Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

34 results about "Flexible impeller" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

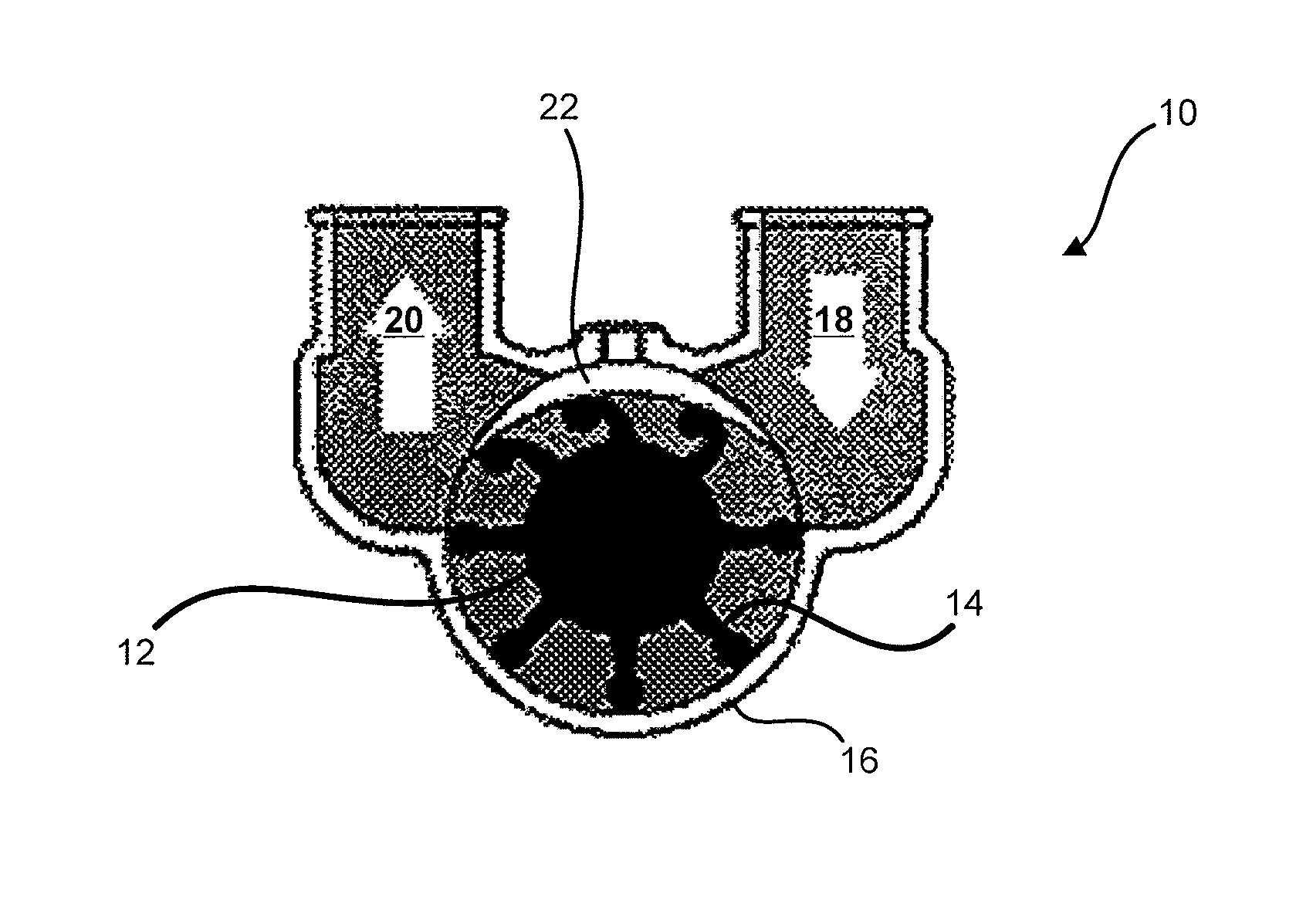

A flexible impeller pump is a positive-displacement pump that, by deforming impeller vanes, draws the liquid into the pump housing and moves it to the discharge port with a constant flow rate. The flexibility of the vanes enables a tight seal to the internal housing, making the pump self-priming, while also permitting bi-directional operation. The output from these pumps tends to be smooth or gentle when compared to the operation of a reciprocating pump (for example). In 1938, Arthur M. Briggs filed a patent for this type of pump.

