Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

321 results about "Dirt digging" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

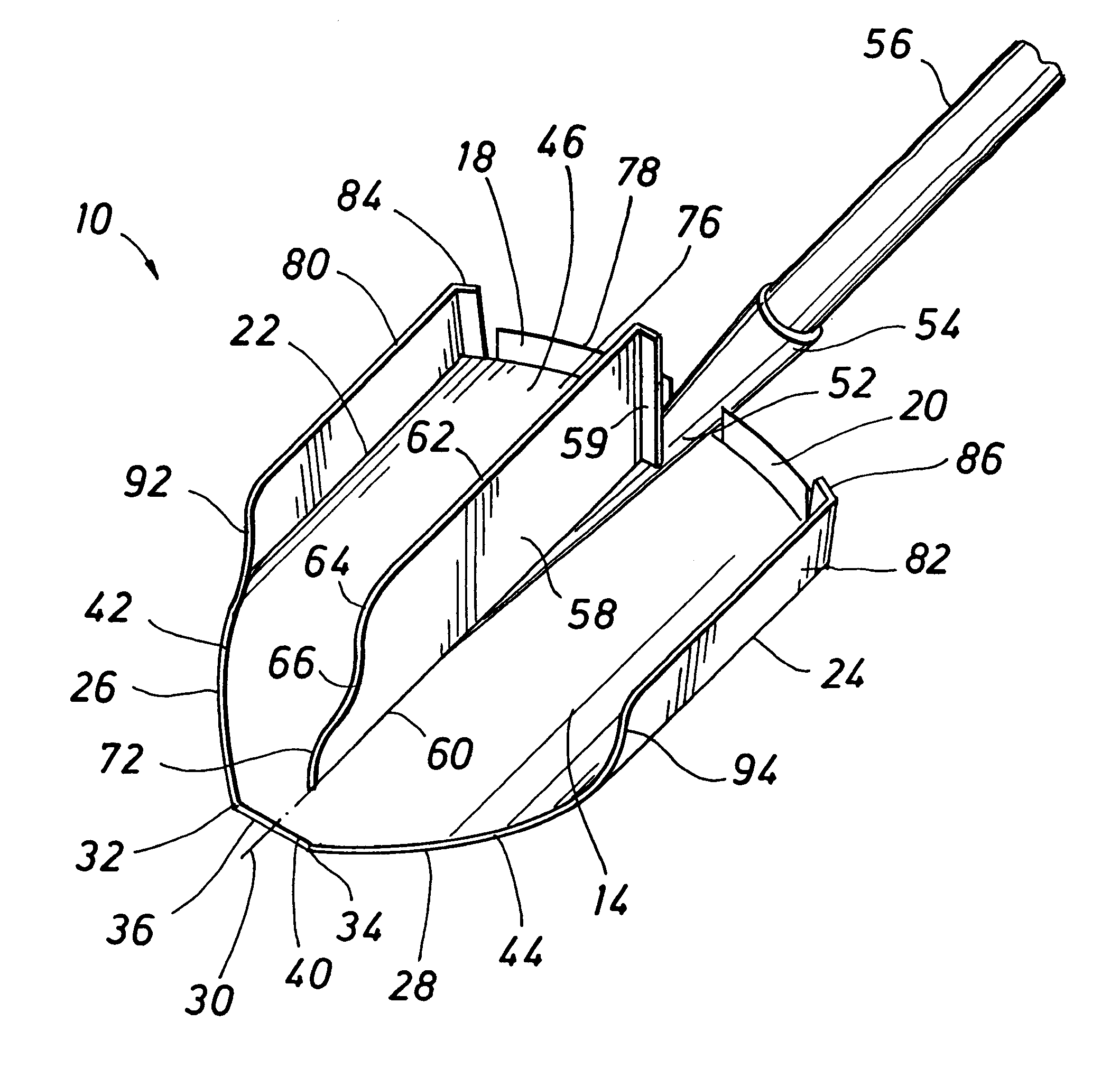

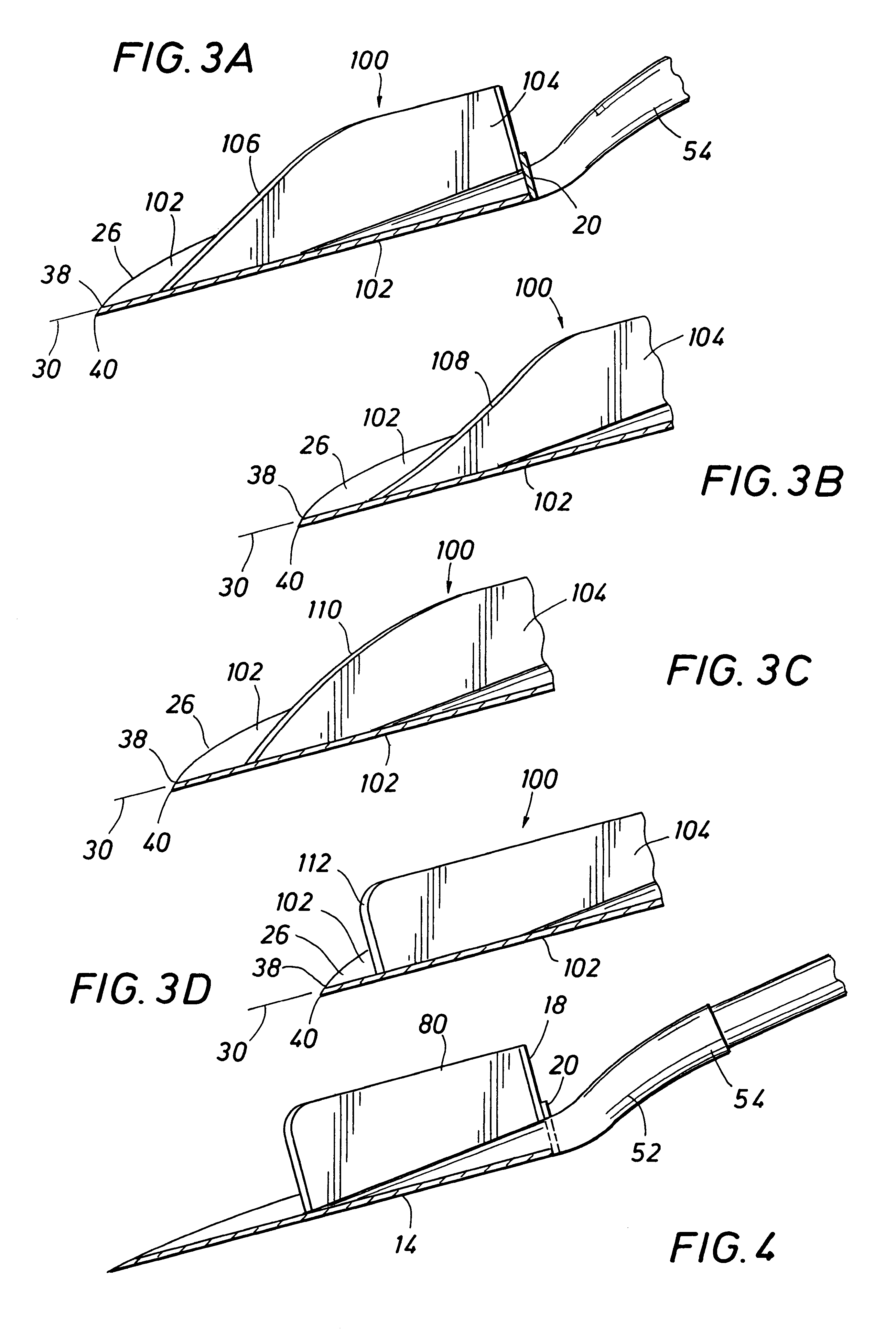

Root cutting shovel

A shovel for manual use, comprising a shovel blade having concave and convex faces and defining a longitudinal center-line and having side edges, an upper edge and a forward cutting edge. The shovel blade defines a handle connector receptable having a shovel handle fixed therein. A root cutting blade is fixed to the shovel blade substantially along the longitudinal center-line and projects from the concave face of the shovel blade. A sharpened root cutting edge is defined on the root cutting blade and is oriented toward the forward cutting edge of the shovel blade. The root cutting edge of the central blade preferably defines an intermediate edge recess and forms a slightly inclined sharp edge section for enhancing root cutting action. A pair of side blades are fixed to side edge portions of the shovel blade and are oriented in diverging relation projecting from the convex face of the shovel blade. The side blades also preferably define forwardly inclined sharpened cutting edges and are located for cutting surface roots at respective sides of the shovel blade to facilitate efficient fracturing of the soil when the shovel blade has penetrated into the soil and is pivoted to pry a soil load loose from the surrounding soil.

Owner:DOUGLAS ORMOND S +1

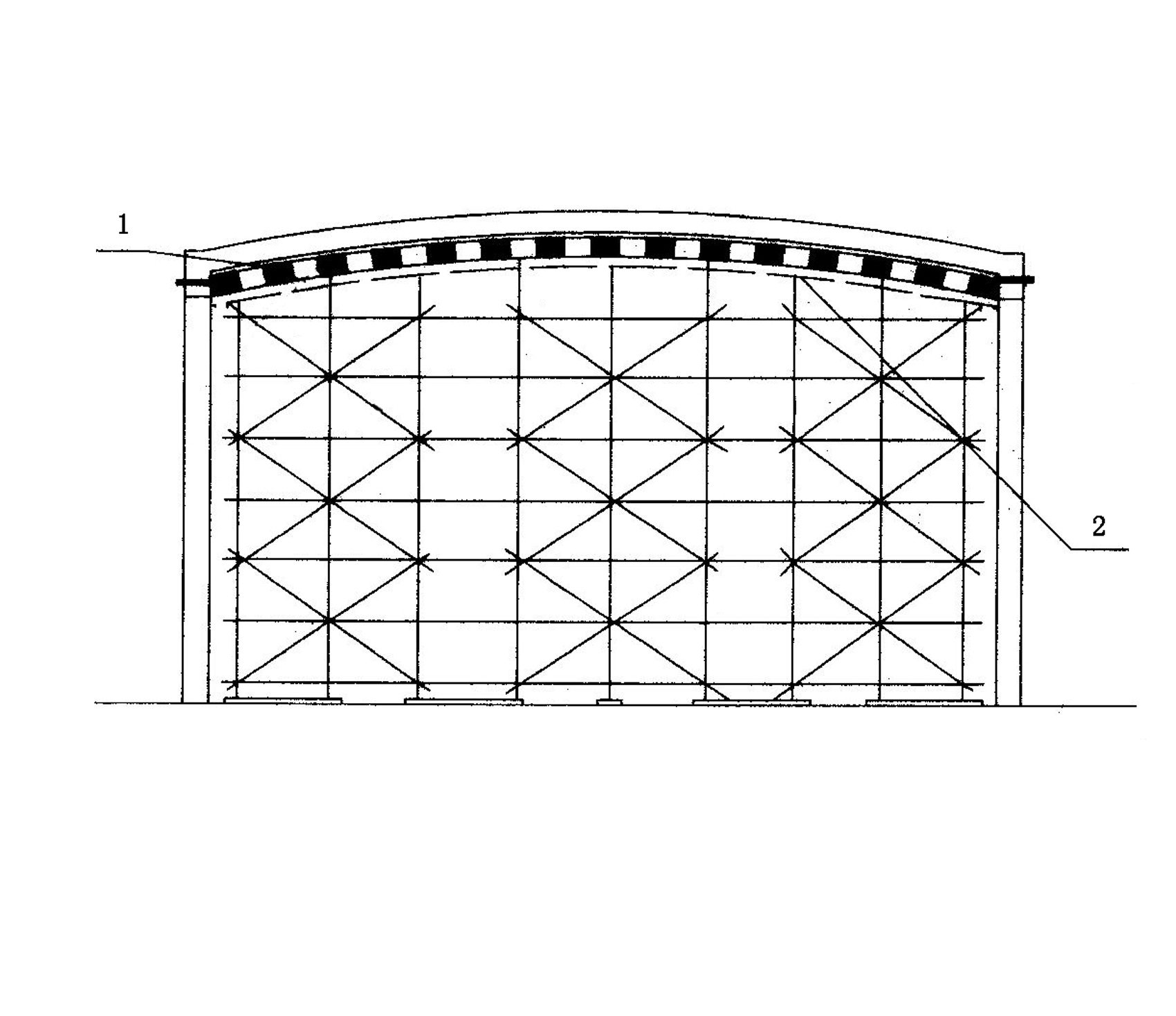

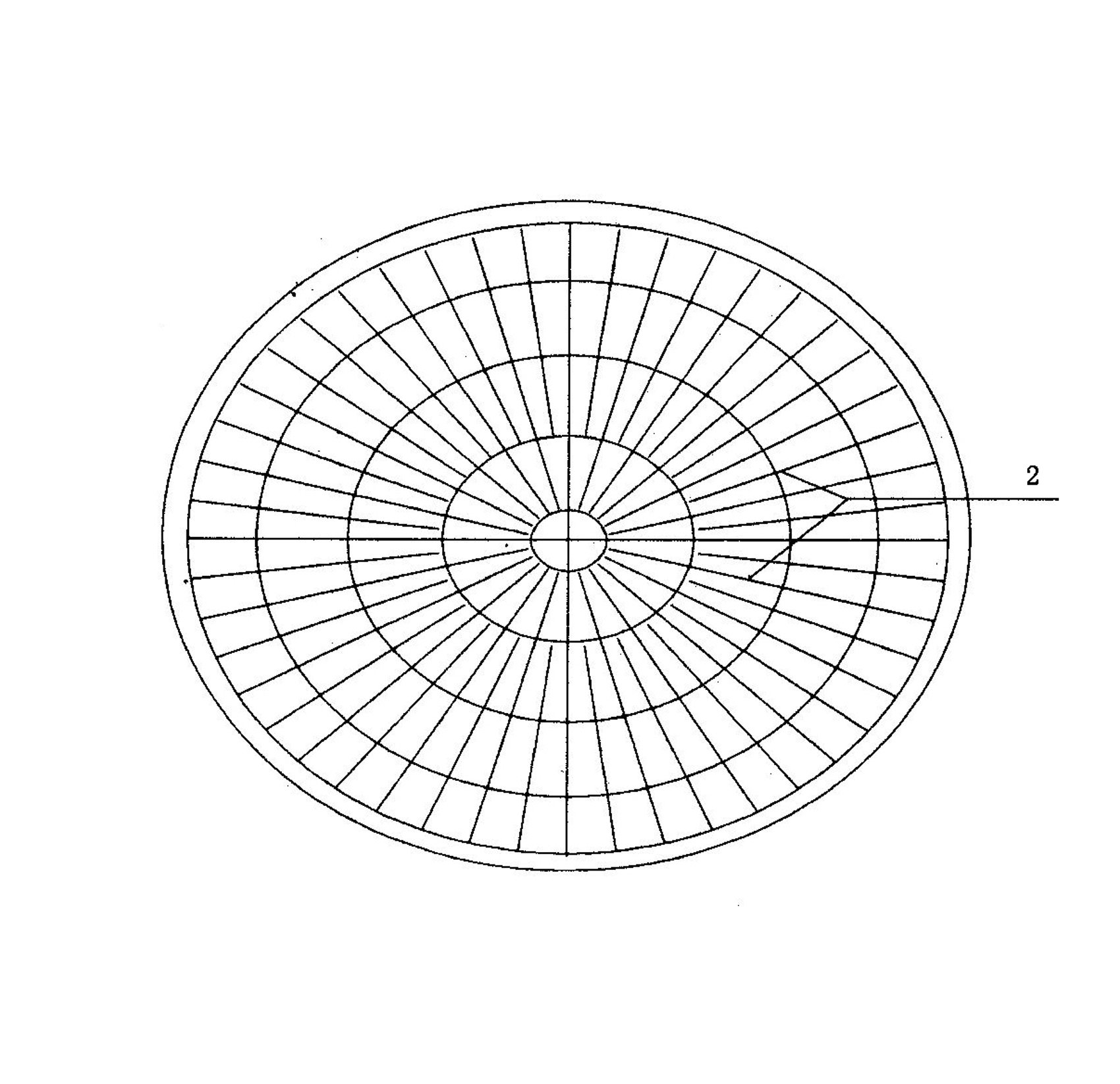

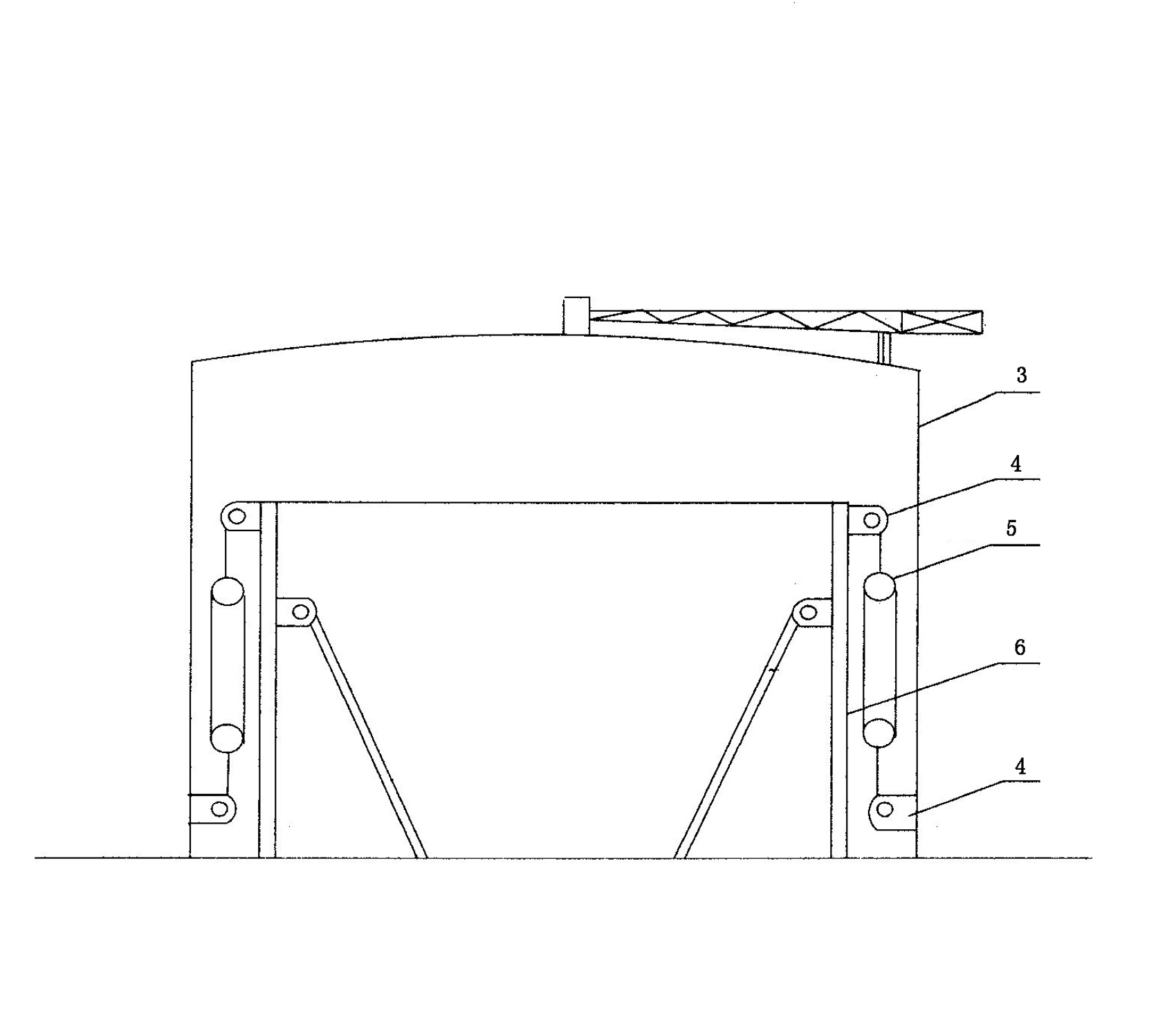

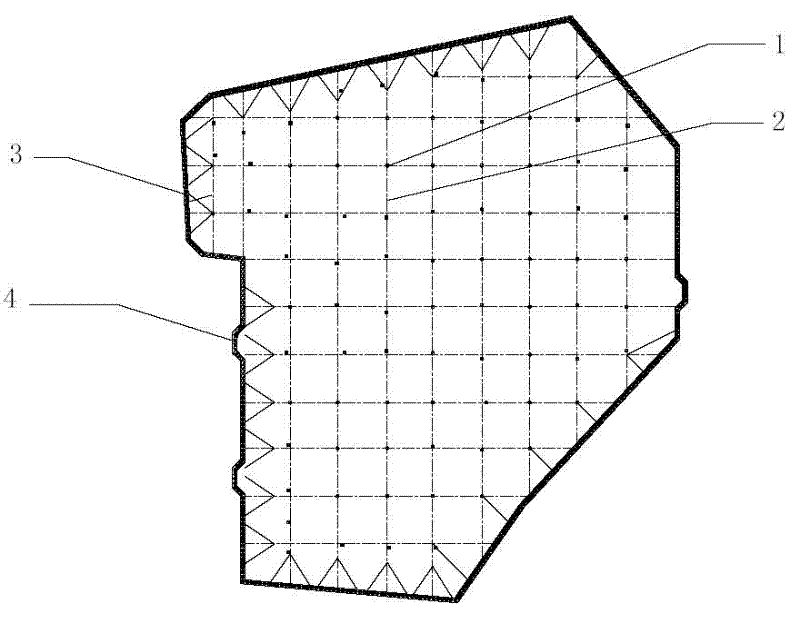

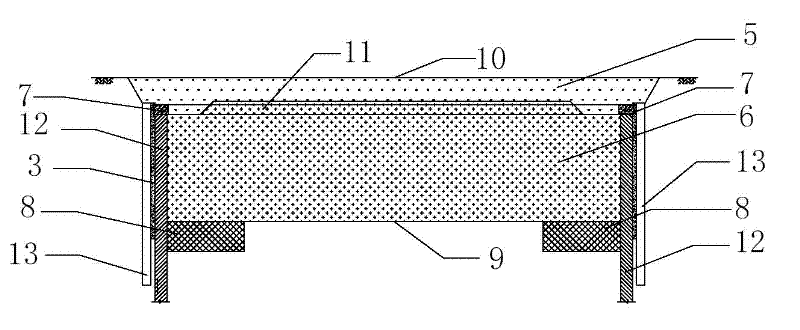

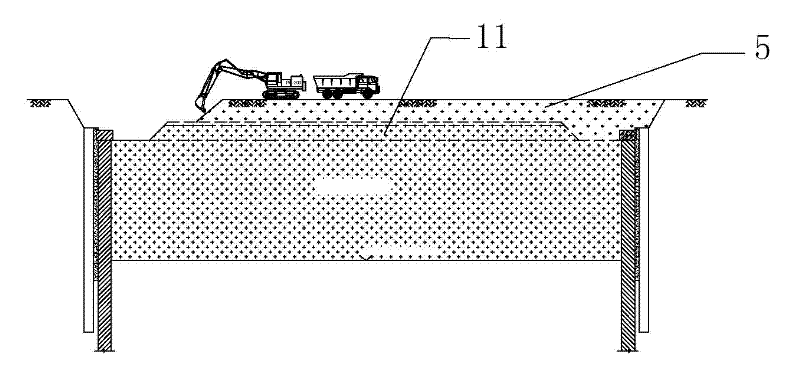

Construction method of soil covering tank

ActiveCN101852031AReduce construction intensityEmission reductionArtificial islandsUnderwater structuresRebarDust emission

The invention relates to a construction method of a soil covering tank for storing product oil and the like, which comprises the following steps of: (A) building a tank chamber of a soil covering tank: firstly, carrying out earth excavation with a method combining a back-acting shovel and manual excavation; then, manufacturing a ring beam, precasting concrete blocks on the spot according to the radian of the ring beam, and building the concrete blocks; carrying out the engineering of steel bars: welding steel bars by machining, and manually binding the steel bars on the spot; carrying out the engineering of templates and scaffolds: taking a bamboo plywood as a top plate template of a concrete thin shell of the tank chamber, designing a camber at the middle part, and taking scaffold tubes as bottom template brackets of the thin shell of the tank; then, carrying out concrete engineering and asphalt sand construction; and finally, carrying out waterproof engineering, thereby completing the construction of the tank chamber of the soil covering tank; and (B) installing a storage tank body of the soil covering tank: firstly, precasting the storage tank body; then, installing a tank bottom plate; installing the tank body, and welding the storage tank; and finally, testing and inspecting to complete the whole construction process of the soil covering tank after the construction is qualified. The invention reduces the occurrence of accidents, increases the benefit and reduces the dust emission.

