Method of improving non-alcohol beer flavour

A technology of non-alcoholic beer and de-alcoholized beer, which is applied in the direction of beer brewing, etc., and can solve the problem of slightly sour and bitter tail

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The method of the present invention mainly aims at the defects of strong sensory acidity and poor taste coordination of non-alcoholic beer produced by dealcoholization by low-temperature distillation method, and adopts a novel production method to improve the taste of non-alcoholic beer, especially through the use of hop products, The bitter quality of the final non-alcoholic beer is controlled within the range of 10-14BU; the alcohol content of the final non-alcoholic beer is kept within the range of 0.4-0.5% (vol) through the control of the backfill ratio of aroma substances and clarified beer.

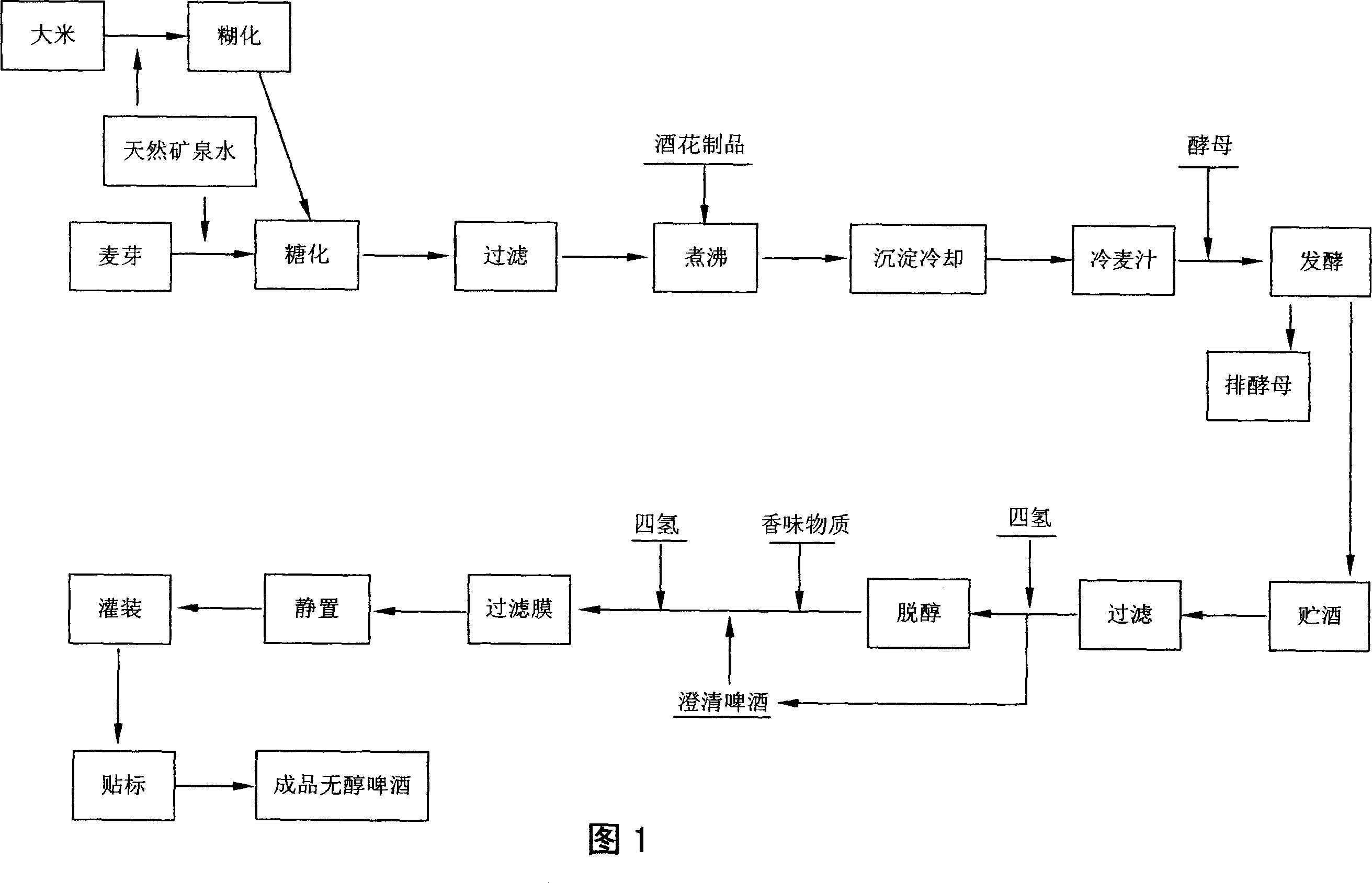

[0032] Please refer to Figure 1, which is a process flow diagram of a method for improving the taste of non-alcoholic beer according to the present invention, including raw material preparation, gelatinization, saccharification, filtration, boiling and adding hop products, precipitation cooling, oxygenation, adding yeast, fermentation, The steps of wine storage, filtration, de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com