Flexible impeller of airlock device of soldering flux recycling machine

A technology of recycling machine and air conditioner, which is applied in the direction of rotary conveyor, conveyor, transportation and packaging, etc., can solve the problems such as burnout of the motor of the air conditioner, blockage of large particle materials, affecting the safe operation of the air conditioner, etc. , to achieve the effect of safe and reliable operation, guaranteed strength and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with the embodiments in the accompanying drawings.

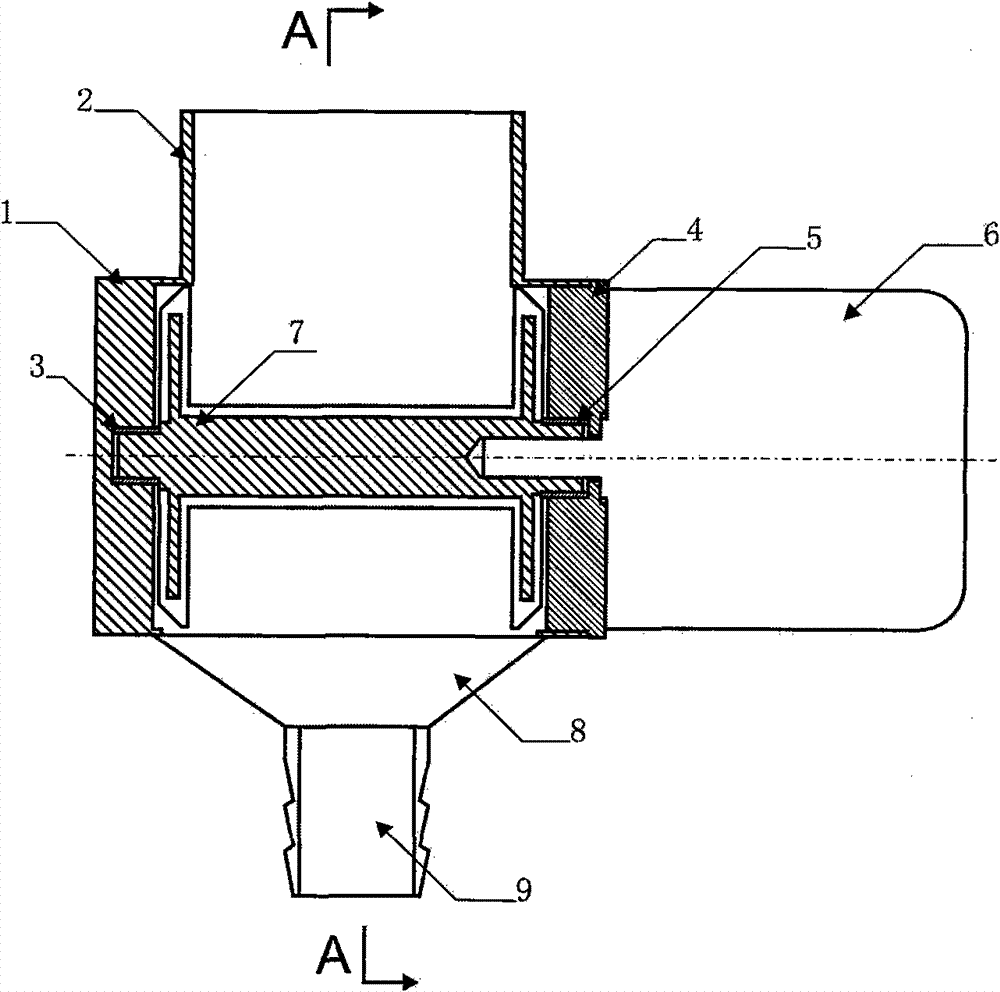

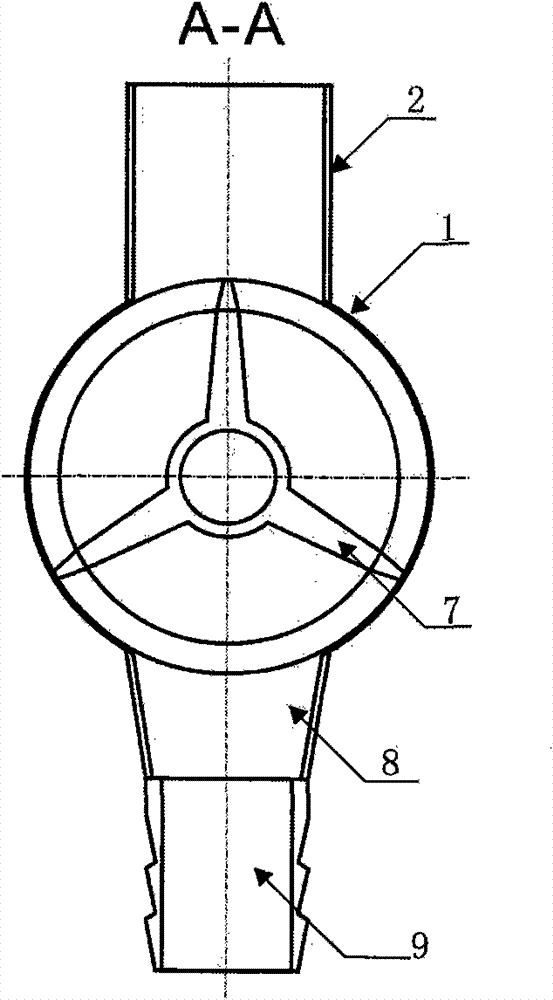

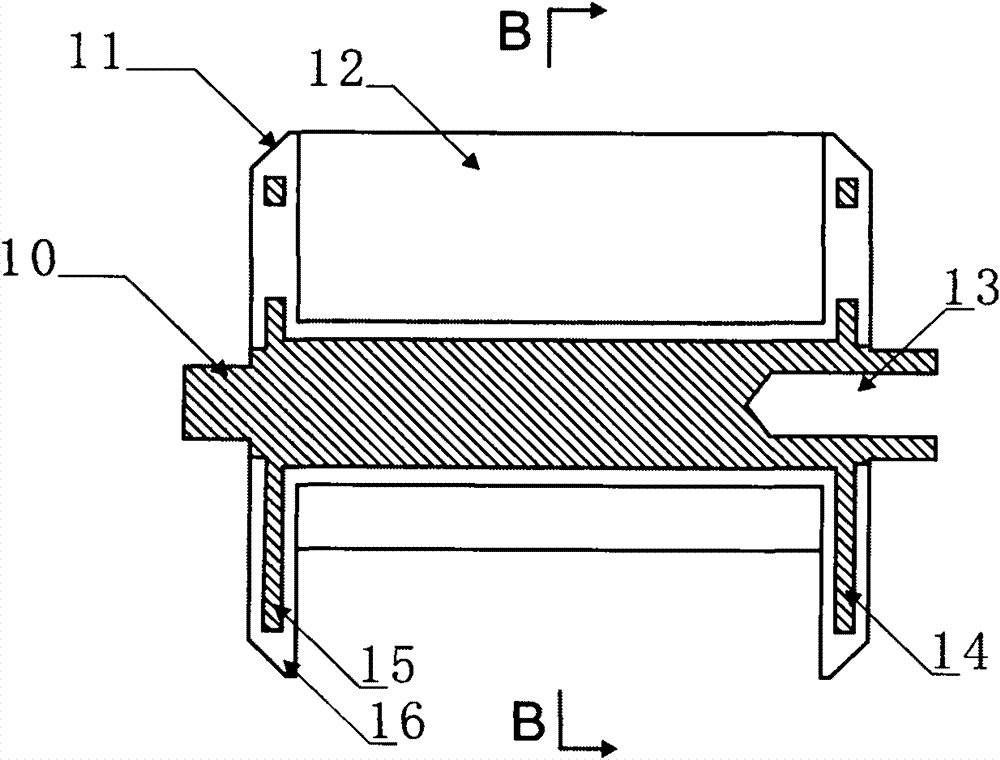

[0015] like Figure 1 to Figure 6 As shown, it includes cylinder 1, feed inlet 2, oil-free bearing 3, end cover 4, oil-free bearing 5, motor 6, impeller 7, lower hopper 8, lower material pipe interface 9, impeller shaft 10, flexible colloid package Covering layer 11, blade 12, motor connection hole 13, second wheel 14, first wheel 15, chamfer 16, flexible glue filling hole 17, etc.

[0016] like figure 1 , figure 2 Shown, is to use a kind of damper of the present invention, comprises horizontal cylinder 1. The upper part of the cylinder body 1 is provided with a feeding port 2 , the lower end of the cylinder body 1 is provided with a lower hopper 8 , and the bottom of the lower hopper 8 is provided with a feeding pipe interface 9 . The feeding pipe interface 9 adopts a tapered structure, which can be easily connected with the feeding pipe, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com