Owner:中国化学工程第四建设有限公司

Construction method for deep-foundation pit excavation

ActiveCN102535474AAdvantages of construction methodReasonable designExcavationsEconomic benefitsStructural engineering

The invention relates to a construction method for deep-foundation pit excavation. After foundation pit fender structure construction is finished, an excavation machine is used for excavating and an earthwork vehicle is used for transporting out the earthwork. The construction method is characterized by comprising the following steps of: a. earthwork excavation for the first time: uniformly excavating from every corner of the foundation pit to the center by dividing three regions in a retreating manner; b. fender supporting structure construction and maintenance: pouring the fender supporting structure, and carrying out next-step construction when the supporting concrete strength achieves 80% of the design strength; and c. earthwork excavation for the second time: carrying out earthwork excavation below the fender supporting structure, selecting excavation equipment, excavating, and transporting out the earthwork in the pit in a two-stage overturning and transferring manner to finish excavation. The construction method for deep-foundation pit excavation has the advantages of being reasonable in construction step design, simple to operate and safe and reliable in excavating engineering, lowering engineering construction cost, saving construction period, and being obvious in economic benefit.

Owner:MCC5 GROUP CORP SHANGHAI

Municipal drainage pipeline slurry balance pipe-jacking construction method

The invention provides a municipal drainage pipeline slurry balance pipe-jacking construction method which includes that on a municipal drainage construction pipeline, every 80-120m pipeline serves as one construction section, a working pit and a receiving pit are adopted in each construction section to serve as pipe-jacking sinking wells, the sinking wells are sunk to be at the designed sinking well height, and then slurry balance machines are used for pipe-jacking construction; and the sinking wells are subjected to groove digging by aid of steel plate piles and water stop curtain supports, the machines are used for earthwork digging in the sinking process, the sinking wells are sunk to the preset depth under the effect of sinking well rebar concrete self weight or external force, and the slurry balance machines are used for pipeline pipe-jacking construction. The municipal drainage pipeline slurry balance pipe-jacking construction method has the advantages of having strong safety, having small influence on close buildings and pipelines, leading the earth surface to have small settlement and shifting, and being short in construction period, saving in manufacture cost, small in floor occupation and the like, solves the technical problems of advanced support construction for rain falling, wide digging range and large damage influence on surrounding pipeline roads, and is especially applicable to construction in narrow places and other complex environment conditions.

Owner:JINAN URBAN CONSTR GRP

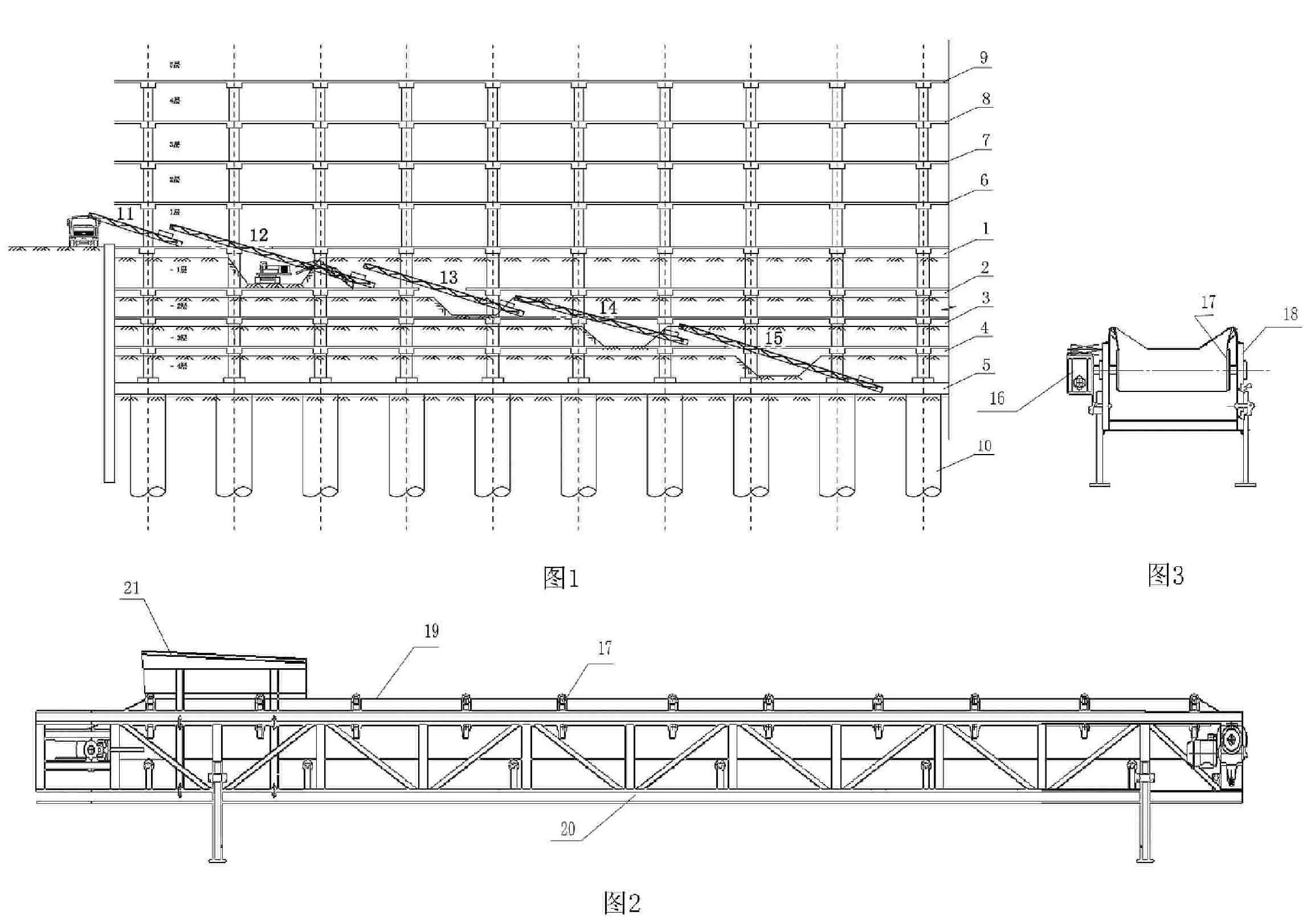

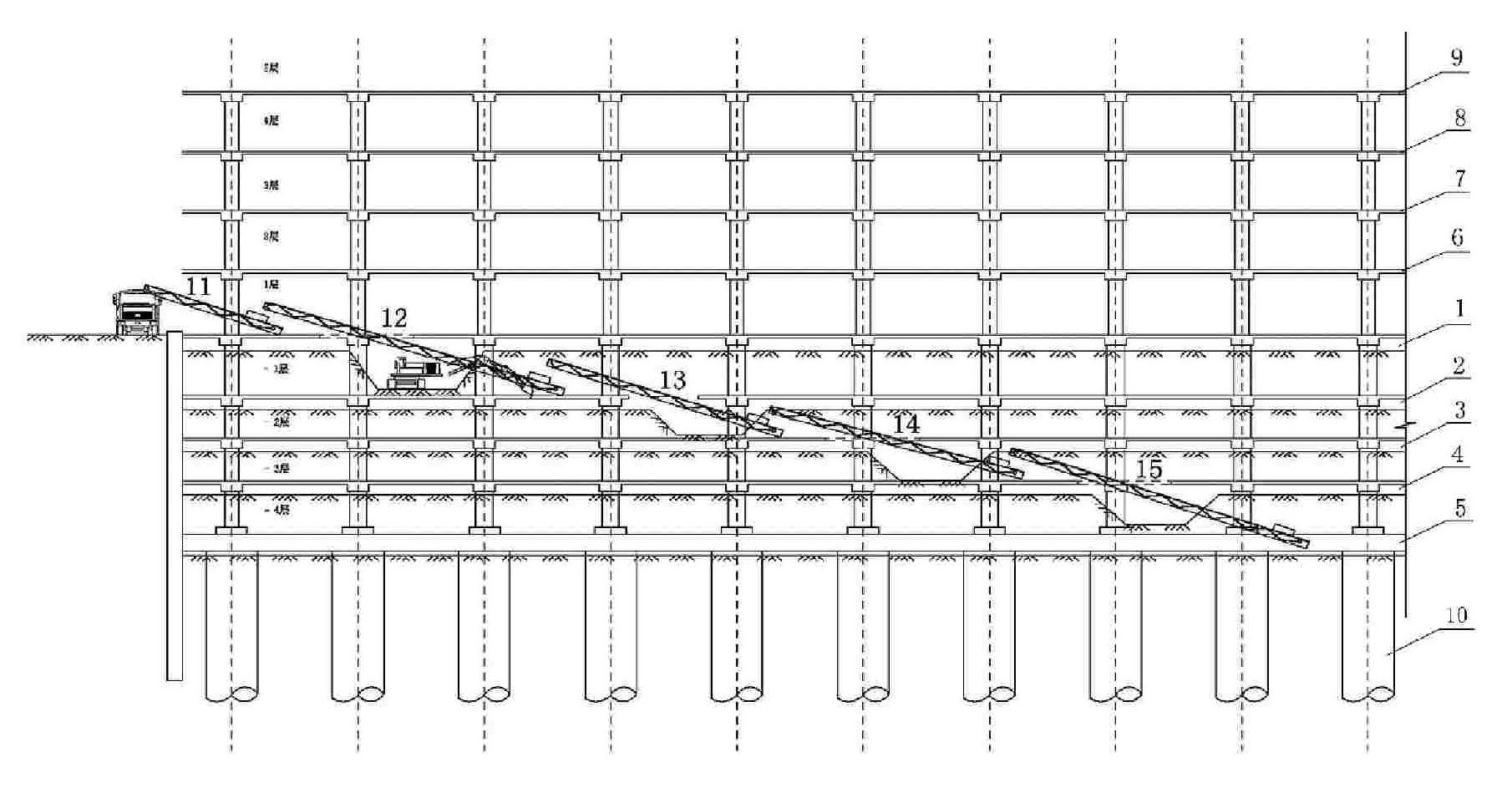

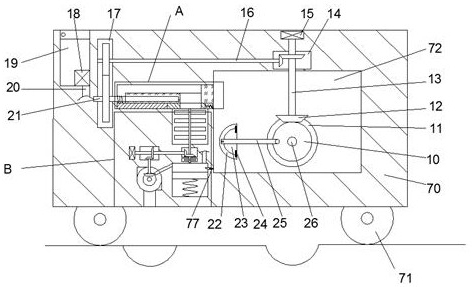

Device and method for vertically transporting earthwork by reverse construction method

InactiveCN101775821AImprove digging efficiencyReduce hole sizeSoil-shifting machines/dredgersExcavationsFloor slabConveyor belt

The invention relates to a device and a method for vertically transporting earthwork by a reverse construction method, which belong to the field of civil construction. In the device, segmental belt-type conveyor belts are adopted as earthwork transporting tools in a deep foundation pit; the conveyor belts pass through reserved holes of floor slabs on each floor; and the earthwork is transported to a dump truck obliquely from the bottom to the top by the conveyor belts. The device is formed by connecting independently segmented and obliquely arranged belt-type conveyor belts end to end; and each floor is provided with at least one conveyor belt which consists of an electric motor, a conveyor belt rack, an unloading tank, a scraping plate, a roller wheel, a roller wheel shaft bracket, a belt, a feeding funnel and an emergency brake device. The device and the method for vertically transporting the earthwork by the reverse construction method can effectively increase the earth volume in single vertical transport, effectively improve excavation efficiency, reduce excavation machines, reduce excavation cost, and simultaneously, reduce the influence of the construction of underground excavation on the simultaneous construction of an upper structure to the minimum.

Owner:CHINA CONSTR FIRST BUILDING GRP CORP LTD +2

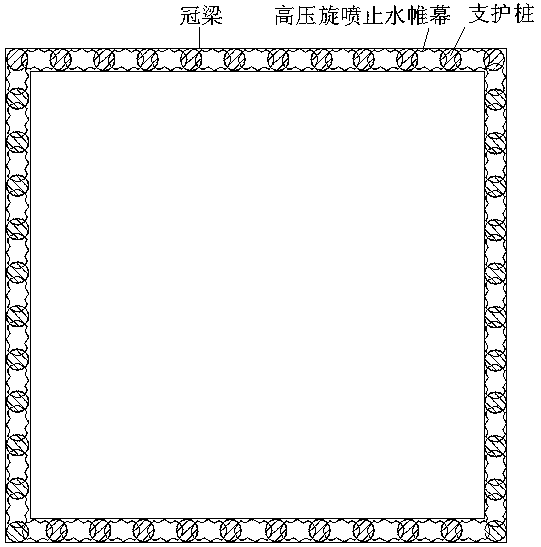

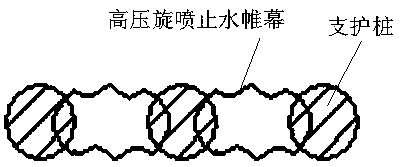

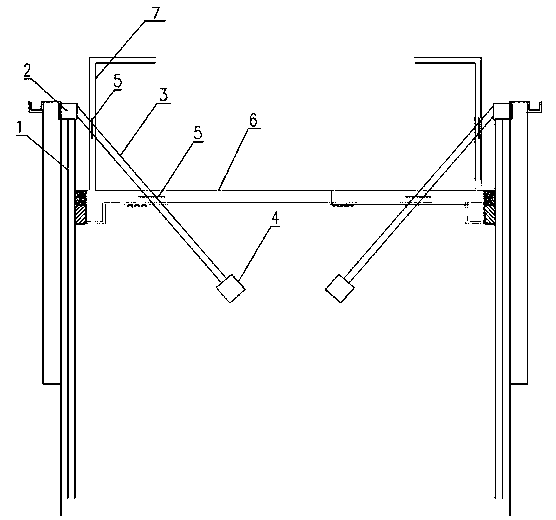

Top-down construction method for intermediately-weathered geology

ActiveCN108060683AShorten the construction periodReasonable forceArtificial islandsExcavationsSupporting systemHigh pressure

The invention discloses a top-down construction method for intermediately-weathered geology. According to the top-down construction method for the intermediately-weathered geology, support piles and high-pressure rotary jet water-stopping curtains are constructed first of all, and meanwhile concrete-filled steel tube stand column piles are arranged at corresponding positions according to design and used as the bearing support during construction; dewatering engineering construction is conducted, earth cutting is conducted above the earth cutting bottom elevation line of a first floor underground, after earth cutting reaches the stipulated depth bottom elevation, a concrete cushion is poured, and then column, beam and slab structures above the earth cutting bottom elevation line of the first floor underground are constructed, and beams and slabs are used as the horizontal support system of a retaining structure; and then earth excavation and pouring of the beam, slab and column structures of each floor are conducted in floor-by-floor and downward manners until bottom sealing of a raft foundation is conducted. By the adoption of the top-down construction method for the intermediately-weathered geology, construction is convenient, rapid, economical and environmentally friendly, the safety of a foundation pit and a pipeline is guaranteed, and the underground space can be utilized to the greatest extent.

Owner:YANJIAN GRP CO LTD

Inclined supporting pile structure for foundation pit support and construction method thereof

InactiveCN103882869AAvoid safety hazardsShorten the construction periodExcavationsBuilding constructionStructural engineering

The invention relates to the field of foundation pit supports, in particular to an inclined supporting pile structure for a foundation pit support and a construction method of the structure. The inclined supporting pile structure for the foundation pit support comprises a fender post, a top beam, a foundation pit base plate, a building structure, an inclined supporting pile, a waterstop device and a soil improved structure, wherein the inclined supporting pile is implanted in primary soil below the foundation pit base plate in an inclined mode by a certain angle, the top end of the inclined supporting pile is fixedly connected with the top end of the fender post, and is embedded inside the top beam, and the whole structure is formed through the inclined supporting column and the top beam. The soil improved structure is fixed to the bottom end of the inclined supporting pile and the periphery of the bottom end of the inclined supporting pile, and the inclined supporting pile, the building structure and the foundation pit base plate penetrate through the waterstop device on the inclined supporting pile. According to the inclined supporting pile structure, the structural design and the construction method are reasonable, the construction period is greatly shortened, the construction cost are greatly reduced, barrier-free earth cutting and structural construction can be achieved, the structure is environmentally friendly and safe, and the potential safety hazards, generated by dismounting the support, of the suspended wall of the foundation pit support are thoroughly avoided.

