Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

40 results about "Lens operations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

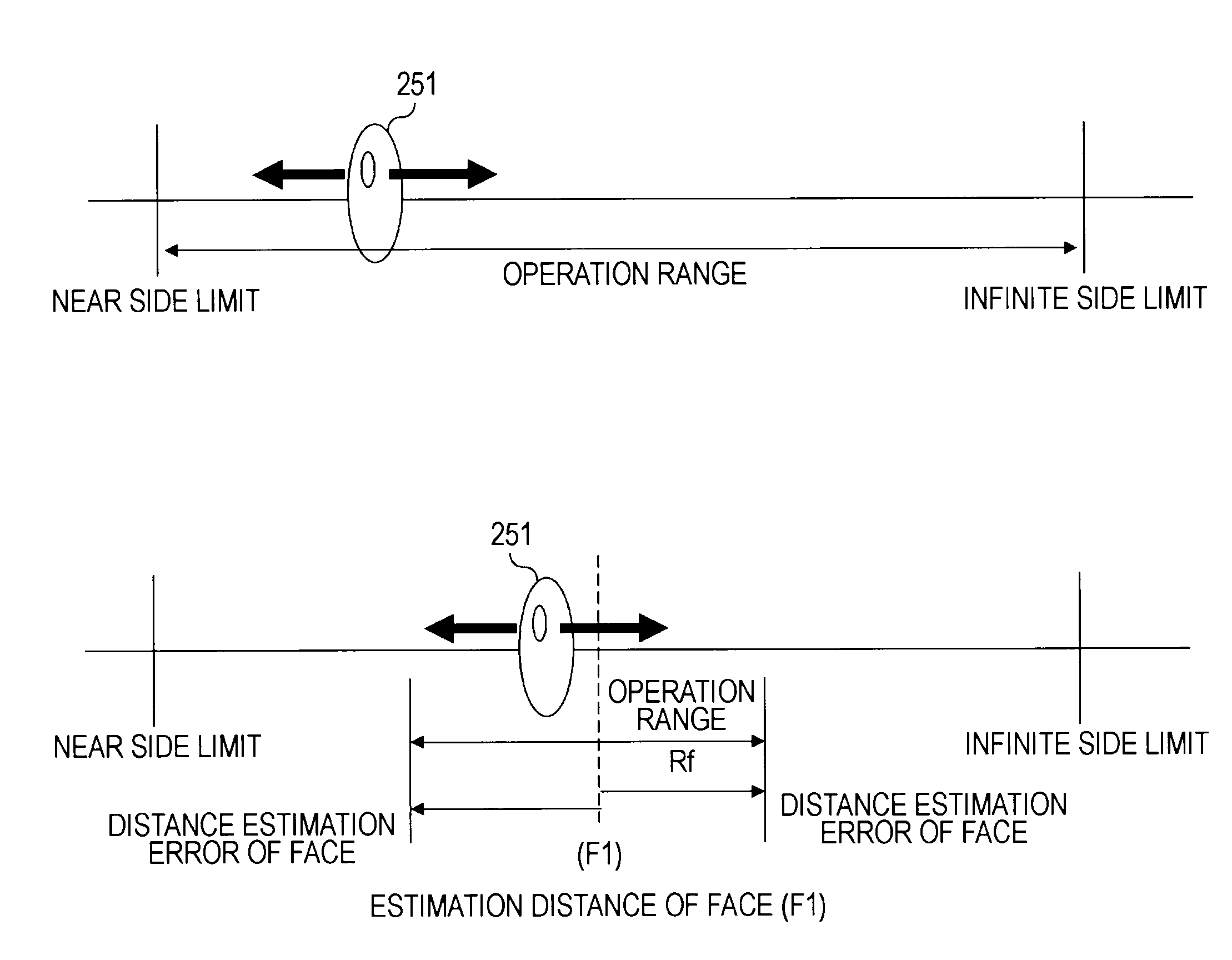

Imaging apparatus, imaging apparatus control method, and computer program

ActiveUS20090073304A1Reduce distanceTelevision system detailsProjector focusing arrangementImage detectionFace size

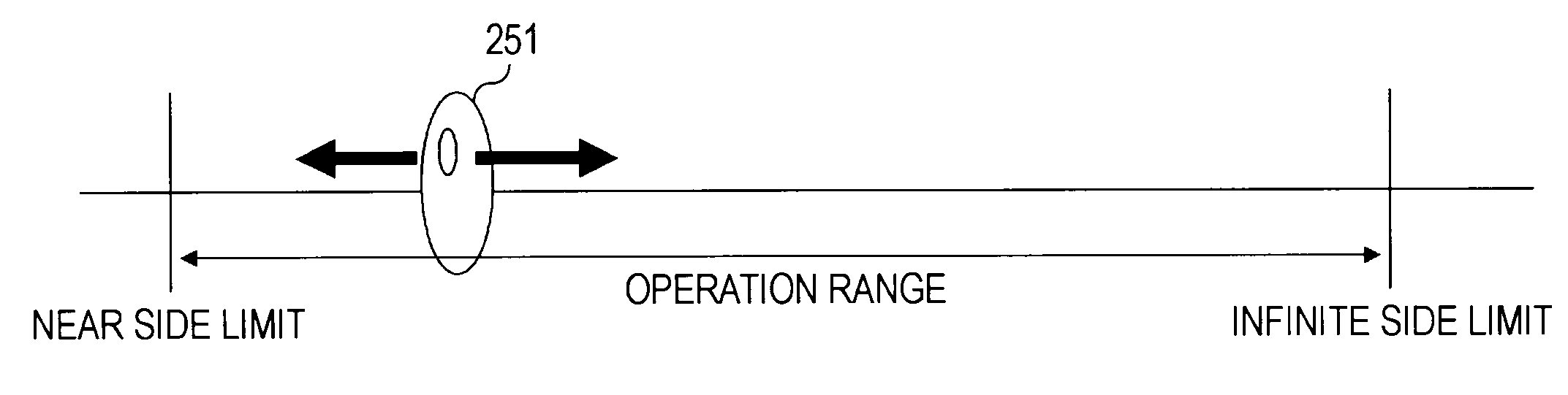

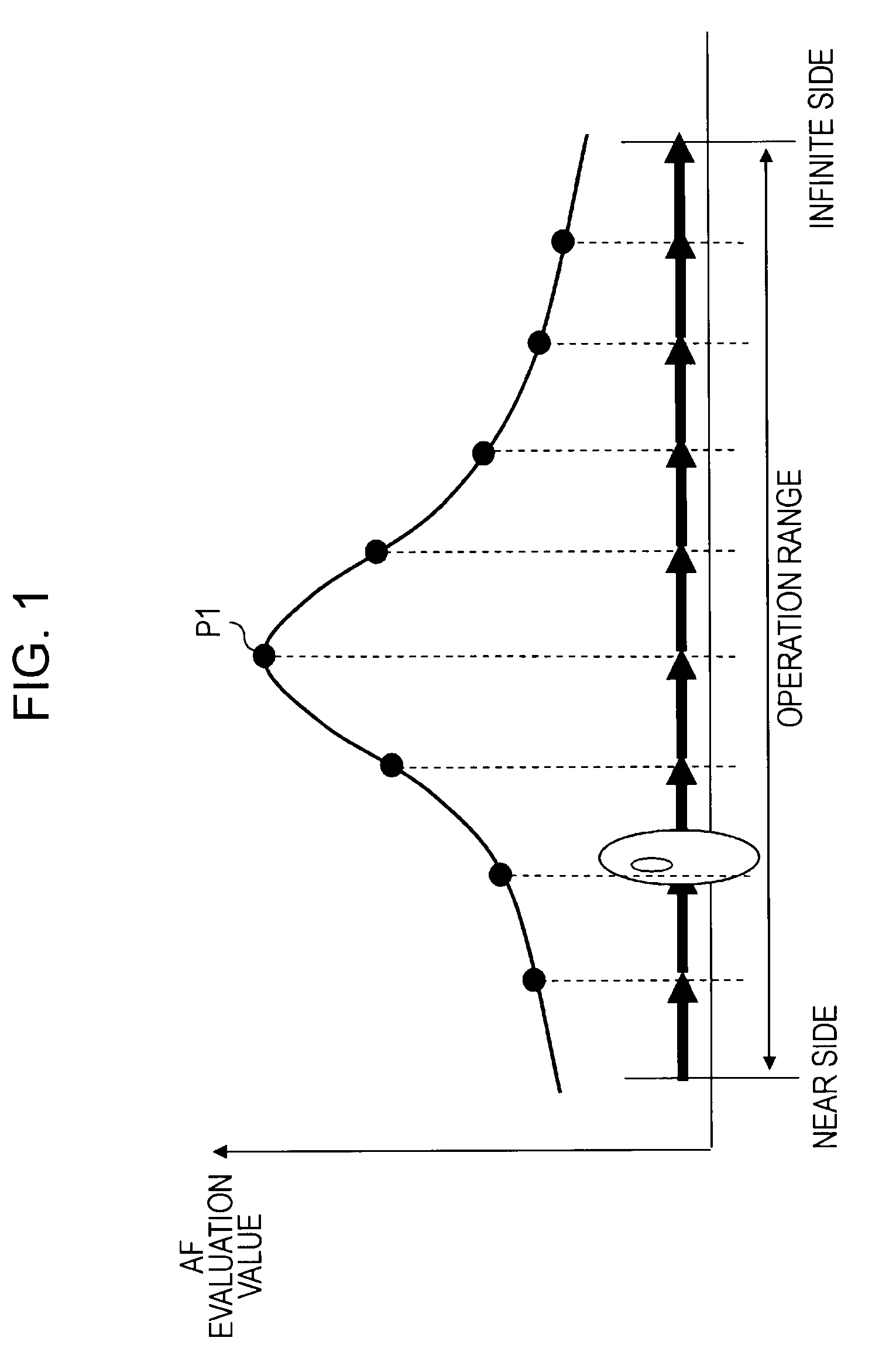

A data processing device includes: a face-detecting unit to detect a face region from an input image input from an imaging unit which images a subject including a face; a setting unit to calculate subject distance based on the face size of the face detected by the face-detecting unit, and set limits as a focus lens operation range before and after a focus lens position with the calculated subject distance as focal distance; a detecting unit to move a focus lens within the limits set by the setting unit, and detect a focal point where a detection value corresponding to the contrast intensity obtained from a face frame including the face detected by the face-detecting unit is not smaller than a threshold; and a control unit to determine, in a case wherein a focal point has been detected within predetermined set time, the focal point thereof as a focus position.

Owner:SONY CORP

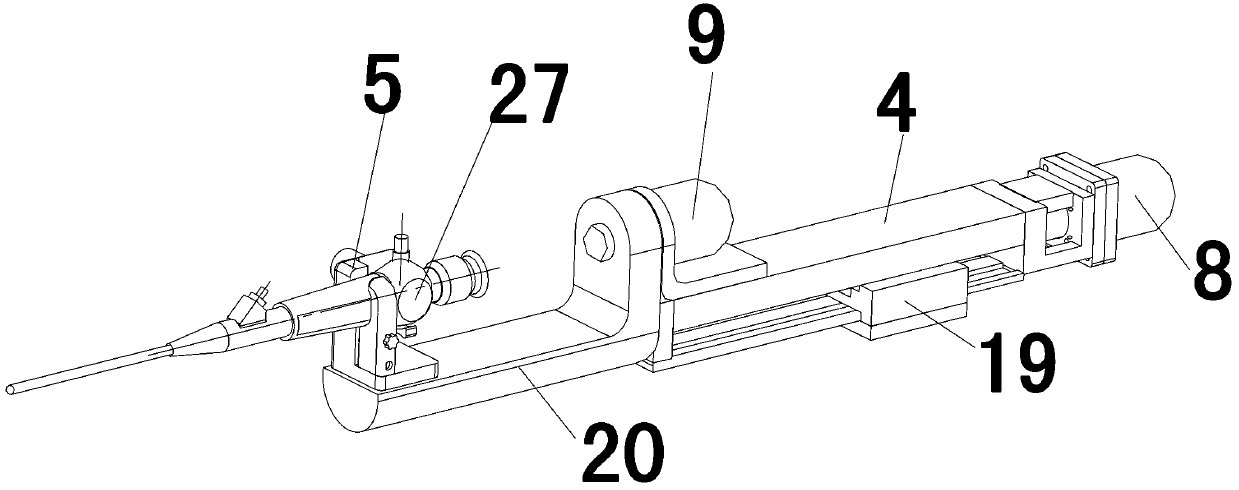

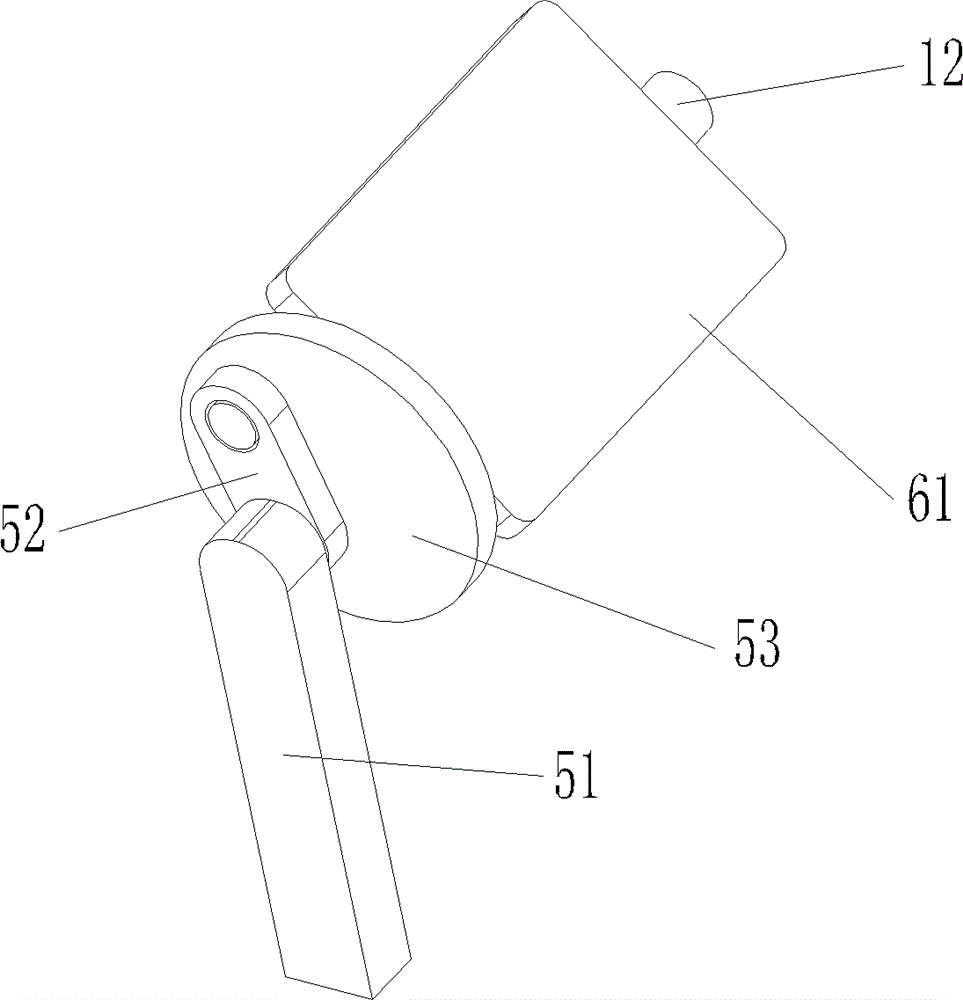

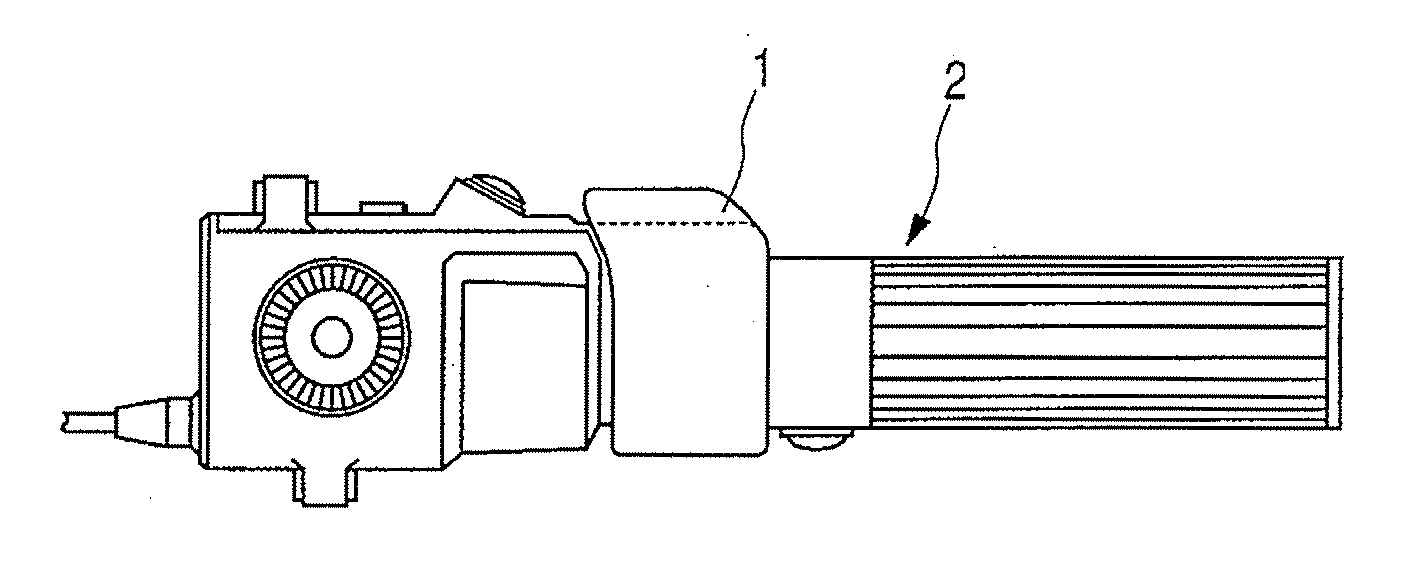

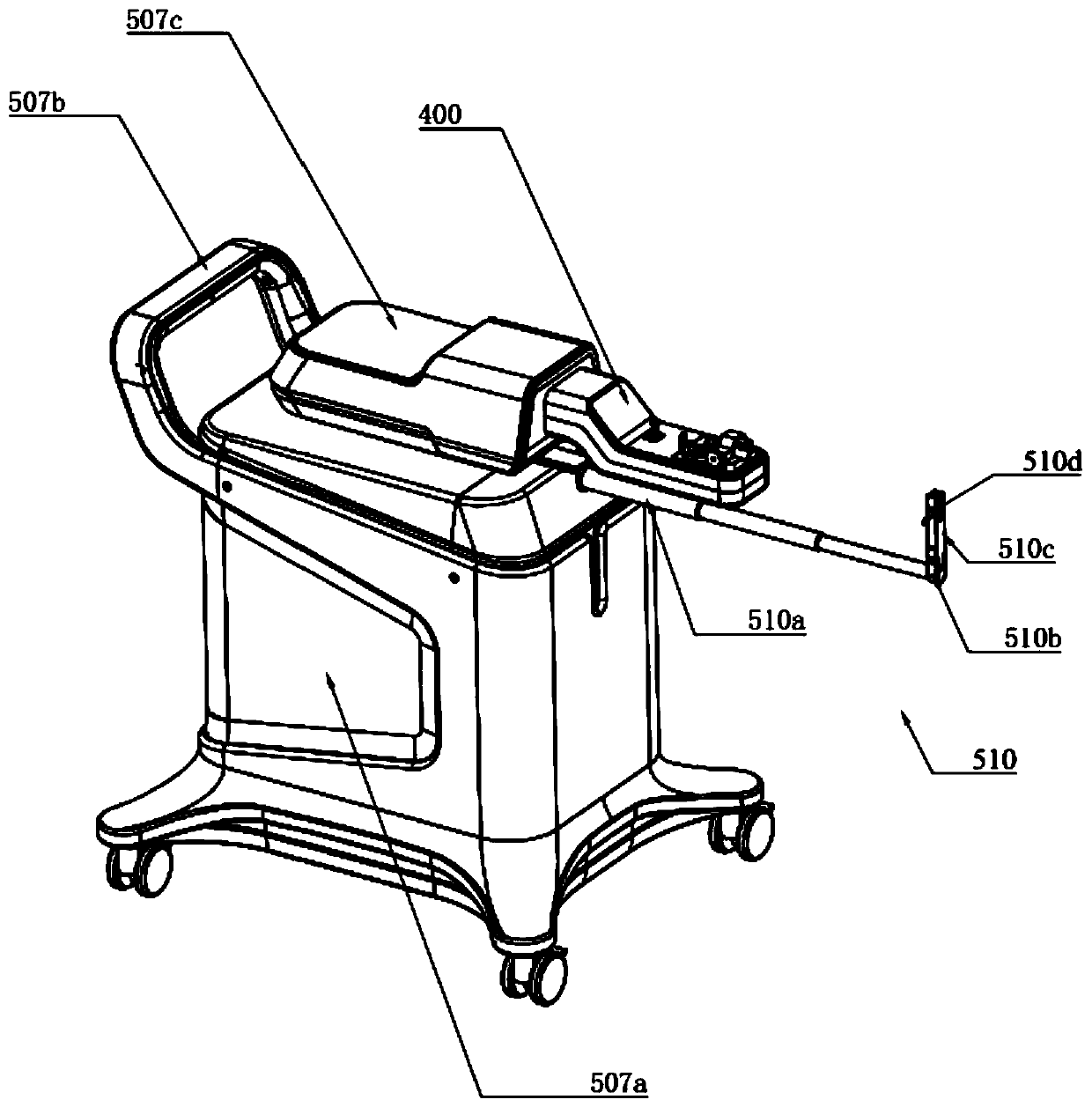

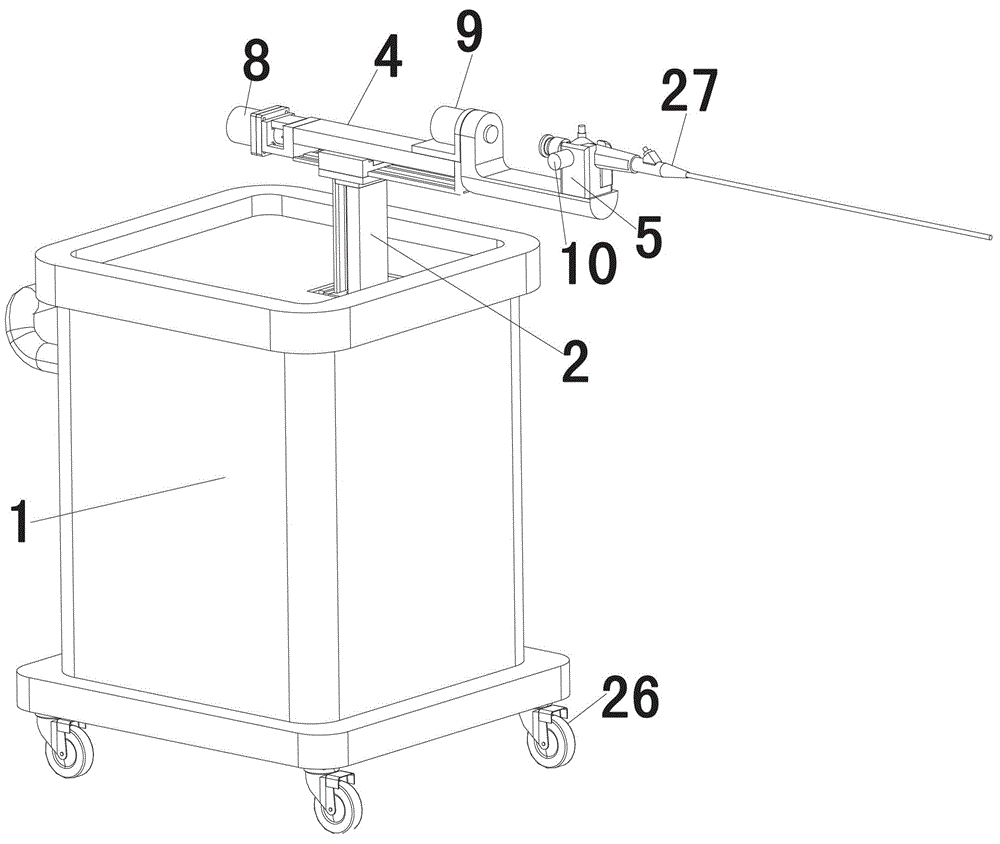

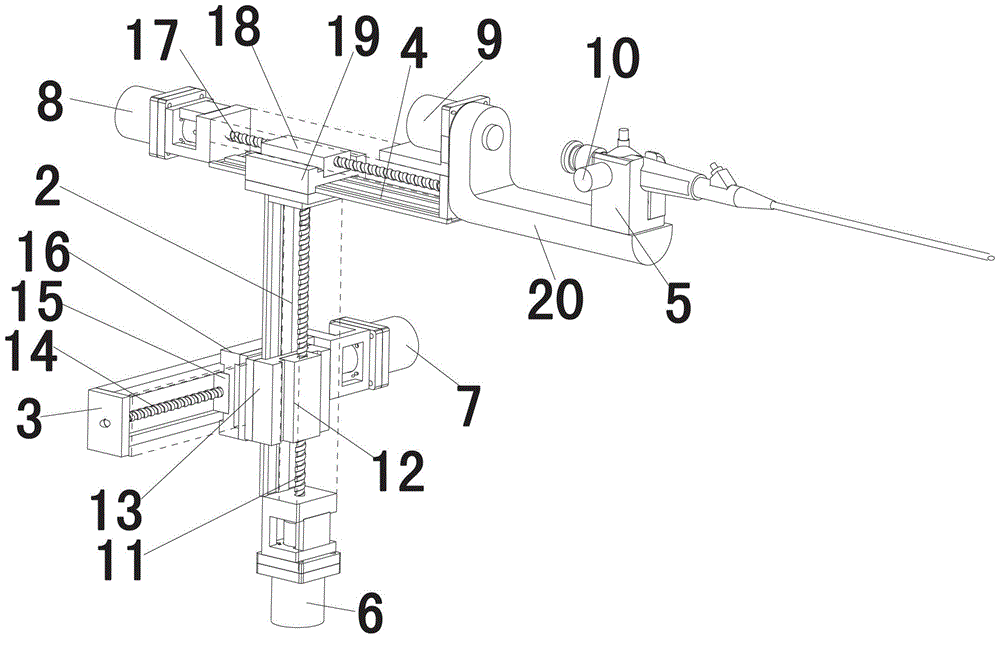

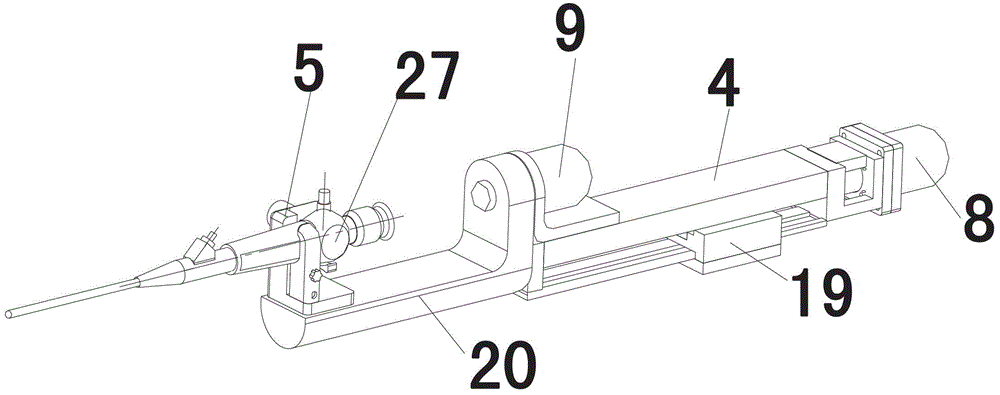

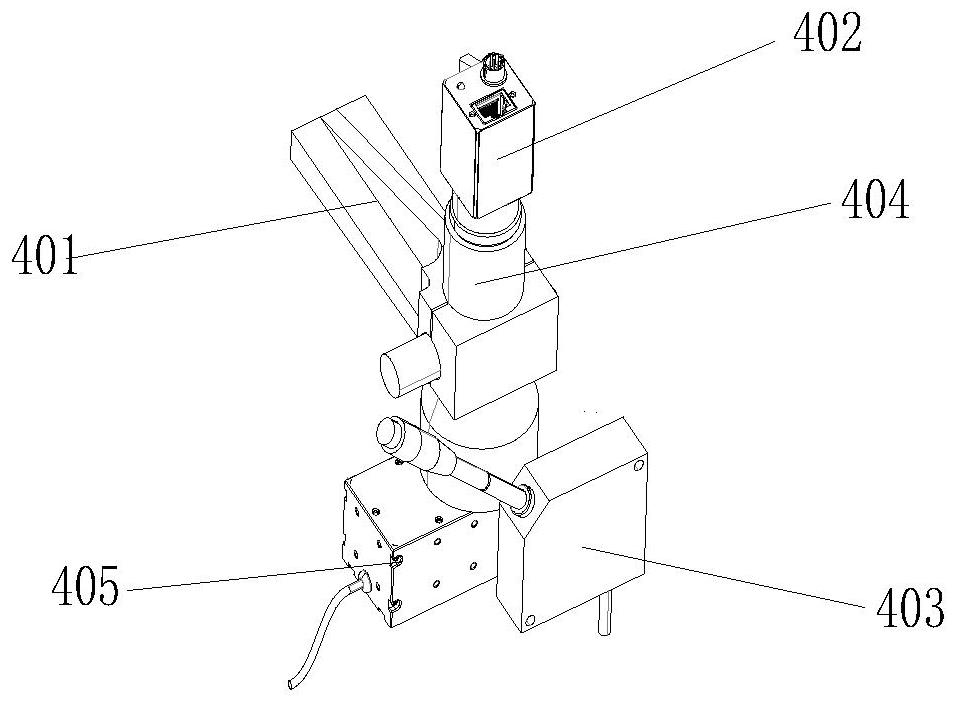

Auxiliary mechanical arm for soft lens operation and method for achieving same

ActiveCN103356294AFive-dimensional movement is goodEasy to useDiagnosticsSurgeryDrive motorEngineering

