Mussel shell removing machine

A shucking machine and mussel technology, applied in the direction of bivalve processing, etc., can solve the problems of mussel extrusion, etc., and achieve the effects of labor saving, high shucking rate, and improvement of processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

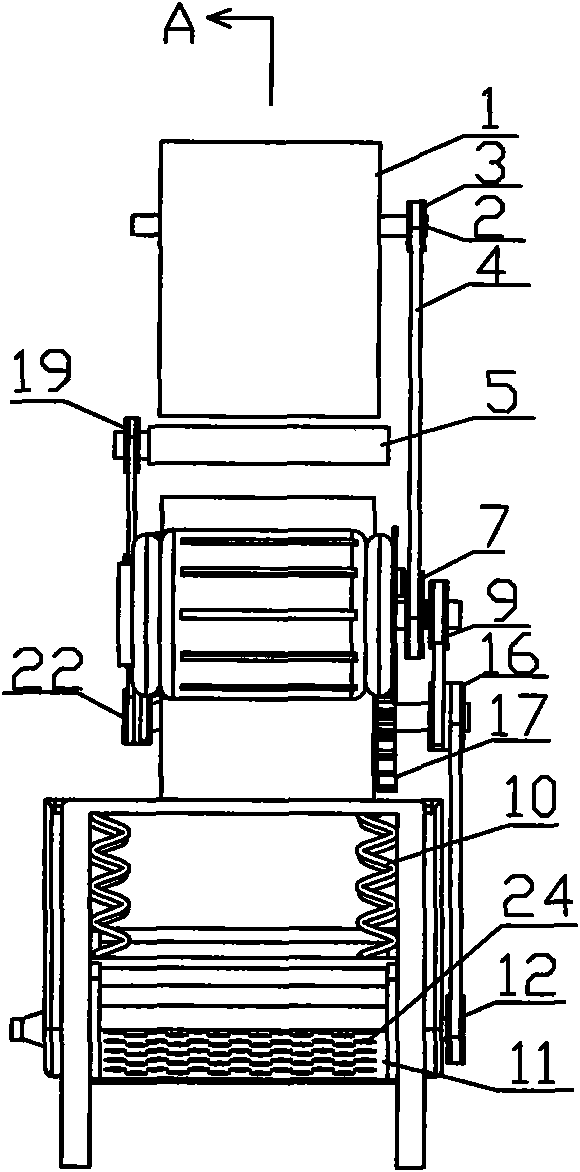

[0016] Refer to the attached figure 1 to attach Figure 5 Shown mussel sheller of the present invention is described in detail below.

[0017] Mussel sheller of the present invention, its structure comprises flaring box 1, shelling box 18 and vibrating screen 11, the bottom of flaring box 1 is provided with conveyor belt 5, and the bottom of conveyor belt 5 is provided with shelling box 18, shelling The bottom of the box 18 is provided with a vibrating screen 11, the top of the flared box 1 is provided with a feed port 25, and the inside is provided with a flexible impeller 26. The flexible impeller is made of rubber material to prevent mussels from being broken. The impeller 26 is connected with the first motor 6, and four symmetrical hair brushes 29 are arranged in the shelling box 18, and the two sides of the upper two hair brushes 29 and the lower two hair brushes 29 are respectively The protruding groove plate 28 is provided, on the one hand, it can guide the flow of mu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com