Owner:郭永

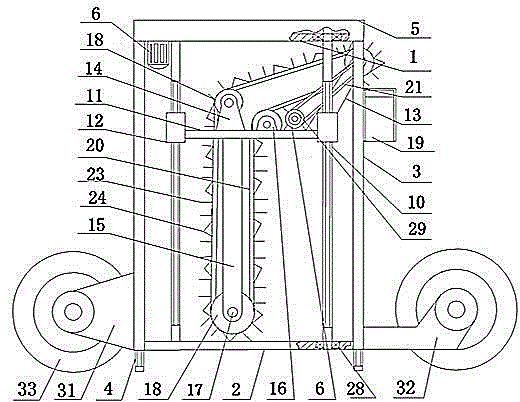

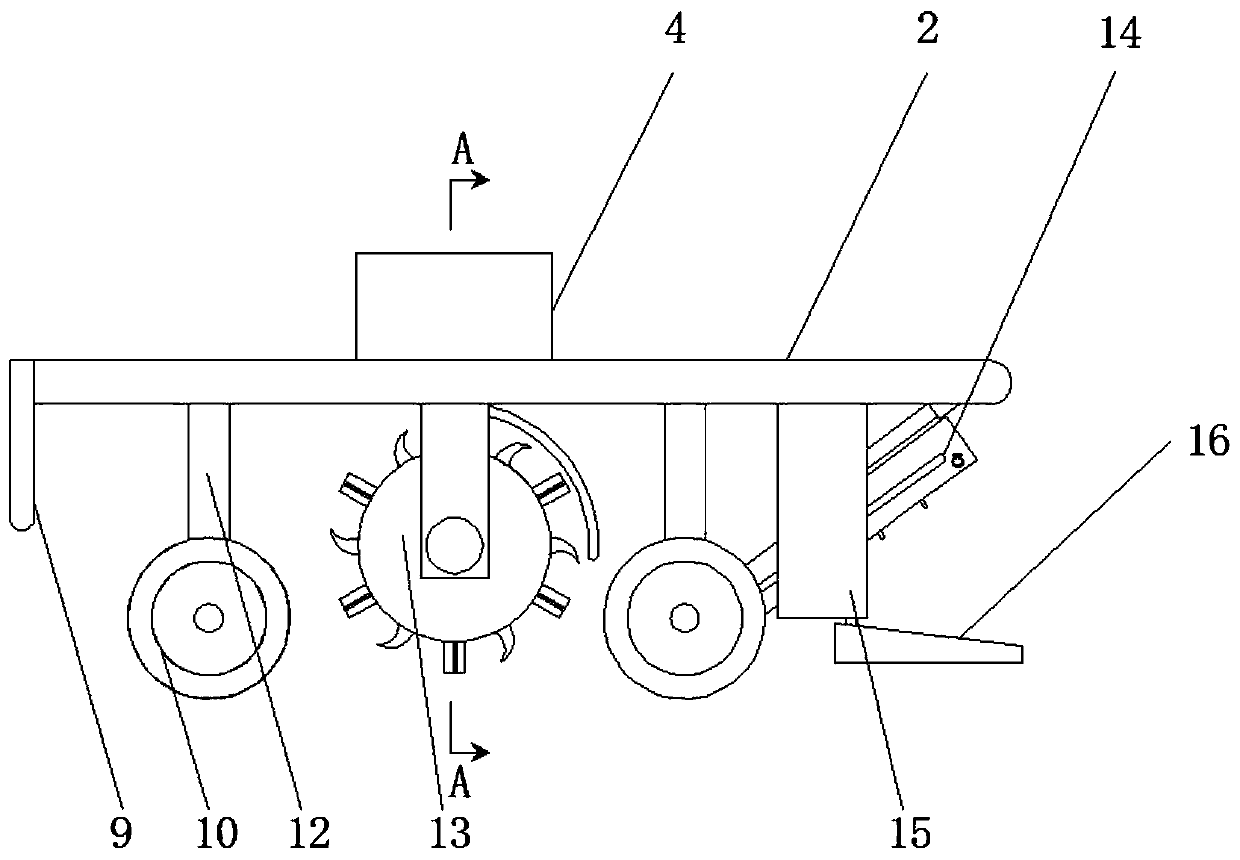

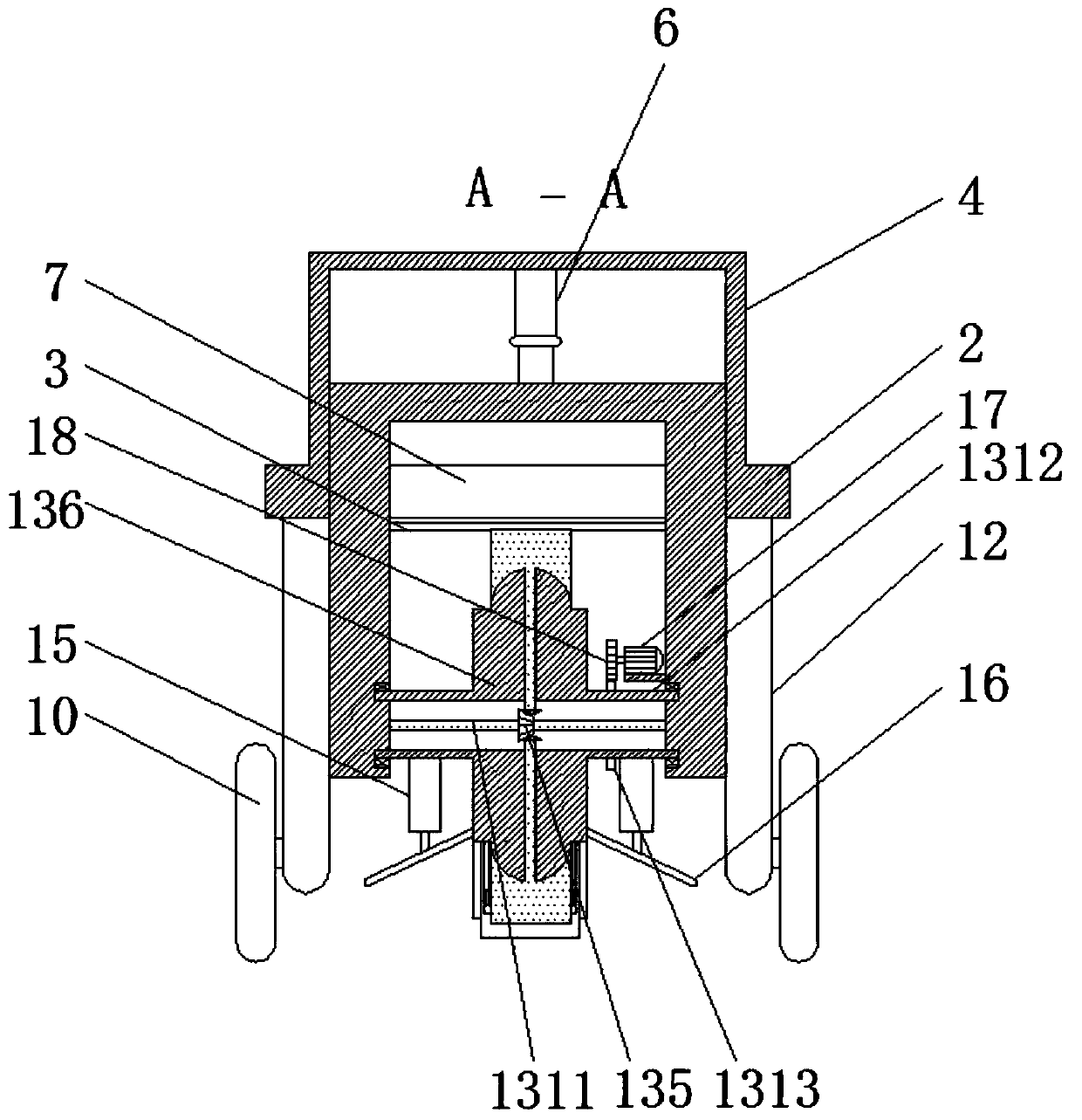

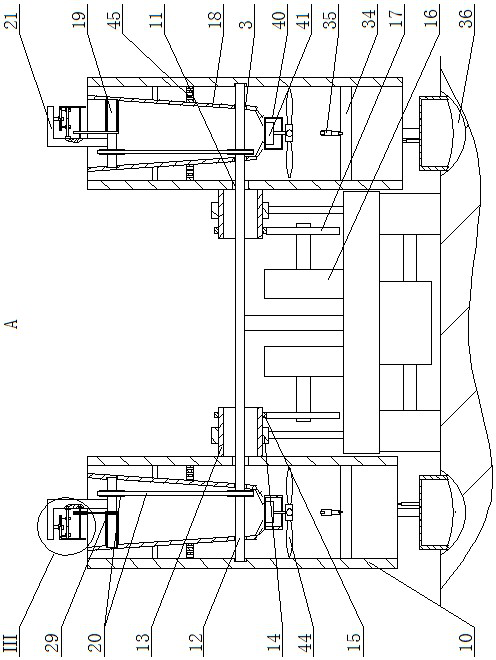

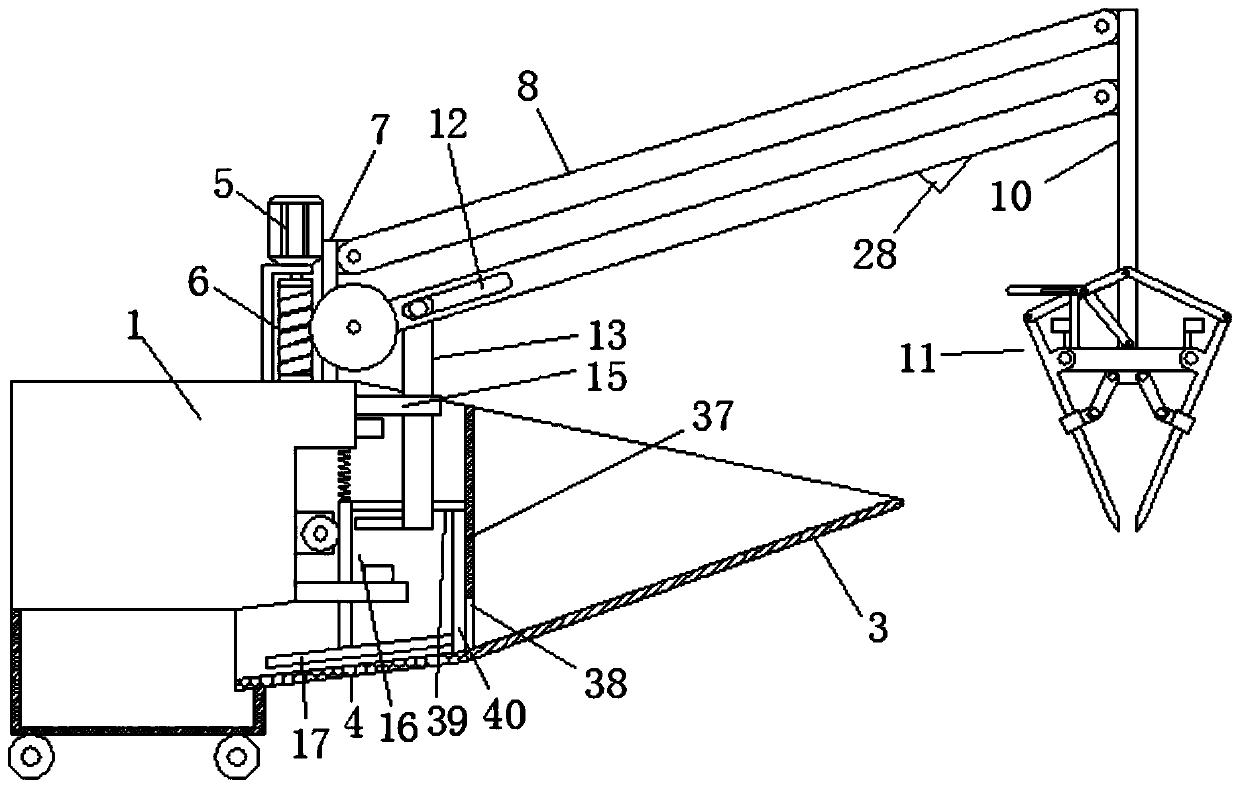

Pit digging ditcher

ActiveCN105239619AEasy to operateSimple structureSoil-shifting machines/dredgersWire rodSoil science

The invention discloses a pit digging ditcher. The pit digging ditcher is composed of three parts of a machine frame, a soil delivering mechanism support and a soil delivering mechanism. According to the pit digging ditcher, the soil delivering mechanism located under a lifting plate (11) is in a vertical state under the action of the soil delivering mechanism support, and the functions of soil loosening, digging and soil lifting can be achieved; the upward side of the lifting plate (11) is in a slope state, and the functions of soil delivering and soil pouring can be achieved. The soil delivering mechanism is operated to make soil loosening teeth to scratch the soil; a soil delivering bucket is filled with the soil, and the soil is lifted to the top through a vertical section of the soil delivering mechanism. A bucket opening of the soil delivering bucket is made to be downwards through a slope section, and the soil falls into a material receiving groove (19) and slides to the ground until the depth of a pit is reached. On the foundation that the pit digging is completed, the pit digging ditcher is pushed to run forwards, and required long-strip deep ditches can be dug. According to the pit digging ditcher, small and deep pits allowing wire rods to be buried therein can be dug, and narrow and deep long-strip trenches allowing pipe fittings, cables and the like to be pre-buried therein can also be dug. The pit digging ditcher is simple in structure, convenient to operate, and capable of bringing convenience to people.

Owner:孙世梁

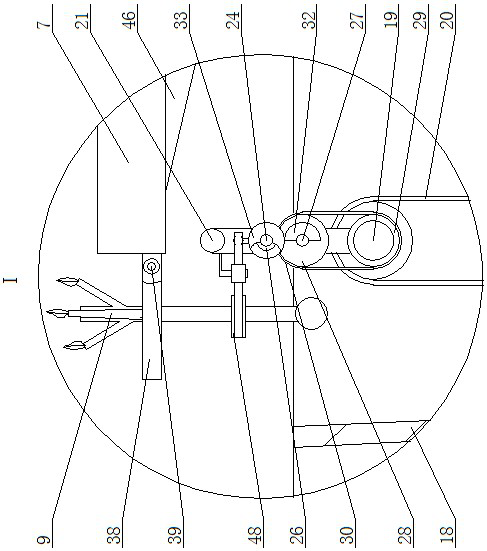

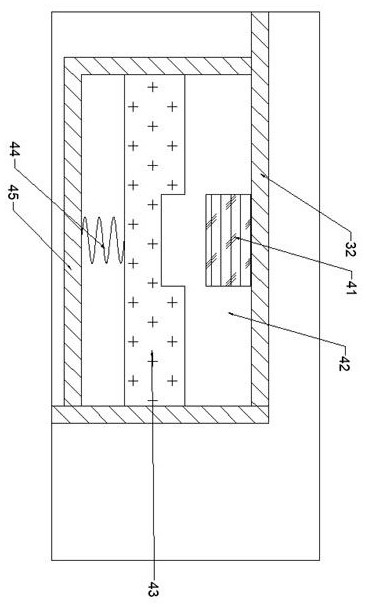

Soil sample collecting and preprocessing device for soil component detection

ActiveCN104977181ASimple and fast operationContinuous operationWithdrawing sample devicesPreparing sample for investigationSoil scienceMechanical engineering

The invention relates to a soil sample collecting and preprocessing device for soil component detection, and fills the technical blank that in the prior art, no apparatus can be used to preprocess a soil sample. In the provided device, a soil baffling sheet is fixedly arranged on the lateral part of a linear module, the soil baffling sheet and a soil digging blade both have a half round structure, and the diameters of the soil baffling sheet and the soil digging blade are the same. The extension line of the diameter of the soil baffling sheet is parallel to the linear module. When a slide table moves to a positive above a cart, the root part of the soil digging blade is connected to the lower end of the soil baffling sheet, and the front end of the soil digging blade is connected to the upper end of the soil baffling sheet. A soil scraping motor is arranged on the linear module, and the output shaft of the soil scraping motor is positioned on the circle center of the soil baffling sheet. A soil scraping brush is arranged on the output shaft of the soil scraping motor, the length of the soil scraping brush is the same as that of the soil baffling sheet, and a soil discharge opening is arranged under the soil baffling sheet. The provided soil sample collecting and preprocessing device can carry out pretreatments such as collecting, drying, pressing, and the like on a soil sample for soil component detection, and thus the soil component and contents of the components can be rapidly obtained.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

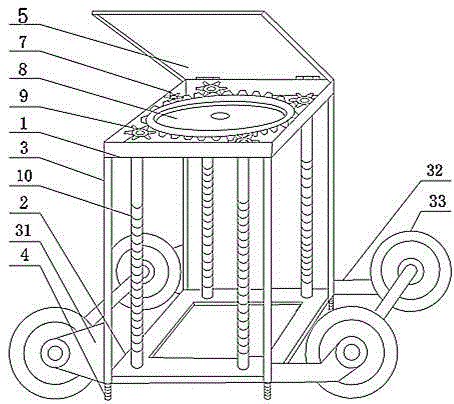

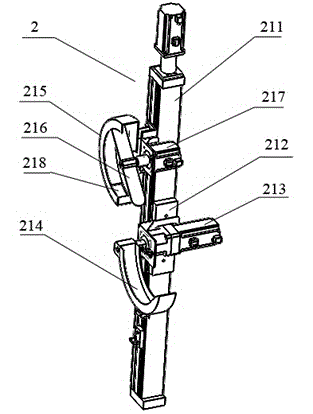

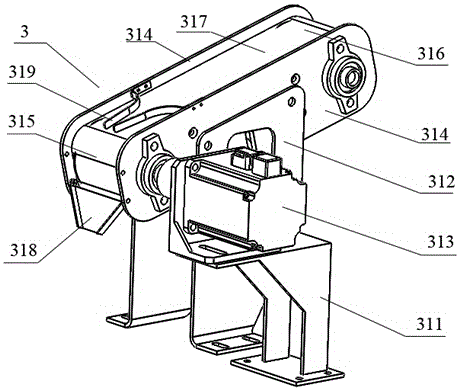

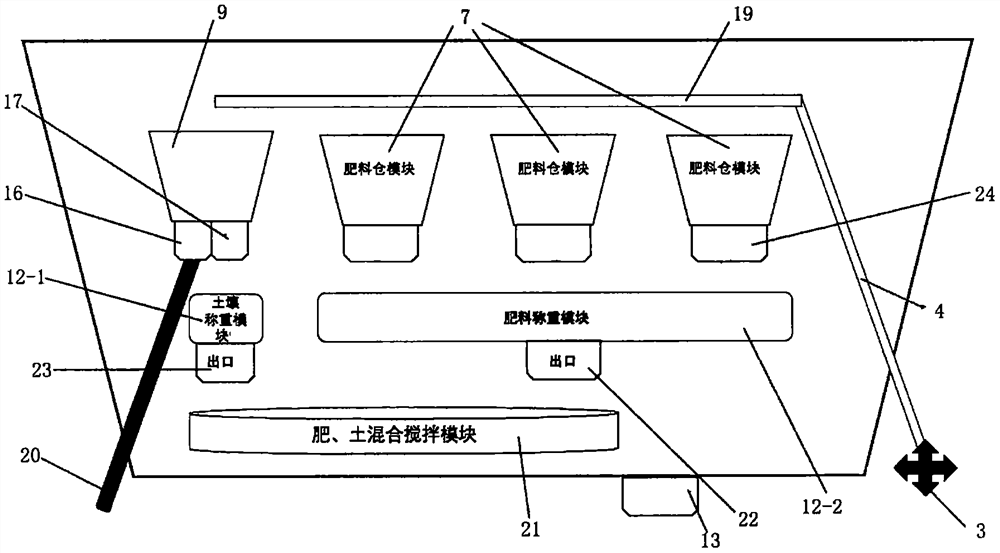

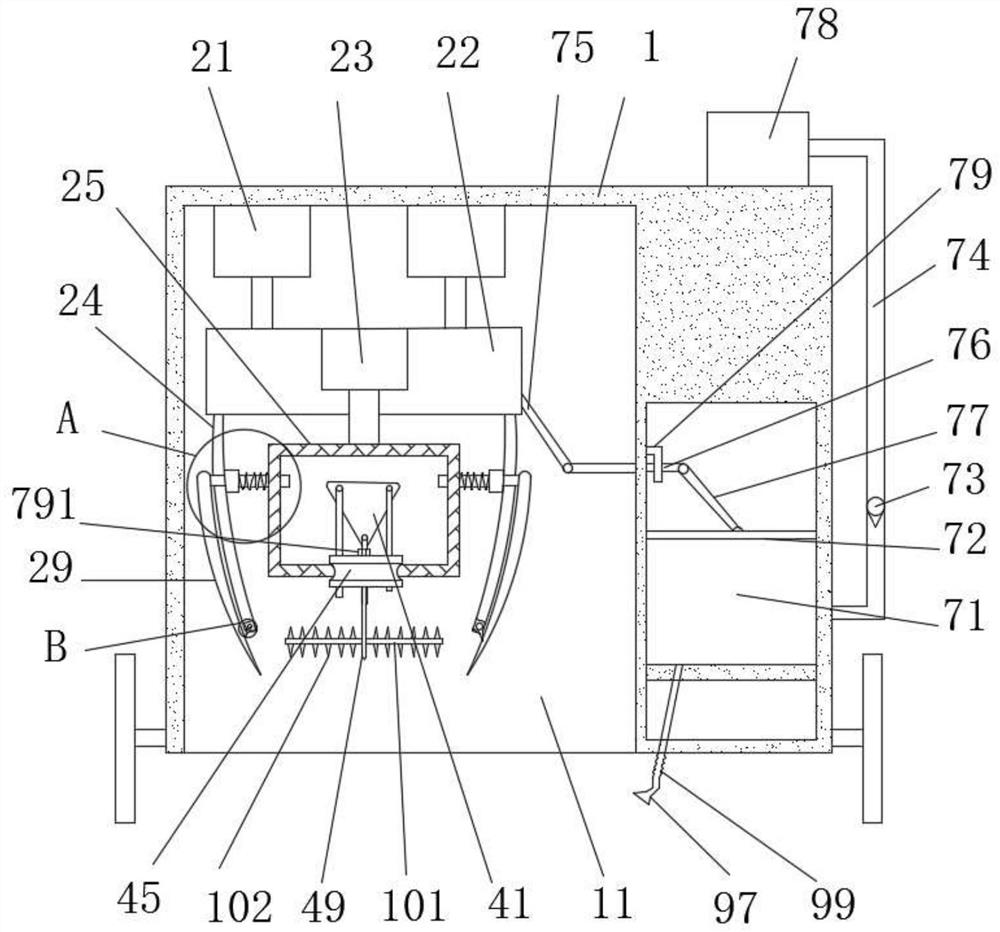

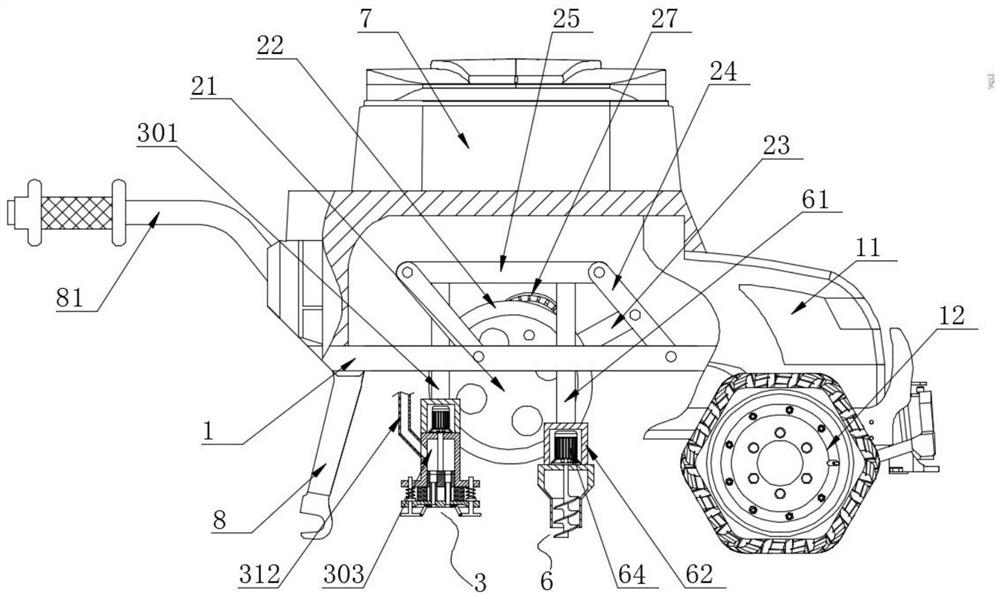

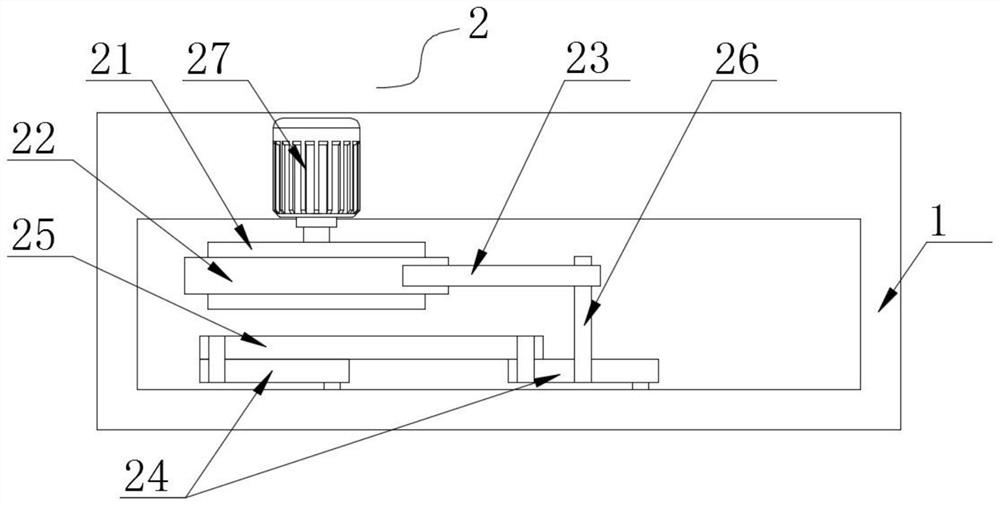

Multifunctional agricultural robot

PendingCN112136423APromote absorptionIncrease profitMeasurement devicesPlantingSoil propertiesSoil science

The invention provides a multifunctional agricultural robot which comprises a fertilizer and soil mixing and stirring mother bin and a driving module, and the fertilizer and soil mixing and stirring mother bin is installed above the driving module through a rapid locking device. The driving module is a wheel type or crawler type driving chassis. The fertilizer and soil mixing and stirring mother bin comprises a rotary bucket, a closed soil upper conveying belt, a human body proximity safety sensor, a laser radar / RFID / visual identification system, a fertilizer bin module, a liquid foliar fertilizer or pesticide application module, a soil bin module, a fertilizer / soil mixing and stirring module, a robot control center, a soil discharging and paving device, a weighing module and a mixed fertilizer and soil discharging opening. The whole process of ditching, soil digging, real-time nutrient detection and analysis, fertilizer preparation, fertilizer mixing, fertilizer application and automatic backfilling is completed at a time. Operation can be achieved on different terrains and soil properties of orchards, small pieces of lands, tea gardens, hills, mountains and the like where large machines cannot enter. The multifunctional agricultural robot has the advantages of being high in analysis speed, simple in operation, free of waste, free of pollution and the like.

