Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

53 results about "Alcohol-free beer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In some parts of the European Union, beer must contain no more than 0.5% ABV if it is labelled "alcohol-free". In Australia, the term "light beer" refers to any beer with less than 3.5% alcohol. Spain is the main consumer and producer of low-alcohol beer in the European Union.

Alcohol-free beer and preparation method thereof

ActiveCN101875899AClean tasteRefreshing tasteAlcoholic beverage preparationBeer brewingAlcohol contentDietary fiber

The invention relates to an alcohol-free beer and a preparation method thereof, and aims to solve the technical problem that the alcohol-free beer in the prior art cannot easily achieve an alcohol content of 0.00 percent and has a long production cycle, a high production cost and the like. The beer of the invention consists of pre-treated beer solution and carbon dioxide filled in the solution, wherein the pre-treated beer solution consists of the following raw materials in percentage by weight: 15 to 25 percent of 10 to 13 percent wort, 0.5 to 1.5 percent of dietary fiber, 2 to 3 percent of syrup, 0.01 to 0.05 percent of acidulant, 0.01 to 0.02 percent of natural flavor, 0.04 to 0.06 percent of pigment and the balance of water; and the pre-treated beer solution also comprises 0.35 to 0.65 percent of carbon dioxide. The alcohol-free beer of the invention has the advantages of mild hop and malt aroma, clean and refreshing mouthfeel, no peculiar smell and capability of greatly reducing the production cycle and reducing cost.

Owner:TSINGTAO BREWERY

Low-alcohol beer or beer-like refreshment beverages containing palatinose

The present invention relates to methods for producing a low-alcohol or alcohol-free beer or a beer-like soft drink as well as a low-alcohol or alcohol-free beer or beer-like soft drink produced through the use of this method.

Owner:SUDZUCKER AG MANNHEIM OCHSENFURT

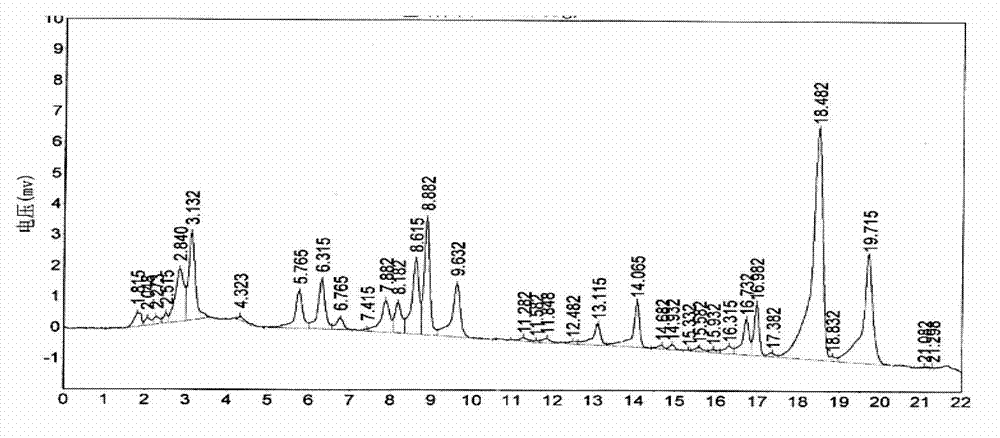

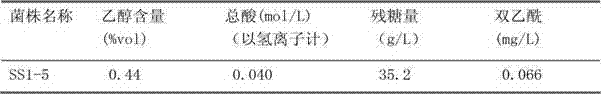

Pichia kluyveri var.kluyveri strain, culture method and application thereof

The invention relates to a pichia kluyveri var.kluyveri strain, a culture method of the pichia kluyveri var.kluyveri strain and an application of the pichia kluyveri var.kluyveri strain; the pichia kluyveri var.kluyveri strain SS1-5 has been preserved in China General Microbiological Culture Collection Center (CGMCC) since December 20, 2010, wherein the address of the CGMCC is Institute of Microbiology, Chinese Academy of Sciences, 3#, First Yard, West Beichen Road, Chaoyang District, Beijing, and the preservation number (CGMCC No.) of the strain is 4494. The strain can be used for brewing low-alcohol beverages that are ample in fruit, low in alcohol content, sweet in mouth feel and closer to alcohol-free beer in flavor and nutrition; meanwhile, the low-alcohol beverages can keep organic nutrition in malt wort in a better way; and therefore, the production technology is simplified, the cost and the energy consumption are reduced and the environmental pollution is alleviated.

Owner:QILU UNIV OF TECH

Method of improving non-alcohol beer flavour

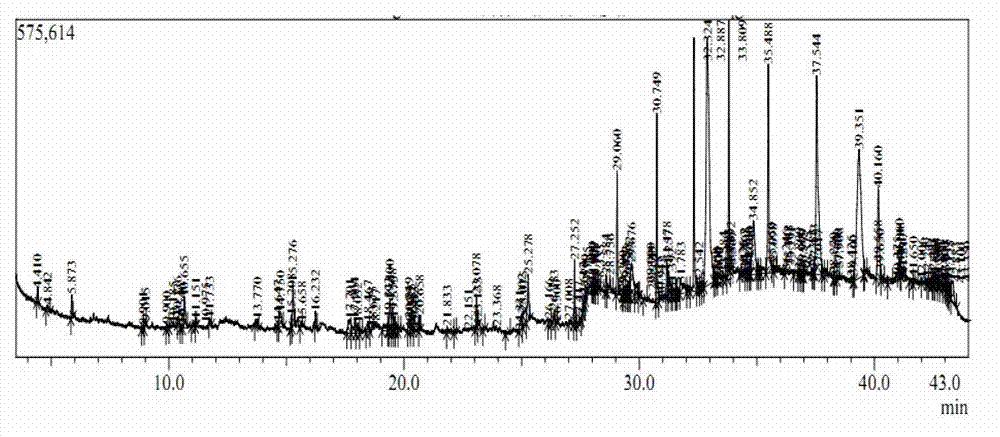

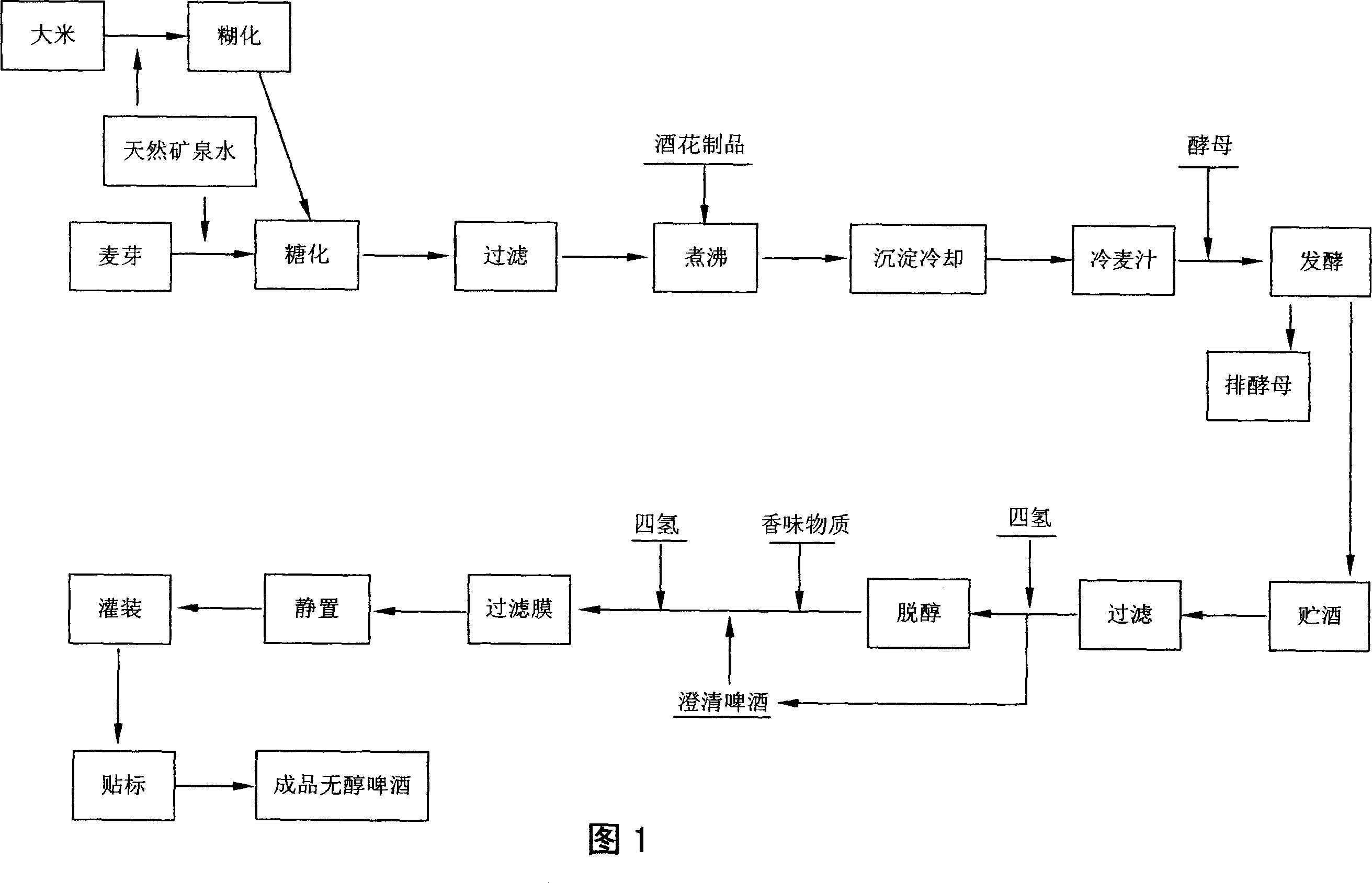

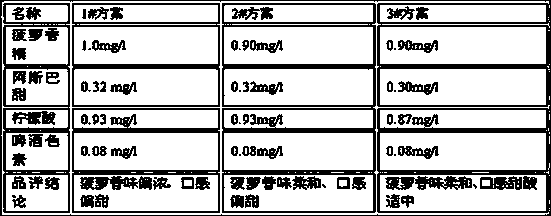

The present invention is method of improving taste of alcohol-free beer and relates to beer making technology. The alcohol-free beer is made with Australia malt, rice and natural mineral water as main materials. Through the using hops product, controlling the fragrant matter and clarified beer returning ratio, lowering the acidity of the alcohol-free beer produced through low temperature distilling process, raising the compatibility between the fragrance and the taste, controlling the final bitter matter content in alcohol-free beer in 10-14 BU and controlling the final alcohol content in 0.4-0.5 vol %, alcohol-free beer with rich fragrance and good taste is produced.

