Device and method for vertically transporting earthwork by reverse construction method

A technology of vertical transportation and reverse method, which is applied in the direction of excavation, infrastructure engineering, earth mover/shovel, etc. It can solve the problems of incapable superstructure construction, huge excavating machinery, and low excavation efficiency, so as to shorten the construction period , Reduce excavation cost and improve excavation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

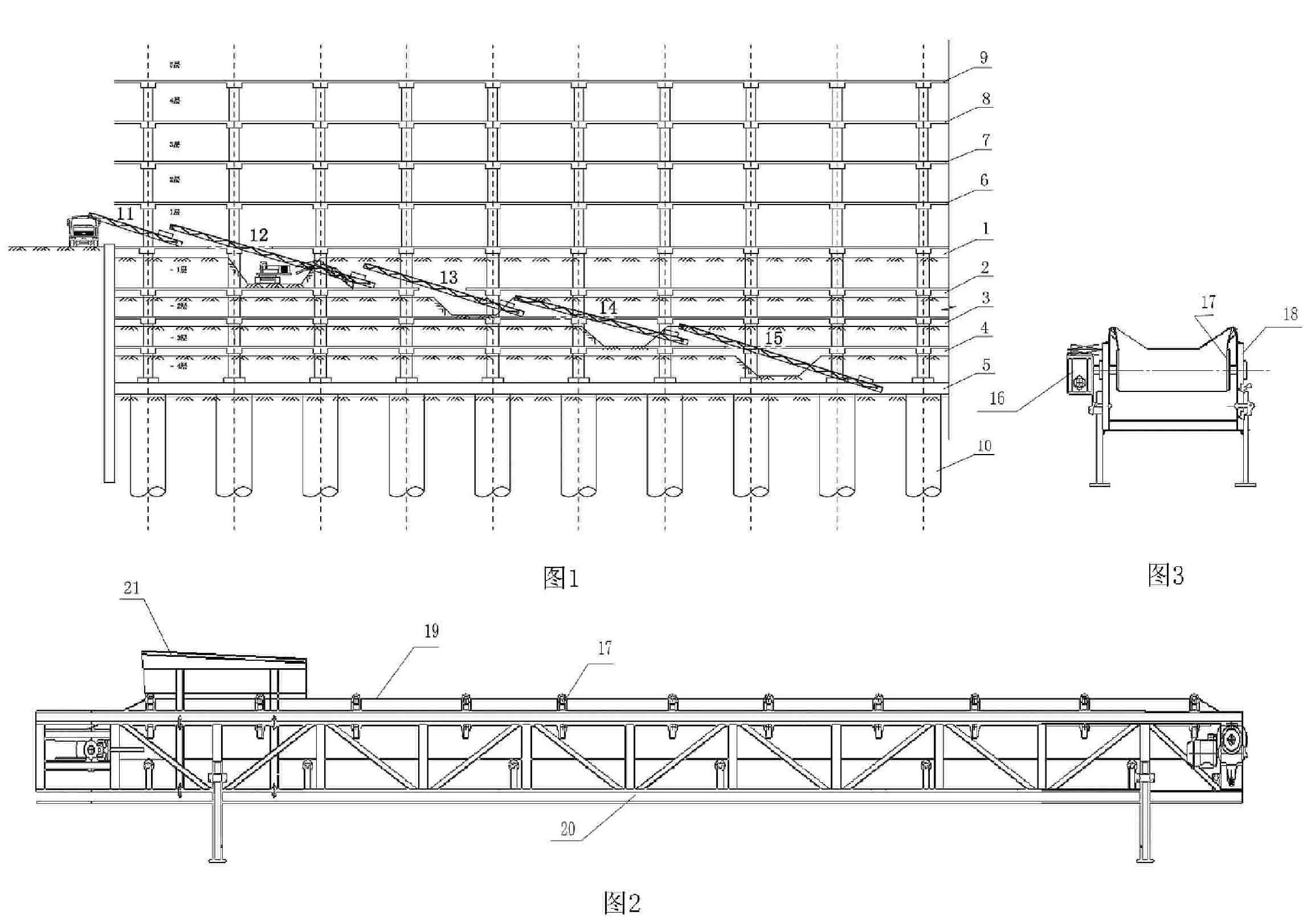

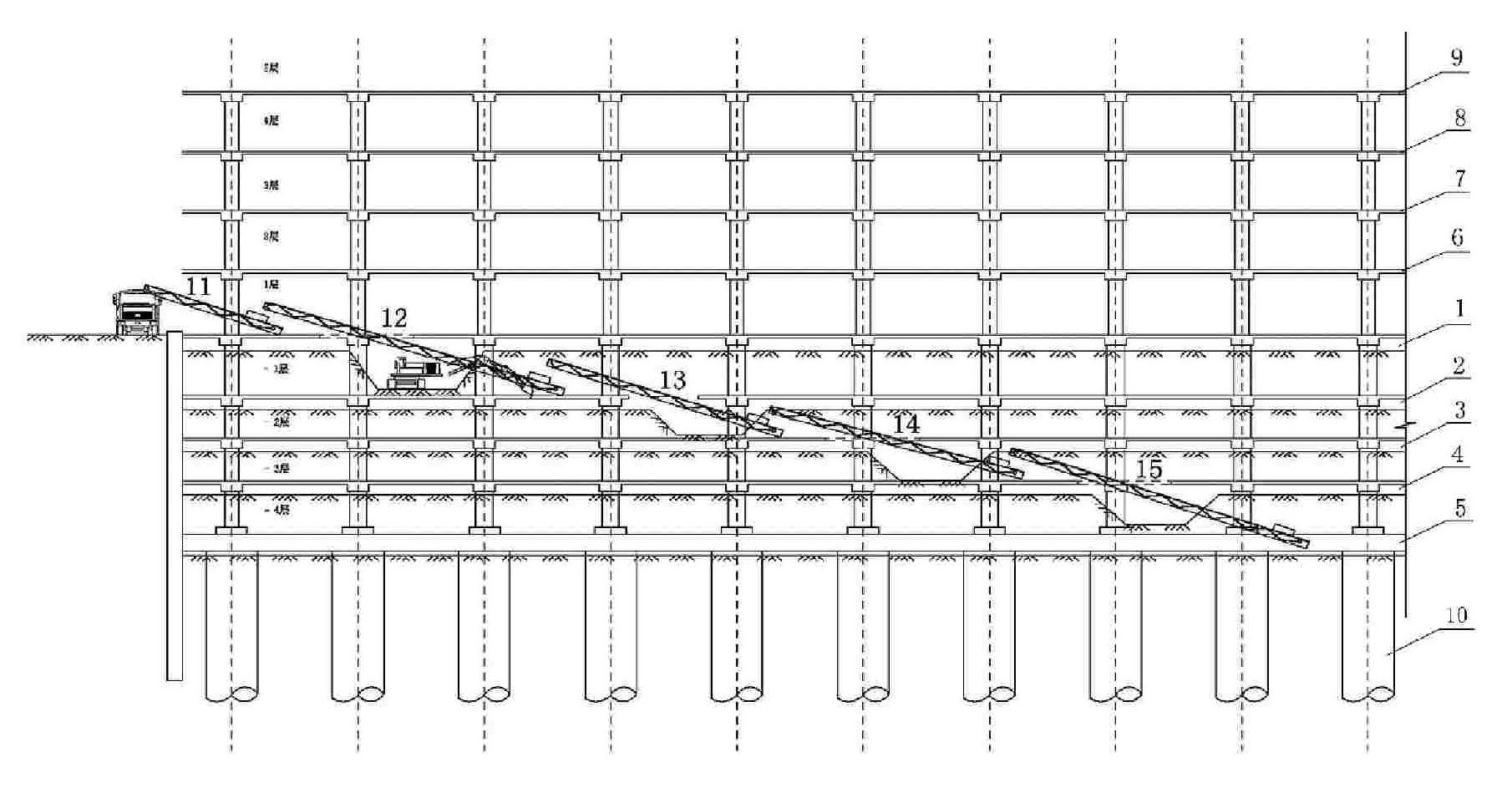

[0029] Attached below Figure 1-3 The present invention is described further:

[0030] Take the basement four floors as an example:

[0031] The general column grid size of the project is 8 meters x 16 meters, and the building size is 140 meters x 70 meters. According to the calculation of construction period and total earthwork, it is divided into 3 sections, each section is about 50 meters long, and a set of independent conveyor belt systems are set up.

[0032] see figure 1 As shown, the earthwork vertical transportation method of reverse method construction of the present invention, it adopts the sectioned belt type conveyor belt as the tool of earthwork vertical transportation, installs the conveyor belt through the technical reserved hole on each floor, and the earthwork is directly connected to the road by the conveyor belt. On the dump truck, the specific construction steps are as follows:

[0033] Step 1: First, carry out the construction of site maintenance struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com