Ultra-thin copper foil with carrier and printed wiring board using ultra-thin copper foil with carrier

a technology of copper foil and printed wiring board, which is applied in the direction of soldering apparatus, instruments, heat measurement, etc., can solve the problems of small peel strength between copper foil and substrate, difficult to produce printed wiring board with reliable and fine wiring pattern, and failure of insulation, so as to improve peel strength and easy etching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

The First Embodiment

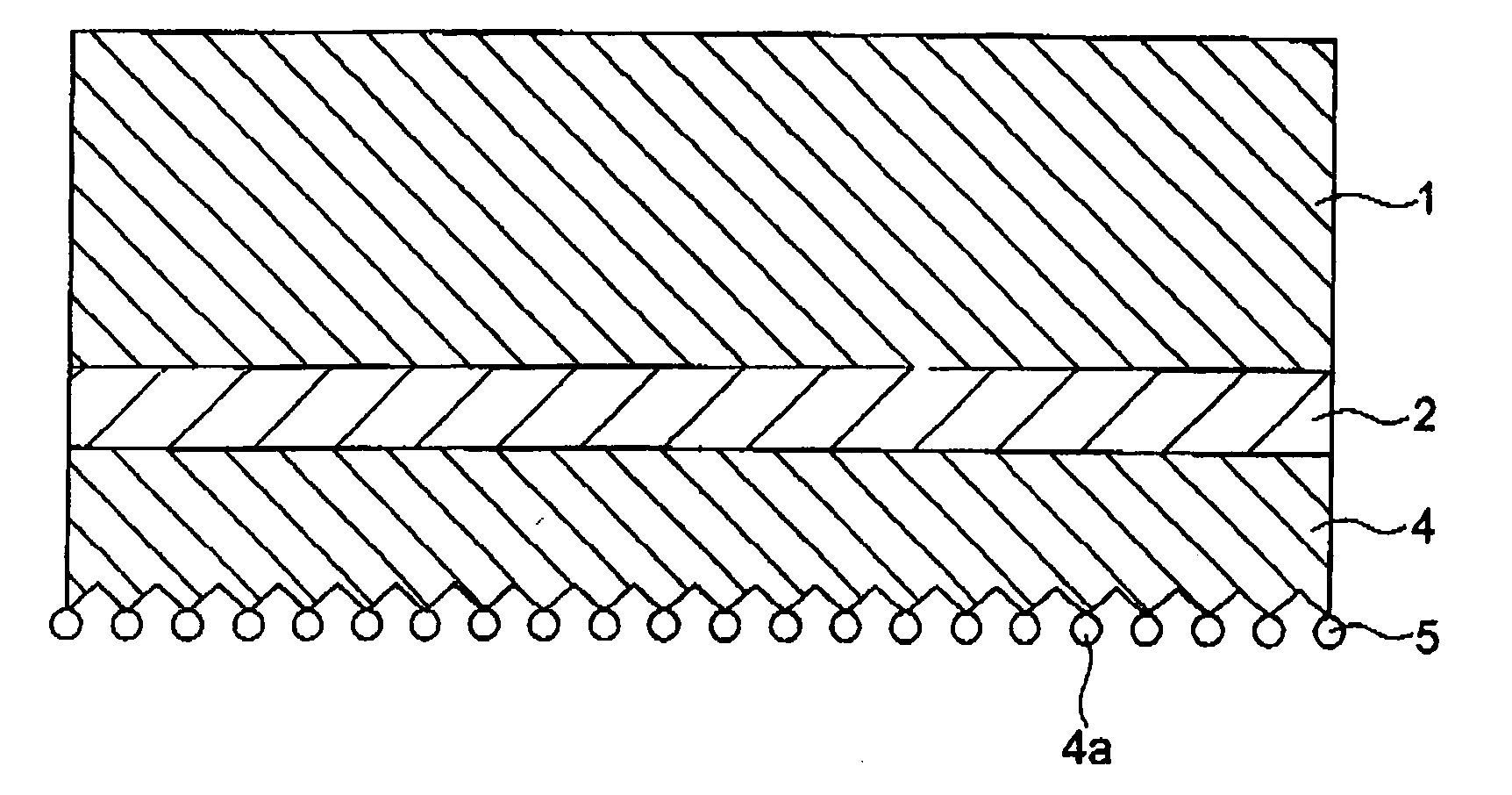

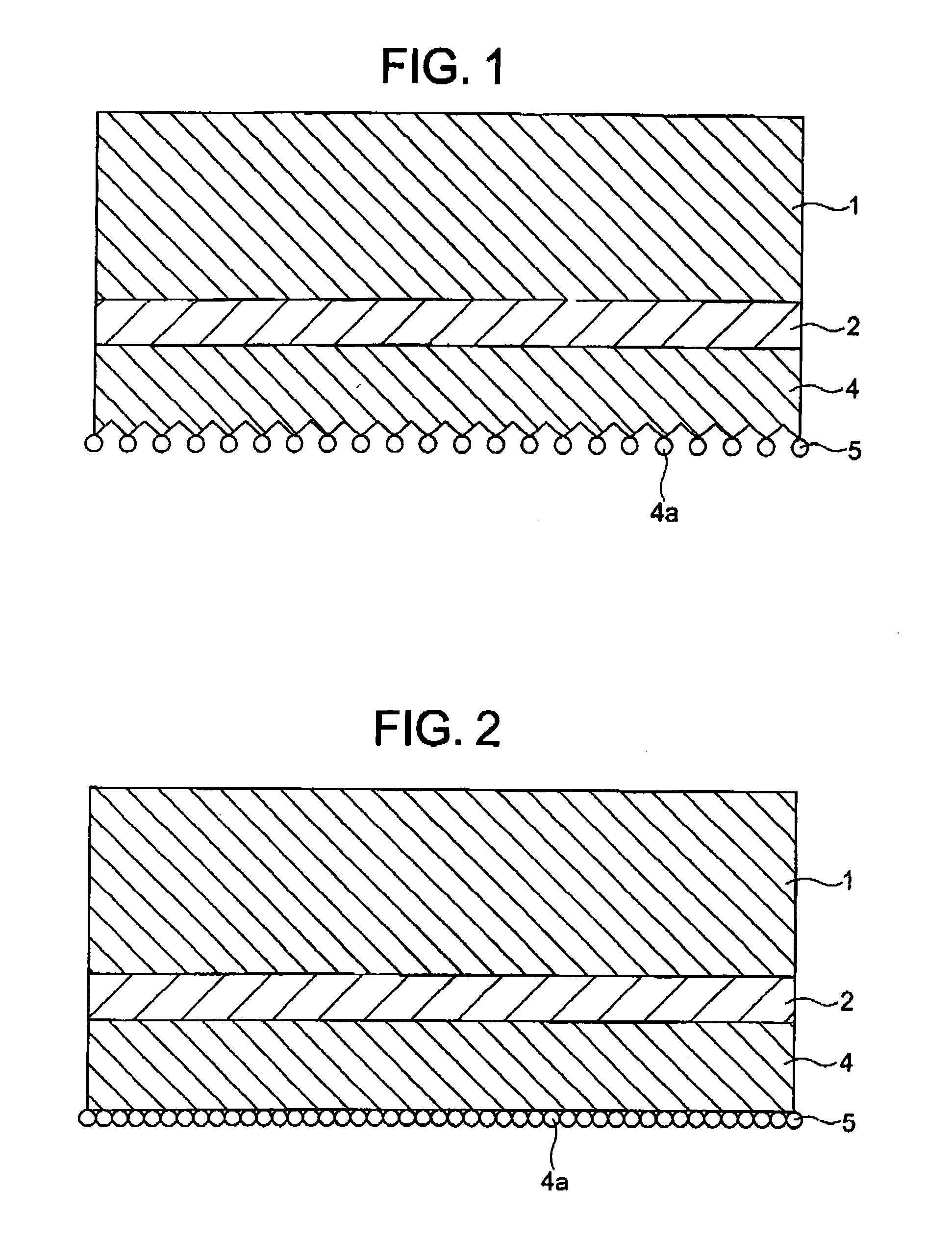

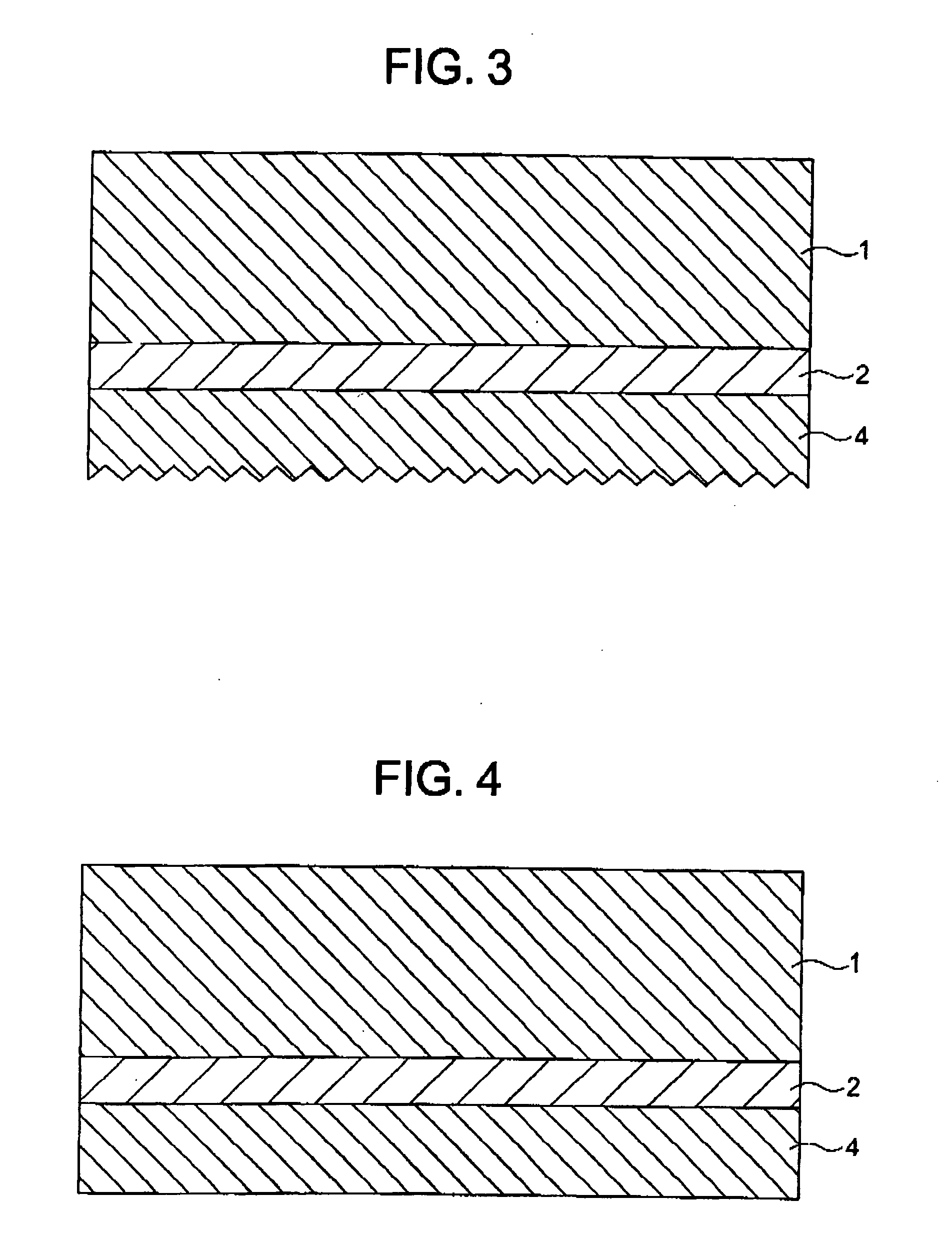

[0085]FIG. 2 shows an ultra-thin copper foil with a carrier foil of the first embodiment of the present invention, a peeling layer 2 is formed on the surface of a carrier foil 1, and an ultra-thin copper foil 4 is formed on the peeling layer 2. The ultra-thin copper foil with a carrier foil of the first embodiment of the present invention is constituted by laminating the carrier foil 1, the peeling layer 2 and the ultra-thin copper foil 4.

[0086] The surface roughness Rz of the surface of the ultra-thin copper foil 4 is 2.5 μm or less and the minimum distance between peaks of salients of a based material is 5 μm or more, and a roughening grain layer 5 consisting of roughening grains 4a is formed on the surface.