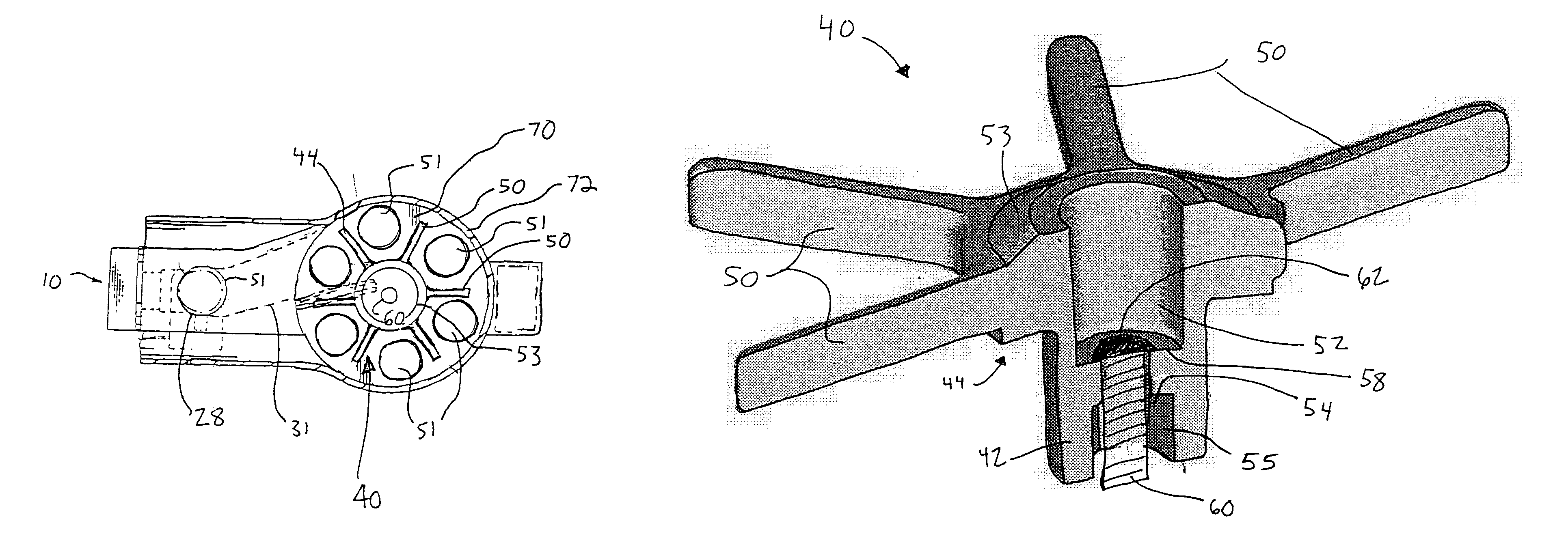

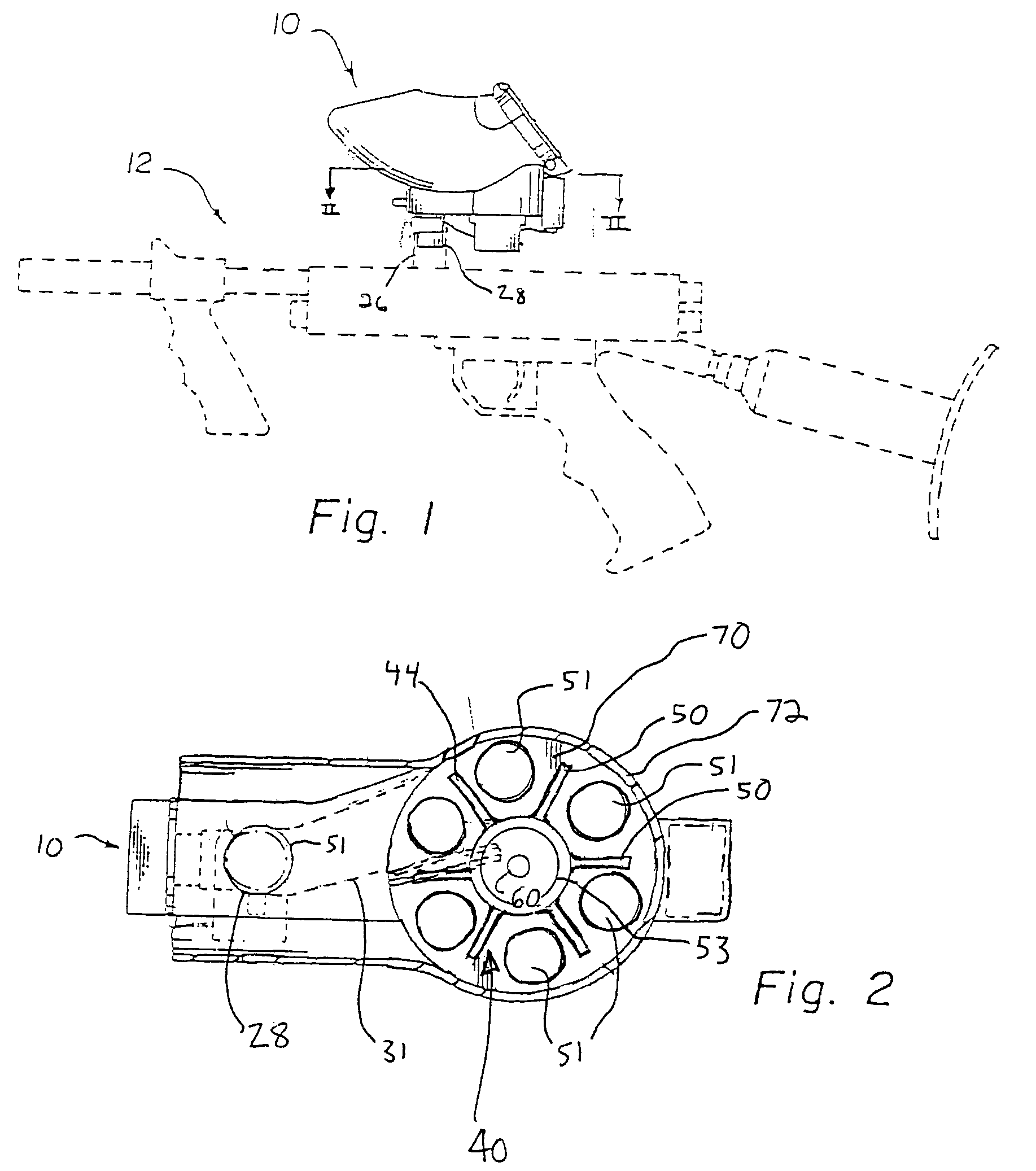

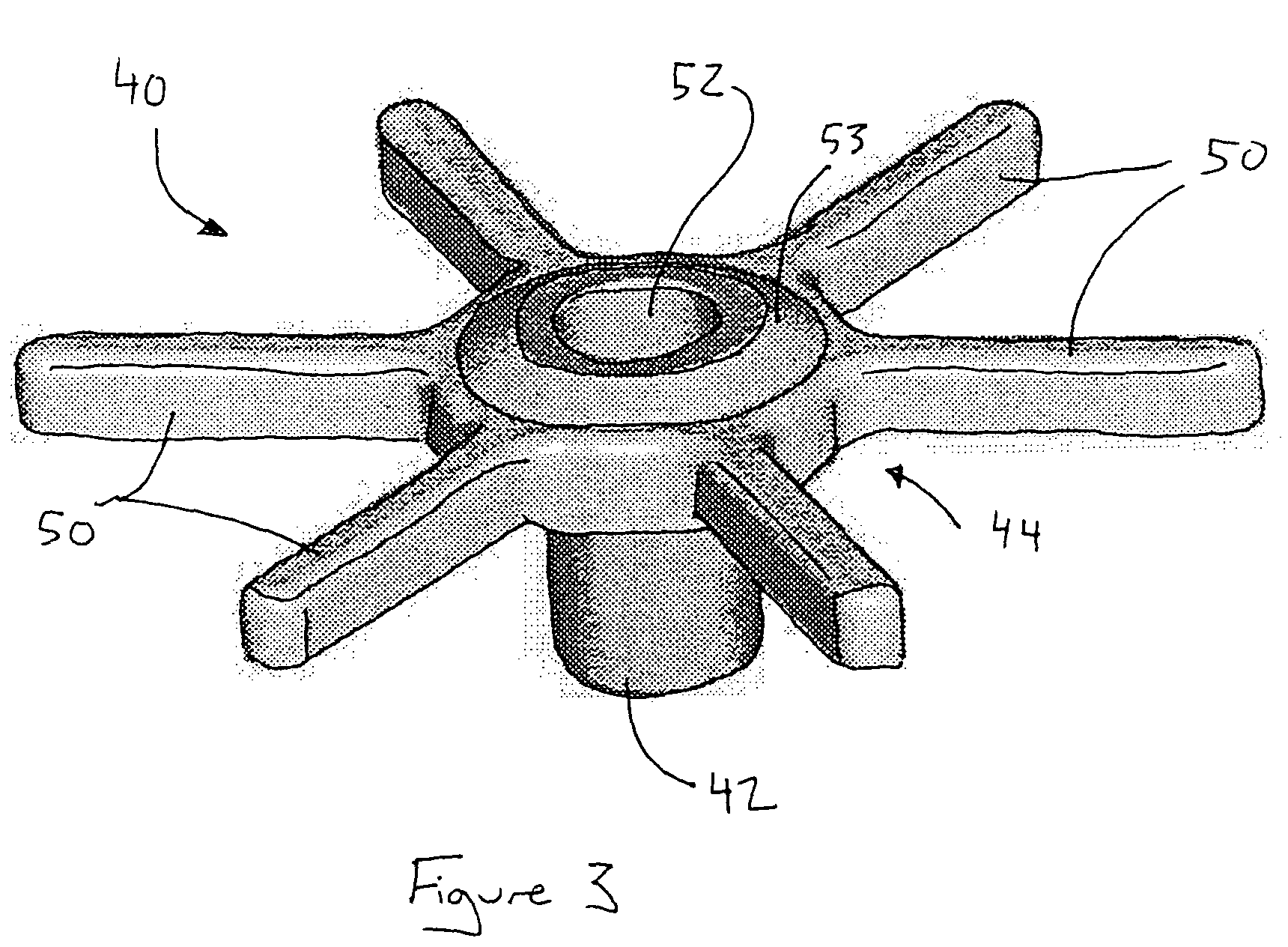

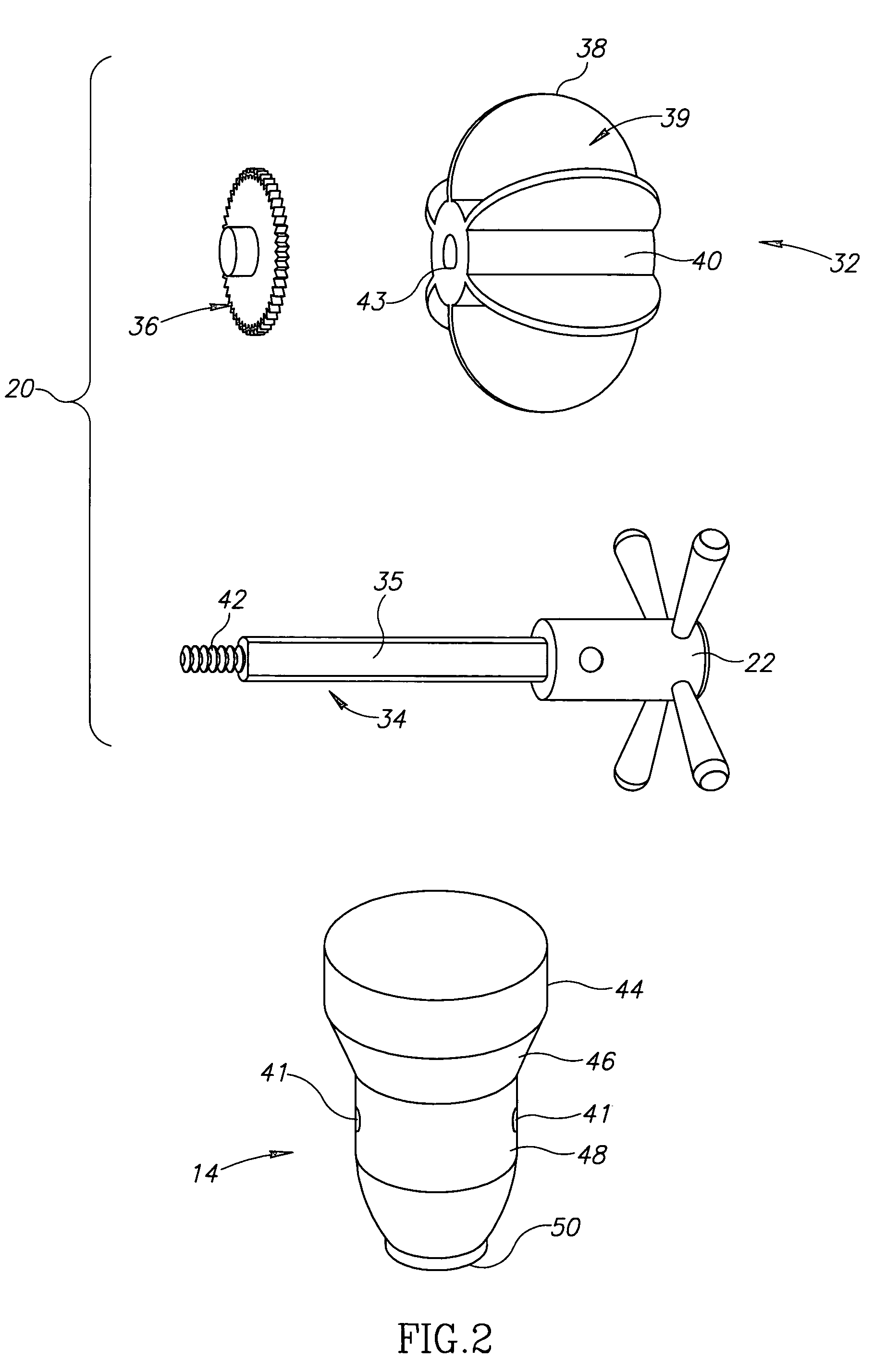

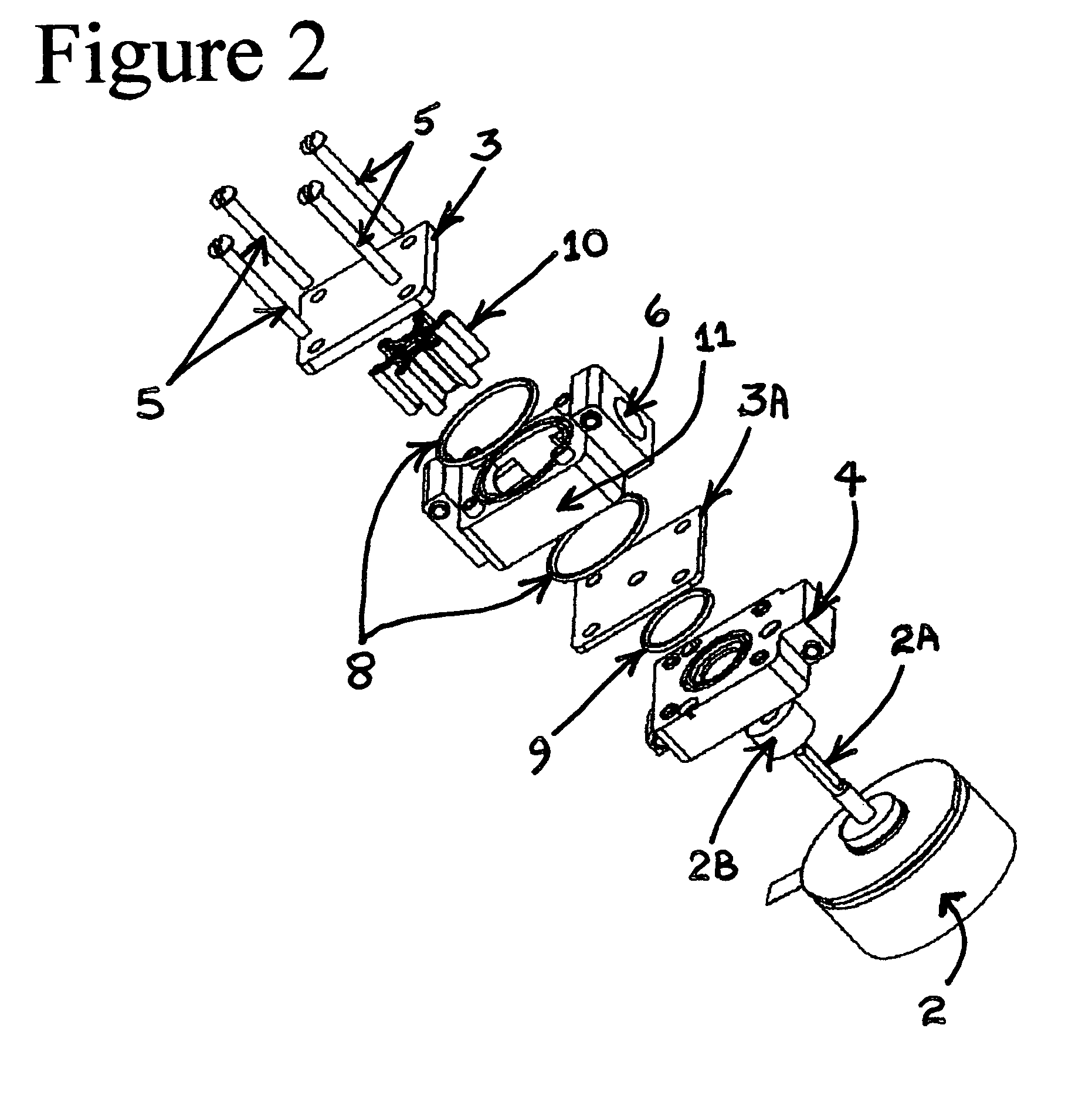

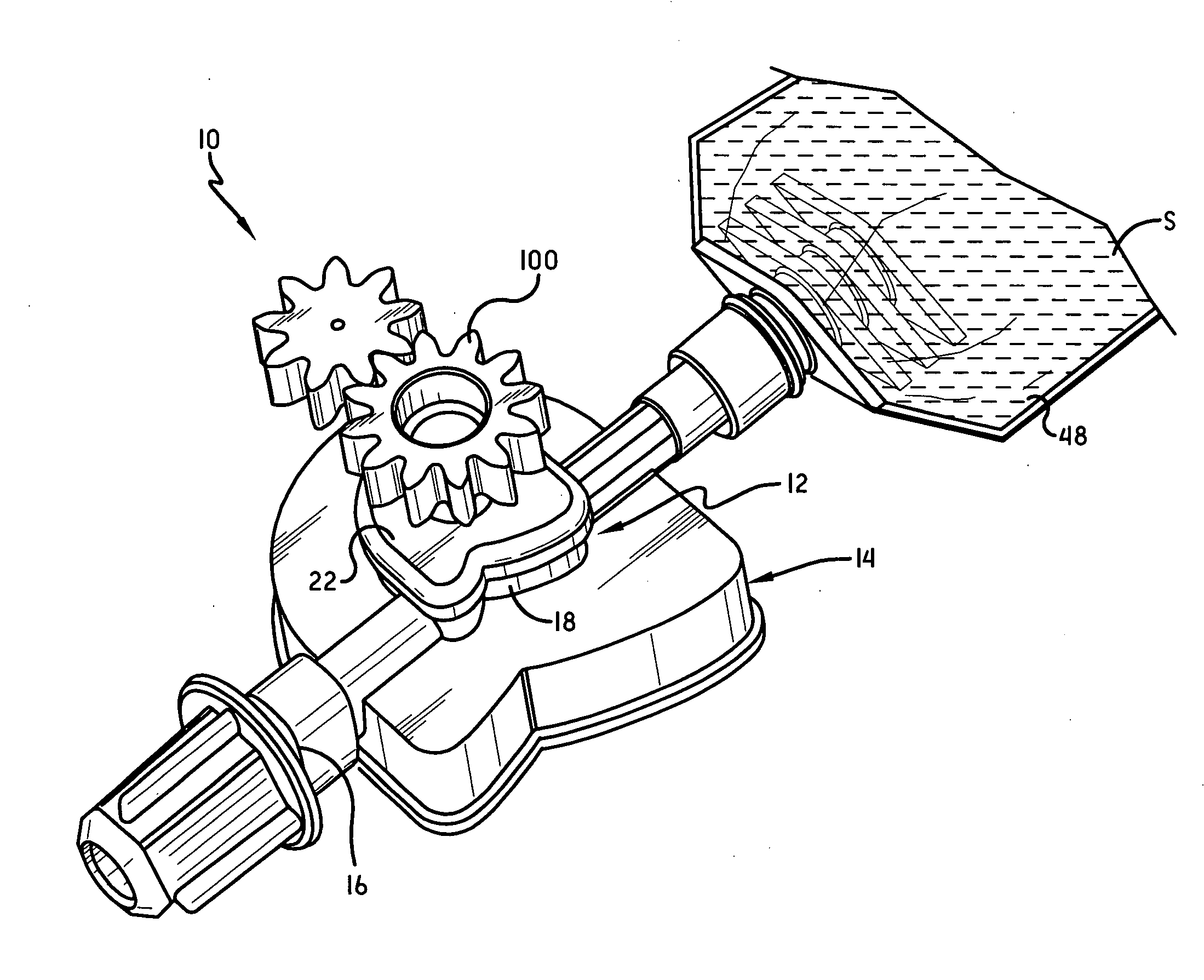

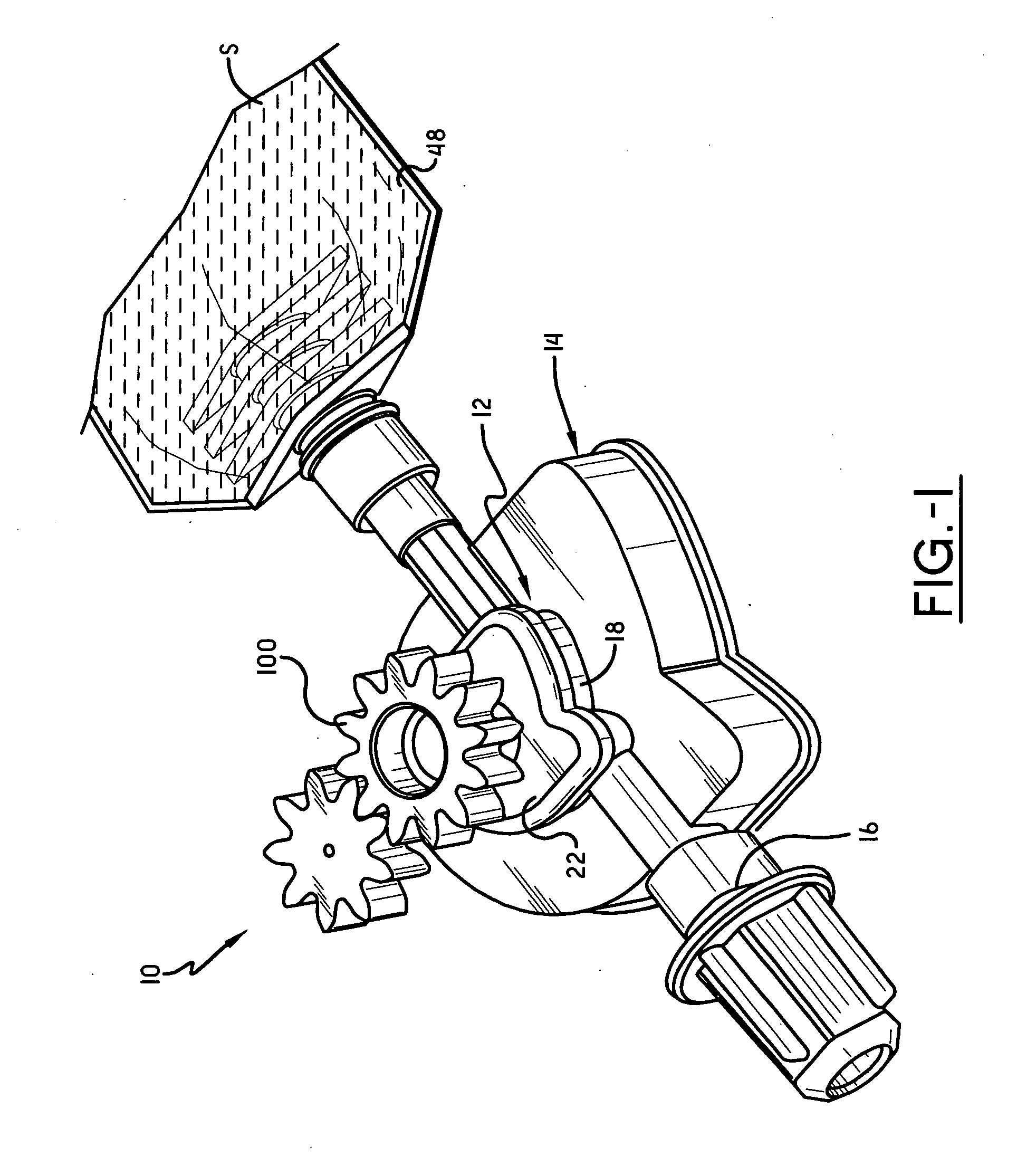

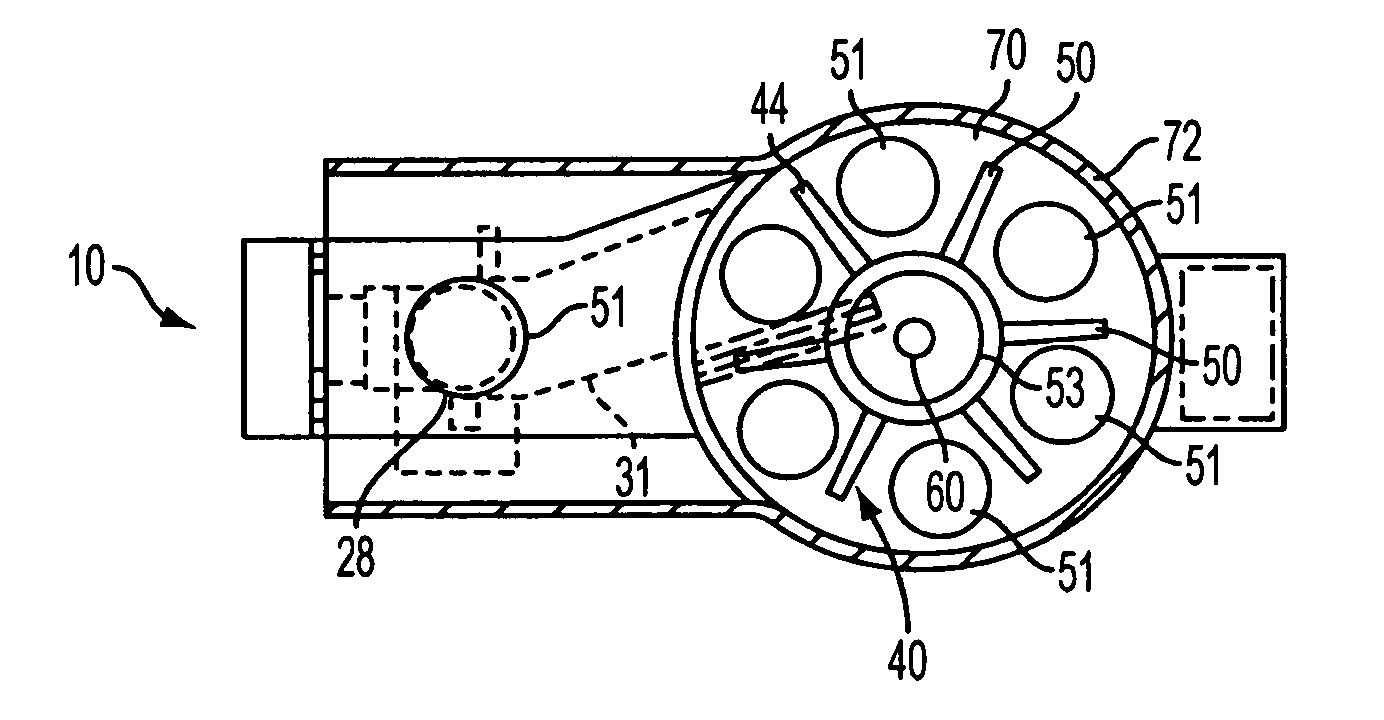

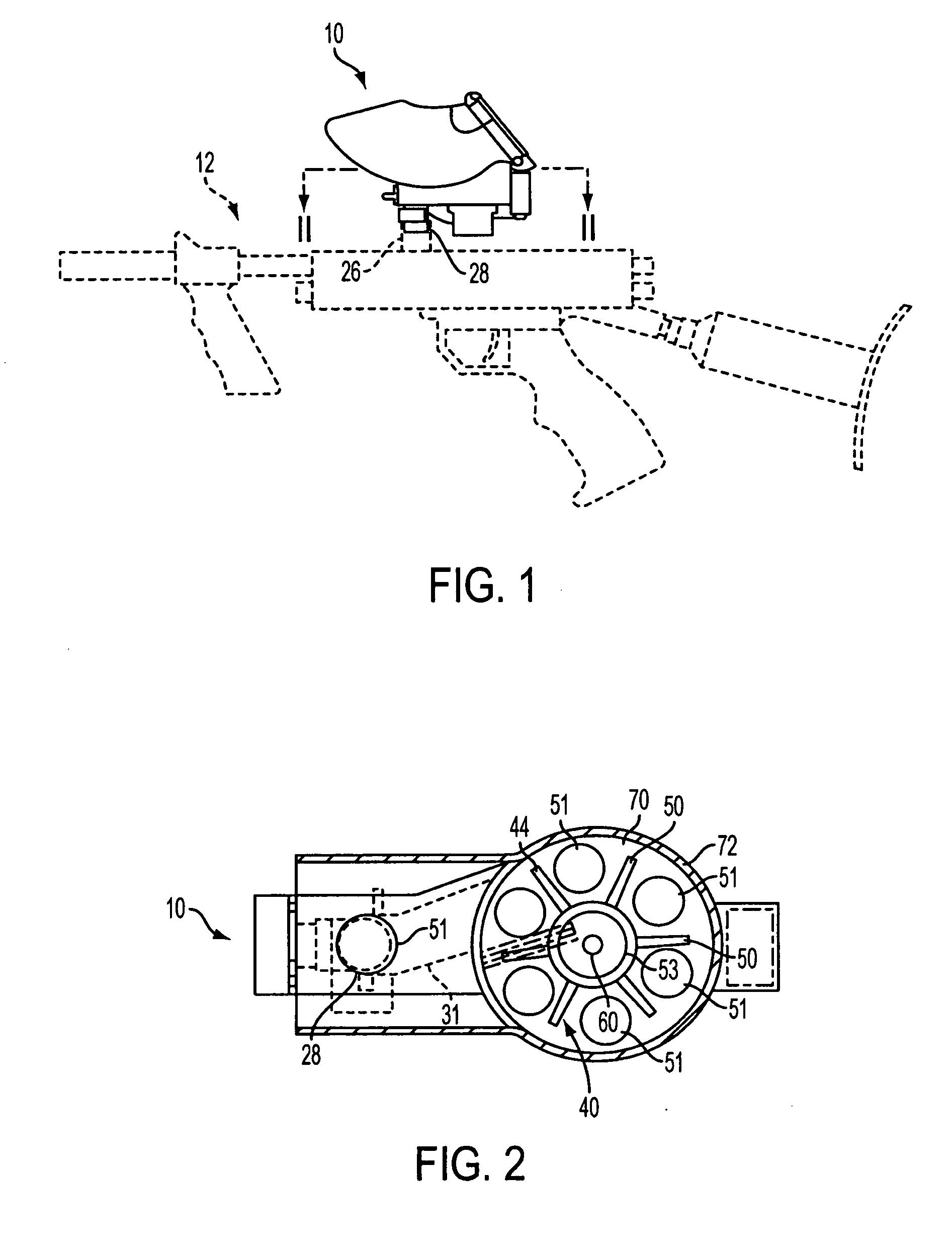

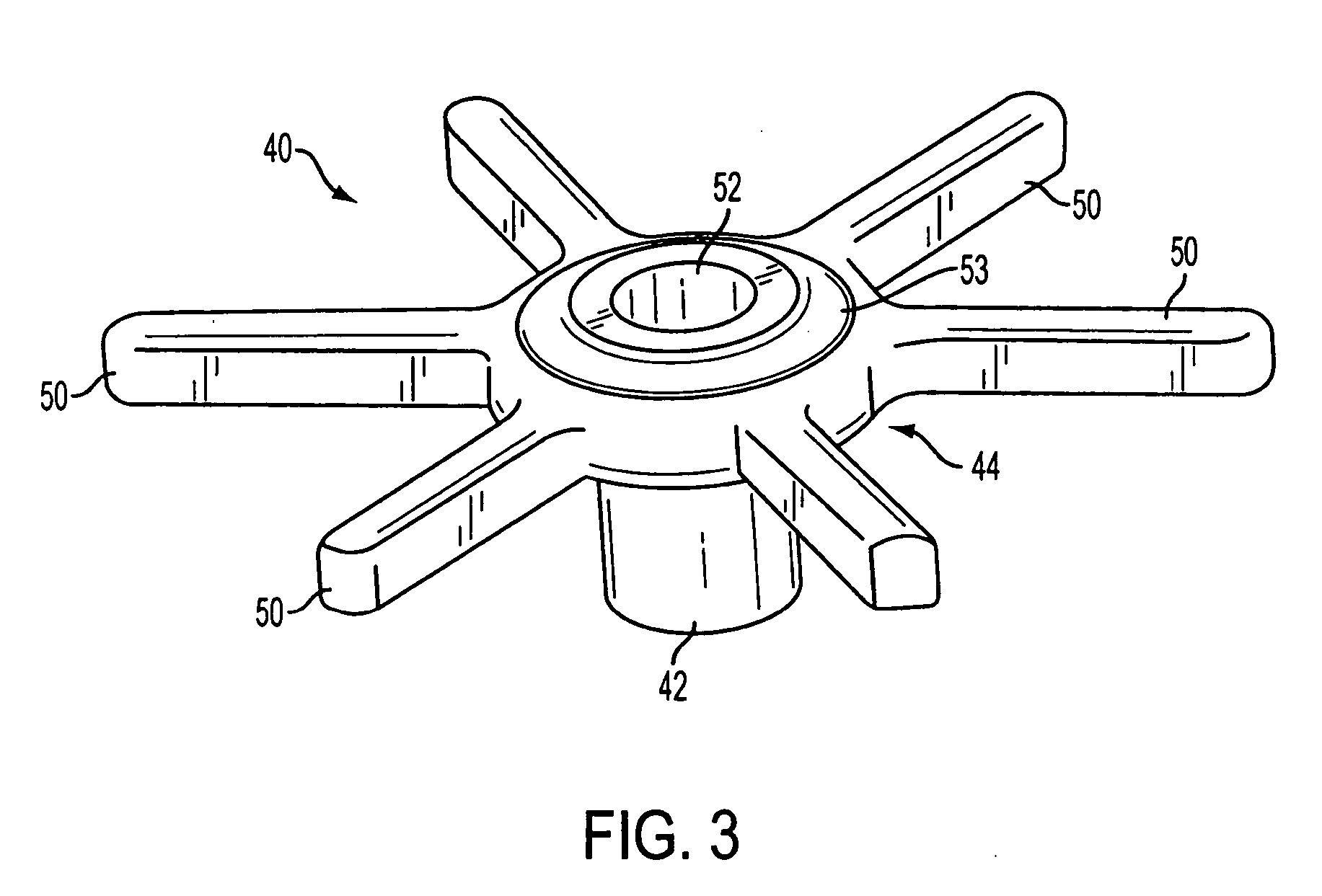

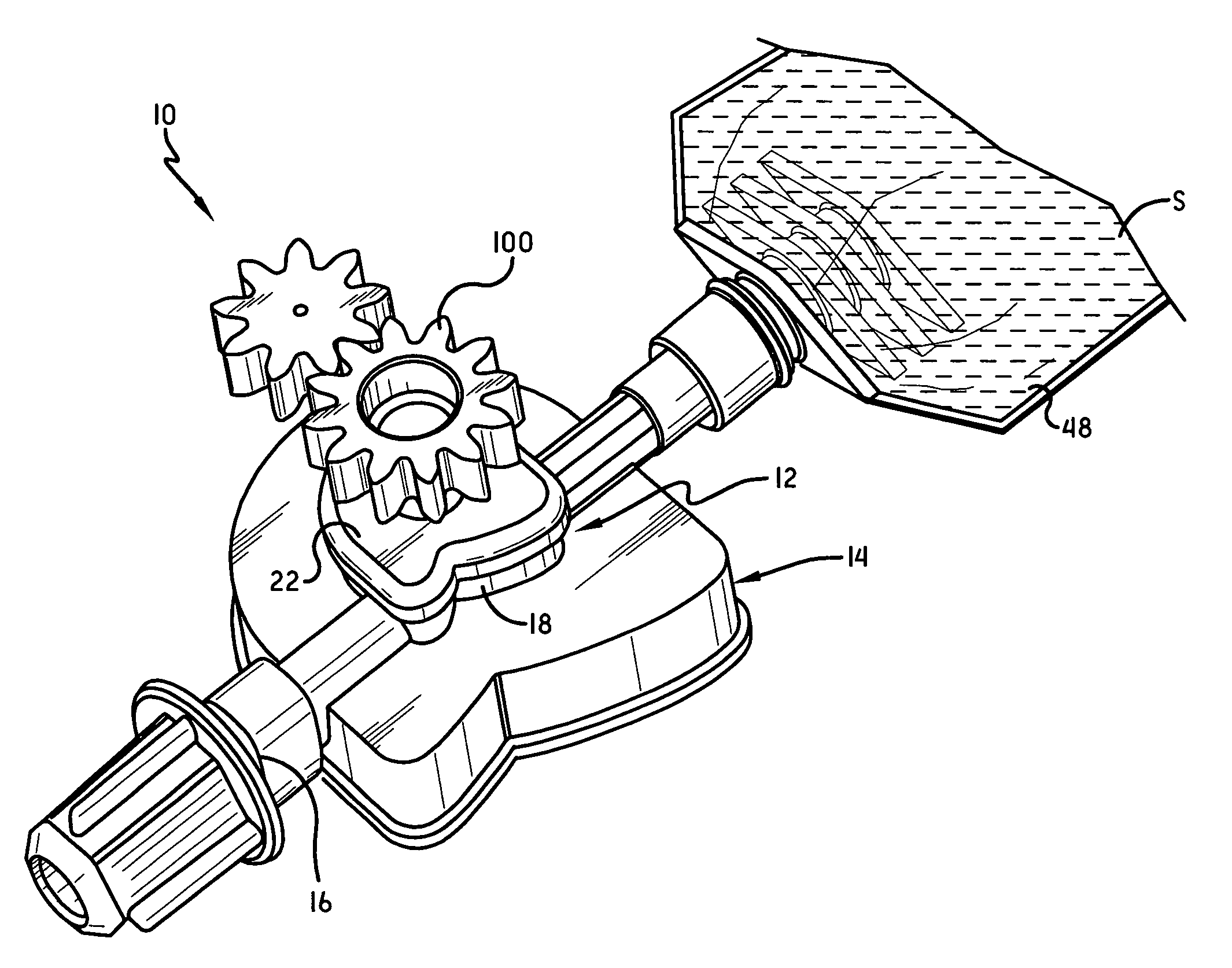

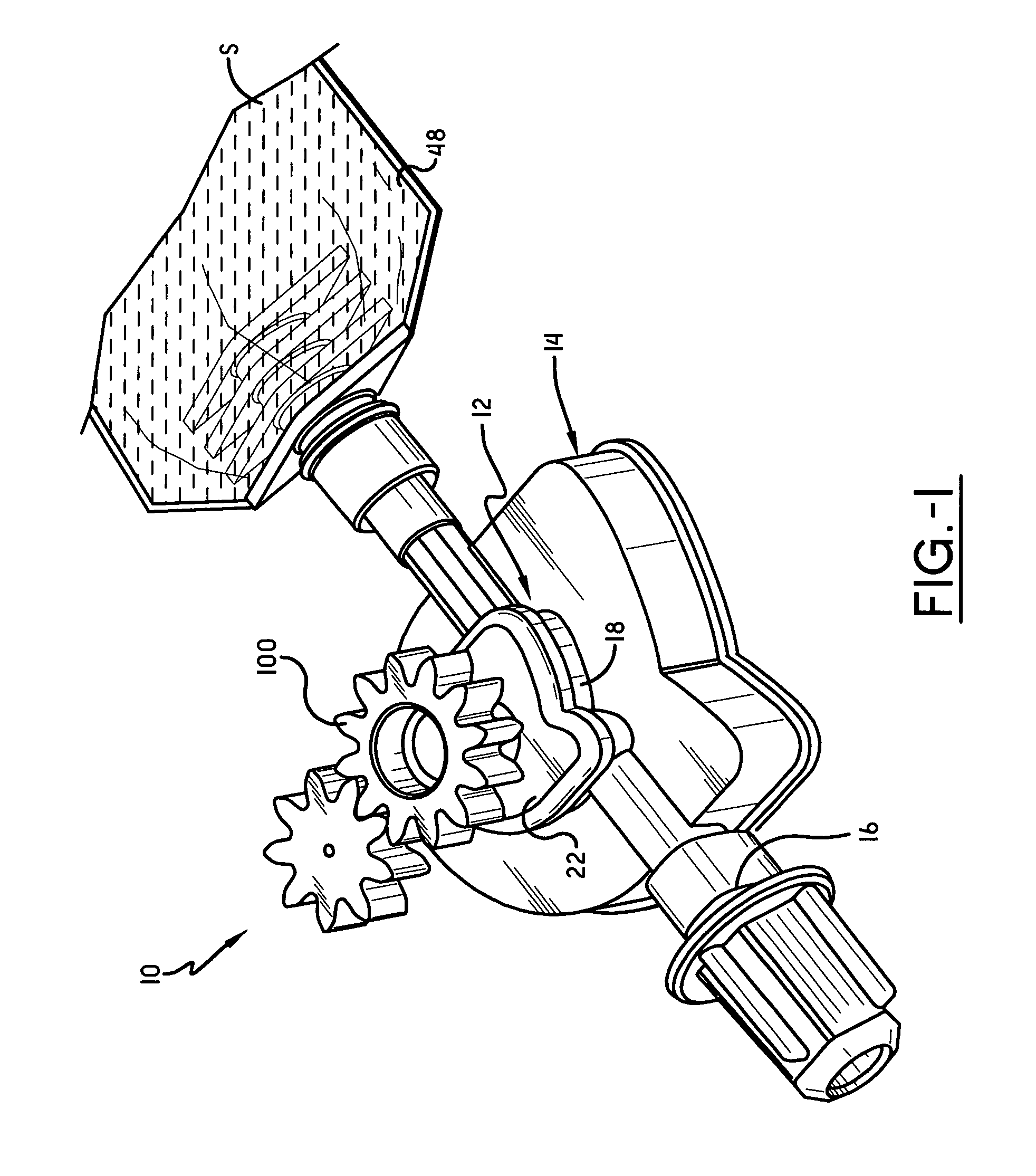

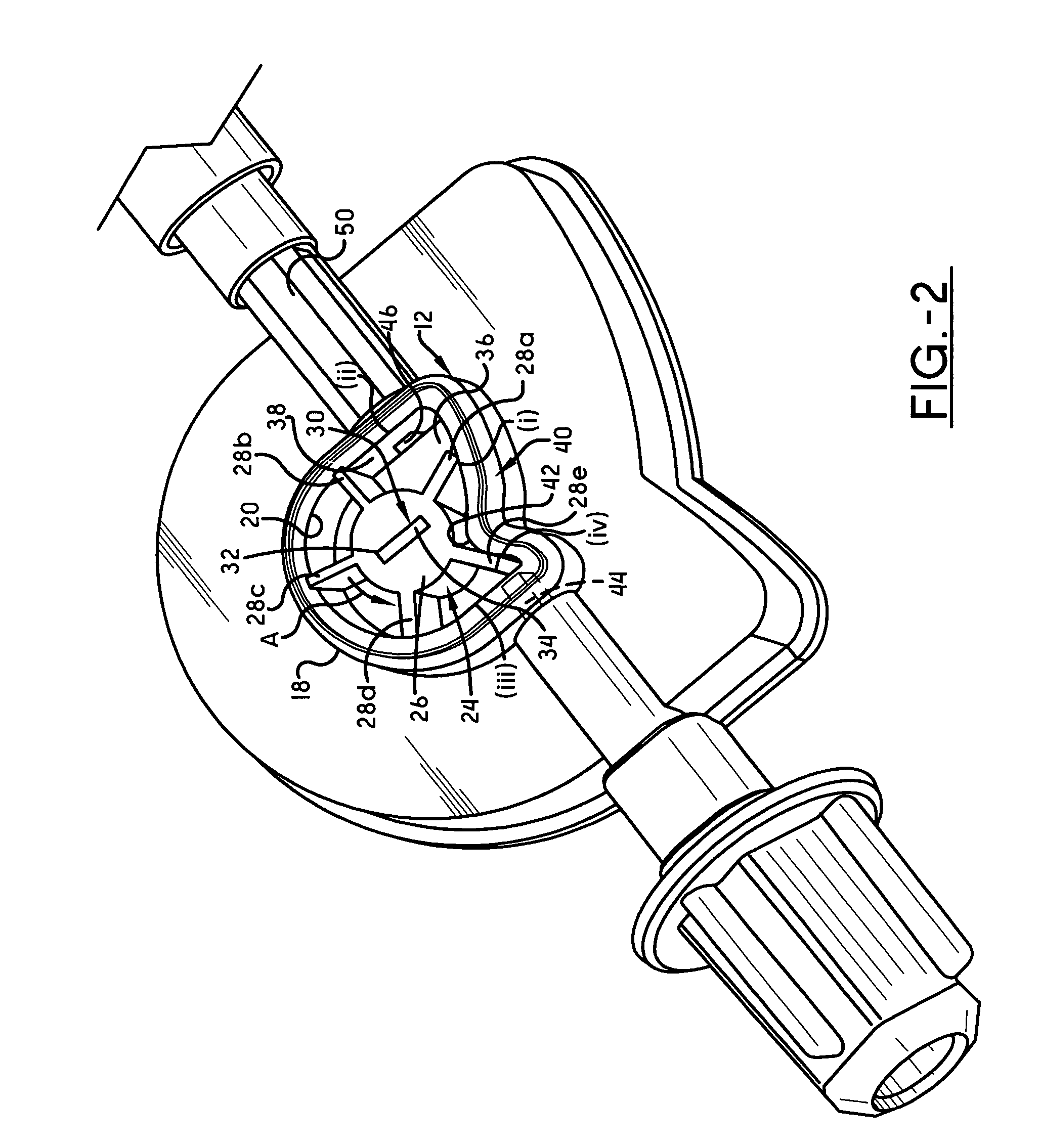

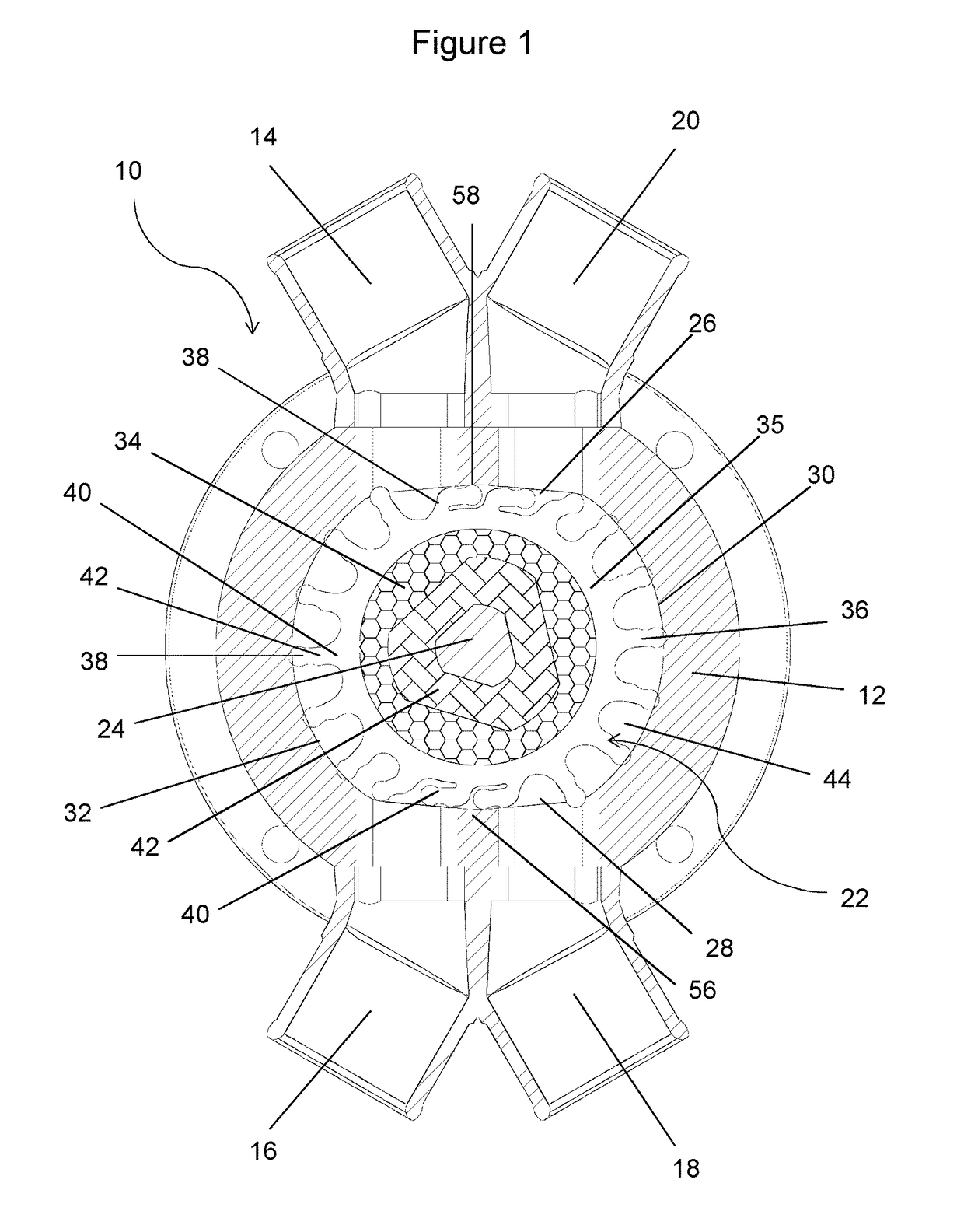

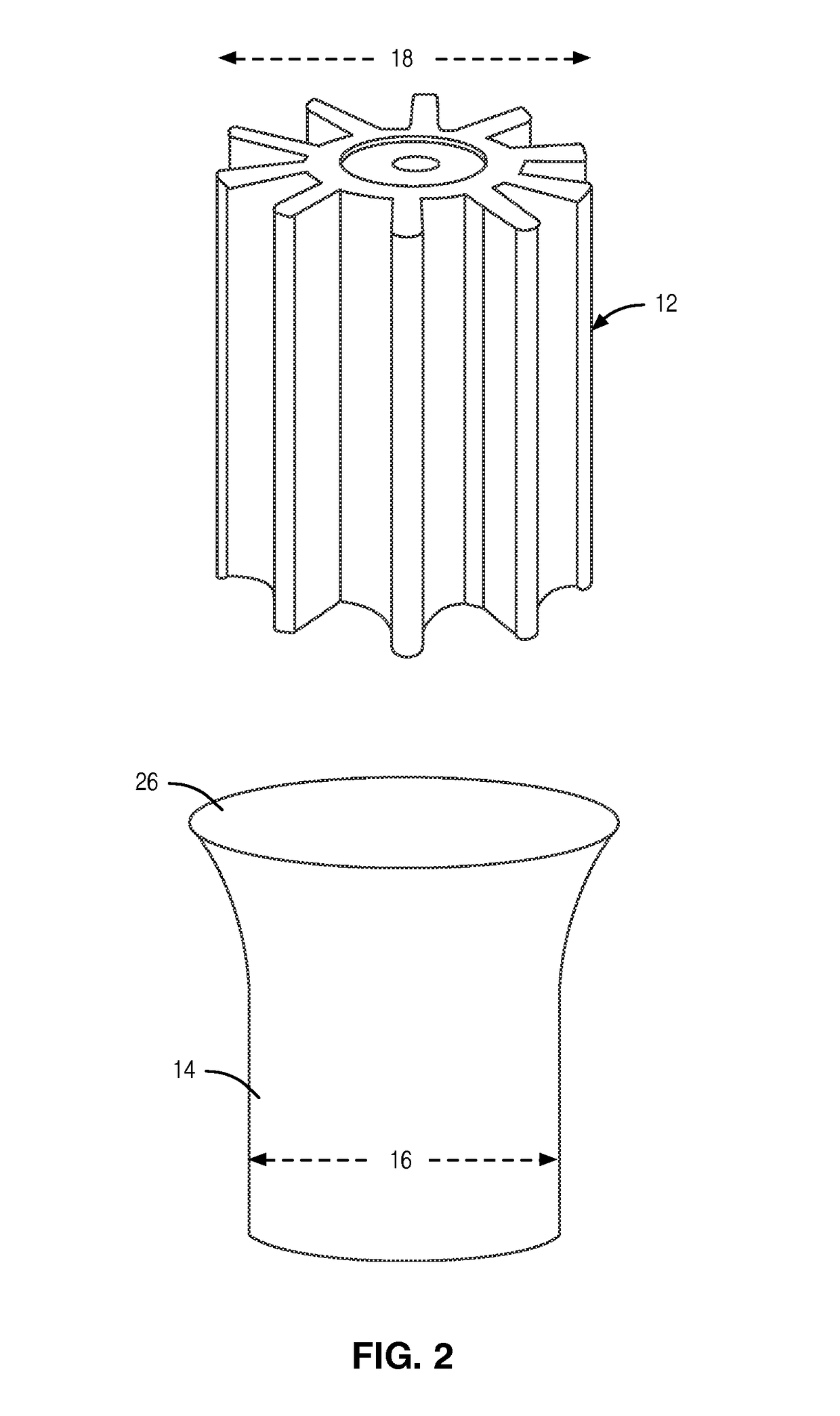

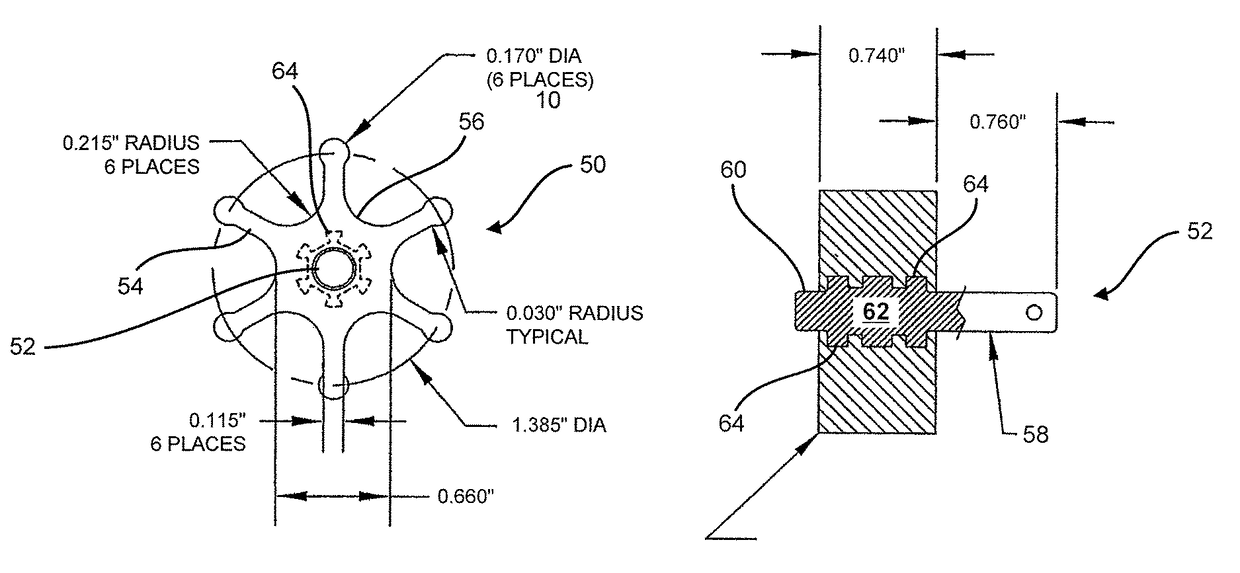

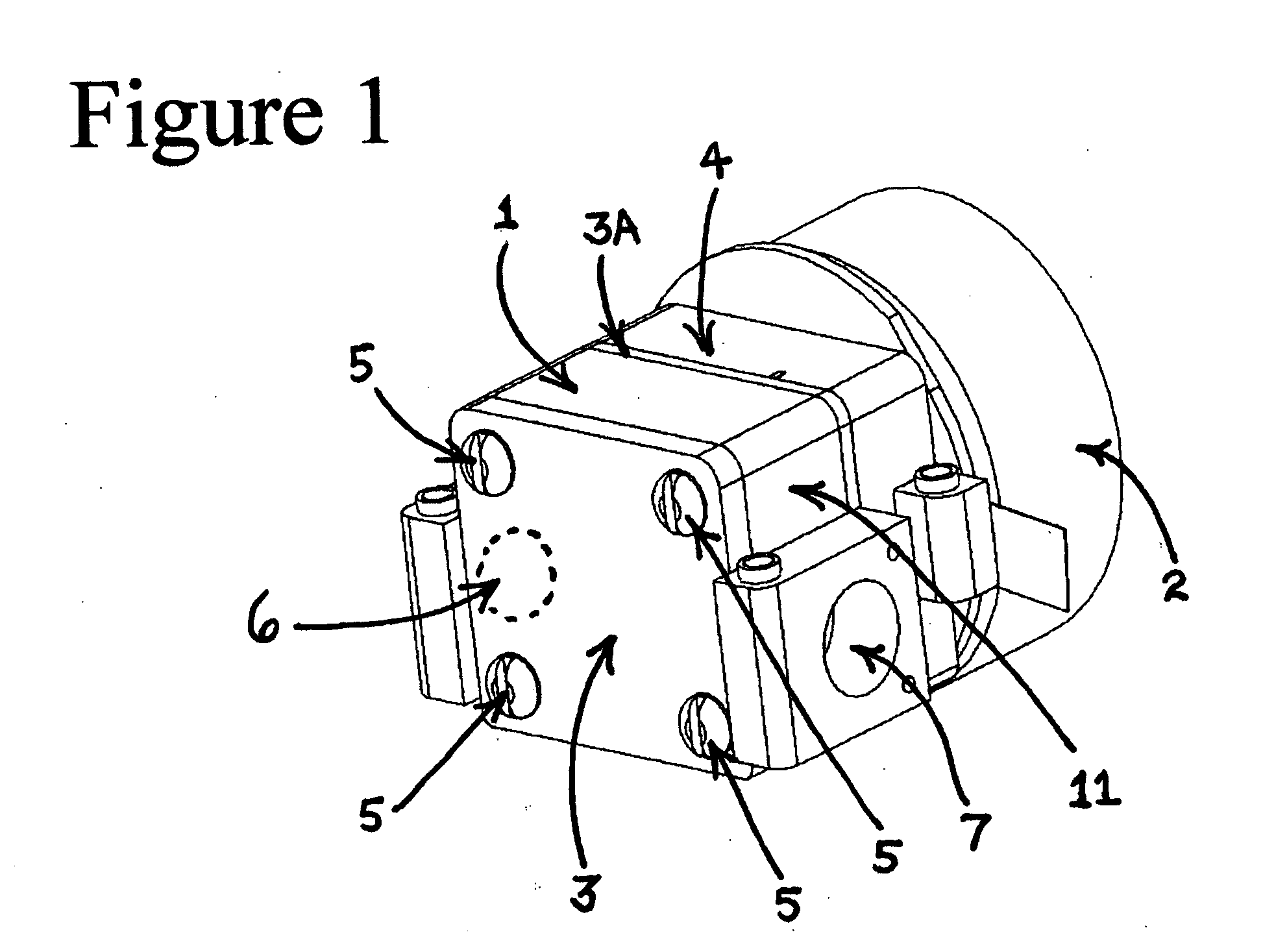

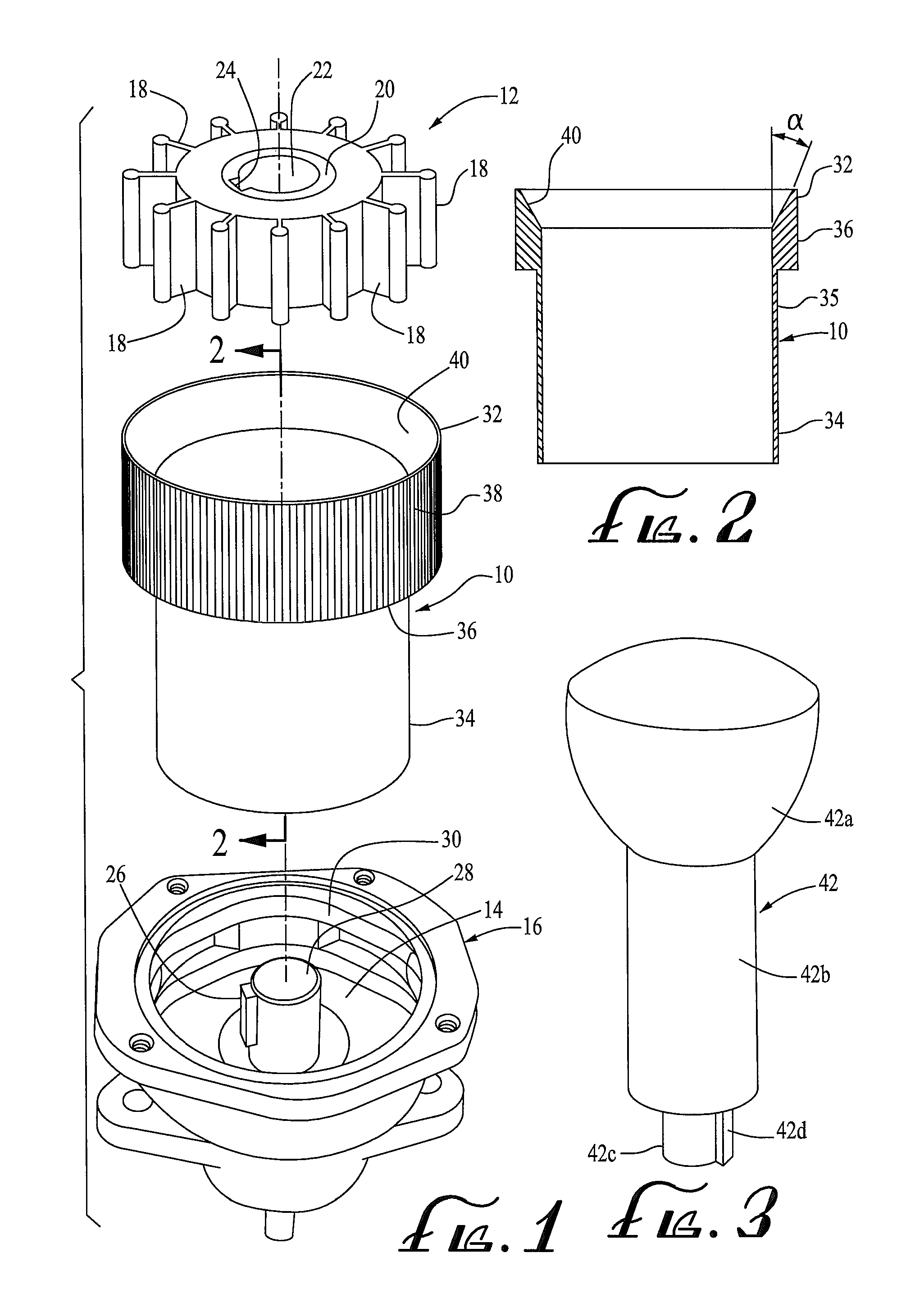

Active feed paintball loader with flexible impeller

An impeller for an active-feed paintball loader has resilient arms that engage paintballs in the lower portion (well) of the loader and advance them to and through the outfeed tube. The resilient arms are sufficiently stiff to move unobstructed paintballs located between the arms, and sufficiently flexible to yield when forced against stationary paintballs so as not to rupture the paintball shells, the arms substantially returning to their original shape when the obstruction is removed. Accordingly, when the motor is shut off, the arms will simply flex backward as they encounter stationary paintballs. Should a paintball jam occur in the vicinity of the impeller, the arm(s) can flex around the jammed ball without breaking it, and help to dislodge it so as to clear the jam.

