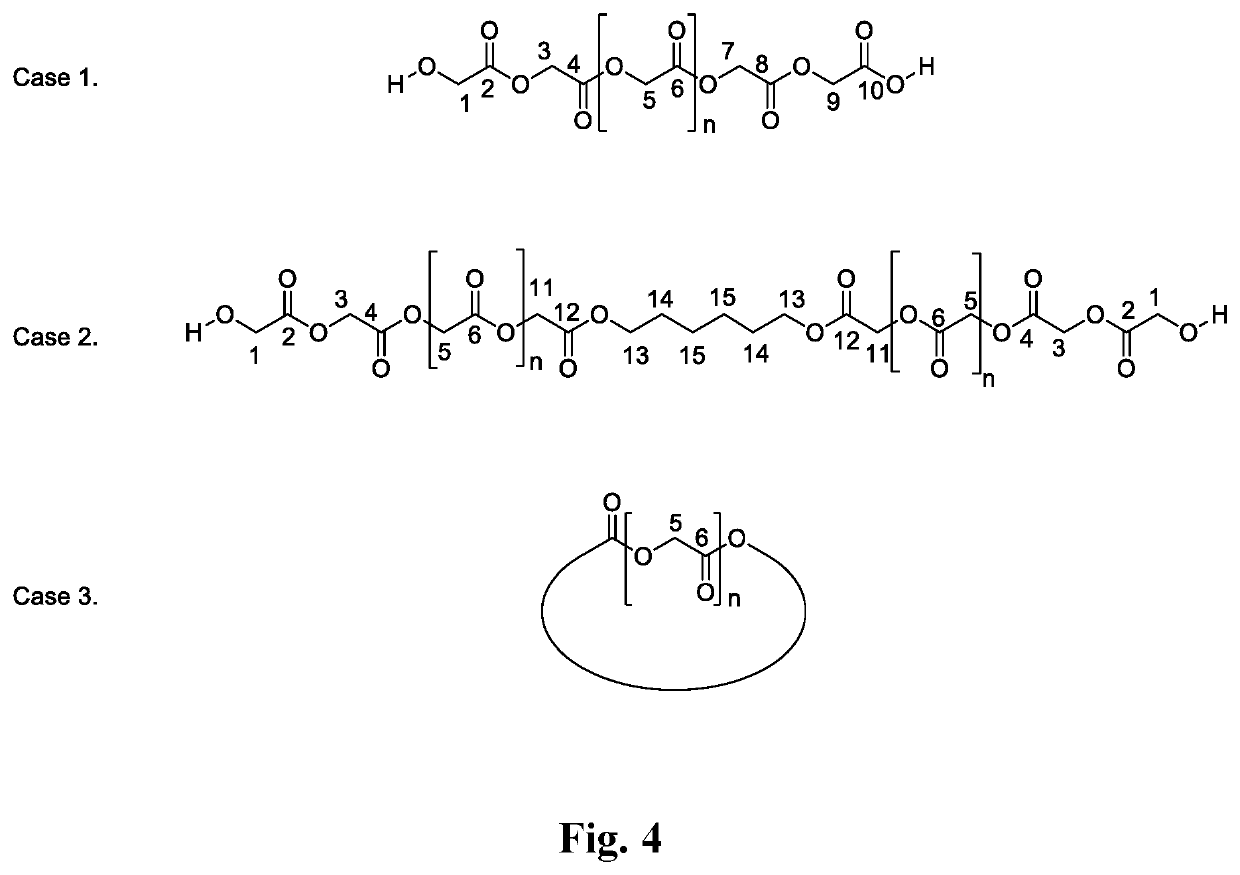

Described herein is a feasible, significantly simplified production method that avoids challenging lactonization steps and converts a low molecular weight aliphatic polyester, consisting of hydroxy acids and a comonomer, whose molecular weight has been increased by step-growth polymerization reactions. The molecular weight of the aliphatic polyester, based on comparison of initial and final weight average molecular weights (Mw,1 / Mw,2), increased significantly at a rate which permits the use of reactive extrusion to produce high molecular weight aliphatic polyesters in a simple, economically feasible manner.

Owner:TEKNOLOGIAN TUTKIMUSKESKUS VTT

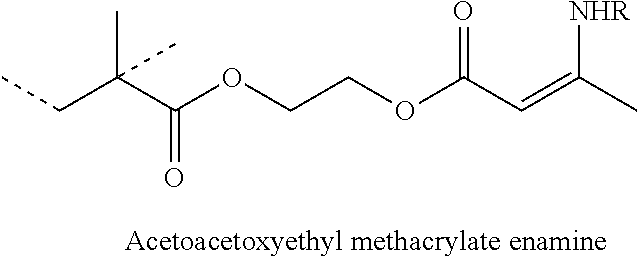

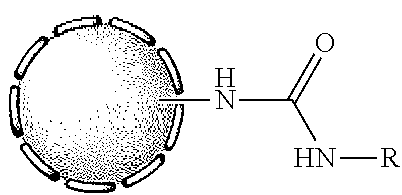

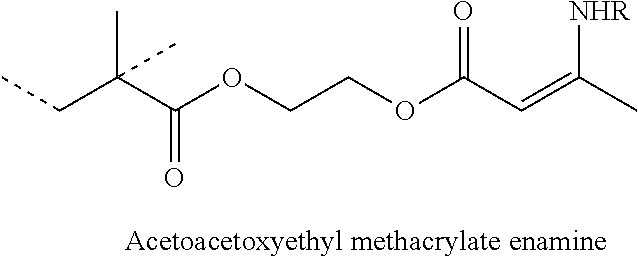

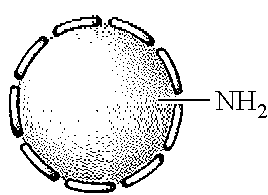

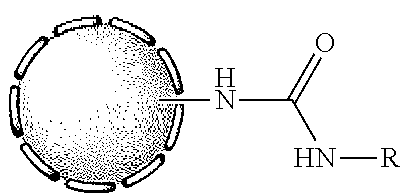

Latex Particles Imbibed With a Thermoplastic Polymer

ActiveUS20120295023A1Eliminating viscosity limitationPolyureas/polyurethane adhesivesOrganic dyesPolymer scienceAdhesive

The present invention relates to a process for imbibing a step-growth polymer into thermoplastic latex particles and a composition made by such a process. The composition is useful, for example, as a coating, an adhesive, a sealant, a primer, a caulk, a stain, or a filler for a variety of substrates.

Owner:ROHM & HAAS CO

Dual functional linear siloxanes, step-growth polymers derived therefrom, and methods of preparation thereof

Linear siloxane polymers having low viscosities, precise molecular weights and two distinct polymer termini are provided. Preferred viscosities are greater than 5 cSt and less than 20,000 cSt, and the preferred functionalities at the polymer termini are one hydrogen and one vinyl group, each attached to a silicon atom. Methods for producing such siloxane polymers are also described In the presence of catalysts, such as Pt0 complexes, these siloxanes undergo step-growth polymerization to form elastomers at temperatures below 150° C.

