Pit digging ditcher

A technology for trenching machines and deep pits, which is applied to earth movers/excavators, construction, etc. It can solve problems such as increased workload, soft soil layer, and impact on project quality, and achieves the effect of easy operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

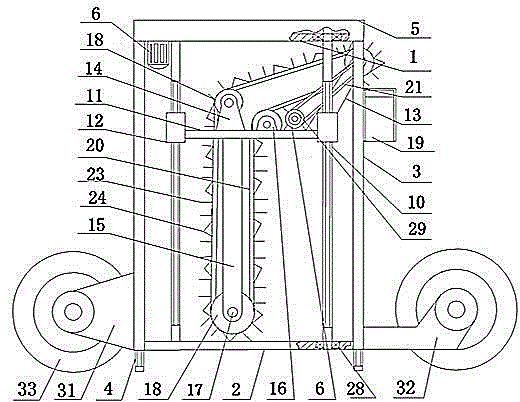

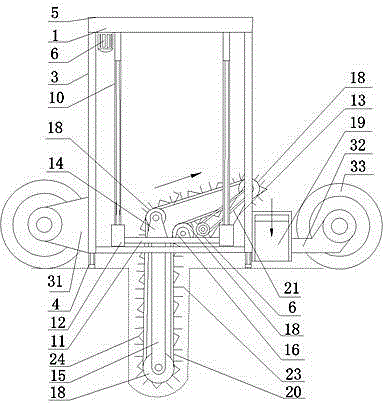

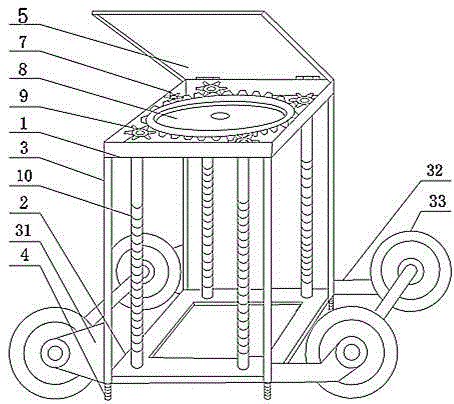

[0028] The technical invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0029] Invention of this technology, a deep pit excavation ditching machine (see figure 1 ), consists of three parts, namely: rack part (see image 3 ); the supporting part of the soil transport mechanism (see Figure 4 ); Part of the soil delivery mechanism (see Figure 5 ).

[0030] ( image 3 ) The frame part is formed by connecting the upper plate 1 of the frame, the lower plate 2 of the frame, and four pillars 3 in the middle. Frame upper plate 1 is provided with DC reduction motor 6, and the output shaft of DC reduction motor 6 is provided with motor gear 7, and motor gear 7 is interlocked with transmission gear 8, drives four lead screw gears 9 positive and negative rotations. Four leading screw gears 9 are respectively installed on the tops of four lifting screw 10, and the upper and lower ends of four lifting screw 10...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com