Owner:KORE OUTDOOR US INC

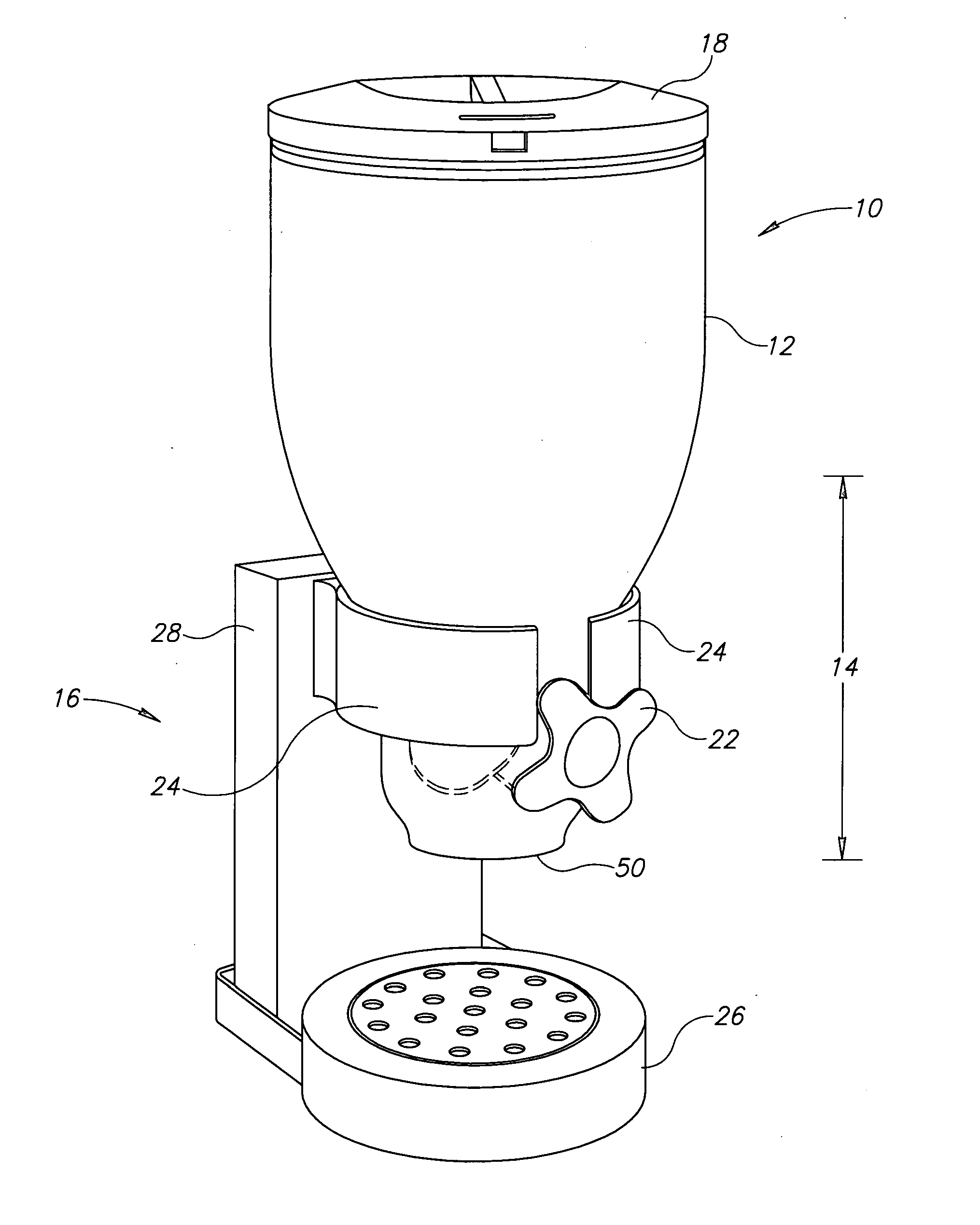

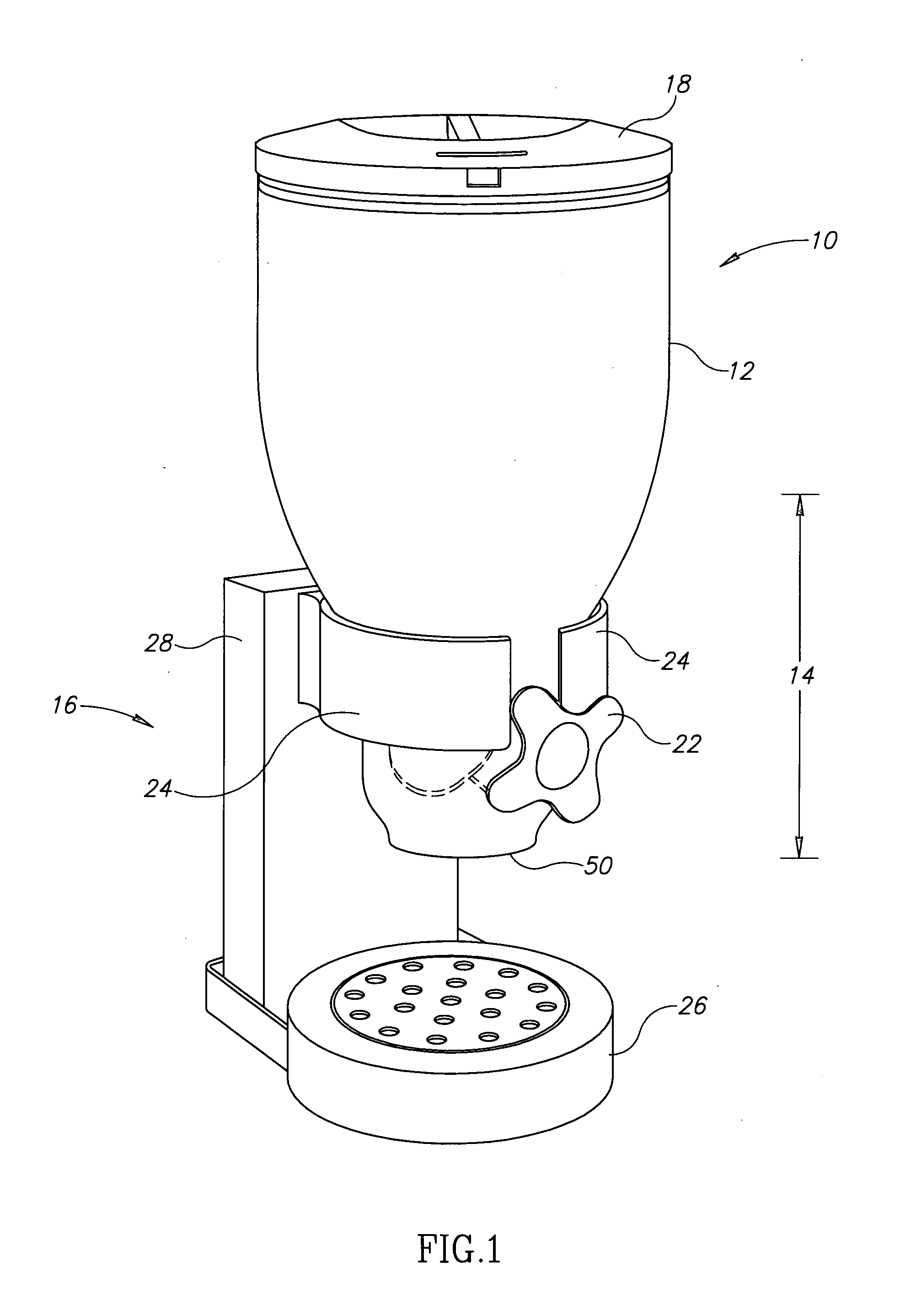

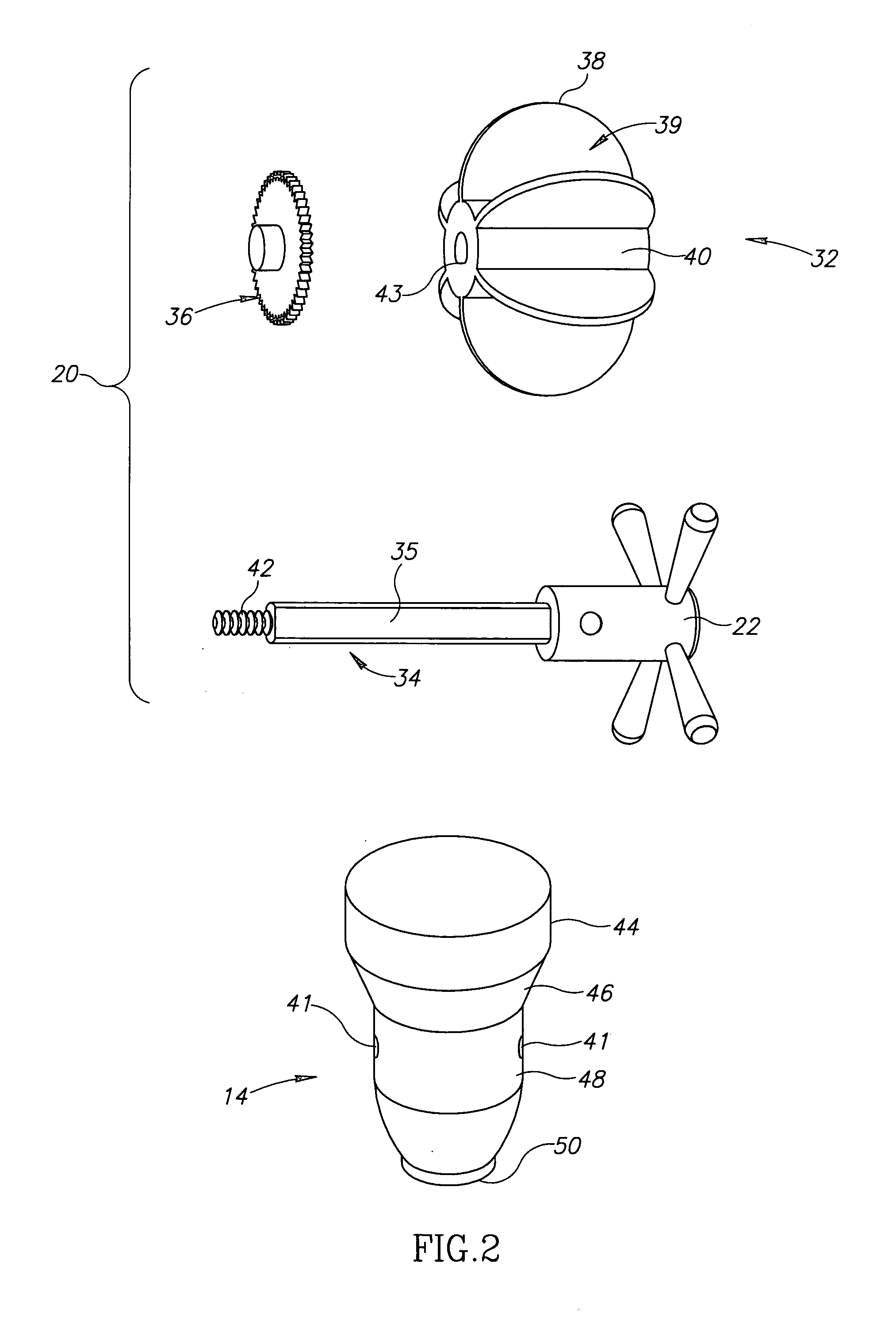

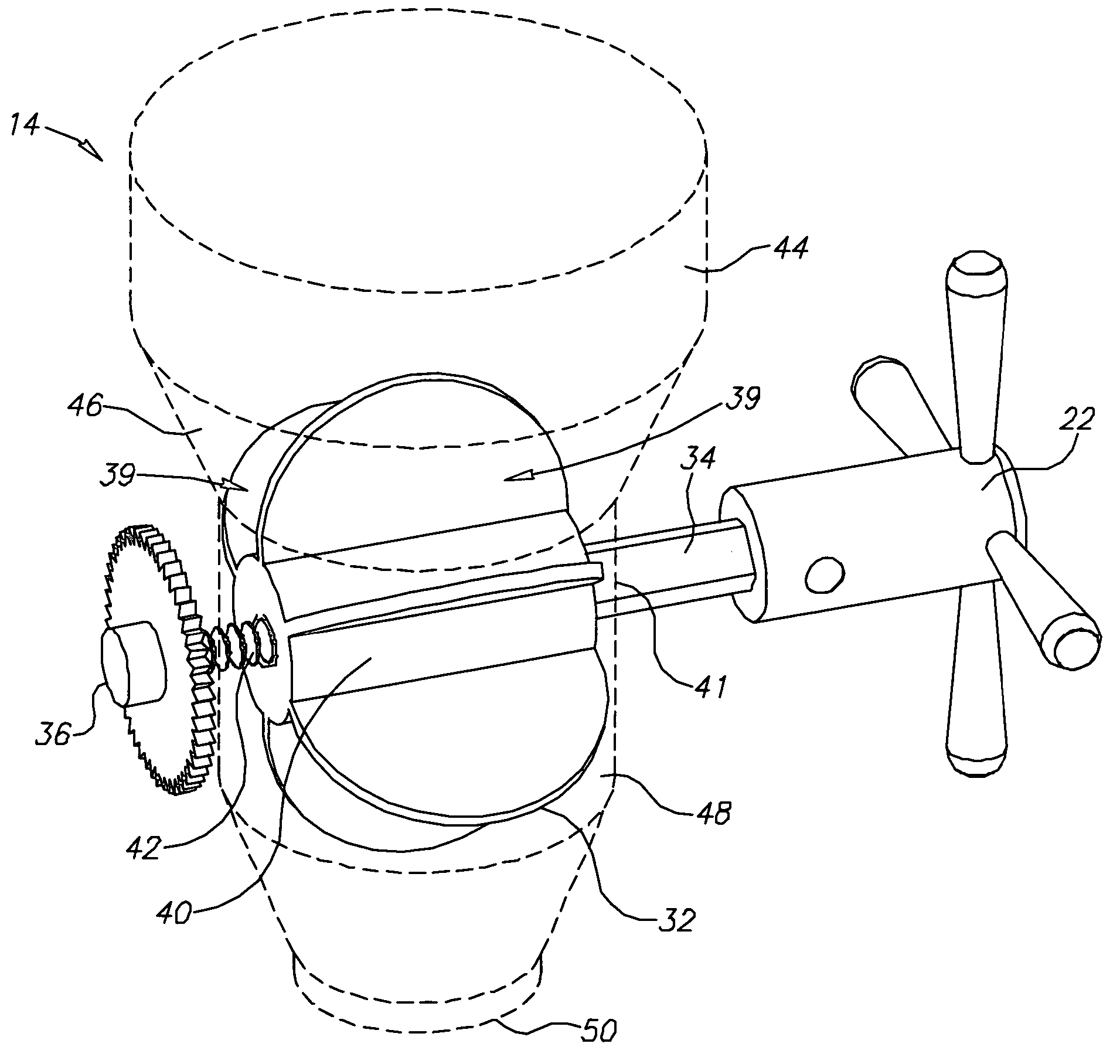

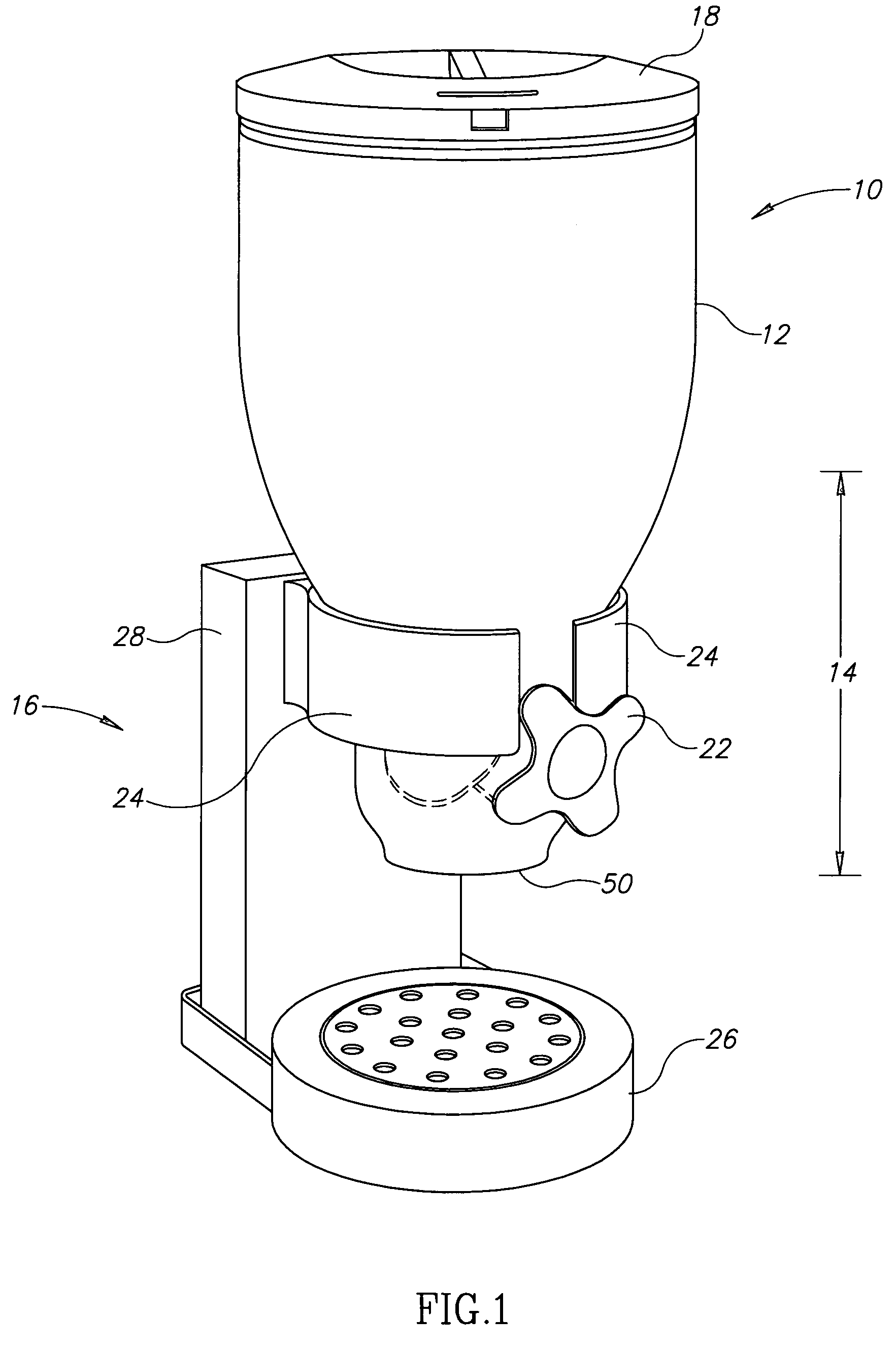

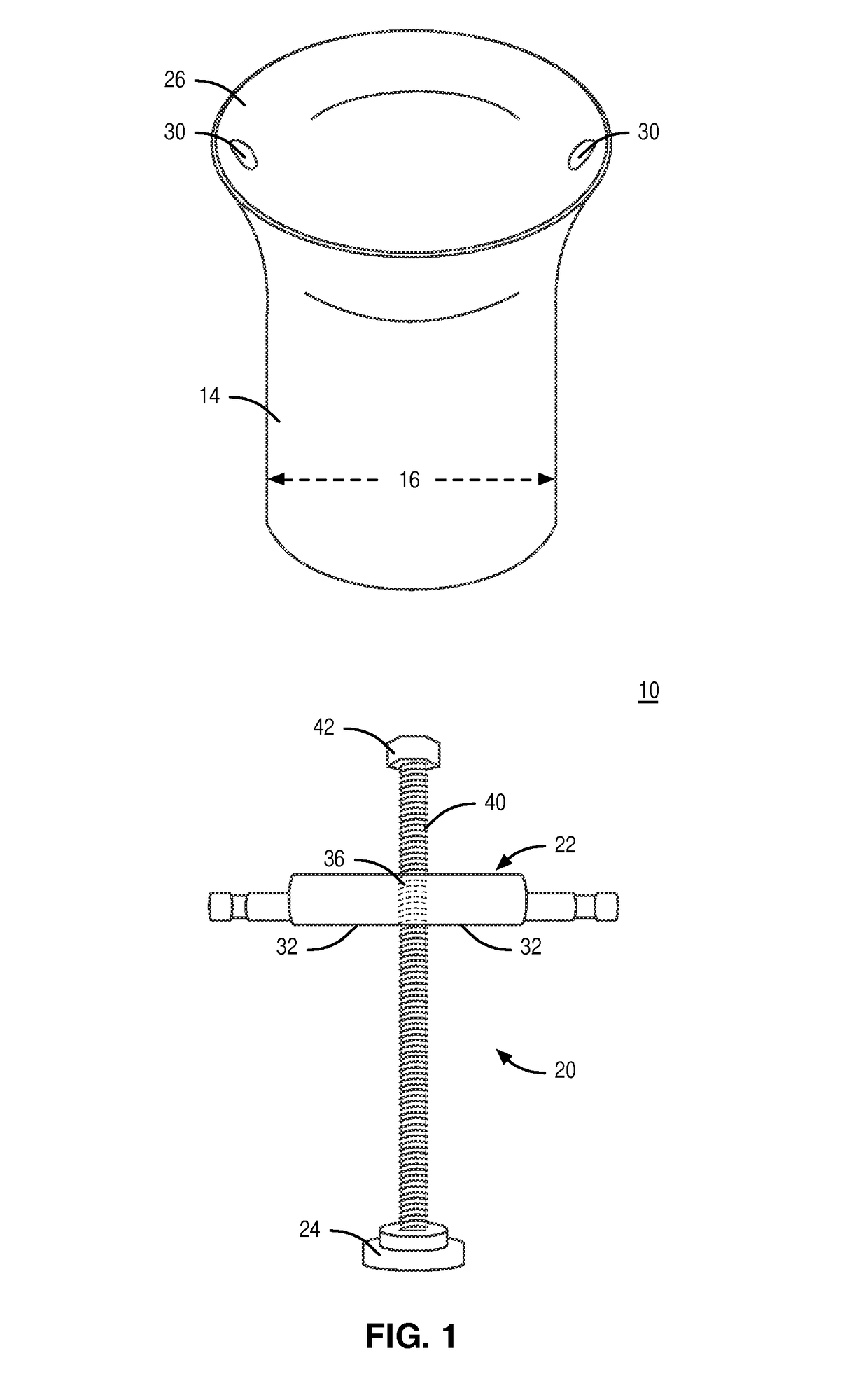

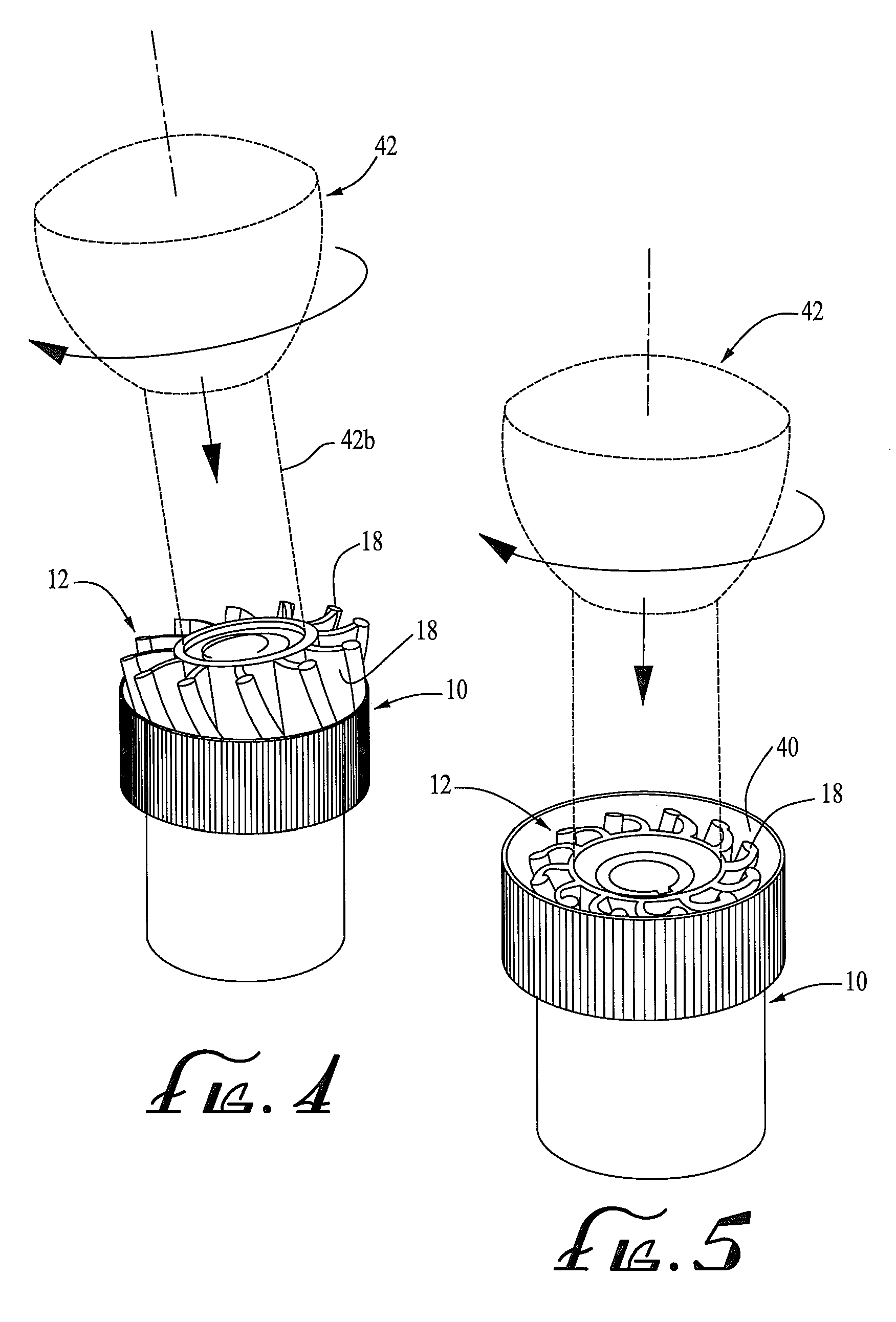

Granular product dispensing system

ActiveUS20060027609A1Easy to fillEasy maintenanceOpening closed containersBottle/container closureSingle supportHollow core

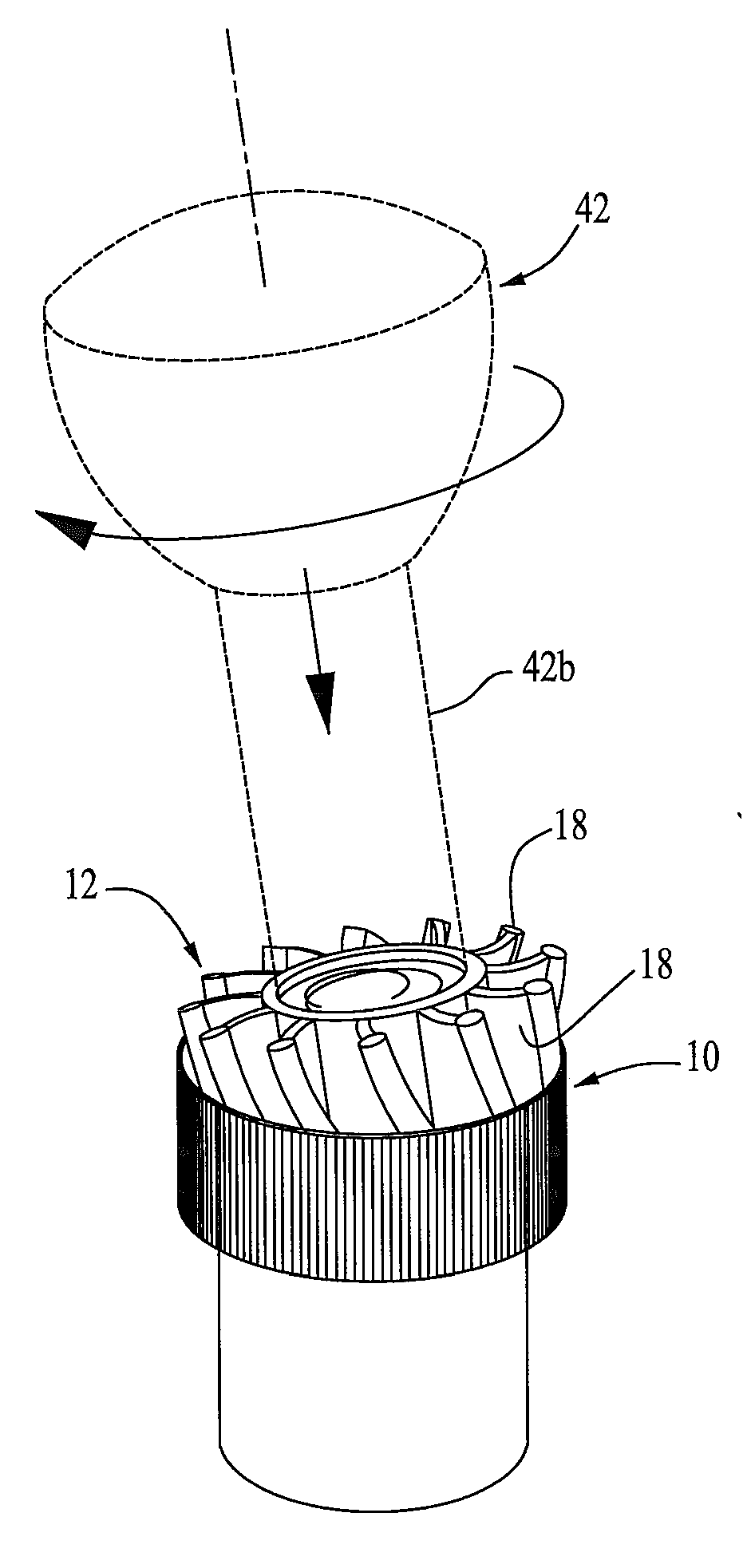

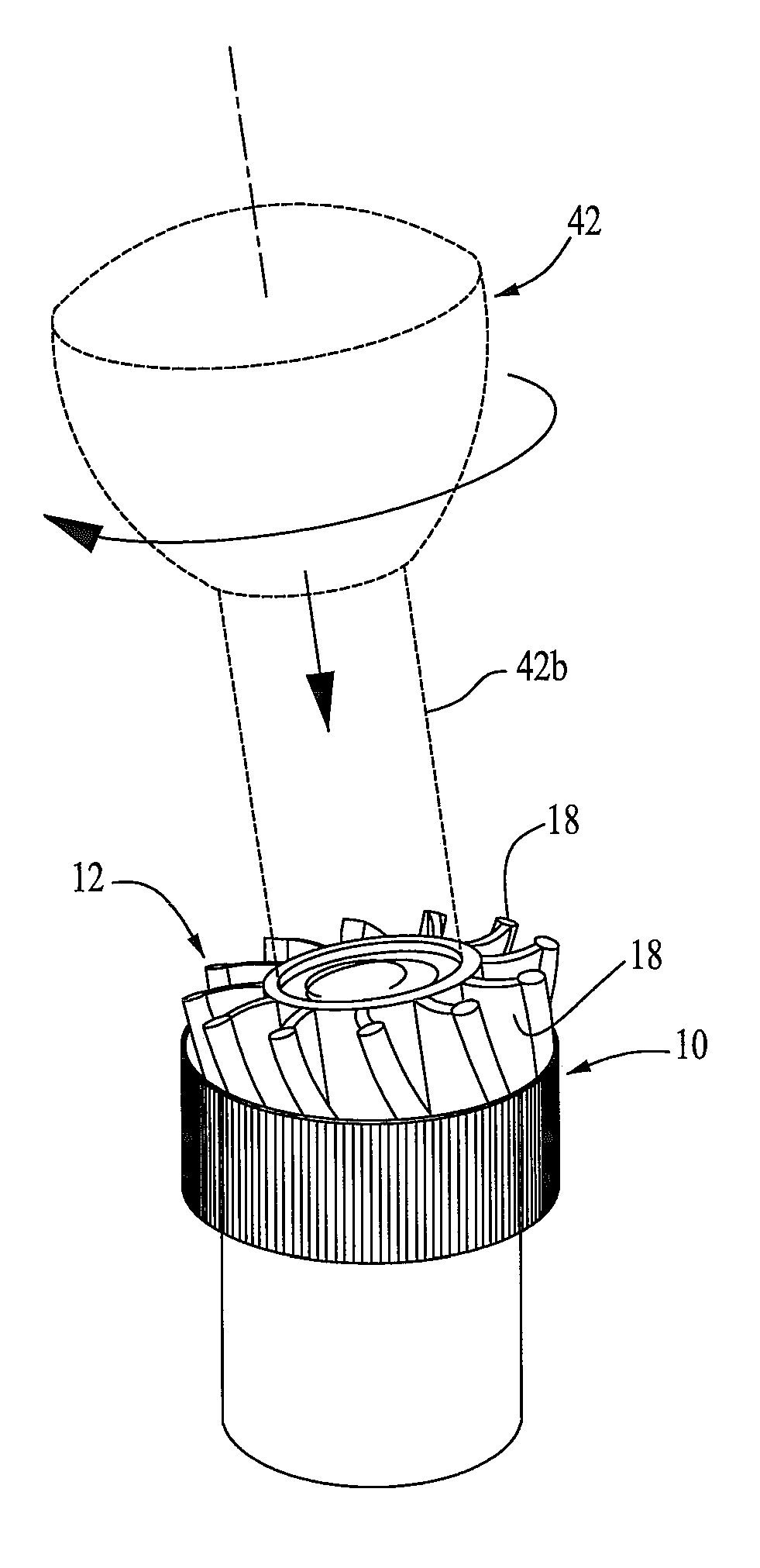

A system for dispensing a granular product. The system includes a refillable, sealable receptacle, having a neck at its lower end, a rotatable and flexible impeller within the neck, with the shape and size of the impeller conforming generally to the shape and size of the neck, providing sealing for maintaining the freshness of the granular product. Preferably the impeller comprises a hollow central core, and a shaft extends through the hollow core into at least one through-hole formed in the neck. A handle is present for turning the shaft to rotate the impeller. A base is provided with a retaining arm for removably receiving the receptacle. The system is capable of easy disassembly for cleaning, by removal of the receptacle and impeller from within the receptacle. Also provided is a multi-system for dispensing a plurality of products; having several receptacles and associated dispensing mechanisms mounted on a single support.