Owner:BEIJING YANJING BREWERY

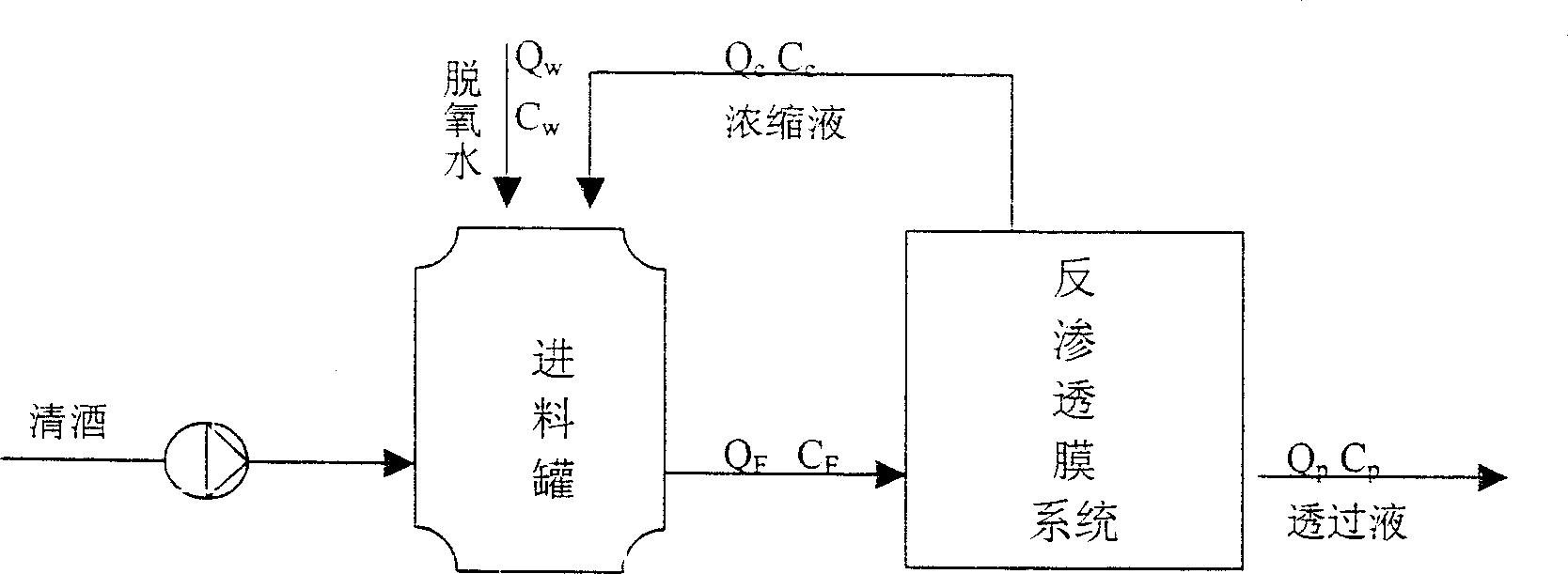

Method for reverse osmosis preparation of alcohol-free beer

ActiveCN1721520AStability is not affectedChange the production processAlcoholic beverage preparationFlavorAlcohol content

The present invention is reverse permeation process of producing alcohol-less beer, and relates to the application of reverse permeation technology in beer producing industry. Beer is pumped into reverse permeating unit, permeated liquid flow rate is controlled to equal to that of replenished deoxidized water, and concentrated liquid is returned into the feeding tank for circulated dealcoholization until alcohol content in beer lower than 0.5 vol%. The reverse permeation is controlled to have the reverse permeated liquid is 4-5 times the volume of the material liquid, the operation pressure of 1.8-2.5 MPa and the temperature of 4-12 deg.c. The reverse permeation process of producing alcohol-less beer can lower alcohol content by over 85 % and has no need of altering the available beer producing process, and the alcohol-less beer has the original flavor of beer maintained and delicious taste.

Owner:JIANGNAN UNIV

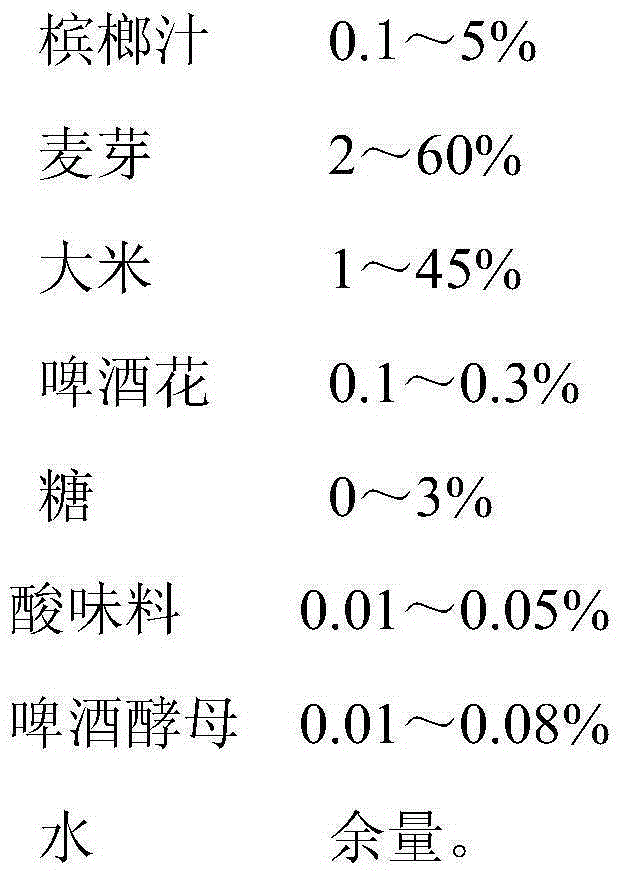

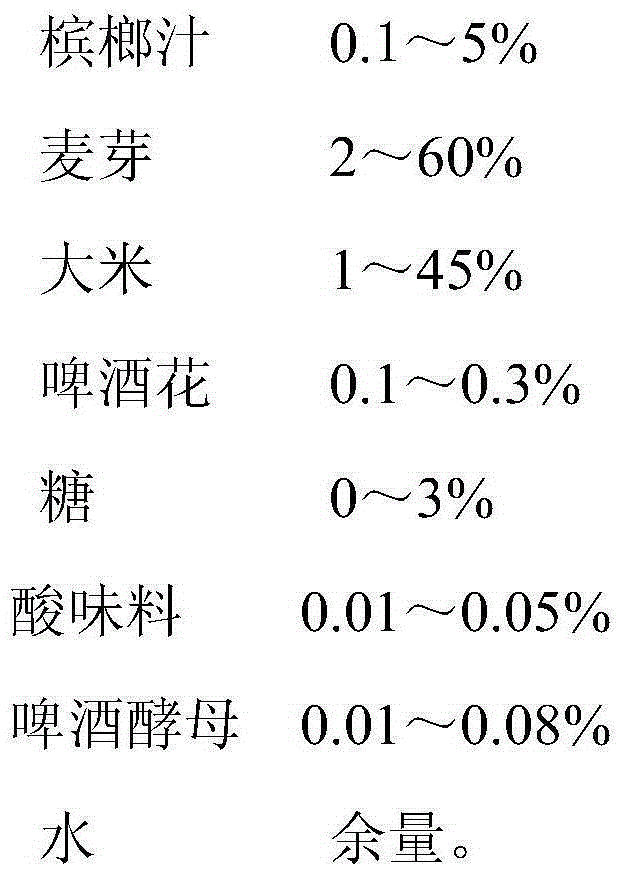

Betel nut flavored alcohol-free beer and preparation method thereof

The invention discloses betel nut flavored alcohol-free beer and a preparation method thereof. The betel nut flavored alcohol-free beer is prepared from, by weight, 0.1-5% of betel nut juice, 2-60% of malt, 1-45% of rice, 0.1-0.3% of humulus lupulus, 0-3% of sugar, 0.01-0.05% of sour seasoning, 0.01-0.08% of bear yeast and the balance water by saccharifying filtering, boiling, fermenting and dealcoholizing. The betel nut flavored alcohol-free beer completely has color and taste features of existing alcohol-free beer, namely mild scent of the humulus lupulus, slight aroma of the malt, clean taste, refreshing and objectionable odor avoidance. In addition, due to addition of the betel nut juice, natural ingredients of fresh betel nut are completely preserved in the betel nut flavored alcohol-free beer.

Owner:许启太

Malt beverage having reduced wort off-flavor and process for production thereof

Owner:KIRIN BREWERY CO LTD

Method for producing alcohol-free beer vinegar and beer vinegar beverage through fermentation

ActiveCN106520423ASimple production processIncrease the concentration of estersBeer fermentationAlcohol contentOrganic acid

The invention provides a method for producing an alcohol-free beer vinegar and an alcohol-free beer vinegar beverage through fermentation. The method comprises the following steps: with barley malt or wort as a raw material, carrying out hybrid-fungus aroma-enhanced beer fermentation by using aroma-producing yeast and beer yeast; and then carrying out hybrid-bacterium acetic acid fermentation by using lactic acid bacteria and Acetobacter rancens so as to obtain the alcohol-free beer vinegar with alcohol content of less than 0.03%. The alcohol-free beer vinegar has soft sour taste and rich aroma and only undergoes simple blending so as to prepare the alcohol-free beer vinegar beverage with rich aroma and agreeable sour and sweet taste. Through hybrid-fungus and hybrid-bacterium fermentation, the composition of organic acid in the beer vinegar can be adjusted, the flavor of the beer vinegar can be improved, and the utilization rate of raw materials can be increased; moreover, lactic acid bacteria produce organic acid and exopolysaccharide in the process of fermentation, so the nutritional value and health-care function of the beer vinegar are improved. The alcohol-free beer vinegar produced in the invention has rich fragrance, delicate aroma of beer and unique taste of vinegar, enables people to enjoy the flavor of beer, prevents unsafe factors caused by alcohol and is especially applicable to consumers inadvisable to drink.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Non-alcoholic beer-flavored beverage with tangy taste

Owner:SUNTORY HLDG LTD

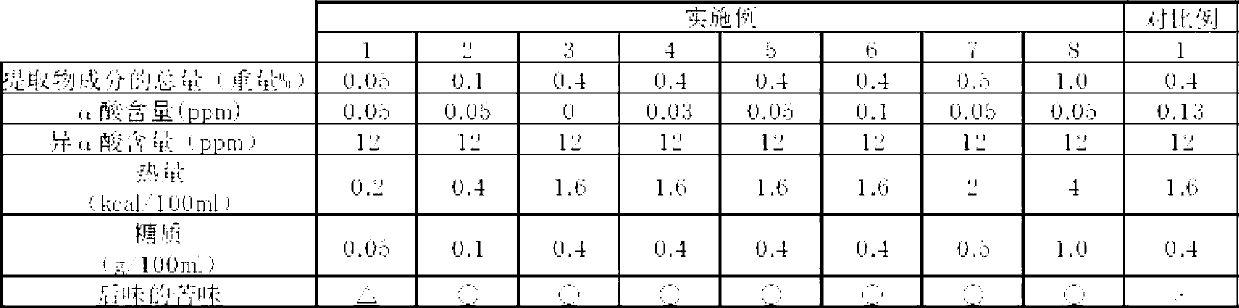

Non-alcoholic beer with improved aftertaste

The purpose of the present invention is to provide a low-carbohydrate, low-calorie non-alcoholic beer with a less unpleasant aftertaste. Provided is a non-alcoholic beer, the alpha-acid content and total extract content of which fall within specific ranges.