Owner:GELEST

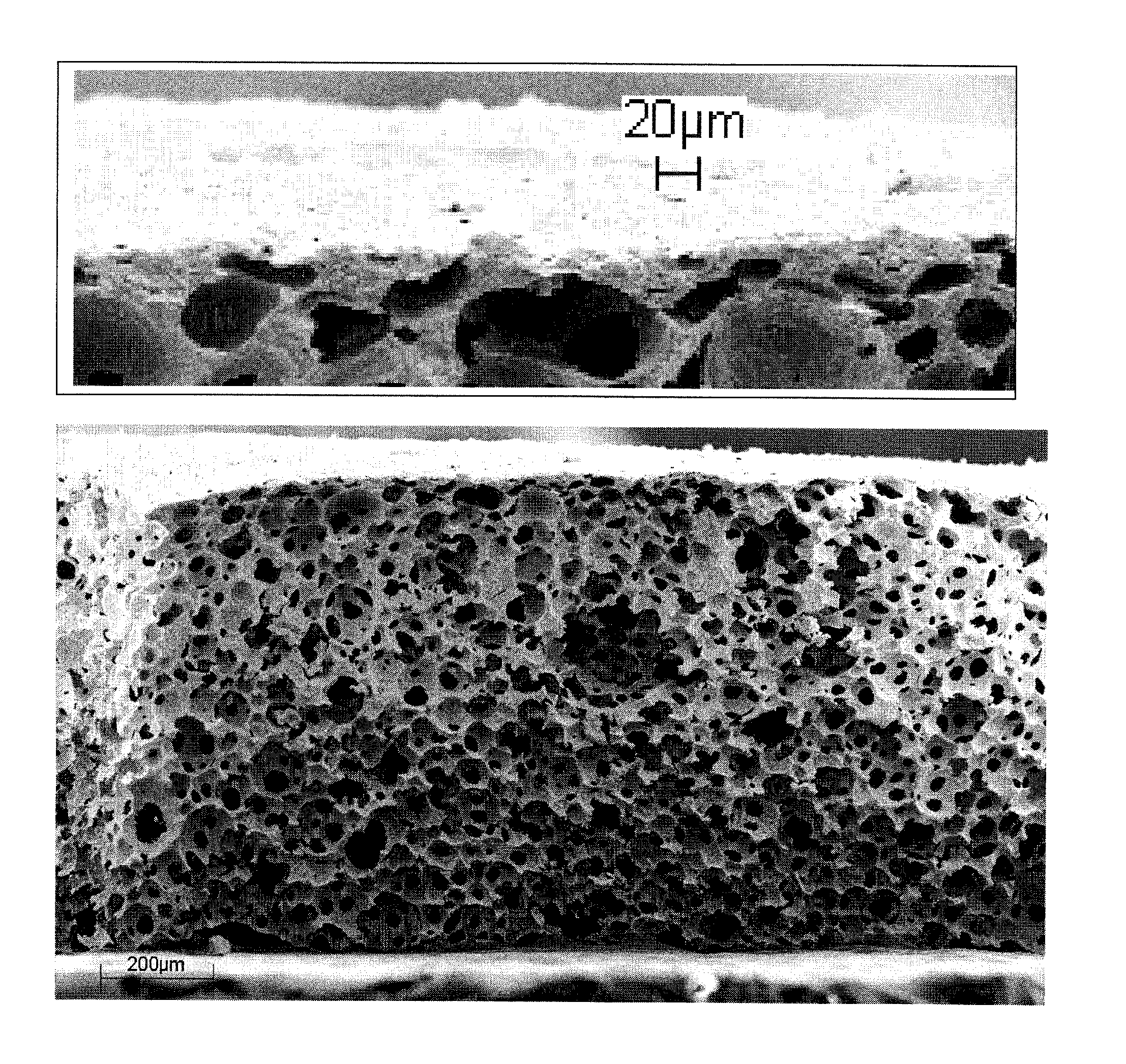

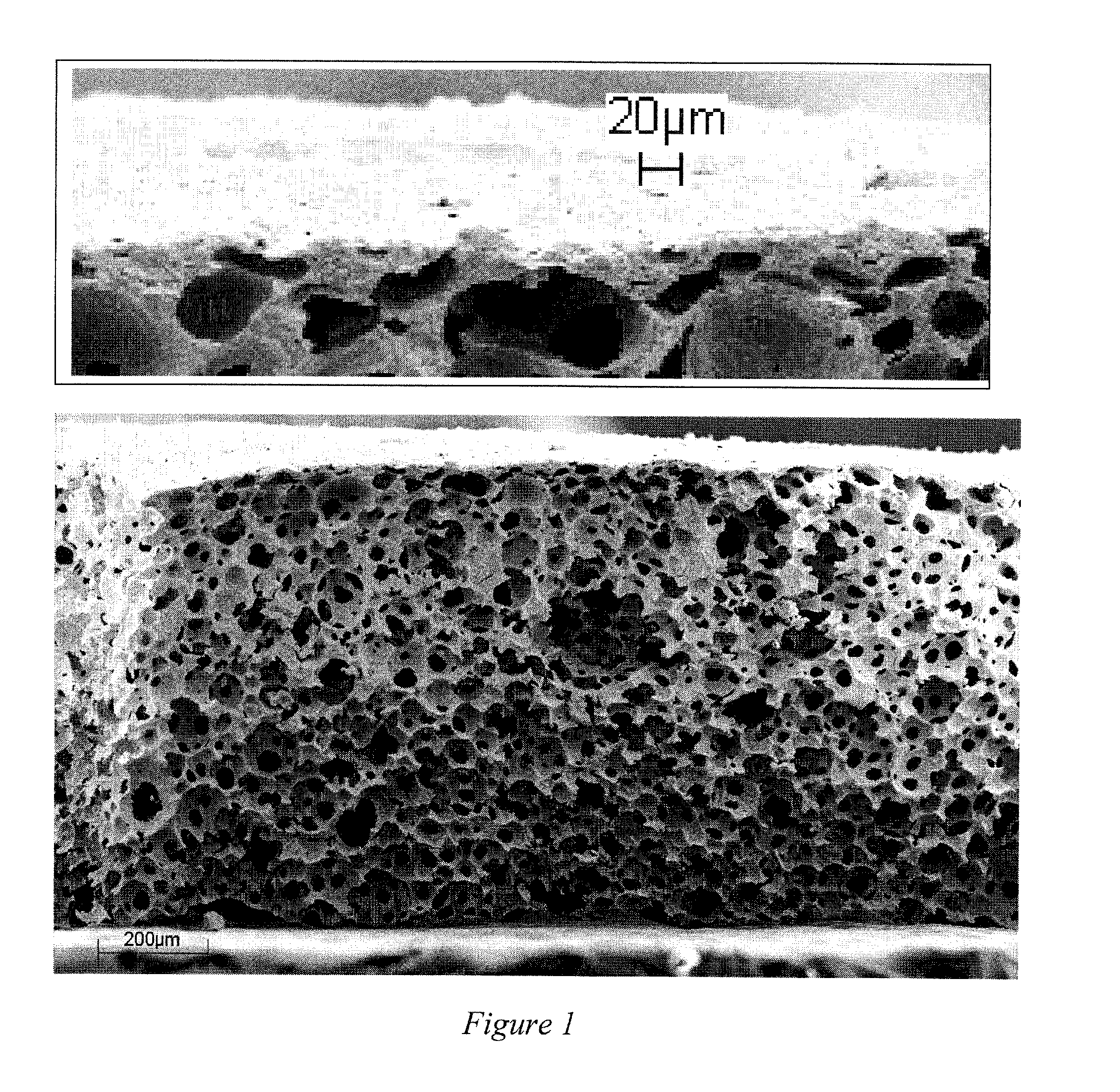

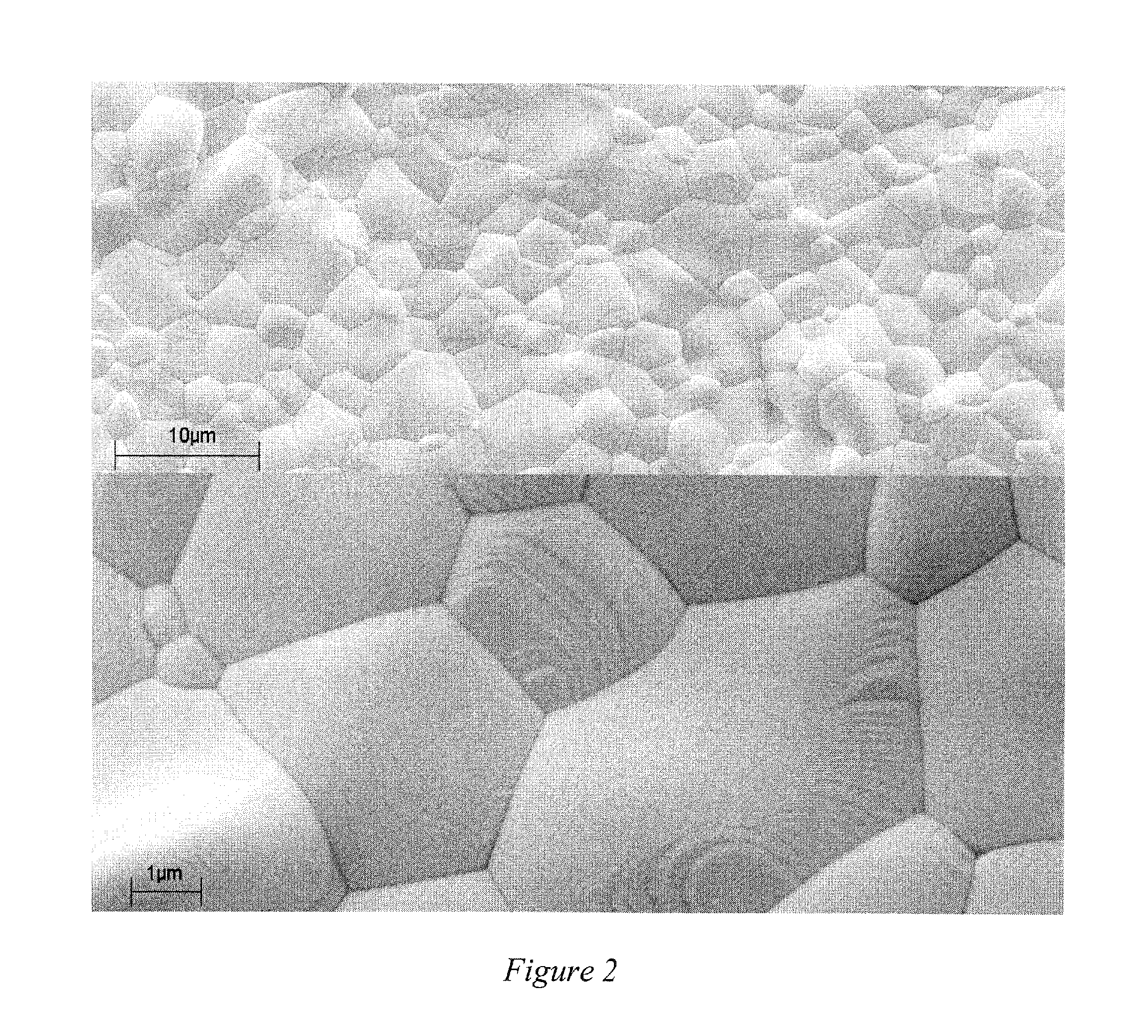

Fabrication of dual structure ceramics by a single step process

ActiveUS20120225270A1Easy to controlComplicated and expensive designLaminationLamination apparatusSingle processSurface layer

The subject invention discloses a method for the preparation of a dual structure cellular ceramic object where a dispersion of a ceramic precursor a chain-growth or step-growth polymer precursor and a solvent is heated to a first temperature at a first rate followed by heating to a second temperature at a second rate and holding the temperature to form a sintered dual structure cellular ceramic object which is then cooled at a third rate to room temperature. The dual structure cellular ceramic object has a dense surface layer over at least a portion of the object that abruptly yet smoothly and continuously transitioning into a porous ceramic.

Owner:UNIV OF FLORIDA RES FOUNDATION INC +1

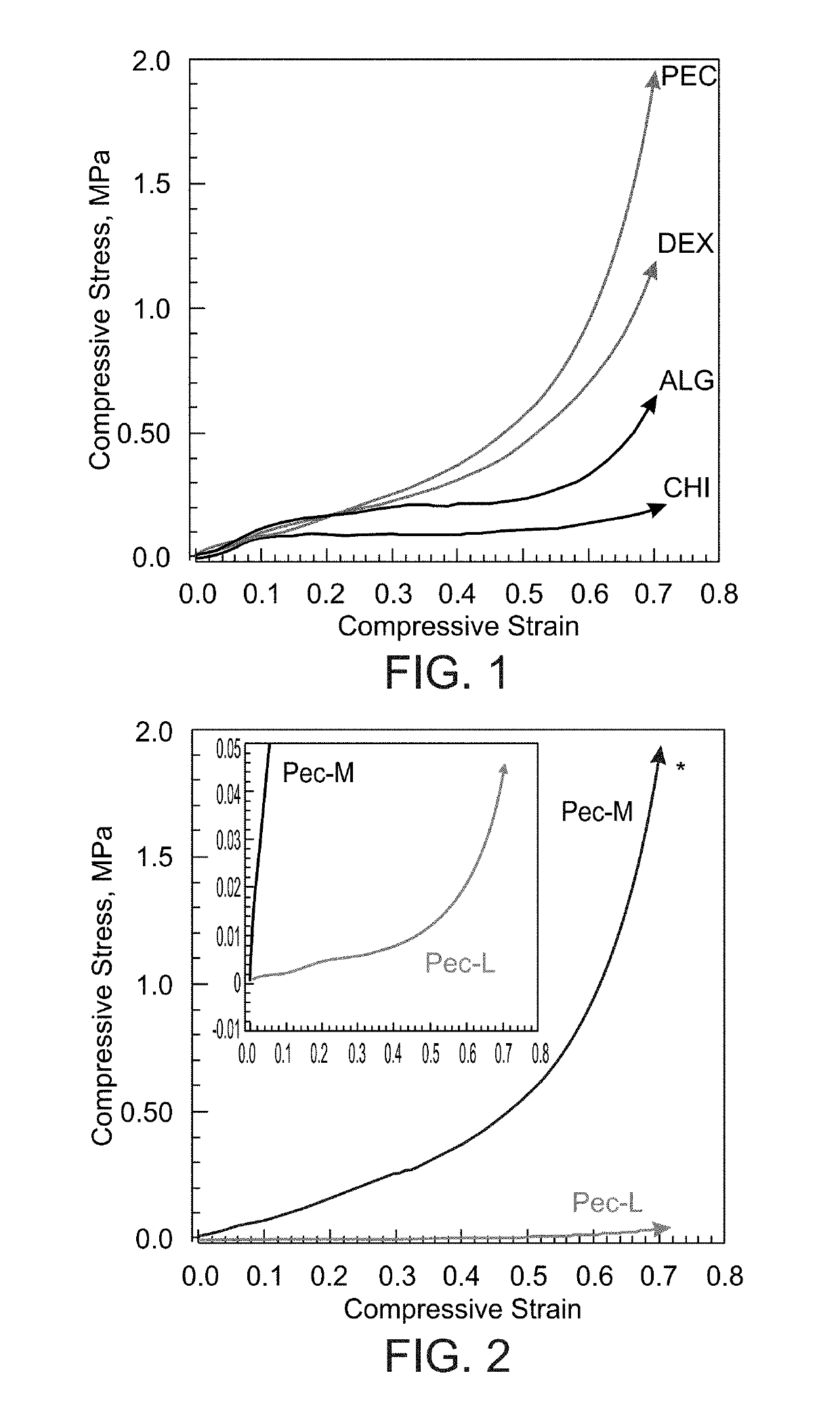

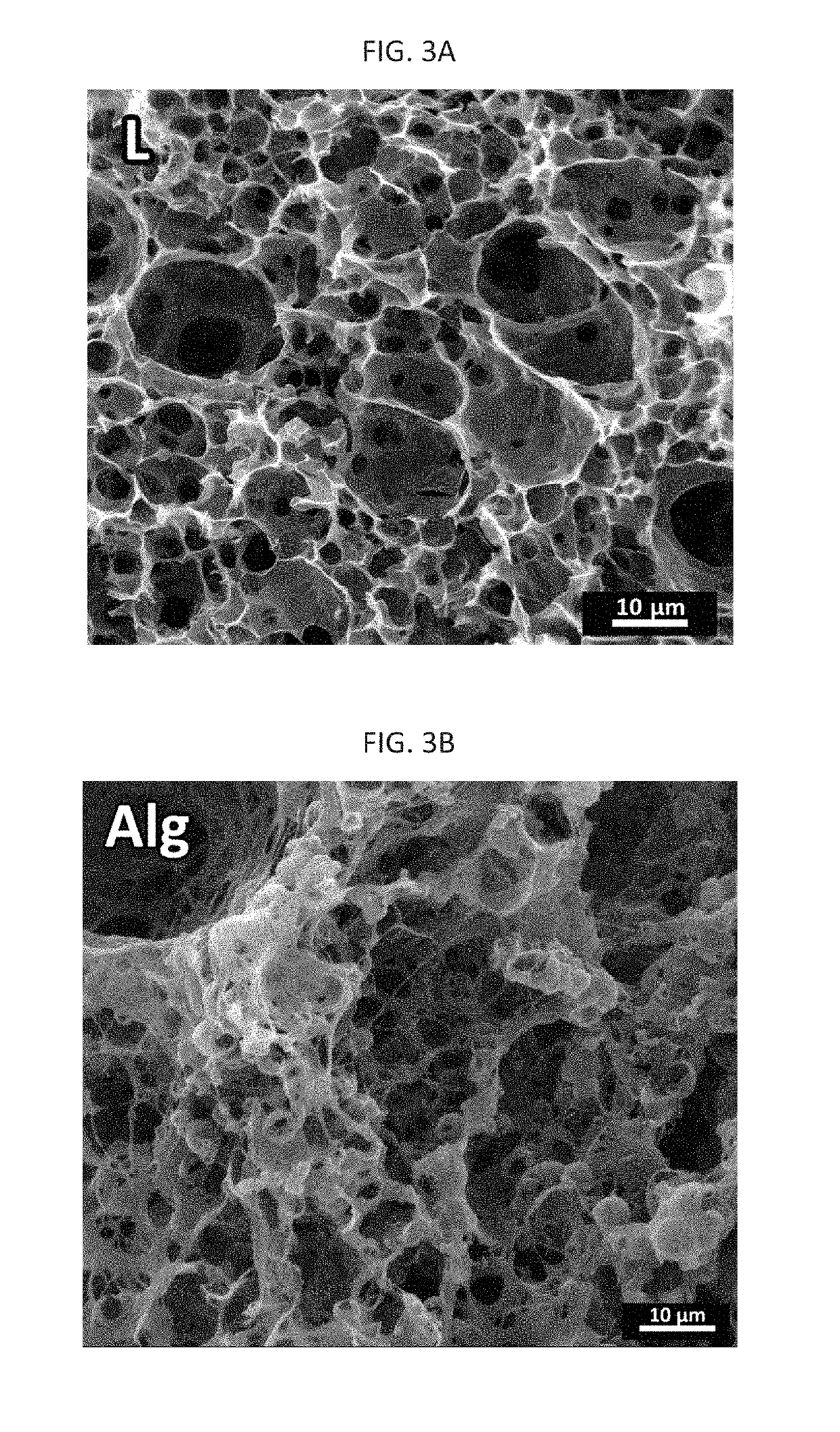

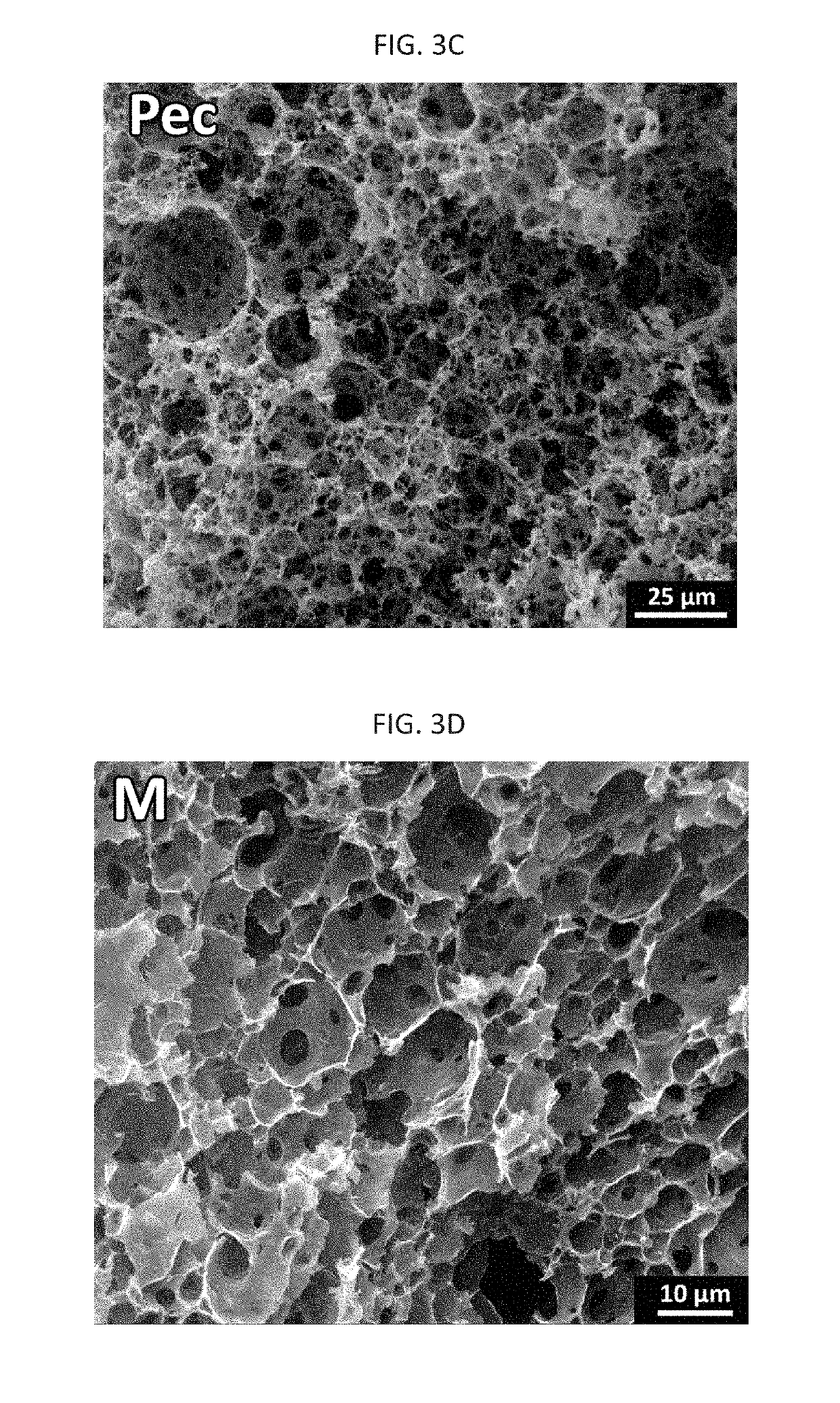

Polyhipes by interfacial step-growth polymerization

A polyHIPE-templated composition-of-matter afforded by interfacial polymerization, comprising a polymer of alternating residues of hydrophobic and hydrophilic monomers. The described composition-of-matter is characterized by an open-, quasi-closed- or a truly closed-cell microstructure, whereas the latter is capable of non-releasably or releasably encapsulating an organic or aqueous composition therein for extended periods of time, as well as various uses thereof.