Owner:GIL GOLD & TAMIR LEVY +1

Granular product dispensing system

InactiveUS7703639B2Easy to fillEasy maintenanceOpening closed containersBottle/container closureSingle supportEngineering

A system for dispensing a granular product. The system includes a refillable, sealable receptacle, having a neck at its lower end, a rotatable and flexible impeller within the neck, with the shape and size of the impeller conforming generally to the shape and size of the neck, providing sealing for maintaining the freshness of the granular product. Preferably the impeller comprises a hollow central core, and a shaft extends through the hollow core into at least one through-hole formed in the neck. A handle is present for turning the shaft to rotate the impeller. A base is provided with a retaining arm for removably receiving the receptacle. The system is capable of easy disassembly for cleaning, by removal of the receptacle and impeller from within the receptacle. Also provided is a multi-system for dispensing a plurality of products; having several receptacles and associated dispensing mechanisms mounted on a single support.

Owner:GIL GOLD & TAMIR LEVY +1

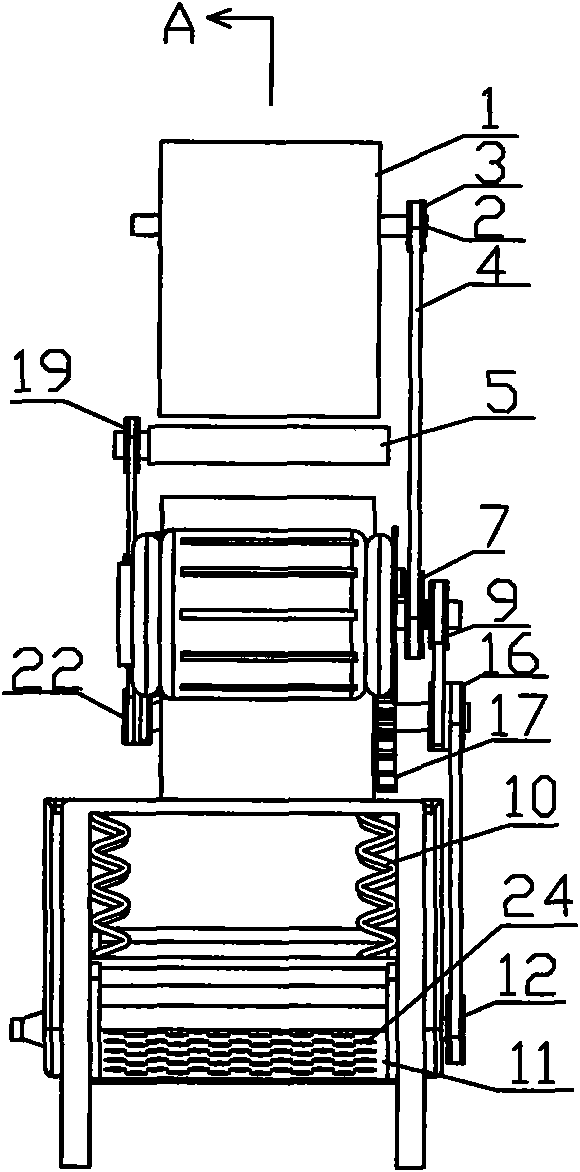

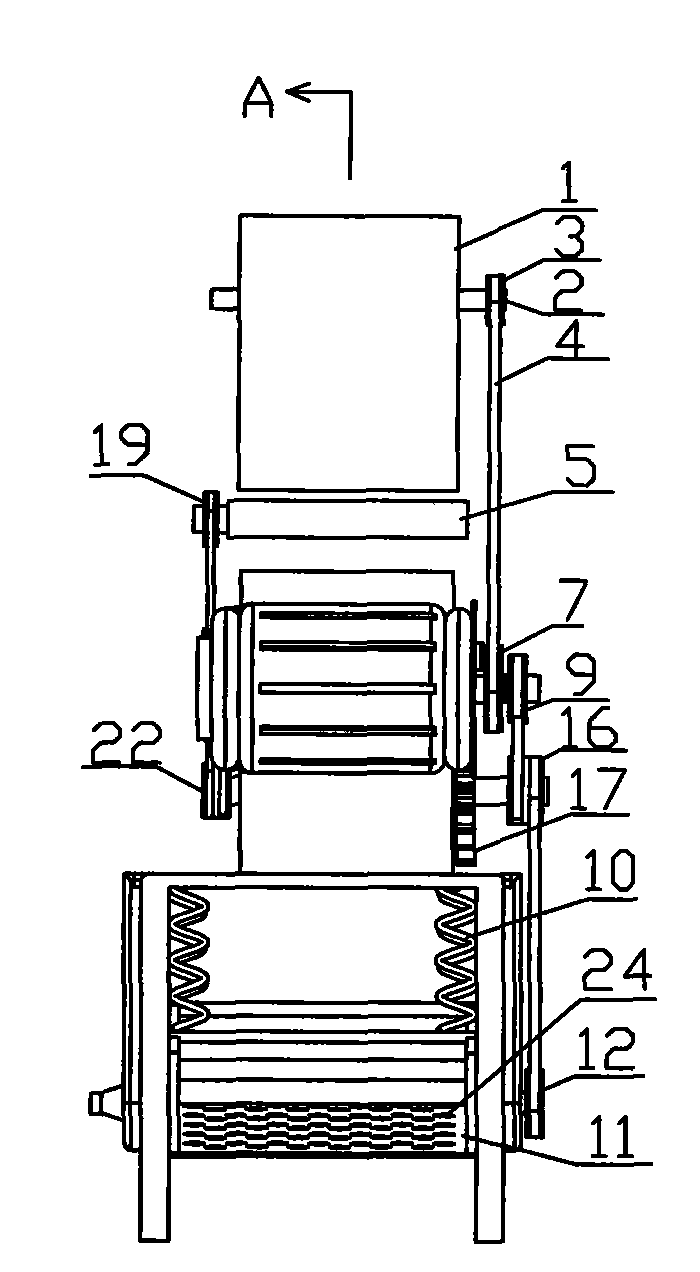

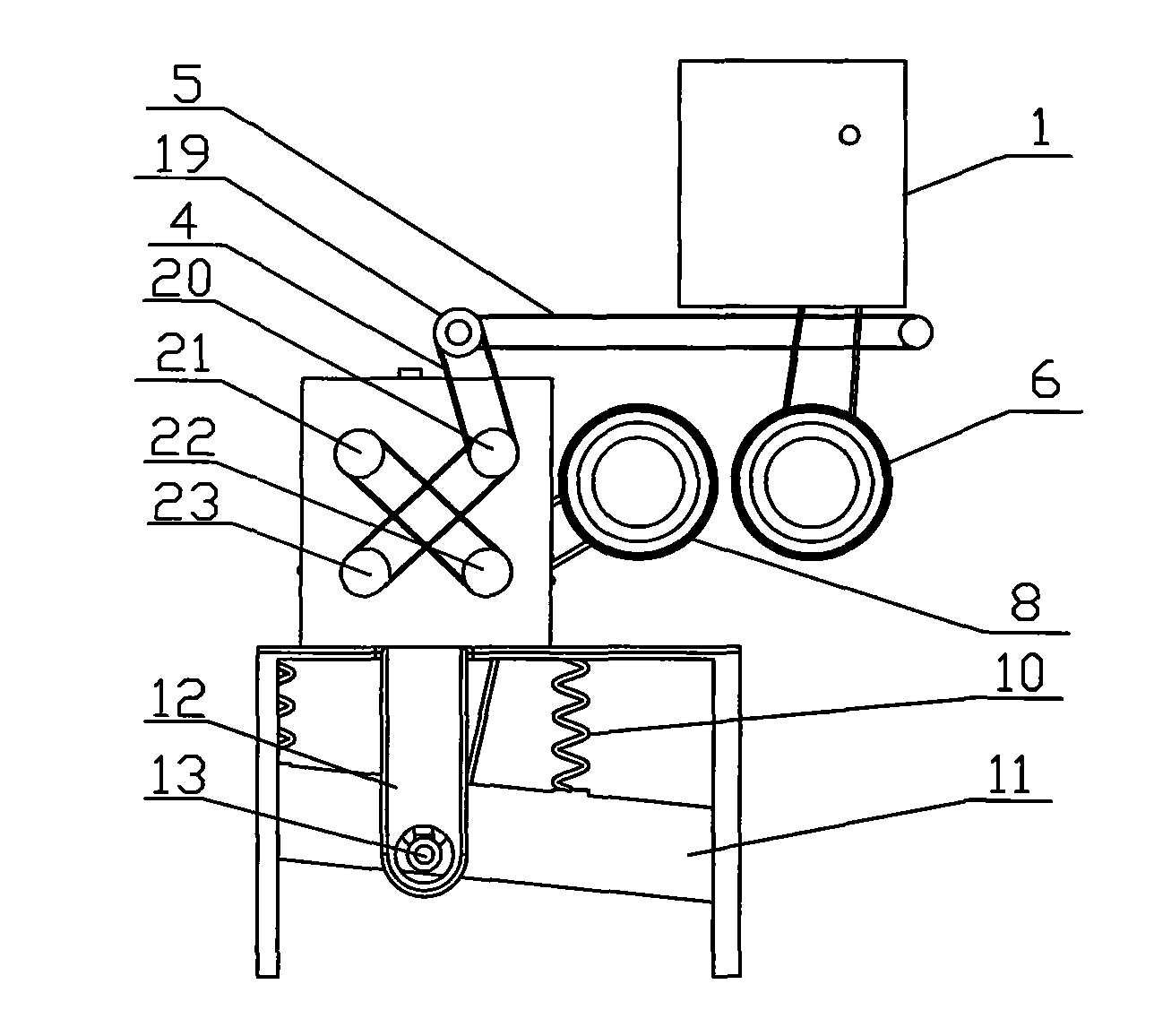

Mussel shell removing machine

InactiveCN101642158AImprove processing efficiencyIncrease profitBivalves processingTransmission beltElectric machinery

The invention discloses a mussel shell removing machine which belongs to shell removing machines. The mussel shell removing machine comprises an opening extension box, a shell removing box and an oscillating screen, wherein the lower part of the opening extension box is provided with a transmission belt; the lower part of the transmission belt is provided with the shell removing box; the lower part of the shell removing box is provided with the oscillating screen; the top of the opening extension box is provided with a feed opening, and the inner part is provided with a flexible impeller; theflexible impeller is connected with a first motor; four symmetrical brushes are arranged in the shell removing box; convex groove plates are respectively arranged between the two brushes at the upperpart and both sides of the two brushes at the lower part; uneven objects are arranged on the convex groove plates; the oscillating screen is connected with a screen frame by a cranked lever; the upperpart of the oscillating screen is connected with the screen frame by a support tension spring; a plurality of screen holes are arranged on the oscillating screen; and the brushes, the oscillating screen and the transmission belt are respectively connected with a second motor. The mussel shell removing machine has the characteristics of realizing automated production, solving the problems of mussel extrusion, and the like due to labor force shortage in the producing process of mussels, and the like.