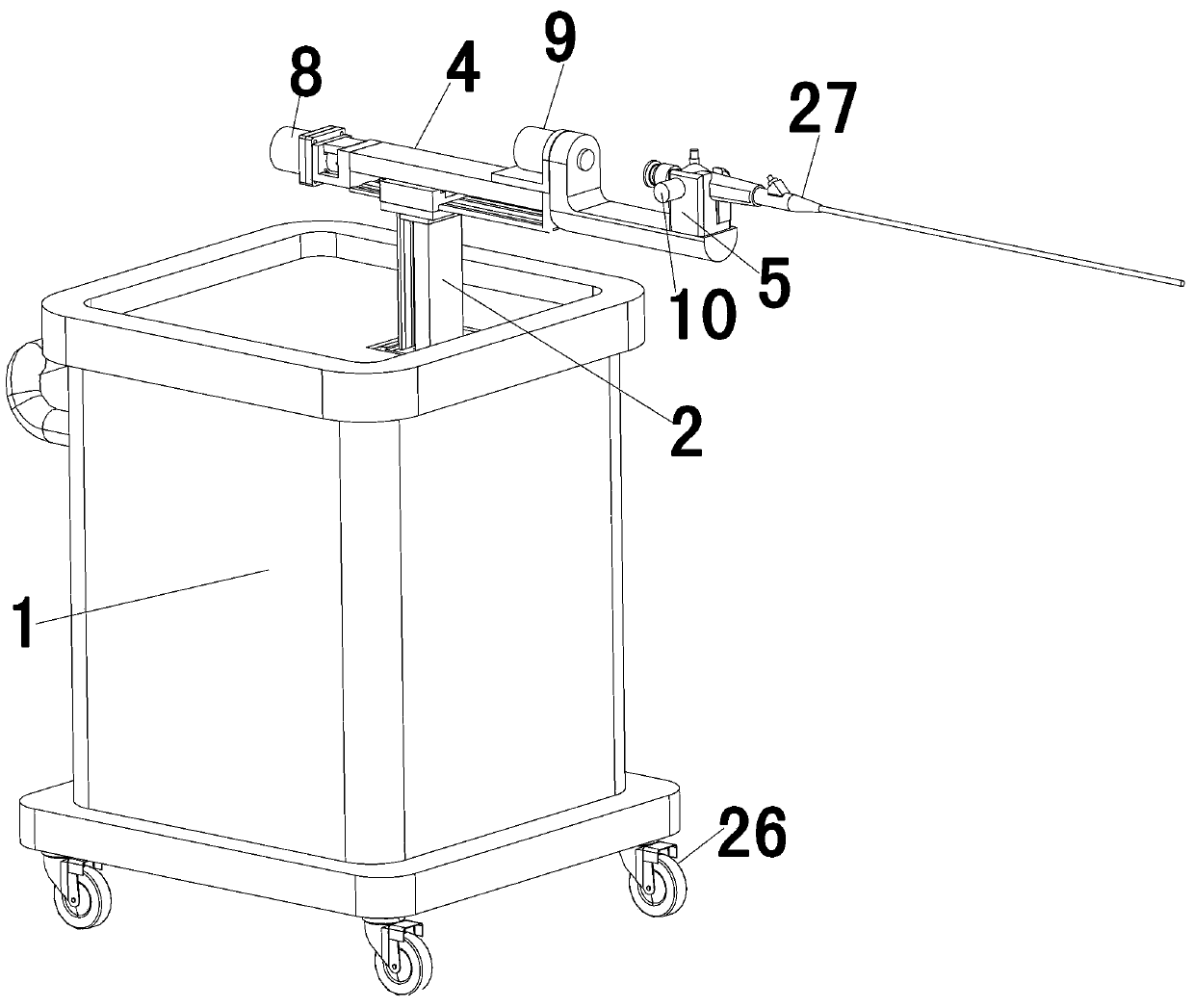

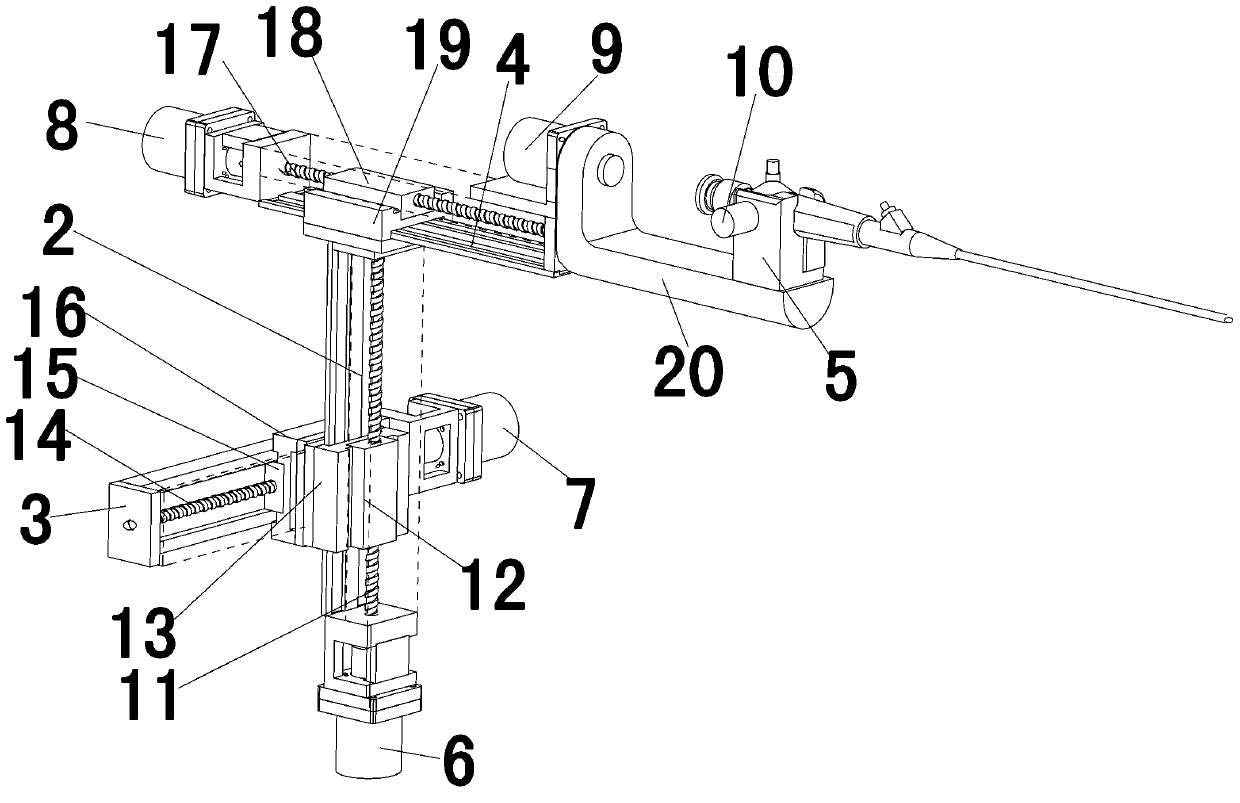

The invention discloses an auxiliary mechanical arm for a soft lens operation. The auxiliary mechanical arm comprises a base, a vertical up-and-down mechanical arm, a horizontal left-and-right mechanical arm, a front-and-back telescopic mechanical arm, a soft lens clamping device, an up-and-down dimension drive motor, a left-and-right dimension drive motor, a front-and-back dimension drive motor, a rotary shaft dimension drive motor and a soft lens shifting disc drive motor. The invention further discloses a method for achieving the auxiliary mechanical arm for the soft lens operation. The auxiliary mechanical arm solves the problems that in the prior art, multi-directional manipulation of a flexible instrument cannot be achieved, complex operation conditions cannot be handled, the matching effect of an existing mechanical arm and the flexible instrument is poor, and the hands of a doctor tremble when the doctor conducts an operation. The auxiliary mechanical arm has the advantages of being simple in structure, low in manufacturing cost, and suitable for the soft lens operation, capable of being used for handling the complex operation conditions, capable of achieving five-dimension motion of a soft lens, good in using effect and the like.

Owner:吴开俊 +1

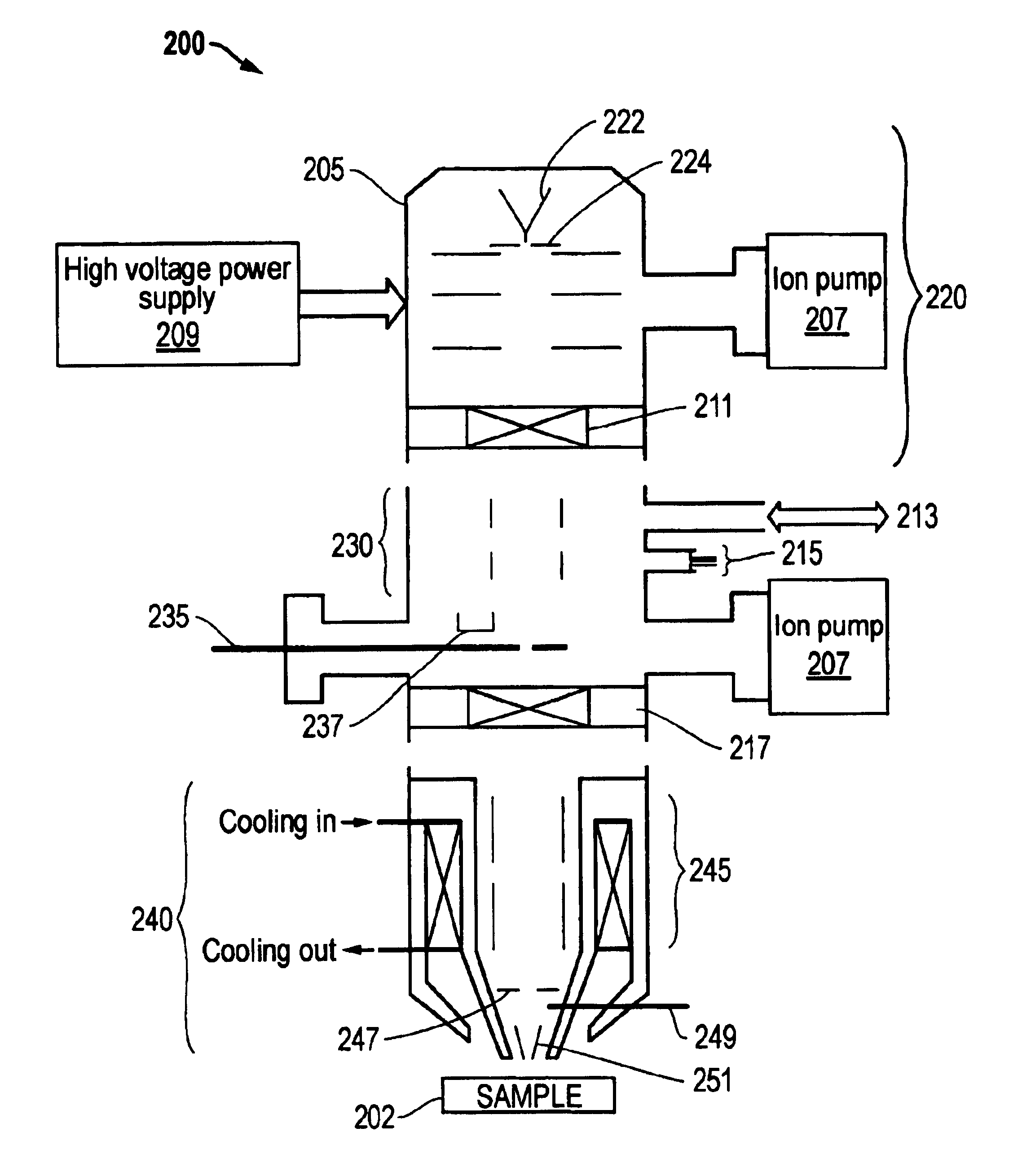

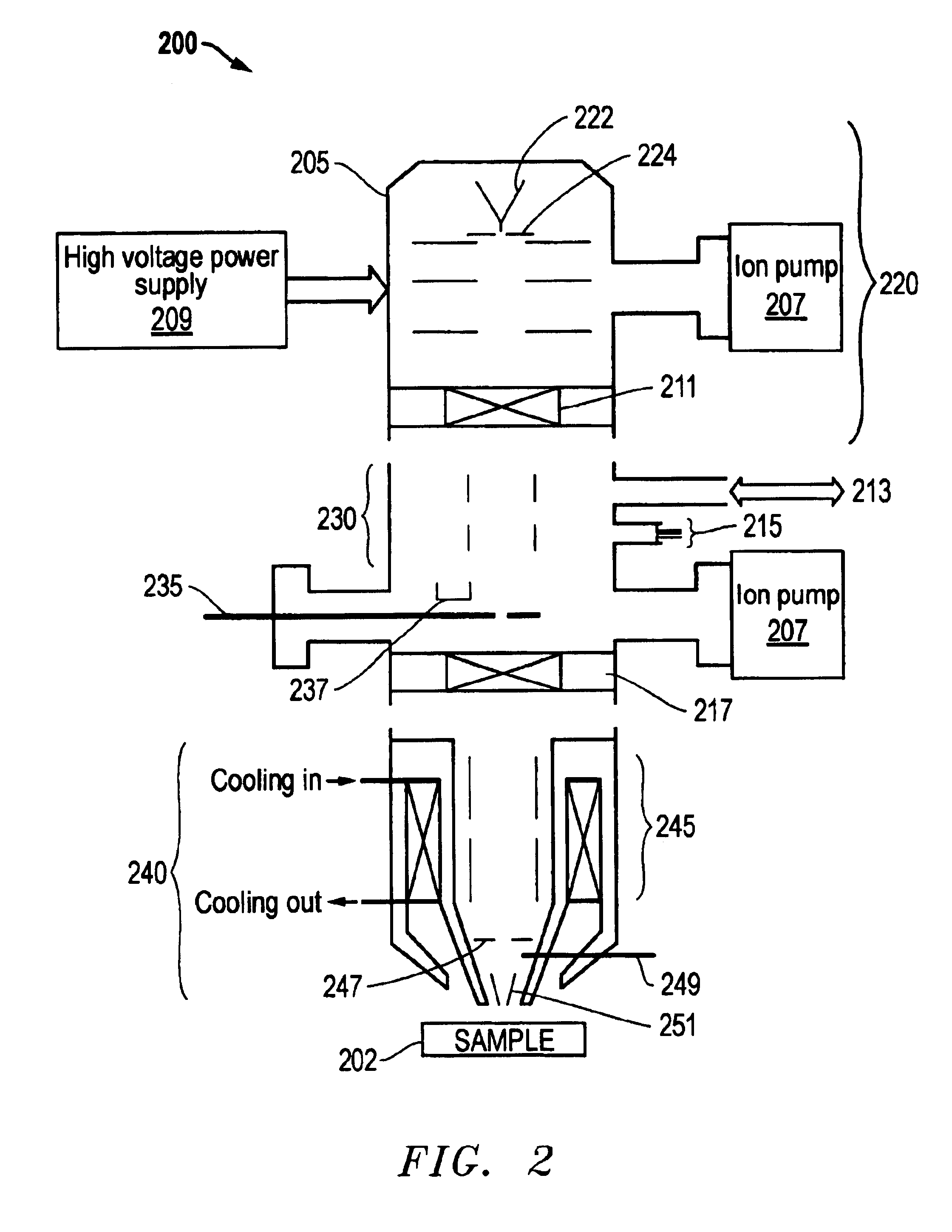

Magnetic lens

InactiveUS6852982B1Constant amount of average heat powerConstant temperature signatureThermometer detailsStability-of-path spectrometersEngineeringLens operations

Owner:FEI CO

Face recognition auto focus apparatus for a moving image

ActiveUS8068164B2Reduce distanceTelevision system detailsProjector focusing arrangementFace sizeImage detection

A data processing device includes: a face-detecting unit to detect a face region from an input image input from an imaging unit which images a subject including a face; a setting unit to calculate subject distance based on the face size of the face detected by the face-detecting unit, and set limits as a focus lens operation range before and after a focus lens position with the calculated subject distance as focal distance; a detecting unit to move a focus lens within the limits set by the setting unit, and detect a focal point where a detection value corresponding to the contrast intensity obtained from a face frame including the face detected by the face-detecting unit is not smaller than a threshold; and a control unit to determine, in a case wherein a focal point has been detected within predetermined set time, the focal point thereof as a focus position.

Owner:SONY CORP

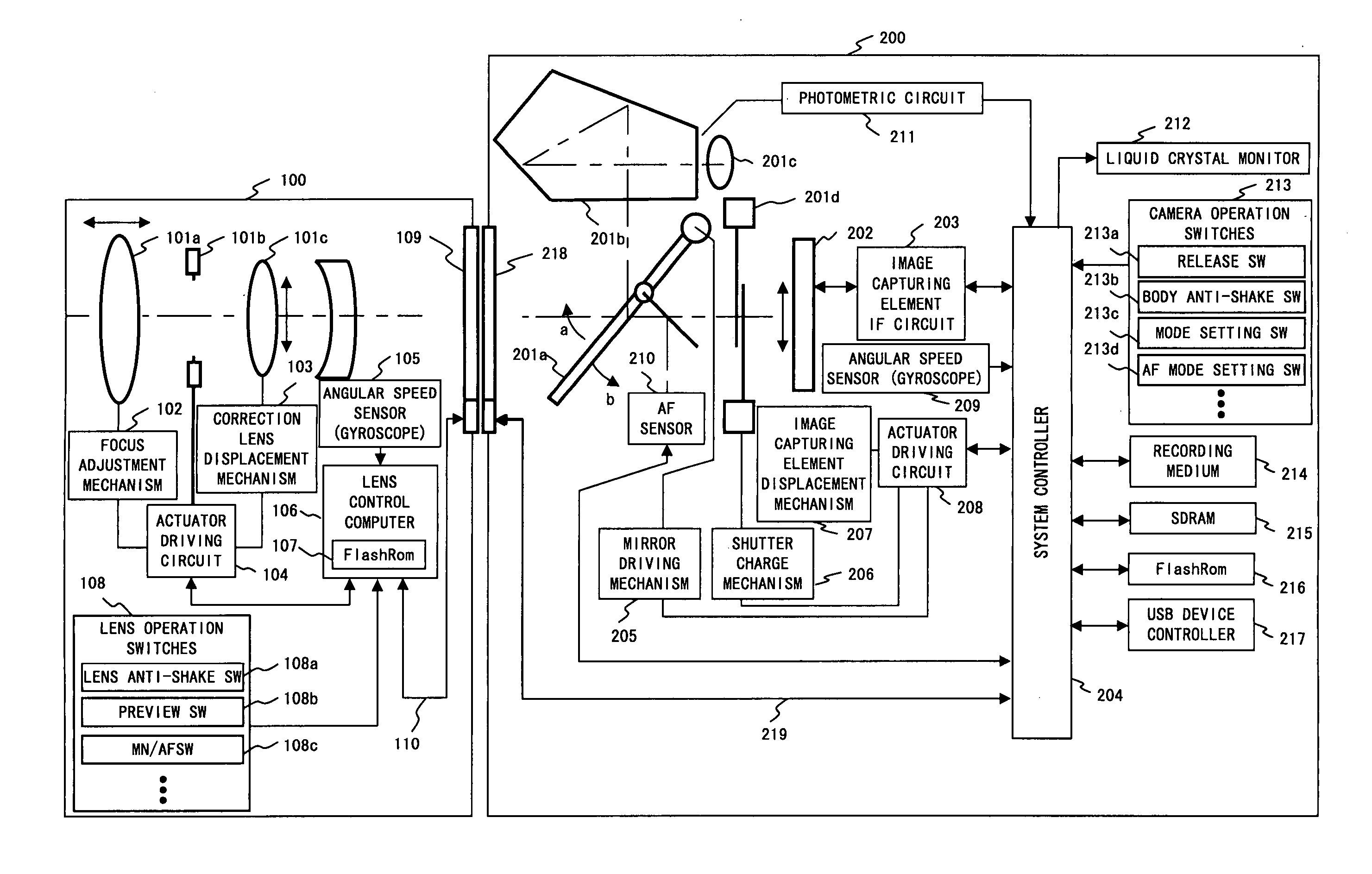

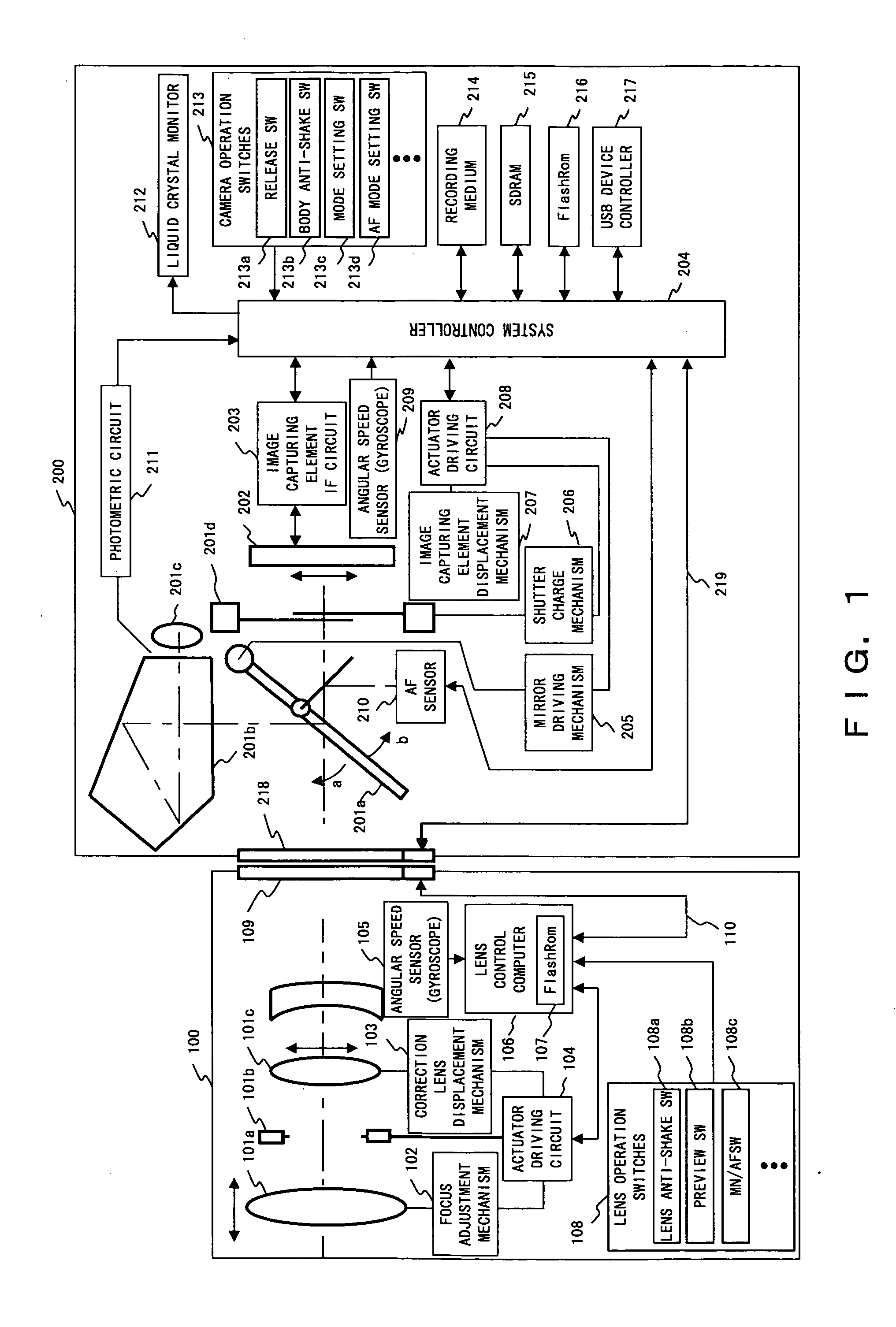

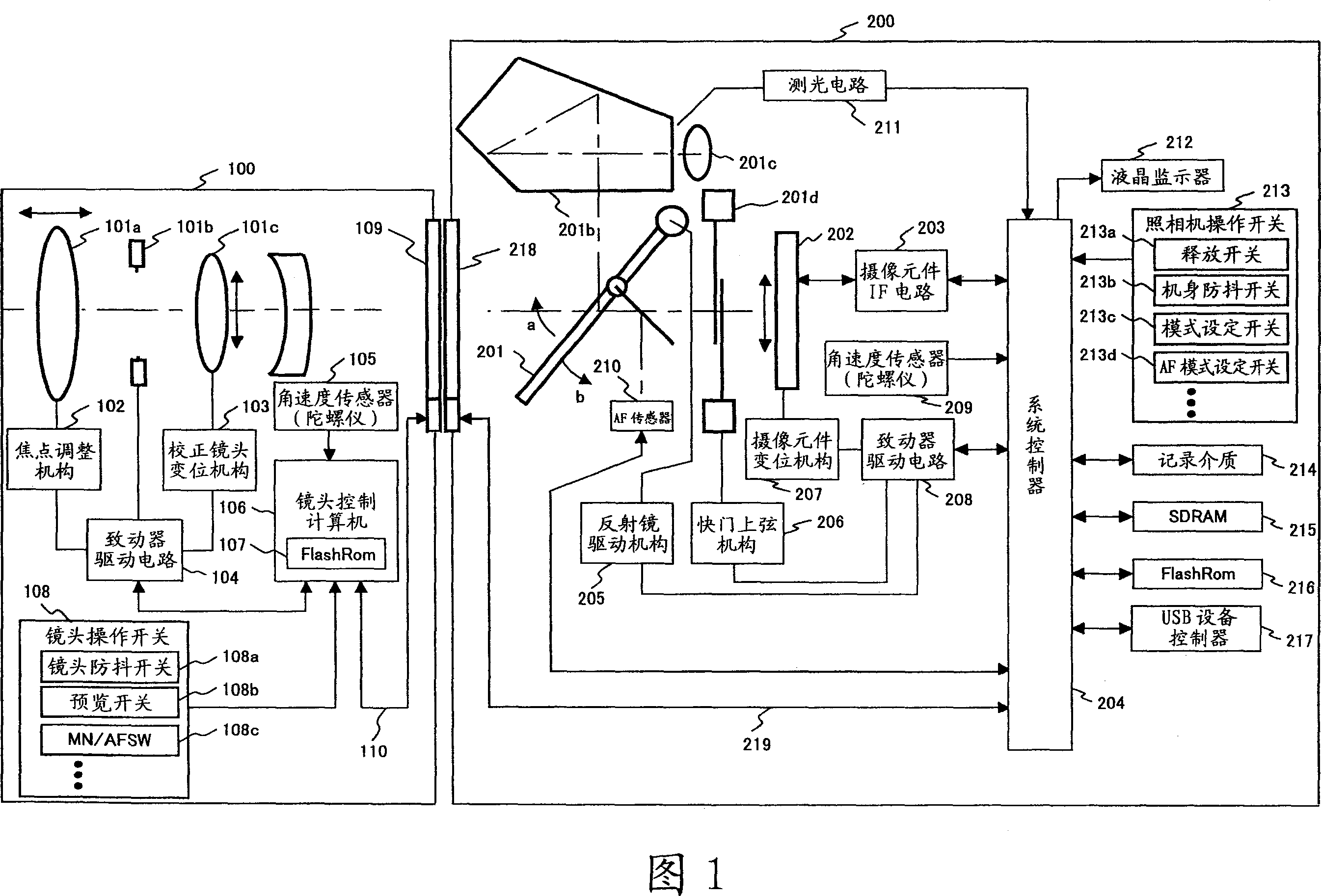

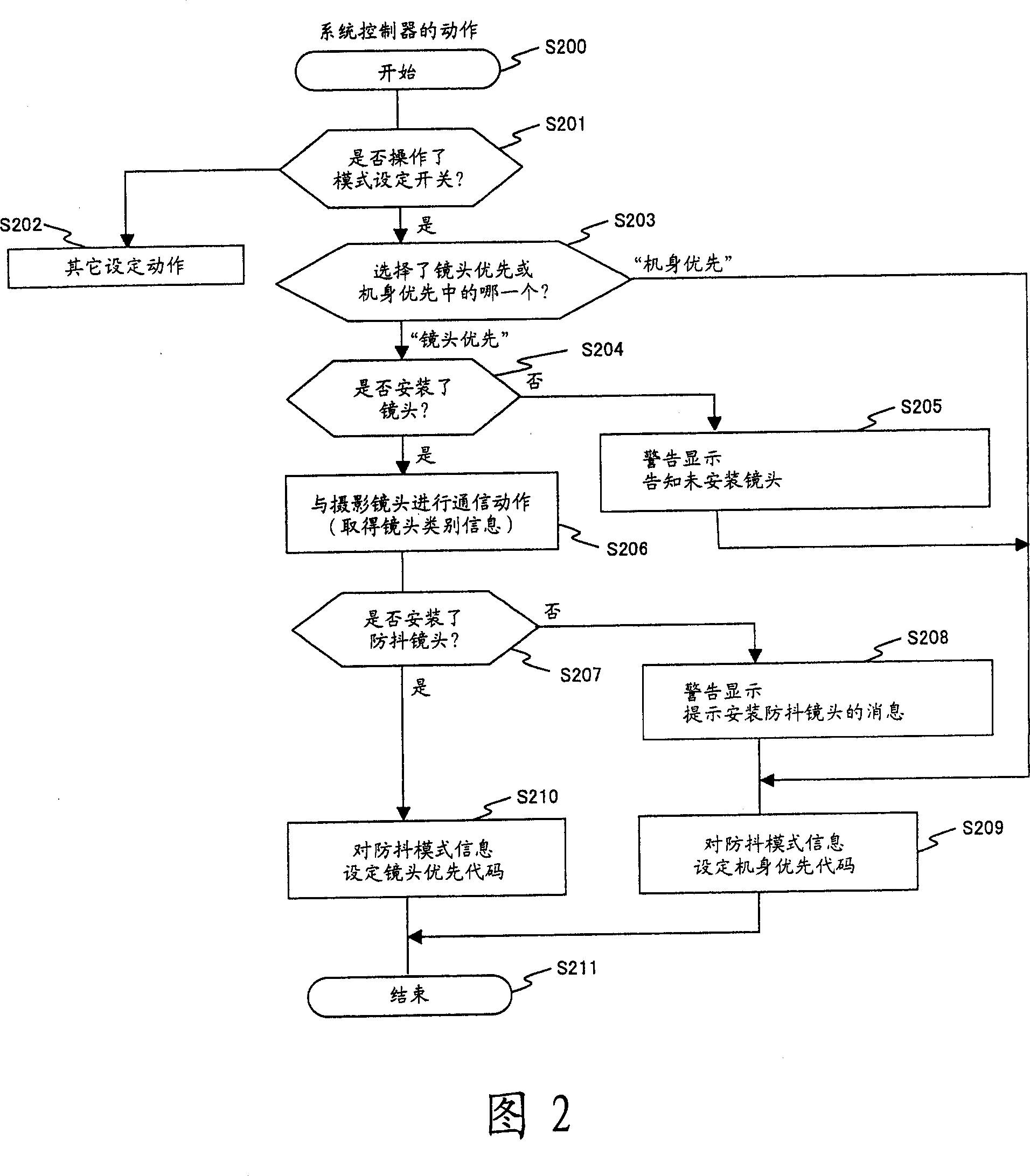

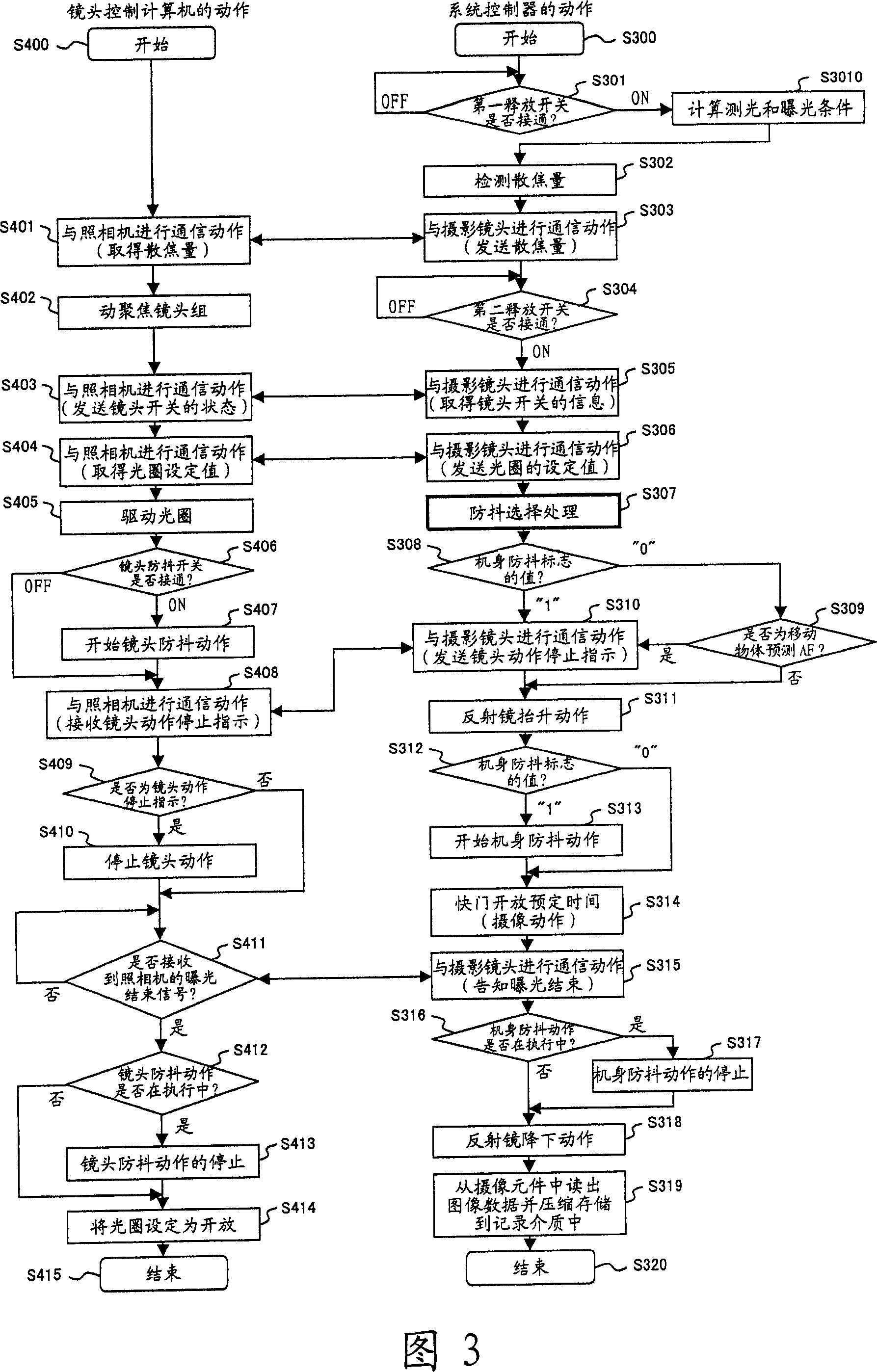

Camera system having image shake correction function

InactiveUS20070122133A1Correct shakingTelevision system detailsPrintersCommunication unitLens operations

In a camera system where a taking lens and a camera body respectively comprise a image shake correction unit for correcting a shake, which occurs on an image on an image capturing surface due to a jiggle of the camera system at the time of shooting, the taking lens and the camera body respectively comprise a communication unit for making a communication between the taking lens and the camera body, and a control is performed so that the communication unit of the camera body transmits a lens operation suspension instruction when the image shake correction unit of the camera body is operated, and the operation of the taking lens is suspended when the communication unit of the taking lens receives the lens operation suspension instruction.

