construction of HD34-1 strain and method for making alcohol-free beer with HD34-1 strain as ferment strain

A technology for fermenting strains and alcohol-free beer, which is applied in the field of fermenting strains for brewing alcohol-free beer and the construction of genetically engineered strains, and can solve problems such as difficulty in wide-scale application, poor stability, and susceptibility to miscellaneous bacteria.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

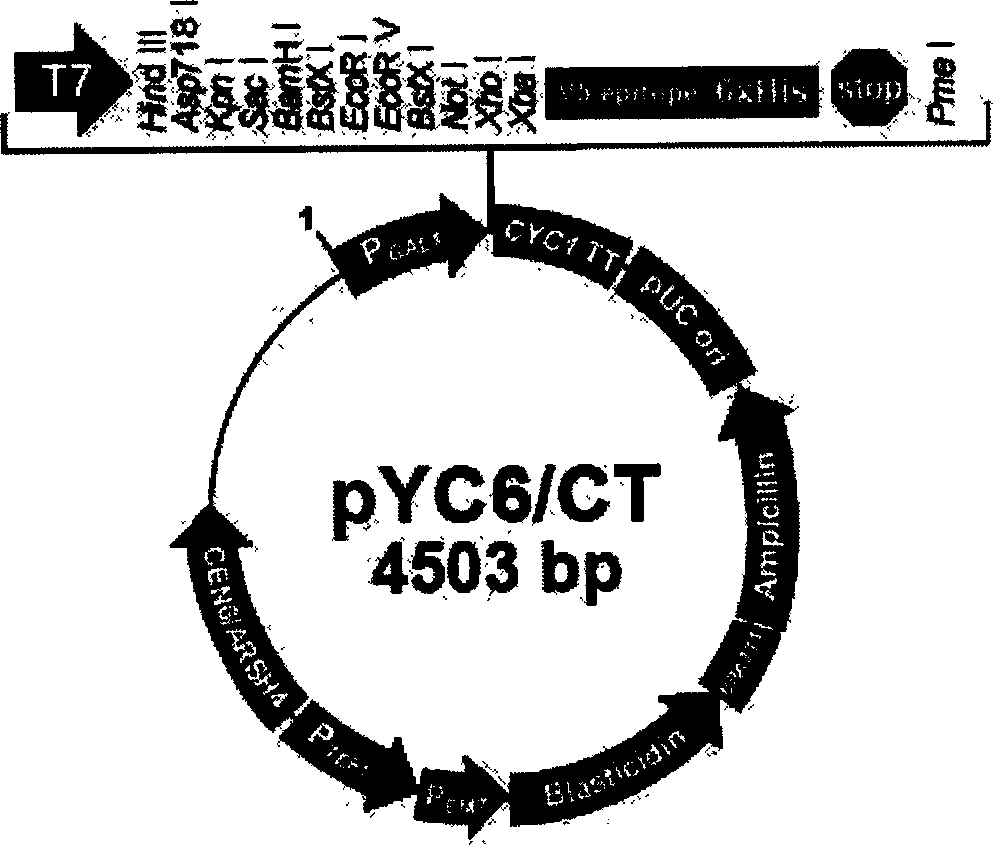

[0005] Specific embodiment one: the genetic engineering bacterial strain HD34-1 of present embodiment is constructed like this: a, design 5 ' end, 3 ' end primers according to the ADH gene sequence registered on GenBank, at 5 ' end primers and 3 ' end primers Recognition sites for Sac I and BamH I were added GAGCTC and GGATCC b, using the PCR method to amplify the ADH gene with the genomic DNA of Bacillus subtilis as a template; c, linking the obtained product with the expression vector pYC6 / CT; d, transforming the constructed recombinant DNA into Saccharomyces cerevisiae HD34 using the LiAc transformation method; e. Preliminary screening was performed on the obtained transformants by the isoenzyme method, and ADH qualitative detection was performed on the strains after the primary screening, and a bacterial strain HD34-1 with high ADH activity was obtained.

specific Embodiment approach 2

[0006] Specific embodiment two: the genetically engineered bacterial strain HD34-1 of the present embodiment is constructed like this:

[0007] a. Design 5′ and 3′ primers according to the ADH gene sequence registered on GenBank, and add Sac I and BamH I recognition sites to the 5′ and 3′ primers respectively GAGCTC and GGATCC :

[0008] Bacillus subtilis ADH (Alcohol Dehydrogenase) gene sequence registered on GenBank NC 000964. for:

[0009] ttat

[0010] 3182941 accgttttag gcgtaaggtt aaagcagcgt ttgtagatcc agttgtatgc tttttcattt

[0011] 3183001 aaatctctag ggtttccgaa ggtttgcgga tctttcattg cttctttaga caagcgttcg

[0012] 3183061 atcatatcag gtgatactcc ctgctcttct aaagtcggca cttctaaatc ttcgaccaga

[0013] 3183121 tcatacatcc aattgacaga tgctttcgca gcttcttctg ttgtcatctt gcttgtatca

[0014] 3183181 ataccgaacg ctttcgcaat acgcgcaaac ttctcaggat agcccttcca gttgtattcc

[0015] 3183241 atgacagggc ccatcat...

specific Embodiment approach 3

[0126] Specific embodiment three: The non-alcoholic beer of this embodiment is realized in the following way: a. Use wort culture medium to activate HD34-1 on a solid slope; b. Transfer the activated strain to 500ml at a temperature of 20-40°C In the wort liquid culture medium, shake the flask for 46-50 hours, the temperature is 20-40 °C, and the rotation speed is 120 rpm; c. Cool the expanded bacterial suspension to 3-5 °C, press 2-5 °C 4% inoculum amount inoculates the expansion strain into the fermenter containing wort; d, then oxygenates the fermenter for 2 to 3 minutes, and ferments at 10 to 14°C; e, measures the sugar content in days, Stop fermentation when the sugar content drops to 5°BX; f, cool down to 3-5°C, leave the tank for a week to obtain non-alcoholic beer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com