Owner:朱雅光

Dry running flexible impeller pump and method of manufacture

Owner:HARVIE MARK R

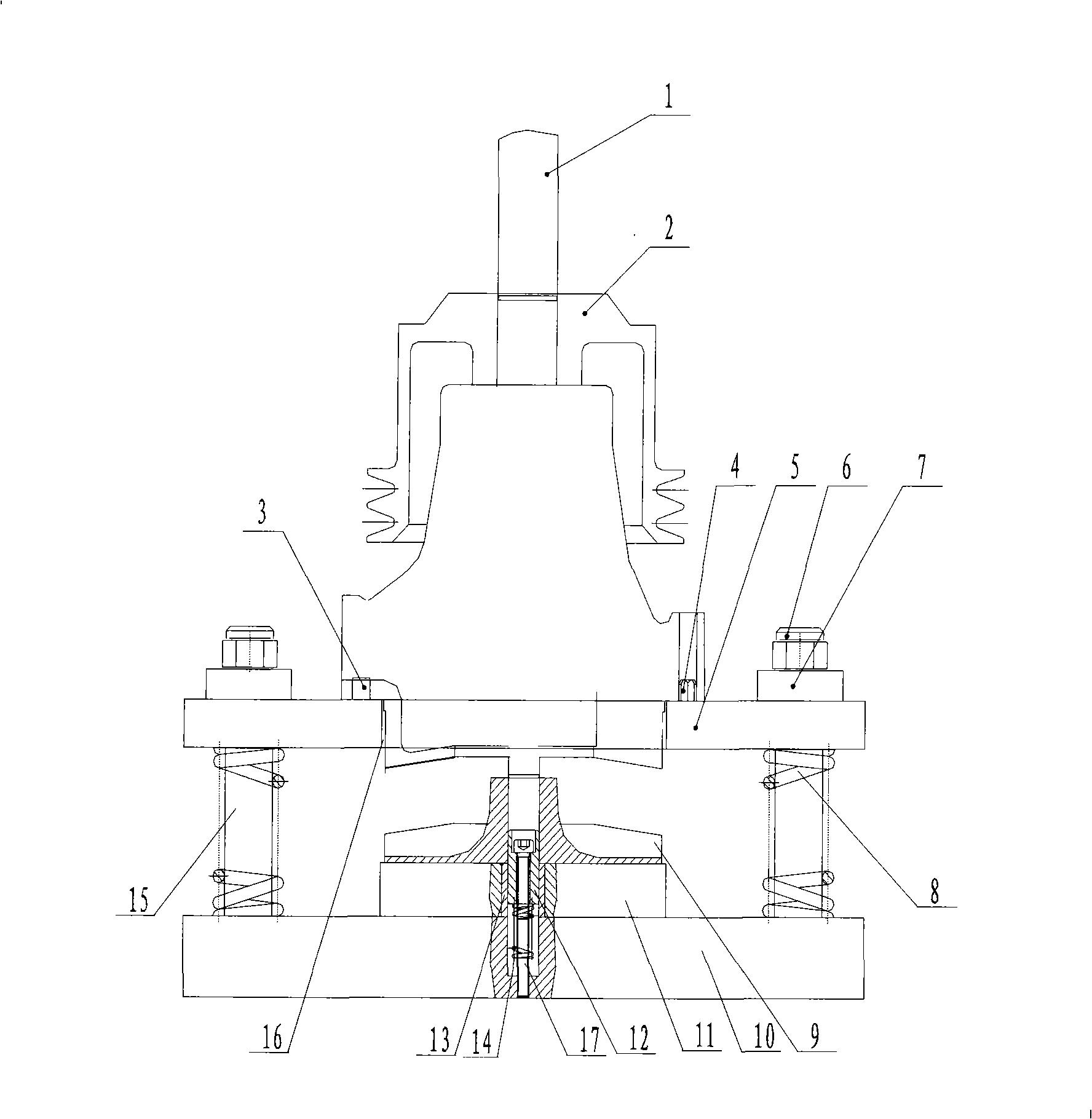

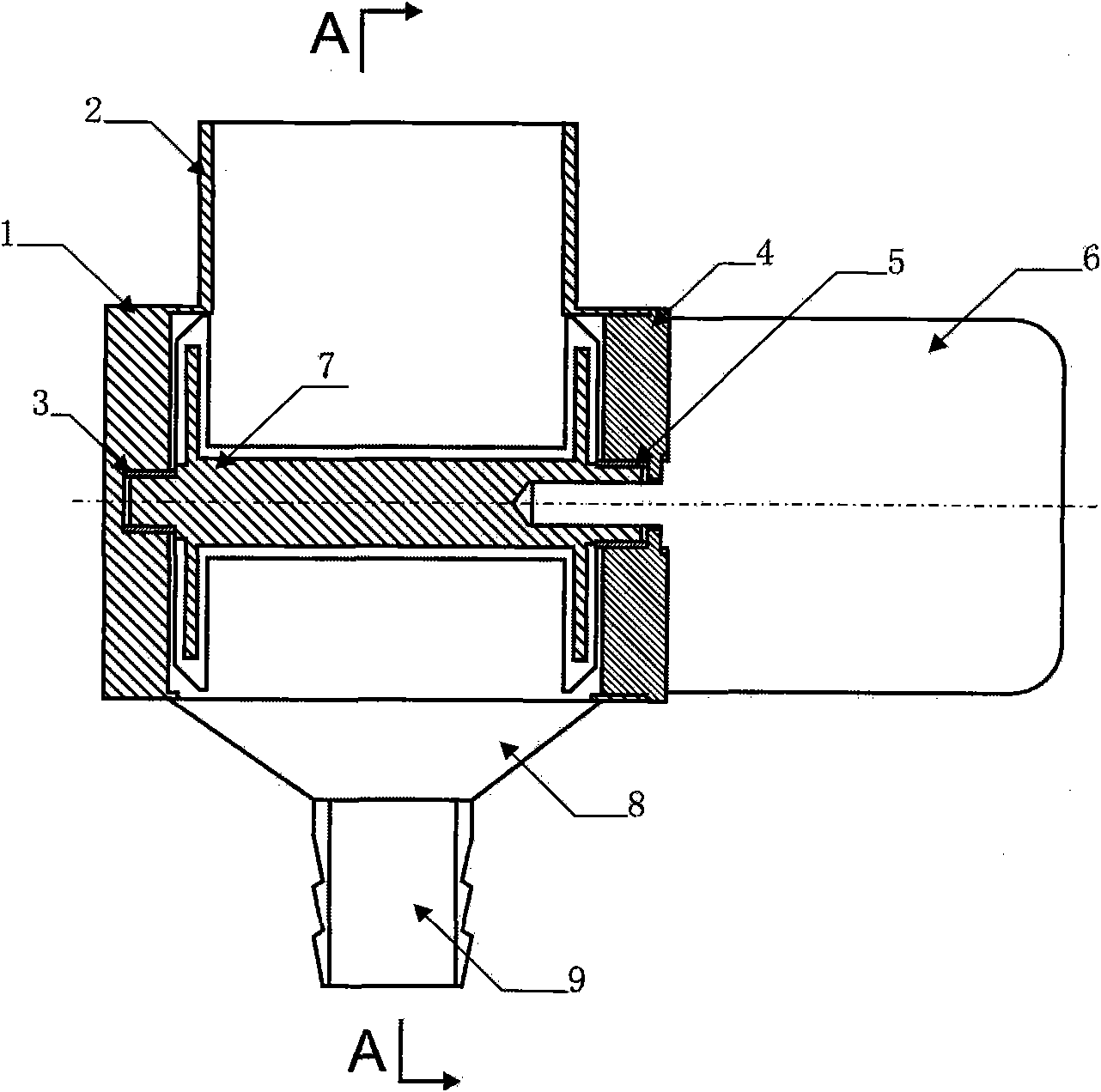

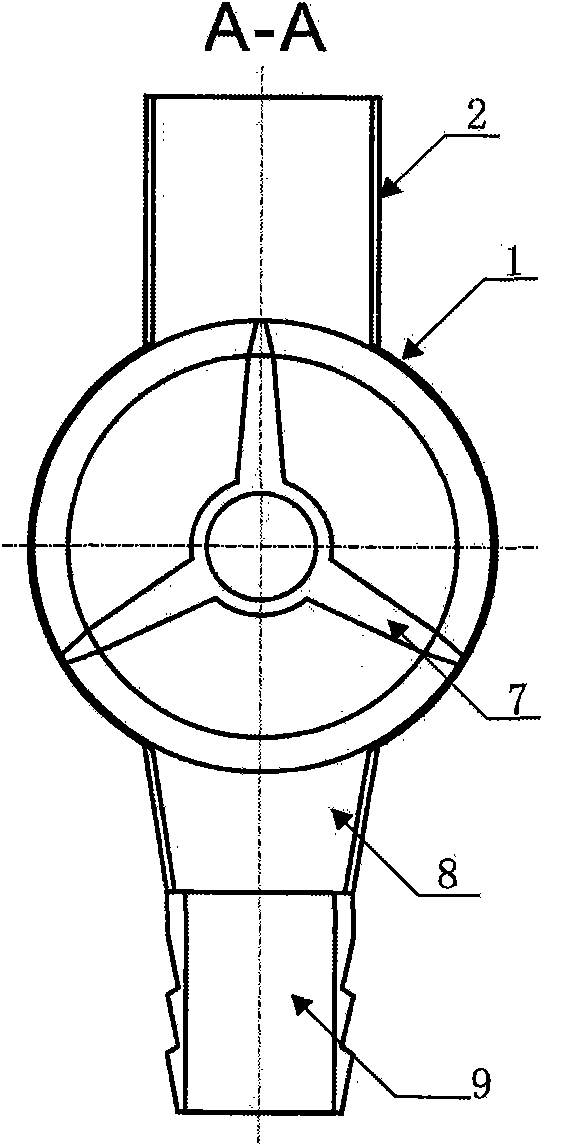

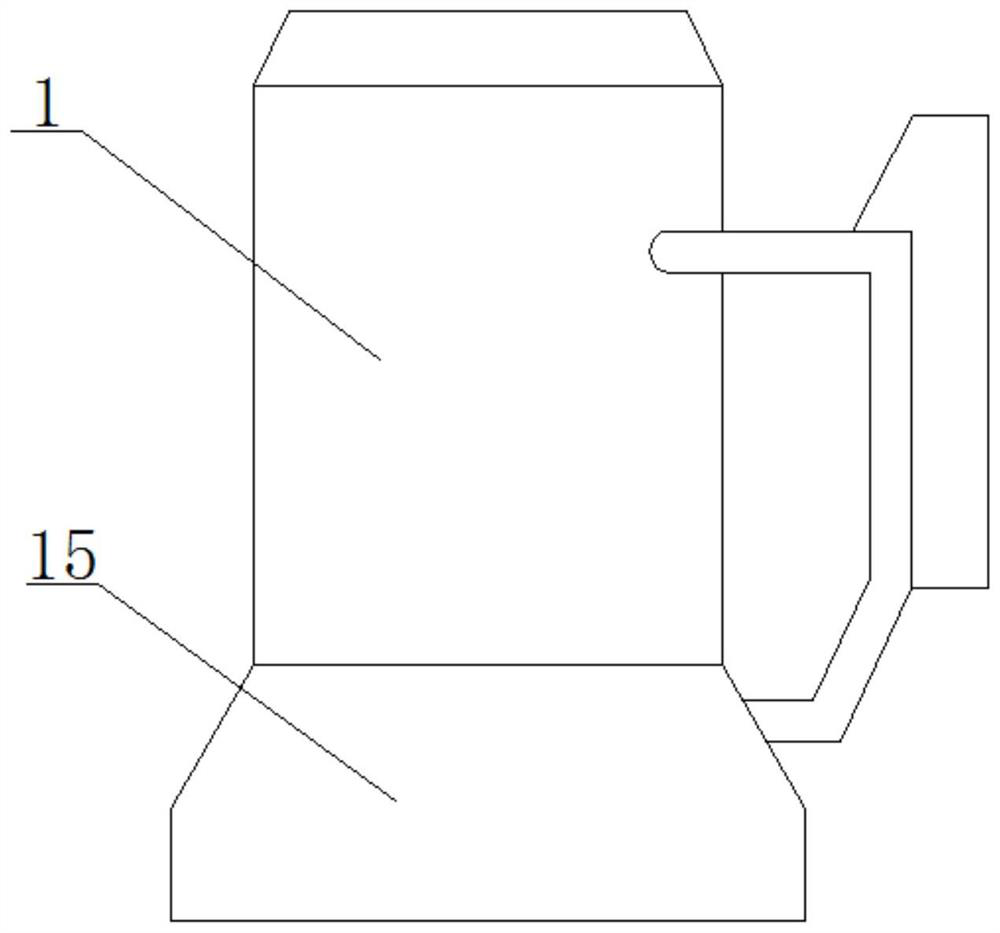

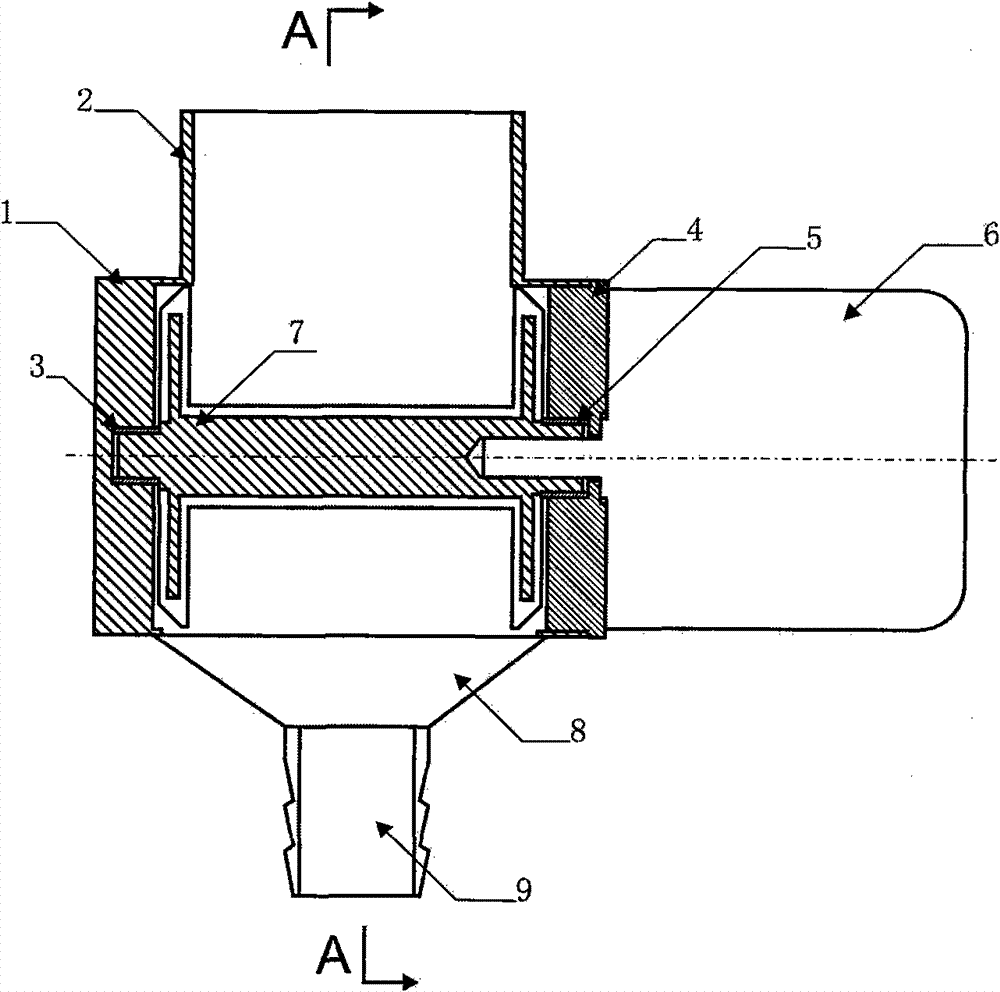

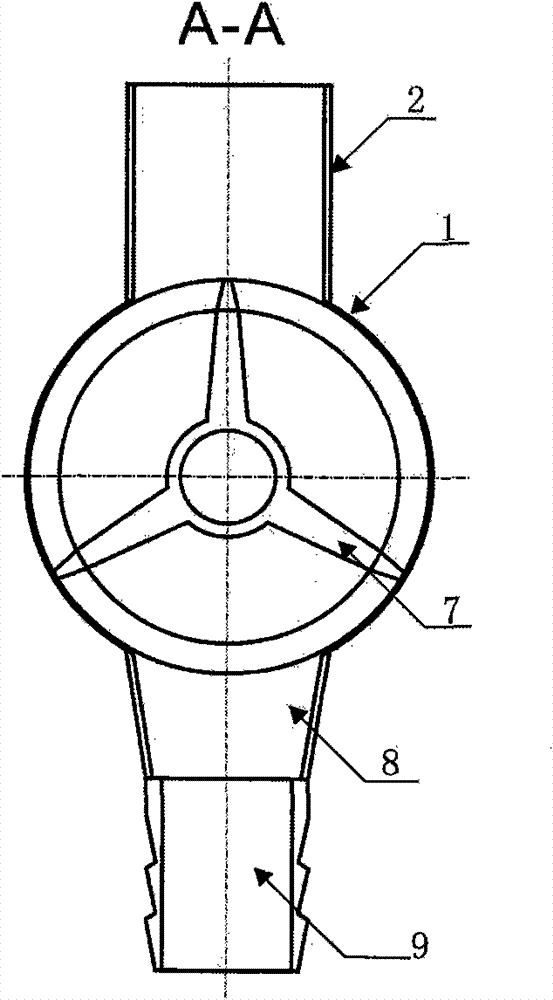

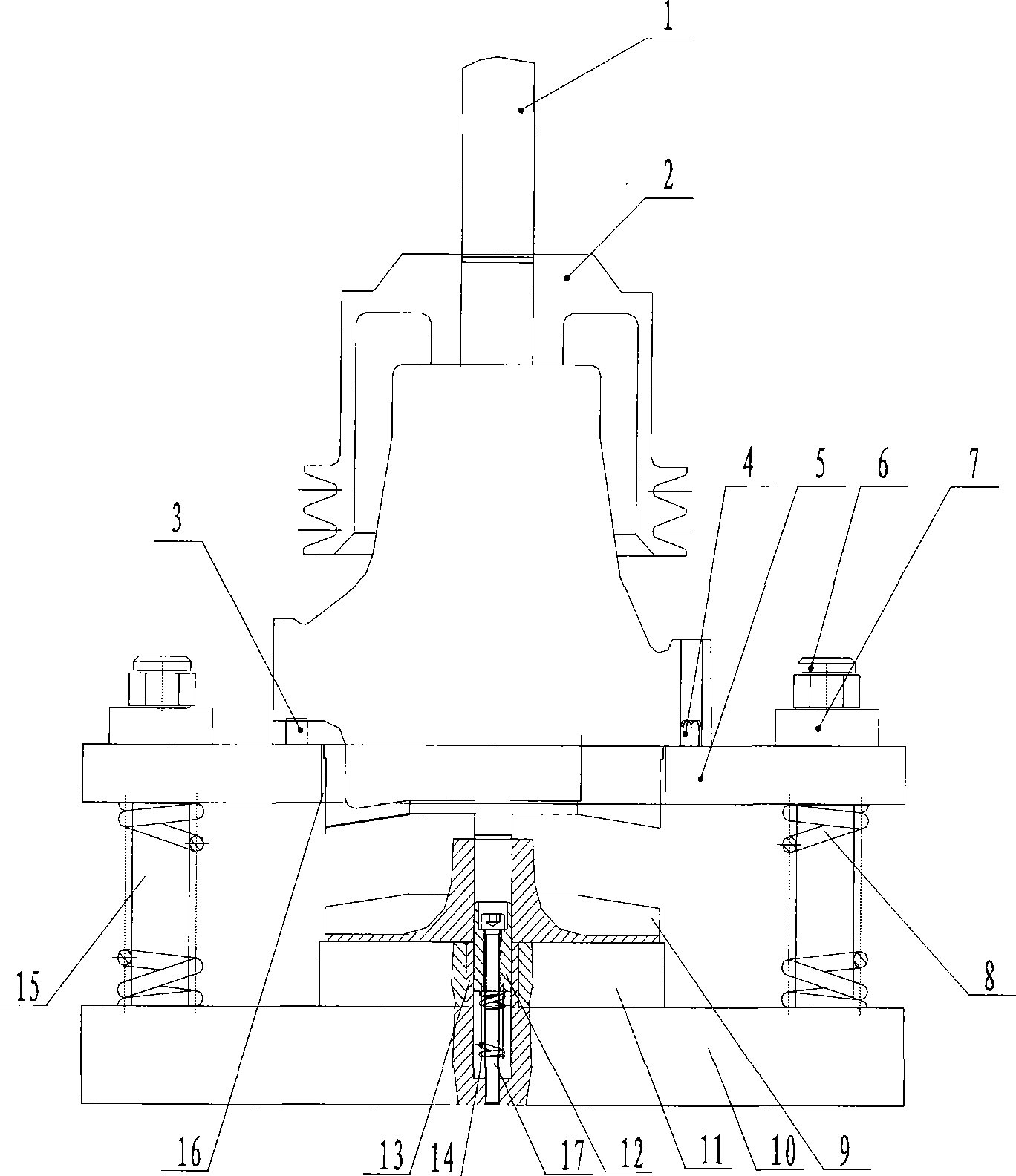

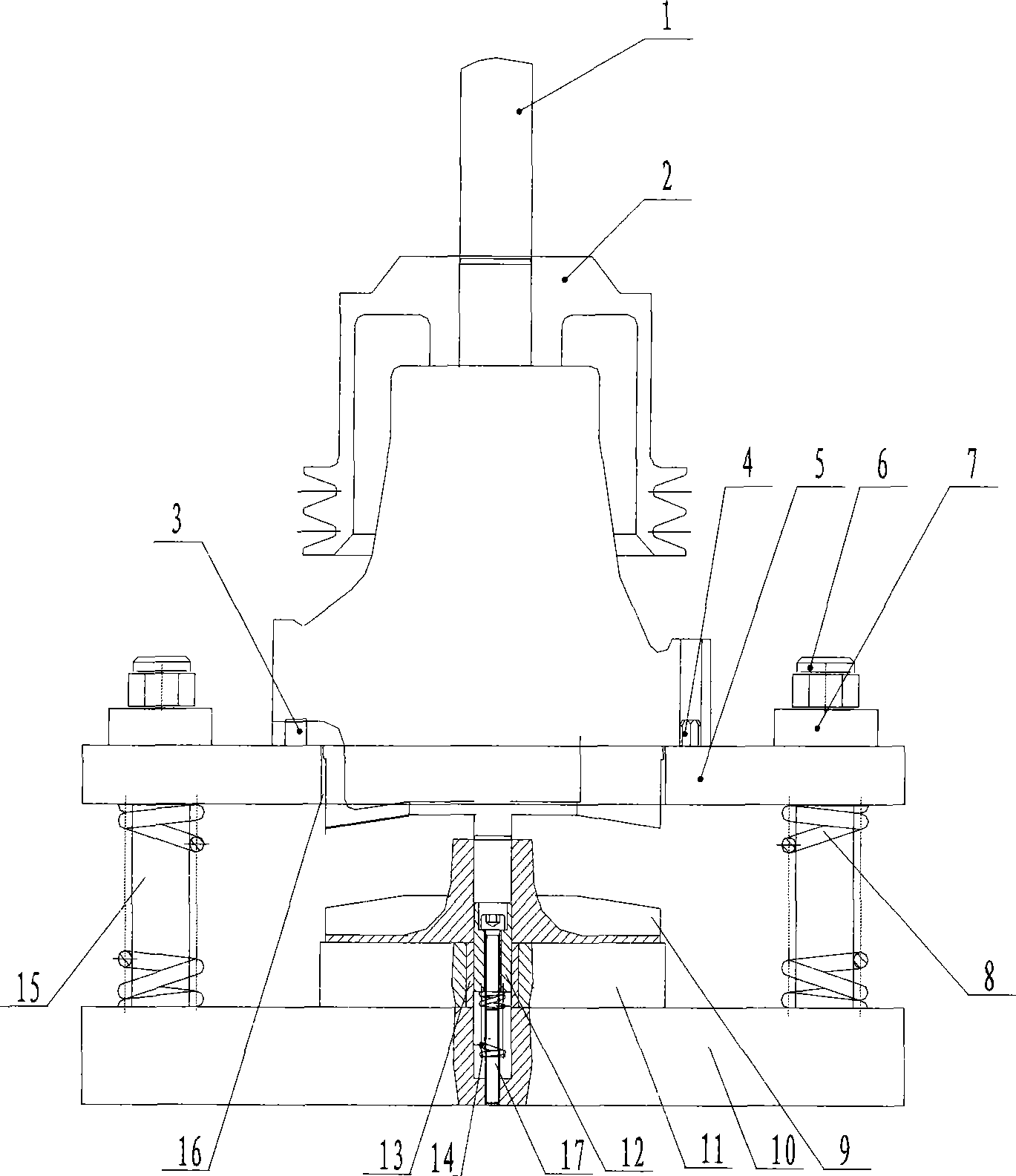

Method and device for press mounting water pump impeller

The invention discloses a pump impeller press mounting device in the pump processing technology field, and a press mounting method thereof; the pump impeller press mounting device is provided with a support plate and is characterized in that four guideposts are arranged on the support plate; a support spring is sheathed at the external part of each guidepost; locating plates are sheathed on the guideposts; the support springs are positioned between the support plate and the locating plates; the central position of the support spring is fixed with a locating block; the center of the locating block is provided with a flexible impeller positioning core axle; the central position of the locating plate is provided with a communicating pore and the impeller can pass through the communicating pore; the locating plate is provided with two positioning pins; positioning holes which are matched with the positioning pins are arranged on a pump component; the matching of the positioning pins and the positioning holes, and the matching of the end face of the pump component and the upper face of the locating plate form one-face two-pin positioning and cause the center of the pump component and the flexible impeller positioning core axle mechanism to be concentric. Compared with the prior art, the invention has compact structure, easy operation and high production efficiency, causes the impeller and a rotating shaft to be assembled accurately, and saves the manufacturing cost of a fixture.

Owner:FEILONG AUTO COMPONENTS CO LTD

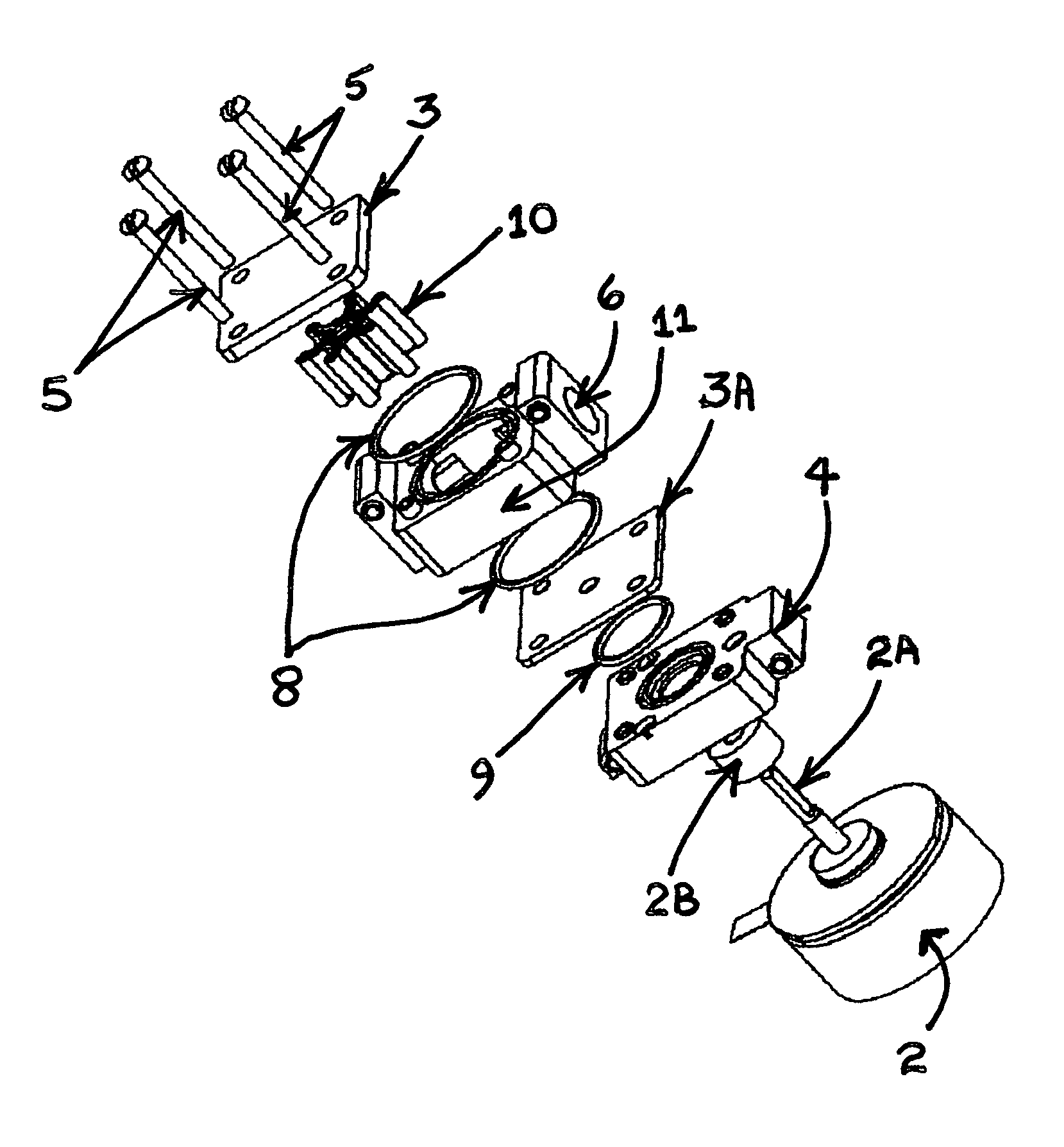

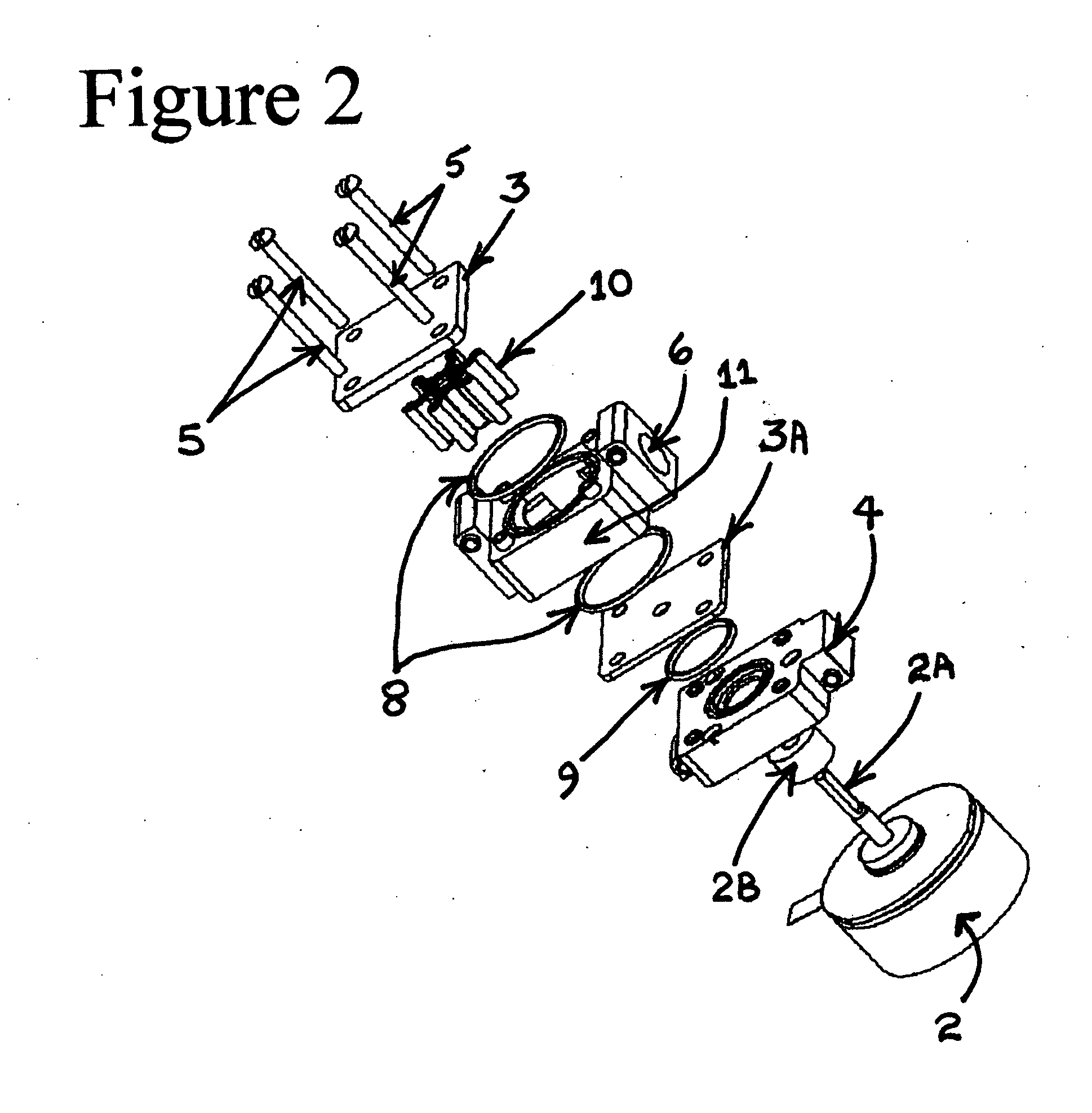

Flexible impeller pumps for mixing individual components

A flexible impeller pump includes first and second component housings. The first component housing includes a first flexible impeller and the second component housing includes a second flexible impeller. As these impellers rotate within their respective housings, they draw in and expel individual components into a common receiving chamber. In a particular application, one component is a foamable liquid, and the other component is air, and a mixture of foamable liquid and air is thus created in the common receiving chamber.

Owner:GOJO IND INC

Active feed paintball loader with flexible impeller

Owner:KORE OUTDOOR US INC

Flexible impeller pumps for mixing individual components

A flexible impeller pump includes first and second component housings. The first component housing includes a first flexible impeller and the second component housing includes a second flexible impeller. As these impellers rotate within their respective housings, they draw in and expel individual components into a common receiving chamber. In a particular application, one component is a foamable liquid, and the other component is air, and a mixture of foamable liquid and air is thus created in the common receiving chamber.