Owner:OLYMPUS IMAGING CORP

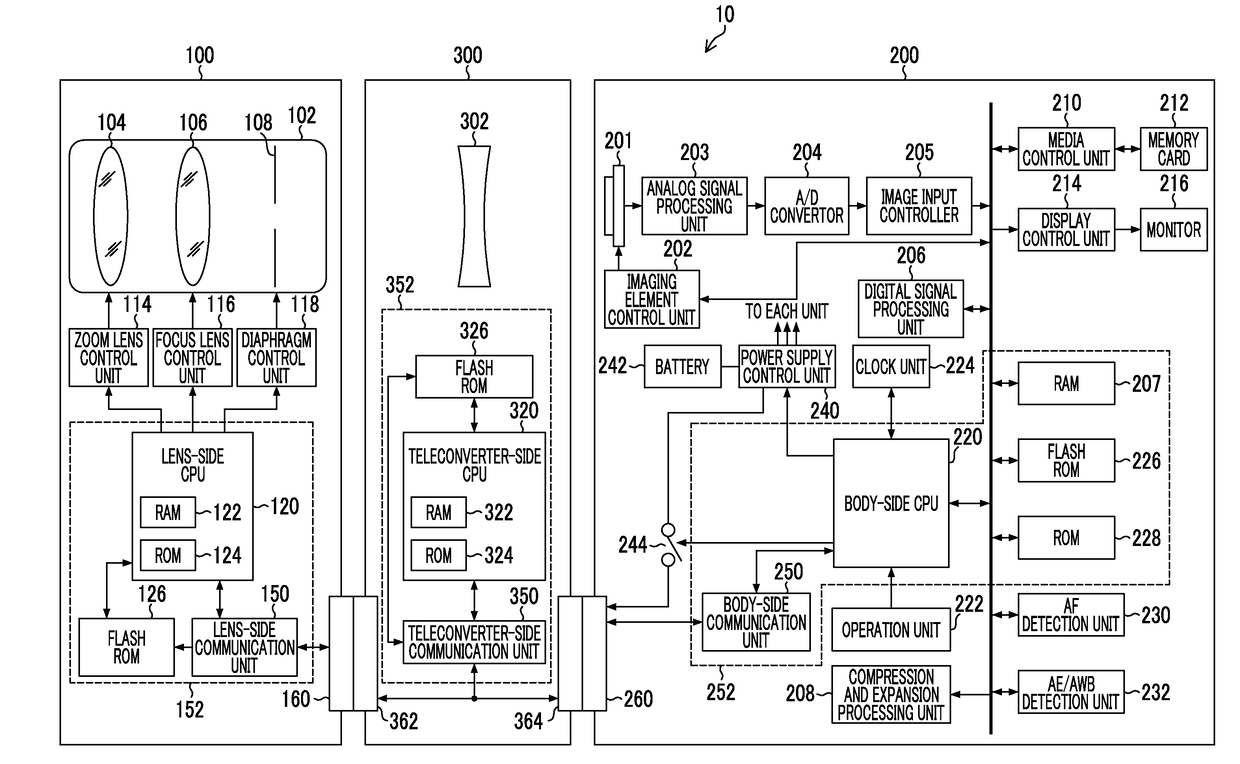

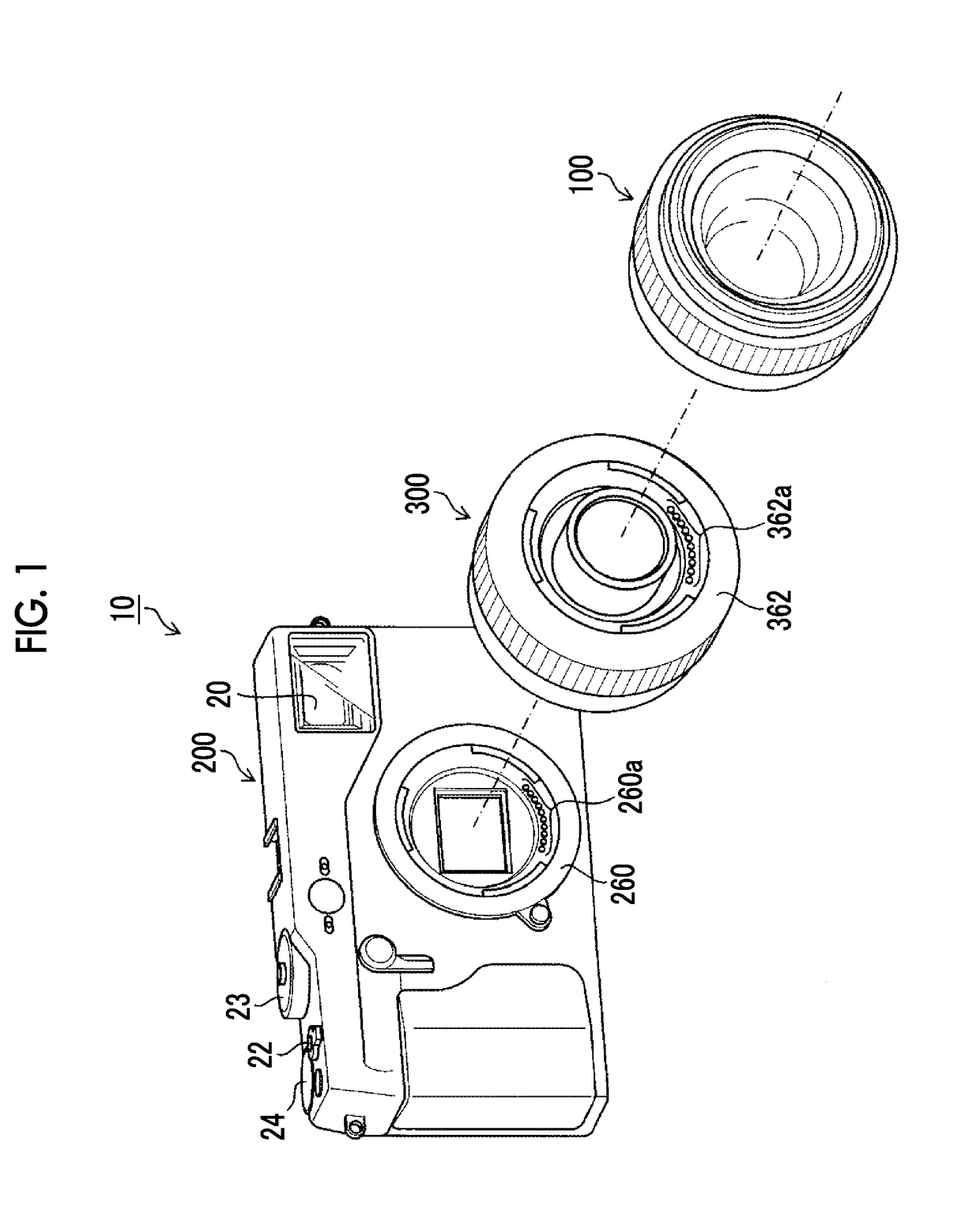

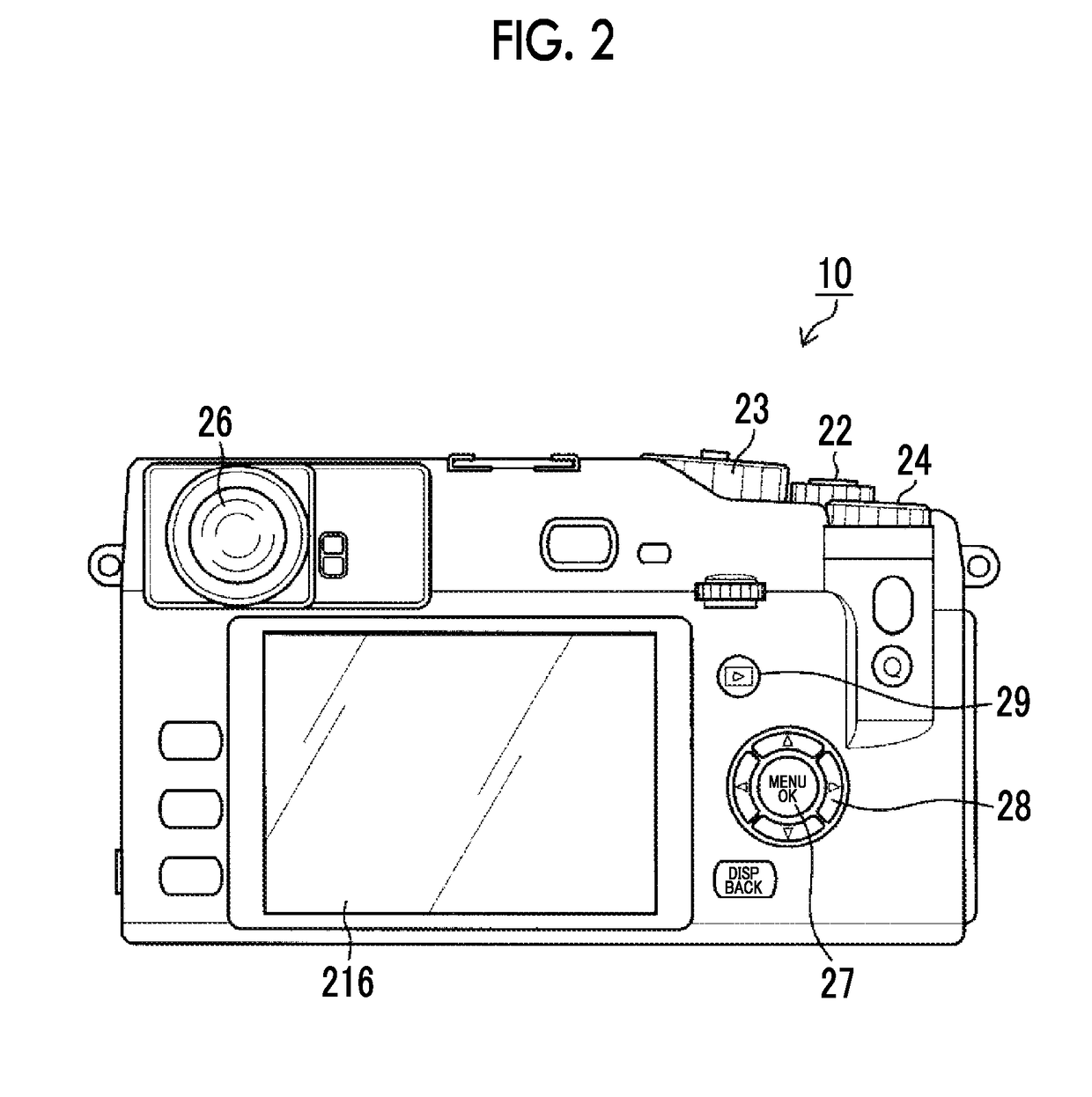

Interchangeable lens, method of operating interchangeable lens, program, lens system, and camera system

ActiveUS20180224721A1Shorten activation timeTelevision system detailsColor television detailsCommunication unitComputer science

A lens system according to a first aspect of the present invention includes an interchangeable lens, and an accessory which is mounted between the interchangeable lens and a camera body. The interchangeable lens is mountable to the camera body via the accessory and includes a lens-side communication unit that communicates with the camera body and the accessory, an accessory information acquisition unit that communicates with the accessory to acquire individual identification information of the accessory, an interchangeable lens information storage unit that stores individual identification information of the interchangeable lens, and an identification information generation unit that generates combination identification information which is information unique to a combination of the interchangeable lens and the accessory on the basis of the acquired individual identification information of the accessory and the stored individual identification information of the interchangeable lens, and the lens-side communication unit transmits the generated combination identification information to the camera body.

Owner:FUJIFILM CORP

Lens capable of changing shooting direction, and operating method thereof

InactiveCN104427213AConvenient selfieConvenient to shoot himTelevision system detailsColor television detailsCamera lensLight guide

The invention relates to a lens capable of changing shooting direction, and an operating method thereof. The lens comprises a lens assembly mounting seat and an optical lens assembly; a light guiding cavity is formed in the lens assembly mounting seat in front of the optical lens assembly and extend along different directions to form at least two light guide grooves; and light through holes are formed in the end portions of the light guide grooves. In addition, the lens also includes a light guide switching device having a light guide element movably arranged in the light guiding cavity; and the light guide switching device is started, so that the light guide element selects to receive an image from one light though hole and guides the image into the optical lens assembly. The operating method is applied to the lens. The lens having a simple structure can be operated conveniently and rapidly.

Owner:VIVO MOBILE COMM CO LTD

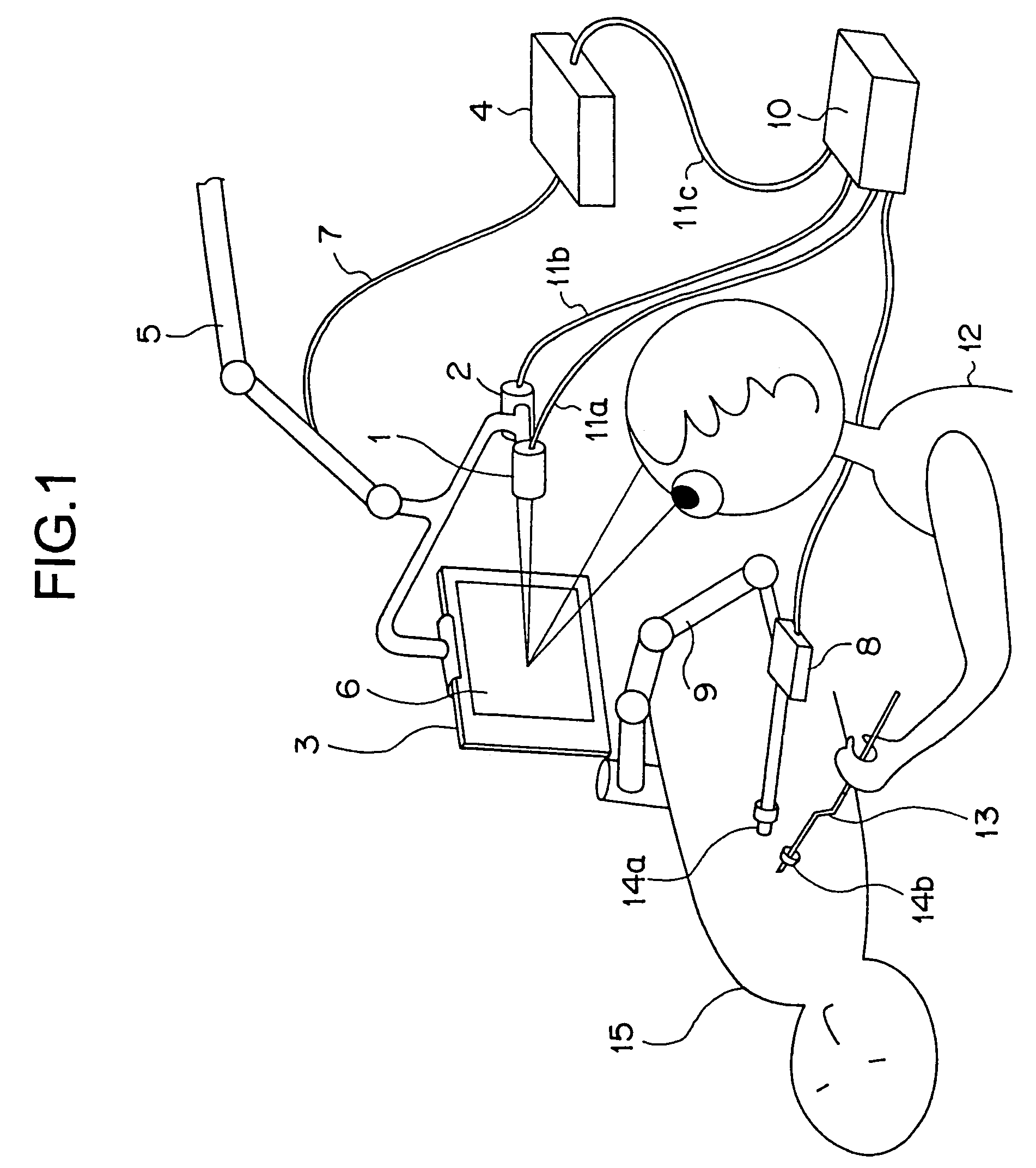

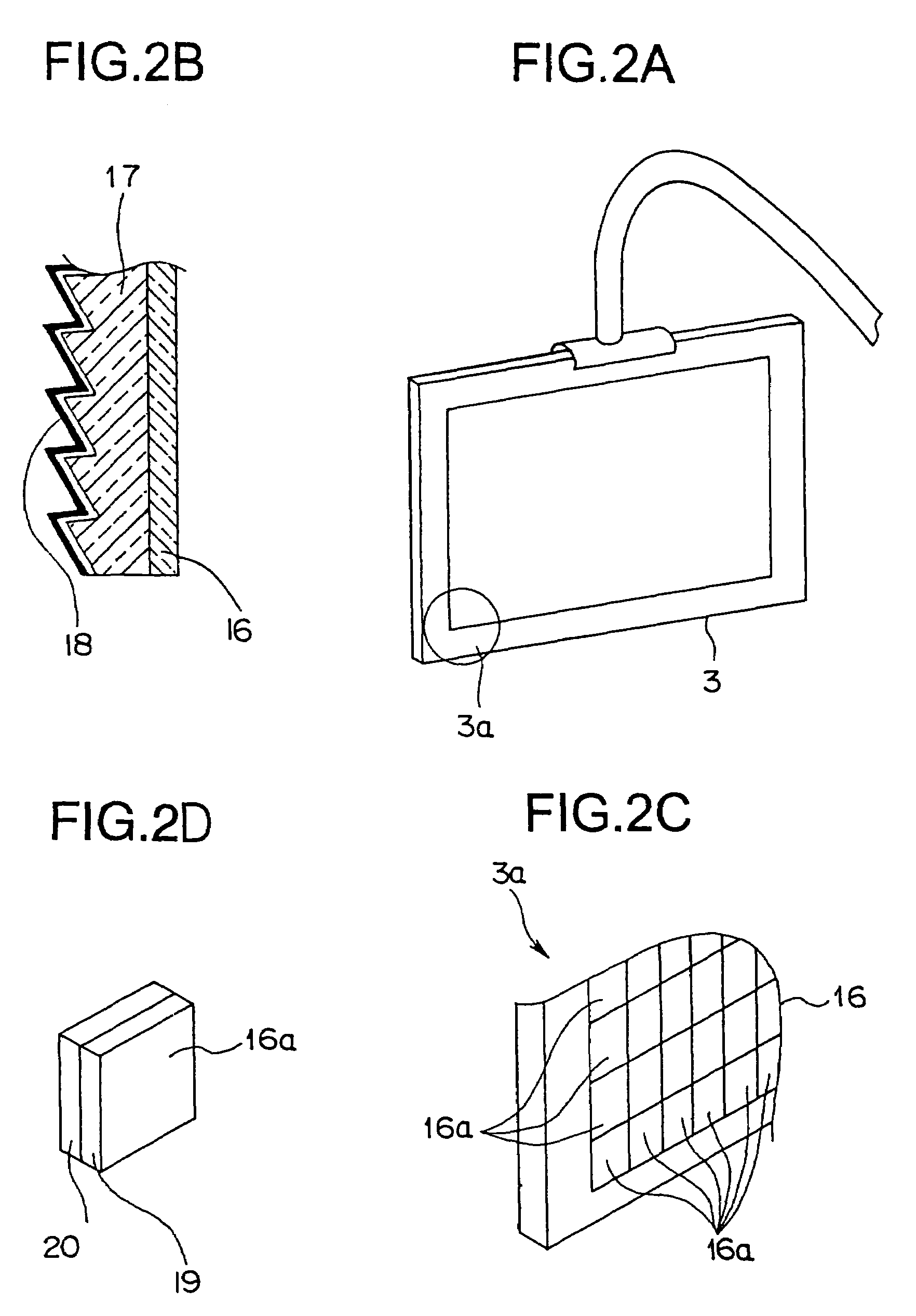

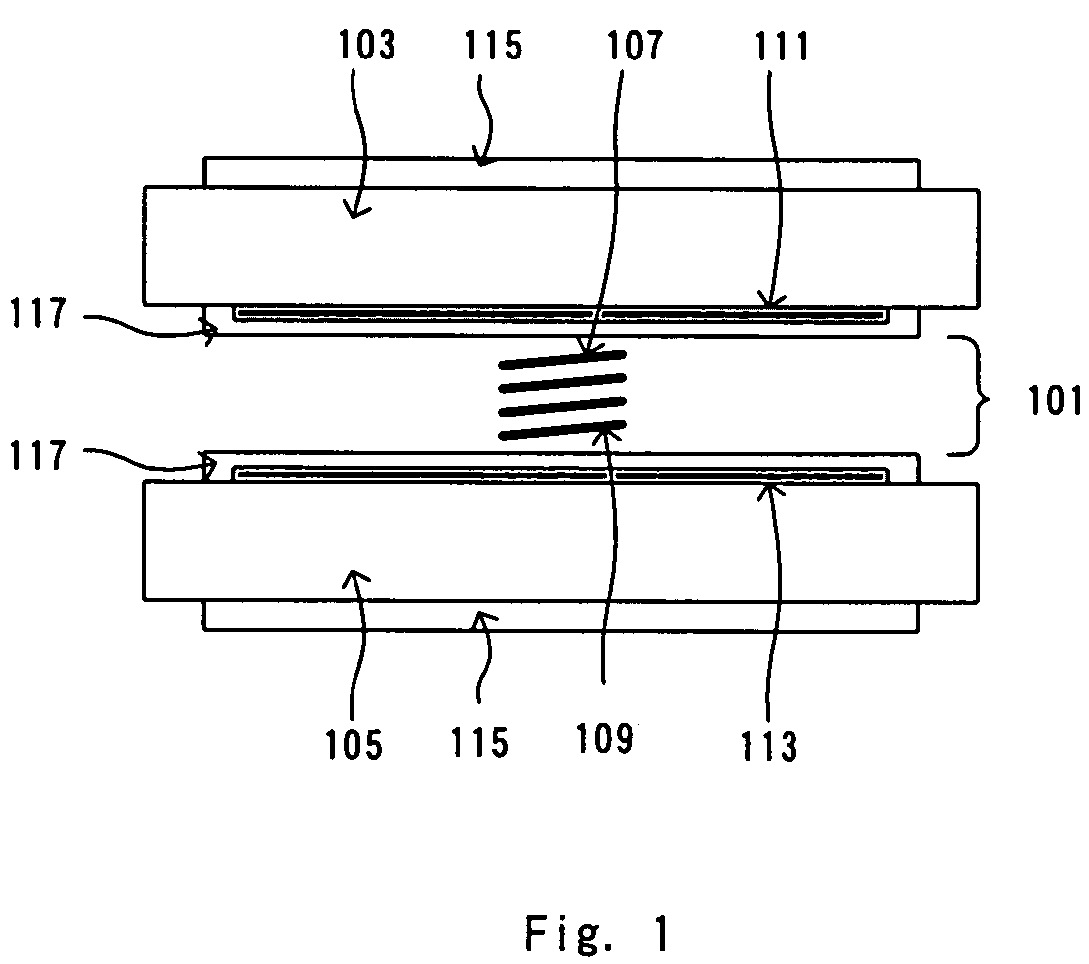

Stereoscopic image observing apparatus

A stereoscopic image observing apparatus includes a right-eye projector 1 and a left-eye projector 2 which illuminate projected light for right and left eyes with the parallax generated based on an image pick-up signal obtained from a stereoscopic endoscope 8, a Fresnel lens 17 which applies and reflects the lens operation with the positive polarity to the projected light of the illuminated images for the right and left eyes, and an optical shift element layer 16 having liquid crystal 20 and a double refraction plate 19 for changing and diffusing on time series the reflecting position of the reflected light of the images for the right and left eyes from the Fresnel lens 17.