Owner:TECHNION RES & DEV FOUND LTD

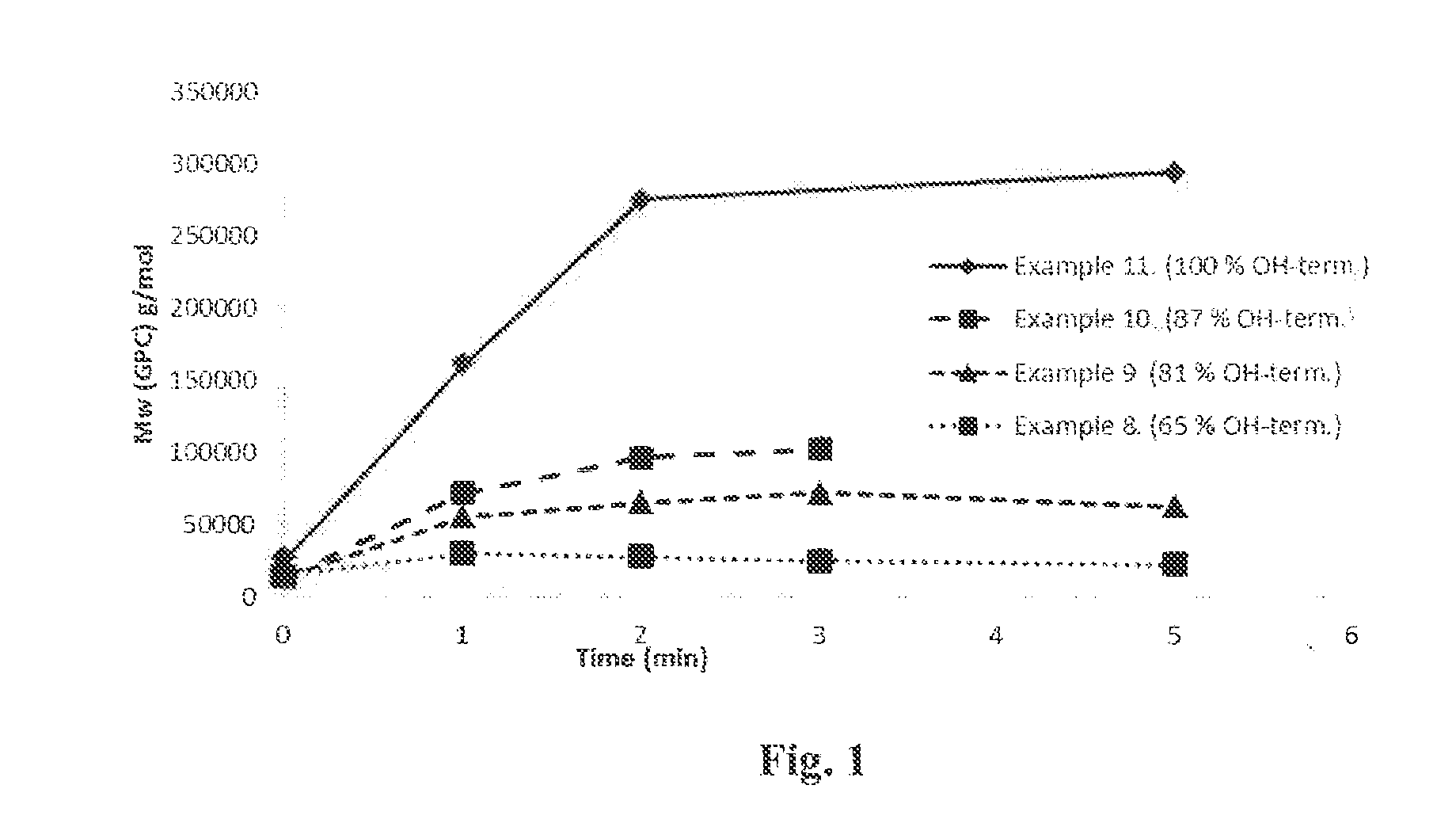

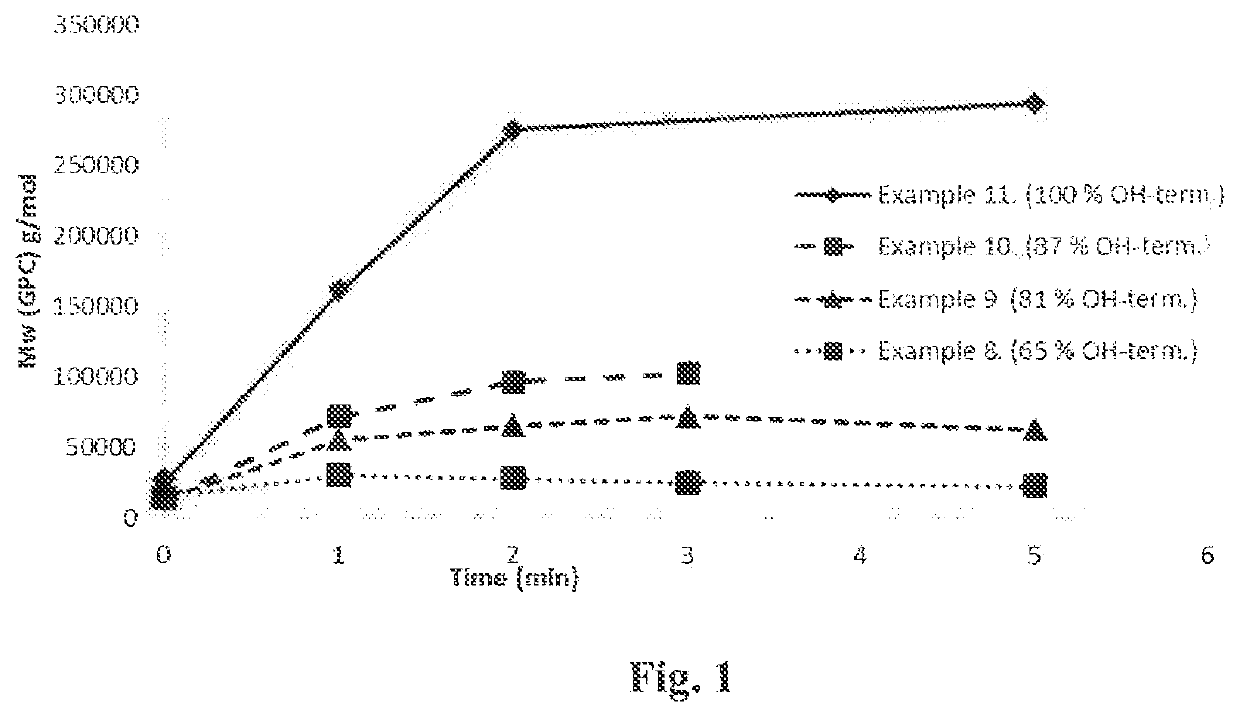

Method of producing glycolic acid polymers

ActiveUS20180201724A1Useful applicationOrganic-compounds/hydrides/coordination-complexes catalystsPolyesterPolymer science

Described herein is a feasible, significantly simplified production method that avoids challenging lactonization steps and converts a low molecular weight aliphatic polyester, consisting of hydroxy acids and a comonomer, whose molecular weight has been increased by step-growth polymerization reactions. The molecular weight of the aliphatic polyester, based on comparison of initial and final weight average molecular weights (Mw,1 / Mw,2), increased significantly at a rate which permits the use of reactive extrusion to produce high molecular weight aliphatic polyesters in a simple, economically feasible manner.

Owner:TEKNOLOGIAN TUTKIMUSKESKUS VTT

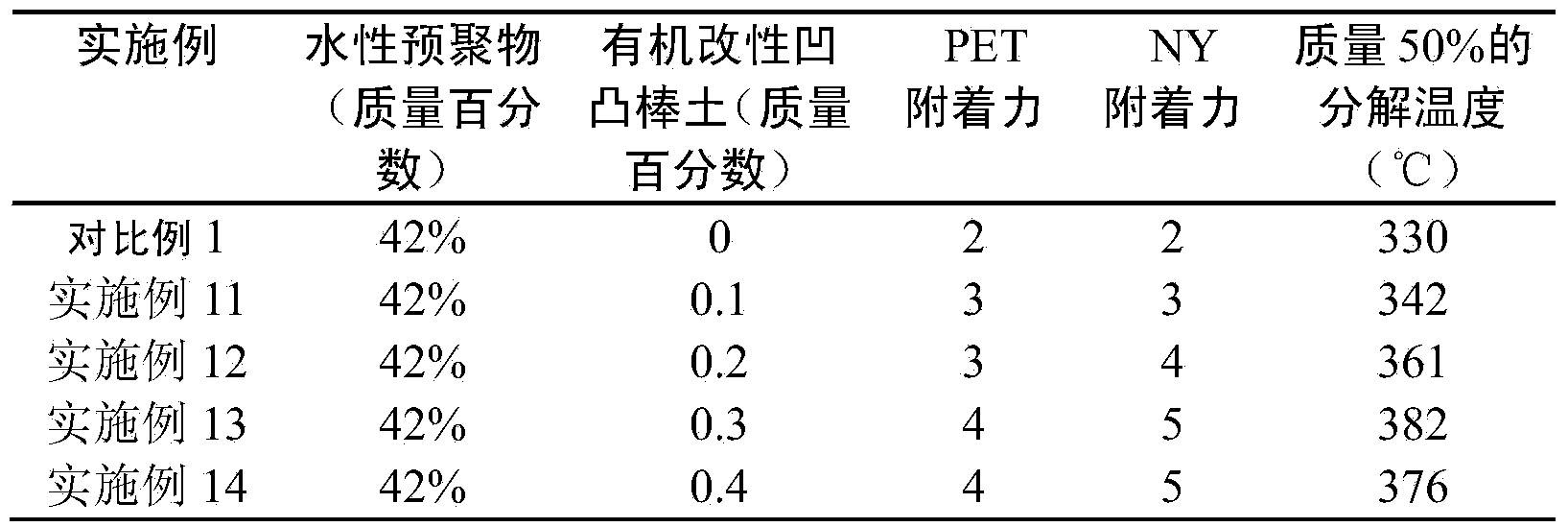

Organic-attapulgite-modified water-based laminating adhesive and preparation method thereof

InactiveCN104232001AGood dispersionImprove adhesionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesWater basedPolyol

The invention discloses an organic-attapulgite-modified water-based laminating adhesive and a preparation method thereof. The adhesive comprises 14-23% of a polymer polyol, 12-22% of a polyisocyanate compound, 0.1-2% of organic modified attapulgite, 2-9% of a chain extender, 2-5% of a neutralizer and 45-55% of deionized water. The polymer polyol, a diisocyanate compound, the attapulgite and the hydrophilic chain extender are used as main raw materials, and the organic-attapulgite-modified water-based laminating adhesive is obtained with a step-growth polymerization synthesis technology. The prepared laminating adhesive takes water as a solvent and has the advantages of large adhesive force, high peeling strength, good heat resistance and environment-friendliness.