Owner:GOJO IND INC

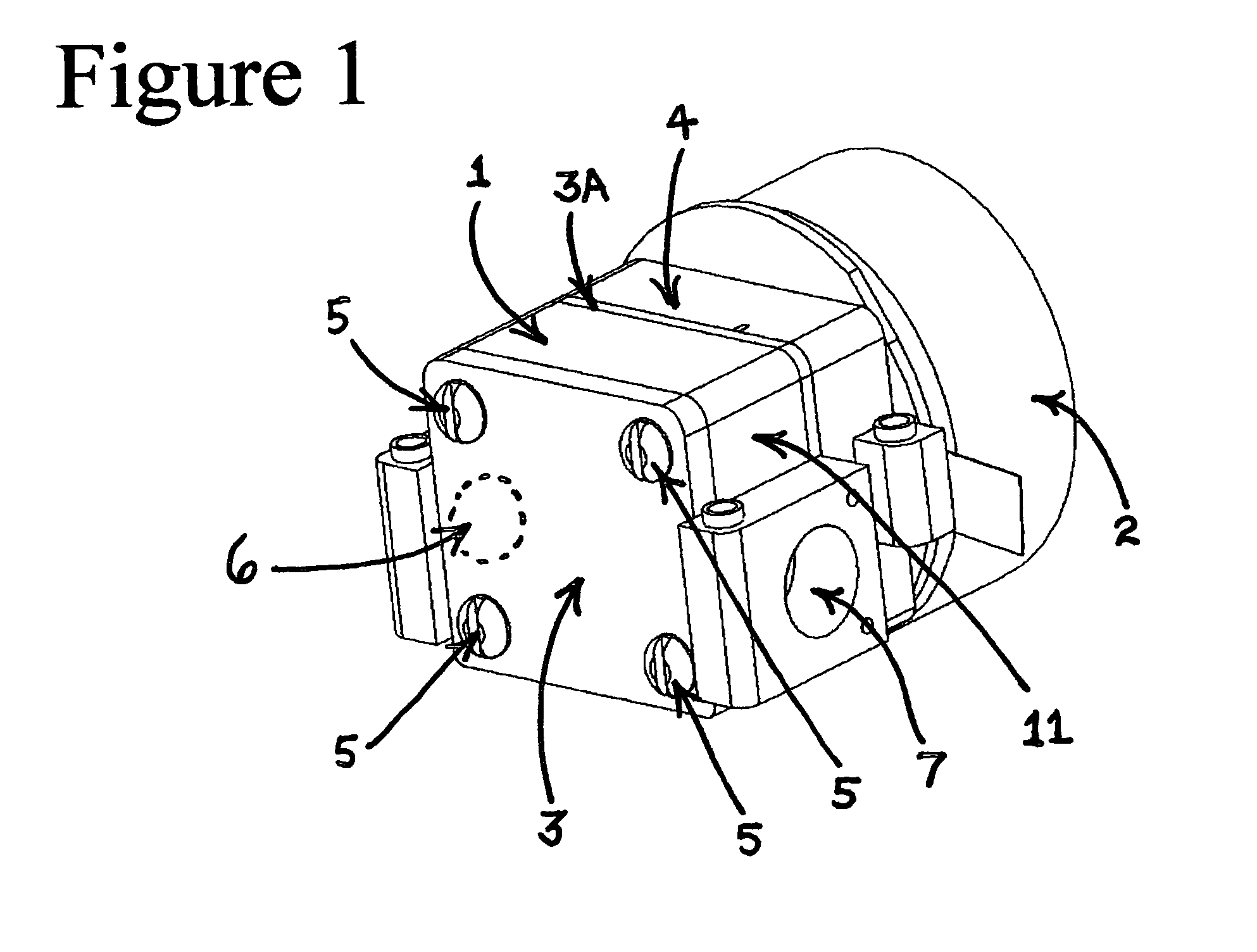

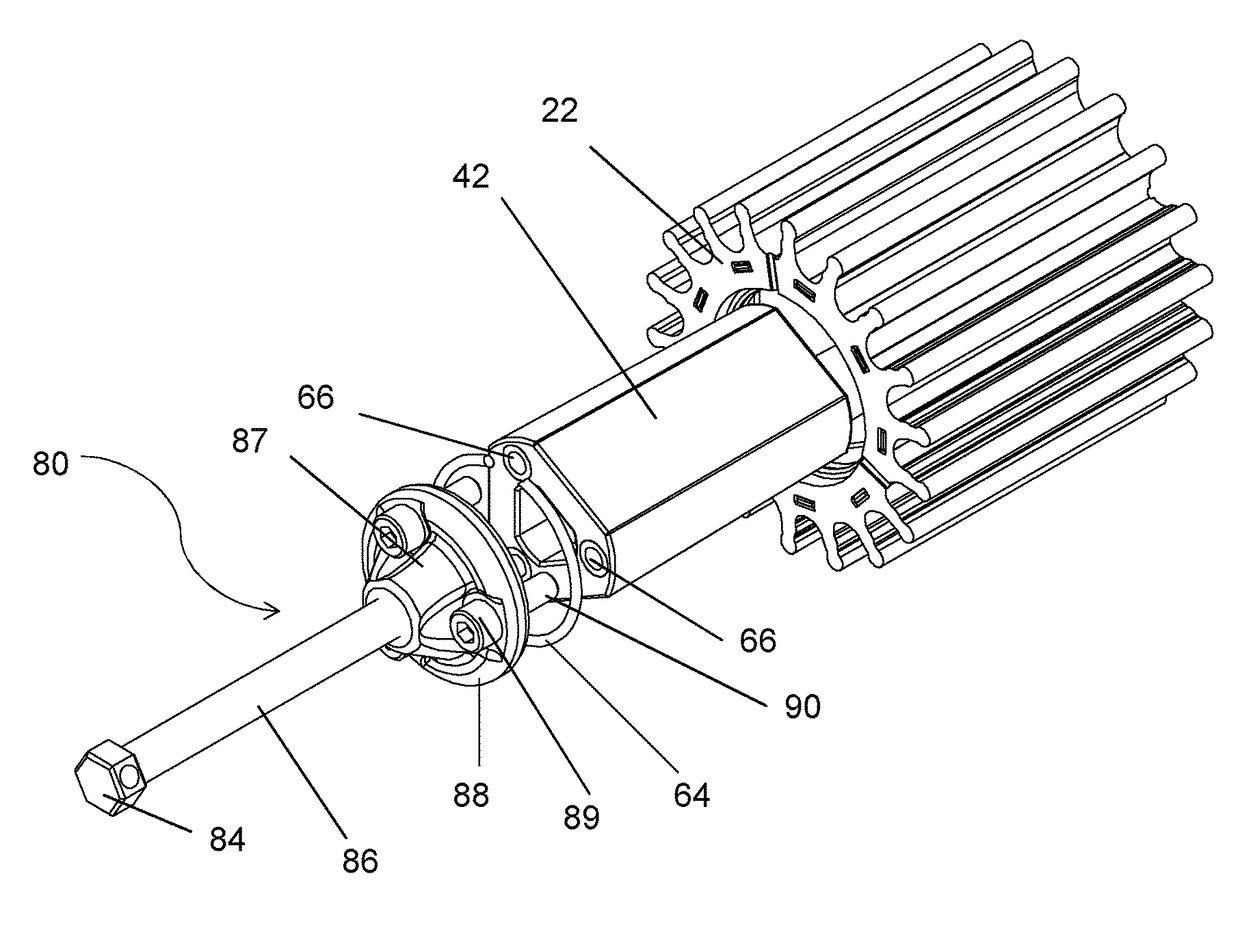

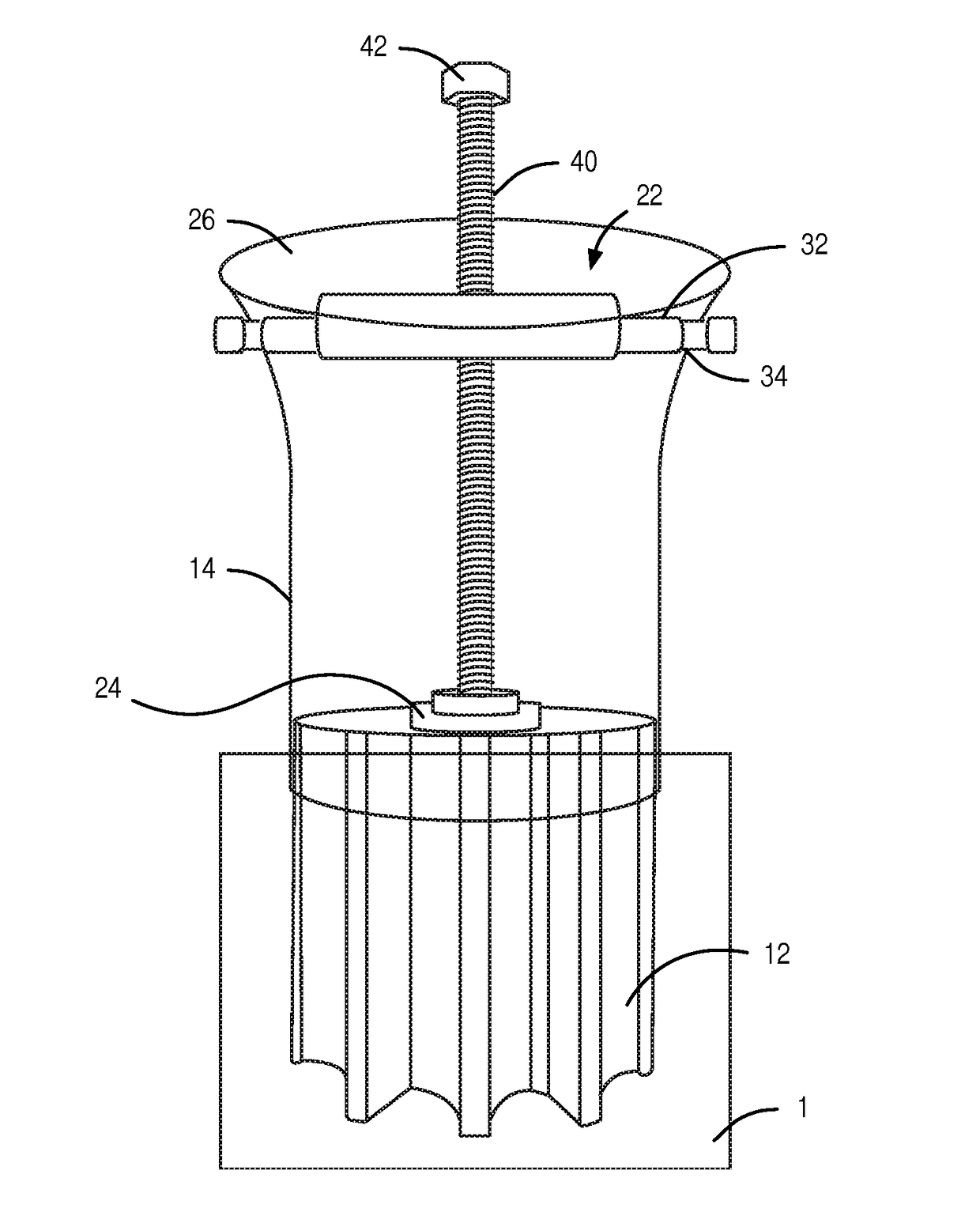

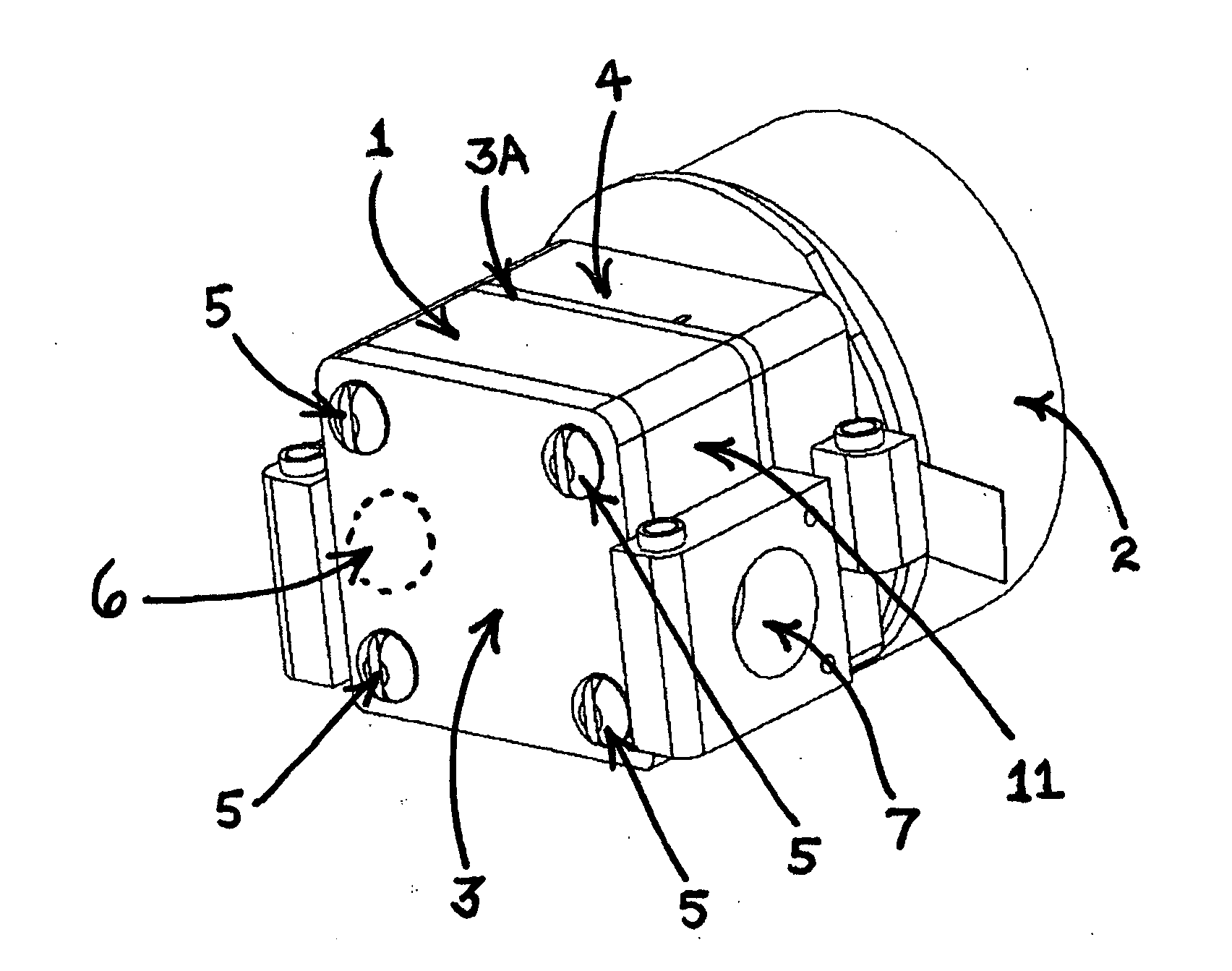

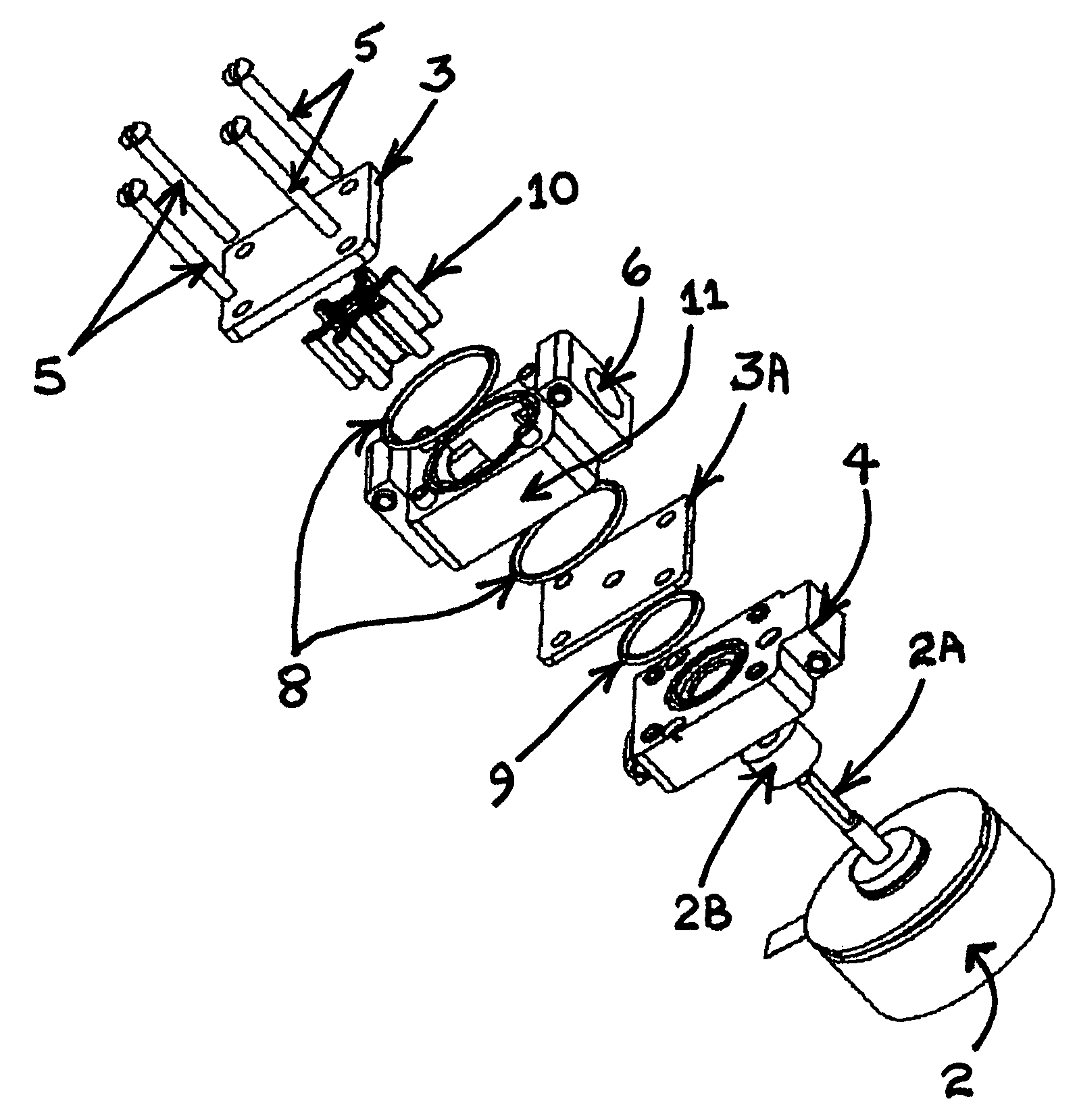

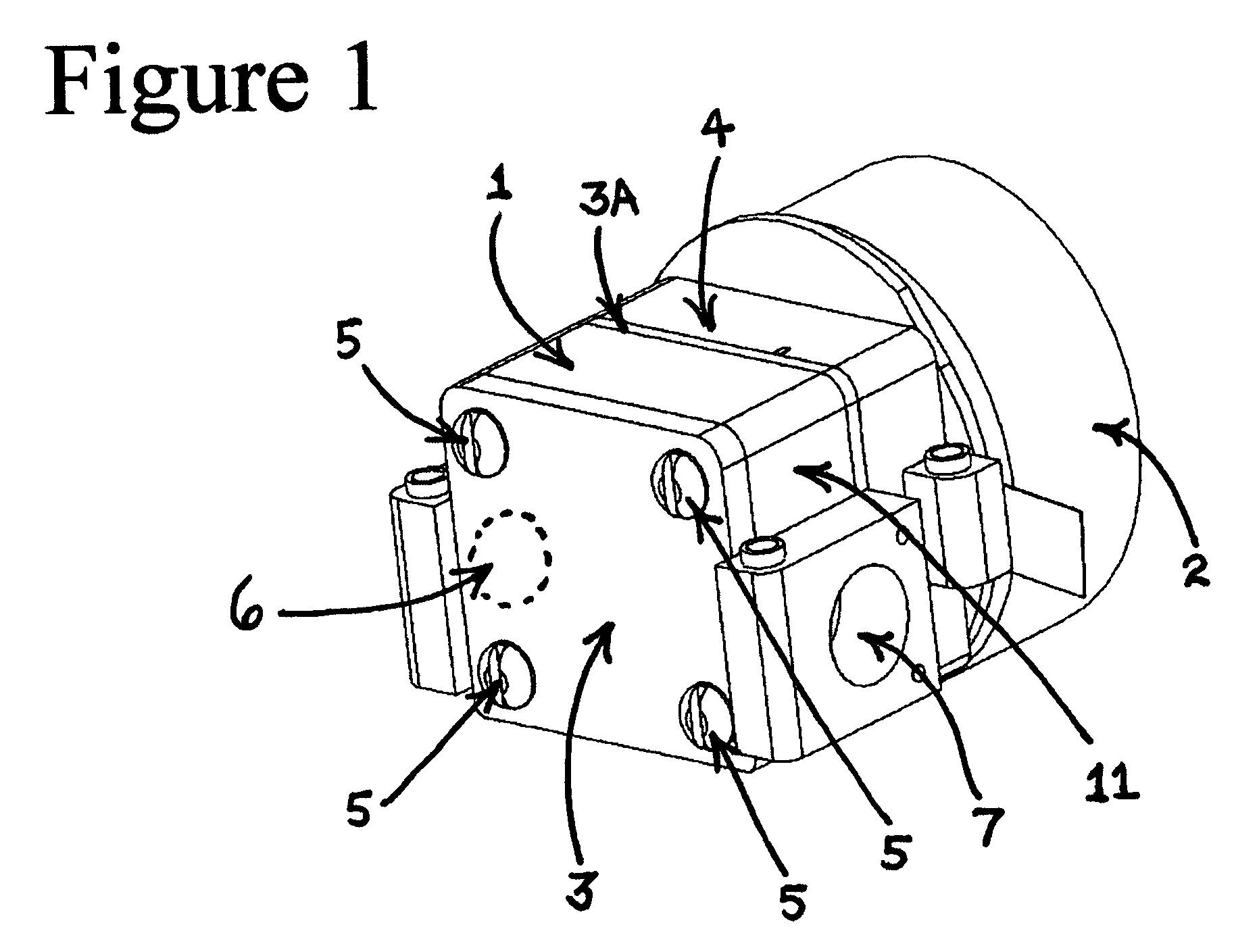

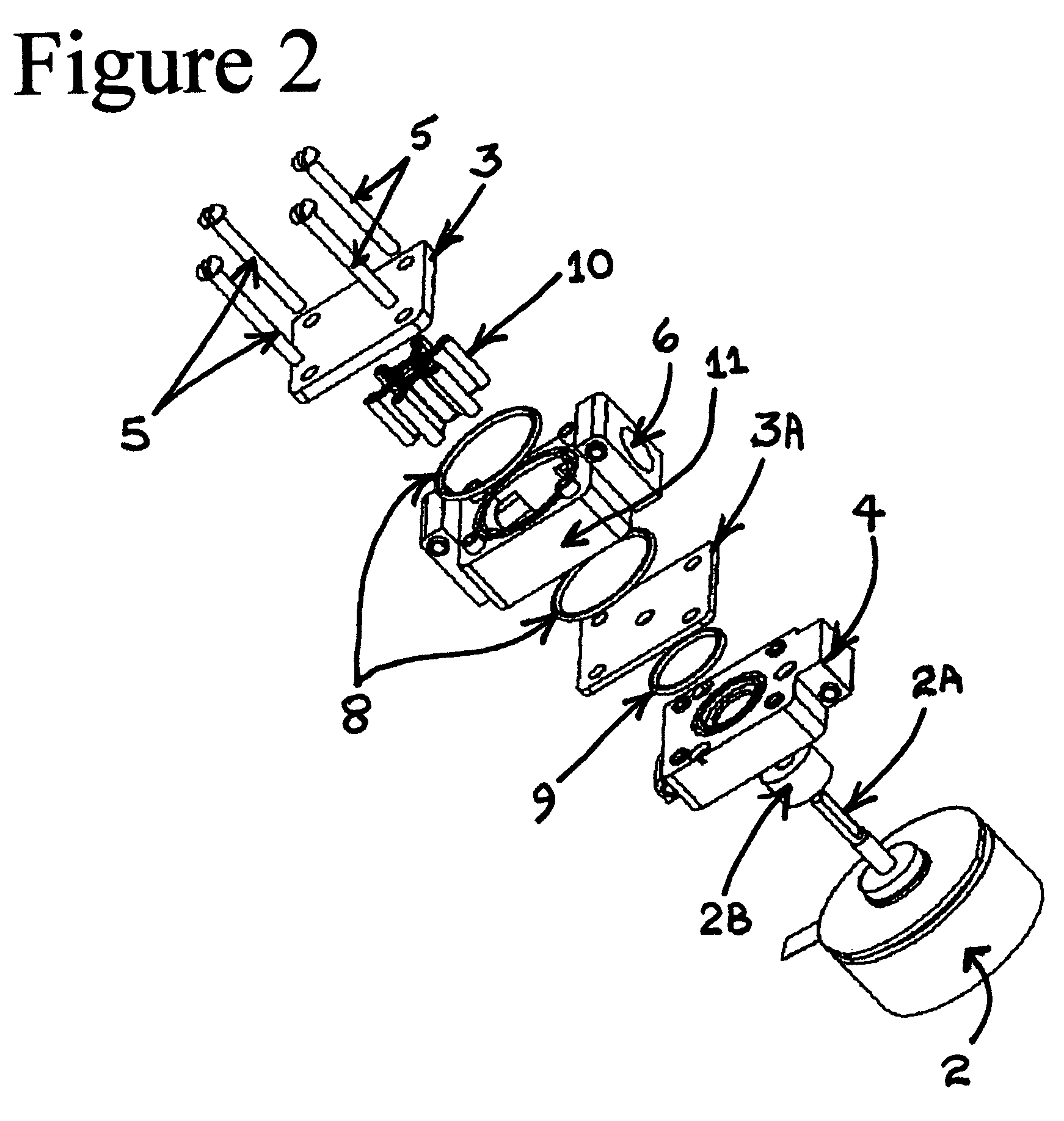

Impeller Installation Tool

ActiveUS20110146044A1Precise positioningEasy to installRotary piston pumpsRotary piston liquid enginesDrive shaftEngineering

A tool for installing a flexible impeller on a drive shaft in the impeller cavity in a water pump including a gripping surface extending about an upper portion of the tool and an open ended channel extending axially through the tool for receiving and releasably retaining a flexible impeller therein in a compressed state. The channel has an upper portion circumscribed by an annular outwardly inclined impeller abutment surface and a lower constant radius portion circumscribed by a depending cylindrical wall. The inclined impeller abutment surface terminates in the constant radius portion.

Owner:PECHERZEWSKI ANDRZEJ

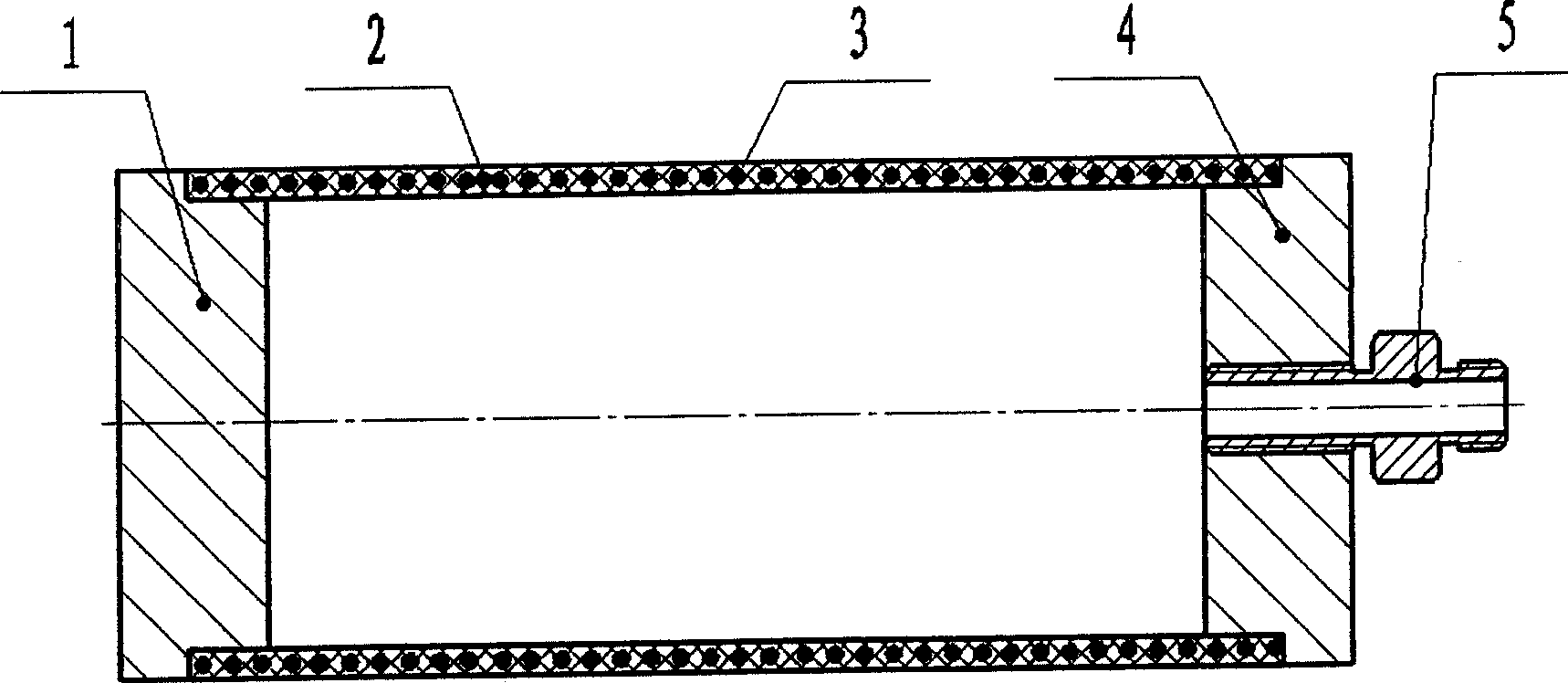

Pneumatic flexible actuator

This invention relates to an air flexible impeller, comprising end caps and rubber pipe with its two end sealed connected to the two end caps via strong glued joint, wherein, one of the end caps is equipped with pipe joint, the pipe wall is nested with a spring to enhance the impeller's elasticity and rigidity. The impeller has simple structure, and convenient assemblage and good hermeticity.

Owner:ZHEJIANG UNIV OF TECH

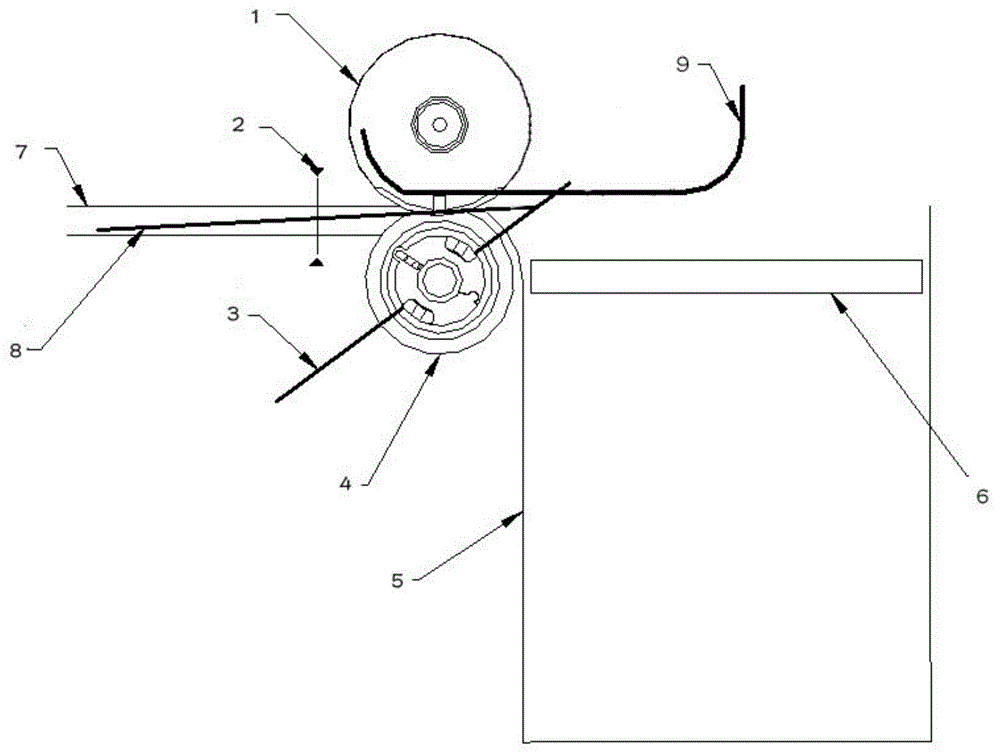

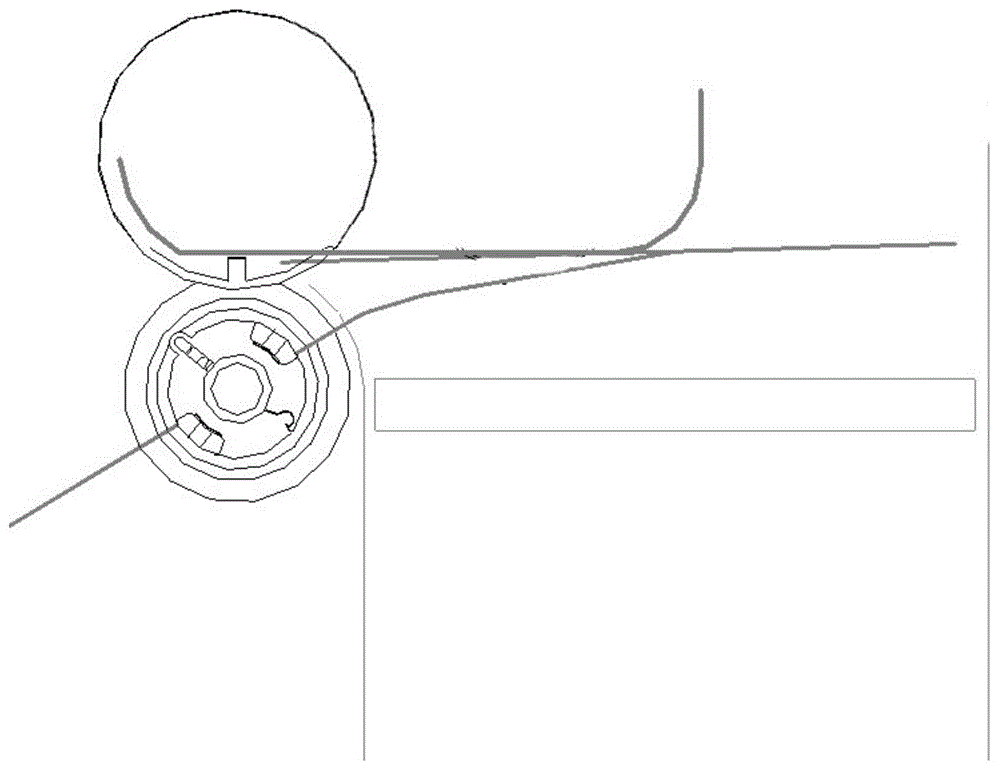

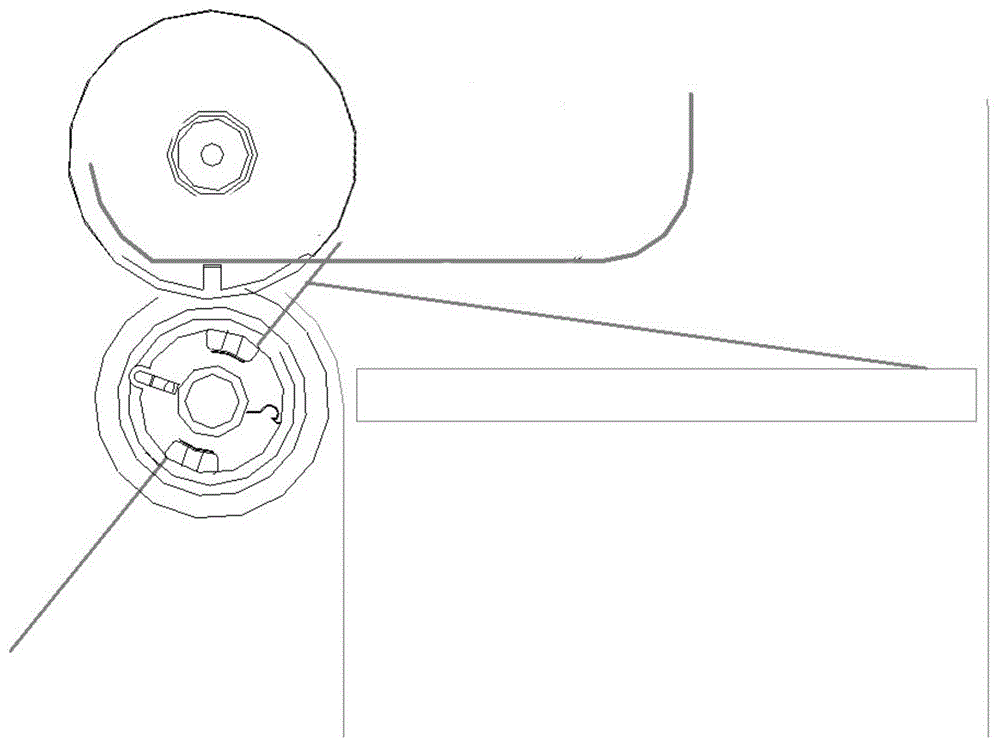

Bank note stacking device

ActiveCN105447962APrevent random tiltingPrevent Flying MoneyCoin/currency accepting devicesEngineeringFlexible impeller

The invention relates to a bank note stacking device of a finance service terminal internal mechanism. The bank note stacking device comprises a machine frame provided with a channel plate for bank note transmission, a friction wheel assembly coaxially arranged on the machine frame, a separating wheel assembly and a flexible impeller. The channel plate is internally provided with a sensor used for detecting entering of bank notes. A guiding plate is arranged at the outer side of the friction wheel assembly, a storage box with a pallet is arranged below one side of the guiding plate, and an abdicating groove for flexible blades is formed on the guiding plate. According to the invention, the channel plate is internally provided with the sensor used for detecting entering of bank notes, the sensor drives the initial positions of the flexible blades of the flexible impeller so as to enable the flexible blades to press the bank notes to the guiding plate when the bank notes enter, a random inclining phenomenon of the bank notes when the bank notes are separated from the separating wheel is avoided, the bank notes are prevented from running away under the high speed rotation of the friction wheel, and the bank notes are separated from the friction wheel assembly and the separating wheel assembly, the bank notes are stripped in a rotation manner and are rightly poked into the pallet of the storage box, so that the stacking of the bank notes is constrained, and the orderly stacking of the bank notes is ensured.

Owner:CASHWAY FINTECH CO LTD

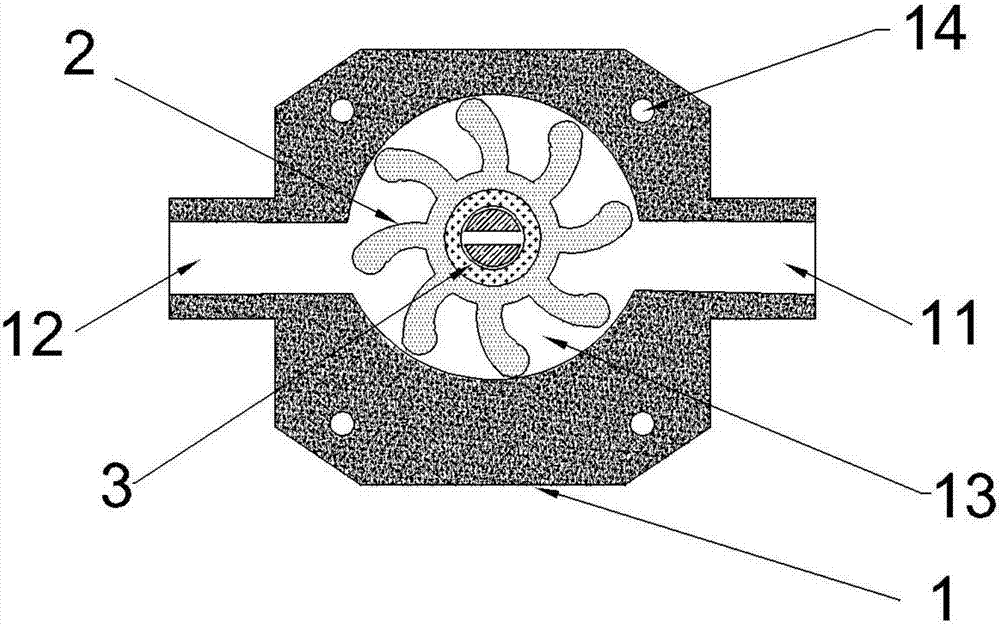

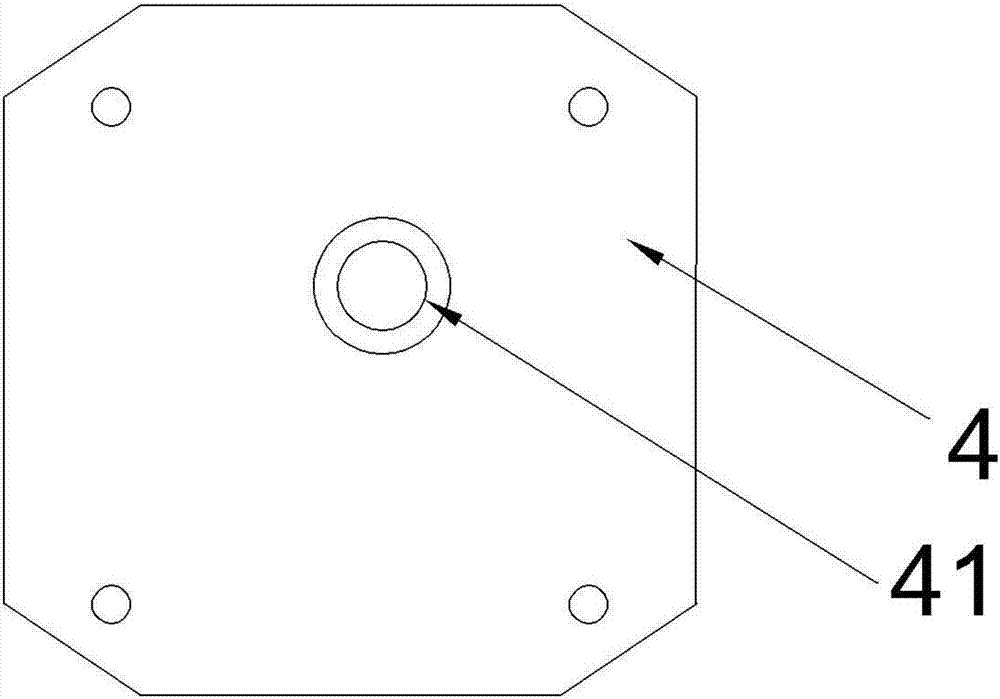

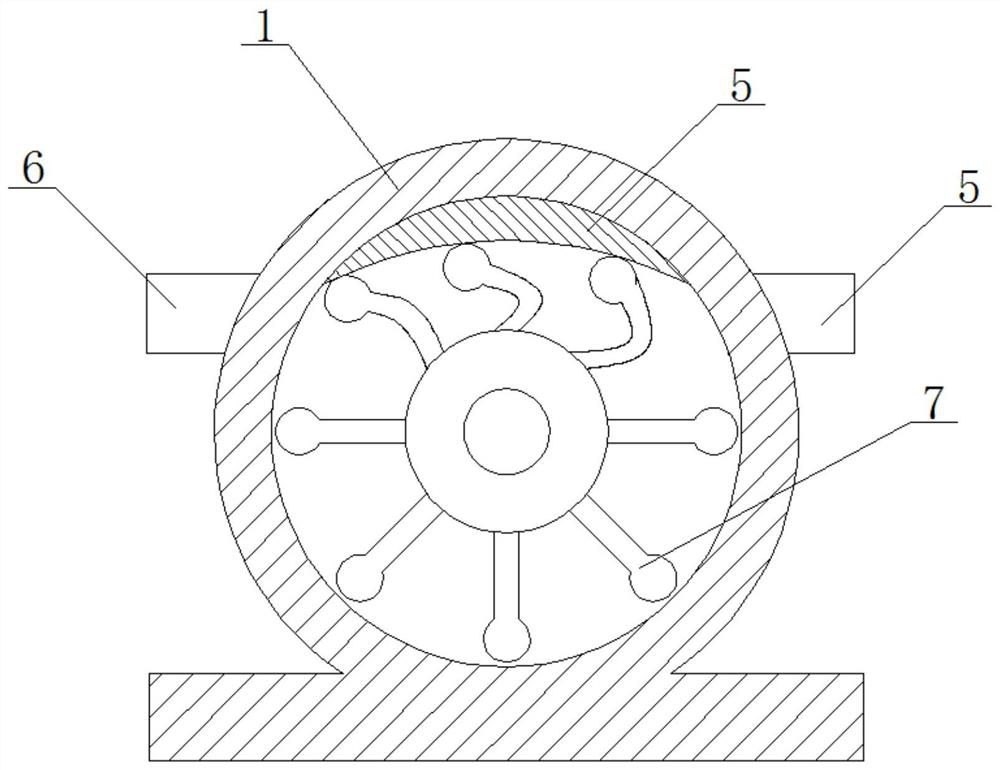

Flexible impeller flowmeter

InactiveCN107036663AHigh measurement accuracyReduce installation costsVolume/mass flow by mechanical effectsRubber materialEngineering

The invention discloses a flexible impeller flowmeter which comprises an impeller mounting seat, an impeller, an impeller mounting shaft and a flow signal sensor. An impeller mounting cavity is formed in the impeller mounting seat, and a liquid inlet pipe and a liquid outlet pipe are oppositely arranged on the two side walls of the impeller mounting seat and communicated with the impeller mounting cavity. The axes of the liquid inlet pipe and the liquid outlet pipe coincide, and the impeller mounting shaft is sleeved with the impeller. The device further comprises a mounting cavity sealing plate, the mounting cavity sealing plate and the impeller mounting cavity are fixedly connected in a sealed mode, a mounting shaft hole is formed in the mounting cavity sealing plate, one end of the impeller mounting shaft is fixedly connected with the mounting shaft hole, and the other end of the impeller mounting shaft is located in the impeller mounting cavity. The impeller and the impeller mounting seat are eccentrically mounted; the impeller and blades on the impeller are made from rubber materials, an existing impeller flowmeter is large in machining difficulty, the precision is greatly influenced by the outside, the disclosed flexible impeller flowmeter is simple in structure, and the measurement precision can be greatly improved.

Owner:ANHUI RUILING GAUGE MFG CO LTD

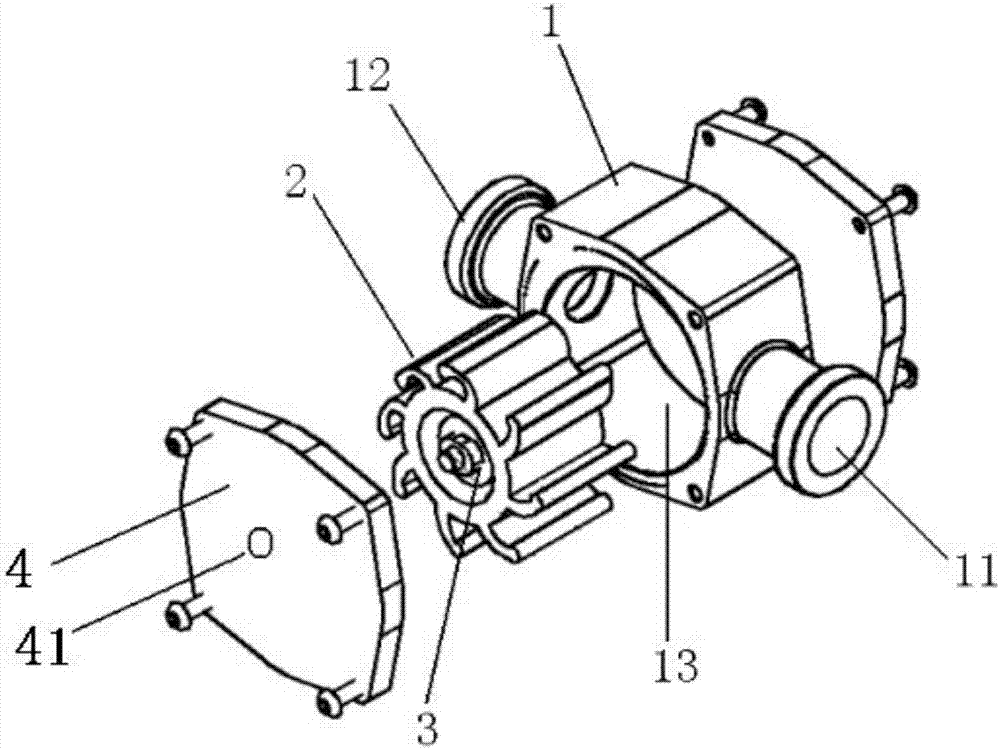

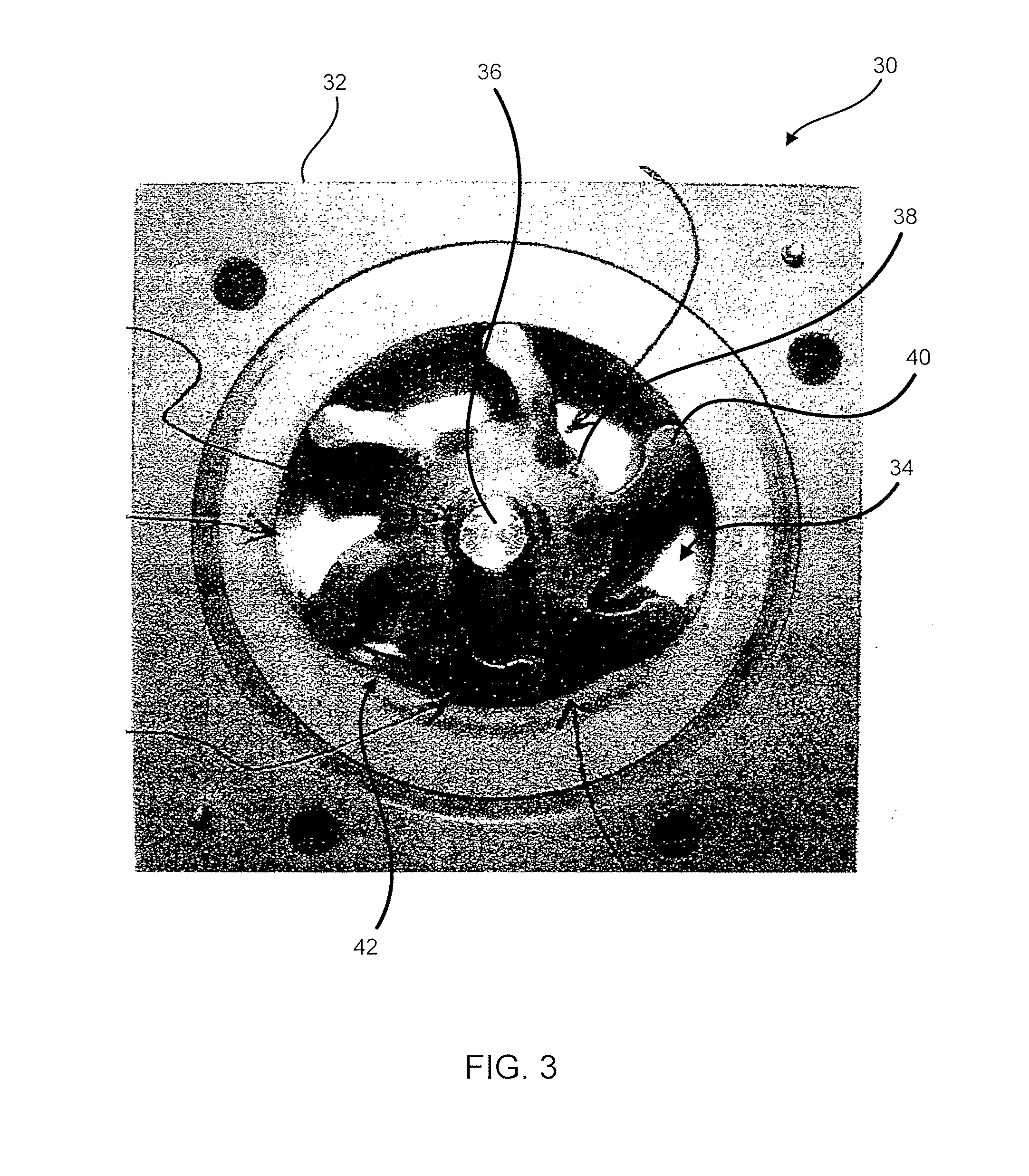

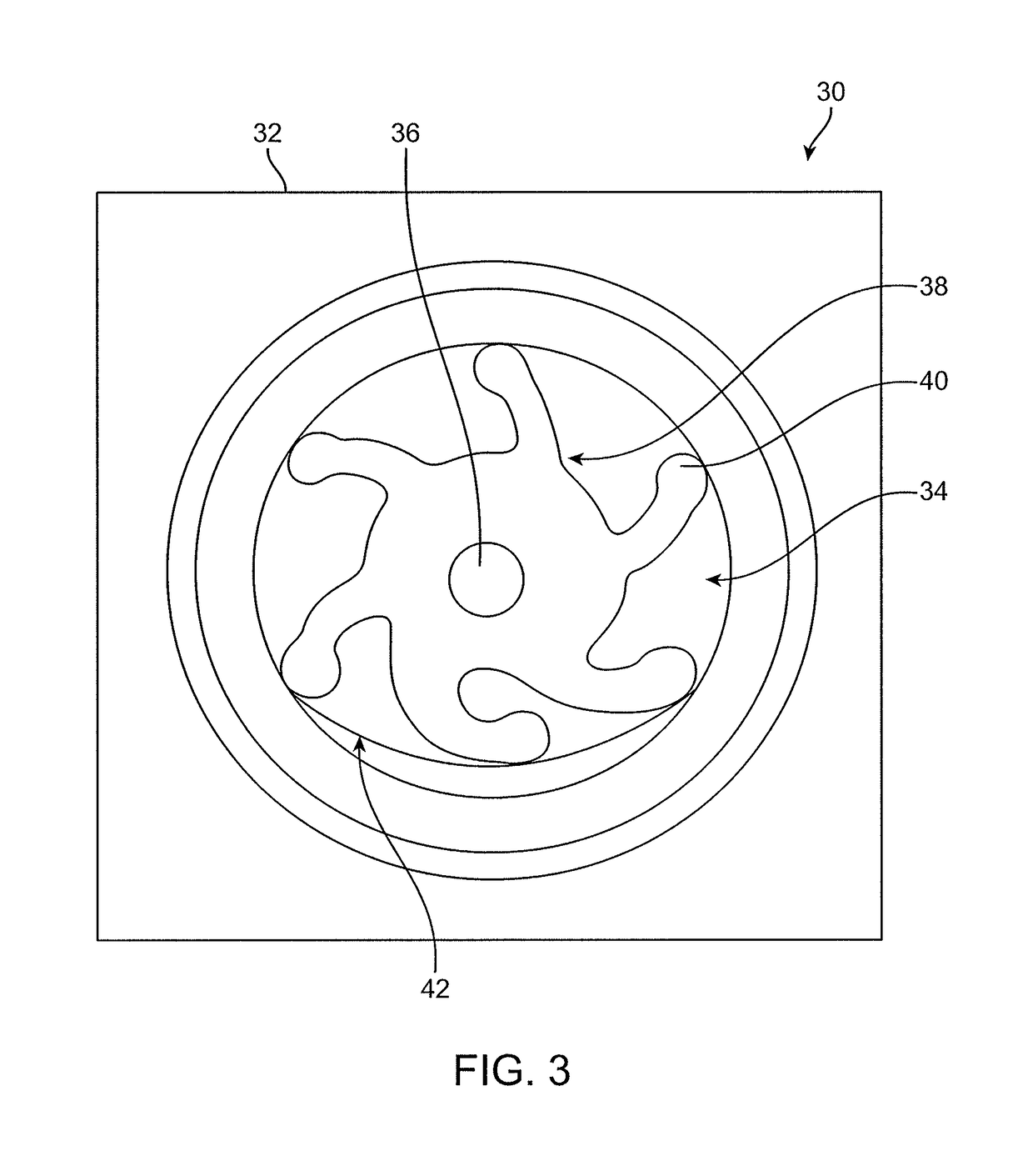

Flexible impeller pump

PendingUS20170130715A1Avoid Insufficient SealingSmall sizeRotary piston pumpsRotary piston liquid enginesDrive shaftEngineering

The present invention relates to improvements in the area of flexible impeller pumps. In particular, the present invention relates to flexible impellers with improved profiles(such as dual sealing lips), which are particularly well-suited to multiple cam pumps. A novel mounting hub configuration for mounting an impeller on a drive shaft is also provided. Pumps comprising such impellers and / or mounting hubs are provided, as are associated methods of installation and removal.