Owner:OLYMPUS CORP

Variable focal length lens device

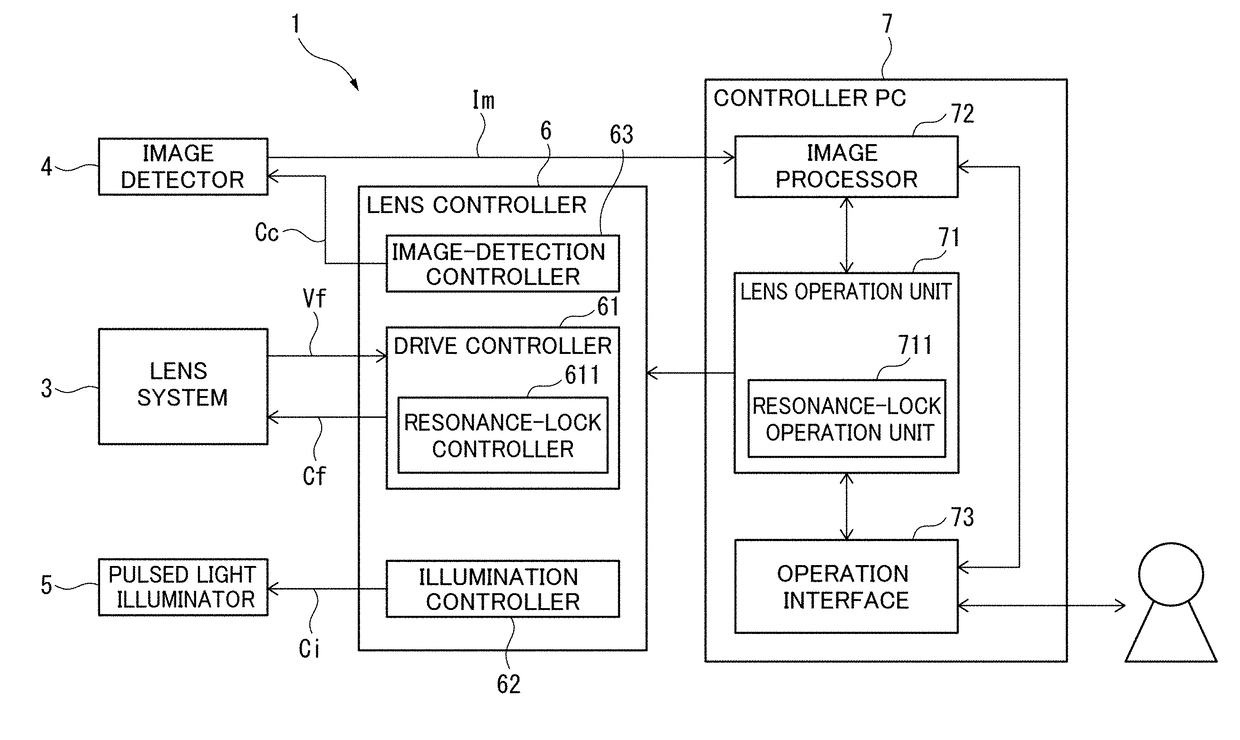

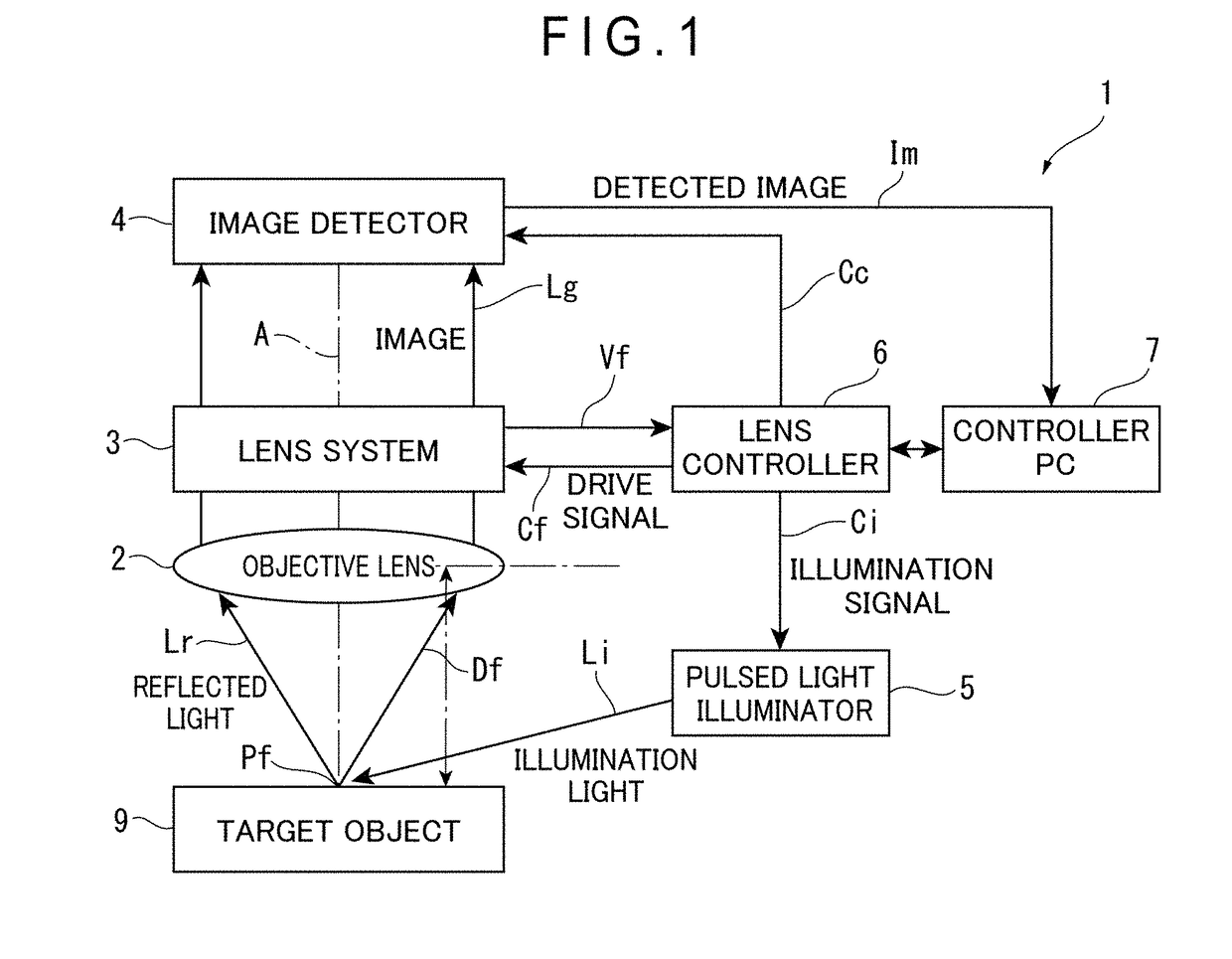

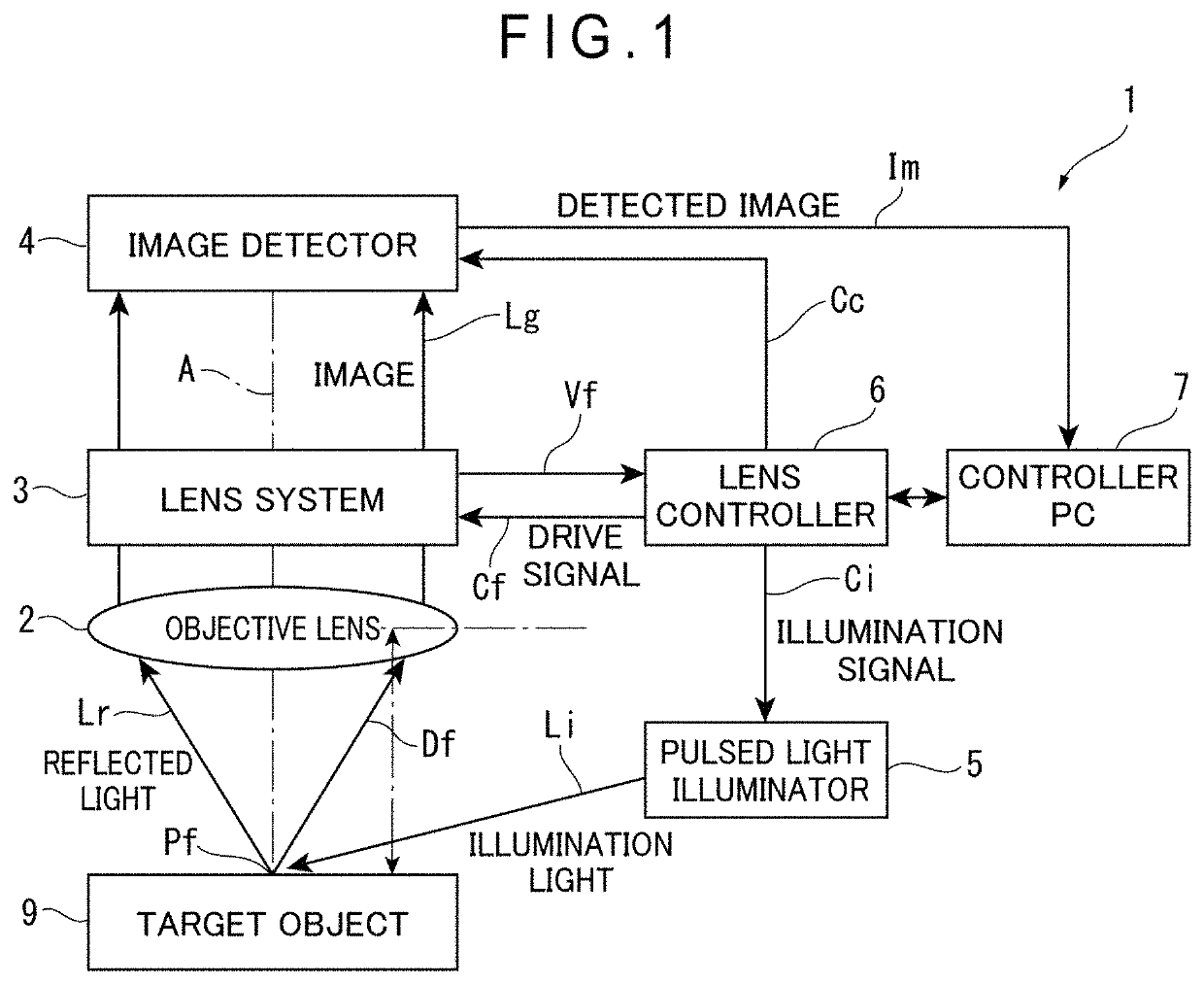

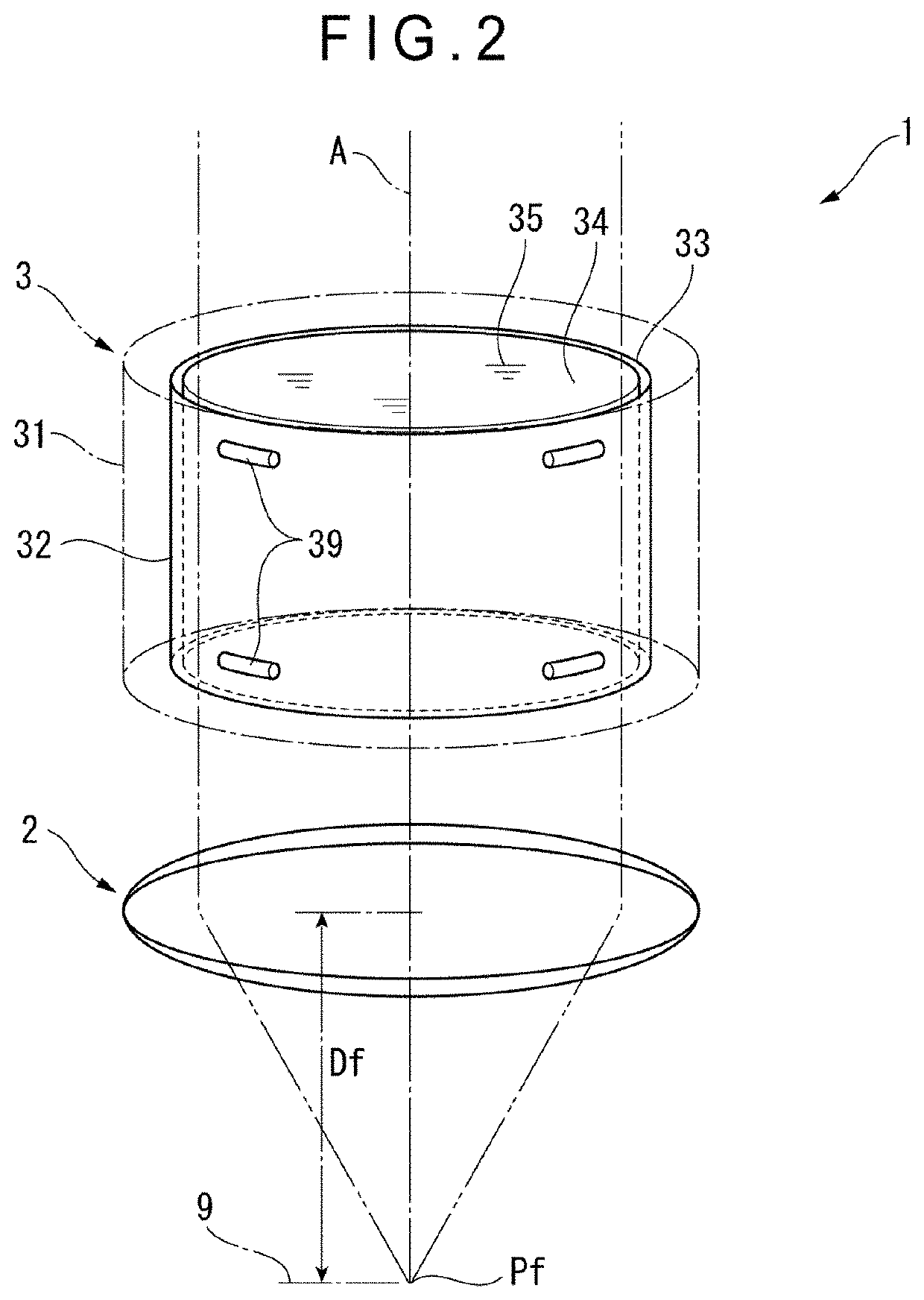

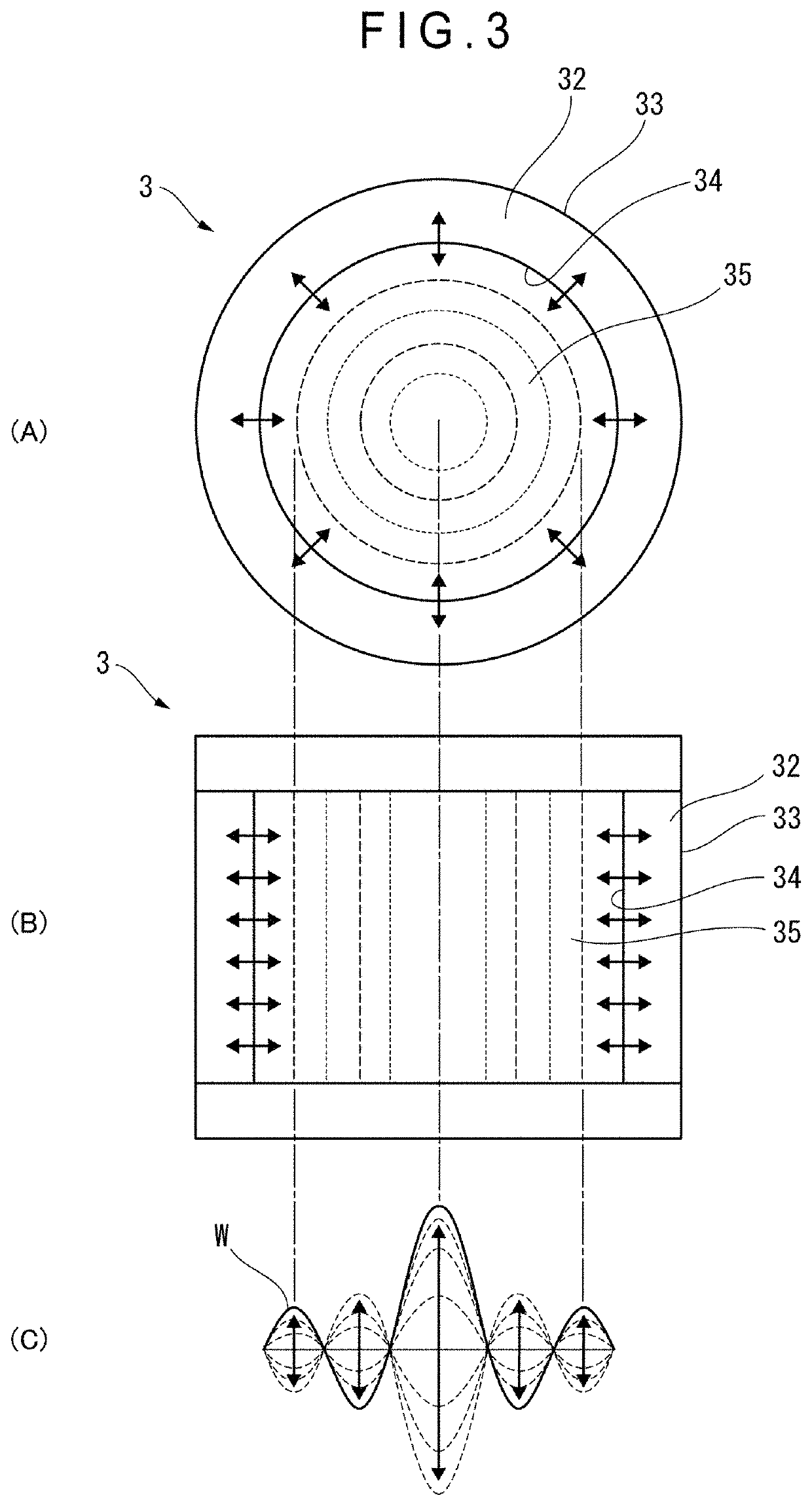

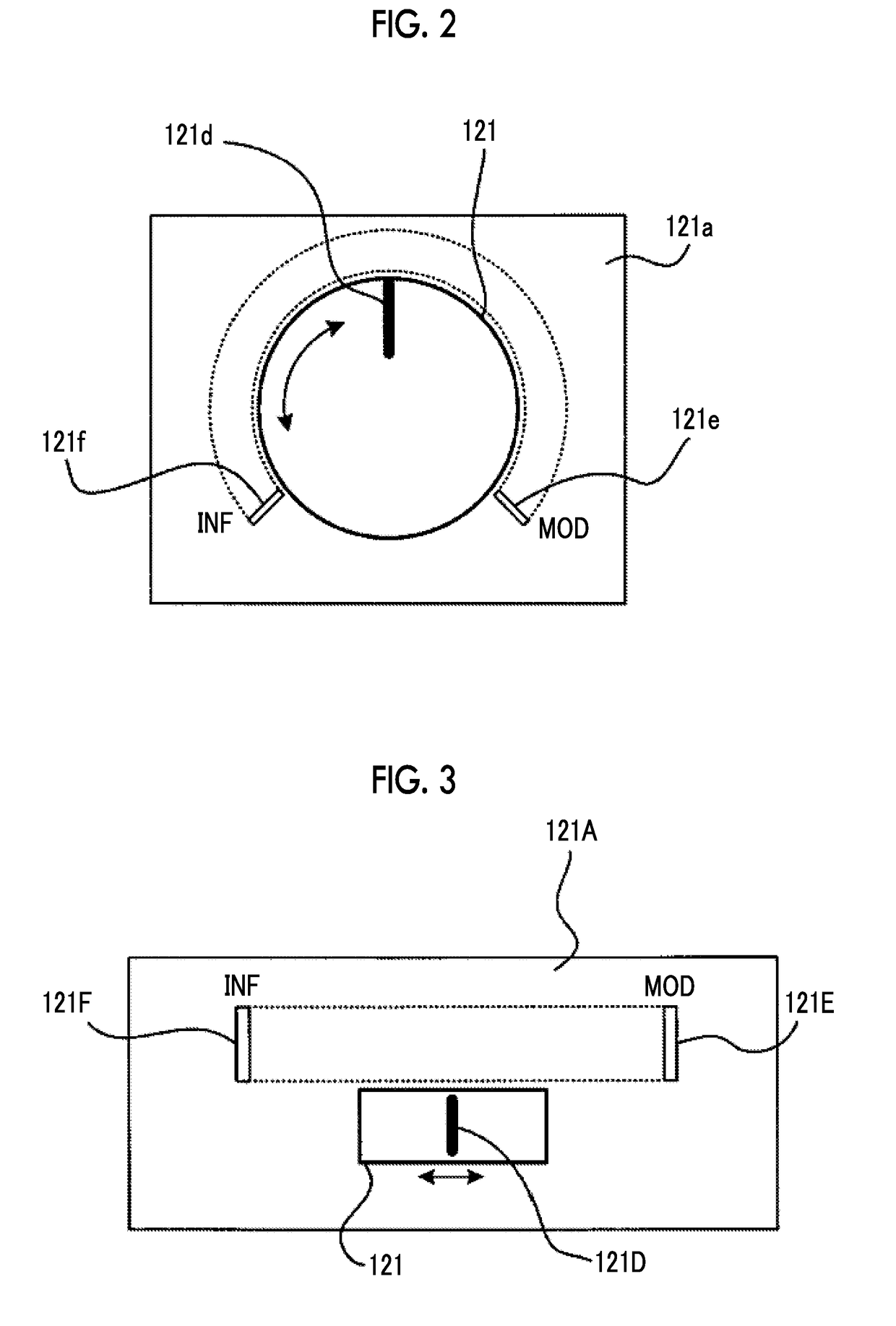

ActiveUS20180314033A1Efficiently formedEasy to modifyTelevision system detailsColor television detailsLens ControllerResonance

A variable focal length lens device includes: a lens system whose refractive index is variable in response to an inputted drive signal; an image detector for detecting an image of a target object through the lens system; a lens controller for outputting the drive signal and an illumination signal; and a lens operation unit for adjusting a frequency and amplitude of the drive signal outputted by the lens controller and an image-detection timing for the image detector. The lens controller includes a resonance-lock controller for tuning the drive signal to a resonance frequency of the lens system. The lens operation unit includes a resonance-lock operation unit for switchably enabling and suspending the resonance-lock controller.

Owner:MITUTOYO CORP

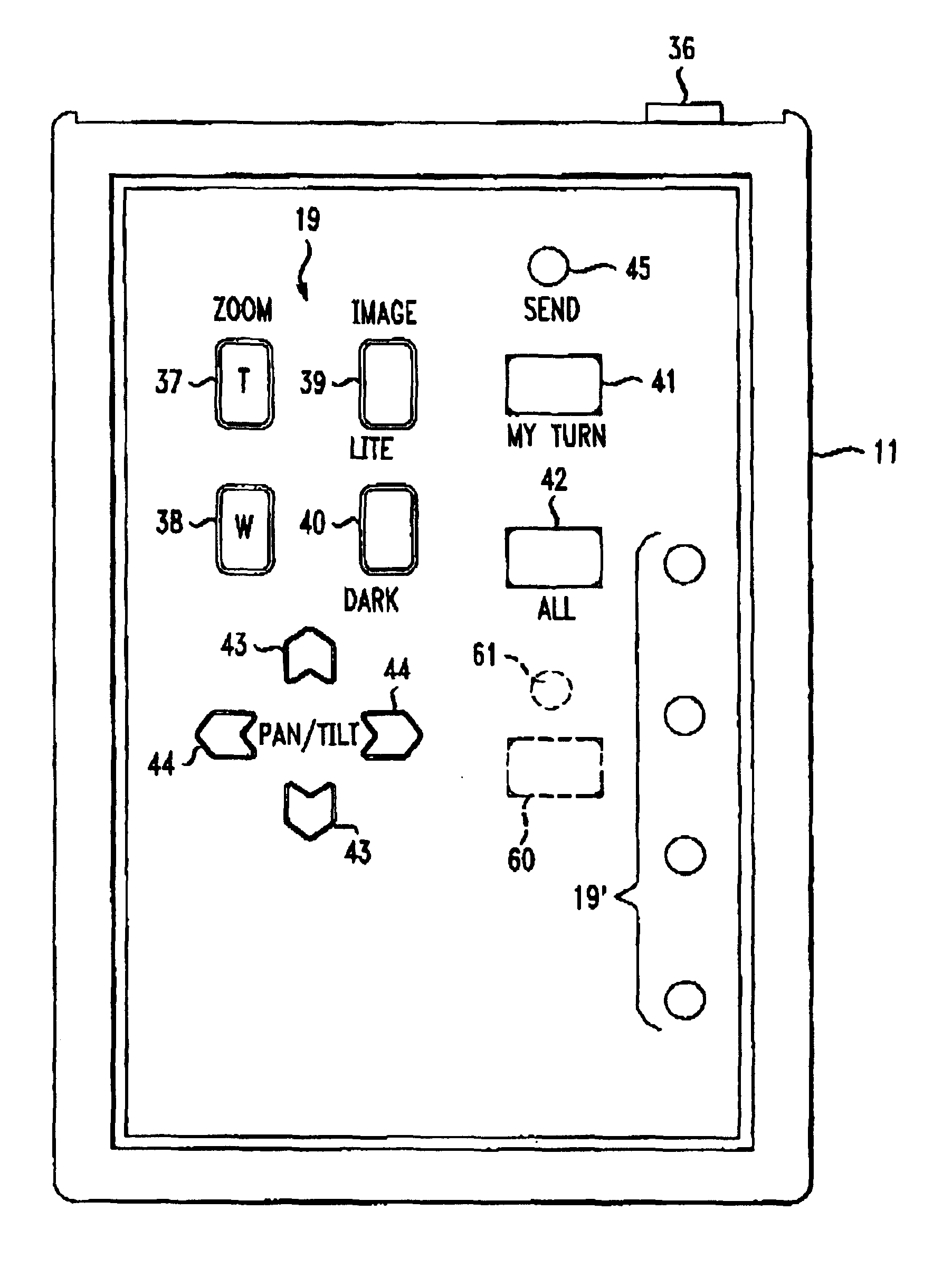

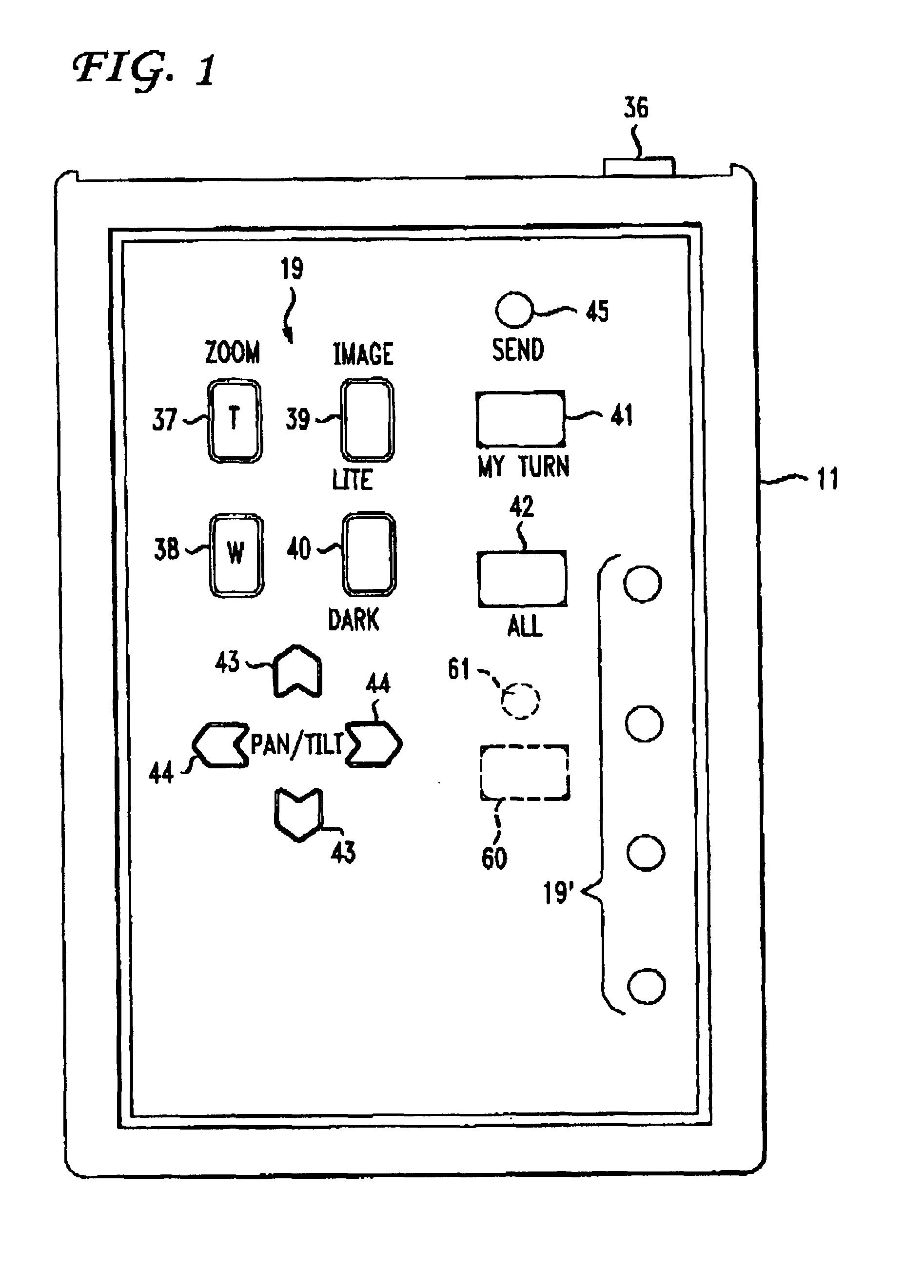

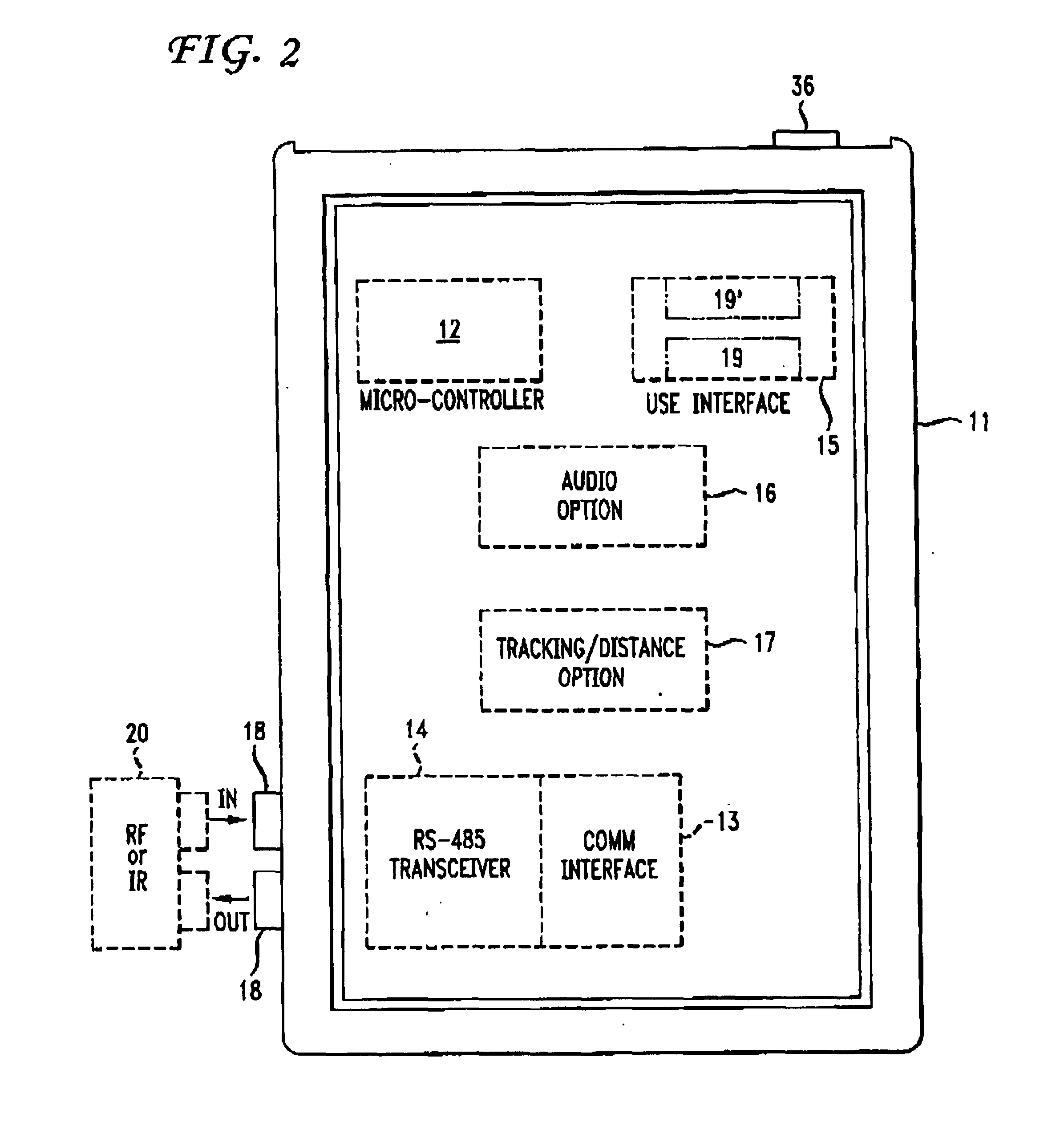

Multi-user camera control system and method

InactiveUS7015953B2Television system detailsTelevision conference systemsCamera controlControl system

A multi-user camera control system with automatic tracking capability for use in video conferencing and similar applications includes a plurality of personal controllers, one for each person utilizing the system. Each personal controller includes a micro-computer controlled keypad and associated communication circuitry as well as optional audio and tracking capability. The controller is programmed with the capability to send commands to the camera system.The system employs programmed, automatically trackable controllers for issuing commands to control most of the functions of a camera including lens operation. Personal locator devices are electrically connected and can be programmed as a master and as slaves. In addition, a master having override features may be provided, as well as a director's locator device for system wide control.