Owner:BAOJI UNIV OF ARTS & SCI

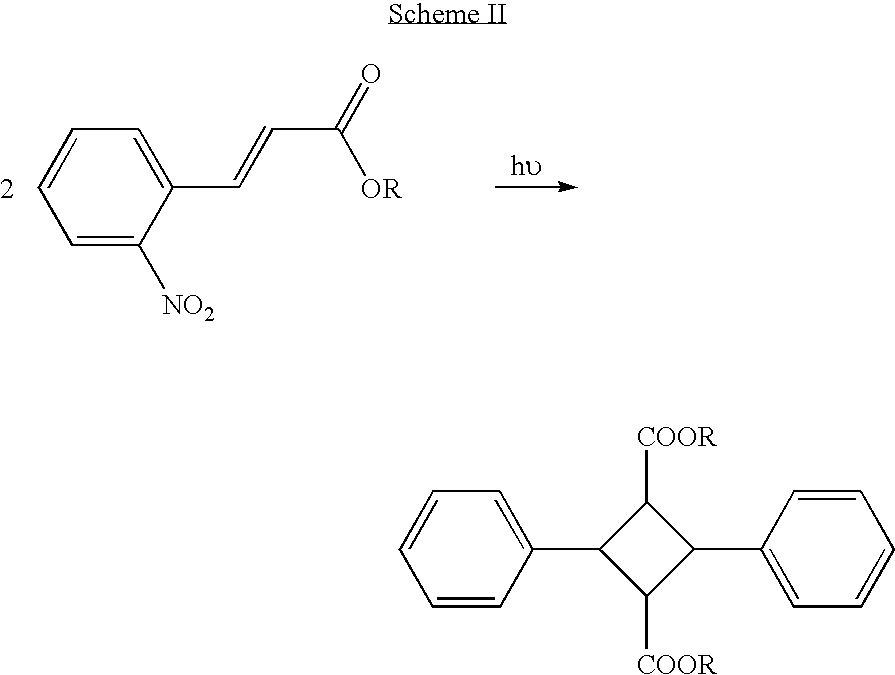

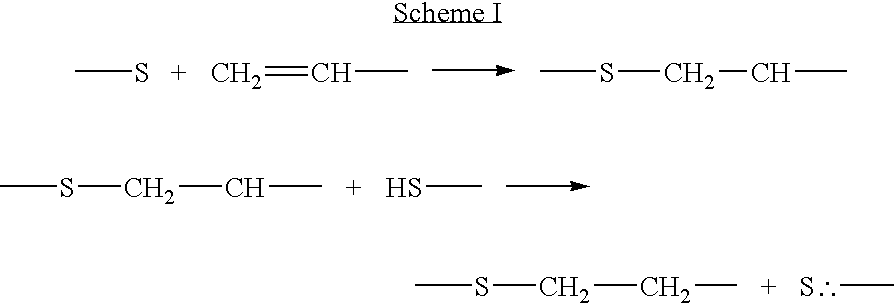

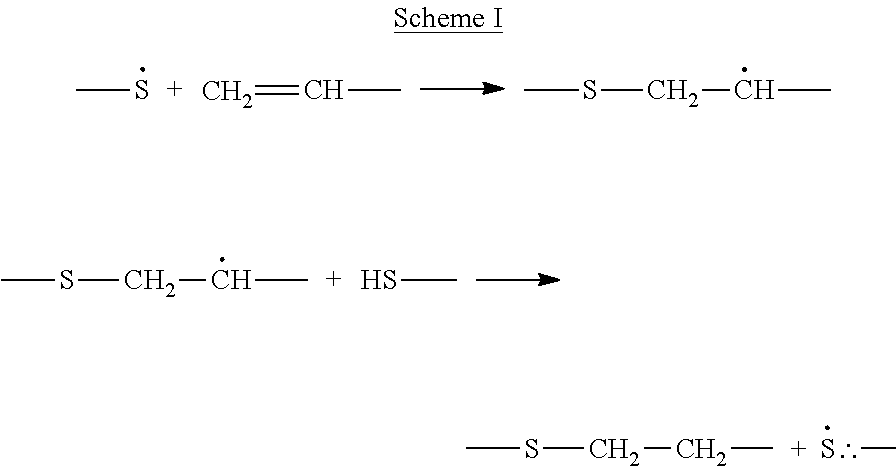

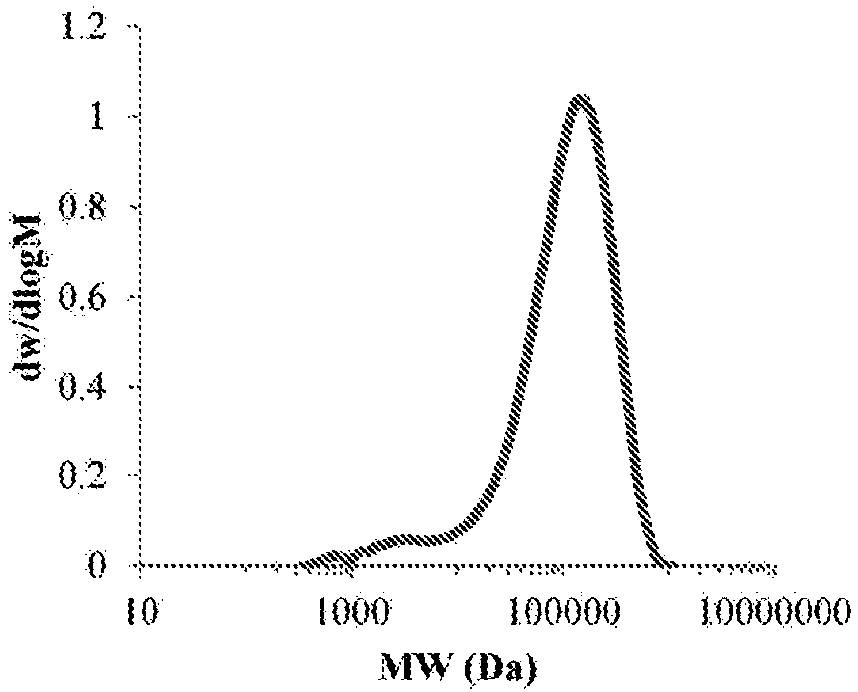

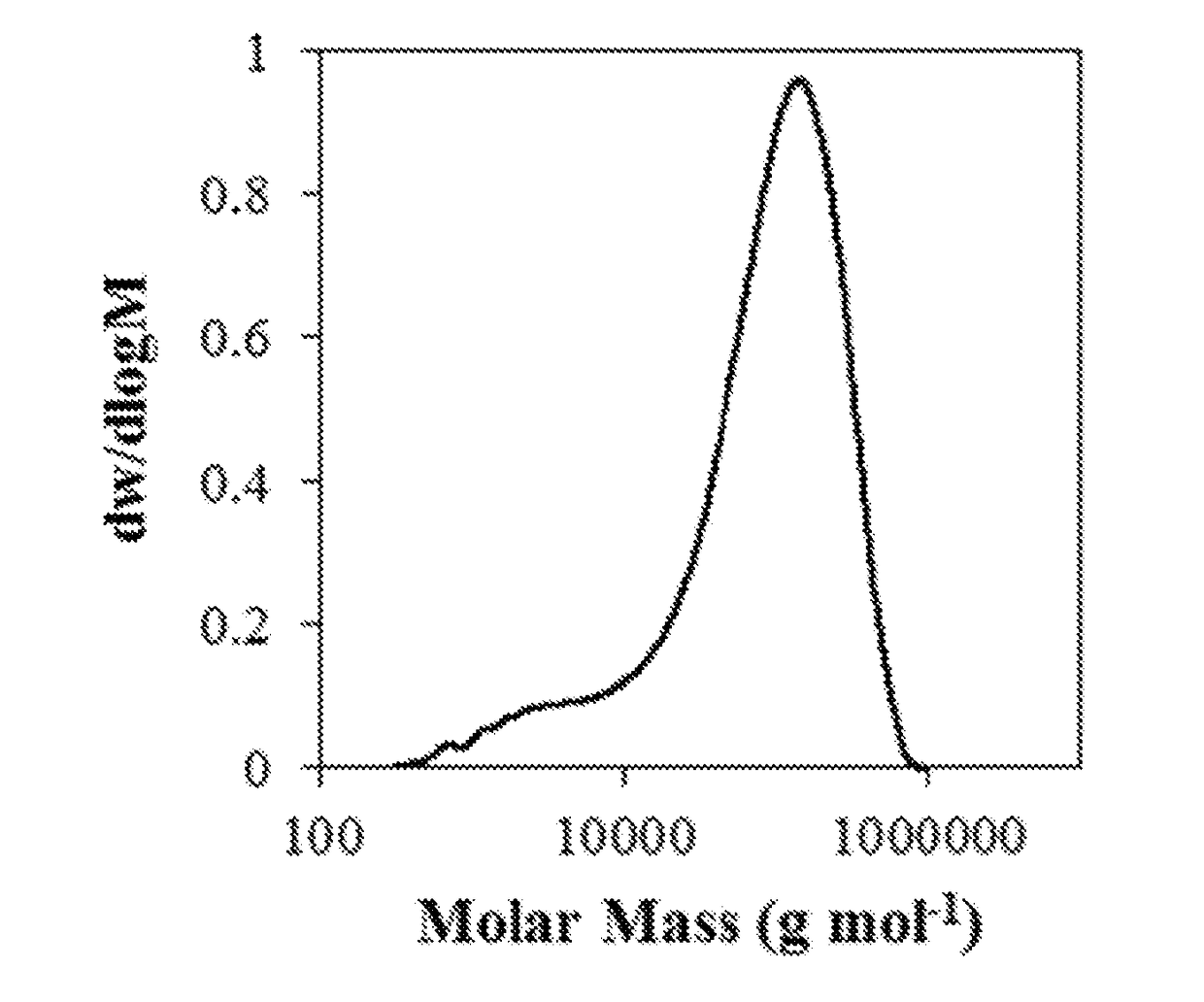

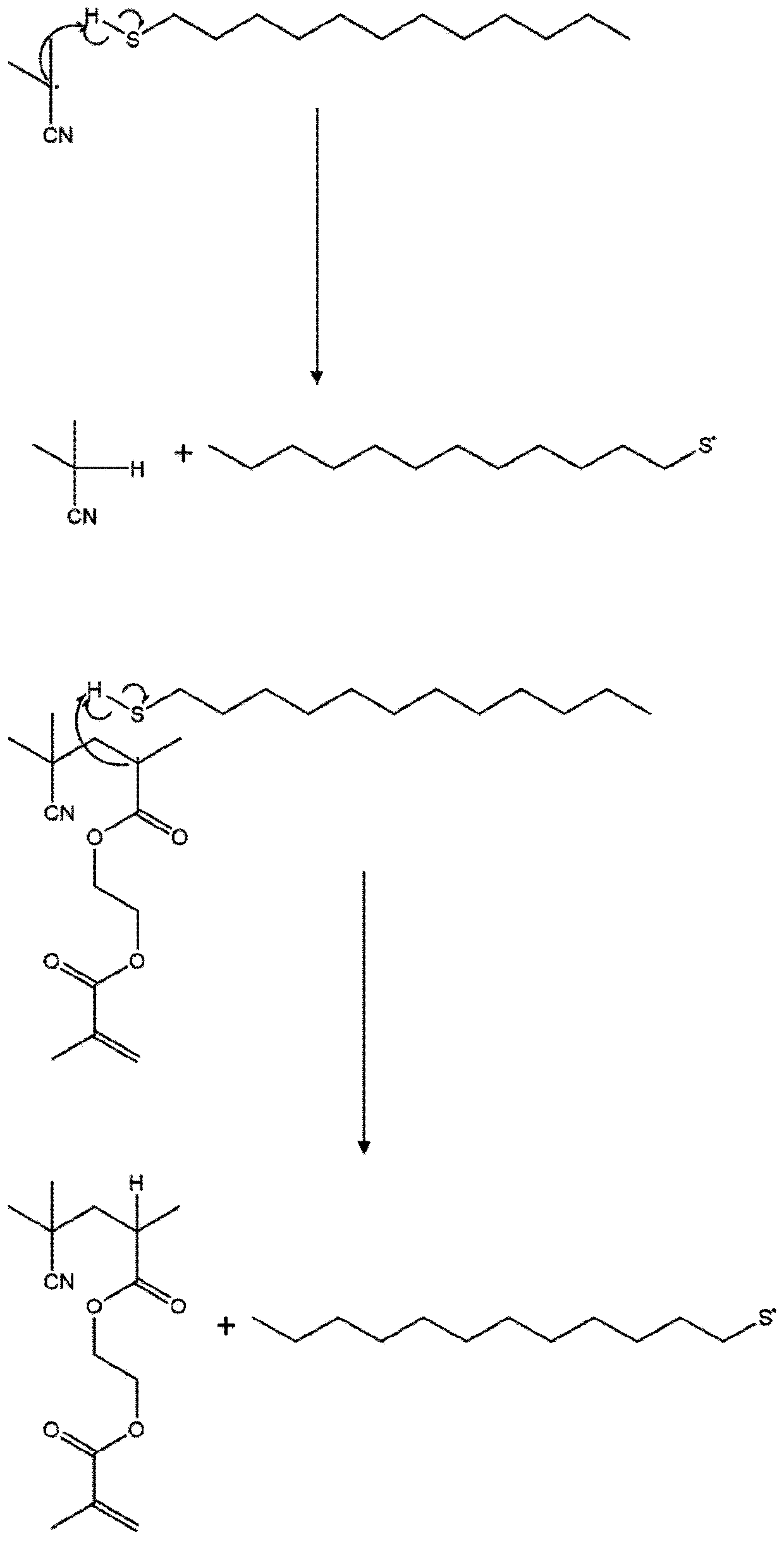

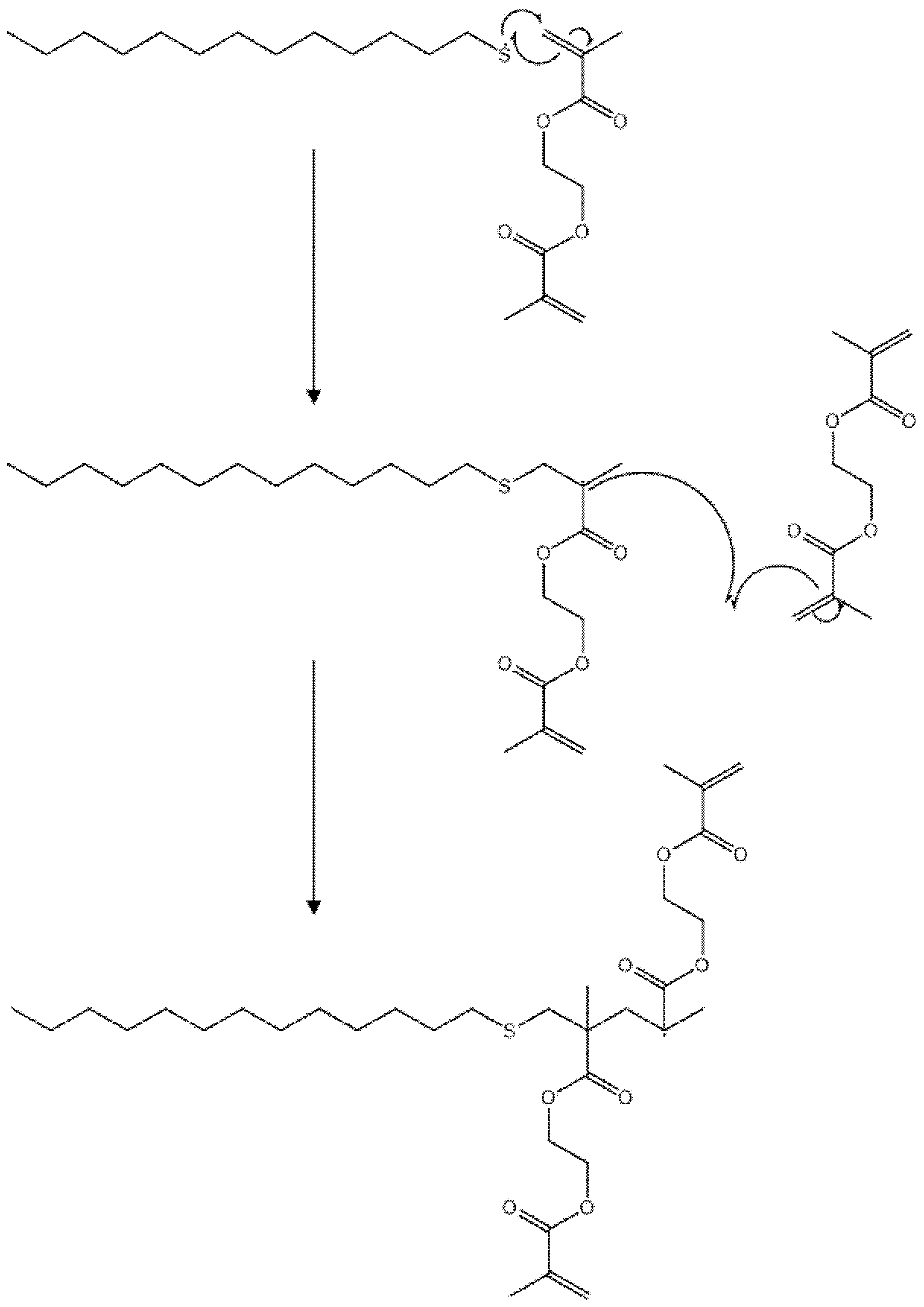

Biomimetic synthetic rubber and methods for controlling its physical properties through backbone double bond stereochemistry

In various embodiments, the present invention provides a strong, synthetic elastomer materials (and related methods for making same) with mechanical properties that are controlled by the stereochemically-defined double bonds within their backbone, yet have physical properties that are derived from monomer selection and defined, modifiable, chain end groups. The use of the organocatalyzed, stereospecific addition of thiols to activated alkynes, affords isolated high molar mass materials (>100 kDa) via step-growth polymerization with high levels of cis- or trans- double bond content. Furthermore, in various aspects of the present invention, it has been found that changing the monomer composition and chain end groups provides additional control over the materials' physical properties to provide more efficient compounding with polar additives. Using this approach to elastomer synthesis, further end group modification and toughening through various vulcanization strategies are also possible.

