Reverse structural steel and bamboo splint soil retaining construction method

A construction method and bamboo plywood technology are applied in excavation, artificial islands, water conservancy projects, etc., to achieve the effect of shortening the construction period, saving the project cost and reducing the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] In order to make the technical means, creative features, goals and functions achieved by the present invention clearer and easier to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and specific embodiments:

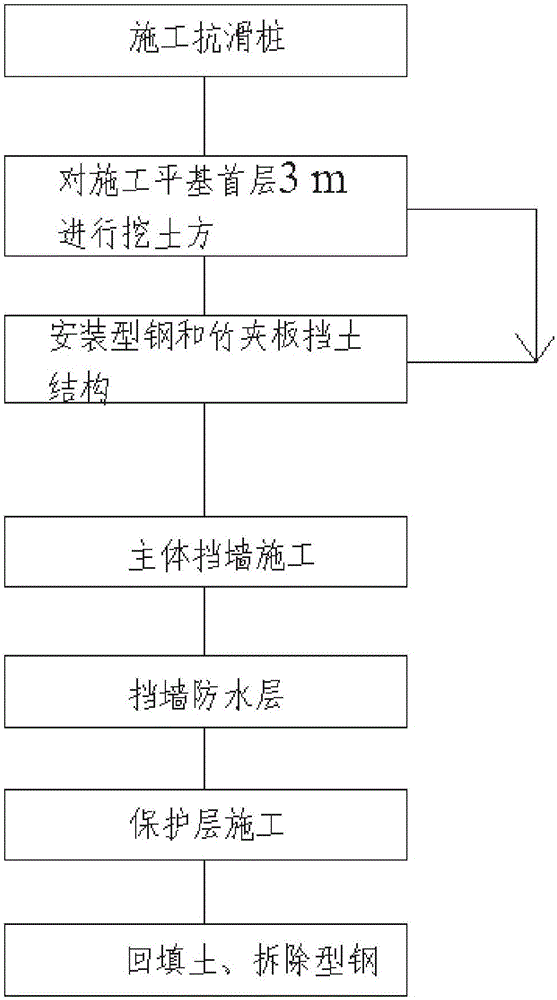

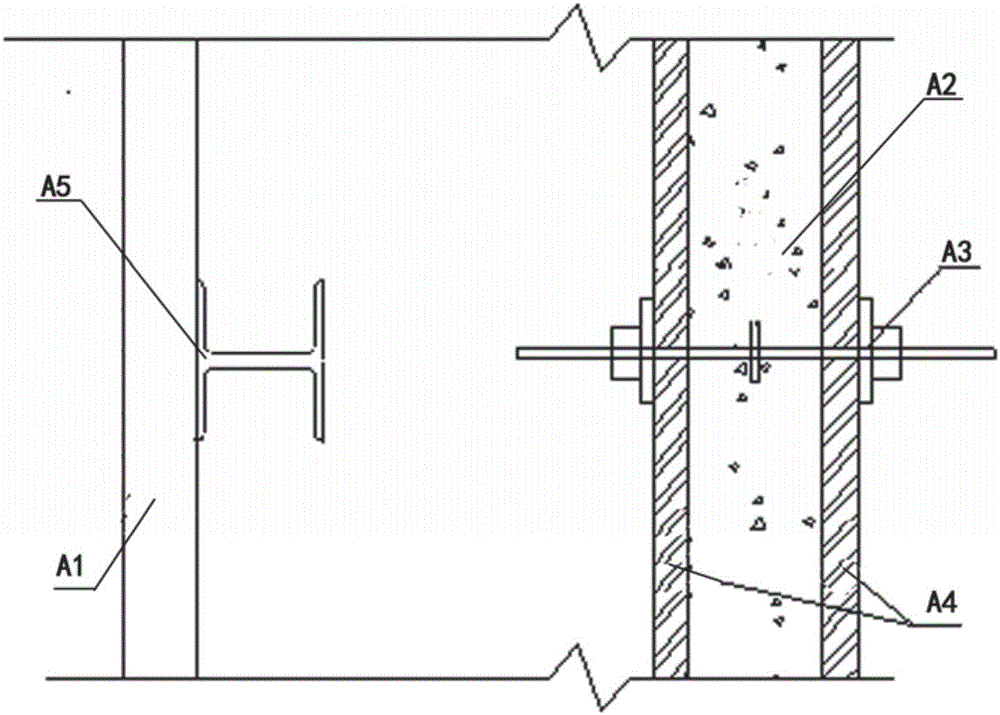

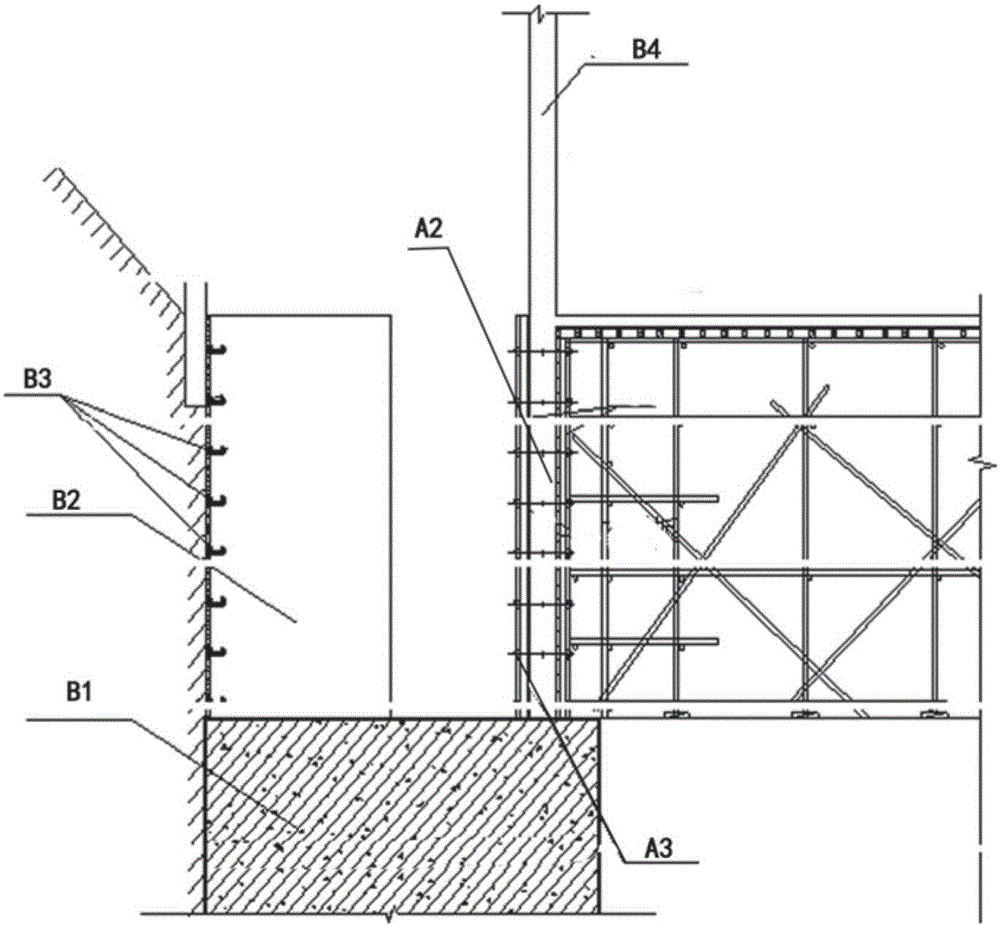

[0025] The present invention proposes a kind of upside-down profiled steel and bamboo plywood retaining soil construction method, and it is suitable for the earthy and rocky filling slopes in general areas below 20m, and the earthy excavation slopes that need vertical slope cutting, including the following steps:

[0026] 1), construction of anti-slide piles; use the polar coordinate method to position and stake out the anti-slide piles at the slope. After the first section of the anti-slide pile retaining wall is formed, use a total station and a level to put the axis and elevation on the retaining wall, and paint Make a mark, and according to the coordinate points after detection, carry out the const...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com