Owner:GVBB HLDG R L

Camera system having image shake correction function

The invention provides a camera system. In the camera system where a taking lens and a camera body respectively comprise a image shake correction unit for correcting a shake, which occurs on an image on an image capturing surface due to a jiggle of the camera system at the time of shooting, the taking lens and the camera body respectively comprise a communication unit for making a communication between the taking lens and the camera body, and a control is performed so that the communication unit of the camera body transmits a lens operation suspension instruction when the image shake correction unit of the camera body is operated, and the operation of the taking lens is suspended when the communication unit of the taking lens receives the lens operation suspension instruction.

Owner:OM DIGITAL SOLUTIONS CORP

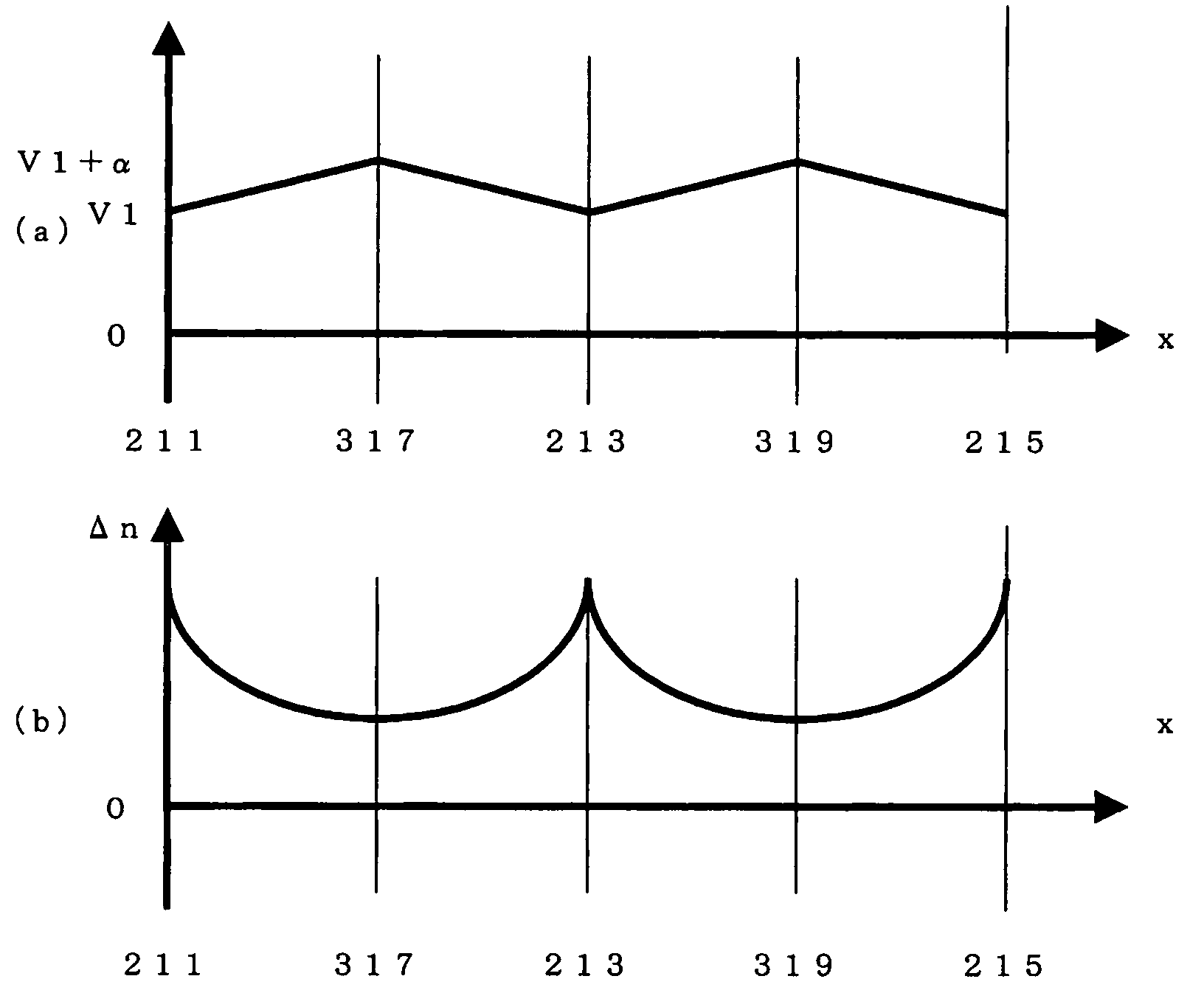

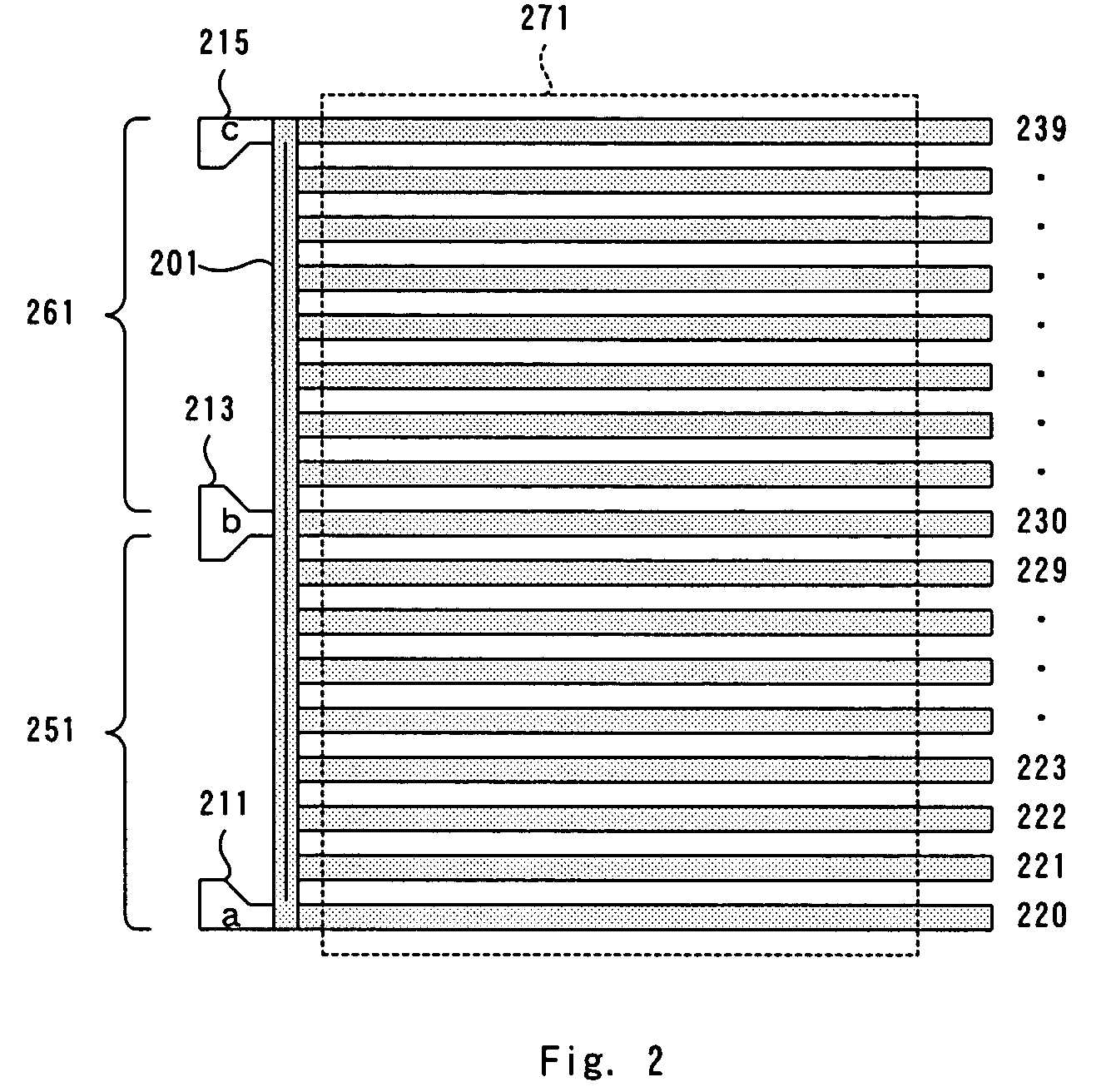

Liquid crystal optical modulator and drive method

ActiveUS7218302B2High-aperture rateSimple structureCathode-ray tube indicatorsNon-linear opticsLens operationsMicro lens array

A liquid crystal optical modulator is operated as a concave lens using a quadratic curve modulation area of a refractive index modulation area of a liquid crystal molecule layer, which is different from a conventional convex lens operation area, without changing the configuration of the liquid crystal optical modulator. In addition, the liquid crystal optical modulator is operated as a concave lens using a quadratic curve modulation area used by a conventional liquid crystal optical modulator as well as an area different from that area to enable the liquid crystal optical modulator to operate as a convex lens and as a concave lens. This makes it possible to perform the concave lens operation, to enlarge the variable focal range, and to form a micro-lens array of variable focal point type.

Owner:CITIZEN WATCH CO LTD

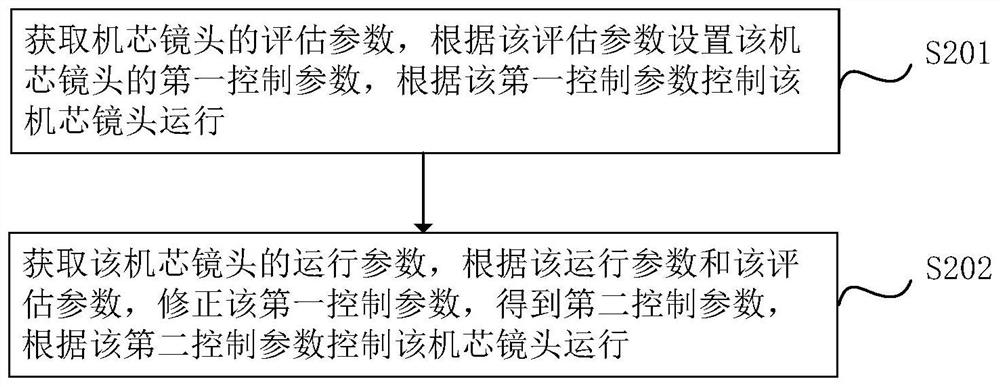

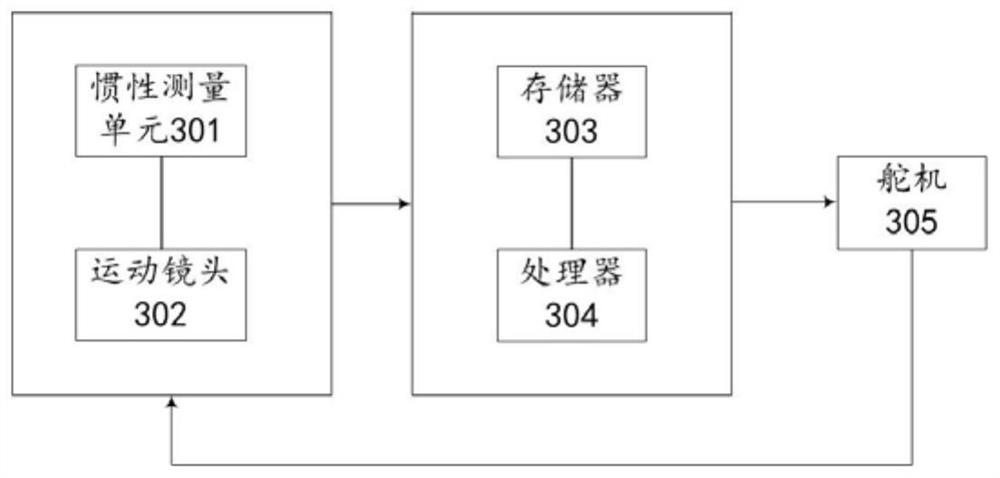

Movement lens operation state control method and device, and computer device

ActiveCN111654617ASolve the problem of easy step lossDifferent running speedTelevision system detailsColor television detailsOphthalmologyEngineering

The invention relates to a movement lens operation state control method and device and a computer device. The movement lens operation state control method comprises the following steps of: obtainingan evaluation parameter of a movement lens; setting a first control parameter of the movement lens according to the evaluation parameter; controlling the movement lens to operate according to the first control parameter; acquiring an operation parameters of the movement lens; according to the operation parameter and the evaluation parameter, correcting the first control parameter to obtain a second control parameter; and controlling the movement lens to operate according to the second control parameter. The control method solves the problem that the movement lens is easy to desynchronize due to a high-rotation-speed control group in related technologies, controls the movement lens to have different operation speeds in different operation periods of the movement lens, reduces the probability of desynchrony of the movement lens, and prolongs the service life of the movement lens.

Owner:ZHEJIANG DAHUA TECH CO LTD

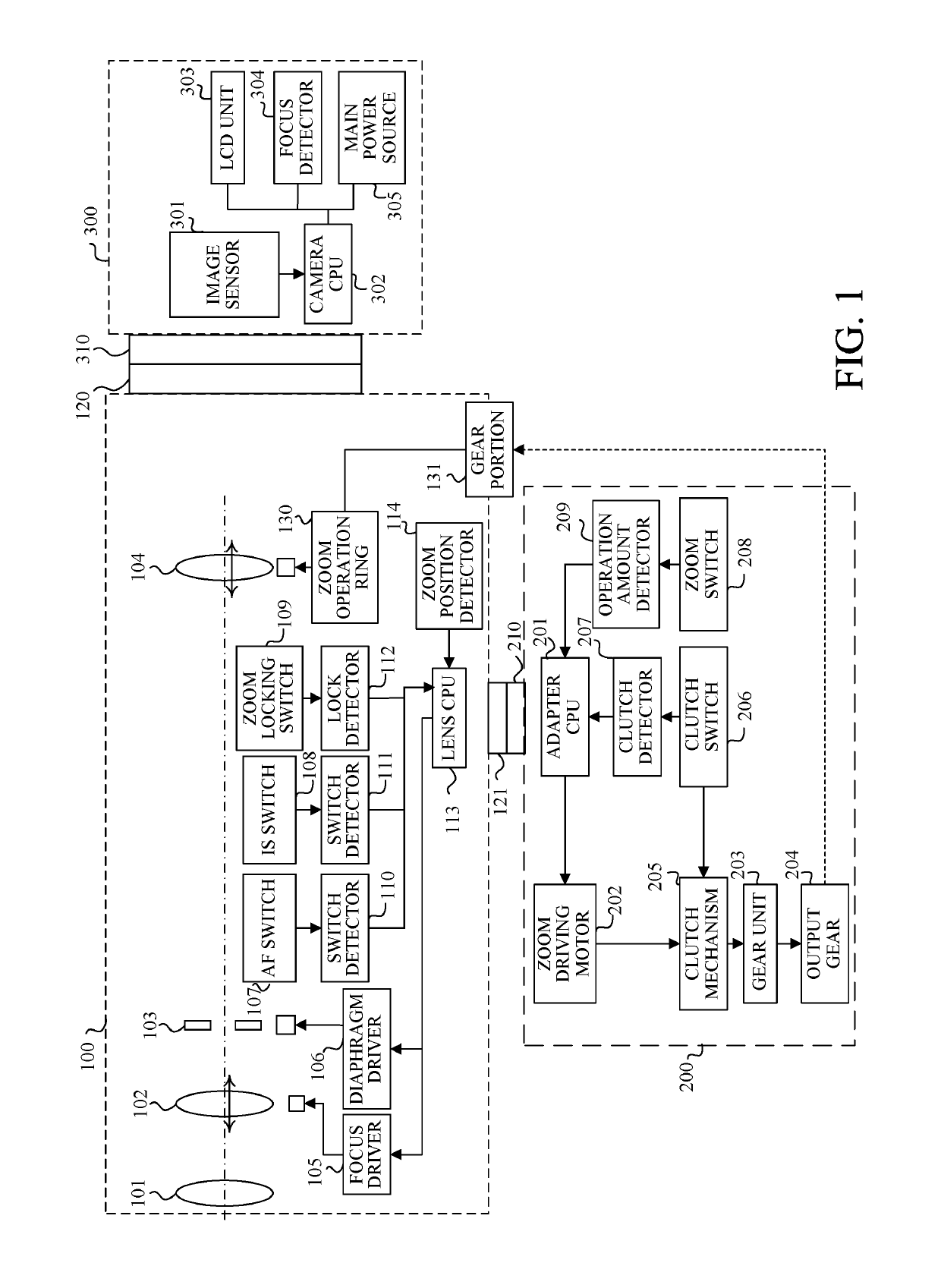

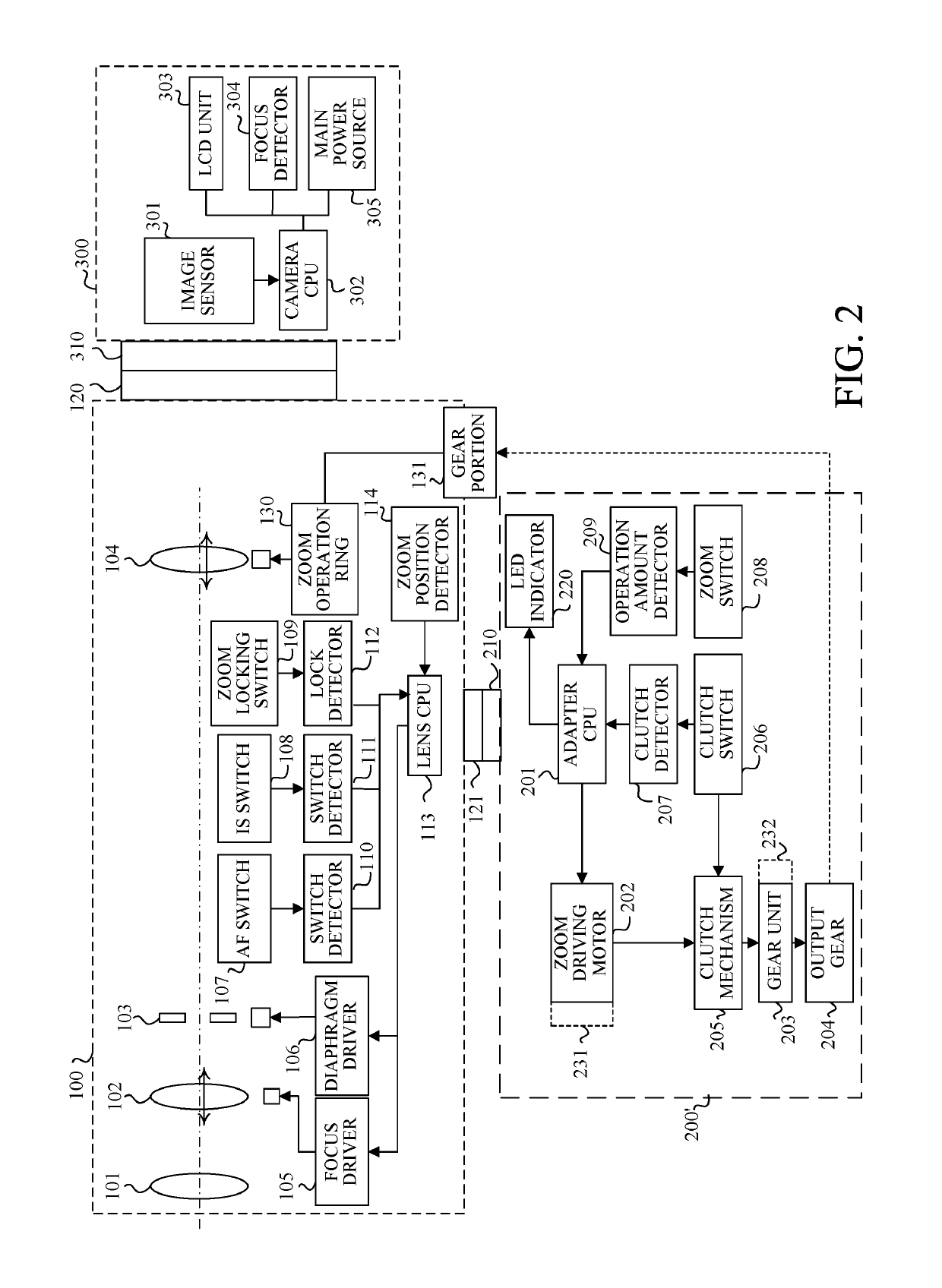

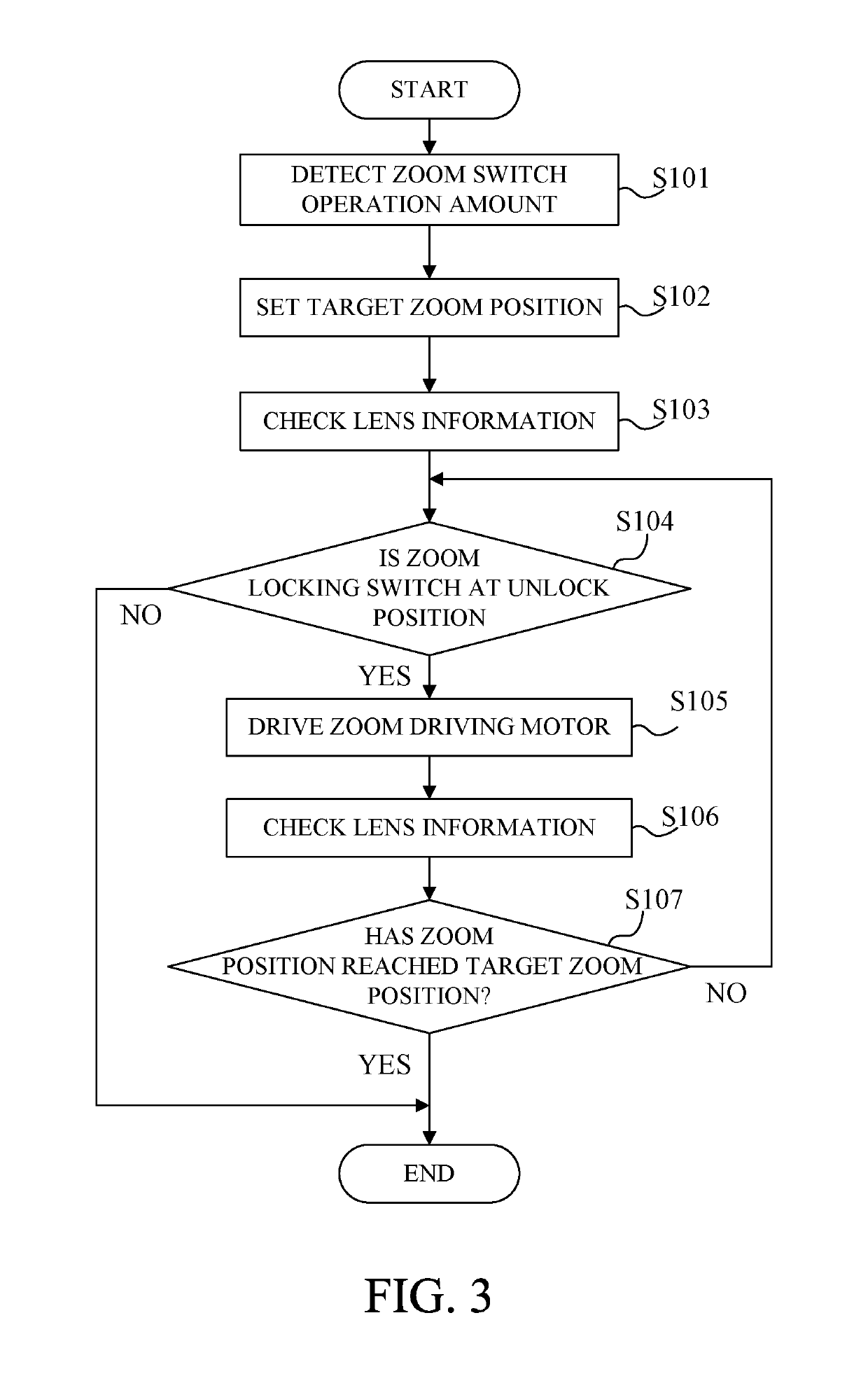

Lens operation device and camera system

InactiveUS20070014559A1Coupling device connectionsElectric discharge tubesLens operationsComputer science