Owner:THE UNIVERSITY OF AKRON +1

Process for sizing paper

The present invention refers to a process for sizing paper which comprises adding to an aqueous suspension containing cellulosic fibres, and optional fillers, (i) an anionic or cationic sizing dispersion; and (ii) a sizing promoter comprising a cationic organic polymer having one or more aromatic groups, and an anionic polymer having one or more aromatic groups, the anionic polymer being a step-growth polymer, a polysaccharide or a naturally occurring aromatic polymer, forming and draining the obtained suspension, wherein the sizing dispersion and sizing promoter are added separately to the aqueous suspension.

Owner:AKZO NOBEL NV

Biomimetic synthetic rubber and methods for controlling its physical properties through backbone double bond stereochemistry by monomer selection and end group modification

In various embodiments, the present invention provides a strong, synthetic elastomer materials (and related methods for making same) with mechanical properties that are controlled by the stereochemically-defined double bonds within their backbone, yet have physical properties that are derived from monomer selection and defined, modifiable, chain end groups. The use of the organocatalyzed, stereospecific addition of thiols to activated alkynes, affords isolated high molar mass materials (>100 kDa) via step-growth polymerization with high levels of cis- or trans-double bond content. Furthermore, in various aspects of the present invention, it has been found that changing the monomer composition and chain end groups provides additional control over the materials' physical properties to provide more efficient compounding with polar additives. Using this approach to elastomer synthesis, further end group modification and toughening through various vulcanization strategies are also possible.

Owner:THE UNIVERSITY OF AKRON

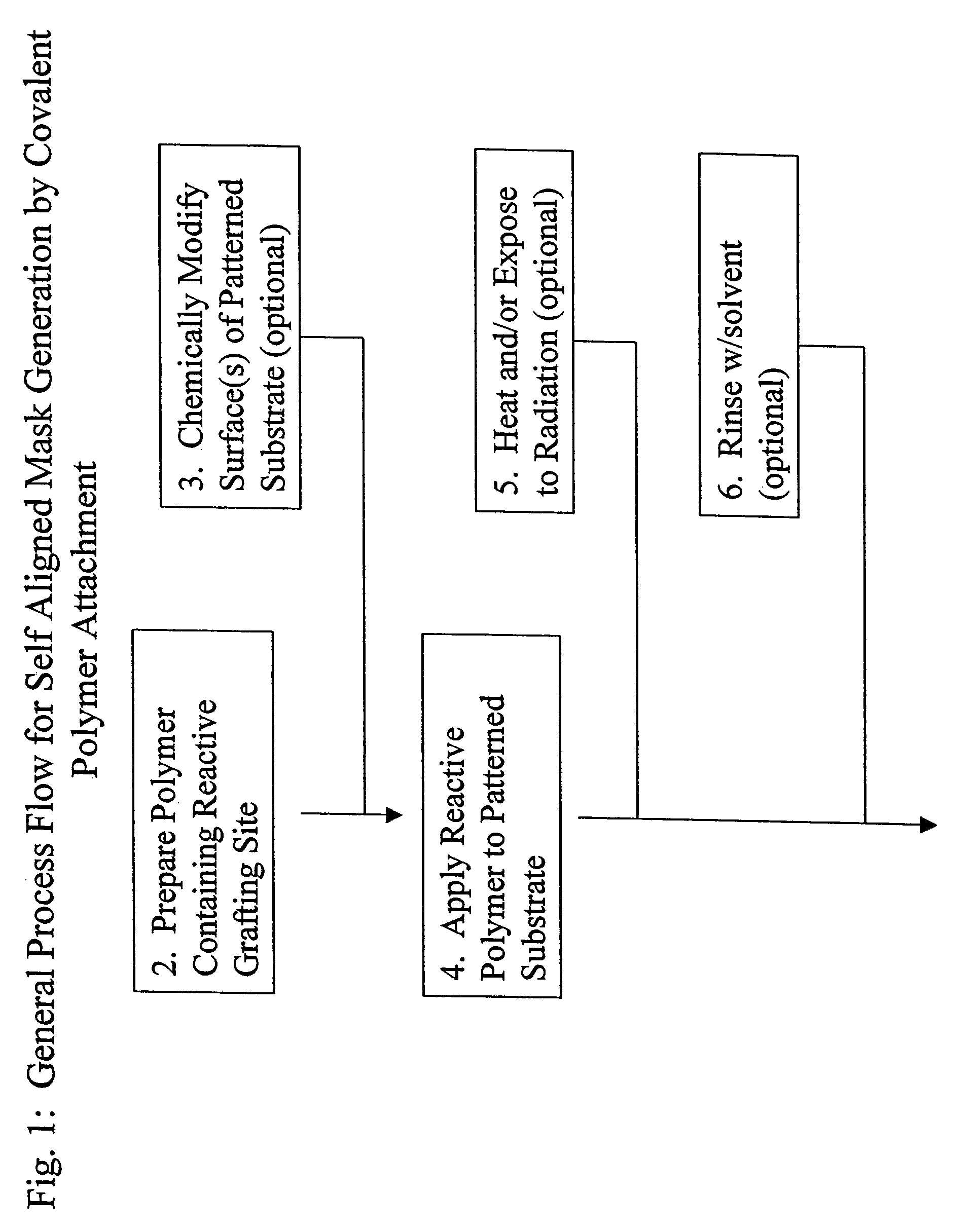

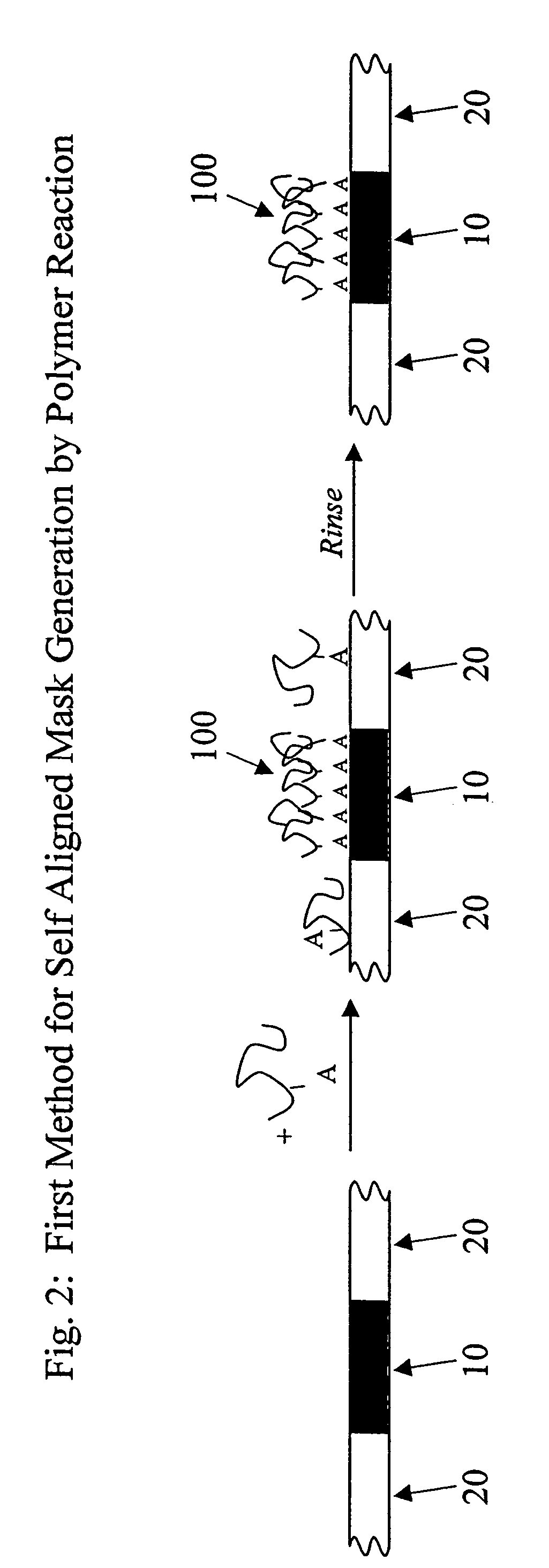

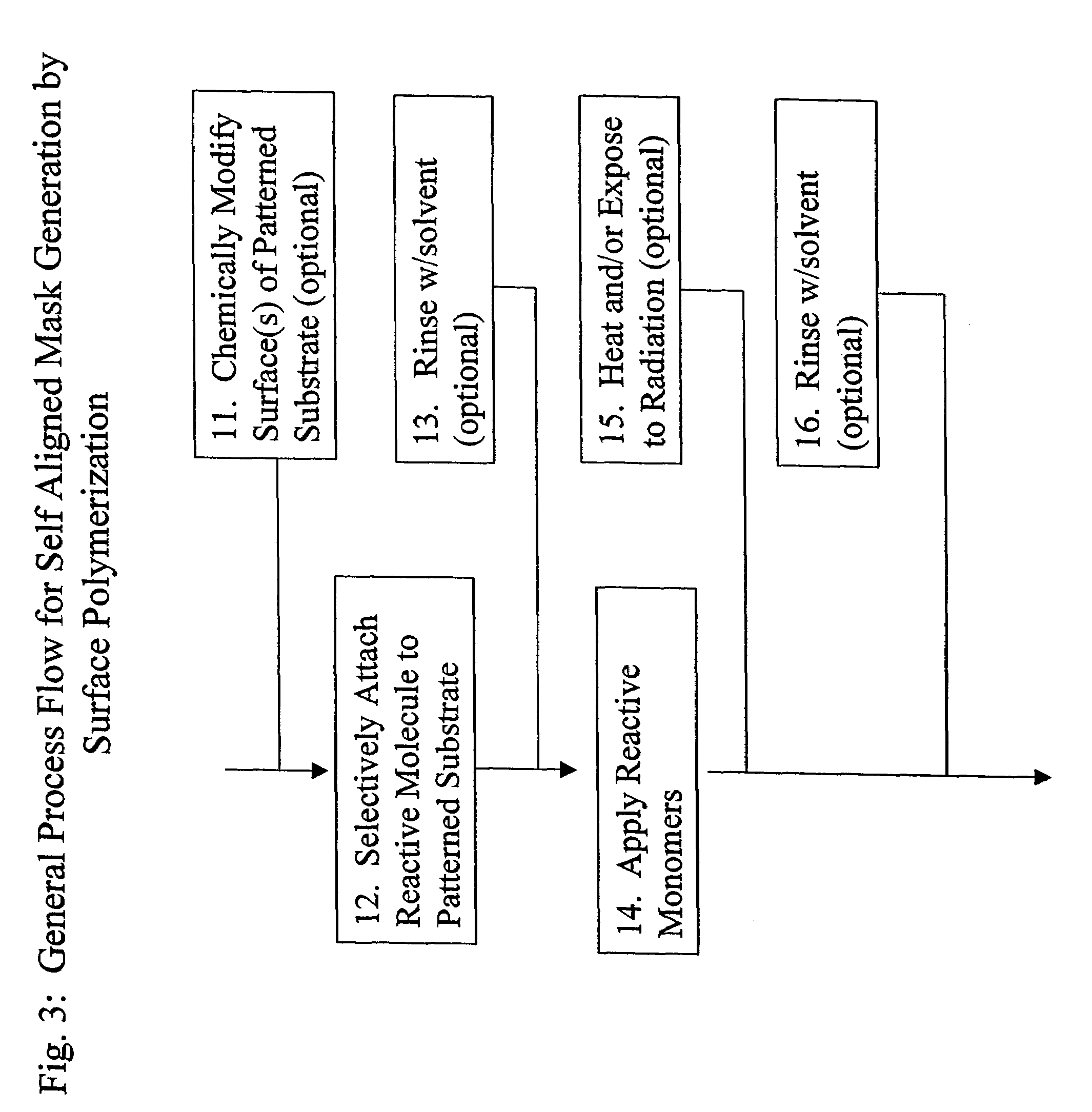

Nonlithographic method to produce masks by selective reaction, articles produced, and composition for same

InactiveUS7485341B2Simple and robustHigh level of protection and reliabilityMaterial nanotechnologySemiconductor/solid-state device manufacturingDielectricAtomic composition

A method for forming a self aligned pattern on an existing pattern on a substrate comprising applying a coating of the masking material to the substrate; and allowing at least a portion of the masking material to preferentially attach to portions of the existing pattern. The pattern is comprised of a first set of regions of the substrate having a first atomic composition and a second set of regions of the substrate having a second atomic composition different from the first composition. The first set of regions may include one or more metal elements and the second set of regions may include a dielectric. The masking material may comprise a polymer containing a reactive grafting site that selectively binds to the portions of the pattern. The masking material may include a polymer that binds to the portions of the pattern to provide a layer of functional groups suitable for polymerization initiation, a reactive molecule having functional groups suitable for polymerization propagation, or a reactive molecule, wherein reaction of the reactive molecule with the portion of the pattern generates a layer having reactive groups, which participate in step growth polymerization. Structures in accordance with the method. Compositions for practicing the method.

