Method for producing non-alcoholic beer-flavored malt beverage

A technology for non-alcoholic beer and malt beverages, which is applied in the field of non-alcoholic beer-flavored malt beverages, and can solve problems such as complicated manufacturing process management, consumer displeasure, and residual wort taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] The harvested barley is dipped in water to germinate moderately, and then roasted with hot air to produce malt. This malt is crushed by a normal method. Then, the crushed malt and warm water are put into the charging tank and mixed to prepare mash. The preparation of the mash was carried out by keeping at 50° C. for 30 minutes. Thereafter, after gradually raising the temperature of the mash, the starch is saccharified by using malt-derived enzymes by keeping the temperature at a predetermined temperature for a certain period of time. The saccharification treatment was carried out by holding at 64.5°C for 10 minutes and at 70°C for 10 minutes. After the saccharification process, after holding at 78 degreeC for 5 minutes, the mash was filtered in the wort lauter tank, and the transparent wort was obtained.

[0052] Maltose was added to the obtained wort to adjust the Brix value to 35.07 (maltose concentration: 46.3% by weight). Next, hydrochloric acid was added theret...

Embodiment 2

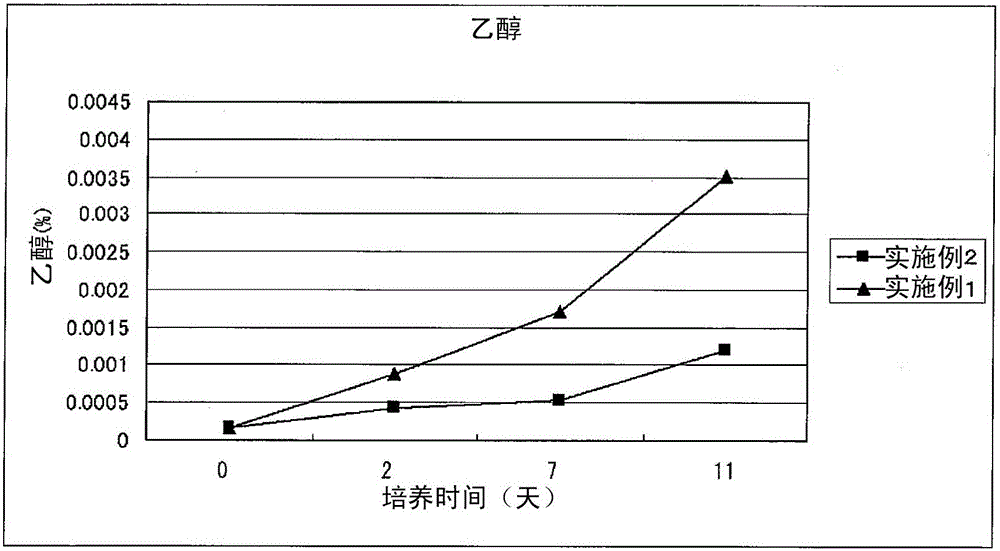

[0059] Except having changed the kind of yeast into sake yeast, it carried out similarly to Example 1, and produced and evaluated the fermented liquid. express the result in figure 1 and Table 2. The ethanol concentration of the fermentation liquid on the 11th day of fermentation was 0.0012% by volume.

[0060] [Table 2]

[0061]

0 days

2 days

7 days

11 days

2MB

26.7

19.5

7.8

2.9

89%

3MB

86.1

69.7

31.5

11.2

87%

Methionaldehyde

49.4

46.5

44

37.8

23%

BA

3.5

3.4

3.6

2.4

31%

PA

110.4

115.7

115

110.1

0%

478

451.9

420.7

381.6

20%

[0062] The fermented liquid on the 0th day of fermentation, the fermented liquid on the 7th day of fermentation, and the fermented liquid on the 11th day of fermentation were used for sensory evaluation. As a result, on the 0th day...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com