Owner:杨立 +4

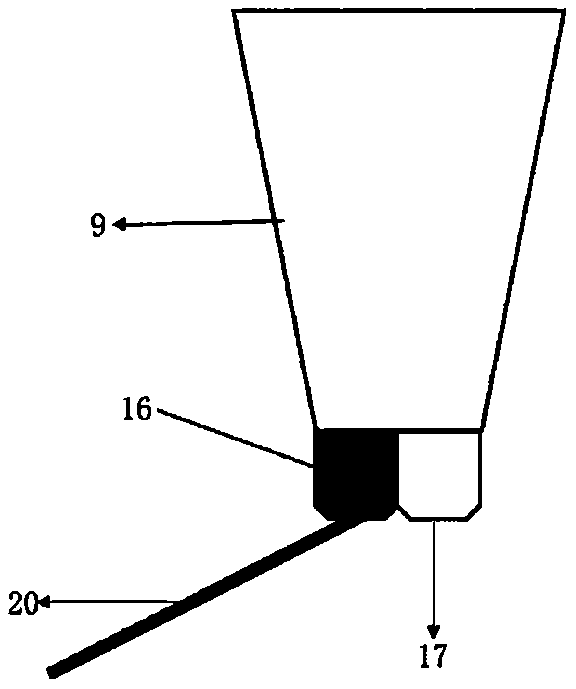

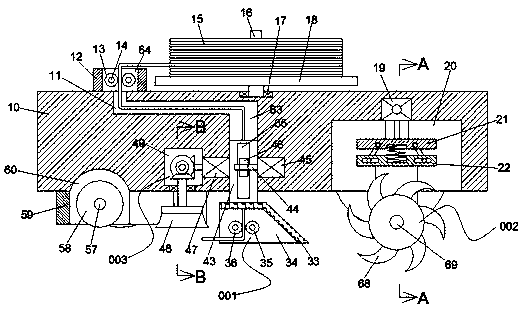

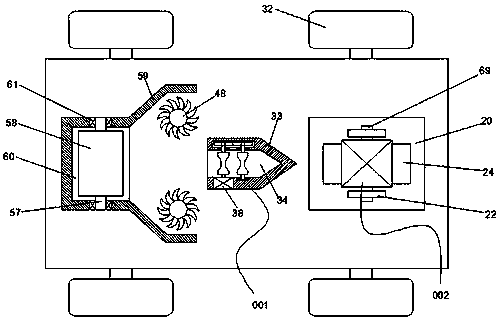

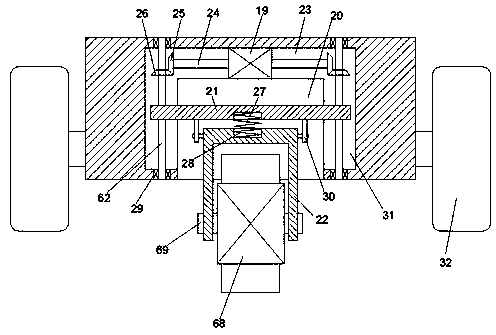

Underground cable trenching and laying machine

ActiveCN111549841AEfficiency advantageSoil-shifting machines/dredgersApparatus for laying cablesDrive wheelElectric machinery

The invention discloses an underground cable trenching and laying machine. The machine comprises a device body provided with a driving wheel. A rotating cable reel is rotatably installed in the upperside end face of the device body through a number one bearing, a cable rod is fixed near the middle position of the upper side end face of the rotating cable reel, and a cable is arranged on a rod body of the cable rod. According to the machine, a cable trench is dug on the ground through an excavating motor drill capable of lifting and lowering, then a depth-adjustable burying device can bury thecable in the excavated cable trench during the advancement of the device body, and the cable trench with the buried cable is landfilled and flattened through a cleaning brush and a rolling compactionwheel near the back of the device body.

Owner:虹峰电缆有限公司

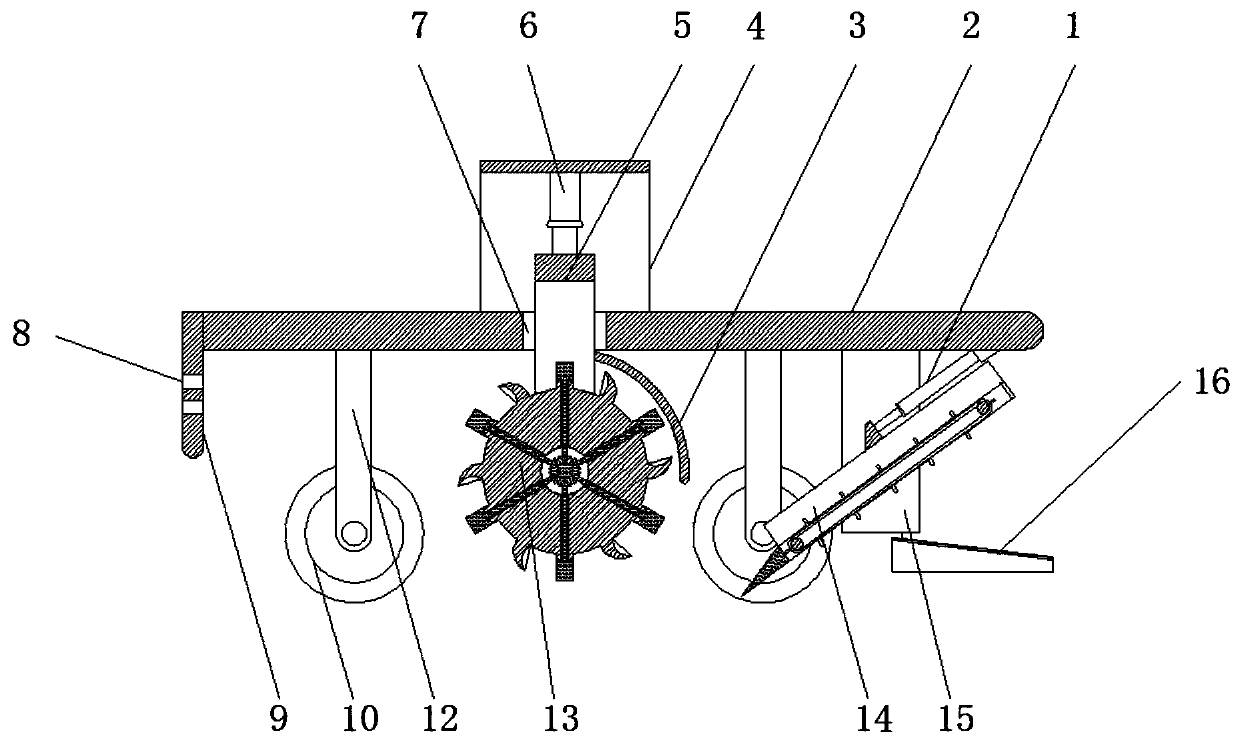

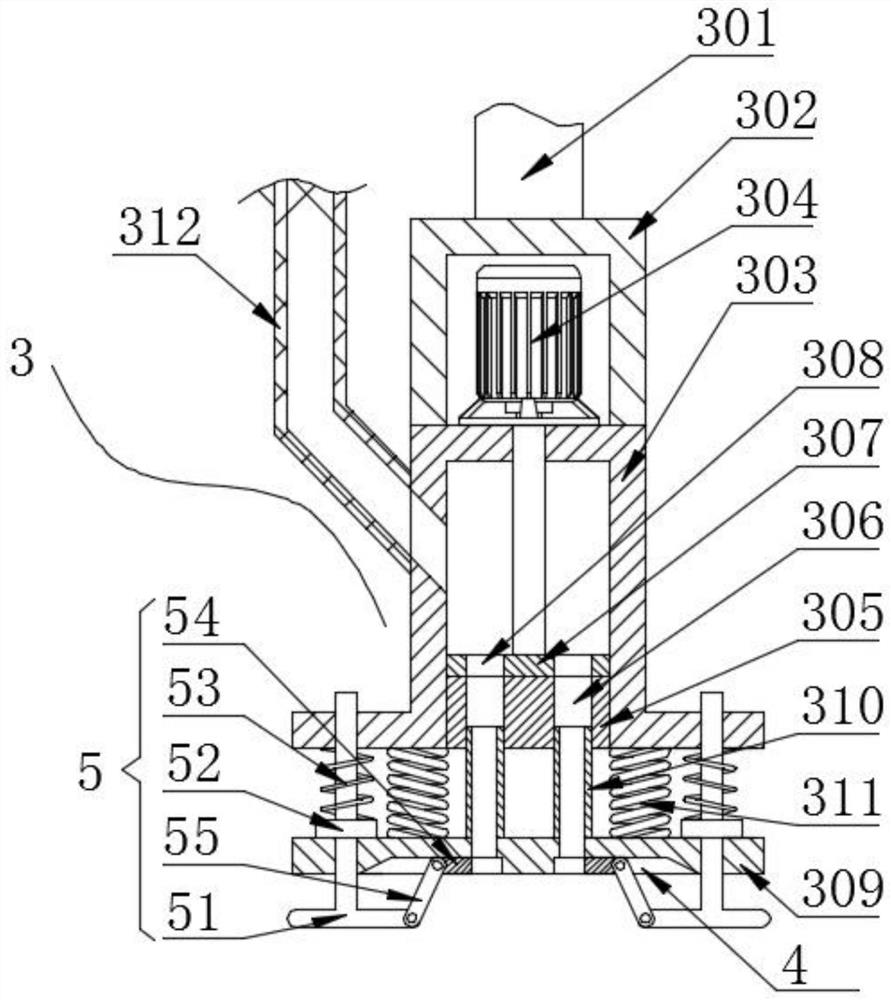

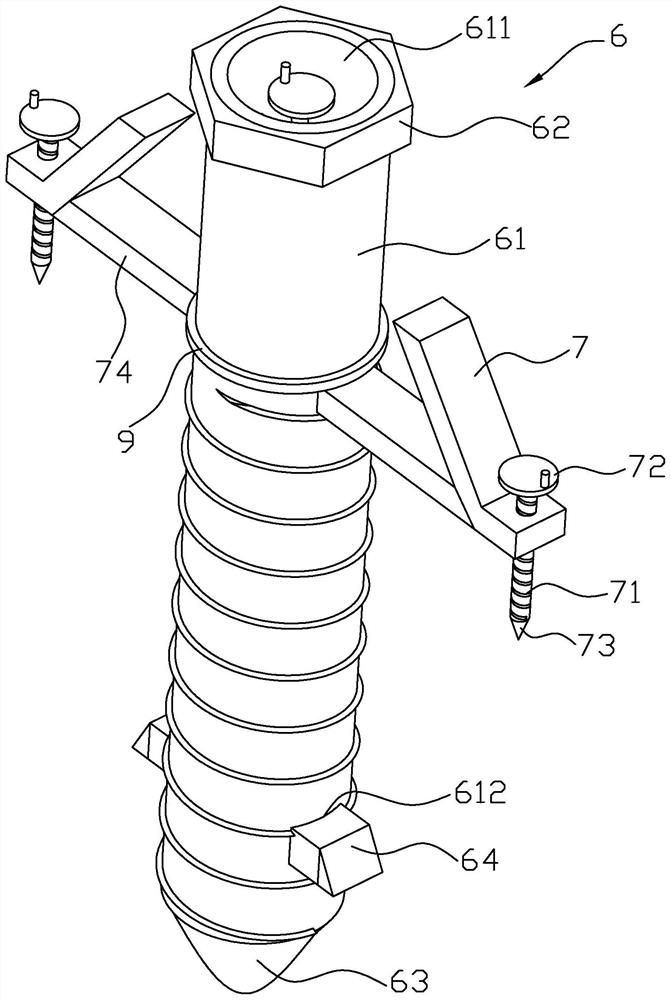

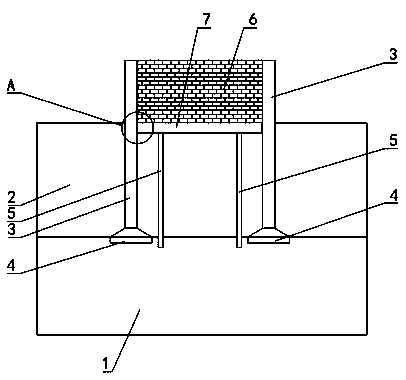

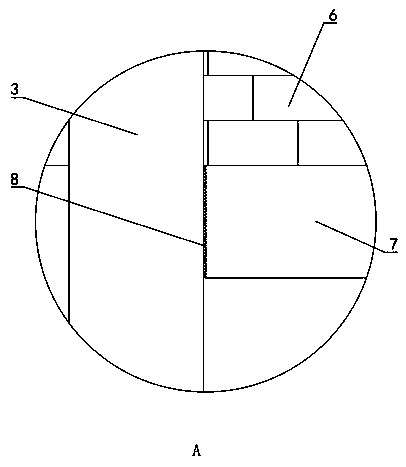

Hole digging and ridging device for garden nursery stock transplanting

ActiveCN111919706AImprove practicalityReduce lossWatering devicesAfforestationAgricultural engineeringStructural engineering

The invention provides a hole digging and ridging device for garden nursery stock transplanting, belongs to the technical field of seedling transplanting devices, and solves the problems that: existing transplanting devices only dig nursery stock lower than a supporting plate, but cannot dig higher nursery stock, so that the practicability of the transplanting devices is reduced. The device comprises a supporting plate, universal wheels are installed at the four included angles of the bottom of the supporting plate, and two handles are symmetrically arranged on the rear side of the upper end face of the supporting plate through two L-shaped supporting rods. A lifting mechanism is matched with a driving mechanism, a soil digging part is lifted upwards through the driving mechanism, the interior of the driving mechanism aligns to the upper ends of nursery stock, after alignment, a controller controls a rotating shaft of a lifting motor to drive a lifting screw to rotate clockwise, so that a lifting mechanism drives the driving mechanism and the soil digging part to sleeve the nursery stock and move downwards, the transplanting device can dig the higher nursery stock, and the practicability of the transplanting device is improved.

Owner:广西八桂种苗高科技集团股份有限公司

Channel ditcher

ActiveCN111576525AAvoid damageExtended service lifeSoil-shifting machines/dredgersSoil scienceStructural engineering

The invention discloses a channel ditcher. The channel ditcher comprises a supporting mechanism and an excavating mechanism; the supporting mechanism comprises a top plate, a mounting plate, a supporting rod, travelling wheels and a U-shaped fixing plate; and the mounting plate is vertically arranged at one end of the top plate, and mounting holes are uniformly formed in the mounting plate. According to the channel ditcher, when a rotating wheel rotates to slowly get close to soil to dig ditches, on one hand, the rotating cross-shaped crushing cutters can crush the soil, the resistance of thesoil to cutting wheels of tooth-shaped soil digging plates is reduced, and then the load of a driving part is reduced; on the other hand, the rotating cross-shaped crushing cutters can crush hard objects conveniently, the damage to the tooth-shaped soil digging plates is avoided, and service life of the tooth-shaped soil digging plates is prolonged; and due to the fact that the cross-shaped crushing cutters and the tooth-shaped soil digging plates are arranged at intervals, in the soil digging process, the soil is crushed and loosened through the rotating cross-shaped crushing cutters firstly,then the crushed soil is conveyed backwards through the tooth-shaped soil digging plates, the steps are repeated in this way, and the working efficiency is improved.

Owner:HUNAN DINGYUAN

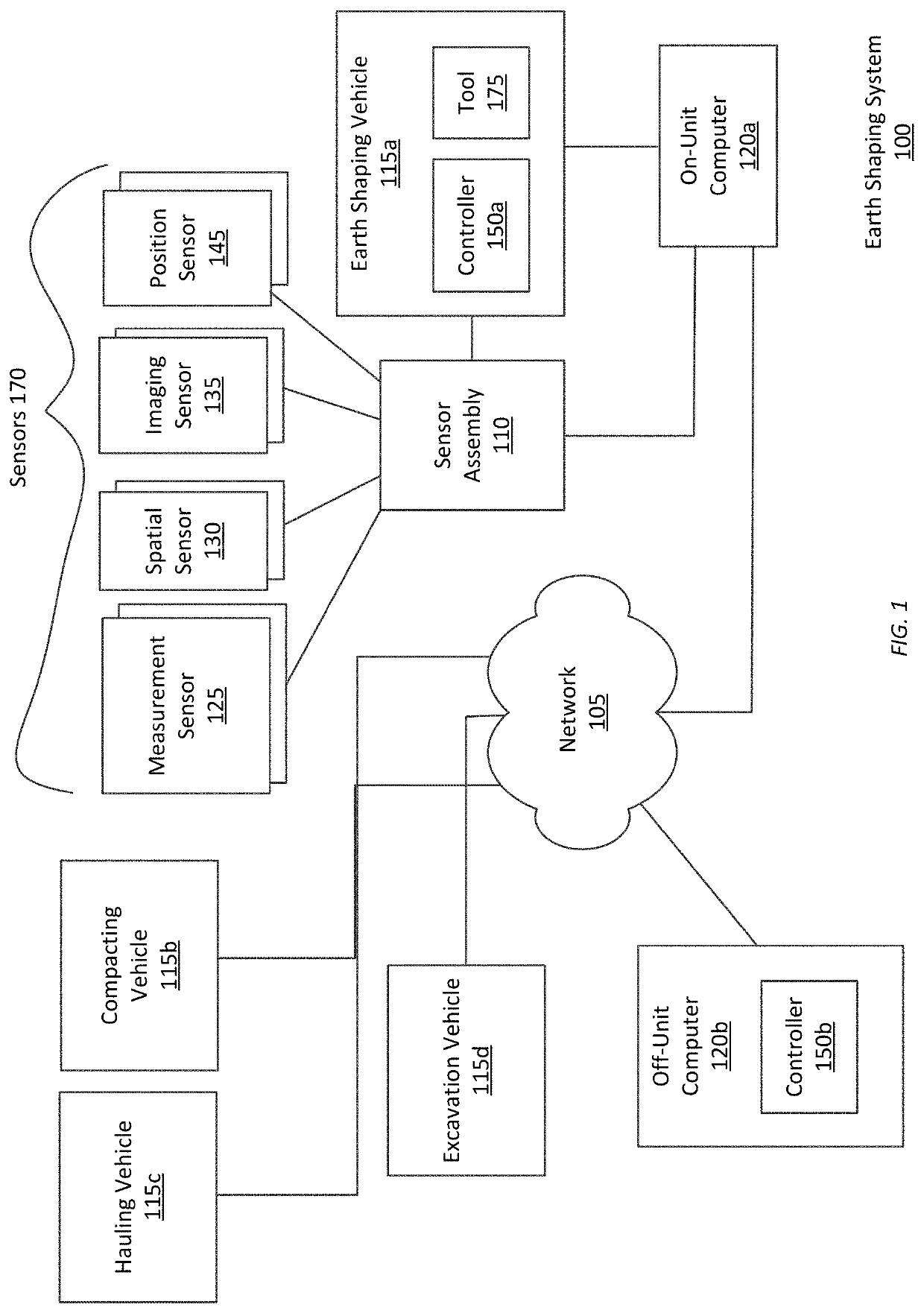

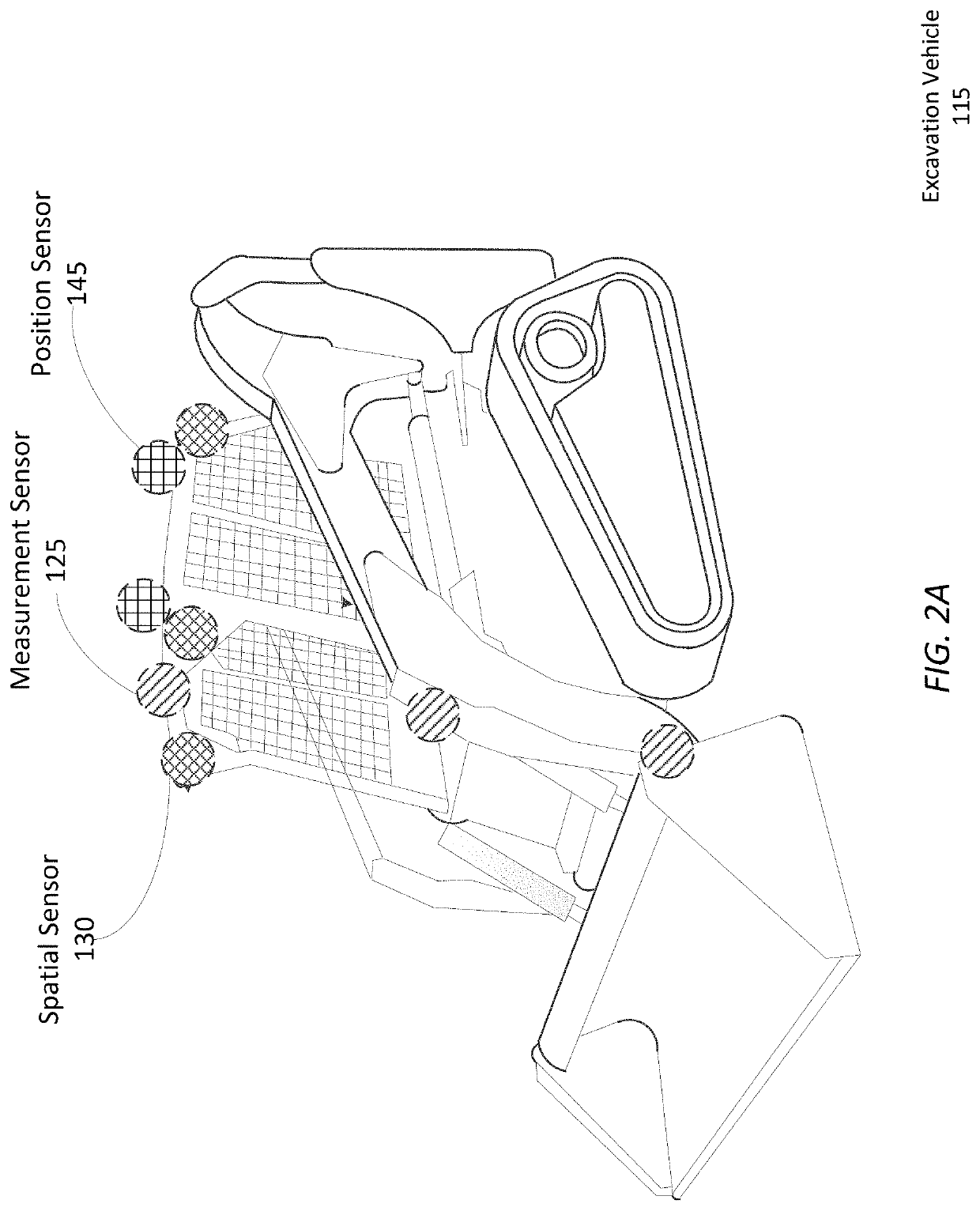

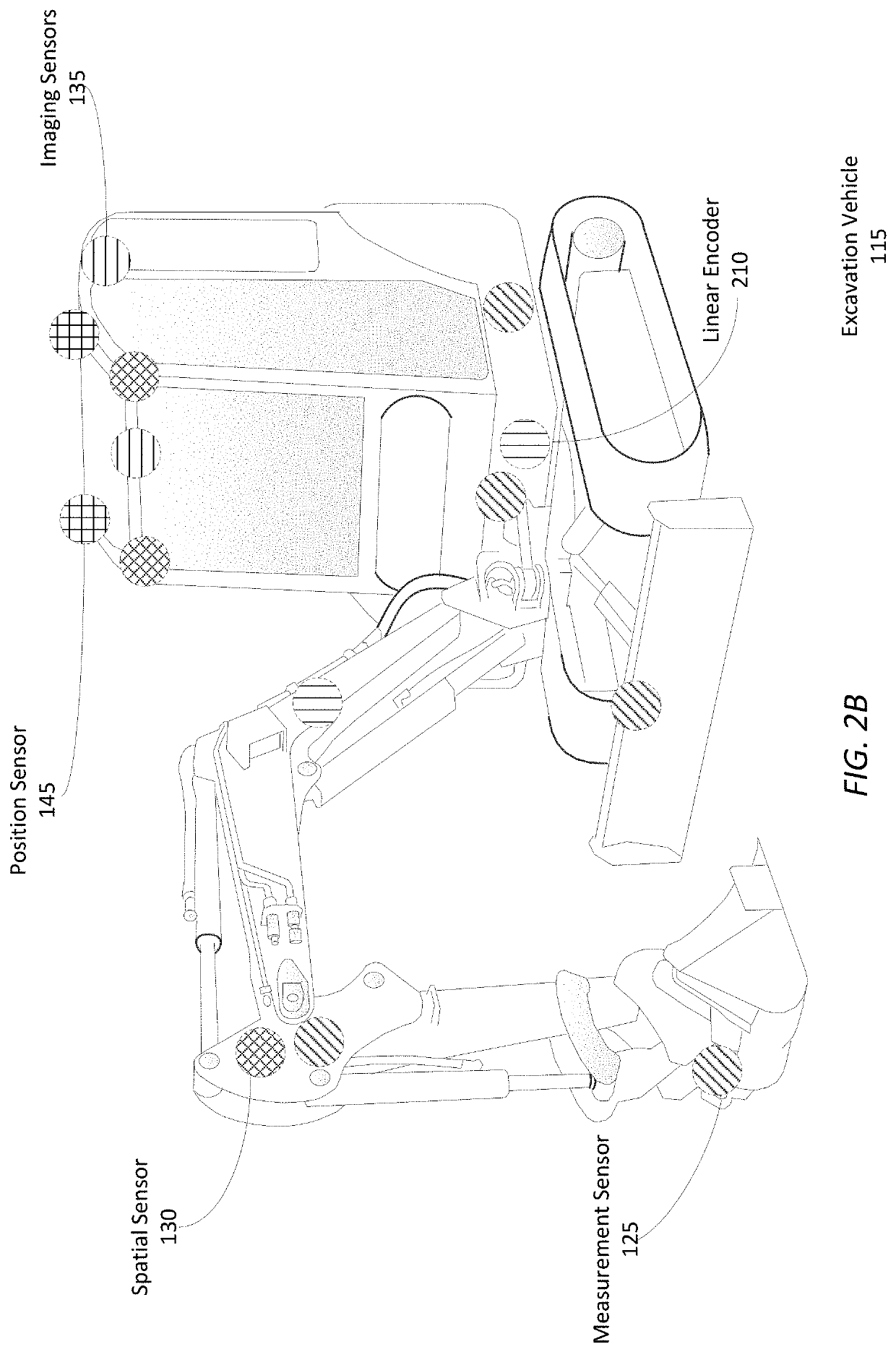

Loading earth into a vehicle using a cooperative fleet of vehicles

ActiveUS20210149403A1Low costReduce needAutonomous decision making processScene recognitionAtmospheric sciencesDirt digging