Owner:SUNTORY HLDG LTD

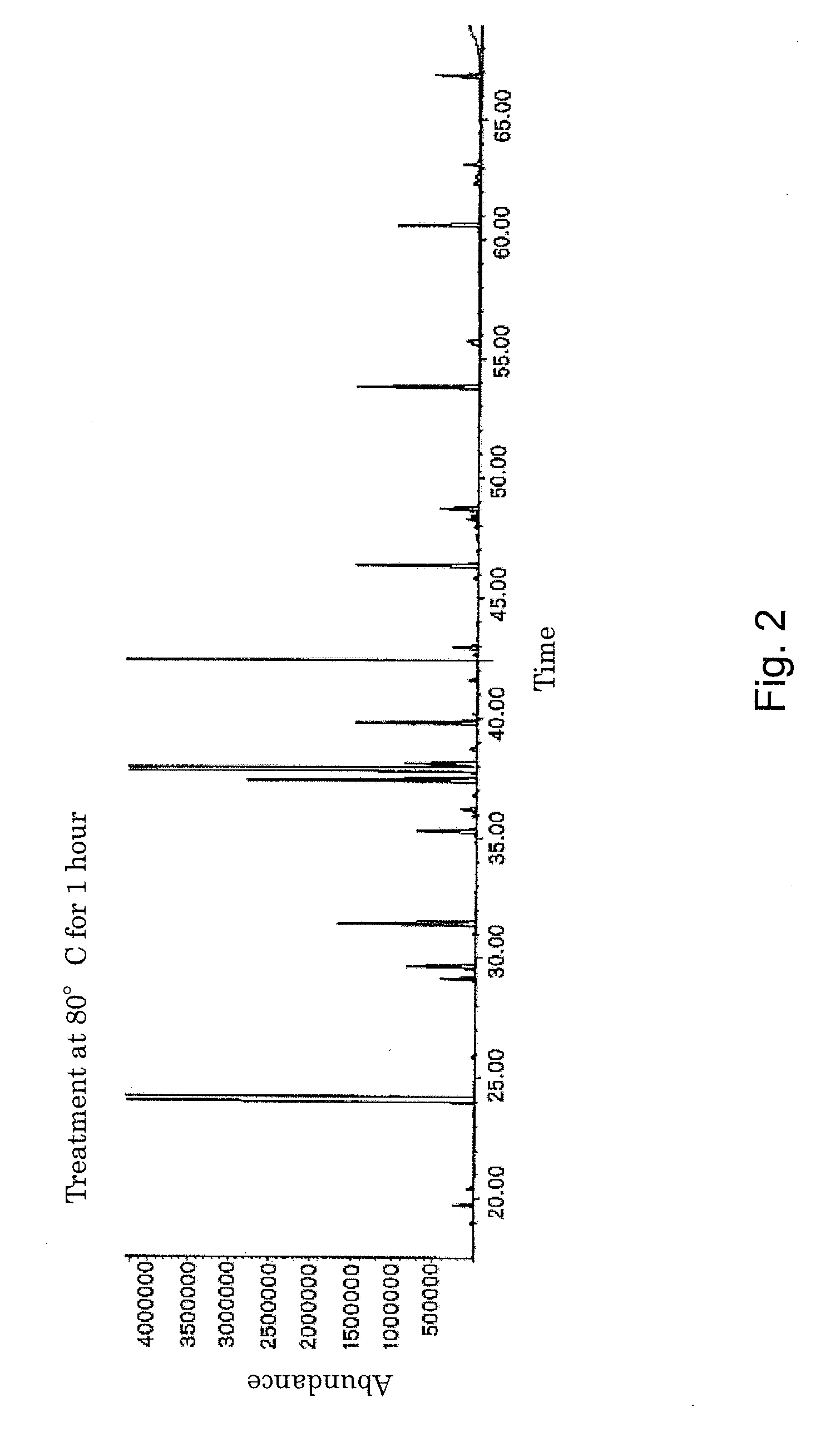

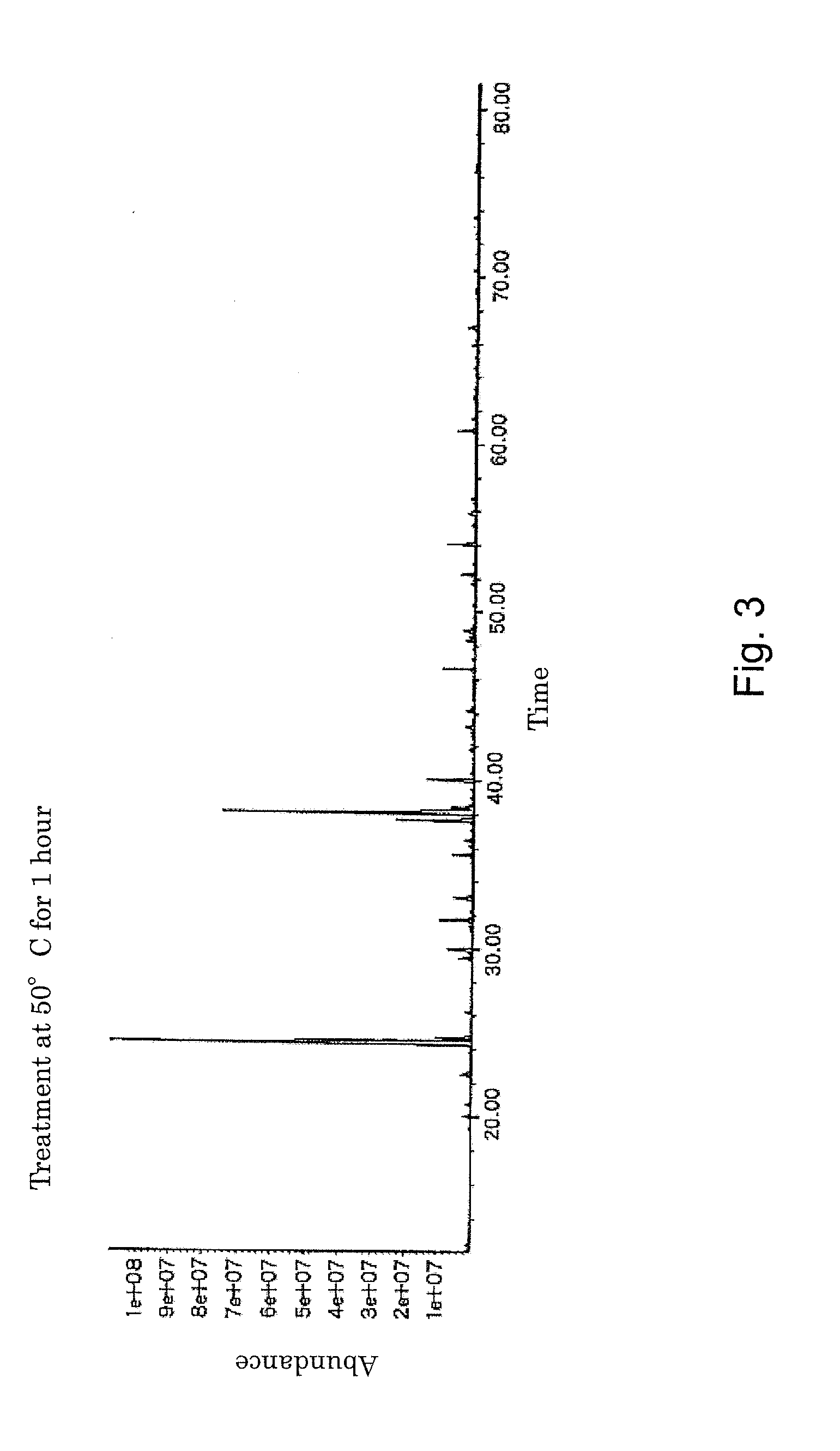

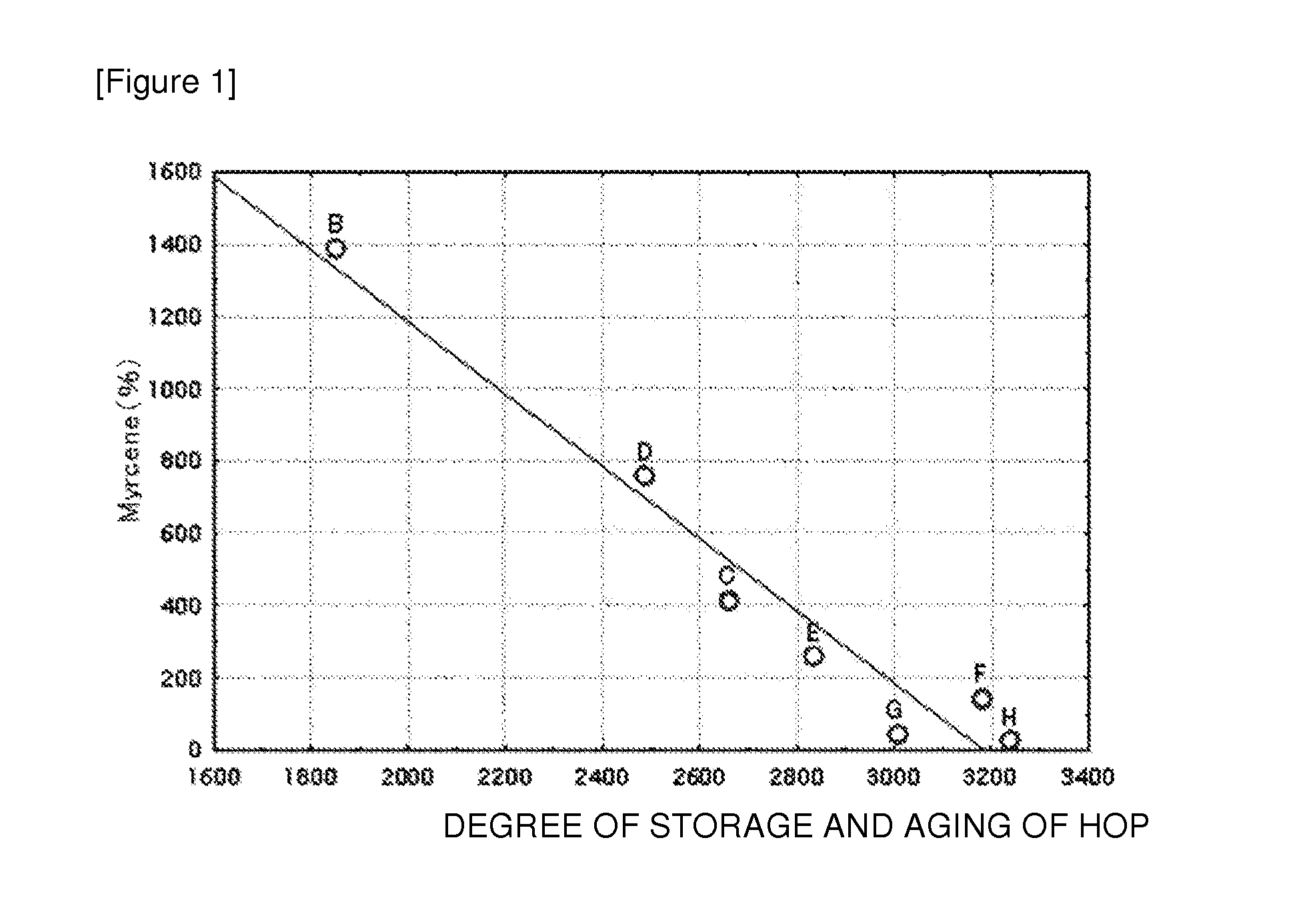

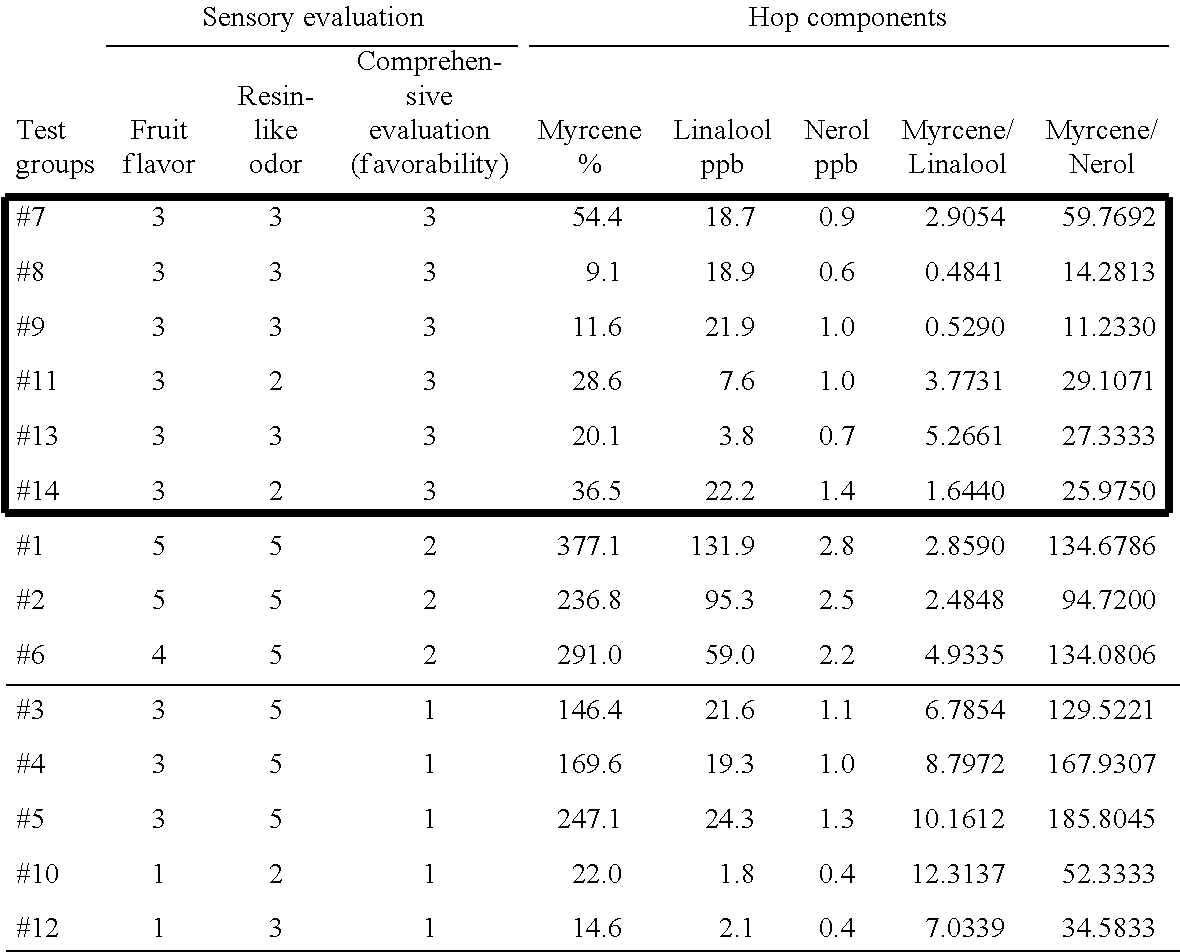

Method for producing alcohol-free beer-taste sparkling beverage having fruity aroma imparted thereto with reduced off flavor

An object of the present invention is to provide a method for producing an alcohol-free beer-taste sparkling beverage imparted with a fruity aroma and a reduced off-flavor; and an alcohol-free beer-taste sparkling beverage imparted with a fruity aroma and a reduced off-flavor produced by the aforesaid production method. “The method for producing an alcohol-free beer-taste sparkling beverage imparted with a fruity aroma and a reduced off-flavor” in the present invention is characterized by use of a hop or a hop component stored and aged in the state of being in contact with air as a hop or a hop component used during a raw material liquid-boiling step, or adjustment of the contents of myrcene, linalool, and nerol in the beer-taste sparkling beverage so as to satisfy five particular numerical ranges by boiling the hop or the hop component in a raw material liquid.