Owner:MARINE FLOW

Mussel shell removing machine

InactiveCN101642158BImprove processing efficiencyIncrease profitBivalves processingTransmission beltElectric machinery

Owner:朱雅光

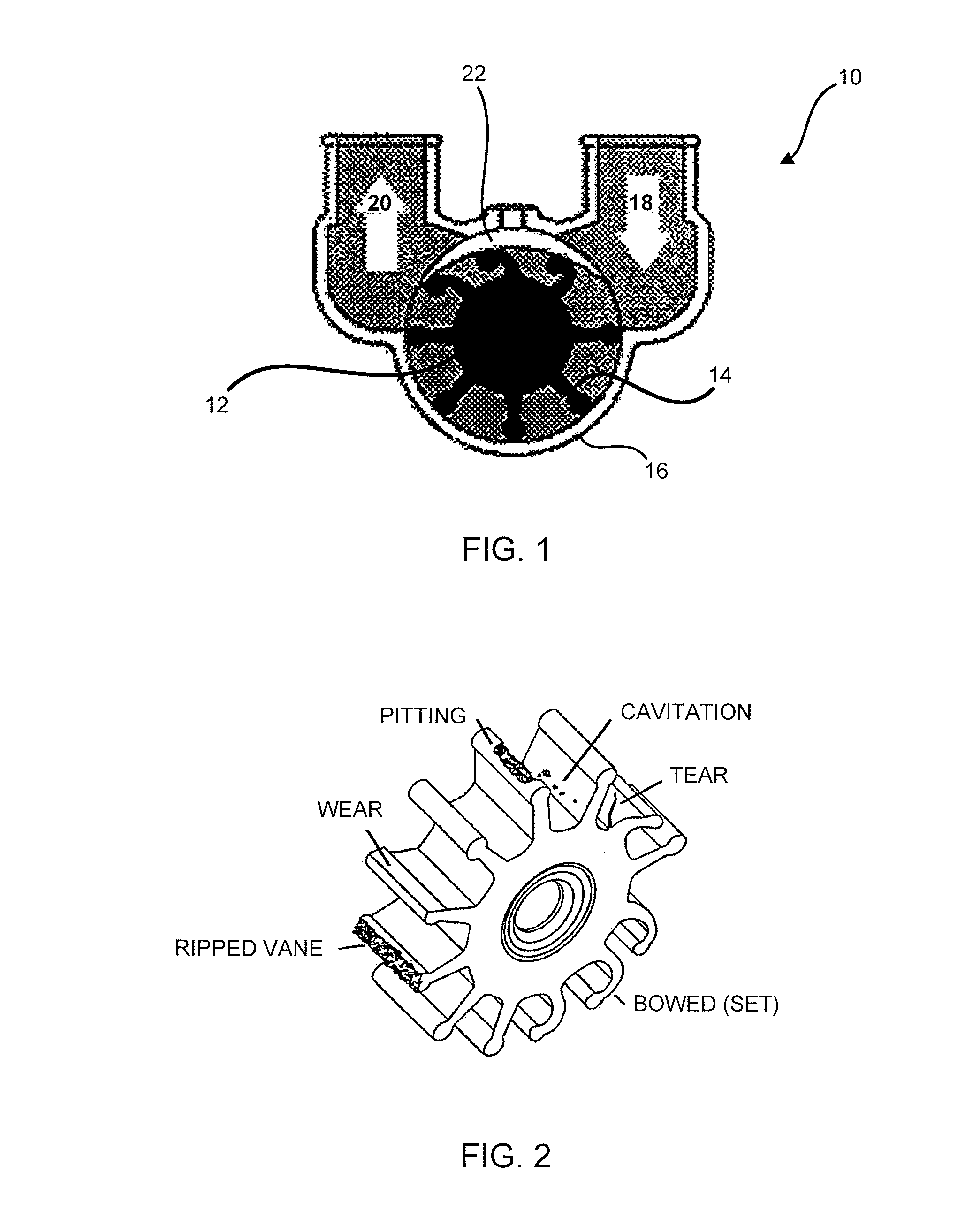

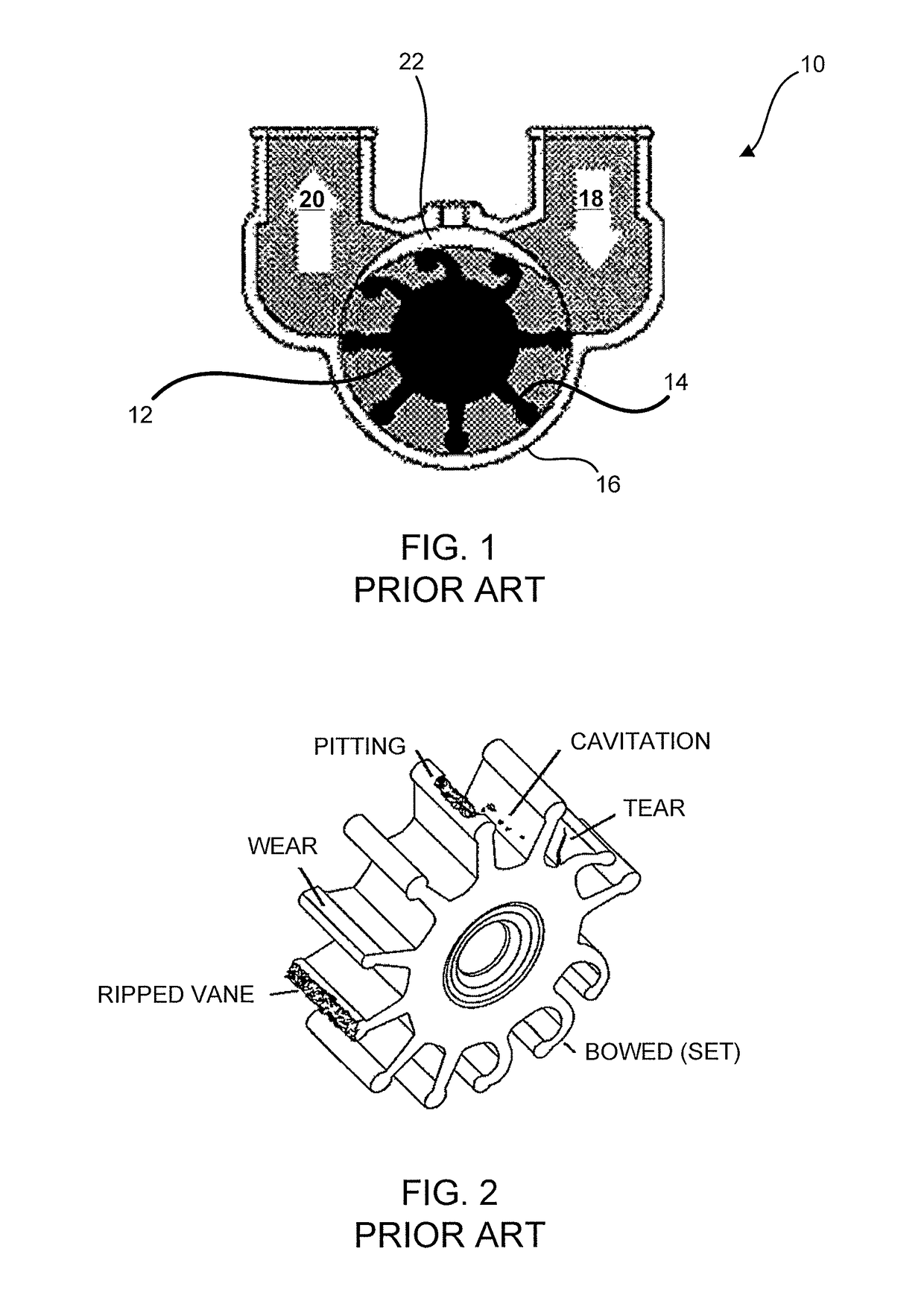

Flexible Impeller Pump

InactiveUS20140301833A1Reduce wearEasy transitionPump componentsLeakage preventionWear resistantEngineering

A flexible impeller pump includes improved flexible impeller geometry, an impeller shaft having protruding portions that produce a stronger and more durable connection between the impeller shaft and the flexible impeller, a smoother housing cam surface, and wear resistant surfaces that are disposed between end faces of the flexible impeller and adjacent housing end walls.

Owner:AUTOMATIC BAR CONTROLS

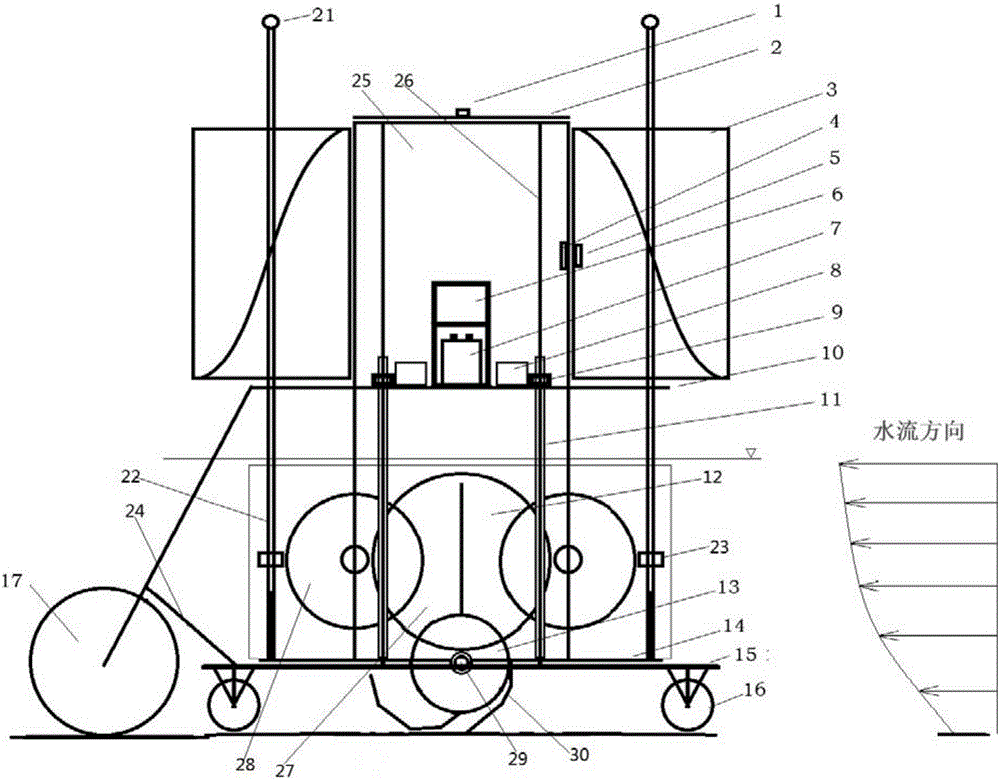

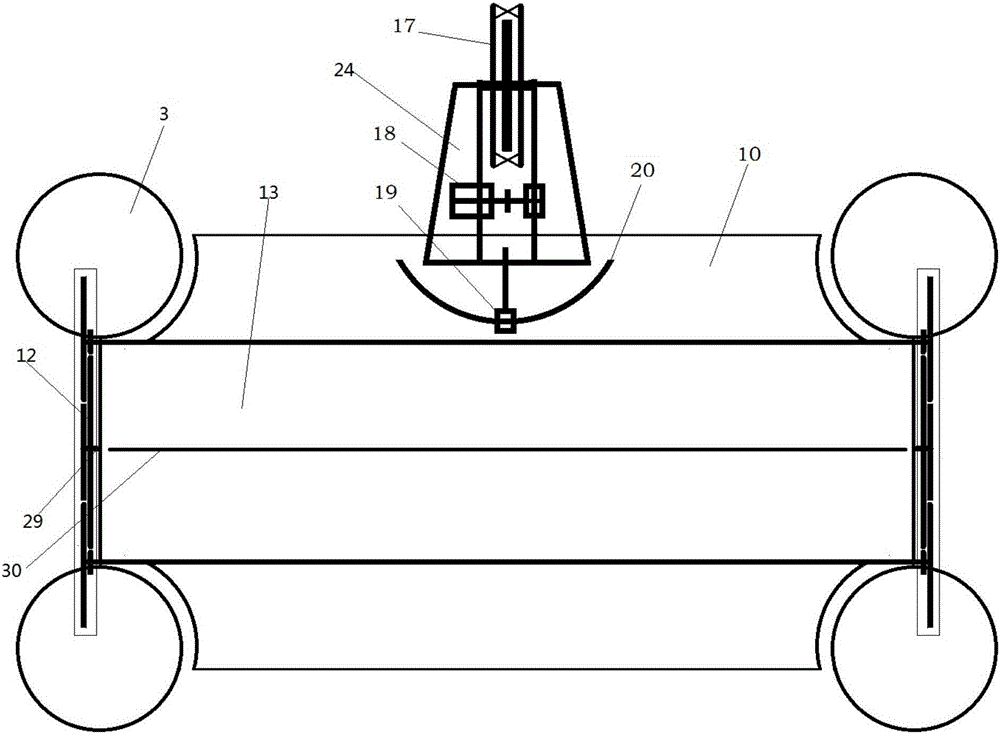

River desilting water vehicle

The invention discloses a river desilting water vehicle which comprises an above-water platform (10), an underwater platform (15) and a lifting platform (14). The middle of the lifting platform (14) is provided with a flexible impeller (13) used for scooping up riverbed silt in a penetrating mode. The four corners of the lifting platform (14) are each provided with a rotary rod (22). Fans (3) are arranged on the portions, located above the above-water platform (10), of the rotary rods (22). The two ends of a drive gear shaft (29) of the flexible impeller (13) are separately engaged with reduction gear sets (12) which are engaged with fan rotary rod gears (23) arranged on the rotary rods (22) in a sleeving mode. According to the river desilting water vehicle, riverbed bottom mud is stirred through kinetic energy of flowing water and transported to downstream ocean along with the flowing water, no secondary transport cost exists, water surface wind energy and solar energy are used as additional power, the desilting efficiency is improved, clean energy is used, and zero-carbon emission is achieved.

Owner:HOHAI UNIV

Impeller installation tool

ActiveUS9957977B1Well formedPump componentsRotary piston pumpsFlexible impellerBiomedical engineering

A tool for installing a flexible impeller within a water pump includes a sleeve having a diameter smaller than an initial diameter of an impeller in a relaxed state, a support extending about an end of the sleeve, and a translation assembly engaged with the support and configured for translating a pushing surface of the translation assembly. In operation, an impeller is contracted into a constrained state and placed in the sleeve, the sleeve is then positioned proximal or in engagement with an opening of the water pump, and the translation assembly is translated such that the pushing surface pushes the impeller into the engine assembly as the translation assembly is translated.

Owner:GLOBAL MARINE PERFORMANCE

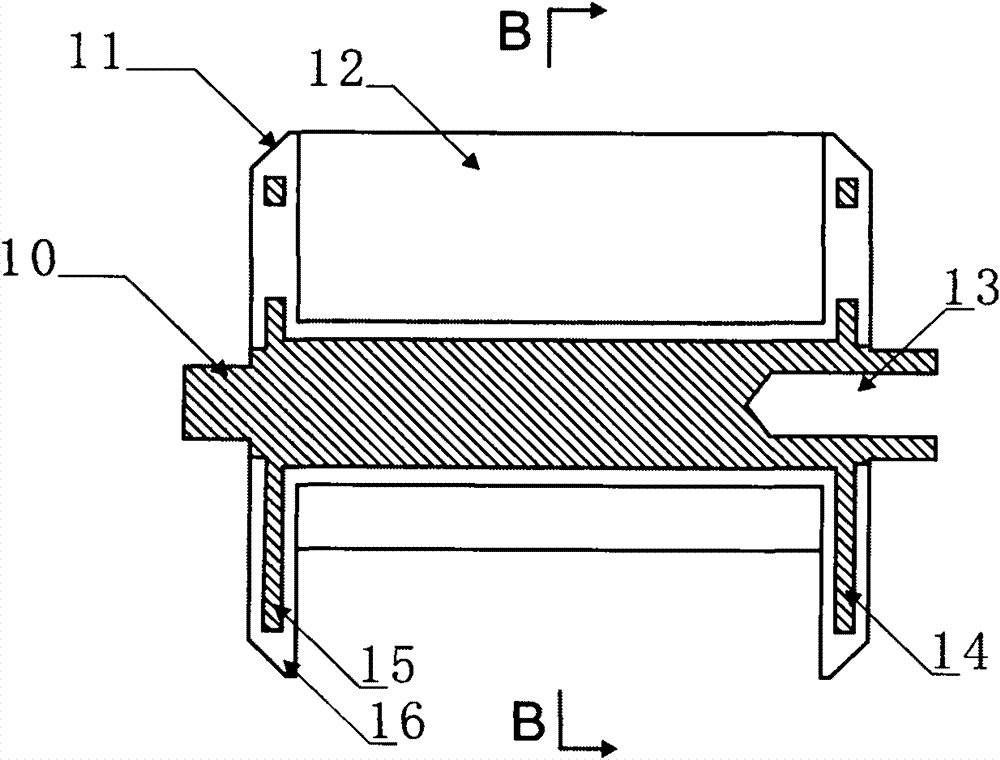

Flexible impeller of airlock device of soldering flux recycling machine

InactiveCN101934922AGuaranteed StrengthGuaranteed stiffnessBulk conveyorsRotary conveyorsColloidEngineering

The invention relates to a flexible impeller of an airlock device of a soldering flux recycling machine, comprising an impeller shaft, a first wheel disc, a second wheel disc and a plurality of blades, wherein the first wheel disc and the second wheel disc are fixedly connected on the impeller shaft; and the plurality of blades are arranged between the first wheel disc and the second wheel disc. The flexible impeller of the airlock device of the soldering flux recycling machine is characterized in that the impeller shaft as well as the first wheel disc and the second wheel disc are made from metal to form a metal impeller framework; a flexible colloid cladding layer is arranged on the outer surface of the metal impeller framework; and the blades are made from the flexible colloid. In the invention, the metal impeller framework is adopted for the impeller to ensure the strength and the rigidity of the impeller; and the flexible colloid cladding layer outside the metal impeller framework and the blades made from the flexible colloid can be both deformed, thereby the phenomena of jamming and blocking by large-particle materials do not occur, and the airlock device is safe and reliable to run.

Owner:邹毓林

Flexible impeller pump

InactiveUS9719508B2Improved vane to main bodyReduce wearPump componentsRotary piston pumpsWear resistantEngineering

A flexible impeller pump includes improved flexible impeller geometry, an impeller shaft having protruding portions that produce a stronger and more durable connection between the impeller shaft and the flexible impeller, a smoother housing cam surface, and wear resistant surfaces that are disposed between end faces of the flexible impeller and adjacent housing end walls.

Owner:AUTOMATIC BAR CONTROLS

Dry running flexible impeller pump and method of manufacture

This invention relates to a Dry Running Flexible Impeller Pump and Method of Manufacture designed to provide a flexible impeller pump capable of being run dry for extended periods of time without damage. The pump's components are comprised of low friction materials limiting the heat of friction created by the impeller in use. The impeller is cast of pre-molding silicone substrate containing a quantity of mold release that will not prevent the deposition of a low friction compound coating on the surface of the impeller in a mold that is treated with a low friction industrial coating. Once the impeller is removed from the mold it is solvent cleaned, vacuum baked at a temperature high enough to drive off residual traces of mold release or compounds used to maintain the silicone substrate in suspension, and then coated with a polymer of Poly Para Xylylene by vacuum deposition.

Owner:HARVIE MARK R

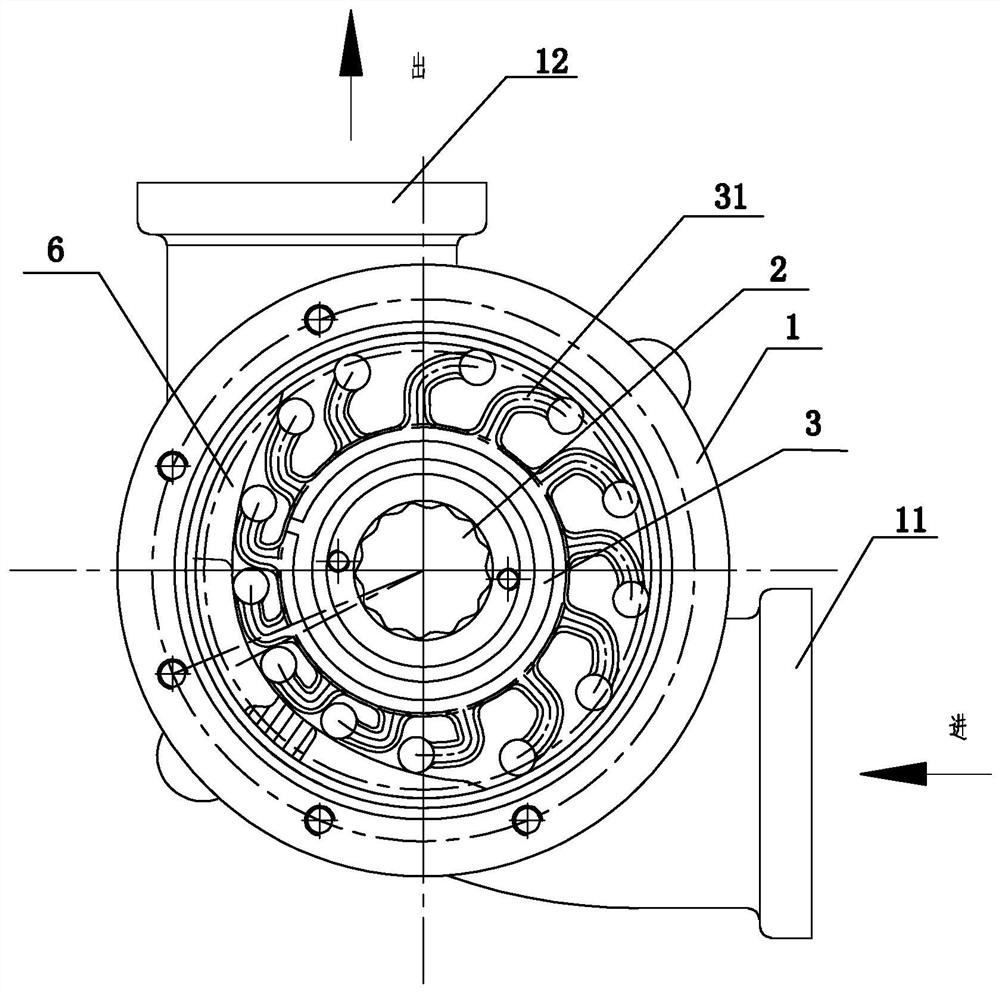

Flexible impeller pump

PendingCN111927766AImprove output performanceAvoid cloggingRotary piston pumpsRotary piston liquid enginesDrive shaftEngineering

The invention relates to the technical field of impeller pumps, and discloses a flexible impeller pump. The flexible impeller pump comprises a pump body, wherein the pump body communicates with a liquid inlet and a liquid outlet, and flexible blades are arranged in the pump body; an eccentric block is connected to the inner side wall of the pump body, the liquid inlet and the liquid outlet are symmetrically arranged relative to the eccentric block, and a filtering and cleaning mechanism is arranged at the liquid inlet; the filtering and cleaning mechanism comprises a filter screen, the filterscreen is connected to the hole wall of the end, far away from the pump body, of the liquid inlet, and the hole wall of the end, close to the pump body, of the liquid inlet is rotationally connected with a supporting shaft through two symmetrically-arranged rotating pieces; and the shaft wall of the supporting shaft is fixedly sleeved with fan blades, and the shaft wall of the supporting shaft isconnected with a driving shaft through a transmission piece. According to the flexible impeller pump, the output effect of the flexible impeller pump on liquid is improved, meanwhile, a cleaning brushrotates on the filter screen in a reciprocating mode with a half circle as the stroke, and the filter screen is cleaned from the inner side of the filter screen, so that the filter screen is prevented from being blocked.

Owner:江苏科密机械制造有限公司

Dry running flexible impeller pump and method of manufacture

This invention relates to a Dry Running Flexible Impeller Pump and Method of Manufacture designed to provide a flexible impeller pump capable of being run dry for extended periods of time without damage. The pump's components are comprised of low friction materials limiting the heat of friction created by the impeller in use. The impeller is cast of pre-molding silicone substrate containing a quantity of mold release that will not prevent the deposition of a low friction compound coating on the surface of the impeller in a mold that is treated with a low friction industrial coating. Once the impeller is removed from the mold it is solvent cleaned, vacuum baked at a temperature high enough to drive off residual traces of mold release or compounds used to maintain the silicone substrate in suspension, and then coated with a polymer of Poly Para Xylylene by vacuum deposition.