Owner:BUILT ROBOTICS INC

Automatic agricultural pit digging, planting and soil burying integrated device

ActiveCN112840794AControl planting densityImprove planningPlantingFurrow making/coveringGear wheelAgricultural engineering

The invention discloses an automatic agricultural pit digging, planting and soil burying integrated device. The automatic agricultural pit digging, planting and soil burying integrated device comprises a vehicle body, wherein a cab is arranged on the vehicle body, a hydraulic rod is arranged on the vehicle body, a movable rod of the hydraulic rod is connected with a transverse plate, a sapling box is arranged on the transverse plate, seedling clamping devices are arranged on the front side and the rear side of the left end of the transverse plate, cylinders are arranged on the front side and the rear side of the vehicle body, first sleeves are arranged in the middles of the cylinders, a first motor is arranged on the vehicle body, a first gear is arranged on the first motor, a first box body is connected with the inner wall of each cylinder, a soil block smashing device is arranged at the bottom of each first box body, an L-shaped rod is arranged on the inner wall of each first box body, an automatic shear fork clamping device is arranged on the lower side of each L-shaped rod, an automatic earth cutting device is arranged at the bottom of each cylinder, and a master controller is arranged in the cab. According to the device, the first motor drives the first gear to rotate, so that the first sleeves are driven to rotate, then the cylinders are driven to rotate, the processes of digging pits, planting saplings and covering soil are alternately carried out, the integrated process is achieved, the planting efficiency is improved, and the soil block smashing devices smash large soil blocks into small blocks, so that the saplings are prevented from being damaged by crashing.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER +1

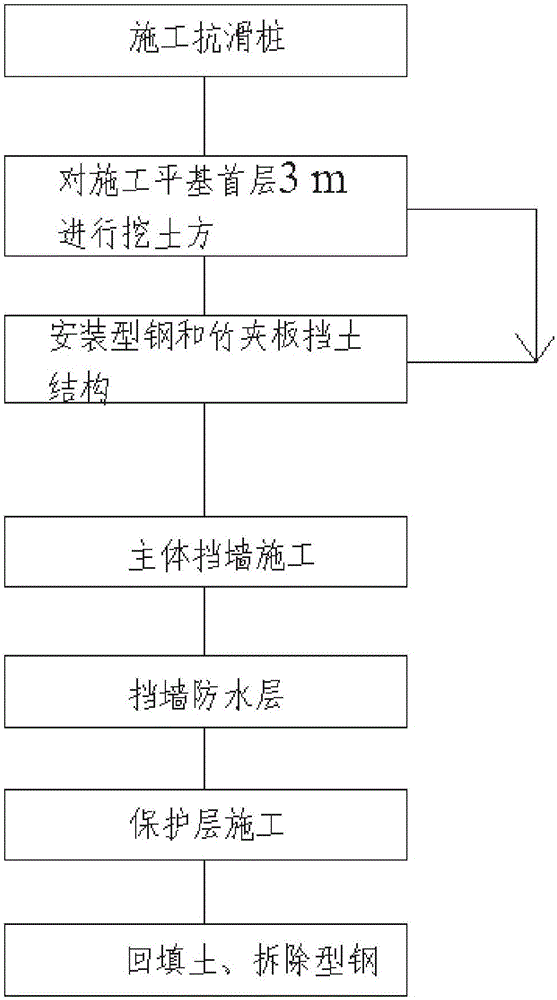

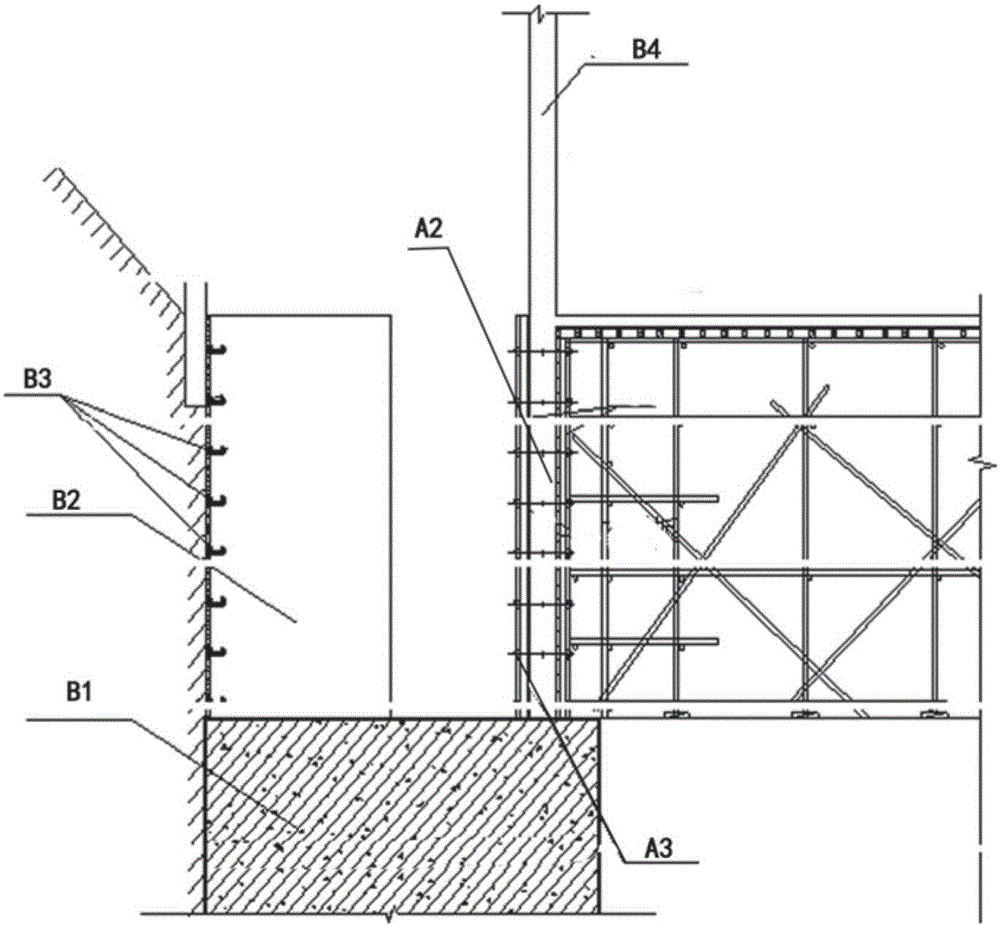

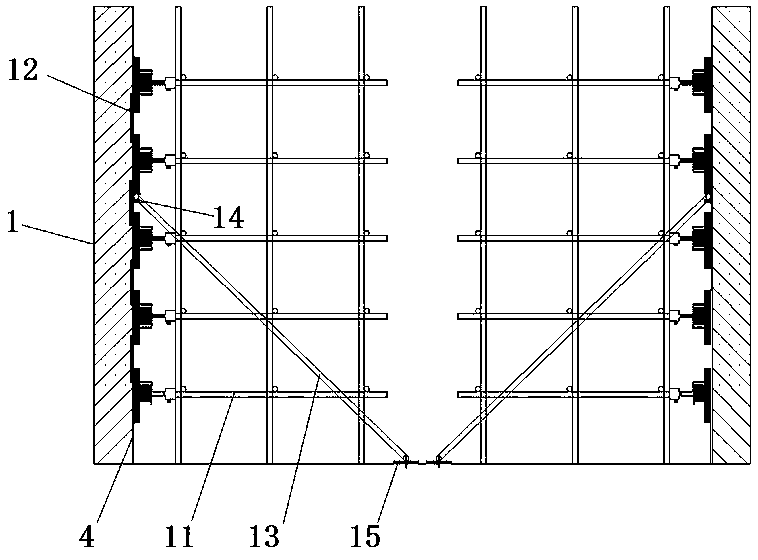

Reverse structural steel and bamboo splint soil retaining construction method

InactiveCN106638675ALow costShorten the construction periodArtificial islandsExcavationsStructural engineeringDirt digging

The invention provides a reverse structural steel and bamboo splint soil retaining construction method. The reverse structural steel and bamboo splint soil retaining construction method comprises the following steps that slide-resistant piles are constructed; earthwork excavation is carried out on a first layer by 3 meters of the construction flat base; temporary supporting is carried out on slopes by connecting the slide-resistant piles in a butted manner and installing structural steel and bamboo splint soil retaining structures; the second step and the third step are circulated every 3 meters till the pile top elevation of an underground building is reached; main barricades, barricade waterproof layers and protective layers are constructed sequentially; earthwork which is 0.5 m high is backfilled and compacted; and the sixth step is circulated every 3 meters from bottom to top till all backfilling is completed. By means of the reverse structural steel and bamboo splint soil retaining construction method, the construction cost can be greatly saved, and the construction period can be remarkably shortened.

Owner:CHONGQING CONSTR RESIDENTIAL ENG +1

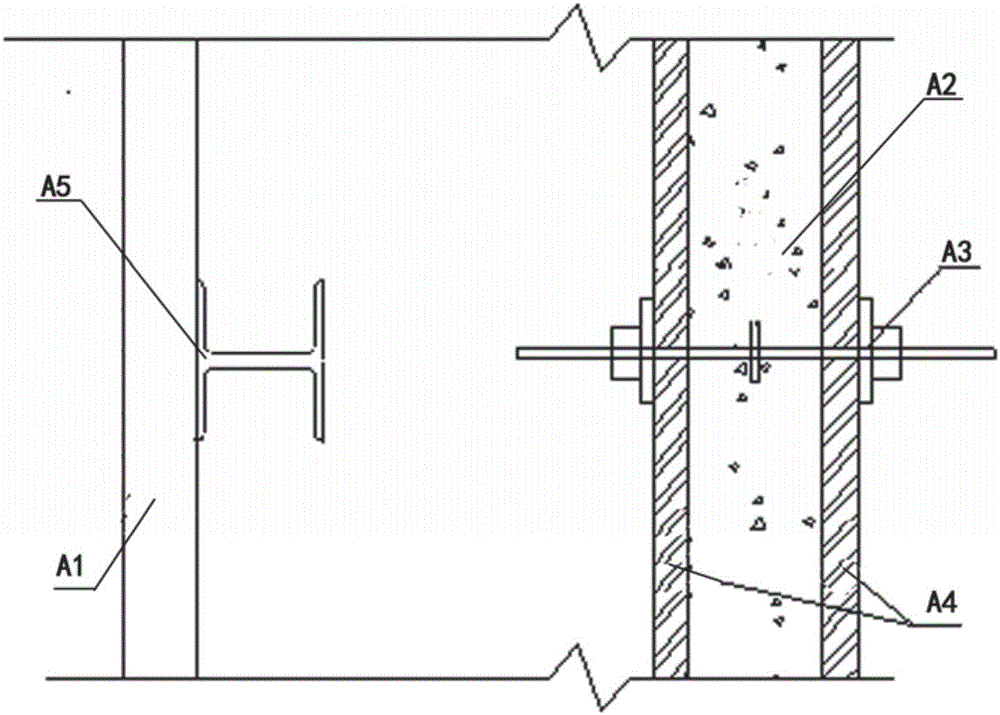

Pipe jacking construction method under sandy gravel geological conditions

The invention discloses a pipe jacking construction method under sandy gravel geological conditions. The pipe jacking construction method comprises the following steps that the position of a working pit and the center position of the pit are determined, the excavation depth of each layer is controlled, and concrete is poured in time; earth excavation, form manufacturing, steel bar engineering, form installation and concrete engineering are sequentially carried out; pipeline jacking comprises processes of earth cutting, jacking, measuring and deviation rectifying, a jack is used for extending apickaxe to push a jacking pipe forwards under the condition that the back retreats from the ground, and jacking is started from the position, located on the guide rail, of the pipe joint until the pipe jacking section is completed; when one-time jacking cannot be carried out, the pipe jacking section is divided into two sections, and sectional jacking is carried out by adopting an intermediate jacking station relay jacking method; shear wedges are arranged in an intermediate jacking station; and backfilling is carried out. The method solves the problem of jacking force of the sandy gravel section jacking pipe.

Owner:BUILDING & MOUNTING ENG CO LTD NO 12 BUREAU MINIST OF RAILWAYS +1

Construction process for large-aperture brick and concrete reverse hanging well

Construction process for a large-aperture brick and concrete reverse hanging well includes a, selecting the position of a working pit; b, excavating the working pit: firstly, uniformly and symmetrically excavating earth along the lower portion of the periphery of a well wall according to positioning lines, secondly, quickly building a well body of a dug portion of the well wall by the aid of MIO bricks and MU7.5 mortar, thirdly, adopting a reinforced concrete structure with the size of 400mmX400mm as a ring beam, fourthly, simultaneously setting a water collecting pit with the size of 500mmX600mm, fifthly, setting a concrete rear backrest according to the trend of pipelines after an established elevator is achieved, and sixthly, discharging the earth and draining water; c, draining water of the foundation pit; and d, manufacturing a working well. The strength of concrete is C20. A reverse construction method is adopted for the brick elliptical reverse hanging well according to the condition of the earth and distribution of a pipe network. Compared with the prior art, the construction method for the large-aperture brick and concrete reverse hanging well is complete, can guarantee construction quality and provides a novel standard for acceptance inspection.