Owner:KIRIN BREWERY CO LTD

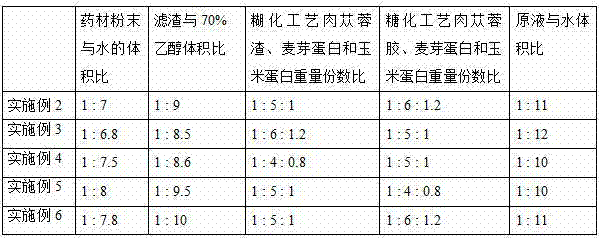

Cistanche salsa alcohol-free beer beverage and manufacturing method thereof

ActiveCN104774702AFit for drinkingReduce boredomAntinoxious agentsBeer brewingBiotechnologyDriver/operator

The invention relates to a cistanche salsa alcohol-free beer beverage and a manufacturing method thereof, and belongs to the field of beverage manufacturing. In the prior art, due to the work nature, drivers can not drink, and meanwhile the drivers can suffer from various occupation diseases during the long-time driving experience; on this basis, the alcohol-free beer beverage which has a healthcare function and can be drunk by the drivers is provided, the cistanche salsa alcohol-free beer beverage is manufactured by adding cistanche salsa extract to raw materials on the aspect of a traditional alcohol-free beer brewage technology, the prepared cistanche salsa alcohol-free beer beverage has a remarkable anti-fatigue effect and can lower the probability of occupational diseases of the drivers, and the cistanche salsa alcohol-free beer beverage is suitable for being drunk by the drivers in the driving process.

Owner:内蒙古中兴华冠生物工程股份有限公司

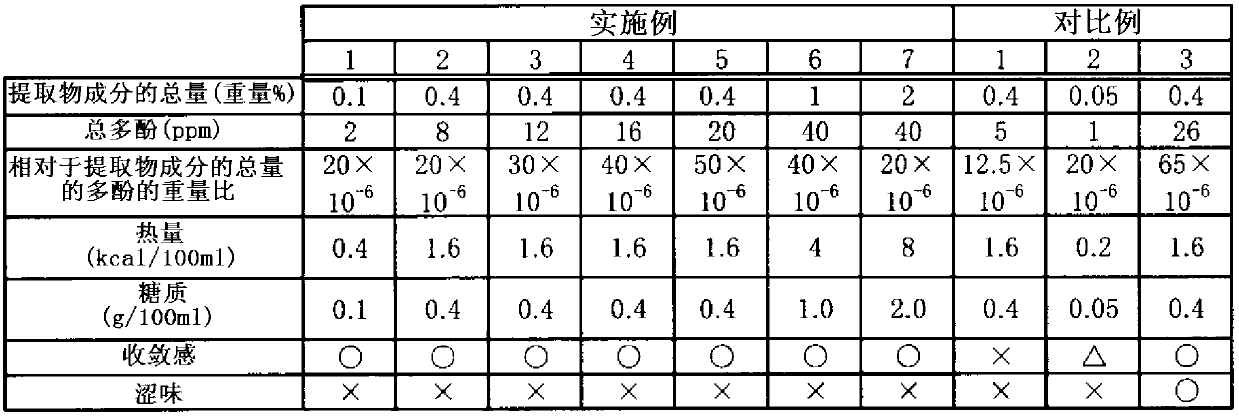

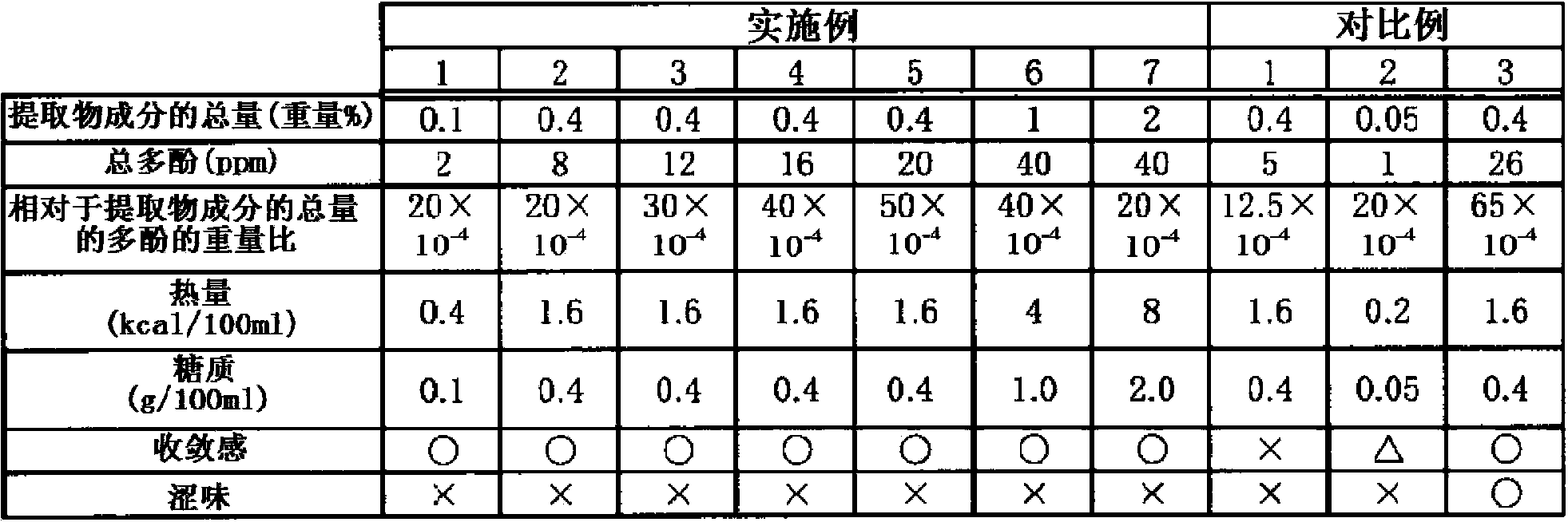

Non-alcohol, beer-taste beverage having shimari in taste

The present invention aims to provide a non-alcohol, beer-taste beverage having Shimari in taste.It provides a non-alcohol beer-taste beverage having a weight ratio of the polyphenol(s) to the total amount of the extract component(s) in a specific range.

Owner:SUNTORY HLDG LTD

Alcohol-free beer flavor beverage with astringency endowed taste

The invention aims to provide an alcohol-free beer flavor beverage with an astringency endowed taste. The invention also provides the alcohol-free beer flavor beverage, and the weight ratio of polyphenol to the total extract is in a specific range.