Owner:CANON KK

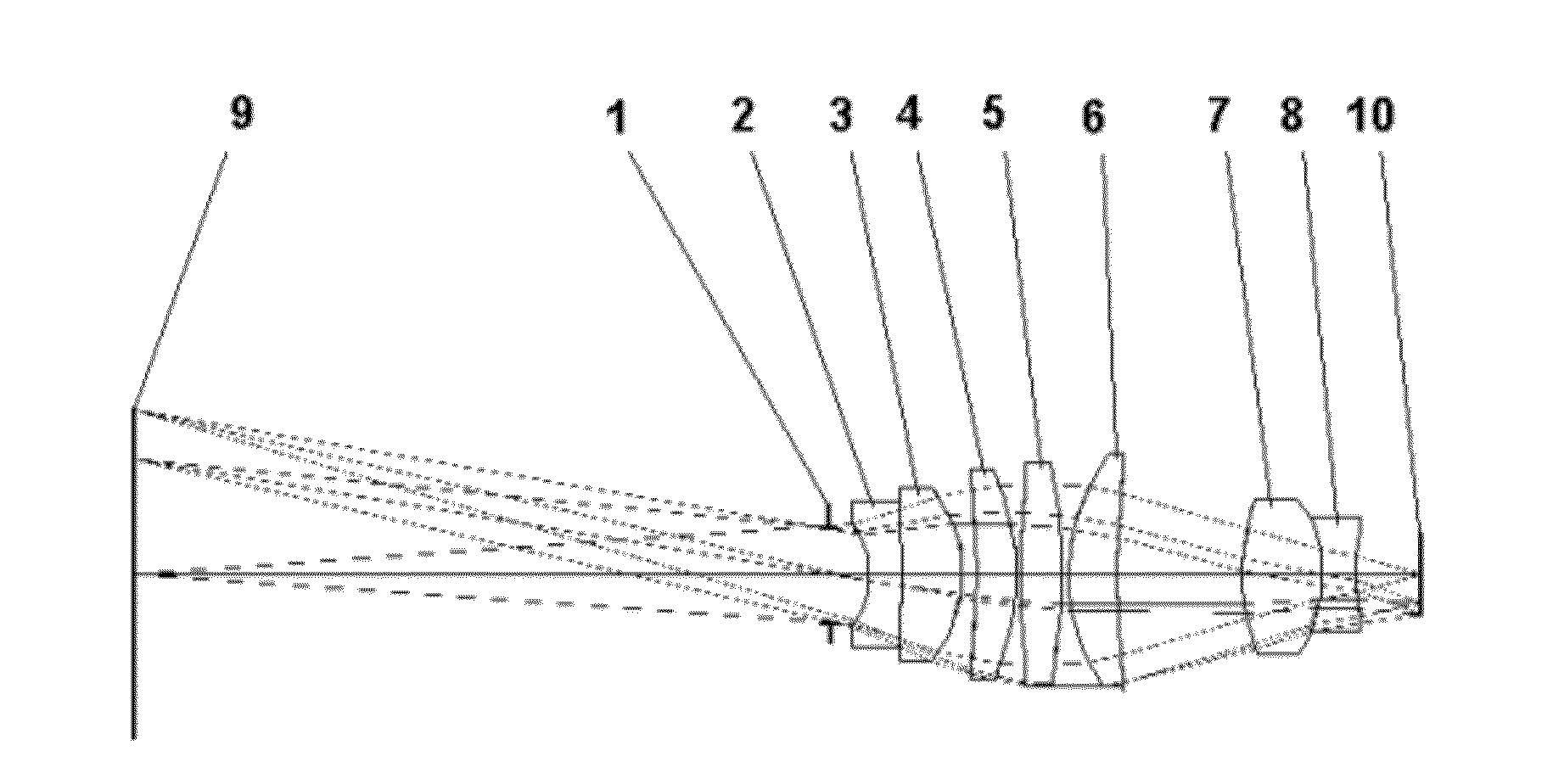

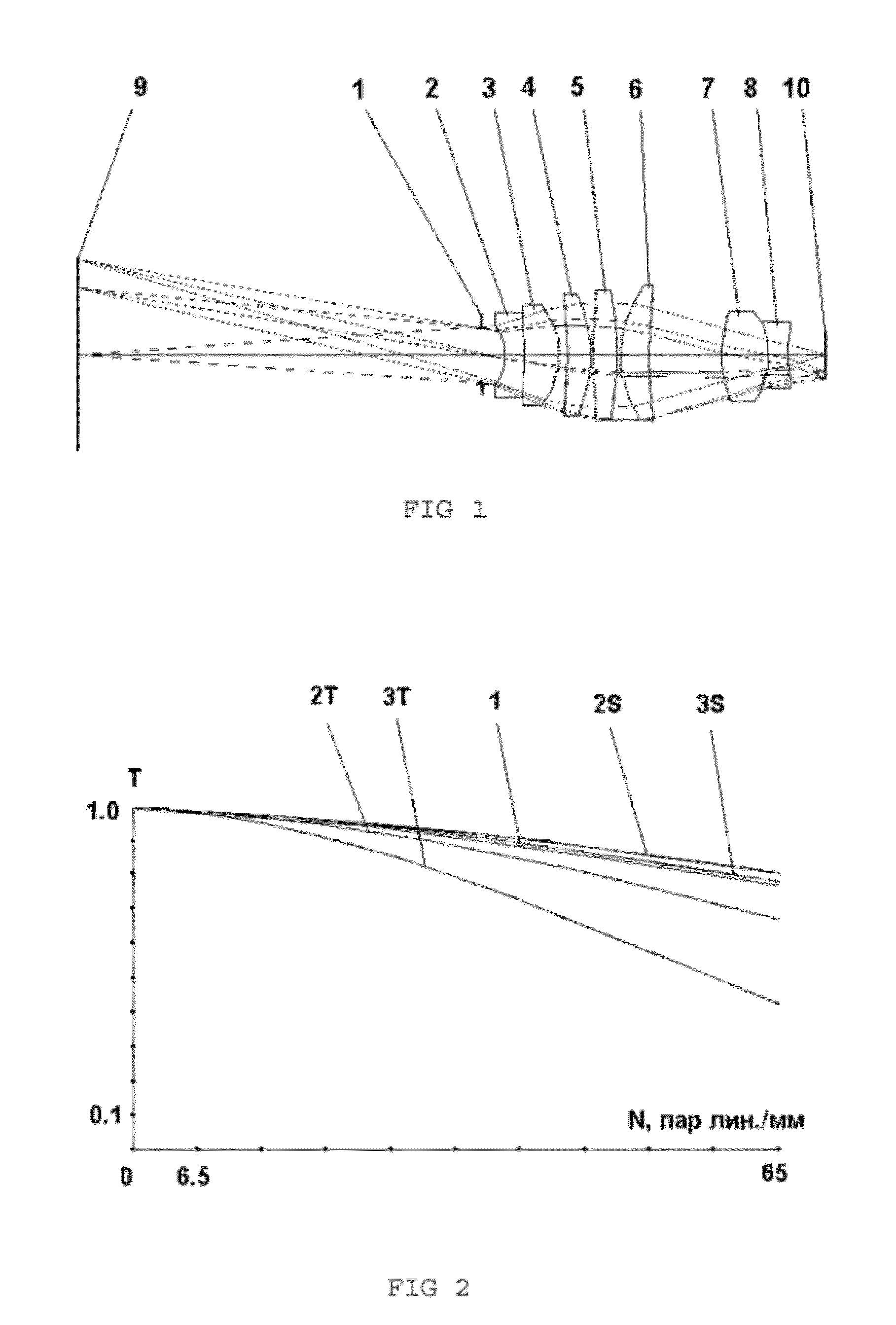

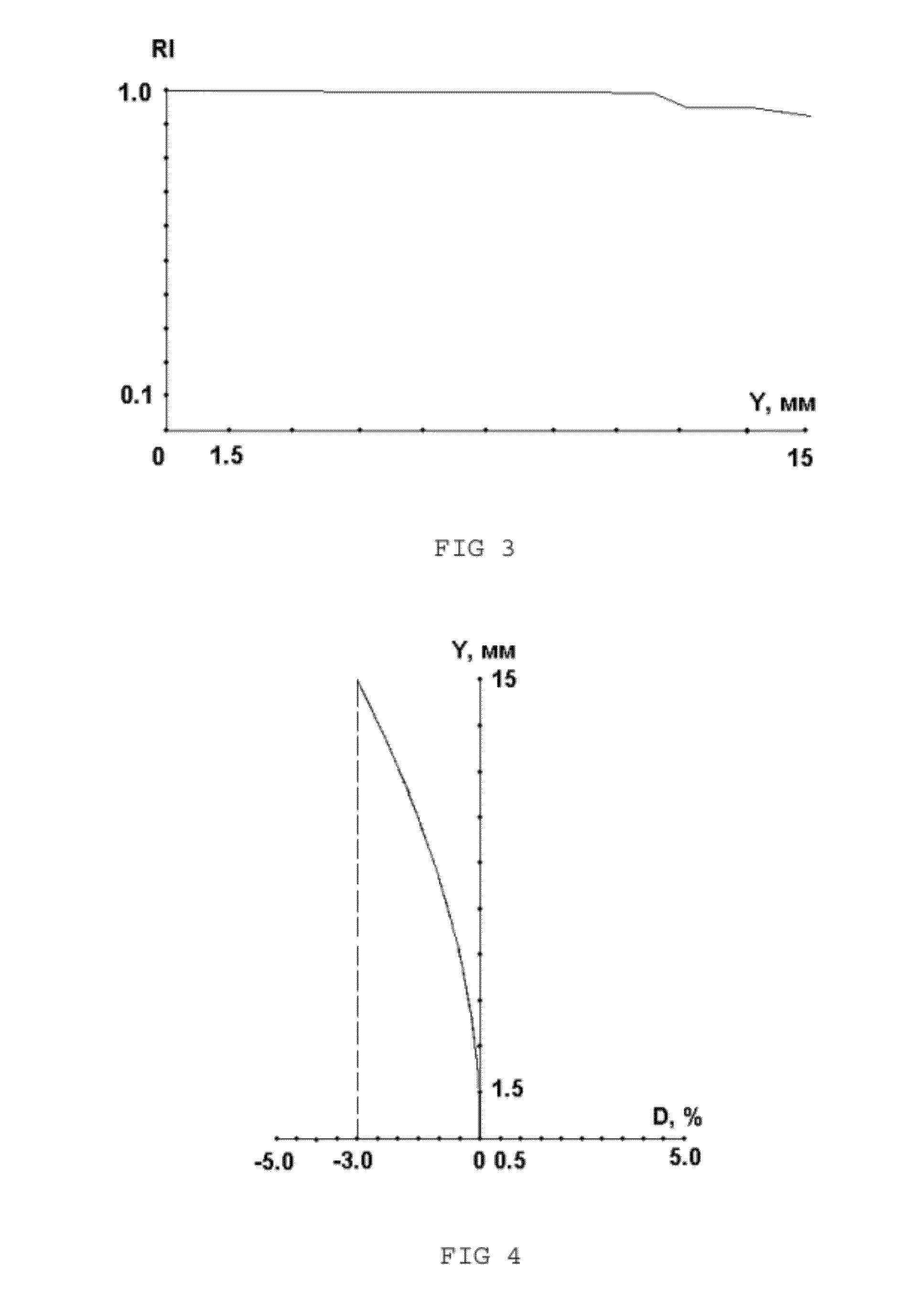

Projection lens

InactiveUS20120206823A1Improve image qualityMinimal value is increasedLensCamera lensImaging quality

The projection lens comprises: the first of the components of negative power, facing with its concave surface to the object and cemented of negative and positive menisci, the second component comprising a positive meniscus, having the concave surface facing an object side, the third one being a biconvex lens, the forth one being a positive meniscus, having the concave surfaces facing an image side, the fifth one being negative, faced with its concave surface to the image and being cemented of biconvex and biconcave lenses. The technical objective is that relative aperture (1:1.8) is increased, brightness at the image edge field is enhanced against that in the centre (0.91), in the image, formed by the lens, the required value of negative distortion is provided (−3%), an image quality is enhanced, conditions of lens operating are provided for the object, located at the finite distance.

Owner:ZAKRYTOE AKCIONERNOE OBSHCHESTVO IMPULS

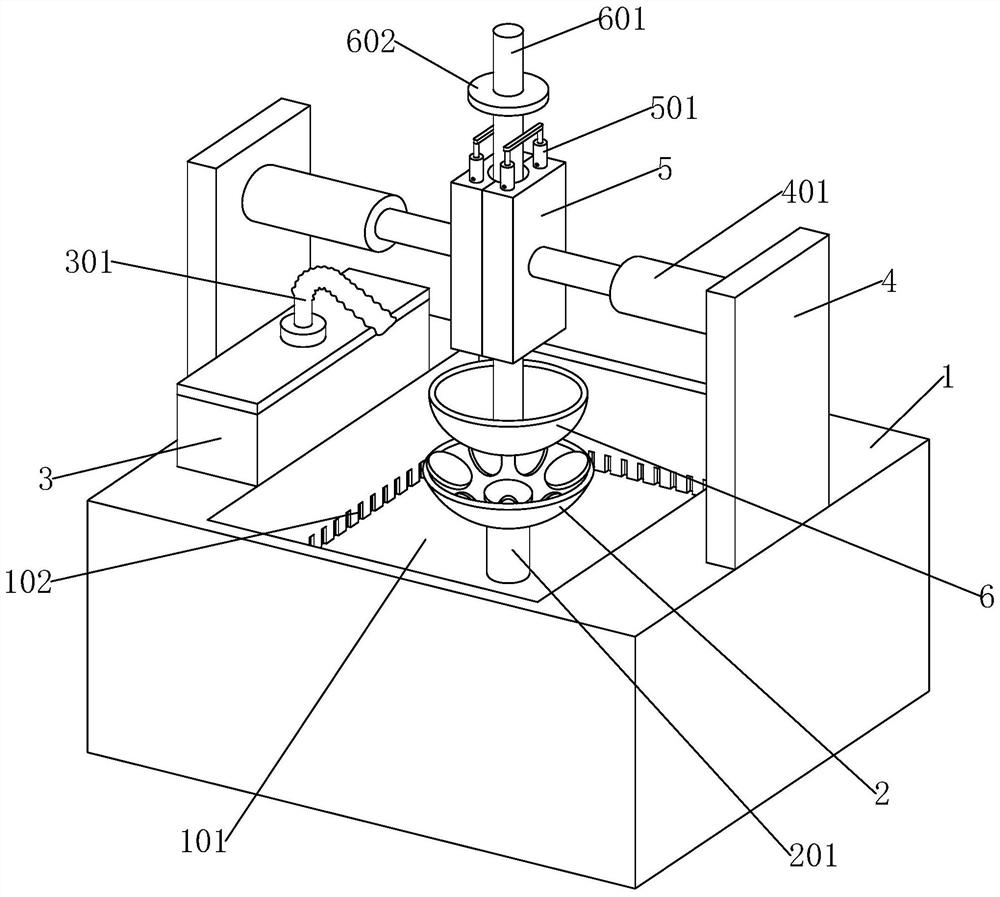

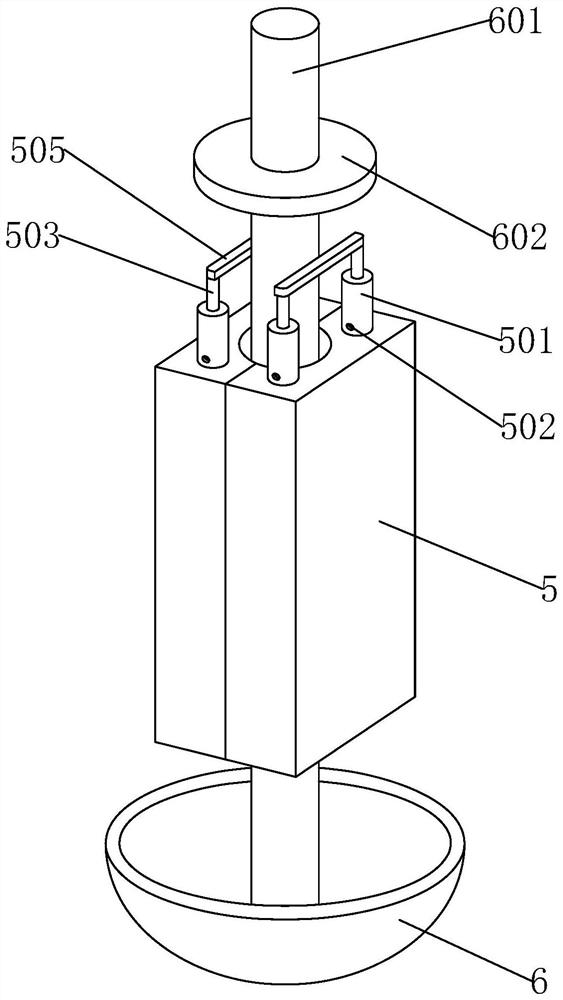

Disc feeding mechanism for infrared lens machining

ActiveCN112388441AAutomatic buffer pressurePrevent crushingOptical surface grinding machinesGrinding drivesLens operationsWorkbench

The invention discloses a disc feeding mechanism for infrared lens machining, and belongs to the technical field of infrared lens machining. According to the technical scheme of the disc feeding mechanism, the disc feeding mechanism comprises a workbench, an infrared lens placement disc and an infrared lens operation disc, wherein the infrared lens placement disc is fixedly mounted on the workbench through a base, the infrared lens operation disc is matched with the infrared lens placement disc for use, a center column used for holding is fixedly mounted on the infrared lens operation disc, two mutually parallel and symmetrical vertical plates are fixedly mounted on the two sides of the upper end surface of the workbench, electric telescopic rods are mounted on the sides, close to each other, of the two vertical plates, the two electric telescopic rods are equal in height and coaxially arranged, clamping blocks are fixedly mounted at the movable ends of the two electric telescopic rods, and grooves are formed in the sides, close to each other, of the two clamping blocks. The disc feeding mechanism for infrared lens machining can automatically buffer the abutting force of the infrared lens operation disc to an infrared lens, prevents the infrared lens from being broken by the infrared lens operation disc in an abutted mode, and is convenient and labor-saving to use.

Owner:江西弘耀光学水晶有限公司

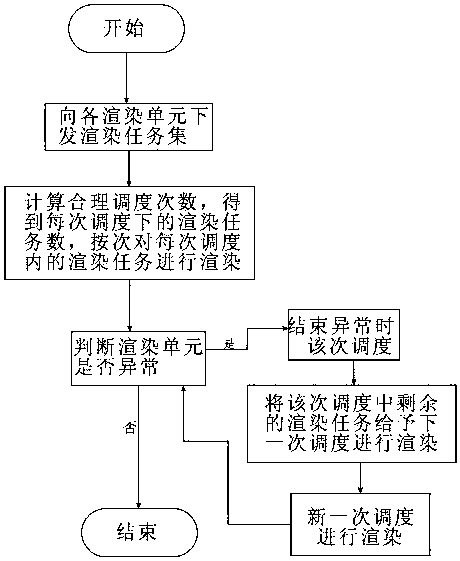

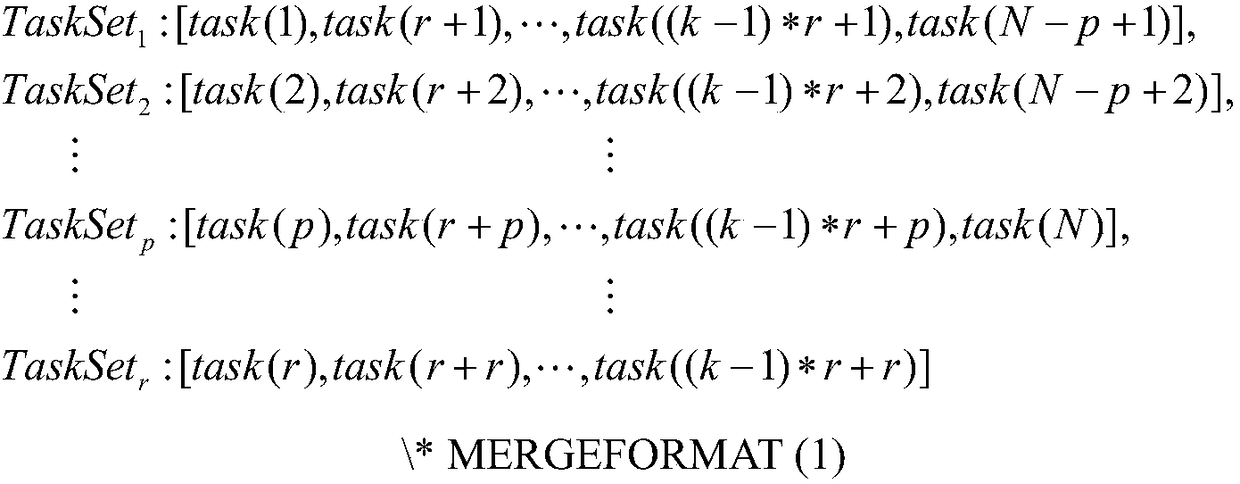

Dynamic scheduling method for rendering task

ActiveCN108415766AIncreased reliability renderingIncrease success rateProgram initiation/switchingAnimationFailure rateAnomaly detection

The invention relates to a dynamic scheduling method for a rendering task. Aiming at the problems of scheduling consumed time of a management system and a rendering unit and rendering abnormity, a traditional solution adopts a one time static scheduling strategy, and then the rendering result has multiple failure frames. The method aims at reducing the lens operation overall rendering failure rate, a multiple dynamic scheduling strategy is adopted, and a rendering task scheduling algorithm is achieved. The core concept of the algorithm is that by means of multiple dynamic scheduling, the rendering result failure problem caused by rendering unit abnormity is reduced as much as possible, by means of real-time rendering unit abnormity detection, the utilization rate of node resources is effectively increased, and the rendering failure rate is lowered.

Owner:洛阳蓝鲸品牌策划有限公司

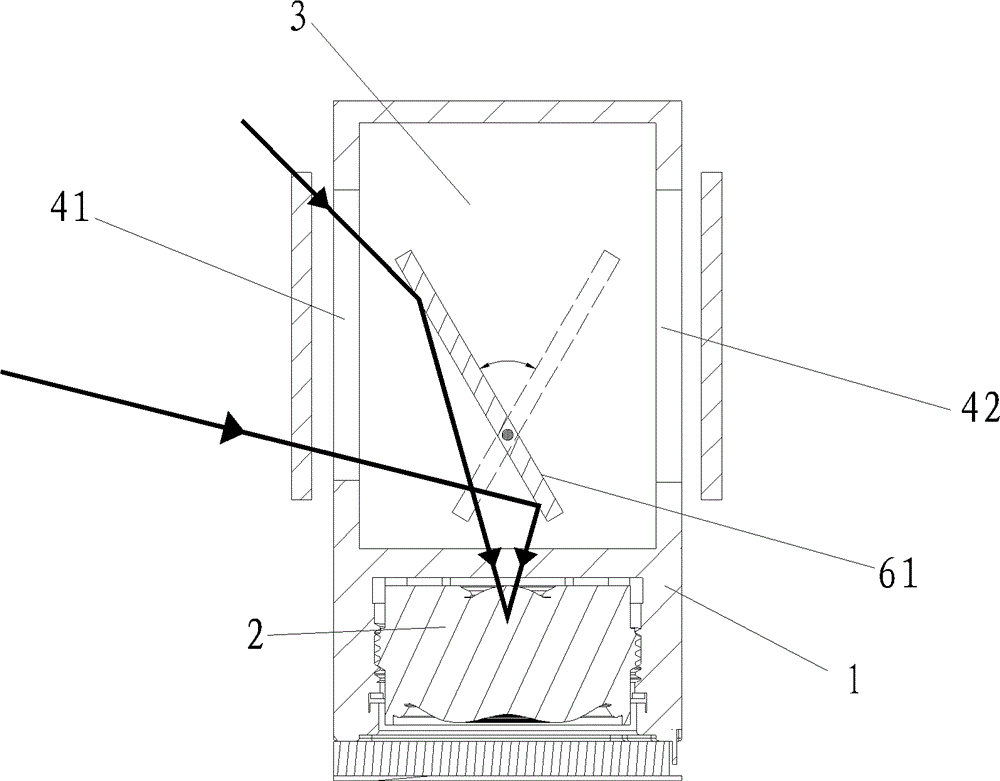

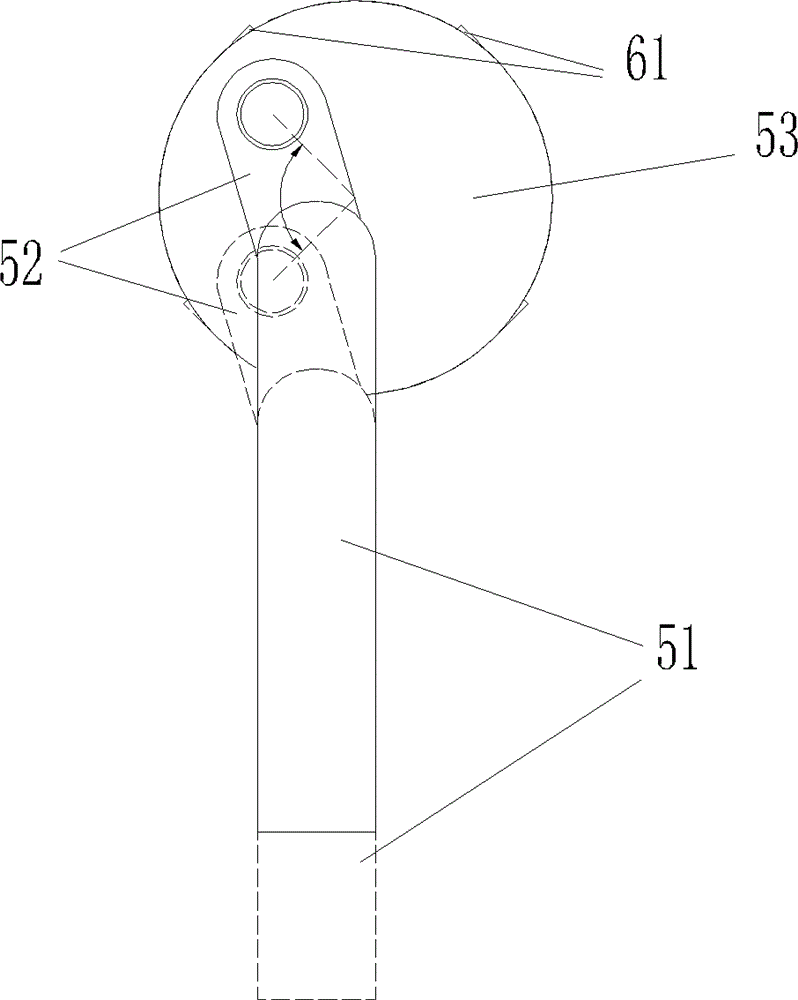

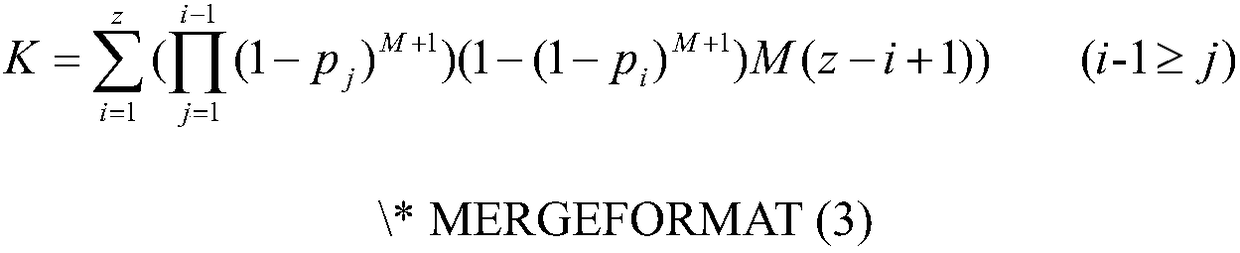

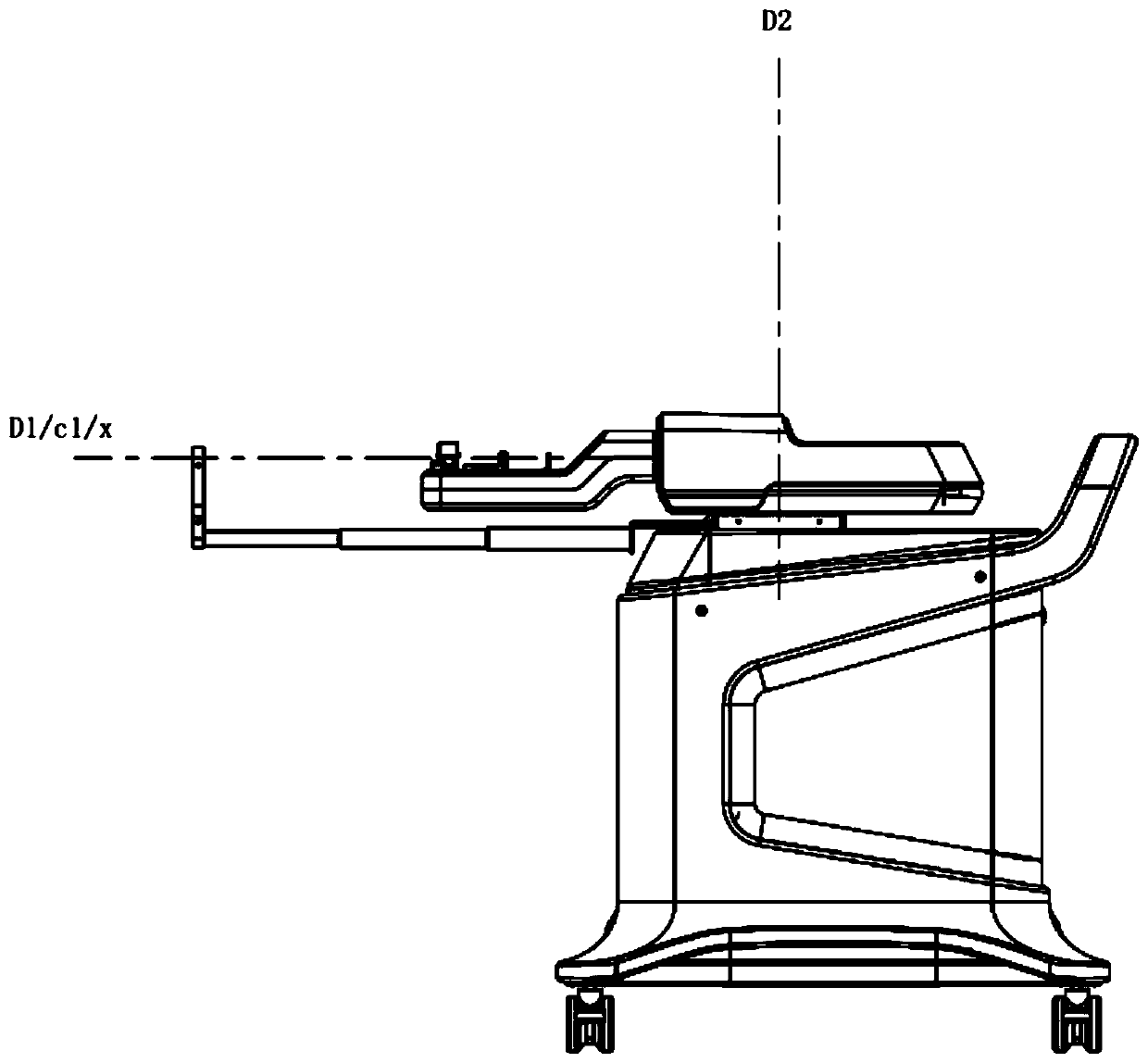

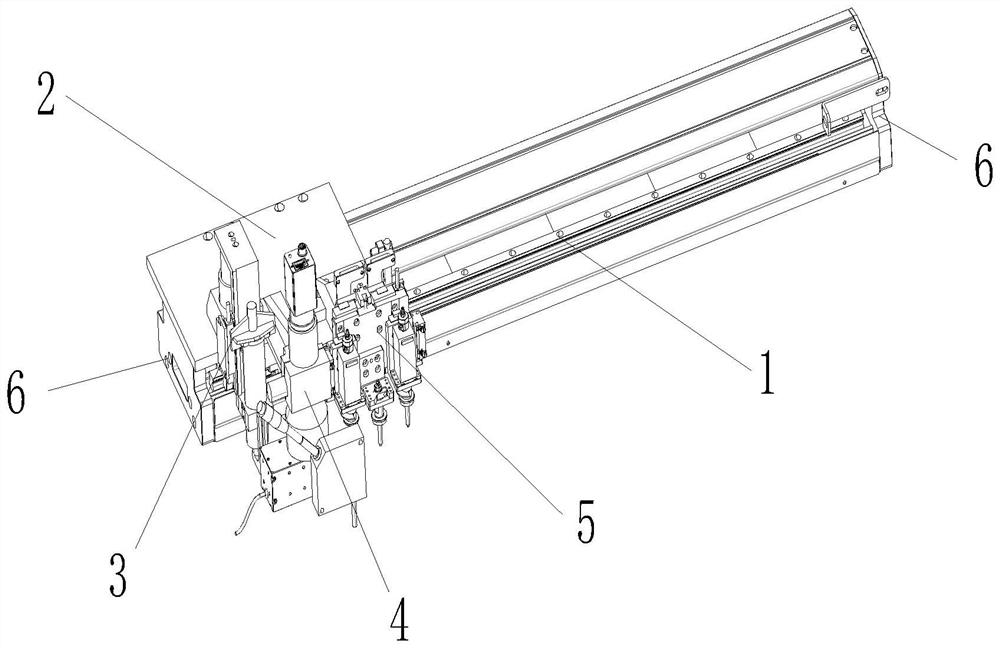

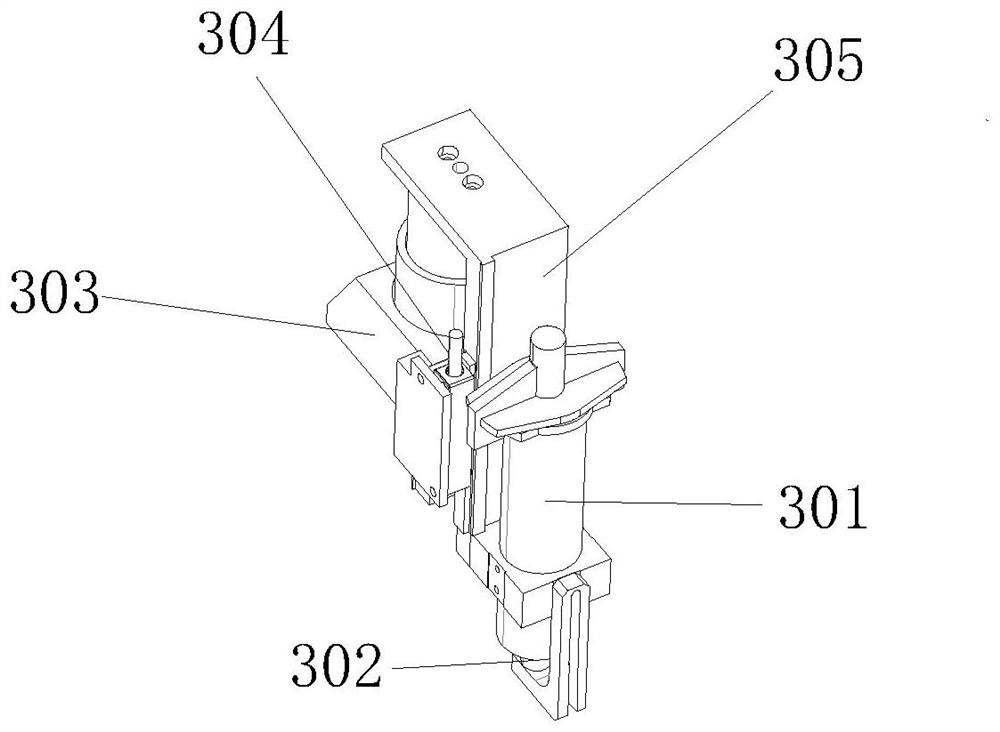

Mechanical arm system suitable for ureteral lithotripsy soft lens surgery

The invention discloses a mechanical arm system suitable for ureteral lithotripsy soft lens surgery. The mechanical arm system comprises an operating arm, a first-dimensional driving device, a second-dimensional driving device and a pivoting driving device. The first-dimensional driving device comprises a first driving motor; a first displacement device comprises a first lead screw and a first lead screw nut, and the first lead screw and the first lead screw nut can relatively rotate around a first displacement axis; and a first detection device is used for converting the rotation of the firstlead screw or the displacement of the first lead screw nut into an electric signal and outputting the electric signal. The mechanical arm system suitable for the ureteral lithotripsy soft lens operation has the beneficial effect that the mechanical arm system suitable for the ureteral lithotripsy soft lens operation can convert resistance received by the driving device into a detectable electricsignal.