[0087] To produce the surface of the ultra-thin copper foil 4 of which the surface roughness Rz is 2.5 μm or less and the minimum distance between peaks of salients of a based material is 5 μm or more, plating is formed by a copper plating solution that ca...

example 1

[0099] (1) Making of an Ultra-Thin Copper Foil

[0100] An untreated electrolytic copper foil having the surface (S surface) roughness of 1.2 μm and the thickness of 35 μm was defined as a carrier foil and on the S surface chromium electroplating was successively performed, a chromium plating layer (peeling layer) of the thickness of 0.005 μm was formed. Next, by using a copper sulfate solution described in the following composition 1 as an electrolytic solution and performing the electrolysis in a condition that the current density was 30 A / dm2 and the temperature of the solution was 50 degrees C., an ultra-thin copper layer (copper foil) having the thickness of 5 μm was electroplated.

(Composition 1)copper sulfate (CuSO4.5H2O) 250 g / l to 350 g / lsulfuric acid (H2SO4) 80 g / l to 120 g / l3-mercapto-1-sodium propanesulfonate 0.5 ppm to 5 ppmhydroxyethyl cellulose 1 ppm to 10 ppmlow-molecular-weight glue (molecular weight 3000) 1 ppm to 10 ppmCl− 10 ppm to 50 ppm

[0101] On the ultra-th...

example 2

[0103] (1) Producing an Ultra-Thin Copper Layer

[0104] An untreated electrolytic copper foil having the surface (S surface) roughness of 1.2 μm and the thickness of 35 μm was defined as a carrier foil and on the S surface chromium electroplating was successively performed, a chromium plating layer (peeling layer) of the thickness of 0.005 μm was formed. Next, by using a copper sulfate solution described in the following composition 1 as an electrolytic solution and performing the electrolysis in a condition that the current density was 10 A / dm2 and the temperature of the solution was 35 degrees C., an ultra-thin copper layer (copper foil) having the thickness of 5 μm was electroplated.

(Composition 2)copper sulfate (CuSO4.5H2O) 240 g / lsulfuric acid (H2SO4) 60 g / lcupracid 210 by Nihon Schering K.K.make up agent 0.5 cc / lbrightening agent (A) 0.5 cc / lbrightening agent (B)using for only complementCl− 30 ppm

Note that as the complement of the brightening agent, the brightening agent (A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| grains diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com