Owner:SUNTORY HLDG LTD

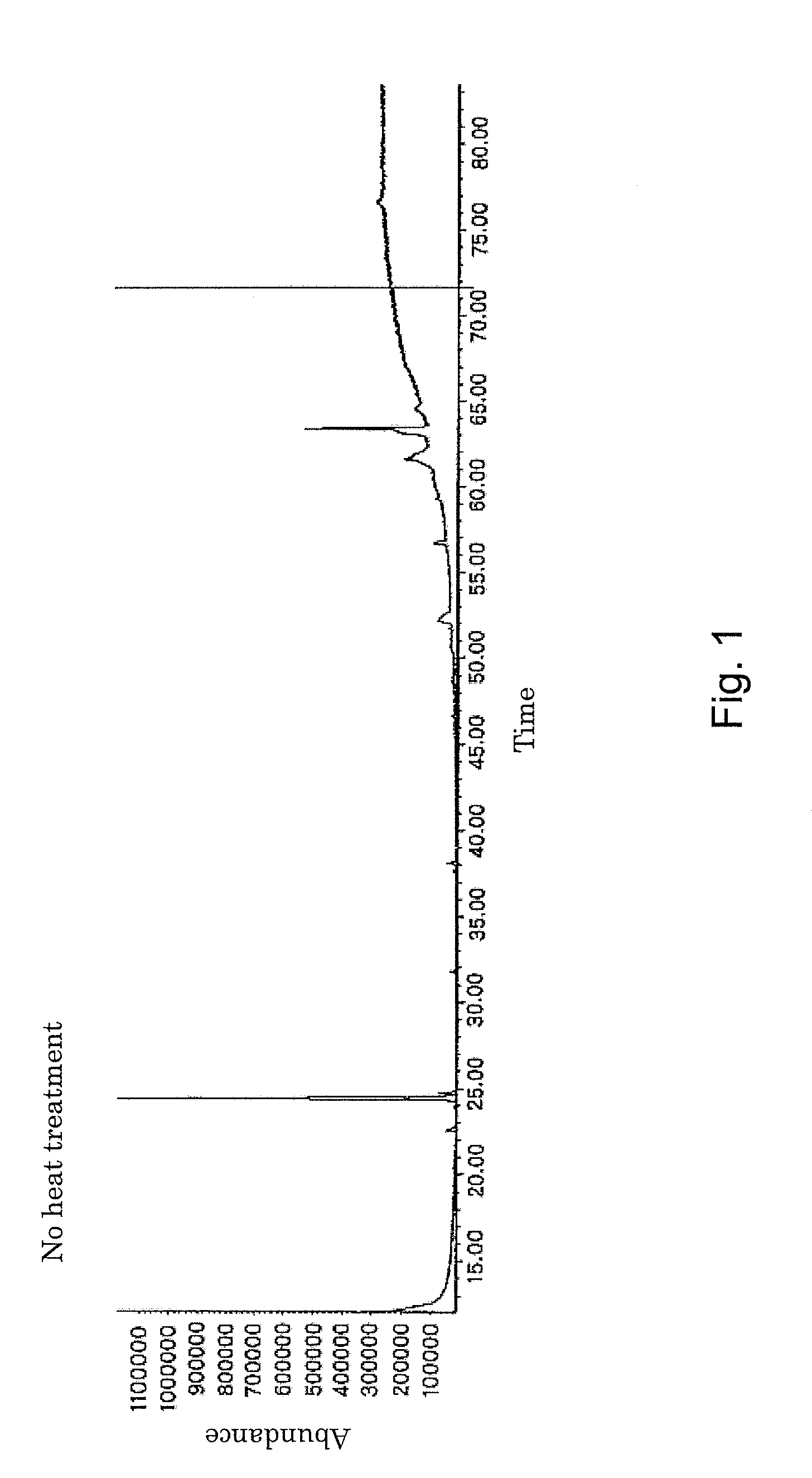

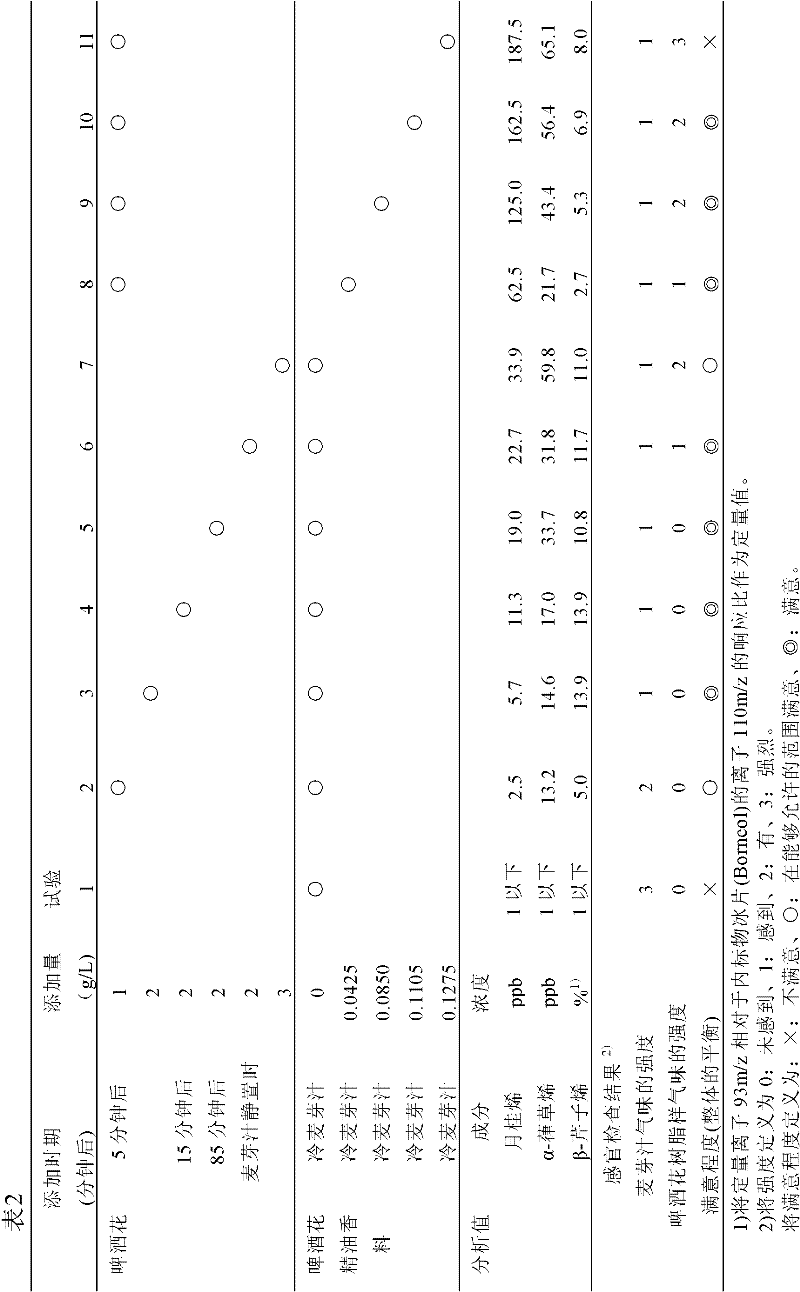

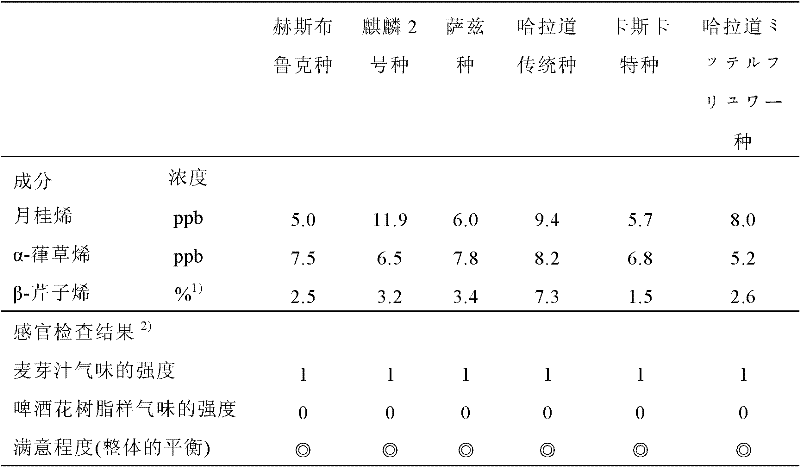

Alcohol-free beer-like malt beverage and method for producing same

Provided is an alcohol-free beer-like malt beverage from wort added with hop component without fermentation, having reduced off-flavor intrinsic to a malt beverage and suppressed nasty smell derived from hop, and retaining an aromatic component of hop. Produced is an alcohol-free beer-like malt beverage having reduced off-flavor and retaining an aromatic component of hop without fermentation, unlike a conventional non-alcohol beer production process, by controlling the content of a hop-derived aromatic component, myrcene, [alpha]-humulene or [beta]-selinene, in the beer-like malt beverage to a specific value. In the present invention, the content of a hop-derived aromatic component in the beer-like malt beverage is controlled by controlling the addition timing or additive amount of hop and / or a hop essential-oil component during a wort-boiling step or the addition amount of a hop essential-oil component in a step after the wort-boiling step.

Owner:KIRIN BREWERY CO LTD

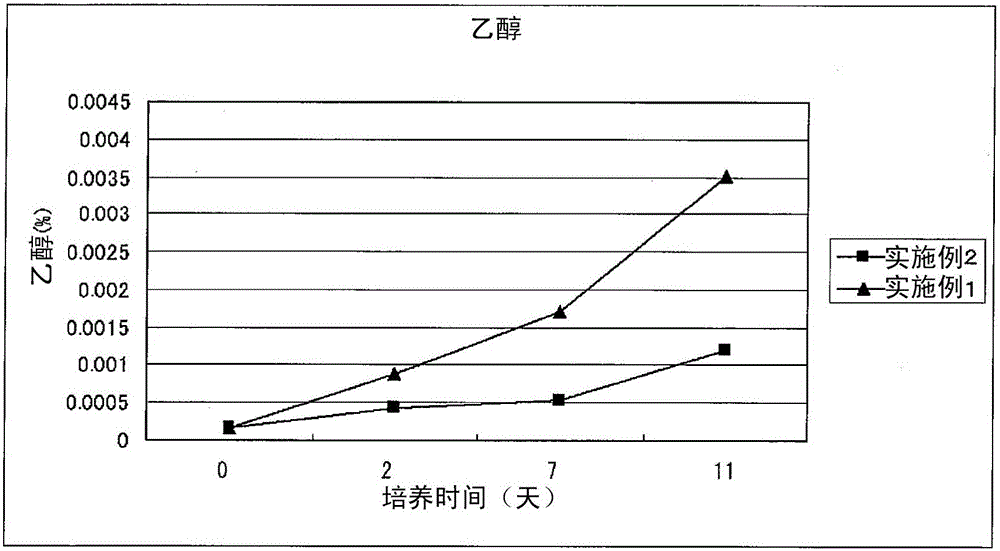

Method for producing non-alcoholic beer-flavored malt beverage

The problem addressed by the present invention is to provide a method that is for producing a non-alcoholic beer-flavored malt beverage and that achieves a low ethanol concentration of less than 0.005 vol% even in the case that fermentation is performed for approximately 3-20 days at a temperature of approximately 3-7°C. The solution to the problem is a method that is for producing a non-alcoholic beer-flavored malt beverage and that includes: a step for adding yeast to a wort having a Brix value of 15-50; and a step for fermenting the wort to which the yeast has been added.

Owner:ASAHI BREWERIES LTD

Alcohol-free beer-like malt beverage and method for producing same

Provided is an alcohol-free beer-like malt beverage from wort added with hop component without fermentation, having reduced off-flavor intrinsic to a malt beverage and suppressed nasty smell derived from hop, and retaining an aromatic component of hop. Produced is an alcohol-free beer-like malt beverage having reduced off-flavor and retaining an aromatic component of hop without fermentation, unlike a conventional non-alcohol beer production process, by controlling the content of a hop-derived aromatic component, myrcene, α-humulene or β-selinene, in the beer-like malt beverage to a specific value. In the present invention, the content of a hop-derived aromatic component in the beer-like malt beverage is controlled by controlling the addition timing or additive amount of hop and / or a hop essential-oil component during a wort-boiling step or the addition amount of a hop essential-oil component in a step after the wort-boiling step.

Owner:KIRIN BREWERY CO LTD

Apple beer and making method thereof

The invention provides apple beer, which is made by using apples as raw materials and adding hops and by a malt- and malt juice-free making process and a making process of classic beer or a making process similar to that of the classic beer. The apple beer is low-alcohol or alcohol-free beer which combines the style of classic beer and the flavor of apple and contains carbon dioxide and a small or micro amount of alcohol. The apple beer has rich and balance nutrients, and high medicinal value and high medical value, and social and economic advantages of saving grains and energy, improving labor productivity and reducing emission of bath solution waste water pollutant. The apple beer can be produced in common beer plants only by adopting a small amount of extra equipment.

Owner:褚丹秋

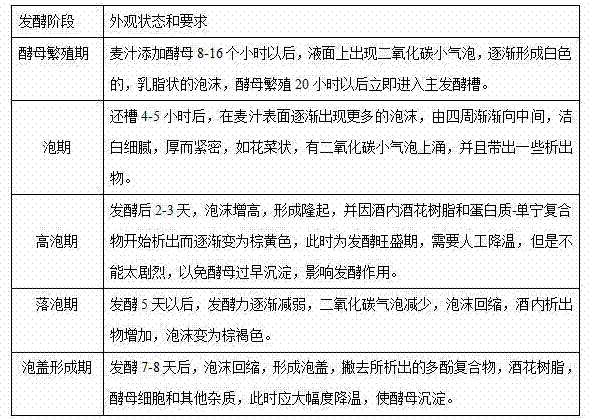

Fermentation method for alcohol-free beer

InactiveCN107699409ASolve the hazardThe fermentation process is simpleBeer fermentationMicroorganism based processesRaw materialChemistry

Belonging to the technical field of fermentation, the invention relates to a fermentation method for alcohol-free beer. The method includes the steps of: 1) raw material proportioning; 2) wort saccharification; 3) wort boiling; and 4) fermentation. The fermentation method for alcohol-free beer provided by the invention has the advantages of simple fermentation, use of existing fermentation equipment for fermentation, and no need for adding other devices, solves the problems of tedious beer fermentation steps, large equipment investment, high production cost, poor taste and the like in the prior art. In addition, the method also can solve the problems of harms to the body and traffic regulation violation brought about by drinking of alcohol beer.

Owner:ZHEJIANG GONGSHANG UNIVERSITY

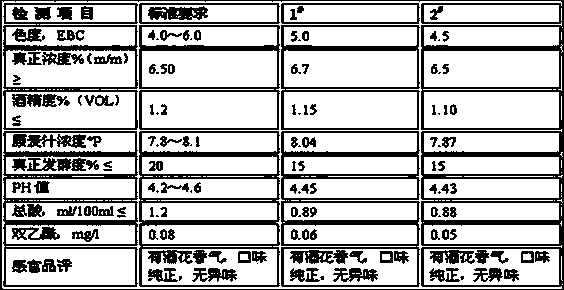

Production method of alcohol-free beer

InactiveCN103710191ASimple processConform to style standardsBeer brewingFood flavorMethods of production

The invention discloses a production method of alcohol-free beer. The production method comprises the following steps: (1) selection of materials; (2) saccharification; (3) fermentation; (4) dilution and seasoning. Compared with the prior art, the production method disclosed by the invention optimizes a limited fermentation process, the physical and chemical indicators and health indicators of the obtained alcohol-free beer product all meet the relevant requirements for the alcohol-free beer in GB4927, and the taste and flavor of the alcohol-free beer also completely conform to the set style standards of fruit and vegetable taste type beer.