Owner:HANGZHOU FIBO LASER HIGH TECH

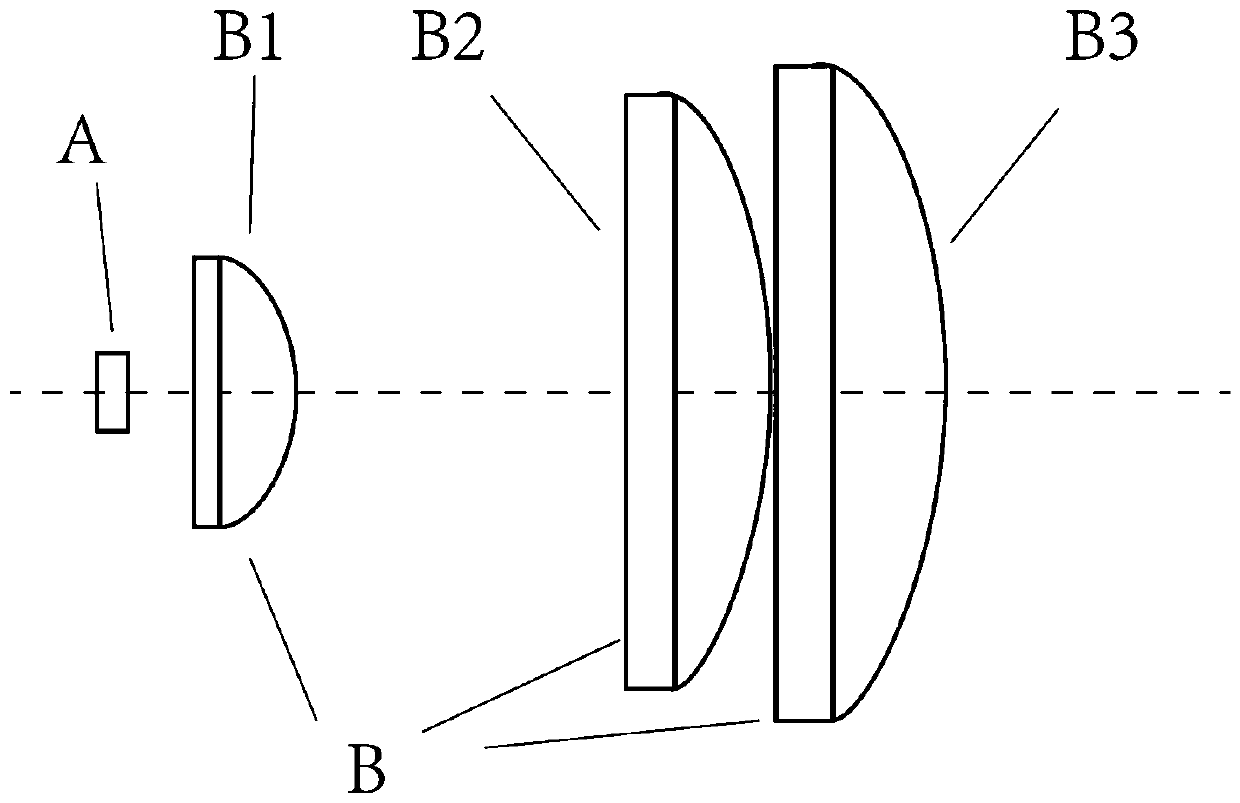

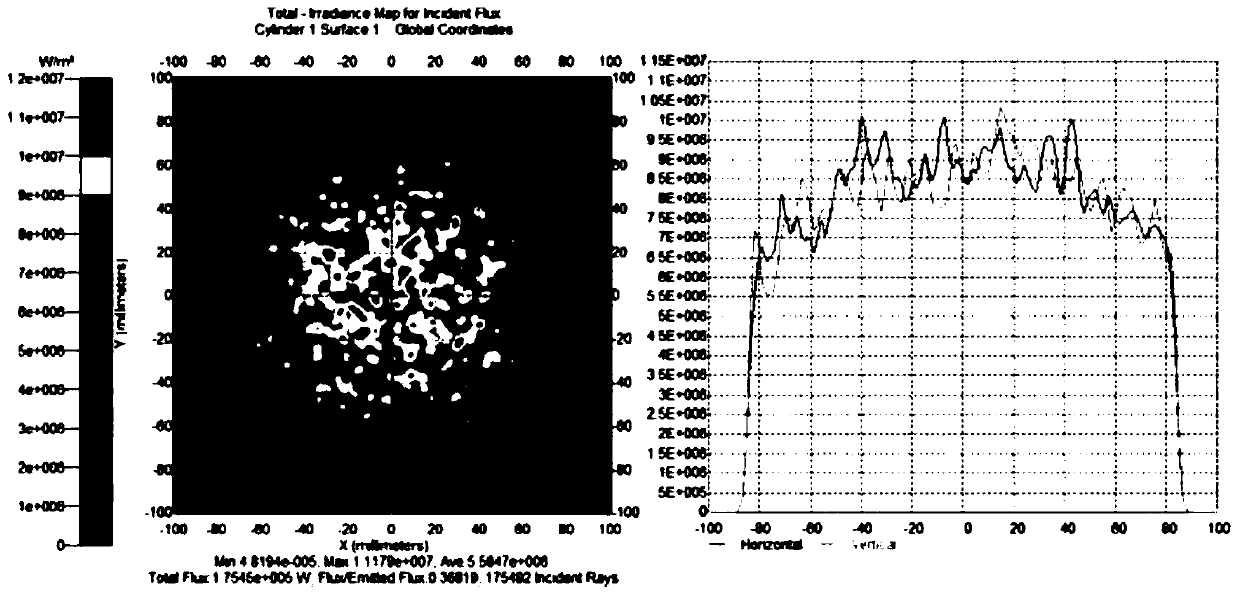

Aberration-eliminating aspheric three-lens operation LED head lamp

InactiveCN111396762APositive and obvious technical effectEffective aspherical three-lens structureMechanical apparatusPortable electric lightingLight spotAspheric lens

The invention belongs to the technical field of optical devices, and particularly relates to an aberration-eliminating aspheric three-lens operation LED head lamp. The aberration-eliminating asphericthree-lens operation LED head lamp comprises an LED light source A and an aberration-eliminating imaging optical lens group B. The imaging optical lens group B comprises a first lens B1, a second lensB2 and a third lens B3. The lens B1 is a spherical lens and is made of a material BK7; the lens B2 is an aspheric lens and is made of a material PMMA; the lens B3 is a spherical lens and is made of amaterial PMMA. Light emitted by the LED lamp sheet sequentially passes through the spherical lens B1, the aspheric lens B2 and the spherical lens B3 from front to back. The optical lens system of thehead lamp not only guarantees the basic uniformity of light spots, but also enables the image edges of the light spots to be clear through an efficient aberration correction method, and the interference of halo on a field of view is reduced.

Owner:FUDAN UNIV +1

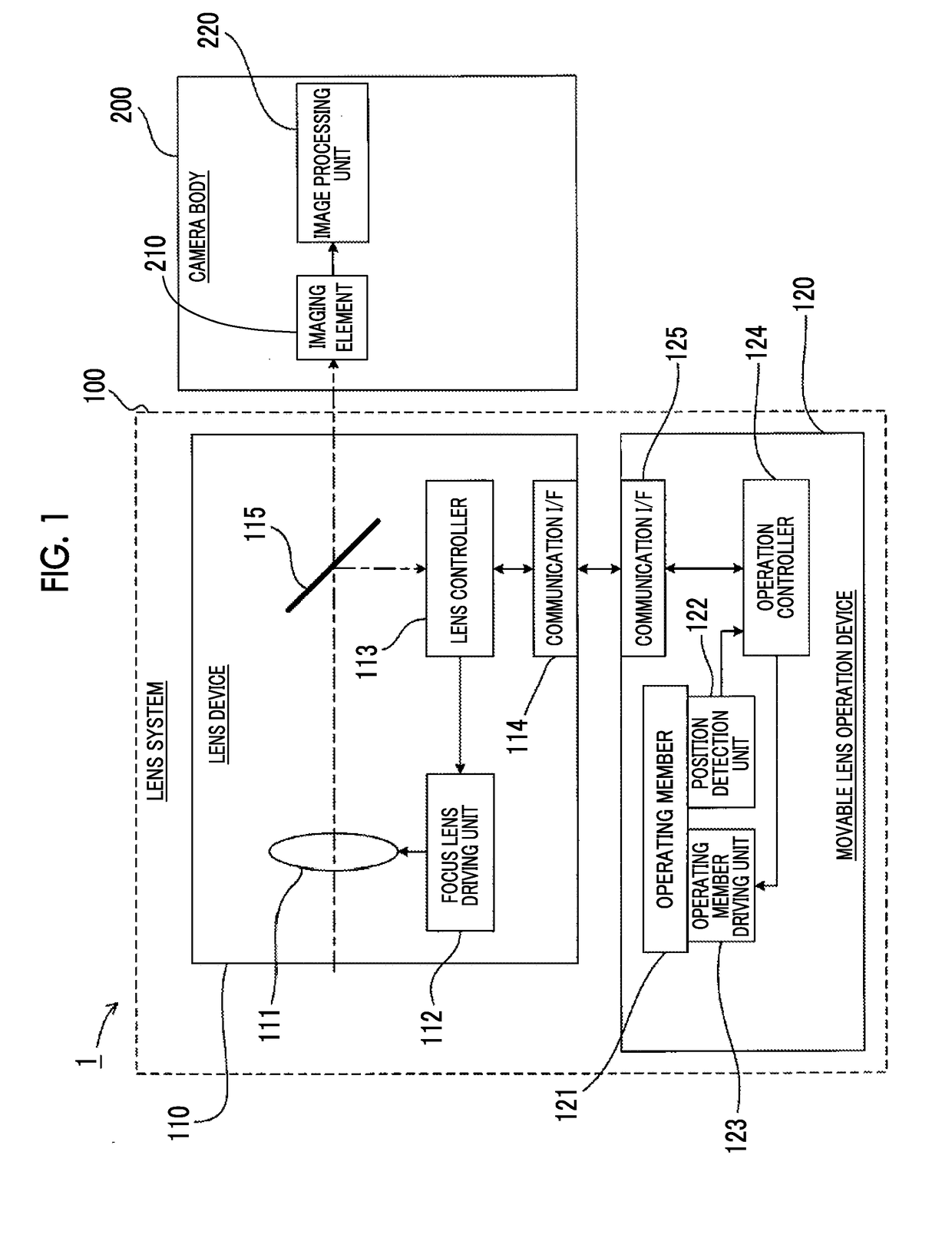

Lens device, lens system, imaging device, movable lens operation device, lens driving method, and lens driving program

ActiveUS11287604B2Simple processTelevision system detailsProjector focusing arrangementOphthalmologyOptical axis

Owner:FUJIFILM CORP

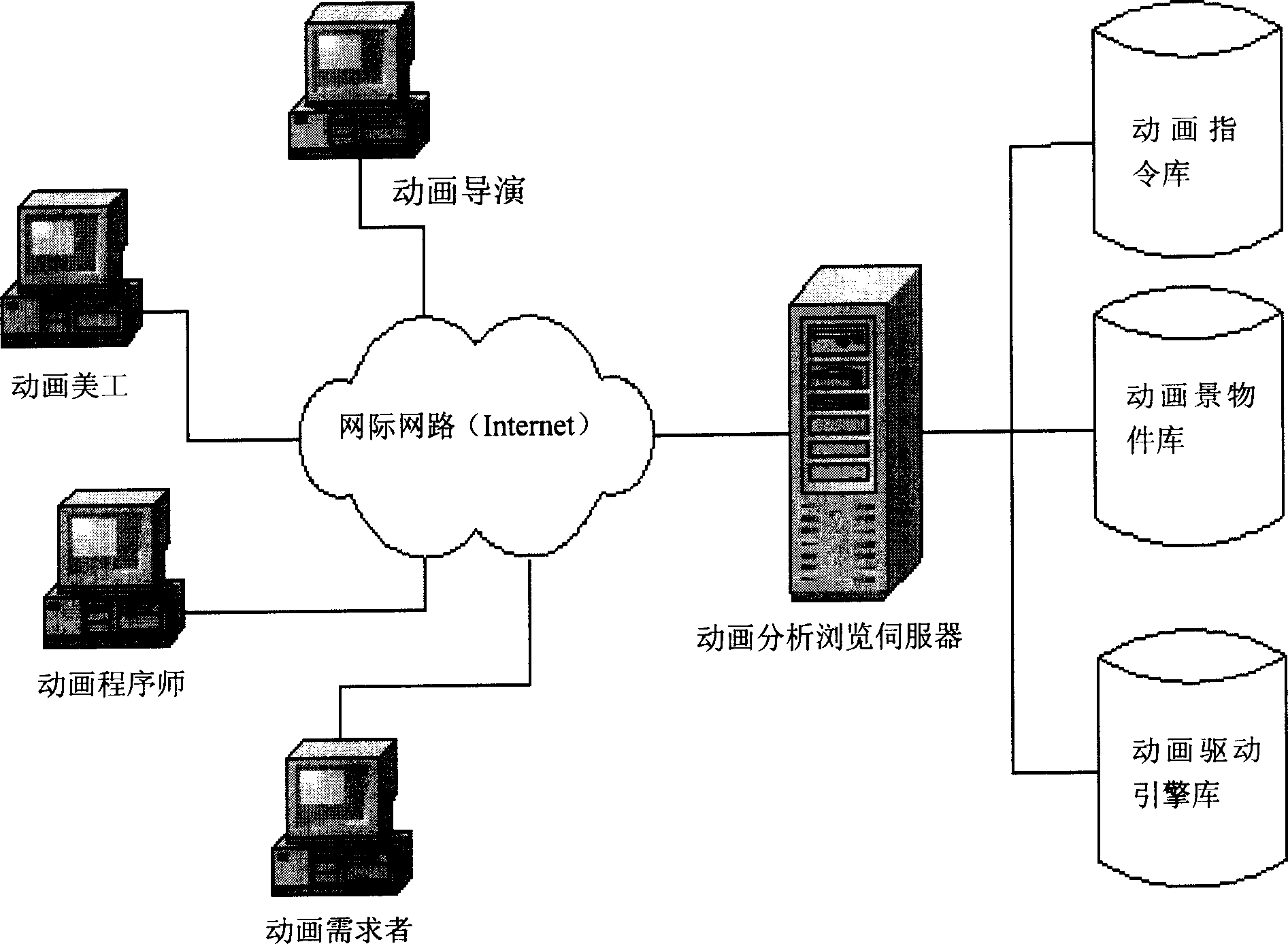

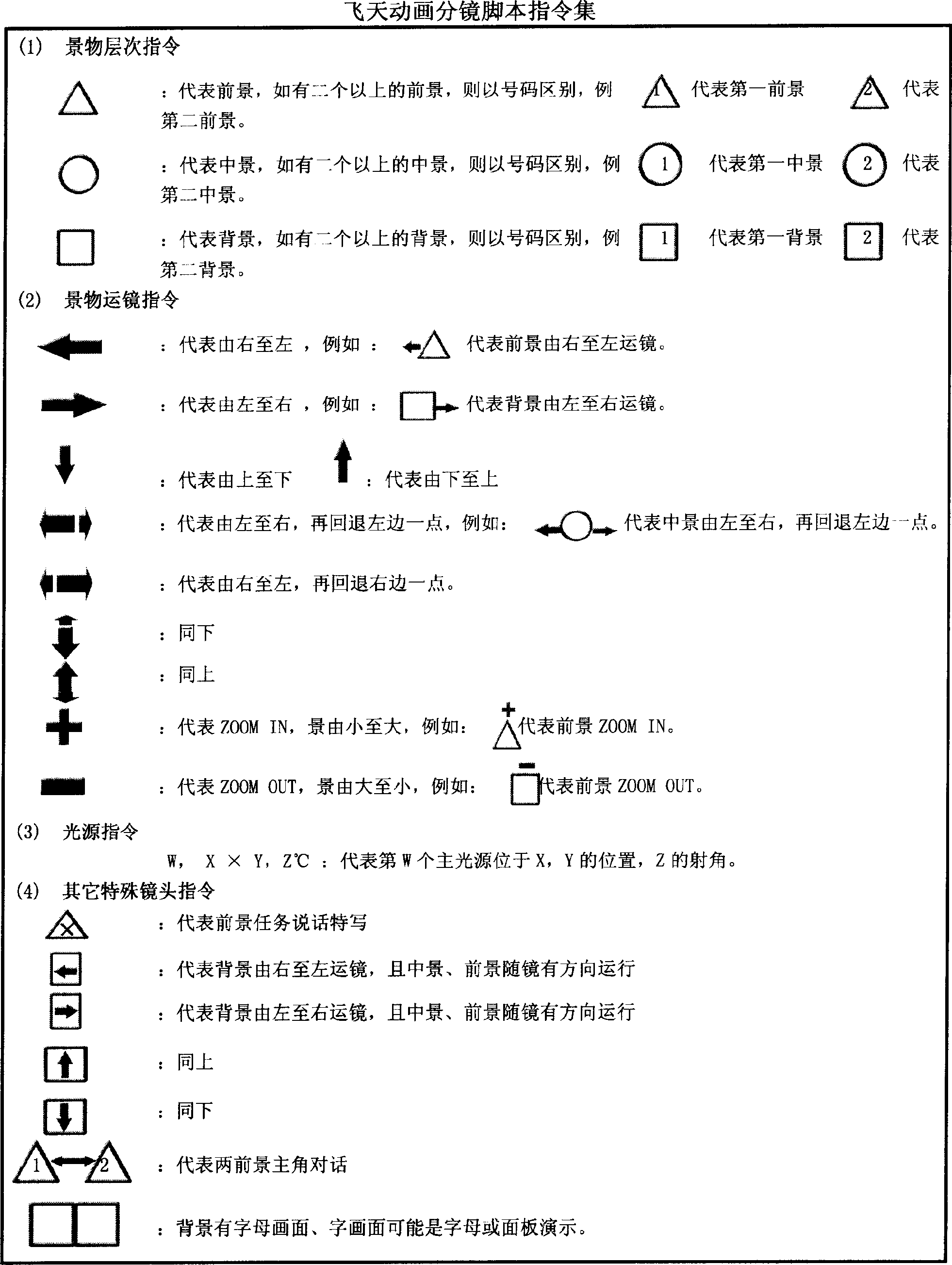

Multiple-layered computer animation continuity script

InactiveCN1704943AUnderstanding Animation IntentSpecial data processing applications3D-image renderingCamera lensComputer animation

This invention discloses a description language and an aid system of a picture structure, scenery motion, light source angle and a lens movement in a computer animation, among which, the picture structure analysis puts forward a multiplayer structure, the scenery motion provides a way that the scenery enters into the picture from all directions, the light source angle tells that a light source has a master source and aid light sources and a glassing rule for distance and an angle and a lens operation mode includes: from top to bottom, from left to the right, from right to the left, from bottom to top, zoom in and zoom out. A computer animation aid design system is disclosed including modules of an animation order analyzer, an animation instruction library, a drive engine, a browser and an animation scenery library.

Owner:杭州草莓资讯有限公司

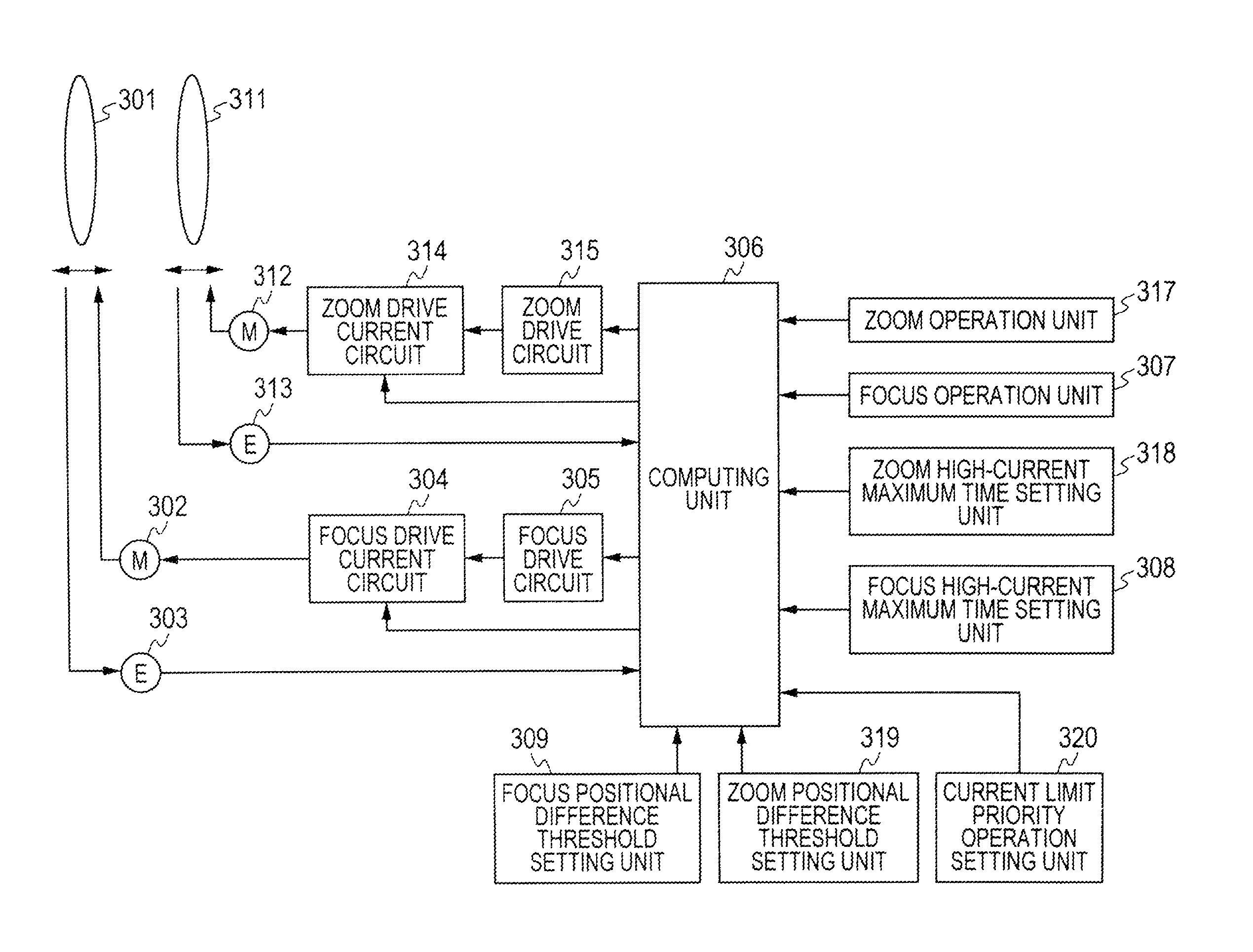

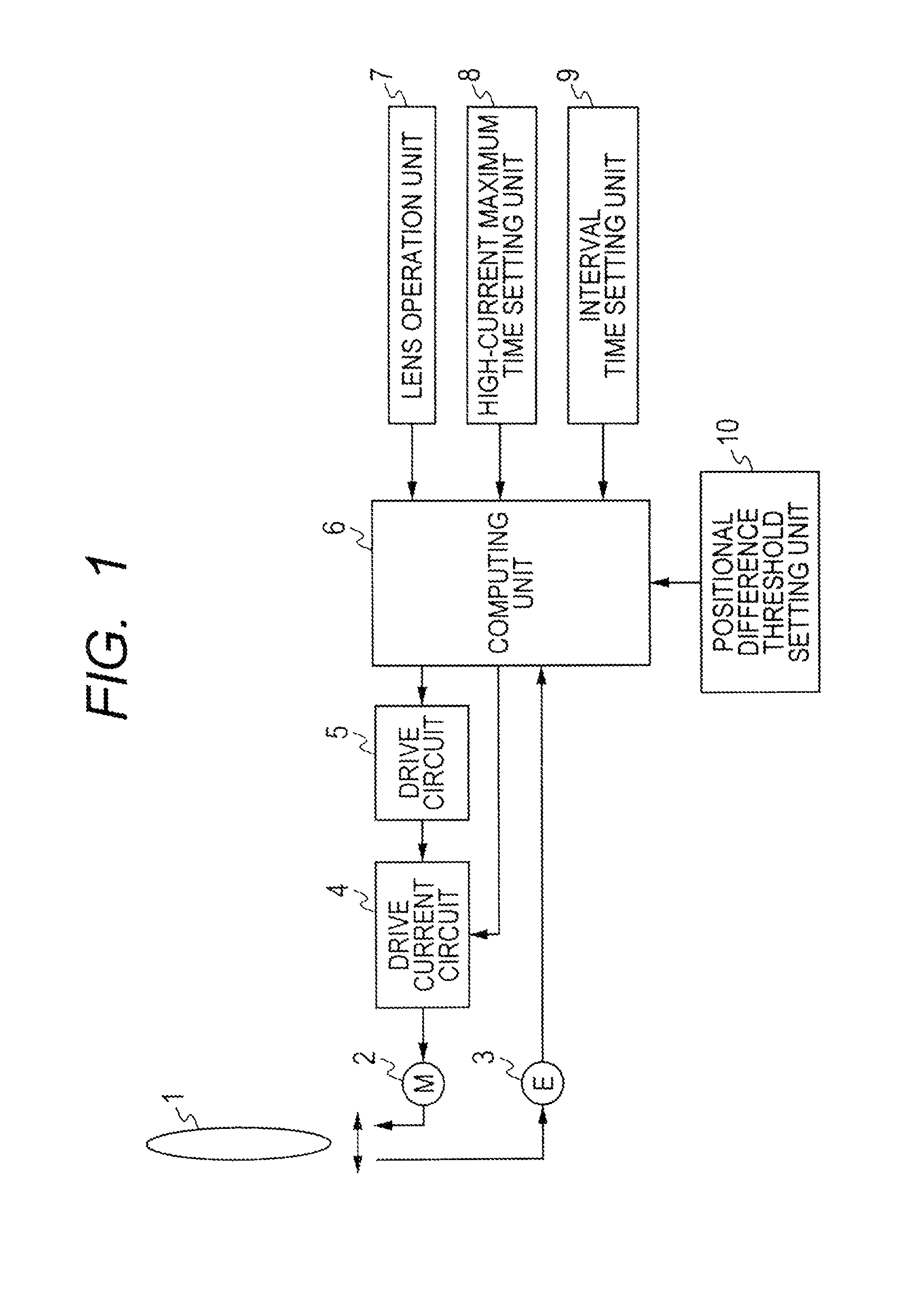

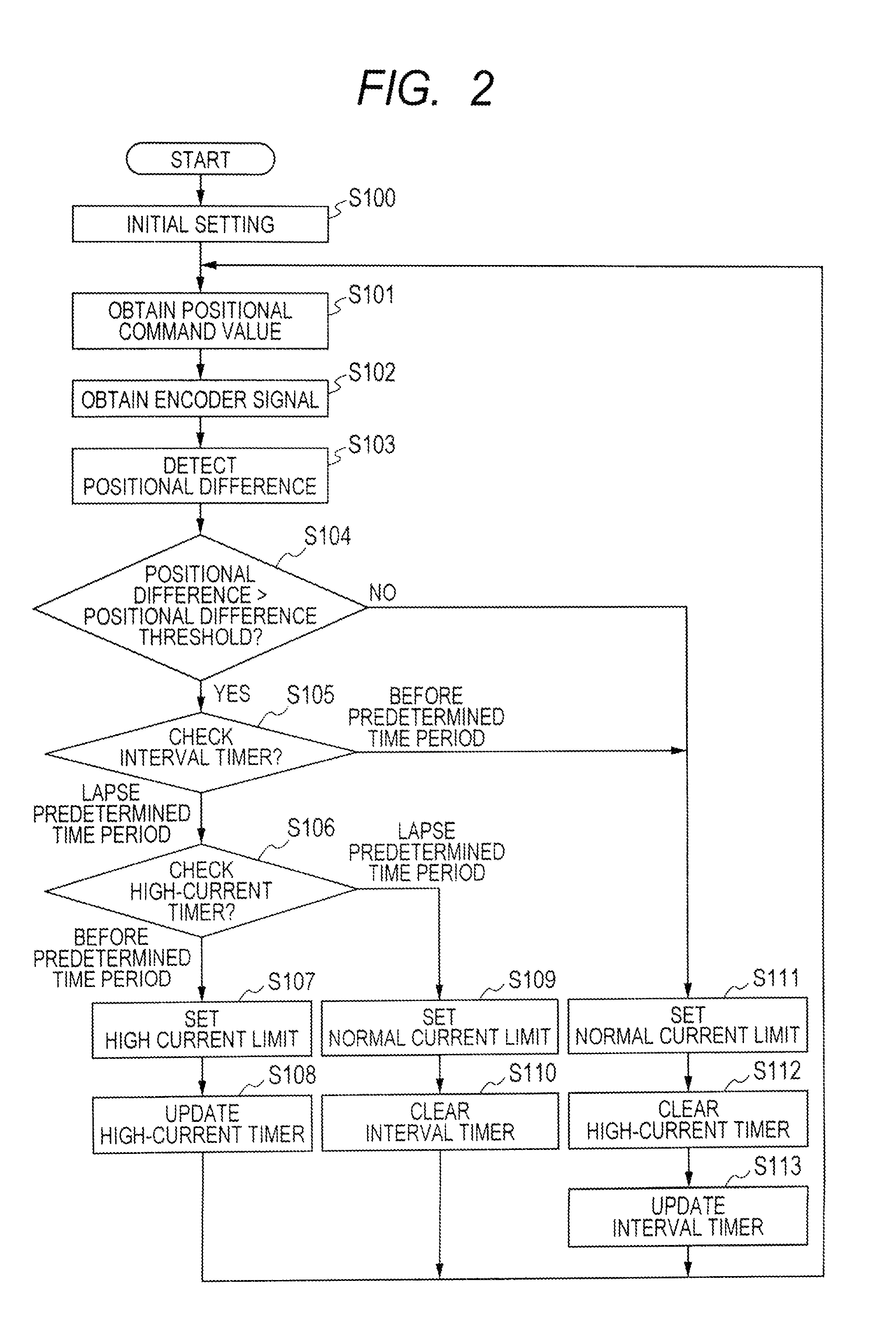

Lens system

InactiveUS8711490B2Improve featuresSignificant valueTelevision system detailsProjector focusing arrangementCamera lensValue set

A lens system includes: a lens unit; a drive unit driving the lens unit in an optical axis direction; a detector detecting a position of the lens unit; a lens operation unit that operates driving of the lens unit; and a computing unit that computes a positional command value for controlling driving of the lens unit based on a signal input from the lens operation unit and controls driving of the lens unit; a time setting unit; and a threshold setting unit setting a positional difference threshold for switching the first and second current values set in the drive unit. When the difference between the positional command value and the lens position is larger than the positional difference threshold and duration after the second current value is set has not exceeded the high-current maximum time, the second current value is set. In other cases, the first current value is set.