Owner:孙冬梁

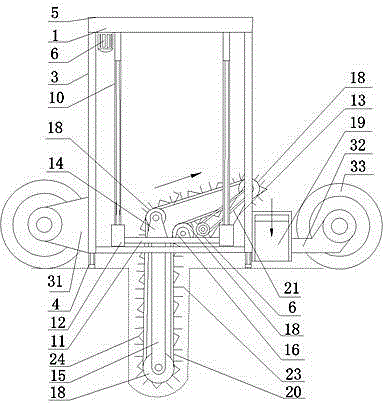

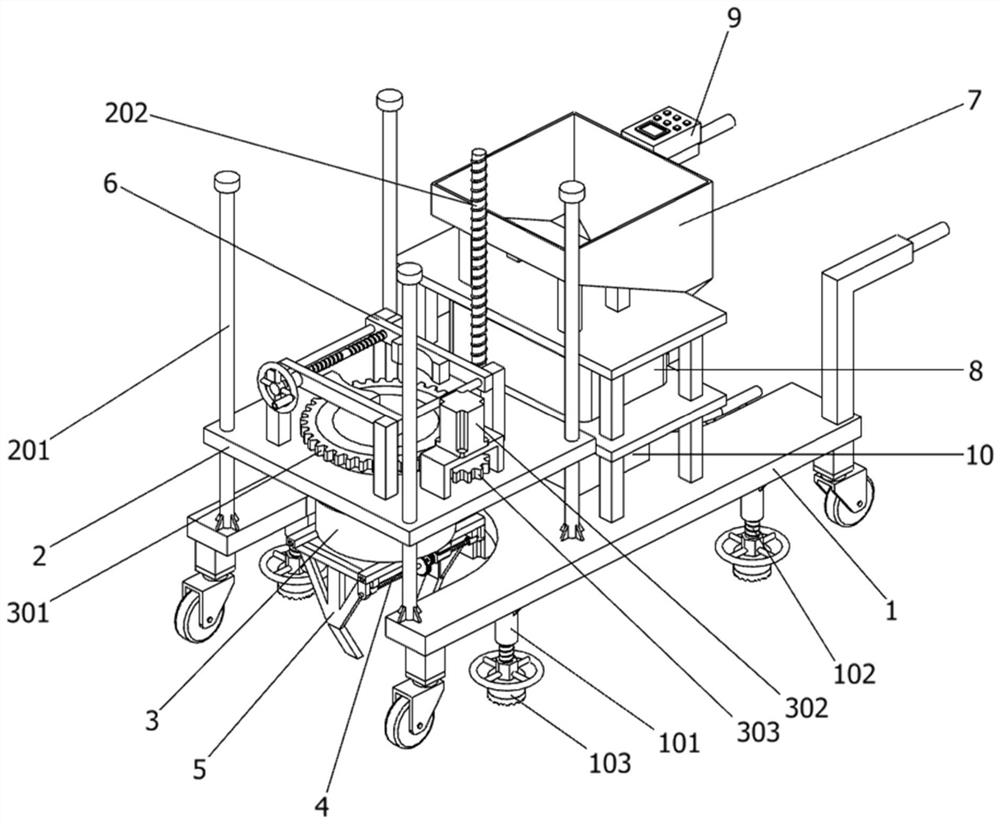

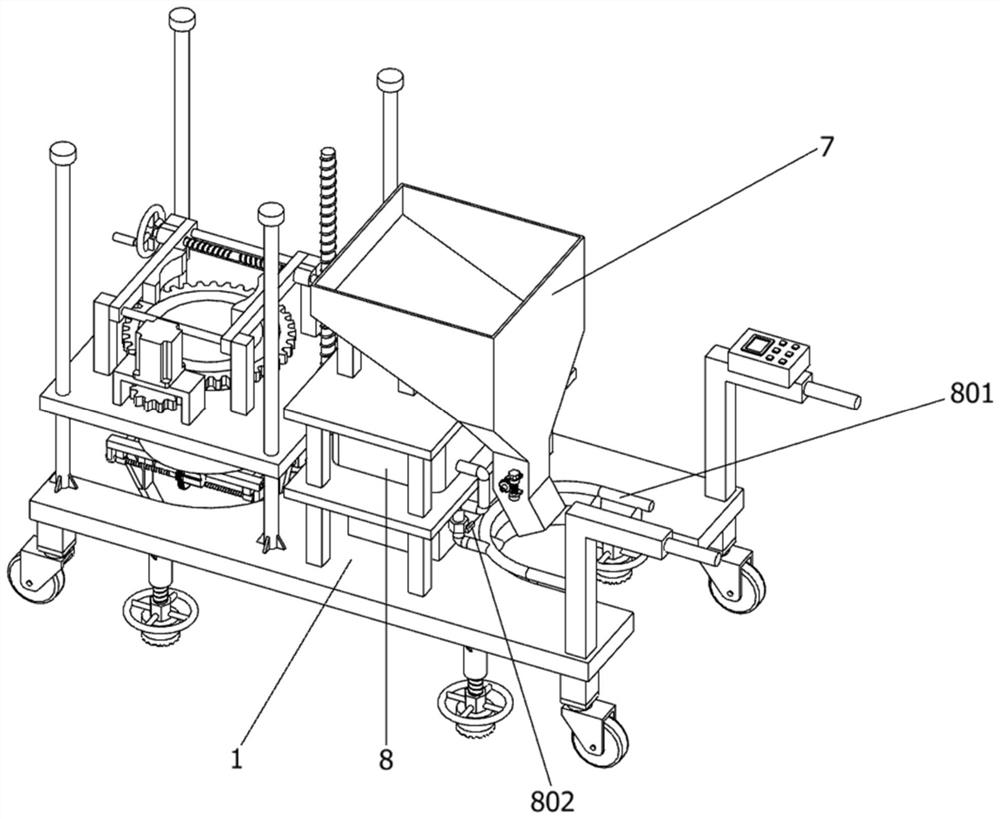

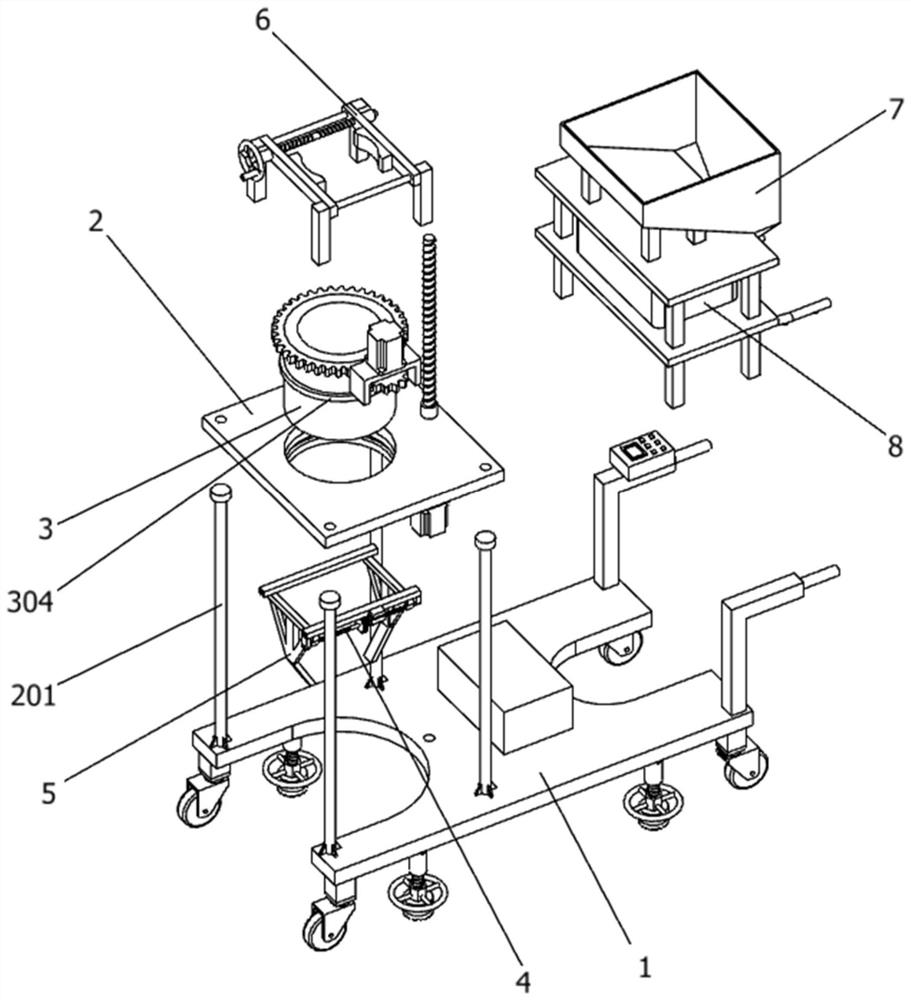

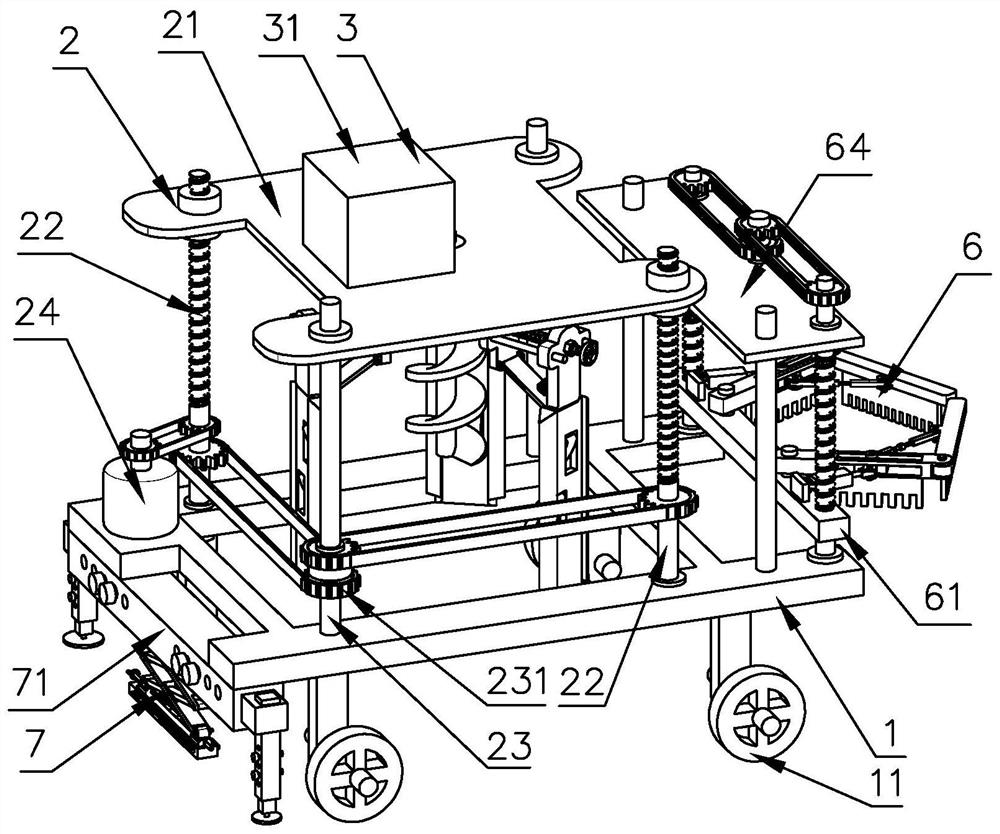

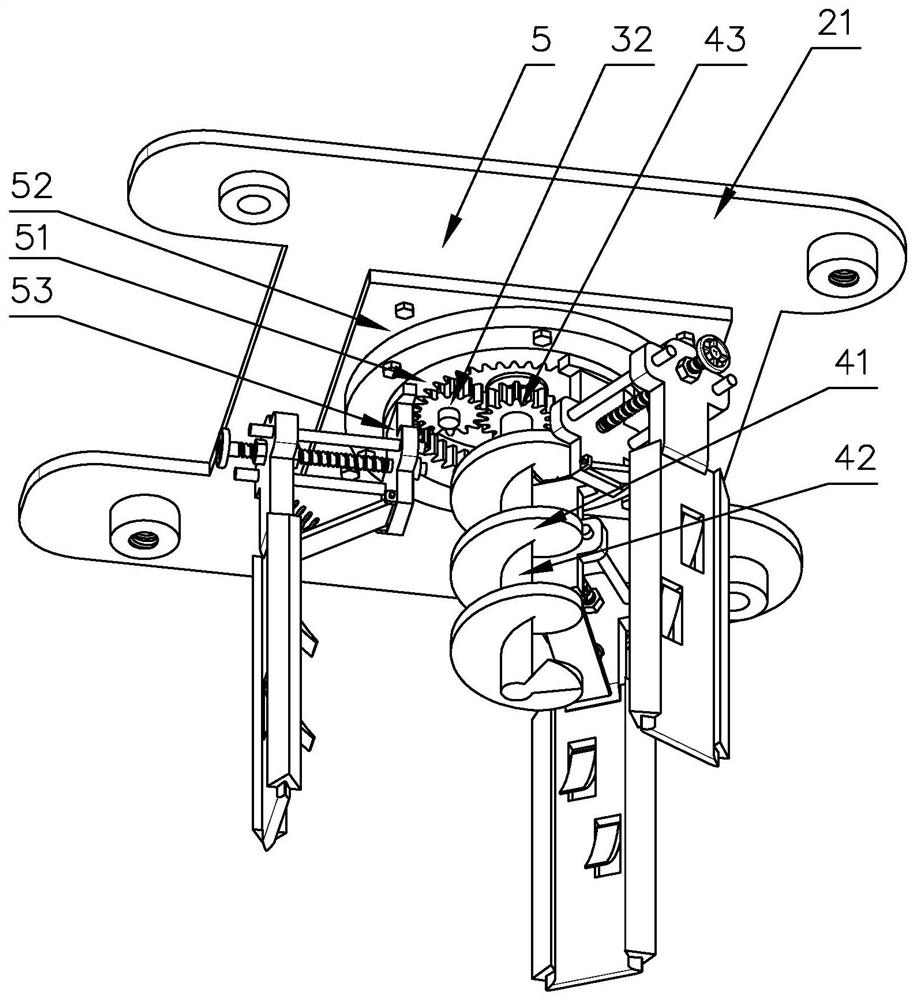

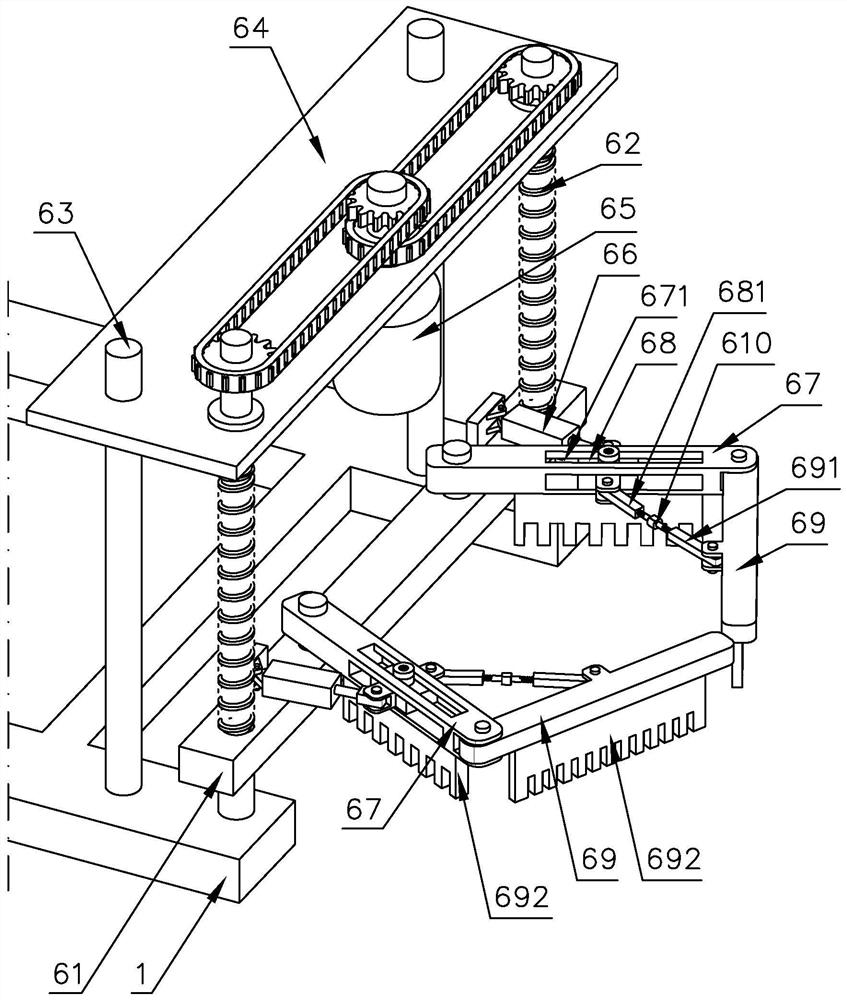

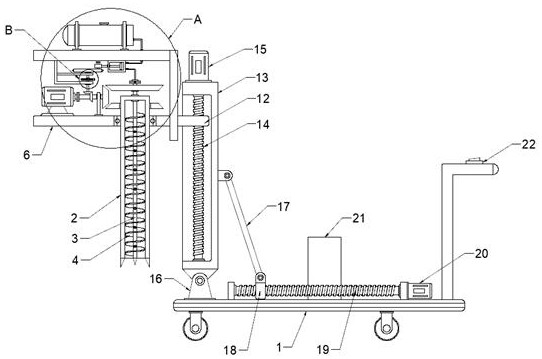

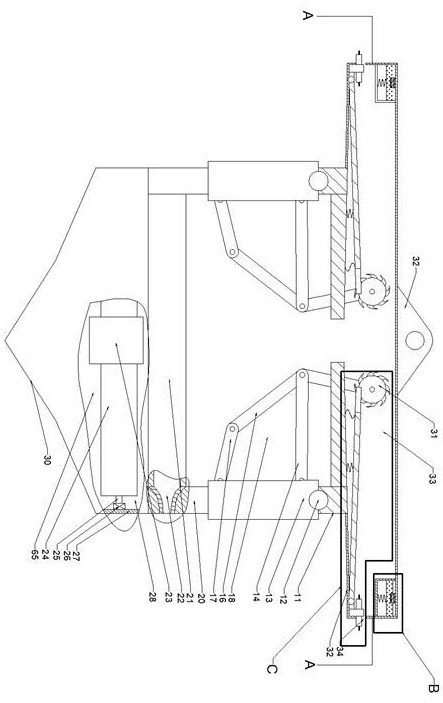

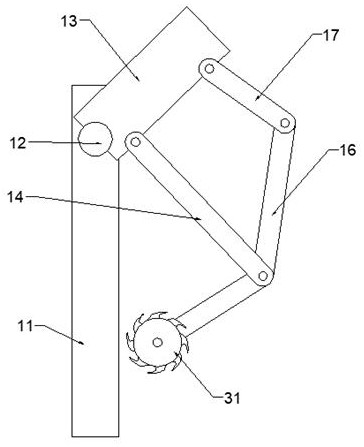

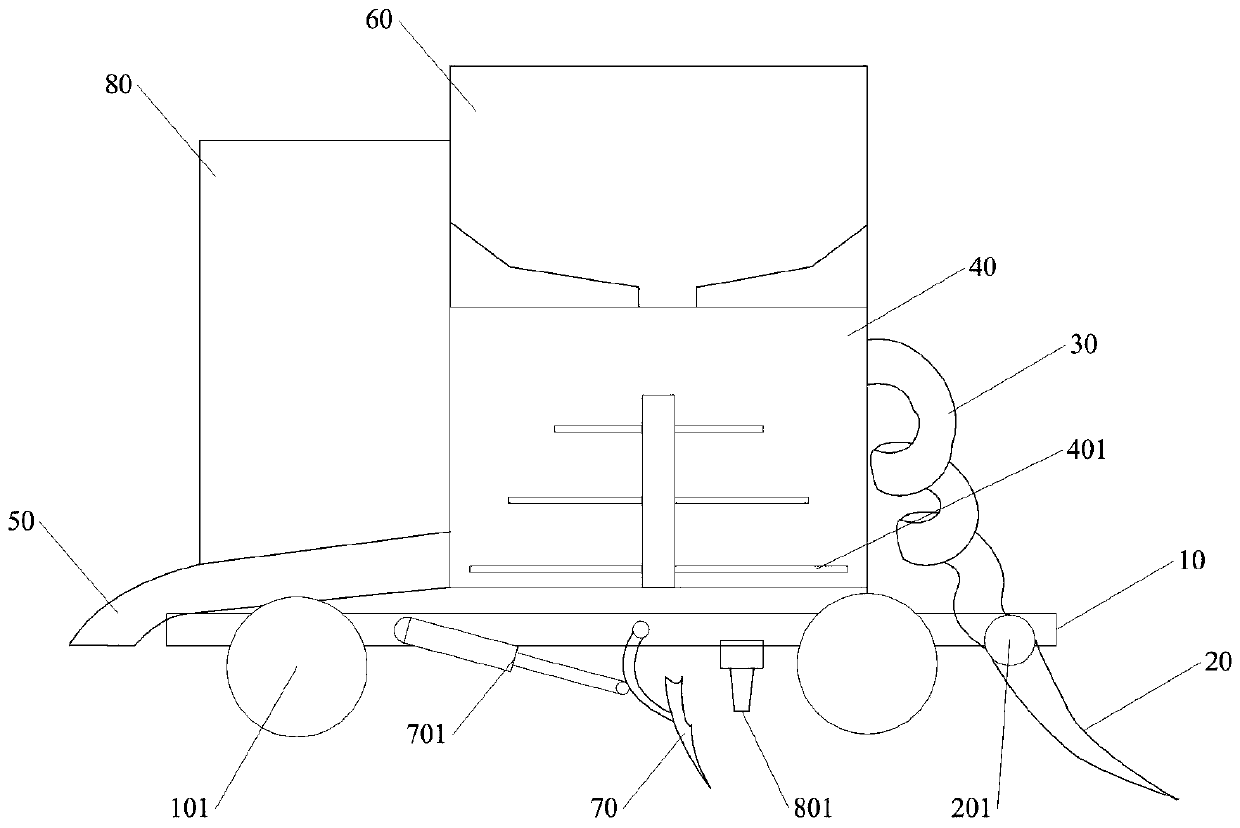

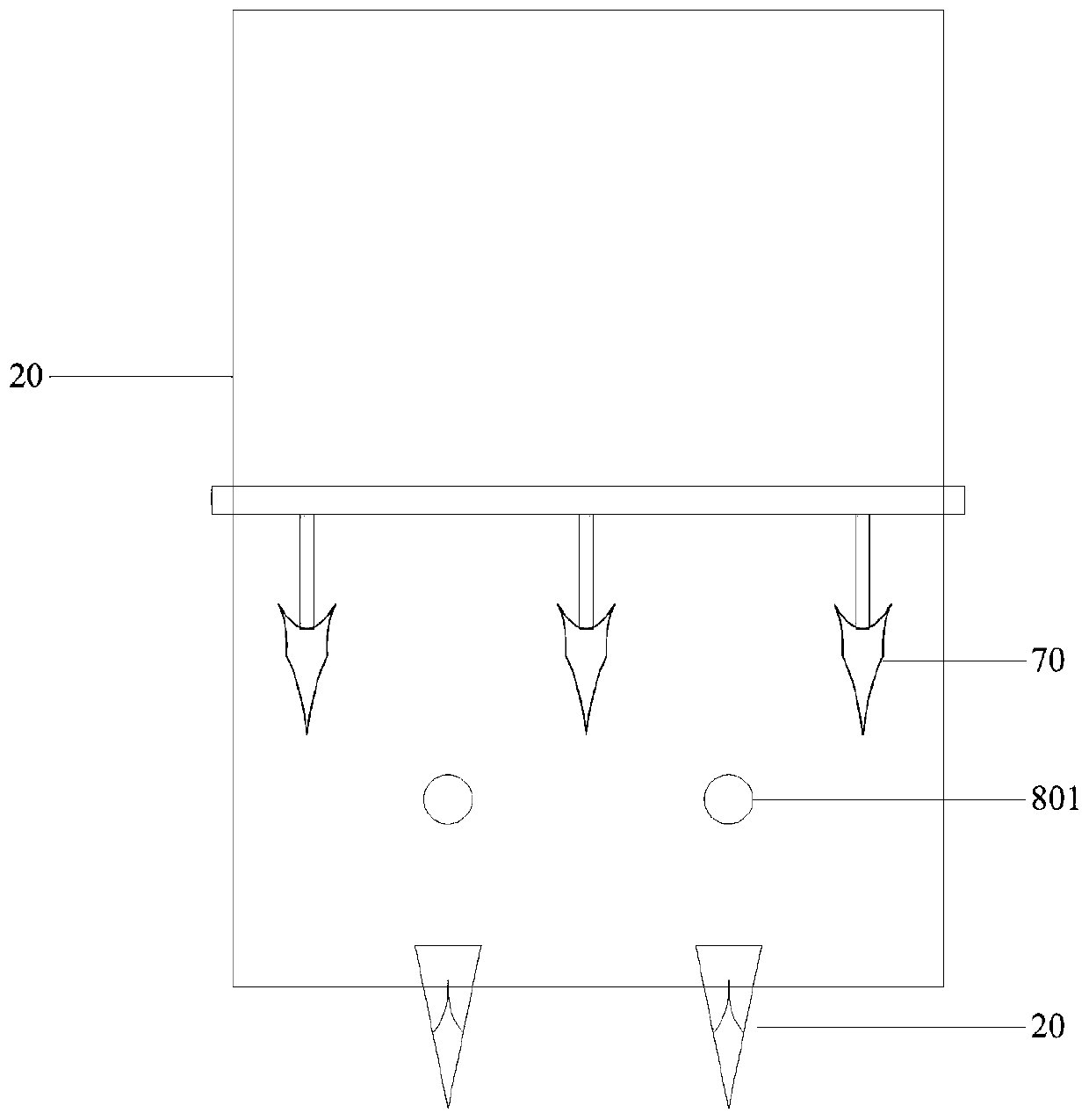

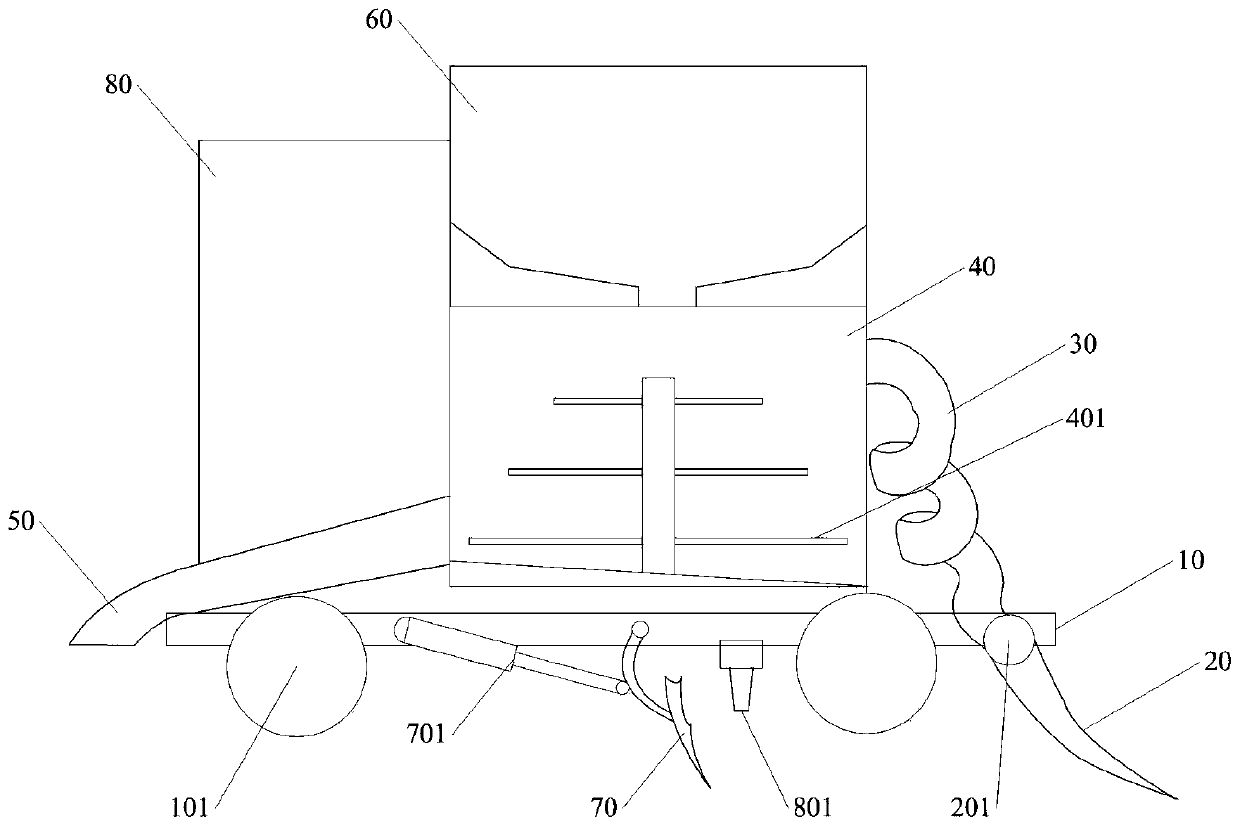

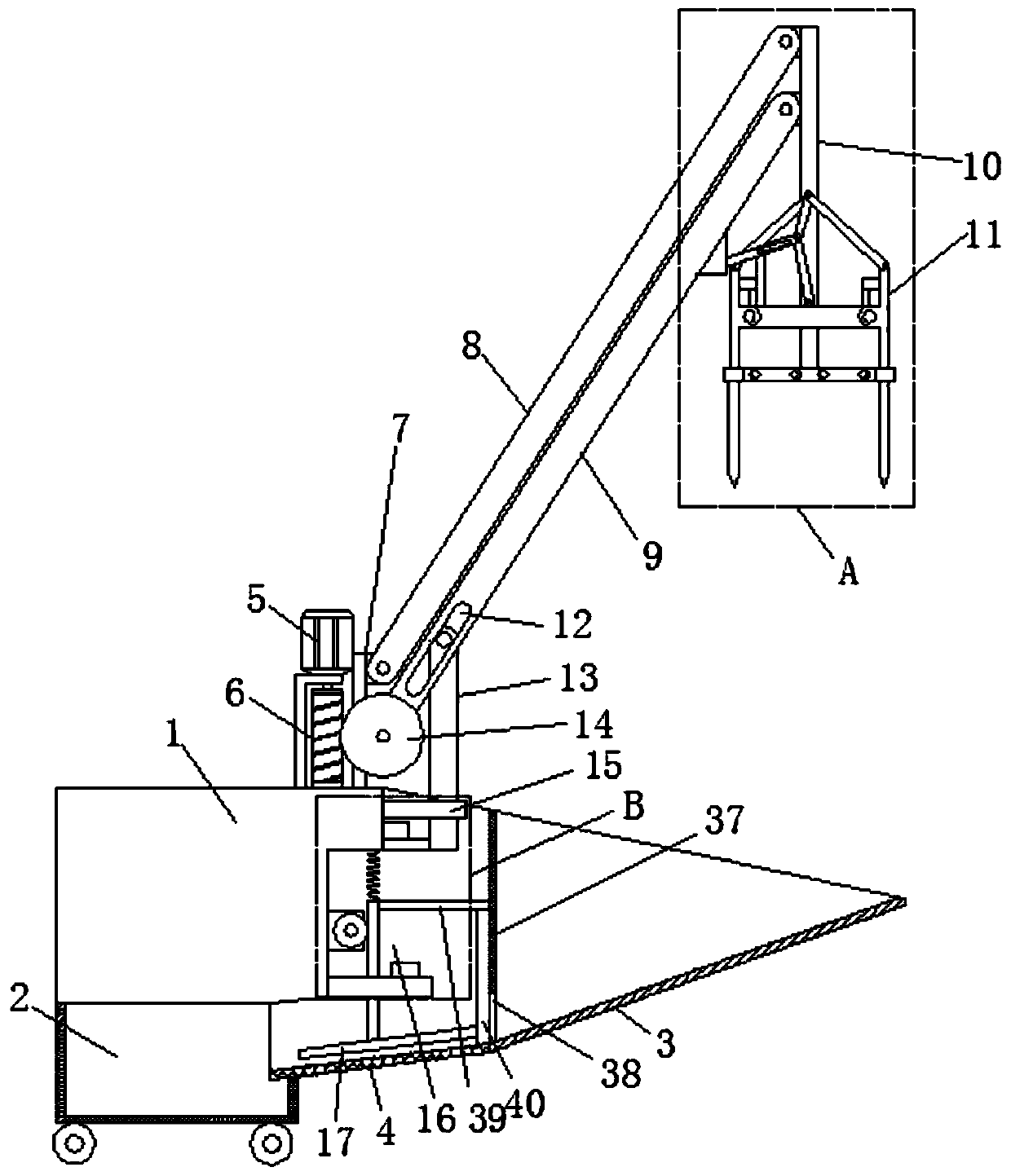

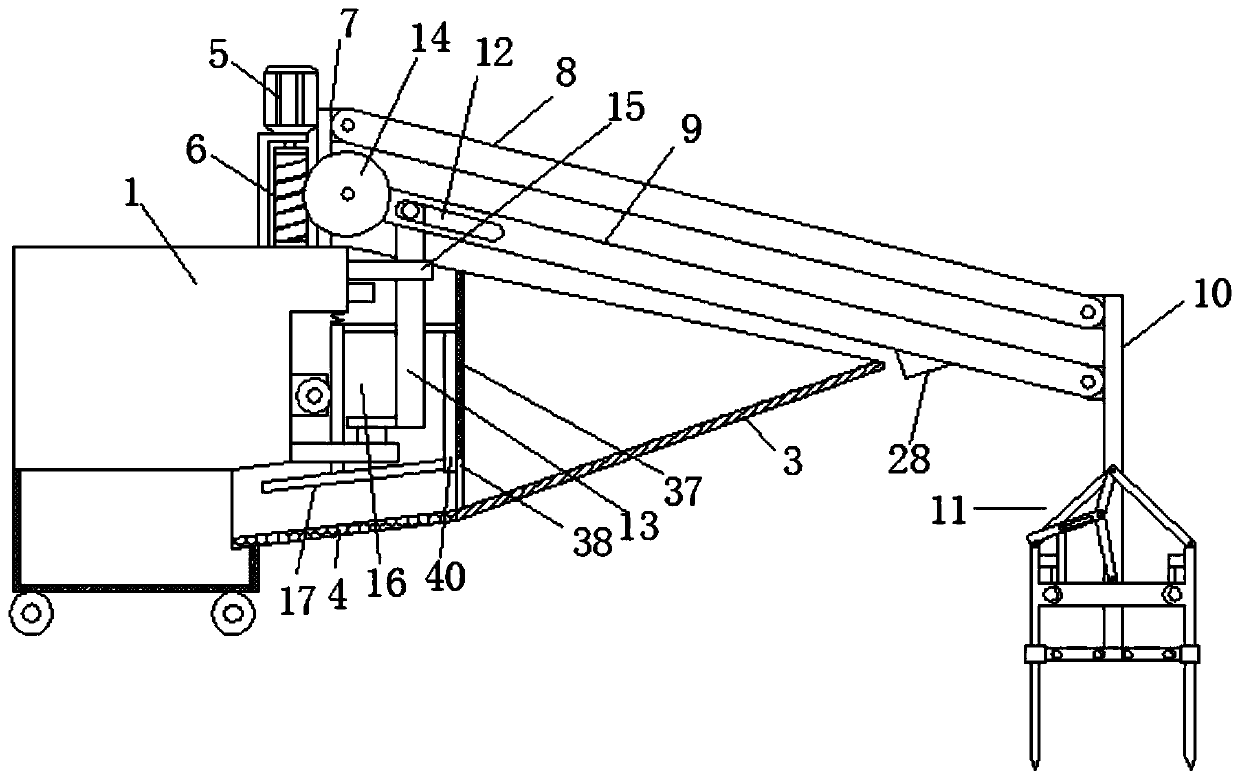

Auxiliary transplanting device for forestry seedlings

ActiveCN113057083AAchieve regulationMeet initial growth needsSpadesPlantingAgricultural engineeringStructural engineering

The invention discloses an auxiliary transplanting device for forestry seedlings. The auxiliary transplanting device comprises a rack, a lifting mechanism, a power mechanism, a soil digging mechanism, a soil loosening mechanism, a hilling mechanism and a supporting mechanism; the lifting mechanism, the power mechanism, the soil digging mechanism, the soil loosening mechanism, the hilling mechanism and the supporting mechanism are borne by the rack; the power mechanism, the soil digging mechanism and the soil loosening mechanism are fixed on the lifting mechanism; the hilling mechanism is located on one side of the lifting mechanism; the supporting mechanism is located on the other side of the lifting mechanism; the lifting mechanism comprises a first supporting plate, first lead screws, first guide shafts and a first motor; and the soil loosening mechanism comprises an inner fluted disk, a fixing disk sleeve, a first fixing plate, a second fixing plate, a second lead screw, a baffle plate and a tension spring. The auxiliary transplanting device for forestry seedlings can loosen the soil around a pit hole while a tree pit is dug and meets preliminary development of a root system after seedling transplanting; and meanwhile, digging, transplanting and hilling are performed synchronously, and time and labor are saved.

Owner:海南明致园林苗木科技有限公司

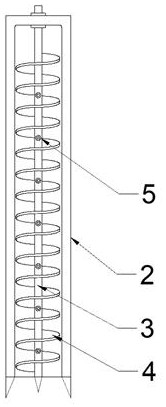

Pit digging device for garden trees

InactiveCN112400413AEasy to storeEasy backfillingPlantingPressurised distribution of liquid fertiliserSoil scienceSpiral blade

The invention relates to the field of garden tree planting equipment, in particular to a pit digging device for garden trees. The pit digging device for the garden trees comprises a vehicle body, a soil digging mechanism arranged at the front side of the vehicle body and an adjusting mechanism for adjusting the position and orientation of the soil digging mechanism. Through the arrangement of thesoil digging mechanism comprising a drilling barrel, a drilling rod and spiral blades and an adjusting assembly comprising a lifting assembly and a rotating assembly, during pit digging operation, thepit digging depth is conveniently controlled, meanwhile, soil is conveniently and temporarily stored in the drilling barrel, later-period soil backfilling operation is facilitated, and the overall tree planting efficiency is improved. By arranging the lifting assembly comprising a first lead screw assembly, the pit digging depth is conveniently adjusted, and meanwhile the soil height is increased; and by arranging a liquid pumping barrel, a liquid medicine barrel and a hollow drilling rod with spraying holes formed in the surface, the nutrient solution and the soil are evenly mixed, the nutrient solution is evenly distributed in the backfilled soil, and the fertilization effect is improved.

Owner:余杏花

Pit digging and soil crushing device for sapling planting

InactiveCN112335375AReduce labor intensitySimple structureSpadesPlantingAgricultural engineeringStructural engineering

The invention belongs to the technical field of sapling planting, and particularly relates to a pit digging and soil crushing device for sapling planting. The pit digging and soil crushing device comprises a machine body, a pit digging cavity is formed in the machine body, a soil digging device is arranged in the pit digging cavity, and the soil digging device comprises an electric push rod, a fixed shell, a hydraulic push rod, a lifting shell, an inclined block and a movable column; and the end, away from the lifting shell, of the movable column is fixedly connected with a pit digging claw, asoil crushing device body is arranged in the fixed shell, and a soil scraping device is arranged at the lower end of the inclined block. According to the pit digging and soil crushing device, by arranging the soil digging device, the electric push rod is started to push the fixed shell to descend, a claw tip of the pit digging claw makes contact with the ground, and the hydraulic push rod is started to drive the pit digging claw to move downwards along the inclined block for soil digging. By means of the pit digging and soil crushing device, the structure is simple, operation is convenient, mechanical soil digging is achieved, labor intensity is low, and a large number of manpower and material resources are saved.

Owner:金寨绿野生态农业科技开发有限公司

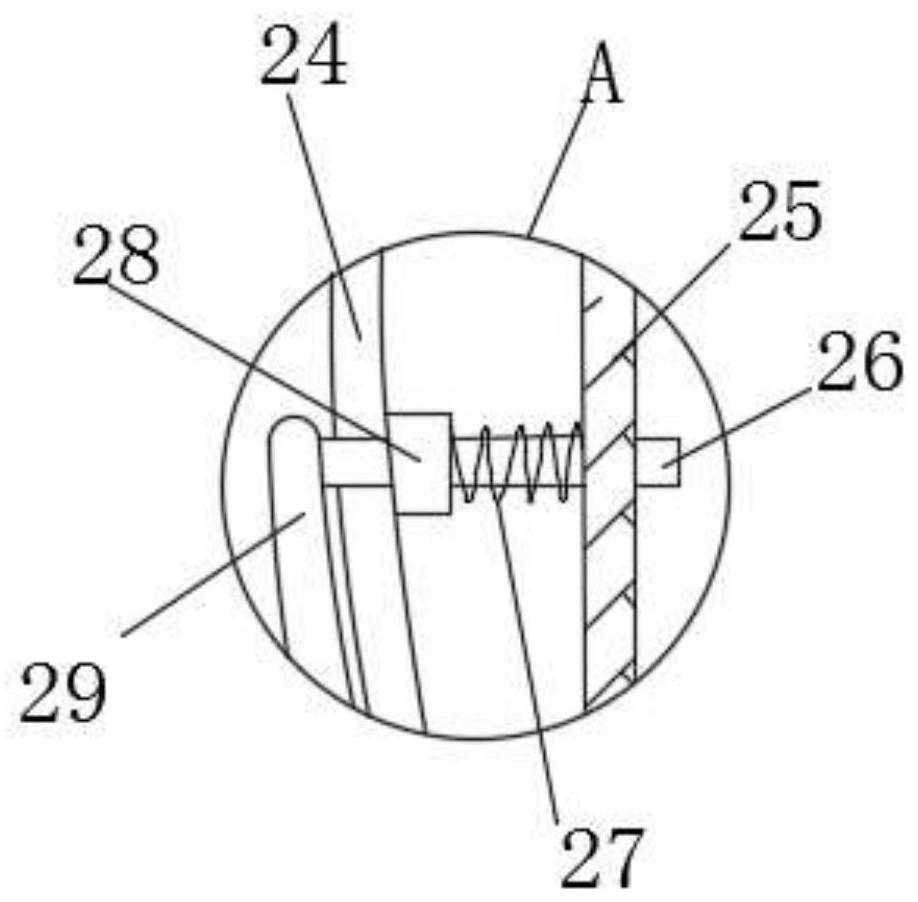

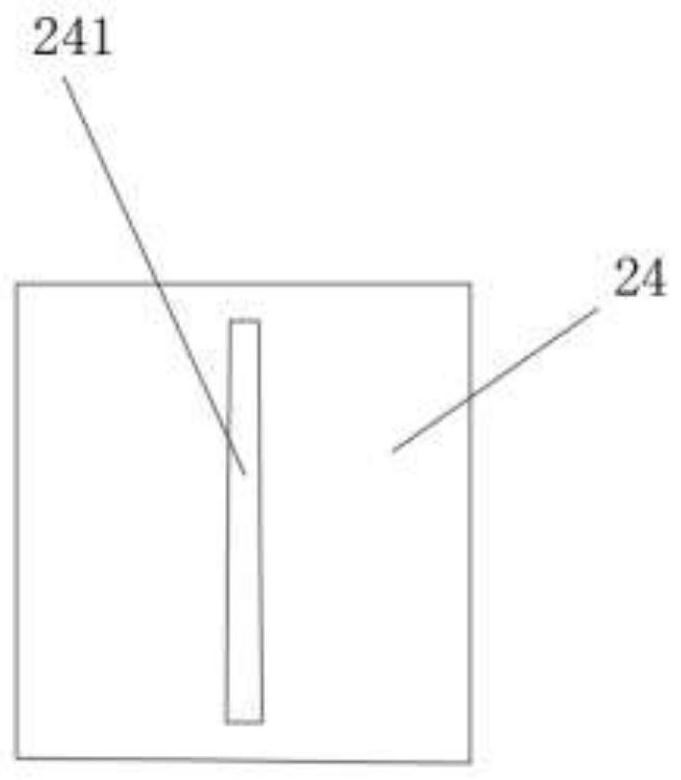

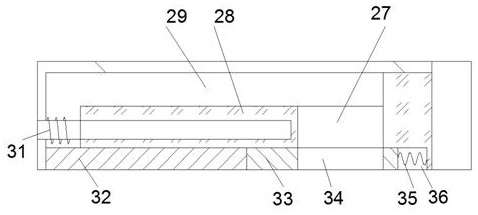

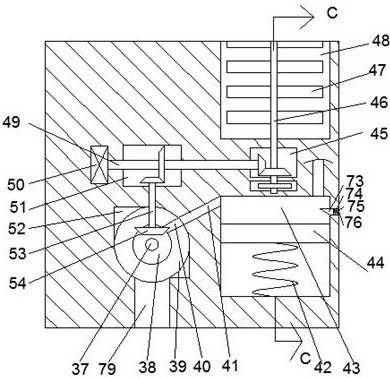

Air-drop isolation block for forest fire

The invention discloses an air-drop isolation block for forest fire. The air-drop isolation block comprises a shell body, wherein a blade sliding space is formed in the upper side of the shell body, an excavating device space is formed in the lower side of the blade sliding space, a device side wall is arranged on the lower side of the excavating device space, a gravity center adjusting space is formed in the lower side of the device side wall, the upper side of the shell body is provided with an inertial control track for changing the position of a blade, and the inertial control track comprises a device upper side wall body fixedly connected to the right side of the shell body. A helicopter can quickly enter the fire field, a sharp cone can be quickly crushed into the soil layer by utilizing gravity so as to quickly form an isolation belt, in the dense area of branches and leaves, the branches and leaves can be cut in the falling process of the isolation block, the fire potential canbe prevented from propagating through branches and leaves, and an soil digging device is arranged when the isolation block lands so as to ensure that the fire potential of the ground cannot diffuse.

