Non-alcoholic beer-flavored beverage with tangy taste

A technology of non-alcoholic beer and beer-flavored beverages, which is applied in the preparation of alcoholic beverages, brewing of beer, and preparation of wort, etc. It can solve the problems of lack of astringency, poor refreshing taste, and lack of balance of bitterness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0087] The present invention will be described more specifically in Examples, but the scope of the present invention is not limited to these Examples.

[0088]

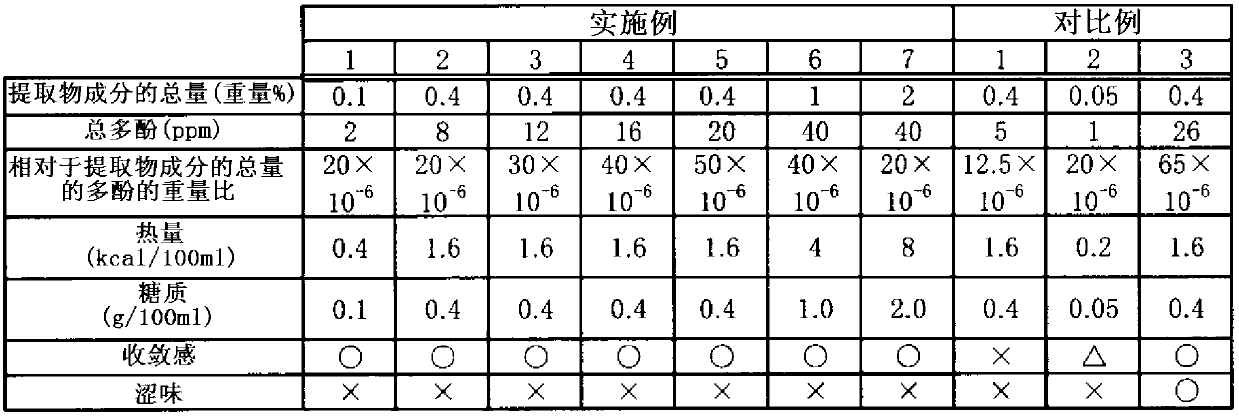

[0089] The non-alcoholic beer-taste beverages (Examples 1 to 7) of the present invention in which the weight ratio of polyphenols to the total amount of extract components is within a desired range and the weight ratio of polyphenols to the total amount of extract components Non-alcoholic beer-taste beverages (Comparative Examples 1 to 3) whose ratio was out of the desired range were produced by the following method.

[0090] Regarding Examples 1 to 7 and Comparative Examples 1 to 3, 20 kg of malt was crushed into an appropriate particle size, and after it was put into a feeding trough, 120 L of warm water was added to make mash at about 50° C. After keeping at 50° C. for 30 minutes, gradually raise the temperature to 65° C. to 72° C. for saccharification for 60 minutes. After the saccharification is completed, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com