Owner:GLOBALFOUNDRIES INC

Method of producing glycolic acid polymers

ActiveUS10227446B2High molecular weightImprove thermal stabilityOrganic-compounds/hydrides/coordination-complexes catalystsPolyesterPolymer science

Described herein is a feasible, significantly simplified production method that avoids challenging lactonization steps and converts a low molecular weight aliphatic polyester, consisting of hydroxy acids and a comonomer, whose molecular weight has been increased by step-growth polymerization reactions. The molecular weight of the aliphatic polyester, based on comparison of initial and final weight average molecular weights (Mw,1 / Mw,2), increased significantly at a rate which permits the use of reactive extrusion to produce high molecular weight aliphatic polyesters in a simple, economically feasible manner.

Owner:TEKNOLOGIAN TUTKIMUSKESKUS VTT

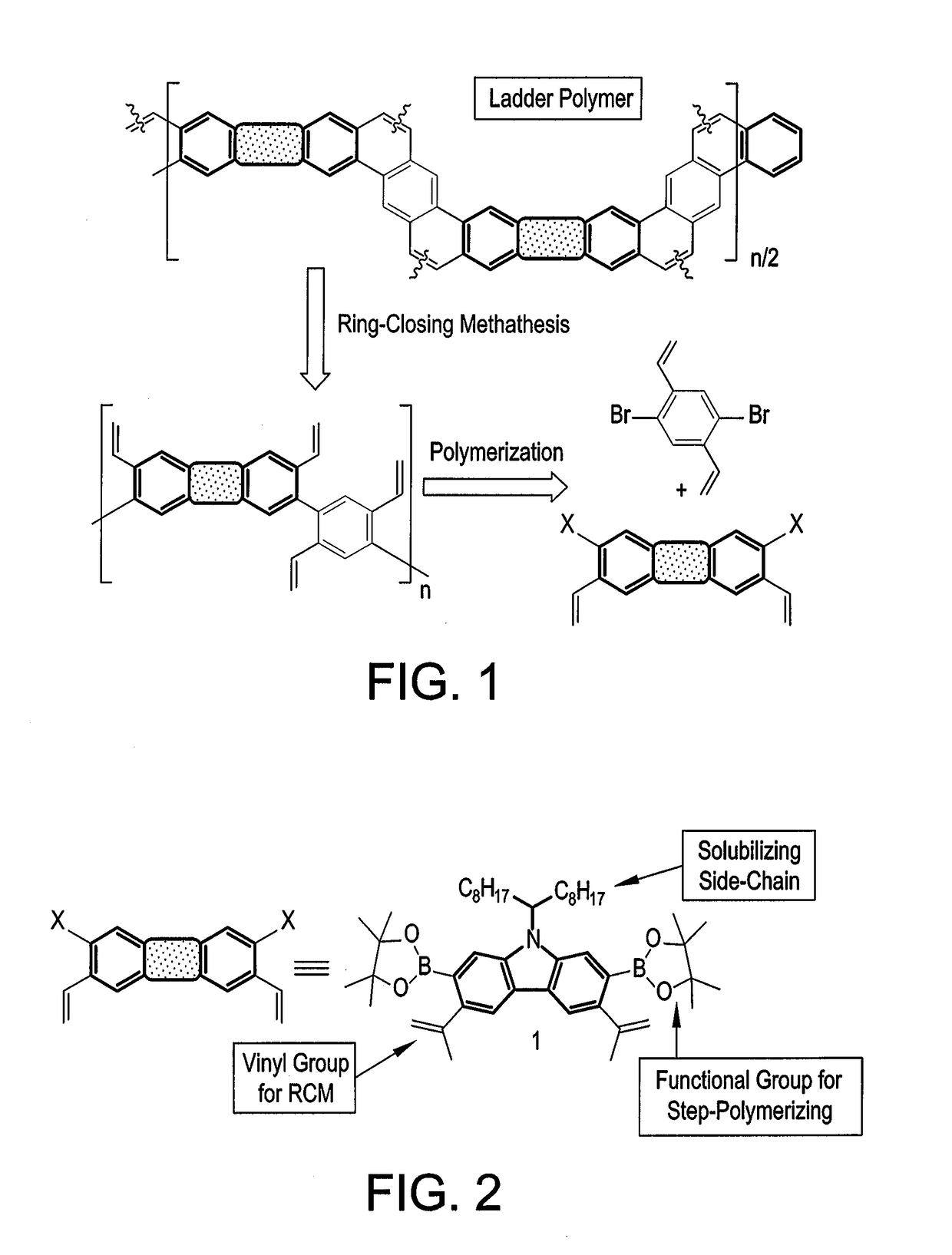

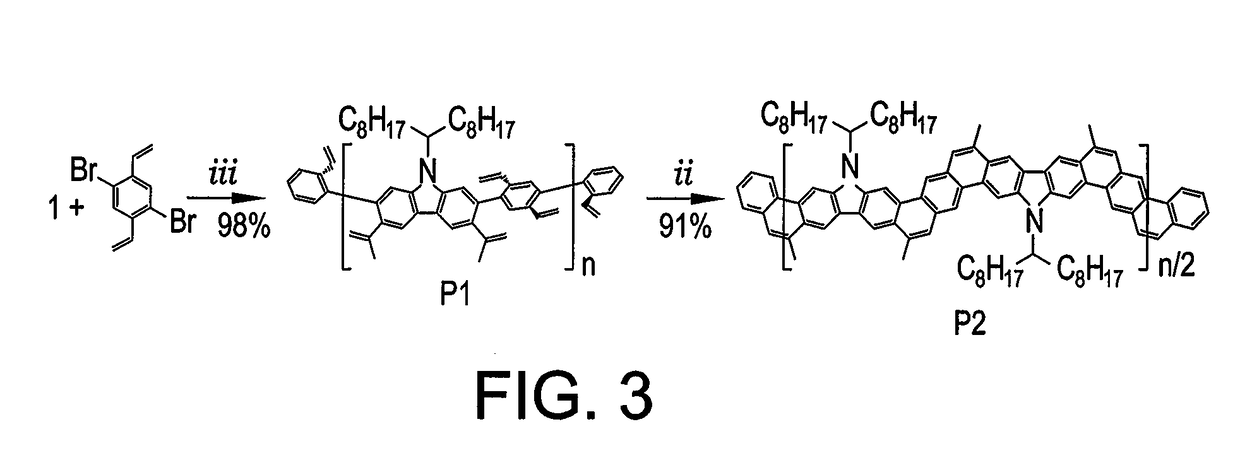

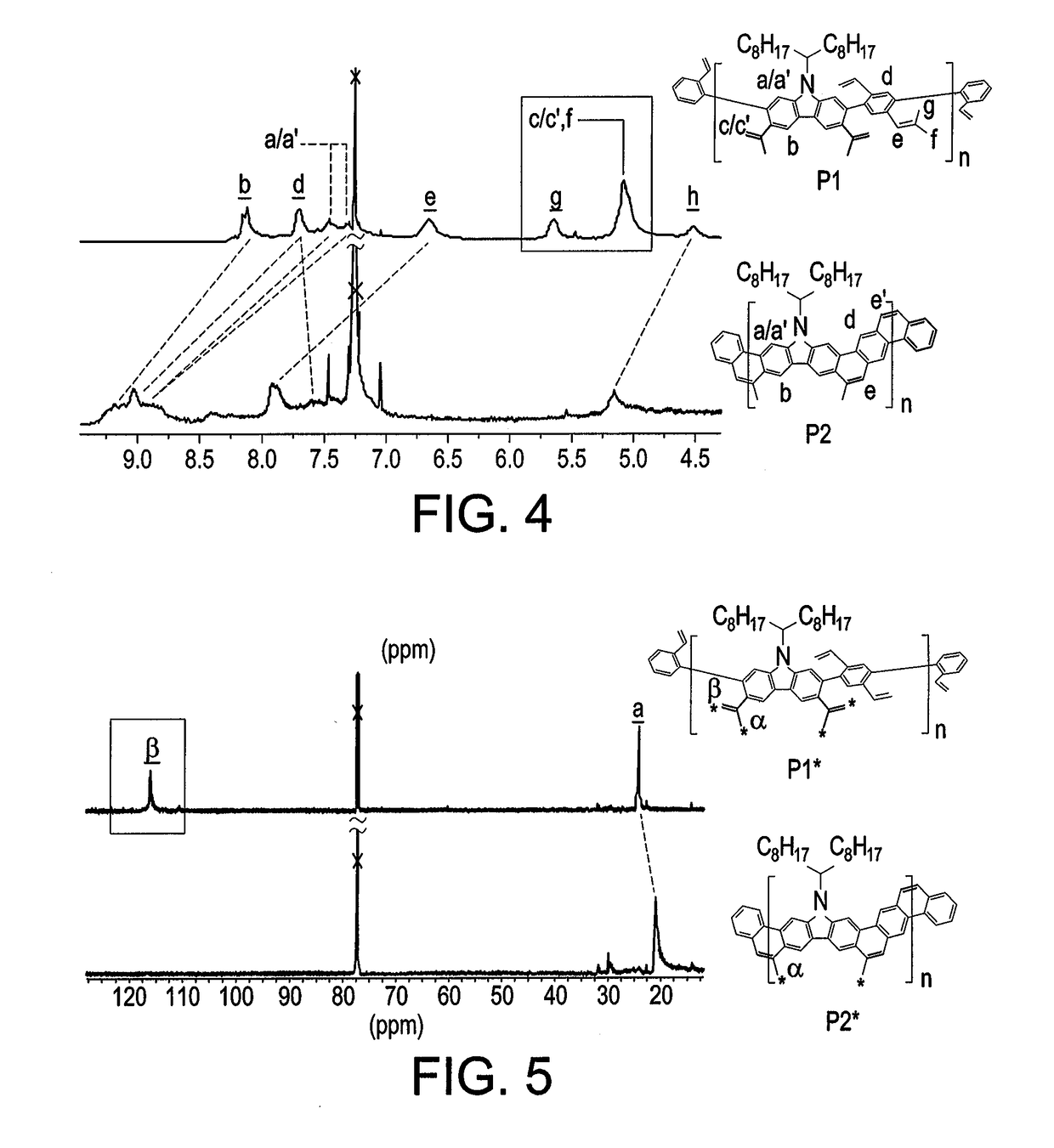

Organic semiconductor polymer

InactiveUS20170260324A1Solid-state devicesSemiconductor/solid-state device manufacturingPhenylboronic acidCarbazole

The organic semiconductor polymers relates to the synthesis of a carbazole-based ladder polymer. The synthesis of the ladder polymer includes forming a precursor conjugated polymer by Suzuki step growth polymerization of 2,7-dibromocarbazole with 1,4-dibromo-2,5-divinylbenzene, followed by end capping with 2-bromostyrene and 2-vinyl-phenylboronic acid. Then, the pendent vinyl groups are closed by ring-closing olefin metathesis to obtain the ladder polymer.