Owner:CANON KK

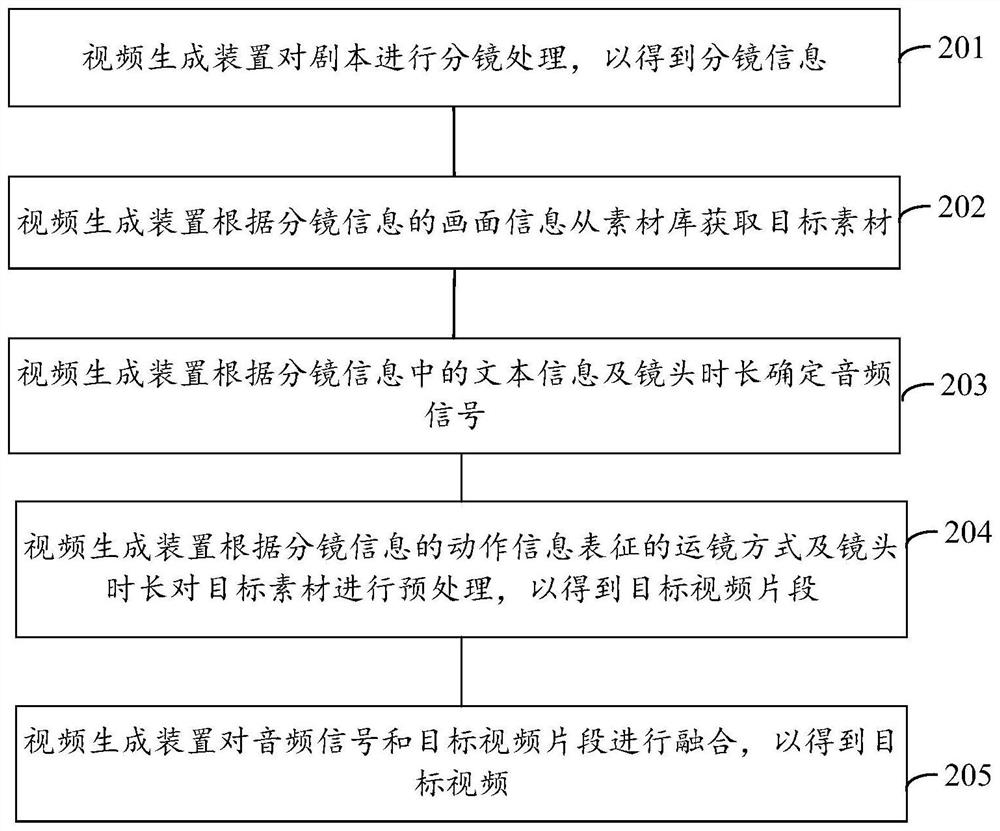

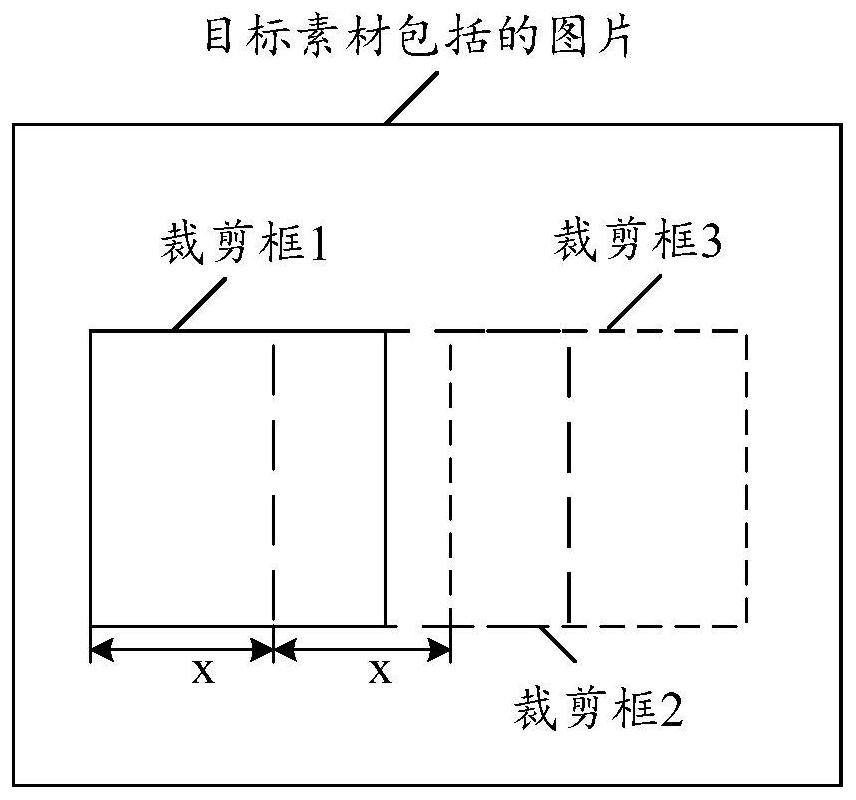

Video generation method and device, electronic equipment and storage medium

PendingCN114567819AVery different stylesIncrease contentSelective content distributionComputer graphics (images)Engineering

The embodiment of the invention discloses a video generation method and device, electronic equipment and a storage medium. The method comprises the following steps: carrying out mirror splitting processing on a script to obtain mirror splitting information; obtaining a target material from a material library according to the picture information of the split information; determining an audio signal according to the text information and the shot duration in the split mirror information; pre-processing the target material according to a lens operation mode and a lens duration represented by the action information of the lens splitting information to obtain a target video clip; and fusing the audio signal and the target video clip to obtain a target video. According to the embodiment of the invention, videos with different styles and rich contents can be obtained, and the video creation difficulty of a user is reduced.

Owner:CHINA PING AN LIFE INSURANCE CO LTD

Variable focal length lens device

ActiveUS10816755B2Efficiently formedEasy to modifyTelevision system detailsColor television detailsLens ControllerImage detection

A variable focal length lens device includes: a lens system whose refractive index is variable in response to an inputted drive signal; an image detector for detecting an image of a target object through the lens system; a lens controller for outputting the drive signal and an illumination signal; and a lens operation unit for adjusting a frequency and amplitude of the drive signal outputted by the lens controller and an image-detection timing for the image detector. The lens controller includes a resonance-lock controller for tuning the drive signal to a resonance frequency of the lens system. The lens operation unit includes a resonance-lock operation unit for switchably enabling and suspending the resonance-lock controller.

Owner:MITUTOYO CORP

Lens device, lens system, imaging device, movable lens operation device,lens driving method, and lens driving program

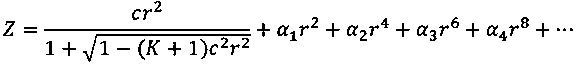

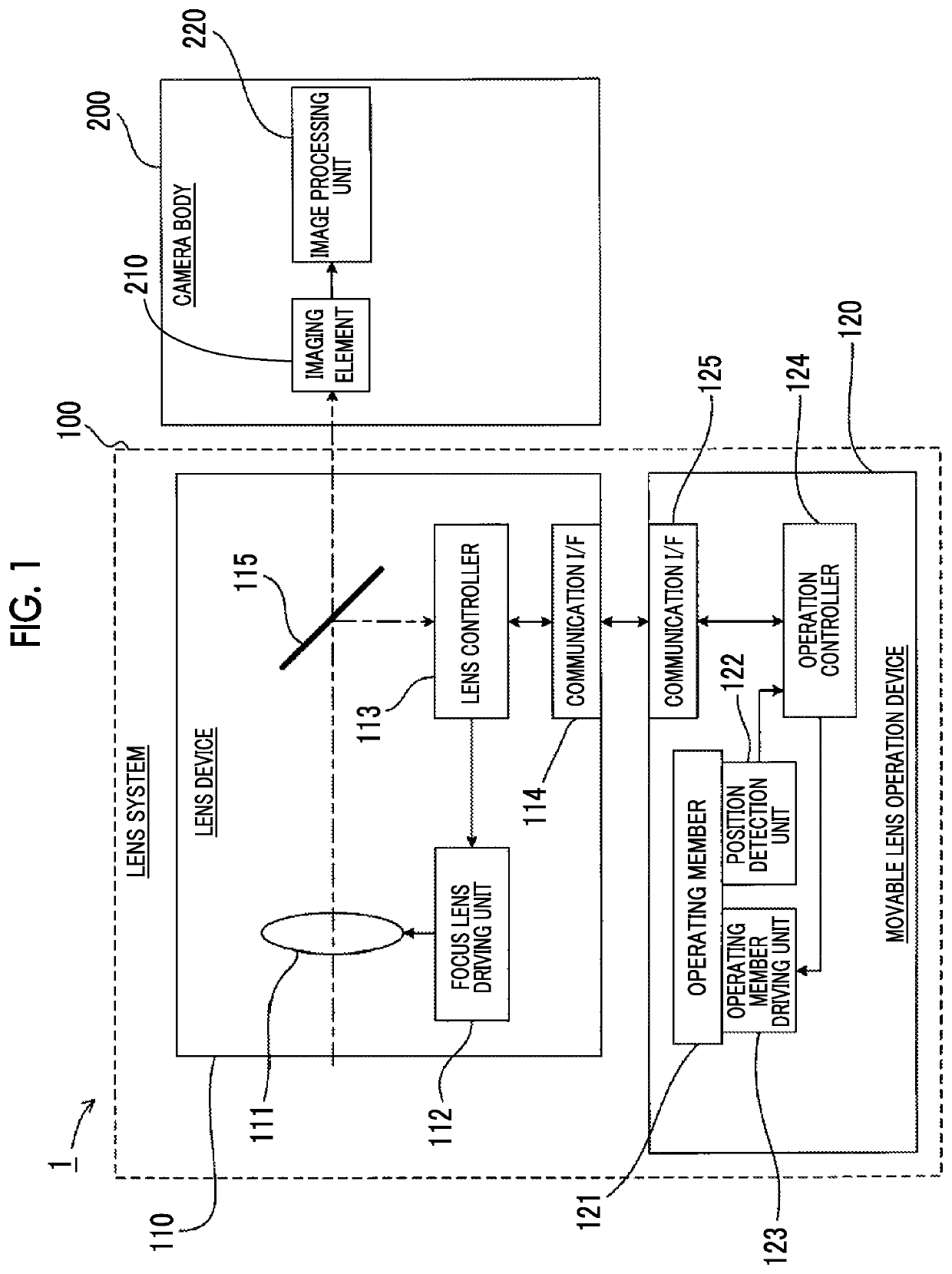

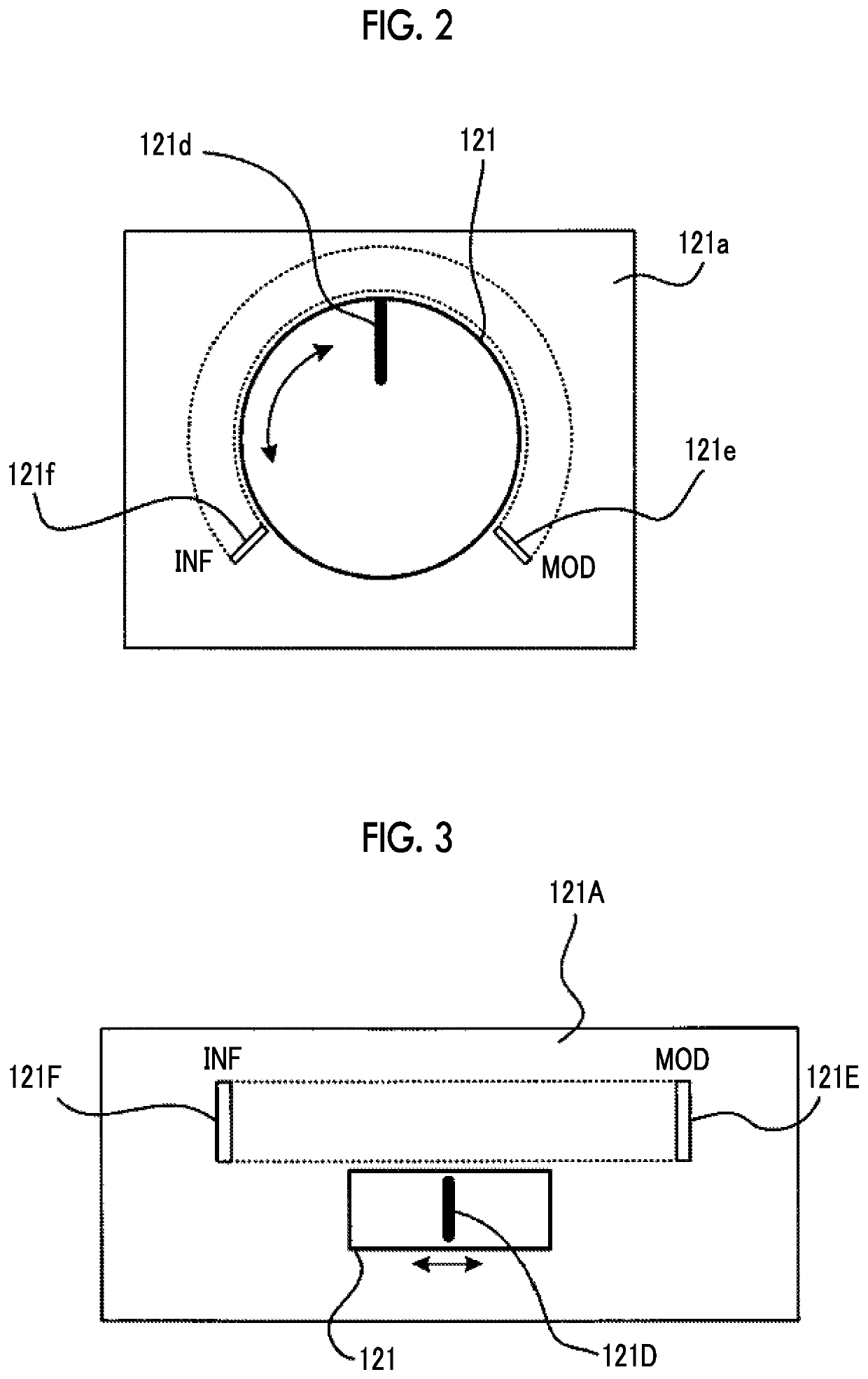

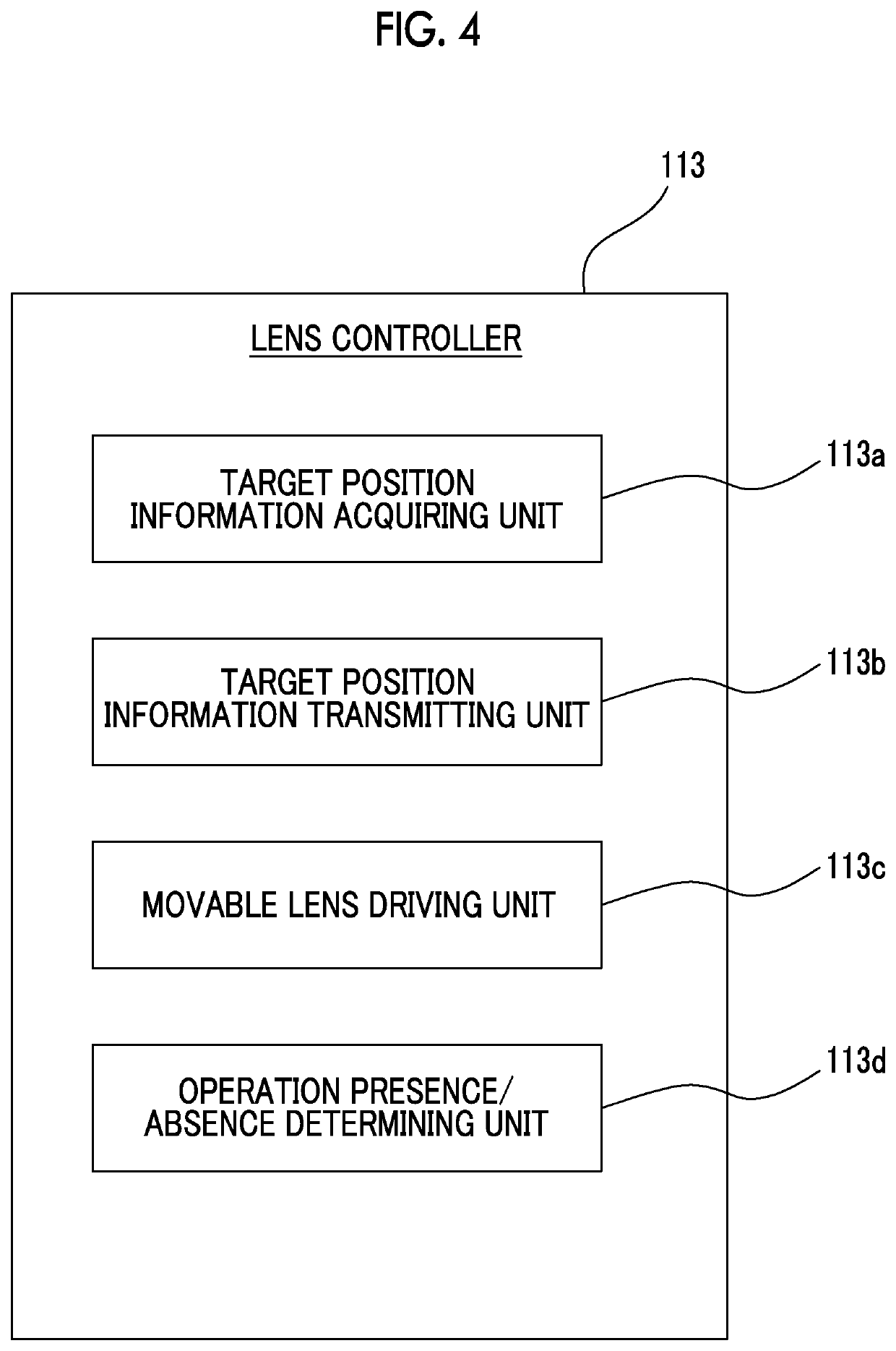

ActiveUS20190025541A1Simple processProjector focusing arrangementCamera focusing arrangementCamera lensOptical axis

A lens device includes: a movable lens capable of being moved in a direction of an optical axis; a target position information acquiring unit that acquires information of a target position of the movable lens; a target position information transmitting unit that transmits the information of the target position to a movable lens operation device including a movable operating member for moving the movable lens and an operating member driving unit that drives the operating member; and a movable lens driving unit that performs first driving for moving the movable lens based on a position of the operating member detected by an operating member position detection unit that detects the position of the operating member, and the operating member driving unit drives the operating member based on the information of the target position.

Owner:FUJIFILM CORP

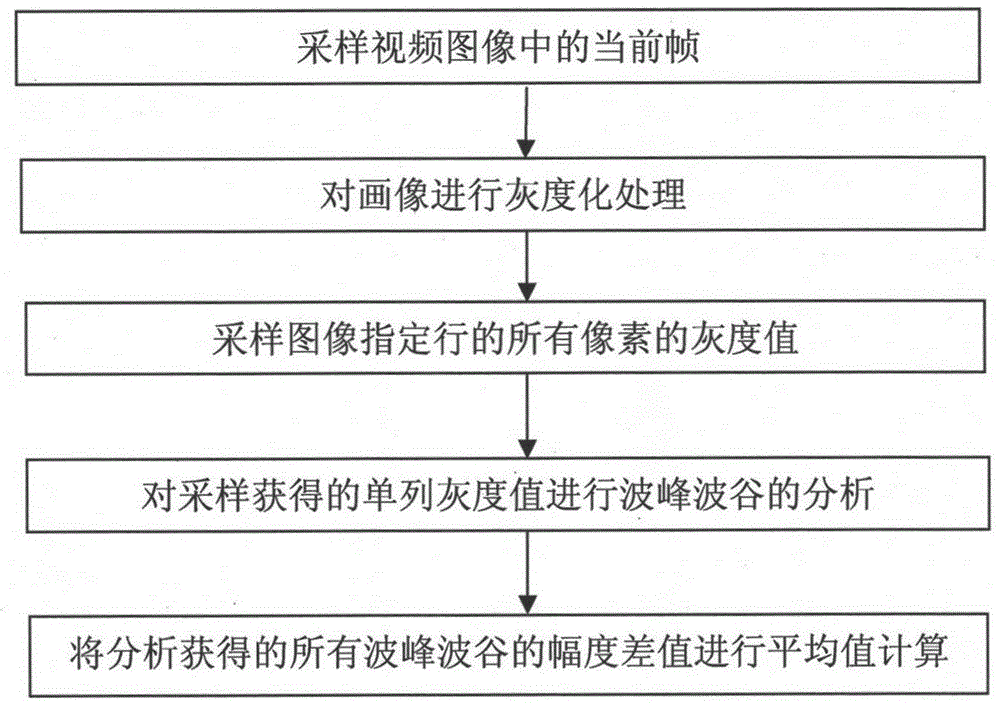

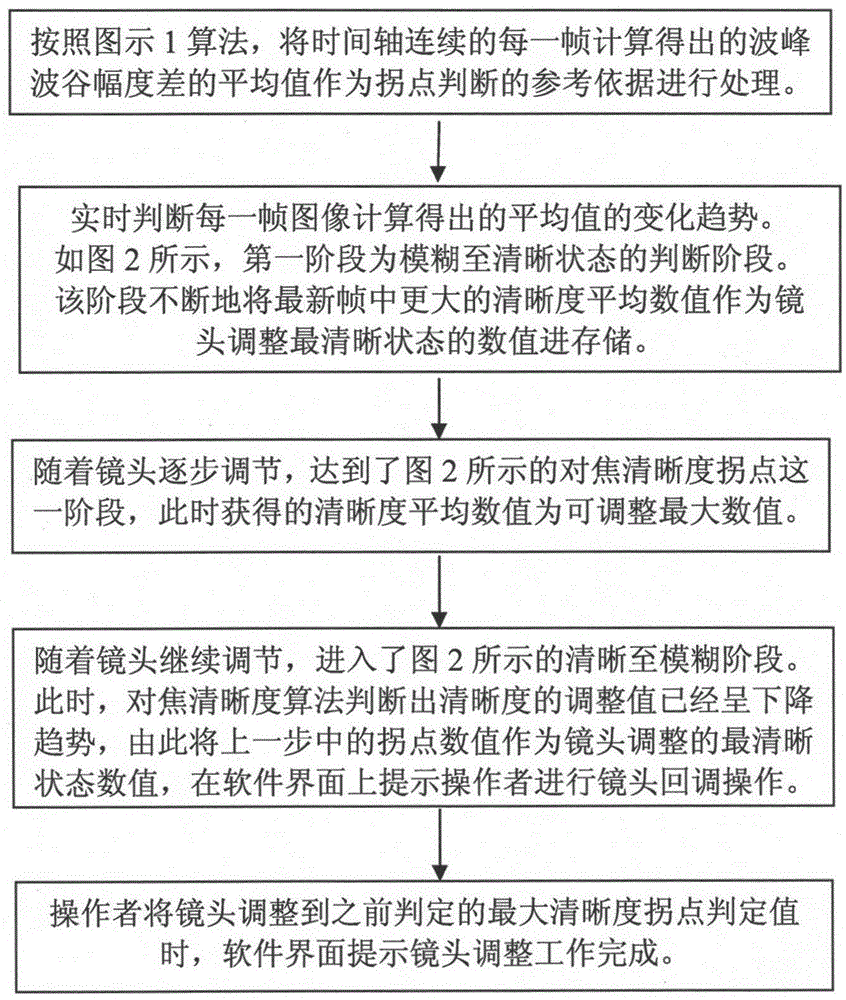

Automatic adjustment method of focus sharpness

ActiveCN104065852BHigh adjustment accuracyReduce labor costsTelevision system detailsColor television detailsDigital signal processingImaging processing

The invention relates to a method for automatically adjusting focus definition. The steps include: connecting a video device to be detected, sampling the image of the video device in real time, and performing digital image processing and analysis on each sampled frame of portrait. In the image processing link, the sampled image is first grayscaled and homogenized, and the original image is converted into an image that can be processed for data analysis. After that, the innovative algorithm of the present invention is used to judge the current sharpness of the lens based on the detection algorithm of the peak and valley inflection points of the image. The present invention can quickly and accurately complete the focusing operation of the equipment lens, and the theoretical value of the number of image sampling frames for dynamic video images can reach 100 frames per second. At the same time, the focus definition adjustment accuracy is high. Through the invention, the precision of focusing adjustment of the video equipment is improved, and the labor cost of the station is reduced at the same time.

Owner:SHANGHAI SUOGUANG VISUAL PRODUCTS CO LTD

Auxiliary mechanical arm for soft lens operation

The invention discloses an auxiliary mechanical arm for a soft lens operation. The auxiliary mechanical arm comprises a base, a vertical up-and-down mechanical arm, a horizontal left-and-right mechanical arm, a front-and-back telescopic mechanical arm, a soft lens clamping device, an up-and-down dimension drive motor, a left-and-right dimension drive motor, a front-and-back dimension drive motor, a rotary shaft dimension drive motor and a soft lens shifting disc drive motor. The invention further discloses a method for achieving the auxiliary mechanical arm for the soft lens operation. The auxiliary mechanical arm solves the problems that in the prior art, multi-directional manipulation of a flexible instrument cannot be achieved, complex operation conditions cannot be handled, the matching effect of an existing mechanical arm and the flexible instrument is poor, and the hands of a doctor tremble when the doctor conducts an operation. The auxiliary mechanical arm has the advantages of being simple in structure, low in manufacturing cost, and suitable for the soft lens operation, capable of being used for handling the complex operation conditions, capable of achieving five-dimension motion of a soft lens, good in using effect and the like.

Owner:吴开俊 +1

Operation equipment of high-precision optical lens

PendingCN114749338AHigh precisionAchieve high precision placementLiquid surface applicatorsGripping headsEngineeringSlide plate

A high-precision optical lens operation device disclosed by the present invention comprises a transverse device and a vacuum machine, the transverse device comprises a group of fixed guide rails and a transverse sliding plate slidably connected to the fixed guide rails through a stator and a rotor, and the transverse sliding plate is further slidably connected with a lifting plate through a stator and a rotor. The operation equipment comprises a transverse alignment structure, a dispensing structure and a grabbing structure, lenses to be assembled only need to be placed at material taking positions, accurate alignment is carried out on an assembly area through a downward vision module and a downward laser measurement module of the alignment structure, and under vision measurement and laser measurement, the assembly efficiency is greatly improved. Rapid and high-precision measurement of the relative position relation is achieved, high-precision placement is achieved, so that subsequent adjustment is reduced, the production efficiency is improved, after one-time precise alignment of the alignment structure is conducted, the work actions of placement and dispensing can be completed on the same mechanism, the problems of repeated alignment and deviation are avoided, and the production efficiency is improved. And the assembly precision in the assembly process is ensured to the maximum extent.

Owner:珠海市硅酷科技有限公司

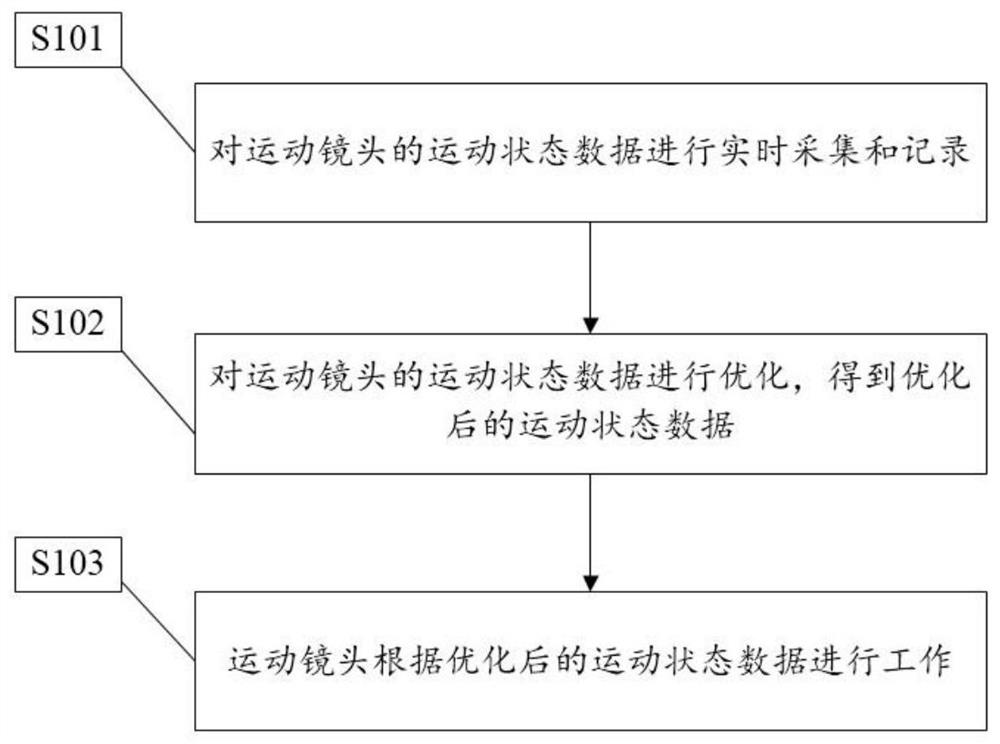

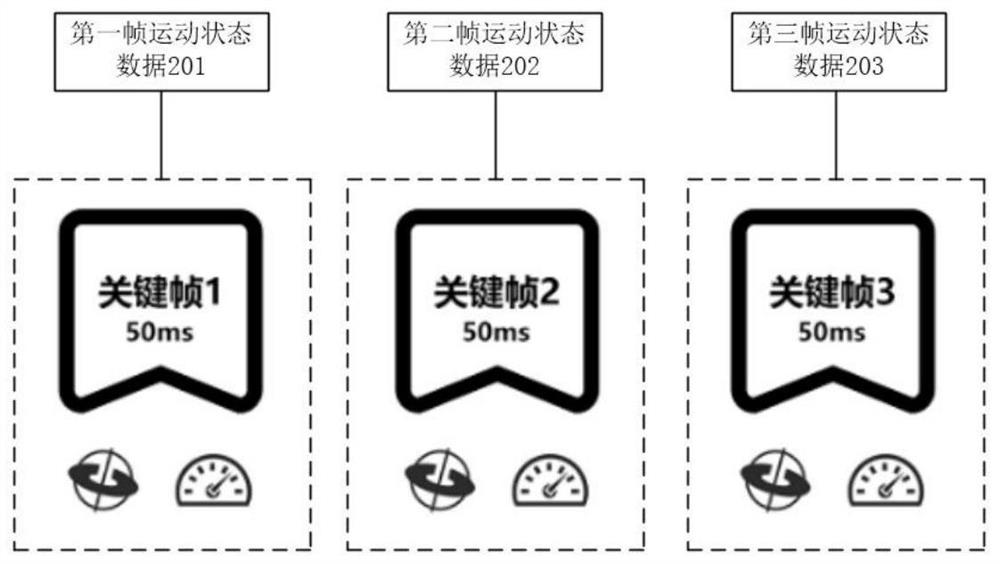

Working method and system of motion lens, and device with storage function

The invention discloses a working method of a moving lens, comprising the following steps: collecting and recording the moving state data of the moving lens in real time; optimizing the moving state data of the moving lens to obtain the optimized moving state data; The motion lens works according to the optimized motion state data. In the working method of the moving lens provided by the present invention, the movement process of the lens is recorded in the form of data, and optimized according to the actual situation, so that the posture and movement of each lens can be precisely controlled, the instability of artificial shooting can be eliminated, and the accuracy can be achieved. , The effect of stabilizing the shooting.

Owner:北京优必选智能机器人有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com