Owner:台州市椒江充盈自动化科技有限公司

Soil heavy metal treatment device and treatment method

InactiveCN111448858AReduce connection pathwayImprove the mixing effectSoil lifting machinesSpadesSoil treatmentSoil science

The invention discloses a soil heavy metal treatment device and treatment method. The soil heavy metal treatment device comprises a vehicle body, at least two soil digging conveying ploughs, at leasttwo screw conveying barrels, a mixing box, a first feeding port and a second feeding port, multiple discharging ports, a distributor, a storage box, at least two soil turning ploughs and a liquid storage box. The soil heavy metal treatment device can spray a heavy metal treatment liquid according to quantity in deeper positions of heavy metal soil while turning, cover the surface layer of turned soil with a soil layer containing heavy metal treatment composition so as to deeply treat the heavy metal contaminated soil by layers and improve the treatment effect effectively. According to the soilheavy metal treatment method, on the basis of the soil heavy metal treatment device, the proper heavy metal treatment liquid and heavy metal treatment composition are provided, so that the soil treatment effect is further improved.

Owner:尤宝旺

Agricultural seeder

InactiveCN111758333AReduce participationAchieve the purpose of sowingPlantingDibble seedersSeederAgricultural engineering

The invention discloses an agricultural seeder, and particularly relates to the technical field of agricultural machinery, the agricultural seeder comprises a chassis, a machine body is fixedly mounted on the chassis, wheels are mounted at the front end of the chassis, a transmission mechanism is arranged in the middle of the chassis, and a seeding and soil pressing mechanism is arranged on the rear side below the transmission mechanism; a soil digging and filling mechanism is arranged on the front side below the transmission mechanism, and anti-blocking mechanisms are arranged on the two sides of the bottom of the sowing and soil pressing mechanism. Through the arrangement of the wheels, the transmission mechanism, the sowing and soil pressing mechanism, the sliding groove, the anti-blocking mechanism and the soil digging and filling mechanism, the transmission mechanism drives the sowing and soil pressing mechanism and the soil digging and filling mechanism to move up and down in a reciprocating mode, the sowing purpose is achieved through the sowing and soil pressing mechanism, and meanwhile the soil pressing purpose can be achieved; and the purposes of earth excavation and earth filling are achieved through the earth excavation and earth filling mechanism, that is, the functions of earth excavation, sowing, earth filling and earth pressing are sequentially achieved throughthe combination of the sowing and earth pressing mechanism and the earth excavation and earth filling mechanism.

Owner:刘智城

Crop field soil remediation device

InactiveCN111644456AImprove food qualityPlantingContaminated soil reclamationSoil scienceSoil remediation

The invention discloses a crop field soil remediation device, which comprises a repairing body. A cavity is formed in the repairing body; an earth cutting device is arranged in the cavity; the earth cutting device comprises an extension shaft which is in running fit with the rear wall of the cavity; the extension shaft is positioned in the cavity and is fixedly connected with a rotating wheel; therotating wheel is fixedly connected with one side of a fixed rod, and the other side of the fixed rod is fixedly connected with a soil digging block; a soil containing groove with an opening facing the rotating wheel is formed in the soil digging block; and telescopic electric push rods capable of sealing the opening of the soil containing groove are symmetrically installed at the opening of thesoil containing groove.

Owner:宁波市庞荣机械科技有限公司

Quick peanut picking device

ActiveCN111226567ASolve residual problemsSave the work process of diggingDigger harvestersAgricultural scienceAgricultural engineering

The present invention relates to the field of quick peanut picking devices and particularly to a quick peanut picking device. The quick peanut picking device comprises a vehicle rack, the vehicle rackis fixedly provided with a driving part, the driving part is connected with a soil digging mechanism through a connecting rod assembly, a granary and a material receiving hopper are fixedly arrangedon the vehicle rack, a soil crushing mechanism is arranged between the granary and the material receiving hopper, besides, the soil crushing mechanism is fixedly arranged on the vehicle rack, and theconnecting rod assembly is connected with the soil crushing mechanism. In the quick peanut picking device, the driving part drives the connecting rod assembly to work, the soil digging mechanism digsout soil blocks and peanuts under function of the connecting rod assembly and the soil blocks and peanuts are lifted and discharged to the material receiving hopper, then the soil crushing mechanism is used to crush the soil blocks, the crushed soil returns to the ground, the peanuts are collected to the granary, a soil turning operation process is saved, besides, the soil blocks are dug out together with the peanuts, the soil blocks and peanuts are then fall into the material receiving hopper, and the quick peanut picking device solves a problem that the peanuts remain in the soil, does not need a secondary picking operation, greatly reduces labor amount and improves production efficiency.