Owner:FANG LEI +2

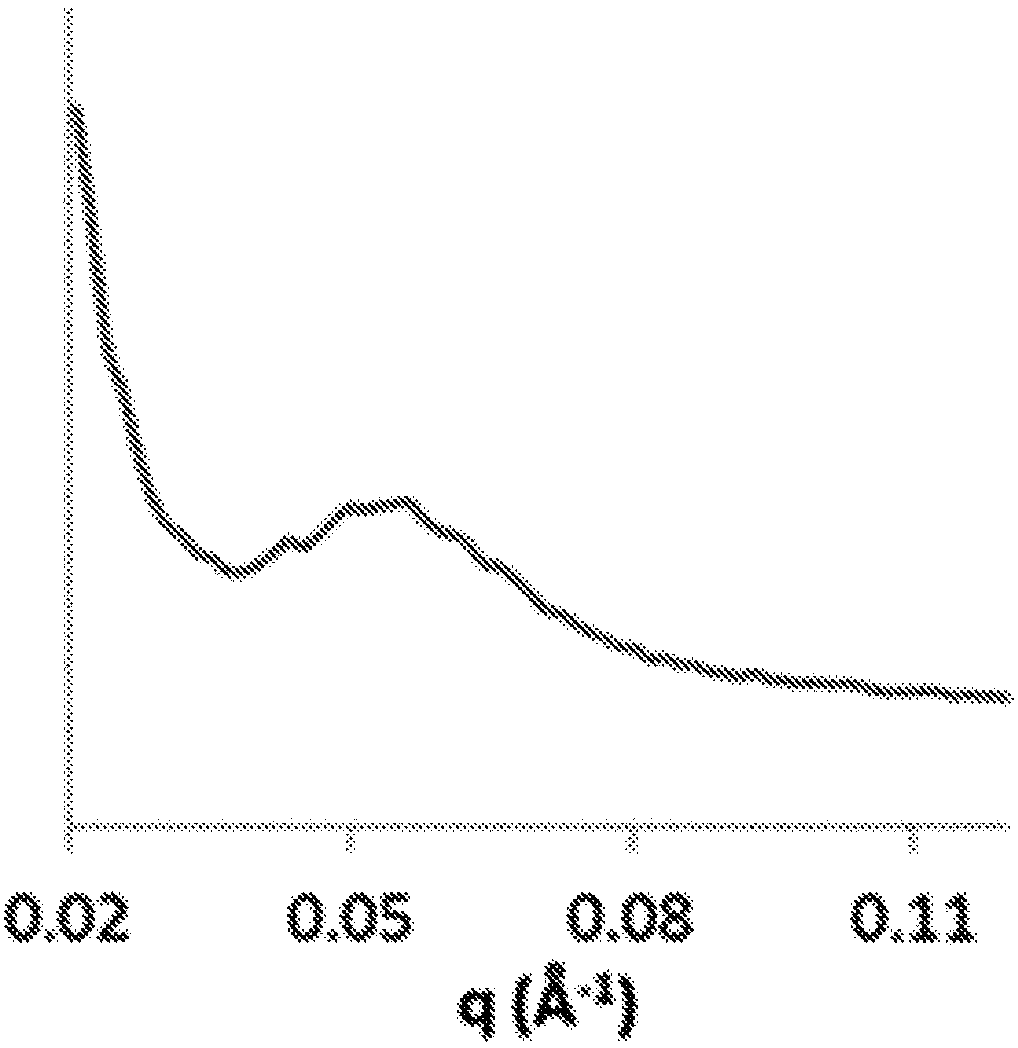

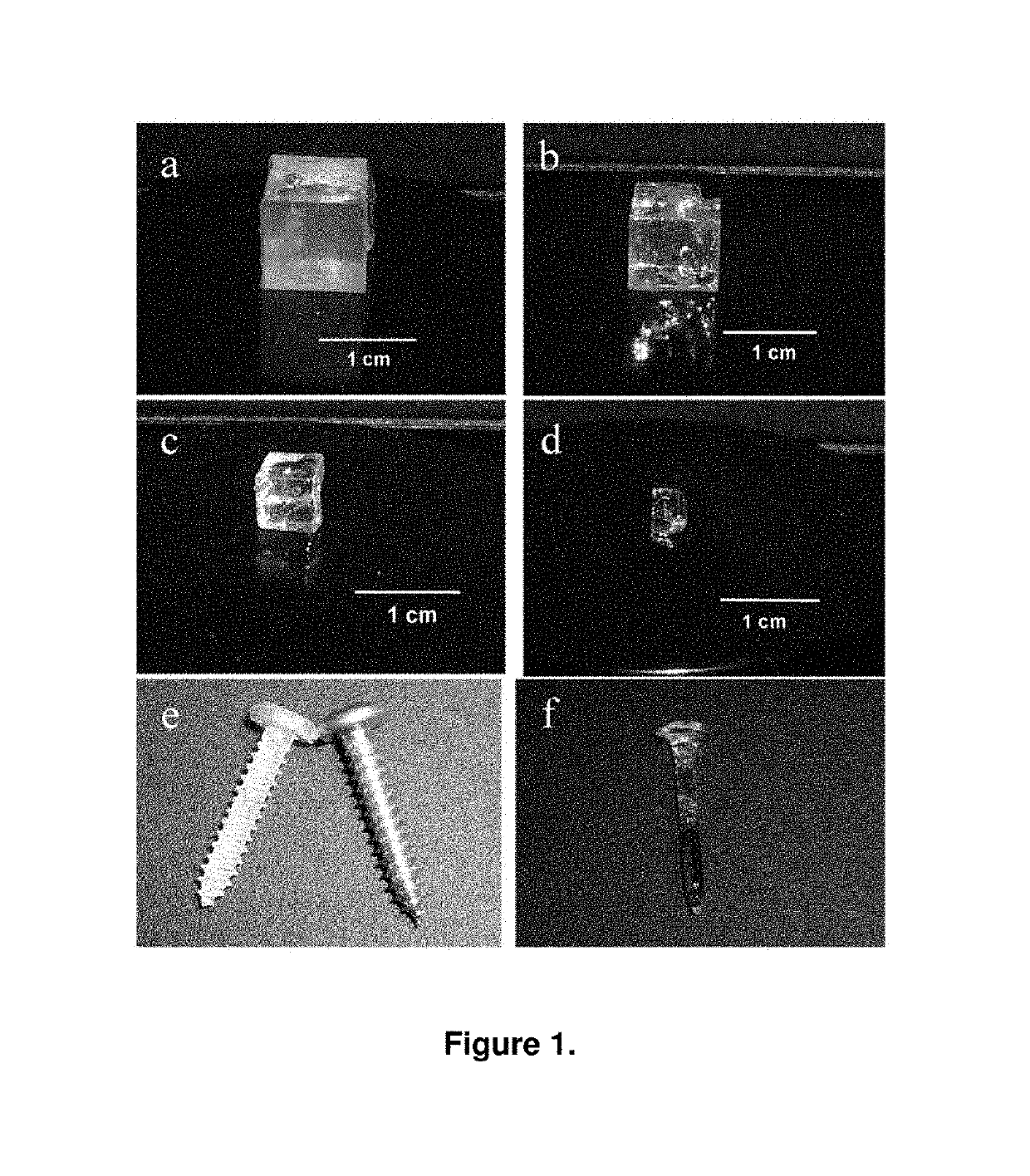

Elastomers with exceptional elongation

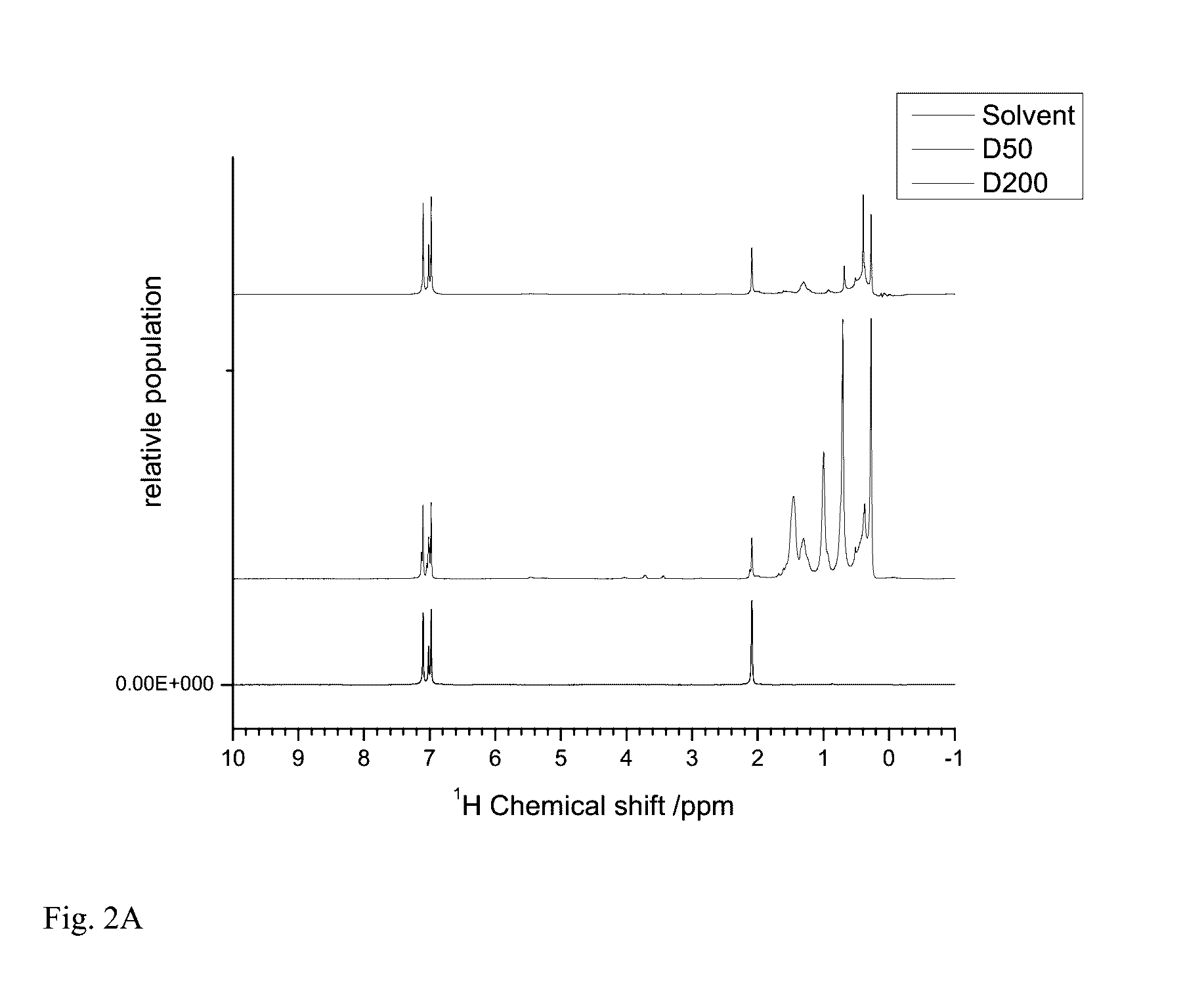

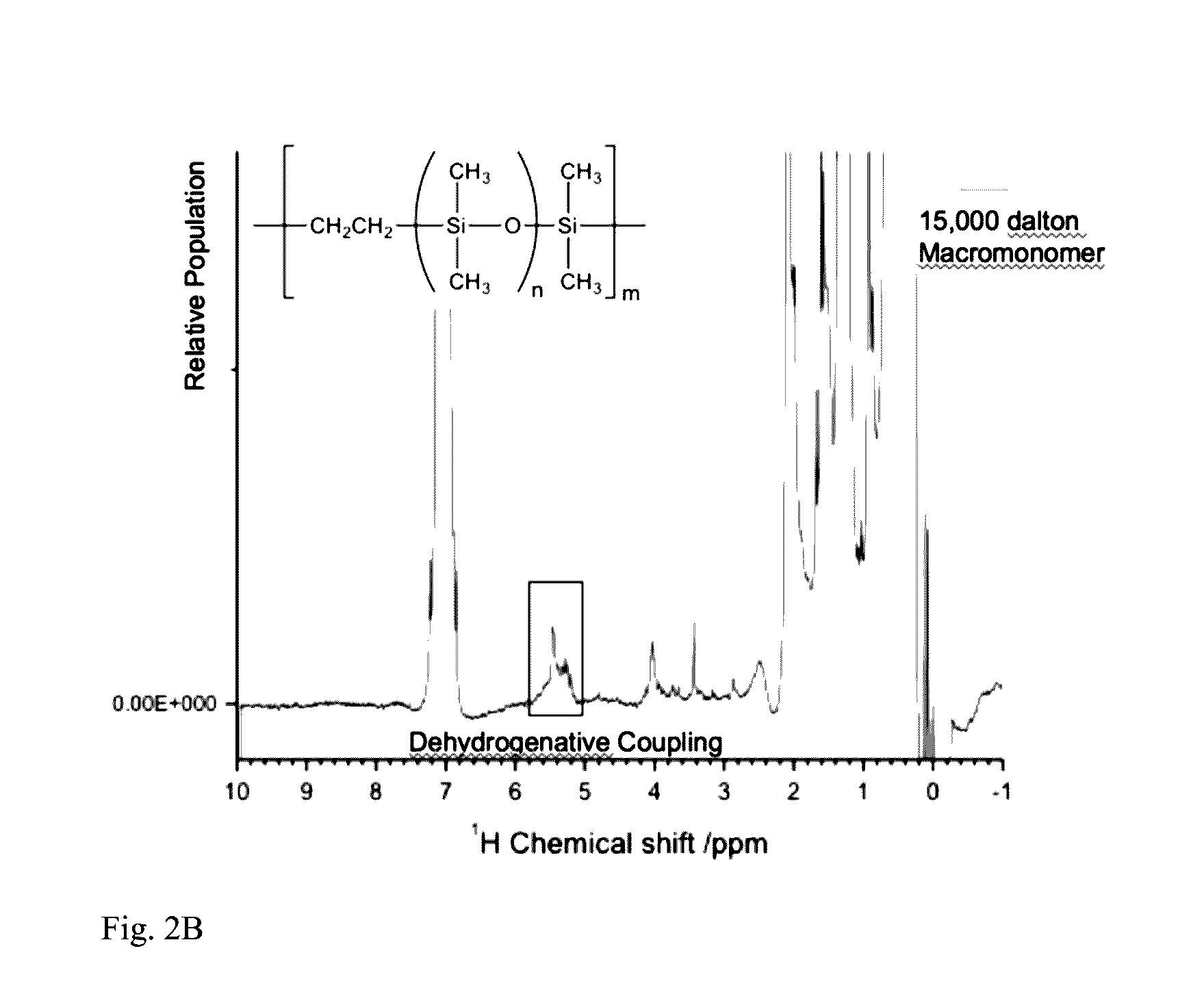

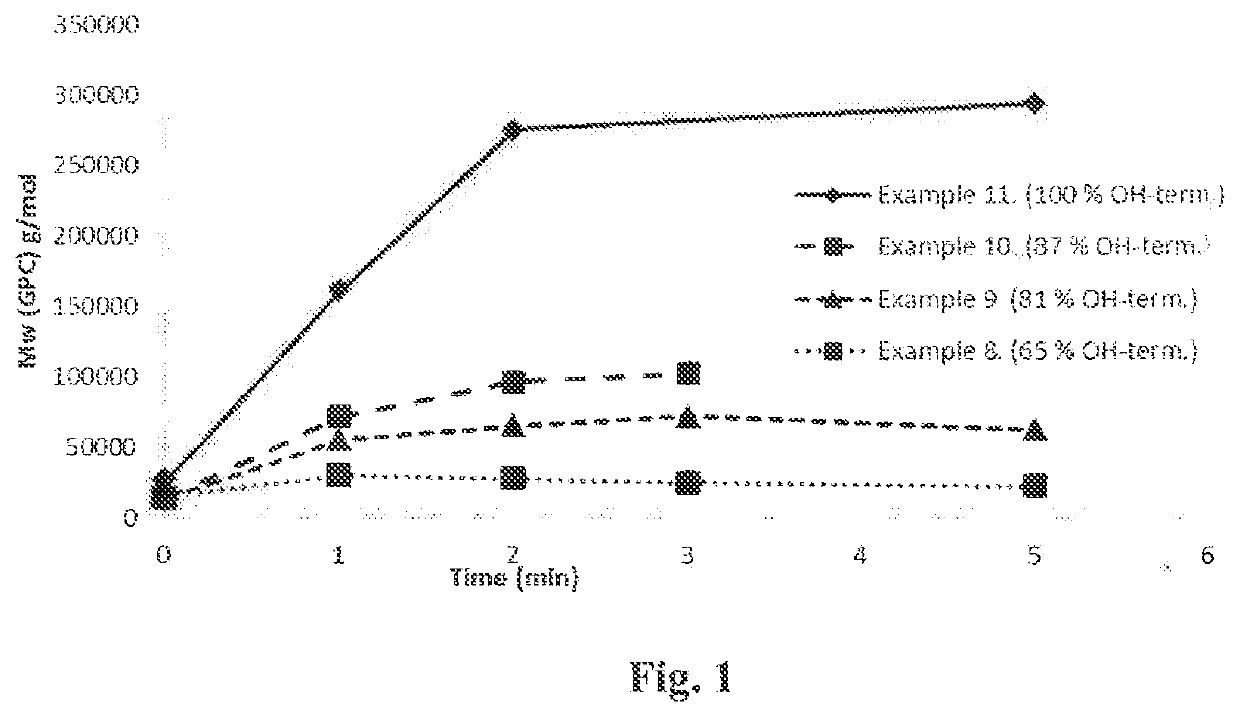

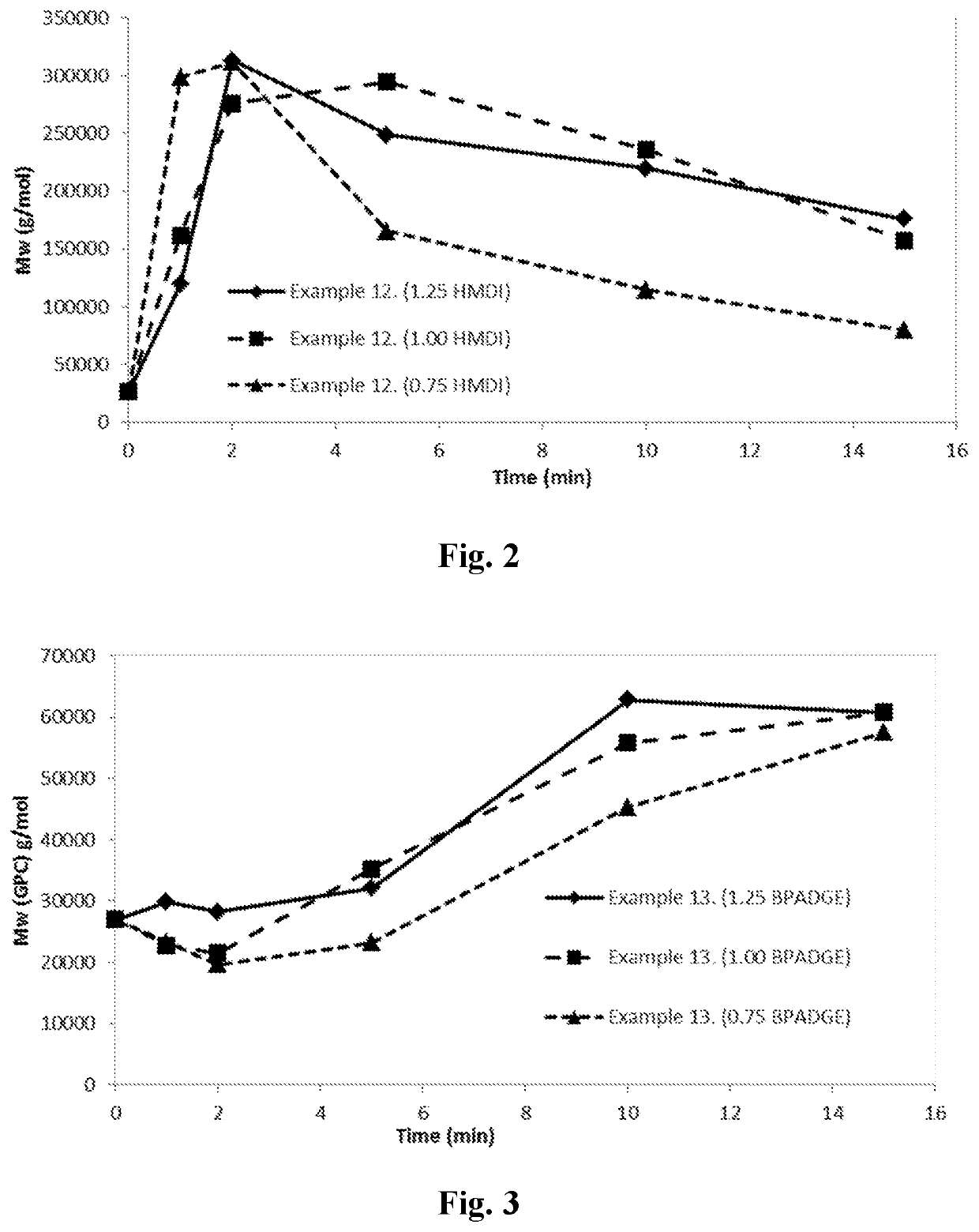

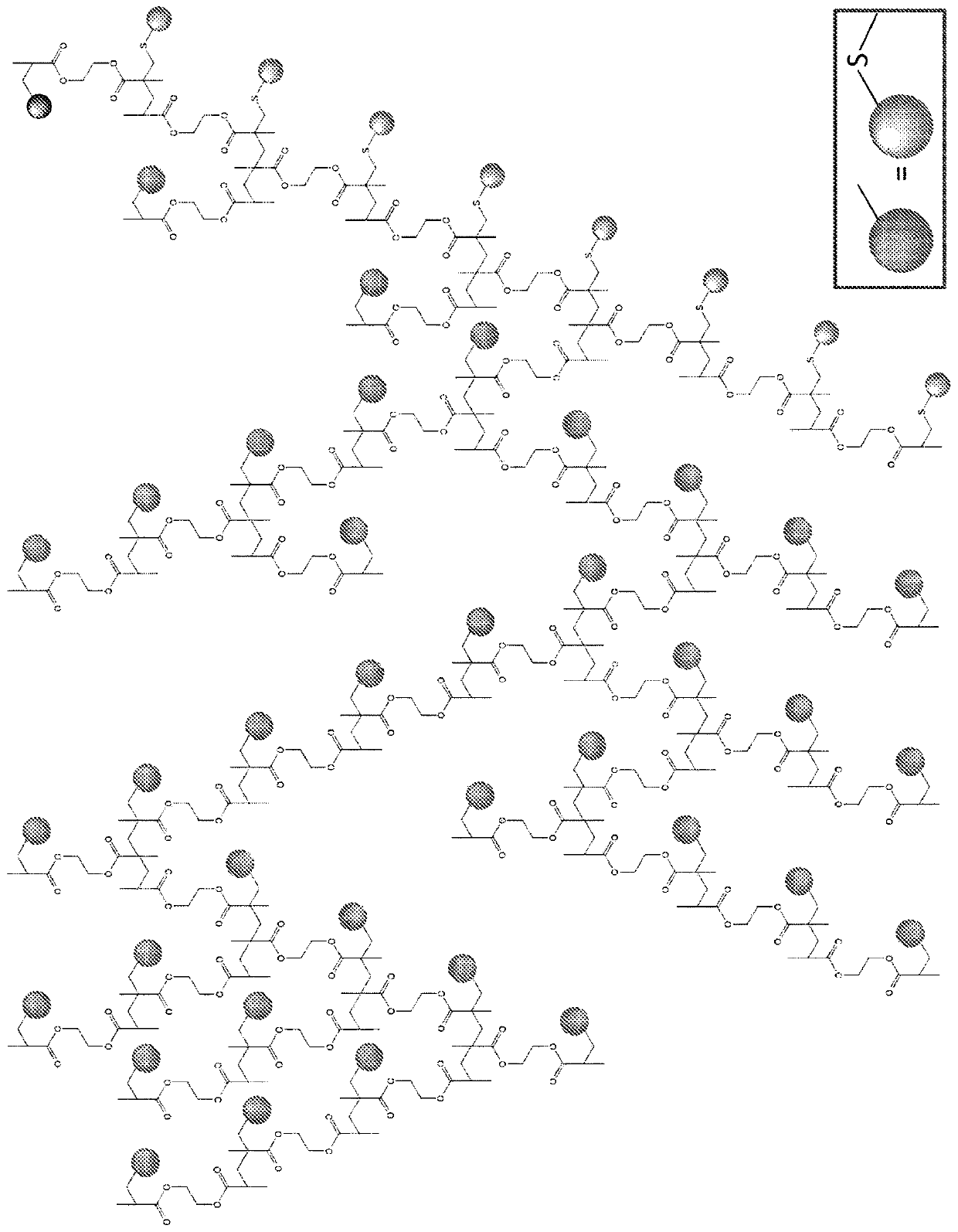

Nanocomposites exhibiting elongation exceeding about 2000%, elastic recovery, and tensile strength exceeding 2.5 MPa are described. A method these elastomers involves performing a catalyzed step growth polymerization of a heterobifunctional siloxane macromonomer compounded with at least about 15 wt % surface passivated silica nanoparticles. The macromonomer has a degree of polymerization of at least about 40 and the silica nanoparticles have nominal diameters of less than about 50 nm.

Owner:GELEST TECH

Glycolic acid polymers and method of producing the same

ActiveUS20200109310A1High molecular weightEfficient use ofPolyurea/polyurethane coatingsMonocomponent synthetic polymer artificial filamentPolyesterPolymer science

Owner:TEKNOLOGIAN TUTKIMUSKESKUS VTT

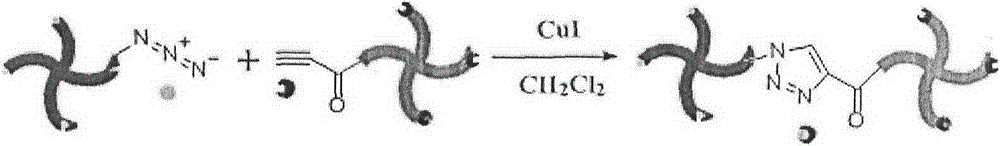

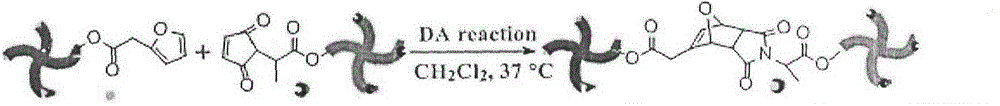

Degradable shape memory high polymer material of regular network structure and preparation method therefor

InactiveCN105017538AImprove mechanical propertiesExcellent shape memory performancePolymer scienceClick chemistry

The invention relates to a degradable shape memory high polymer material of a regular network structure and a preparation method therefor. The degradable shape memory high polymer material is characterized in that the degradable shape memory high polymer material of the regular network structure is obtained through step-growth polymerization of various equal-arm-length tetrahedral structure four-arm macromonomers with different special functional groups by utilizing an efficient click chemistry method. Different components of the network and compatibility and network soft and hard area distribution can be adjusted by selecting different four-arm macromonomers, so that the material has suitable microphase separation and different phase inversion temperatures to endow the shape memory performance. The preparation method can control the microstructure, shape memory performance, thermodynamic property and degradability of the material by adjusting the contents, types and molecular weights of the four-arm macromonomers, and is an effective method for obtaining the degradable shape memory high polymer material with excellent shape memory performance and high mechanical performance.

Owner:CHENGDU ORGANIC CHEM CO LTD CHINESE ACAD OF SCI

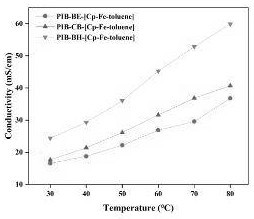

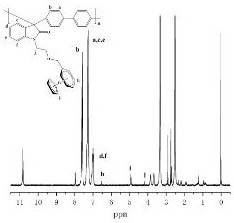

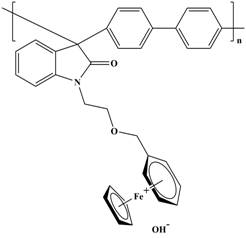

Preparation method of novel ferrocene derivative anion exchange membrane

The invention provides a novel ferrocene derivative anion exchange membrane and a preparation method thereof. The anion exchange membrane comprises ethyl side chain type polyisatin biphenyl, butyl side chain type polyisatin biphenyl and hexyl side chain type polyisatin biphenyl according to different lengths of grafted side chains. The invention also provides a novel ferrocene derivative anion exchange membrane and a preparation method thereof. According to the method, a polyisatin biphenyl polymer is prepared by utilizing a step-by-step growth polymerization reaction catalyzed by superacid, and the anion exchange membrane containing the ferrocene derivative is prepared by virtue of a nucleophilic substitution reaction. The hydroxyl conductivity of the novel ferrocene derivative anion exchange membrane disclosed by the invention at 80 DEG C is 0.059 S / cm.

