Pneumatic flexible actuator

A flexible drive, pneumatic technology, applied in the direction of manipulators, manufacturing tools, etc., can solve the problems of poor rigidity, large structure size, troublesome installation and fixation, etc., and achieve the effect of high rigidity, good sealing and convenient installation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

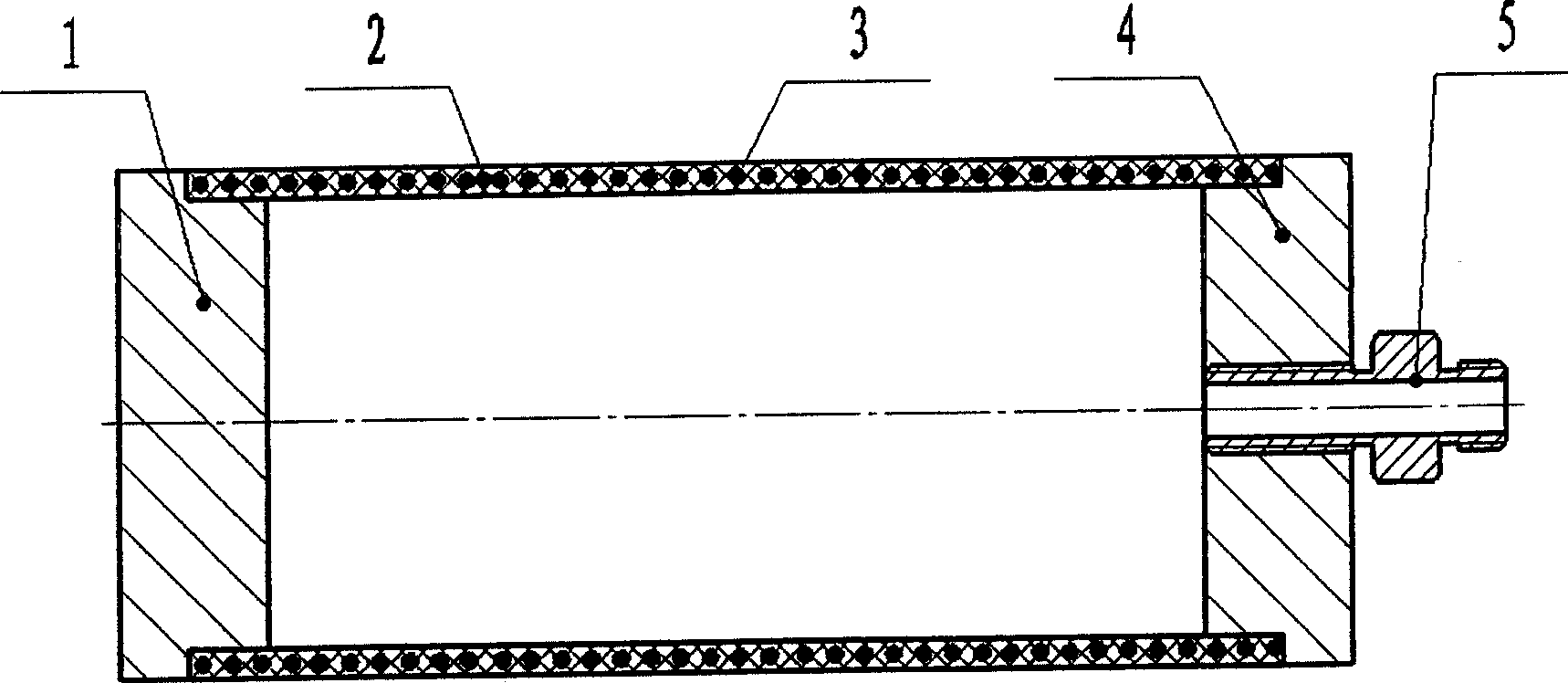

[0009] refer to figure 1 , a pneumatic flexible driver, including a left end cover 1, a rubber tube 2, a spring 3 nested in the wall of the rubber tube, a right end cover 4, and a pipe joint 5, the two ends of the rubber tube 2 are respectively connected to the left end The cover 1 and the right end cover 4 are sealed and connected by superglue, and can also be sealed and connected in other ways. There is a threaded hole in the middle part of the right end cap 4, and the pipe joint 5 is installed on the right end cap 4 through threads, so that the inner cavity of the rubber tube 2 communicates with the atmosphere through the pipe joint 5.

[0010] The working principle of the present invention is: the compressed gas is filled into the inner cavity of the rubber tube 2 through the pipe joint 5 and the right end cover 4, and under the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com