Method and device for press mounting water pump impeller

A water pump impeller and press-fitting device technology, which is applied to parts, pumps, and pump components of pumping devices for elastic fluids, and can solve problems such as high production costs, inconvenient production replacement, and impact on efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

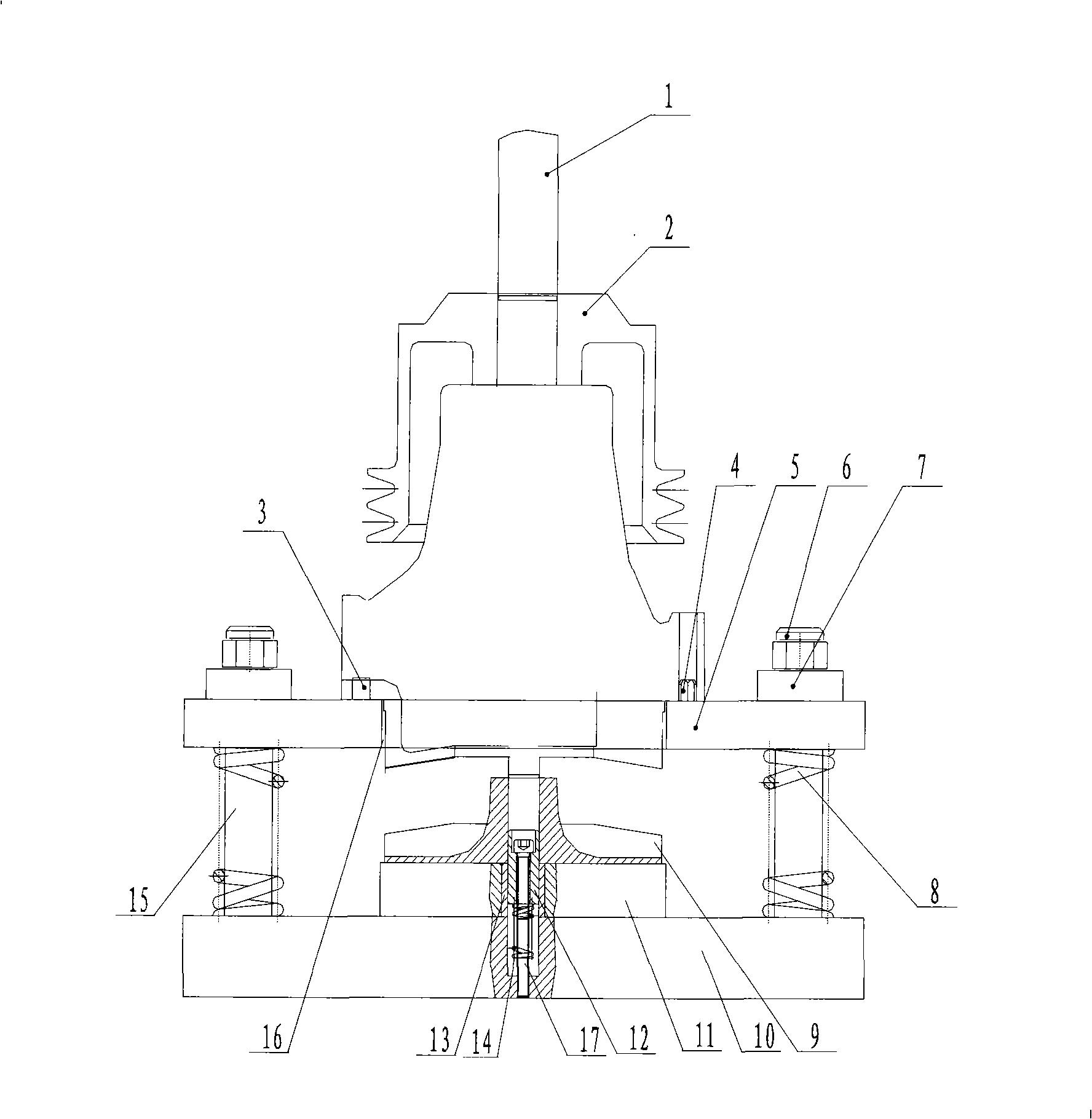

[0012] Such as figure 1 The water pump impeller pressing device shown has a support plate 10, four guide columns 15 are arranged on the four corners of the support plate, each guide column 15 is equipped with a support spring 8 outside, and a positioning plate 5 is set on the guide column 15 , the support spring 8 is located between the support plate 10 and the positioning plate 5 , and the upper end of the guide column 15 presses the positioning plate 5 through the washer 7 and the nut 6 . The center position of the support plate 10 is fixed with a positioning block 11, and the center of the positioning block and the support plate is provided with a step hole. The step hole is located at the position of the positioning iron and is fitted with a bushing 13. Block 11, the water pump impeller 9 can be set on the impeller positioning mandrel 12, a compression spring 14 is provided in the step hole, the compression spring 14 supports the impeller positioning mandrel 12, and the so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com