Owner:YANJING BEER HENAN YUESHAN

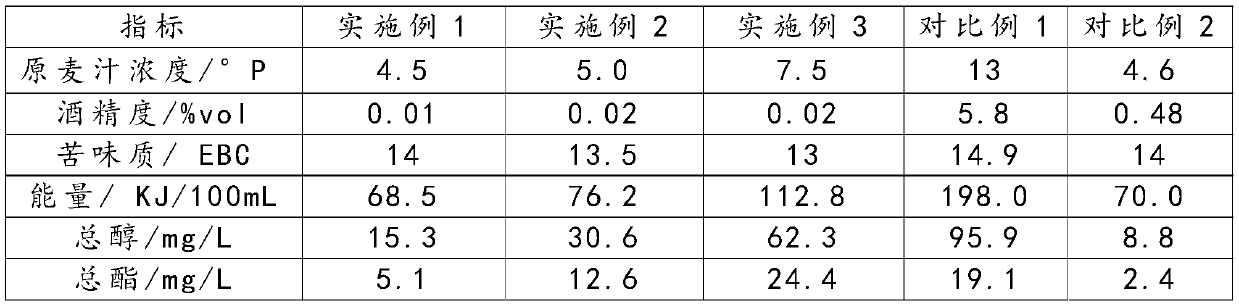

0.0% vol alcohol-free Lager beer and preparation method thereof

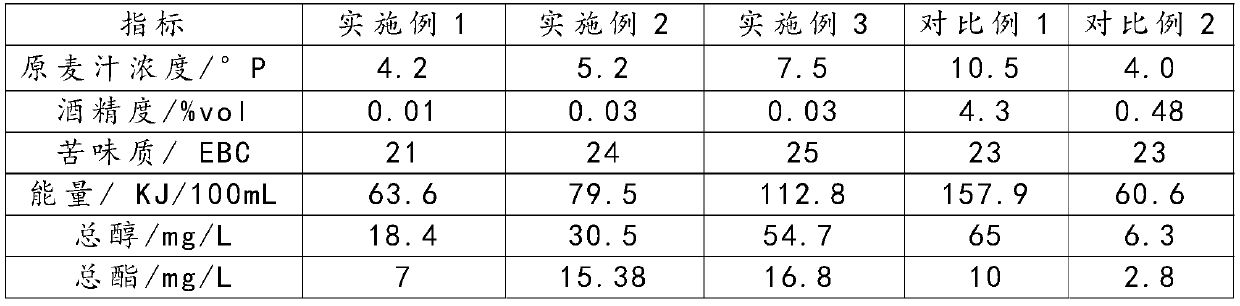

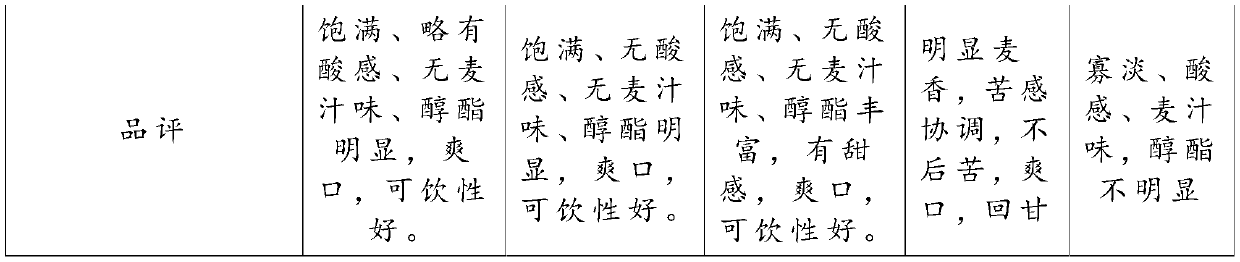

InactiveCN110591875ALow alcohol contentHigh nutritional valueAlcoholic beverage preparationBeer brewingAlcohol contentAlcohol free

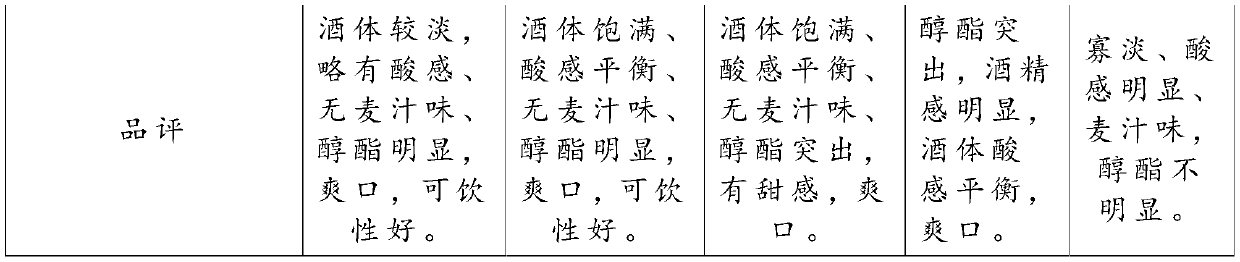

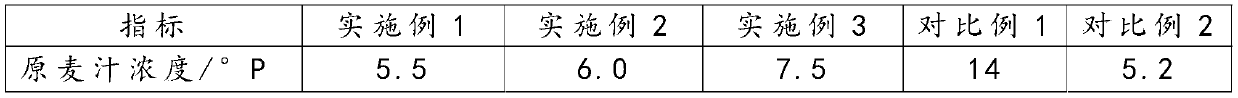

The invention provides a 0.0% vol alcohol-free Lager beer and a preparation method thereof, belongs to the technical field of beer brewing, and can solve problems that the existing alcohol-free beer lacks alcohol ester flavor of traditional beer, and has a light taste and a prominent sour mouthfeel. The 0.0% vol alcohol-free Lager beer has an alcohol content of less than 0.05% vol, a bitter substance of 10 EBC-15 EBC, a raw wort concentration of 4.5 plato -7.5 plato, a carbon dioxide content of 0.5% mass-0.60% mass, a total alcohol of 15 mg / L or more, and a total ester of 5 mg / L or more. The beer is prepared by the following steps: sequentially subjecting classic Lager beer to steps of preheating, degassing, dealcoholization, cooling, filling with carbon dioxide, post-modification, filtration, stabilization, and filling to obtain the 0.0% vol alcohol-free Lager beer.

Owner:TSINGTAO BREWERY

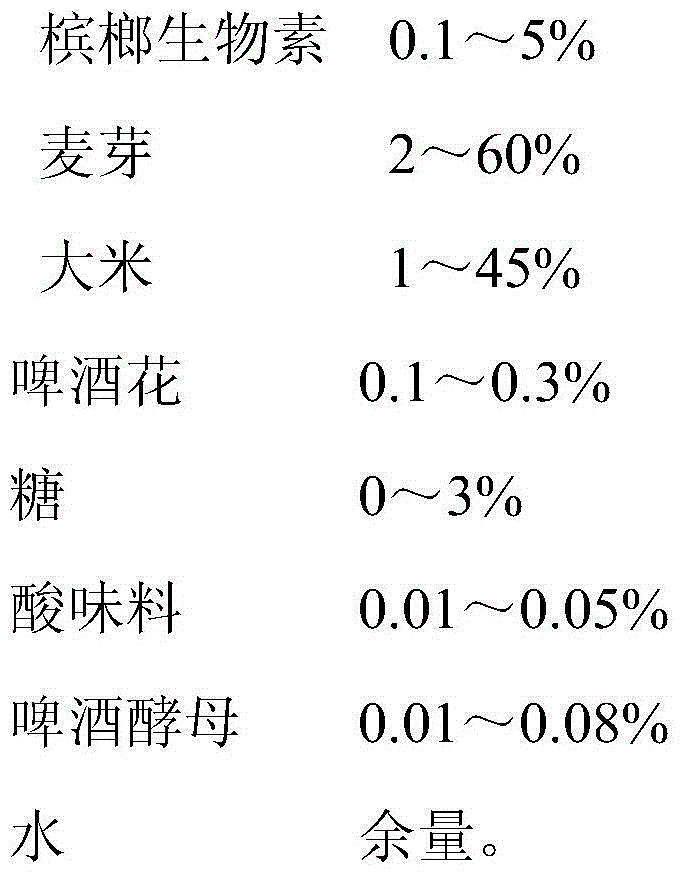

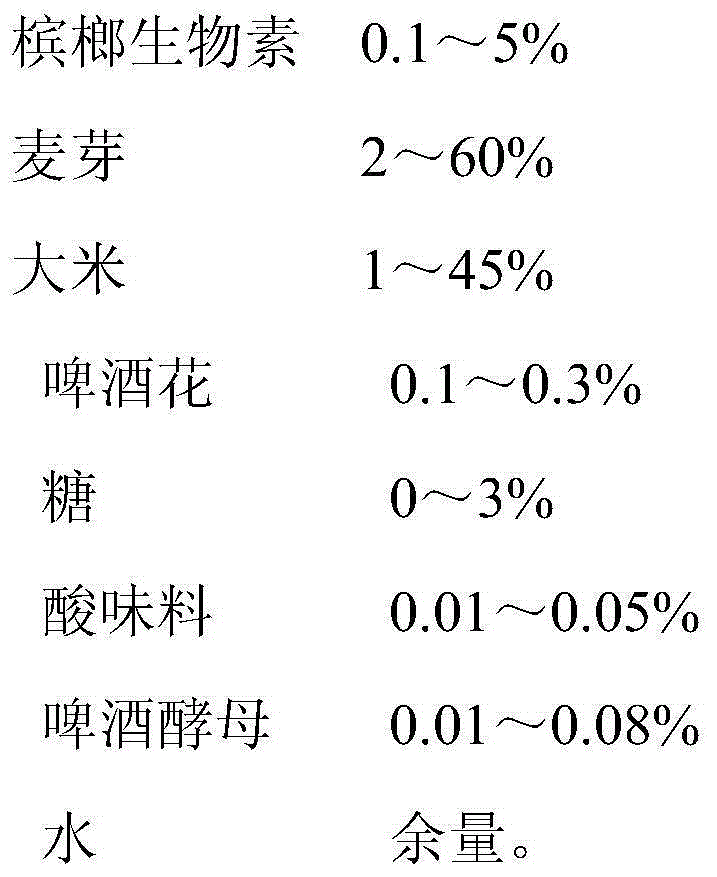

Betel nut alcohol-free beer and preparing method thereof

InactiveCN105238606AAlcoholic beverage preparationMicroorganism based processesAdditive ingredientBetel

The invention discloses a betel nut alcohol-free beer and a preparing method thereof. The betel nut alcohol-free beer is prepared from, by weight, 0.1% to 5% of betel nut biotin, 2% to 60% of malt, 1% to 45% of rice, 0.1% to 0.3% of lupulus, 0% to 3% of sugar, 0.01% to 0.05% of sour seasoning, 0.01% to 0.08% of beer yeast and the balance water in a saccharifying, filtering, boiling, fermenting and dealcoholizing mode. The betel nut alcohol-free beer completely has the color and taste characteristics of an existing alcohol-free beer; in other words, the beer has the slight lupulus aroma and the slight malt aroma, and is clean, tasty and refreshing in mouthfeel and free of smells. In addition, the betel nut biotin is added into the betel nut alcohol-free beer, and the natural ingredients of fresh betel nut are completely reserved.

Owner:许启太

Non-alcohol, beer-taste beverage having substantiality in taste

InactiveUS20140342077A1Strong astringencyWort preparationAlcoholic beverage preparationPolyphenolChemistry

The present invention aims to provide a non-alcohol, beer-taste beverage having Shimari in taste. It provides a non-alcohol beer-taste beverage having a weight ratio of the polyphenol(s) to the total amount of the extract component(s) in a specific range.