Owner:温州美女媄酒有限公司

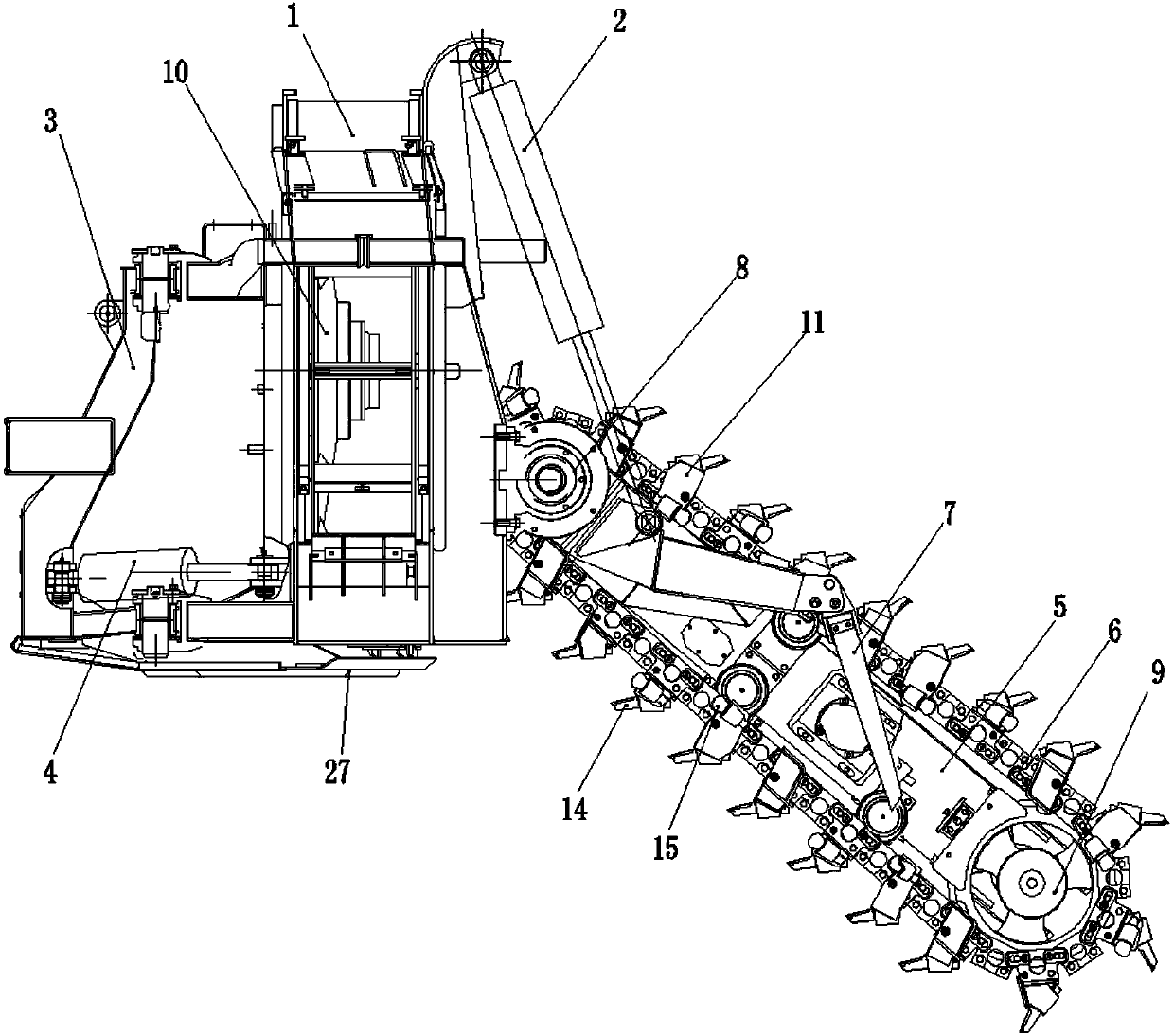

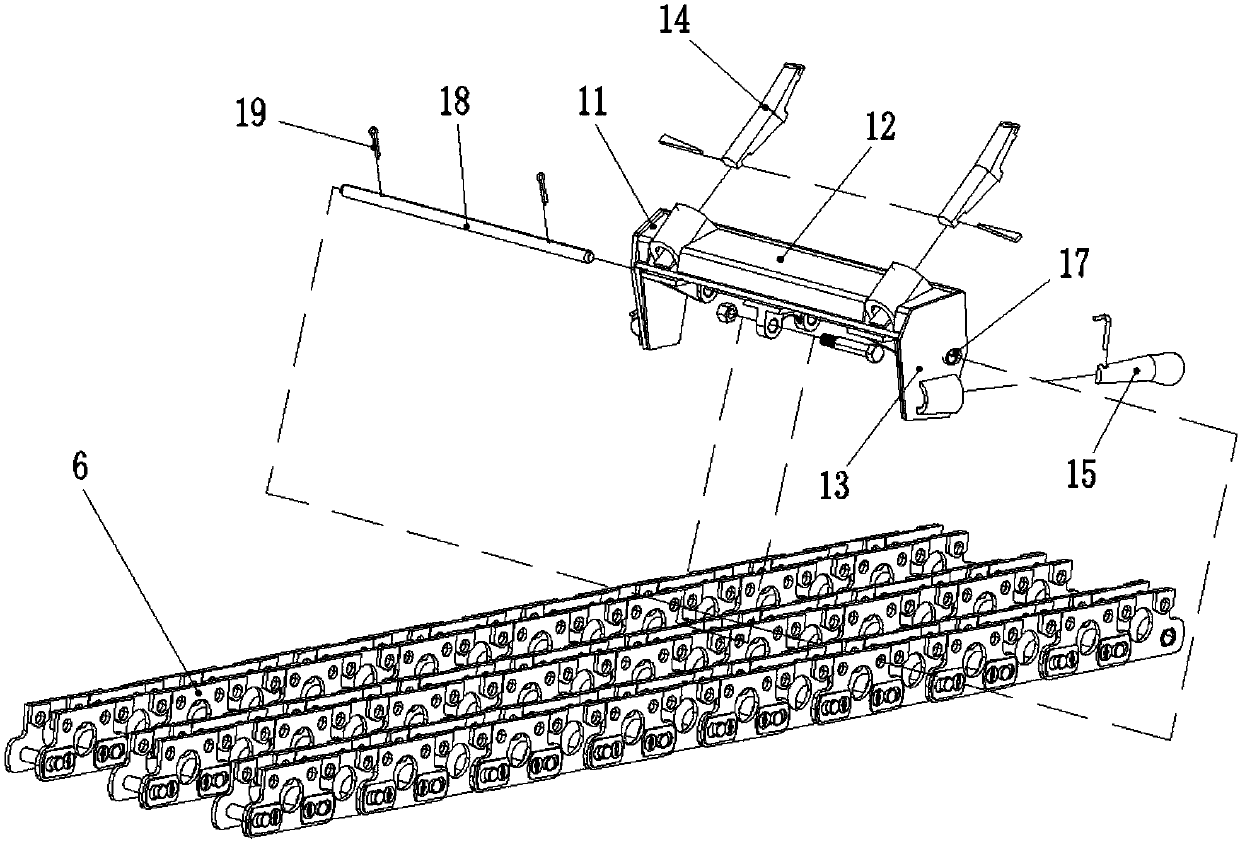

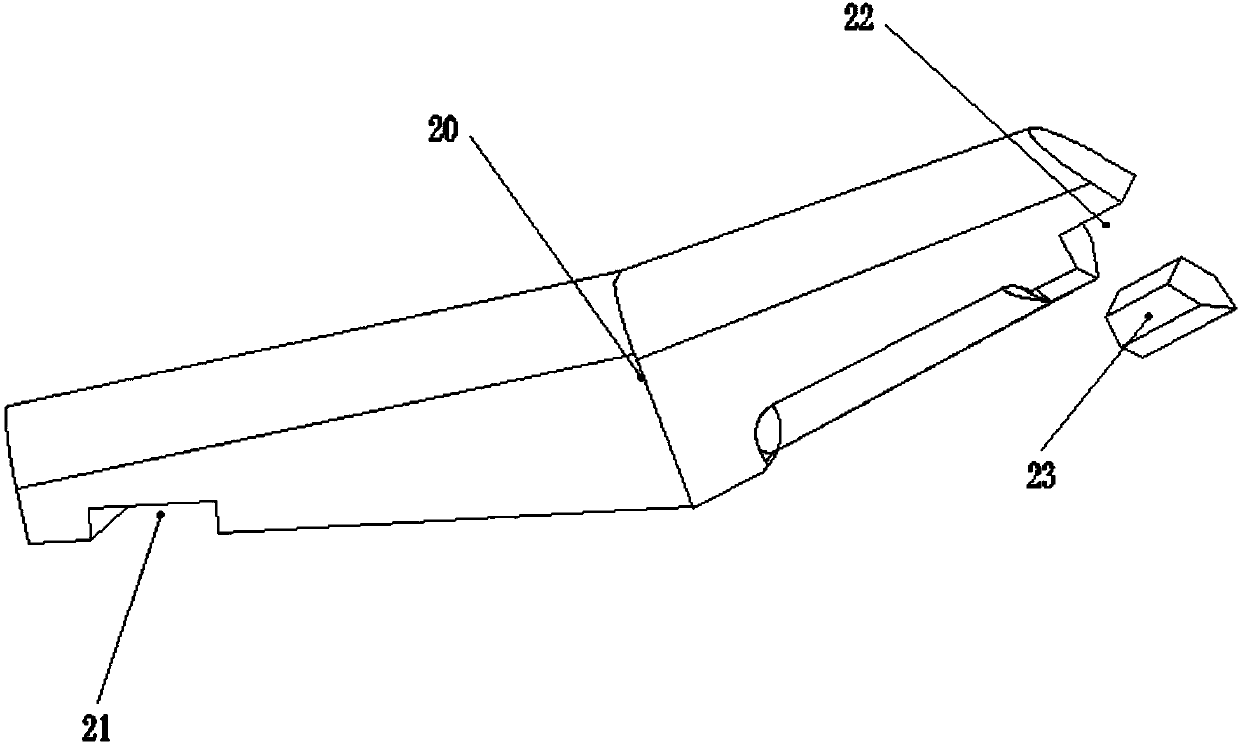

Chain pole type pit and trench digging operation device

PendingCN107938731AIncrease widthRealize automatic adjustmentMechanical machines/dredgersElectric controlDirt digging

The invention discloses a chain pole type pit and trench digging operation device. One side of a frame is hinged to a support, a swinging oil cylinder is arranged between the frame and the support, anoutput device is fixed on the frame, one end of a pitching oil cylinder is connected with a chain frame, the other end of the pitching oil cylinder is connected with the frame, and the pitching oil cylinder is used for controlling an excavation mechanism to swing up and down. Through work of an excavation device, pits and trenches can be dug in the ground, the pit and trench digging depths can becontrolled by controlling the pitching oil cylinder, earth and stone dug out by the excavation device are thrown out through the output device, the arranged swinging oil cylinder can control swingingof the output device and the excavation device, and thus the pit and trench digging depths can be enlarged. The pitching oil cylinder can be driven in an electric control manner, and automatic adjustment of the driving speed is realized. The arranged excavation device can complete excavation of various kinds of soil, horse stone soil, ore beds and frozen earth.

Owner:SHANDONG YATAI MACHINERY

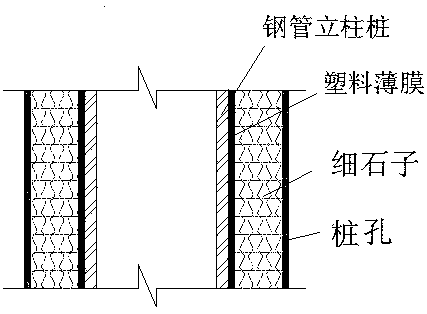

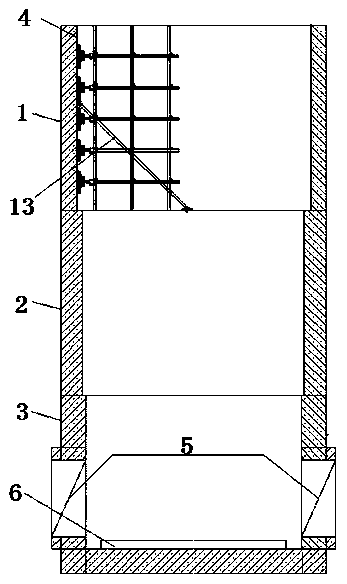

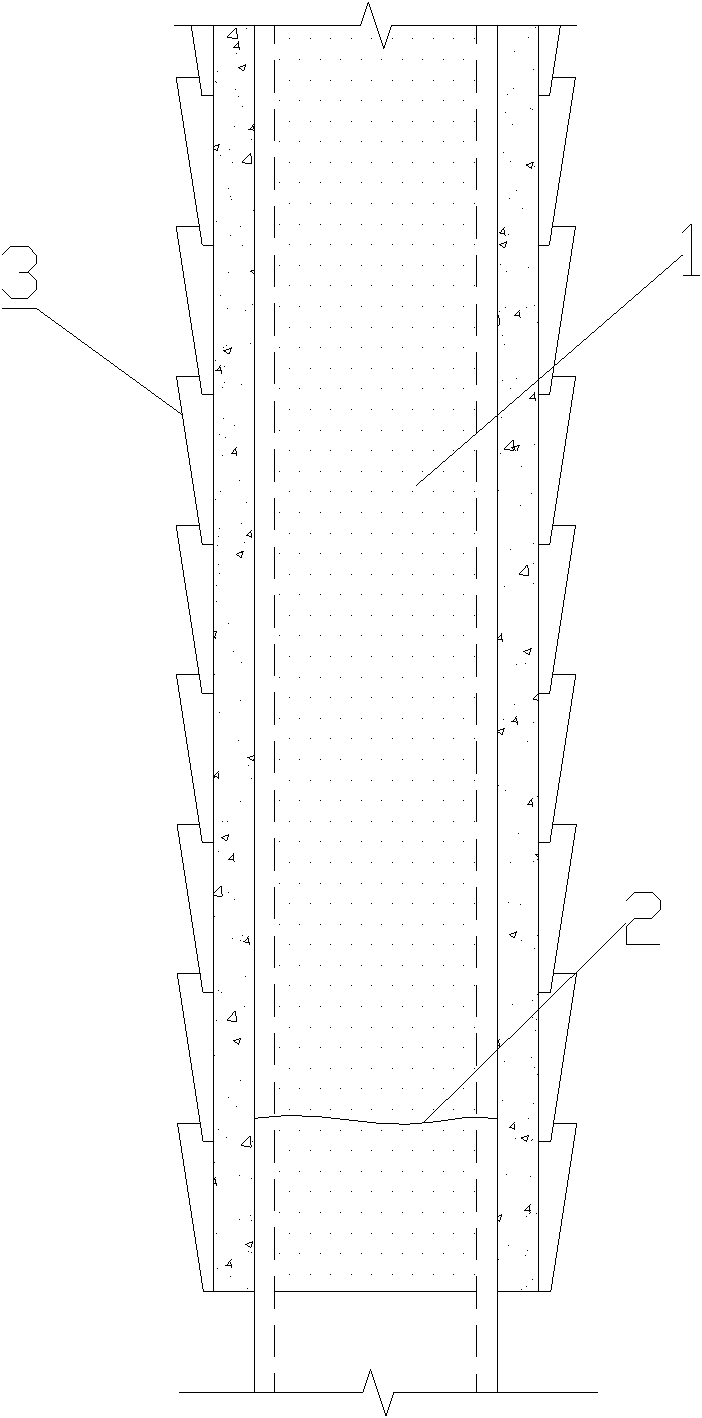

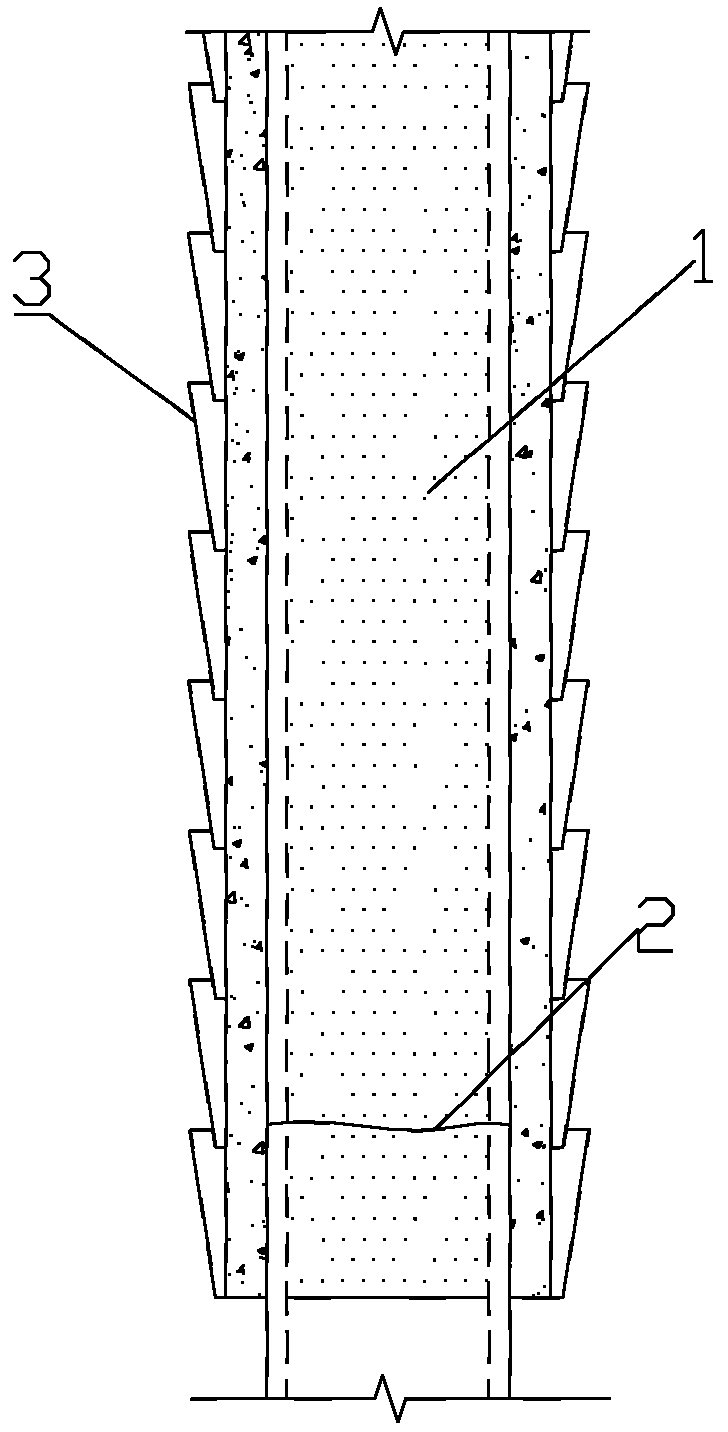

Tubular pile defect processing method

InactiveCN102505685ASimple processSimple construction operationBulkheads/pilesReinforced concreteRebar

The invention discloses a tubular pile defect processing method. A tubular pile has a serious defect at the places below the place 2m below the top of the pile. The method is characterized in that: step 1, drawing out soil in the tubular pile to certain depth below the defect; step 2, filling reinforced concrete in the tubular pile to reinforce the pile, wherein the filling depth is about 2m below the defect; step 3, timbering the tubular pile through a pile casing which surrounds the tubular pile and digging out soil between the circumference of the tubular pile and the pile casing at a depth of about 2m below the defect; and step 4, pouring reinforced concrete into the area between the circumference of the tubular pile and the pile casing to a depth equal to the digging depth in step 3. The method disclosed by the invention is simple in process and low in cost and is easy to construct.

Owner:TUS DESIGN GRP CO LTD

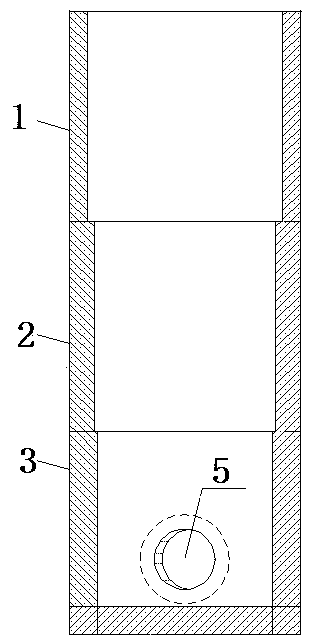

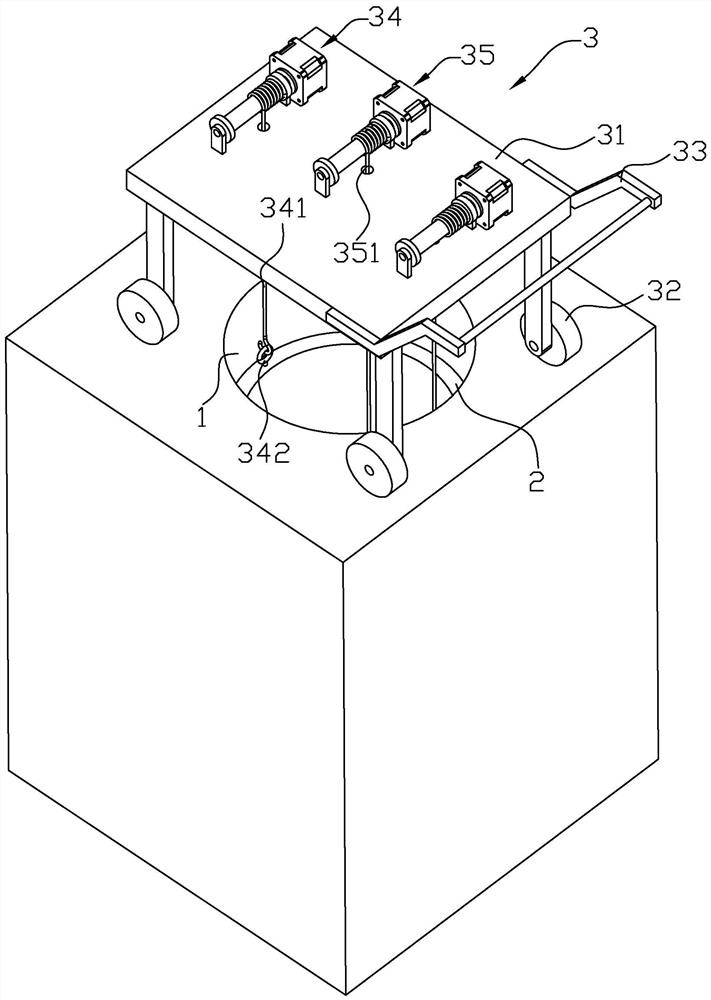

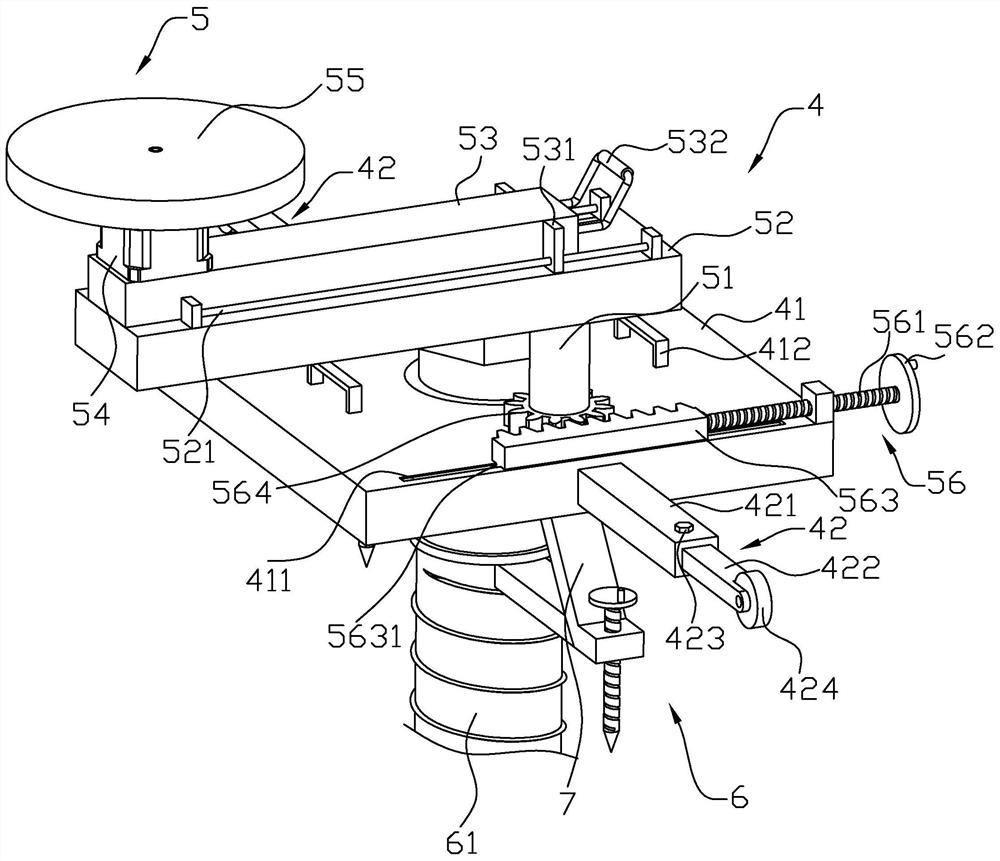

Open caisson construction method

ActiveCN111733856AAvoid damageJust sand itGrinding carriagesBase supporting structuresArchitectural engineeringPipe

The invention relates to an open caisson construction method. The open caisson construction method comprises the following steps that firstly, an elevating device is used for lifting a well pipe and comprises a movable frame, wheels and a handrail; secondly, a grinding device is used for grinding an obstacle, a second winch is arranged on the top of the movable frame and comprises a second steel strand, the grinding device comprises a rack and a grinding mechanism, when the obstacle in an open caisson needs to be ground, the second winch is started firstly, then, the rack can be placed to thebottom of the open caisson, and then the grinding mechanism is used for grinding the obstacle; thirdly, the grinding device is moved out, the second winch is started, and accordingly the grinding device can be moved out; fourthly, the well pipe is loosened, a lifting lug and the well pipe are separated by rotating the lifting lug, then, a first winch is used for making the lifting lug and the wellpipe separated, and accordingly the well pipe can be loosened; and fifthly, soil excavation continues, and the steps from the first step to the fourth step are repeatedly conducted if the obstacle isencountered in the soil excavation process. By means of the open caisson construction method, the possibility of well pipe damage can be reduced.

Owner:安徽杰智建设工程有限公司

Deep back filling soil infilled wall foundation construction method

InactiveCN110924404AAvoid crackingGuaranteed stabilityEmbankmentsBulkheads/pilesSoil scienceCement slurry

The invention discloses a deep back filling soil infilled wall foundation construction method, and belongs to the technical field of building construction. The method is characterized by comprising the following steps that step 1), a steel pipe pile (5) positioning line and a grade beam (7) controlling line are arranged on a back filling soil layer (2); step 2), pile holes are drilled in the backfilling soil layer (2) and a rock layer (1), and the steel pipe piles (5) are stretched into the pile holes; step 3), cement slurry is poured into the steel pipe piles (5); step 4) the position of theground beam controlling line is subjected to soil digging and is cleaned to be flat to form a ground beam pouring cavity, and separating layers are arranged between the ground beam pouring cavity andthe back filling soil layer (2) and between the ground beam pouring cavity and structural columns (3); step 5), ground beam steel bars and cushion layer steel bars are bound, and concrete pouring iscarried out to form a ground beam (7) and a cushion layer; and step 6), an infilled wall (6) is built on the cushion layer. According to the deep back filling soil infilled wall foundation construction method, the situations of pipeline deforming and infilled wall cracking caused by back filling soil settlement are avoided.

Owner:山东天齐置业集团股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com