Owner:CHANGCHUN UNIV OF TECH

Glycolic acid polymers and method of producing the same

ActiveUS11214704B2High molecular weightEfficient use ofPolyurea/polyurethane coatingsMonocomponent polyesters artificial filamentPolyesterPolymer science

Described herein is a feasible, significantly simplified production method that avoids challenging lactonization steps and converts a low molecular weight aliphatic polyester, consisting of hydroxy acids and a comonomer, whose molecular weight has been increased by step-growth polymerization reactions. The molecular weight of the aliphatic polyester, based on comparison of initial and final weight average molecular weights (Mw,1 / Mw,2), increased significantly at a rate which permits the use of reactive extrusion to produce high molecular weight aliphatic polyesters in a simple, economically feasible manner.

Owner:TEKNOLOGIAN TUTKIMUSKESKUS VTT

Polymers

Owner:UNIV OF LIVERPOOL

Latex particles imbibed with a thermoplastic polymer

Owner:ROHM & HAAS CO

Biomimetic synthetic rubber and methods for controlling its physical properties through backbone double bond stereochemistry by monomer selection and end group modification

In various embodiments, the present invention provides a strong, synthetic elastomer materials (and related methods for making same) with mechanical properties that are controlled by the stereochemically-defined double bonds within their backbone, yet have physical properties that are derived from monomer selection and defined, modifiable, chain end groups. The use of the organocatalyzed, stereospecific addition of thiols to activated alkynes, affords isolated high molar mass materials (>100 kDa) via step-growth polymerization with high levels of cis- or trans-double bond content. Furthermore, in various aspects of the present invention, it has been found that changing the monomer composition and chain end groups provides additional control over the materials' physical properties to provide more efficient compounding with polar additives. Using this approach to elastomer synthesis, further end group modification and toughening through various vulcanization strategies are also possible.

Owner:THE UNIVERSITY OF AKRON

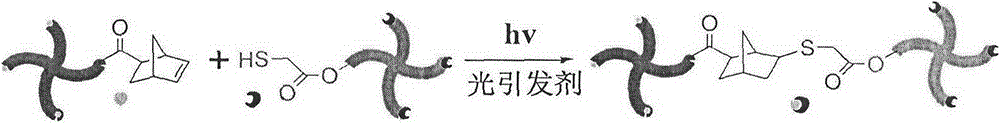

Elastomeric and degradable polyanhydride by step-growth thiol-ene photopolymerization

The present the invention is directed to a process and the new materials that are biodegradable for medical use, particularly for drug delivery, therapeutic devices and gene therapy / delivery. The invention illustrates a method of producing a degradable material using polymers made from thiol compounds and alkene / alkyene compounds, wherein one of these compounds contains one or more anhydride groups; and using a thiol-ene step-growth polymerization process, initiated by a free radical initiator. The polymerization process is initiated through photochemical, redox or thermal means, or any combination thereof.

Owner:CLARKSON UNIVERSITY

Compatibilized multipolymer composition containing particulate filler

InactiveUS20090043031A1Group 4/14 element organic compoundsPlastic/resin/waxes insulatorsParticulatesOligomer

Owner:EI DU PONT DE NEMOURS & CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com