Owner:SUNTORY HLDG LTD

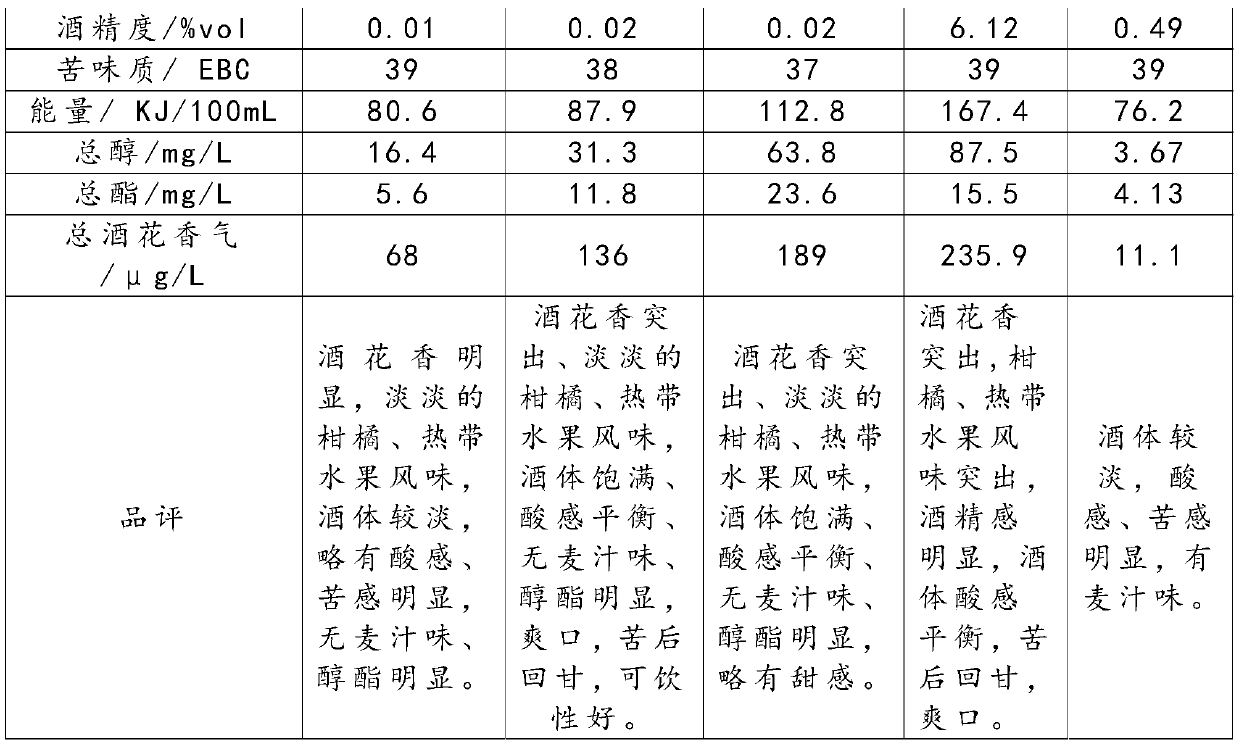

0.0%vol alcohol-free IPA beer and preparation method thereof

InactiveCN110616134ATypical flavorTypical hop aromaAlcoholic beverage preparationBeer brewingFlavorAlcohol content

The invention provides 0.0%vol alcohol-free IPA beer and a preparation method thereof, belongs to the technical field of beer brewing, and can solve the problems that existing alcohol-free beer lacksthe alcohol ester flavor of traditional beer, and has light mouthfeel and prominent acid mouthfeel. The technical scheme comprises the 0.0%vol alcohol-free IPA beer, wherein the alcohol content of thebeer is less than 0.05% vol, bitterness substances are in a range of 30EBC-60EBC, the original wort concentration is 5.5-7.5 Plato, the carbon dioxide content is 0.50-0.60 %mass, the total alcohol concentration is more than or equal to 15mg / L, the total ester concentration is more than or equal to 5mg / L, and the total hop aroma is more than or equal to 50 [mu]g / L. The beer is prepared by the following steps: sequentially carrying out preheating, degassing, dealcoholizing, cooling, carbon dioxide filling, post-modifying, stabilizing and filling on IPA beer to prepare the 0.0%vol alcohol-free IPA beer.

Owner:TSINGTAO BREWERY

Non-alcoholic fermented beer having improved flavour

PendingUS20210189306A1Efficient removalBeer fermentationAlcoholic beverage preparationBiotechnologyMolecular sieve

The invention provides a process of producing a non-alcoholic beer comprising the steps of:fermenting the wort with live yeast to produce a fermented wort;subjecting the fermented wort to one or more further process steps to produce a non-alcoholic beer; andintroducing the non-alcoholic beer in a sealed container; wherein either the fermentation produces a non-alcoholic fermented wort or wherein the fermentation produces an alcoholic fermented wort and alcohol is subsequently removed to produce a non-alcoholic fermented wort or a non-alcoholic beer; and wherein the heated wort, the non-alcoholic fermented wort and / or the non-alcoholic beer is contacted with a hydrophobic silicate-based molecular sieve.Flavour substances contributing to undesirable flavour notes in non-alcoholic beer can be removed effectively during production by contacting wort before or after fermentation with a hydrophobic silicate-based molecular sieve, provided the wort contains virtually no alcohol.

Owner:HEINEKEN SUPPLY CHAIN BV

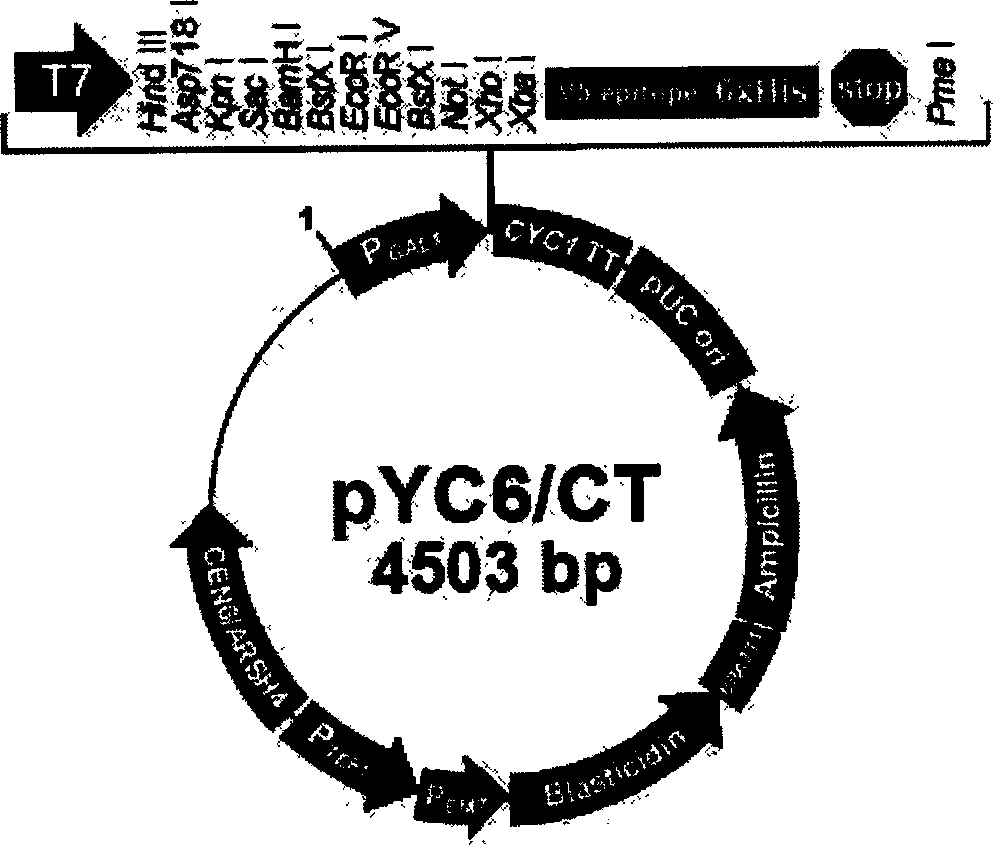

construction of HD34-1 strain and method for making alcohol-free beer with HD34-1 strain as ferment strain

InactiveCN1594547AOvercome many disadvantages of production processSimple production processFungiFermentationZymogenBiotechnology

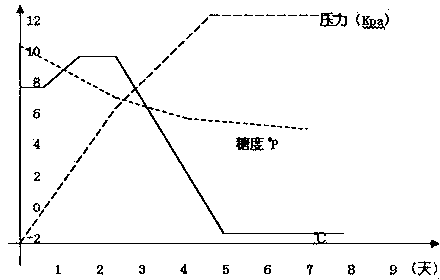

The invention relates to a method of engineered bacterium HD34-1 construction and alcohol free beer brewing using engineered bacterium HD34-1 as zymogen. HD34-1 is constructed as follows: a.designing 5' and 3' primer; b. amplifying ADH gene; c. connecting with expression vector pYC6 / CT; d. transforming Saccharomyces cerevisiae HD34; e. screening transformer to obatain HD34-1 strain. Alcohol free beer brewing method using HD34-1 as zymogen is as follows : a. activating HD34-1; b. switching strain to medium and shaking culture; c. inoculating strain to be amplified in malt juice containing fermenter; d. aerating and fermenting e.determing the sugar degree, and stopping fermentation when sugar degree decrease to 5 DEG BX; f. lowering the temperature. The inventive strain can catalyze positive reaction of primary alcohol with aldehyde, lower ethanol yield and simplify the process.

Owner:HEILONGJIANG UNIV

Preparation method of seaweed alcohol-free beer based on marine microorganism enzyme and seaweed alcohol-free beer

The invention provides a preparation method of seaweed alcohol-free beer based on a marine microorganism enzyme and the seaweed alcohol-free beer and belongs to the technical field of food processing,aiming at solving the problem that seaweed has a fishy smell, enabling the obtained seaweed alcohol-free beer to have good drinkable performance and keeping corresponding functions of the seaweed. The preparation method provided by the invention comprises the following steps: preparing a seaweed enzyme, preparing alcohol-free beer, preparing pre-treated seaweed alcohol-free beer, filtering the pre-treated seaweed alcohol-free beer to obtain the seaweed alcohol-free beer and the like. By adopting the seaweed alcohol-free beer provided by the invention, the problem that the seaweed has the fishy smell is solved; meanwhile, the seaweed alcohol-free beer has good drinkable performance and the corresponding functions of the seaweed are kept.

Owner:TSINGTAO BREWERY

0.0% vol alcohol-free Pilsner beer and preparation method thereof

InactiveCN110577879ALow alcohol contentHigh nutritional valueAlcoholic beverage preparationBeer brewingFlavorAlcohol free

The invention provides 0.0% vol alcohol-free Pilsner beer and a preparation method thereof, and belongs to the technical field of beer brewage. The problems that alcohol-free beer at present lacks thealcohol ester flavor of traditional beer, and has weak taste and outstanding acid sensation can be solved. According to the technical scheme, the 0.0% vol alcohol-free Pilsner beer is included, the alcoholic strength of the beer is smaller than 0.05% vol, amaroid is 20 EBC to 25 EBC, the original wort concentration is 4.5 plato degrees to 7.5 plato degrees, the carbon dioxide content is 0.50% mass to 0.60% mass, the total alcohol is larger than or equal to 15 mg / L, and the total ester is larger than or equal to 5 mg / L. the beer is prepared through the following steps that the Pilsner beer issequentially subjected to preheating, degassing, dealcoholization, cooling, carbon dioxide filling, post modification, filtering, stabilization and filling, and the 0.0% vol alcohol-free Pilsner beeris prepared.

Owner:TSINGTAO BREWERY

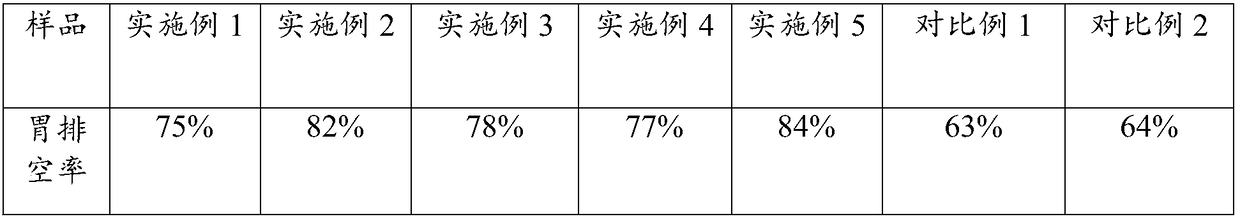

Nonalcoholic beer causing no satiety to human after drinking and preparation method thereof

ActiveCN108893215AOvercome the shortcomings of poor drinkability and easy satietyReduce satietyBeer brewingDietary fiberFood grade

The invention provides nonalcoholic beer causing no satiety to human after drinking and a preparation method thereof, belongs to the technical field of beers, and is intended to solve the problem thatnonalcoholic beer has poor drinkability during consumption and easily causes satiety. The nonalcoholic beer causing no satiety to human after drinking is prepared by pretreating a beer solution by wheat juice, dietary fiber, glycerol and food-grade citric acid and water, and carbonating the pretreated beer solution, wherein upon wort preparation, emptying rate of malt and hops used as materials herein is greater than 77%; bitterness of the wheat juice is lower than 10 IBU. The nonalcoholic beer effectively increases stomach emptying rate and causes less satiety.