Owner:HARVIE MARK R

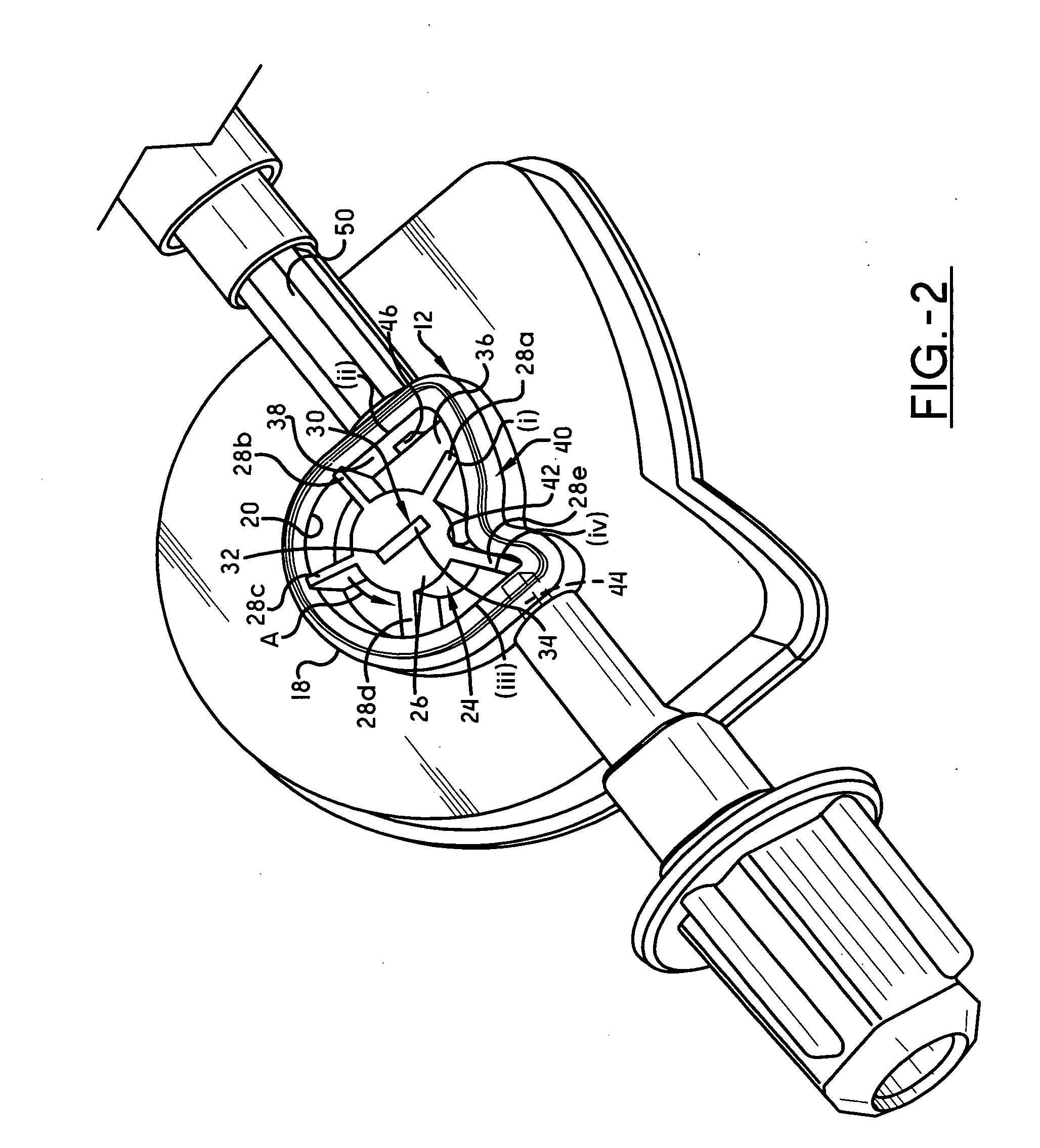

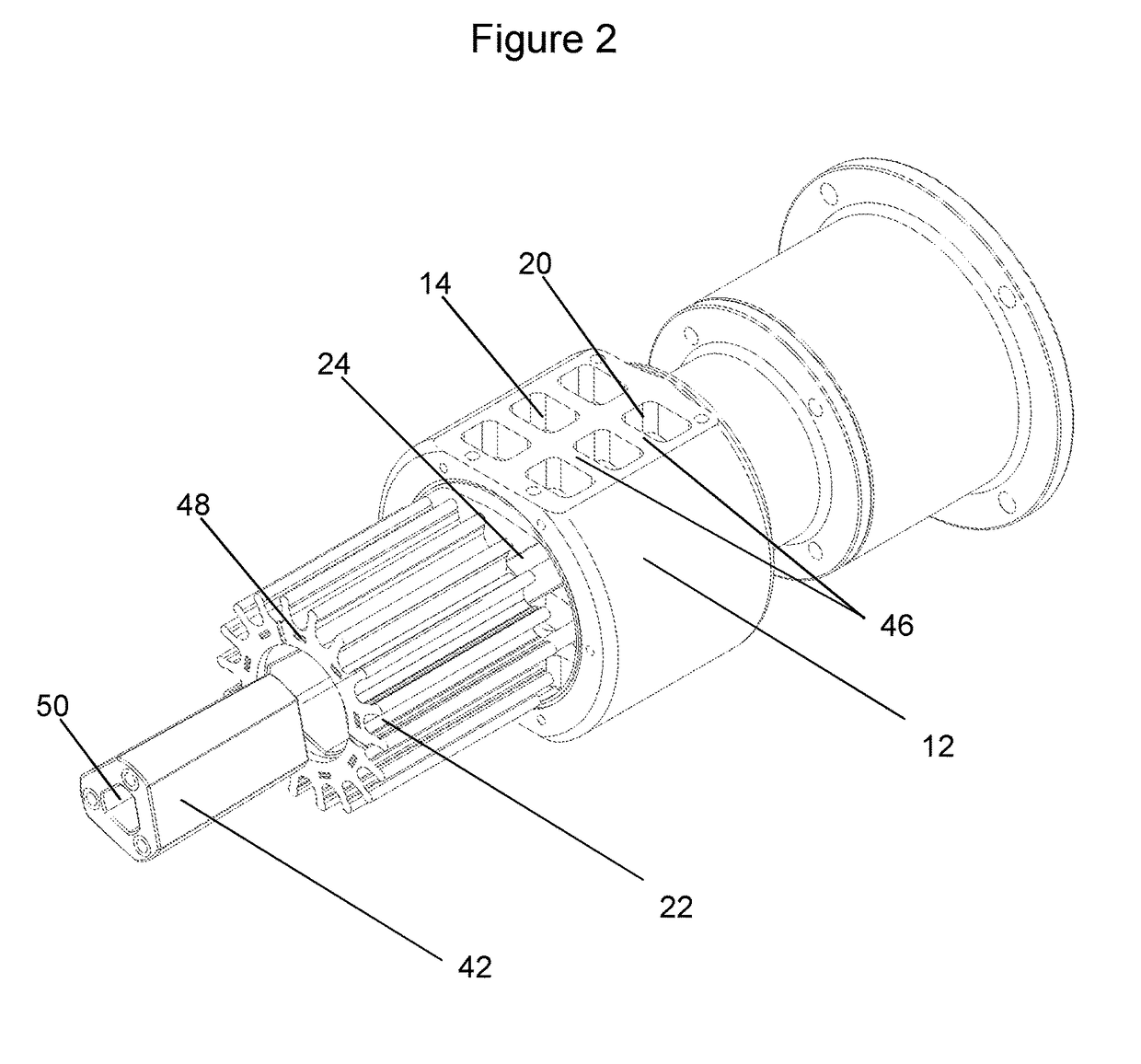

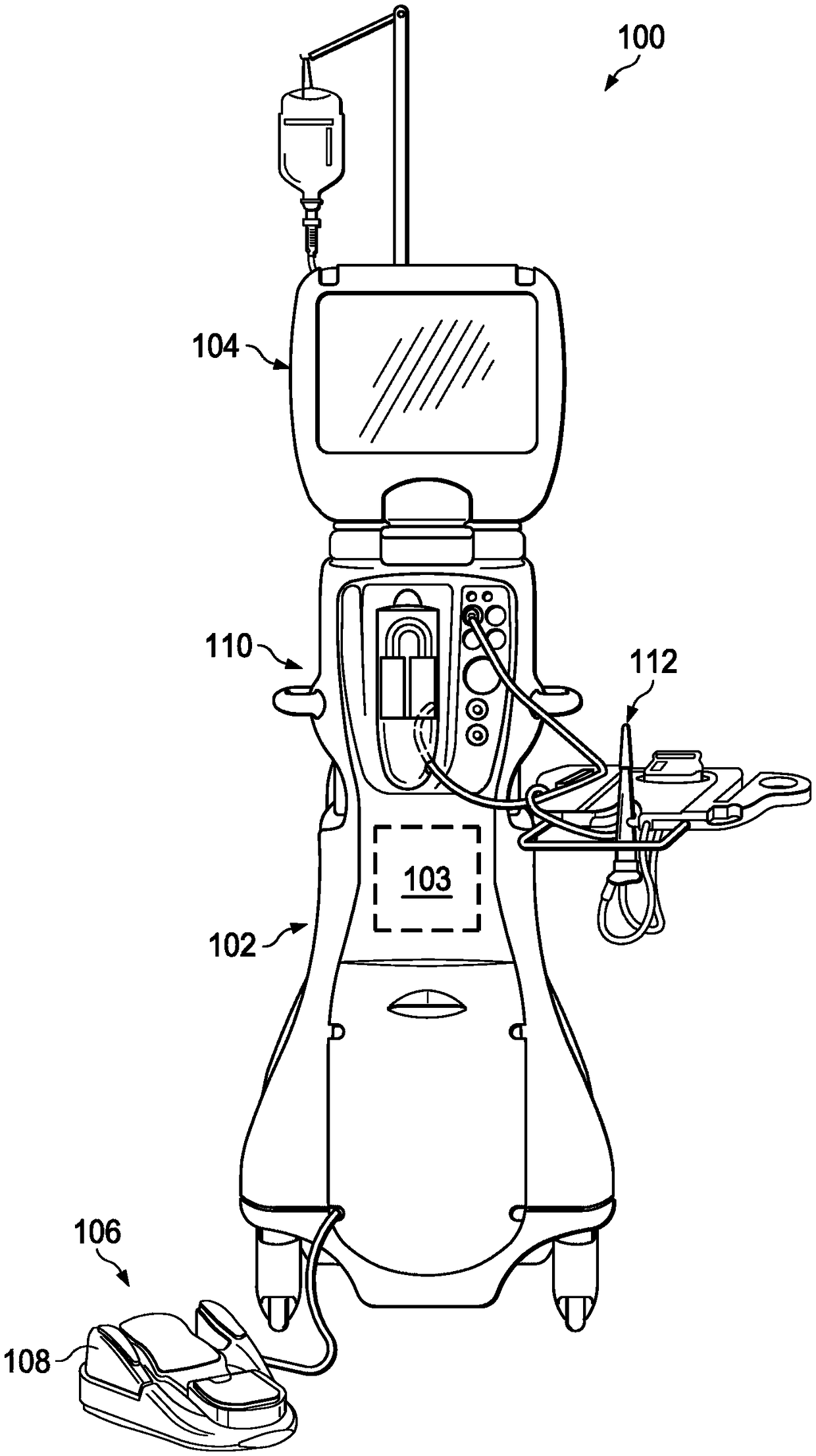

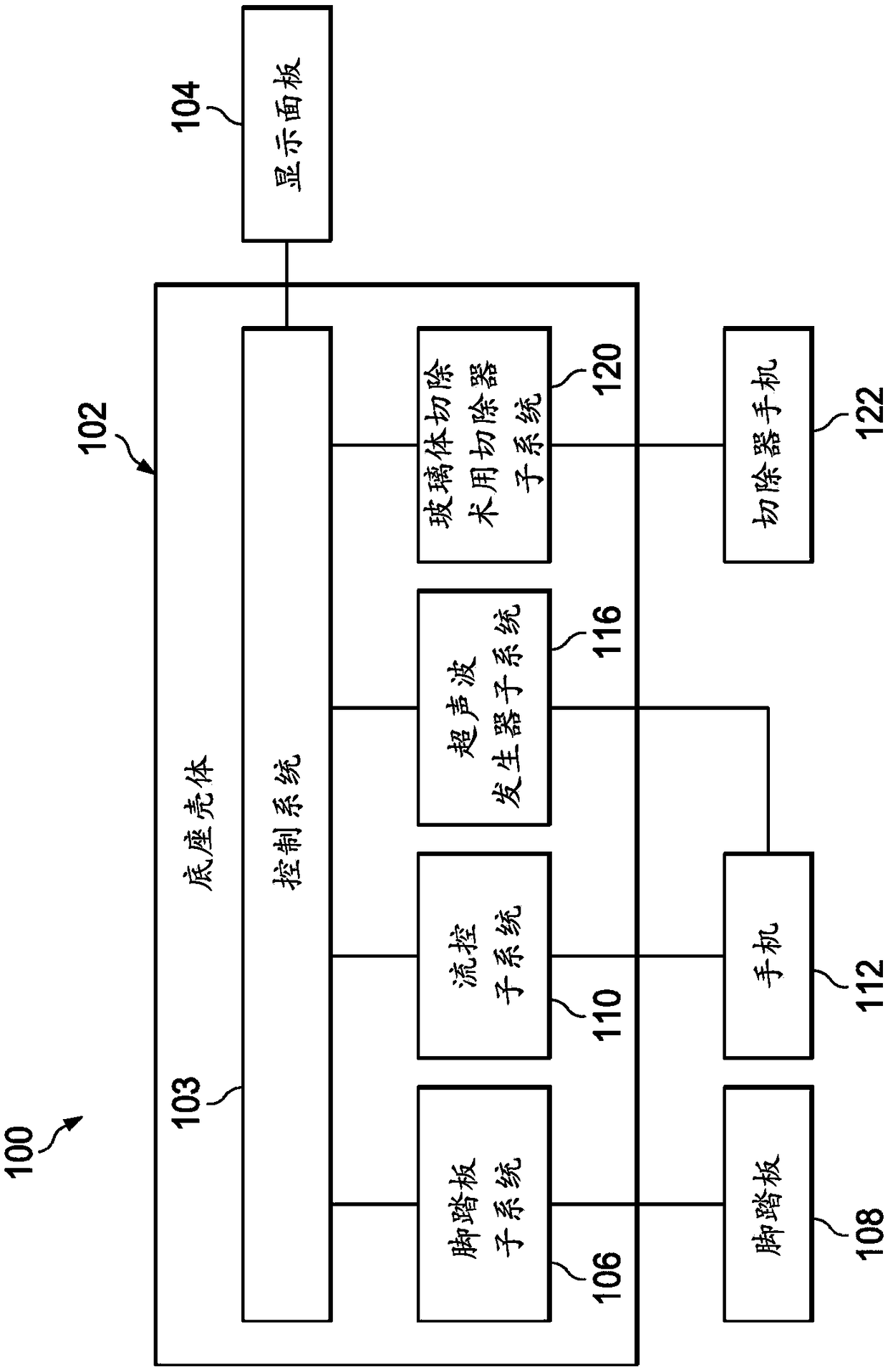

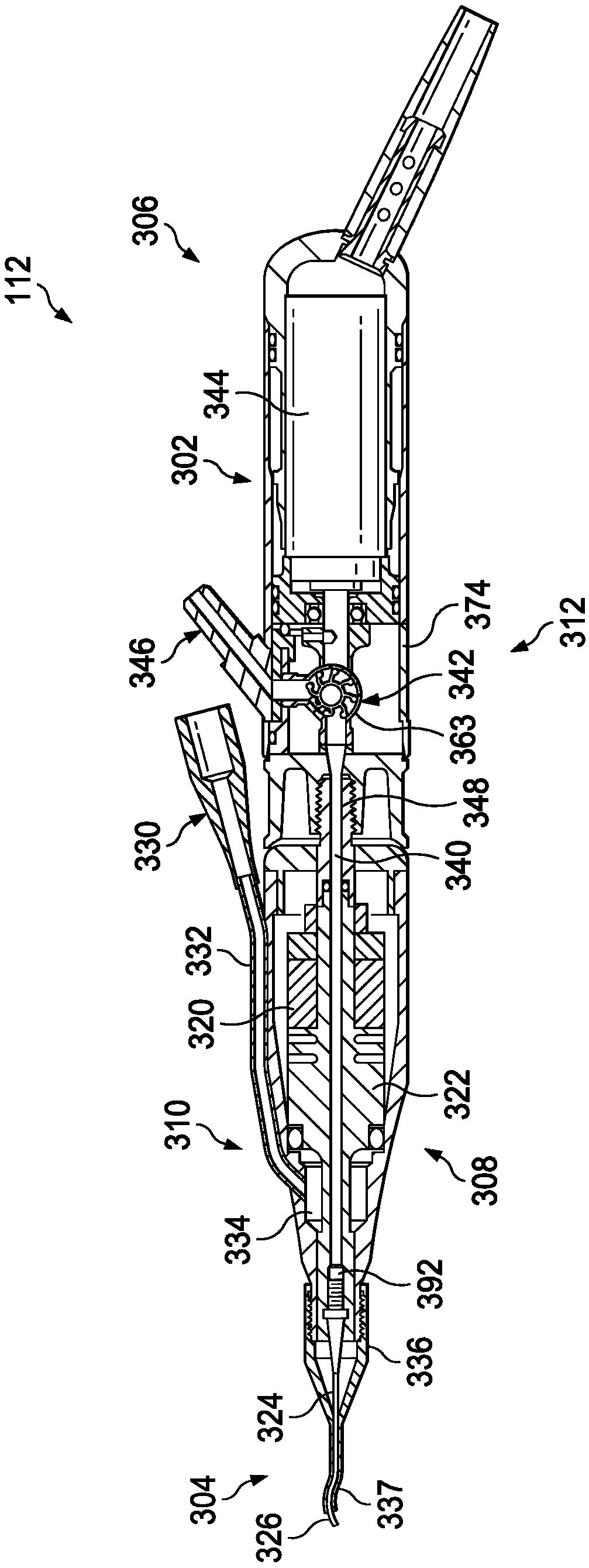

Phacoemulsification handpiece with flexible impeller pump

A phacoemulsification system that includes a hand-graspable body and a phacoemulsification needle extending from a distal portion of the body is disclosed herein. The phacoemulsification system may also include an impeller pump carried by the hand-graspable body and configured to convey an aspiration fluid from a surgical site. The impeller pump may include an aspiration motor and a flexible impeller coupled to and rotatably driven by the aspiration motor. The flexible impeller may be arranged to aspirate fluid and emulsified lens tissue from the surgical site.

Owner:NOVARTIS AG

Impeller installation tool

ActiveUS8312607B2Minimize necessary compressionPrecise positioningRotary piston pumpsRotary piston liquid enginesDrive shaftAbutment

A tool for installing a flexible impeller on a drive shaft in the impeller cavity in a water pump including a gripping surface extending about an upper portion of the tool and an open ended channel extending axially through the tool for receiving and releasably retaining a flexible impeller therein in a compressed state. The channel has an upper portion circumscribed by an annular outwardly inclined impeller abutment surface and a lower constant radius portion circumscribed by a depending cylindrical wall. The inclined impeller abutment surface terminates in the constant radius portion.

Owner:PECHERZEWSKI ANDRZEJ

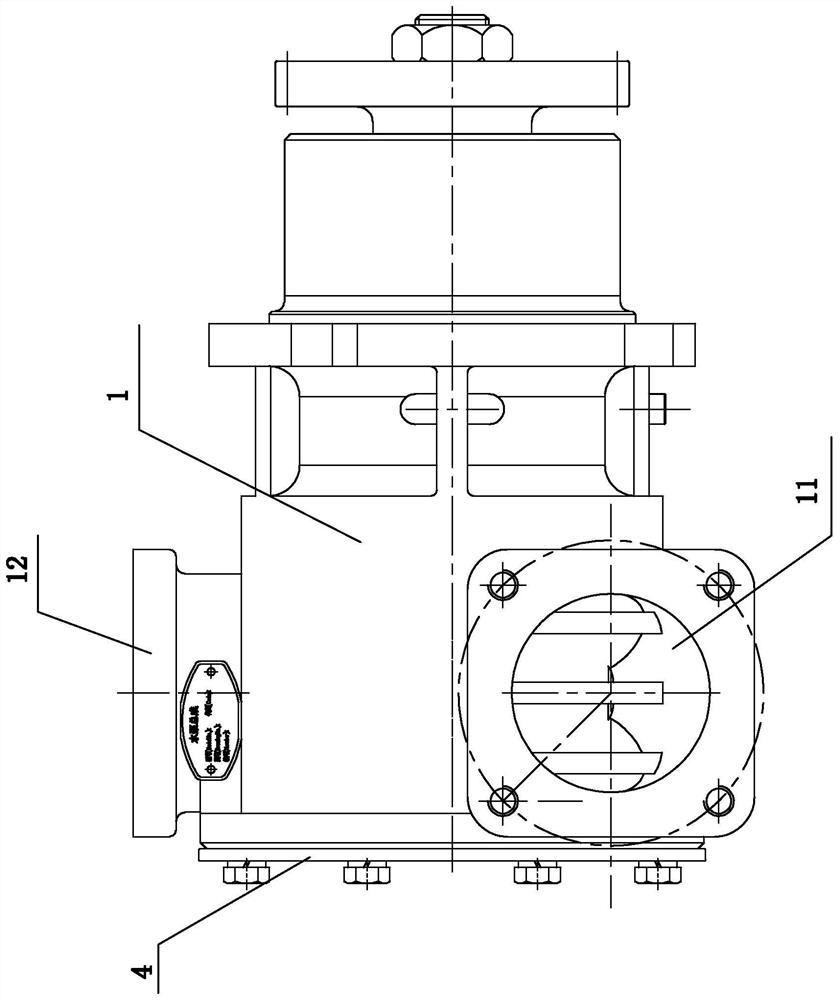

Flexible impeller sea water pump

PendingCN112177971AImprove efficiencyReduce pressure differencePump componentsPumpsOutfallCentrifugal force

The invention relates to a water pump, in particular to a flexible impeller sea water pump. The flexible impeller sea water pump comprises a pump body, a water inlet is formed in the bottom of the pump body, a water outlet is formed in the top of the pump body, an impeller shaft and a flexible impeller arranged on the impeller shaft are arranged in the pump body, an end cover is arranged on the pump body, partition plates capable of adjusting the axial compression amount of an impeller are arranged at the two ends of the impeller, two annular grooves are arranged on potions, in a water inlet end area of the water pump, of the partition plates, the grooves respectively communicate with the root and the top of an impeller blade fin groove, fan-shaped grooves are formed in the back of the partition plates, namely in the pump body and the cover plate respectively to communicate the two annular grooves in the partition plates, and the annular groove in the tops of the partition plates directly communicates with a water inlet of the water pump. The invention aims to provides the flexible impeller sea water pump, the communicating grooves are additionally formed in the partition plates atthe two ends of the impeller, the water inlet of the water pump communicates with the root of the the impeller blade fin groove under the condition that no centrifugal force influence exists, and fluid at the water inlet is introduced into the root of the blade fin groove with negative pressure generated caused by the centrifugal force influence, so that the flow output and efficiency of the seawater pump are improved.

Owner:浙江华工汽车零部件有限公司

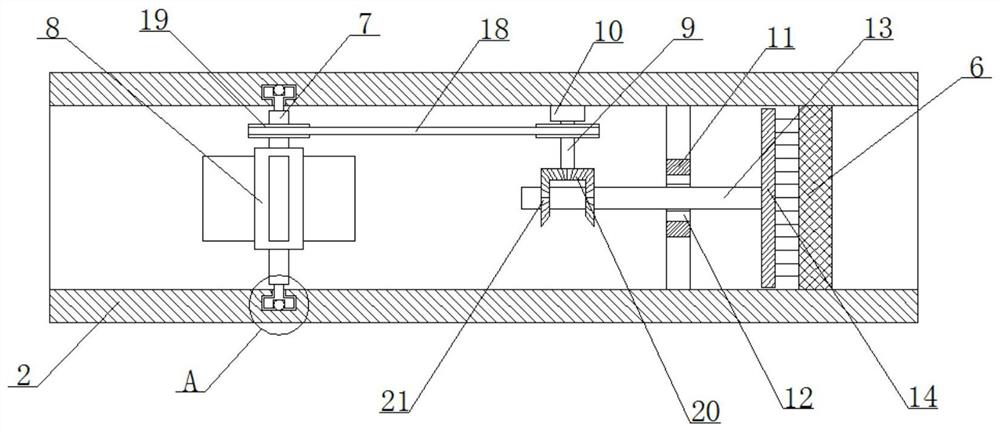

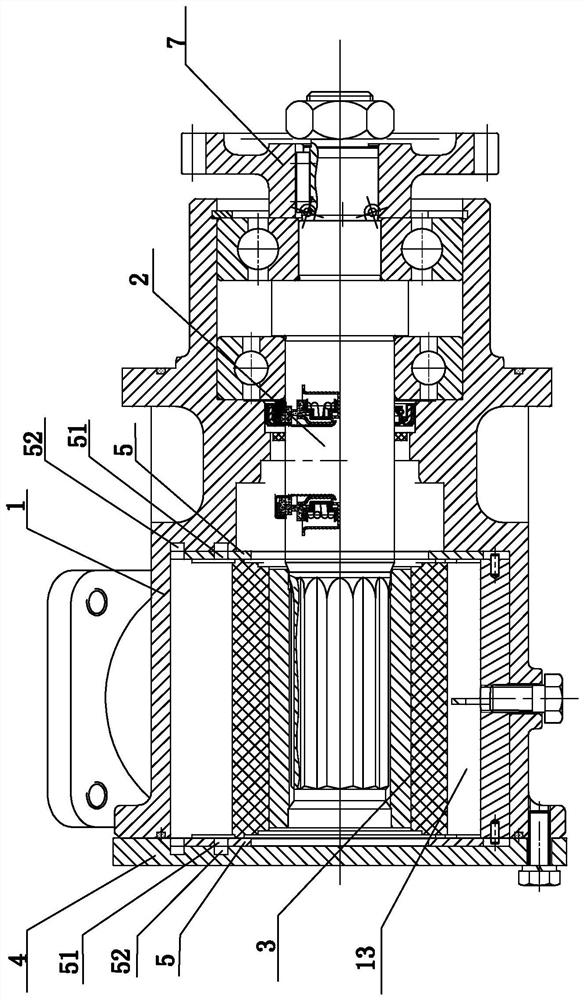

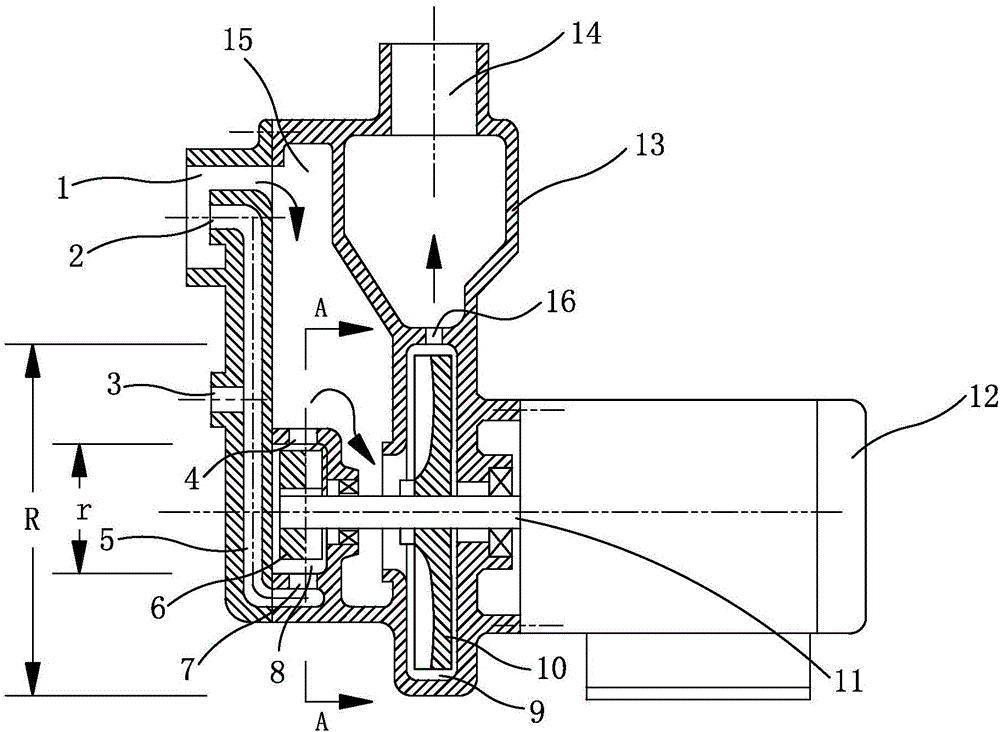

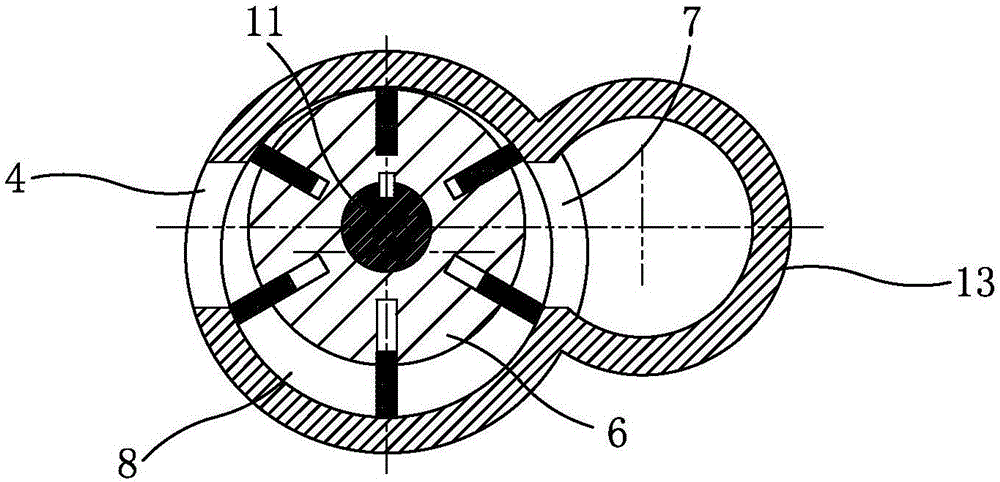

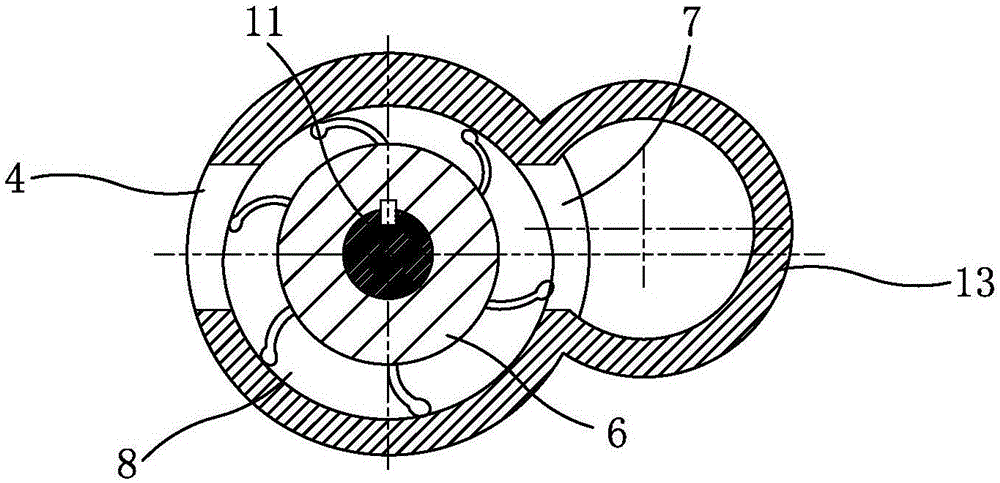

Non-filling large-flow self-sucking pump and use method thereof

ActiveCN106762689AReasonable structural designSimple structureRotary piston pumpsRotary piston liquid enginesEngineeringFlexible impeller

The invention relates to a non-filling large-flow self-sucking pump and a use method thereof and is designed to solve the technical problems that an existing large-flow self-sucking pump of the same type is excessively high in production cost and large in size, and filling is required when a large-flow impeller pump is used as the self-sucking pump. The self-sucking pump comprises a pump body assembly and motors and is mainly characterized in that motor output shafts of the motors are connected with an impeller and a blade rotor correspondingly, the blade rotor is a child-mother blade wheel or a flexible impeller wheel, the blade rotor is arranged in a blade work cavity of a pump body, the impeller is arranged in an impeller work cavity of the pump body, a small liquid inlet a and small liquid inlet b of the pump body communicate with the blade work cavity through a liquid feeding pipe, a large liquid inlet and an outlet of the blade work cavity communicate with the impeller work cavity through a liquid injection cavity, a pump outlet of the pump body communicates with the impeller work cavity through an outlet of the impeller work cavity, and the small liquid inlet a, the small liquid inlet b and the liquid feeding pipe (5) are arranged to be of an F shape. If the small liquid inlet a or the small liquid inlet b is sealed, the small liquid inlet b or the small liquid inlet a is opened.

Owner:宁波市镇海德瑞普电器有限公司

Flexible impeller of airlock device of soldering flux recycling machine

InactiveCN101934922BGuaranteed StrengthGuaranteed stiffnessBulk conveyorsRotary conveyorsColloidEngineering

The invention relates to a flexible impeller of an airlock device of a soldering flux recycling machine, comprising an impeller shaft, a first wheel disc, a second wheel disc and a plurality of blades, wherein the first wheel disc and the second wheel disc are fixedly connected on the impeller shaft; and the plurality of blades are arranged between the first wheel disc and the second wheel disc. The flexible impeller of the airlock device of the soldering flux recycling machine is characterized in that the impeller shaft as well as the first wheel disc and the second wheel disc are made from metal to form a metal impeller framework; a flexible colloid cladding layer is arranged on the outer surface of the metal impeller framework; and the blades are made from the flexible colloid. In the invention, the metal impeller framework is adopted for the impeller to ensure the strength and the rigidity of the impeller; and the flexible colloid cladding layer outside the metal impeller framework and the blades made from the flexible colloid can be both deformed, thereby the phenomena of jamming and blocking by large-particle materials do not occur, and the airlock device is safe and reliable to run.

Owner:邹毓林

Method and device for press mounting water pump impeller

The invention discloses a pump impeller press mounting device in the pump processing technology field, and a press mounting method thereof; the pump impeller press mounting device is provided with a support plate and is characterized in that four guideposts are arranged on the support plate; a support spring is sheathed at the external part of each guidepost; locating plates are sheathed on the guideposts; the support springs are positioned between the support plate and the locating plates; the central position of the support spring is fixed with a locating block; the center of the locating block is provided with a flexible impeller positioning core axle; the central position of the locating plate is provided with a communicating pore and the impeller can pass through the communicating pore; the locating plate is provided with two positioning pins; positioning holes which are matched with the positioning pins are arranged on a pump component; the matching of the positioning pins and the positioning holes, and the matching of the end face of the pump component and the upper face of the locating plate form one-face two-pin positioning and cause the center of the pump component and the flexible impeller positioning core axle mechanism to be concentric. Compared with the prior art, the invention has compact structure, easy operation and high production efficiency, causes the impeller and a rotating shaft to be assembled accurately, and saves the manufacturing cost of a fixture.

Owner:FEILONG AUTO COMPONENTS CO LTD

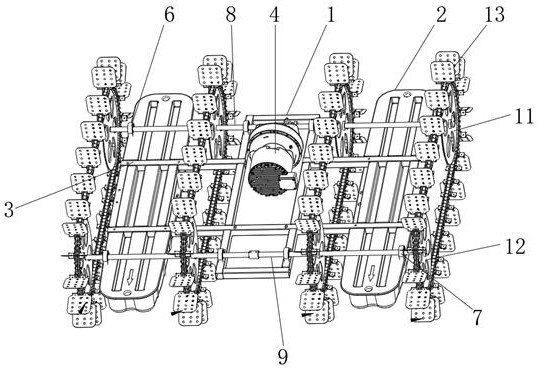

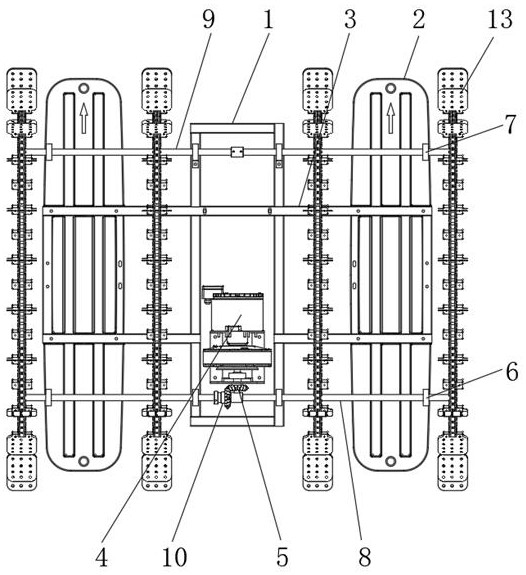

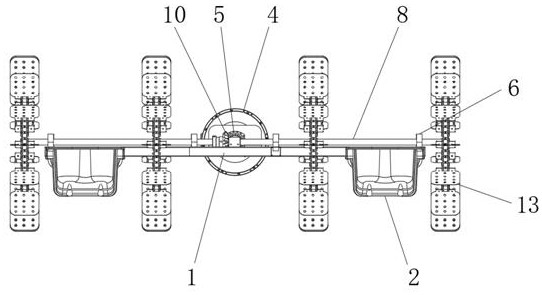

Permanent magnet motor flexible impeller aerator

PendingCN112790150ALarge spanImprove oxygenation effectWater aerationPisciculture and aquariaDrive shaftControl engineering

The invention discloses a permanent magnet motor flexible impeller aerator. Two sides of a frame body are connected with two pontoons through a cross beam, a driving motor is arranged on the upper surface of the frame body, a first bevel gear is arranged on an output shaft of the driving motor, a second bevel gear is arranged on a driving shaft, the second bevel gear is meshed with the first bevel gear, driving chain wheels are arranged at two ends of the driving shaft and are located between the frame body and the floating pontoons and on the outer sides of the floating pontoons, driven chain wheels are arranged at two ends of the driven shaft and are located between the frame body and the floating pontoons and on the outer sides of the floating pontoons, and a chain impeller is arranged between each driving chain wheel and the corresponding driven chain wheel. The permanent magnet motor flexible impeller aerator is reasonable in structure, chains are adopted to be connected with the driving chain wheels and the driven chain wheels, the span is larger, the moving stability and the oxygenation effect are obviously improved compared with traditional impellers, the driving chain wheels and the driven chain wheels are fixed through the driving shaft and the driven shaft respectively, the driving shaft is connected with a first support, the driven shaft is connected with a second support, and the stability is further guaranteed.

Owner:NANTONG HUAYU ELECTRONICS +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com