Owner:TSINGTAO BREWERY

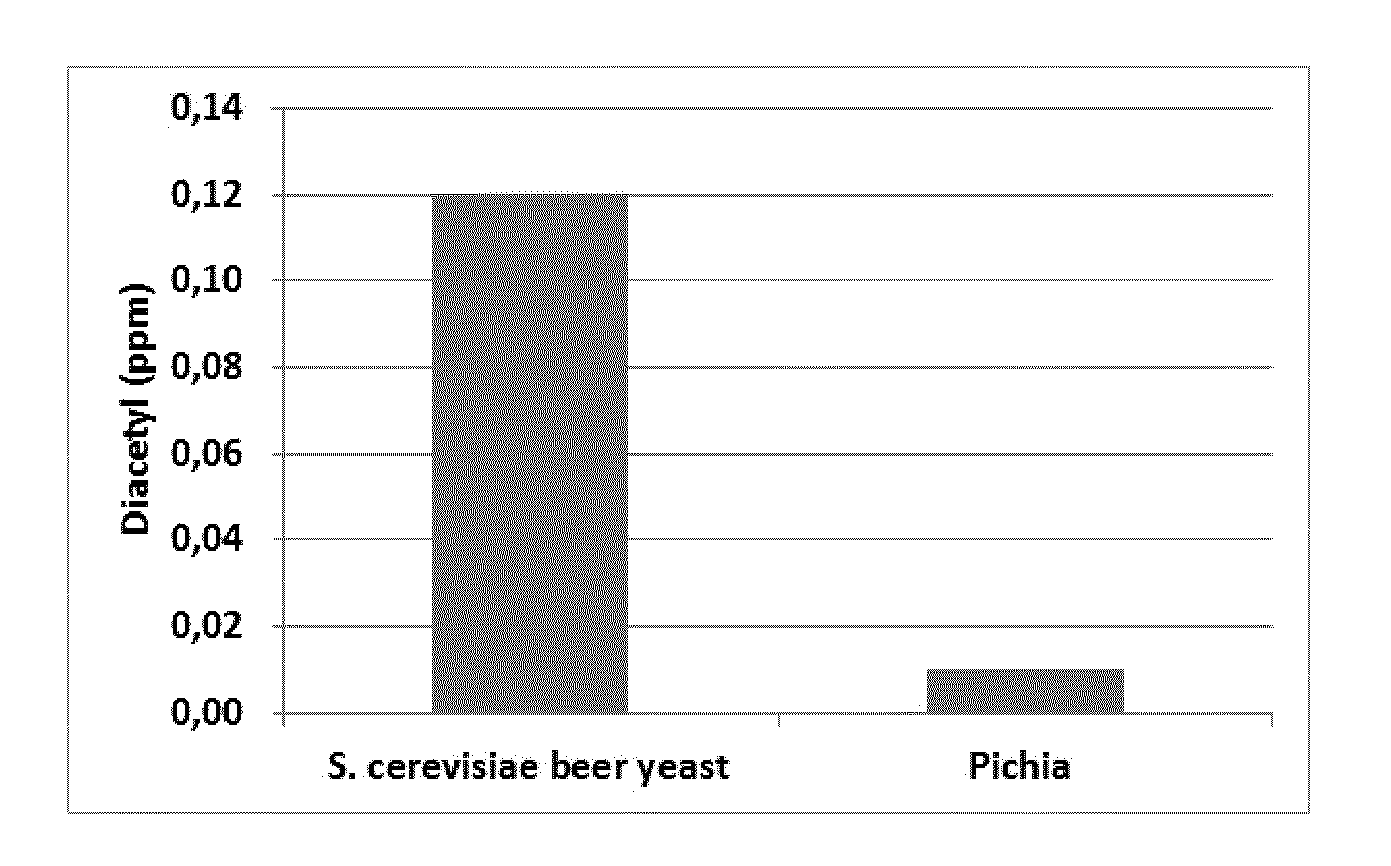

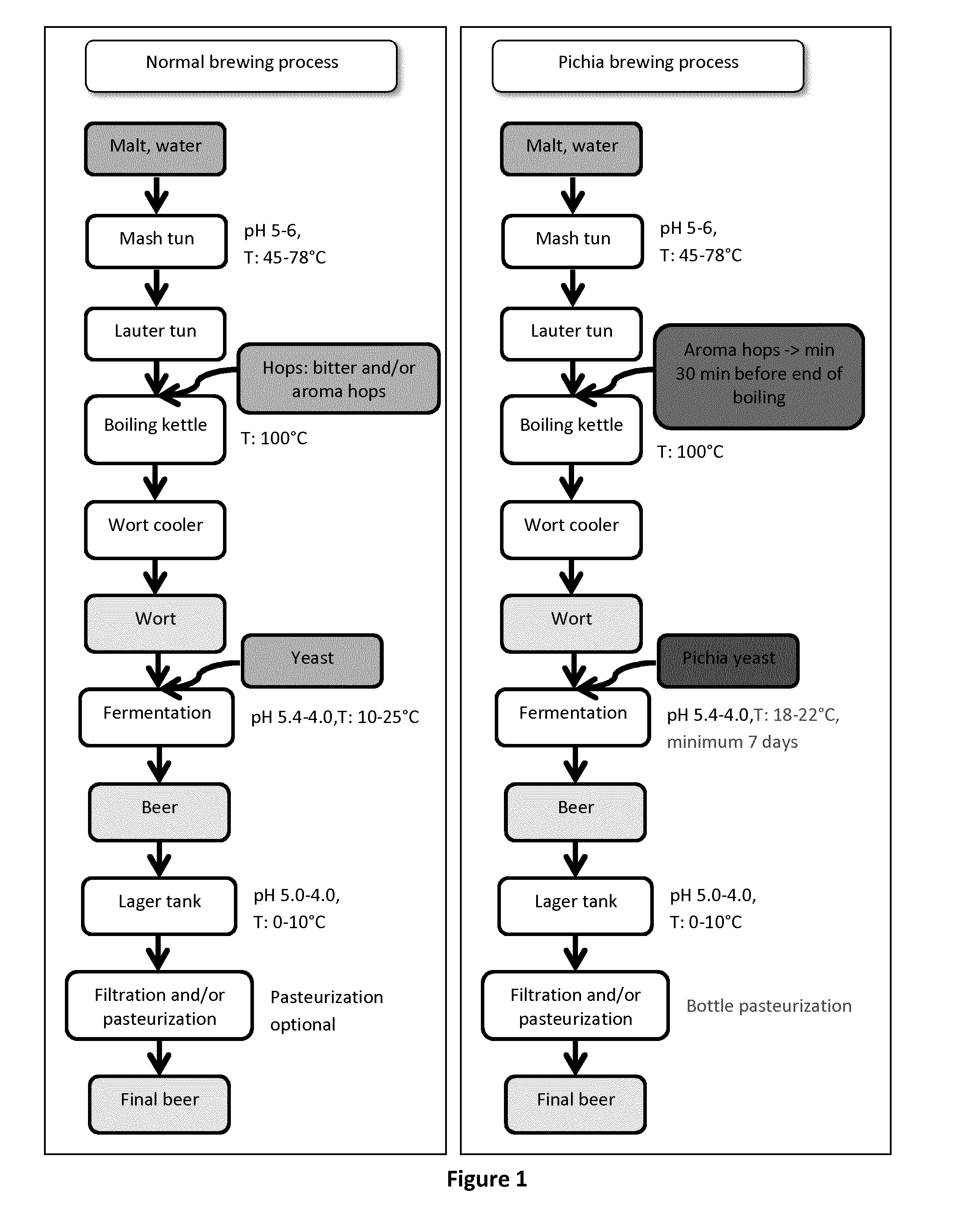

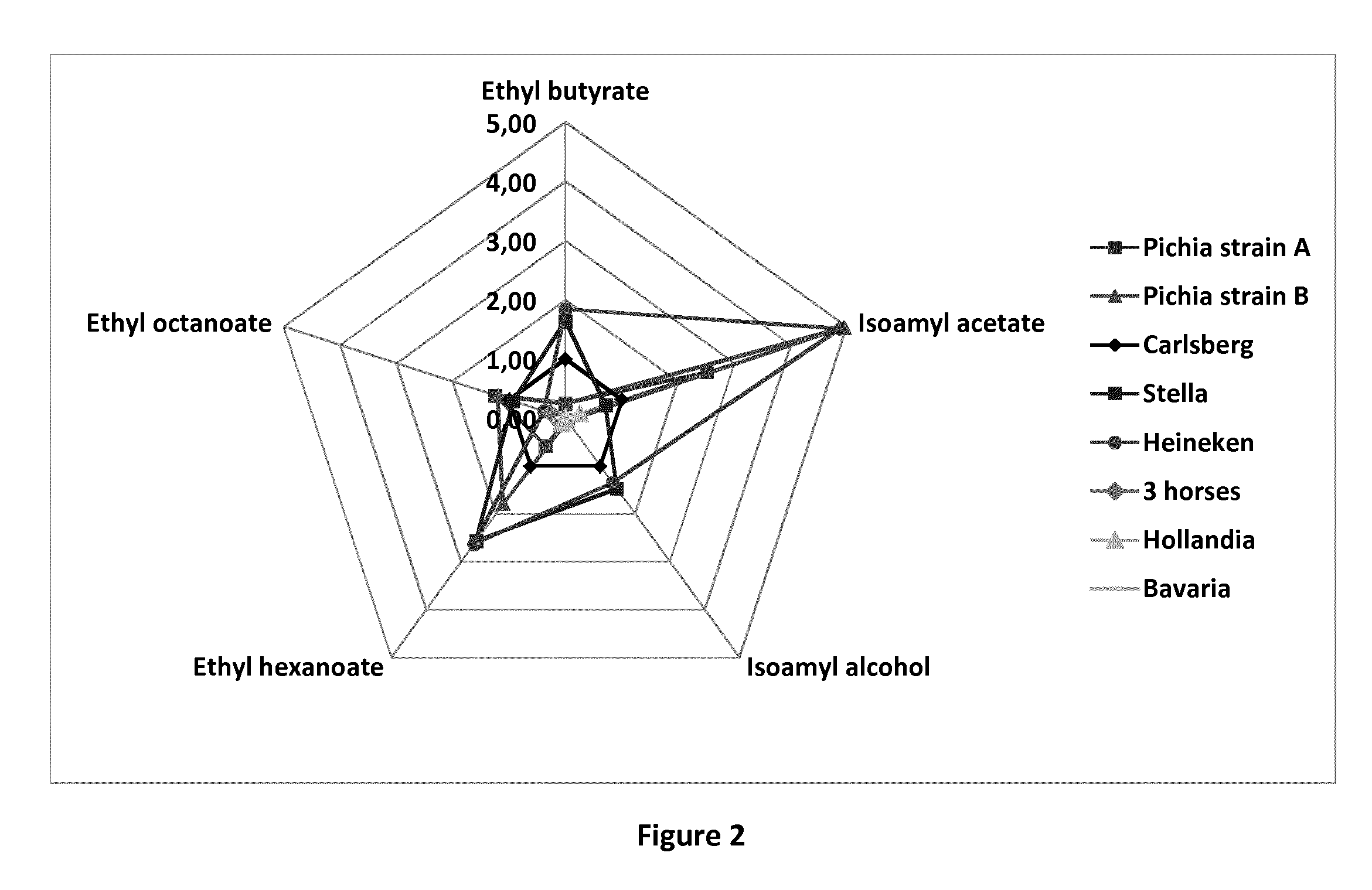

Production of low-alcohol or alcohol-free beer with Pichia kluyveri yeast strains

It has unexpectedly been found that a low alcohol or alcohol-free beverage, with a flavor profile very close to a beer of at least 4% (vol / vol) alcohol, can be produced by using Pichia kluyveri yeast strains. In particular, Pichia kluyveri yeast strains only use the glucose in the wort, and have the ability of converting this substrate into a high concentration of specific flavor compounds, which are normally produced by Saccharomyces ssp. yeast strains used for the brewing of beer. In this way the Pichia kluyveri yeast strains can be used to produce either a low alcohol or alcohol-free beverage, depending on the glucose levels in the wort. The main flavor compounds produced by Pichia kluyveri in the fermentation of wort are isoamyl acetate, isoamyl alcohol, ethyl butyrate, ethyl hexanoate and ethyl octanoate.

Owner:CHR HANSEN AS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com